Machine frame of cantilevered mode digital control flame plasma cutting machine

A plasma cutting machine and cantilever technology, applied in plasma welding equipment, gas flame welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of low control accuracy, inflexibility, affecting the use accuracy, etc., and achieve high repeatability , accurate positioning, reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

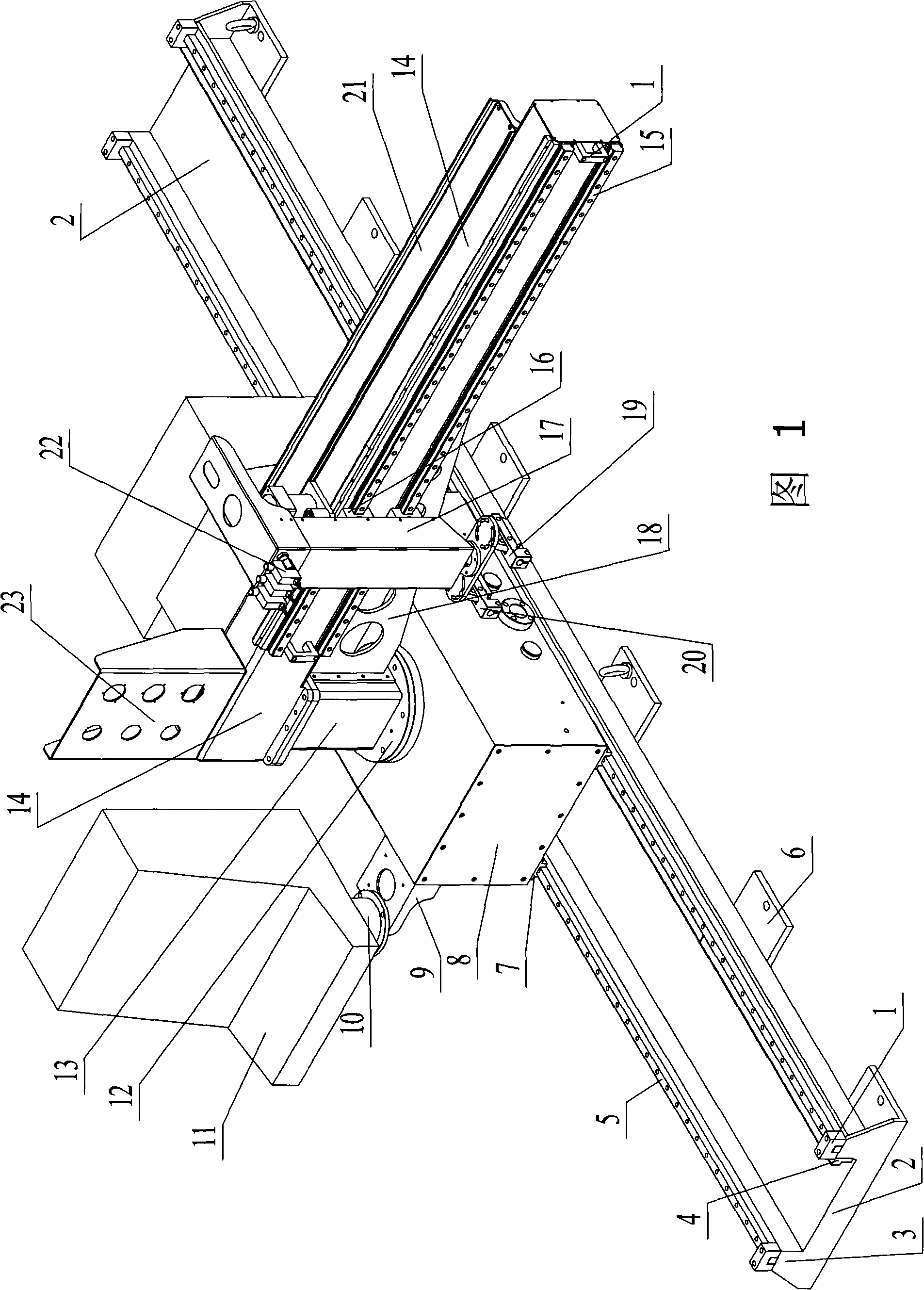

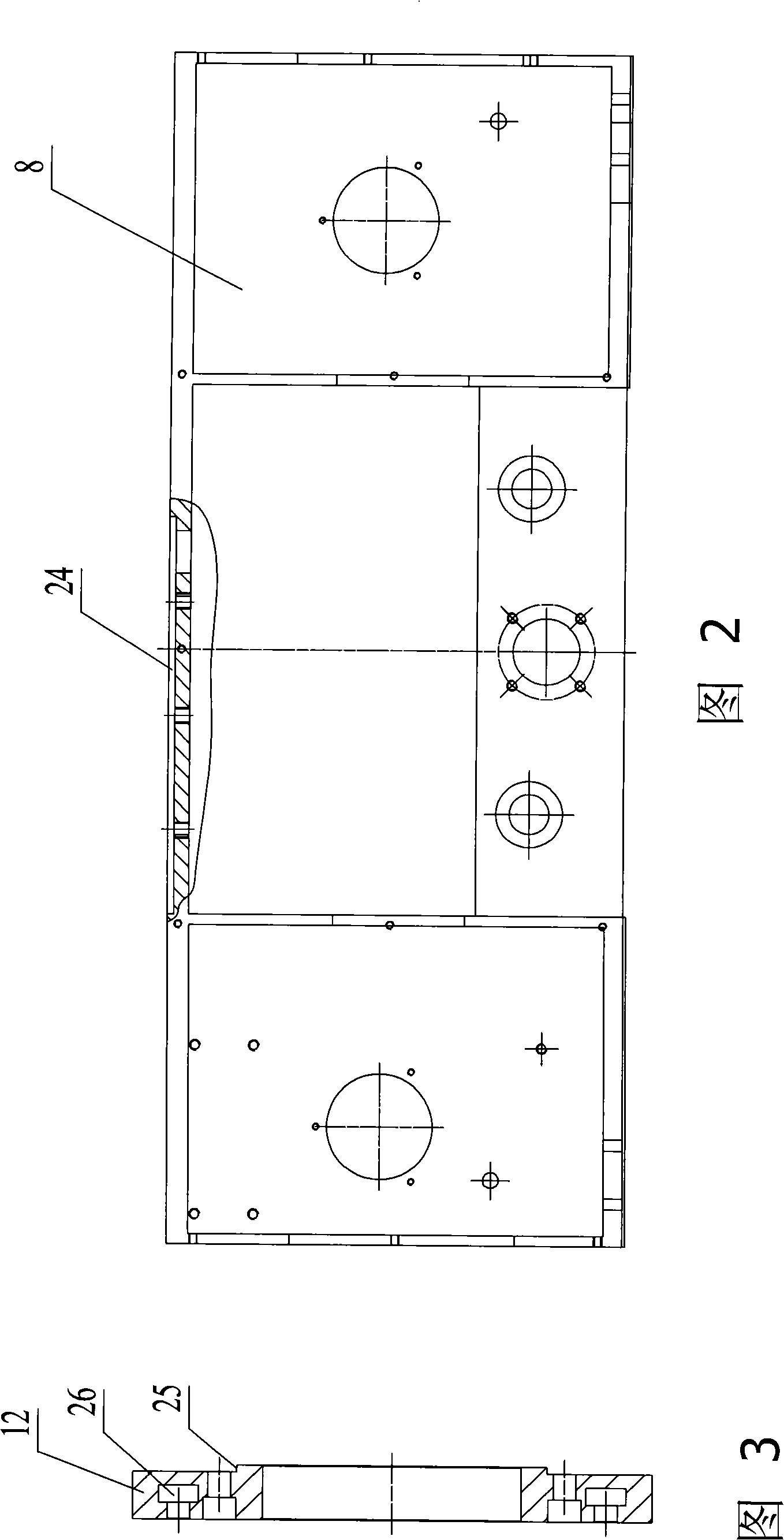

[0016] In the figure, 1. Block, 2. Machine base, 3. Underframe side sealing plate, 4. Inner reinforcement plate, 5. Longitudinal guide rail, 6. Base fixing plate, 7. Longitudinal slider, 8. Underframe, 9. System support frame, 10. System slewing ring, 11. System control box, 12. Turntable, 13. Column, 14. Cross arm, 15. Transverse guide rail, 16. Double-axis slider, 17. Lifting frame, 18. Support ribs.

[0017] As shown in the figure: there is a rotary disc 12 between the chassis 8 and the column 13, the bottom of the rotary disc 12 is connected to the chassis 8, the column 13 is connected to the upper part of the rotary disc 12; the upper part of the column 13 is connected Cross arm 14, transverse guide rail 15 is set on cross arm 14, on cross arm 14, the elevating frame 17 that can move on cross arm 14 is set, on elevating frame 17, transverse slide block 16 is set, and described transverse slide block 16 and The transverse guide rail 15 is slidably connected. The transver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com