Patents

Literature

57 results about "Cutting-plane method" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In mathematical optimization, the cutting-plane method is any of a variety of optimization methods that iteratively refine a feasible set or objective function by means of linear inequalities, termed cuts. Such procedures are commonly used to find integer solutions to mixed integer linear programming (MILP) problems, as well as to solve general, not necessarily differentiable convex optimization problems. The use of cutting planes to solve MILP was introduced by Ralph E. Gomory.

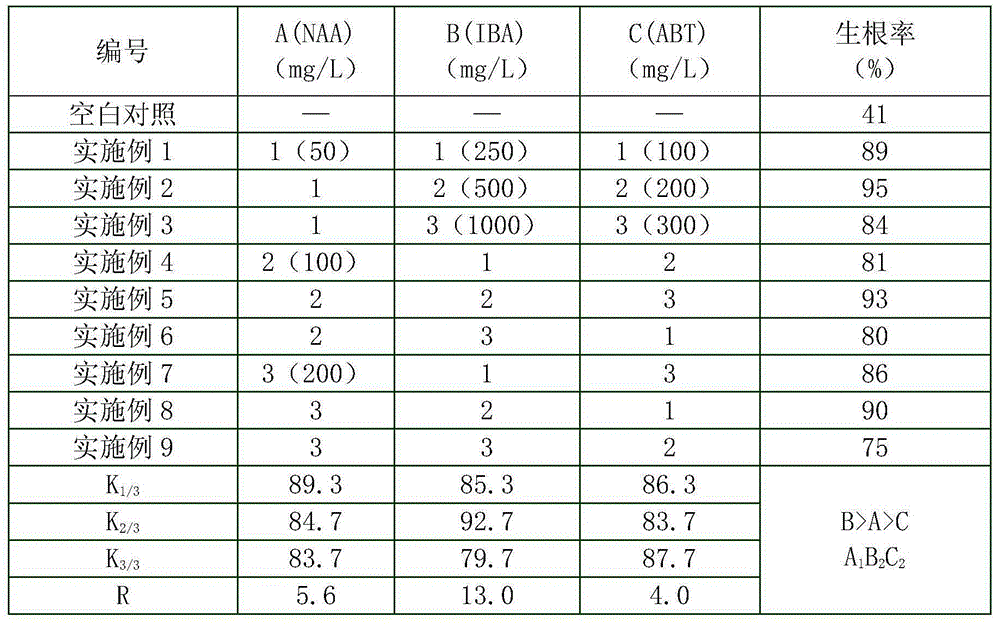

Wild peach cutting seedling method

InactiveCN103518512AHigh rooting rateHigh activityCultivating equipmentsHorticultureTemperature differenceCutting-plane method

The invention provides a wild peach cutting seedling method. The wild peach cutting seedling method includes the following steps of cutting selection, cutting preparation, cutting and cutting aftertreatment. Semi-lignification epicormic branches are used as cuttings, and compared with hard branches, the rooting ratio is increased; the lower ends of the cuttings are immersed in a growth regulating agent before being cut, after the cuttings are cut into a seedbed, the growth regulating agent is dropwise added to matrixes around the cuttings, the lower ends of the cuttings are affected by the growth regulating agent twice, and therefore the activity and the rooting ratio of the cuttings can be greatly increased; water mist is sprayed to the cuttings at intervals, the humidity in a shading shed can be effectively maintained, and rooting of the cuttings is facilitated; the seedbed is heated, the effect of temperature difference change between day and night on the cuttings can be avoided, and the normal rooting environment of the cuttings is guaranteed. In conclusion, the cutting method is simple in steps, the cuttings are convenient to manage, short in period and high in survival rate, and a large number of seedlings can be cultivated in a short time.

Owner:周家学

Laser measurement marking-off cutting method for big-width plate

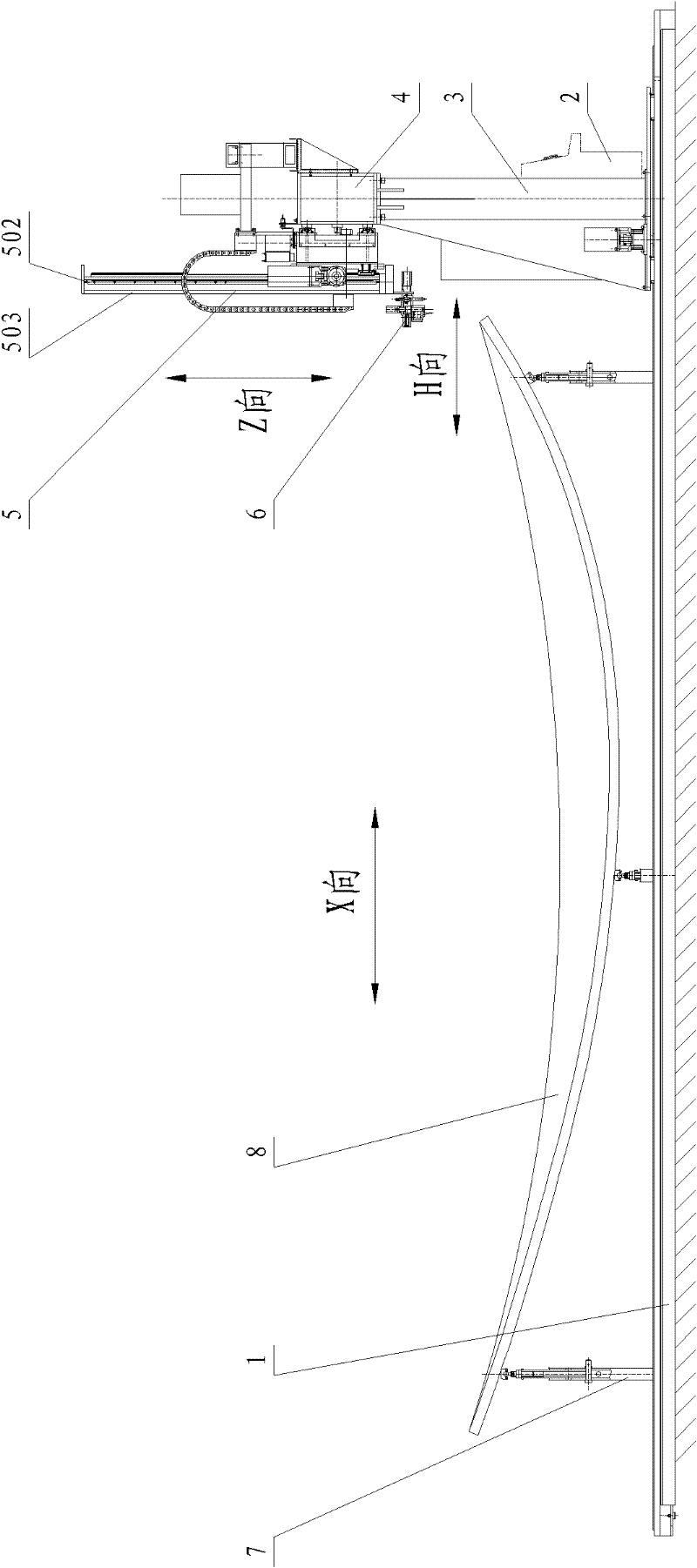

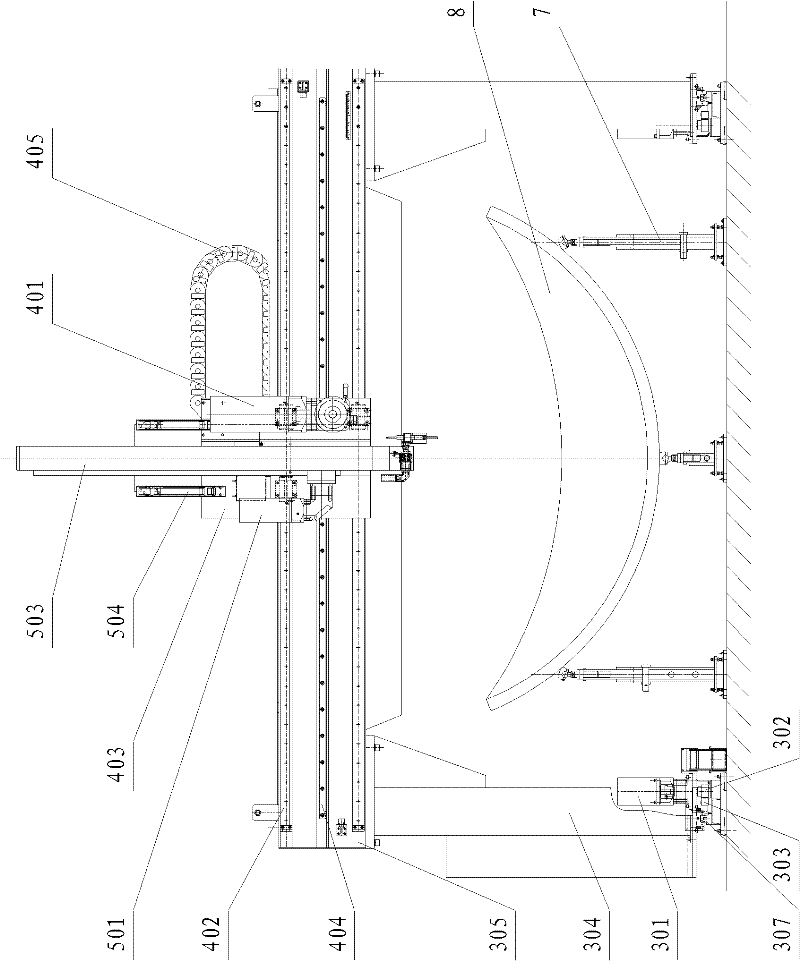

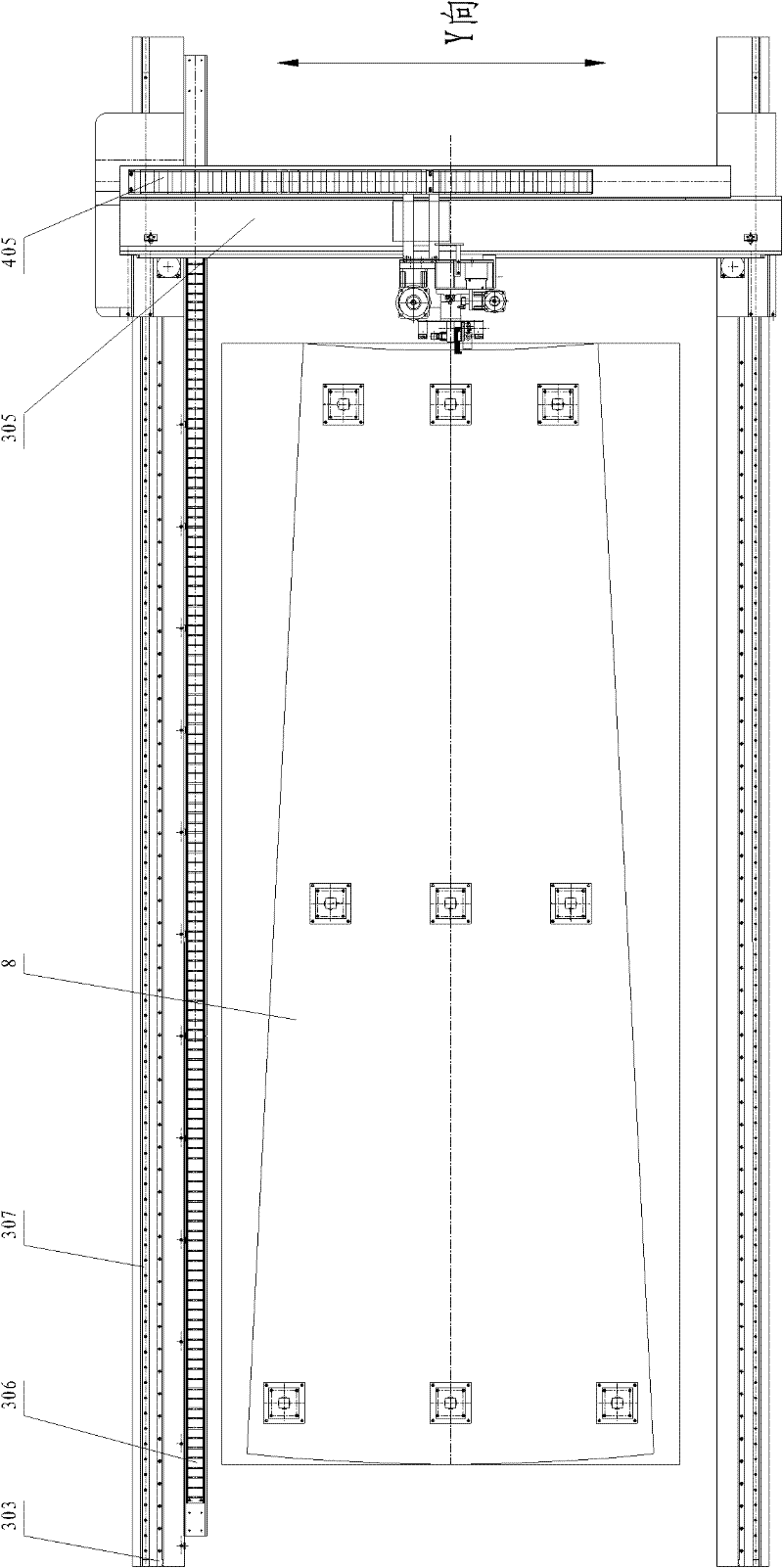

InactiveCN102528208ARealize three-dimensional processingAutomatically form processing pathsGas flame welding apparatusEngineeringFile comparison

The invention relates to a plate processing method, in particular to a laser measurement marking-off cutting method for a big-width plate. The method comprises the following steps of: suspending a workpiece to be cut onto a workbench; scanning the workpiece by using a camera arranged on a five-axis gantry measurement marking-off cutter to obtain coordinates of the surface characteristics of the workpiece; performing difference compensation fitting by using control software to obtain the profile surface of the workpiece; performing data comparison between the profile surface and an ideal model; automatically generating a marking-off locus; conveying the marking-off locus to the five-axis gantry measurement marking-off cutter; starting laser marking-off; conveying the path coordinates of the laser marking-off to a cutter; and after laser marking-off is completed, cutting according to the laser marking-off locus by using the cutter. Due to the adoption of the method disclosed by the invention, three-dimensional processing can be realized, the data characteristics of a three-dimensional surface are acquired automatically, a processing path is generated automatically, high measuring accuracy, high stability, high speed and high consistence are achieved, and a marking-off product is closer to an ideal curved surface.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Intelligent joining-cutting method for large electrified wire netting equipment overloading on-line sensitiveness

InactiveCN101299530ACalculation speedEmergency protective circuit arrangementsSingle network parallel feeding arrangementsElectric power systemElectric network

An intelligent intertripping method of the power pool device overload online sensitivity is provided, wherein a generator and a load in the power system are used as the node injection current; the node voltage equation of the network is I[N]=Y[N]U[N]; the linear coefficient matrix between the branch current and the node injection current are called as the correlation degree coefficient matrix of the network as C (lambda), and lambda <ki> shows the element in the matrix, and the expression is C(lambda)=YA[T]Y[N-1]. The optimal cutting machine, and the cutting load control point are selected according to the corresponding rank of C (lambda). The invention can reflect the physical condition of the system according to the fact, the scheme to look for the optimal cutting machine, and the cutting load control point is simple, the computing speed is fast, which can be applied in the online computation of the electric network operation load control.

Owner:JIANGSU ELECTRIC POWER CO

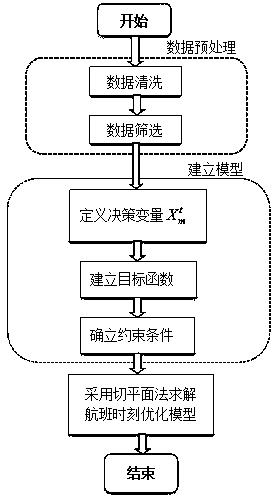

Single airport flight season change time slot optimization method based on historical operation data driving

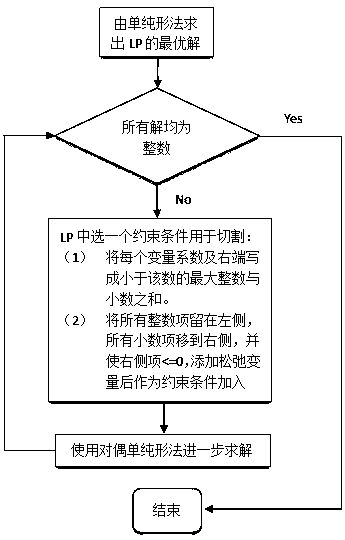

The invention discloses a single airport flight season change time slot optimization method based on historical operation data driving. The method comprises the following steps of 1) acquiring historical data information; 2) preprocessing acquired historical operation data; 3) constructing an optimization model of data driving, firstly, according to distribution of flight to a time slot, defininga 0-1 type integer decision variable, then, based on historical real operation data, taking a minimized deviation airline company request time and flight delay as a target and establishing a minimizedtarget function, and then, determining a constraint condition, and acquiring the optimization model of data driving; and 4) according to the established optimization model of data driving, using a cutting plane method to solve and acquiring optimal distribution of a season change flight time slot. By using the single airport flight season change time slot optimization method based on the data driving, a quantitative auxiliary decision tool is provided for a flight plan making manager and the flight season change time slot can be programmed scientifically and reasonably.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

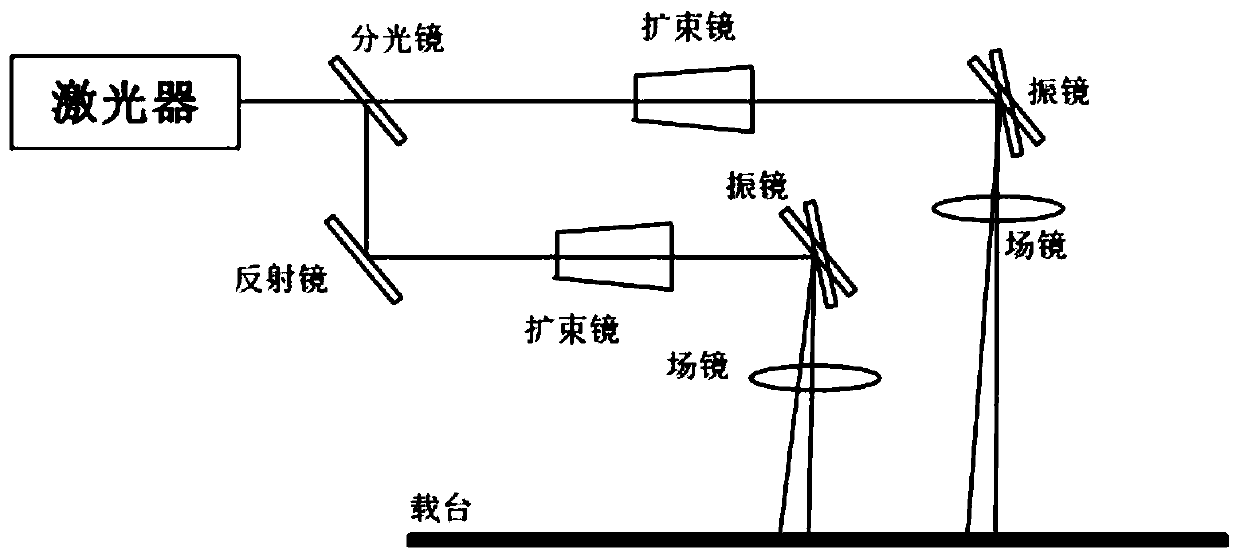

Quick laser scanning and cutting method

ActiveCN105522284AHigh speedShorten the lengthLaser beam welding apparatusNumerical controlLaser scanning

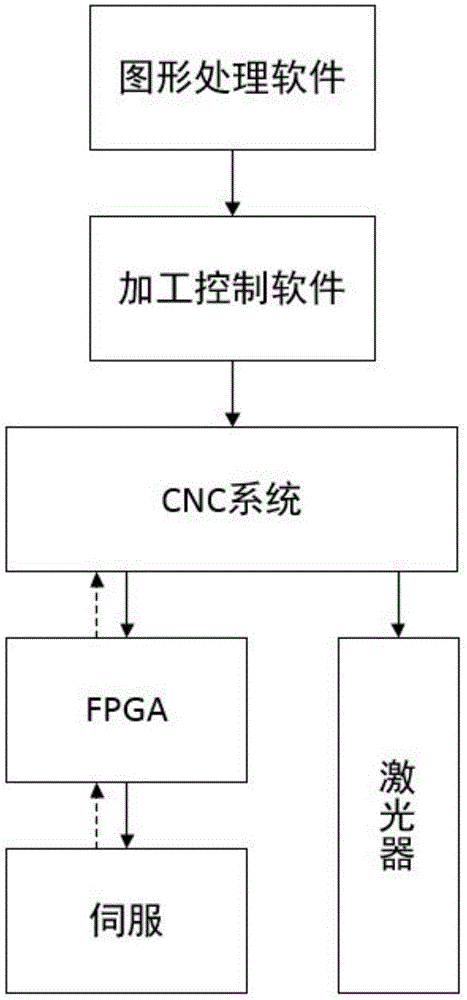

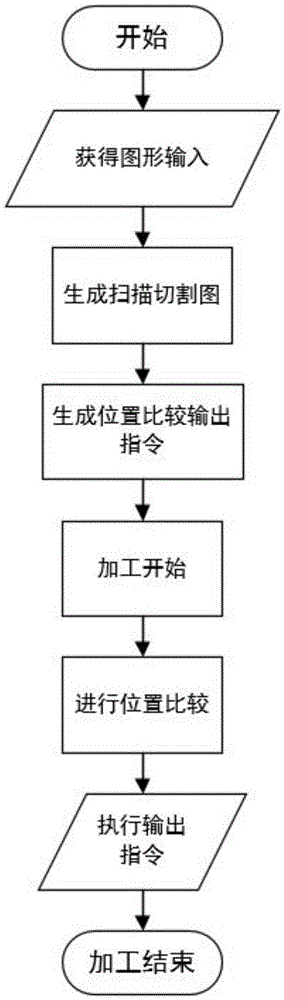

The invention relates to the field of laser cutting, in particular to a quick laser scanning and cutting method. The method comprises graphic processing software for acquiring graphic processing, machining control software for controlling a computer numerical control (CNC) system, the CNC system for controlling a machine tool servo and a laser device, a field programmable gate array (FPGA) system for processing and transferring signals, the servo for controlling a machine tool to move and the laser device which is used for producing lasers to carry out cutting and is provided with a pulse width modulation (PWM) switching system. The quick laser scanning and cutting method is characterized in that the method comprises the following steps that starting is carried out, a graph is input, a scanning and cutting pattern is generated, a position comparison and output instruction is generated, machining is started, position comparison is conducted, an output instruction is carried out, and stopping is conducted. Compared with the prior art, cutting and air moving paths of machining motion are optimized through a cutting line scanning mode, acceleration times and deceleration times in the motion process are decreased effectively, and the average speed of cutting and the average speed of air moving are increased; accordingly, the cutting motion time and the air moving motion time are shortened, and the purpose of quick cutting is achieved.

