Patents

Literature

1212 results about "Plasma cutting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Plasma cutting is a process that cuts through electrically conductive materials by means of an accelerated jet of hot plasma. Typical materials cut with a plasma torch include steel, stainless steel, aluminum, brass and copper, although other conductive metals may be cut as well. Plasma cutting is often used in fabrication shops, automotive repair and restoration, industrial construction, and salvage and scrapping operations. Due to the high speed and precision cuts combined with low cost, plasma cutting sees widespread use from large-scale industrial CNC applications down to small hobbyist shops.

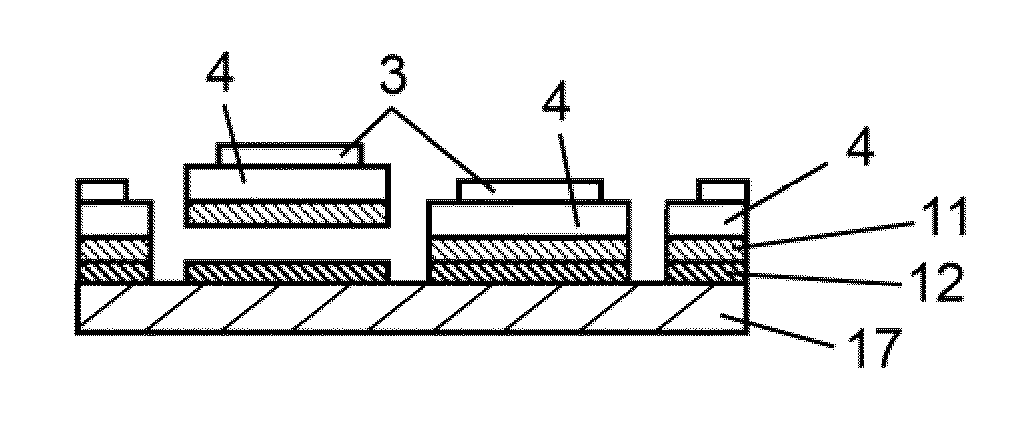

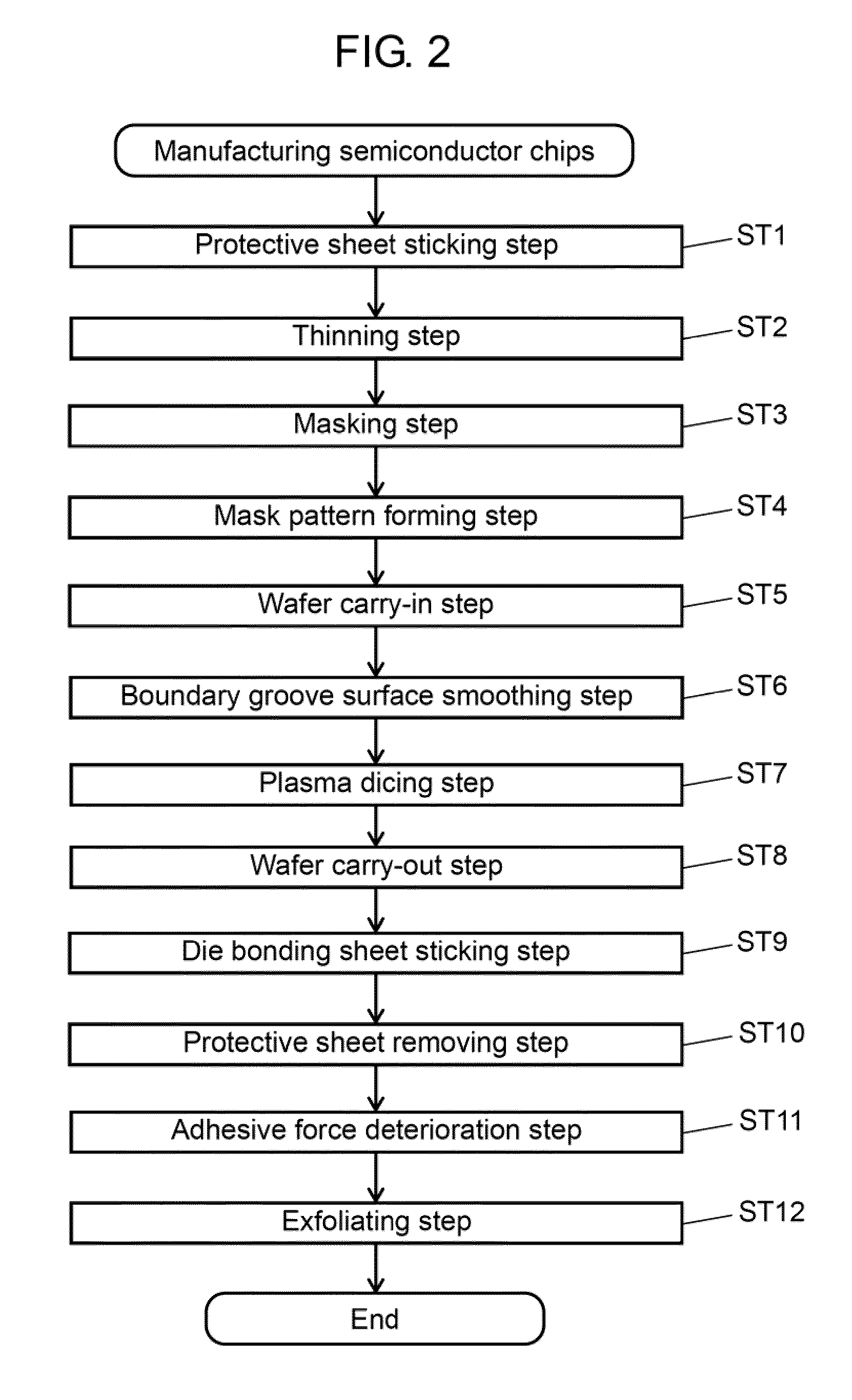

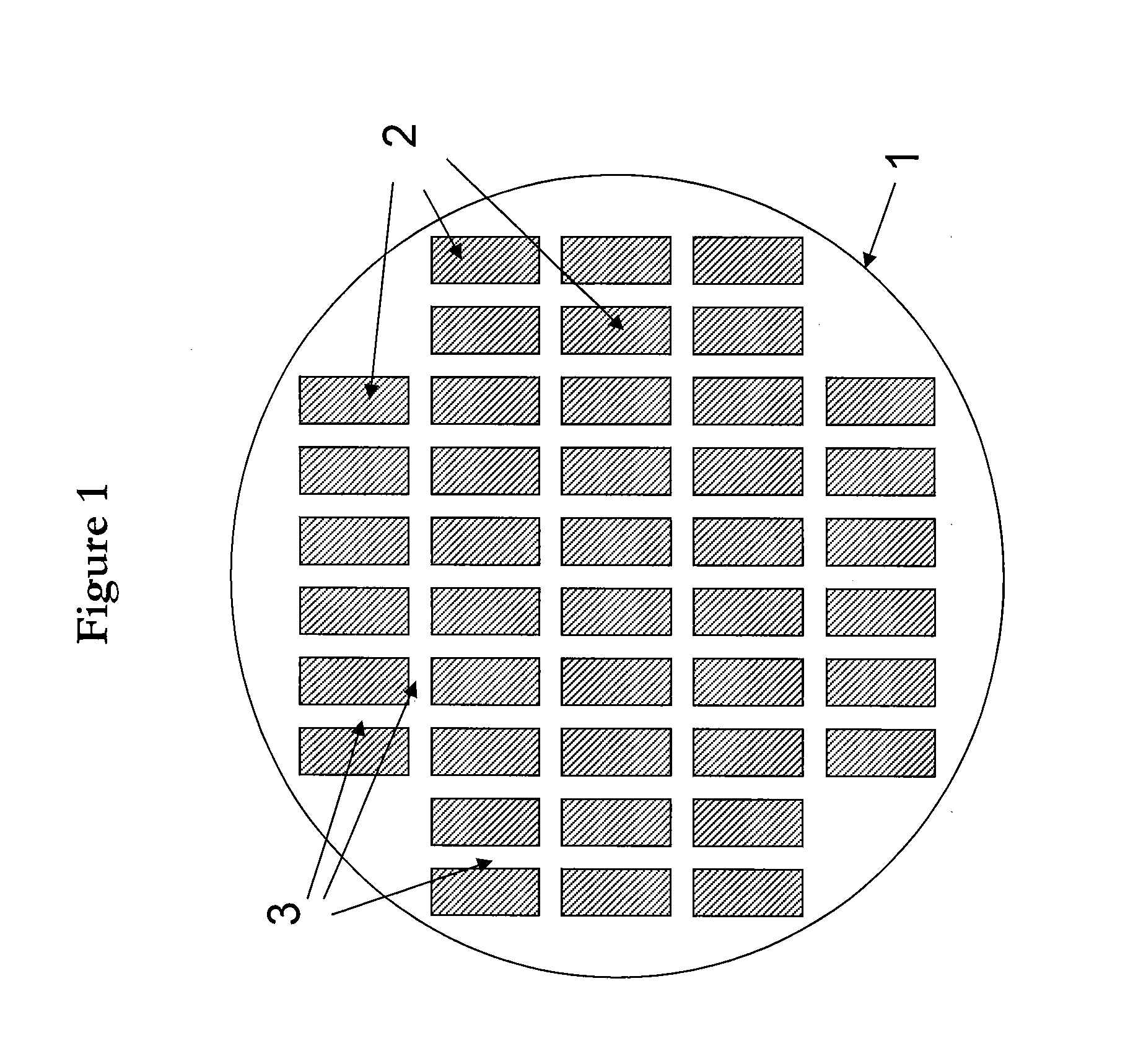

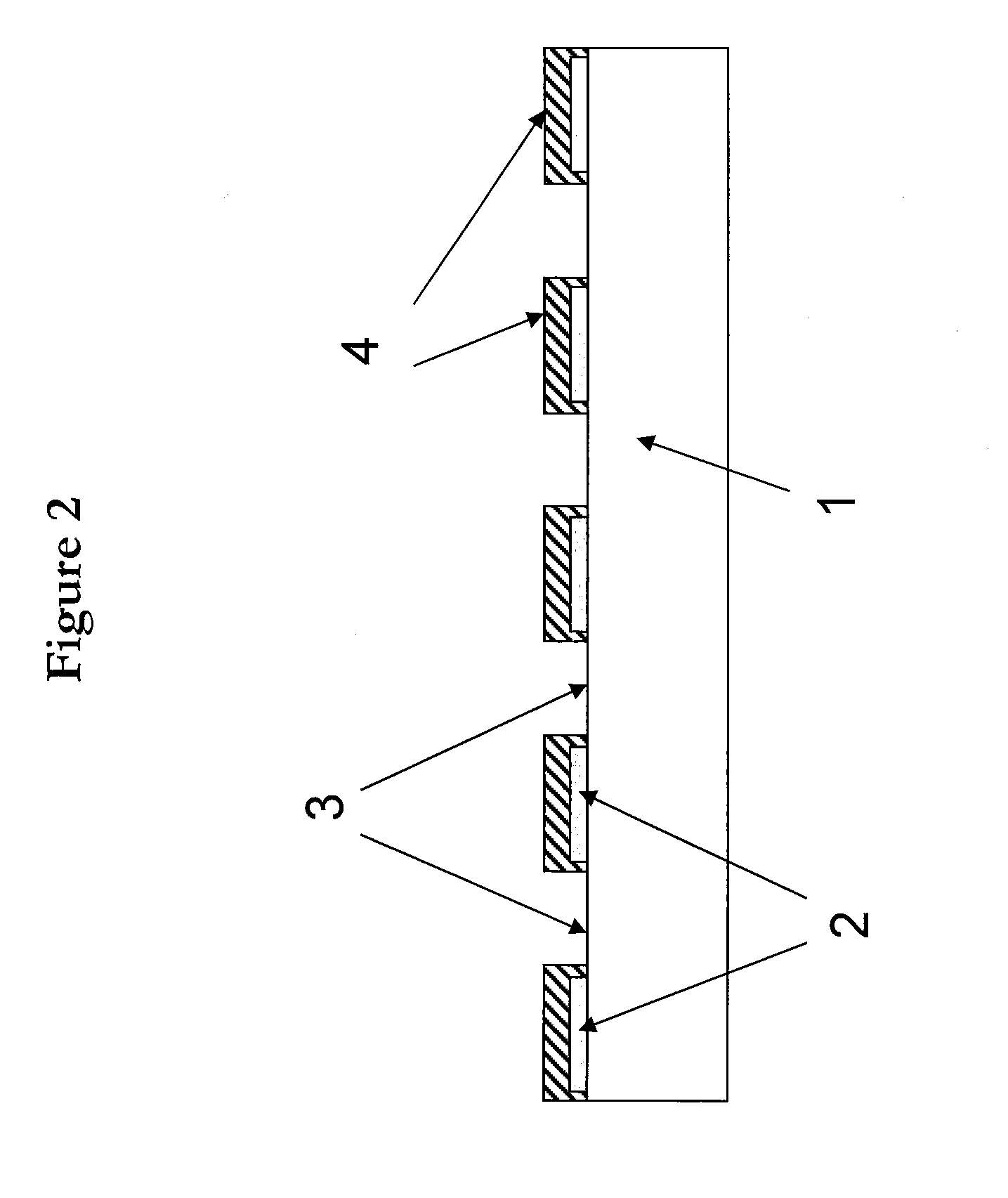

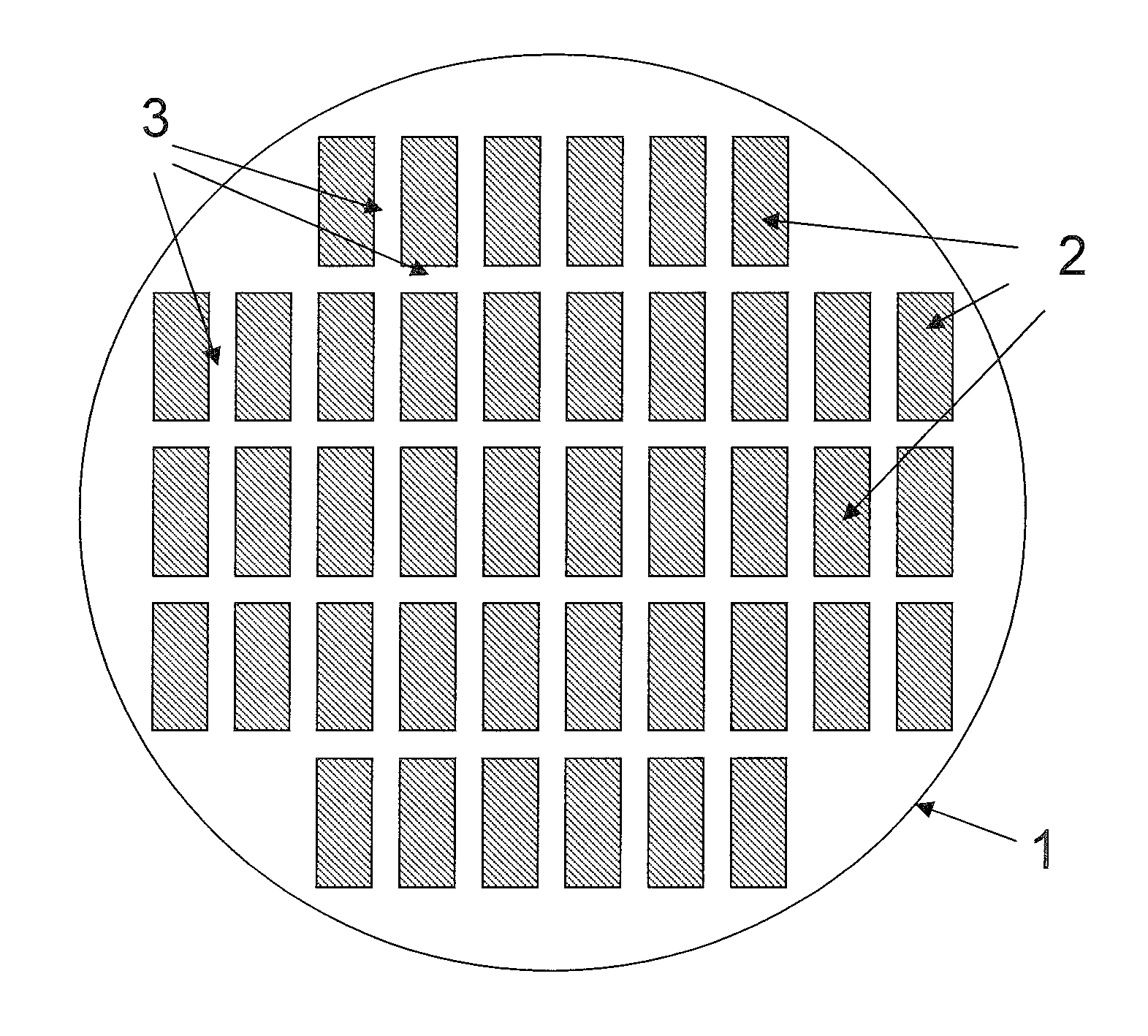

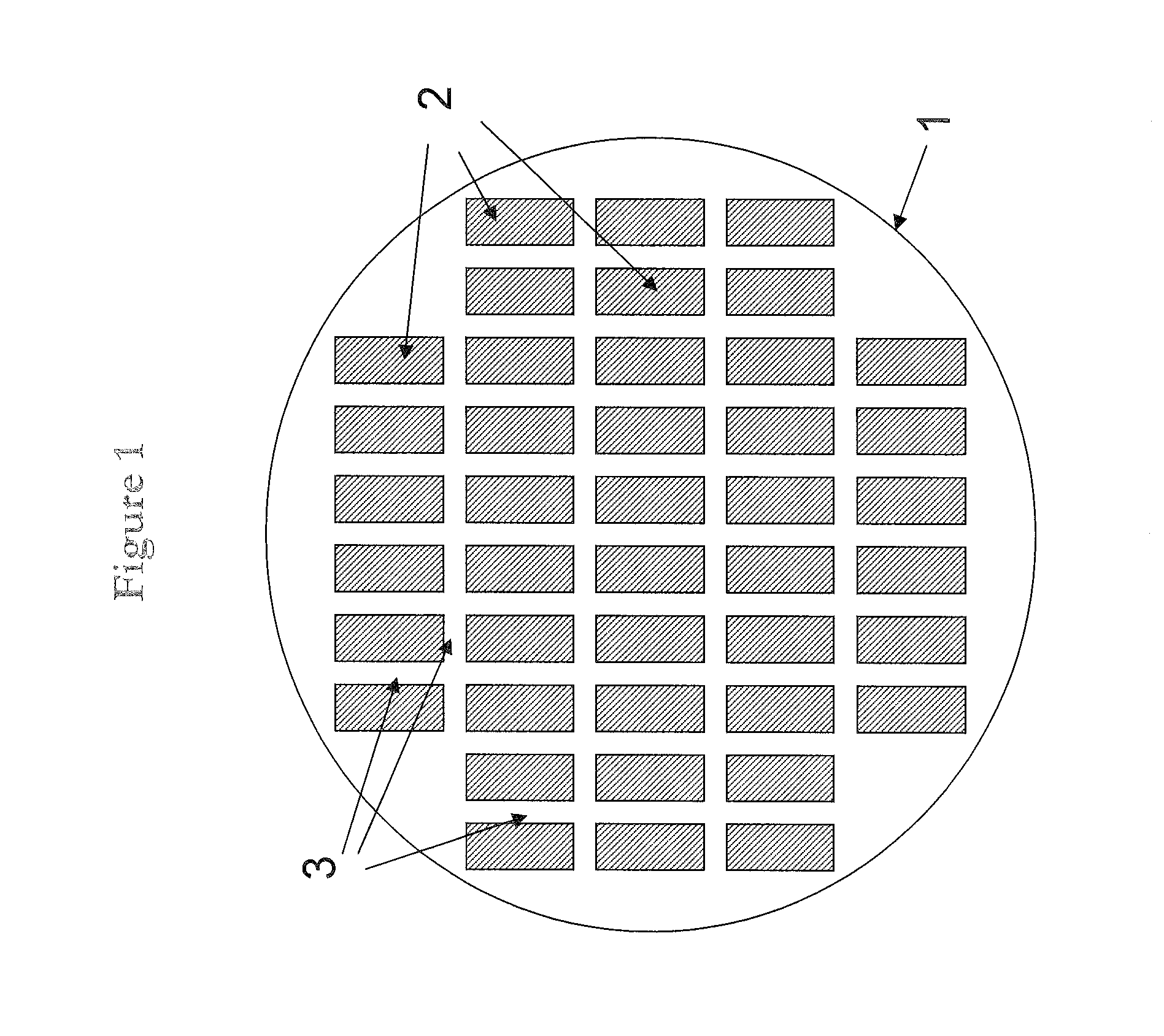

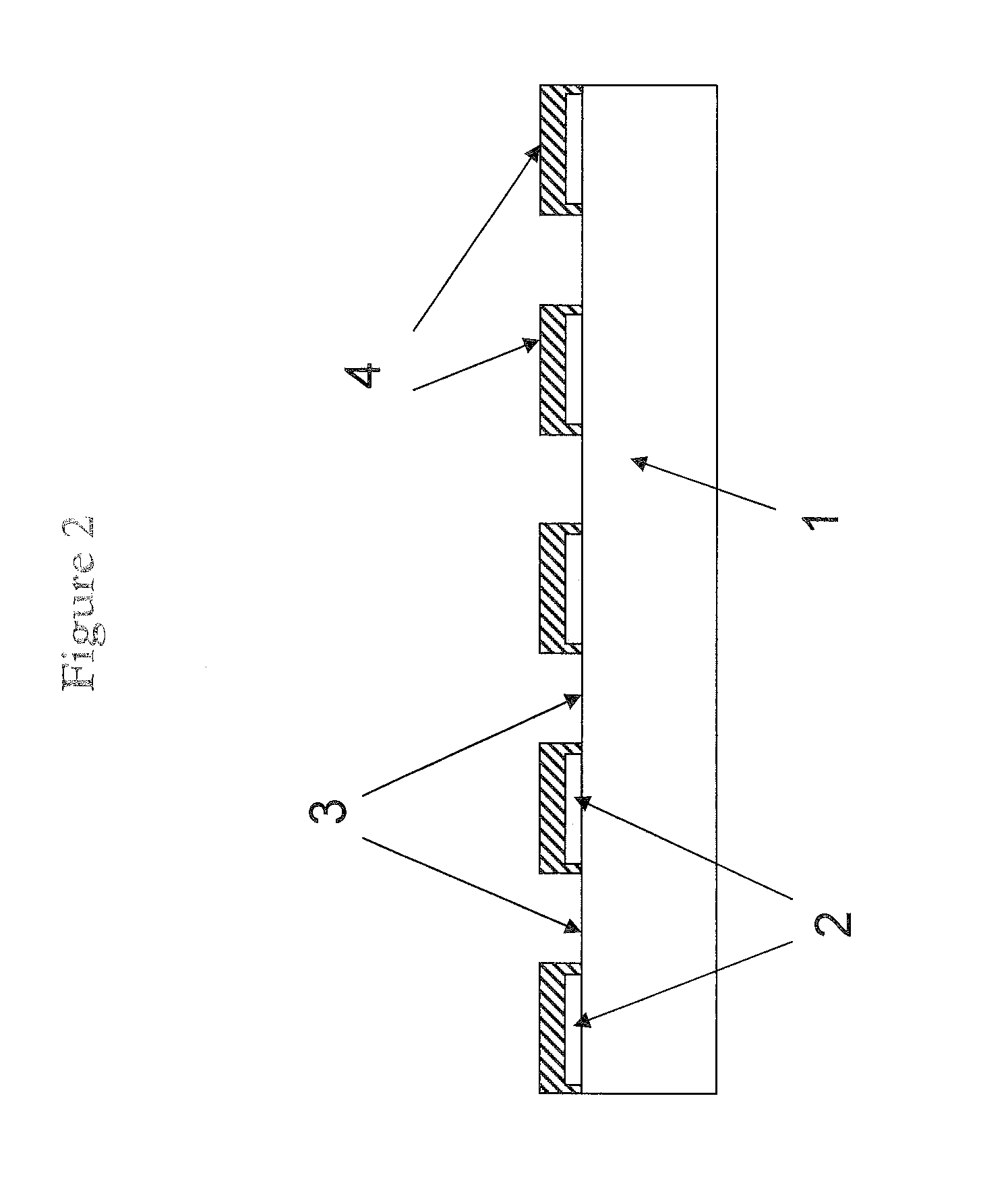

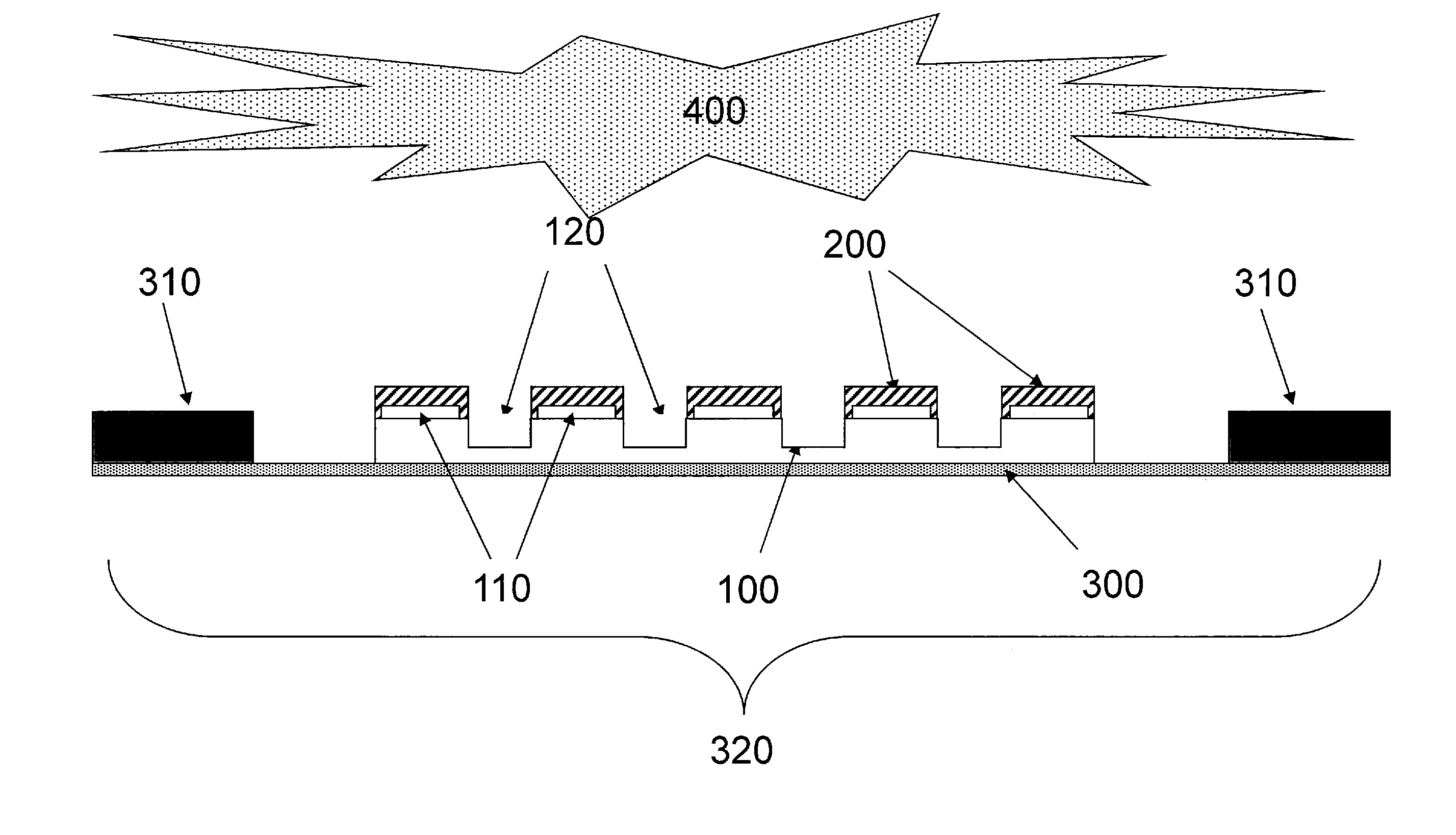

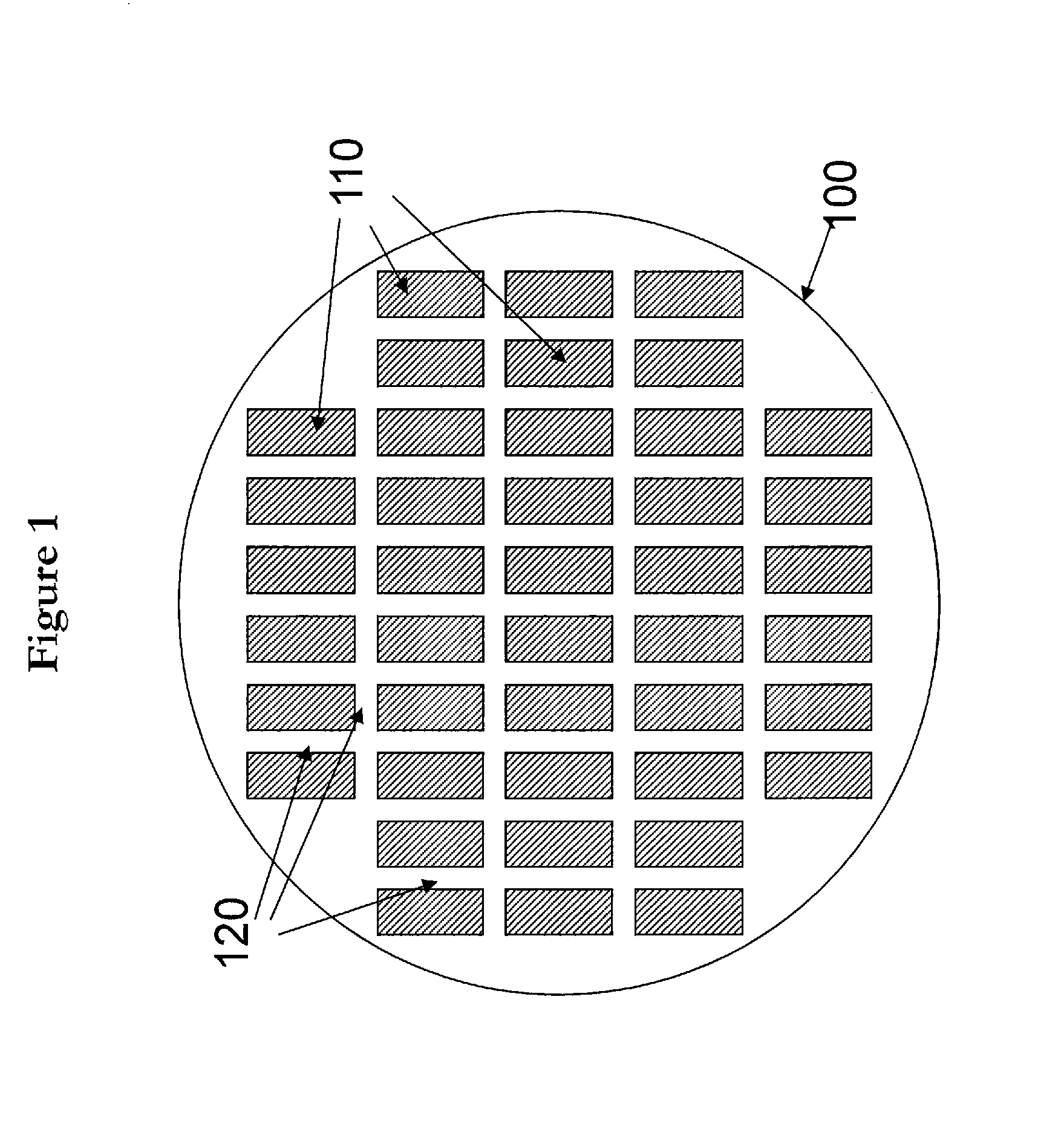

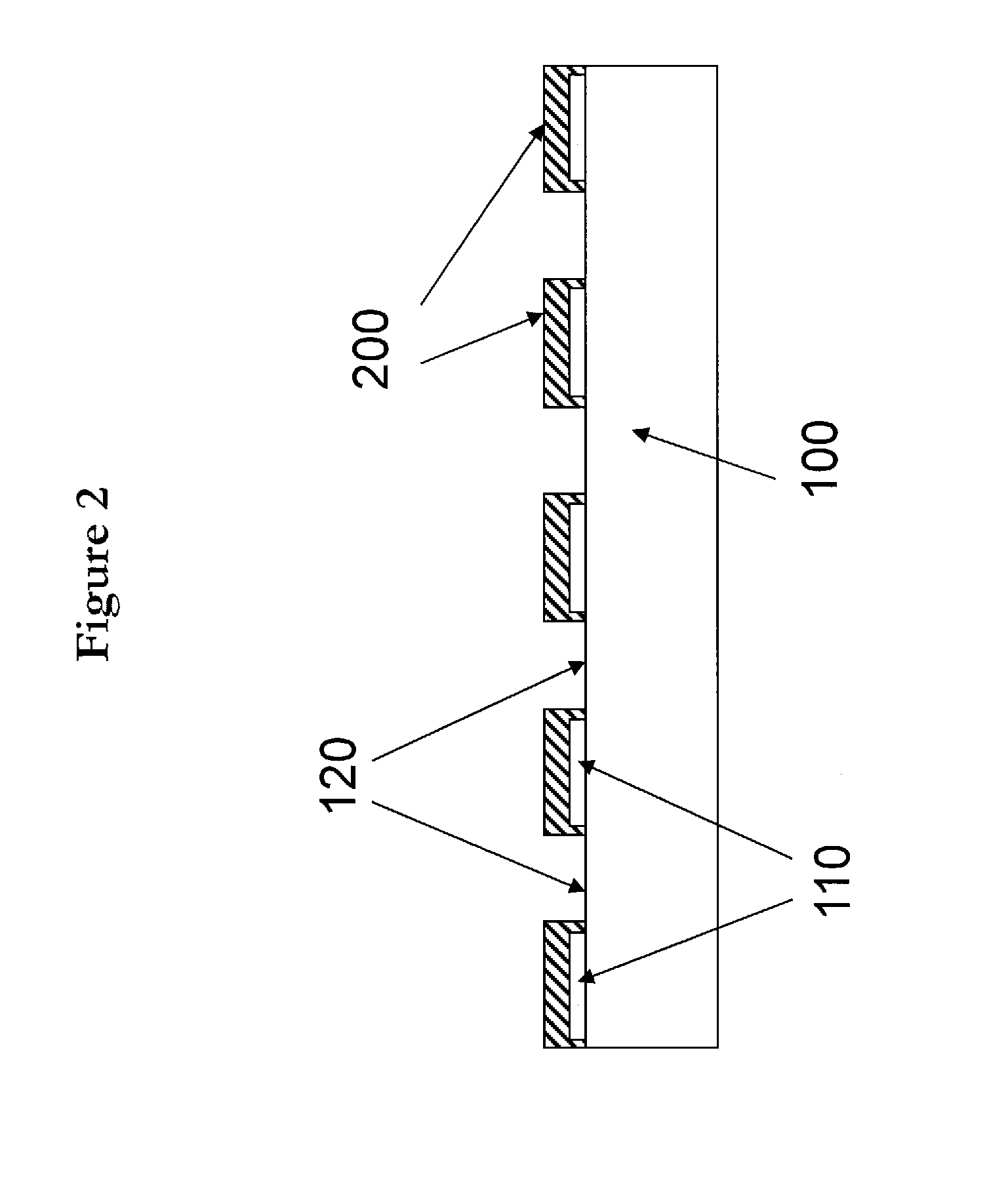

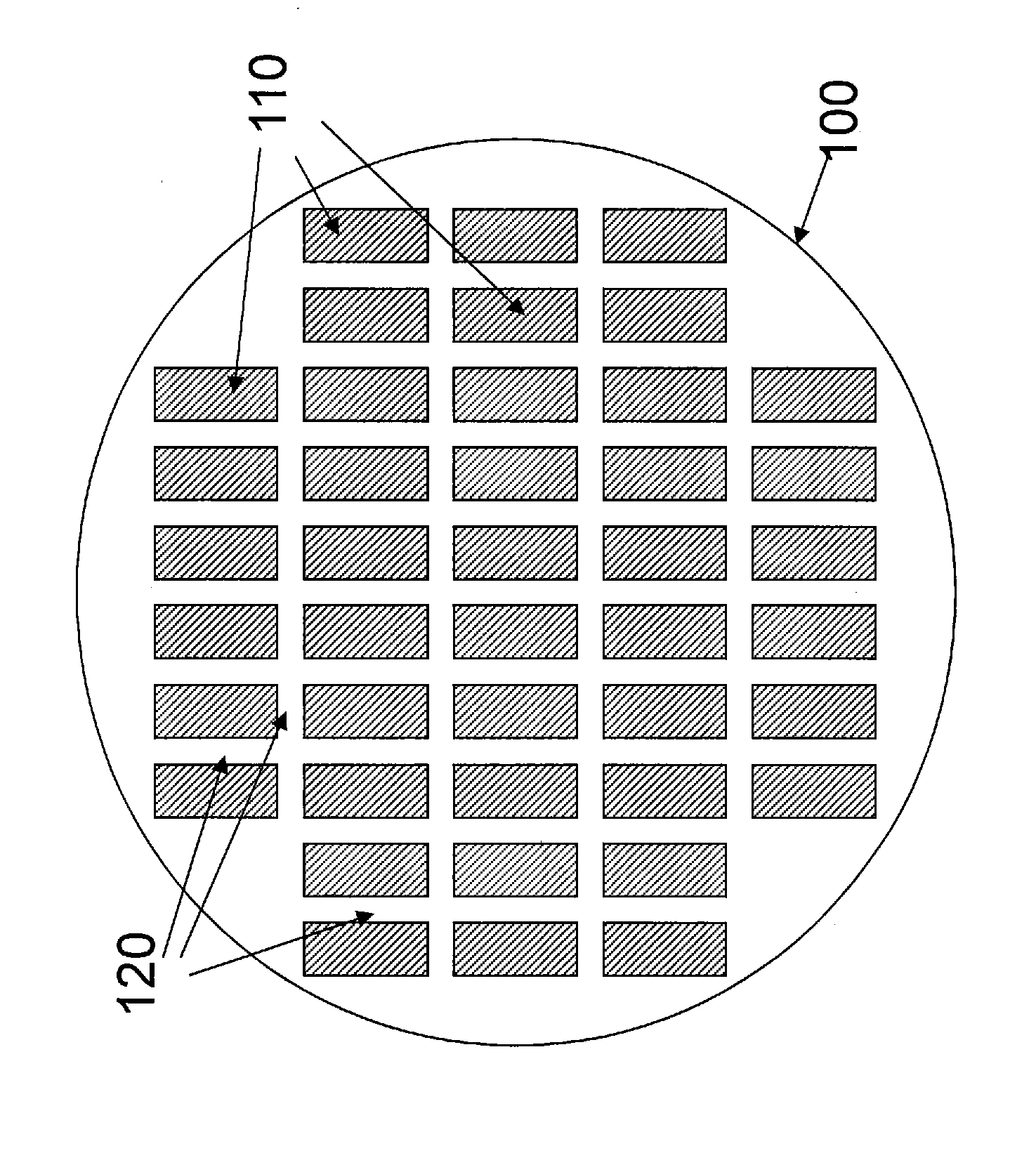

Plasma dicing apparatus and method of manufacturing semiconductor chips

InactiveUS20100048001A1Improve workabilityFacilitates carrying a semiconductor waferSemiconductor/solid-state device testing/measurementElectric discharge tubesSemiconductor chipVacuum chamber

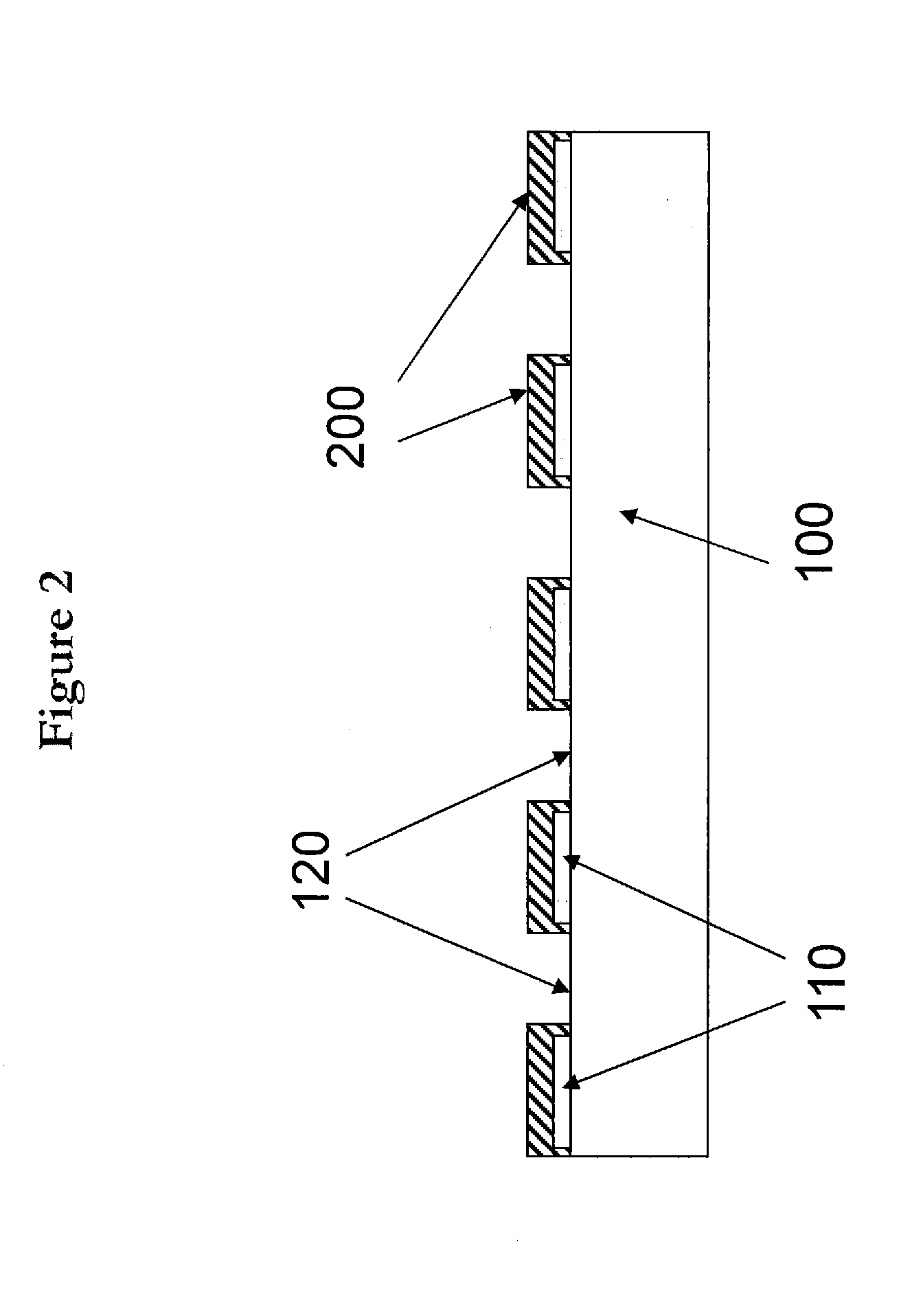

A plasma dicing apparatus in which a semiconductor wafer with a protective sheet stuck thereonto covering the entire circuit-forming surface and with an etching-resistant mask member stuck on the back surface opposite to the circuit-forming surface is mounted on a mounting stage; plasma etching is performed using the mask member as a mask; and the semiconductor wafer is diced into plural semiconductor chips. The plasma dicing apparatus includes a ring-shaped frame member retaining the outer circumference of the mask member extending off the outer circumference of the semiconductor wafer. The mounting stage is composed of a wafer supporting part supporting a semiconductor wafer and a frame member supporting part supporting the frame member. This facilitates carrying a semiconductor wafer into and out of the vacuum chamber.

