Patents

Literature

49results about How to "Reduce heating load" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

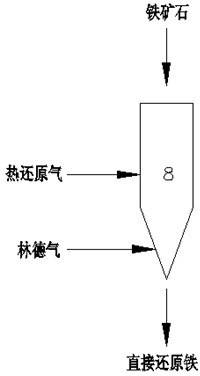

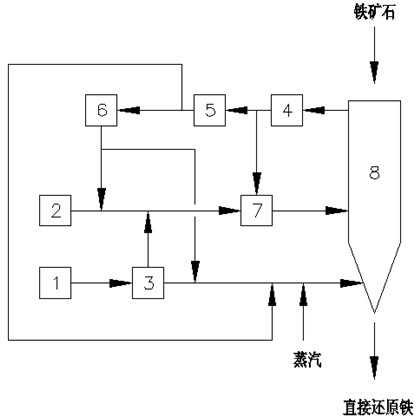

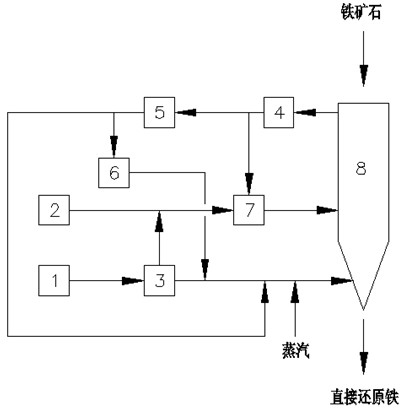

Method and device for producing direct reduced iron by using gas-based reduction shaft furnace

The invention discloses a method and device for producing direct reduced iron by using a gas-based reduction shaft furnace. Coal reducing gas and coke oven gas are mixed and supplied to a shaft furnace so as to produce direct reduced iron. The method comprises the following steps: separating the coke oven gas into hydrogen gas and linde gas, mixing the hydrogen gas with the coal reducing gas and using as reducing gas to reduce iron ores, and using the linde gas as cooling gas to cool direct reduced iron. The device for realizing the method comprises a shaft furnace, a coke oven gas source, a coal gasification device, a coke oven gas hydrogen-extracting device and a gas heating device. In the invention, coal gasification devices of different sizes can be flexibly used with a coke oven gas supply device, thereby reducing the size of the coal gasification device and effectively using the coke oven gas. Meanwhile, the invention cancels the minor cycle of a cooling section of a common shaft furnace, saves the equipment and investment, and brings the heat of direct reduced iron to a reducing section, thereby saving the heating load of the system reducing gas.

Owner:CISDI SHANGHAI ENG CO LTD +1

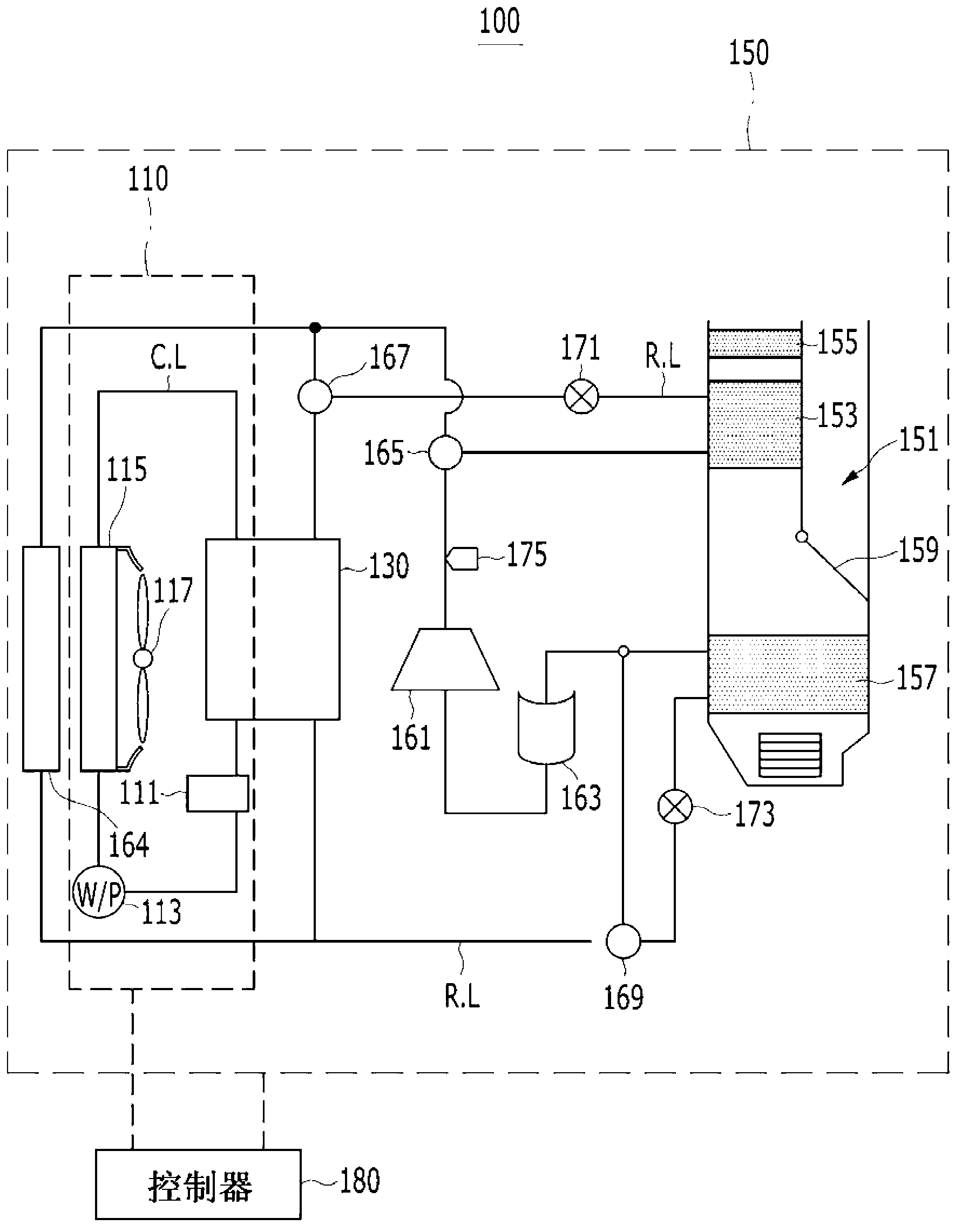

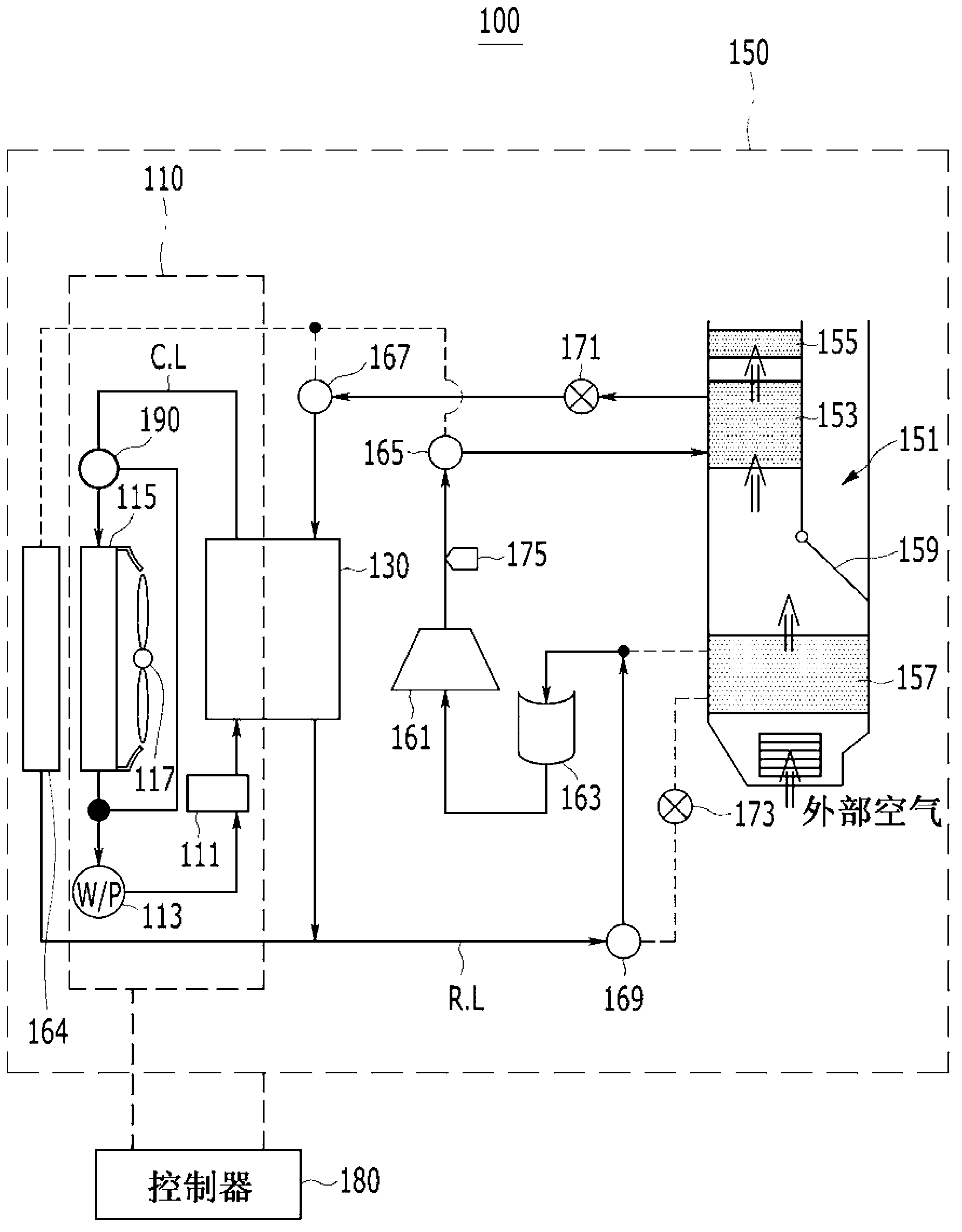

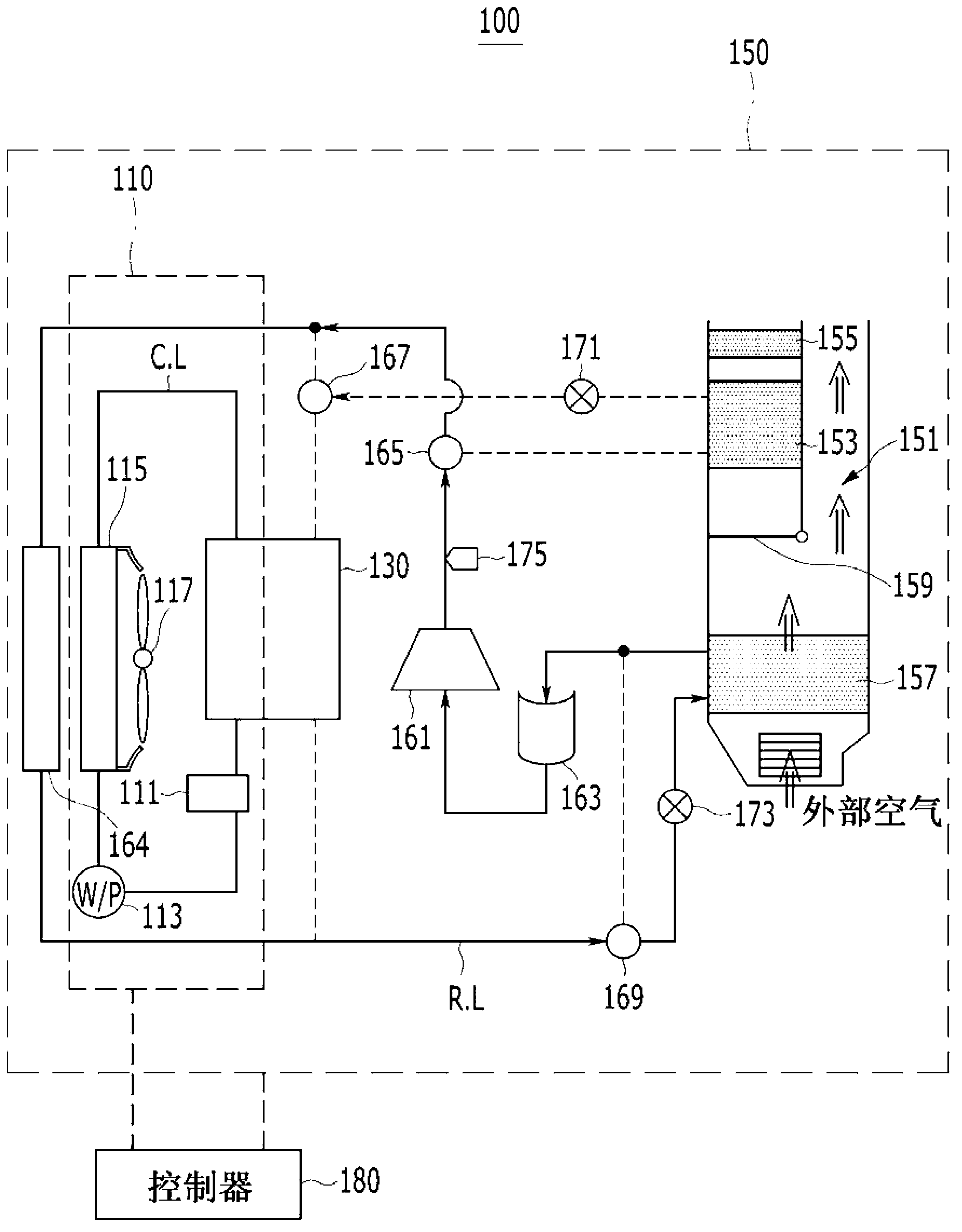

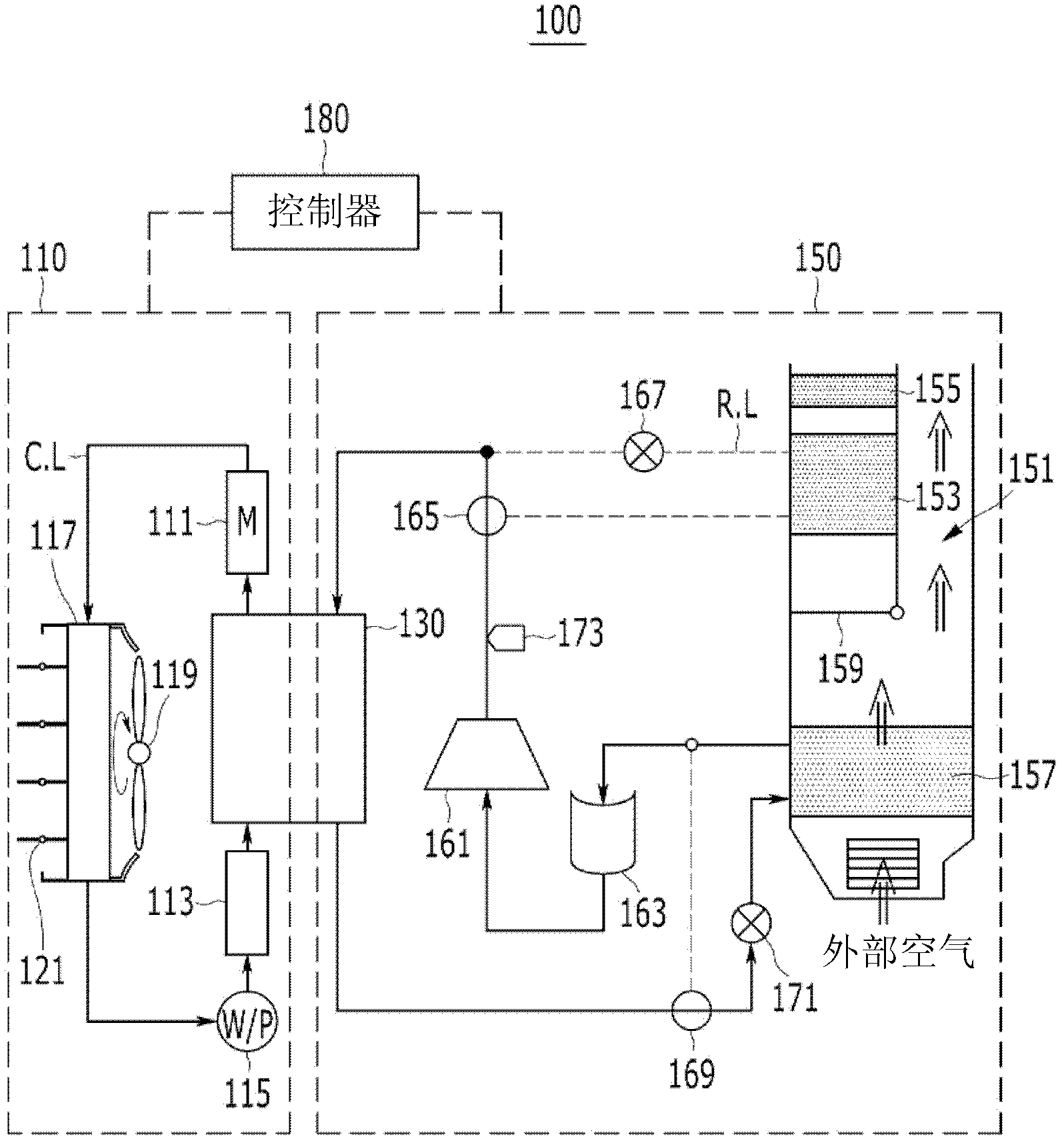

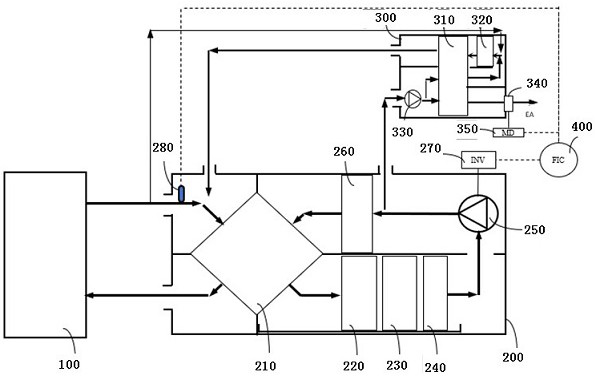

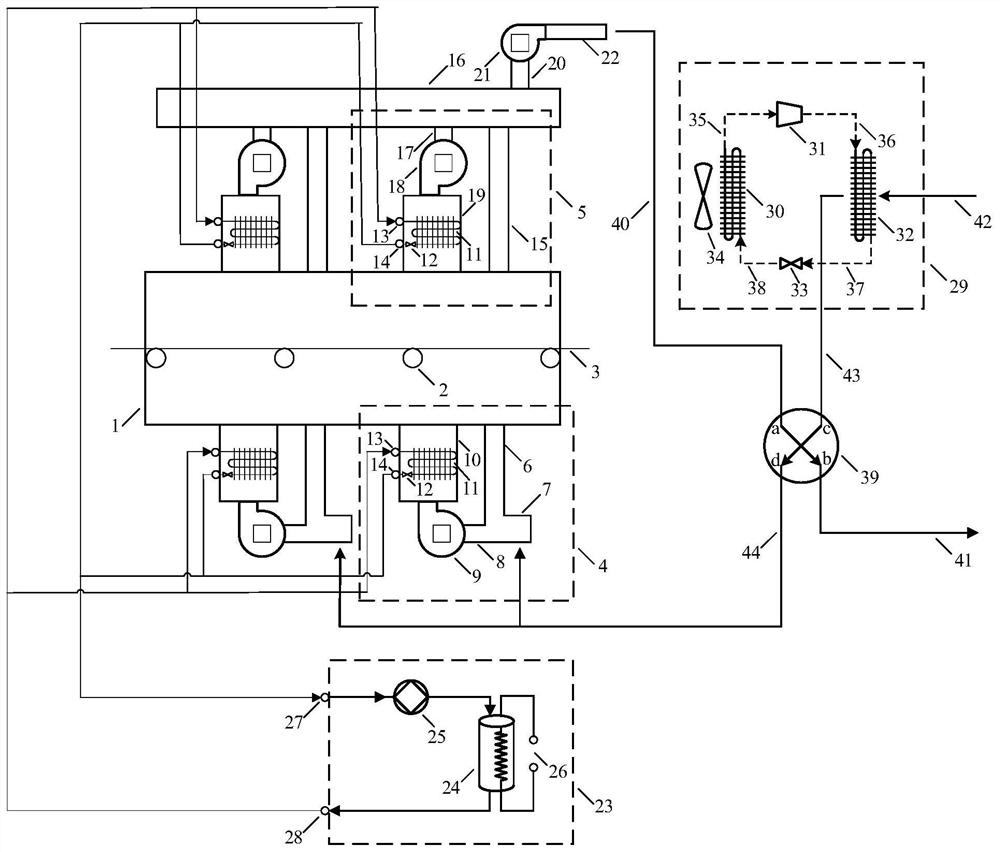

Heat pump system for vehicle

ActiveCN102840710AExtended driving distancePrevent increased power usageMechanical apparatusAir-treating devicesEngineeringAir conditioning

A heat pump system may include a cooling assembly disposed on a vehicle to circulate electric devices with coolant through a cooling line, wherein the cooling assembly includes a radiator disposed at a front side of the vehicle, uses a water pump to circulate coolant through the cooling line, and cools the supplied coolant through heat exchange with outside air, and a cooling fan that blows wind through the radiator, an air conditioning assembly connected to a refrigerant line connected to the cooling assembly to control heating and cooling, and a heat exchanger connected to the cooling line such that the coolant is circulated therein, selectively uses the waste heat generated from the electric devices according to modes to vary the temperature of the coolant, and is connected to the refrigerant line of the air conditioning assembly such that an inflow refrigerant exchanges heat with the coolant.

