Method for real-time monitoring gas heating furnace flame on the basis of ROI average image analysis

An average image and gas heating technology, which is applied in the direction of instruments, character and pattern recognition, computer parts, etc., can solve the problems of unsuitable gas industrial heating furnace flame monitoring, burner flame crosstalk, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following describes the implementation of the present invention in detail with reference to the drawings and examples, but the examples should not be construed as limiting the present invention.

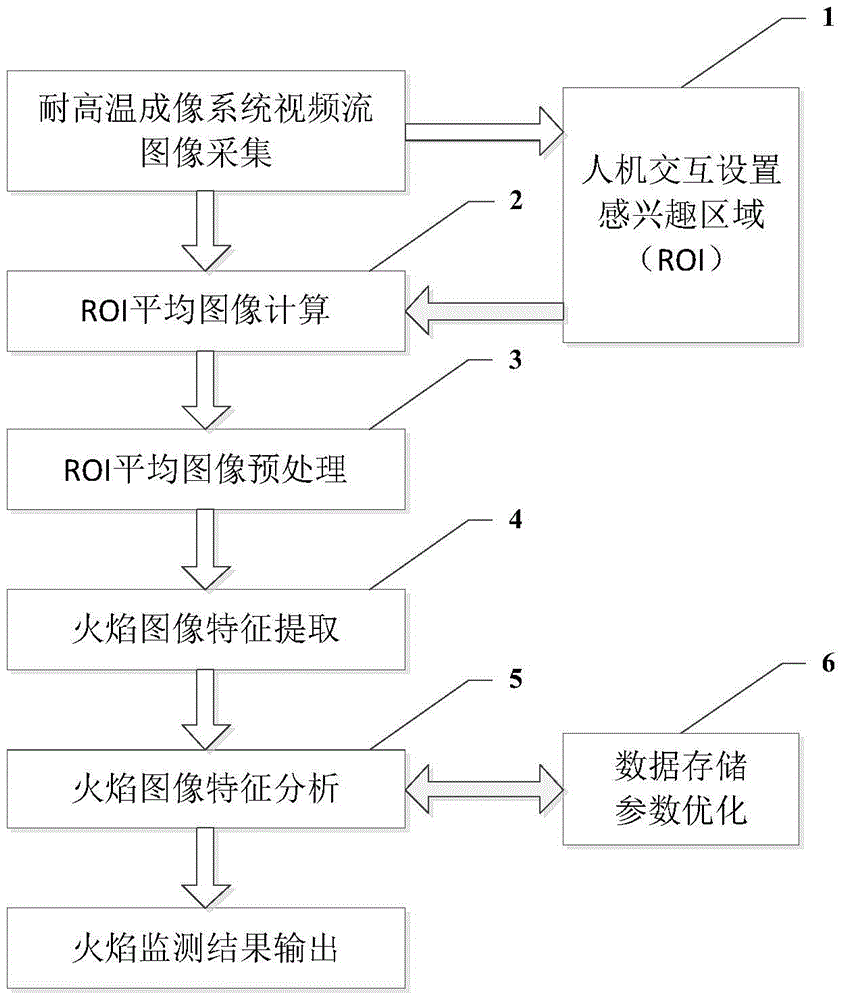

[0036] See figure 1 The method for real-time flame monitoring of a gas heating furnace based on ROI average image analysis described in the present invention includes the following steps:

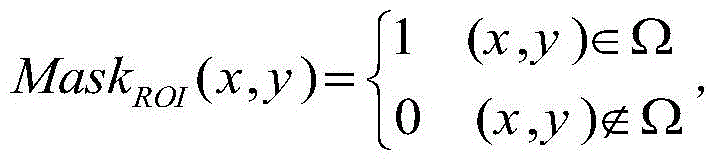

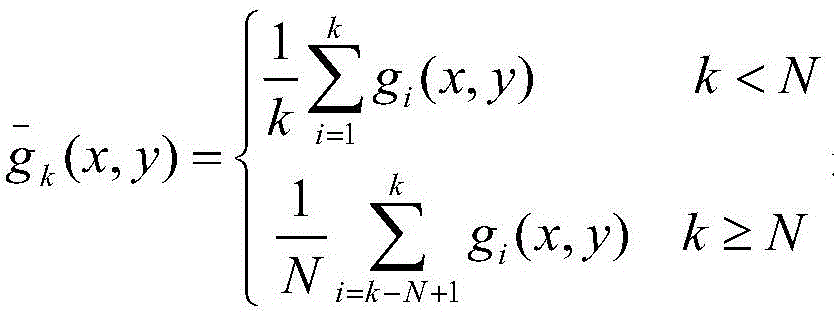

[0037] Step 1: Under normal combustion conditions, collect a frame of image from the high temperature imaging system, select the flame region of interest (ROI) around the burner using human-computer interaction, record the ROI coordinate information, and save it as a template. In actual work, the position of the fire detection lens extending into the furnace in the high temperature imaging system and the burner nozzle in the furnace are relatively fixed. The specific method is: after the hardware of the monitoring system is ready, open the monitoring system software, and for each channel of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com