Patents

Literature

824results about How to "High repeatability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

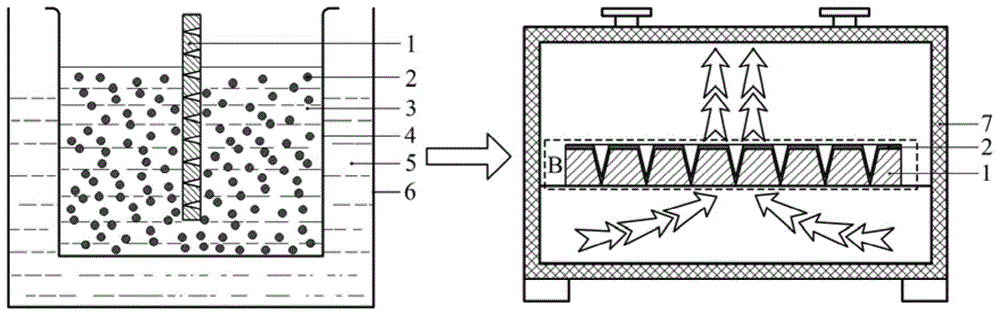

Preparation of SAPO-34 molecular sieve film for selectively separating methane gas

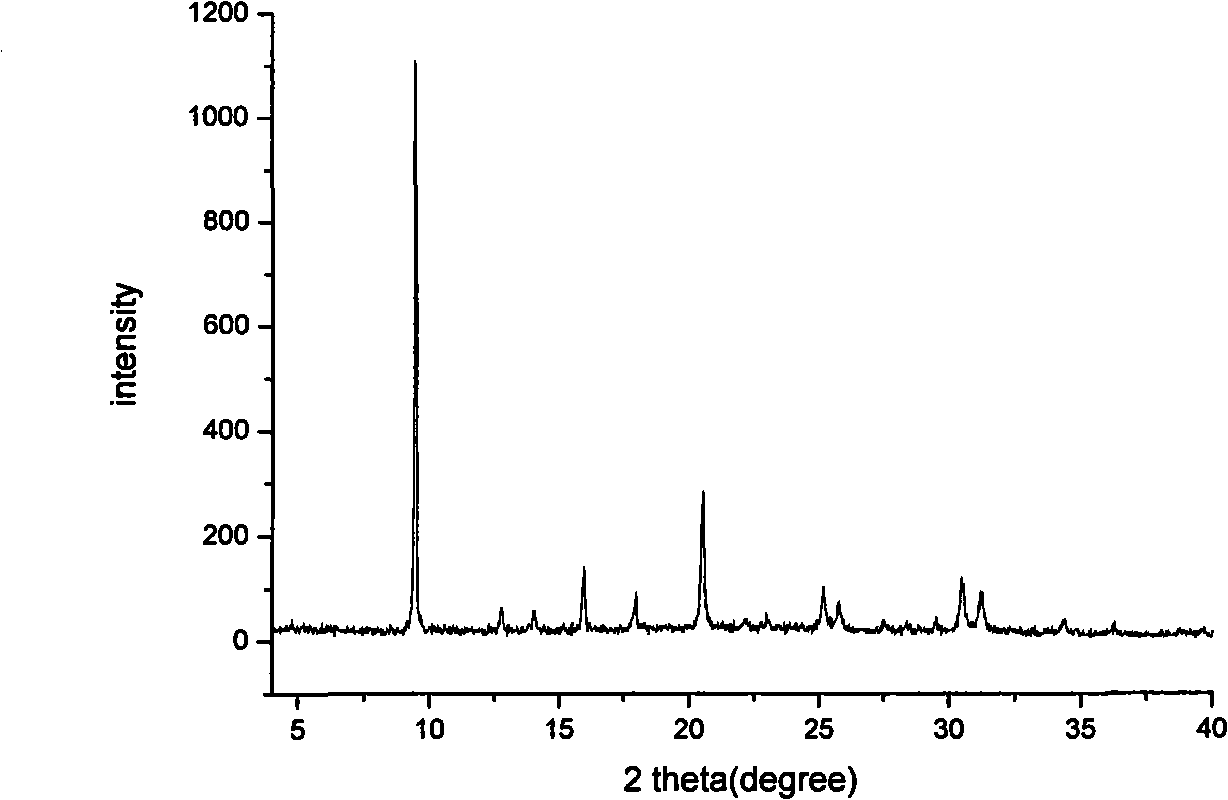

InactiveCN101279207AHigh repeatabilityGood orientationSemi-permeable membranesPhosphoric acidMolecular sieve

The invention relates to a novel method of SAPO-34 molecular sieve membrane for selectively separating methane gas by crystal guidance and secondary synthesis. The method includes three steps, namely synthesizing crystal seed, preparing basement membrane of crystal seed and synthesizing SAPO-34 molecular sieve membrane, in particular to the following steps: phosphoric acid, TEAOH and silica sol are added into adequately hydrolyzed aluminium isopropoxide to prepare a crystal seed solution of the molecular sieve and the molecular sieve composite mother solution; the crystal seed solution of the molecular sieve is prepared to be suspension after crystallization and rinsing for dripping onto a treated carrier; a basement membrane of crystal seed acquired is placed in a reaction kettle and is added with the molecular sieve composite mother solution for crystallization at a temperature ranging from 150 DEG C to 180 DEG C for 3 through 20 days, which is taken out for cleaning and drying and then is followed with actively removing a template agent at a temperature ranging from 400 DEG C to 600 DEG C. Synthesizing the molecular sieve membrane with the method of the invention is suitable for various porous supports with smooth surface, which is of high repetitiveness, good orientation, excellent separating property and ultrahigh gas permeability and is suitable for industrial application.

Owner:JILIN UNIV

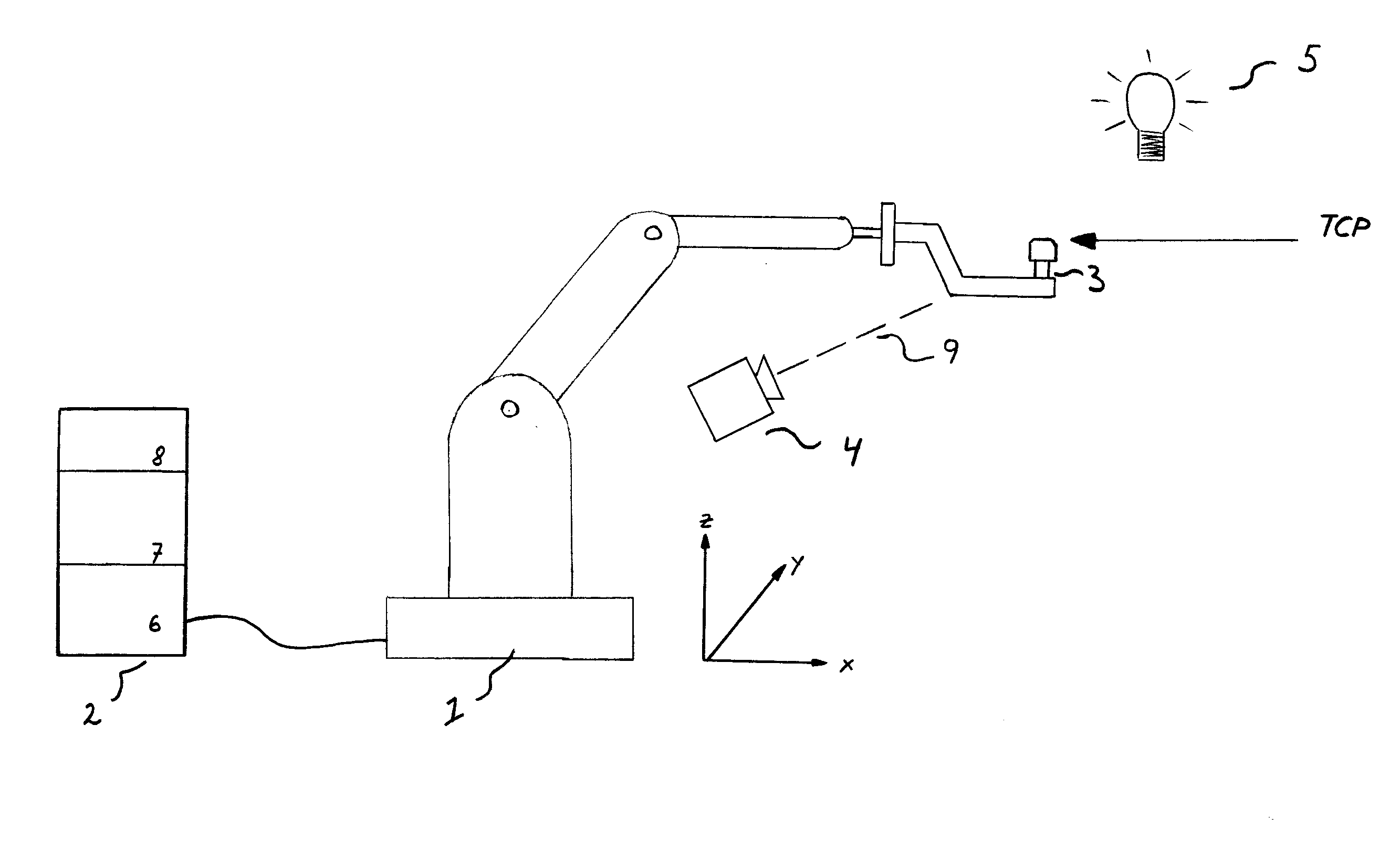

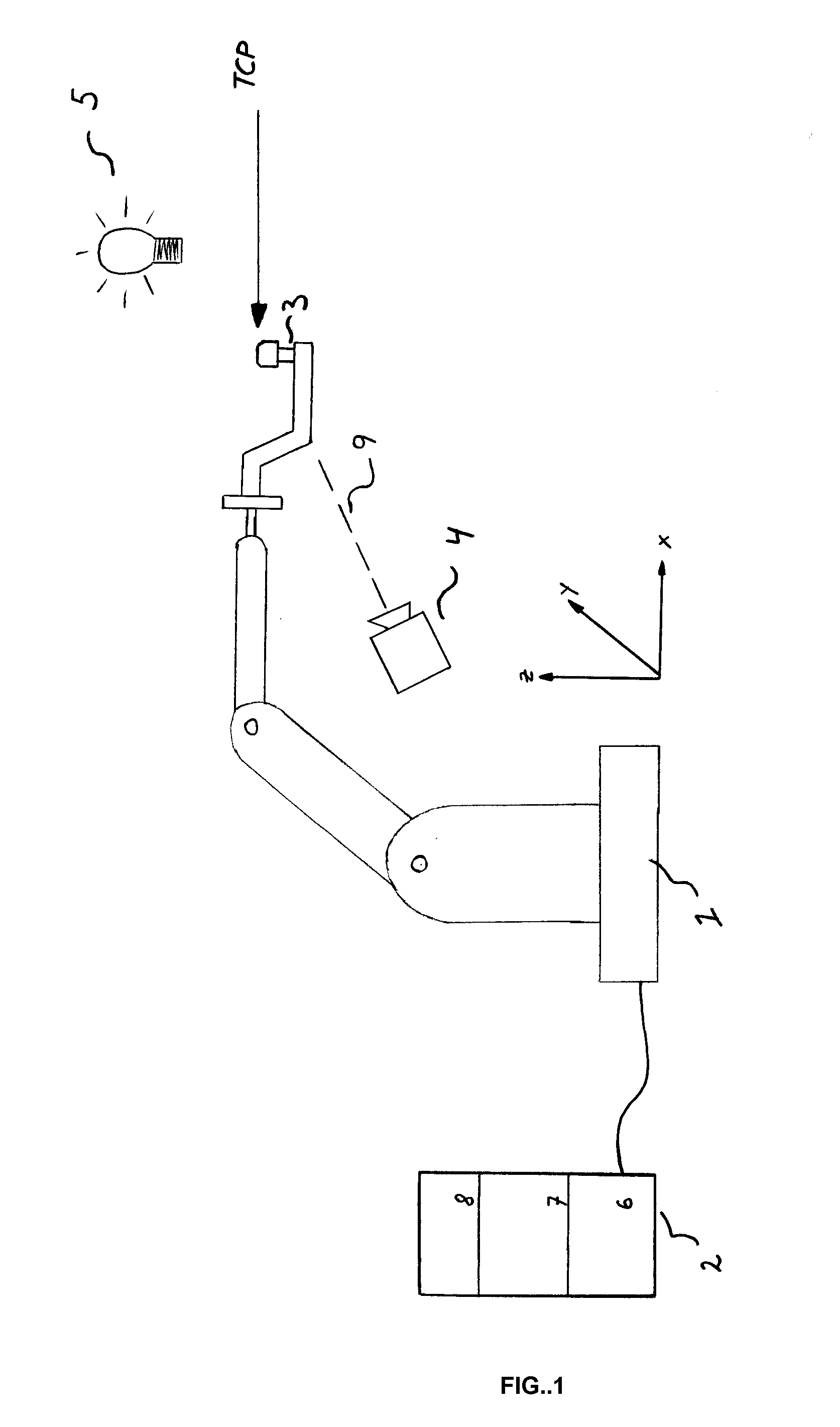

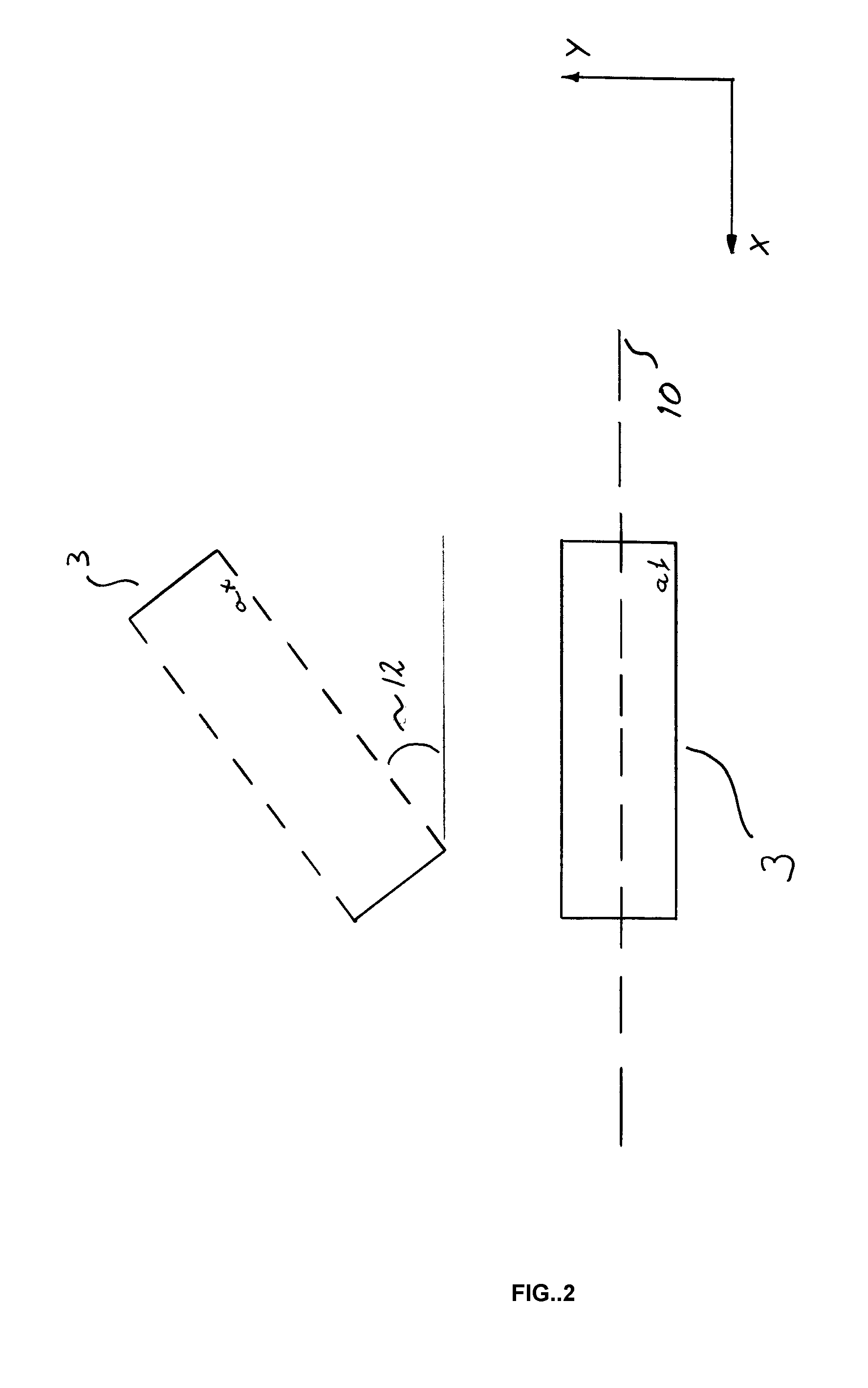

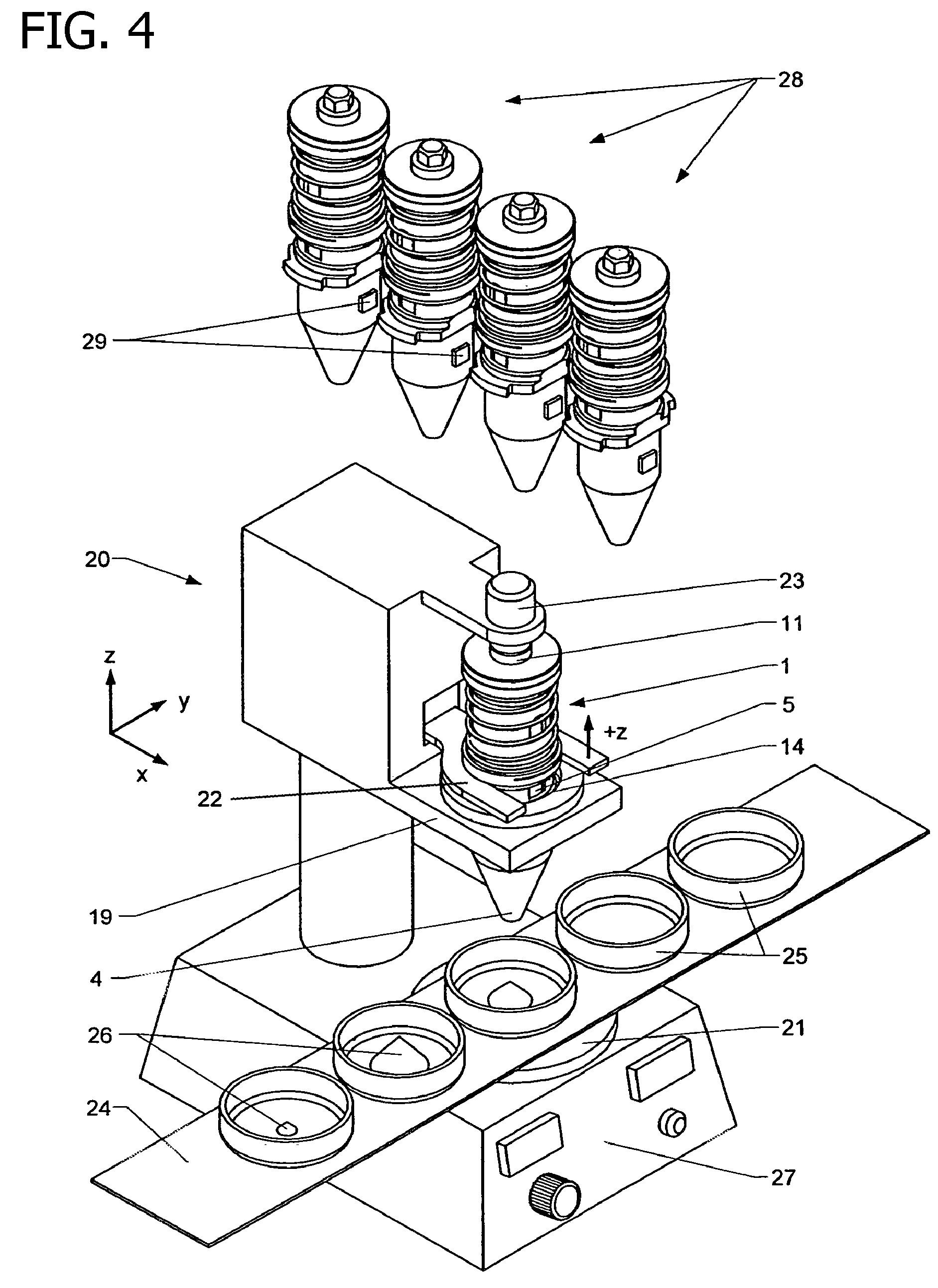

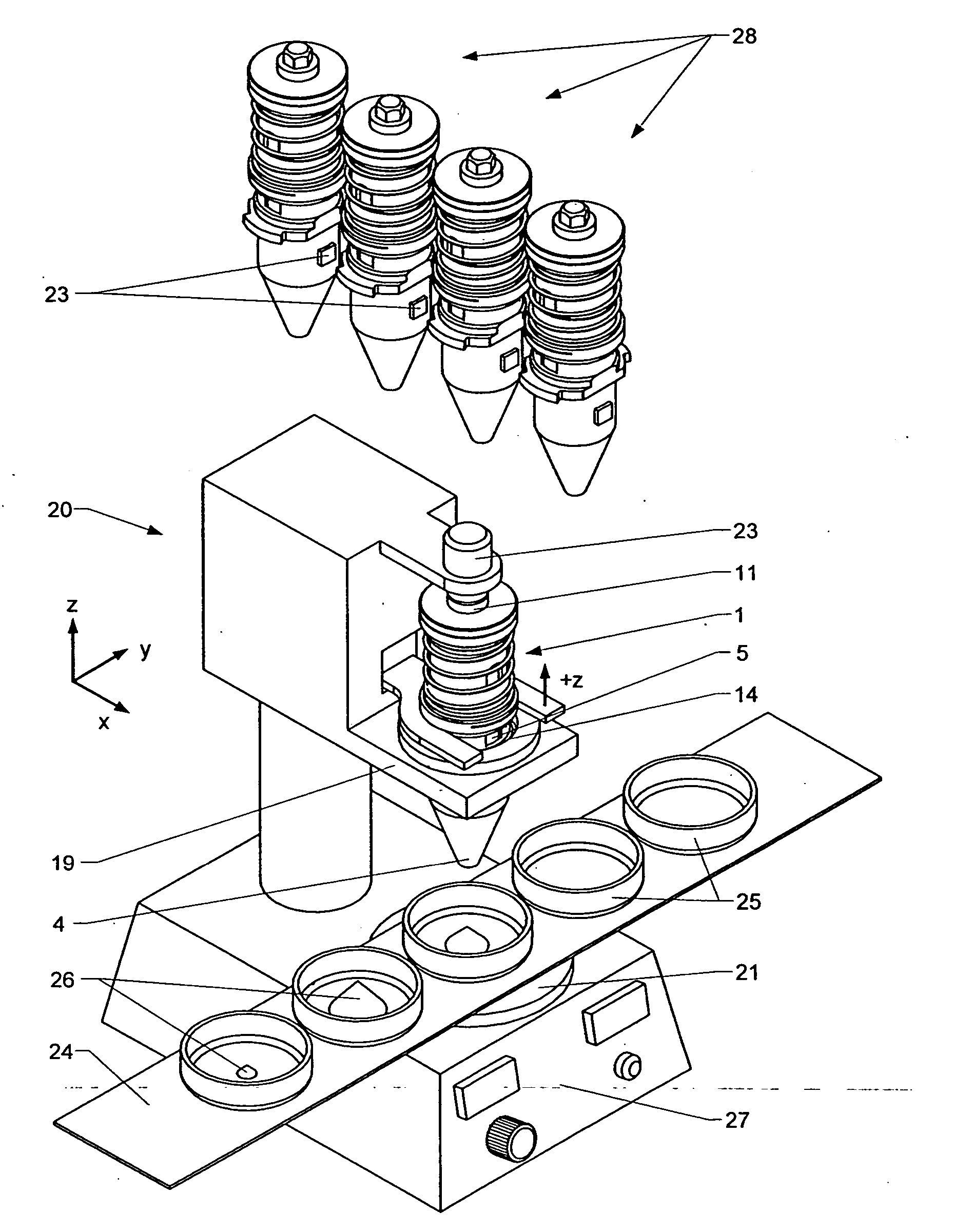

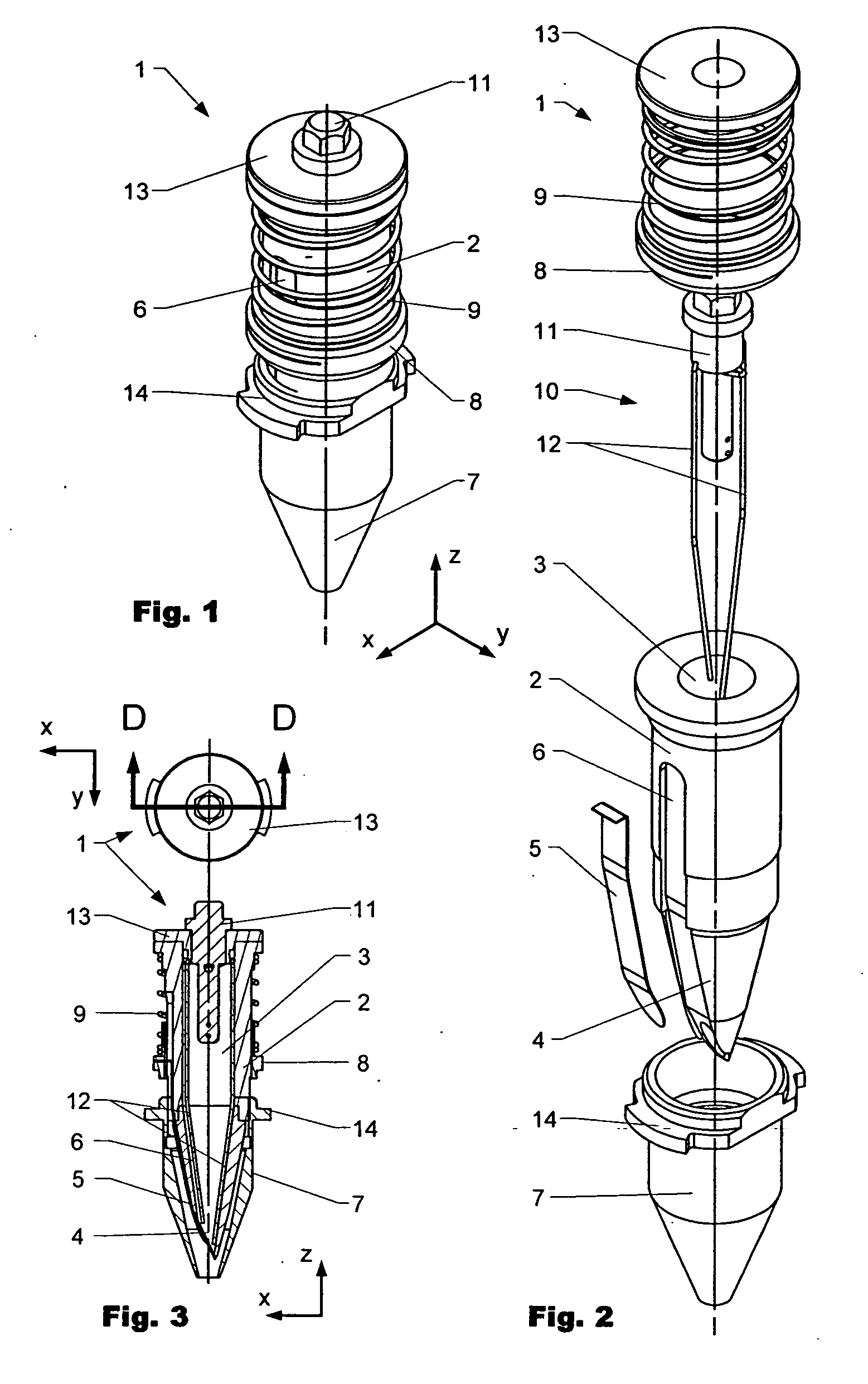

Device and Method for Calibrating the Center Point of a Tool Mounted on a Robot by Means of a Camera

InactiveUS20080252248A1High repeat accuracyHigh operate availabilityProgramme-controlled manipulatorComputer controlImage basedSituated computing

A device and a method for tool center point calibration of an industrial robot. The device is intended to calibrate an industrial robot with respect to a tool mounted on the robot. The device includes a camera designed to take a plurality of images of at least part of the robot tool for a plurality of different tool orientations, an image-processing unit designed to determine the positions of the robot tool in the orientations based on the images, a calculation module adapted to calculate the position of the center point of the robot tool, based on the determined positions, and a control module adapted to calculate the corrective movements of the robot.