Owner:HYUNDAI MOTOR CO LTD +1

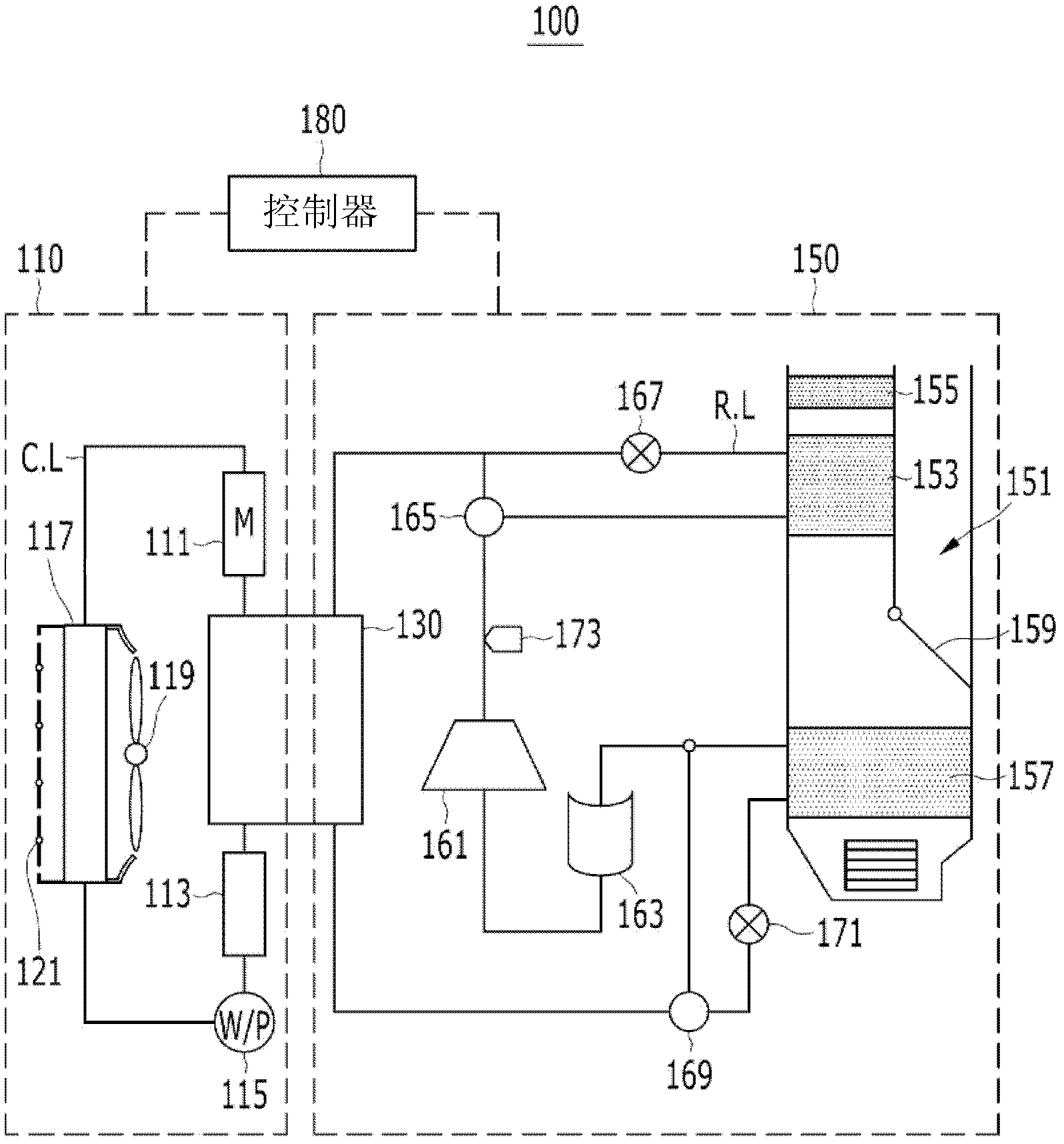

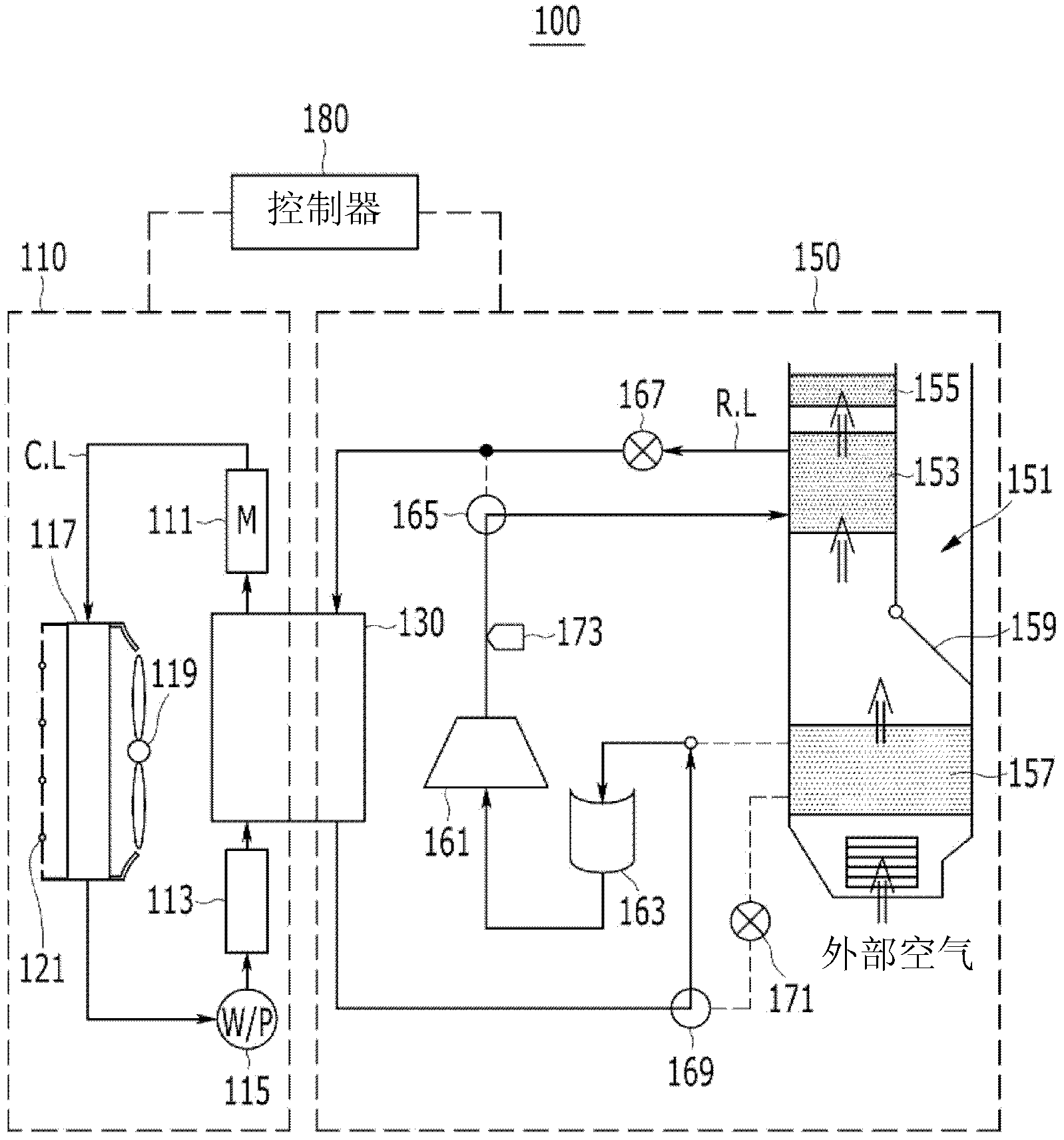

Heat pump system for vehicle

ActiveCN102692095AImprove the heating effectImprove dehumidification effectAir-treating devicesHeat pumpsProcess engineeringHeat pump

The invention discloses a heat pump system for a vehicle, including a water cooled condenser that uses a coolant as a heat exchange media and uses waste heat generated from a motor and an electronic device to improve heating performance, efficiency, and dehumidifying performance. A control method is also described.

Owner:HYUNDAI MOTOR CO LTD +1

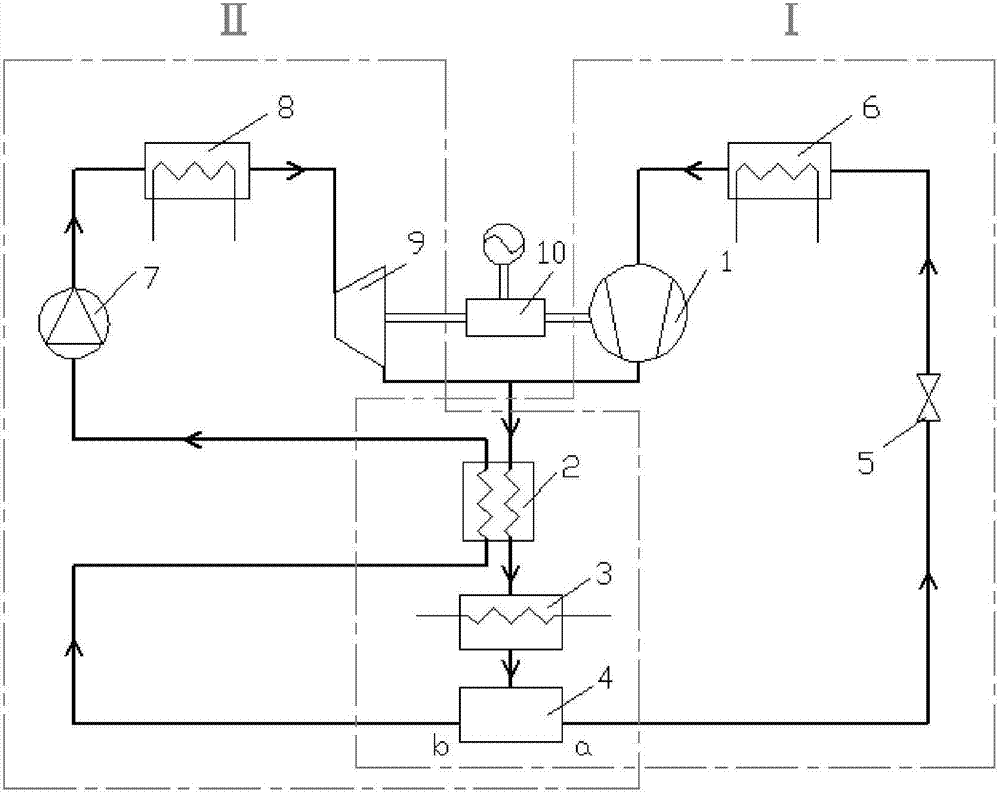

Device for combining power cycle with compression type refrigerating cycle

InactiveCN103075839ASave electricityReduce condensation loadFrom solar energyGeothermal energy generationPower cycleToxic industrial waste

The invention discloses a device for combining power cycle with compression type refrigerating cycle, which can be used for simultaneously completing power cycle and compression type refrigerating cycle. The device comprises a compressor, a heat regenerator, a condenser, a reservoir, a throttle valve, an evaporator I, a working medium pump, an evaporator II, an expander and a transmission device, which are connected according to a rule. According to the device disclosed by the invention, medium-low-grade energy sources such as solar energy, geothermal energy and industrial waste heat can be utilized for driving the expander to apply work, so that the compressor is driven by the output shaft work to operate for achieving the power cycle and the refrigerating cycle. Meanwhile, the device can also be used for generating power when the operation of a refrigerating working condition is not needed. The heat regenerator is additionally arranged in the device, so that the load of the heater is reduced while the load of the condenser is reduced. The reservoir is arranged, so that the two cycles are operated independently, thereby ensuring stable refrigerating to a user. The device disclosed by the invention has a good application prospect in underserved areas of power or small areas or cold supply, and is of significance to energy conservation and emission reduction.

Owner:SOUTHEAST UNIV

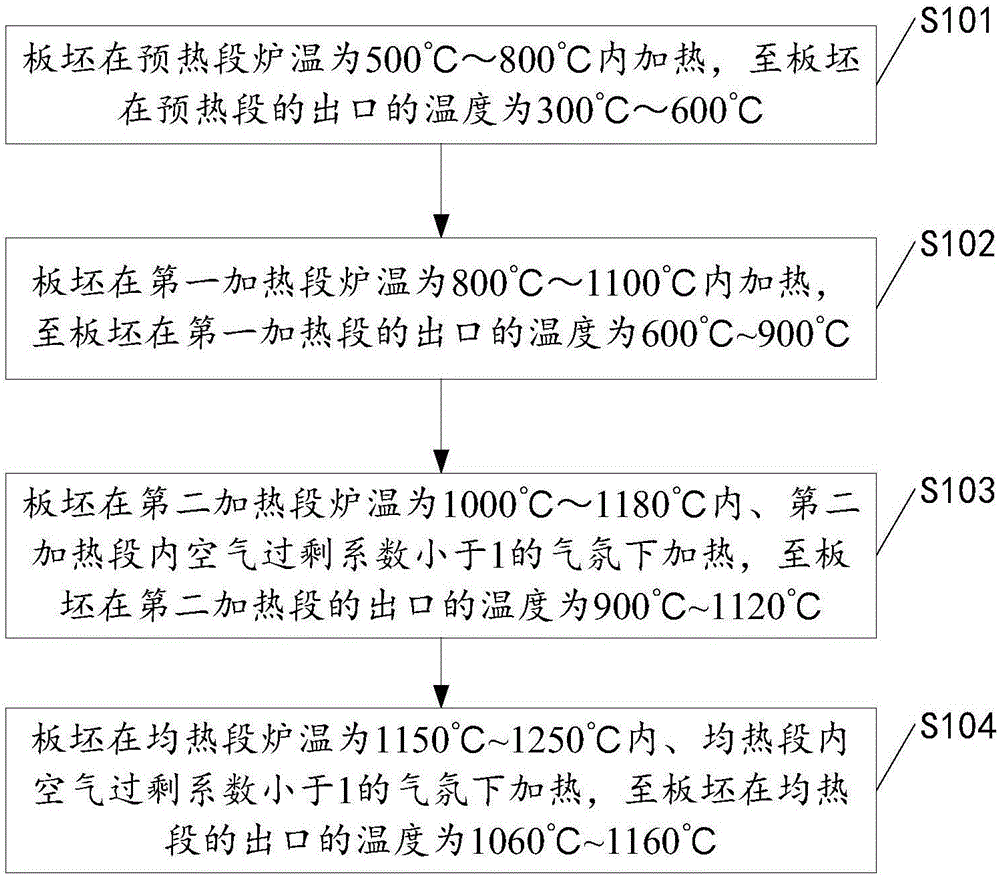

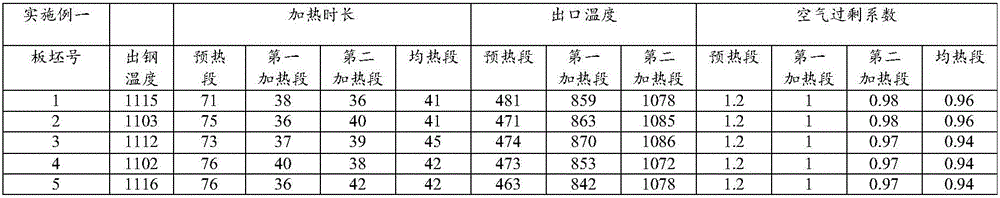

Heating method for IF steel in ferrite rolling

ActiveCN106694567AOptimize heating curveReduce heating loadTemperature control deviceFurnace temperatureAtmosphere

The invention provides a heating method for IF steel in ferrite rolling and is applied to the technical field of hot rolling. A slab is heated in a preheating section at the furnace temperature ranging from 500 DEG C to 800 DEG C till the temperature of the slab at an outlet of the preheating section ranges from 300 DEG C to 600 DEG C; the slab is heated in a first heating section at the furnace temperature ranging from 800 DEG C to 1100 DEG C till the temperature of the slab at an outlet of the first heating section ranges from 600 DEG C to 900 DEG C; the slab is heated in a second heating section at the furnace temperature ranging from 1000 DEG C to 1180 DEG C and in the atmosphere that the coefficient of excess air in the second heating section is smaller than 1 till the temperature of the slab at an outlet of the second heating section ranges from 900 DEG C to 1120 DEG C; and the slab is heated in a soaking section at the furnace temperature ranging from 1150 DEG C to 1250 DEG C and in the atmosphere that the coefficient of excess air in the soaking section is smaller than 1 till the temperature of the slab at an outlet of the soaking section ranges from 1060 DEG C to 1160 DEG C. The heating method solves the technical problem that when an existing hot rolling technology is applied to IF steel rolling, the quality of rolled finished products is low, and the overall quality of the rolled finished products is improved.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

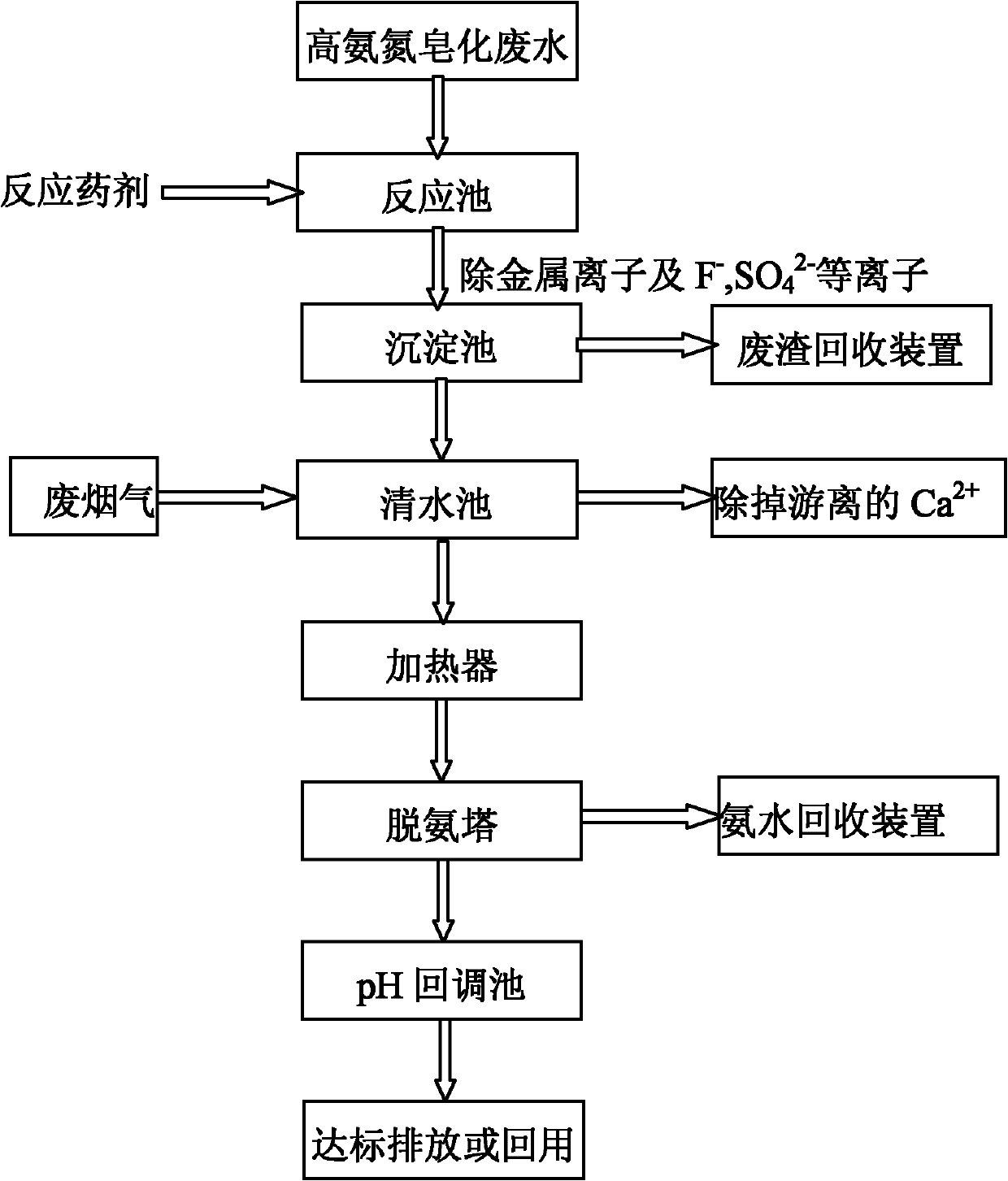

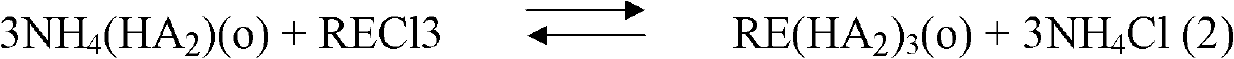

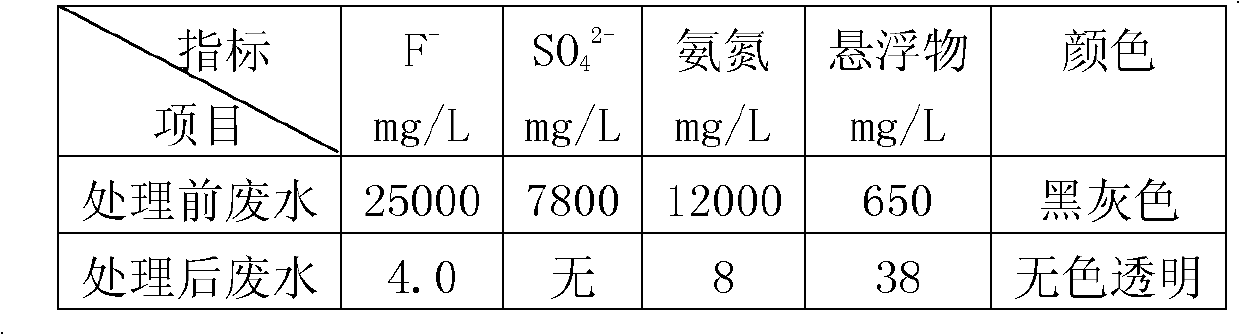

Deep treatment technology of high-ammonia nitrogen rare earth wet process-smelted saponifying wastewater

ActiveCN102167467ASolve processing problemsEliminate scaling problemsProductsReagentsRare earthTower

The invention discloses a deep treatment technology of high-ammonia nitrogen rare earth wet process-smelted saponifying wastewater. The technology is characterized by comprising the steps of: adding a reaction medicament into rare earth wet process-smelted extract liquor saponifying wastewater for reacting; precipitating after the reacting; separating out solid waste residue; feeding CO2-containing waste gas into clean water; leading the Ca2+ content in the wastewater to be less than 0.01mol / L; filtering; adjusting the PH value of the wastewater to be 10.5-11.0, and heating to be 55-65DEG C; feeding the adjusted wastewater into a deaminizing tower for performing negative pressure ammonia stilling type deamination; and adjusting the PH value of the wastewater to be 6-9 after the deaminizing. By matching the unslaked lime, the waste gas with the negative pressure stilled ammonia, the method can be used for removing not only various metal plasmas in the rare earth wet process-smelted extract liquor saponifying wastewater, such as F1<-> and SO4<2-> and the like, but also ignored calcium ions, so that the scaling problem of follow-up equipment is avoided, and the waste gas generated by a boiler is further treated.

