Patents

Literature

465 results about "Increased diameter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

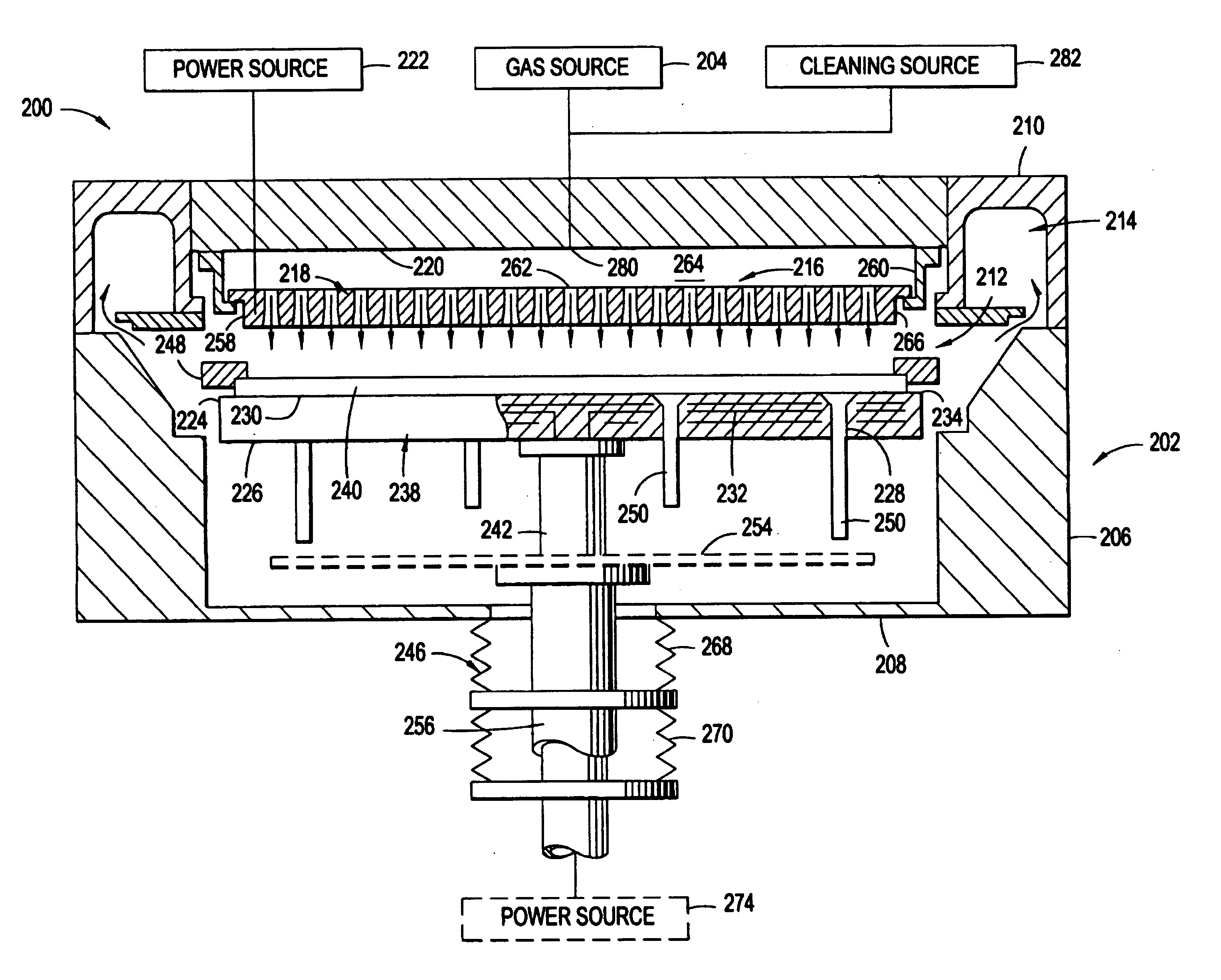

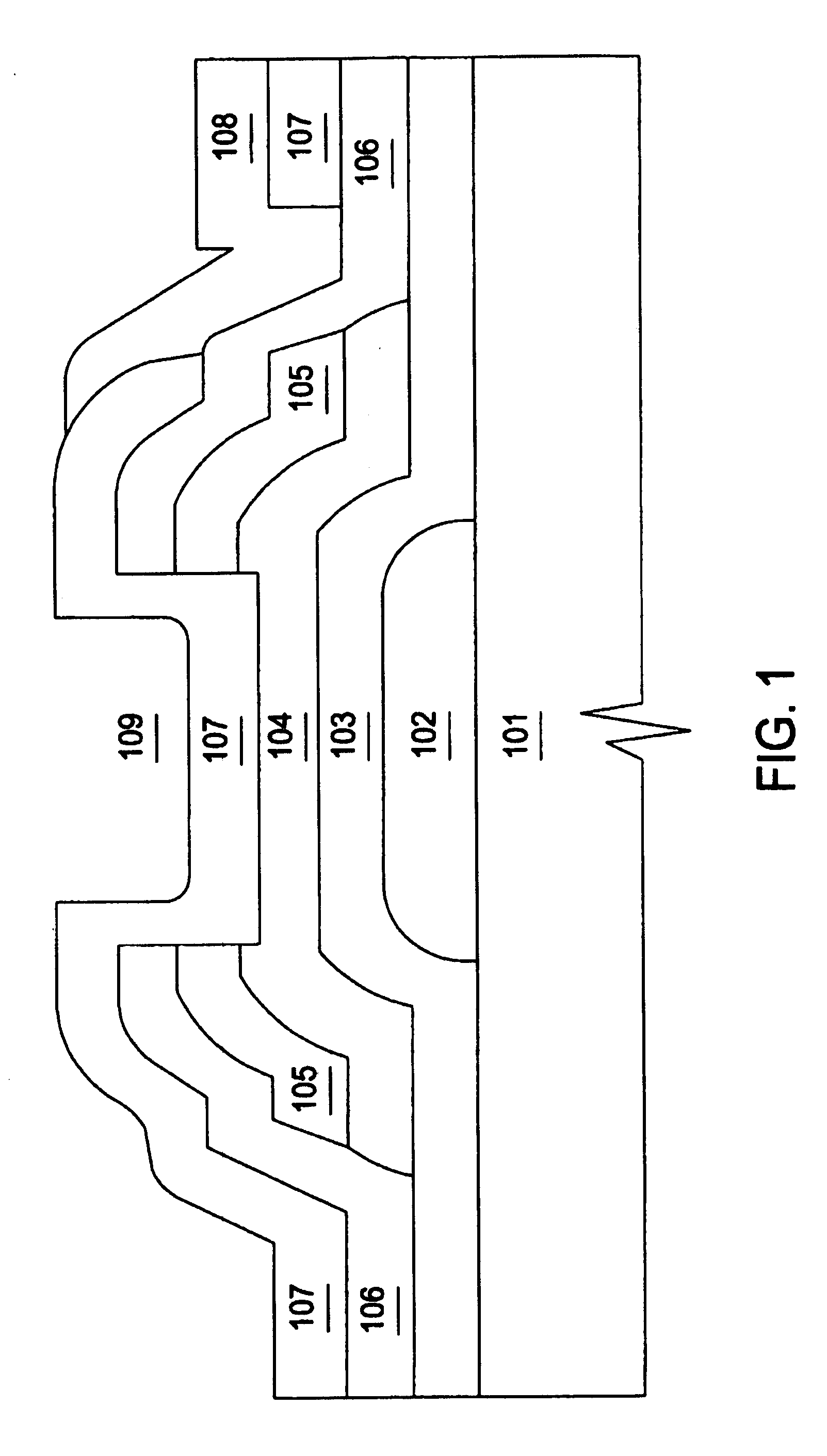

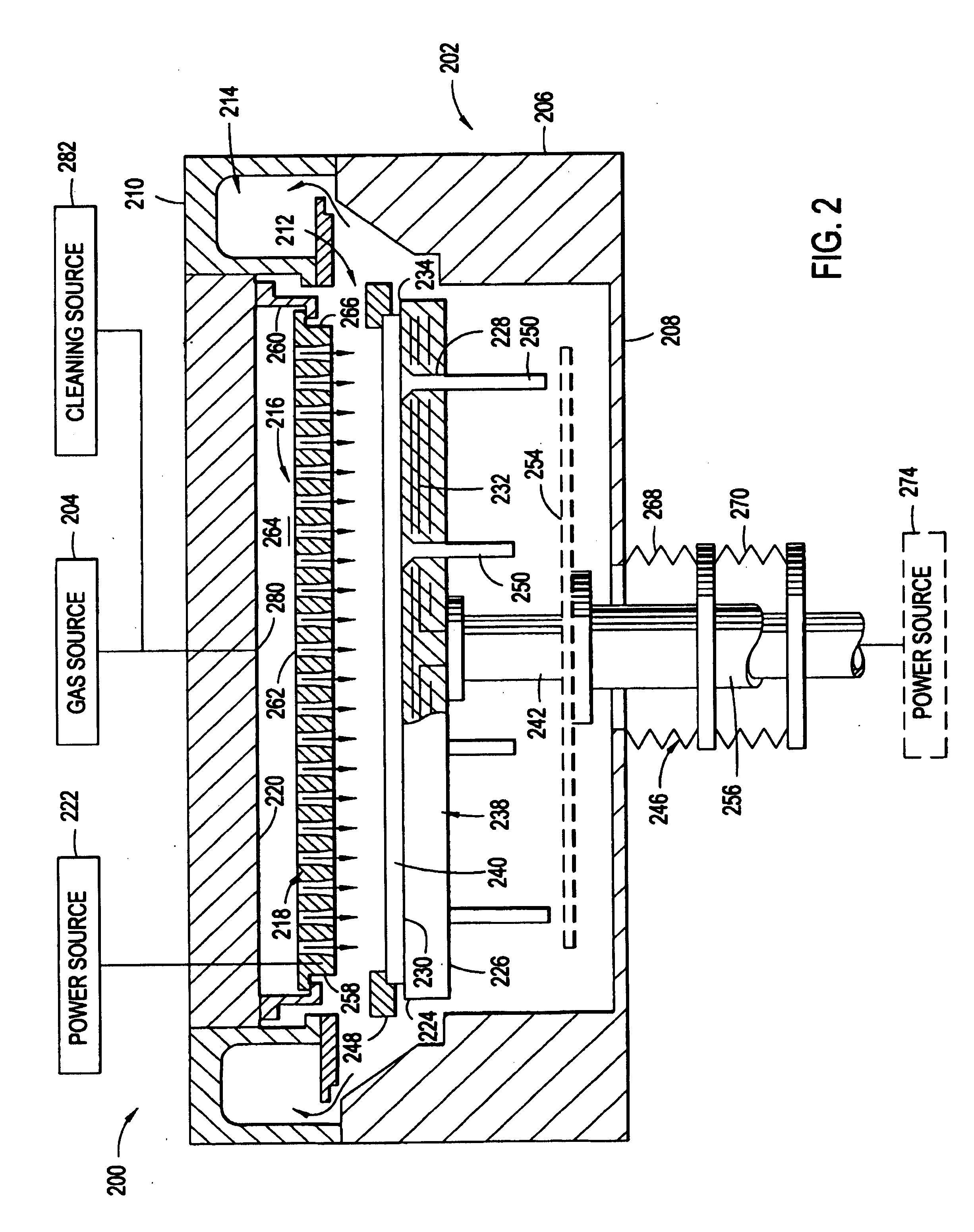

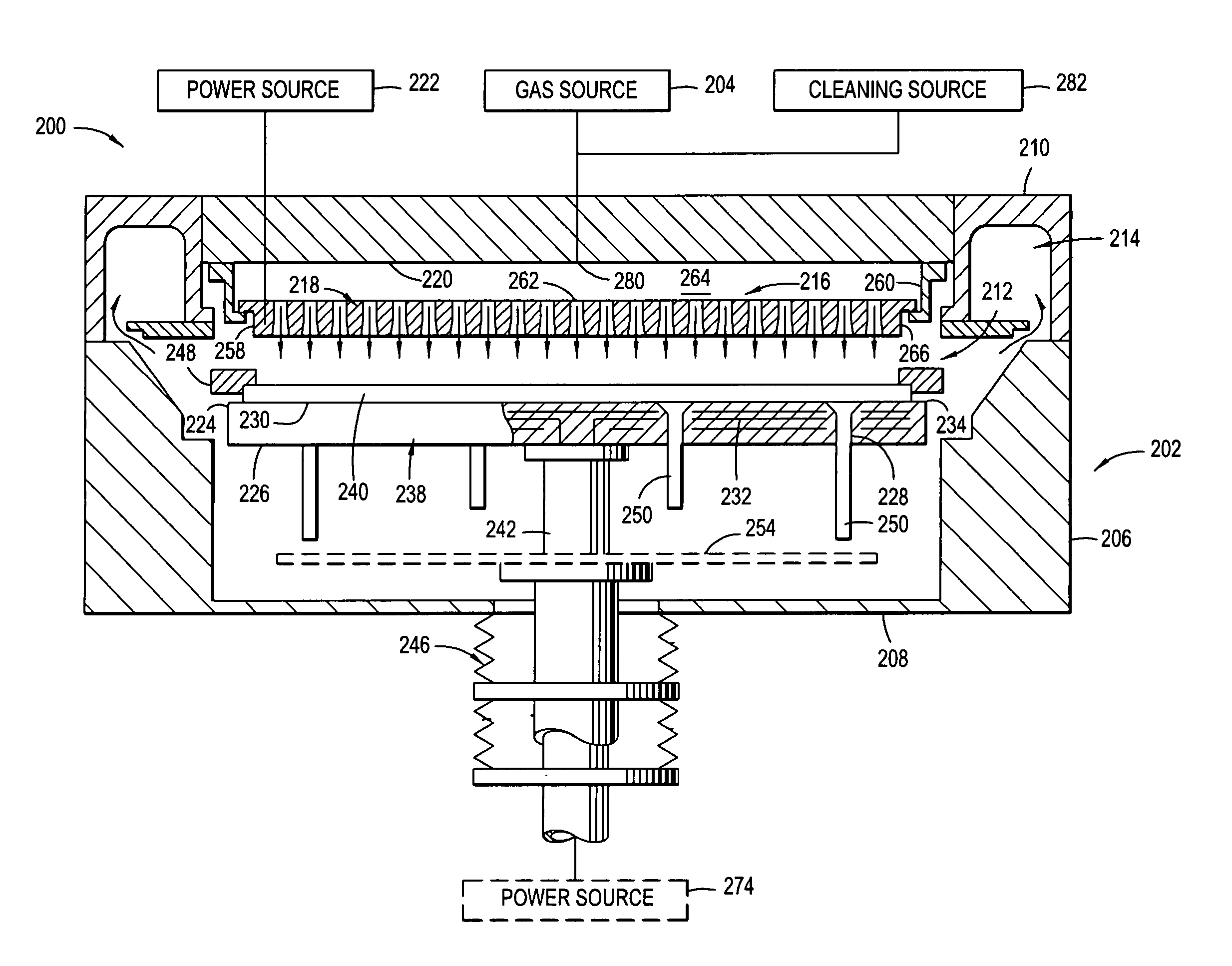

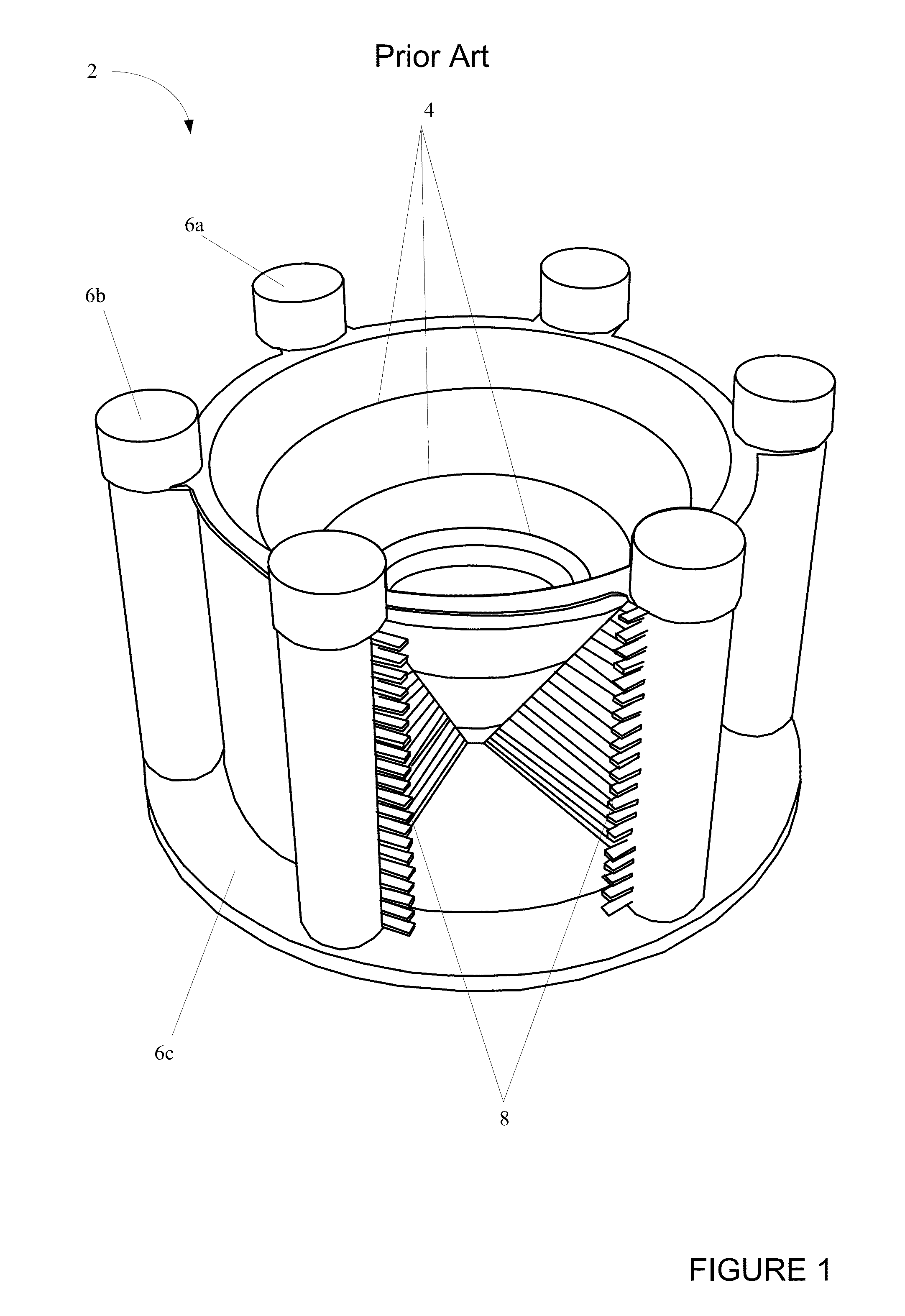

Plasma uniformity control by gas diffuser hole design

ActiveUS20050251990A1Electric discharge tubesSemiconductor/solid-state device manufacturingEngineeringVolumetric Mass Density

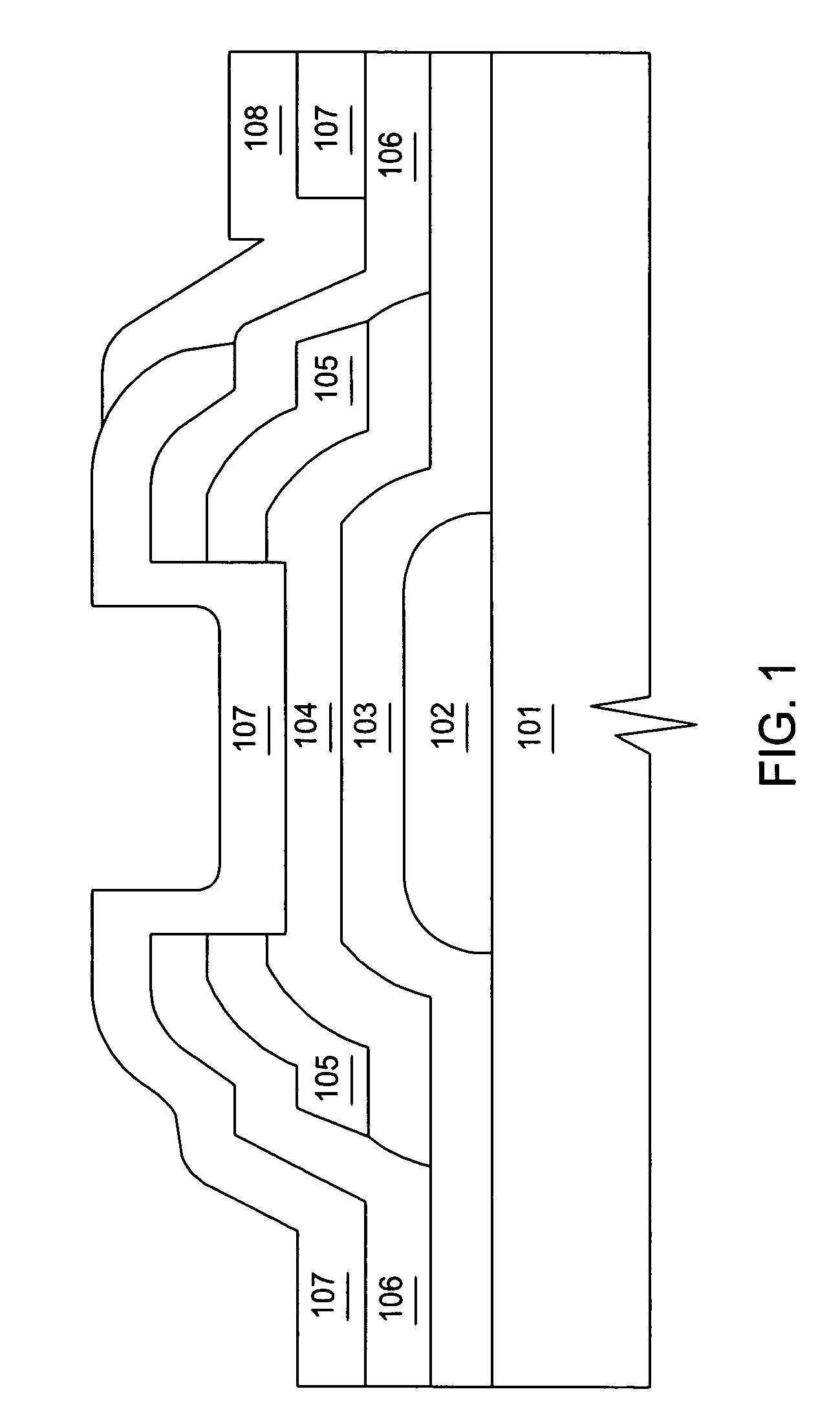

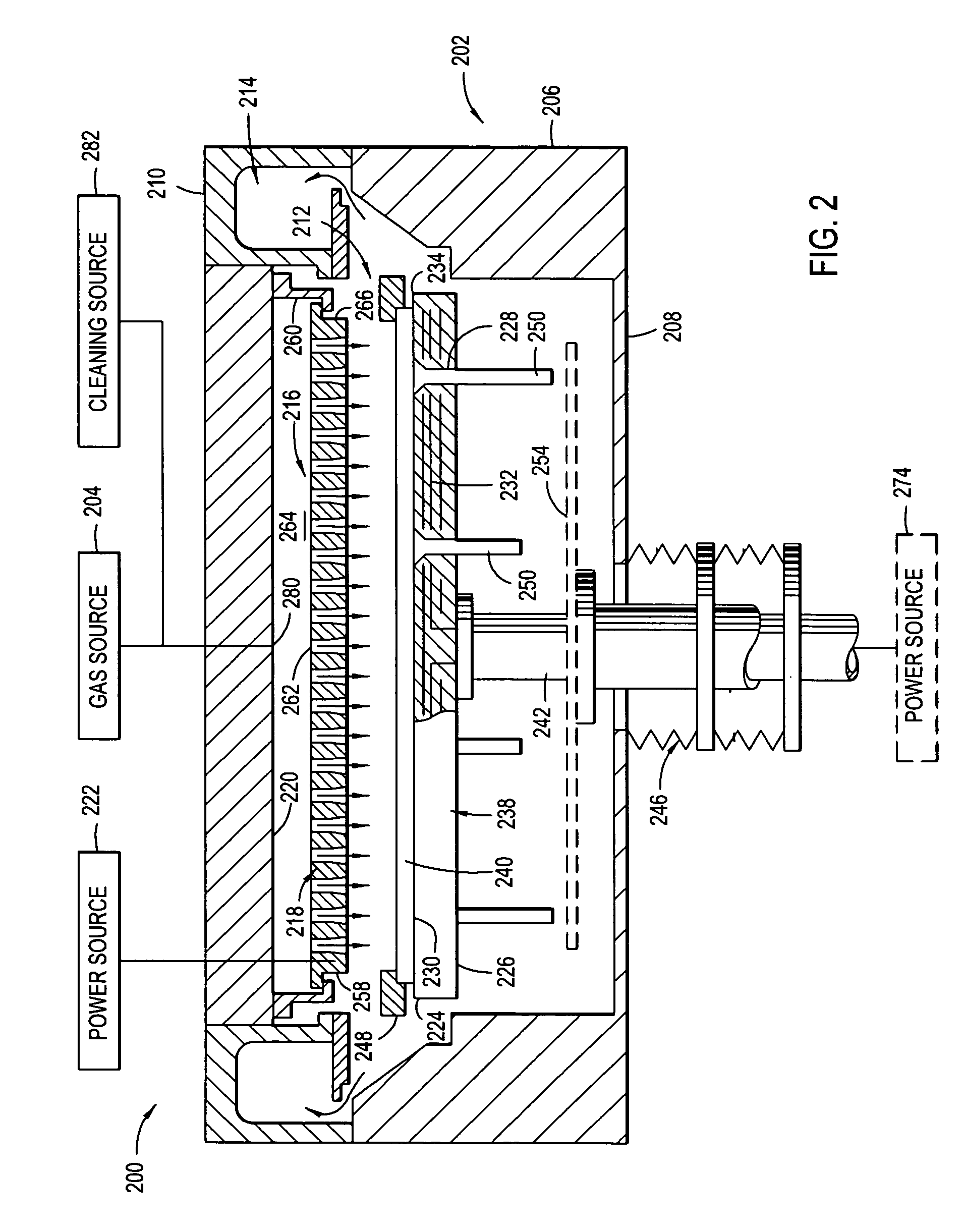

Embodiments of a gas diffuser plate for distributing gas in a processing chamber are provided. The gas distribution plate includes a diffuser plate having an upstream side and a downstream side, and a plurality of gas passages passing between the upstream and downstream sides of the diffuser plate. The gas passages include hollow cathode cavities at the downstream side to enhance plasma ionization. The depths, the diameters, the surface area and density of hollow cathode cavities of the gas passages that extend to the downstream end can be gradually increased from the center to the edge of the diffuser plate to improve the film thickness and property uniformity across the substrate. The increasing diameters, depths and surface areas from the center to the edge of the diffuser plate can be created by bending the diffuser plate toward downstream side, followed by machining out the convex downstream side. Bending the diffuser plate can be accomplished by a thermal process or a vacuum process. The increasing diameters, depths and surface areas from the center to the edge of the diffuser plate can also be created computer numerically controlled machining. Diffuser plates with gradually increasing diameters, depths and surface areas of the hollow cathode cavities from the center to the edge of the diffuser plate have been shown to produce improved uniformities of film thickness and film properties.

Owner:APPLIED MATERIALS INC

Plasma uniformity control by gas diffuser hole design

InactiveUS20060236934A1Electric discharge tubesSemiconductor/solid-state device manufacturingEngineeringVolumetric Mass Density

Embodiments of a gas diffuser plate for distributing gas in a processing chamber are provided. The gas distribution plate includes a diffuser plate having an upstream side and a downstream side, and a plurality of gas passages passing between the upstream and downstream sides of the diffuser plate. The gas passages include hollow cathode cavities at the downstream side to enhance plasma ionization. The depths, the diameters, the surface area and density of hollow cathode cavities of the gas passages that extend to the downstream end can be gradually increased from the center to the edge of the diffuser plate to improve the film thickness and property uniformity across the substrate. The increasing diameters, depths and surface areas from the center to the edge of the diffuser plate can be created by bending the diffuser plate toward downstream side, followed by machining out the convex downstream side. Bending the diffuser plate can be accomplished by a thermal process or a vacuum process. The increasing diameters, depths and surface areas from the center to the edge of the diffuser plate can also be created computer numerically controlled machining. Diffuser plates with gradually increasing diameters, depths and surface areas of the hollow cathode cavities from the center to the edge of the diffuser plate have been shown to produce improved uniformities of film thickness and film properties.

