Patents

Literature

2258 results about "Spray tower" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A spray tower (or spray column or spray chamber) is gas-liquid contactor used to achieve mass and heat transfer between a continuous gas phase (that can contain dispersed solid particles) and a dispersed liquid phase. It consists of an empty cylindrical vessel made of steel or plastic, and nozzles that spray liquid into the vessel. The inlet gas stream usually enters at the bottom of the tower and moves upward, while the liquid is sprayed downward from one or more levels. This flow of inlet gas and liquid in opposite directions is called countercurrent flow.

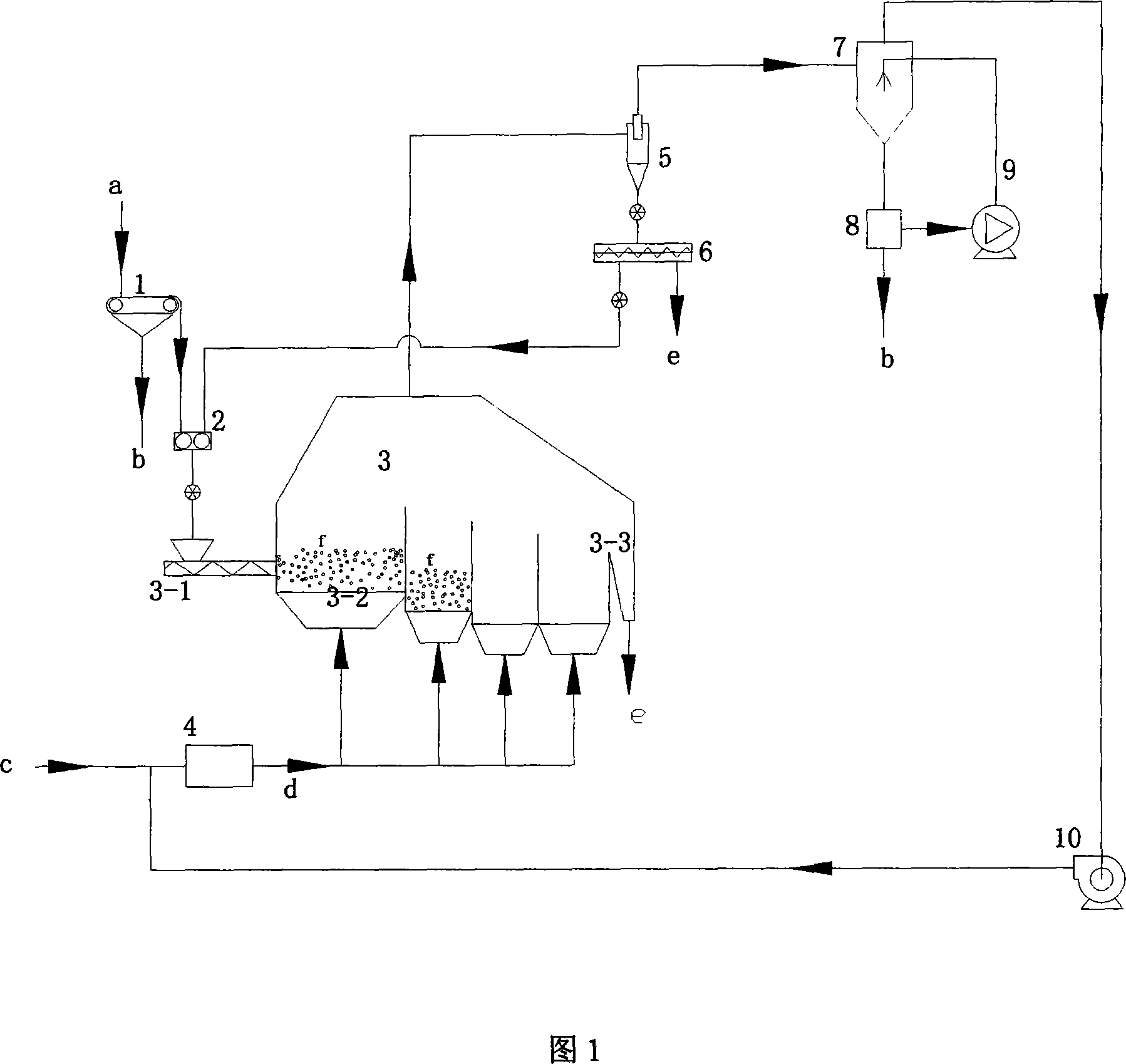

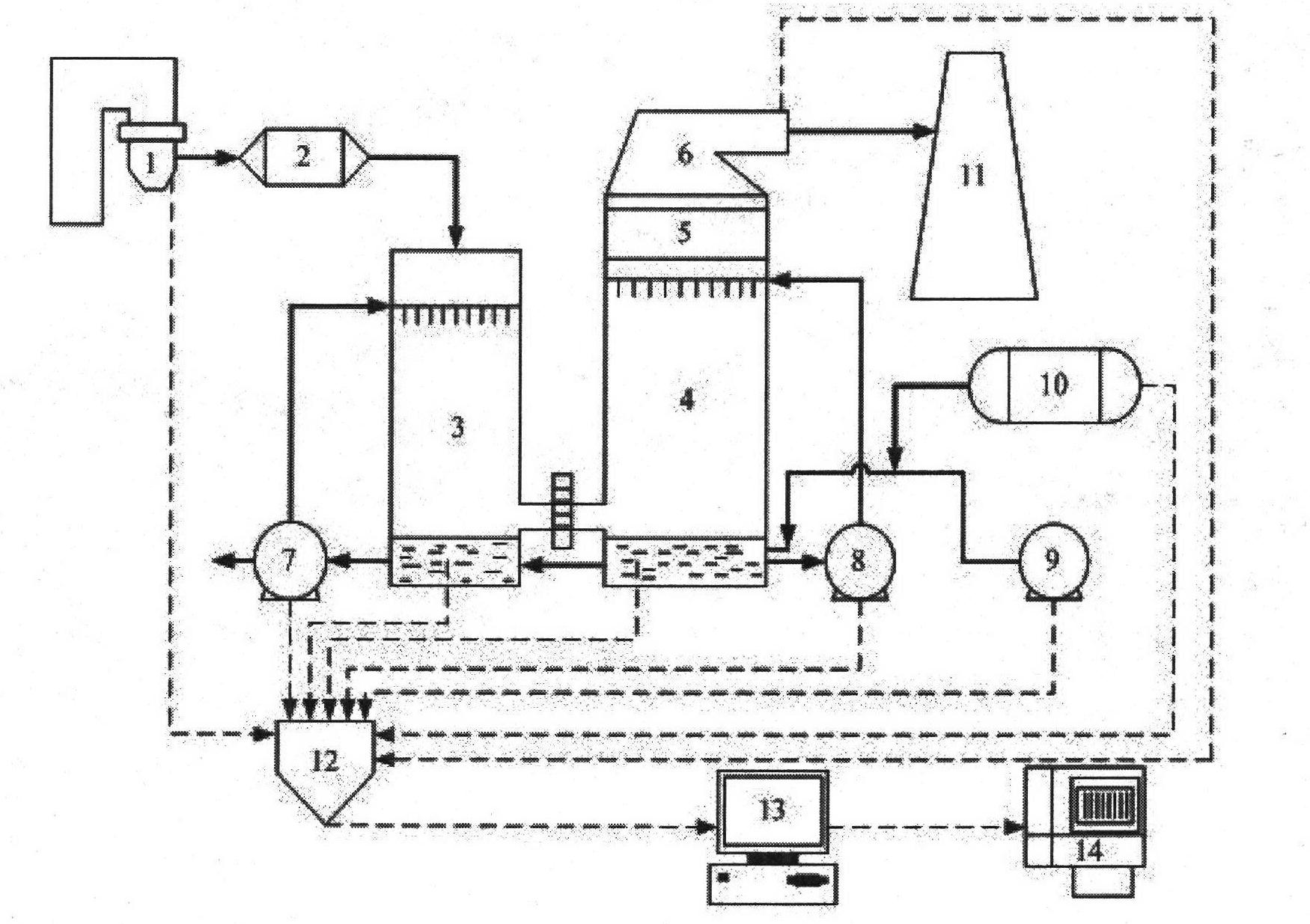

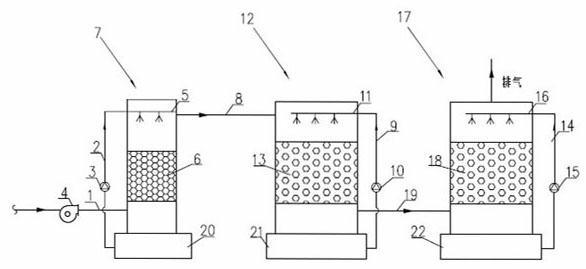

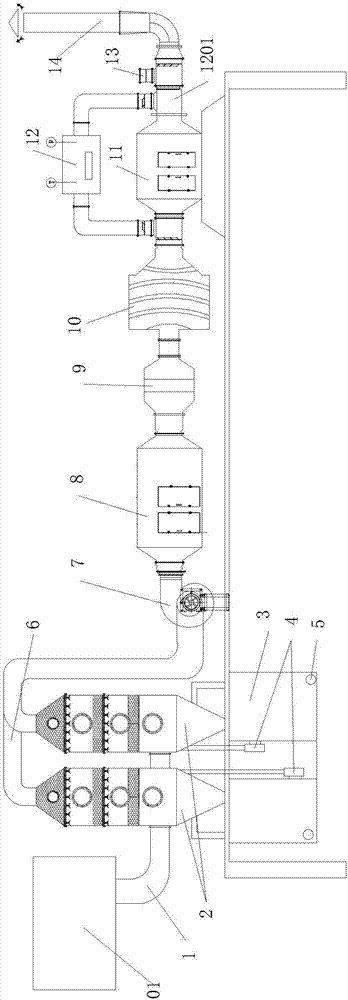

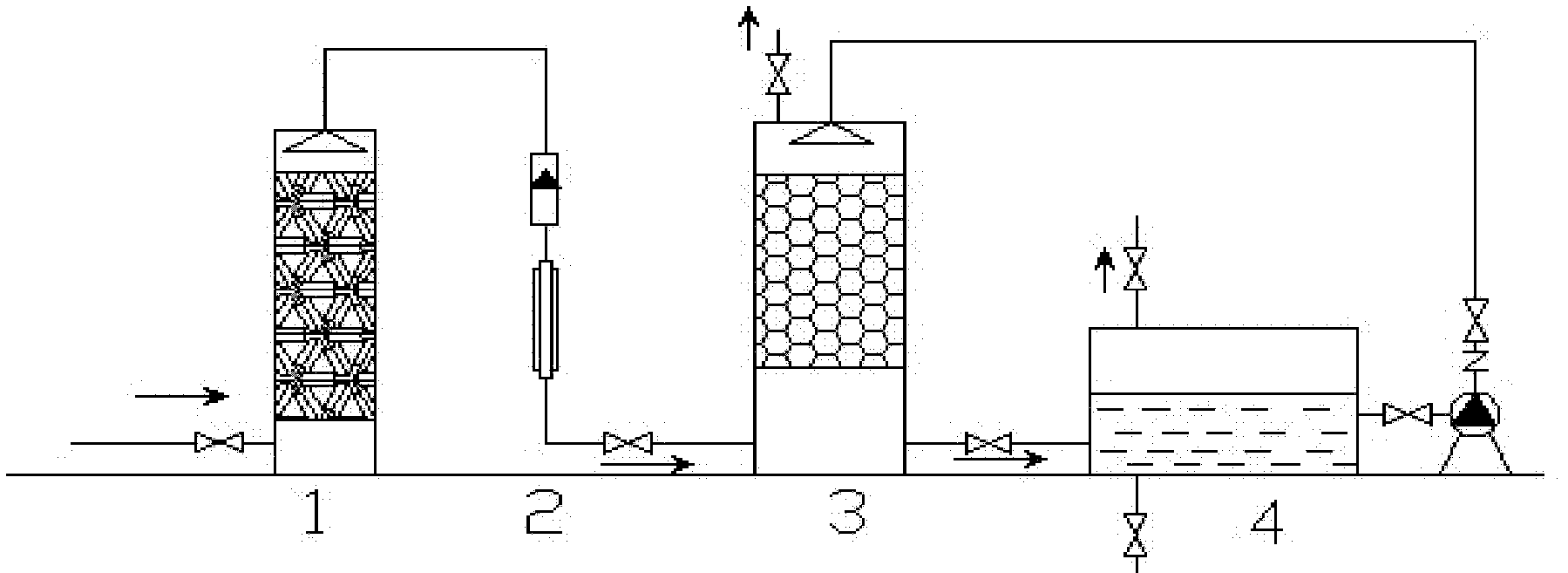

Enclosed multi-chamber fluidized bed drying method for sludge

InactiveCN101186422AUniform humidityReduce breakageSludge treatment by de-watering/drying/thickeningLiquid wasteFluidized bed drying

