Patents

Literature

8017results about How to "Quick assembly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

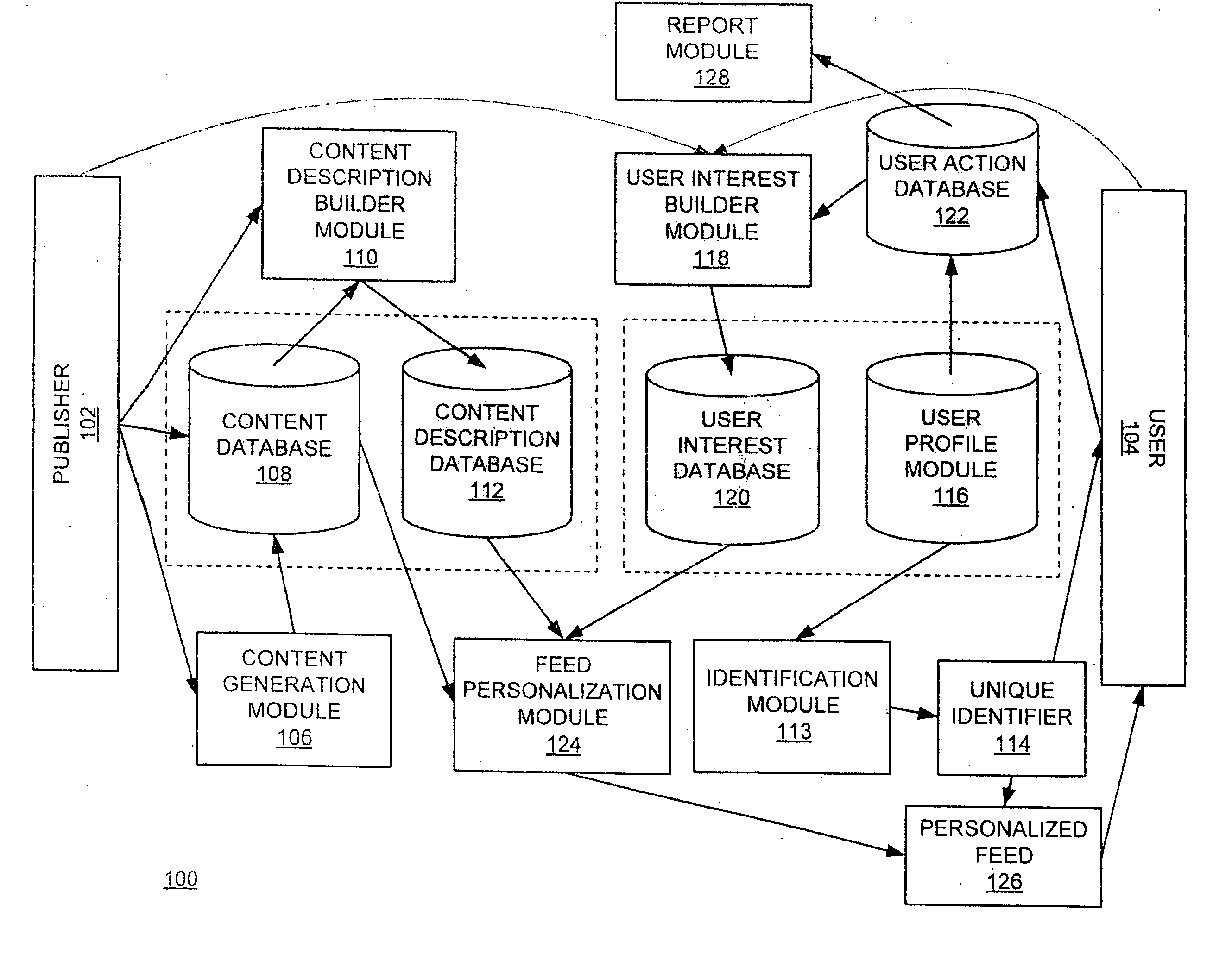

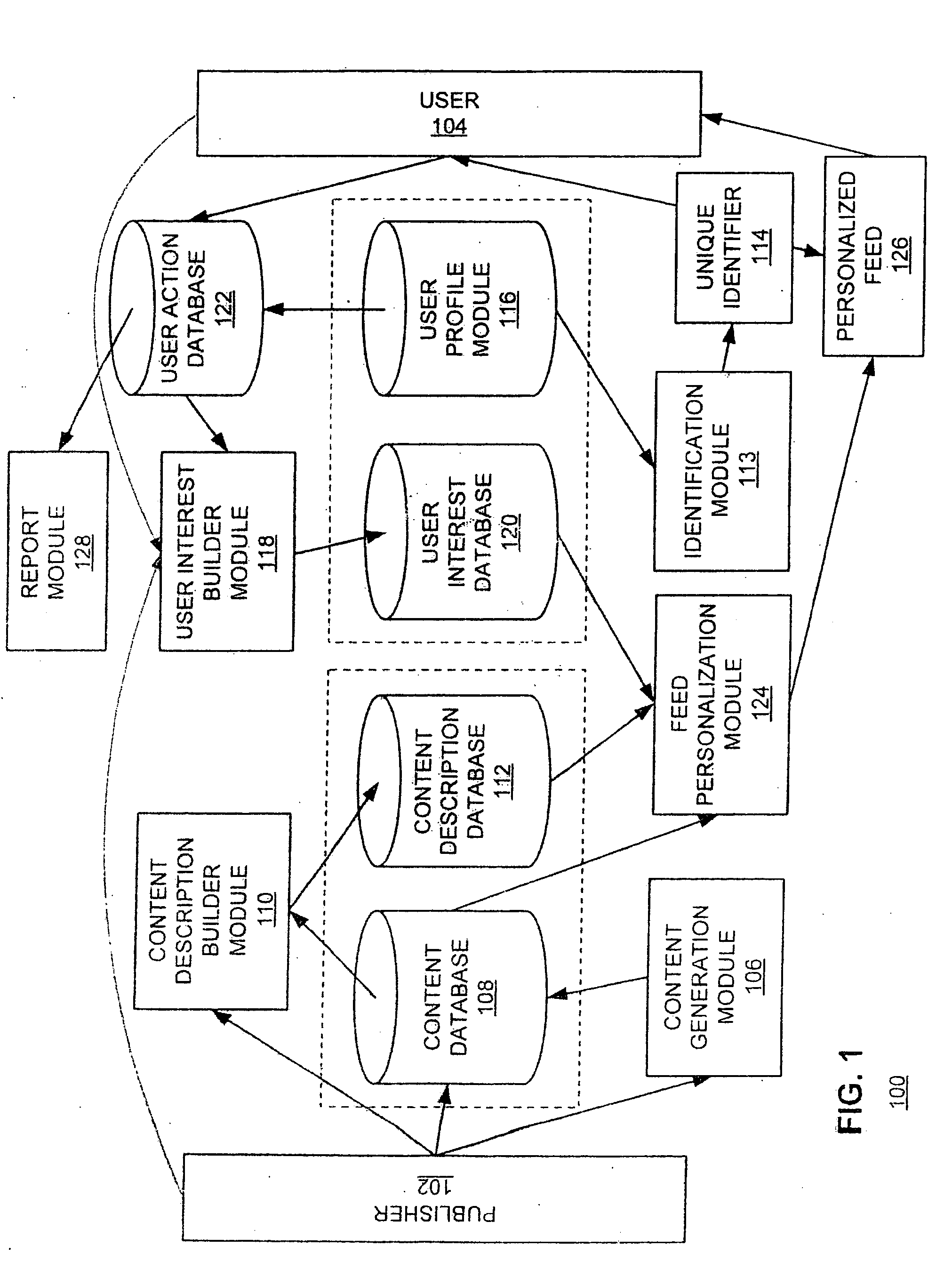

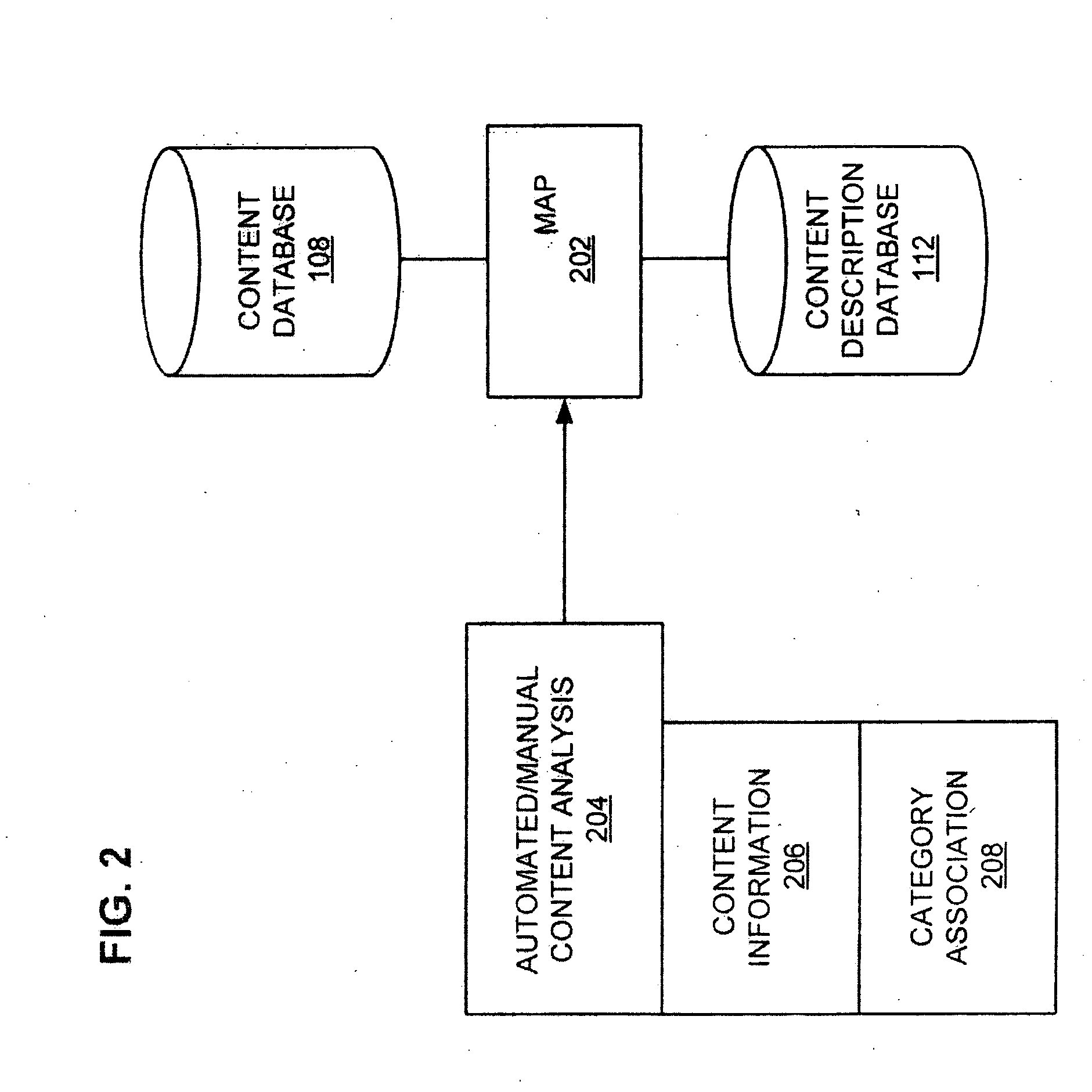

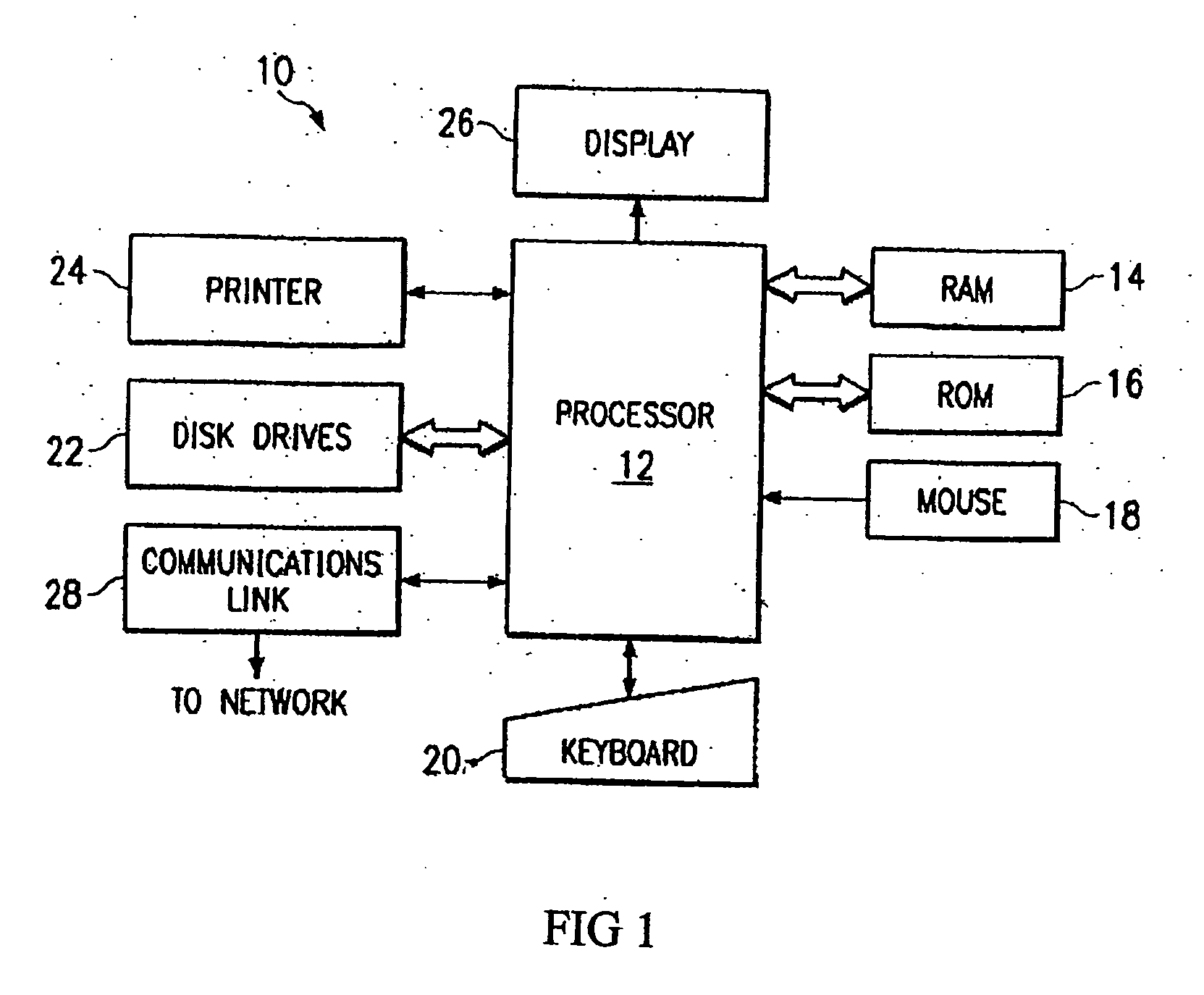

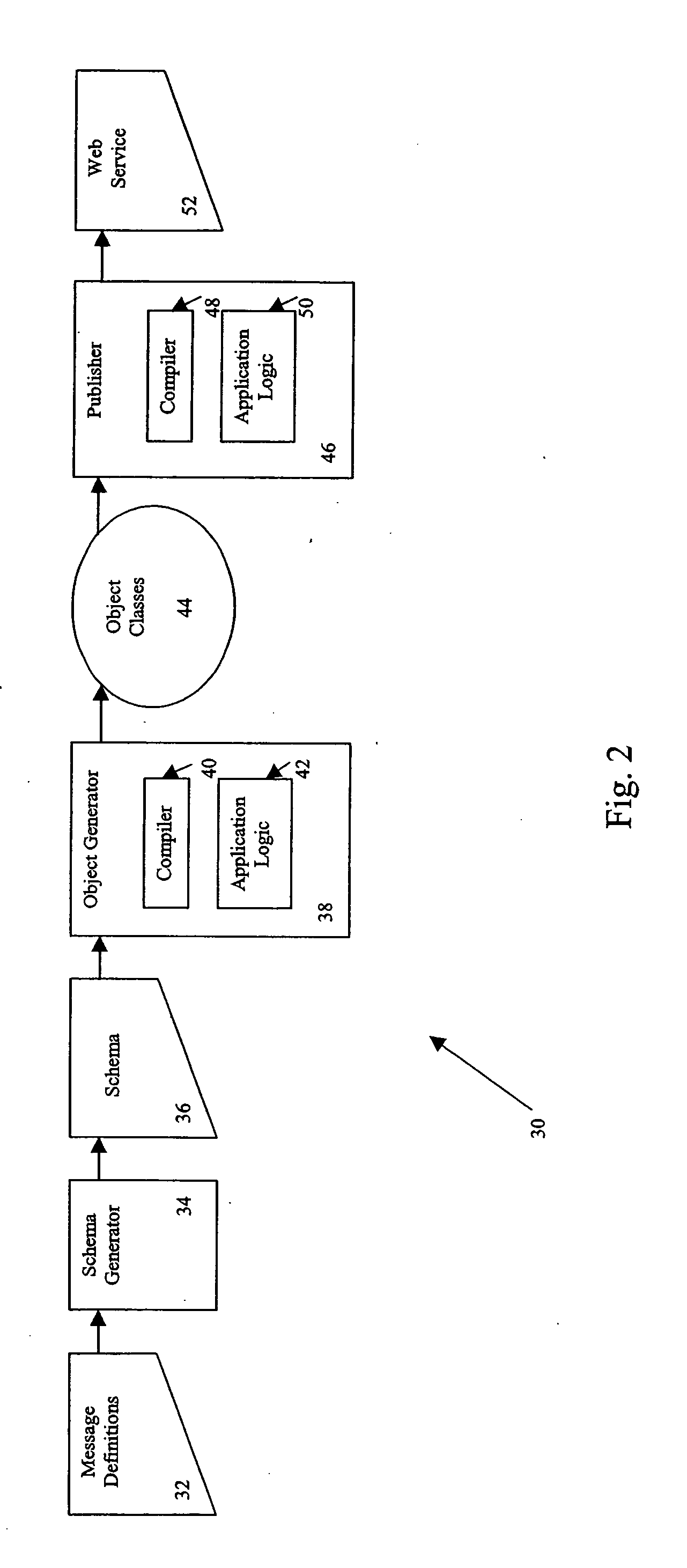

Data extraction for feed generation

ActiveUS20060167860A1Quick assemblyDigital data processing detailsMultiple digital computer combinationsTemplate matchingUnstructured data

A system (and a method) automatically generates a feed from structured or unstructured data. The system identifies a resource having two or more data elements. The resource is matched with a pre-defined template. The pre-defined template is structured for a feed and includes a plurality of fields. The system extracts data elements from the two or more data elements of the resources. Each extracted data element corresponds to a field or the plurality of fields in the pre-defined template. Each extracted data element is then merged into the corresponding field or the plurality of fields in the pre-defined template to generate the feed.

Owner:SIMPLEFEED

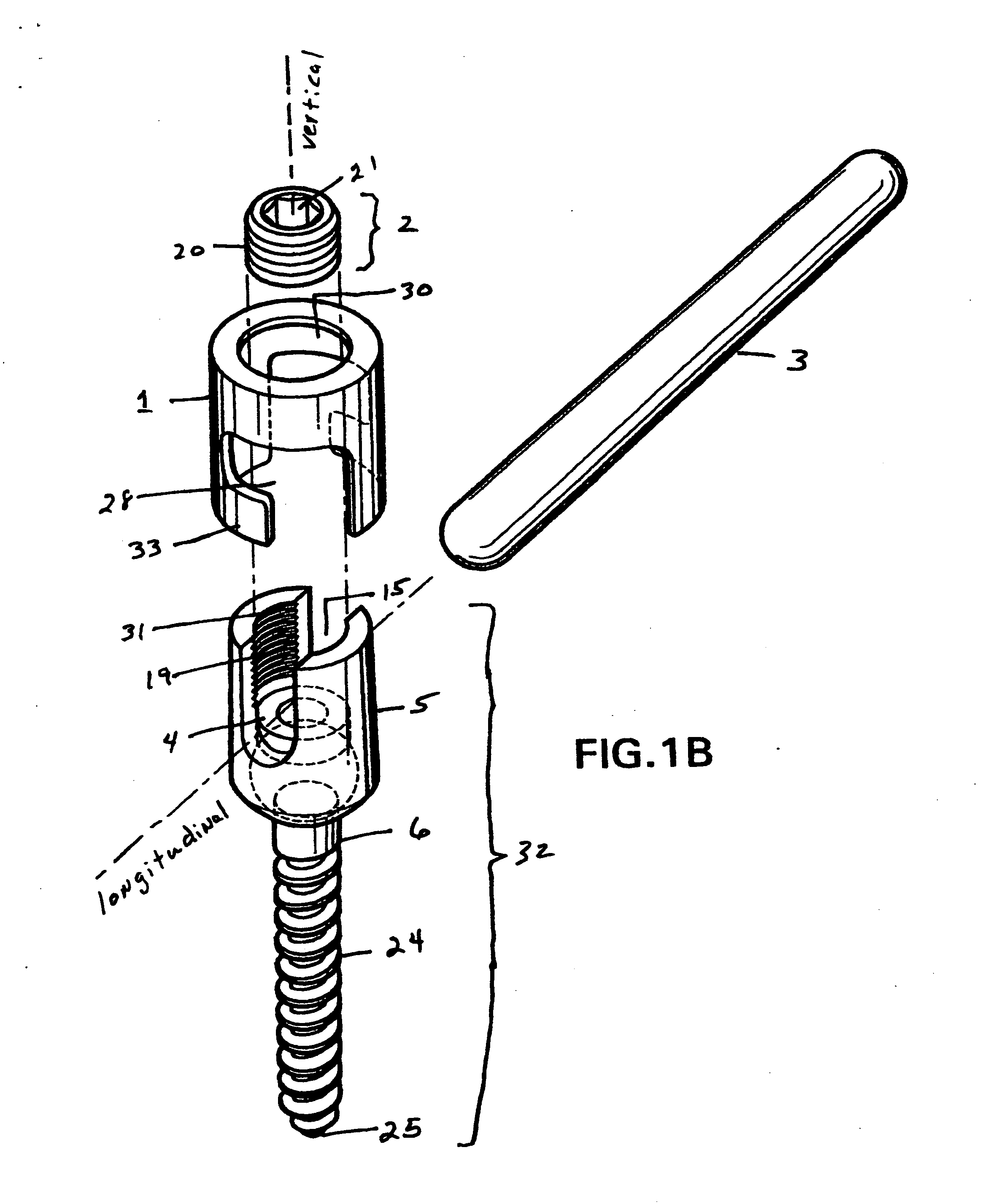

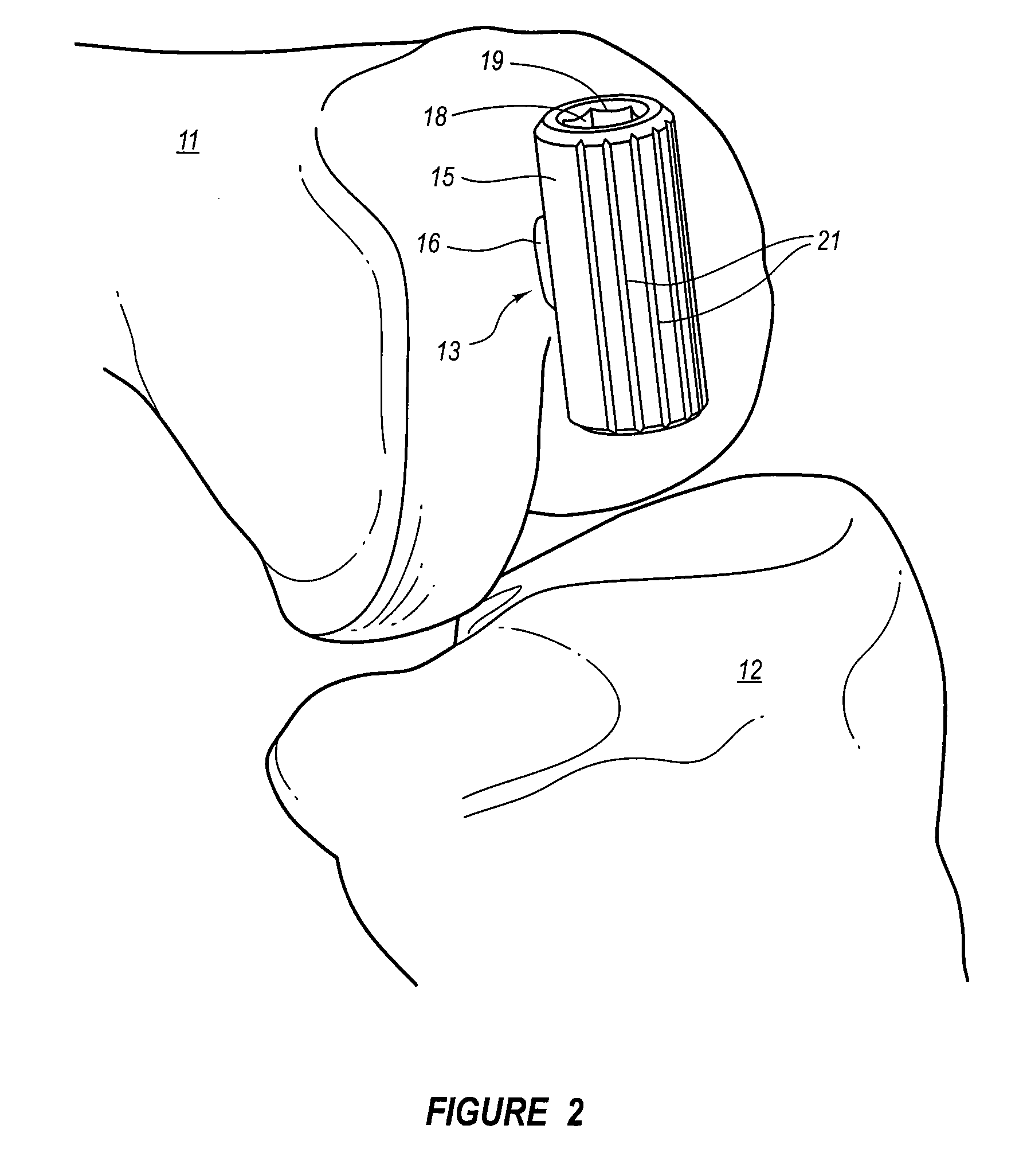

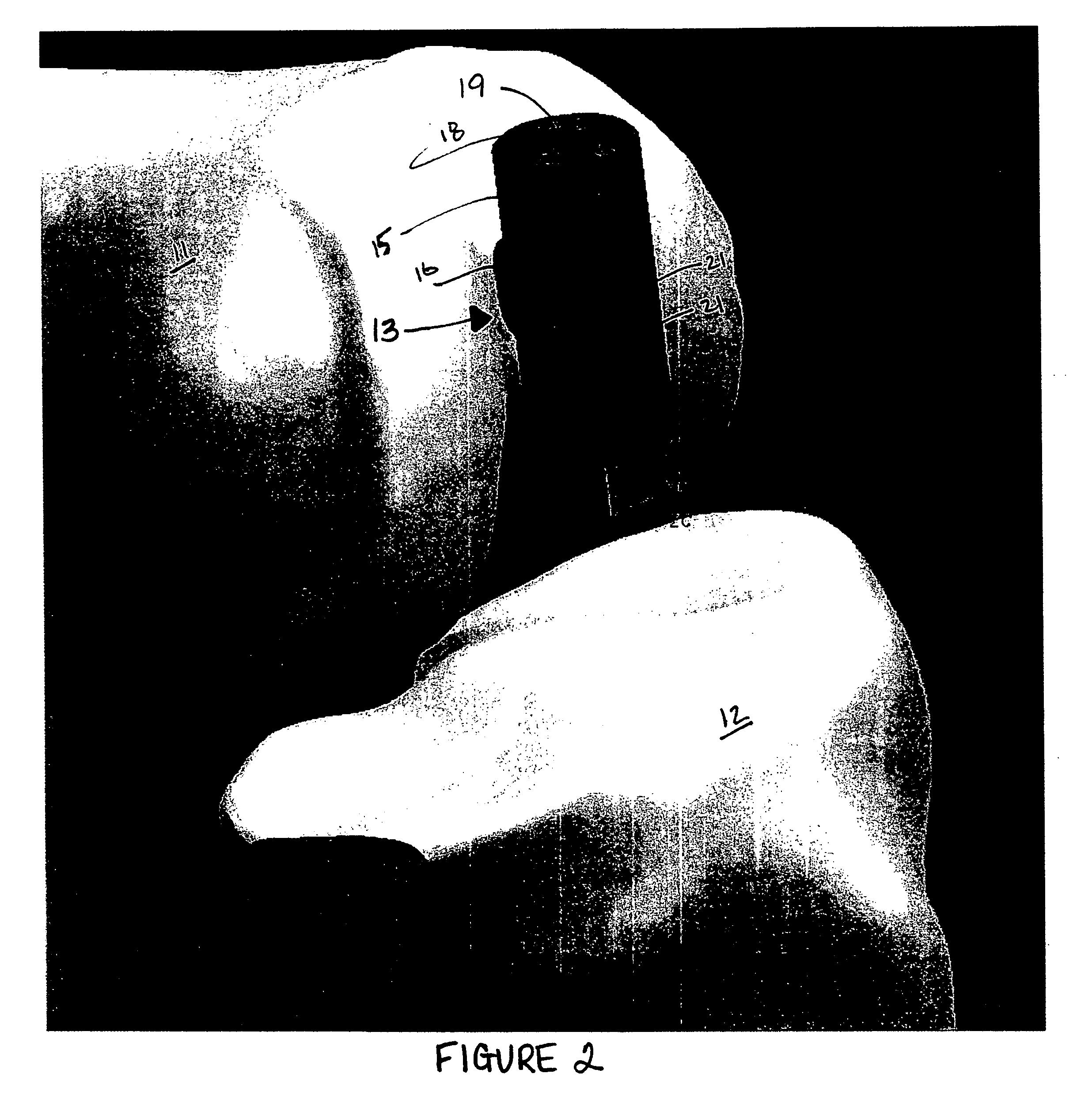

Device for securing spinal rods

InactiveUS20070055242A1Easily and accurately ascertainLess timeSuture equipmentsInternal osteosythesisPedicle screwBiomedical engineering

The present invention is directed to a device for securing a spinal rod to a fixation device such as a pedicle screw or a lamina hook. The device disclosed herein includes a head portion configured to receive a spinal rod, a locking cap configured to engage the head portion and the spinal rod upon rotation of the locking cap relative to the head portion to secure the position of the head portion and the locking cap relative to the spinal rod, and a fastener portion extending from the head portion and configured to engage the spine. The fastener portion of the device can be in the form of a screw, hook or clamp, or any other configuration known in the art.

Owner:BAILLY FR EMILE

Closure system

ActiveUS20090184189A1Reduce in quantityTorque felt by the knob may be constantSnap fastenersGlovesFast releaseEngineering

In some embodiments, a cam assembly and strap based closure system using a spiral is configured for bringing two sides of an article together. In some embodiments, when the user inserts the strap into the cam assembly and turns a knob, the strap is driven into the cam assembly and the strap pins engage one or more cam spirals. In some embodiments, the system is configured such that strap pins may be engaged at a constant angle which may be self-locking. In some embodiments, the system may be infinitely adjustable and the torque felt by the knob may be constant. In some embodiments, the system may be configured to be a quick release system and may allow rapid insertion of the strap for faster operation.

Owner:BOA TECHNOLOGY

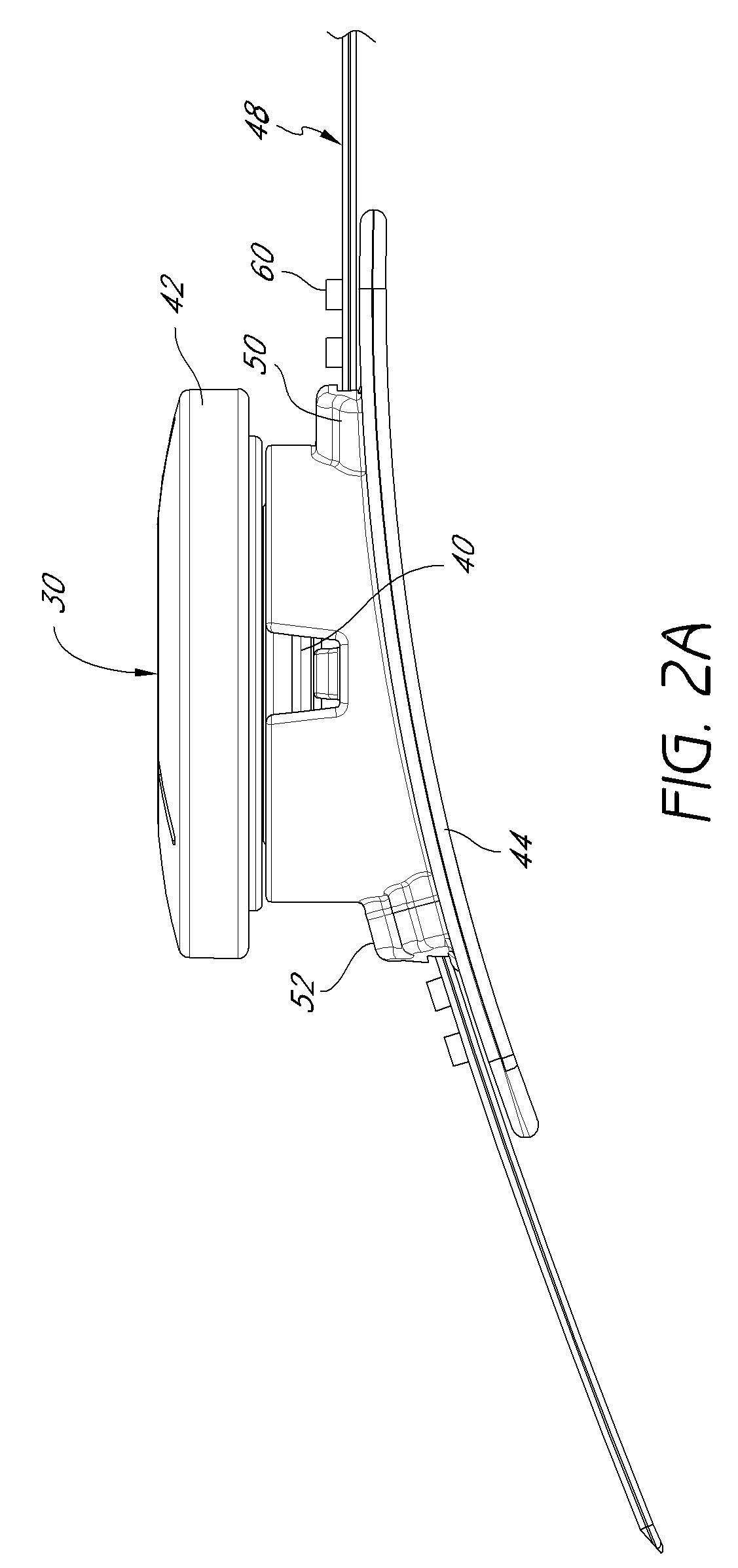

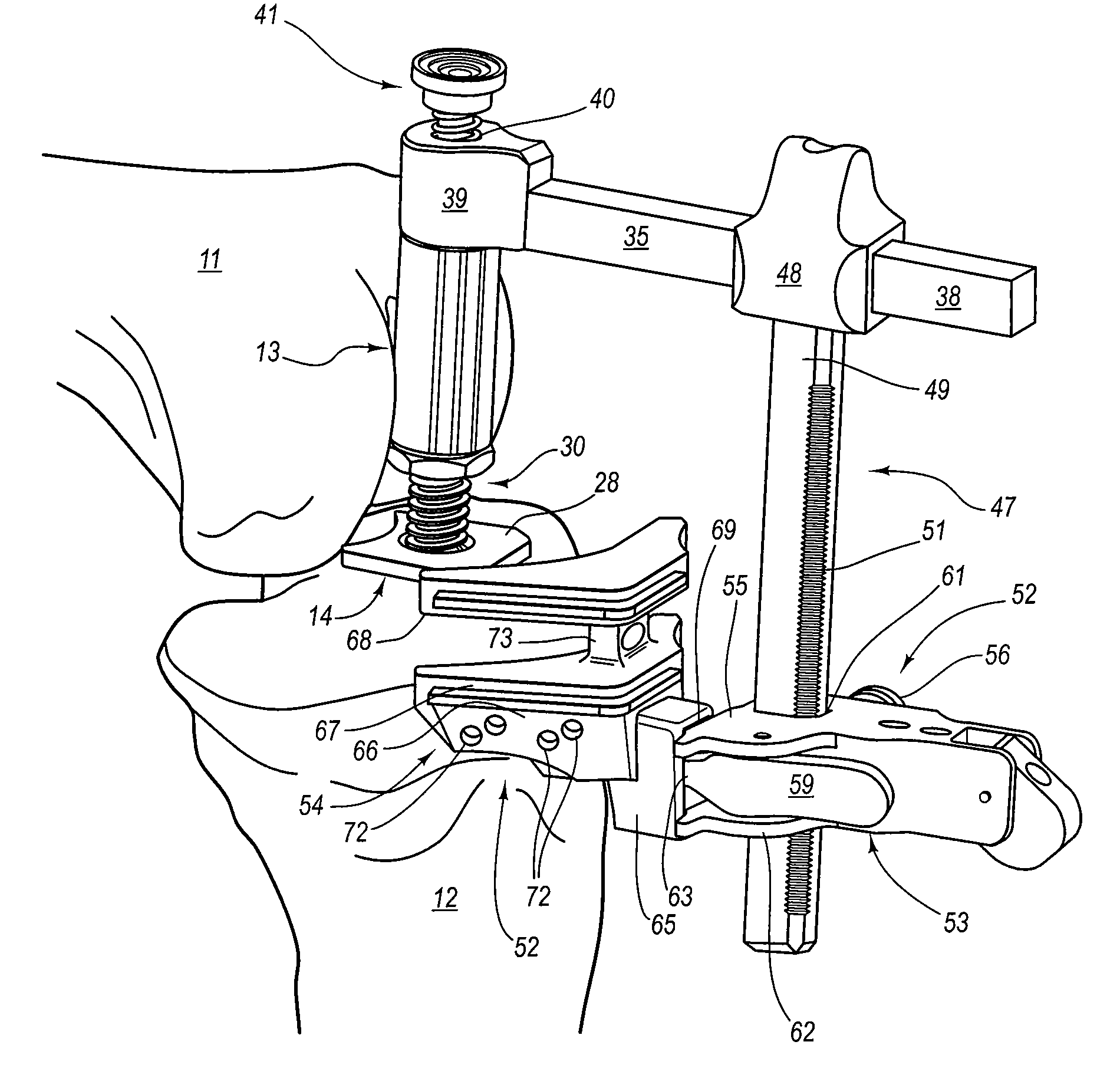

Arthroplasty systems and methods for optimally aligning and tensioning a knee prosthesis

ActiveUS20090043310A1Small and noninvasive approachQuick disassemblyInternal osteosythesisDiagnosticsTibiaKnee Joint

A combination of a first assembly for guiding resection of a femur and tibia of a knee joint and a second assembly including femoral and tibial knee components. The combination of the first assembly and the second assembly provides optimal placement and positioning of the femoral and tibial knee components to achieve near-normal knee kinematics and tension. The preparation for and placement of the prosthetic knee components provides medial-pivoting kinematics mimicking that of the natural knee thereby promoting improved outcome for the patient.

