Patents

Literature

1685 results about "Gas heating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

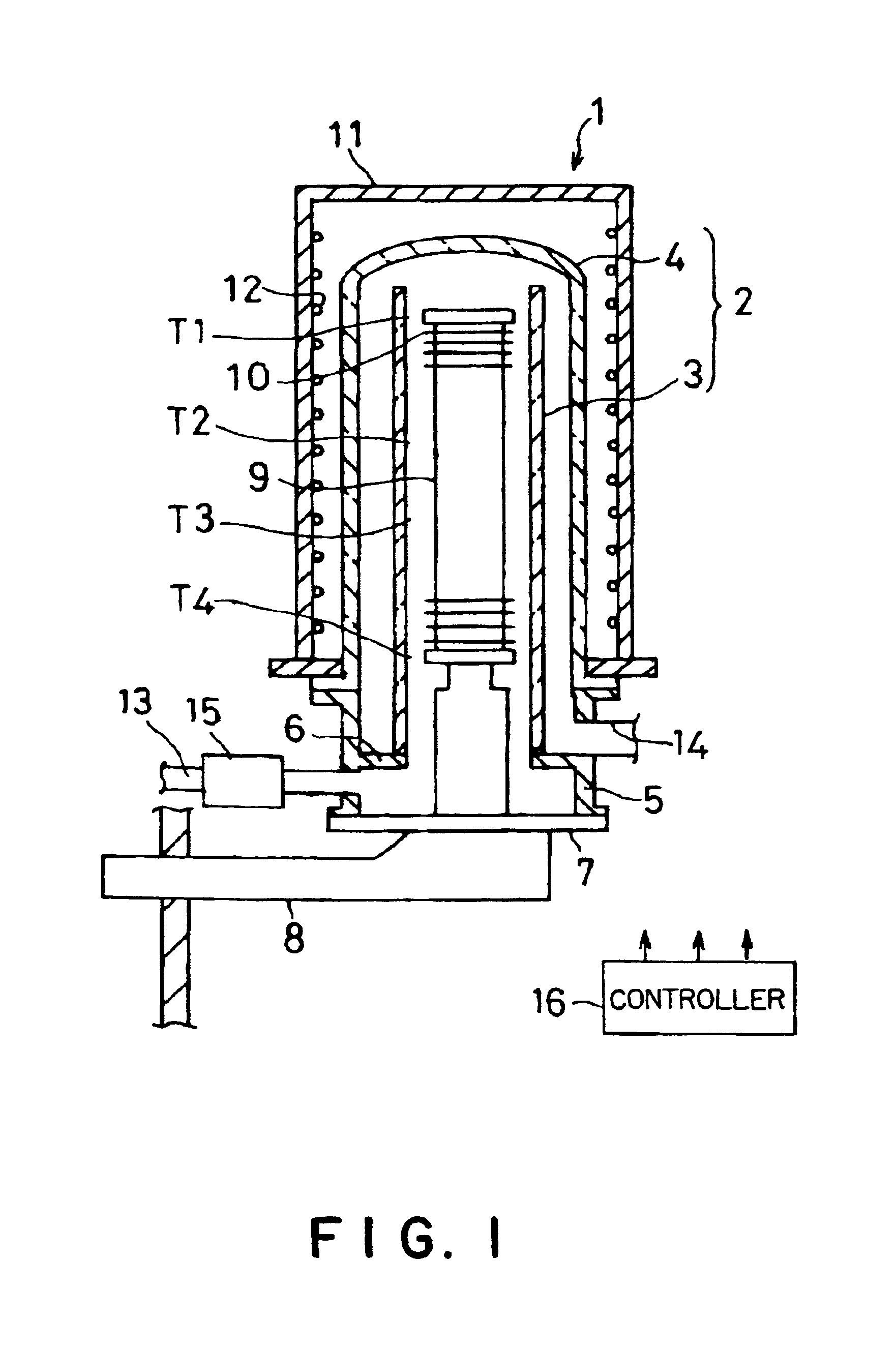

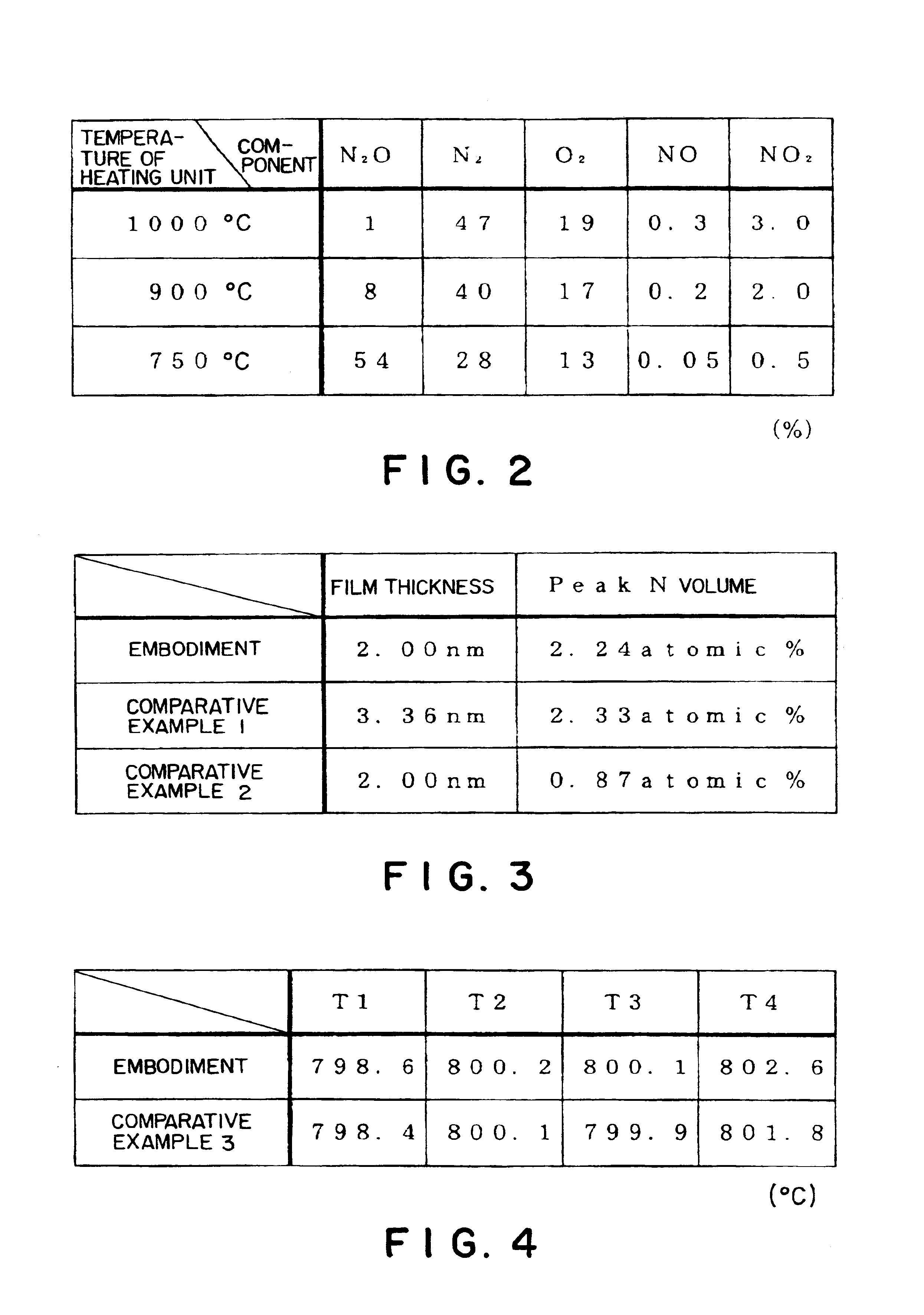

Method of forming oxynitride film or the like and system for carrying out the same

InactiveUS6884295B2High film forming ratePromote oxidationSemiconductor/solid-state device manufacturingWater heatersReaction temperatureProduct gas

This invention is an oxynitride film forming method including: a reaction chamber heating step of heating a reaction chamber to a predetermined temperature, the reaction chamber containing an object to be processed; a gas heating step of heating a process gas to a temperature not lower than a reaction temperature at which an oxynitride film can be formed, the process gas consisting of dinitrogen oxide gas; and a film forming step of forming an oxynitride film on the object to be processed by supplying the heated process gas into the heated processing chamber. The temperature to which the reaction chamber is heated in the reaction chamber heating step is set at a temperature below a temperature at which the process gas undergoes a reaction.

Owner:TOKYO ELECTRON LTD

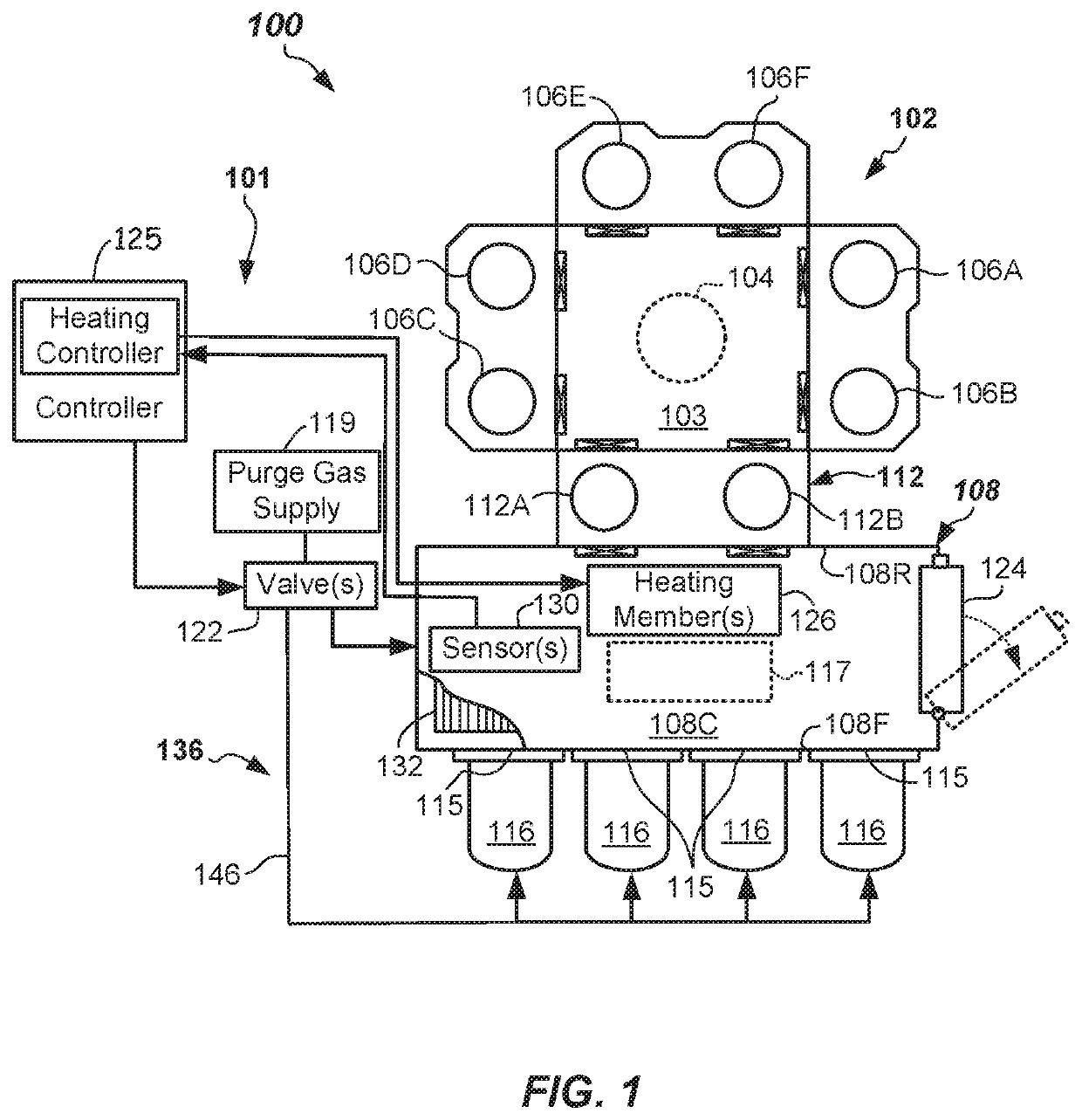

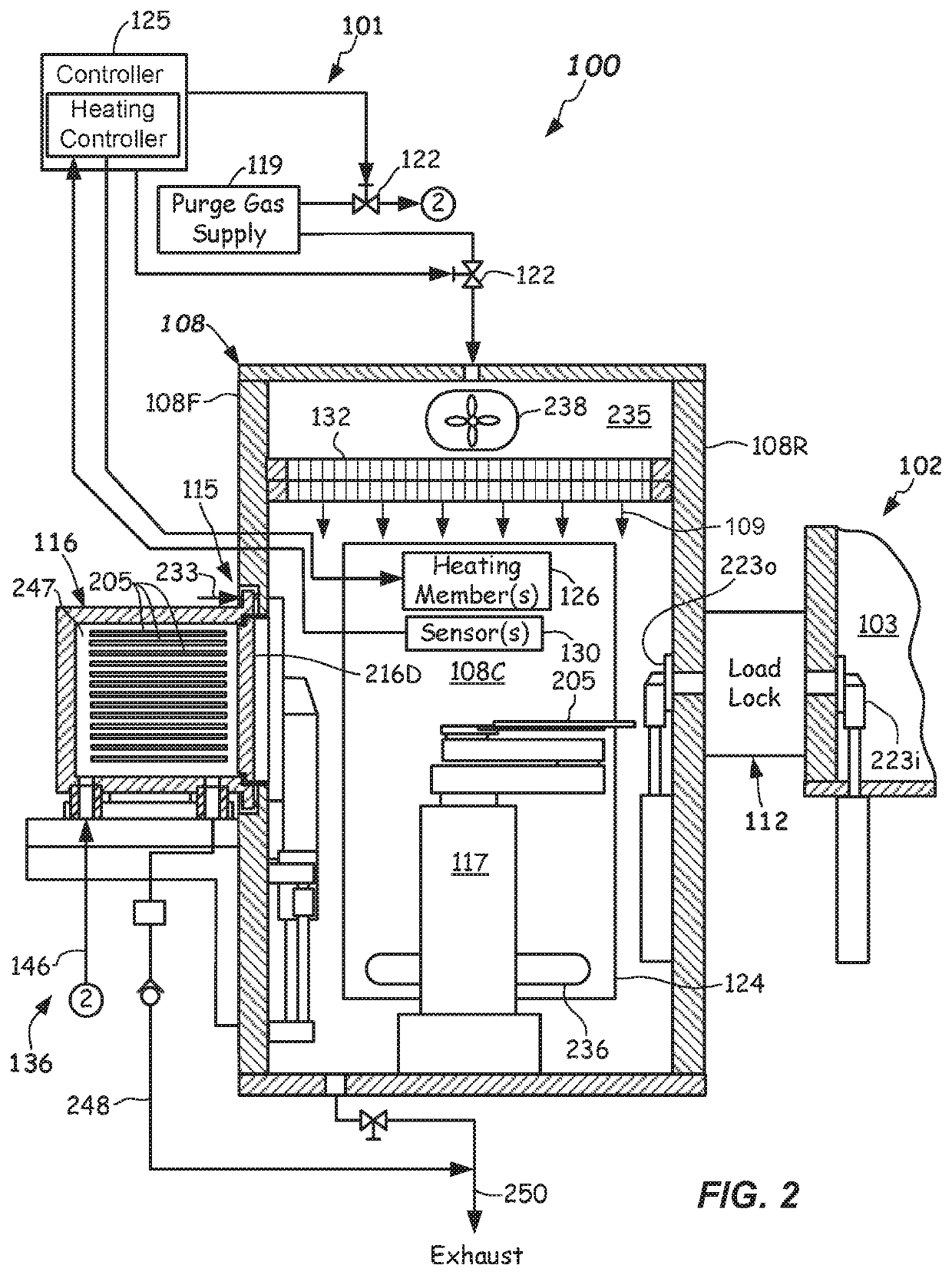

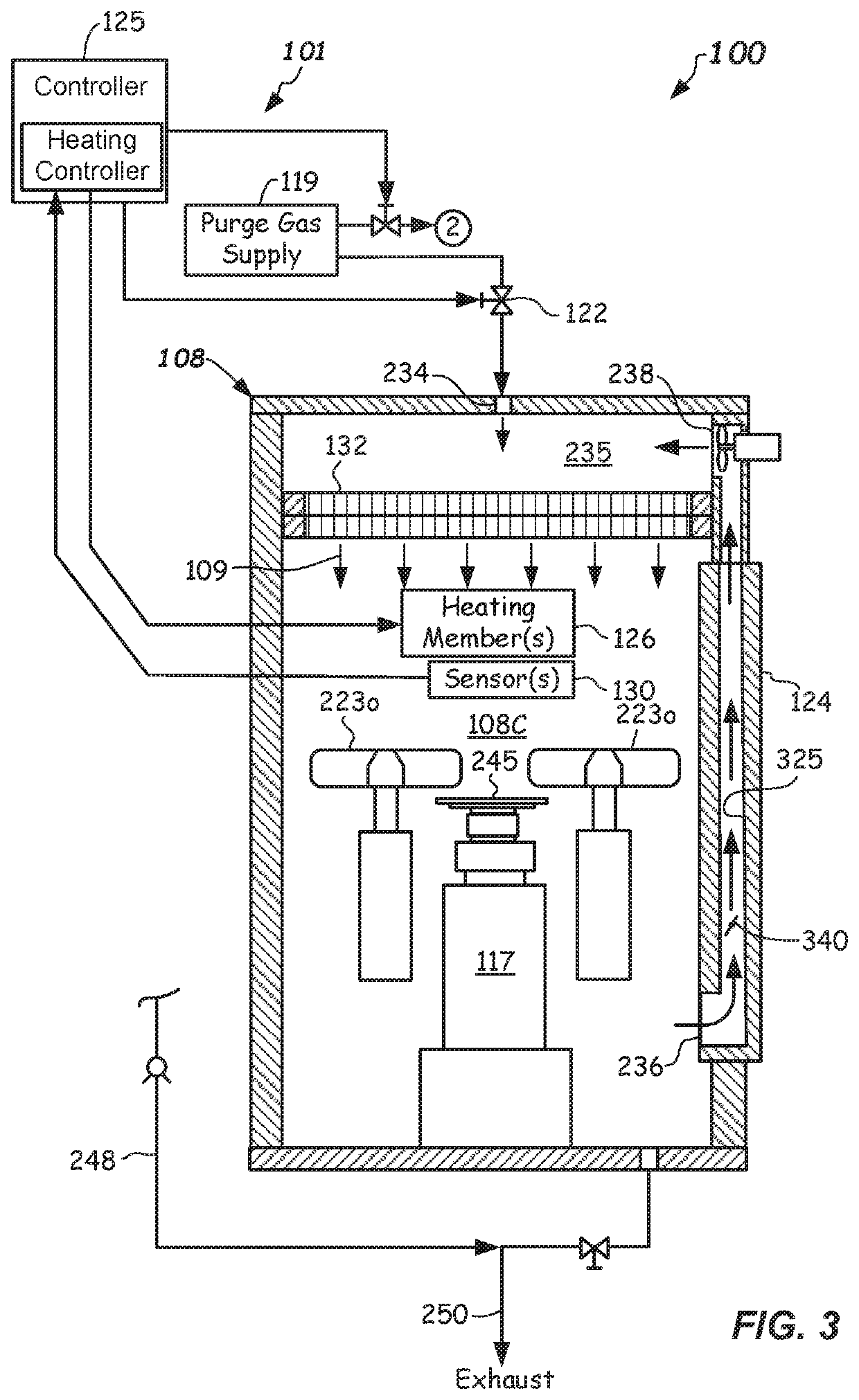

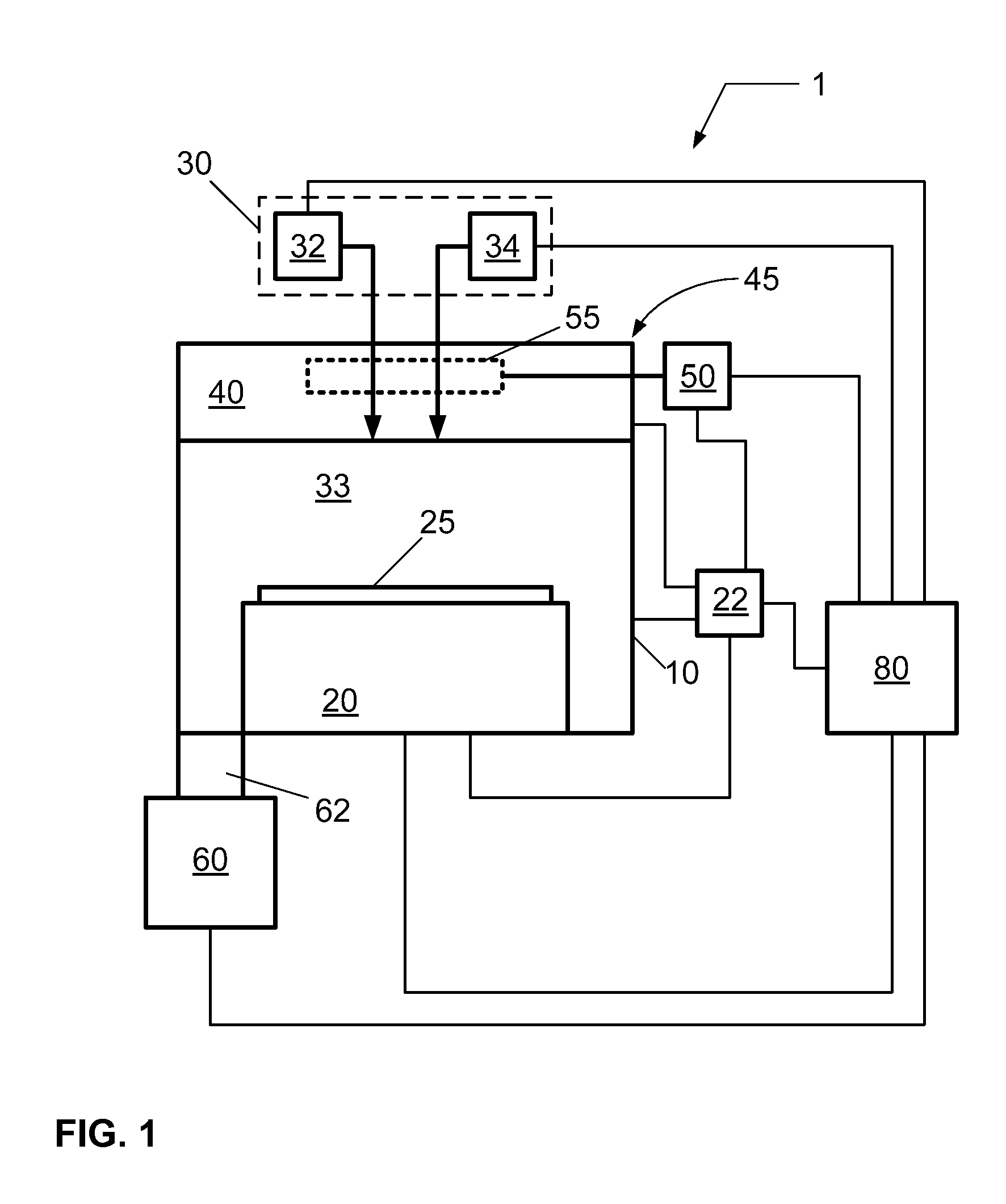

Substrate manufacturing apparatus and methods with factory interface chamber heating

PendingUS20190362989A1Reduce heatGas treatmentDispersed particle filtrationChemical compoundManufactured apparatus

Electronic device processing apparatus including a factory interface chamber purge apparatus with purge gas heating. The factory interface chamber purge apparatus includes one or more heating elements configured to heat the purge gas. In some embodiments, the provision of heated purge gas to the chamber filter assembly can rapidly reduce moisture contamination after the access door is opened for factory interface servicing. In further embodiments, the provision of heated purge gas to the factory interface chamber can aid in desorbing certain chemical compounds from the substrates following processing when a low-humidity environment is provided. Purge control methods and apparatus are described, as are numerous other aspects.

Owner:APPLIED MATERIALS INC

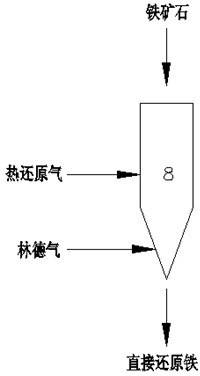

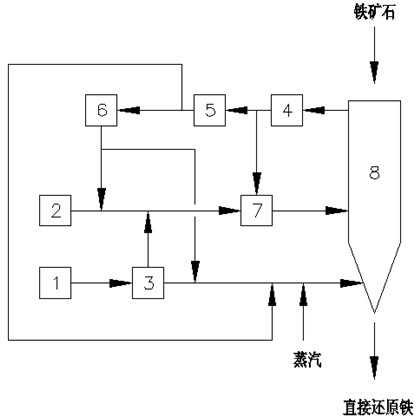

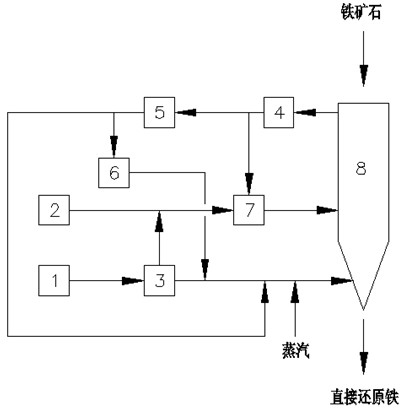

Method and device for producing direct reduced iron by using gas-based reduction shaft furnace

The invention discloses a method and device for producing direct reduced iron by using a gas-based reduction shaft furnace. Coal reducing gas and coke oven gas are mixed and supplied to a shaft furnace so as to produce direct reduced iron. The method comprises the following steps: separating the coke oven gas into hydrogen gas and linde gas, mixing the hydrogen gas with the coal reducing gas and using as reducing gas to reduce iron ores, and using the linde gas as cooling gas to cool direct reduced iron. The device for realizing the method comprises a shaft furnace, a coke oven gas source, a coal gasification device, a coke oven gas hydrogen-extracting device and a gas heating device. In the invention, coal gasification devices of different sizes can be flexibly used with a coke oven gas supply device, thereby reducing the size of the coal gasification device and effectively using the coke oven gas. Meanwhile, the invention cancels the minor cycle of a cooling section of a common shaft furnace, saves the equipment and investment, and brings the heat of direct reduced iron to a reducing section, thereby saving the heating load of the system reducing gas.

Owner:CISDI SHANGHAI ENG CO LTD +1

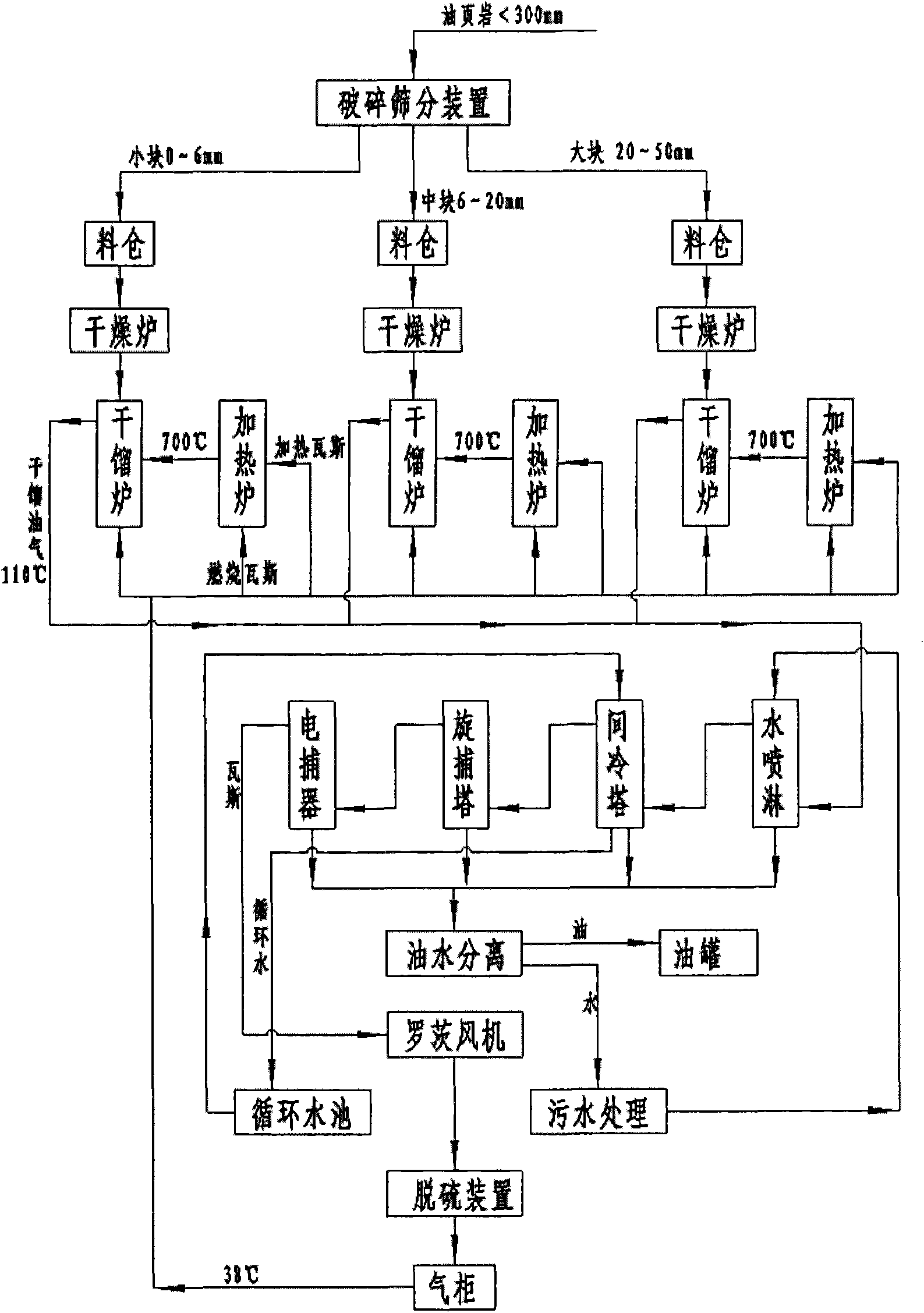

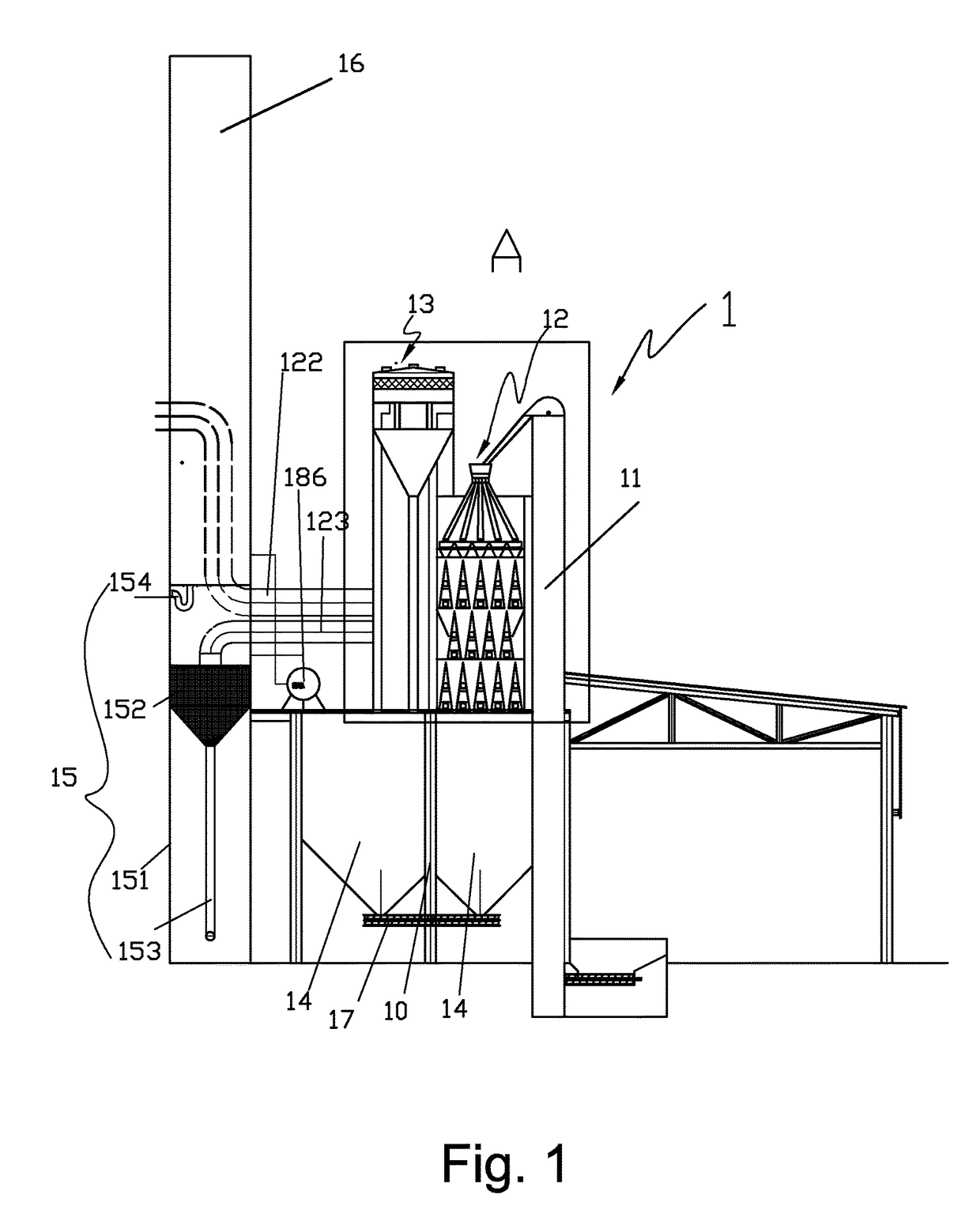

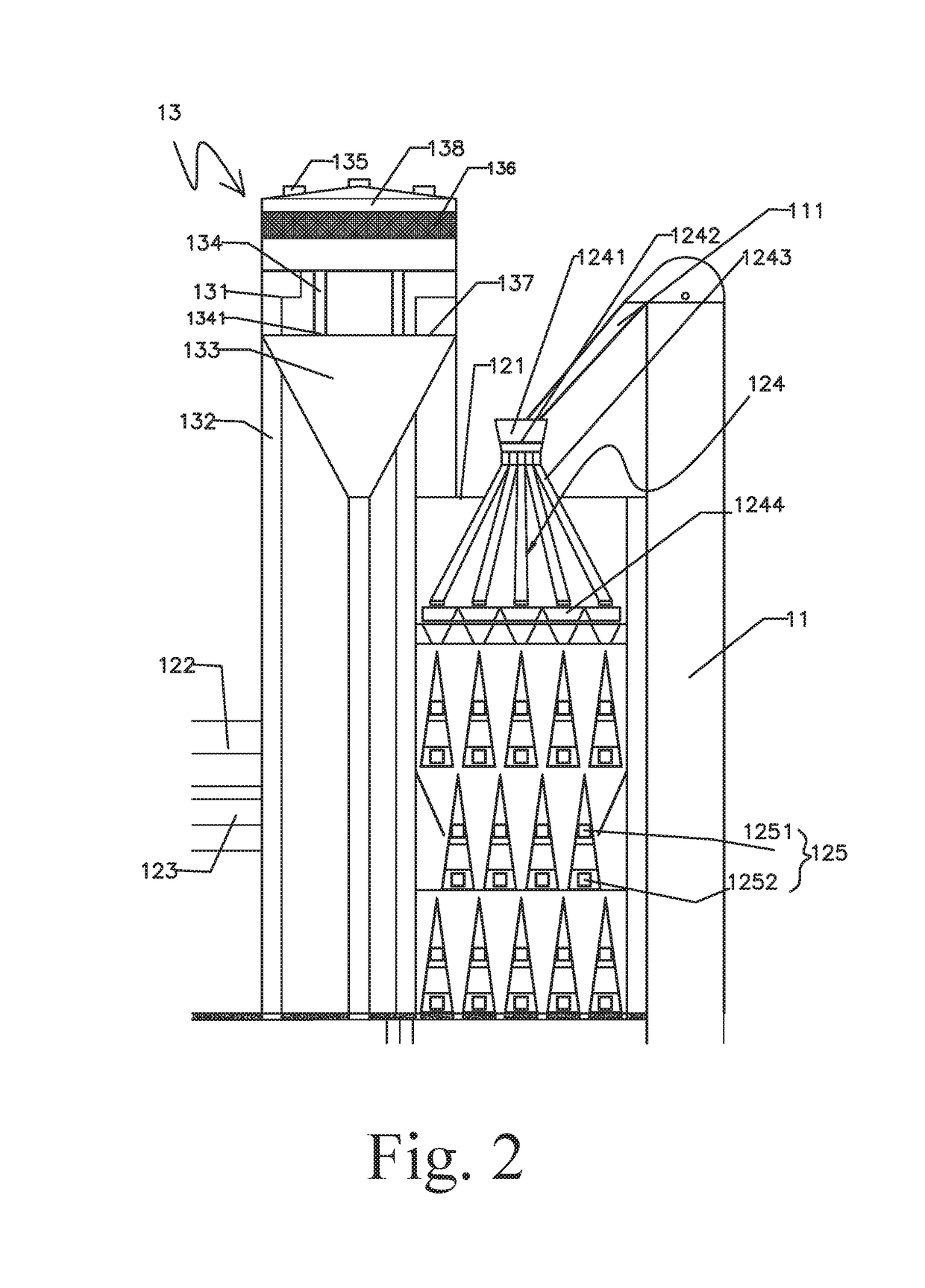

Huadian type process and device for dry distillation of oil shale

ActiveCN101942313AGuaranteed to be heatedGuaranteed temperature requirementsDirect heating destructive distillationCombustible gas purificationHeat carrierCooling tower

The invention provides a process and device for carrying out stage dry distillation on oil shale under the state of full recycle, with the gas as the heat carrier. The oil shale is divided into three different sizes (such as 0-6mm, 6-20mm and 20-50mm) through crushing and screening, and the oil shale is firstly dried and heated to the temperature between 50 DEG C and 150 DEG C by the waste smoke exhausted from gas heating furnaces and then enters into the different sizes of furnaces for dry distillation to undergo dry distillation. After being treated by water spraying and an indirect cooling tower, a rotary trapper and an electric trapper for oil collection, the dry distillation oil and gas undergo oil-gas-water separation, and after separation, the oil enters into a storage tank, the water enters into a circulating water tank and the first part of gases serves as the heat carrier and is recycled, the second part of gases is used as the fuels for the heating furnaces and the third part of gases is used as the fuel gases for power generation.