Owner:ABB (SCHWEIZ) AG

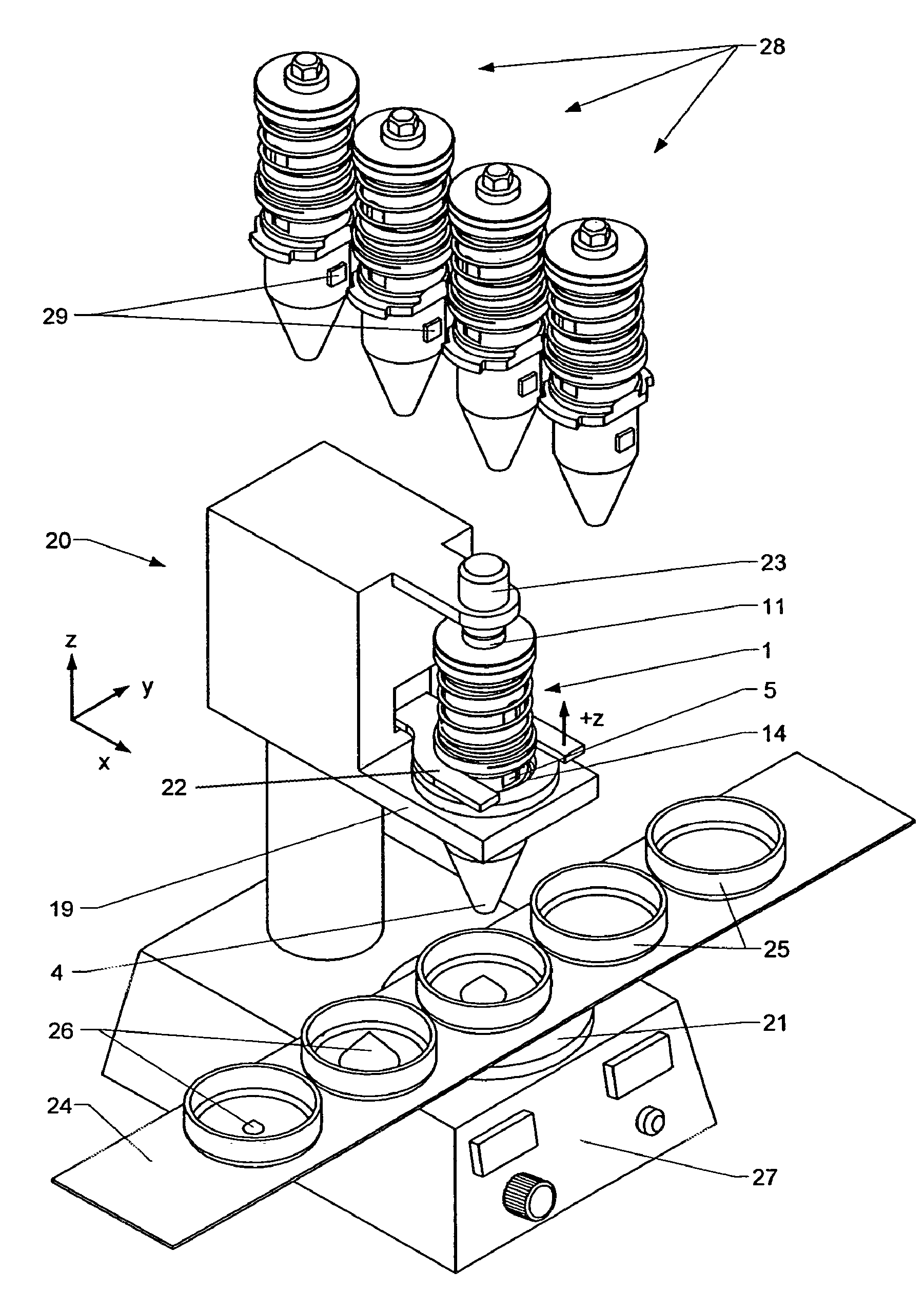

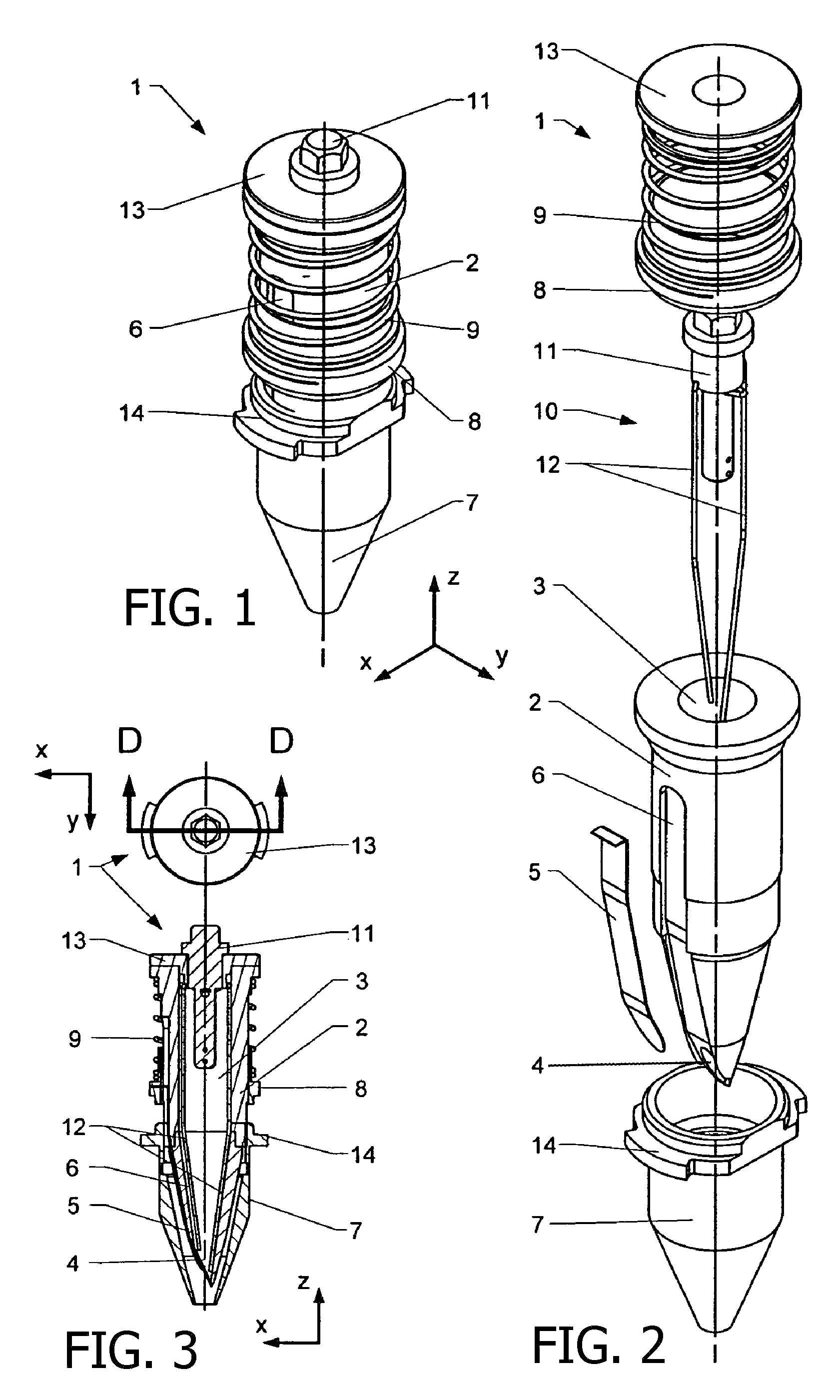

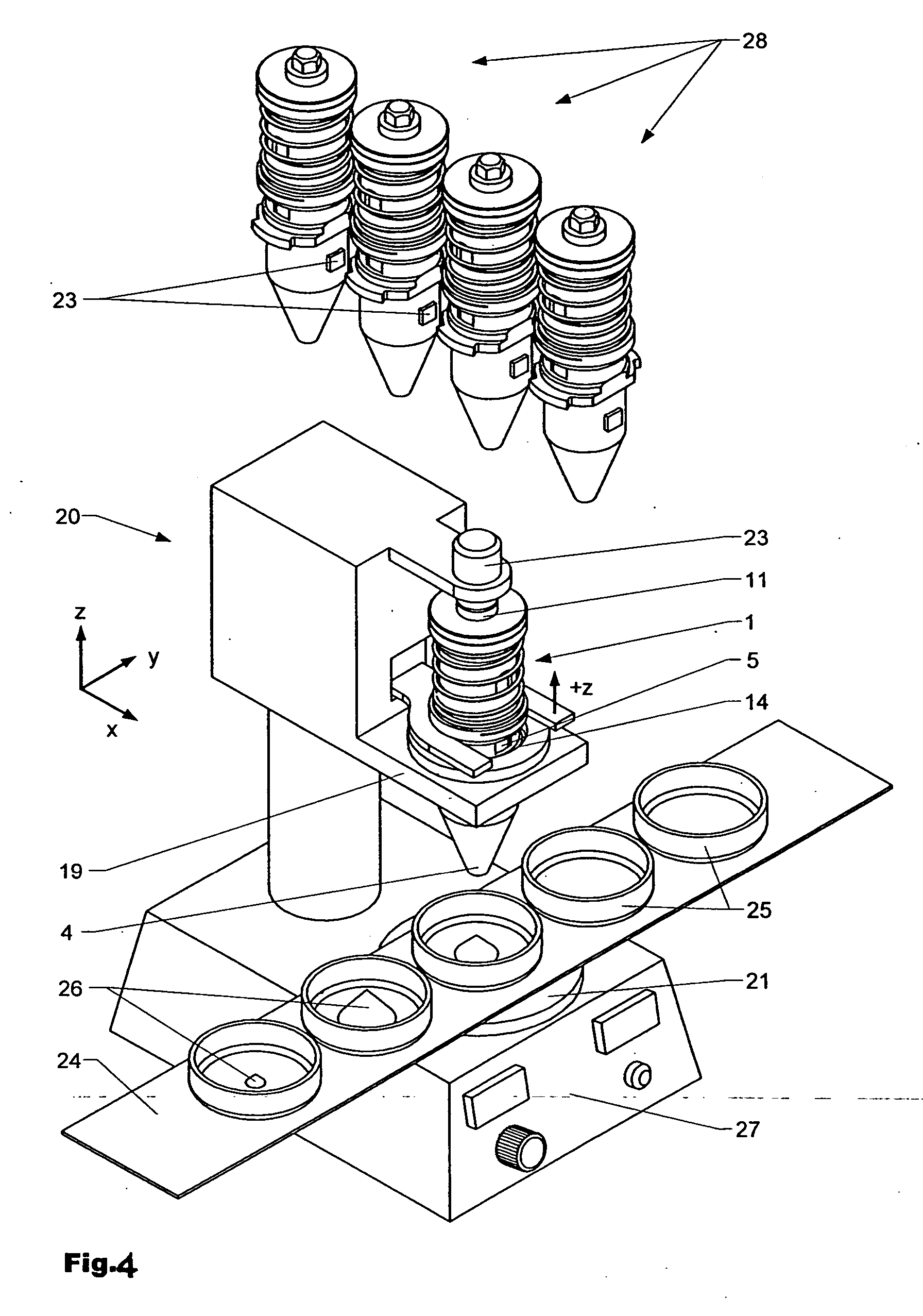

Apparatus and methods for storing and dispensing solid material

InactiveUS7614429B2Easy to fillEasy to emptyLarge containersLaboratory glasswaresGate valveControl unit

The invention is directed to a dispensing unit suitable to precisely dispense material in powdery and / or granular form. The dispensing device comprises an gate valve opening sealingly closed by a blend. A control unit, which is interconnected to a scaling device, controls the opening of the gate valve opening by the position of the blend. The precise amount of the material is adjusted in relation to the signal of the scaling device.

Owner:FREESLATE

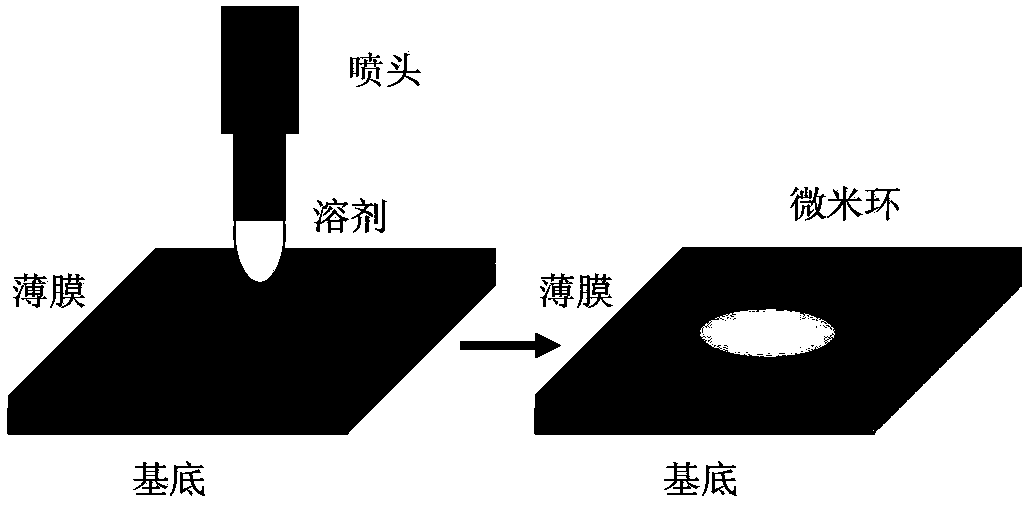

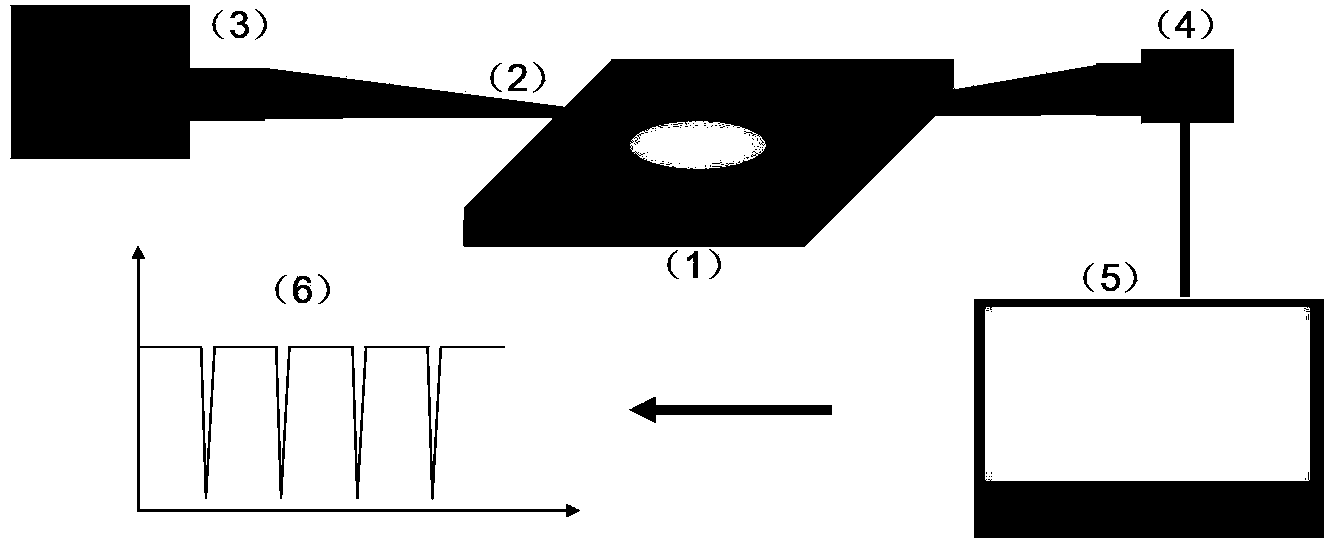

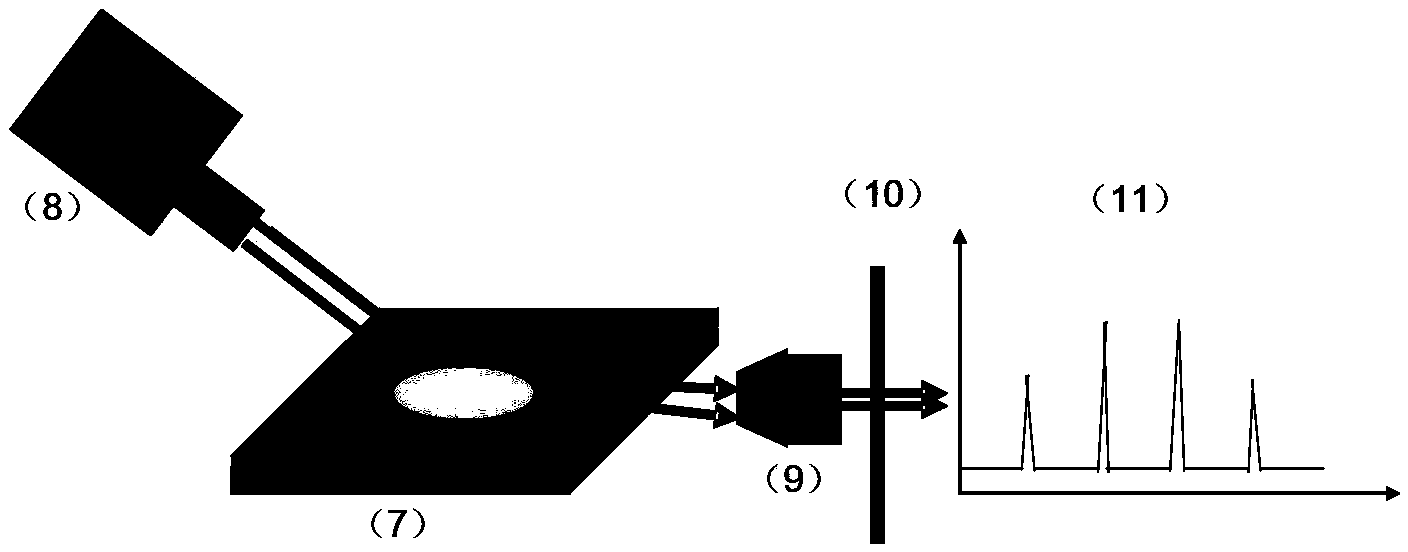

Whispering gallery mode photonic device and preparation method thereof

ActiveCN104253372ARealize the coupling effectSolve patterningOptical resonator shape and constructionWhispering galleryArray data structure

The invention provides a whispering gallery mode photonic device and a preparation method thereof. According to the preparation method of a micro ring array structure, solvent droplets are utilized to dissolve a polymer film, so that a "coffee ring effect" can be generated, and therefore, polymer can be accumulated at the periphery of liquid so as to form an annular structure of which the height is obviously different from the height of the film, and conduction and confinement of light in the polymer structure can be realized; and light signals are inputted to the micron ring structure through utilizing excitation, scattering or near field coupling modes, so that a resonance effect in a whispering gallery mode can be realized. The prepared micron ring structure can be adopted as a high-quality factor optical micro cavity, so that a modulation-mode spectrum can be obtained, the width of spectral lines of the spectrum being significantly narrowed; a whispering gallery-mode light amplification stimulated emission can be realized through optical gain; and in a multi-ring coupled array structure, light signal processing and high sensitive response to outside stimuli can be realized according to the wavelength change information of the modulated spectrum and laser modes.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Apparatus and method for storing and dispensing material, especially in micro quantities and in combination with limited starting amounts

InactiveUS20070006942A1Improve accuracyMaximum flexibilityLarge containersLaboratory glasswaresGate valveControl unit

The invention is directed to a dispensing unit suitable to precisely dispense material in powdery and / or granular form. The dispensing device comprises an gate valve opening sealingly closed by a blend. A control unit, which is interconnected to a scaling device, controls the opening of the gate valve opening by the position of the blend. The precise amount of the material is adjusted in relation to the signal of the scaling device.

Owner:FREESLATE

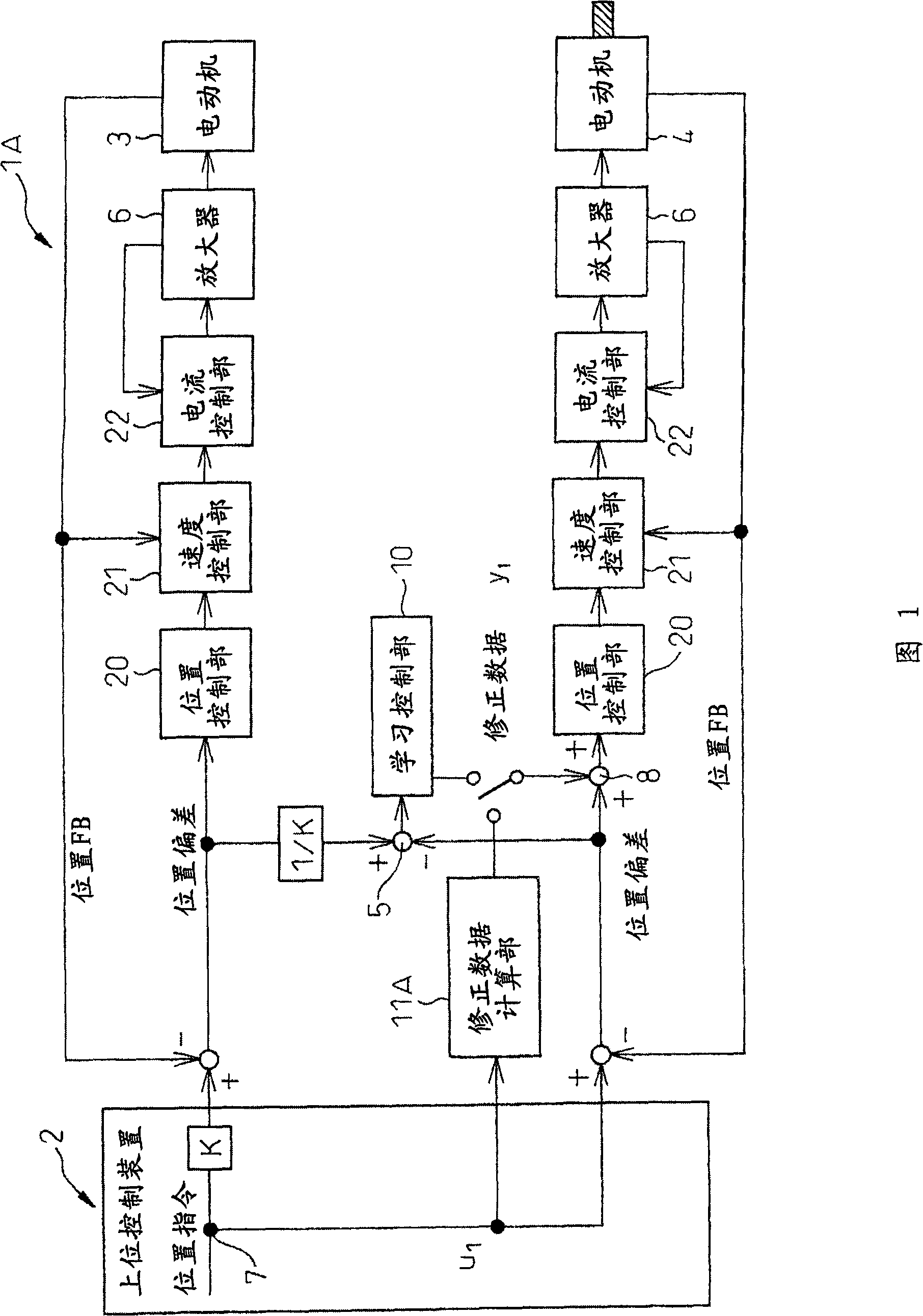

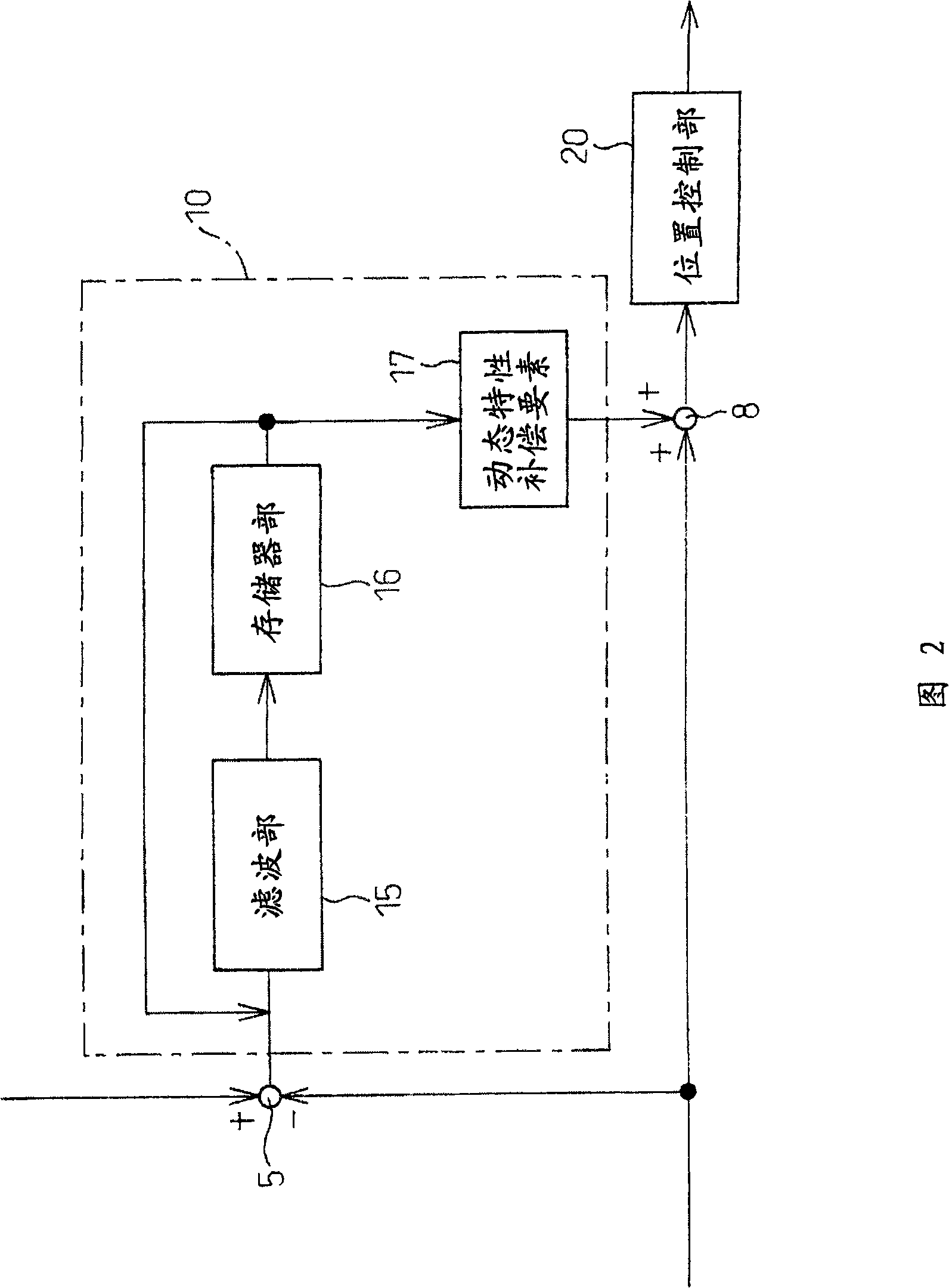

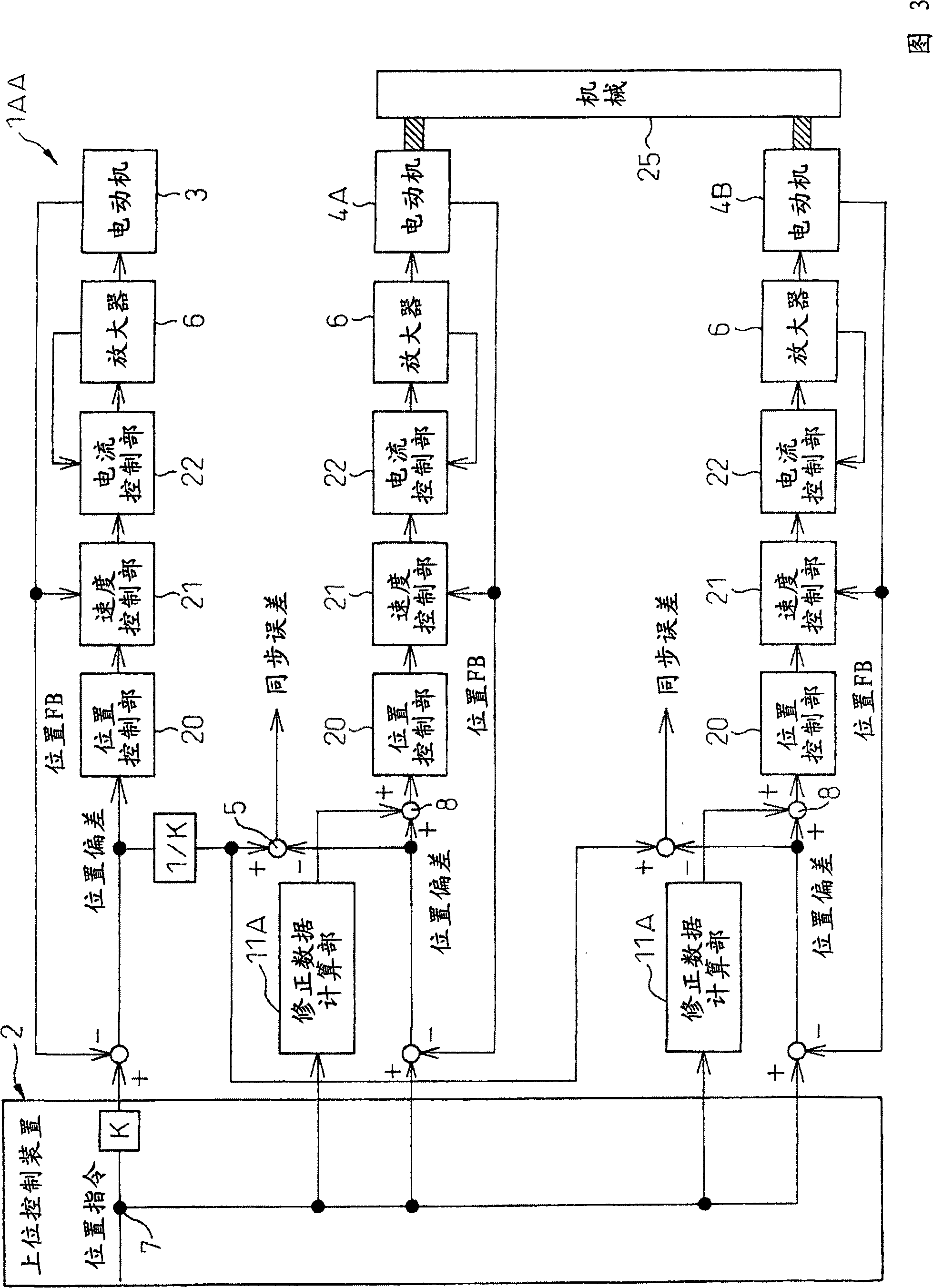

Servo controller

InactiveCN101261509AHigh repeatabilityAvoid position shiftThread cutting machinesNumerical controlSynchronous controlDrive shaft

A servo controller for synchronously controlling a master driving source for driving a driving shaft and a slave driving source for driving a driven shaft, having a position control section that performs a position control based on a positional deviation which is a difference between a position command value given to the slave driving source and a feedback value detected from the slave driving source, an operational section that calculates a synchronization error which is a difference of the positional deviation between the master driving source and the slave driving source, and a correction data calculating section that calculates first correction data for correcting the positional deviation of the slave driving source.

