Patents

Literature

45results about How to "Reduce cooling consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for drying hydrogen chloride gas

InactiveCN101759150AImprove conversion rateReduce manufacturing costChlorine/hydrogen-chloride purificationDispersed particle separationSpray towerChemistry

The invention relates to a method for drying a hydrogen chloride gas, which comprises: allowing the hydrogen chloride gas containing water to rise from the bottom part of a drying spray tower along the inner cavity of the drying spray tower; spraying silicon tetrachloride in the inner cavity of the drying spray tower; performing the spray treatment of the hydrogen chloride gas; allowing the sprayed hydrogen chloride gas and the silicon tetrachloride mixed with the hydrogen chloride gas to enter a condenser from the top part of the drying spray tower to perform condensation treatment; and discharging the dried hydrogen chloride gas from the condenser. The silicon tetrachloride decomposes upon the contact with water to form the hydrogen chloride gas and silicon dioxide. The drying of the HCl by using the silicon tetrachloride has the advantages that: the generated HCl can be reused; the water content of the hydrogen chloride gas is reduced to below 50ppm; the conversion rate of silicon powder is improved; the production cost is reduced; the maximum temperature requirement by equipment for operation is 0 DEG C; the cold energy consumption is low; the equipment investment is small; the energy consumption is reduced; and the environmental pollution is relieved.

Owner:SHANDONG XINLONG TECH

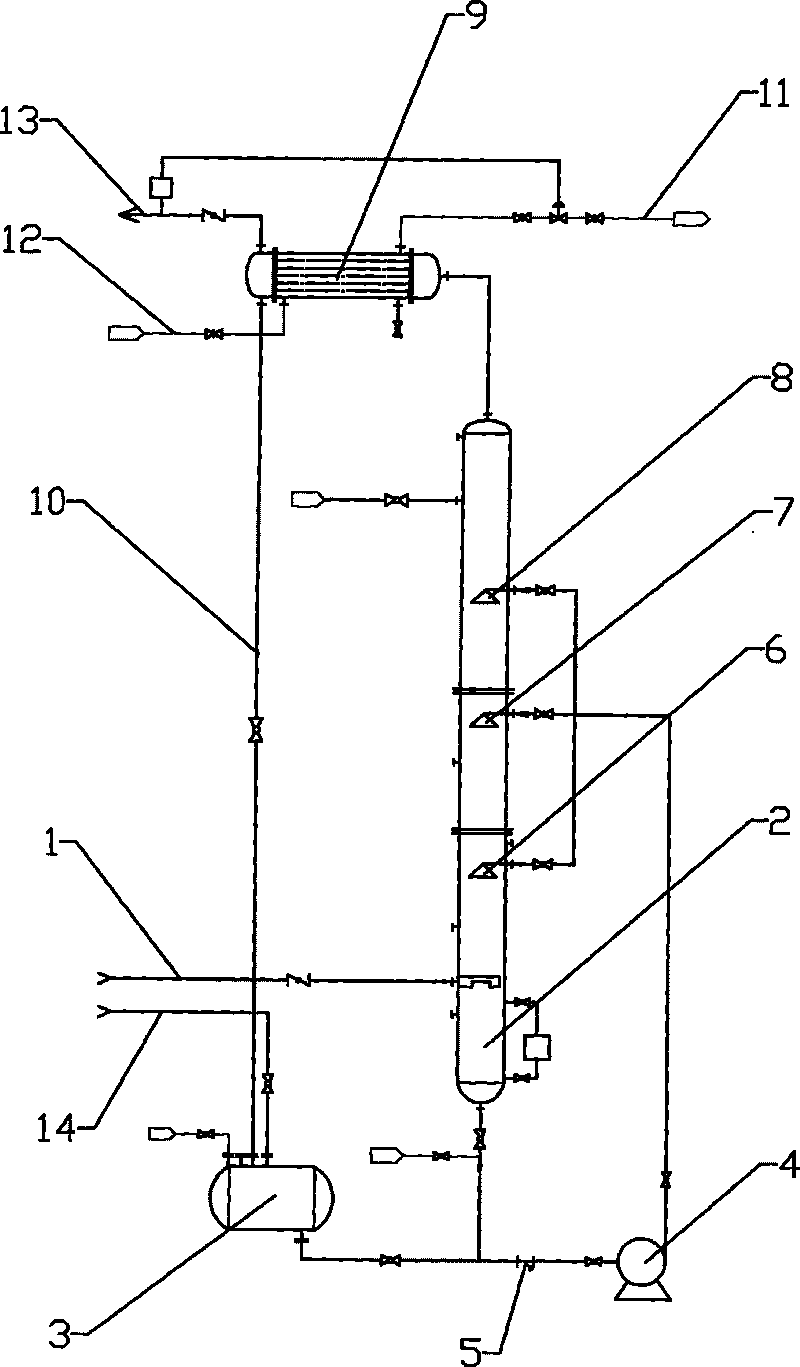

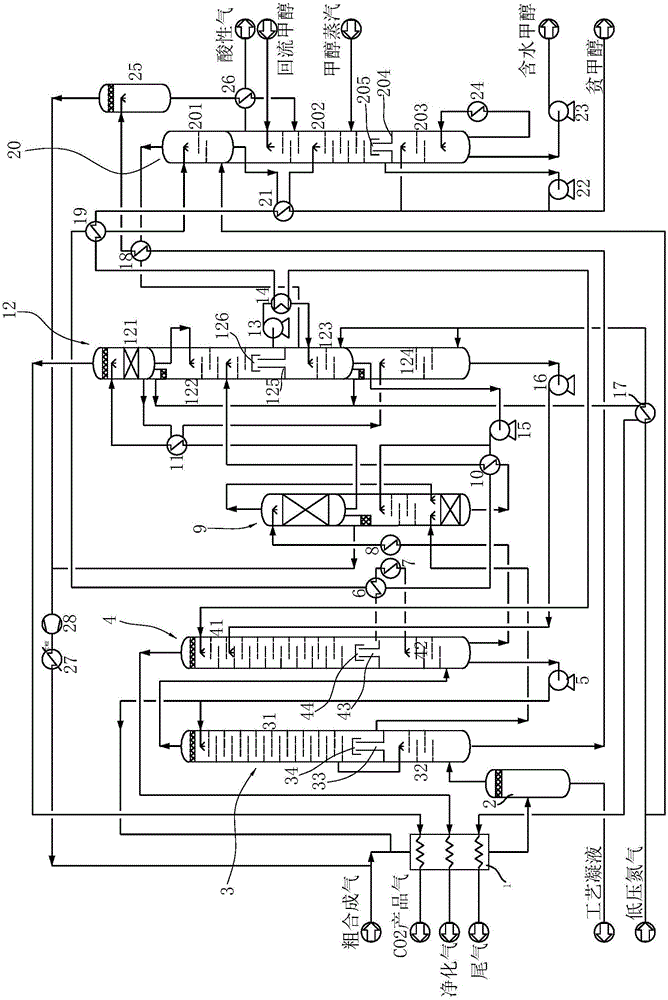

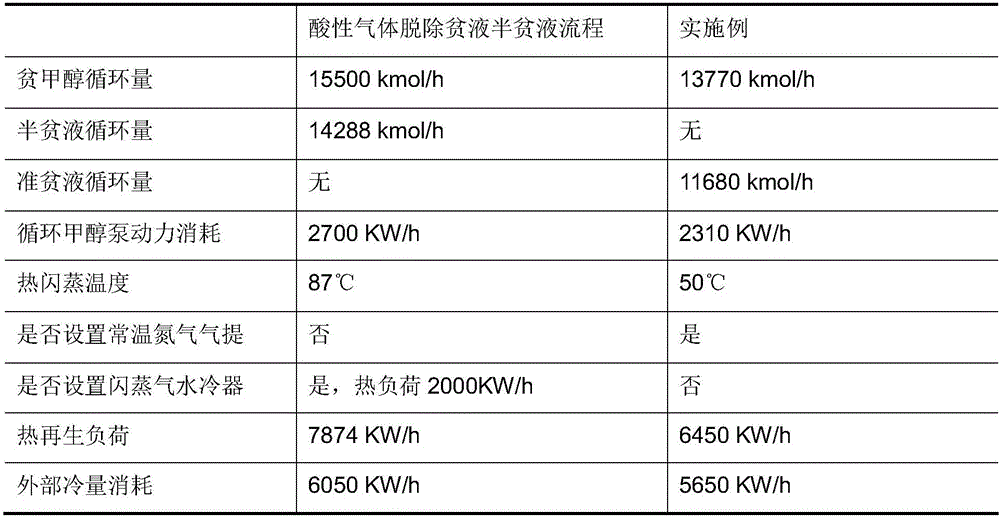

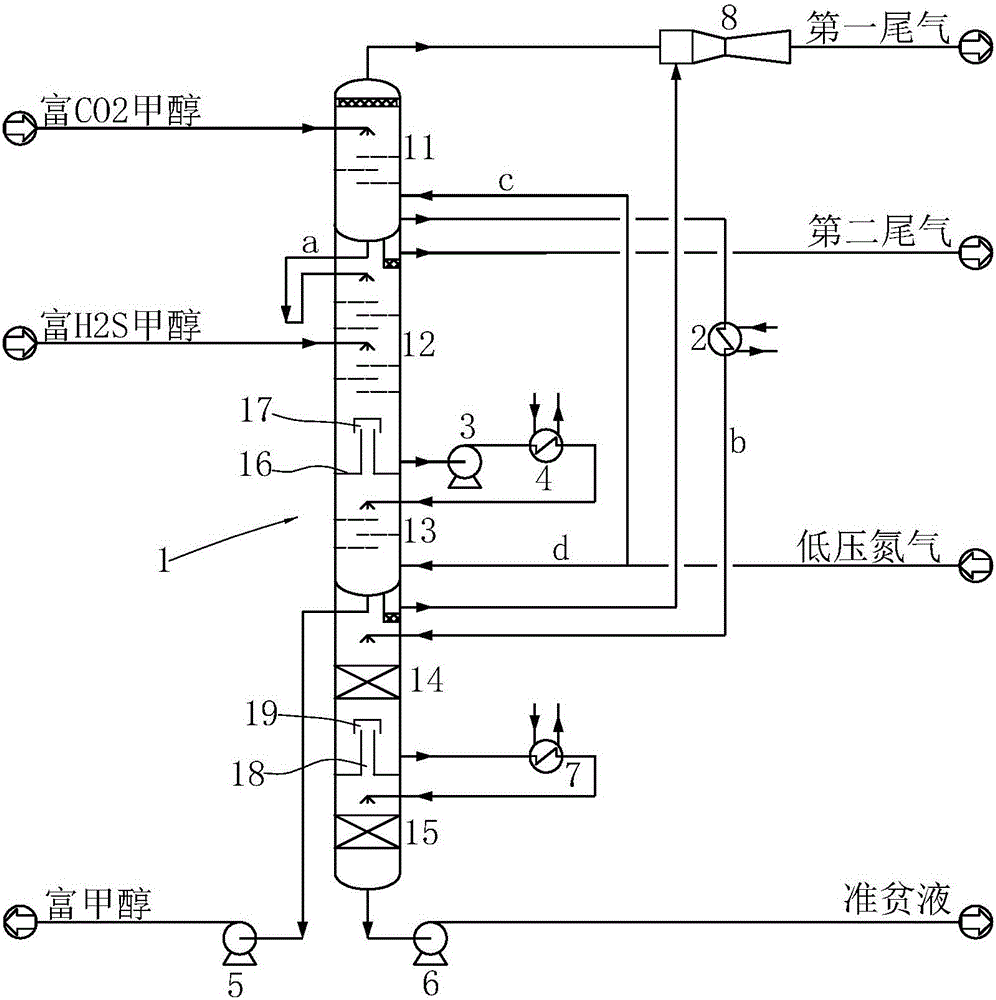

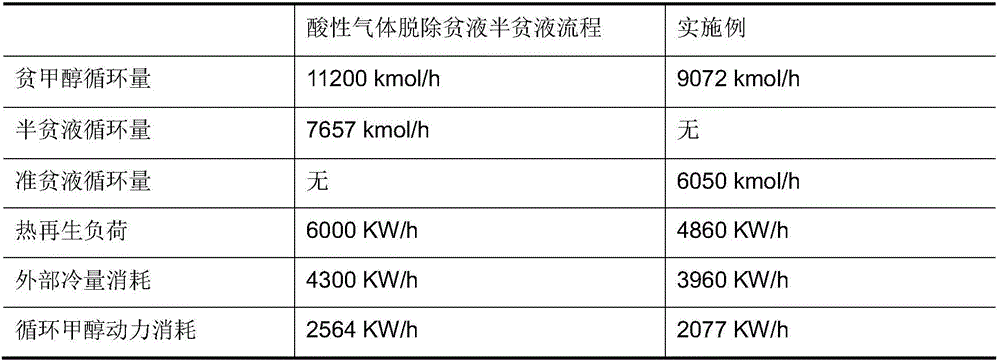

Acidic gas removal process used for pulverized coal gasification

ActiveCN106479578AStrong absorption capacityReduce circulationChemical industryGas purification by non-gaseous materials condensationChemistryProduct gas

Owner:SINOPEC NINGBO ENG +2

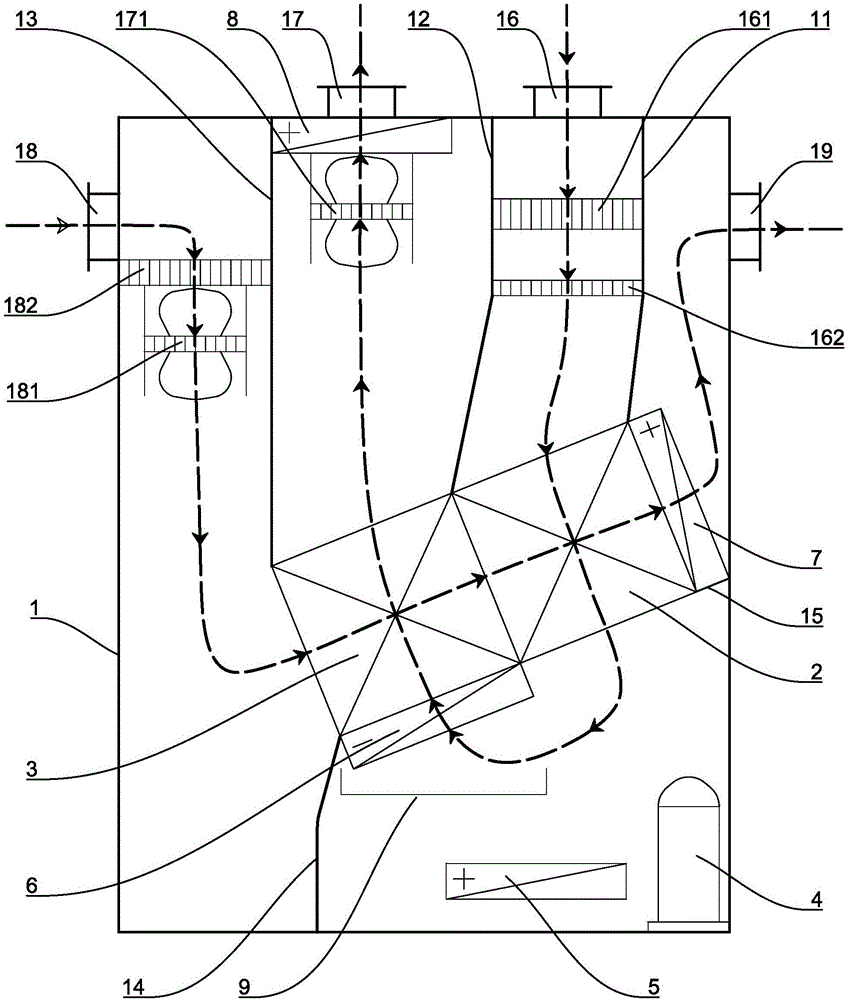

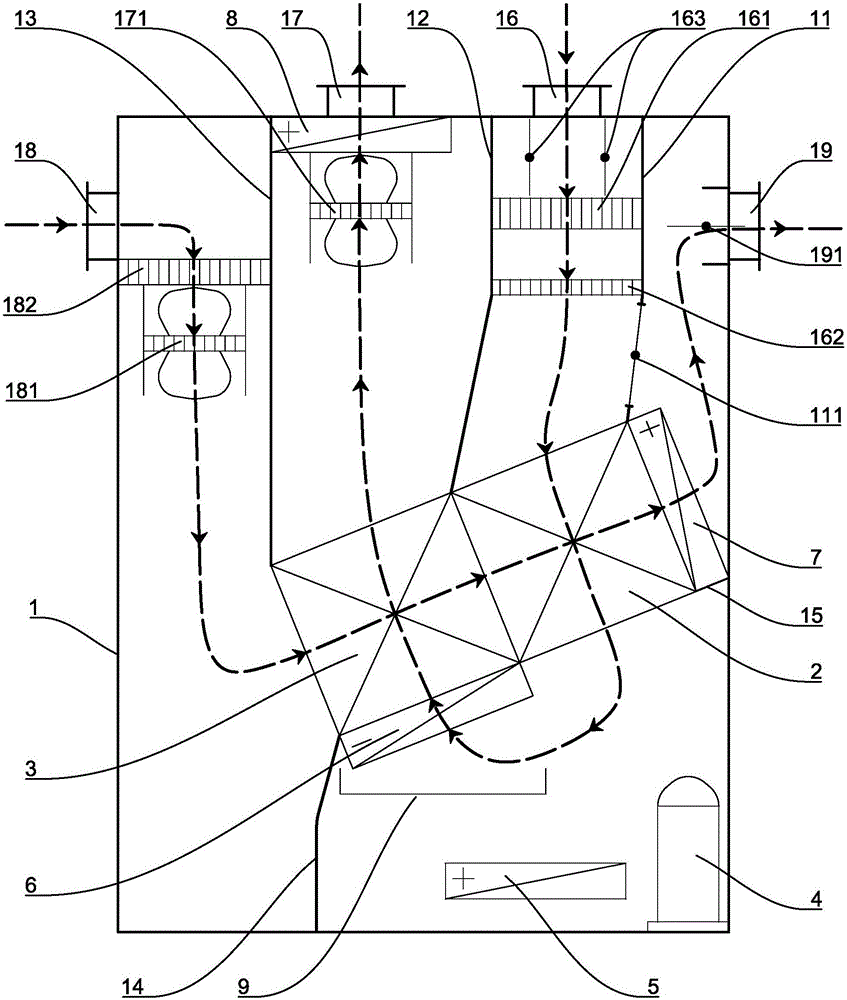

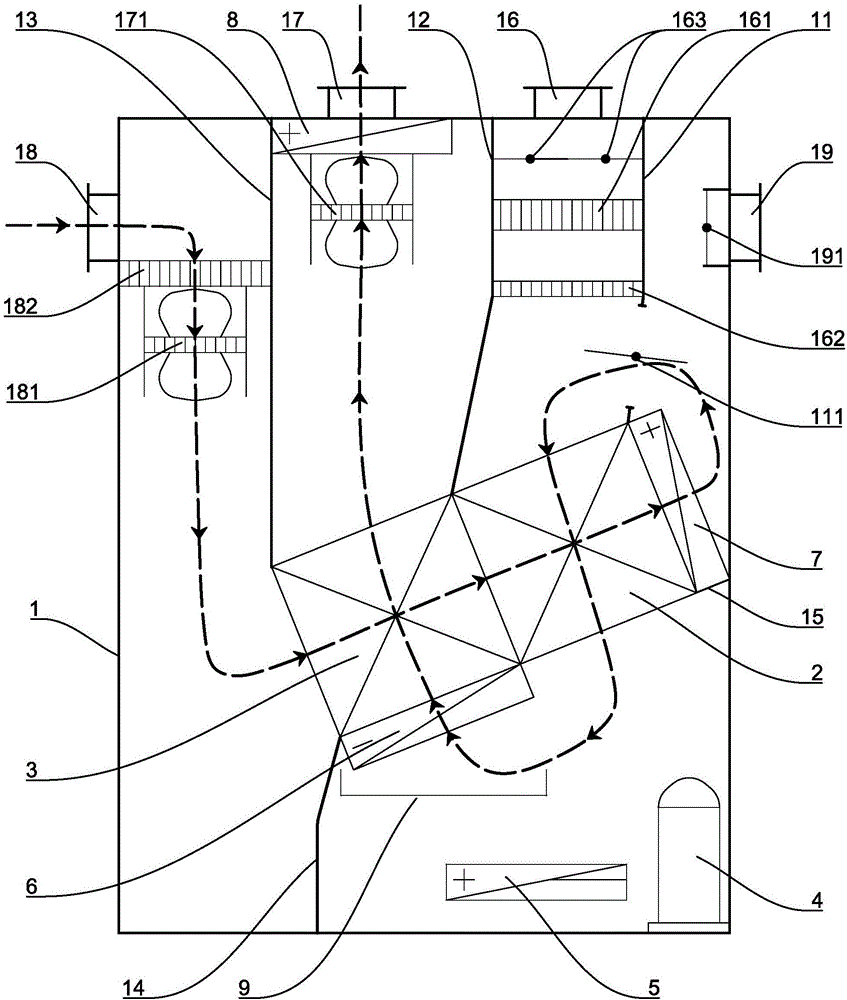

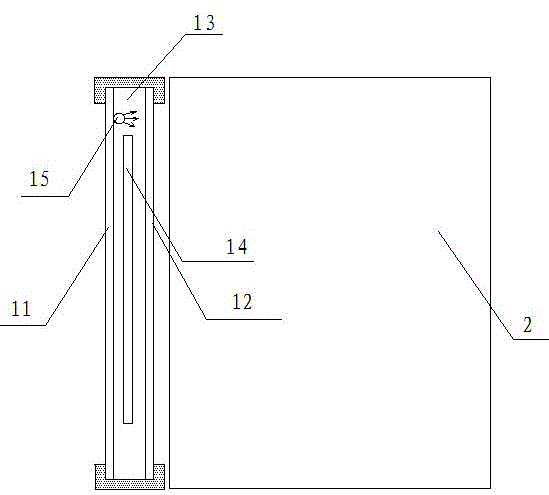

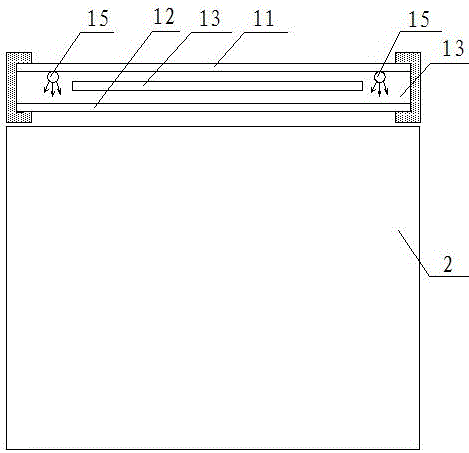

Fresh air handling unit with internal circulation and heat recovery

ActiveCN106839354ASimple structureImprove heat recoveryEnergy recovery in ventilation and heatingMechanical apparatusBusiness efficiencyFresh air

The invention relates to a fresh air handling unit with internal circulation and heat recovery. The fresh air handling unit comprises a shell, a first plate heat exchanger, a second plate heat exchanger, a compressor, a water-cooling condenser and an evaporator, the first plate heat exchanger and the second plate heat exchanger are arranged side by side, a first partitioning plate is arranged between the upper side of the right end of the first plate heat exchanger and the top wall of the shell, a second partitioning plate is arranged between the connecting position of the first plate heat exchanger and the second plate heat exchanger and the top wall of the shell, a third partitioning plate is arranged between the upper side of the left end of the second plate heat exchanger and the top wall of the shell, a fourth partitioning plate is arranged between the lower side of the left end of the second plate heat exchanger and the bottom wall of the shell, and a fifth partitioning plate is arranged between the lower side of the right end of the first plate heat exchanger and the right wall of the shell. A fresh air port and an air delivery port are formed in the top wall of the shell, an air-returning port and an air-discharging port are formed in the left side wall and right side wall of the shell, and the evaporator is arranged on the lower side of the second plate heat exchanger side by side. The fresh air handling unit has the advantages of being simple in structure and high in heat recovery rate and energy efficiency ratio, and can achieve intelligent control and low-energy-consumption operation.

