Droplet cutting method and droplet cross-section analysis method

A technology of cutting method and analysis method, applied in the direction of analysis materials, preparation of test samples, instruments, etc., can solve problems such as unrealization and difficulty in cross-section exposure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

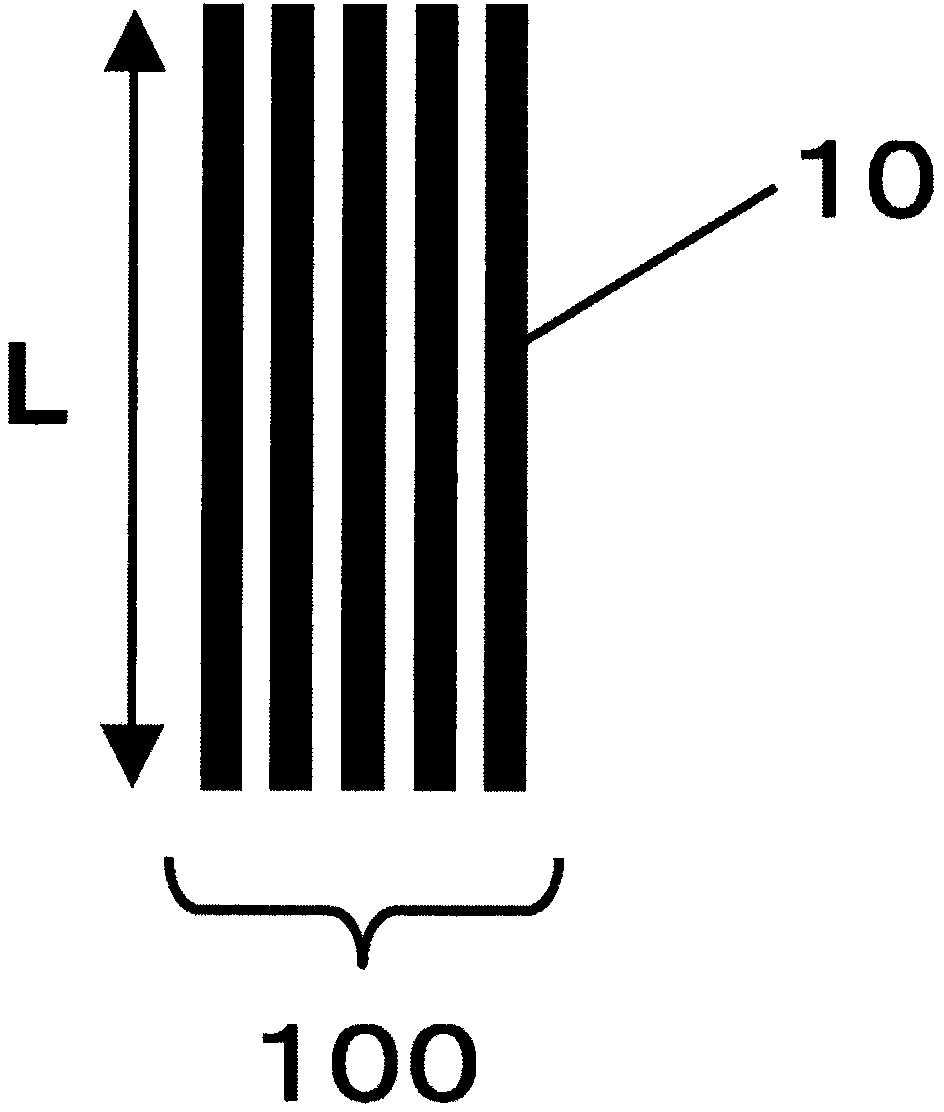

[0107] Using a sputtering device (manufactured by ULVAC, RFS-200), an Al thin film (thickness 5 nm) was formed on a silicon wafer (manufactured by Silicon Technology Co., Ltd.) as a substrate. A sputtering device (manufactured by ULVAC, RFS-200) was used to deposit an Fe thin film (thickness 0.35 nm) on the Al thin film.