Owner:FANUC LTD

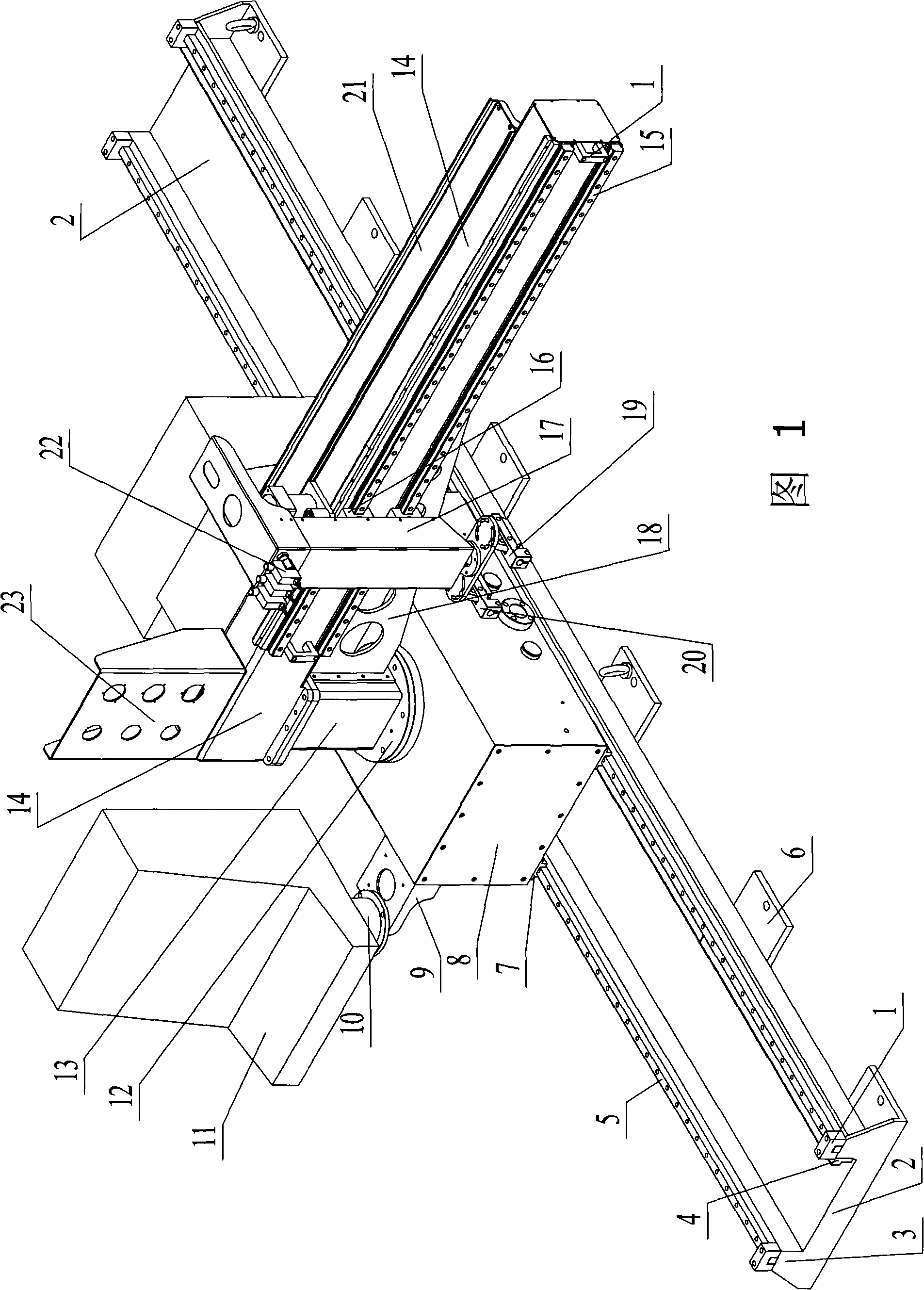

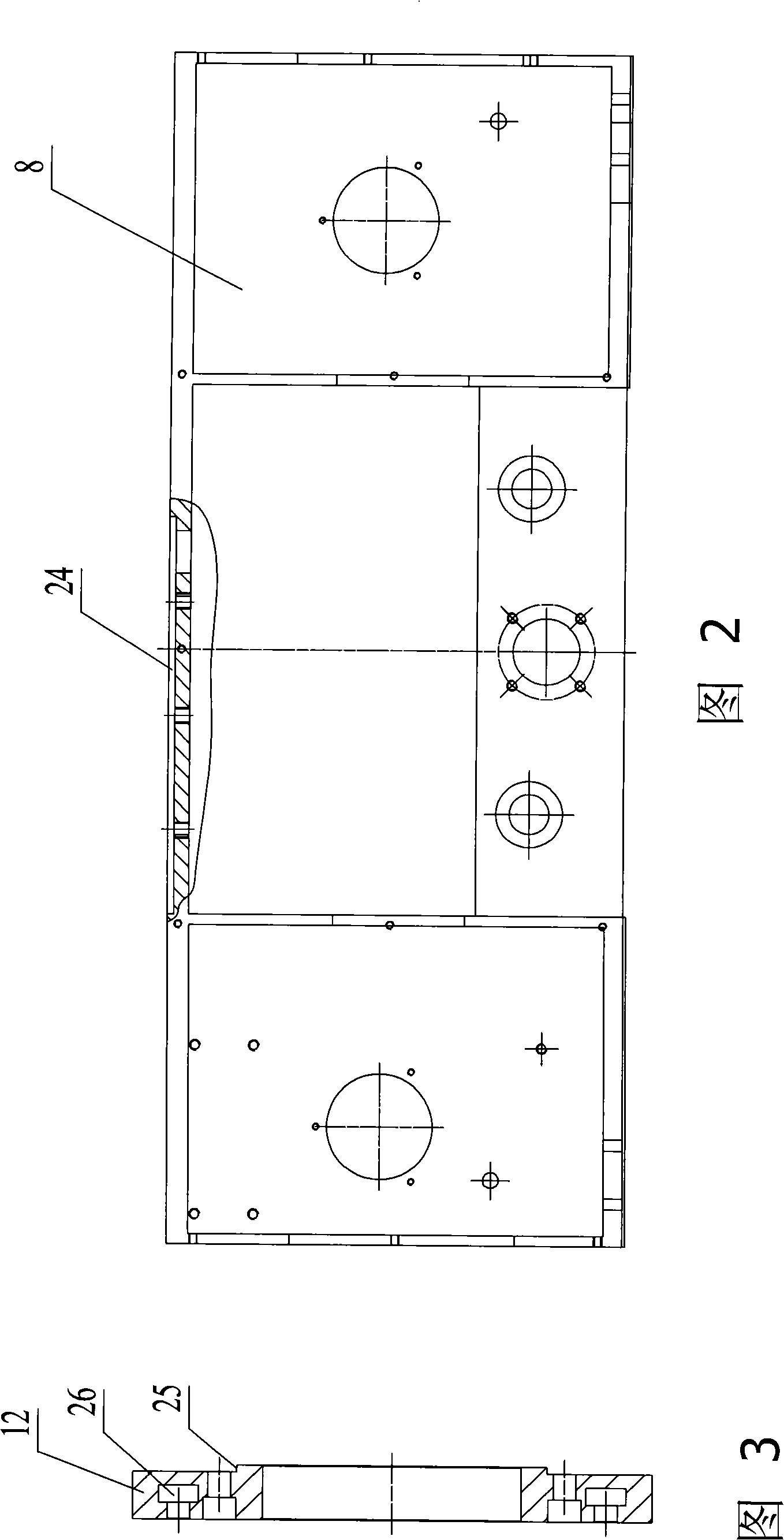

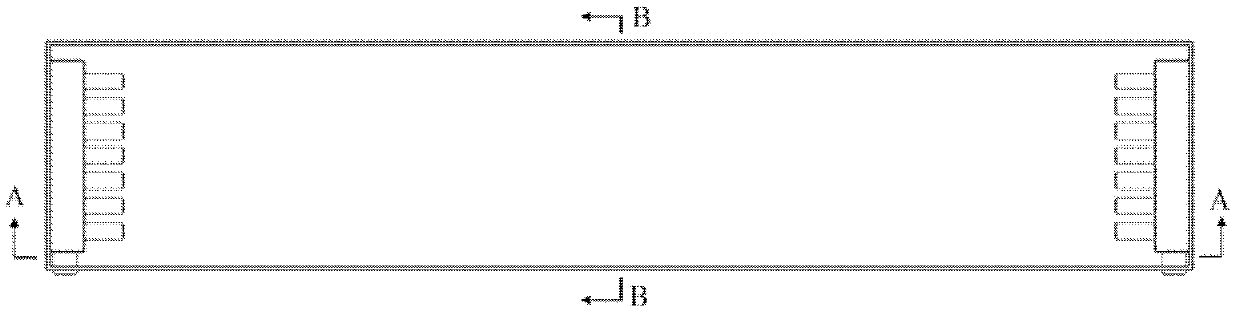

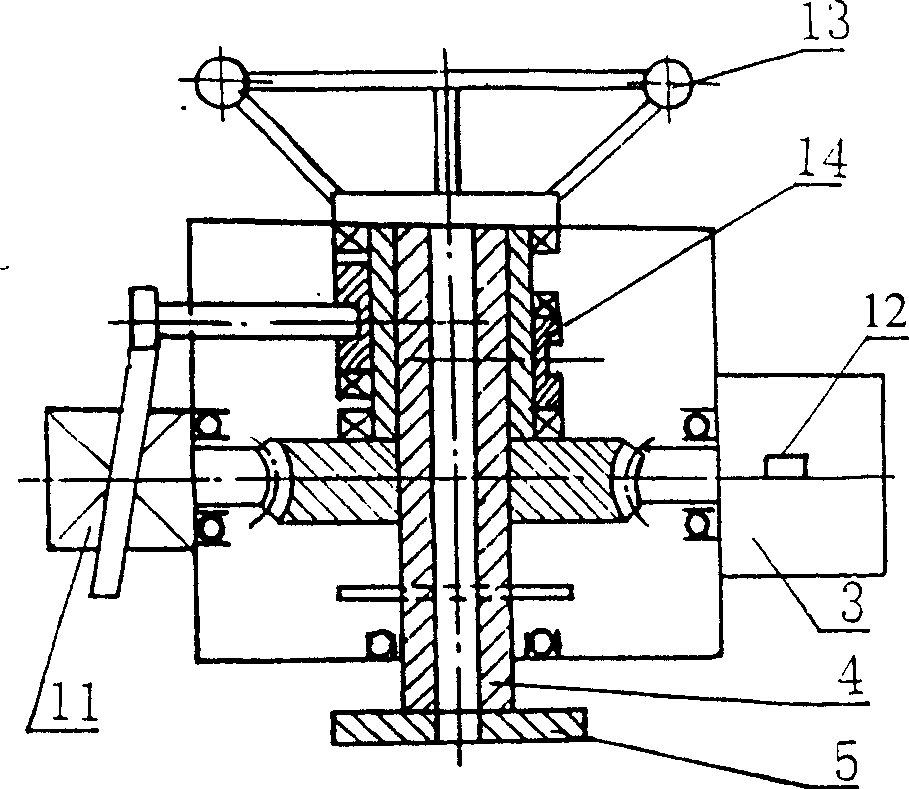

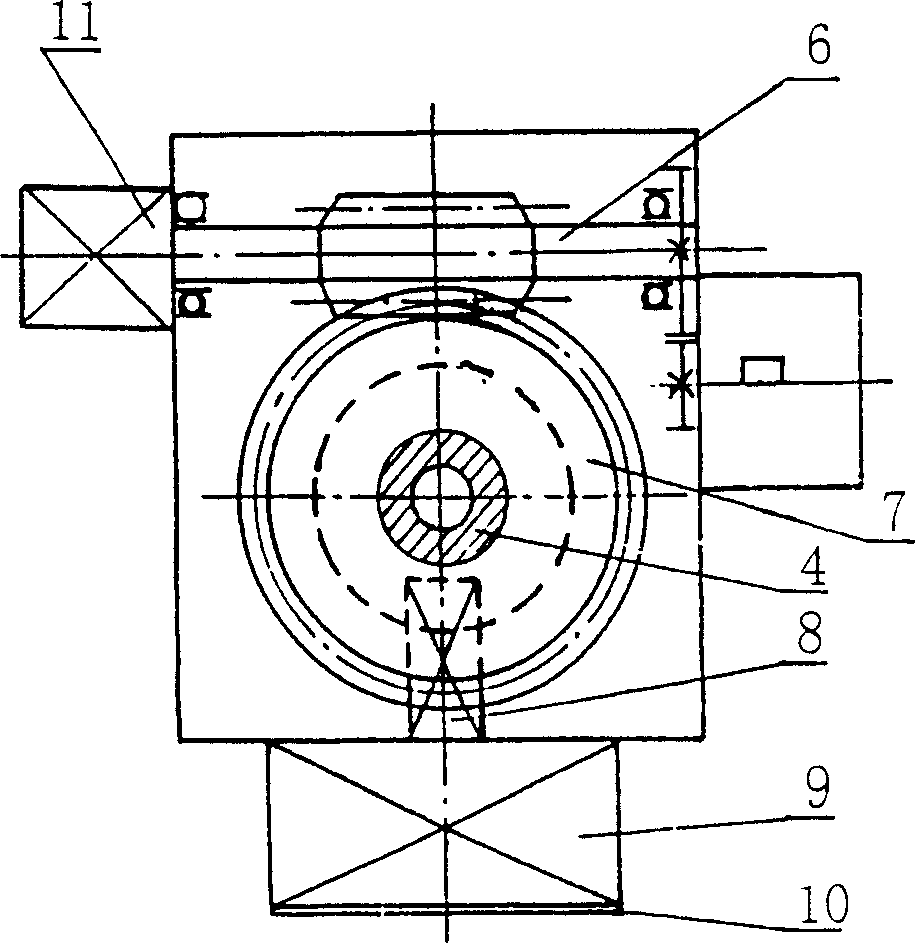

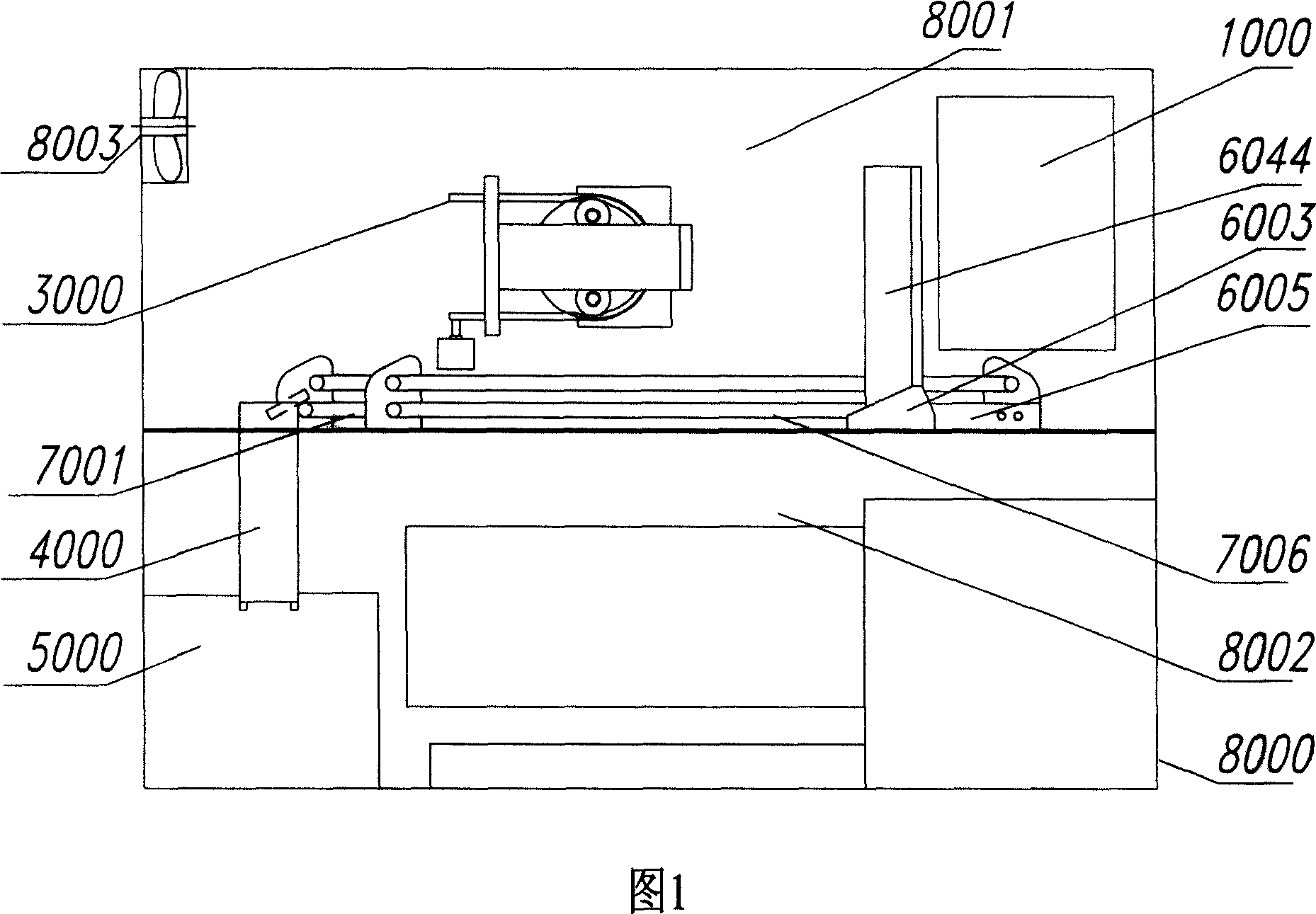

Machine frame of cantilevered mode digital control flame plasma cutting machine

ActiveCN101298120ATurn easilyReasonable designWelding/cutting auxillary devicesAuxillary welding devicesNumerical controlEngineering

The invention relates to a flame plasma cutting machine, in particular to a frame of the cantilever-typed numerical control flame plasma cutting machine. According to the technical proposal provided by the invention, a turning mechanism is arranged between an underframe and a vertical column; the bottom part of the turning mechanism is connected with the underframe; the vertical column is connected with the upper part of the turning mechanism; the upper part of the vertical column is connected with a transverse arm provided with a cross slide way; the transverse arm is provided with a lifting frame which can move on the transverse arm; the lifting frame is provided with a transverse sliding block connected with the cross slide way in a sliding way. The flame plasma cutting machine can facilitate the transportation and installation and improve the repeated precision and positioning angle.

Owner:无锡聚合科创发展有限公司

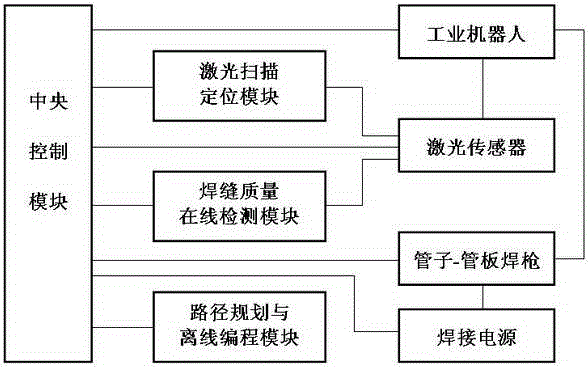

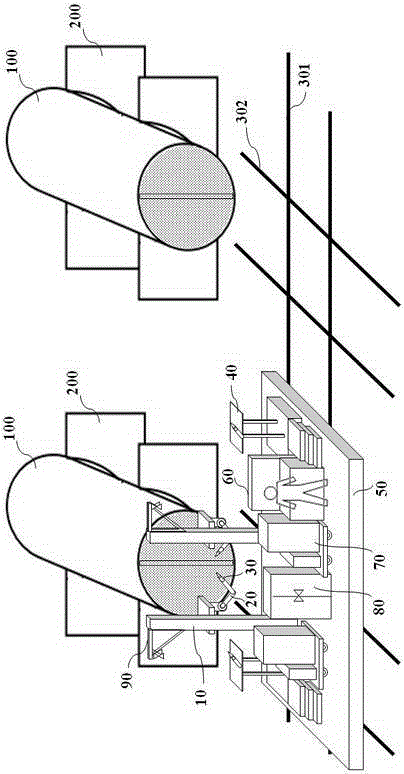

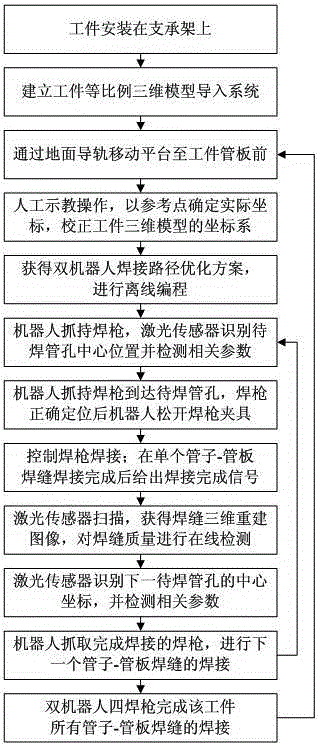

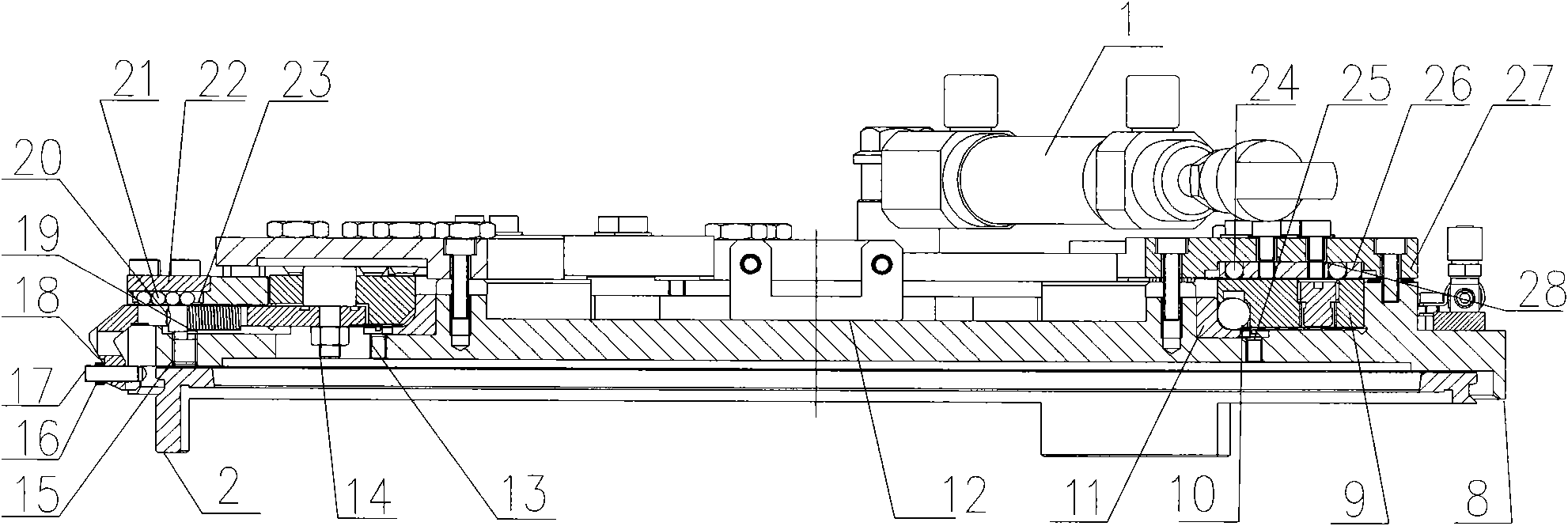

Robot welding system and welding method thereof

ActiveCN105195868AImprove work efficiencyHigh repeatabilityProgramme-controlled manipulatorHeat exchange apparatusLaser scanningVapor generator

The invention provides a robot welding system and a welding method thereof and suitable for pipe-pipe plate welding for a vapor generator of a main device in a nuclear island. According to the invention, a path planning and off-line programming module is used for planning an anti-collision welding path for an industrial robot and performing off-line programming on a planned scheme; a laser scanning positioning module obtains the circle centre coordinate of a pipe hole according to scanning results and performing initial welding position identification and autonomous guiding; the two industrial robots controlled by a central control module are matched with four pipe-pipe plate welding guns to perform welding on all pipe-pipe plate welding lines on a pipe plate; and an on-line welding line quality detection module obtains a three-dimensional reconstruction image according to welding line laser scanning results and performing on-line detection on welding line quality according to morphologies of the welding lines. Due to adoption of the system and the method disclosed by the invention, the pipe-pipe plate welding efficiency is improved, and the stability of the welding line quality is ensured.

Owner:SHANGHAI ELECTRIC NUCLEAR POWER EQUIP CO LTD

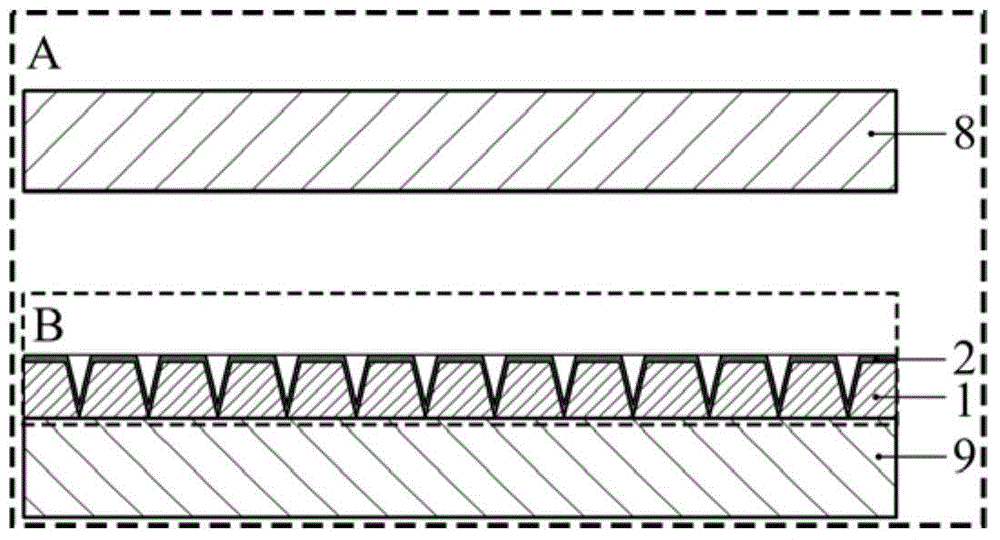

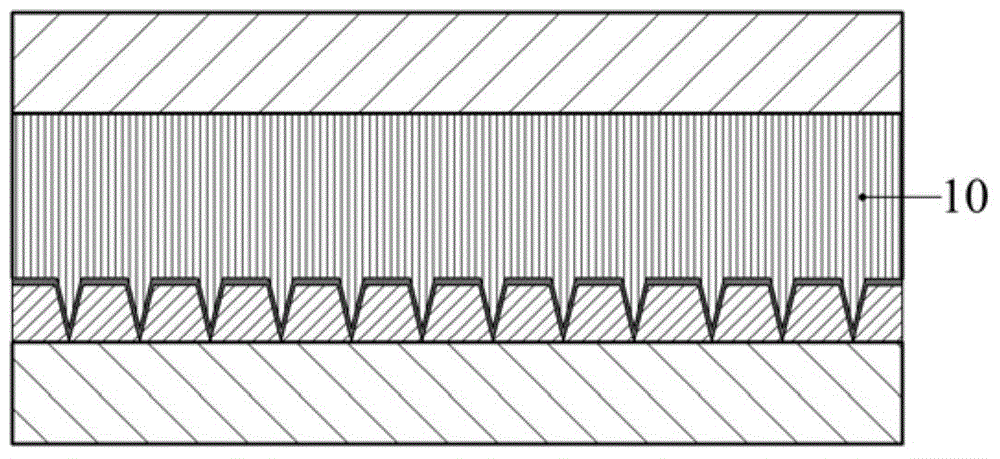

Preparation method and application of super-hydrophobic and adhesion-adjustable surface with micro-nano composite structure

The invention relates to a preparation method for a super-hydrophobic and adhesion-adjustable surface with a micro-nano composite structure. The preparation method comprises the following steps: a, preparing a dual-level composite microstructure template according to wetting characteristics needed by a product surface; b, preparing a solution from a hydrophilic / hydrophobic nanoparticle and absolute ethyl alcohol according to adhesion characteristics needed by the product surface, immersing the dual-level composite microstructure template into the solution, carrying out ultrasonic dispersion, then taking the treated microstructure template out and drying the treated microstructure template so as to obtain a three-level micro-nano composite structure template; c, fixing the obtained template on the surface of a die cavity, injecting high-molecular melt into the cavity by using an injection machine, carrying out pressure maintaining and then carrying out cooling and molding; and d, separating a molded high-molecular product from an injection die by using a demolding apparatus. The hydrophilic / hydrophobic nanoparticle is adhered on the surface or embedded into the surface layer of the dual-level composite microstructure on the surface of the molded high-molecular product, and the molded high-molecular product surface has the characteristics of super-hydrophobicity and adjustable adhesion and can realize flexible switching between a lotus leaf effect and a petal effect.

Owner:SOUTH CHINA UNIV OF TECH

Plunger pump type hydraulic injection moulding machine system driven by servo motor and control method thereof

The invention discloses a plunger pump type hydraulic injection moulding machine system driven by a servo motor. The system comprises an oil tank, a servo pump, a mould height motor, a mould clamping cylinder, an ejector cylinder, a movable ejection cylinder, a glue-ejecting cylinder, a glue-smelting motor and an electronic ruler measurement sensor and also comprises a computer controller, a pressure and speed comprehensive control module, a servo driver, the servo motor and a pressure sensor. The invention also discloses a control method of the plunger pump type hydraulic injection moulding machine system driven by the servo motor. In the control method, the pressure sensor and the torque control of the servo motor are adopted, the multilevel control of pressure and flow can be realized;real-time closed-loop control is adopted to control the pressure and flow during injection moulding; and in the control process, the instructions on the pressure and flow are compared with feedbacks in real time and some parameters such as the speed, pressure and current at each moment are controlled accurately, thus effectively realizing technical motions such as the mould open / closing, ejection, glue ejection and glue smelting of the injection molding machine and the closed-loop follow control of the oil cylinder. The method of the invention has the advantages of high precision, high speed and efficiency, energy-saving, environmental friend, low noise and the like.