Owner:PANASONIC CORP

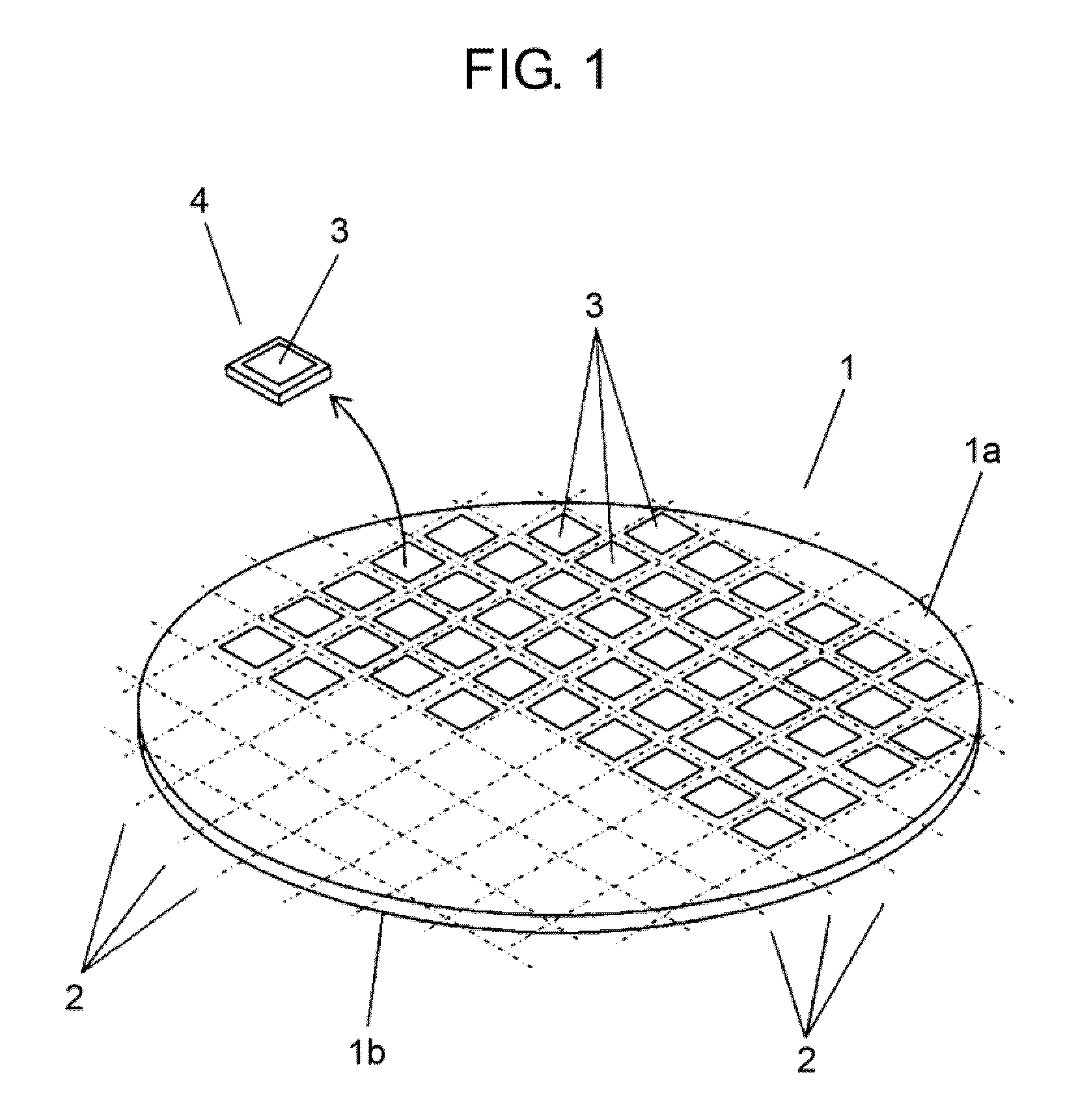

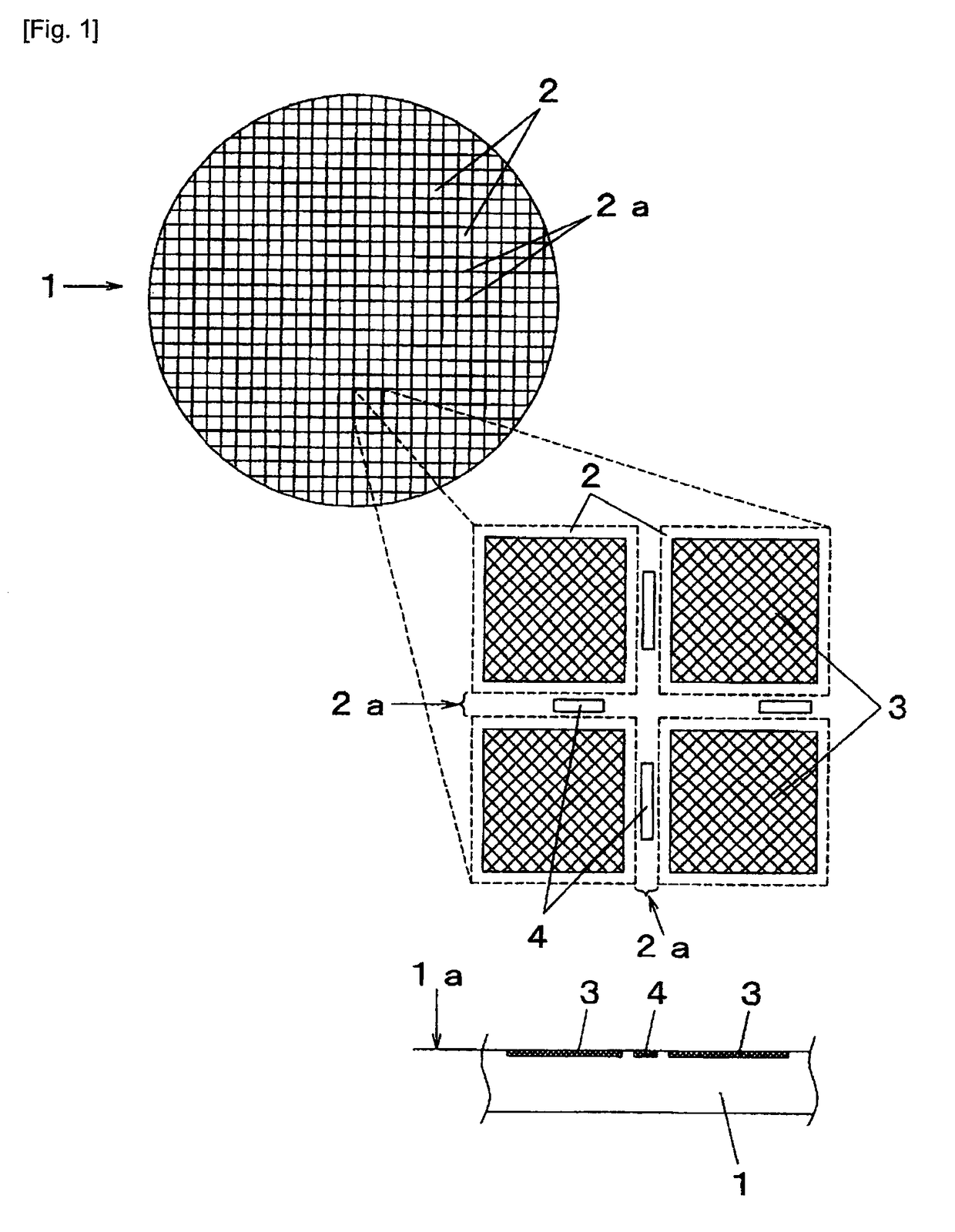

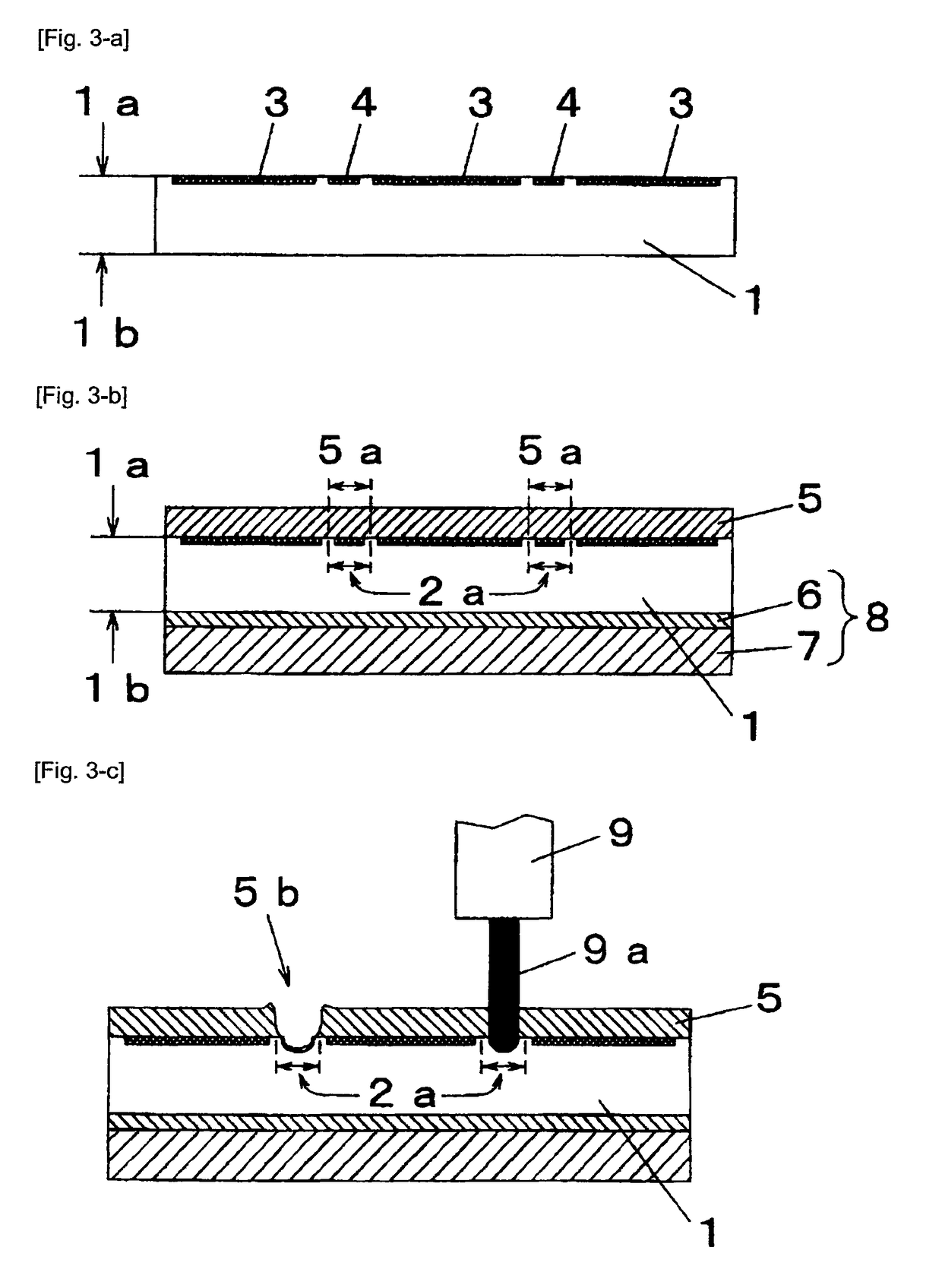

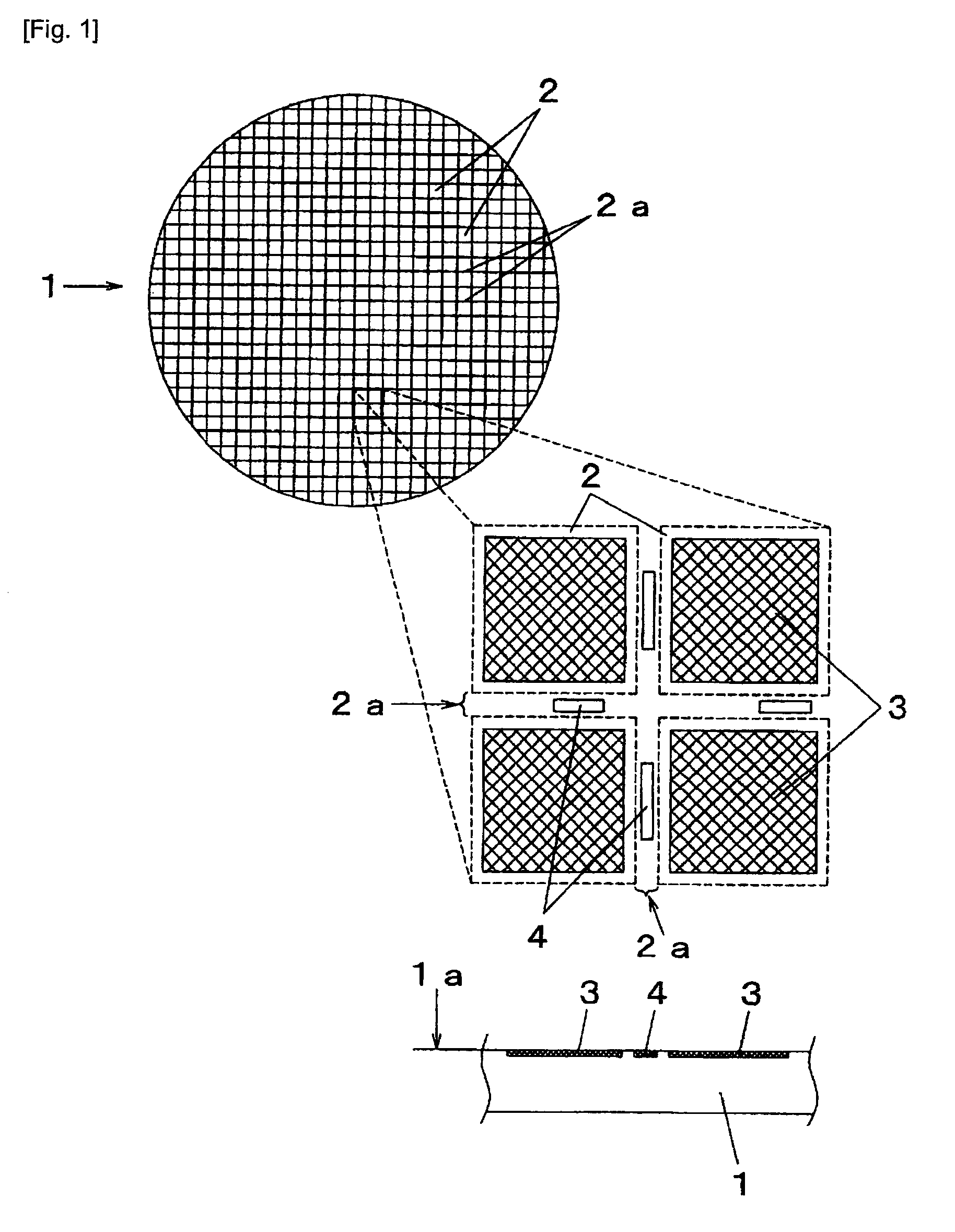

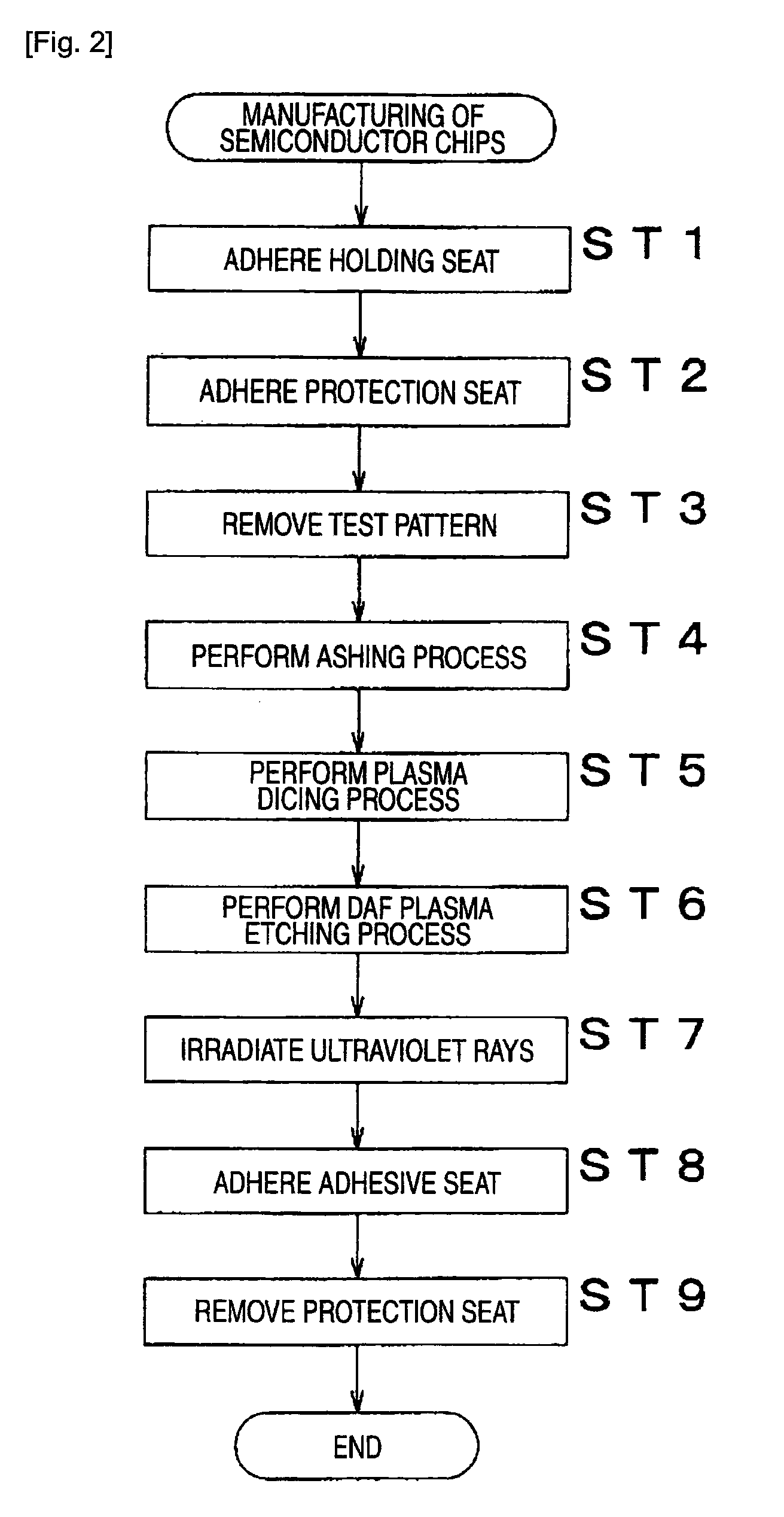

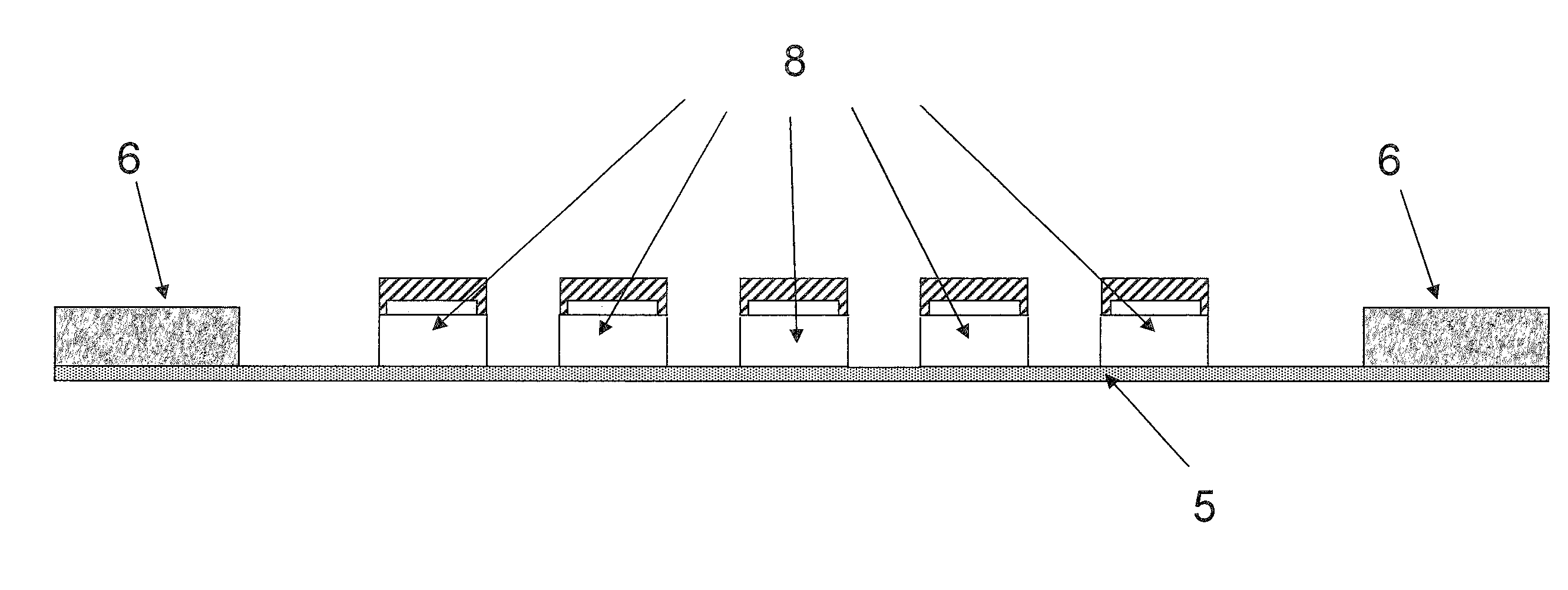

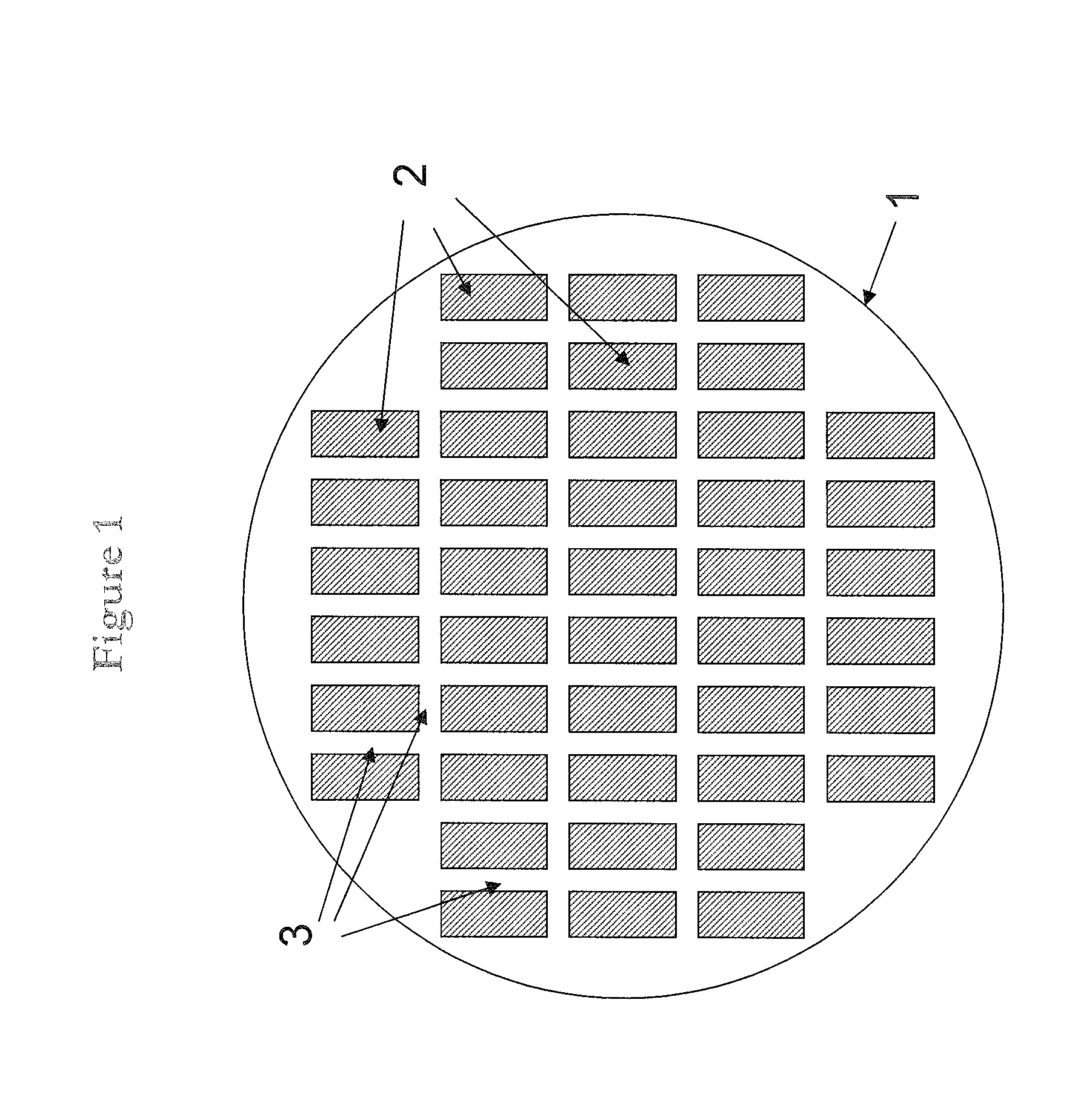

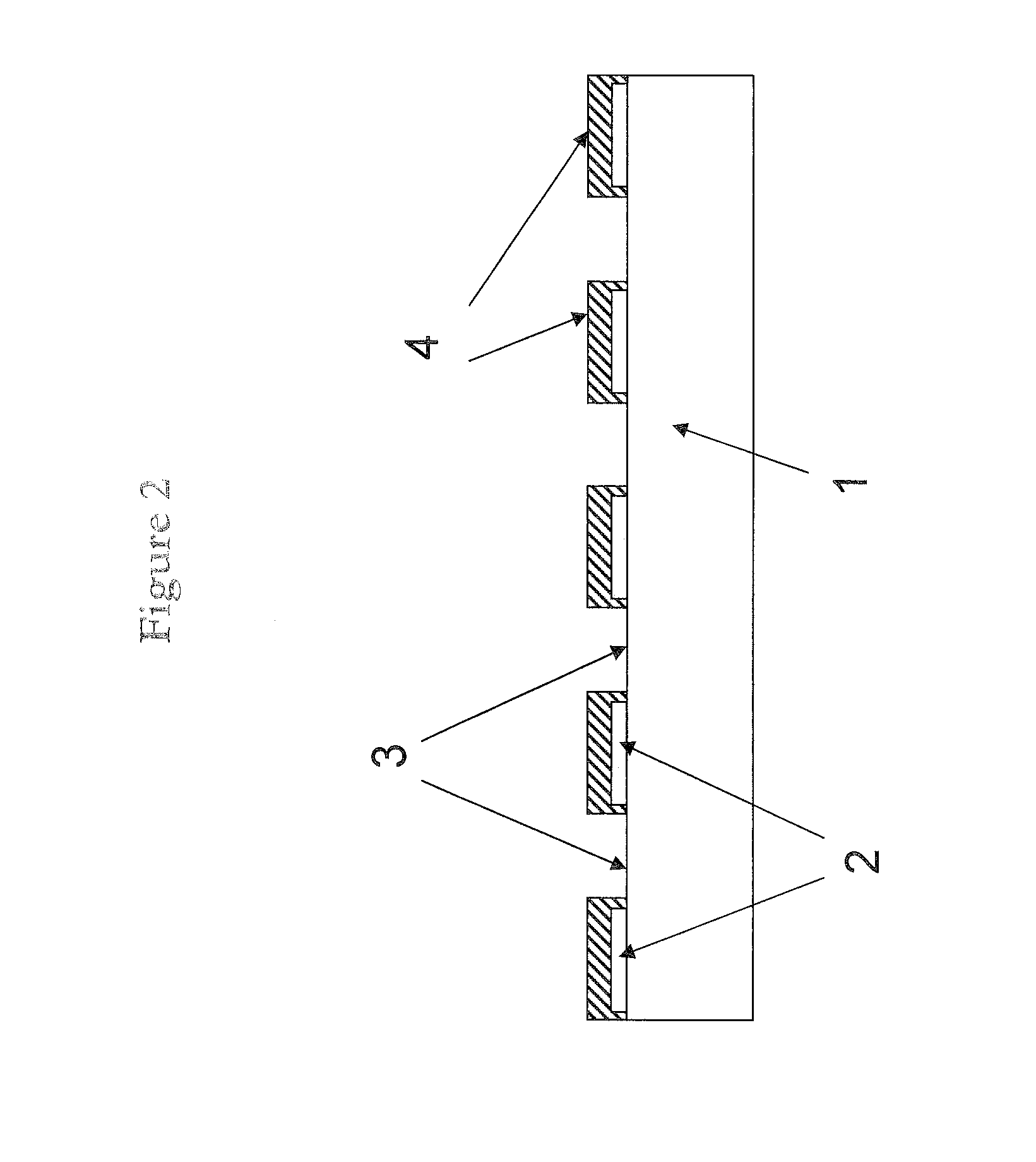

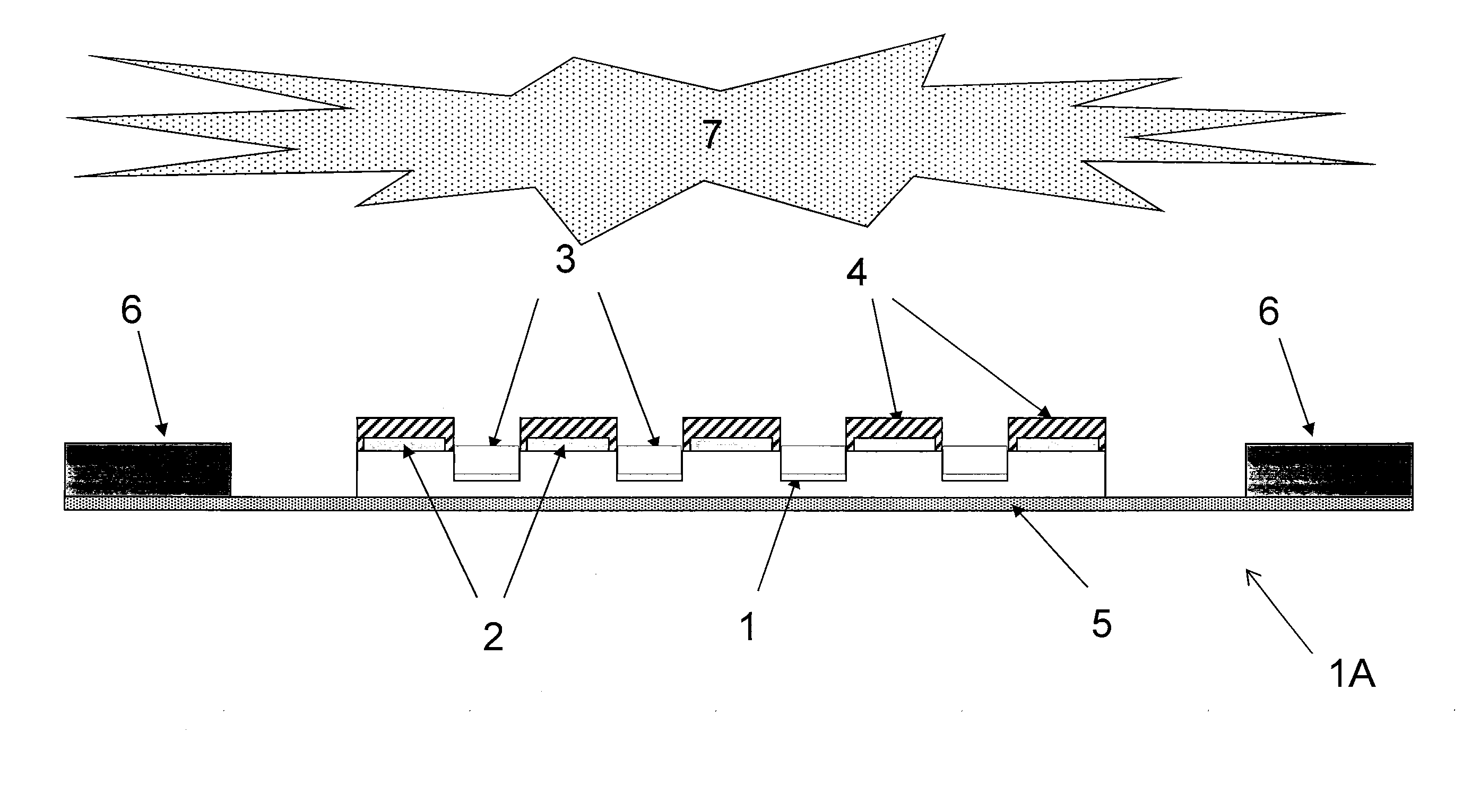

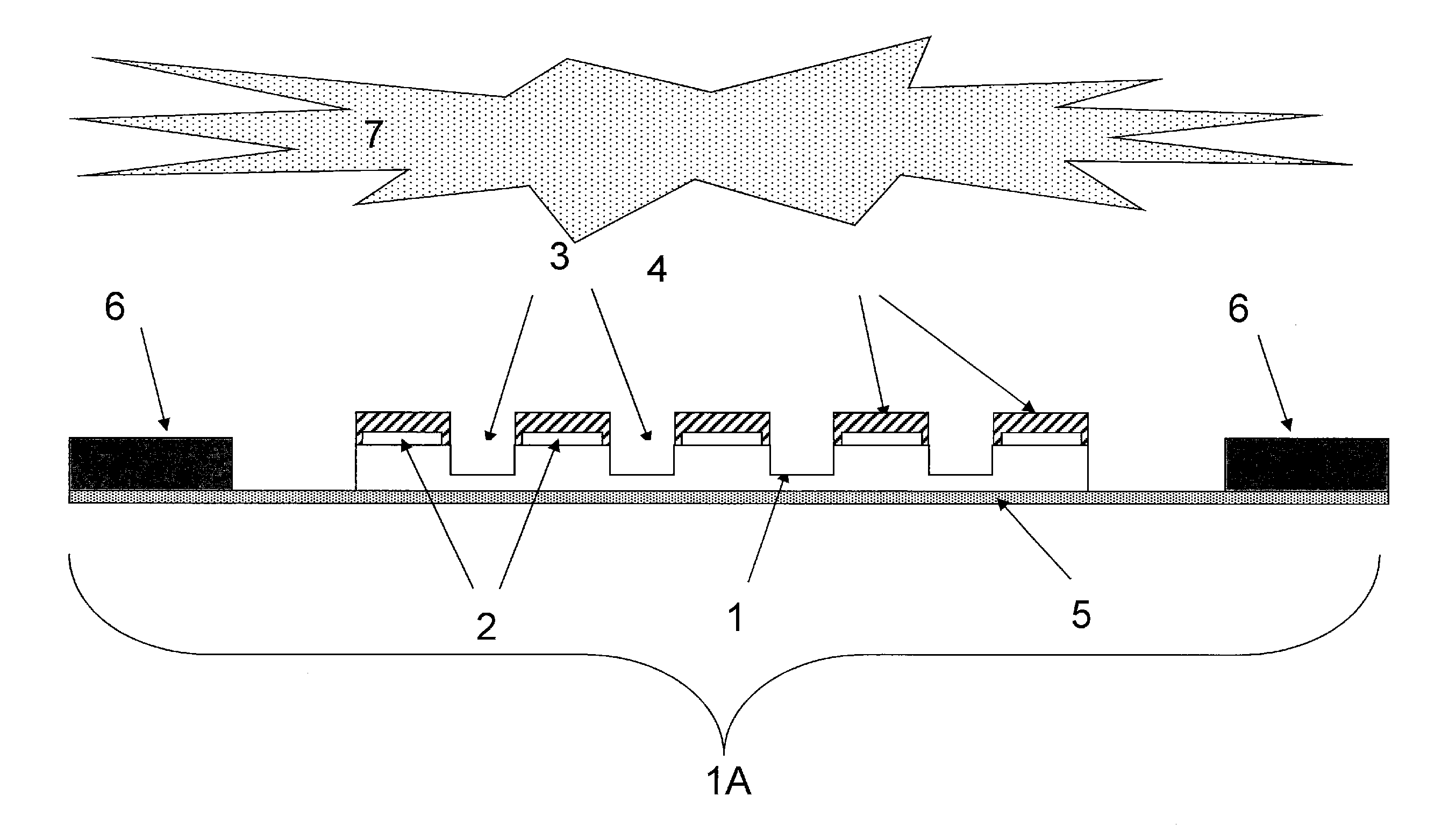

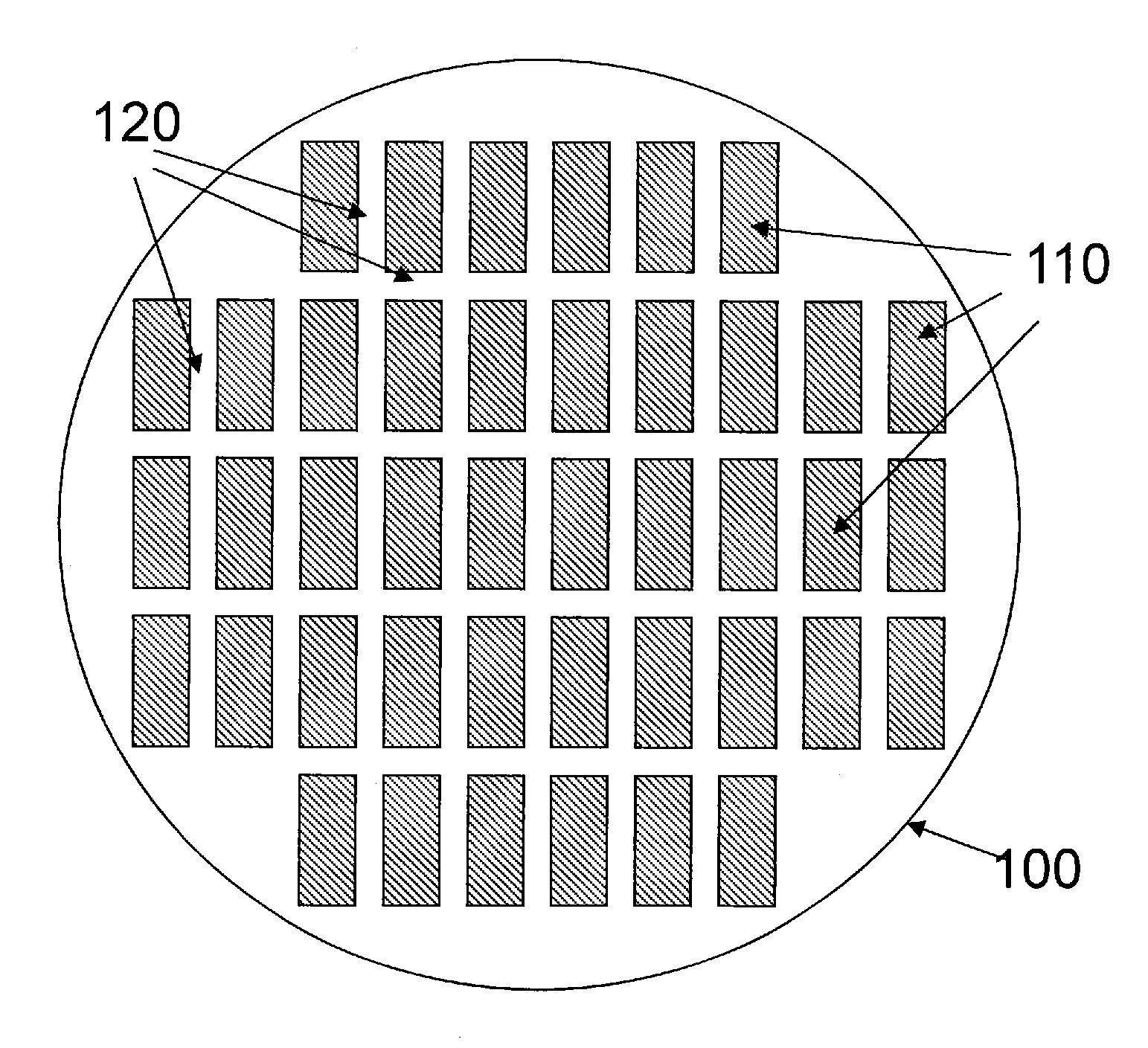

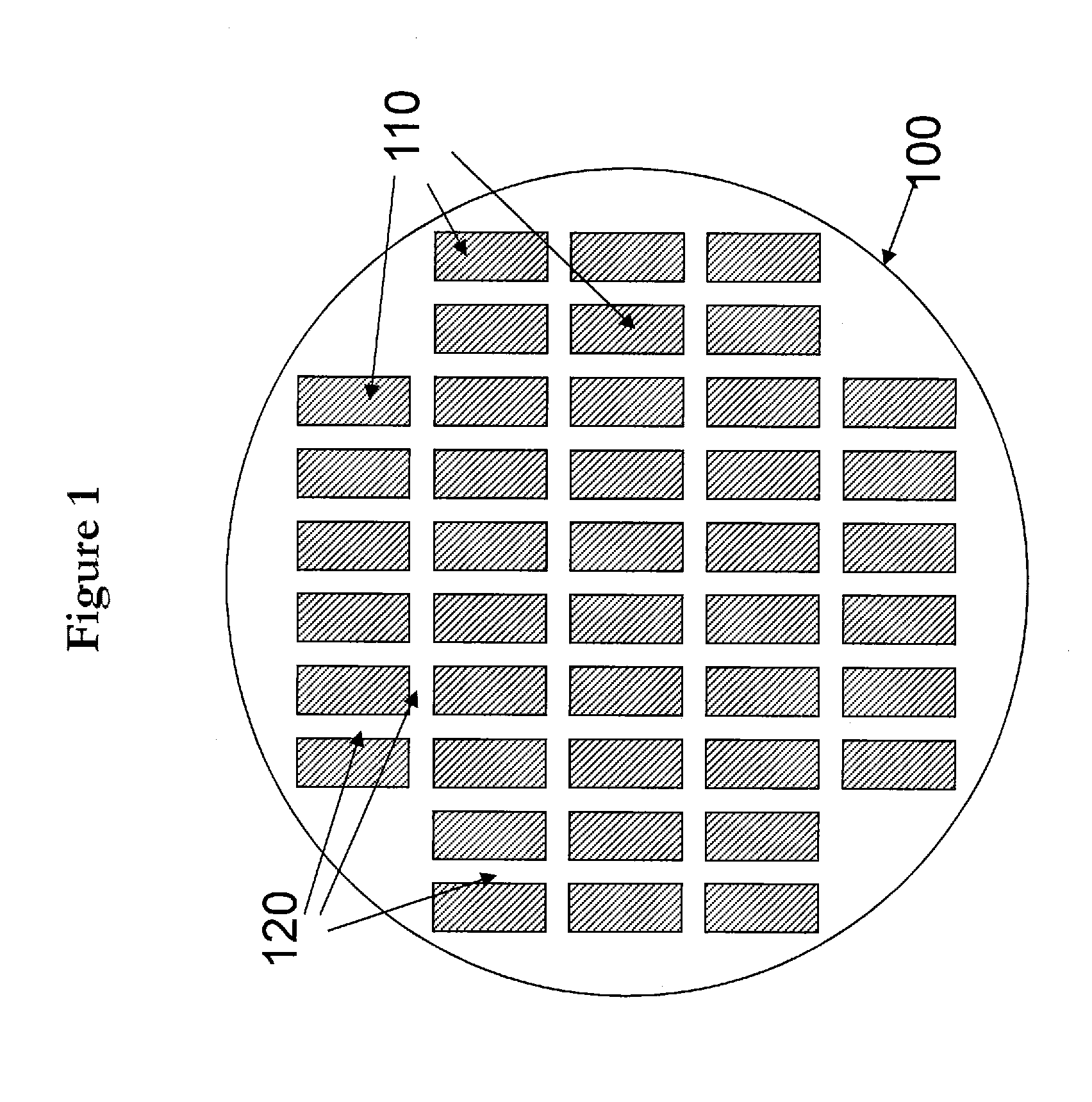

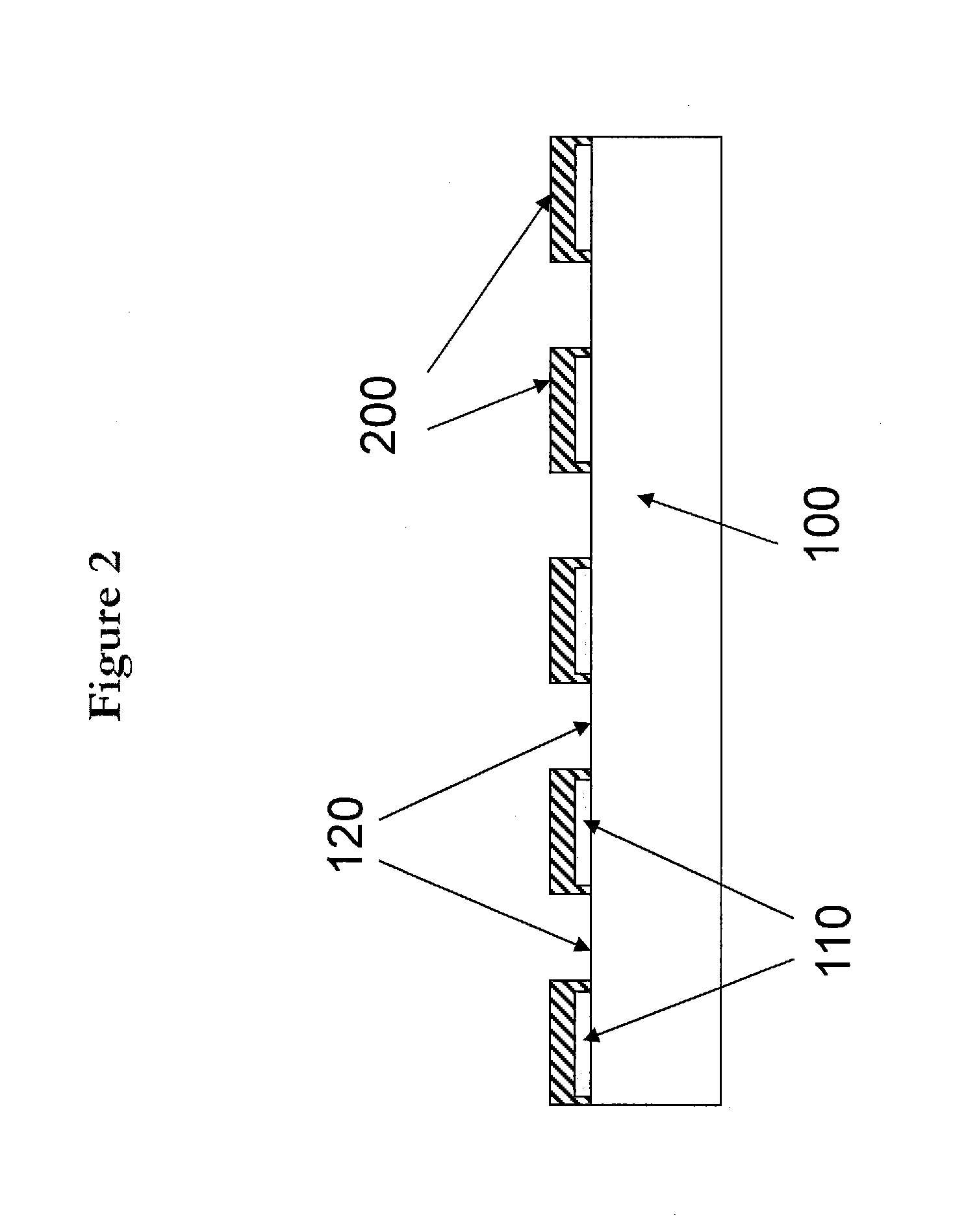

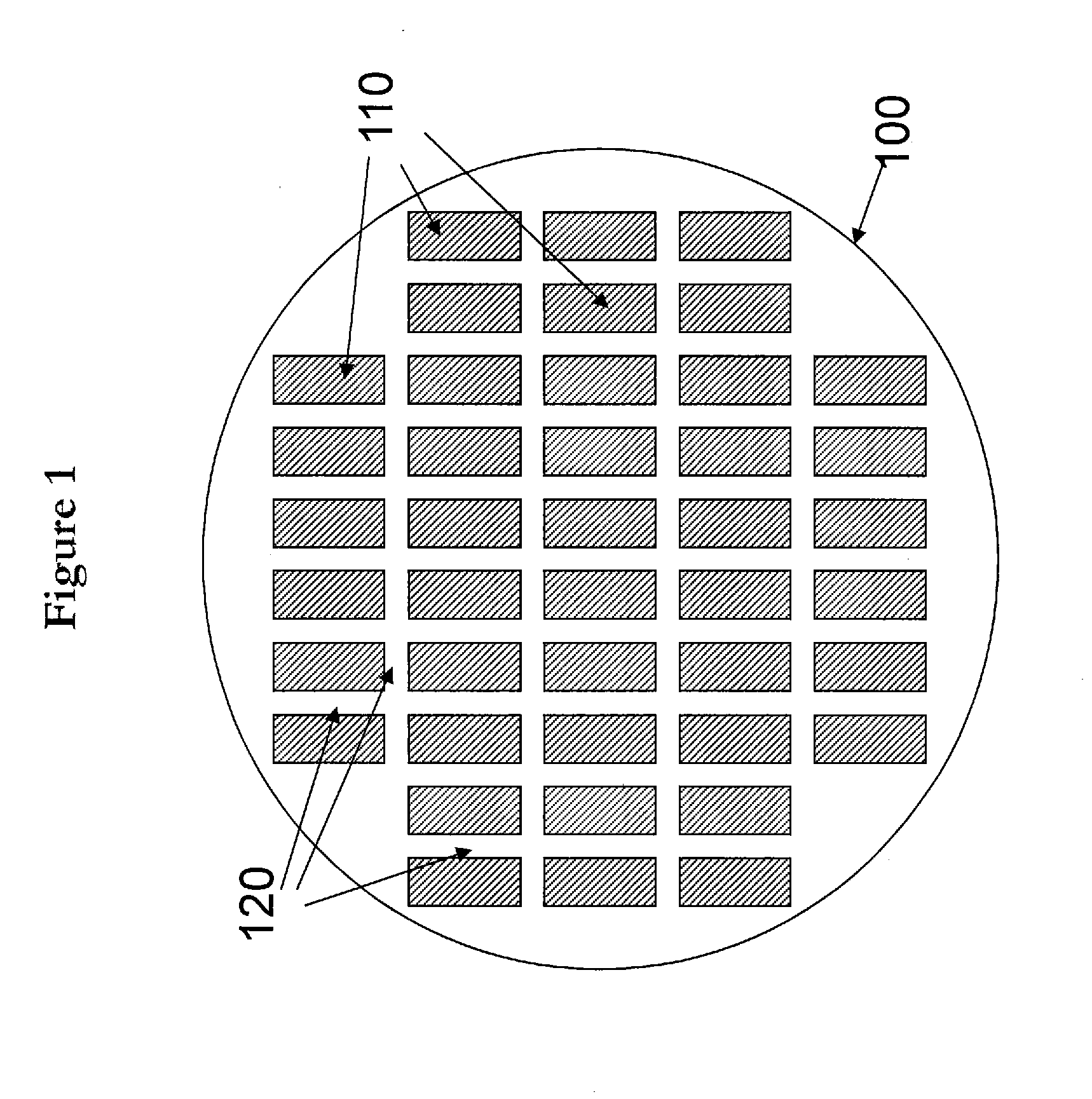

Method of manufacturing semiconductor chip using laser light and plasma dicing

ActiveUS7906410B2Improve efficiencySimple stepsSolid-state devicesSemiconductor/solid-state device manufacturingGeneral purposeSemiconductor chip

In a method in which a semiconductor wafer 1 having integrated circuits 3 formed in a plurality of chip regions and test patterns 4 formed in scribe lines 2a is divided by a plasma etching process so as to manufacture individual semiconductor chips, in the semiconductor wafer 1, a protection sheet 5 which constitutes a mask in the plasma etching process is adhered onto a front plane 1a thereof where the integrated circuits 3 have been formed; since laser light 9a is irradiated along the scribe lines 2a, only a predetermined width of the protection sheet 5 is removed so as to form a mask having a plasma dicing-purpose opening portion 5b; and also, the test patterns 4 are removed by the laser light 9a in combination with a front plane layer of the semiconductor wafer 1. As a result, the test patterns 4 can be removed in a higher efficiency and in simple steps, while the general purpose characteristic can be secured.

Owner:PANASONIC CORP

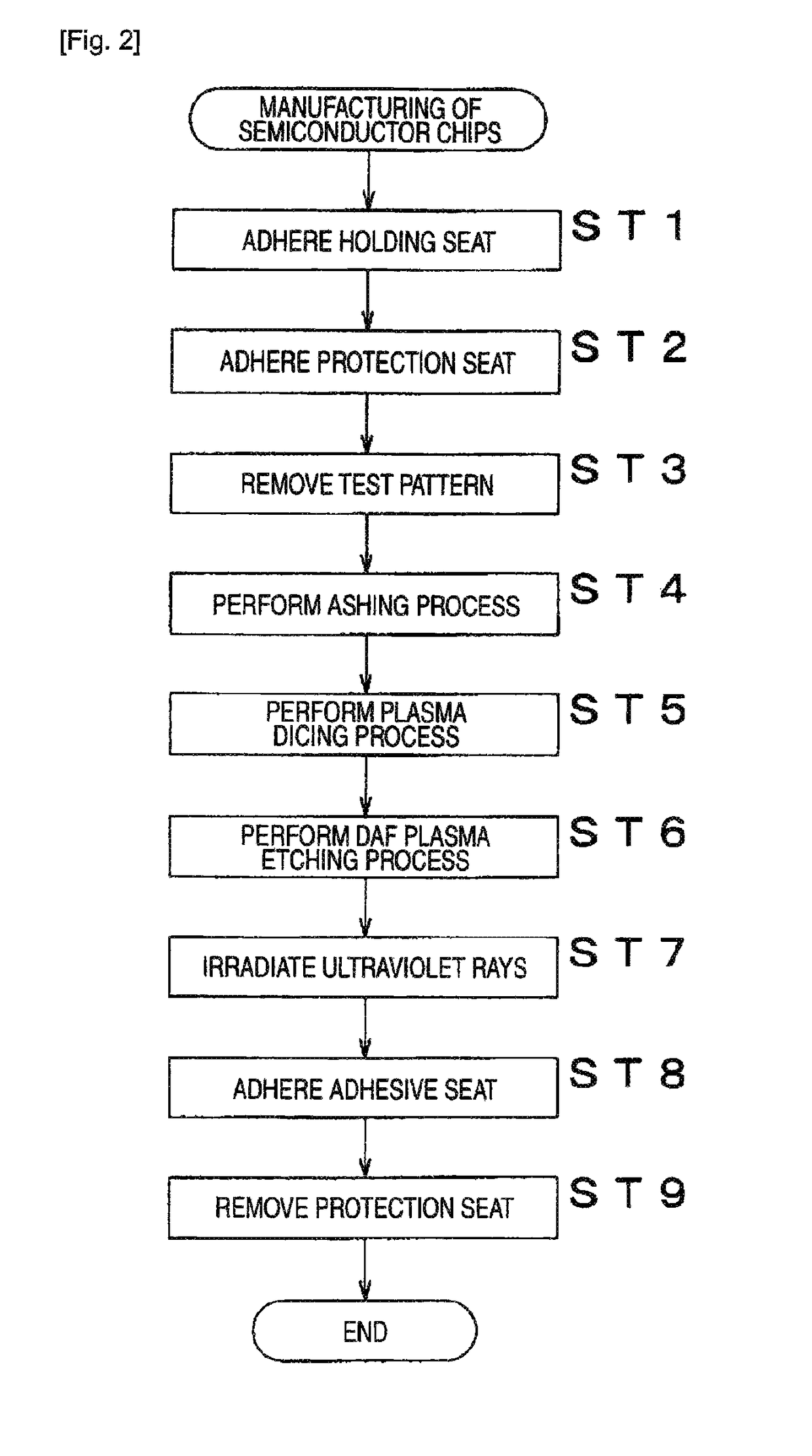

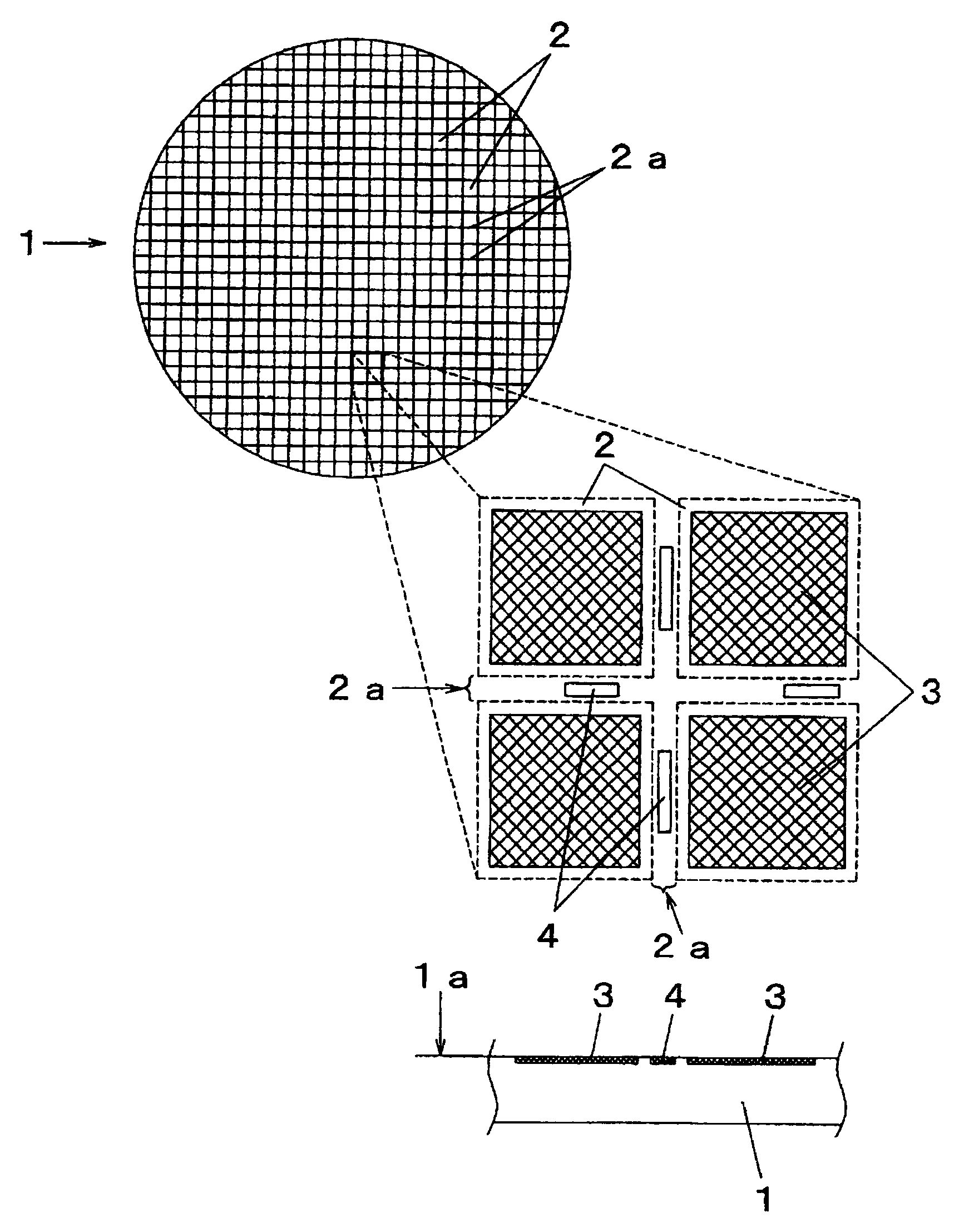

Method of manufacturing semiconductor chip