Owner:辽宁成大能源科技有限公司

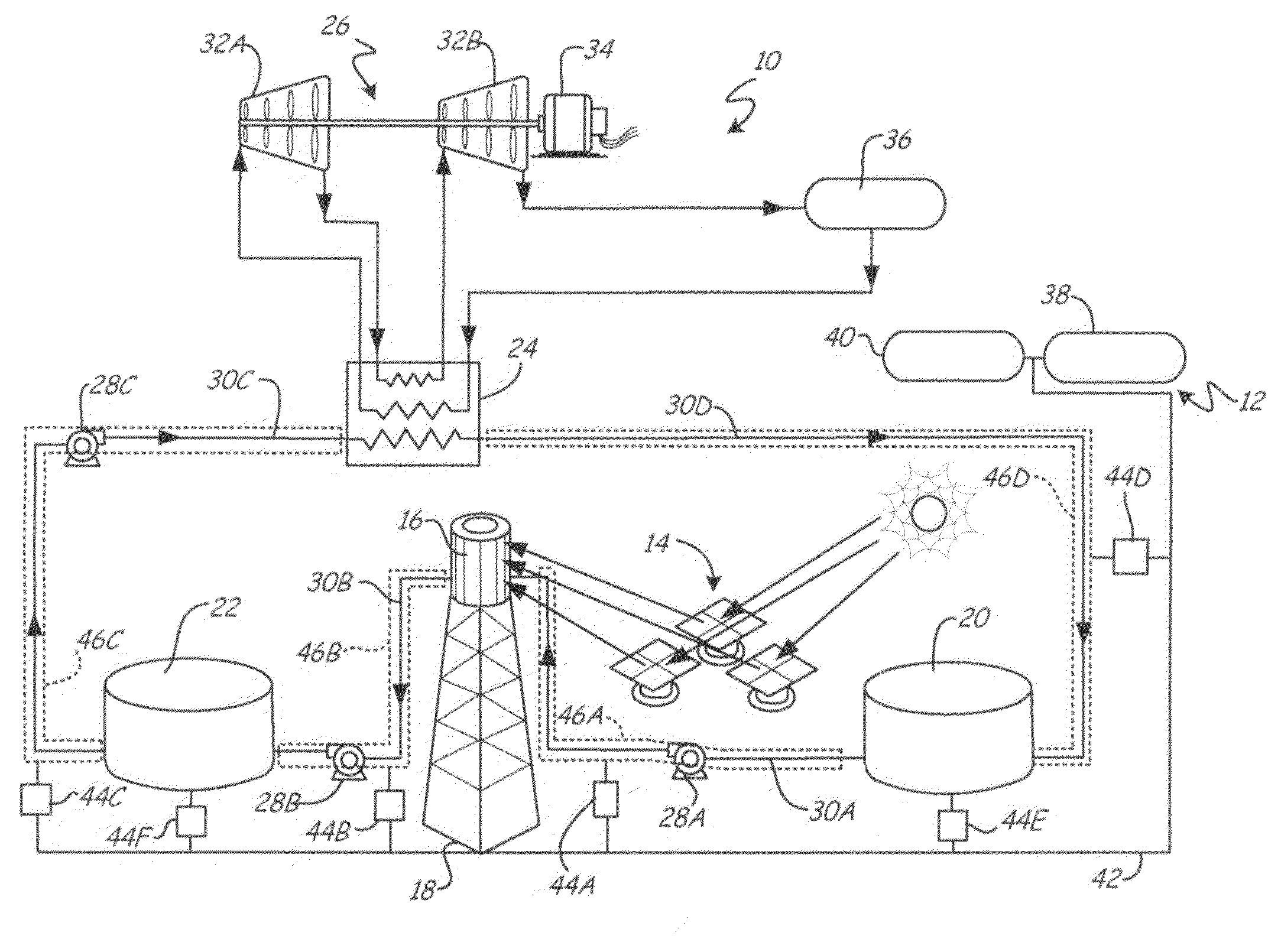

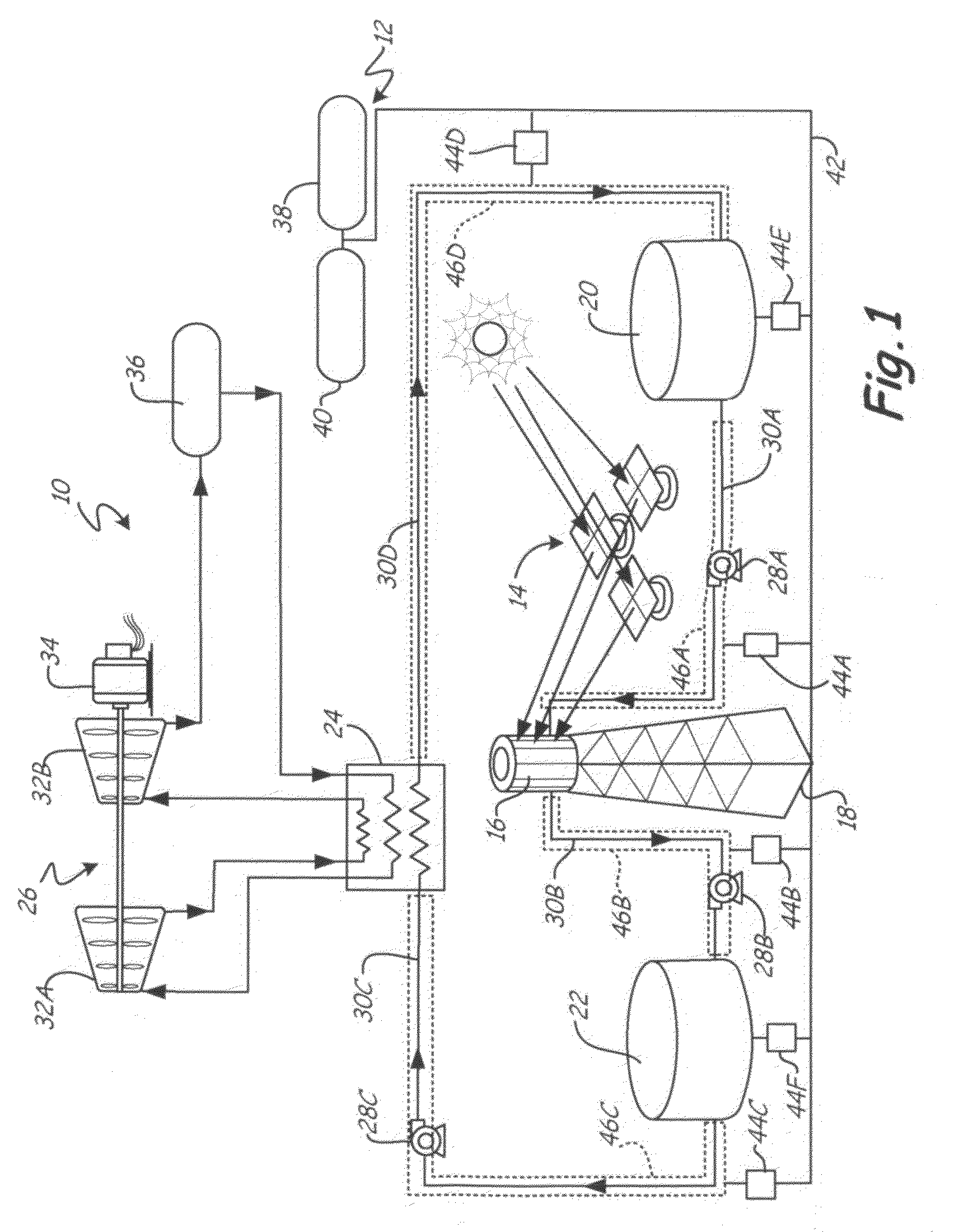

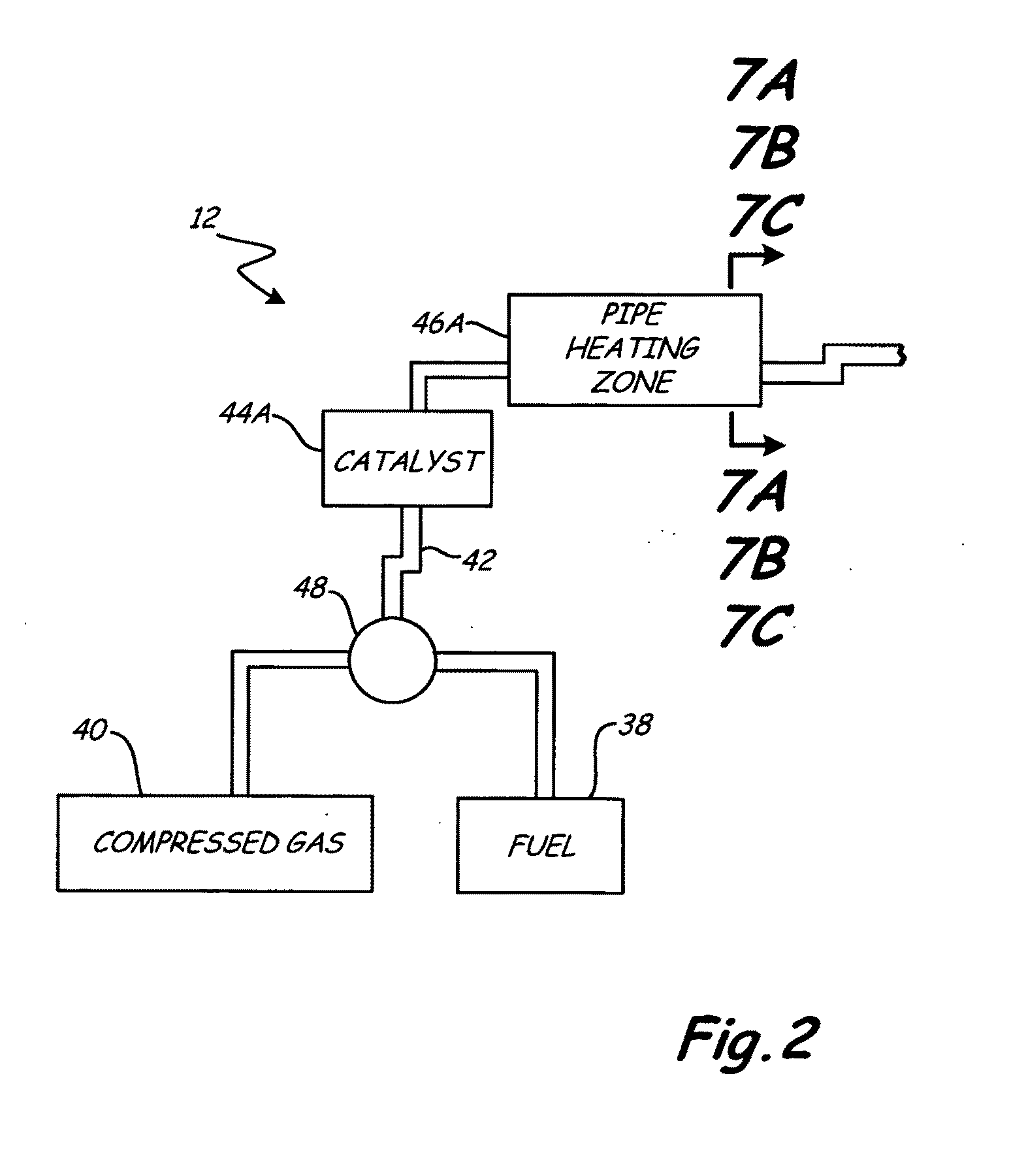

Catalyzed hot gas heating system for concentrated solar power generation systems

A solar power generation system includes a fluid housing, a solar collector, and a heating system. The fluid housing contains a heat transfer medium. The solar collector concentrates solar energy onto the heat transfer medium. The heating system includes at least one gas tank containing a gas and fluidically connected to a first catalyst. The first catalyst is configured to catalyze gas from the gas tank to create hot gas. The heating system also includes a first hot gas pipe fluidically connected to the first catalyst and positioned with respect to the fluid housing such that hot gas flowing through the first hot gas pipe comes into thermal contact with the heat transfer medium within the fluid housing.

Owner:SOLARRESERVE TECH

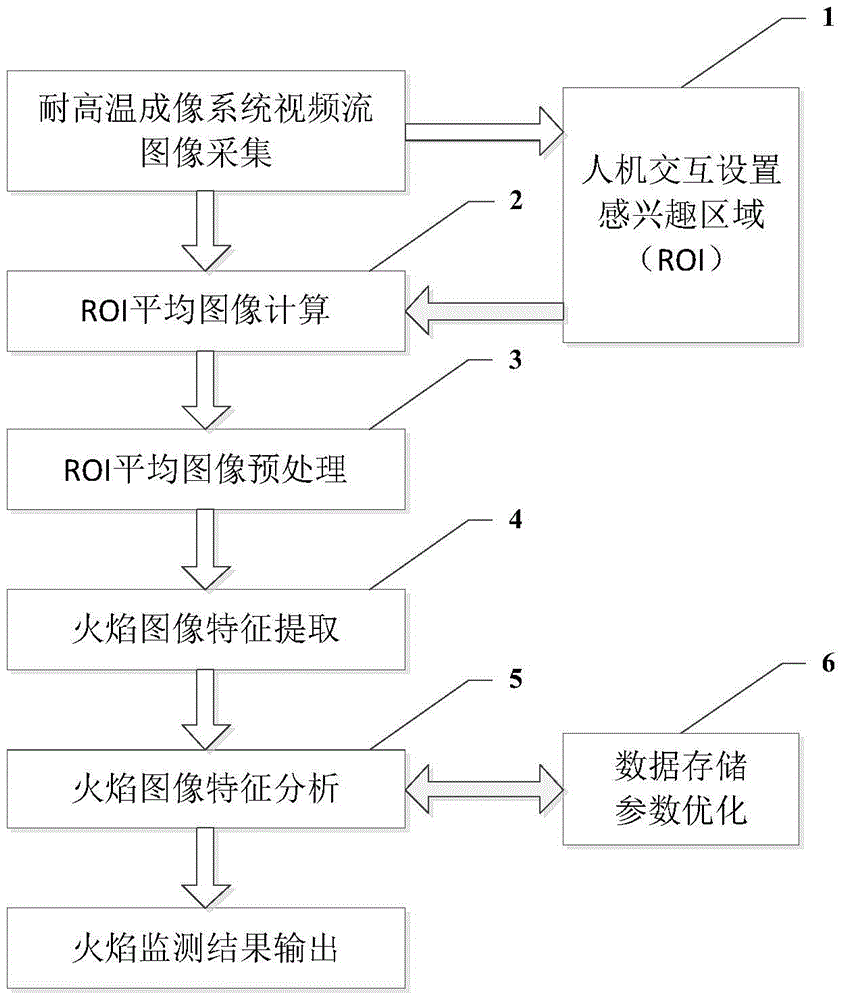

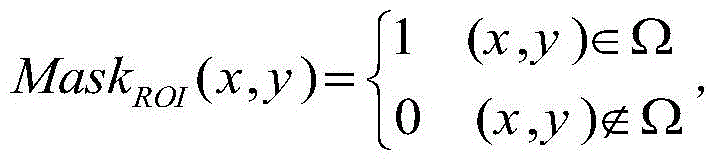

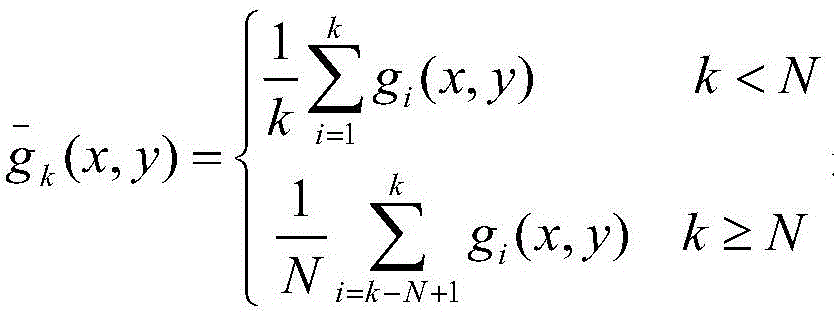

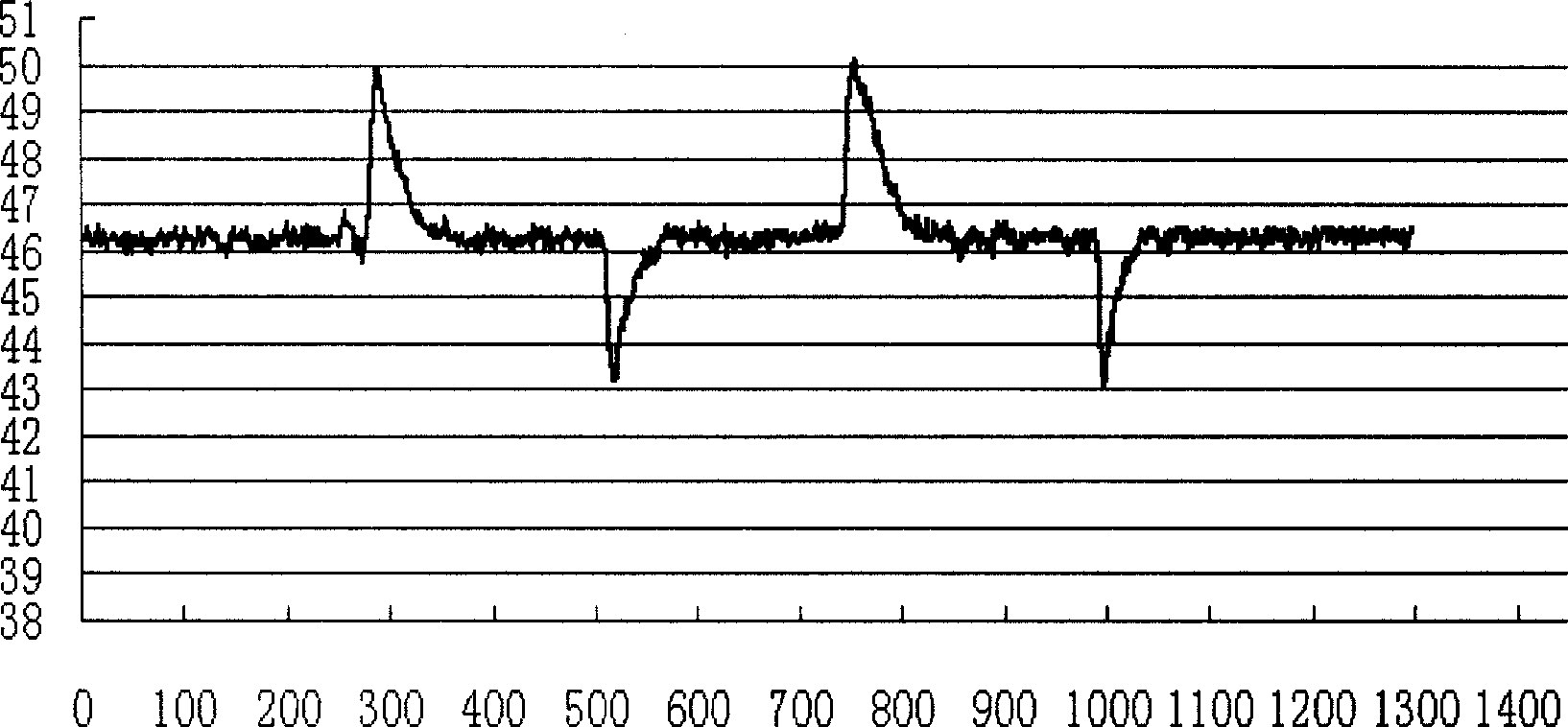

Method for real-time monitoring gas heating furnace flame on the basis of ROI average image analysis

InactiveCN105678295AAccurate monitoringReduce noise interferenceCharacter and pattern recognitionVideo monitoringLightness

The invention discloses a method for real-time monitoring gas heating furnace flame on the basis of ROI average image analysis which belongs to the field of industrial heating furnace flame video monitoring. The method comprises following steps: 1) setting a flame region of interest(ROI) through a human-computer interaction method; 2) extracting a ROI image from a flame monitoring video flow and calculating an average image; 3) pre-treating the ROI average image, including noise smoothing, threshold segmenting, morphological processing, to determine the most probable flame pixel region; 4) extracting flame features from the pre-treated image, comprising flame region area, average brightness, mass center and flame color principal components; 5) synthetically analyzing flame feature, establishing judgment rules, automatically identifying flame burning status and outputting; 6) establishing off-line self-study model by use of historical data, optimizing system parameters, increasing method robustness. The method can be applied for real-time monitoring combustion conditions of gas heating furnace with single-burner or multi-burner and guarantees safety of industrial production.

Owner:WUHAN UNIV OF SCI & TECH

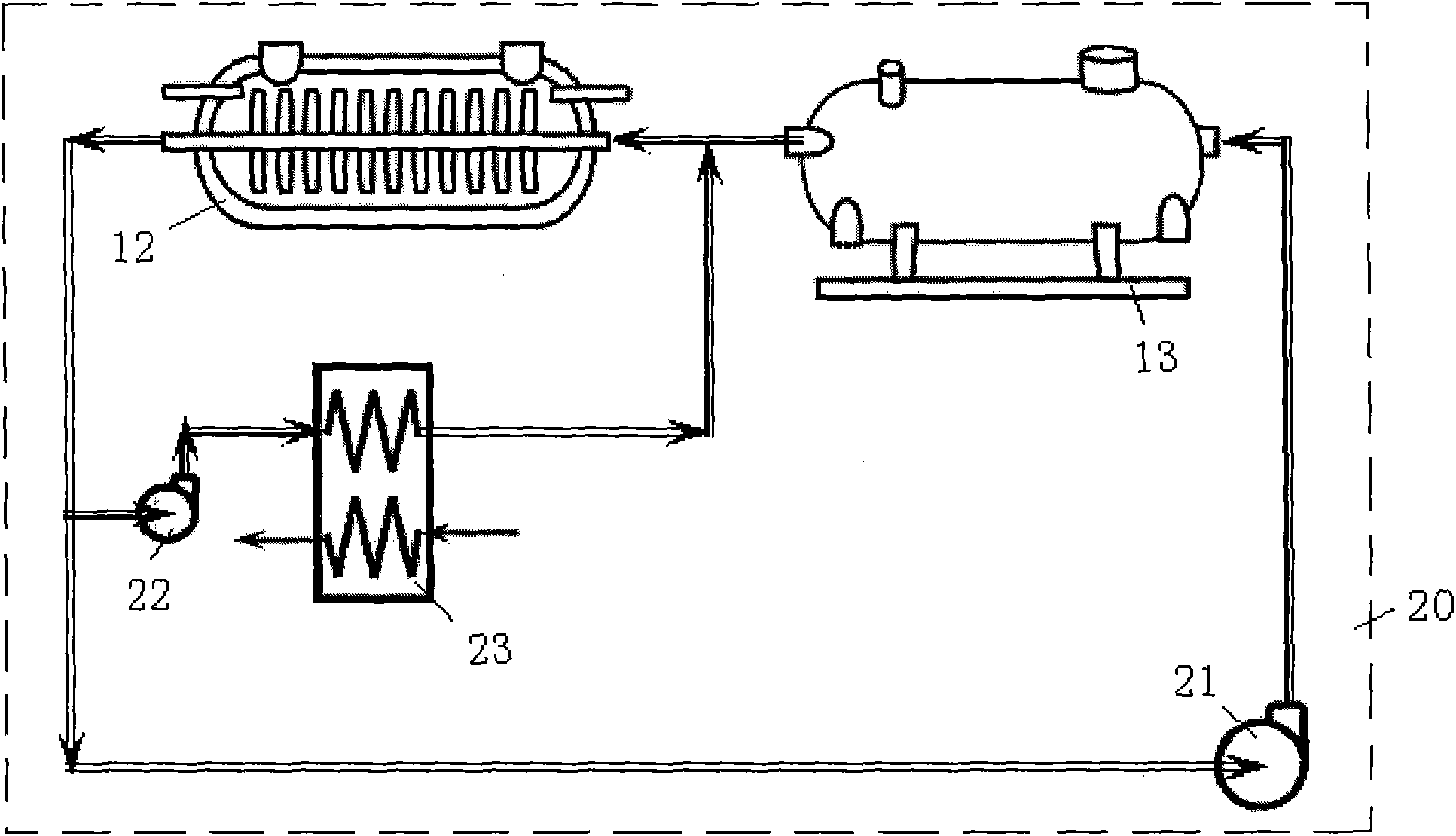

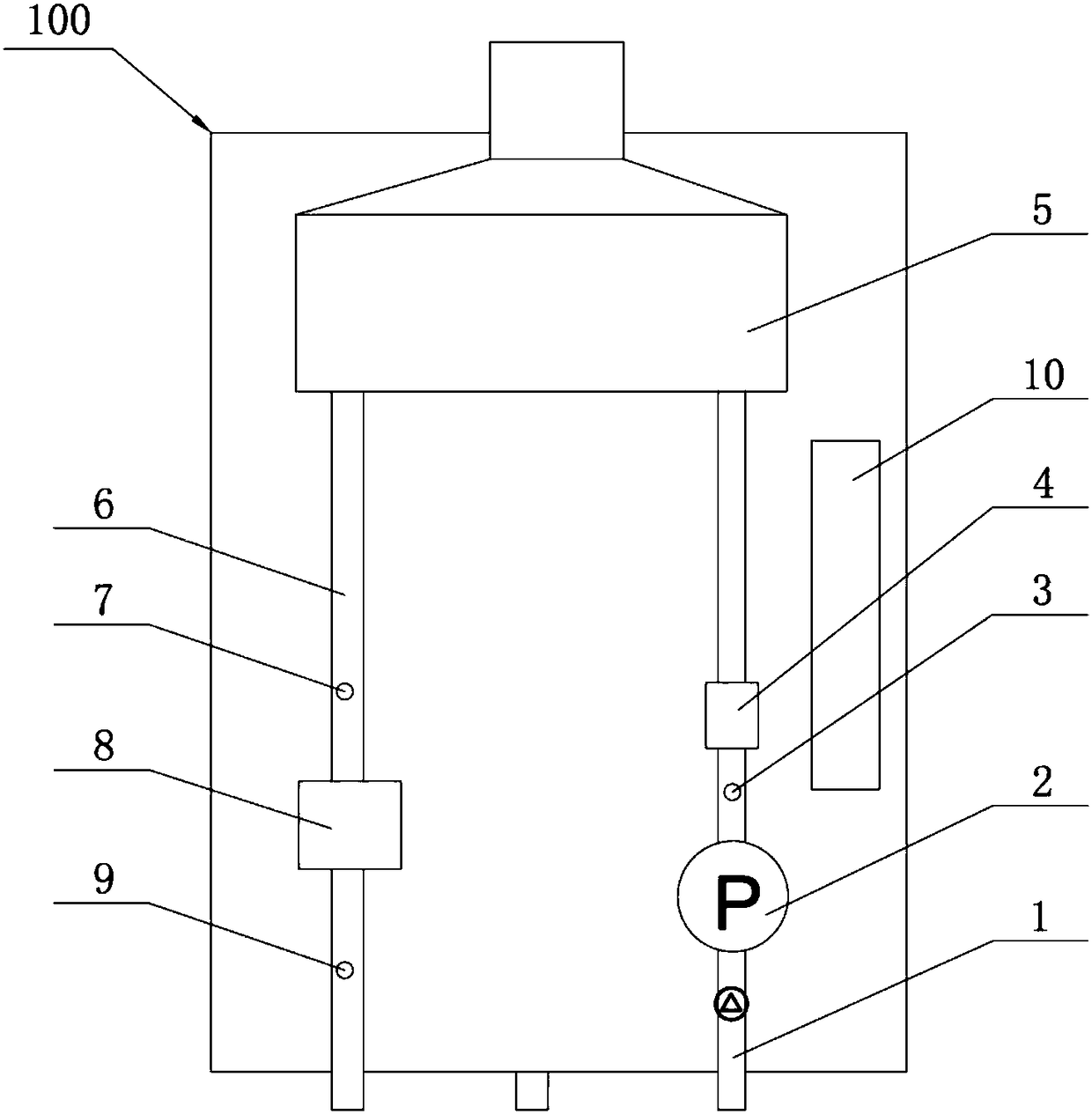

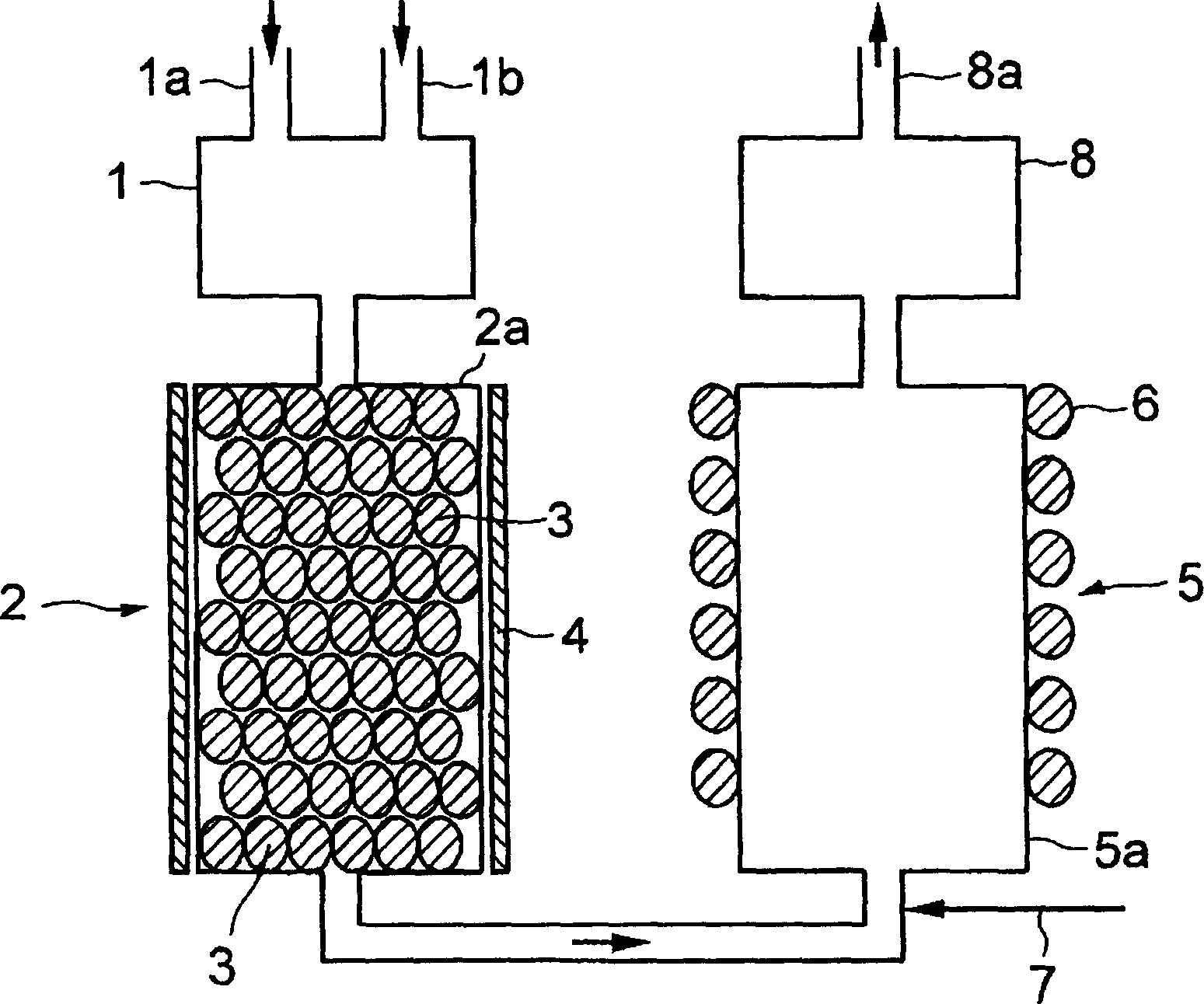

Pneumoperitoneum gas heating and humidifying apparatus and device for inducing pneumoperitoneum

InactiveUS20030028139A1Lighting and heating apparatusDiagnosticsGas cylinderCarbon dioxide gas cylinder E

The present invention aims to provide a pneumoperitoneum gas heating and humidifying apparatus and a pneumoperitoneum device employing this apparatus, in which there is no contamination of the carbon dioxide gas with bacteria, a clean humidified gas is obtained, and the temperature of gas for which the relay was halted and then restarted does not rise excessively. This pneumoperitoneum gas heating and humidifying apparatus provided with an airline, a water conduit which is provided to at least a portion of the outer periphery of this airline, and water supply ports which are connected to the water conduit, wherein at least a portion of the wall of the airline facing the water conduit is formed of a water permeable membrane. The present invention further provides a pneumoperitoneum device in which a carbon dioxide gas cylinder, a gas flow regulator, and a trocar catheter are sequentially connected via piping.

Owner:SENKO MED INSTR MFG CO LTD

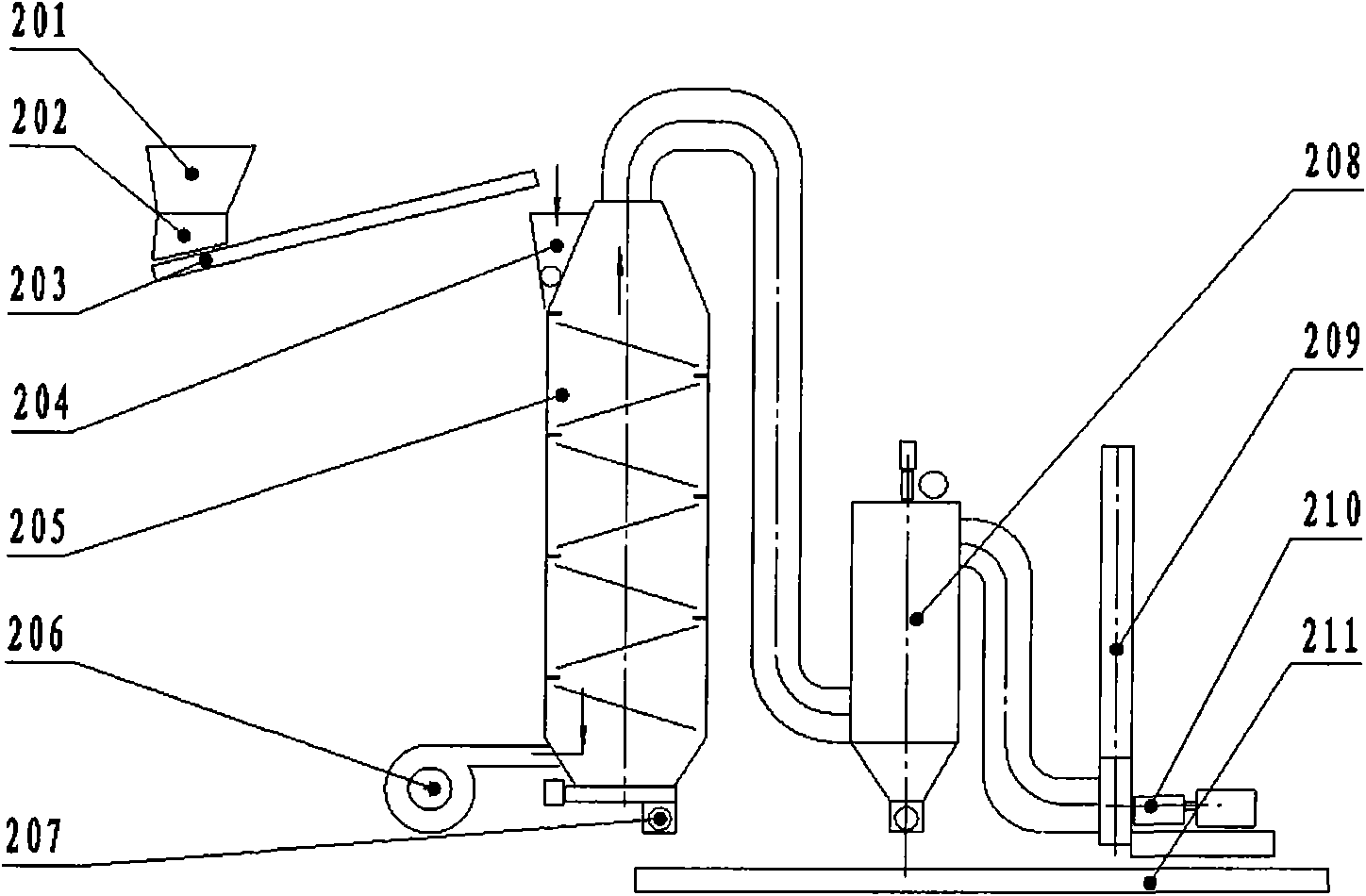

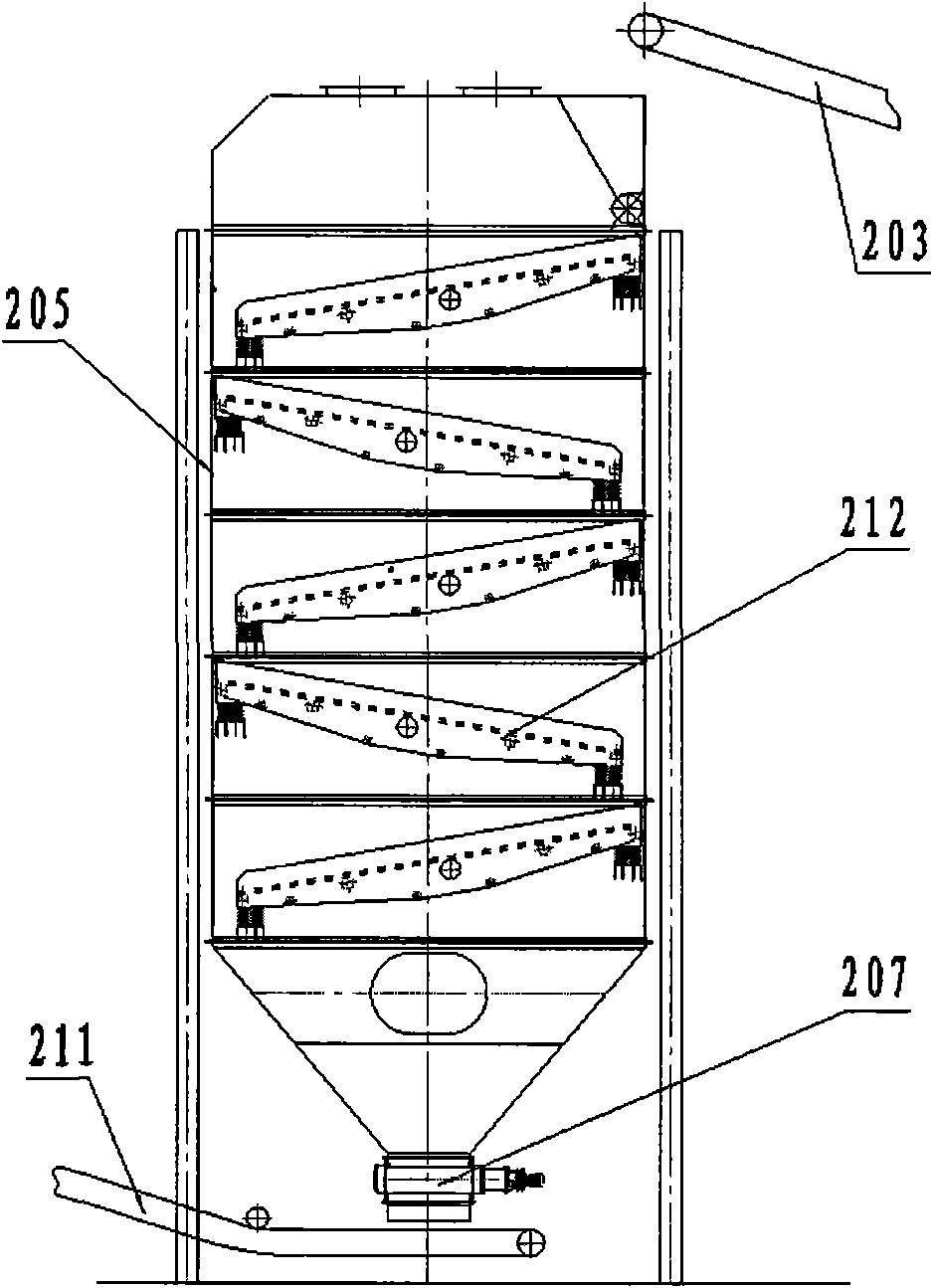

Spiral push type low temperature pyrolysis carbonation furnace

InactiveCN102154019AImprove product qualityQuality improvementBiofuelsEnergy inputElectricityLower grade

The invention discloses a spiral push type low temperature pyrolysis carbonation furnace which comprises a bracket and a furnace body, wherein the furnace body is provided with a feed port and a discharge hole; the furnace body comprises an inner heating cylinder and an outer heating cylinder which are sleeved together; the tail end of the inner heating cylinder penetrates out of the outer heating cylinder; the tail end of the inner heating cylinder is provided with an tail gas outlet; the outer heating cylinder is provided with a high temperature smoke gas inlet and a high temperature smoke gas outlet; a plurality of deflectors are misplaced on the inner wall of the outer heating cylinder and the outer wall of the inner heating cylinder; and a plurality of hollow material transportation screws penetrate through the furnace, and the inside of the furnace body is provided with an electricity or smoke gas heating device. Because a double-layer tube-in-tube structure and a spiral push type pyrolysis carbonation mode are adopted and the tail gas outlet is arranged at the tail end of the inner heating cylinder, the spiral push type low temperature pyrolysis carbonation furnace has the characteristics that raw material adaptability is wide and a structure is simple, tail gas waste heat and low-grade pyrolysis carbonized gas can be fully utilized, thermal efficiency is high, and the like.