Owner:上海柏楚电子科技股份有限公司

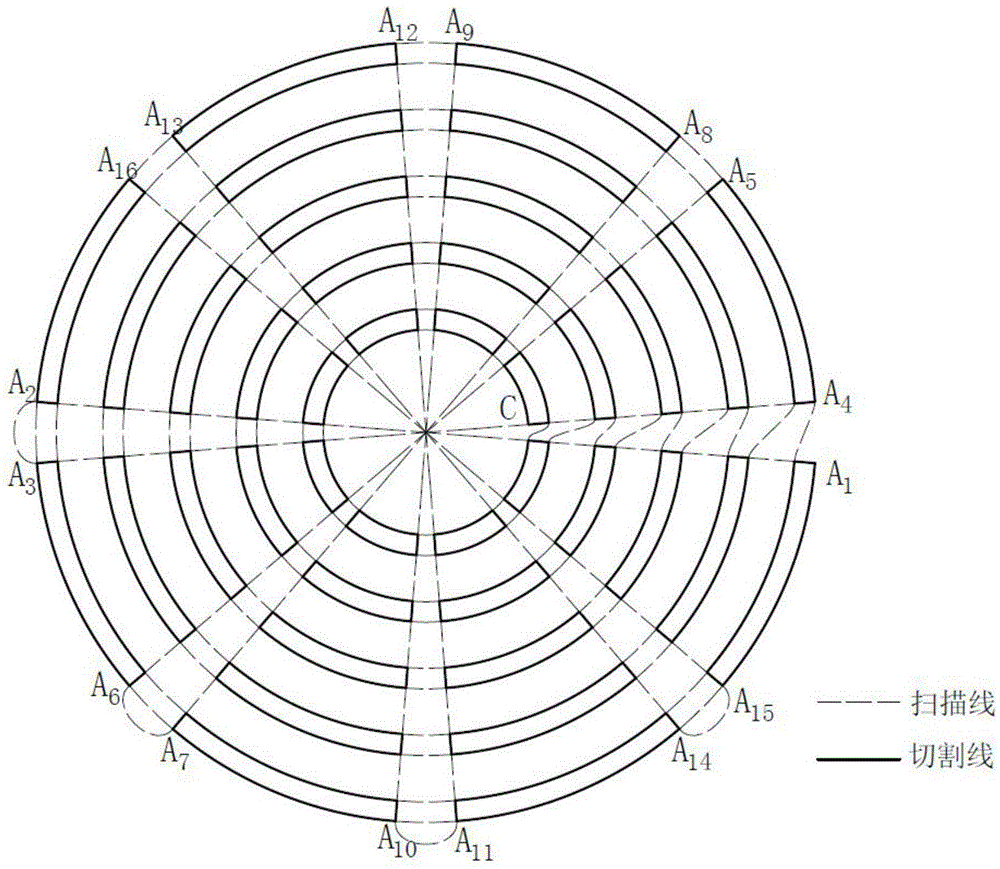

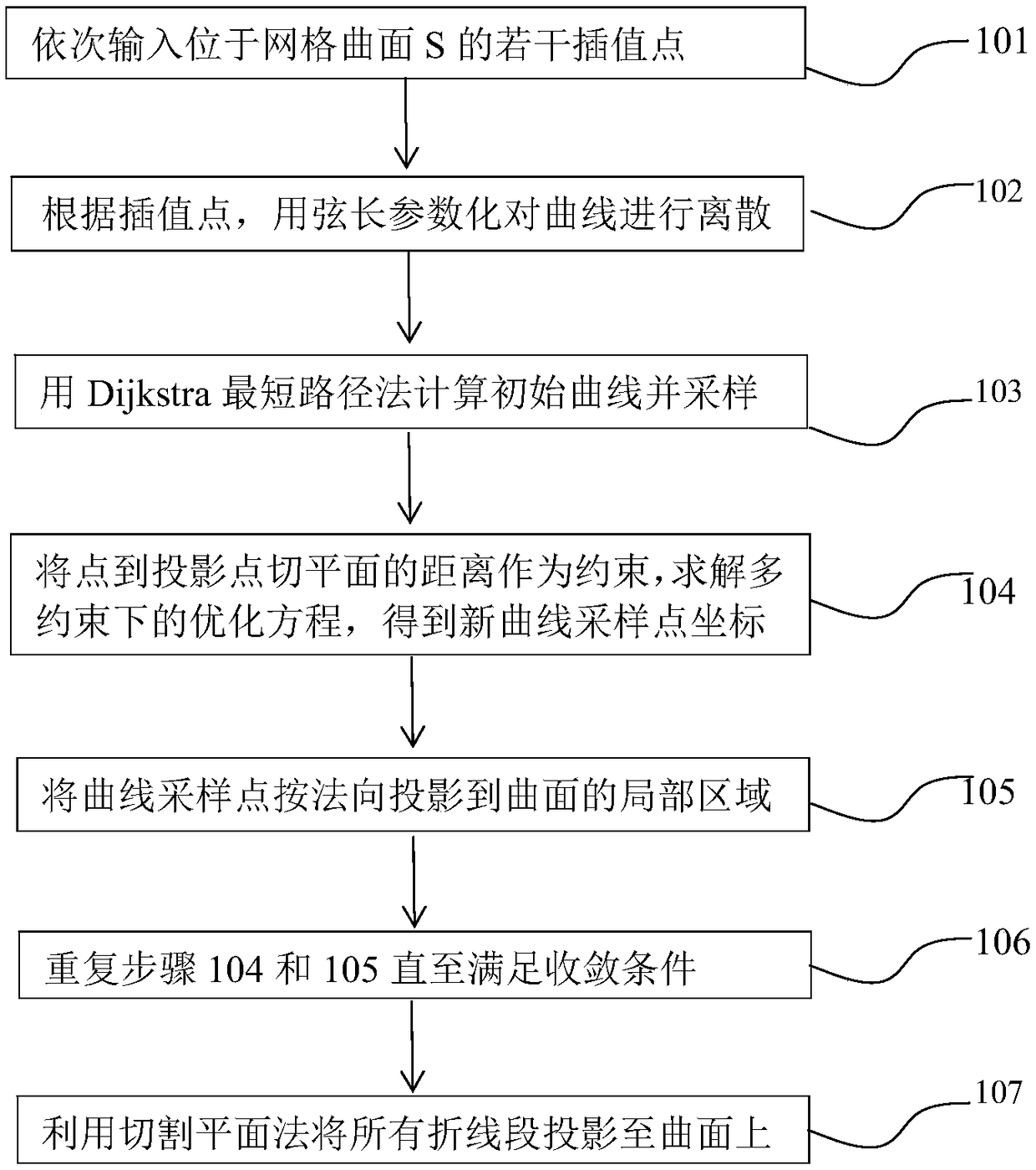

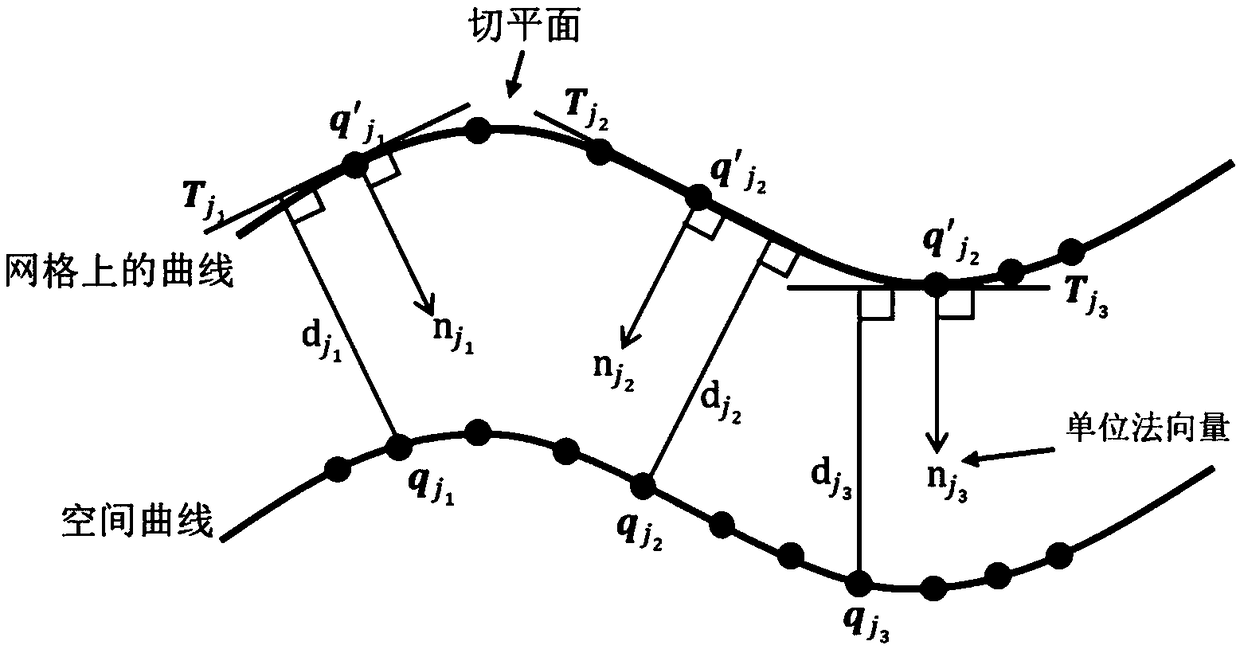

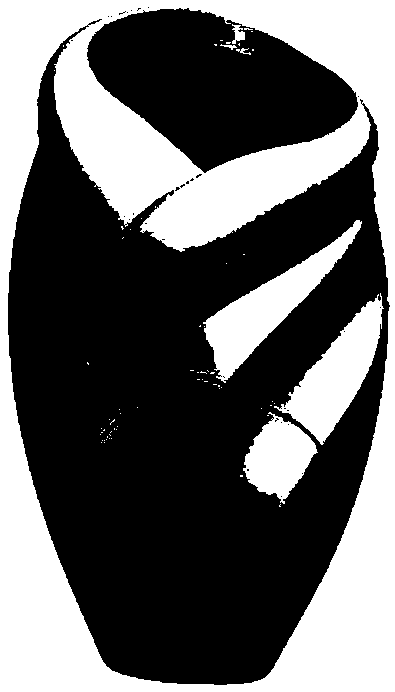

A mesh surface curve design method based on distance constraint

ActiveCN109360272AImprove efficiencyImprove robustness3D modellingDistance constraintsCutting-plane method

The invention discloses a mesh surface curve design method based on distance constraint. The designed curve passes through a given interpolation point and is smooth (in the sense of discreteness) andstrictly located on the mesh surface. The method transforms the complex manifold constraints into distance constraints and describes them as optimization problems together with smooth constraints andinterpolation constraints. The local surface is approximated by the tangent plane, and the distance constraint is relaxed to the distance from the point to the tangent plane. Because the points on thecurve used to calculate the distance are interdependent with their corresponding tangent points, a global-local iterative strategy is adopted and Gauss- Newton idea method is used to control its convergence behavior: in the whole stage, it is relaxed into a convex optimization problem by distance approximation to solve the iterative step size; In the local phase, a robust and efficient projectionmethod is used to map the optimized curves to the surface to update the tangent points. Finally, all the relaxed polygons are mapped to the mesh surface by using the cutting plane method. Compared with the existing methods, this method has many advantages in efficiency, robustness and application range.

Owner:ZHEJIANG SCI-TECH UNIV

Chinese mesona herb cutting planting method

InactiveCN104396487AHigh rooting rateHigh activitySeed and root treatmentPlant cultivationCutting-plane methodHigh survival rate

The invention provides a Chinese mesona herb cutting planting method comprising the steps of A, cutting selection, B, cutting preparation, C, cutting and planting, and D, cutting post-treatment. According to the invention, half-lignified softwood branches are adopted as cuttings. Compared with that with pure softwood branches, a rooting rate is improved. The lower ends of cuttings are soaked by using a growth regulator before planting; and the growth regulator is dropped into the substrate around the cuttings when the cuttings are planted into a field. With the effects and influences of twice growth regulator application, cutting activity and rooting rate can be greatly enhanced. Water mist is intermittently sprayed to the cuttings, such that field humidity can be effectively maintained, and cutting rooting can be promoted. A shading treatment is carried out in the planting field, such that the influence of direct sunlight to the cuttings during the day can be prevented, and a normal rooting environment for the cuttings is ensured. In summary, the cutting method provided by the invention has the advantages of simple steps, convenient management, short period, and high survival rate. With the method, a large amount of seedlings can be planted in a field within a short period of time.

Owner:陆川县大鹏现代农业发展有限公司

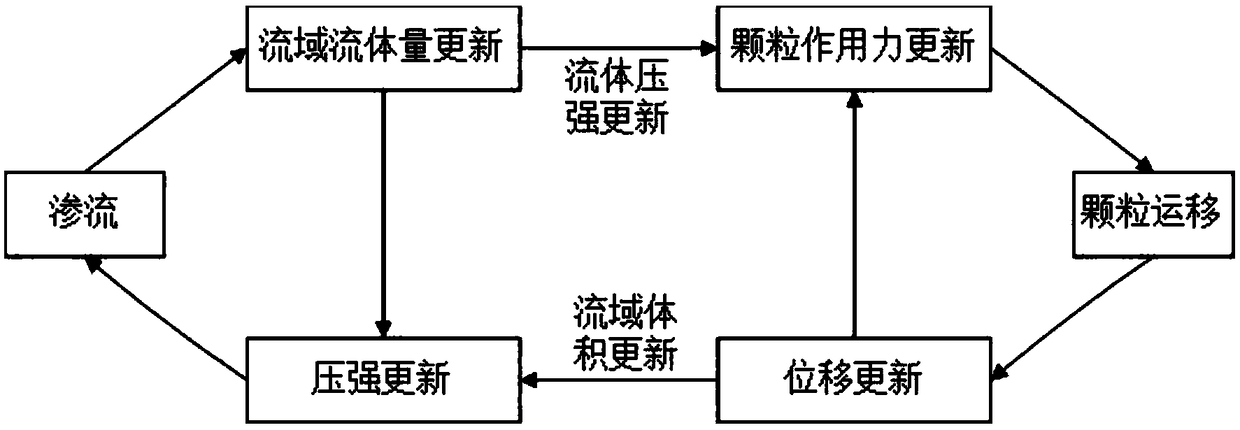

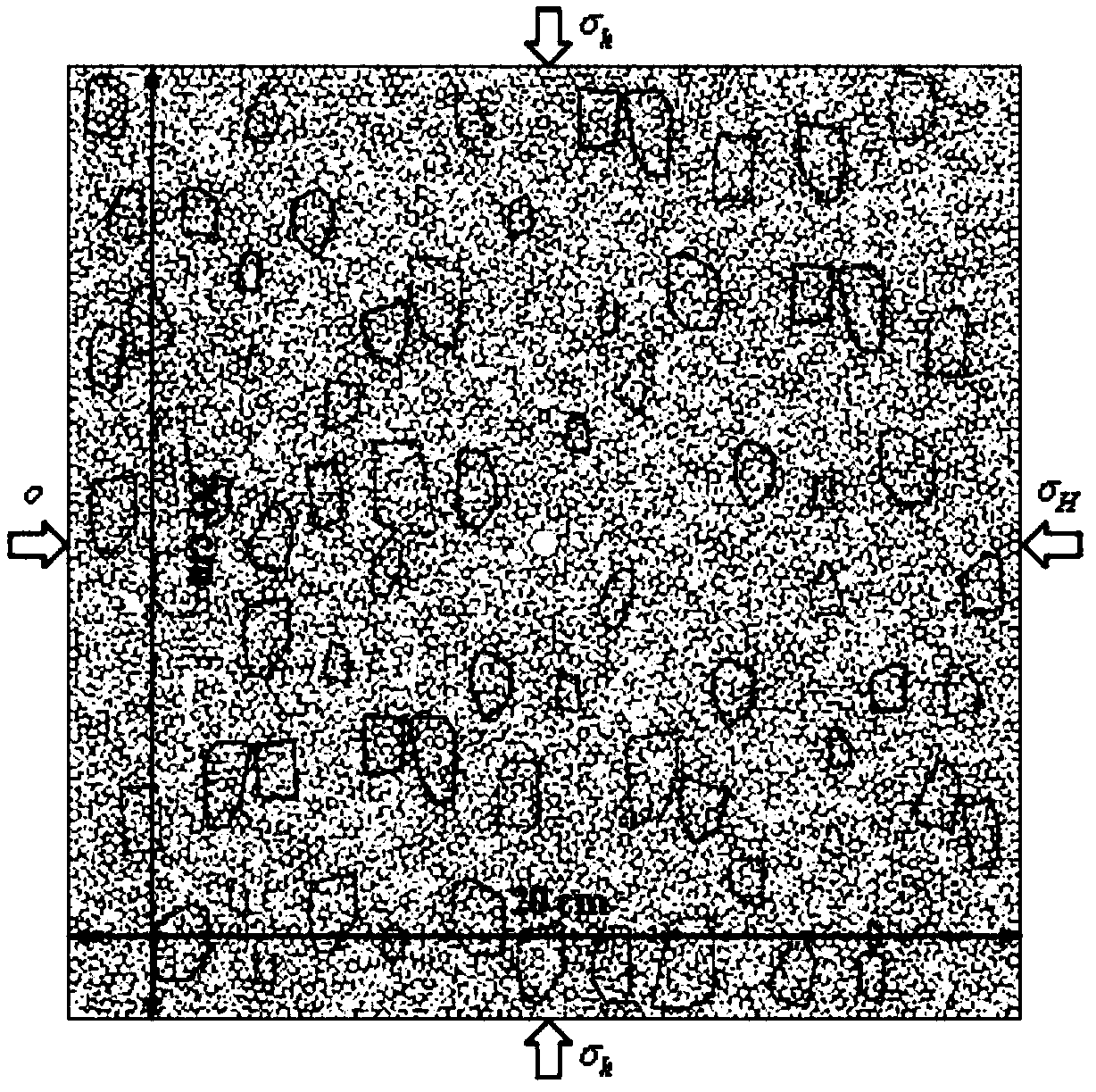

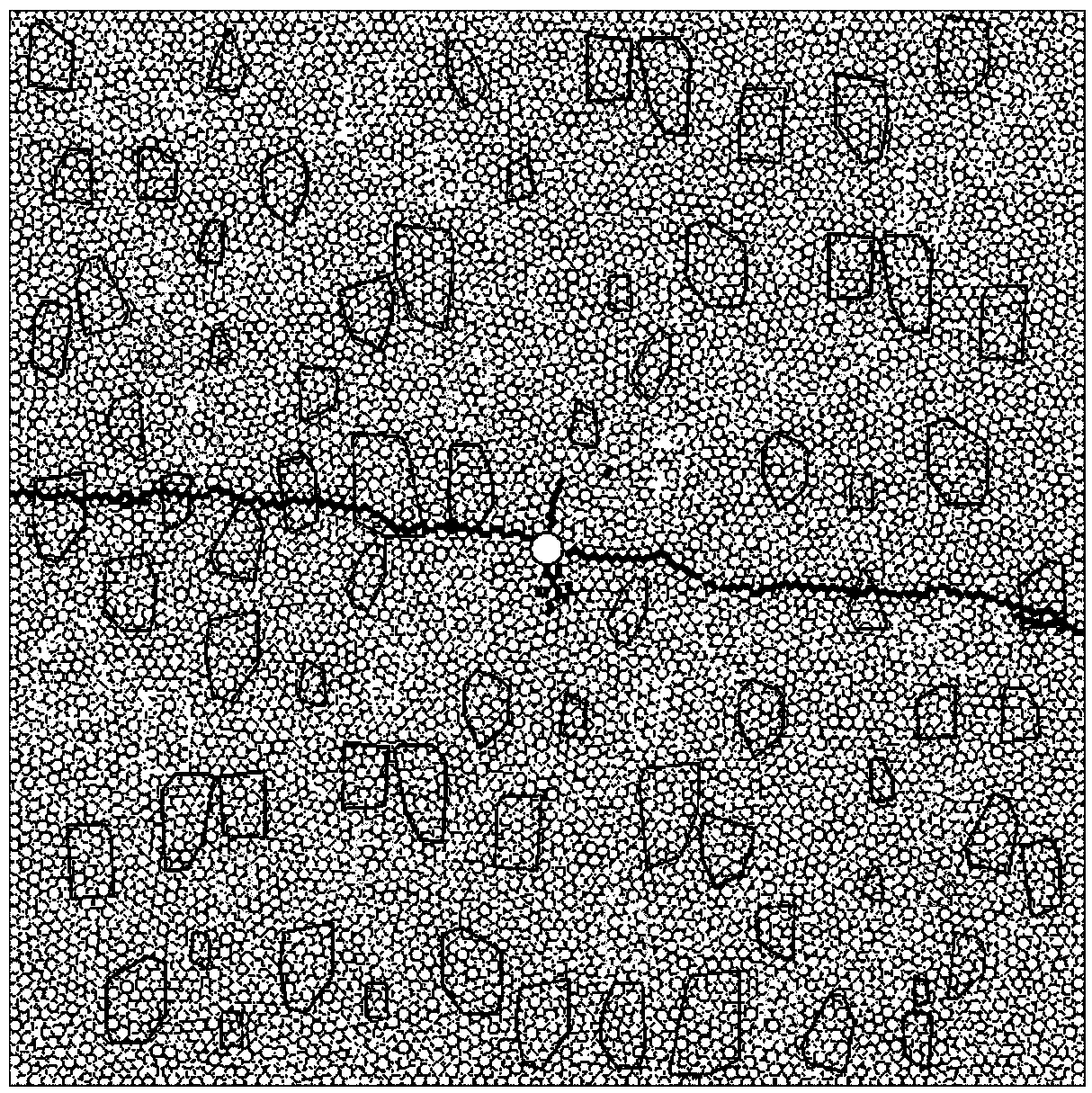

Glutenite hydrofracture simulation method based on discrete element

ActiveCN109374867AAccurate captureAccurately reproduce interactionsEarth material testingDiscrete element methodHydraulic fracturing

The invention relates to a glutinite hydrofracture simulation method based on a discrete element. The method comprises the following steps of: S1, constructing a wall and a well bore, generating particles according to a size grading curve, and performing initial balance calculation, S2, dividing the particles into a matrix and gravel by a cutting method, endowing the matrix and the gravel with different cementing parameters, S3, adding a seepage field and endowing a corresponding flow parameter, S4, applying confining pressure on the external wall based on a servo system, setting a fluid injection speed, S5, monitoring cementing states of the particles in real time, and judging whether micro cracks are generated according to the cementing states, and S6, continuing simulation till penetration of hydraulic cracks occurs. The glutinite hydrofracture simulation method based on the discrete element can characterize crack initiation and expansion mechanisms of the hydraulic cracks preciselyfrom a microscale, and accurately capture a macro distribution morphology of the hydraulic cracks, so that the understanding of a field engineer on an expansion rule of the hydraulic cracks of a glutinite reservoir is enhanced; and a fracture design is improved.