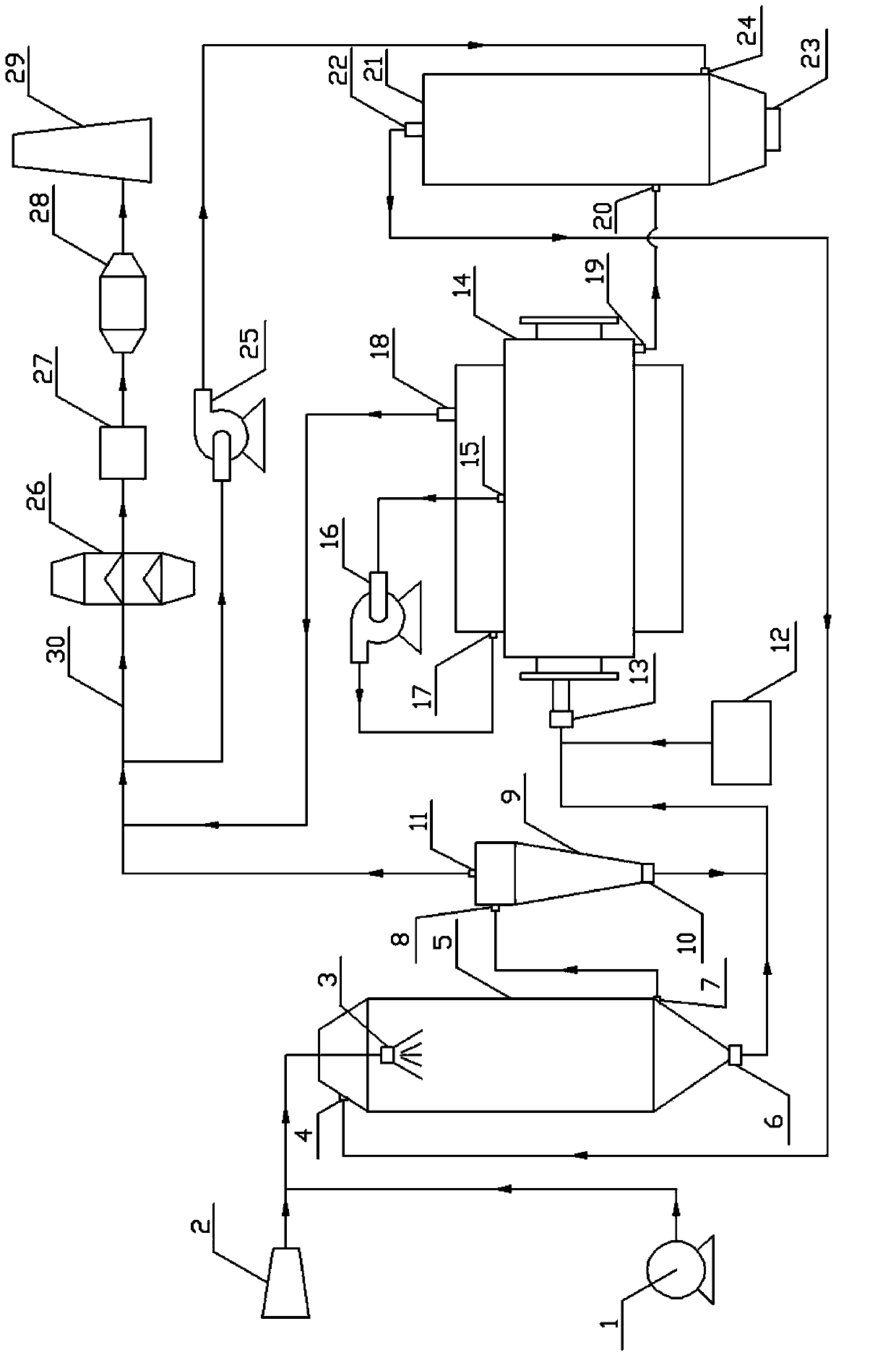

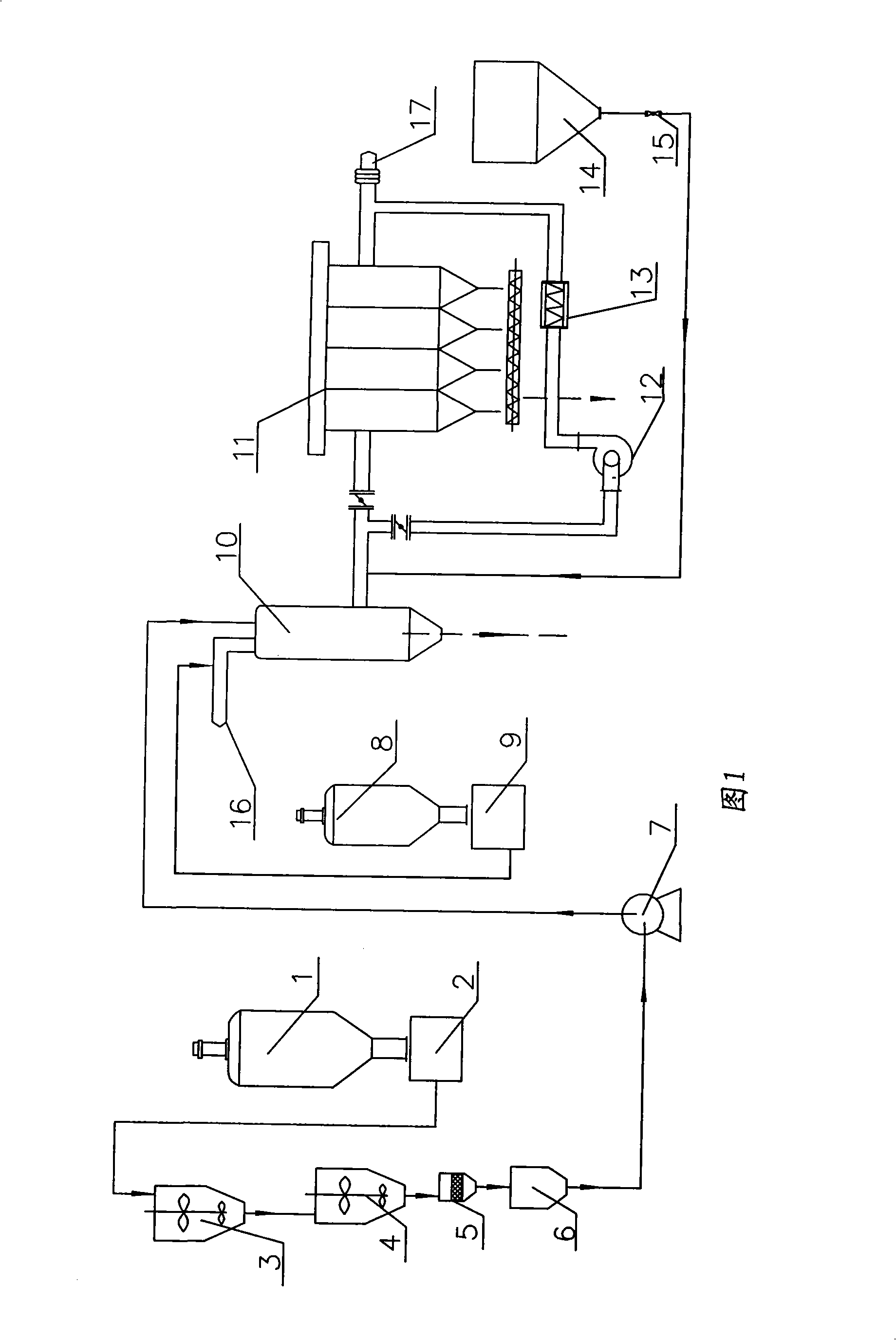

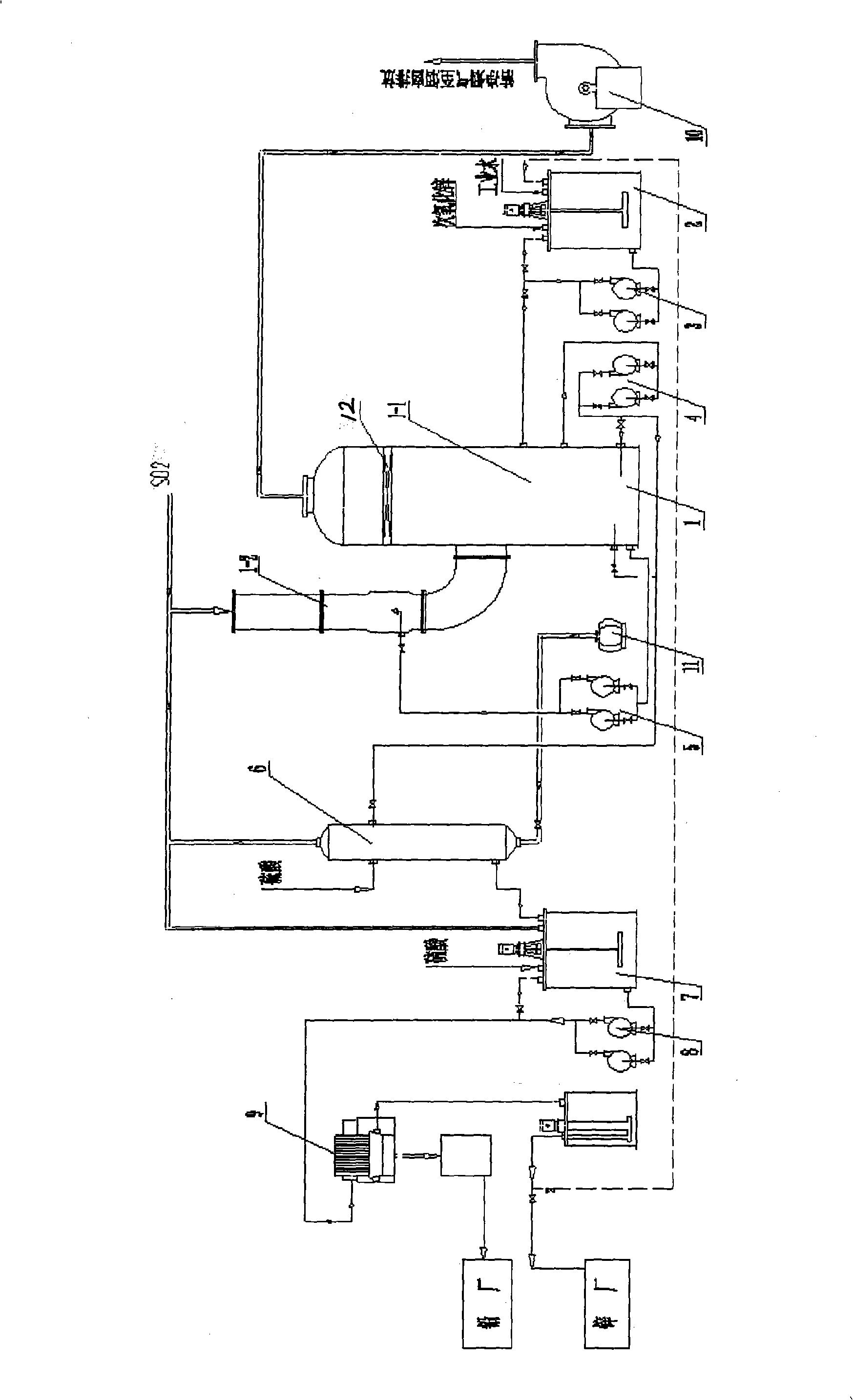

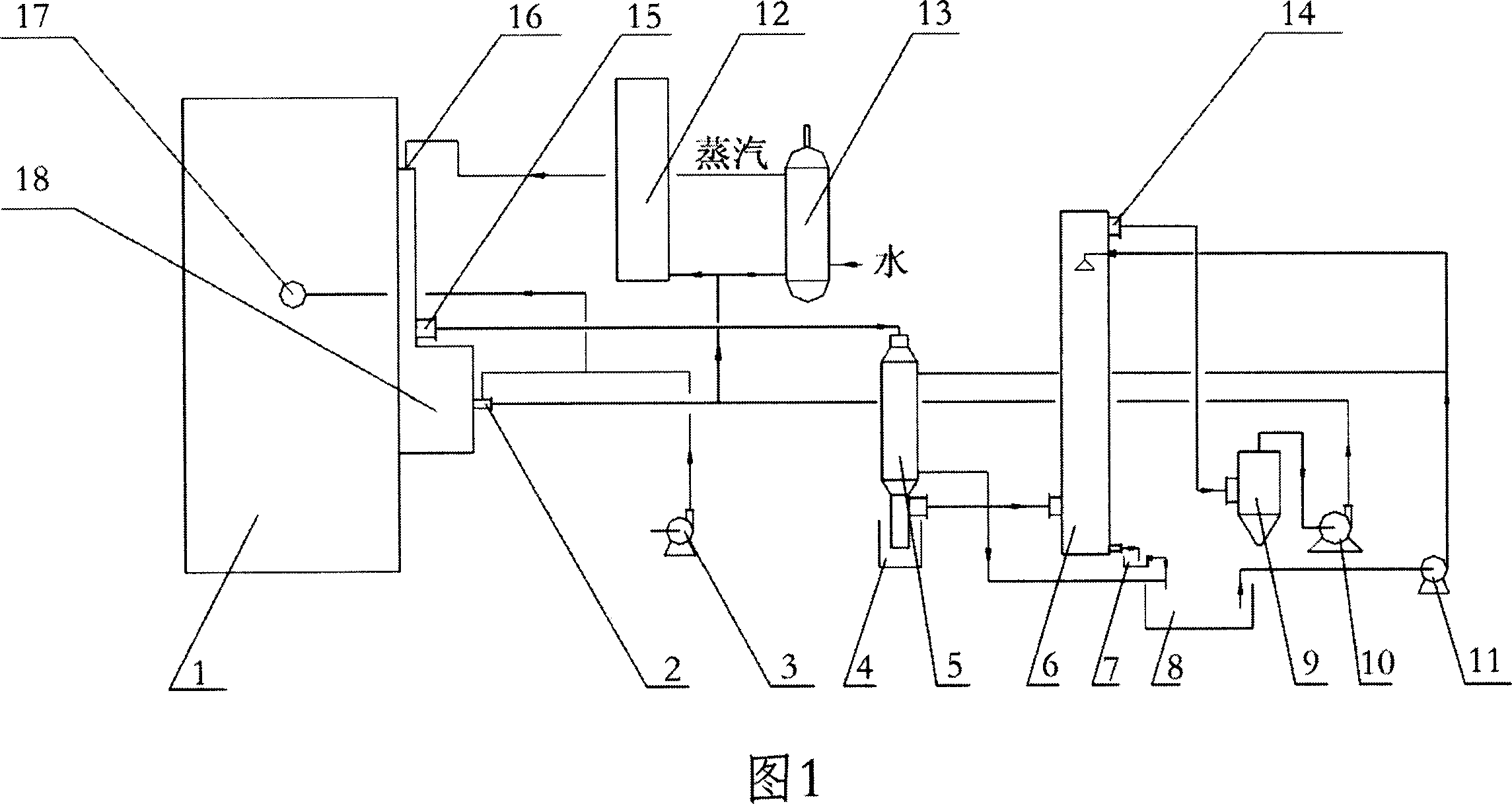

A closed multi-room fluidized bed sludge drying method is provided, which is a sludge drying method having the advantages of simple equipment structure, convenient operation, strong sludge adaptability, high thermal efficiency, safety, continuity, stability, etc. After the mechanically dewatered sludge is mixed with the back-mixed sludge, the mixture is dried room by room in an inert particles multi-room fluidized bed dryer (3). The first room and the second room of the inert particles multi-room fluidized bed dryer (3) adopt inert particles (f) as heat storage medium. Gas from a cyclone separator (5) goes through a spray tower (7) and returns into an air heating unit (4) through a circulating fan (10). Part of dried sludge (e) at the lower part of the cyclone separator (5) enters the inert particles multi-room fluidized bed dryer (3) through the back-mixing in a mixer (2). Waste liquid from the bottom of the spray tower (7) enters a waste liquid circulating pool (8), with part of waste liquid circulating into the spray tower (7) and part into a sewage treatment system.

Owner:SOUTHEAST UNIV

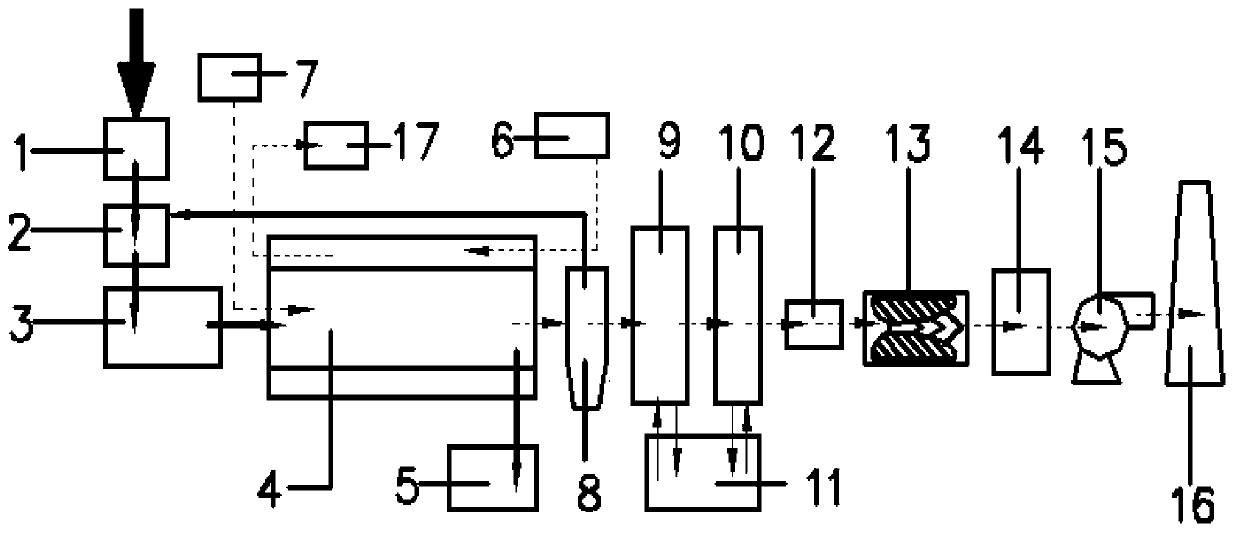

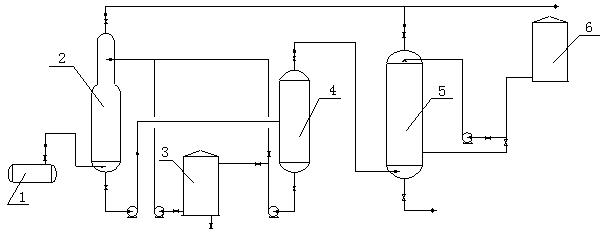

Method and device for repairing contaminated soil with persistent organic pollutants

ActiveCN103272838AAvoid condensationAchieving Removal EfficiencyContaminated soil reclamationAir filterCyclonic spray scrubber

The invention relates to a method for repairing contaminated soil, and aims at providing a method and a device for repairing contaminated soil with persistent organic pollutants. The device comprises a separator, a material hopper, a material feeder and an indirect-heating thermal desorbing device which are connected with one another in sequence, wherein a soil emission device is connected to the bottom of the heating thermal desorbing device; a combustion system, a waste heat utilization device and an inert gas generator are respectively connected with the indirect-heating thermal desorbing device; the combustion system is connected with an outer barrel, and the inert gas generator is connected with an inner barrel; and a tail gas processing component comprises a cyclone dust extractor, a primary spray tower, a secondary regulating spray tower, a dehumidifier, a plasma reactor, an air filter, an induced draft fan and an exhaust barrel which are connected with one another in sequence. According to the method and the device for repairing contaminated soil with persistent organic pollutants disclosed by the invention, the amount of exhaust gas needing processing is less, water consumption is low, the persistent organic pollutants are thoroughly removed, the operation cost is reduced by 30%-60%, and the contaminated soil with persistent organic pollutants can be economically and effectively processed.

Owner:ZHEJIANG UNIV

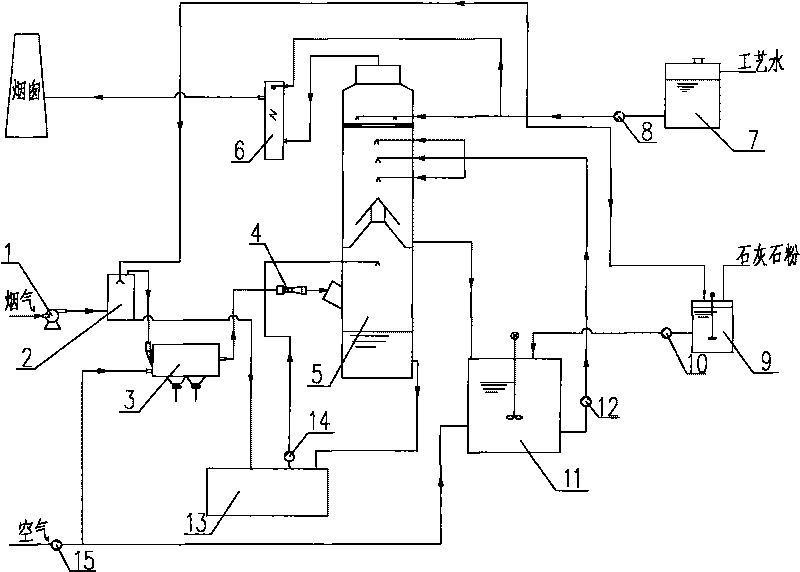

Simultaneous removing device and method of various pollutants by electrocatalytical oxidation combining lime-gypsum method

ActiveCN101716463ALow investment costThe process is simple and reliableUsing liquid separation agentElectricityMulti pollutant

The invention discloses simultaneous removing device and method of various pollutants by an electrocatalytical oxidation combining lime-gypsum method. The device comprises a spraying and cooling device, an electrostatic enhancement reactor, a Venturi device, a double-circulation integrated absorption tower of various pollutants and a wet type electrostatic defroster, wherein after smoke is cooled by the spraying and cooling device, the smoke enters the electrostatic enhancement reactor and is subjected to corona discharge processing in a corona discharge area formed in the electrostatic enhancement reactor; the processed smoke enters the double-circulation integrated absorption tower of various pollutants and is sprayed to remove dust and absorb in the absorption tower; and the purified smoke sequentially enters a corrugated plate defroster and the electrostatic defroster on the upper part of a spraying tower so as to remove aerosol in the smoke. The invention has the advantages that various pollutants can be simultaneously removed, and meanwhile, the pollution of fine granules and the aerosol can be effectively controlled; various pollutants can have higher removal efficiency; and the removal and the absorption of by-products cannot cause secondary pollution to environment.

Owner:ZHEJIANG UNIV

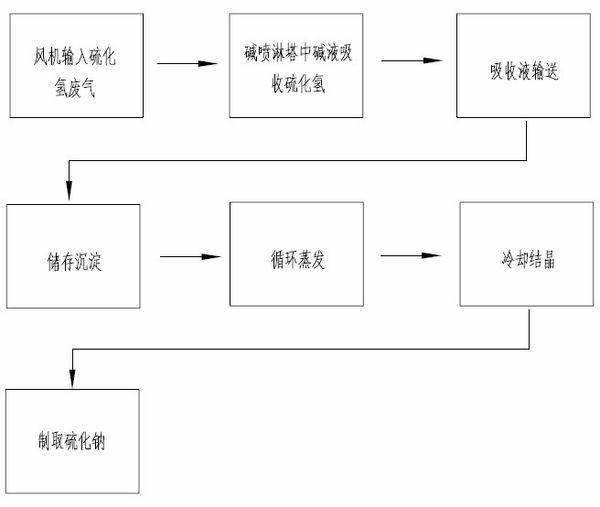

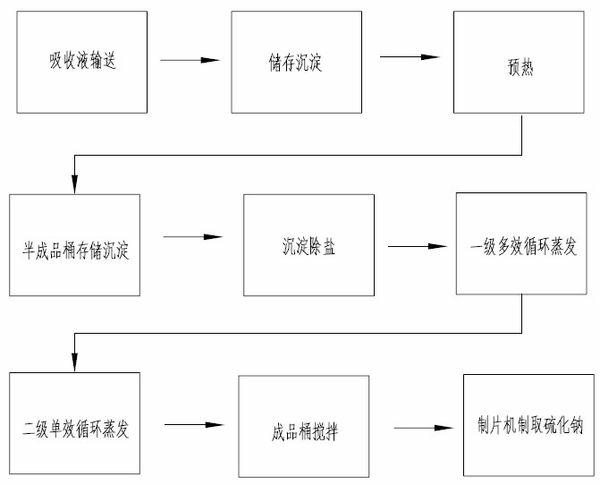

Method for preparing sodium sulfide from hydrogen sulfide waste gas produced in production of viscose fibre

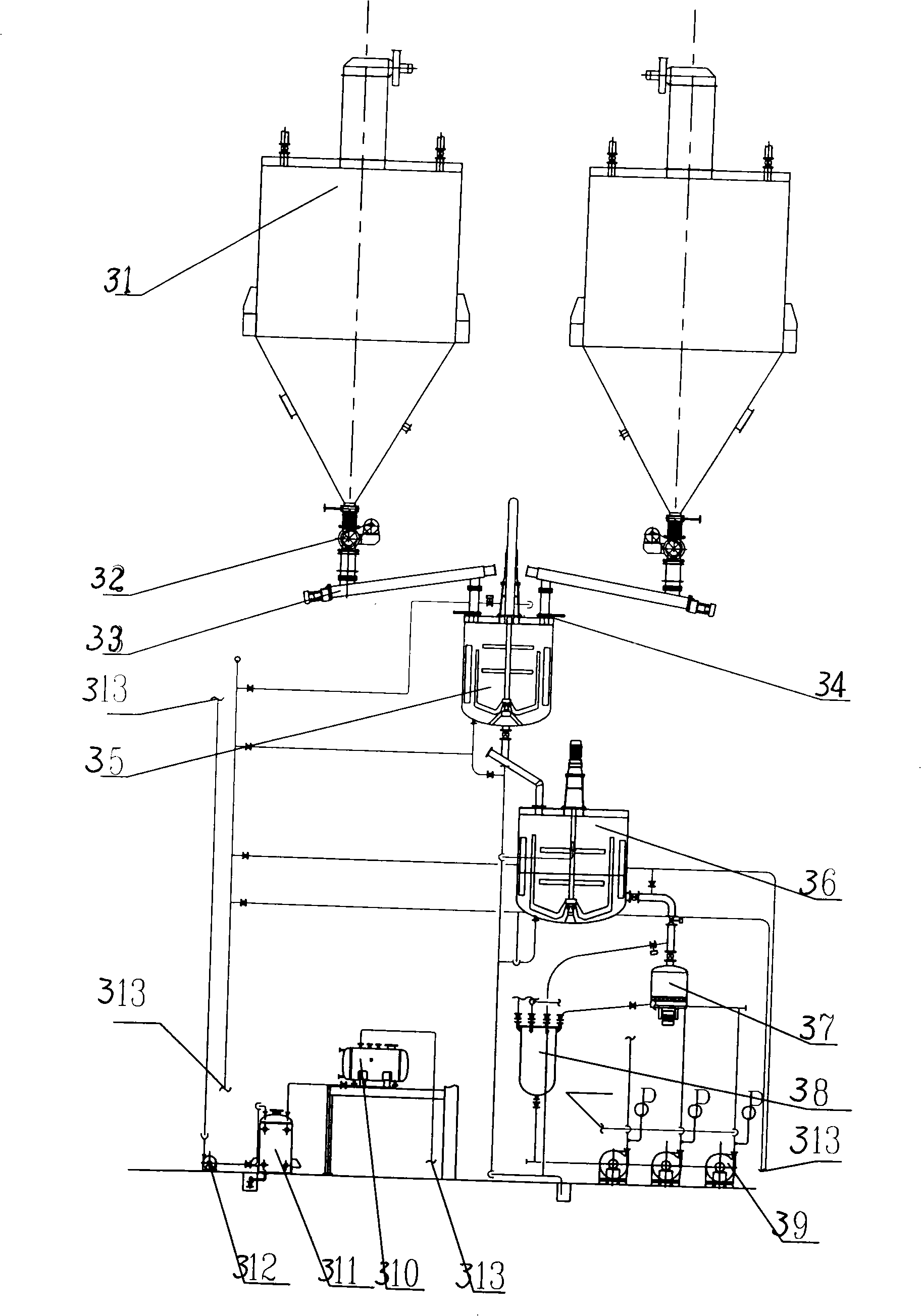

InactiveCN102515112AAchieve optimized generationIncrease production costAlkali metal sulfides/polysulfidesImpurityWaste gas

The invention relates to the field of production of viscose fibre in the textile industry, in particular to a method for preparing sodium sulfide from hydrogen sulfide waste gas produced in the production of the viscose fibre. The method comprises the steps as follows: A, the waste gas is fed into an alkali spray tower; B, hydrogen sulfide is absorbed in an alkali liquor in the alkali spray tower; C, impurities are removed; D, a preheated absorption liquid is delivered into a primary multi-effect evaporator; E, a solution is subject to settlement and desalination; F, the desalinated solution is filled into a semi-finished product barrel, and caustic soda is added into the desalinated solution; G, the solution in the semi-finished product barrel is delivered into a secondary single-effect evaporator; H, after undergoing the secondary evaporation, the solution is filled into a finished product barrel, and then is stirred for crystallization; and I, crystal sodium sulfide is made into tablets. The method has the advantage of realizing the optimal generation of sodium sulfide through the setting of processing parameters such as the size of main equipment, the pore diameter of a delivery pipeline, wind volume, wind velocity, the concentration of the alkali liquor, absorption time, circulating evaporation time, evaporation temperature, evaporation vacuum degree, precipitation time, stirring velocity, the rotational speed of a tablet making machine, and the like.