Owner:SOUTH CHINA UNIV OF TECH

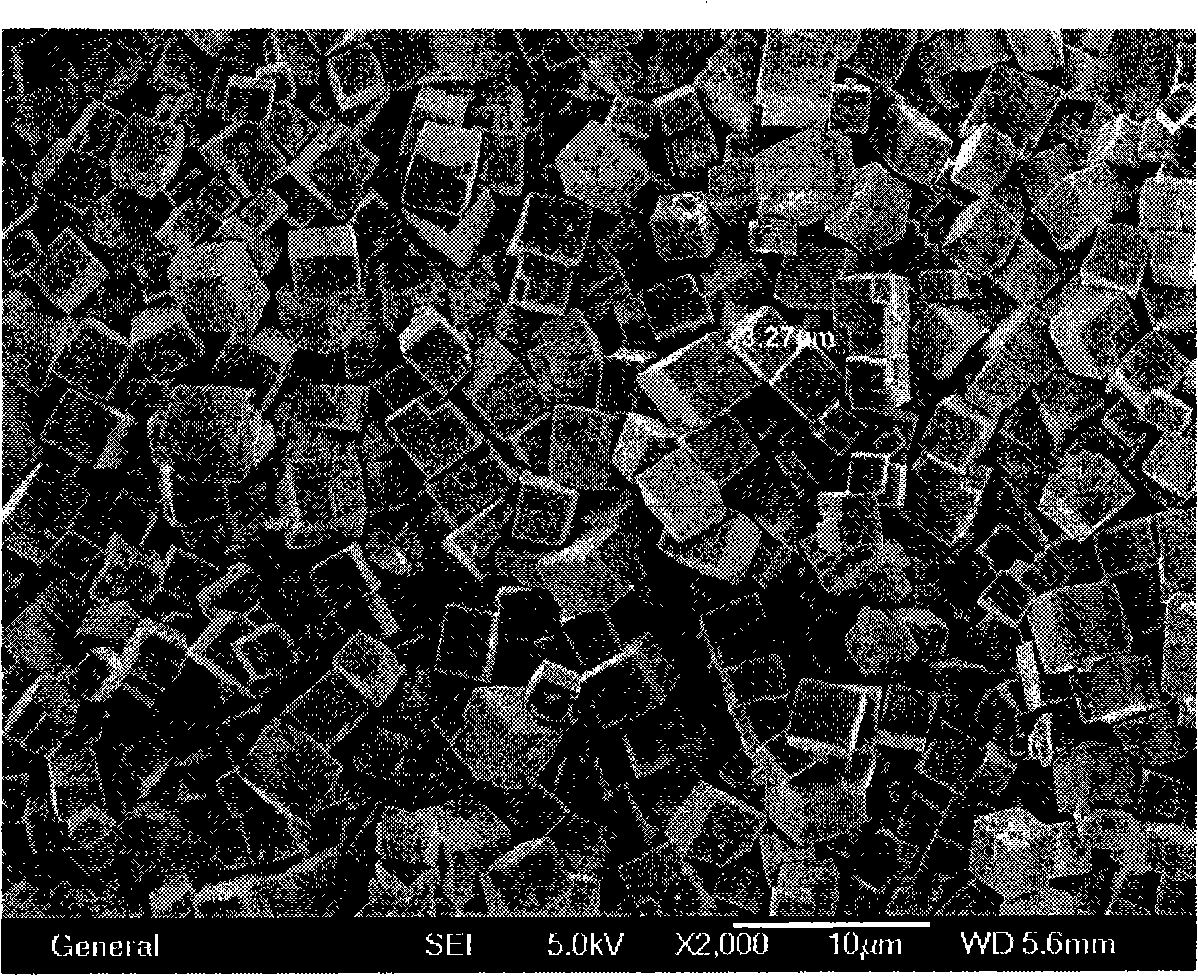

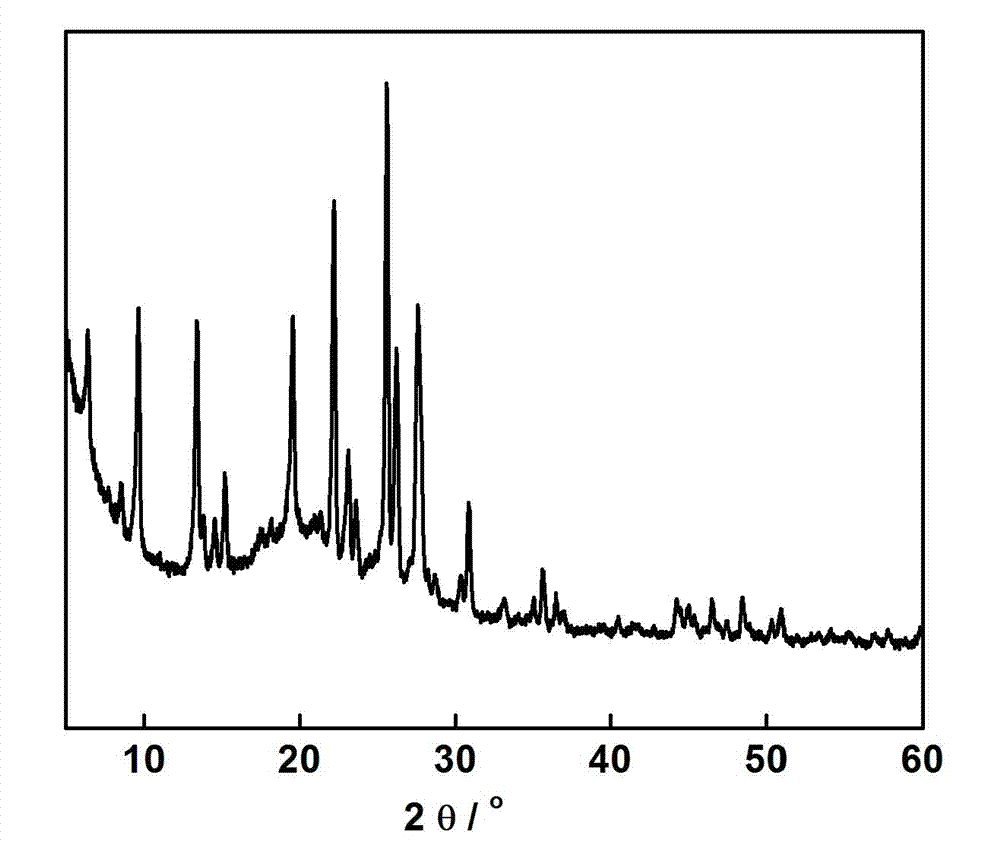

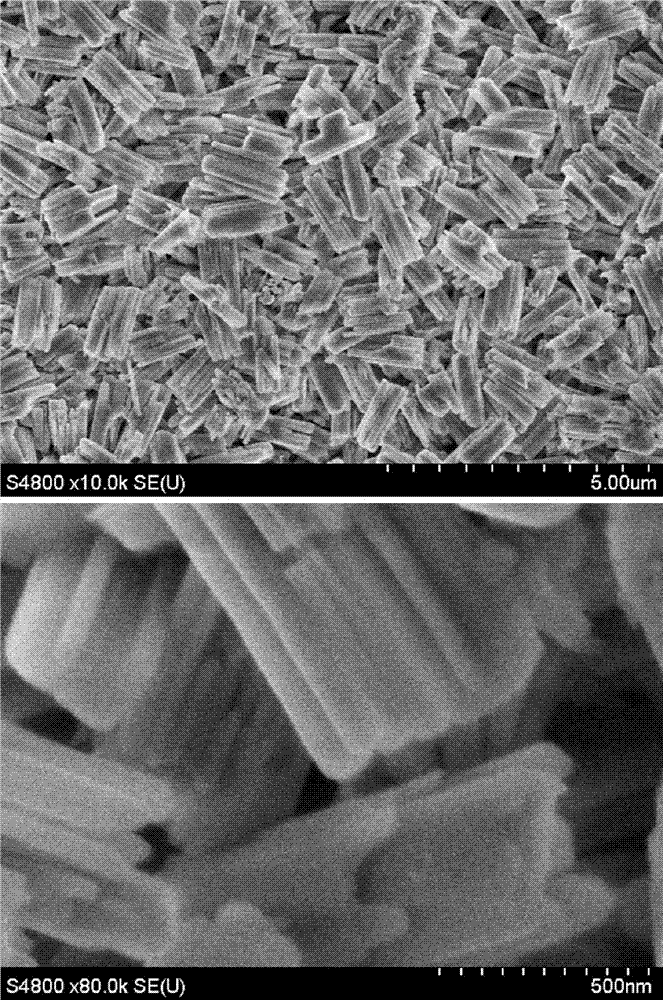

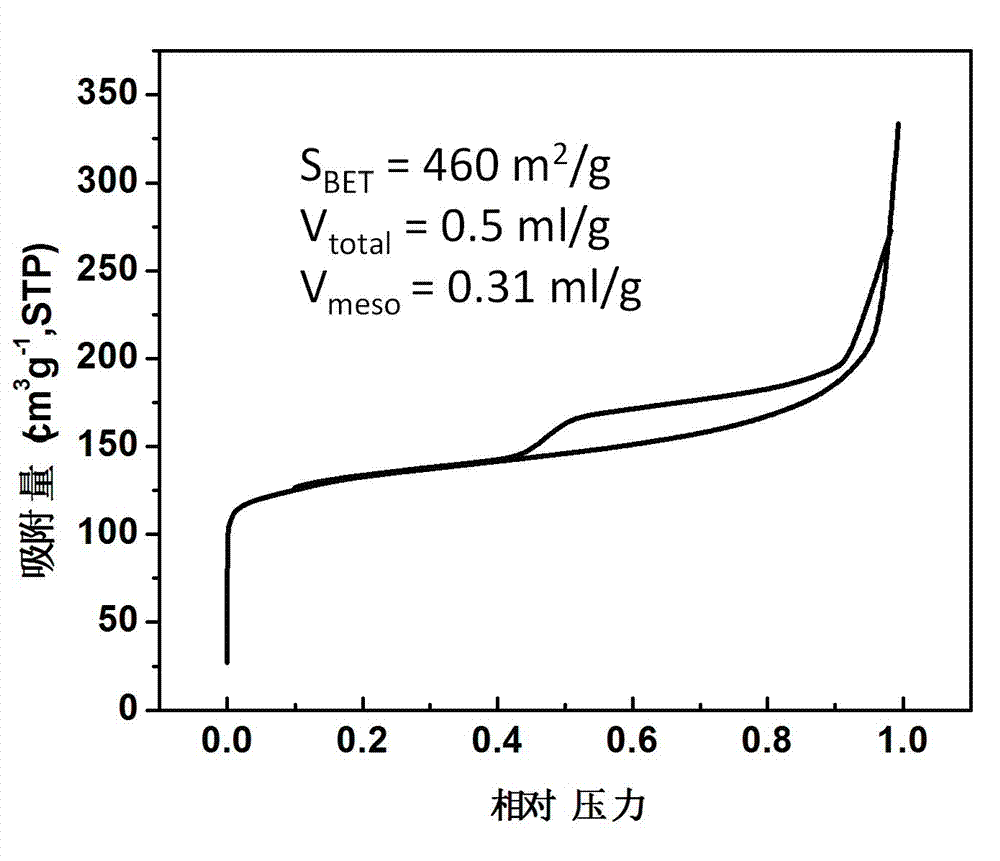

Preparation method for nanometer mordenite molecular sieve with multi-stage holes

ActiveCN103482645AThe synthesis method is simpleHigh repeatabilityMaterial nanotechnologyMordenite aluminosilicate zeoliteMolecular sieveChemistry

The invention discloses a preparation method for a nanometer mordenite molecular sieve with multi-stage holes. In the method, a novel cationic surfactant is used as a template agent for directly synthesizing the nanometer mordenite molecular sieve with the multi-stage holes through hydro-thermal synthesis; the raw materials for preparing the nanometer mordenite molecular sieve comprise a silicon source, the template agent, an alkali source, an aluminium source and water, and the molar ratio of the silicon source to the template agent to the alkali source to the aluminium source to the water is 1 : (0.005-1.0) : (0.3-0.7) : (0.01-0.1) : (30-200). Compared with the prior art, the preparation method has the most remarkable advantages that the novel cationic surfactant is used as a single structure-directing agent for synthesizing the mordenite molecular sieve with both the multi-stage holes and the nanometer crystalline grain size in one step, the synthetic method is simple, the repeatability is high, and the prepared mordenite molecular sieve has the advantages of high crystallinity, high purity and the like.

Owner:EAST CHINA NORMAL UNIVERSITY

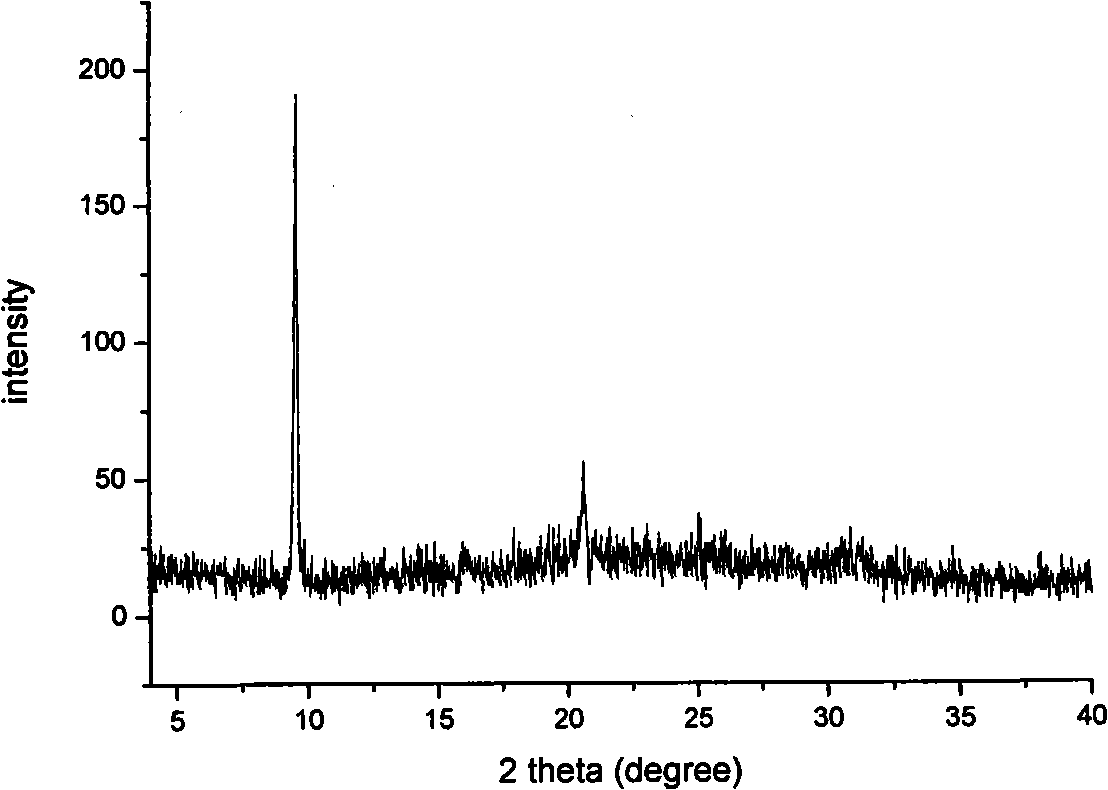

Method for synthesizing NaA zeolite membrane on macroporous carrier

ActiveCN101890306AGood separation performanceHigh repeatabilityMembranesDistillationCrystalliteZeolite

The invention discloses a method for synthesizing a NaA zeolite membrane on a macroporous carrier, and belongs to the technical field of chemical engineering separation. The method is characterized by comprising the following steps of: coating a continuous and uniform crystal seed layer on the surface of a carrier by a hot-dipping process-swabbing process aiming at macroporous carriers of variousmaterials provided by domestic markets; and regulating and controlling the growth of a synthetic membrane and the separation property of the membrane by the difference of the crystal grain sizes of acrystal seed, wherein the NaA zeolite membrane has high separation property and is synthesized by preparing a synthetic solution of Na2O, SiO2, Al2O3 and H2O in a mole ratio of 1-20:2-5:1:100-1,000 and performing dynamic hydrothermal crystallization in a circulating air oven. The method has the effects and the advantages that: the synthesized NaA zeolite membrane has high separation property and high repeatability, is suitable for large-scale application and has important industrial application value.

Owner:DALIAN UNIV OF TECH

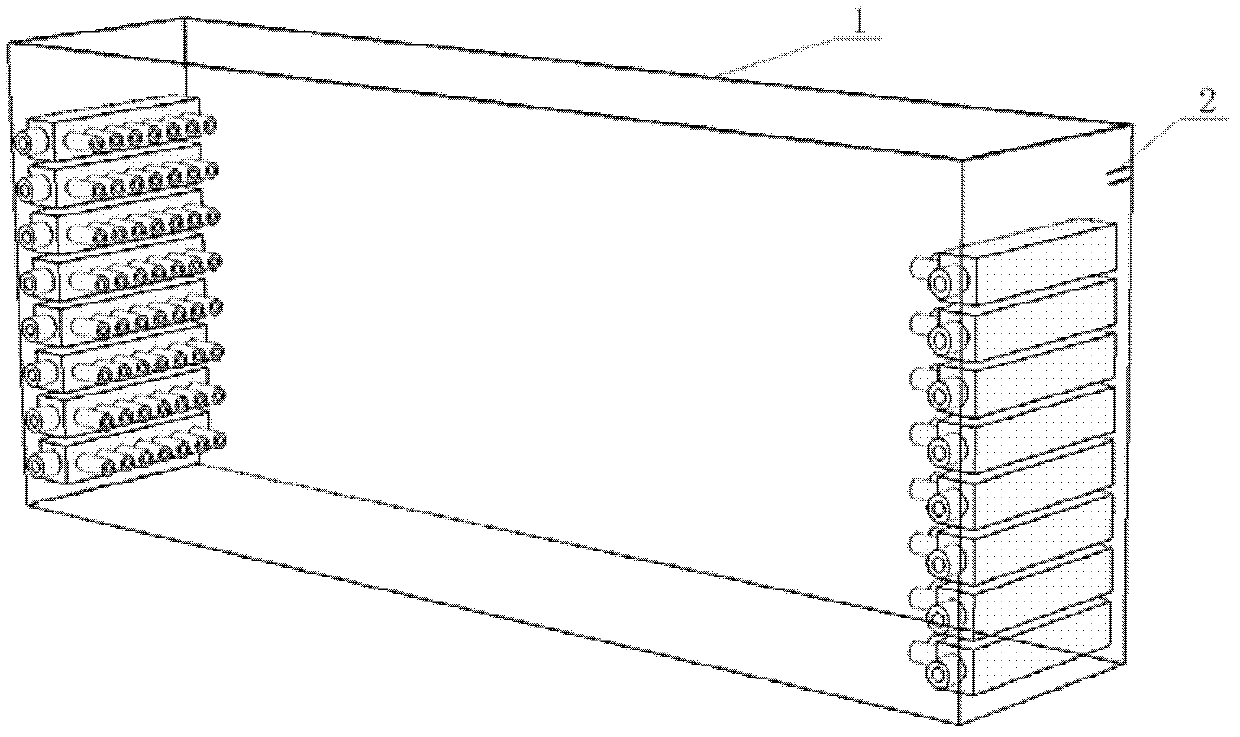

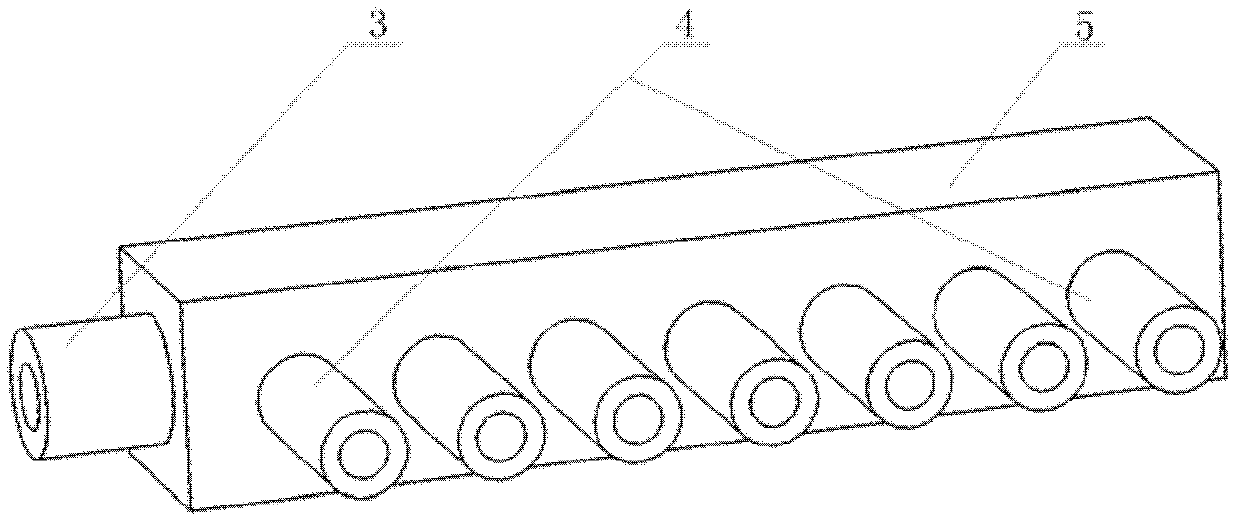

Device for simulating complex stratified flowing water bodies and simulation method thereof

InactiveCN102636330AHigh repeatabilityWidely applicableHydrodynamic testingWater reservoirLoop control

The invention discloses a device for simulating complex stratified flowing water bodies and a simulation method thereof. The device comprises multiple circulating water channels and multiple flow-rate closed loop control systems, wherein the multiple circulating water channels include a square water channel, one inner side face of the square water channel is provided with multiple water inlet module sets, and a side face (opposite to the water inlet module sets) in the square water channel is provided with multiple water outlet module sets; and the multiple flow-rate closed loop control systems comprise a water inlet module flow-rate control system for controlling water inlet of the water inlet module sets and a water outlet module flow-rate control system for controlling water outlet of the water outlet module sets, water in a water storage pool, after sequentially flowing through a water pump and the water inlet module flow-rate control system, flows into the water inlet module sets, and water discharged from the water outlet module sets, after flowing through the water outlet module flow-rate control system and a vacuum pump, flows into the water storage pool. According to the invention, various complex water flow forms can be constructed in a same water channel; and the device and method disclosed by the invention have the advantages of strong adaptability, good reproducibility, high similarity of reconstructed flow fields, simple control method, and the like.

Owner:HOHAI UNIV CHANGZHOU

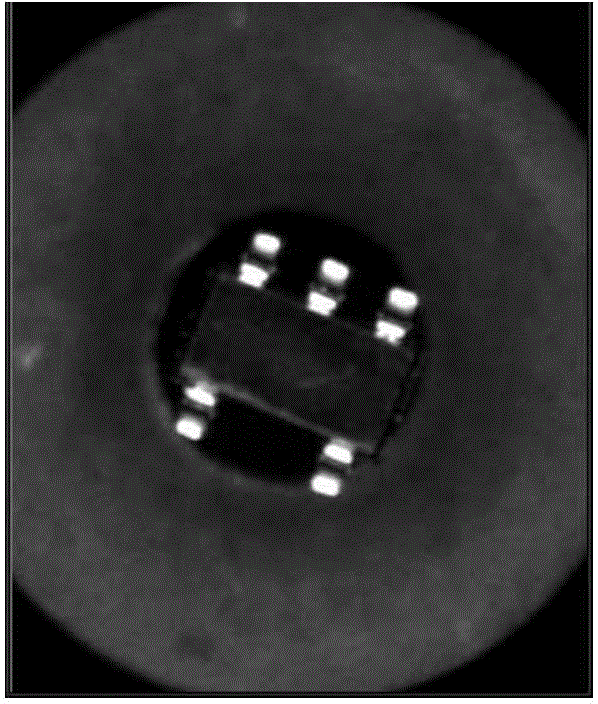

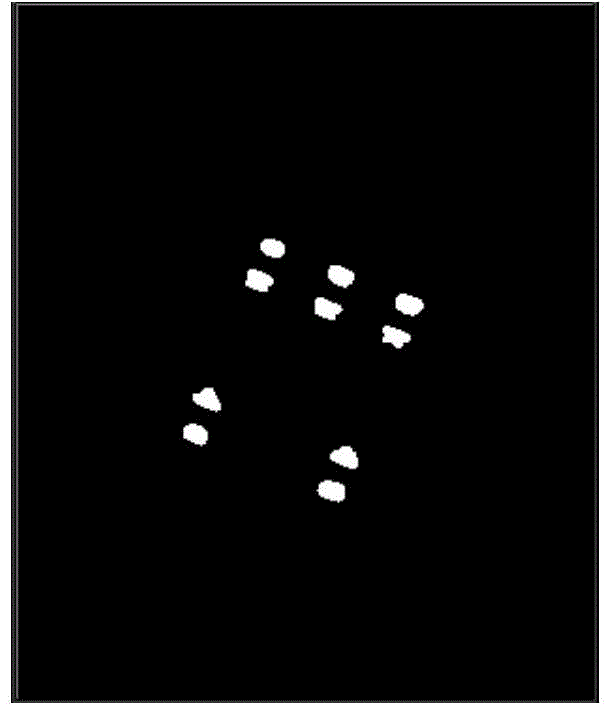

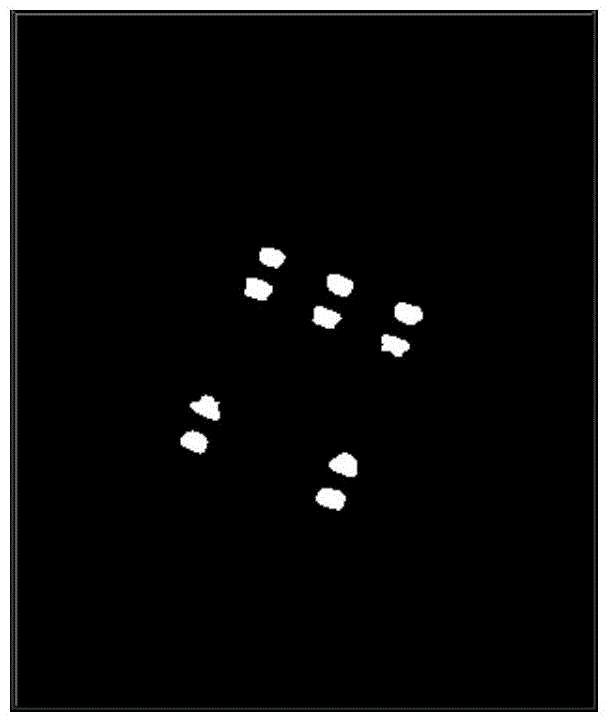

TR element locating and defect detecting method based on vision

ActiveCN104990926AAchieve positioningRealize functionOptically investigating flaws/contaminationMinimum bounding rectangleVisual perception

The invention discloses a TR element locating and defect detecting method based on vision and relates to a TR element vision locating and defect detecting method based on the vision. The TR element locating and defect detecting method based on the vision solves the problems that in the prior art personal errors exist, the precision is low, the real-time performance is poor, and the calculation result is sensitive to illumination. The TR element locating and defect detecting method based on the vision is achieved through the steps that an area image is binarized, an outer boundary point set is extracted, an effective boundary point set is searched, a minimum enclosing rectangle is searched, the effective boundary point set is classified, affine transformation is conducted on the binary image, the type of the TR element is checked, the effective boundary point set is classified again and numbered, a pin straight line is fitted, a pin foot straight line is fitted, TR element detailed information is determined, and the defect of the pin of the TR element is checked. The method comprises multiple technologies including grey value filtering, four-field rapid contour tracing, the dual axial rotation method searching the minimum enclosing rectangle and other innovative technologies. The TR element locating and defect detecting method based on the vision is mainly applied to element locating and detection fields in a chip mounter vision system.

Owner:宁波智能装备研究院有限公司

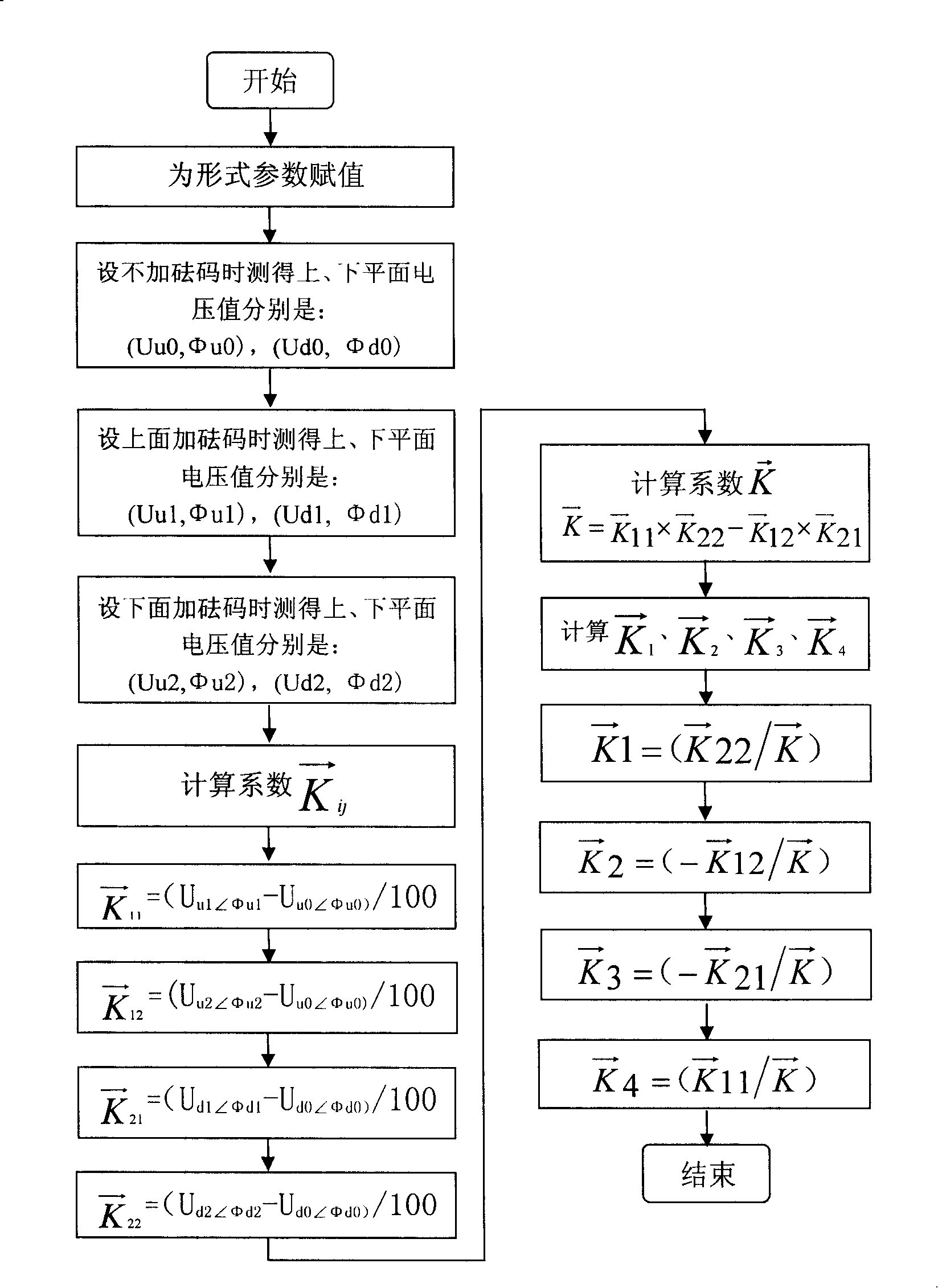

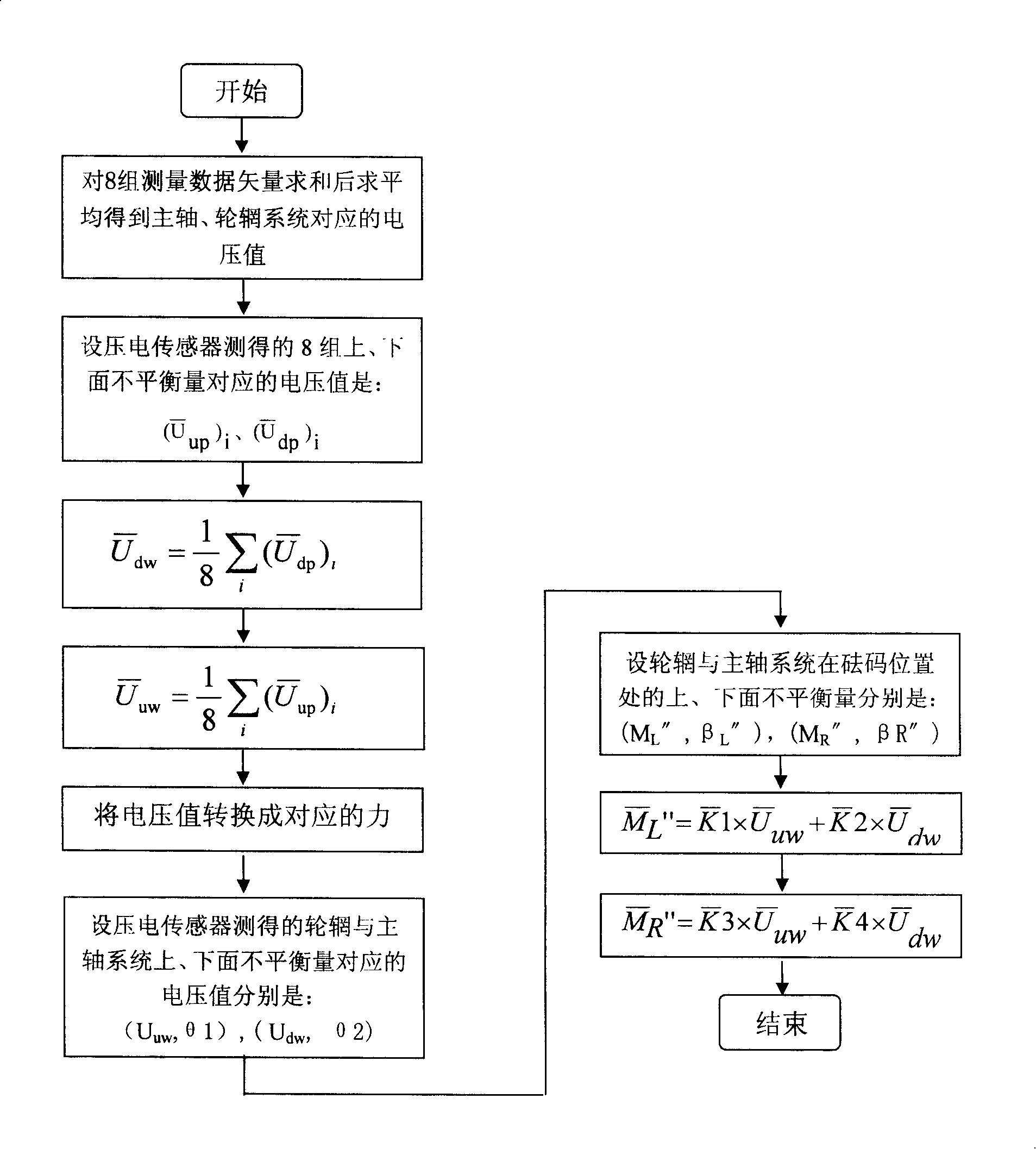

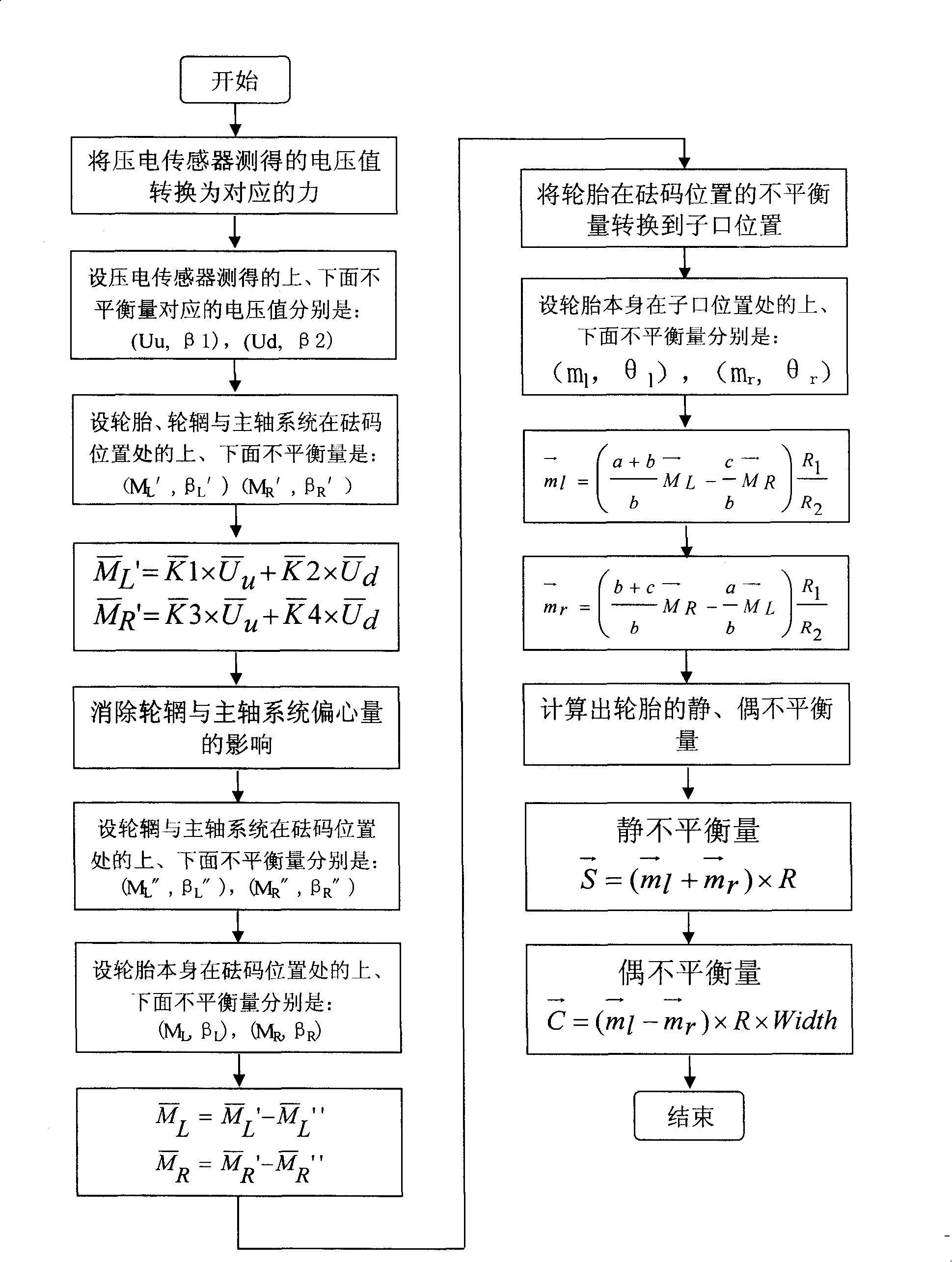

Method for calibrating and measuring unbalance amount of tire

InactiveCN101196427AHigh measurement accuracyHigh repeatabilityStatic/dynamic balance measurementVehicle tyre testingMeasurement precisionPiezoelectric sensor

The invention discloses a tyre unbalance amount marking and measuring method, which comprises a tyre unbalance amount marking part being composed of amount marking and eccentricity revising and a tyre unbalance amount measuring part. Wherein, the work finished in the amount marking part is to count the proportion factor between the voltage value measured by the piezoelectric sensor and the practical force worked on the tyre; the work finished in the eccentricity revising part is to use the proportion factor obtained in amount marking to measure and count the unbalance amount of a main shaft and a rim system; the measuring of the tyre unbalance amount is that: according to the proportion factor measured in amount marking and the unbalance amount of the main shaft and the rim system, the practical unbalance amount of tyre is measured and calculated. The invention improves the reliability and stability of data sampling and also can conduct rectifying a deviation automatically, therefore improving the measuring precision and repeating precision of the tyre unbalance amount and reducing error.