Owner:QINGDAO UNIV OF SCI & TECH

Cutting propagation method of brucea javanica

The invention discloses a cutting propagation method of brucea javanica. The method includes the steps that a, selecting and treating cutting slips, wherein robust branches without disease or pest damage are selected and sheared into the cutting slips, and the bases of the cutting slips are placed in a disinfectant to be soaked for 25 min and then placed in a rooting inducer to be soaked for 3h; b, preparing a matrix and a seedbed, wherein peat soil is adopted as the cutting matrix, and a uniform mixture of vermiculite and fine river sand is disinfected through a disinfectant and then made into the seedbed with the thickness of 30 cm; c, performing cutting, wherein the cutting slips are obliquely placed in the matrix of the seedbed in a cutting mode by the depth 2 / 3 of the length of the cutting slips; d, managing the seedbed after cutting, wherein a sunshade net is erected, water is sprayed to the seedbed in the morning and evening every day, 800-fold thiophanate methyl is sprayed once every week 7 days later and is sprayed twice in all, a 1 / 2 MS nutrient solution is sprayed 7 days later, and culturing is performed till rooting and seedling emergence. By adopting the cutting method for propagating brucea javanica seedlings, the propagation speed of brucea javanica can be increased, and powerful guarantee is provided for scientific research and large-scale planting of brucea javanica.

Owner:GUANGXI BOTANICAL GARDEN OF MEDICINAL PLANTS

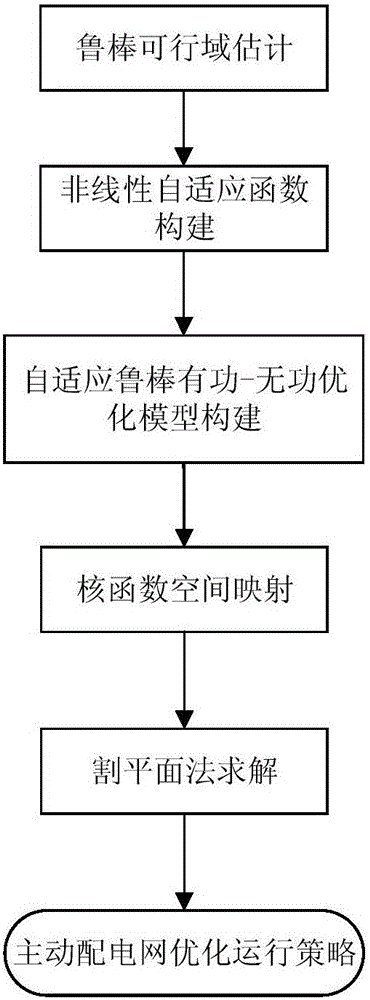

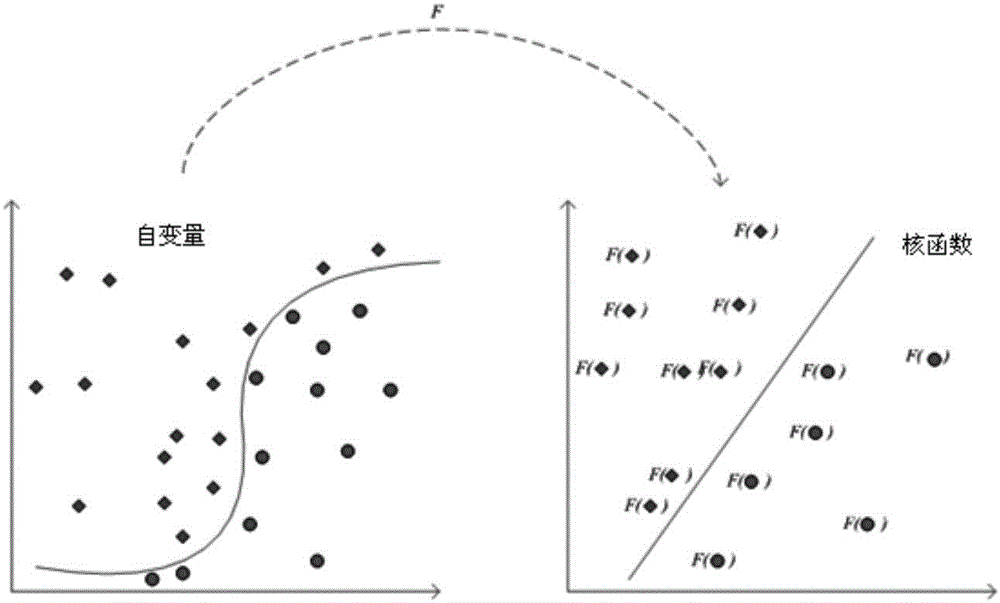

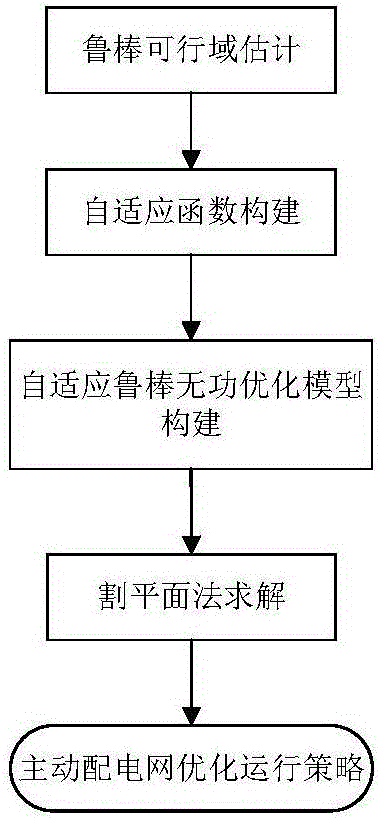

Self-adaptive Robust optimization method for active distribution network considering large number of renewable energy connected grids

ActiveCN106849162AAchieve real-time optimizationGuaranteed safe operationSingle network parallel feeding arrangementsOptimal decisionElectric power system

The invention discloses a self-adaptive Robust optimization method for an active distribution network considering a large number of renewable energy connected grids. The method comprises the steps of estimation of a Robust feasible region, construction of a nonlinear self-adaptive function, construction of a self-adaptive Robust active-power-reactive-power optimization model, mapping of kernel function space, and solution with a cutting-plane method and an optimization operation strategy of the active distribution network. According to the method, to solve height uncertainty of the large-scale renewable energy connected grids, an idea of Robust optimization is introduced, and the safe operation of a power system under an optimal decision is guaranteed; a self-adaptive technology is introduced, and self-adaptive changes of the optimal decision with uncertain variables are achieved; a self-adaptive Robust active-power-reactive-power optimization model of the active distribution network is established, and the economy and efficiency of the distribution network under the optimal decision are ensured, a kernel function method and a cutting-plane solution strategy are adopted, the efficient and fast solution of an original problem is achieved, and the reliability, economy and safety during an operation process of the active distribution network are ensured.

Owner:SOUTHEAST UNIV

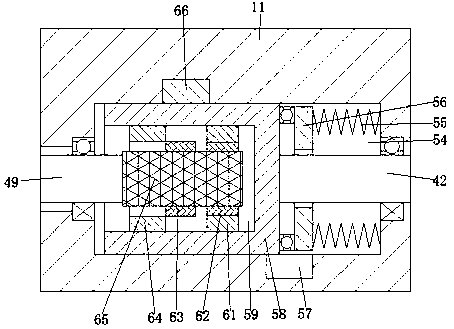

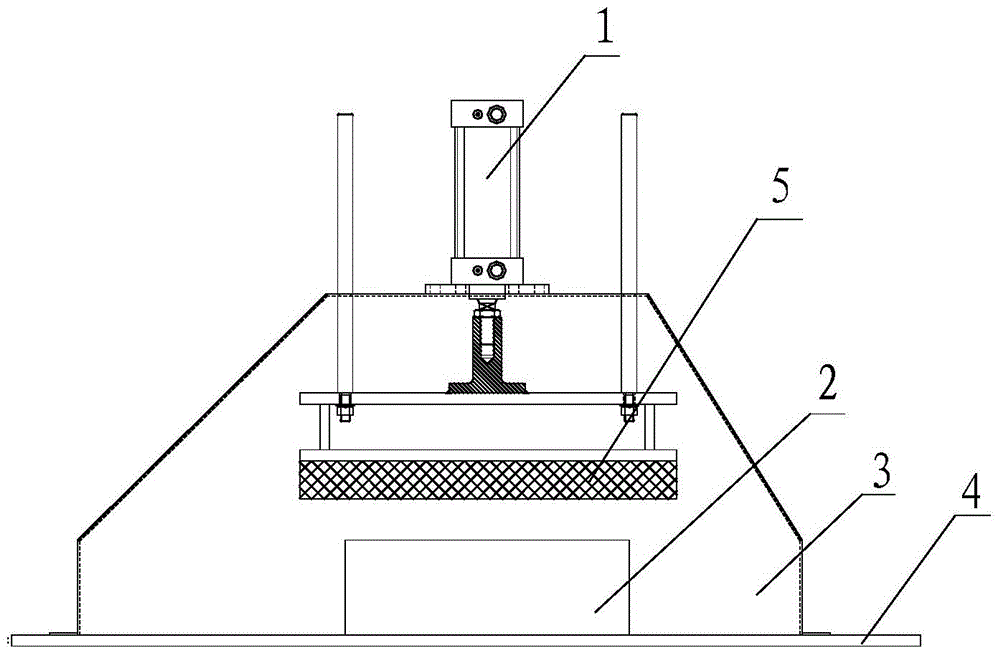

Abrasive cutting device and cutting method

PendingCN110170908APrecise weight controlGrinding feed controlGrinding machinesEngineeringCutting-plane method

The invention provides an abrasive cutting device and a cutting method. The abrasive cutting device comprises a first laser distance sensor, a master control device and an abrasive disk. The first laser distance sensor is in communication connection with the master control device. The laser distance sensor is used for acquiring the data about the outer diameter of a rod material. The master control device is used for determining the current material segment length according to the outer diameter of the rod material, the material density of the rod material and the set material segment weight.The master control device controls the abrasive disk to carry out rotary cutting on the rod material according to the determined material segment length. With the abrasive cutting device and the cutting method, the working efficiency can be improved, the labor intensity cn be reduced, and the quality of products is improved at the same time. According to the abrasive cutting device and the cuttingmethod, cutting feeding can be controlled by the cutting device quantitively, the weight of each cut material segment is accurately controlled, the weight deviation might be caused is reduced, and the requirements on the indexes of a jacking breaking device are reduced.

Owner:BEIJING BIAM ALLOYS +2

A self-adapted method for setting protection interval of overlapping cutting method

InactiveCN101192846AReduce operational complexityReduce bit error rateRadio/inductive link selection arrangementsRadio transmission for post communicationSignal-to-noise ratio (imaging)Cutting-plane method

The invention discloses a method for protecting interval by adopting an adaptive set overlapping shearing approach. A transmitting end sends given data of a receiving end. The receiving end receives the data and calculates the data error to determine the location and length of frequency domain equalization protection interval. The invention further discloses a method for protecting interval by adopting an adaptive set overlapping shearing approach. If the SNR is smaller than the preset SNR threshold value, the protection interval is set as 0; otherwise, the transmitting end sends given data of the receiving end and the receiving end receives the data to calculate the data error and determine frequency domain equalization protection interval. The invention can effectively reduce bit error rate and further reduce the operation complexity of the frequency domain equalizer while the system performance is not reduced.

Owner:ZTE CORP

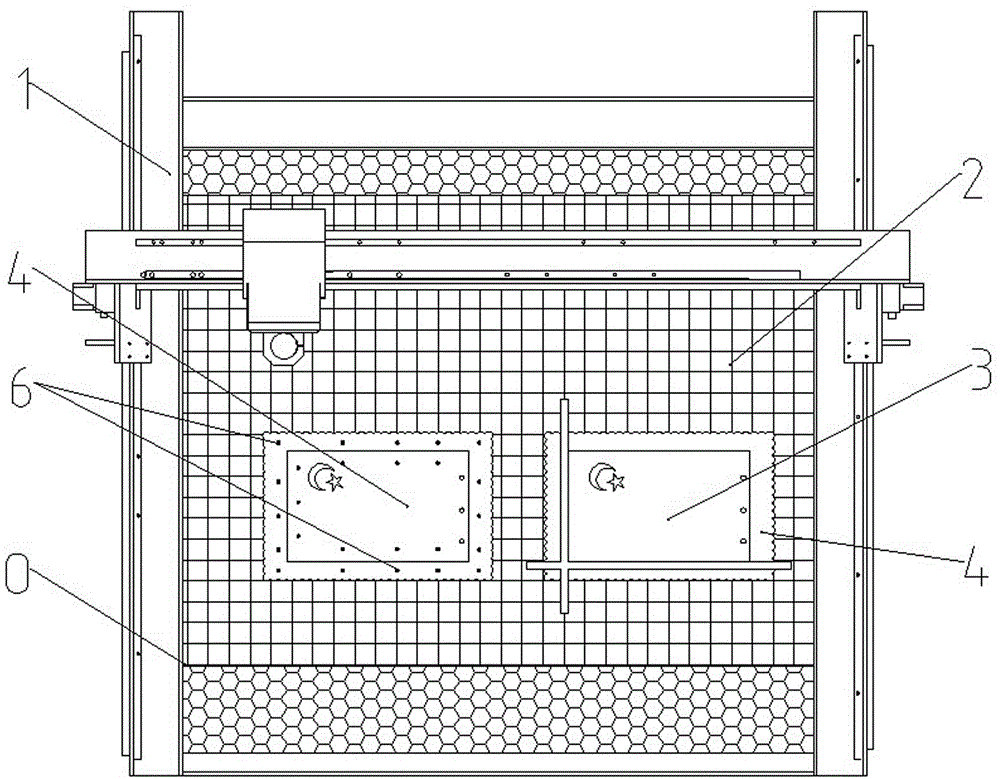

Automatic optical fiber laser cutting equipment and cutting method thereof

InactiveCN108714743ASimple structureEasy to operateEdge grinding machinesLaser beam welding apparatusLaser cuttingCutting-plane method

The invention discloses automatic optical fiber laser cutting equipment and a cutting method thereof. The automatic optical fiber laser cutting equipment comprises a device main body and a laser cutting device in the device main body, wherein the laser cutting device comprises a first cavity; the first cavity is formed in the device main body in a manner of penetrating through the left and right parts; a second cavity is formed in the inner wall of the circumferential side of the first cavity in a communicating manner; and a first rotating block is rotatably arranged in the second cavity. Nowadays, for part manufacturing, flame cutting or saw web cutting is mostly adopted to cut off profile, then, next processing is carried out, and the manner can be adopted in the case of lower machiningaccuracy requirement and lower material cost; and however, in the case of high-precision machining or higher material cost, the material of a saw kerf influences certain precision and causes waste ofthe material cost, and laser cutting is high in machining precision, small in saw kerf and high in machining efficiency. The invention aims to design a device to solve the problem.

