Patents

Literature

67 results about "Cutting sequence" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In digital geometry, a cutting sequence is a sequence of symbols whose elements correspond to the individual grid lines crossed ("cut") as a curve crosses a square grid. Sturmian words are a special case of cutting sequences where the curves are straight lines of irrational slope.

Method, device, storage medium and computer device for planning laser cutting path

ActiveCN108857092AImprove scienceImprove rationalityLaser beam welding apparatusLaser cuttingComputer science

The invention relates to a method, device, storage medium and computer device for planning a laser cutting path, wherein the part information and layout information of a part to be cut are obtained; numbering processing on the part to be cut is carried out so as to obtain a serial number combination; according to the number combination, the part information and the layout information, the information of a shortest cutting path is obtained; according to the number combination, part information and layout information corresponding to the information of the shortest cutting path, the cutting pathis planned to obtain the path planning information. By carrying out numbering and combination on the part to be cut, after calculating the length of the cutting path corresponding to each combination, a combination corresponding to the shortest path is selected as the optimal part cutting sequence and the path planning is carried out so as to ensure the integral cutting path is the shortest, so that the laser cutting time is shortened, the laser cutting efficiency is improved, and the scientificity and the rationality of the laser cutting path planning are improved.

Owner:HANS LASER TECH IND GRP CO LTD +1

Route planning method for moving carrier

InactiveCN108896048AAccurate divisionImprove work efficiencyNavigational calculation instrumentsSpecial data processing applicationsSequence planningSimulation

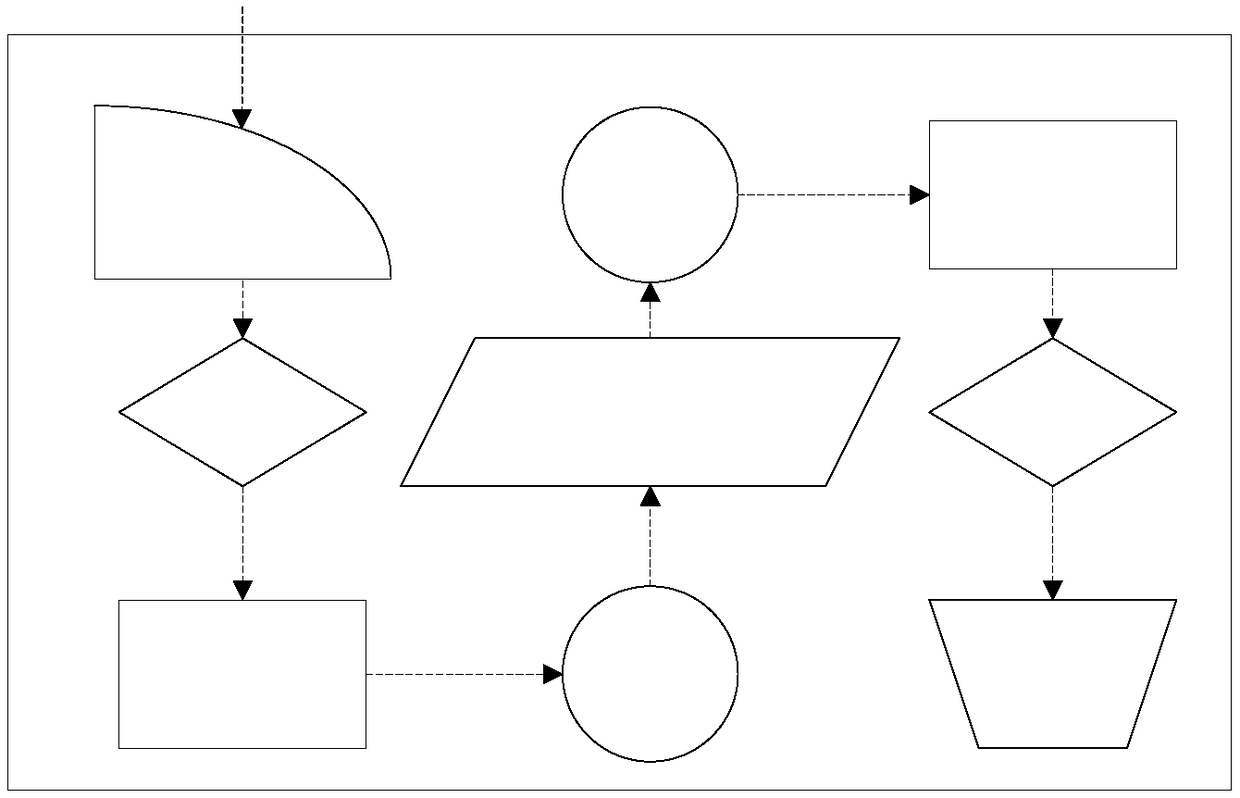

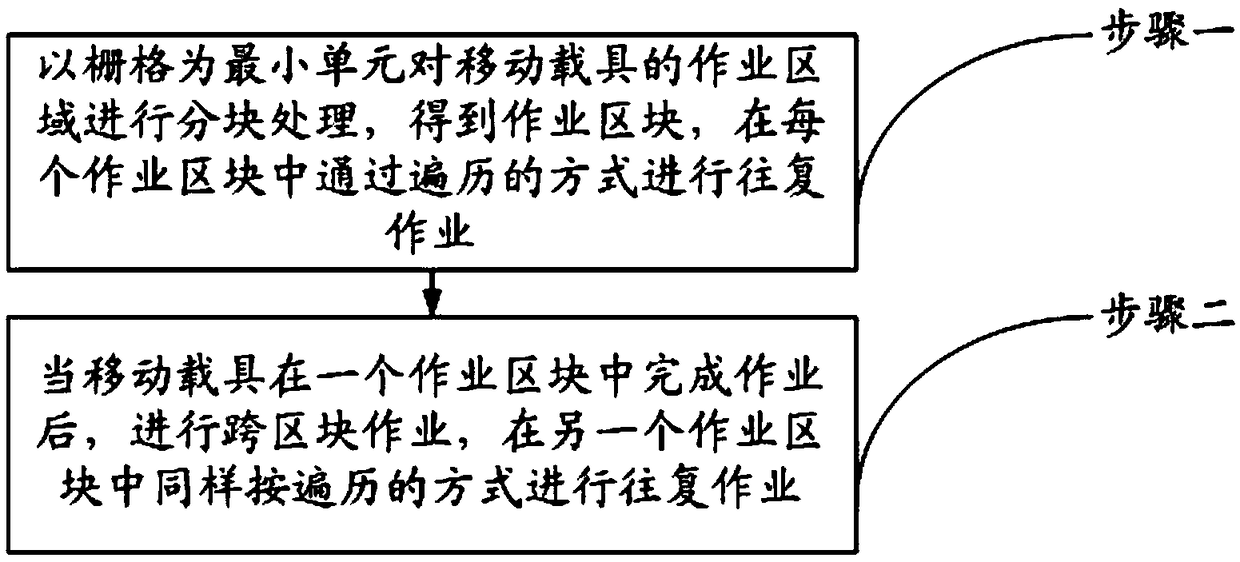

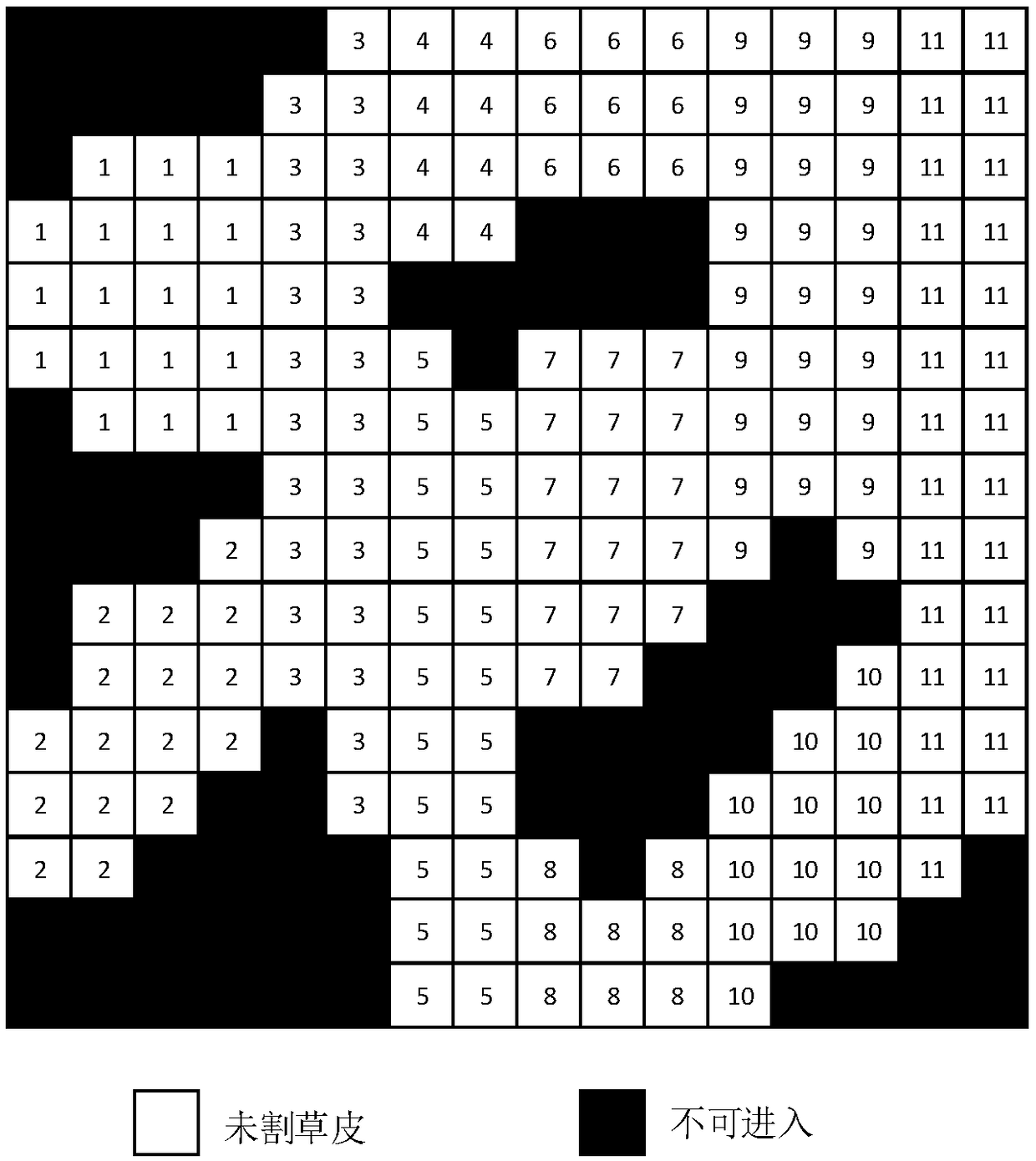

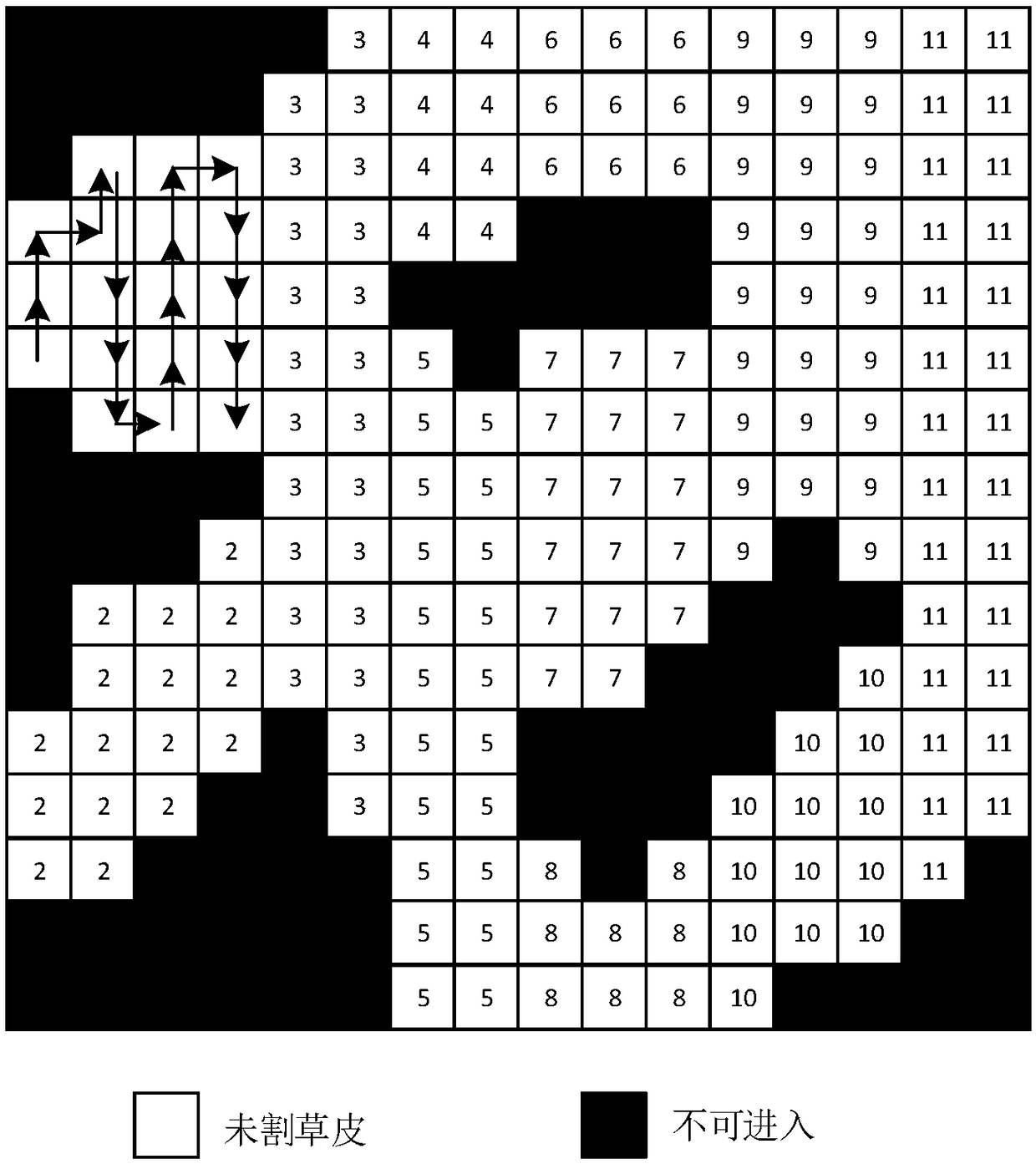

The invention provides a route planning method for a moving carrier and belongs to the field of navigation. The method comprises the following steps: taking a grid as a minimal unit for performing partitioning treatment on an operation area of the moving carrier, thereby acquiring operation blocks; performing reciprocating operation in each operation block in an ergodic manner; performing trans-block operation after the moving carrier finishes the operation in each operation block, and performing reciprocating operation in another operation block in the same ergodic manner. The moving carrieris capable of acquiring a plurality of operation blocks through a block cutting algorithm on the basis of an electronic grid map of the known information and the operation routes in the blocks are planned in each operation block through a reciprocating traversing route planning algorithm; the cutting sequence between the blocks is planned through a trans-block operation sequence planning algorithmafter the operation is finished in the present block; various algorithms are utilized to accurately divide the routes in the operation area and the working efficiency can be finally promoted.

Owner:ZHEJIANG YAT ELECTRICAL APPLIANCE CO LTD +1

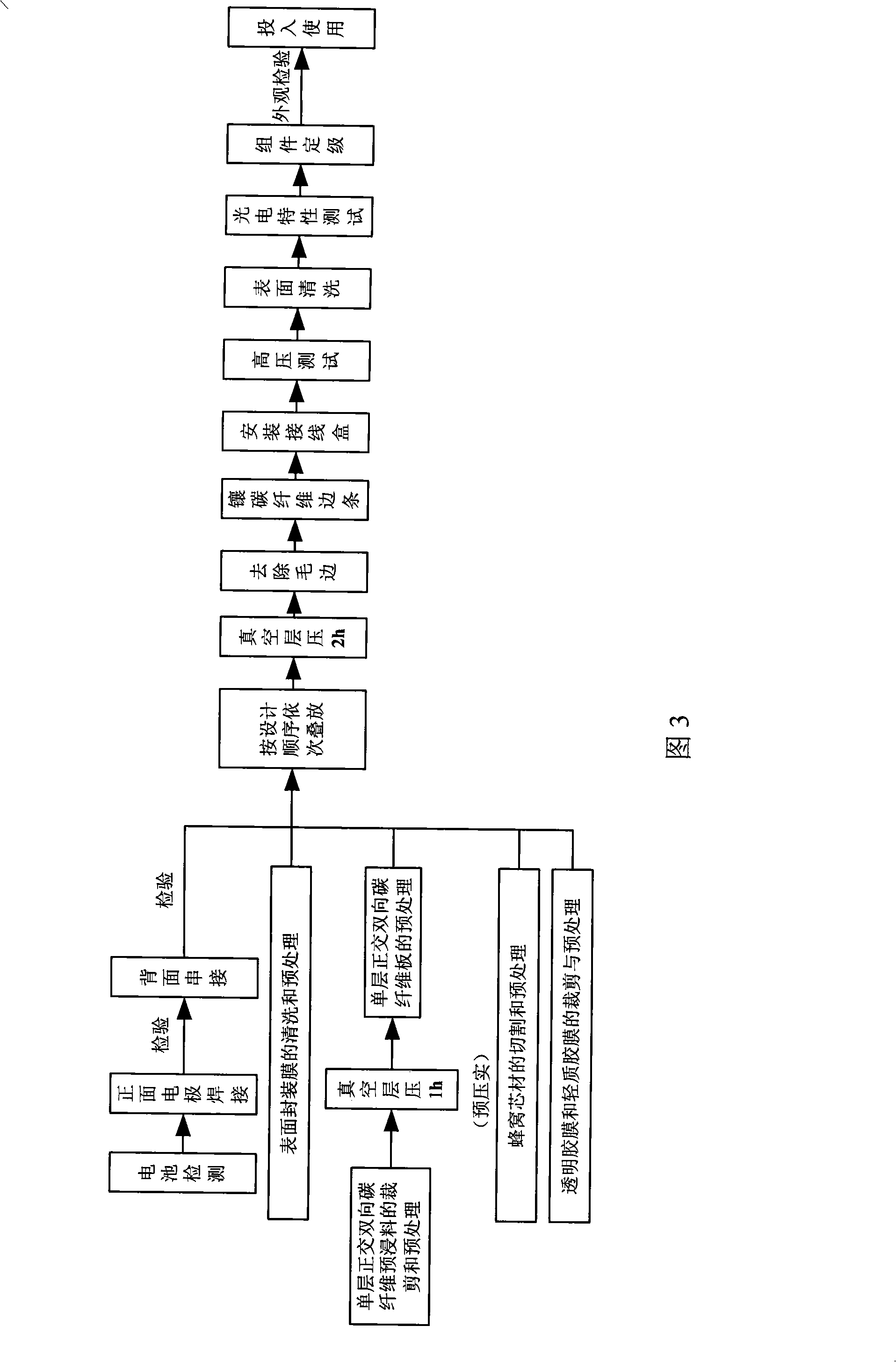

Solar cell module and preparation method thereof

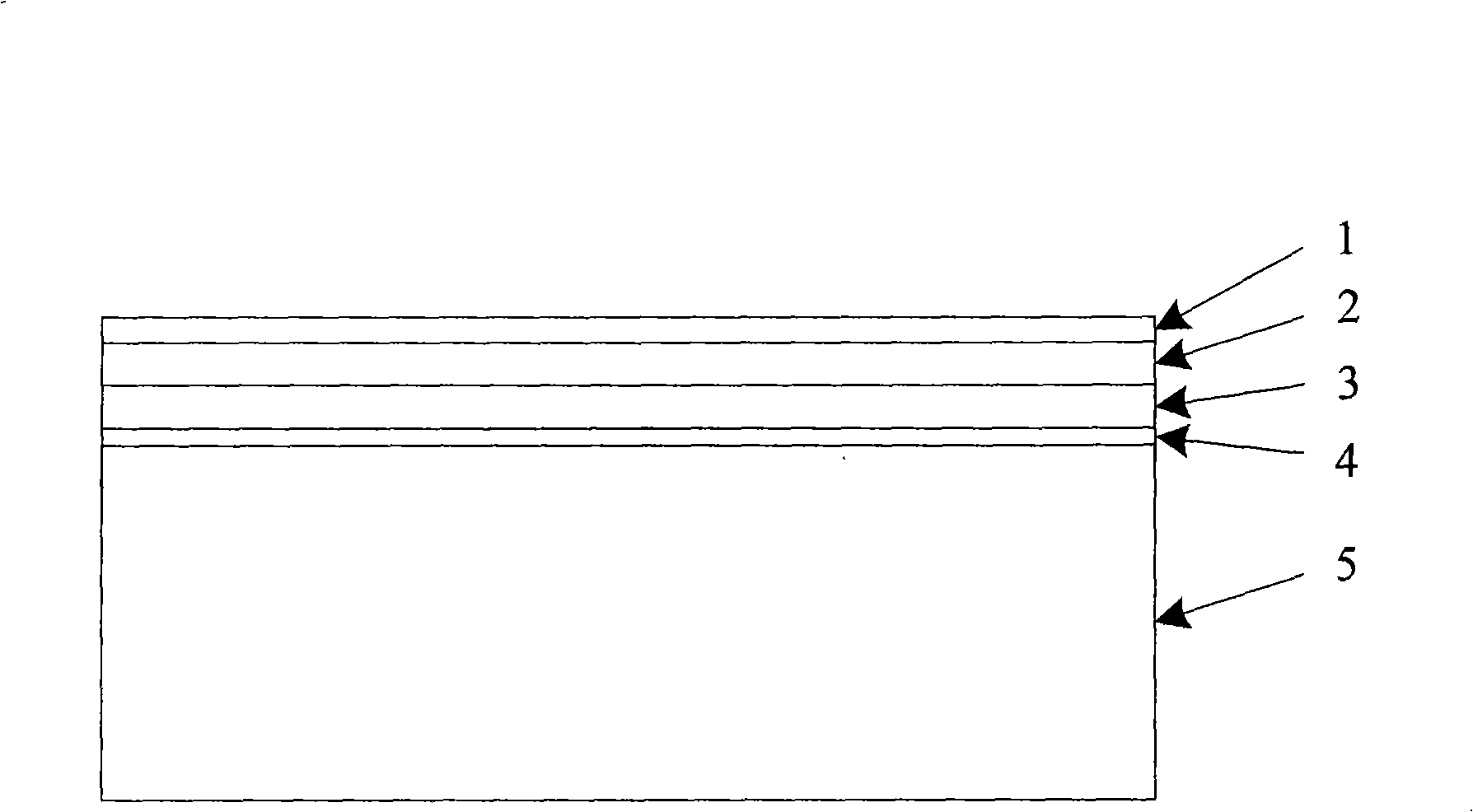

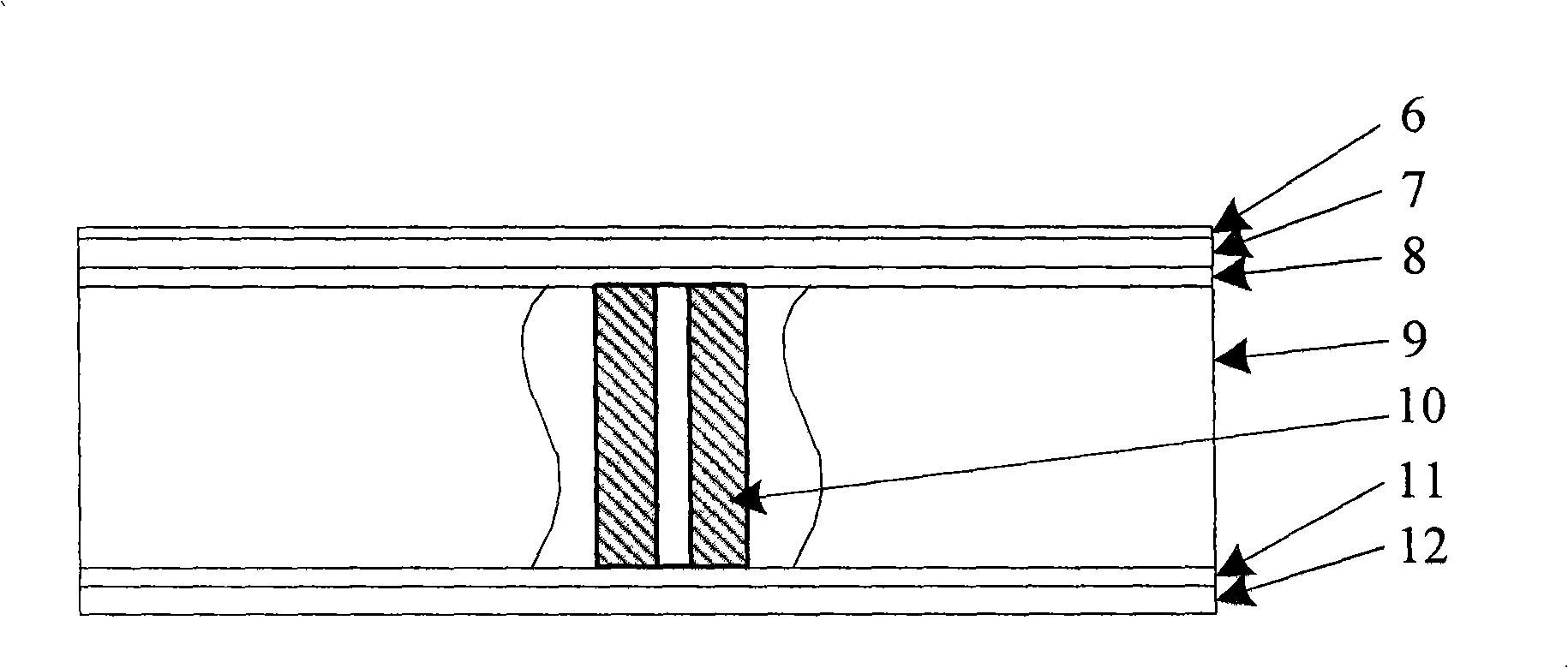

ActiveCN101320760AEfficient outputTo achieve the purpose of lightweightFinal product manufacturePhotovoltaic energy generationFiberStrake

The invention provides a solar module which is composed of a surface sealing film, a transparent adhesive film, a solar cell, a lightweight adhesive film A and an isolated substrate which are stacked from the top to the bottom in order; and the isolated substrate is composed of an isolated film, a carbon-fiber sheet, a lightweight adhesive film B, a honeycomb core, a lightweight adhesive film C and the carbon-fiber sheet which are stacked from the top to the bottom in order, wherein the honeycomb core inside also needs to be appropriately added embedded parts according to concrete operating requirements. The technical scheme of a preparation method of the solar module comprises following steps: (1) making use of an oven to match with a vacuum air pump to process a pre-compacting treatment for a carbon-fiber prepreg; (2) meanwhile, processing a welding sequence of the solar cell; (3) processing a cutting sequence; (4) processing a laminating technology treatment; (5) processing post treatment procedures which in order are: removing raw edges, embedding strakes, arranging a junction box, measuring high voltage, cleaning the surface, measuring photo-electrical output characteristics, classifying components, and examining the appearance. The solar module has the advantages of lightweight, high efficiency and good low-temperature characteristics, and being very suitable to being applied in the stratosphere.