Owner:CHOI SOO YOUNG +9

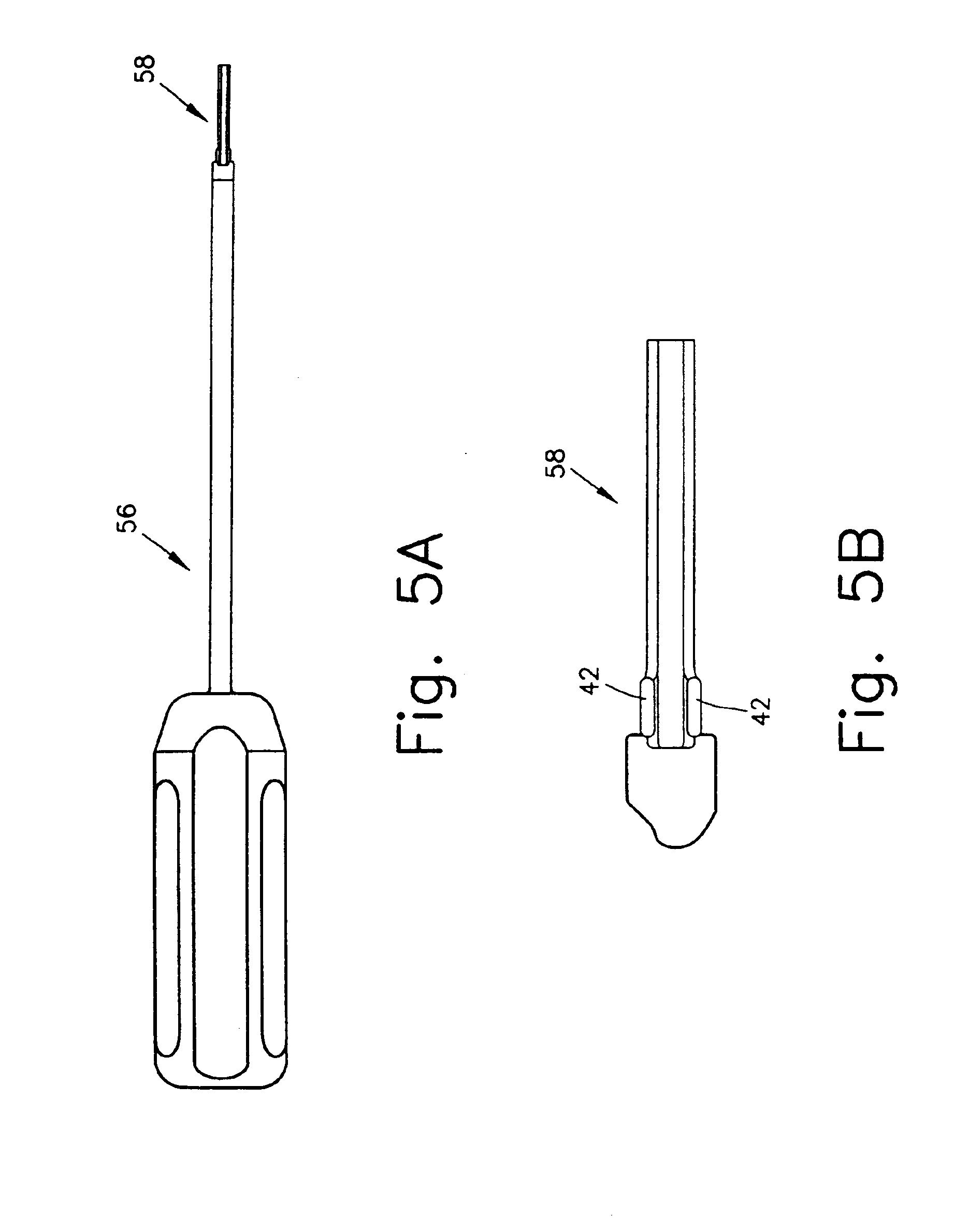

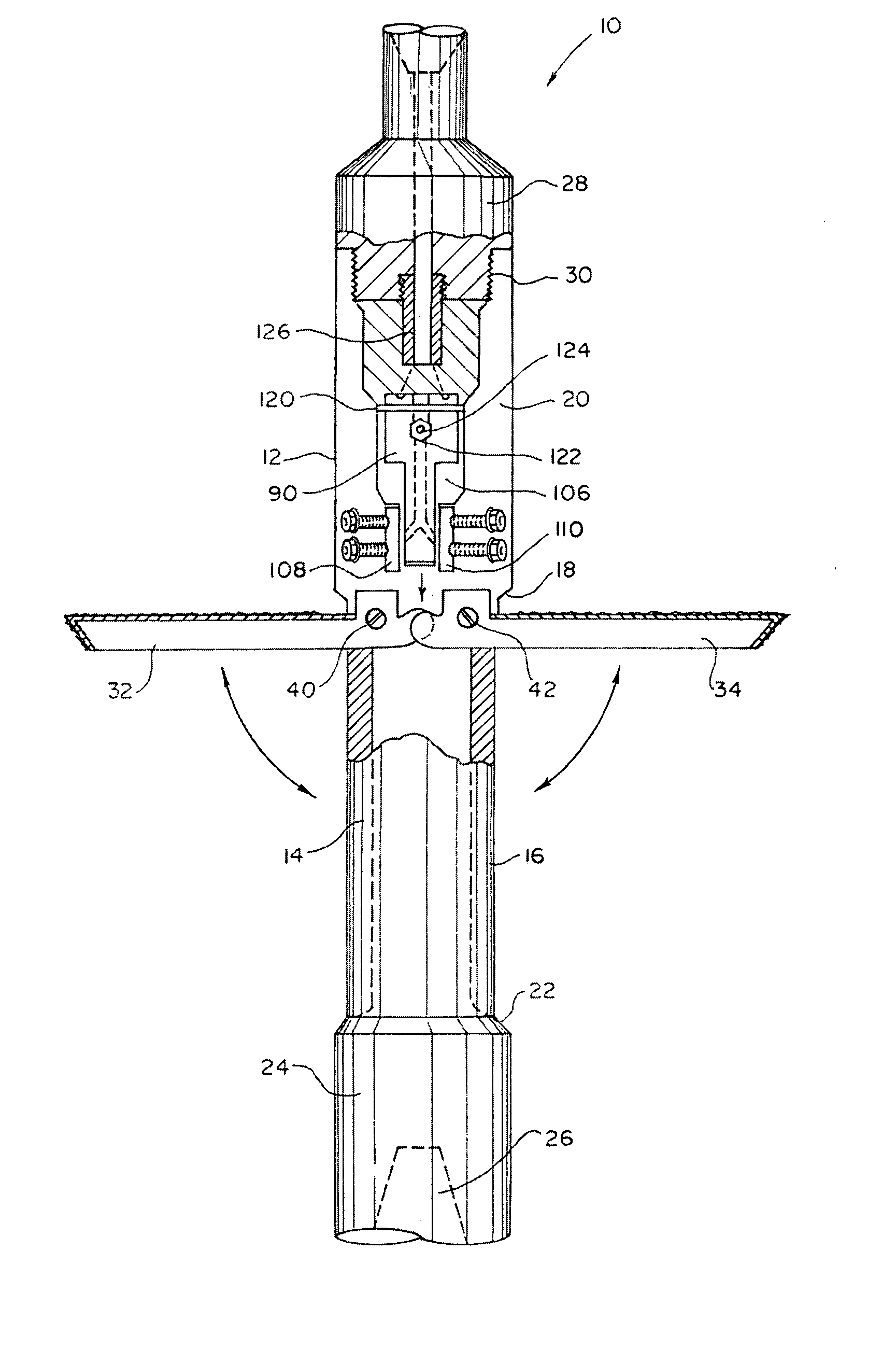

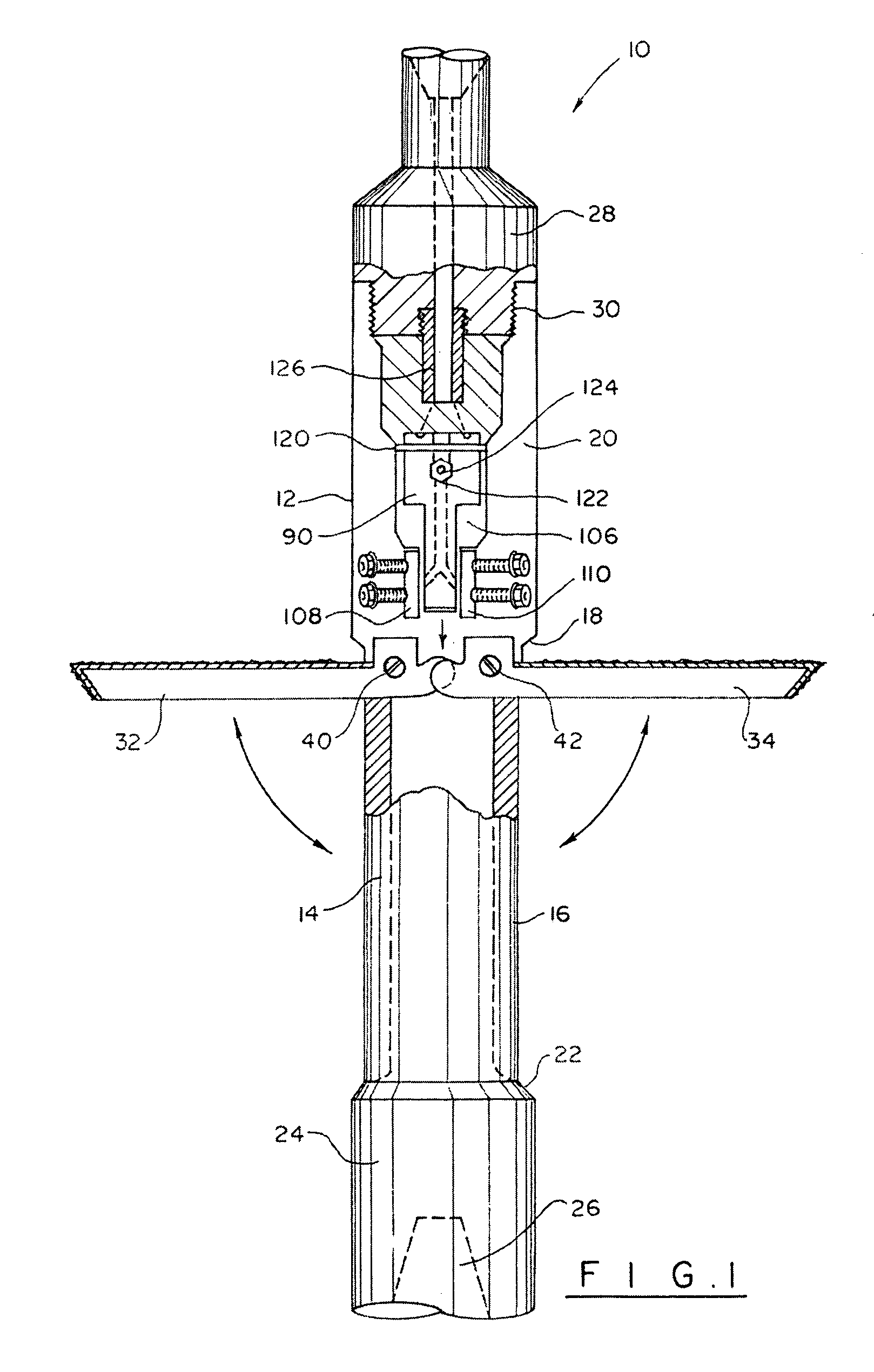

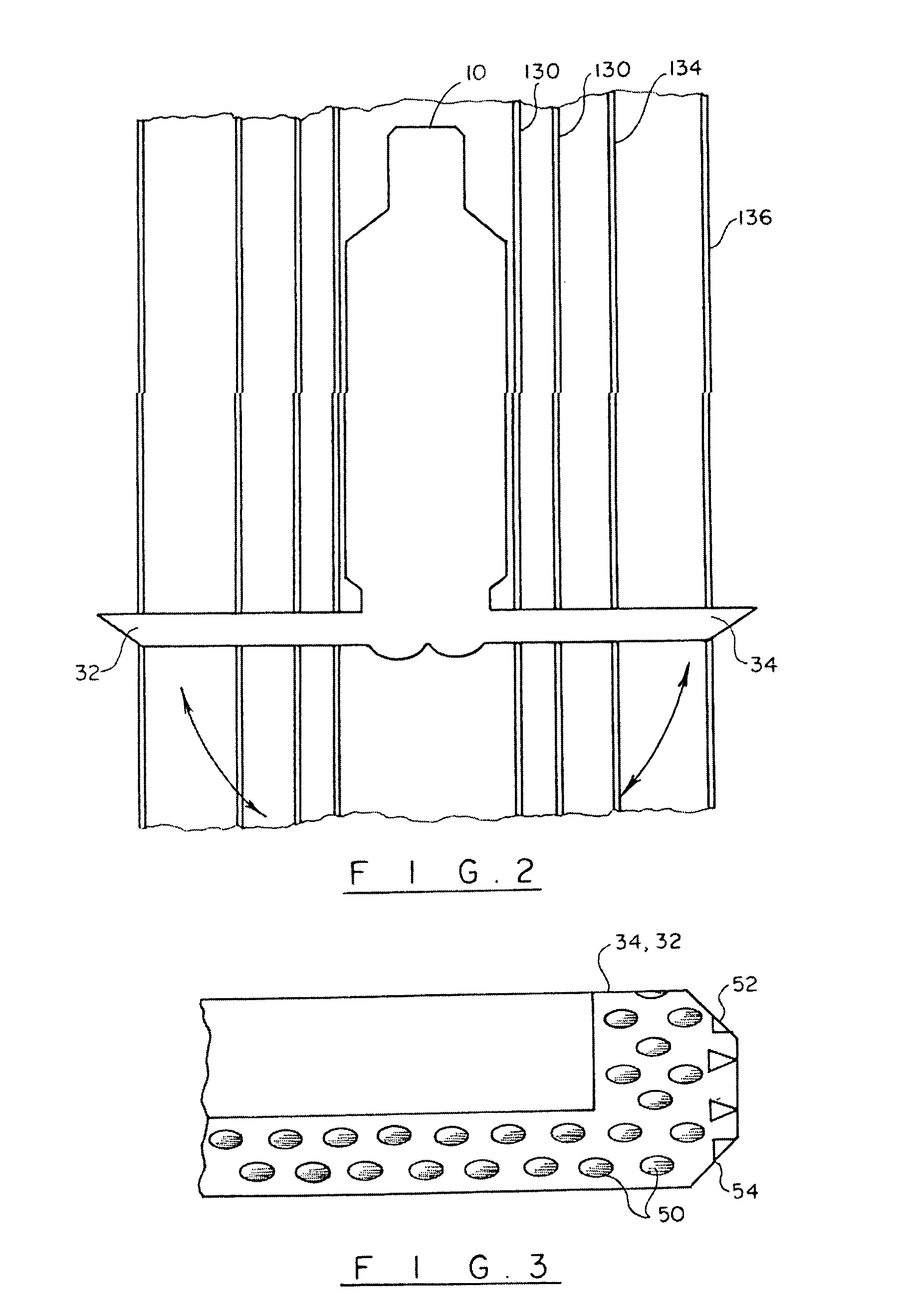

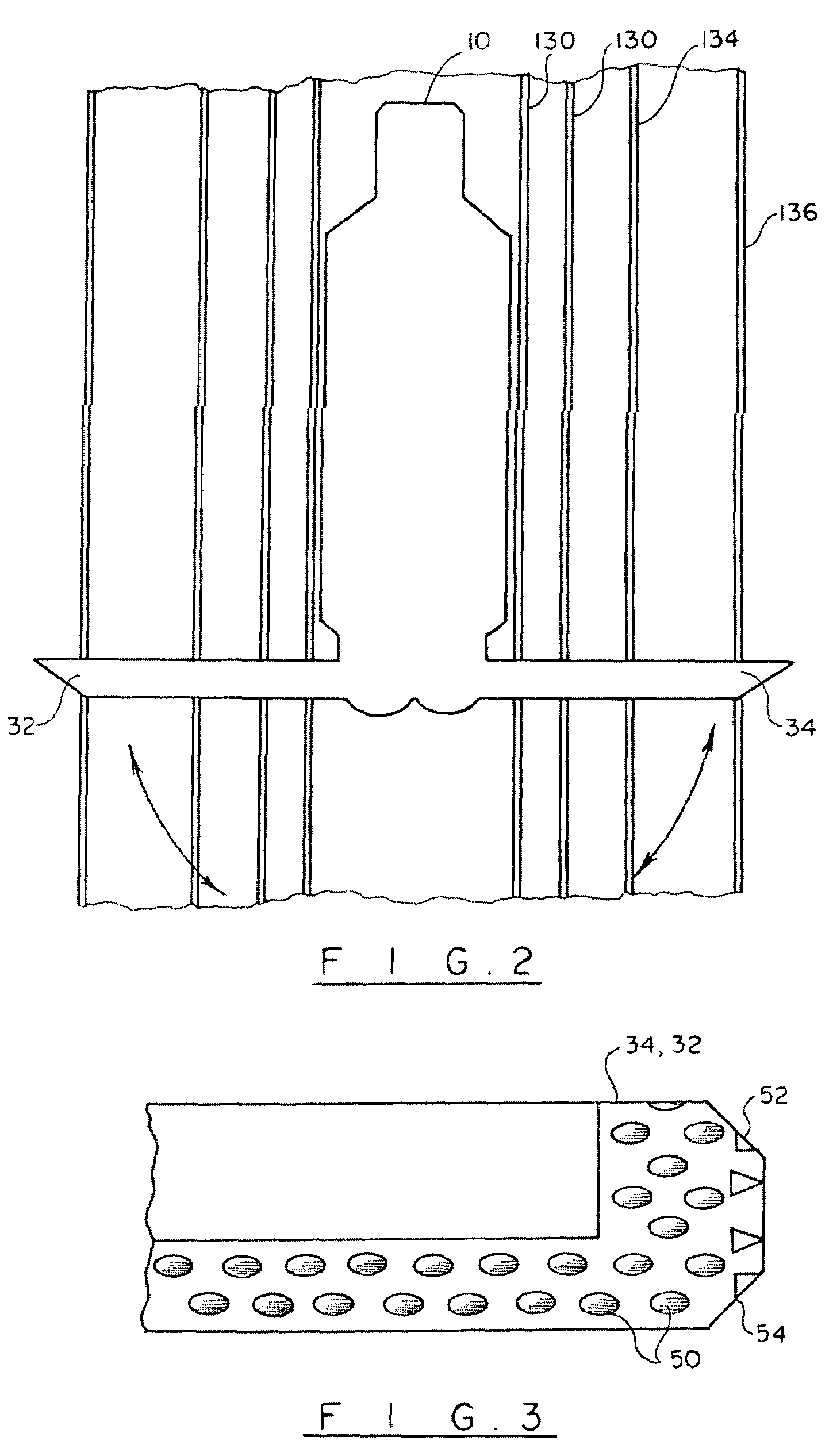

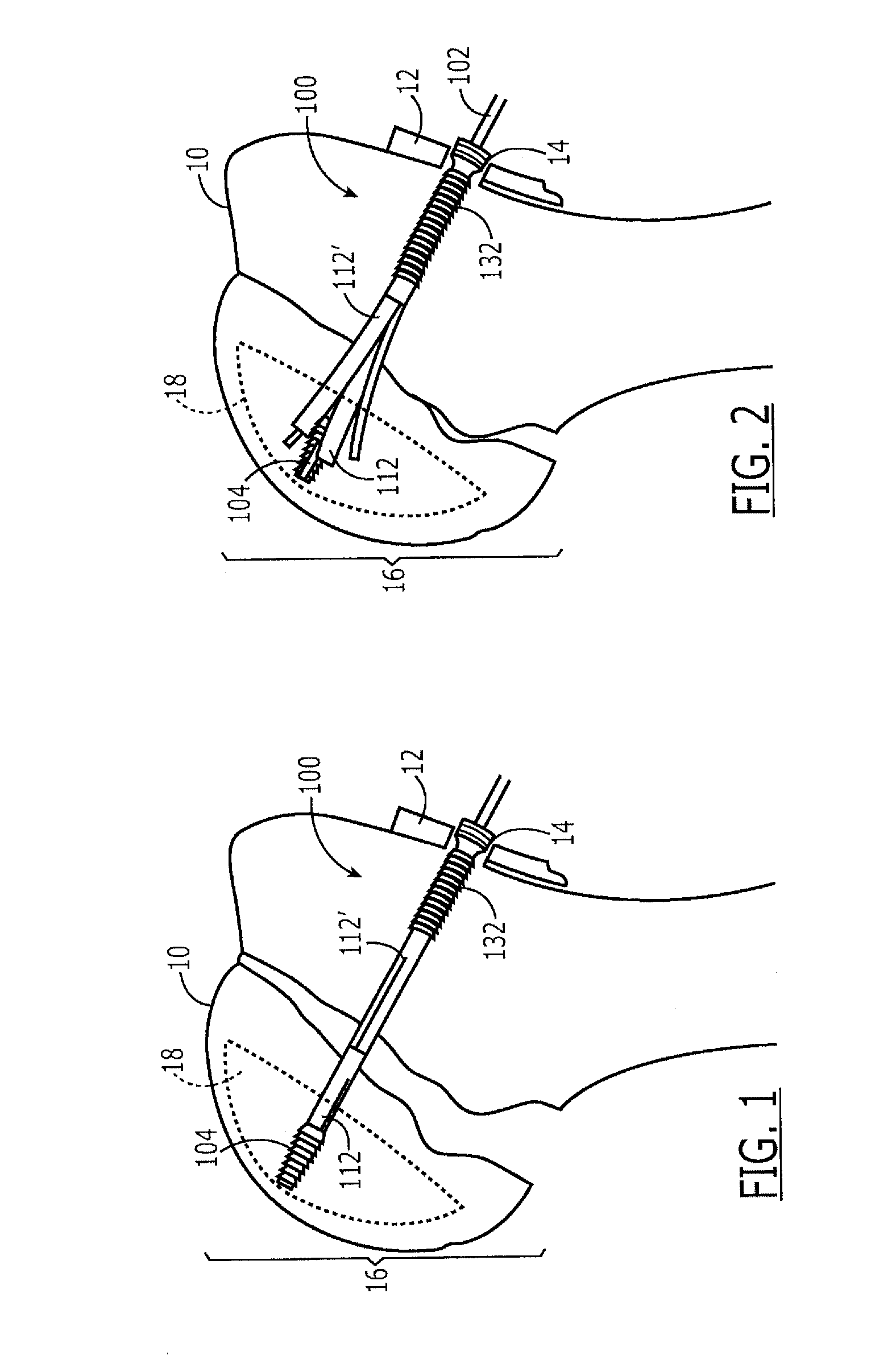

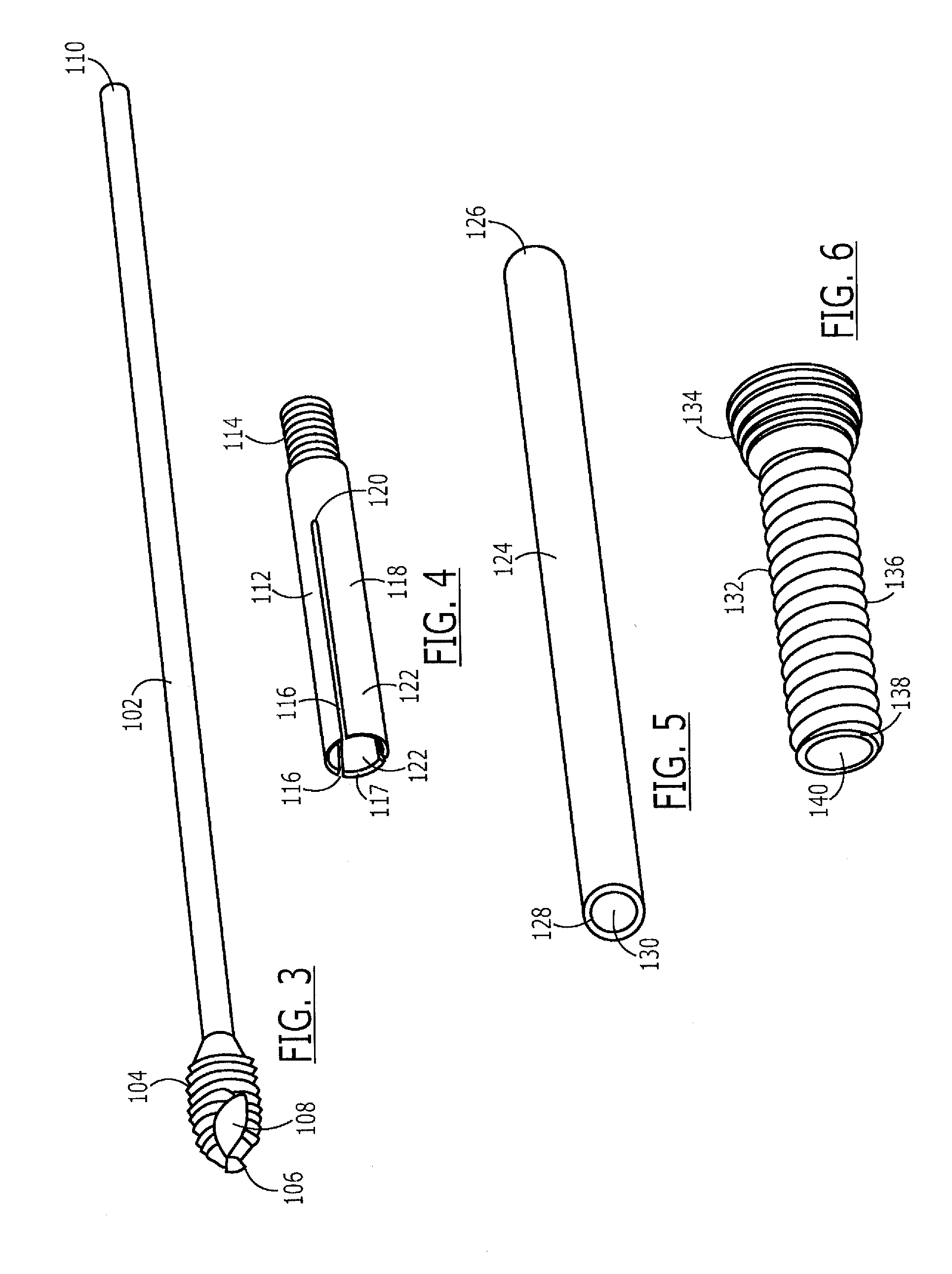

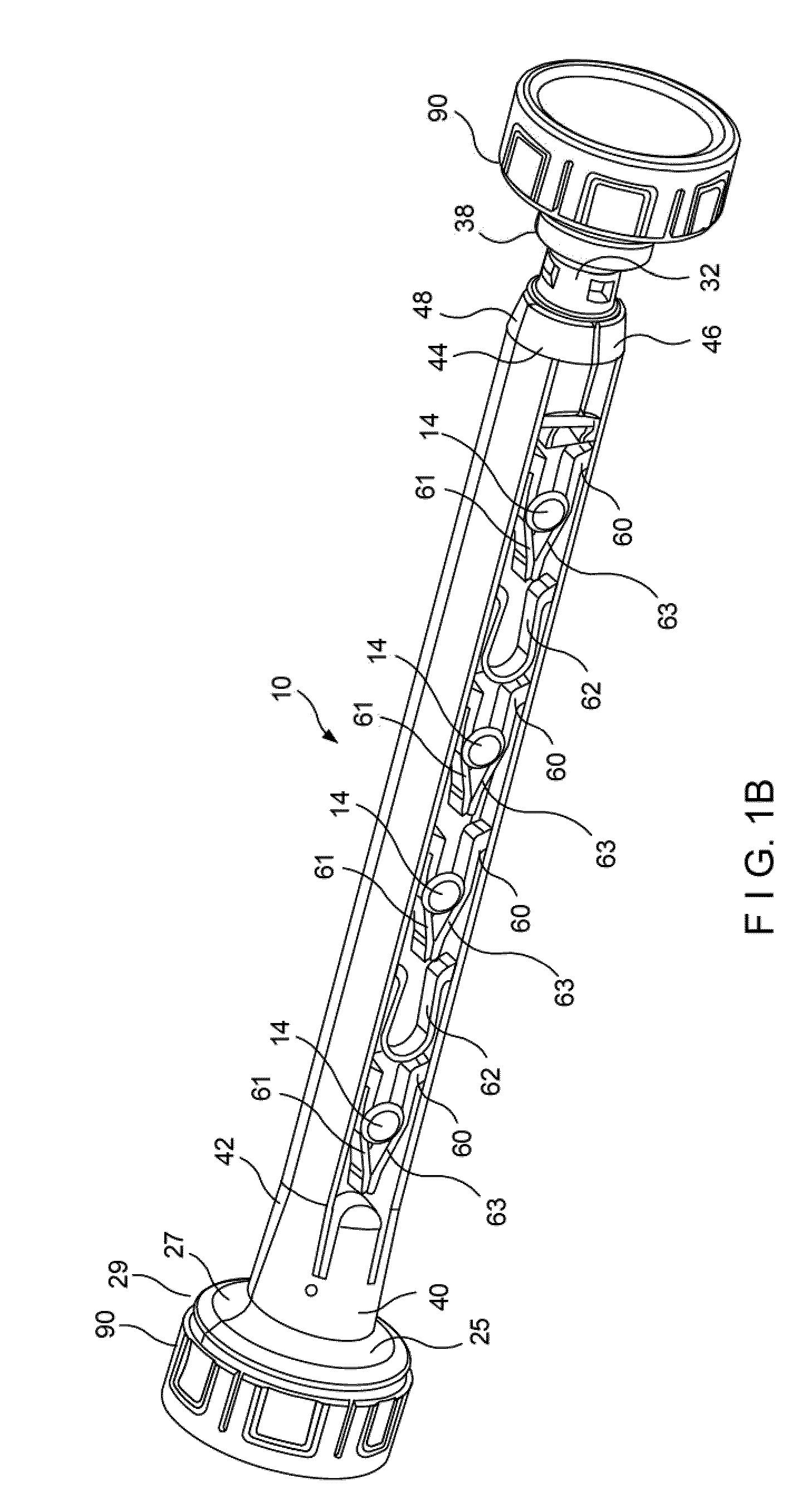

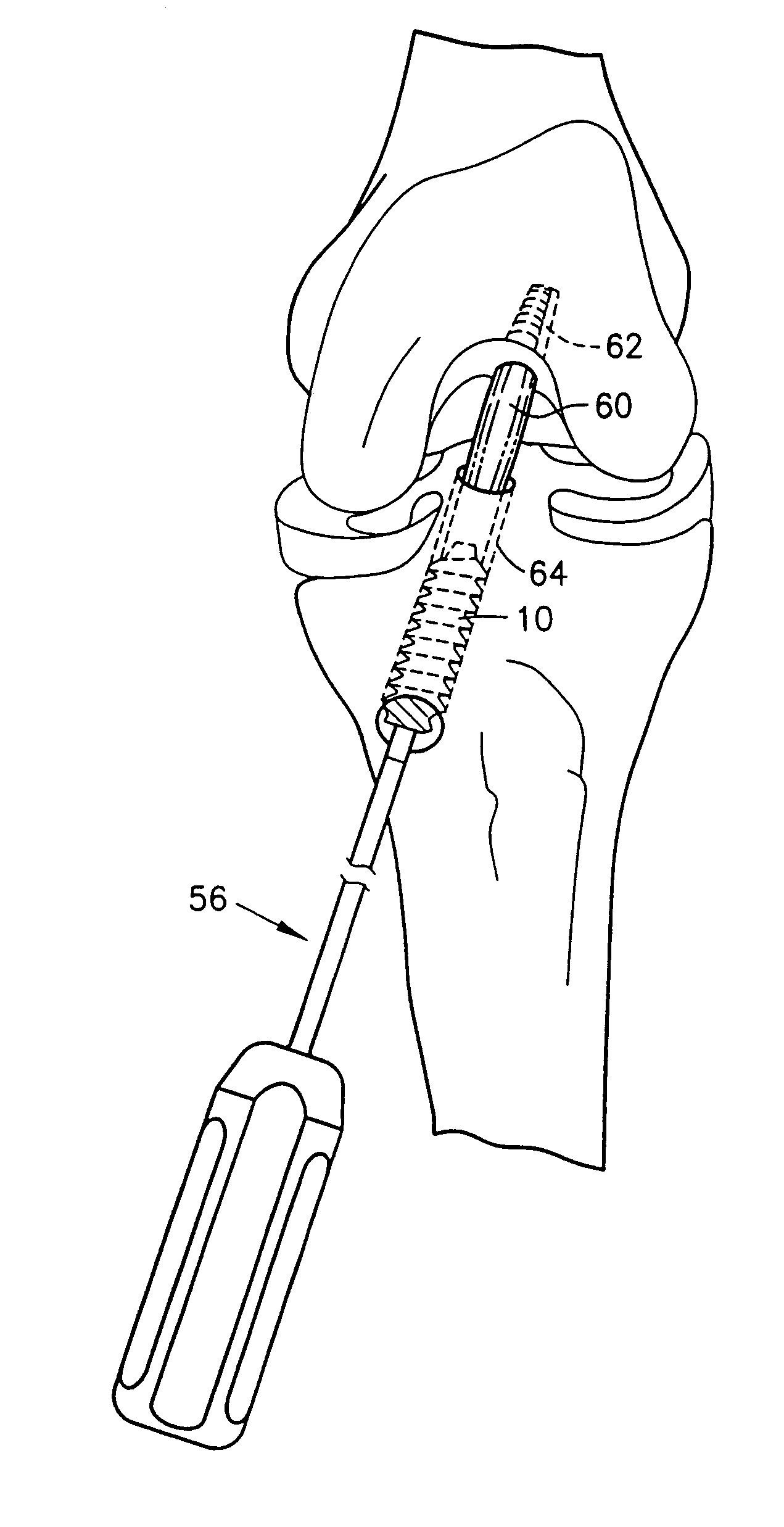

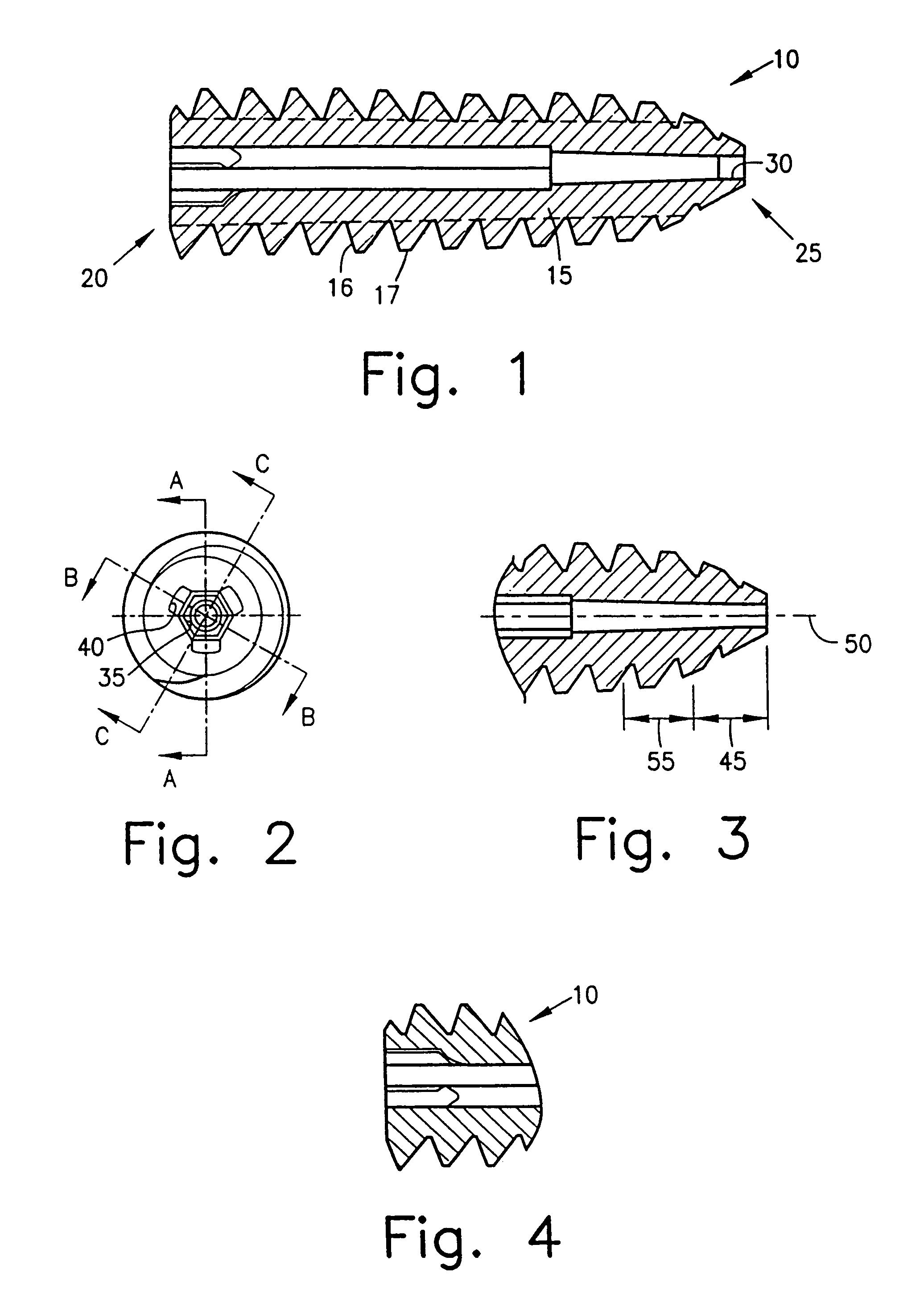

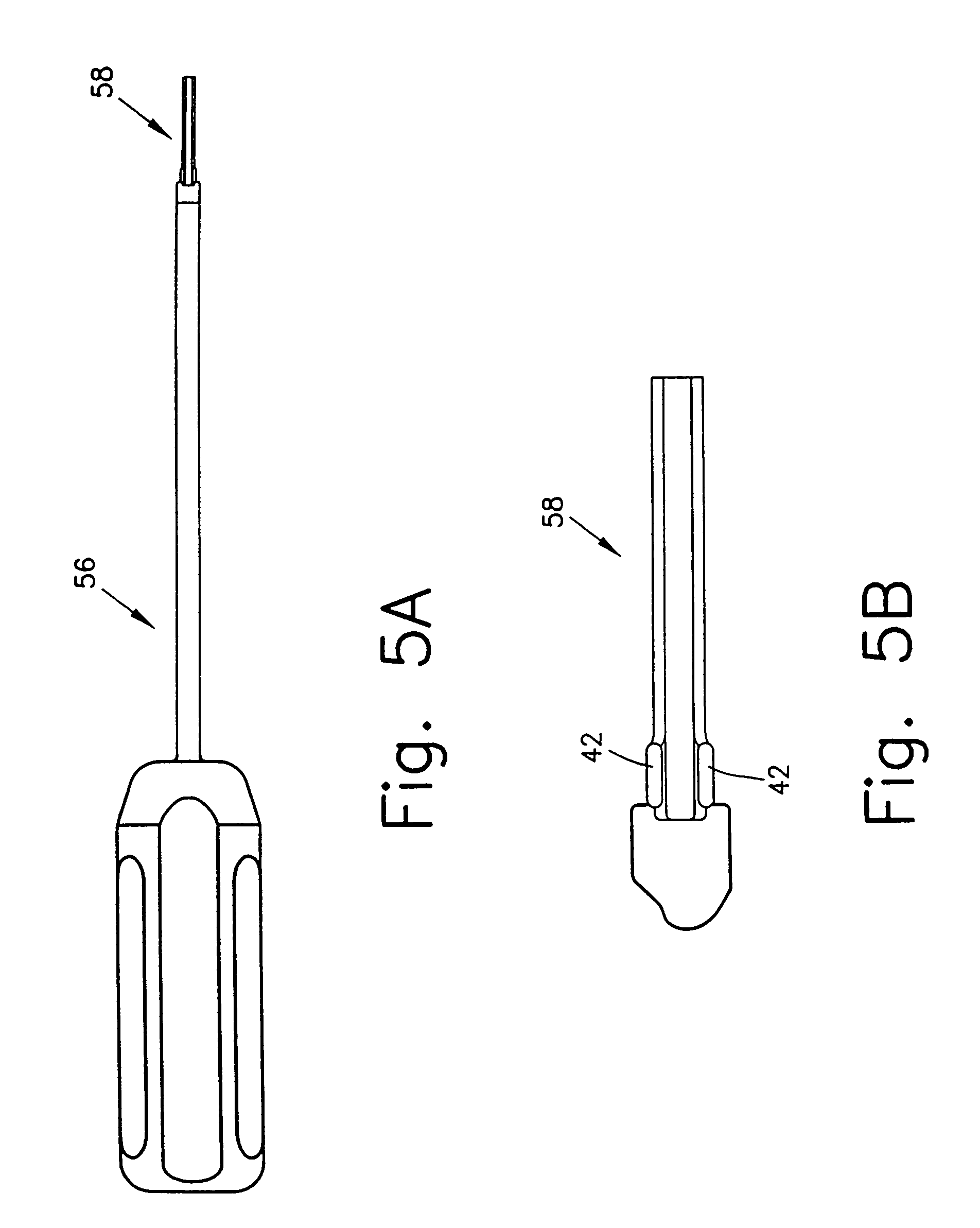

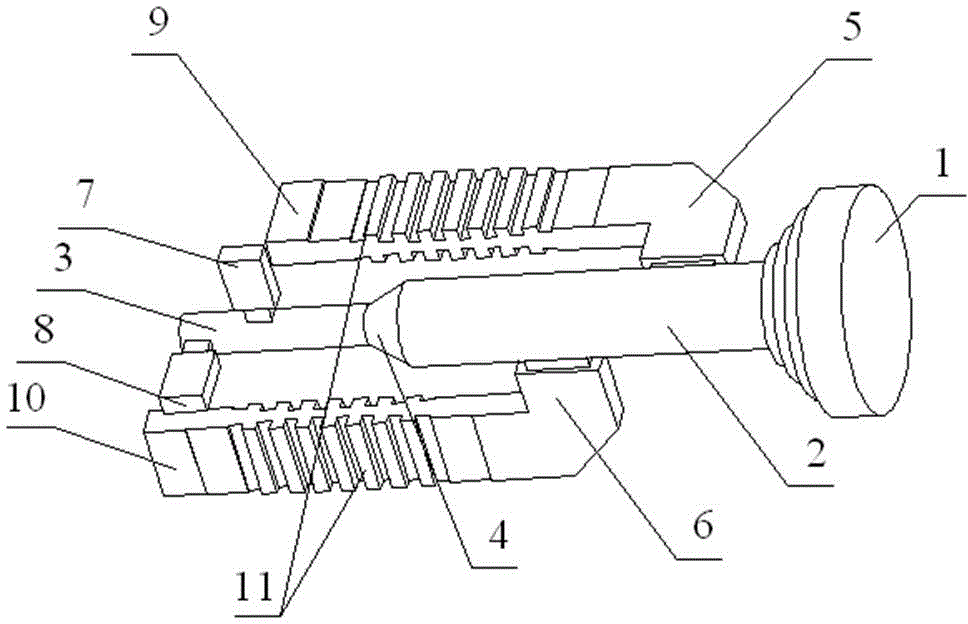

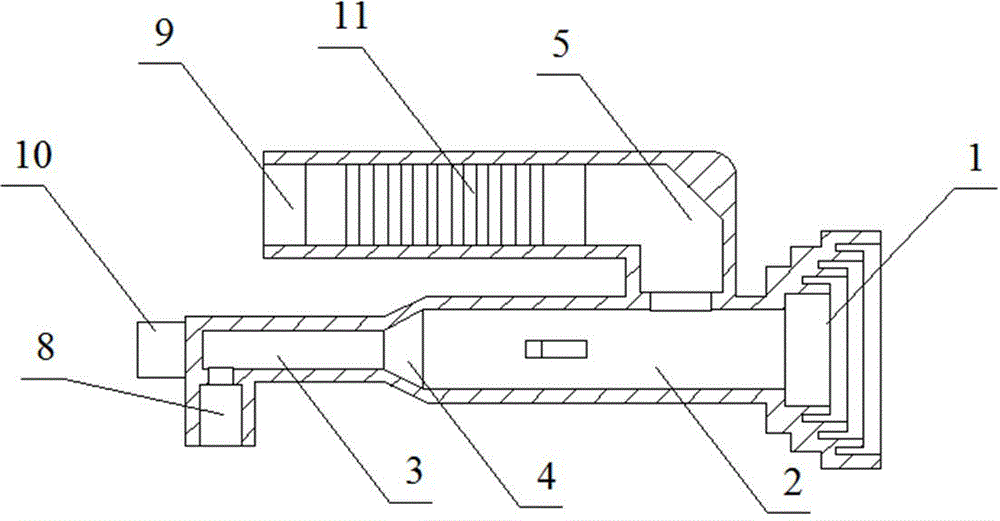

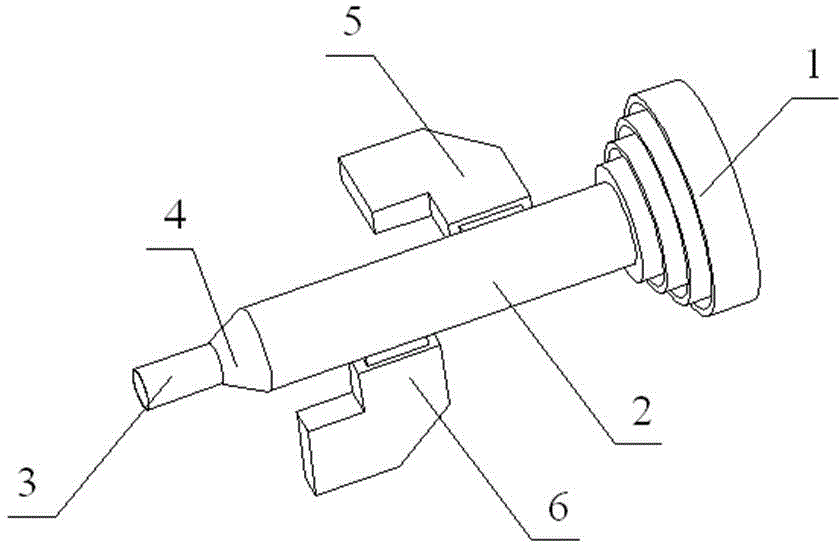

Tapered bioabsorbable interference screw for endosteal fixation of ligaments

InactiveUS6875216B2Easy to insertEasy to fixSuture equipmentsInternal osteosythesisBone tunnelInterference screws

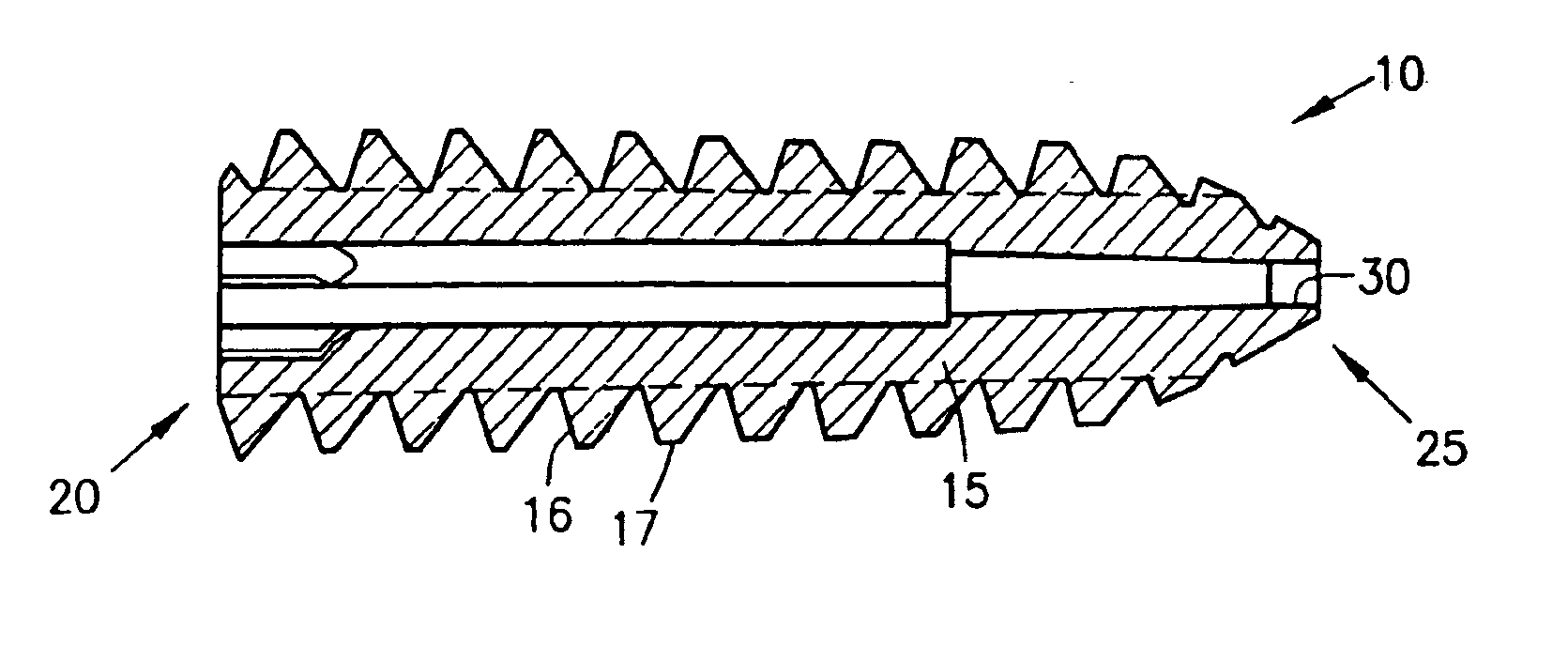

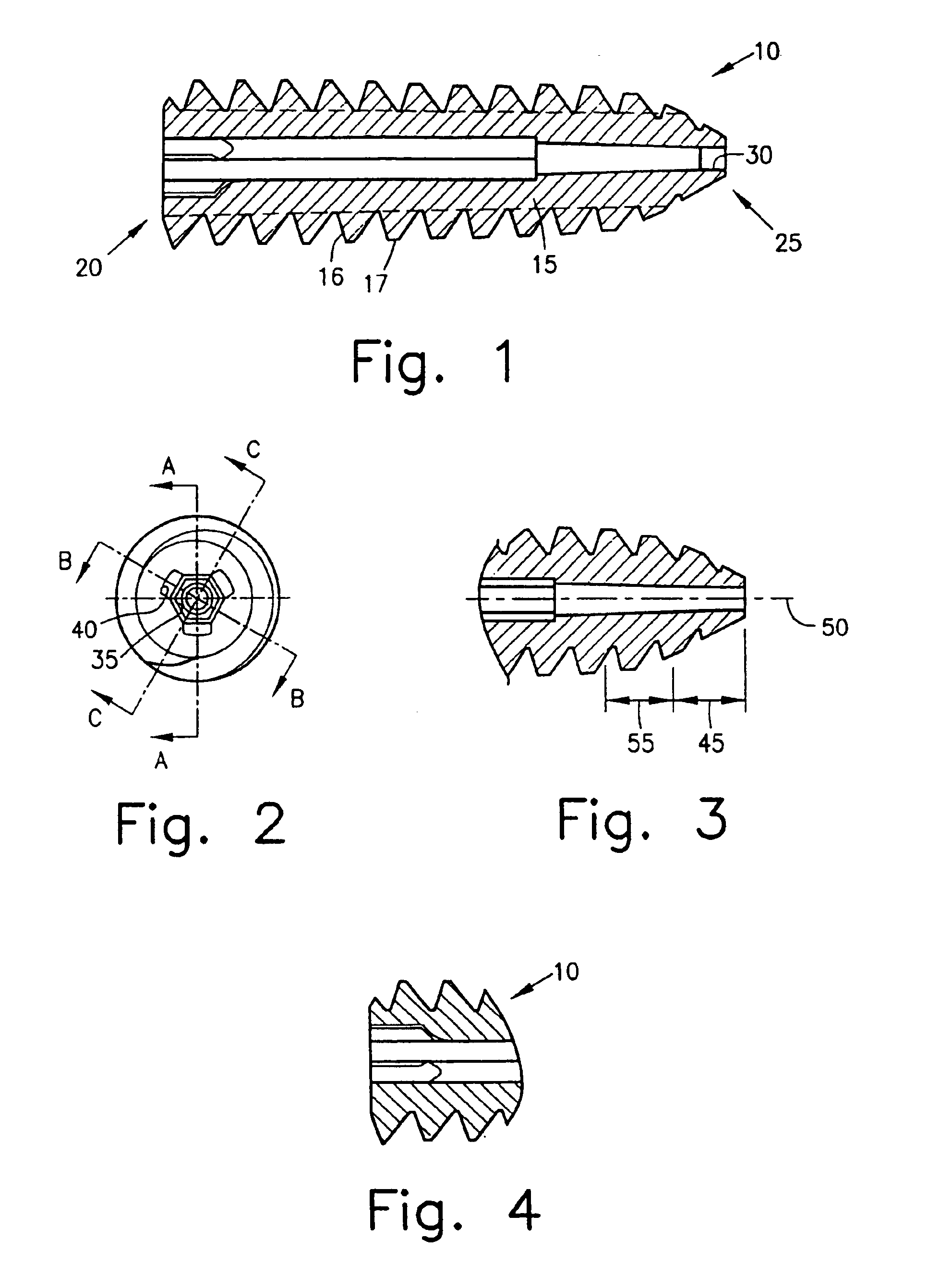

A bioabsorbable interference screw having a tapered profile which extends along substantially the entire length of the screw. The tapered profile makes the screw easy to insert while providing superior fixation resulting from a progressively increasing diameter. Upon insertion, the screw engages cortical bone at the back end of the bone tunnel and fills all but 5-10 mm. of the tunnel, thereby providing increased fixation strength while also promoting fast healing. The screw includes a head provided with a specially designed drive socket with radially extending slots at its outer end for receiving corresponding protrusions on the shaft of screwdriver. The drive socket optimizes the torque capacity of the screw. To maintain wall thickness, the socket has a taper corresponding to the tapered outer profile of the screw. The taper of the socket also permits easy insertion of the tip and shaft of the driver into the screw.