Owner:HUNDRED TECH CO LTD

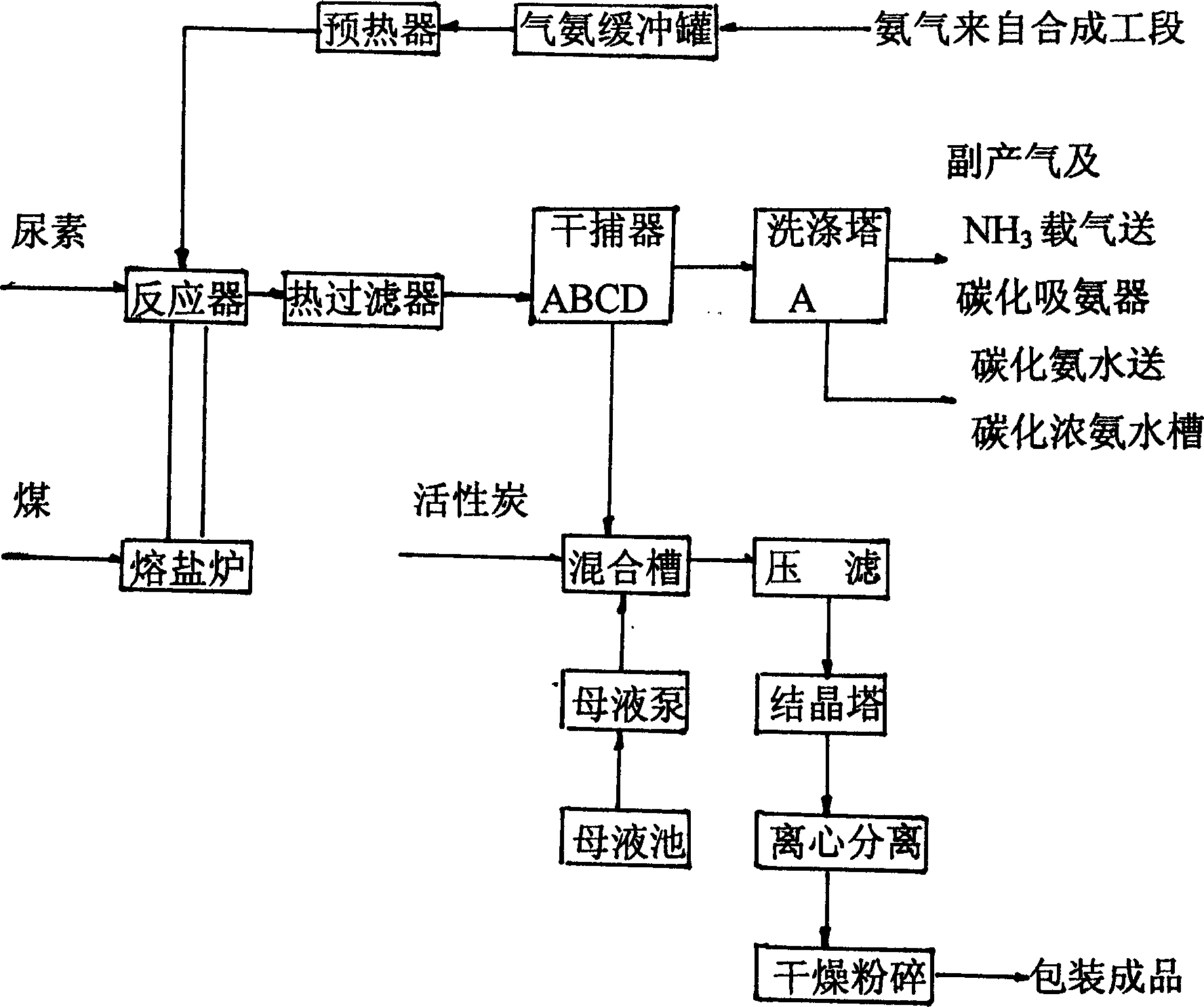

Melamine and ammonium carbonate joint production technology

InactiveCN1651419ASimple processStable productionOrganic chemistryAmmonium carbonates/bicarbonatesDiammonium carbonateChemistry

A process for preparing cyanuramide and ammonium dicarbonate includes preheating ammonia gas as carrier, introducing it to fluidized-bed reactor, pumping urea in said reactor, high-temp catalytic decomposing to generaet the reactive gas containing cyanuramide, CO2 and ammonia, filtering, cooling to educe out cyanuramide, washing the tail gas by ammonia water, coding, carbonizing to obtain cabonized ammonia water, preparing ammonium dicarbonate, mixing said cyanuramide with its mother liquid, thermal dissolving, filtering, cooling for crystallizing, centrifugal separating, drying and pulverizing to obtain finished cyanuramide.