Owner:BEIHANG UNIV

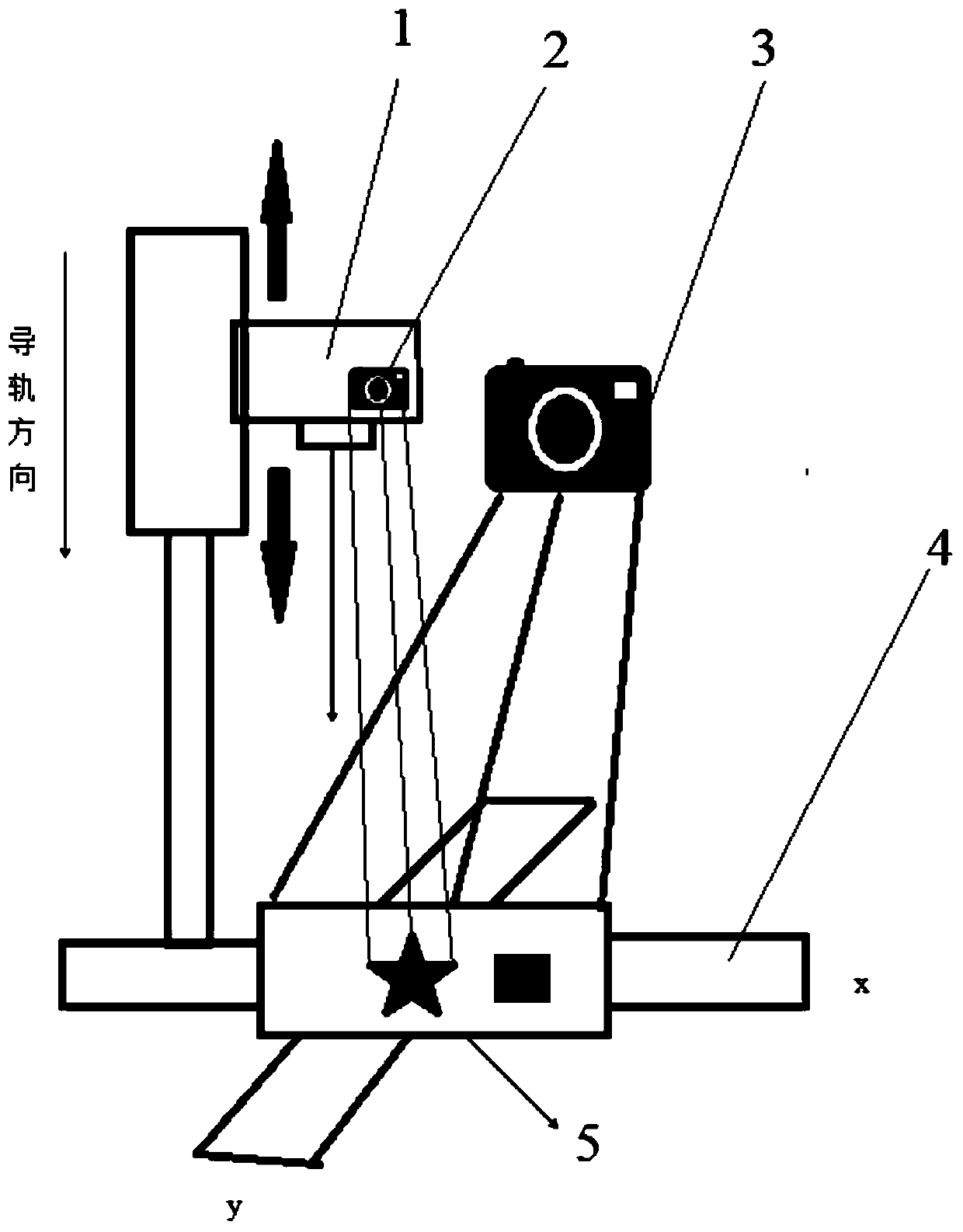

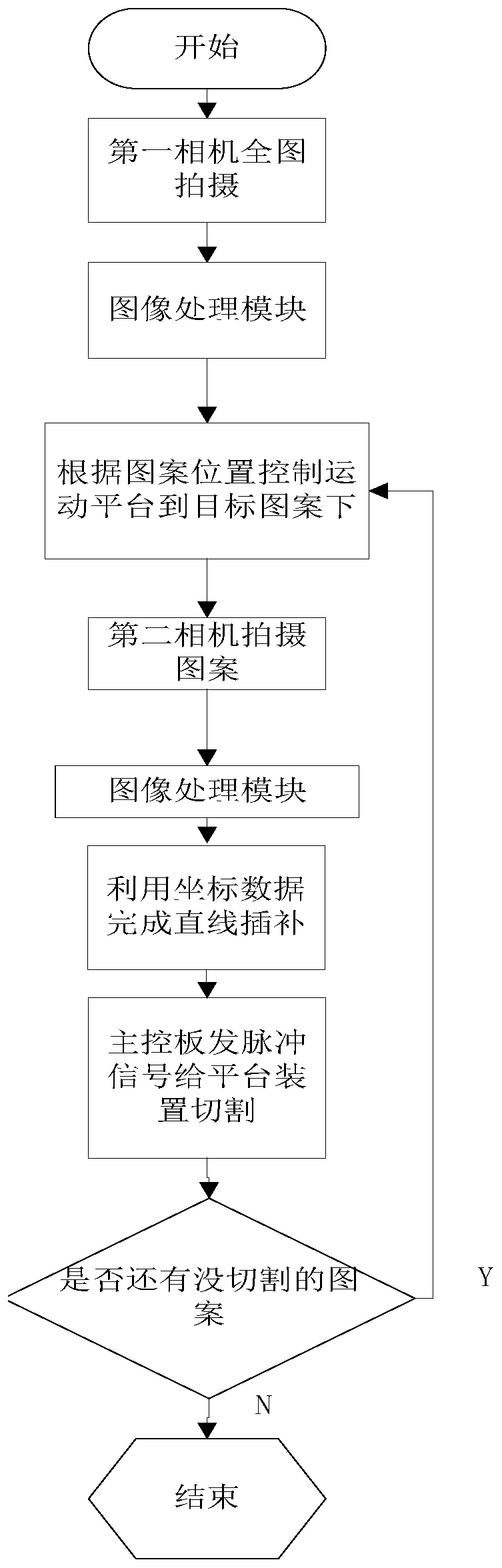

Laser cutting system based on image recognition

InactiveCN110153567AReduce the problem of long routesShorten the timeLaser beam welding apparatusNumerical controlGraphics

The invention provides a laser cutting system based on image recognition. The system comprises an image acquisition module, an image processing module, a path planning module, a coordinate calculationmodule, a laser cutting unit and a main control unit, wherein the image acquisition module comprises a first camera and a second camera, and the first camera is used for acquiring the integral graphof the graph to be cut; the image processing module is connected with the image acquisition module; the path planning module is connected with the image processing module and is used for dividing thewhole graph acquired by the first camera into a plurality of unit patterns, acquiring the position of each unit pattern and planning the cutting sequence of each unit pattern to acquire the shortest cutting path, and the second camera is used for acquiring the local graph of each unit pattern; the coordinate calculation module is used for calculating coordinate information of the local graphs shotby the second camera after being processed by the image processing module; and the laser cutting unit comprises a laser head and a numerical control objective table. With the system, when multi-target cutting is required for complicated patterns, an optimal cutting path can be obtained, and the required patterns can be obtained through cutting more accurately.

Owner:JIANGSU UNIV

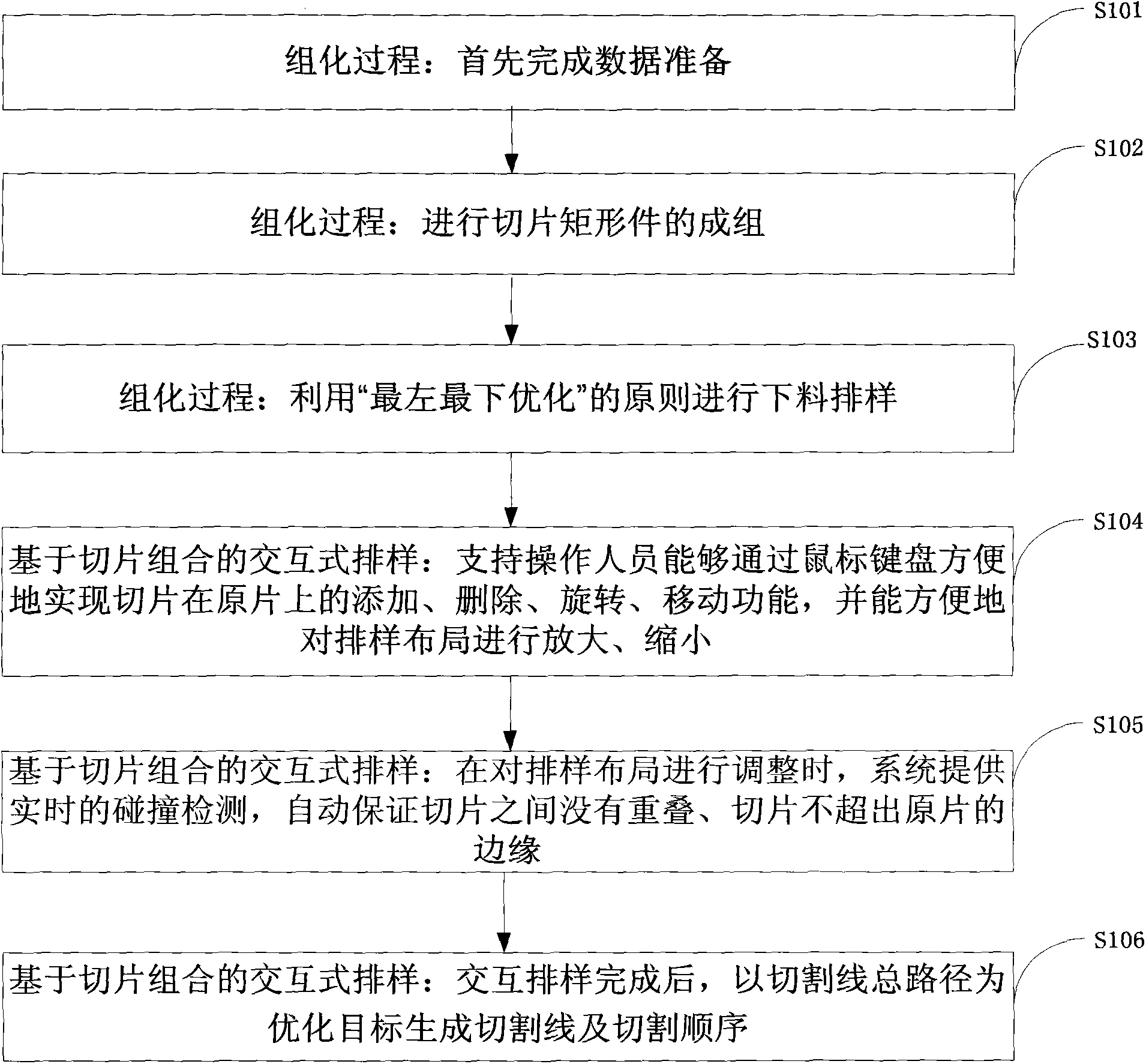

Two-dimensional rectangular part interactive layout optimization method based on grouping technology

ActiveCN103559554ASolving Interactive Nesting ProblemsSolve build problemsForecastingCollision detectionMan machine

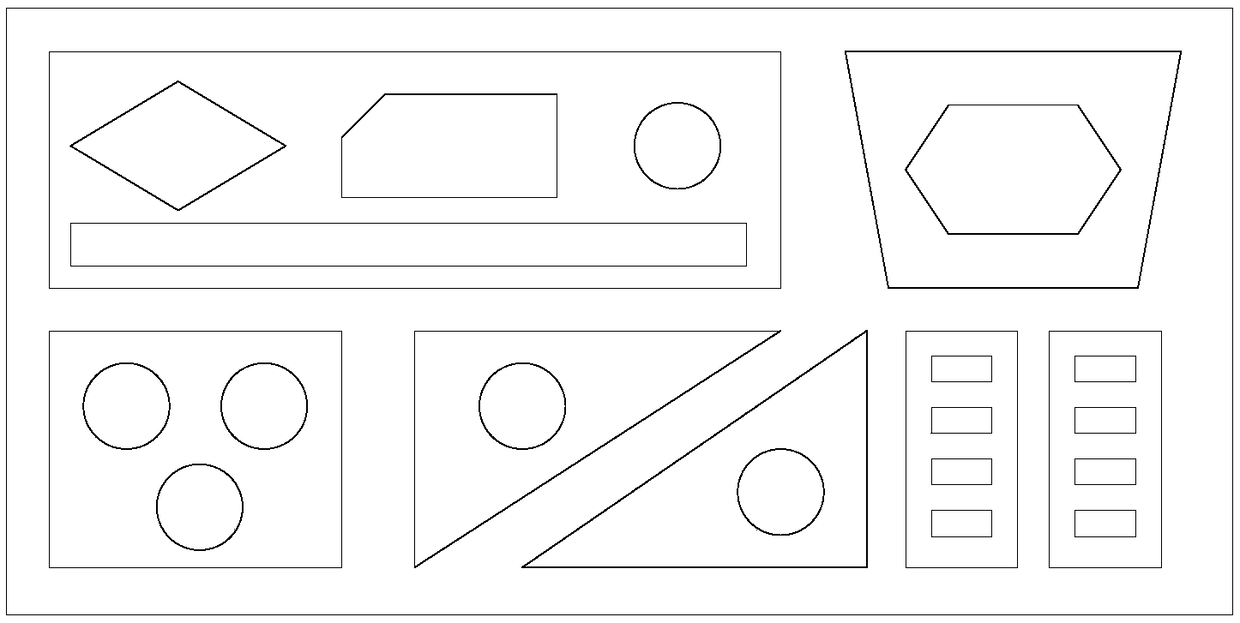

The invention discloses a two-dimensional rectangular part interactive layout optimization method based on a grouping technology. The method includes the steps that firstly, data preparation is completed; grouping of sliced rectangular parts is performed; a leftmost and bottommost optimization principle is used for material discharging and layout; the functions that an operator can adding, deleting, rotating and moving slices on an original sheet conveniently through a mouse and a keyboard are supported, and the layout can be zoomed in and zoomed out conveniently; when the layout is regulated, a system provides real-time collision detection, and the situations that the slices do not overlap and cannot exceed the edge of the original sheet are guaranteed automatically; after interactive layout is completed, a cutting line total path is used as an optimization objective to generate cutting lines and cutting sequences. According to the two-dimensional rectangular part interactive layout optimization method, in the rectangular part discharging process, the problems of follow-up processes, workshop transportation, utilization of residual blank areas after the layout, raw material defect avoiding and temporary slice adding are considered, and problems generated by man-machine interactive layout and the cutting lines after layout are solved.

Owner:GUANGDONG UNIV OF TECH

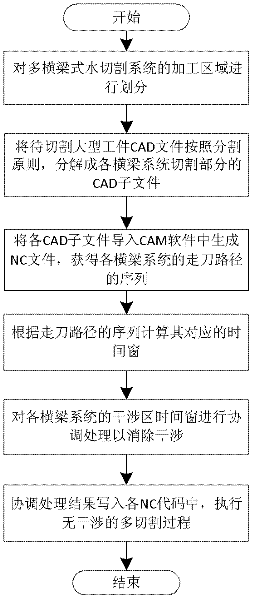

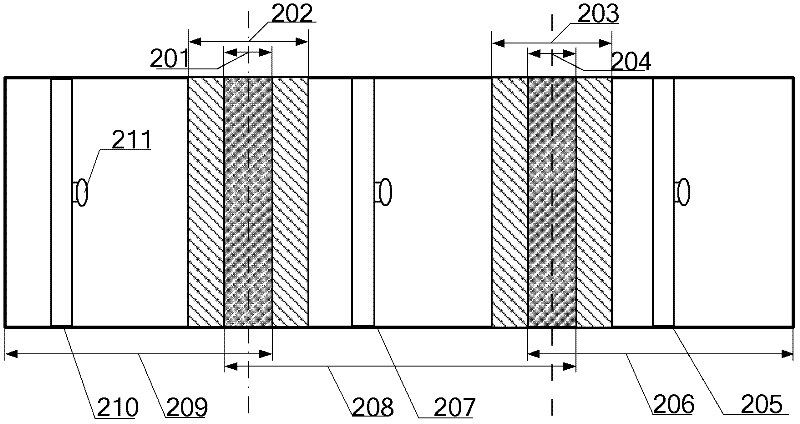

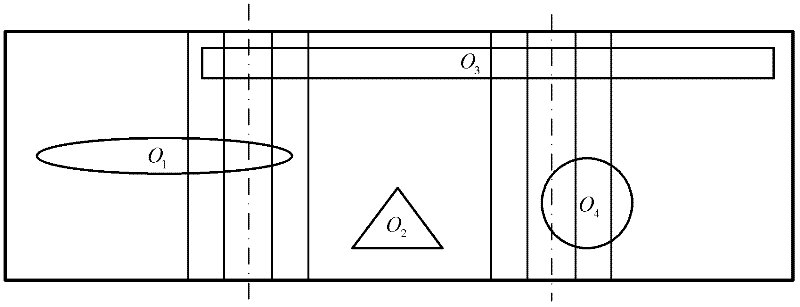

Cutting process offline coordination method of multi-beam type water jet cutting system

InactiveCN102346459ANo need to change KAEliminate interferenceProgramme controlComputer controlNumerical controlComputer-aided

The invention provides a cutting process offline coordination method of multi-beam type water jet cutting system. The method comprises the following steps: dividing a processing area of the multi-beam water cutting system; inputting a CAD (computer-aided design) file of a large workpiece to be cut, and decomposing and allocating the cutting contour accordingly to form the CAD sub-file of the cutting part of each beam system; importing each CAD sub-file into water cutting CAM (computer-aided manufacturing) software to generate an executable NC (numerical control) code file, and reading the NC code file to obtain a sequence of the cutting path of each beam system; calculating a time window executed by each path in each cutting sequence, and coordinating the time windows in an interference area so as to achieve the purpose of avoiding mutual interference between two adjacent beams; and writing the coordination result into the original NC code file, downloading the NC code file to a CNC (computer numerical controller) of each beam system, and executing the multi-beam water cutting process. According to the invention, smooth and non-interference execution of a parallel cutting processes of a water cutting system with more than three beams can be realized.