Owner:胡小多

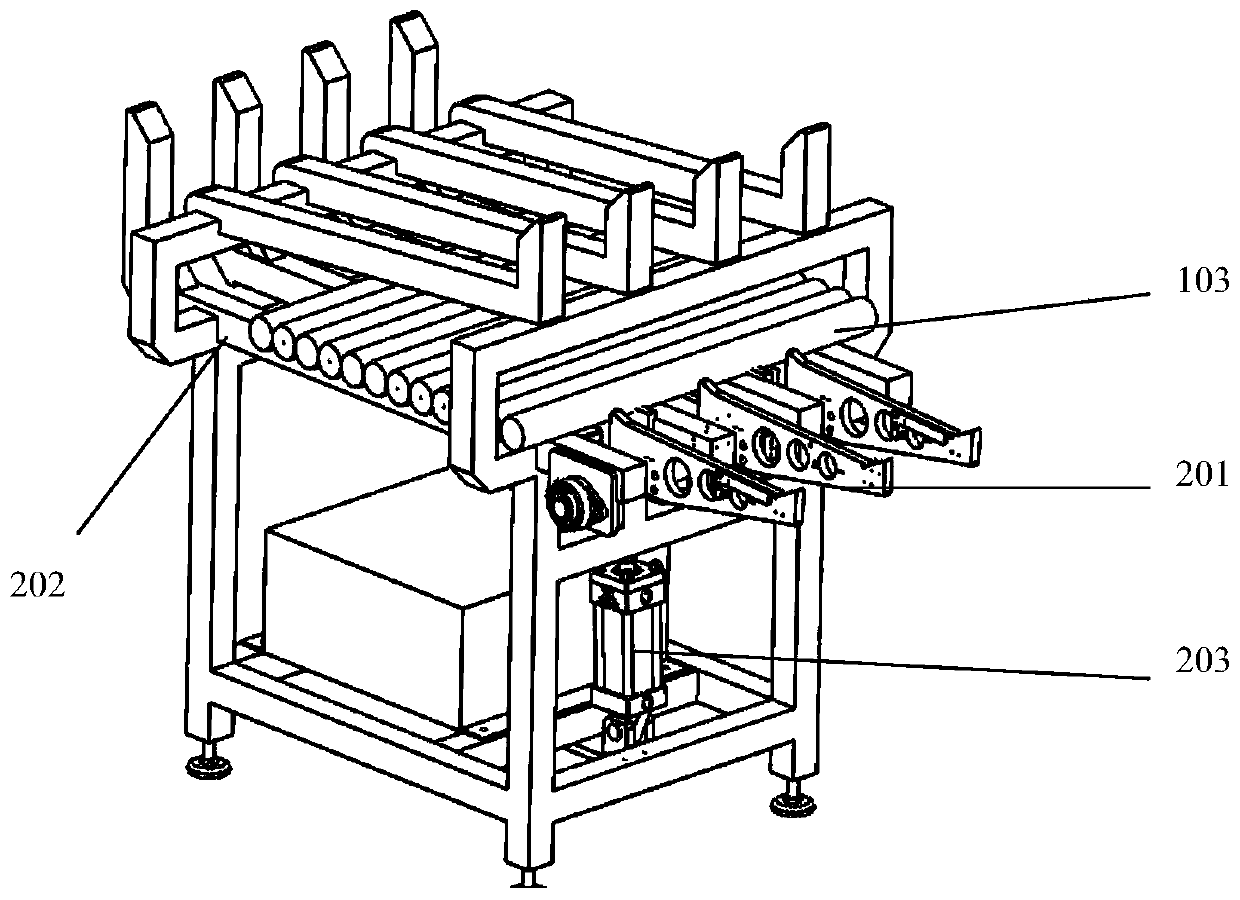

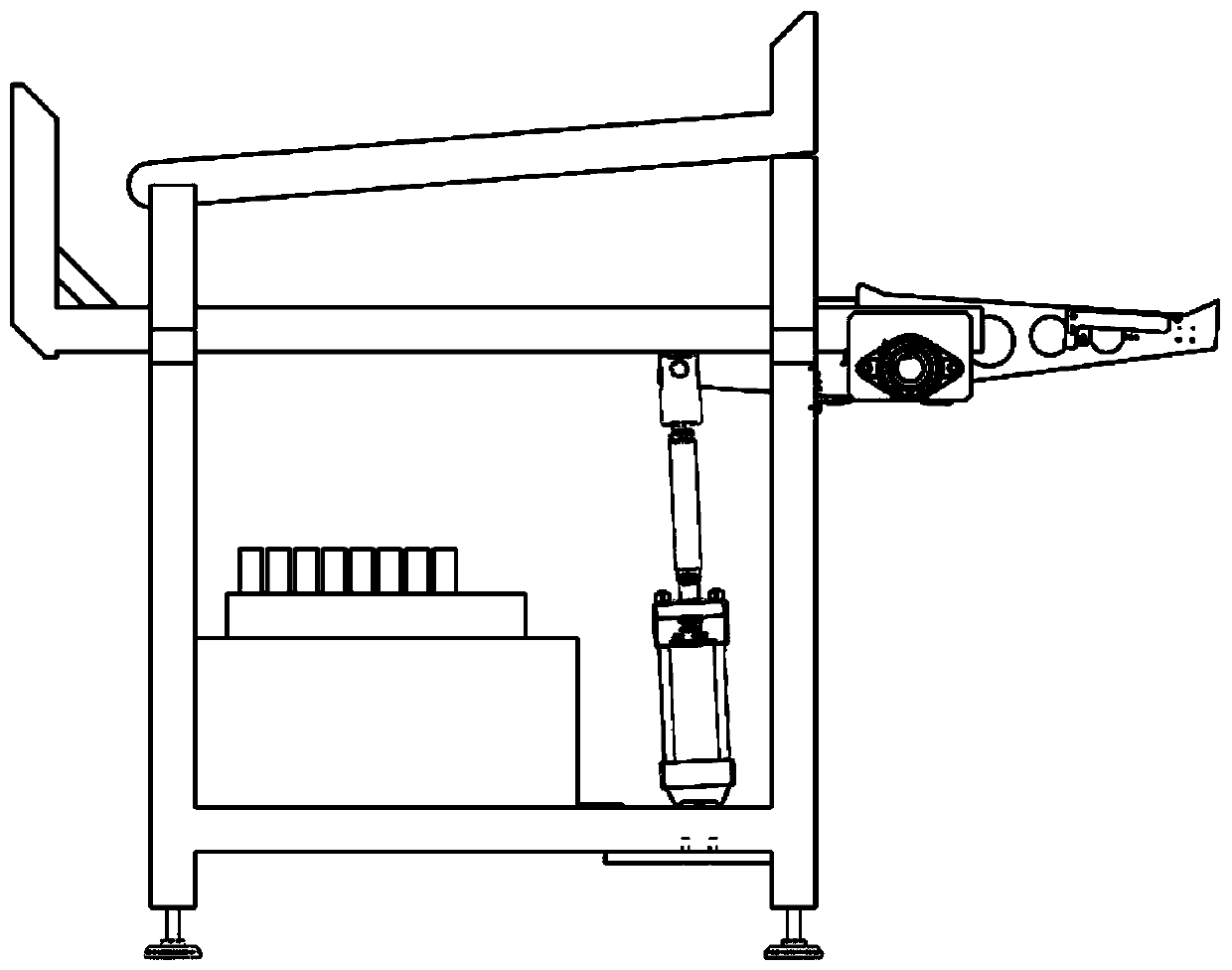

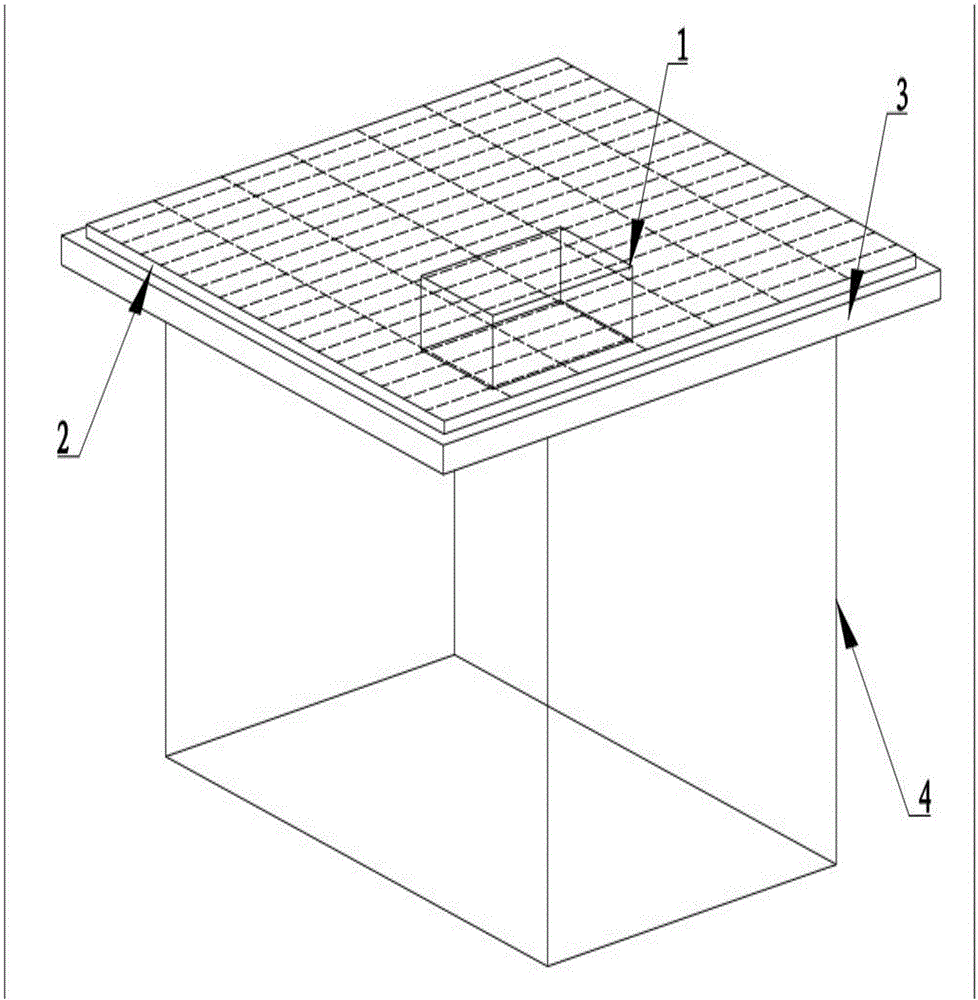

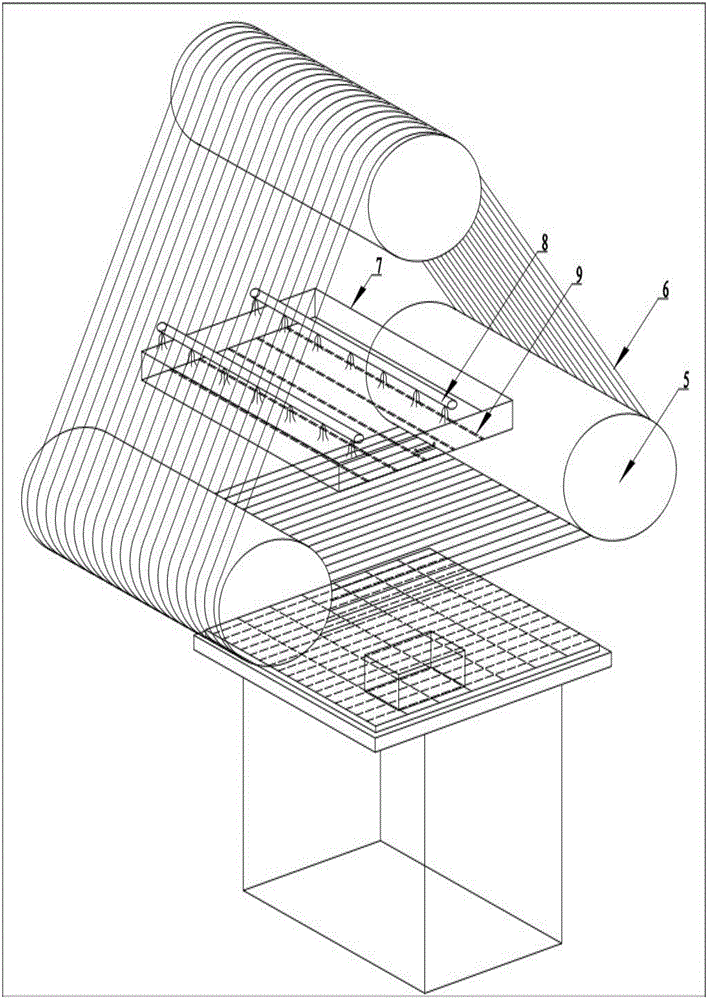

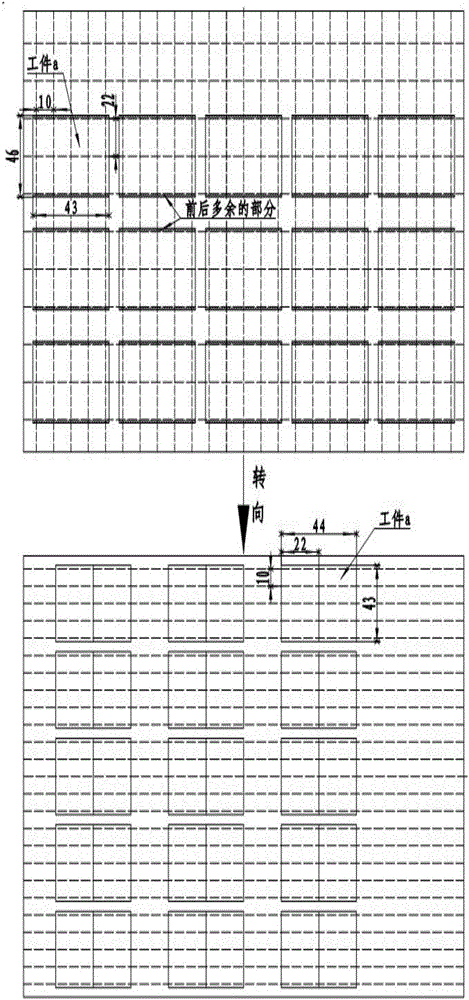

Multiple wire turning cutting method and equipment

ActiveCN106738392AReduce turnaround timeReduce the chance of badWorking accessoriesFine working devicesTurnover timeWire cutting

The invention discloses a multiple wire turning cutting method and equipment. The multiple wire turning cutting equipment is a multiple wire cutting machine and comprises a square multiple wire cutting base plate and a working table; two or more multiple wire cutting machines can be used for performing combined cutting. Compared with the conventional multiple wire cutting method and equipment, the multiple wire turning cutting method and equipment has the benefits that rapid cutting is realized, time spent on the intermediate auxiliary section is cut down, the material turnover time is reduced generally, cosmetic defects possibly caused during the material turnover process can be reduced, and the product quality is improved.

Owner:京磁材料科技股份有限公司

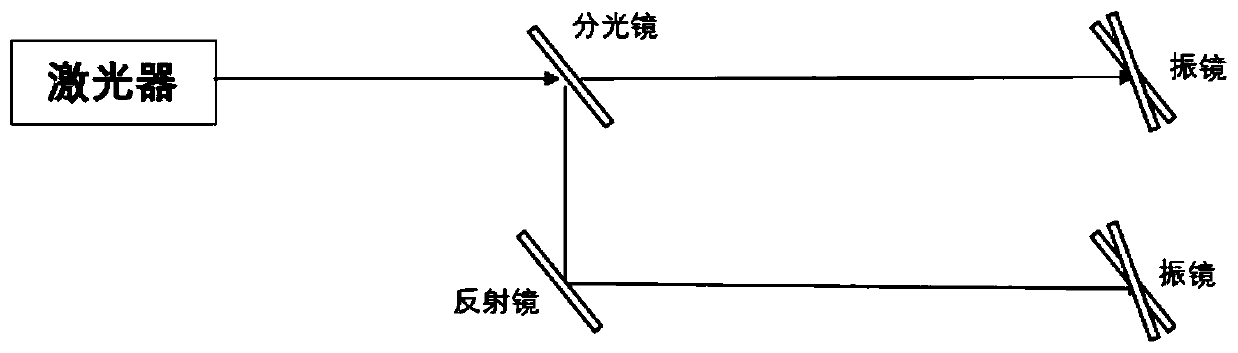

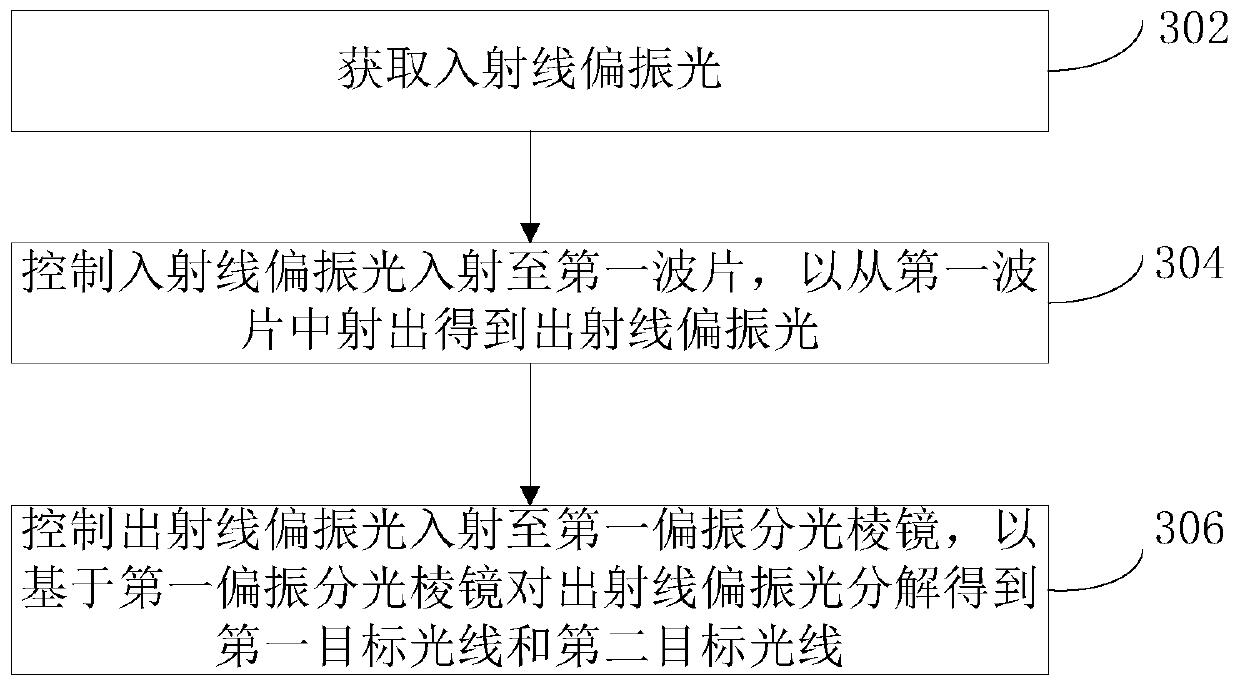

Light segmentation method, laser-based cutting method, equipment and system

ActiveCN110369863ASolve the problem of inconsistent output light energyLaser beam welding apparatusOptical elementsGrismLight energy

The invention provides a light segmentation method, a laser-based cutting method, equipment and system. The method comprises the following steps that incident linearly polarized light is acquired; incident linearly polarized light is controlled to be incident to a first wave plate to obtain emergent linearly polarized light; and the emergent linearly polarized light is controlled to be incident toa first polarization beam splitter, and first target light and second target light are obtained by decomposing the emergent linearly polarized light on the basis of the first polarization beam splitter, wherein the amplitude of the first target light is the product of the amplitude of the emergent linearly polarized light and the cosine of a third included angle, the amplitude of the second target light is the product of the amplitude of the emergent linearly polarized light and the sine of a third included angle, and the third included angle is the included angle between the light vector ofthe emergent linearly polarized light and the first target light. According to the light segmentation method, the problem that the light loss or insecurity is caused by an adopted passive shielding mode due to the fact that light path output light energy is inconsistent and can not flexibly control the independent switches of a plurality light paths due to the fact that a film layer of a light splitter is difficult to achieve standard proportion light splitting in the prior art is solved.