Owner:ARTHREX

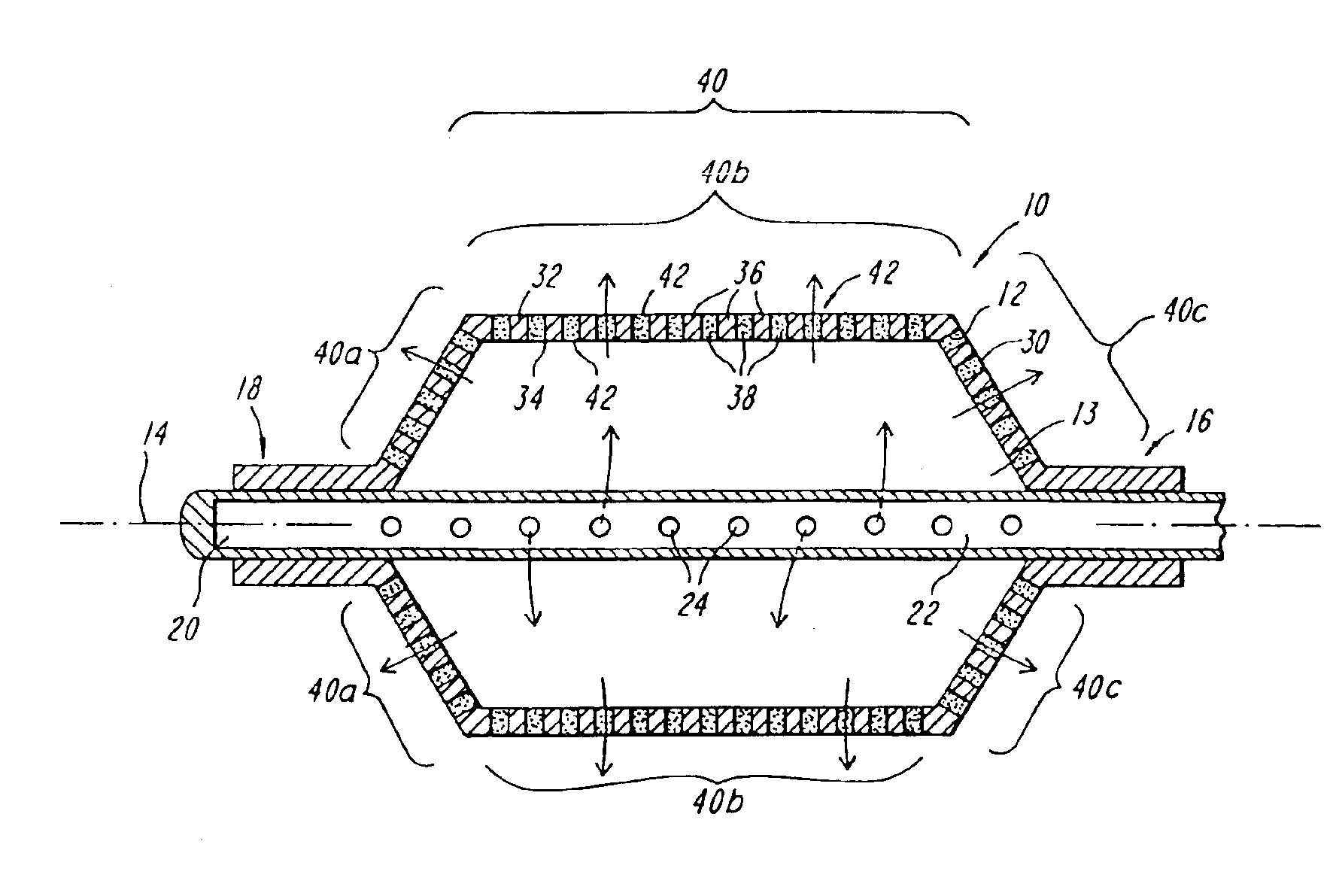

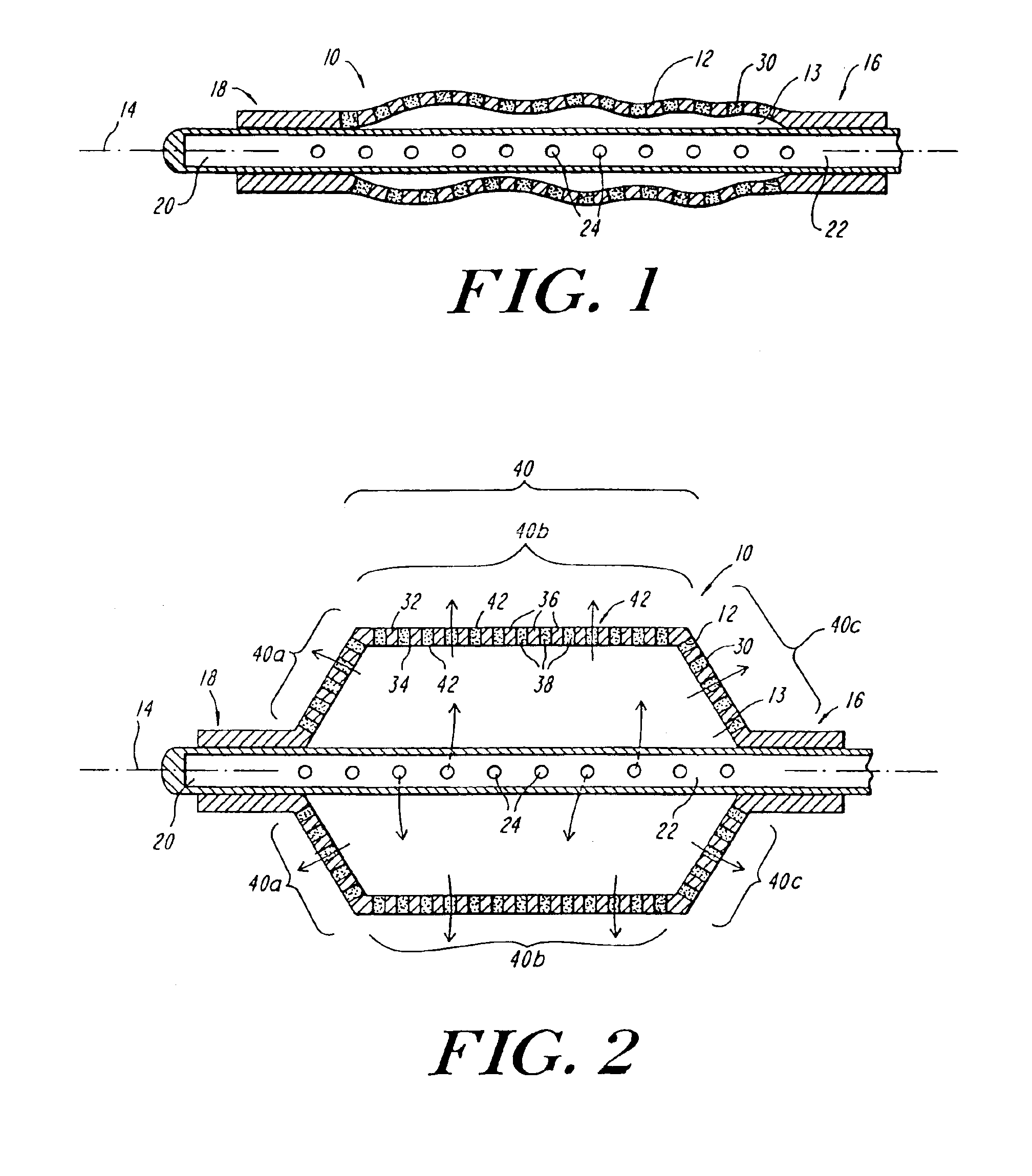

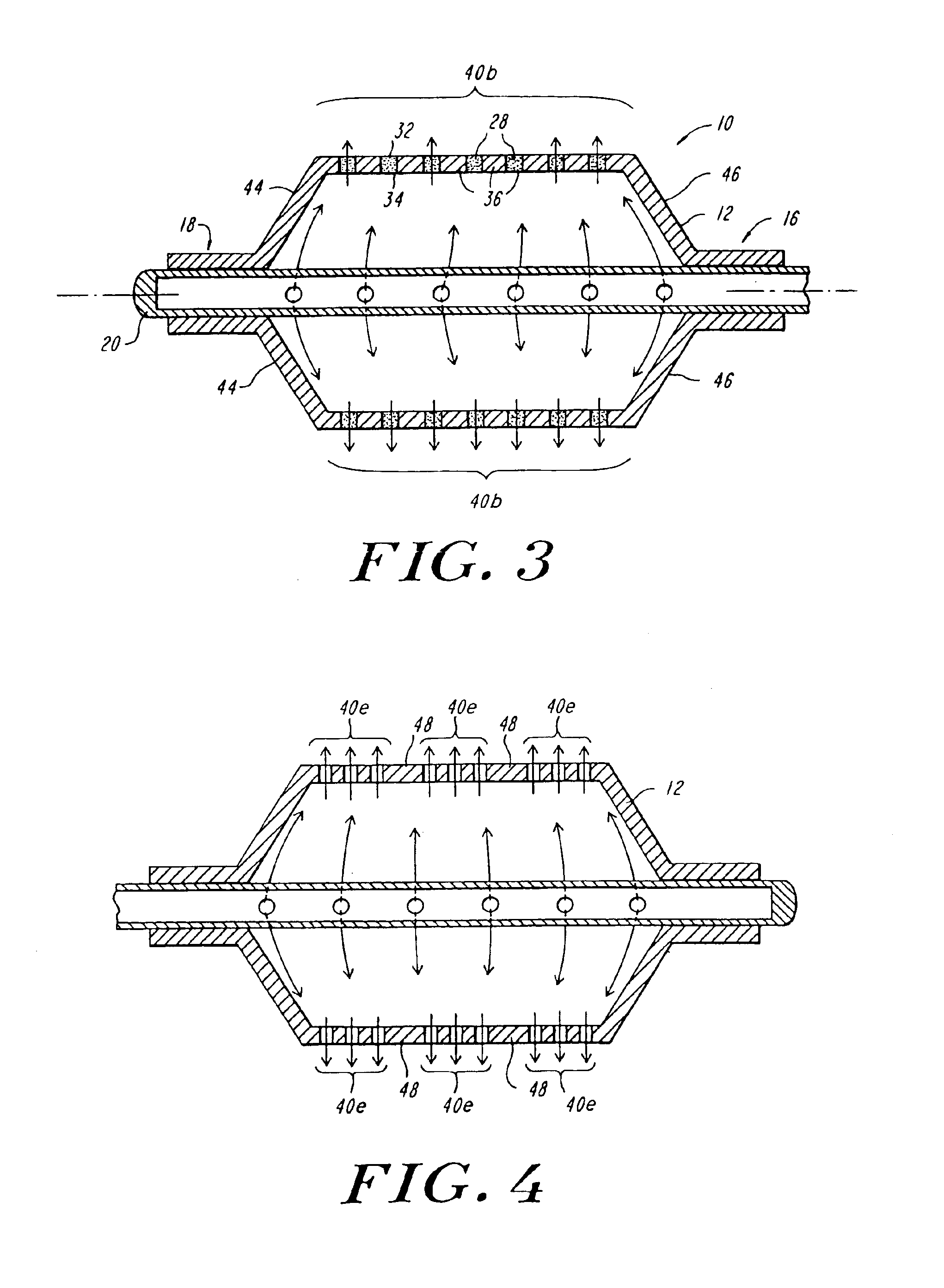

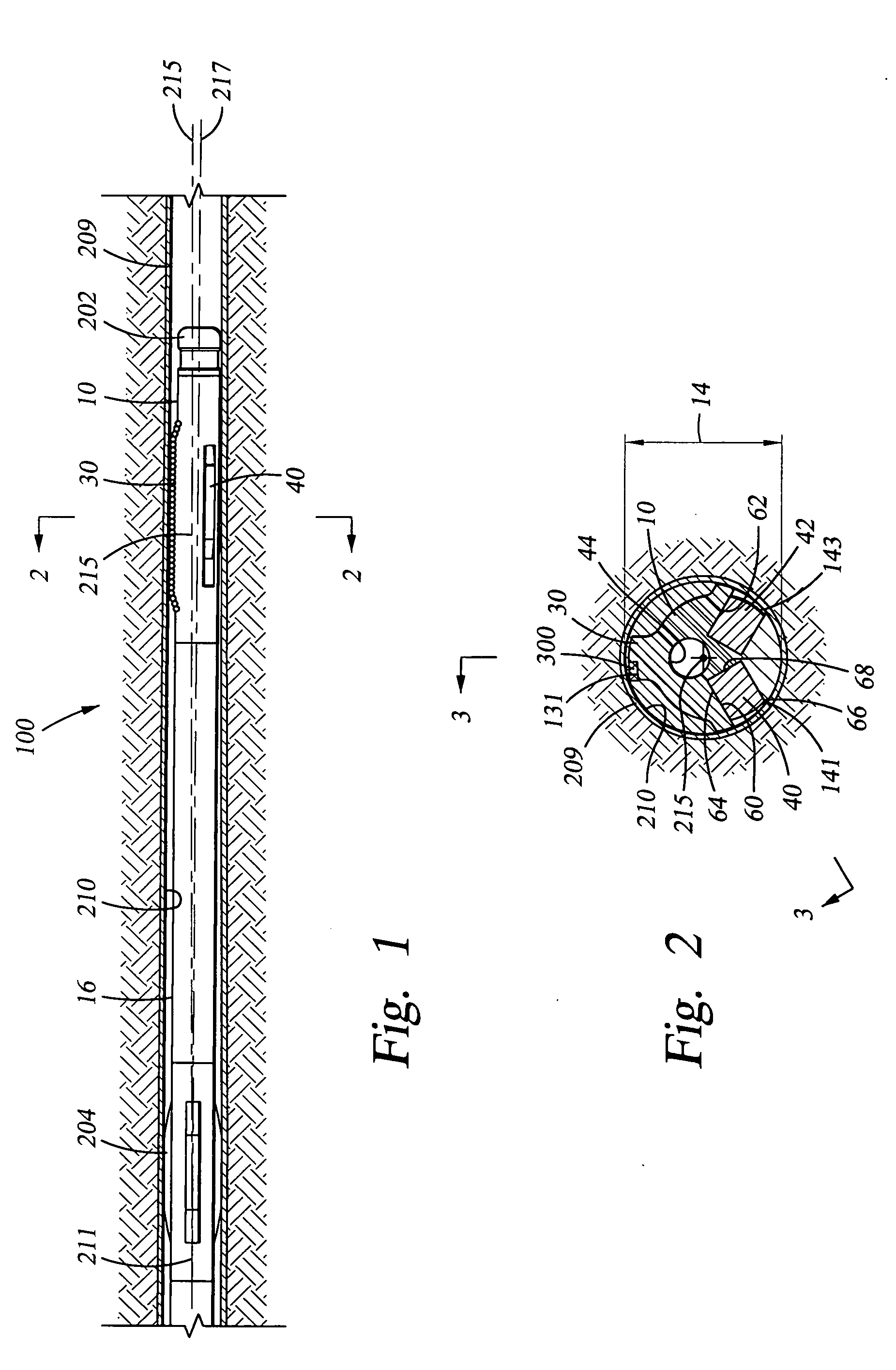

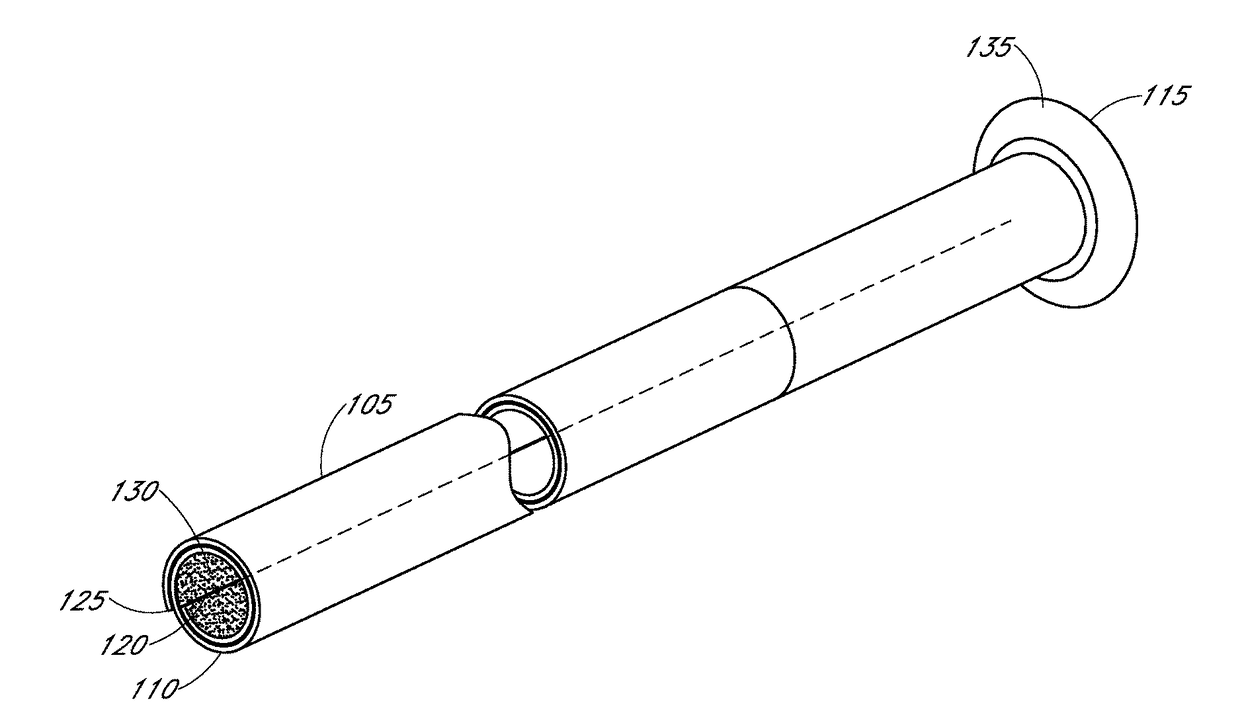

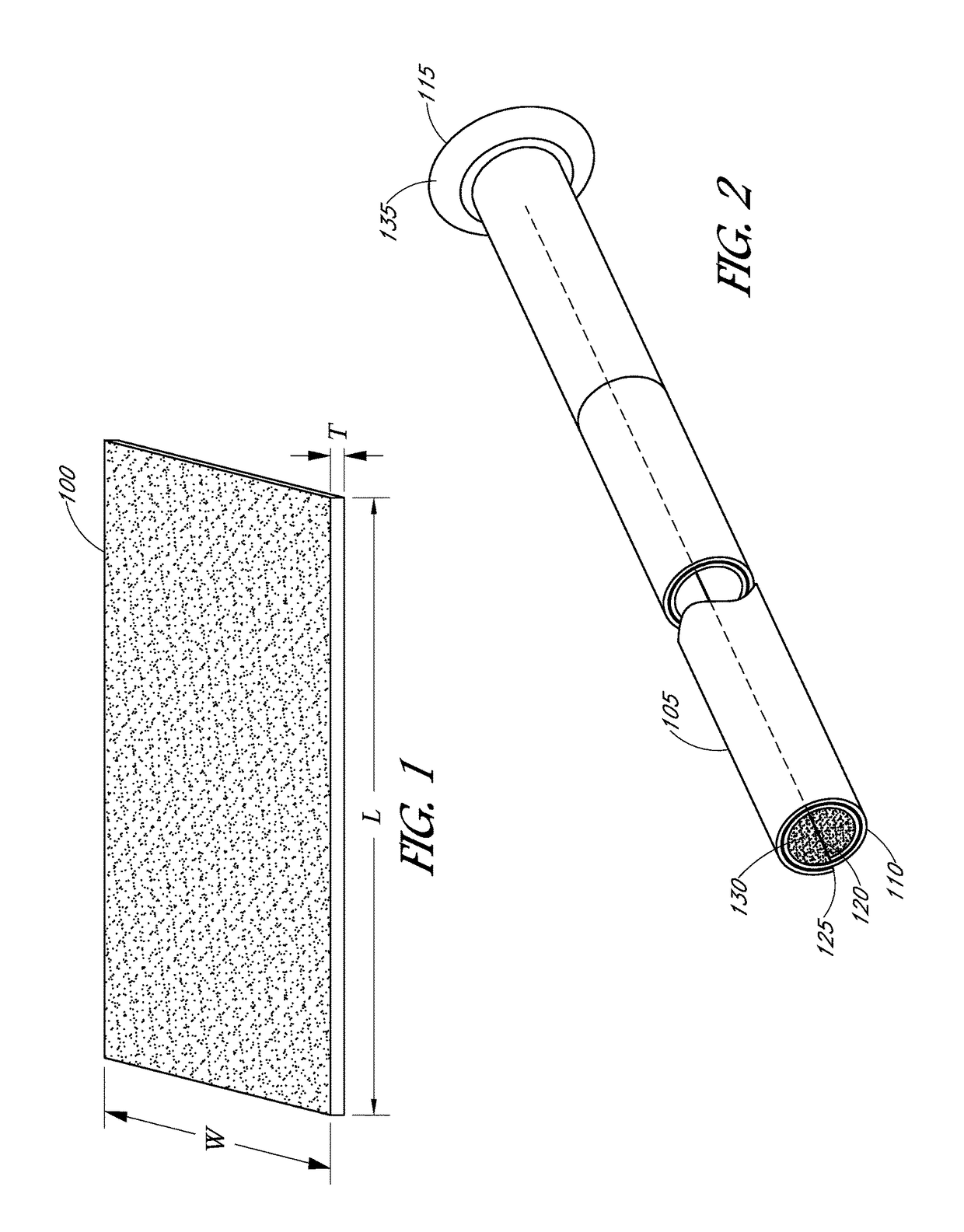

Expandable fluoropolymer device for delivery of therapeutic agents and method of making

A radially expandable fluid delivery device for delivering a fluid to a treatment site within the body is disclosed. The fluid delivery device is constructed of a microporous, biocompatible fluoropolymer material having a microstructure that can provide a controlled, uniform, low-velocity fluid distribution through the walls of the fluid delivery device to effectively deliver fluid to the treatment site without damaging tissue proximate the walls of the device. The fluid delivery device includes a tubular member defined by a wall having a thickness transverse to the longitudinal axis of the tubular member and extending between an inner and an outer surface. The wall is characterized by a microstructure of nodes interconnected by fibrils. The tubular member is deployable from a first, reduced diameter configuration to a second, increased diameter configuration upon the introduction of a pressurized fluid to the lumen. The tubular member includes at least one microporous portion having a porosity sufficient for the pressurized fluid to permeate through the wall. Substantially all of the nodes within the microporous portion are oriented such that spaces between the nodes form micro-channels extending from the inner surface-to the outer surface of the wall.

Owner:ATRIUM MEDICAL

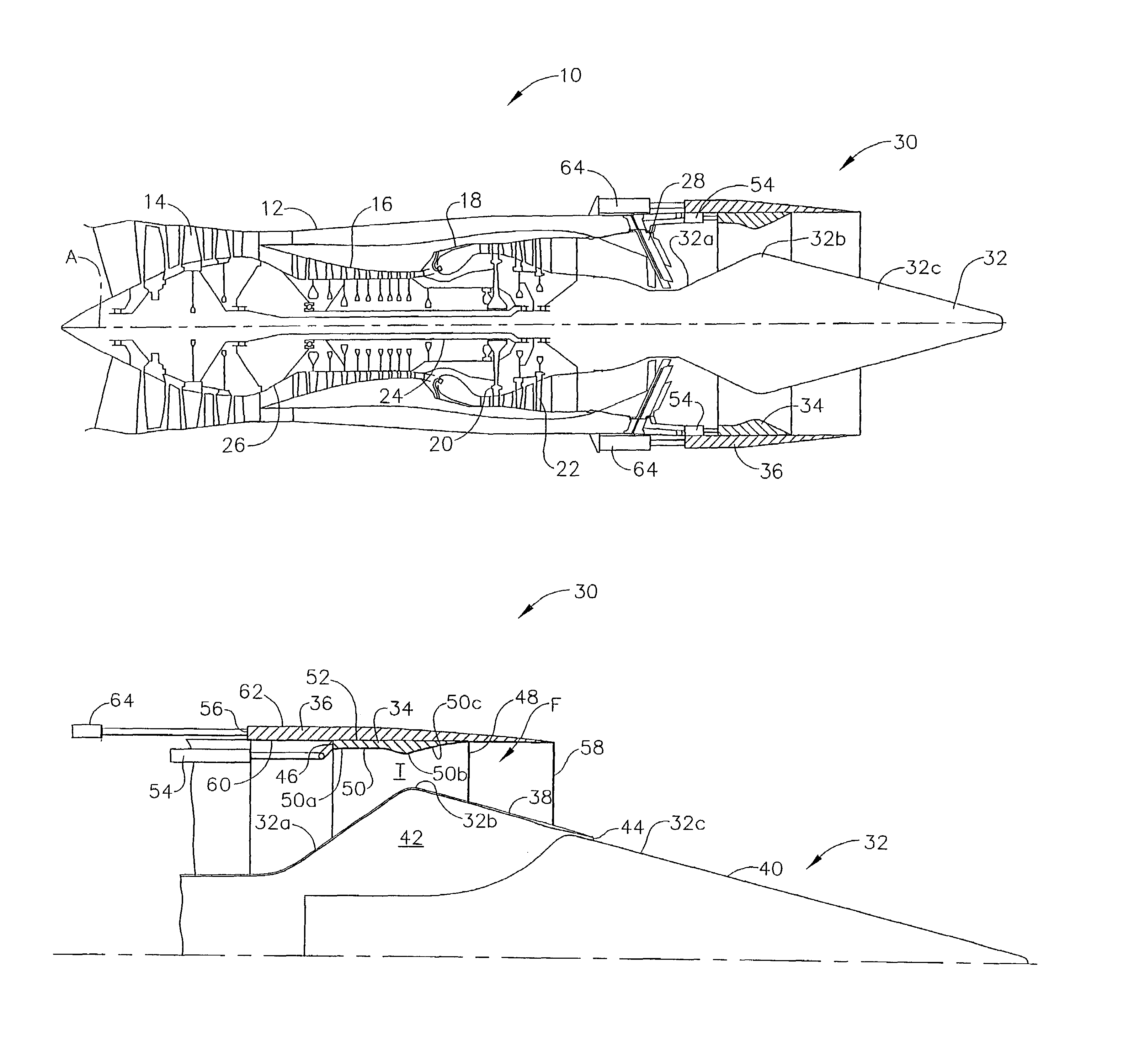

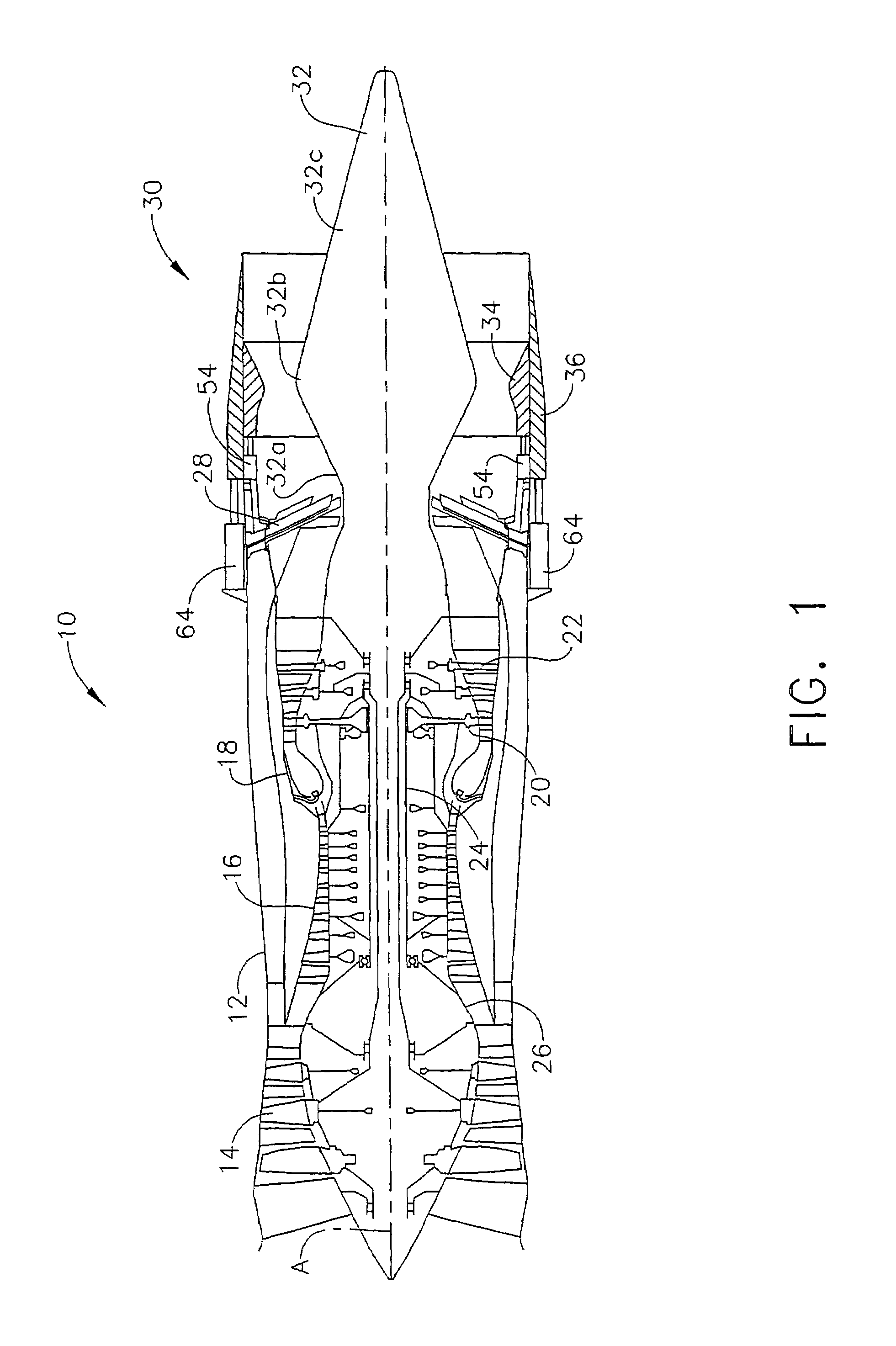

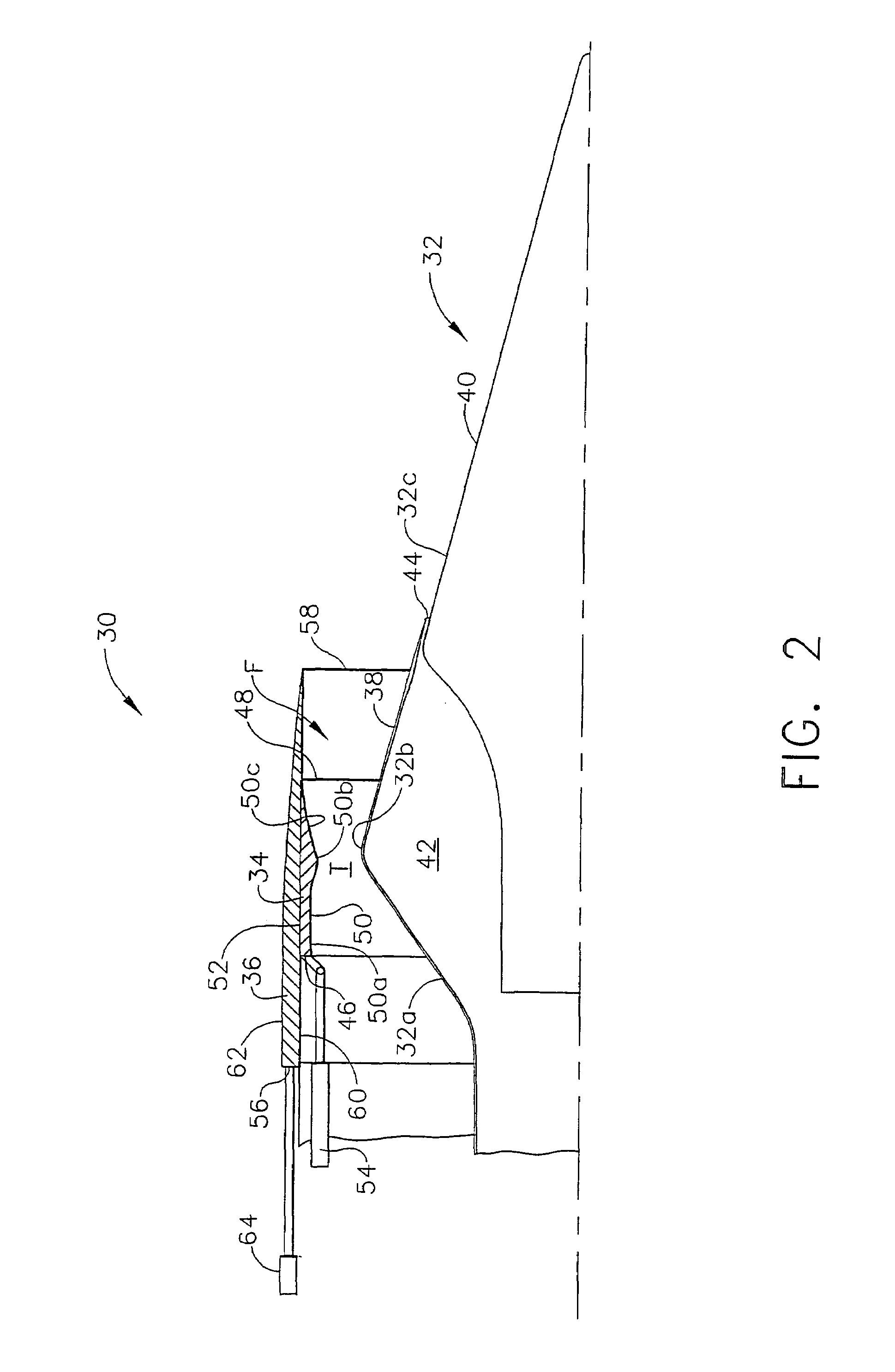

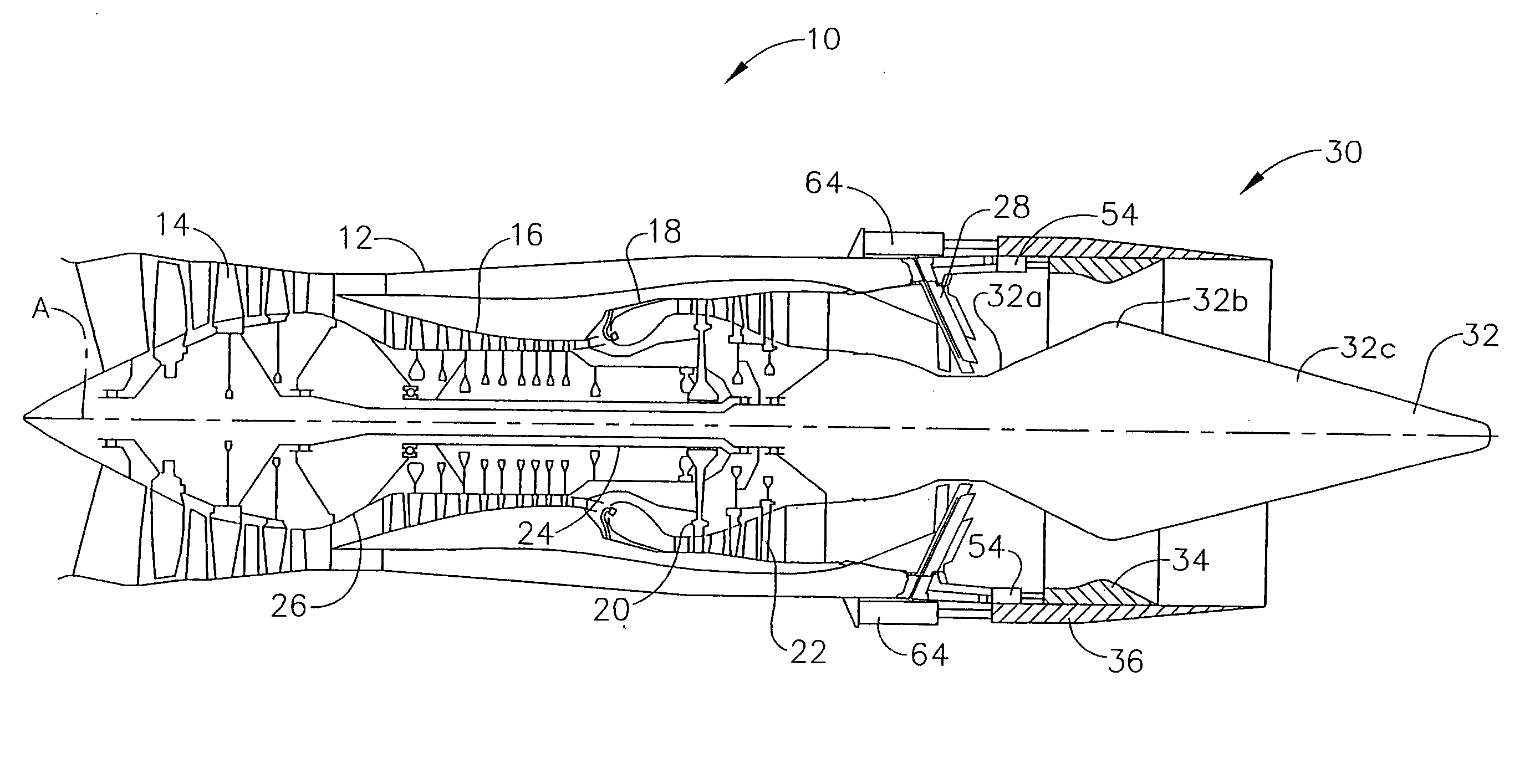

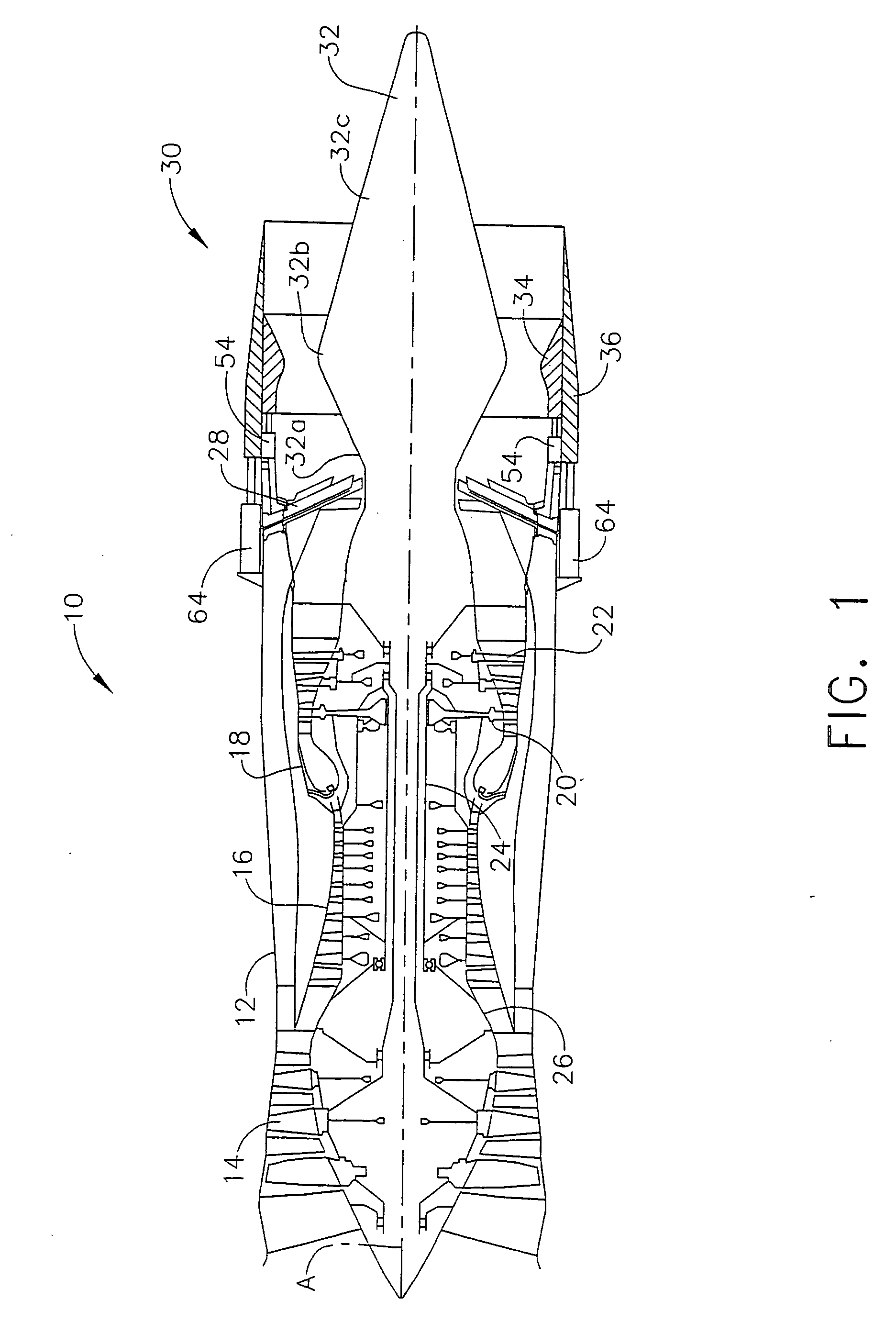

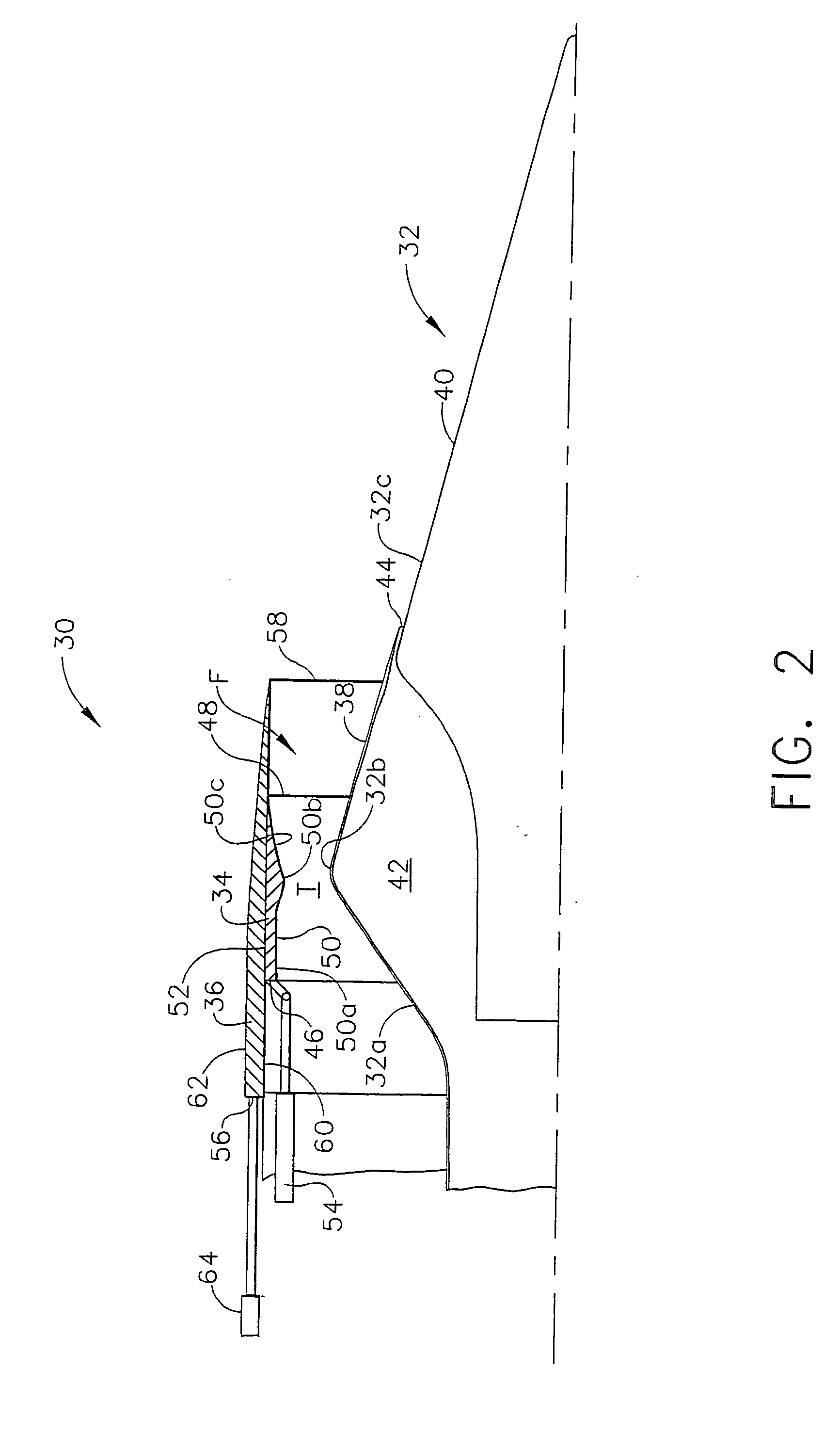

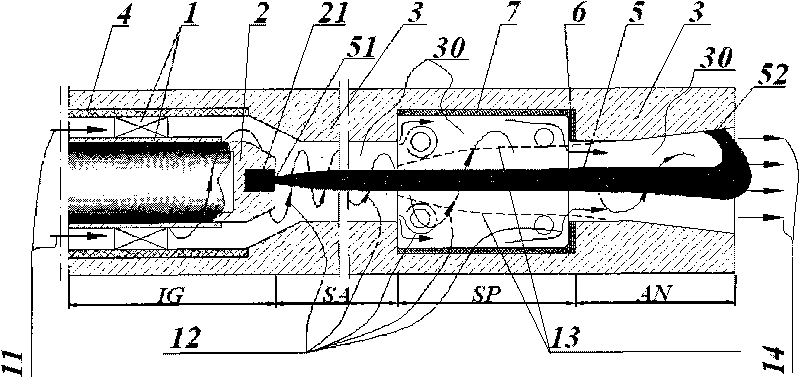

Split shroud exhaust nozzle

A variable geometry convergent-divergent nozzle for a gas turbine engine includes a centerbody extending rearward along a longitudinal axis of the engine which has a throat section of increased diameter. An inner shroud surrounds the centerbody and cooperates with the centerbody to define the throat of the nozzle. An outer shroud surrounds the inner shroud and cooperates with the centerbody to define the exit area of the nozzle. Both shrouds are independently translatable to provide independent control of the nozzle throat area and the nozzle expansion ratio.