Owner:SOUTHEAST UNIV

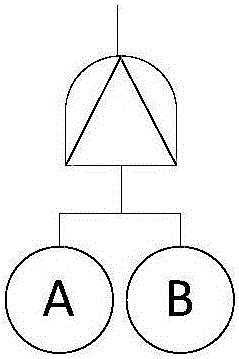

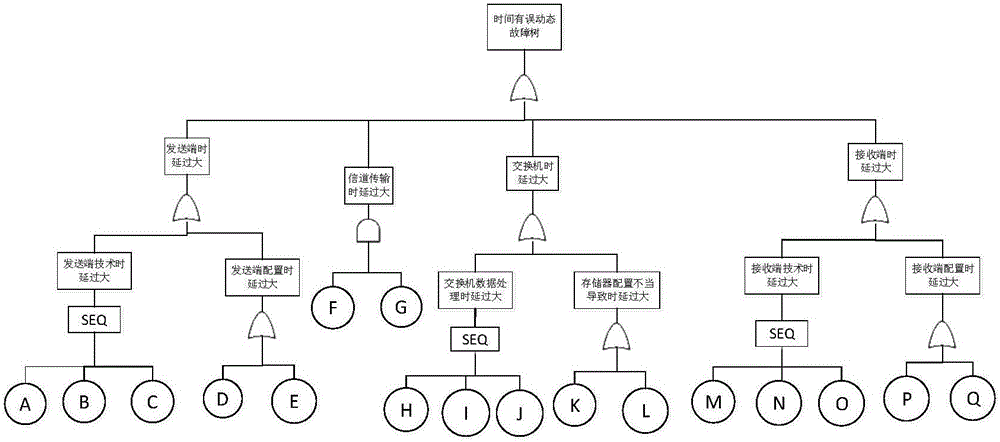

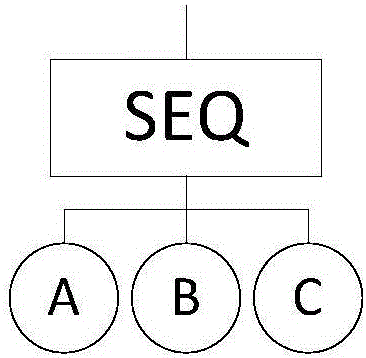

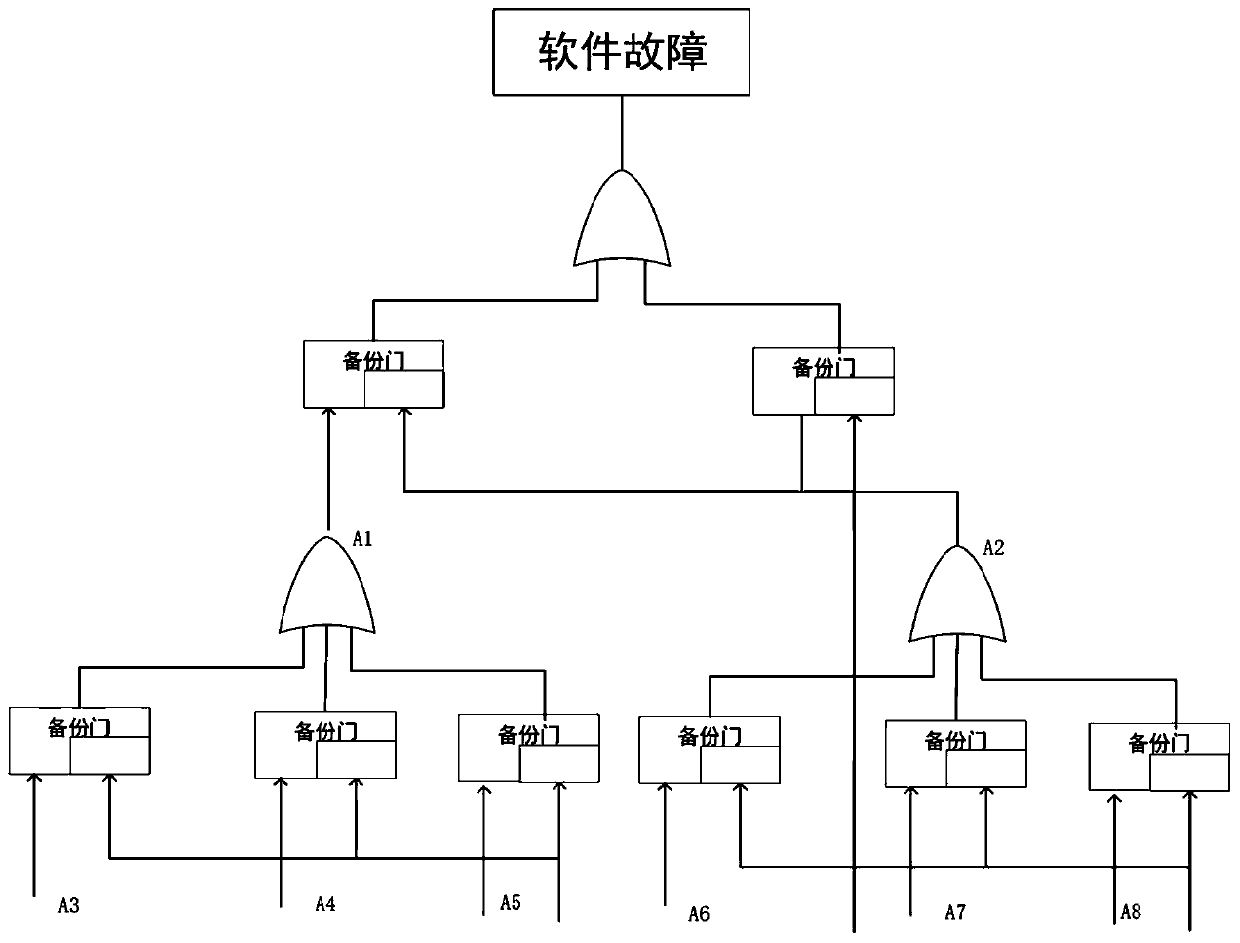

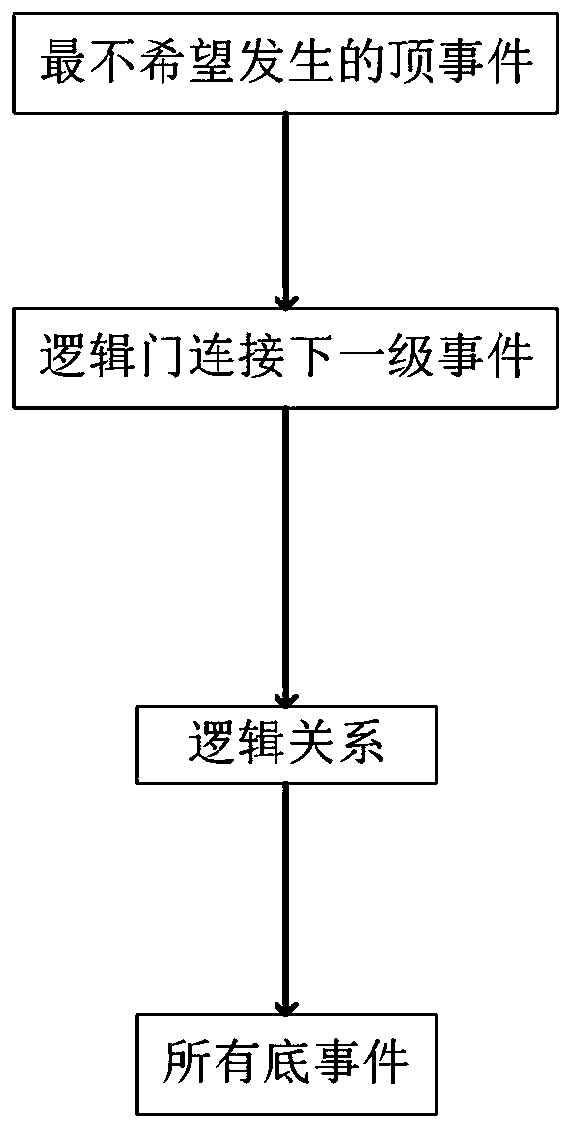

A cut sequence set-based dynamic fault tree Monte-Carlo simulation quantitative calculation method

InactiveCN106021647AQuantitative calculation is beneficial toDesign optimisation/simulationSpecial data processing applicationsReliability designDependability

The invention provides a cut sequence set-based dynamic fault tree Monte-Carlo simulation quantitative calculation method and relates to the technical field of reliability and safety (safe system engineering). The method comprises the steps of performing left-to-right depth-first traversal on different dynamic logic gates, and acquiring the minimum cut sequence set of a dynamic fault tree according to the cut sequence conversion rules of dynamic logic gates; employing the Monte-Carlo simulation method and comparing the sample failure time of events with the minimum cut sequence set, and recording a failure once if the time meets the occurrence order of events in the minimum cut sequence set and the occurrence time of the last event is within set system operation time. The method can provide important information for reliability design, improvement, enhancement and troubleshooting in engineering. The Monte-Carlo simulation is performed based on cut sequence sets, so that secondary conversion of a DFT, for example, to Markov, the Bayesian network or a failure time tree, is avoided and the quantitative calculation procedures are optimized.

Owner:BEIHANG UNIV

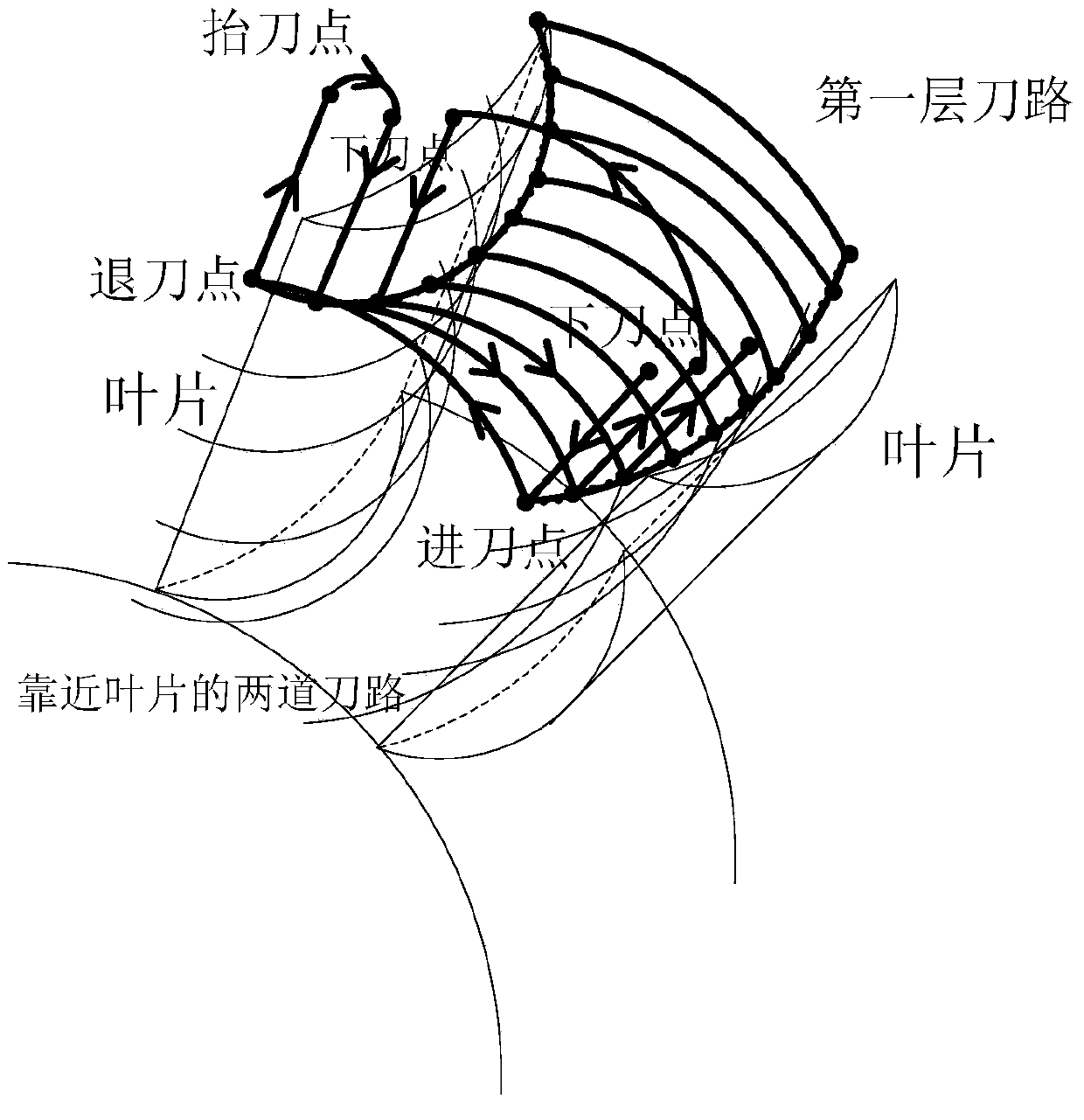

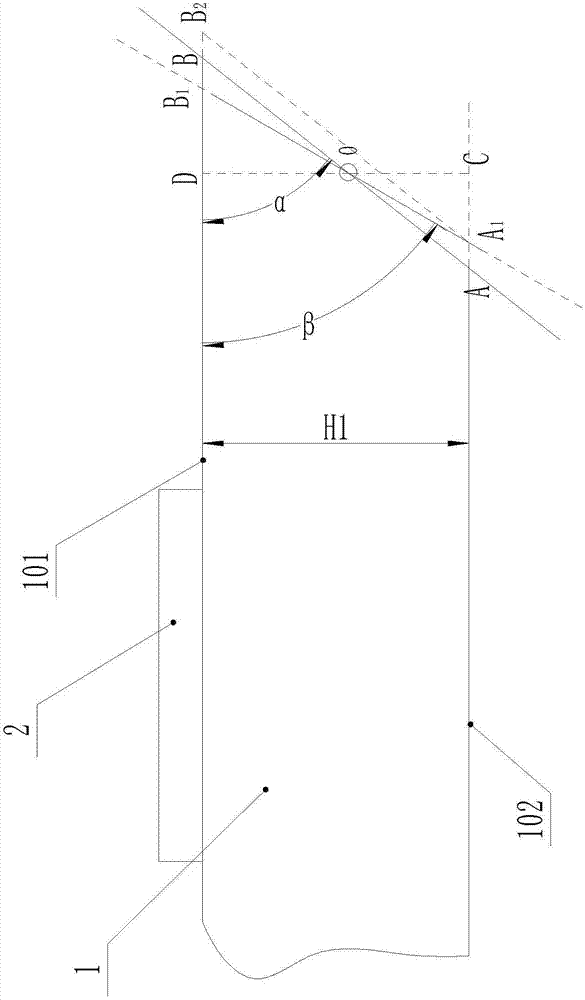

Circumferential fixed-width cutting path planning method for rough machining of integrated impeller

The invention discloses a circumferential fixed-width cutting path planning method for the rough machining of an integrated impeller. The method comprises the following steps: generating a tool path source file of an axial cutting tool path, and analyzing position coordinates and a tool axis vector of each tool position point; equally dividing the axial cutting tool path into delta according to an axial width; interpolating circumferential cutting tool paths between the corresponding equal dividing tool position points on the axial cutting tool path; calculating a tool position point top rake tendency of each circumferential cutting tool path, and determining feeding points and retraction points on the basis of the tool position point top rake tendencies; interpolating a lowering point and a lifting point of each circumferential cutting tool path; interpolating a connecting tool path between every two adjacent circumferential cutting tool paths; connecting the axial cutting tool path with each circumferential cutting tool path to obtain an integrated cutting path according to a cutting sequence. According to the planning method, by the cutting path for the rough machining of the integrated impeller, the phenomenon of tool path redundancy is avoided, high effective cutting rate is achieved, a cutting tool is kept in a positive top rake cutting state most of the time, abrasion can be effectively reduced, and the cutting tool can be protected.

Owner:HUAZHONG UNIV OF SCI & TECH

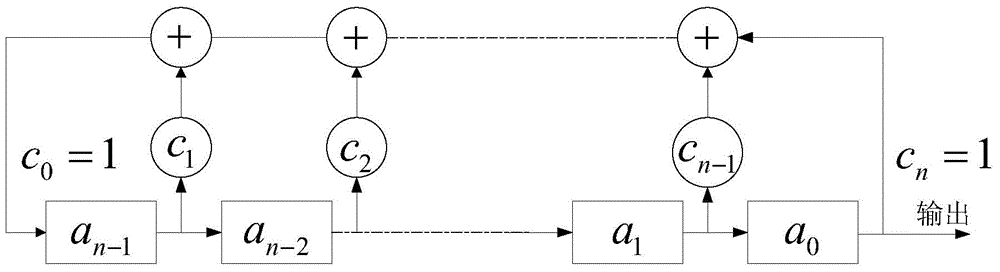

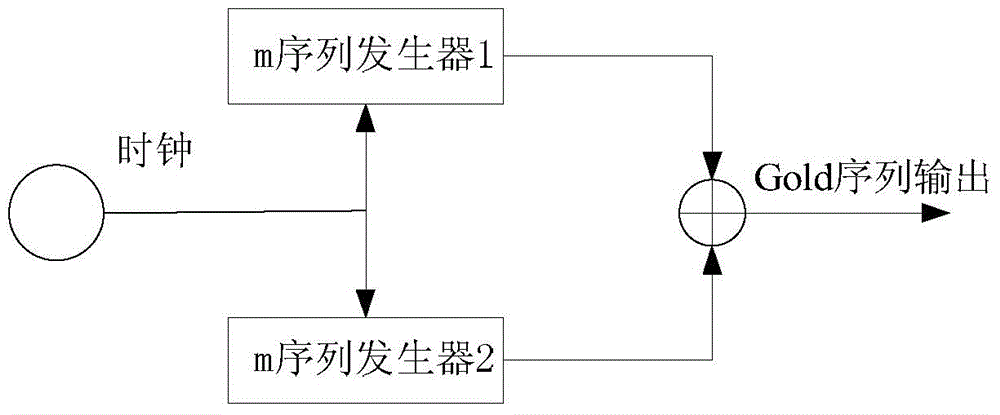

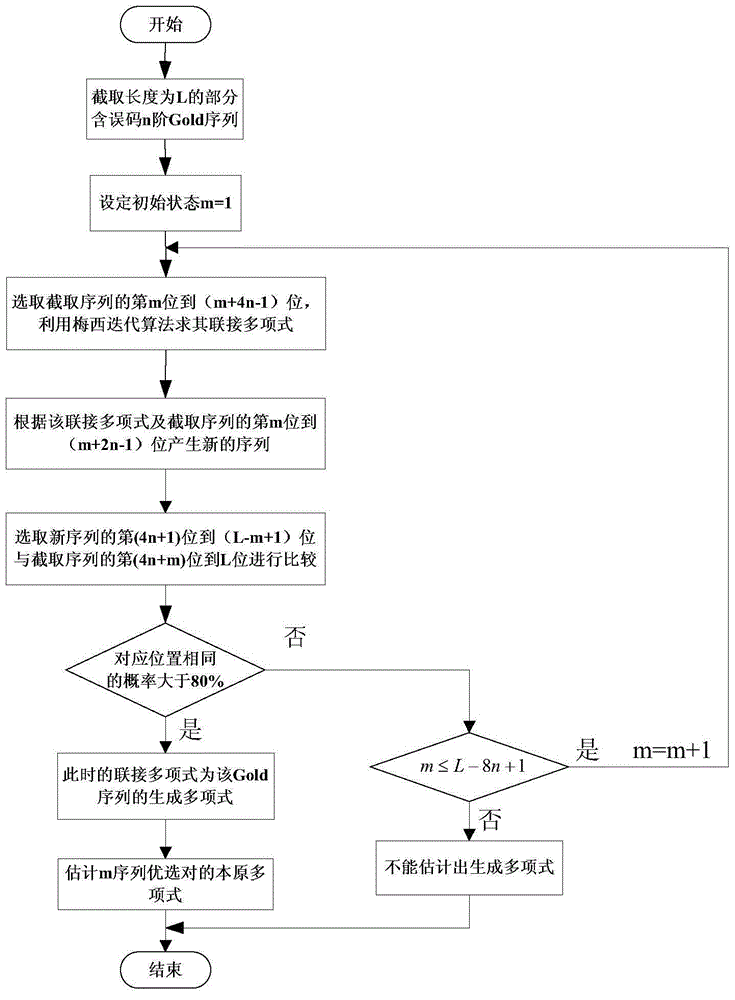

Parameter estimation method of Gold sequence

The invention provides a parameter estimation method of a Gold sequence. The Gold sequence is a pseudo-random sequence with better mutual correlation property compared with the m sequence and is widely applied to modern communication. Parameters of the Gold sequence are important components of the Gold sequence, but less research on parameter estimation is done. Aiming to solve problems existing in estimating parameters of the Gold sequence, the invention provides a parameter estimation method of the Gold sequence based on the Messi iterative algorithm. According to the method, firstly, according to partial sequences cut from the Gold sequence, a generator polynomial is estimated adopting the Messi iteration algorithm, and then, the primitive polynomial of an m sequence preferred pair which generates the Gold sequence is estimated through adopting the polynomial division. When the cut sequence lengths are shorter and error codes appear, the method can effectively estimate parameters of the Gold sequence.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