Owner:RASMUSSEN INSTR LLC

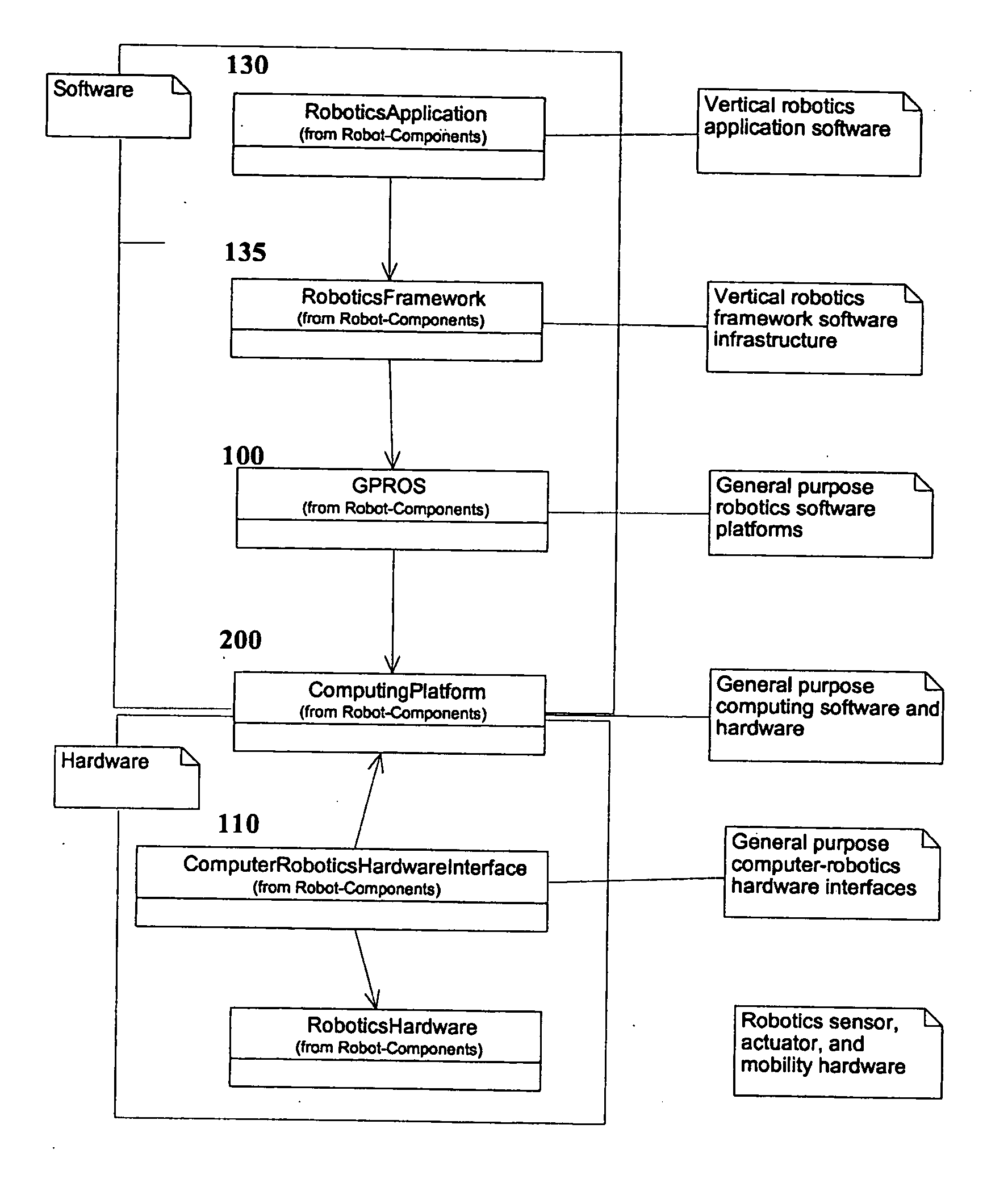

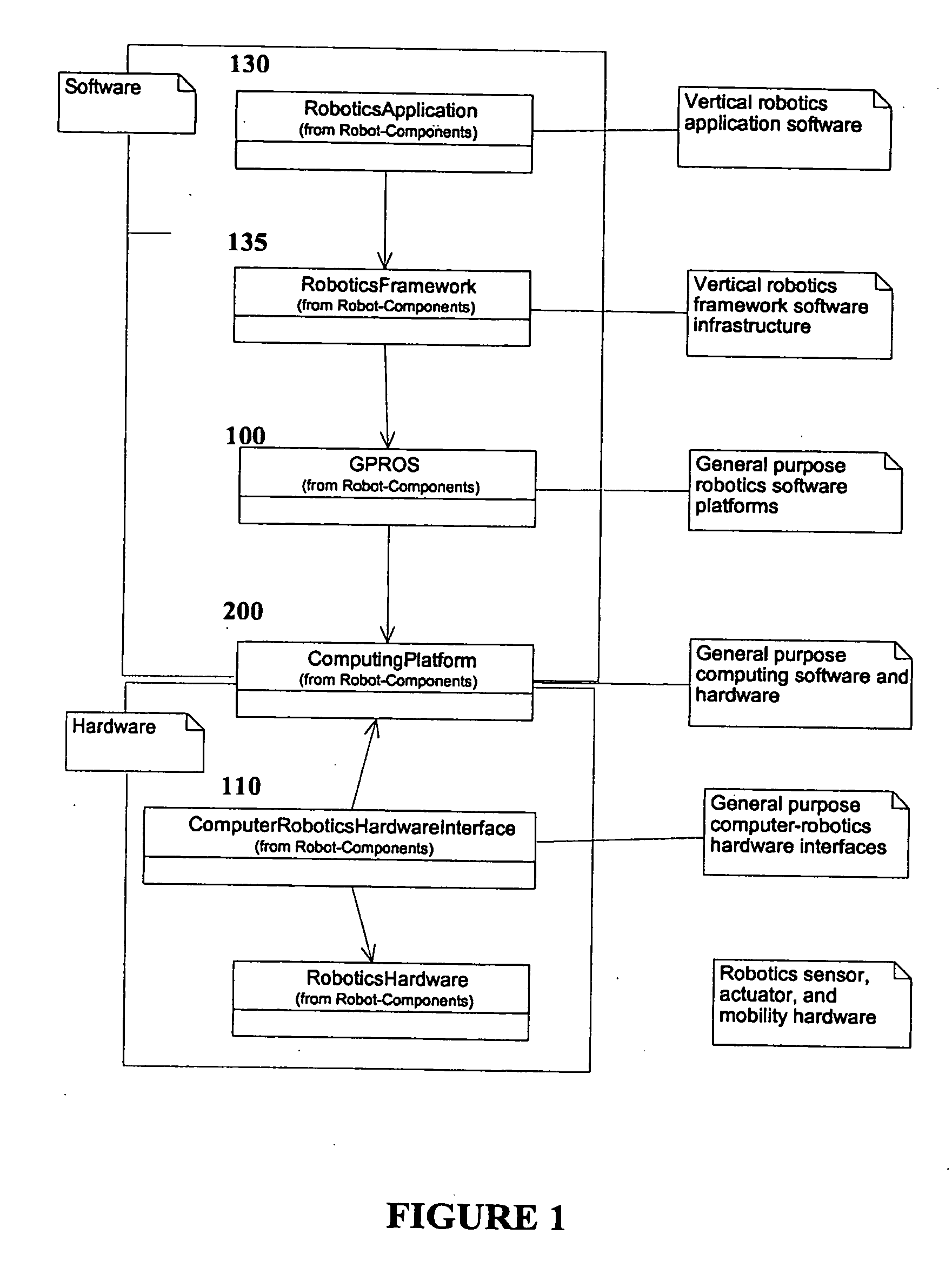

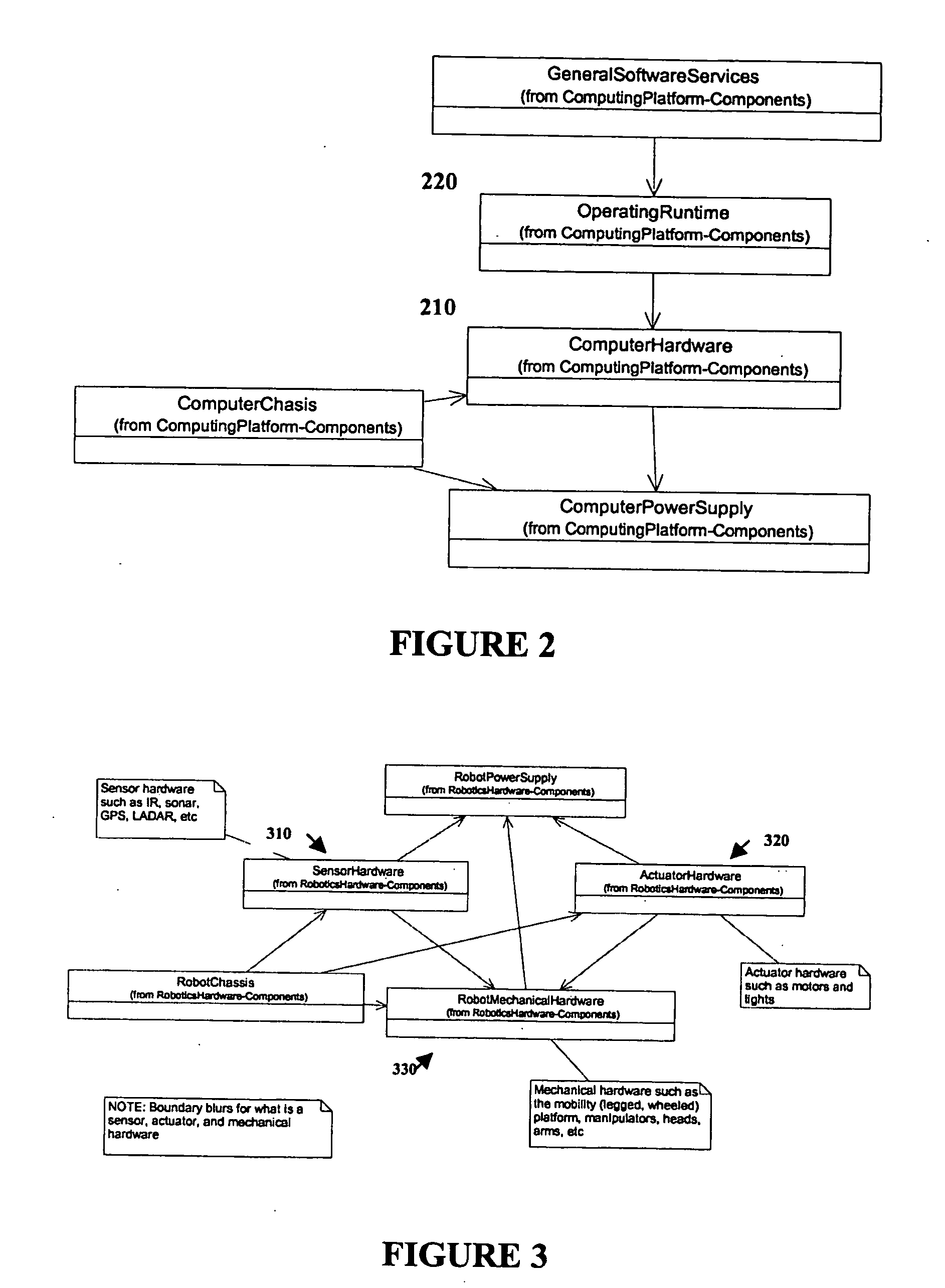

General purpose robotics operating system

ActiveUS20070208442A1Great ease of communicationAdapt quicklyAutonomous decision making processSpecial data processing applicationsGeneral purposeOperational system

The present invention provides a general purpose operating system that shows particular usefulness in the robotics and automation fields. The operating system provides individual services and the combination and interconnections of such services using built-in service extensions, built-in completely configurable generic services, and a way to plug in additional service extensions to yield a comprehensive and cohesive framework for developing, configuring, assembling, constructing, deploying, and managing robotics and / or automation applications.

Owner:PERRONE ROBOTICS

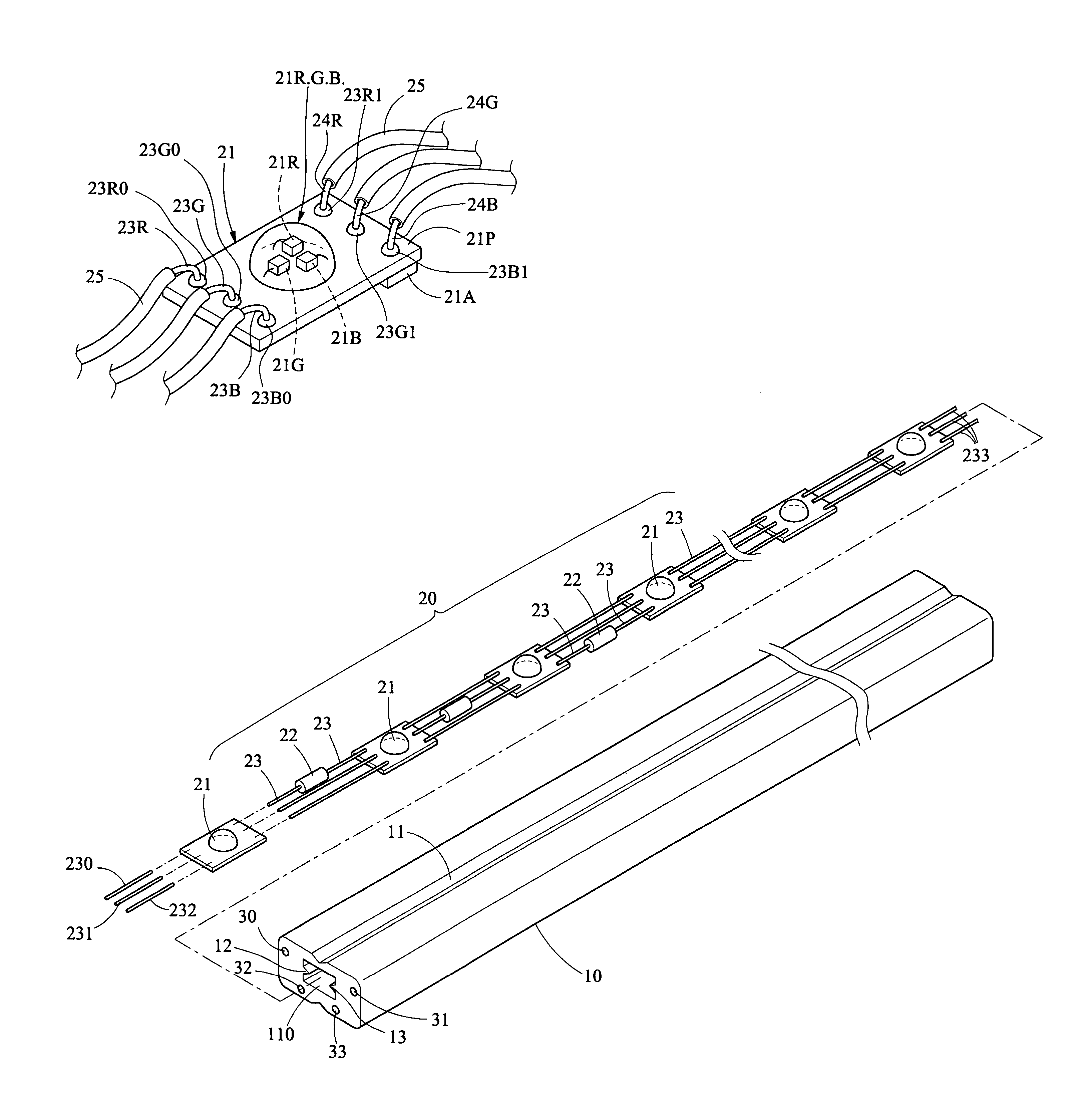

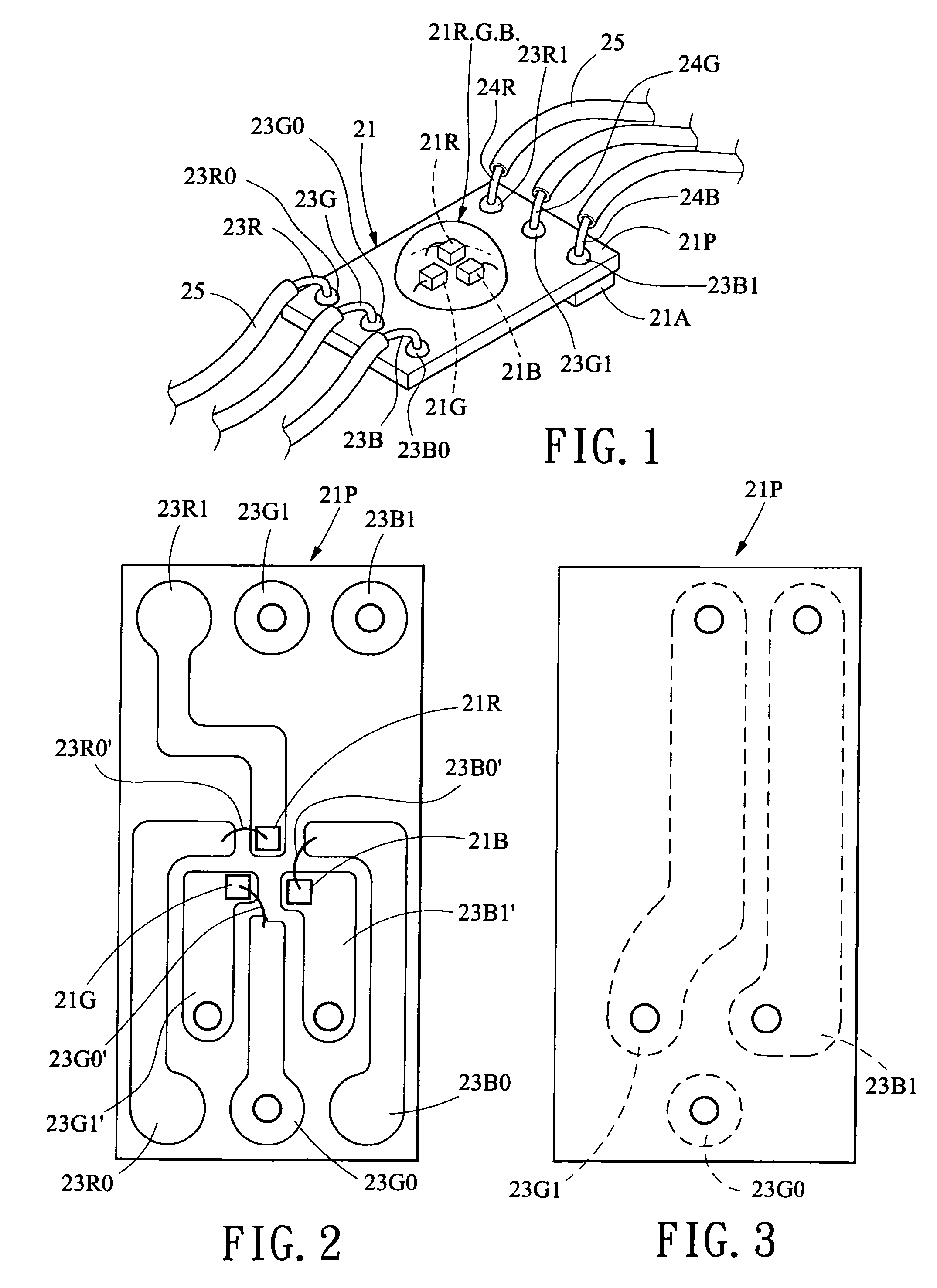

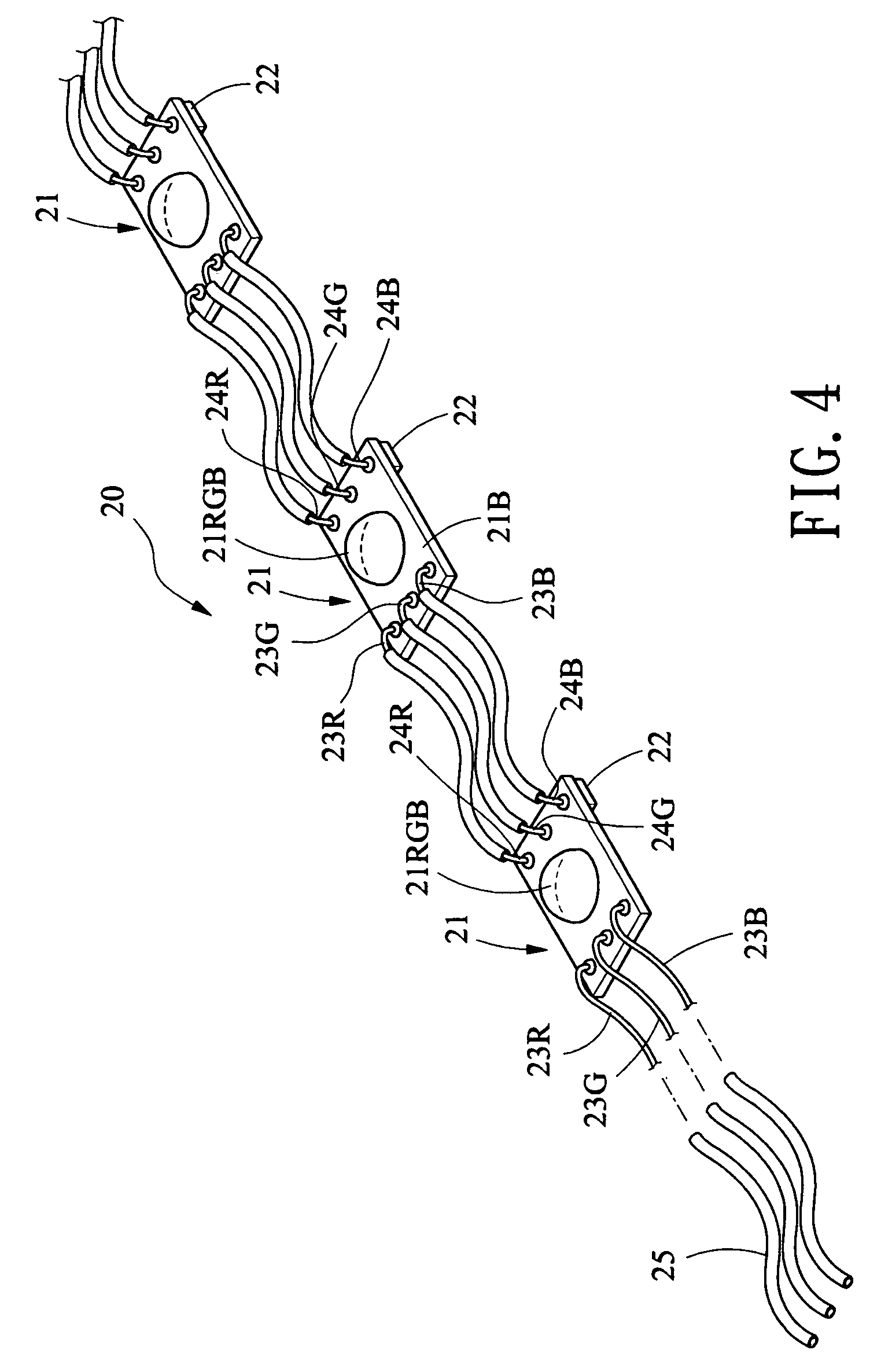

Full-color flexible light source device

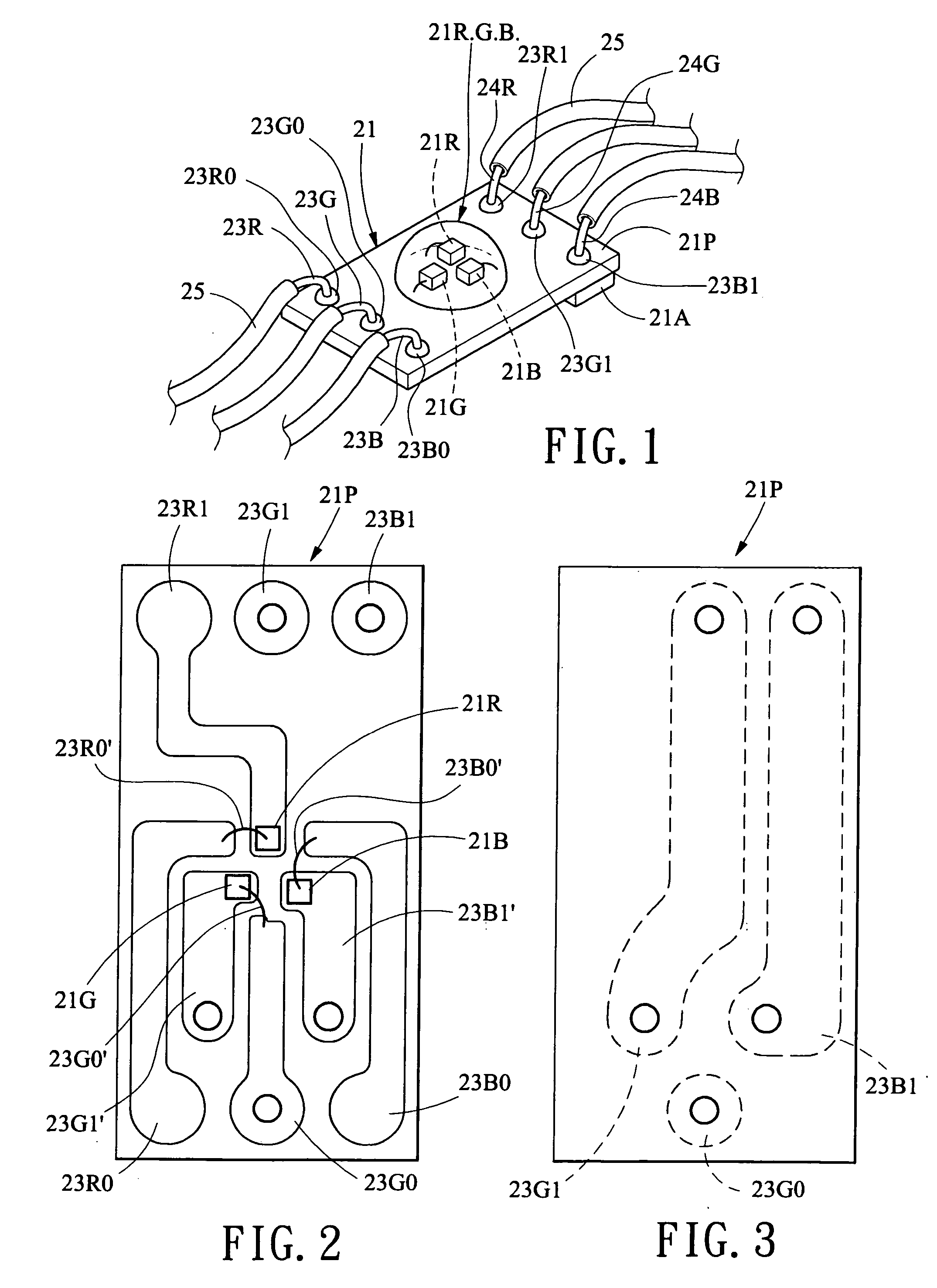

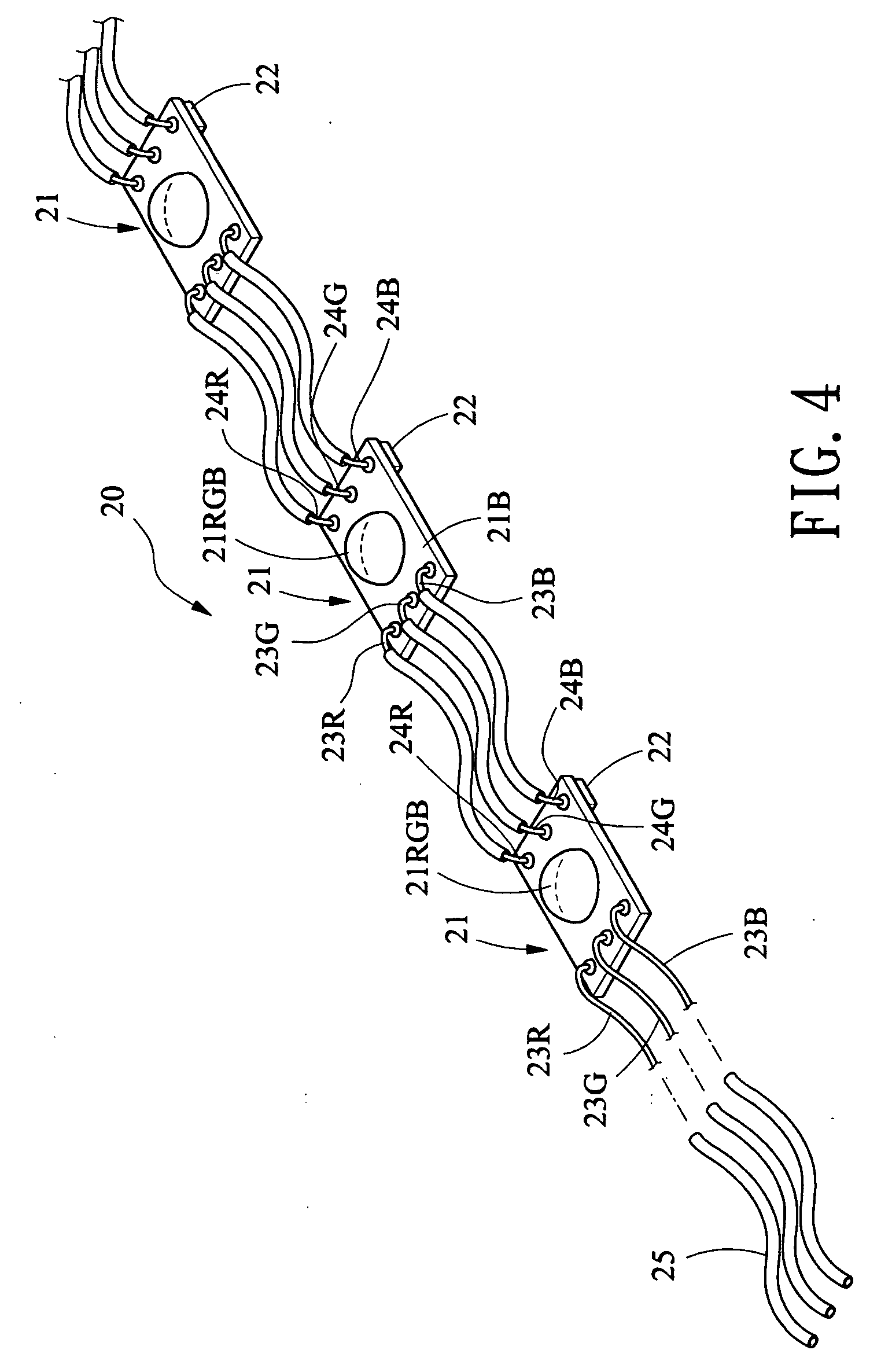

ActiveUS7140751B2Quick assemblyUniform lightLight source combinationsPoint-like light sourceGreen ledFull color

A full-color flexible light source device is disclosed. The device includes a plurality of light source units each comprises a red LED, a green LED, and a blue LED arranged in the shape of a triangle. Each of the R, G, and B LEDs is a bare chip and the R, G, and B LEDs are encapsulated as a C.O.B. type RGB light source unit. The device is able to emit a uniform light. Also, the device has an increased tensile strength and flexibility as well as has waterproof and vibration-proof features. In other embodiments, the device is encapsulated by elongated, flexible, parallelepiped inner and outer fixing members or formed on a strip.

Owner:HAYASHIBARA BIOCHEMICAL LAB INC

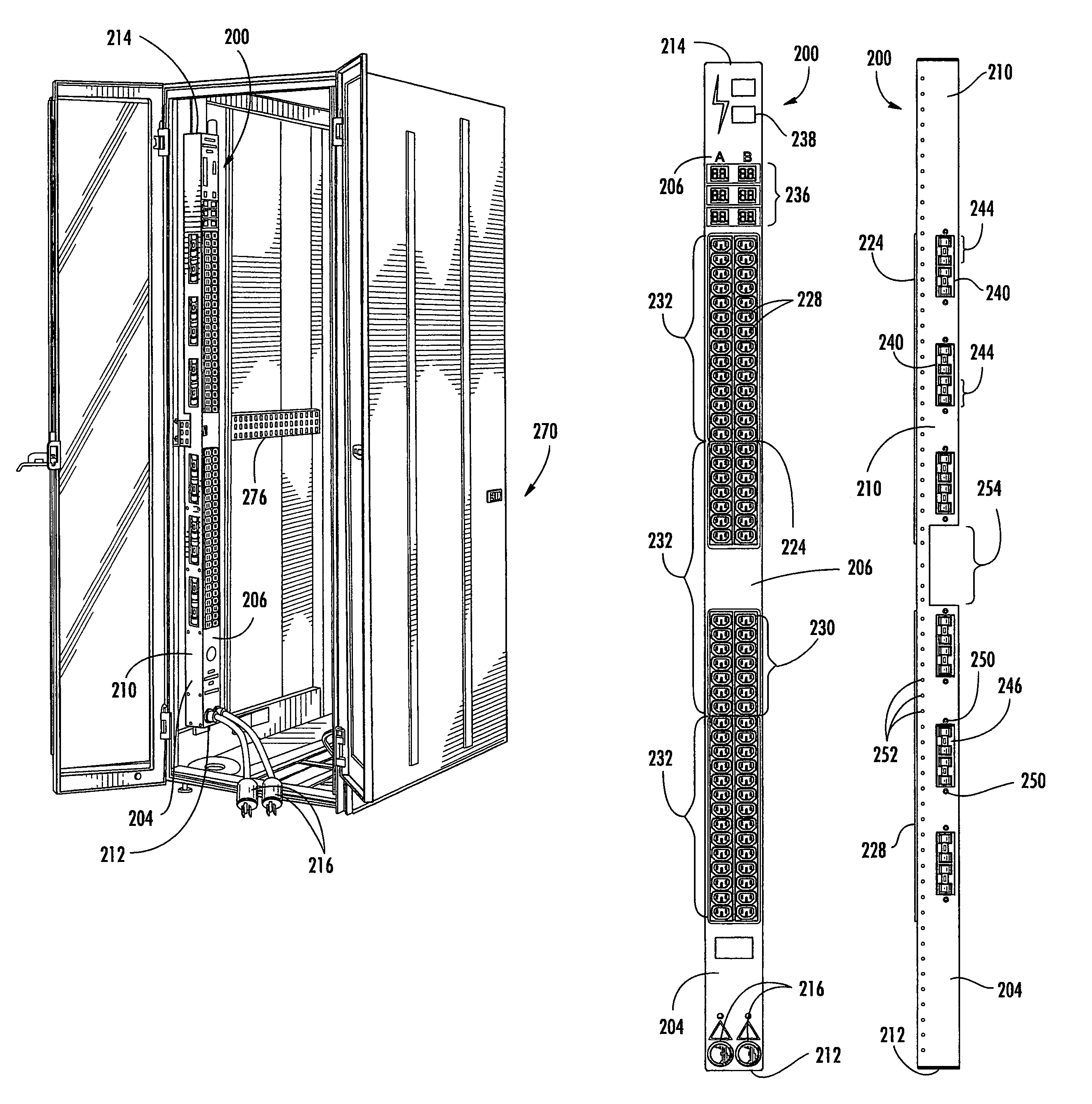

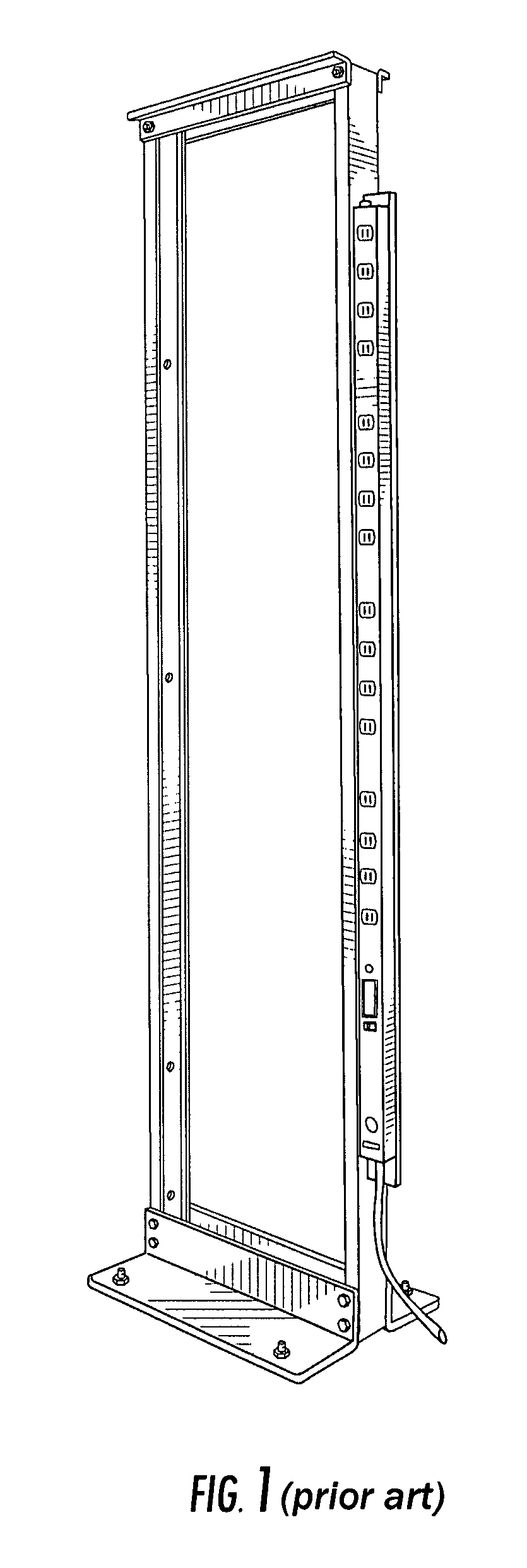

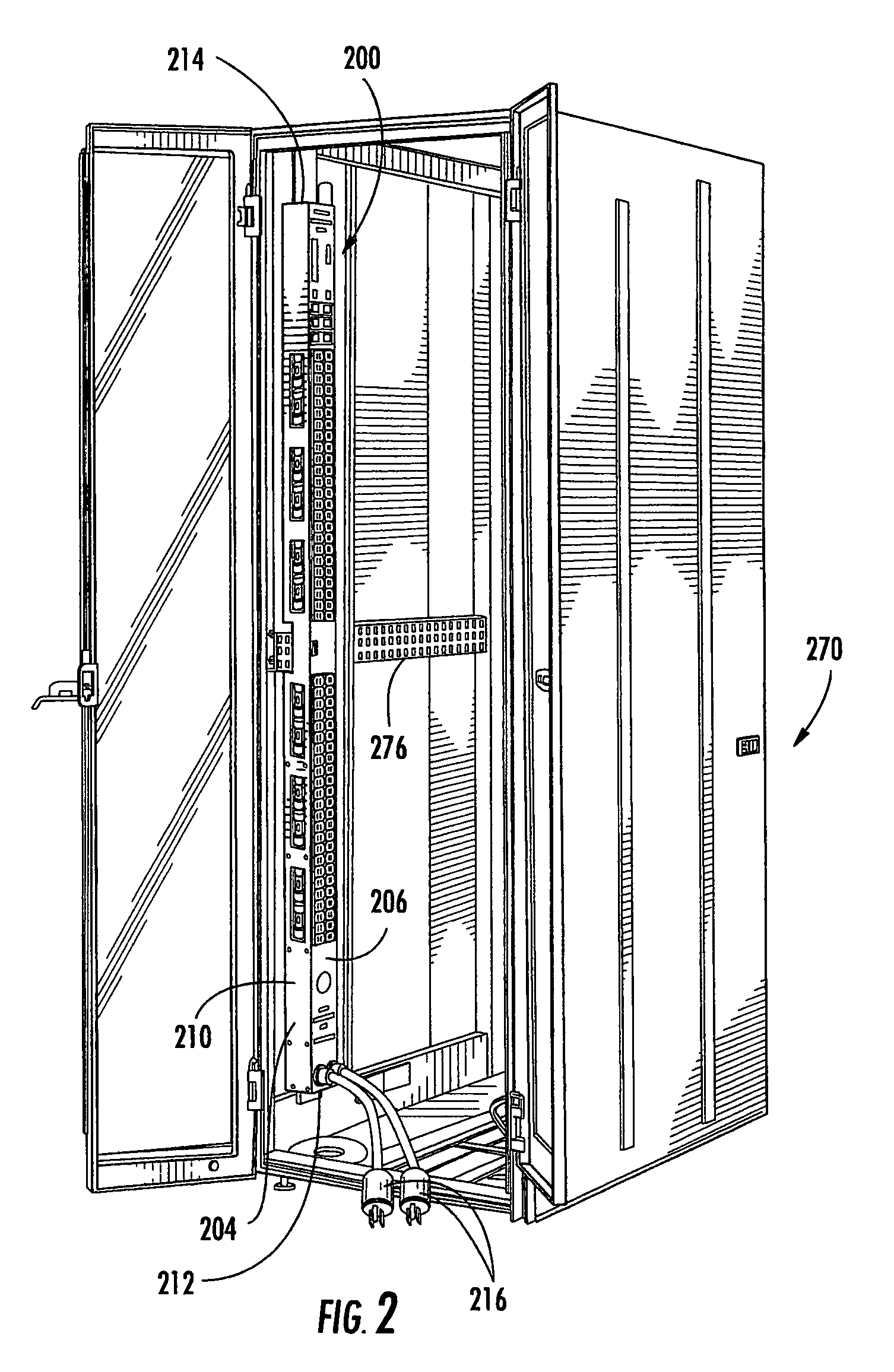

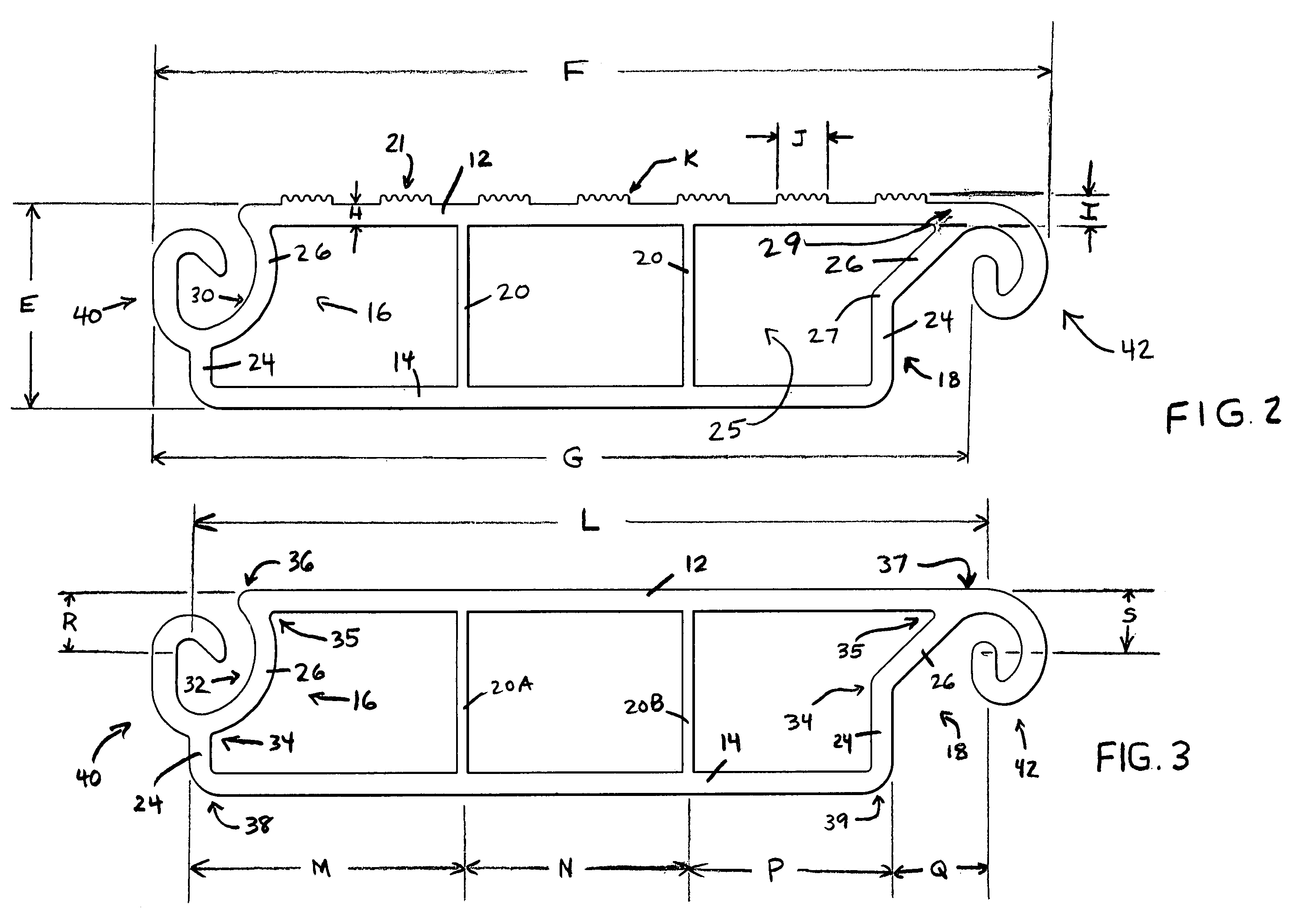

Ganged outlet power distribution apparatus

InactiveUS7268998B2Reduce in quantityLow costServersSubstation/switching arrangement casingsEngineeringDistributed power

A power distribution unit is provided that may be used to distribute power to a plurality of electronic devices. The power distribution unit may have one or more outlet gangs with integral components providing a plurality of individual power outlets. Each outlet gang may be associated with one or more power rails which deliver power to each power outlet. A connector may be located on each power rail. The power distribution unit may include a connector board for connection to two or more electronic components, such as outlet gangs. Fuse access windows may be provided to provide access to a fuse holder. The power distribution unit may have a housing having a mounting channel formed therein, which may allow the power distribution unit to be mounted in relatively to a rack having a protrusion which may be received by the mounting channel.