ActiveUS20100173474A1Improve efficiencySimple stepsSolid-state devicesSemiconductor/solid-state device manufacturingGeneral purposeSemiconductor chip

In a method in which a semiconductor wafer 1 having integrated circuits 3 formed in a plurality of chip regions and test patterns 4 formed in scribe lines 2a is divided by a plasma etching process so as to manufacture individual semiconductor chips, in the semiconductor wafer 1, a protection seat 5 which constitutes a mask in the plasma etching process is adhered onto a front plane 1a thereof where the integrated circuits 3 have been formed; since laser light 9a is irradiated along the scribe lines 2a, only a predetermined width of the protection seat 5 is removed so as to form a mask having a plasma dicing-purpose opening portion 5b; and also, the test patterns 4 are removed by the laser light 9a in combination with a front plane layer of the semiconductor wafer 1. As a result, the test patterns 4 can be removed in a higher efficiency and in simple steps, while the general purpose characteristic can be secured.

Owner:PANASONIC CORP

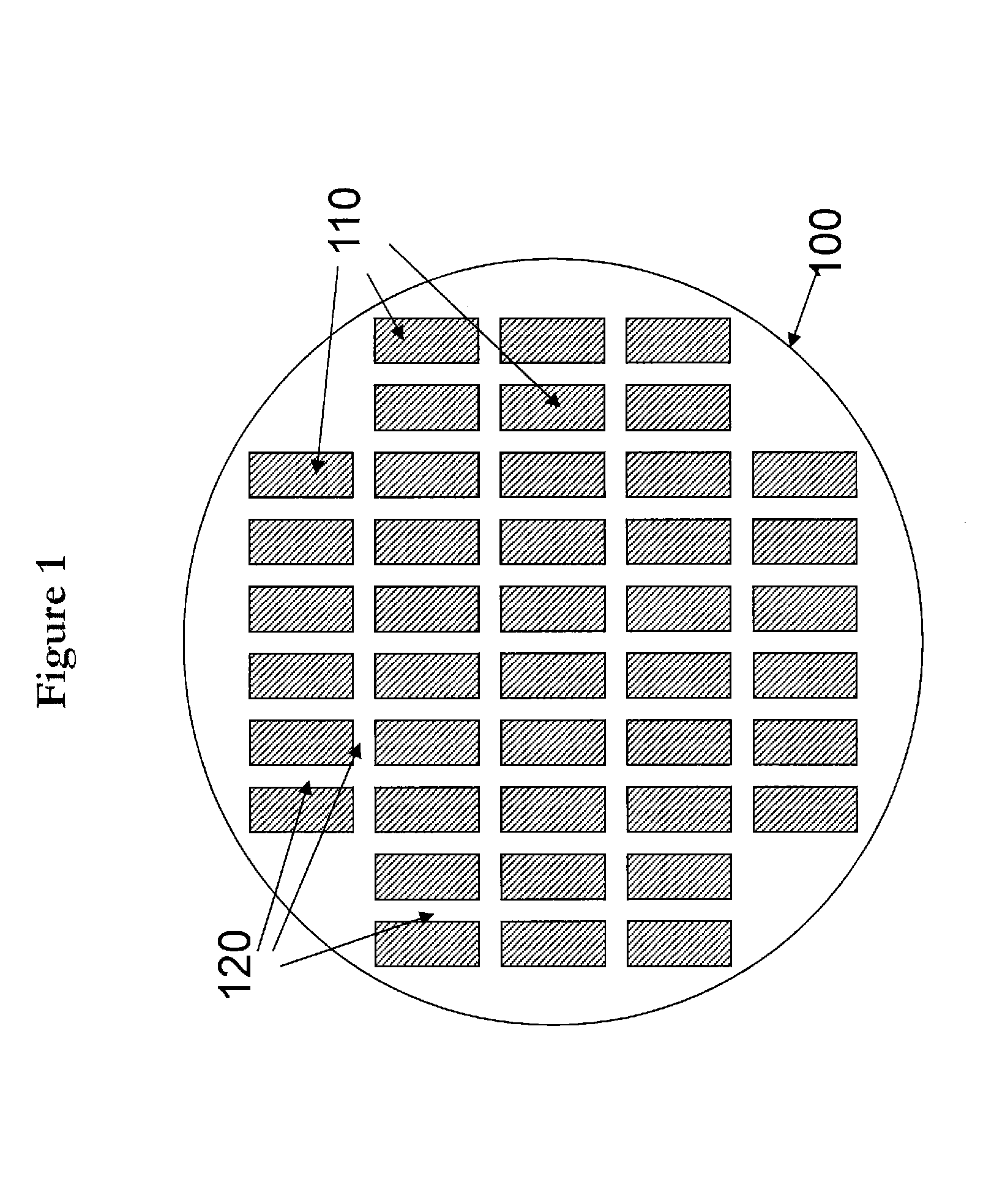

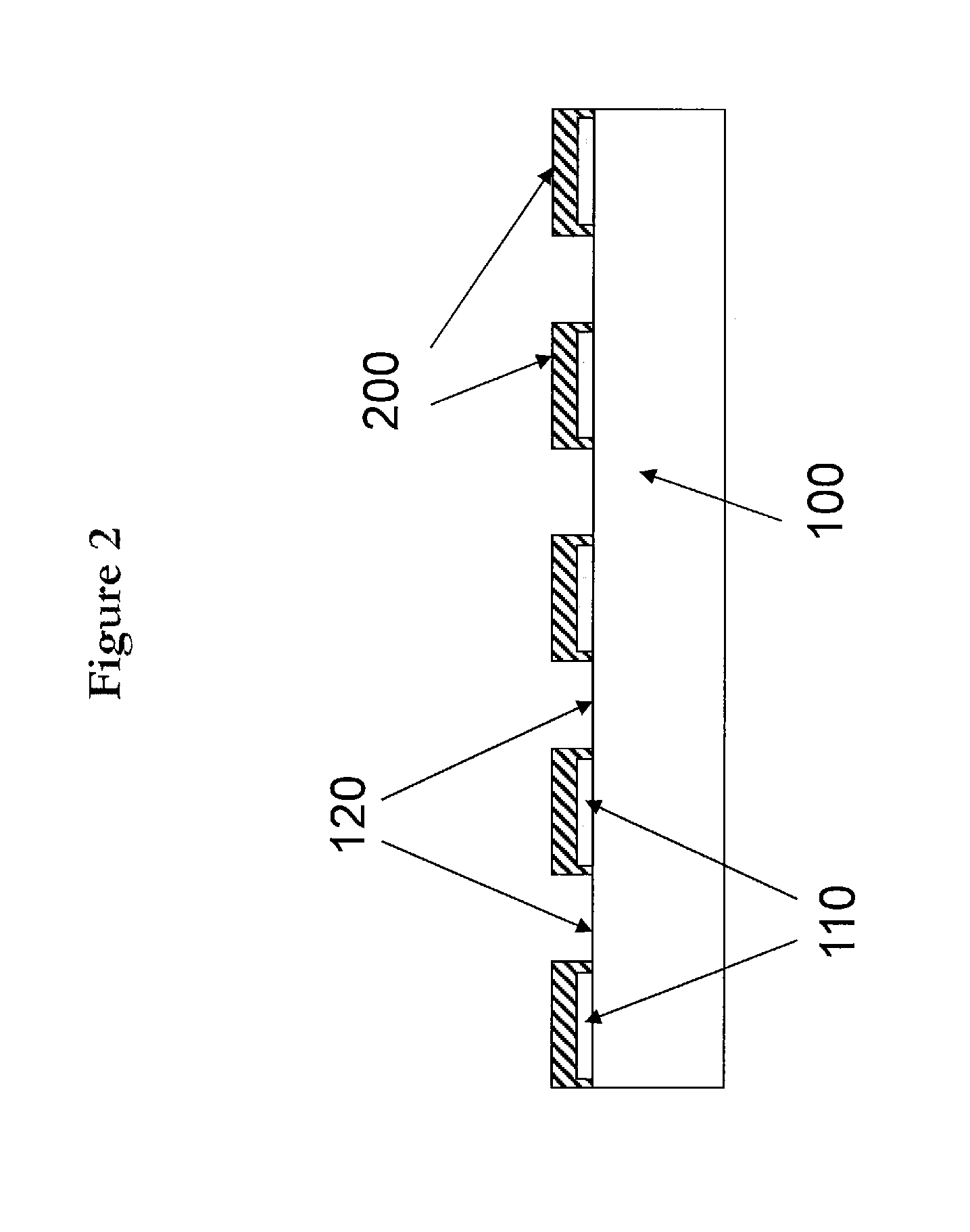

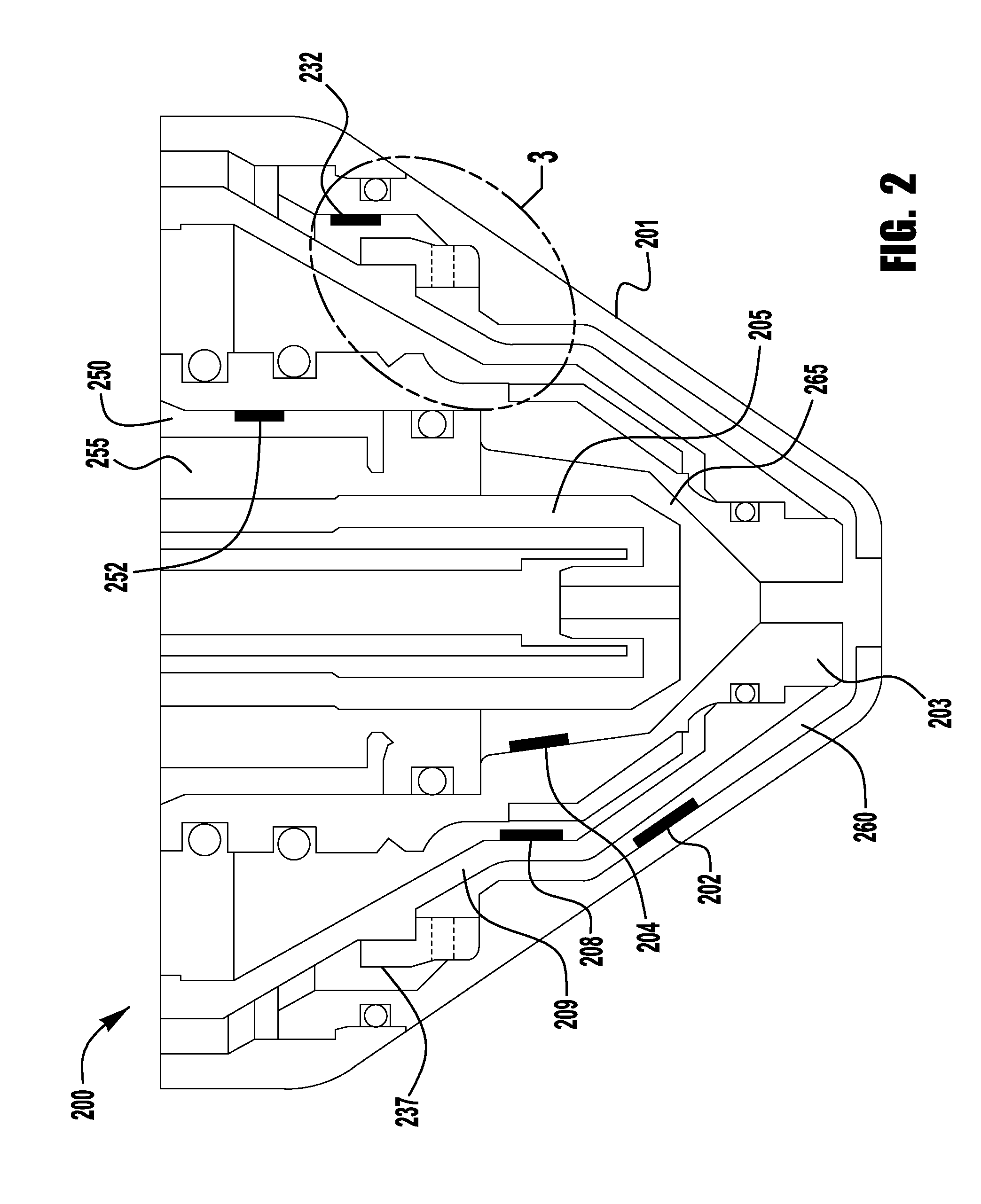

Method and Apparatus for Plasma Dicing a Semi-conductor Wafer

ActiveUS20120238073A1Protection from damageReduce undercuttingElectric discharge tubesSolid-state devicesEngineeringSemiconductor

The present invention provides a method for plasma dicing a substrate. The method comprising providing a process chamber having a wall; providing a plasma source adjacent to the wall of the process chamber; providing a work piece support within the process chamber; placing the substrate onto a support film on a frame to form a work piece work piece; loading the work piece onto the work piece support; providing a cover ring disposed above the work piece; generating a plasma through the plasma source; and etching the work piece through the generated plasma.