Owner:江苏华威龙玖环保科技有限公司

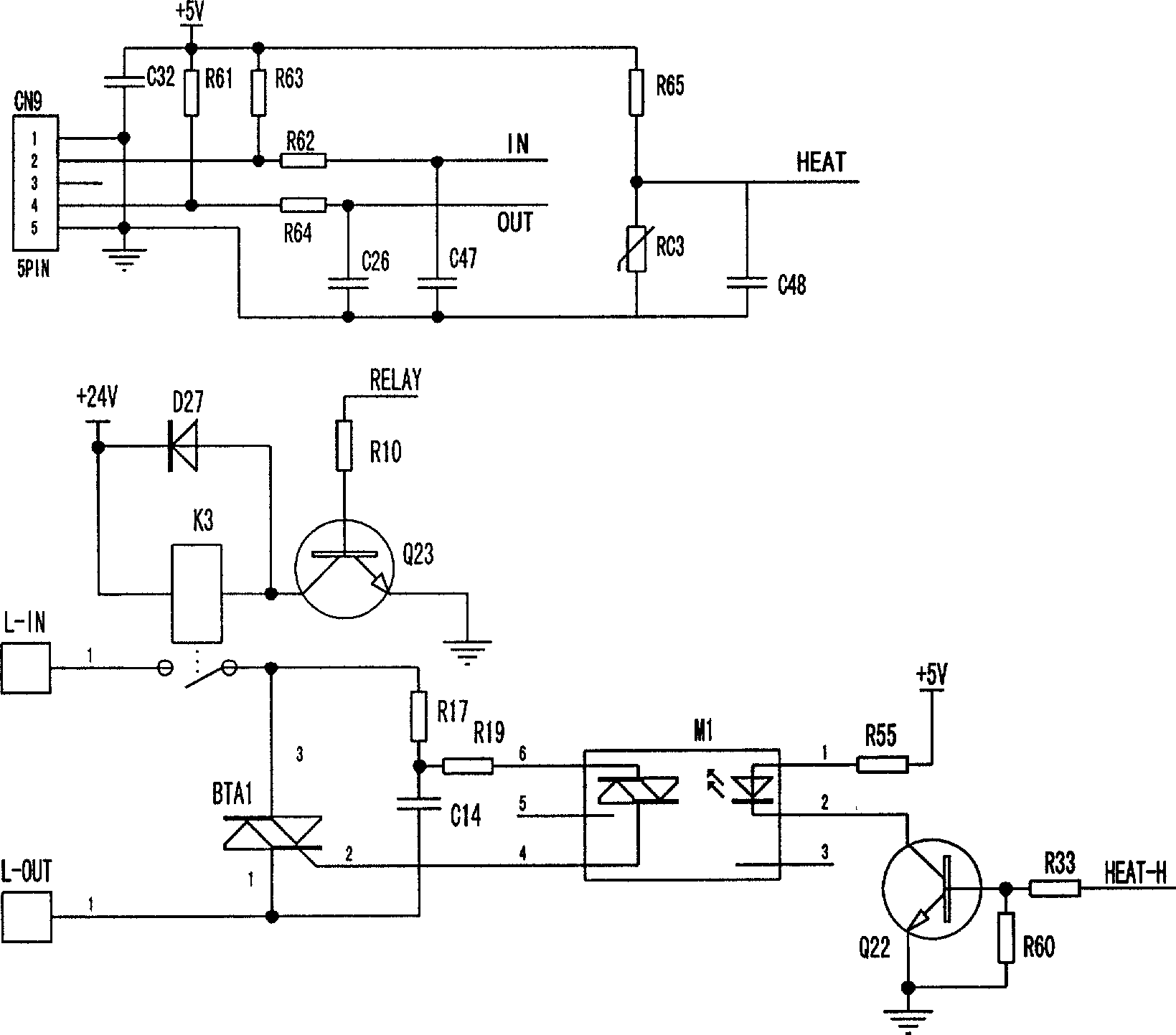

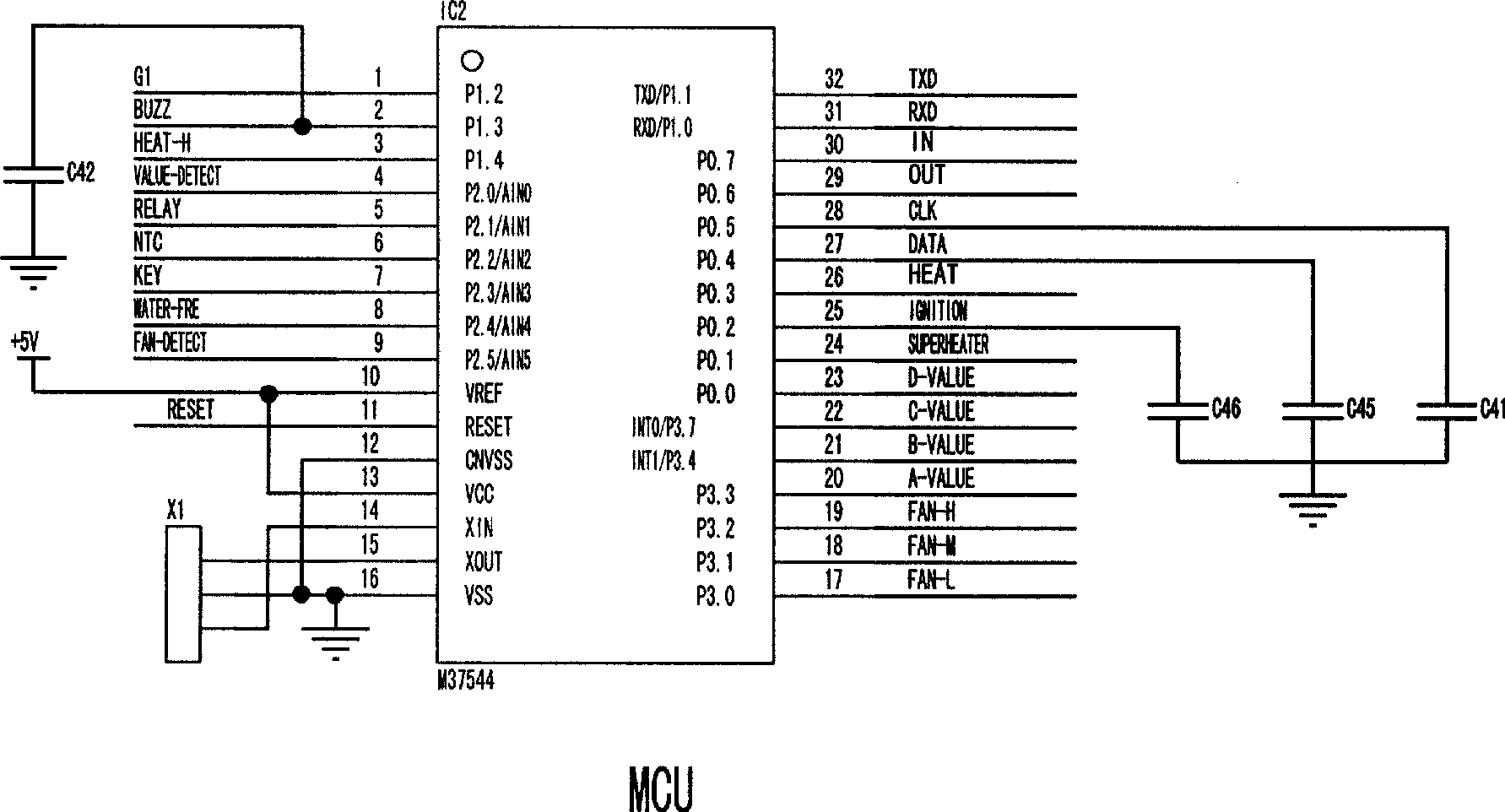

Mixed energy thermostatic control water heater

InactiveCN101424447ASimple structureReduce startup timeSpace heating and ventilation detailsWater heatersElectricityWater flow

The invention relates to a hybrid-energy thermostatic control water heater, which belongs to the technical field of water heaters. The water heater comprises a gas heating part, an electric heating part and a control circuit, wherein the control circuit comprises an electric energy output control device; the electric heating part consists of a water flow channel and an electric heating device arranged in the water flow channel; the gas heating part and the water flow channel of the electric heating part form a series or parallel flow passage; an ultimate water outlet of the flow passage is provided with a temperature sensor; the output end of the temperature sensor is connected with the signal input end of the control circuit; the signal input end is connected with the controlled end of the electric energy output control device through the control circuit; and the output end of the electric energy output control device is connected with the electric heating device. The water heater has the advantages that the water heater is very sensitive and accurate in temperature regulation, and can effectively guarantee the temperature constancy of effluent water.

Owner:A O SMITH CHINA WATER HEATER CO LTD

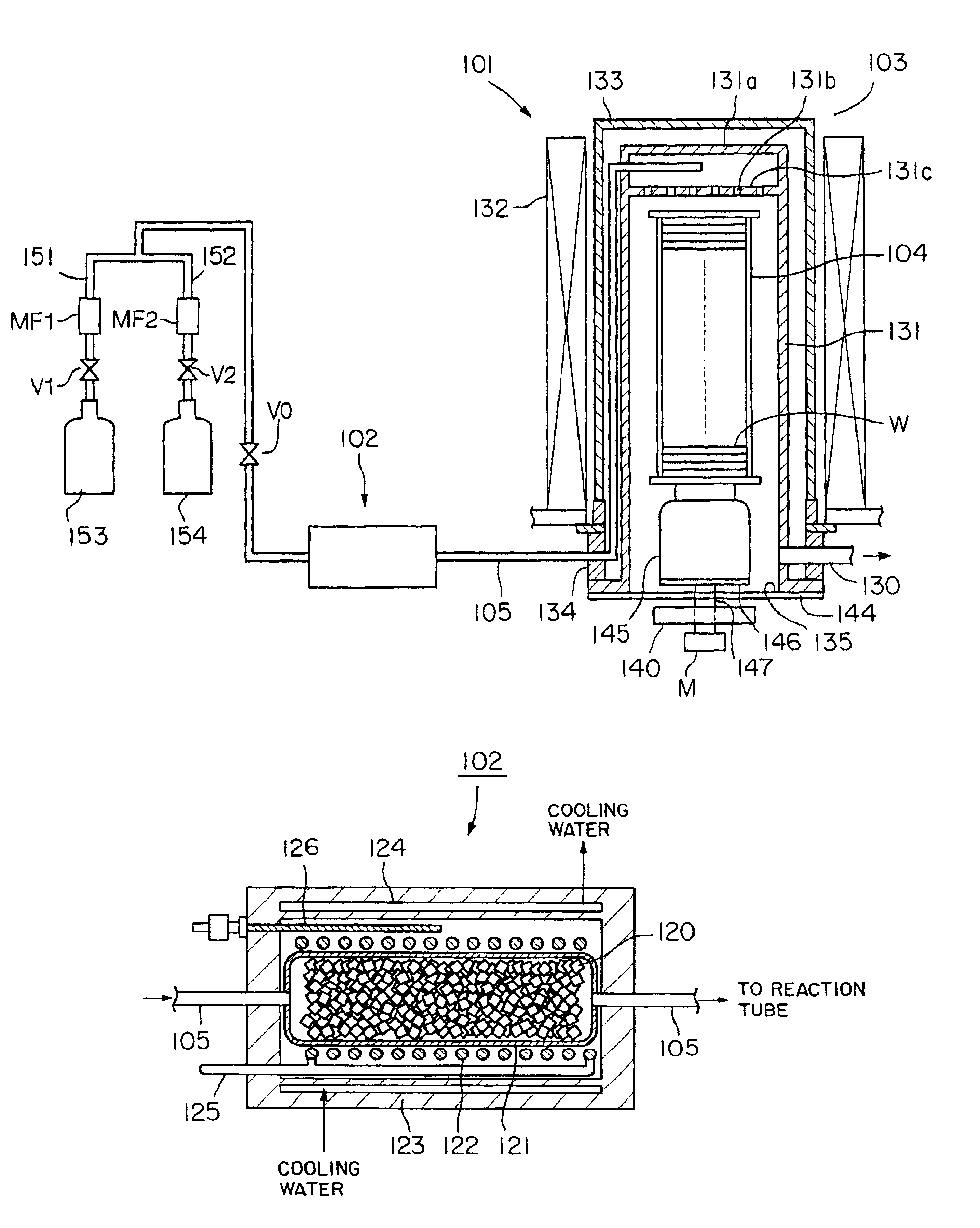

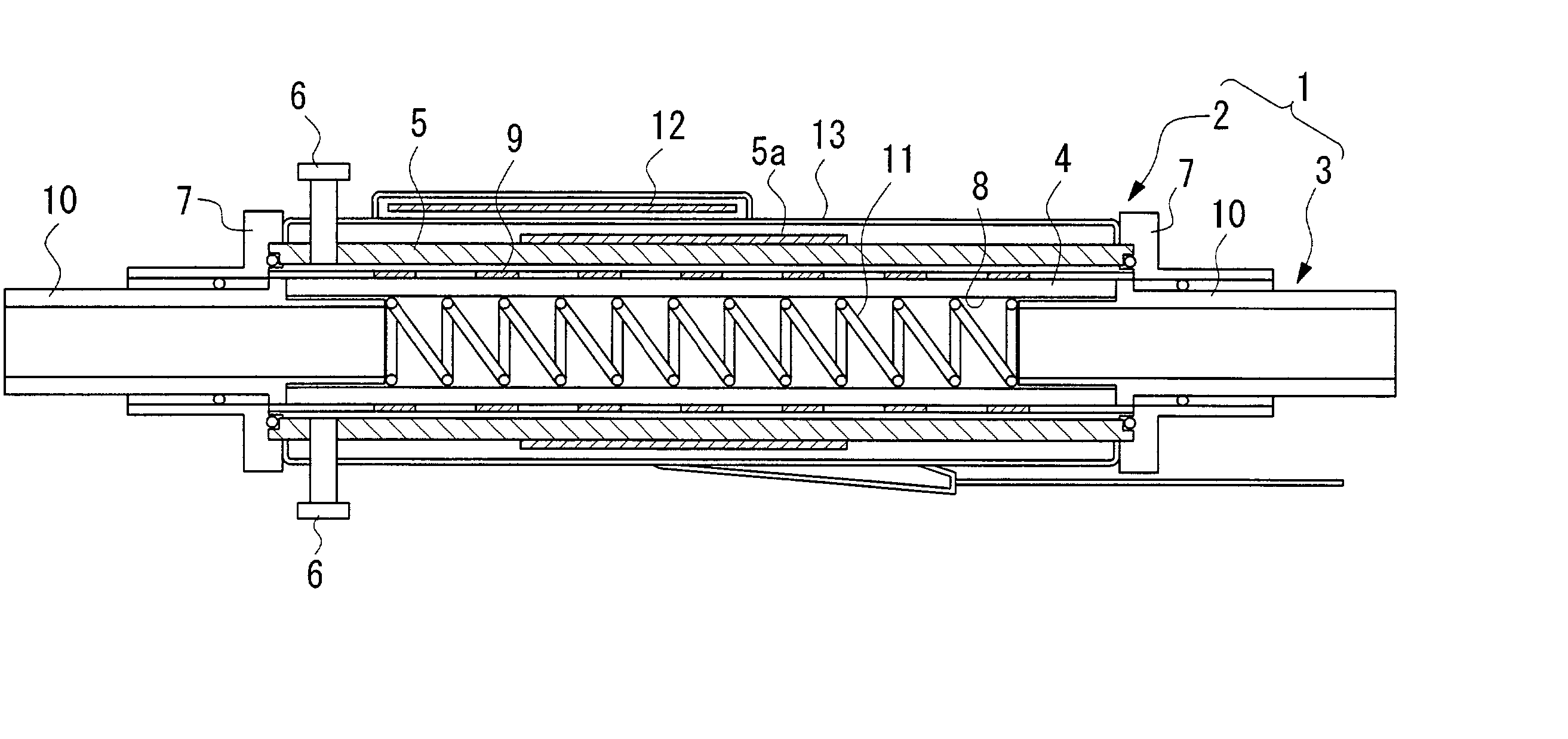

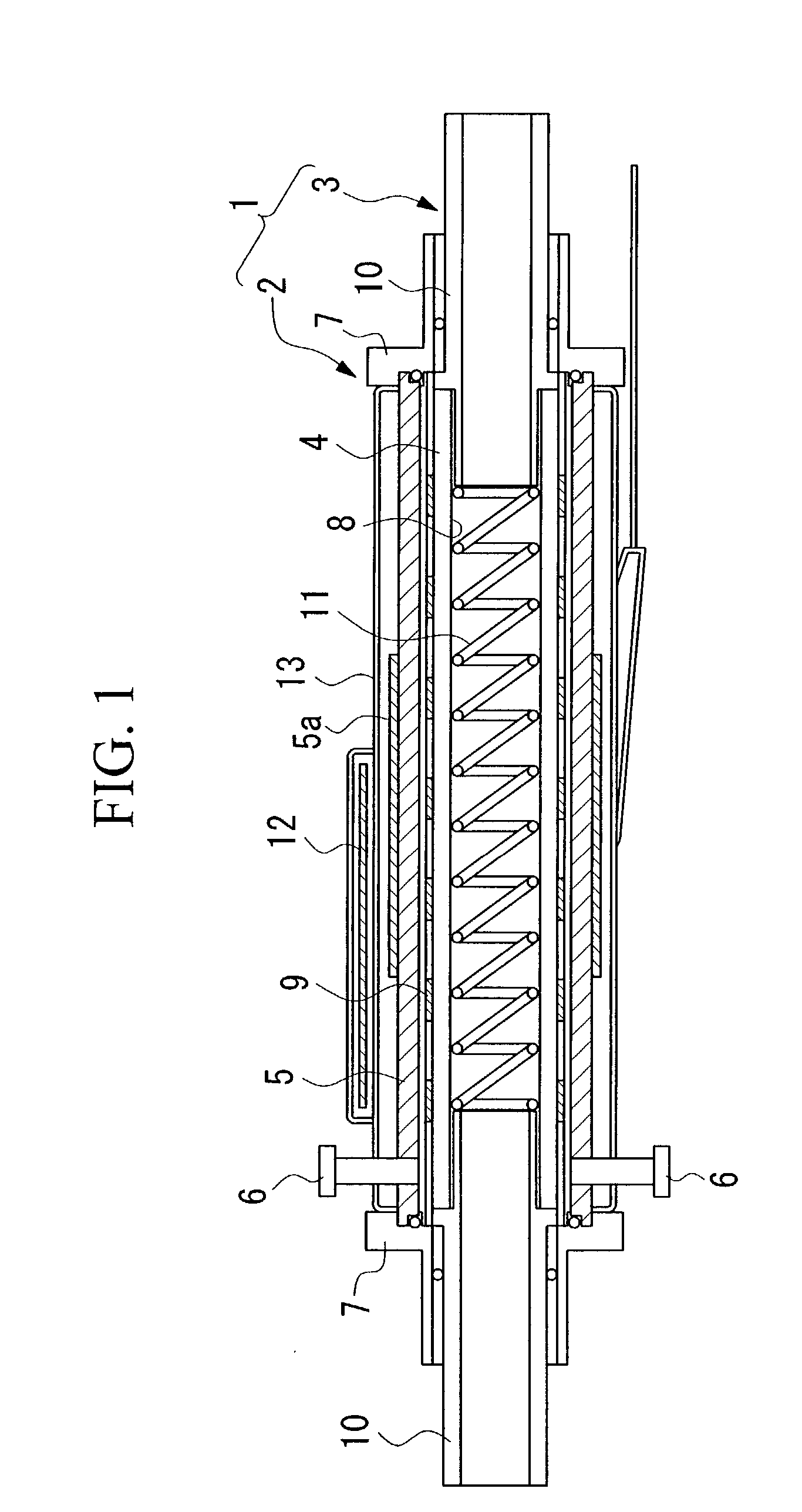

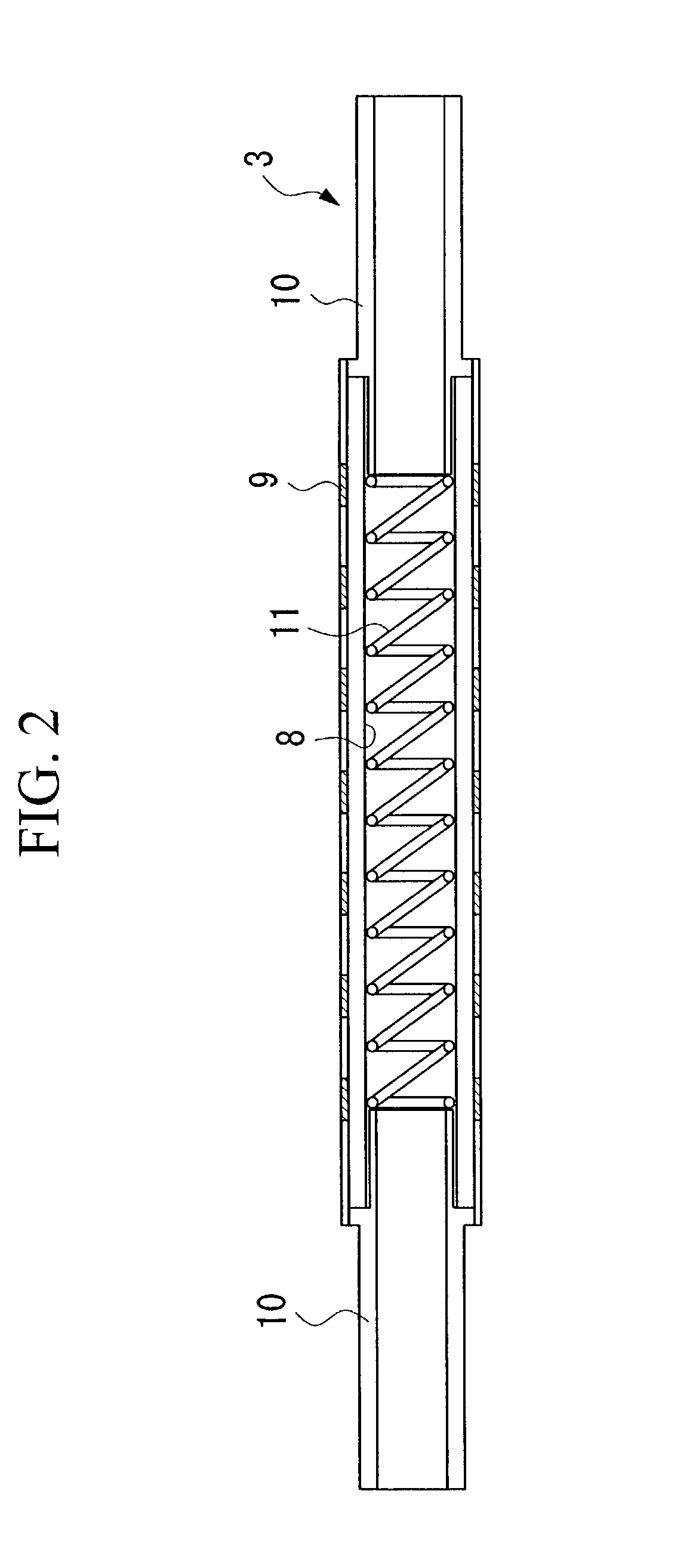

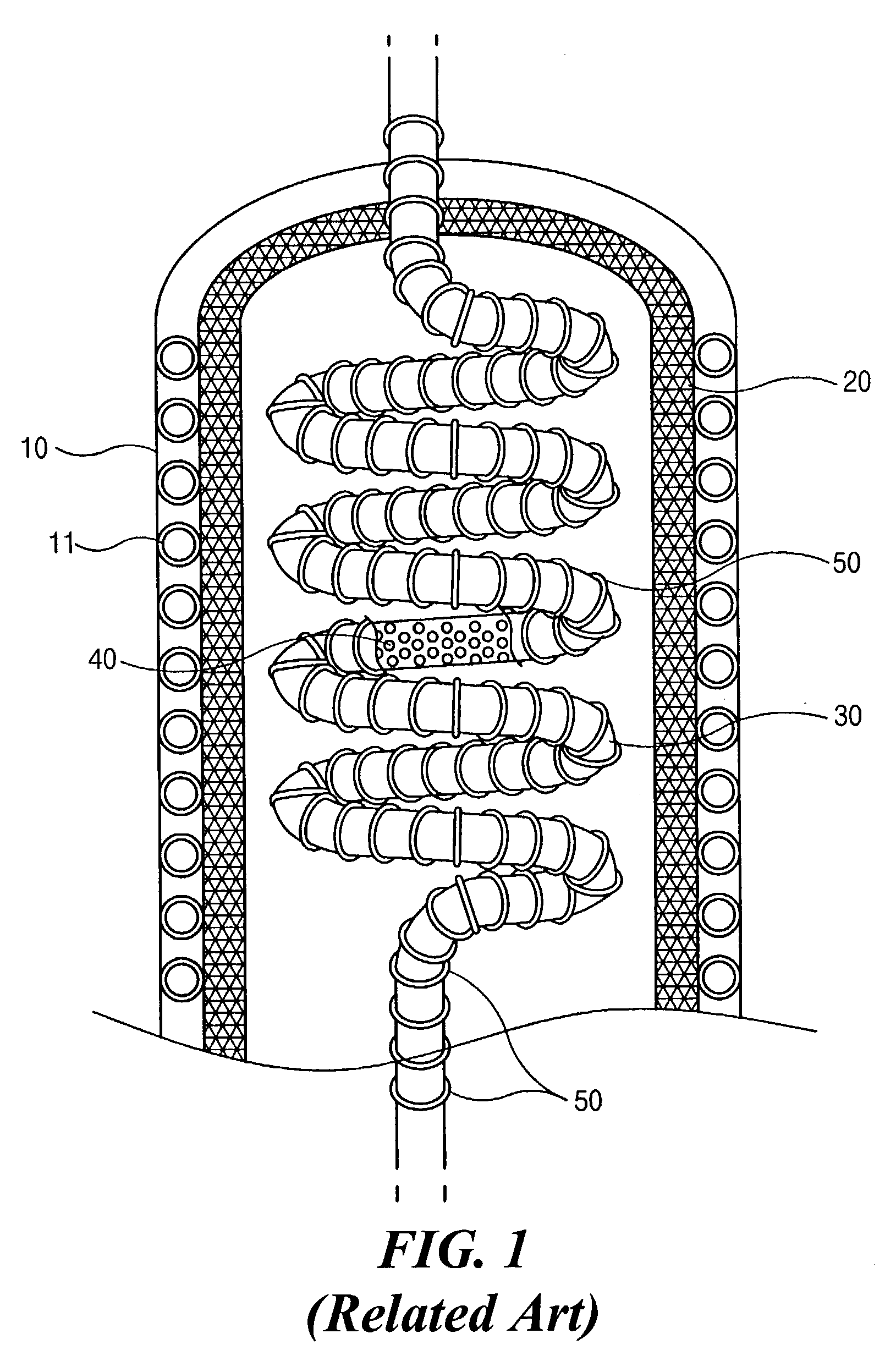

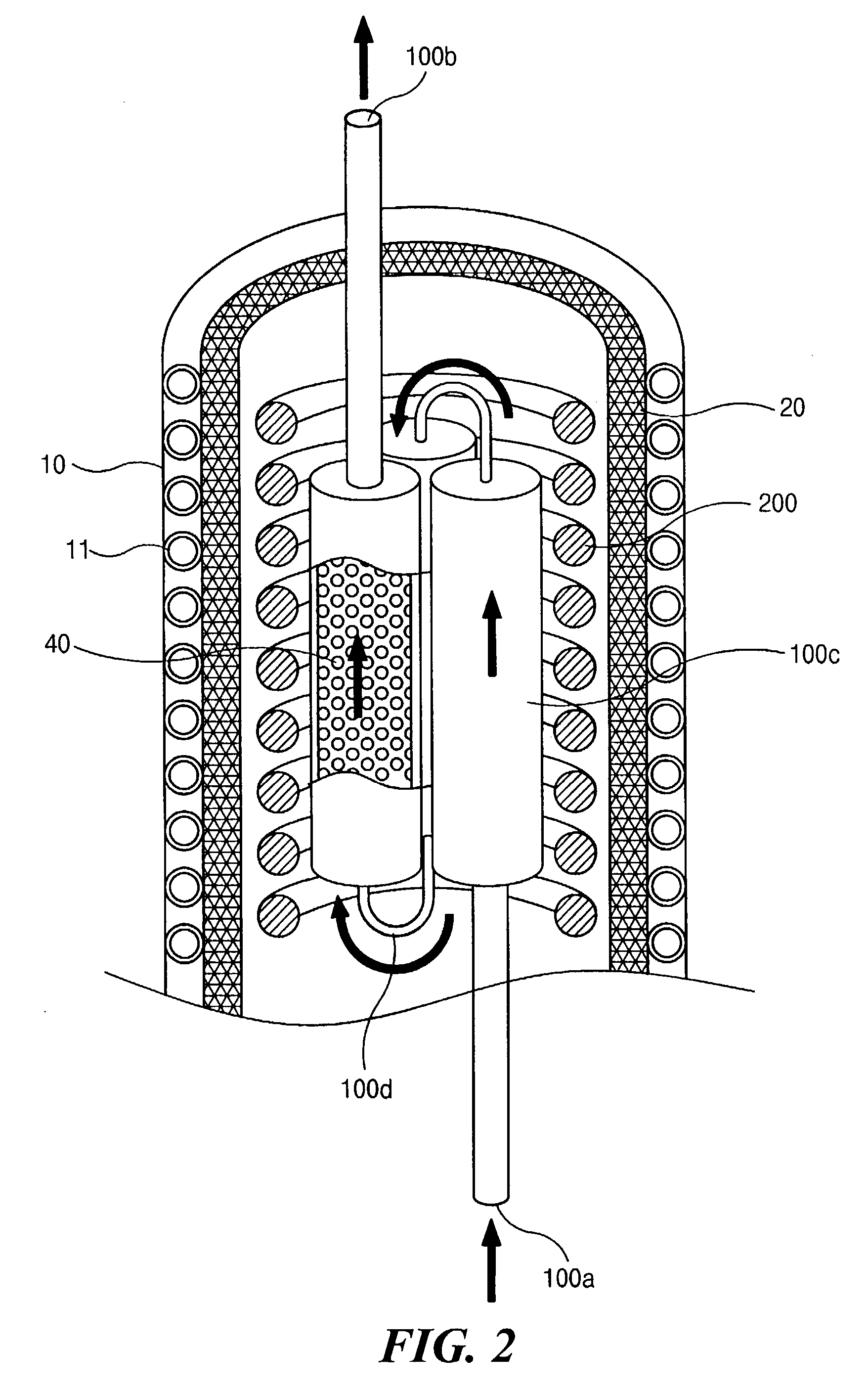

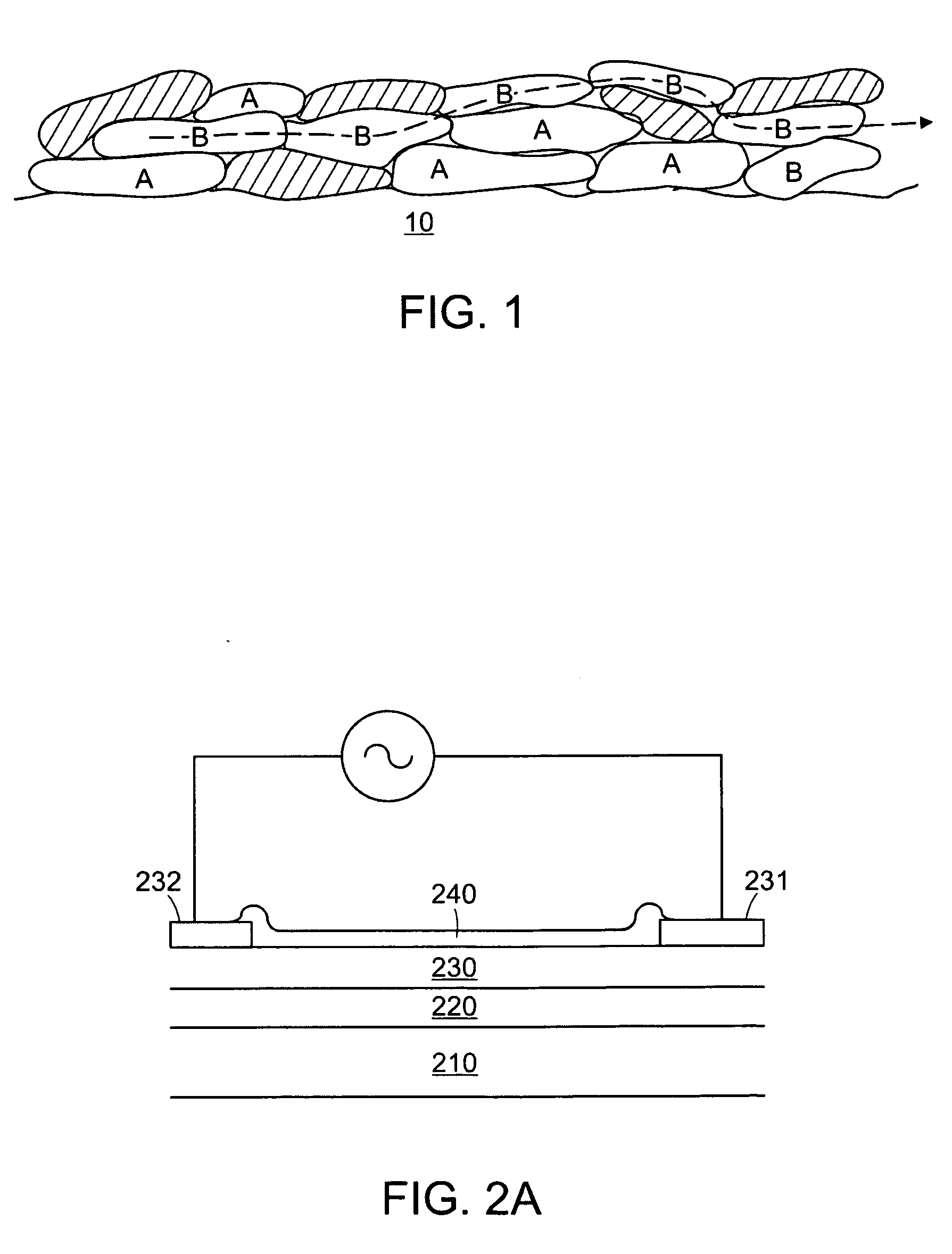

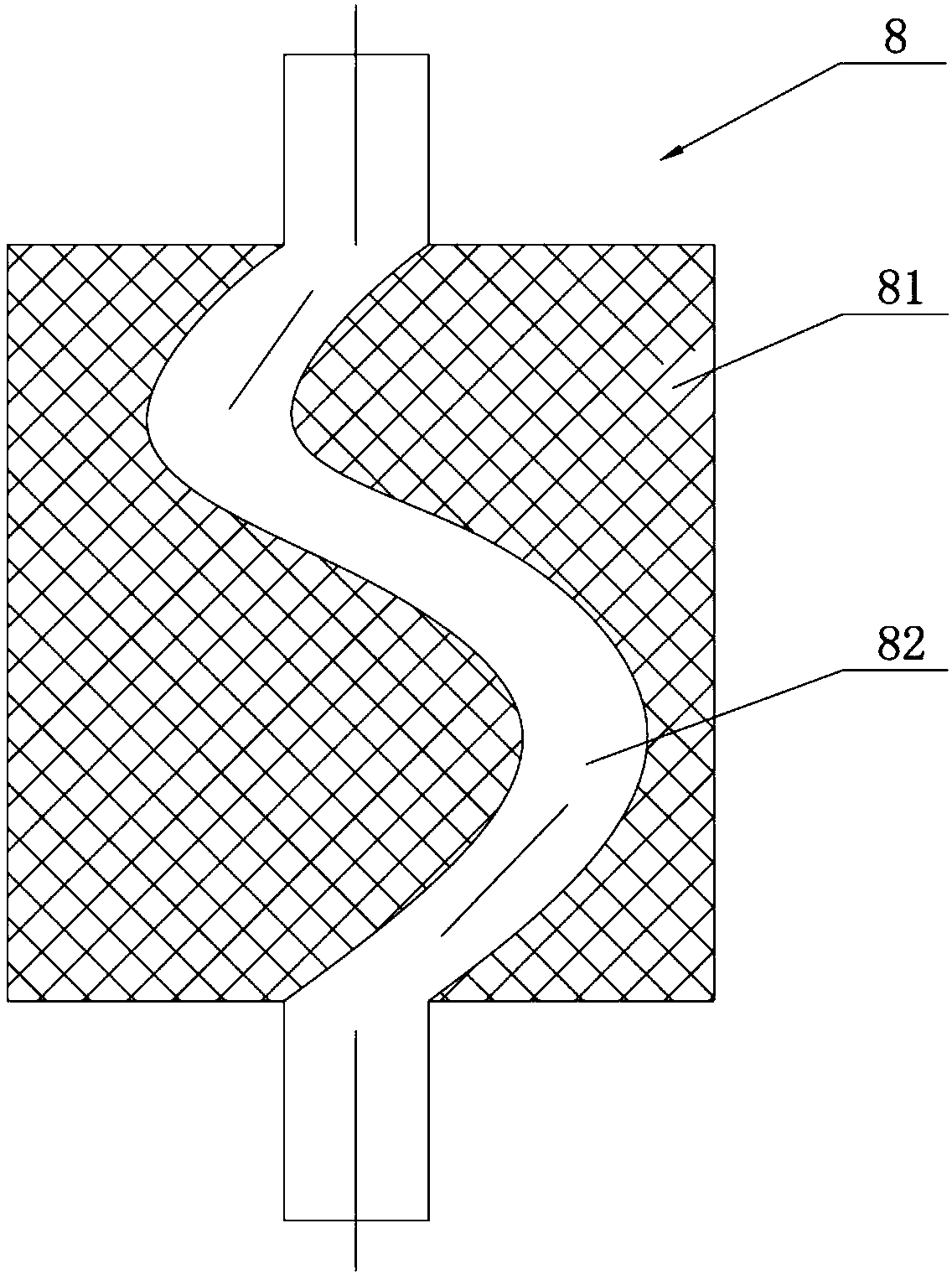

Gas heating apparatus for chemical vapor deposition process and semiconductor device fabrication method using same

InactiveUS20030221617A1Semiconductor/solid-state device manufacturingStationary tubular conduit assembliesGas phaseCoil spring

The present invention provides a gas heating apparatus that activates reaction gases for a chemical vapor deposition. The gas heating apparatus includes a chamber becoming enclosures of the gas heating apparatus; a heat insulating material 20 formed on an inner surface of the chamber so as to thermally insulate the inside of the chamber from the outside; a quartz tube having a gas inflow pipe, a gas outflow pipe, enlarged-pipe portions and abridged-pipe portion, wherein the enlarged-pipe portions and the abridged-pipe portions are alternately repeated and constitute a zigzag shape in an up-and-down direction in the chamber; a plurality of ceramic balls located inside the enlarged-pipe portions of the quartz tube; and a heater having a shape of coil spring and surrounding the zigzag shape of the quartz tube in the chamber.