Owner:YIBIN HIEST FIBER +2

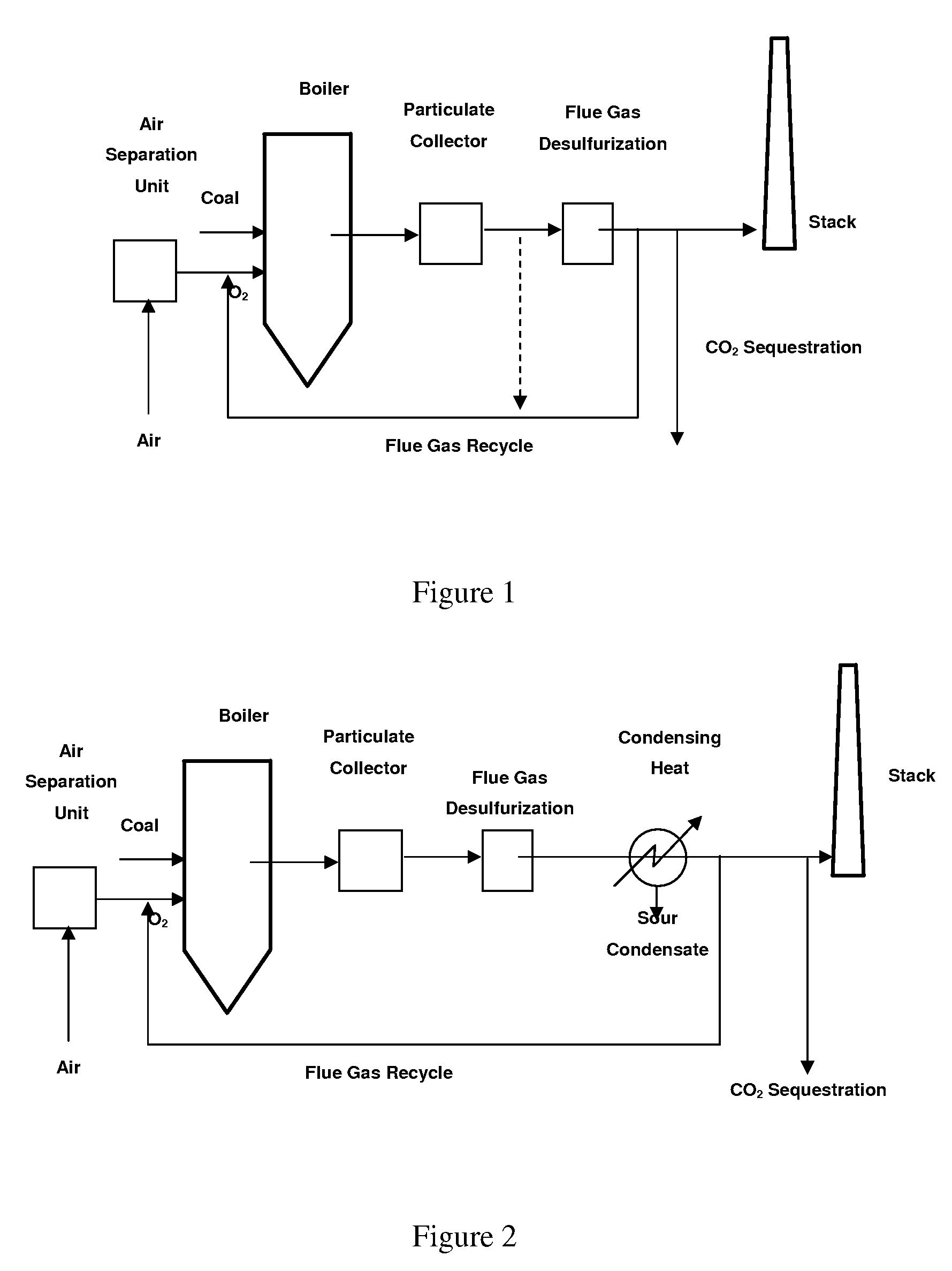

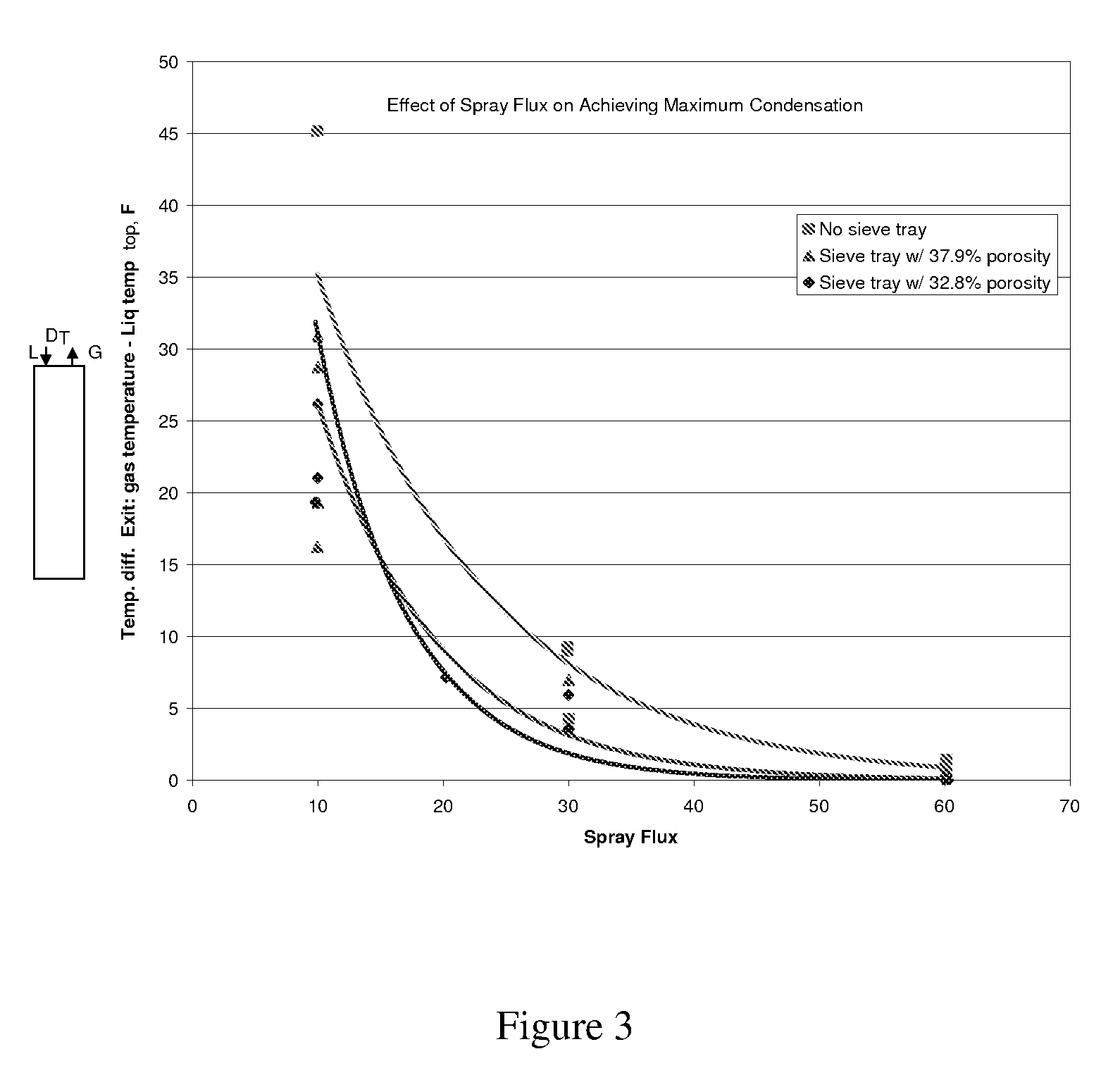

Process for controlling the moisture concentration of a combustion flue gas

InactiveUS20070243119A1Reduce concentrationReducing the moisture of the flue gasUsing liquid separation agentHydrogen sulfidesSprayerWater vapor

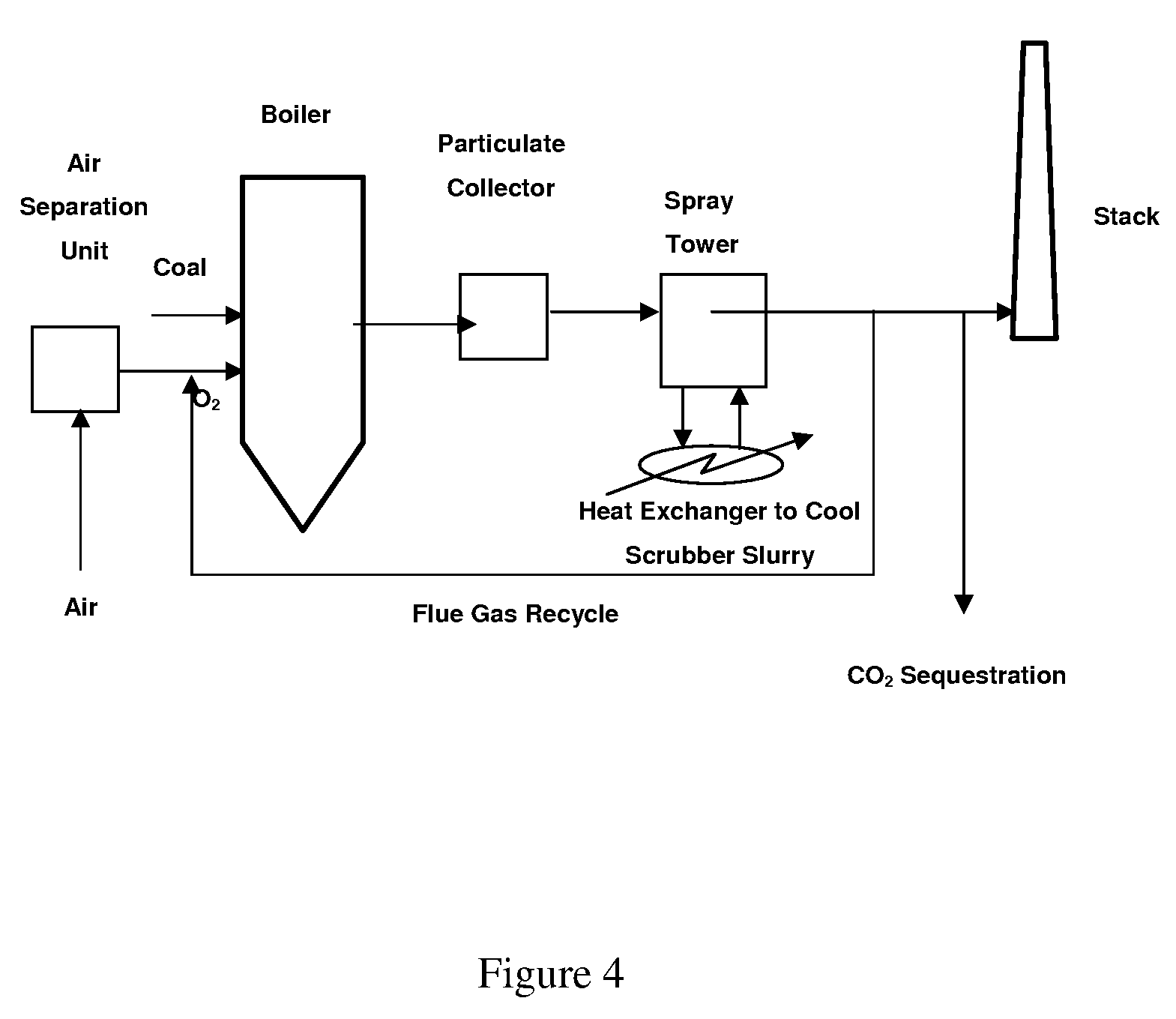

The invention is related to a system for removal of moisture and contaminants from recirculated flue gas which is used for combustion in fossil fuel power plants. The system includes a spray tower having an inlet at one end of the housing and an outlet at an opposite end of the housing for channeling the flue gas into and out of the housing. Sprayers are located in the housing for spraying the flue gas with a liquid reagent to remove contaminants, including SO2, from the flue gas. A heat exchanger is integrally connected to the housing. The heat exchanger cools the liquid reagent before the reagent is sprayed onto the flue gas stream. The sprayers quench the flue gas stream with the cooled liquid reagent. The cooling of the liquid reagent to a temperature below the flue gas water vapor dew point improves the condensation of the water vapor in the flue gas during the spraying process. The flue gas exits the system with a lower moisture content and is redirected to burner for combustion. As a result, the efficiency the combustion process will improve with less moisture in the flue gas.

Owner:THE BABCOCK & WILCOX CO

Integrated treatment and utilizing device for recovering and denitrating smoke waste heat and condensate water of natural gas

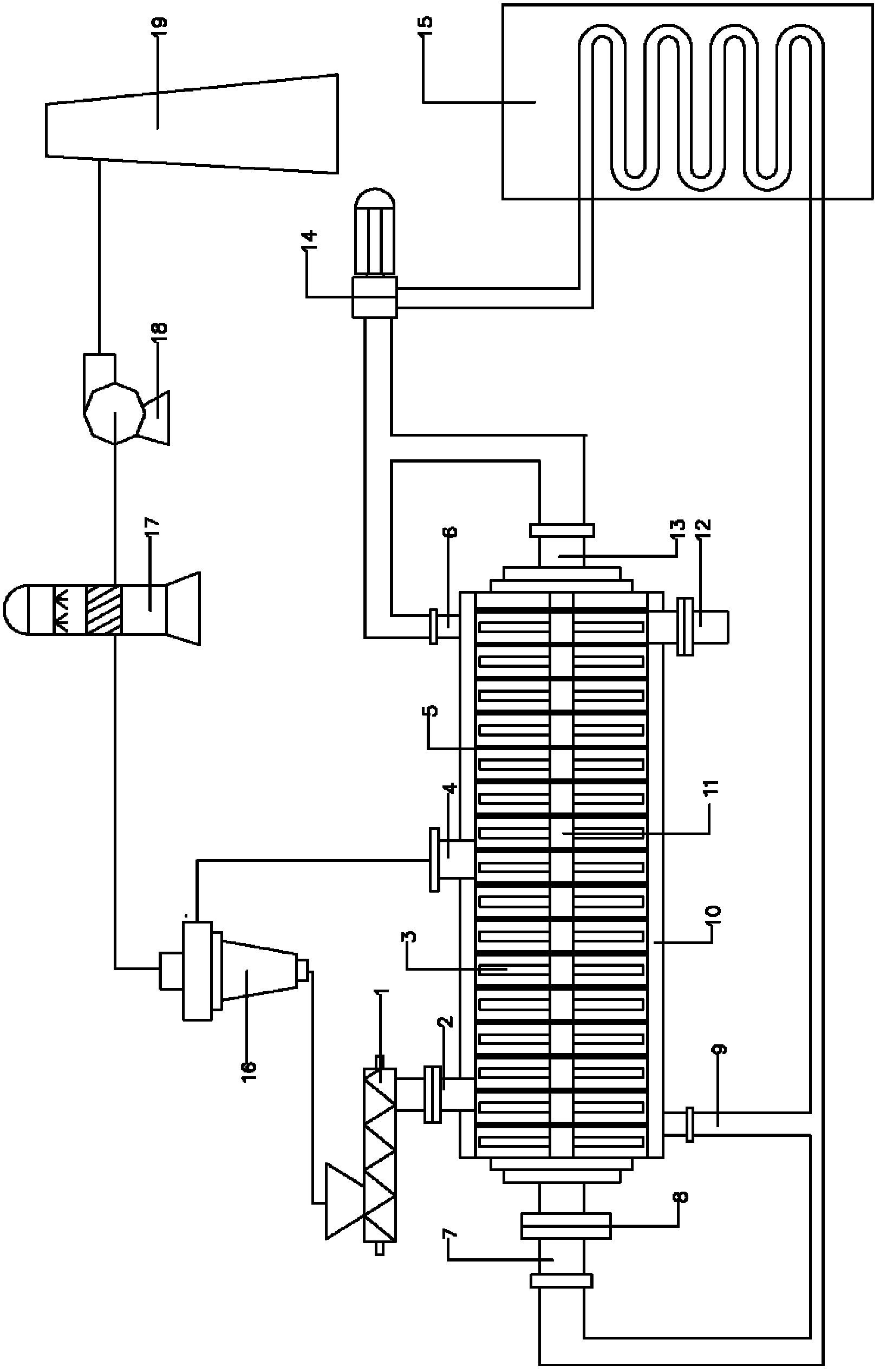

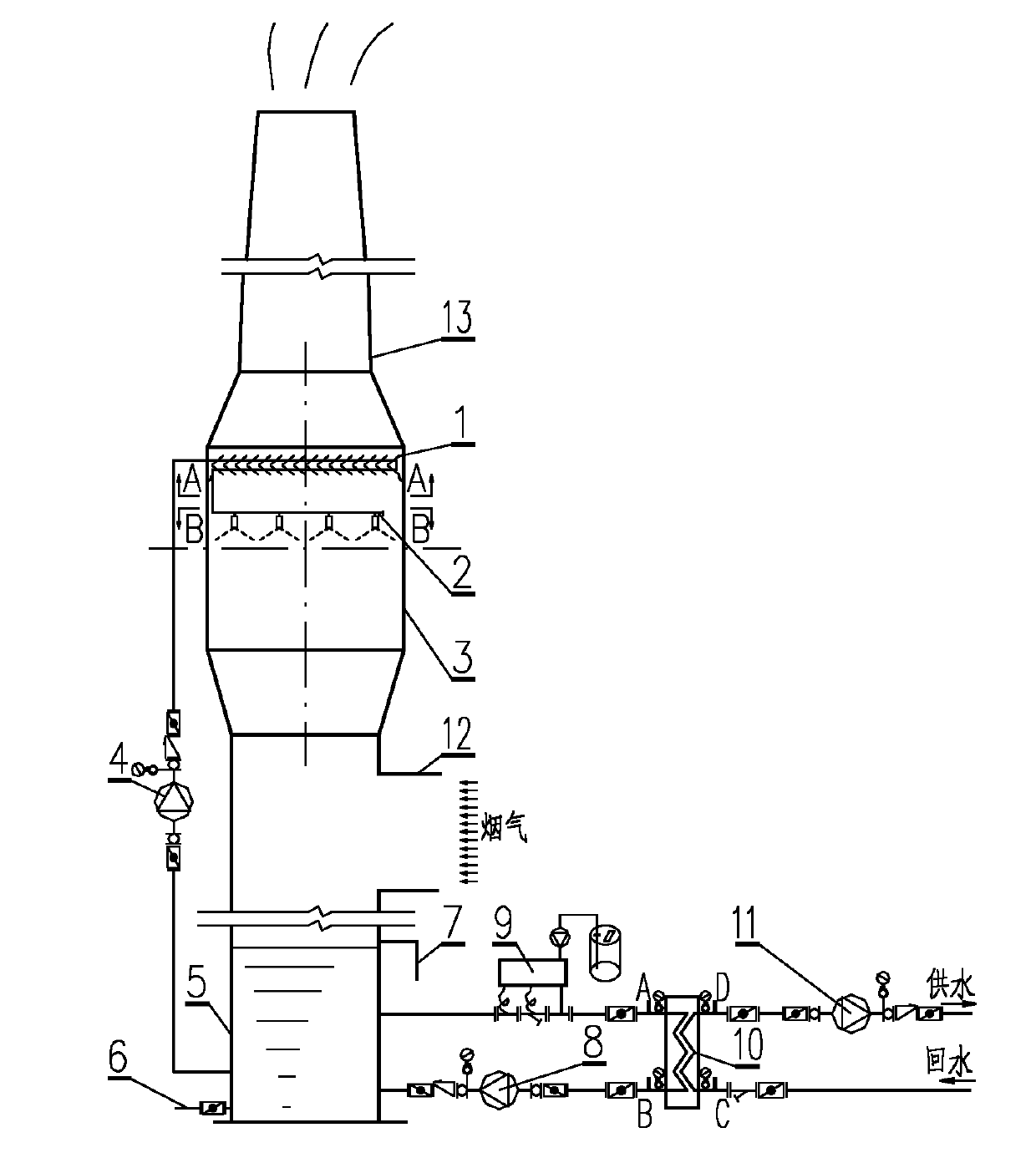

InactiveCN103721538AFew partsLow costLighting and heating apparatusDispersed particle separationWater qualityCogeneration

The invention relates to an integrated treatment utilizing device of recovering and denitrating smoke waste heat and condensate water of natural gas. The device is characterized by comprising a direct contact type spray tower, an injection device, an ozone generator, a water quality treatment device, a circular water pump, a heat pump and a spray device. The direct contact spray tower is provided with a smoke outlet and an inlet flue, wherein the injection device is arranged in the inlet flue and is communicated with the ozone generator through an air blower; a water tank is arranged at the bottom of the direct contact type spray tower, and an overflow hole is formed in the outer wall of the water tank; a circular cooling water outlet is formed in the bottom of the water tank, the circular cooling water outlet is communicated with a heat pump cold end inlet through the circular water pump, and the circular water pump inlet is communicated with an alkali liquor tank at the same time; the heat pump cold end outlet is communicated with a spraying device which is arranged in the direct contact type spray tower. The device provided by the invention can be widely applied to comprehensive treatment of smoke of the natural gas in natural gas boiler rooms, gas-steam combined cycle thermal power plants and gas heat, electricity and cold cogeneration systems with centralized heating sources.

Owner:TSINGHUA UNIV

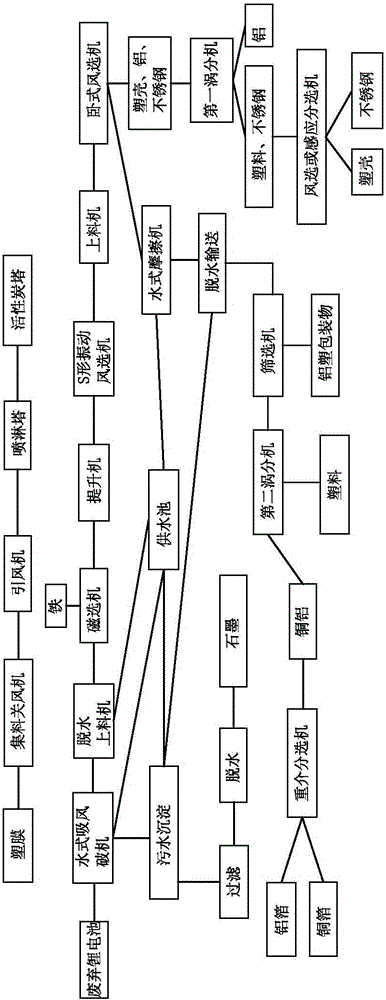

Method for smashing, detaching and recycling lithium battery

ActiveCN105811040AAvoid it happening againImprove processing efficiencyWaste accumulators reclaimingBattery recyclingCyclic processWater source

The invention relates to a method for smashing, detaching and recycling a lithium battery. Plastics, diaphragms, stainless steel, aluminium plastic films, aluminium, plastics, copper foils, aluminium foils, graphite and other materials are sorted from waste lithium batteries through a water type air-suction smashing machine, a magnetic separator, a horizontal type winnowing machine, a water-type friction machine, a first vortex separator, a second vortex separator and the like; the sorting purity can reach 94-99%; various kinds of harmful gases generated in the production process of the lithium batteries are processed by spray towers and activated carbon, and then the standardized gases are discharged; all the water required in the production process is recycled without an externally-discharged water source; and in addition, the water is precipitated, filtered and added with chemical drugs in the cycle process to carry out water treatment. According to the method, the waste batteries are not required to be pre-processed; instead, the waste batteries can be smashed, detached and recycled directly; therefore, the processing quality and processing efficiency of the waste batteries can be greatly improved; and in addition, pollutant emissions in the processing process can be effectively controlled.