Owner:GENERAL ELECTRIC CO

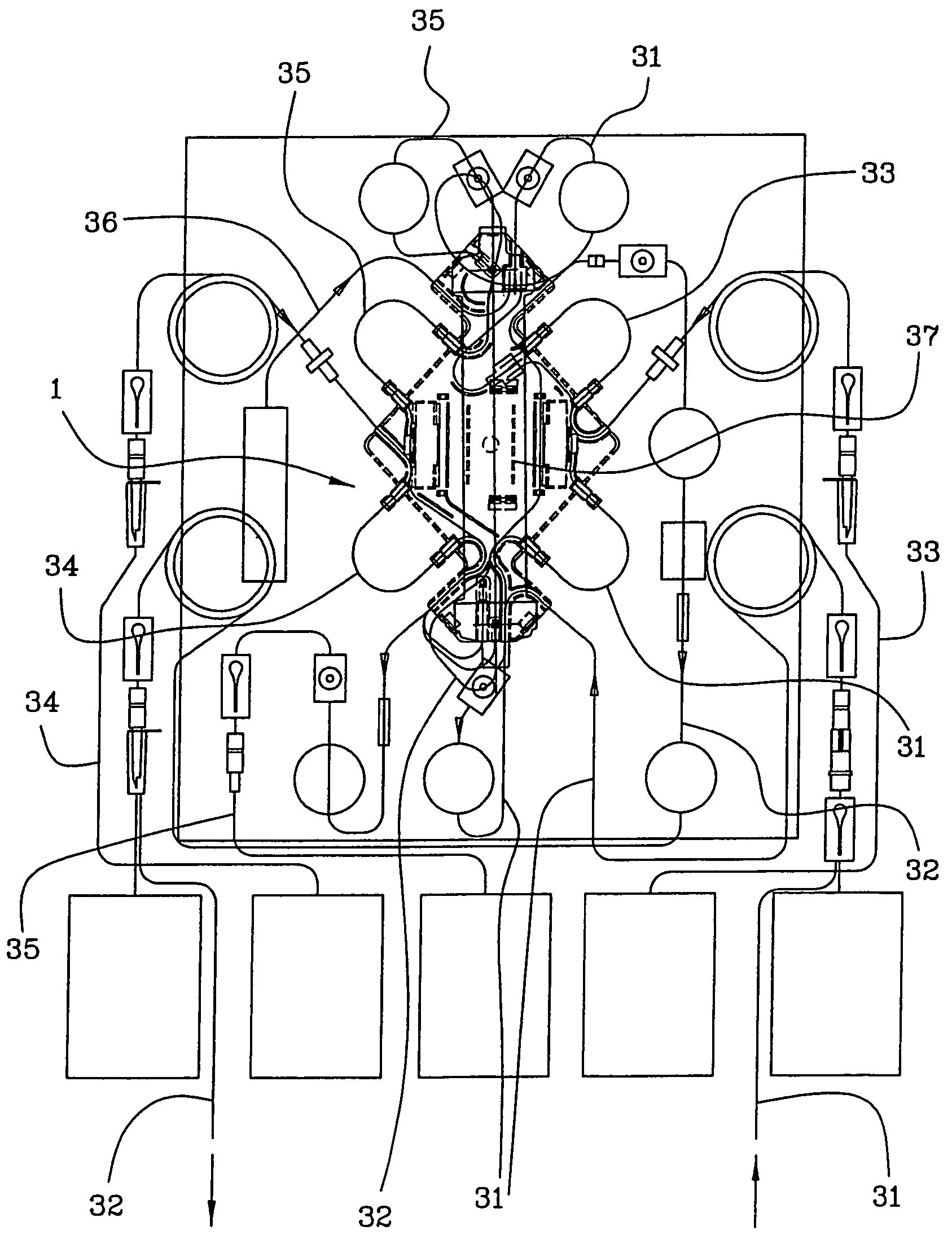

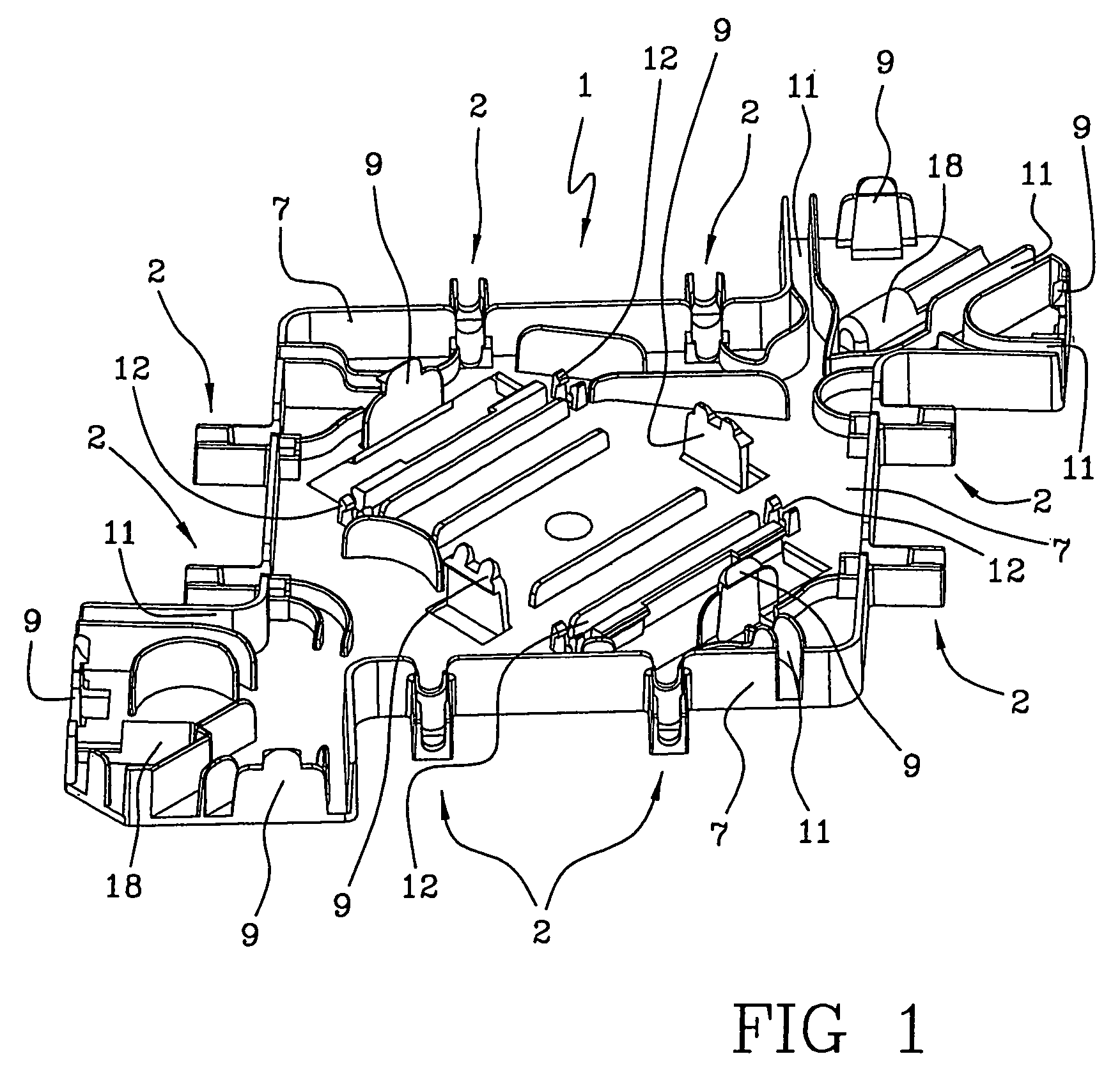

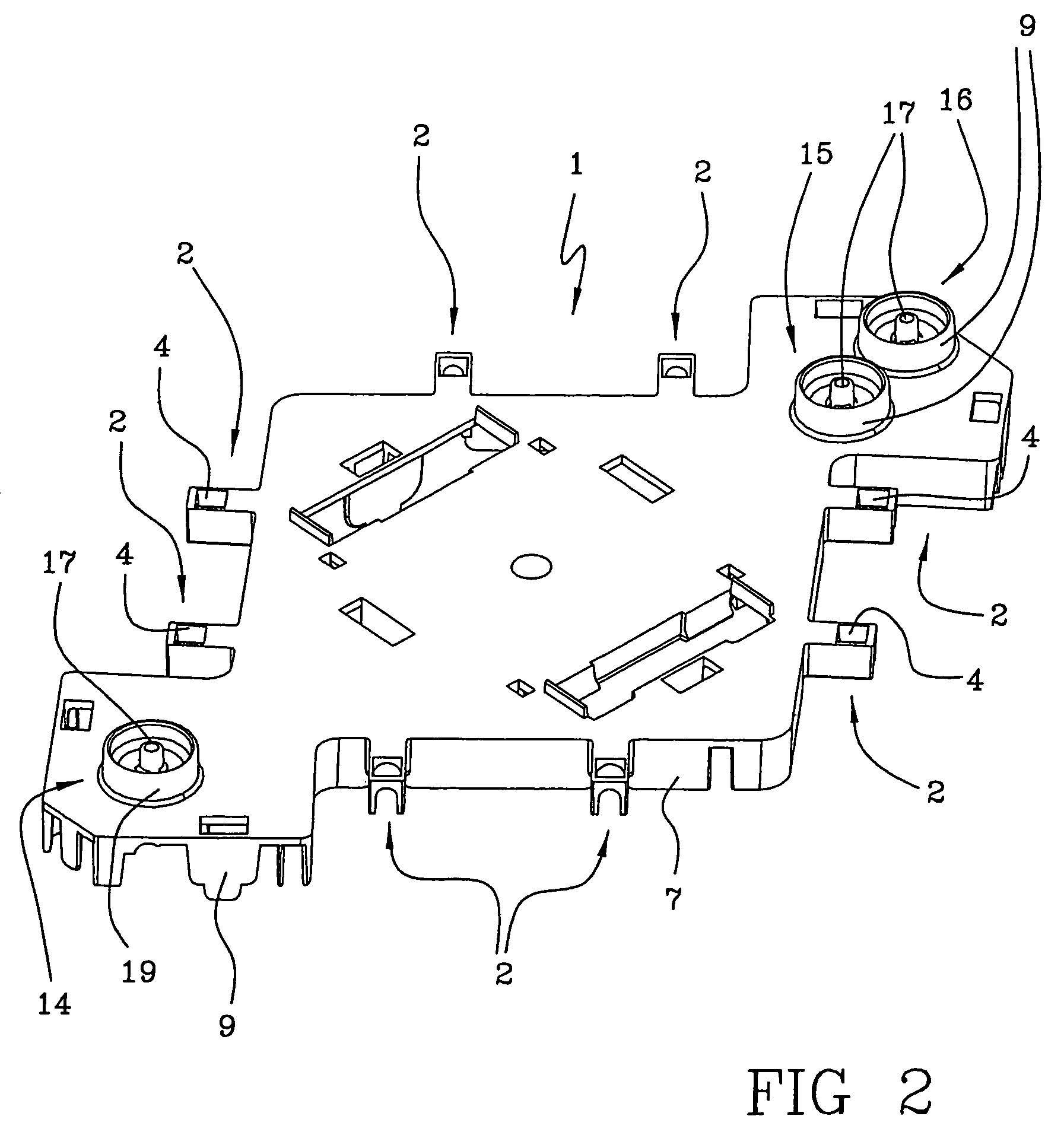

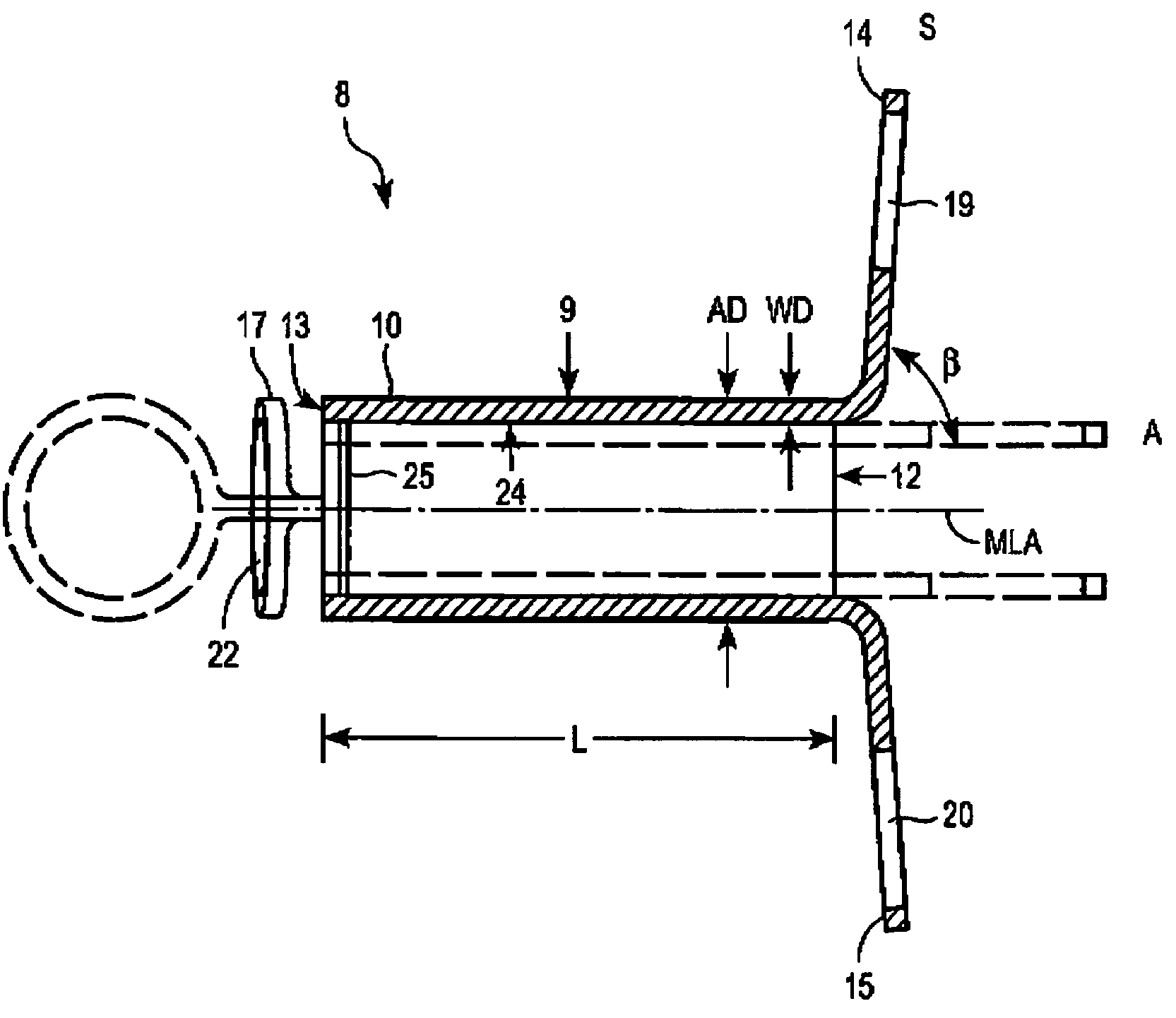

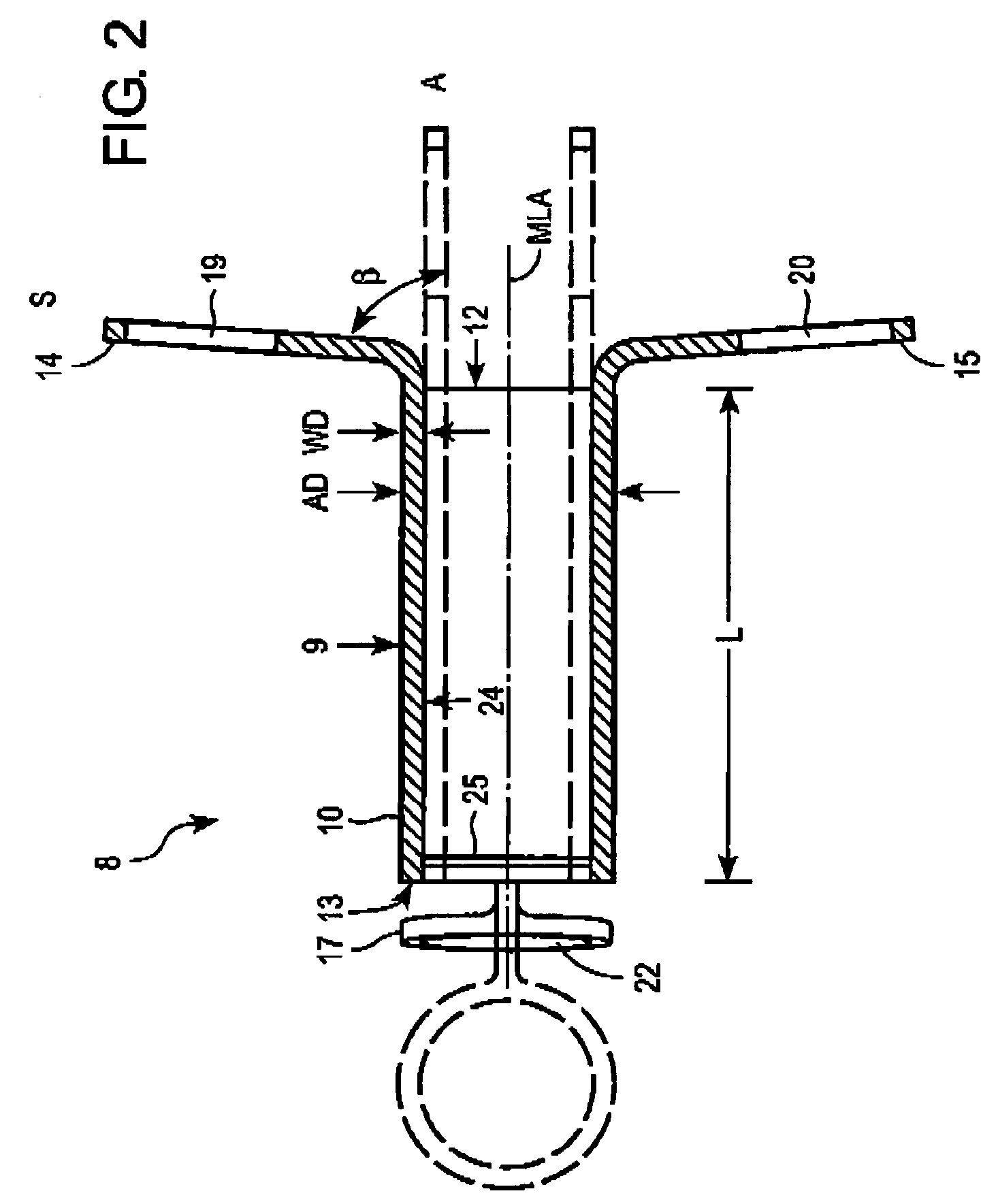

Support element, an integrated module for extracorporeal blood treatment comprising the support element, an apparatus for extracorporeal blood treatment equipped with the integrated module, and an assembly process for an integrated module for extracorporeal blood treatment

ActiveUS7232418B2Quick assemblyEasy to operateEngine diaphragmsSolvent extractionIntensive treatmentBlood treatments

An integrated module for extracorporeal blood treatment has a flat-shaped support element which exhibits on an internal face thereof a complex of fluid distribution lines and on an external face thereof a high-flow dialyzer. The support element has a base body which exhibits fixture seatings, each of which houses an axially extended tract of a fluid distribution line. The tract of the fluid distribution line, with respect to adjacent tracts, has an increased diameter due to the presence of a junction collar made of a rigid material. Each fixture seating exhibits two axial locators for positioning the axially extended tract of a fluid distribution line in a fixed position. The locators interact with the junction collar, and the distribution lines can be fixed to the base body by a resilient fixture of the junction collars in the seatings without gluing. The module is configured to be mounted on an apparatus for intensive treatment of renal insufficiency.

Owner:GAMBRO LUNDIA AB

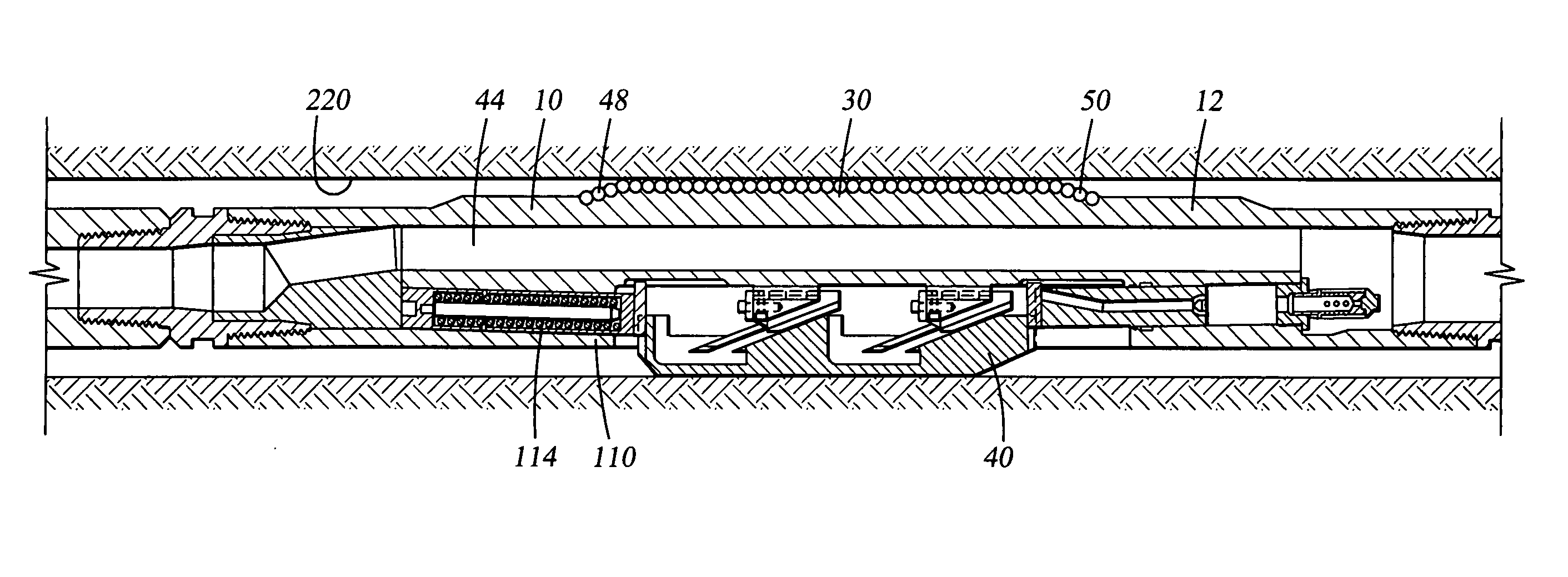

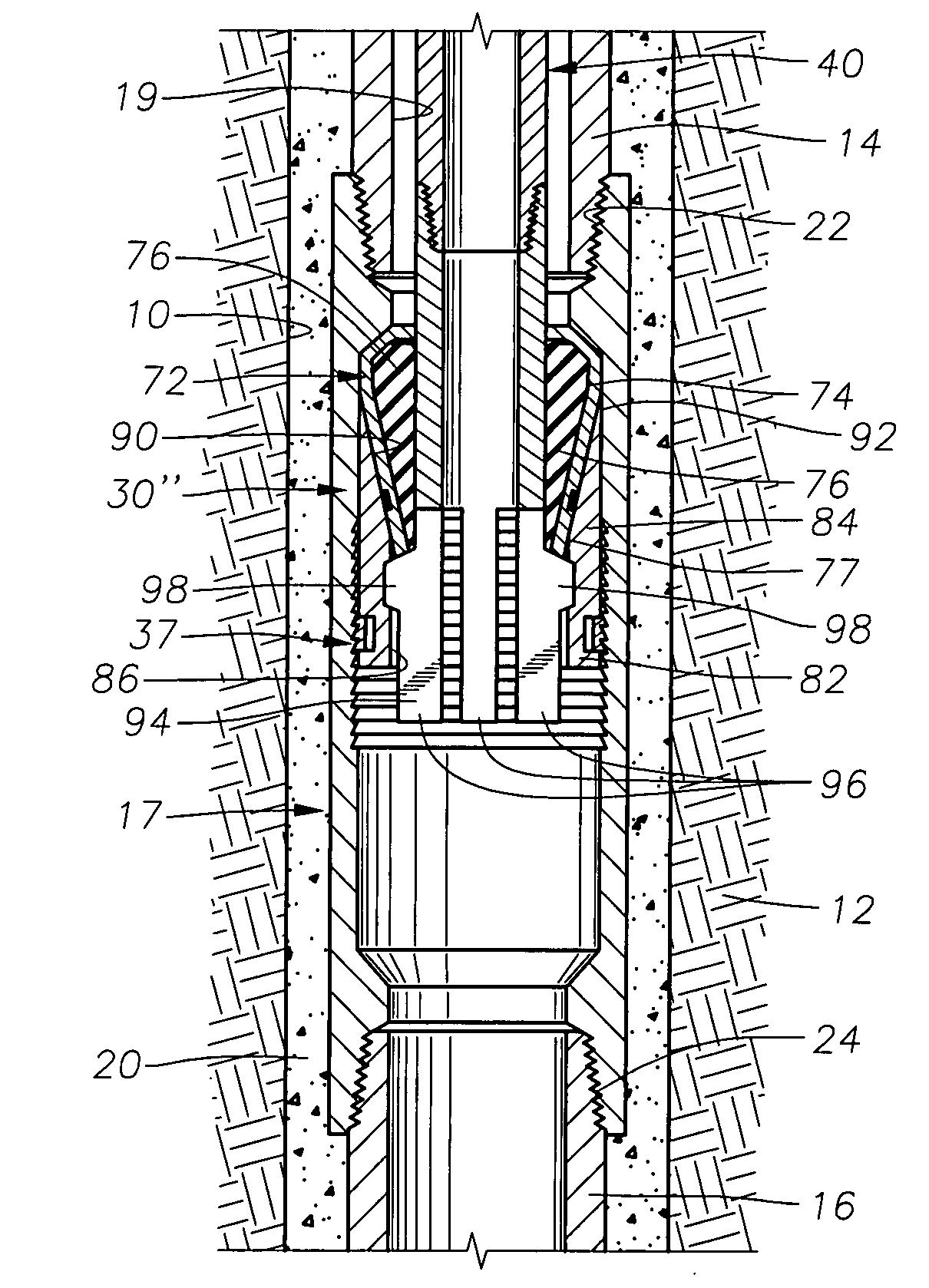

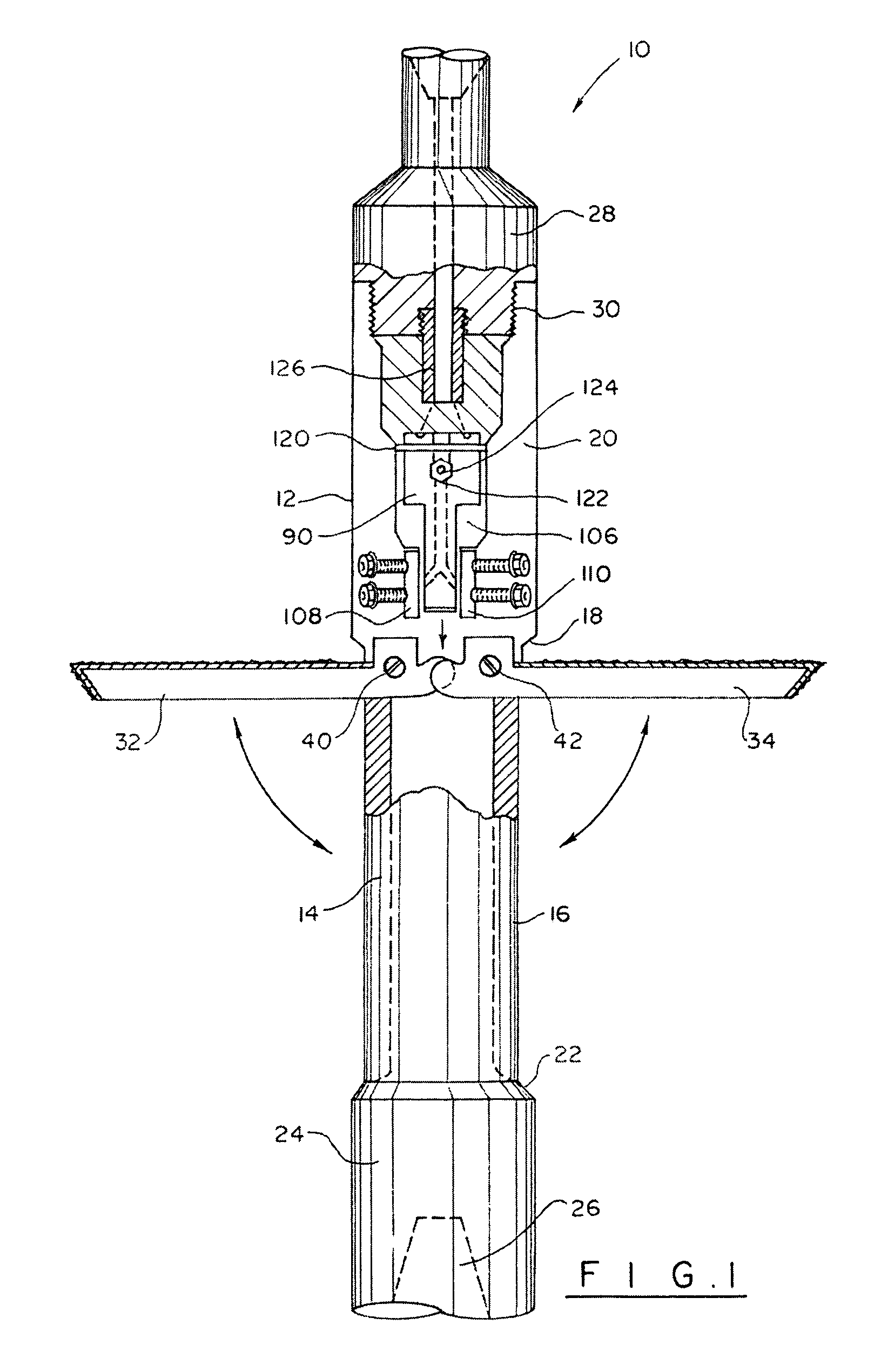

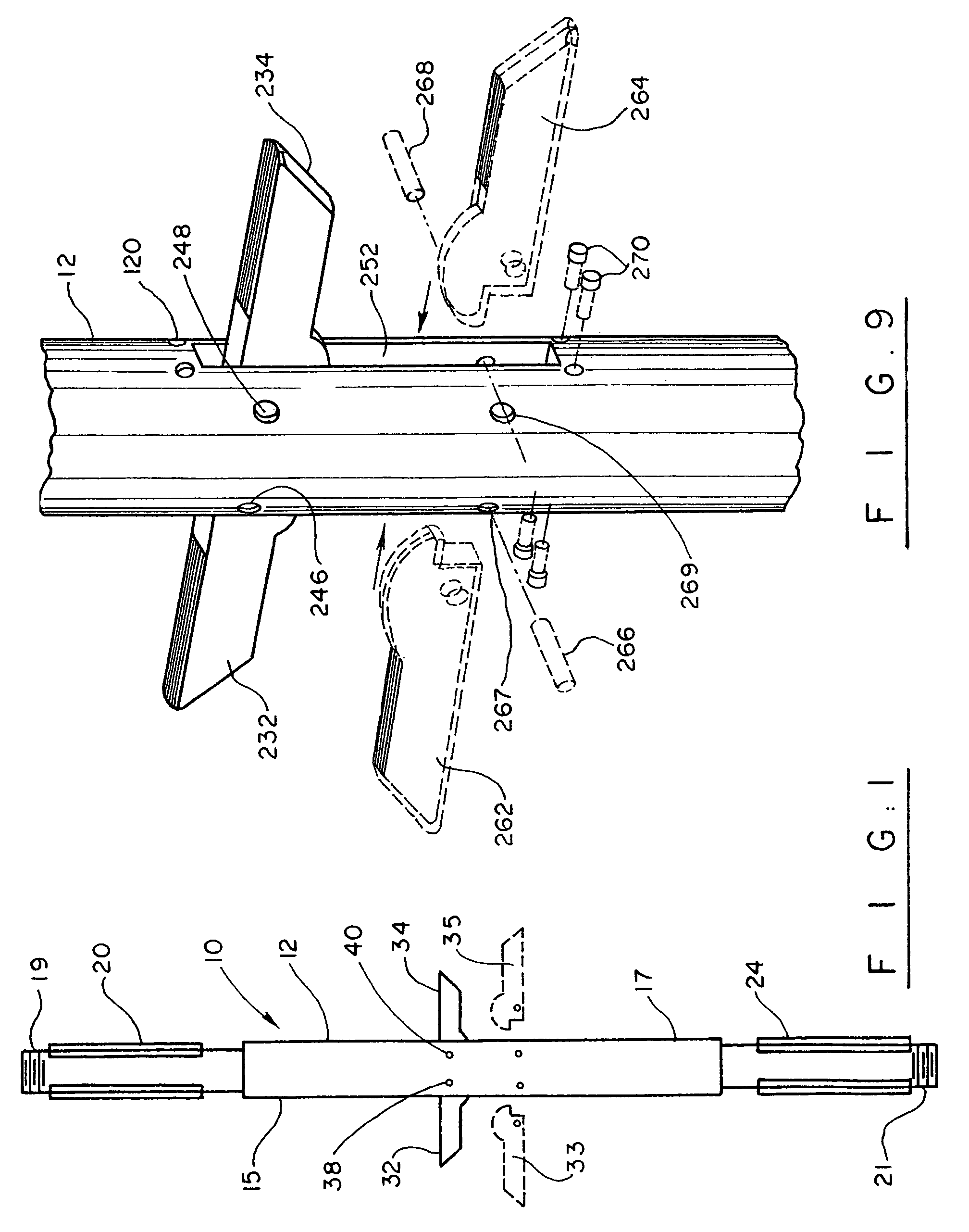

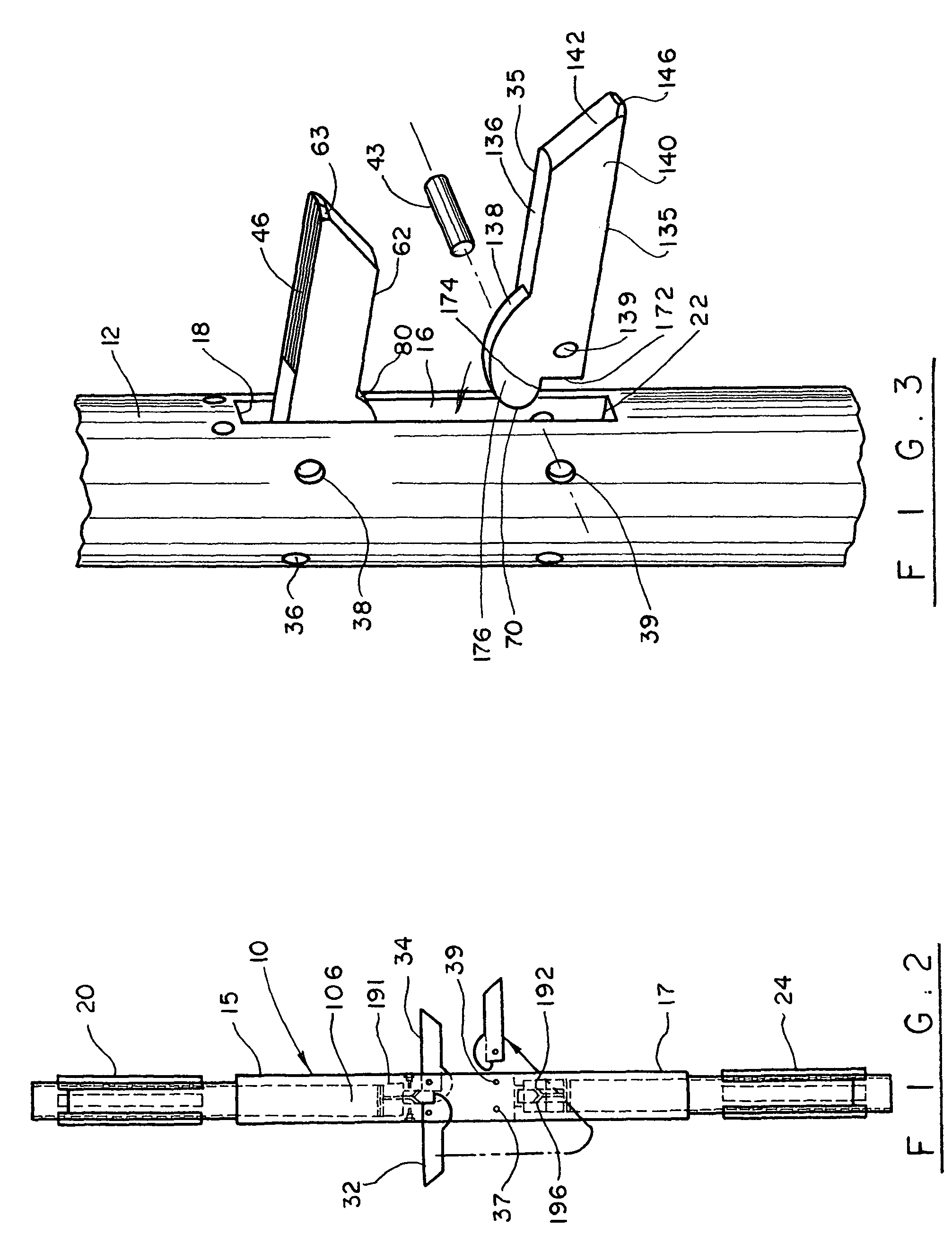

Apparatus and method for drilling and reaming a borehole

A drilling assembly and an eccentric, adjustable diameter reamer are disclosed. The reamer includes cutter elements mounted on at least a first fixed blade for reaming a previously-formed borehole or for forming a borehole of increased diameter beneath an existing cased borehole. The method and apparatus provide for stabilizing the drilling assembly so that the reamer may be used in back reaming the hole. Retainer means, such as shear pins or spring-biased reciprocating latch members, are provided to prevent premature extension of the reamer's moveable members, including blades and pistons. The shear pins are preferably accessible from the outer surface of the reamer housing so as to expedite field replacement of the shear pins without requiring disassembly of the reamer. The spring-biased latching members repeatedly latch and unlatch so that field replacement is not required, and so that the movable members may be extended and contracted multiple times while the reamer is downhole.