Owner:PLASMA THERM

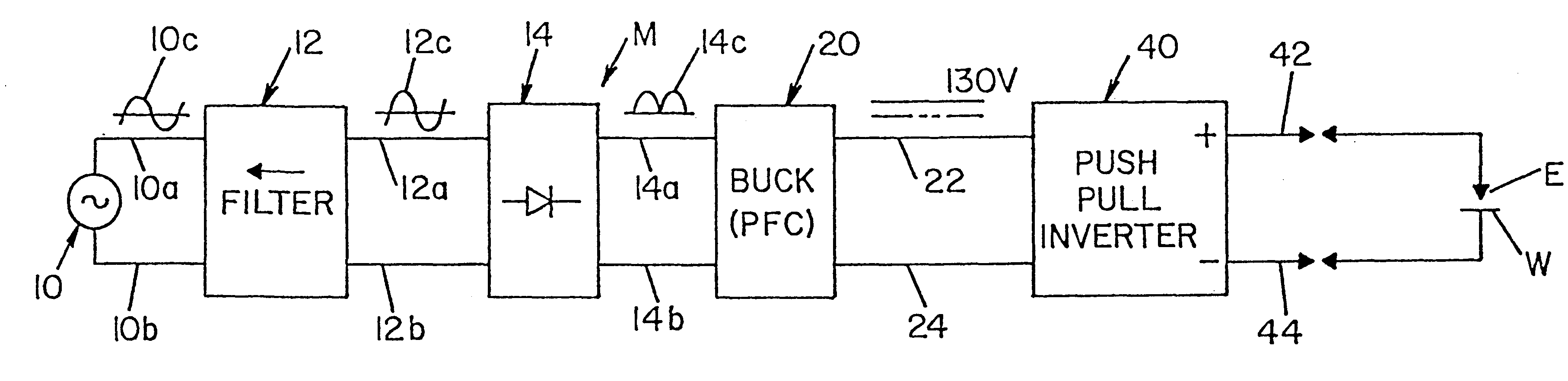

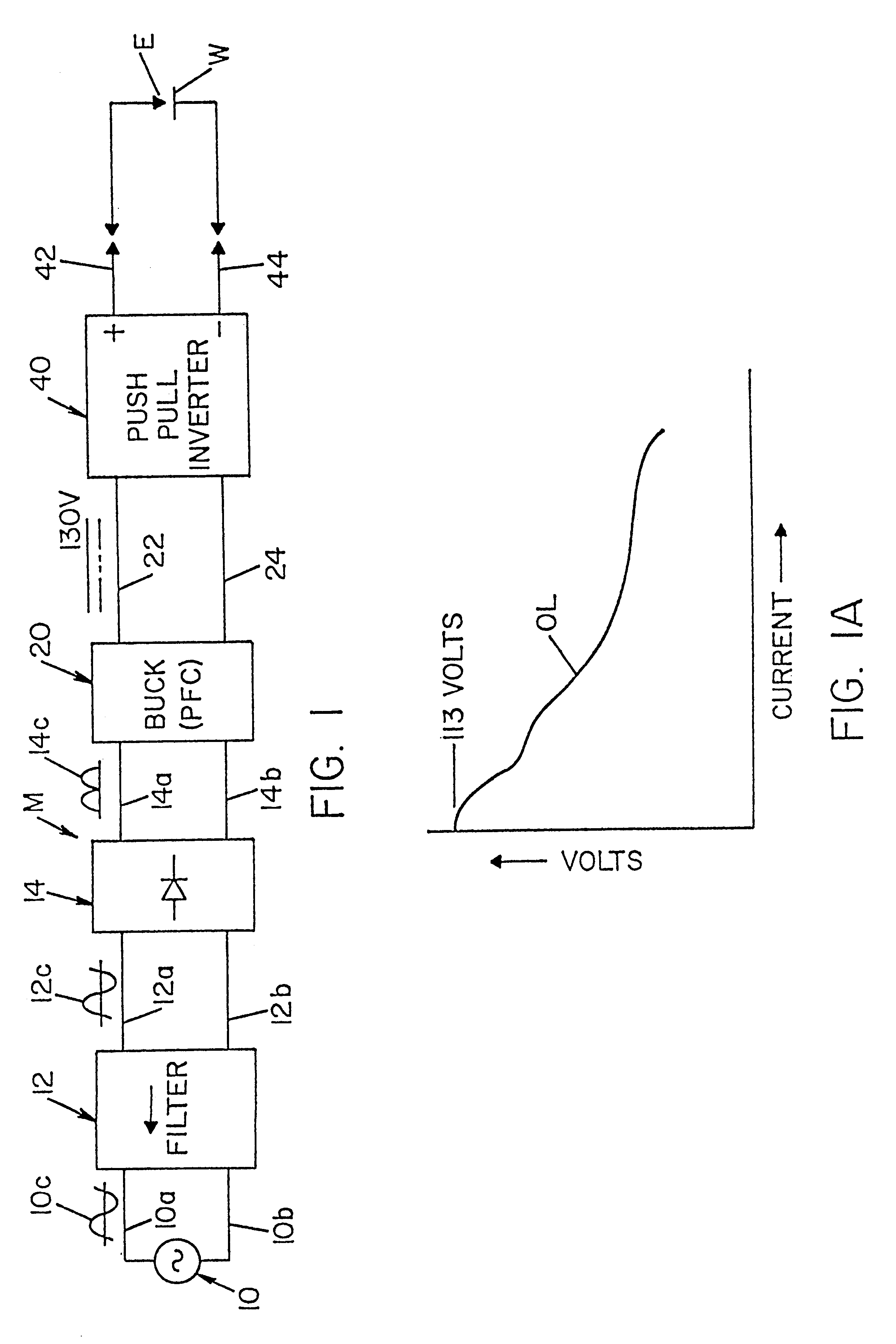

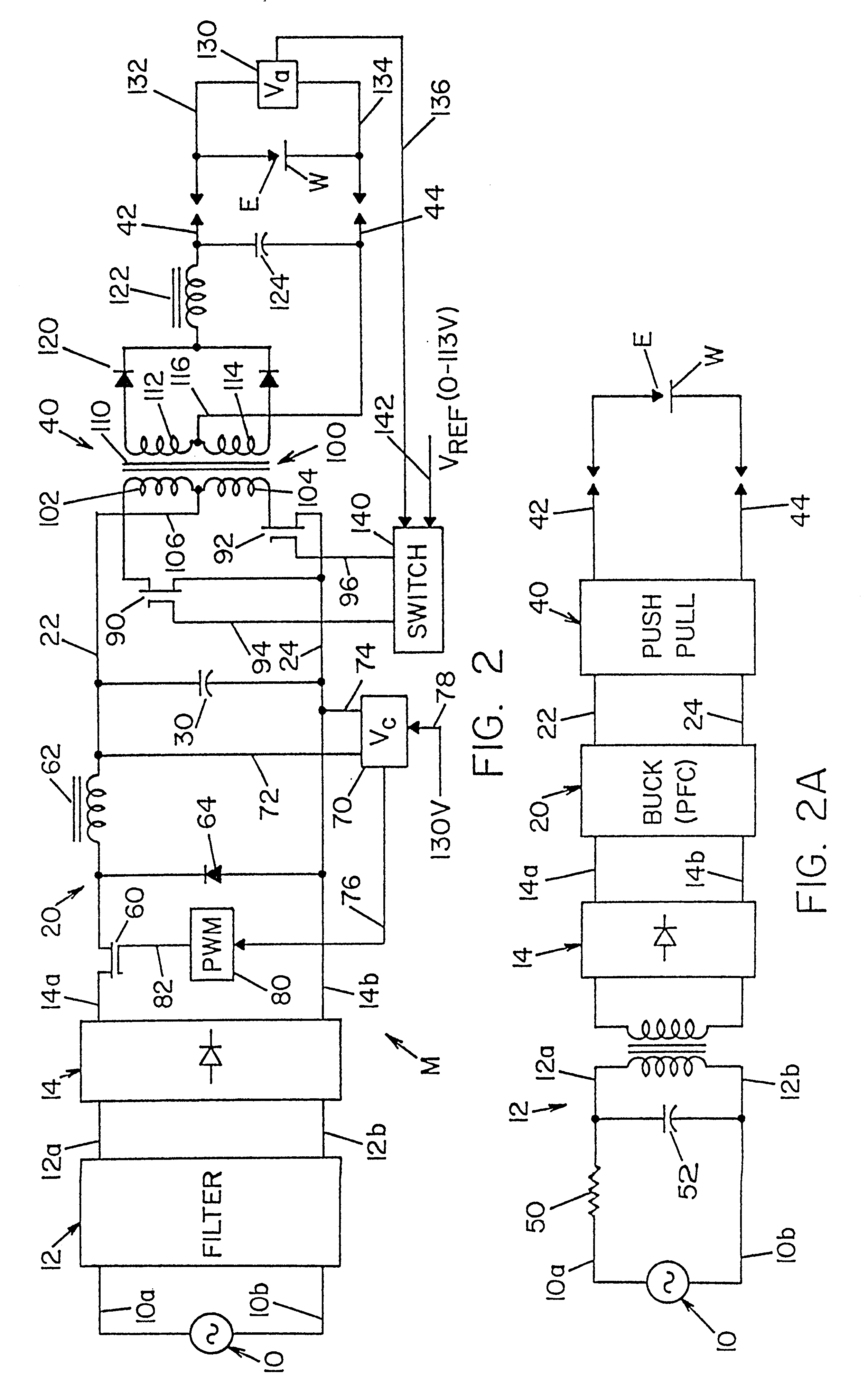

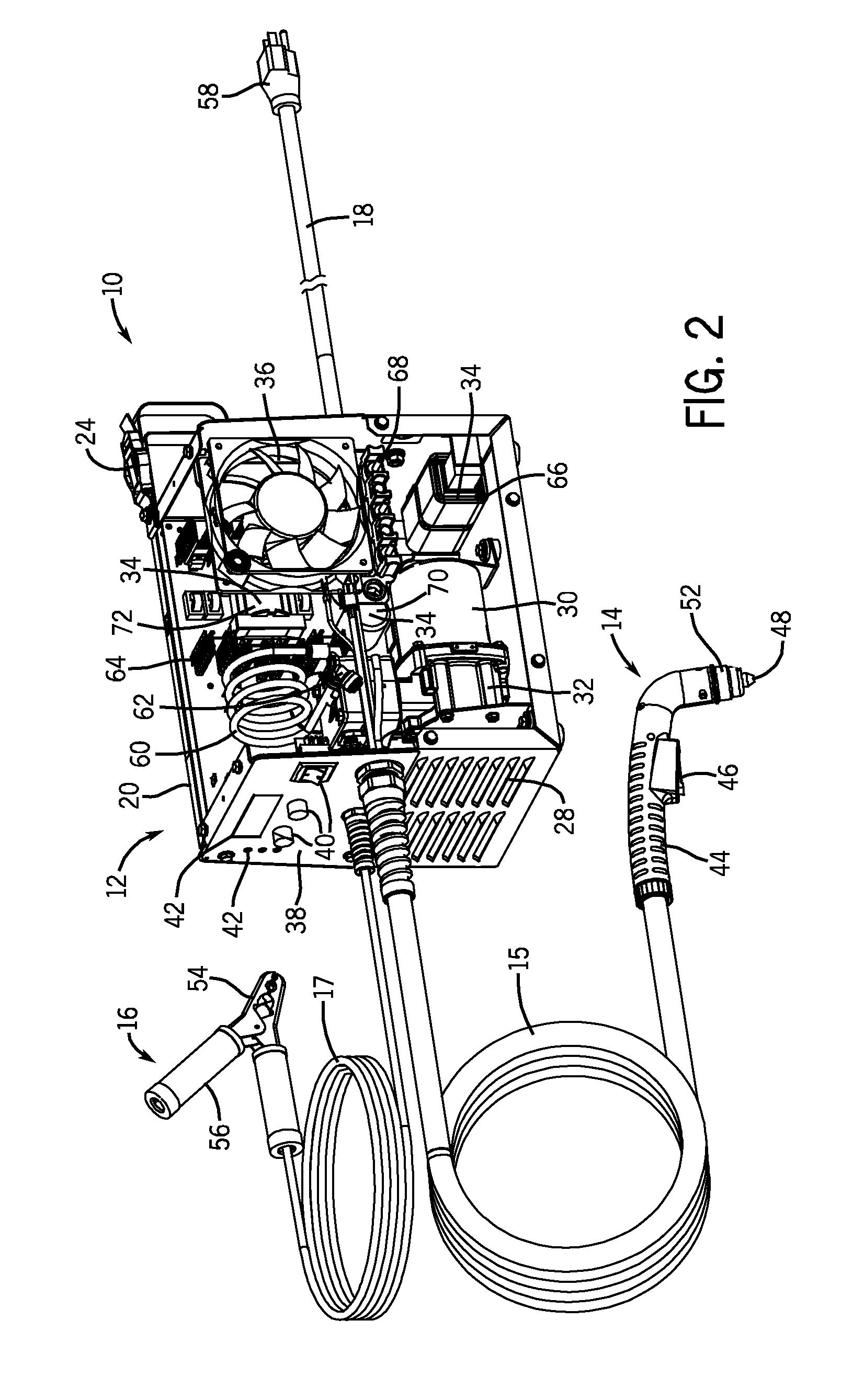

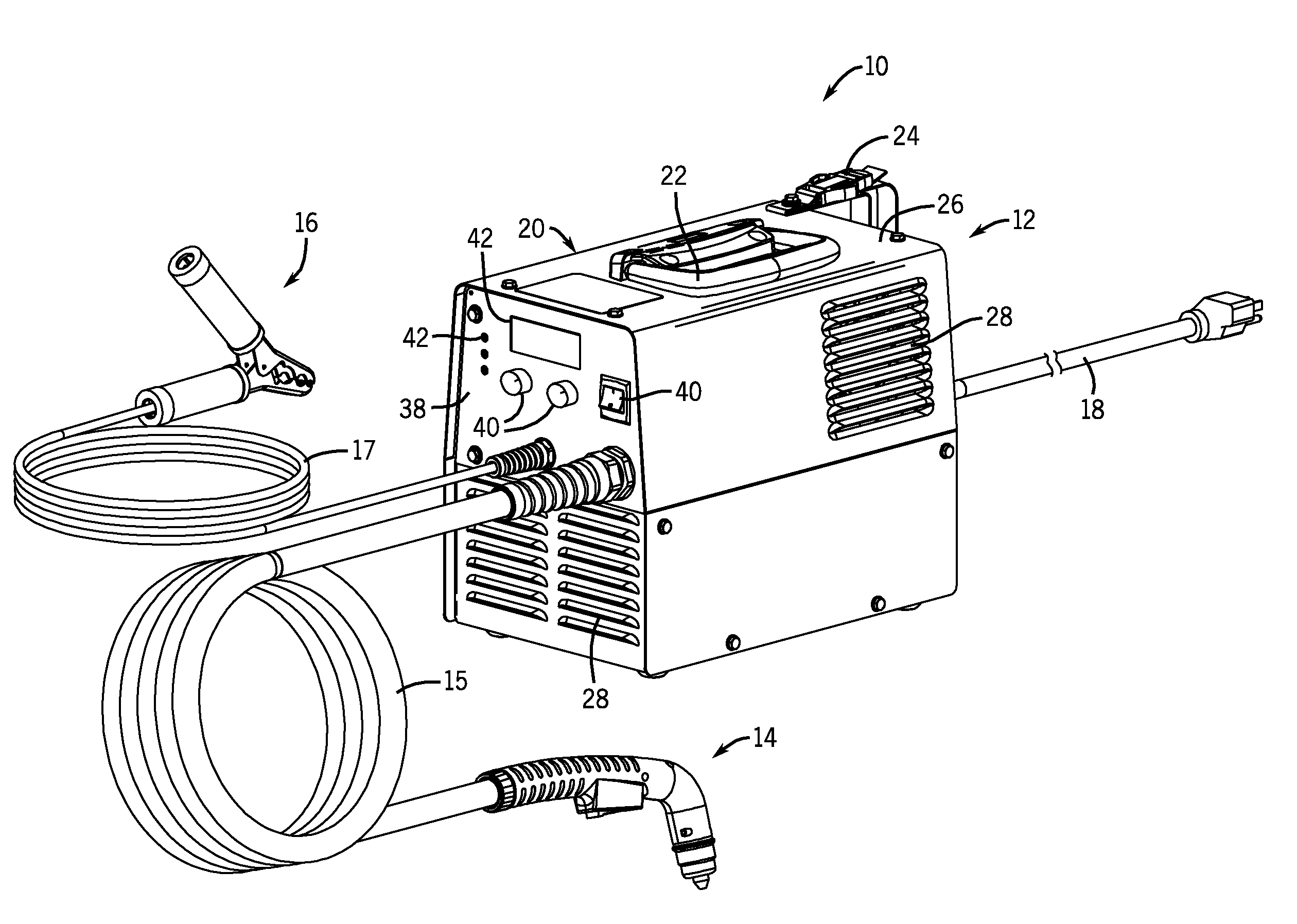

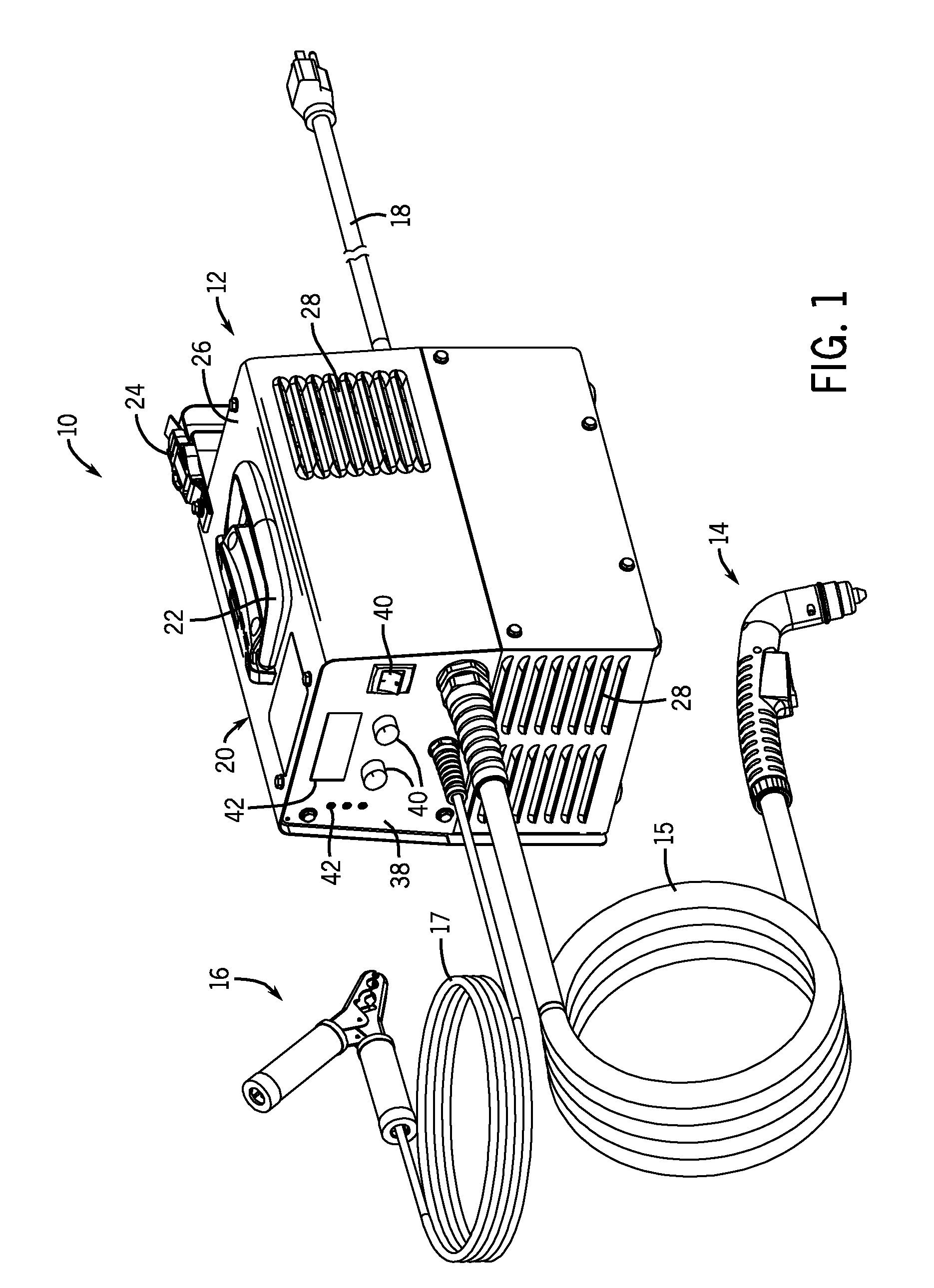

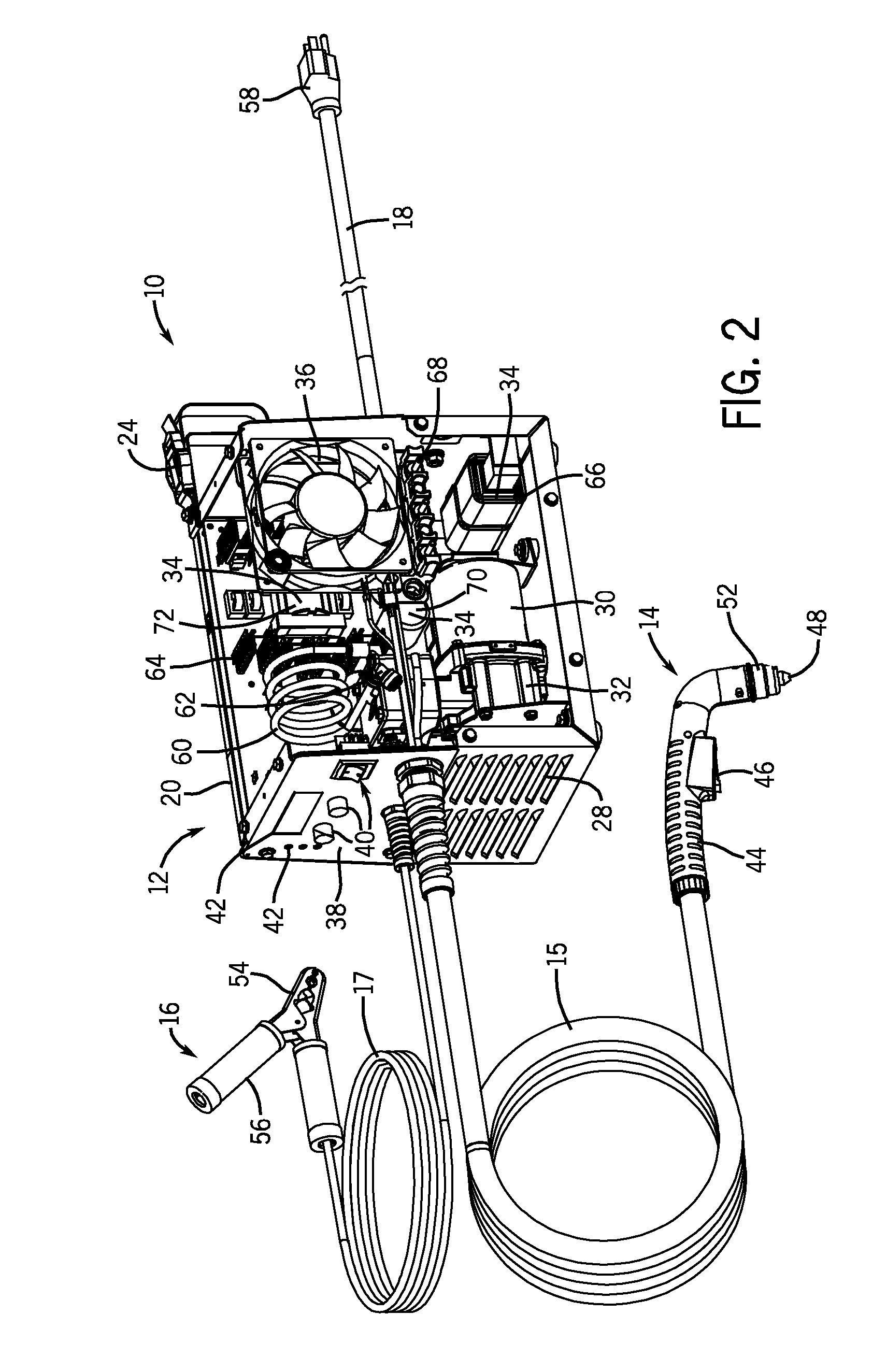

Electric ARC welder and plasma cutter

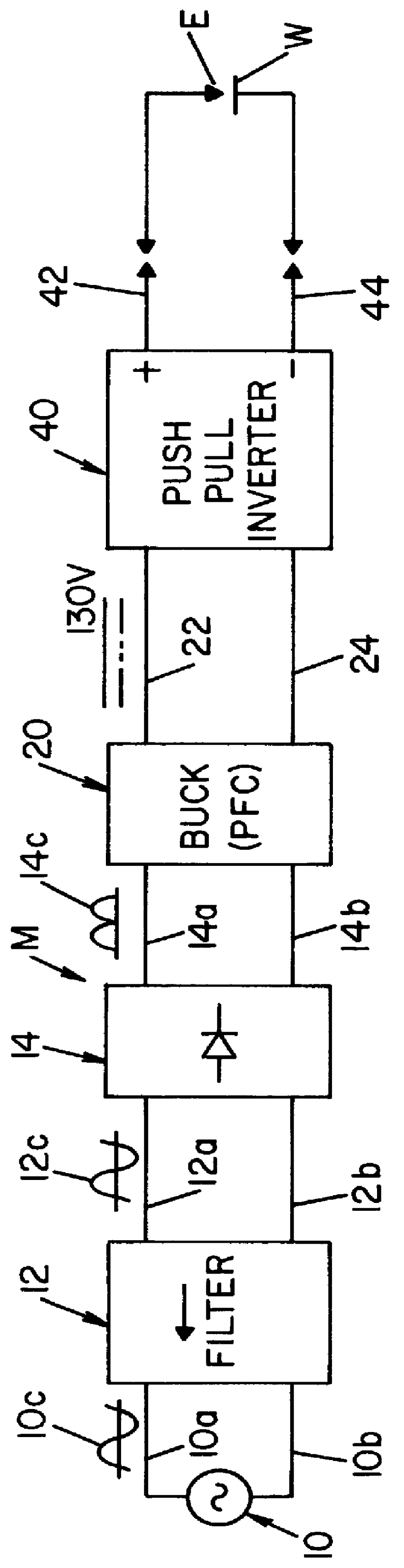

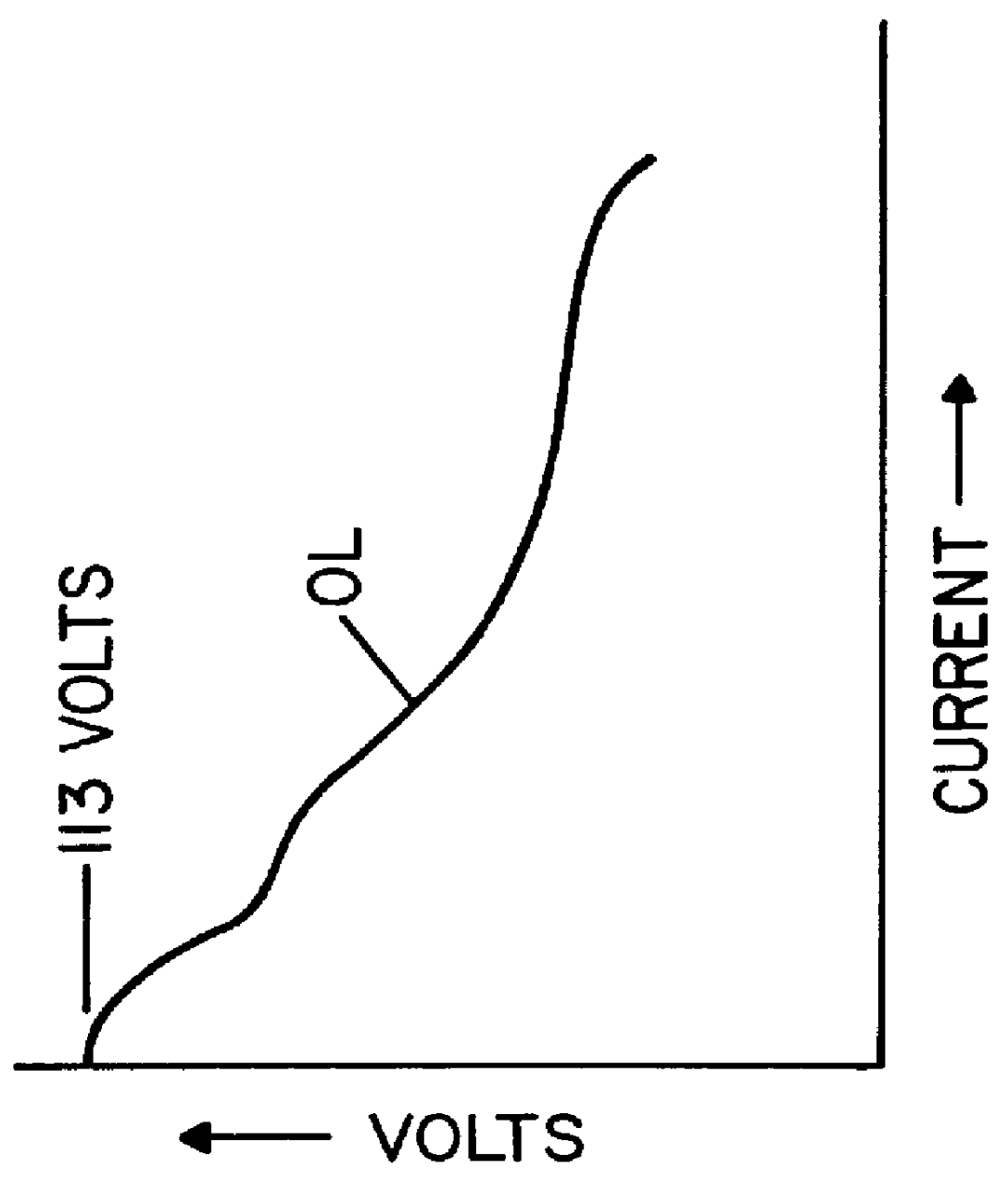

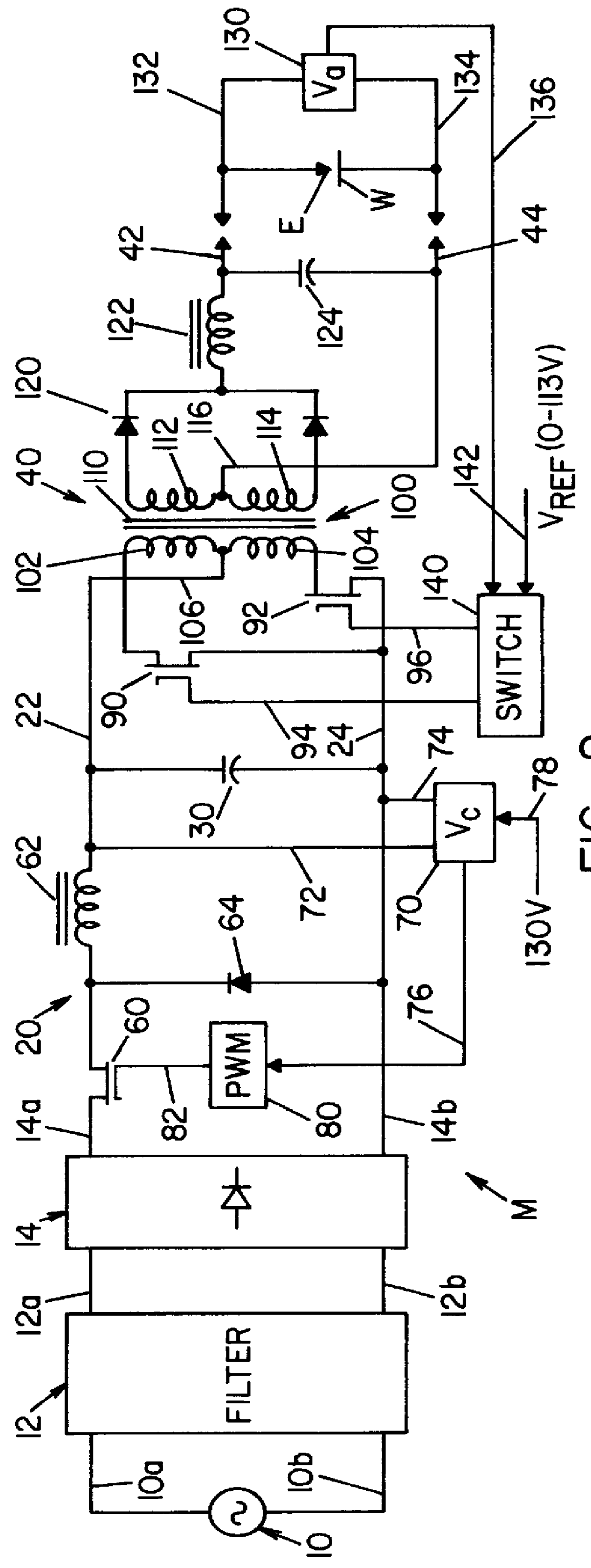

InactiveUS6023037AReduce Harmonic DistortionImprove power factorAc-dc conversion without reversalConversion with intermediate conversion to dcFull waveTransformer coupling

A single phase power supply module for electric arc welders and plasma arc cutters comprising: a single phase input stage; positive and negative output terminals; a full wave rectifier connected to the input stage for rectifying the single phase voltage at the input stage; a buck converter type power factor correcting circuit for controlling current flow from the input stage to the rectifier, which buck converter has an output capacitor regulated to an intermediate voltage in the range of 100-150 volts; and, a high speed DC to DC converter having an internal transformer coupling applying voltage across the output terminals and means for regulating the applied voltage to an output voltage in the range of 0-113 volts. The module is universal and several can be connected in parallel, in series or to switch networks to construct several welders or cutters.

Owner:LINCOLN GLOBAL INC

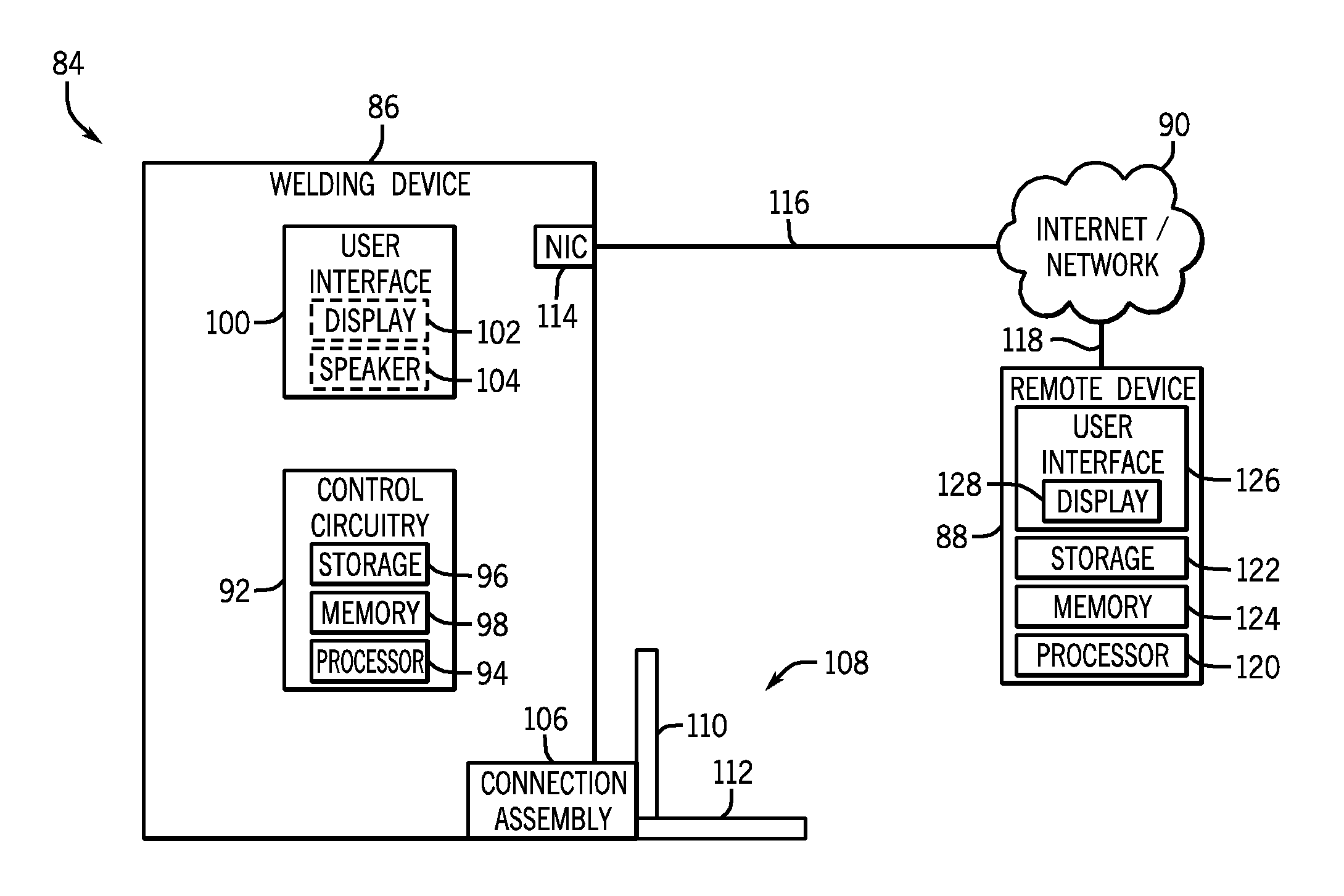

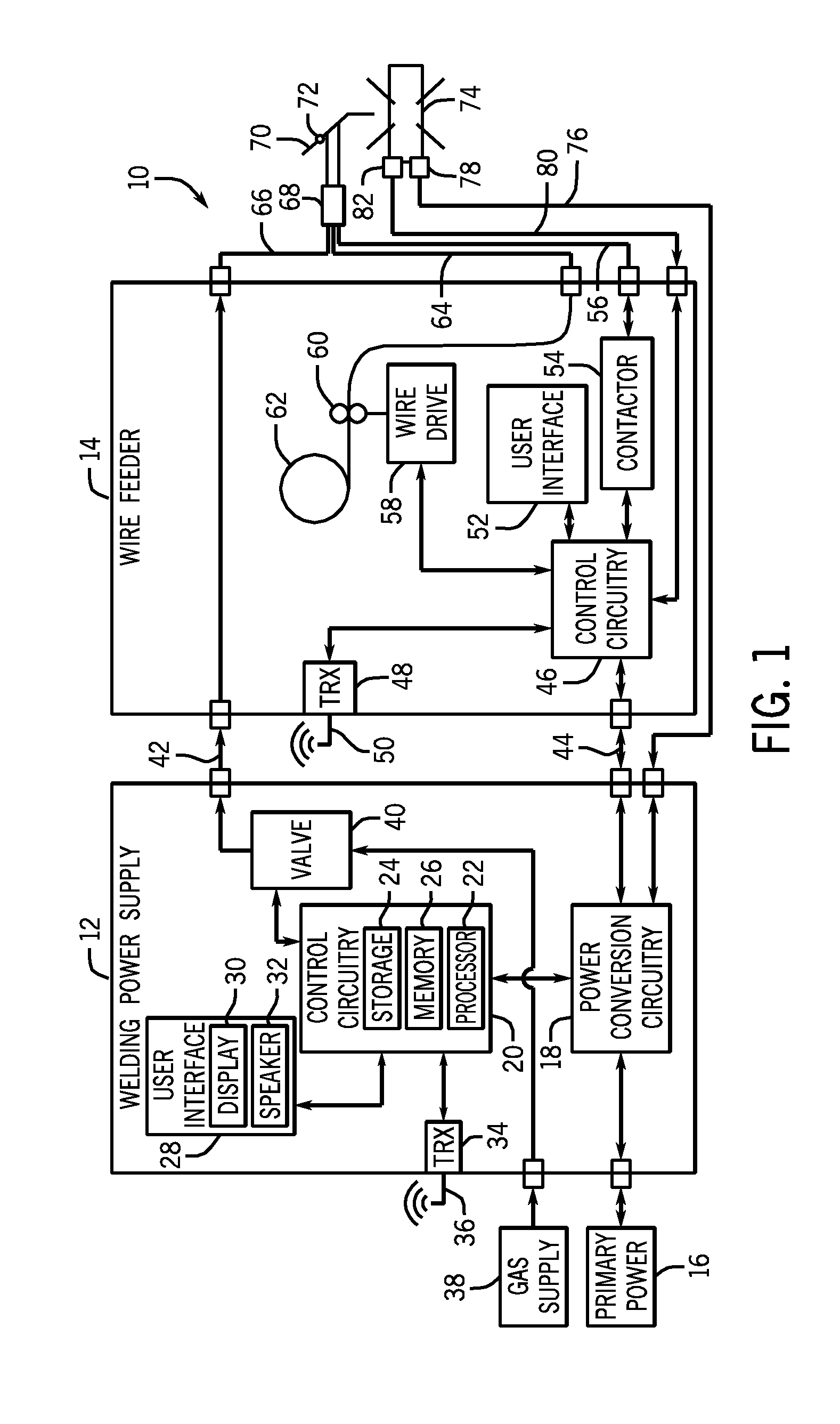

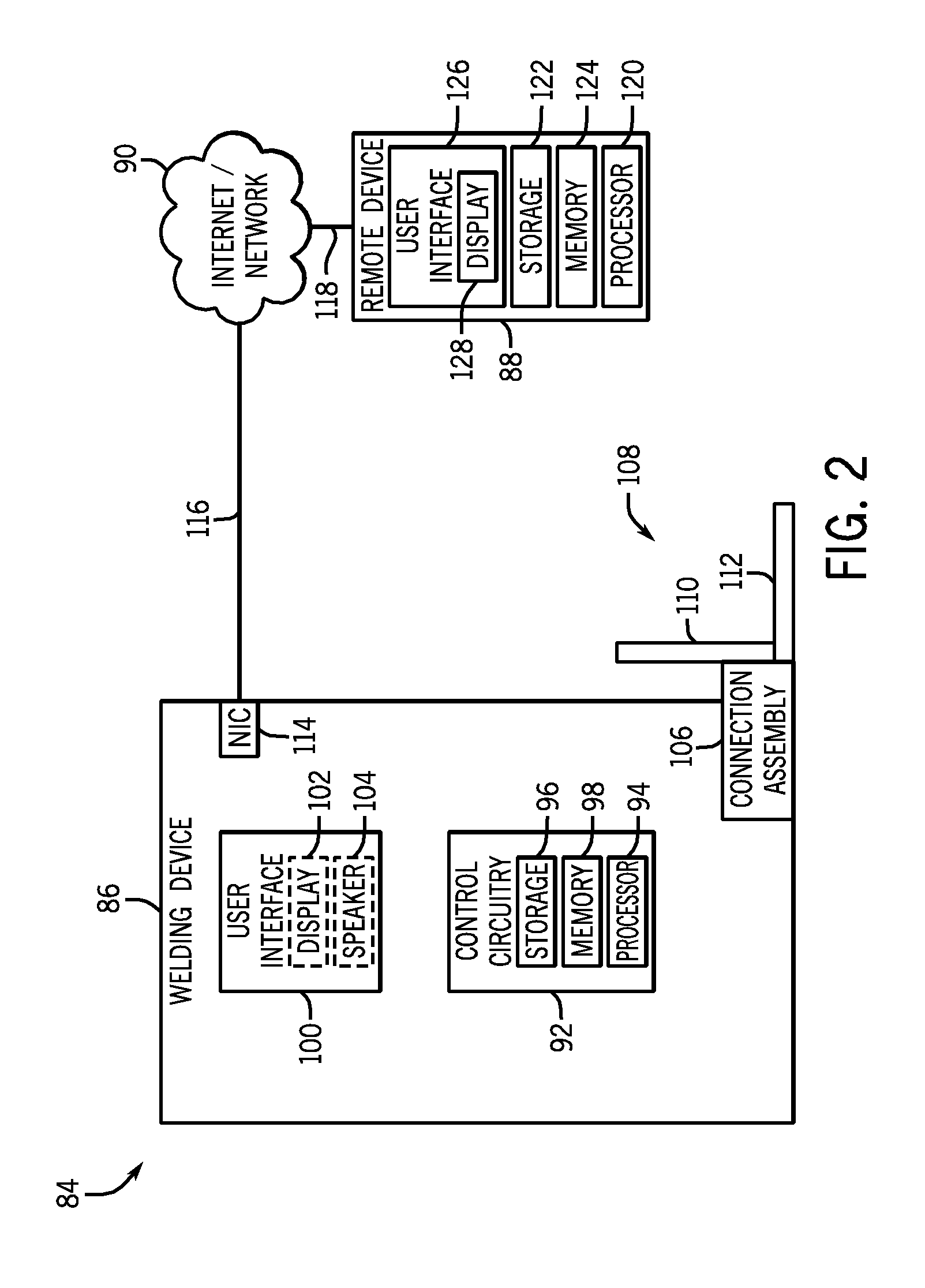

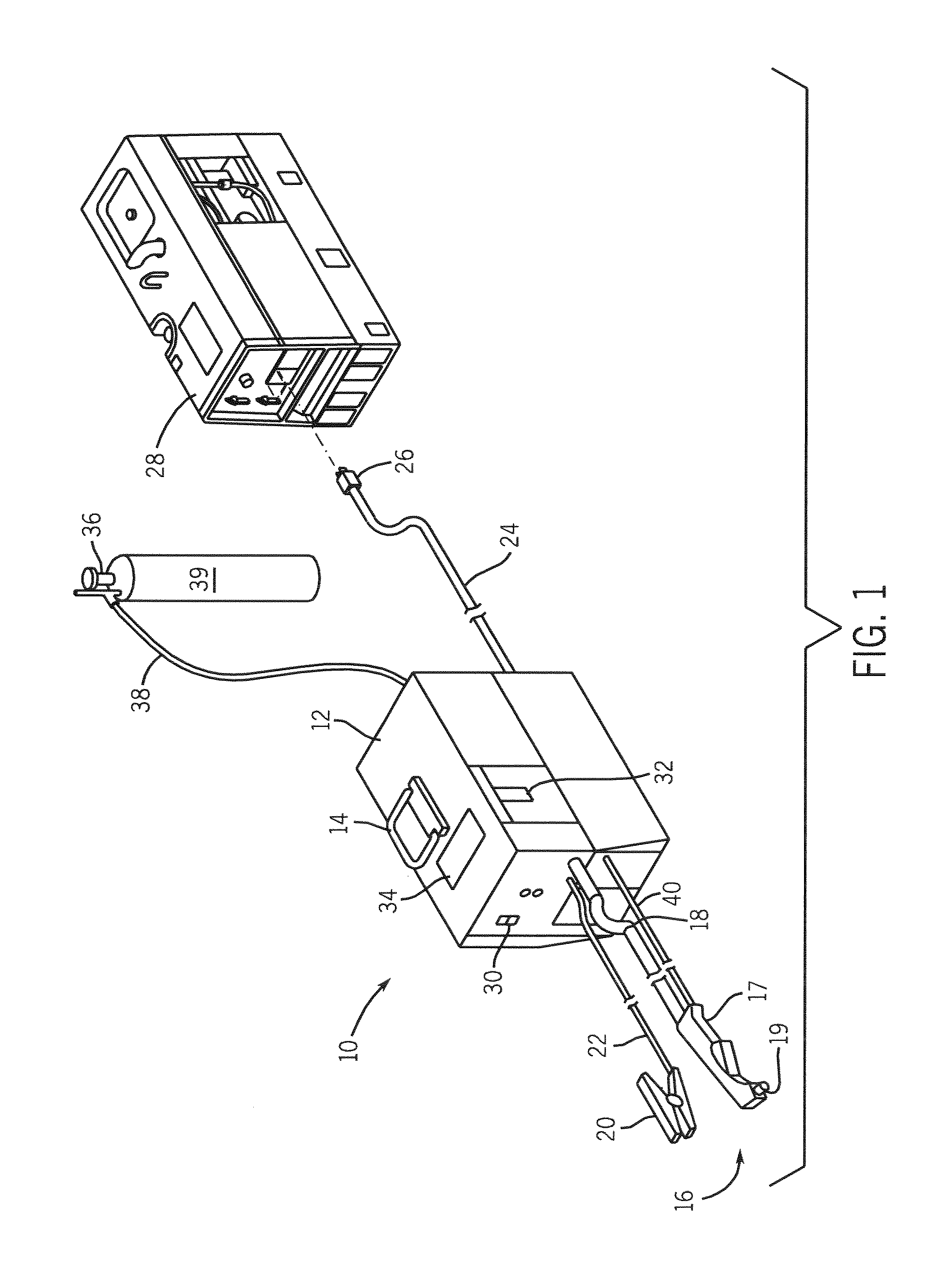

Systems and methods for training a welding operator

A welding, plasma cutting, or heat induction system to train a welding operator. The system includes a display configured to show a prerecorded video selected from multiple prerecorded videos. The prerecorded videos correspond to a welding application, a plasma cutting application, a heat induction application, or some combination thereof.

Owner:ILLINOIS TOOL WORKS INC

Method and Apparatus for Plasma Dicing a Semi-conductor Wafer

ActiveUS20130065378A1Protection from damageReduce undercuttingElectric discharge tubesSolid-state devicesEngineeringSemiconductor

The present invention provides a method for plasma dicing a substrate. The method comprising providing a process chamber having a wall; providing a plasma source adjacent to the wall of the process chamber; providing a work piece support within the process chamber; placing the substrate onto a support film on a frame to form a work piece work piece; loading the work piece onto the work piece support; providing a cover ring disposed above the work piece; generating a plasma through the plasma source; and etching the work piece through the generated plasma.

Owner:PLASMA THERM

Electric arc welder and plasma cutter

InactiveUS6177645B1Reduce Harmonic DistortionImprove power factorAc-dc conversion without reversalConversion with intermediate conversion to dcFull waveEngineering

A single phase power supply module for electric arc welders and plasma arc cutters comprising: a single phase input stage; positive and negative output terminals; a full wave rectifier connected to the input stage for rectifying the single phase voltage at the input stage; a buck converter type power factor correcting circuit for controlling current flow from the input stage to the rectifier, which buck converter has an output capacitor regulated to an intermediate voltage in the range of 100-150 volts; and, a high speed DC to DC converter having an internal transformer coupling applying voltage across the output terminals and means for regulating the applied voltage to an output voltage in the range of 0-113 volts. The module is universal and several can be connected in parallel, in series or to switch networks to construct several welders or cutters.

Owner:LINCOLN GLOBAL INC

Method and Apparatus for Plasma Dicing a Semi-conductor Wafer

ActiveUS20130230972A1Protection from damageReduce undercuttingElectric discharge tubesSolid-state devicesSemiconductorPlasma cutting

The present invention provides a method for plasma dicing a substrate. The method comprising providing a process chamber having a wall; providing a plasma source adjacent to the wall of the process chamber; providing a work piece support within the process chamber; placing the substrate onto a support film on a frame to form a work piece work piece; loading the work piece onto the work piece support; providing a cover ring disposed above the work piece; generating a plasma through the plasma source; and etching the work piece through the generated plasma.

