Reduction of reactive gas attack on substrate heater

a technology for reducing reactive gas attack and substrate heater, which is applied in the direction of cleaning hollow articles, coatings, chemistry apparatuses and processes, etc., can solve the problems of damage to the substrate support surface, reduce damage to the substrate support, reduce damage such as alfx formation, and reduce aluminum fluoride formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

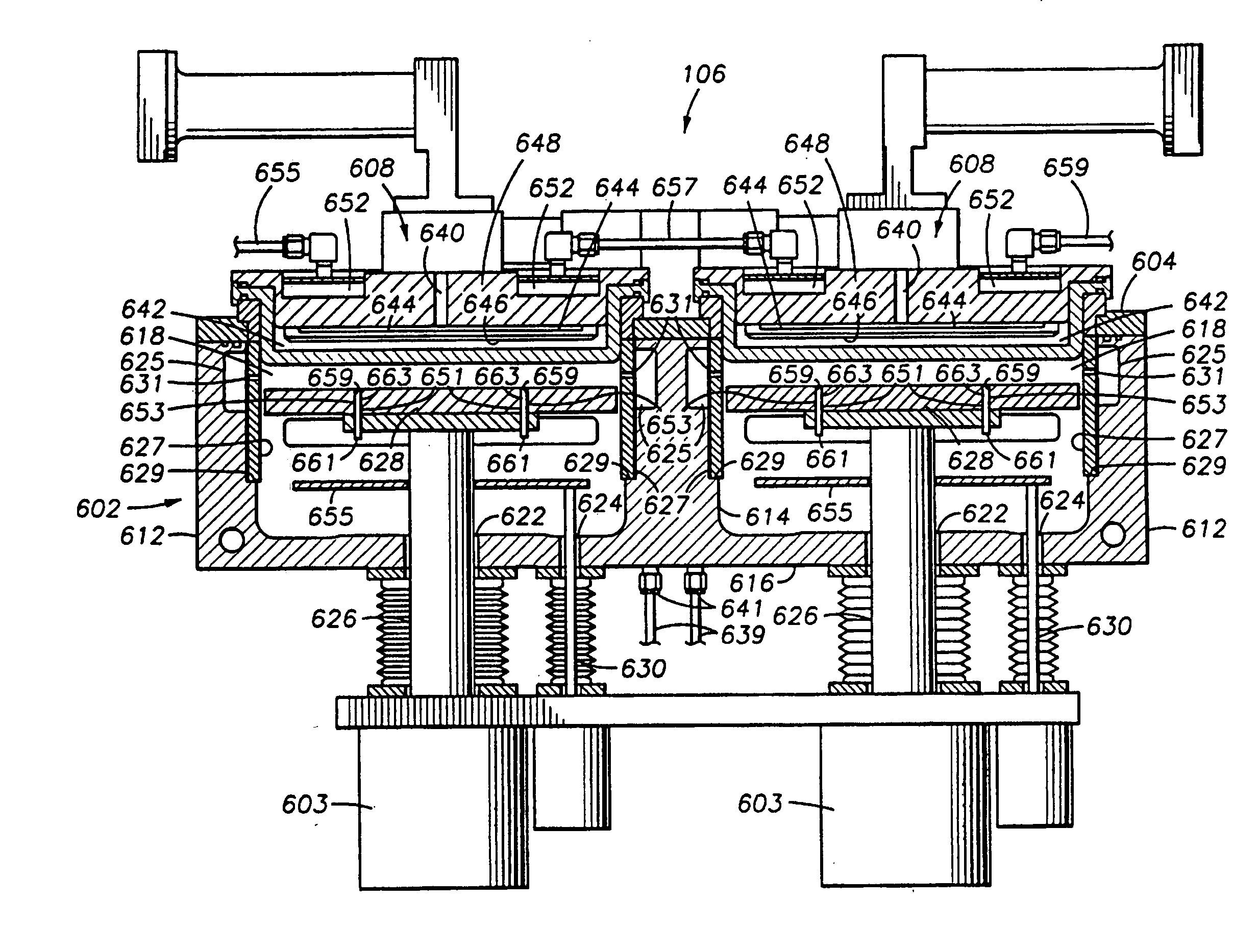

[0019]FIG. 1 shows a perspective view of one embodiment of a tandem processing chamber 106 of the present invention. Chamber body 602 is mounted or otherwise connected to a transfer chamber and includes two processing regions in which individual wafers are concurrently processed. The chamber body 602 supports a lid 604 which is hingedly attached to the chamber body 602 and includes one or more gas distribution systems 608 disposed therethrough for delivering reactant and cleaning gases into multiple processing regions.