Owner:哈尔滨巴特瑞资源再生科技有限公司

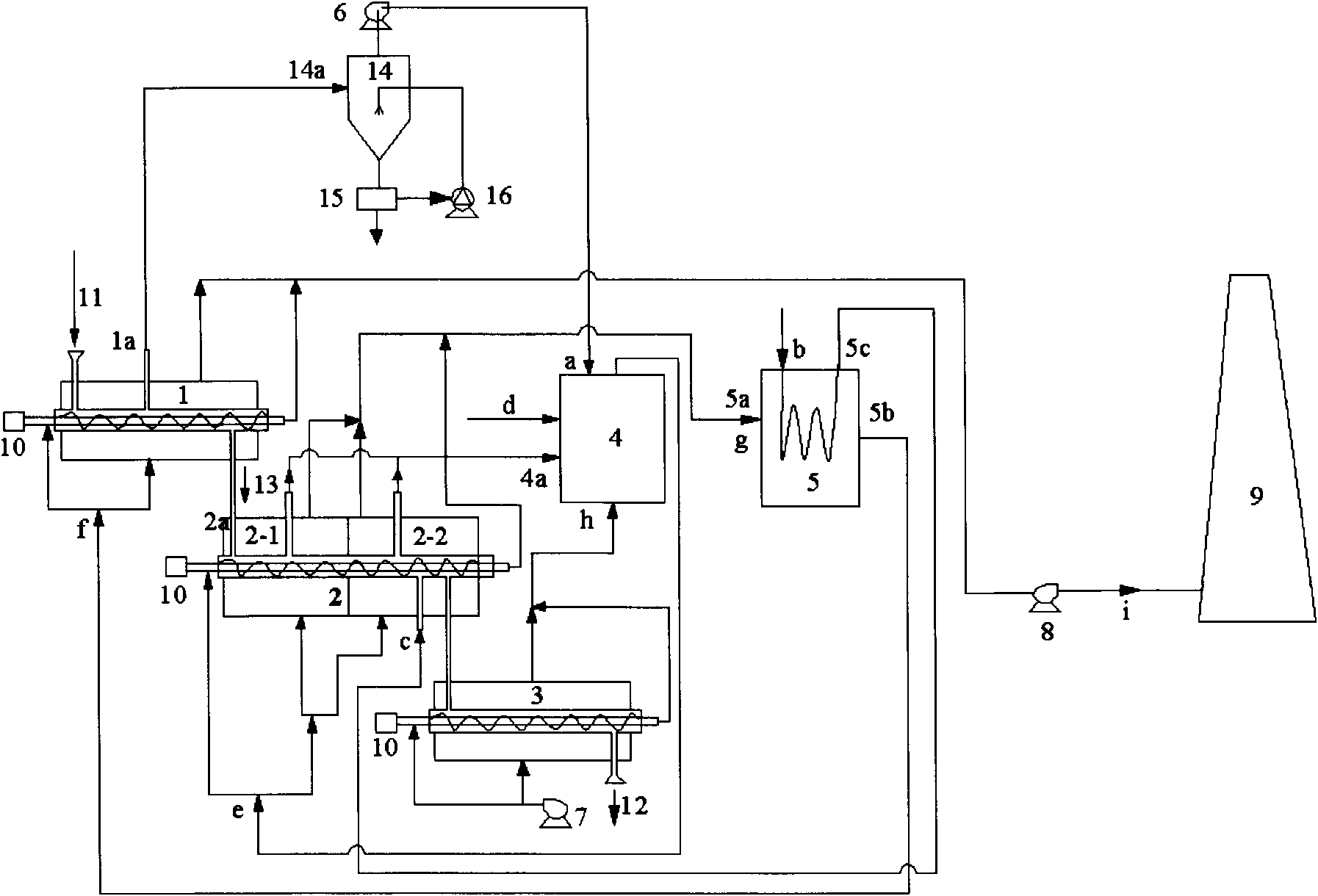

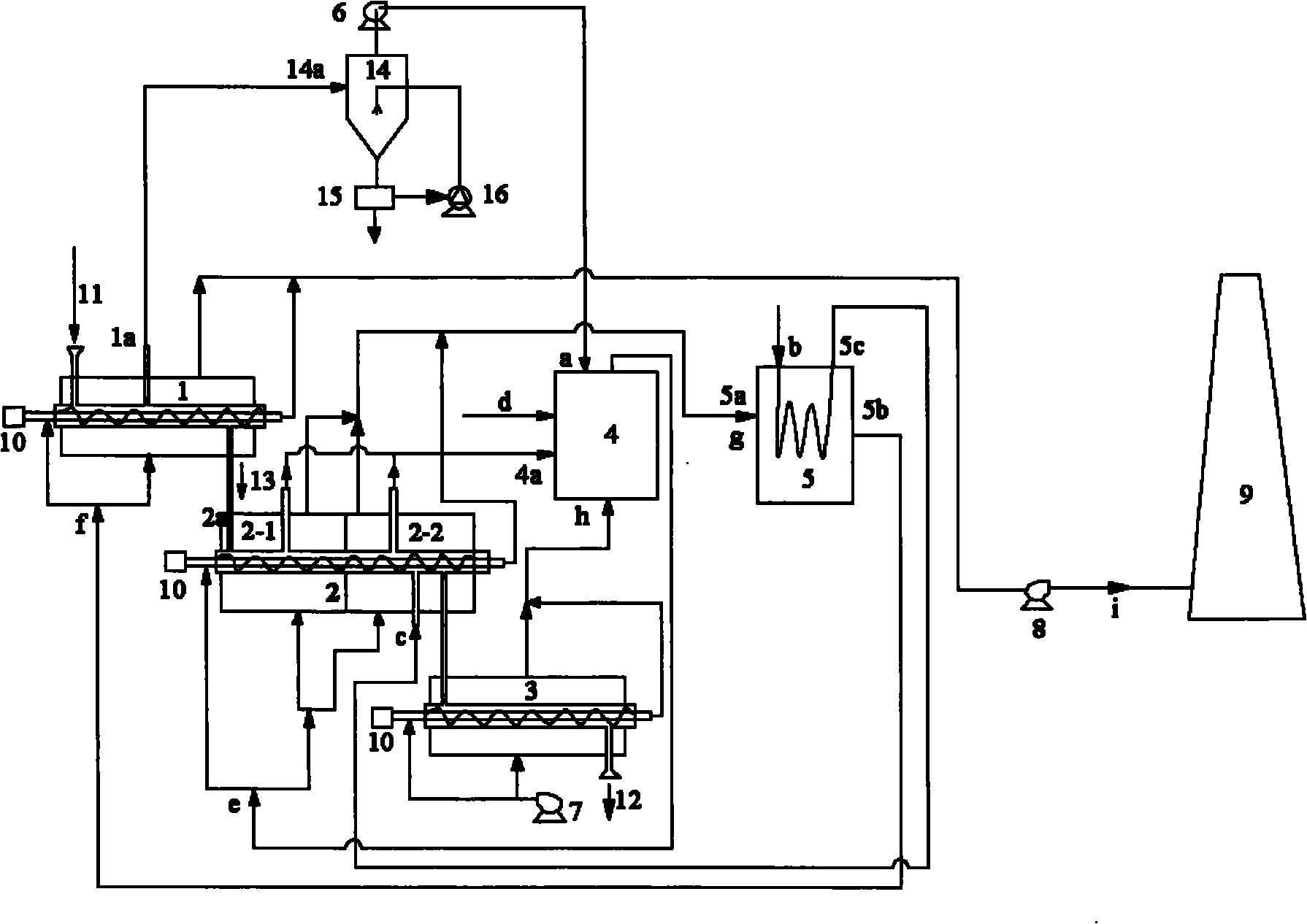

Device and method for continuously preparing active carbon by biomass in bulk

InactiveCN101885487ASolve for uniformityAvoid intermediate manual linksCarbon compoundsEnergy inputCombustionCarbonization

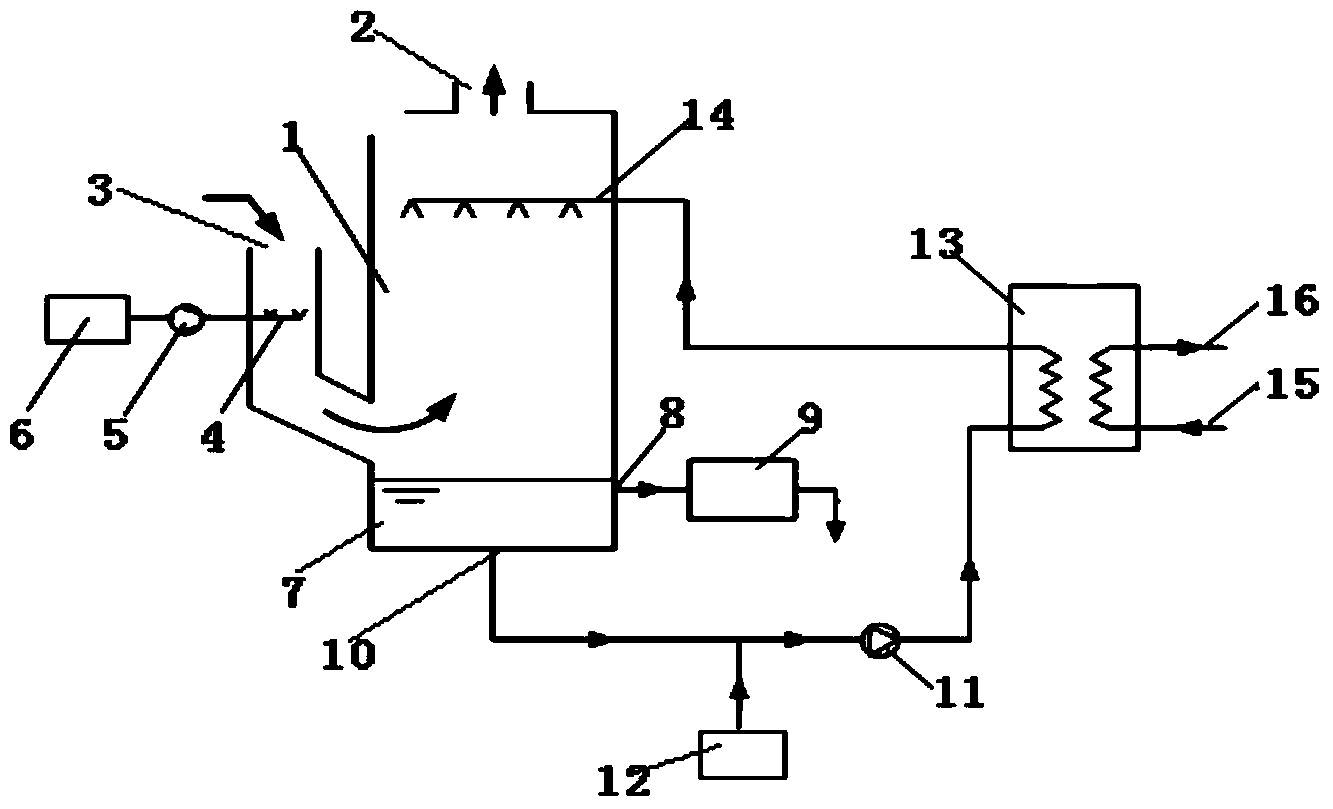

The invention relates to a device and a method for continuously preparing active carbon by a biomass in bulk. The invention is characterized in that the device comprises a spiral dryer (1), a spiral carbonization activation device (2), a spiral cooling device (3), a combustion furnace (4), a waste heat boiler (5), a circulating fan (6), a blower (7), an induced fan (8), a chimney (9), a velocity modulation motor (10), a spray tower (14), a waste liquor circulation pool (15), and a circulation water pump (16), wherein the spiral dryer (1) is provided with a feed port (11), a waste air outlet(1a), a material outlet after drying (13), a coil and a sleeve; and the spiral carbonization activation device (2) comprises a carbonization section (2-1) and an activation section (2-2) communicated with the carbonization section (2-1). By using the invention, the defects of low heat utilization efficiency, low drying / carbonization / activation efficiencies, discontinuous production course and the like in the existing active carbon preparation technology are overcome.

Owner:SOUTHEAST UNIV

One step spray-drying process

Capsules encapsulating an active or functional ingredient are obtainable by a process in which a feed that includes this ingredient is dispersed in the form of drops in a spraying tower and exposed to a temperature in the range of −20° C. to 500° C. In the tower, a cloud of suspended powdering agent provides a coating and prevents the capsules from sticking together and a reactant is provided to react with a polymer or film-forming carrier of the active ingredient so as to modify the water solution properties of the capsule walls.

Owner:FIRMENICH SA

Sludge reduction and recycling treatment device and sludge treatment method

InactiveCN104211274AAchieve recyclingHarmlessSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisOxygenCoal pyrolysis

Provided are a sludge reduction and recycling treatment device and a sludge treatment method. The method includes the steps of performing spray drying on dewatered sludge, mixing coal pyrolysis, using pyrolytic carbon incineration ash as a raw building material, recycling pyrolysis oil and pyrolysis gas as supplement energy, performing up-to-standard discharging on flue gas emitted by a pyrolysis furnace after subjecting the flue gas to treatment in a spray tower, a mist removal device and an activated carbon adsorption bed, and supplying an incinerator with low heat of the pyrolysis furnace. The sludge reduction and recycling treatment device and the sludge treatment method have the advantages of being capable of achieving a sludge recycling recovery rate of 95%, a sludge reduction rate of over 96%, a heavy metal solidification rate of 95% and zero emission of pollutants; the generation of harmful gas such as dioxin is inhibited due to fully-enclosed oxygen-free environment pyrolysis and sulfur in coal; residual dioxin can be decomposed by being burnt at the temperature above 950 DEG C so as to ensure no generation and emission of dioxin in an entire reaction process of a system; a mixture of flue gas, low heat, pyrolysis gas and pyrolysis oil can be recycled, so that energy consumption and treatment costs are reduced.

Owner:天津德人生态环境科技集团有限公司

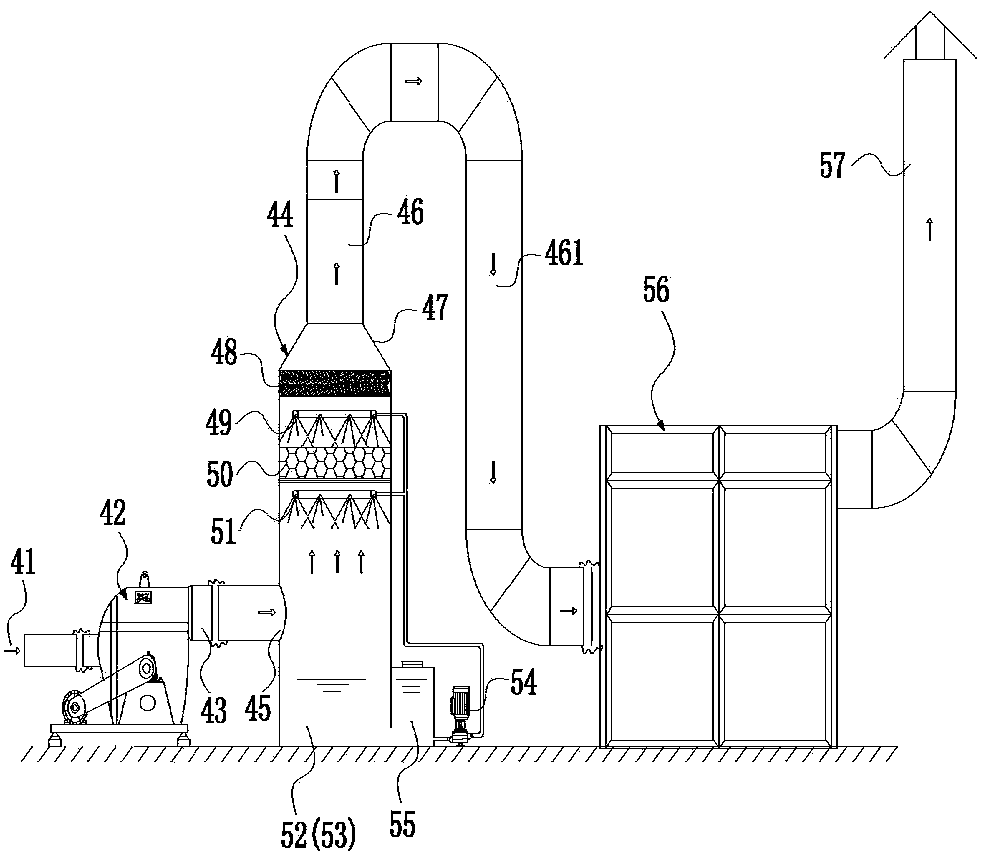

Semi-dry method refuse burning fume cleaning treatment method and system thereof

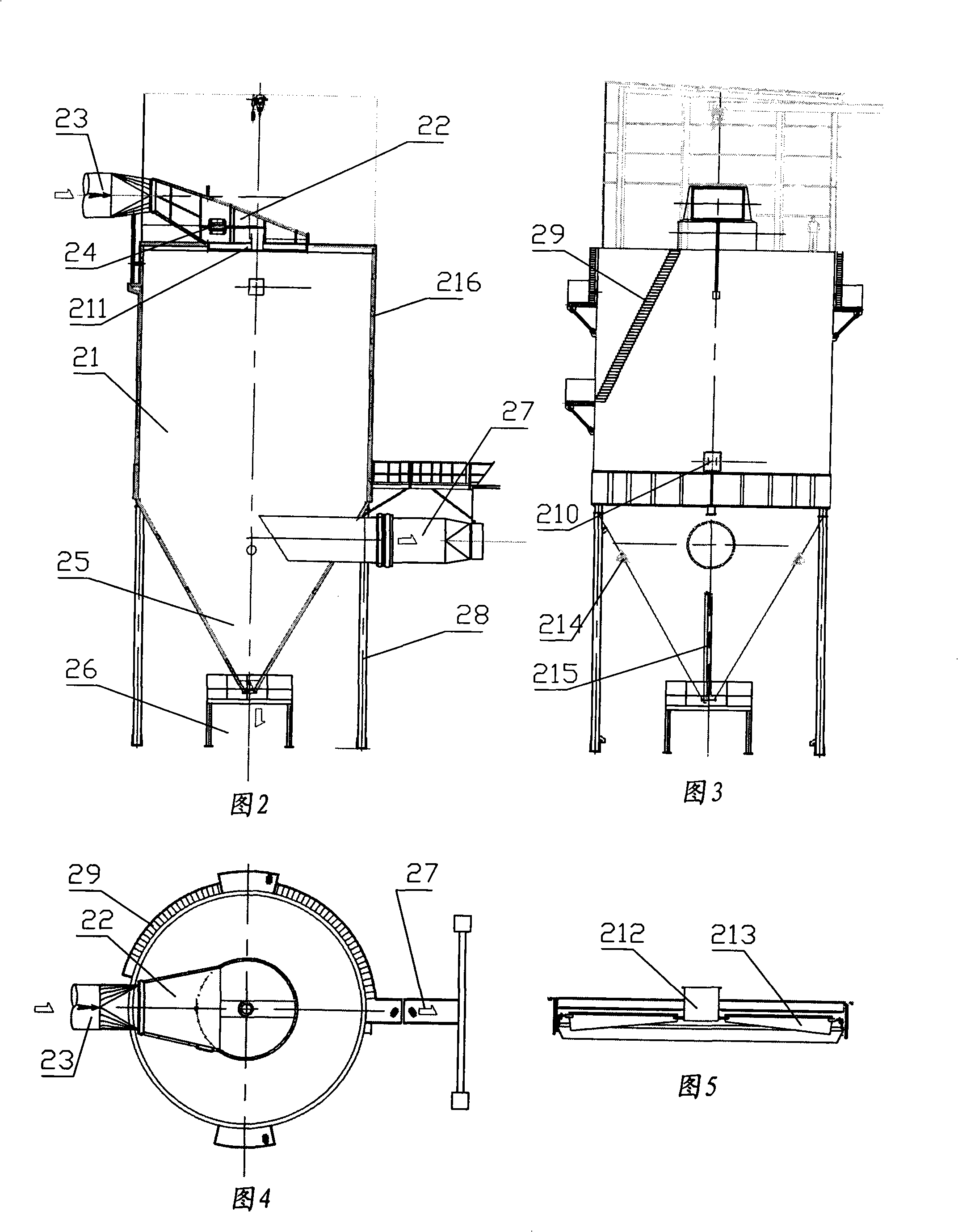

ActiveCN101310835AEvenly distributedImprove absorption efficiencyDispersed particle separationAutomatic controlWater discharge

The invention provides a semi-dry garbage incineration flue gas purifying treatment method and a system device thereof, flue gas enters a spray tower from a waste heat boiler, activated carbon is injected into a horizontal inlet flue to remove dioxin and heavy metals in the flue gas; the flue gas is simultaneously carried out the reaction with a high specific surface area alkaline neutralizer, most of the harmful substances in the flue gas are purified by generating chemical reactions with the alkaline neutralizer; when the flue gas passes through a filter layer which is formed by granule materials in a bag dust collector, gaseous pollutants can still be reacted with non-reacted lime and activated carbon in the filter layer to be further purified. The system device can lead the flue gas and the high specific surface area lime emulsion to achieve the best contact area, thus ensuring the best flue gas retention time, achieving the full heat transfer and the chemical and heat transfer process; furthermore, the spray is even, the anti-blockage and the anti-corrosion performances are better; a lime emulsion preparation device can automatically control and prepare the concentration and the using amount of the emulsion to be participated in the reaction according the content of wastes in the ingredients of the flue gas and the temperature of the flue gas; the usage and the regulation of the neutralizer are flexible. The system device further has the advantages of low investment cost, strong load adaptability and no waste water discharge, etc.

Owner:DESIGN INST OF CHONGQING IRON & STEEL GRP

System for drying persistent organic pollutants (POPs) polluted soil through flue gas waste heat

ActiveCN102615097ANo diffusionNo secondary pollutionCombination devicesContaminated soil reclamationHeat conductingEngineering

The invention relates to a polluted soil treatment technology and aims to provide a system for drying persistent organic pollutants (POPs) polluted soil through flue gas waste heat. The system comprises a self-cleaning blade dryer, a heat-conducting oil pump and a heat exchanger, wherein an extraction opening is formed on the upper side of a shell of the self-cleaning blade dryer and is connectedwith a dust remover; a lower outlet of the dust remover is connected with a feeder; an upper outlet of the dust remover is connected with a spray tower, the spray tower is connected with a draught fan, and the draught fan is connected with an exhaust funnel; and the heat exchanger is arranged in a tail flue gas channel of another independent thermal desorption device, and tail gas exhausted by the thermal desorption device serves as a heat exchange medium. By the system, soil drying and tail gas treatment are integrated, the tail flue gas of the independent thermal desorption device serves asa heat source of heat-conducting oil of a drying machine, on-site construction and installation are easily performed, a low-grade heat source is fully utilized, the energy consumption in the soil drying process is reduced, and the energy is saved; and moreover, the whole system has a compact structure and high drying speed, occupies a small space and can be continuously operated.