Owner:尹明大

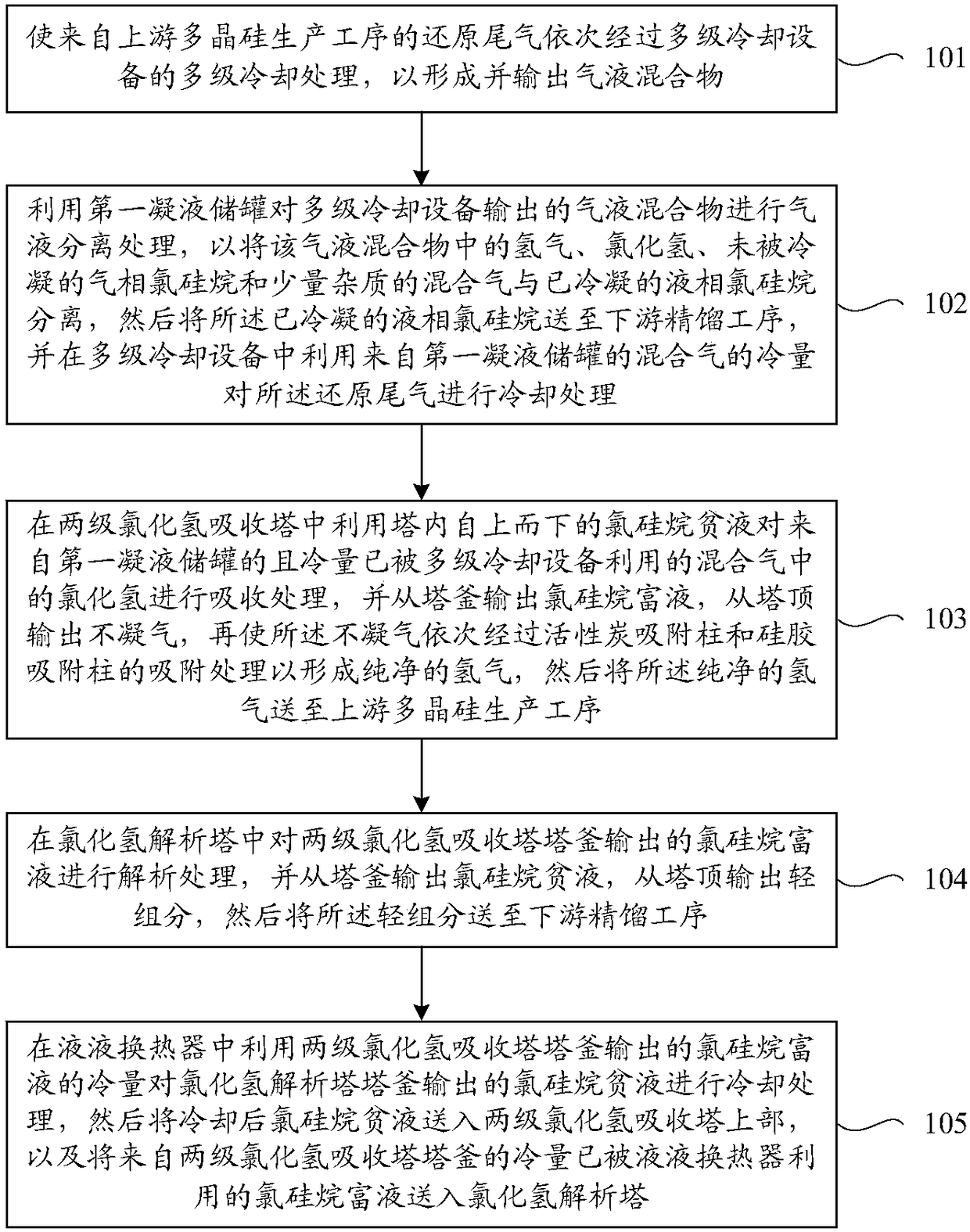

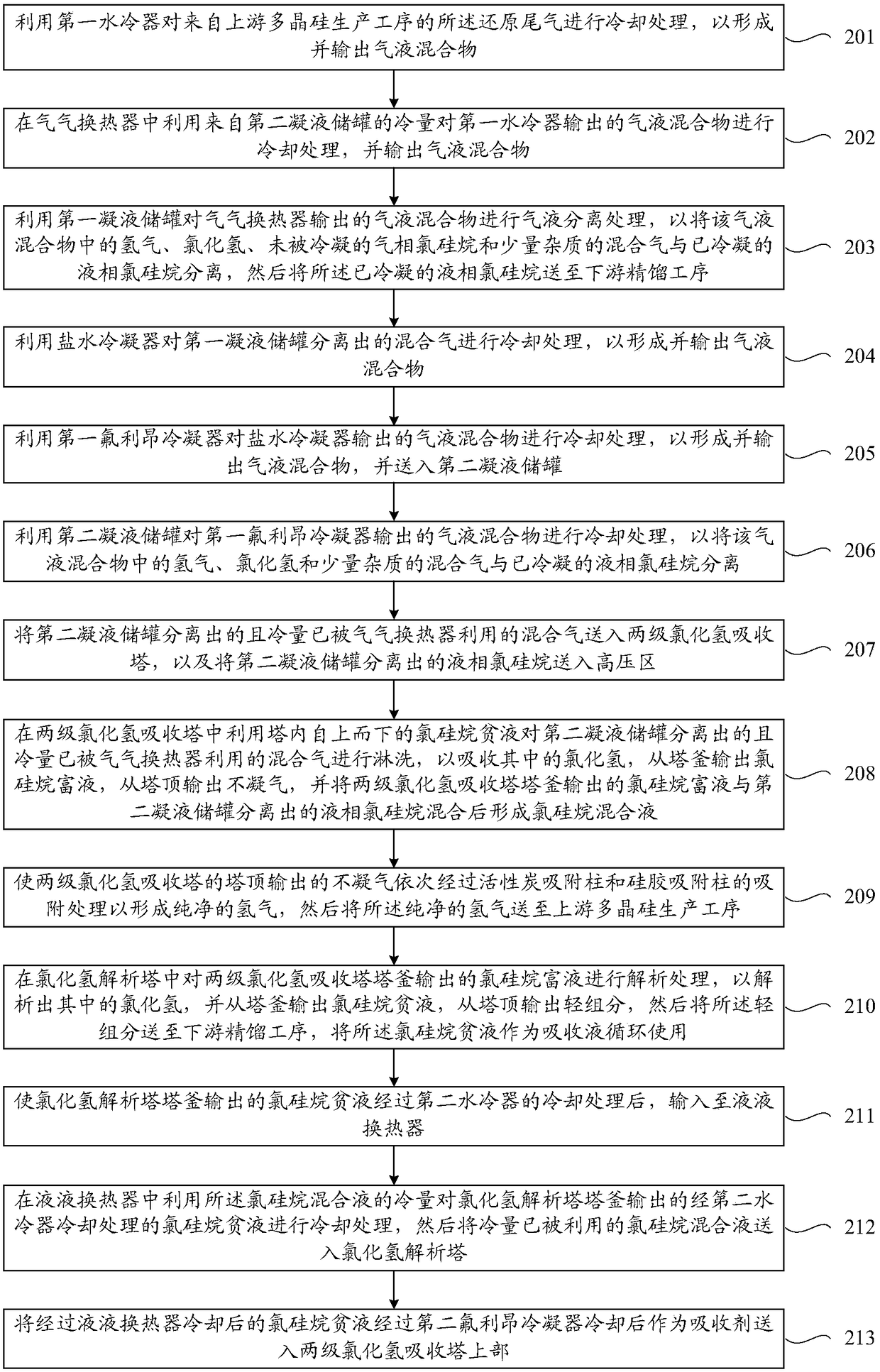

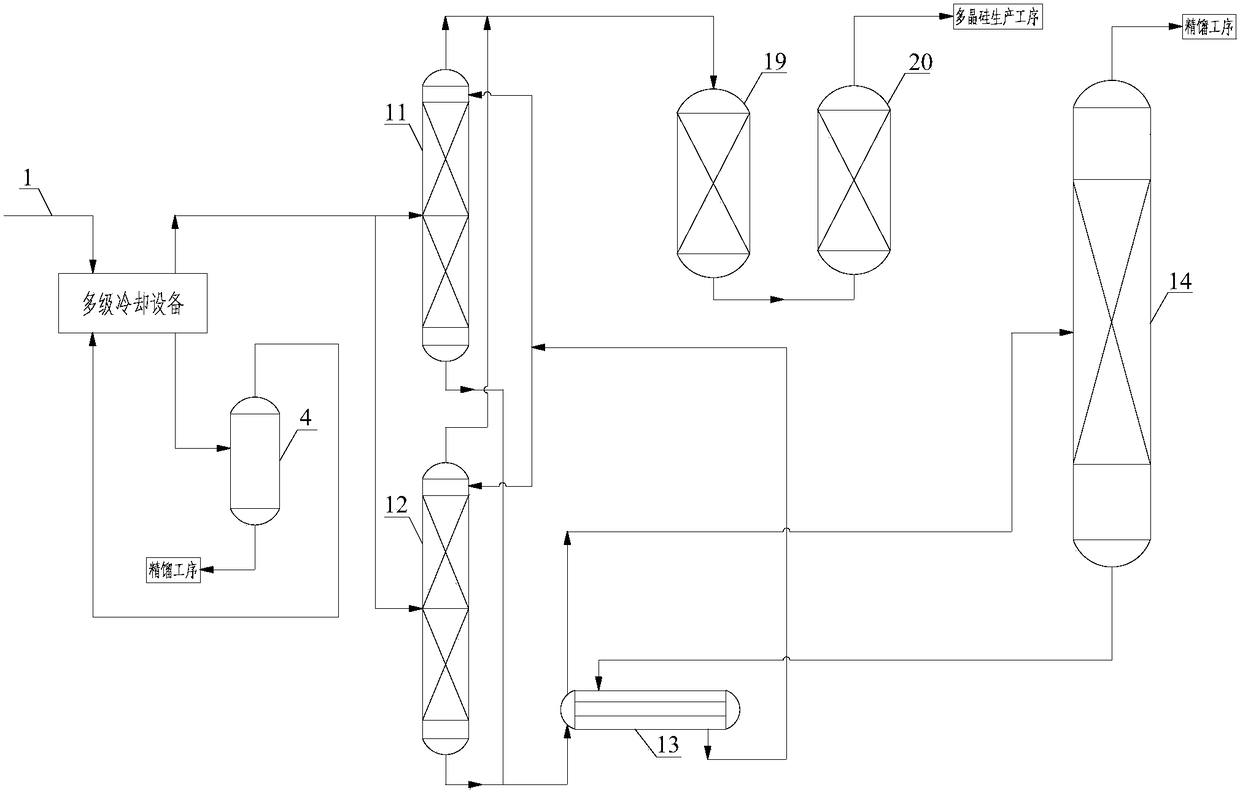

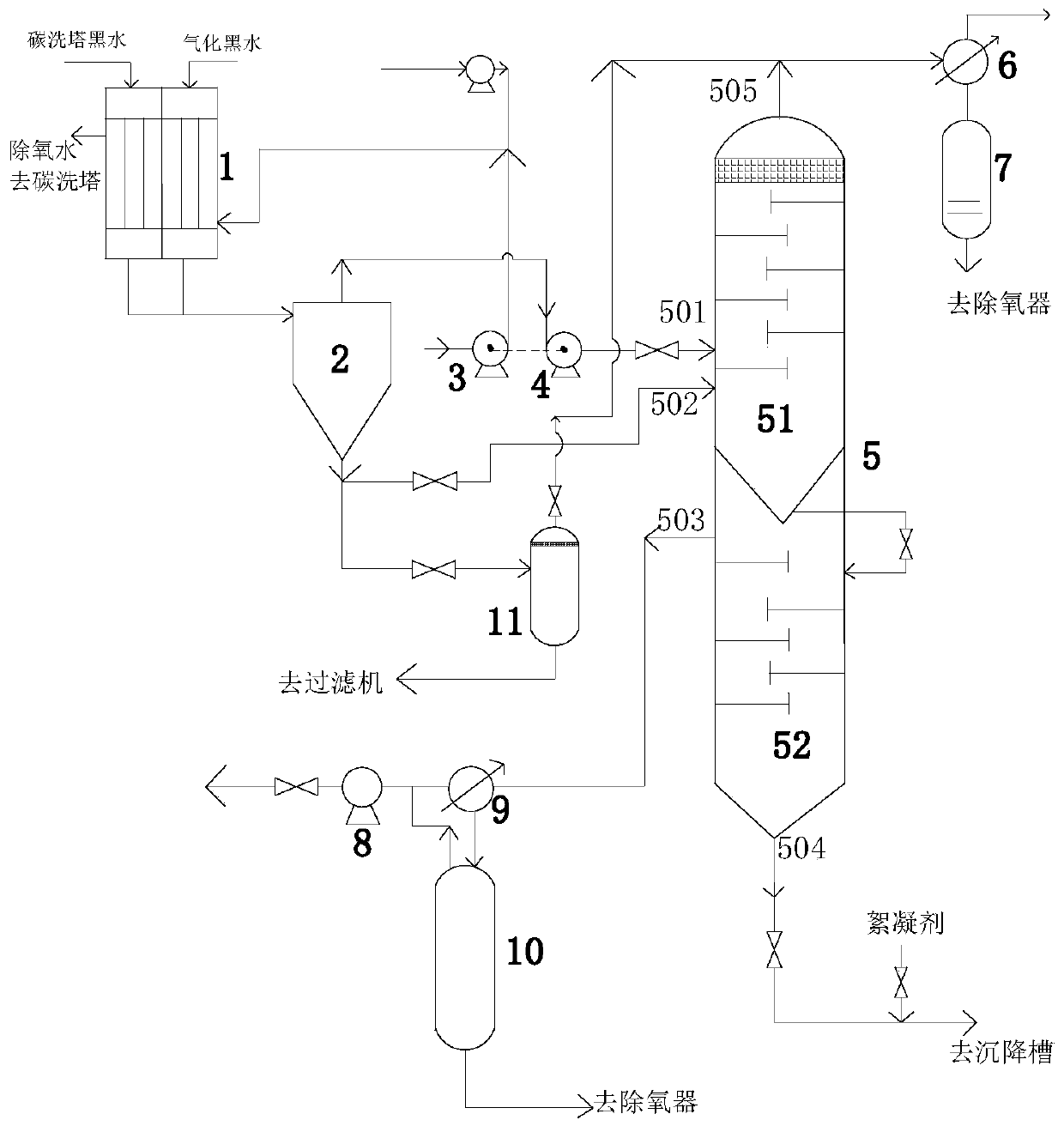

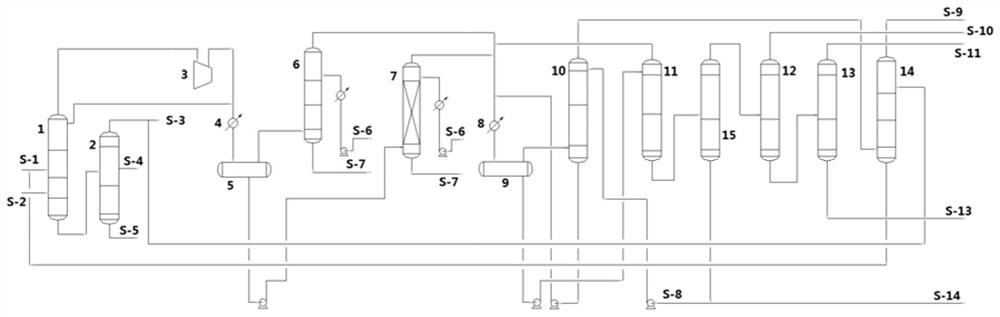

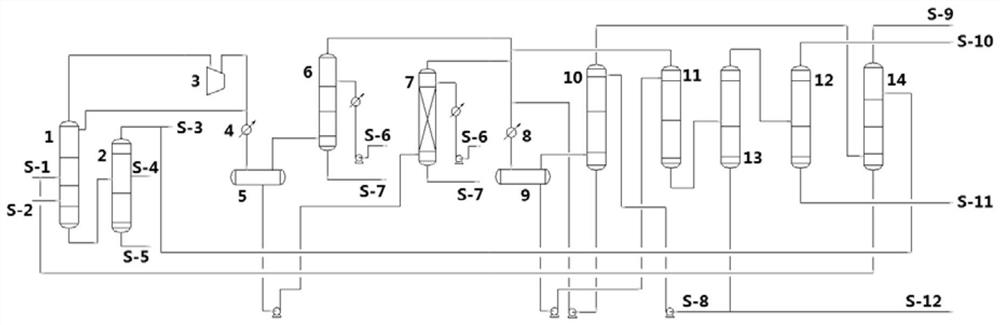

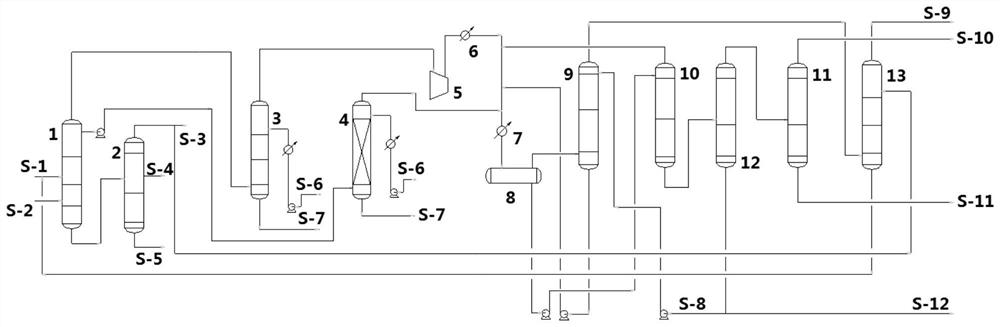

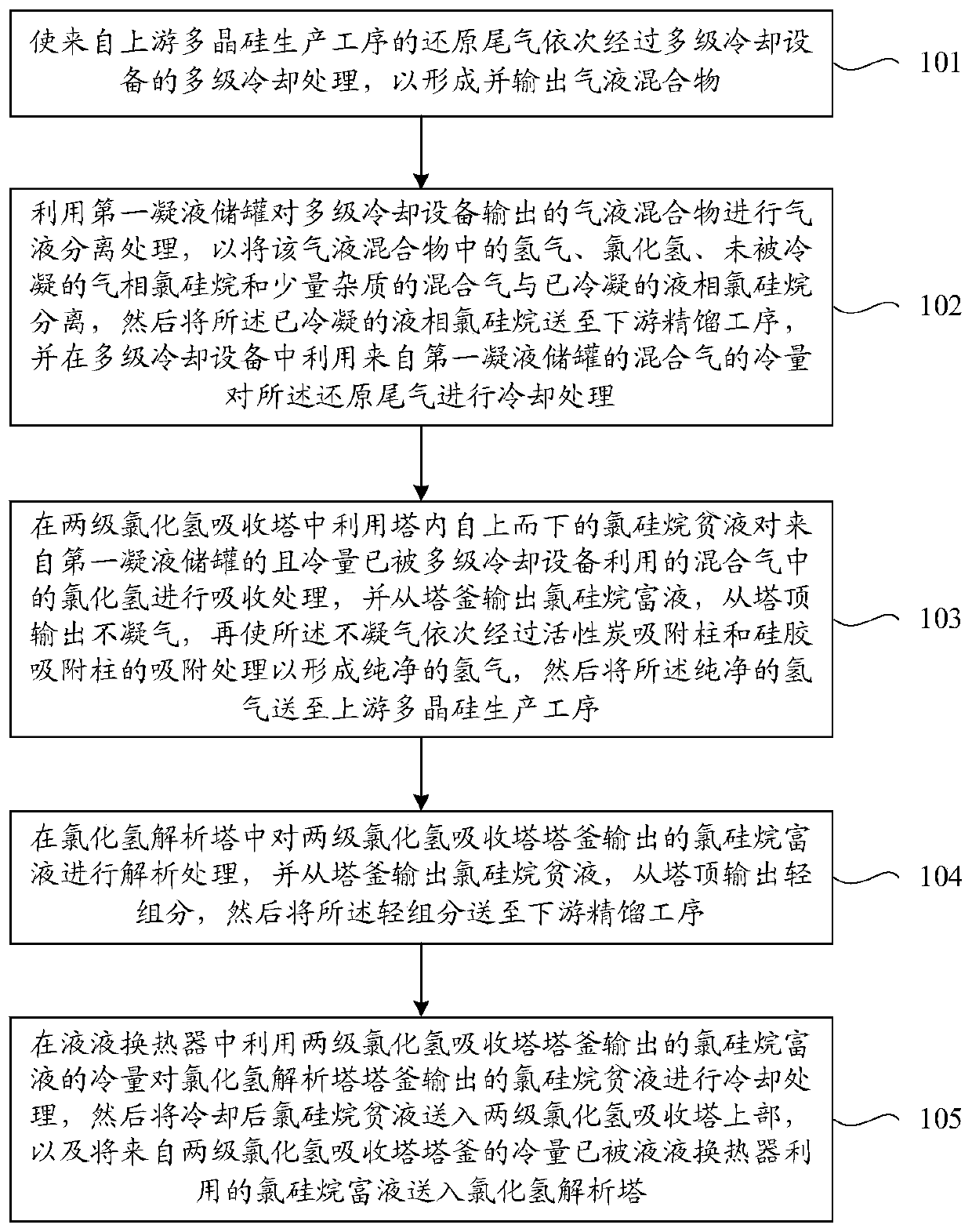

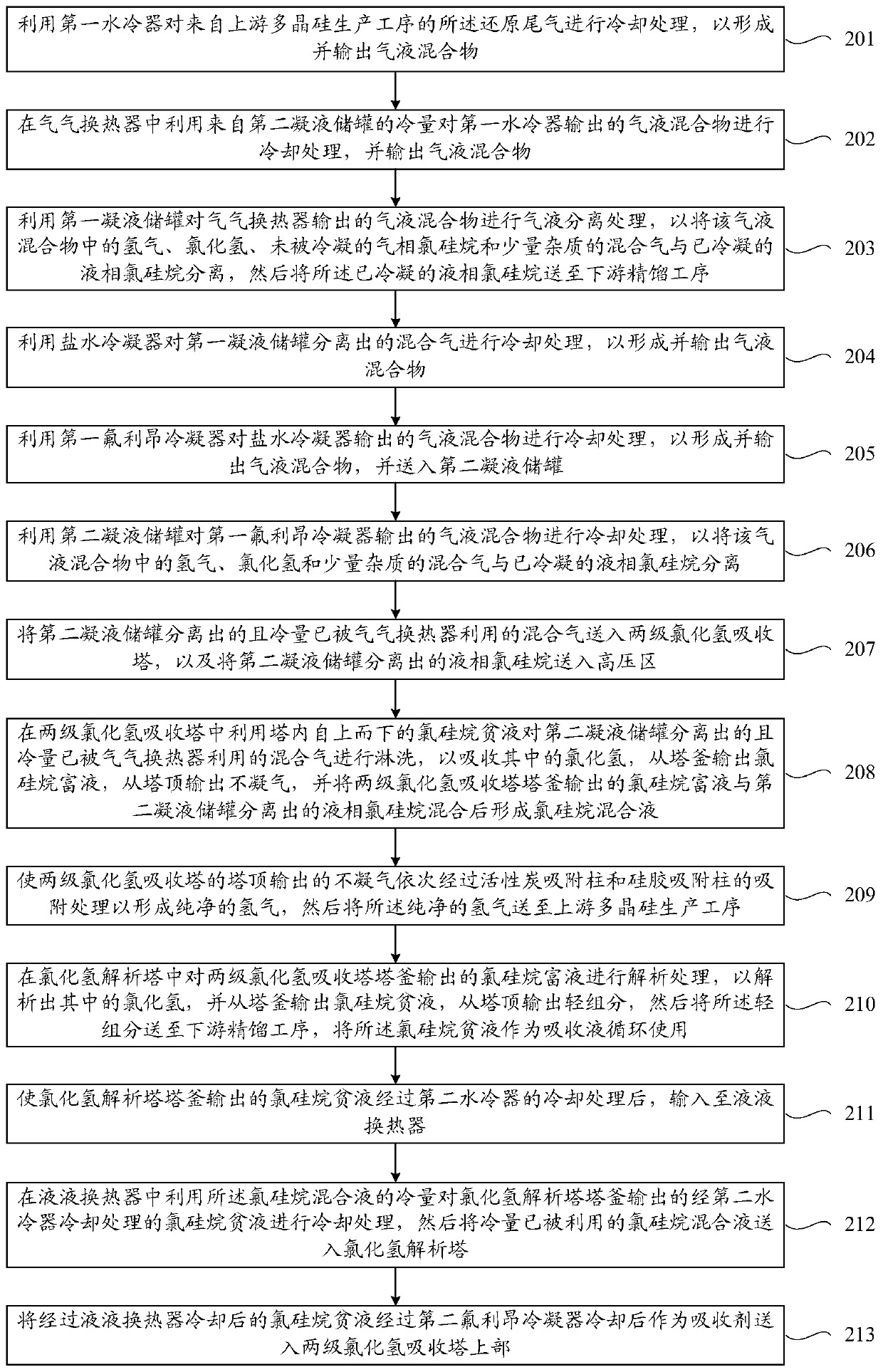

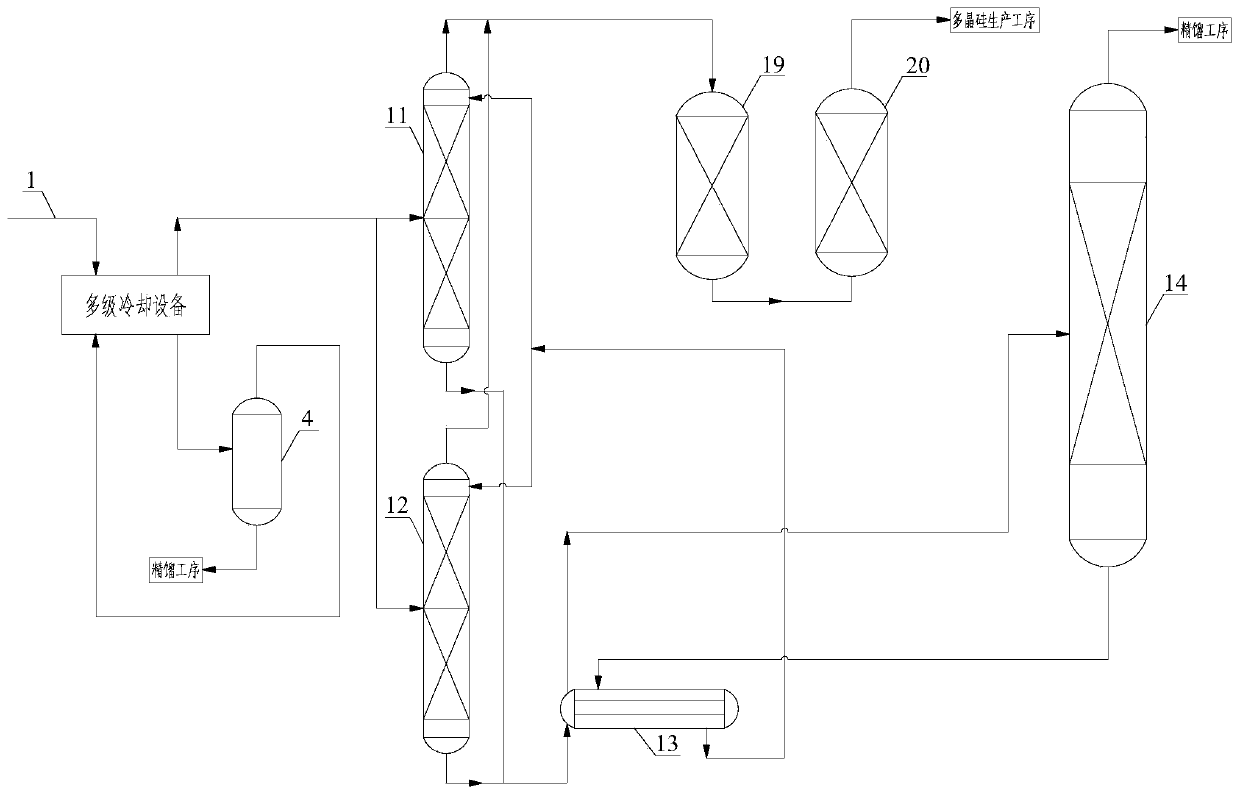

Deep purification method and system of polycrystalline silicon reduction exhaust gas

ActiveCN108534463ALow costReduce energy consumptionSolidificationGas treatmentPurification methodsHydrogen

The invention provides a deep purification method of polycrystalline silicon reduction exhaust gas, comprising: performing multiple stages of cooling treatment successively on reduction exhaust gas soas to discharge gas-liquid mixture; performing gas-liquid separation on the gas-liquid mixture, using cold capacity of separated mixed gas to cool the reduction exhaust gas; using chlorosilane barrenliquor that runs from top to bottom inside a two-stage hydrogen chloride absorbing column to absorb, in the column, hydrogen chloride in the mixed gas with the cold capacity already utilized; stripping, in a hydrogen chloride stripper, chlorosilane rich liquor discharged from the bottom of the hydrogen chloride absorbing column, and discharging fluorosilicon barren liquor from the bottom and light components from the top; using the cold capacity of chlorosilane rich liquor, discharged from the bottom of the two-stage hydrogen chloride absorbing column, to cool the chlorosilane barren liquor discharged from the bottom of the hydrogen chloride stripper. Correspondingly, a deep purification system is provided. The deep purification method and system have the advantages that the quality of recycled hydrogen meets the corresponding requirements of electronic polycrystalline silicone, extra cold consumption is decreased, and load of the absorbing column is relieved.

Owner:XINTE ENERGY

Display refrigerator with transparent display screen

InactiveCN106263841AReduce energy consumptionSolve technical problems with high energy consumptionShow cabinetsRefrigerator carTemperature difference

The invention discloses a display refrigerator with a transparent display screen, which solves the technical problem of high integral energy consumption in the existing display refrigerator with the transparent display screen. The display refrigerator comprises a transparent door body, wherein the transparent door body at least consists of an outer transparent layer and an inner transparent layer; the outer transparent layer is kept away from a refrigerator box, and the inner transparent layer corresponds to the outer transparent layer; a cavity is formed between the outer transparent layer and the inner transparent layer; the transparent display screen is arranged in the cavity; a light source is arranged at the side of the transparent display screen, and the light emitting direction of the light source faces the refrigerator box. The display refrigerator has the advantages that the light source of the display objects in the refrigerator and the light source of the transparent display screen can be provided by only one group of light source, so that the integral energy consumption of the display refrigerator with the transparent display screen is decreased, the heat emitted by the light source in the refrigerator box is reduced, and the consumption of cold is reduced in the refrigerating circulation design; the light source in the transparent door body can provide a heat source for removing fog and dew of the door body, so that the condensate of the transparent door body of the refrigerator caused by cold and heat temperature difference of the interior and exterior of the refrigerator box is effectively reduced.

Owner:QINGDAO HAIER SPECIAL ICEBOX

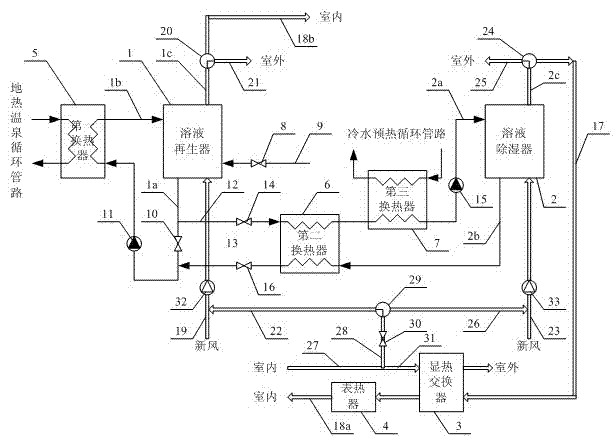

Solution humidity-regulation air treatment system utilizing geothermal hot spring resources and treatment method thereof

ActiveCN103528154AReduce conversion lossIncrease profitSpace heating and ventilation safety systemsLighting and heating apparatusAir treatmentEngineering

The invention provides a solution humidity-regulation air treatment system utilizing geothermal hot spring resources and a treatment method for performing dehumidification and humidification on indoor air. According to the solution humidity-regulation air treatment system, the geothermal hot spring resources are directly utilized as a heat source to achieve regeneration of a humidity regulating solution and accordingly conversion energy sources such as electric energy are avoided so as to achieve energy conservation and emission reduction; meanwhile humidity regulating treatment and temperature regulating treatment on treated air are separated from each other through structural optimization and accordingly refrigeration coefficients of a surface air cooler can be improved, the efficiency of the temperature regulating treatment and the humidity regulating treatment can be improved, the energy consumption of the surface air cooler can be reduced, and energy sources can be saved; dual functions of cooling dehumidification and warming humidification can be achieved and the solution humidity-regulation air treatment system can be suitable for summer and winter air conditioning just through simple conversion control and accordingly the problem that solution humidity-regulation air conditioning systems are single in function in the prior art is solved and the market application prospect of the solution humidity-regulation air treatment system is extended.

Owner:CHONGQING UNIV

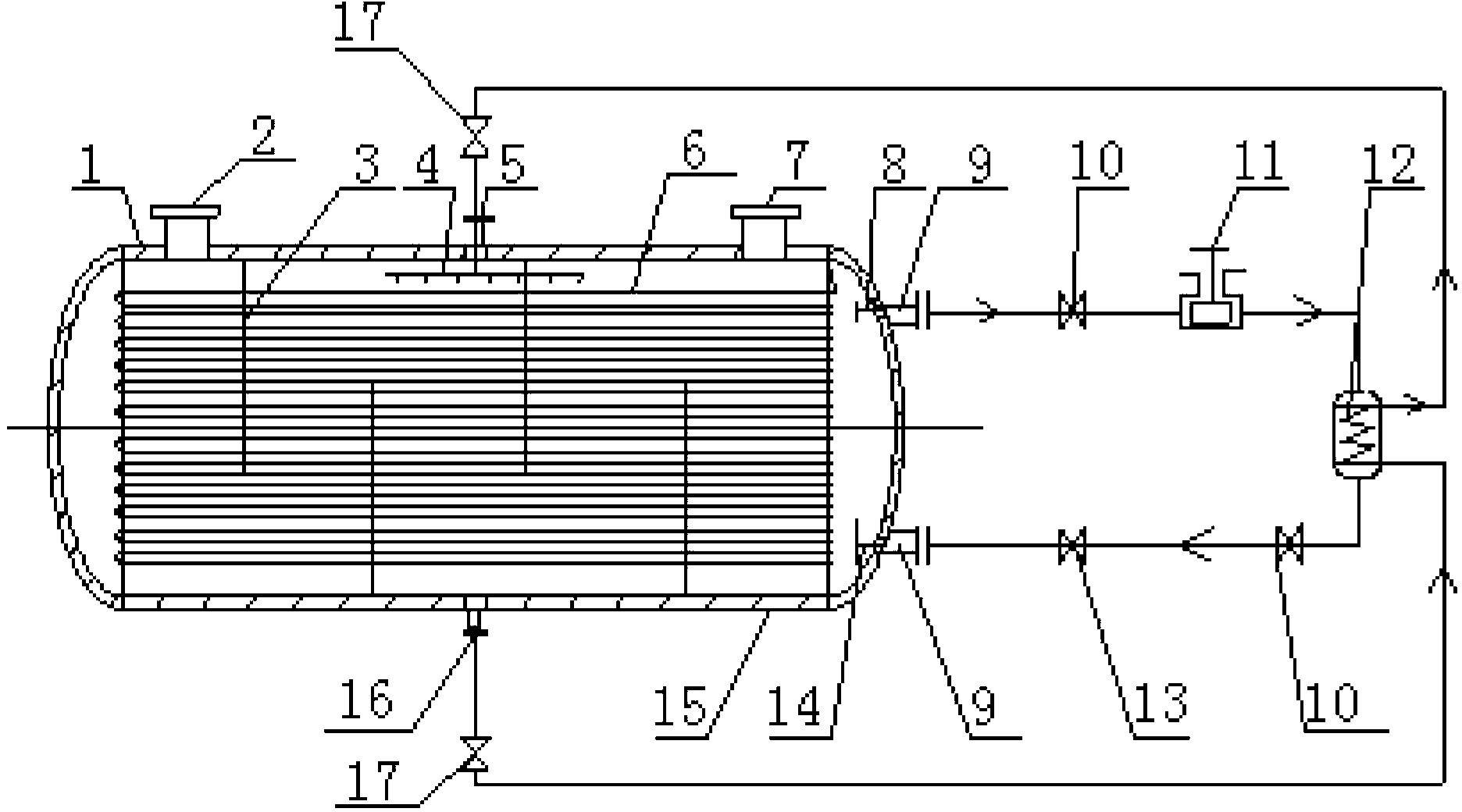

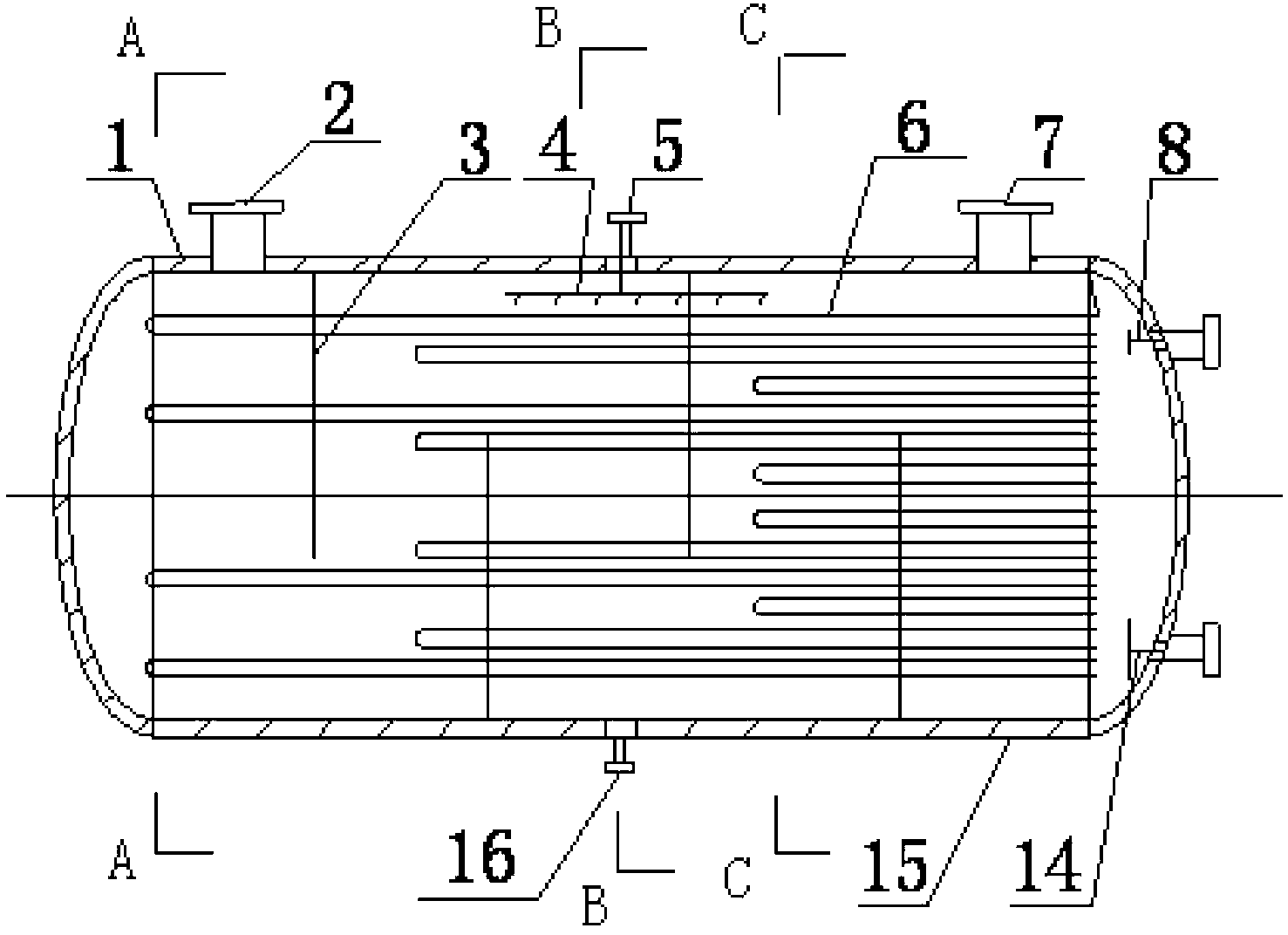

Conduction-variable vacuum water catching device

The invention discloses a conduction-variable vacuum water catching device and belongs to the technical field of vacuum water catching. The vacuum water catching device comprises a water catcher, a refrigerating system and an auxiliary unit; a condenser tube shortens gradually in length in the direction from the gas inlet to the gas outlet, so that the conduction capacity of the water catcher varies from large to small when gas flows in the water catcher; a casing adopts a modified taper, and circular and round baffle plates are adopted for the inside of the taper casing, therefore the conduction capacity of the water catcher also varies from large to small when the gas flows in the water catcher, moreover, the efficiency for catching steam is improved, and the refrigerating capacity consumption is reduced. As the device adopts cooling water circulation for defrosting or deicing, reuse of waste water as well as heat energy is achieved, and purposes of high efficiency, energy saving and emission reduction are achieved; the device is simple in structure, low in construction cost, convenience in use and maintenance, and large in application range, and can be used wherever the steam is required to be caught.