Owner:PLASMA THERM

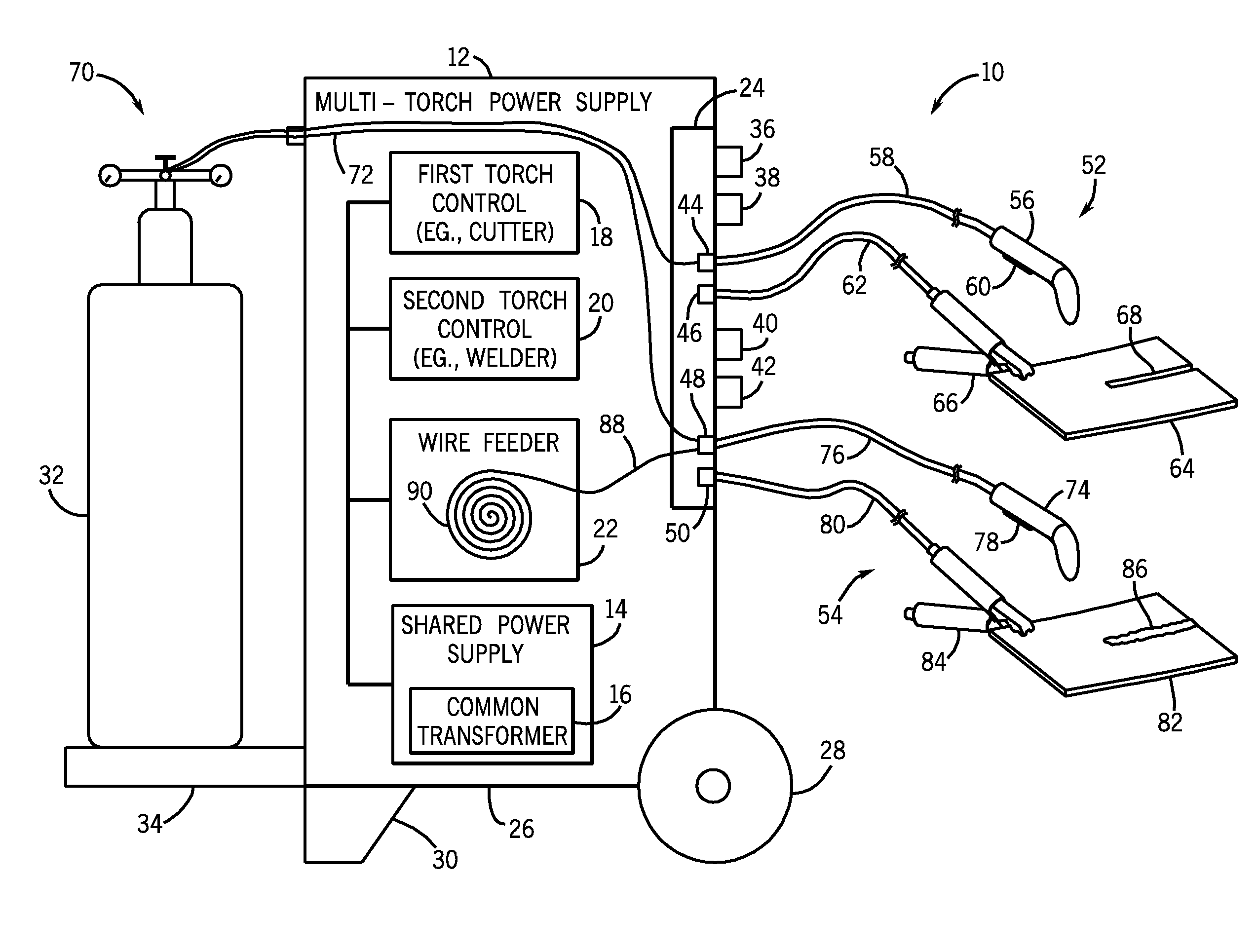

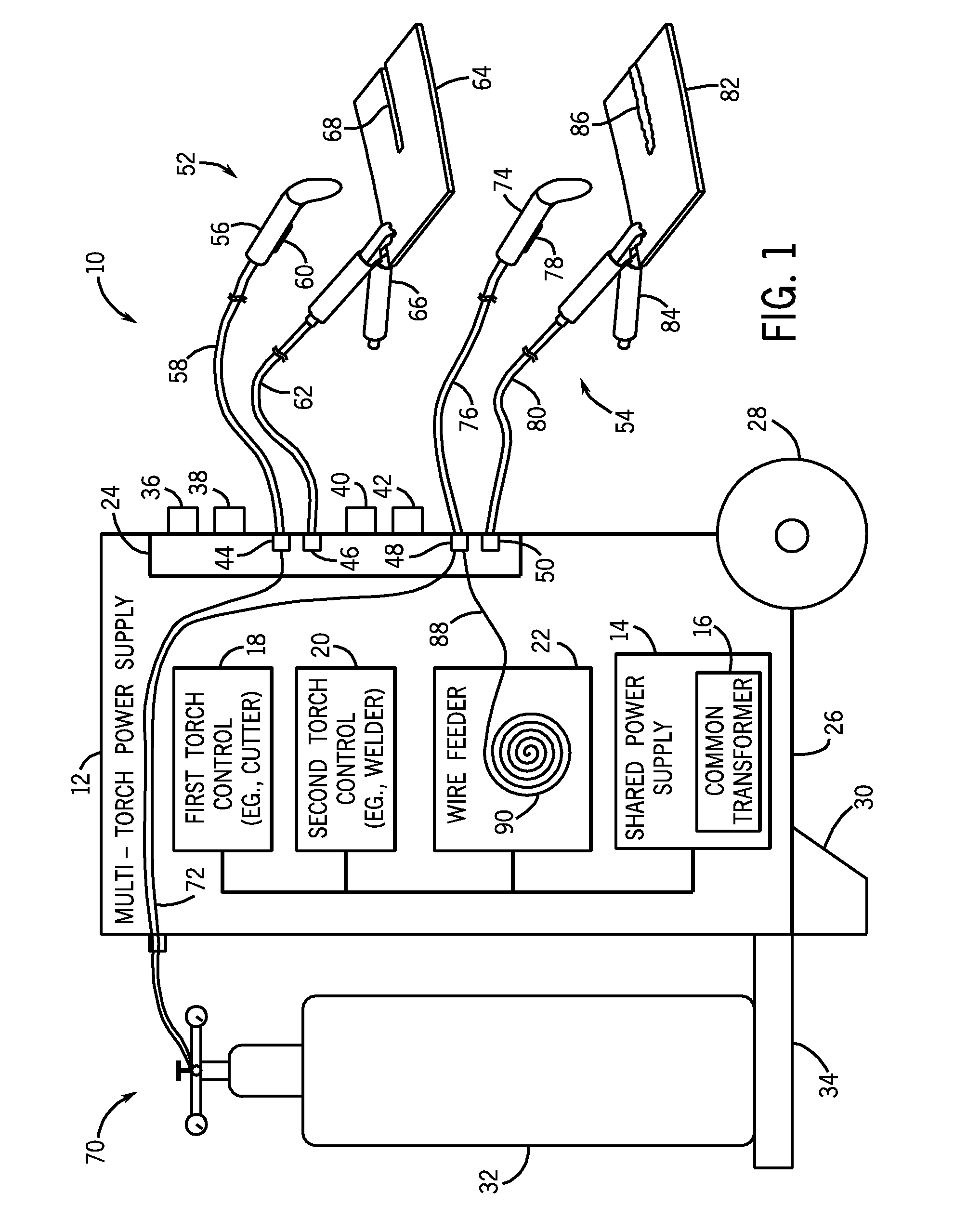

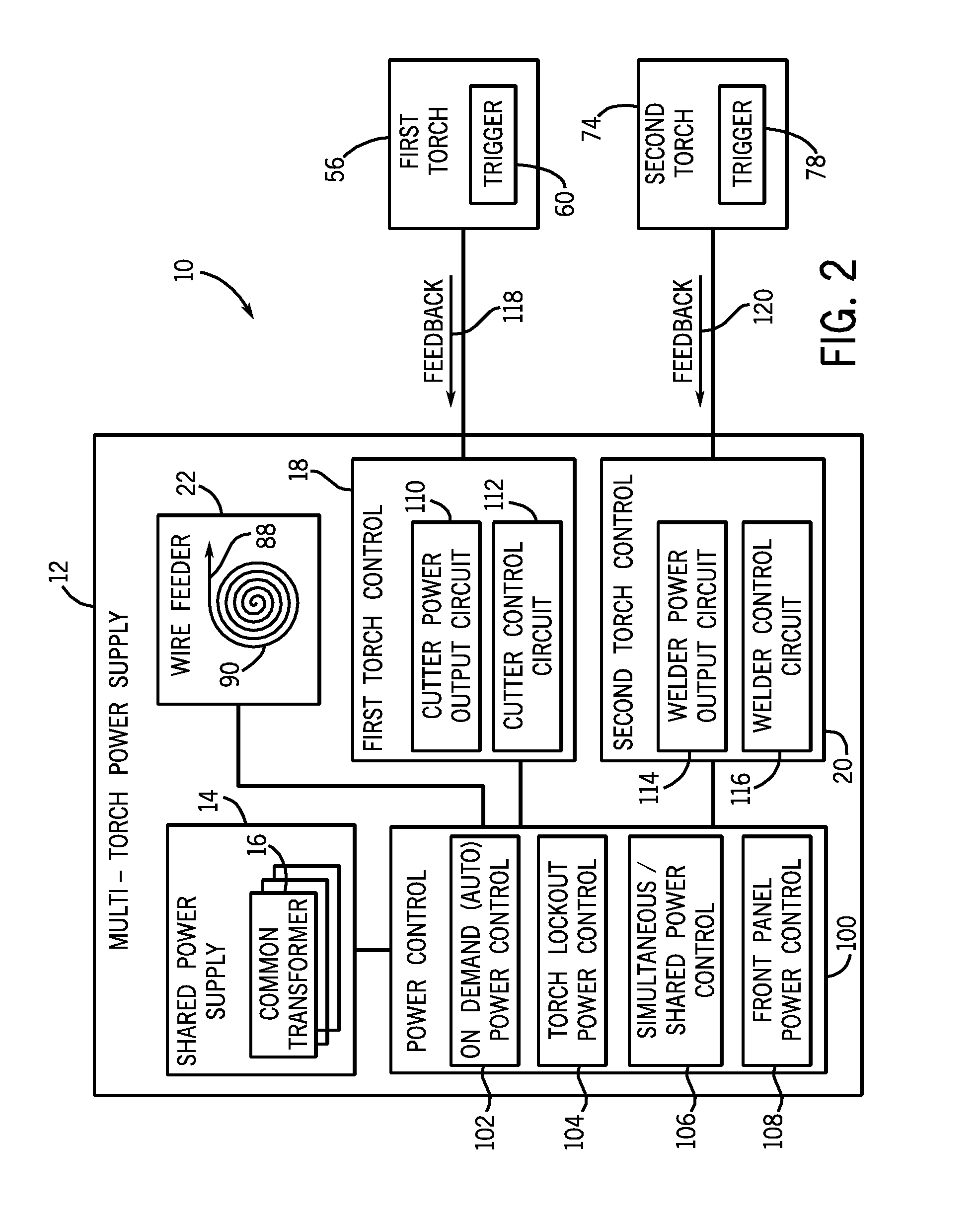

Welding and plasma cutting method and system

A system, in some embodiments, includes a multi-torch power supply. The power supply has a first circuit configured to control output to a first electrical torch, and a second circuit configured to control output to a second electrical torch. The power supply also has a power source configured to supply power to the first and second circuits to enable both independent and simultaneous operation of the first and second electrical torches.

Owner:ILLINOIS TOOL WORKS INC

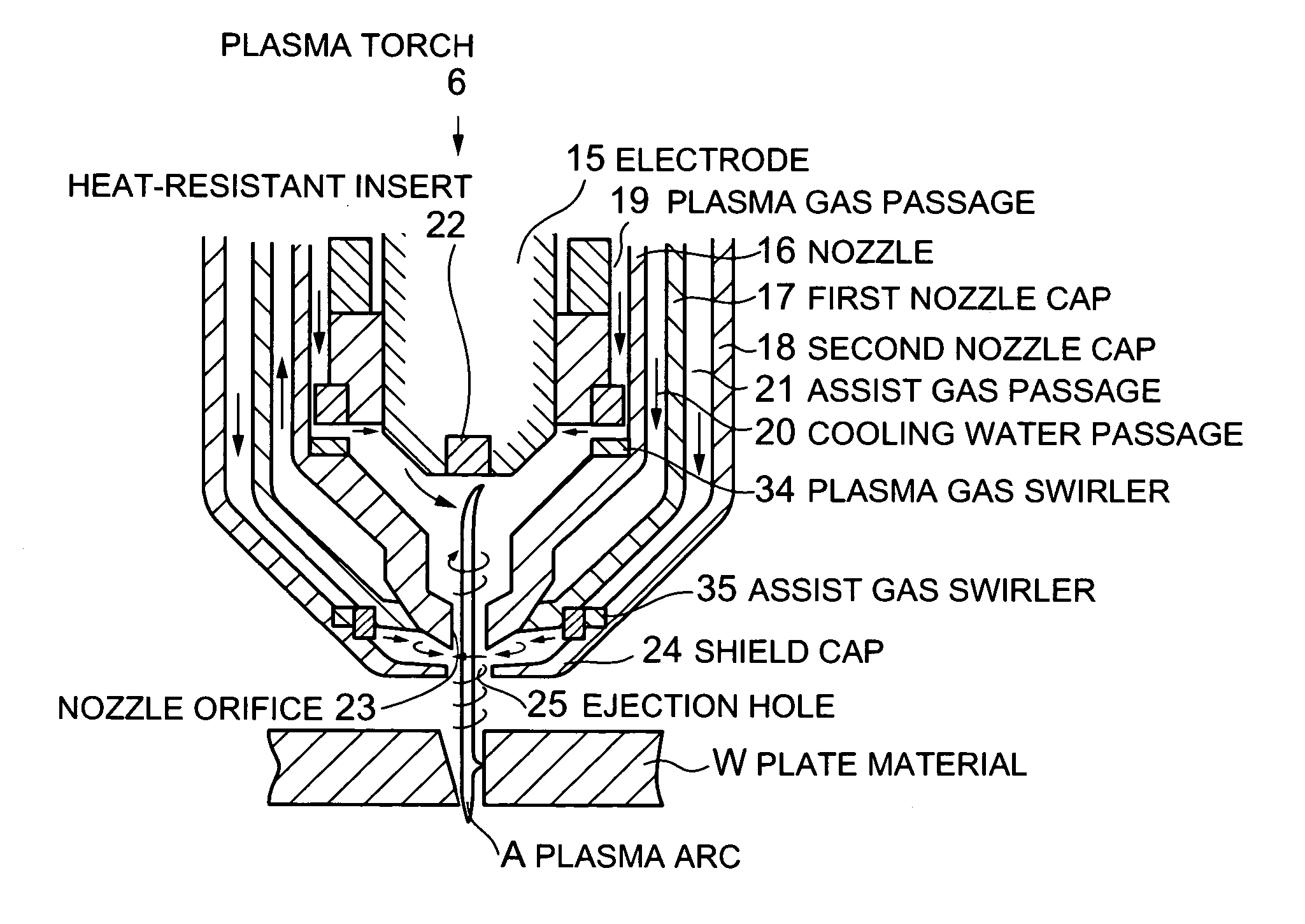

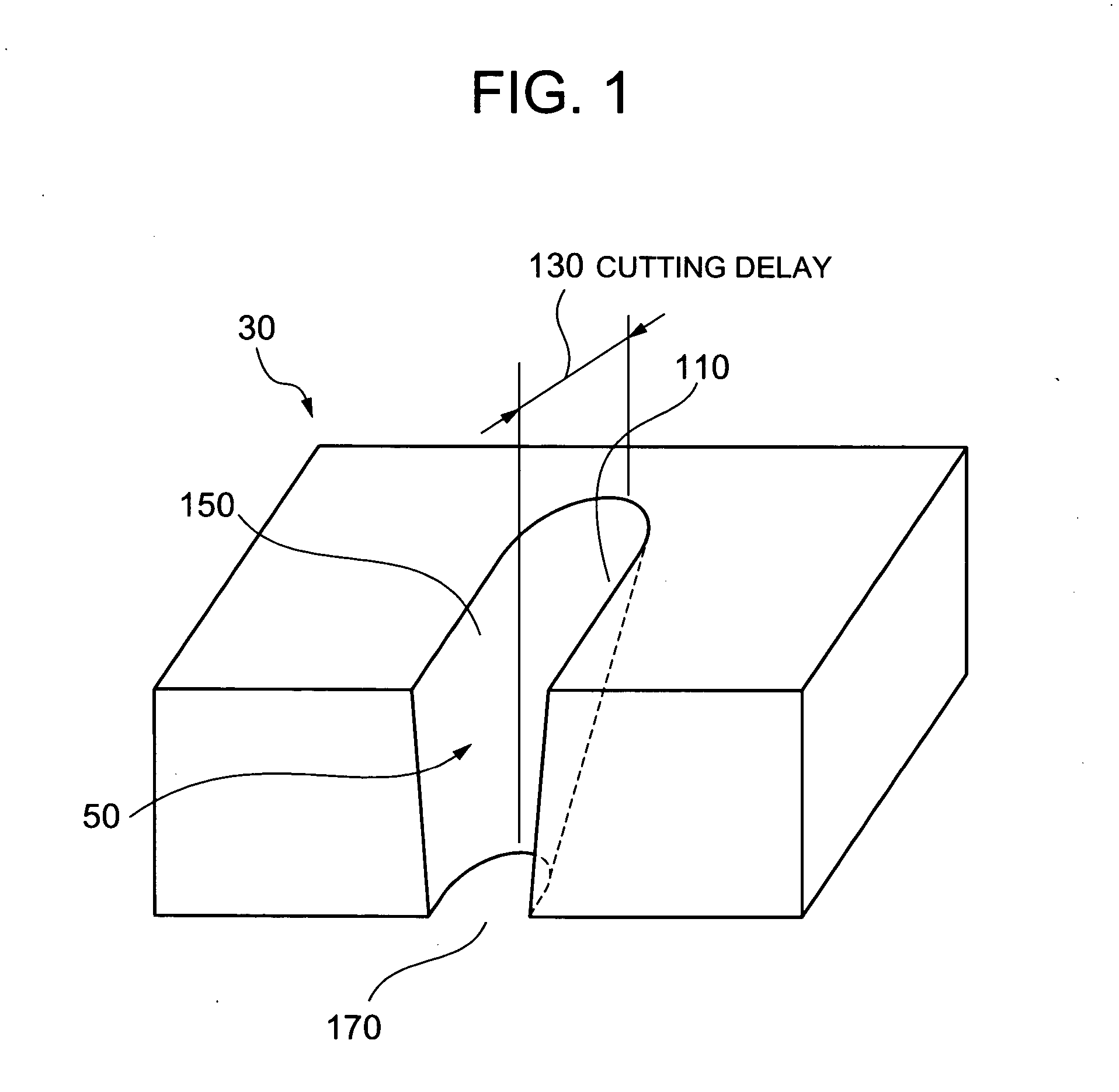

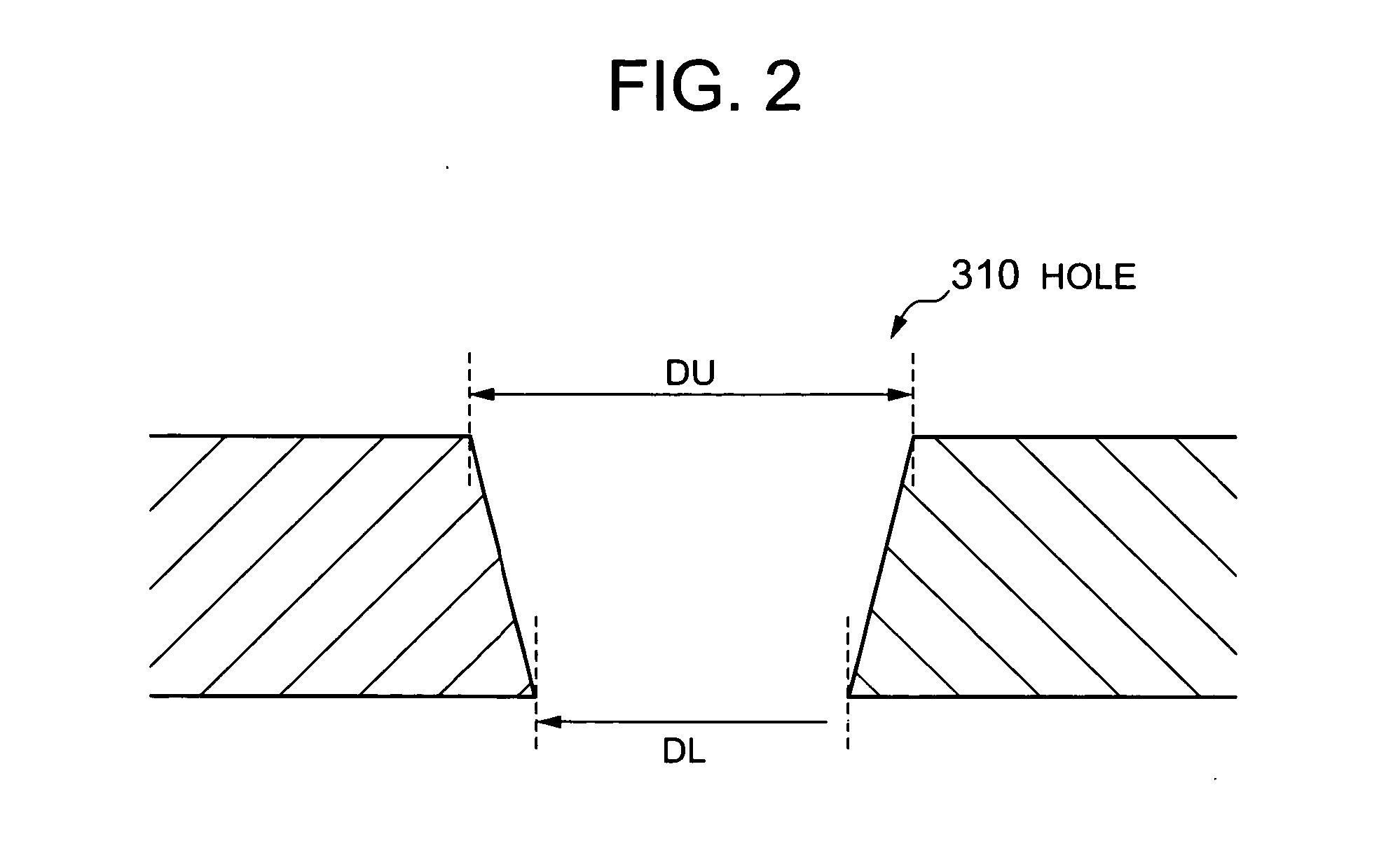

Plasma cutting apparatus and control unit thereof

ActiveUS20050035093A1Improve cut qualityWelding/cutting auxillary devicesArc welding apparatusEngineeringPlasma Gases

Cutting quality of the product, in particular, hole cutting quality, in plasma arc cutting is improved. A control unit, which controls a plasma cutting apparatus for cutting a product from a plate material by moving a plasma torch at a cutting speed along a cutting path corresponding to the product shape to cut the plate material, while supplying an arc current and a plasma gas to the plasma torch and forming a plasma arc from a nozzle of the plasma torch to the plate material, conducts control so that, when a hole is cut, a cutting speed is lower, a value of the arc current value is smaller, and a plasma gas flow rate or pressure is less than those when a contour is cut.

Owner:KOMATSU IND CORP

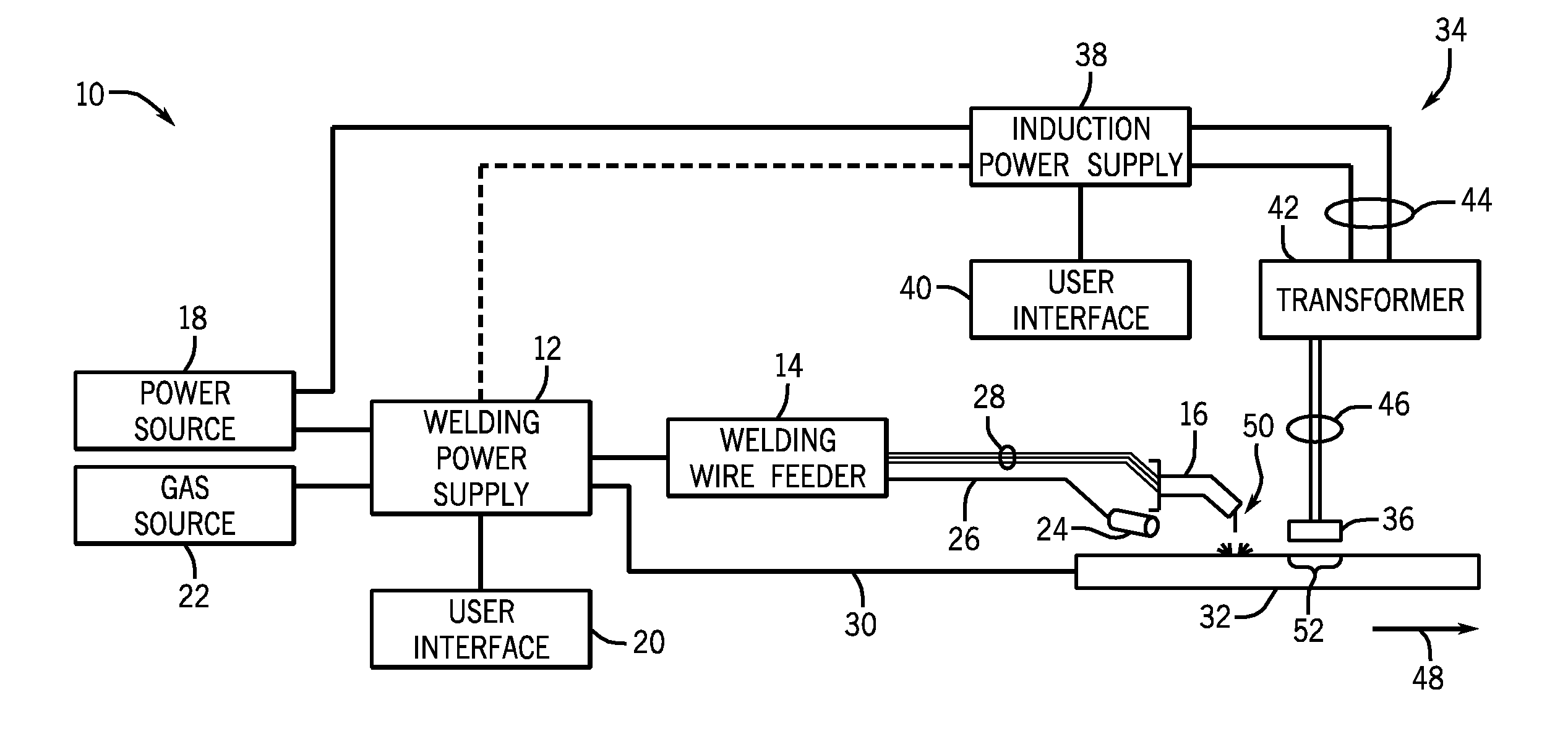

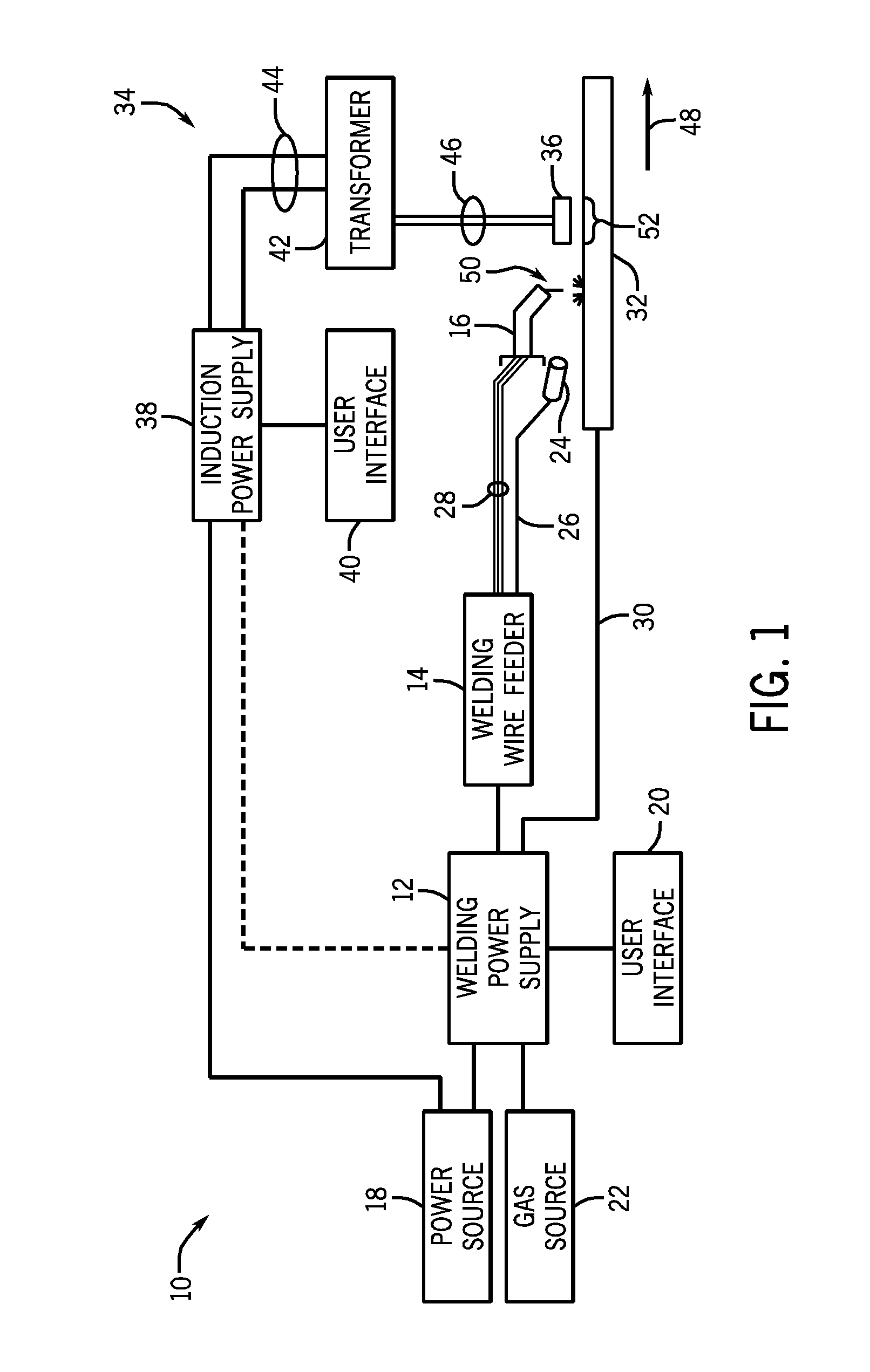

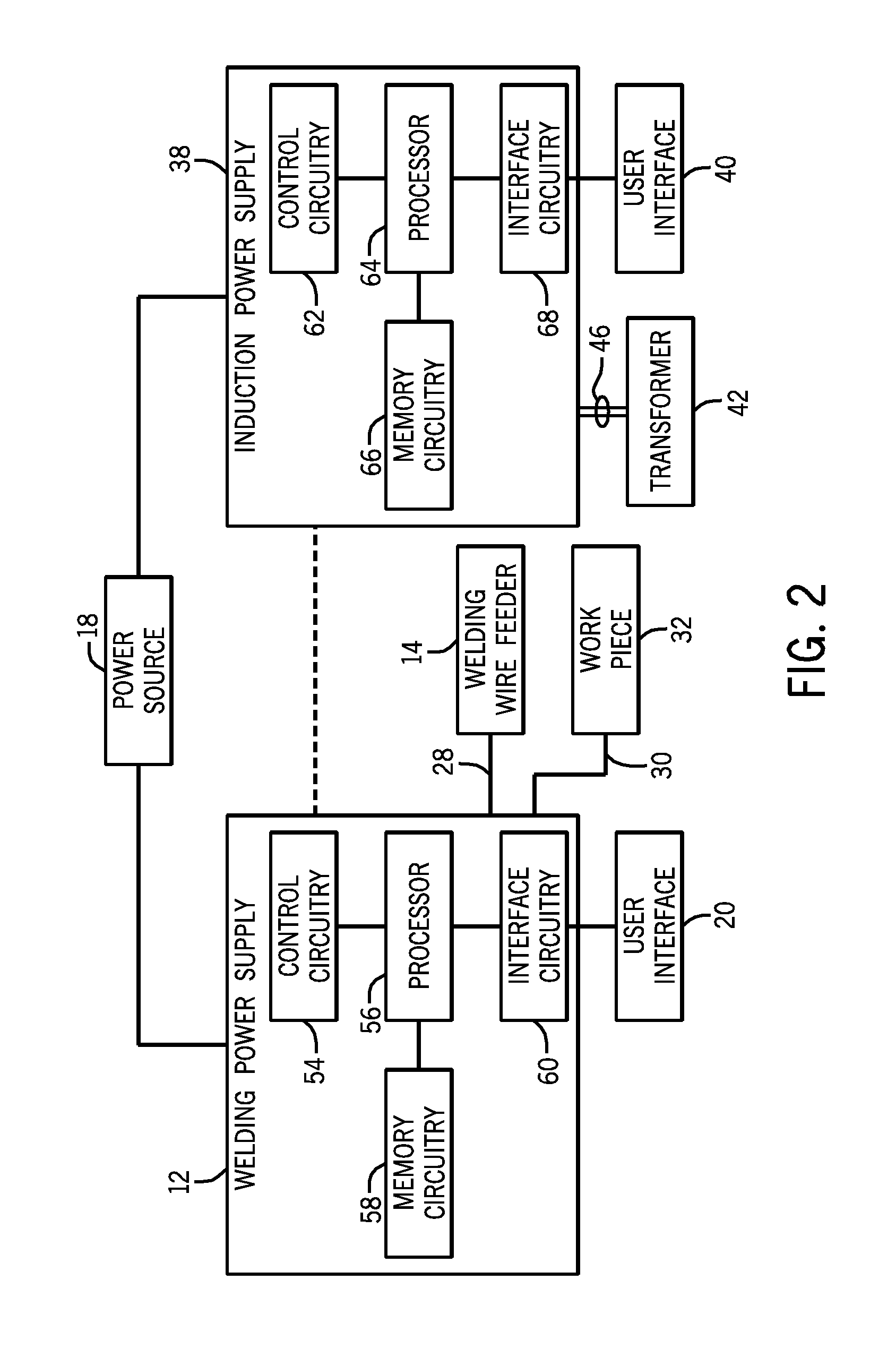

Auxiliary welding heating system

An auxiliary welding heating system includes an induction heating coil disposed adjacent to a welding torch or plasma cutter. The auxiliary welding heating system further includes an induction power supply configured to generate an alternating current and a step-down transformer coupled to the induction power supply. The induction heating coil is coupled to the step-down transformer and is configured to receive the alternating current and induce eddy currents in a welding work piece to heat the welding work piece before an advancing welding arc or plasma cut to a homologous temperature of at least approximately 0.5.

Owner:ILLINOIS TOOL WORKS INC

Automatic Cutting Device and Production Method for Beveled Product

InactiveUS20090250445A1Welding/cutting auxillary devicesArc welding apparatusPlasma cuttingMultiple stages

A plasma cutting device performs cutting in a plurality of stages. In a first cutting sub-process, a manufactured product is cut out from a base material upon a stage according to an NC program. Next, images of respective regions in the vicinities of proper positions at two corner points of the manufactured product which has been cut out are photographed by an image sensor, the actual positions of these two corner points of the manufactured product are detected from these images which have been photographed, and the translation distances and the rotational angle between the actual positions which have been detected and the proper positions are calculated. The NC program is corrected. And, in a subsequent cutting sub-process, additional cutting for beveling is carried out upon cutting surfaces at the outer circumference of the manufactured product, according to the corrected NC program.

Owner:KOMATSU IND CORP

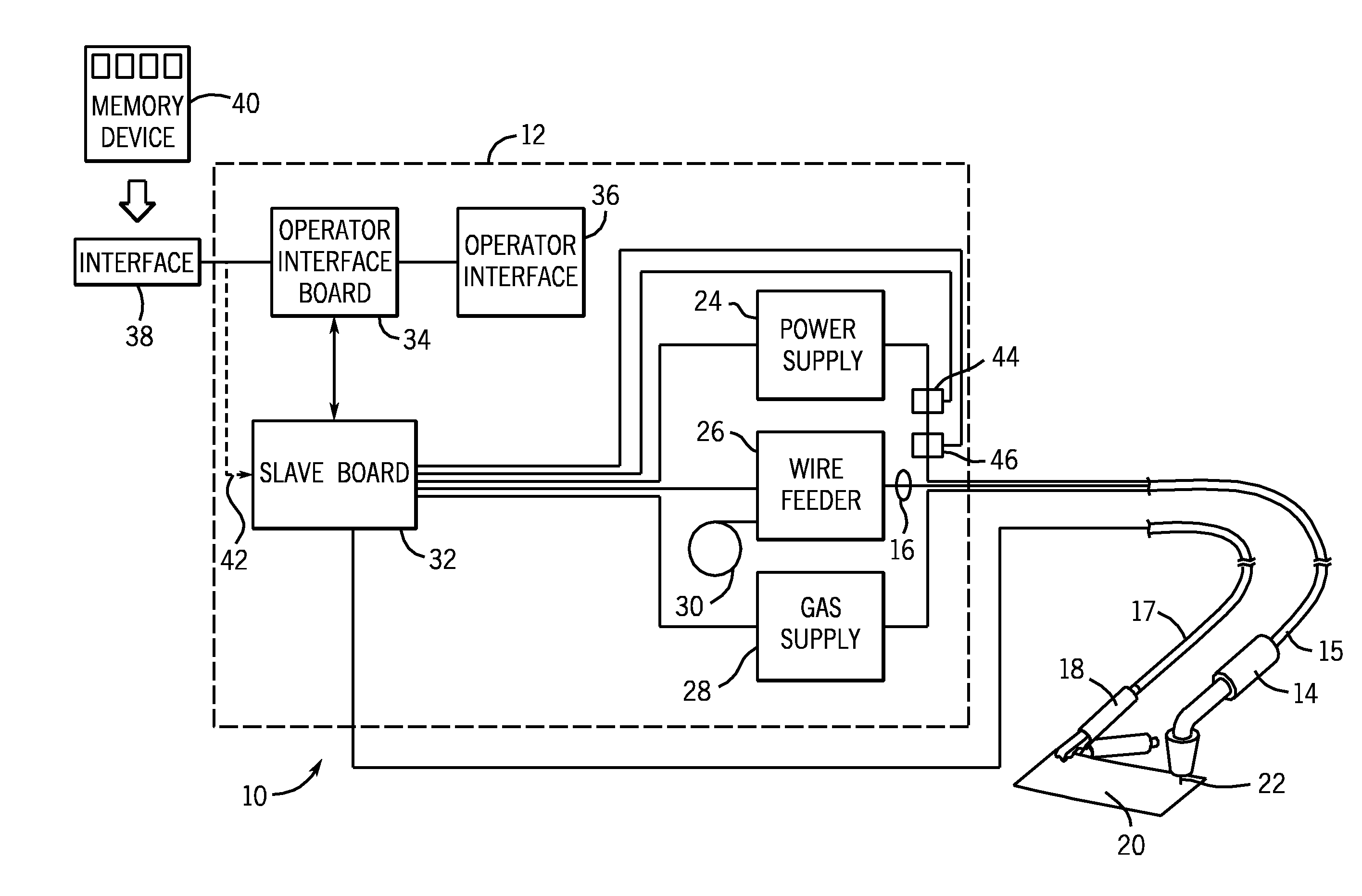

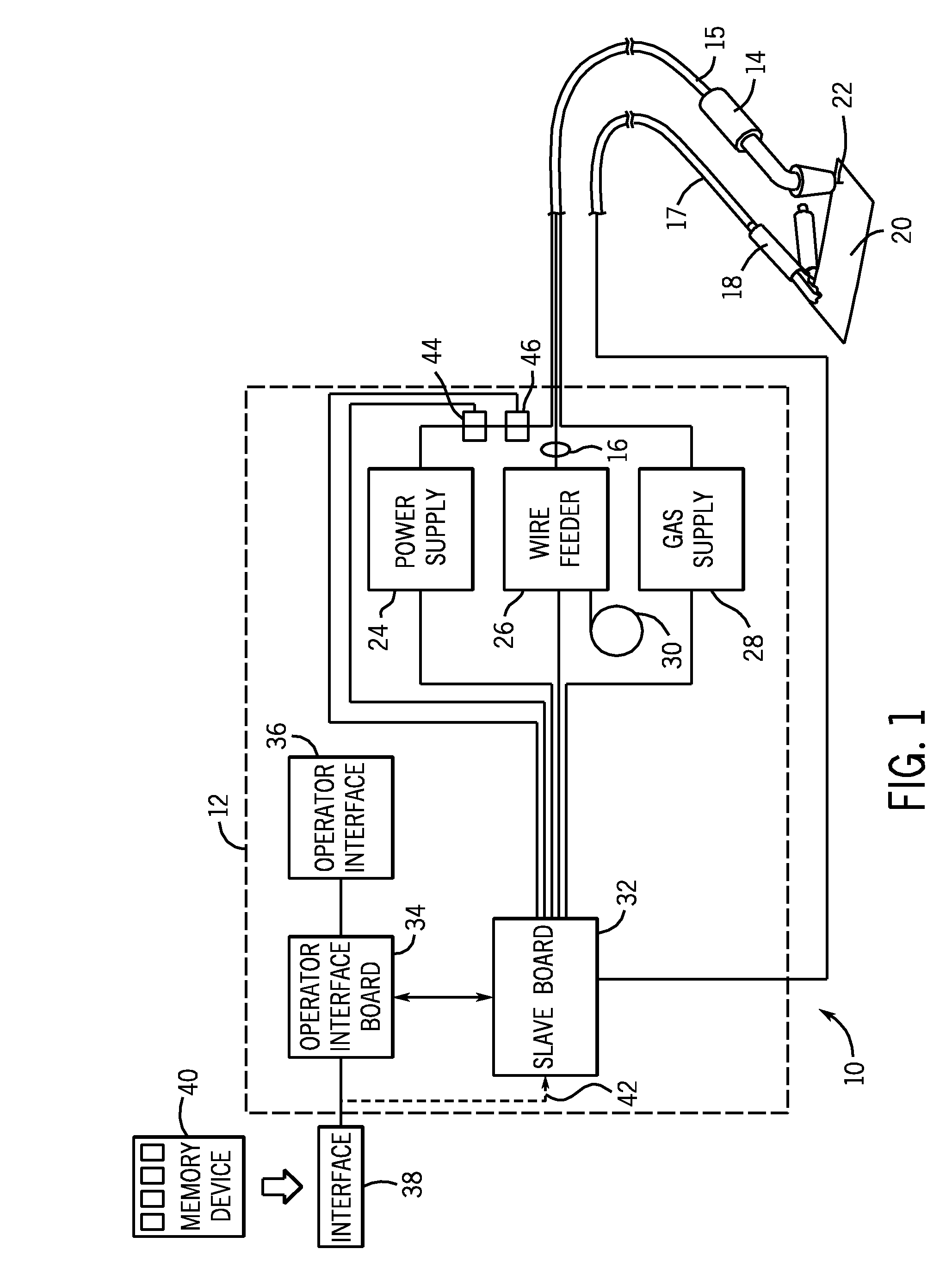

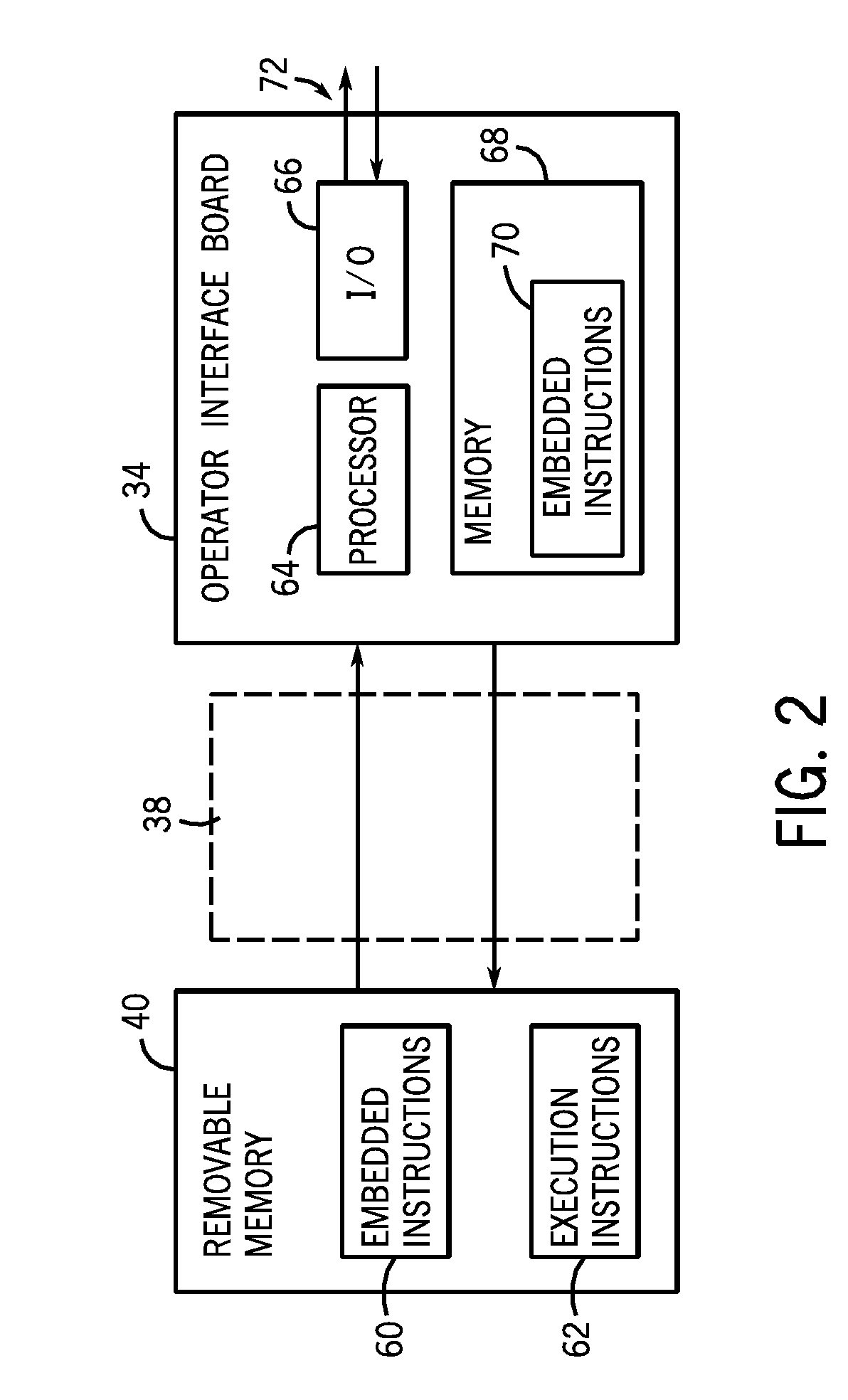

Embedded firmware updating system and method

InactiveUS20090222804A1Low costReduce laborMemory adressing/allocation/relocationArc welding apparatusPlasma cuttingWelding

A system and method is described for updating firmware in a welding or plasma cutting system. A removable memory device containing updated firmware code and a set of execution instructions is interfaced with one or more component boards. The execution instructions are executed on a processor of the welding or plasma cutting system to load the updated firmware code stored on the removable memory device into memory of the welding or plasma cutting system via an interface, generally overwriting the old firmware code.