Owner:张芝泉

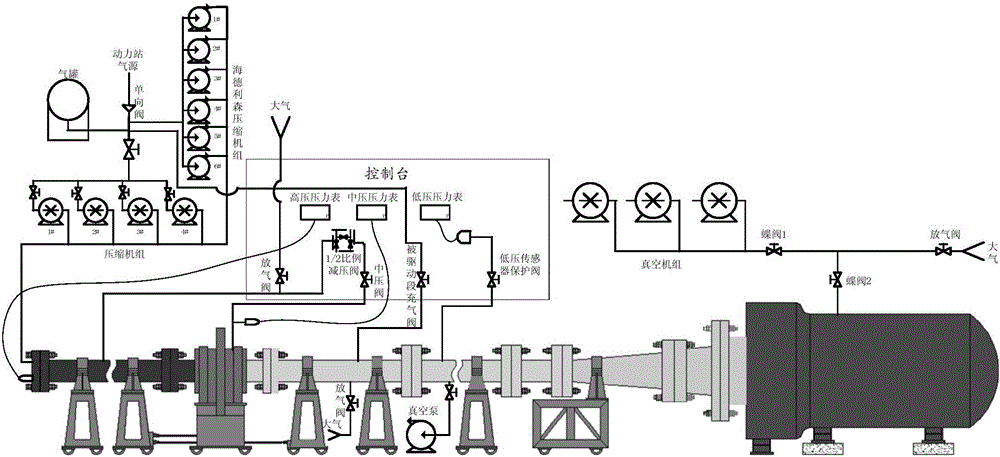

Pulse wind tunnel operation control system and pulse wind tunnel operation control method

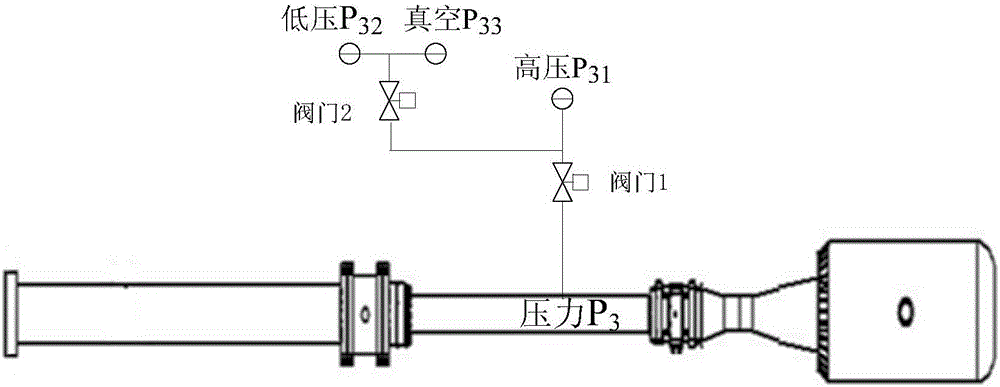

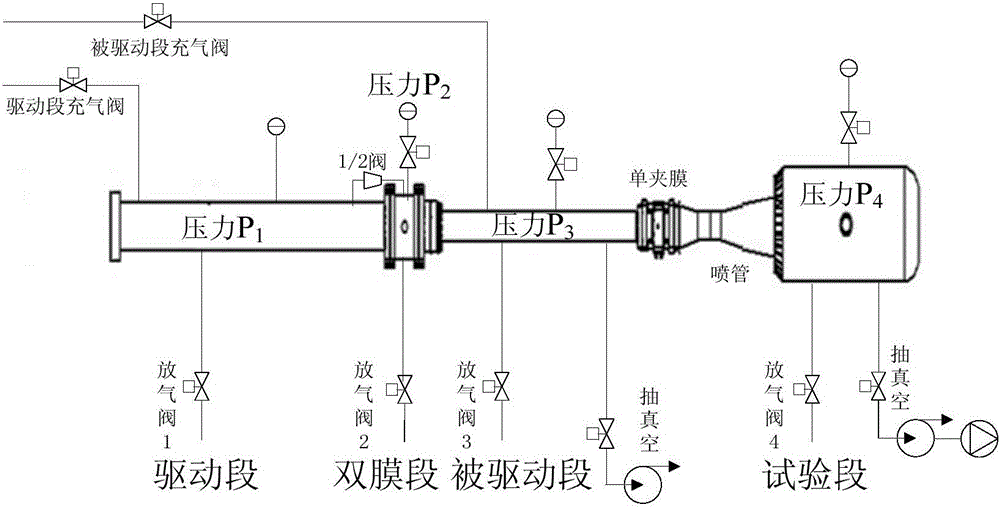

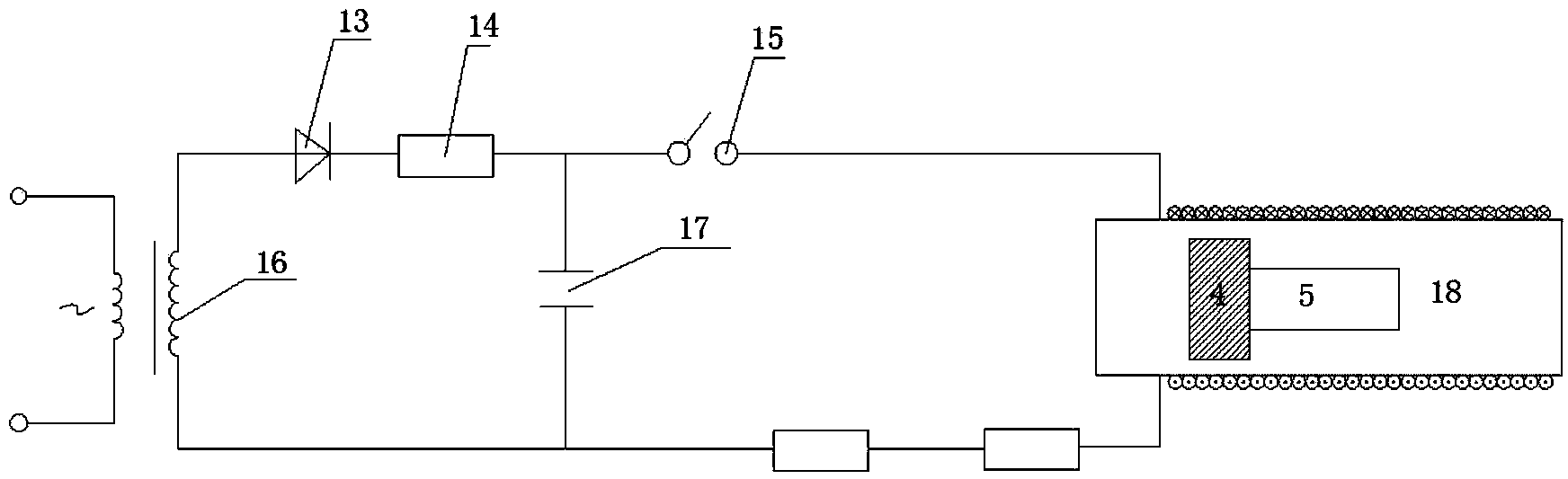

ActiveCN106840582AEnsure the safety of personnel operationHigh repeatabilityAerodynamic testingAutomatic controlAutomotive engineering

The invention relates to a pulse wind tunnel operation control system and pulse wind tunnel operation control method. The system comprises a PLC module, a driving section inflation valve, a driving section deflation valve, a driving section pressure sensor, a 1 / 2 valve, a double film section deflation valve, a double film section pressure sensor, a driven section inflation valve, a driven section deflation valve, a driven section pressure measuring module, a driven section vacuum pumping valve, a test section deflation valve, a test section vacuum pumping valve, a test section pressure sensor and a vacuum machine tool; the PLC module achieves automatic control in a wind tunnel test process, a distributed control mode is adopted, all operation is completed in a test control room, there is need to enter a field for work, a high pressure air source is isolated, and the personnel operation safety is guaranteed.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

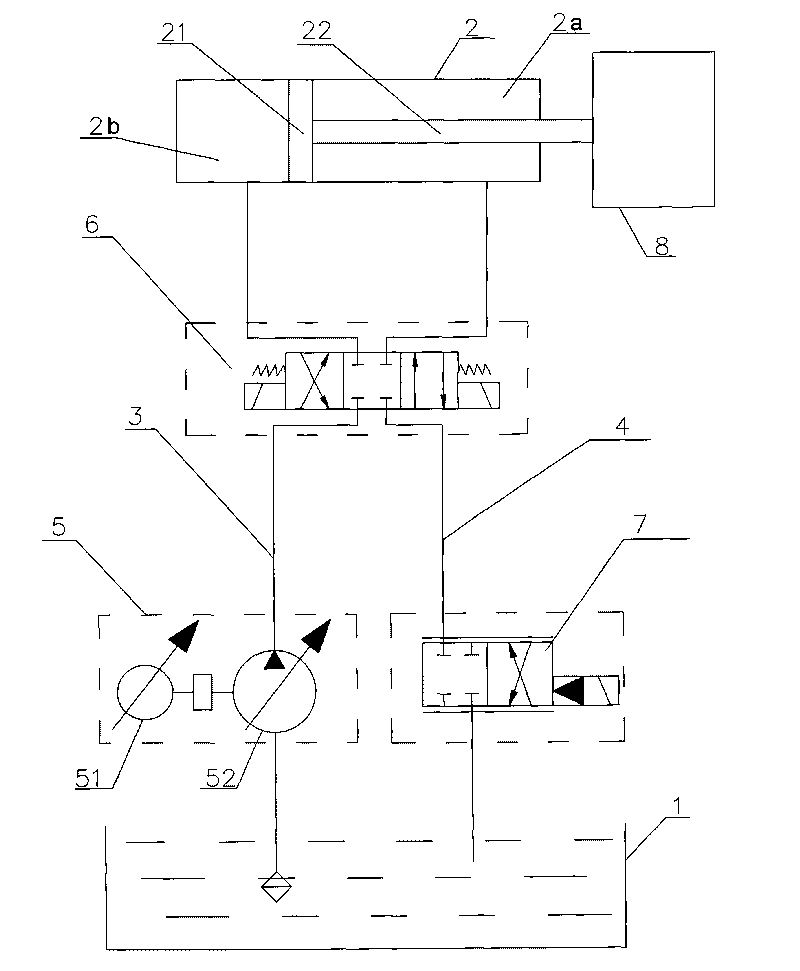

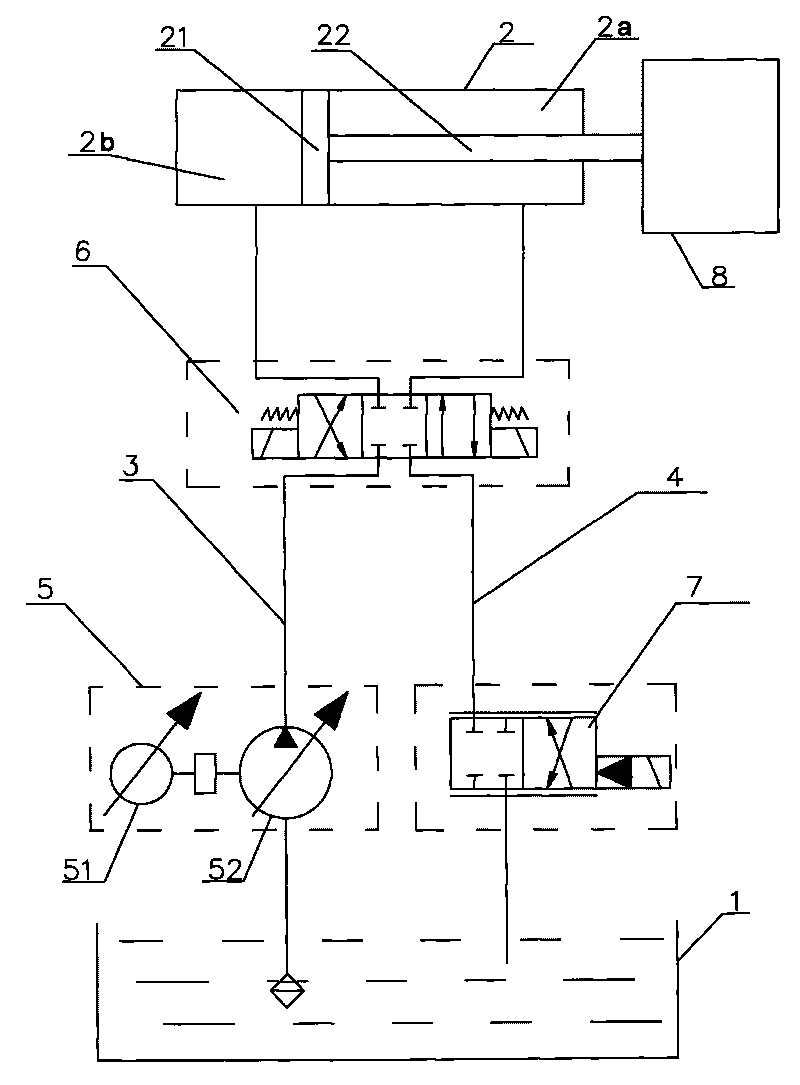

Quick mould opening/closing control structure and control method of toggle type injection molding machine

The invention relates to a quick mould opening / closing control structure and a control method of a toggle type injection molding machine comprising an oil supply oil tank, a mould opening / closing hydraulic cylinder, a main oil pipeline, an oil return pipeline, a servo hydraulic driving device, a directional control valve and a proportional flow valve with feedback. By the device, the servo hydraulic driving device is utilized to provide pressure oil required by mould opening / closing, the pressure oil enters a mould opening / closing oil cylinder, then the set value of the mould opening / closing pressure is reasonably increased by utilizing the performance of the servo hydraulic driving device, and the speed tracing pressure of the pressure oil keeps high-speed running with large flow rate inthe mould opening / closing process; the proportional flow valve with the feedback is reasonably regulated at a mould closing stop stage and a mould opening termination stage to control the magnitude of the oil return quantity, oil return resistance is provided to prohibit the movement of a movable template, the rigid impact of the template to a machine in the high-speed running process is reduced,the mould opening / closing running is stable, and the accuracy of a stop position is high; and the quick mould opening / closing control structure and the method realize the advantages of high speed, high accuracy, high efficiency, low energy consumption and the like.

Owner:DONGHUA MACHINERY

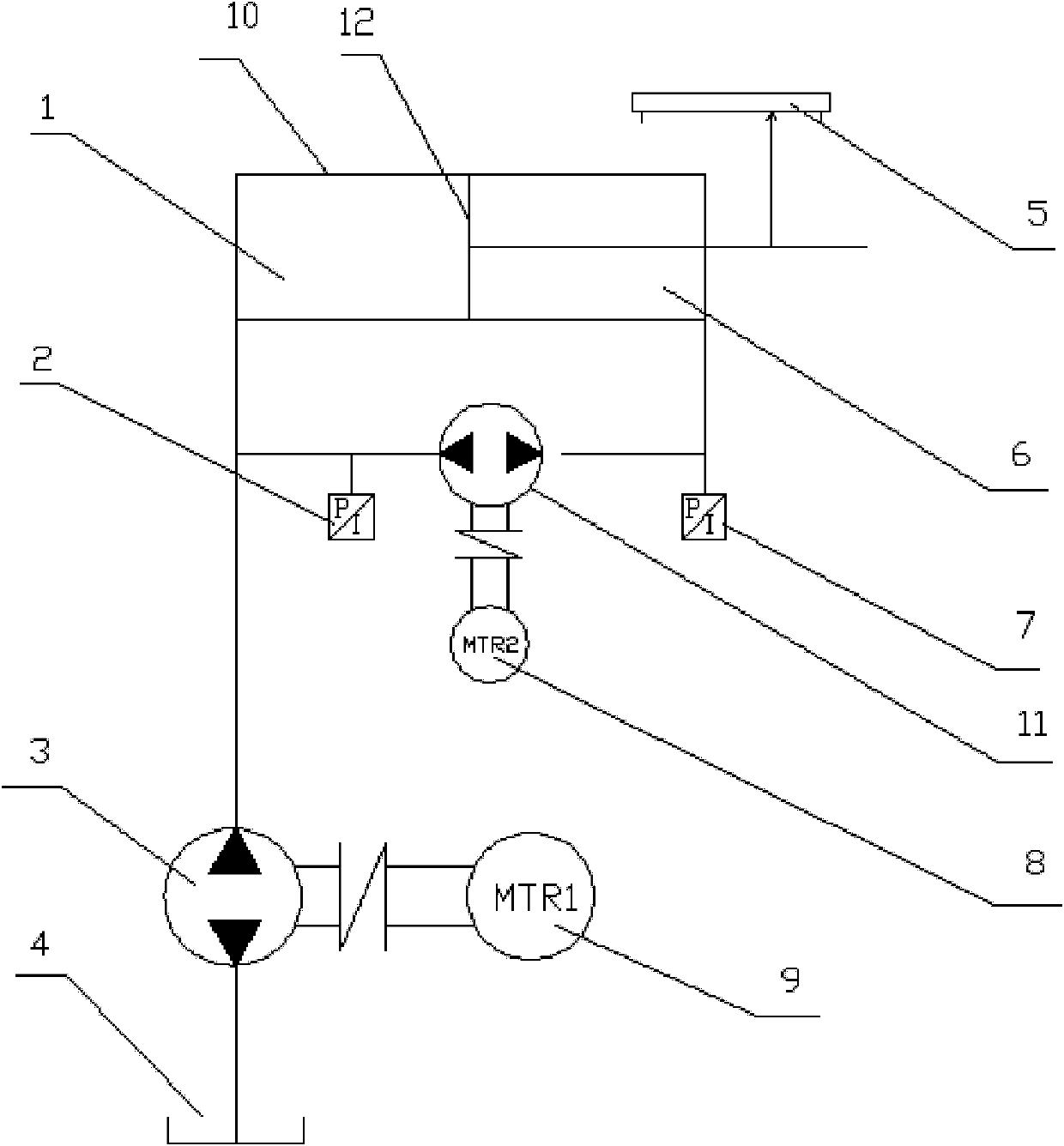

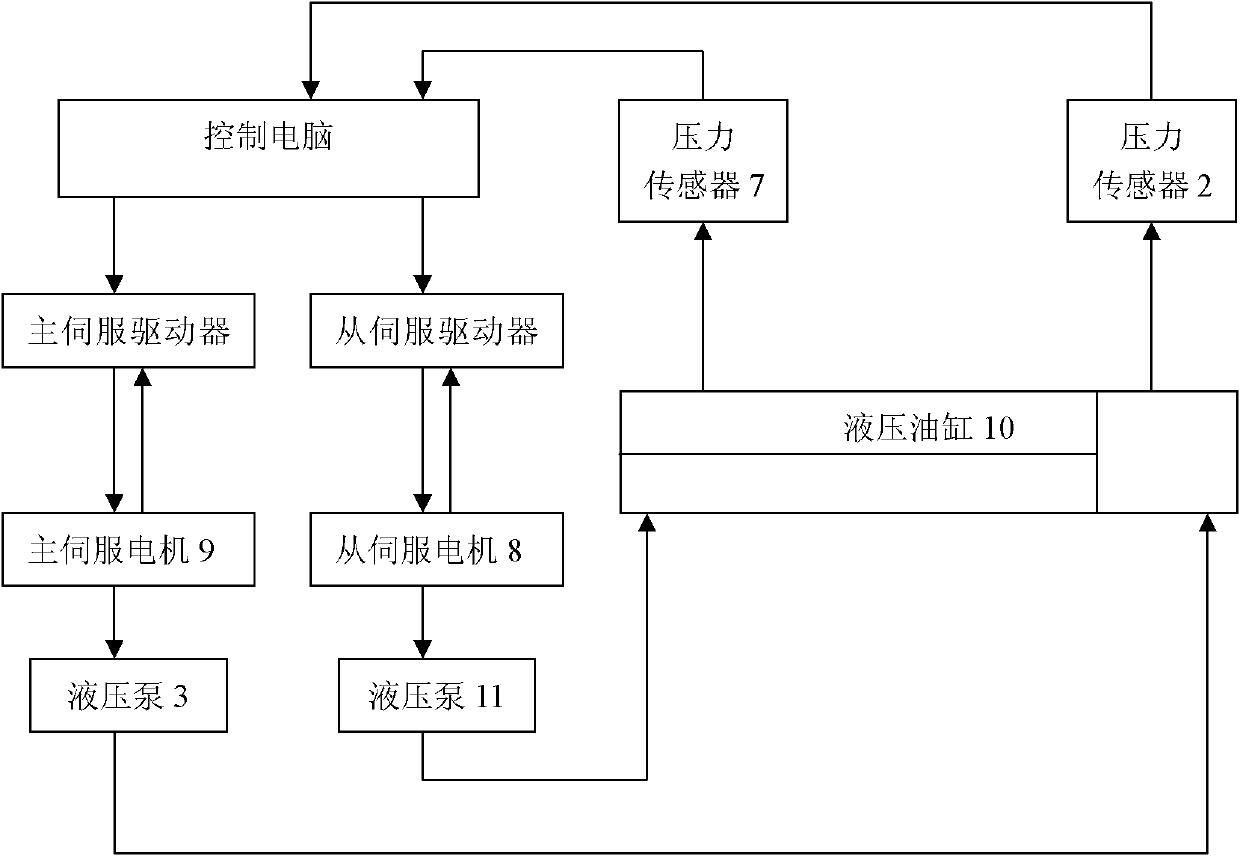

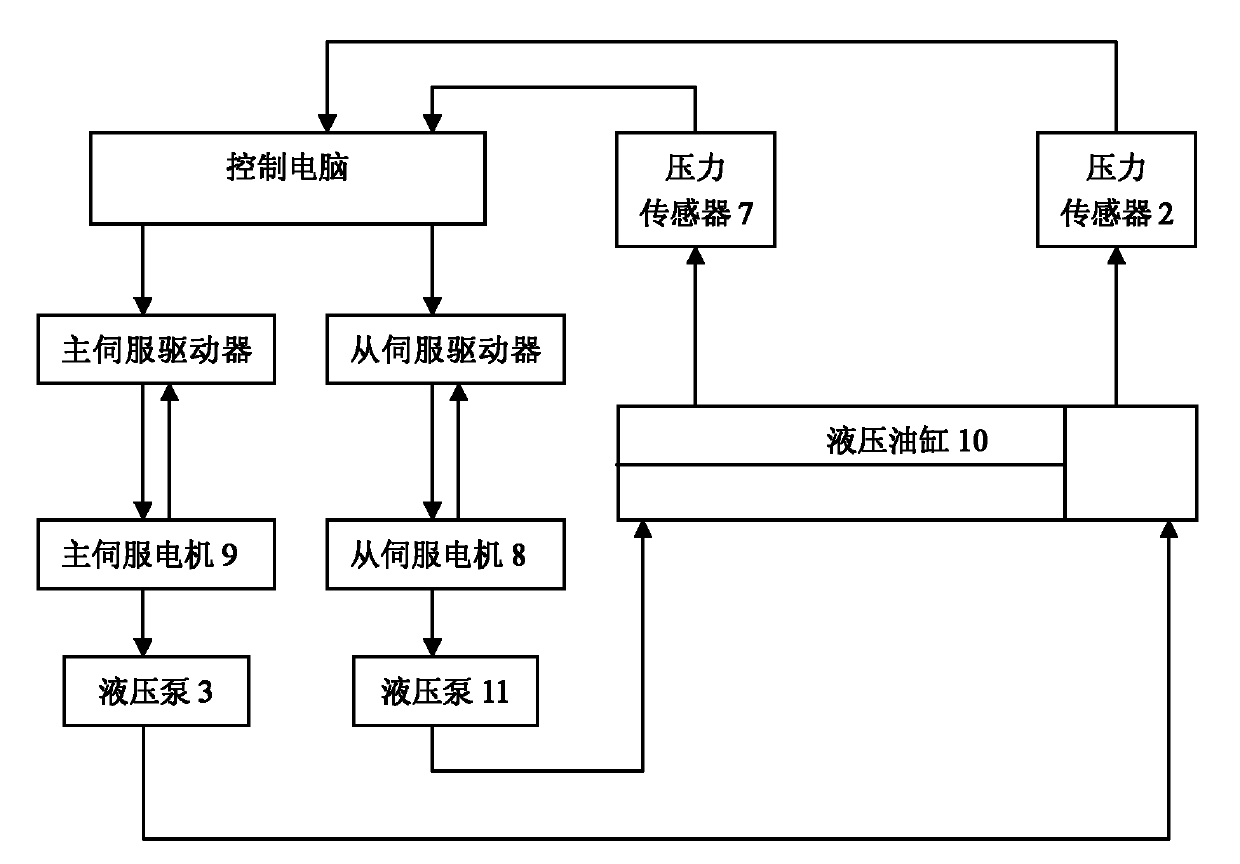

High-precision hydraulic servo control system

The invention relates to a high-precision hydraulic servo control system which comprises a control computer, an oil cylinder, a position sensor, pressure sensors, a driving servo motor with a hydraulic pump, a driven servo motor with a hydraulic pump, a driving servo driver and a driven servo driver. A control system for controlling the motors comprises pressure sensors, the servo drivers and the control computer, the servo drivers and the control computer are connected with the motors, the oil cylinder is connected with the position sensor for detecting the actual position of the oil cylinder, and a rod cavity and a rodless cavity of the oil cylinder are respectively provided with the pressure sensors for detecting and feeding back the oil pressure of an oil outlet and an oil inlet to the control computer which controls the rotating speed and the torque of the driving motor and controls pressure and flow needed by an oil pump output system by calculating and processing a pressure signal fed back from the rodless cavity. The control computer calculates and processes a pressure signal fed back from the rod cavity and outputs a control signal to the servo drivers to control the output pressure and the output flow of the oil pump by controlling the rotating speed and the torque of the driven motor. Oil is sucked from the oil outlet into the driven motor when the oil cylinder in an accelerating process, and the pressure of the oil outlet is backed when the oil cylinder in a decelerating process.

Owner:NINGBO ANXIN CNC TECH

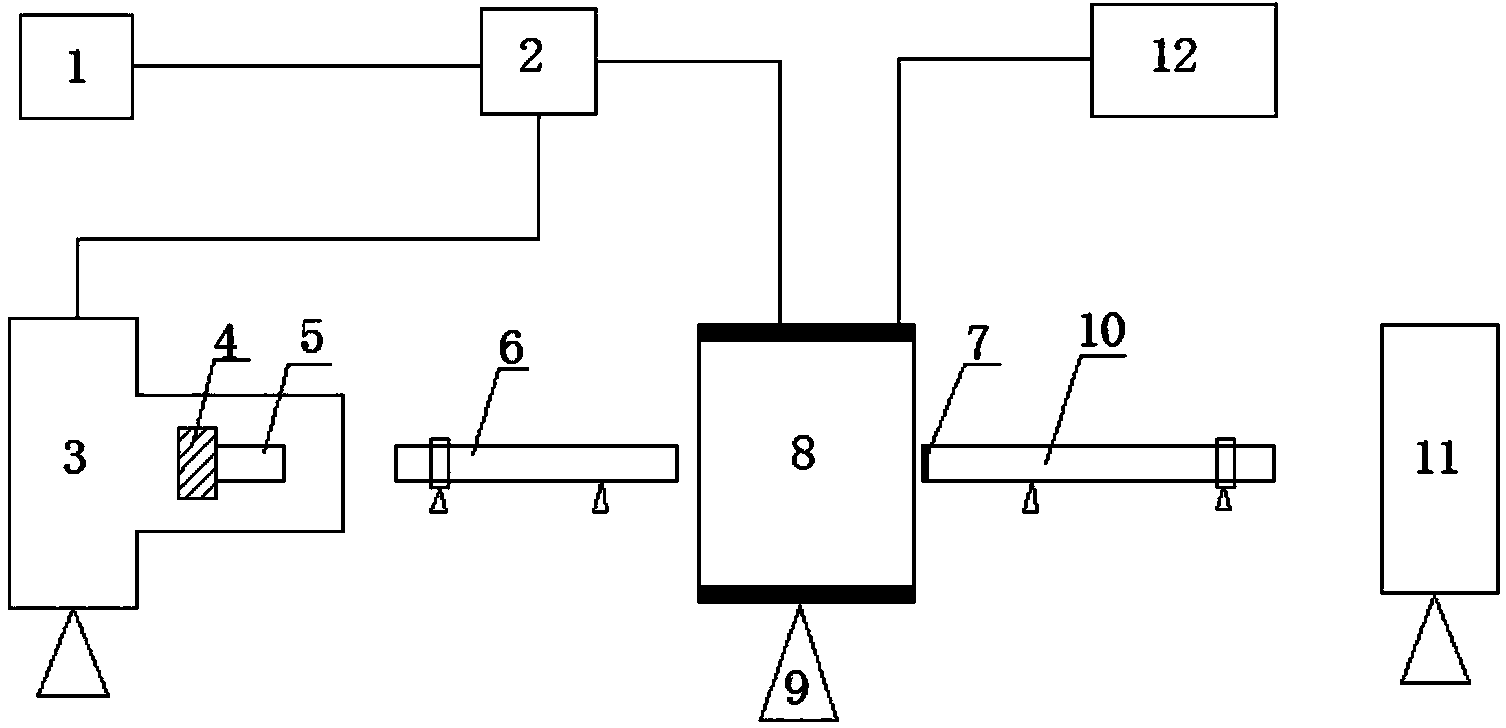

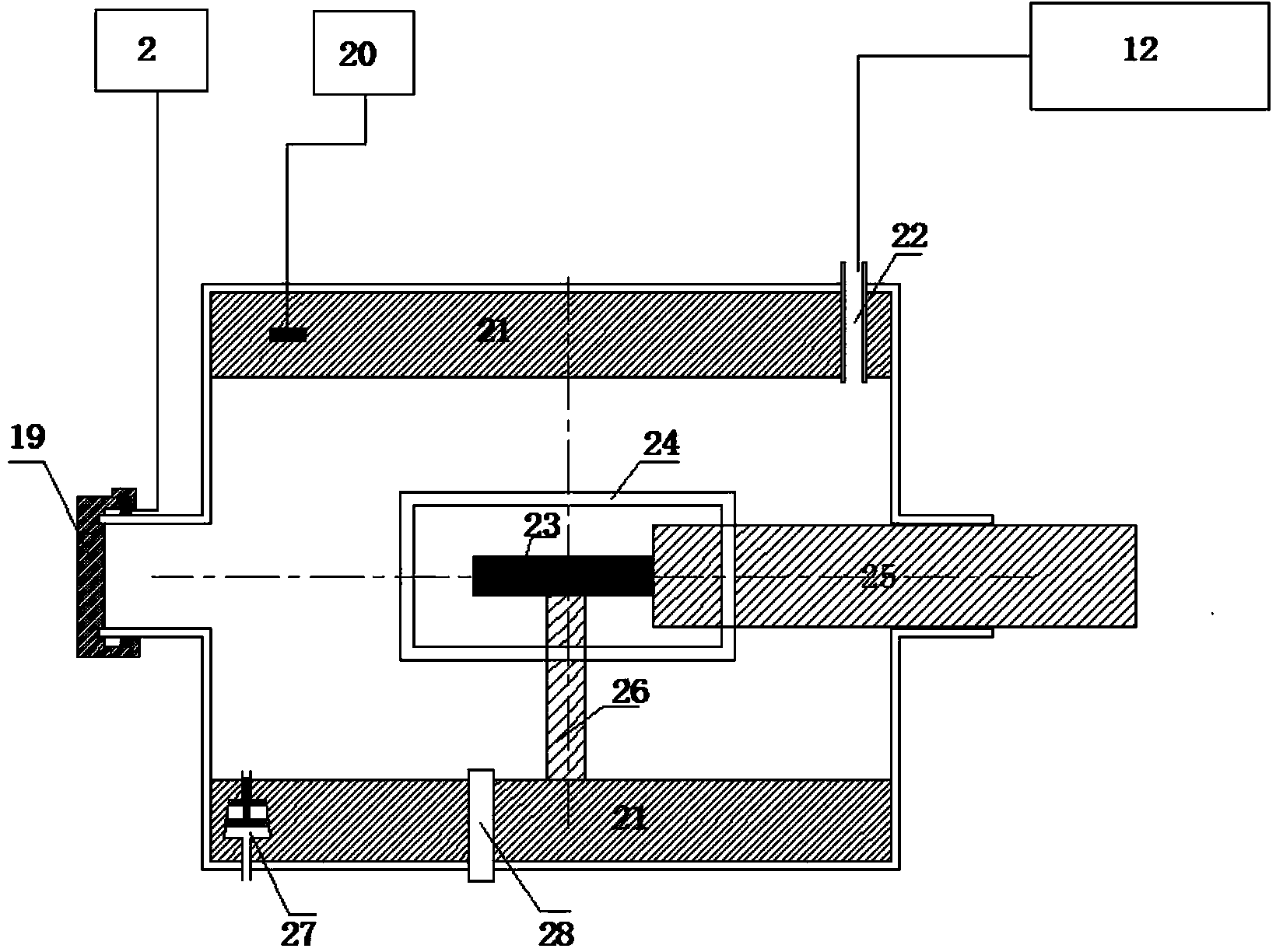

Hopkinson pressure bar experimental apparatus

InactiveCN103868806AAvoid Complexity and UncertaintyHigh repeatabilityStrength propertiesStress waveEngineering

The invention discloses a Hopkinson pressure bar experimental apparatus. The Hopkinson pressure bar experimental apparatus is characterized by comprising an electromagnetic trigger switch (1), a heating furnace door automatic opening switch (2), an electromagnetic driving device (3), a driving panel (4), a bullet (5), an incident pole (6), a force sensor (7), a heating furnace (8), a heating furnace supporting device (9), a transmitting pole (10), a buffer device (11) and an air compressing and filtering device (12); and the heating furnace is designed for preventing a test piece from being oxidized at a high temperature while heating the test piece and keeping the temperature of the test piece; as high temperature can influence the conduction of stress wave, the digital image correlation (DIC) technology is used for obtaining the change images of the test piece and analyzing the strain, the force sensor is used for analyzing stress, so as to obtain a stress strain curve. The Hopkinson pressure bar is combined with the electromagnetic driving technology and the DIC technology, and therefore the application range of the Hopkinson pressure bar experiment is expanded and a new method for acquiring dynamic parameters of high temperature materials is provided.