Owner:ZHEJIANG UNIV

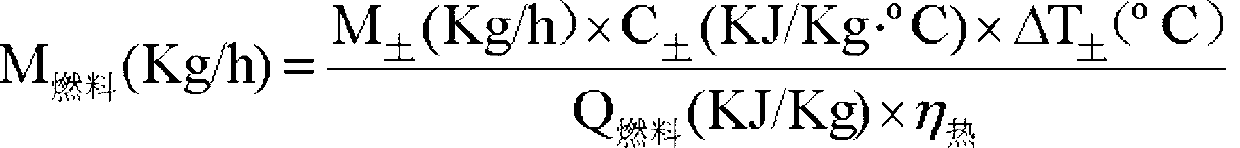

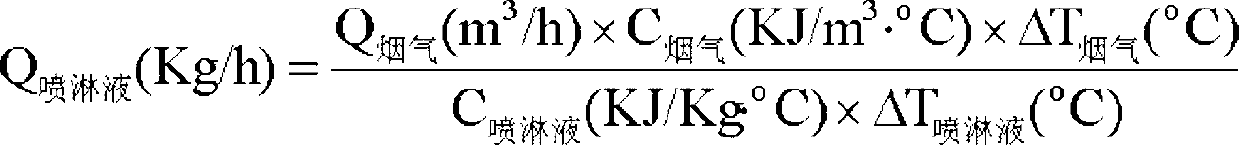

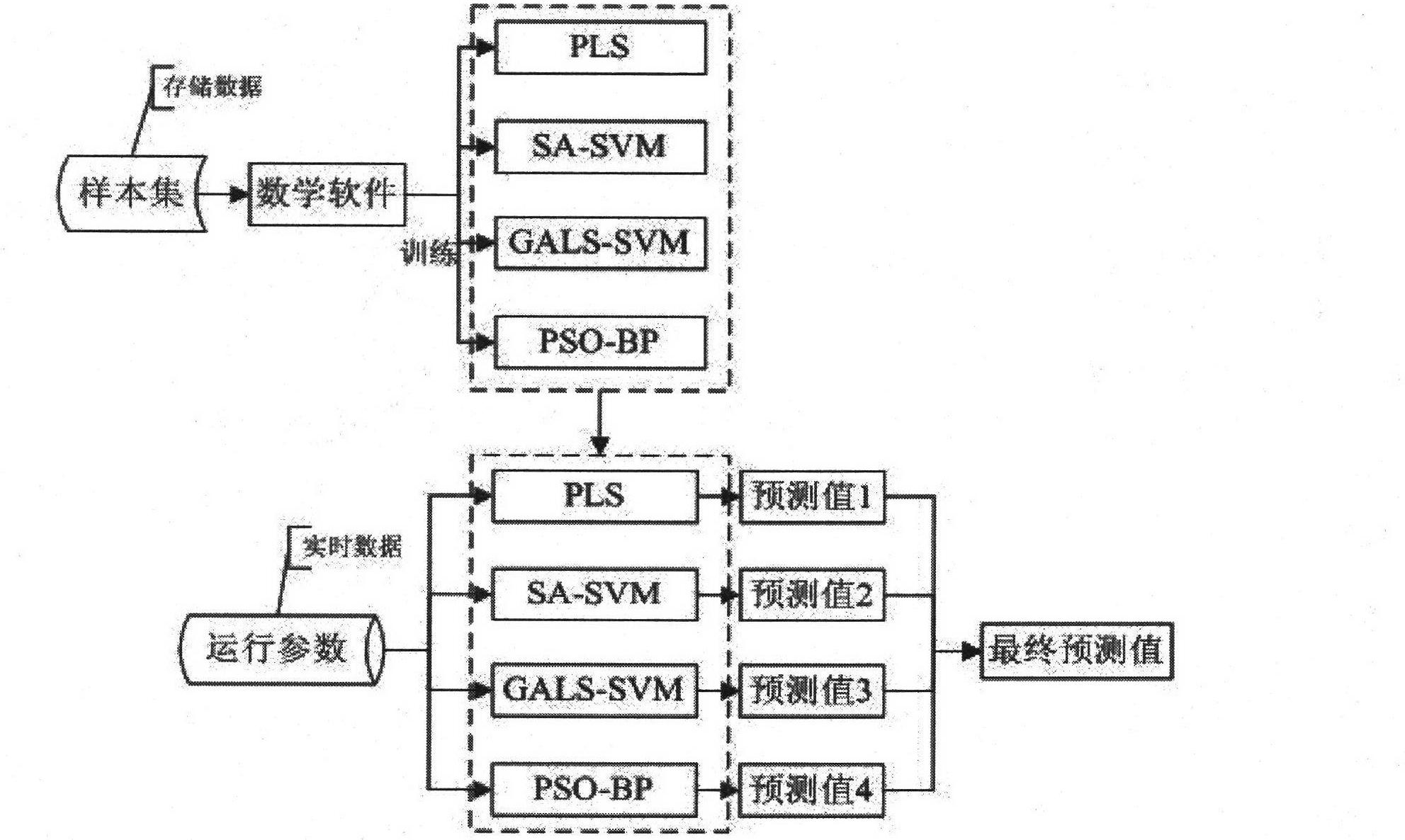

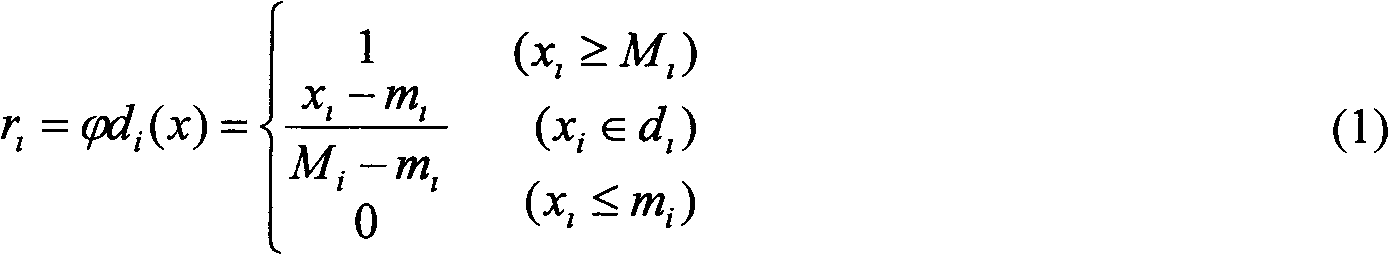

Method for predicting ammonia process flue gas desulphurization efficiency based on multiple parameters

InactiveCN102693451AReal-time monitoring of desulfurization efficiencyThe method is scientific and reasonableDispersed particle separationBiological neural network modelsPredictive methodsSlurry

The invention relates to a method for predicting ammonia process flue gas desulphurization efficiency based on multiple parameters. The method is characterized by comprising the following steps of: selecting four different artificial intelligent computation models and taking parameters acquired in an ammonia process desulphurization system operational process such as multiple groups of flue gas amounts, flow of a circulating pump, the flow of a concentration pump, the ammonia concentration, the concentration of absorption liquid, the liquid-gas ratio, the inlet flue gas temperature, the ammonia consumption, the density of spraying slurry, the pH value of slurry of a spraying tower and the pH value of the slurry of a pre-washing tower as input variables of the four models; respectively training each model, and establishing a non-linear function relationship between four desulphurization parameters and the desulphurization efficiency; then respectively transmitting parameters monitored in real time into the trained artificial intelligent model, and predicting the desulphurization efficiency; and taking the average value of two predicted values in the middle as a final predicted value... The method disclosed by the invention can be used for better predicting the ammonia process desulphurization efficiency and has the characteristics of higher stability and stronger prediction capability compared with single model prediction.

Owner:NORTHEAST DIANLI UNIVERSITY

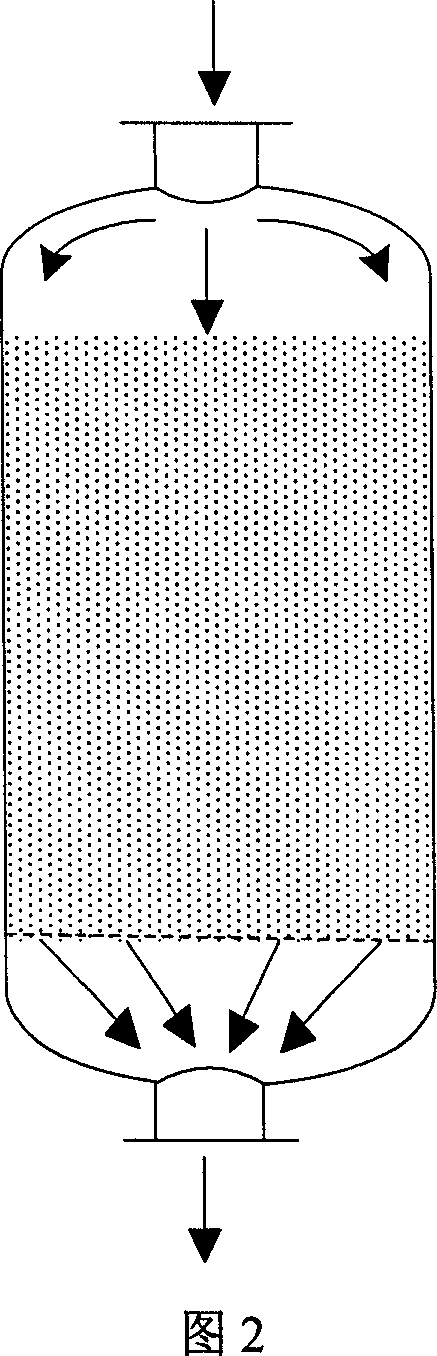

Method and equipment for atomizing, cooling and granulating nylon polymer

The invention relates to a method for spraying, cooling and granulating a nylon polymer. The method comprises the following steps of: conveying a nylon polymer melt in a reaction kettle to a pressure sprayer on the top of a spraying tower by a heat-insulating pipeline under the pressure action, spraying the nylon polymer melt from the pressure sprayer, dispersing into fine fog drips, flashing moisture in the fog drips at high temperature, and drying quickly; cooling the high-temperature fog drips by cooling gas which enters the spraying tower to form uniform nylon solid granules, and settling the nylon solid granules in the tower; opening a gas outlet of the spraying tower, starting a draught fan, leading mixed gas in the spraying tower out of the gas outlet, and maintaining pressure of -100 to 20 Pa in the spraying tower; and collecting the nylon solid granules which drop to the bottom of the spraying tower, grading, and packaging to form a finished product. The invention also provides equipment for spraying, cooling and granulating the nylon polymer. By the method and the equipment, the discharge speed is improved, the granularity is increased, and discharged materials can be protected by nitrogen to prevent the materials from being oxidized; and the device is high in controllability and regulation performance.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

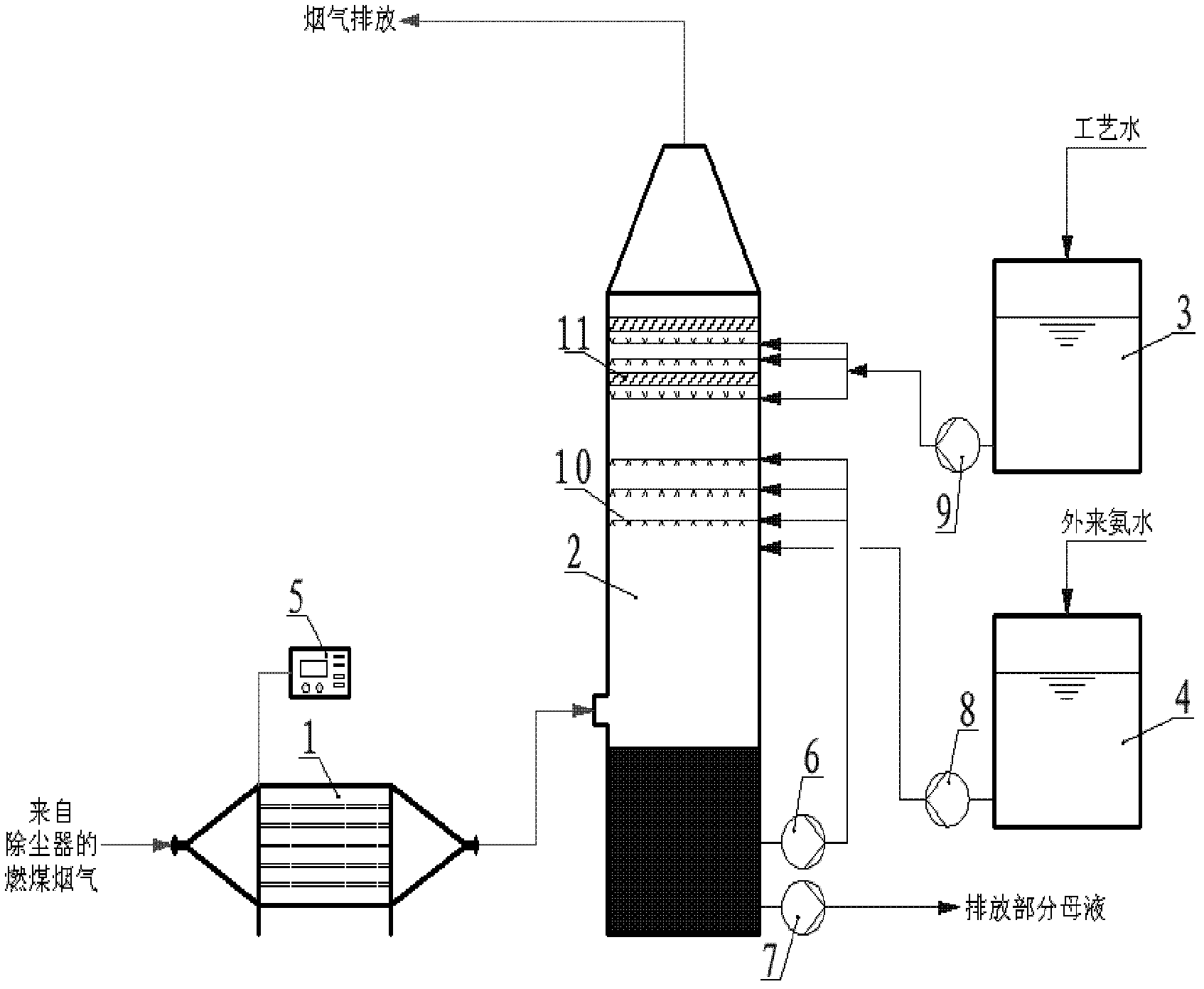

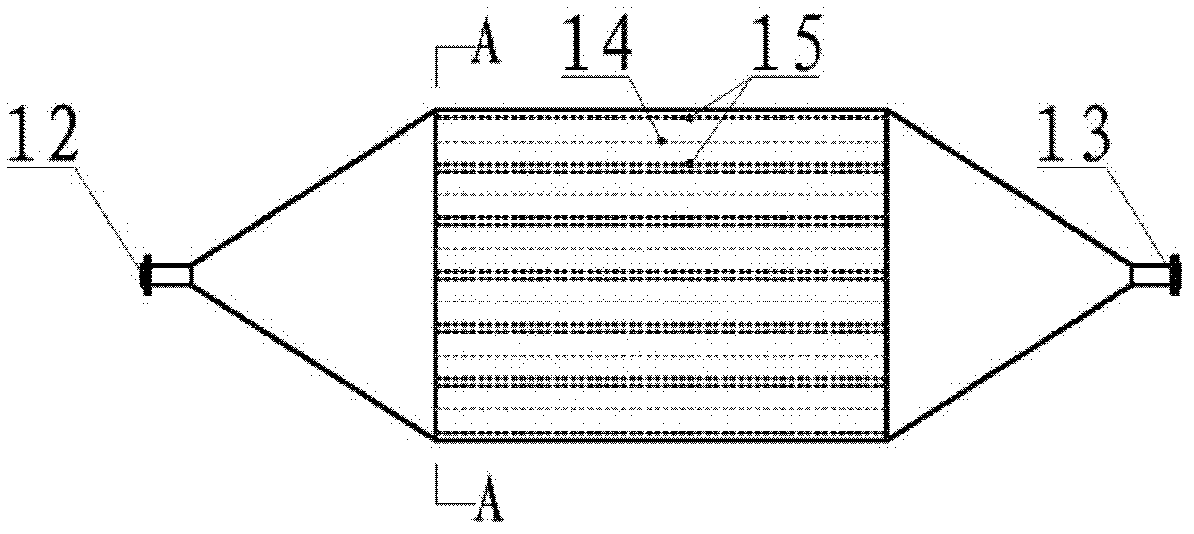

Coal-fired flue gas desulphurization denitration process and desulphurization denitration device thereof

InactiveCN102500207AImprove absorption rateHigh removal rateAmmonium nitratesDispersed particle separationLow temperature plasmaChemistry

The invention discloses a coal-fired flue gas simultaneous desulphurization denitration process by low temperature plasma oxidation combined with ammonia-method wet absorption; the process comprises two processes of low temperature plasma oxidation and ammonia-method wet absorption; coal-fired flue gas to be treated is firstly introduced into a low temperature plasma reactor through a flue, and thus 40%-50% of NO in the flue gas is oxidized into NO2; the conditioned flue gas is introduced into a simultaneous desulphurization denitration spray tower, and fully contacts ammonia water absorption liquid so as to remove SO2 and NOx in the flue gas and discharge the flue gas; the absorption liquid at the bottom of the simultaneous desulphurization denitration spray tower is delivered into a spray layer again for recycle through an absorption liquid circulating pump; ammonia water in an ammonia water groove is supplied continuously to the spray tower through an ammonia water pump; and a part of mother liquor is discharged through a mother liquor transfer pump. The process of the invention is applicable to the simultaneous desulphurization denitration treatment of coal-fired flue gas, and the device of the invention has the advantages of good pollutant removing effect, simple equipment, less land occupation, convenient operation, and convenience for management.

Owner:SOUTHEAST UNIV

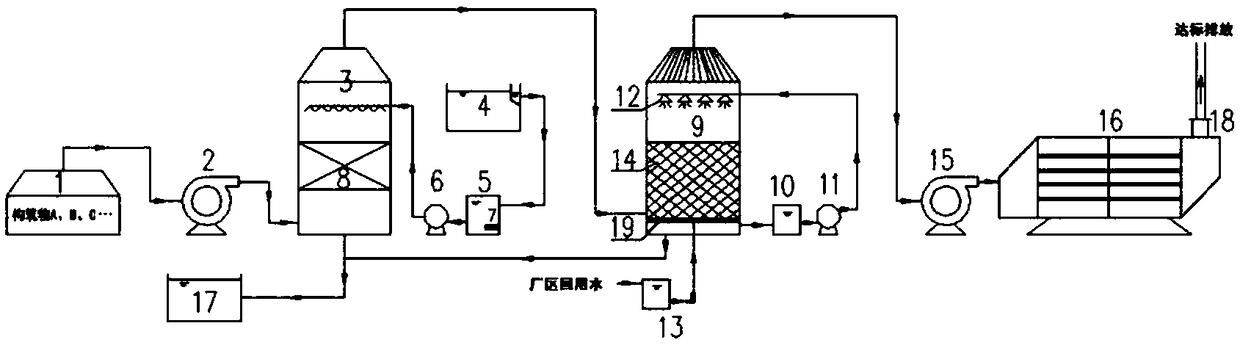

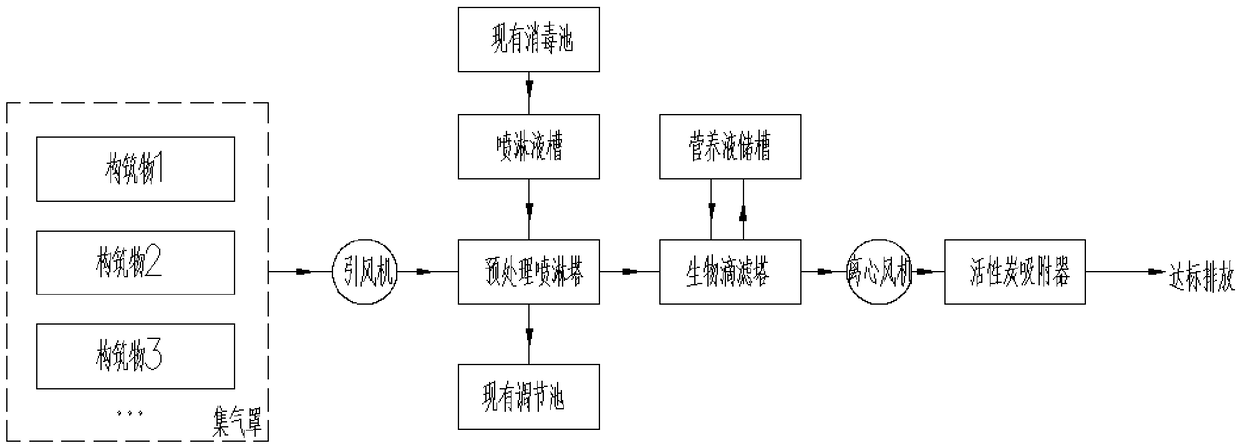

Sewage treatment plant odor collection and treatment system and method

PendingCN108854355AAvoid cloggingNo cloggingCombination devicesGas treatmentLiquid wasteSpray nozzle

The invention discloses a sewage treatment plant odor collection and treatment system and method. The system comprises a gas collecting cover, a draft fan, a pretreatment spraying tower, a sterilization pool, a biological drip filtering tower, a centrifugal fan, an active carbon adsorption device and a regulating pool, wherein the gas collecting cover is arranged above a building pool body radiating odor, and is communicated with the lower part of a pretreatment spraying tower through the draft fan; the sterilization pool is communicated with the upper part of the pretreatment spraying tower;waste liquid discharged from the bottom of the pretreatment spraying tower flows back to the regulating pool through a pipeline; the lower part of the biological drip filtering tower is communicated with the top of the pretreatment spraying tower through a pipeline; odor subjected to pretreatment enters the biological drip filtering tower; a group of spray nozzles are arranged on the top of the biological drip filtering tower and downwards and intermittently spray nutrition liquid; the active carbon adsorption device is communicated with the top of the biological drip filtering tower through acentrifugal fan and is used for performing further treatment on the waste gas treated in the biological drip filtering tower and then discharging the waste gas in a standard reaching way. The investment is saved; the occupied area is small; the equipment is simple; the deodorization efficiency is high; the pollution bearing load is high; the operation cost is low.

Owner:HUBEI JUNJI WATER TREATMENT

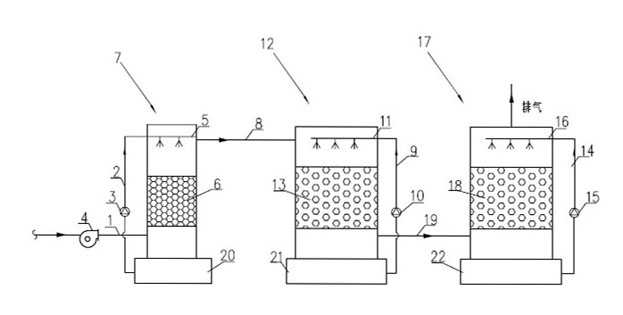

Method for treating odors produced by drying sewage sludge

InactiveCN102068878AReduce usageAvoid temperature riseDispersed particle separationSecondary emissionChemical reaction

The invention discloses a method for treating odors produced by drying sewage sludge. The method comprises the following steps: (1) delivering odors exhausted by a sewage sludge drying system to a pretreatment tower through a fan to be rinsed with clean water, wherein the components soluble in water in the odors are absorbed by the clean water, and the odors are cooled at the same time; (2) rinsing the pretreated odors in a primary spraying tower, wherein the acid gases and volatile organic compound gases in the odors are subjected to chemical reaction with the spraying solution with strong oxidability and alkalinity in the primary spraying tower and are absorbed; (3) rinsing the remaining gases after treatment in the step (2) in a secondary spraying tower, wherein alkaline gases in the gases are subjected to neutralization reaction with the acid spraying solution in the secondary spraying tower and are absorbed; and (4) exhausting the tail gases after treatment in the step (3) through an exhaust pipe. After the odors produced by drying the sewage sludge are treated by the method disclosed by the invention, the obtained tail gases can reach the secondary emission standard in the Emission Standards for Odor Pollutants (GB14554-93).