Owner:LIAOYANG BOSHI FLUID EQUIP

Method for preparing methyl hydrogen silicone oil from organic silicon by-product

The invention relates to a method for preparing methyl hydrogen silicone oil from an organic silicon by-product. The method comprises the steps of carrying out cohydrolysis reaction under certain conditions by virtue of the organic silicon by-product, namely dichloromethylsilane, an end-capping agent, namely chlorotrimethylsilane and recycled washing dilute acid, carrying out back flushing by virtue of compressed air so as to remove hydrogen chloride produced during hydrolysis, standing for layering after the reaction is finished, carrying out washing deacidification on an upper solution for multiple times, and carrying out neutralization, filtration and devolatiligation procedures on products, so as to obtain finished methyl hydrogen silicone oil. Practices prove that methyl hydrogen silicone oil prepared by virtue of the method has controllable viscosity and stable quality and is easy to industrialize, and the comprehensive utilization value of the organic silicon by-product, namely dichloromethylsilane is greatly increased.

Owner:HUBEI XINGRUI SILICON MATERIAL CO LTD

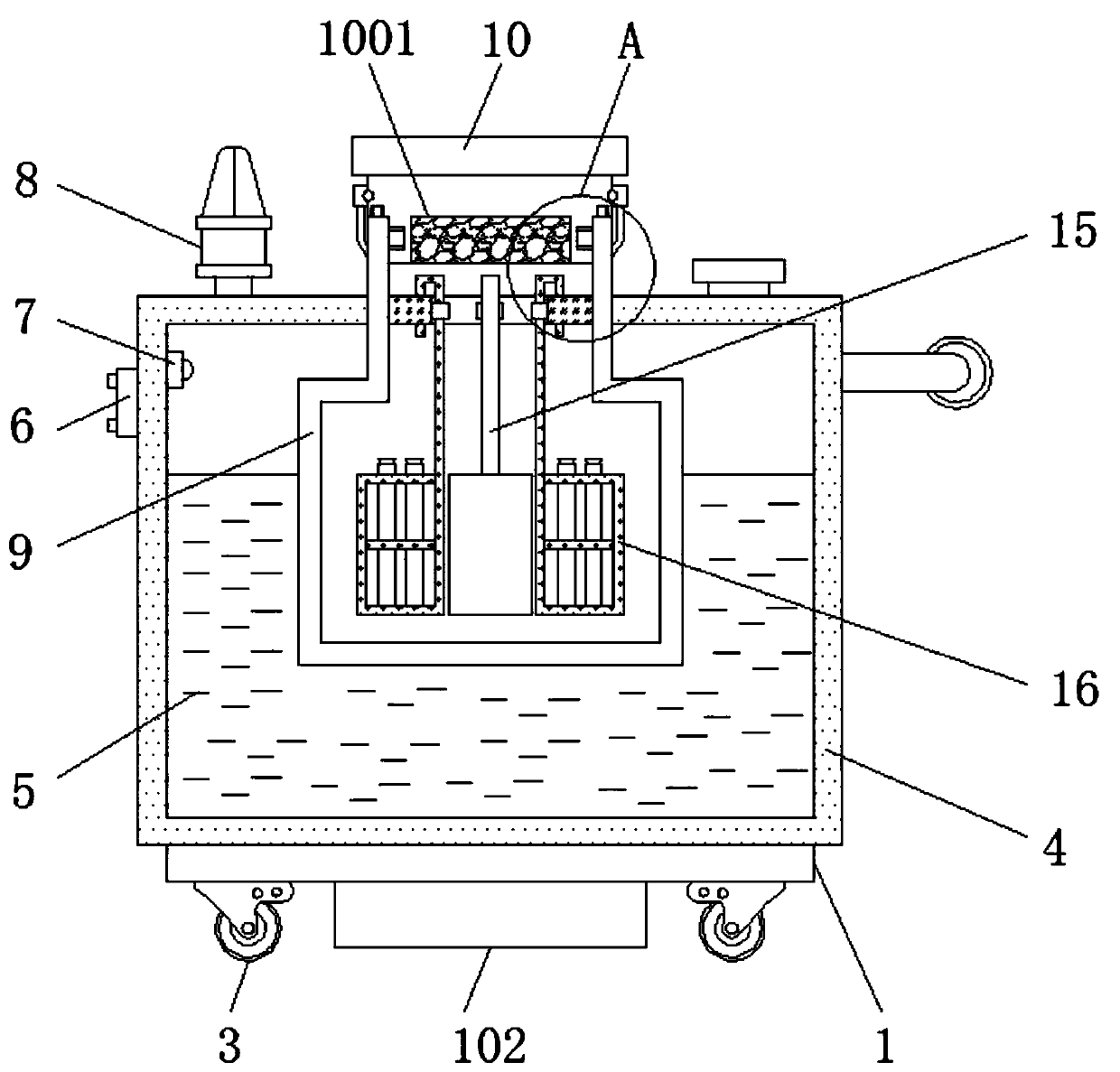

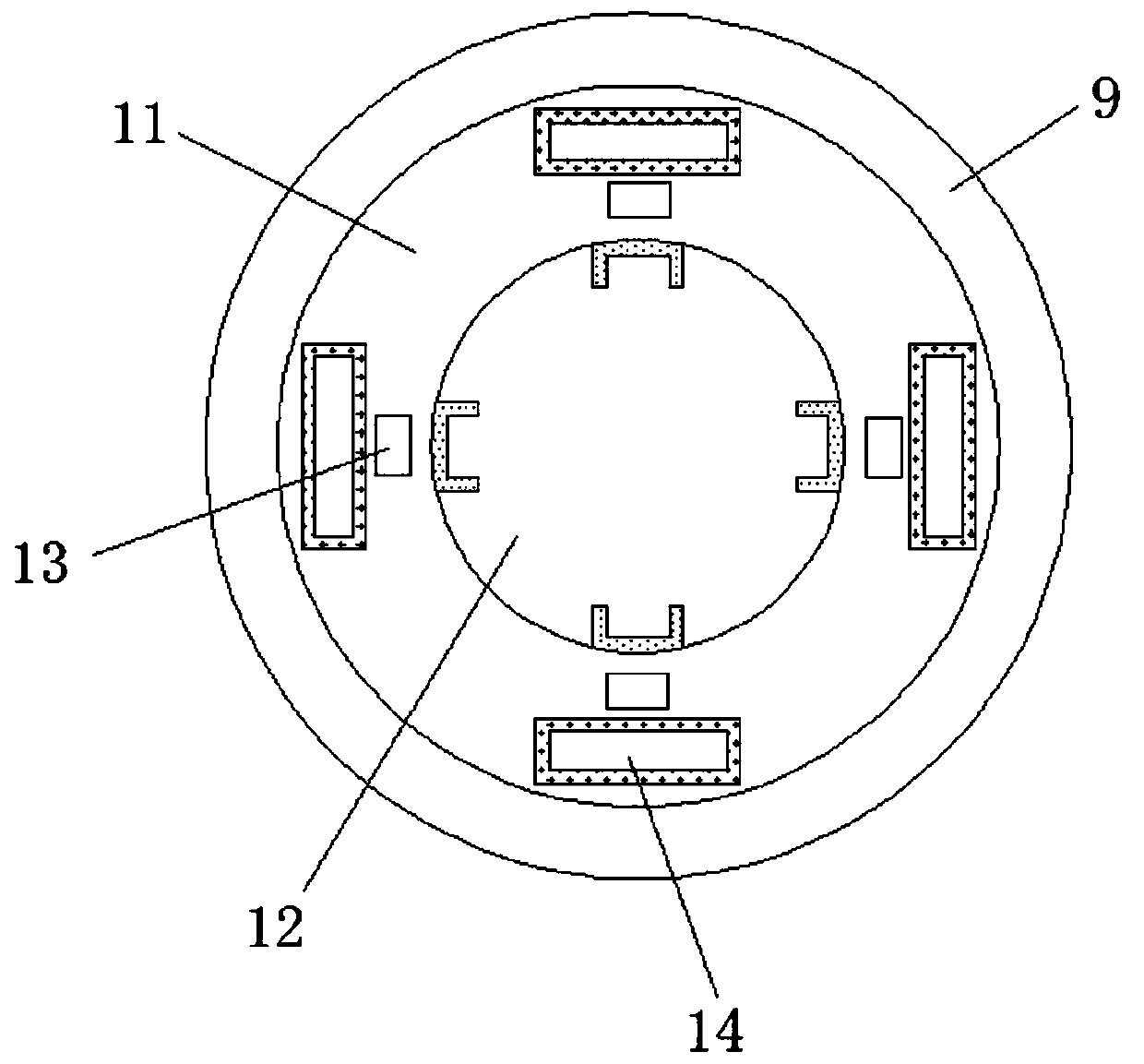

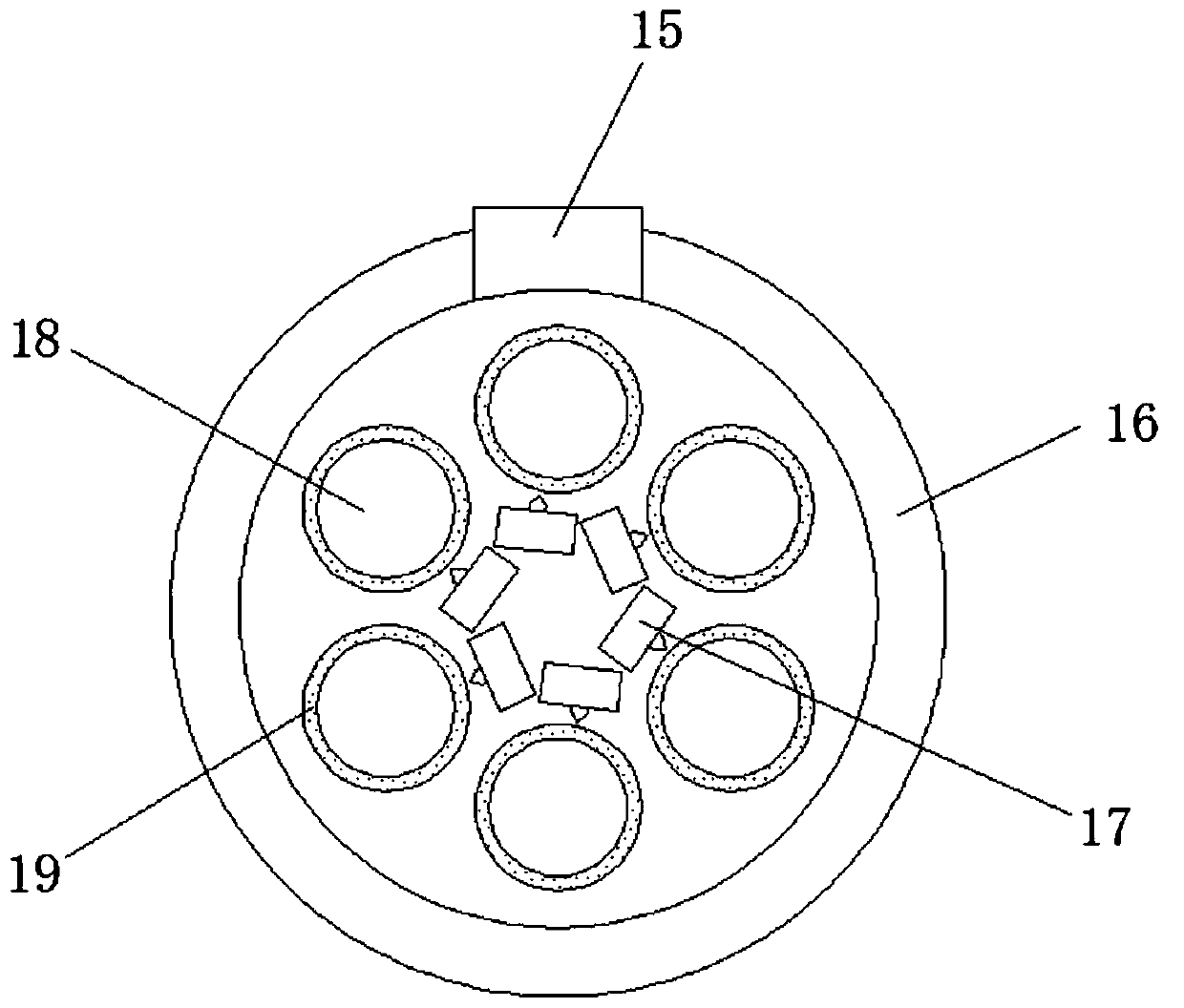

Refrigeration storage device for preserving stem cells

InactiveCN111543425AEasy to freezeEasy to subdivideDead animal preservationThermal insulationEngineering

The invention discloses a refrigeration and cryopreservation device for preserving stem cells. The hanger comprises a supporting seat and a hook rod, a placement box is arranged in the supporting seat; moving wheels are arranged at the lower end of the supporting base, a device body is arranged at the upper end of the supporting base, and an inner shell and liquid nitrogen are arranged in the device body; the liquid nitrogen is arranged between the inner shell and the device body, a controller is arranged on the outer side of the device body, a temperature sensor is arranged on the inner sidewall of the device body, and an early warning signal lamp is arranged at the upper end of the device body. In the refrigeration and cryopreservation device, hanging notches and classification labels are distributed on the supporting plate frame in an annular array mode, wherein hanging notches can be used for hanging and fixing the storage rack; therefore, according to information of stem cell cryopreservation samples stored in different storage racks, information remarks can be made on corresponding classification labels, so that different types of stem cell cryopreservation samples are easily distinguished; in addition, a second thermal insulation layer and a third thermal insulation layer are arranged, and under the action of the second thermal insulation layer and the third thermal insulation layer, cold consumption of liquid nitrogen is reduced.

Owner:杨慧慧

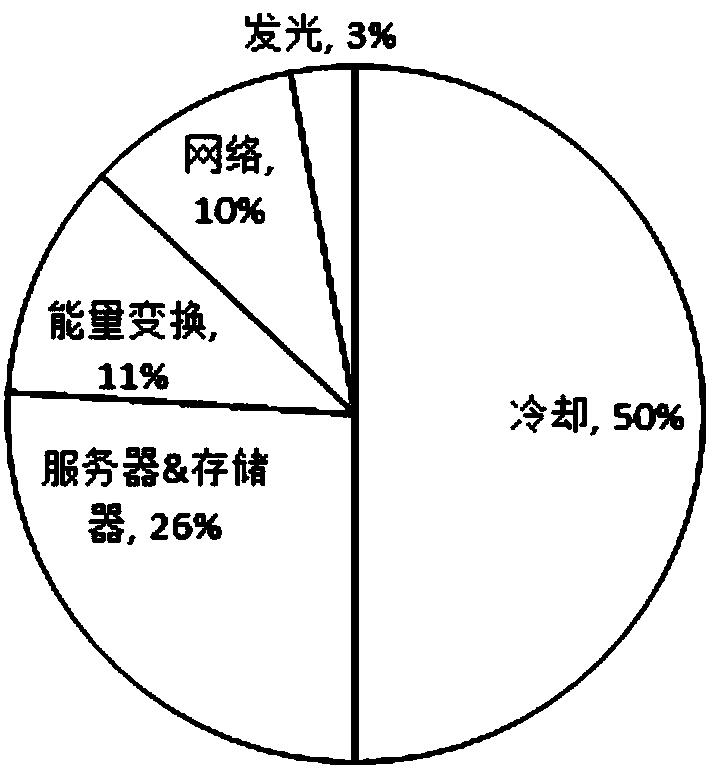

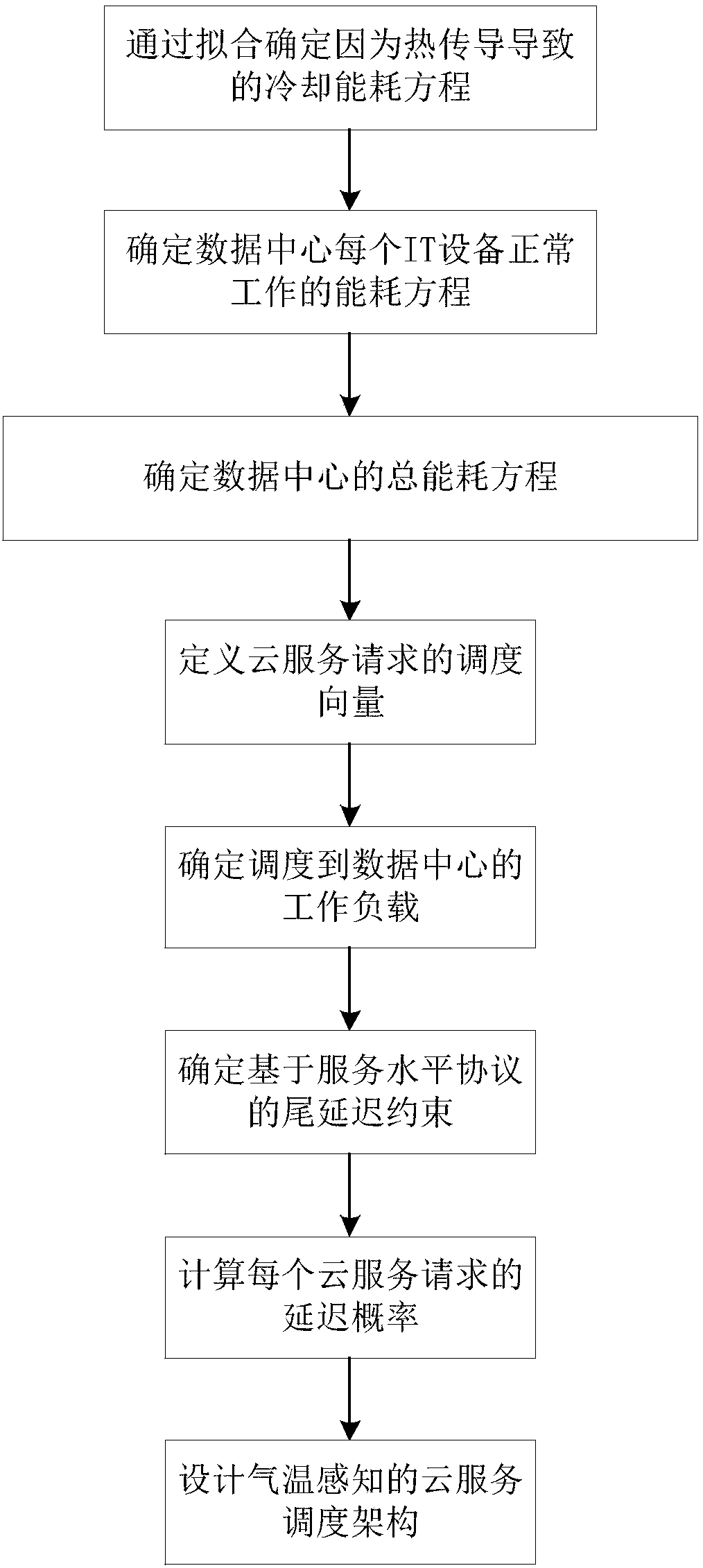

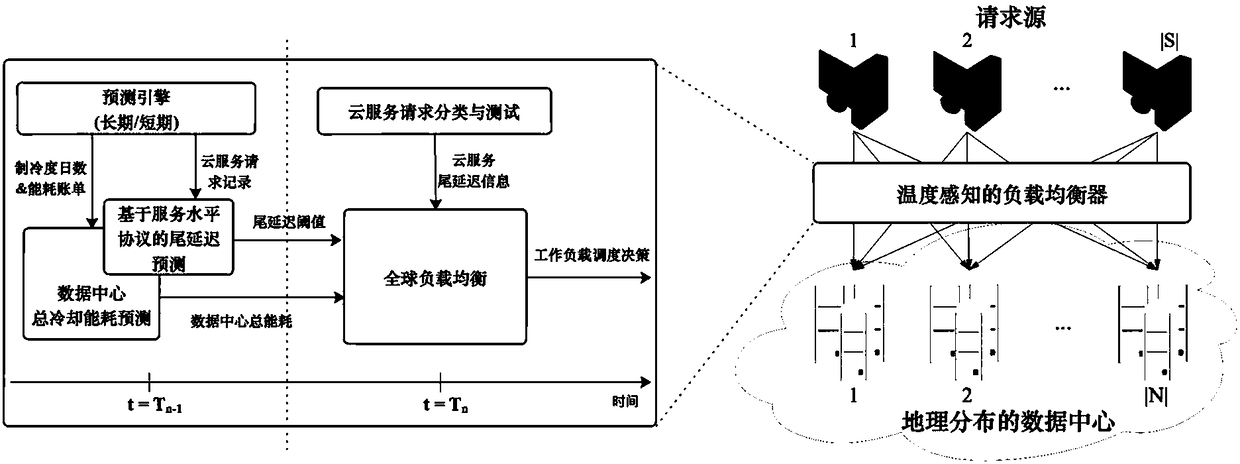

Cross-data center energy-saving load balancing method based on regional temperature differentiation

InactiveCN108334406AReduce cooling consumptionSatisfy the tail delay constraintResource allocationEnergy efficient computingData centerCooling energy

The invention provides a cross-data center energy-saving load balancing method based on regional temperature differentiation. The method comprises the steps that a cooling energy consumption equationcaused by heat conduction is determined by fitting; an energy consumption equation of each IT device operating normally in a data center is determined; a total energy consumption equation of the datacenter is determined; a scheduling vector of a cloud service request is defined; a workload dispatched to the data center is determined; a tail delay constraint based on a service level protocol is determined; a delay probability of each cloud service request is calculated; and a temperature-aware cloud service scheduling architecture is constructed. The cross-data center energy-saving load balancing method based on the regional temperature differentiation has the advantages that the total cooling consumption of the data center is reduced under the condition of ensuring that the cloud servicesatisfies the tail delay requirement of the service level protocol, and the cloud service can still satisfy the tail delay constraint based on the service level protocol at the same time.