Owner:JIANGSU HUASHAN ENVIRONMENTAL PROTECTION TECH

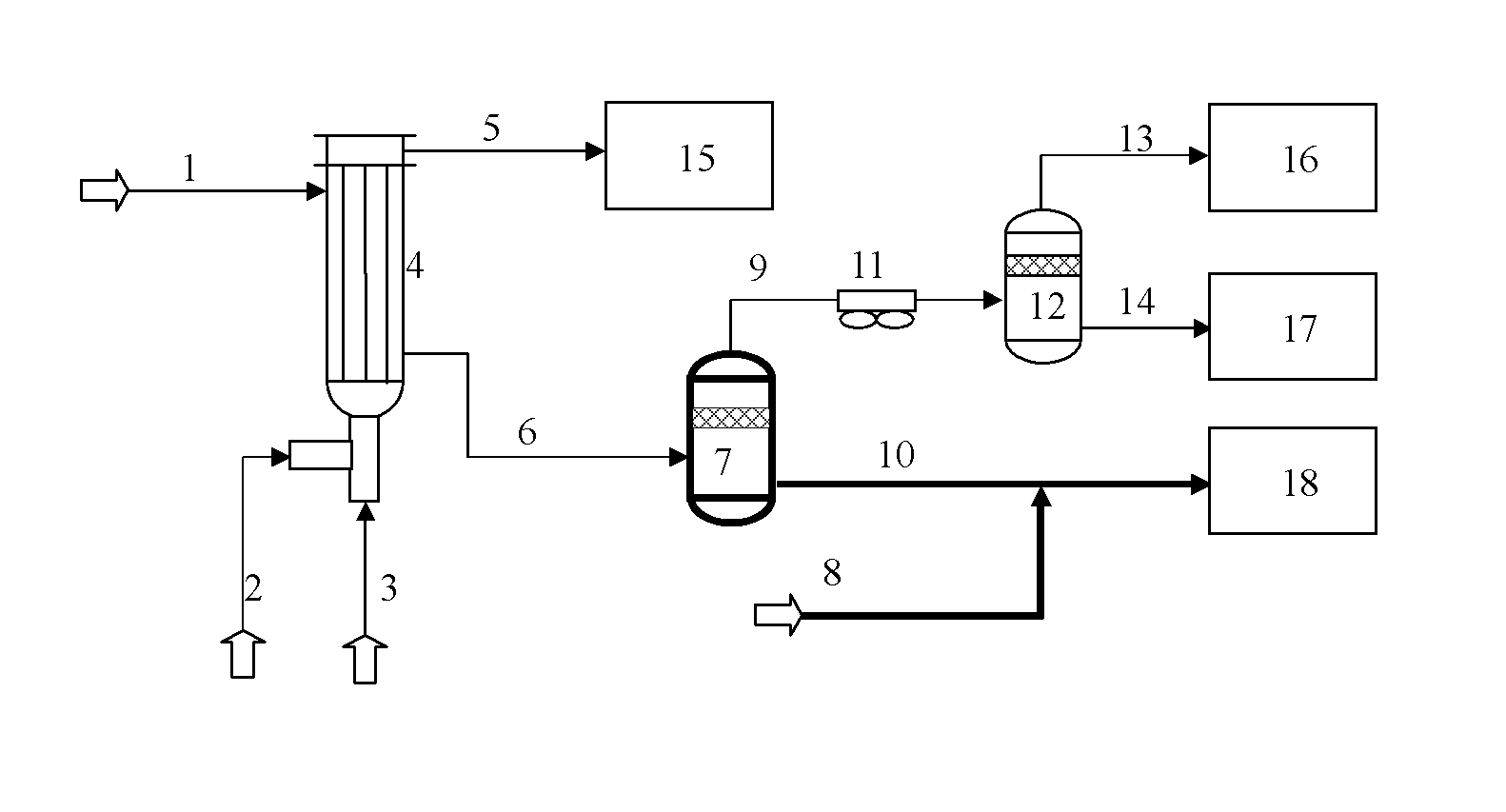

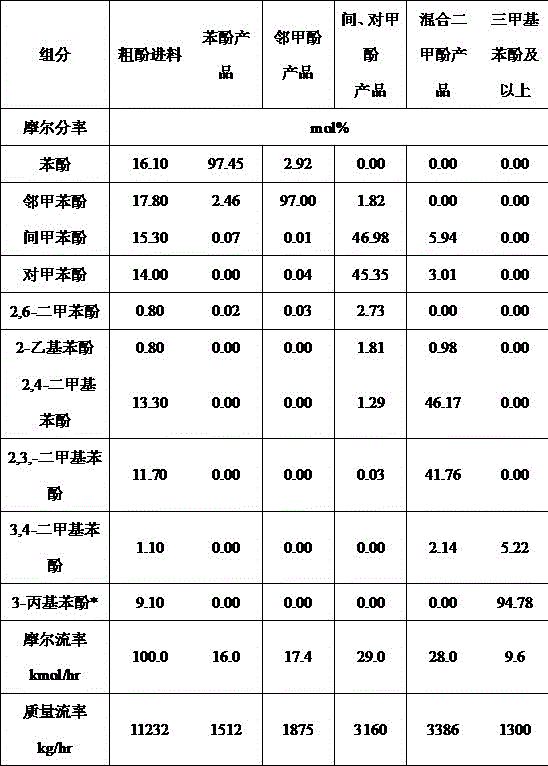

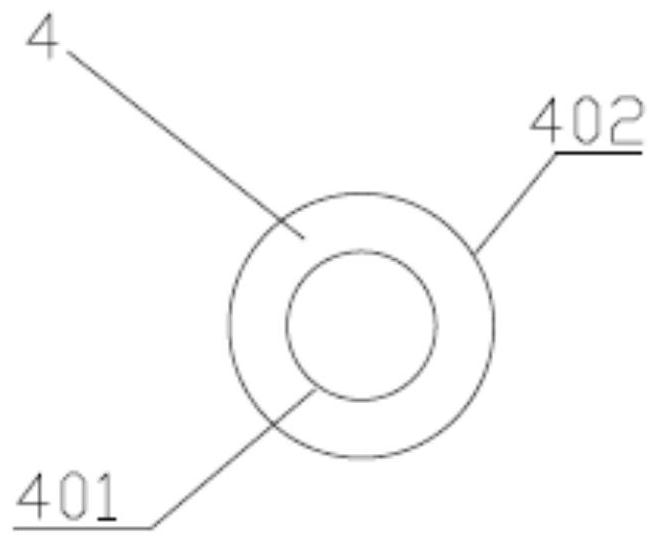

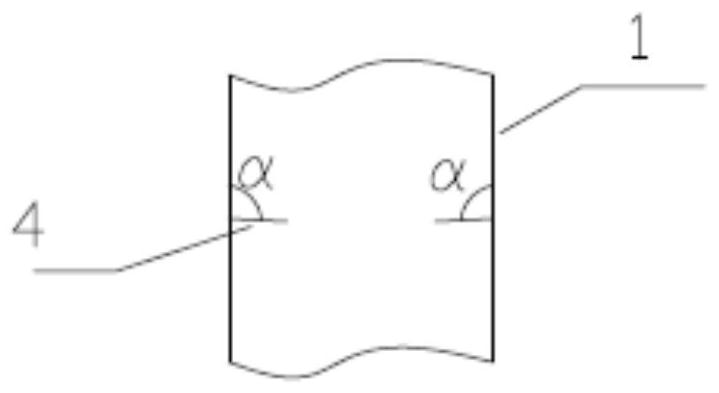

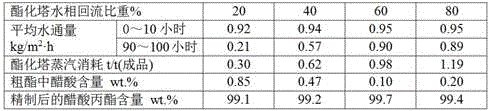

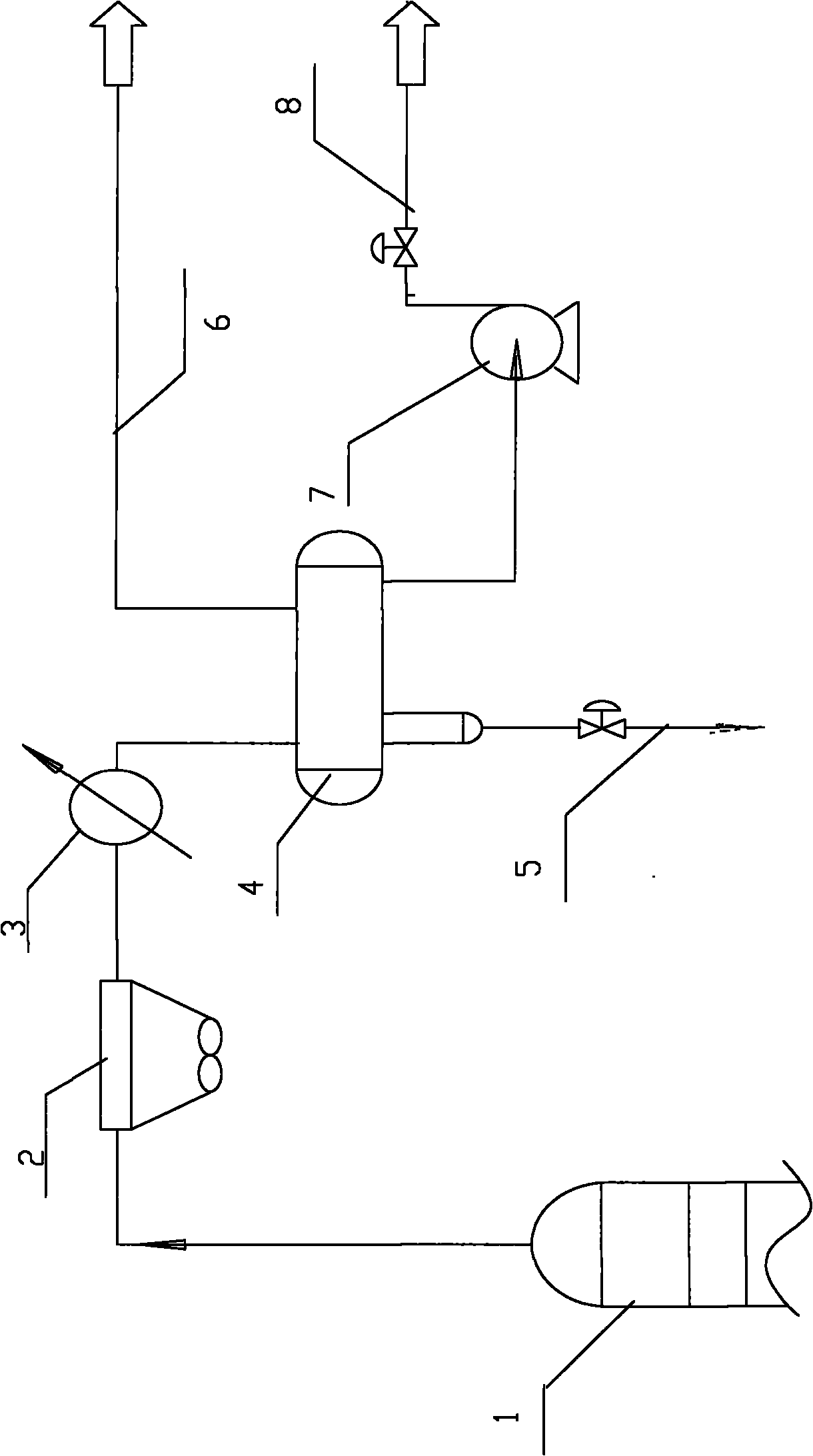

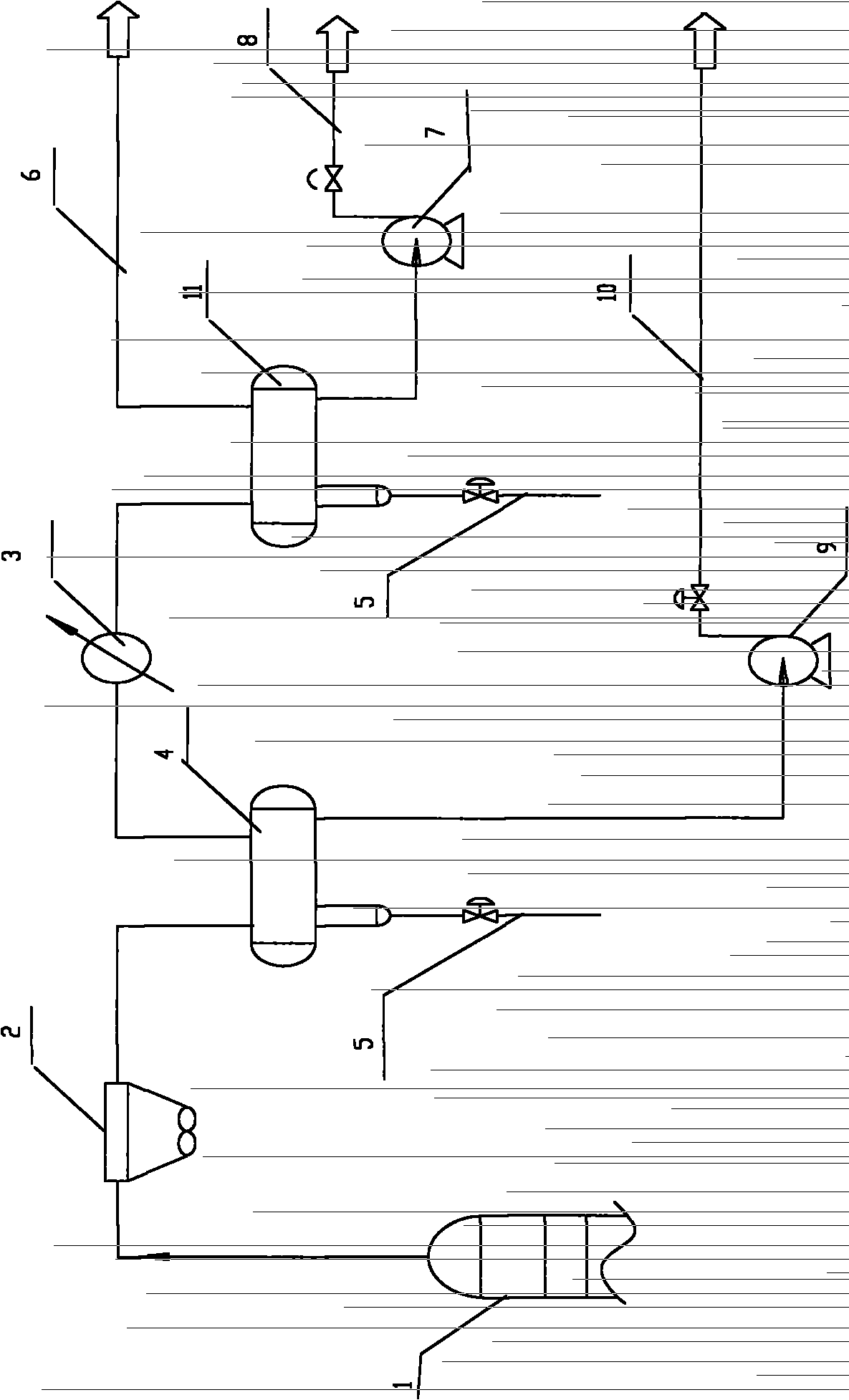

Separation method and separation device for reform reaction product

ActiveCN103725306AReduce cooling effectReduce heating effectHydrocarbon distillationFluid phaseFractionation

The invention relates to a separation method and separation device for a reform reaction product, and particularly relates to a hydrogen pre separation method of the reform reaction product. The separation method mainly includes the following steps: the reform reaction product (1) and reform reaction feed materials (2, 3), after heat transfer by (4), directly enters into an additionally arranged pre separation tank (7); a pre separation gas phase (9), after cooling by an air cooler(11), enters a subsequent separation tank (12) and a recontact part for separating circulating hydrogen (13) and high purity hydrogen; a pre separation liquid phase (10), after mixing with a recontact tank liquid phase (8), directly enters into a subsequent fractionation part. The separation method reduces the flow quantity of repeated cooling and heating material flows, reduces the heating load of the fractionation part, and alleviates the contradiction of summer cooling underload, and compared with the prior art, the separation method reduces the cooling load by 14.5%, reduces the heating load by 18.2%, and is remarkable in energy-saving effect.