Owner:SHANGHAI PRECISION MEASUREMENT SEMICON TECH INC

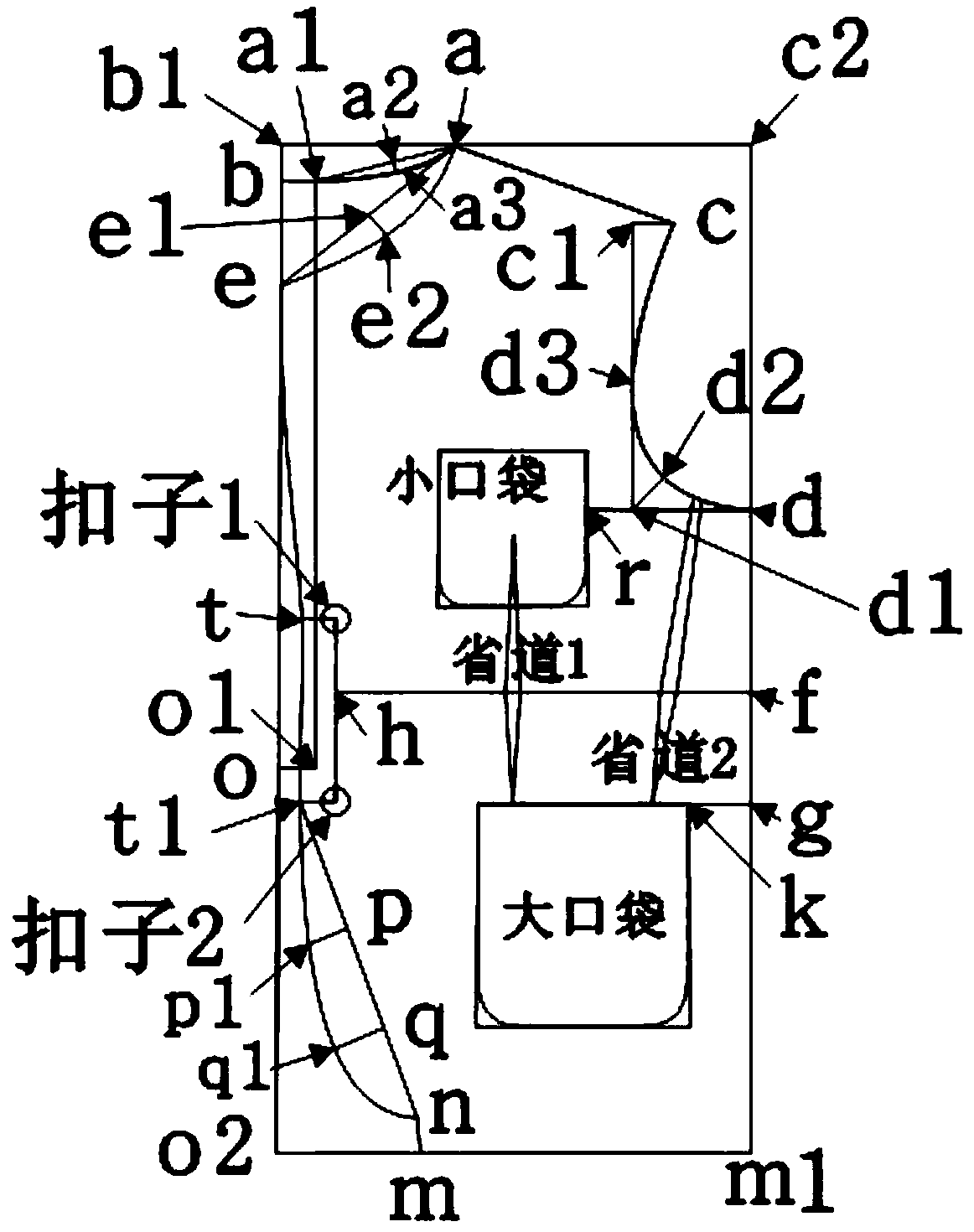

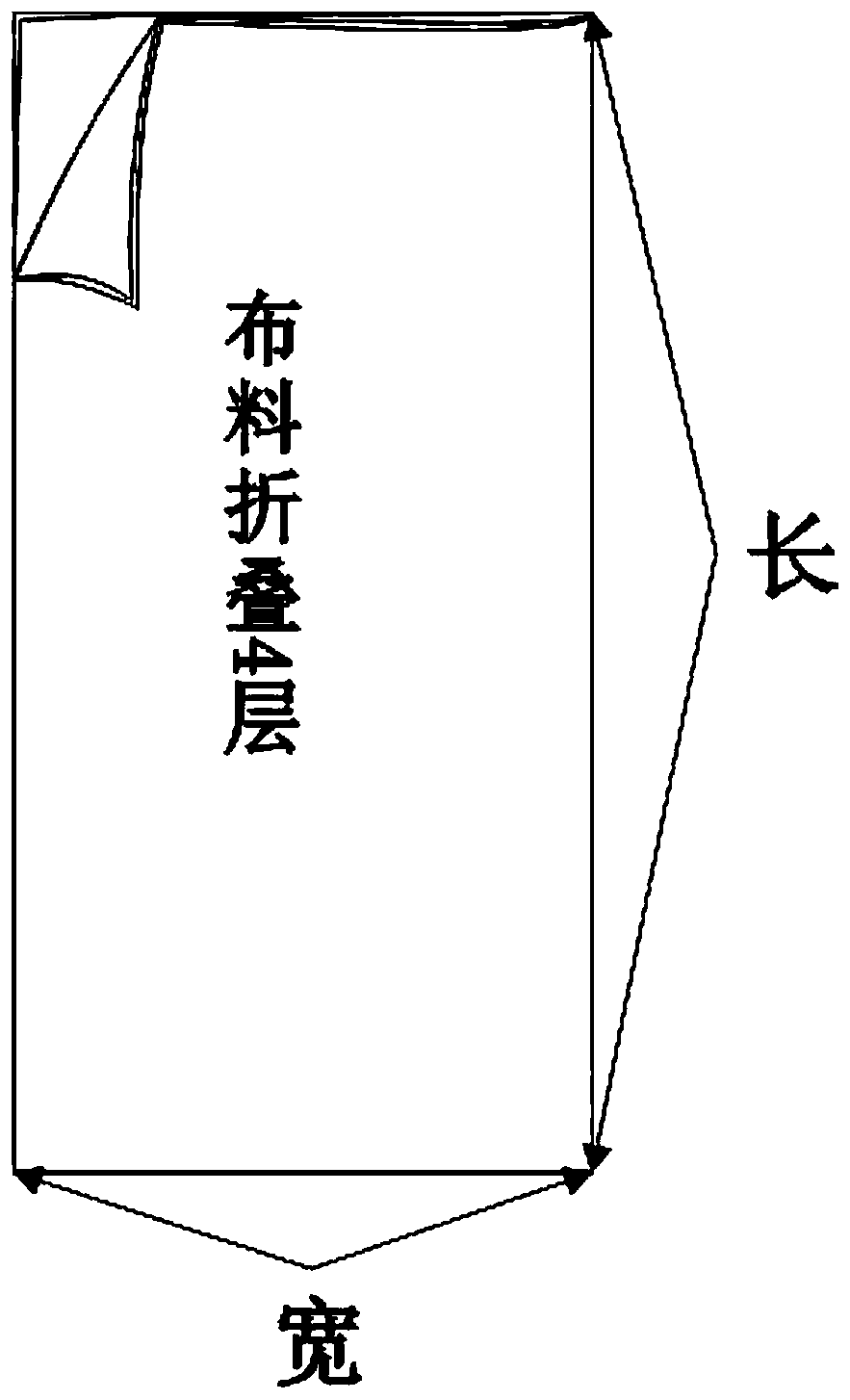

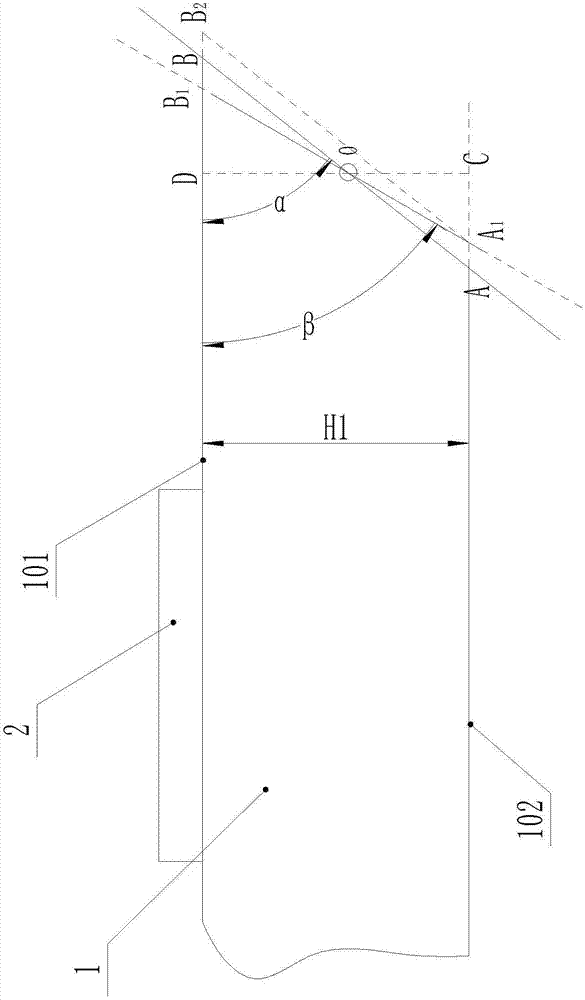

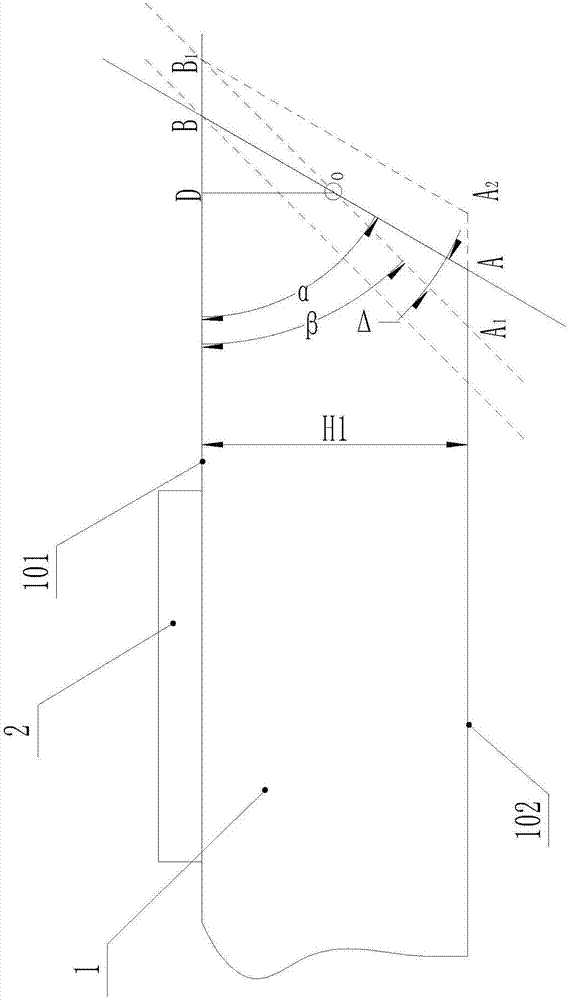

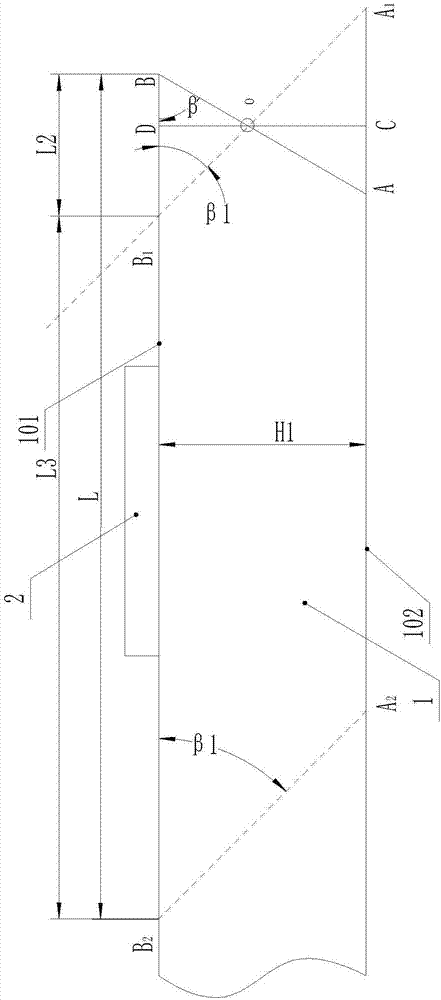

Folding type raw-seam cutting method for body pieces of children western suits

ActiveCN110013059ASolve matching problemsSolve the proportional relationshipJacketsFront neckEngineering

The invention provides a folding type raw-seam cutting method for body pieces of children western suits. The method comprises front body piece cutting and rear body piece cutting. The front body piececutting and rear body piece cutting are both carried out on folded four layers of cloth, shoulders, armholes, side seams and bottom edges of the body pieces are shared structures of the front and rear body pieces of the western suits, and the front and rear body pieces of the western suits adopt the piling-cutting drawing method. The cutting process of the body pieces of the western suits comprises an armhole and shoulder co-cutting method, a rear neck and back co-cutting method, a front neck and lapel round hem co-cutting method, a bottom edge and side beam separate-cutting method. The folding cutting for the body pieces of the children western suits comprises the cutting for the western suits of children who are 4-13 years old, totally, the cutting of 7 sizes is set. The method has twoadvantages, one, the cloth folding piling-cutting drawing method is used for rapidly drawing the body piece structures of the western suits, thus errors are reduced, second, four major cutting steps are used for completing the raw-seam cutting of the body pieces, compared with the traditional cutting method adopting 12 steps, the method provided by the invention has the advantage that 8 steps arereduced, and thus the cutting efficiency is improved.

Owner:XIJING UNIV

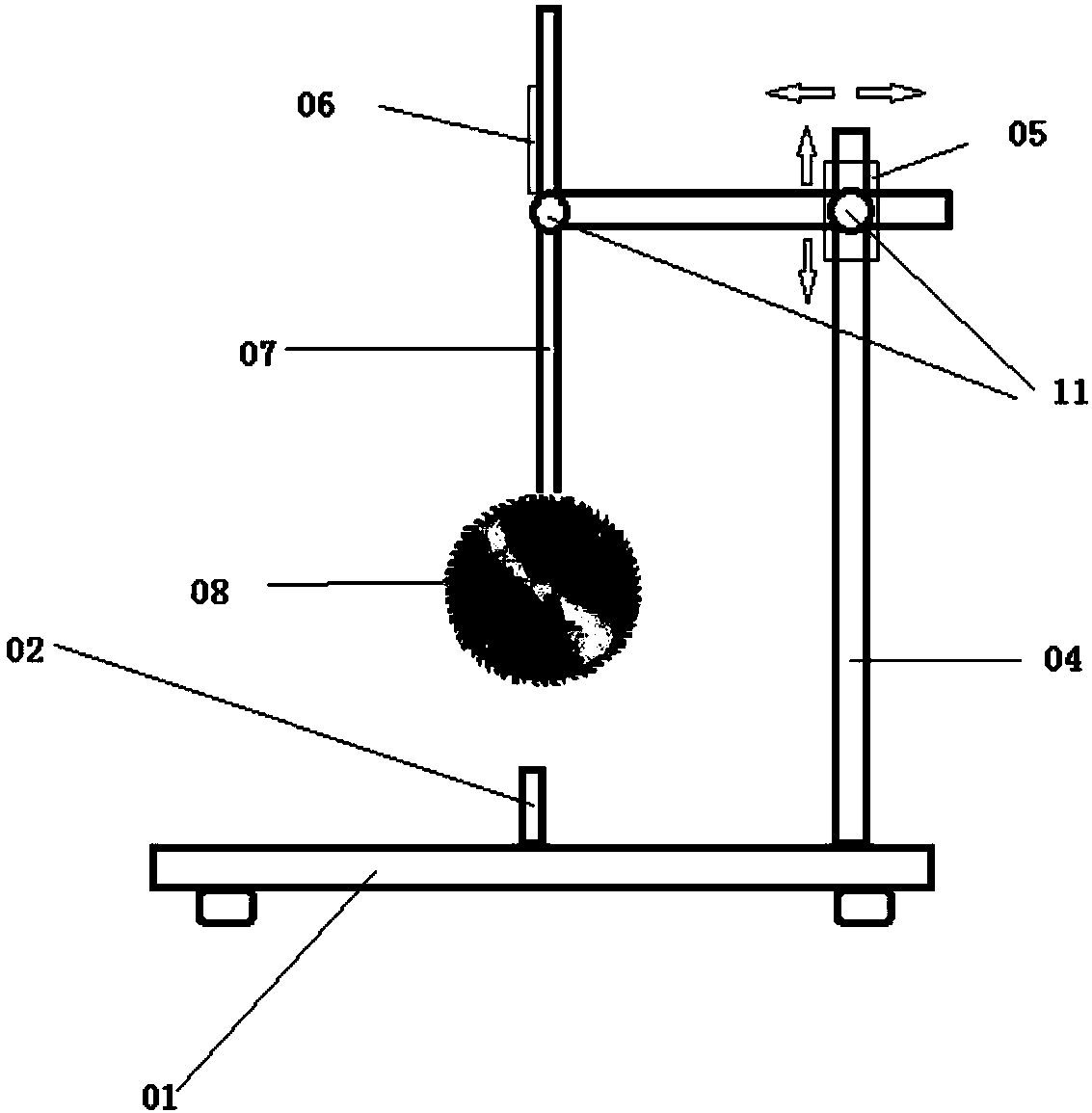

Saw cutting method of square pipe saw cutting machine

ActiveCN107052446AIncrease profitReduce manufacturing costMetal sawing devicesControl systemCutting-plane method

The invention discloses a saw cutting method of a square pipe saw cutting machine. The saw cutting method includes the following steps that firstly, a task list of a list form is input in a control system of the saw cutting machine, wherein the task list includes a production piece task list, and the production piece task list comprises end portion angles and lengths of the two ends of each production piece and the length and width size information of square pipes; secondly, the control system reads and analyzes all parameters of the production pieces in the production piece task list and conducts simulation cutting, wherein according to the principle of analysis, the angles are analyzed before the lengths; thirdly, various simulation cutting sequences are achieved after analysis and simulation are completed, and the primary optimal simulation cutting sequence with the highest square pipe utilization rate is selected; and fourthly, the raw material square pipes are subjected to saw cutting through the square pipe saw cutting machine according to the primary optimal simulation cutting sequence. The saw cutting method is suitable for cutting of the various square pipes of different specifications at the same time, the utilization rate of each raw material square pipe is increased, the after-product length is decreased, and therefore cost is reduced.

Owner:苏州斯马拓智能化装备有限公司

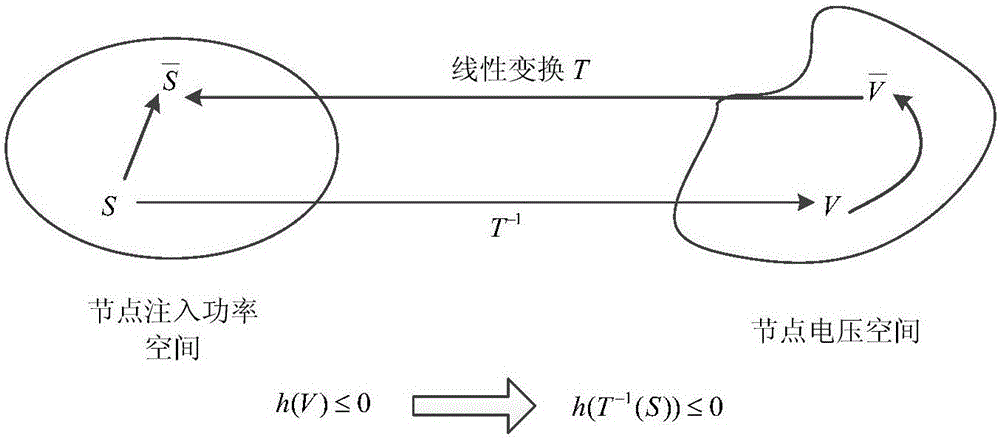

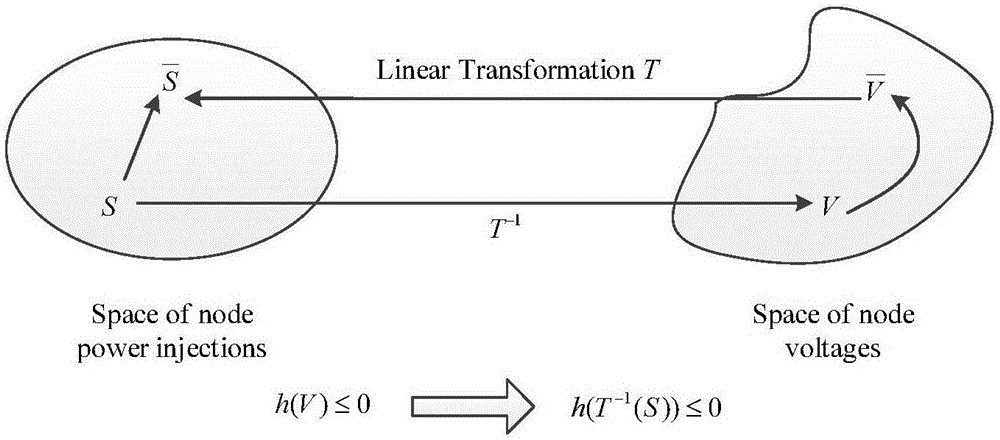

Self-adaption robust reactive power optimization method for active power distribution network

ActiveCN106849119AMeet safety requirementsGuaranteed uptimeReactive power adjustment/elimination/compensationReactive power compensationVoltage vectorTidal Model

The invention discloses a self-adaption robust reactive power optimization method for an active power distribution network. The method comprises the following steps that on the basis of a traditional tidal model, a similar linear tidal model is constructed, a similar mapping relation between a node injection power vector a node voltage vector is obtained, and then a decision variable feasible region of power distribution network reactive power optimization is obtained; on the basis of the robust optimization theory, a self-adaption function between the best decision and the uncertain variable is constructed, and then the self-adaption robust reactive optimization model is constructed; on the basis of the self-adaption robust reactive optimization model, a solution strategy of a cutting plane method is put forward, an original question is decomposed into two sub-questions, and the solution of the original question is obtained through alternate iteration of the two sub-questions. According to the method, the robust optimization thought is introduced, the solution strategy of the cutting plane method is put forward, efficient and rapid solution is achieved, and economical, safe and efficient operation of the active power distribution network under the uncertain condition is ensured.