Owner:JUSUNG ENG

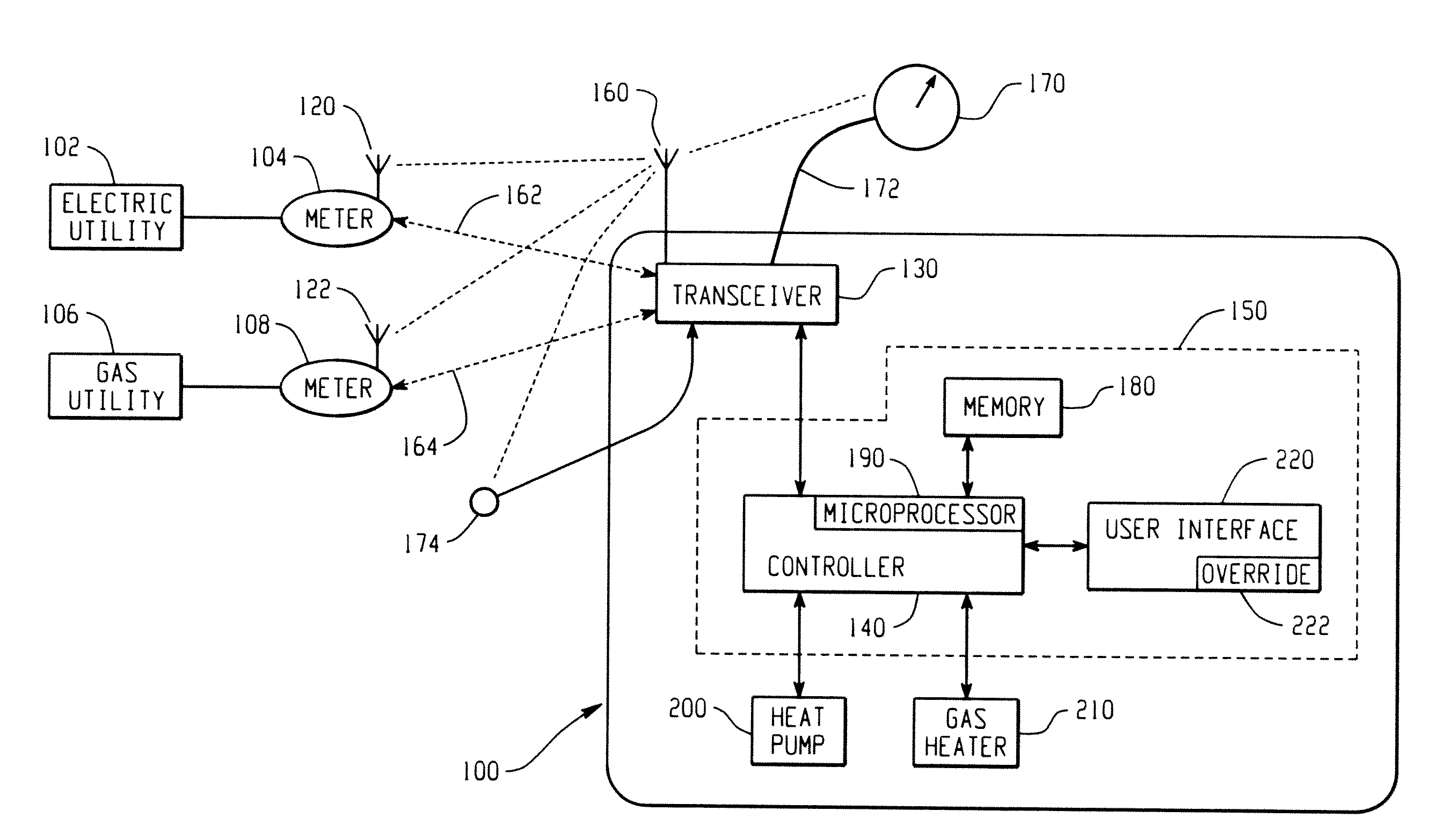

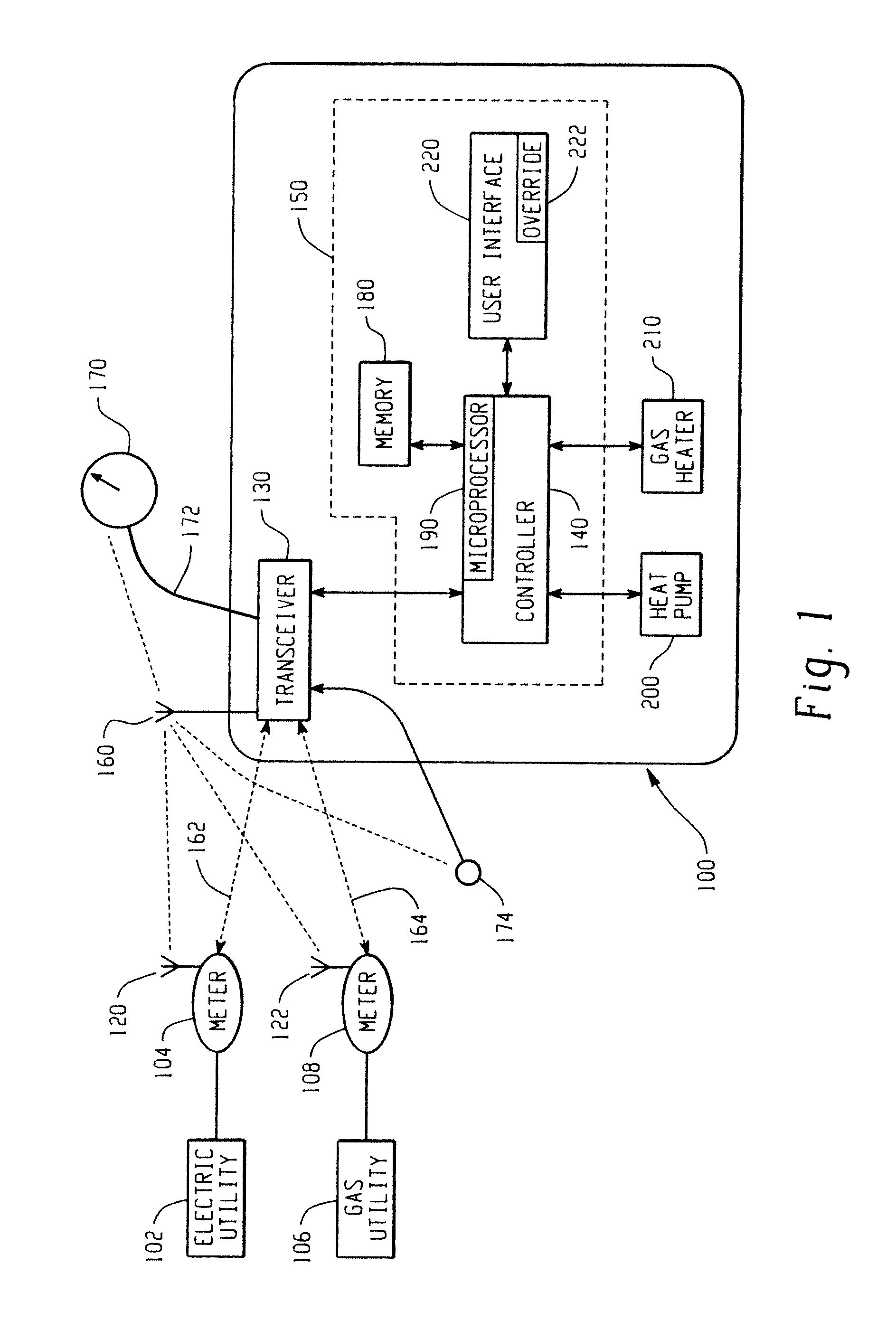

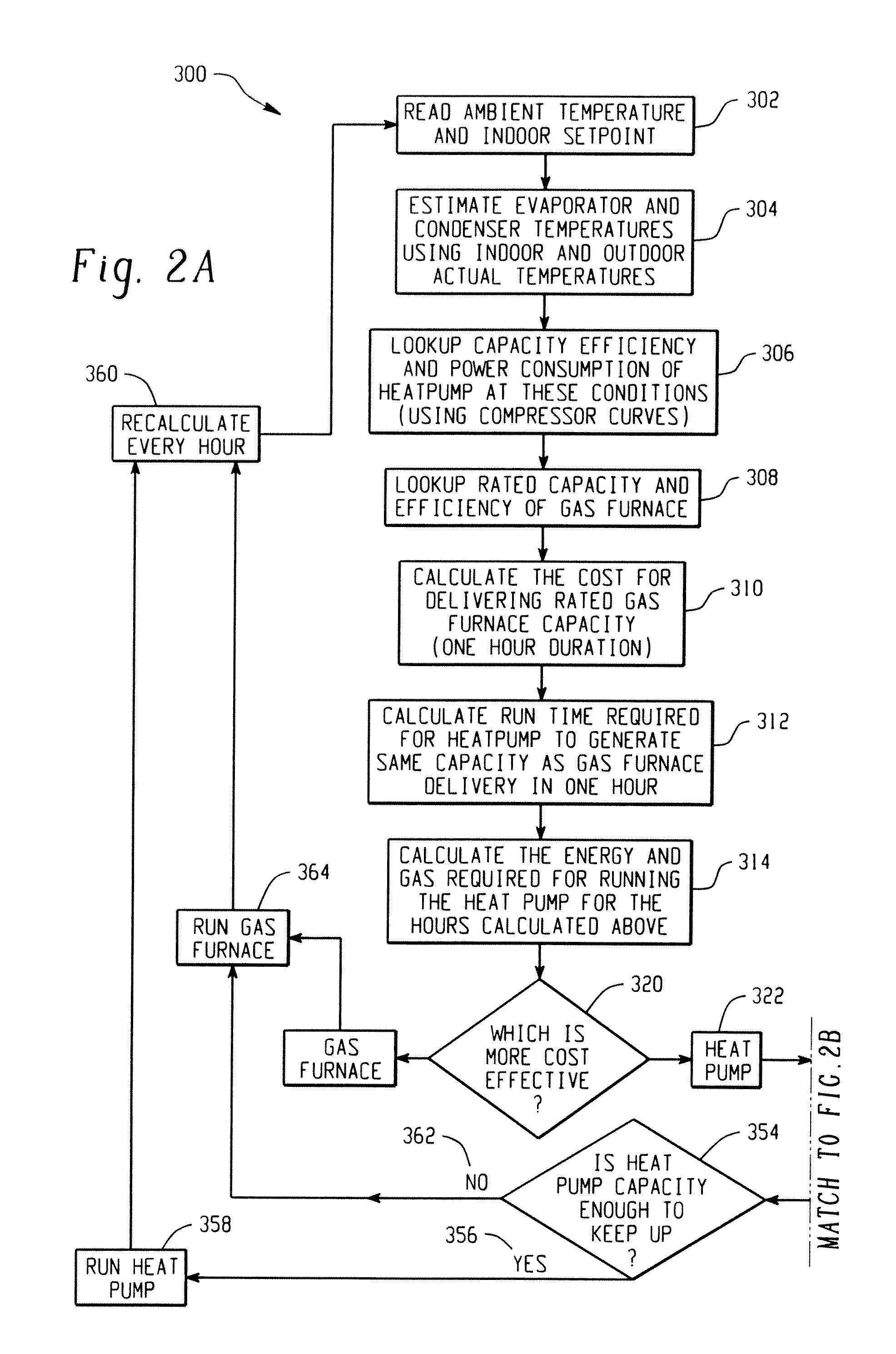

Smart hybrid thermostat

InactiveUS20120029725A1Improve efficiencyIncrease savingsHeating fuelMechanical apparatusGas heaterControl engineering

A system and method for controlling operation of a hybrid heating system that includes a heat pump and a gas heater is disclosed. Peak demand or pricing information is received from gas and electric utilities, and outdoor ambient temperature data is also fed to a smart hybrid thermostat. A controller processes this data and calculates overall efficiency of operating the heat pump versus the gas heater by accessing stored performance data relating to the heat pump in memory.

Owner:GENERAL ELECTRIC CO

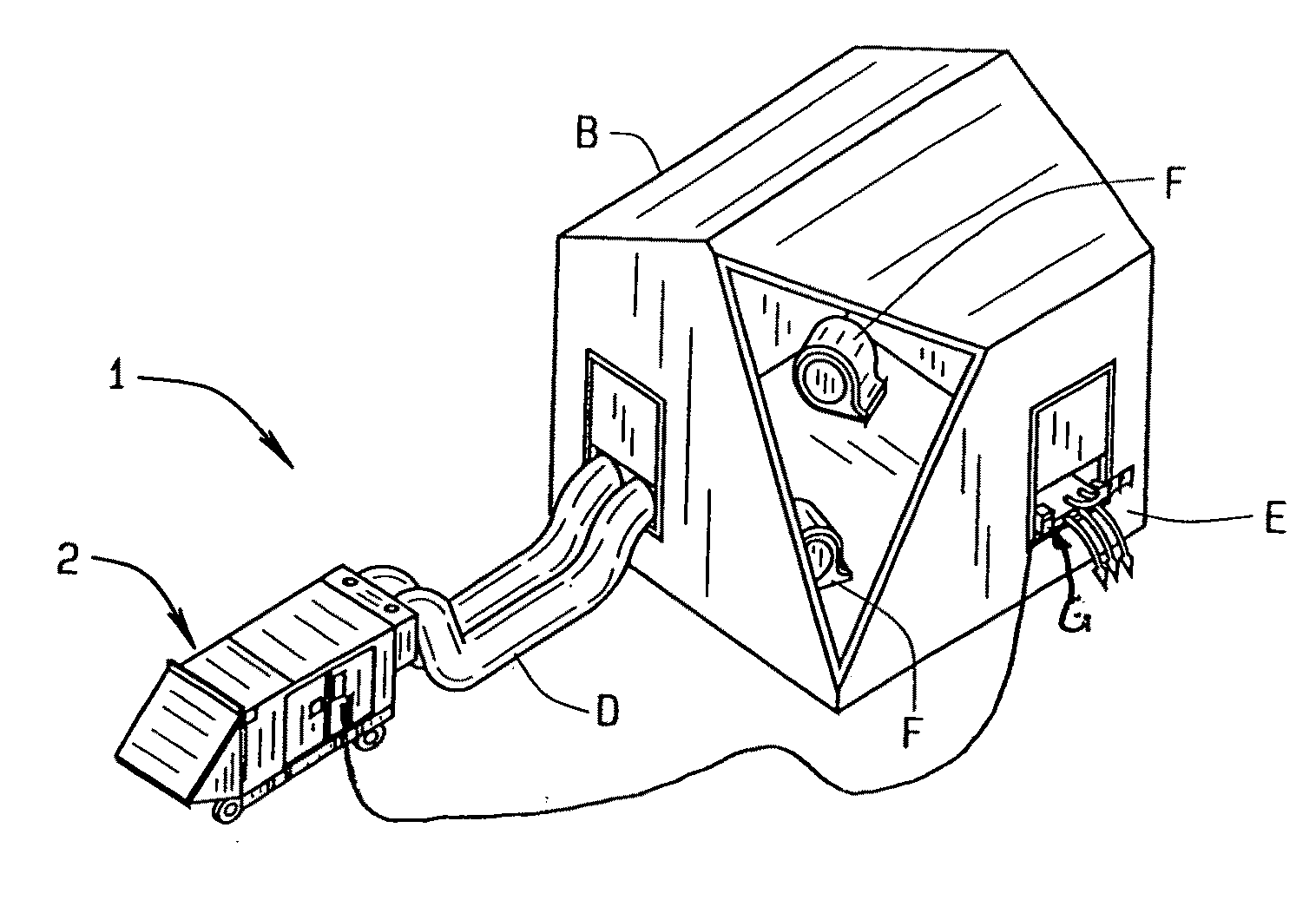

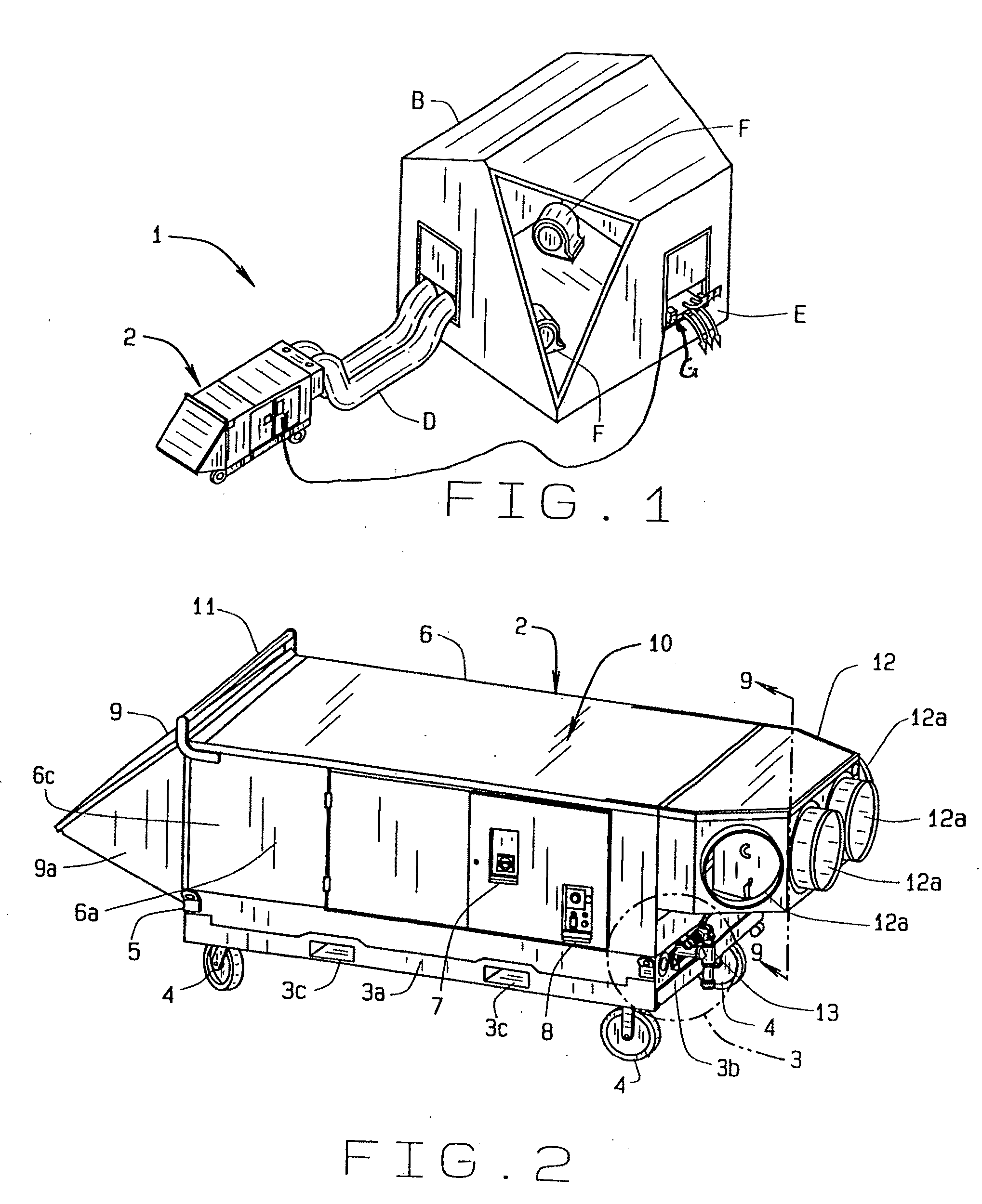

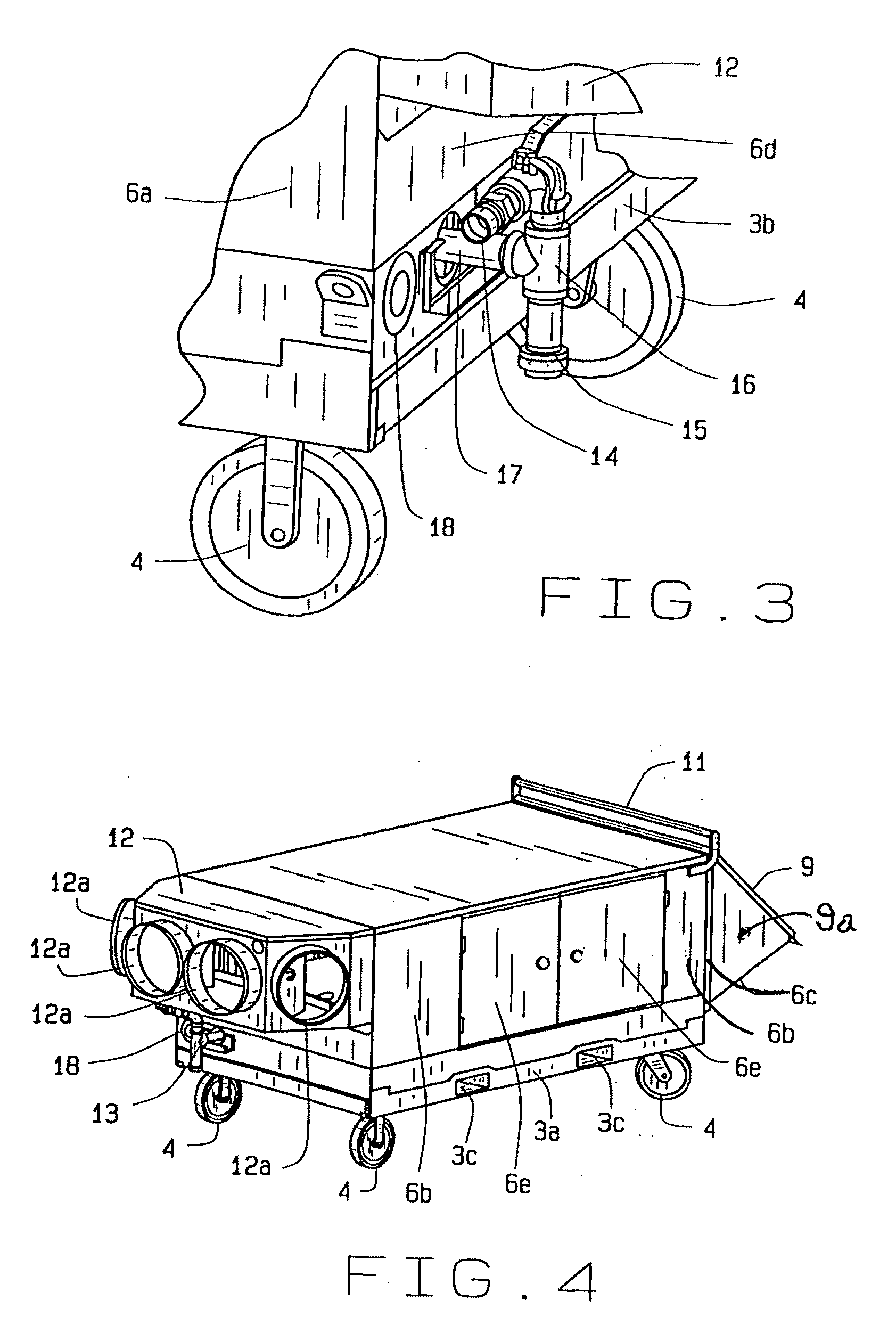

Heater and controls for extraction of moisture and biological organisms from structures

InactiveUS20100024244A1Tremendous ability to absorb water vaporFuel supply regulationDrying solid materials with heatGas heaterAtmospheric air

A gas heater with specialized controls allows an operator to deploy a single device to heat and to dry when extracting moisture from a structure. The heater has a fan in a blow thru arrangement ahead of a burner. The burner uses either natural gas or liquefied petroleum gas. The heater has air flow, fan motor, temperature, and ignition controls and sensors. The heater delivers high temperature air to the structure that hastens evaporation as the heated air absorbs great concentrations of water vapor. Then the moisture laden heated air exits the building as the heater draws in fresh air, ducts it into a structure, and pressurizes the structure. This moisture laden air then leaks from the building through select windows using the energy imparted from the fan and then exhausts the moisture to the atmosphere, drying the structure.