Owner:CHINA PETROCHEMICAL CORP +1

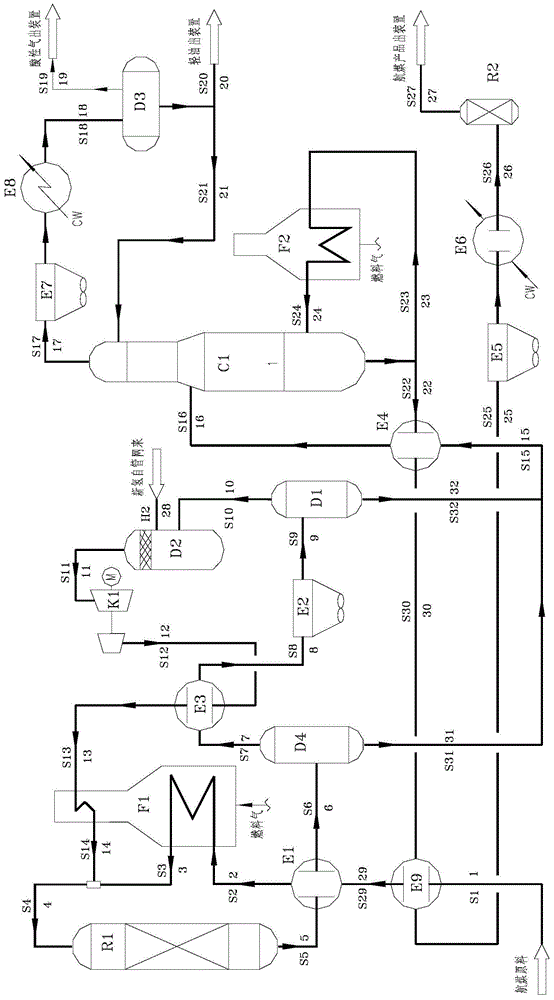

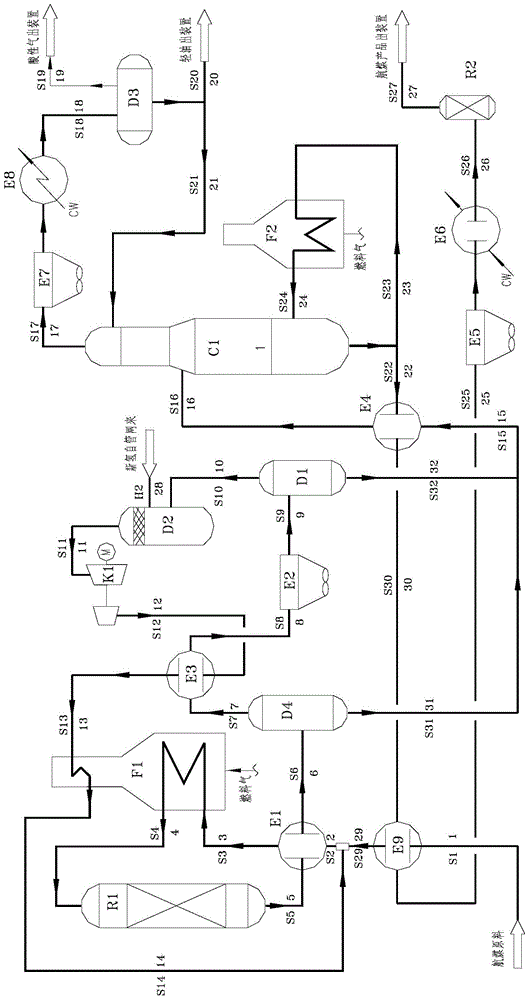

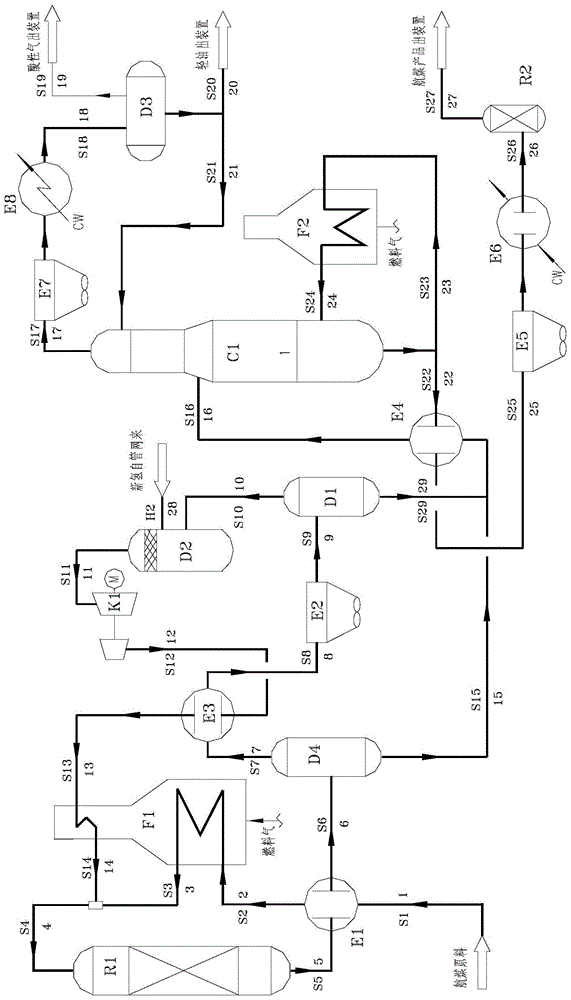

Kerosene-hydrogenation production process and system

InactiveCN105670689AImprove recycling efficiencyReduce energy consumptionTreatment with hydrotreatment processesHydrogenKerosene

The invention discloses a kerosene-hydrogenation production process. The process comprises a reaction part and a fractionation part, wherein a reaction product of the reaction part directly enters a high-pressure hot separator without being cooled after exchanging heat with raw materials, a flash steam phase is cooled to about 50 DEG C through an air cooler after exchanging heat with recycle hydrogen or new hydrogen and then enters a high-pressure cold separator, and high-temperature reaction products separated from the bottoms of the high-pressure hot separator and the high-pressure cold separator exchange heat with refined kerosene from the bottom of a fractionating tower and are sent to the fractionation part. Compared with the prior art, the kerosene-hydrogenation production process is improved, the energy recycle efficiency of a device can be effectively improved and the energy consumption of the device is reduced with the process. The invention further provides a kerosene-hydrogenation production system adopting the kerosene-hydrogenation production process.

Owner:BEIJING YANSHAN YULONG PEC

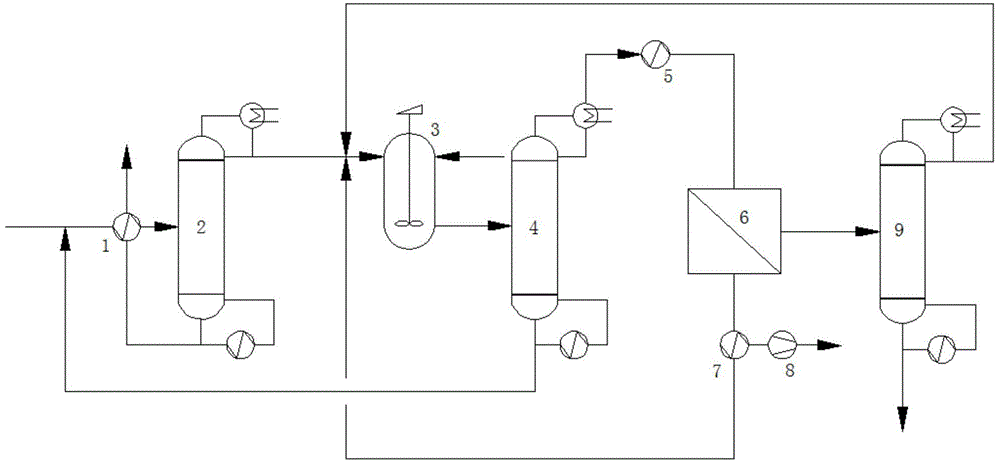

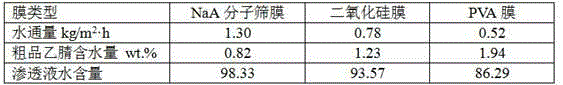

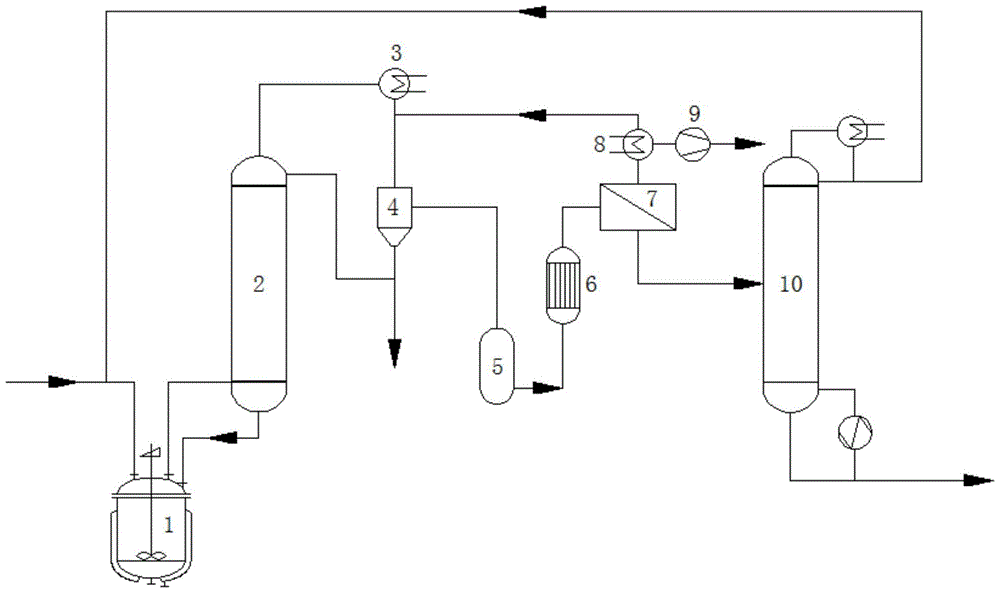

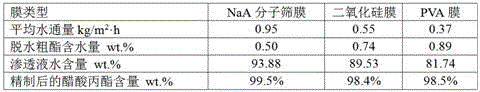

Method and device for recycling and refining acetonitrile in ceftriaxone sodium synthesis

ActiveCN104926690ASimple processImprove securityCarboxylic acid nitrile purification/separationSodium ceftriaxonePhysical chemistry

The invention relates to a method and device for recycling and refining acetonitrile in ceftriaxone sodium synthesis. The method includes the following steps: acetonitrile waste liquid in ceftriaxone sodium synthesis is fed into a first rectifying tower, and parts of water and heavy components are removed in a rectifying mode; rectified acetonitrile liquid is obtained after concentrating is carried out and fed into a neutralization tank for pH value adjustment; the neutralized rectified acetonitrile liquid is fed into a second rectifying tower for further impurity removing, the rectified acetonitrile liquid enters a pervaporation membrane separation unit after impurities are removed in the second rectifying tower, residual liquid in a kettle is returned to the first rectifying tower, and the acetonitrile in the residual liquid is recycled; the crude acetonitrile is obtained after the liquid is separated through the pervaporation membrane separation unit, water and a small amount of acetonitrile in a solution on the feed liquid side permeate a pervaporation membrane in a steam mode to obtain permeating liquid, the permeating liquid is condensed to be returned to the neutralization tank, and the acetonitrile in the permeating liquid is recycled; the crude acetonitrile obtained through the pervaporation membrane separation unit is fed into a third rectifying tower to be refined, the finished acetonitrile is obtained, acetonitrile-water azeotrope obtained after rectifying of the third rectifying tower is returned to the second rectifying tower, and the acetonitrile in the acetonitrile-water azeotrope is recycled.

Owner:JIANGSU NINE HEAVEN HIGH TECH

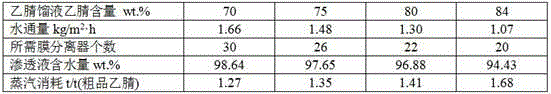

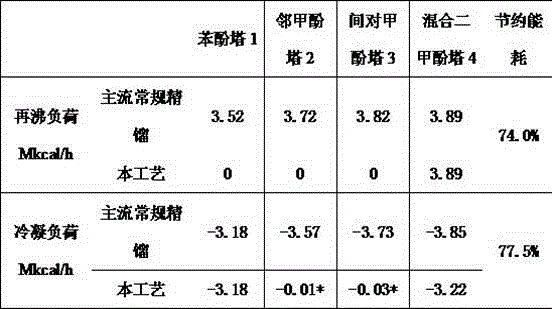

Vacuum four-column differential pressure thermal coupling device and method for refining of crude phenol

InactiveCN106039750AReduce cooling loadReduce heating loadOrganic chemistryOrganic compound preparationDifferential pressureBoiling point

The invention discloses a vacuum four-column differential pressure thermal coupling device and method for refining of crude phenol. The invention is characterized in that through the crude phenol refining method and device with high performance, energy efficiency and high product recovery rate, it is possible to obtain products such as high-purity phenol, o-cresol, m-p-cresol, and mixed xylenol and tricresol; the invention has the advantages that a product segmenting line is designed by using stable and reliable continuous rectifying process, operation conditions of designed by using boiling point differences and ratio of various components in the crude phenol so as to meet the vacuum thermal coupling process, the method can save higher than 70% of cooling load and higher than 70% of heating load when compared to an existing mainstream continuous rectifying process, better product purity and yield can be achieved, and the method is a highly competitive and advantageous process.

Owner:CHANGLING PETRO CHEM ENG DESIGN

Separation method and device for reforming reaction product

ActiveCN103725306BReduce cooling effectReduce heating effectHydrocarbon distillationFluid phaseFractionation

The invention relates to a separation method and separation device for a reform reaction product, and particularly relates to a hydrogen pre separation method of the reform reaction product. The separation method mainly includes the following steps: the reform reaction product (1) and reform reaction feed materials (2, 3), after heat transfer by (4), directly enters into an additionally arranged pre separation tank (7); a pre separation gas phase (9), after cooling by an air cooler(11), enters a subsequent separation tank (12) and a recontact part for separating circulating hydrogen (13) and high purity hydrogen; a pre separation liquid phase (10), after mixing with a recontact tank liquid phase (8), directly enters into a subsequent fractionation part. The separation method reduces the flow quantity of repeated cooling and heating material flows, reduces the heating load of the fractionation part, and alleviates the contradiction of summer cooling underload, and compared with the prior art, the separation method reduces the cooling load by 14.5%, reduces the heating load by 18.2%, and is remarkable in energy-saving effect.

Owner:CHINA PETROCHEMICAL CORP +1

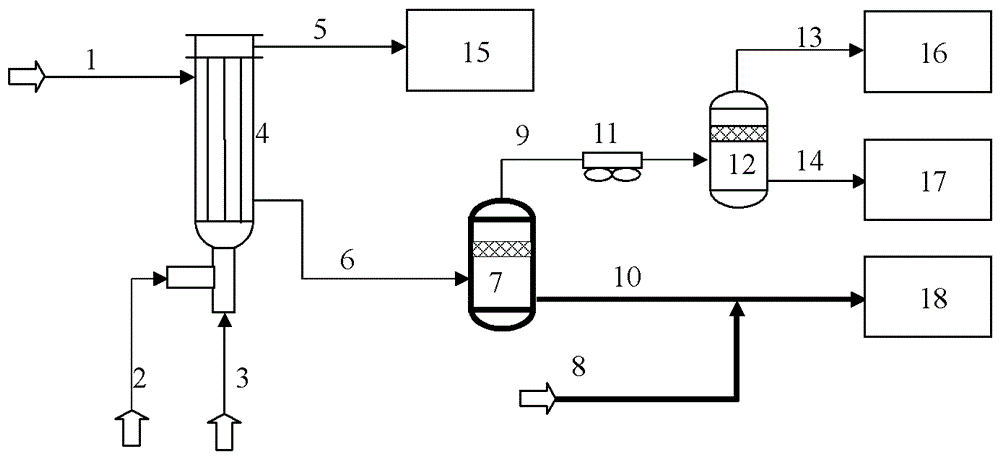

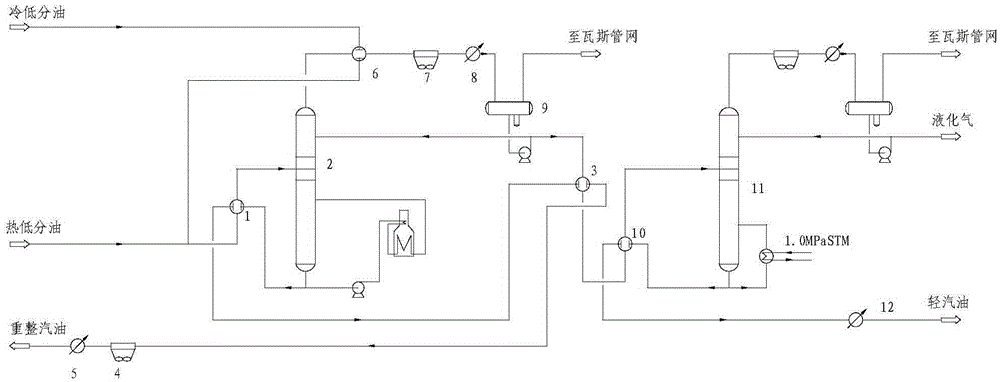

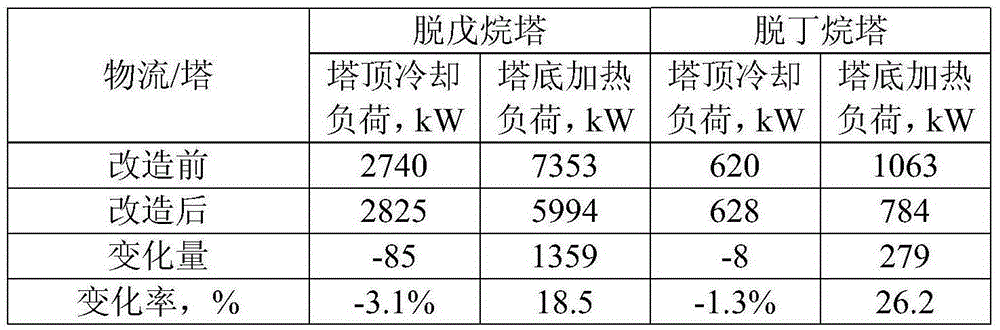

Reforming heat recycling technology and device

ActiveCN105331389AImprove heat transfer effectRaise feed temperatureCatalytic naphtha reformingProcess engineeringBase oil

The invention provides a reforming heat recycling technology and device. The technology comprises the steps of recycling top oil gas heat of a depentanizer, strengthening heat exchange of fed materials of the depentanizer and base oil of the depentanizer and improving heat exchange of the base oil of the depentanizer and fed materials of a debutanizer. The invention further provides the reforming heat recycling device, wherein cold low-separated oil and hot low-separated oil of a reaction oil gas separating unit are connected with a feeding port of the depentanizer through a heat exchange unit, and top oil of the depentanizer is connected with a feeding port of the debutanizer through the heat exchange unit. According to the reforming heat recycling technology and device, the temperature of the fed materials of the depentanizer and the debutanizer can be increased, and the load of a reboiling furnace at the bottom of the depentanizer and the heating load of the bottom of the debutanizer are reduced; compared with the prior art, fuel consumption of the depentanizer can be reduced by 10%-20%, steam consumption of the debutanizer can be reduced by about 10%-30%, and the obvious energy saving effect is achieved.

Owner:SHANGHAI YOUHUA PROCESS INTEGRATED TECH CO LTD

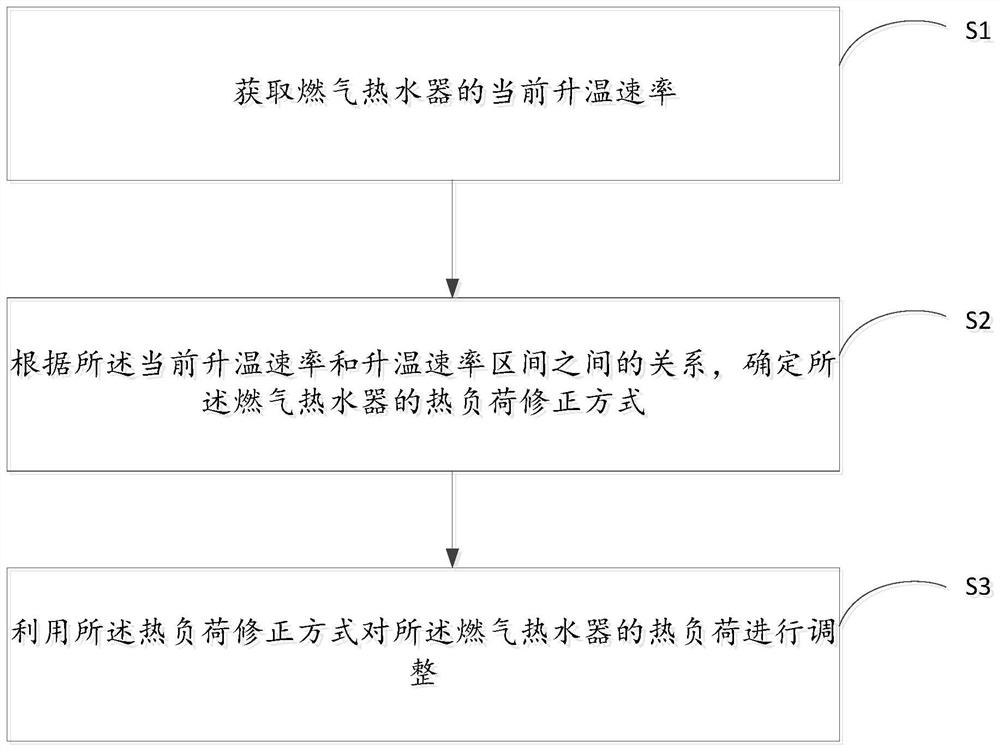

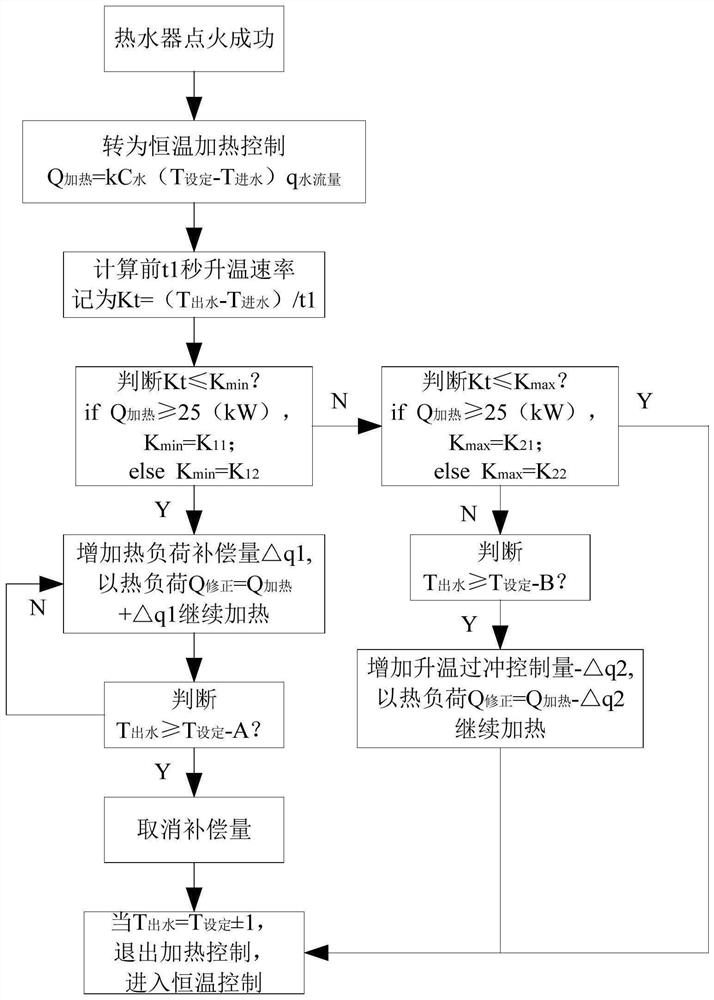

Control method and control device of gas water heater

ActiveCN114183929AIncrease heating rateIncrease heat loadControl of fluid heatersThermodynamicsEngineering

The invention discloses a control method and device for a gas water heater. The control method comprises the steps that the current heating rate of the gas water heater is obtained; according to the relation between the current heating rate and the heating rate interval, the thermal load correction mode of the gas water heater is determined; and the thermal load of the gas water heater is adjusted in the thermal load correction mode. Through the arrangement, the thermal load correction mode of the gas water heater can be determined according to the relation between the current heating rate and the heating rate interval, and the heating power of the gas water heater is adjusted through the thermal load correction mode, so that the heating thermal load and the heating rate of the gas water heater can be adjusted and controlled. Therefore, the temperature rise overshoot can be reduced while the heating speed is increased.

