Push-to-expand mandrel for stretch-wrap hand tool

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

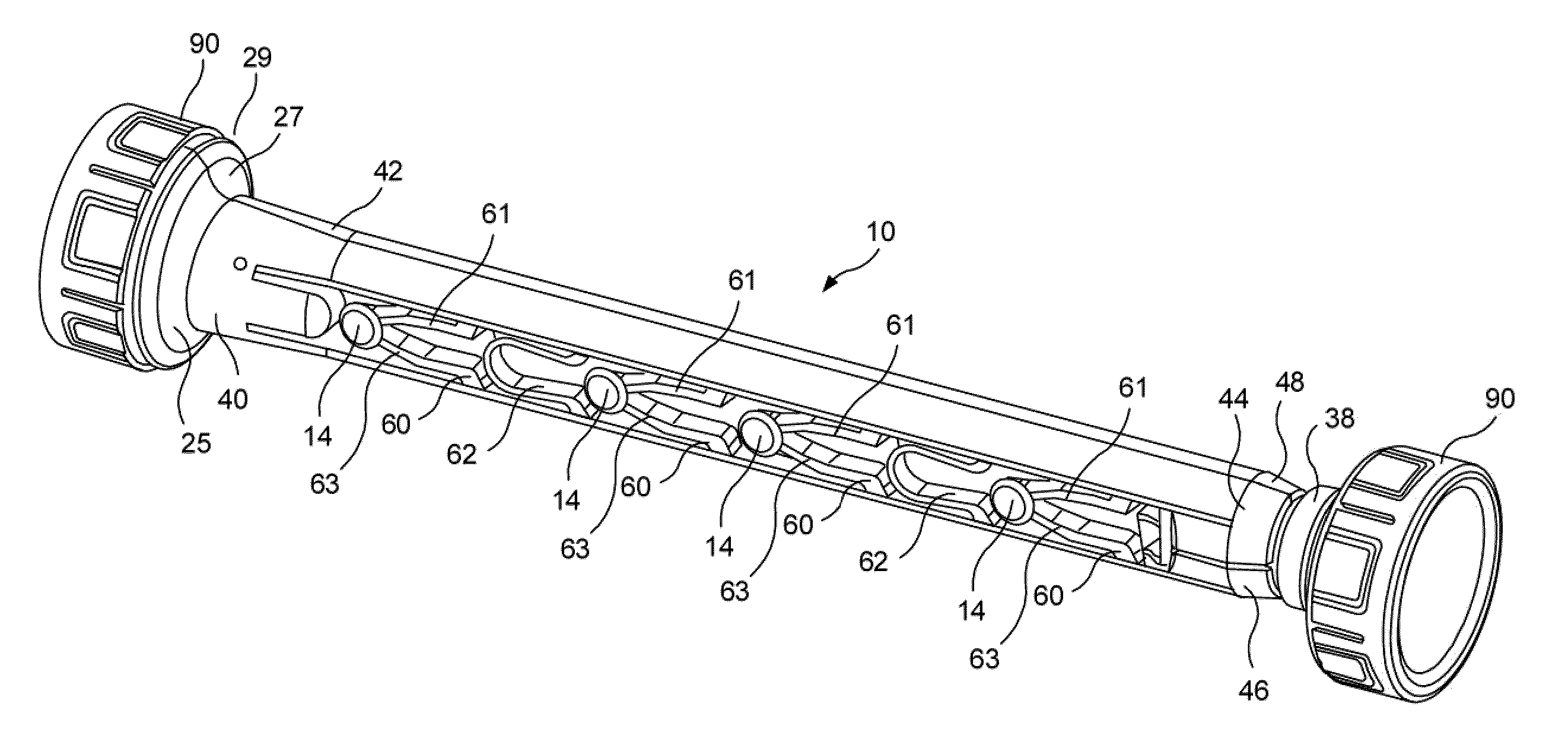

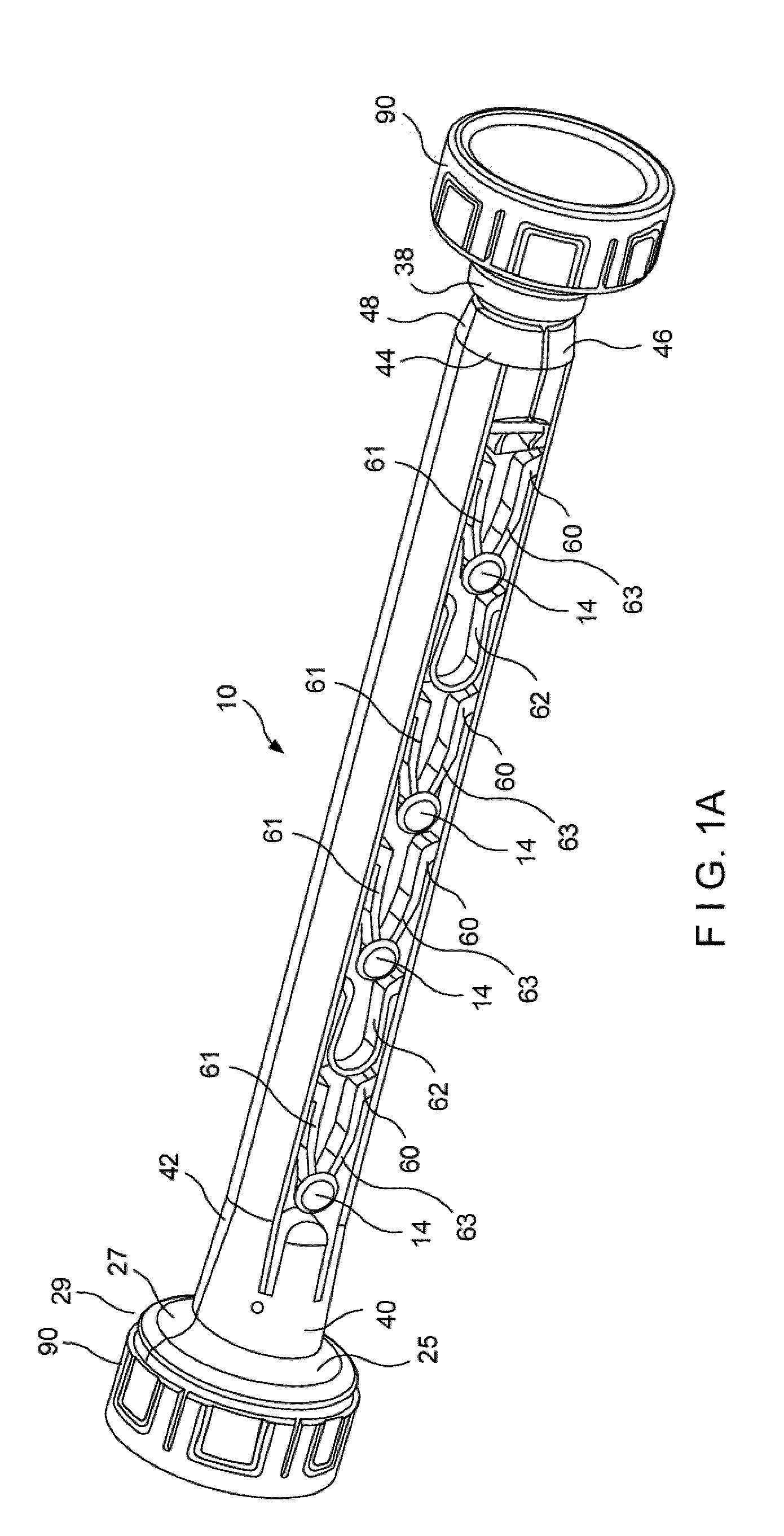

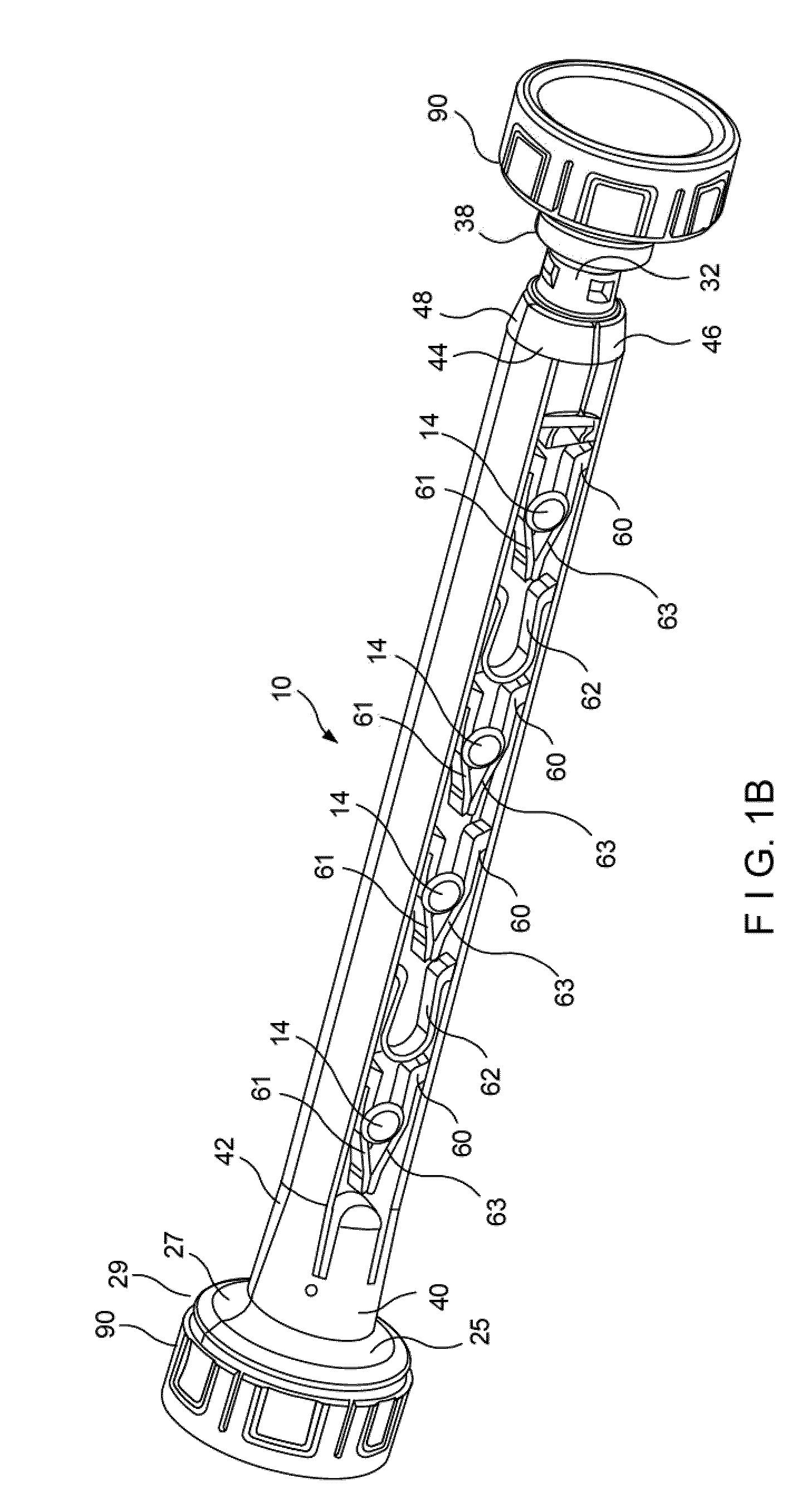

[0037]Referring now to the drawings in detail wherein like numerals indicate like elements throughout the several views, one sees that FIGS. 1A, 1B, 2, 3 and 4 are various views of a first embodiment of dispenser 10. Dispenser 10 includes a central shaft 12, with a square or rectangular cross section, with cam lugs 14 protruding from two opposing sides of central shaft 12. Cam lugs 14 can be integrally molded with central shaft or can be attached thereto. The cam lugs 14 include expanded or bulbous heads 15 which serve to slidingly engage the mandrels thereto. Central shaft 12 includes first end 16 and second end 18. First end 16 of shaft 12 includes a portion 32 of circular cross section and further includes longitudinal blind aperture 34 which receives longitudinal male portion or stem 36 of first cup 38 thereby holding cup 38 so that first cup 38 moves in concert with central shaft 12. First cup 38 can be replaced with an axially oriented handle 39 as illustrated in FIG. 17. Seco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

| Tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com