Owner:POTTER GARY J

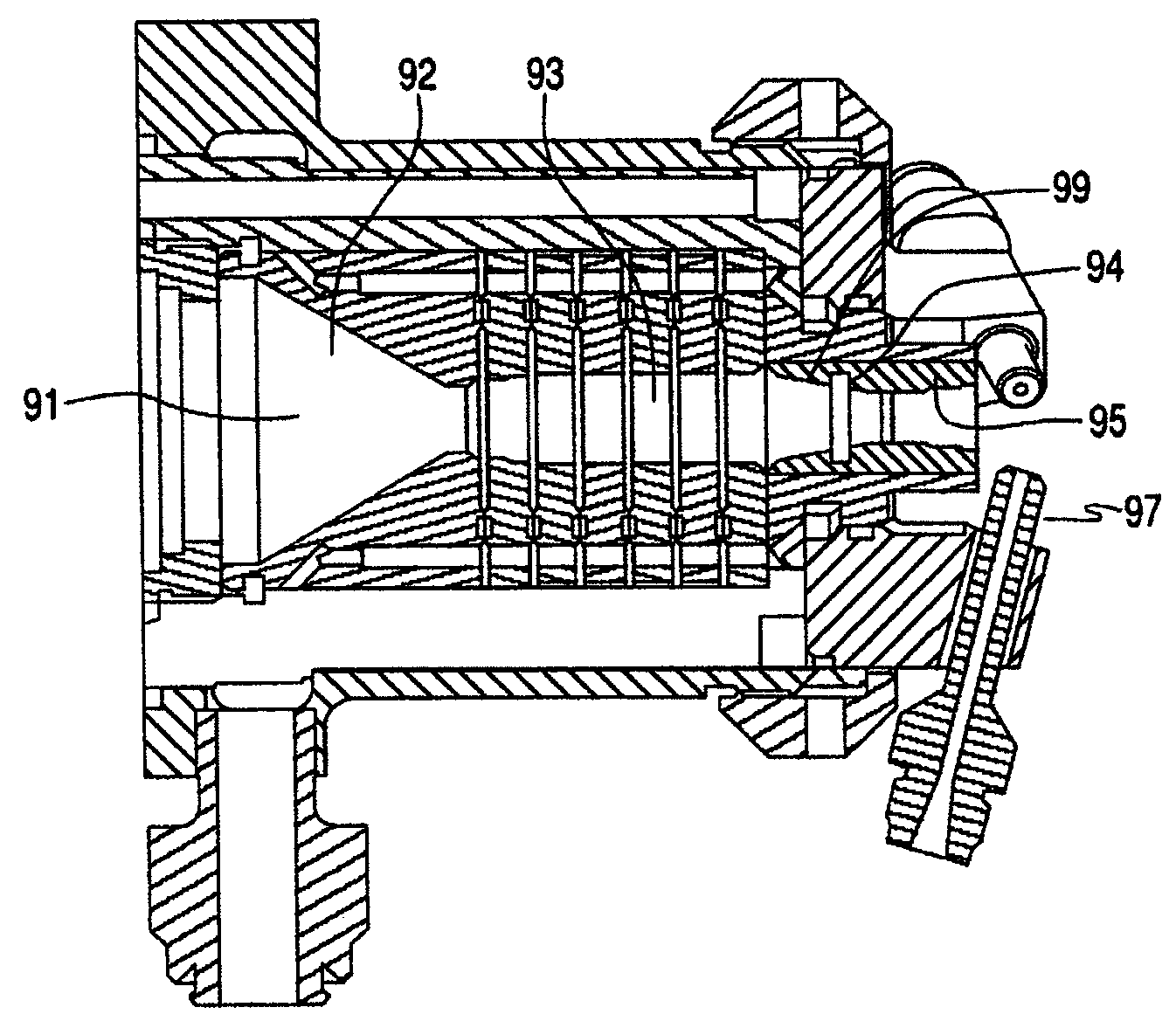

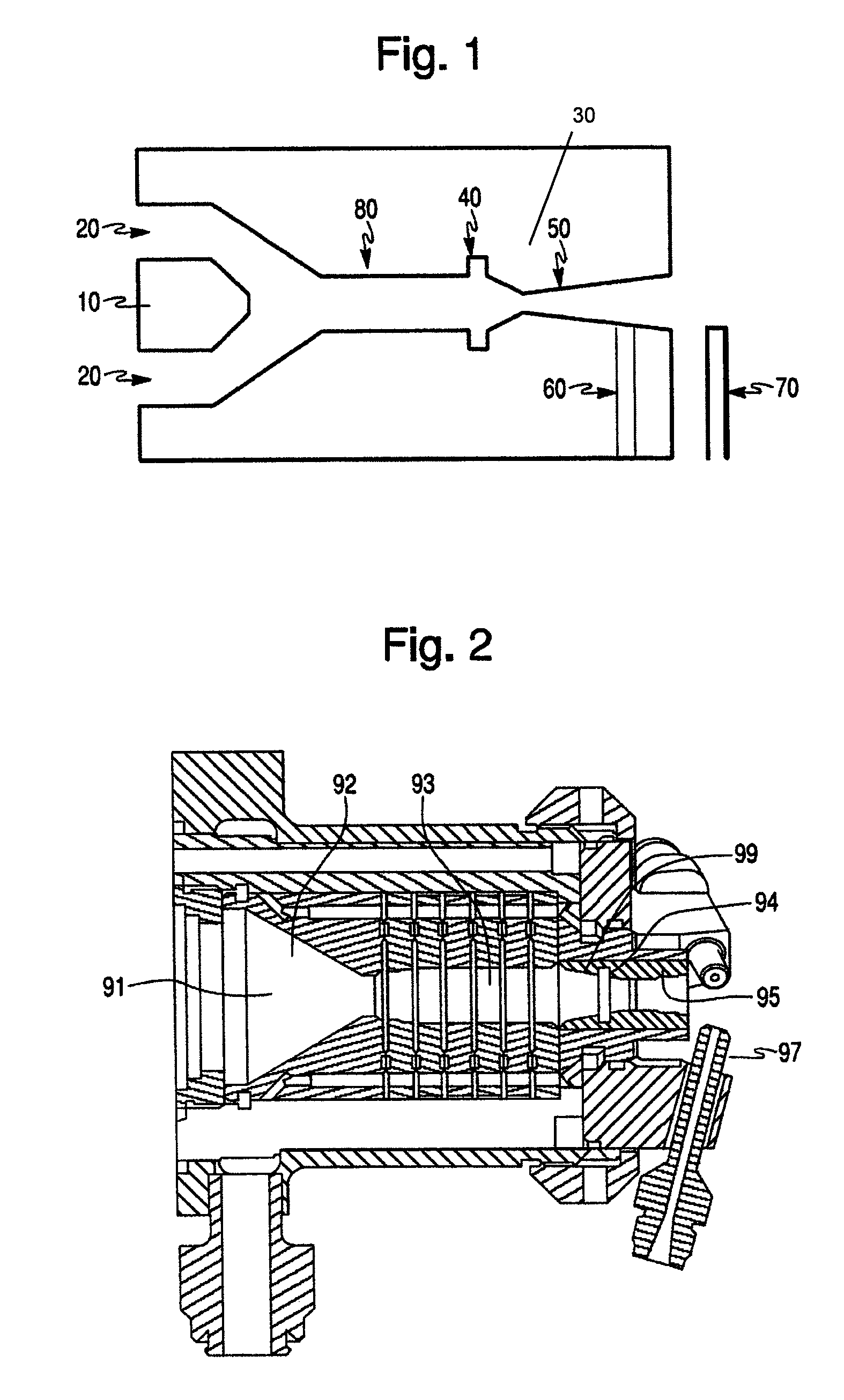

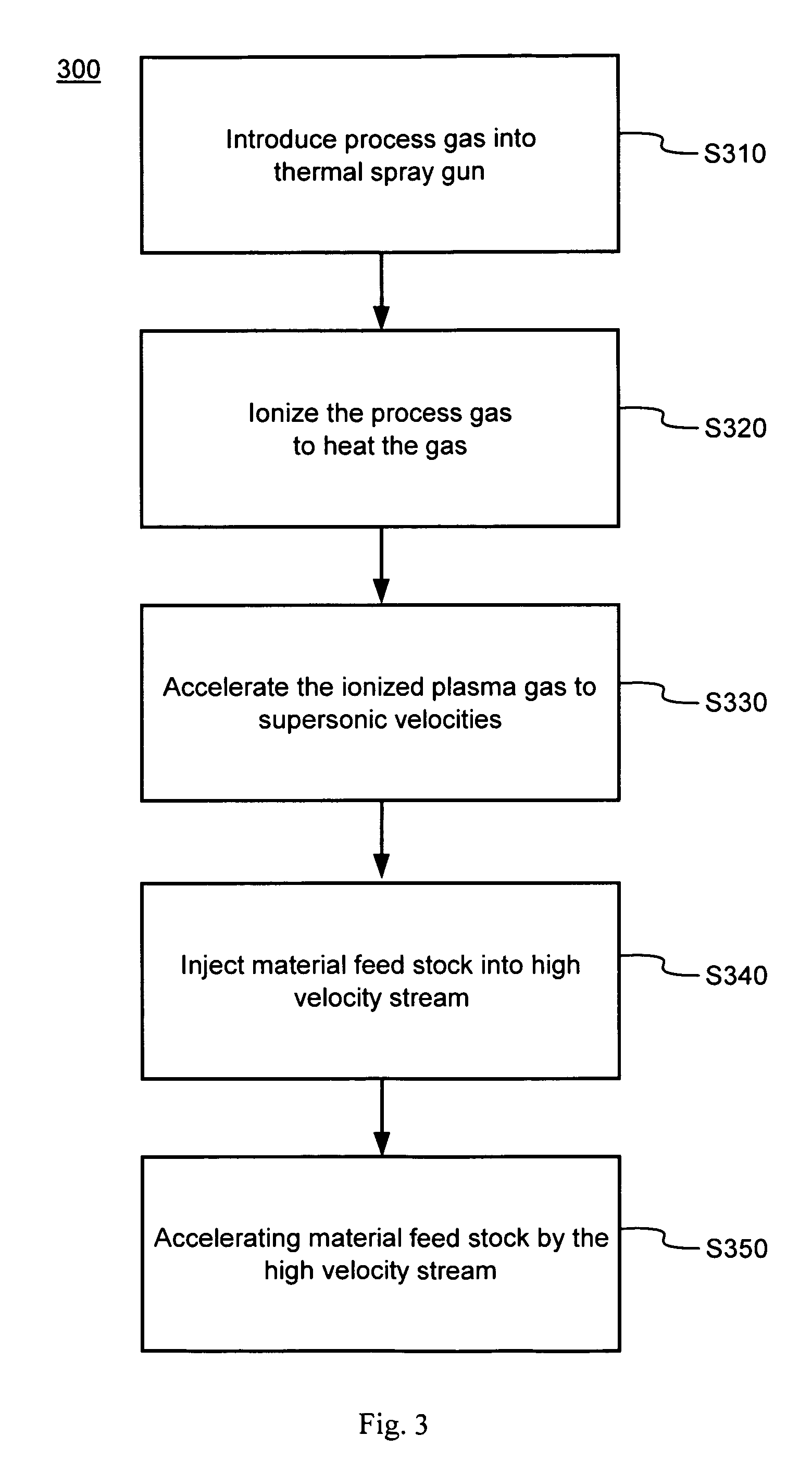

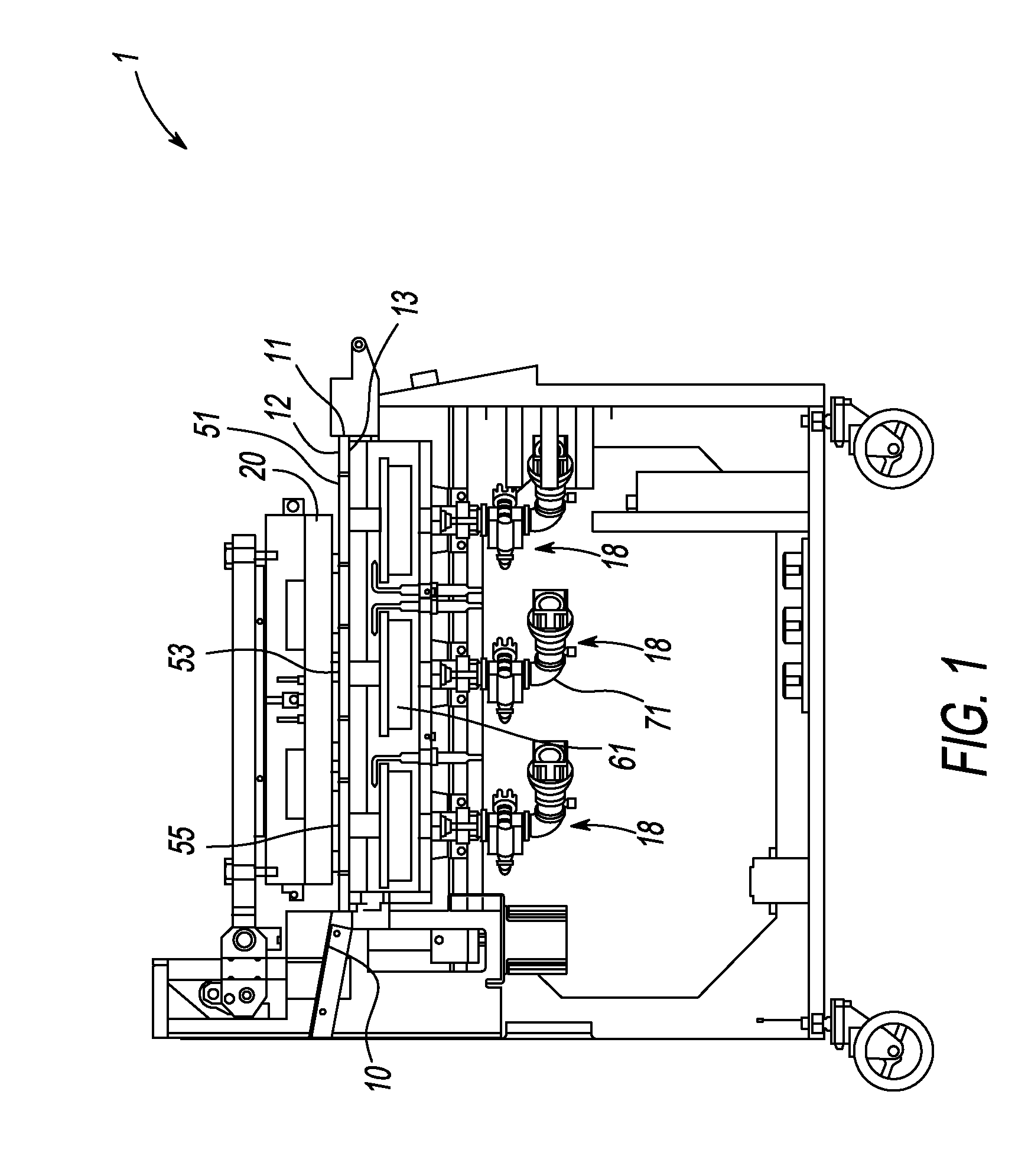

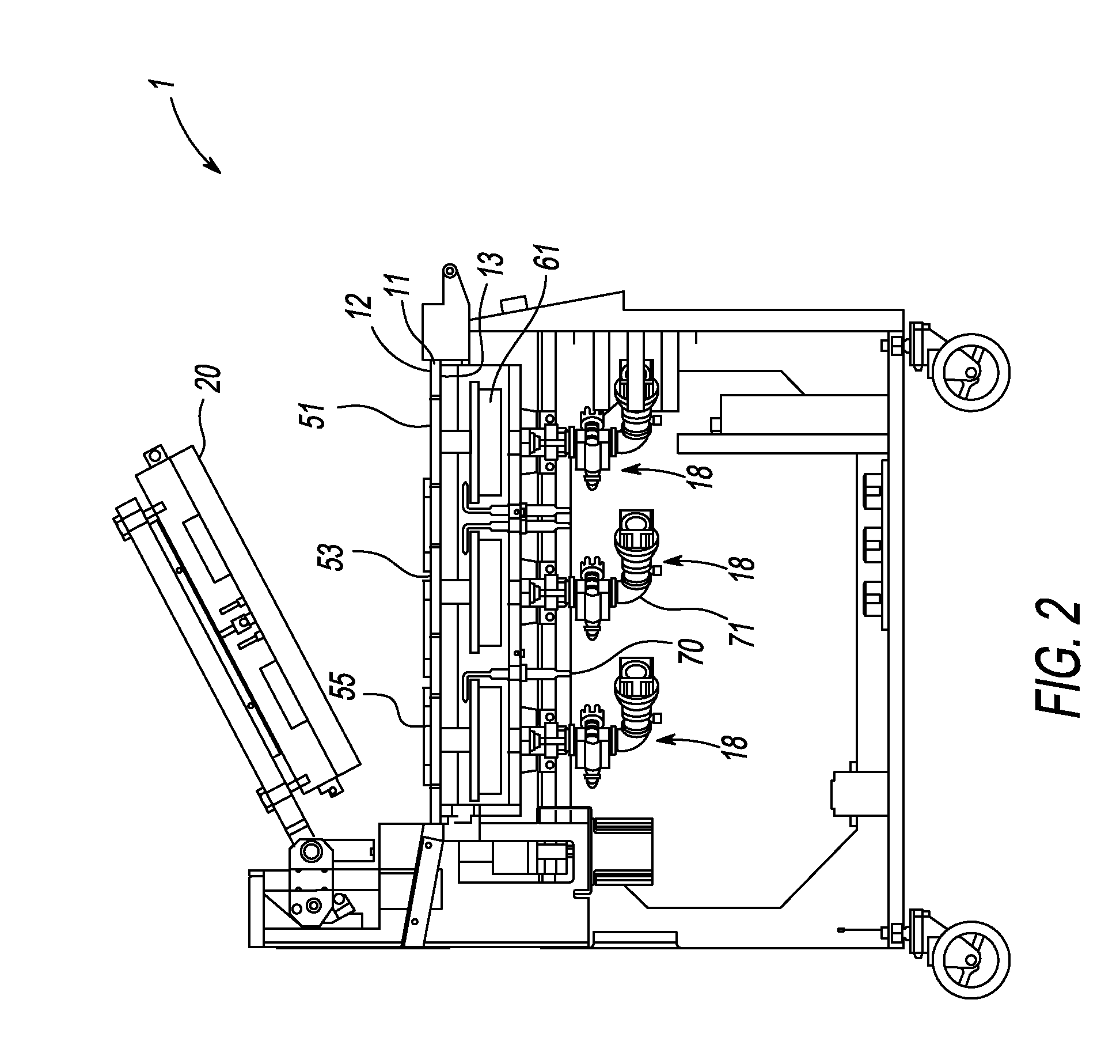

Hybrid plasma-cold spray method and apparatus

ActiveUS7582846B2Wide range of operationsImprove processing effectivenessMolten spray coatingArc welding apparatusStress conditionsProcess engineering

The present invention provides a method and apparatus of producing a dense coating with desirable stress conditions similar to coatings produced by a cold spray processes, but with higher process efficiencies and lower gas consumption. The inventive process combines features of a plasma process method of gas heating and a cold spray process to accelerate the gas, incorporating these elements into a single hybrid process.

Owner:SULZER METCO (US) INC

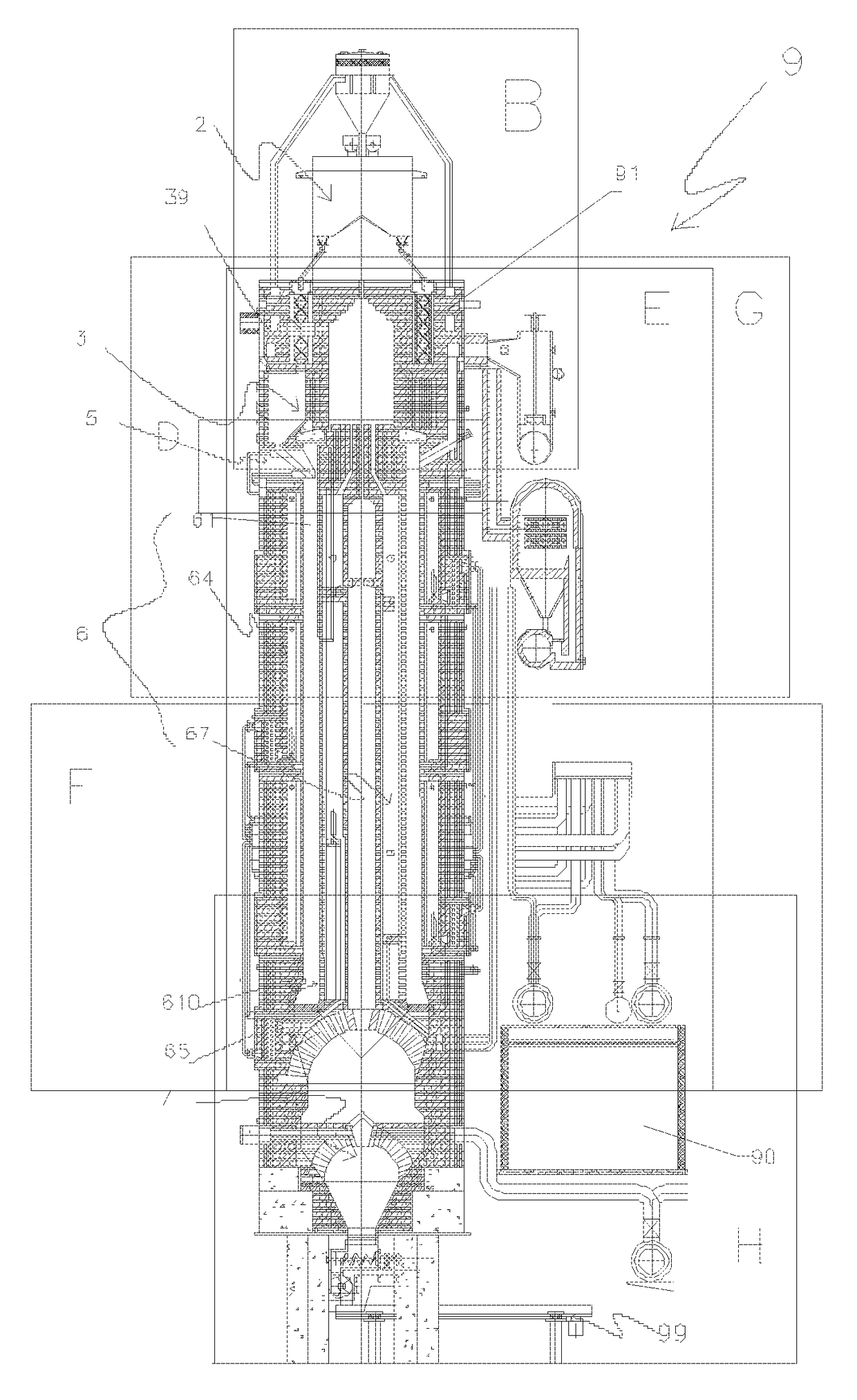

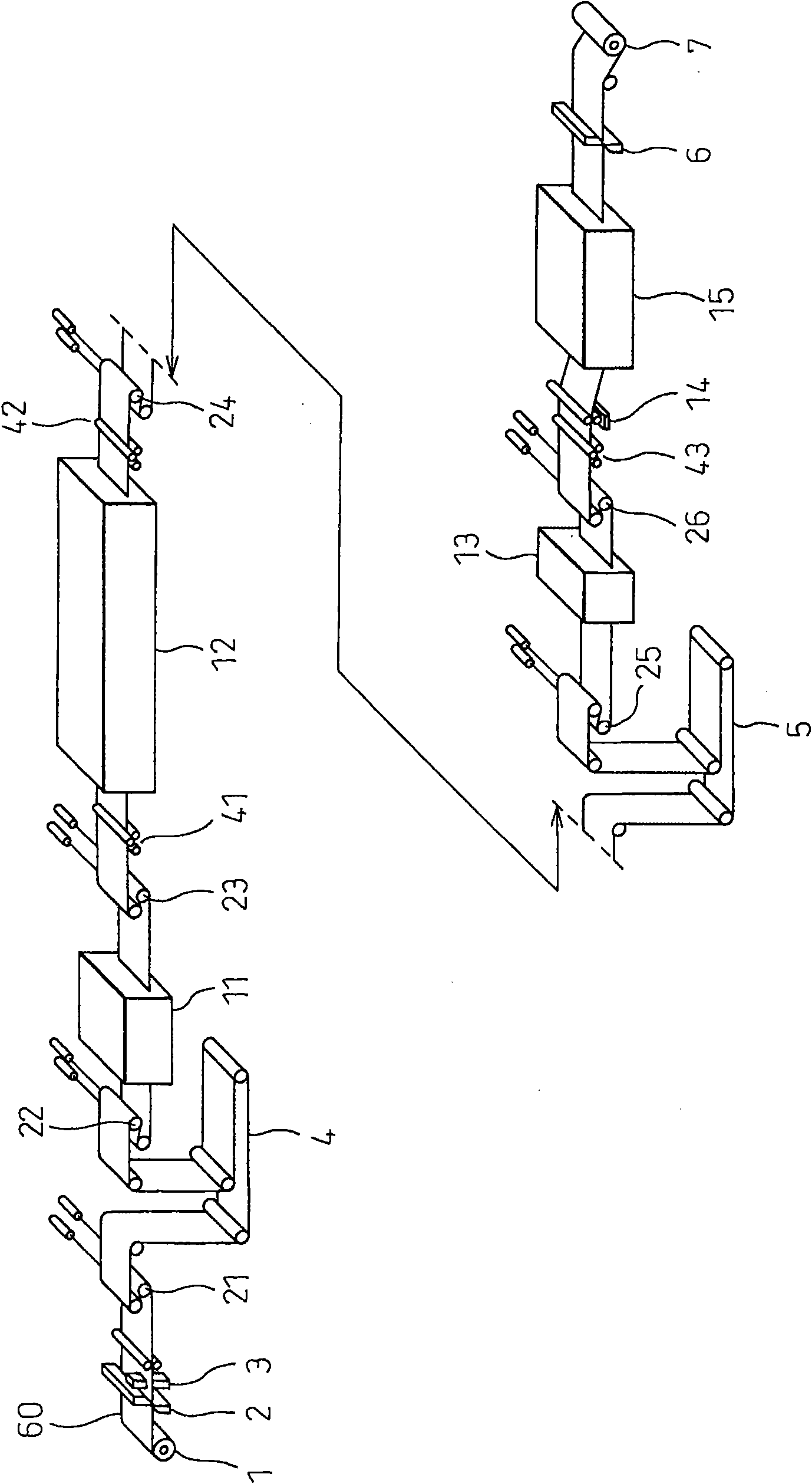

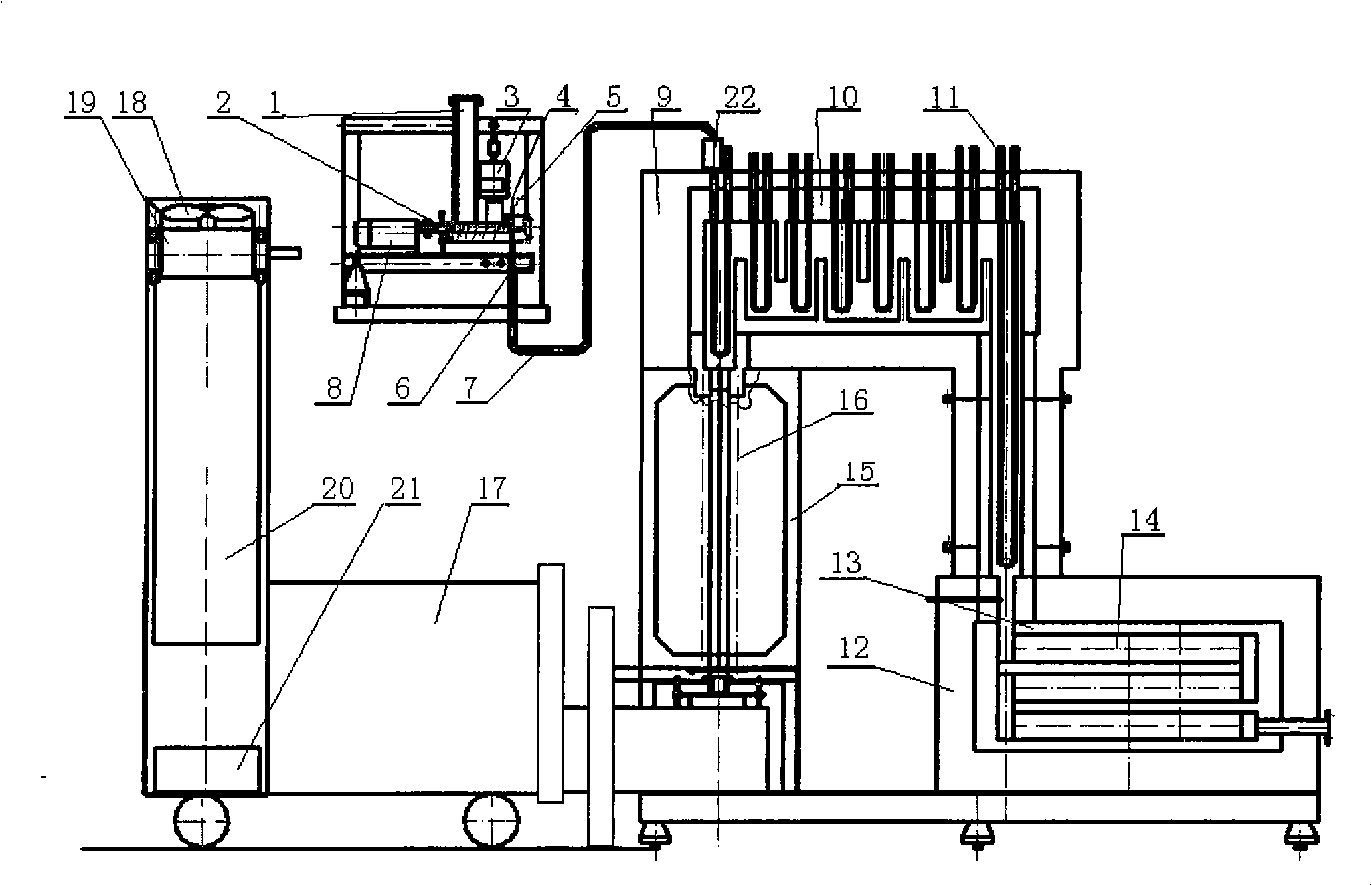

Thermal cycle continuous automated coal pyrolyzing furnace

InactiveUS10047296B2Improve efficiencyReduce coking costCoke quenchingCombustible gas coke oven heatingProcess engineeringGas heating

A thermal cycle continuous automated coal pyrolyzing furnace, includes a furnace body, a coal feeding device, a preheating device, an inputting coal regulating bunker, an inputting coal cooling device, a coal pyrolyzation coking device, a coke modification device, a dry quenching device and a raw gas exporting device; wherein the coal feeding device, the pre-heating device, the inputting coal regulating bunker, the inputting coal cooling device, the coal pyrolyzation coking device, the coke modification device, the dry quenching device and the raw gas exporting device are all integrated on the furnace body; the coal pyrolyzation coking device includes a coking chamber, an external combustion gas heating device, an internal combustion gas heating device and a flame path bow. Utilizing the coal pyrolyzing furnace is capable of achieving continuously quenching, so as to improve quenching efficiency and decrease quenching cost.

Owner:SHANXI XINLI ENERGY TECH

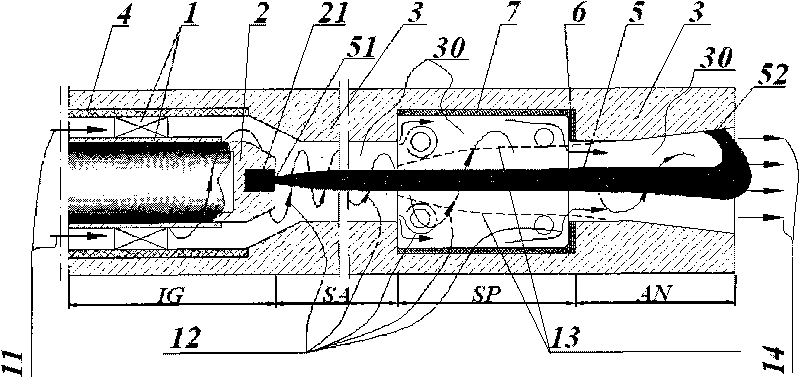

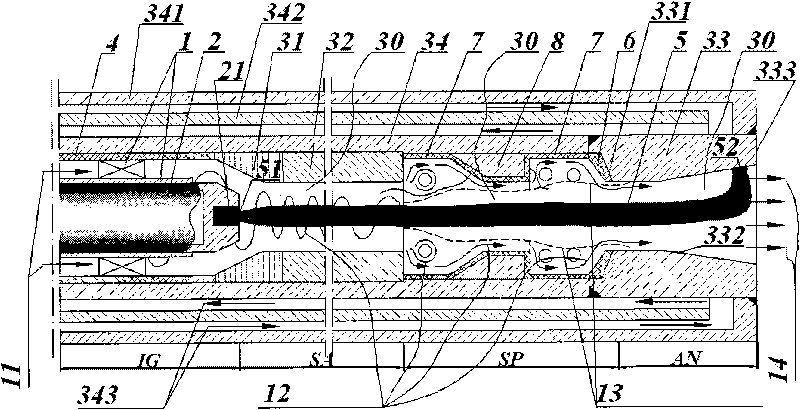

Anode for non-transferred arc plasma torch and plasma torch

The invention relates to an anode for an arc plasma torch and a non-transferred arc plasma torch with the anode. The anode comprises a stable arc section and an anode nozzle section which have evenly varied diameters, a burble section which is connected with the two sections and is provided with a groove with increasing diameter, wherein an insulating material is filled in the burble section. The plasma torch comprises a swirler, a cathode, the anode and a cathode-anode isolation sleeve which are arranged coaxially. Working gas flows into the stable arc section by rotation of the swirler, and restricts arc in an axle center position stably; the burble section ensures that air flow generates high frequency turbulence to drive an arc stream to swing in high frequency randomly and constantly impacts the inlet side of the anode nozzle; and the anode arc root moves quickly under the action of high speed air flow. The non-transferred arc plasma torch can obviously improve the arc voltage, the jump frequency and the moving speed of the anode arc root, reduces heat consumption, has the characteristics of high power, low electrode loss rate, high heat conversion efficiency, wide operation parameter range, small arc voltage fluctuation and the like, and is particularly suitable for gas heating.

Owner:UNIV OF SCI & TECH OF CHINA +1

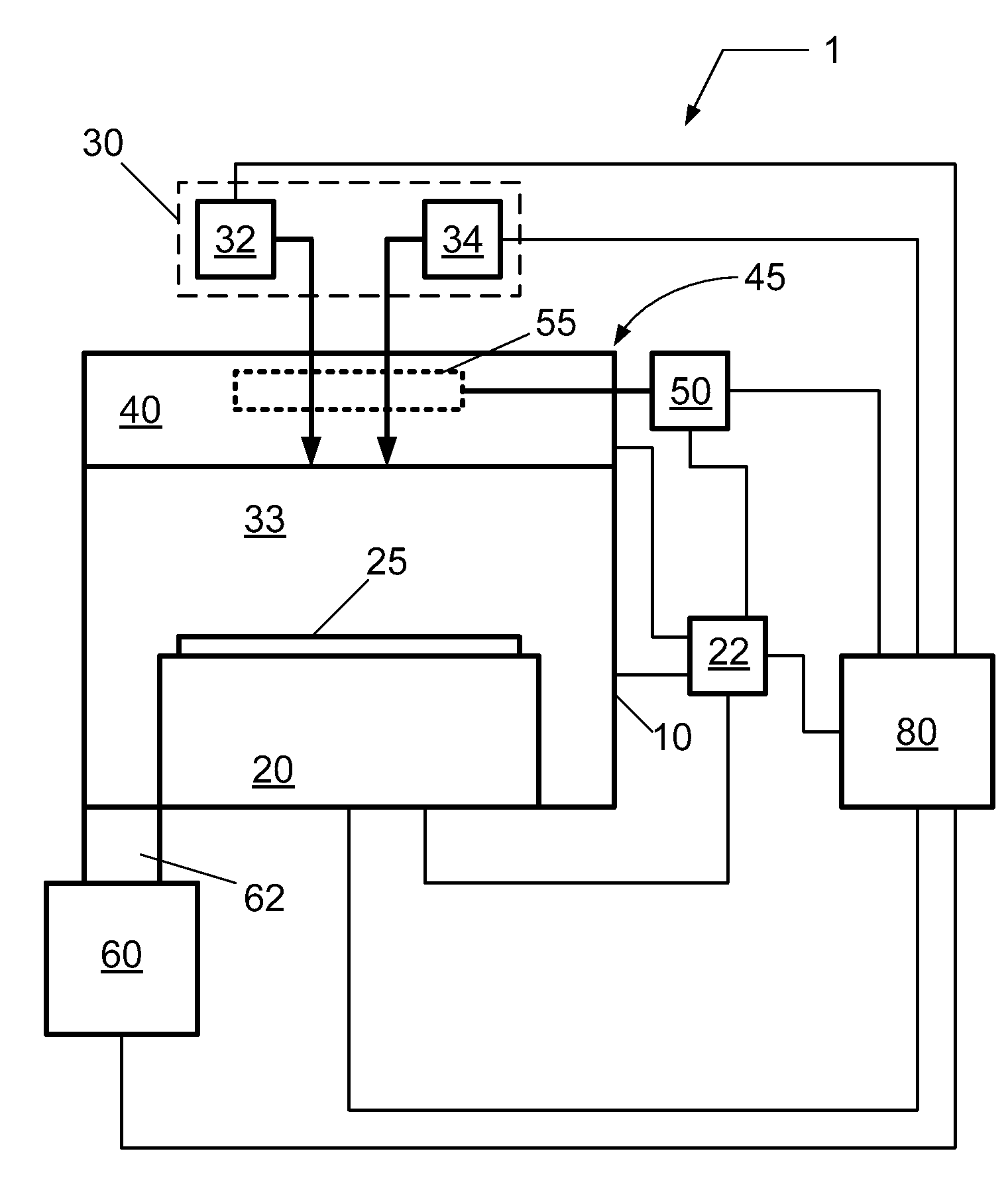

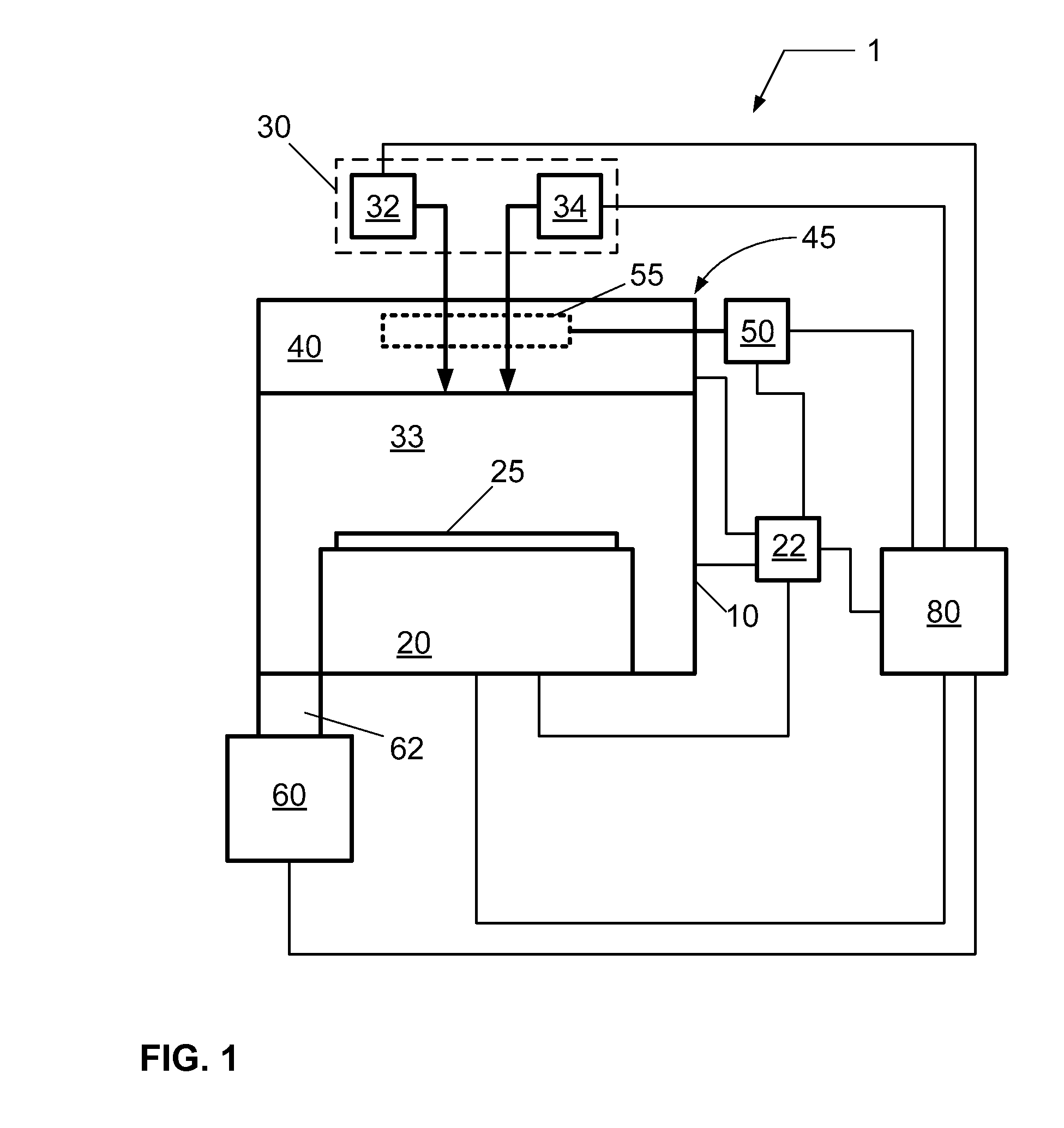

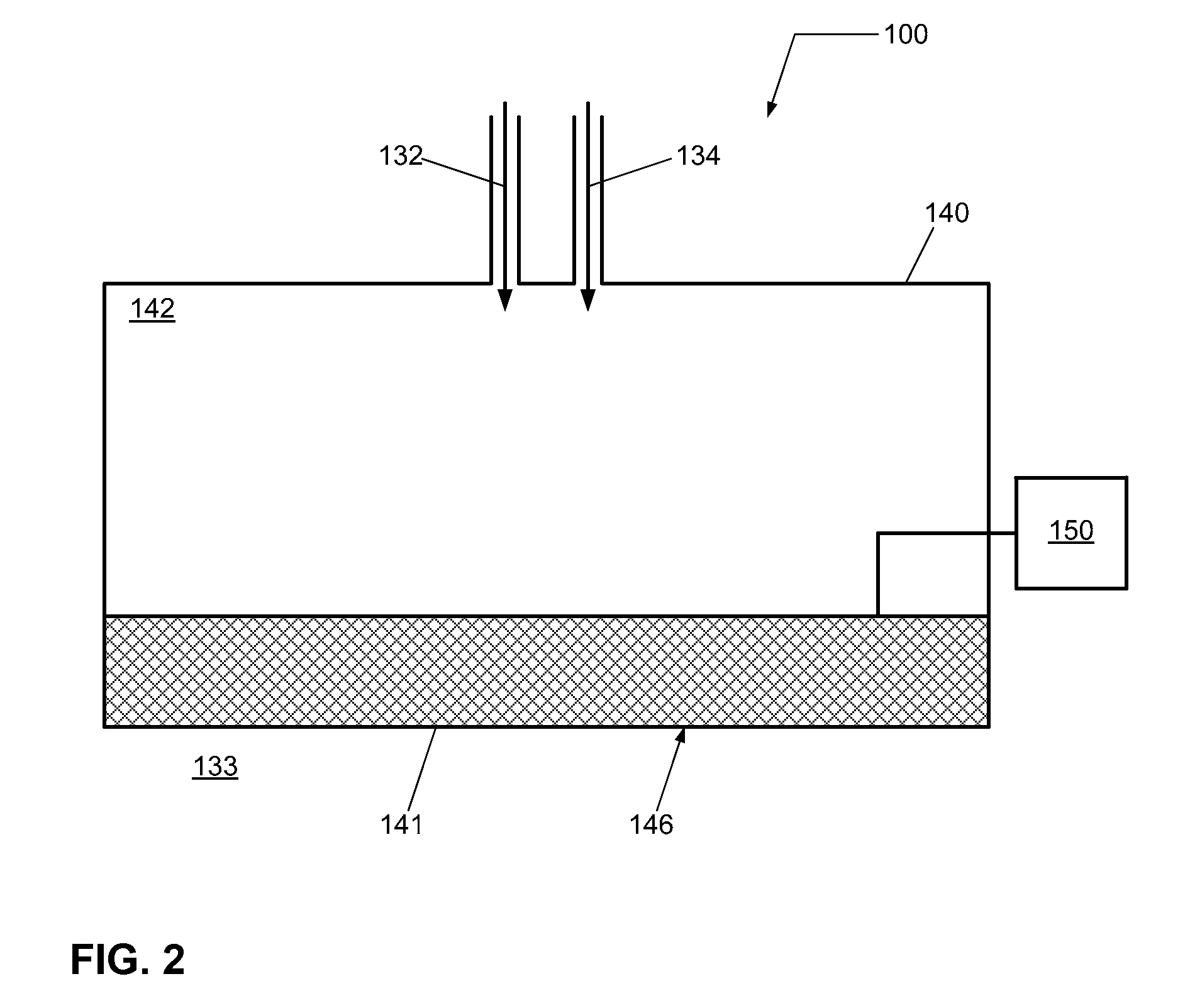

Gas heating device for a vapor deposition system

InactiveUS20090223452A1Reduce slippageIncrease temperatureVacuum evaporation coatingSputtering coatingElectrical resistance and conductanceGas phase

A method and system for depositing a thin film on a substrate using a vapor deposition process is described. The processing system comprises a gas heating device for heating one or more constituents of a film forming composition. The gas heating device comprises one or more resistive heating elements configured to receive an electrical current from one or more power sources. Additionally, the gas heating device comprises a mounting structure configured to support the one or more resistive heating elements. Furthermore, the gas heating device comprises one or more static mounting devices coupled to the mounting structure and configured to fixedly couple the one or more resistive heating elements to the mounting structure, and one or more dynamic mounting devices coupled to the mounting structure and configured to automatically compensate for changes in a length of each of the one or more resistive heating elements.

