Automatic wall-building machine

A wall-laying machine and automatic technology, applied in the direction of construction, building structure, building materials processing, etc., can solve the problems of low efficiency, labor intensity of operators, and large safety hazards, etc., to achieve convenient operation, reduce labor intensity, Eliminate the effect of cumbersome steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

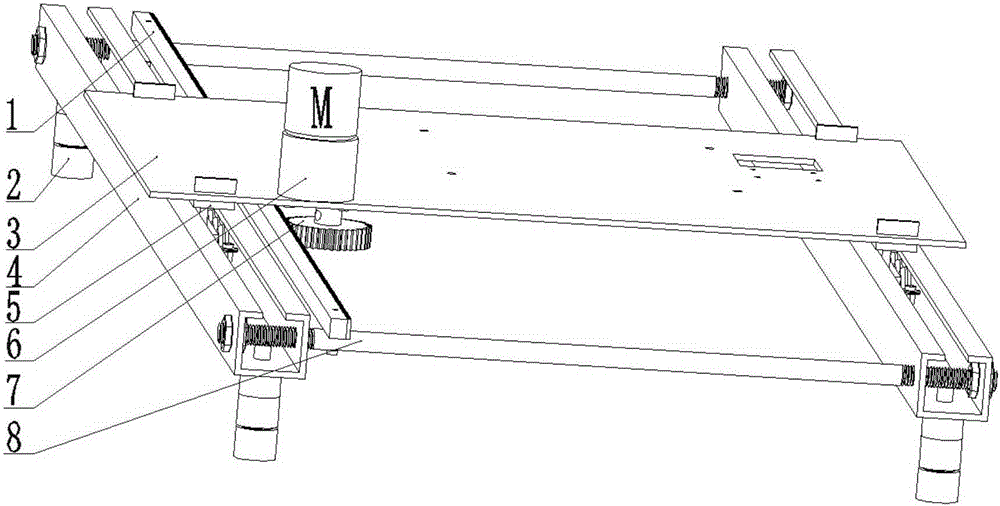

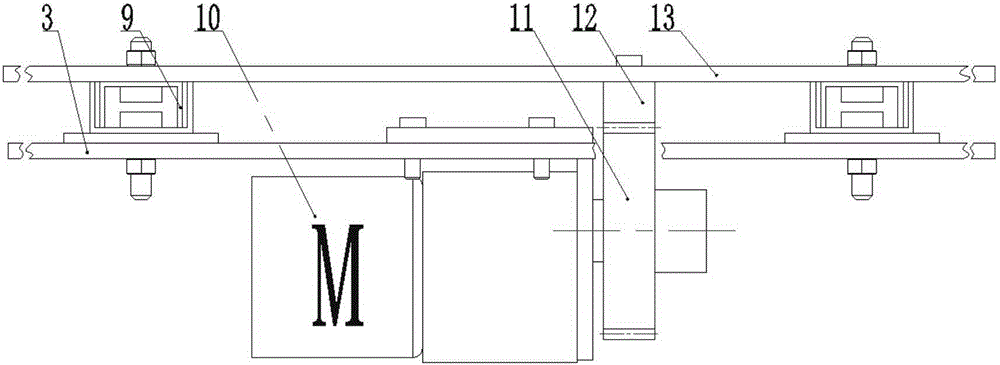

[0033] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

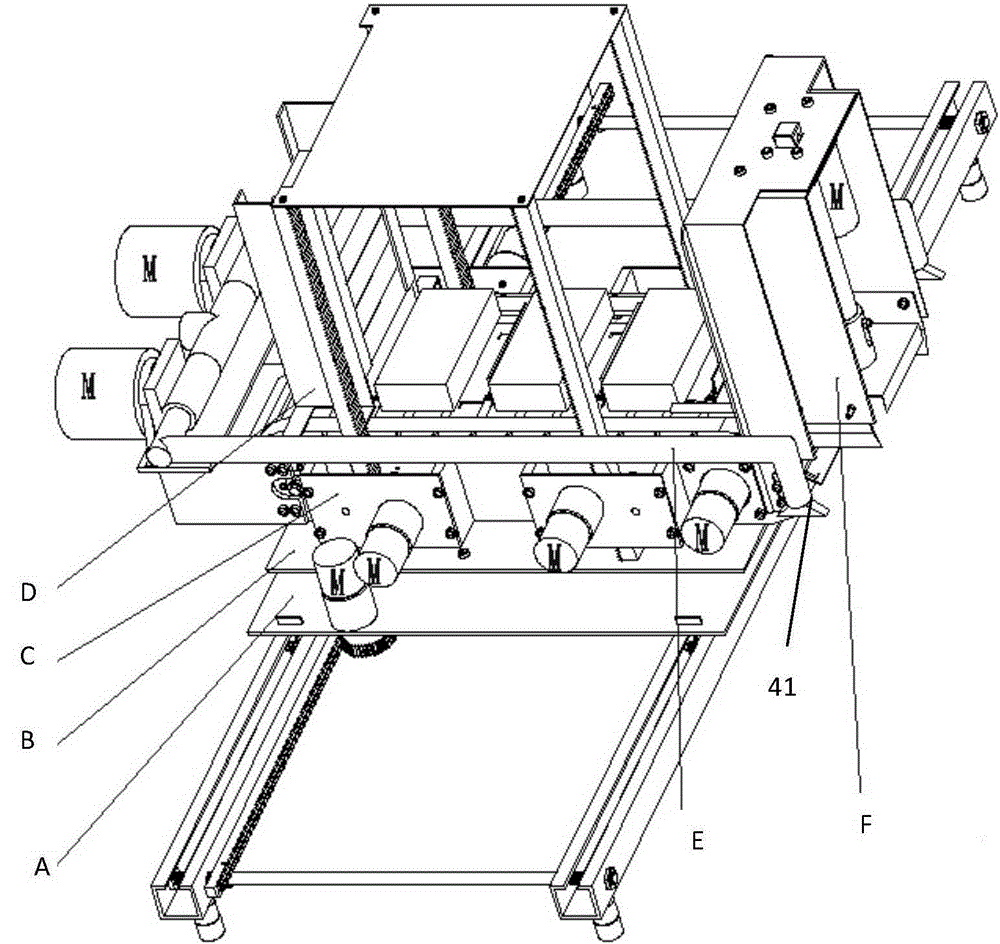

[0034] Refer to attached Figure 1-10 , The automatic wall-laying machine of this embodiment includes a longitudinal movement mechanism A, a transverse movement mechanism B, a vertical lifting mechanism C, a brick transmission mechanism D, a mortar spraying mechanism E, and a brick falling mechanism F. Each mechanism and the cooperation structure between the mechanisms will be described in detail below.

[0035] Longitudinal movement mechanism A comprises two parallel guide rails 4, adjustment screw rod 8, adjustment support foot 2, six-wheel guide wheel 5, base plate 3, motor 6, gear 7, rack 1, two guide rails 4 are arranged in parallel, two guide rails 4 two The ends are respectively fixedly connected by a screw rod 8 which can adjust the distance of the guide rail, and the screw rod 8 is perpendicular to the guide rail 4 . Two height...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com