Owner:SOUTHEAST UNIV

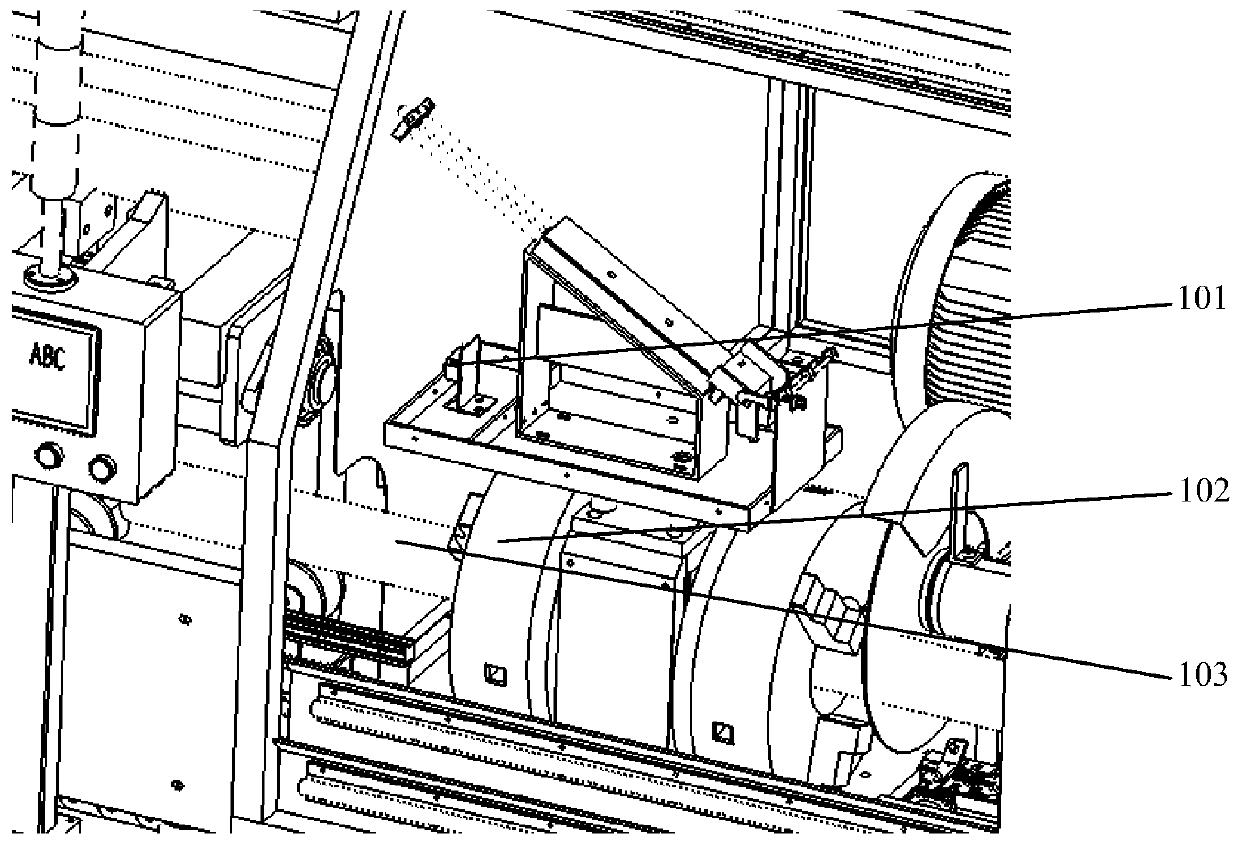

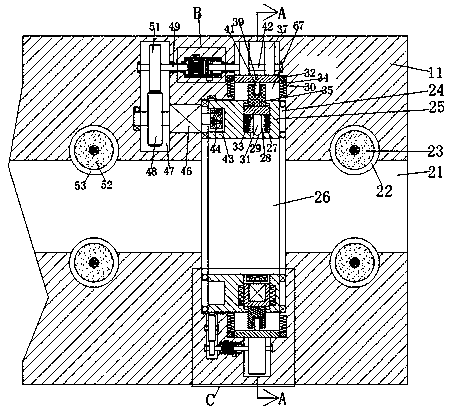

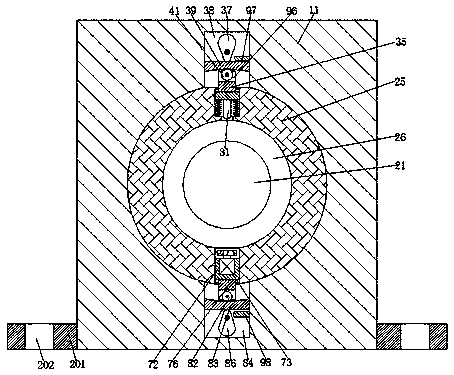

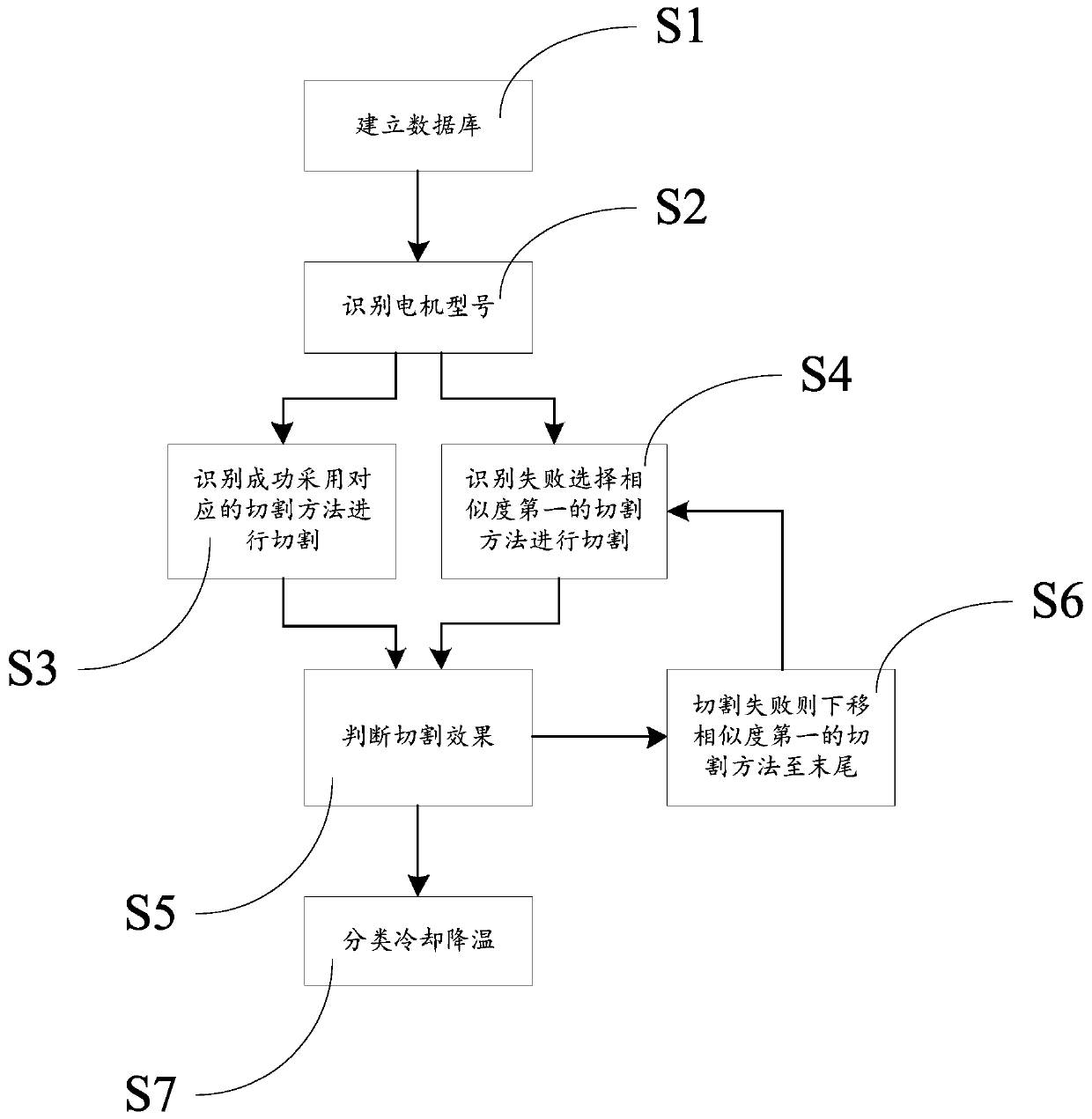

Intelligent cutting method of scrapped motor

ActiveCN110404923AImprove cutting efficiencyReduce labor intensitySolid waste disposalManufacturing dynamo-electric machinesEngineeringCutting-plane method

The embodiment of the invention discloses an intelligent cutting method of a scrapped motor. The intelligent cutting method comprises the following steps that S1, a database corresponding to the modelof the scrapped motor and the cutting method is established; S2, the model of the scrapped motor is identified according to the appearance of the scrapped motor, the step 3 is successfully entered, and if identifying is failed, the step 4 is entered; S3, the cutting method is acquired according to the model of the scrapped motor, the cutting machine is guided to cut, and the step 5 is entered; S4, sorting is carried out in the database according to the sequence from high to low of the appearance similarity of the scrapped motor, the cutting method corresponding to the model of the motor arranged at the first position is selected, the cutting machine is guided to cut, and the step 5 is entered; S5, whether cutting is successful or not is judged according to the appearance of the scrapped motor; and S6, the motor arranged in the first position is moved to the last position in the database for the motor which is failed in cutting. According to the method, automatic cutting can be adopted, so that the cutting efficiency is improved, the labor intensity is reduced, meanwhile, data can be continuously accumulated in the cutting process, and the cutting method is optimized.

Owner:河南格林循环电子废弃物处置有限公司 +1

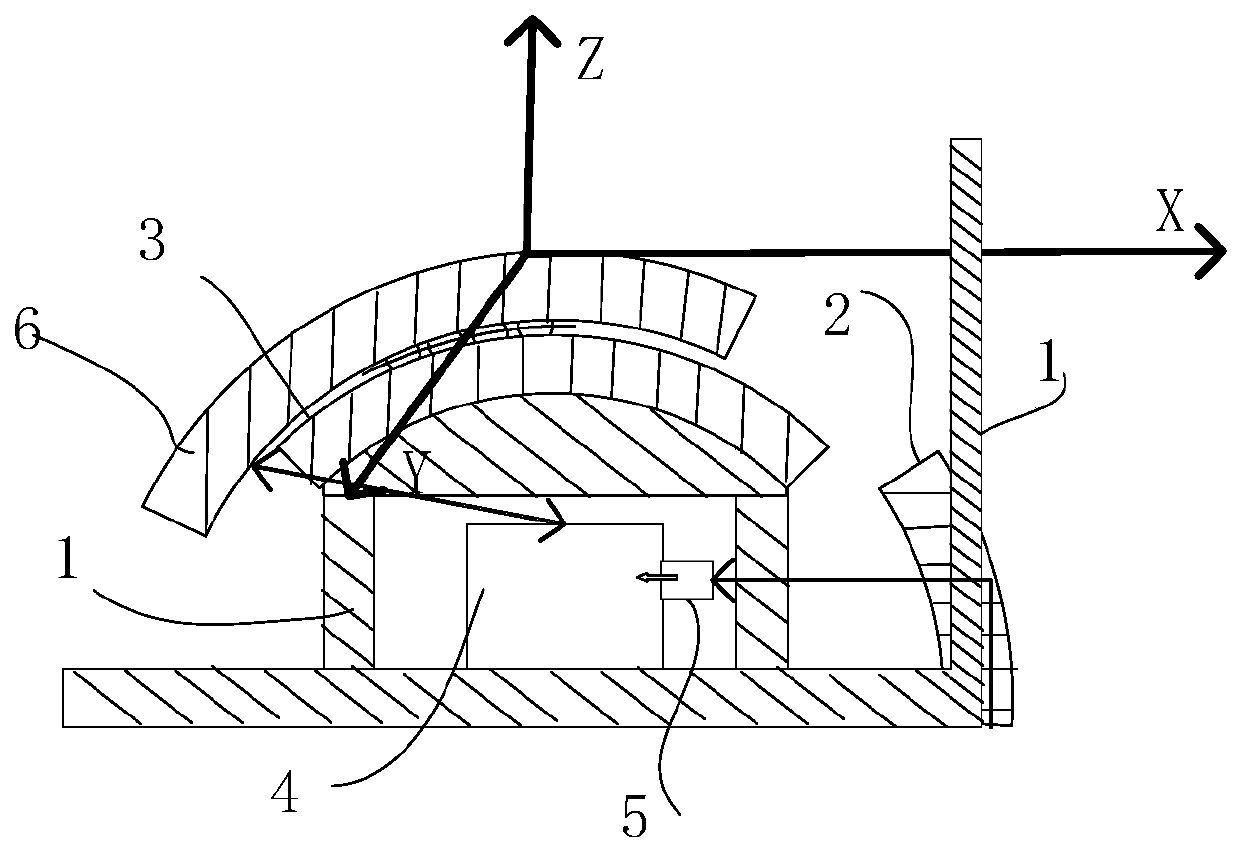

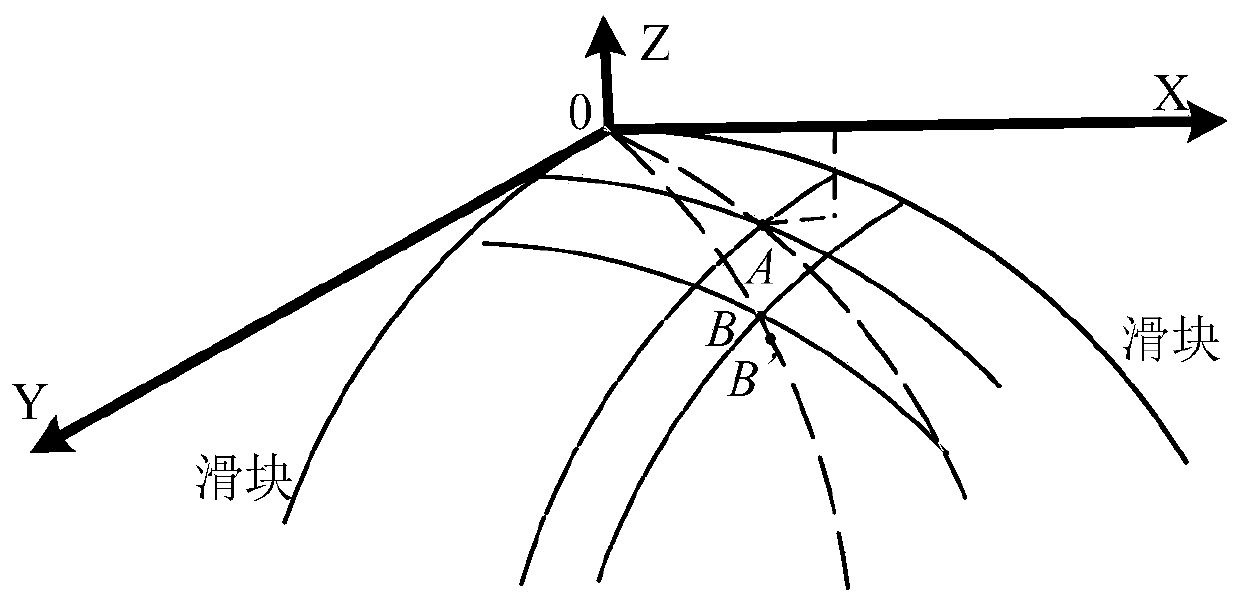

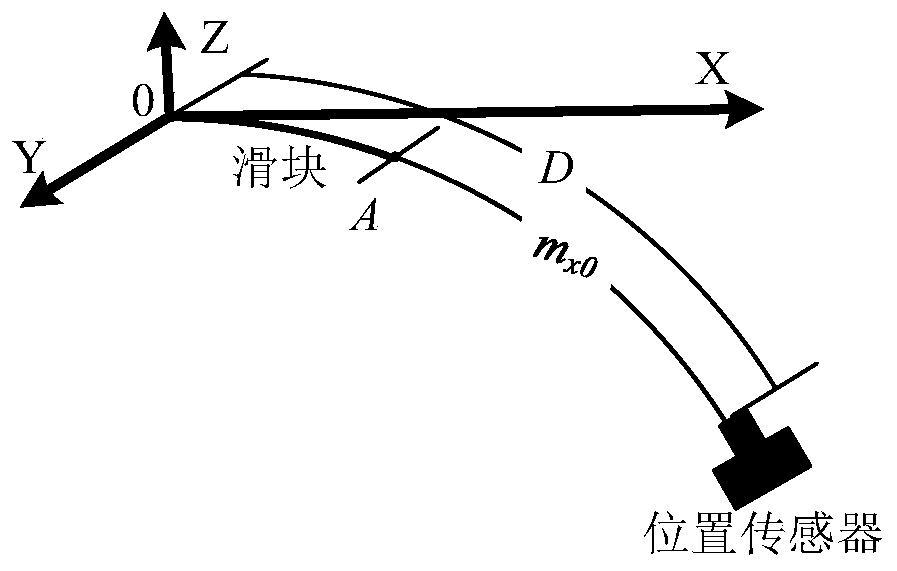

Detection device of curve-surface mobile platform, working method of detection device and cutting method

The invention provides a detection device of a curve-surface mobile platform, a working method of the detection device and a cutting method. The curve-surface mobile platform comprises a curve-surface guide rail, a sliding block, a driving unit, a position sensing unit, a calculation unit and an analysis unit, wherein the driving unit is used for driving the sliding block to move on a curve-surface guide rail, the position sensing unit is used for detecting a position parameter of the sliding block on the curve-surface guide rail and sending the position parameter to the calculation unit, the calculation unit is used for acquiring an ideal position and an actual position of the sliding block according to the parameter and the received position parameter of the mobile platform, and the analysis unit is used for analyzing moving deviation of the sliding block according to the difference between the ideal position and the actual position.

Owner:NINGBO UNIV +2

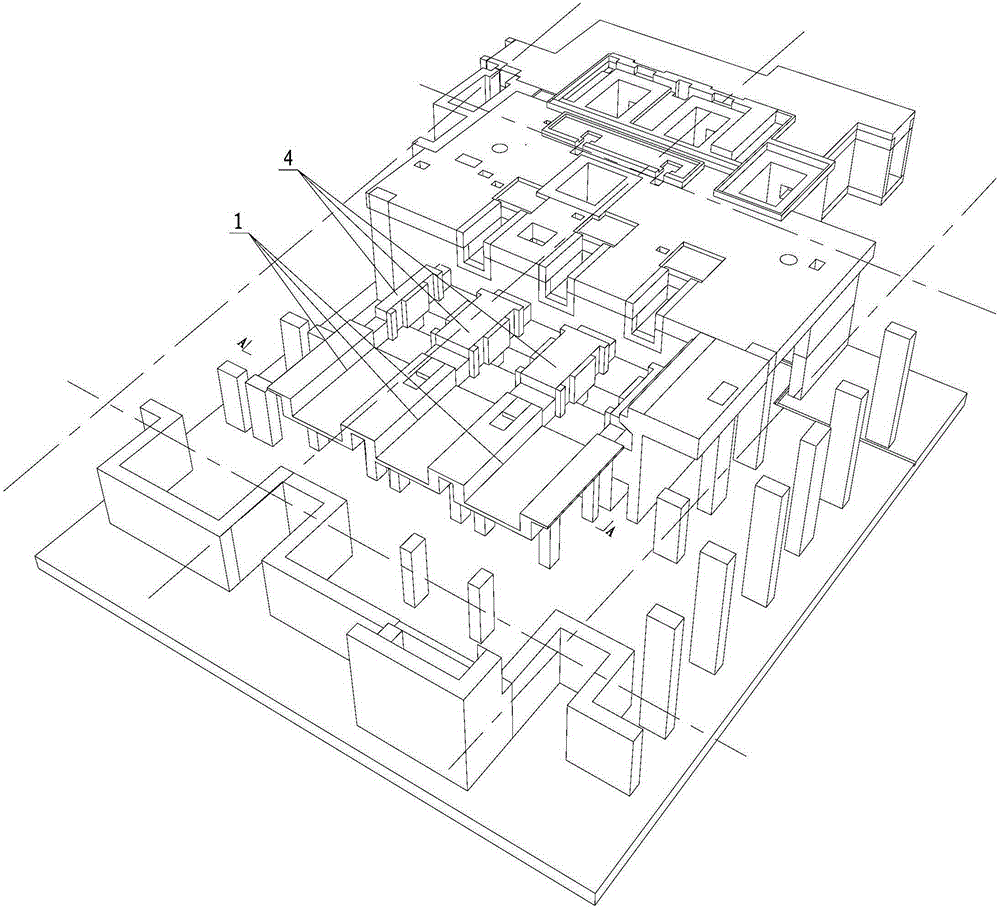

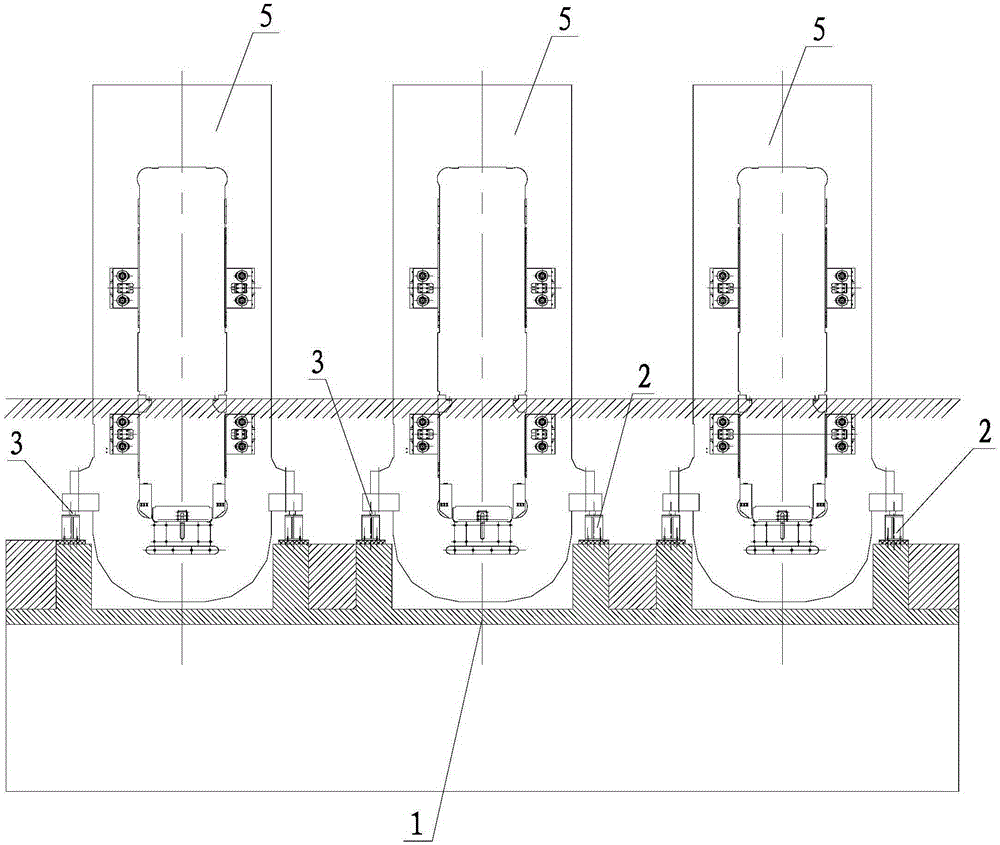

An online installation method of rolling mill in existing rolling line

ActiveCN103469813BMeet the requirements for online installationSimple structureMetal rolling stand detailsFoundation engineeringCutting-plane methodUnderground space

The invention discloses an online mounting method for mills on existing rolling lines and belongs to the technical field of metallurgical production equipment mounting. According to the method, the construction cost is low, the efficiency is high, and mounting and operation are convenient. The method comprises dismantling online complex underground space concrete structures at positions on existing rolling lines, where mills are required to be added, through a dustless wire saw cutting method; planting reinforcement bars at positions of roll changing devices at dismantled positions, pouring bearing structures with the section in a concave structure, and mounting steel beams and push rails on the bearing structures; assembling newly added mills on the push rails, and pushing the push rails onto mill foundations.