Owner:SERVER TECHNOLOGY

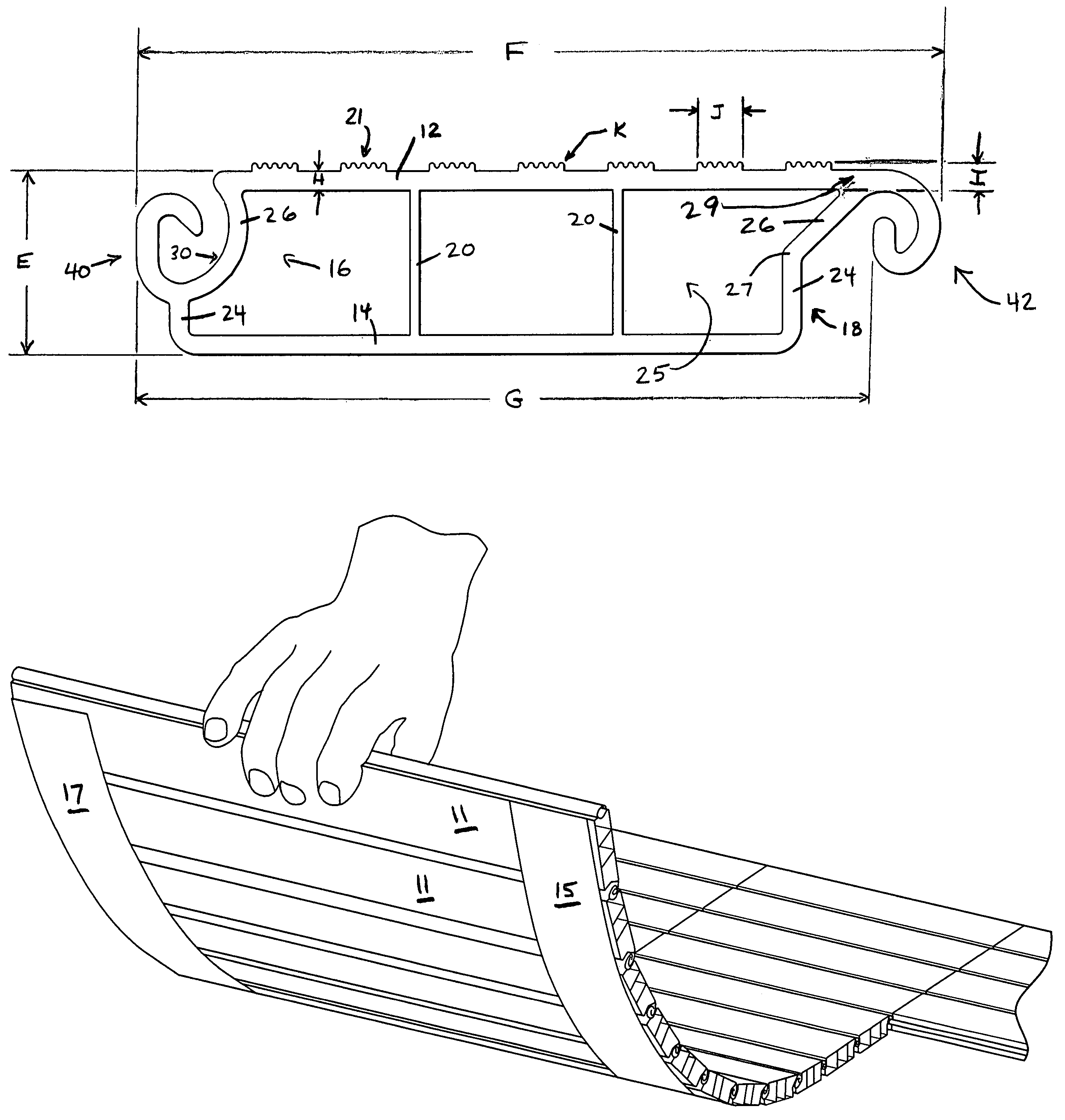

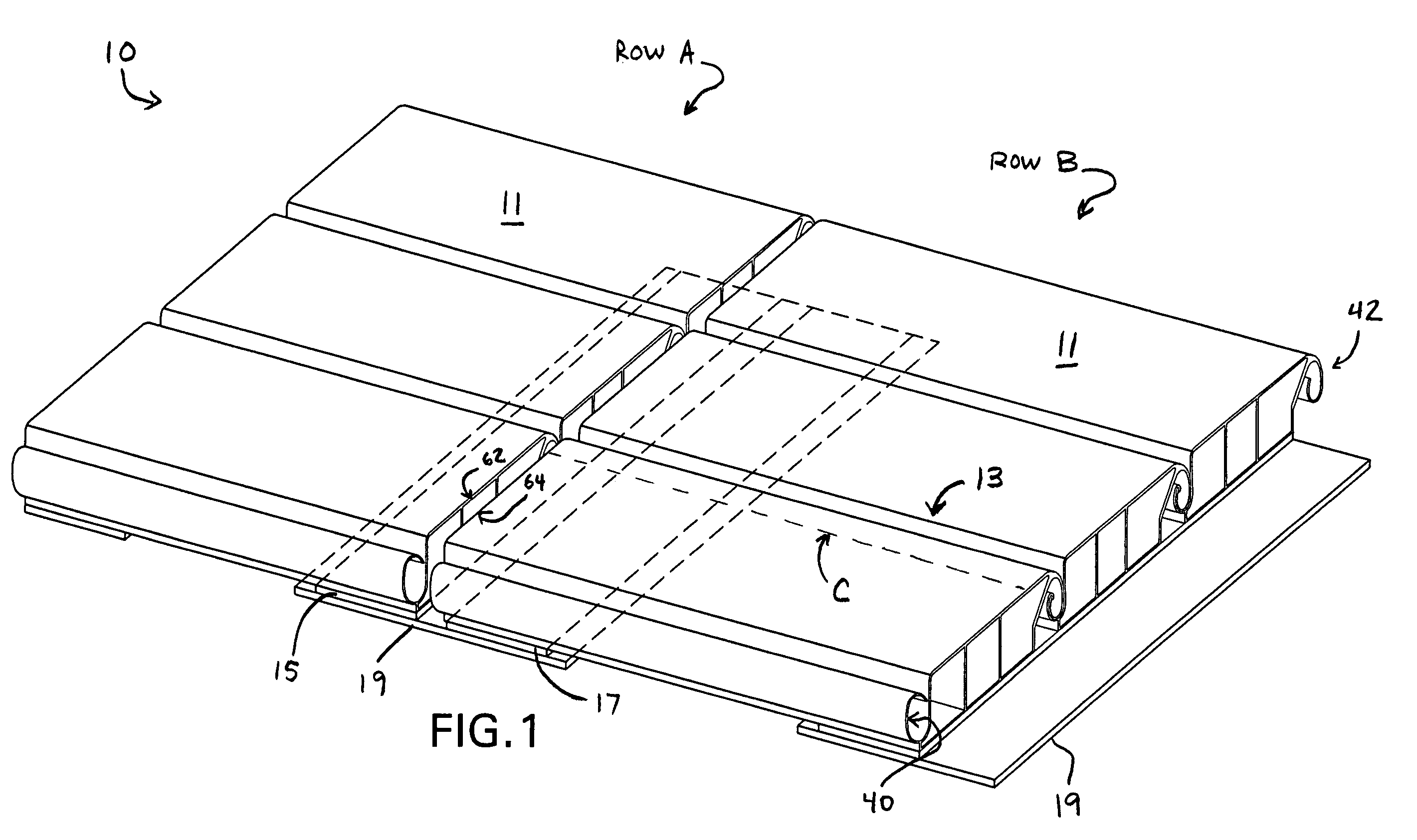

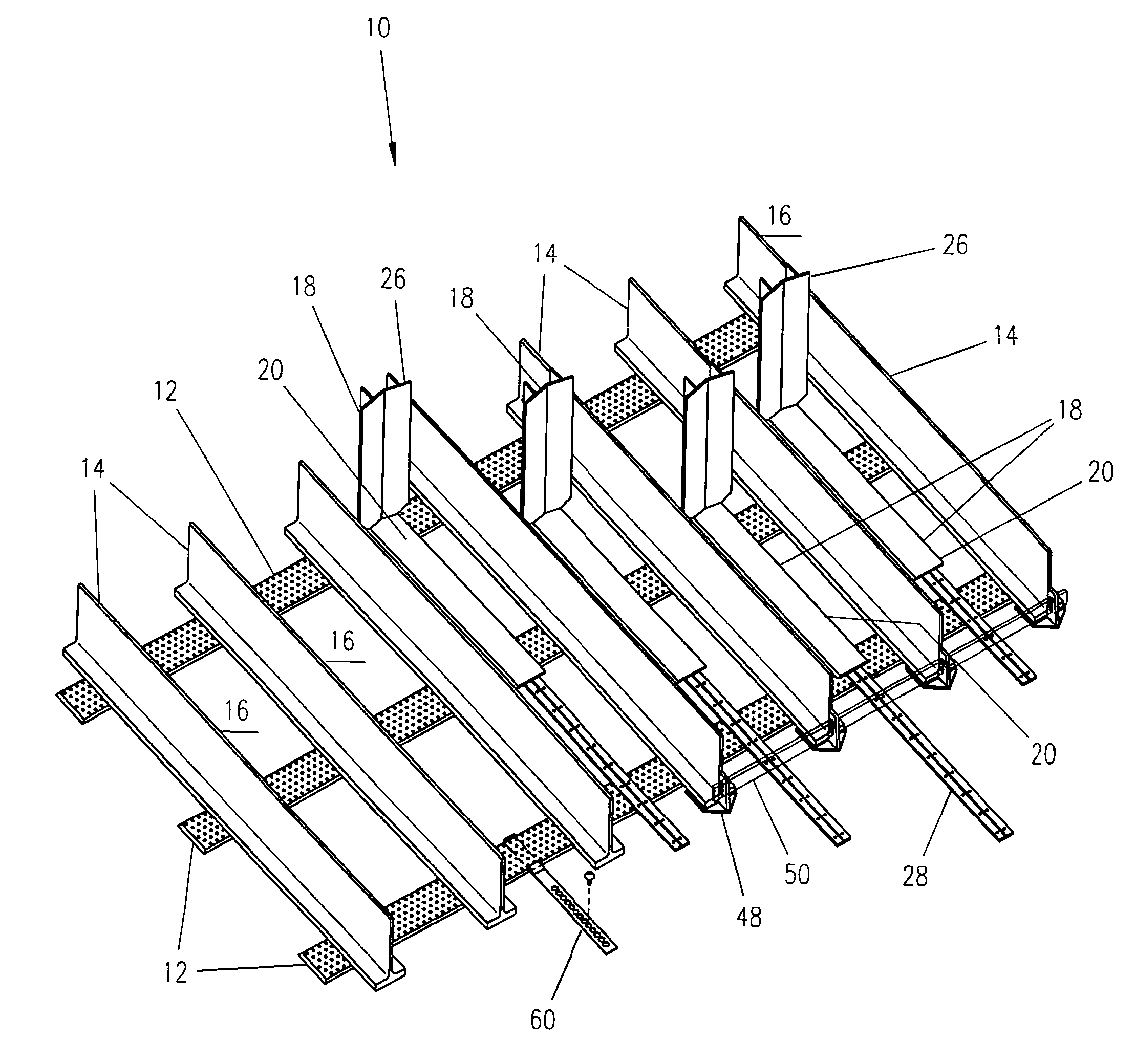

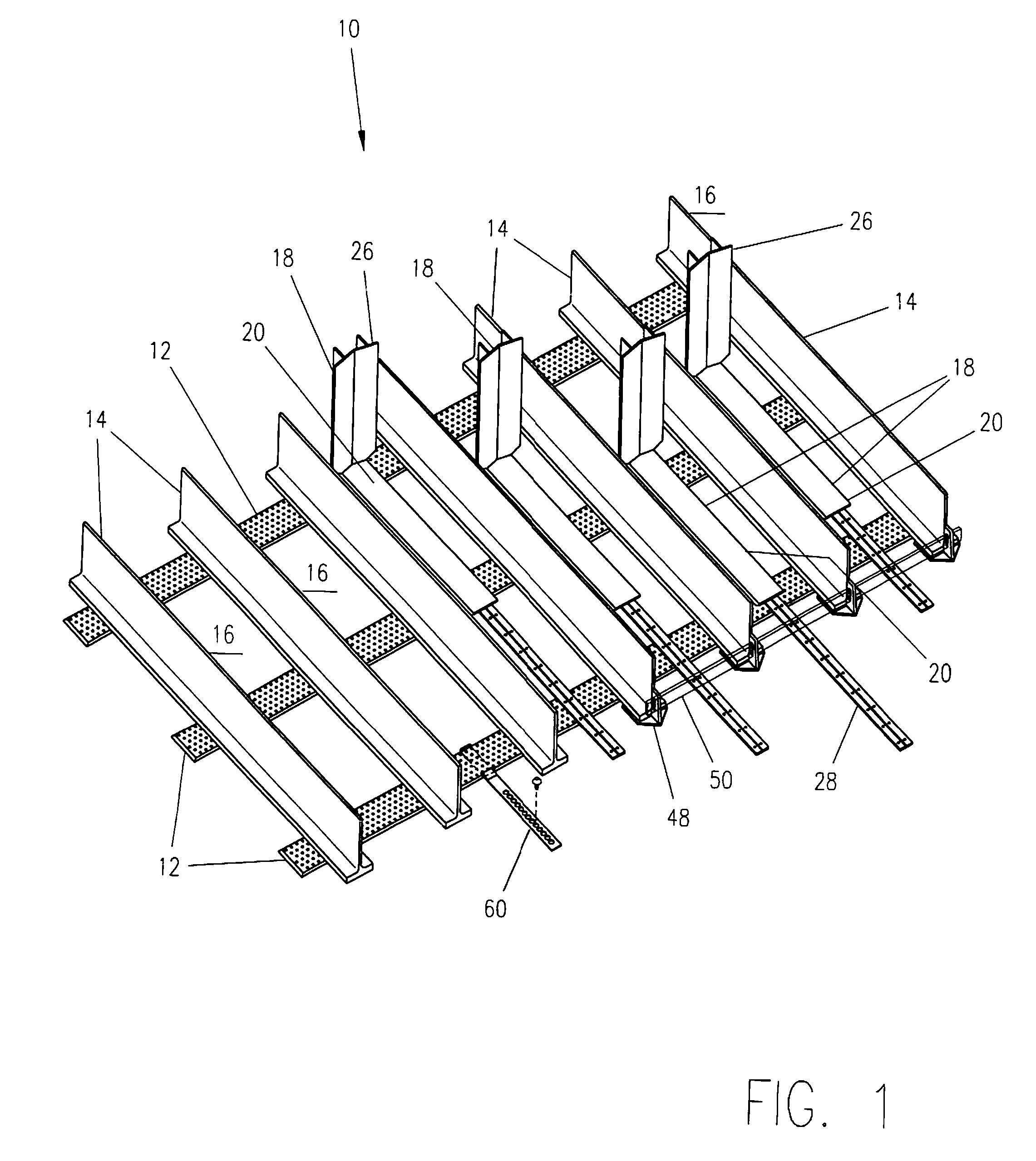

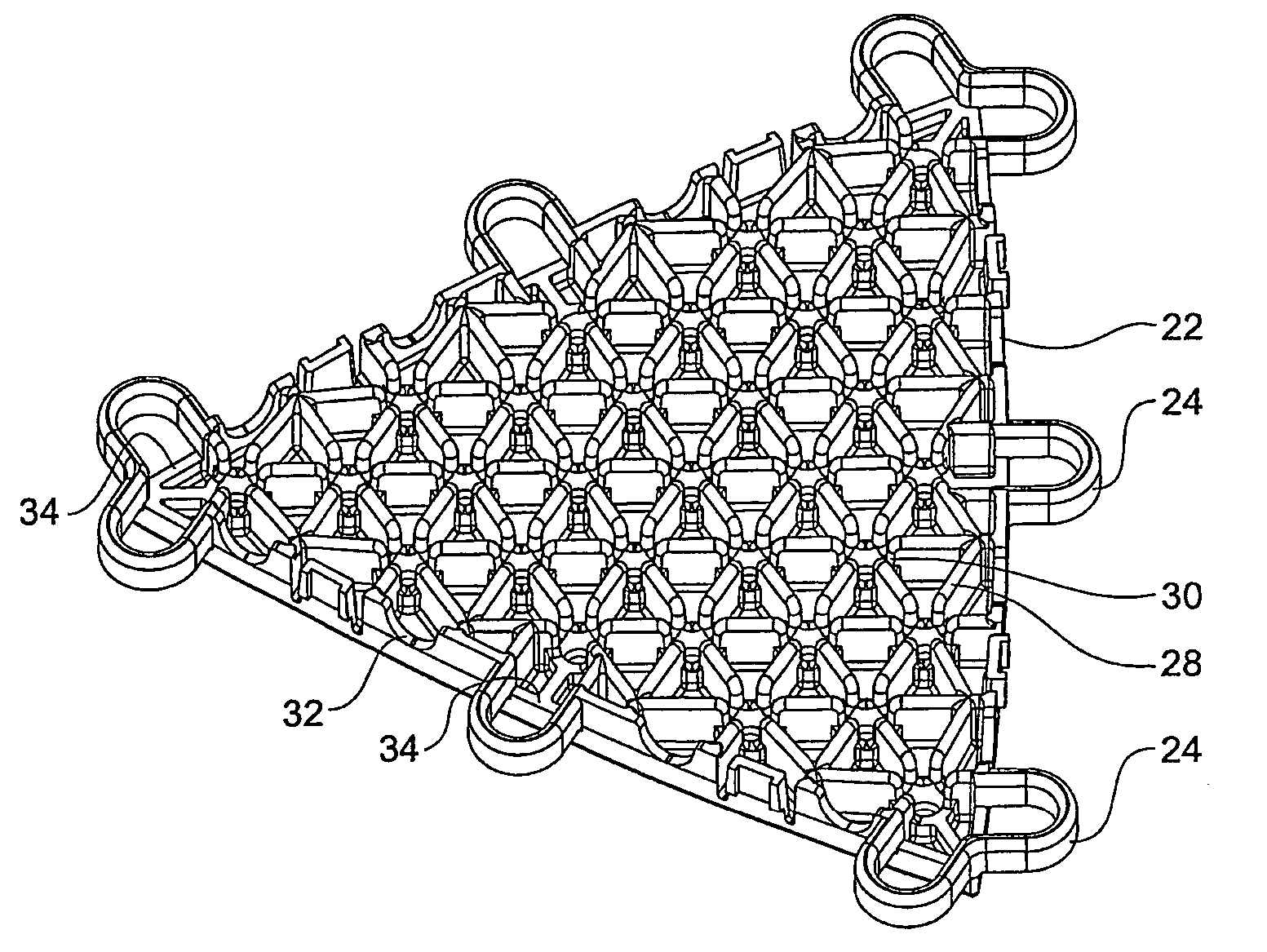

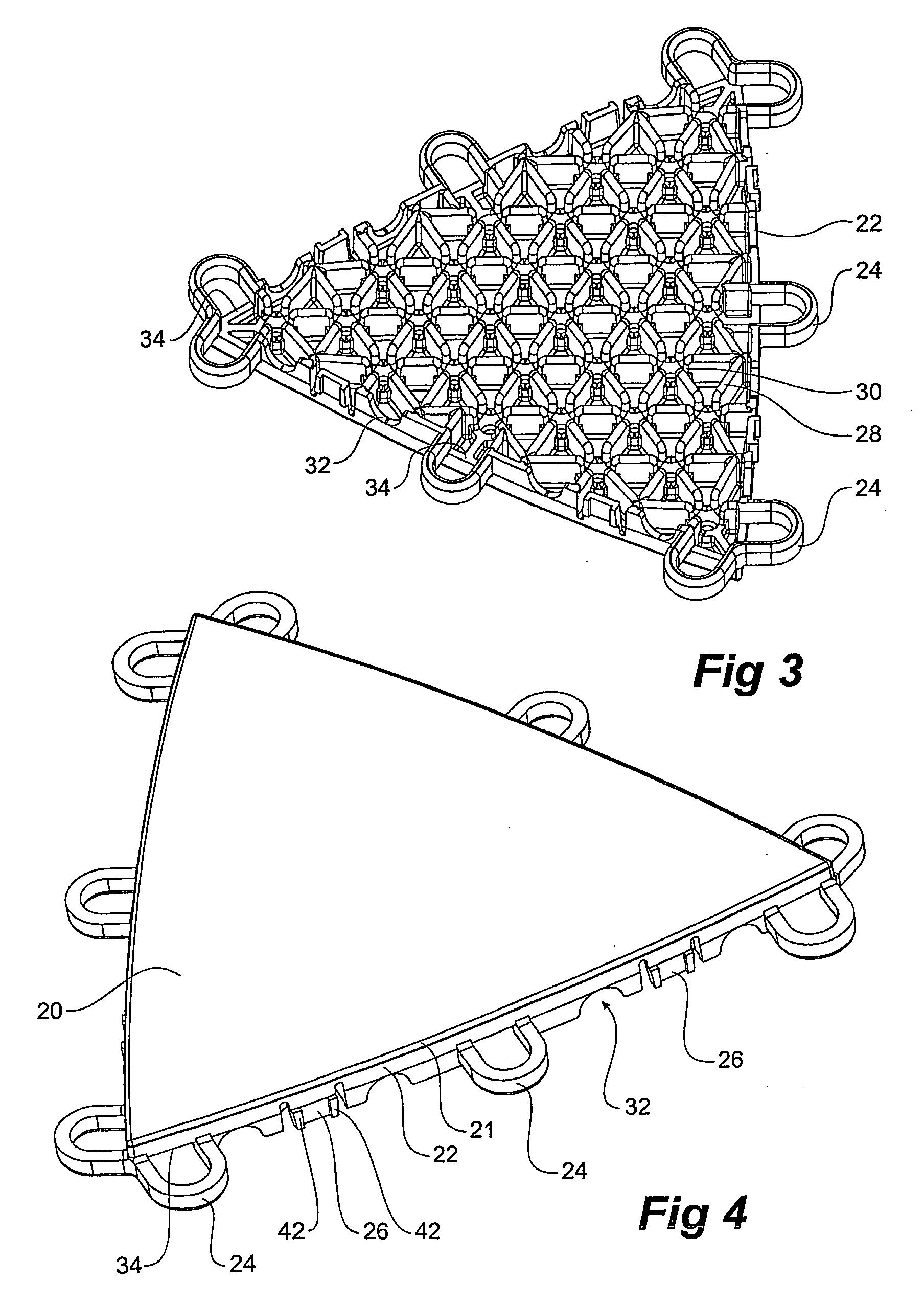

Roll-up surface, system and method

ActiveUS7090430B1Maintain strengthQuick assemblyCovering/liningsSingle unit pavingsEngineeringHinge angle

The present invention provides a ground flooring device, system and method which includes connectable slats or panels having connection means which allow a series of slats to be quickly assembled, rolled up for storage or transport, and unrolled for deployment. The connection means can comprise specially adapted hinge members provided on the edges of the panels for flexible, yet secure attachment. The slats can be secured in a series, and a series of slats can be secured in multiple rows to create a solid, manipulable floor readily deployable on ground areas of virtually any shape.

Owner:GROUND FLOOR SYST

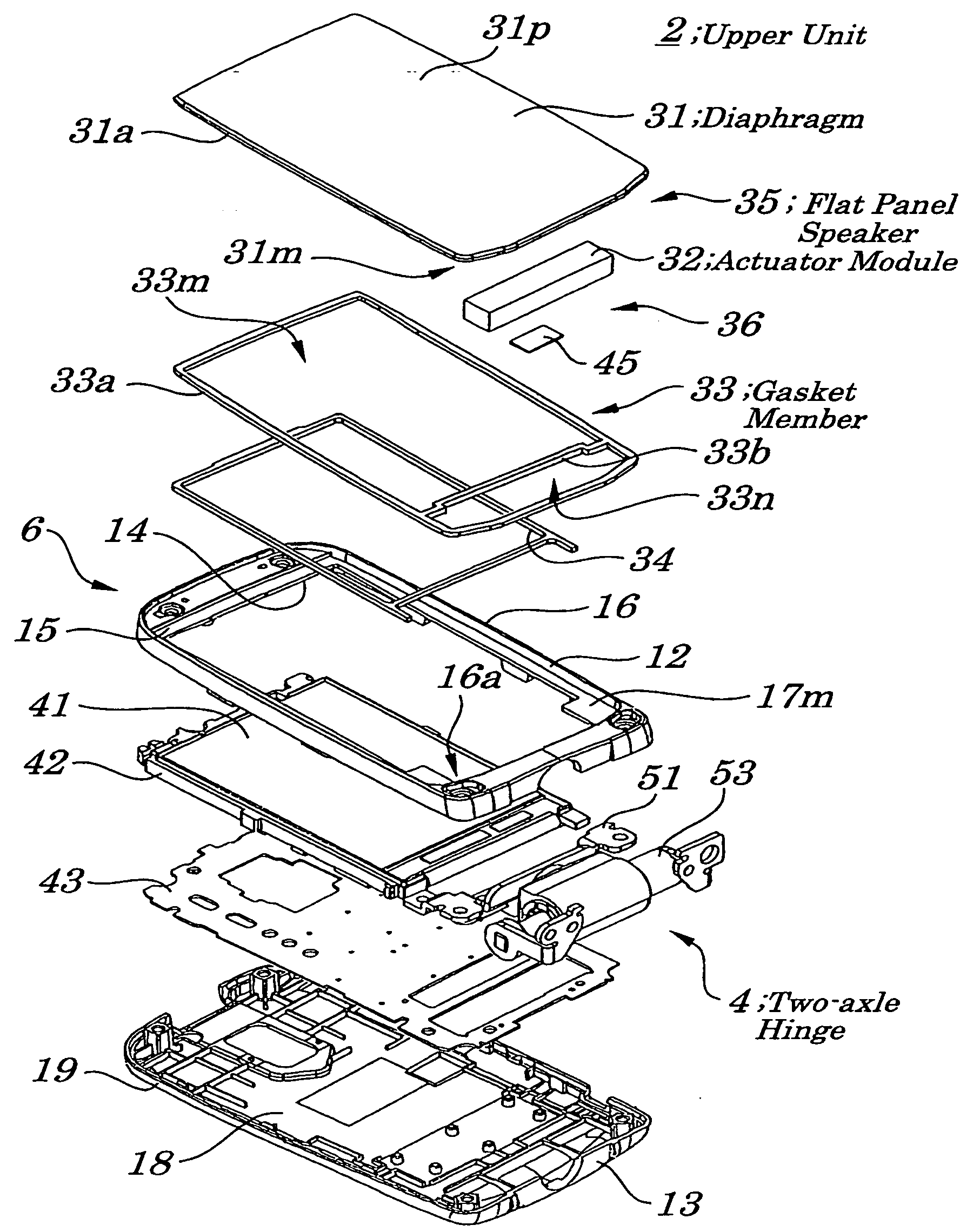

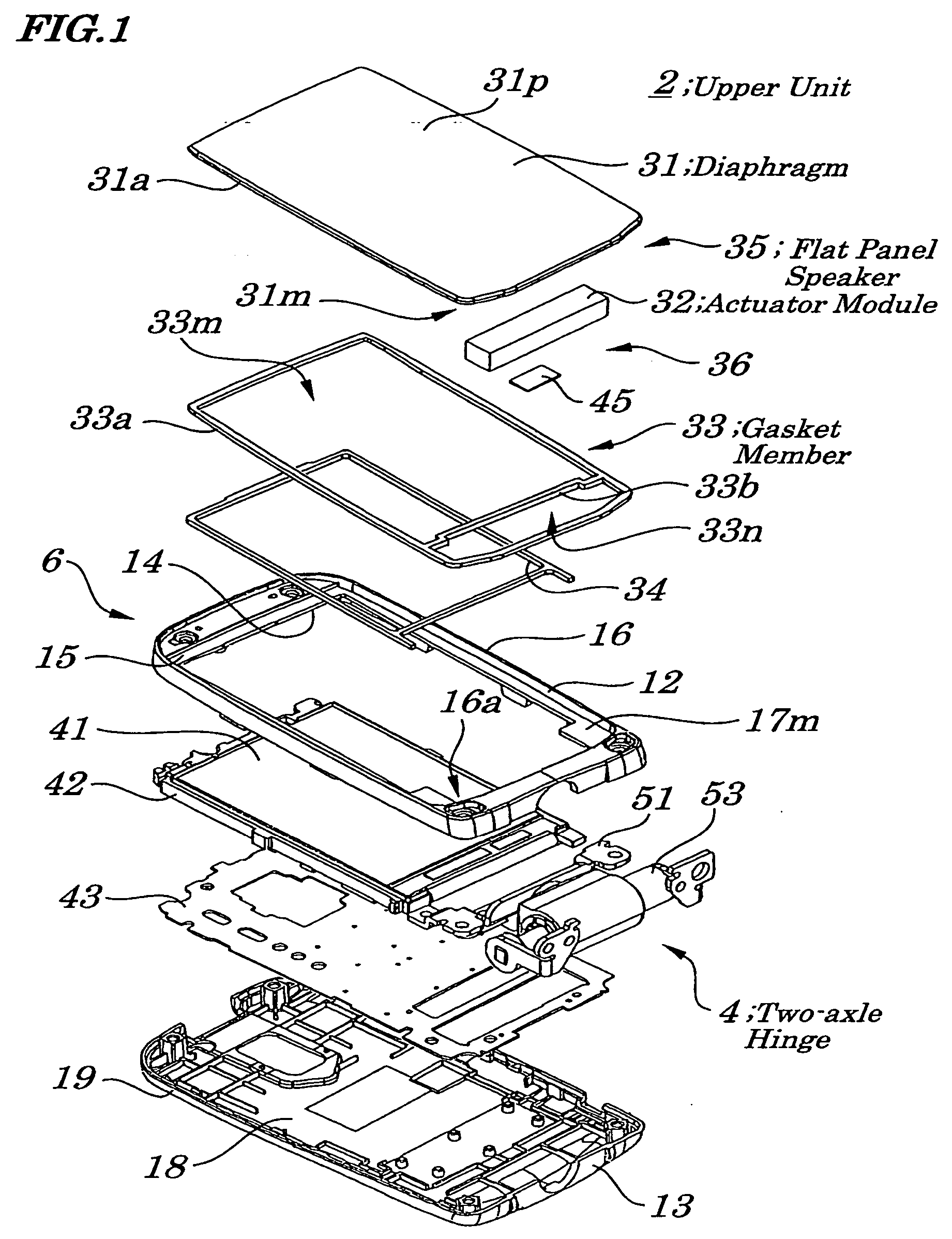

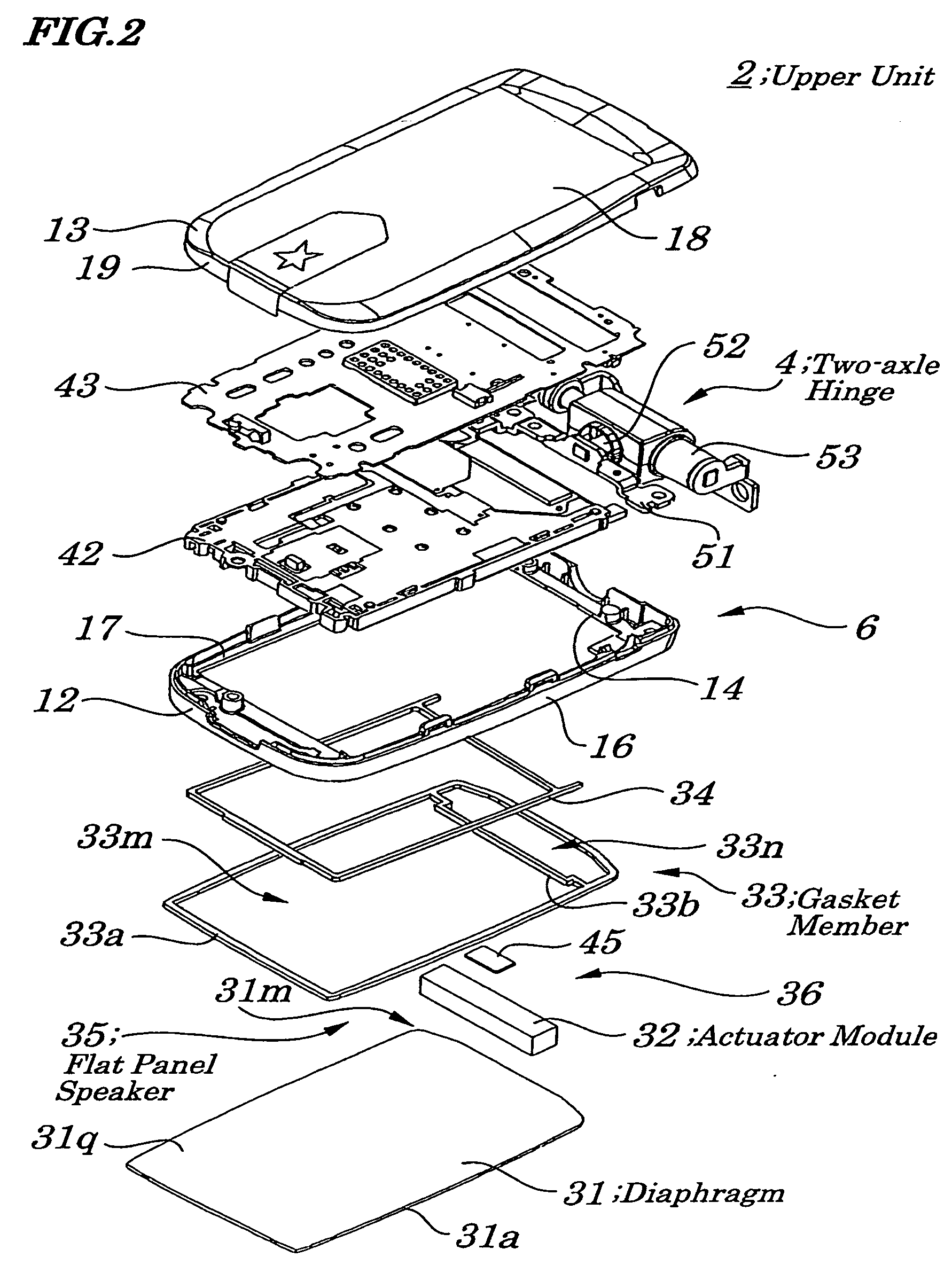

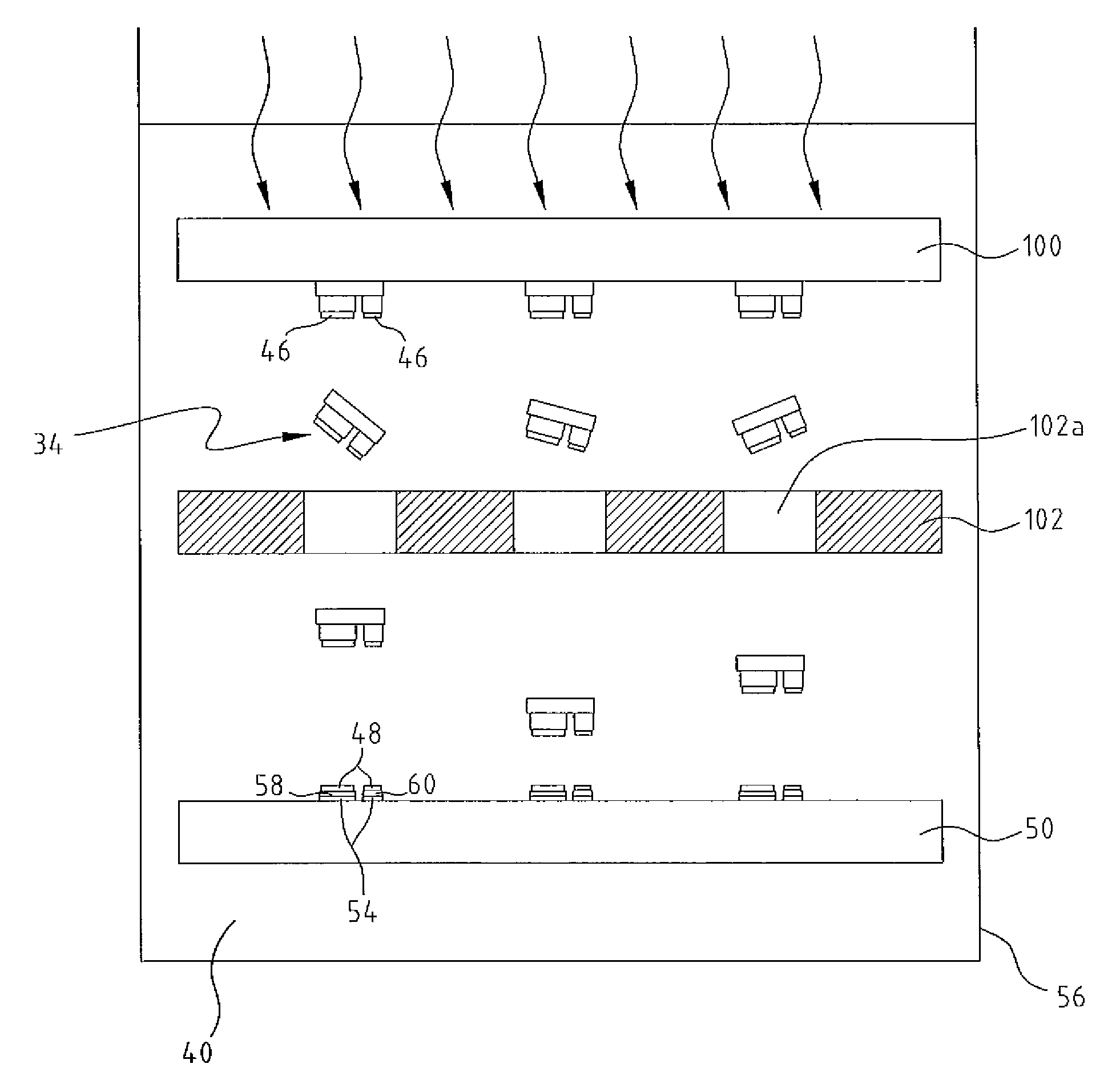

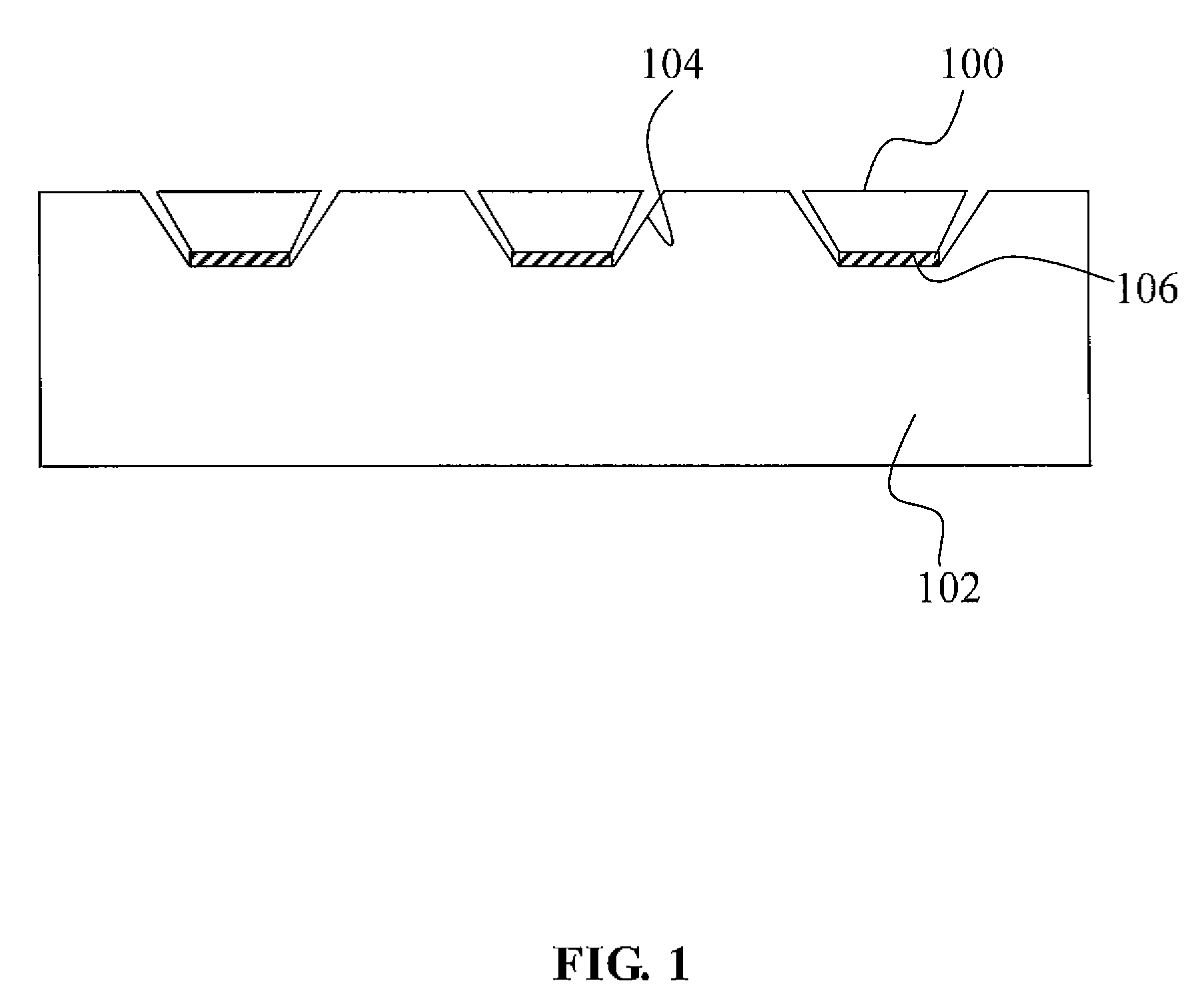

Gasket member, diaphragm, flat panel speaker, method of mounting same flat panel speaker, and method of assembling electronic device

InactiveUS20060140439A1Improve display qualityImprove featuresLoudspeaker transducer fixingPiezoelectric/electrostrictive transducersLiquid-crystal displayEngineering

A method of mounting a flat panel speaker is provided which is capable of reliably preventing entry of dust and of shortening assembling time. By bonding a gasket member to a diaphragm, by pasting a separator to a gasket member side opposite to the diaphragm and, by sandwiching the diaphragm and the gasket member from both sides, a gasket-attached diaphragm is fabricated. After peeling off a protecting sheet on a rear side of the gasket-attached diaphragm, the actuator module is bonded to the diaphragm. Then, after peeling the separator from the gasket-attached diaphragm, positioning is performed on the diaphragm and the gasket member is bonded to a putting-face of the front case. The entry of dust into a region corresponding to a liquid crystal display panel is blocked by a partitioning portion of the gasket member.