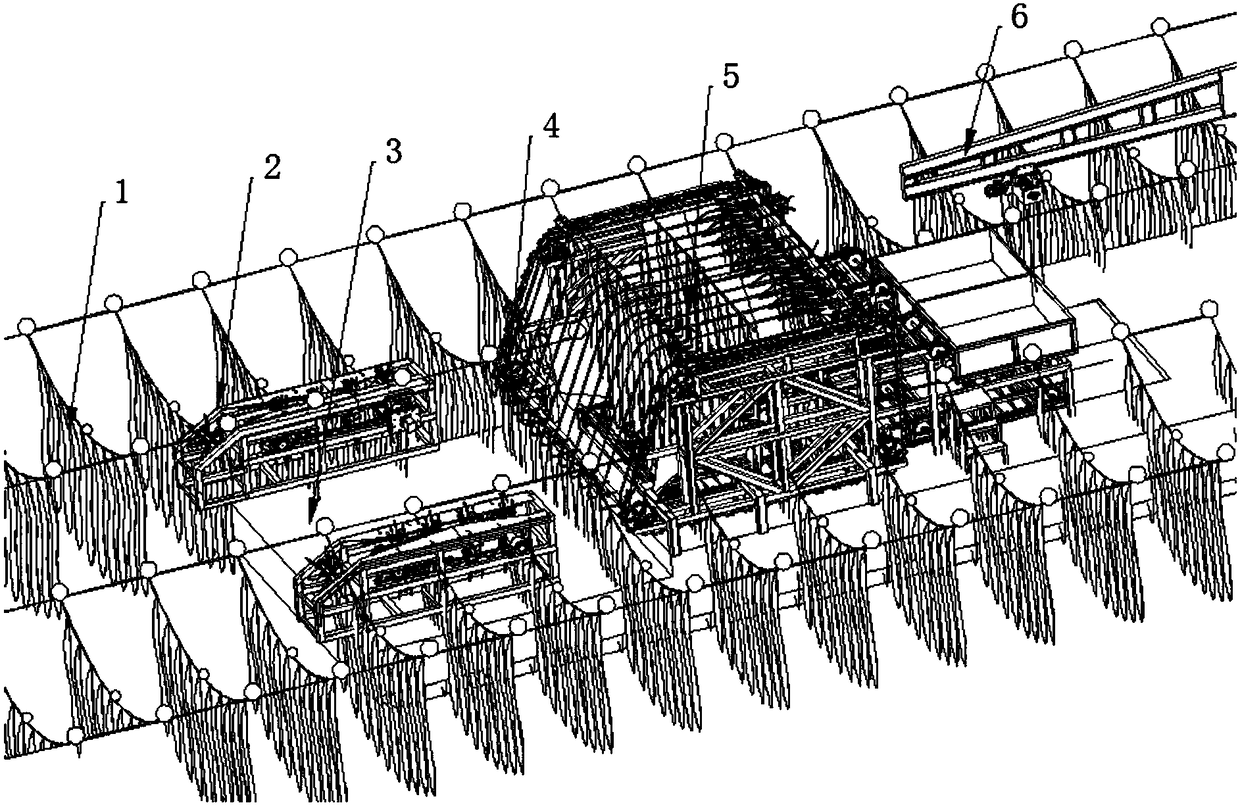

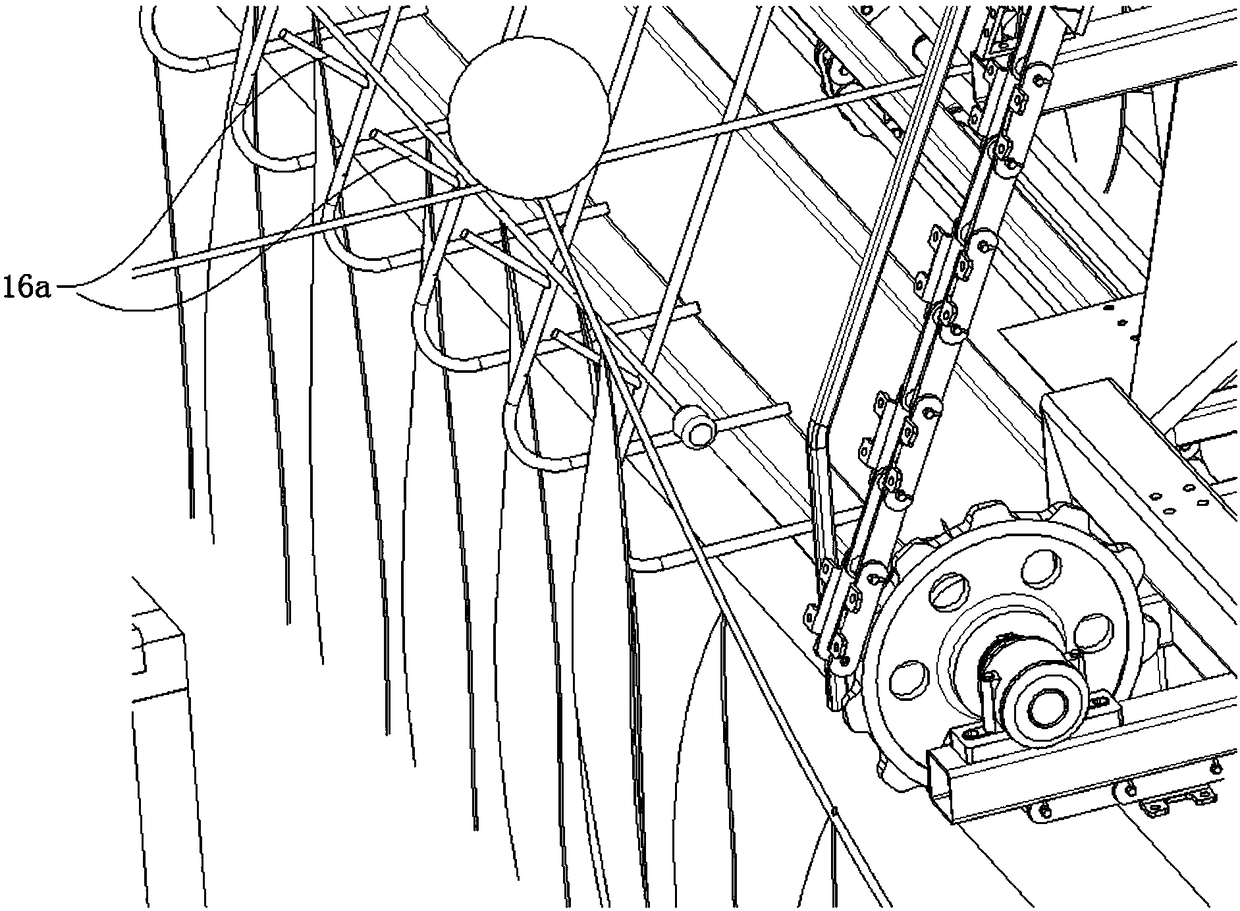

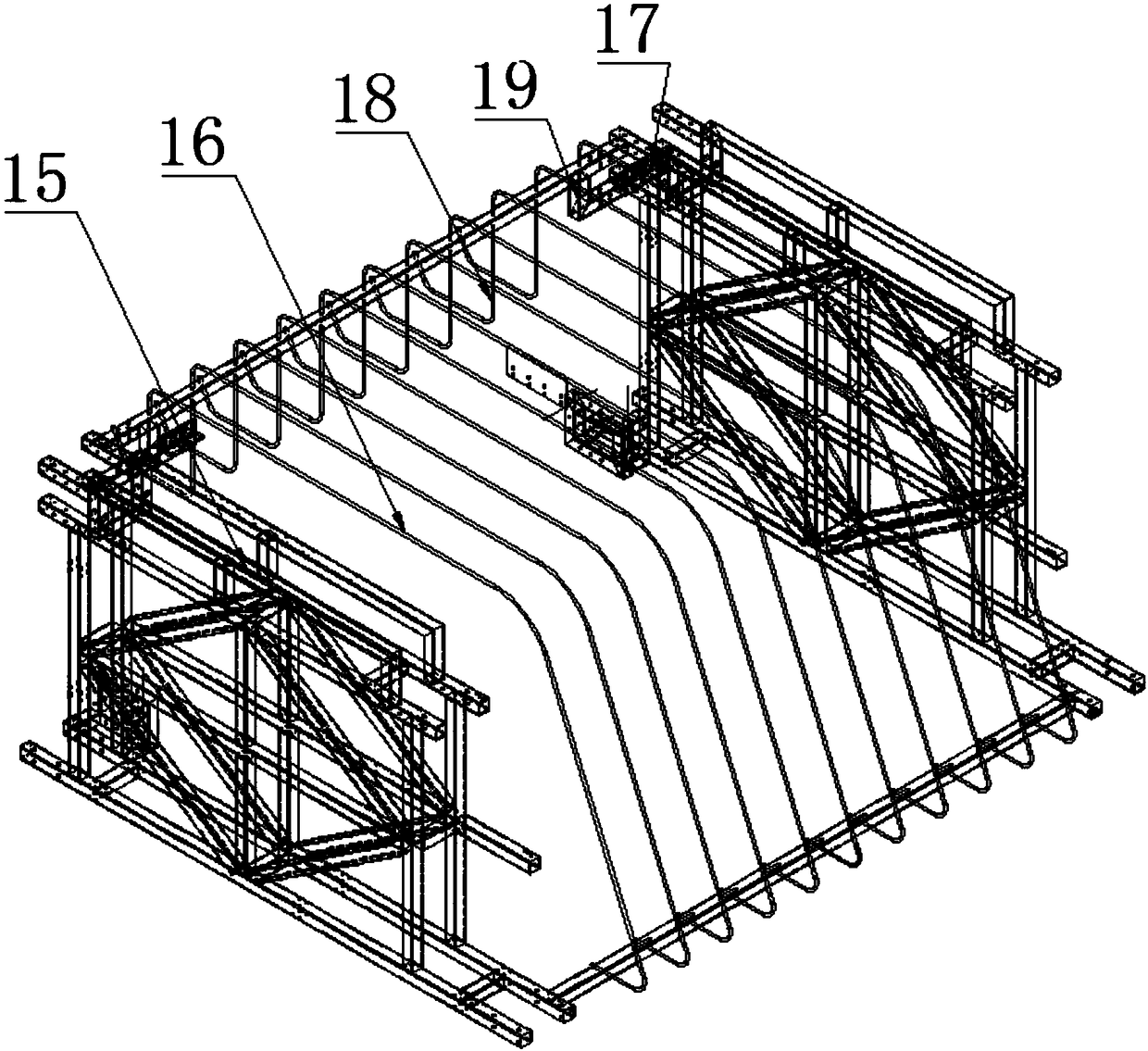

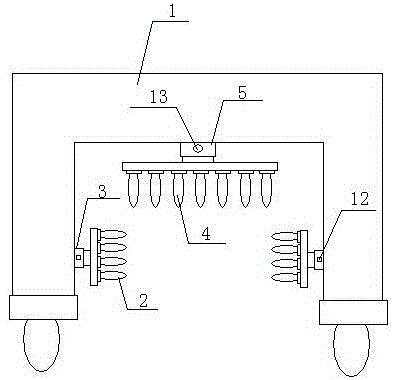

Kelp automatic cutting and rope removing device

PendingCN108377724ASolve the strength problemSolve efficiency problemsHarvestersClimate change adaptationAgricultural engineeringEngineering

The invention relates to a kelp automatic cutting and rope removing device. A plurality of seedling rope guide supporting rods are arranged on a frame body assembly side by side. A hook is arranged atthe bottom of the front end of the seedling rope guide supporting rod. One or more bundles of kelp are located between every two adjacent hooks on seedling ropes. Claw fastening devices are arrangedon the two sides of each seedling rope guide supporting rod and can fasten the corresponding seedling rope towards the two sides. The seedling ropes and the kelp on the seedling ropes are conveyed backwards by the claw fastening devices along the seedling rope guide supporting rods. A plurality of cutting mechanisms for overall cutting the kelp on the seedling ropes are arranged on the frame bodyassembly at different heights according to the cutting sequence from bottom to top. A stirring wheel mechanism is arranged at the tail portion of the frame body assembly and can rotate to stir the seedling ropes on the seedling rope guide supporting rods so that the seedling ropes can fall into collecting grooves on the lower side one by one. By means of the kelp automatic cutting and rope removing device, the problems that in an existing fresh kelp processing process, in the working links of kelp placing, cutting, segmenting and packaging and seeding rope removing, labor intensity is large, and efficiency is low are solved.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

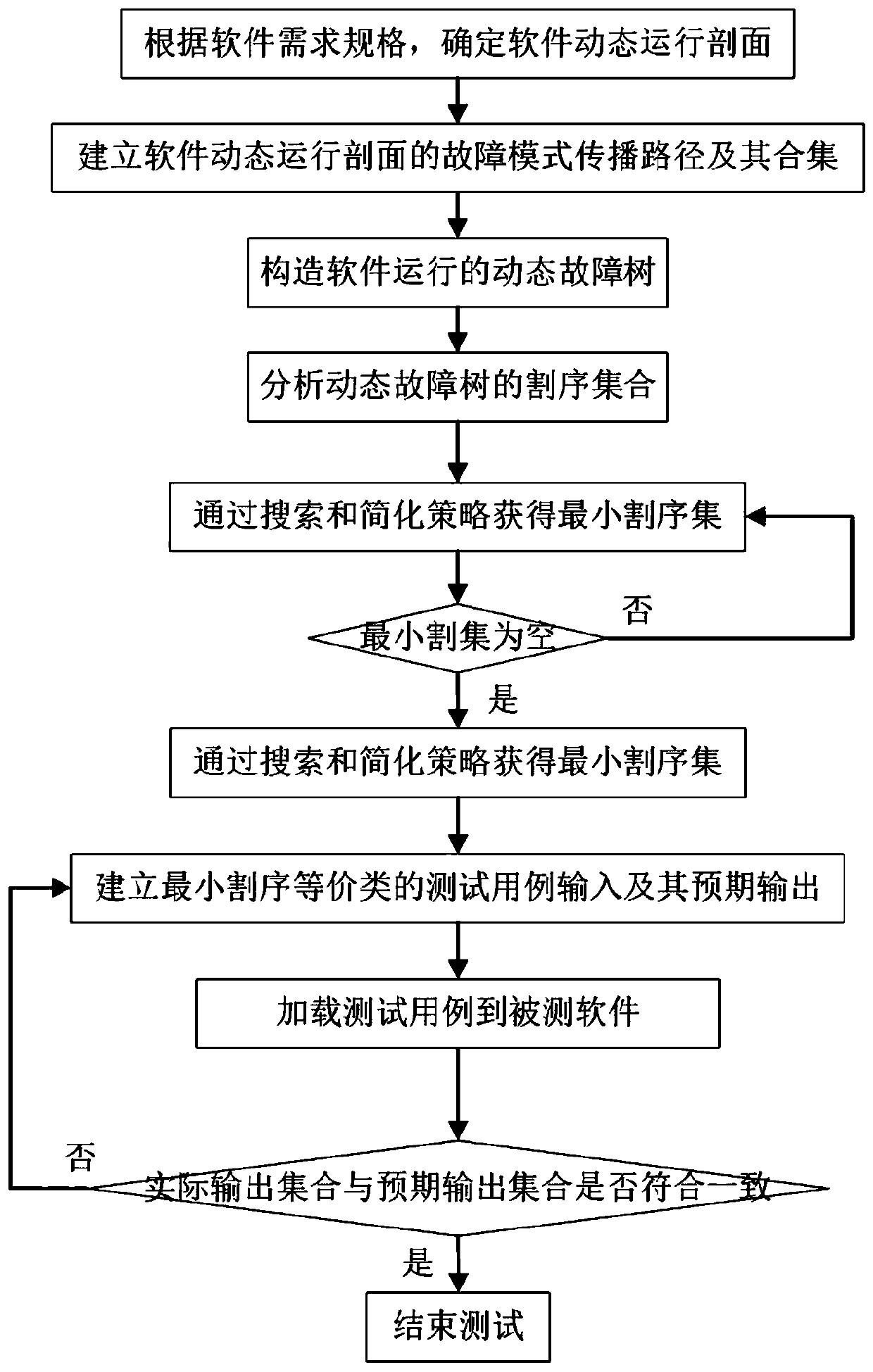

Embedded satellite-borne software test case generation method based on dynamic fault tree

The invention provides an embedded satellite-borne software test case generation method based on a dynamic fault tree. The embedded satellite-borne software test case generation method comprises the following steps: (1) determining an on-orbit actual dynamic operation profile and an input space of tested software; (2) establishing a fault mode propagation path and a fault mode set of the operationprofile; (3) establishing a dynamic fault tree; (4) constructing a cutting sequence set corresponding to the dynamic fault tree, and determining a minimum cutting sequence set in the cutting sequenceset; (5) establishing test case input and expected output of the minimum cut sequence equivalent class, and generating a test case; (6) loading the test case, running the tested software, and takinginput data as execution input to obtain actual output; and (7) checking whether the actual output set is consistent with the expected output set. The test case generated by the method has the advantages of low coupling degree, high efficiency, high granularity and high reusability.

Owner:SHANGHAI ENG CENT FOR MICROSATELLITES

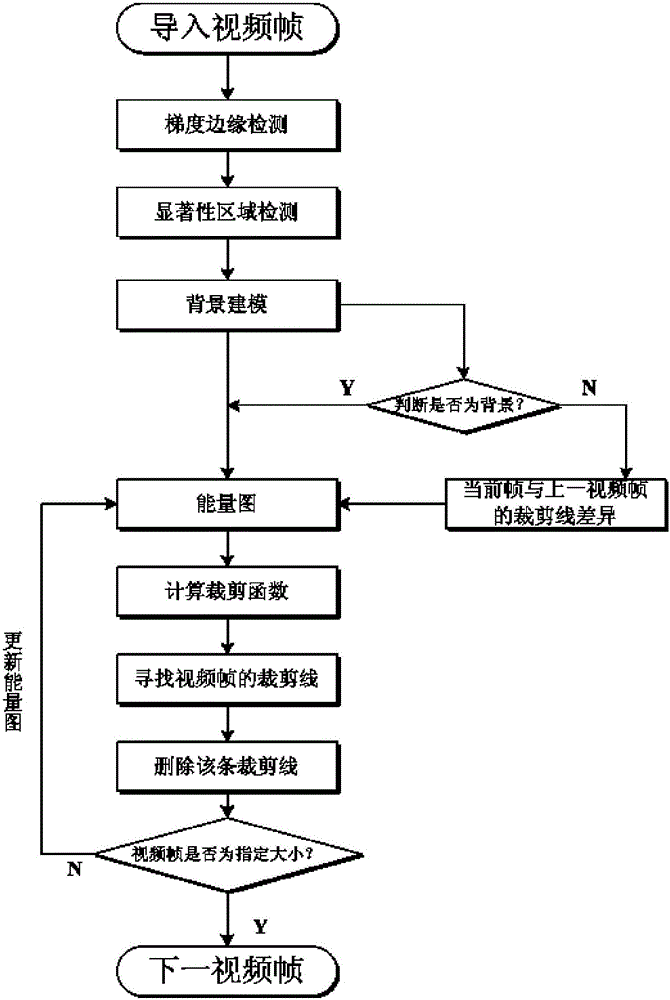

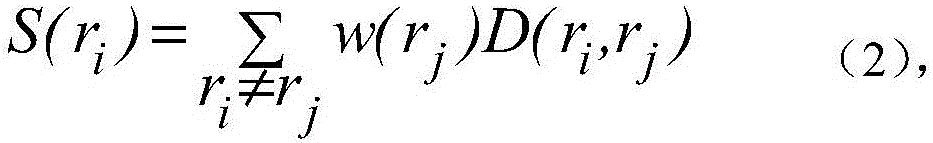

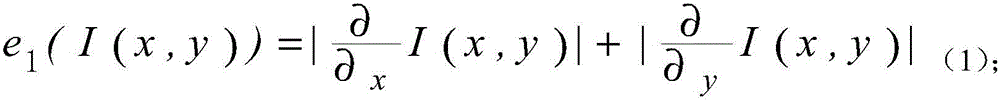

Static state background video compression algorithm based on motion perception

InactiveCN105959707ANo jitterMaintain the space-time continuumDigital video signal modificationWire cuttingMotion perception

The invention discloses a static background video compression method based on motion perception. First, edge gradient detection and salient area detection are respectively performed on video streams to obtain edge information and salient information, and then background modeling is performed, and the vibe algorithm is used to detect Motion information, according to the motion information, calculate the space-time difference between the current frame of the moving target and the cropping line of the previous video frame, so that the cropped video maintains the continuity of space and time between the front and rear frames; according to the energy map, calculate the edge change The cost function avoids edge distortion, and the dynamic programming algorithm is used to calculate the clipping function; define an optimization function for clipping order, and select the clipping lines to be removed in the horizontal and vertical directions. The present invention utilizes edge detection, saliency detection, target detection and temporal-spatial correlation to apply the image line cropping method to video compression.

Owner:HEFEI UNIV OF TECH

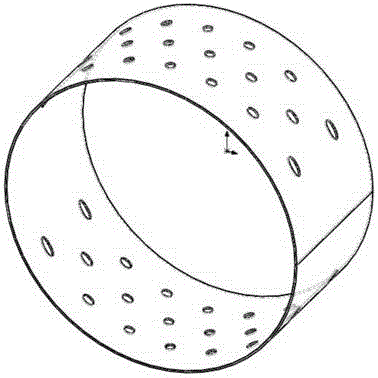

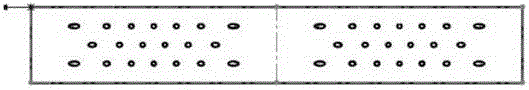

Method for numerical control forming of large quantity of holes in stainless steel cylinder

InactiveCN104028955AWill not deformGuaranteed positioning accuracyPlasma welding apparatusManufacturing technologyThree dimensional graphics

The invention provides a method for numerical control forming of a large quantity of holes in a stainless steel cylinder and belongs to the technical field of stainless steel carbonizers and similar containers or towers. The method comprises the following steps: a cylinder hole forming three-dimensional diagram is drawn by use of three-dimensional graphics software, the three-dimensional diagram of each section of the cylinder is unfolded according to a layout and converted into a graphic format which can be recognized by a numerical control cutting machine, an addition amount, a striking arc length, a cutting direction and a cutting order are set in a numerical control system according to the material of the cylinder and a plasma cutting method, all holes are cut by use of intermittent plasmas, the sections of the cylinder are molded and the unfitness of butt joint of end faces are controlled, and after welding is finished, the connection parts of the holes are planed and polishing is carried out to obtain the desired hole orientation. The method has the advantages that the problem of difficult, unsafe and inaccurate forming of a large quantity of holes by use of riveting after the stainless steel cylinder is molded is solved, and horizontal welding of 198 cooling water pipes in a stainless steel carbonizer with the cylinder.

Owner:XINXING ENERGY EQUIP +1

Urgent and accurate control method and system of large-scale interruptible load

PendingCN109687471AScale upMeet the needs of interruptible load controlProgramme controlPower network operation systems integrationControl systemMaster station

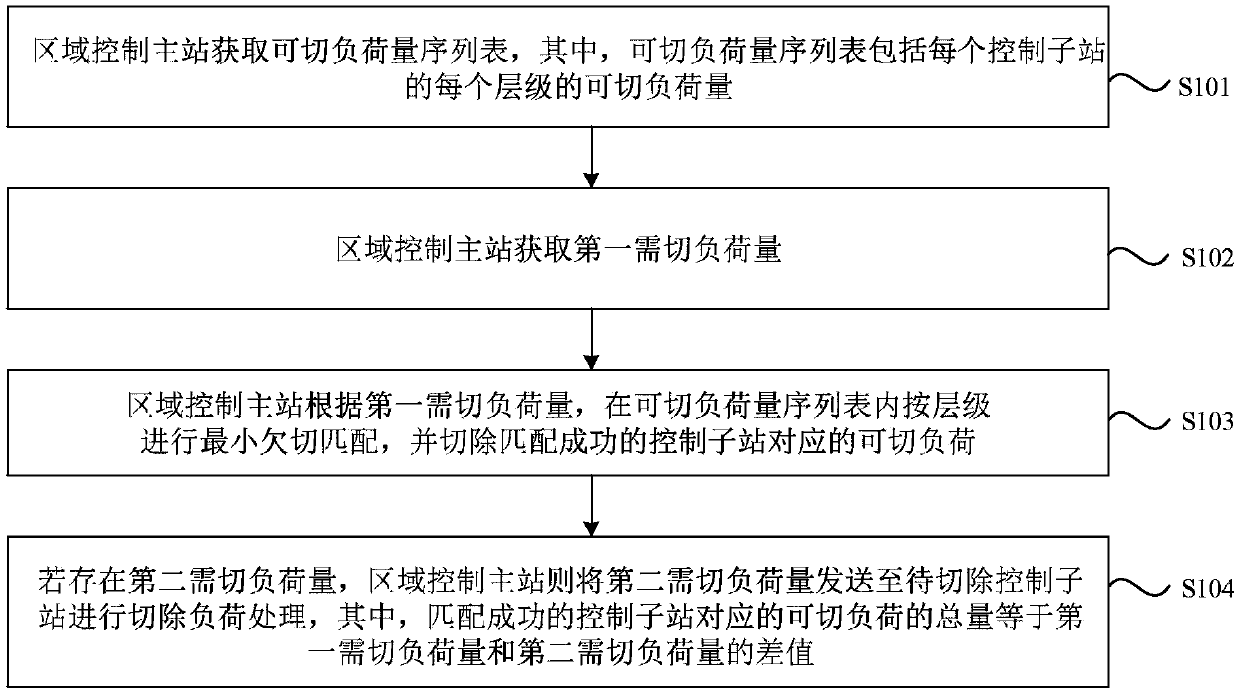

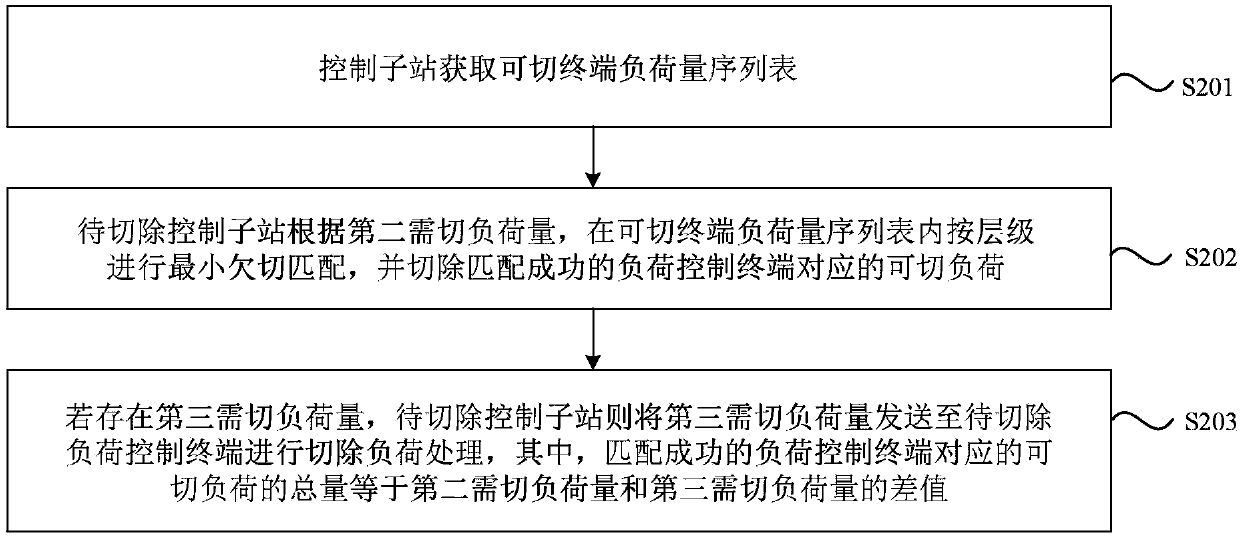

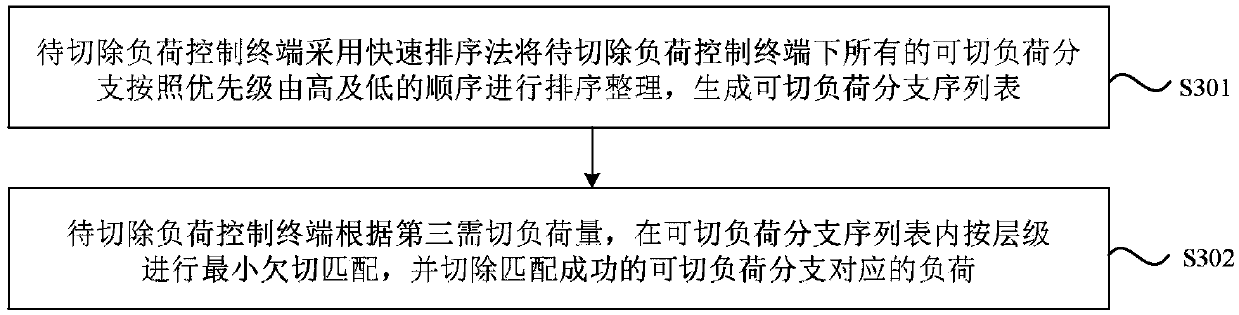

The embodiment of the invention discloses an urgent and accurate control method and system of a large-scale interruptible load. The urgent and accurate control method of the large-scale interruptibleload comprises the steps that an area control master station obtains a load capacity cutting sequence table; the area control master station obtains a first load capacity to be cut; the area control master station performs minimum undercut matching according to the first load capacity to be cut, and cuts off a successfully matching load cutting corresponding to control substations; if a second load capacity to be cut exists, the area control master station sends the second load capacity to be cut to the corresponding control substations for load cutting processing. According to the urgent andaccurate control system of the large-scale interruptible load, large-scale dispersive and interruptible load station connection is met, minimum undercut matching is carried out layer by layer, accurate and rapid cutting of the interruptible load according to priority ranking is realized, and the problem of large-area outage loss due to the fact that a large amount of interruptible loads and non-interruptible loads on cut circuits cannot accurately distinguished and the unbalanced capacity is larger after measures are executed is solved.