Owner:GREE ELECTRIC APPLIANCES INC

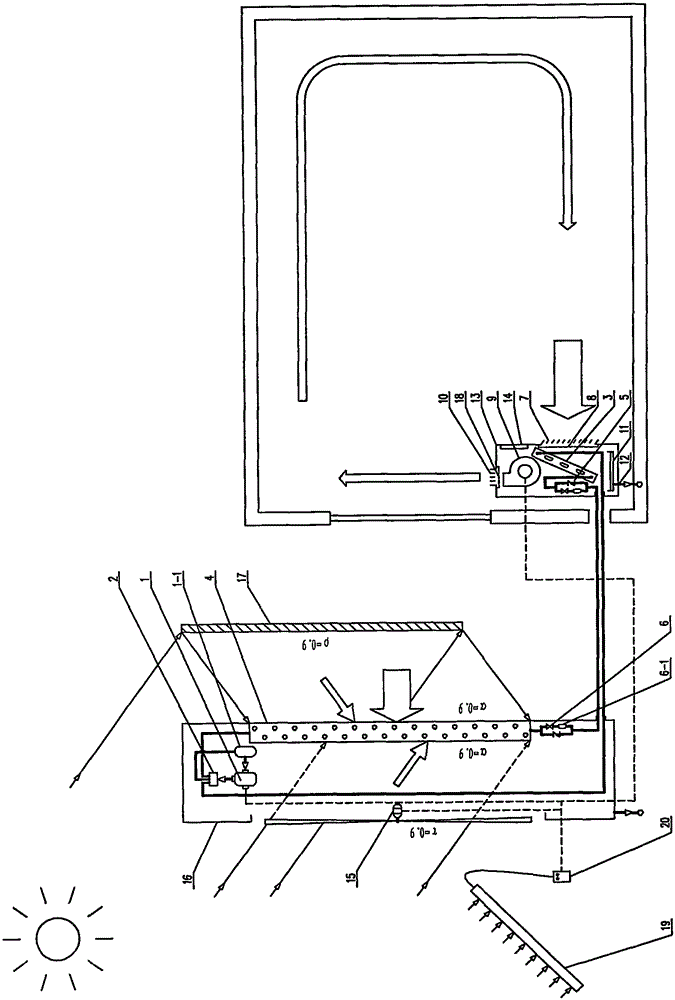

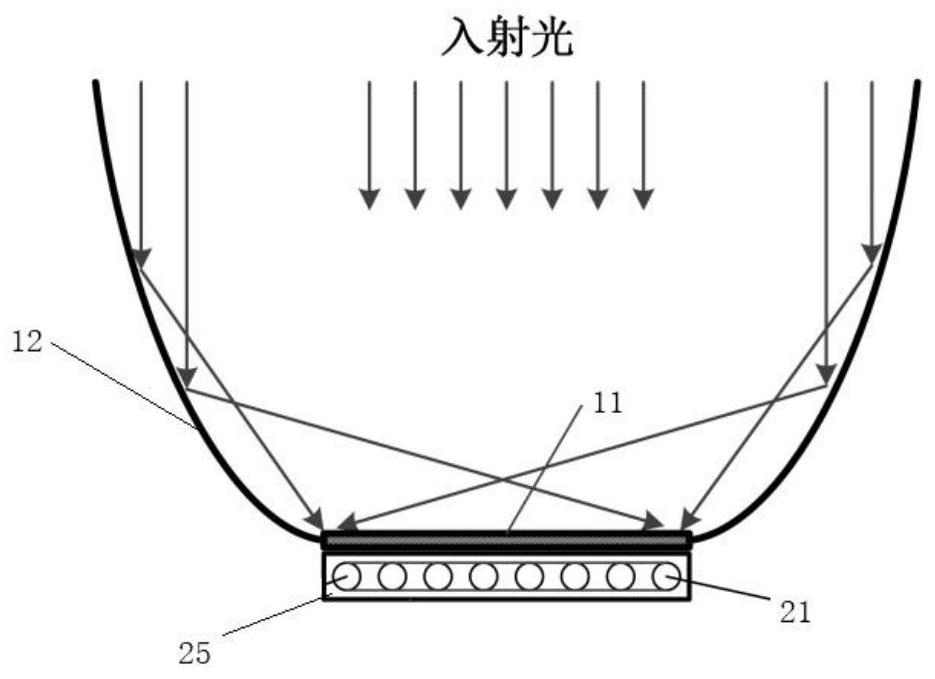

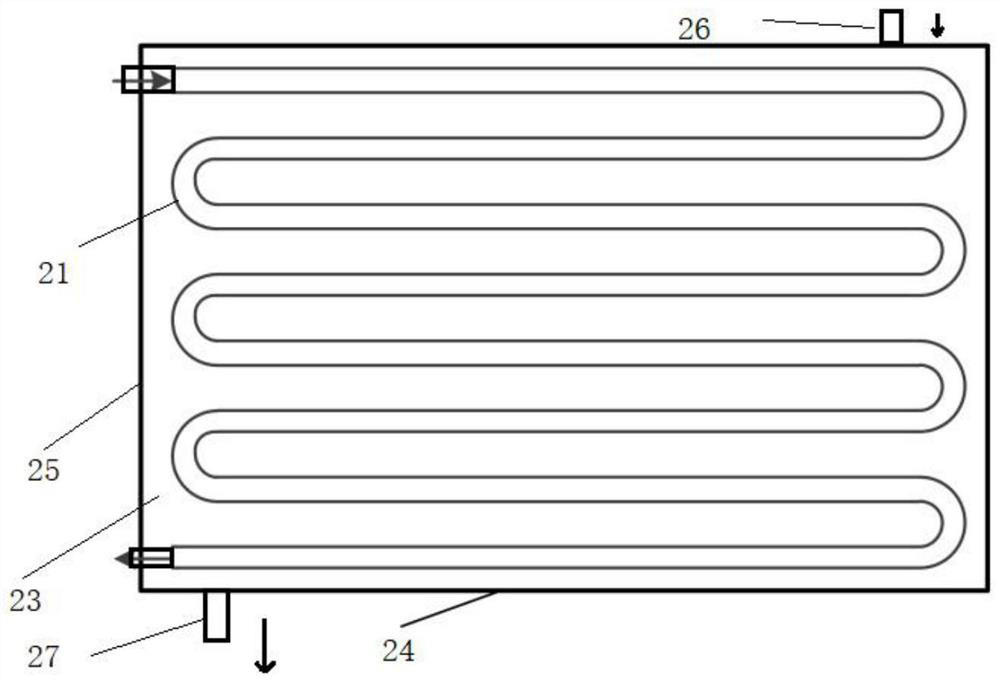

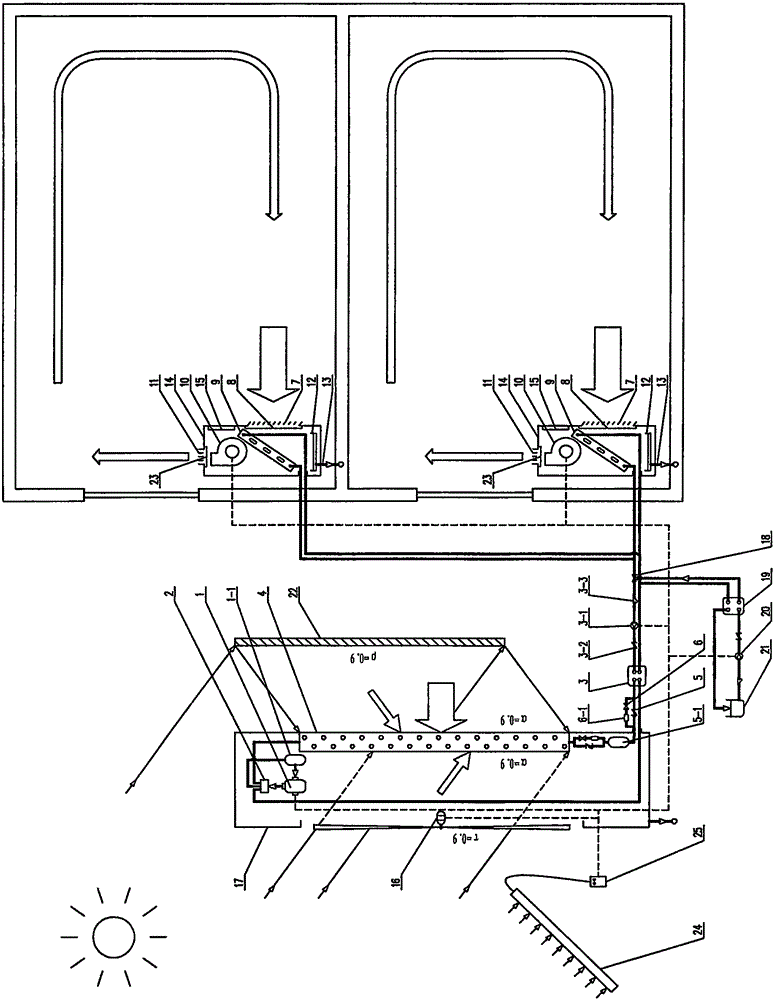

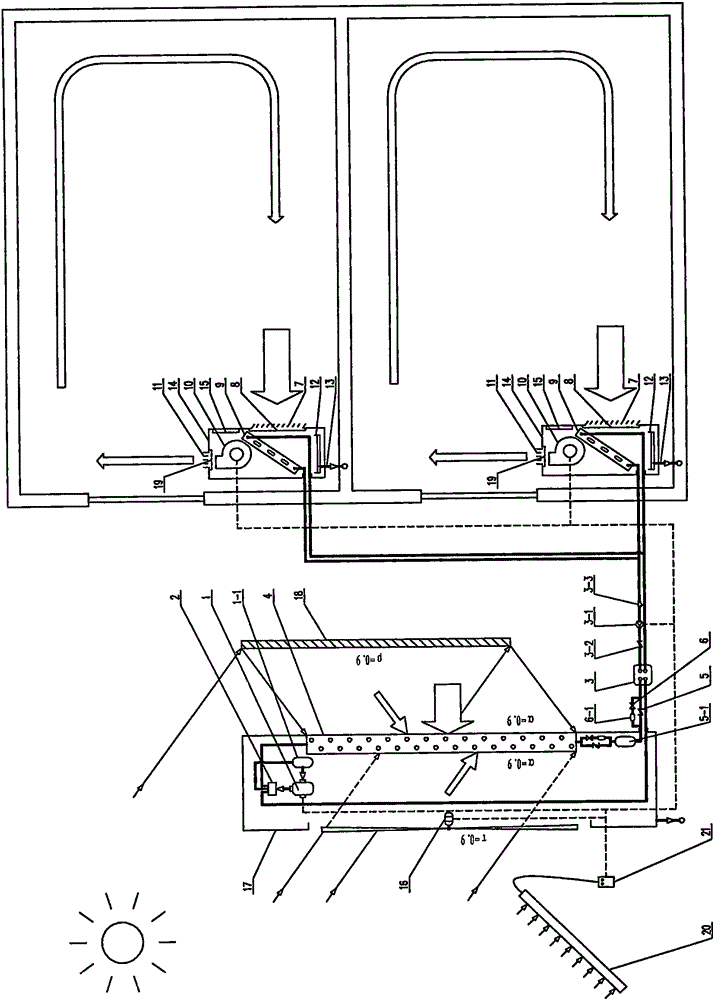

Upward air curtain split heat pump air conditioner driven by air-solar hybrid source

InactiveCN105003987AImprove the blackness of the black cavityImprove absorption rateLighting and heating apparatusAir conditioning systemsBusiness efficiencyCondensation temperature

The invention discloses an upward air curtain split heat pump air conditioner driven by an air-solar hybrid source. (1) Solar energy is absorbed via a reflector, a transparent blade, and a fin hohlraum, air energy is absorbed via a fin, and integrated design of a solar energy absorber and an air fin evaporator is realized; (2) an air-solar hybrid source split heat pump air conditioner is built, and the evaporation temperature is improved; (3) in a mode of unified heating of the vertical upward air curtain and the air conditioner high-efficiency tail end, a condensation temperature is reduced; (4) the heating capacity of the heat pump and the energy efficiency ratio are improved through reducing a cyclic temperature difference; and (5) the solar energy is used for driving the heat pump in a high-efficiency and cheap photo-thermal conversion form, and the application threshold of the solar split heat pump air conditioner is reduced.

Owner:侴乔力 +1

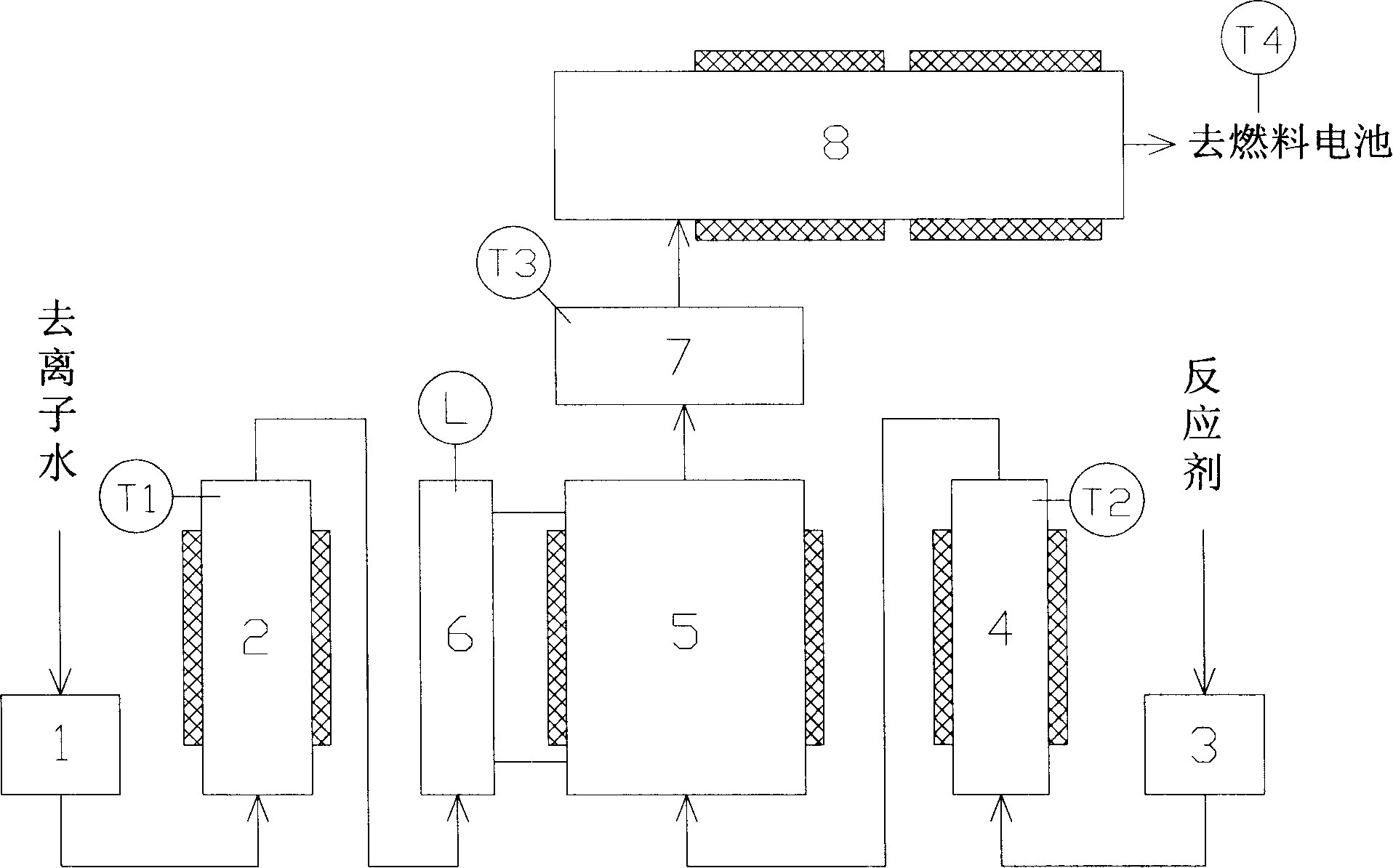

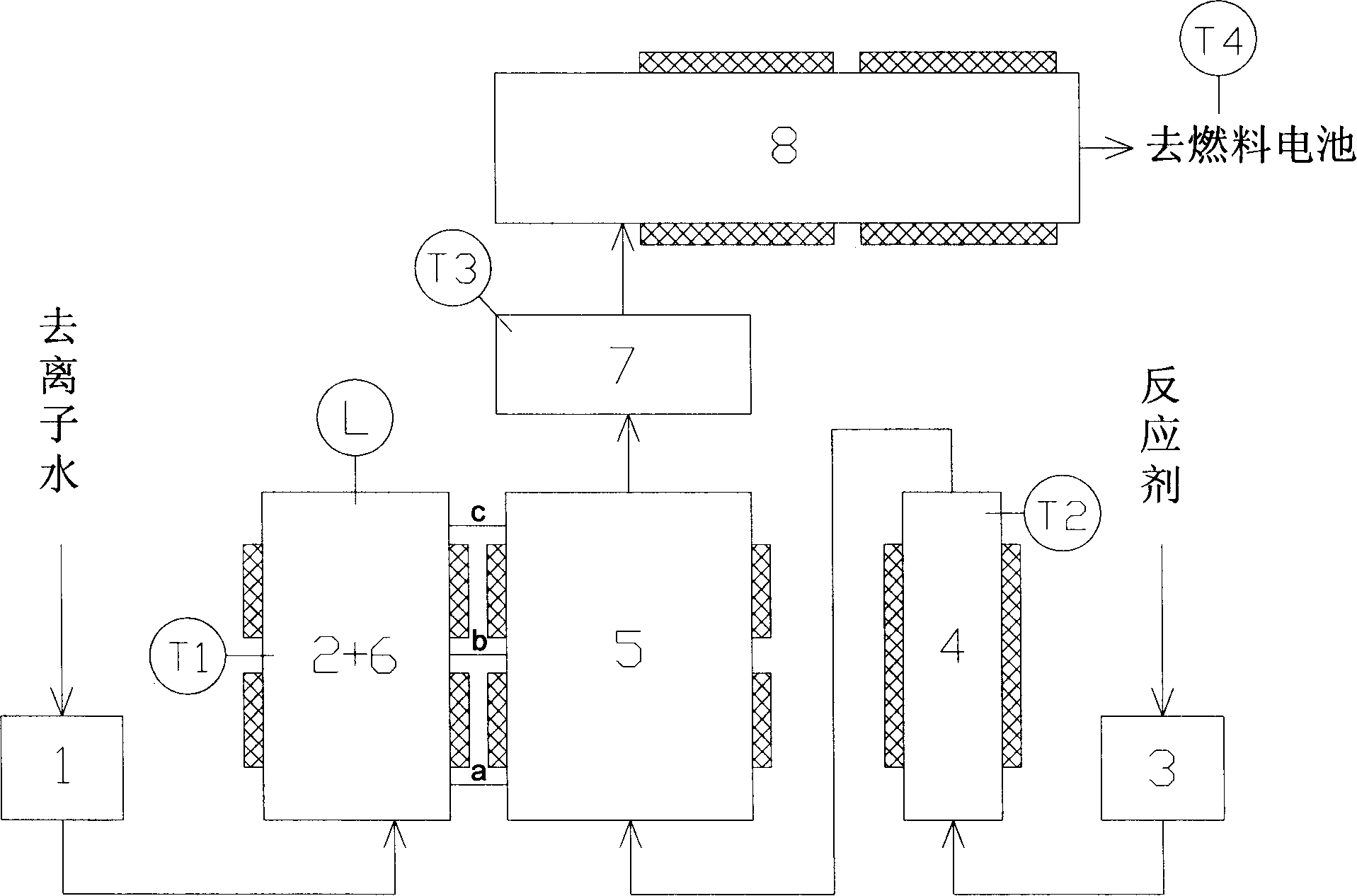

Humidification system for small-sized PEM fuel battery test platform

InactiveCN101165953AReduce heating loadAxial temperature difference is smallFuel cell auxillariesElectrical testingGas phaseControl system

This invention provides a gas heating and wetting system used in test platforms of small PEM fuel batteries, which applies a method of preheating gas-phase and liquid-phase to a preset temperature for increasing the control accuracy of a small wetting system so as to reduce load of heating of a wetter, in which, deionized water entering into an wetting system and the reactant gas can be pre-designed to a bit higher than saturated temperature by a control system in terms of the flow of the wetted reactant gas, thus, the gas reactant entering into the wetter imbibes by transmitting medium under the temperature closing to saturation so as to reduce axial temperature difference of the wetter.

Owner:SHANGHAI PALTON FUEL CELL SYST

Organic gas recovery modular assembly and coating machine waste gas treatment system

PendingCN113842746AReduce running power consumptionIncrease operating frequencyGas treatmentDispersed particle separationExhaust fumesProcess engineering

The invention provides an organic gas recovery modular assembly and a coating machine waste gas treatment system. The organic gas recovery modular assembly is characterized in that an organic gas concentration sensor is arranged on the exhaust pipeline, connected with a drying oven, of the organic gas recovery modular assembly, so that the air supply amount and the air exhaust amount of the drying oven can be dynamically adjusted according to the detected concentration of organic gas in a production device, on the premise that the concentration of the organic gas in the drying oven is maintained within an allowable concentration range required by the design process, the power consumption of operation of a fan is reduced as much as possible, the heating load required by an oven heater is reduced, energy is saved, and the operation cost of the system is reduced.