Owner:广州中洲环保科技有限公司

VOC (volatile organic compound) waste gas treatment system

ActiveCN104028086AEasy to handleImprove efficiencyCombination devicesUsing liquid separation agentActivated carbonEnvironmental engineering

The invention discloses a VOC (volatile organic compound) waste gas treatment system. The VOC waste gas treatment system sequentially comprises a fan, a padding spray tower device, an ultraviolet activated carbon integrated device and a purified gas discharge opening, wherein the fan is connected with a VOC waste gas source; the padding spray tower device is connected with an air outlet of the fan; the ultraviolet activated carbon integrated device is connected to an air outlet of the padding spray tower device; the purified gas discharge opening is connected to the ultraviolet activated carbon integrated device. Waste gas is treated efficiently by the design of combining the padding spray tower with the ultraviolet activated carbon integrated purifier. Firstly, the padding spray tower is used for spraying washing; organic waste gas is dissolved into a purifying liquid well by multi-surface hollow spheres; then air water of a defogging layer is matched to share efficiently, so that gas after primary treatment is obtained by the padding spray tower. The gas after primary treatment is treated by the ultraviolet activated carbon integrated purifier, and clean gas reaching the standard is discharged out. The size of the device is reduced; the waste gas treatment efficiency is high; the purification cost is reduced; the purification standard reaching effect is ensured.

Owner:DONGGUAN CITY HUANSHUN ENVIRONMENTAL PROTECTION EQUIP IND

Secondary zinc oxide slurry treating light concentration SO2 flue gas method and device thereof

ActiveCN101254393ASolve the blockageImprove absorption efficiencyDispersed particle separationSlurryDevice failure

The invention relates to a method which adopts secondary zinc oxide slurry to treat SO2 off-gas having low concentration, as well as the device thereof, and has the following steps: water or filtrate is used for preparing slurry together with secondary zinc oxide; the slurry is delivered to the liquid collecting trough of a torrential scrubber; the slurry in the liquid collecting trough is pumped into the reverse spraying tower nozzle of the torrential scrubber through a circulation pump, the slurry is delivered to an oxidation tower through an agitator pump, sulfuric acid is added from the top part of the oxidation tower, compressed air is input from the bottom end, the oxidated slurry is discharged into an acid hydrolysis trough, and the acid hydrolysis slurry is pumped into a box filter press through a pressing filter pump for realizing solid-liquid separation; the secondary zinc oxide slurry is adopted to absorb the SO2 in the smelter off-gas, so as to enable the processed off-gas to reach standard discharge, and reduce the pollution to the environment caused by the SO2 off-gas of a lead-zinc smeltery, thereby having the advantages of high operating rate, good working condition, low equipment failure rate, high desulfurization efficiency, etc., and enabling the sulfur, zinc and lead resources to be comprehensively utilized.

Owner:HENAN YUGUANG GOLD & LEAD

Contact-type advanced recycling system for waste heat of low-temperature flue gas

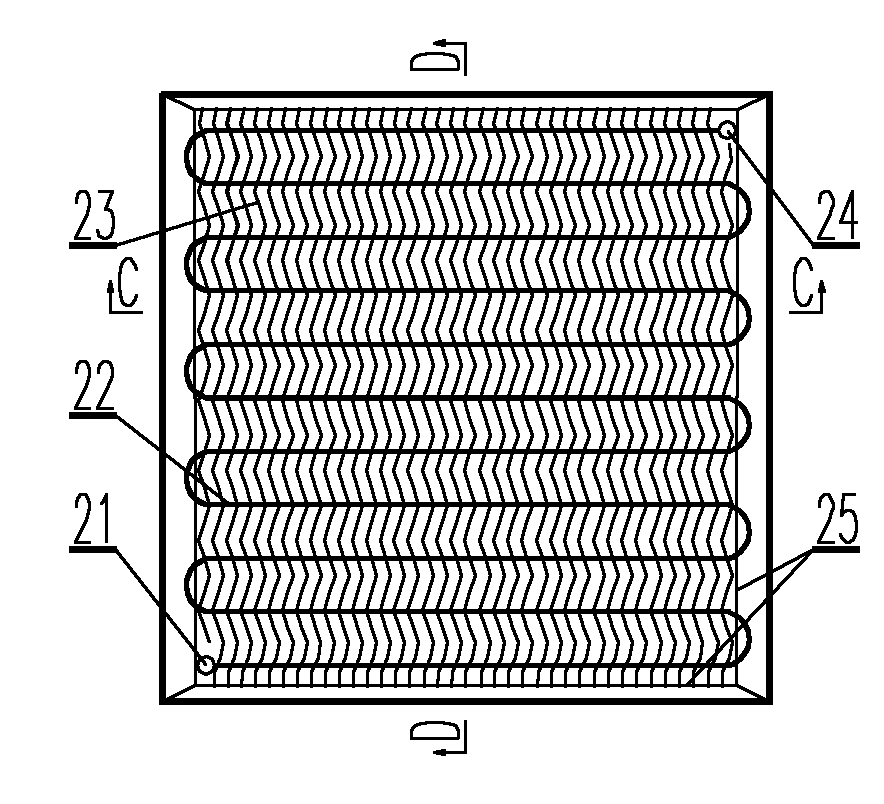

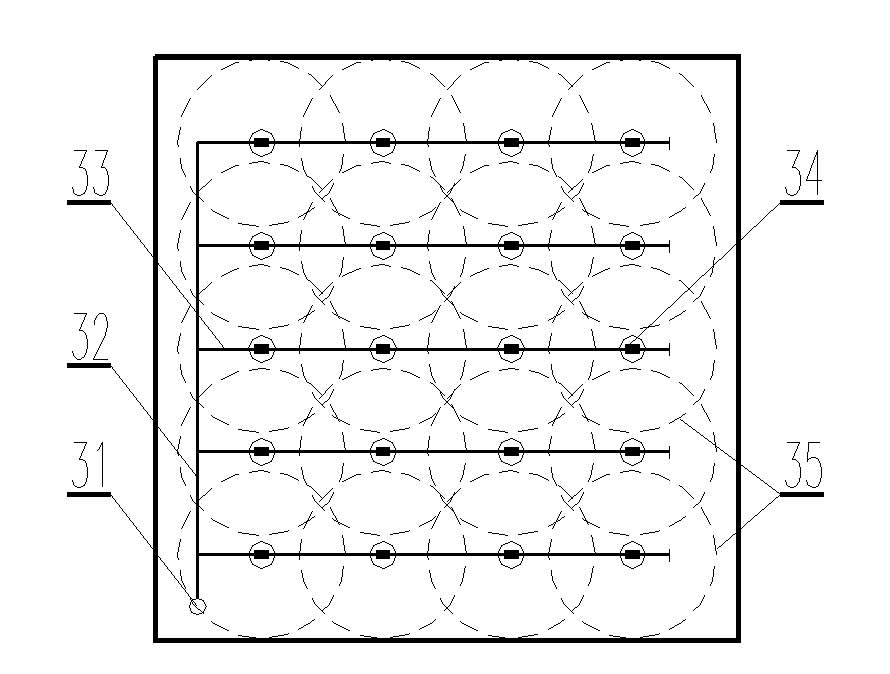

InactiveCN102168888AIncrease surface areaReduce volumeUsing liquid separation agentEnergy efficient heating/coolingWater vaporWater storage tank

The invention relates to a contact-type advanced recycling system for the waste heat of low-temperature flue gas, and belongs to the technical field of the advanced recycling of the waste heat of the flue gas. The system comprises a contact-type advanced recycling subsystem for the waste heat of the low-temperature flue gas, a heat storage and water quality maintaining purification subsystem and a waste heat output utilization subsystem, wherein the contact-type advanced recycling subsystem for the waste heat of the low-temperature flue gas mainly comprises a water retaining condenser with a multifunctional fin, a water distributor, a contact-type spray tower and a spray pump; the heat storage and water quality maintaining purification subsystem mainly comprises a hot water sedimentation water storage tank, a drainage pipe, an overflow pipe, a circulating pump and an full-automatic water quality measuring control maintainer; and the waste heat output utilization subsystem mainly comprises a plate-type heat exchanger and a water feeding pump. By utilizing the contact-type advanced recycling system, the sensible heat of the flue gas is recovered, and a large amount of water vapor latent heat in liquid and gas fuel flue gas is also recovered; therefore, the contact-type advanced recycling system has the effects of washing and purifying the flue gas and the effects of washing and weakening acid corrosion on equipment and flues.

Owner:TSINGHUA UNIV +1

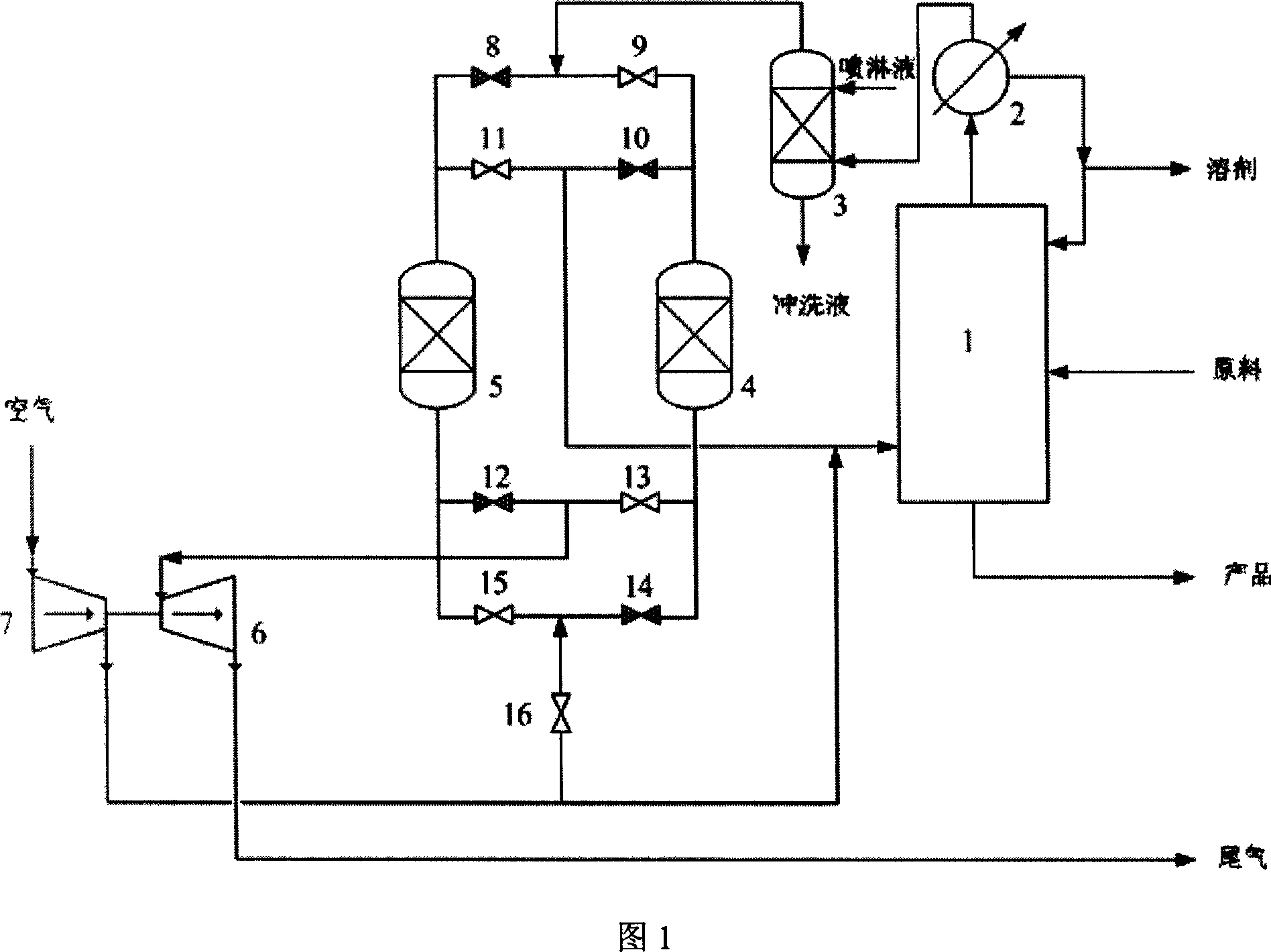

Process and apparatus for purifying arene oxidizing tail gas

InactiveCN1973958ALow costEase of industrial applicationOrganic compound preparationDispersed particle separationSorbentDesorption

The present invention discloses process and apparatus for purifying arene oxidizing tail gas. Two adsorbing beds with filled adsorbent are adopted for alternate adsorption and desorption of organic matter from the tail gas. While one adsorbing bed adsorbs organic matter from the tail gas, the other one desorbs to recover organic matter with compressed air or nitrogen as the desorbing gas and to regenerate the adsorbent, with the desorbed organic matter being returned to the oxidizing system together with the desorbing gas for reuse. The present invention needs no additional desorbed gas treating apparatus and recovers organic matter directly with the tail gas treating apparatus in the oxidizing system, such as condenser, spraying tower, gas waster, etc. The present invention has low adsorption purifying cost and is suitable for industrial use.

Owner:ZHEJIANG UNIV

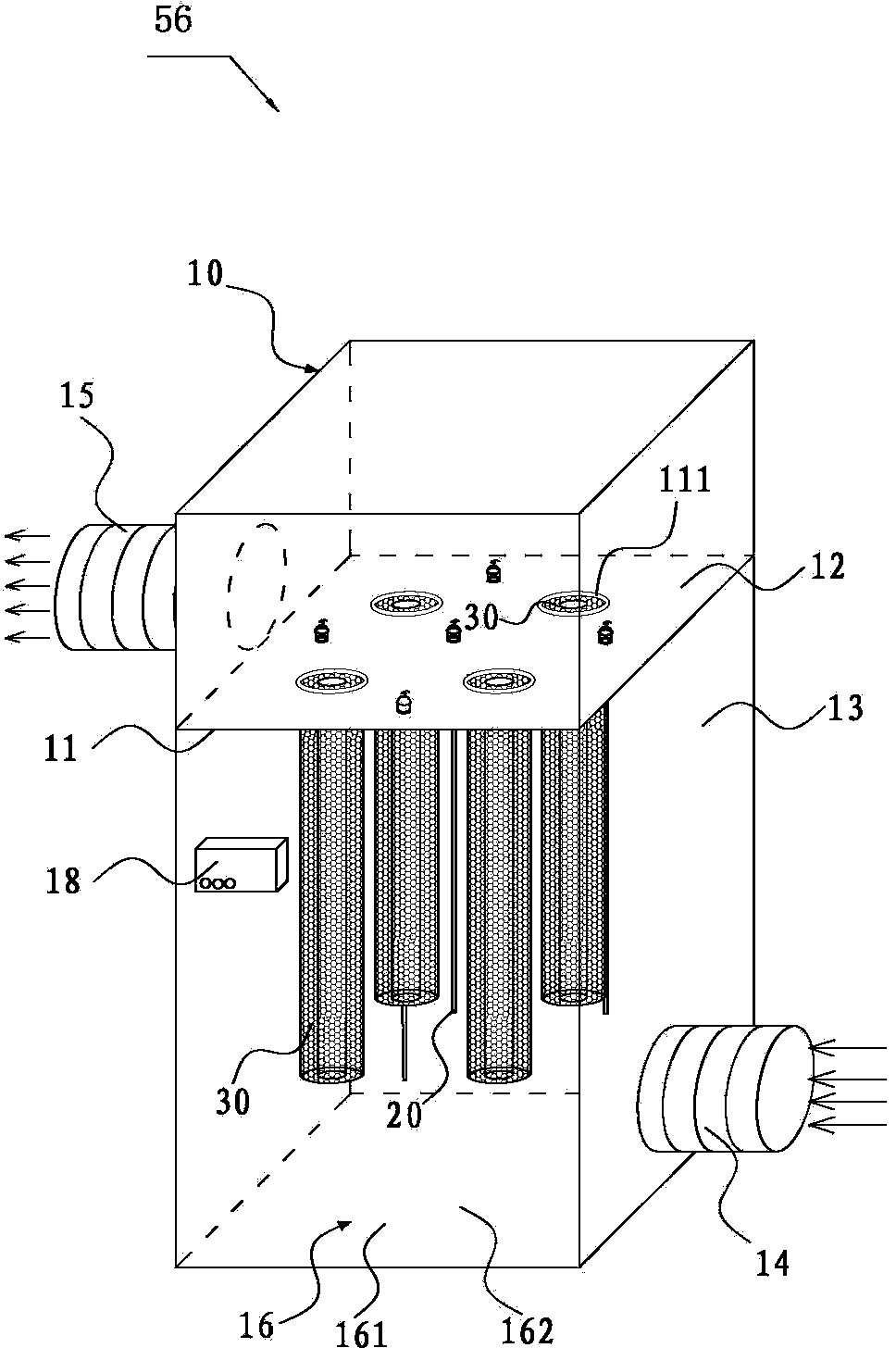

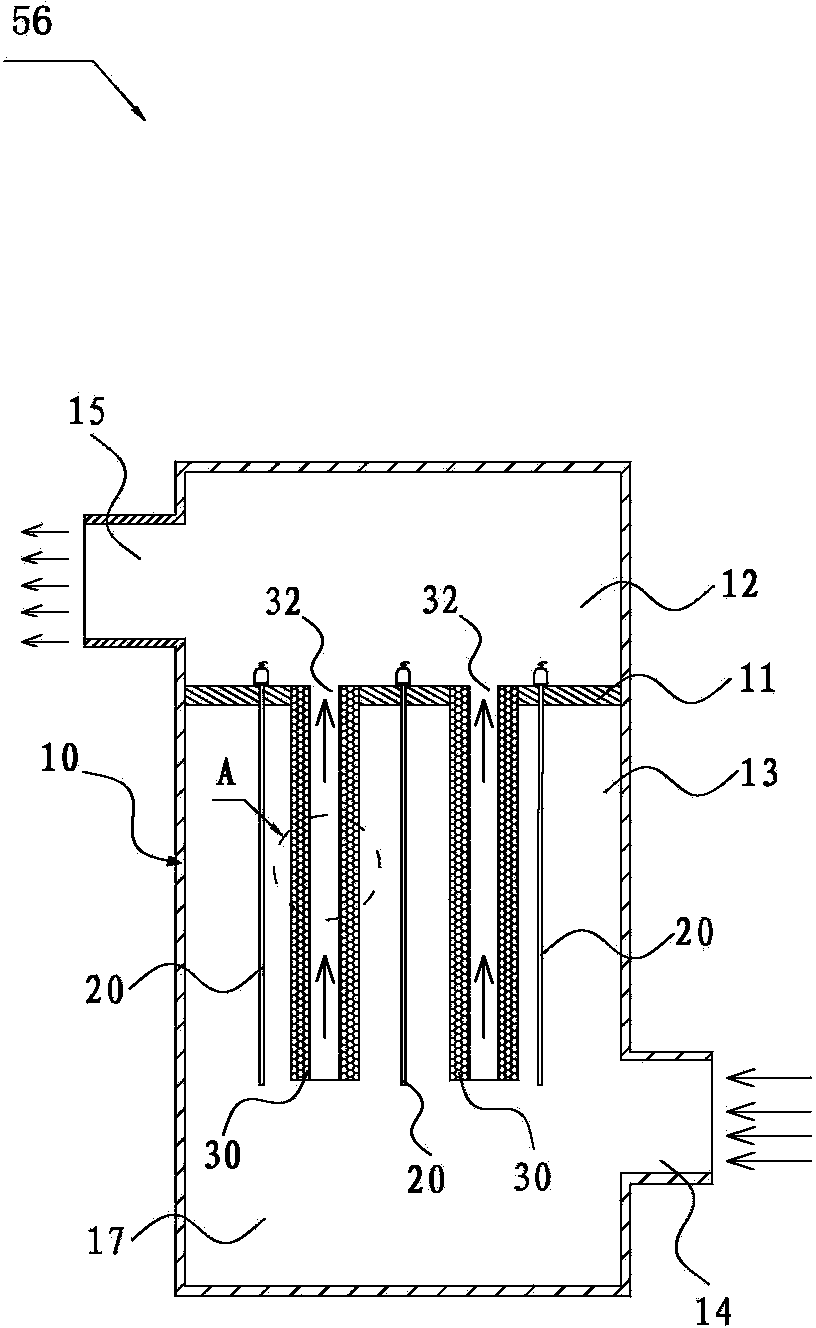

Paint spray waste gas treatment integrated device

InactiveCN107149845AReduce paint odorIncrease contact surfaceCombination devicesGas treatmentTreatment effectSpray tower

The invention relates to a paint spray waste gas treatment integrated device and a process thereof, belonging to the technical field of environment protection. The bottoms of spray towers are connected with a ventilation device of a paint spray workshop through guide air tubes, the two spray towers are connected with corresponding circulating water tanks through a circulating water pump, the circulating water tanks are internally provided with water tank detection devices, the tops of the spray towers are provided with output ducts, the output ducts are provided with intelligent detectors, tail ends of the output ducts are connected with a centrifugal fan, and the other end of the centrifugal fan is connected with a fog filter. The paint spray waste gas treatment integrated device has a reasonable structure design, has a simple process, is convenient to operate, is highly flexible, has high stability and a high waste gas treatment effect, is low in running cost, can treat waste gas of different paint spray workshops at the same time and has high efficiency; and the treatment device is low in cost, has a high use ratio, and can achieve a better environment protection effect.

Owner:张荟芬

Method of producing propionic acid and propionate by microorganism fermentation

ActiveCN101748163AImprove securitySolve consumptionMicroorganism based processesCarboxylic acid salt preparationChemical synthesisPropanoic acid

The invention relates to a method of producing propionic acid and propionate by microorganism fermentation, which is characterized by using microorganism fermentation technology to produce propionic acid; with propionibacterium, charging the nitrogen into basic fermentation culture medium which takes glycerin as a carbon source for anaerobic fermentation culture; movably adding the aqueous solution of calcium hydroxide, or the alkaline solution or the saline solution of sodium hydroxide and calcium carbonate with the ongoing of fermentation, adjusting the fermentation liquor and maintaining the pH value between 6.5 to 7.5; movably adding the aqueous solution of glycerin after the fermentation preformed for a period of time; the fermentation is finished when the content of glycerin stops increasing and is more than 35g / L; and then filtering the fermentation liquor through a pressure filter, getting the filtered solution, charging the filtered solution into a spray tower for spray drying, and the dried powder is the propionate product. The invention has the effects: the method can substitute the existing chemical synthesis to produce propionic acid, remarkably improving the safety of the propionic acid product, and is a green food additive; moreover, the problem of consumption of non-renewable resources (such as oil) can be solved without a secondary processing, the negative impact generated by chemical synthesis can be prevented, and the process flow and the cost can be saved; and the invention particularly opens up an industrialization stage of the propionic acid production by fermentation and the simultaneous production of the propionate.