Owner:JIANGSU ELECTRIC POWER CO +1

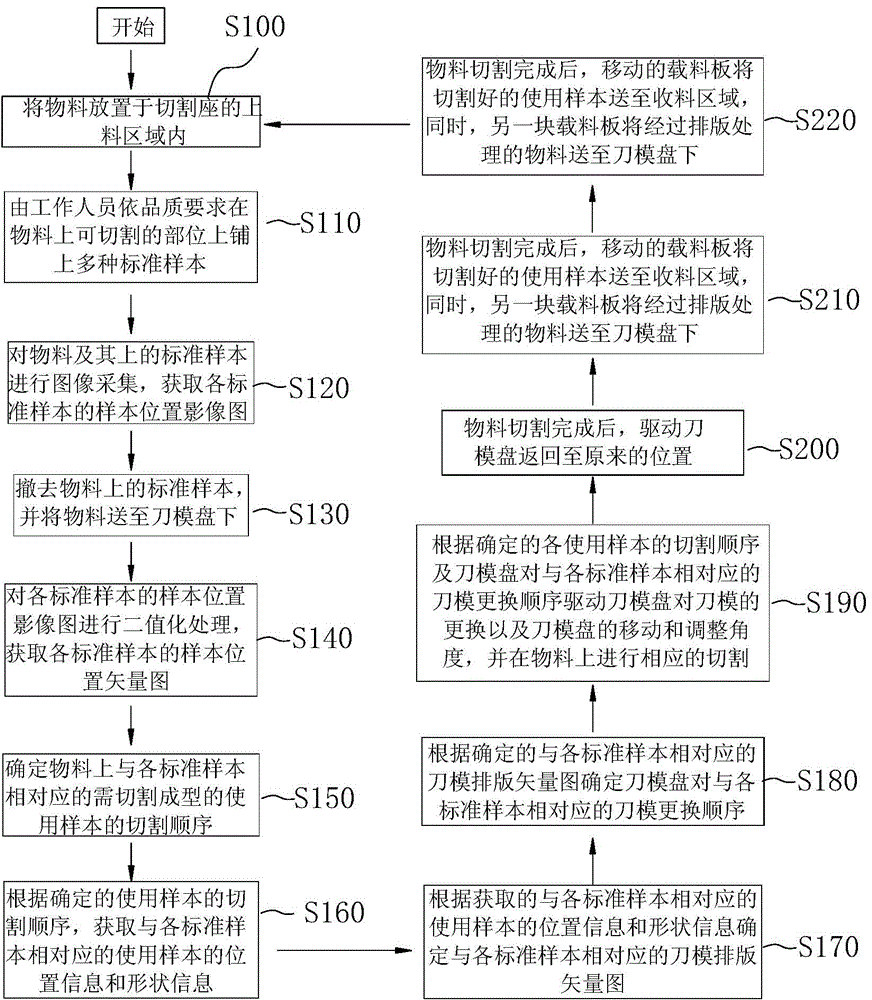

Cable pre-cutting process method

InactiveCN104409169AReduce the total amount of handlingReduce the difficulty of protectionCable/conductor manufactureRelevant informationEngineering

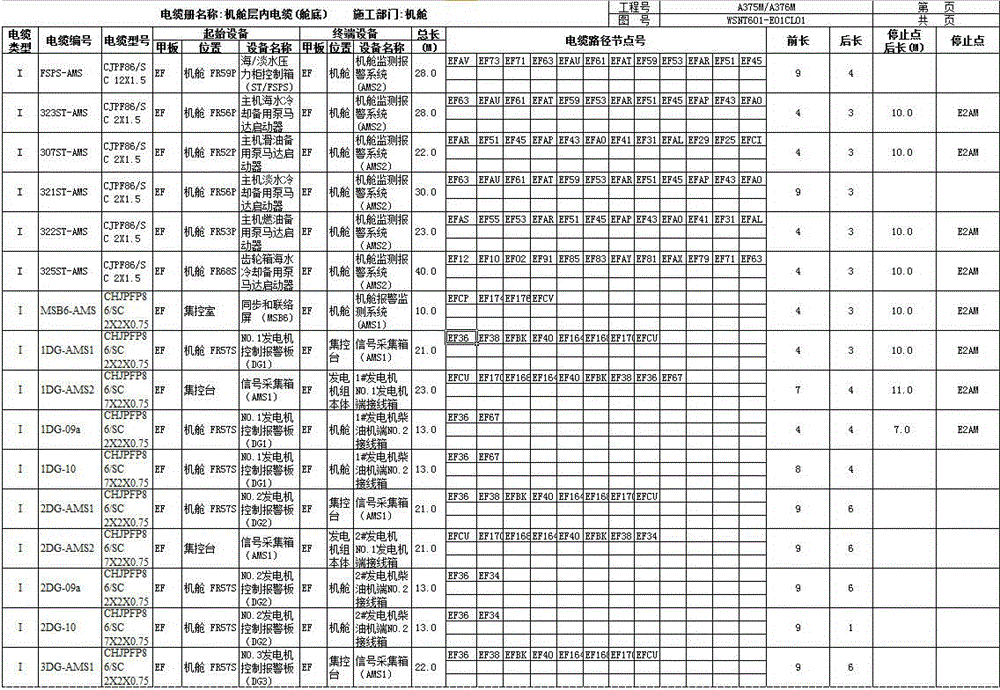

The invention discloses a cable pre-cutting process method, and aims to solve the problem of high cable cutting cost caused by a large cable total quantity and high protection difficulty in a cable cutting process in the prior art. The cable pre-cutting process method comprises the following steps: compiling information of pre-cut cables into a cable book, wherein in the compiling process of the cable book, summarized content comprises relevant information such as pages of each district cable and each bus cable, the statistical lengths of cables of various specifications in a whole ship, and the total length of the cable book; cutting the cables according to analytical data of the cable book; and sequencing and coiling the cut cables into a cable barrel according to the analytical data, wherein front cables in the cable book are coiled into the cable barrel firstly, and a cable cutting sequence is reverse to the sequence in the cable book, so that attention needs to be paid to a cable paving sequence and the front length or back length of a cable stopping point during compiling of the cable book. After application of the cable pre-cutting process method, the total cable carrying quantity is effectively reduced; the cable protection difficulty is lowered; and convenience is brought to production.

Owner:NANTONG BEST MARINE ENG

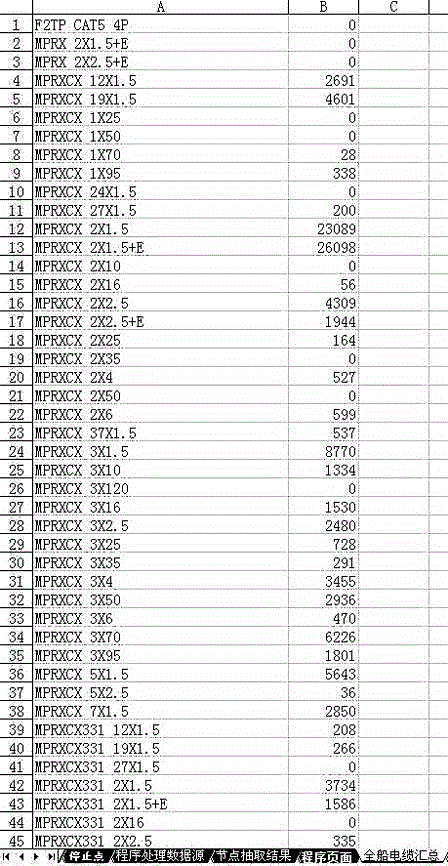

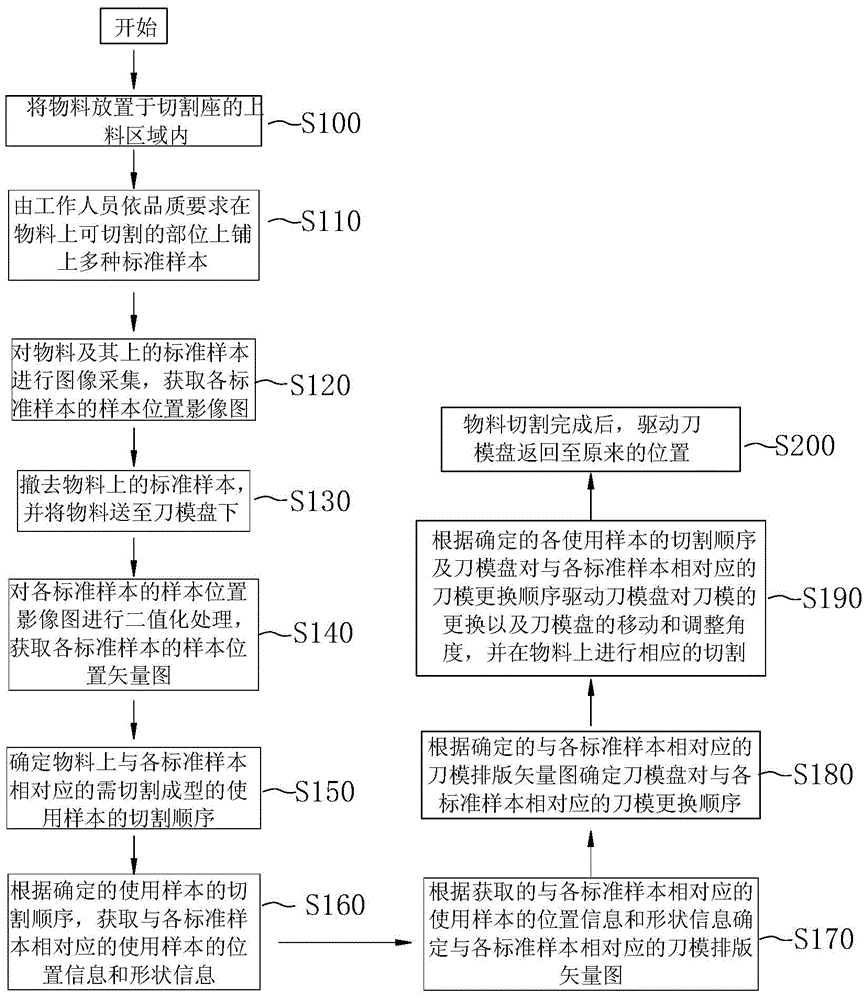

Automatic material cutting and forming method and system thereof

ActiveCN104908105ARealize automatic cuttingImprove applicabilityMetal working apparatusVector diagramStandard samples

The invention discloses an automatic material cutting and forming method and a system thereof. The method comprises the steps that materials are flattened and placed in a feeding area of a cutting seat; multiple standard samples are laid on the material portions which can be cut by a worker according to the quality requirements; image acquisition is performed on each standard sample on the materials to acquire a sample position striograph of each standard sample; the standard samples on the materials are removed, and the materials are conveyed to the position under a cutting die plate; a sample position vector diagram, in the DXF, of each standard sample is acquired; the cutting sequence of the using samples needing to be cut and formed on the materials is determined; a cutting die type setting vector diagram is acquired; corresponding cutting is performed on the materials according to the cutting sequence of the using samples and the cutting die type setting vector diagram; after material cutting is finished, the cutting die plate returns to an original position. According to the automatic material cutting and forming method and the system thereof, not only are the optimizing type setting applicability and speedability of the standard samples on the materials with different shapes greatly improved, but also automatic cutting of the materials is achieved, and time and labor are saved.

Owner:DONGGUAN LEANERP SOFTWARE

Method for preparing enzyme through coexpression of recombinant protease and molecular chaperone

InactiveCN102250846AEffective enzyme removalNo residueMicroorganism based processesOxidoreductasesEscherichia coliProteinase activity

The invention discloses a method for preparing enzyme through coexpression of recombinant protease and molecular chaperone. In the method, recombinant plasmids for encoding formaldehyde dehydrogenase and formaldehyde superoxide dismutase are respectively converted into expression strains containing molecular chaperone coexpression plasmids, so that protease and the molecular chaperone are co-expressed and soluble recombinant expression of the protease (comprising histidine tag or not comprising the histidine tag) is achieved. The formaldehyde dehydrogenase, the formaldehyde superoxide dismutase and the histidine tag are subjected to fusion expression, soluble recombinant protein is subjected to affinity purification by the histidine tag to form the protein with the purity of over 90 percent, and about 1 milligram of protease can be obtained when 1 gram of thalli are obtained averagely. An enterokinase cutting sequence is introduced between the histidine tag and the protease, the tag can be removed through enzyme cutting, and amino acid carrier residue is absent. By the method, the soluble expression of the protease in an Escherichia coli expression system can be promoted, and massive recombinant protease can be efficiently prepared through purification.