Owner:苏州兆和通风设备制造有限公司

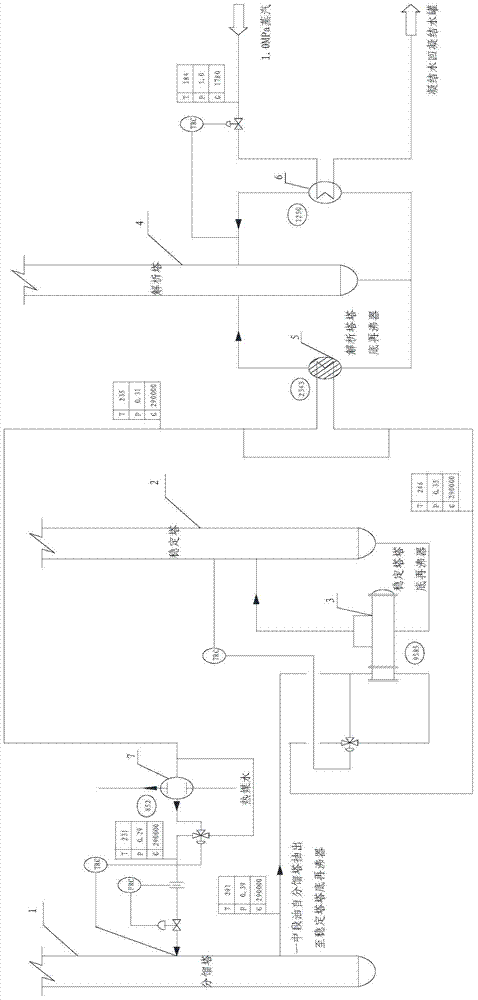

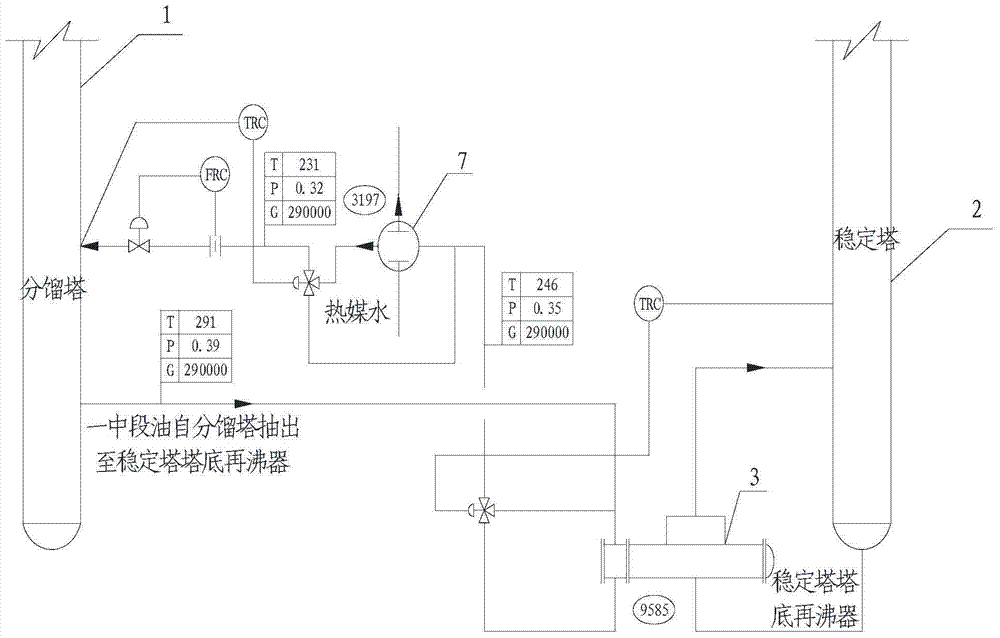

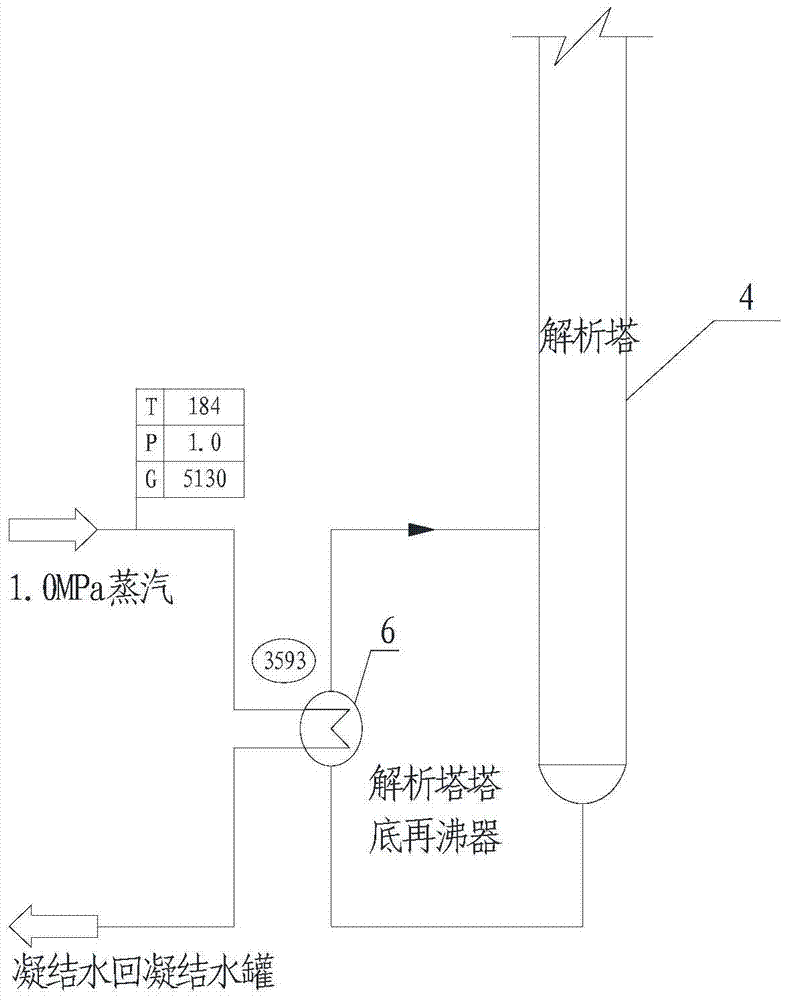

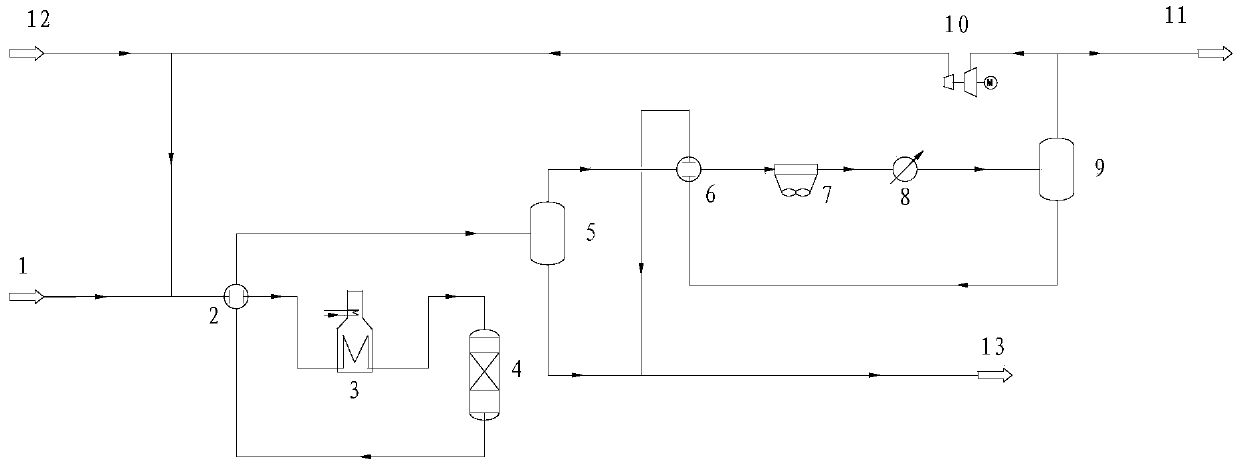

Heat Utilization System and Heat Utilization Method for Middle Stage Oil of Catalytic Cracking Unit

ActiveCN105623722BReduce dosageImprove heat utilization gradeTreatment with plural serial stages onlyReboilerEngineering

The invention provides a catalytic cracker primary midsection oil heat utilization system. The system comprises a fractionating tower, a stabilizing tower system, a resolution tower system and a heat medium water-to-water heat exchanger, wherein the stabilizing tower system comprises a stabilizing tower and a stabilizing tower bottom reboiler; the resolution tower system comprises a resolution tower and a resolution tower bottom reboiler; a primary midsection oil outlet of the fractionating tower is connected with the stabilizing tower bottom reboiler, and the resolution tower bottom reboiler is connected with the heat medium water-to-water heat exchanger; and a primary midsection oil outlet of the heat medium water-to-water heat exchanger is connected with a feed port of the fractionating tower. By regulating the heat exchange process, the system and method fully utilize the heat of the high-temperature position of the primary midsection oil, continuously utilize the primary midsection oil as the heat source of the stabilizing tower bottom reboiler and the resolution tower bottom, and reduce the steam consumption for the resolution tower bottom reboiler, thereby finally achieving the goal of lowering the energy consumption of the catalytic cracker.

Owner:SHANGHAI YOUHUA PROCESS INTEGRATED TECH CO LTD

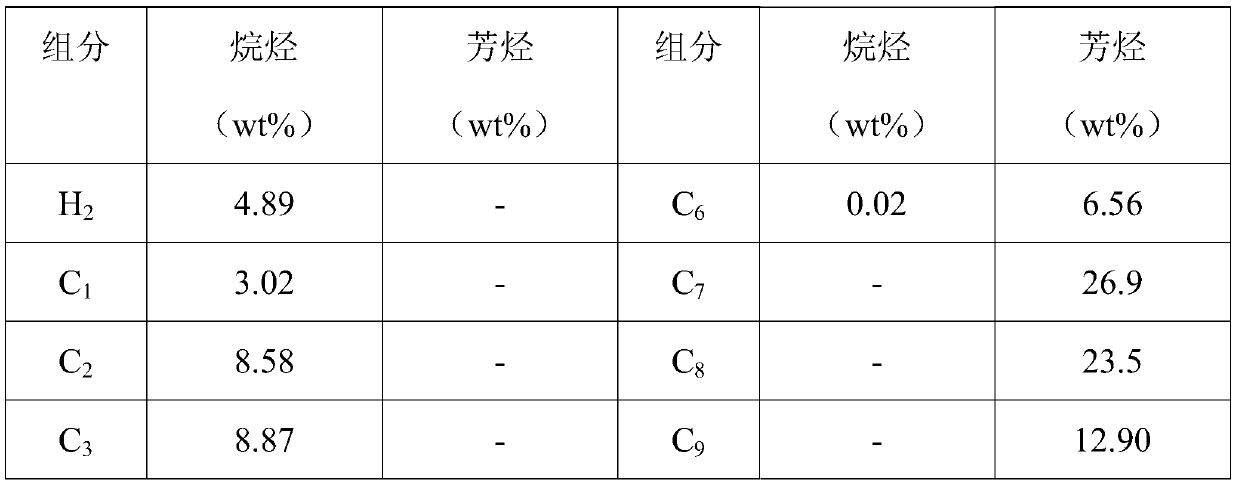

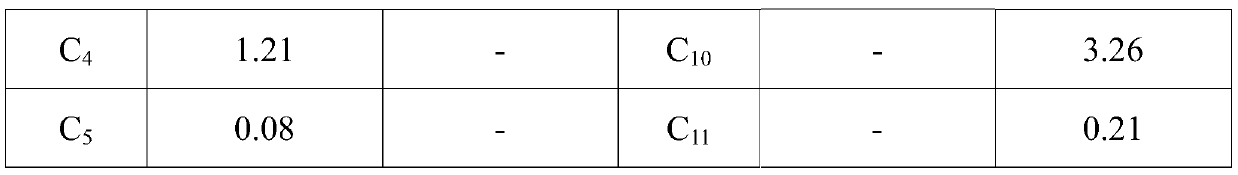

Xylene disproportionation reaction product separation system based on thermal high-pressure separation process and separation method of the xylene disproportionation reaction product separation system

InactiveCN105498269AReduce heating loadAvoid repeated cooling-heating processesMultiple-effect/fractional condensationDispersed particle separationChemistryWater cooler

The invention provides a xylene disproportionation reaction product separation system based on a thermal high-pressure separation process and a separation method of the xylene disproportionation reaction product separation system. The system comprises a disproportionation reaction system and a reaction product separation system, which are connected in sequence, wherein the reaction product separation system comprises a thermal high-pressure separation tank, a heat exchanger, an air cooler, a water cooler and a reaction product separation tank; a gas discharging hole of the thermal high-pressure separation tank is sequentially connected with the heat exchanger, the air cooler, the water cooler and a feeding hole of the reaction product separation tank; a liquid discharging hole of the reaction product separation tank is connected with the heat exchanger. According to the xylene disproportionation reaction product separation system, under the condition of basically not influencing the purity of circulating hydrogen and the yield of aromatic hydrocarbon, repeated cooling and heating processes of thermal high-pressure separation liquid are reduced; a heating load of a subsequent fractionation system is reduced; meanwhile, the flow of a gas phase of the thermal high-pressure separation tank is obviously reduced and a cooling load of the reaction product is extremely reduced; compared with the prior art, the cooling load is reduced by more than 30 percent, the heating load is reduced by more than 50 percent and an energy-saving effect is remarkable.

Owner:SHANGHAI YOUHUA PROCESS INTEGRATED TECH CO LTD

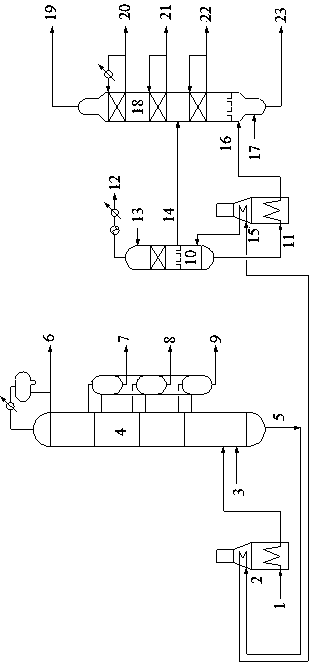

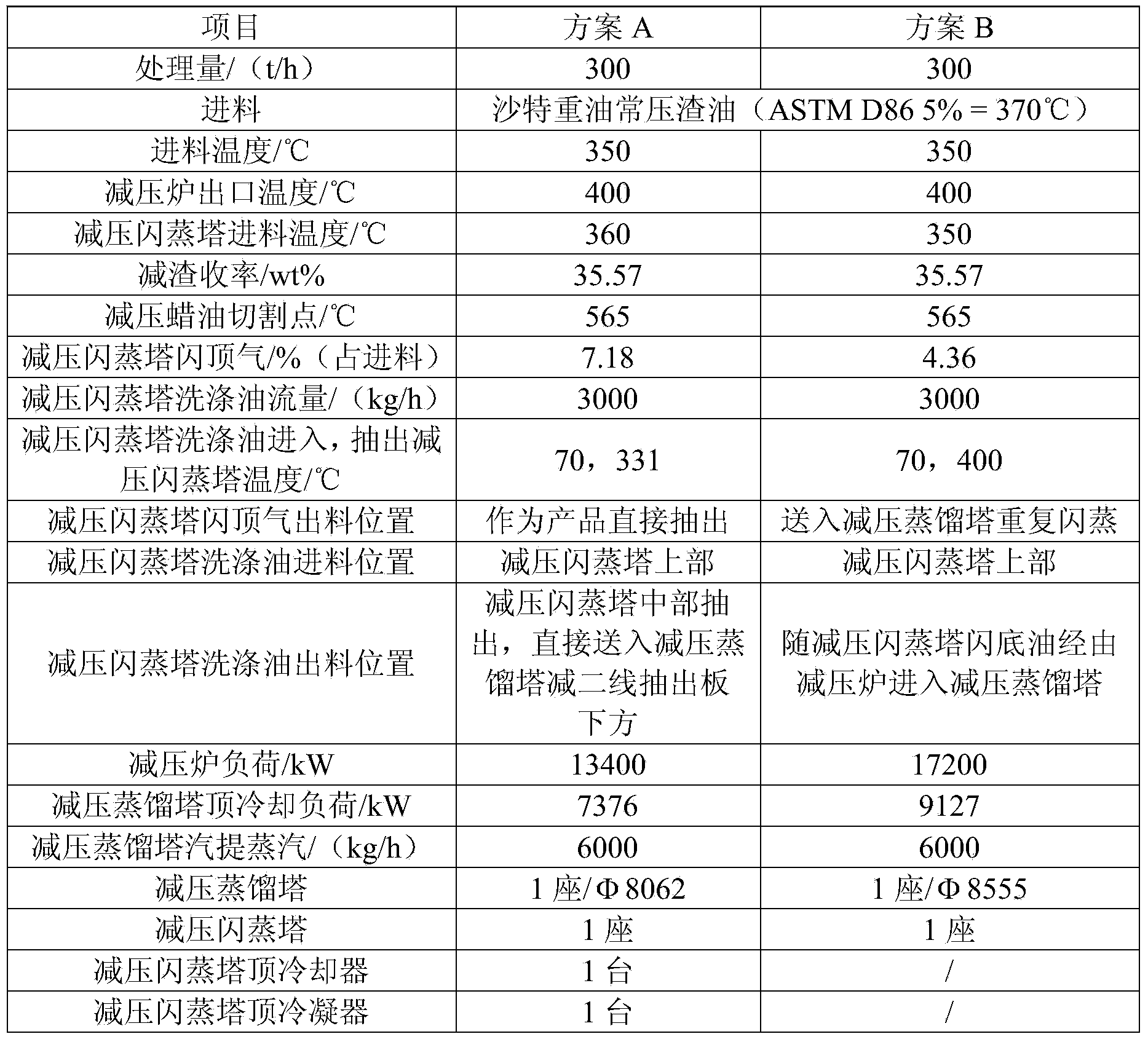

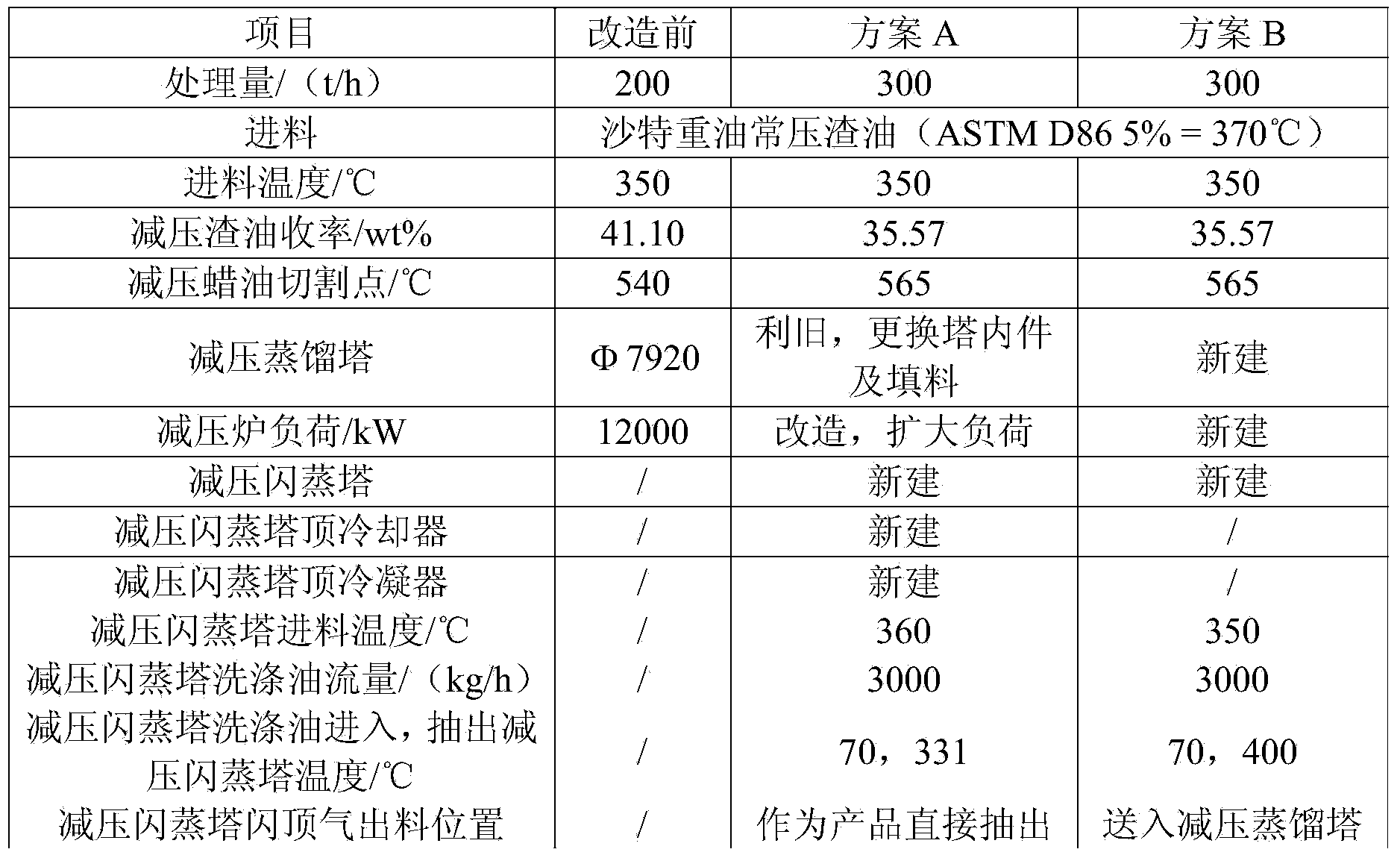

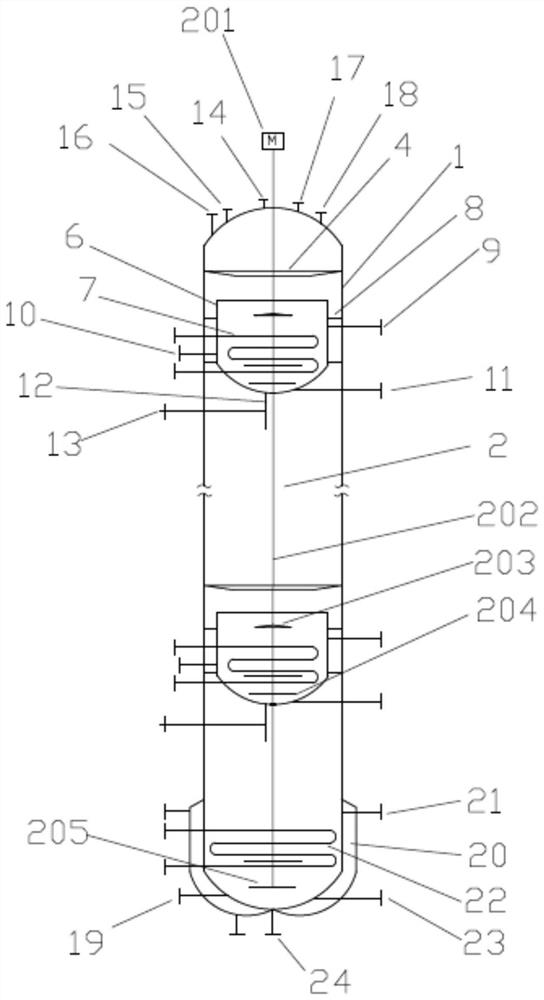

Crude oil reduced pressure distillation method for eliminating choke point in pressure reduction process

