Method and device for producing direct reduced iron by using gas-based reduction shaft furnace

A technology for reducing iron and gas heating device, applied in the field of iron and steel metallurgy, can solve the problems of large scale of coal gasification equipment, high energy consumption, inability to flexibly adapt to the energy equipment of iron and steel plants, etc., to save equipment and investment, reduce energy consumption, save energy Effect of heating load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

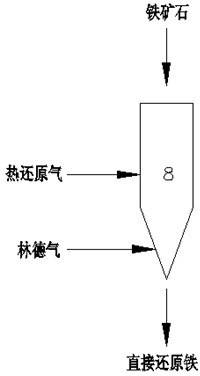

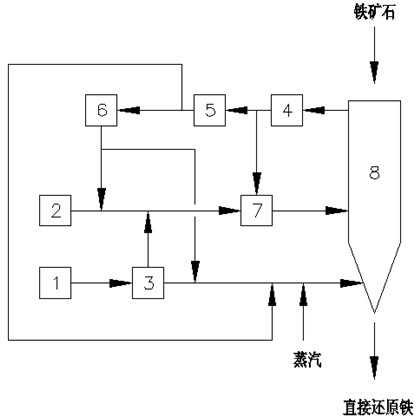

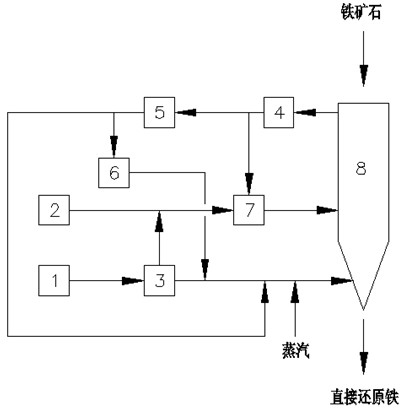

[0026] figure 1 It is a schematic diagram of the invention principle of the present invention. As shown in the figure, the method for producing direct reduced iron in a gas-based reduction shaft furnace of the present invention separates coke oven gas into hydrogen and Linde gas (hydrogen is separated from coke oven gas, and the remaining The coal gas mainly composed of hydrocarbons is called Linde gas), the hydrogen gas is mixed with the coal-based reducing gas and heated to become a hot reducing gas, and the hot reducing gas enters the reduction section of the shaft furnace 8 to participate in the reduction reaction, and the Linde gas The gas enters the shaft furnace 8 from the bottom of the cooling section of the shaft furnace 8 and fully contacts the direct reduced iron to exchange heat.

[0027] As a further improvement of the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com