Owner:上海近岸科技有限公司

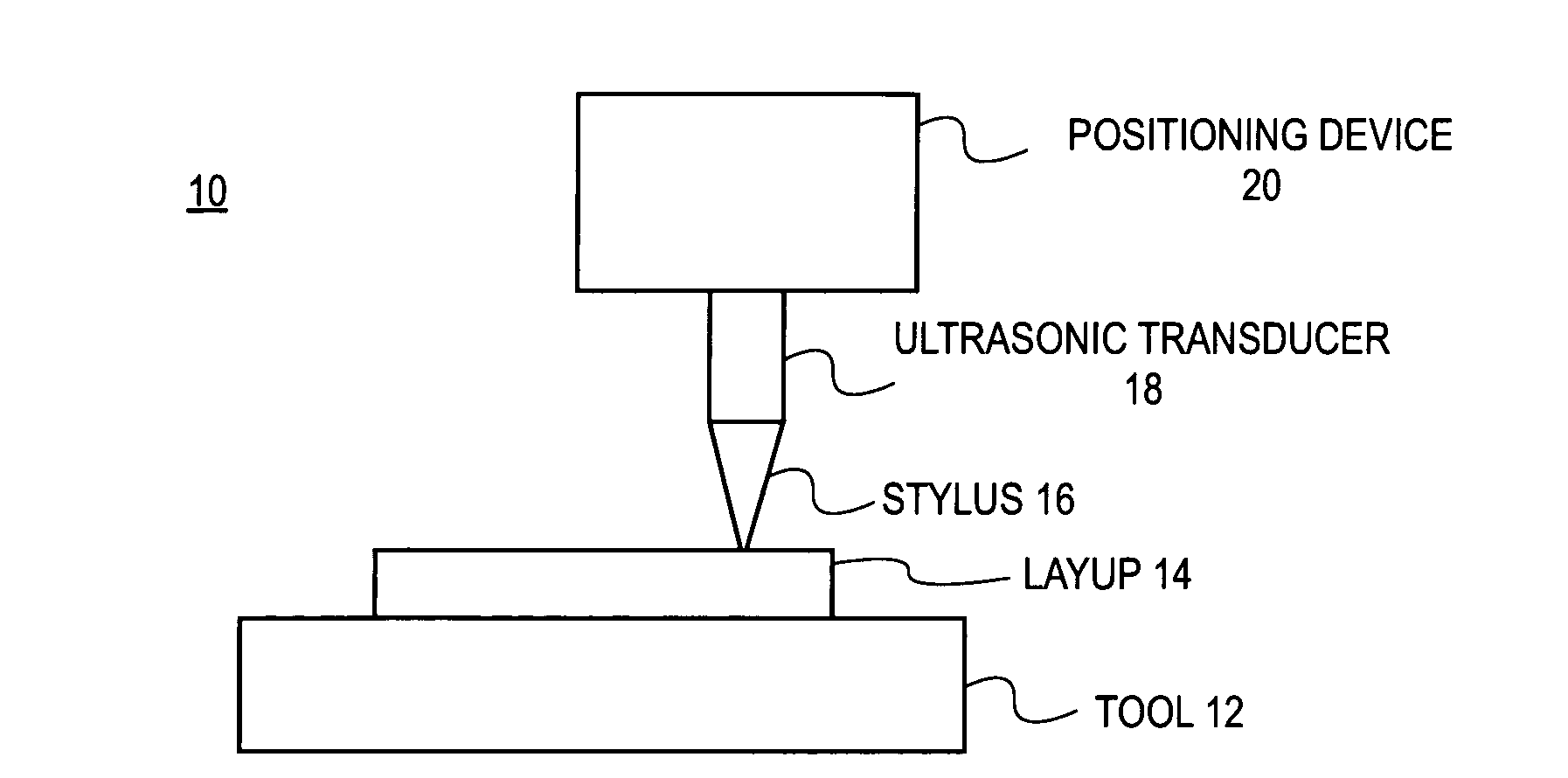

Laser cutting system

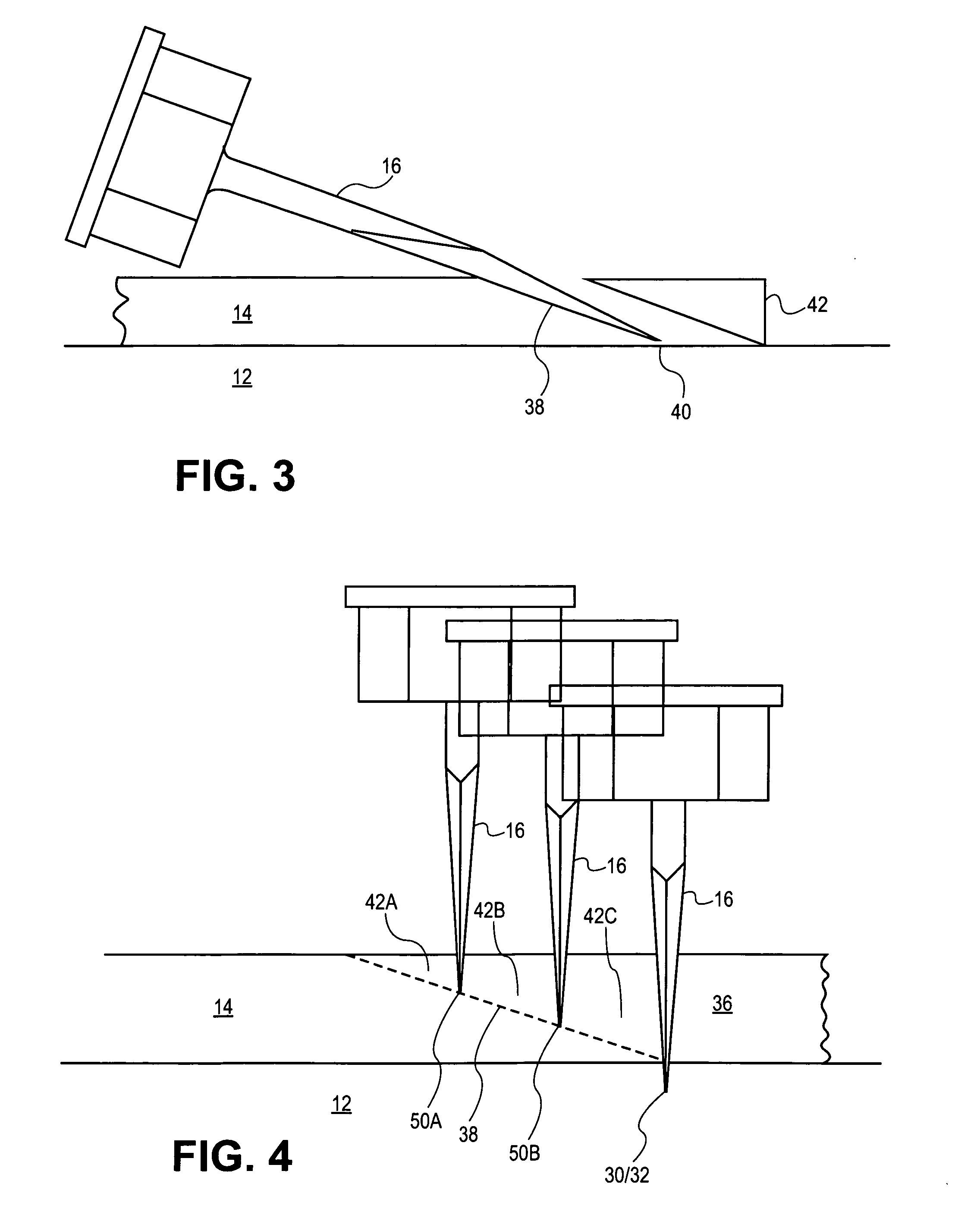

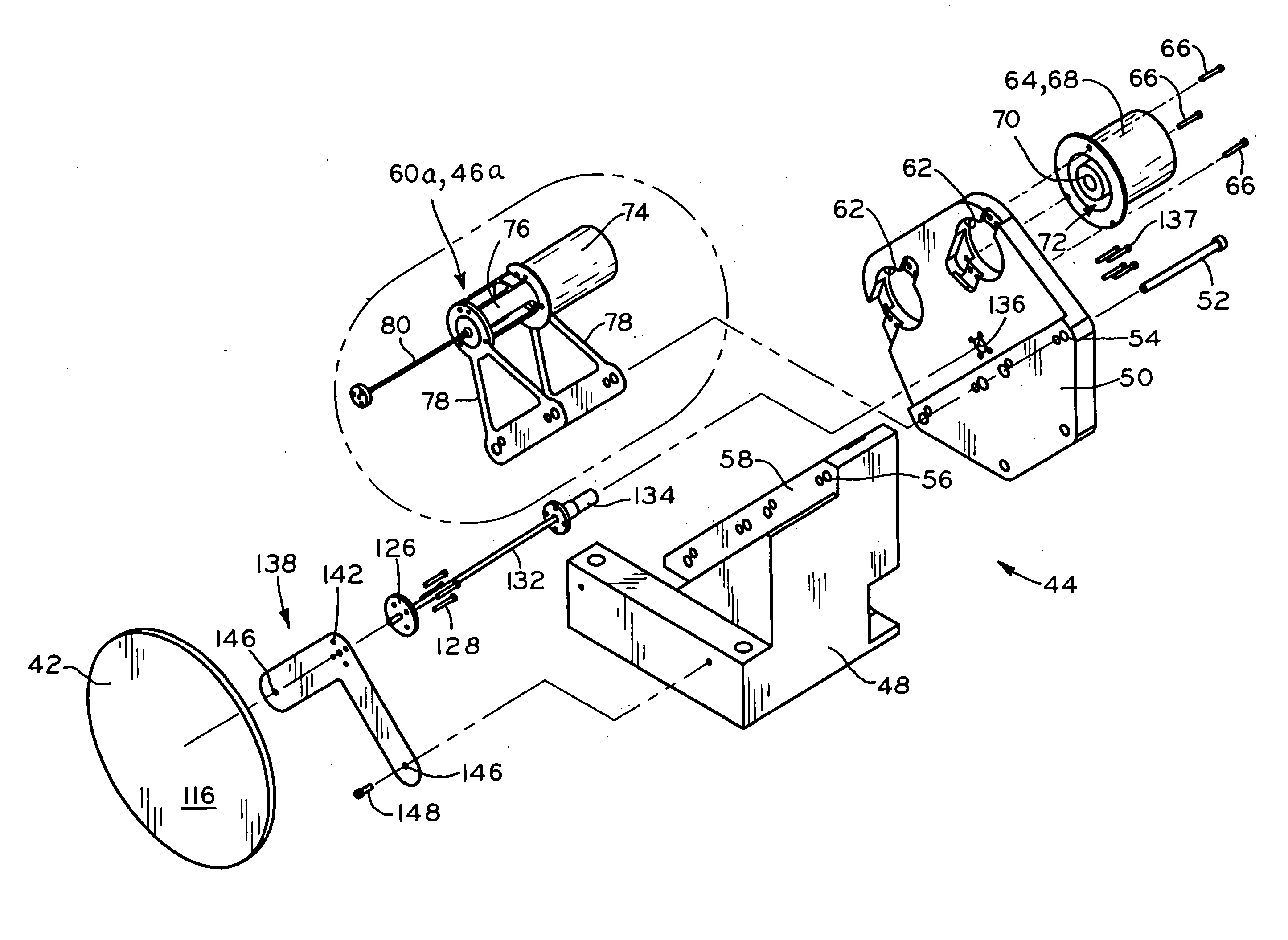

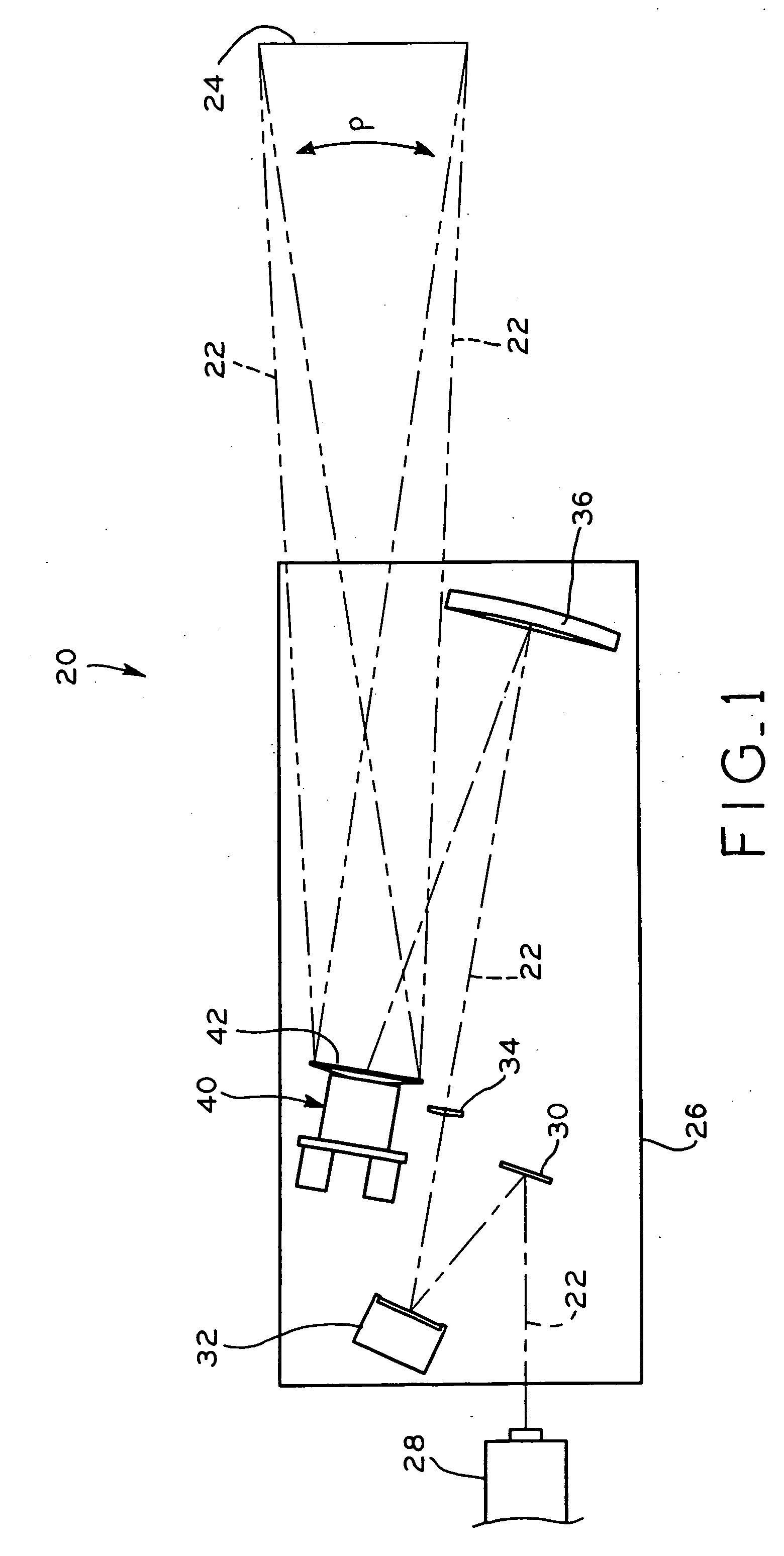

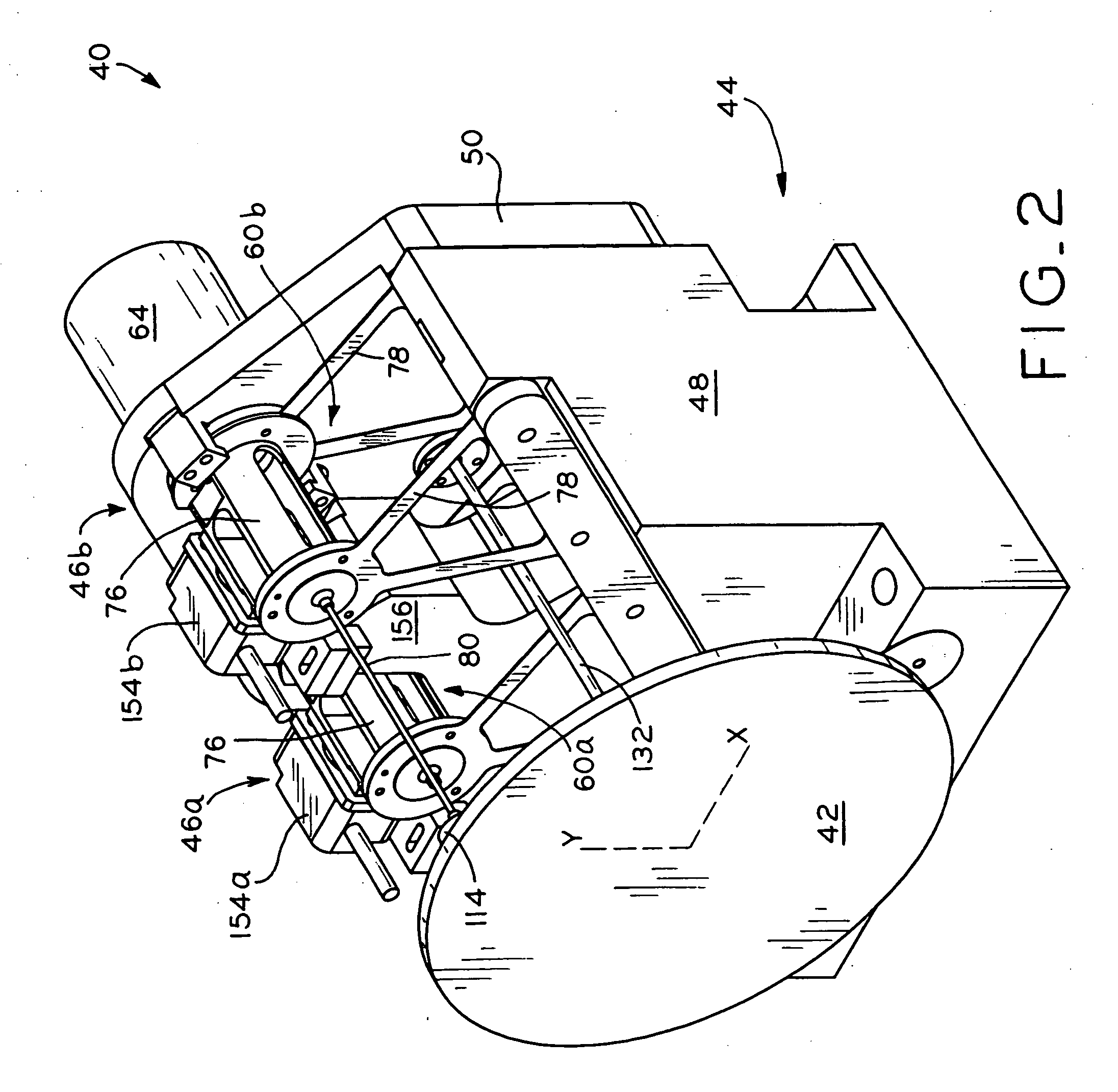

InactiveUS20060044655A1Increase computing speedEasy to assembleMountingsLaser beam welding apparatusBobbinEngineering

A laser cutting system, including a steering mirror assembly for directing a laser beam through a predetermined cutting path along a workpiece or substrate material. The steering mirror assembly includes a base, and a mirror pivotally supported on the base by a flexure assembly which confines pivotal movement of the mirror about a vertical Y-axis and / or about a horizontal X-axis. A pair of electrical actuator assemblies include movable bobbin assemblies connected to the mirror by control rod flexures at locations on the mirror which are spaced 90° apart from one another. In operation, selective electrical energization of the actuator assemblies controls movement of the bobbin assemblies to pivot the mirror about the vertical Y-axis and / or about the horizontal X-axis throughout a number of angular orientations to thereby direct the laser beam through a predetermined cutting operation pattern along the substrate surface to cut materials from the substrate. The flexure arrangements which support the mirror on the base and which connect the bobbin assemblies to the mirror facilitate substantially frictionless movement of the bobbin assemblies and the mirror, which allows the mirror to pivot at high operational speeds during the cutting sequence.

Owner:DOT INTPROP

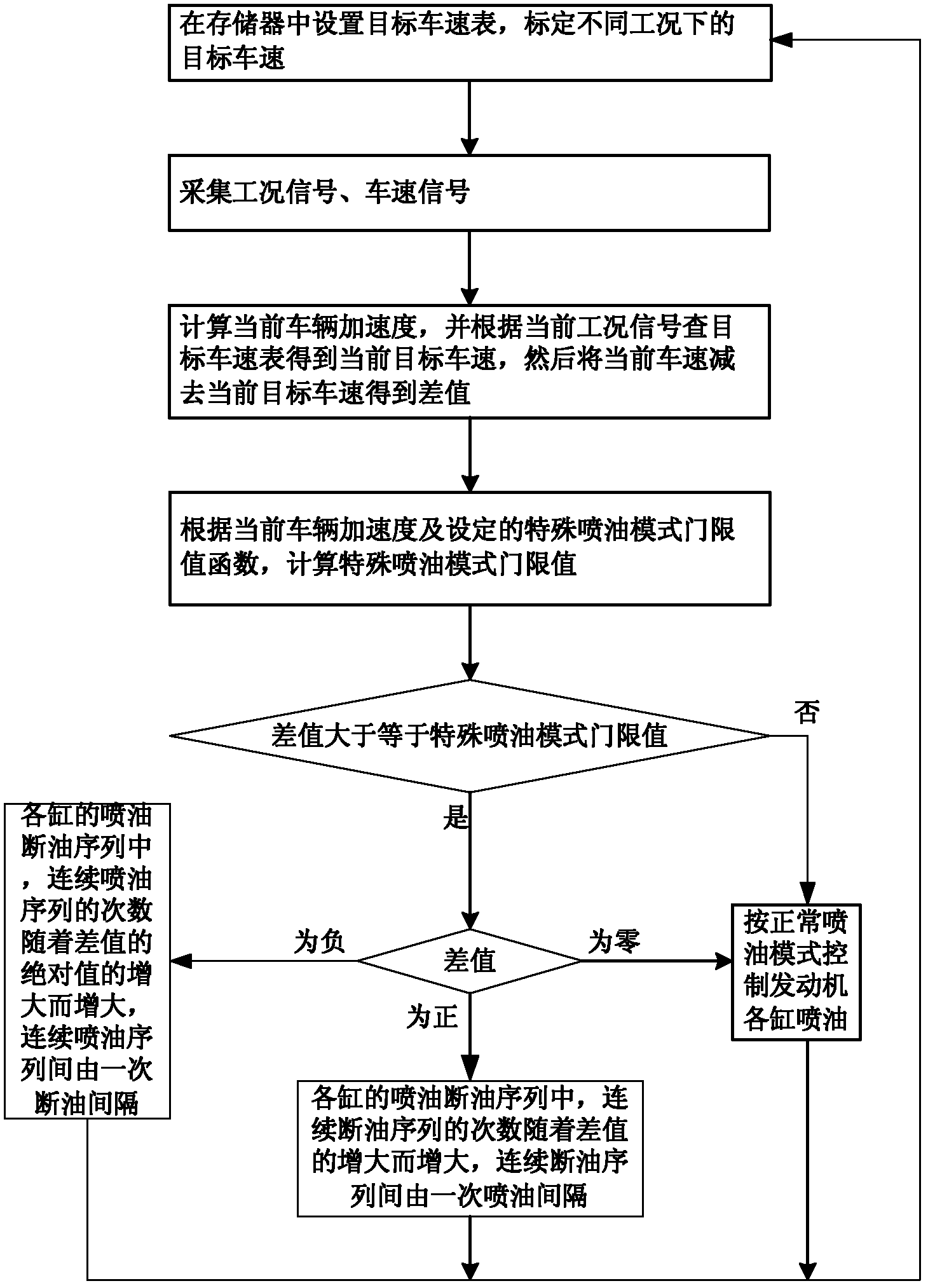

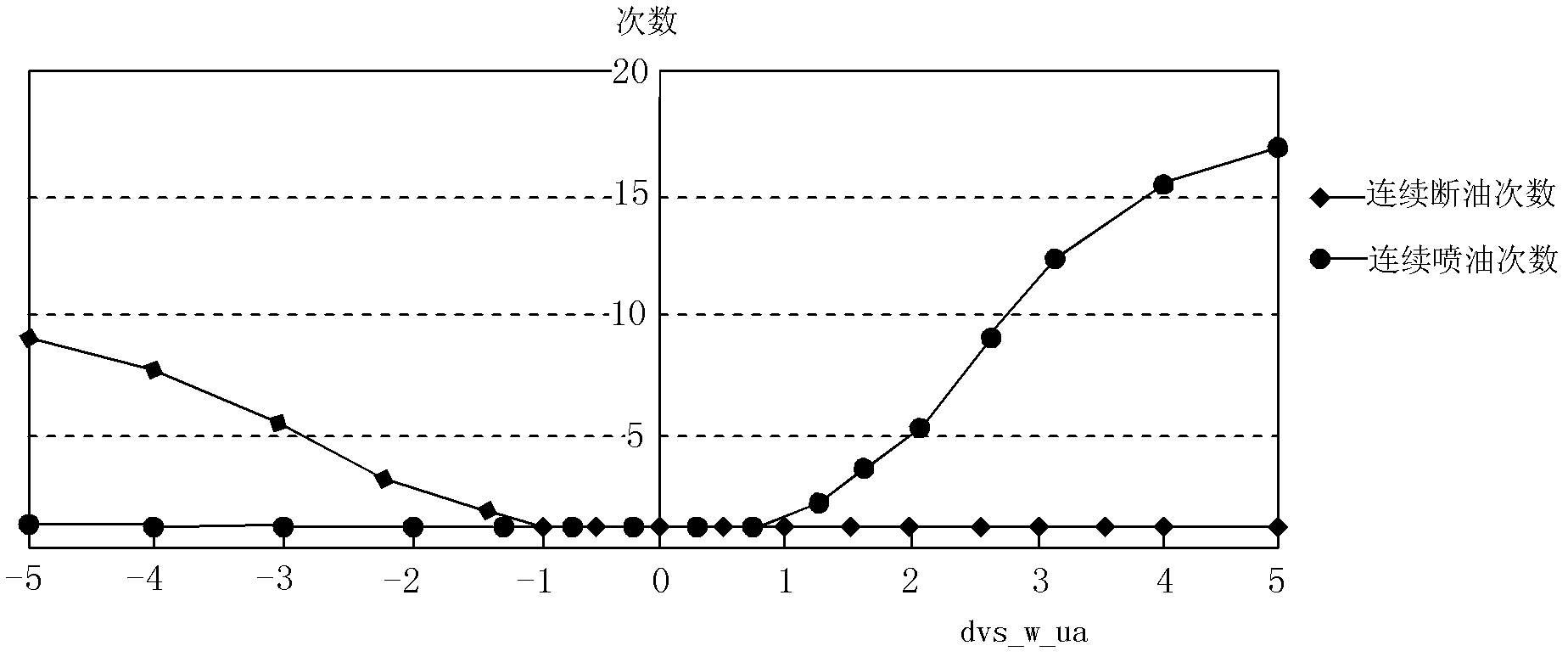

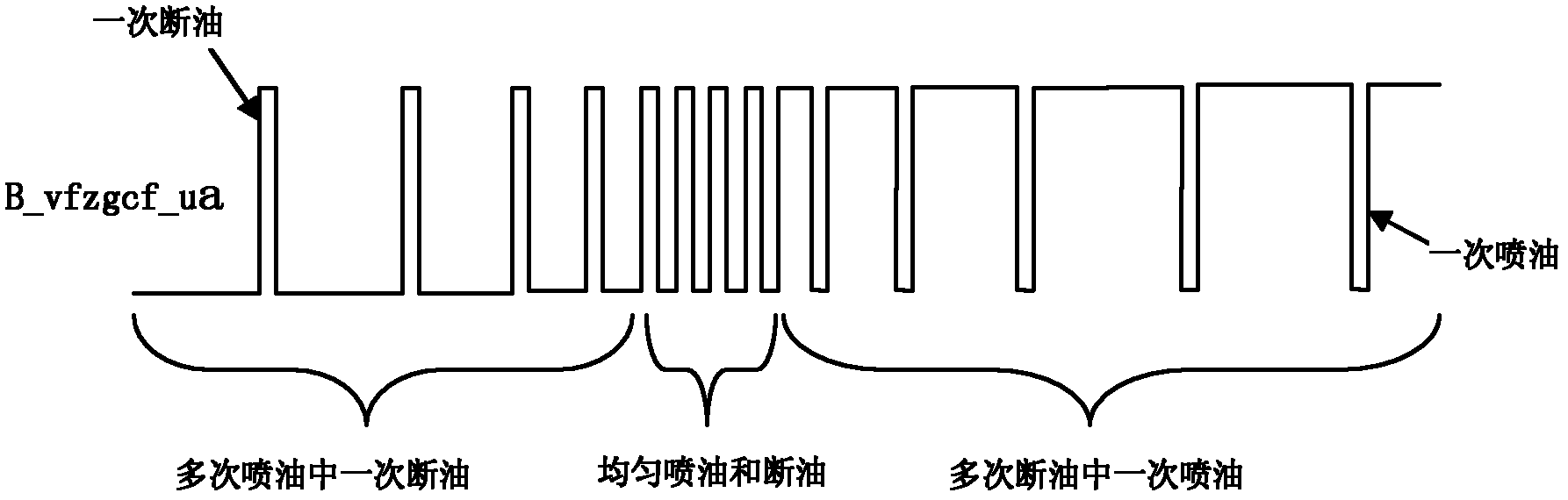

Automobile speed control method for electronic fuel injection automobile

ActiveCN102434301AGuaranteed smooth progressRealize vehicle speed controlElectrical controlMachines/enginesSingle-cylinder engineCutting sequence

The invention discloses an automobile speed control method for an electronic fuel injection automobile, which can calculate automobile accelerated speed based on automobile speed signals, achieve current objective automobile speed according to current work condition, obtain a differential value by using the current automobile speed to subtract the current objective automobile speed, and calculate a special fuel injection mode threshold value according to current automobile acceleration speed. When the differential value is larger than or equal to the special fuel injection mode threshold value and the differential value is minus, number of times of continuous fuel injection sequence in fuel injection fuel cut sequence of each cylinder increases with enlargement of the absolute value of the differential value, and the continuous fuel injection sequence is separated by one fuel cut. When the differential value is zero, the fuel injection fuel cut sequence of each cylinder is in normal fuel injection mode. When the differential value is positive, number of times of continuous fuel cut sequence in fuel injection fuel cut sequence of each cylinder increases with enlargement of the differential value, and the continuous fuel cut sequence is separated by one fuel injection. The automobile speed control method for the electronic fuel injection automobile can effectively limit automobile of the electronic fuel injection automobile with a single cylinder engine or a multiple cylinder engine, and the automobile speed is small in fluctuation.

Owner:UNITED AUTOMOTIVE ELECTRONICS SYST

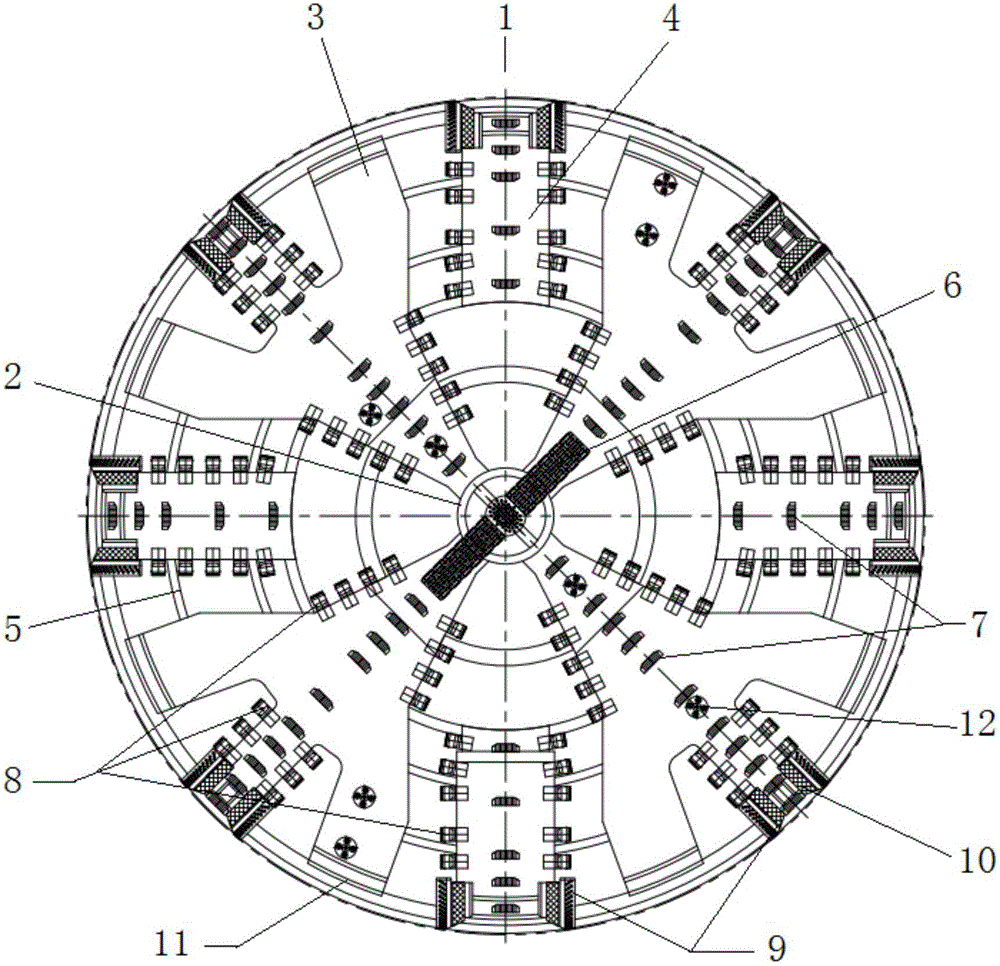

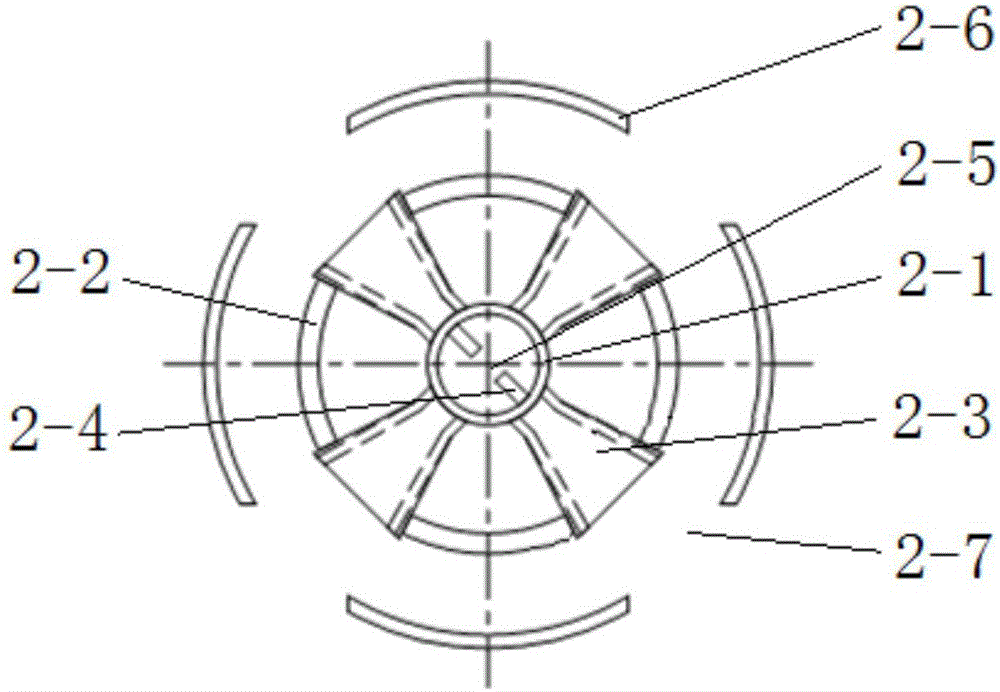

Shield tunneling machine cutterhead suitable for expansible old clay

The invention discloses a shield tunneling machine cutterhead suitable for expansible old clay. The shield tunneling machine cutterhead comprises a cutterhead body, a combined faceplate is arranged at the center of the cutterhead body, four main ribbed plates and four spokes are arranged around the combined faceplate, the main ribbed plates and the combined faceplate are connected to form a cross, the spokes are arranged on the cutterhead body between each two adjacent main ribbed plates, the tail ends of the spokes are fixed to the combined faceplate, the spokes and the main ribbed plates are fixed through steel grids which are annularly arranged at intervals, a reinforced central fishtail scraper which is arranged along the diameter direction is mounted at the center of the combined faceplate, and the reinforced central fishtail scraper is coincident with a central line of the two main ribbed plates on a same straight line. The shield tunneling machine is novel in structural design, aperture rate of the cutterhead is increased, fluidity of muck is improved, probability of forming a mud cake on the cutter head is avoided, cutting track and cutting sequence of the cutterhead are optimized, wear resistance of the whole cutterhead is improved, adaptability of a shield tunneling machine in expanding oil clay is improved effectively, and shield tunneling construction efficiency is improved.