Owner:HUNAN UNIV

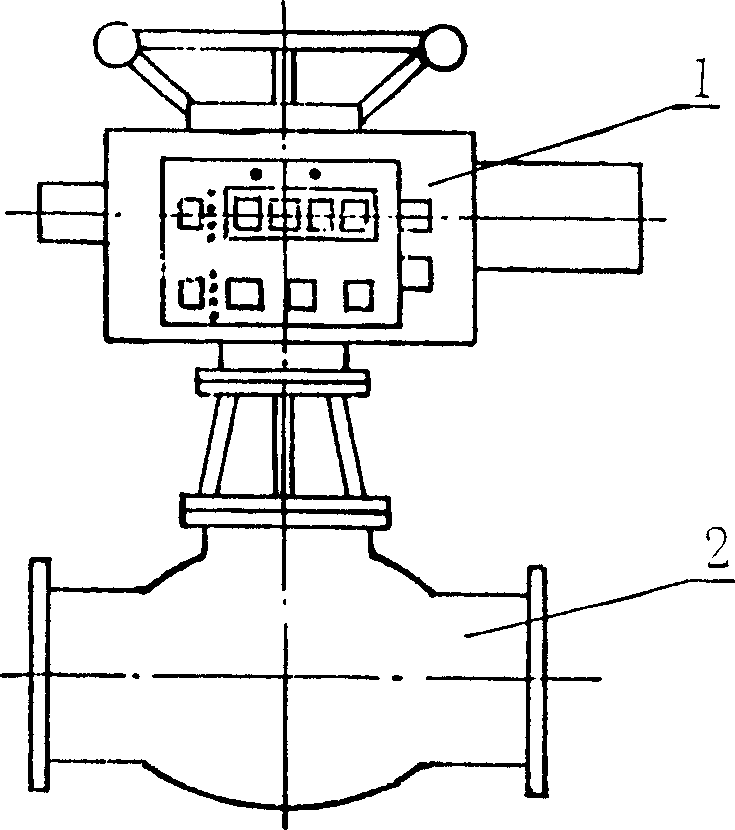

Intelligent type valve electrical device

InactiveCN1570440ASafe and reliable workSlow down or avoid "water hammer" phenomenonOperating means/releasing devices for valvesMicrocontrollerElectric control

The intelligence valve electrically controlled installment belongs uses the sensor monitor and the micro electron technology control valves uses the electrically operated installment. The main characteristic is: In the mechanism which has has partially established the non- electronic contact type examination output shaft torque value the strength value sensor and the examination valve operates the electro-optical sensor, in the electric motor supposes the temperature sensor; Its electric control are partial is the modular microcomputer control system, in is equipped with AVR high speed to insert the type monolithic integrated circuit the controller module, receives various sensors the monitor signal to control the power control module after processing, then control motor active status. This invention solved the traditional technology to plant the structure complex, security bad, difficult problem and so on reliability, this equipment was the light integration of machinery high tech product, its structure simple, security good, precision high, the reliability was high, could to the valve entire work process realization automatic monitor and the monitoring.

Owner:郭振兴

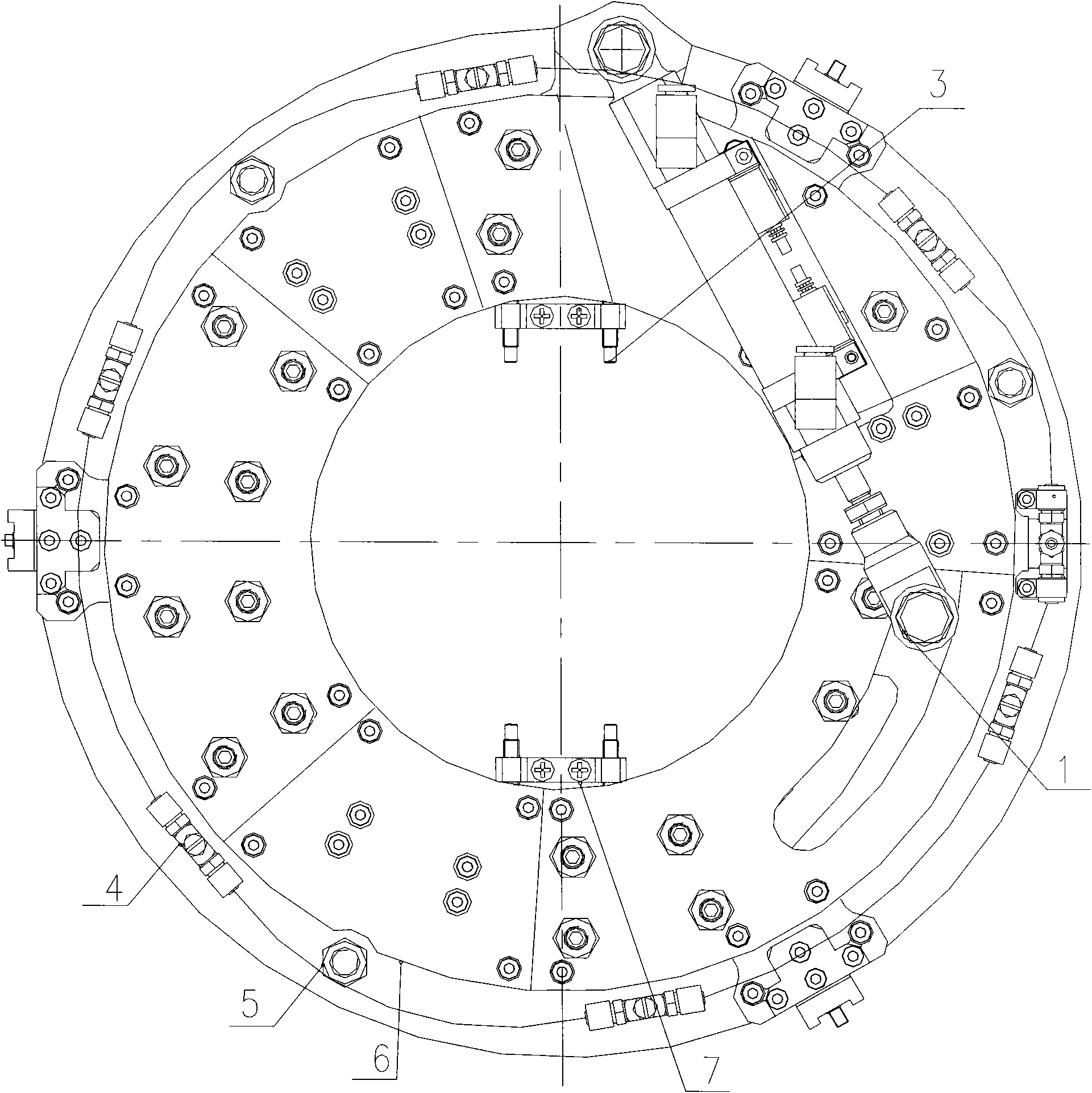

Silicon chip edge protection device and application method thereof

ActiveCN102141735AExchangeHigh precisionPhotomechanical exposure apparatusMicrolithography exposure apparatusLinear motionRadial motion

The invention discloses a silicon chip edge protection device and an application method thereof. A cylinder, one end of which is arranged on a fixed disc and the other end of which is arranged on a three-eccentric cam disc, horizontally stretches and swings to drive the three-eccentric cam disc arranged on the fixed disc to perform circular motion; by a method of converting a linear motion into aplurality of equal synchronous radial motions in a vector conversion form, the linear swing is converted into the circular motion; the three-eccentric cam disc drives eccentric grooves on the cam disc to perform circular motion around respective circle center, so that a circular motion is converted a plurality of synchronous eccentric motions; the three-eccentric cam disc drives cams in the eccentric grooves to perform radial motion, so that the plurality of synchronous eccentric motions are converted into synchronous radial motions; and cam followers drive protection claws to perform radial motion, and the protection claws grip or lay down protection rings, so that exchange of the protection rings or other articles is realized. The device has high precision, good reliability, high repeated precision, simple structure, low need of power source and high synchronism.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

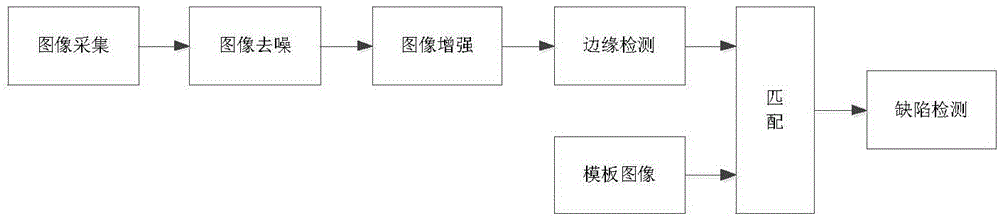

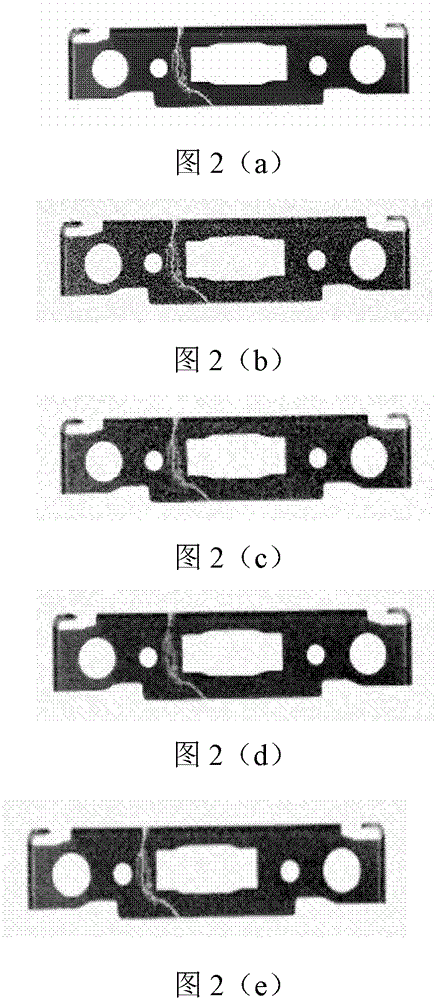

Punched workpiece defect detection method based on image processing

InactiveCN105069807AIncrease contrastHigh repeatabilityImage enhancementImage analysisImage denoisingImaging processing

The present invention discloses a punched workpiece defect detection method based on image processing. The method comprises the concrete steps of obtaining a punched workpiece image and using an adaptive voting fast median filtering method to carry out image denoising processing, using Contourlet transform and a niche particle swarm optimization algorithm to carry out image enhancement and carrying out edge detection processing on the image, and finally carrying out punched workpiece defect detection. According to the method, the Contourlet transform and the niche particle swarm optimization algorithm are used to carry out image enhancement, the image overall contrast is raised, the edge detail of the workpiece image is enhanced, the repeatability of the workpiece detection is increased, for the characteristic that the defect part edge in the punched workpiece image is obvious, the invention provides an edge detection based on the integration of a neural network and a rapid fuzzy algorithm, and while the detection cost is reduced, the detection efficiency is greatly improved.

Owner:XI'AN POLYTECHNIC UNIVERSITY

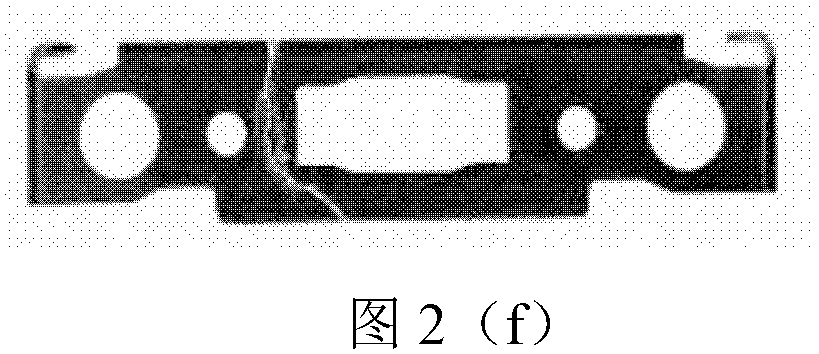

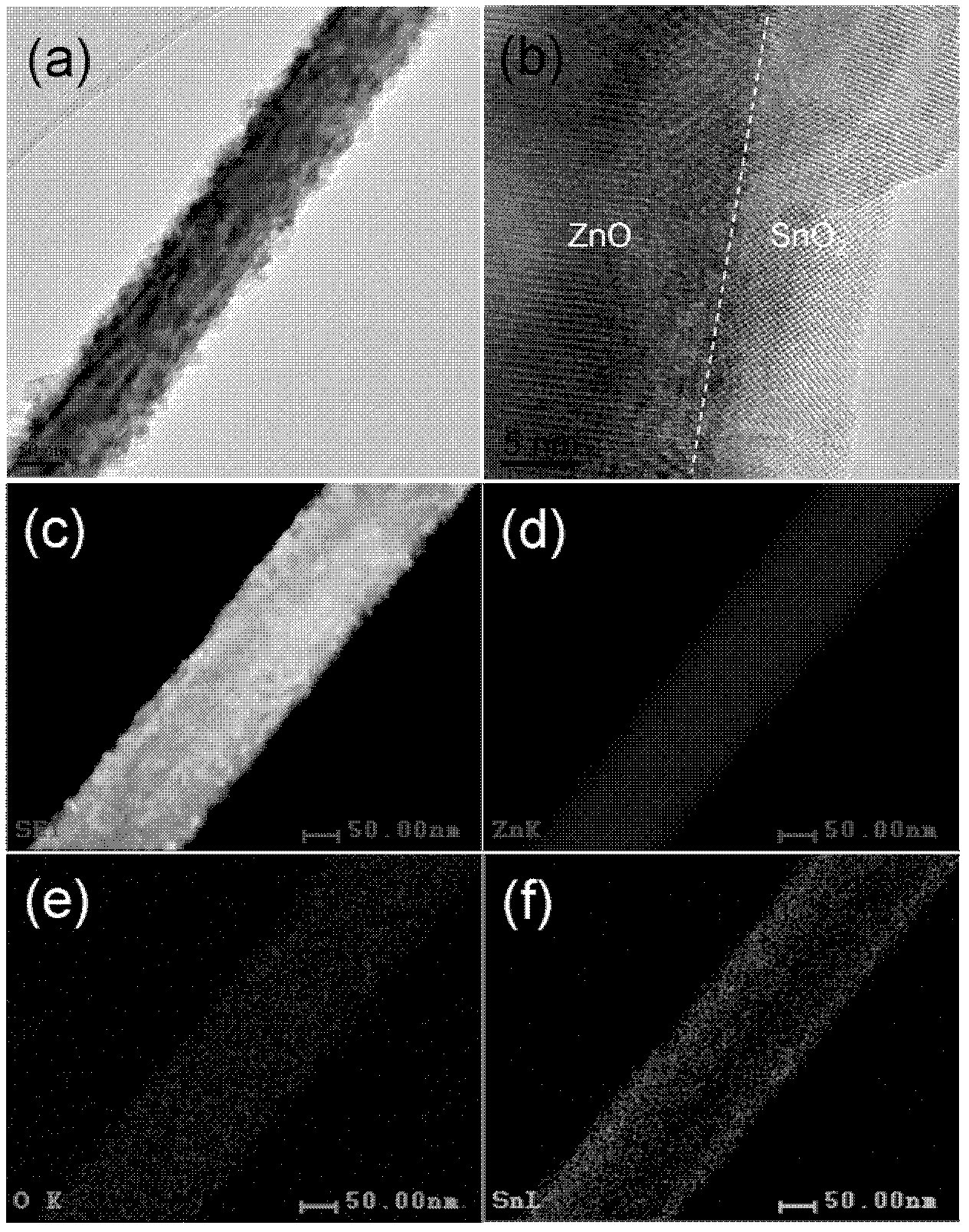

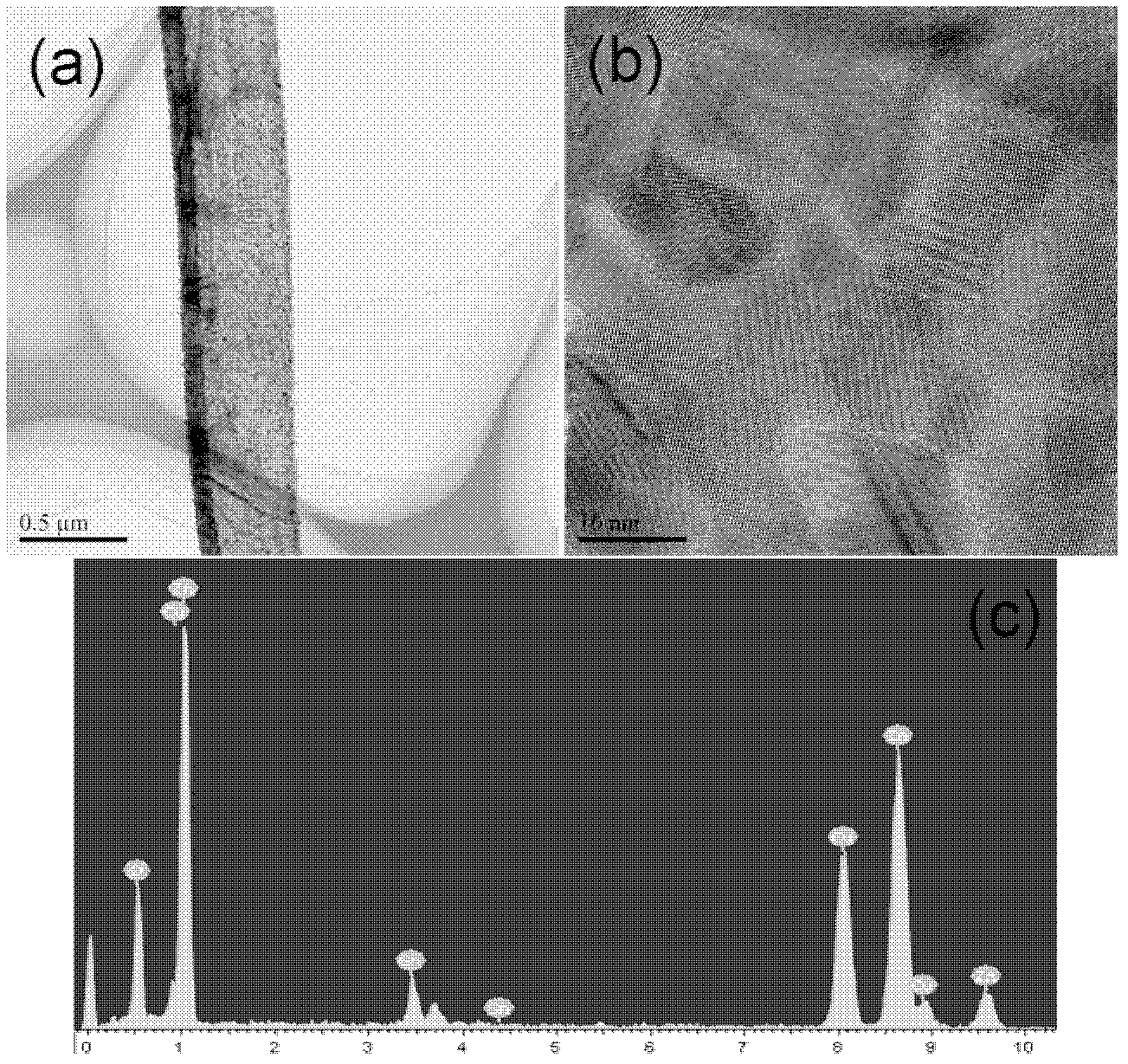

Method for preparing one-dimensional ZnO/SnO2 core/shell structure nano heterojunction semiconductor material

ActiveCN102618849AHigh repeatabilityIncrease success rateMaterial nanotechnologyChemical vapor deposition coatingPhoto catalysisSolar cell

The invention discloses a method for preparing a one-dimensional ZnO / SnO2 core / shell structure nano heterojunction semiconductor material. According to the method, a one-dimensional ZnO nanomaterial is coated with SnO2 through thermal evaporation to form the one-dimensional ZnO / SnO2 core / shell structure nano heterojunction semiconductor material. The method is high in repeatability and controllability, and environment-friendly, and the SnO2 is coated uniformly. The prepared one-dimensional ZnO / SnO2 core / shell structure nano heterojunction semiconductor material has high research value and wide application prospect in the fields of solar cells, gas sensors, photocatalysis and the like.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

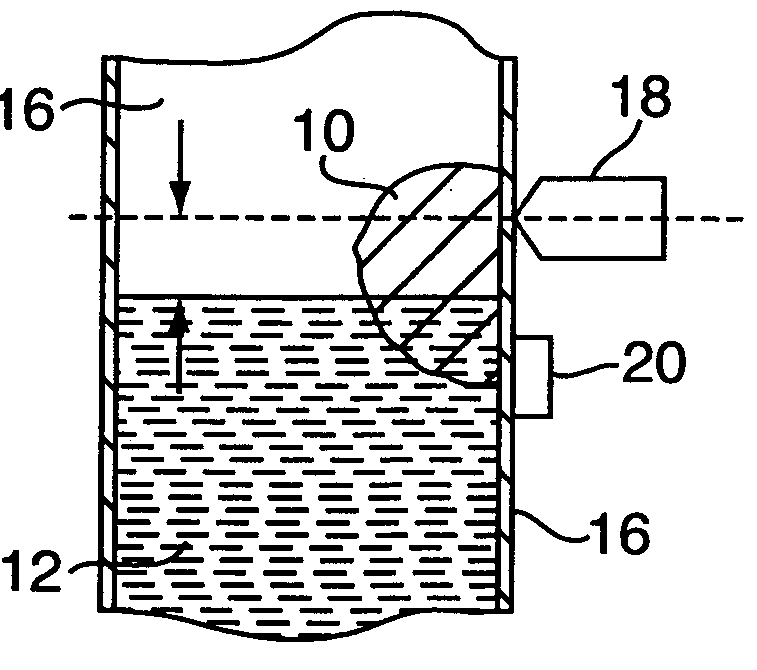

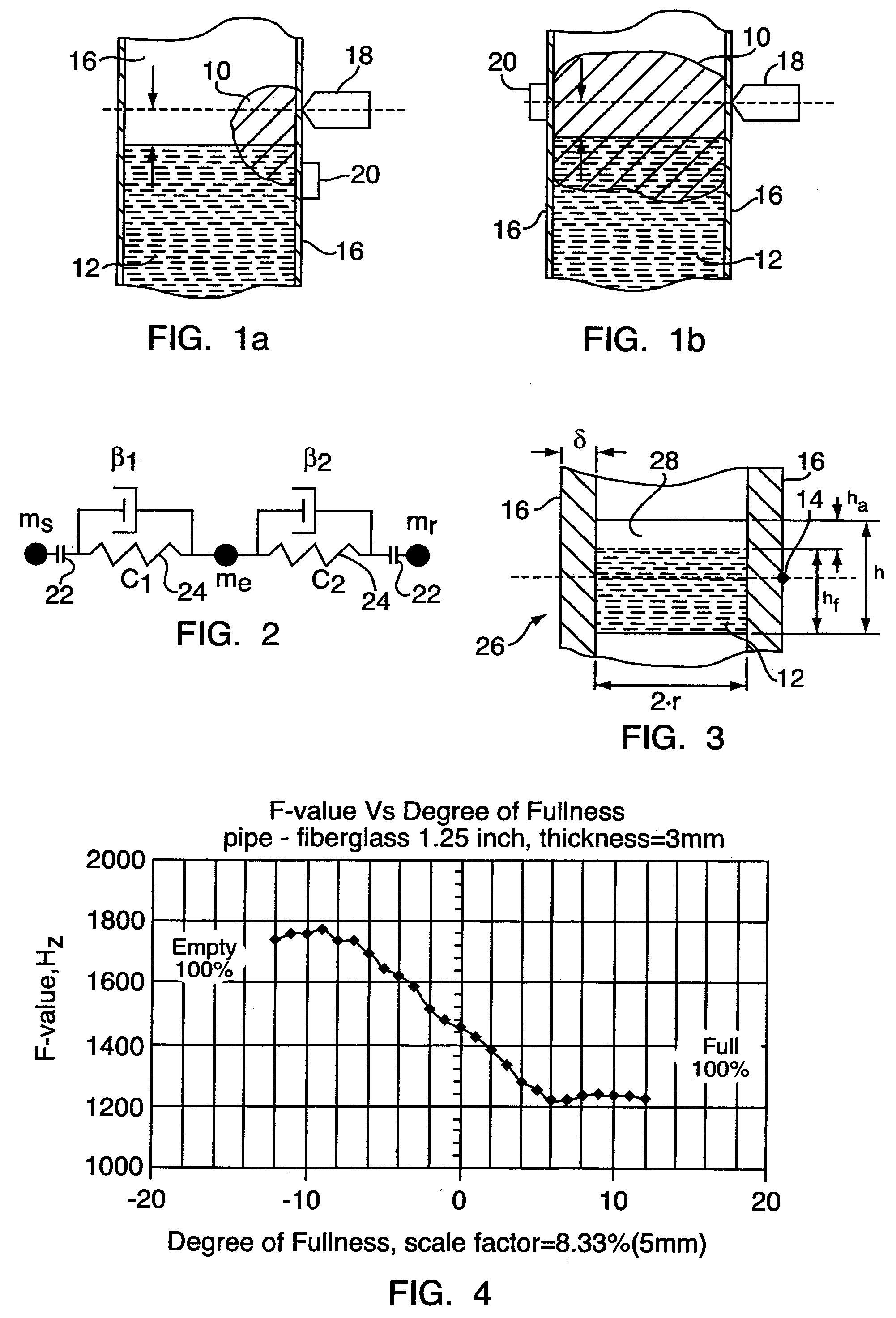

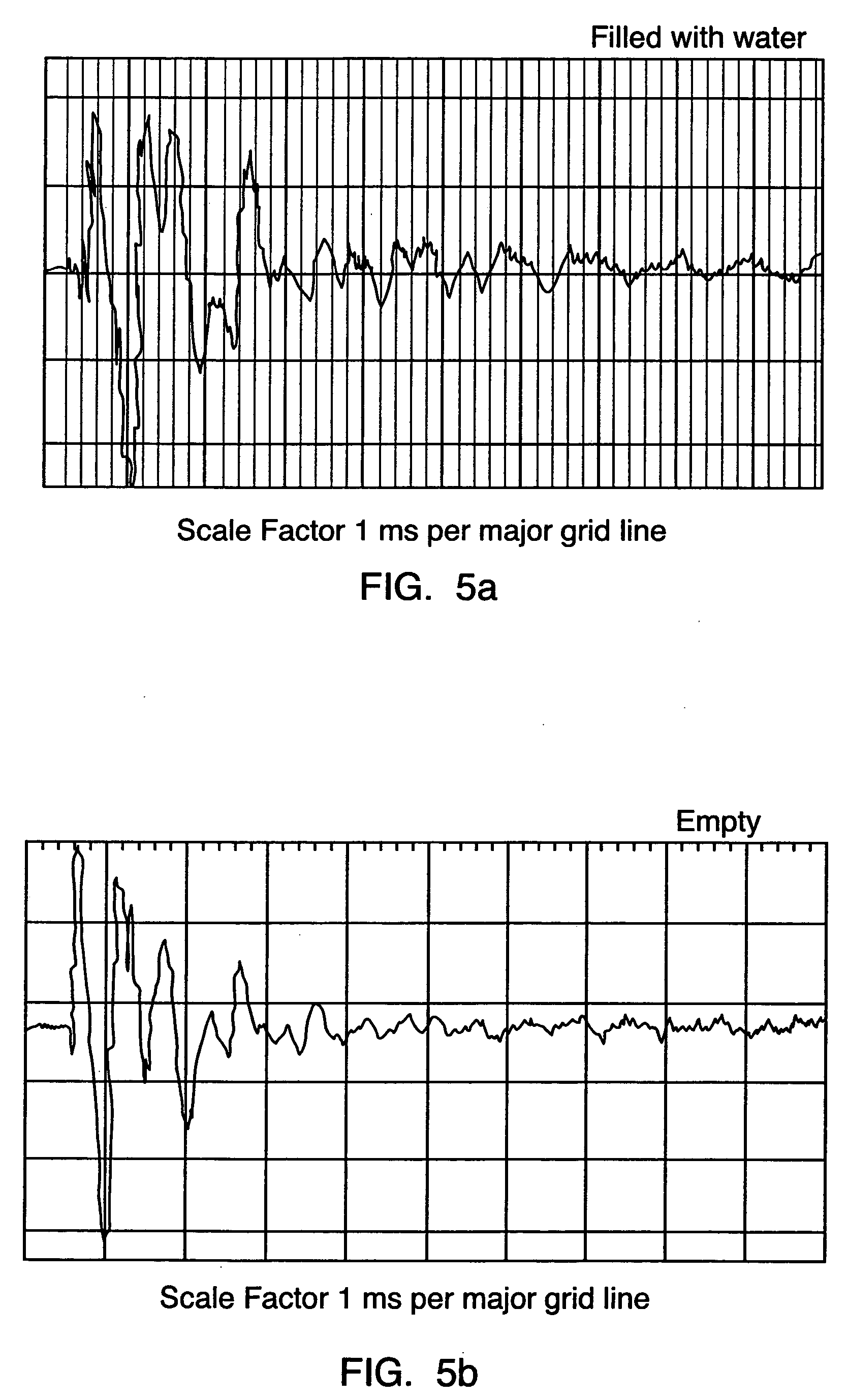

Non-invasive method for detecting and measuring filling material in vessels

ActiveUS20050178198A1High repeatabilityHigh accuracyTesting/calibration apparatusMachines/enginesFilling materialsNon invasive

A non-invasive method for measuring the level of filling material in a vessel and for detecting the presence of the filling material in the vessel at a predetermined set point level is based on monitoring the oscillation of the vessel's outside wall that follows an impact load applied to the external surface of the vessel's wall. The method may employ short range level measurement and long range level measurement procedures. The short-range level measurement utilizes the macro-dynamic properties of the oscillating space in the vicinity of the center of the impact. The long-range level measurement utilizes the properties of the transverse elastic waves propagating along the vessel's wall after the impact. The value of the measured level may be determined by a joint evaluation of the output of the short range level measurement procedure and the output of the long range level measurement procedure.