Owner:SHANGHAI JIAO TONG UNIV

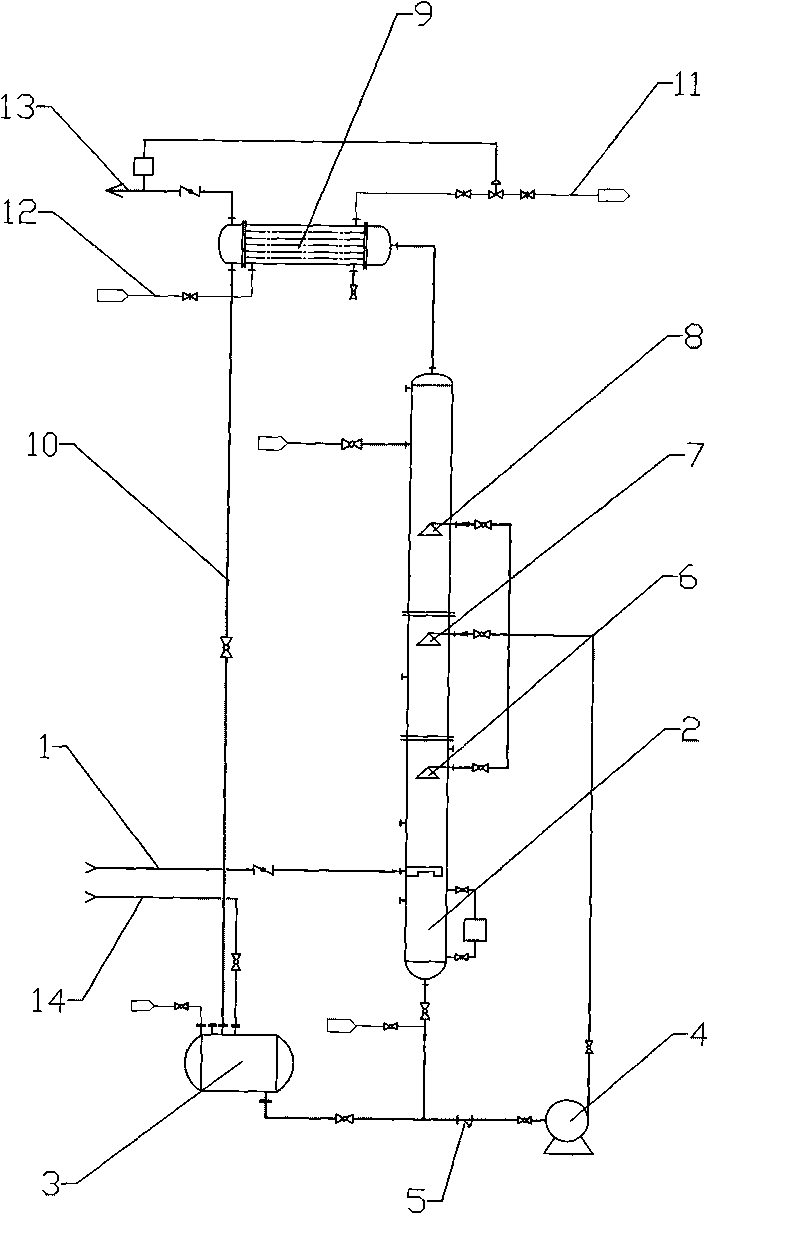

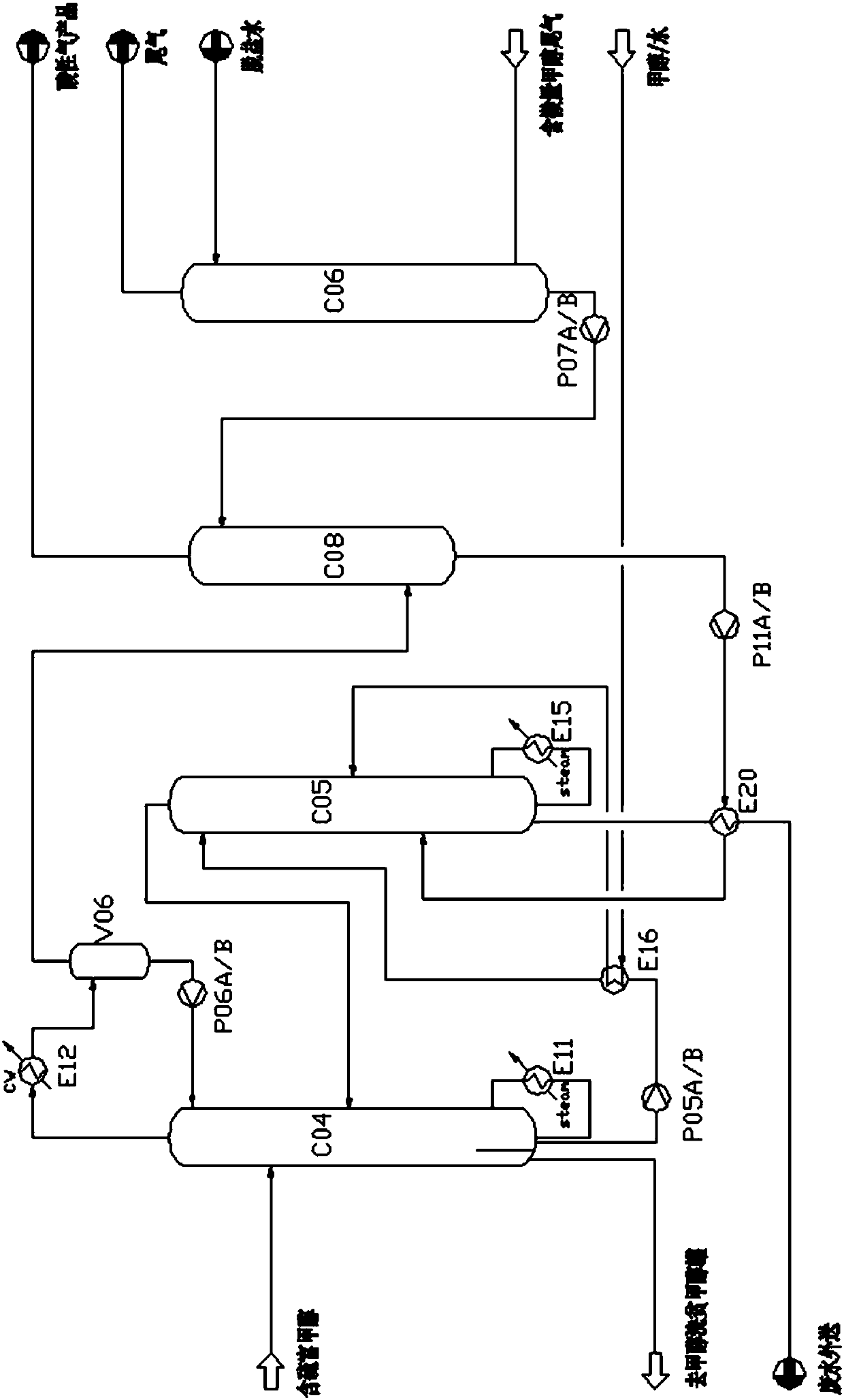

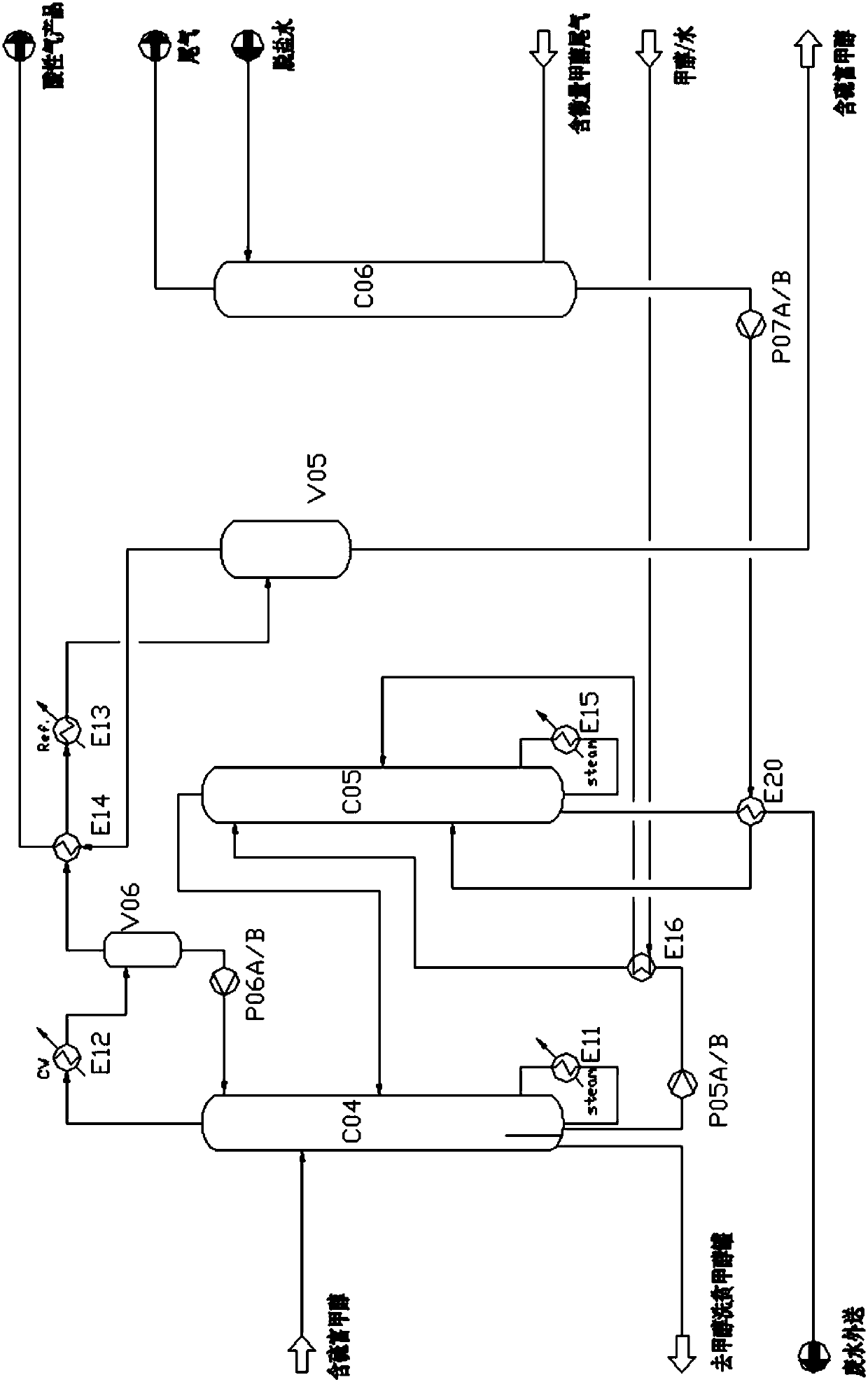

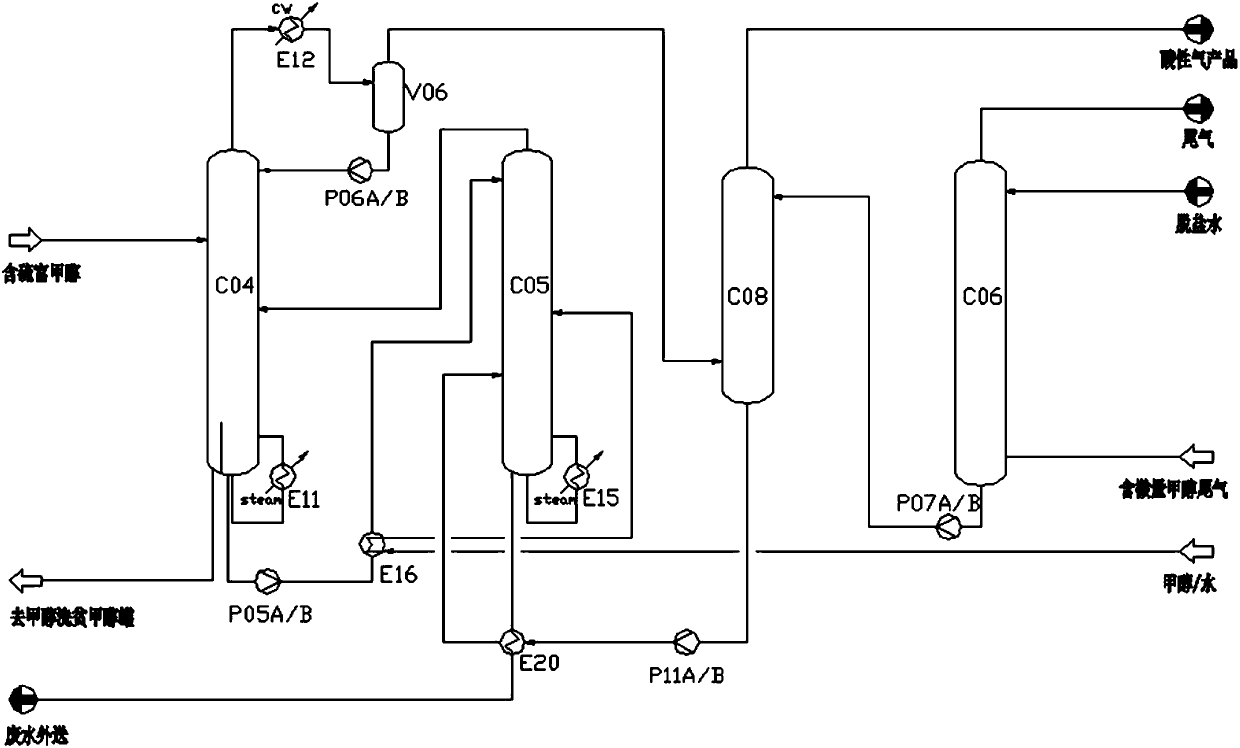

Method of recovering methanol from acidic gas in Rectisol unit

InactiveCN109701363AHigh recovery rateReduce cooling consumptionDispersed particle separationHydroxy compound separation/purificationPhysical chemistryRectisol

The application discloses a method of recovering methanol from acidic gas in a Rectisol unit. The recovery process aims to the methanol in the acidic gas in the Rectisol unit, wherein wastewater fromthe bottom of a tail gas washing column is employed to wash the acidic gas, thus selectively absorbing methanol under low pressure at normal temperature to recover the methanol. The method not only increases recovery rate of methanol and reduces cost, but also reduces consumption of cooling capacity of the unit and avoids accumulation of impurities, such as hydrocarbons, organo-sulfur and the like.

Owner:DALIAN JIACHUN GAS PURIFICATION TECH DEV

Method for preparing hexamethyldisiloxane by using organic silicon by-product

InactiveCN105061483AReduce heatReduce cooling consumptionSilicon organic compoundsHydrolysisHydrogen chloride

The invention provides a method for preparing hexamethyldisiloxane by using an organic silicon by-product. According to the method, the organic silicon by-product chlorotrimethylsilane and recycled washing diluted hydrochloric acid are subjected to hydrolysis under a certain condition, hydrogen chloride gas generated by hydrolysis is removed through reverse blowing of compressed air, after reaction is compelled, the product is left to stand for layering, and an upper solution is washed with water for multiple times for deacidification and then rectified at normal pressure, so that the hexamethyldisiloxane finished product is obtained. Practice proves hexamethyldisiloxane prepared through the method provided by the invention is stable in quality, simple in process and easy to produce industrially and the comprehensive utilization value of the organic silicon by-product chlorotrimethylsilane is increased greatly.

Owner:HUBEI XINGRUI SILICON MATERIAL CO LTD

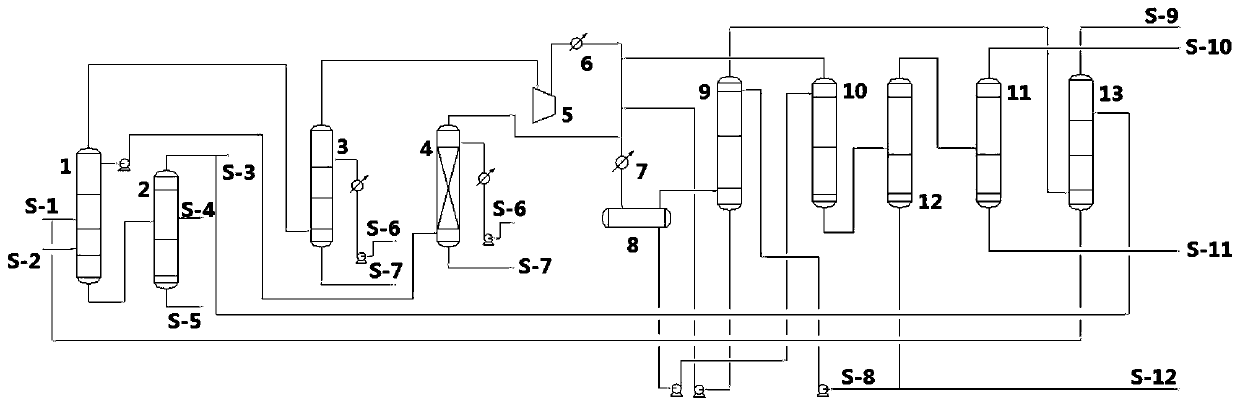

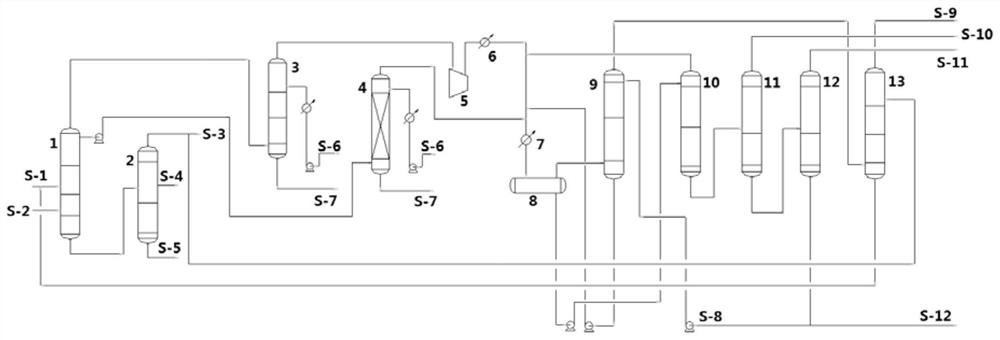

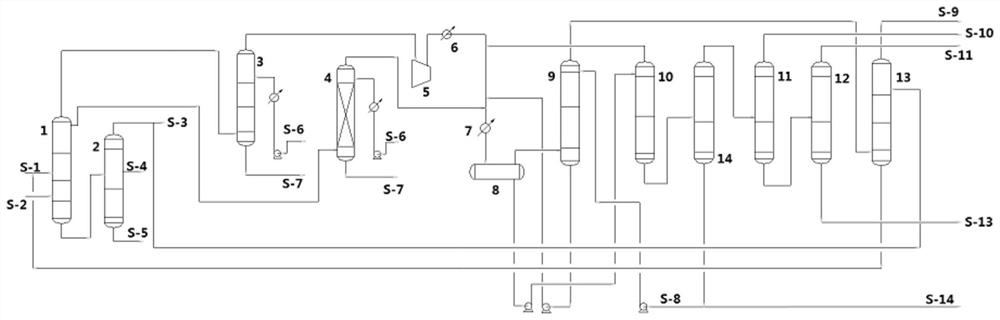

Light hydrocarbon recovery method and device

ActiveCN111394120ANo secondary separation requiredAchieve separationHydrocarbon distillation control/regulationLiquid hydrocarbon mixture recoveryChemistryProcess engineering

The invention belongs to the field of oil refining and chemical engineering, and particularly discloses a light hydrocarbon recovery method and device. The method is simple in process, mild in operation conditions and low in cold energy consumption. Separation and recovery of light hydrocarbon in the hydrocracking process can be realized by utilizing less equipment, and especially, efficient separation and recovery of ethane, propane and C4 component can be achieved, wherein the ethane recovery rate reaches 97 wt% or above, the propane recovery rate reaches 98 wt% or above, the content of methane in recovered ethane is not larger than 1 vol%, and the content of ethane in recovered propane is not larger than 300 ppmv.