Owner:LENOVO INNOVATIONS LTD HONG KONG

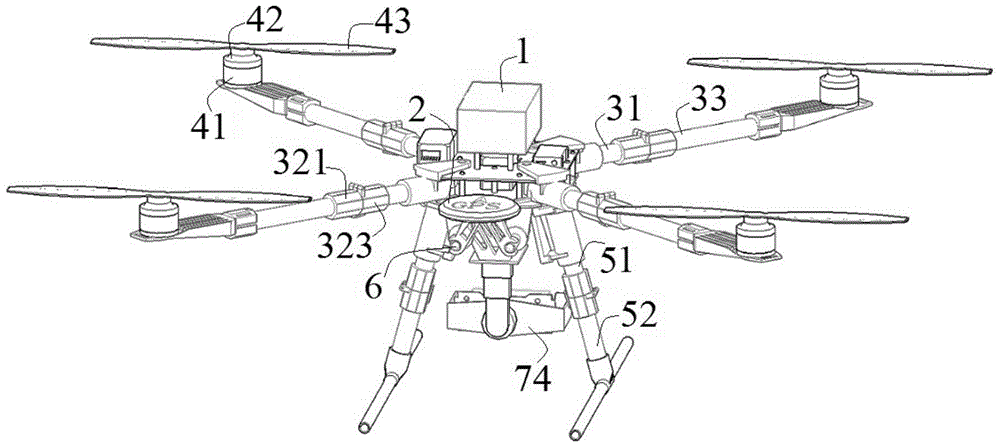

Multi-rotor unmanned aerial vehicle for fast surveying and surveying method of multi-rotor unmanned aerial vehicle

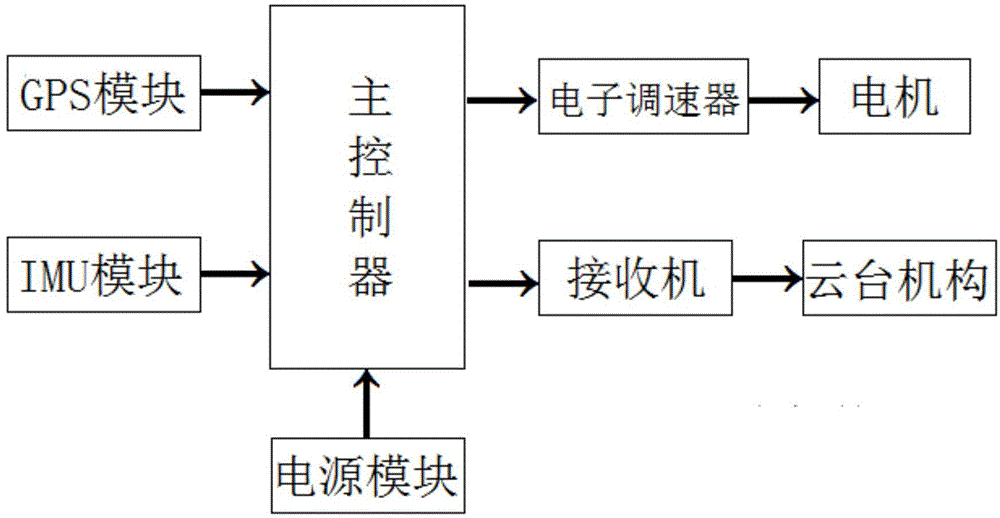

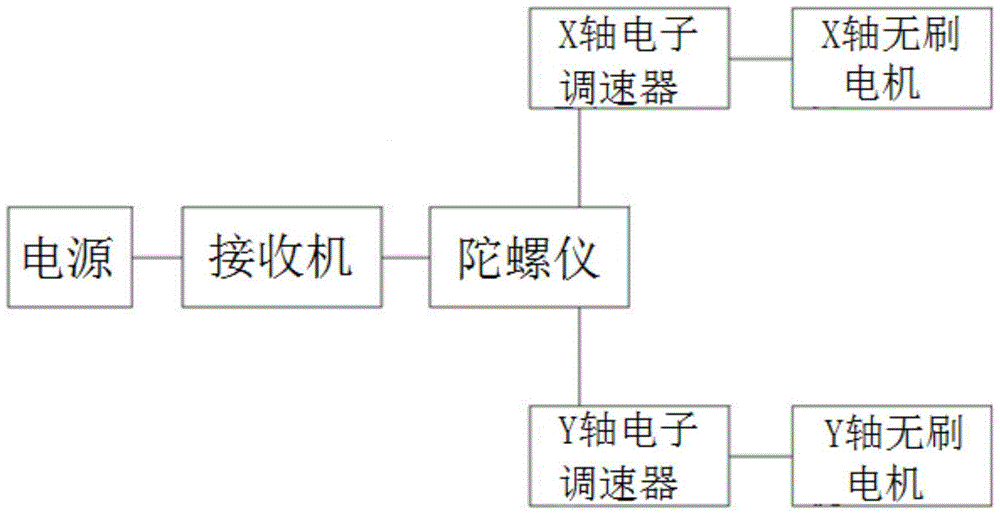

InactiveCN104386249APrecise positioningAccurate flight attitudeAircraft componentsRotocraftAviationCamera lens

The invention discloses a multi-rotor unmanned aerial vehicle for fast surveying and a surveying method of the multi-rotor unmanned aerial vehicle, and belongs to the technical field of aviation surveying. The multi-rotor unmanned aerial vehicle comprises a rack, flight lifting mechanisms, a cloud deck mechanism and a control mechanism, wherein four plane arms extend out from the rack along a plane body, the lower part of the plane body is provided with foot stools, the plane arms and the foot stools are of foldable structures; and the flight lifting mechanisms are arranged at tail ends of the four plane arms, the cloud deck mechanism is mounted at the bottom of the unmanned aerial vehicle body through a mounting rod; the cloud deck mechanism is provided with a camera and is used for regulating an optical axis of the camera to be always perpendicular to the ground; and the control mechanism is used for controlling the unmanned aerial vehicle to fly to the appointed height and regulating the overturn of the cloud deck mechanism. The surveying method disclosed by the invention can be used for determining the relation between the shooting height and the imaging proportion by analyzing camera lens parameters, and then setting the flight line of the unmanned aerial vehicle. Through the adoption of the unmanned aerial vehicle, the surveying result can be fast obtained, and the surveying precision and efficiency are high.

Owner:安徽靓马信息科技股份有限公司

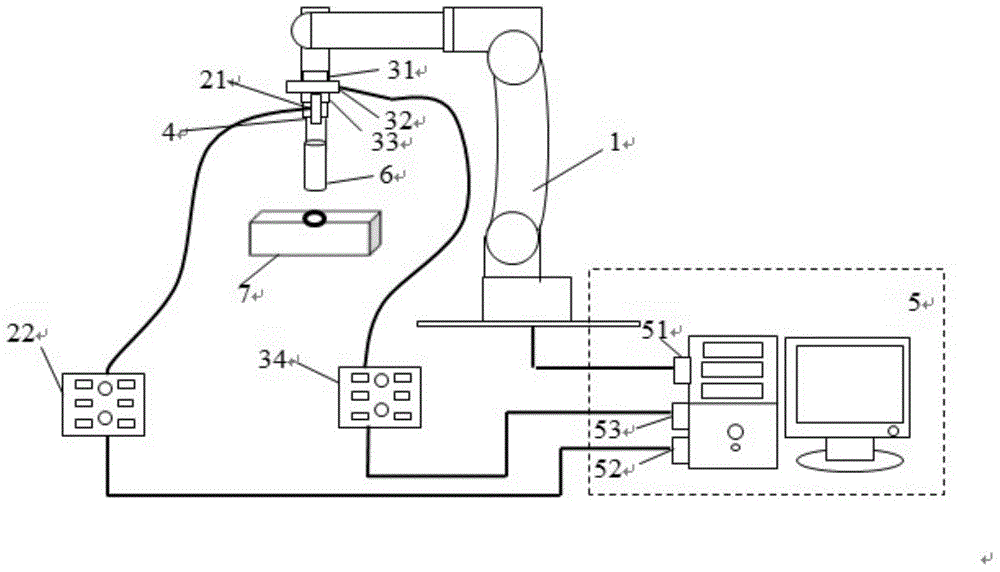

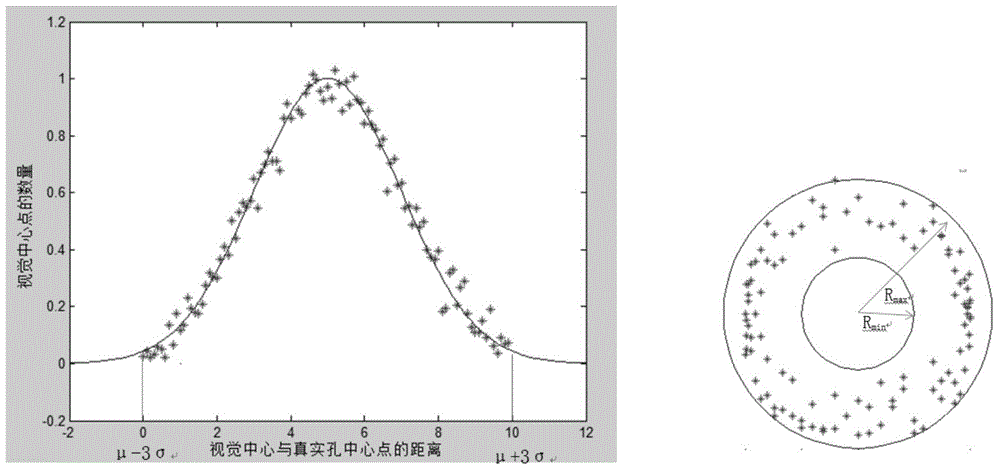

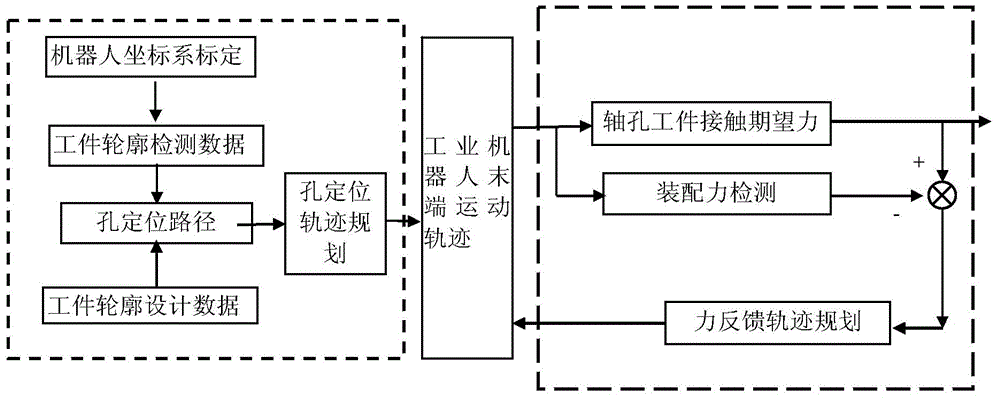

Method and system for assembling robot based on visual sense and force feedback control

ActiveCN104057290AQuick assemblyEffective positioningProgramme-controlled manipulatorMetal working apparatusSimulationVision based

The invention discloses a system for assembling a robot based on visual sense and force feedback control. The system comprises an industrial robot, a workpiece contour detection unit, an assembling force detection unit, a clamping unit and a system control host machine, wherein the industrial robot is used for driving the tail end to move according to a control command of the system control host machine; the assembling force detection unit is used for acquiring the contact force between a shaft workpiece and a hole during the assembling process; the clamping unit is used for clamping the shaft workpiece; the workpiece contour detection unit is used for acquiring the measured data of workpiece contour; the system control host machine is used for receiving the position and the force data and positioning the assembled workpiece according to received data so as to generate the control command to be sent to the industrial robot. The invention further discloses a method for assembling the robot based on visual sense and force feedback control. Rapid hole positioning is carried out and the optimal path of assembling is planned according to the three-dimensional data of hole contour and the force feedback data when the axle hole is assembled, and thus high-precision self-assembling of the axle hole is realized.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

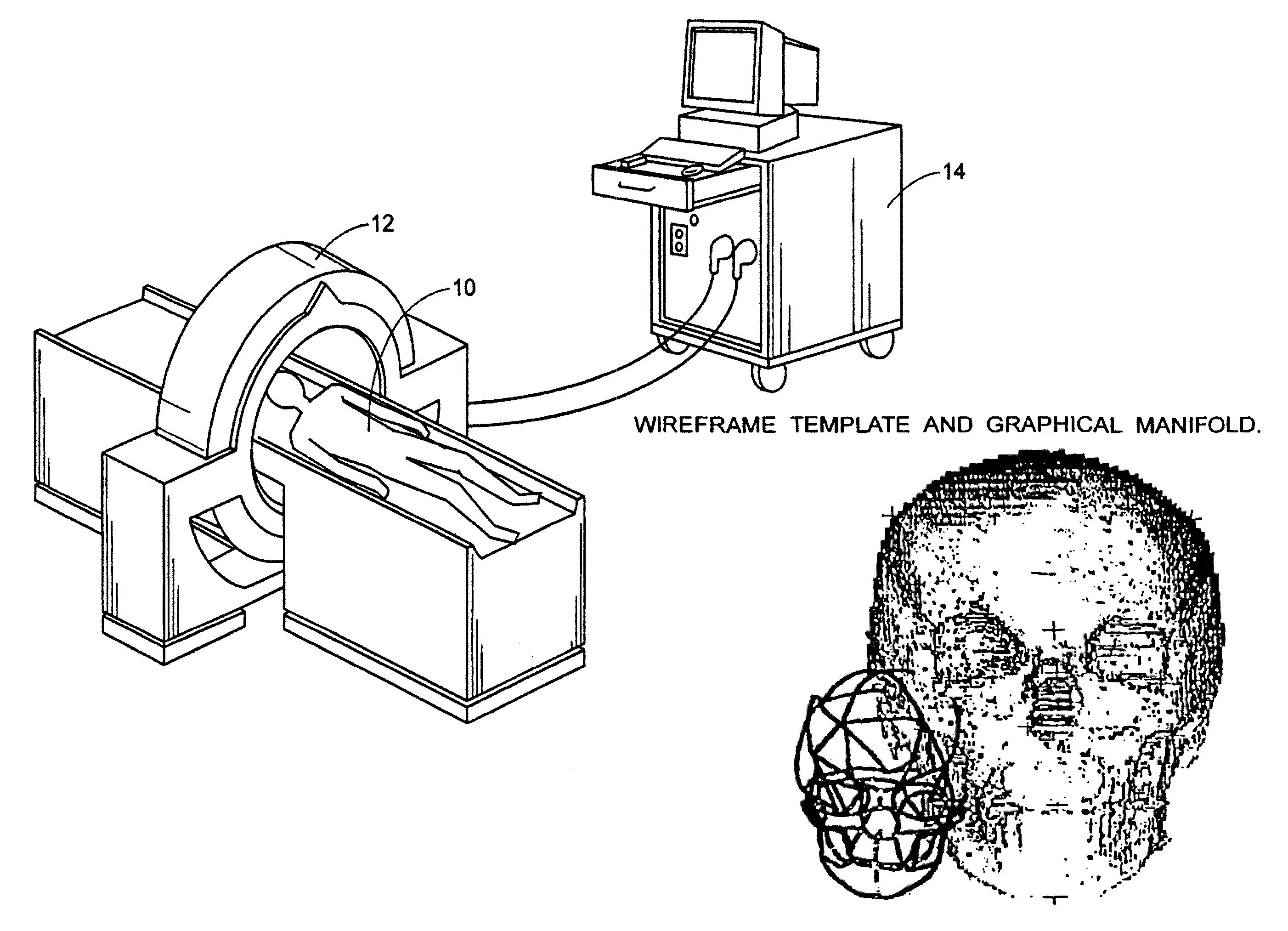

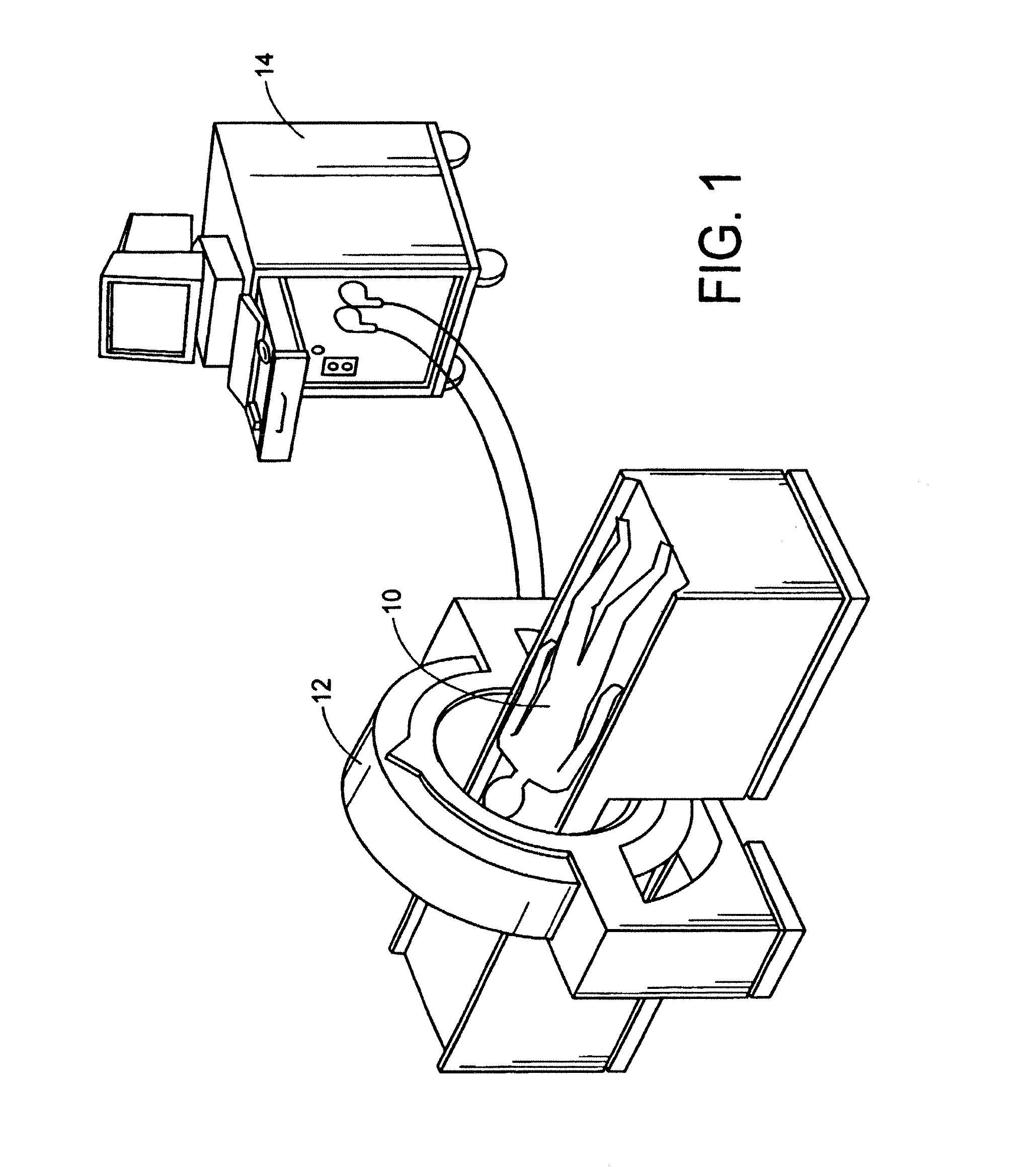

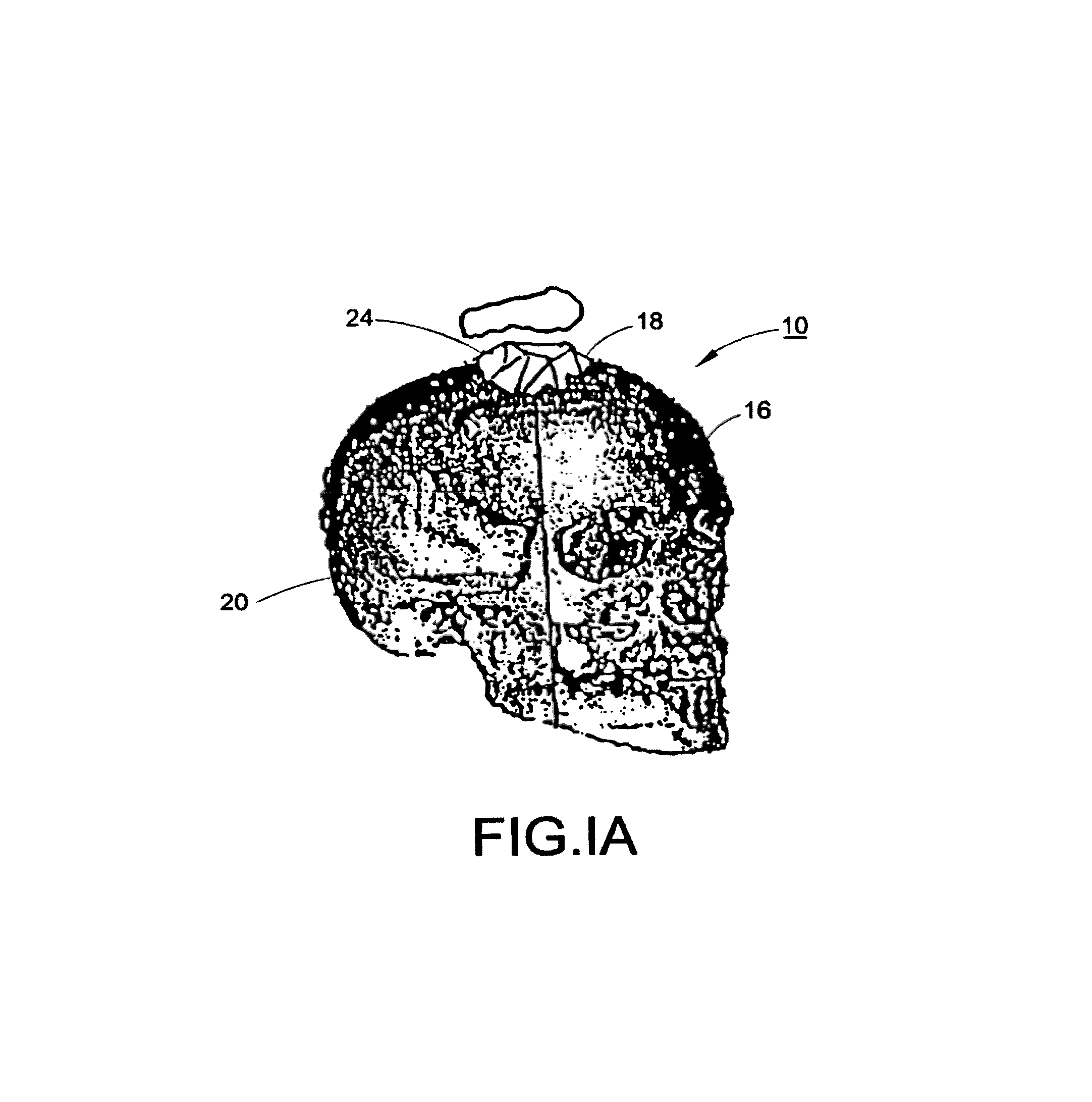

Producing a three dimensional model of an implant

InactiveUS8781557B2Quick assemblyProgramme controlAdditive manufacturing apparatusDimensional modelingMedical device

Determining a shape of a medical device to be implanted into a subject produces an image including a defective portion and a non-defective portion of a surface of a tissue of interest included in the subject. The tissue of interest is segmented within the image. A template, representing a normative shape of an external anatomical surface of the tissue of interest, is superimposed to span the defective portion. An external shape of an implant, is determined as a function of respective shapes of the defective portion as seen in the template, for repairing the defective portion.

Owner:OSTEOPLASTICS

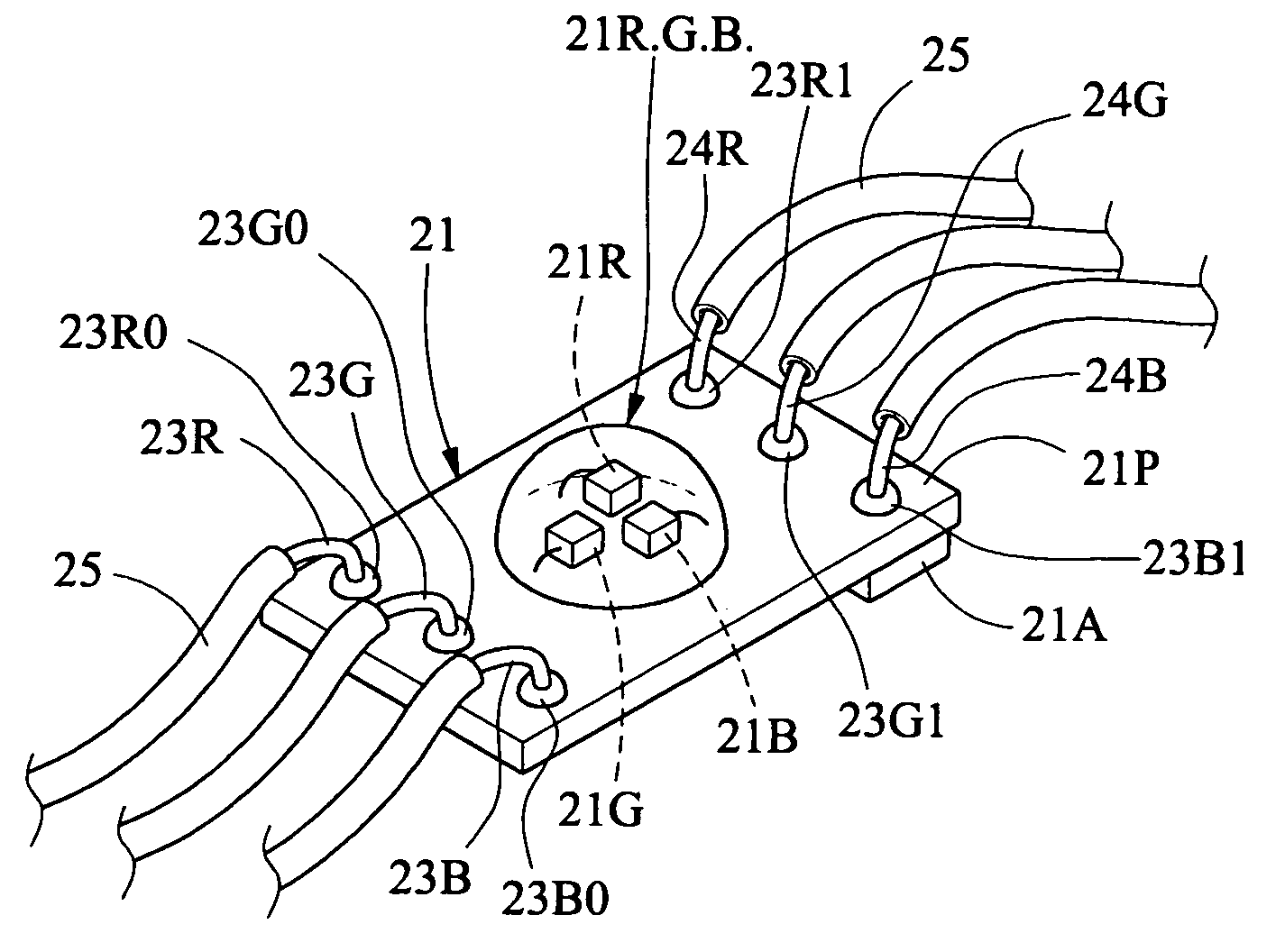

Shelf divider system

InactiveUS20070256992A1Prevent from fallConserve shelf spaceRacksShow shelvesEngineeringMechanical engineering

There is provided a shelf divider system for organizing, moving, and displaying merchandize items on a store shelf. A plurality of dividers attach perpendicularly to a plurality of base strips by inserting knobs on the dividers into mating holes in the base strips. Each adjacent pair of dividers forms a channel for the merchandise. Merchandize carriers slide over the base strips between each adjacent pair of dividers. A pull strap is attached to the front end of each carrier for pulling it forward for moving the merchandize items forward on the shelf. The pull straps have longitudinal grooves therein for dividing the pull straps longitudinally into two narrower pull straps. The merchandize items are prevented from falling from the front of the shelf by transparent guards attached to guard holders. The shelf divider system may be attached to the shelf by clips, which attach a base strip to the shelf.

Owner:OLSON CARL

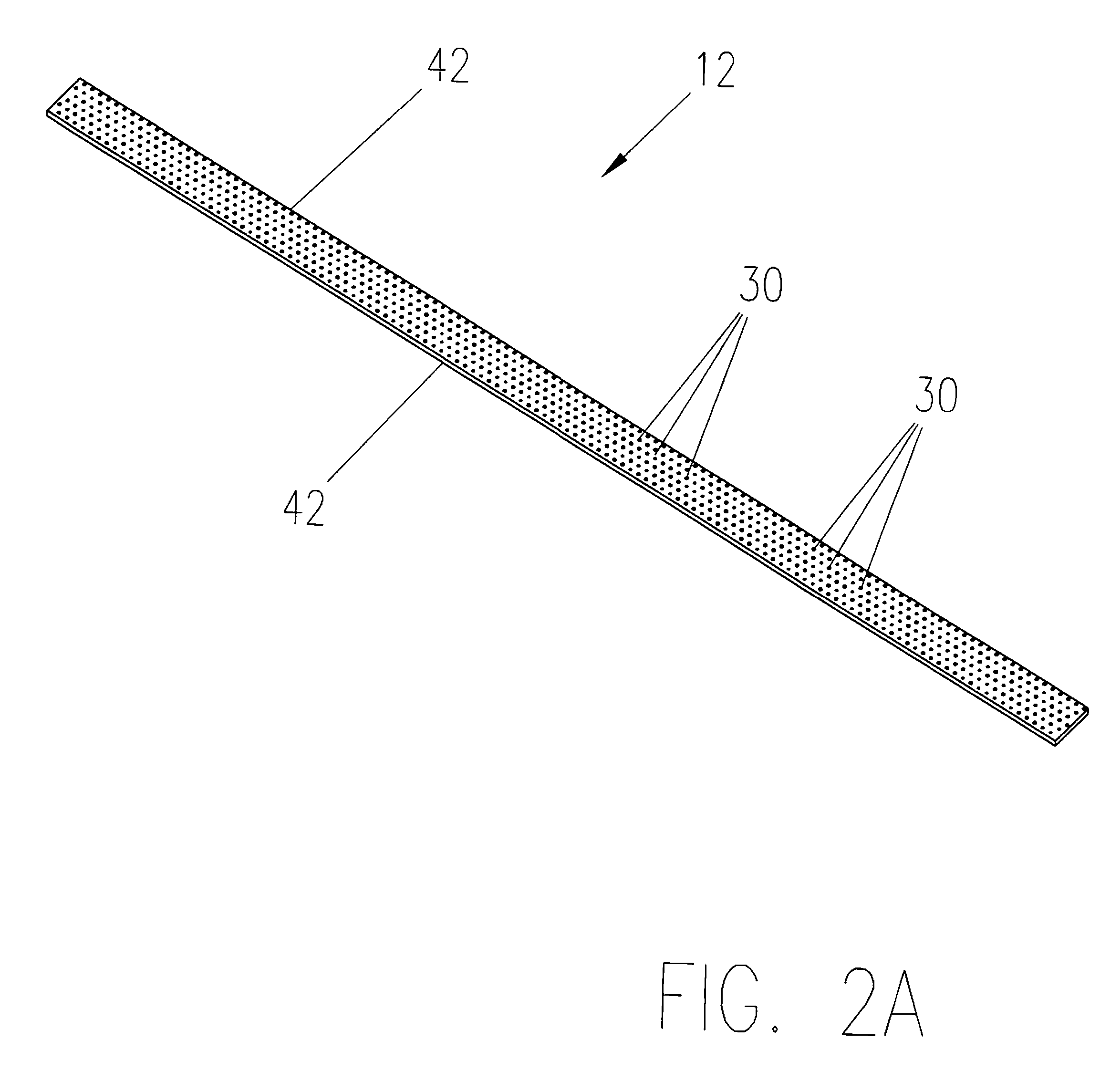

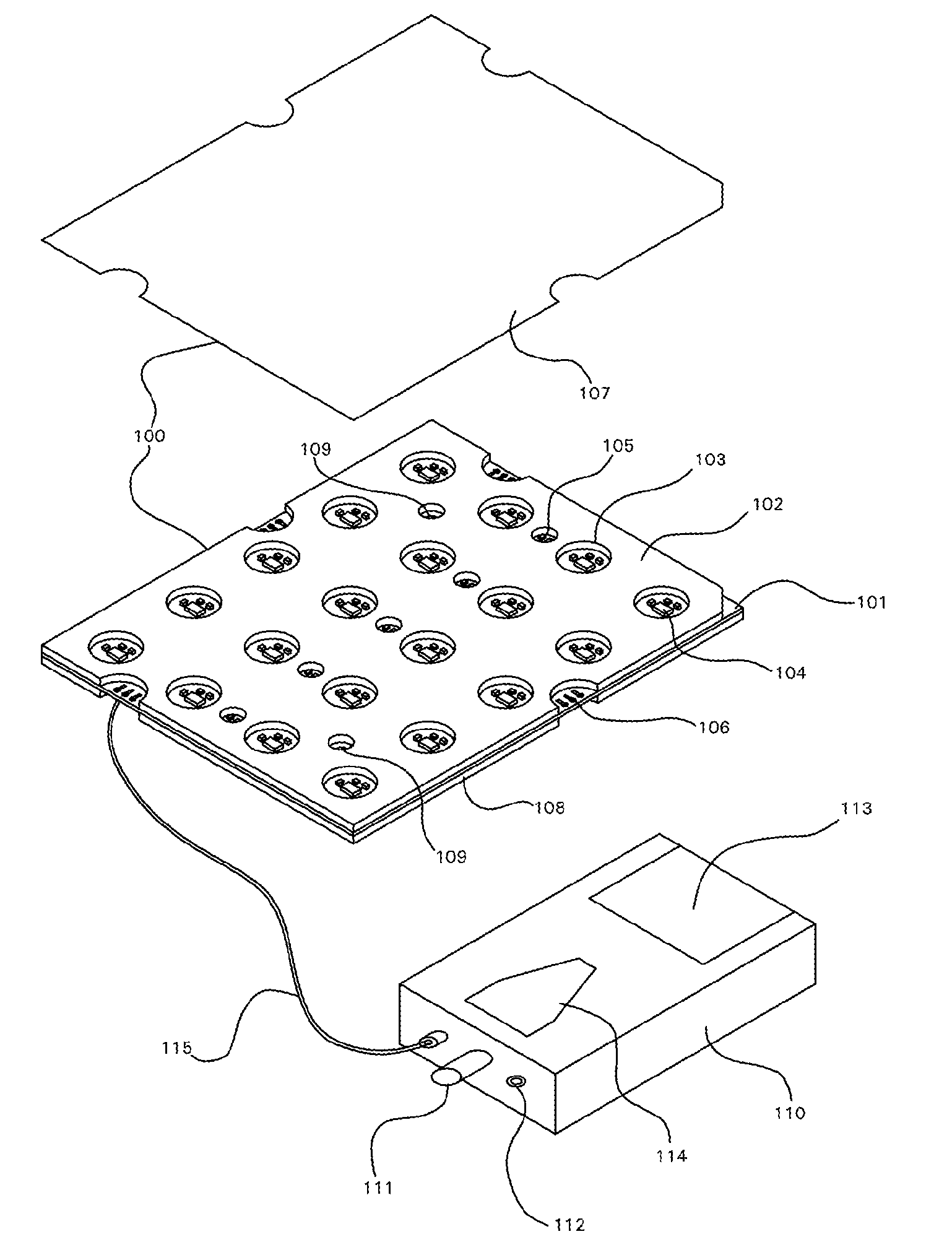

Full-color flexible light source device

ActiveUS20050213321A1Quick assemblyUniform lightLight source combinationsPoint-like light sourceGreen ledFull color

A full-color flexible light source device is disclosed. The device includes a plurality of light source units each comprises a red LED, a green LED, and a blue LED arranged in the shape of a triangle. Each of the R, G, and B LEDs is a bare chip and the R, G, and B LEDs are encapsulated as a C.O.B. type RGB light source unit. The device is able to emit a uniform light. Also, the device has an increased tensile strength and flexibility as well as has waterproof and vibration-proof features. In other embodiments, the device is encapsulated by elongated, flexible, parallelepiped inner and outer fixing members or formed on a strip.

Owner:HAYASHIBARA BIOCHEMICAL LAB INC

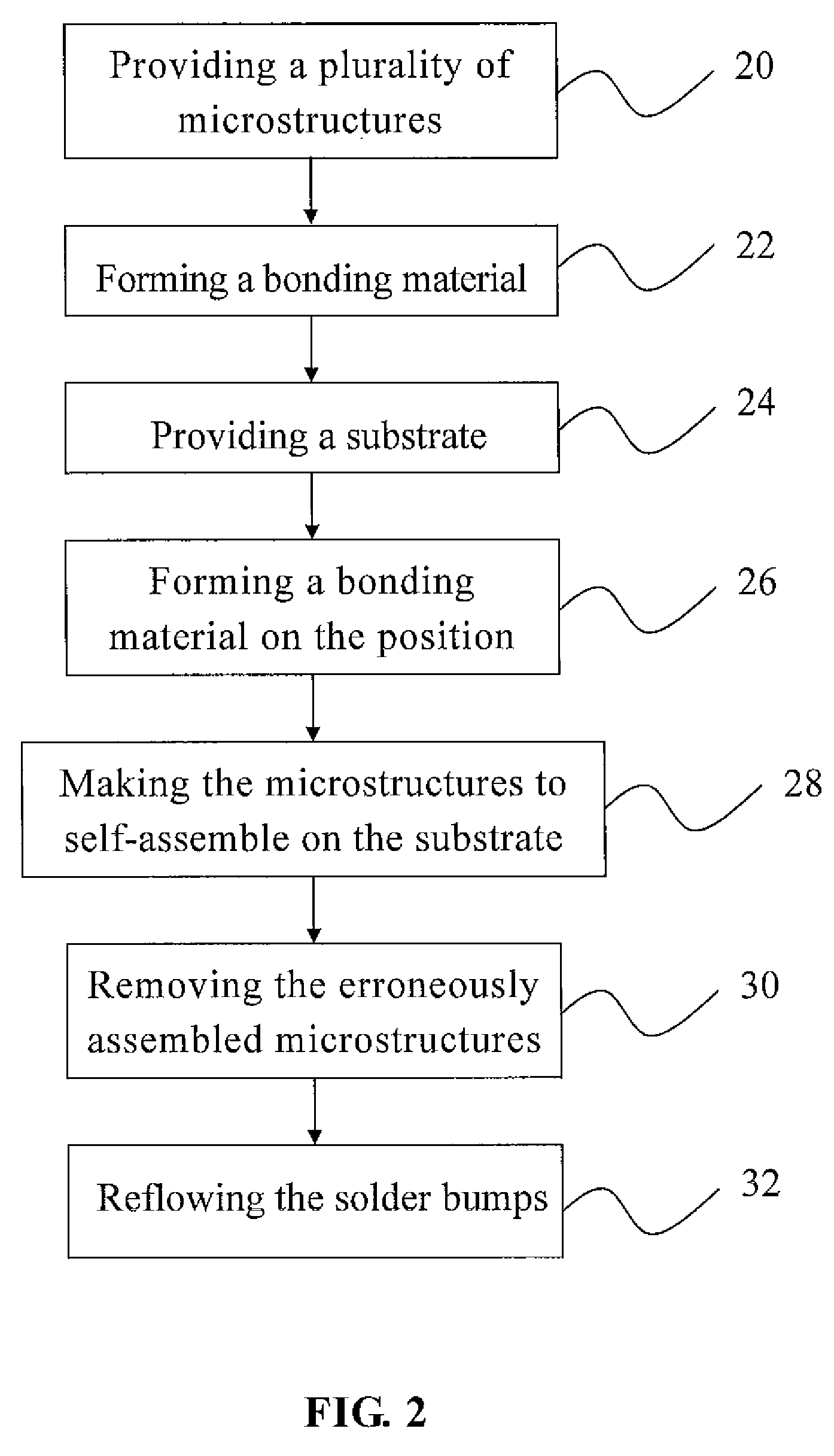

Method for self-assembling microstructures

InactiveUS20080023435A1Precise positioningImproved and easy processSolid-state devicesMicrostructural device assemblyPresent methodElectrical connection

A method for self-assembling a plurality of microstructures onto a substrate comprising using a bonding material to make the microstructure assembled onto the substrate by a physical attraction force The microstructures are self-aligned with the substrate, and further permanently fixed on and electrical connection with the substrate by the solder bumps between the microstructures and the substrate, which is formed by the solder bumps via reflow process. There is no need for the using of the conventional pick-and-place device in the present method. The present method could be applied to light emitting diodes, RFID tags, micro-integrated circuits or other types of microstructures.

