Method for drying hydrogen chloride gas

A technology of hydrogen chloride gas and drying method, which is applied to the production raw material in the production of trichlorosilane and the drying field of hydrogen chloride gas in the production of trichlorosilane, can solve the problems of high energy consumption, reduced silicon powder conversion rate, large investment and the like , to reduce the probability of equipment blockage, reduce equipment investment, and reduce environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

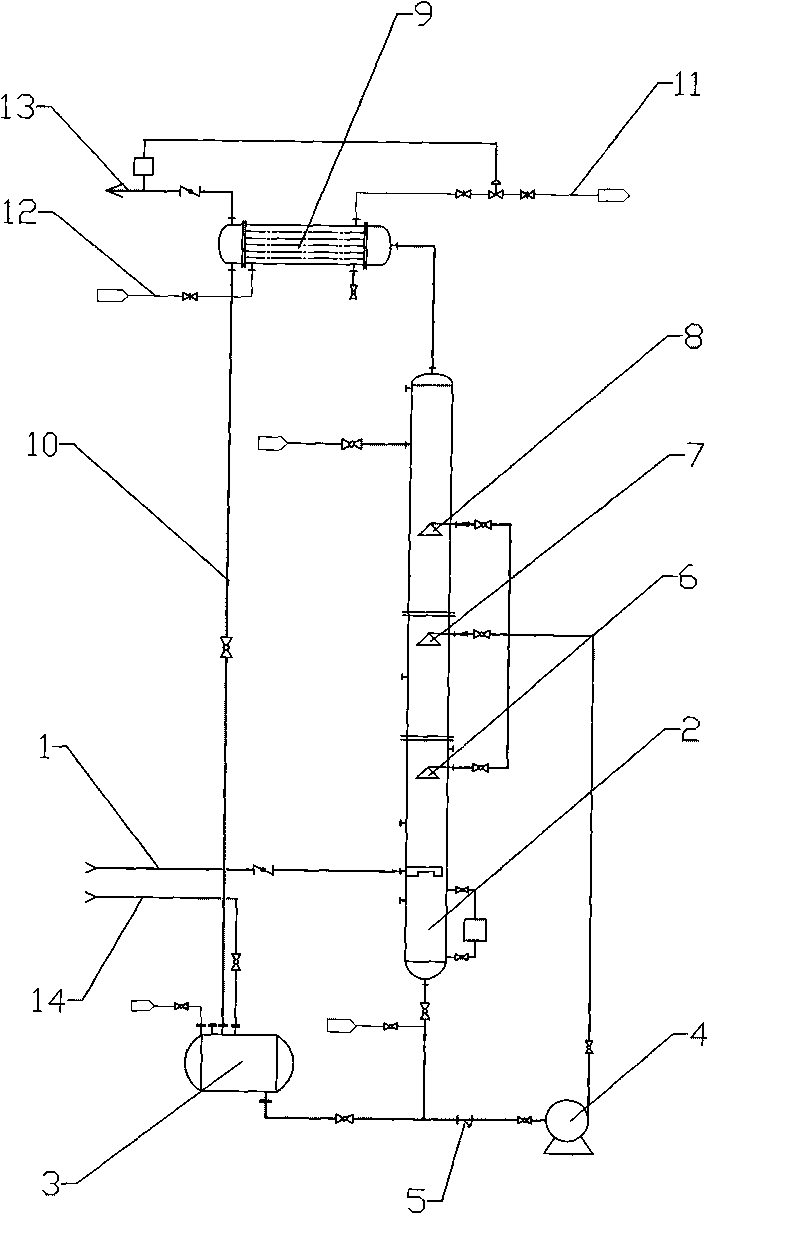

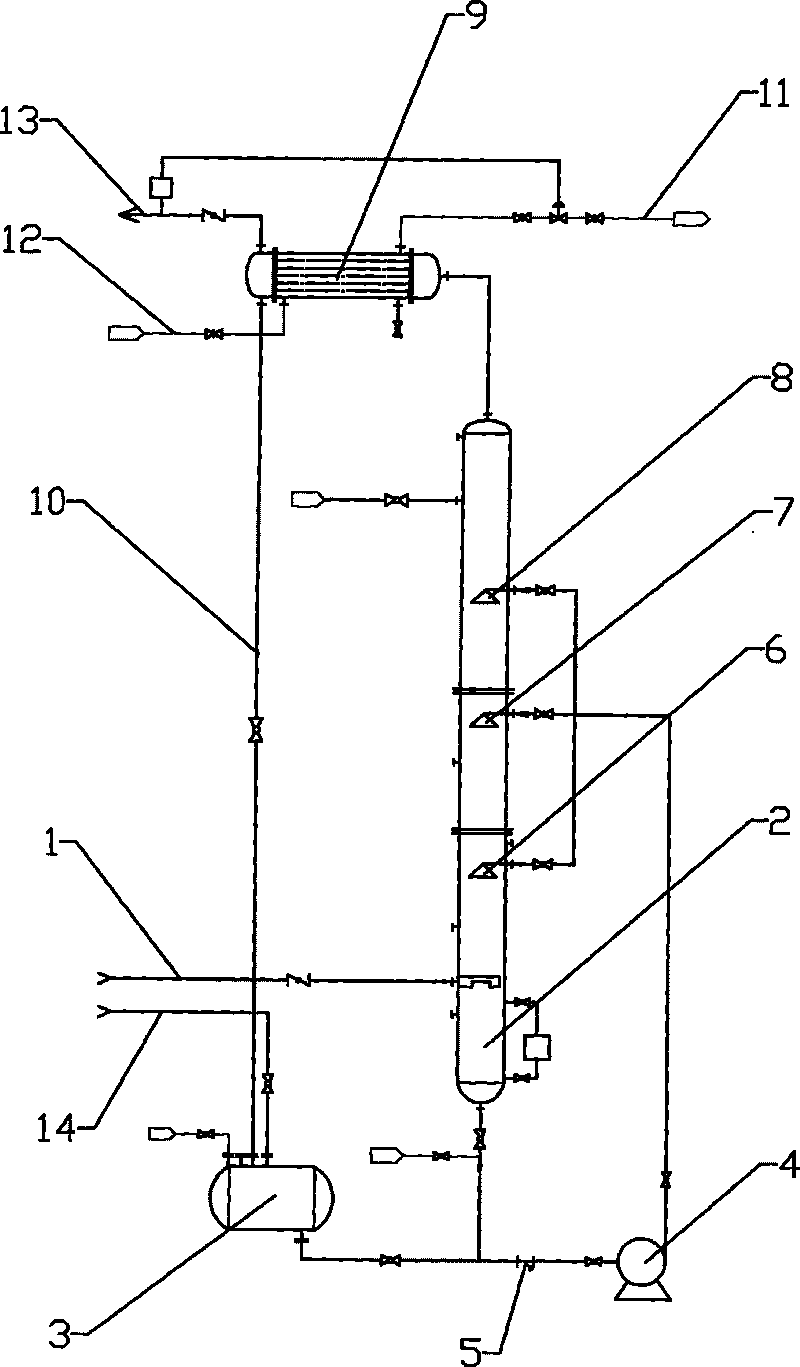

[0024] Embodiment 1, a kind of drying method of hydrogen chloride gas, the hydrogen chloride gas containing moisture comes out from the production workshop and enters the bottom of the drying spray tower 2 through the pipeline 1, and the intake flow rate of the hydrogen chloride gas is 900Nm 3 / h, the temperature is 35°C, the pressure is 130kPaG, the water content is 8000-10000ppm, from the bottom along the inner cavity of the drying spray tower 2, the silicon tetrachloride is stored in the circulation tank 3, and the silicon tetrachloride passes through the filter 5 After filtering, it is extracted from the circulation tank 3 by the circulation pump 4, and is pumped into the drying spray tower 2, from the spray head 6 arranged at the bottom of the dry spray tower 2, the spray head 7 of the middle part and the spray head of the upper part 8. The hydrogen chloride gas is sprayed sequentially. The hydrogen chloride gas produced after the hydrolysis of silicon tetrachloride meets ...

Embodiment 2