Owner:SINOPEC ENG +1

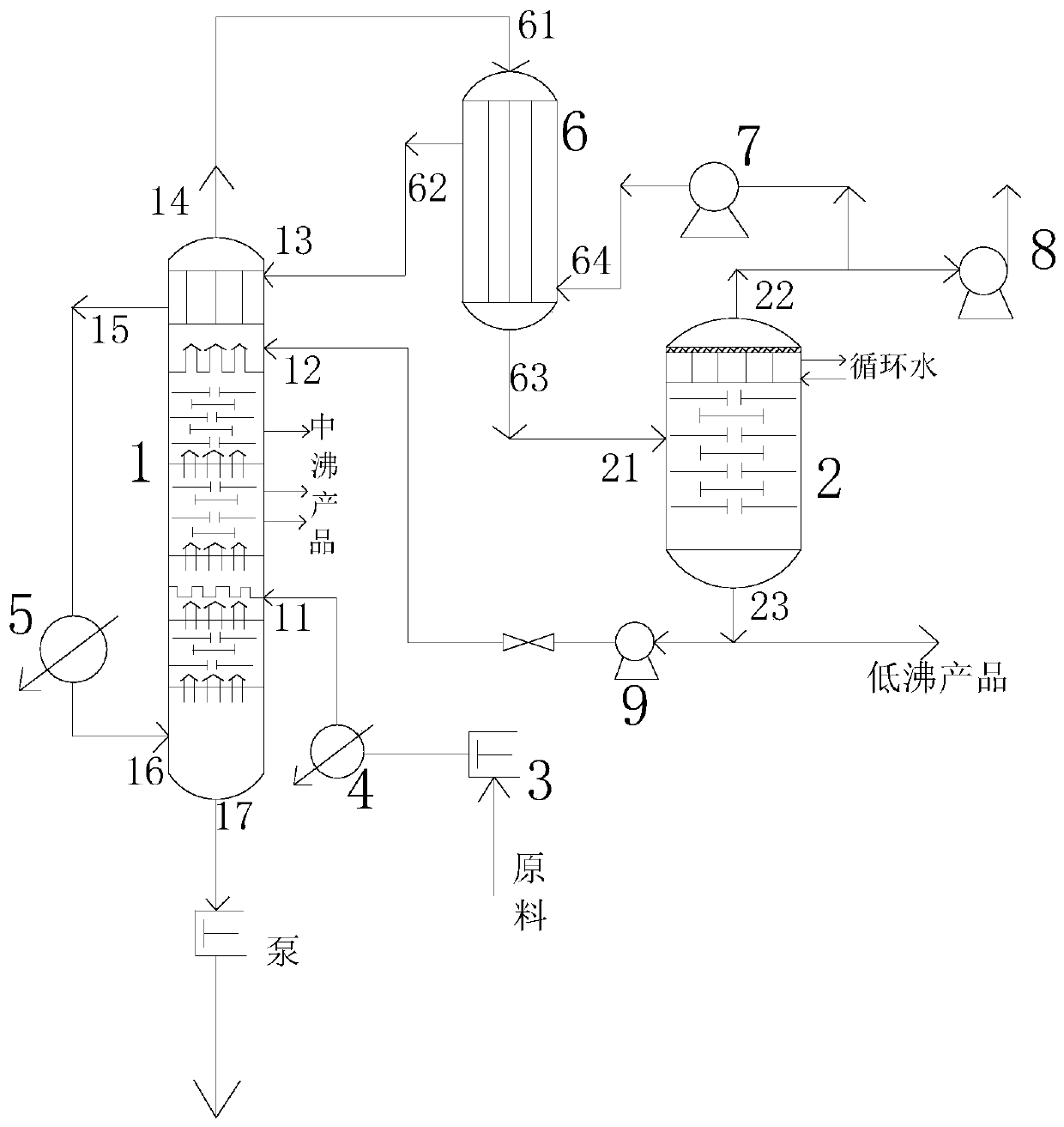

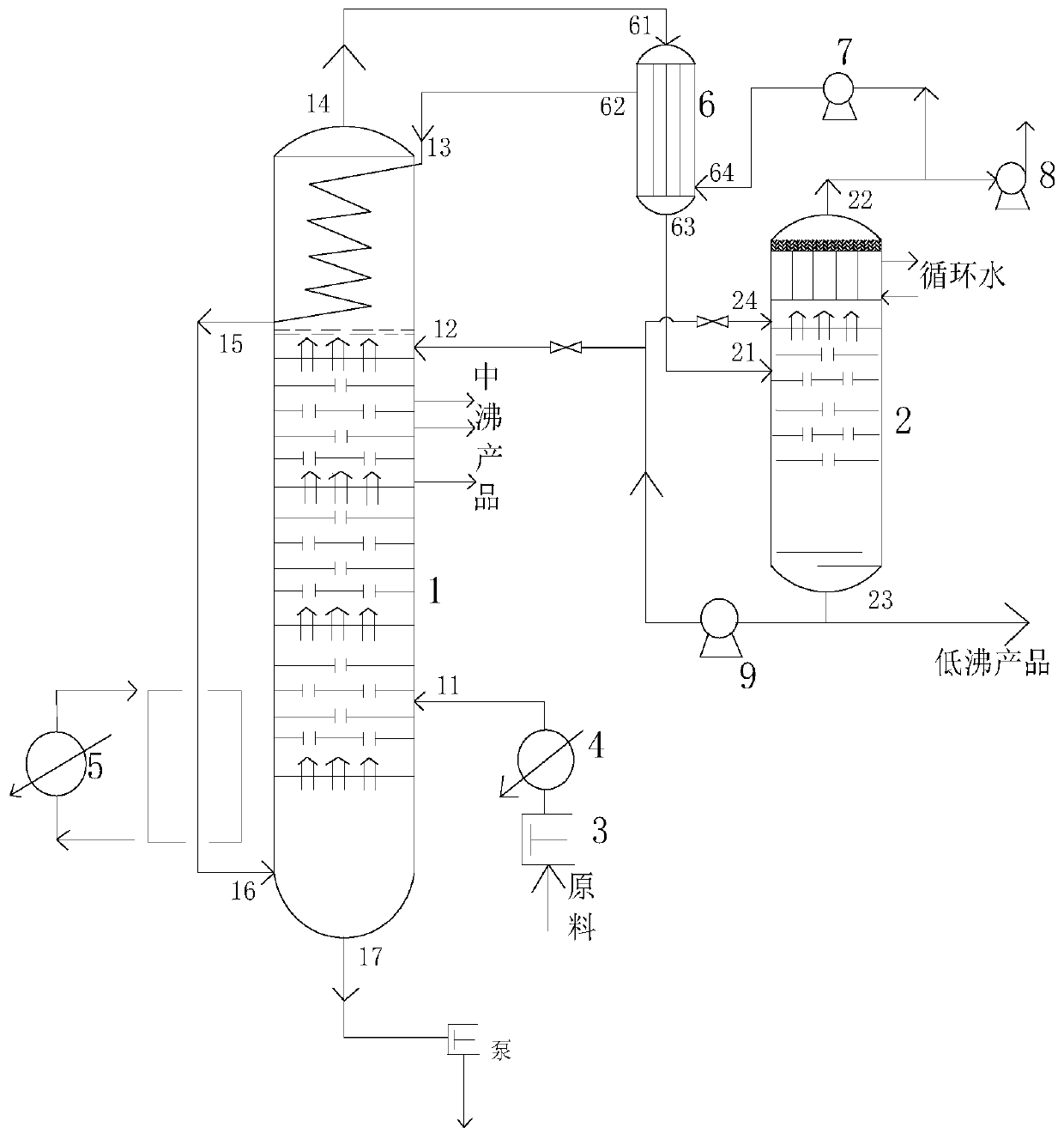

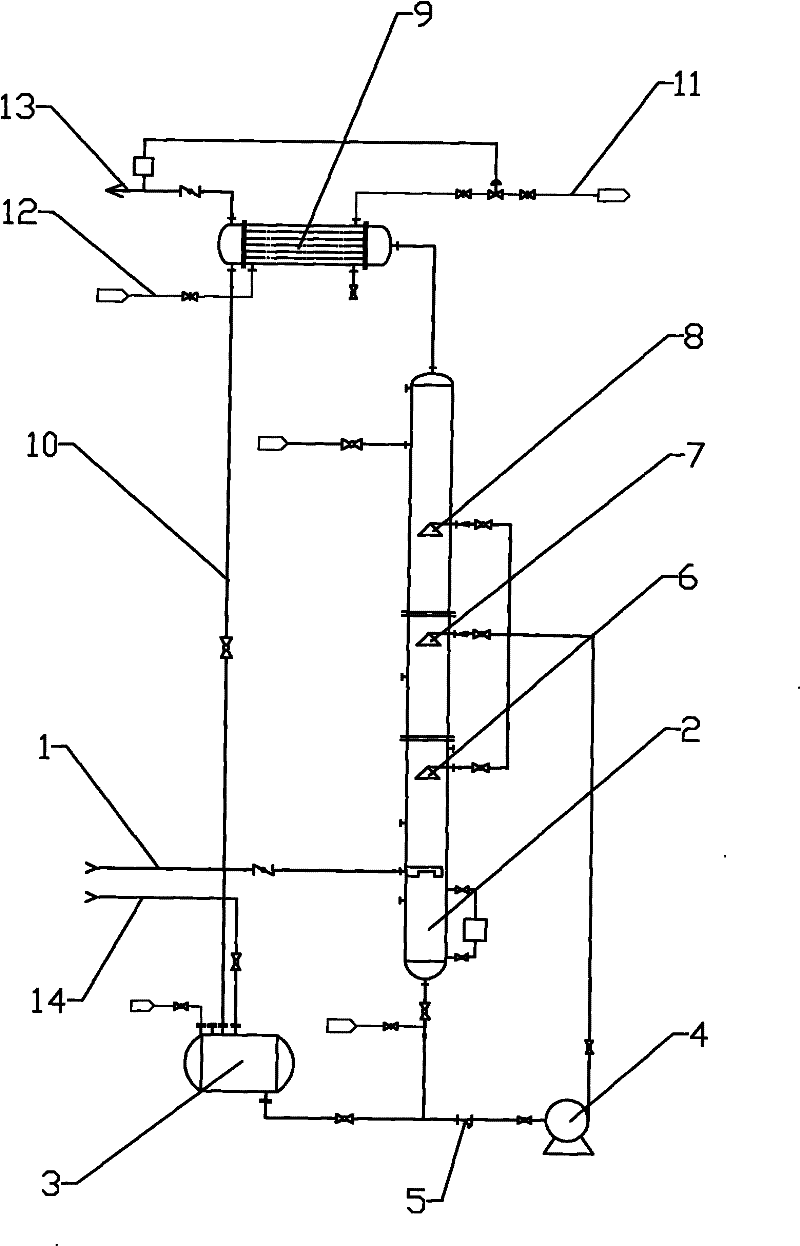

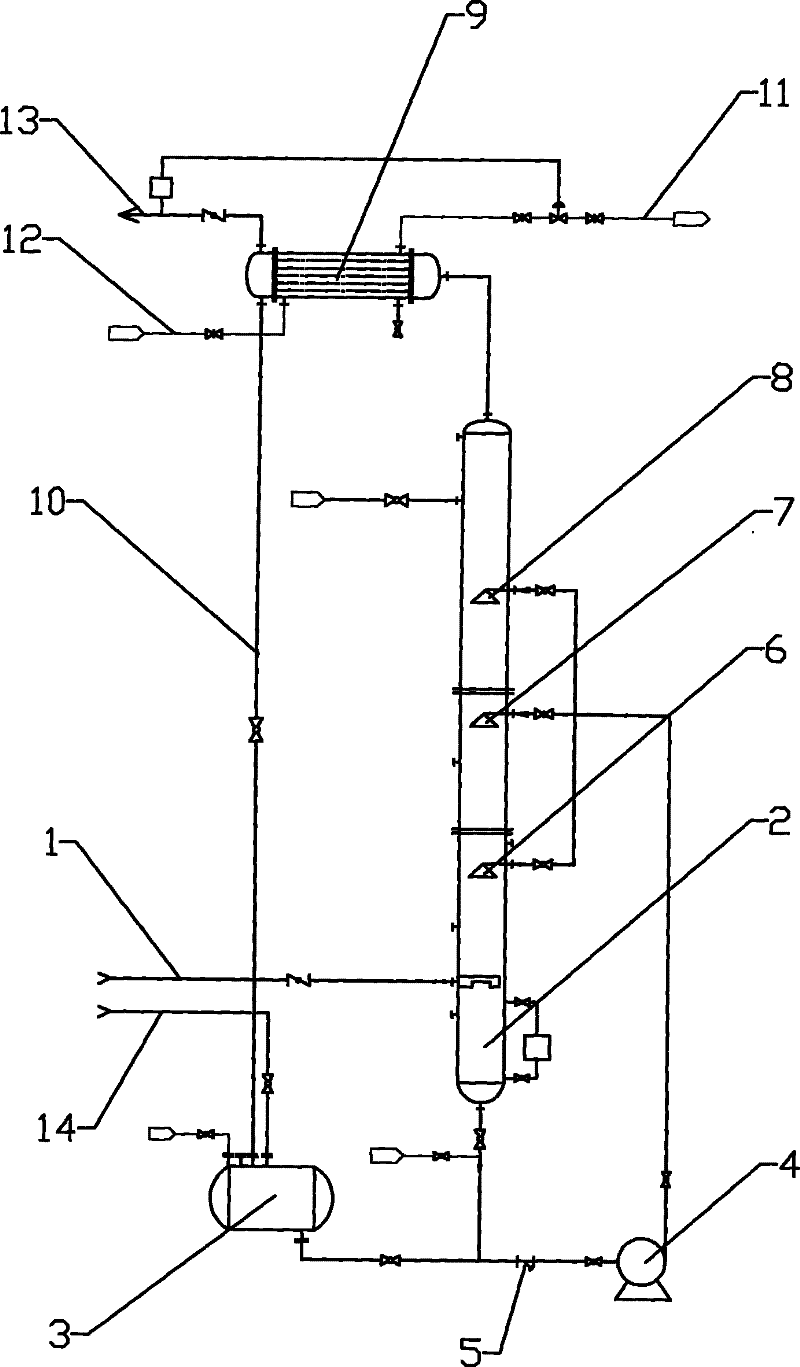

Energy-saving carrier gas stripping system and stripping process

PendingCN111450561AAchieve enrichment separationReduce heatEnergy recuperation in distillationVacuum distillation separationGas heaterEngineering

The invention belongs to the technical field of stripping separation, and relates to an energy-saving carrier gas stripping system and stripping process. The energy-saving carrier gas stripping systemcomprises a gas stripping tower, a separation tank, a raw material heater, a carrier gas heater and a gas circulation heat exchanger, wherein a heat exchange and mass transfer section is arranged atthe inner top of the gas stripping tower, and the gas stripping tower, the gas circulation heat exchanger and the heat exchange and mass transfer section sequentially communicate with each other through pipelines; the gas circulation heat exchanger, the separation tank and the gas stripping tower sequentially communicate with each other through pipelines; the raw material heater communicates withthe gas stripping tower; the heat exchange and mass transfer section, the carrier gas heater and the gas stripping tower are sequentially communicate with each other through pipelines; and the heat exchange and mass transfer section comprises a heat exchange tube and a filler, and the heat exchange tube is a tubular heat exchange tube or a coiled tube type heat exchange tube. According to the invention, separation temperature is low, different carrier gas heating modes are adopted for heat exchange and mass transfer, enrichment and separation of one or more substances are achieved through stripping and rectification, separation effect is good, heat of the system is recycled, heat consumption and cold consumption of separation are reduced, and energy consumption is saved by 30%-50%.

Owner:陕西聚能新创煤化科技有限公司

Method and device for decreasing temperature of central air conditioner through clear water

InactiveCN105423468AUniform water pressureTake advantage ofMechanical apparatusSpace heating and ventilation safety systemsSpray nozzleEngineering

The invention discloses a method for decreasing the temperature of a central air conditioner through clear water. The clear water at the temperature of 20+ / -2 DEG C is conveyed into spraying pipes vertically distributed in a central air conditioner chamber through a chilled water pipeline, the clear water in the spraying pipes is sprayed to air in the central air conditioner chamber through nozzles arranged on the spraying pipes to achieve heat-humidity exchange, and the clear water subjected to heat-humidity exchange falls into a spraying pool below the central air conditioner chamber; the clear water falling into the spraying pool enters a refrigeration station through an overflowing pipe, and then a water pump is used for pumping the clear water entering the refrigeration station into a main water producing pipe network. By means of the method, the energy consumption of the central air conditioner in summer is effectively lowered, resources are fully utilized, the objectives of saving energy and reducing emission are achieved, and the purpose of clean and environment-friendly production is achieved.