Owner:CHINA 19TH METALLURGICAL CORP

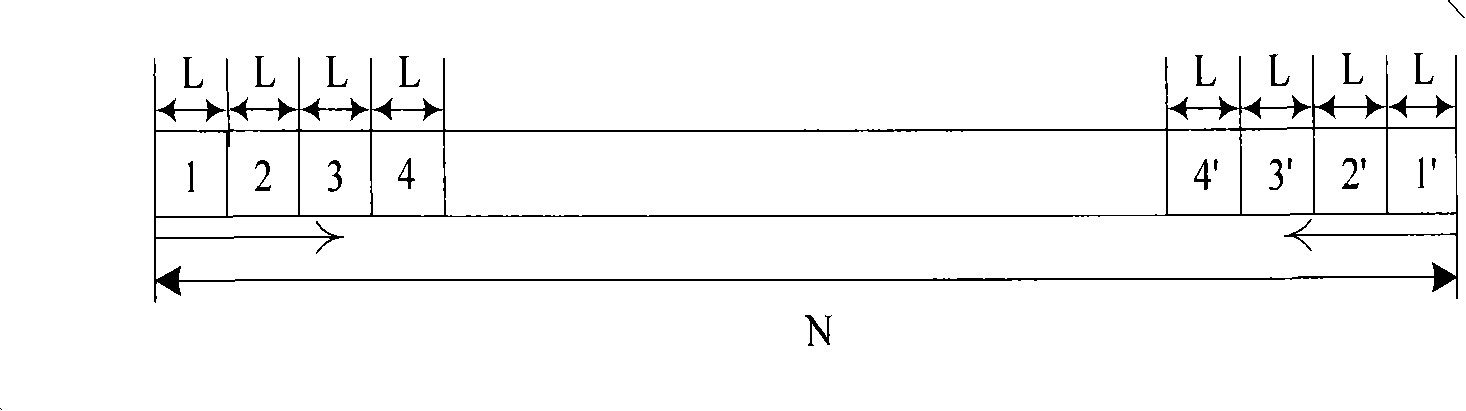

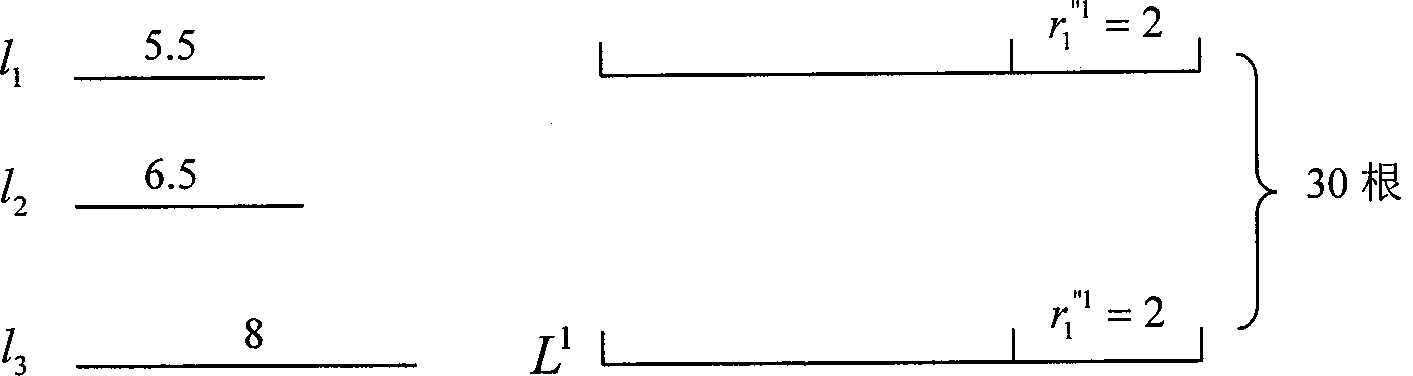

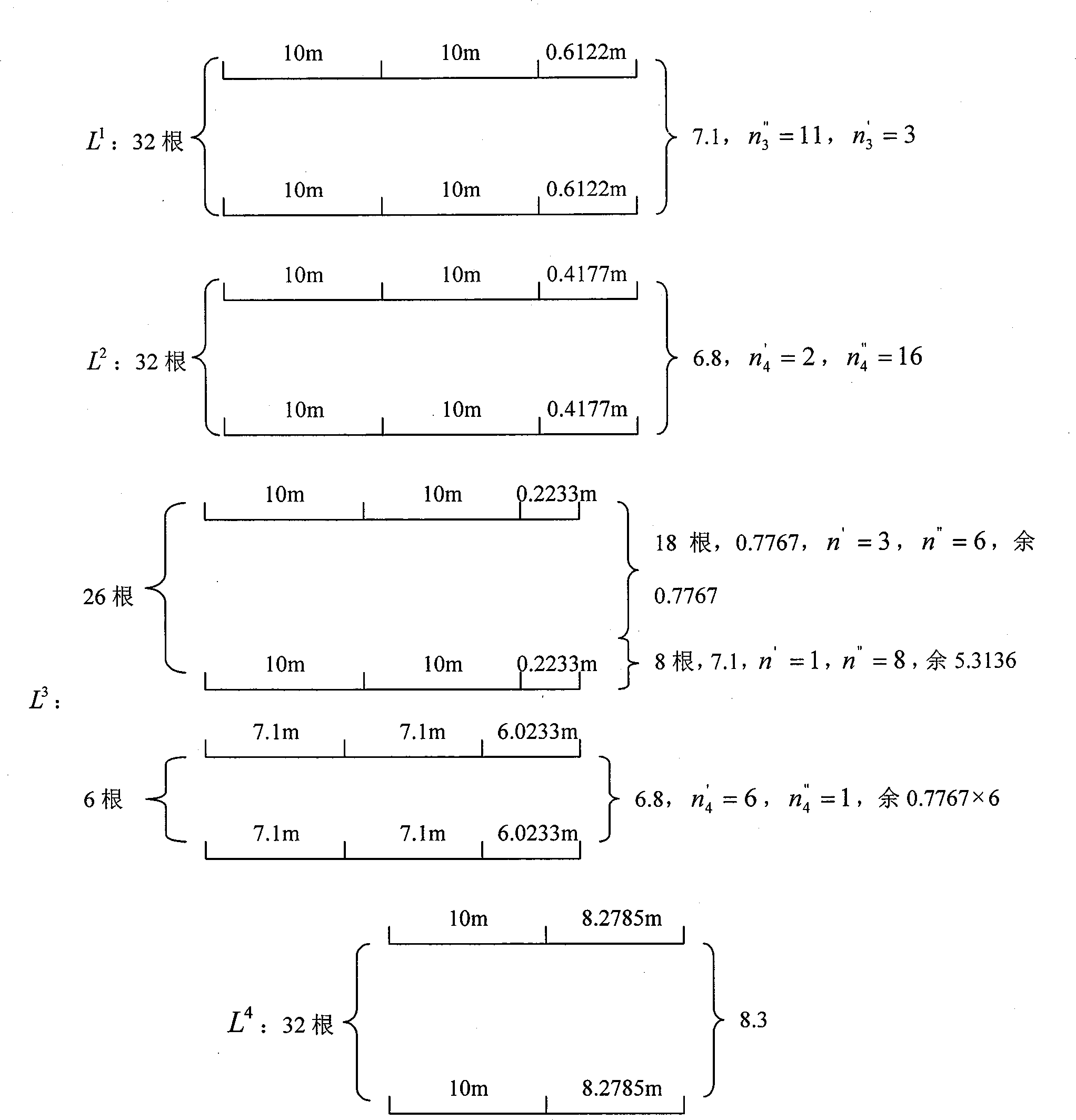

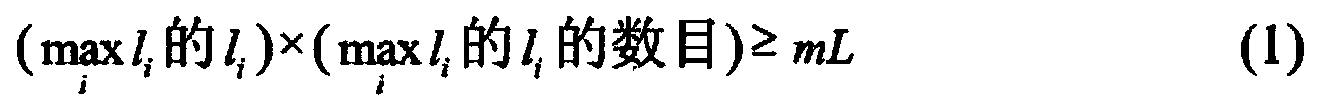

Raw material-saving one-dimensional stock-cutting method

InactiveCN101739606BReduce manufacturing costSave resourcesResourcesSpecial data processing applicationsProcess engineeringCutting-plane method

The invention relates to a raw material-saving one-dimensional stock-cutting method. The method can work out the optimum solution of one-dimensional stock-cutting problems in an environment with uncertain constraint conditions so as to improve the utilization ratio of raw materials to the utmost extent, and reduce the production of waste materials. The method comprises the following steps: firstly, splicing an uncut raw material into m result pipes with the length of L, wherein the length of the rest part of the result pipes is shorter than the that of the raw material; secondly, cutting the raw material by adopting the optimum cutting method, and splicing the rest part of the result pipes by using the cut raw material; and finally, checking whether the constraint condition 1 is satisfied, if the constraint condition 1 is not satisfied, performing appropriate readjustments. By adopting an idea of nonnumeric calculation, the raw material-saving one-dimensional stock-cutting method can be used for solving the one-dimensional stock-cutting problems under the condition with a plurality of constraint conditions comprising the uncertain constraint conditions, the optimum cutting and splicing method is selected through skillful comparisons, and the optimum solution is worked out, so the maximum utilization of the raw material is realized.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

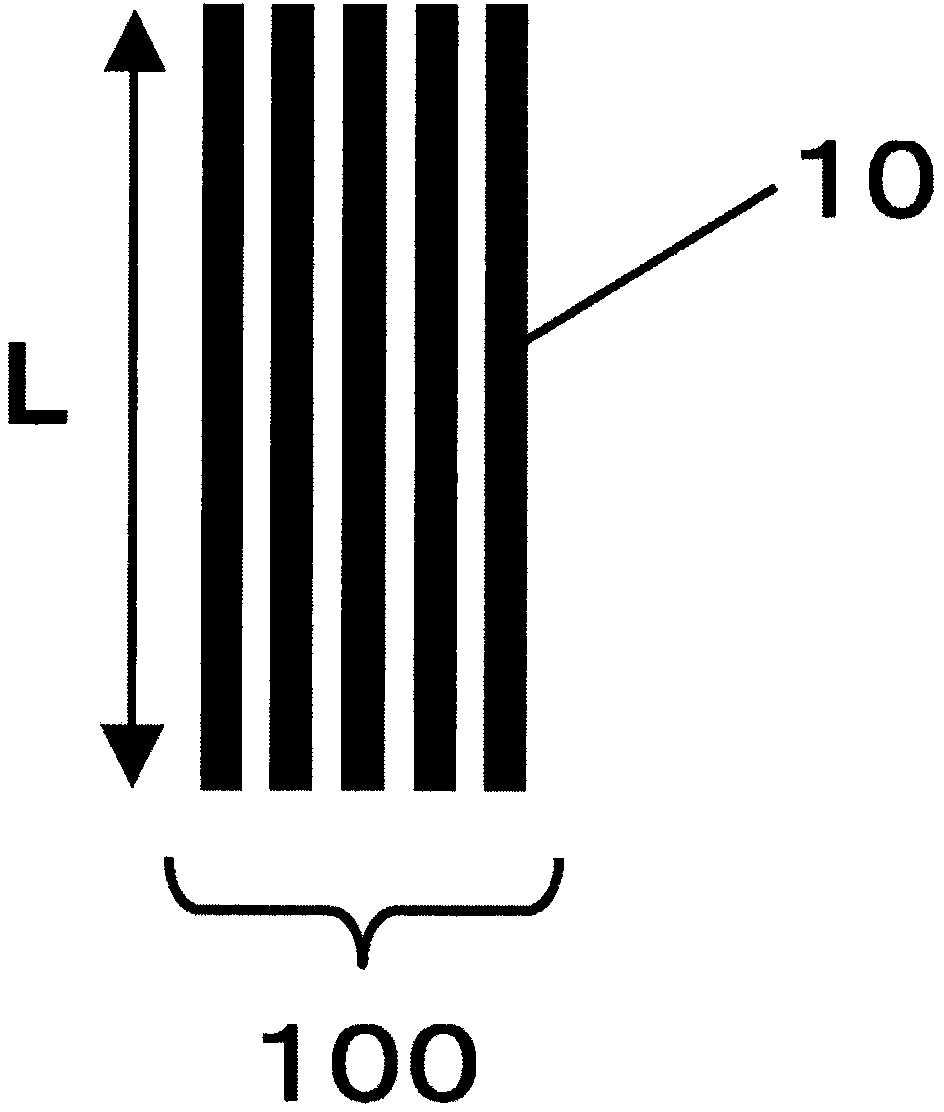

Droplet cutting method and droplet cross-section analysis method

InactiveCN104412094AElectric discharge tubesWithdrawing sample devicesCarbon nanotubeCutting-plane method

Owner:NITTO DENKO CORP

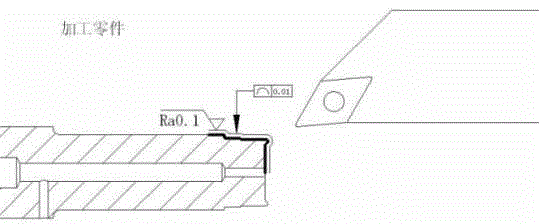

Quenched steel part dry state and wet state coordinated cutting method

InactiveCN104128618AImprove machining accuracyImprove surface roughnessEngineeringCutting-plane method

The invention discloses a quenched steel part dry state and wet state coordinated cutting method. The method includes the steps that firstly, a numerically controlled lathe system machining program is compiled; secondly, the specification of a blade and the type of a tool bar are determined, and cutting parameters and the lane tip zero compensation amount are input in a tool setting mode; thirdly, tempered three jaws are utilized to clamp a workpiece; fourthly, a part is roughly turned and the allowance is left in a single side, wherein cutting liquid is not used in the machining process; fifthly, the part is machined in a semi-finish mode, and the allowance is formed, wherein the cutting liquid is not used in the machining process; sixthly, the cooling liquid is started to be sprayed on a lathe tool bit, and the external diameter and the end face are machined in place together. According to the quenched steel part dry state and wet state coordinated cutting method, the defects in the prior art are overcome, the rejection rate of parts are effectively reduced, the machining difficulty of the parts is lowered, and staff efficiency is improved.

Owner:JOUDER PRECISION INDAL KUSN

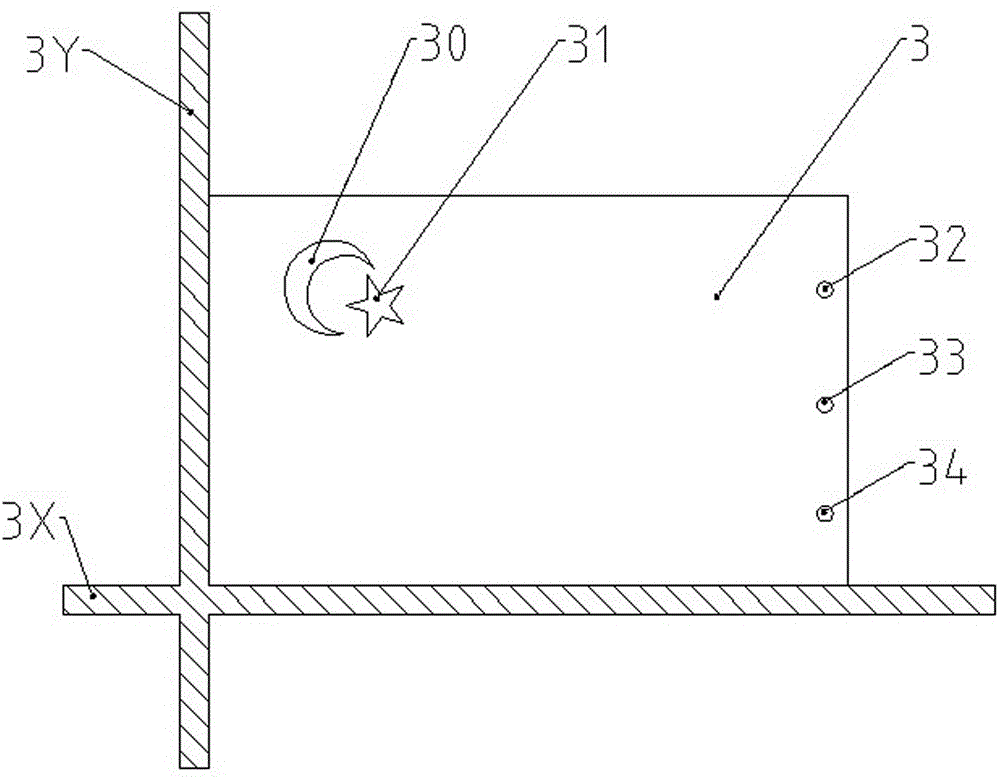

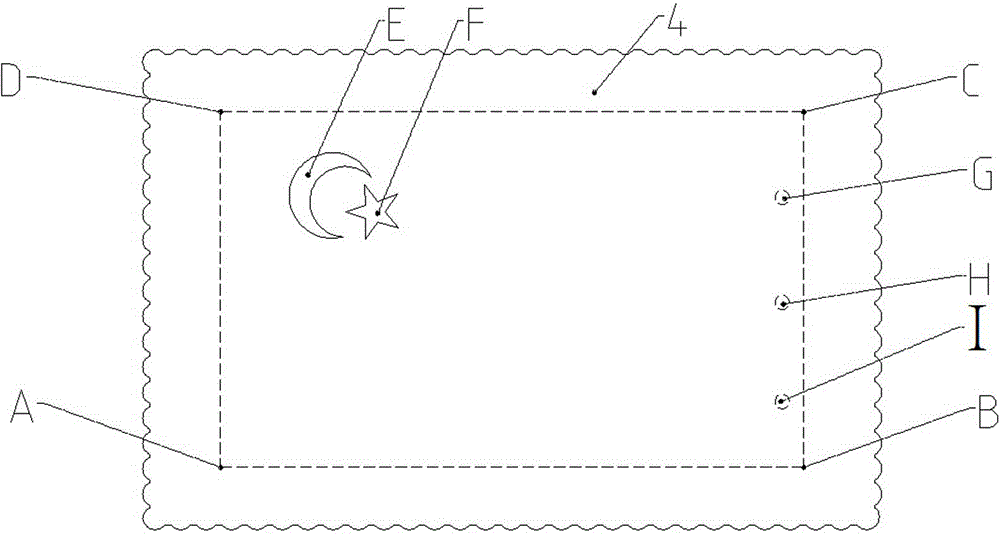

Flag textile cutting special tool and cutting method

ActiveCN104862944AImprove positioning accuracyPrecise processingSevering textilesNumerical controlGrating

The invention provides a flag textile cutting special tool and a cutting method, digital cutting can be carried out on printed grey cloths according to design drawing, machining accuracy is high, the reject rate is low, and labor and time are saved. A grating plate with scale marks is fixed on a deck plate of a numerical control cutting machine, the tool further comprises a flag sample plate made of transparent materials, and at least one pattern marking strip is marked on the flag sample plate. The cutting method comprises the steps of drawing CAD drawing of the flag, fixing the grating plate, fixing a flag grey cloth according to the grating plate and the flag sample plate, carrying out initialization on numerical control cutting machine, and starting the numerical control cutting machine to carry out flag cutting.

Owner:ANHUI HUAMAO TEXTILE

Seamless pipe fitting cutting process for towing head device

The invention discloses a seamless pipe fitting cutting process for a towing head device. The seamless pipe fitting cutting process for the towing head device is realized by the following steps of: blanking an entire seamless steel pipe according to a dipped finish size needed by a seamless pipe fitting during practical use; selectively processing a seamless pipe fitting of a corresponding size according to the length of the reset of the seamless steel pipe; and blanking according to the dipped finish size. Through repeated calculation and improvements, angular cut blanking is performed by using a cutting method, so that the utilization ratio of the seamless pipe is increased, and the product cost is lowered.

