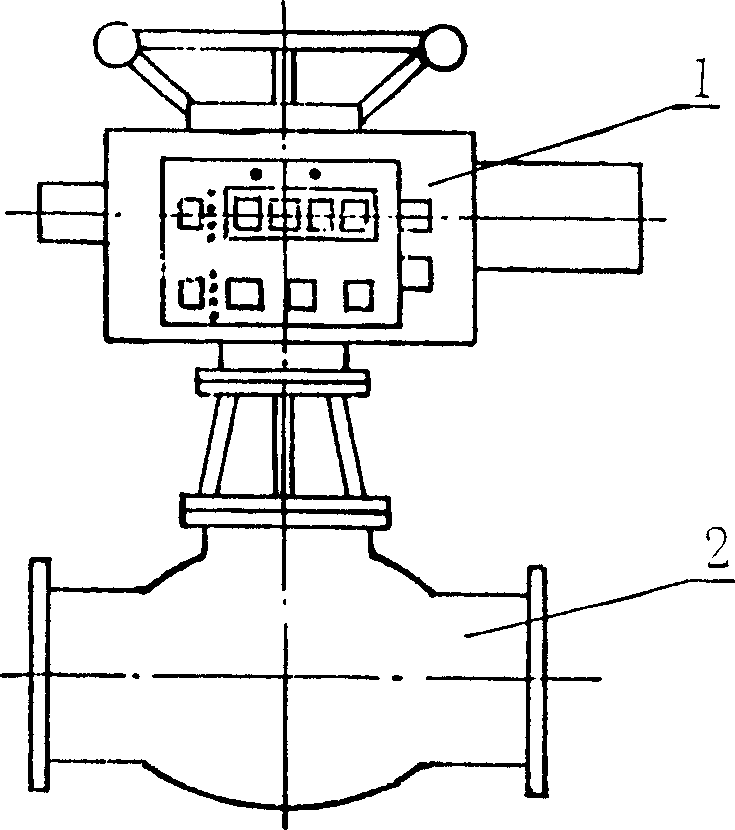

Intelligent type valve electrical device

An electric and intelligent technology for valves, applied in the direction of valve devices, valve operation/release devices, valve details, etc., can solve problems such as zero drift, intermittent analog signals, precision distortion, etc., to protect the pipe network system and solve complex structures , the effect of high repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