Owner:ILLINOIS TOOL WORKS INC

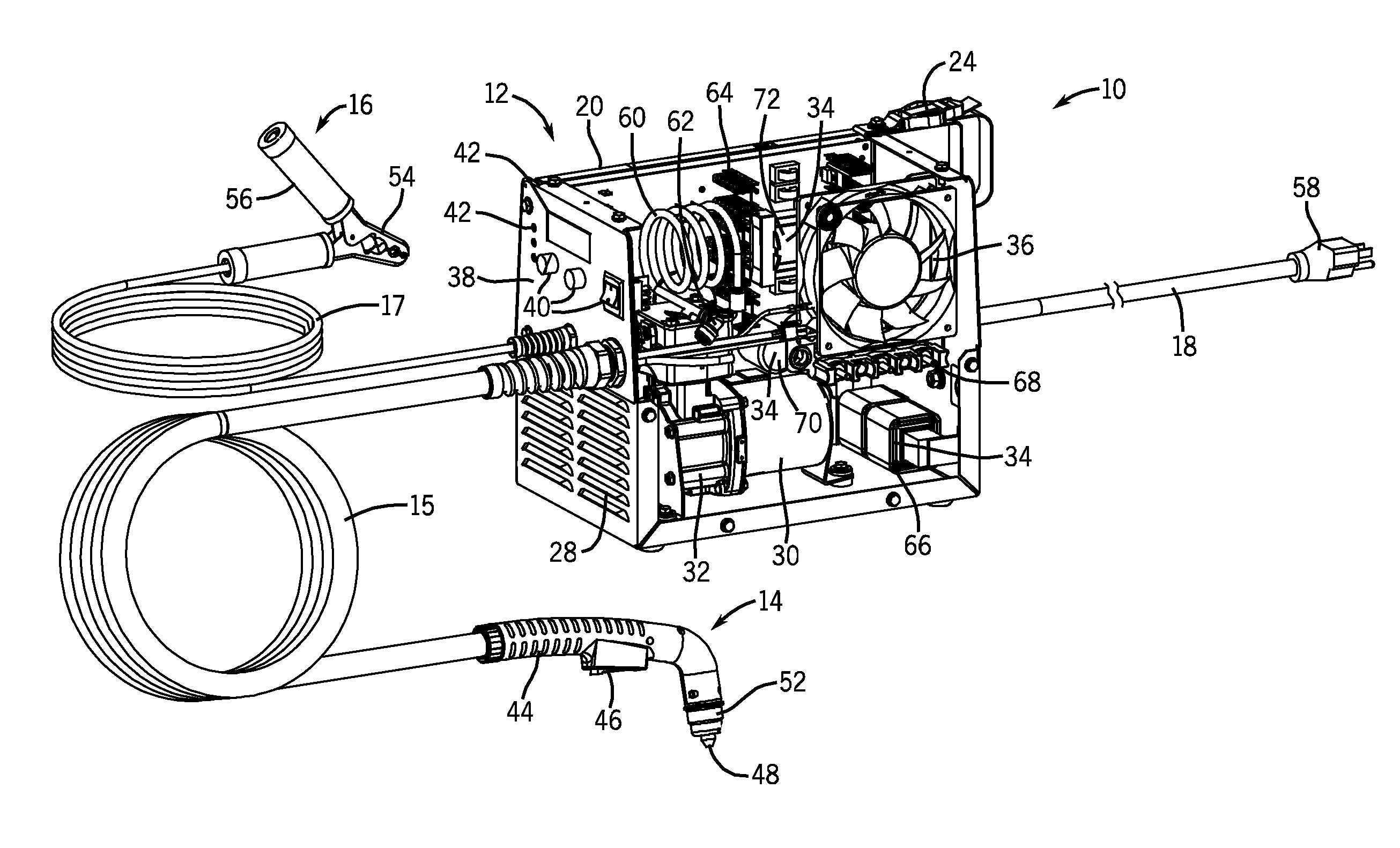

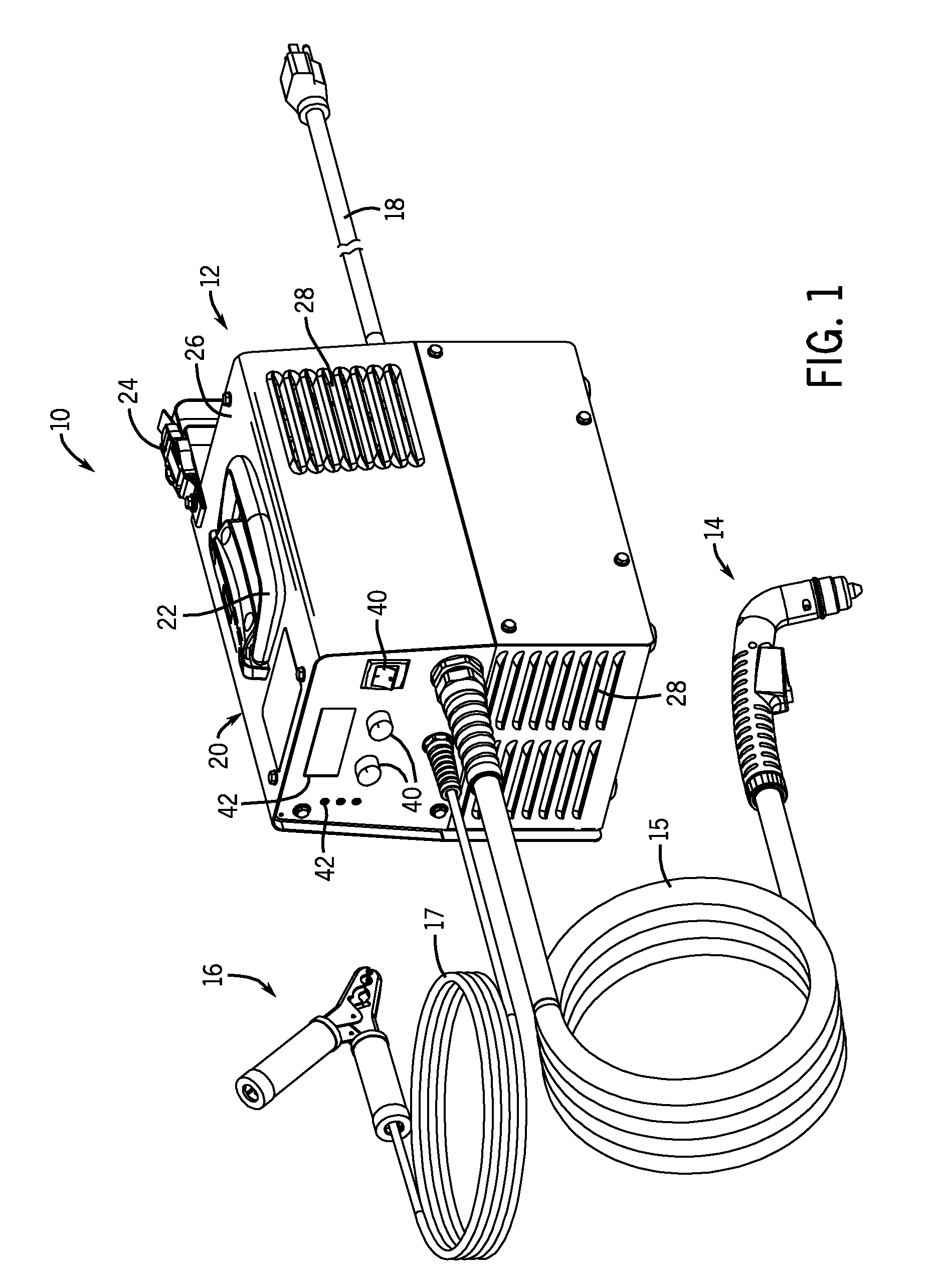

Plasma cutter having high power density

Owner:ILLINOIS TOOL WORKS INC

Method and Apparatus for Plasma Dicing a Semi-conductor Wafer

ActiveUS20130344683A1Protection from damageElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringSemiconductor

The present invention provides a method for plasma processing a substrate, the method comprising providing a process chamber having a wall; providing a plasma source adjacent to the wall of the process chamber; providing a work piece support within the process chamber; loading a work piece onto the work piece support, the work piece having a support film, a frame and the substrate; providing at least two cutting regions on the substrate, the cutting regions being positioned between all adjacent device structures on the substrate; generating a plasma using the plasma source; and processing the work piece using the generated plasma.

Owner:PLASMA THERM

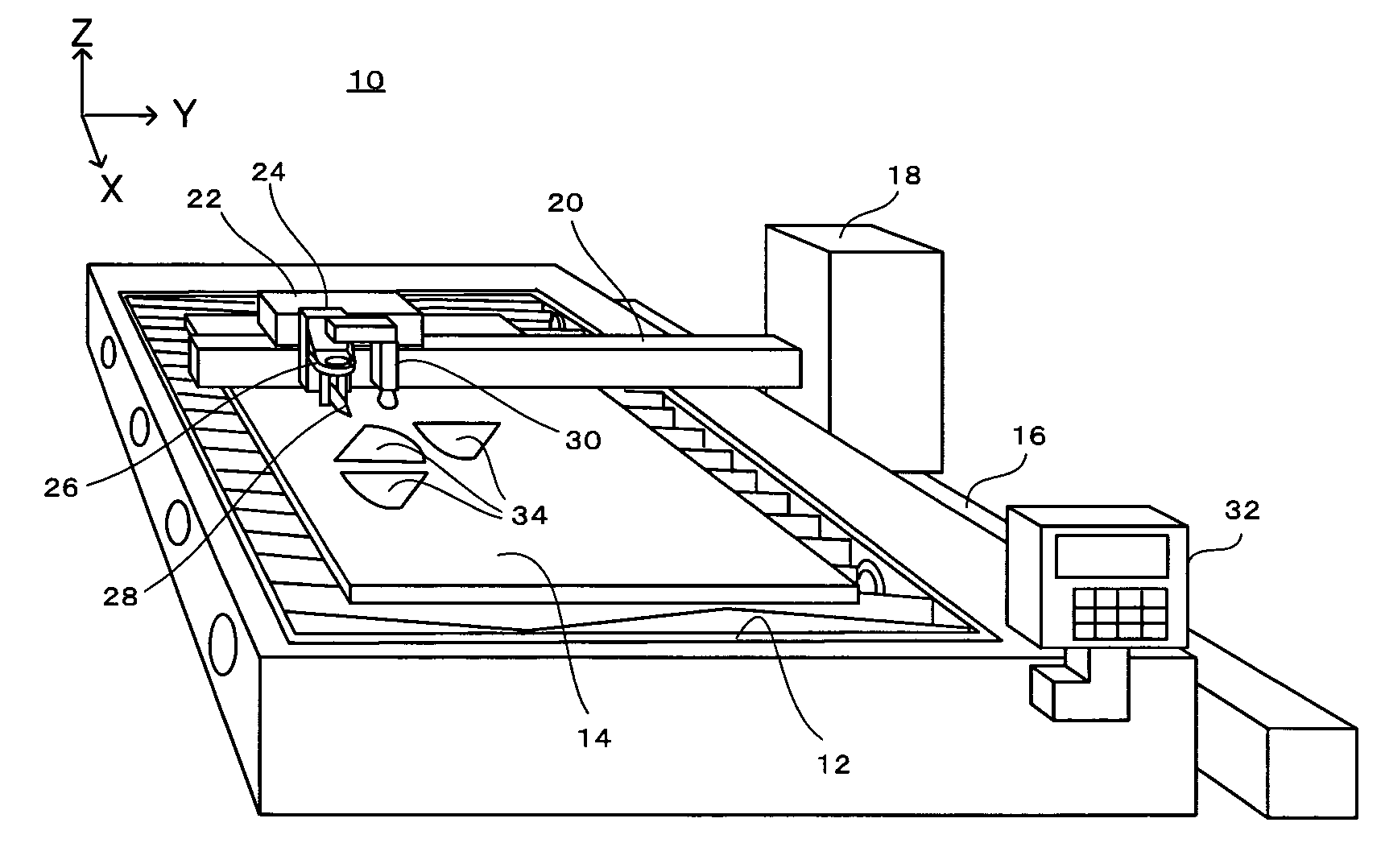

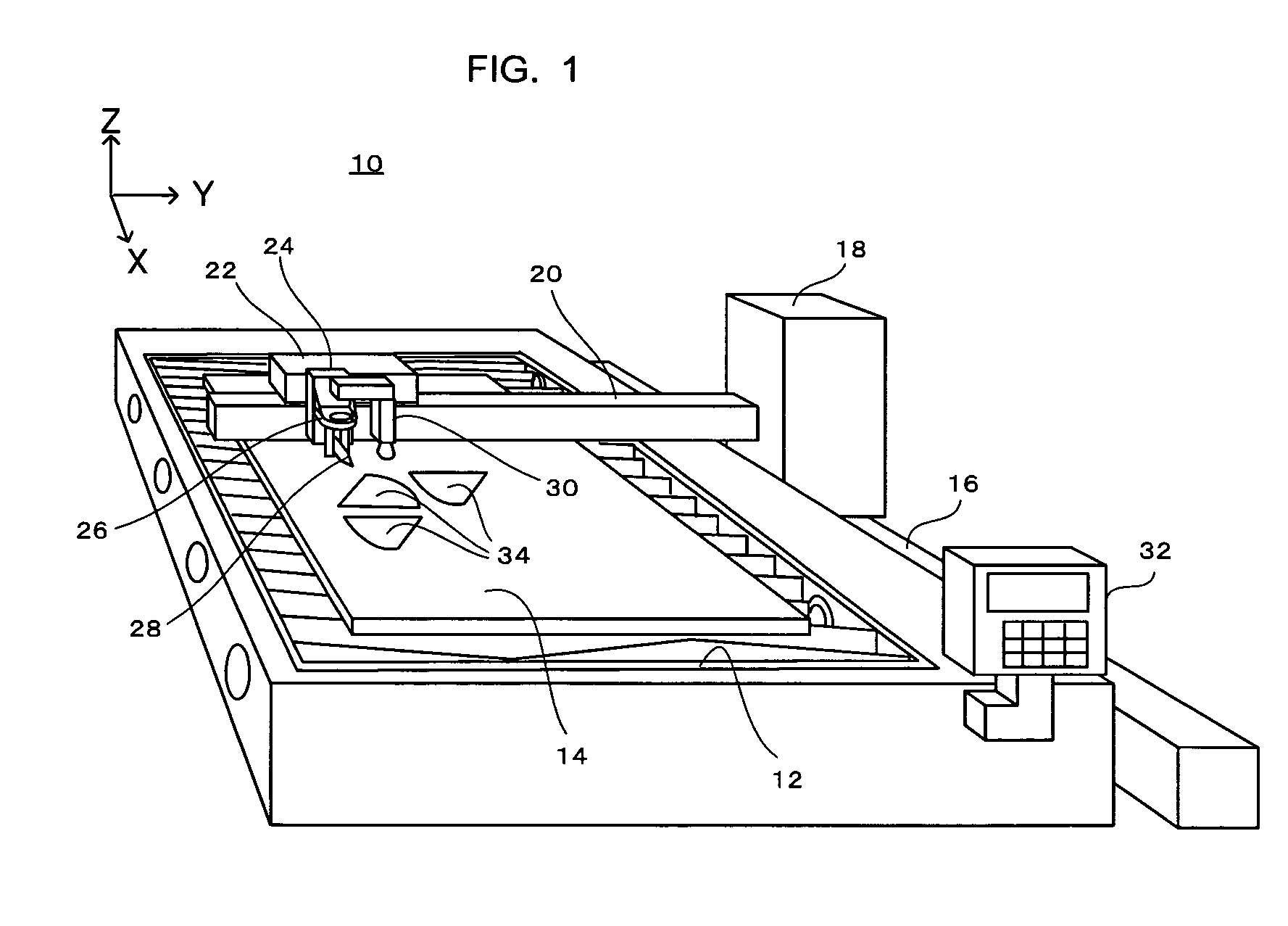

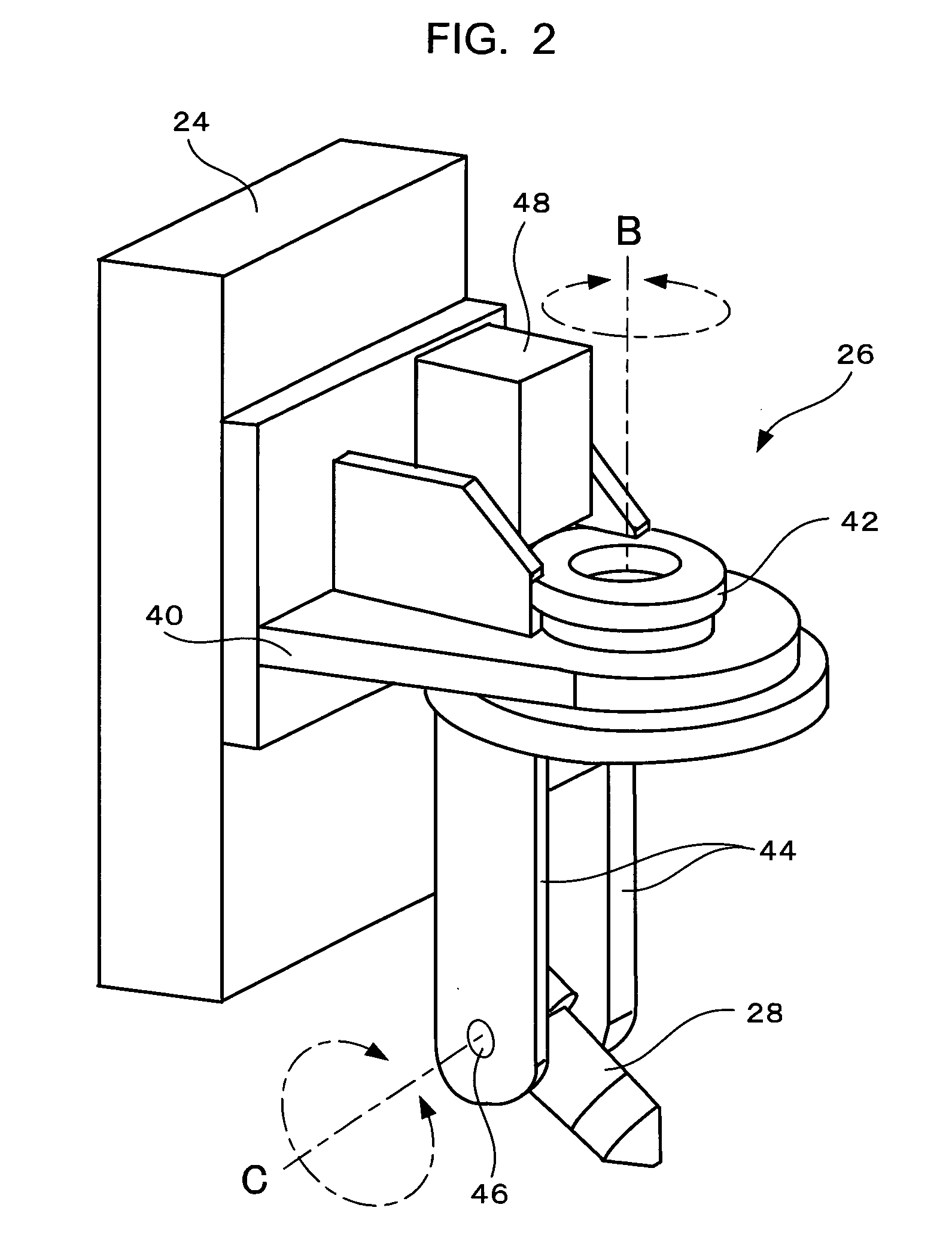

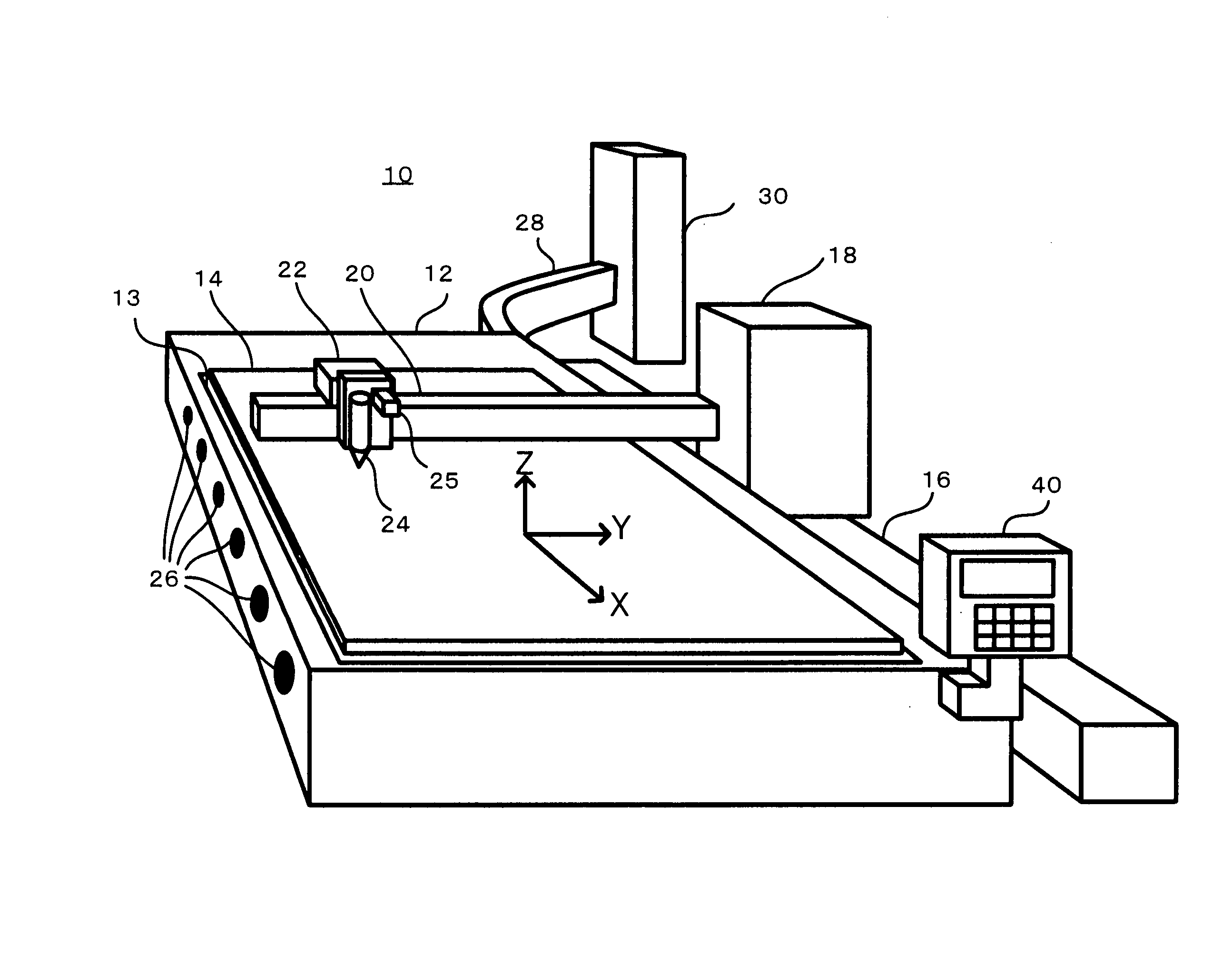

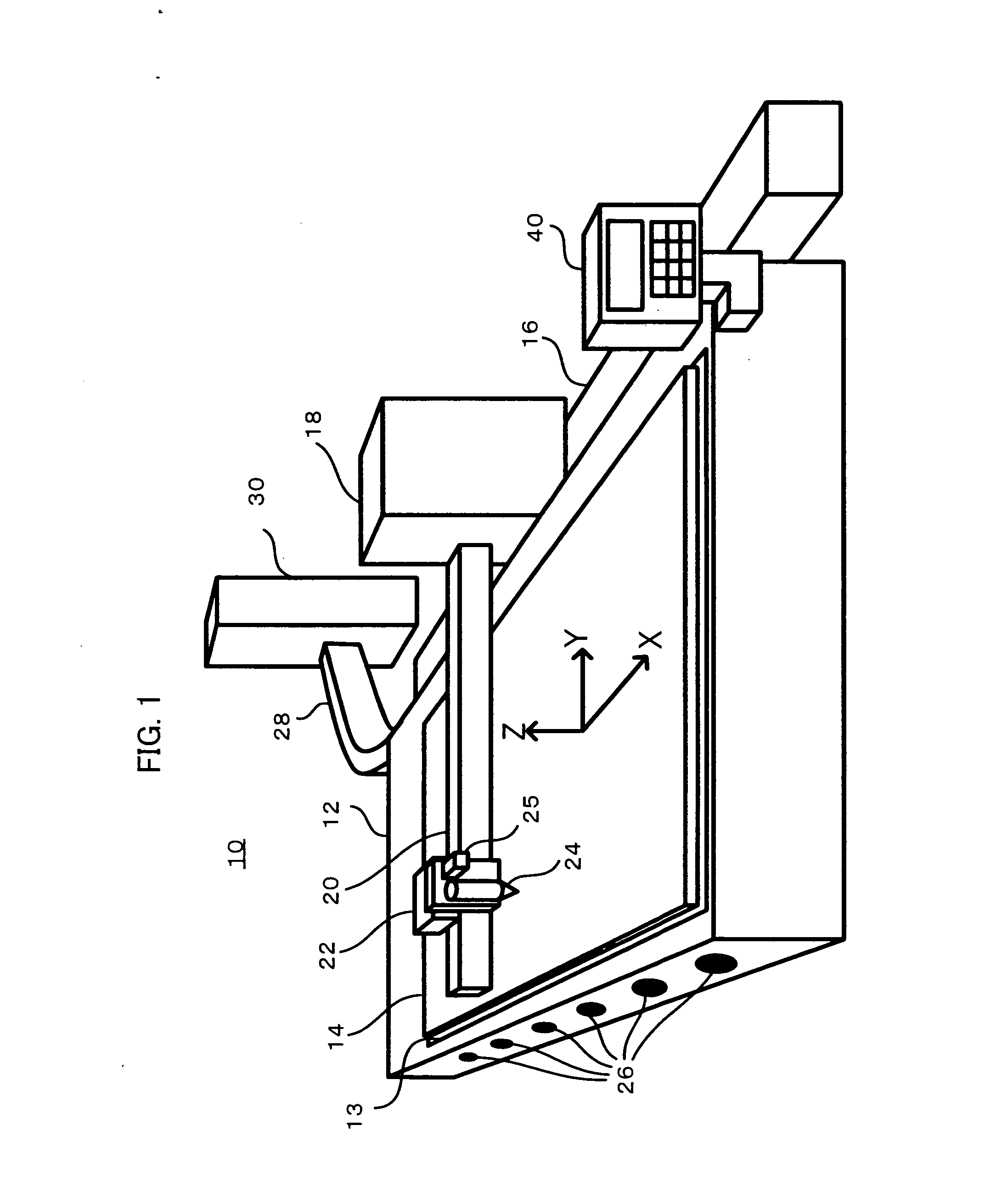

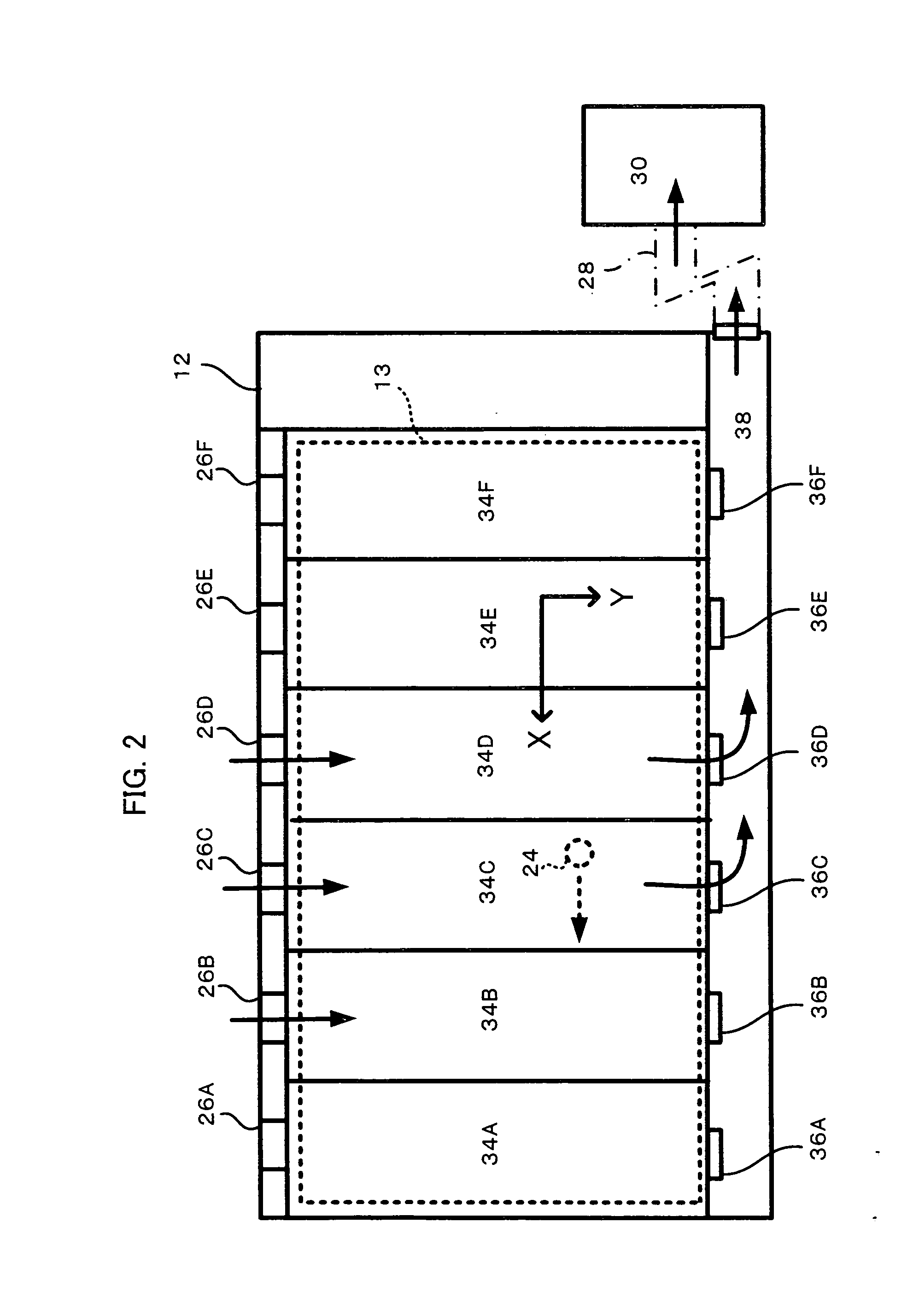

Cutting Machine and Method of Moving Cutting Head

InactiveUS20080066596A1Increase costImprove throughputAutomatic control devicesWelding/cutting auxillary devicesReciprocating motionEngineering

In a thermal cutting machine such as plasma cutting machine or a laser cutting machine, control of the moving speed of a cutting head (24) is improved so as to increase throughput of the cutting machine with increase in cost restricted. Products are cut out one by one from a plate member (14) while a cutting head (24) is moved relative to the plate member (14) on a table (12). In this process, when the cutting head (24) is fast-forwarded without performing cutting to a position at which cutting of each product starts, the speed of movement in the direction (Y-axis direction) along a short side of the table (12) is controlled at a speed higher than that of the movement in the direction (X-axis direction) along a long side of the table. The pattern of a sequence of cutting out the products from the plate member (14) is a meandering pattern in which reciprocation in the Y-axis direction dominates and the movement in the X-direction is one time one way. Exhaust chambers are arranged in the X-axis direction in the table (12), and the exhaust chambers are driven as the cutting head (24) moves in the X-axis direction.

Owner:KOMATSU IND CORP

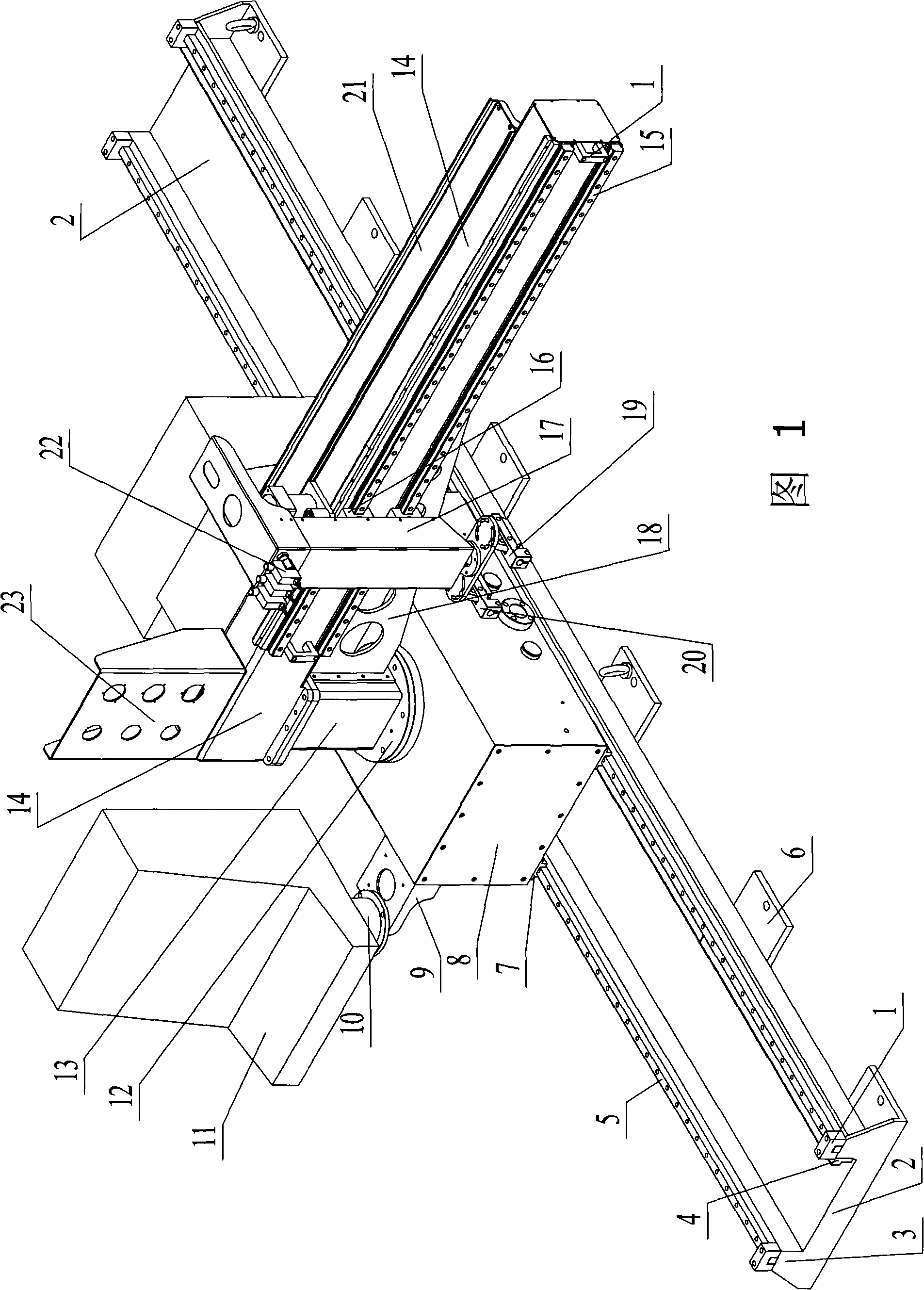

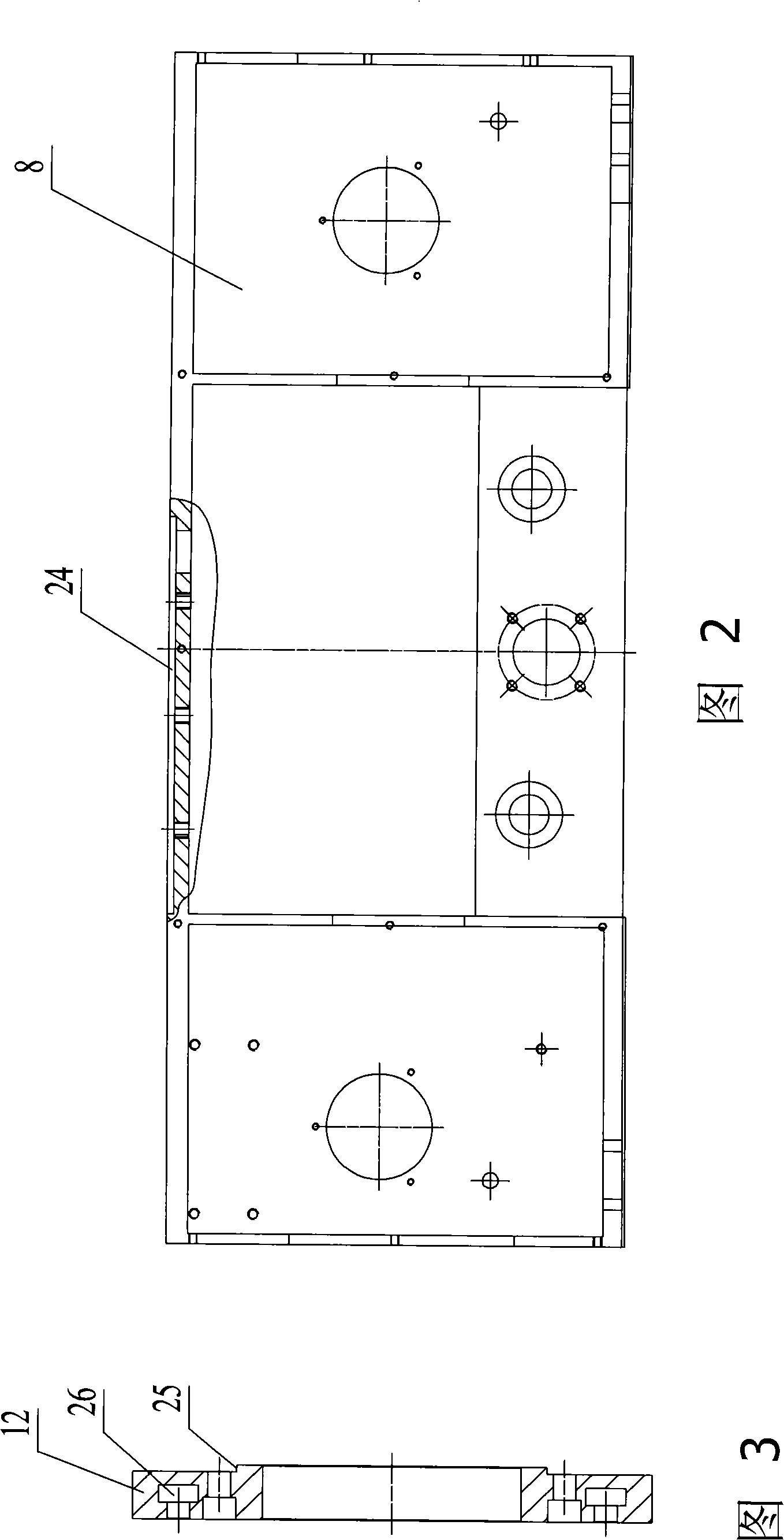

Machine frame of cantilevered mode digital control flame plasma cutting machine

ActiveCN101298120ATurn easilyReasonable designWelding/cutting auxillary devicesAuxillary welding devicesNumerical controlEngineering

The invention relates to a flame plasma cutting machine, in particular to a frame of the cantilever-typed numerical control flame plasma cutting machine. According to the technical proposal provided by the invention, a turning mechanism is arranged between an underframe and a vertical column; the bottom part of the turning mechanism is connected with the underframe; the vertical column is connected with the upper part of the turning mechanism; the upper part of the vertical column is connected with a transverse arm provided with a cross slide way; the transverse arm is provided with a lifting frame which can move on the transverse arm; the lifting frame is provided with a transverse sliding block connected with the cross slide way in a sliding way. The flame plasma cutting machine can facilitate the transportation and installation and improve the repeated precision and positioning angle.