Owner:NAT TAIWAN UNIV

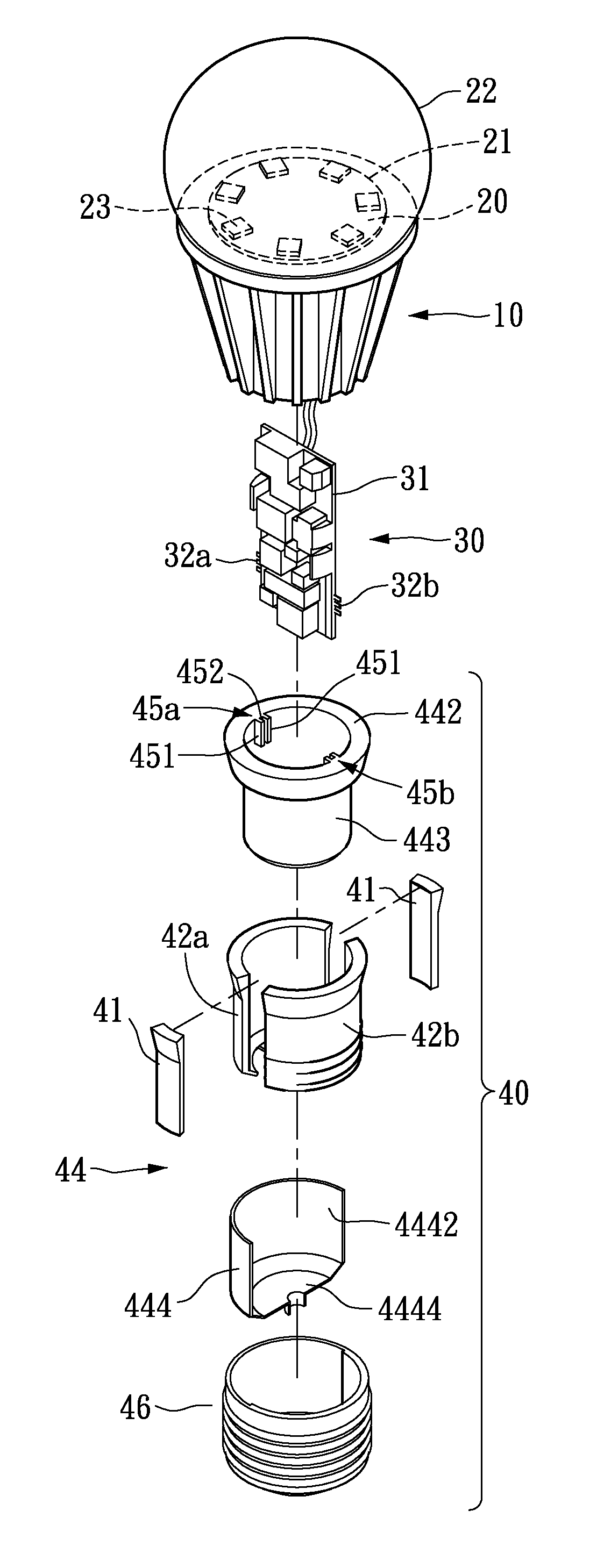

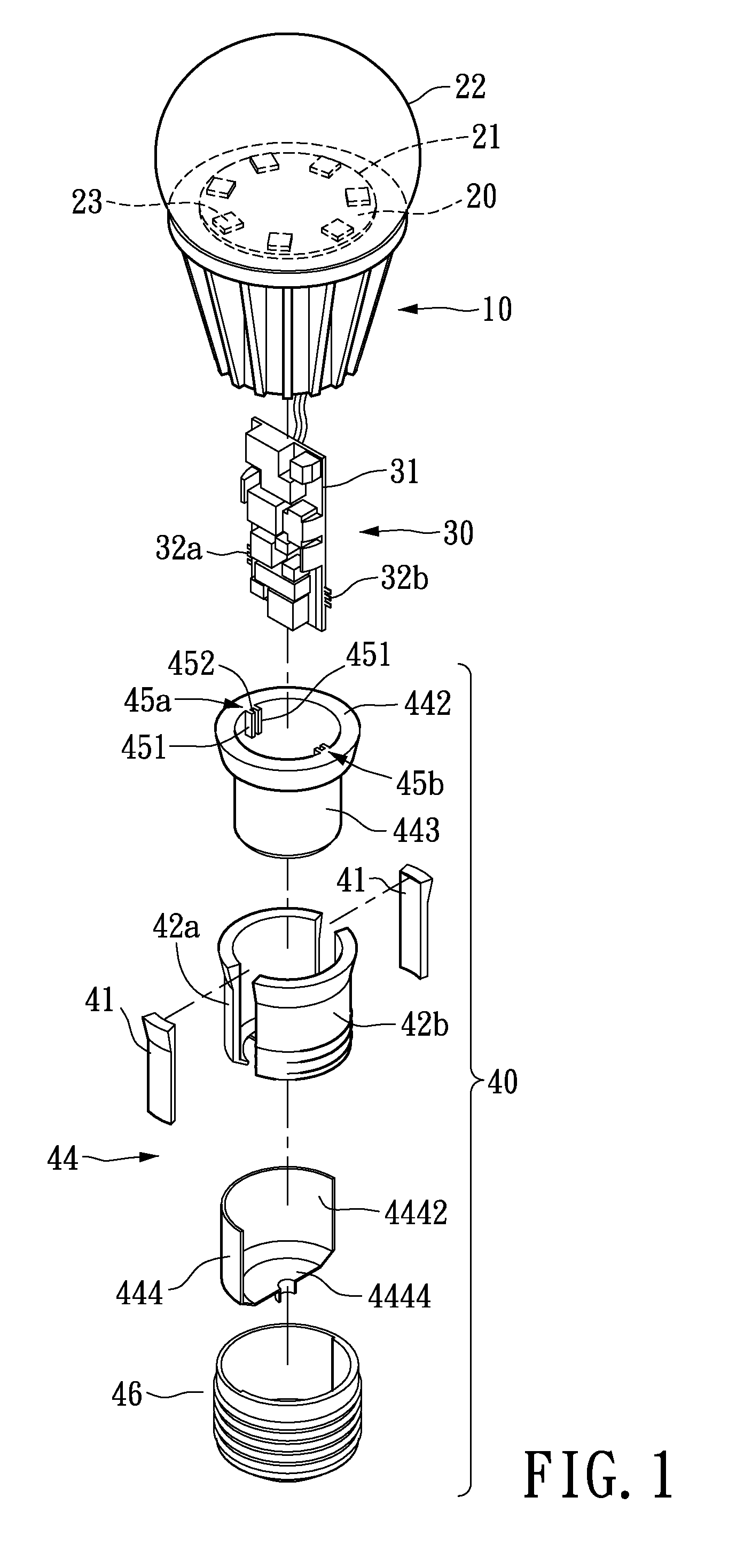

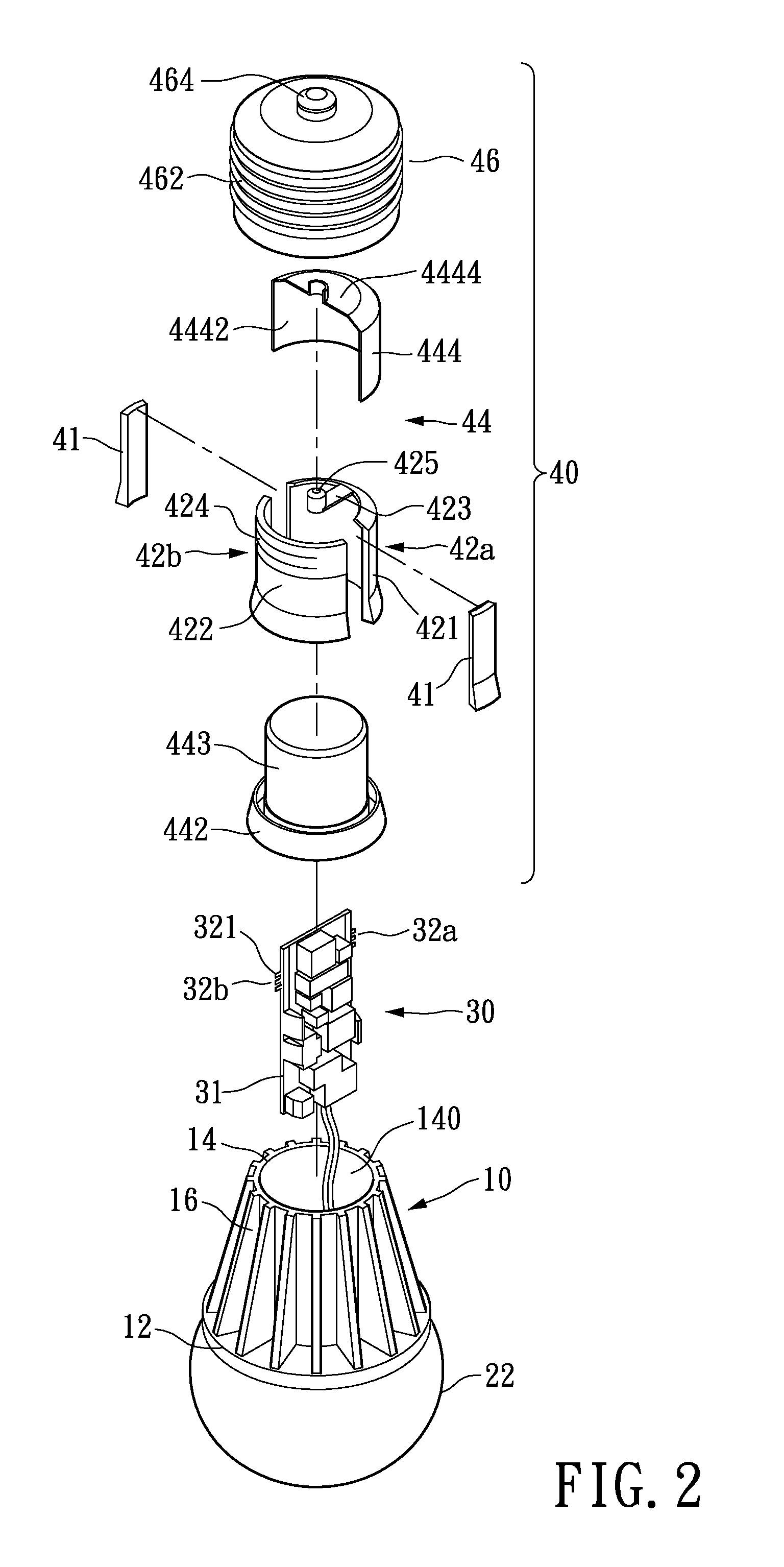

Illumination device

ActiveUS8696168B2Simplify the assembly processImprove cooling effectPoint-like light sourceLighting support devicesElectrical connectionEngineering

An illumination device having enhanced thermal dissipating capacity is provided. The illumination device includes a heat sink, an LED module, a cover, an LED driver, and a lamp base. The LED module is disposed at one end of the heat sink. The cover covers the LED module. The LED driver is in connection with the LED module, and includes a circuit board and at least one electrical contact member disposed on the circuit board. The lamp base is connected to the other end of the heat sink, and comprises an insulating unit, a first electrode, a second electrode and at least one contact port. The contact port is arranged on the lateral interior of the insulating unit, so that the electrical contact member of the LED driver may establish electrical connection with the lamp base.

Owner:LITE ON TECH CORP +1

Autonomous, back-packable computer-controlled breakaway unmanned aerial vehicle (UAV)

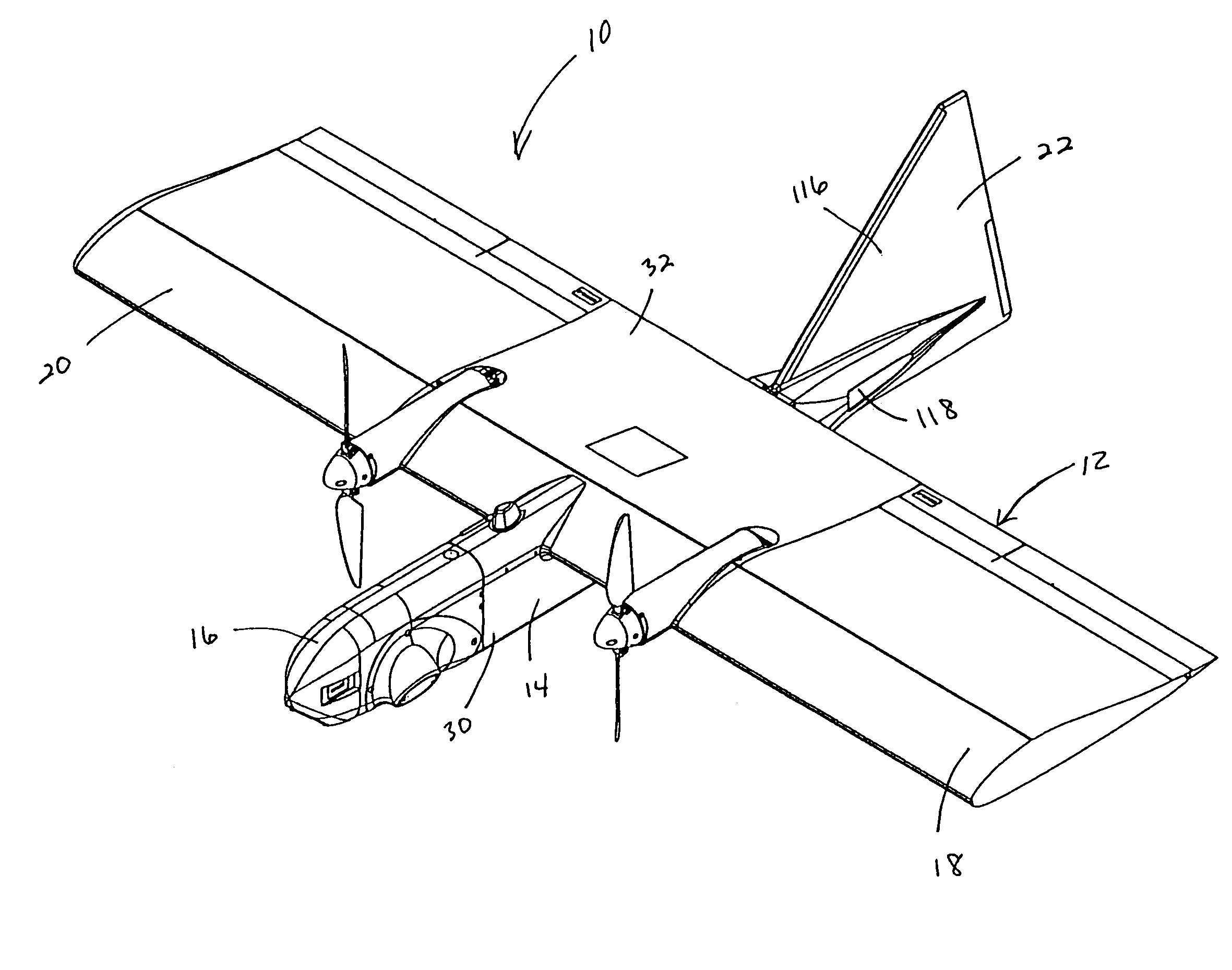

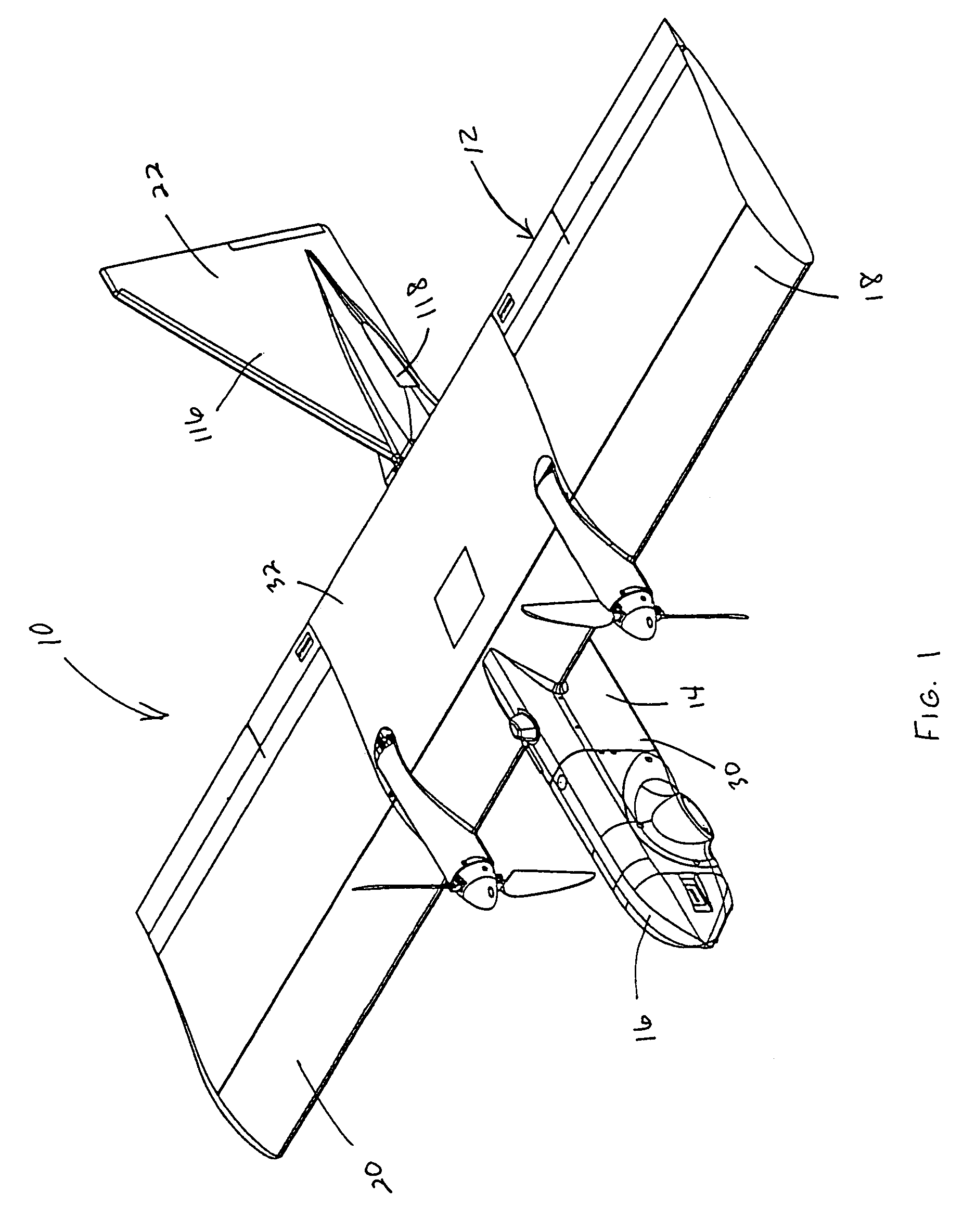

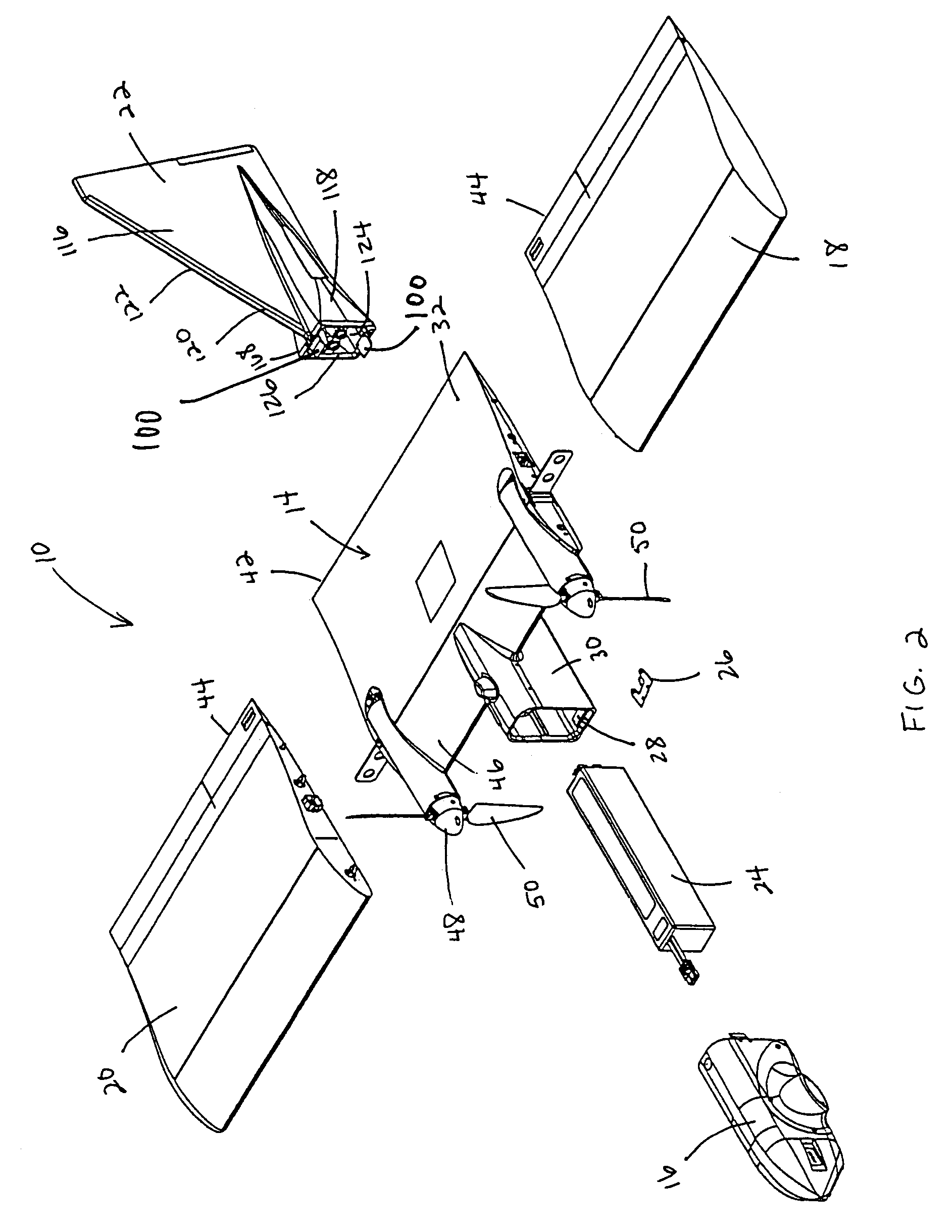

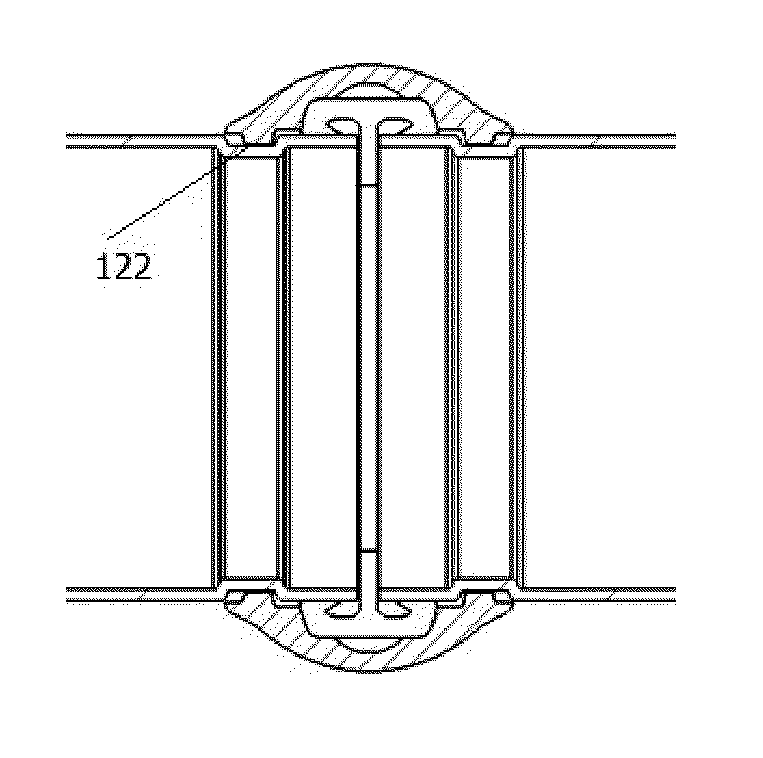

InactiveUS7237750B2Quick assemblyOvercome problemsUnmanned aerial vehiclesLuggageData retrievalModularity

A modular unmanned aerial vehicle (UAV) having a fuselage, a nose cone, a left wing piece, a right wing piece, and a tail section. The tail section and nose cone each join to the fuselage through mating bulkhead structures that provide quick connection capability while being readily separated so as to enable the UAV to break apart at these connection points and thereby absorb or dissipate impact upon landing. The UAV is capable of rapid assembly in the field for two-man launch and data retrieval, as well as quick disassembly into these five component parts for transport and storage in a highly compact transport case that can be carried as a backpack.

Owner:L 3 COMM CORP

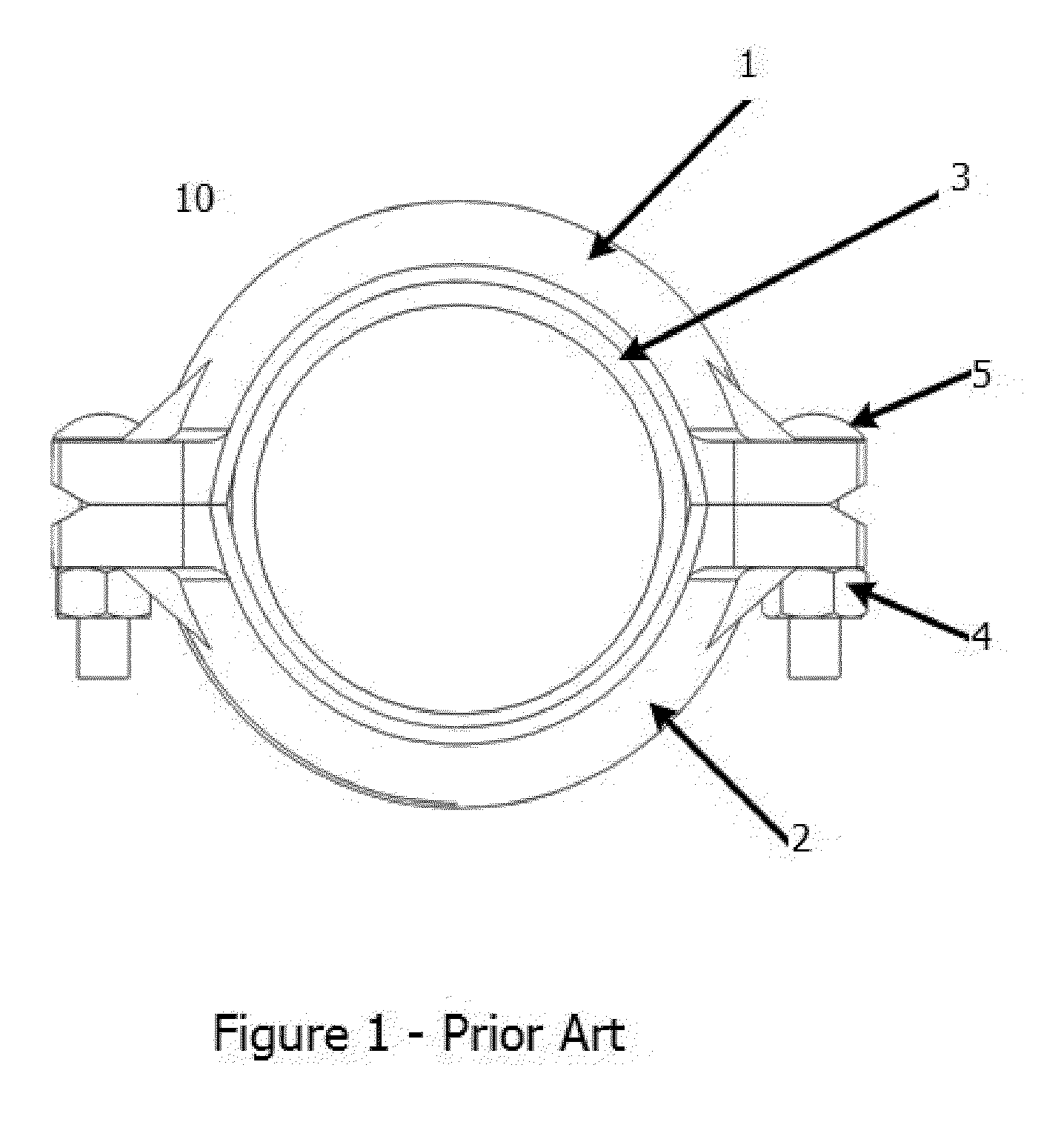

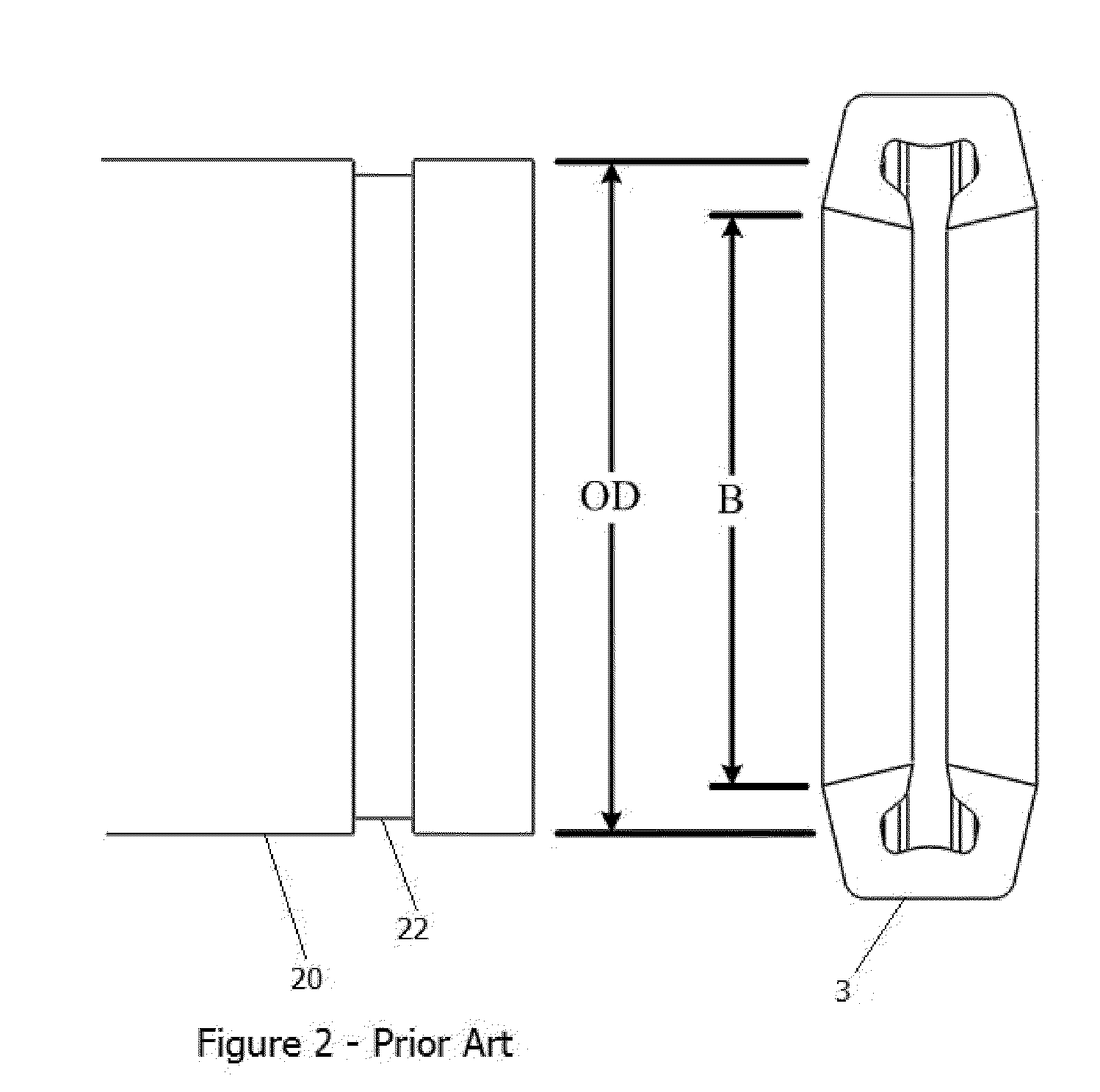

4-Way Compression Grooved Coupling

InactiveUS20110154646A1Improve installation efficiencyEliminate relative motionSleeve/socket jointsFlanged jointsCouplingEngineering

A pre-assembled pipe coupling for joining and sealing two grooved-ended pipe segments without disassembling the coupling is disclosed. The coupling has a housing with upper and lower arcuate housing segments and left and right bridge segments. Each bridge segment has at least one set of dihedrally angled faces that engage corresponding faces each in the upper and lower housing segments. Drawing the upper and lower segments inwardly together along a first axis, presses each bridge segment inward along a second axis roughly tangential to the first axis. All segments are loosely pre-assembled with bolts and nuts into a coupling and all segments each have radially inwardly projecting lands that mate with end grooves in the pipes to be joined. The coupling also has a one-piece circular sealing gasket that has an inward circumferential and centrally positioned pipe stop that has an inner diameter smaller than an outer diameter of the pipes to be joined. The gasket has two circumferential sealing lips axially outward from the pipe stop, the inner diameter each sealing lip larger than the outer diameter of the pipe segments to be joined.Method for joining and sealing two grooved-ended pipe segments with a pre-assembled pipe coupling, without disassembling the coupling, is also disclosed.