InactiveCN103865565AIncrease temperatureIncrease top flash volumeVacuum distillationFractionationEconomic benefits

The invention discloses a crude oil reduced pressure distillation method for eliminating a choke point in a pressure reduction process. The method comprises the following steps: firstly, performing heat exchange on atmospheric pressure residual oil through an atmospheric pressure furnace convection section and a reduced pressure furnace convection section, raising the temperature by 5-20 DEG C, then feeding the residual oil into a reduced pressure flash column, operating the reduced pressure flash column at 5-30kPa, at the same time, introducing reduced pressure flash column light lube oil as washing oil from the upper part of a reduced pressure distillation column, performing heat exchange on a gas on the top of the reduced pressure flash column, condensing, cooling and directly extracting the gas as a product, extracting the washing oil in the middle of the reduced pressure flash column, feeding the washing oil below a light lube oil extracting plate of the reduced pressure flash column, feeding the flash base oil of the reduced pressure flash column into a reduced pressure furnace, heating to be 370-410 DEG C, feeding into the reduced pressure distillation column through an oil transfer line, performing reduced pressure fractionation, and then extracting products of different fractions from a side line of the reduced pressure distillation column. The method improves the crude oil reduced pressure distillation process, eliminates the choke points of the reduced pressure furnace and the reduced pressure distillation column, reduces energy consumption, improves the treatment capacity and increases the economic benefits of a device.

Owner:SUN YAT SEN UNIV

Reaction tower with reaction shallow pools and method for preparing ethylene carbonate by using reaction tower

ActiveCN113842858AImprove conversion rateLittle aggregationProcess control/regulationOrganic chemistryReaction zoneGlycol synthesis

The invention provides a reaction tower with reaction shallow pools and a method for preparing ethylene carbonate by using the reaction tower. The reaction tower comprises a tower body and a stirrer, the interior of the tower body is divided into an upper reaction area and a tower kettle reaction area, a plurality of stages of reaction shallow pools are arranged in the upper reaction area from top to bottom and are used for realizing graded reaction, and a liquid collecting ring is arranged above each stage of reaction shallow pool and is used for collecting condensate; and the stirrer is used for stirring the reaction liquid in the tower body. The reaction tower for preparing ethylene carbonate has the advantages of being feasible, energy-saving, efficient, high in urea conversion rate, small in ethylene glycol polymerization amount, small in ethylene carbonate decomposition amount, high in yield and the like.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI +1

Upward air curtain multi-union type heat pump air conditioner driven through air solar composite source

InactiveCN105135562AImprove the blackness of the black cavityImprove absorption rateHeat pumpsCorrosion preventionBusiness efficiencyCondensation temperature

The invention discloses an upward air curtain multi-union type heat pump air conditioner driven through an air solar composite source. Firstly, solar energy is absorbed through a reflector, transparent blades and a finned black cavity, air energy is absorbed through fins, and a solar absorber and an air fin evaporator are integrally designed; secondly, an air and solar composite source multi-union type heat pump air conditioner is established to increase the evaporation temperature; thirdly, the condensation temperature is decreased through the vertical upward air curtain unified heating and efficient air conditioner tail end form; fourthly, the heating capacity and the energy efficiency ratio are increased by reducing the circulation temperature difference; and fifthly, the solar energy is utilized for driving the heat pump through an efficient and cheap photo-thermal converting form, and the application threshold of the solar multi-union type heat pump air conditioner is lowered.