Owner:无锡聚合科创发展有限公司

Method and Apparatus for Plasma Dicing a Semi-conductor Wafer

ActiveUS20130230974A1Protection from damageLow ion densitySemiconductor/solid-state device testing/measurementElectric discharge tubesEngineeringSemiconductor

The present invention provides a method for plasma dicing a substrate. The method comprising providing a process chamber having a wall; providing a plasma source adjacent to the wall of the process chamber; providing a work piece support within the process chamber; placing the substrate onto a support film on a frame to form a work piece work piece; loading the work piece onto the work piece support; providing a clamping electrode for electrostatically clamping the work piece to the work piece support; providing a mechanical partition between the plasma source and the work piece; generating a plasma through the plasma source; and etching the work piece through the generated plasma.

Owner:PLASMA THERM

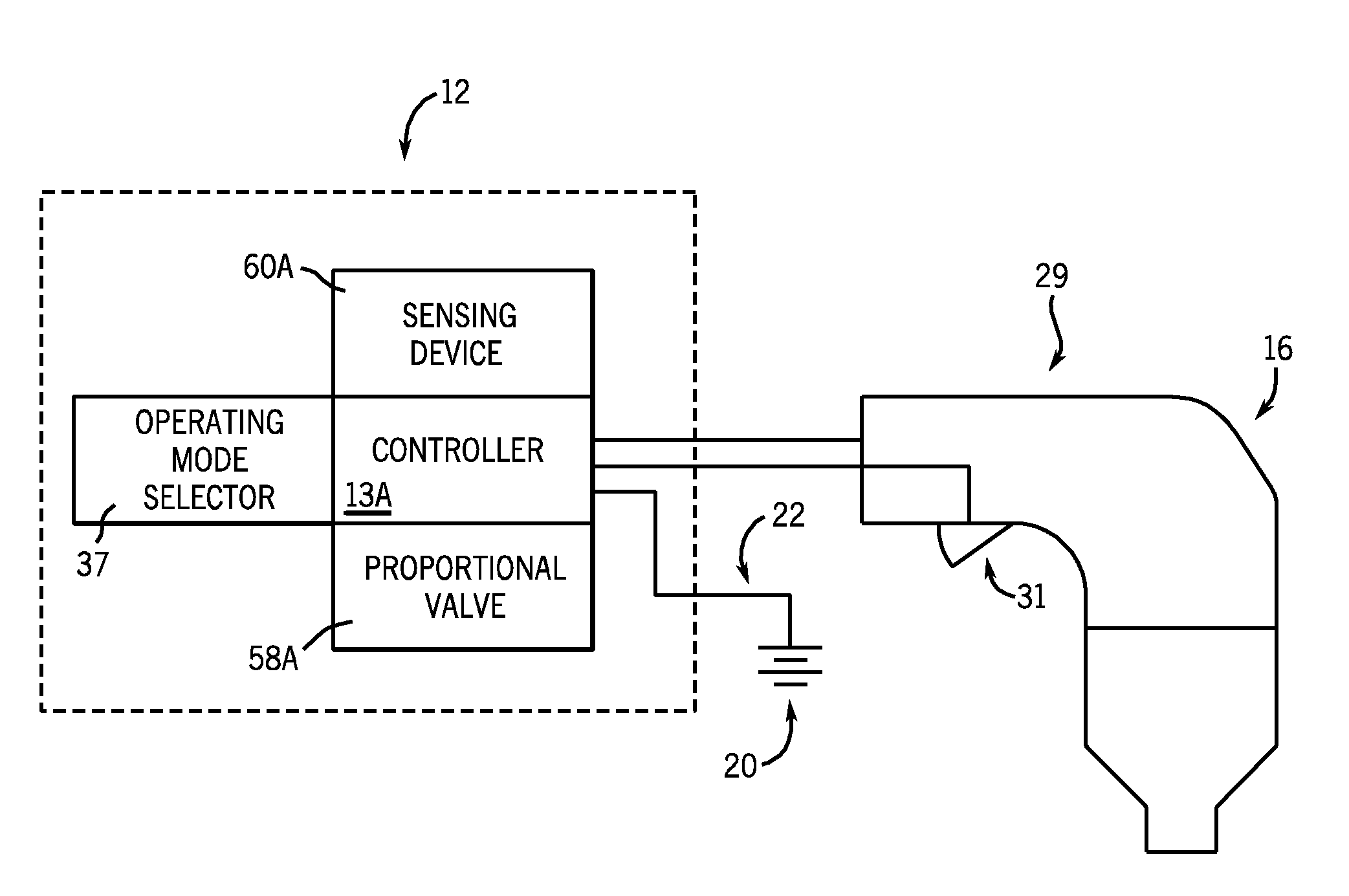

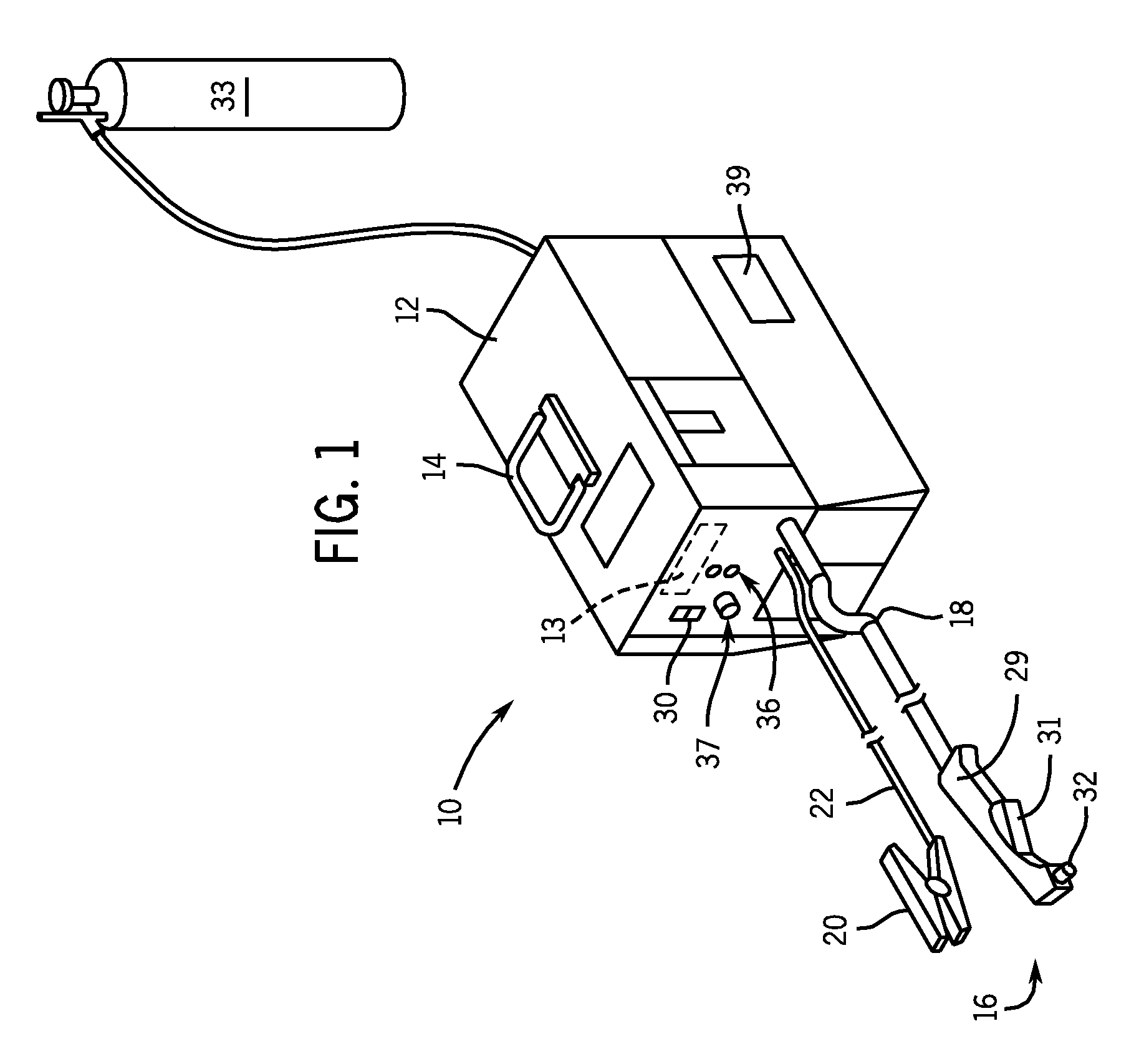

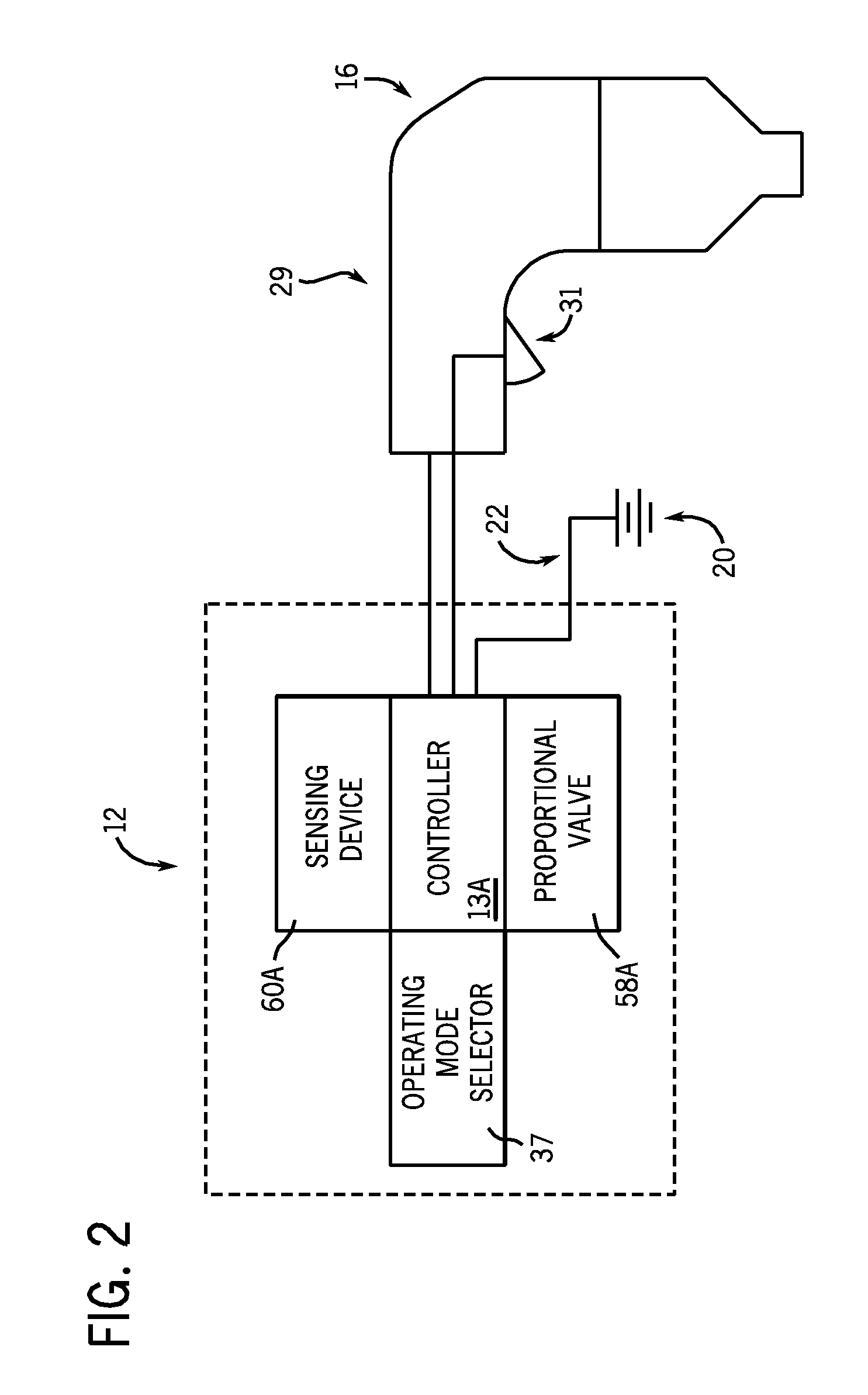

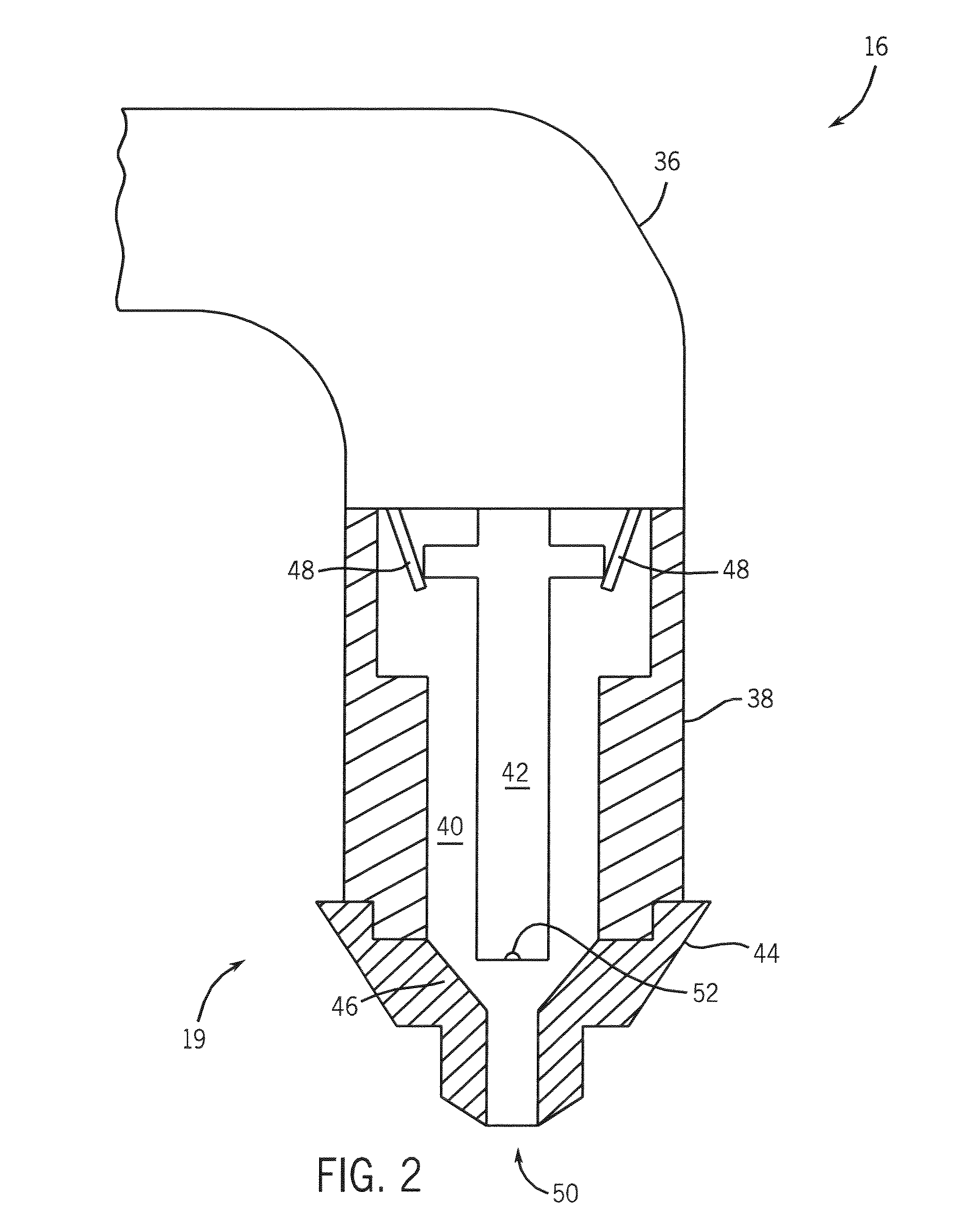

Method and apparatus for automatically controlling gas pressure for a plasma cutter

A system for providing a dynamically controlled plasma cutting system. The plasma cutting system includes a proportional valve and a sensing device arrangement and a controller connected to this arrangement. The system is configured to dynamically control gas flow in a plasma torch. The system measures gas pressure at a proportional valve and makes necessary gas pressure adjustments in the system by way of controlling a drive signal sent to the proportional valve to control gas flow.

Owner:ILLINOIS TOOL WORKS INC

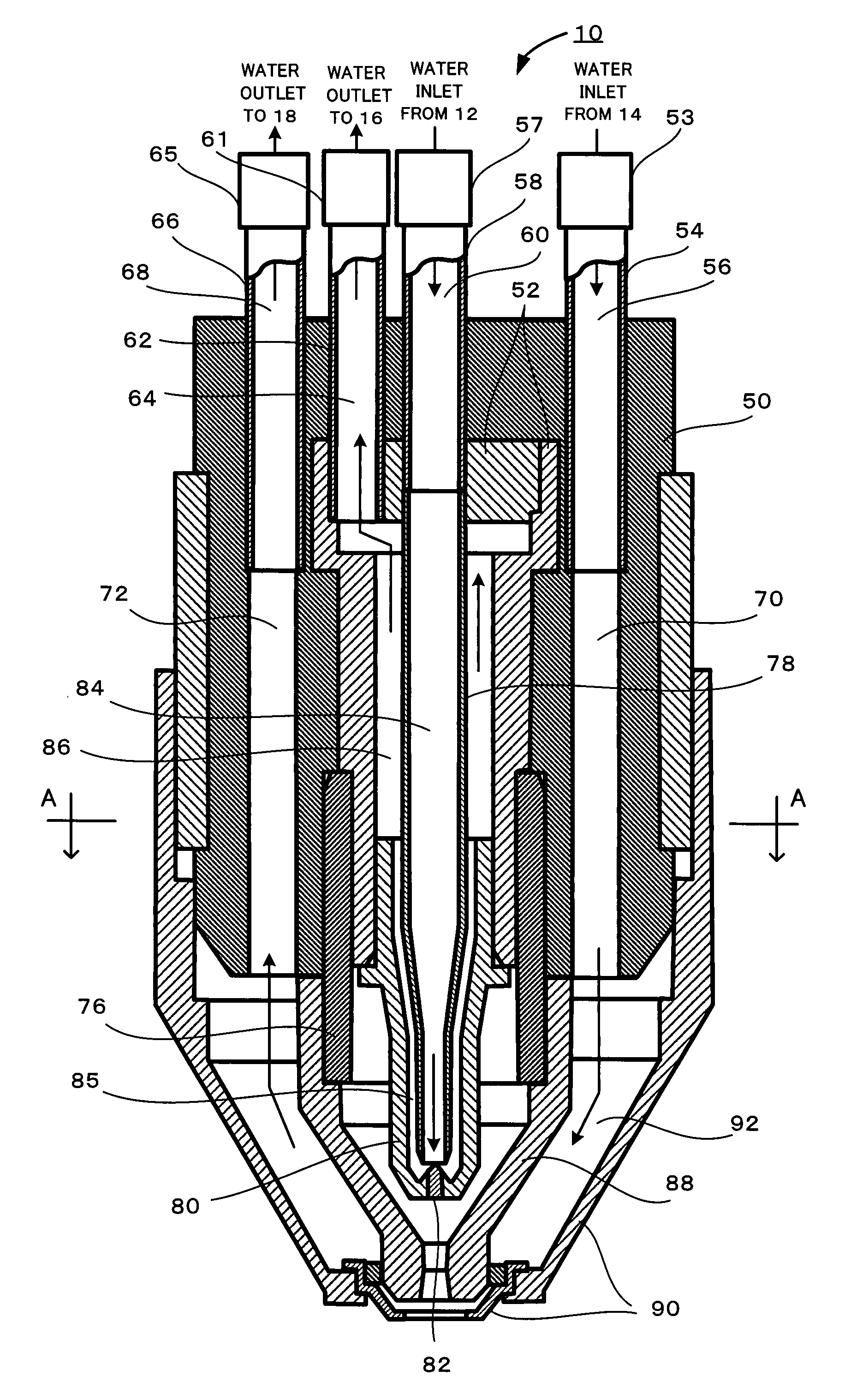

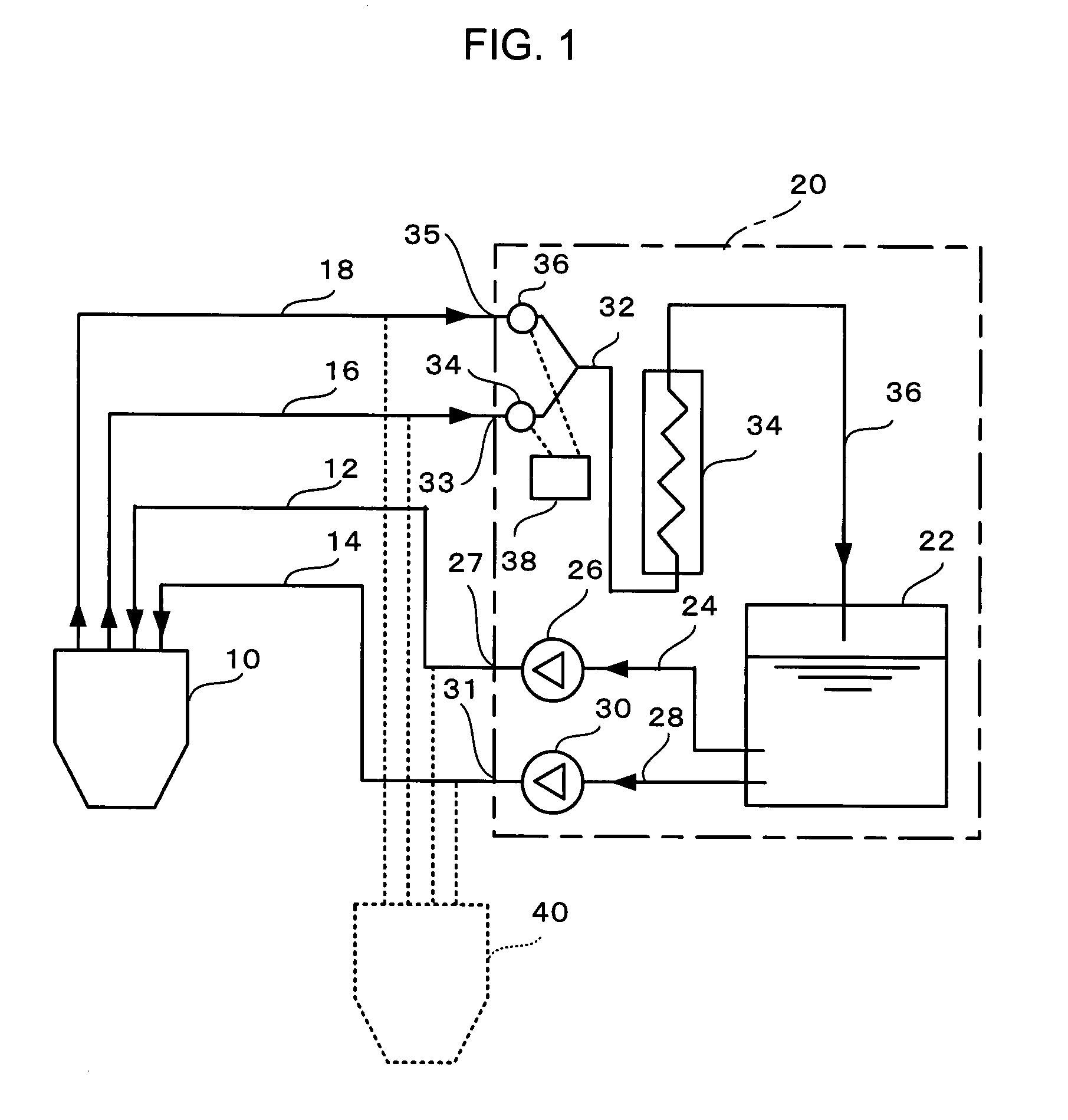

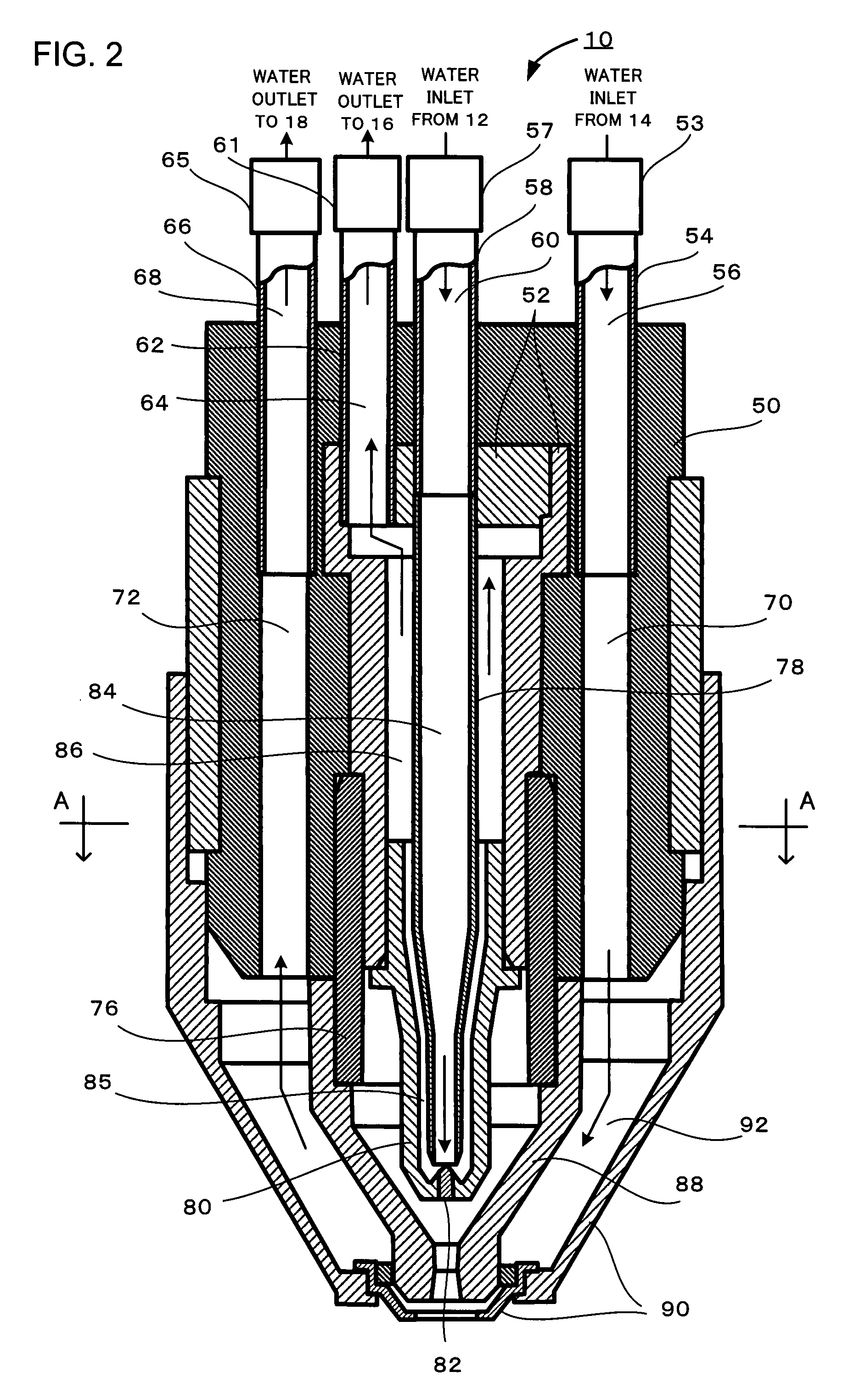

Plasma cutting device, plasma torch, and cooling device for plasma torch

ActiveUS20080093346A1Simple and easy mannerIncreased durabilityWelding electrode featuresPlasma techniqueEngineeringPlasma cutting

In order to increase the flow rate of coolant liquid supplied to the nozzle (88) of a plasma torch (10) and to extend the life of the plasma torch (10), within the plasma torch (10), an electrode coolant liquid passage (60, 84, 85, 86, and 64 which supplies coolant liquid to an electrode (80), and a nozzle coolant liquid passage (56, 70, 92, 72 and 68) which supplies coolant liquid to the nozzle (88), are provided separately as independent coolant liquid passages which extend in parallel, and which are mutually electrically insulated from one another. Moreover, the flow rate of coolant liquid in the nozzle coolant liquid passage is greater than the flow rate of coolant liquid in the electrode coolant liquid passage.

Owner:KOMATSU LTD +1

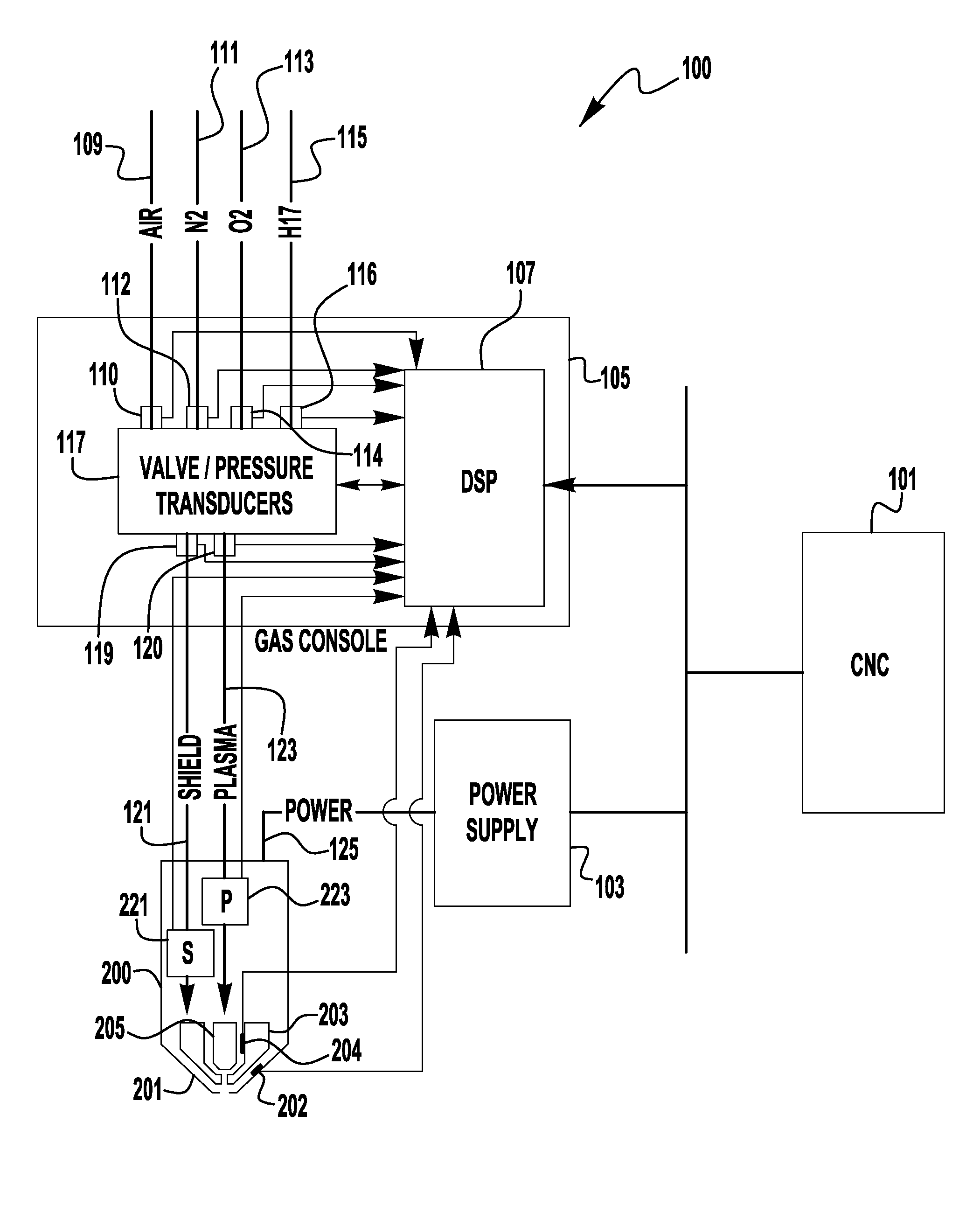

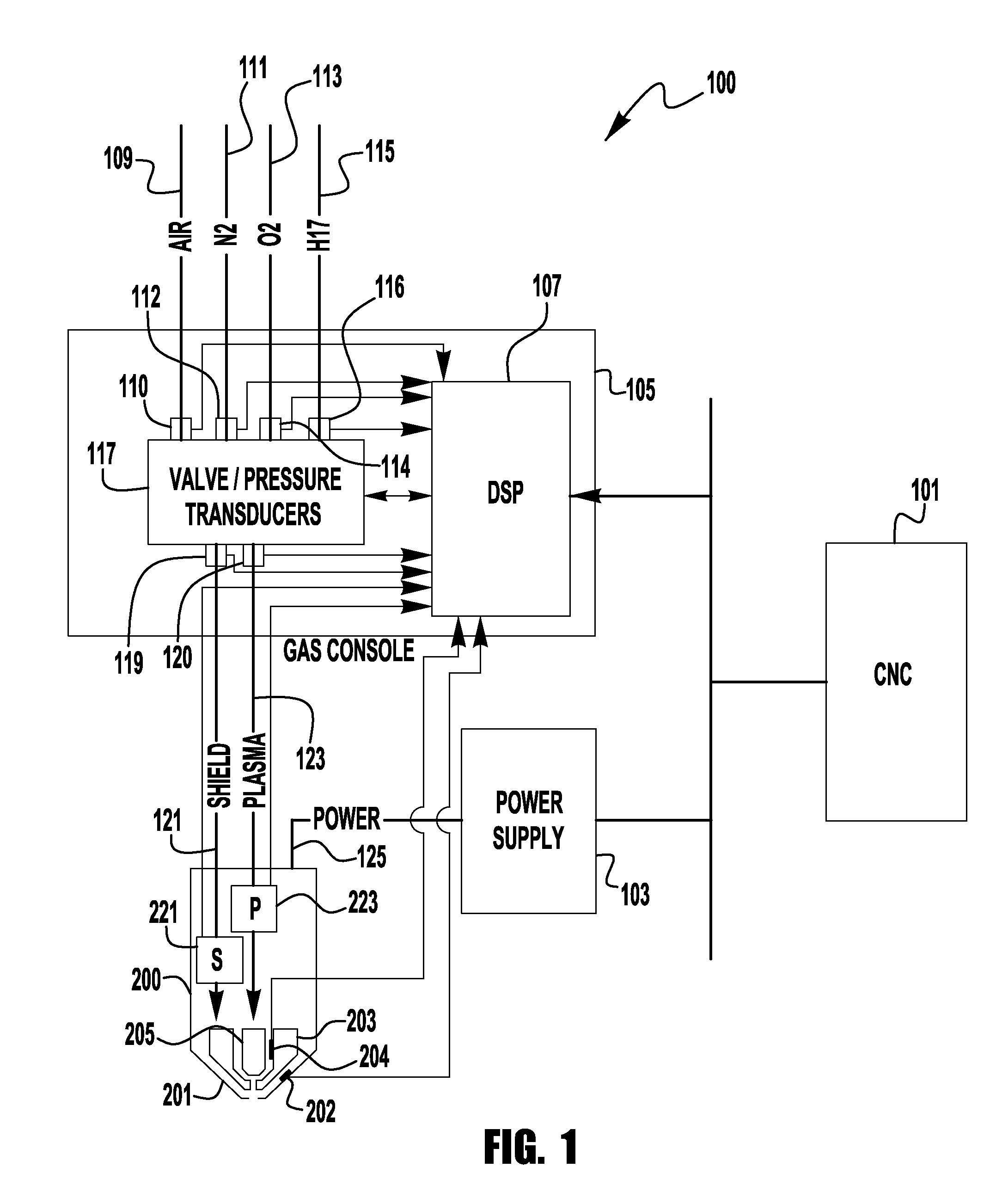

Adaptive plasma cutting system and method

A plasma torch system and method is provided, in which the system utilizes a number of pressure sensors throughout the system and the torch to detect the flow / pressure of shield and plasma gas during operation. The detected pressures are used by the system to dynamically control the system pressures to optimize the cutting operation.

Owner:LINCOLN GLOBAL INC

Method and Apparatus for Plasma Dicing a Semi-Conductor Wafer

ActiveUS20140242780A1Protection from damageSemiconductor/solid-state device testing/measurementElectric discharge tubesEngineeringSemiconductor

The present invention provides a method for plasma dicing a substrate. The method comprising: providing a process chamber having a wall; providing a plasma source adjacent to the wall of the process chamber; providing a work piece support within the process chamber; placing the substrate on a carrier support to form a work piece; providing an intermediate ring interposed between the substrate and the frame; loading the work piece onto the work piece support; generating a plasma through the plasma source; and etching the work piece through the generated plasma.