Owner:HALLIBURTON ENERGY SERVICES INC

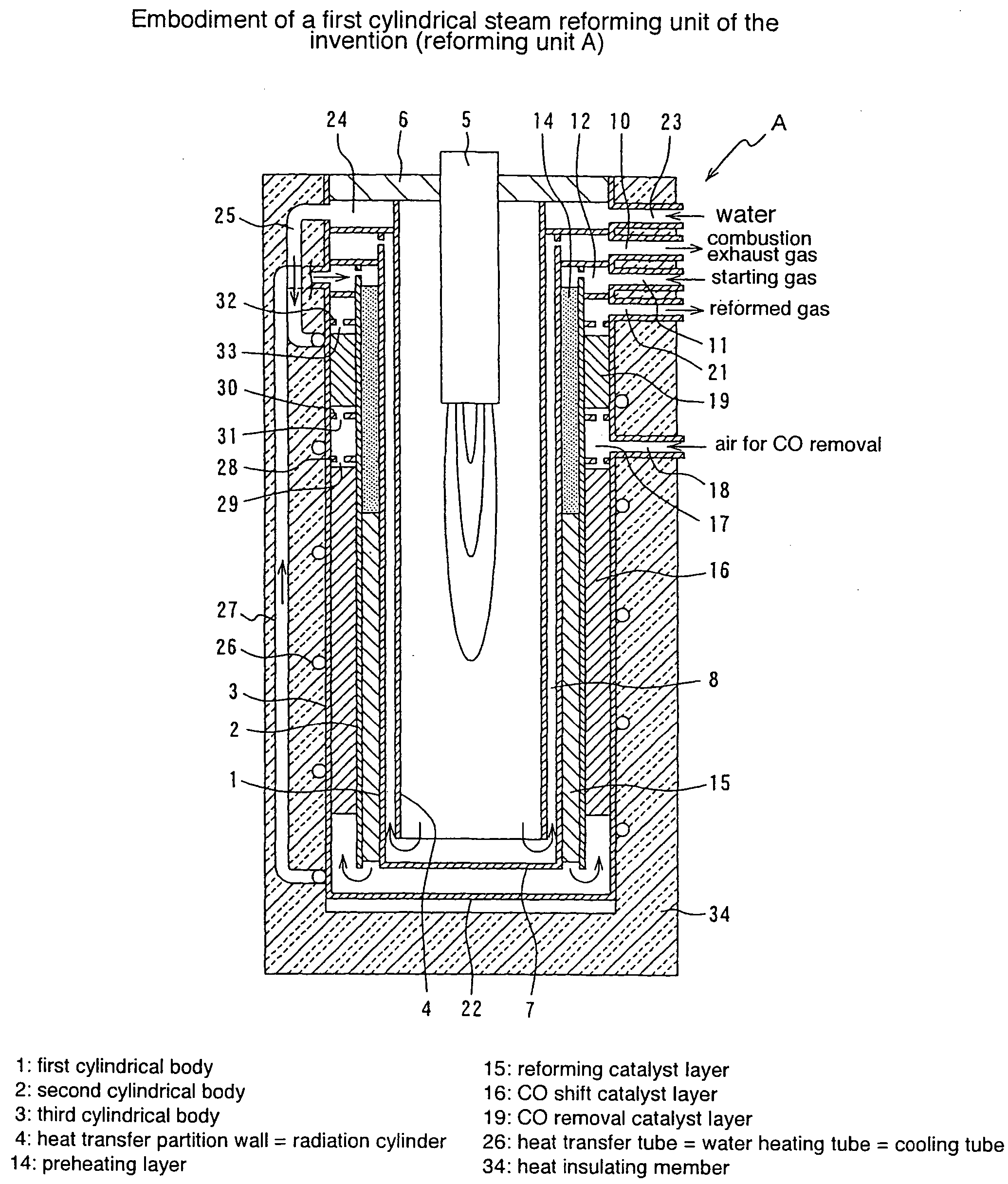

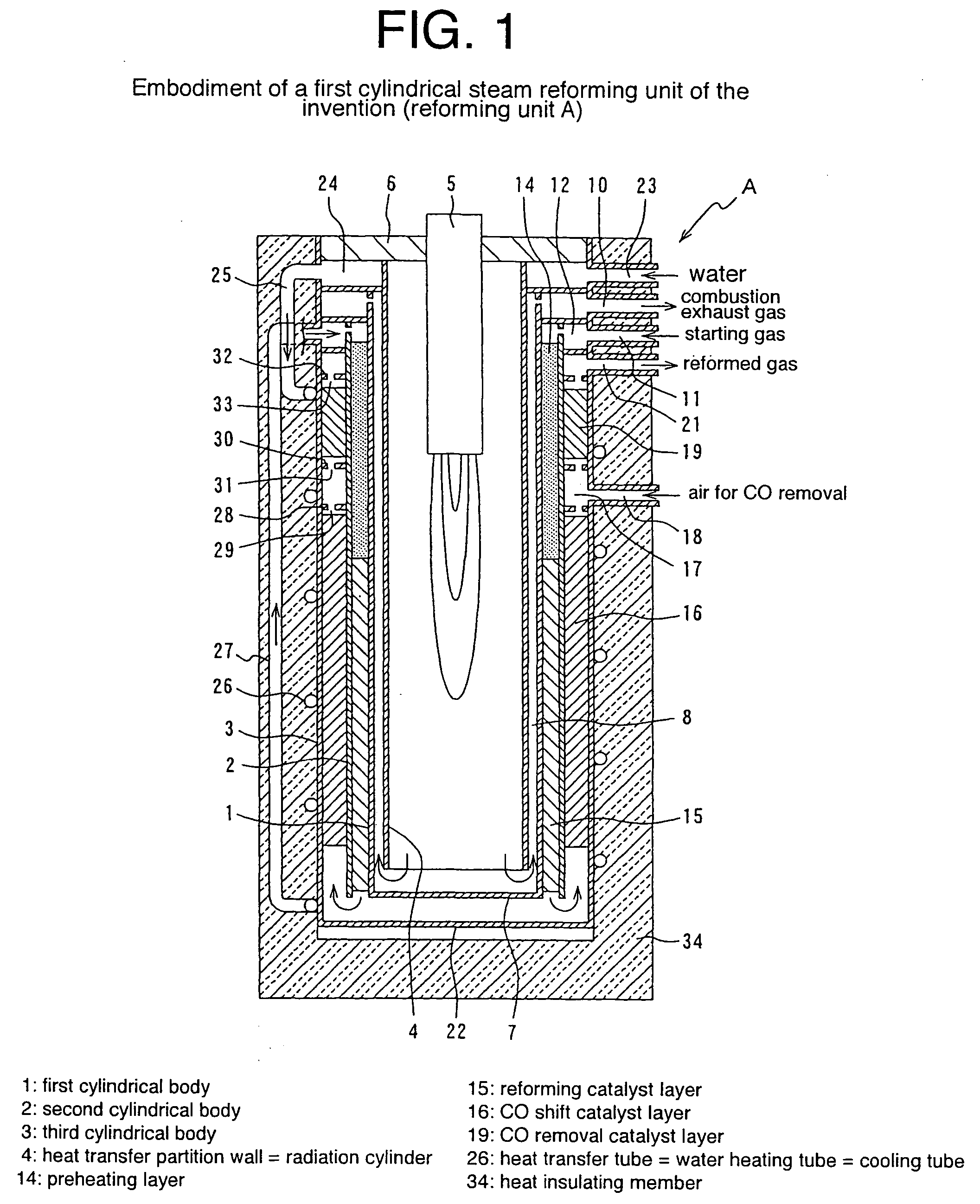

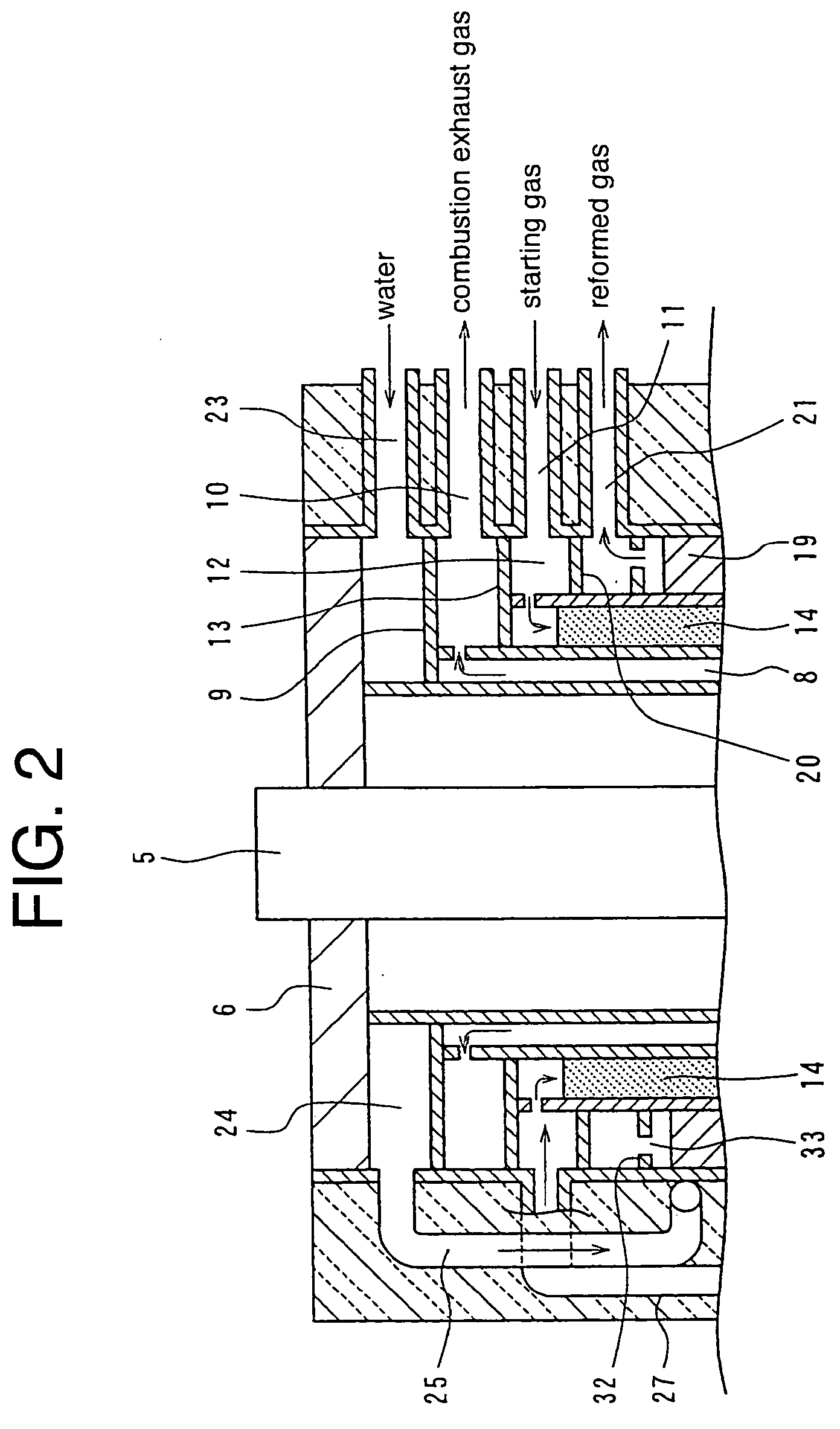

Cylindrical water vapor reforming unit

InactiveUS20040144029A1Small sizePass smoothlyHydrogen/synthetic gas productionChemical/physical/physico-chemical processesSteam reformingInsulation layer

A cylindrical steam reforming unit comprising a plurality of cylindrical bodies consisting of a first cylindrical body, a second cylindrical body and a third cylindrical body of successively increasing diameters disposed in a concentric spaced relation, a radiation cylinder disposed within and concentrically with the first cylindrical body, a burner disposed in the radial central portion of the radiation cylinder, and a reforming catalyst layer with a reforming catalyst filled in a gap between the first and second cylindrical bodies, wherein a CO shift catalyst layer and a CO removal catalyst layer are disposed in a gap between the second and third cylindrical bodies, the CO shift catalyst layer being formed in a gap with the direction of flow reversed at one axial end of the reforming catalyst layer and through a heat recovery layer of predetermined length. According to this reforming unit, without internally disposing a heat insulation layer, a cooling mechanism or the like, the reforming catalyst layer, CO shift catalyst layer, and CO removal catalyst layer can be integrated, achieving various useful effects, including size and weight reductions and the shortening of startup time.

Owner:TOKYO GAS CO LTD

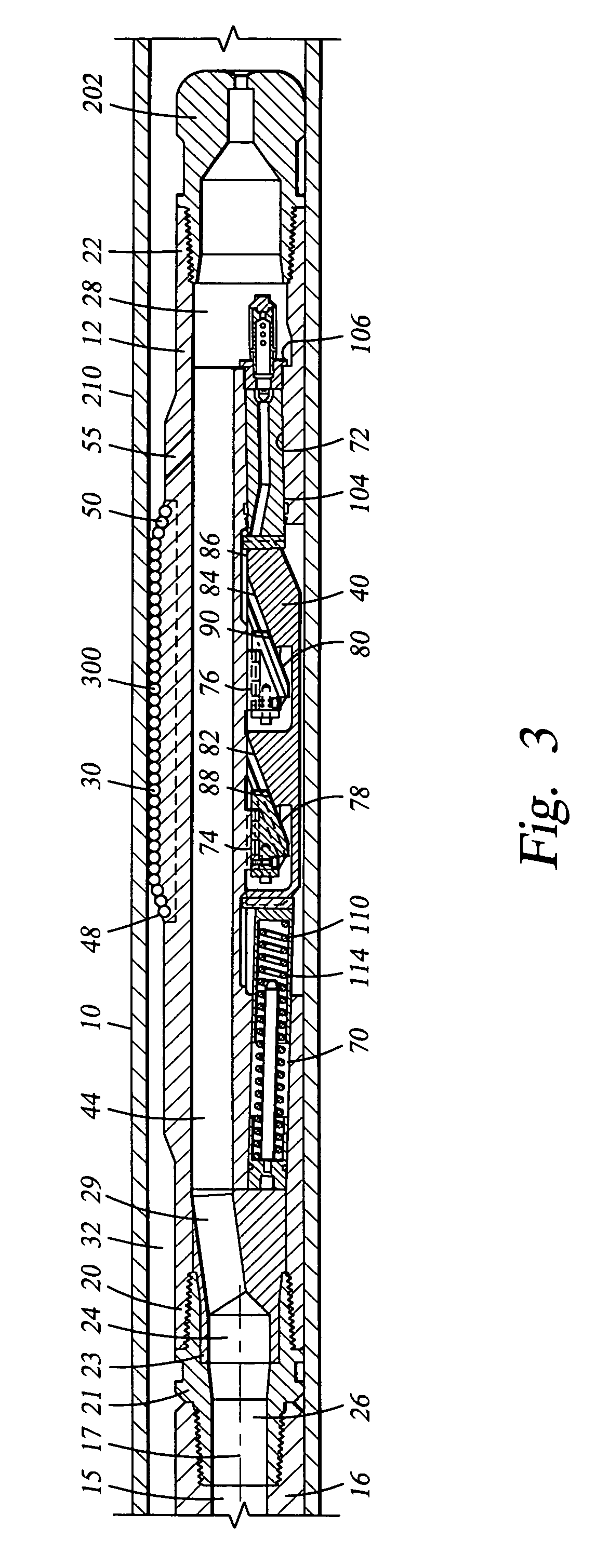

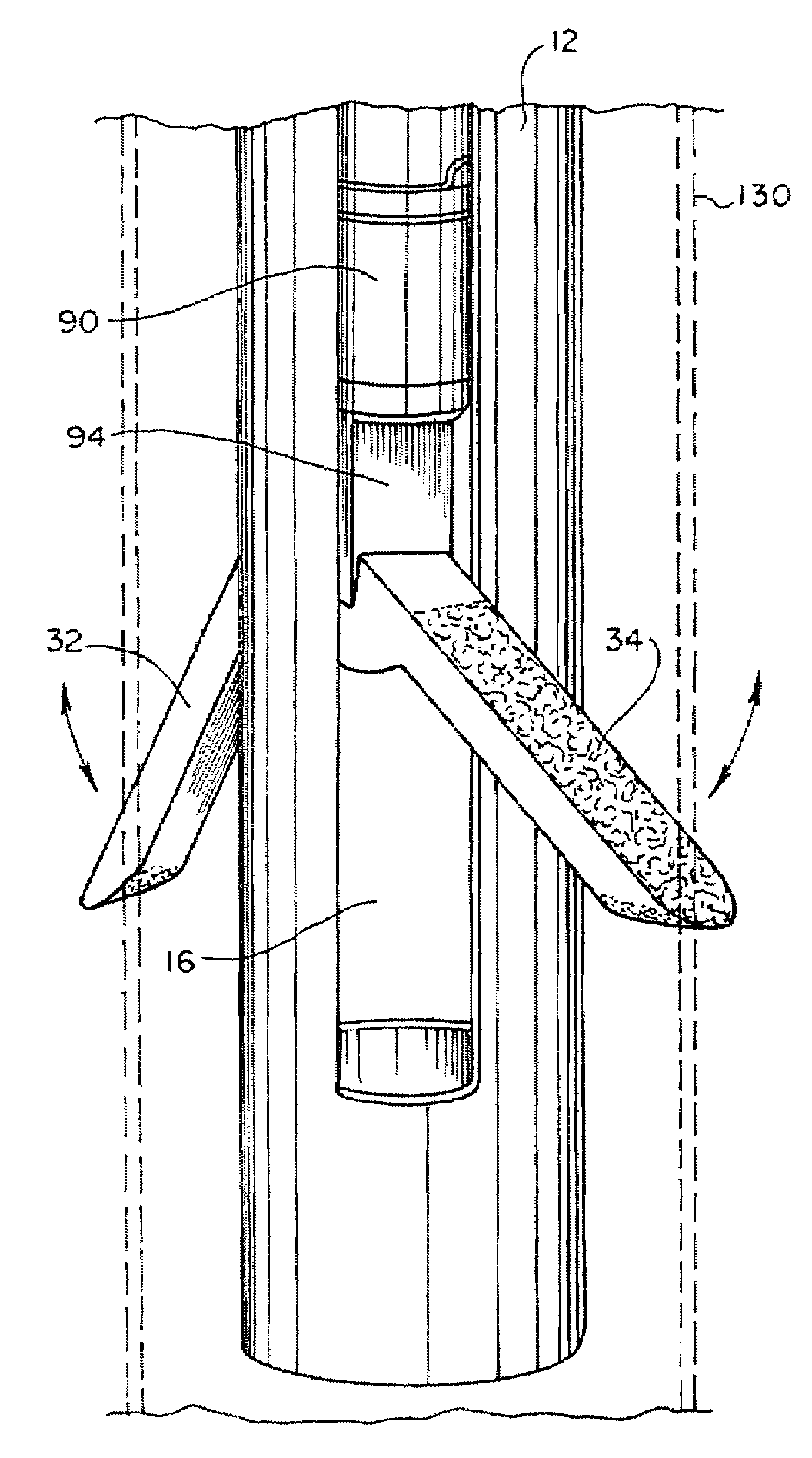

Casing cutter

Casing cutter for severing multiple tubulars in a well bore has a pair of cutter blades pivotally mounted on a support body. The blades are pivotally mounted for gradual movement outside of the support body when downward force is applied to proximate ends of the cutter blades. The support body is rotated inside the innermost of the multiple tubulars, while the cutter blades sever the tubulars of progressively increasing diameter.

Owner:ABRADO

Large bore packer and methods of setting same

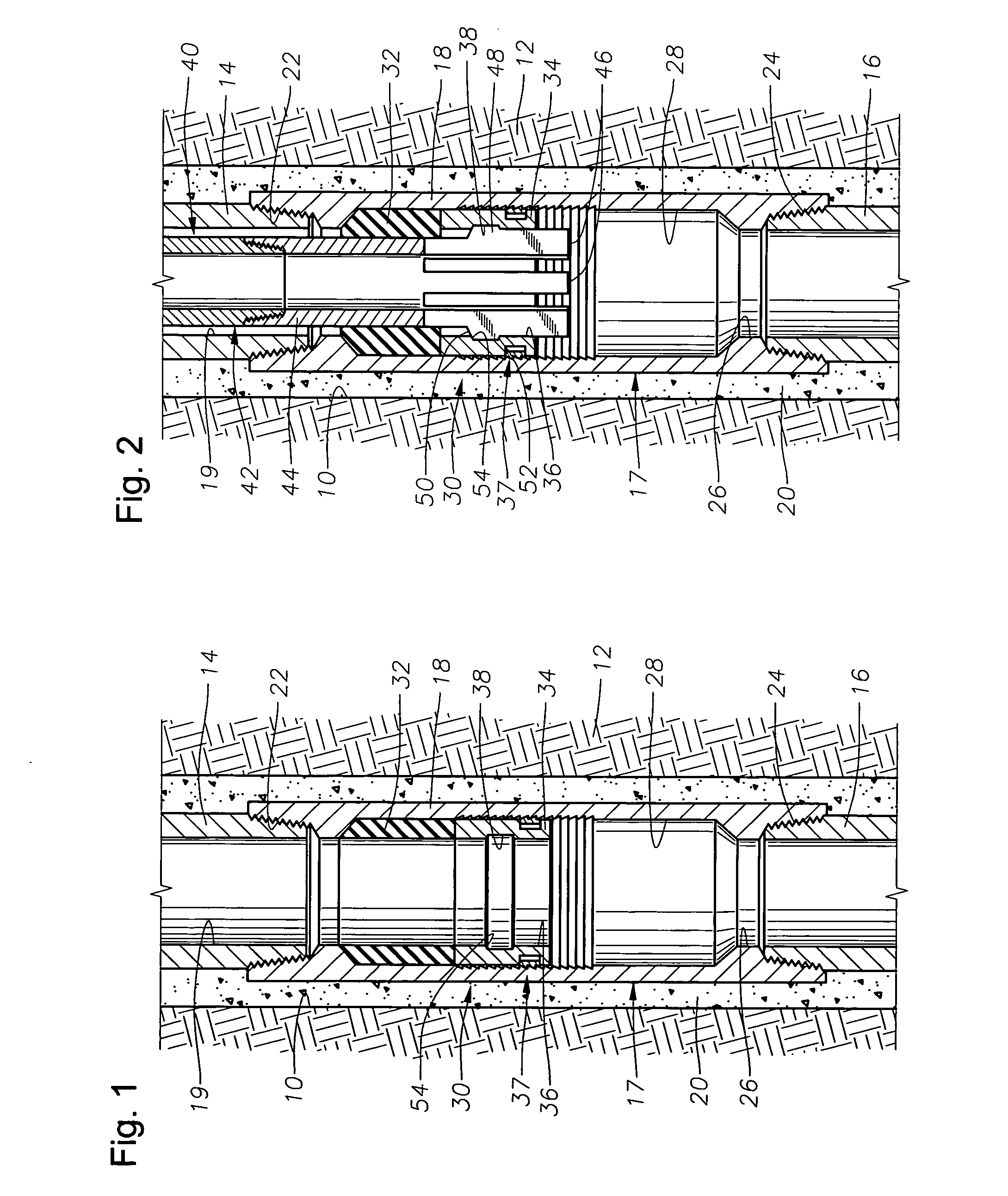

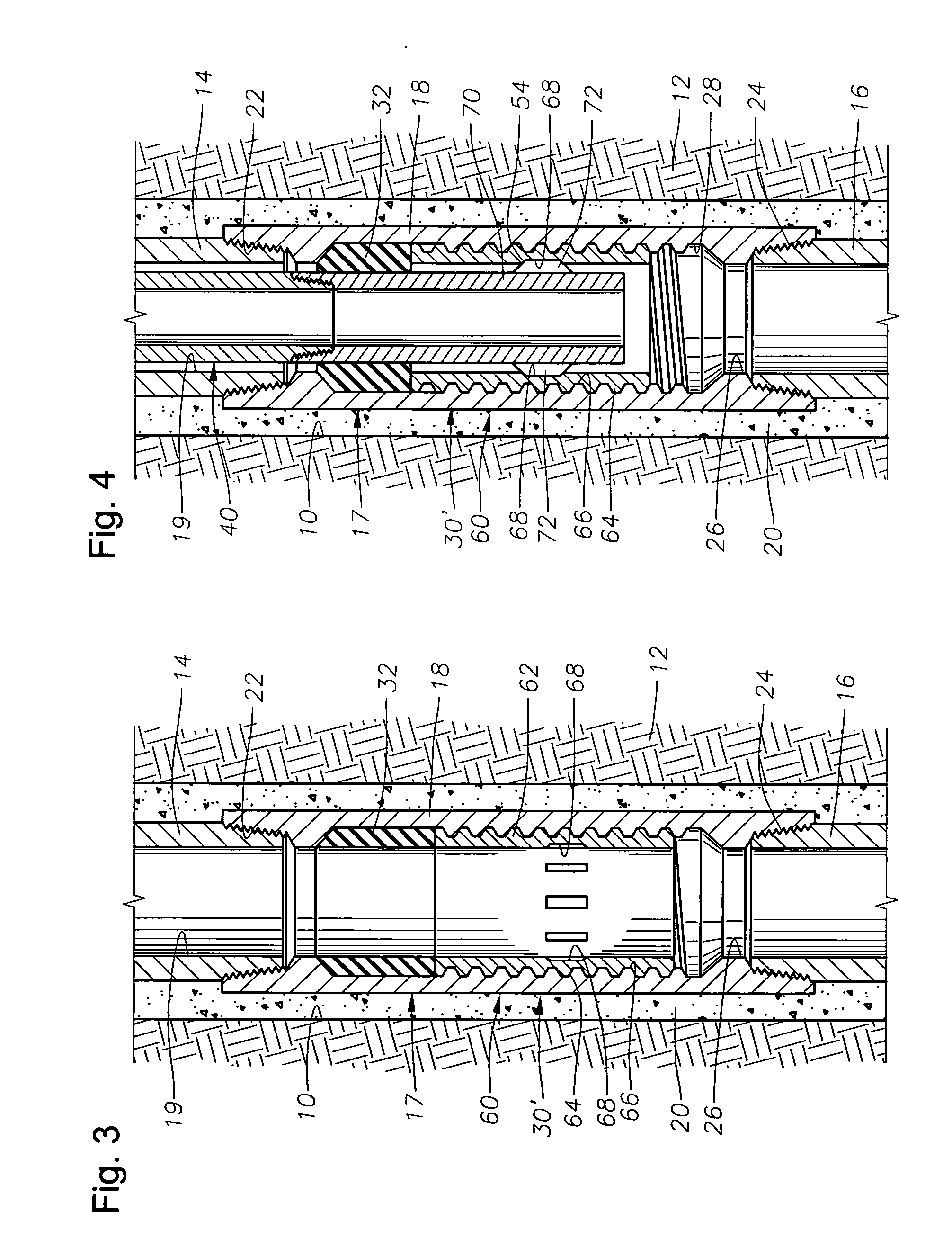

InactiveUS20080110643A1Increase the diameterSaving useable cross-sectional areaDrilling rodsConstructionsMechanical engineeringWellbore

Devices and methods for setting a packer inside a wellbore with little appreciable reduction of the useable area of the wellbore. The outer casing or liner of the wellbore contains one or more integrated casing coupler joints having an increased diameter chamber portion. A large bore packing element is carried within the increased diameter chamber portion. The packing element may be selectively actuated to form a seal against an interior tubular member. Because the packing element is located within the chamber portion of the casing coupler, the packer may be set while saving useable cross-sectional area within the casing.

Owner:BAKER HUGHES INC

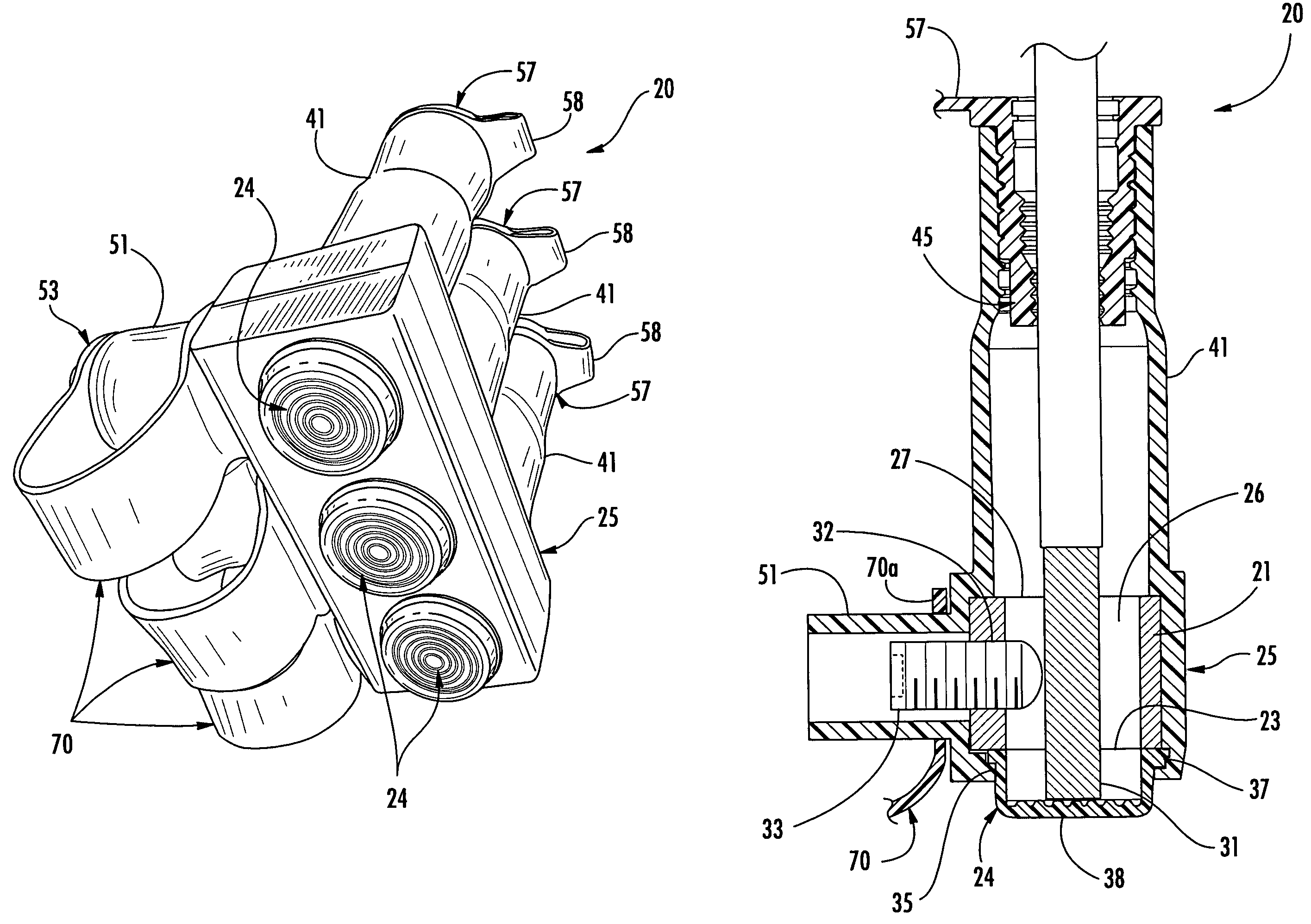

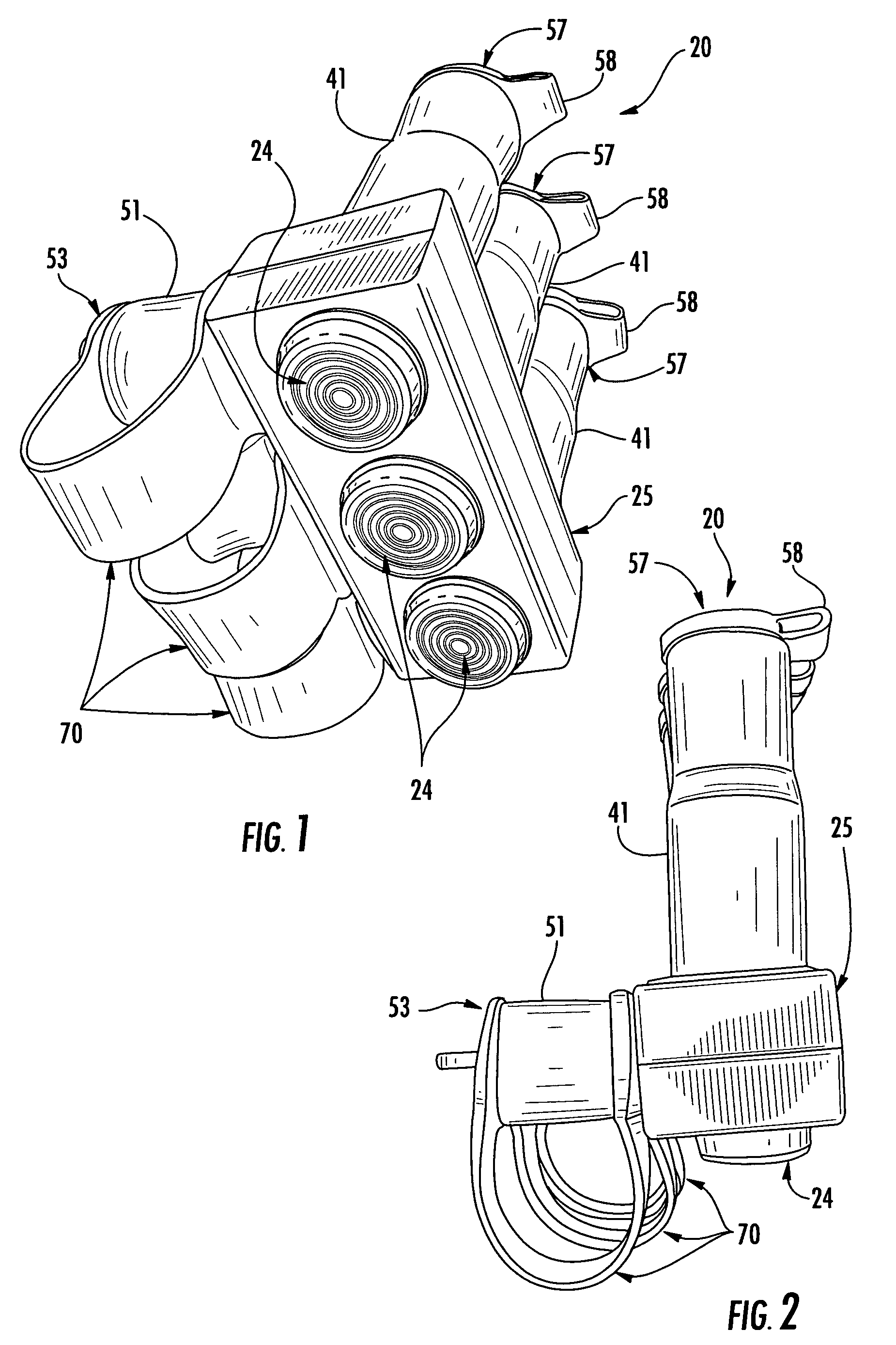

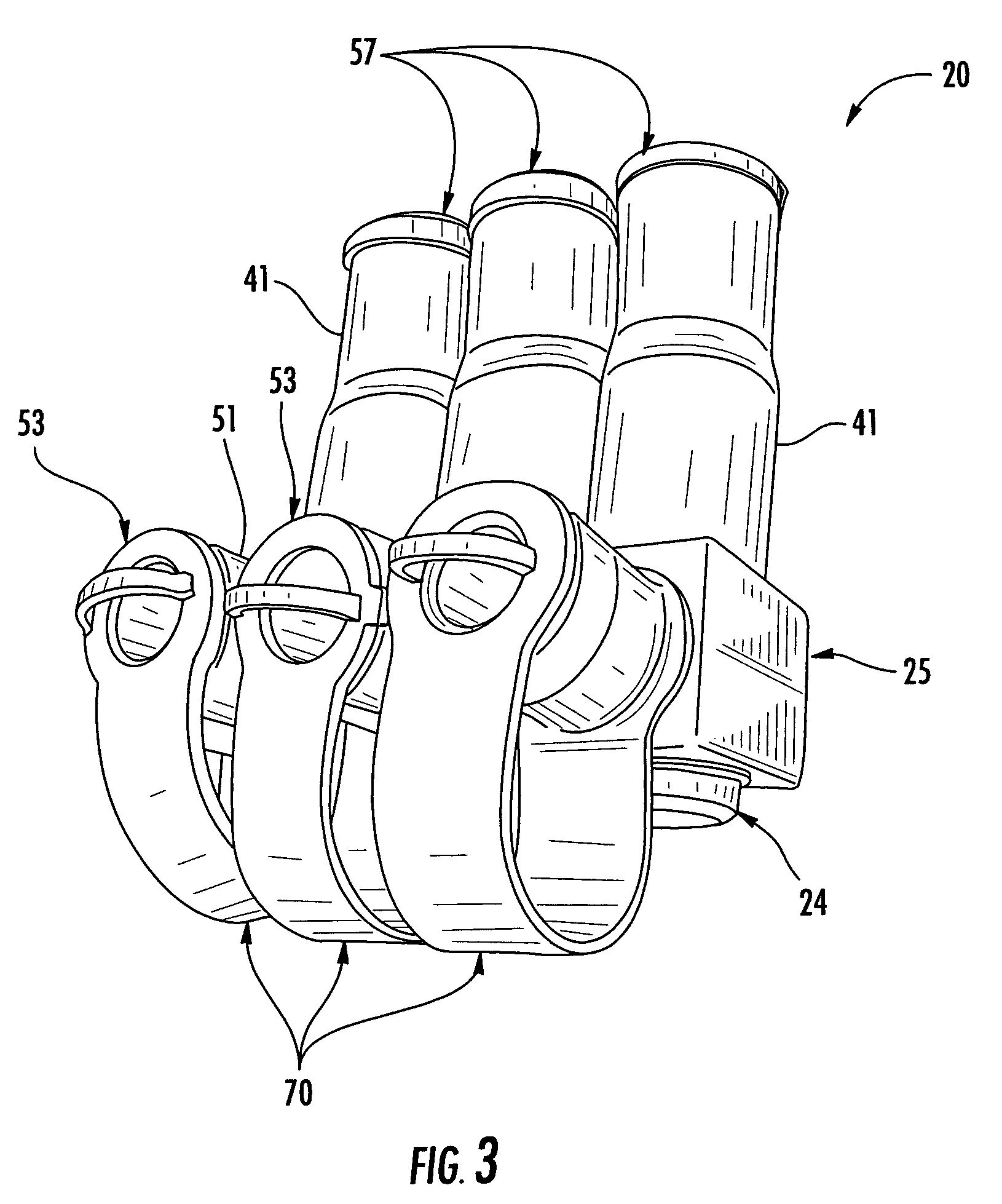

Tube connector

Owner:BIO PURE TECH LTD

Casing cutter

Owner:ABRADO

Split shroud exhaust nozzle

ActiveUS20060016171A1Increase the diameterReduce the overall diameterCosmonautic vehiclesEngine manufactureNozzle throatVariable geometry

A variable geometry convergent-divergent nozzle for a gas turbine engine includes a centerbody extending rearward along a longitudinal axis of the engine which has a throat section of increased diameter. An inner shroud surrounds the centerbody and cooperates with the centerbody to define the throat of the nozzle. An outer shroud surrounds the inner shroud and cooperates with the centerbody to define the exit area of the nozzle. Both shrouds are independently translatable to provide independent control of the nozzle throat area and the nozzle expansion ratio.