Owner:ULTIMO MEASUREMENT

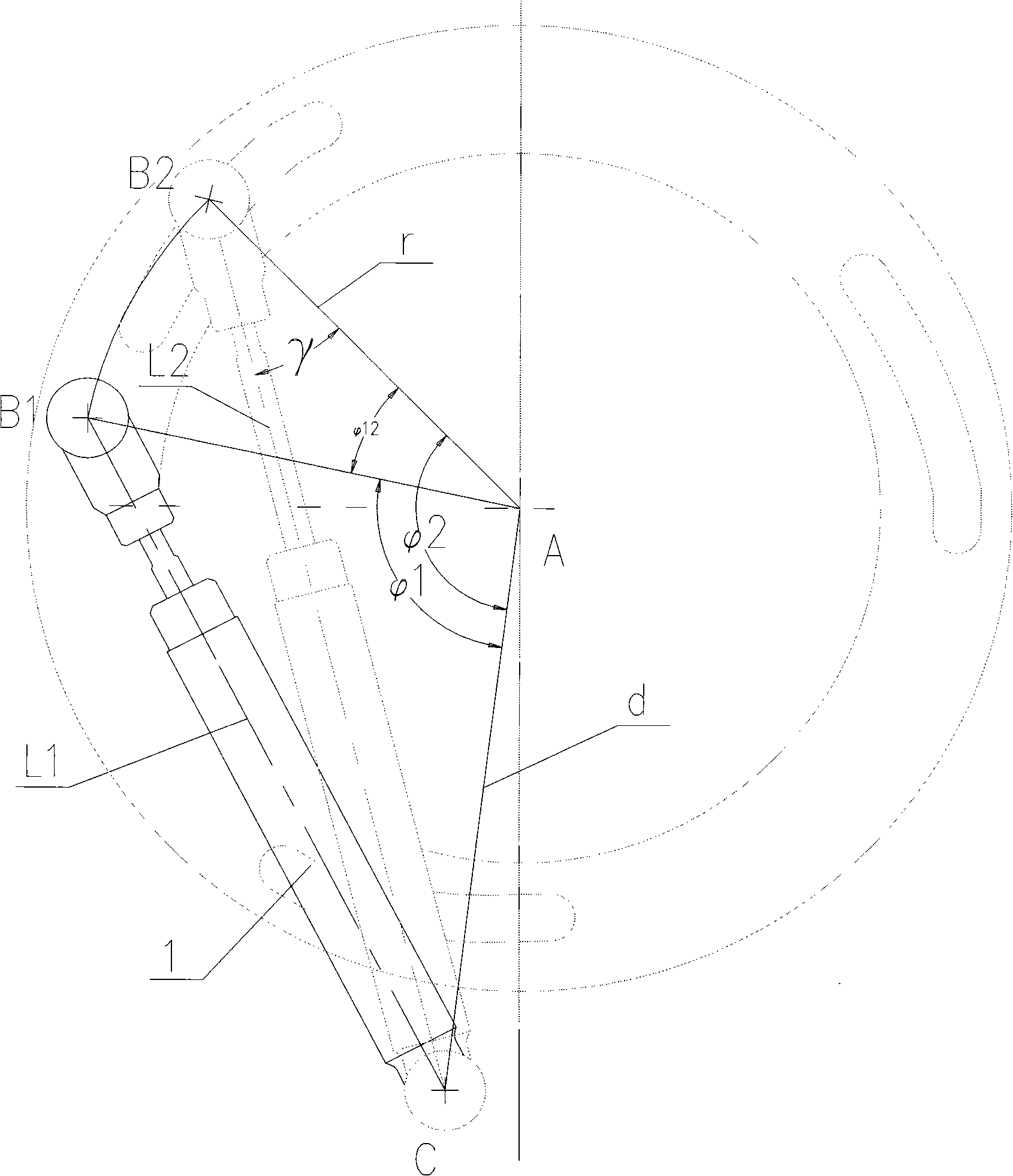

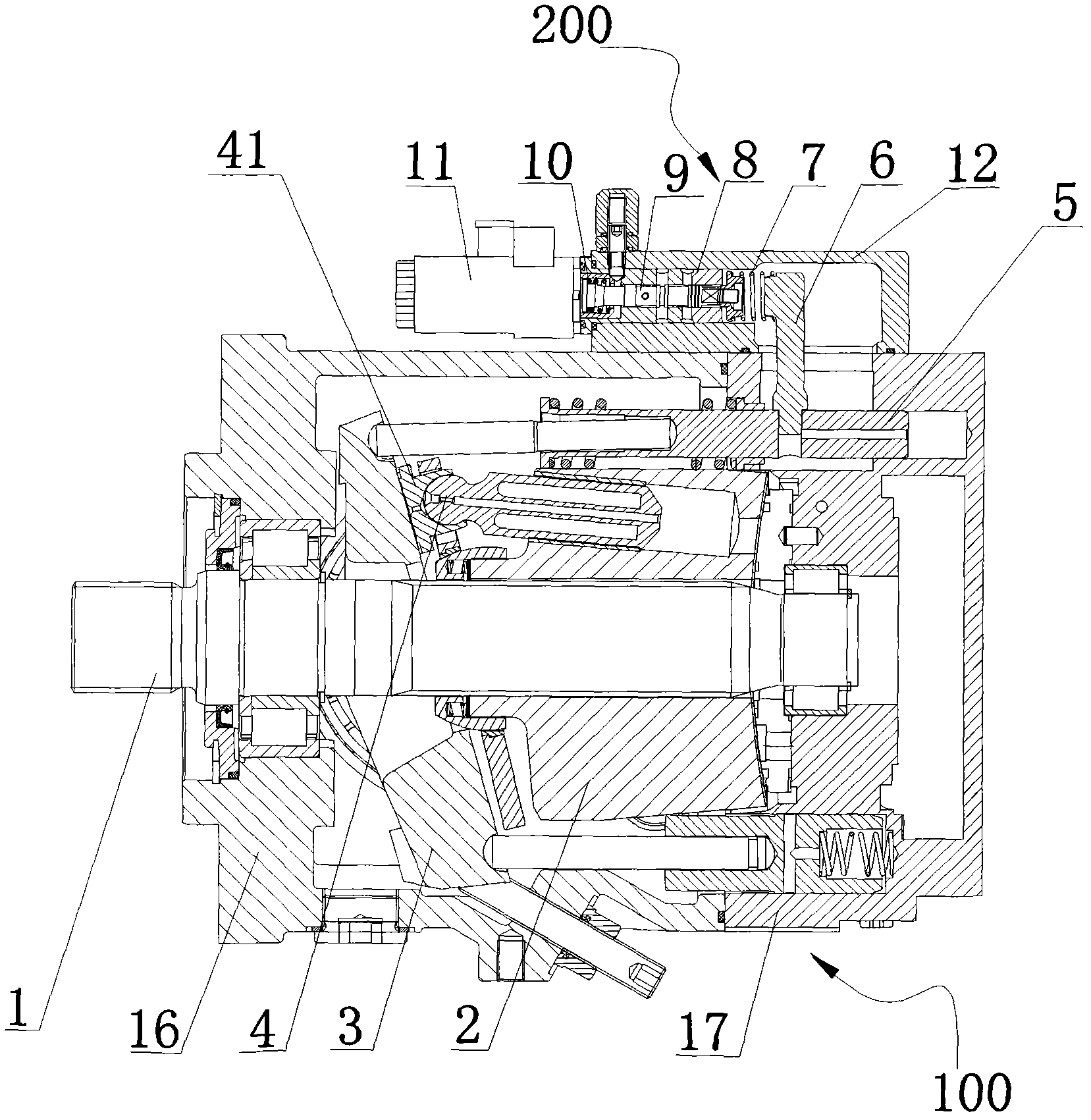

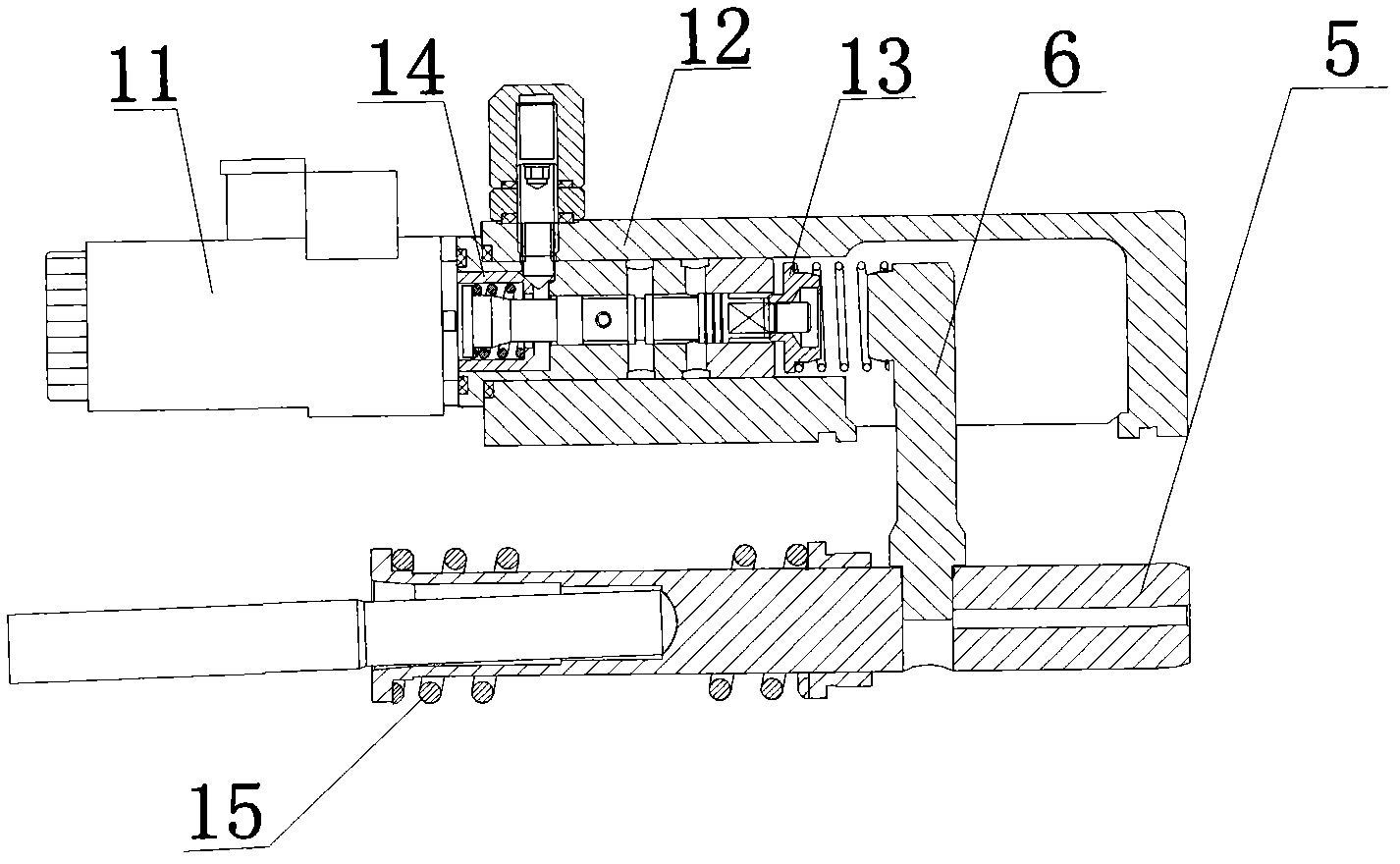

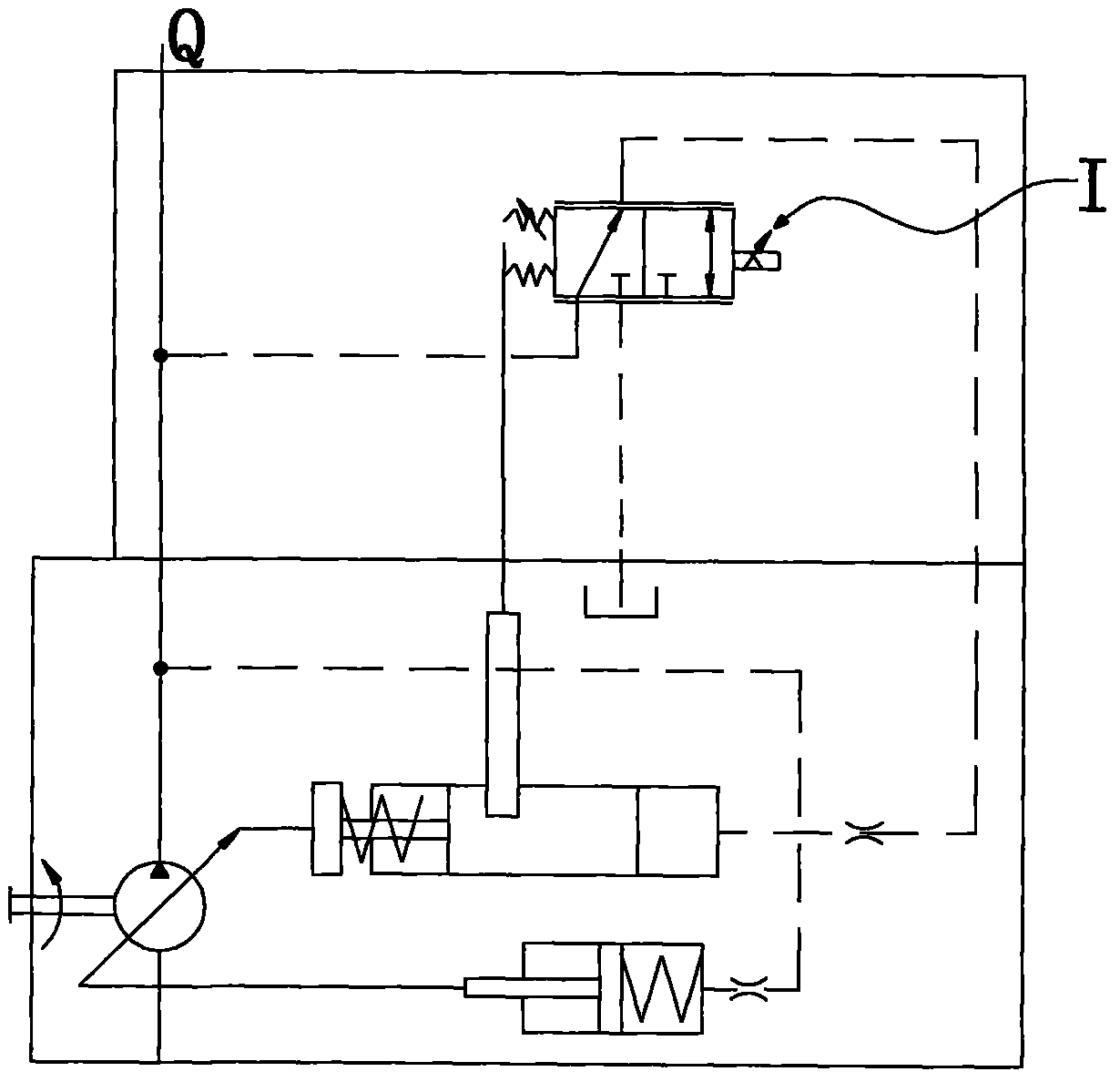

Position-spring-force feedback type electric proportional variable axial plunger pump

ActiveCN101956686ASensitiveHigh repeatabilityPositive-displacement liquid enginesMulti-cylinder pumpsElectricityPower flow

The invention discloses a position-spring-force feedback type electric proportional variable axial plunger pump. The plunger pump comprises a variable plunger pump body and a variable mechanism arranged on one side of the variable plunger pump body, wherein the variable mechanism comprises a control piston, a feedback rod, a feedback spring, a valve core, a valve bush, a pre-compression spring, a proportional electromagnet and the like; and the body part and the variable mechanism are connected through the feedback rod and the feedback spring. The movement of the valve core is controlled through the change of the current of the proportional electromagnet to allow oil in the control valve to enter big and small cavities of the variable piston and allow the variable piston to move left and right so as to control the movement of a swash plate; and at the same time, the feedback rod arranged on the control piston feeds back to control the displacement of the piston and the feedback spring is compressed to transmit a force to the valve core to make the valve core positioned at a new place, so that the delivery volume of the pump and the input signal input into the proportional electromagnet are approximate to a linear proportional relationship. The servo control of electromagnetic force-pump delivery is realized in the form of position-spring-force feedback.

Owner:SAIKESI HYDRAULIC TECH CO LTD

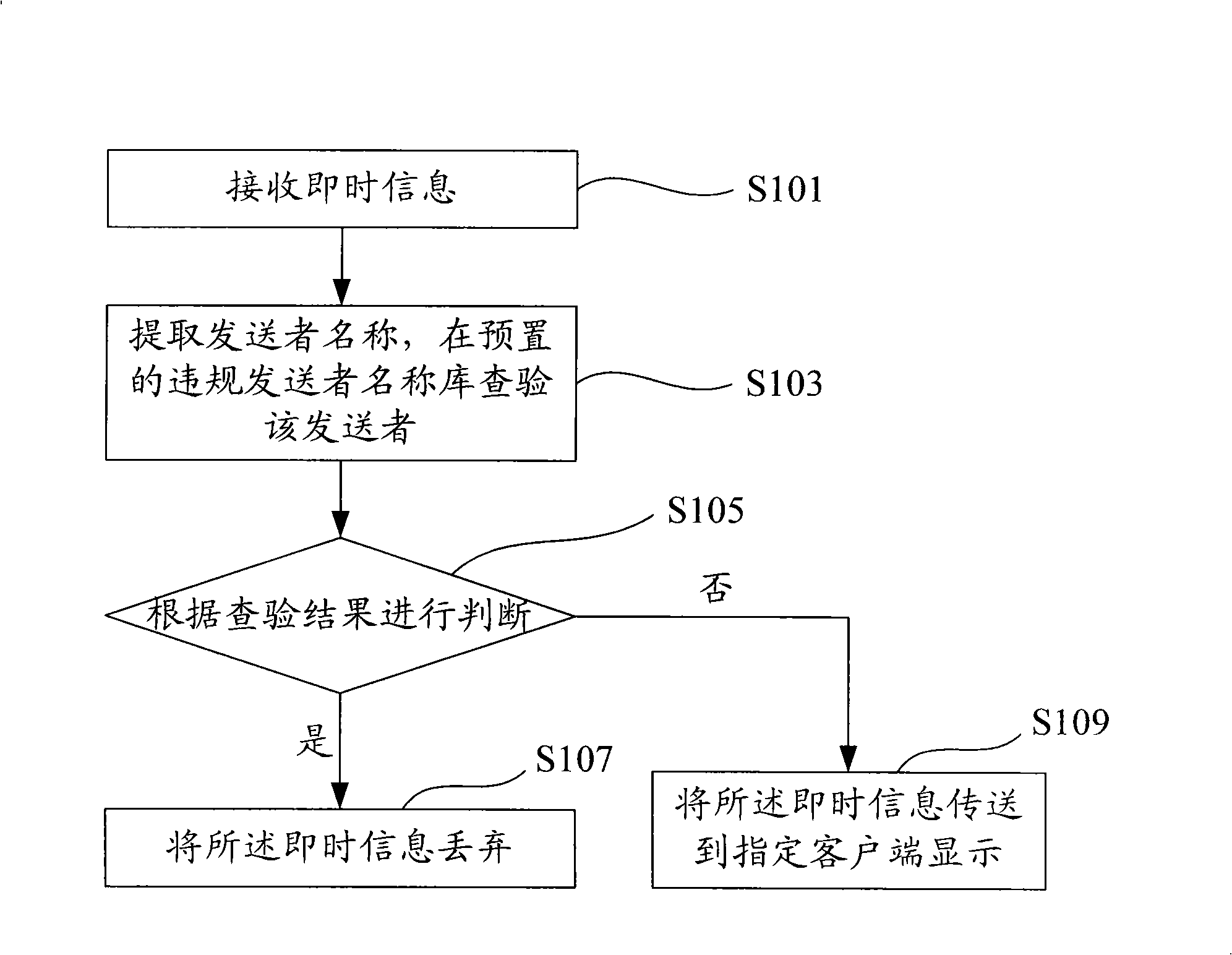

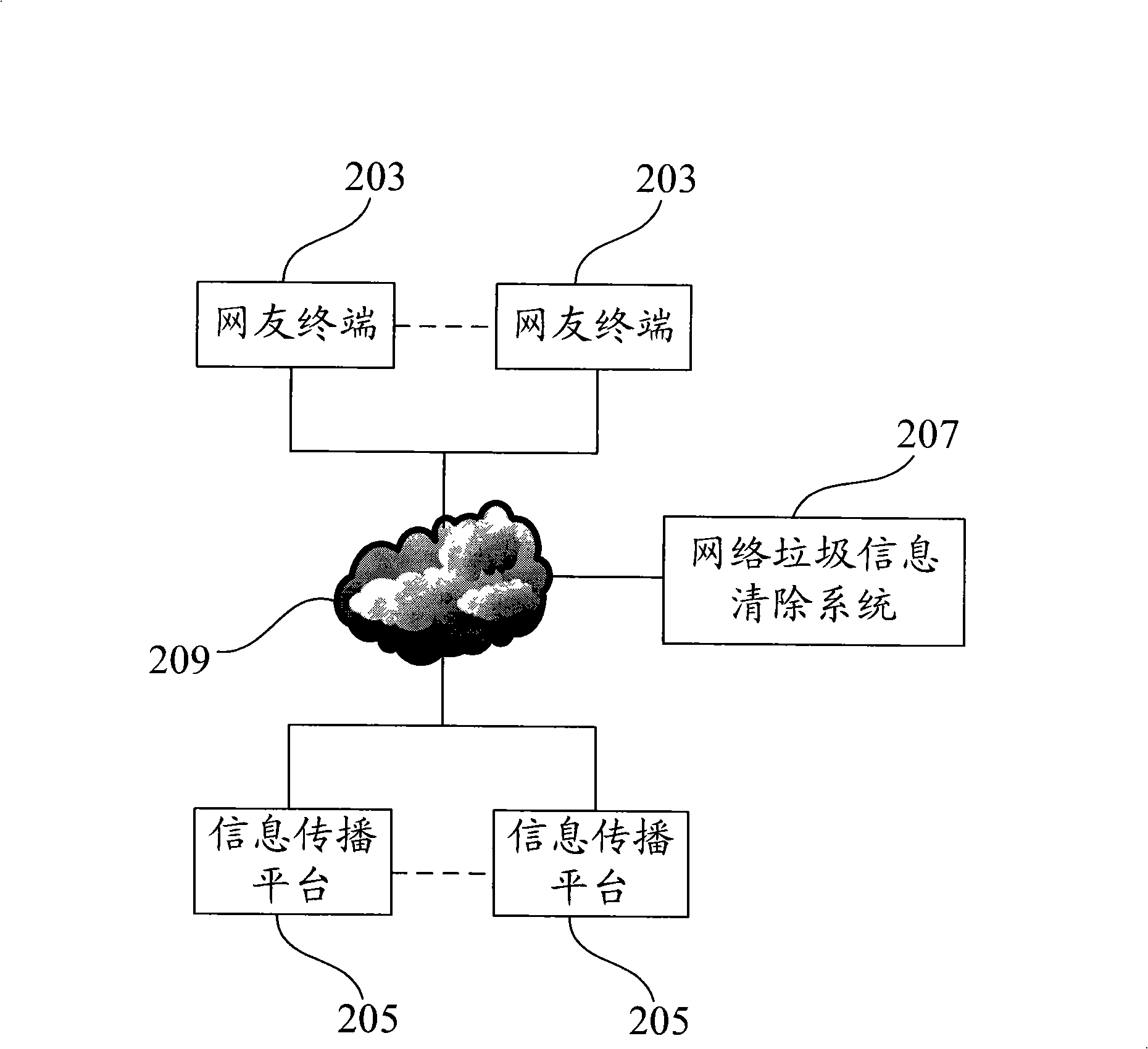

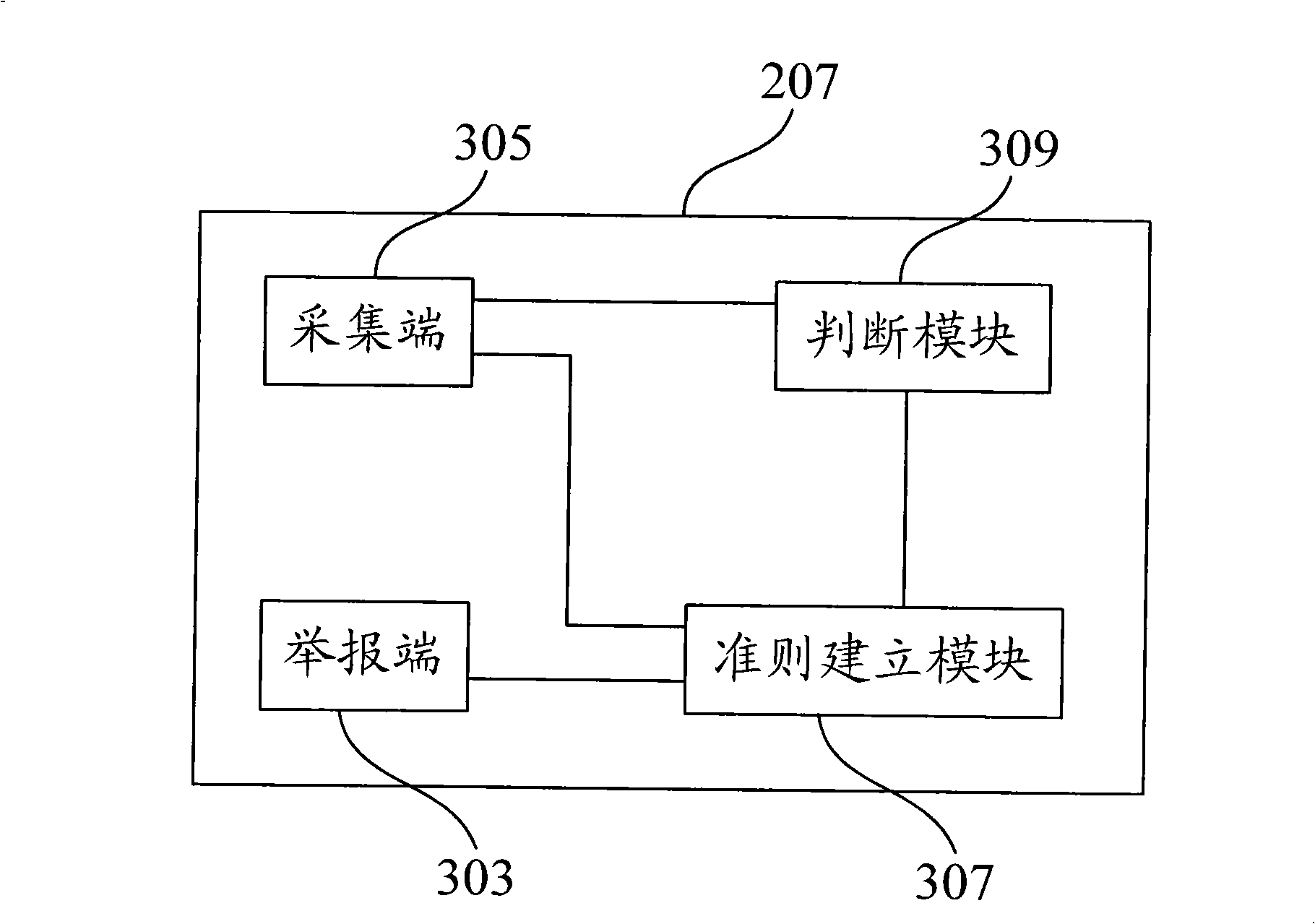

Network rubbish information filtering architecture, Network rubbish information cleaning system and method thereof

ActiveCN101340308AA large amountHigh repeatabilityData switching networksInformation dispersalInternet privacy

The invention provides a cyber rubbish information filtering structure, a cyber rubbish information scavenging system and a method thereof; wherein, the cyber rubbish information filtering structure comprises a plurality of net friend terminals, at least one information transmission platform and a cyber rubbish information scavenging system; the information transmission platform is connected with the net friend terminals by internet; the cyber rubbish information scavenging system is respectively connected with the net friend terminals and the information transmission platform by internet; the cyber rubbish information scavenging system comprises at least an accusation end, a collection end, a criterion establishment module and a judgment module. The structure, the system and the method have the advantages that the rubbish information of one or more information transmission platforms can filtered through the cyber rubbish information scavenging system; large amount of rubbish information can effectively prevented from being copied and spread and scavenge mistakenly or miss rubbish information are not exist.

Owner:翁时锋 +1

Automatic counting instrument for body cell of milk / bacteria through direct microscopic method

InactiveCN101050416ASimple structureImprove counting accuracyBioreactor/fermenter combinationsBiological substance pretreatmentsMilk sampleEngineering

This invention provides a direct microscopic examination method milk somatic cells / bacteria automatic counter. The automatic counter comprises: a sampling / smearing apparatus, a dyeing apparatus, a washing / drying apparatus, a microscopic detecting apparatus, a convey apparatus for conveying the milk sample as well as glass slide to and out of the sampling / smearing zone, and another convey apparatus for conveying the smeared glass slide to the dyeing zone, washing / drying zone and microscopic detecting zone, which comprises multi-stage glass slide convey mechanisms and glass slide running mechanisms. The automatic analyzer comprises a smearing apparatus, a dyeing apparatus, a washing / drying apparatus a microscopic detecting apparatus and a control apparatus for convey apparatuses. This invention divides direct microscopic examination method milk somatic cells / bacteria analysis and assay into multiple mechanical actions performed by different apparatuses, and sets corresponding working positions and working zones. The working positions and working zones are connected via the convey apparatuses, and can reasonably and effectively perform automatic detection under the control of the control apparatus. The automatic counter has high counting precision and repeat precision, and the working efficiency is largely increased.