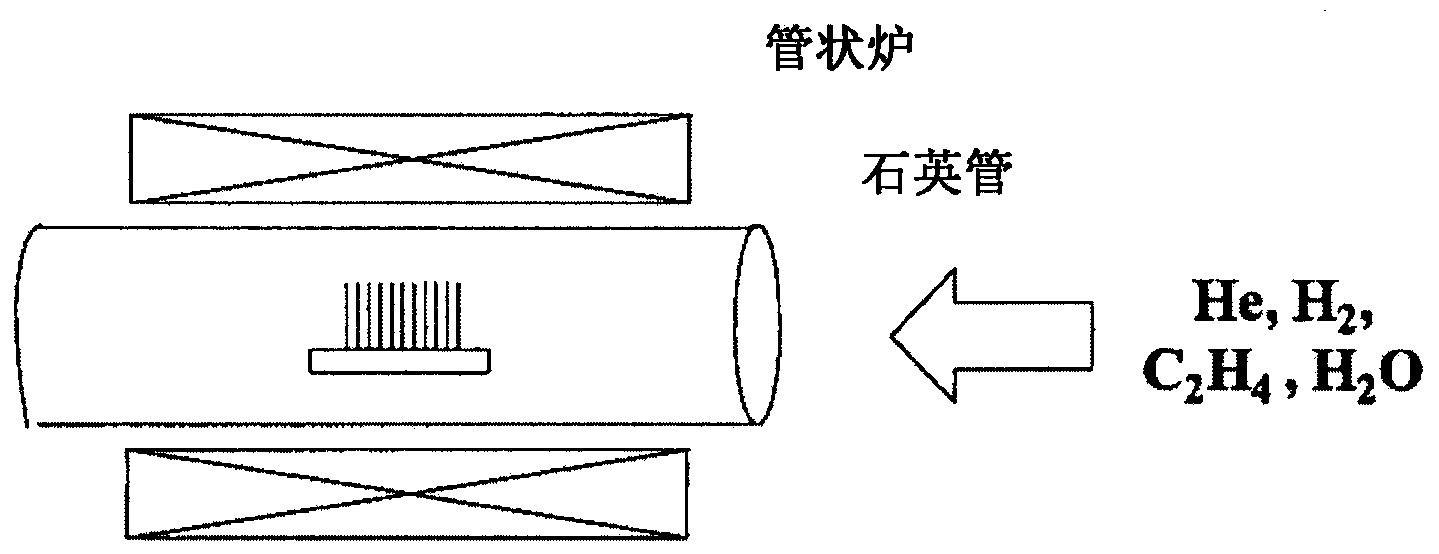

[0108] After that, place the substrate In the quartz tube, circulate a helium / hydrogen (90 / 50sccm) mixed gas that holds 600 ppm of moisture into the quartz tube for 30 minutes to replace the inside of the tube. After that, a tubular electric furnace was used to raise the temperature in the tube to 765°C and stabilize it at 765°C. Keep the temperature at 765℃, fill the tube with helium / hydrogen / ethylene (85 / 50 / 5sccm, moisture content 600ppm) mixed gas, and leave it for 4 minutes to grow carbon nanotubes on the substrate to obtain carbon nanotubes in the length direction Up-oriented carbon nanotube assembly (1).

[0109] The length of the carbon nanotube aggrega...

Embodiment 2

[0115] Using a sputtering device (manufactured by ULVAC, RFS-200), an aluminum oxide film (thickness 20 nm) was formed on a silicon wafer (manufactured by Silicon Technology Co., Ltd.) as a substrate. A sputtering device (manufactured by ULVAC, RFS-200) was used to deposit an Fe thin film (thickness: 1 nm) on the aluminum oxide thin film.

[0116] After that, place the substrate In the quartz tube, circulate a helium / hydrogen (90 / 50sccm) mixed gas that holds 600 ppm of moisture into the quartz tube for 30 minutes to replace the inside of the tube. After that, a tubular electric furnace was used to raise the temperature in the tube to 765°C and stabilize it at 765°C. Keep the temperature at 765℃, fill the tube with helium / hydrogen / ethylene (85 / 50 / 5sccm, moisture content 600ppm) mixed gas, and leave it for 10 minutes to grow carbon nanotubes on the substrate to obtain carbon nanotubes in the length direction Up-oriented carbon nanotube assembly (2).

[0117] The length of the carb...

Embodiment 3

[0122] Using a sputtering device (manufactured by ULVAC, RFS-200), an Al film (thickness 5 nm) was formed on a silicon wafer (manufactured by Silicon Technology Co., Ltd.) as a substrate. A sputtering device (manufactured by ULVAC, RFS-200) was used to deposit an Fe thin film (thickness 2 nm) on the Al thin film.

[0123] After that, place the substrate In the quartz tube, circulate a helium / hydrogen (90 / 50sccm) mixed gas that holds 600 ppm of moisture into the quartz tube for 30 minutes to replace the inside of the tube. After that, a tubular electric furnace was used to raise the temperature in the tube to 765°C and stabilize it at 765°C. Keep the temperature at 765℃, fill the tube with helium / hydrogen / ethylene (85 / 50 / 5sccm, moisture content 600ppm) mixed gas, and leave it for 20 minutes to grow carbon nanotubes on the substrate to obtain carbon nanotubes in the length direction Up-oriented carbon nanotube assembly (3).

[0124] The length of the carbon nanotube aggregate (3) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com