Owner:GENERAL ELECTRIC CO

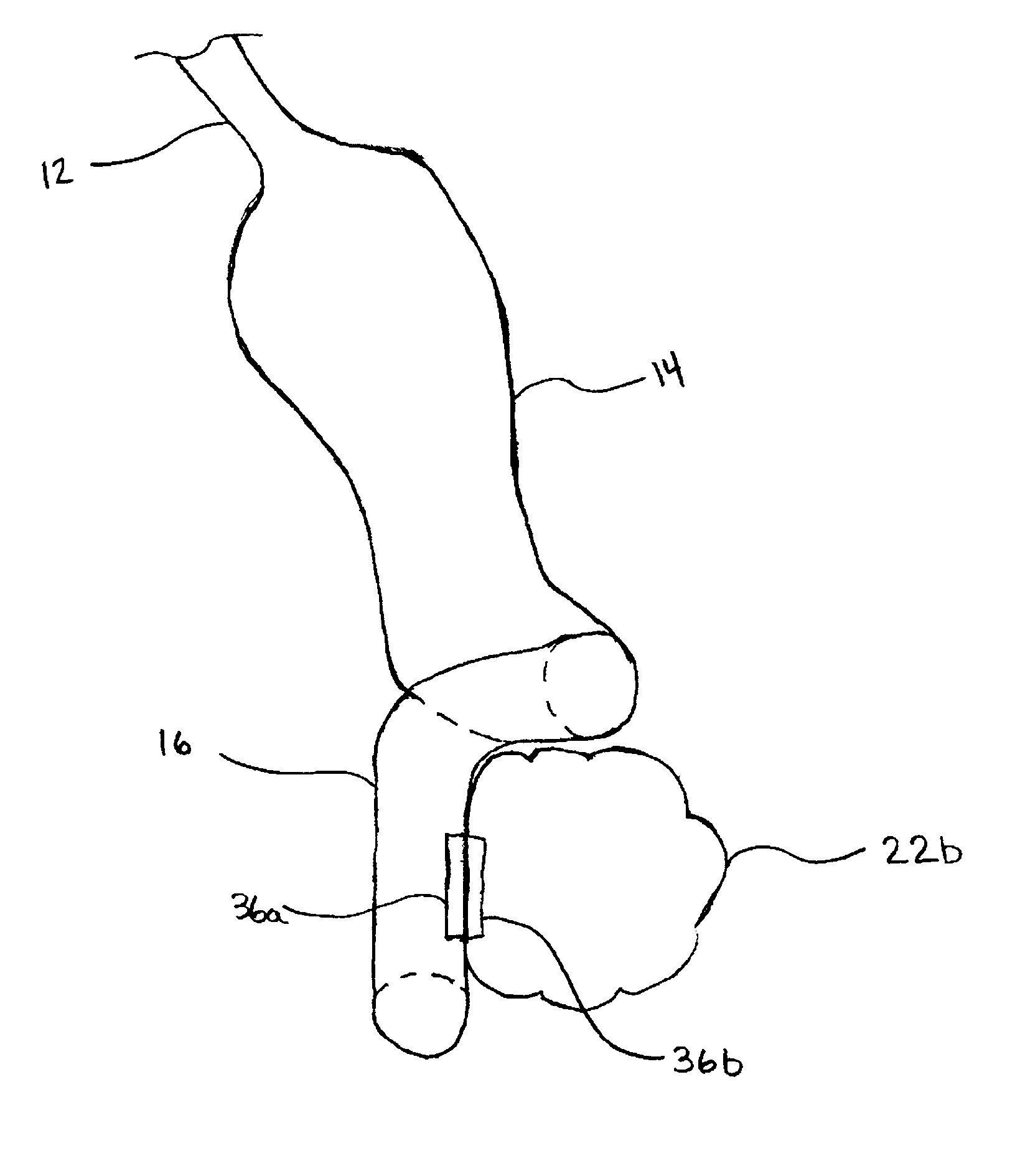

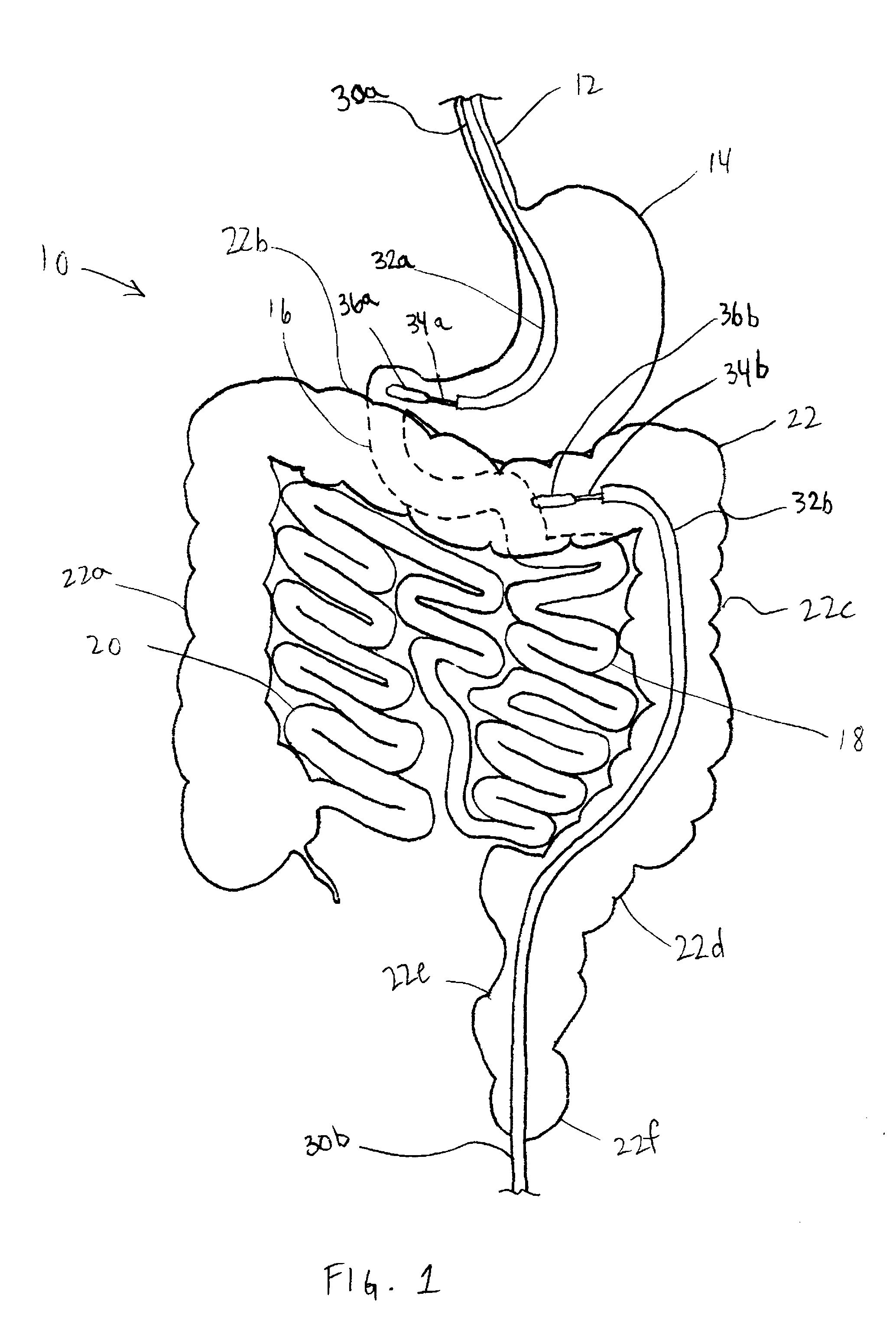

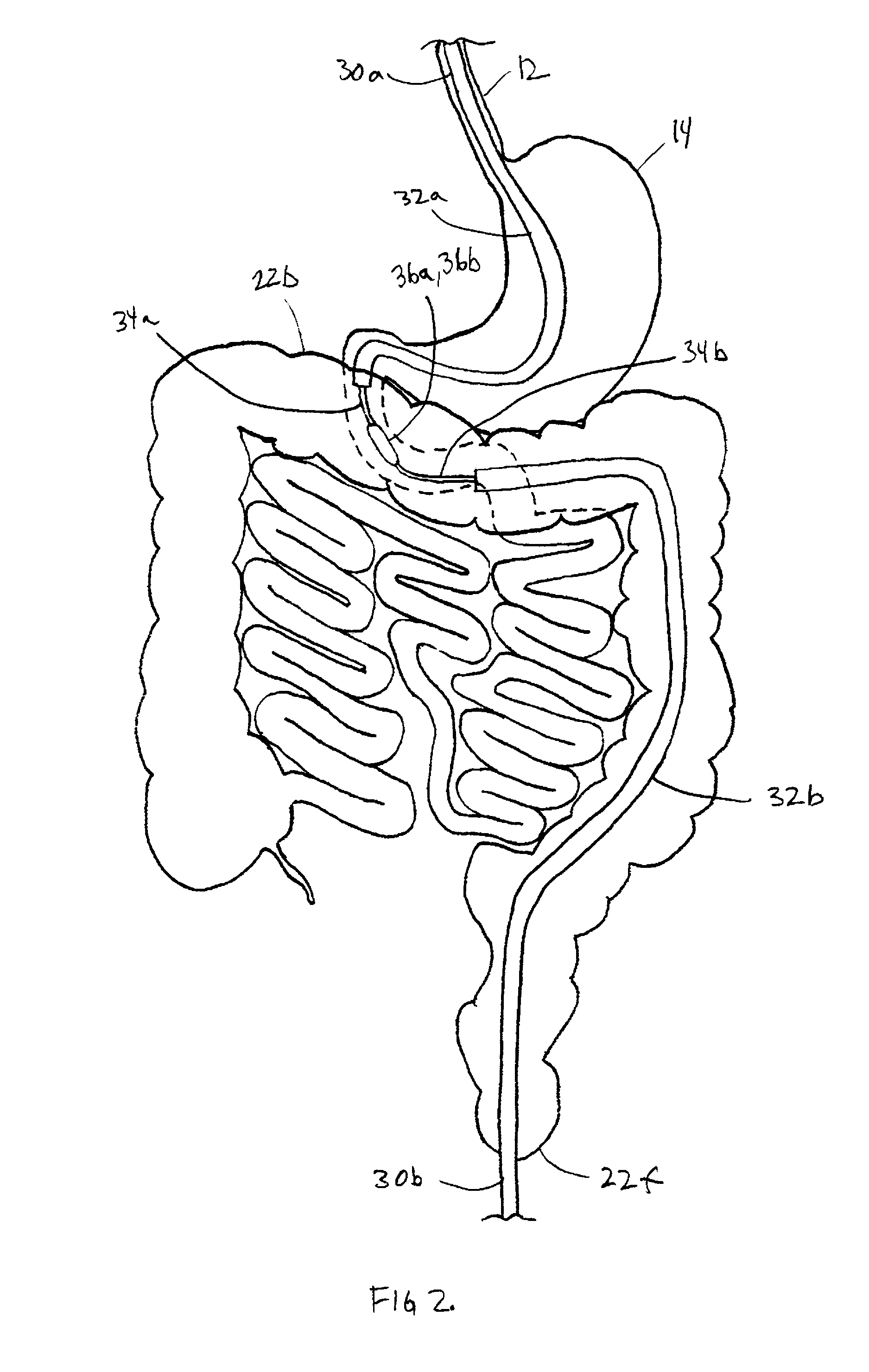

Incisionless Gastric Bypass Method And Devices

InactiveUS20110144560A1Eliminate needTriggering early satietyIntravenous devicesSurgical forcepsAnastomotic urethroplastyGastric bypass

A system and method for endoscopically forming an anastomosis between two naturally adjacent points in the digestive tract. The system and method utilizes elongate magnetic devices that, when connected across a tissue boundary, necrose tissue until an anastomosis forms and the devices are passed naturally. Despite the elongate shape of the devices, the resulting anastomosis is substantially round. As such, round anastomoses can be formed having increased diameters merely by increasing the lengths of the devices, obviating the need for wider endoscopes.