Owner:SHURJOINT METALS INC

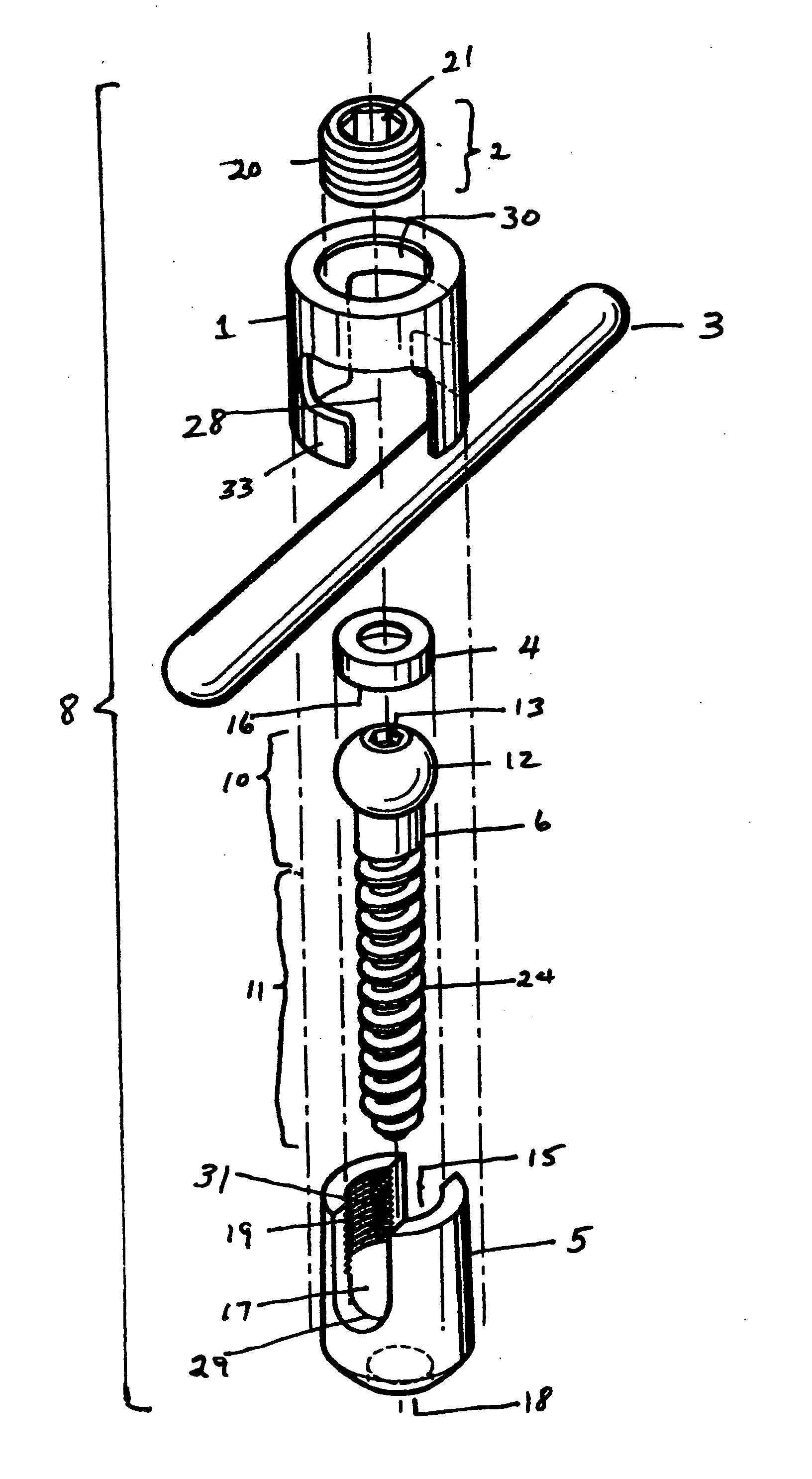

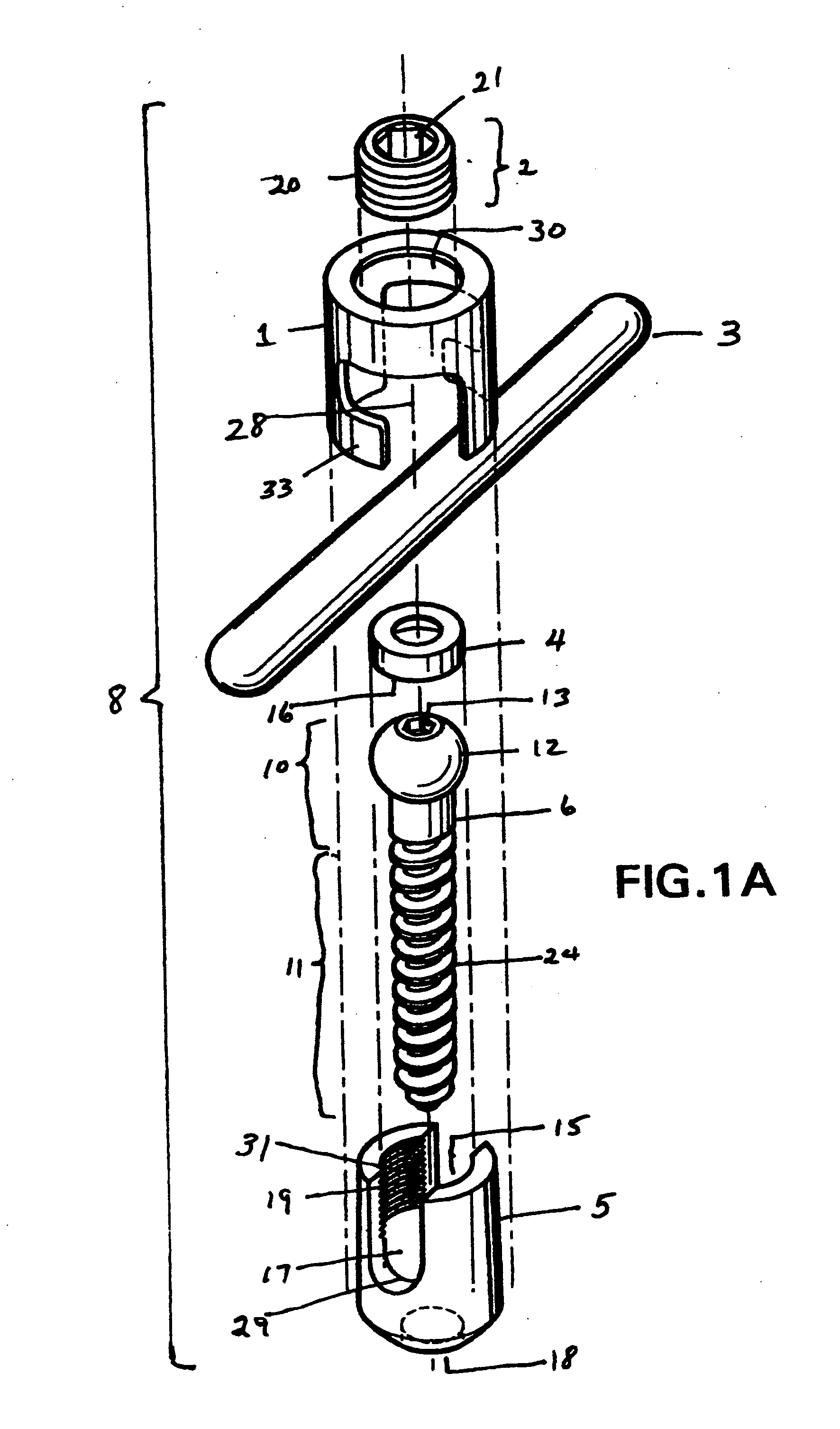

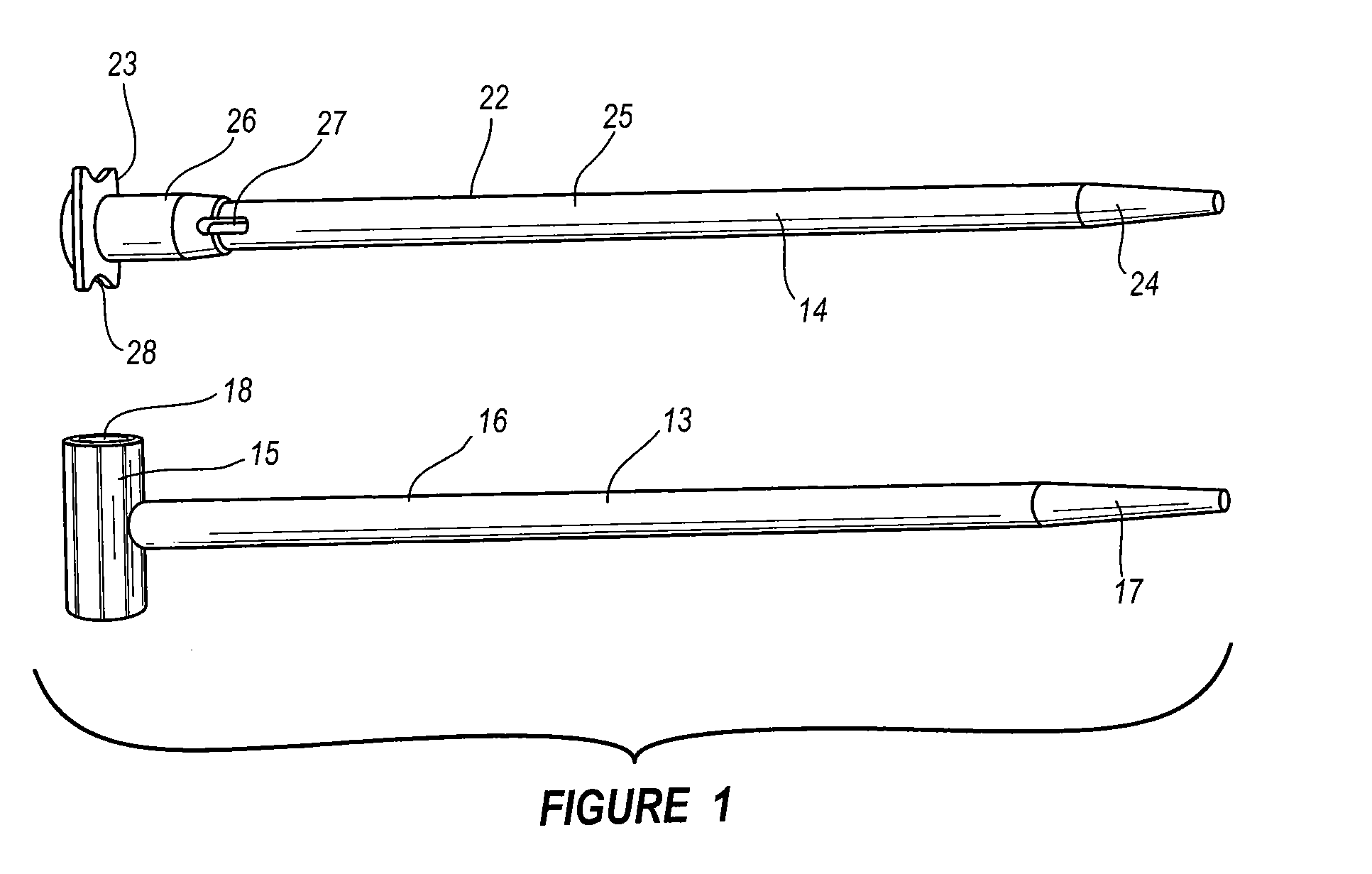

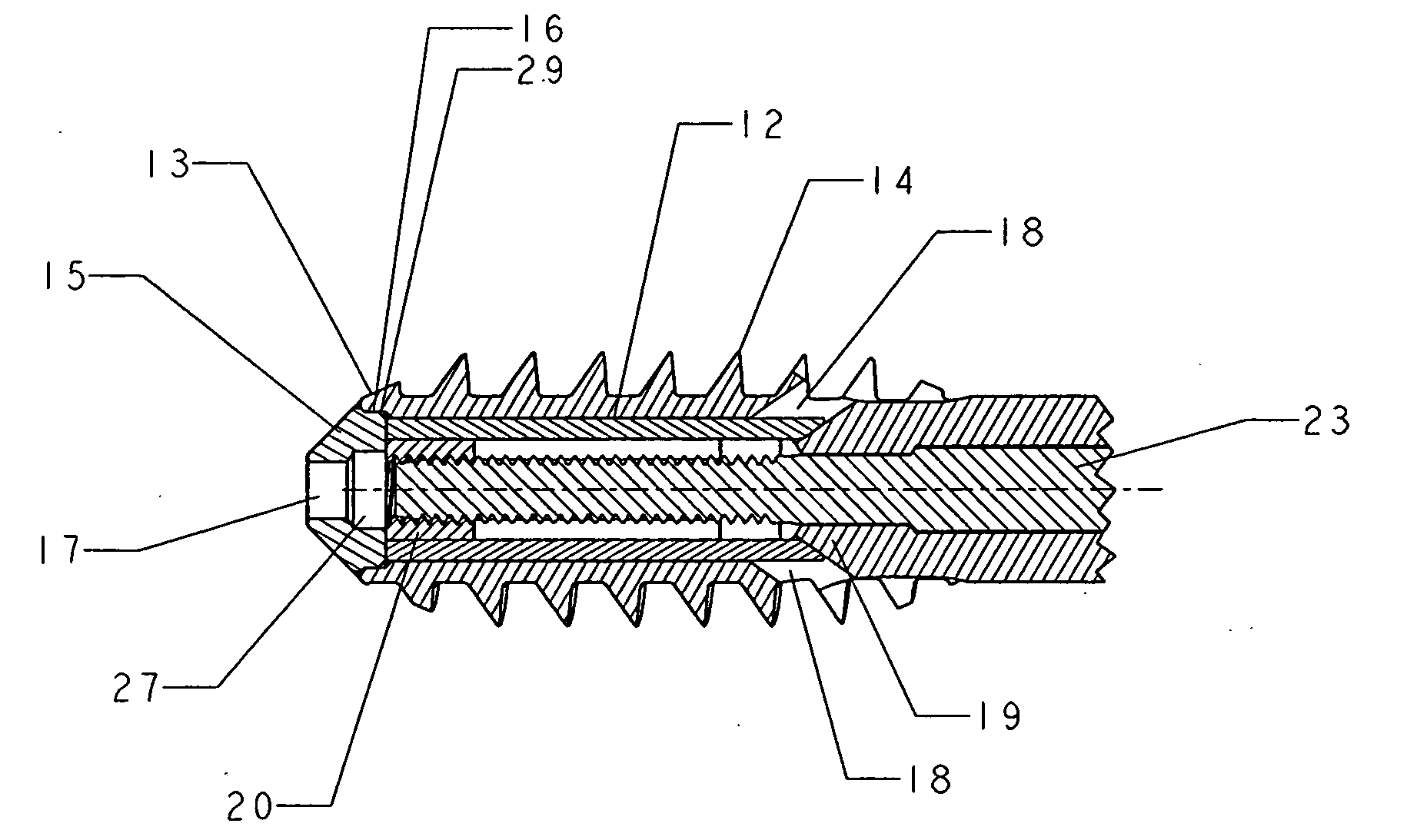

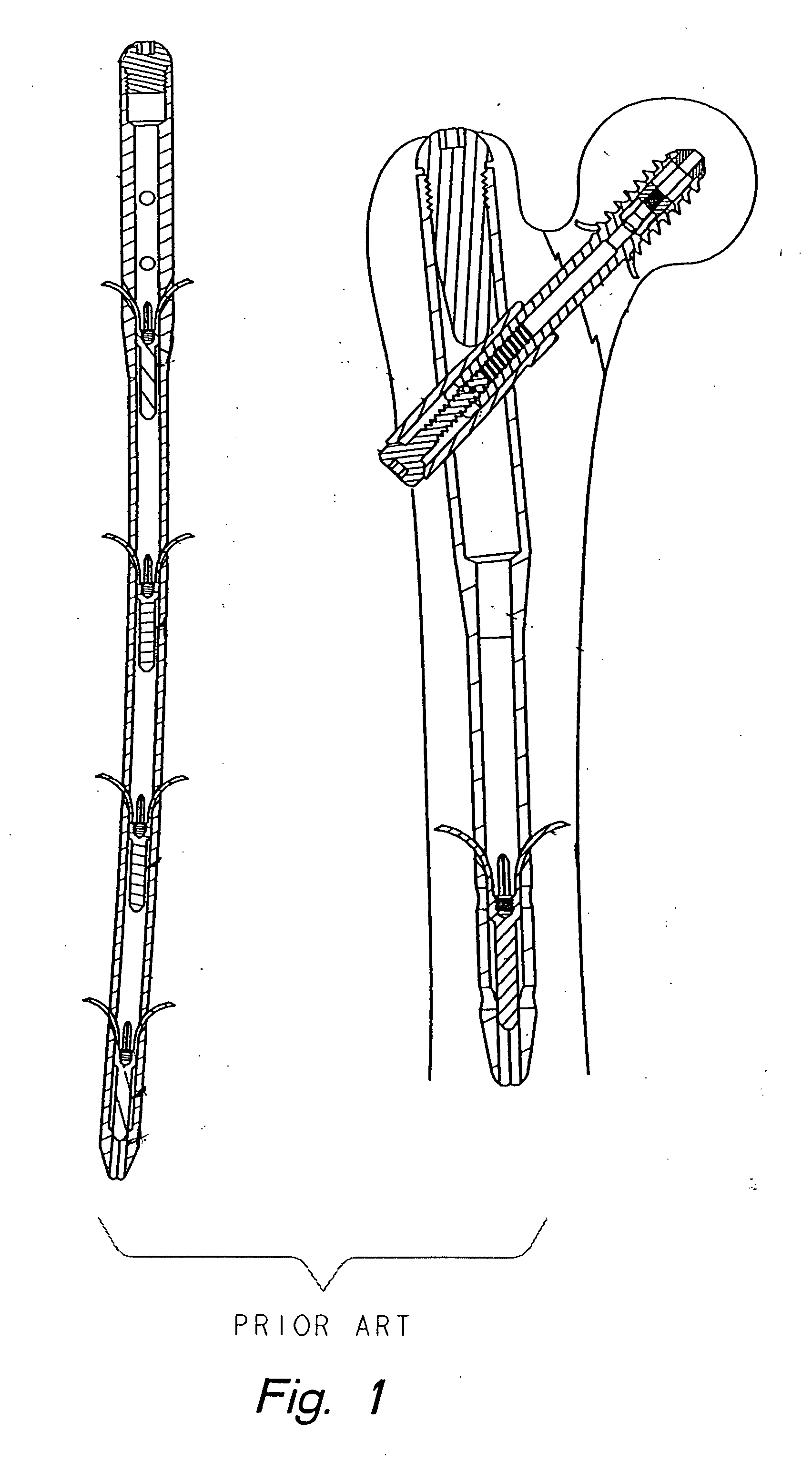

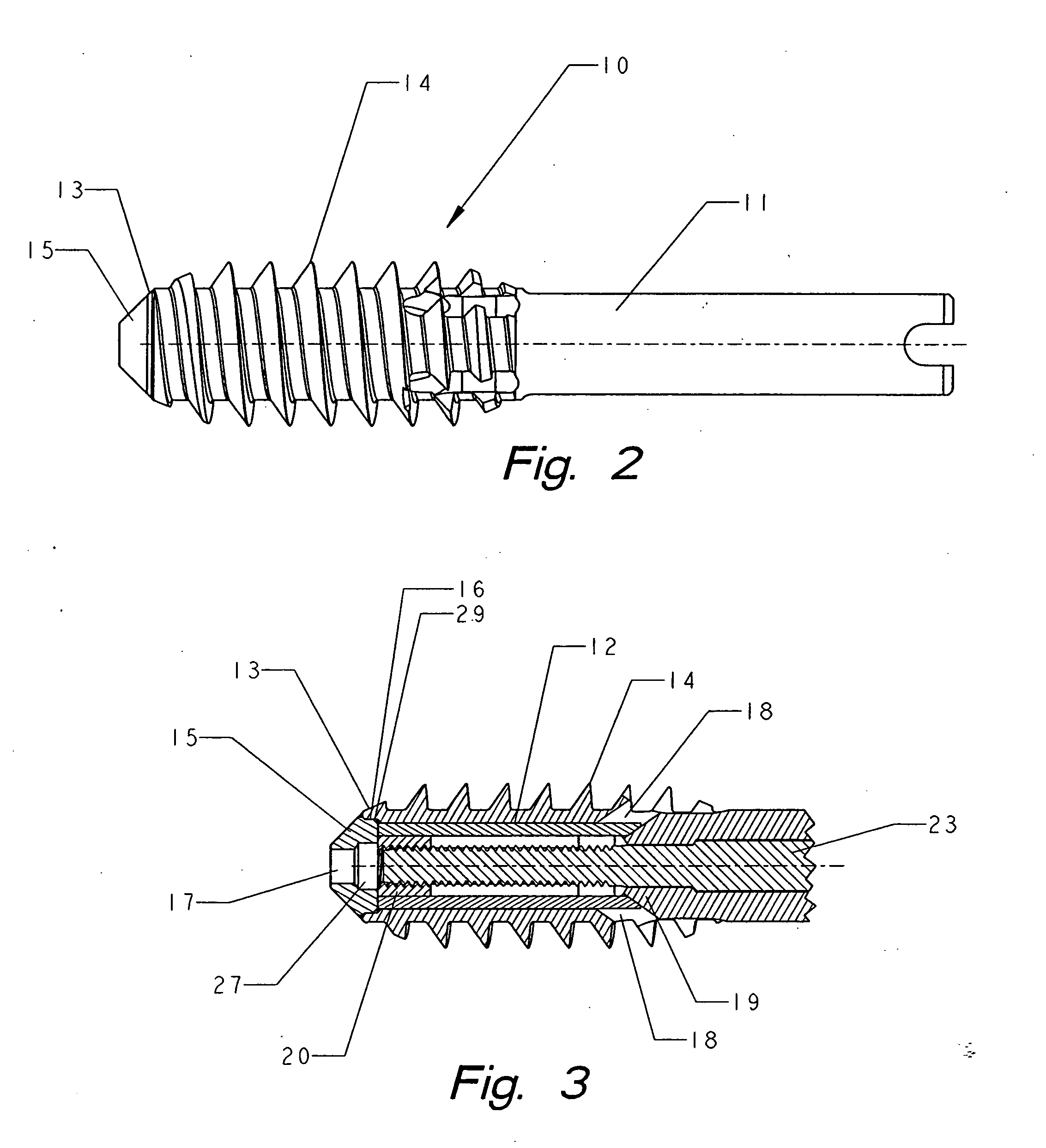

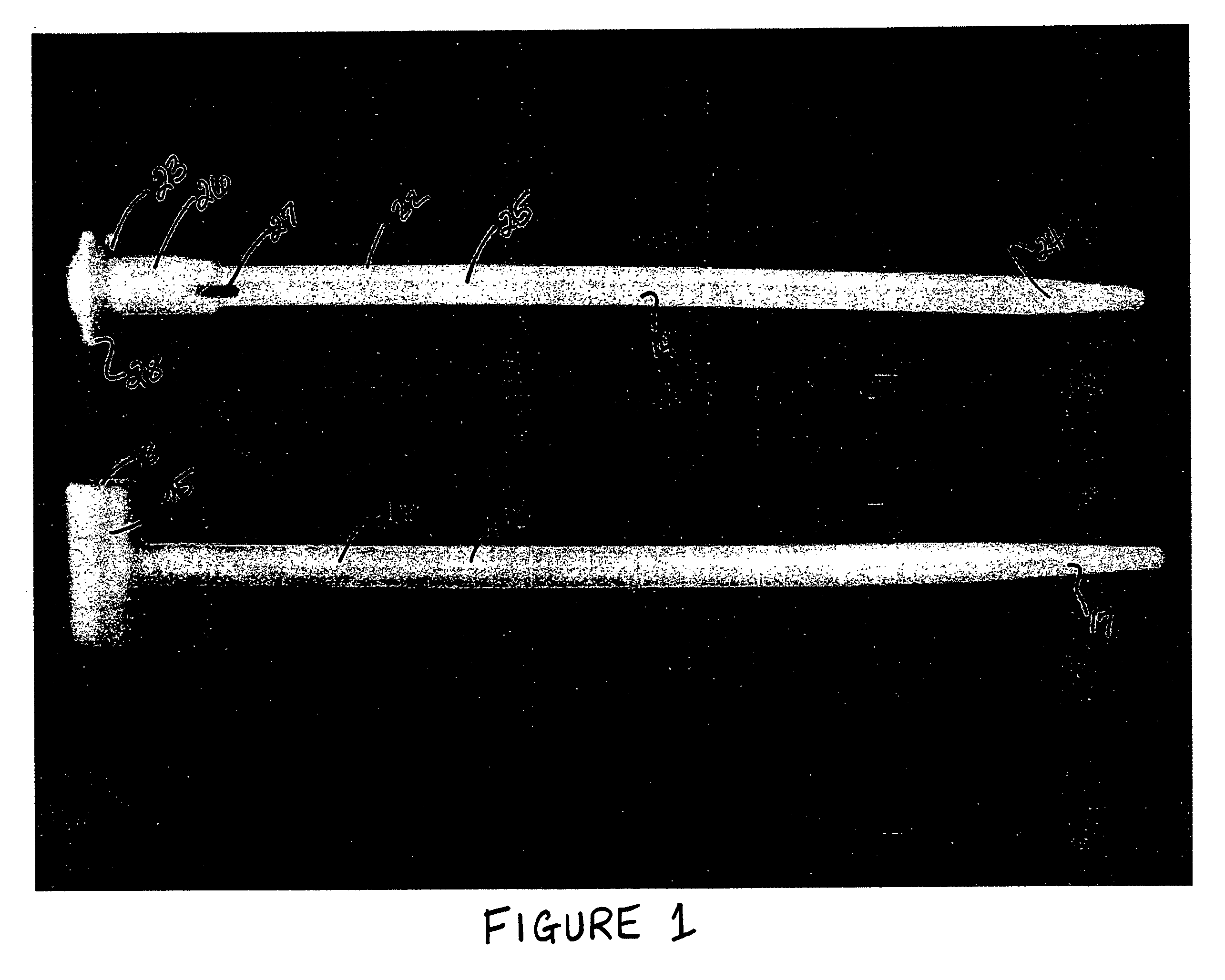

Intramedullary screw and tang for orthopedic surgery

InactiveUS20050177158A1Simple componentsQuick assemblyInternal osteosythesisJoint implantsEngineeringLag screw

One method of reducing fractures in long bones is to insert an intramedullary screw through the bone canal across the fracture and deploy tangs to increase the purchase of the screw. Compression is then applied along the screw to bring the broken bone together. An improved low cost lag screw has a cannulated shaft with a shaped bore in the leading end. A similarly shaped tang body is movably disposed in the leading end bore. The tang body has several tangs laser welded about the periphery and extending from the tang body. The shaped surfaces of the bore have exit holes and the ends of the tangs are adjacent the holes. An end cap is laser welded to the leading end of the shaft.

Owner:DOUBLER ROBERT L +1

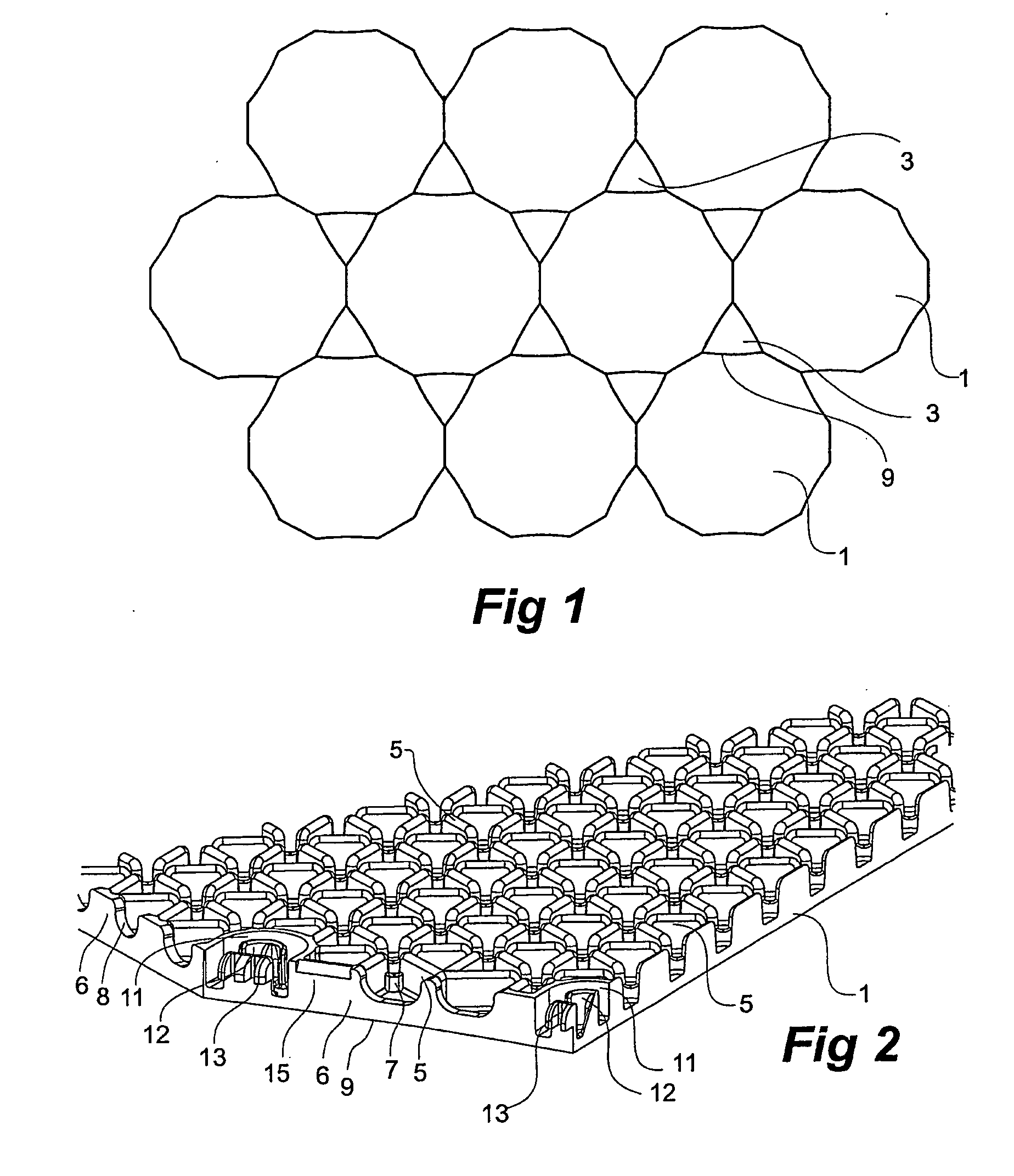

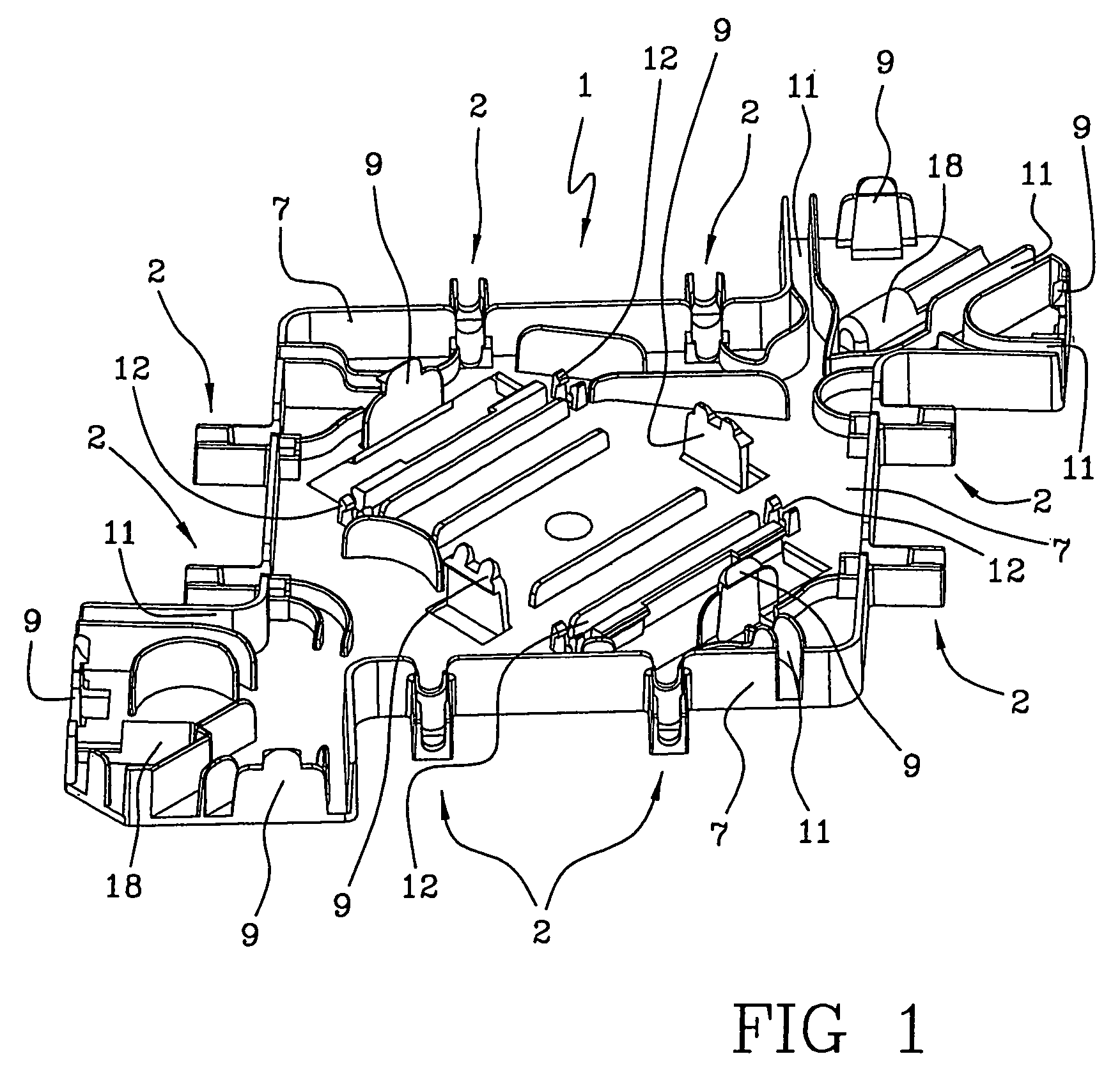

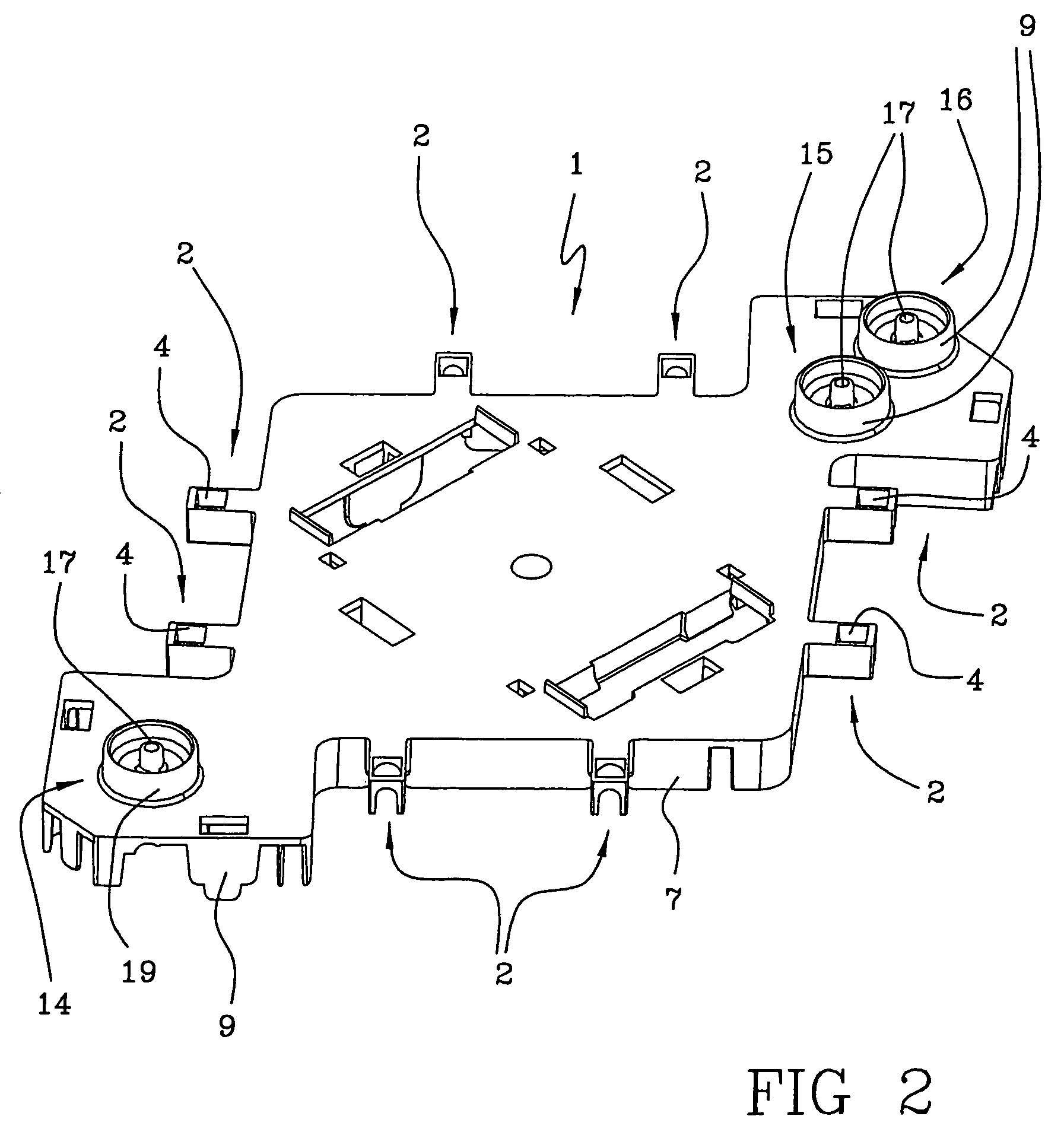

Modular plastic flooring

A modular plastic floor assembly formed from a plurality of shaped tiles (1) and a plurality of shaped connector tiles (3). The shape tiles are substantially larger than the shaped connector tiles and the shaped connector tiles fit into interstices between the shaped tiles when the floor assembly is formed. Each of the shaped tiles and the shaped connector tiles have a substantially planar upper surface (20) and a support array (5, 28) extending from a lower surface of the body. The shaped tiles have connectors (11) and the shaped connector tiles have complementary connectors (24). The connectors are adapted to interengage to interlock the shaped tiles to adjacent shaped connector tiles. Resiliently loaded fingers (118) allow for expansion and contraction between the adjacent tiles. The support array may include resiliently moulded shock absorbing portions (141). The upper surface may have in-mould decoration to provide a surface with changed appearance, frictional properties and / or surface hardness.

Owner:DESIGN DEV COMMLISE

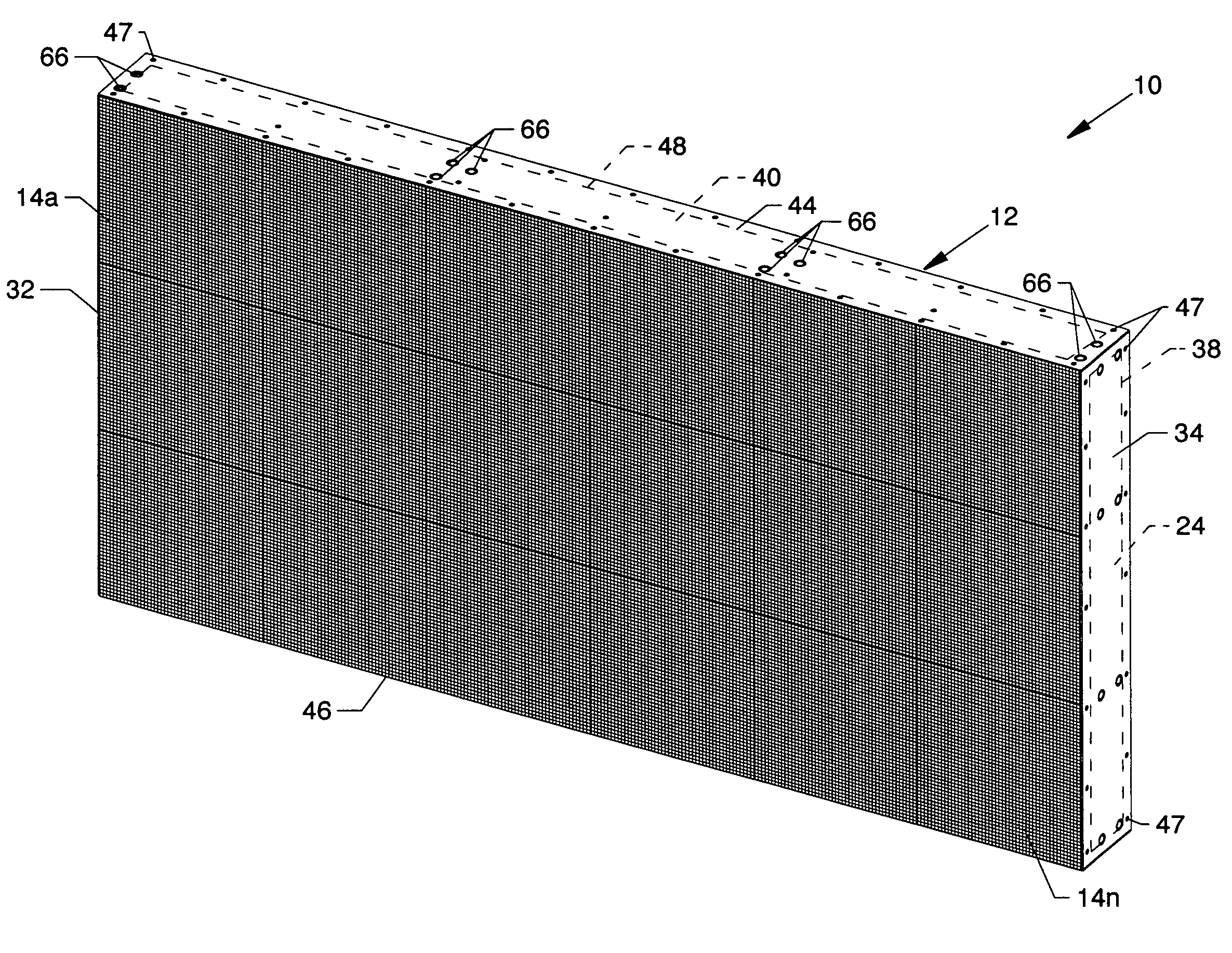

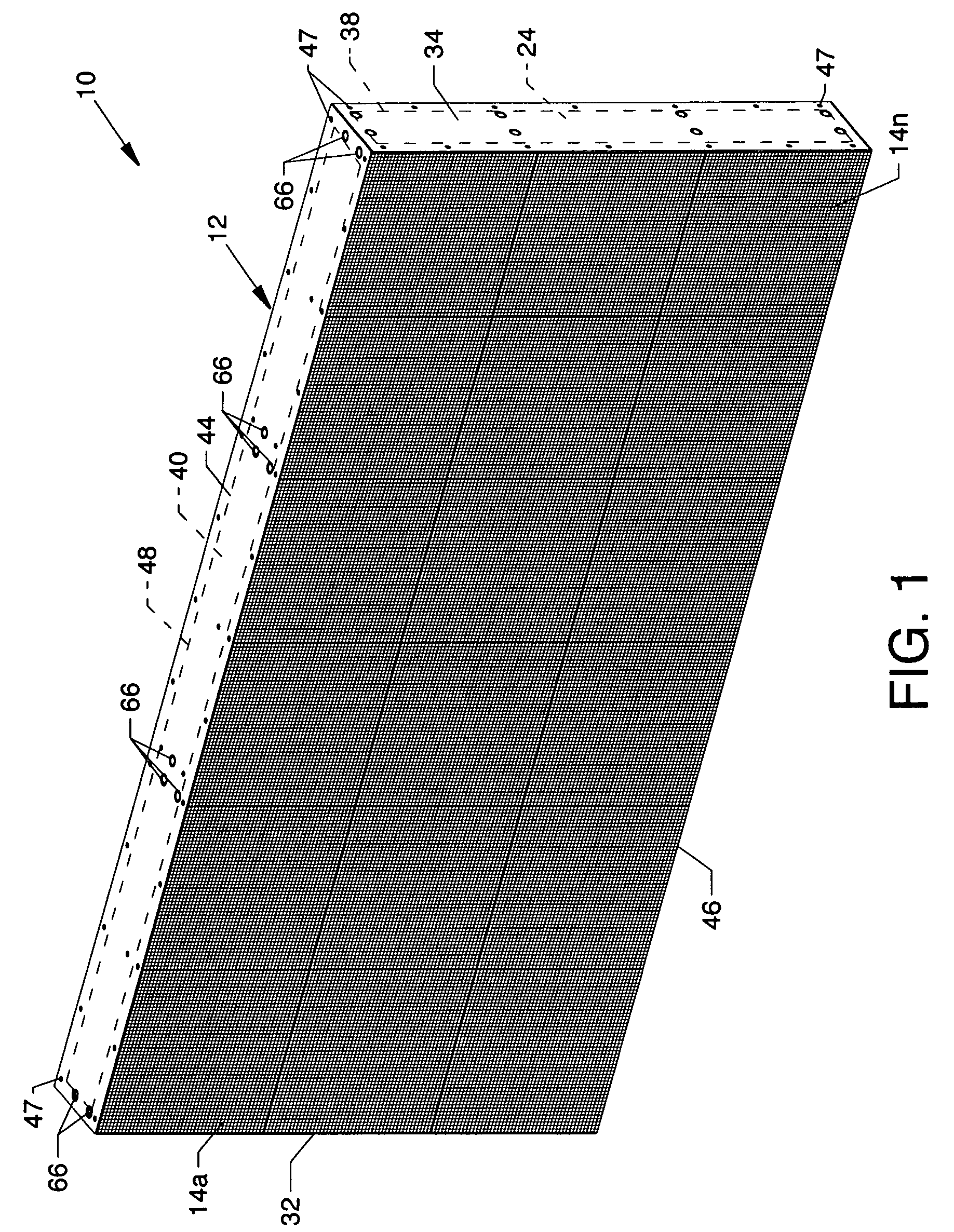

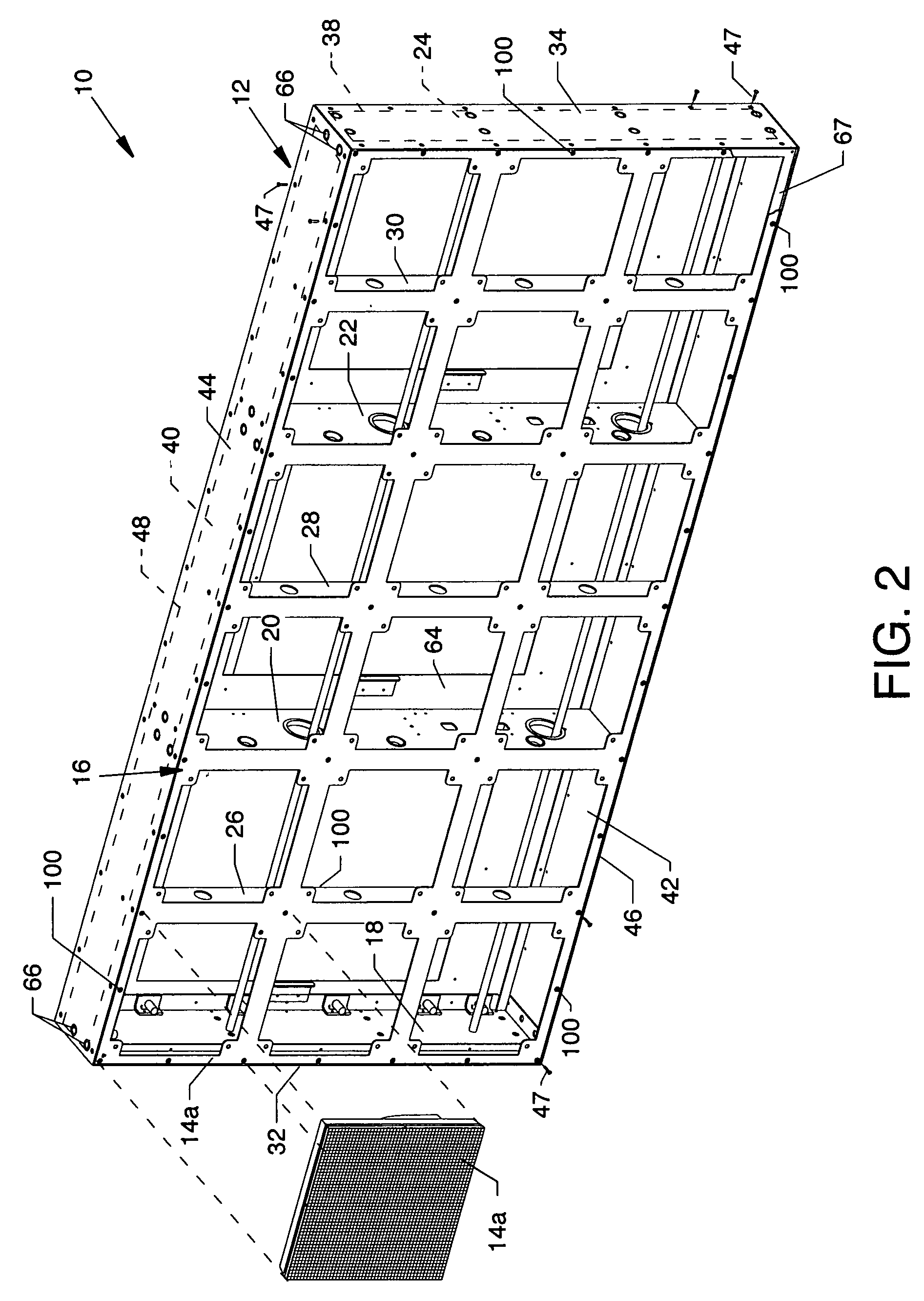

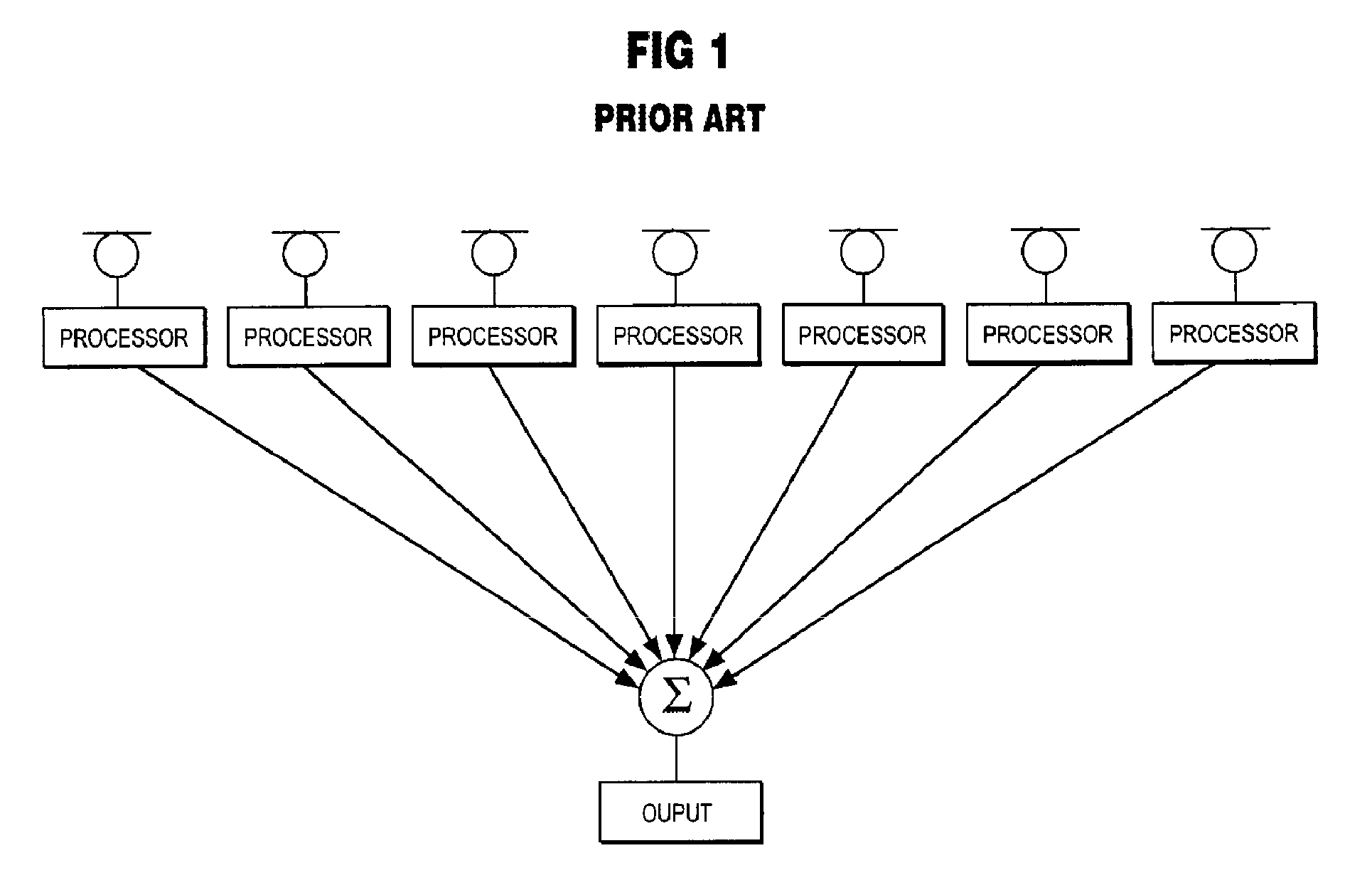

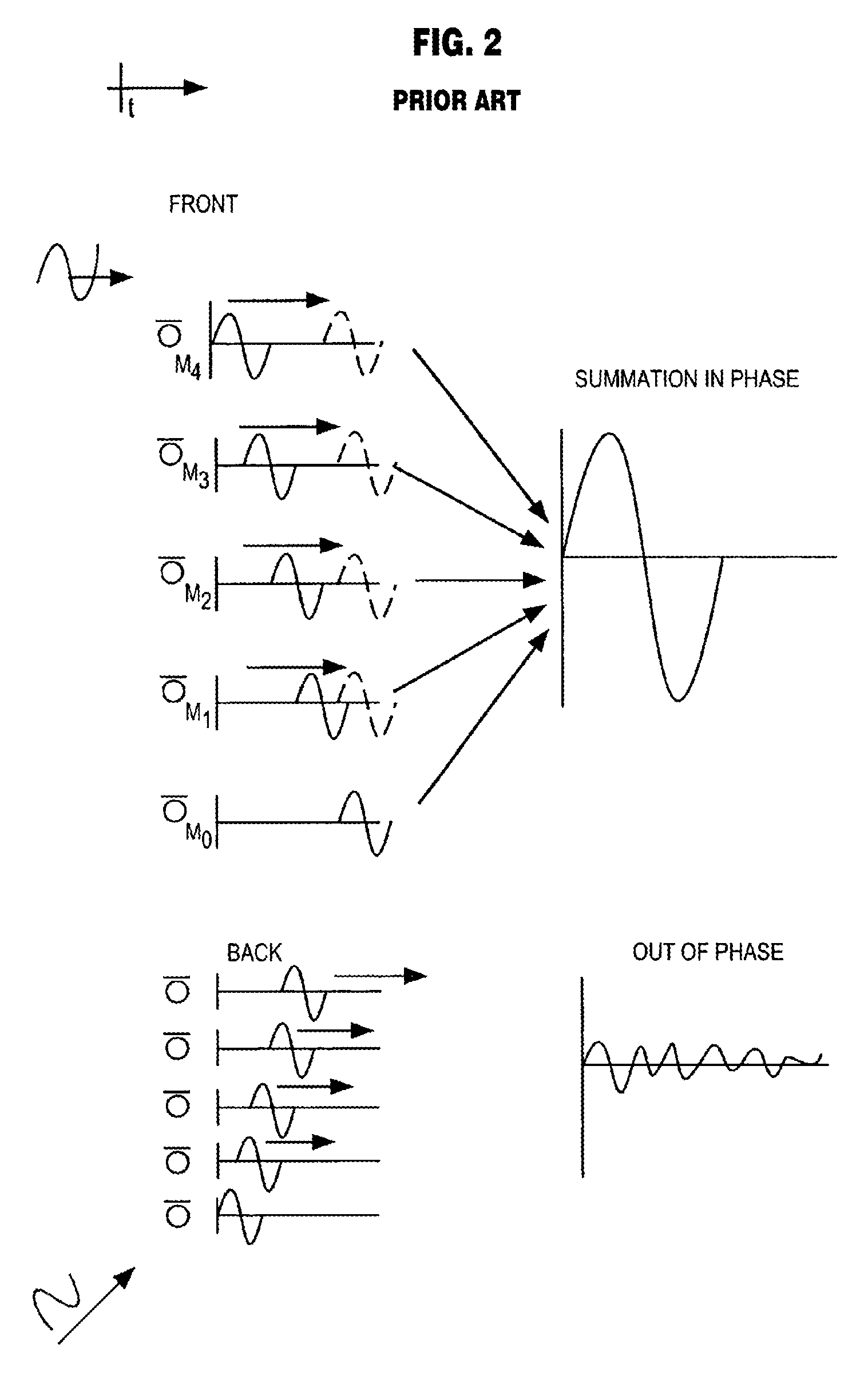

Modular and scalable directional audio array with novel filtering

ActiveUS8213634B1Robust and modular and highly scalableSufficient powerMicrophonesLoudspeakersSensor arrayUltrasonic sensor

A directional sensor array system generally for remote audio collection applications that is modular, scalable, and robust with the modules assembled in layers. The invention can alternatively employ sensors other than microphones, such as ultrasonic transducers and accelerometers. In the preferred embodiment, the sensors are mounted on tiles, each of which performs its own local beamforming using a low-impedance resistive summation technique. The tiles are constructed in a layered, sandwiched fashion and incorporate integral protection from wind, sand, dust, moisture, radio frequency noise, vibration, ambient acoustic noise, and directional acoustic noise, as well as provide inter-sensor isolation. Multiple tiles can be joined together physically and electrically. When joined, a secondary parallel beamforming is performed on the bus using electrical summation. Due to the techniques employed, large scale arrays are feasible at low power consumption—for example, an array of 400 microphone elements can be powered for over 6 hours by a single 9 volt battery.