Owner:意葆(上海)生物科技有限公司

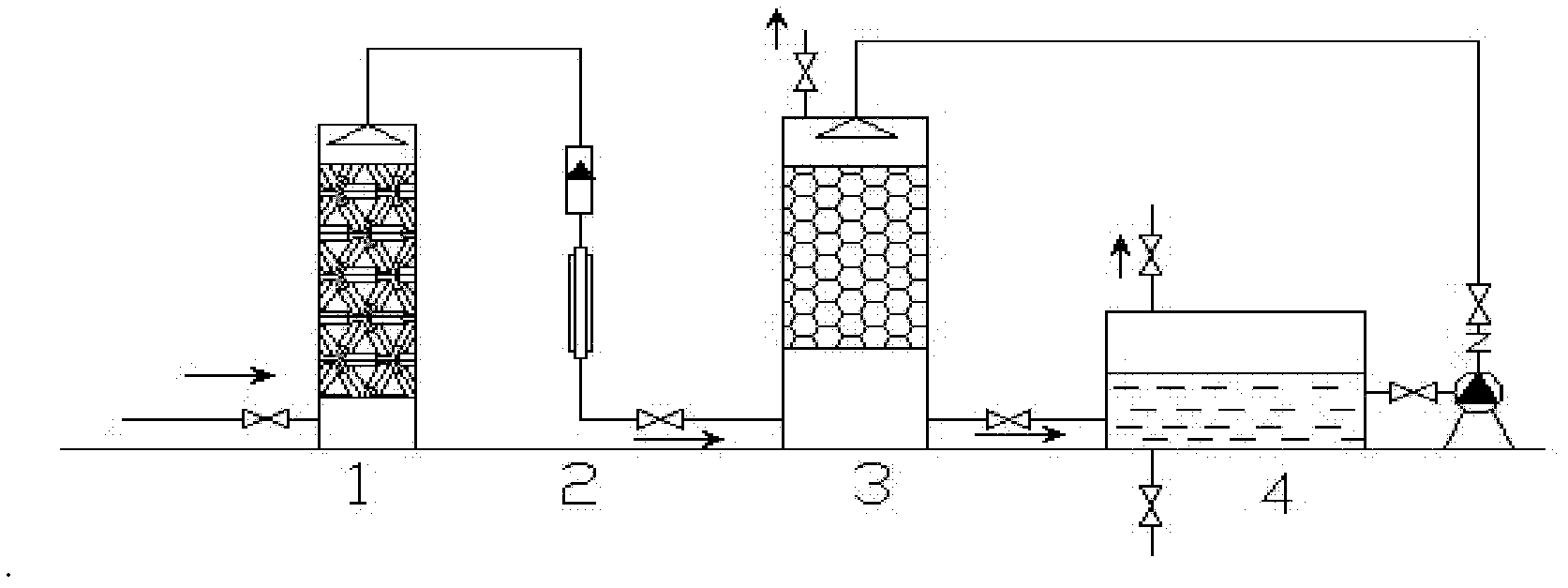

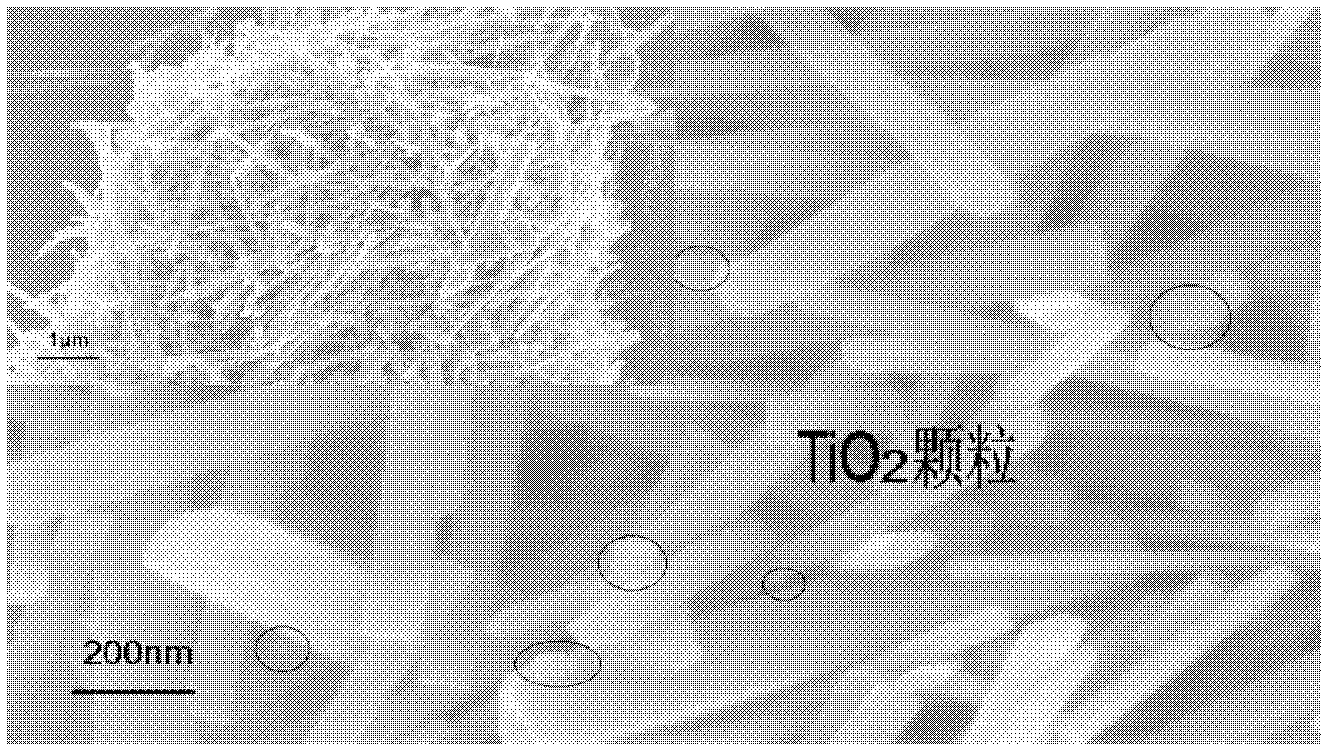

Method for removing VOCs by UV light catalytic oxidation cooperating with biofiltration

ActiveCN102423611AHigh efficiency decomposition and removalImprove removal efficiencyDispersed particle separationAir quality improvementActivity regulationIndustrial gas

The invention, belonging to the technical field of air environmental pollution treatment, biofiltration and environmental pollution treatment, discloses a method for removing volatile organic chemicals (VOCs) by using nano Na2Ti6O13 / TiO2 UV light catalytic oxidation cooperating with biofiltration. The method comprises the following steps that: organic waste gases enter into a photocatalytic device through a spray tower for catalyzing, then the gases enter into a biofiltering tower for filtering from the bottom of the biofiltering tower, wherein, the organic waste gases enter into the photocatalytic device for catalytic reaction, and partial VOCs are subject to photocatalytic oxidation by a nano Na2Ti6O13 / TiO2 catalyst to form a water-soluble compound; in the biofiltering tower, the rest VOCs are degraded into CO2 and water and then discharged by specific biological bacterial species, and the biofiltering tower is communicated with a microbe activity regulation system to regulate the activity of the bacteria. The invention can efficiently decompose the VOCs in industrial waste gases, and can widely applied in treating the industrial gases containing VOCs.

Owner:广州狮岭皮革皮具产业研究中心有限公司 +1

Device and method for processing acid gas of refinery plant

InactiveCN103638802ARealize resource utilizationHigh puritySulfur compoundsDispersed particle separationResource utilizationSpray tower

The invention relates to a device for processing acid gas of a refinery plant. The device comprises a liquid separating tank, a supergravity machine, an absorbent regeneration tower, an absorbent storing tank, an alkali liquid spraying tower and an alkali liquid storing tank, wherein an air outlet of the liquid separating tank is communicated with an air inlet at the lower part of the supergravity machine; a liquid outlet at the bottom of the supergravity machine is connected to the absorbent regeneration tower through a liquid outlet pipe with a pump, and a liquid outlet at the bottom of the absorbent regeneration tower is communicated with the absorbent storing tank; a liquid outlet of the absorbent storing tank is communicated with a liquid inlet at the upper part of the supergravity machine, an air outlet at the top of the absorbent regeneration tower is communicated with an air inlet at the lower part of the alkali liquid spraying tower, and a liquid inlet at the top of the alkali liquid spraying tower is communicated with a liquid outlet of the alkali liquid storing tank. The device provided by the invention has the advantages that the supergravity technology is adopted to process the acid gas of the refinery plant, the H2S content after purifying reach 99%, H2S is continuously absorbed by adopting alkali liquid in a circulating manner to prepare NaHS, the equipment is simple, the investment is small, the desulphurization efficiency is high, the device does not have secondary pollution, and the device has the efficient resource utilization rate.

Owner:CHINA CONSTR IND & ENERGY ENG GRP CO LTD

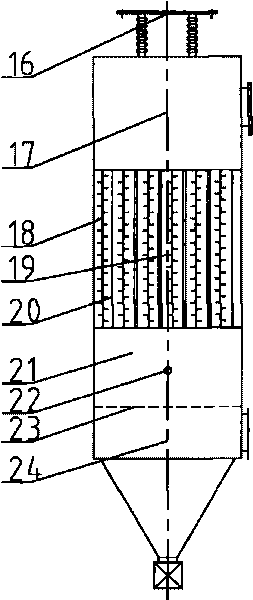

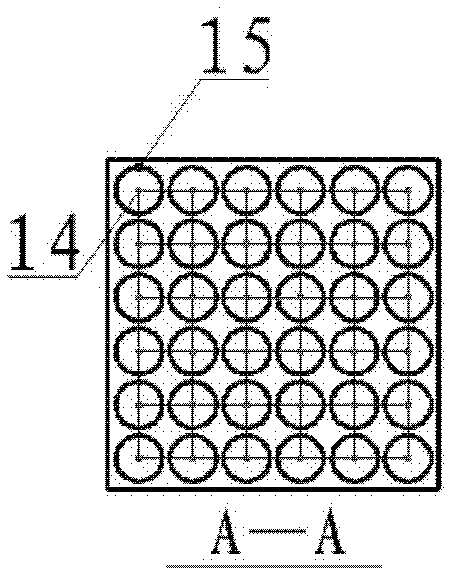

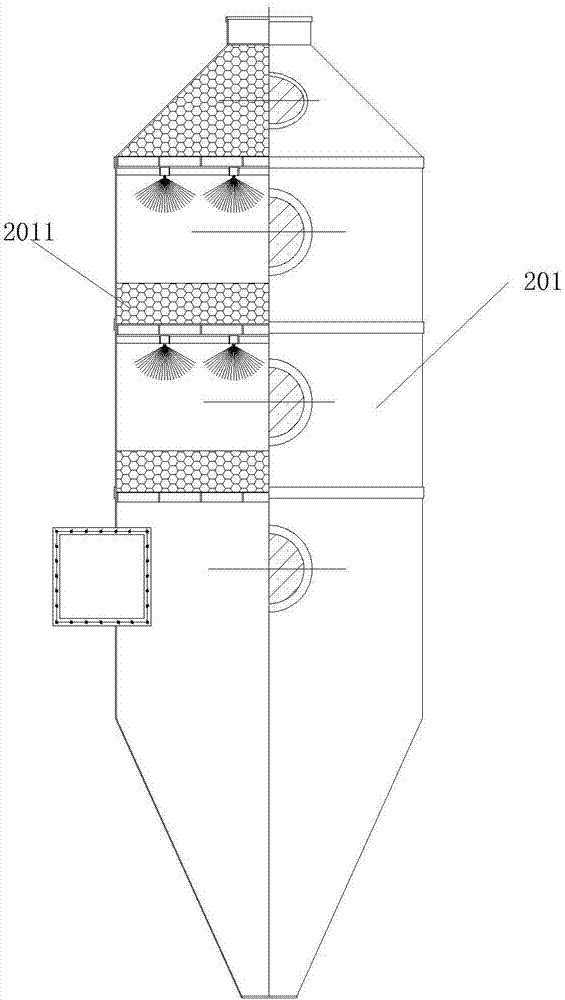

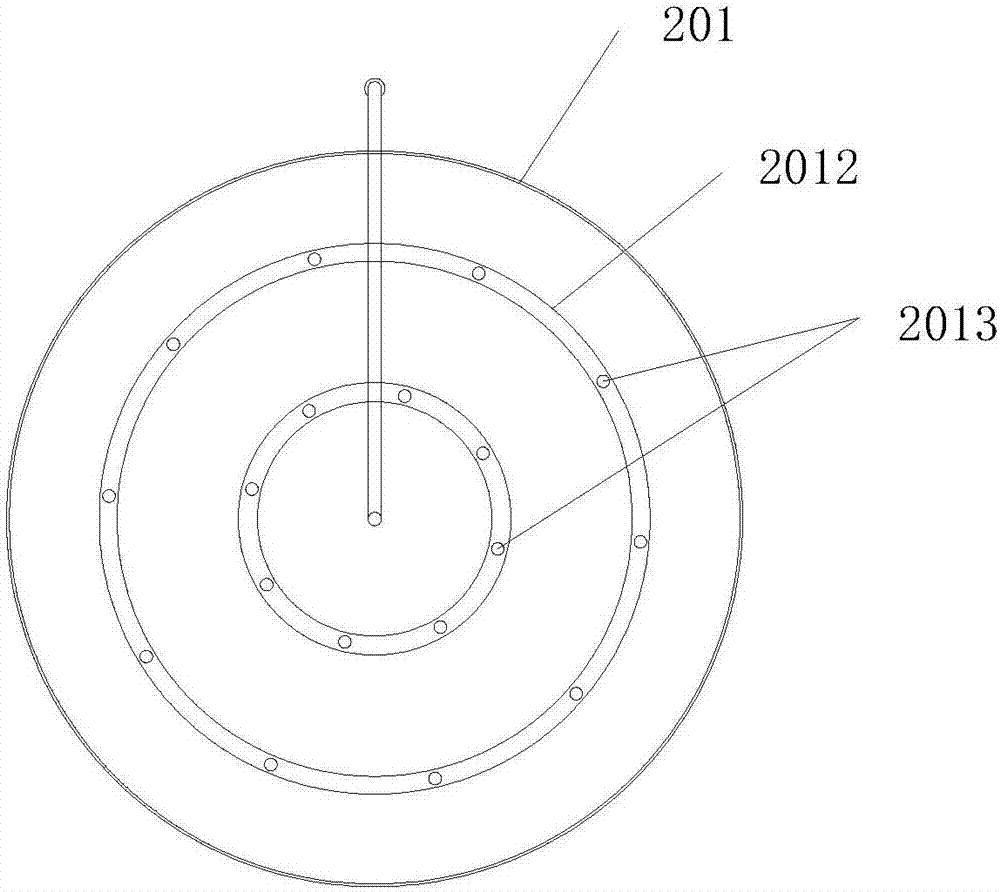

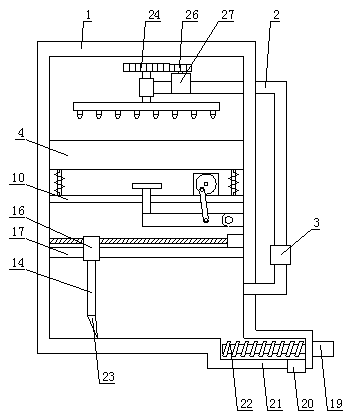

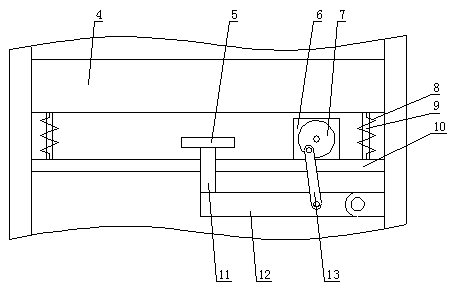

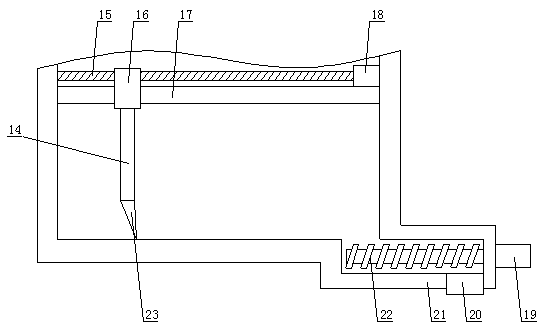

Spraying tower with function of cleaning filling layer

InactiveCN107812424AAchieve cleanupIn the spray tower of the cleaning function, it is realized by cleaningGas treatmentUsing liquid separation agentSludgeSewage outfall

The invention relates to a spray tower with the function of cleaning the packing layer, which includes a body, a water pipe, a packing layer and a water pump, and also includes a spraying mechanism, a cleaning mechanism and a sewage discharge mechanism. The cleaning mechanism includes a first support rod and a knocking block , a first transmission rod, a second transmission rod, a first drive assembly and two springs, the blowdown mechanism includes a second drive assembly, a second support rod, a moving block, a connecting rod, a scraper and a blowdown assembly, which has In the spray tower with packing layer cleaning function, the packing layer is beaten by the cleaning mechanism, and the dirt in the packing layer is cleaned out under the action of inertia, and the packing layer is sprayed by the spraying mechanism, thus realizing the cleaning of the packing layer. The cleaning of the packing layer can be kept clean, thereby improving the purification effect of the spray tower. Not only that, the sludge deposited in the spray tower is cleaned through the sewage discharge mechanism, which not only improves the efficiency of cleaning sludge in the spray tower, It also prevents sludge from clogging the sewage outlet.

Owner:南京市雨花台区创新创业法治宣传与法律服务中心

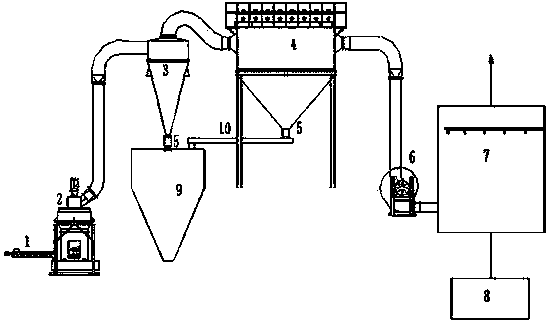

Active carbon dust-free grinding device and method

InactiveCN103521334AReduce pollutionImprove working environmentGrain treatmentsEngineeringTreatment system

The invention relates to an active carbon dust-free grinding device and a method. A feeding screw conveyer of the device is installed in a feed port of a raymond mill. The discharge port of the raymond mill is connected sequentially to a cyclone separator, a pulsed bag-type dust collector and a centrifugal fan through negative pressure pipelines. Bottom discharge ports of the cyclone separator and the pulsed bag-type dust collector are both provided with a rotary valve. The bottom of the cyclone separator is provided with a finished-product bunker. The rotary valves are connected to the finished-product bunker. The rotary valve of the pulsed bag-type dust collector is connected to a finished-product screw conveyer connected to the finished-product bunker. An air outlet of the centrifugal fan is connected to a spray tower through a dust discharging pipeline. The spray tower is connected to a recovery tank. According to the active carbon dust-free grinding device and the method, a negative grinding device and an exhaust gas treatment system are adopted; the structure is simple and reasonable; the production method can be implemented easily; dust pollution in a grinding process in largely reduced, thus providing a good working environment for workers; and the active carbon in the dust can be collected and utilized, thus avoiding waste effectively.