Owner:CHINA RAILWAY 16 BUREAU GRP BEIJING METRO ENG CONSTR +1

Saw cutting method of square pipe saw cutting machine

ActiveCN107052446AIncrease profitReduce manufacturing costMetal sawing devicesControl systemCutting-plane method

The invention discloses a saw cutting method of a square pipe saw cutting machine. The saw cutting method includes the following steps that firstly, a task list of a list form is input in a control system of the saw cutting machine, wherein the task list includes a production piece task list, and the production piece task list comprises end portion angles and lengths of the two ends of each production piece and the length and width size information of square pipes; secondly, the control system reads and analyzes all parameters of the production pieces in the production piece task list and conducts simulation cutting, wherein according to the principle of analysis, the angles are analyzed before the lengths; thirdly, various simulation cutting sequences are achieved after analysis and simulation are completed, and the primary optimal simulation cutting sequence with the highest square pipe utilization rate is selected; and fourthly, the raw material square pipes are subjected to saw cutting through the square pipe saw cutting machine according to the primary optimal simulation cutting sequence. The saw cutting method is suitable for cutting of the various square pipes of different specifications at the same time, the utilization rate of each raw material square pipe is increased, the after-product length is decreased, and therefore cost is reduced.

Owner:苏州斯马拓智能化装备有限公司

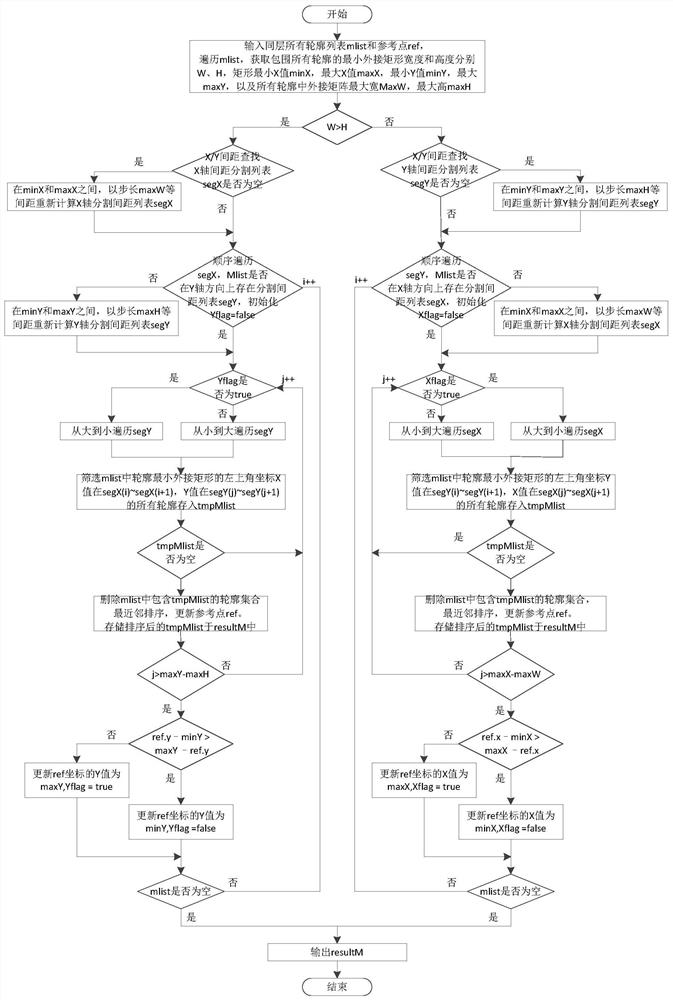

Cutting path optimization method and device and computer readable storage medium

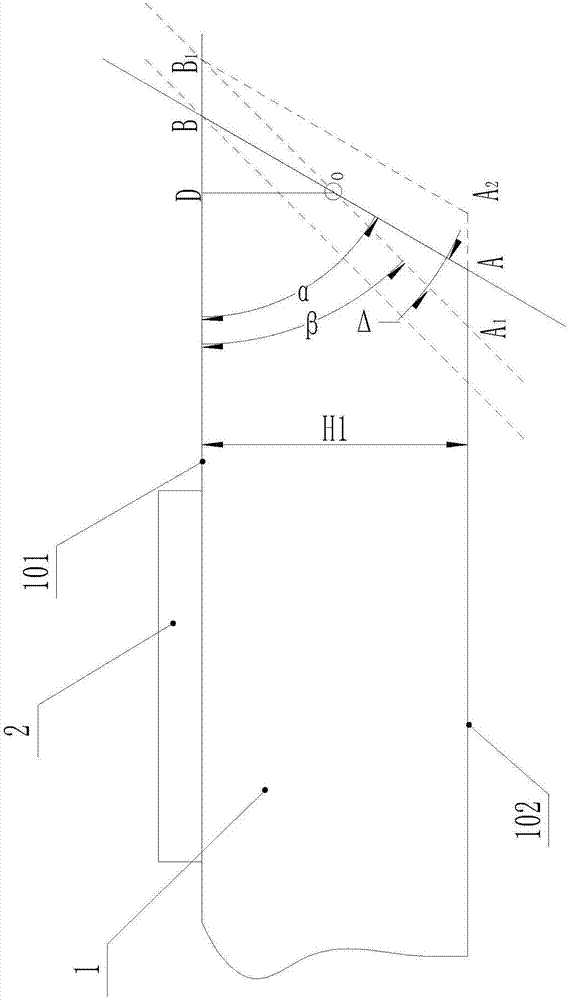

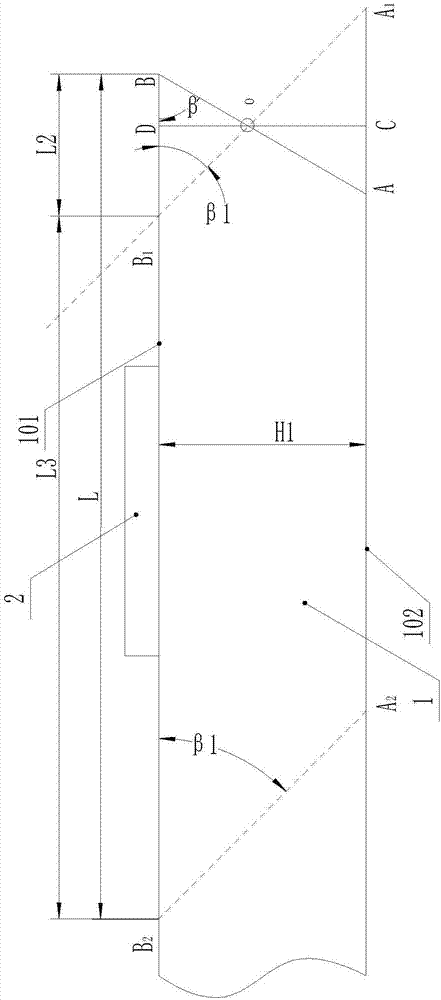

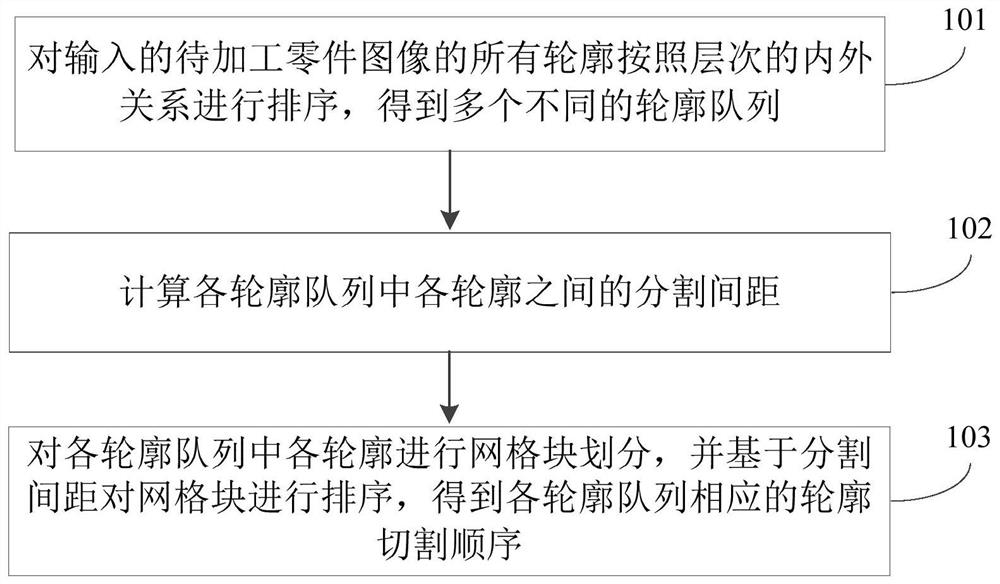

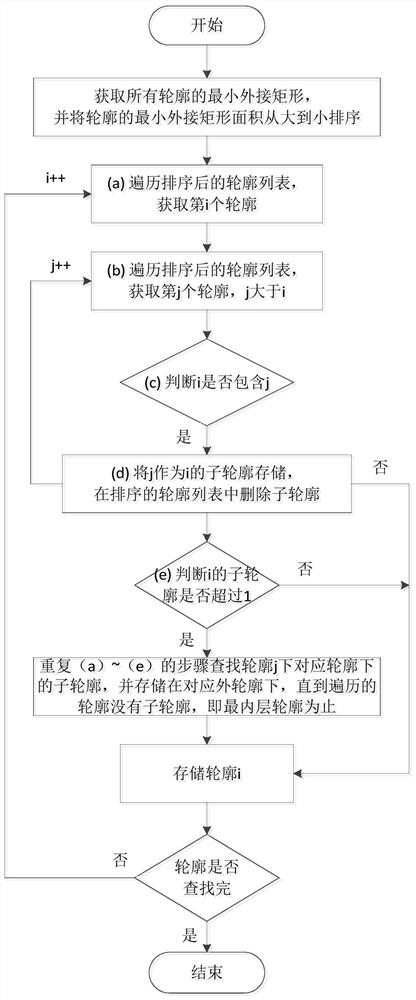

PendingCN112935575AGuaranteed optimized efficiencyImprove effectivenessLaser beam welding apparatusNumerical controlPathPingAlgorithm

The invention discloses a cutting path optimization method and device and a computer readable storage medium. The method comprises the following steps: carrying out sorting of all contours of an input to-be-machined part image according to the internal and external relation of a hierarchy to obtain a plurality of different contour queues; calculating a segmentation distance between the contours in each contour queue; and carrying out grid block division on each contour in each contour queue, and sorting the grid blocks based on the segmentation distance to obtain a contour cutting sequence corresponding to each contour queue. Through implementation of the cutting path optimization method and device and the computer readable storage medium, an analysis mode of the machined part from the global to the local is adopted; and the adaptive grid blocks are designed to segment the contours of the to-be-machined parts, and then path optimization is carried out on the contours of the grid blocks, so that the space shift distance between the contours of the parts is as short as possible, effectiveness of a path optimization result is improved, the calculation amount of path optimization is relatively small, and the path optimization efficiency is effectively ensured.

Owner:HANS LASER TECH IND GRP CO LTD +1

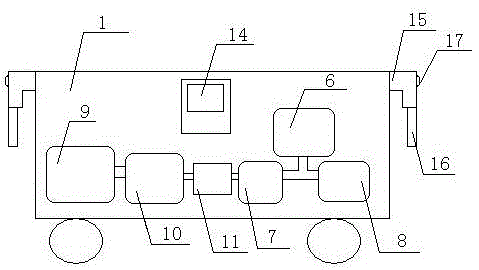

Intelligent hedge trimming car

InactiveCN105557336AAutomate pruningSimple and fast operationHedge trimming apparatusCuttersElectric machineryEngineering

The invention relates to an intelligent hedge trimming car. The car comprises a car body. Horizontal cutters are respectively arranged on the left and right sides in the car body. The horizontal cutters are connected on the car body through automatically telescopic mechanical traction arms. Vertical cutters are arranged on the upper part in the car body. The vertical cutters are connected on the car body through an elevation mechanical arm. The horizontal cutters and the vertical cutters are all controlled by a cutting control device arranged outside the car body. The cutting control device comprises a cutting motor used for providing cutting power, a variable speed motor used for controlling cutting speed, and a step motor used for controlling a cutting sequence. A driving device used for driving the car body to travel is arranged outside the car body. The driving device comprises a driving motor used for driving the car body to travel, and a reciprocating motor used for driving the car body to perform reciprocating movements back and forth. A timing device used for controlling car body travelling time and cutting time is arranged outside the car body. With the above improvement, the intelligent hedge trimming car can realize automatic trimming, and has the characteristics of simple operation and good safety.

