Method for numerical control forming of large quantity of holes in stainless steel cylinder

A technology of stainless steel cylinder and quantity, which is applied in welding equipment, metal processing equipment, plasma welding equipment, etc., can solve the problems of unsafe, inaccurate, and difficult opening of a large number of holes, and achieve convenient riveting operation, high efficiency, and shortened The effect of the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

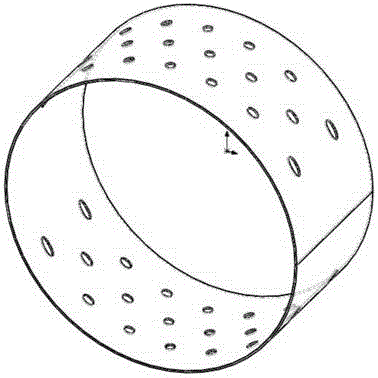

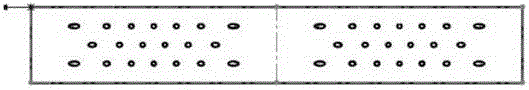

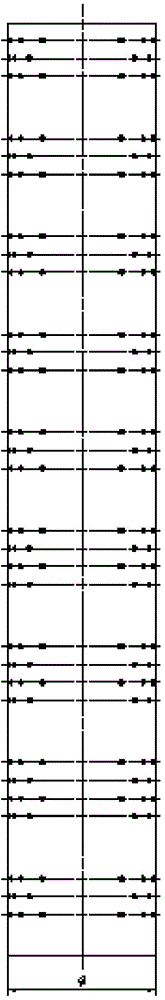

[0030] The method of opening a large number of numerically controlled holes on the stainless steel cylinder is: firstly, typesetting the cylinder in the axial and circumferential directions according to the material plate width according to the figure, using 3D drawing software to draw a three-dimensional diagram of the cylinder opening, and according to the layout drawing , expand the three-dimensional map of each barrel section from the longitudinal weld, import the expanded view of each barrel section into the CNC cutting machine control system, and set the increase amount, arc length, cutting direction and cutting sequence in the CNC control system , use plasma to cut out each hole intermittently; leave 4 points at the polar axis so that the cut part is still connected with the base material, plan off the connection part between each hole and the base material after forming and welding, and grind the required hole direction according to the diagram, Finally, assemble and we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com