Owner:徐州天正活性炭厂

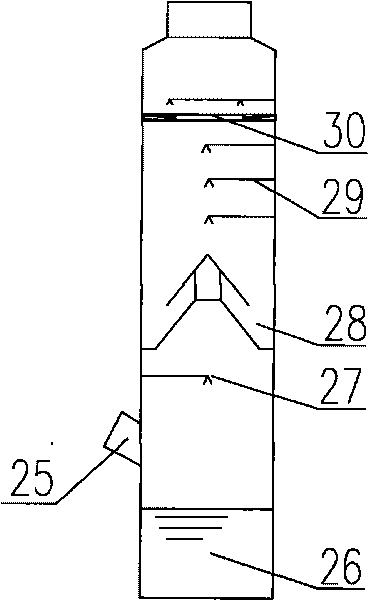

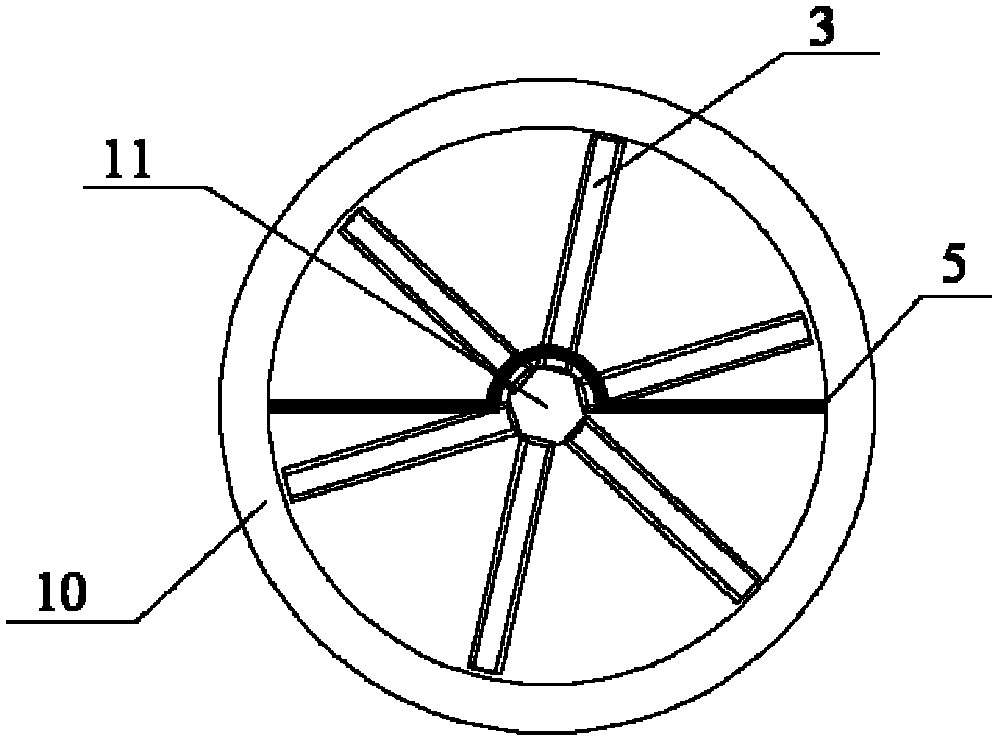

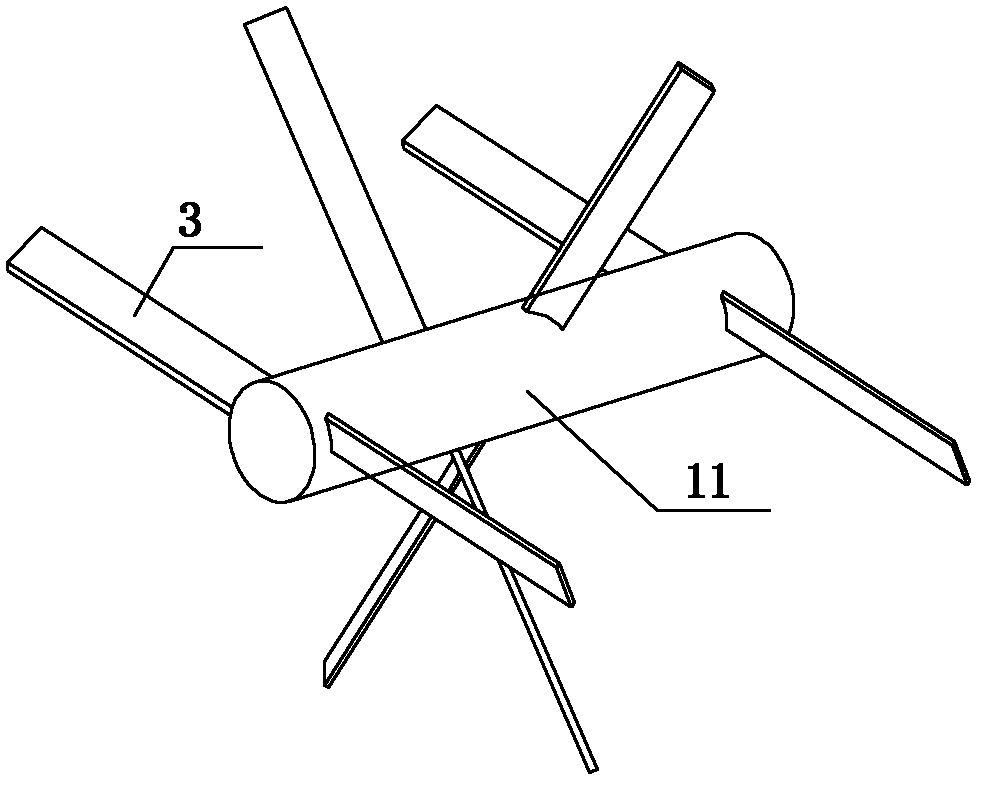

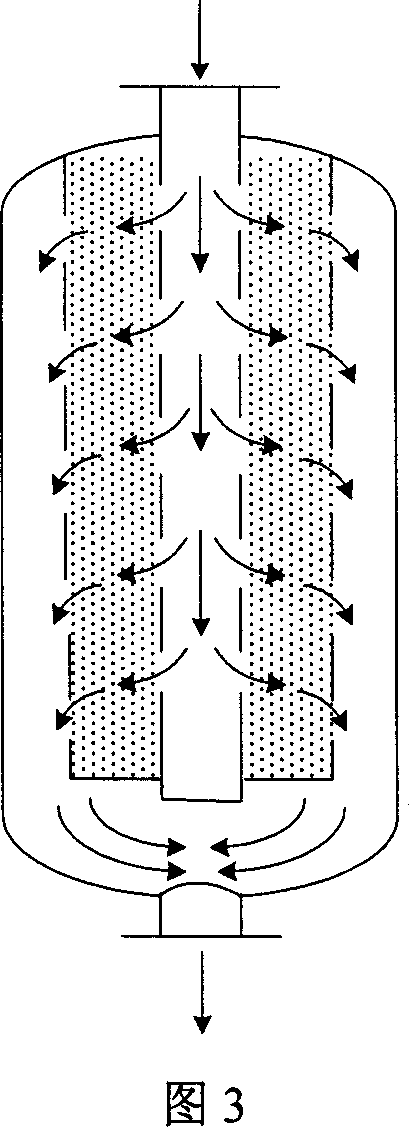

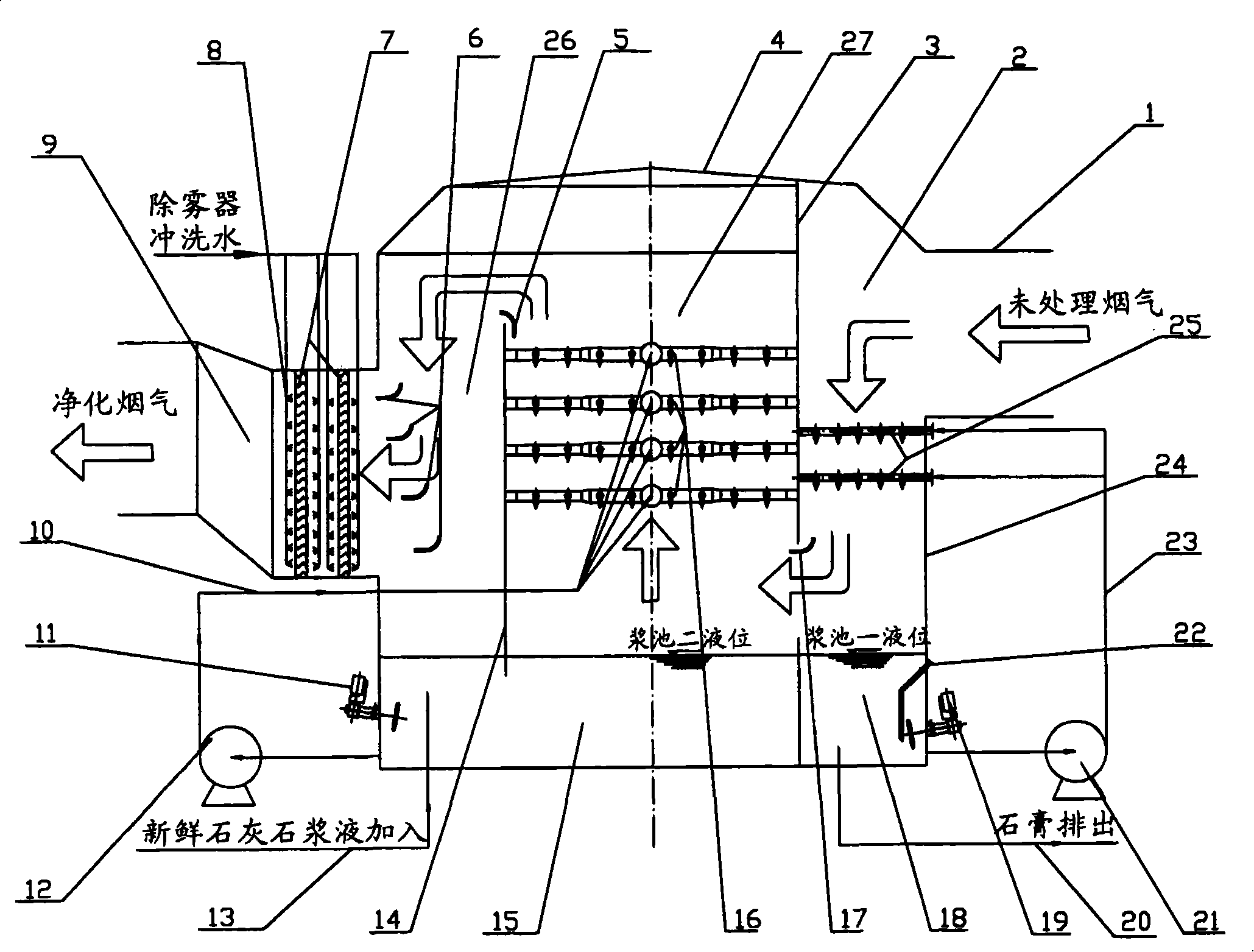

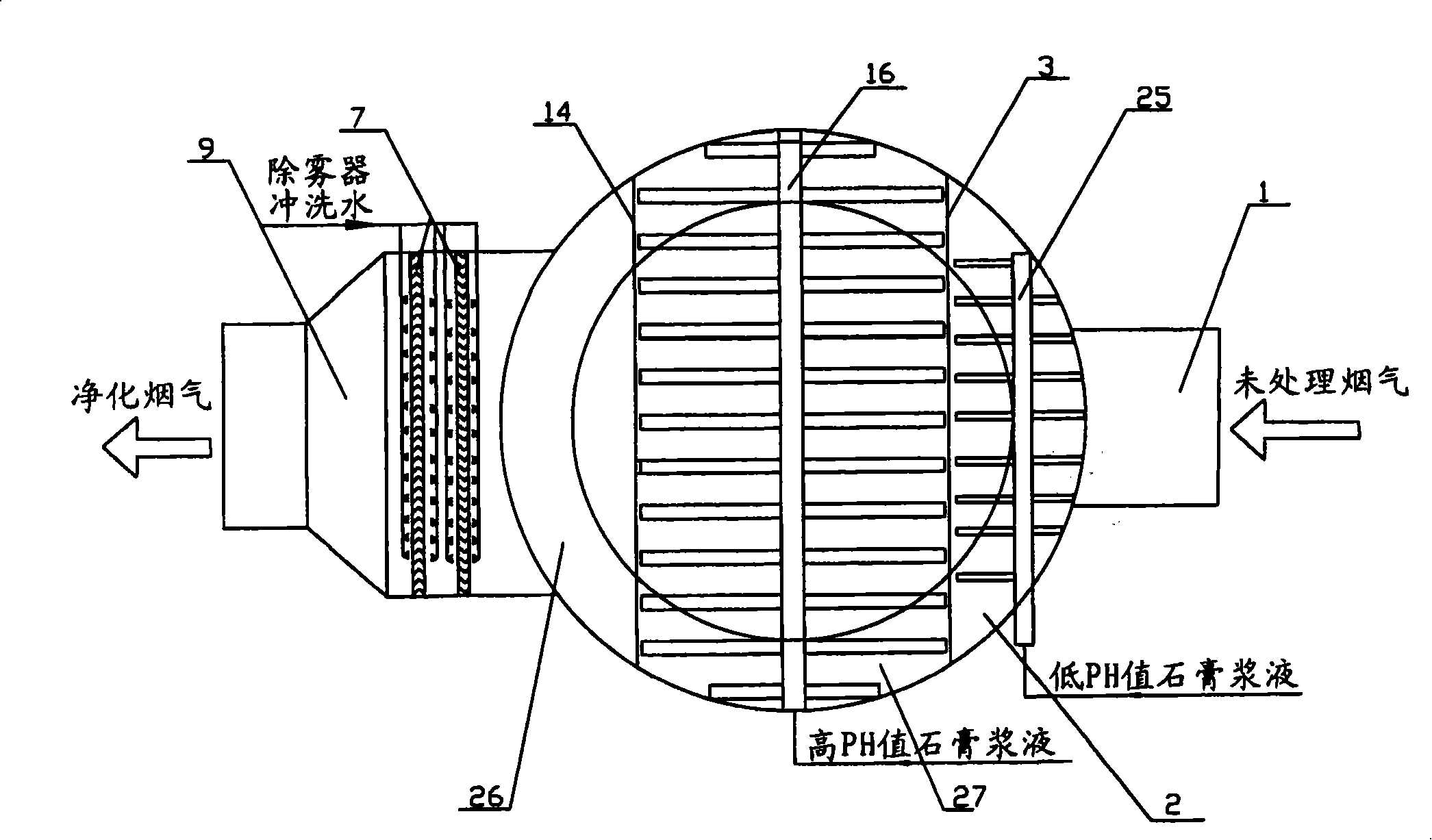

A spray tower for flue gas desulfurization and its running method

ActiveCN101161332ASmall footprintReduced support structureDispersed particle separationFlue gasEngineering

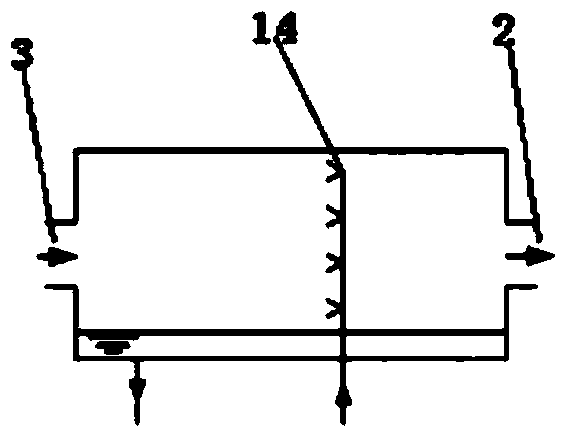

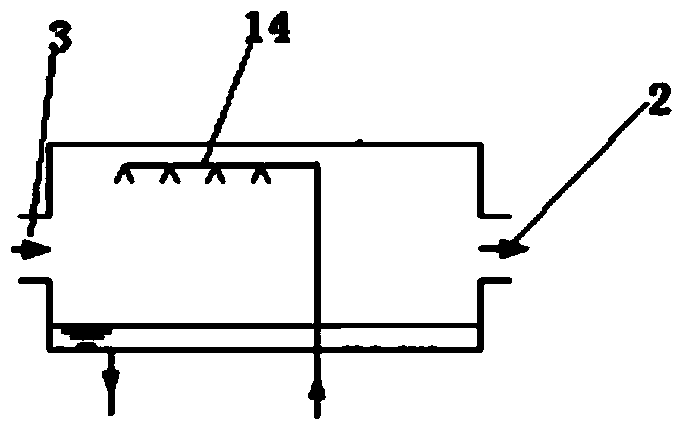

The present invention relates to a cylindrical spraying tower for eliminating the sulfur dioxide in the flue gas and a method for eliminating the sulfur dioxide in the flue gas with the spraying tower thereof, wherein the spraying tower is provided with two vertical clapboards and is provided with a defroster at the outlet, the clapboard is provided with an opening thereby dividing the absorbing area to three areas and dividing the serous fluid tank into two sections. The flue gas contacts with the spraying serous fluid concurrently and then countercurrent in the area of the absorbing area and is discharged through the defroster. The excellent desulfurizing effect is realized and the method is especially suitable for the wet limestone gypsum flue gas desulfurization technique of the large-scale thermal power plant with the power more than 300MW.

Owner:BEIJING BOOTES ELECTRIC POWER SCI & TECH

Activated char activating devices and methods thereof

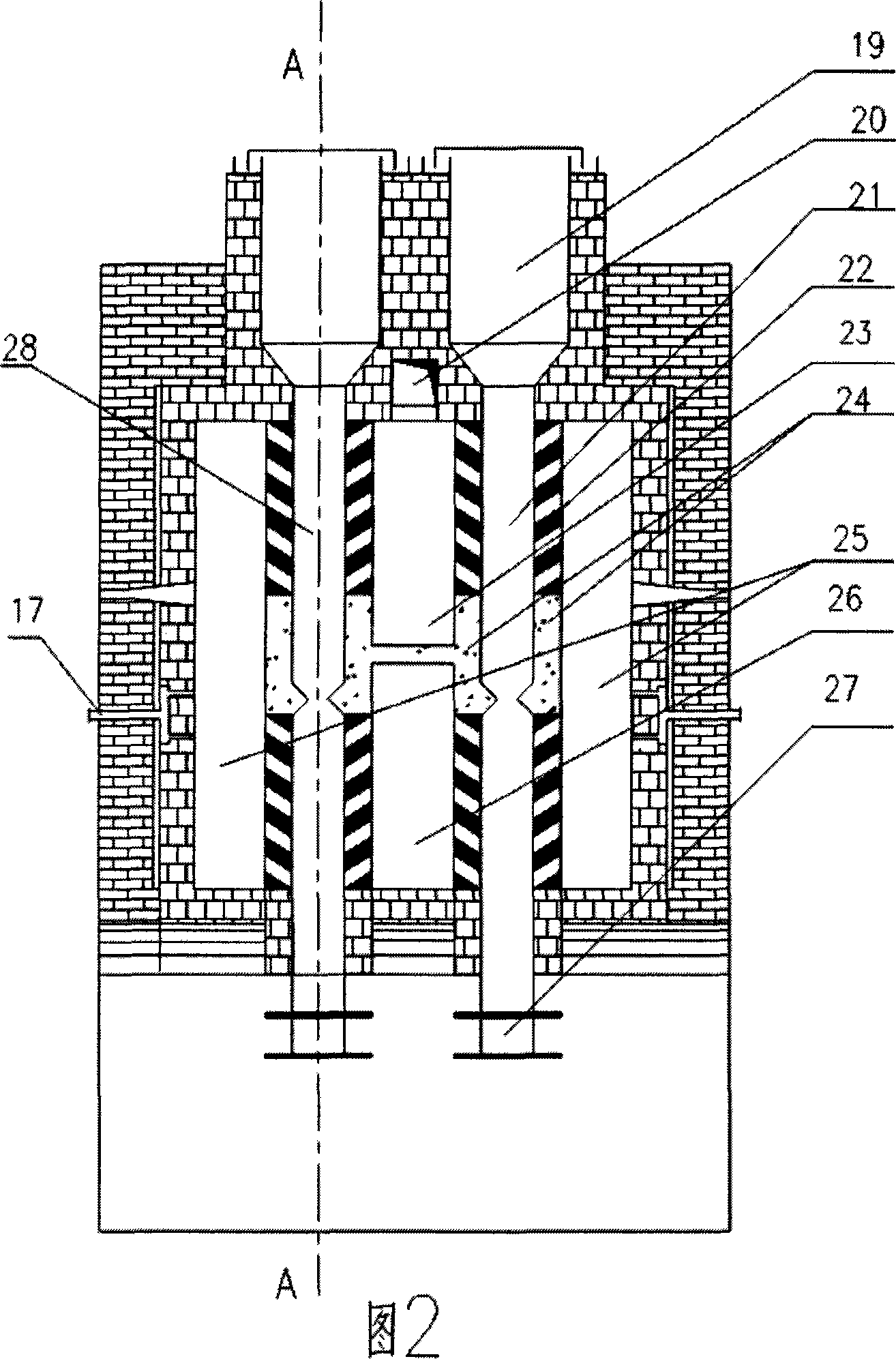

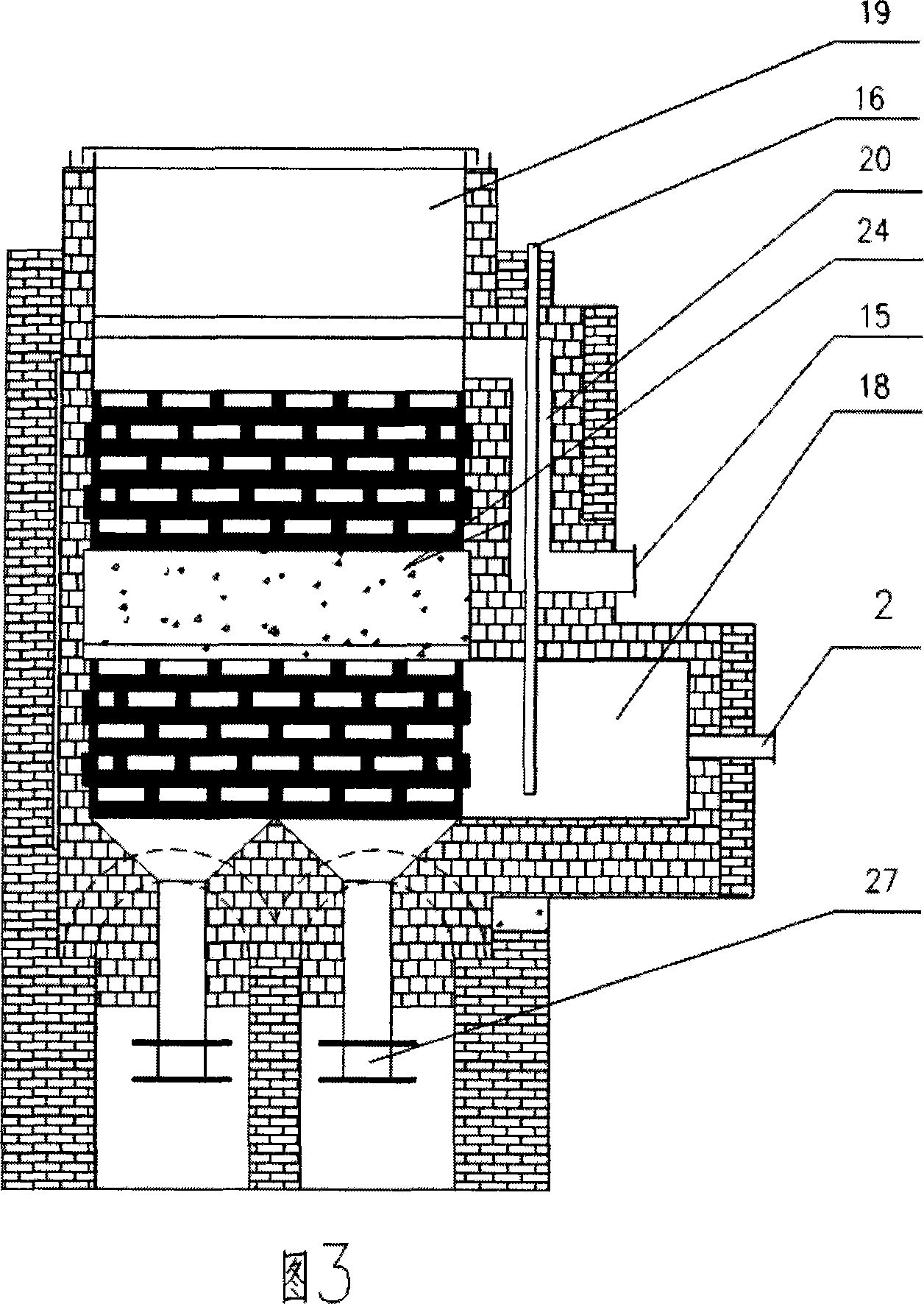

The present invention discloses active carbon activating apparatus and process. The activating apparatus consists of one louver type activating furnace and one gas circulating system. The activating furnace laid with louver bricks has one activating channel with one middle flue and two side flues, one combustor communicated to the activating channel in the lower part, and one discharge unit in the bottom. The gas circulating system consists of activating gas outlet, heat exchanger, spraying tower, steam-water separator, gas blower, gas nozzle, afterheat boiler, combustor and blow-down stack connected through pipeline. The technology of the present invention may be applied in activating active carbon of different granularity, and has short activating period, convenient operation and other advantages.

Owner:傅方堃

Waste gas treatment method in production of fragant peony extract

ActiveCN104524946ALight weightIncrease added valueDispersed particle separationEssential-oils/perfumesComing outHigh concentration

The invention discloses a waste gas treatment method in the production of fragant peony extract. The waste gas treatment method includes the following steps of 1 cooling at low temperature, wherein waste gas generated in the production is concentrated and conveyed into a low-temperature condenser to be cooled at the low temperature, the cooling temperature is 0 DEG C-4 DEG C, and essential oil in the waste gas is separated preliminarily and enters a low-temperature storage tank; 2 absorbing though a spray tower, wherein the waste gas coming out enters the spray tower to be treated, the spray tower comprises four levels connected in series, and liquid phase substances at the four levels of the spray tower are low-concentration alkali liquor added with xanthan gum, high-concentration alkali liquor added with xanthan gum, high-concentration alkali liquor added with xanthan gum and water respectively; 3 high-altitude exhaust, wherein the treated gas is conveyed to a chimney in a factory through a pipeline and exhausted to the high altitude.

Owner:XUZHOU YUANHE ANIMAL HUSBANDRY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com