Owner:TOKYO ELECTRON LTD

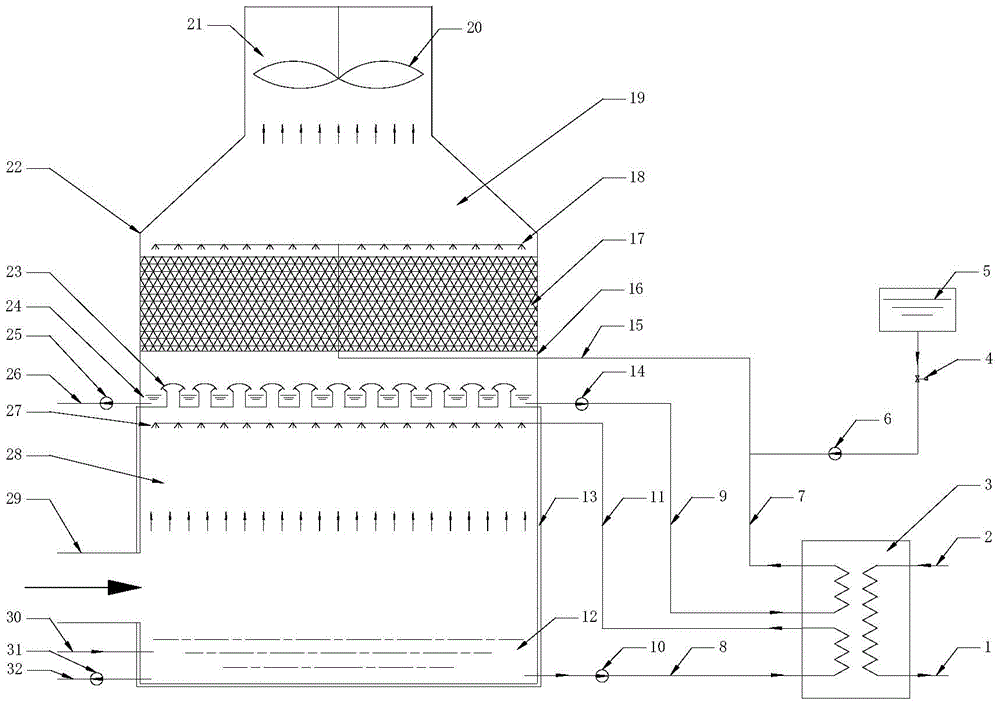

Smoke purifying and residual heat deep recycling integrated device

InactiveCN104014236ASimple structureImprove heat transfer effectUsing liquid separation agentTrickle coolersWater qualityRecuperator

The invention discloses a smoke purifying and residual heat deep recycling integrated device, which comprises a purification and heat exchange tower, a smoke system and a heat exchanger, wherein the inside of the purification and heat exchange tower is partitioned into a spraying chamber at the lower part and a filling chamber at the upper part by a wind cap layer; the spraying chamber comprises a spraying layer and a water pool; the water pool is connected with a water supply system, a water treatment pump, a water quality treatment system and a water circulation pump respectively; the outlet of the water circulation pump is connected with the heating hot water inlet of the heat exchanger; the outlet of the water pool is connected with the spraying layer; a smoke inlet is formed in the tower wall above the water pool; the filling chamber comprises a slurry distribution layer, a filling layer, a slurry pool and a slurry supply device; the slurry pool is connected with a slurry treatment pump, a slurry treatment system and a slurry circulation pump; the outlet of the slurry circulation pump is connected with the heating slurry inlet of the heat exchanger and the outlet of the slurry pool is connected with the slurry supply device. The smoke purifying and residual heat deep recycling integrated device is applicable to comprehensive treatment of tail smoke in gas heating, power and cooling triple combination distribution type systems, natural gas boilers, gas-steam combined circulation and fuel power stations.

Owner:NANJING KESEN KENEN ENVIRONMENT & ENERGY

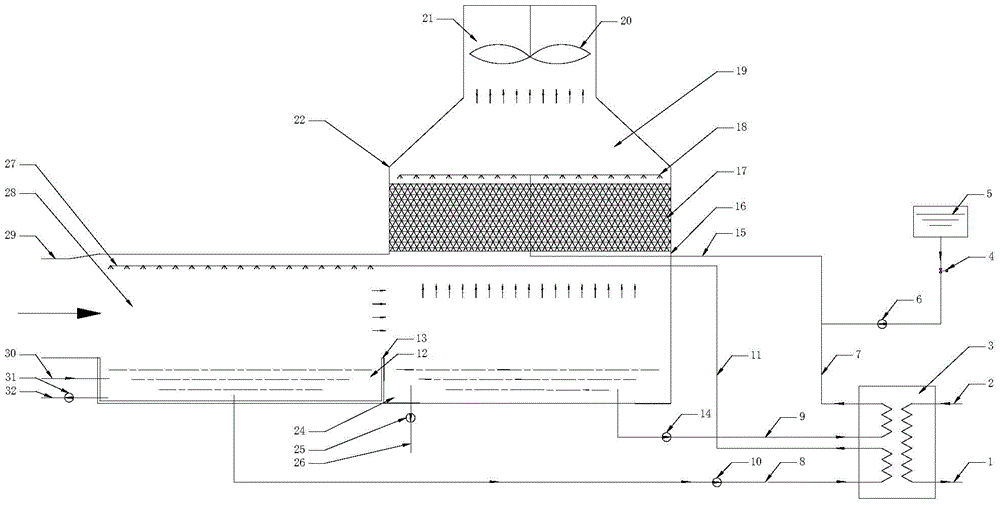

Method of continuous annealing for steel strip with curie point and continuous annealing apparatus therefor

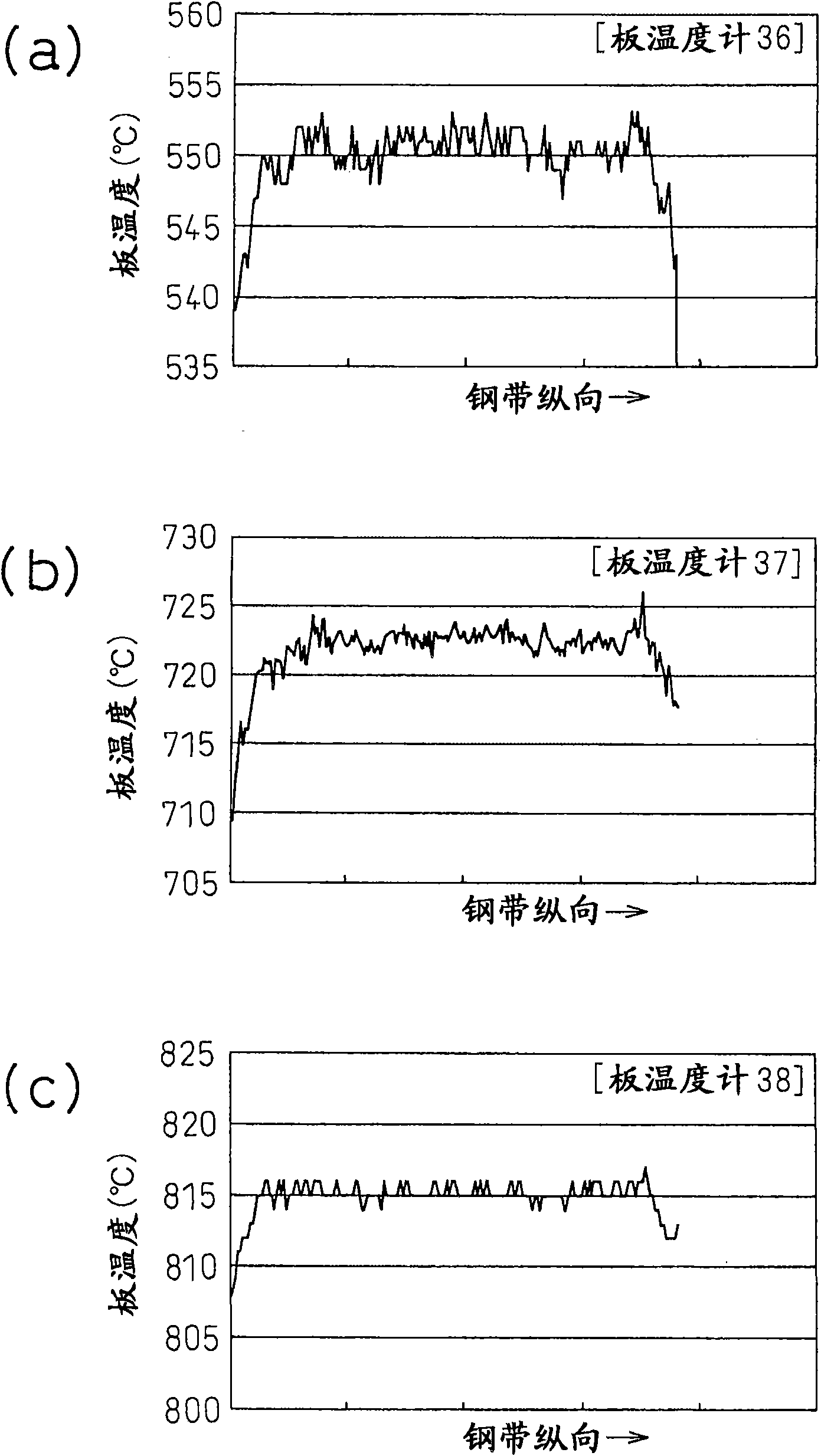

ActiveCN101652485AHeating evenlyBig quality improvementIncreasing energy efficiencyFurnace typesContinuous annealingGas heating

In the continuous annealing of a steel strip with Curie point (Tc) at an annealing temperature exceeding Tc with the use of a continuous annealing equipment composed of a heating area, a soaking areaand a cooling area, the heating treatment in the heating area is divided into three regions. In the first heating area, the steel strip is heated to below Tc-50 DEG C by radiant heating means by gas heating and / or radiant heating means by an electric heater. In the subsequent second heating area, the heated steel strip is heated to the region of Tc-30 DEG C to Tc-5 DEG C by solenoid coil high-frequency induction heating means. In the final third heating area, the heated steel strip is heated to a treatment target temperature exceeding Tc by radiant heating means by gas heating and / or radiant heating means by an electric heater. Accordingly, there can be attained uniform annealing in the longitudinal direction of the steel strip with Curie point.

Owner:NIPPON STEEL CORP

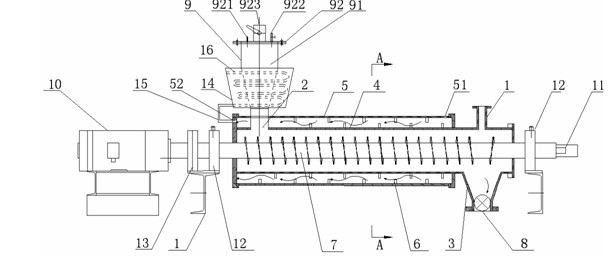

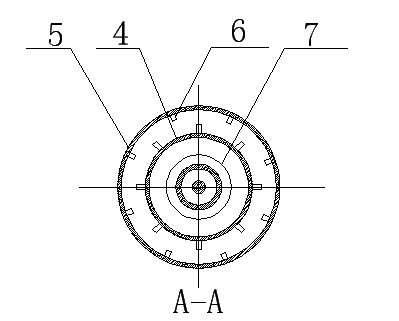

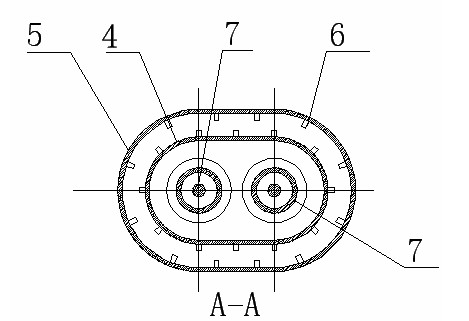

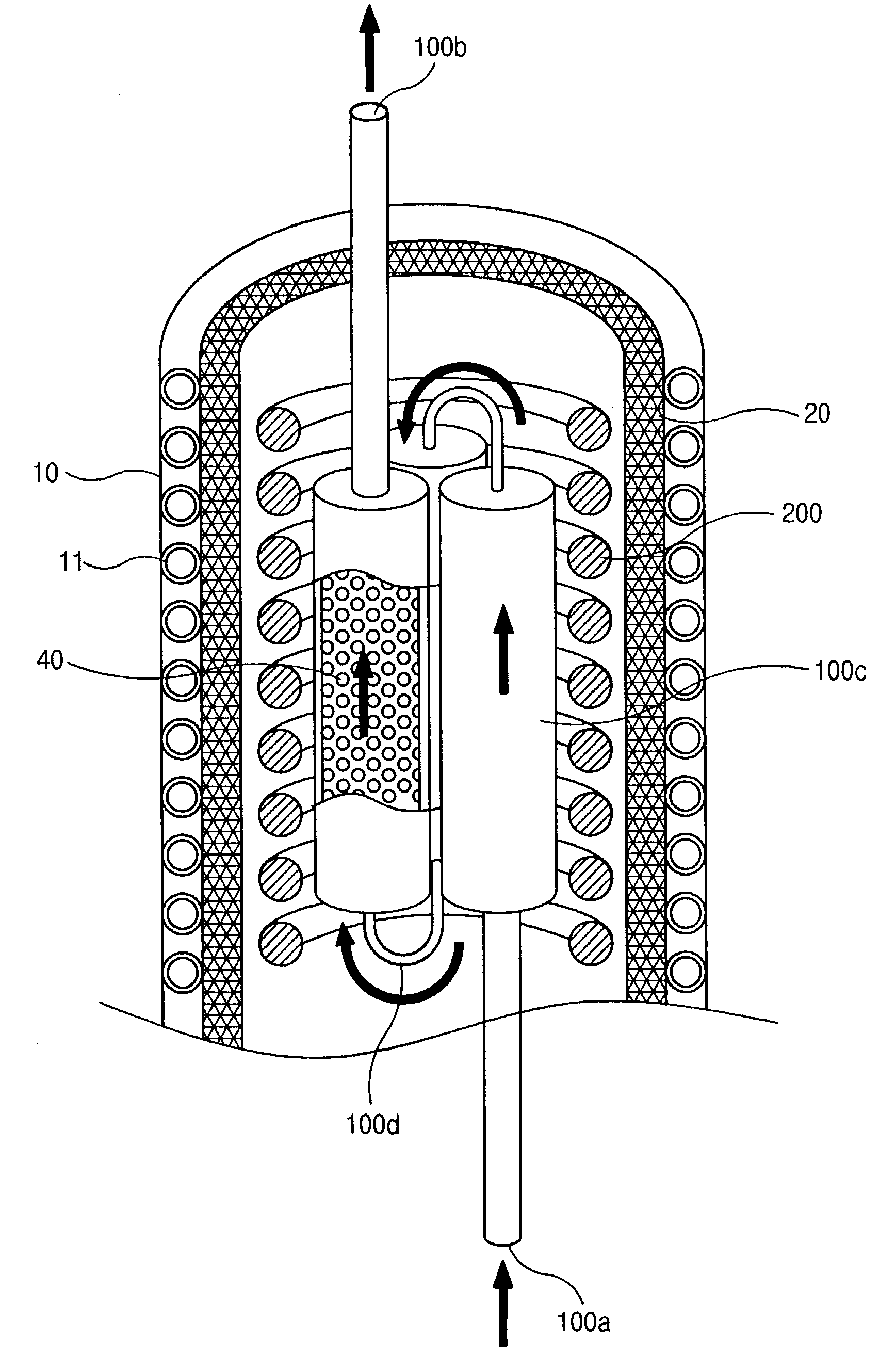

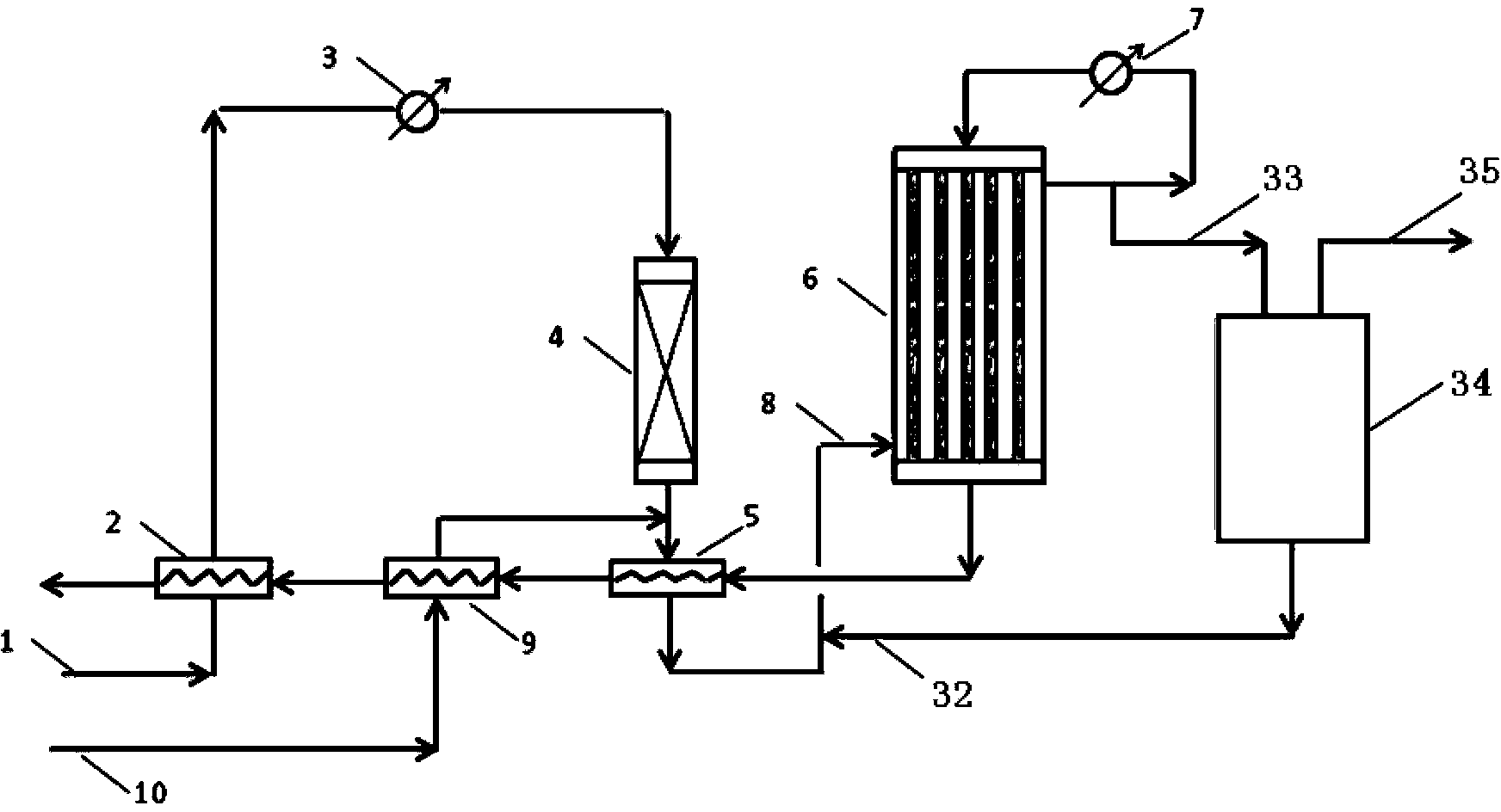

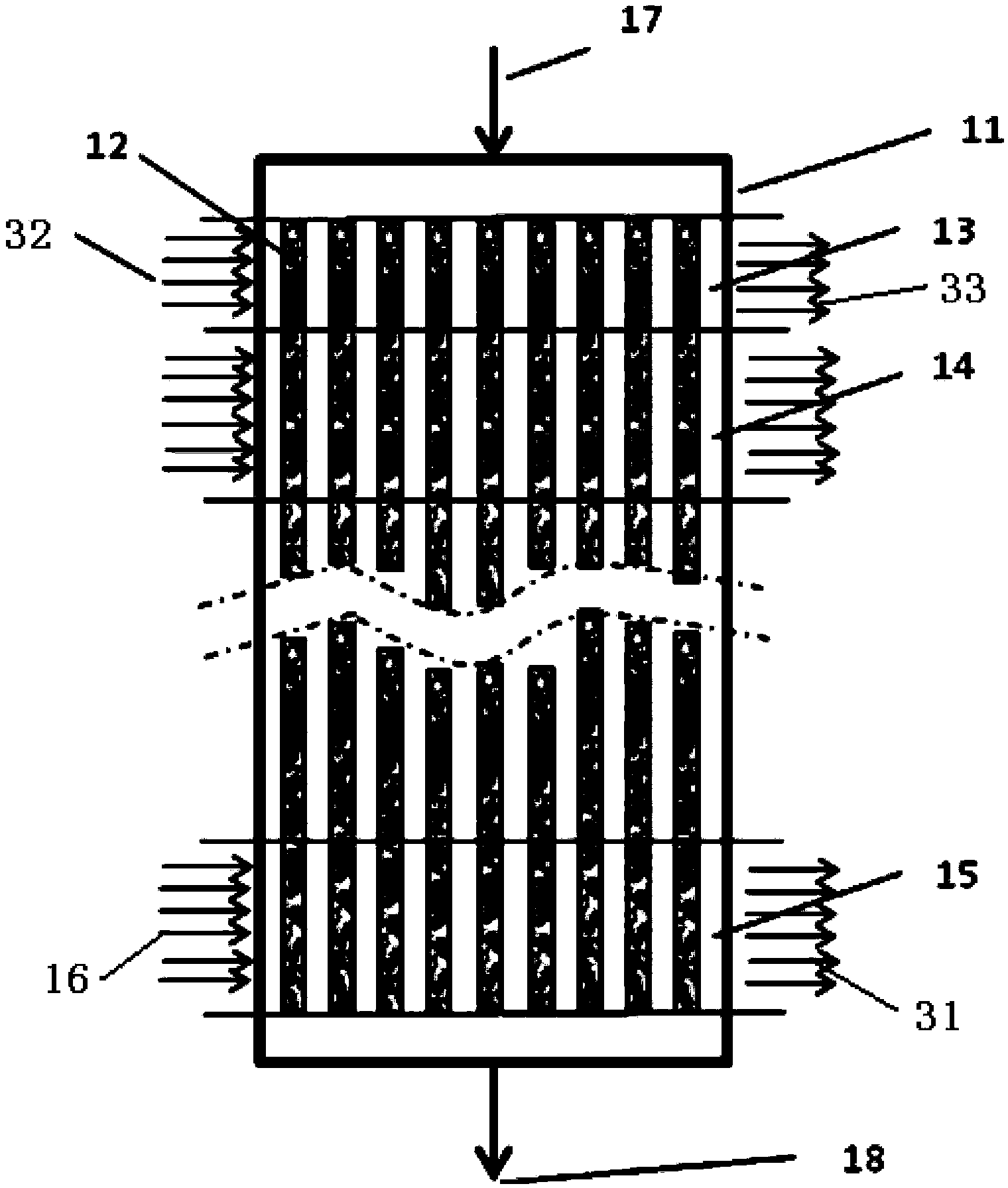

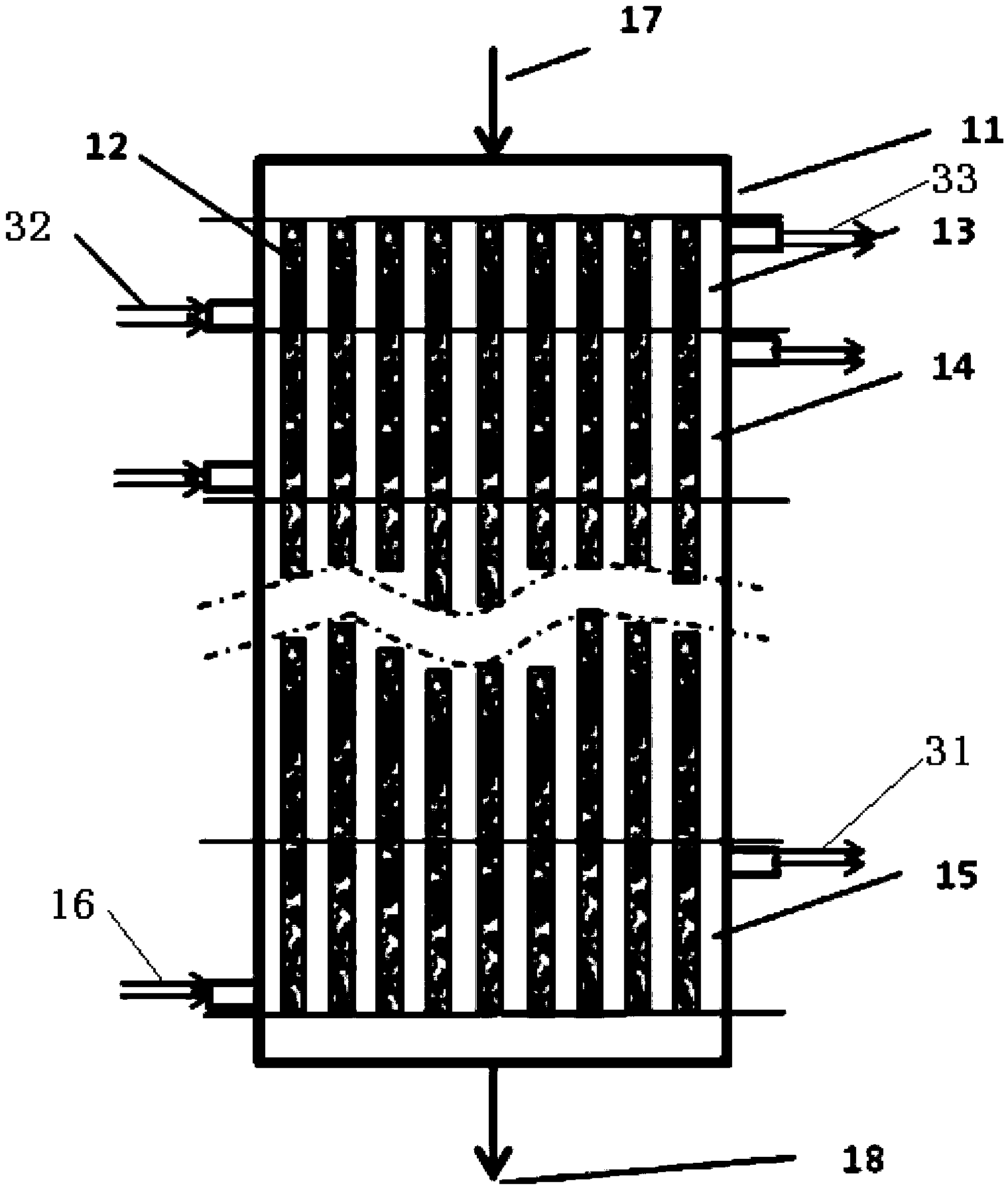

Combined heat exchange type multi-shell side methanol-to-olefin fixed bed production equipment and production method thereof

InactiveCN103908929AReduce loadHigh activityChemical industryHydrocarbon from oxygen organic compoundsWater vaporFixed bed

Belonging to the technical field of olefin production, the invention relates to combined heat exchange type multi-shell side methanol-to-olefin fixed bed production equipment and a production method thereof, thereby solving the technical problems of complex reaction equipment and difficult control of heat transfer in existing fixed bed reactors. The invention firstly puts forward the combined at exchange type multi-shell side methanol-to-olefin fixed bed production equipment, which includes a main reactor. Partition plates are mounted between an upper tube plate and a lower tube plate of the main reactor, and divide the cavity surrounded by the upper tube plate, the lower tube plate and the reactor body into 2-10 heat exchange shell sides that are not communicated to each other. The heat exchange shell sides include a first heat exchange shell side and the rest heat exchange shell sides, and column tubes run through the partition plates. The reactor body of each heat exchange shell side is provided with a cooling medium inlet and a cooling medium outlet. The invention also provides a method for production of olefin by the equipment. By means of combined high efficiency heat exchange, the proportion of water vapor in the feed gas and the load of a feed gas heating furnace can be reduced.

Owner:INNOVATIVE COAL CHEMICAL DESIGN INSTITUTE (SHANGHAI) CO LTD

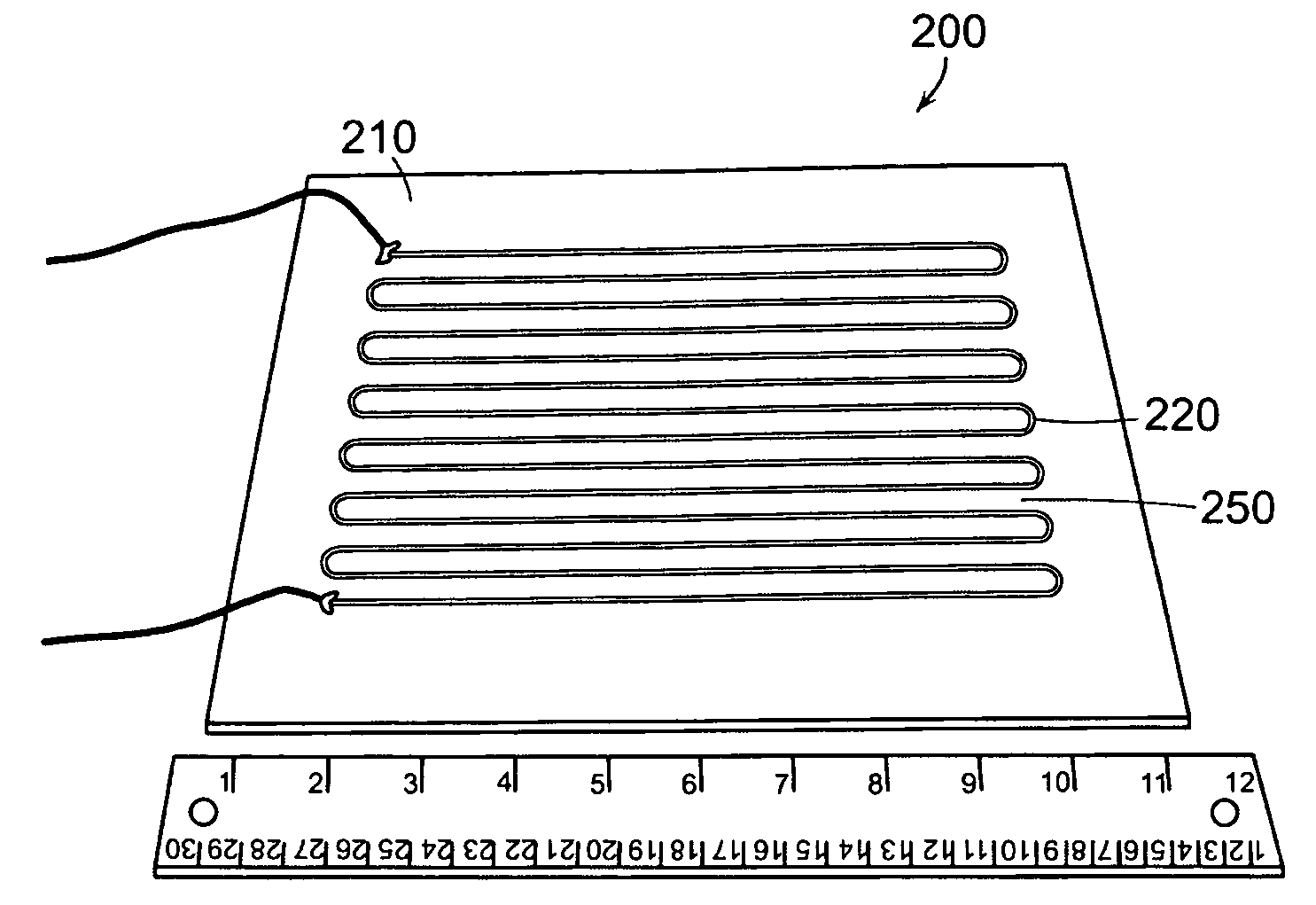

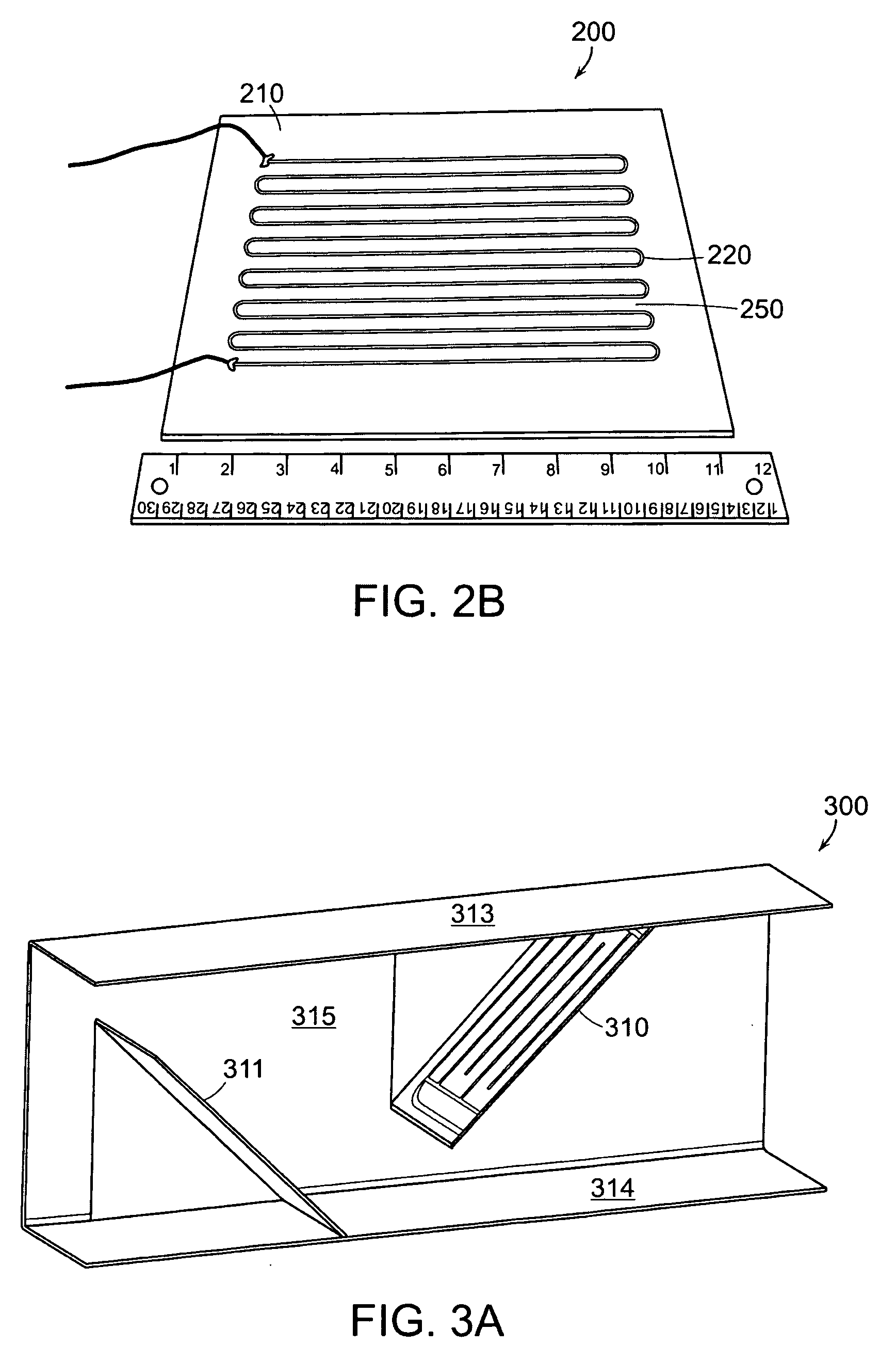

Gas heating apparatus and methods

InactiveUS20080217324A1High resistivityLess-expensive to manufactureDomestic stoves or rangesMolten spray coatingThermal sprayingGas heater

A thermally sprayed gas heater comprises a gas flow apparatus that propels a gas through a housing; and a thermally sprayed heater bonded to a surface of the apparatus, the heater positioned to heat the gas flow in the housing. In other aspects, a heater system for a turbulent flow gas duct comprises a duct having a gas flow channel, the channel having a shaped surface providing turbulent gas flow in the channel, and a thermally sprayed heater positioned to heat the gas flow in the channel.