Owner:DANIEL TECH

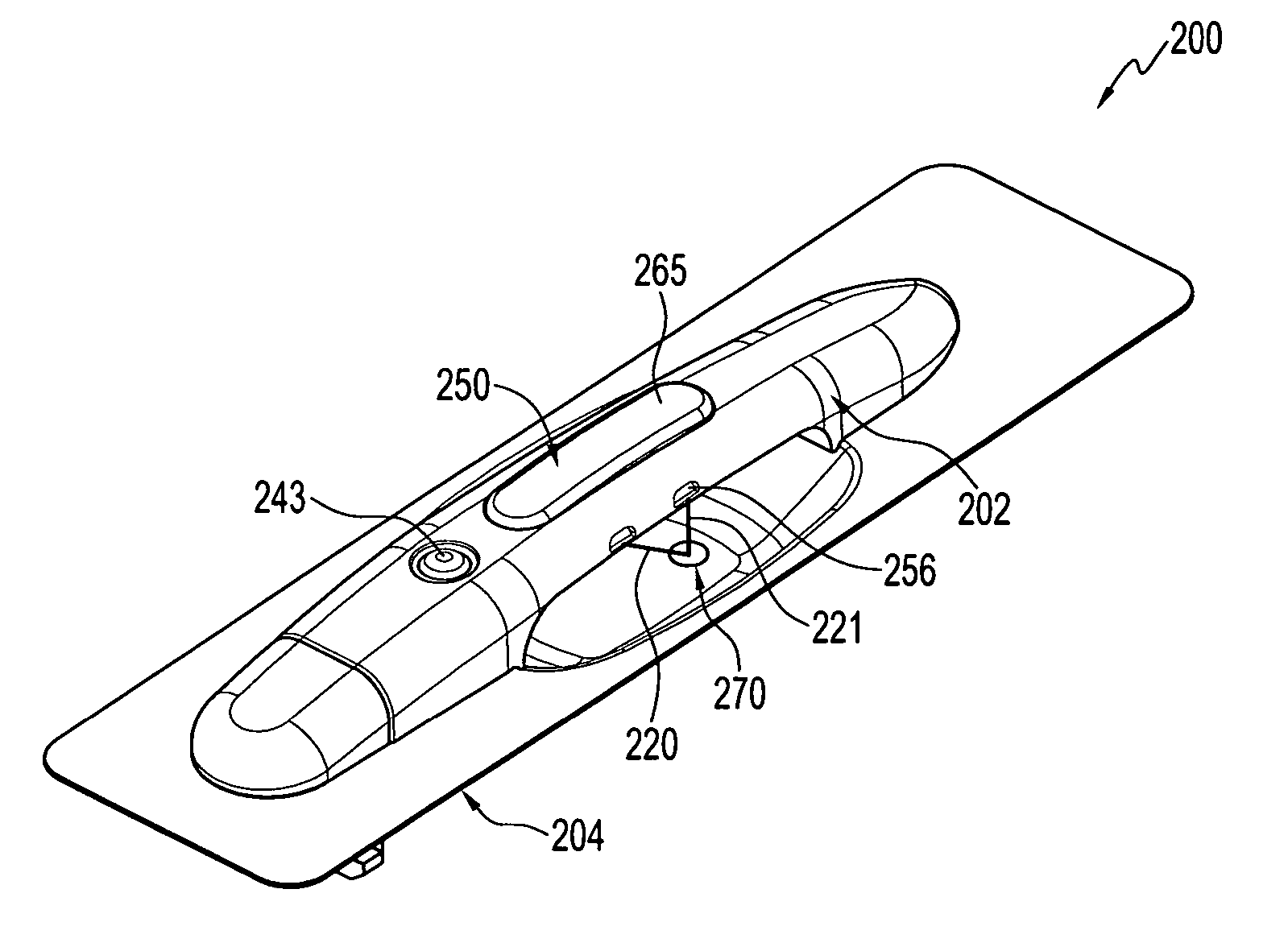

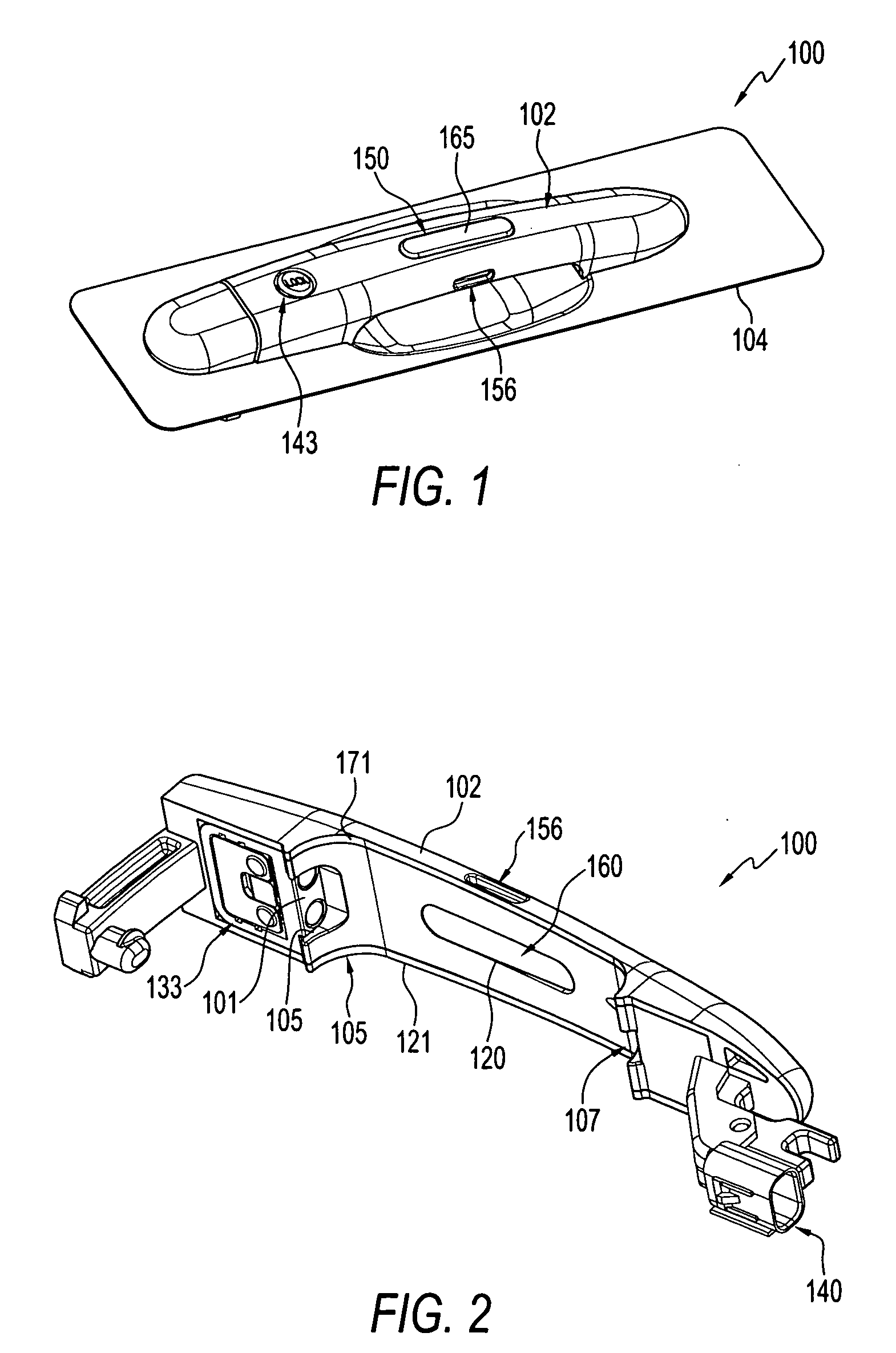

Passive entry sensor system

InactiveUS20060226953A1Easy constructionAvoid the needElectric signal transmission systemsDigital data processing detailsElectromagnetic radiationBiological activation

Passive entry sensor systems and associated sensors are disclosed. The system sensor is arranged in the handle of a door or directly mounted to the door skin. When mounted in the handle, the sensor provides an electromagnetic radiation beam transmitted either along the length of the handle between opposite ends thereof or between the handle and the door so that the beam can be at least partially interrupted or modified by a user actuating the handle. When mounted directly to the door skin, the sensor provides an electromagnetic radiation beam transmitted between the handle and the door. The sensor system includes indicators for indicating system status to the user, back-up switches for detecting a pull on the handle, locking switches for activation by a user to lock or unlock the door and backlight and ground light lighting.

Owner:HONEYWELL INT INC

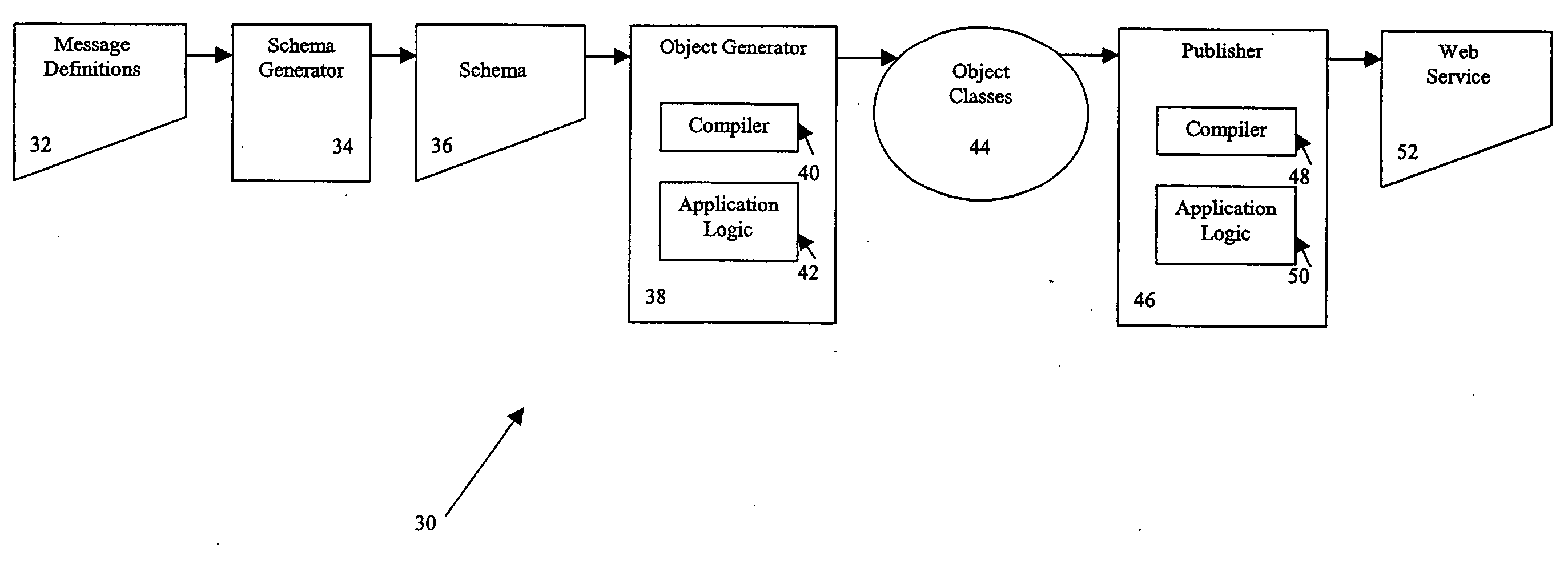

Transaction processing architecture

InactiveUS20050091639A1Improve securityQuick and efficient creationNatural language data processingWebsite content managementPaper documentFinancial transaction

One aspect of the invention is a transaction processing system comprising a software service operable to receive a transaction request and to generate a first object associated with the transaction request. An object generator may convert the first object into a first document written in a self-describing language. A document generator may convert the first document into a first transaction message according to a schema associated with a first transaction type determinable from the first document.

Owner:HEWLETT-PACKARD ENTERPRISE DEV LP

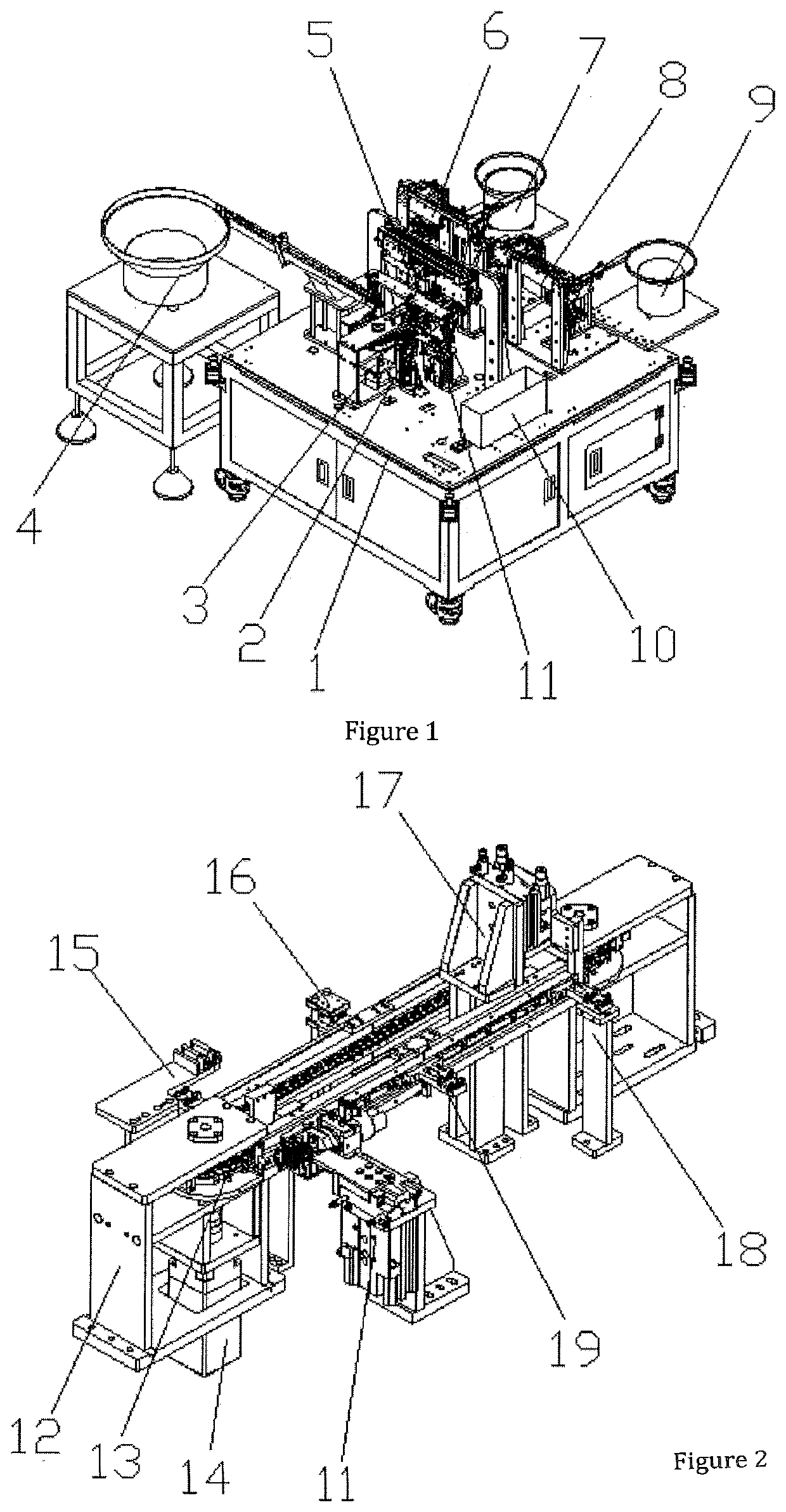

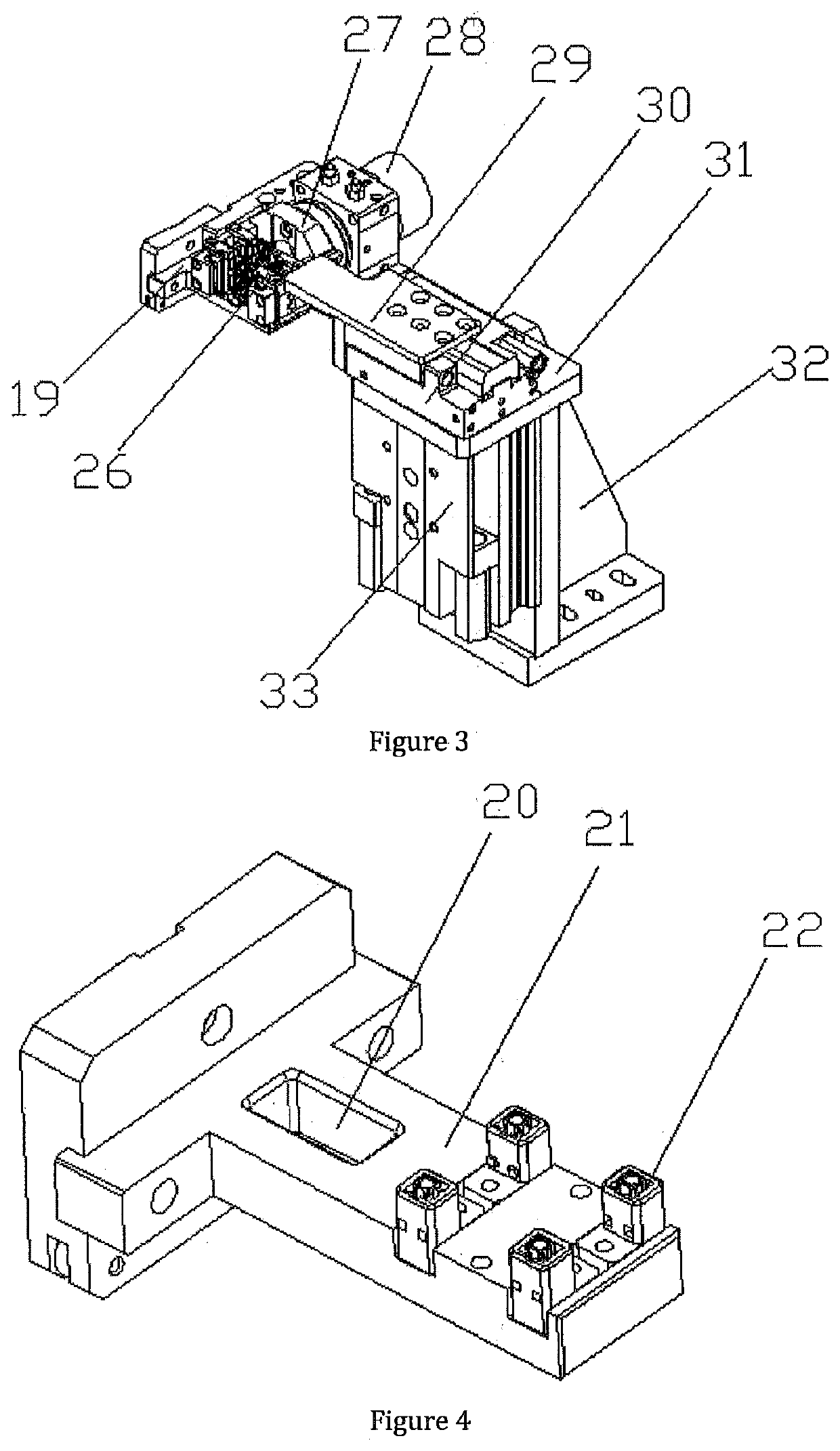

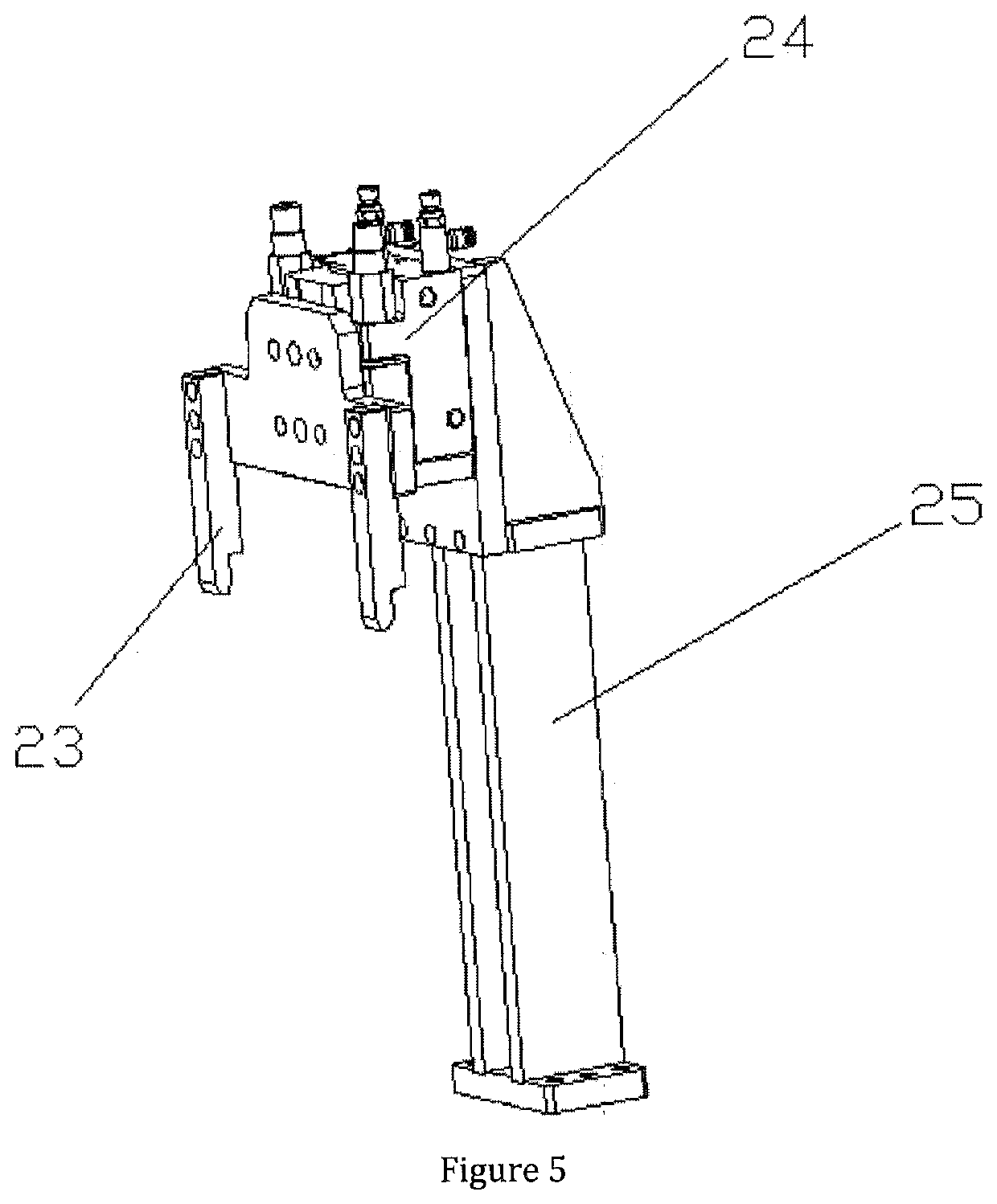

Automatic spring fastener assembly machine

ActiveUS20190337105A1Completed efficientlyCompleted fastContact member assembly/disassemblyAssembly machinesRobot handEngineering

The present invention relates to an automatic spring fastener assembly machine, including a rack and a power control box, and the rack is provided with a circulating conveying device, and a rubber casing feeding device, a fastener feeding device and a spring loading device which are in turn arranged around the circulating conveying device. The rubber casing feeding device includes a rubber casing vibration tray disposed to the left front side of the circulating conveying device, and the rubber casing feeding vibration tray is connected with a rubber casing distributing block through the rubber casing conveying track. The upper side of the circulating conveying device is provided with a rubber casing transportation manipulator, and the right front side thereof is provided with a rubber casing clamping device located below the rubber casing transportation manipulator, and a fastener pushing in device fitting the circulating conveying device is disposed under the rubber casing clamping device. In the present invention, material feeding and conveying is done by the circulating conveying device, and fasteners are fitted into corresponding holes on the rubber casings from a higher position with the fastener pushing in device, which can be completed fast and efficiently, is easy to operate, realize quick assembly of spring fasteners and improve working efficiency.

Owner:DONGGUAN UNIV OF TECH

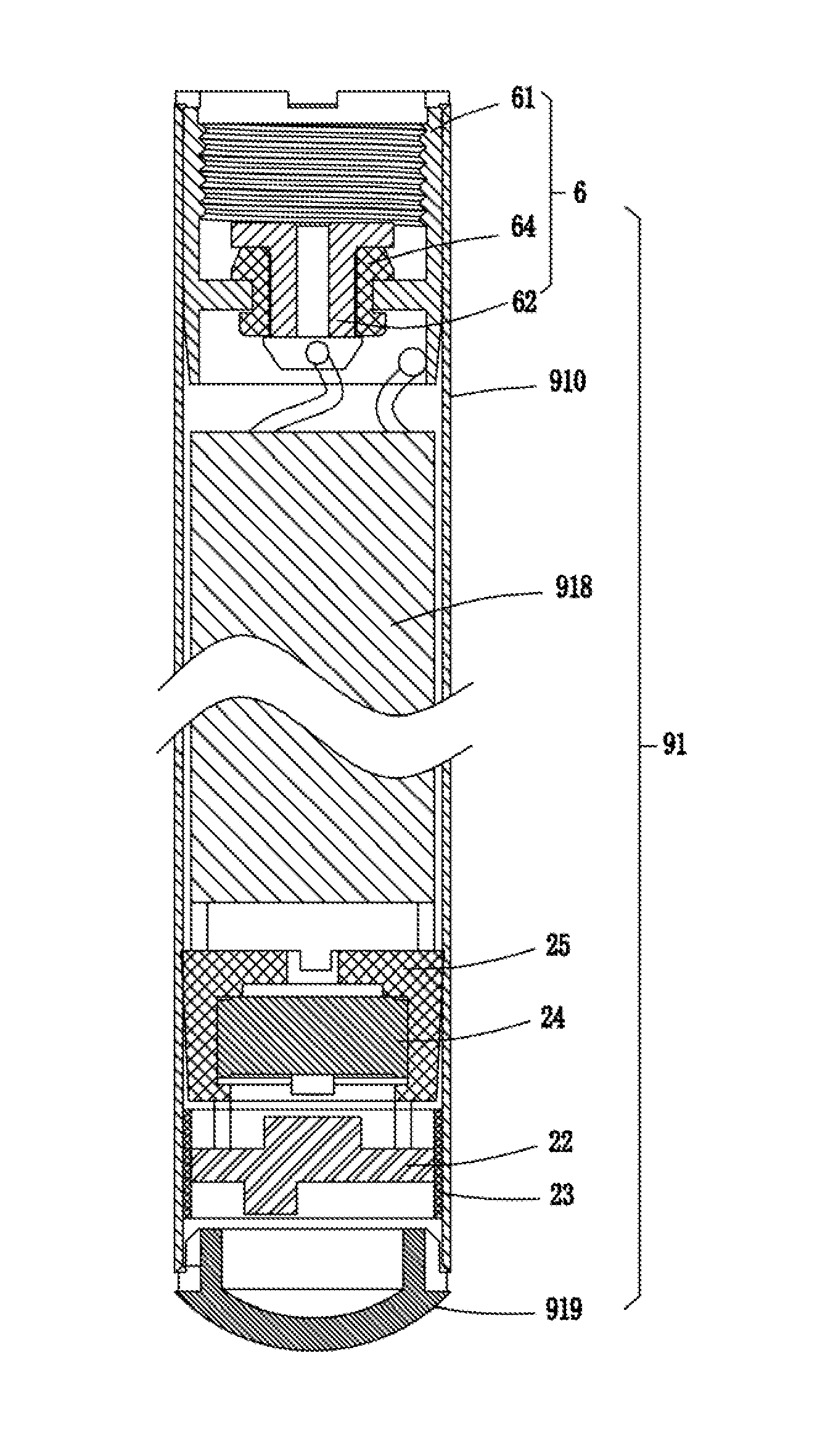

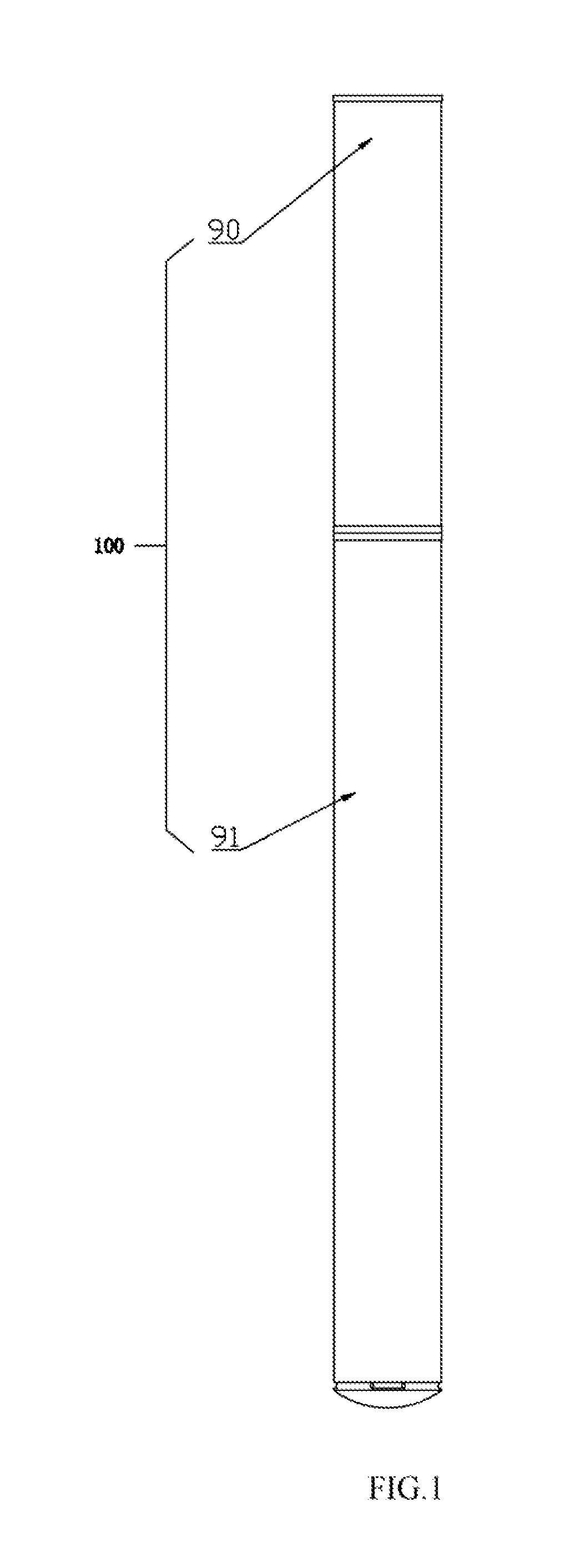

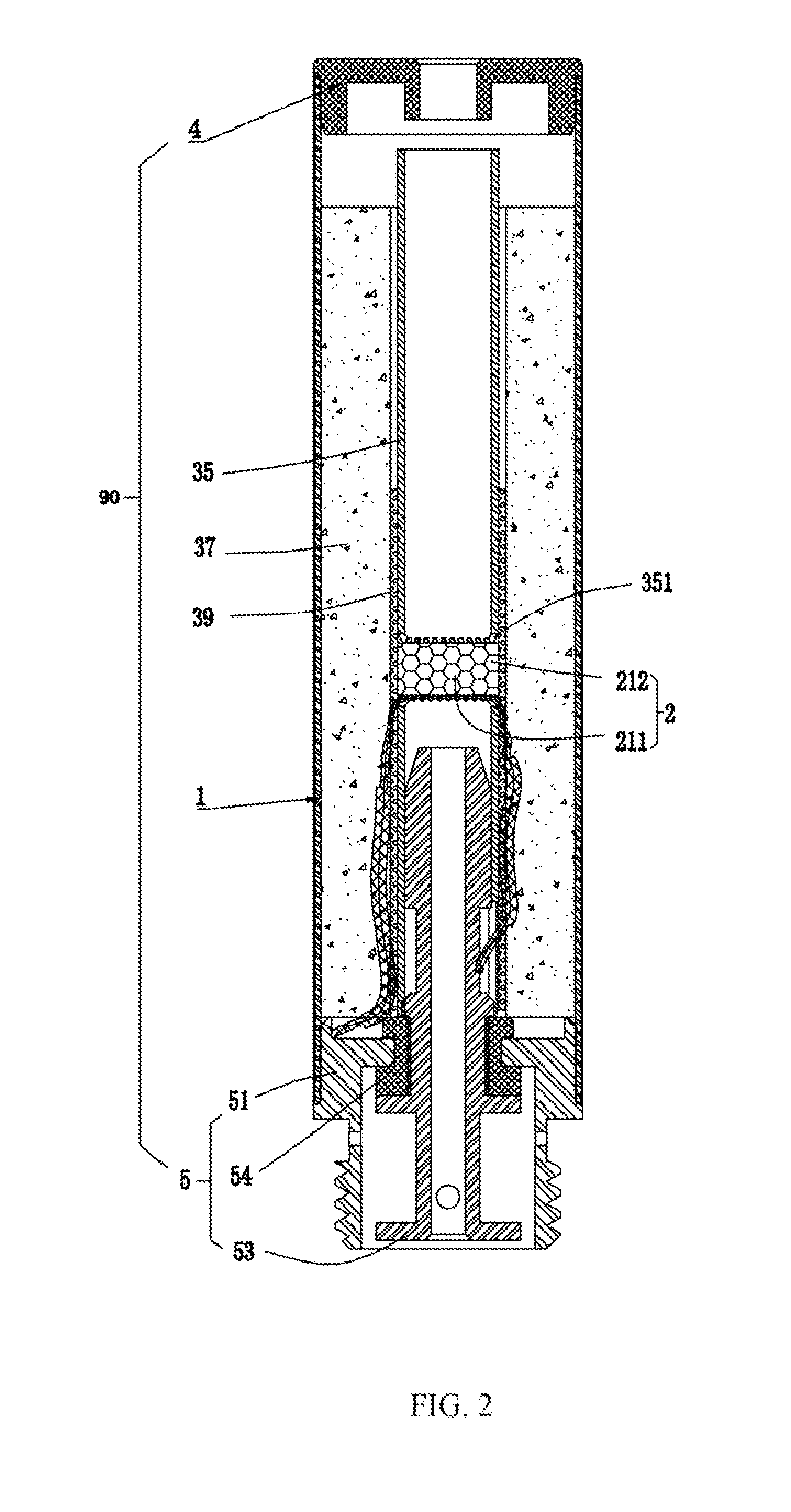

Electronic cigarette

InactiveUS20160113325A1Quickly and conveniently assembledEasy to operateTobacco pipesTobacco devicesElectrical batteryEngineering

An electronic cigarette comprising a housing and, arranged within the housing, an atomizer apparatus and a power supply control apparatus used for providing power supply to the atomizer apparatus and for controlling the working of same. The power supply control apparatus comprises a battery, a microphone, and a control panel. The microphone and the control panel are both arranged at one end of the battery. The microphone is adjacent to the battery. The control panel is arranged in proximity to an opening end of the housing and is adjacent to the microphone. The microphone and the control panel are insulated and separated from each other. The electronic cigarette is structurally simple and is easy and convenient to assemble.