Owner:PLASMA THERM

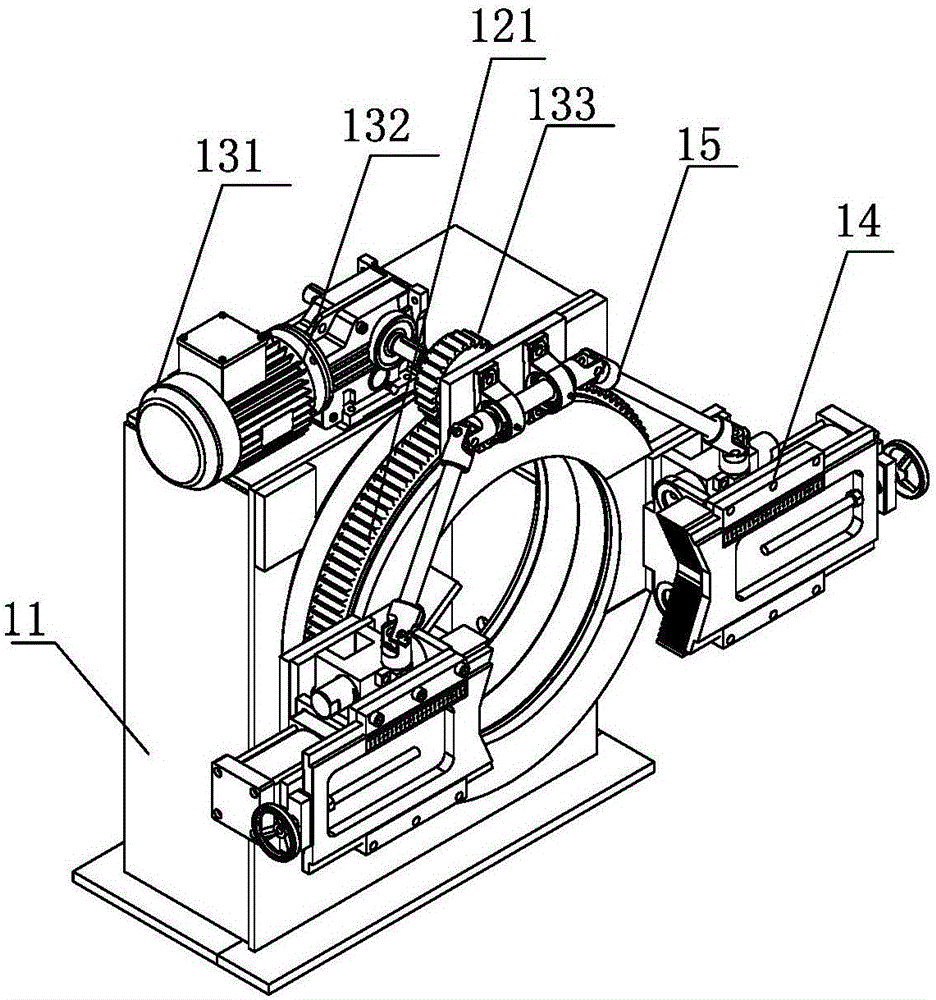

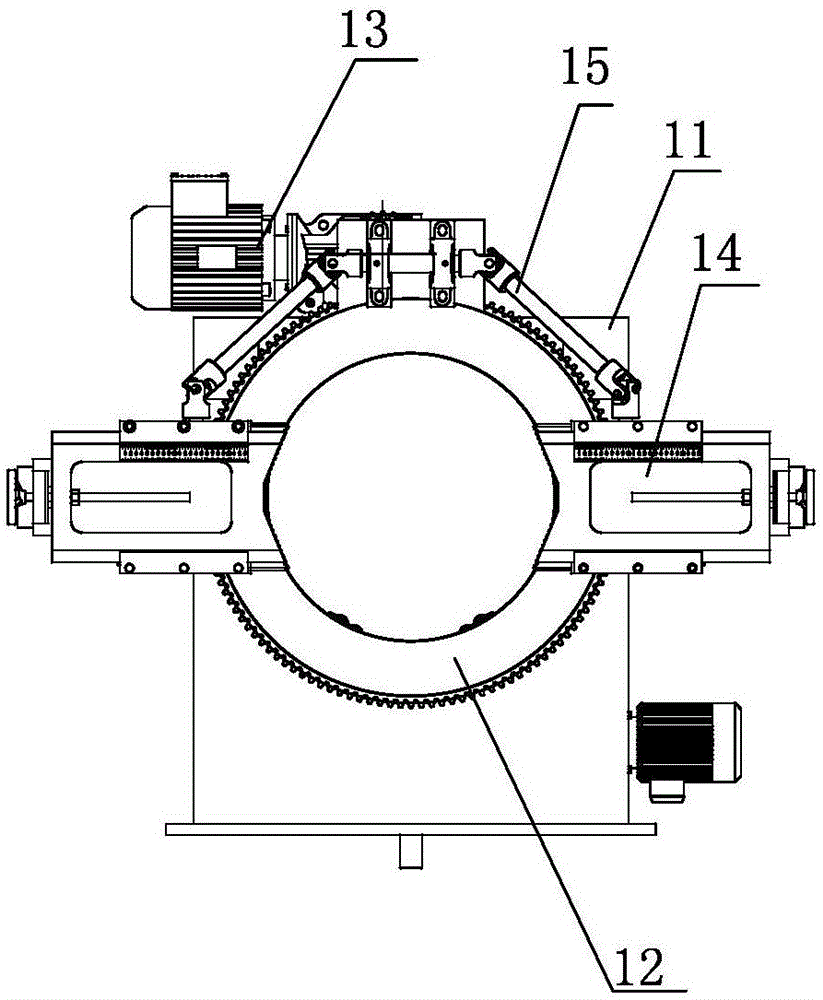

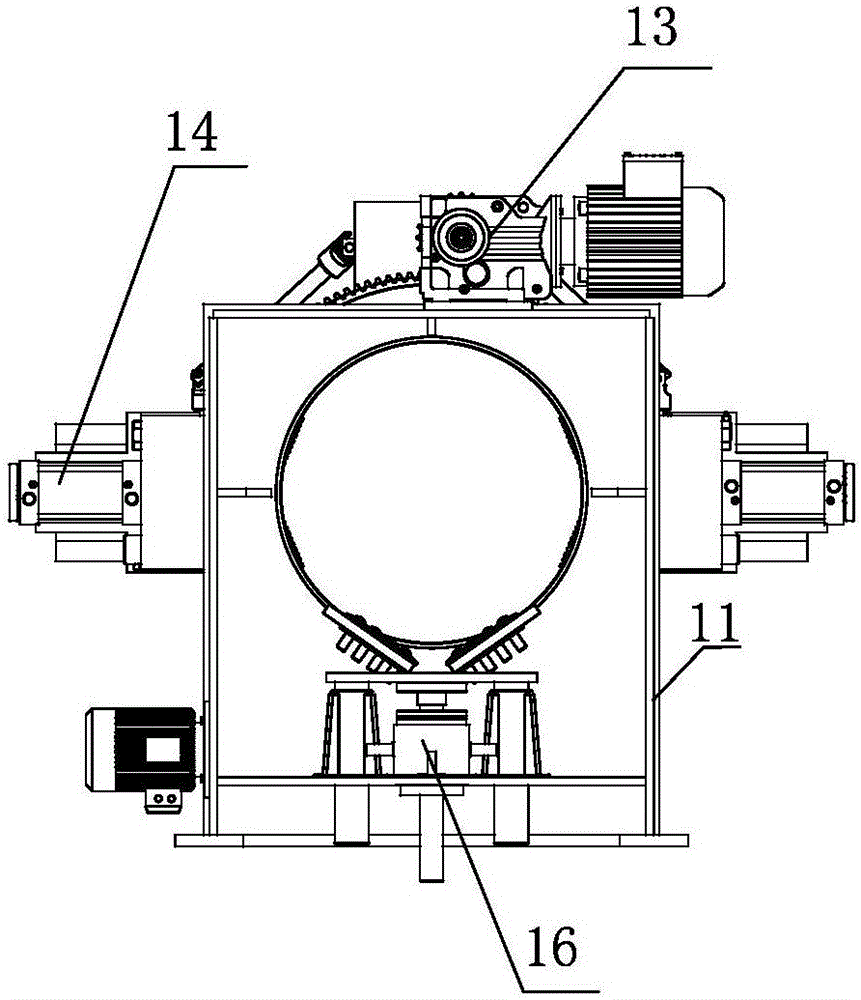

Double-direction synchronous rotating and clamping device for steel pipe cutting

ActiveCN106238887AEfficient cuttingRealize two-way synchronous clampingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSteel tube

The invention provides a double-direction synchronous rotating and clamping device for steel pipe cutting. The technical problem that in the cutting process of a steel pipe, clamping and rotating can not be achieved is solved. The device comprises a clamping mounting frame, a rotary disc mechanism, a clamping mechanism and a double-direction synchronous clamping drive connection mechanism; a lifting mechanism is arranged at the rear end of the clamping mounting frame, and the clamping mechanism comprises a fine adjustment mechanism; a turnover discharging device is arranged in front of the rotating and clamping mechanism; the device has the beneficial effects that in the process of using a plasma cutting machine for cutting the steel pipe, the steel pipe is synchronously clamped in a double-direction manner and driven to rotate, and the steel pipe cutting process is more efficient.

Owner:SHANDONG COMP SCI CENTNAT SUPERCOMP CENT IN JINAN

Plasma Cutter Having Thermal Model for Component Protection

A system is provided that includes a torch power unit. The torch power unit includes a monitor and / or control configured to determine a temperature of a component of the torch power unit based on the one or more inputs without a direct temperature measurement of the component. A method of operation is provided that includes receiving one or more inputs associated with a device, and estimating a temperature of the device based on the one or inputs without directly measuring temperature of the device. A tangible machine-readable medium is provided that includes code for determining a thermal capacity of the device, code for determining a thermal resistance of the device, and code for determining a temperature of the device based on thermal capacity and the thermal resistance method.

Owner:ILLINOIS TOOL WORKS INC

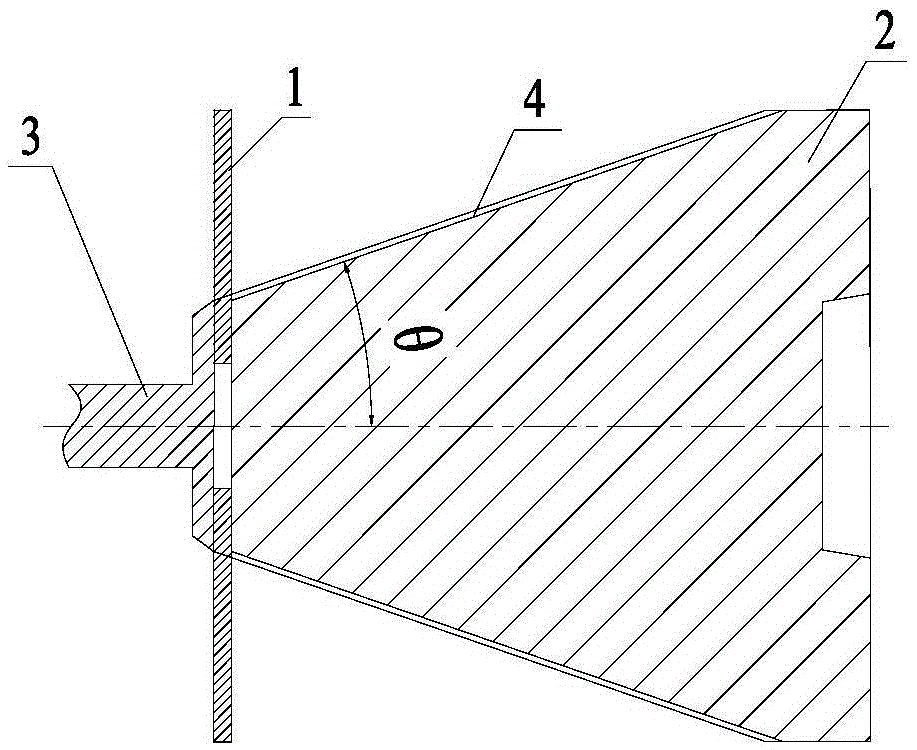

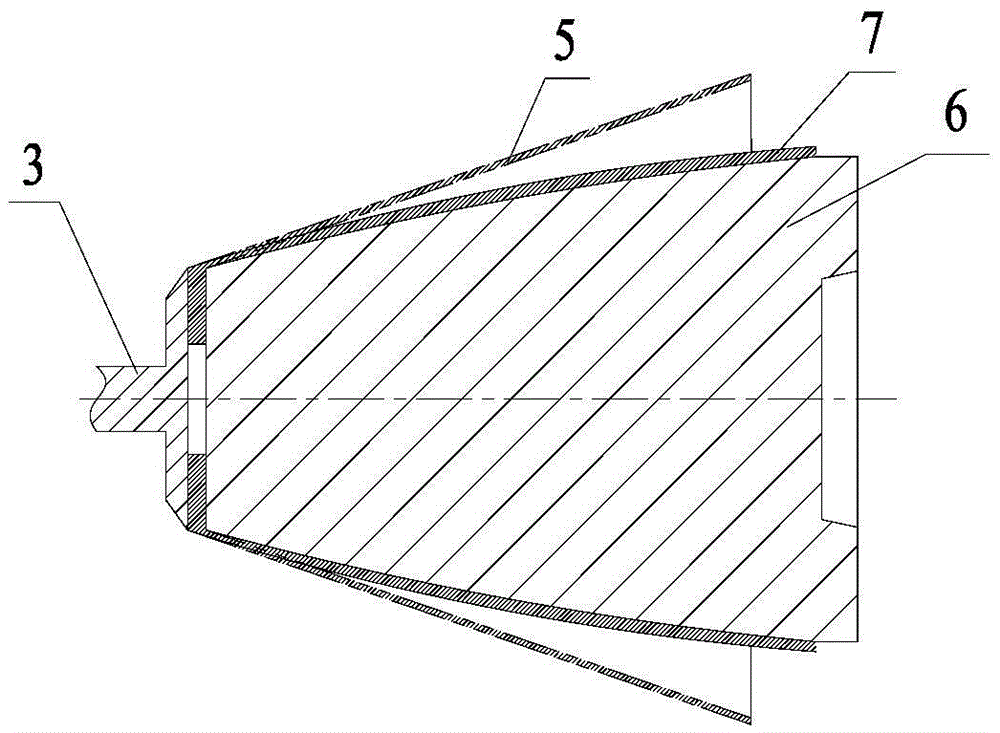

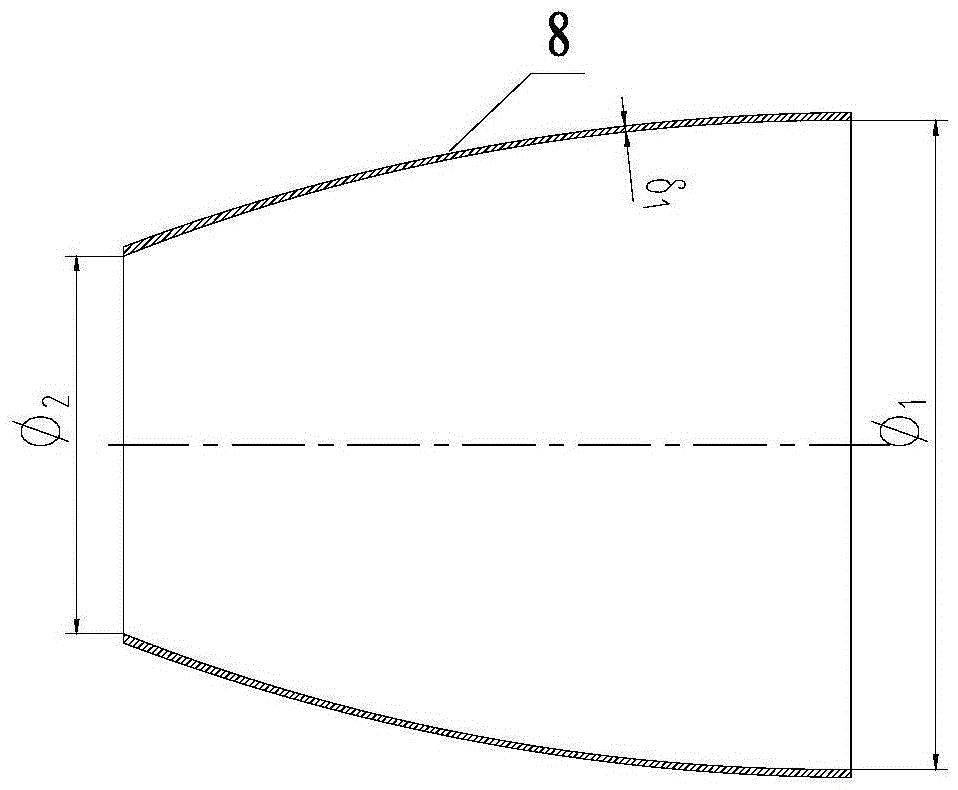

Spinning machining method for aluminium alloy thin-walled revolution body

ActiveCN105537449AMeet sizeFulfil requirementsHollow articles5005 aluminium alloy5052 aluminium alloy

The invention discloses a spinning machining method for an aluminium alloy thin-walled revolution body. The spinning machining method comprises the following steps: producing an aluminium alloy spun blank with required dimensions, and carrying out annealing treatment on the aluminium alloy spun blank; carrying out shearing spinning on the aluminium alloy spun blank to obtain a primary conical barrel; carrying out annealing treatment on the primary conical barrel, and cutting a process allowance at a large end to form a secondary conical barrel; carrying out common spinning on the secondary conical barrel on a spinning machine to obtain a pre-spun aluminium alloy thin-walled revolution body; and carrying out annealing treatment and surface polishing treatment on the pre-spun blank, and then cutting process allowances at the two ends of a spun part by using a plasma cutting machine, so as to obtain the aluminium alloy thin-walled revolution body meeting process requirements. According to the invention, the aluminium alloy thin-walled revolution body is machined by virtue of the technologies of shearing spinning and common spinning; the dimension and structural performance requirements of a bullet shell are met; a machining method and a stamping-welding method can be replaced; and a low-cost and efficient machining method is provided for machining for an aluminium alloy shell of a bullet.

Owner:湖北三江航天江北机械工程有限公司

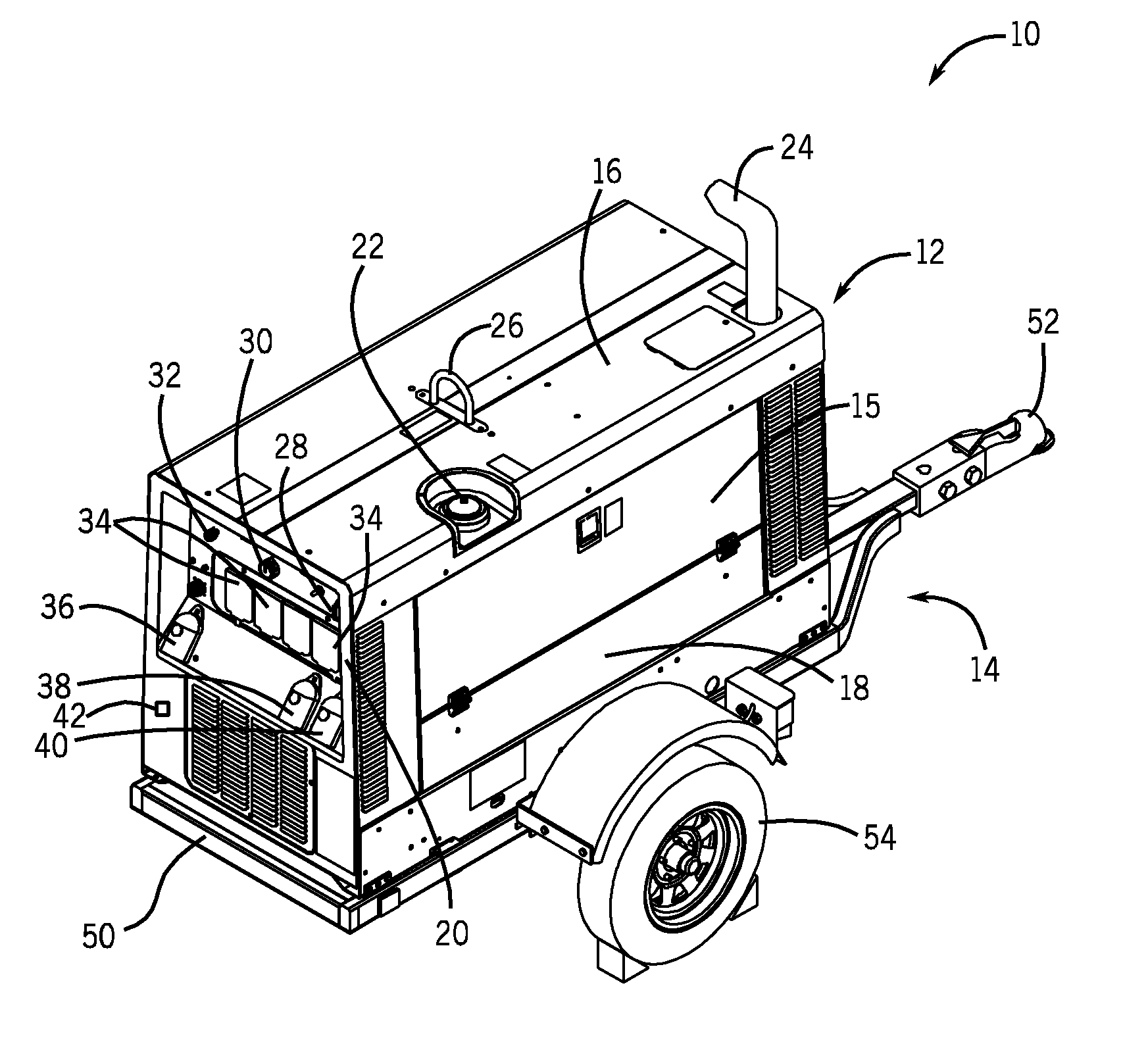

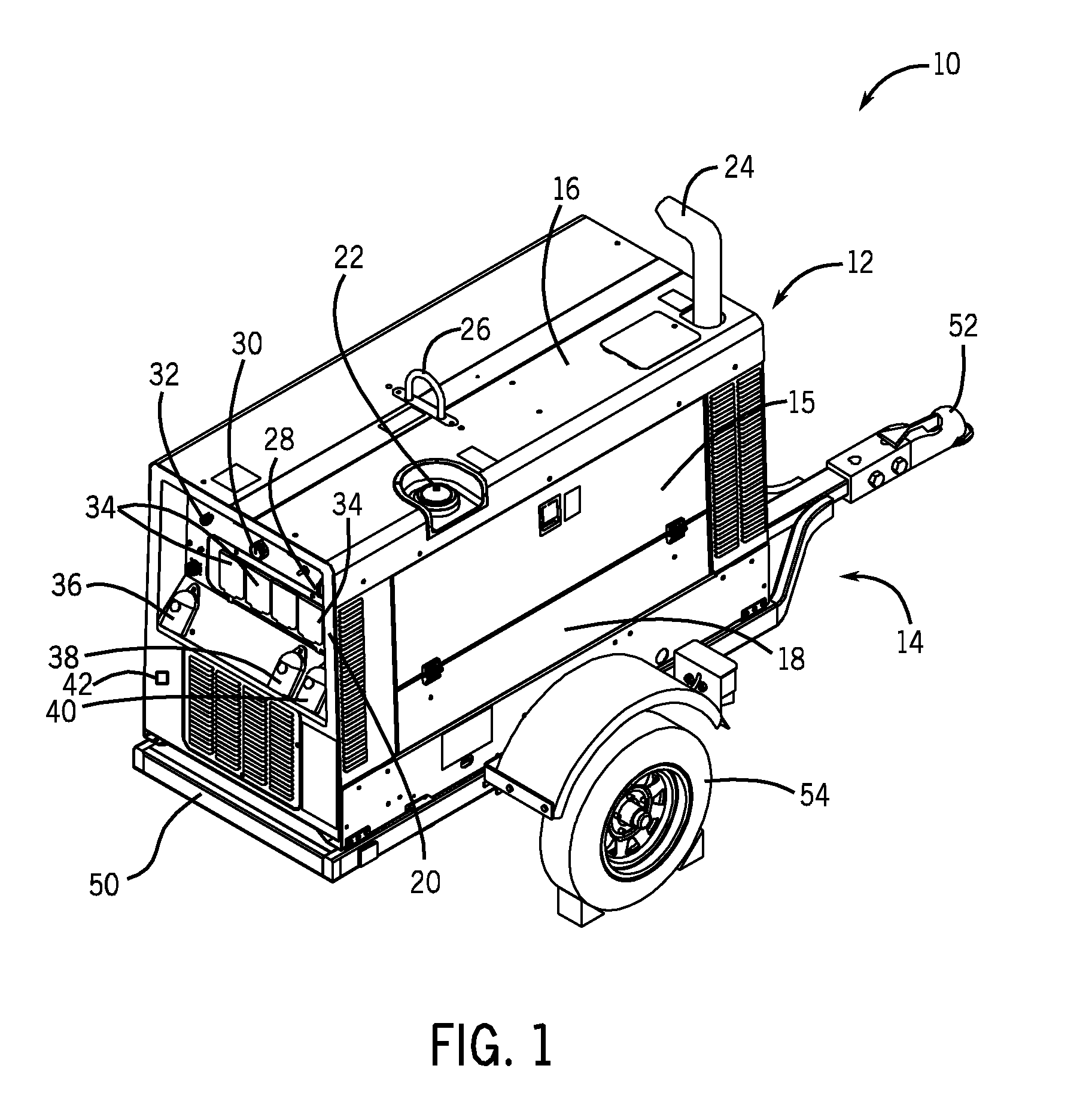

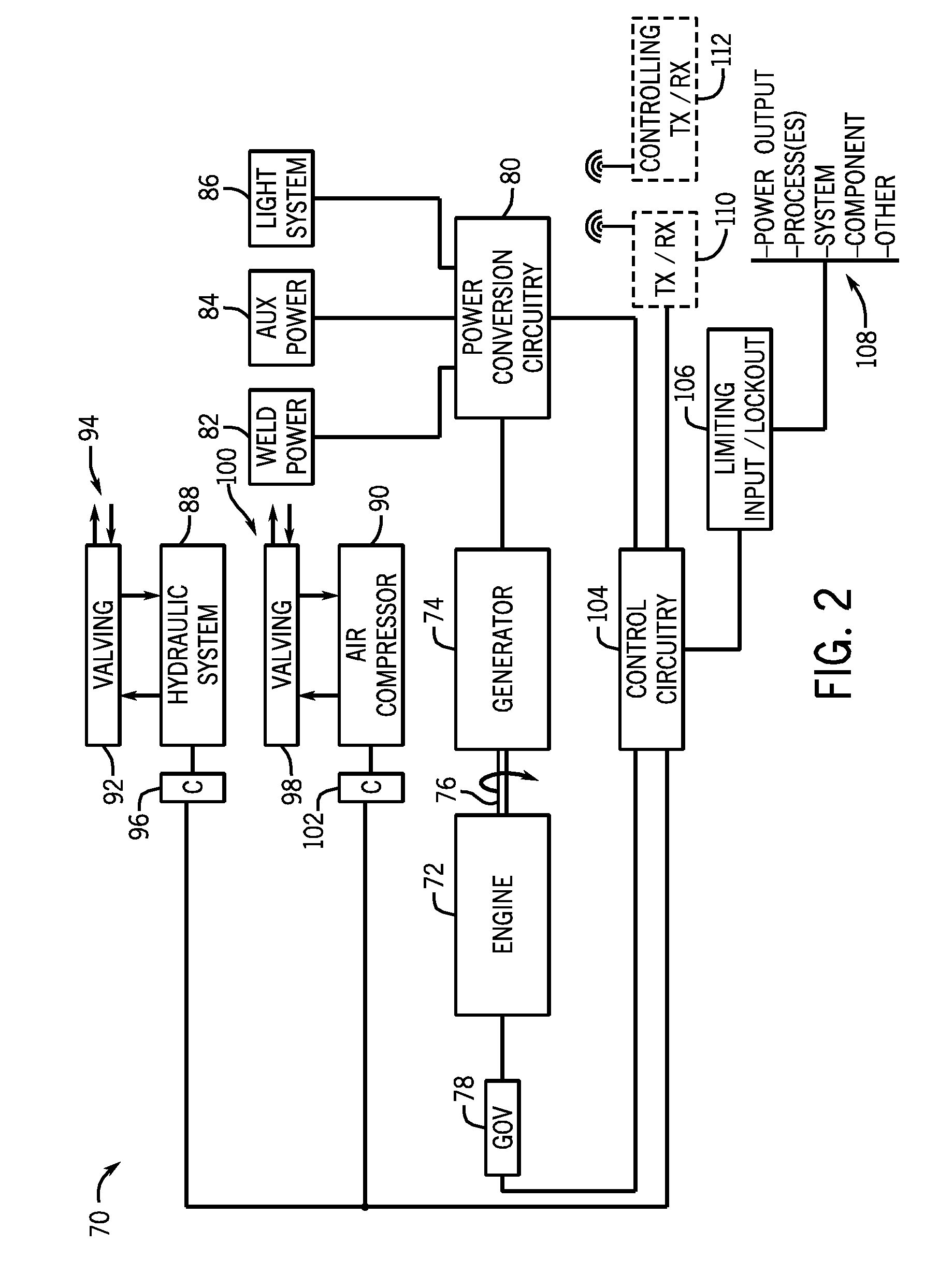

System and method for limiting welding output and ancillary features

A system and method for limiting welding output and ancillary features is provided. In one embodiment, a portable generator system includes a power generator configured to generate electrical power appropriate for welding or plasma cutting. The generator system also includes power conversion circuitry coupled to the power generator and configured to receive power from the power generator and to provide output power. The generator system includes at least operator accessible input for receiving an operator input parameter. The generator system also includes an output power limiting device not adjustable by the operator and configured to selectively limit output power from the power conversion circuitry.

Owner:ILLINOIS TOOL WORKS INC

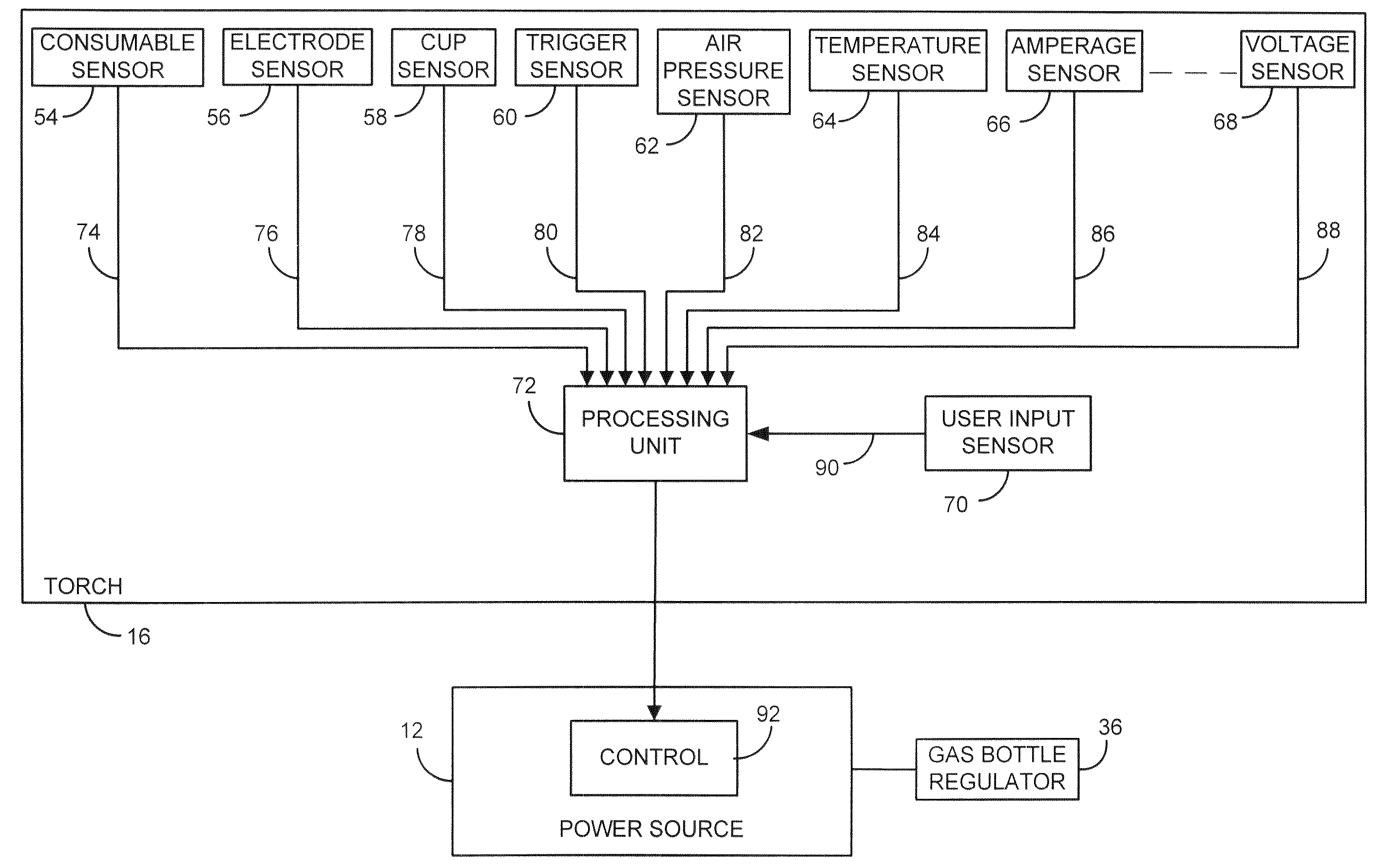

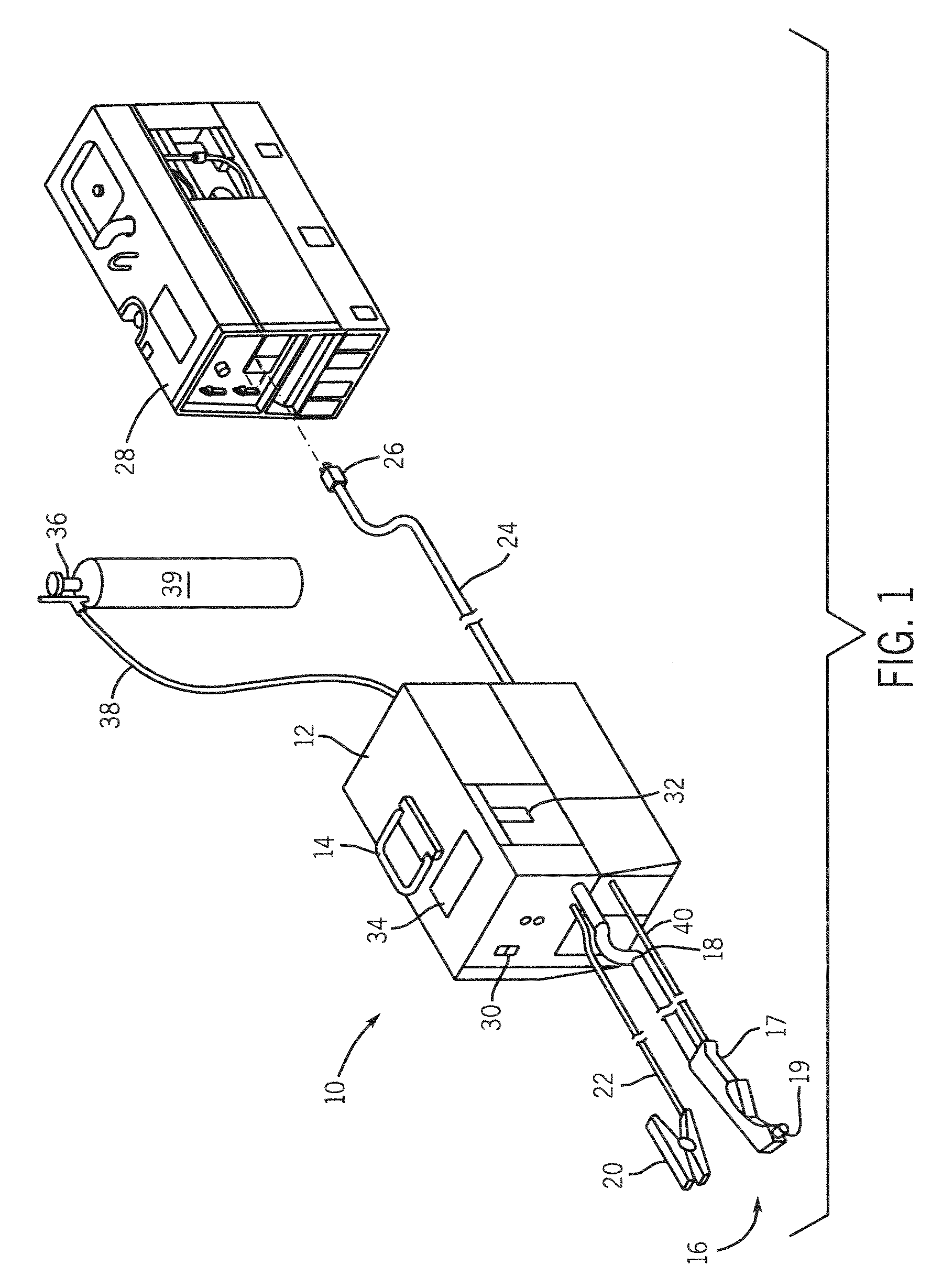

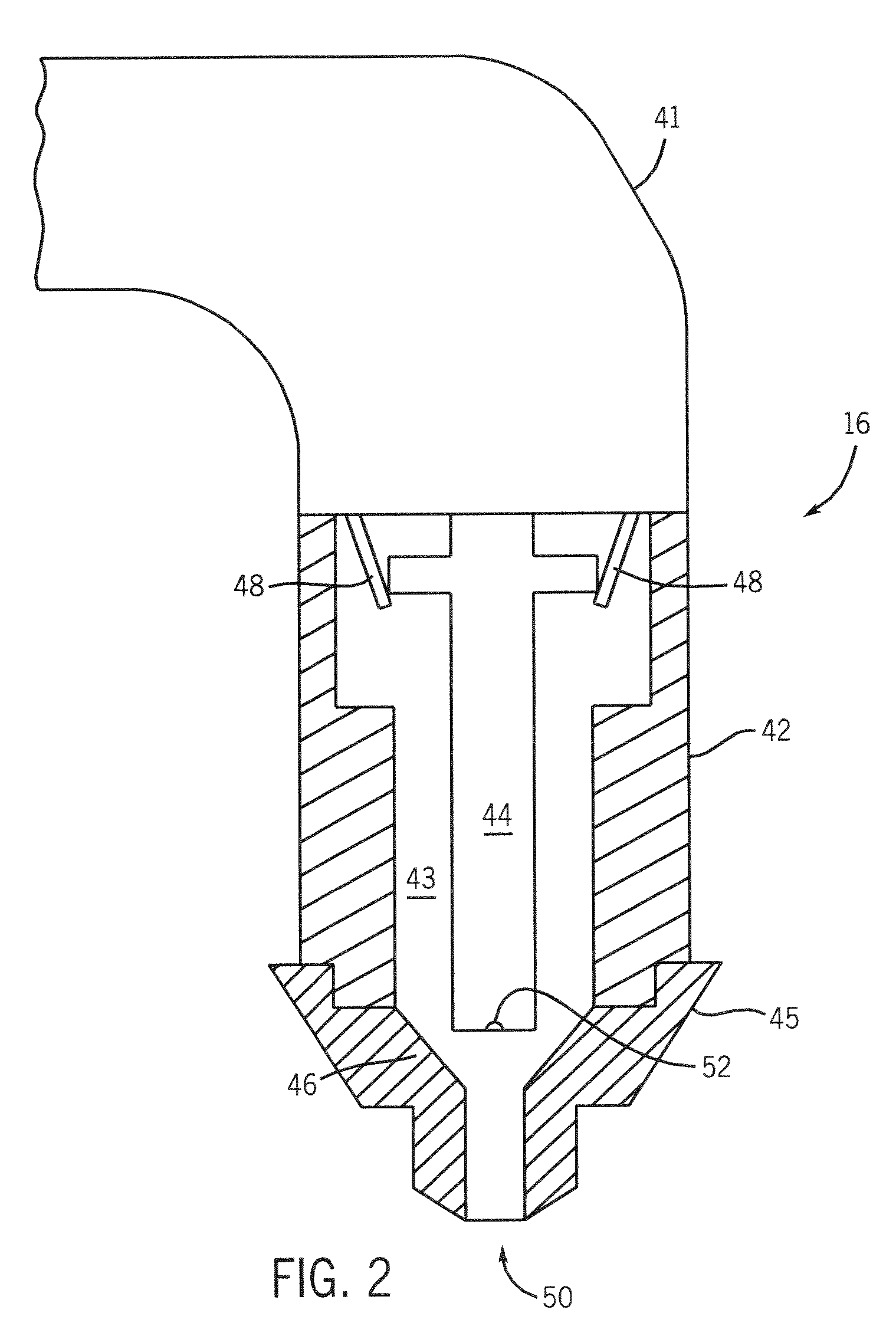

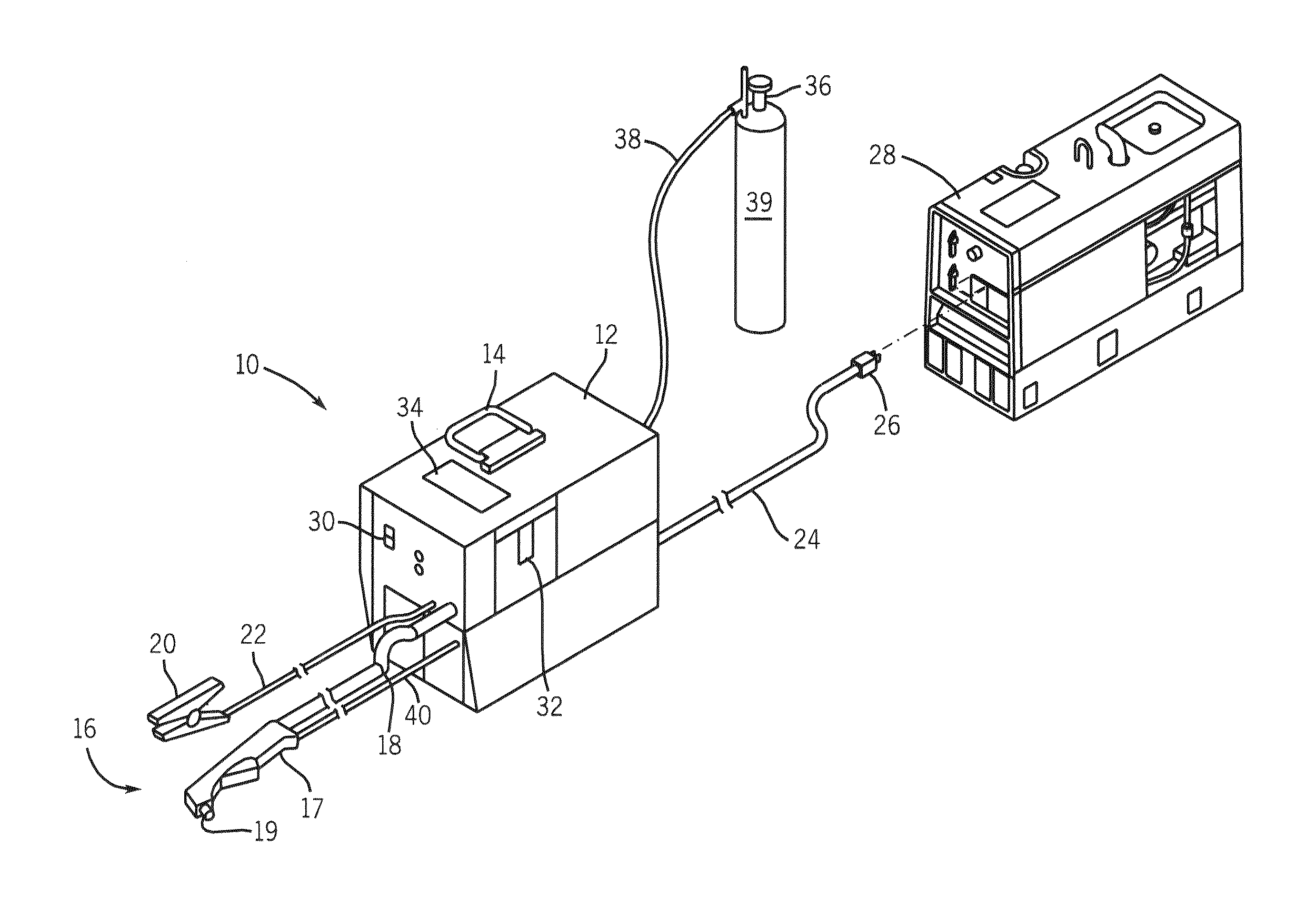

Method and apparatus for localized control of a plasma cutter

InactiveUS6992262B2Reduce communication linksShort response timeArc welding apparatusPlasma welding apparatusEngineeringPlasma cutting

The present invention is directed to a system and method for a plasma cutting system including a plasma cutting power source and a plasma torch operationally connected to the plasma cutting power source. A processing unit is disposed within the plasma torch and is configured to control the plasma cutting power source during a plasma cutting process based on operational feedback gathered of the plasma cutting process.

Owner:ILLINOIS TOOL WORKS INC

Plasma-cutting torch with integrated high frequency starter

InactiveUS7022935B1Low voltage requirementReduce componentsArc welding apparatusPlasma welding apparatusTorchPlasma cutting

Owner:ILLINOIS TOOL WORKS INC

Method and Apparatus for Plasma Dicing a Semi-conductor Wafer

ActiveUS20130230971A1Protection from damageElectric discharge tubesSolid-state devicesEngineeringSemiconductor

The present invention provides a method for plasma processing a substrate. The method comprising providing a process chamber having a wall; providing a plasma source adjacent to the wall of the process chamber; providing a work piece support within the process chamber; loading a work piece onto the work piece support, the work piece having a support film, a frame and the substrate; providing a cover ring above the work piece, the cover ring having at least one perforated region, and at least one non-perforated region; generating a plasma using the plasma source; and processing the work piece using the generated plasma.

Owner:PLASMA THERM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com