Owner:YIBIN HIEST FIBER

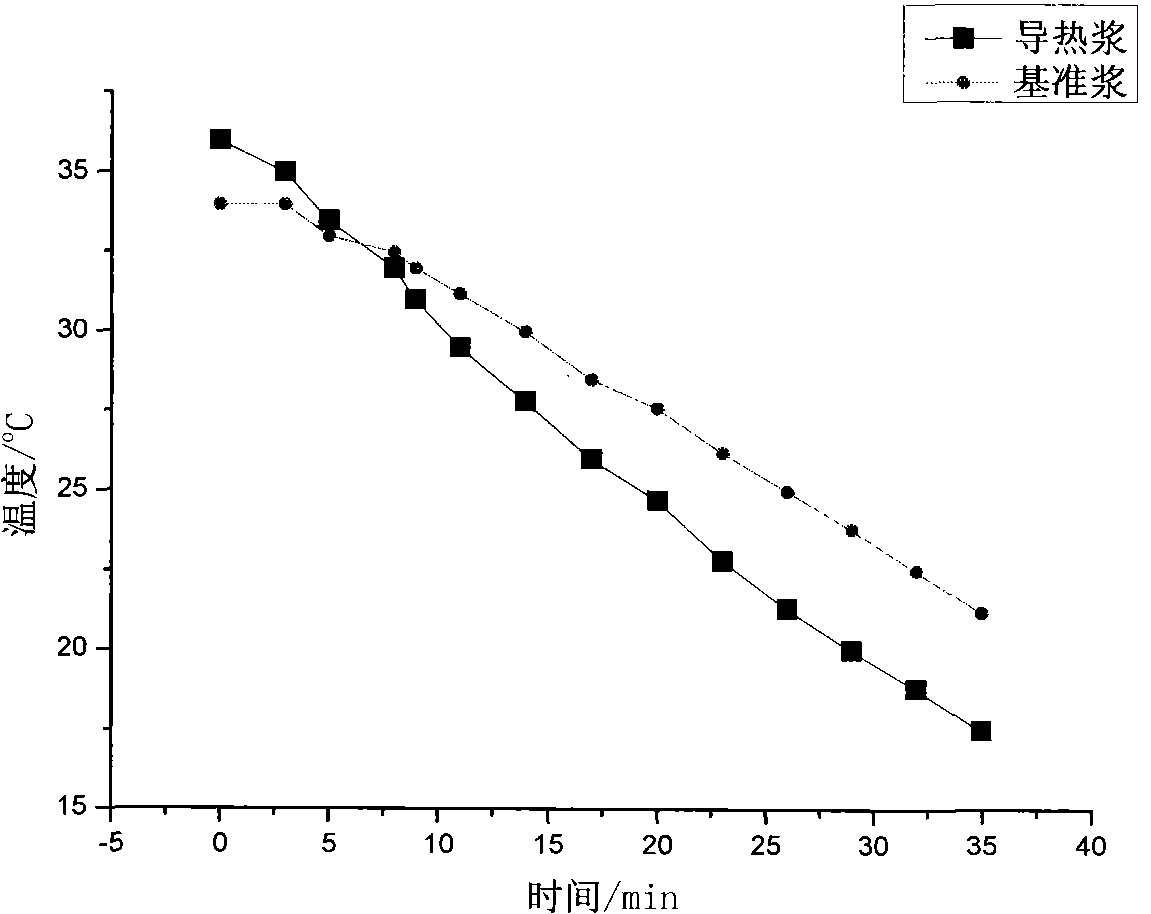

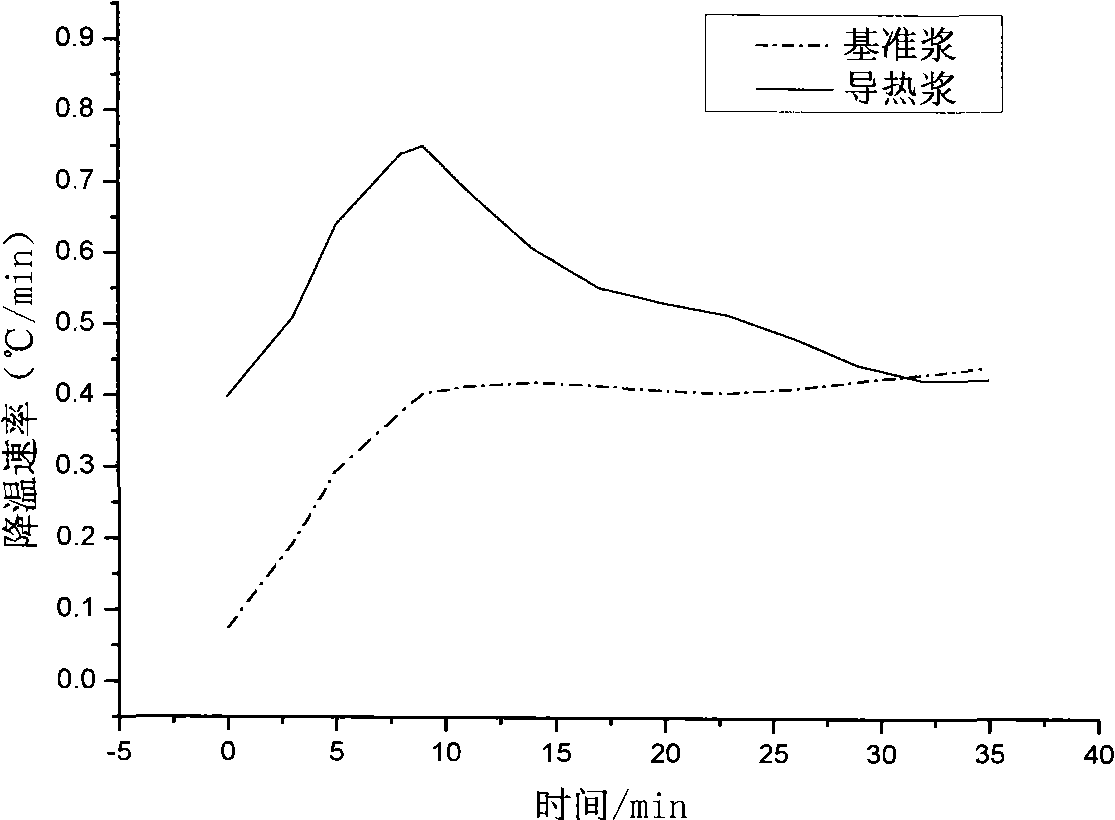

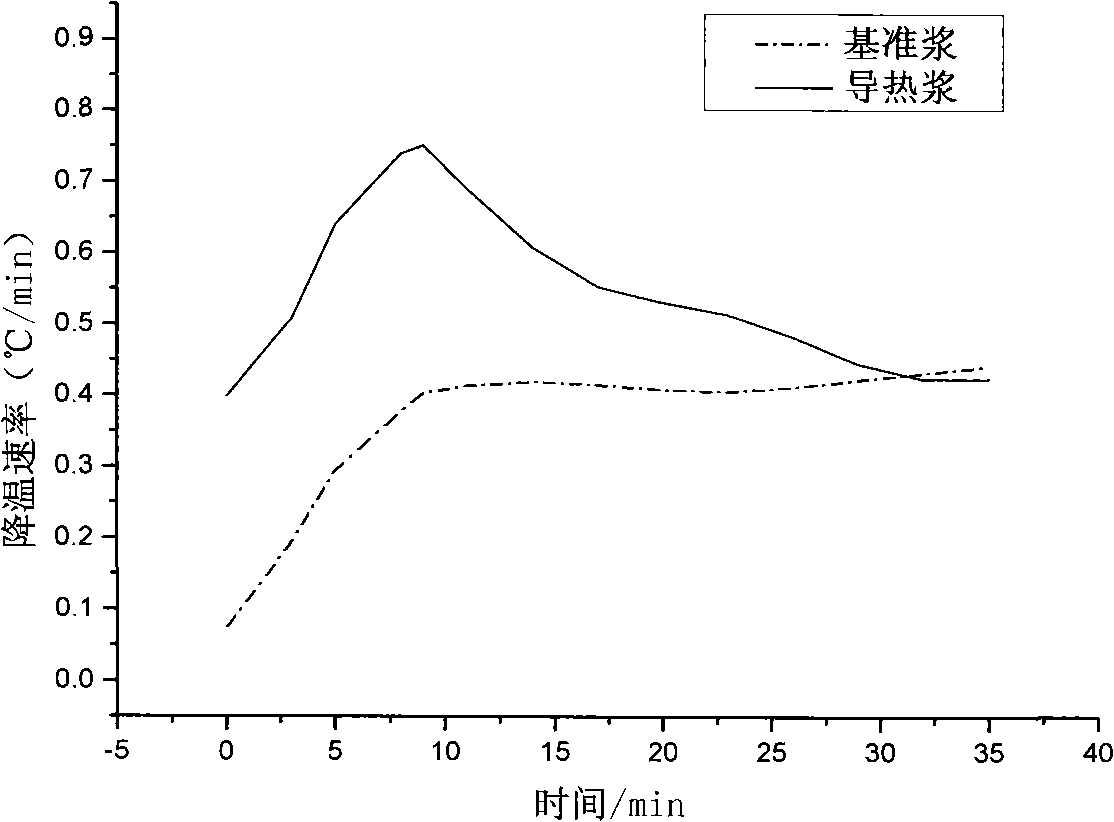

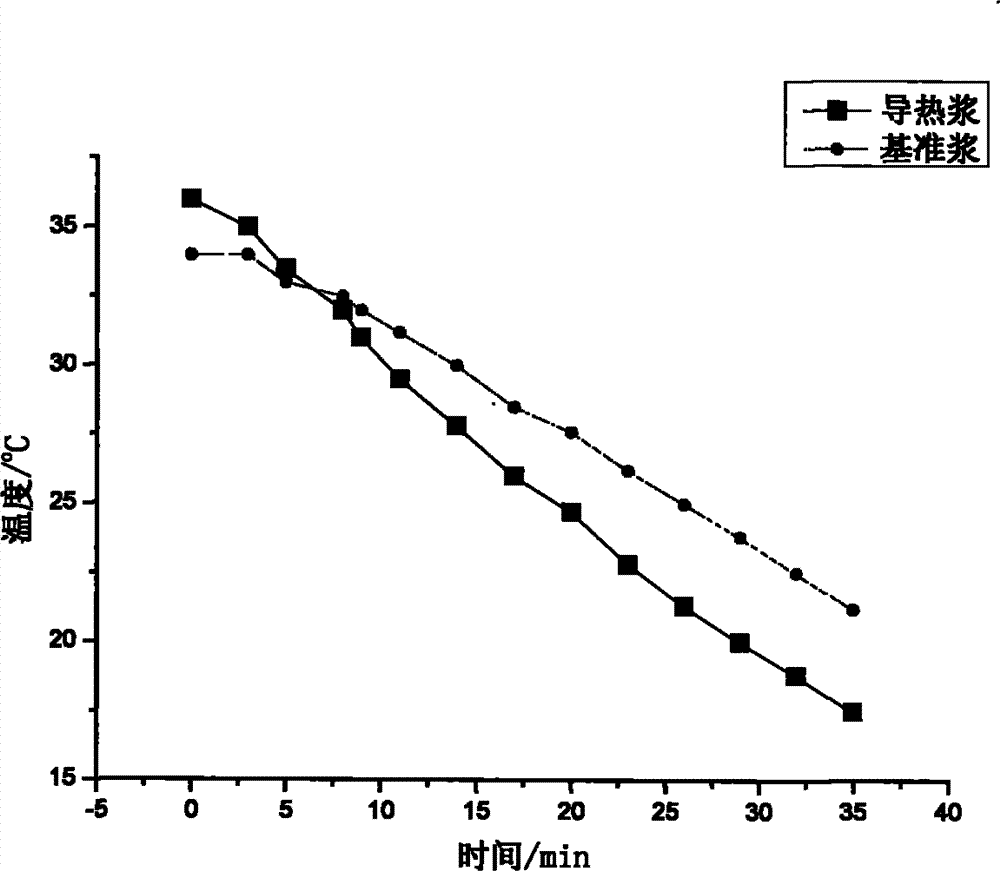

Thermal conducting water-stop slurry material and preparation and application thereof

ActiveCN101792658AGood thermal conductivityReduce cooling consumptionUnderground chambersHeat-exchange elementsFilling materialsMetallurgy

The invention discloses a thermal conducting water-stop slurry material and preparation and application thereof. The thermal conducting water-stop slurry comprises the following raw materials in percentage by weight: 0.5-20% of system stabilizing agents, 5-40% of heat conducting agents, 5-50% of filling materials, 0.5-5% of fluidizing agents and 35-65% of water. The thermal conducting water-stop slurry has good thermal conduction performance, excellent water-stop performance and high stability, can be free of segregation and weeping in a long time and can be used as the thermal conducting working medium in the construction methods of freezing the casing box through shield break in and break out and stopping water.

Owner:SHANGHAI CONSTRUCTION GROUP

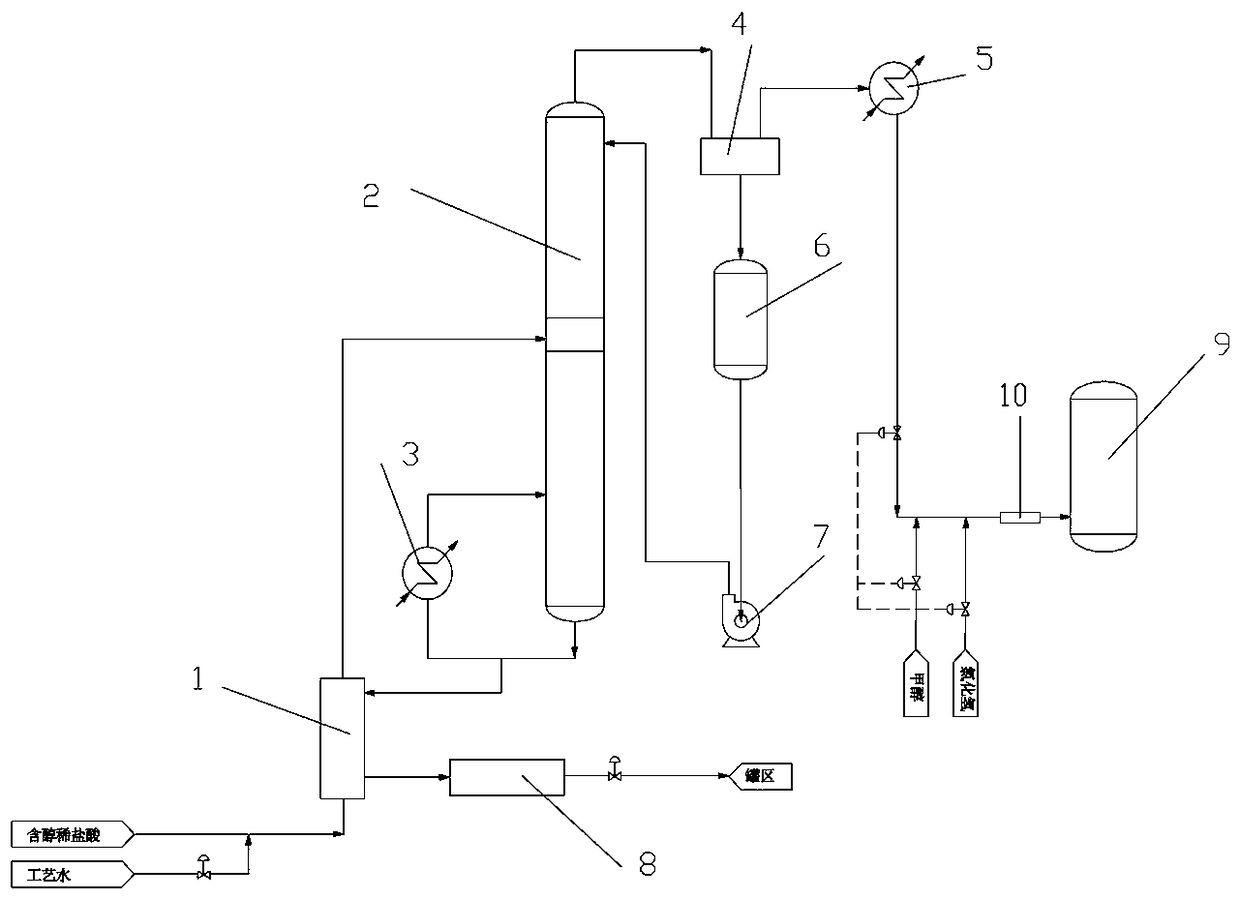

Process and device for recycling methanol in production of methyl chloride

InactiveCN108440244AReduce heating loadReduce pollutionOrganic compound preparationChemical industryRefluxGas phase

The invention relates to a process for recycling methanol in production of methyl chloride. The process comprises the following steps: adjusting the concentration of diluted hydrochloric acid containing methanol with process water, and introducing the obtained diluted hydrochloric acid containing methanol into a methanol recovery tower; subjecting hydrochloric acid in the recovery tower to heat-exchanging, and carrying out pumping into a storage tank; cooling a tower-top gas phase material through a partial condenser, and allowing a condensate to return to a reflux tank for refluxing; and subjecting methanol non-condensable gas to overheating through a superheater, then mixing the overheated methanol non-condensable gas with mass flow of hydrogen chloride-methanol gas through a pipeline mixer, and allowing an obtained mixture to enter a methyl chloride synthesis kettle so as to synthesize the methyl chloride. The process provided by the invention has simple flow and low equipment investment, aims to save energy and reduce consumption, and reduces environmental pollution. According to the invention, through cyclic utilization of methanol, the production cost of the methyl chloride is reduced, and good economic benefits and environmental protection benefits are achieved.

Owner:HUBEI XINGFA CHEM GRP CO LTD

A kind of method utilizing organosilicon by-product to prepare methyl hydrogen silicone oil

The invention relates to a method for preparing methyl hydrogen silicone oil from an organic silicon by-product. The method comprises the steps of carrying out cohydrolysis reaction under certain conditions by virtue of the organic silicon by-product, namely dichloromethylsilane, an end-capping agent, namely chlorotrimethylsilane and recycled washing dilute acid, carrying out back flushing by virtue of compressed air so as to remove hydrogen chloride produced during hydrolysis, standing for layering after the reaction is finished, carrying out washing deacidification on an upper solution for multiple times, and carrying out neutralization, filtration and devolatiligation procedures on products, so as to obtain finished methyl hydrogen silicone oil. Practices prove that methyl hydrogen silicone oil prepared by virtue of the method has controllable viscosity and stable quality and is easy to industrialize, and the comprehensive utilization value of the organic silicon by-product, namely dichloromethylsilane is greatly increased.

Owner:HUBEI XINGRUI SILICON MATERIAL CO LTD

Thermal conducting water-stop slurry material and preparation and application thereof

ActiveCN101792658BImprove thermal conductivityEfficient deliveryUnderground chambersHeat-exchange elementsHeat conductingMetallurgy

The invention discloses a thermal conducting water-stop slurry material and preparation and application thereof. The thermal conducting water-stop slurry comprises the following raw materials in percentage by weight: 0.5-20% of system stabilizing agents, 5-40% of heat conducting agents, 5-50% of filling materials, 0.5-5% of fluidizing agents and 35-65% of water. The thermal conducting water-stop slurry has good thermal conduction performance, excellent water-stop performance and high stability, can be free of segregation and weeping in a long time and can be used as the thermal conducting working medium in the construction methods of freezing the casing box through shield break in and break out and stopping water.

Owner:SHANGHAI CONSTRUCTION GROUP

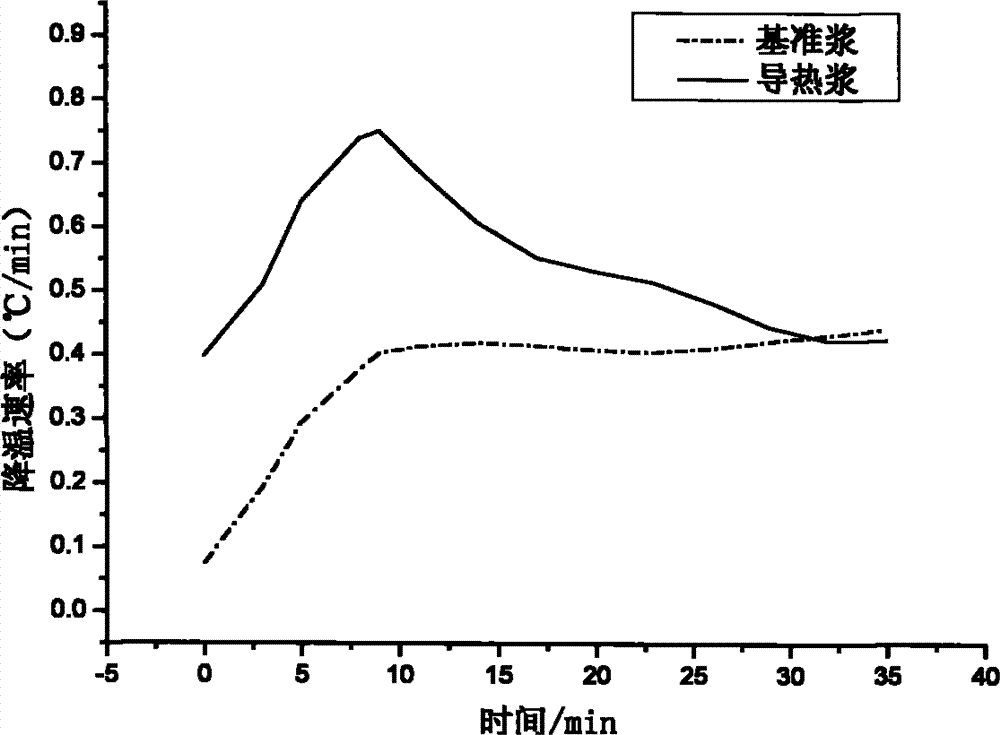

Coal gasification black water treatment system and treatment process

PendingCN111453906ARealize separate recyclingAchieve recyclingWater/sewage treatment by centrifugal separationSpecific water treatment objectivesBlackwaterWater treatment system

The invention belongs to the technical field of coal chemical industry and relates to a coal gasification black water treatment system and a treatment process. The treatment comprises a deoxygenated water heater, a vortex separator, a hydraulic deoxygenated water pump, a hydraulic turbine pump, a separation tank, a normal-pressure gas cooler and a vacuum gas cooler, wherein the deoxygenated waterheater is connected with the vortex separator; the top end of the vortex separator is connected with the separation tank through the hydraulic turbine pump; and the bottom end of the vortex separatoris connected with the separation tank and the separator; heat and kinetic energy in the black water are recycled separately, the heat is recycled into a carbon washing tower, and the kinetic energy serves as a part of power source of the hydraulic deoxygenated water pump; the low-temperature black water with heat recovered is further separated after being subjected to coarse separation; and the separated saturated steam can be recycled as process gas. According to the invention, heat, kinetic energy and steam in the black water can be recycled, so that the cold consumption and kinetic consumption of the black water of the system can be reduced, the operation and maintenance workload is low, the process flow is short, the equipment is less, and the investment is small.

Owner:陕西聚能新创煤化科技有限公司

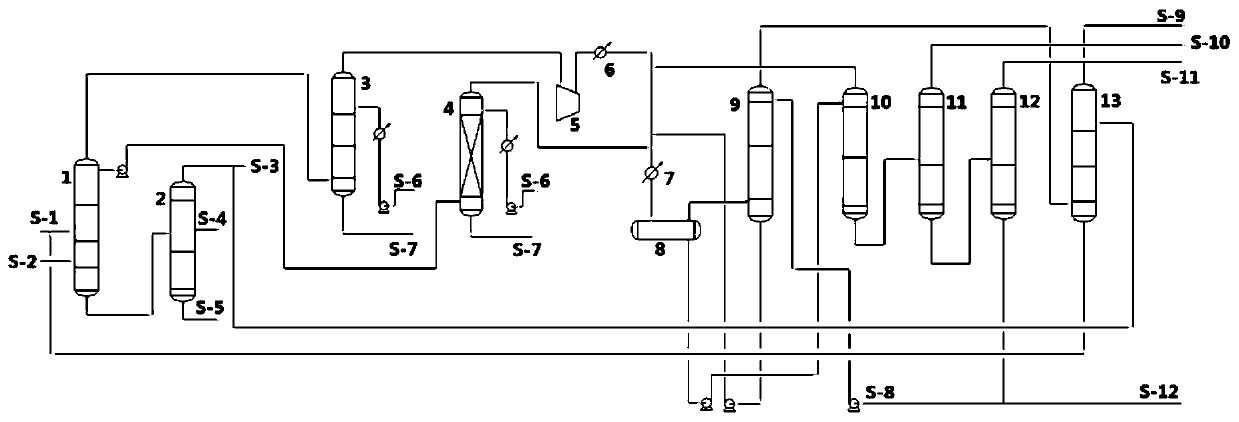

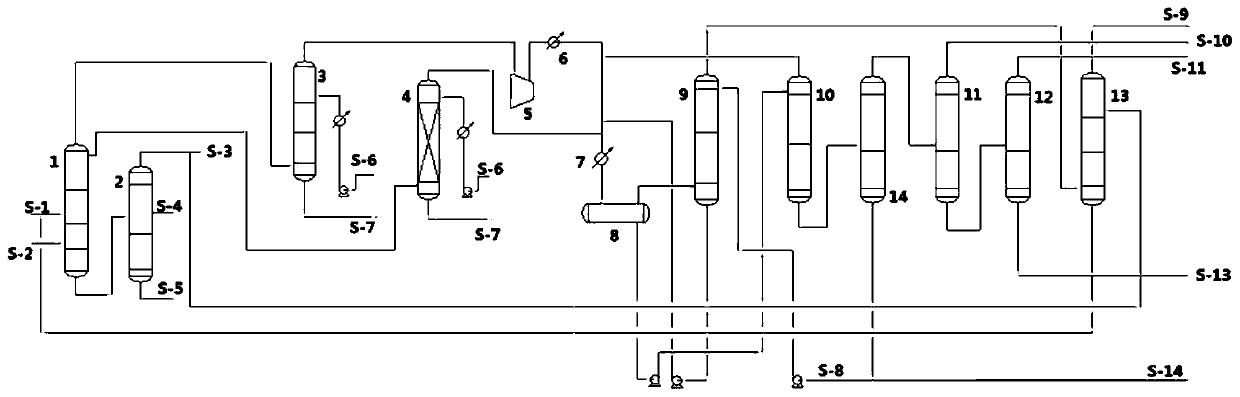

A light hydrocarbon recovery method and device

ActiveCN112521968BNo secondary separation requiredAchieve separationLiquid hydrocarbon mixture recoveryDistillation purification/separationChemical industryProcess engineering

The invention belongs to the field of oil refining and chemical industry, and specifically discloses a method and device for recovering light hydrocarbons. The process of the method is simple, the operating conditions are moderate, the cooling capacity consumption is small, and the light hydrocarbons in the hydrocracking process can be recovered by using less equipment. The separation and recovery of ethane, propane and carbon four components can be achieved in particular. The recovery rate of ethane is over 97wt%, the recovery rate of propane is over 98wt%, and the methane content in the recovered ethane Not more than 1vol%, and the ethane content in the recovered propane is not more than 300ppmv.