Owner:GAGNER MICHEL M D

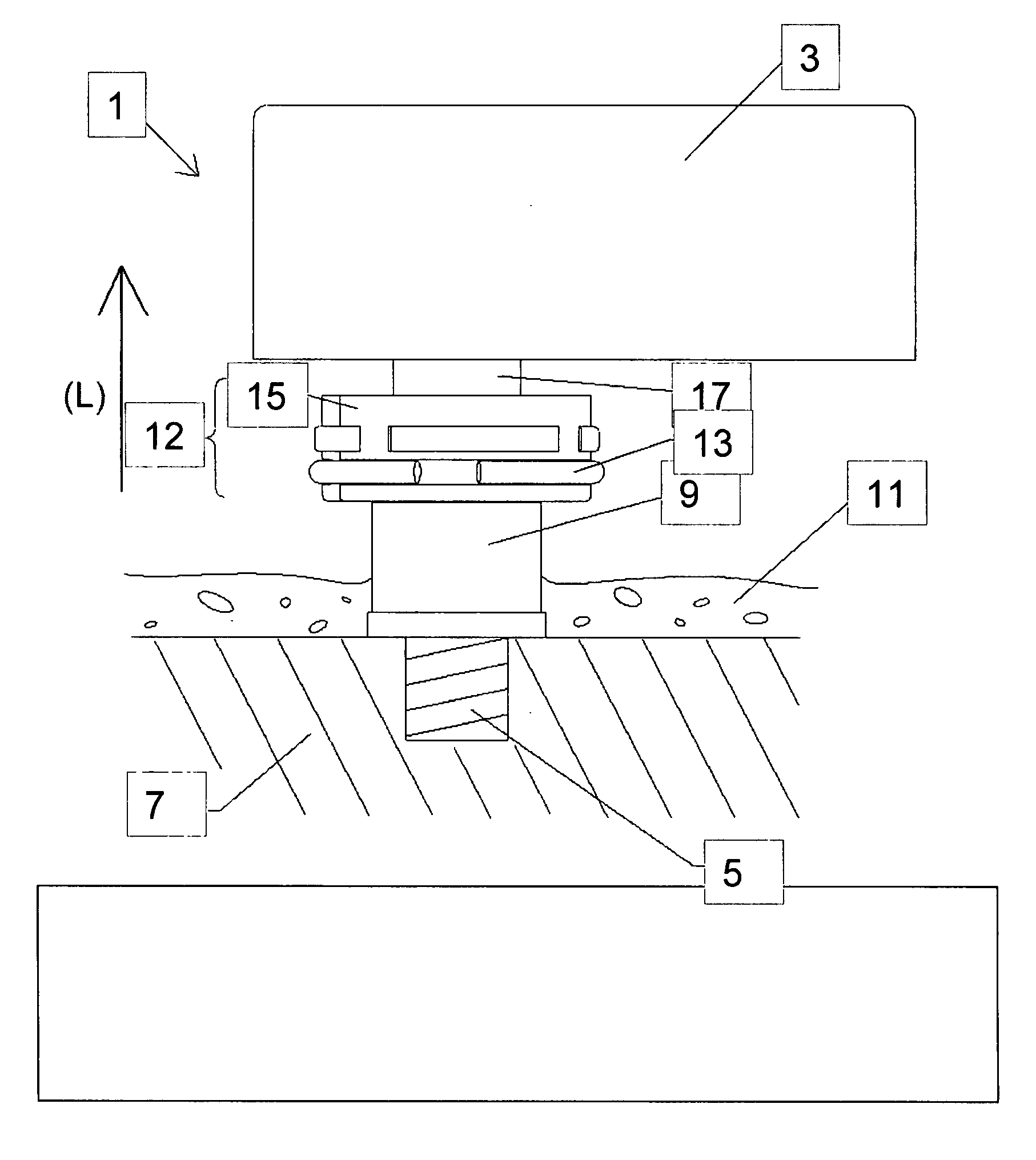

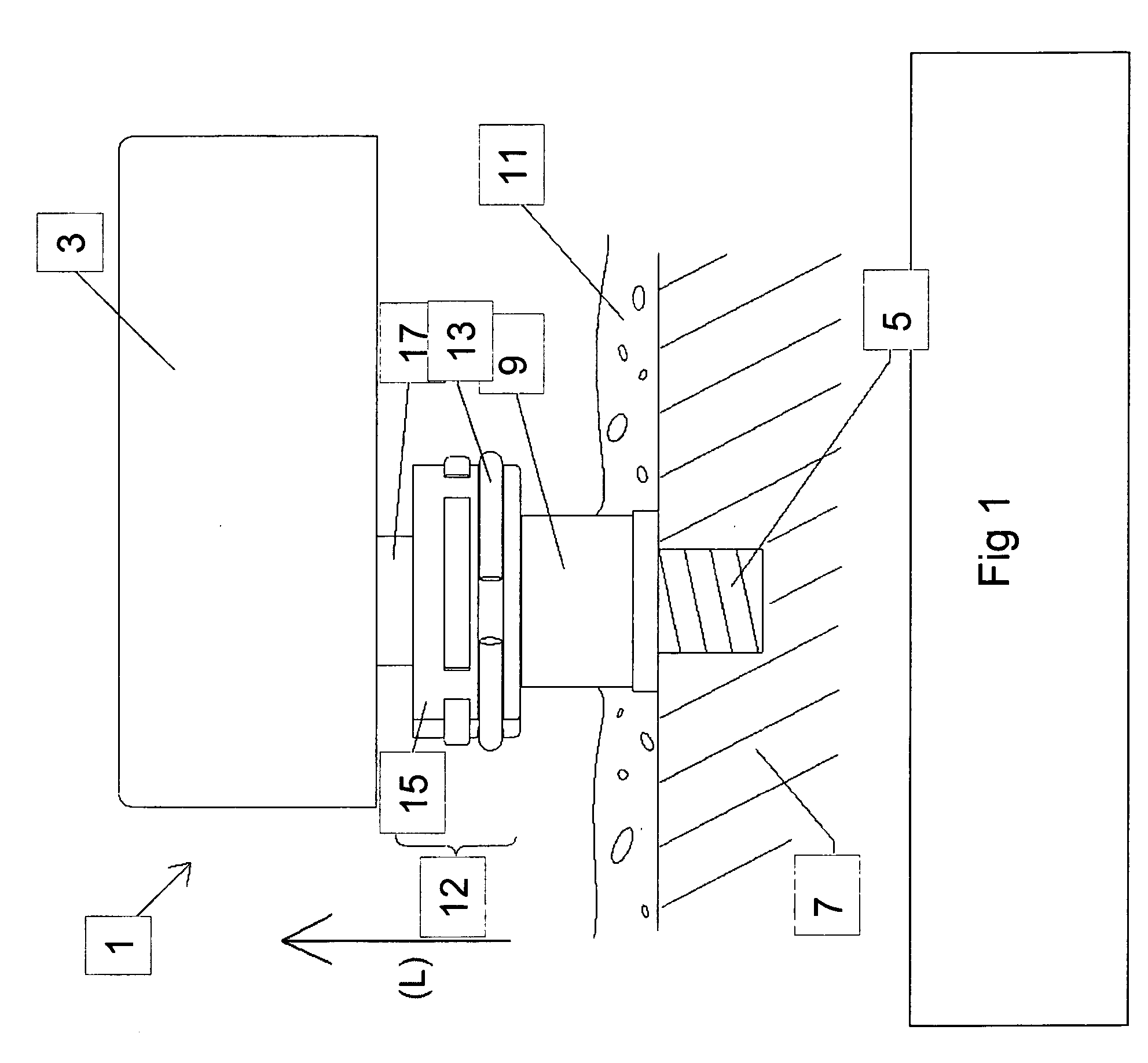

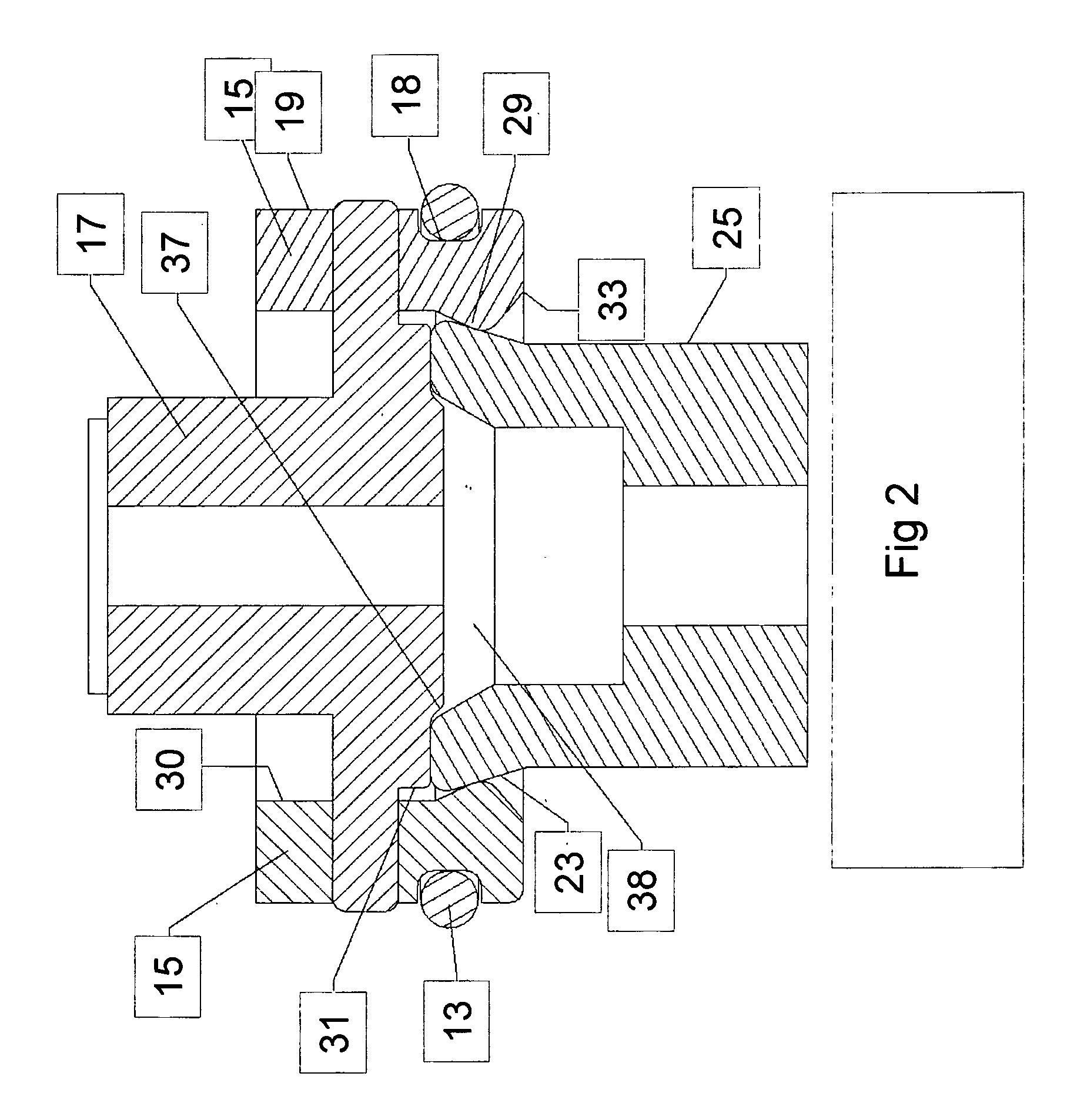

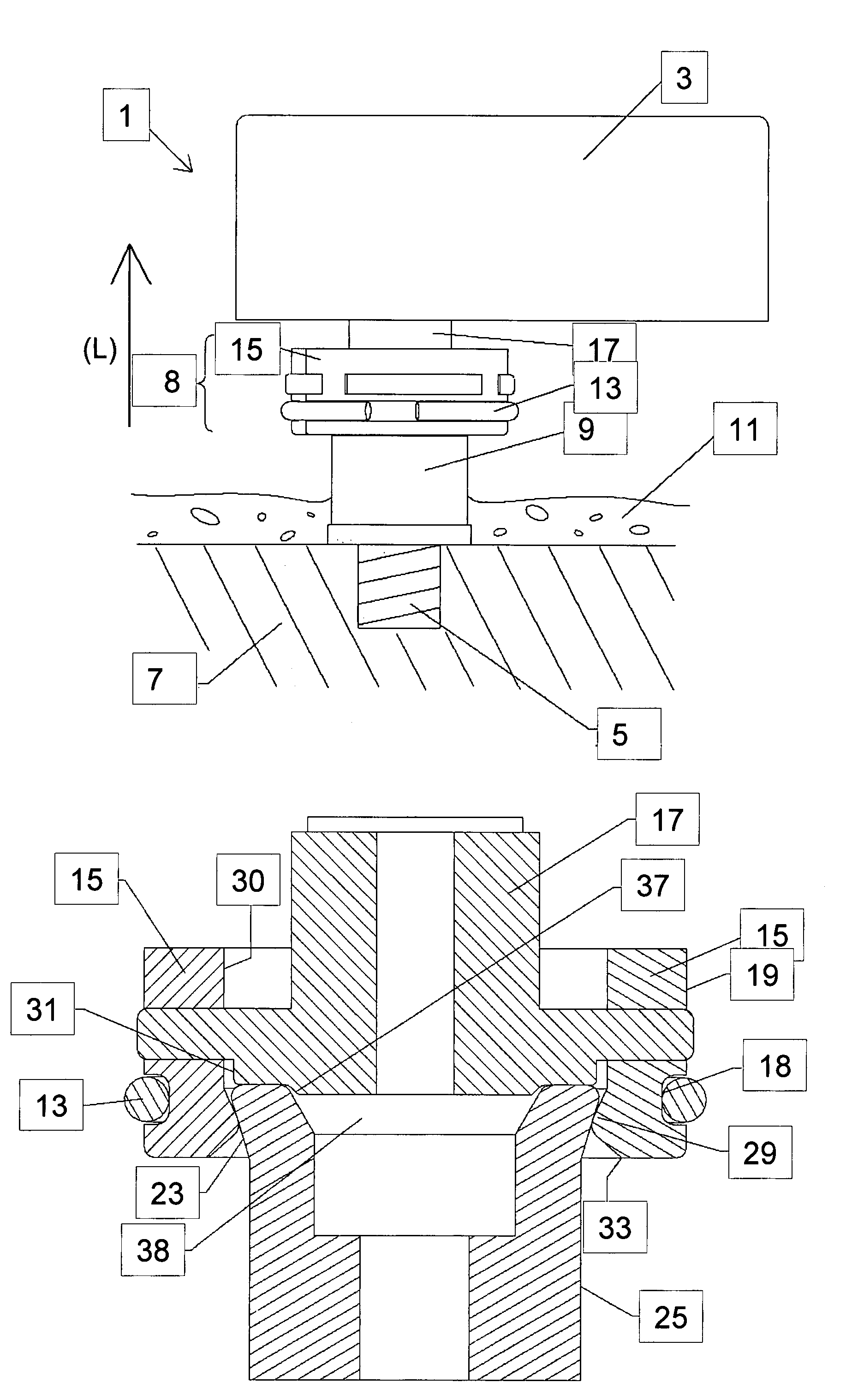

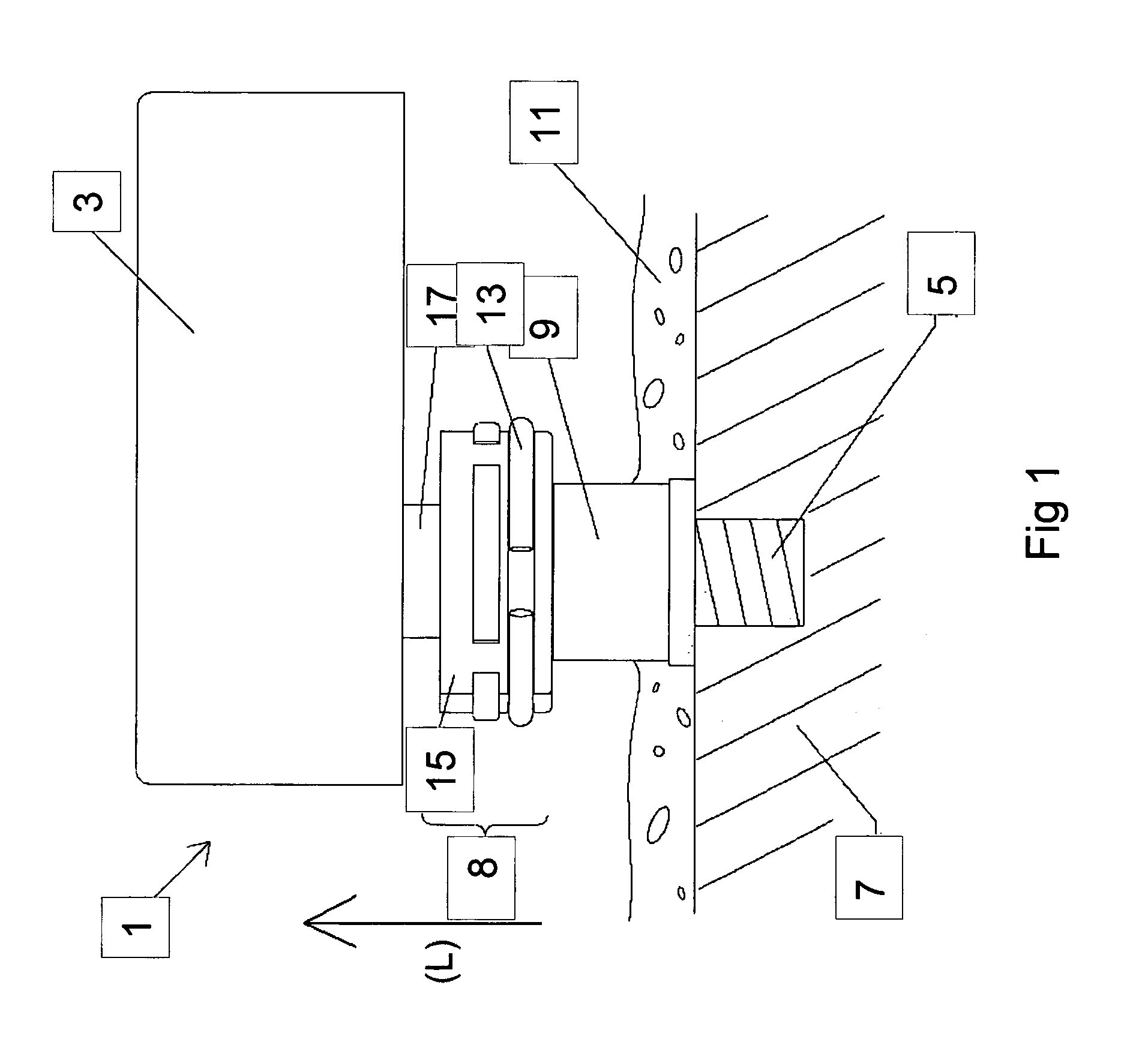

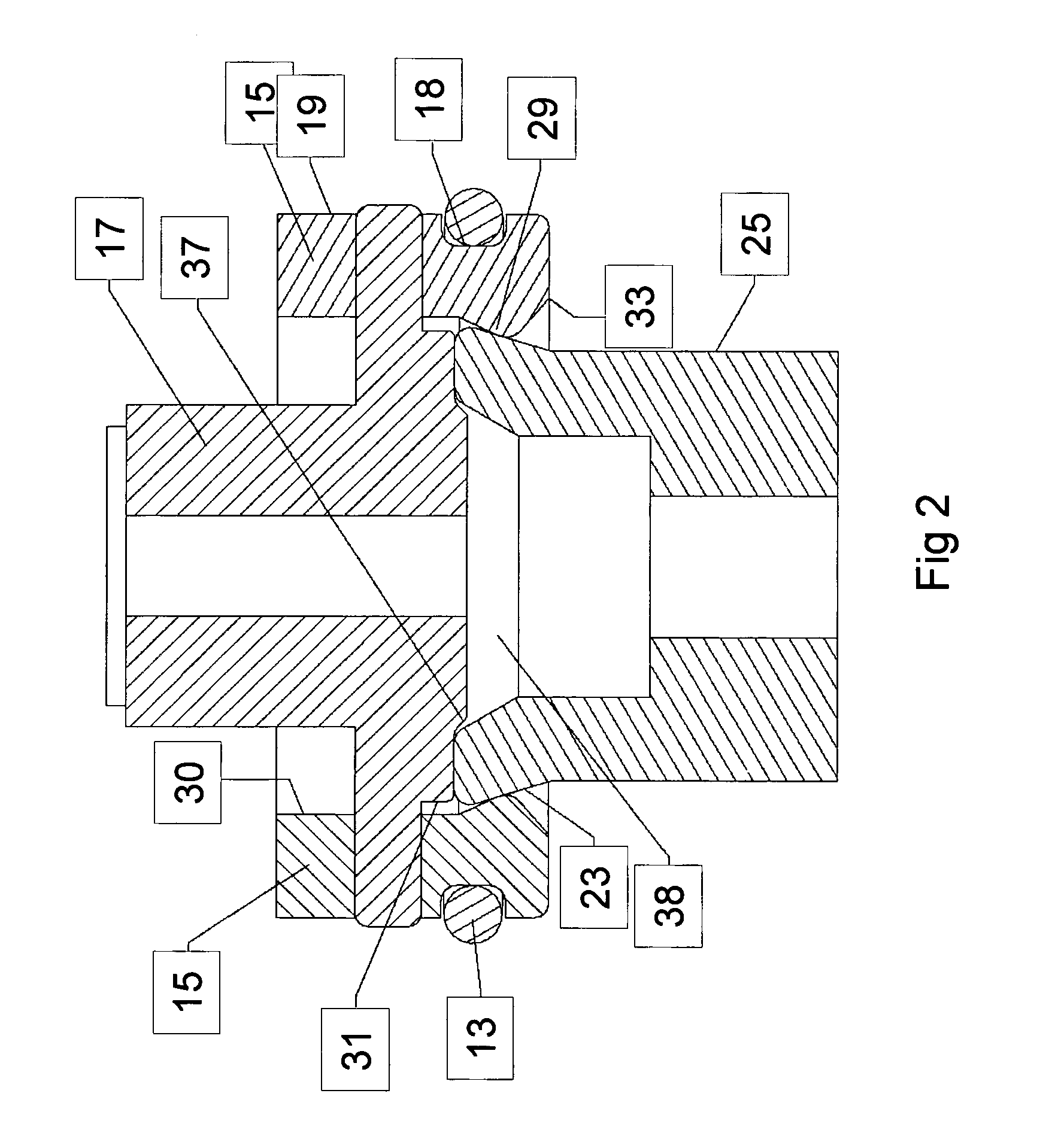

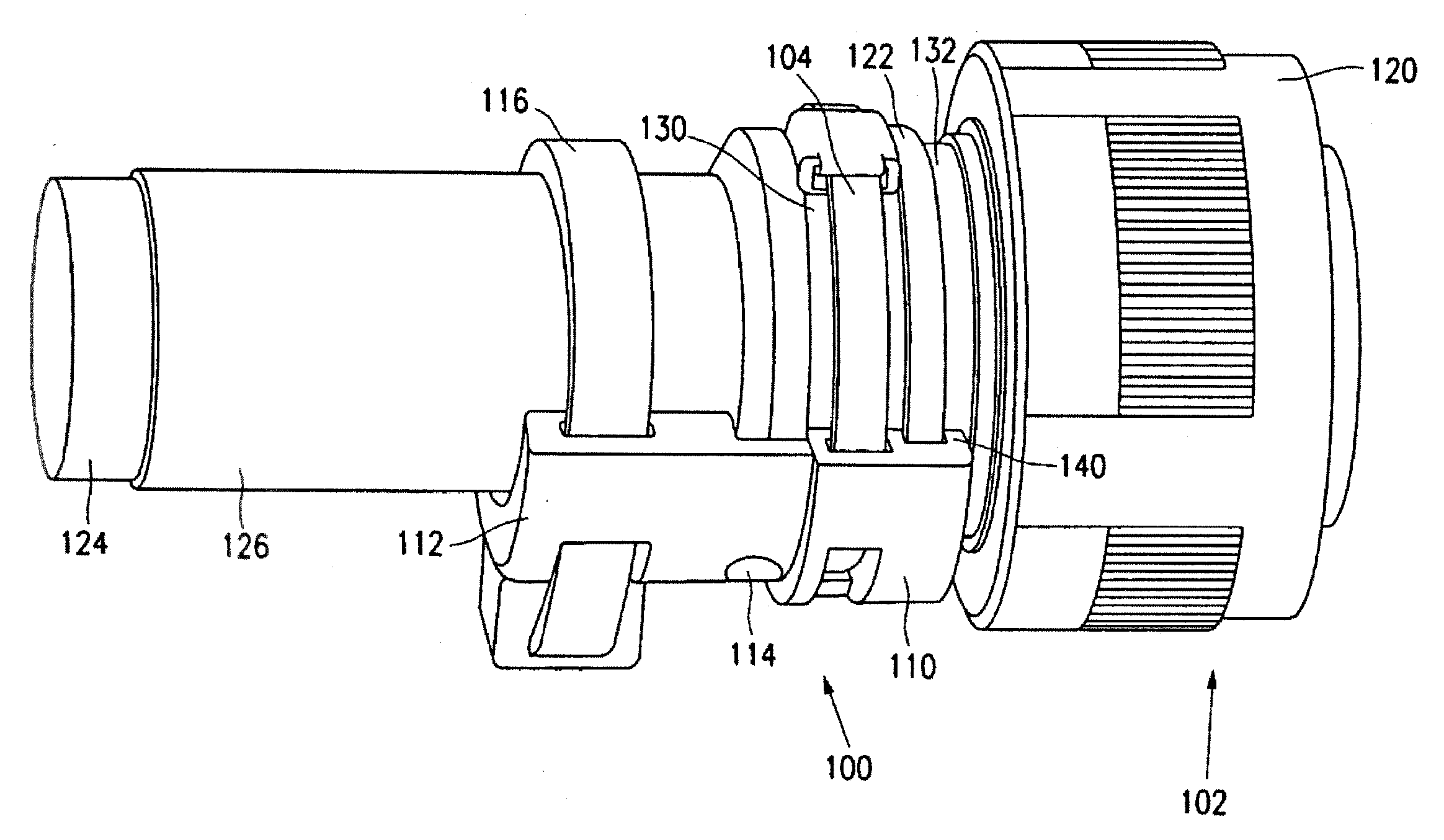

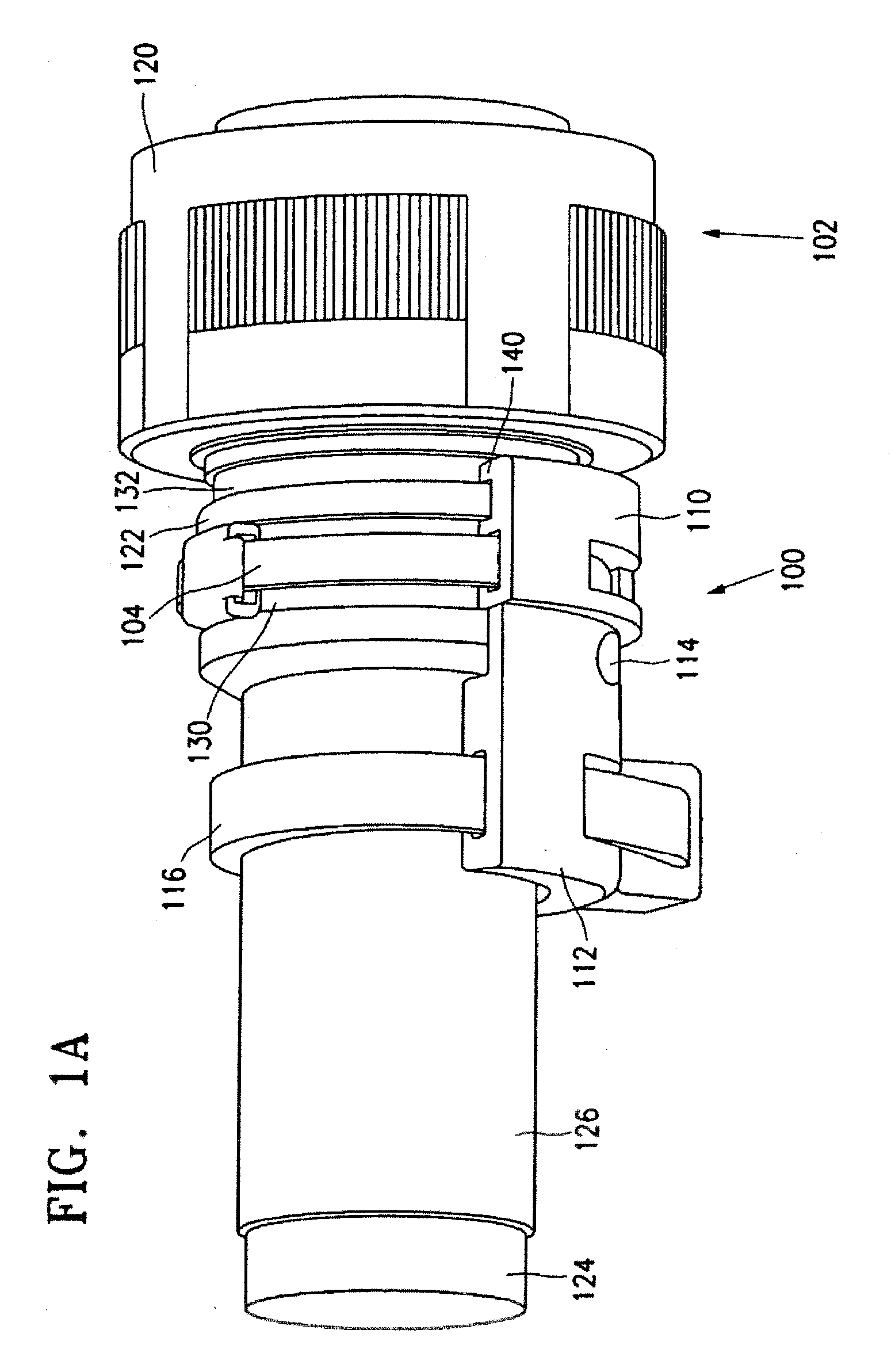

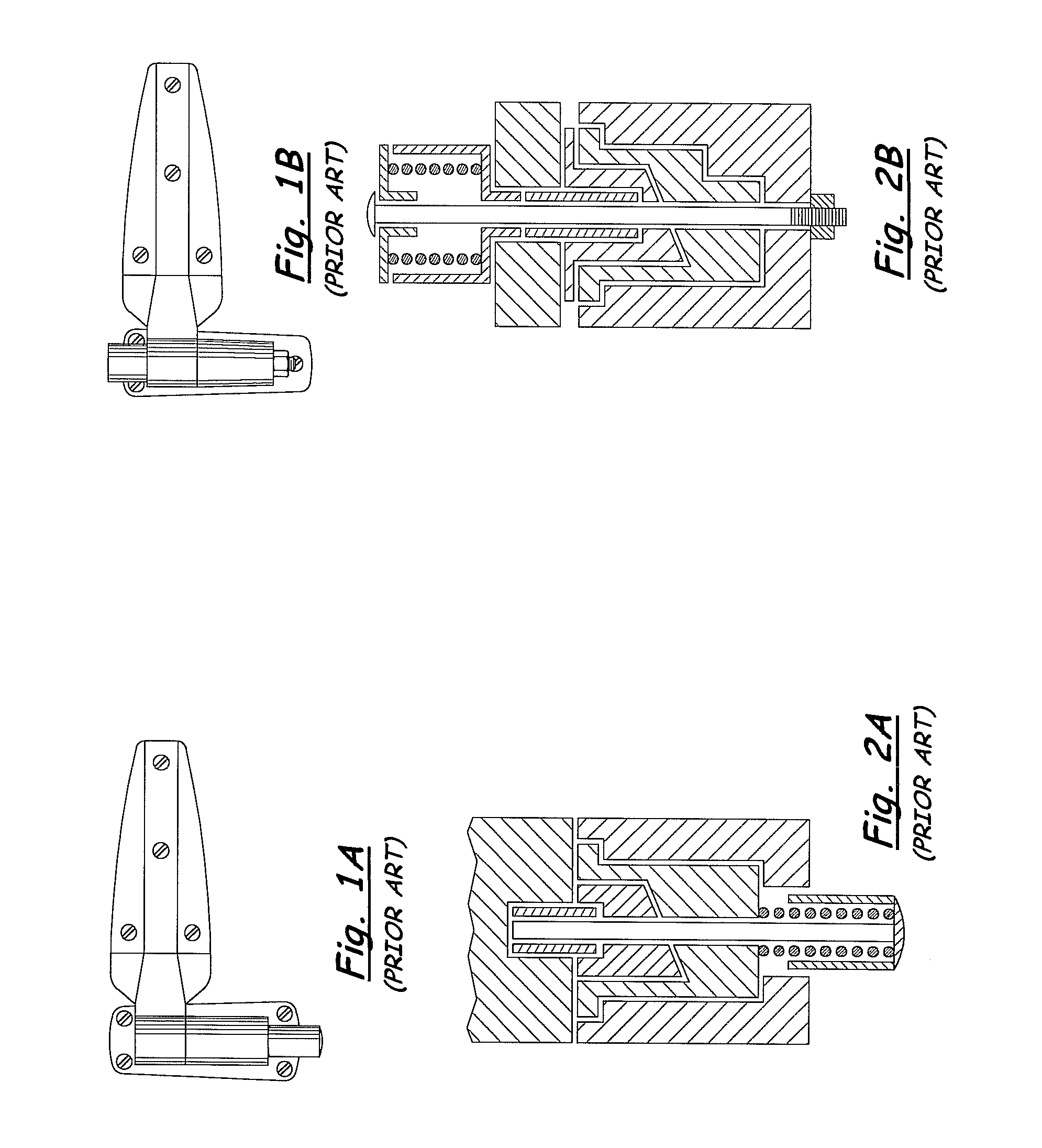

Connector system

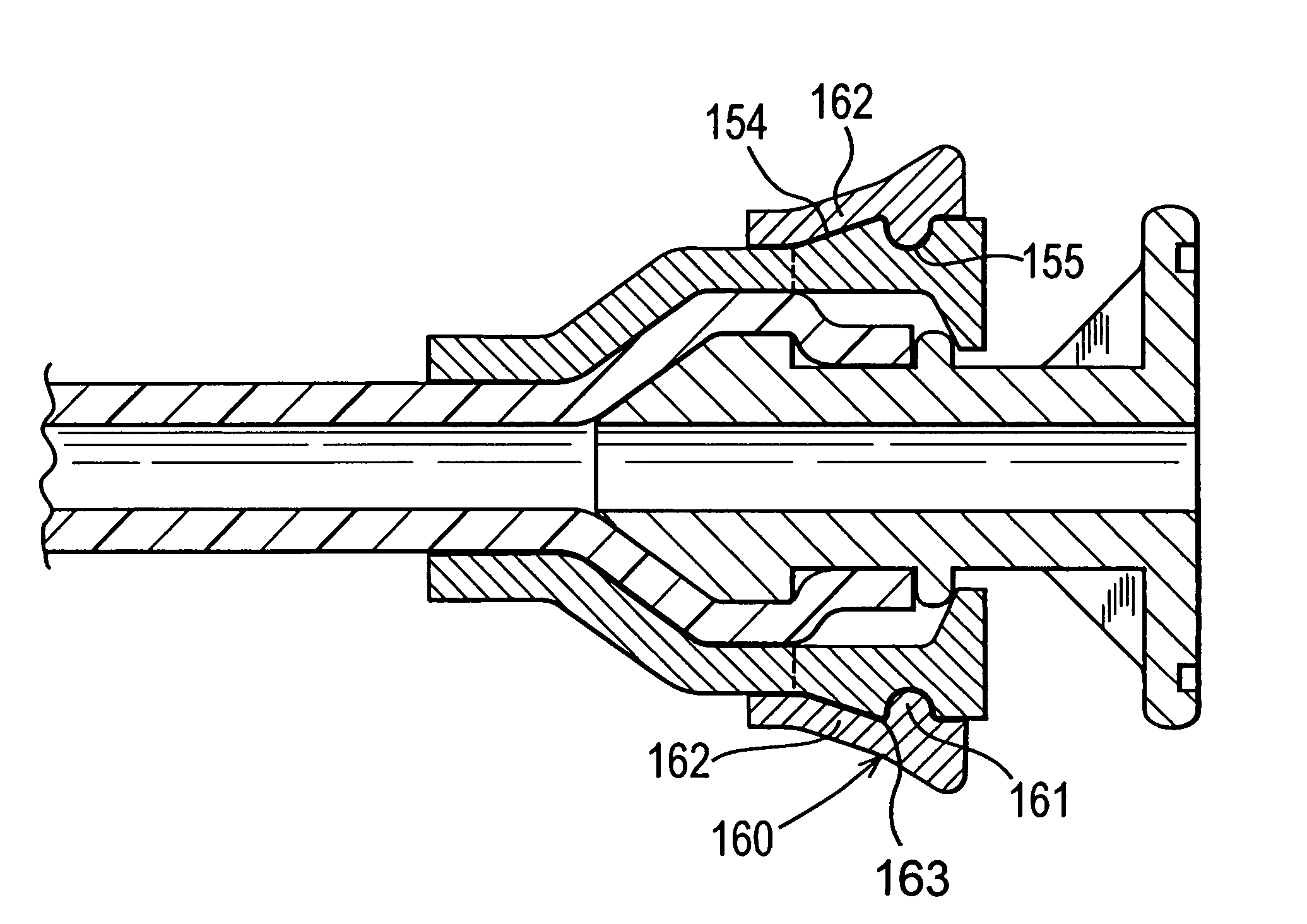

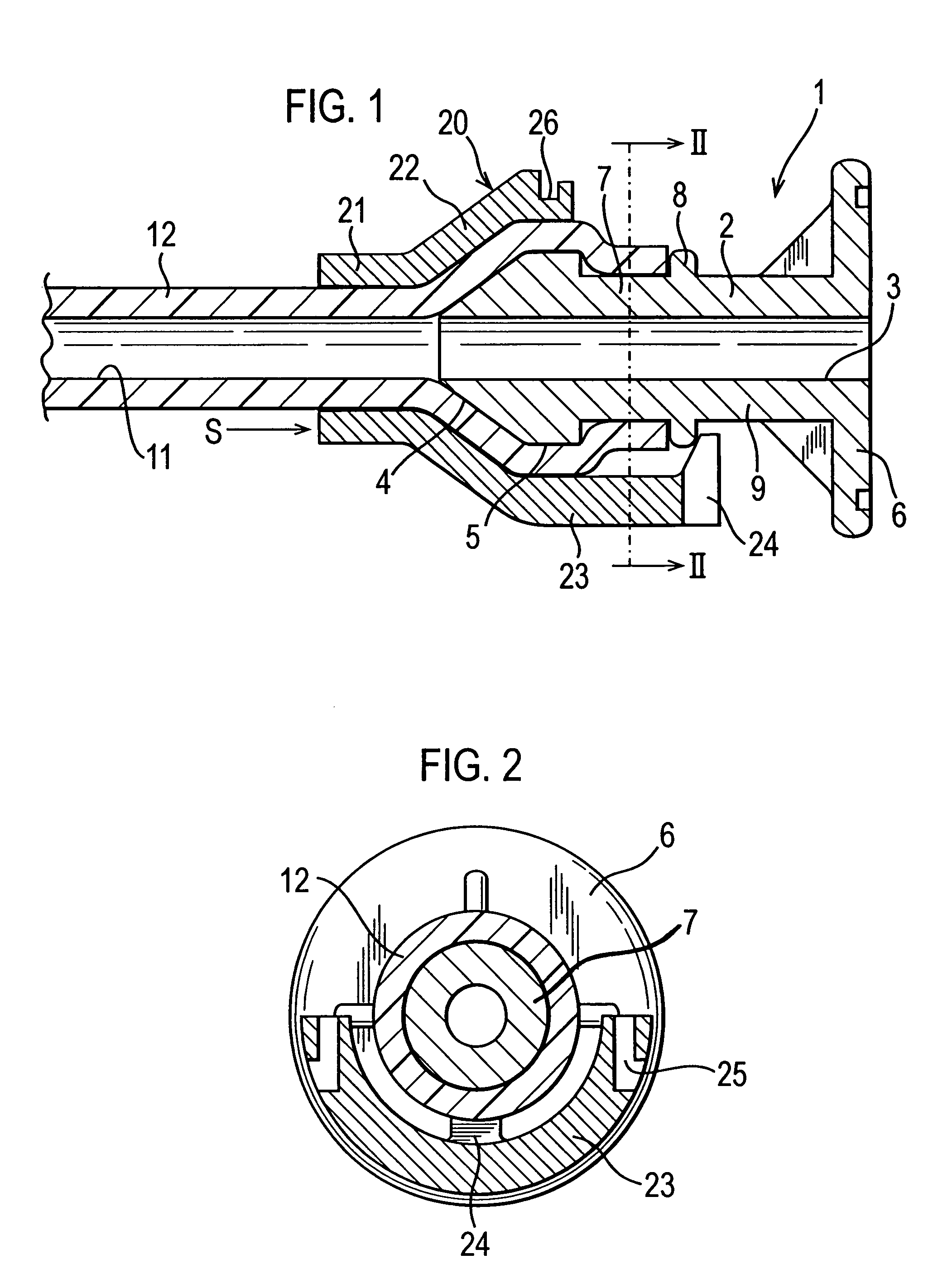

ActiveUS20050248158A1Easy to removeEasy to replaceFlanged jointsBone conduction transducer hearing devicesCouplingEngineering

A connector system for interconnecting a hearing aid (3) with a fixture (5) anchored in a bone segment (7). An abutment (9) has a contact surface (21) with is a substantially circular surface. A connector plate (17) with a substantially circular connector contact surface (20) is in contact with the abutment contact surface (21) when the hearing aid (3) is connected to the abutment (9). The abutment (9) has a wide abutment coupling area and a narrow portion. The abutment coupling area is enclosable by coupling shoes (15). The coupling shoes (15) exert a pressure against the abutment coupling area disposed on a mantle surface (25) of the abutment. The coupling shoes are movable in a radial direction relative to the connector plate (17). The coupling area has an increasing diameter in a lateral direction (L). A coupling area (29) of the coupling shoes has an increasing diameter in the lateral direction (L) to exert a pressure on the abutment (9) against a connector contact surface when the coupling shoes (15) are pressed in the radial direction against the abutment (9).

Owner:OTICON MEDICAL

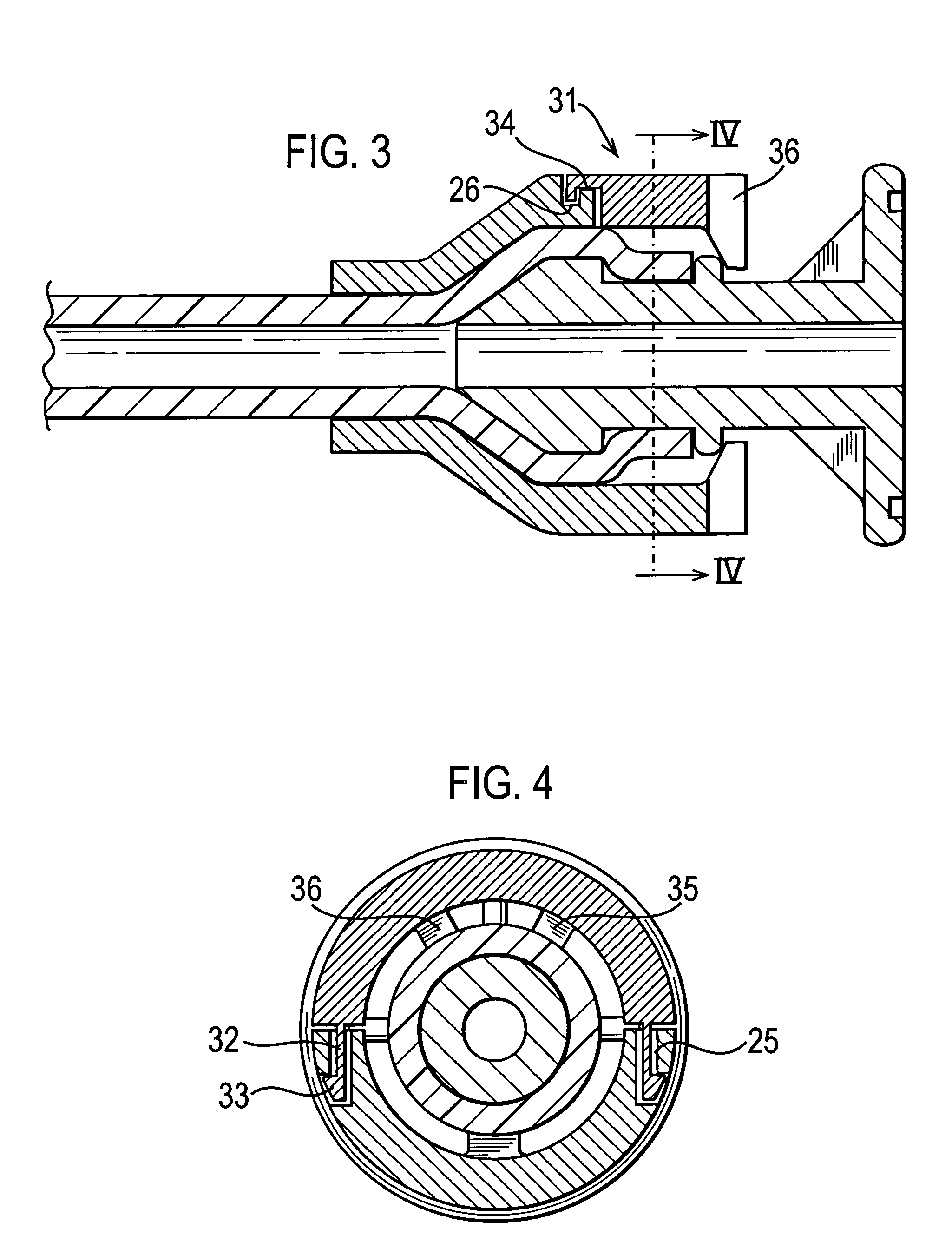

Connector system

ActiveUS7021676B2Easy to removeEasy to replaceFlanged jointsBone conduction transducer hearing devicesCouplingHearing aid

A connector system for interconnecting a hearing aid (3) with a fixture (5) anchored in a bone segment (7). An abutment (9) has a contact surface (21) with is a substantially circular surface. A connector plate (17) with a substantially circular connector contact surface (20) is in contact with the abutment contact surface (21) when the hearing aid (3) is connected to the abutment (9). The abutment (9) has a wide abutment coupling area and a narrow portion. The abutment coupling area is enclosable by coupling shoes (15). The coupling shoes (15) exert a pressure against the abutment coupling area disposed on a mantle surface (25) of the abutment. The coupling shoes are movable in a radial direction relative to the connector plate (17). The coupling area has an increasing diameter in a lateral direction (L). A coupling area (29) of the coupling shoes has an increasing diameter in the lateral direction (L) to exert a pressure on the abutment (9) against a connector contact surface when the coupling shoes (15) are pressed in the radial direction against the abutment (9).

Owner:OTICON MEDICAL

Tracheostoma spacer, tracheotomy method, and device for inserting a tracheostoma spacer

The invention relates to a tracheostoma spacer with a tubular support framework. The support framework can be expand from an initial state to a supporting state of increased diameter and has a fixing element at the ends. The tracheostoma spacer is intended for use as a spacer in a tracheostoma (an opening in the trachea). The invention further relates to a device for inserting a tracheostoma spacer into a tracheostoma with a cutting instrument in the form of a trocar, the tracheostoma spacer being able to be positioned on the shaft of said trocar. A cover sleeve is also provided which can be moved on the shaft over a tracheostoma spacer positioned there.

Owner:BREATHE TECHNOLOGIES INC

Expandable Bone Support

A bone fixation device comprises a rod extending from a proximal end located external to the body in an operative configuration to a distal end comprising an increased diameter tip sized and shaped to be received in a subchondral layer in the operative configuration and a first bushing slidably received over the rod, a distal portion of the first bushing comprising a plurality of arms separable from one another to spread radially outward from the rod as the first bushing is moved distally over the tip of the rod in combination with a cannulated element slidably received over the rod, the cannulated element sized and shaped to engage a proximal end of the first bushing, a portion thereof located external to the bone in the operative configuration so that a distally directed force applied thereto moves the first bushing distally over the rod spreading the arms radially outward.

Owner:DEPUY SYNTHES PROD INC

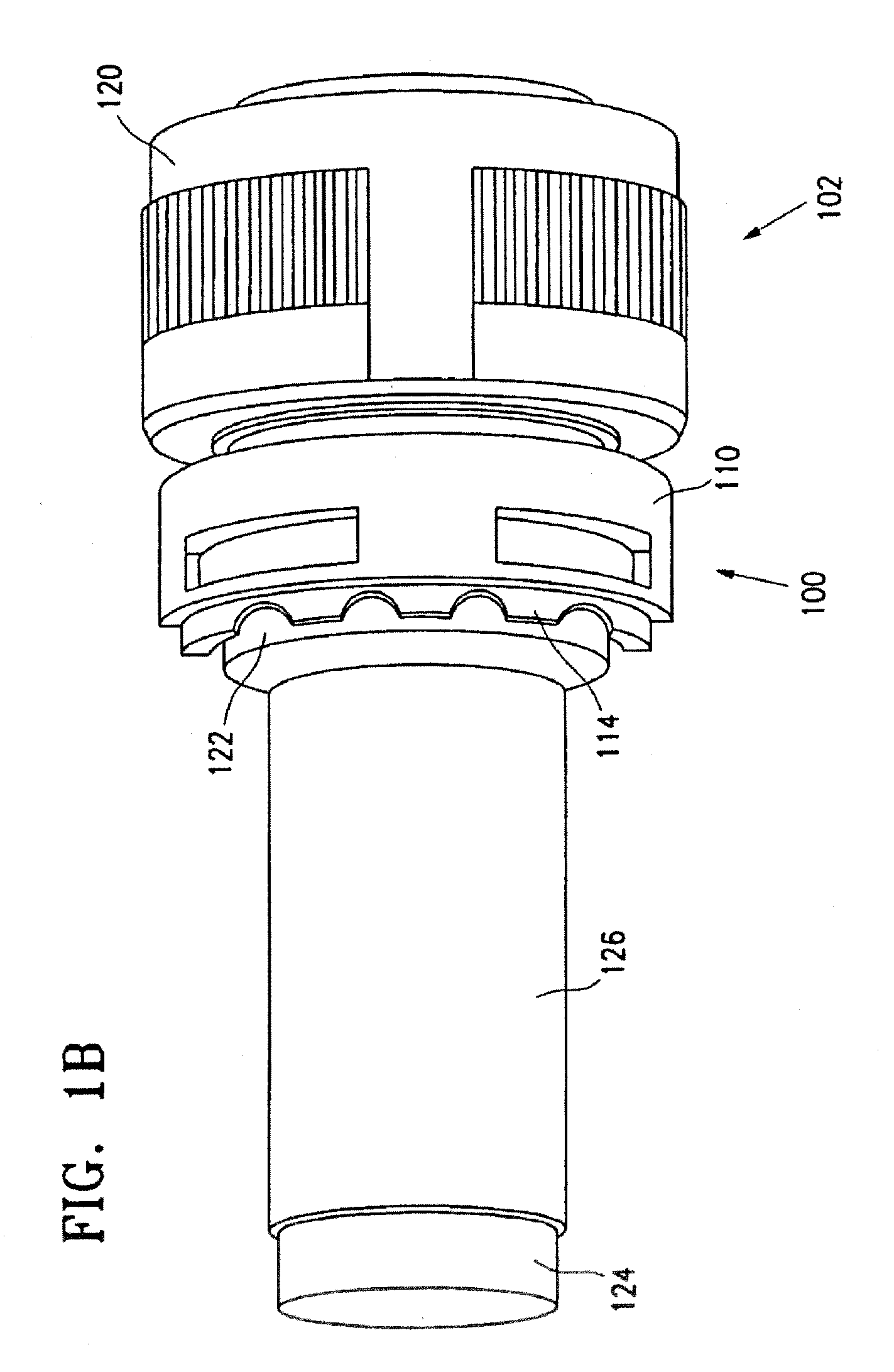

Backshell device for a connector

ActiveUS20080009173A1Strain relief to the wiring harnessProvide strain reliefRelieving strain on wire connectionCoupling contact membersEngineeringMechanical engineering

A backshell device and assembly are provided for achieved improved signal integrity, wherein the design of the backshell device is less complicated, more light weight, and easier to build and use than existing devices. In one embodiment, the backshell device can be coupled to adaptor which is coupled to a connector. The backshell device generally comprises a mounting section coupled to the adaptor, and an extension section extending from the mounting section. The extension section preferably comprises an increased-diameter section configured to accommodate a non-staggered or aligned arrangement of a plurality of solder sleeves of the wiring harness.

Owner:DEUT ENGINEERED CONNECTING DEVICES

Electrical connector including insulating boots and associated methods

ActiveUS7094094B2Well formedSecuring/insulating coupling contact membersCouplings bases/casesEngineeringElectrical connector

An electrical connector includes an electrically conductive body having spaced apart cable-receiving passageways for receiving respective electrical cable ends. The electrically conductive body may also have at least one respective fastener-receiving passageway intersecting each of the cable-receiving passageways. An insulating cover may be on the electrically conductive body and include an integrally molded respective tubular cable inlet aligned with each cable inlet opening. A respective insulating boot may be received in each of the tubular cable inlets. Each insulating boot may include a tubular sidewall having a progressively increasing diameter to an open outer end thereof, a removable boot closure cap for removable positioning in the open outer end of the tubular sidewall, and an integrally molded tether connecting the removable boot closure cap to the tubular sidewall.

Owner:THOMAS & BETTS INT INC

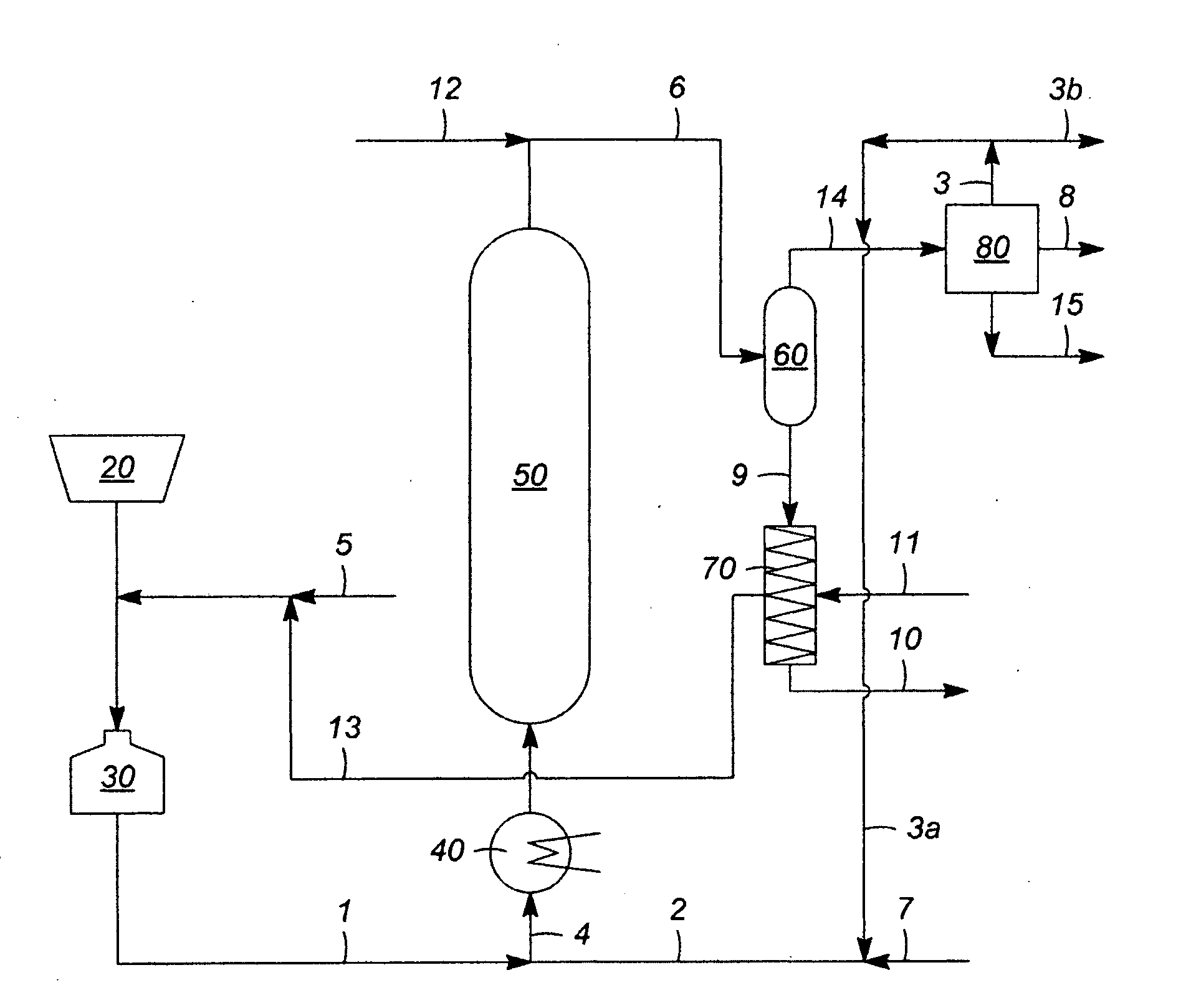

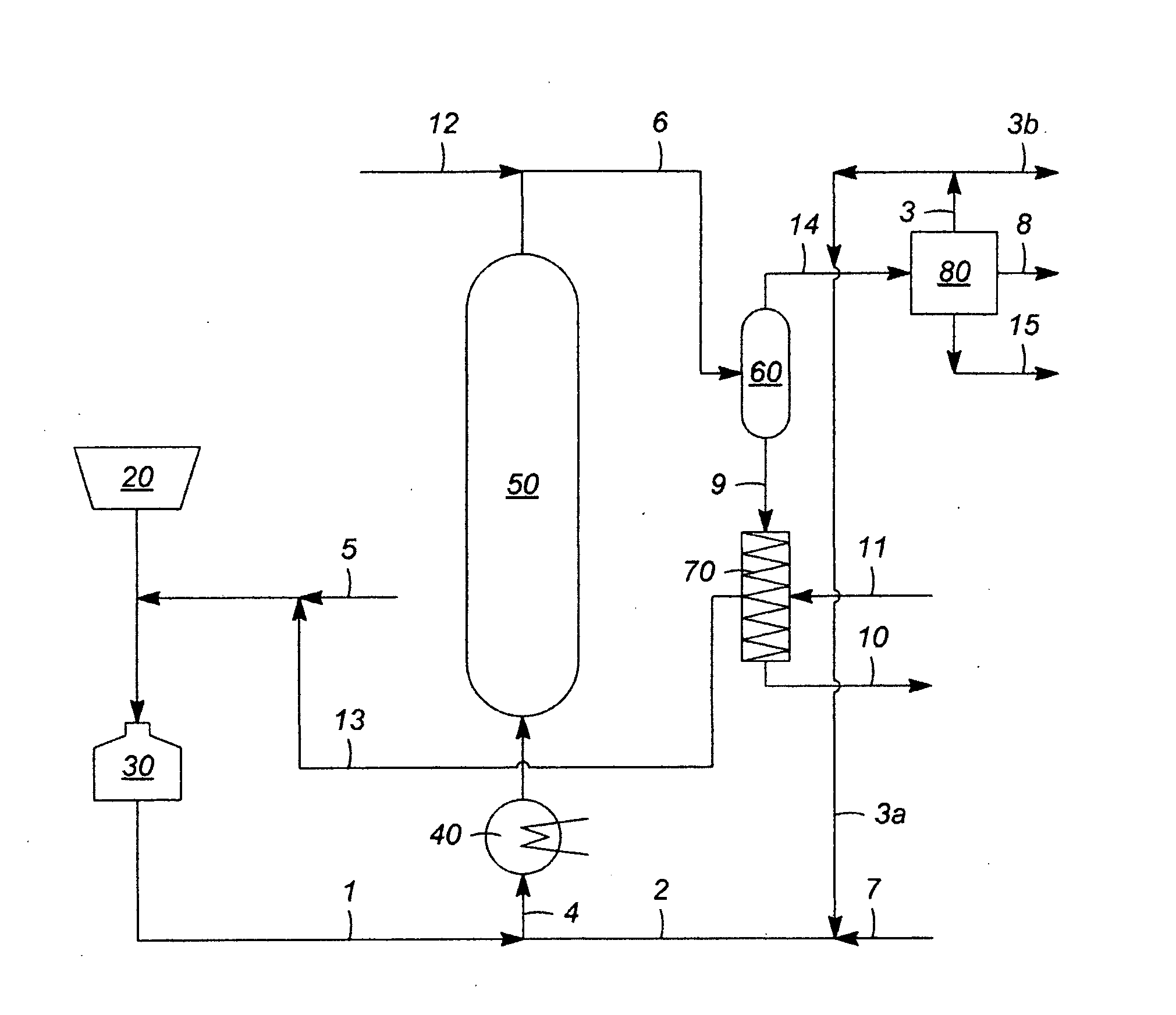

Solids Management in Slurry Hydroprocessing

InactiveUS20100122939A1EfficiencyPromote precipitationLiquid hydrocarbon mixture productionHydrocarbon oil crackingLiquid productParticulates

The recovery of solids, and particularly solid particulates used as catalysts in slurry hydroprocessing, from asphaltene containing hydrocarbons is improved by controlling asphaltene precipitation. The formation of agglomerates of the solid particulates, having an increased diameter, results in the presence of precipitated asphaltenes, possibly due to flocculation. Asphaltene precipitation is controlled by varying process parameters or introducing additional diluent or flush streams that change the polarity of an asphaltene containing liquid product recovered from an effluent of a slurry hydroprocessing reaction zone.

Owner:UOP LLC

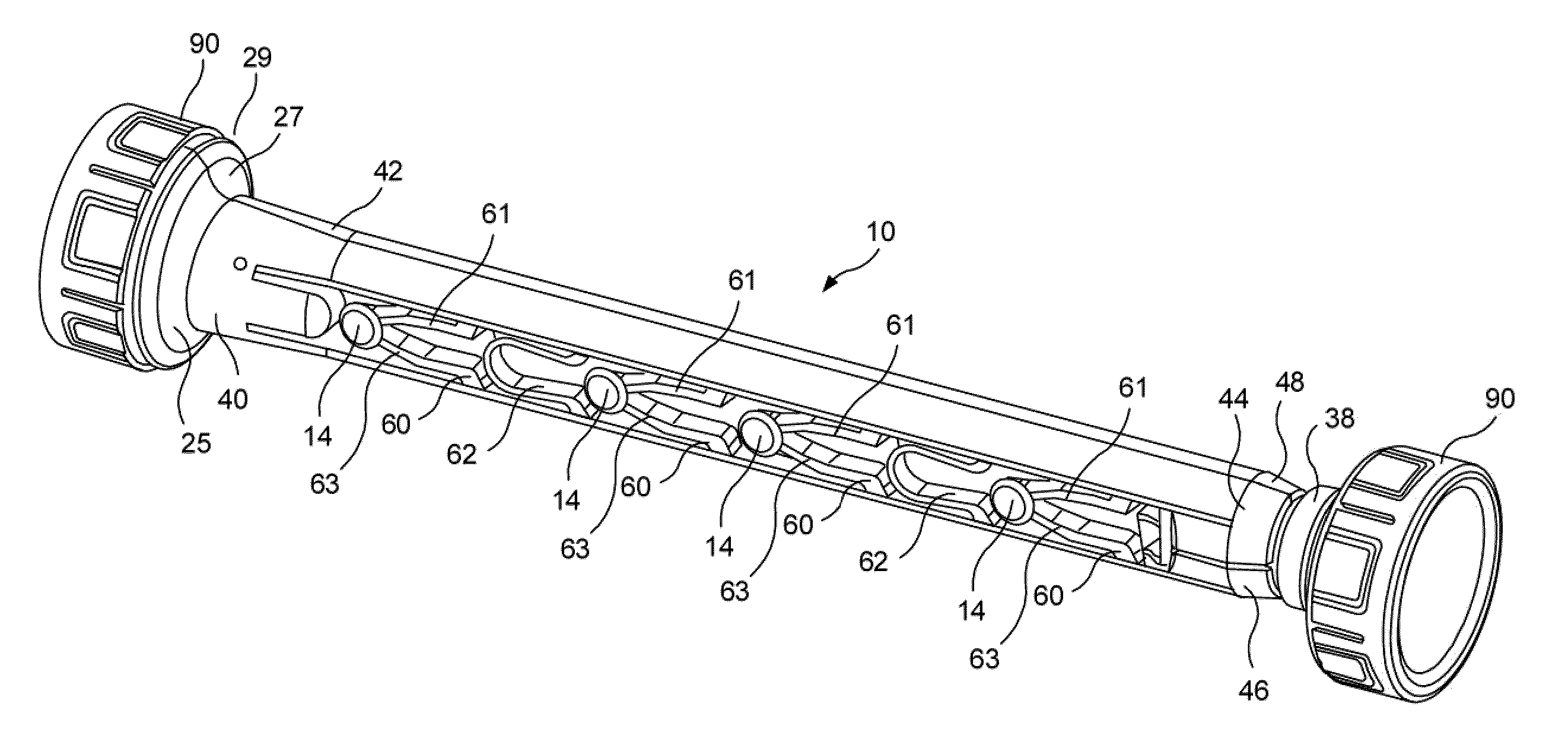

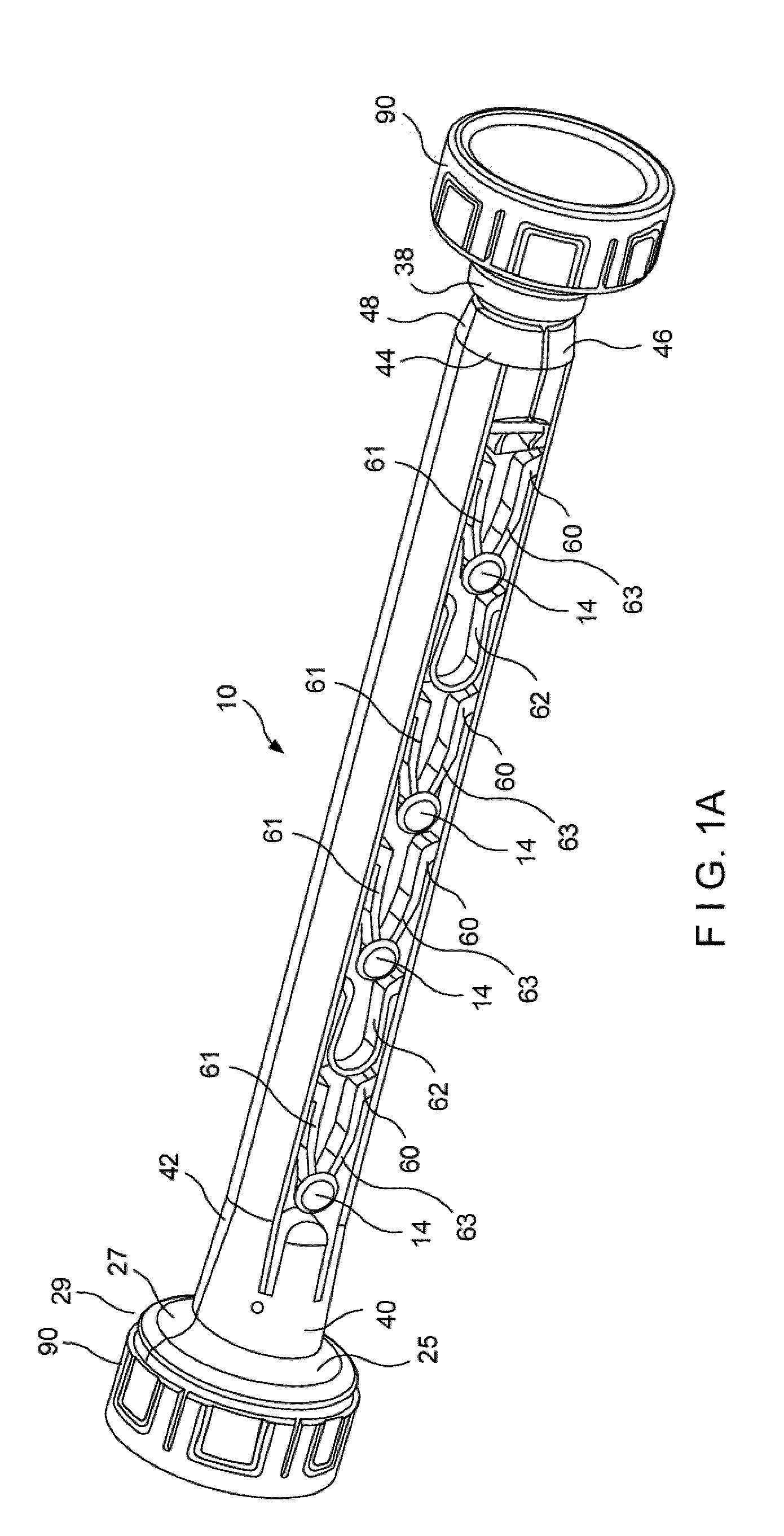

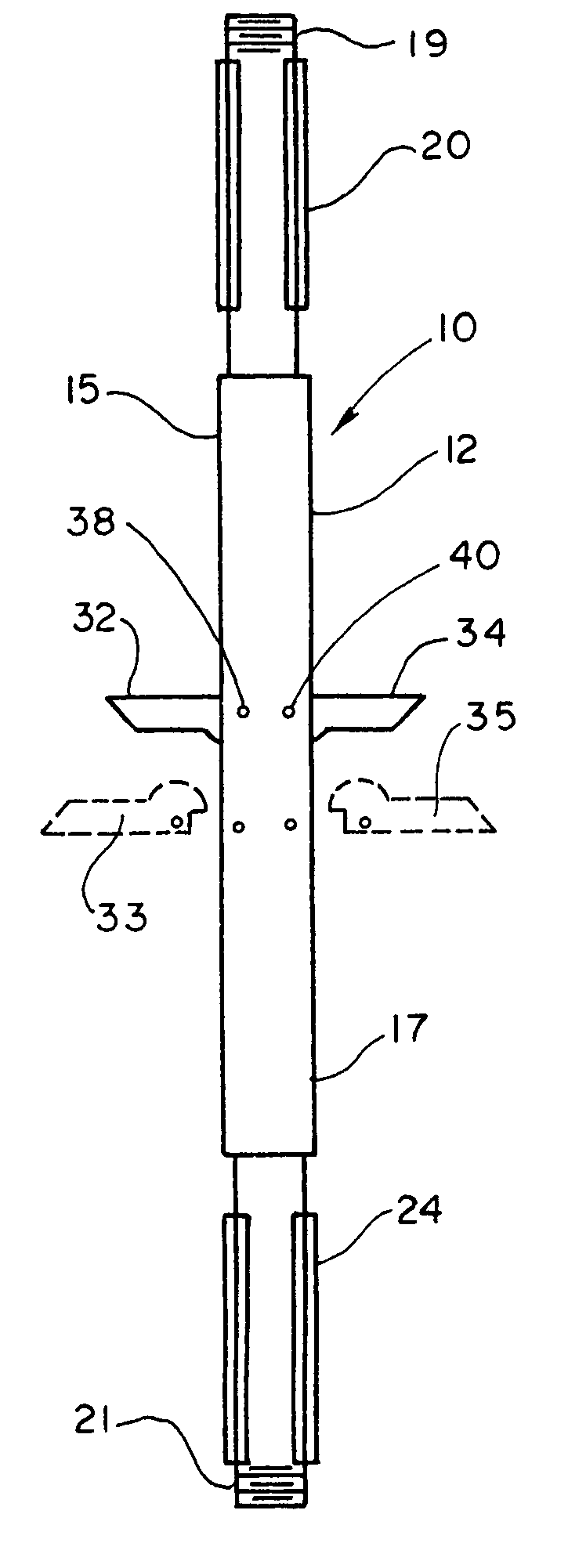

Push-to-expand mandrel for stretch-wrap hand tool

The present disclosure relates to a dispenser for use with rolls of film material, particularly coreless rolls. The mandrels of the dispenser can move between a retracted position wherein the dispenser has a reduced diameter, such as for when the dispenser is being inserted into a roll of film, and an increased diameter, such as for when the film is being dispensed from the dispenser. The mandrels have sections which are joined by various spring configurations and are formed as being axially slidable with respect to a central shaft with lug elements. As the mandrel is slid along the central shaft, the lug elements deflect the spring configurations outwardly so as move the mandrels radially outwardly and increase the radius of the dispenser.