[0025] Embodiment 2, a kind of drying method of hydrogen chloride gas, the hydrogen chloride gas containing moisture comes out from the production workshop and enters the bottom of the drying spray tower 2 through the pipeline 1, and the intake flow rate of the hydrogen chloride gas is 950Nm 3 / h, the temperature is 40°C, the pressure is 140kPaG, the water content is 8000-10000ppm, from the bottom along the inner cavity of the drying spray tower 2, the silicon tetrachloride is stored in the circulation tank 3, and the silicon tetrachloride passes through the filter 5 After filtering, it is extracted from the circulation tank 3 by the circulation pump 4, and is pumped into the drying spray tower 2, from the spray head 6 arranged at the bottom of the dry spray tower 2, the spray head 7 of the middle part and the spray head of the upper part 8. The hydrogen chloride gas is sprayed sequentially, and the hydrogen chloride gas produced after the hydrolysis of silicon tetrachloride me...

Embodiment 3

[0026] Embodiment 3, a kind of drying method of hydrogen chloride gas, the hydrogen chloride gas containing moisture comes out from the production workshop and enters the bottom of the drying spray tower 2 through the pipeline 1, and the intake flow rate of the hydrogen chloride gas is 1000Nm 3 / h, the temperature is 45°C, the pressure is 150kPaG, the water content is 8000-10000ppm, from the bottom along the inner cavity of the drying spray tower 2, the silicon tetrachloride is stored in the circulation tank 3, and the silicon tetrachloride passes through the filter 5 After filtering, it is extracted from the circulation tank 3 by the circulation pump 4, and is pumped into the drying spray tower 2, from the spray head 6, the spray head 7 in the middle part and the spray head on the top of the dry spray tower 2, which are arranged on the bottom of the dry spray tower 2. 8 The hydrogen chloride gas is sprayed sequentially, the hydrogen chloride gas produced after the hydrolysis o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com