Owner:HANGZHOU ULTRASUN TECH

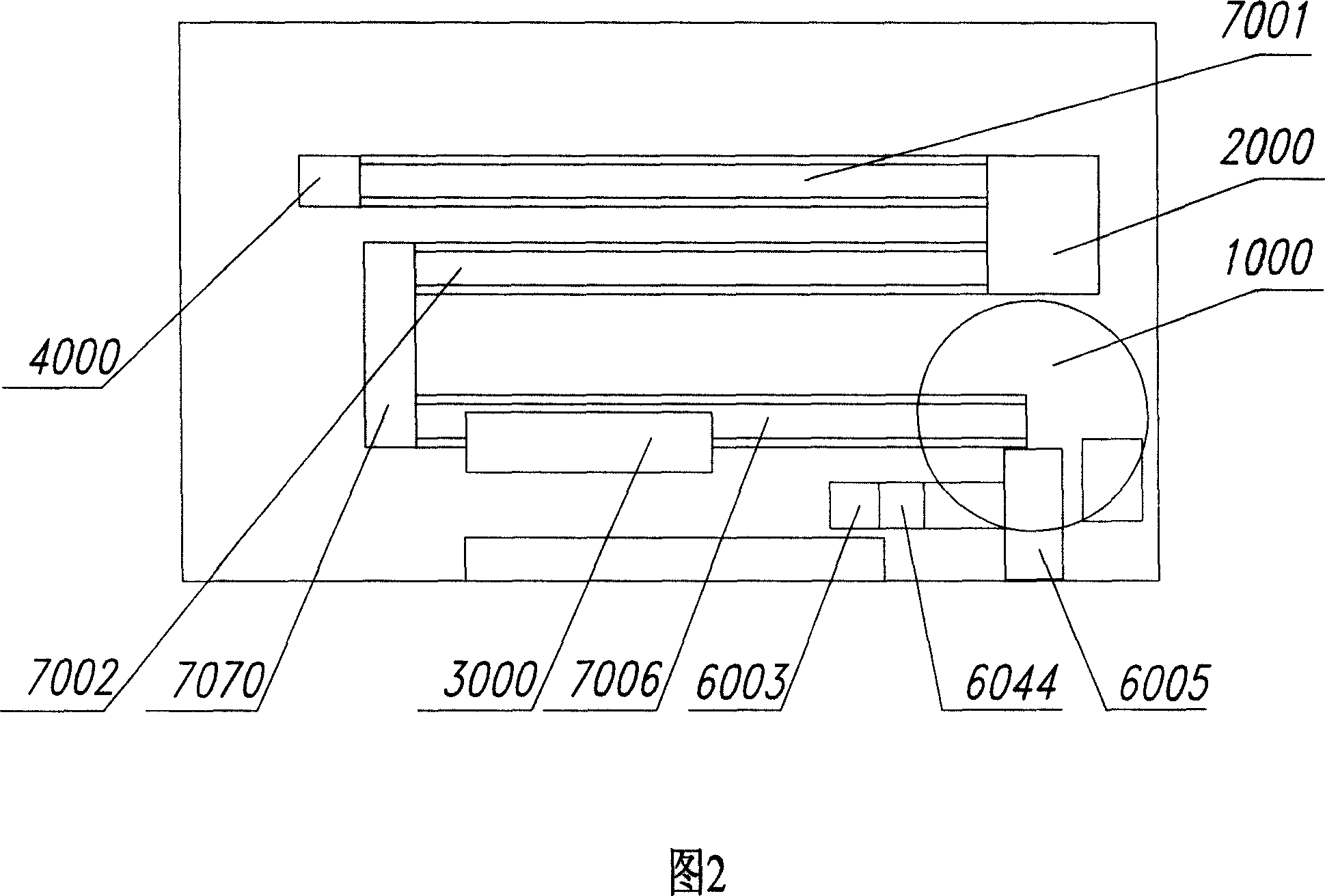

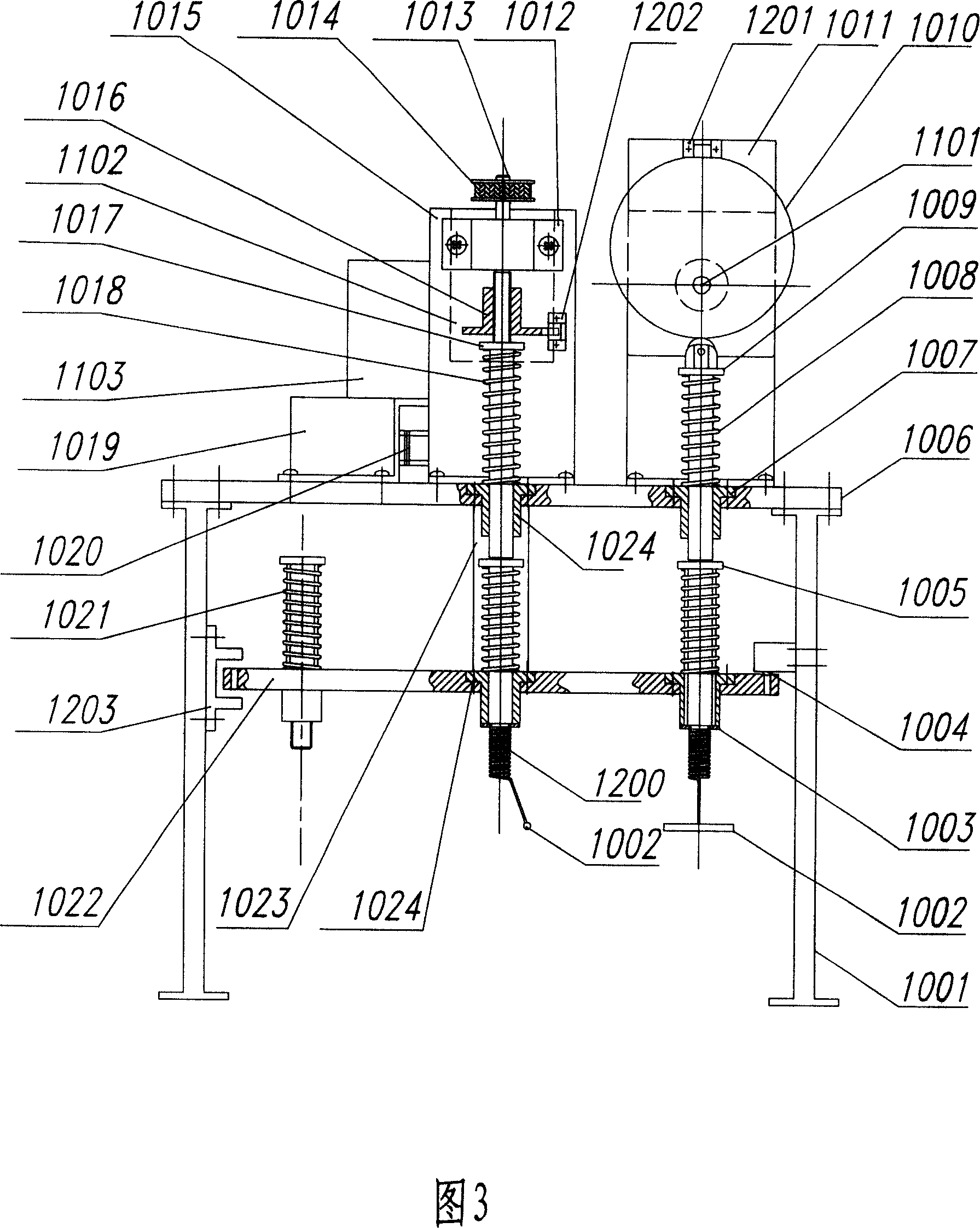

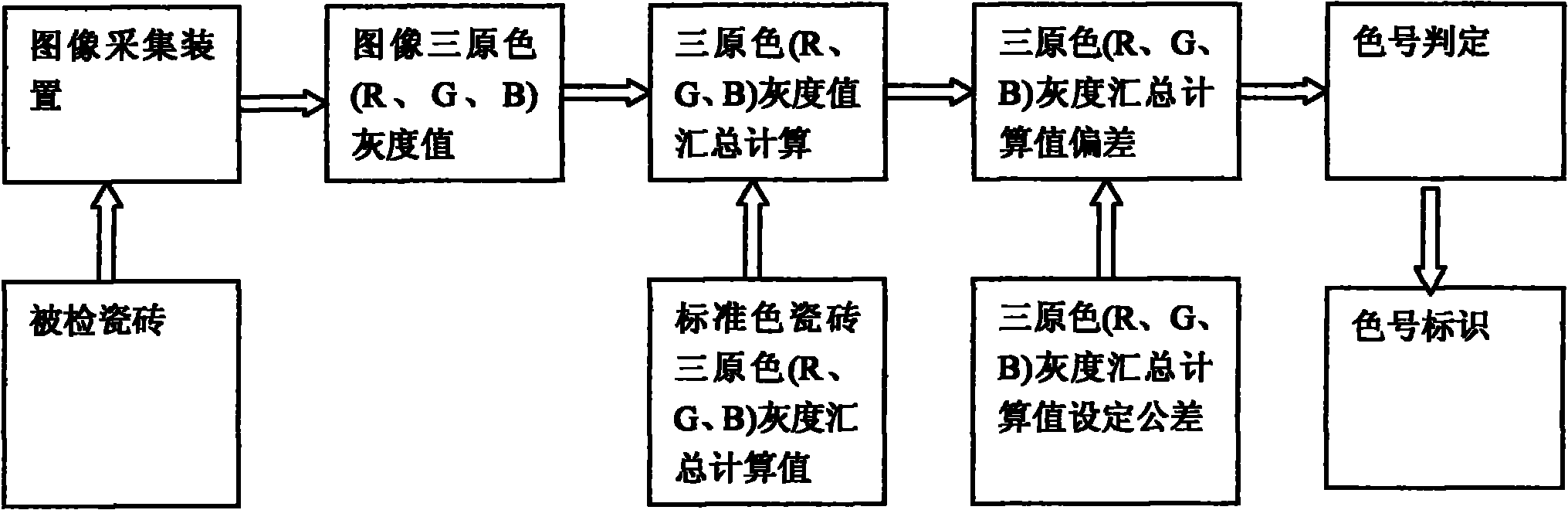

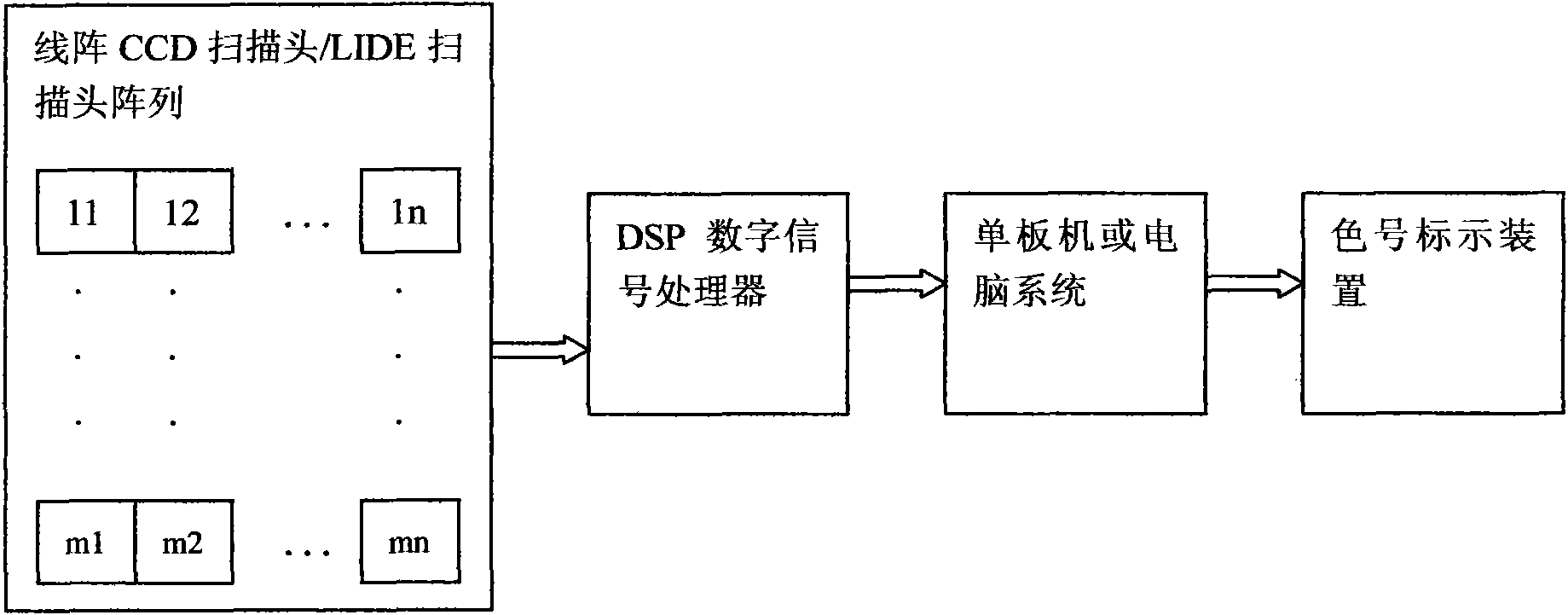

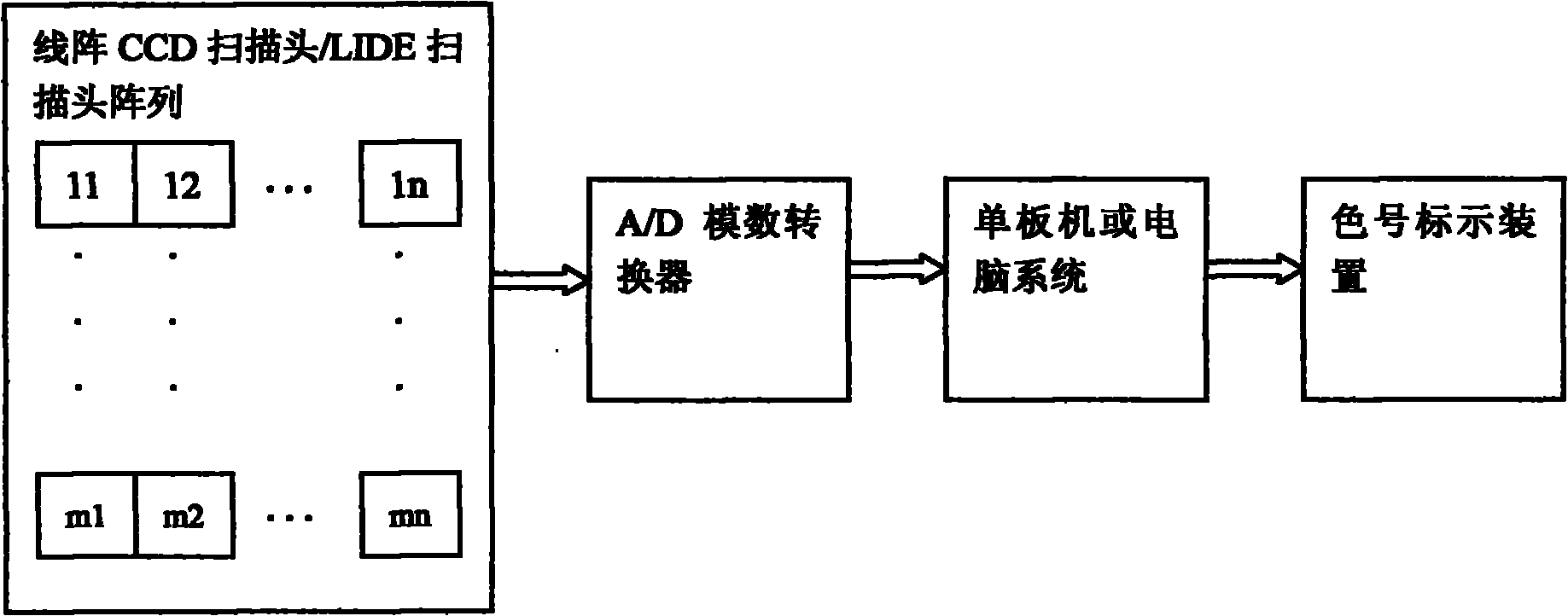

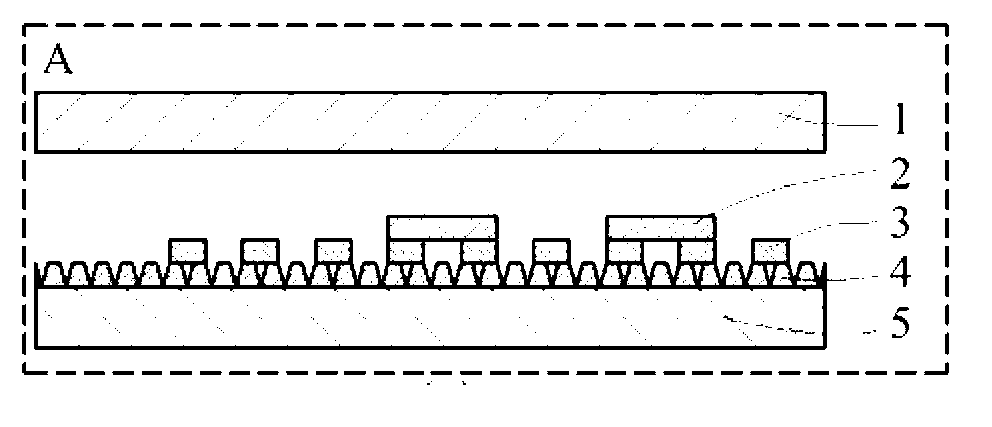

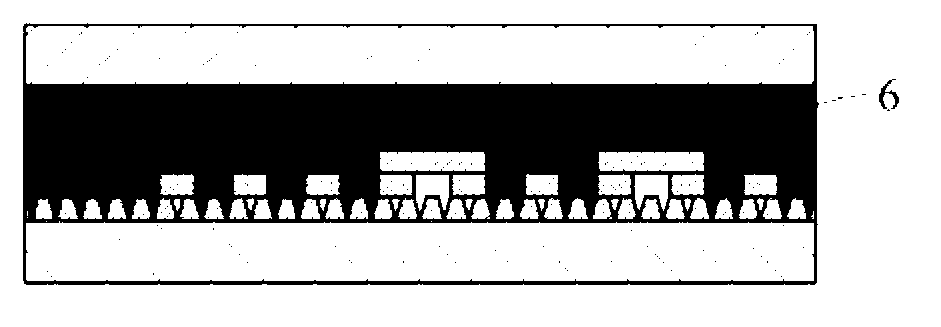

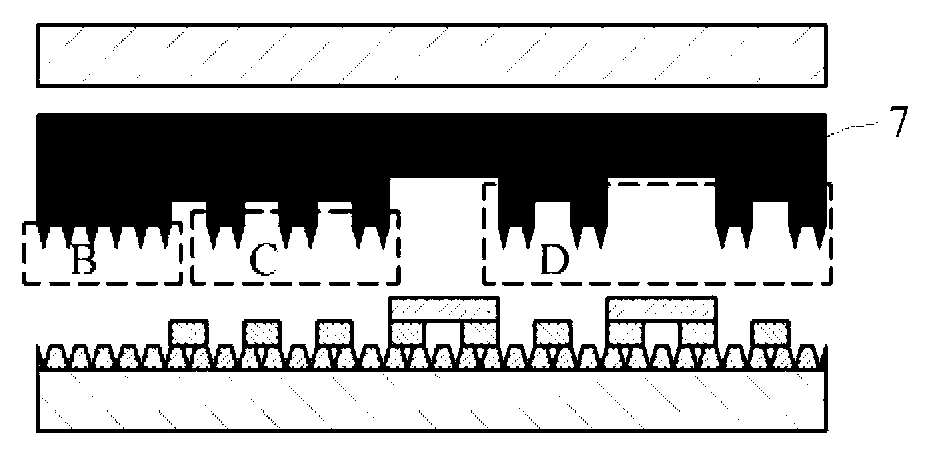

Method for automatic color separation of ceramic tiles

InactiveCN102095499ASimple structureQuick responseMaterial analysis by optical meansColor measuring using electric radiation detectorsComputer sciencePrimary color

The invention discloses a method for automatic color separation of ceramic tiles, and more specifically, relates to a method for classifying ceramic tiles in different colors by quantitatively determining color values of the surface pictures of the ceramic tiles and then comparing the color values with a standard color value. The method is characterized by regarding a summarized calculation value of gray-scale values of three primary colors (RGB: Red Green Blue) of the surface pictures of the ceramic tiles as the reference for judging color numbers of the ceramic tiles. The method has the advantages of: realizing online color separation of the ceramic tiles, enhancing the accuracy of color separation, reducing labor intensity of workers and raising the automation level of separation of the ceramic tiles.

Owner:程好学

Preparation method and application of super hydrophobic surface with composite microstructure

ActiveCN103101147AReduce processGuaranteed continuityCoatingsInjection molding machineMaterials science

The invention relates to a preparation method of a super hydrophobic surface with a composite microstructure. The preparation method comprises the following steps of: a, manufacturing a composite microstructure moldboard with more than two scale micro features according to the wetting features required by a product surface, and fixing the composite microstructure moldboard on the surface of an injection molding die cavity; b, utilizing the injection molding machine to inject a macromolecule fusant in the injection molding die cavity, carrying out pressure maintaining on the fusant through the one-way or bi-directional compression of the volume of the die cavity or the axial movement of the screw rod of the injection molding machine, and subsequently cooling and shaping; and c, isolating a macromolecule product and an injection mold through a stripper apparatus, and obtaining the super hydrophobic surface. According to the preparation method, the composite microstructure on an accurate copying moldboard, the microstructure surface and macromolecule products with various functions are obtained, and the preparation method belongs to the technical field for preparing the hydrophobic surface.

Owner:SOUTH CHINA UNIV OF TECH

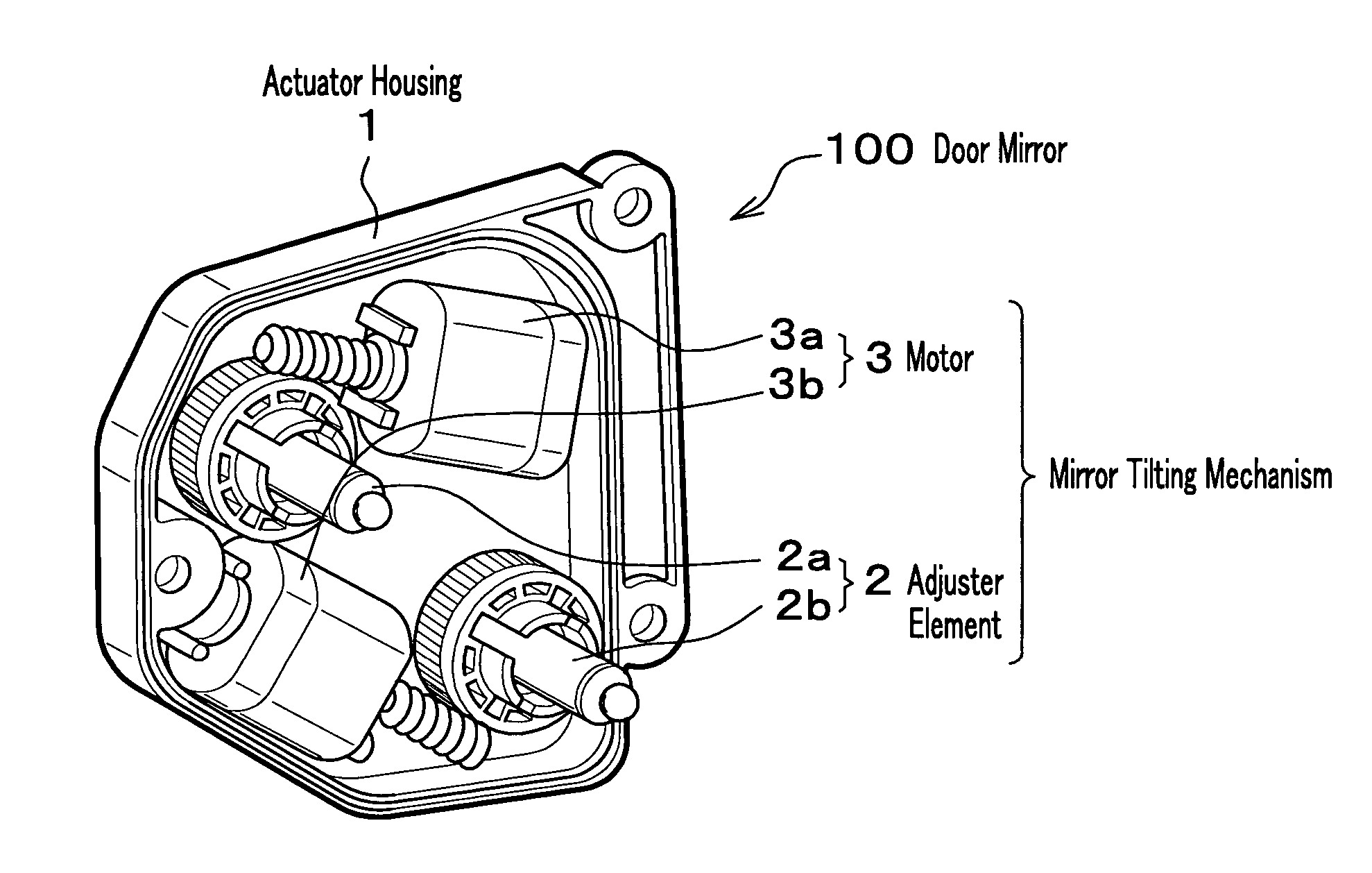

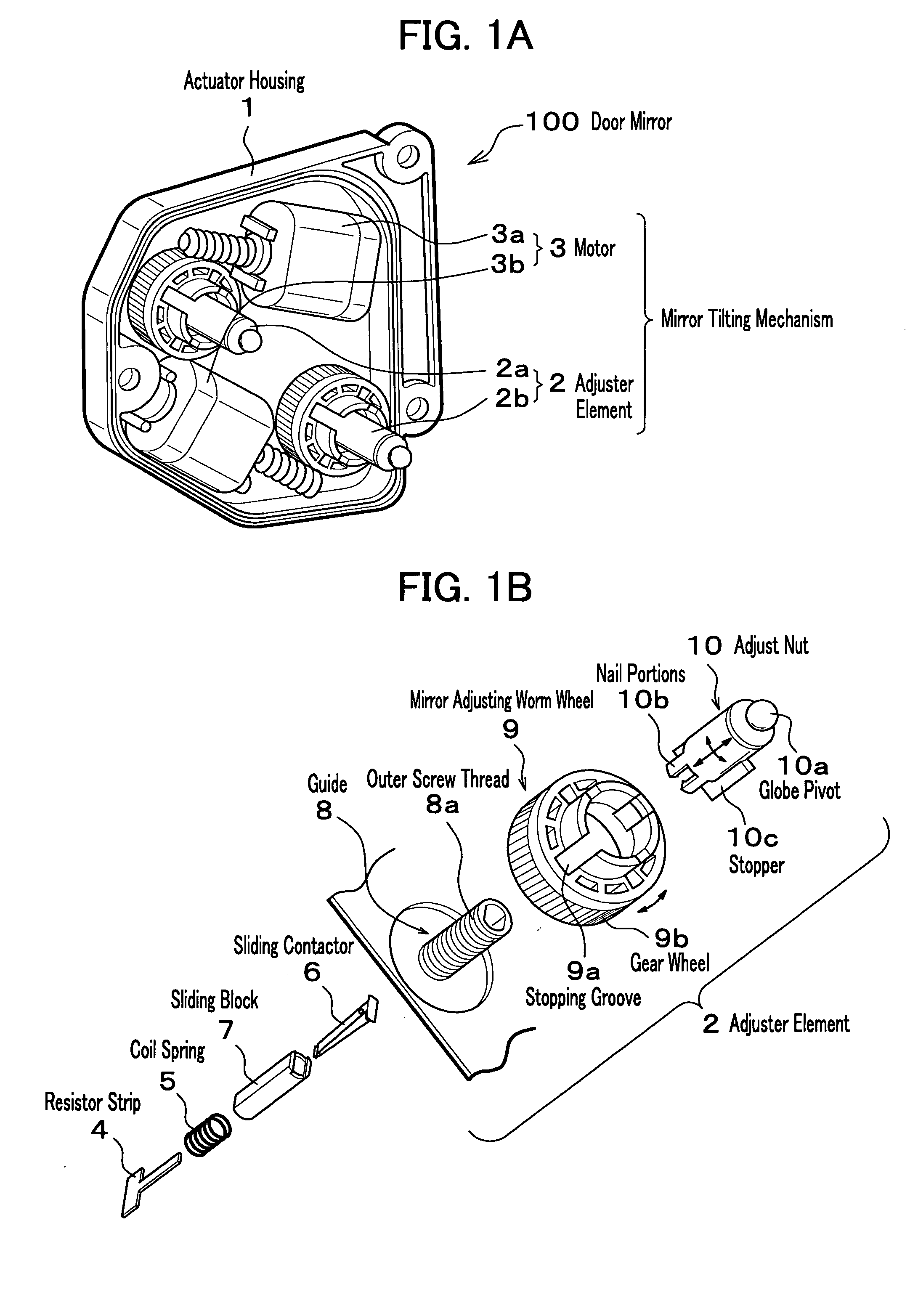

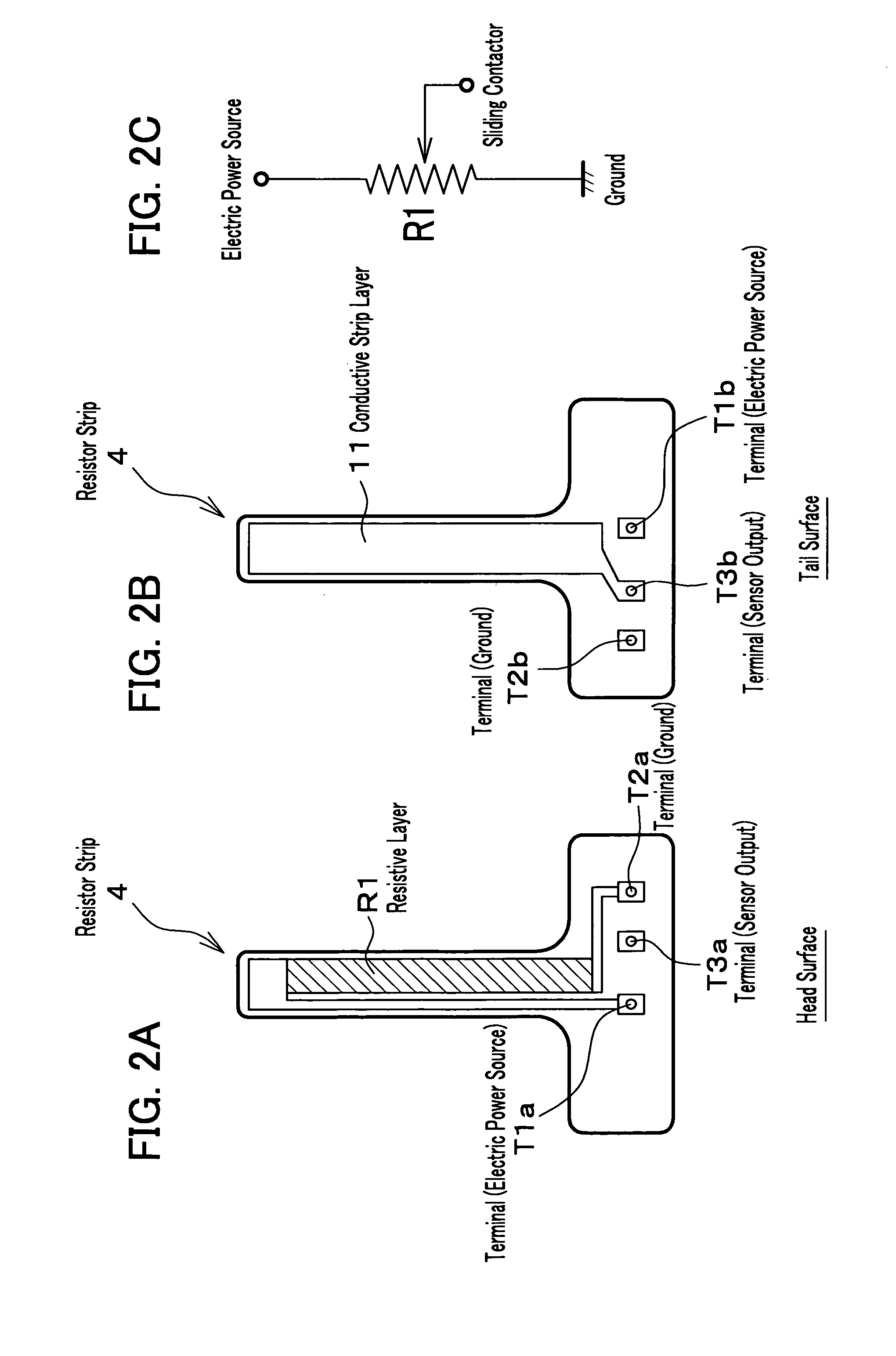

Mirror angle transducer and mirror tilting mechanism

A mirror angle transducer that detects tilting angles of a mirror applied to vehicles, wherein the tiling angle is adjusted by an adjuster element installed in an actuator housing, comprises a guide that has a non-circular hollow and composes the adjuster element, a sliding block that has a hole and is inserted into the non-circular hollow of the guide, a resistor strip that has a resistive layer and a conductive strip layer on one surface and the other surface, respectively and is set in the hole of the sliding block, a sliding contactor that makes electrical contact with the resistor by pinching and sliding on the surfaces of the resistor strip, and a coupling means that provides mechanically tight combining of the sliding contactor to the sliding block so that a stable and reproducible positioning of the electrical contactor on the resistor strip is obtained.

Owner:MURAKAMI CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com