Owner:REGAL WARE

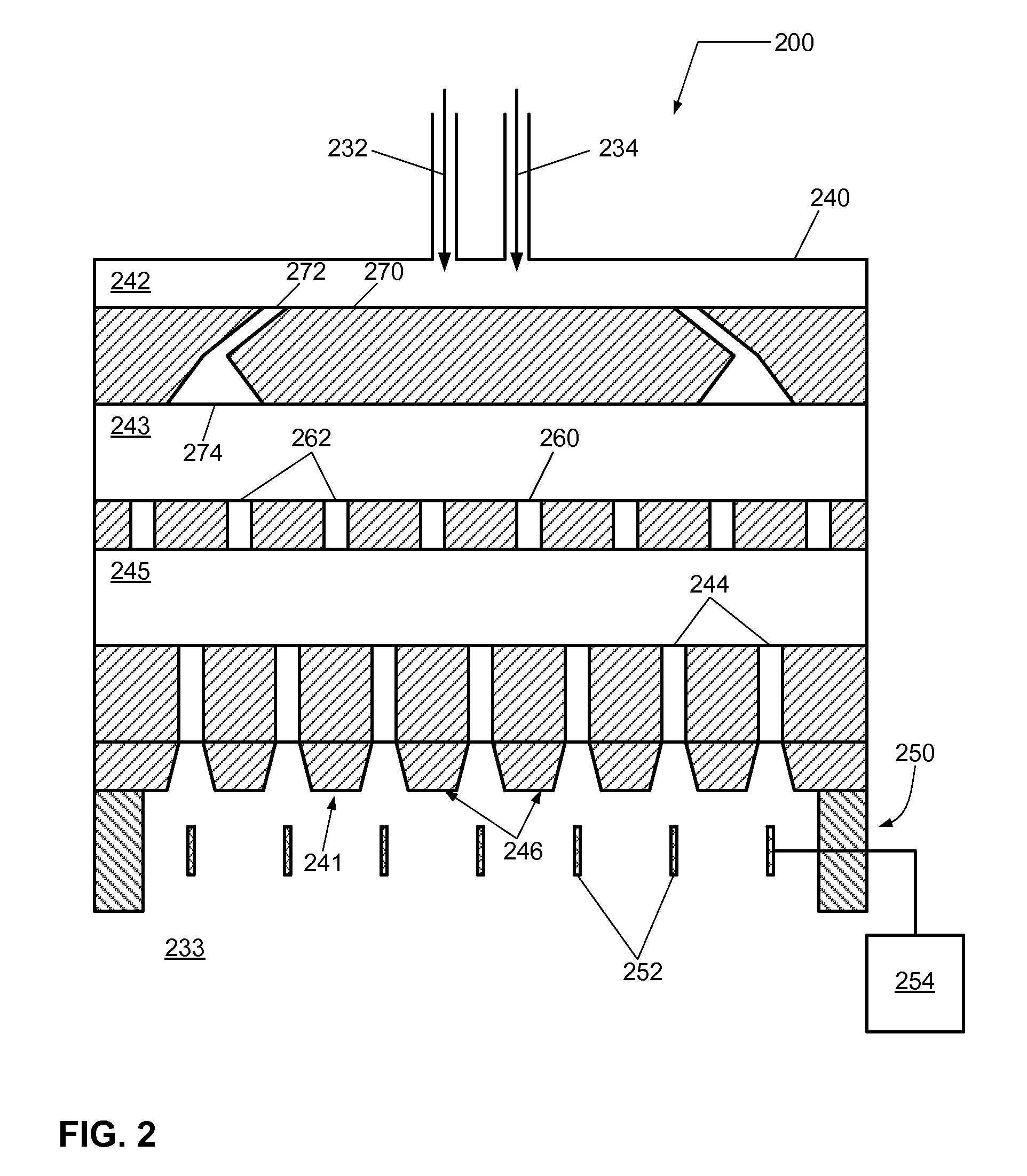

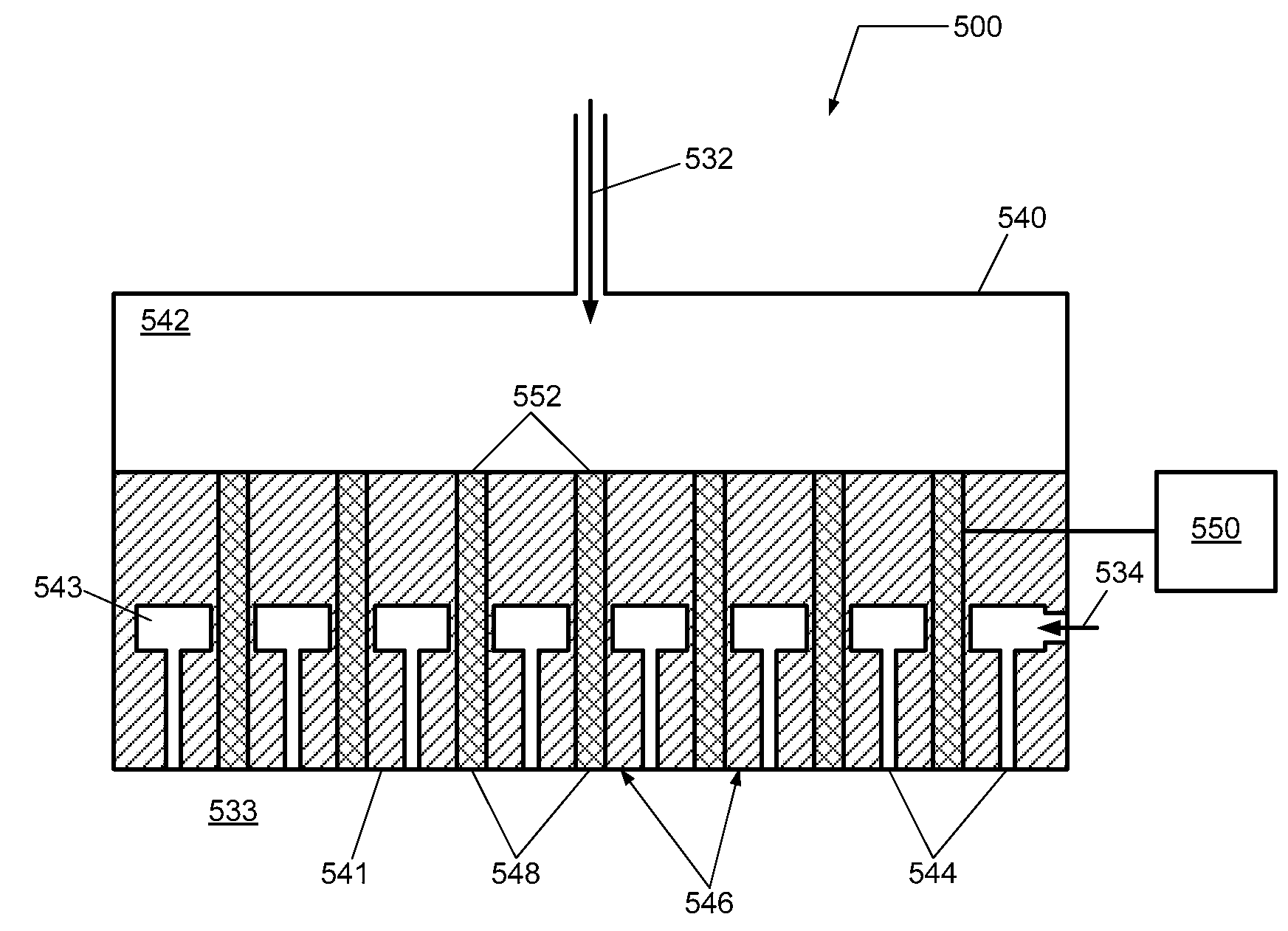

Porous gas heating device for a vapor deposition system

InactiveUS20090226614A1Increase temperatureChemical vapor deposition coatingTemperature controlGas phase

A method and system for treating a substrate is described. For example, the method and system may be used to deposit a thin film on a substrate using a vapor deposition process. The processing system comprises a gas distribution device for controlling the temperature of a process gas, such as one or more constituents of a film forming composition. The gas distribution device comprises one or more porous gas distribution elements configured to be temperature controlled and distribute a process gas flowing through the one or more porous gas distribution elements. The gas distribution device may be configured to pyrolize the process gas.

Owner:TOKYO ELECTRON LTD

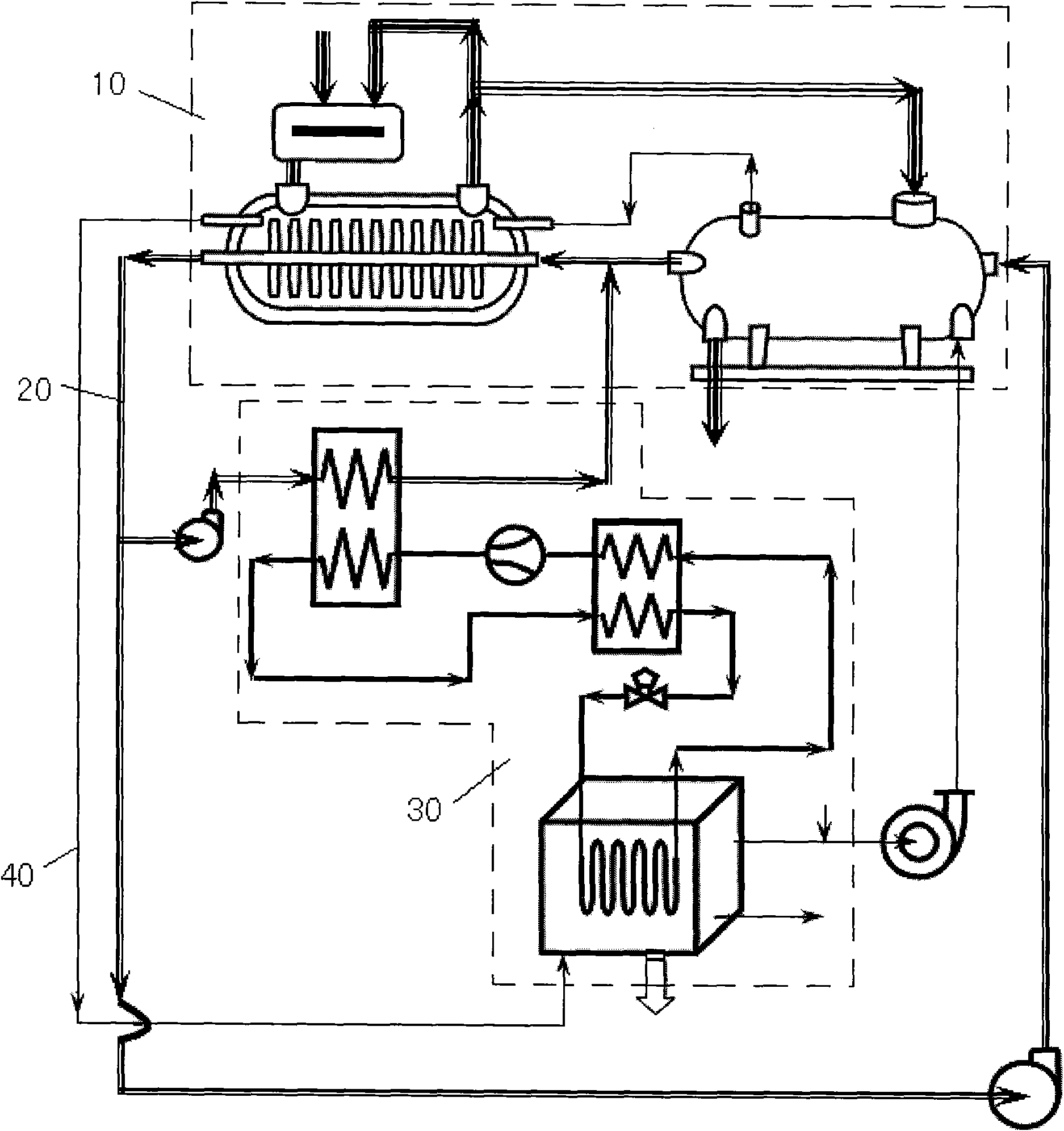

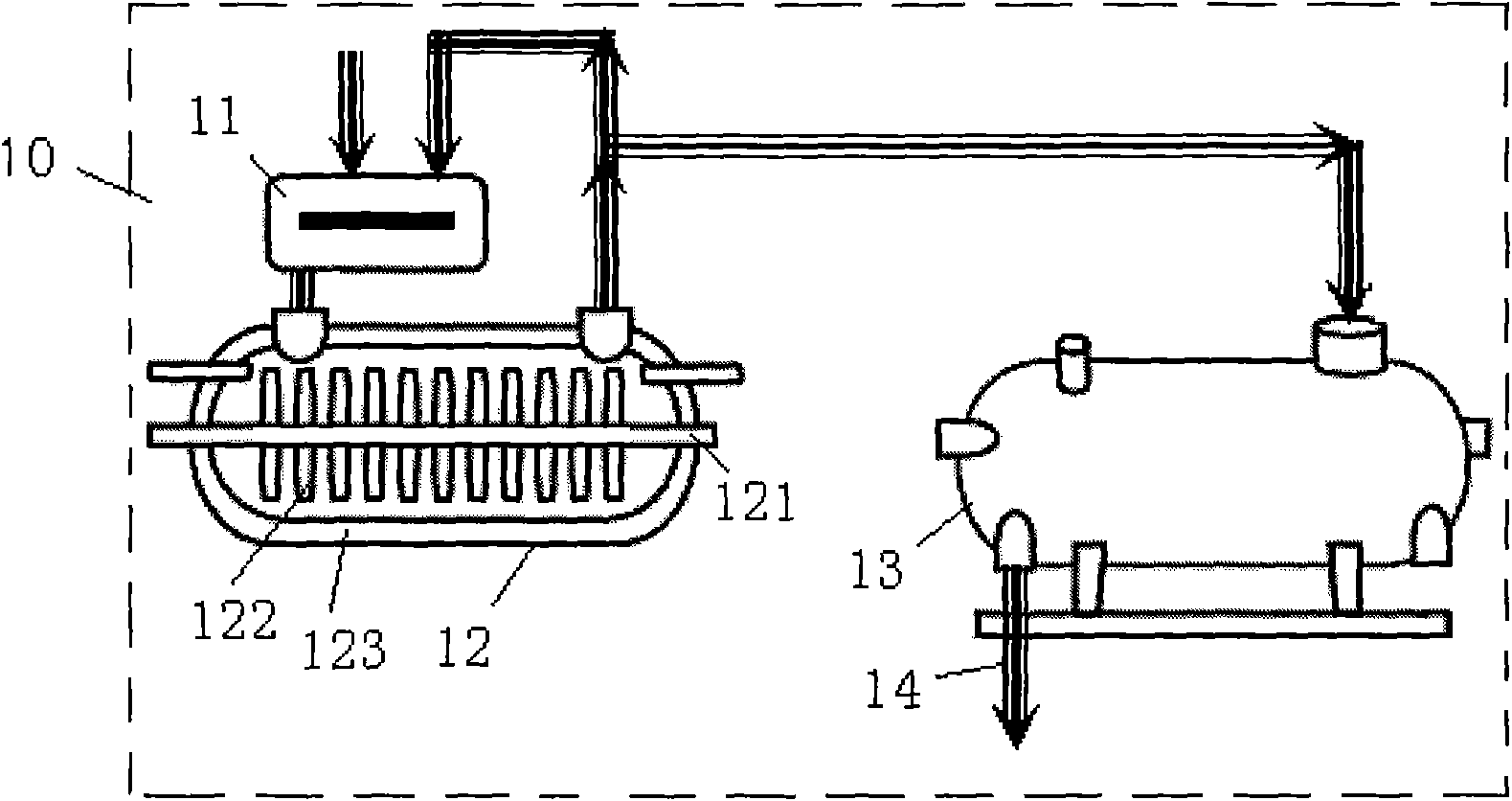

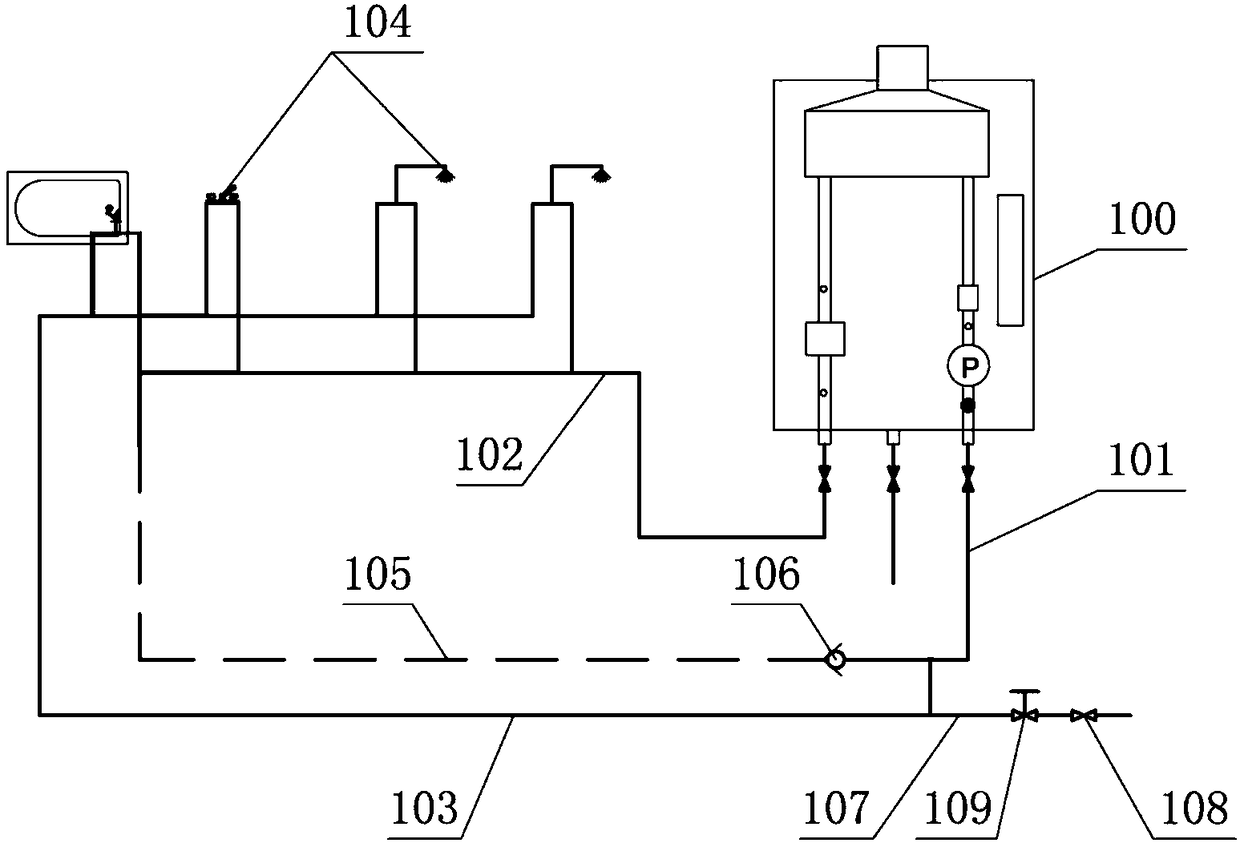

Mud drying and incinerating integrated system and use method thereof

ActiveCN101618931ARaise the evaporation temperatureMeet energy needsSludge treatment by de-watering/drying/thickeningIncinerator apparatusSludgeSlag

The invention relates to a mud drying and incinerating integrated system and a use method thereof. The mud drying and incinerating integrated system comprises a mud drying and incinerating loop, a hot water circulation loop, a heat pump auxiliary heat supplying loop and a carrier gas heating and waste heat recovering loop; the mud drying and incinerating loop comprises a dried mud back- mixing device, a mud dryer and a mud incinerator on which a slag outlet is arranged; the hot water circulation loop comprises two water pumps, a condenser, the mud dryer and the incinerator; the heat pump auxiliary heat supplying loop comprises an evaporator, an internal heat exchanger, a compressor, a throttle valve and the condenser; and the carrier gas heating and waste heat recovering loop comprises an air compressor, the evaporator, the mud incinerator and the mud dryer. The waste heat recovered from an incinerating and drying device and a heat pump drying device by a heat pump is taken as a heat source, and the heat pump assists in supplying heat, thereby improving the mud drying output and lowering the energy consumption for drying mud. The invention can be widely applied in various mud processing fields.

Owner:TSINGHUA UNIV +3

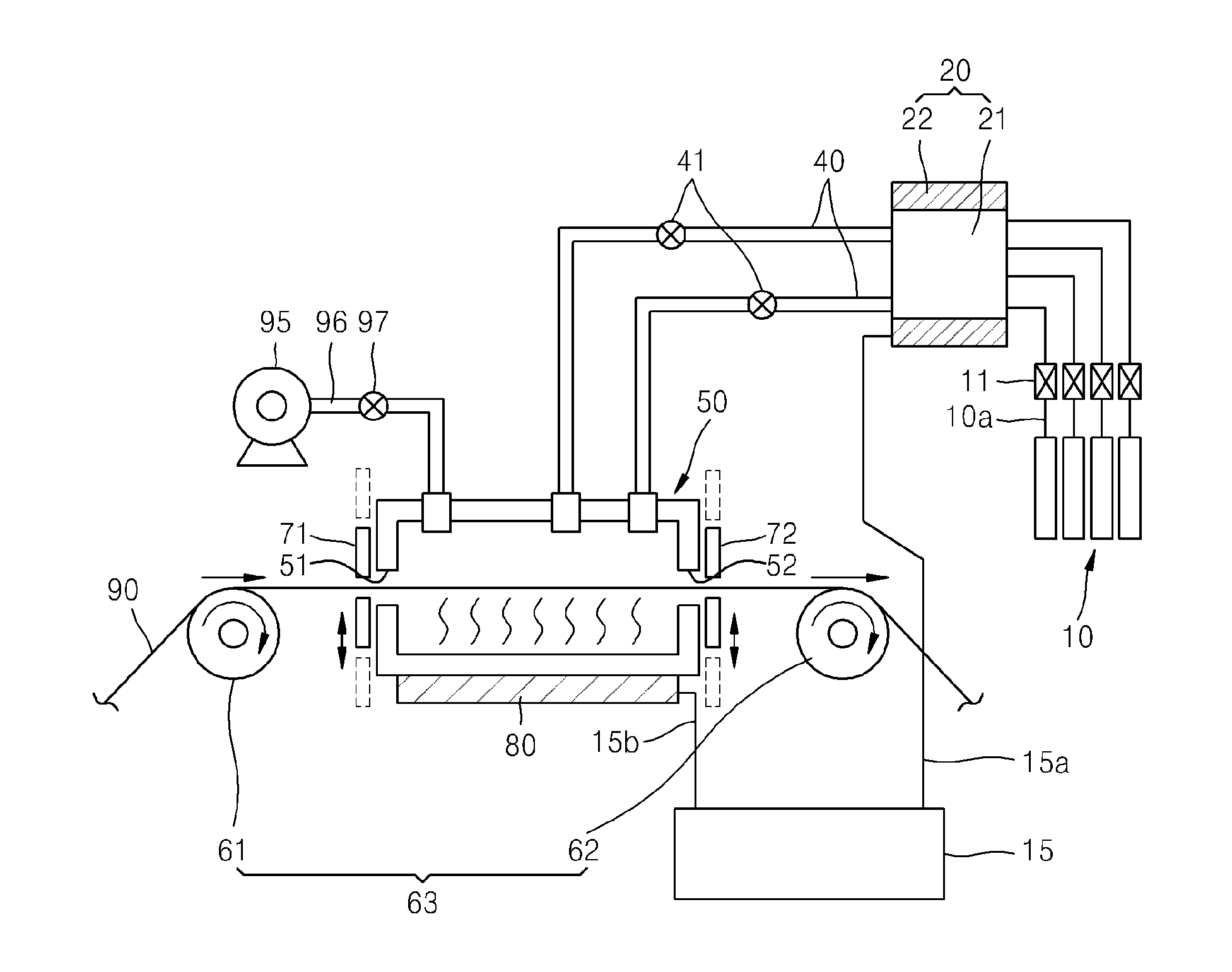

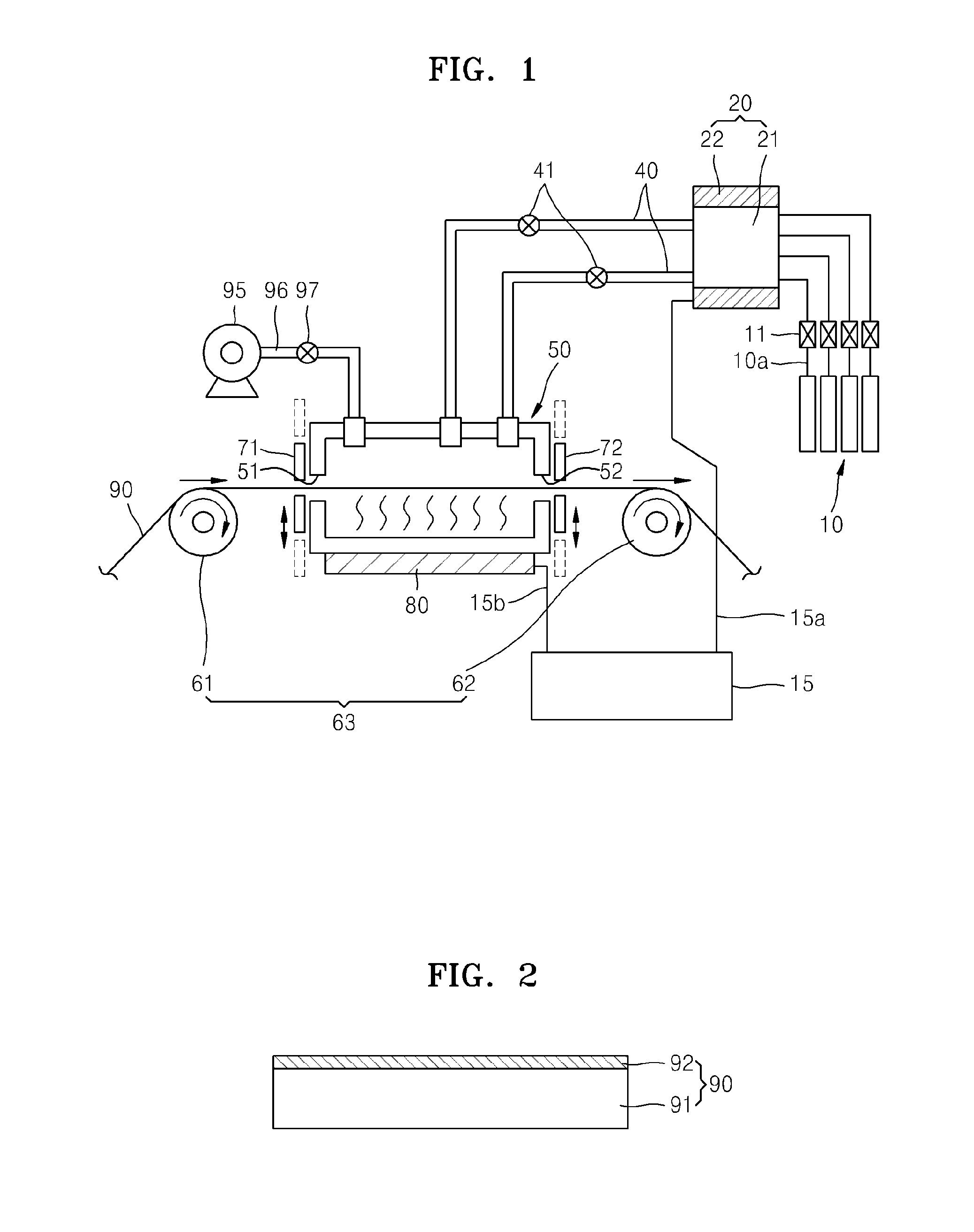

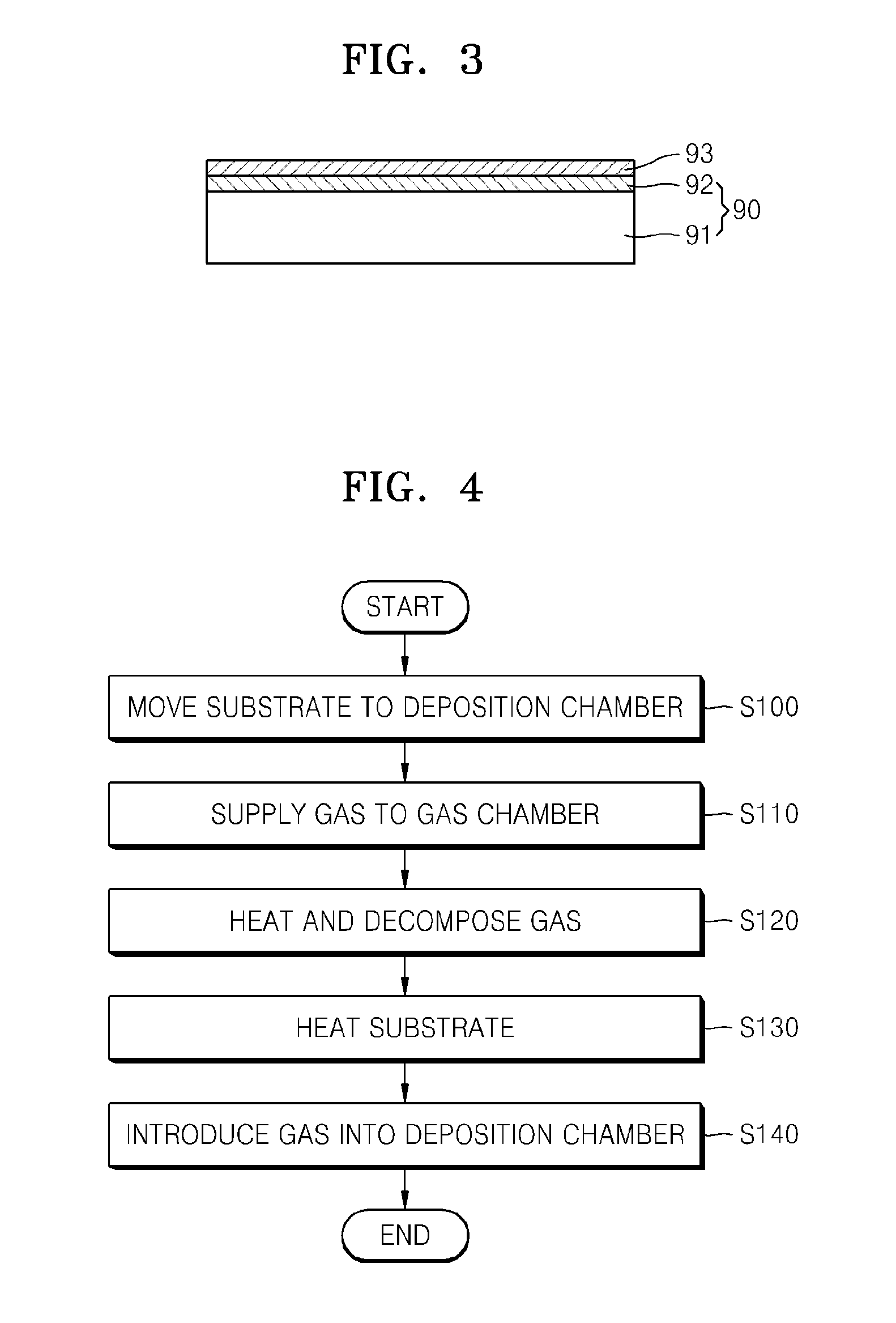

Graphene manufacturing apparatus and method

InactiveUS20130122220A1Economically manufacturedMaterial nanotechnologyVacuum evaporation coatingManufactured apparatusProcess engineering

Owner:HANWHA TECHWIN CO LTD

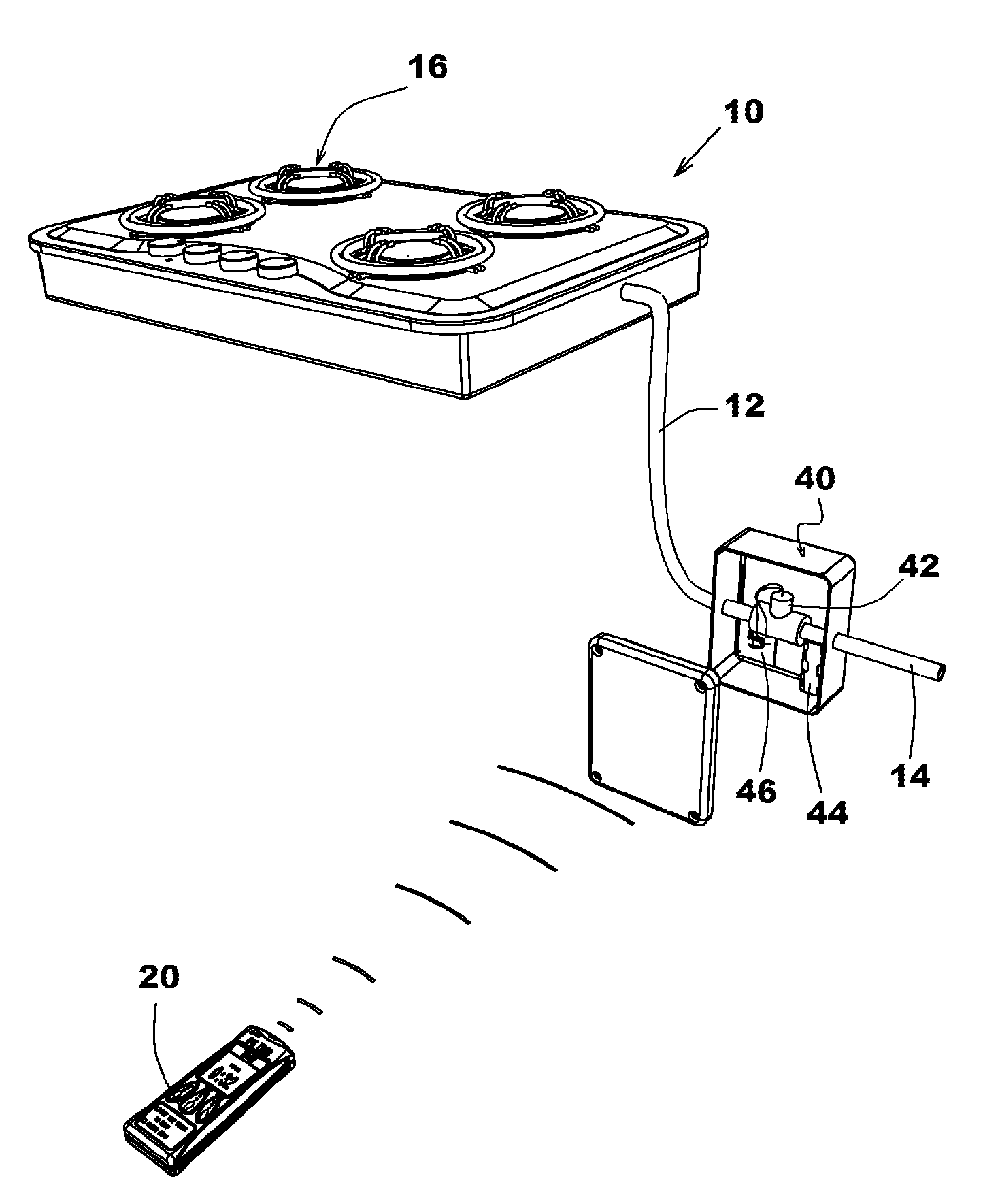

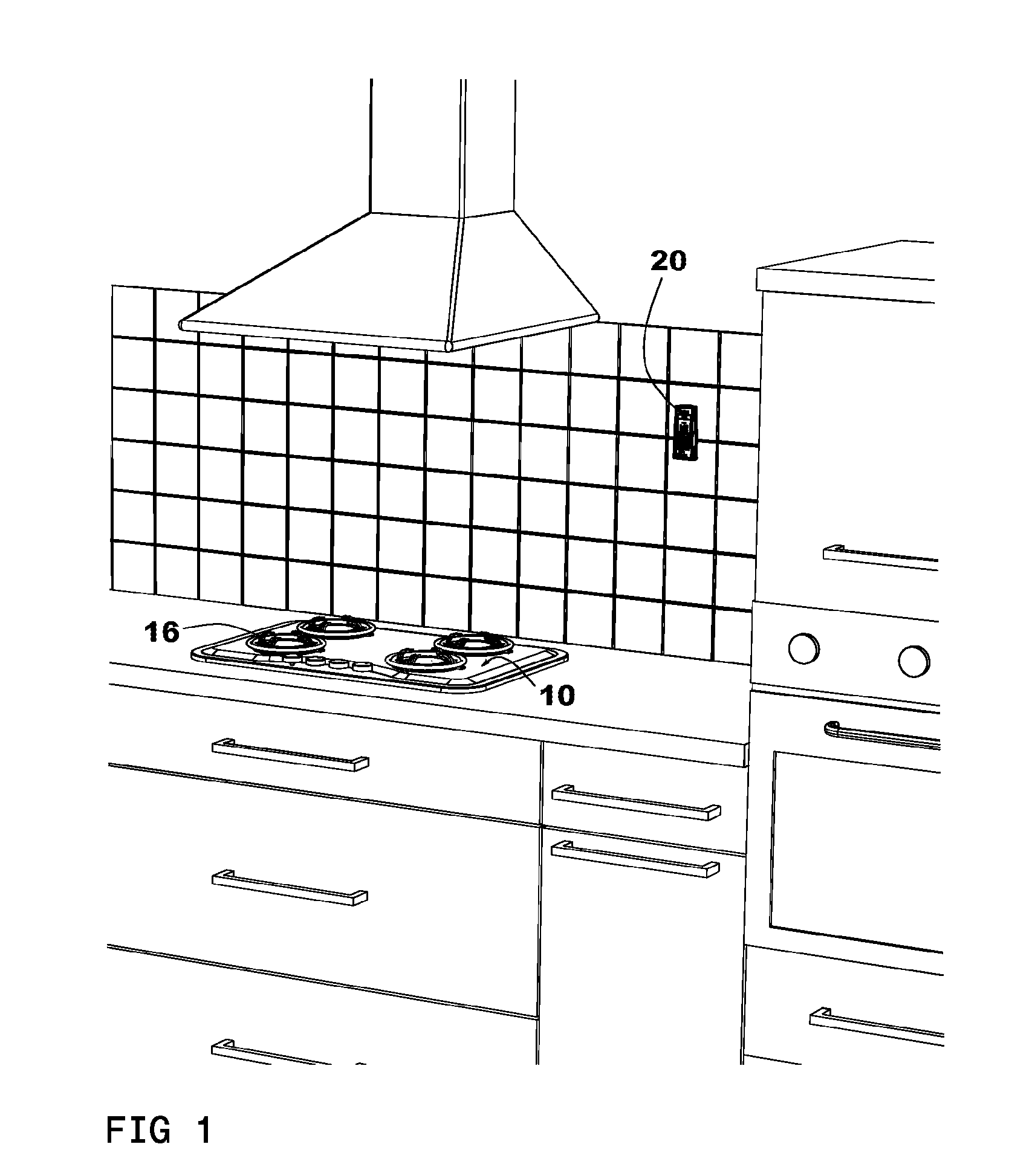

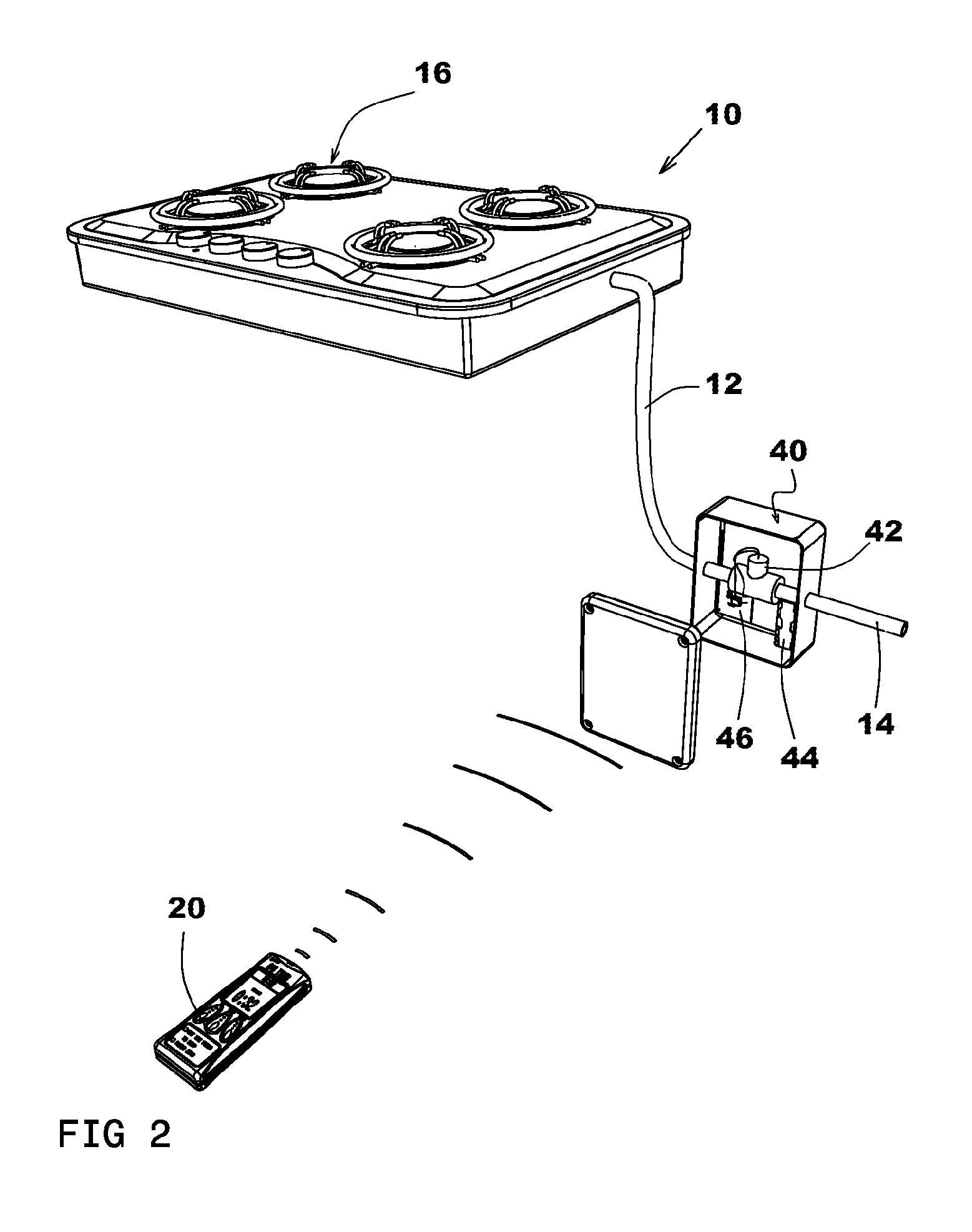

System for controlling gas supply to a gas heater

In one aspect, the present invention is directed to a system for controlling the gas supply to a gas heater (such as a gas stove, a heating stove, and so on), the system comprising: an electric valve, for blocking and unblocking a gas supplying pipe to said gas heater; a control unit, for controlling the operation of said electric valve; a timer, for determining a delay in activation of said electric valve to block said gas supply; and a remote-control unit, for providing, in a mobile manner, user interface for setting said timer; and a processing unit, for concentrating information from said timer, and activating the operation of blocking gas supply passage whenever the time of said timer runs out.