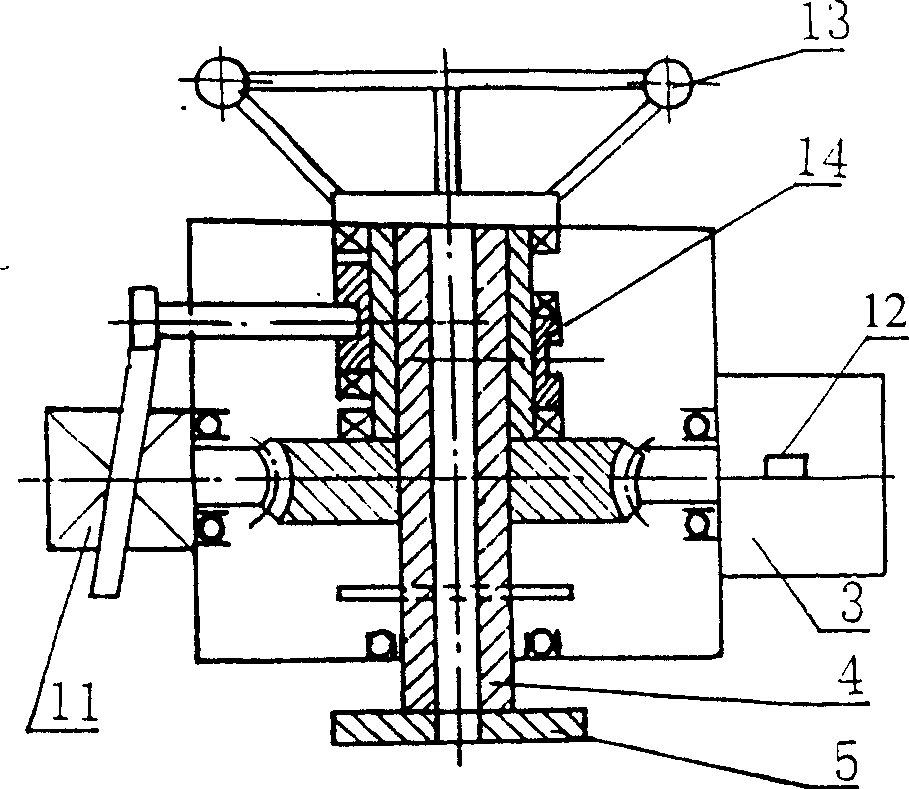

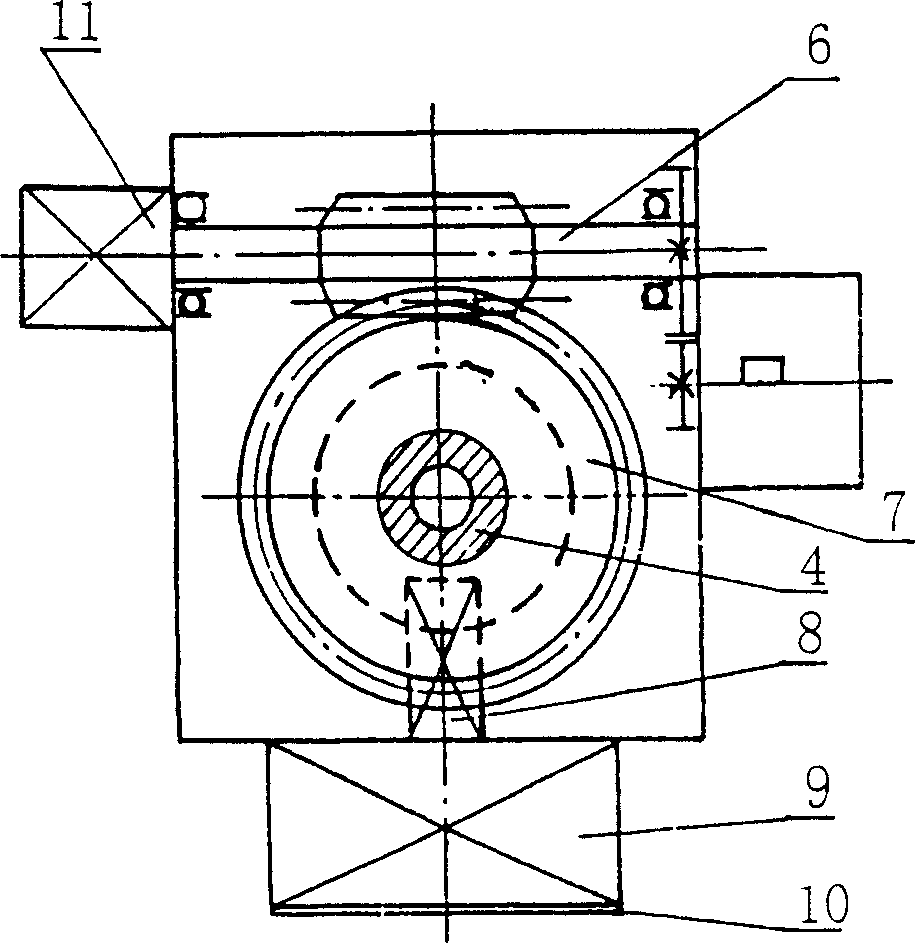

[0048] The multi-turn valve electric device is composed of a mechanical structure part and an electric control part. The mechanical part maintains the existing structure, that is, it is still equipped with a motor, a reduction mechanism, and a drive mechanism. The reduction mechanism includes a gear pair and a worm pair, and the drive mechanism includes a worm gear. 7 and its output shaft 4, the flange connection plate 5 and the hand wheel mechanism 13 connected to one end of the output shaft, and the manual-electric switching device 14 located between the hand wheel and the output shaft.

[0049] The feature of the present invention is that the mechanical structure part is only used as the carrier for the mechanical motion transmission of the valve electric device, and does not participate in the detection and control of the valve. It is set independently from the electric control part 9 . The original electromechanical torque control mechanism and valve opening control mechan...

Embodiment 2

[0066] Part-rotary valve electric device, the output shaft torque value detector in this device adopts a magnetic coupler, and other structures are the same as in Embodiment 1.

[0067] see below Figure 8 , the magnetic coupling is installed between the worm shaft 6 and the motor 3, and the magnetic coupling is composed of an armature 43 coaxially sleeved on the motor shaft 38 and a permanent magnet 40 fixed in the worm shaft end sleeve 39, The armature is cup-shaped, the permanent magnet is cylindrical, and the permanent magnet 40 is sleeved outside the armature 43. The two are coaxial, and there is a sliding fit between the armature and the permanent magnet. There is a compression collar 41 on the top of the permanent magnet.

[0068] The working process of the magnetic coupler is that when the motor 3 rotates, the motor shaft 38 drives the armature 43 to rotate, and the permanent magnet 40 and the worm shaft 6 rotate together within the set torque value, and drive the code...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com