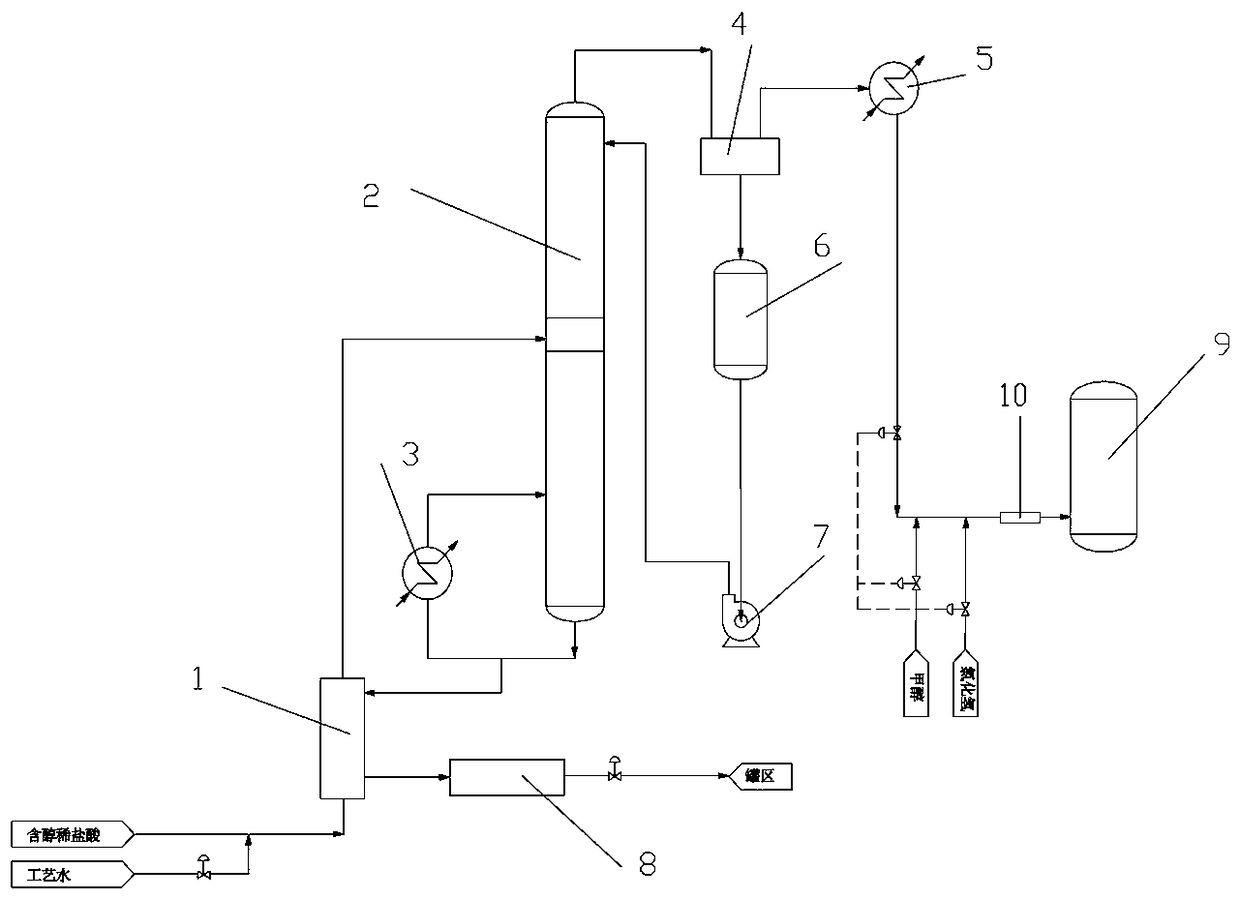

Process and device for recycling methanol in production of methyl chloride

A technology of methanol recovery and methanol recovery tower, which is applied in the chemical industry, preparation of organic compounds, sustainable manufacturing/processing, etc., can solve problems such as waste and environmental protection, and achieve the effects of small equipment investment, reduced production costs, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The mass fraction of hydrogen chloride from the methyl chloride synthesis water washing tower is about 19%, the alcohol-containing dilute hydrochloric acid with a mass fraction of methanol of 5% is mixed with process water at a flow rate of 10t / h and 0.5t / h respectively, and then enters the preheater, and is recovered with methanol The hydrochloric acid is extracted from the bottom of the tower for heat exchange, and the alcohol-containing dilute hydrochloric acid is preheated to 90°C and enters the methanol recovery tower. 0.5MPa(G) steam is passed into the reboiler to provide heat to the methanol recovery tower, the temperature at the top of the methanol recovery tower is controlled at 105-110°C, and the pressure at the top of the methanol recovery tower is controlled at 0.2MPa(G). The gas phase at the top of the methanol recovery tower enters the partial condenser, and part of the gas phase condenses into the methanol reflux tank, and is sent back to the methanol reco...

Embodiment 2

[0019] Alcohol-containing dilute hydrochloric acid with a mass fraction of 23% hydrogen chloride and a mass fraction of methanol of 5.5% from the methyl chloride synthesis water washing tower is 12t / h, mixed with process water 2.82t / h, and enters the methanol preheater together, and is extracted with the bottom of the methanol recovery tower After heat exchange, the hydrochloric acid enters the methanol recovery tower at a temperature of 90°C. The reboiler of the methanol recovery tower is heated by 0.5MPa (G) steam, the temperature of the tower bottom is 142°C, and the pressure at the top of the tower is controlled to 0.2MPa by adjusting the discharge of non-condensable gas. The gas phase at the top of the methanol recovery tower enters the partial condenser, and the condensate enters the methanol reflux tank for reflux. The non-condensable gas is about 695kg / h superheated to 125°C and mixed with hydrogen chloride-methanol gas in the pipeline mixer to enter the synthesis react...

Embodiment 3

[0021] Alcohol-containing dilute hydrochloric acid with a mass fraction of 18% hydrogen chloride and a mass fraction of methanol of 5% from the methyl chloride synthesis water washing tower enters the methanol preheater 10t / h, and after heat exchange with the hydrochloric acid produced at the bottom of the methanol recovery tower, the temperature is 95°C and enters methanol recovery tower. The reboiler of the methanol recovery tower is heated by 0.5MPa (G) steam, the temperature of the tower bottom is 150°C, and the pressure at the top of the tower is controlled to 0.22MPa by adjusting the discharge of non-condensable gas. The gas phase at the top of the methanol recovery tower enters the partial condenser, and the condensate enters the methanol reflux tank for reflux, and the reflux ratio R=15. The methanol content in the non-condensable gas is about 94%, superheated to 125°C and mixed with hydrogen chloride-methanol gas in the pipeline mixer to enter the synthesis reactor fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com