Owner:天津迎新船舶机械有限公司

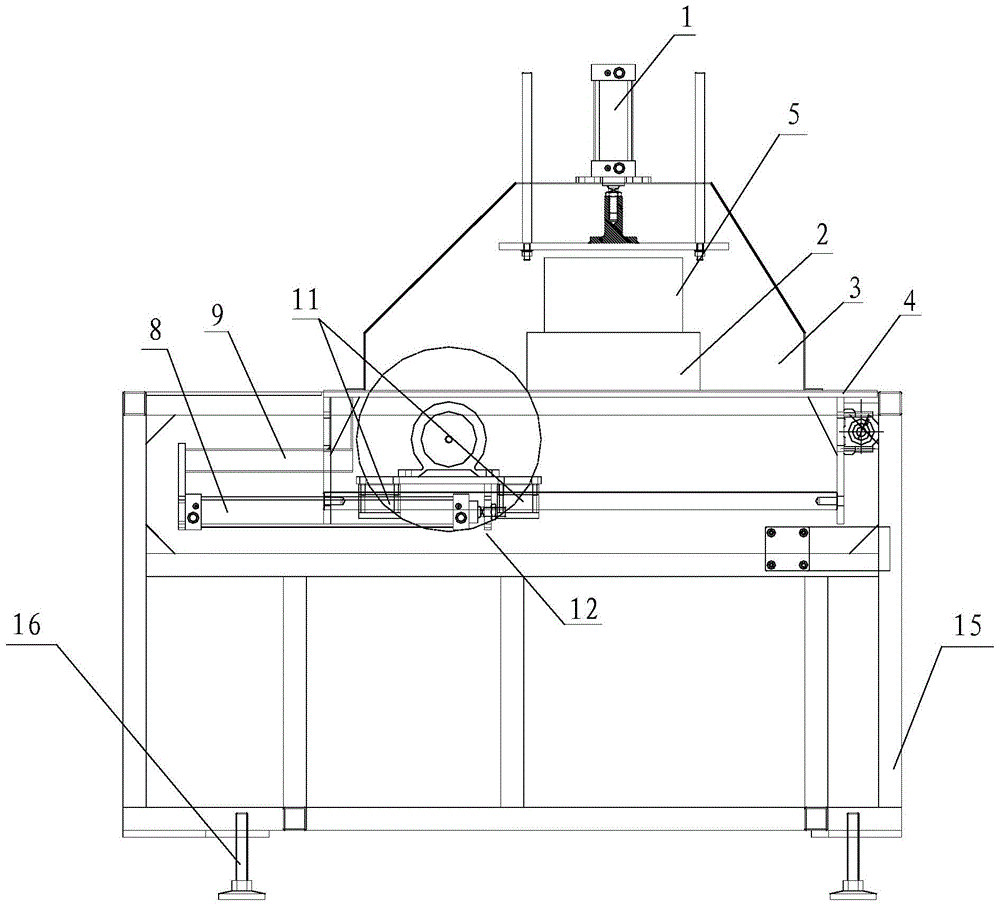

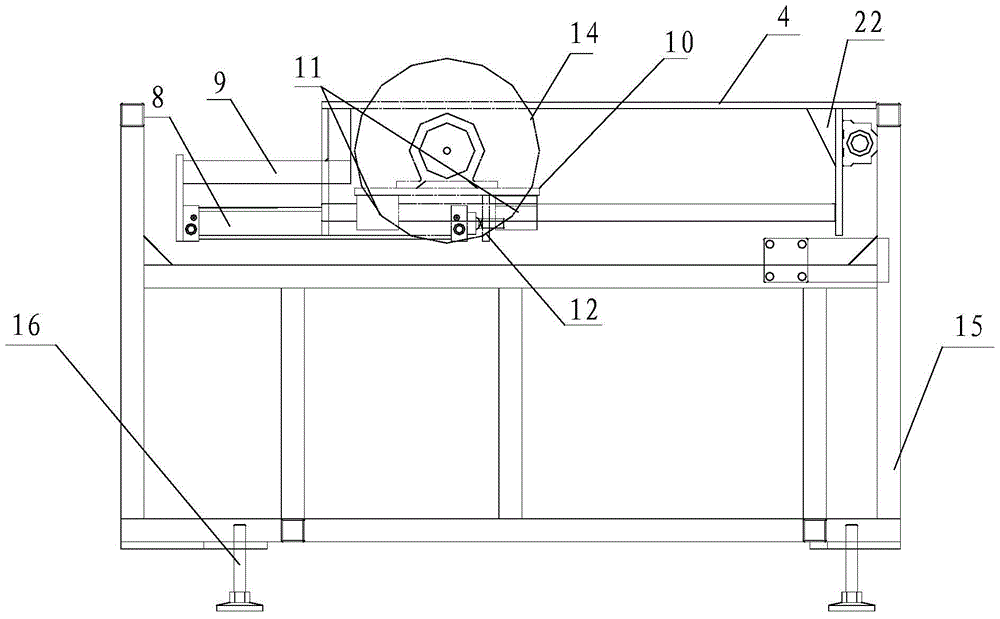

Automatic cutting machine and cutting method for nylon heat insulation strip production line

ActiveCN103612273BSimple structureCompact and reasonable structureMetal working apparatusProduction lineEngineering

The invention relates to automatic cutting machines and a cutting method for a nylon heat-insulation strip production line. The cutting method includes setting the two automatic cutting machines, starting motors, and enabling strip compressing cylinders to act to compress nylon heat-insulation strips; pushing the corresponding motor to one side of the corresponding nylon heat-insulation strip by the aid of a corresponding saw blade cylinder, and enabling saw blades mounted at ends of output shafts of the motors to be in contact with the nylon heat-insulation strips to cut the nylon heat-insulation strips; withdrawing the motors to original stations by the aid of the saw blade cylinders after the nylon heat-insulation strips are cut; enabling the strip compressing cylinders to act so as and withdrawing the strip compressing cylinders to original stations; pushing workbenches to act by the aid of front and rear cylinders and separating the cut heat-insulation strips from saw blade protective covers; pushing the workbenches to be lifted and turned by the aid of the front and rear cylinders and pouring the heat-insulation strips into storage hoppers. The two automatic cutting machines synchronously run under the control of a PLC (programmable logic control) panel. The automatic cutting machines and the cutting method have the advantages that strip compressing, rotation of the motors and feed cutting can be carried out step by step under the control of the PLC panel, and accordingly the automatic cutting machines are high in automation degree and can be precisely controlled; the two cutting machines are used with each other, a set quantity of heat-insulation strips with the set lengths can be automatically cut under the control of counting relays, so that different production requirements can be met.

Owner:WUHAN YUANFA NEW MATERIAL

Cyclobalanopsis gilva seedling cutting method

InactiveCN104686188AHigh rooting rateImprove survival rateCultivating equipmentsHorticultureCutting-plane methodZoology

The invention relates to plant breeding methods, in particular to a cyclobalanopsis gilva seedling cutting method. The method includes the following steps that a scion is collected, and the scion is made to be a cutting slip with the length being 8-10 cm, wherein three leaves on the top of the cutting slip are kept, and the 2 / 5 area of each leaf is reserved; an upper notch of the cutting slip is a flat opening, the scion is treated by hormones, the scion is placed in a plug tray in a cuttage mode, sufficient watering is conducted, a sunshade net is built over a cutting bed, the temperature is controlled to be 13-28 DEG C, the relative humidity is kept more than 80%, and water is sprayed once or twice or three times; carbendazim is sprayed weekly. According to the cyclobalanopsis gilva seedling cutting method, cuttage vegetative propagation is adopted, the good characteristic of a parent body can be kept, the rooting percentage of cyclobalanopsis gilva reaches up to 80.4%, the average root length is 3.52 cm, and the average rooting number is 5.55. The survival rate of good seedlings is increased on the premise that the production cycle is shortened, the breeding speed is high, the invested cost is low, operation is easy and convenient, the character is stable, and popularization and large-scale afforestation of the good cyclobalanopsis gilva seedlings can be facilitated.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

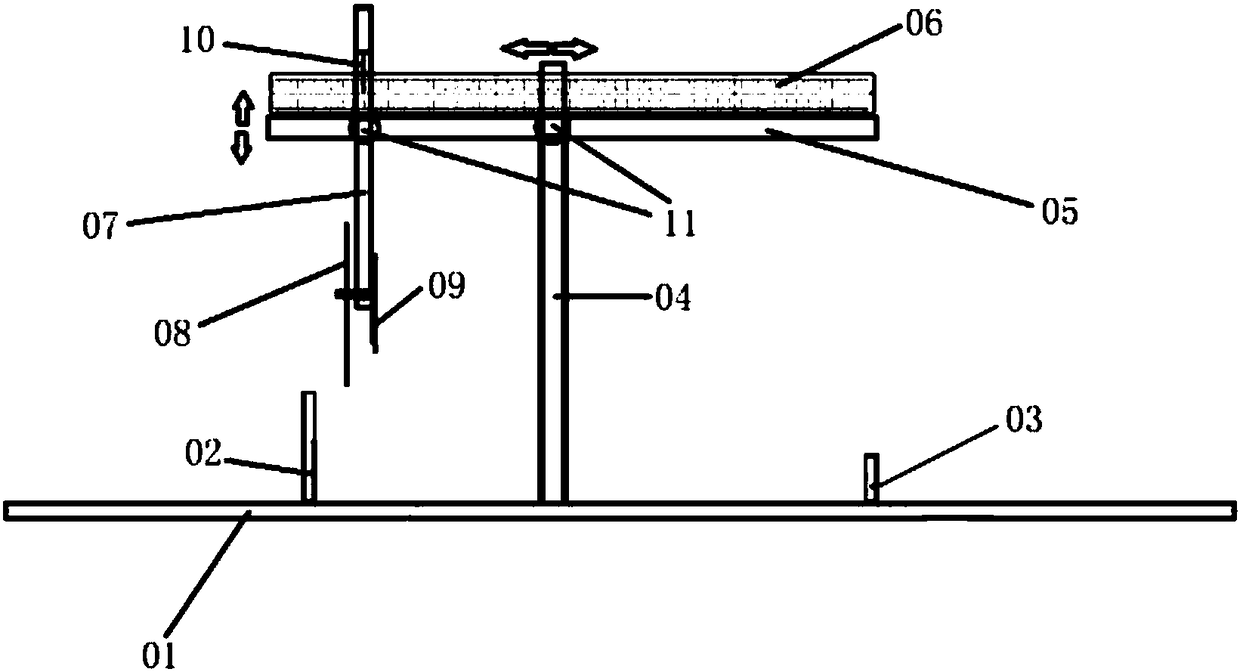

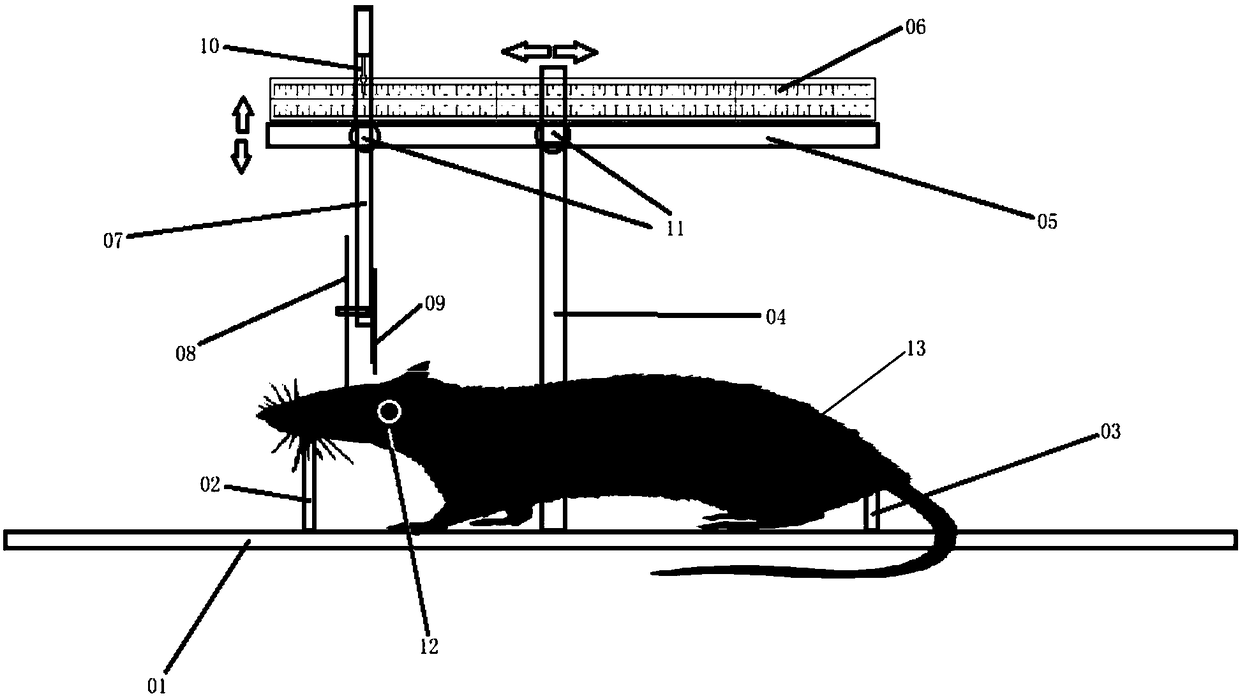

Central nerve fast precise cutting device and cutting method for experimental animal cadaver specimens

PendingCN109223236AEasy to fixAdd positioning functionAnimal fetteringSurgical veterinarySpinal columnFixation point

The present invention relates to the field of neuroanatomy and biological experiment, and discloses a central nerve fast precise cutting device and a cutting method for experimental animal cadaver specimens. The cutting device comprises a chassis, an incisor fixation point, a tail vertebra fixation point and two ear rods. A strut perpendicular to the chassis is also fixed on the chassis; A cross bar parallel to the chassis is fixed on the support; Fixing a positioning corresponding scale parallel to the cross bar on the cross bar and the strut; A vertical bar perpendicular to the chassis is movably fixed to the cross bar; The vertical bar can move up and down, back and forth and left and right relative to the chassis; The bottom end of the vertical bar is fixed with a cutting part and a positioning pin; The anterior fontanel or spinal column of the cadaver specimen was positioned by moving the vertical bar with the positioning needle. The cutting component is used for transverse cutting of the cadaver specimen perpendicular to the spinal column of the cadaver specimen after positioning is completed, and the cutting component is used for transverse cutting of the cadaver specimen perpendicular to the spinal column. The central nervous system is located precisely, and the cutting operation is quick, simple and labor-saving.

Owner:上海积发生物科技有限公司

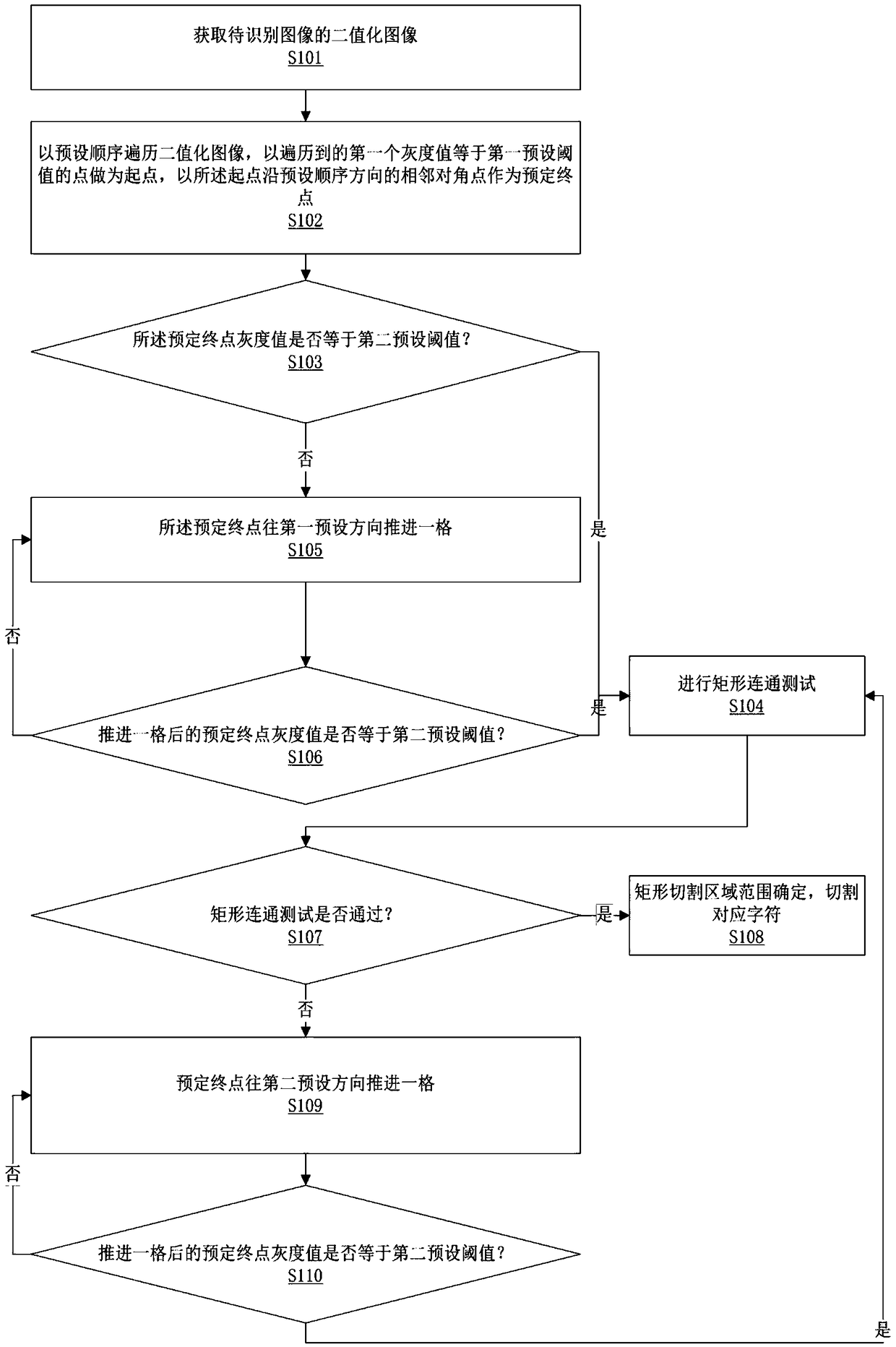

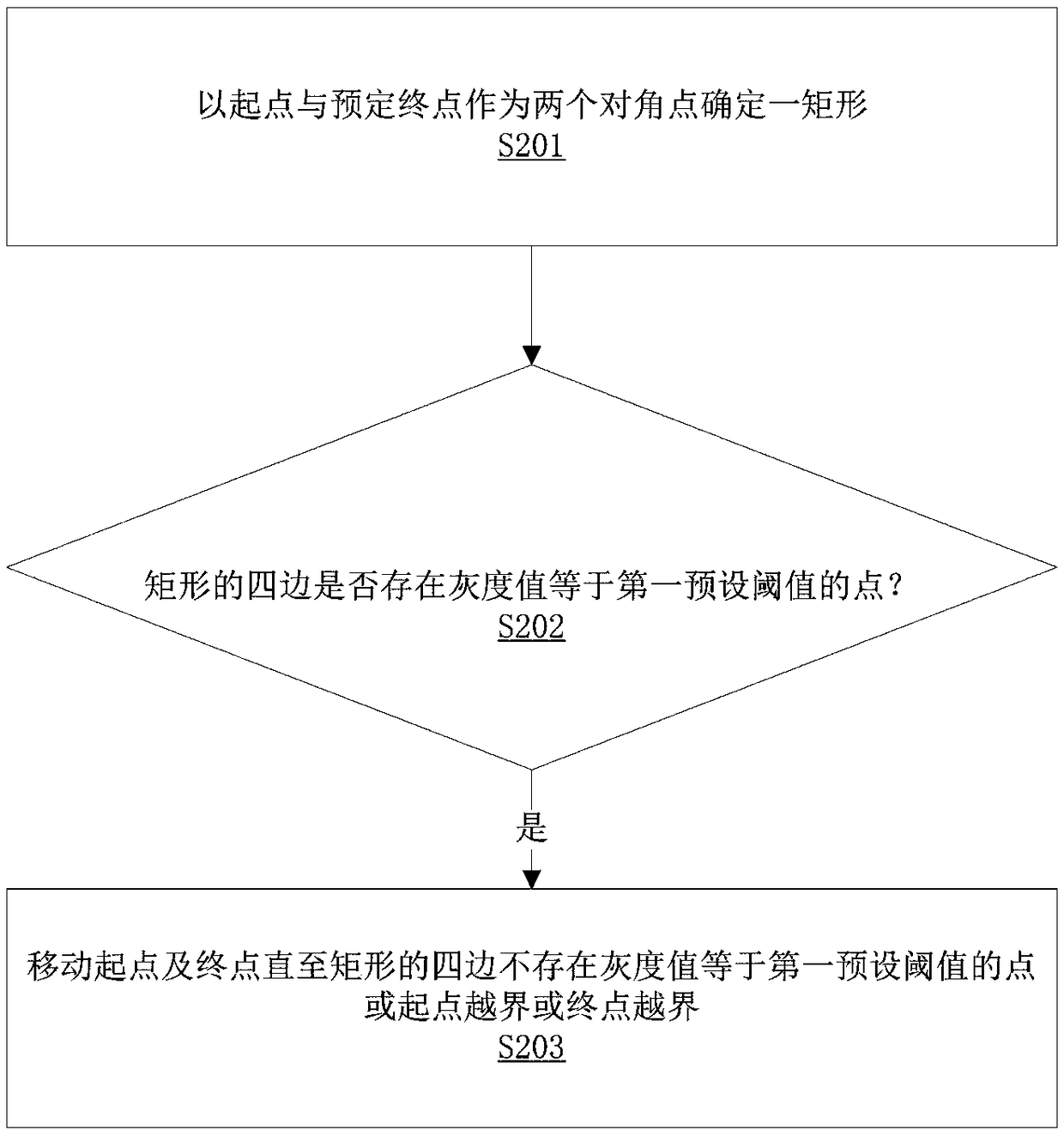

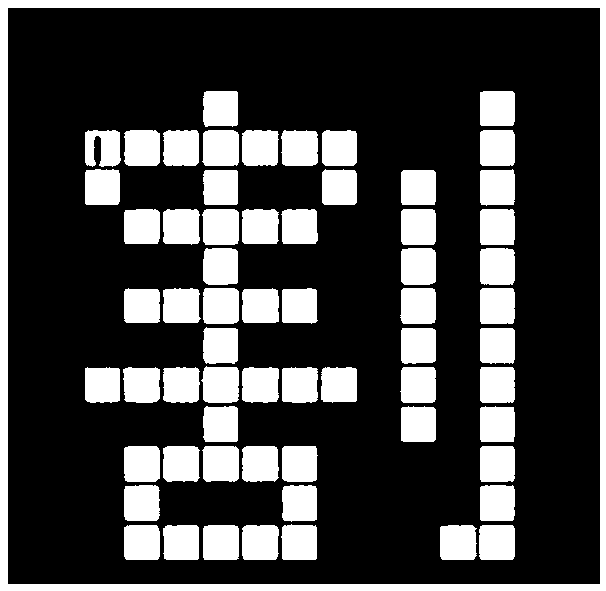

An image character recognition and cutting method and a storage device

ActiveCN109145916AQuick cutFor precise cuttingCharacter and pattern recognitionAlgorithmCutting-plane method

The invention relates to the field of image character recognition, in particular to an image character recognition cutting method and a storage device. The method comprises the steps of: obtaining a binary image of an image to be recognized; a binary image being traversed in a preset order, judging whether the gray value of the predetermined end point is equal to the second preset threshold valueby taking the traversed first gray value equal to the first preset threshold value as a starting point and taking the adjacent diagonal points along the preset sequence direction of the starting pointas a preset end point, and if the gray value of the predetermined end point is equal to the second preset threshold value, performing a rectangular connection test; if the rectangular connectivity test passes, the range of the rectangular cutting area being determined, and the corresponding character being cut. As the cutting method is adopted, even image text with disordered position and multiple lines of content and different sizes can be flexibly and effectively cut quickly and accurately, and a large number of repetitive search and positioning processes can be effectively reduced, and therectangular range can be quickly determined and the cutting can be carried out.

Owner:福建多多云科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com