Owner:侴乔力 +1

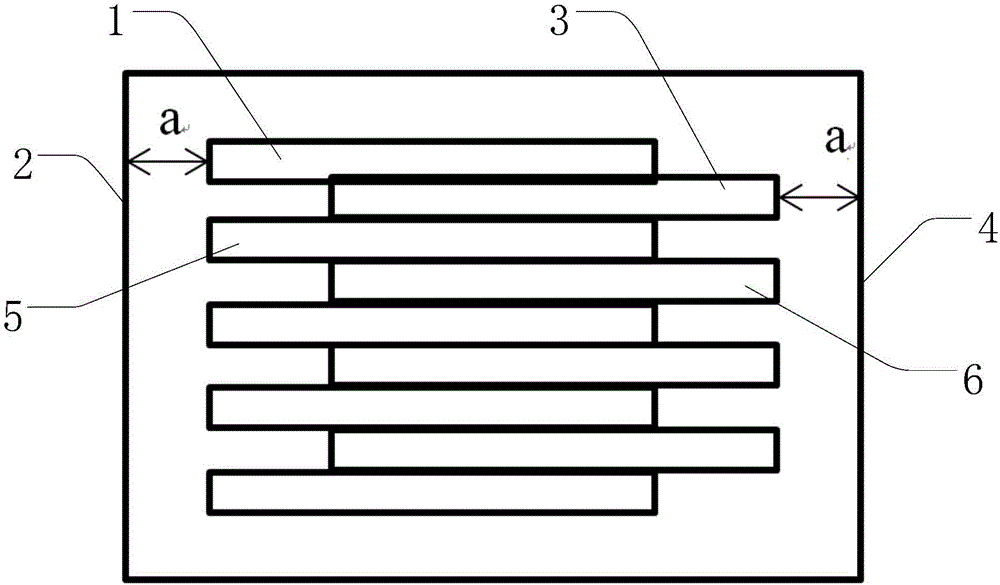

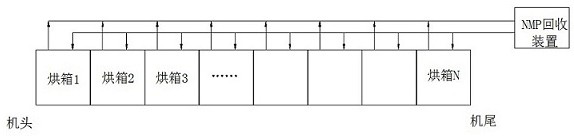

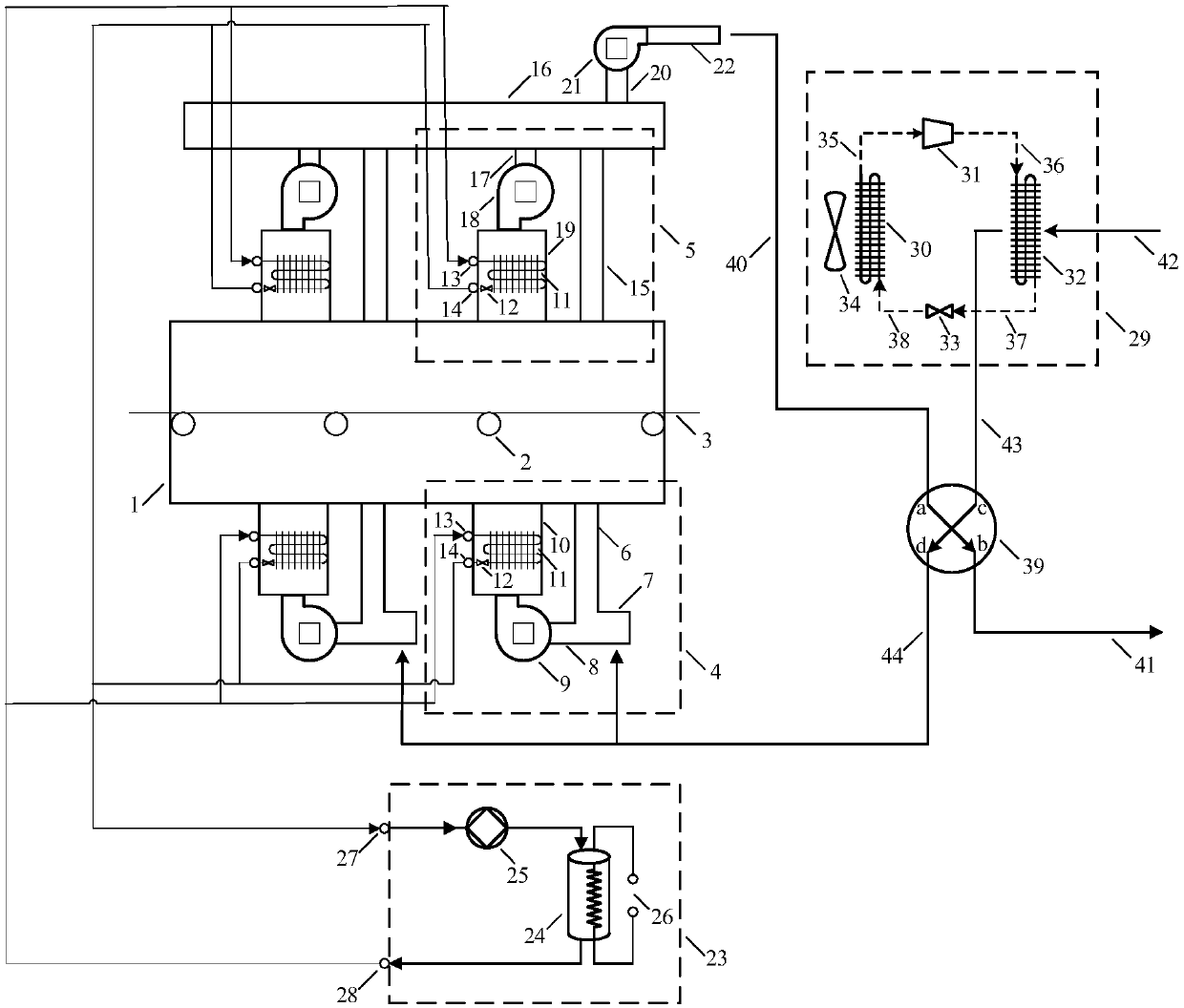

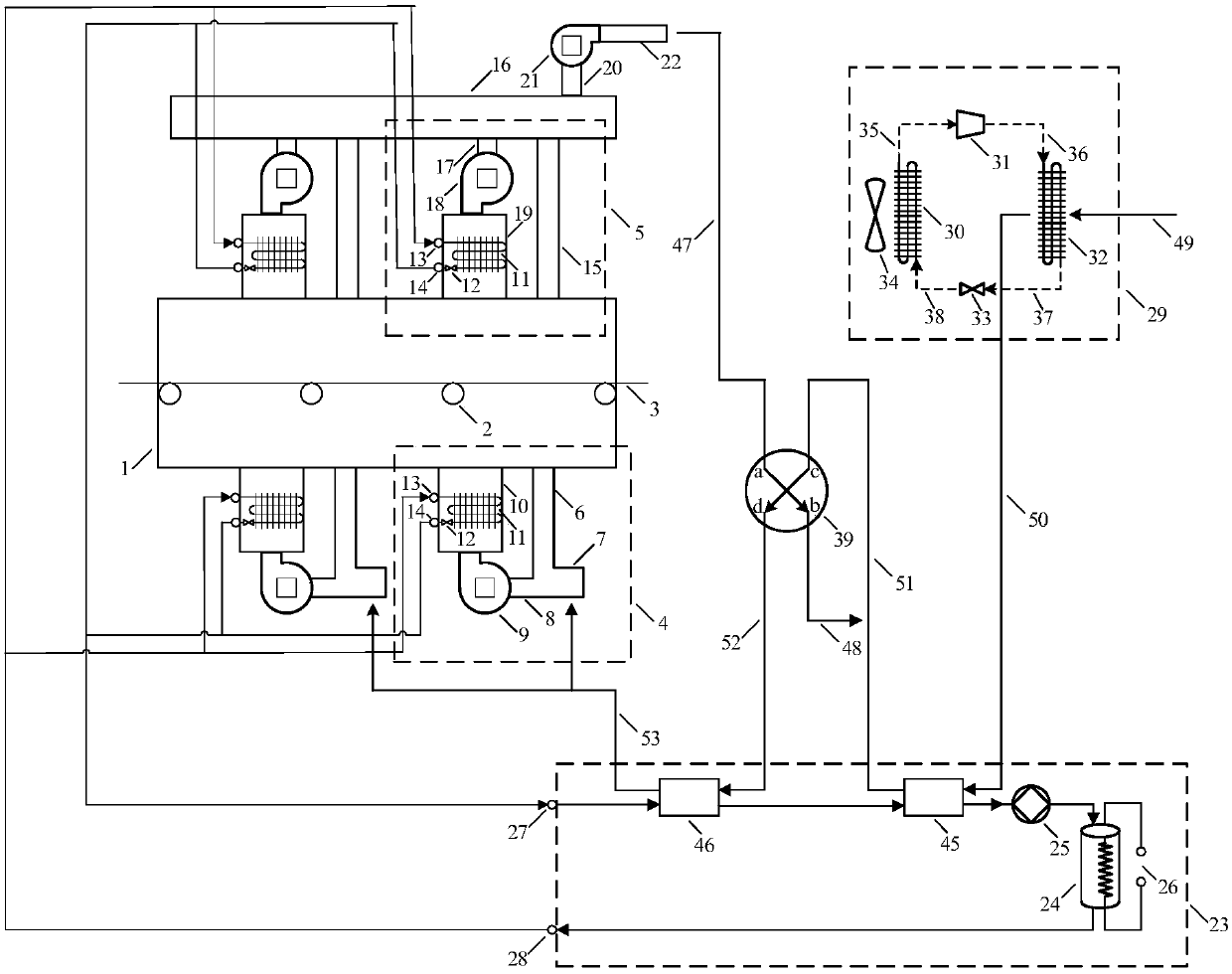

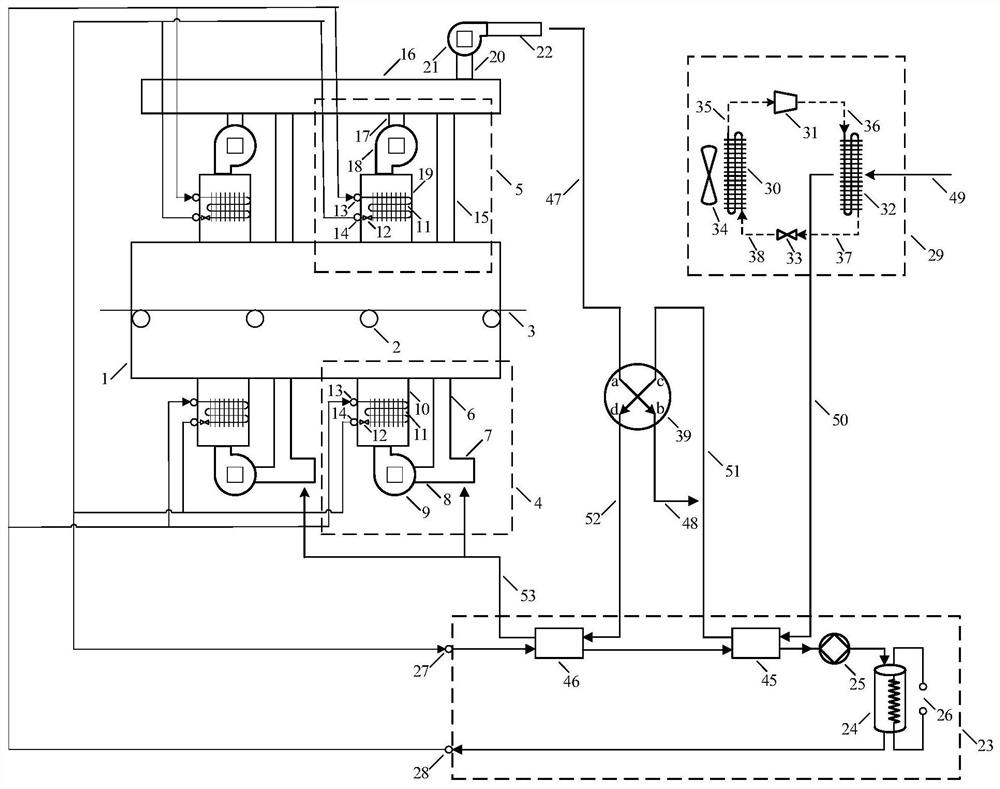

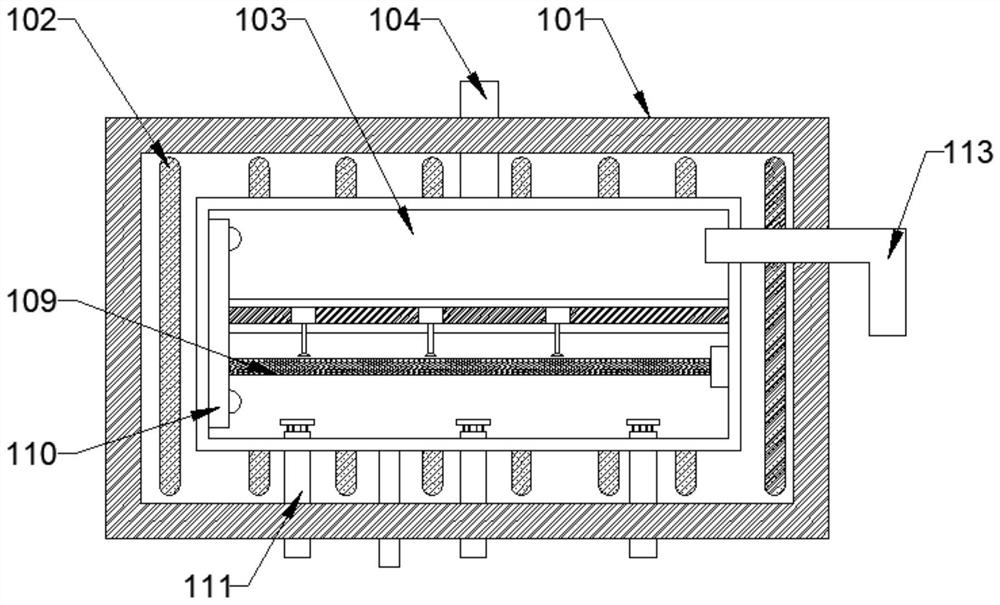

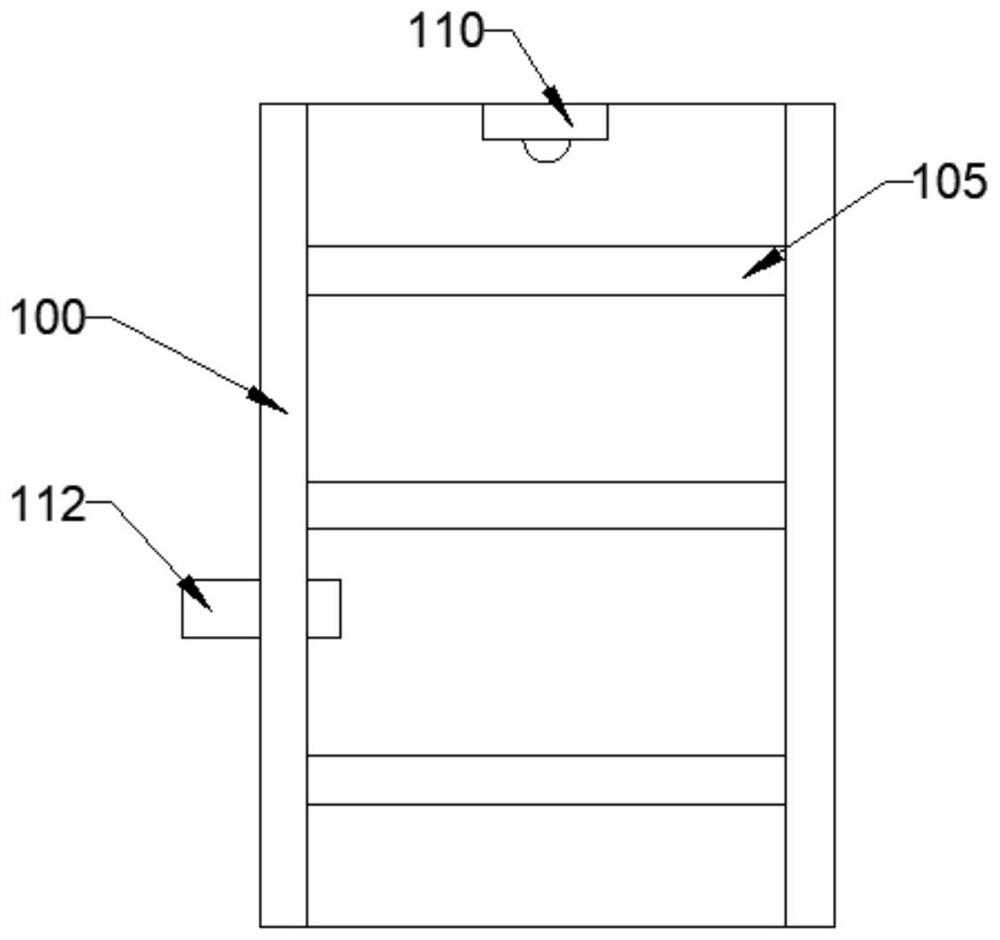

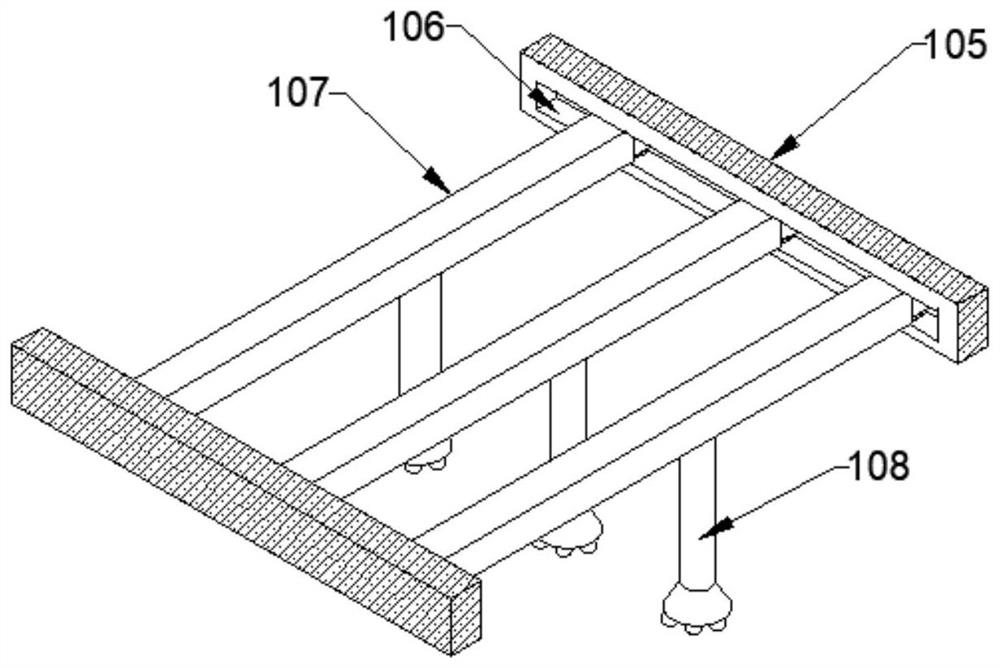

Lithium battery pole piece coater drying system adopting heat pump heat recovery and barrel pump circulating

ActiveCN109569989AReduce security risksLarge latent heat of phase changeHeat pumpsHeat recovery systemsFresh airPole piece

The invention relates to a lithium battery pole piece coater drying system adopting heat pump heat recovery and barrel pump circulating. The lithium battery pole piece coater drying system comprises adrying channel, a long air channel, an air discharging assembly, a lower heating assembly, an upper heating assembly, a heat pump system, a host and an air heat exchanger, wherein the lower heating assembly and the upper heating assembly are used for heating the drying channel. The host is used for achieving heat exchange between an air channel of the lower heating assembly and an air channel ofthe upper heating assembly, and the heat pump system is used for conducting heat exchange with fresh air; the air heat exchanger comprises two air flow passages conducting heat exchange mutually; an inlet of the first air flow passage communicates with an air channel of the heat pump system, and an outlet of the first air flow passage communicates with the air channel of the lower heating assembly; and an inlet of the second air flow passage communicates with the air discharging assembly and receives the air discharged by the air discharging assembly, and an outlet of the second air flow passage serves as a discharging opening. Compared with the prior art, the high-temperature requirement of lithium battery pole piece drying is met through heat pump heat recovery and barrel pump circulating, the heating load of the lithium battery pole piece drying system is lowered as far as possible, and meanwhile potential safety hazards are reduced.

Owner:江苏博纳致远装备科技有限公司

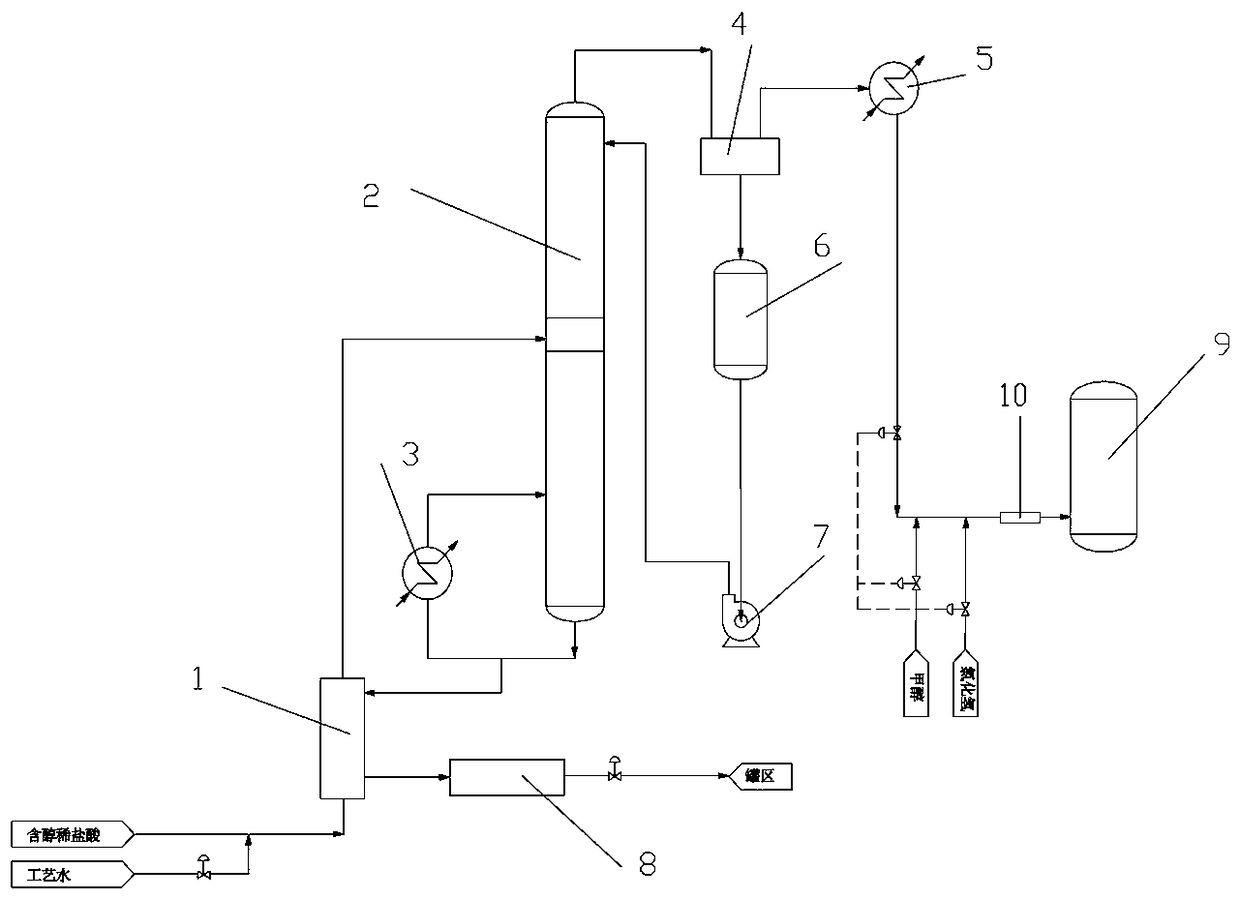

Process and device for recycling methanol in production of methyl chloride

InactiveCN108440244AReduce heating loadReduce pollutionOrganic compound preparationChemical industryRefluxGas phase

The invention relates to a process for recycling methanol in production of methyl chloride. The process comprises the following steps: adjusting the concentration of diluted hydrochloric acid containing methanol with process water, and introducing the obtained diluted hydrochloric acid containing methanol into a methanol recovery tower; subjecting hydrochloric acid in the recovery tower to heat-exchanging, and carrying out pumping into a storage tank; cooling a tower-top gas phase material through a partial condenser, and allowing a condensate to return to a reflux tank for refluxing; and subjecting methanol non-condensable gas to overheating through a superheater, then mixing the overheated methanol non-condensable gas with mass flow of hydrogen chloride-methanol gas through a pipeline mixer, and allowing an obtained mixture to enter a methyl chloride synthesis kettle so as to synthesize the methyl chloride. The process provided by the invention has simple flow and low equipment investment, aims to save energy and reduce consumption, and reduces environmental pollution. According to the invention, through cyclic utilization of methanol, the production cost of the methyl chloride is reduced, and good economic benefits and environmental protection benefits are achieved.

Owner:HUBEI XINGFA CHEM GRP CO LTD

Lithium battery pole piece coating machine drying system using heat pump heat recovery and barrel pump circulation

ActiveCN109569989BReduce security risksLarge latent heat of phase changeHeat pumpsHeat recovery systemsFresh airEngineering

The invention relates to a lithium battery pole piece coater drying system adopting heat pump heat recovery and barrel pump circulating. The lithium battery pole piece coater drying system comprises adrying channel, a long air channel, an air discharging assembly, a lower heating assembly, an upper heating assembly, a heat pump system, a host and an air heat exchanger, wherein the lower heating assembly and the upper heating assembly are used for heating the drying channel. The host is used for achieving heat exchange between an air channel of the lower heating assembly and an air channel ofthe upper heating assembly, and the heat pump system is used for conducting heat exchange with fresh air; the air heat exchanger comprises two air flow passages conducting heat exchange mutually; an inlet of the first air flow passage communicates with an air channel of the heat pump system, and an outlet of the first air flow passage communicates with the air channel of the lower heating assembly; and an inlet of the second air flow passage communicates with the air discharging assembly and receives the air discharged by the air discharging assembly, and an outlet of the second air flow passage serves as a discharging opening. Compared with the prior art, the high-temperature requirement of lithium battery pole piece drying is met through heat pump heat recovery and barrel pump circulating, the heating load of the lithium battery pole piece drying system is lowered as far as possible, and meanwhile potential safety hazards are reduced.

Owner:江苏博纳致远装备科技有限公司

Method for continuously producing L-calcium lactate

ActiveCN112679340AGuaranteed solid contentPromote crystallizationDrying machine combinationsDrying gas arrangementsCrystallization rateCrystal

The invention discloses a method for continuously producing L-calcium lactate, wherein the method comprises the steps: step A, adding an L-calcium lactate solution into a heating storage mechanism, and heating and concentrating the calcium lactate solution; step B, introducing the concentrated calcium lactate solution into a cooling mechanism, and cooling and crystallizing the calcium lactate solution; step C, conveying the cooled and crystallized L-calcium lactate crystals into a drying mechanism; step D, conveying the dried L-calcium lactate crystals into a crushing mechanism; and step E,carrying out uniform crushing by the crushing mechanism to obtain L-calcium lactate powder. According to the invention, the processing amount of the L-calcium lactate solution is large and the crystallization rate is high.

Owner:河南金丹乳酸科技股份有限公司

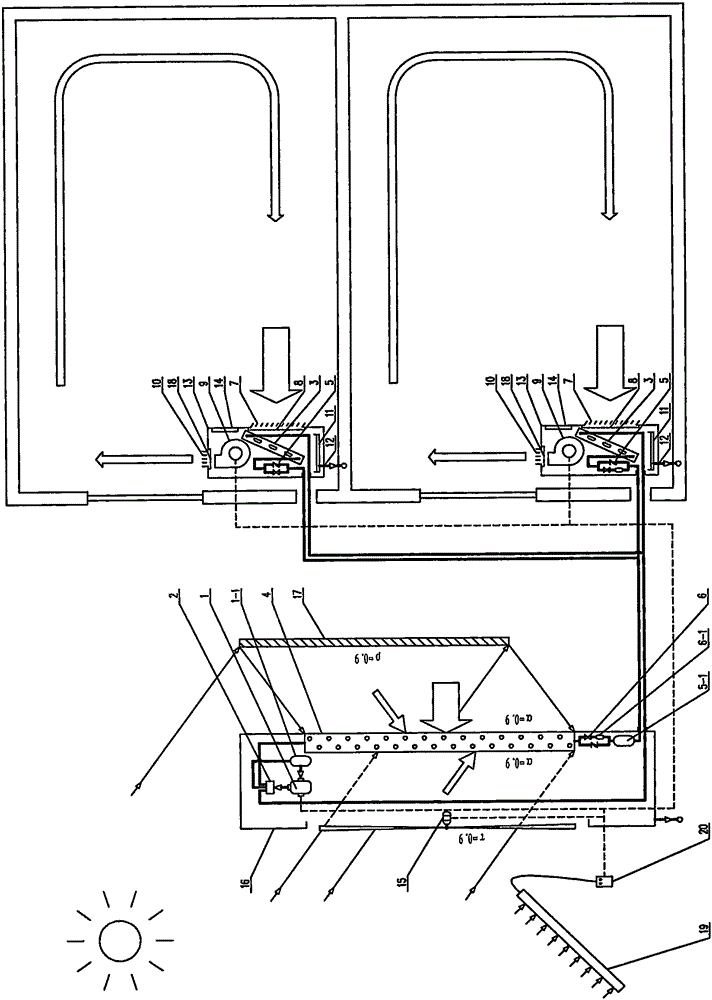

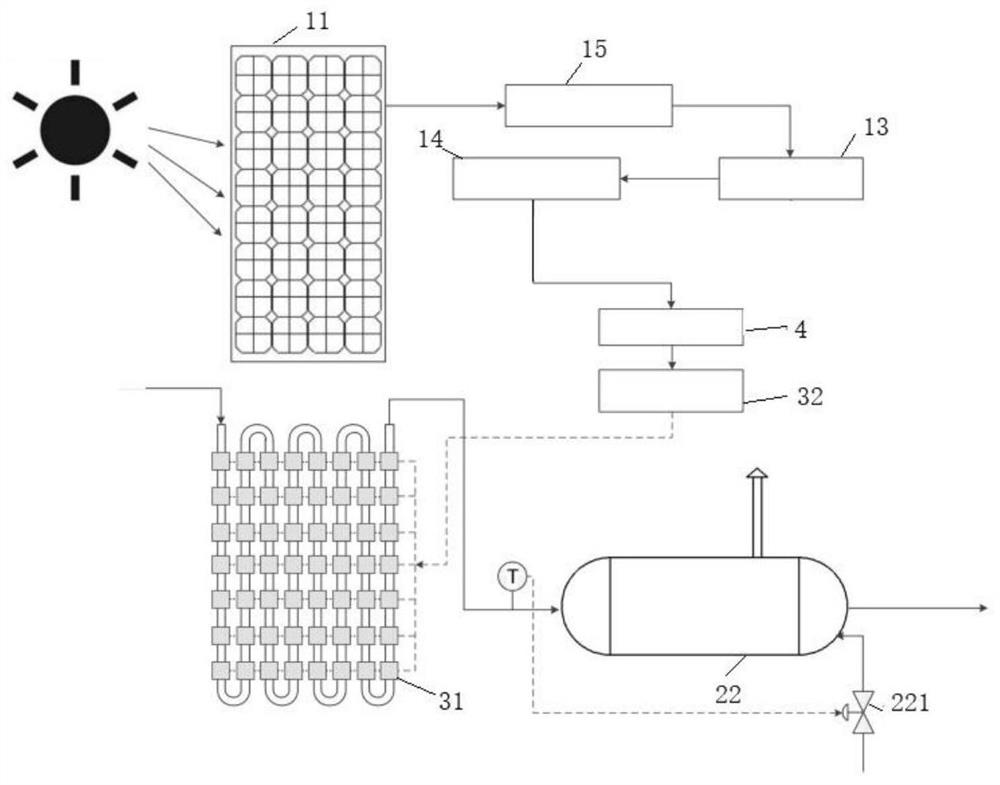

Photovoltaic and photo-thermal integrated heating system and operation method thereof

PendingCN113725988AReduce heating loadReduce consumptionSolar heating energyBatteries circuit arrangementsCogenerationElectric heating

The invention relates to the technical field of energy, in particular to a photovoltaic and photo-thermal integrated heating system and an operation method thereof. The system comprises a photovoltaic power generation module, a photo-thermal module, an electric heating module and a control module. The photovoltaic power generation module comprises a photovoltaic power generation unit; the photo-thermal module is used for absorbing waste heat dissipated by the photovoltaic power generation unit in the power generation process; the photo-thermal module and the electric heating module can be used for heating a medium to be heated. The system has the following characteristics that photovoltaic and photo-thermal of solar energy are combined, so that the energy consumption and the heating cost are reduced; the condensation unit is added to further improve the light energy collection area and power, and is integrated with the heat exchange function of the photo-thermal module to avoid the reduction of the efficiency of the power generation module caused by the temperature, and is used for heating the to-be-heated medium to realize cogeneration; when a medium is electrically heated, electromagnetic heating is used, so that the problems of loss and slow heat transfer caused by contact type heating can be avoided, rapid heating can be realized, and the energy utilization efficiency is improved.

Owner:XI'AN PETROLEUM UNIVERSITY

A refining method and device for esterification synthesis of n-propyl acetate

ActiveCN104557529BSimple processImprove securityOrganic compound preparationCarboxylic acid esters separation/purificationPurification methodsN-Propyl alcohol

Owner:JIANGSU NINE HEAVEN HIGH TECH

Delayed coking method

ActiveCN102234533BReduce loadIncrease processing volumeHydrocarbon distillationTreatment with plural serial stages onlyNaphthaFractionation

The invention discloses a delayed coking method which comprises the following steps: cooling oil and gas at an oil-gas separation tank top of a fractionation tower to 70-100 DEG C by an air cooler at the fractionation tower top, introducing the oil and gas to a first-stage oil-gas separation tank at the fractionation tower top, separating first-stage coked naphtha and gas, cooling the separated gas to 50-30 DEG C by a rear cooler at the fractionation tower top, introducing the cooled gas to a second-stage oil-gas separation tank at the fractionation tower top, and introducing the separated gas from the second-stage oil-gas separation tank at the fractionation tower top to an absorbing and stabilizing system.

Owner:CHINA PETROCHEMICAL CORP +1

Air-solar-combining-source-driving household type heat pump air-conditioning water heating unit

InactiveCN105066510AImprove the blackness of the black cavityImprove absorption rateHeating and refrigeration combinationsBusiness efficiencyCondensation temperature

The invention discloses an air-solar-combining-source-driving household type heat pump air-conditioning water heating unit. The air-solar-combining-source-driving household type heat pump air-conditioning water heating unit is characterized in that (1) solar energy is absorbed through a reflecting mirror, transparent blades and black fin cavities, air energy is absorbed through fins, and the design that a solar absorber and an air fin evaporator are integrated is achieved; (2) the air-solar-combining-source-driving household type heat pump air-conditioning water heating unit is built to increase the evaporation temperature; (3) the condensation temperature is decreased in a vertically-upward air-curtain unified heating manner and an efficient air-conditioning tail end manner; (4) the heating amount and the energy efficiency ratio of a heat pump are increased by reducing the circulation temperature difference; and (5) the solar energy is used in an efficient and low-price photo-thermal conversion manner to drive the heat pump, and the application threshold of solar household type heat pump air-conditioning hot water is lowered.

Owner:侴乔力 +1

Upward air curtain household type heat pump air conditioner driven by air and sun composite source

InactiveCN105066297AImprove the blackness of the black cavityImprove absorption rateMechanical apparatusCondensate preventionBusiness efficiencyCondensation temperature

The invention provides an upward air curtain household type heat pump air conditioner driven by an air and sun composite source. Firstly, a reflecting mirror, transparent blades and a fin black cavity are used for absorbing solar energy, air energy is absorbed through fins, and a solar energy absorber and an air fin evaporator can be integrally designed; secondly, the air and sun composite source household type heat pump air conditioner is constructed, and evaporation temperature is raised; thirdly, by means of unified heating of a vertical upward air curtain and a high-efficiency tail end type of the air conditioner, condensation temperature is lowered; fourthly, by reducing the circulation temperature difference, the heating capacity and the energy efficiency ratio of a heat pump are increased; and fifthly, solar energy is utilized in a high-efficiency and low-price optothermal conversion type to drive the heat pump, and the application threshold of the solar household type heat pump air conditioner is lowered.

Owner:侴乔力 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com