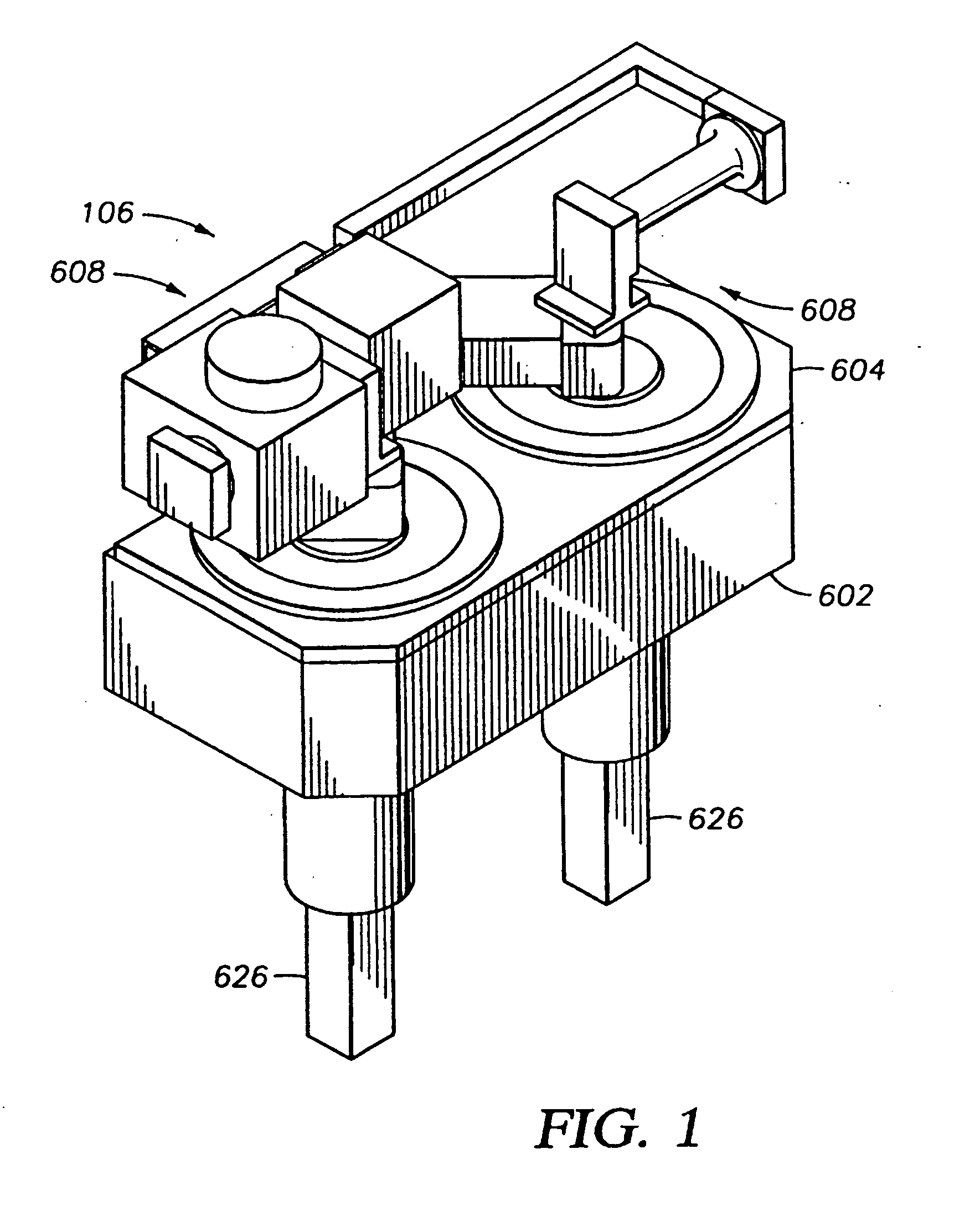

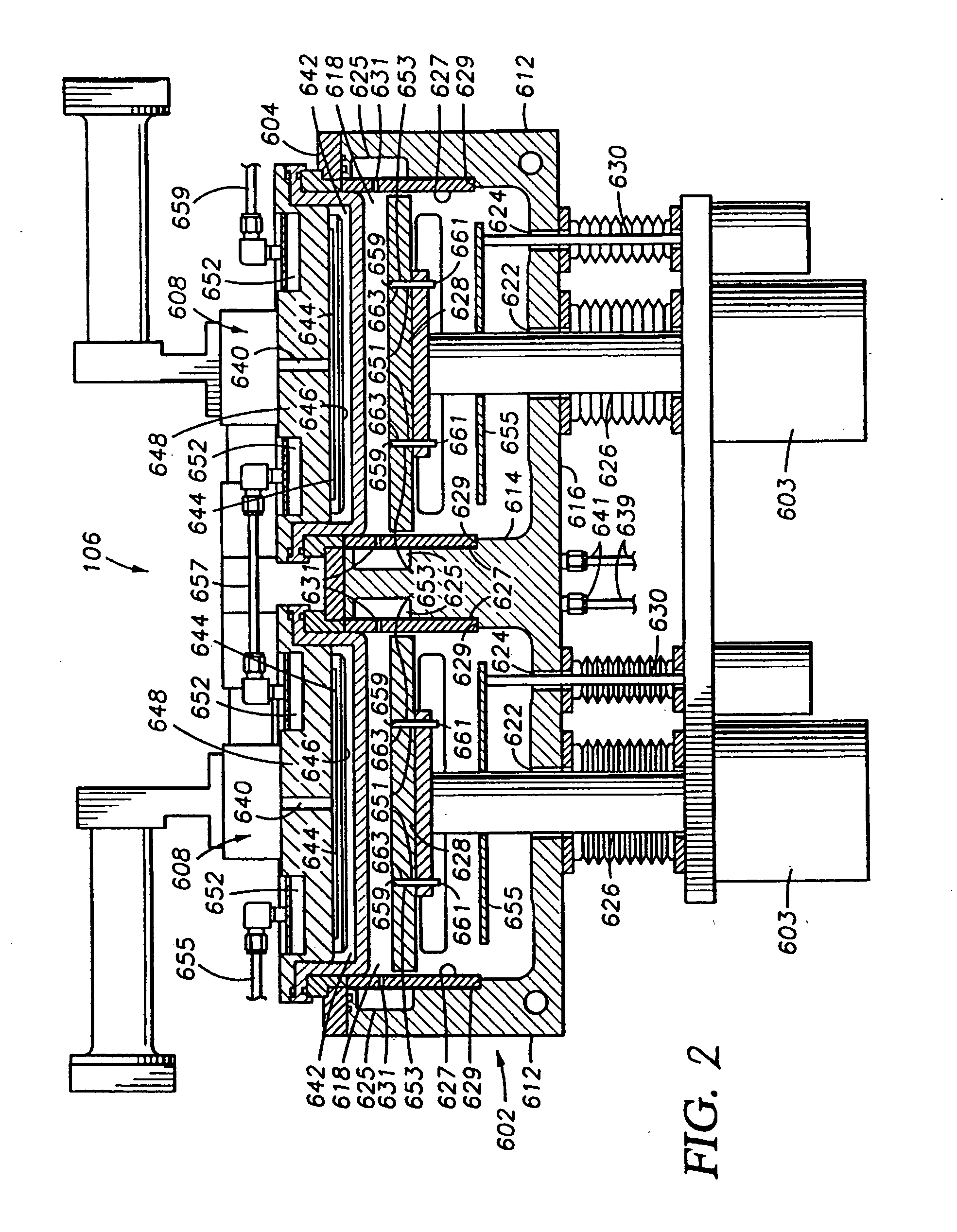

[0020]FIG. 2 shows a schematic cross-sectional view of the chamber 106 defining two processing regions 618, 620. Chamber body 602 includes sidewall 612, interior wall 614 and bottom wall 616 which define the two processing regions 618, 620. The bottom wall 616 in each processing region 618, 620 defines at least two passages 622, 624 through which a stem 626 of a pedestal heater 628 and a rod 630 of a wafer lift pin assembly are disposed, respectively. A pedestal lift ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com