Owner:KIMREE HI TECH

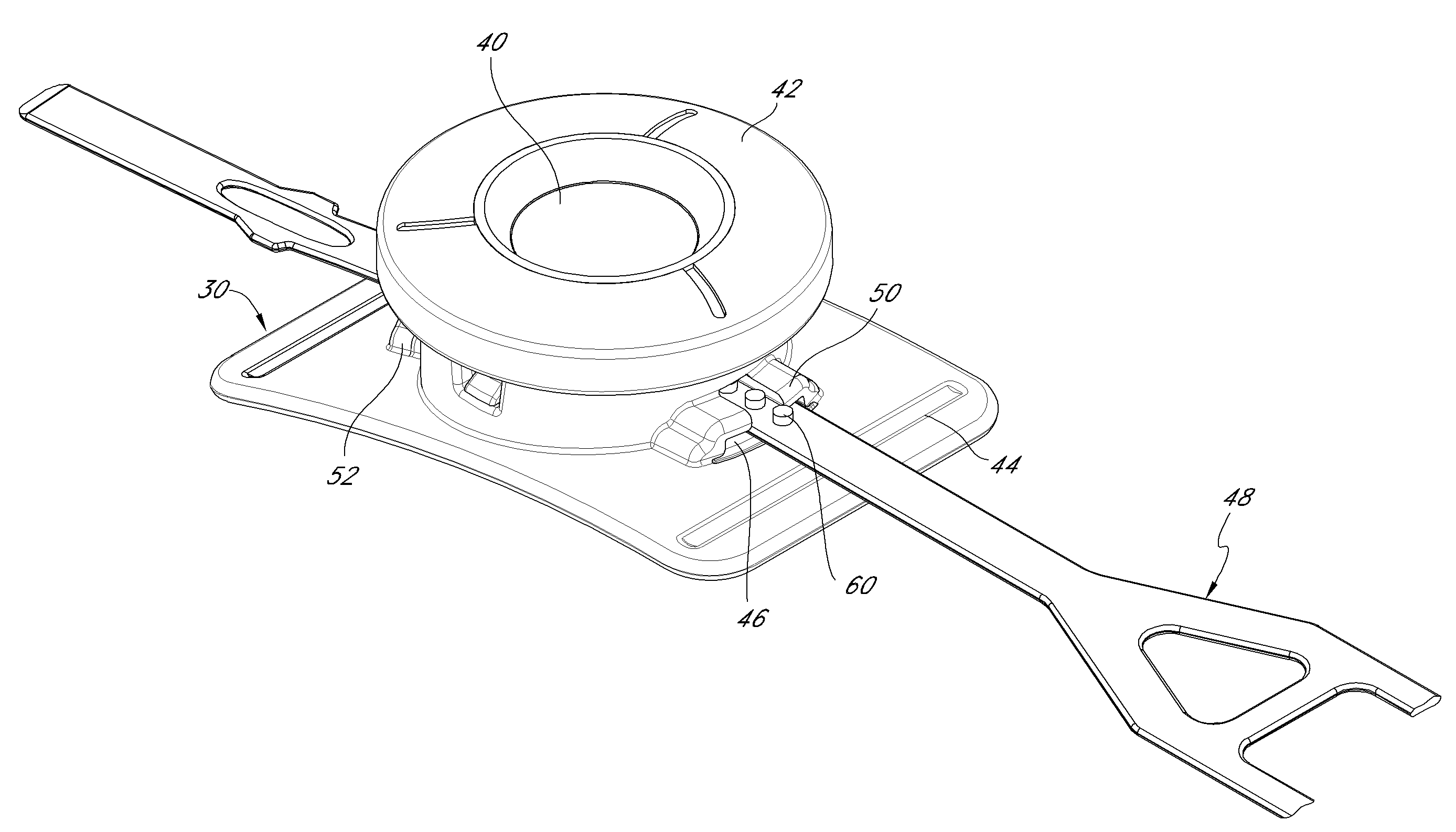

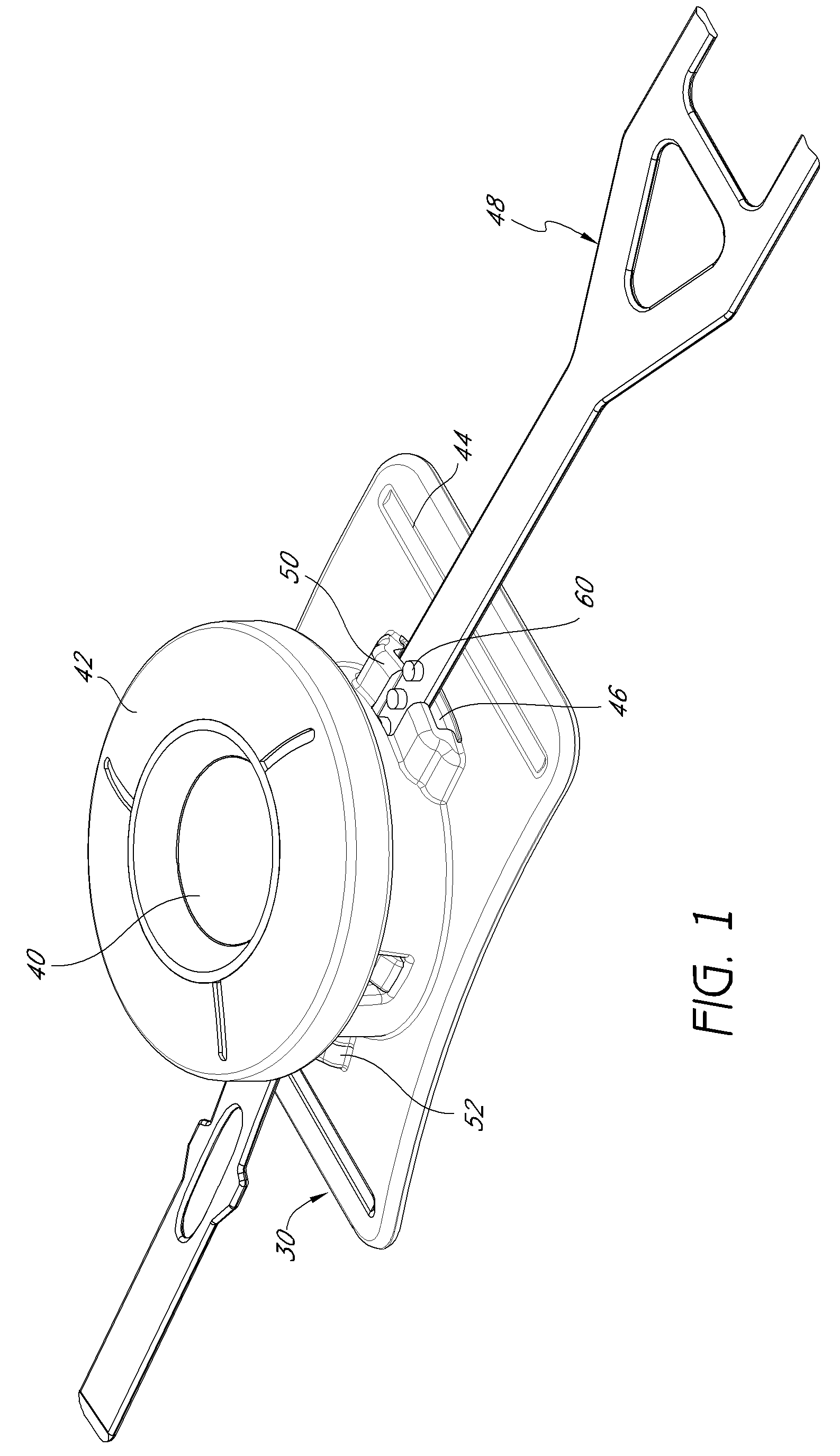

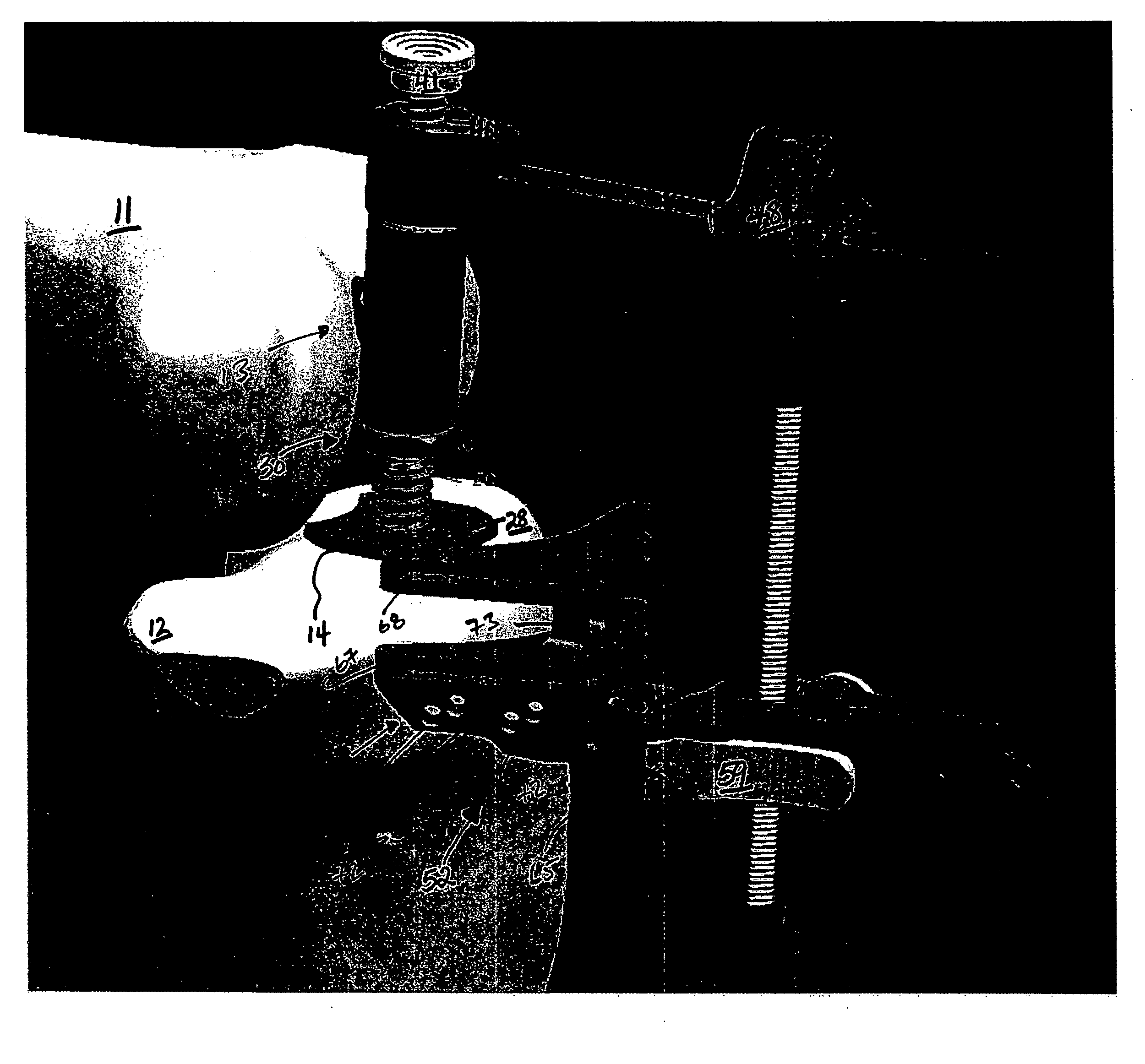

Guide assembly for guiding cuts to a femur and tibia during a knee arthroplasty

ActiveUS20060189998A1Small and noninvasive approachQuick disassemblyInternal osteosythesisJoint implantsTibiaDistraction

An assembly for guiding resection of a femur and tibia of a knee joint in preparation for installing a femoral and tibial knee components. For example, the assembly can include tibial and femoral IM rods to which are connected through a torque bolt that allows controlled adjustment of the distraction of the tibia and femur during cut positioning in a range of flexion angles. Also, the assembly is usable with relatively small, noninvasive approaches to the knee joint by way of relatively narrow, low profile components that attach to tibial and femoral IM rods. Further, the assembly includes several quick-release components to allow fast assembly and disassembly in a surgical setting. Each of these aspects, along with the ability of the assembly to accurately guide initial reference cuts to the tibia and femur, promotes an improved outcome for the patient.

Owner:RASMUSSEN INSTR LLC

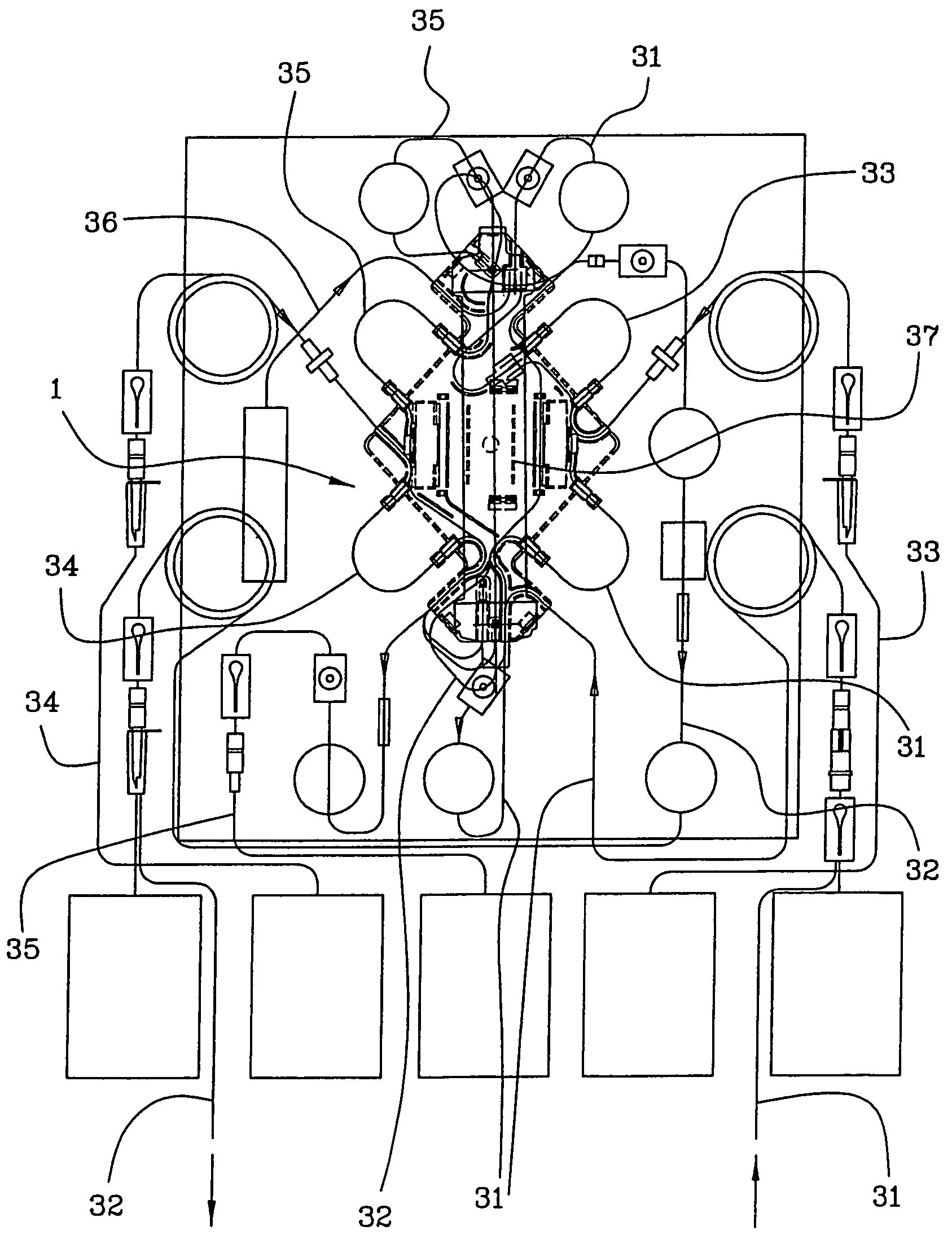

Support element, an integrated module for extracorporeal blood treatment comprising the support element, an apparatus for extracorporeal blood treatment equipped with the integrated module, and an assembly process for an integrated module for extracorporeal blood treatment

ActiveUS7232418B2Quick assemblyEasy to operateEngine diaphragmsSolvent extractionIntensive treatmentBlood treatments

An integrated module for extracorporeal blood treatment has a flat-shaped support element which exhibits on an internal face thereof a complex of fluid distribution lines and on an external face thereof a high-flow dialyzer. The support element has a base body which exhibits fixture seatings, each of which houses an axially extended tract of a fluid distribution line. The tract of the fluid distribution line, with respect to adjacent tracts, has an increased diameter due to the presence of a junction collar made of a rigid material. Each fixture seating exhibits two axial locators for positioning the axially extended tract of a fluid distribution line in a fixed position. The locators interact with the junction collar, and the distribution lines can be fixed to the base body by a resilient fixture of the junction collars in the seatings without gluing. The module is configured to be mounted on an apparatus for intensive treatment of renal insufficiency.

Owner:GAMBRO LUNDIA AB

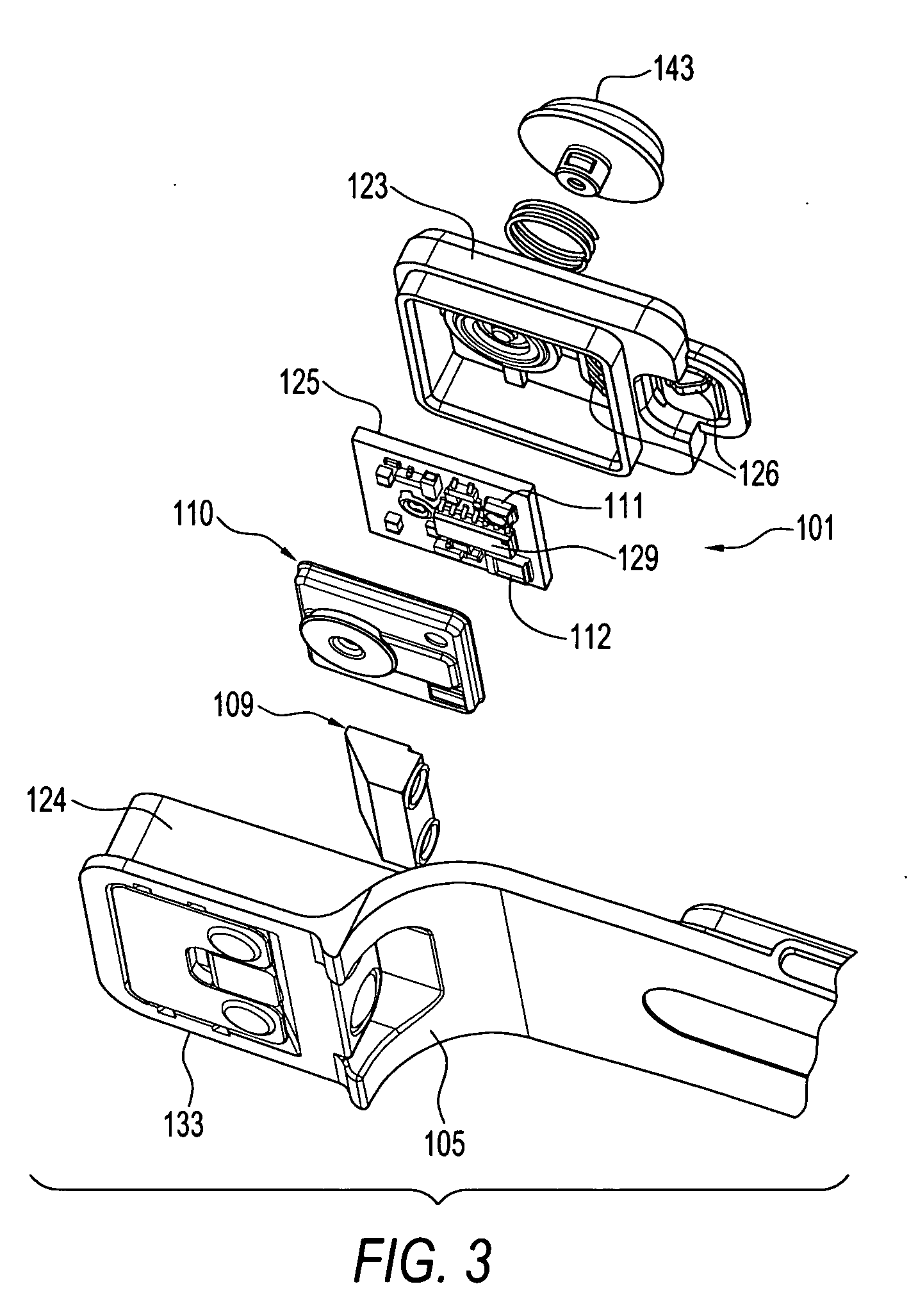

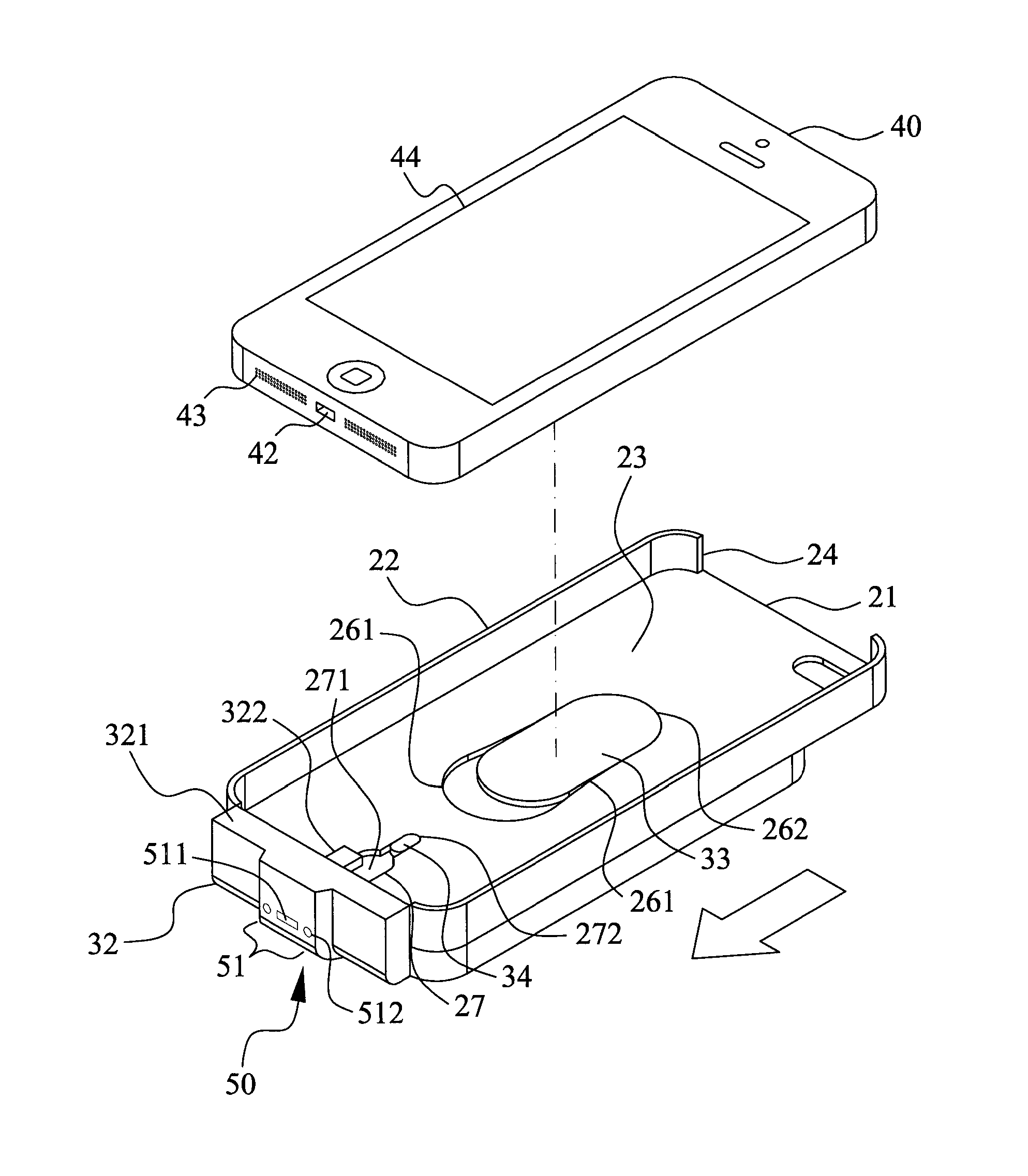

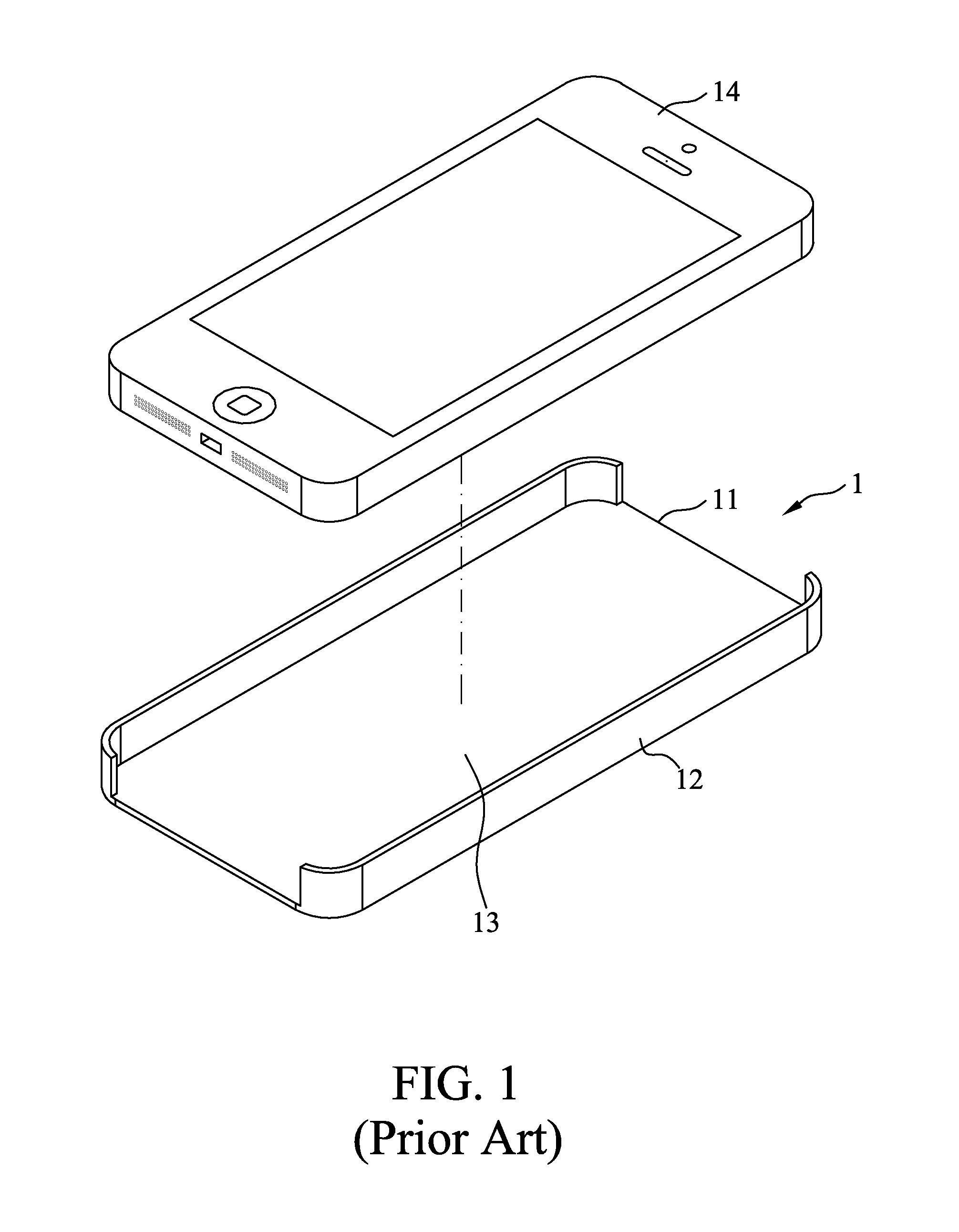

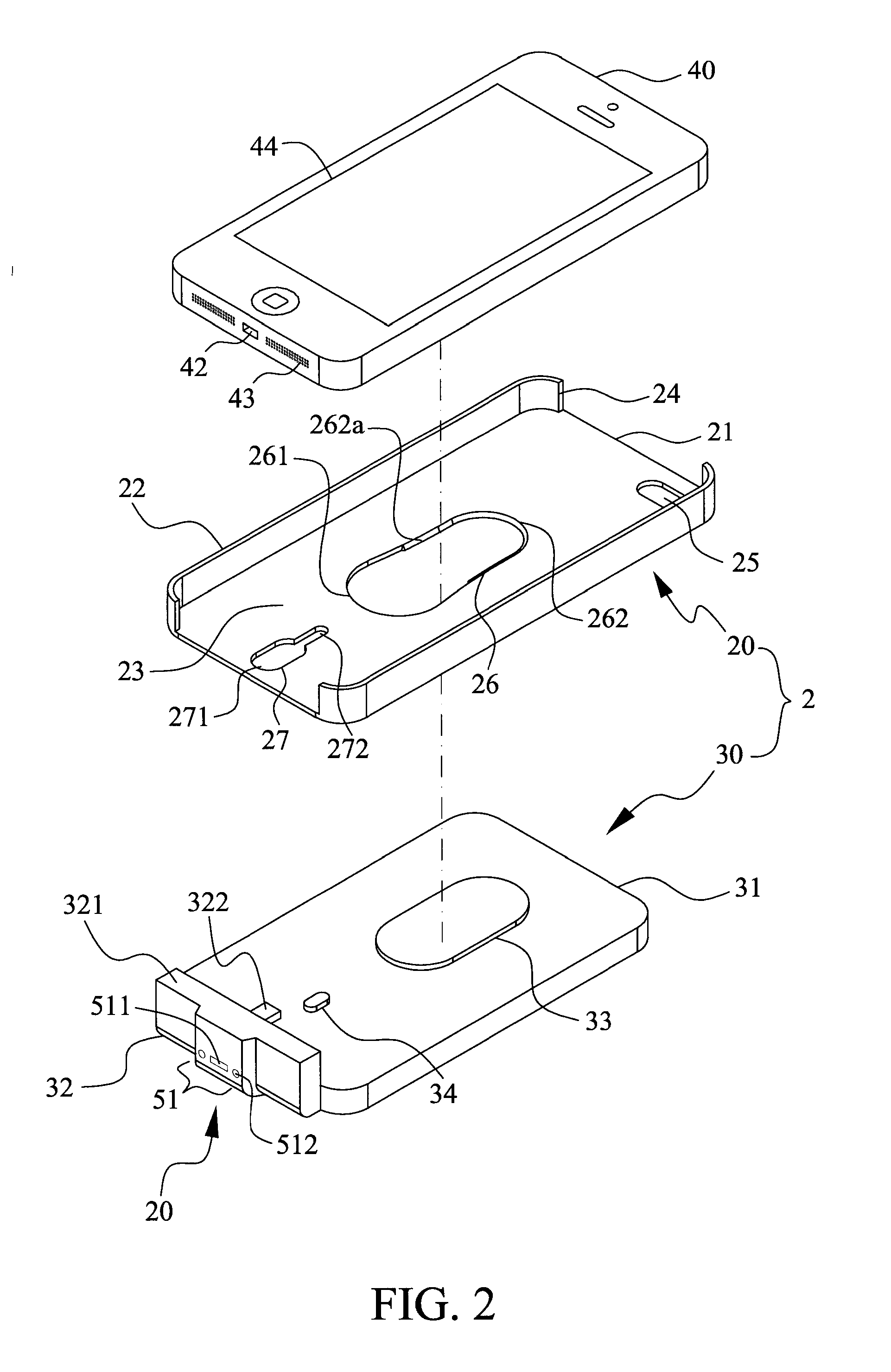

Multifunctional protective case for electronic device

InactiveUS20150172431A1Function increaseQuick assemblyOther accessoriesDevices with bluetooth interfacesHand heldEngineering

Owner:TRIANGUS GRP

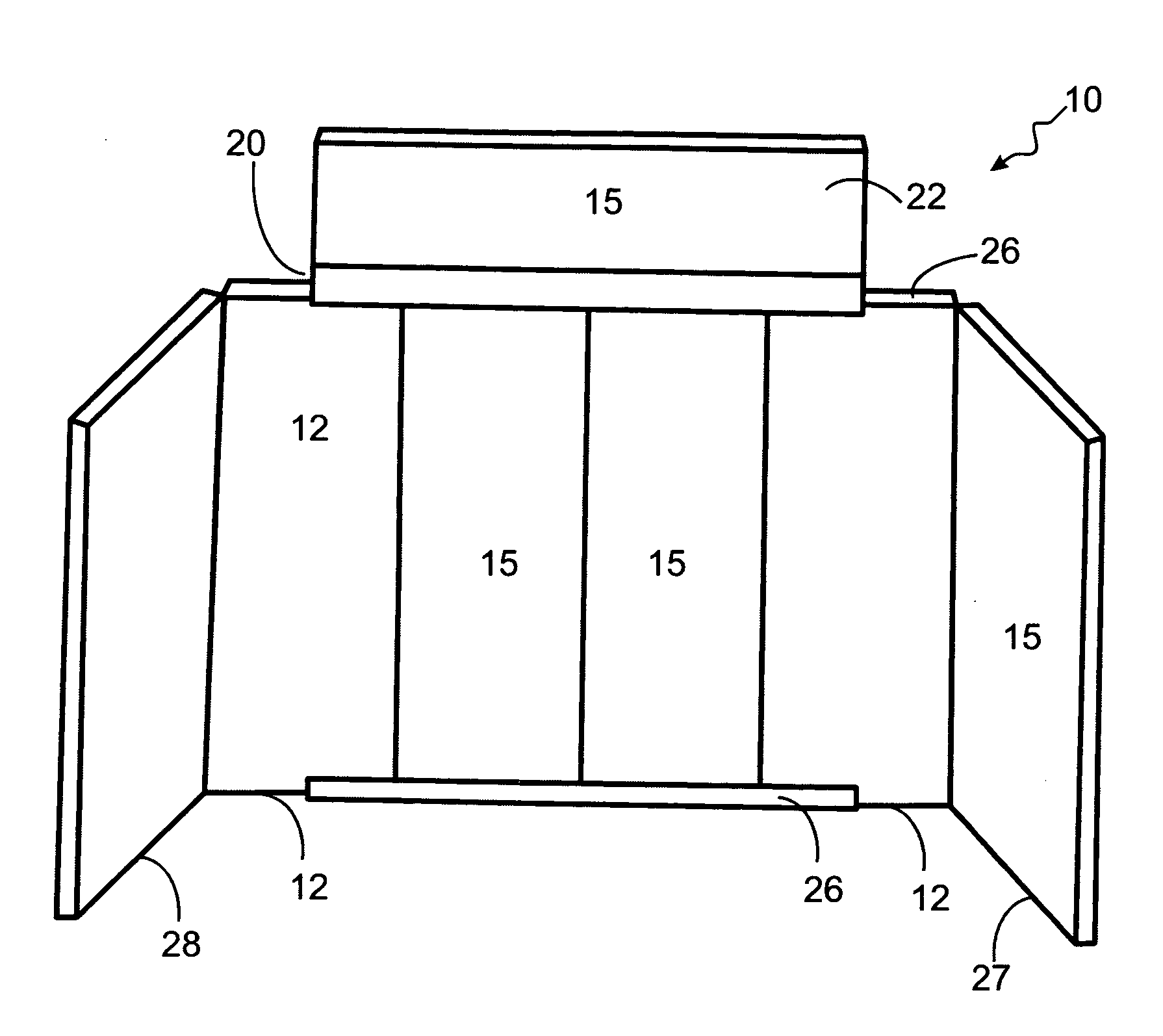

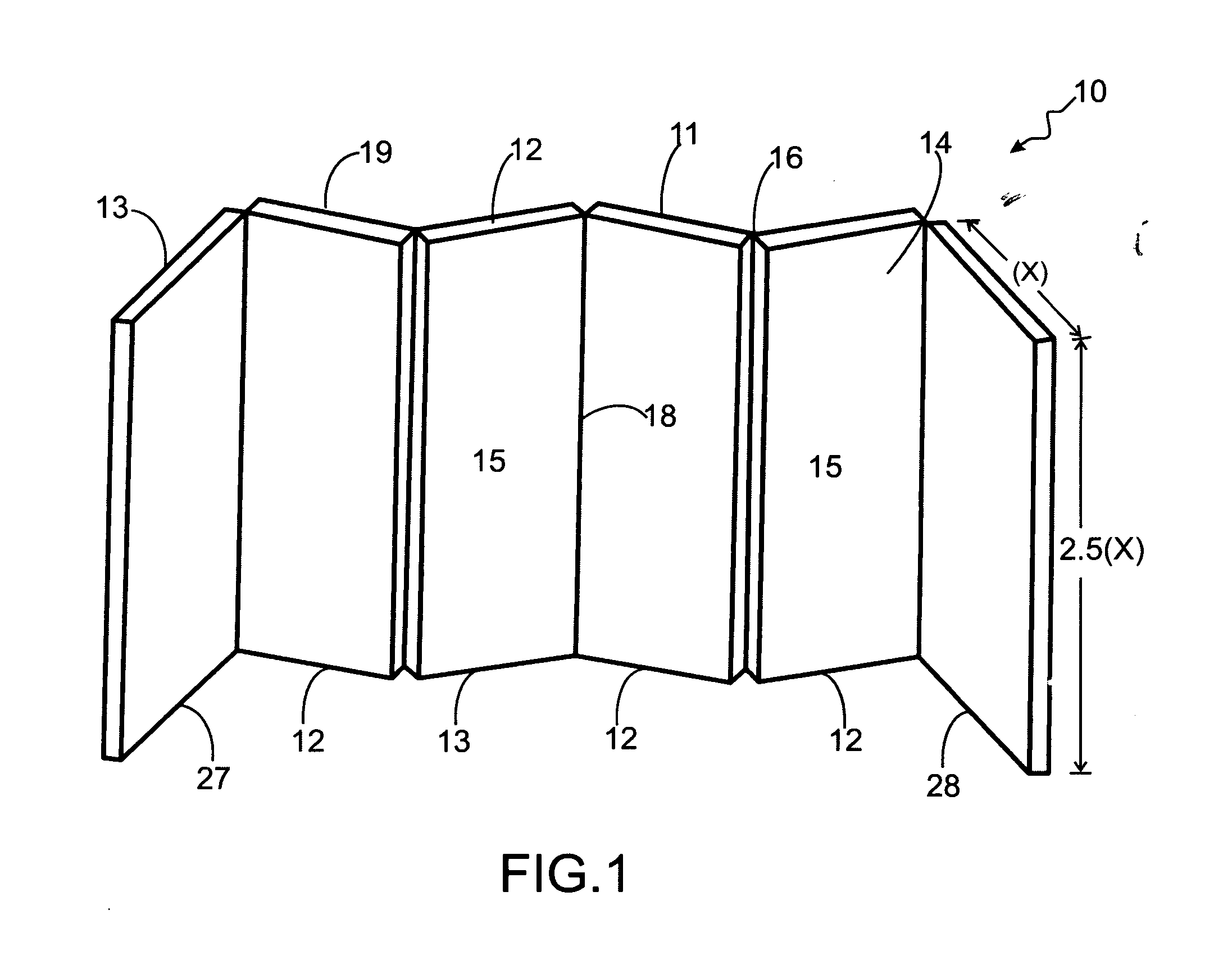

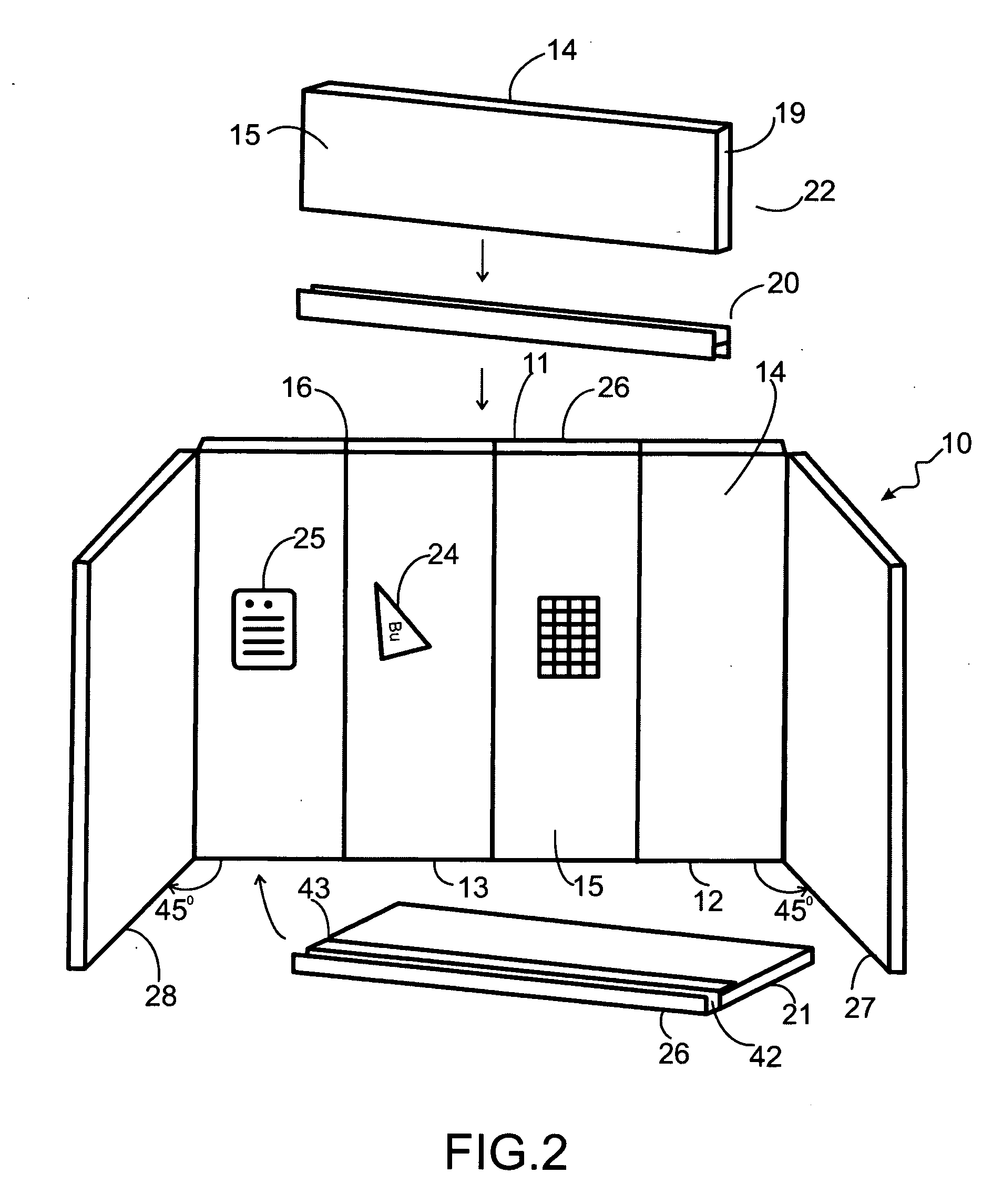

Portable presentation display device

The present invention comprises a presentation display device that is portable and easy to assemble and disassemble. The invention includes a plurality of movably hinged display panels as described. The display panels are composed of a foam core material coupled between two outer sheet layers made of foldable, tear resistant material. The invention also includes a connecting means comprising a removable connecting bracket which may be used to attach one or more display panels along the outer edges of the movable hinged panels thereby expanding the height and width of the display area of the device. The disclosure further includes a support means comprising a detachable support bracket used to vertically stabilize the device while it sits above a planar surface such as the floor, or a desktop.

Owner:HOUSSAIN VAZGEN +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com