Owner:SINOPEC ENG +1

Method for drying hydrogen chloride gas

InactiveCN101759150BImprove conversion rateReduce manufacturing costChlorine/hydrogen-chloride purificationDispersed particle separationProduct gasSpray tower

Owner:SHANDONG XINLONG TECH

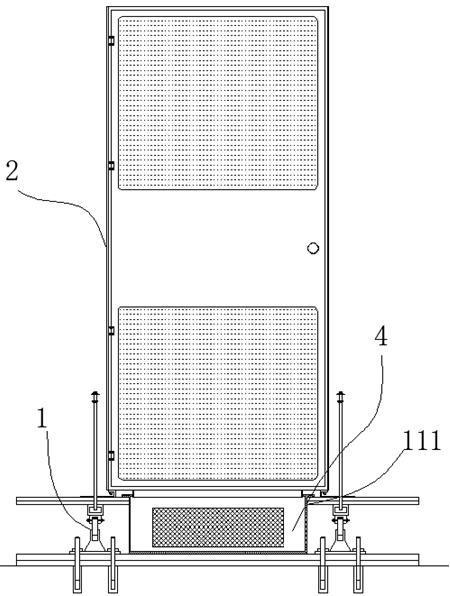

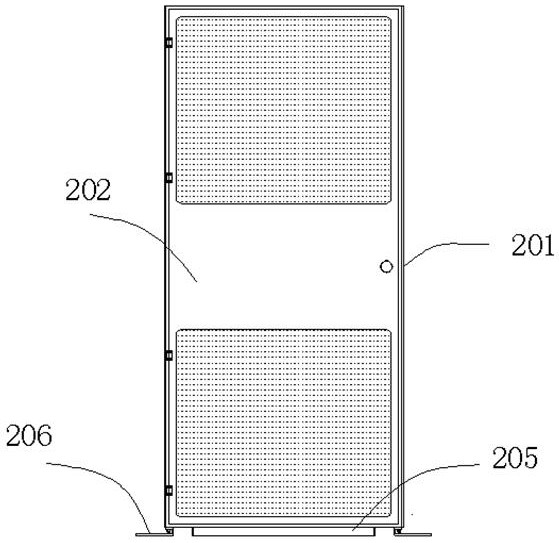

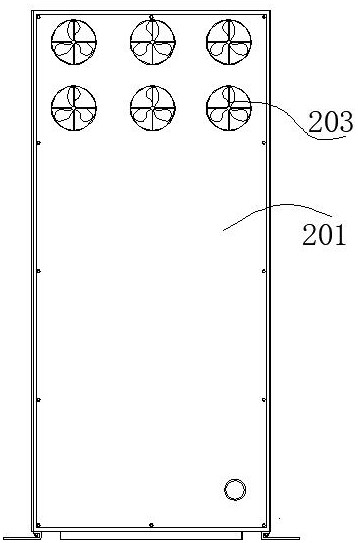

Power distribution cabinet capable of supplying air from bottom and heat dissipation method

PendingCN113315006ASmall branch spaceRealize heat dissipationSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsCold airKeel

The invention discloses a power distribution cabinet capable of supplying air from the bottom and a heat dissipation method. The power distribution cabinet comprises a base structure laid in a machine room and a cabinet body structure installed at the top of the base structure. The base structure comprises keels laid on the ground, and the keels are longitudinally arranged. The keels are mainly used for bearing load, and the keels are light steel keels which are light in weight and sufficient in supporting capacity. A plurality of height adjusting mechanisms are mounted at the bottoms of the keels; through the height adjusting mechanisms, horizontal supporting of the keels on the uneven ground can be achieved; vertical rods are welded at the upper ends of the keels; and heat insulation cotton is laid between the adjacent keels in the transverse direction. The device can reduce the cold air distribution loss, and enables the cold air to effectively act on each power distribution cabinet.

Owner:邵慧艳

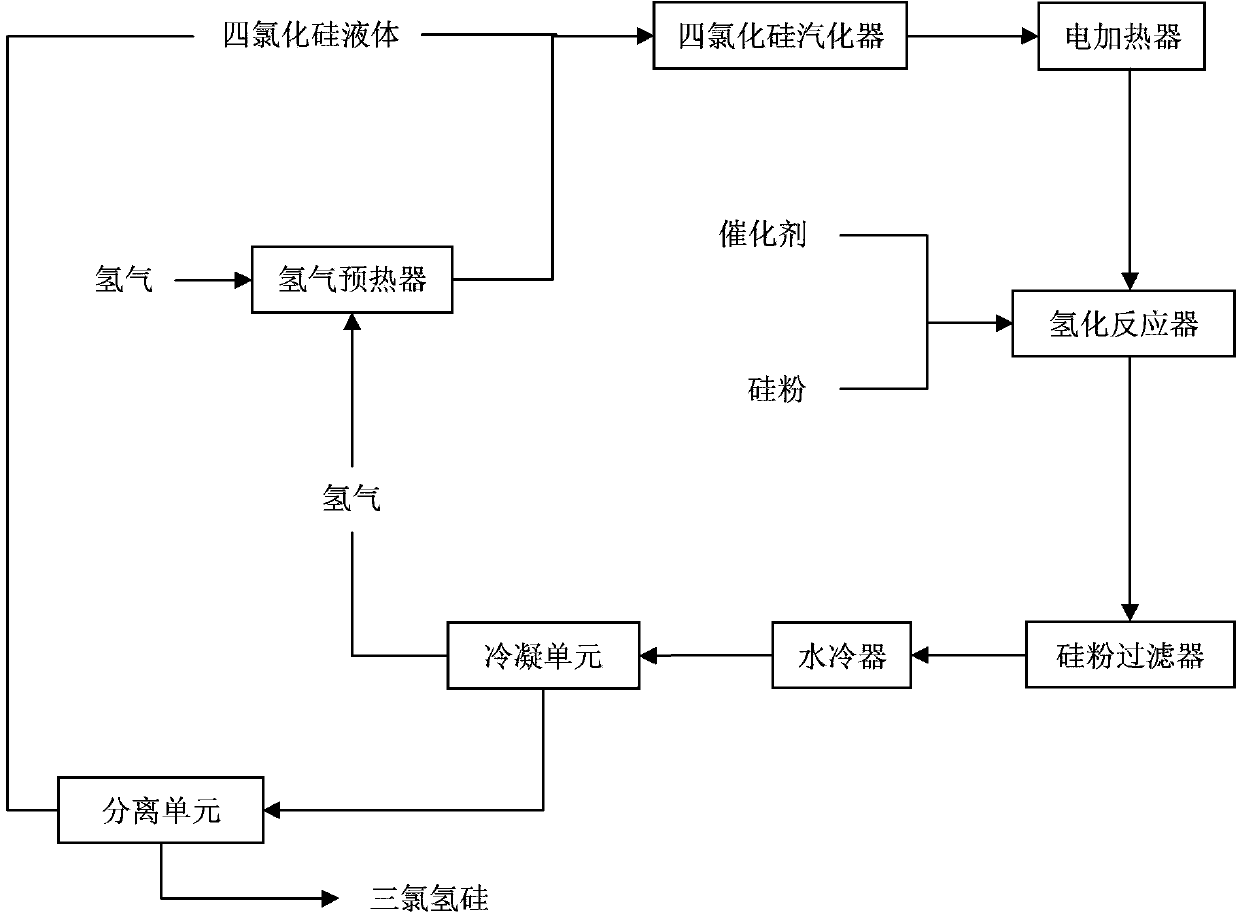

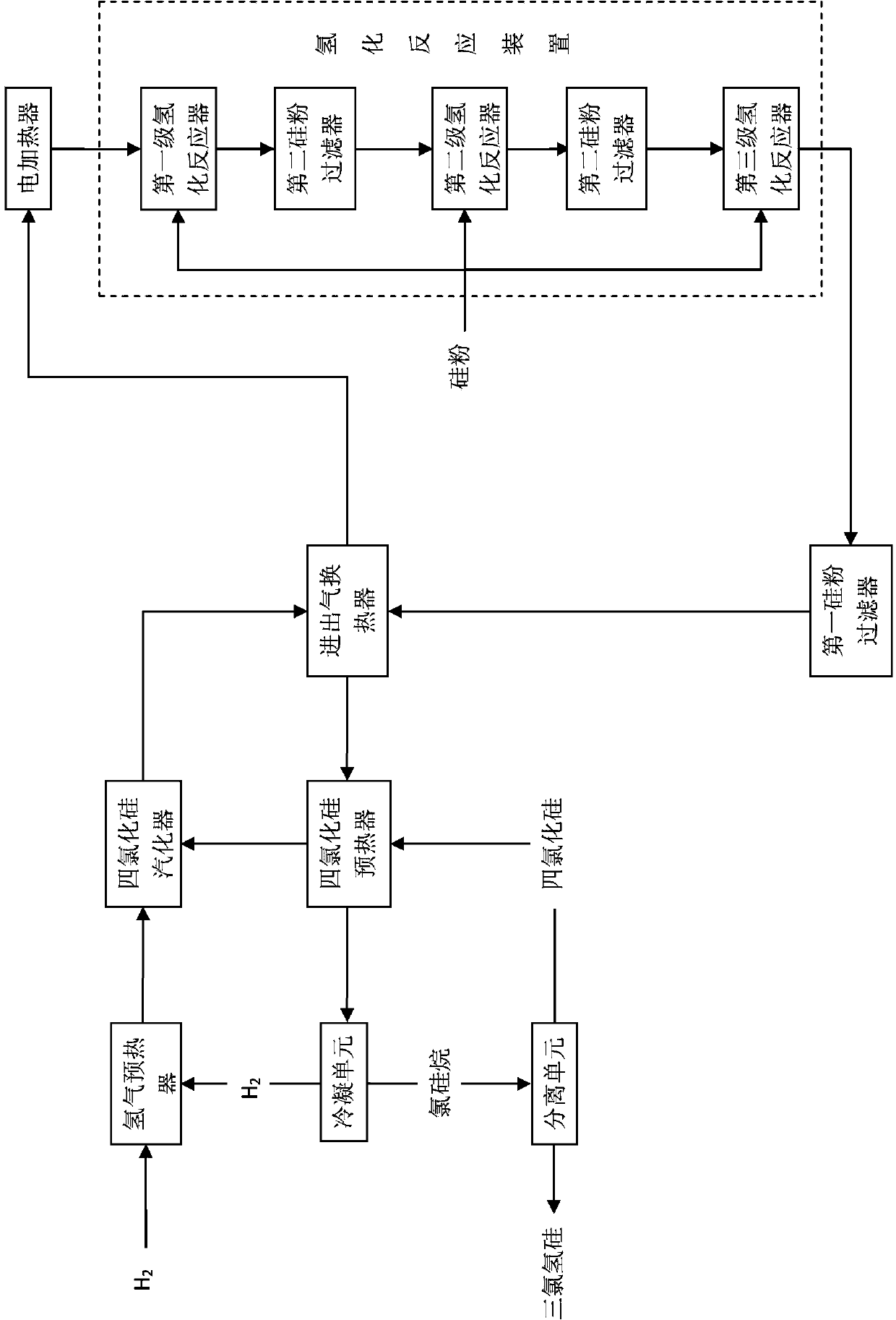

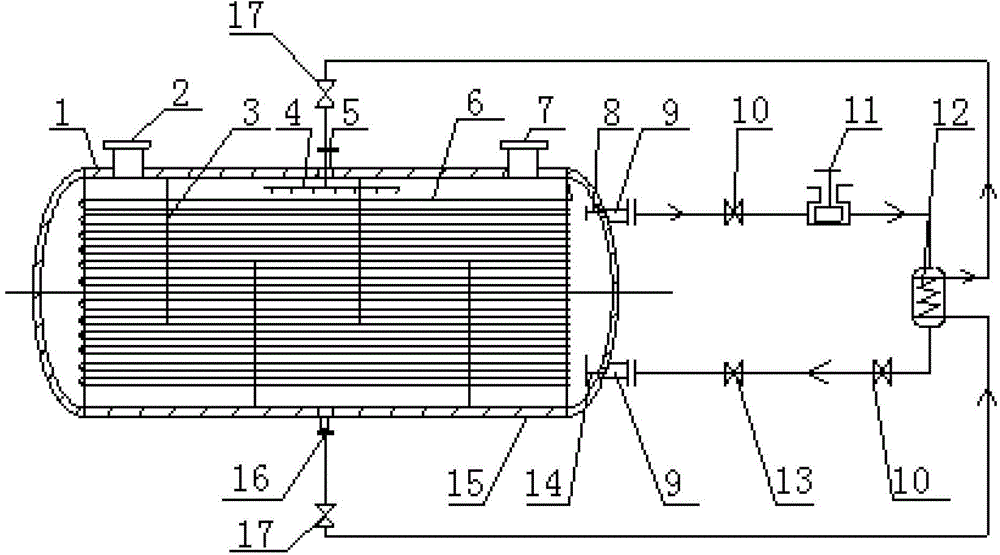

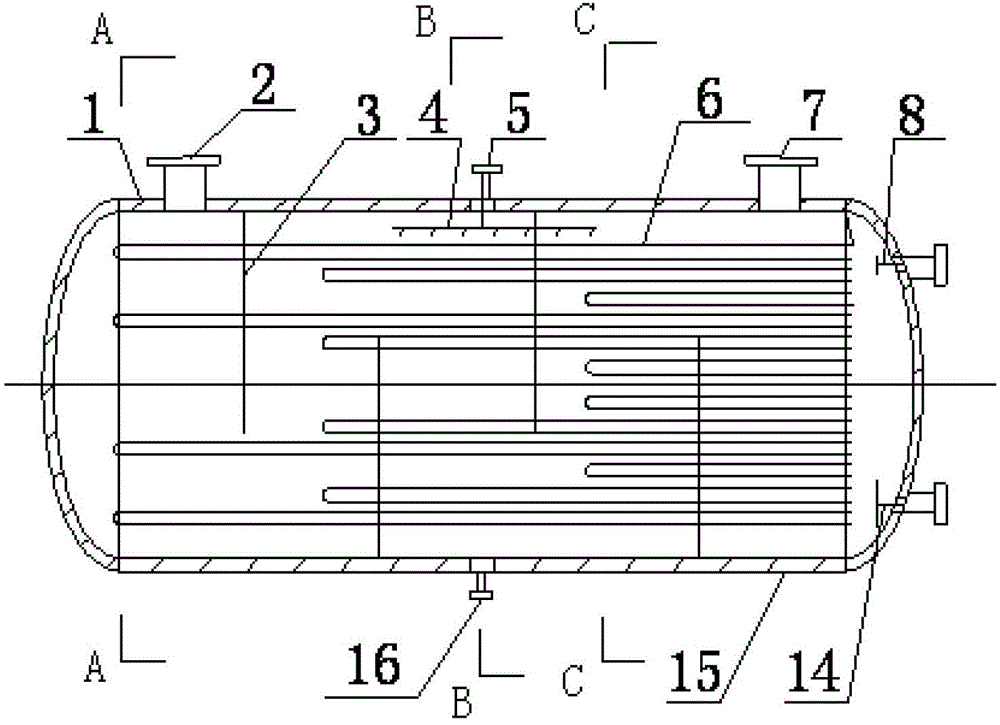

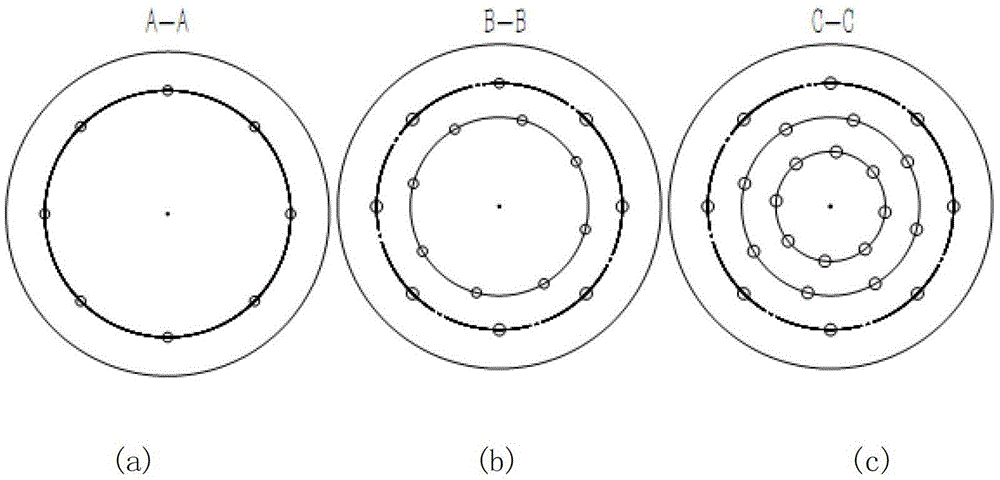

System and method for producing trichlorosilane by cold hydrogenation of silicon tetrachloride

ActiveCN103101913BIncrease reaction spaceExtended reaction timeHalogenated silanesHydrogenation reactionHydrogenation process

The invention discloses a system and a method for producing trichlorosilane by cold hydrogenation of silicon tetrachloride. The system comprises a hydrogenation reaction device, wherein the hydrogenation reaction device is used for carrying out a cold hydrogenation reaction on raw materials including silicon tetrachloride, hydrogen and silicon powder to generate needed trichlorosilane; and the hydrogenation reaction device comprises multi-stage hydrogenation reactors connected in series. When the hydrogenation reaction device works, silicon tetrachloride sequentially passes through each stage of hydrogenation reactor, in which a cold hydrogenation reaction is carried out respectively. At least two hydrogenation reactors are connected in series, so that a one-time hydrogenation rate is far more than that of the conventional cold hydrogenation process added with a catalyst, thus various of consumption, such as heat energy, electric energy and the like for production of trichlorosilane are indirectly reduced. As no catalyst is used in the method, a lot of costs required by purchasing of the catalyst are saved; compared with wearing on pipelines and equipment caused by addition of the catalyst in the prior art, the cold hydrogenation system can be operated stably for a long period of time, and a produced trichlorosilane product has better quality.

Owner:巴彦淖尔聚光硅业有限公司

Conduction-variable vacuum water catching device

The invention discloses a conduction-variable vacuum water catching device and belongs to the technical field of vacuum water catching. The vacuum water catching device comprises a water catcher, a refrigerating system and an auxiliary unit; a condenser tube shortens gradually in length in the direction from the gas inlet to the gas outlet, so that the conduction capacity of the water catcher varies from large to small when gas flows in the water catcher; a casing adopts a modified taper, and circular and round baffle plates are adopted for the inside of the taper casing, therefore the conduction capacity of the water catcher also varies from large to small when the gas flows in the water catcher, moreover, the efficiency for catching steam is improved, and the refrigerating capacity consumption is reduced. As the device adopts cooling water circulation for defrosting or deicing, reuse of waste water as well as heat energy is achieved, and purposes of high efficiency, energy saving and emission reduction are achieved; the device is simple in structure, low in construction cost, convenience in use and maintenance, and large in application range, and can be used wherever the steam is required to be caught.

Owner:LIAOYANG BOSHI FLUID EQUIP

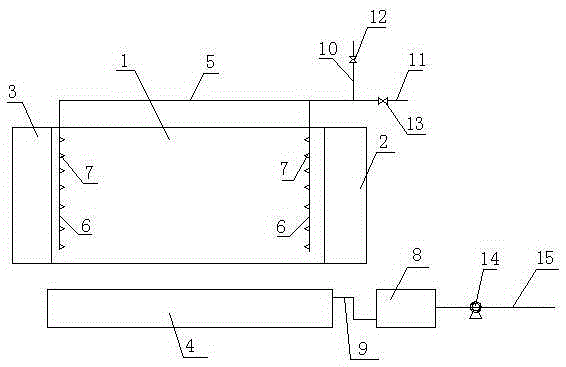

Cooling process for potassium nitrate production

PendingCN112797728AReduce cooling consumptionDomestic cooling apparatusLighting and heating apparatusChemistryProcess engineering

The invention relates to a cooling process for potassium nitrate production, which comprises a cooling tank, wherein a cooling mode of the cooling tank adopts internal cooling or external cooling which is selected according to the temperature of mother liquor, the external cooling adopts a spraying water tank, the cooling tank is arranged in the spraying water tank, the internal cooling adopts an internal coil pipe, the internal coil pipe is arranged in the cooling tank; low-temperature magnesium chloride is input into the inner coil pipe, a buffer pool is arranged on one side of the spraying water pool, a cooling pipe is arranged in the buffer pool, the cooling pipe is connected to the inner coil pipe; and after the absorption temperature of the low-temperature magnesium chloride is increased, the low-temperature magnesium chloride is cooled through the cooling pipe and finally stored. The cooling process has the advantages that when the temperature of the mother liquor is 80-50 DEG C, external cooling is adopted, that is, tap water is sprayed to the cooling tank through the spraying water tank; when the temperature of the mother liquor is gradually reduced and the temperature of the mother liquor is lower than 50 DEG C, water spraying is stopped, internal cooling is adopted, that is, low-temperature magnesium chloride is input into the inner coil pipe, so that the cooling capacity consumption of the low-temperature magnesium chloride can be reduced.

Owner:安徽胜达化工科技有限公司

Energy-saving acidic gas re-absorption technology matching with coal water slurry gasification

ActiveCN106390685AReduce energy consumption andStrong absorption capacityChemical industryDispersed particle separationCoal waterInjector

Owner:SINOPEC NINGBO ENG +2

A light hydrocarbon recovery method and device

ActiveCN111394120BNo secondary separation requiredAchieve separationHydrocarbon distillation control/regulationLiquid hydrocarbon mixture recoveryChemical industryProcess engineering

The invention belongs to the fields of oil refining and chemical industry, and specifically discloses a light hydrocarbon recovery method and device. The method has simple process, moderate operating conditions, low consumption of cooling energy, and can realize the recovery of light hydrocarbons in the hydrocracking process with less equipment. The separation and recovery of ethane, propane and carbon four components can be realized in particular, wherein the recovery rate of ethane is over 97wt%, the recovery rate of propane is over 98wt%, and the methane content in the recovered ethane is Not more than 1 vol%, and the ethane content in the recovered propane is not more than 300ppmv.

Owner:SINOPEC ENG +1

Method and system for deep purification of polysilicon reduction tail gas

ActiveCN108534463BLow costReduce energy consumptionSolidificationLiquefactionPurification methodsPhysical chemistry

The invention provides a deep purification method for polysilicon reduction tail gas. Cool the reduction tail gas; in the two-stage hydrogen chloride absorption tower, use the top-down chlorosilane lean liquid in the tower to absorb the hydrogen chloride in the mixed gas whose cooling capacity has been used; The chlorosilane-rich liquid output from the bottom of the absorption tower is analyzed and treated, and the lean liquid of chlorosilane is output from the bottom of the tower, and the light component is output from the top of the tower; The chlorosilane poor liquid output from the analysis column kettle is cooled. Accordingly, a deep purification system is provided. The invention makes the quality of recovered hydrogen meet the corresponding requirement of electronic-grade polysilicon, and at the same time reduces the consumption of additional refrigeration and lightens the load of the absorption tower.

Owner:XINTE ENERGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com