Owner:贾春燕

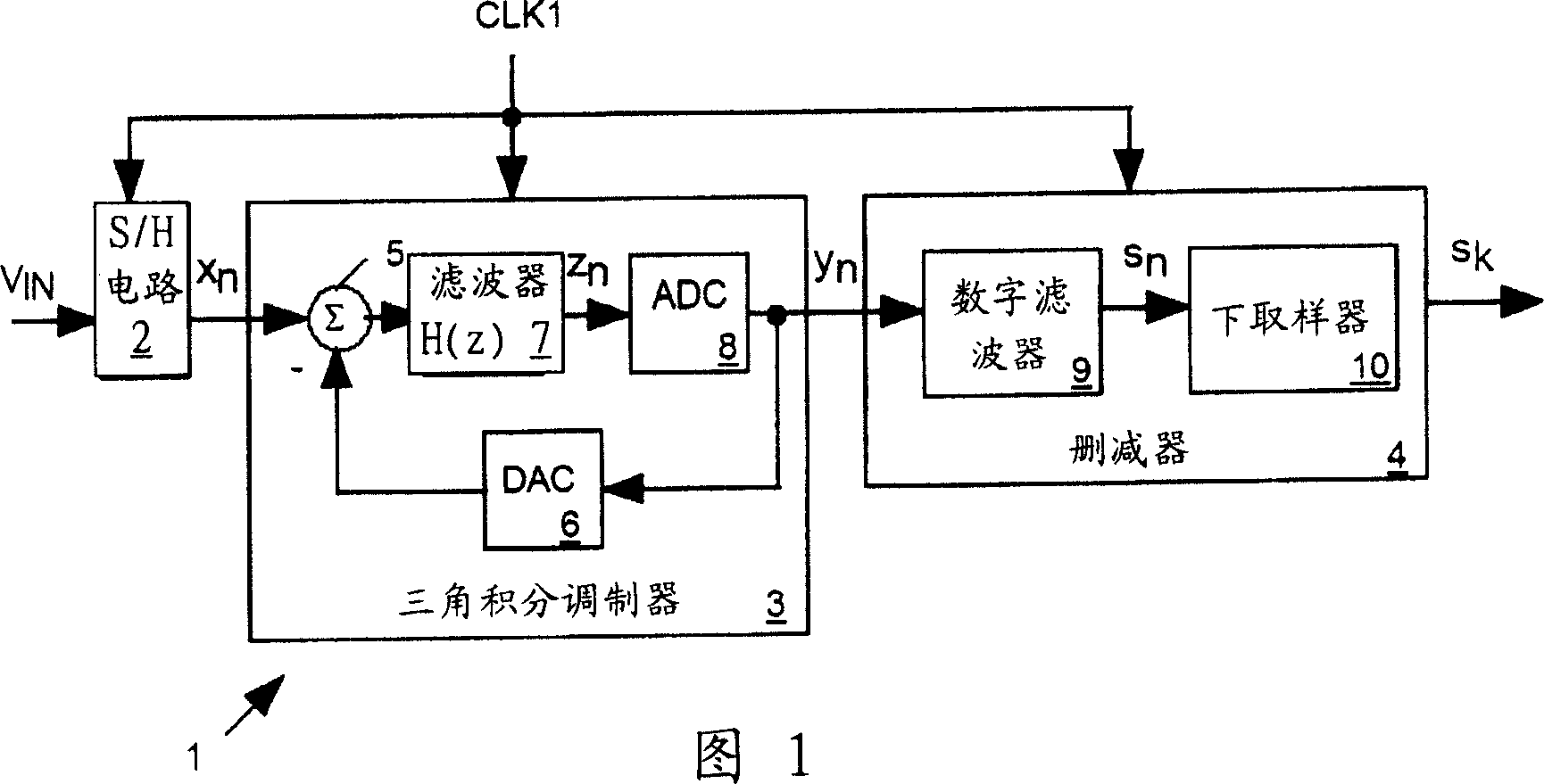

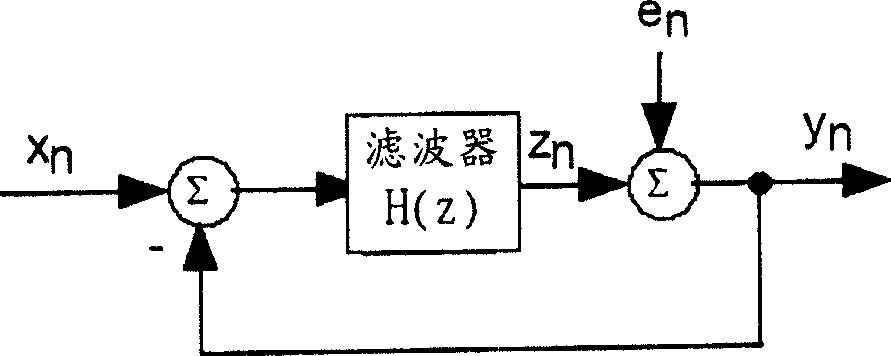

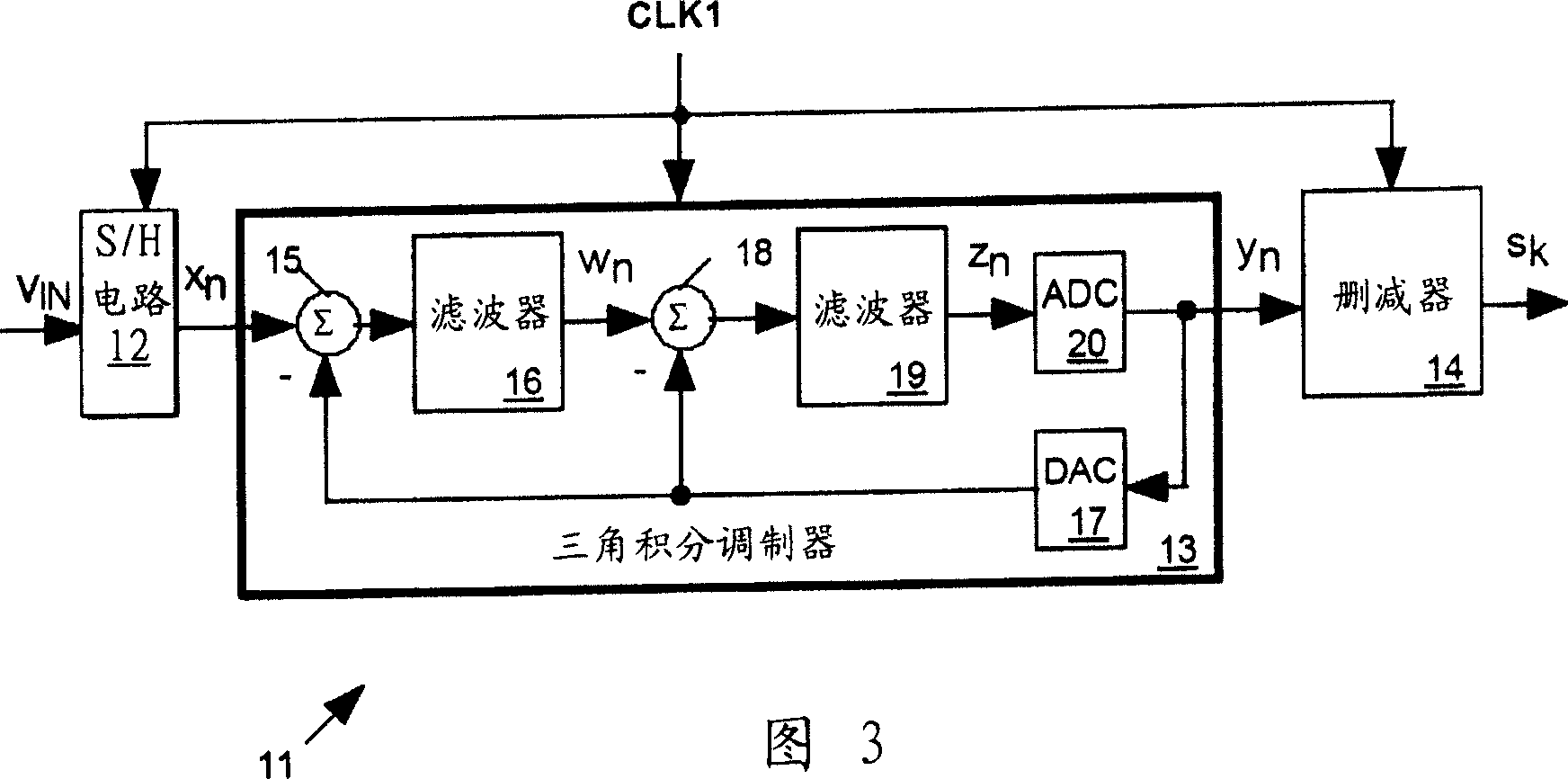

Multi-thread parallel processing sigma-delta ADC

Owner:REALTEK SEMICON CORP

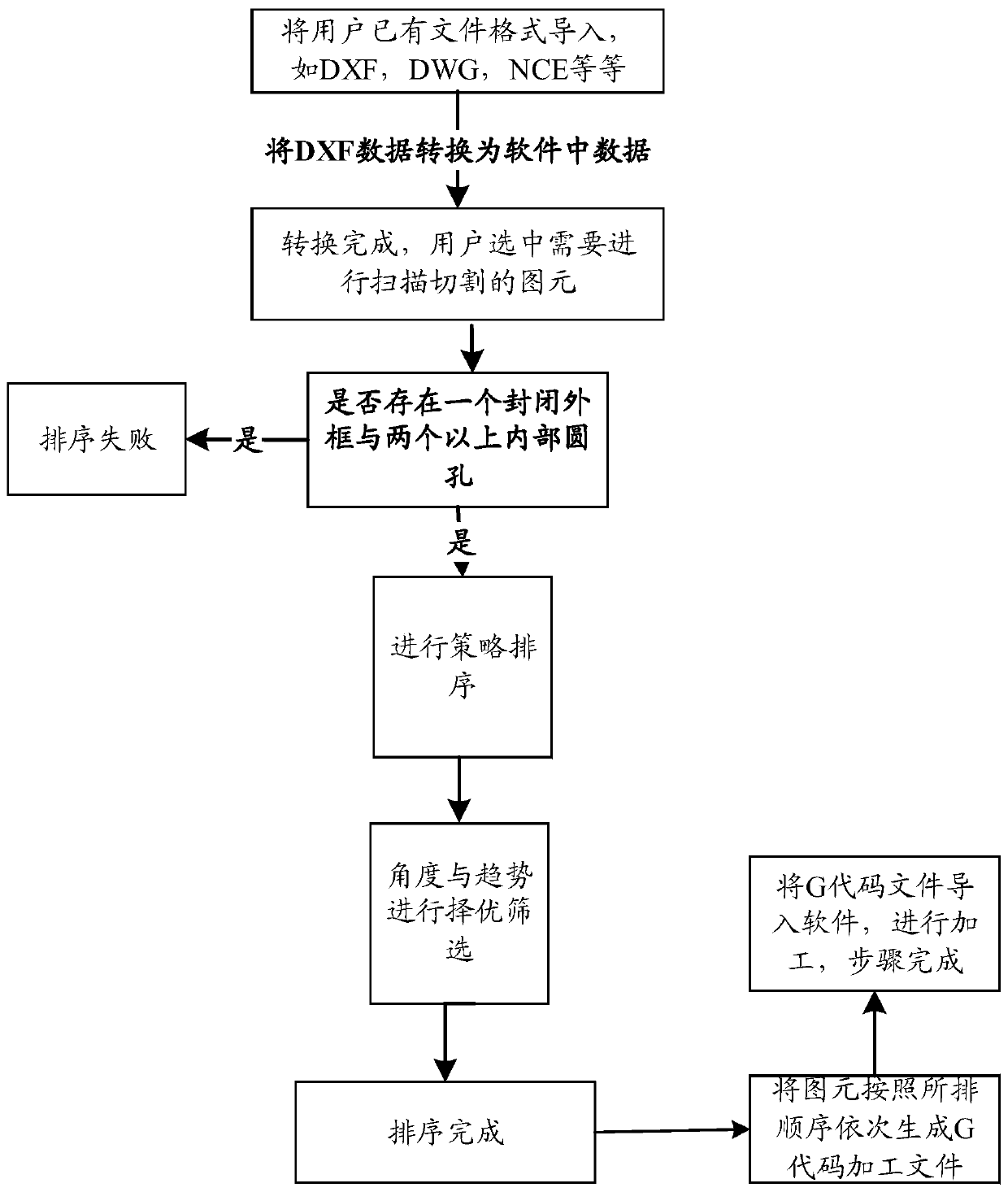

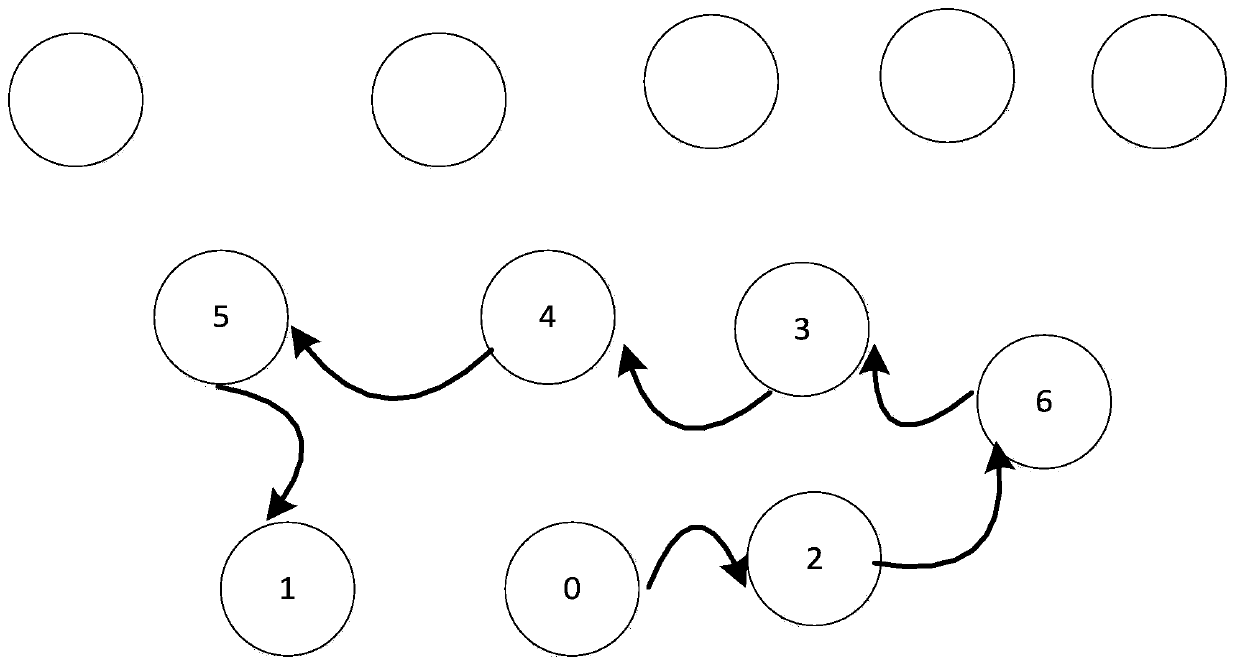

Graph cutting and sorting processing method applied to laser cutting numerical control machining

ActiveCN110968039AOvercome singleOvercome rigid flawsProgramme controlComputer controlGraphicsAlgorithm

The invention relates to a graph cutting and sorting processing method applied to laser cutting numerical control machining. The method comprises the following steps of: importing a CAD file into a laser numerical control system, converting the CAD file into primitive data according to a file format, and selecting primitive data to be machined; judging whether at least one closed outer frame primitive exists in the selected primitive data and at least two circular hole primitives exist in the selected primitive data or not, wherein if so, the steps are continued, and otherwise, the sorting fails; performing strategy sorting on the processing angle and the processing path trend direction of the primitive data; and sequentially converting the primitive data into G code processing files according to a sorting result, importing the G code processing files and processing the G code processing files. By the adoption of the graph cutting and sorting processing method applied to laser cuttingnumerical control machining, the cutting sequence can be connected into a straight line according to the rule that the round holes are formed from bottom to top or from left to right, the round holesconnected front and back can be in parallel transition, the cutting efficiency is improved, and the machining effect can be improved.

Owner:SHANGHAI WEIHONG ELECTRONICS TECH +1

Ultra small size chip cutting technology

InactiveCN108933103AImprove cutting stabilitySemiconductor/solid-state device manufacturingEngineeringWafer bonding

The invention discloses an ultra small size chip cutting technology. The technology includes steps of (1) fixing a wafer bonded with a scribing film on the back face on a chip ring; (2) putting the wafer and the chip ring into an oven for roasting; (3) putting the wafer subjected to roasting into a cutting machine and selecting a program for cutting, wherein the cutting sequence is first cutting along the short direction of the chip and then cutting along the long edge direction of the chip. According to the invention, the cutting technology of cutting along the short edge direction first andcutting along the long edge direction then is innovatively adopted, at the same time, a blue film roasting parameter, a cutting parameter and a scribing knife of a Z2 main shaft are adjusted so as tobreak a conventional cutting mode. The invention provides the ultra small size chip cutting technology. According to the invention, the chip yield rate of both of a testing chip and a client chip reach over 99.5% and chip cutting stability of different parts in one wafer is also improved greatly.

Owner:NINGBO CHIPEX SEMICON

Experiment method for simulating roadway fully-mechanized excavating process

ActiveCN106771058AIn line with production practiceEasy to operateEarth material testingExperimental methodsHeater Rod

The invention discloses an experiment method for simulating a roadway fully-mechanized excavating process and belongs to the field of similar simulated experiment base research. When a model is paved at a roadway position, a blocky paraffin block body with the size the same as that of the designed roadway is pre-buried, and a heating hole and a flow guide hole are formed in the block paraffin block body according to the heat energy radiation range of a heating stick and the heated melting condition of the blocky paraffin; a heating hole and a flow guide hole the same as those of the blocky paraffin are formed at the position, corresponding to the roadway, of a cover plate of an experiment rack, and the heating stick and a flow guide pipe with a heating layer are sequentially embedded into the holes and are numbered; in the experiment process, heating is controlled selectively according to the serial number of the heating stick, so that the melted blocky paraffin flows out of the nearest flow guide pipe with the heating layer, and roadway simulated excavation is realized under the conditions of different cutting sequences and different cutting routes. The experiment method is suitable for simulating a roadway fully-mechanized excavating process, accords with product practice, and is easy to operate and easy to implement.

Owner:CHINA UNIV OF MINING & TECH

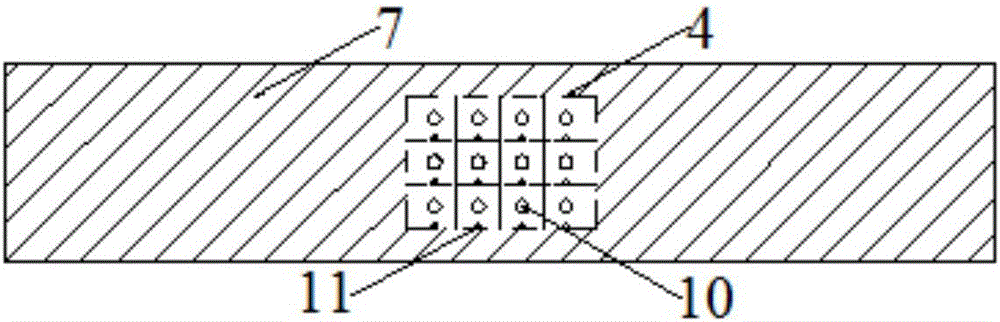

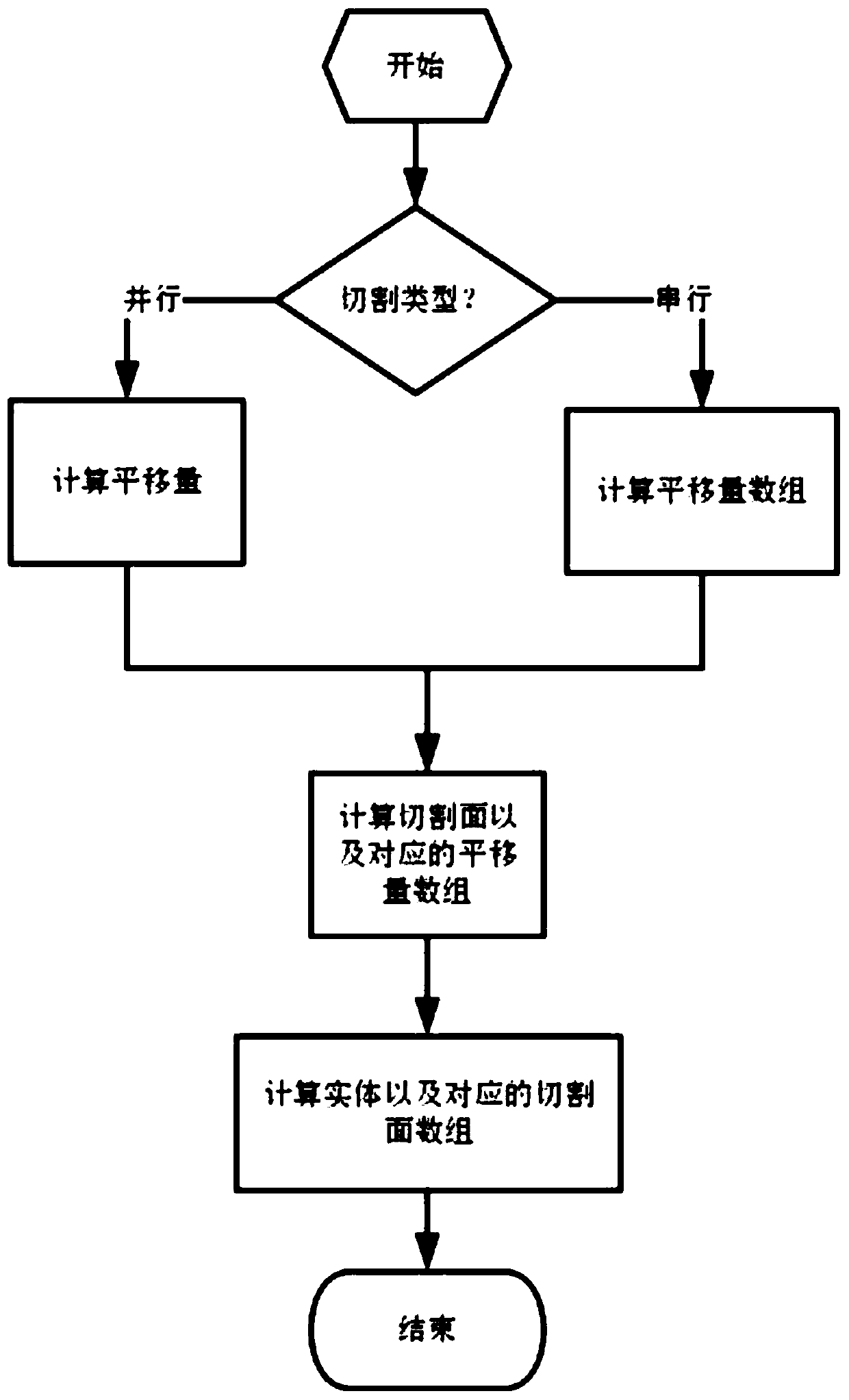

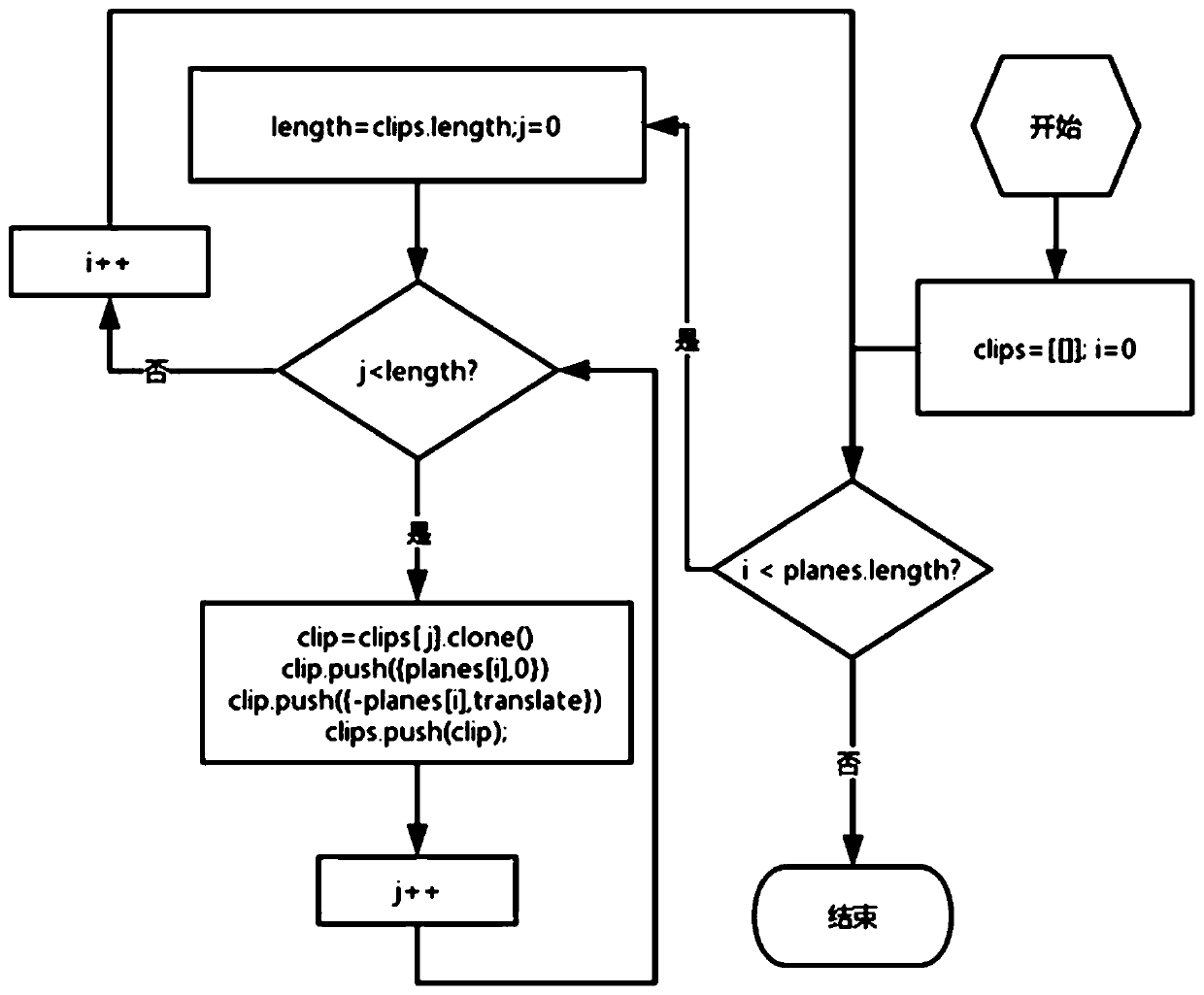

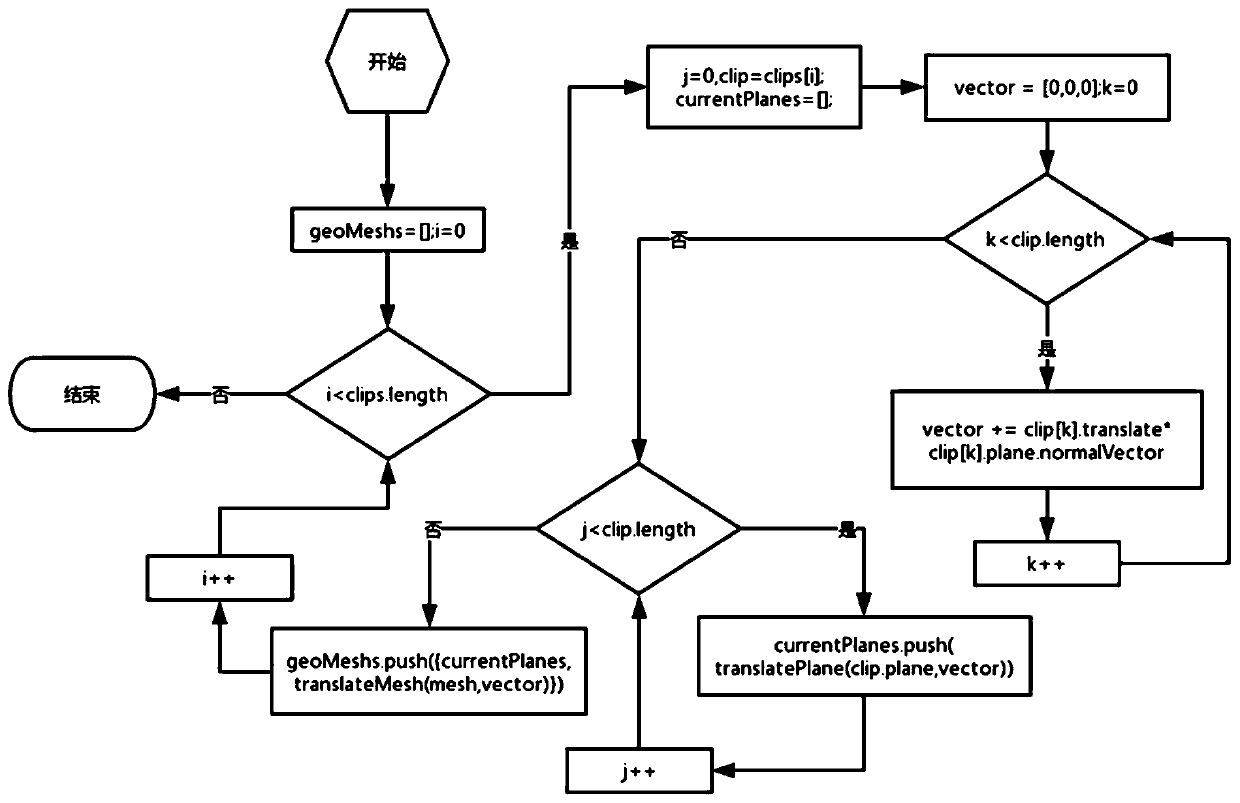

Parameter-based dynamic geometric three-dimensional graph cutting implementation method

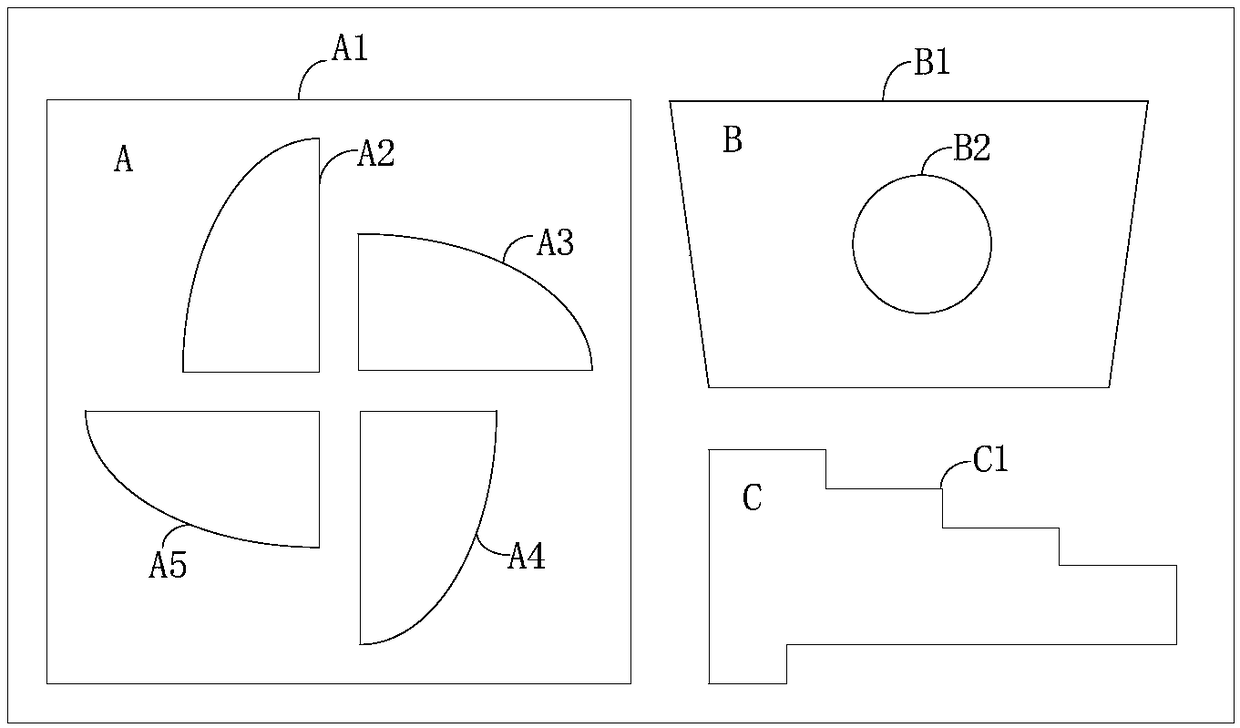

ActiveCN110428506AHave pursuasive powerMeet teaching needsAnimationTeaching apparatusGraphicsAnimation

The invention discloses a parameter-based dynamic geometric three-dimensional graph cutting implementation method, which comprises the following steps of: setting cutting attributes which comprise a cutting plane, a cutting type, a cutting control variable and cutting displacement, and the cutting control variable is a variable associated with a cutting animation; the cutting displacement is the maximum displacement of the cutting animation; the cutting surfaces are one or more planes, and the cutting types comprise serial cutting and parallel cutting; and the movement amount of the cut three-dimensional graph in the cutting process is determined according to the cutting control variable and the cutting displacement, the normal direction of the cutting surface determines the animation cutting direction of the cut three-dimensional graph on the plane, and the cutting process of the three-dimensional graph is dynamically displayed. According to the method, the multiple cutting surfaces are used for cutting the three-dimensional graph, the cutting rate is dynamically controlled through the parameters to achieve the dynamic cutting effect, the cutting sequence is expanded, parallel cutting and serial cutting are included and selected by a user, persuasion is better achieved, and the teaching requirement is met.

Owner:CHENGDU JINGZHONG EDUCATIONAL SOFTWARE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com