Owner:ILLINOIS TOOL WORKS INC

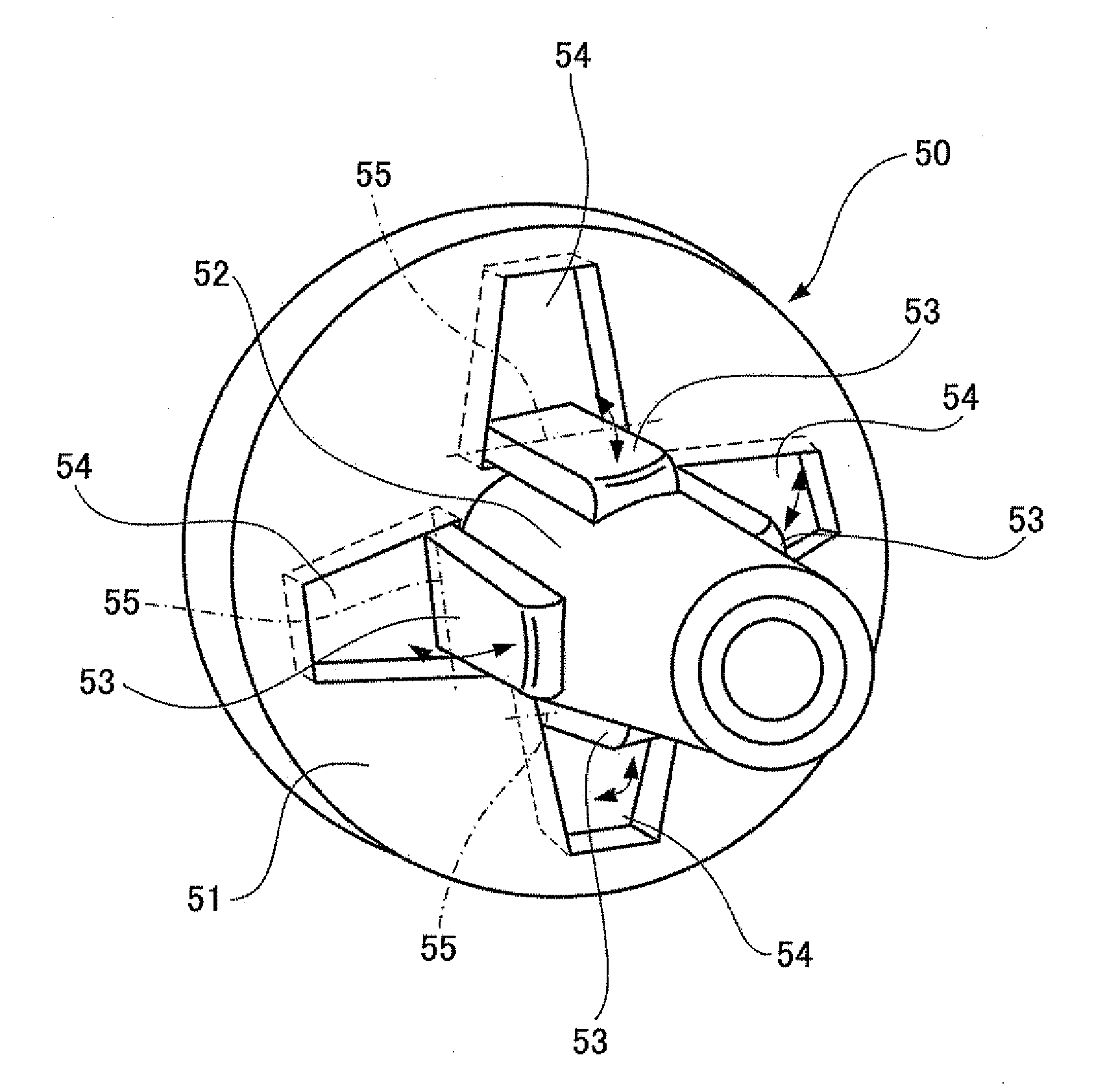

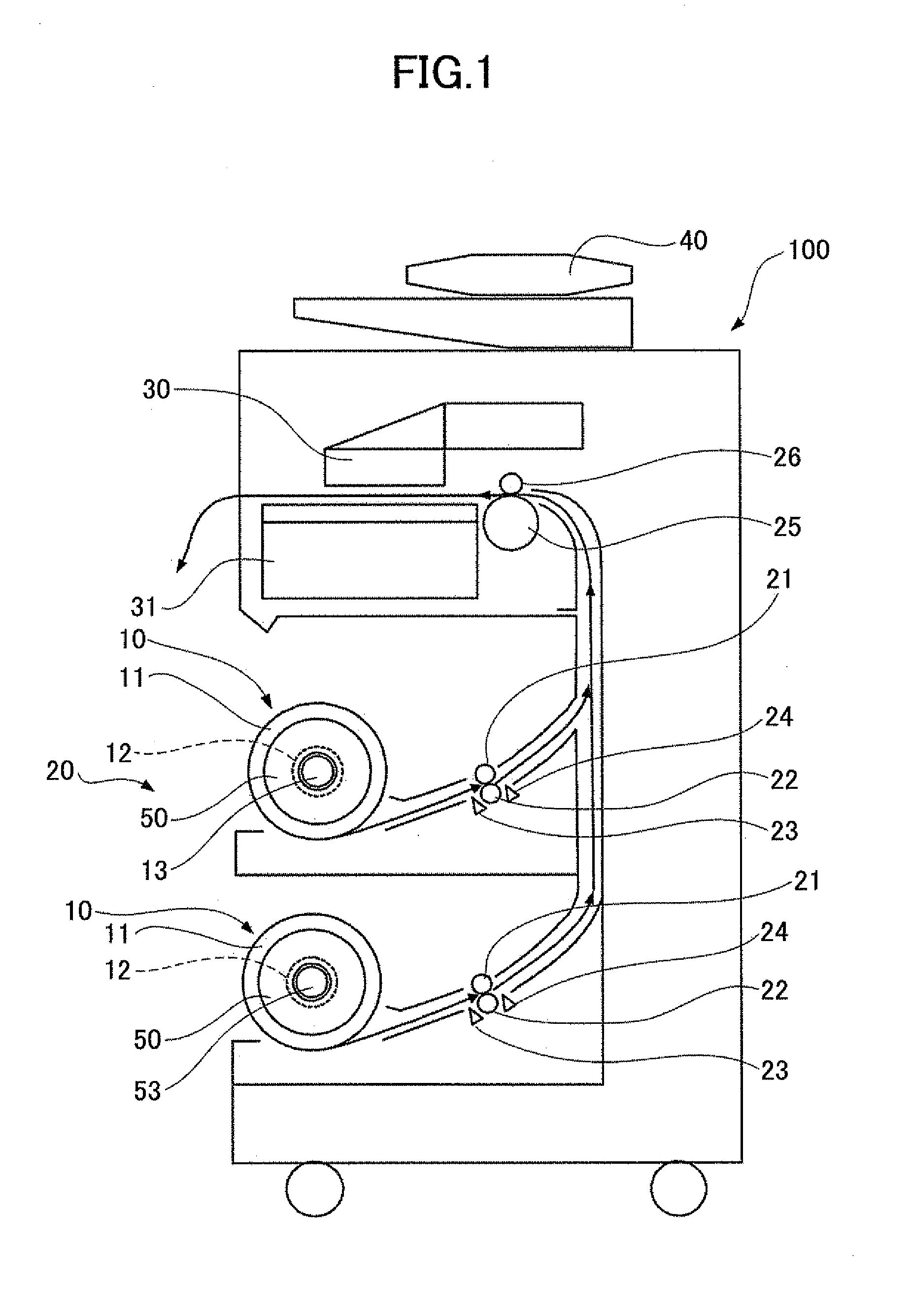

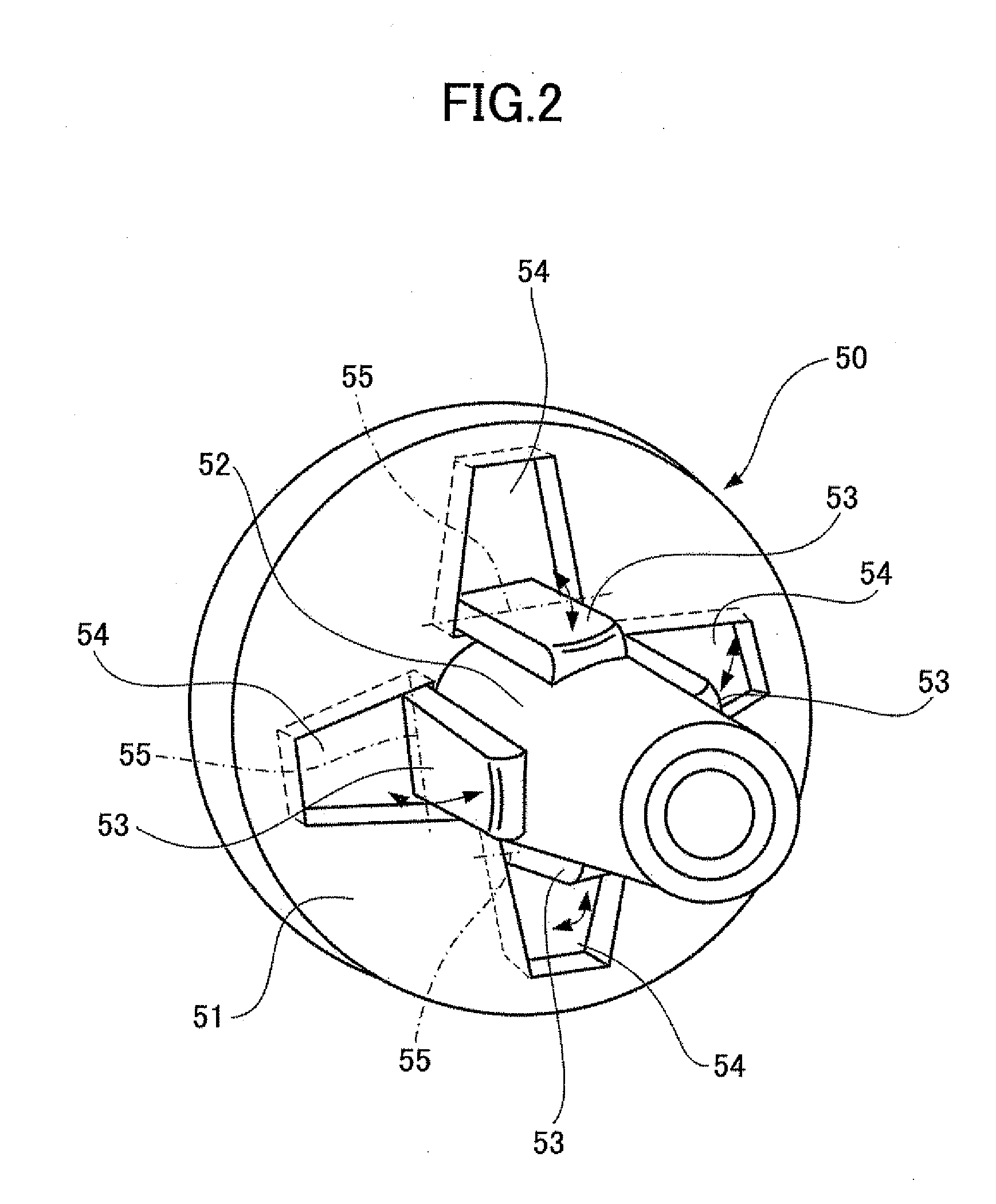

Roll medium holding unit, roll sheet feeder, and image forming apparatus

A roll medium holding unit is disclosed that includes a core part configured to be inserted in a core pipe of a roll medium; and plural diameter-increasing members configured to be variably arranged at corresponding first positions provided along a periphery of the core part and arranged at corresponding second positions provided away from the core part. The roll medium holding unit is capable of being set in a first holding state where the diameter-increasing members arranged at an outer peripheral surface of the core part support the roll medium with the diameter-increasing members arranged at the corresponding first positions and capable of being set in a second holding state where the core part of a holding member supports the roll medium with the diameter-increasing members arranged at the corresponding second positions.

Owner:RICOH KK

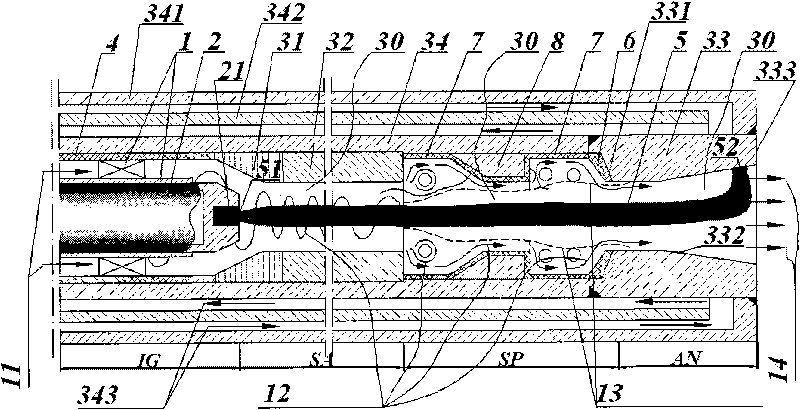

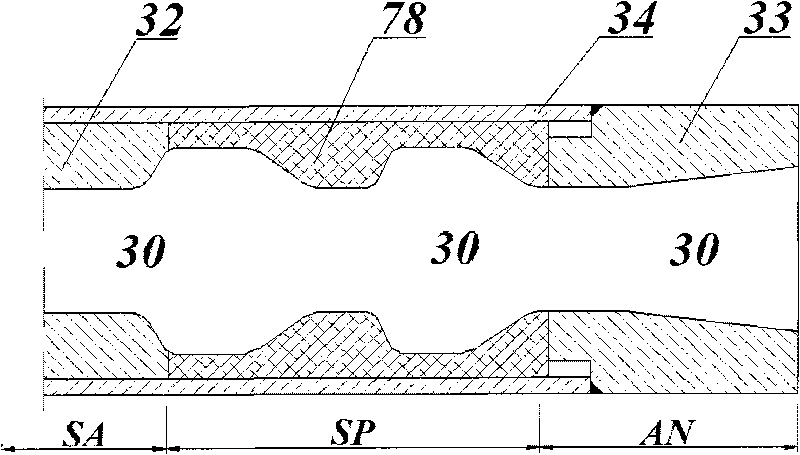

Anode for non-transferred arc plasma torch and plasma torch

The invention relates to an anode for an arc plasma torch and a non-transferred arc plasma torch with the anode. The anode comprises a stable arc section and an anode nozzle section which have evenly varied diameters, a burble section which is connected with the two sections and is provided with a groove with increasing diameter, wherein an insulating material is filled in the burble section. The plasma torch comprises a swirler, a cathode, the anode and a cathode-anode isolation sleeve which are arranged coaxially. Working gas flows into the stable arc section by rotation of the swirler, and restricts arc in an axle center position stably; the burble section ensures that air flow generates high frequency turbulence to drive an arc stream to swing in high frequency randomly and constantly impacts the inlet side of the anode nozzle; and the anode arc root moves quickly under the action of high speed air flow. The non-transferred arc plasma torch can obviously improve the arc voltage, the jump frequency and the moving speed of the anode arc root, reduces heat consumption, has the characteristics of high power, low electrode loss rate, high heat conversion efficiency, wide operation parameter range, small arc voltage fluctuation and the like, and is particularly suitable for gas heating.

Owner:UNIV OF SCI & TECH OF CHINA +1

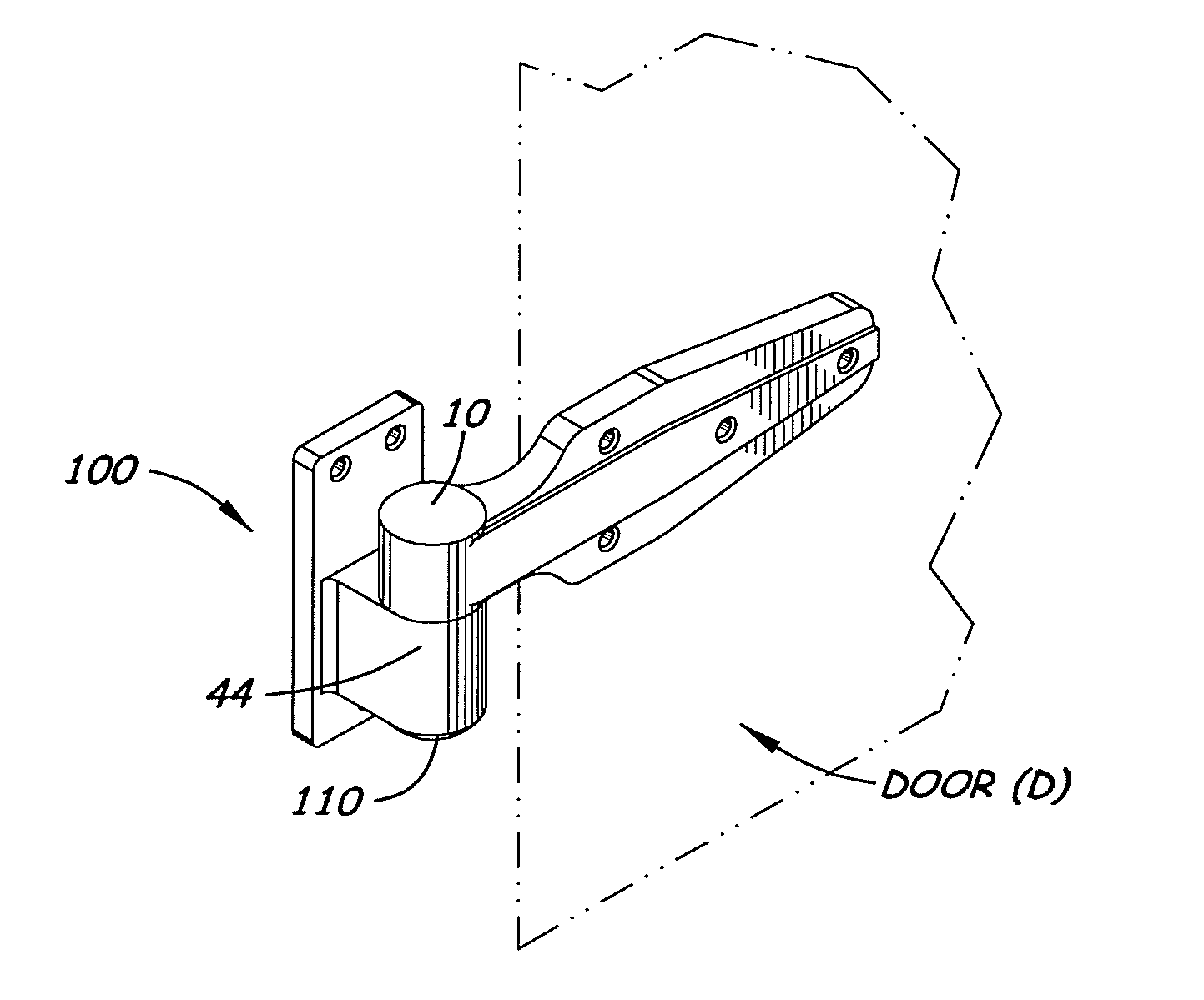

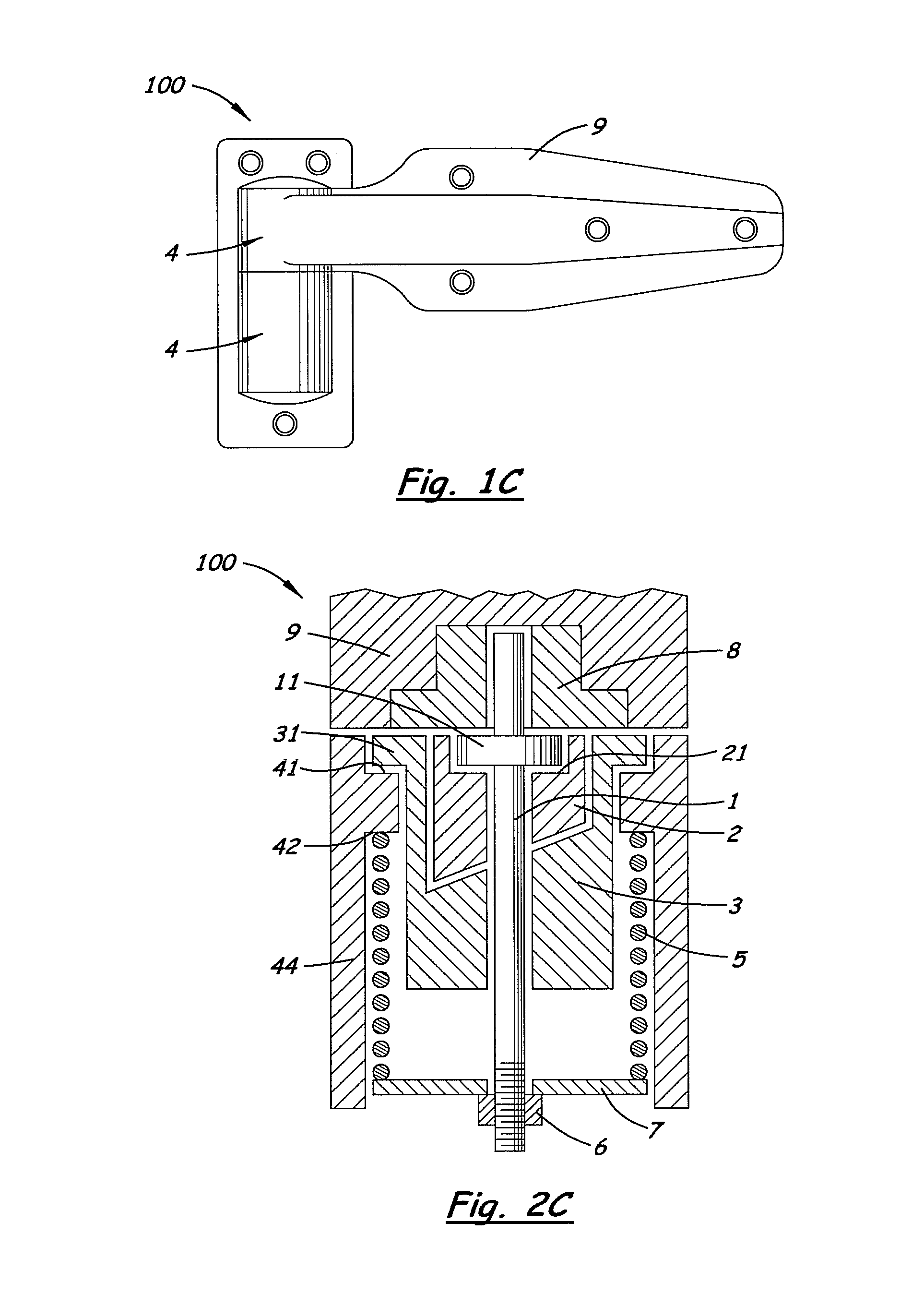

Self-closing hinge

ActiveUS7945996B2Reduce the overall heightIncrease the diameterHingesWing openersGravity assistEngineering

A compact and aesthetically-pleasing self-closing door hinge comprises a gravity-assist feature and preferably a spring-assist feature, wherein the spring may be easily adjustable, replaceable, and even left out of the hinge. The preferred embodiment is reversible for easily changing from a right-opening to a left-opening door, and includes hinge lift-off capability, wherein the door and the blade connecting the door to the hinge body may be lifted up off the body of the hinge without any significant disassembly of the hinge. The spring is preferably placed around the gravity-assist cams of the hinge, rather than above or below the cams, which arrangement significantly reduces the overall height of the hinge with only slightly increased diameter of the hinge main body. The preferred hinge has no bolts or other fasteners visible or protruding out from the main housing of the hinge, and the preferred hinge has no exposed spring sleeve.

Owner:BOISE STATE UNIVERSITY

Reversible casing cutter

Casing cutter for severing multiple tubulars in a well bore has a pair of cutter blades pivotally mounted on a support body. The blades are pivotally mounted for gradual movement outside of the support body when downward force is applied to proximate ends of the cutter blades. The support body is rotated inside the innermost of the multiple tubulars, while the cutter blades sever the tubulars of progressively increasing diameter. Should the cutter blades or pivotal connections become unusable, the tool body can be rotated about the vertical axis and secured to a downhole string by the opposite end. A substitute pair of cutter blades are then engaged on the tool body and operated to cut the casings similar to the first set of the cutter blades.

Owner:ABRADO

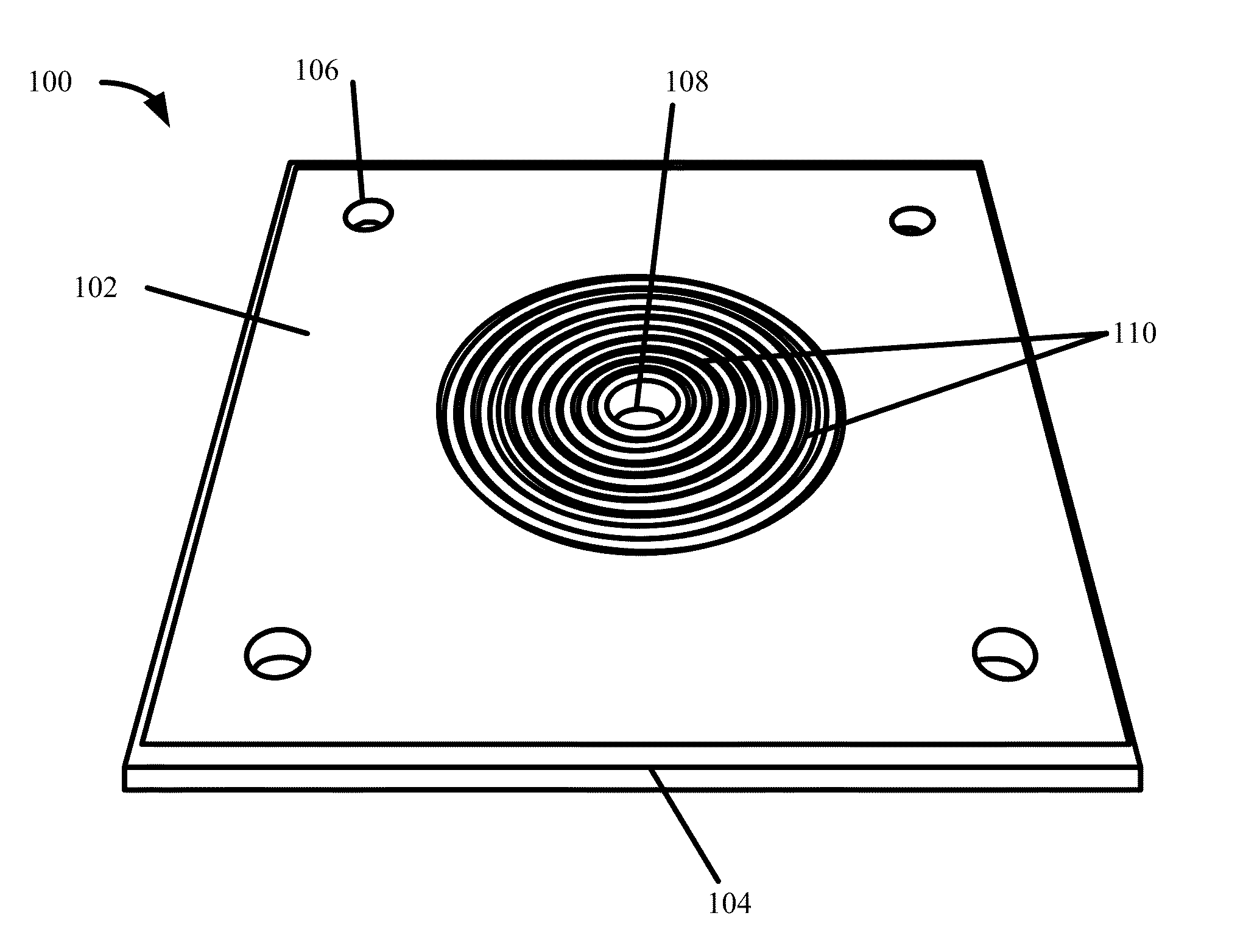

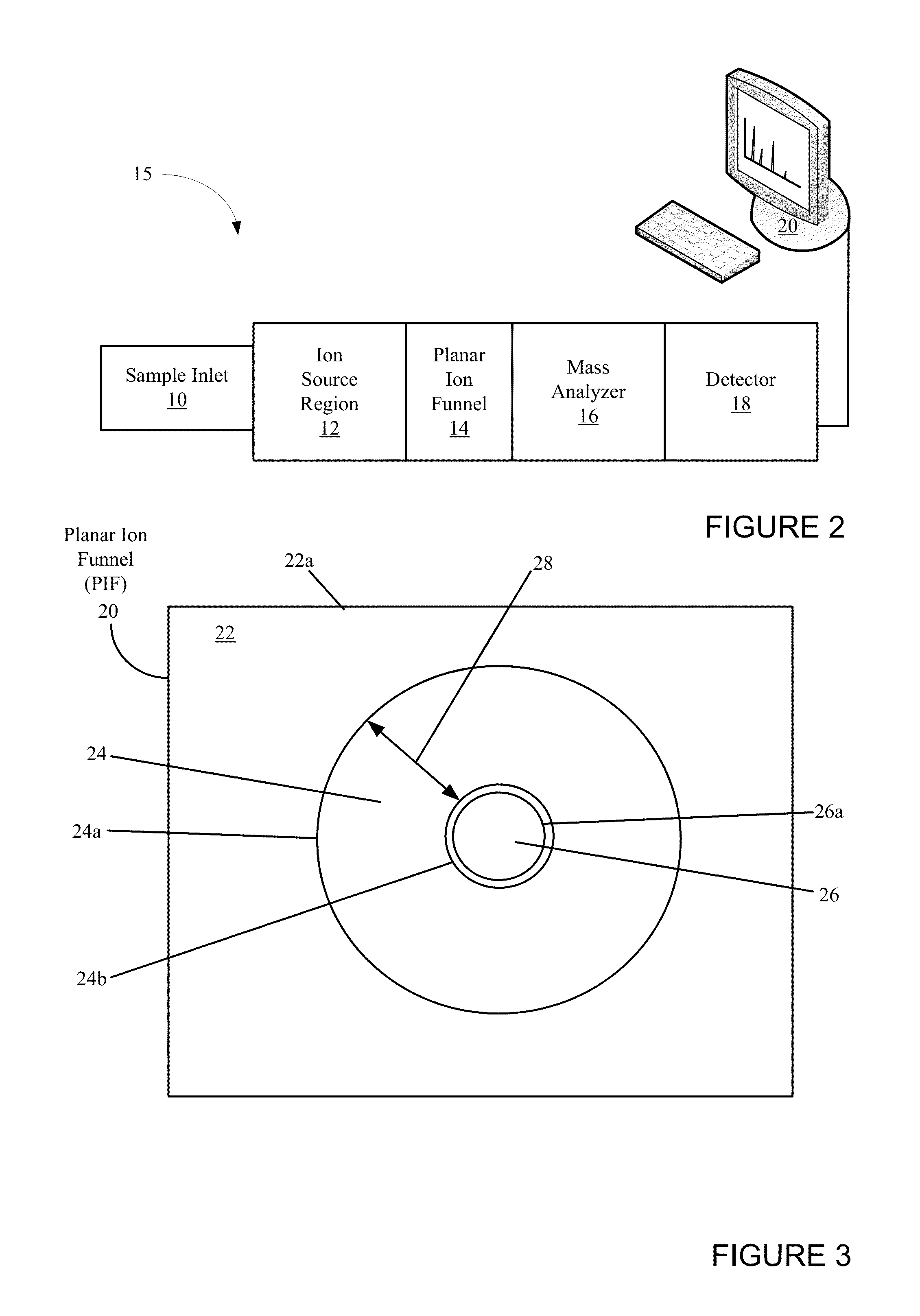

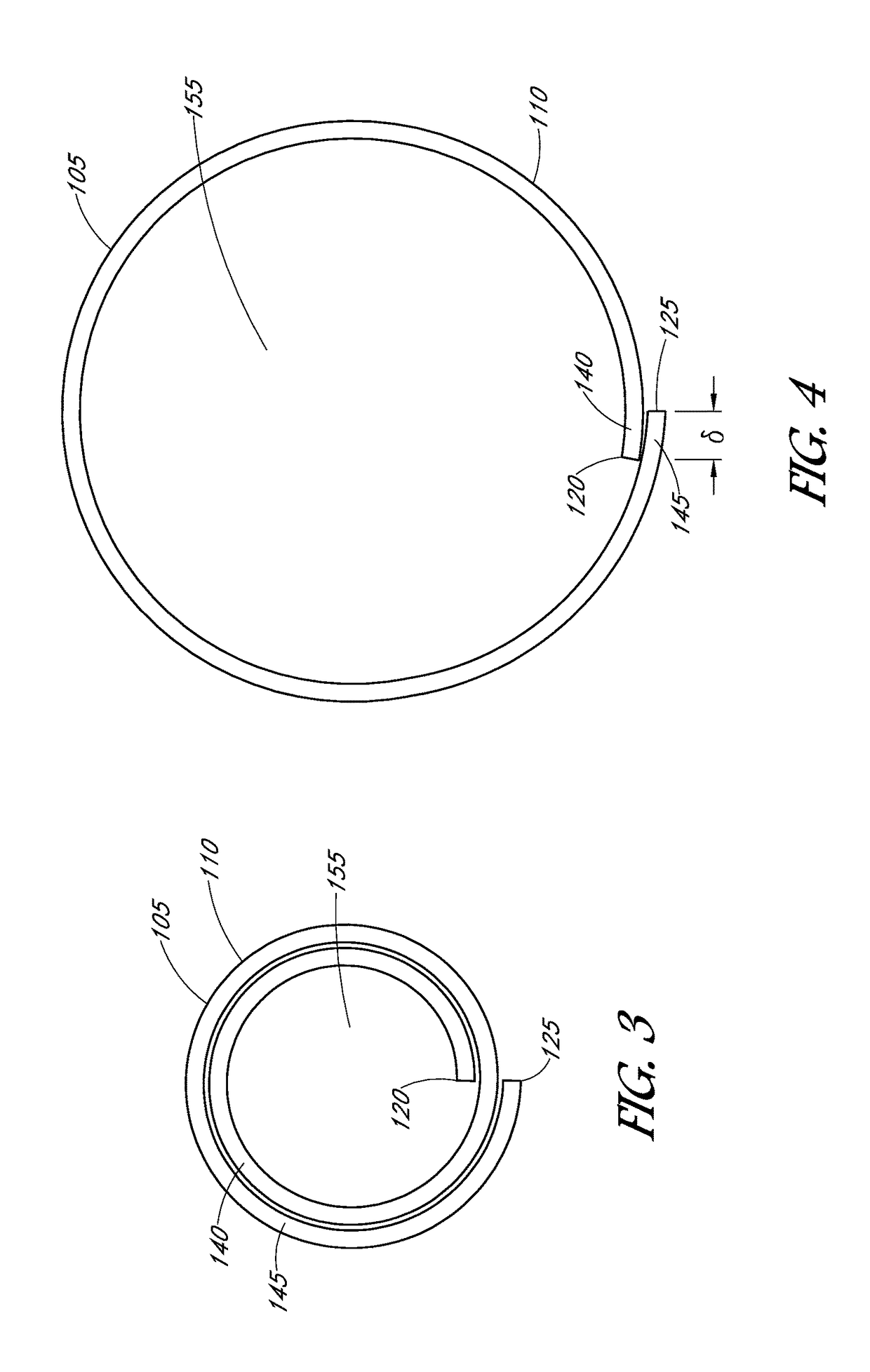

Planar ion funnel

InactiveUS20130120894A1Efficient use ofElectronics SimplifiedParticle separator tubesPlanar substrateOptoelectronics

A planar ion funnel is disclosed that can be used for ion control. In one application, the planar ion funnel can be used for ion control in a mass spectrometer. The planar ion funnel can be formed on a surface of a substantially planar substrate including an orifice. An electrically conductive structure can be formed on a top surface of the substrate that surrounds the orifice. In operation, a power can be applied to the conductive structure that causes an electric field to be generated that draws ions into and through the orifice. In one embodiment, the orifice can be circular and the conductive structure can be a series of nested rings of increasing diameter surrounding the orifice.

Owner:SRI INTERNATIONAL

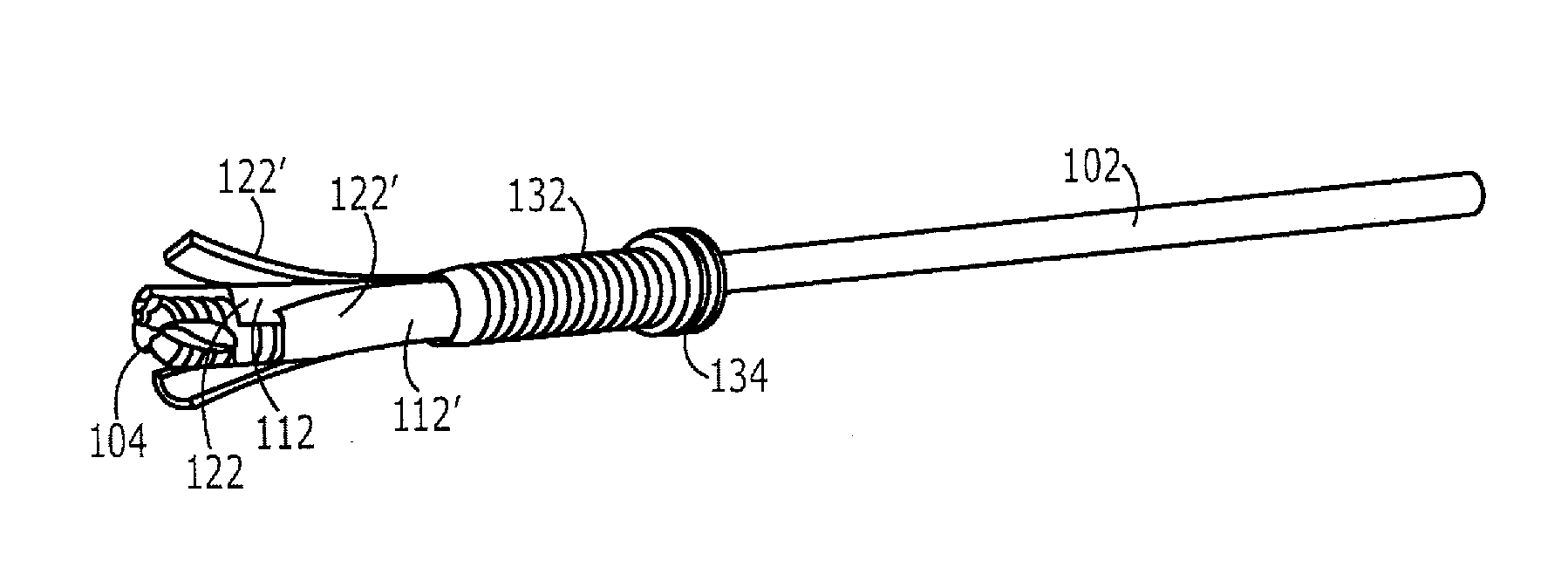

Bioabsorbable interference screw for endosteal fixation of ligaments

InactiveUS7322986B2Easy to insertEasy to fixSuture equipmentsInternal osteosythesisBone tunnelInterference screws

A bioabsorbable interference screw having a tapered profile which extends along substantially the entire length of the screw. The tapered profile makes the screw easy to insert while providing superior fixation resulting from a progressively increasing diameter. Upon insertion, the screw engages cortical bone at the back end of the bone tunnel and fills all but 5-10 mm. of the tunnel, thereby providing increased fixation strength while also promoting fast healing. The screw includes a head provided with a specially designed drive socket with radially extending slots at its outer end for receiving corresponding protrusions on the shaft of screwdriver. The drive socket optimizes the torque capacity of the screw. To maintain wall thickness, the socket has a taper corresponding to the tapered outer profile of the screw. The taper of the socket also permits easy insertion of the tip and shaft of the driver into the screw.

Owner:ARTHREX INC

Dual-band and dual-polarization millimeter wave feed source

ActiveCN104979638ASimple structureBreak through the technical problem of dual-frequency dual-polarization millimeter-wave feedWaveguide hornsSimultaneous aerial operationsLow-pass filterDual mode

The invention provides a dual-band and dual-polarization millimeter wave feed source which comprises a radiation end, a Ka-band orthogonal mode coupling and a W-band orthogonal mode coupling. The radiation end and the couplings use a waveguide structure. Dual bands and dual polarization are realized through single caliber. A high band is located in the middle. Low bands carry out feeding from sides. A high-band dual-mode feed source is connected with an external orthogonal mode coupling. The low bands carry out feeding from a circular waveguide segment with increasing diameter. The dual-polarization feed source has a simple main structure, and breaks through the technical problems of the dual-band and dual-polarization millimeter wave feed source. In order to prevent crosstalk and improve the feed source performance, a filter is added on an output rectangular waveguide segment of a low-band orthogonal mode coupling. The filter is a low-pass filter which has low-band passband and high-band stop-band. Two kinds of polarization exit waveguide of two bands are respectively located in four directions of a major radiation waveguide axis, are in pairwise orthogonal, are staggered up and down, are not located in the same level, and are easily connected with rear end waveguide.

Owner:ANHUI SUN CREATE ELECTRONICS

Expandable sheath and methods of use

Disclosed herein are expandable introducer sheaths and methods of making and using the same. The sheaths minimize trauma to a patient's vasculature by allowing for temporary expansion of a portion of the sheath state after passage of the device. The sheath includes a rolled inner member having a detachable flap structure at its distal tip that facilitates expansion of the sheath lumen to increase diameters. Also, the flap structure reduces the number of layers at the tip, lowering push forces. An elastomeric free end of the tip helps reduce push and retrieval forces for balloons and implants. The expandable sheath includes an elastic outer layer that compresses the inner member and flap back into the rolled, compressed condition after the passage of the device.

Owner:ADVANCED CARDIOLOGY ENG SOLUTIONS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com