Owner:BRENNER DANI

Multifunctional general-purpose coal fines combustion test apparatus and method

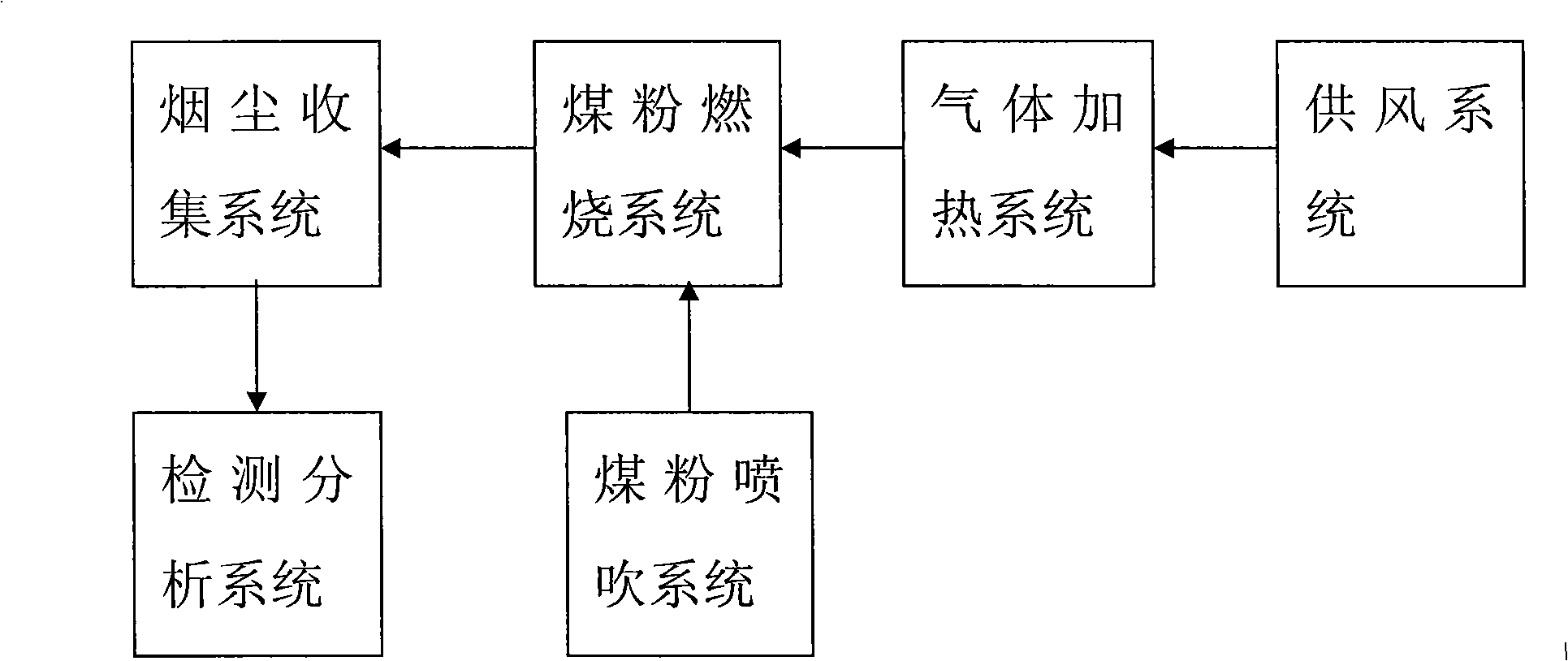

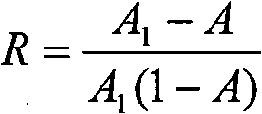

InactiveCN101349688ASmall delivery volume fluctuation rangeEasy to operateWeighing by removing componentBlast furnace componentsGeneral purposeCombustion

The invention relates to a multifunctional general purpose pulverized coal firing test device and a method thereof, which is characterized in that a regulating speed motor is connected with a spiral flood dragon shaft in a pulverized coal barrel, and the spiral flood dragon shaft in the pulverized coal barrel near the upper portion of the end cap of the regulating speed motor is opened with a feed inlet, and a high-pressure air current inlet is positively arranged above the other end of the spiral flood dragon shaft, and a pulverized coal outlet is positively arranged under the spiral flood dragon shaft. The total weight of a pulverized coal apron quantitive conveyor is totally acted on a weighing sensor through a suspended frame. The method comprises supplying wind for a gas heating system, starting the regulating speed motor when temperatures of a high-temperature heating furnace and a pulverized coal combustion furnace reach requirements, and spraying pulverized coal from the pulverized coal outlet to mix with high-temperature warm air to be burned in a combustion furnace pipe. A pulverized coal blowing system of the pulverized coal firing test device is stable and reliable to run, the fluctuation range of transport capacity is less than 5%, and the temperature of the pulverized coal combustion furnace can reach 1300 DEG C.

Owner:NORTHEASTERN UNIV

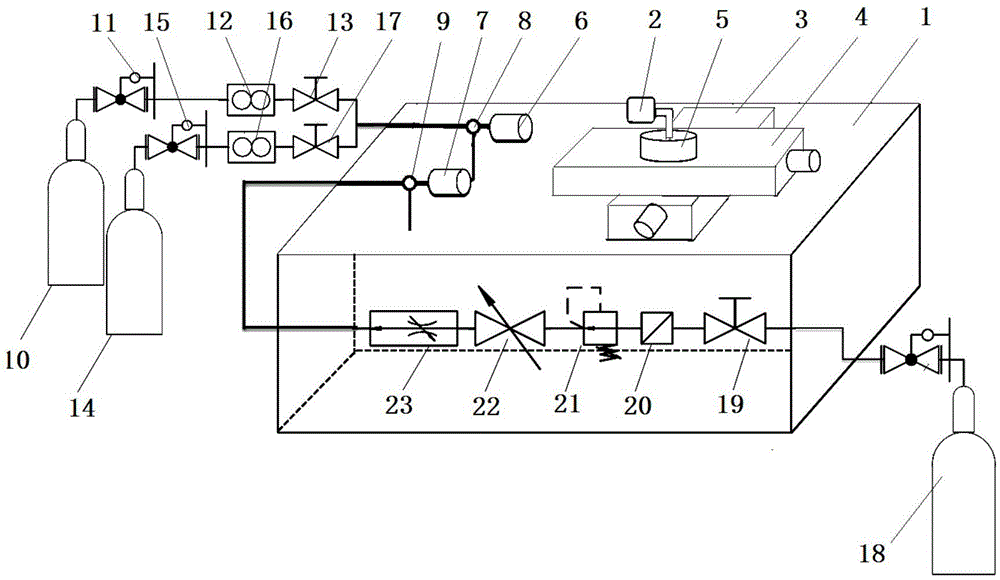

Combined loading test device

InactiveCN105571968AReal working environmentRealize the heating effectInvestigating abrasion/wear resistanceEngineeringTest platform

The invention relates to the field of thermal performance test and cooling efficiency test of thermal protection systems of aircraft, in particular to a combined loading test device. The combined loading test device comprises a test platform, a gas heating component which is used for heating a test piece, an air flow cooling component which is used for cooling the test piece, a temperature monitoring device which is used for acquiring the temperature information of the test piece in real time, and a control device which is used for controlling the gas heating component and the air flow cooling component according to the temperature information. According to the combined loading test device, the test piece is heated by the gas heating component, so that the disadvantages in the conventional heating mode are overcome; the shear effect caused by high-temperature air flow convection heating environment and air flow scouring, and the oxidation corrosion effect of a combustion product on the surface coating of a component when the test piece is used are truly simulated, and the working environment of the test piece can be truly simulated.

Owner:CHINA AIRPLANT STRENGTH RES INST

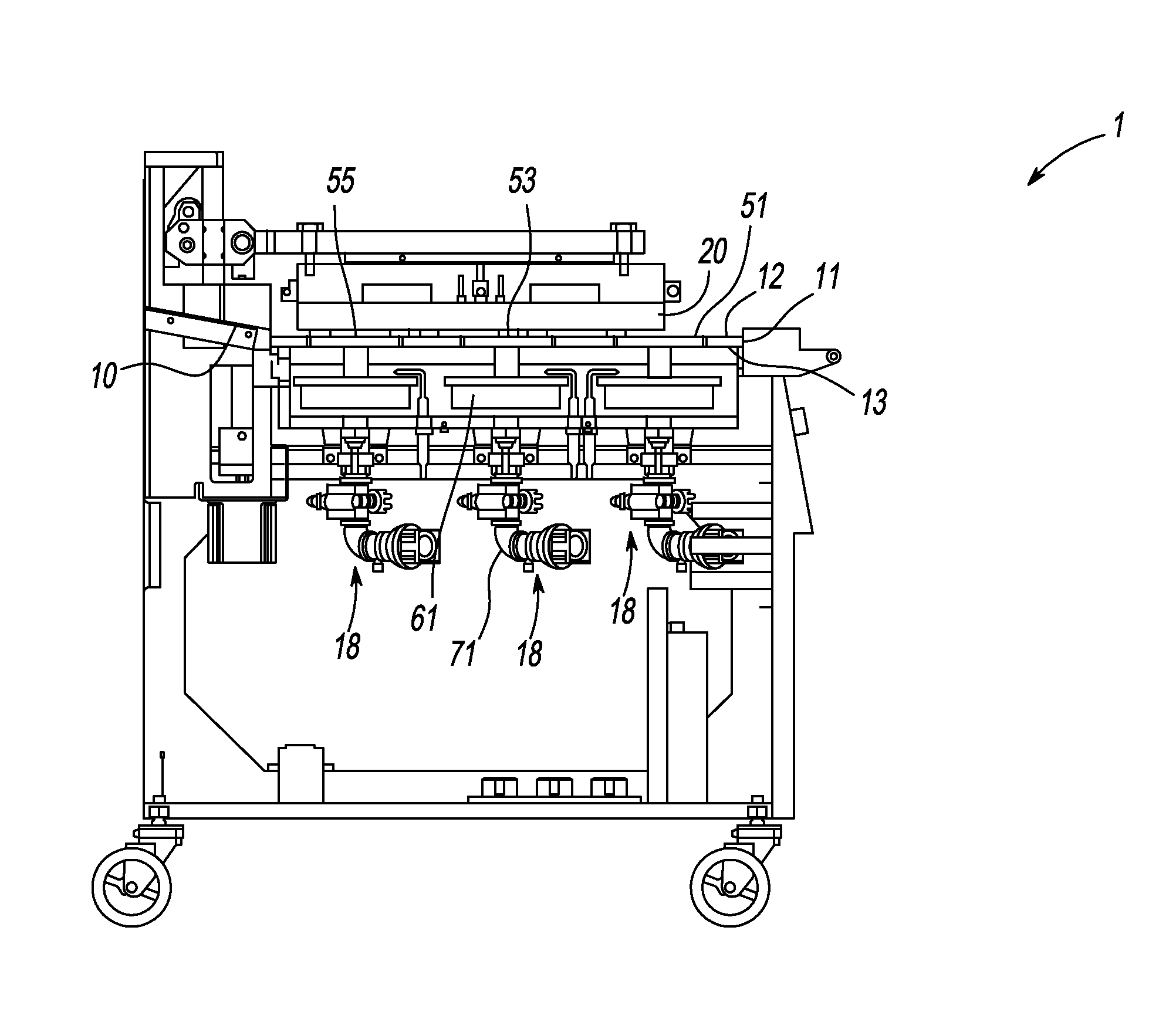

Cooking grill with multiple gas heating zones front to back for improved grill plate temperature management

ActiveUS20140161953A1Improved grill plate temperature managementEasy to manageMilk preservationBoiling over preventionElectricityProcess engineering

The grill of the present disclosure provides multiple heating zones within a front-to-back direction of each cooking platen. Each cooking zone has a heating element associated therewith. The heating elements can be independently controlled, so that each of the heating zones can be operated at a different temperature if necessary. A controller can monitor and adjust the heat output of each element with a temperature probe that measures the temperature of the surface of the grill plate. One or more of the heating elements can be a gas burner. Electrical heating elements may also be used.

Owner:GARLAND COMML IND

Electrically auxiliary preheating circulation gas water heater, preheating circulation system and control method

ActiveCN109297179AMeet the requirement of hot water available at any time without waiting for water releaseMeet available requirementsWater heatersElectricityEngineering

The invention belongs to the technical field of gas water heaters and discloses an electrically auxiliary preheating circulation gas water heater, a preheating circulation system and a control method.According to the electrically auxiliary preheating circulation gas water heater, a water outlet pipeline is provided with an intelligent heating module connected to a controller, after a preheating circulation function of the gas water heater is started, if the temperature of water heated by the minimum heat load of the gas water heater is higher than the set water outlet temperature Ts, the controller stops gas heating and controls the intelligent heating module to start, and the water is heated to the set water outlet temperature Ts. Through the gas water heater, when the water is heated with gas by the minimum heat load, if the temperature of the heated water is still higher than the set water outlet temperature, gas heating can be stopped, heating is conducted through the intelligentheating module till water is heated to the needed set water outlet temperature, and the requirements that on the premise that zero cold water is achieved, the problem of uneven water outlet temperatures is avoided, a user does not need to draw off water to wait for hot water, and hot water is available at any time are met.

Owner:QINGDAO ECONOMIC & TECHN DEV ZONE HAIER WATER HEATER

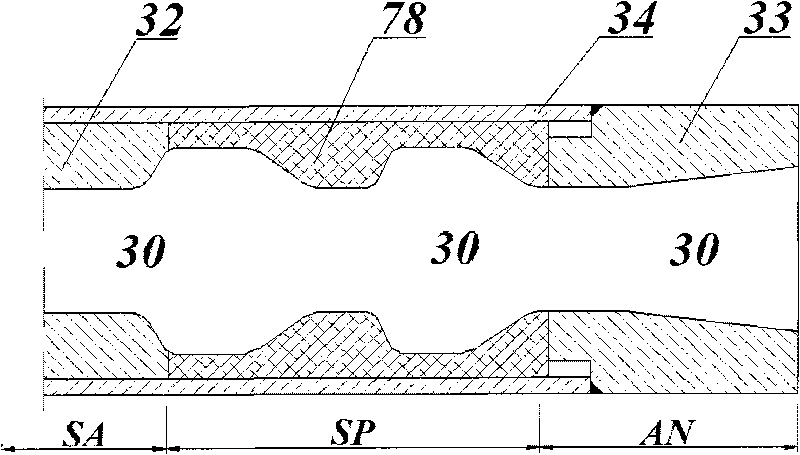

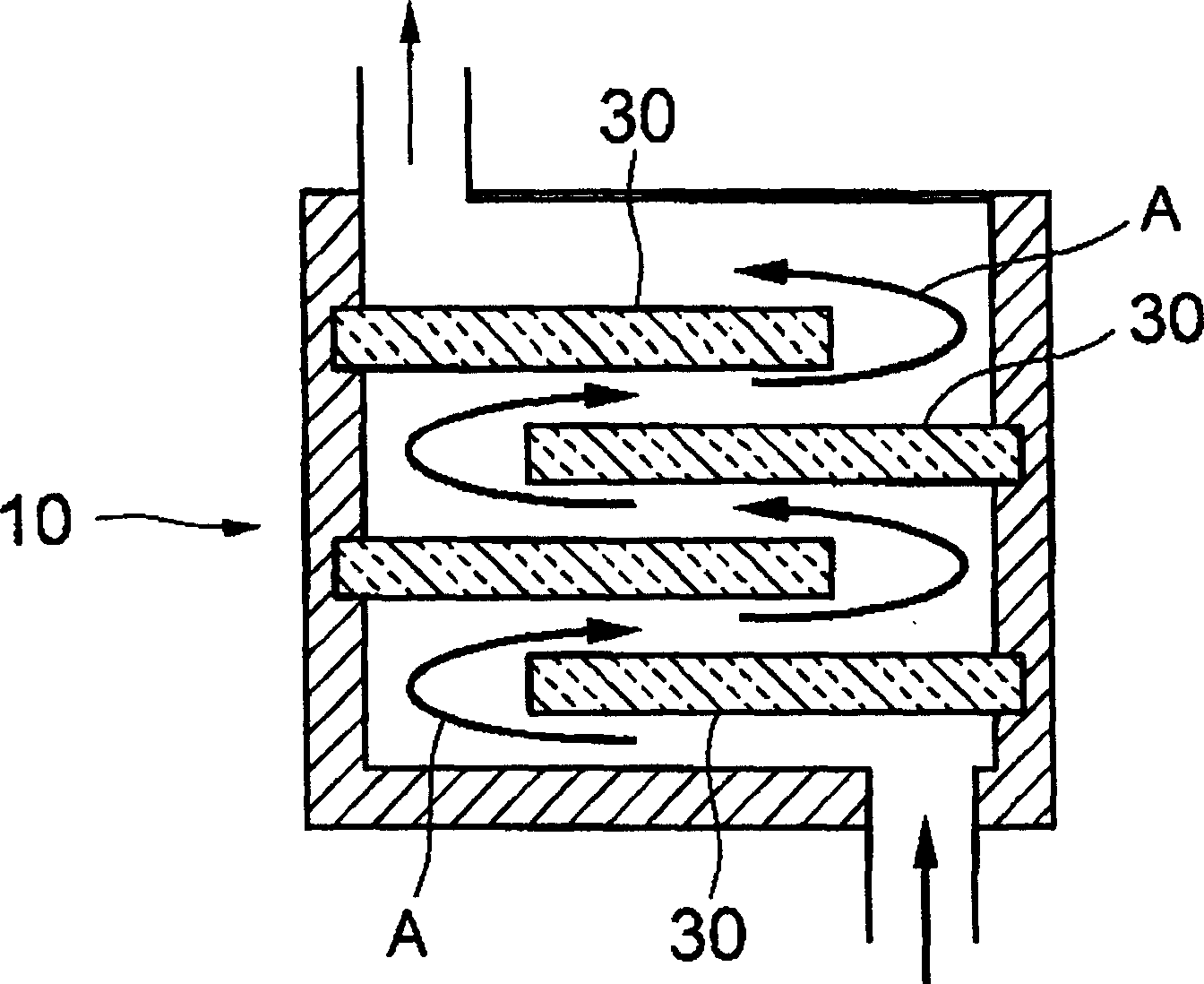

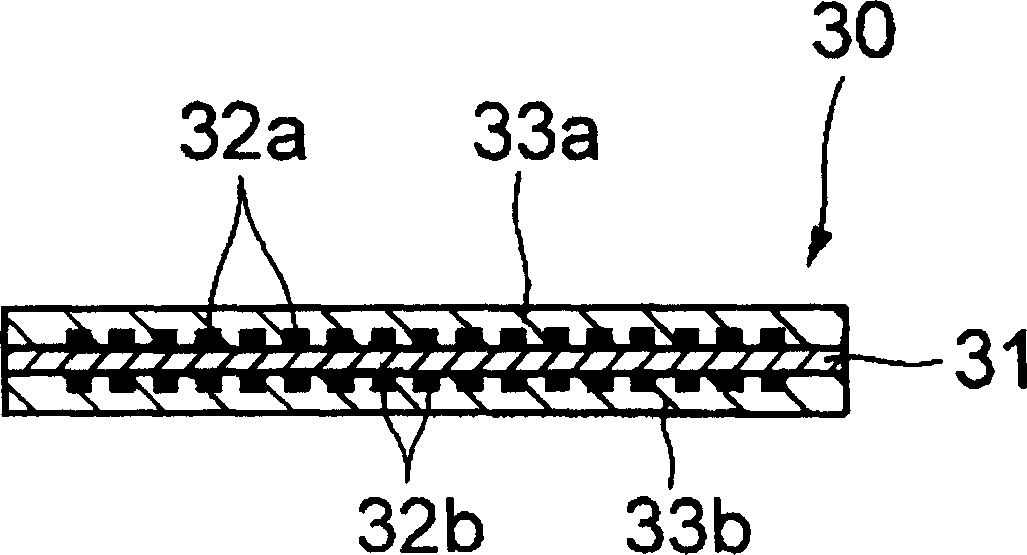

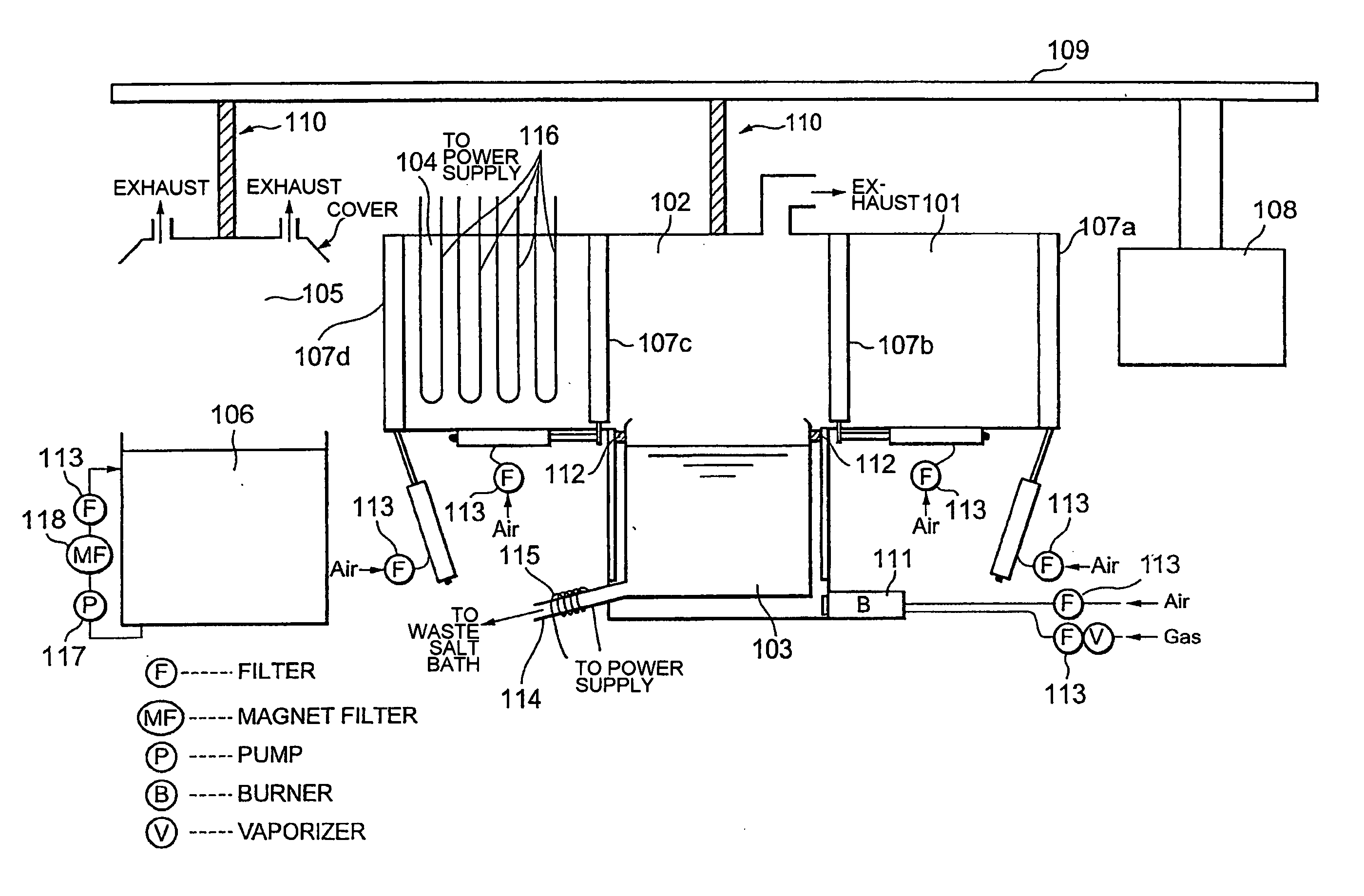

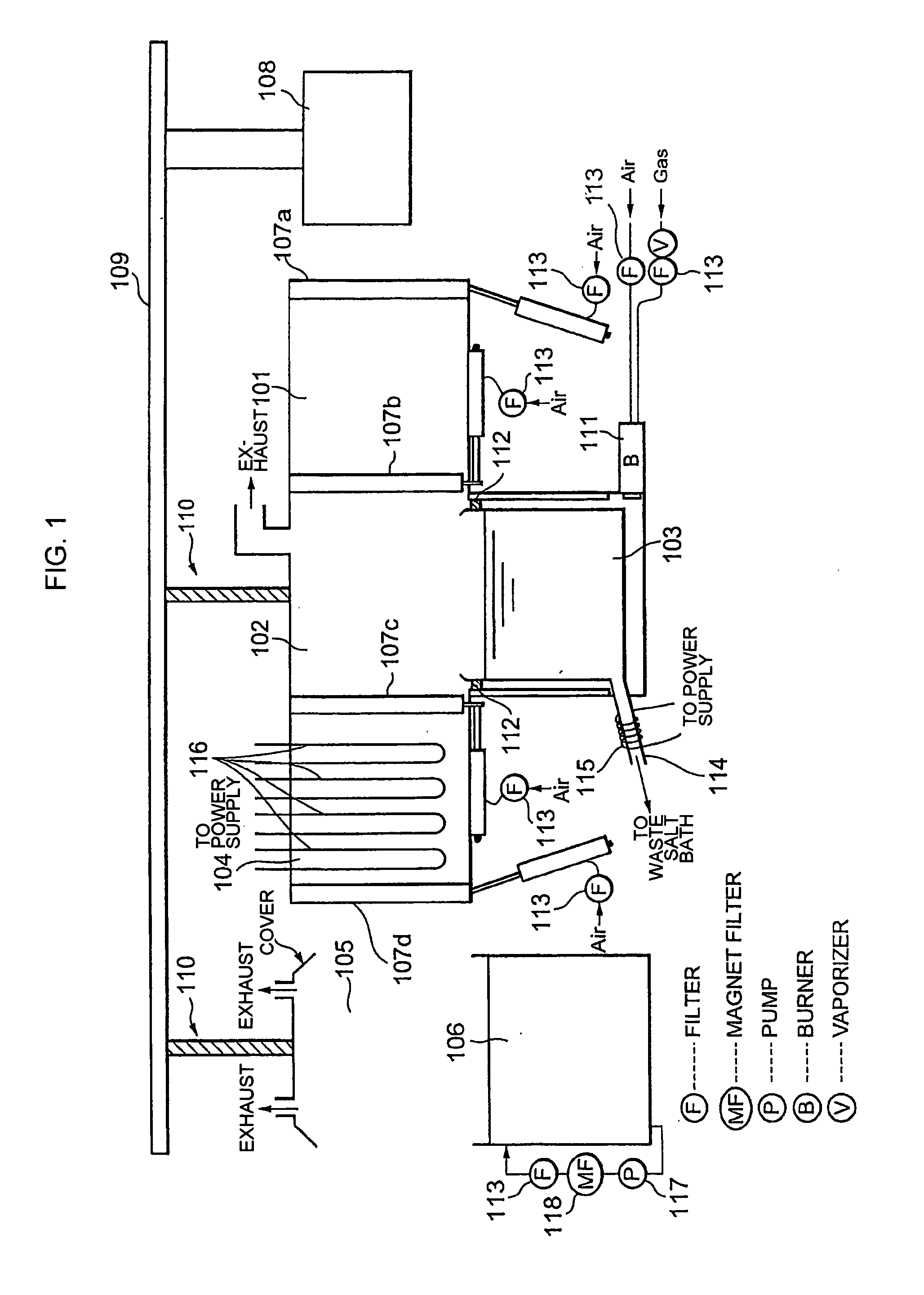

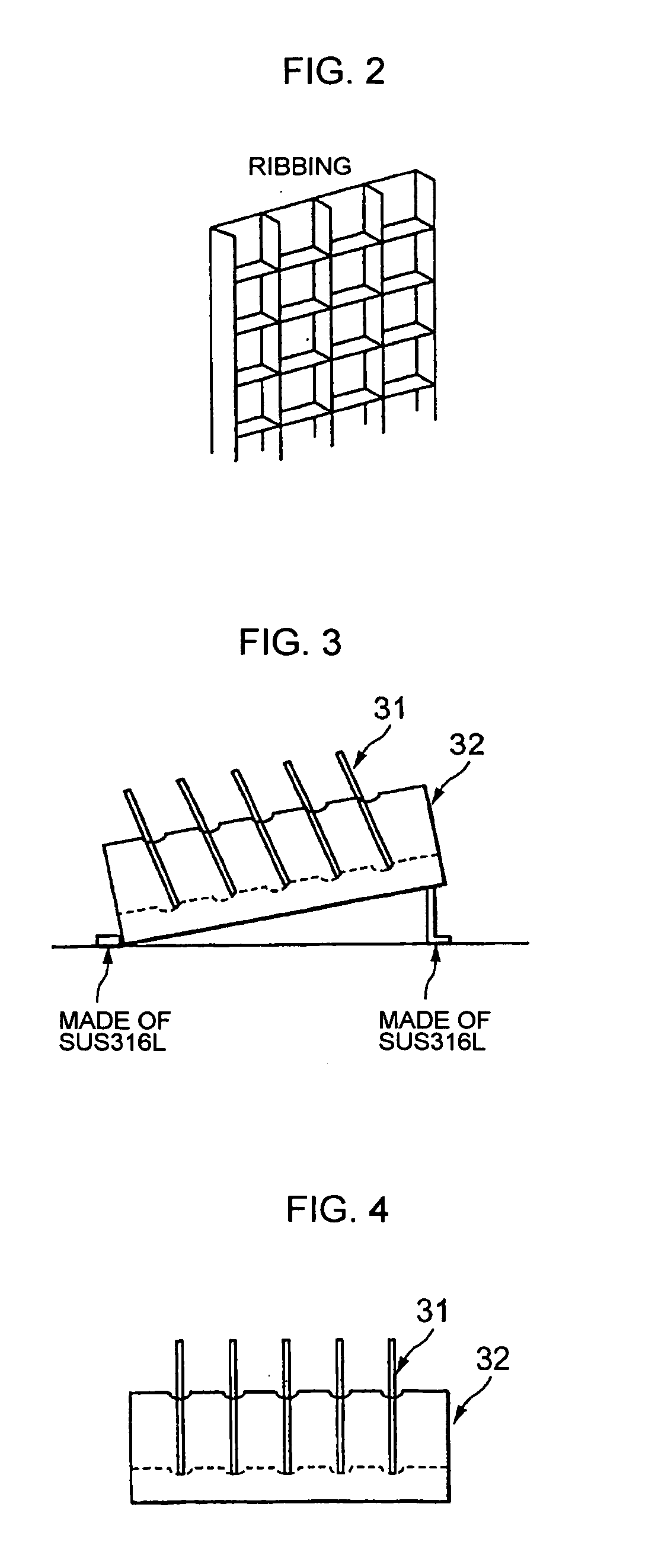

Gas heating method and gas heating device

InactiveCN1685180AEfficient heatingDispersed particle separationSemiconductor/solid-state device manufacturingDiluentExhaust fumes

Made available are a gas-heating method and a small-scale, energy-saving gas-heating device that, utilizing heaters that enable high-speed gas heat-up without being corroded by the gas, make possible the direct, efficient heating of gases. A plurality of platelike ceramic heaters 30 , or heater units in which a number of ceramic heaters are combined, is arranged in a staggered-ledge formation within a flow path or heating chamber for gases to create a zigzag gas flow-path A; gas supplied to the gas flow-path A is heated directly by the ceramic heaters 30 or heater units. This gas-heating device 10 can be utilized, in apparatuses that process NOx:containing exhaust gases or noxious / poisonous exhaust gases, for heating the exhaust gases and their diluent gases.

Owner:SUMITOMO ELECTRIC IND LTD

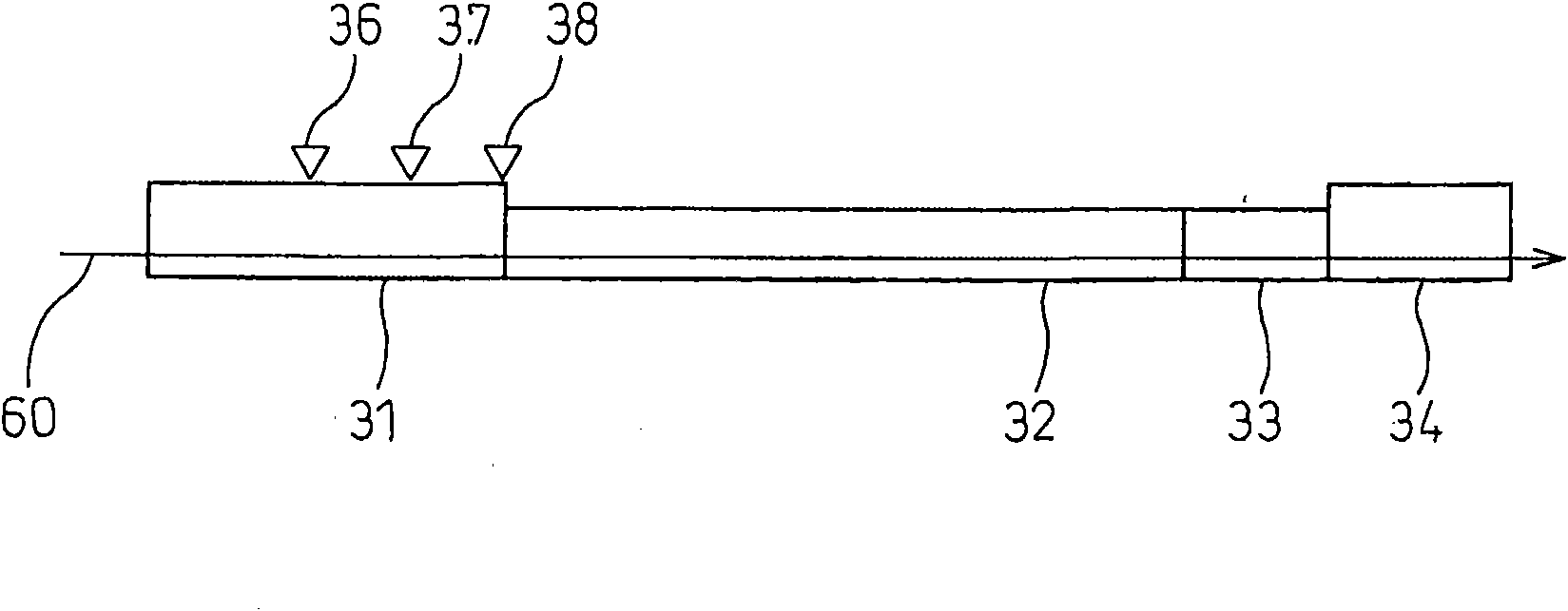

Magnetic disk glass substrate manufacturing method and magnetic disk manufacturing method

InactiveUS20050284179A1Improve recording densityImprove seismic performanceMetallurgyCompound (substance)

A magnetic disk glass substrate manufacturing method includes a step of polishing a surface of a glass substrate to a mirror surface, a gas heating process step of causing a heated atmosphere and the glass substrate to contact each other so as to heat the glass substrate at a temperature T0, a step of causing a chemically strengthening salt melted exceeding a freezing temperature TF and the glass substrate to contact each other so as to chemically strengthen the glass substrate at a temperature T1, a gas cooling process step of causing a gas coolant and the glass substrate to contact each other so as to cool the glass substrate to a temperature T2, and a liquid cooling process step of causing a liquid coolant and the glass substrate to contact each other so as to cool the glass substrate to a temperature T3, the above-mentioned steps being included in this order, wherein the temperature T2 is set to a temperature less than the freezing temperature TF of the chemical strengthening salt in a gas cooling process.

Owner:HOYA CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com