Active carbon dust-free grinding device and method

A technology of activated carbon and dust powder, which is applied in the direction of grain processing, etc., can solve the problems of large dust, which affects the health of production workers and the environmental quality of surrounding areas, and achieves the effects of avoiding waste, simple and reasonable structure, and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

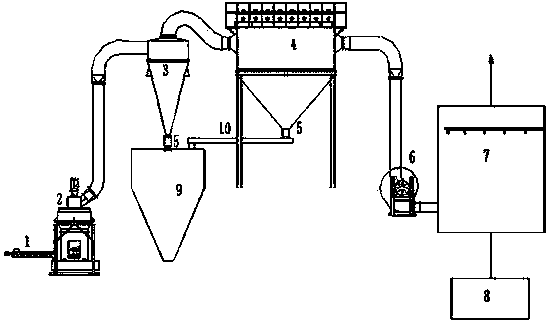

[0014] In the attached drawing, an activated carbon dust-free grinding device includes a feeding screw conveyor 1, a Raymond mill 2, a cyclone separator 3, a pulse bag filter 4, a centrifugal fan 6, a spray tower 7, and a recovery tank 8. , Finished product silo 9, finished product screw conveyor 10 and auxiliary pipelines; the feed screw conveyor 1 is installed at the feed port of the Raymond machine 2, and the discharge port of the Raymond machine 2 is provided by a negative pressure pipeline The cyclone separator 3, the pulse bag filter 4, and the centrifugal fan 6 are connected in sequence; the bottom discharge port of the cyclone separator 3 and the pulse bag filter 4 are all equipped with a fan 5; the lower part of the cyclone separator 3 is provided There is a finished product silo 9, and a parallel shut-off fan 5 is connected to the finished silo 9; the shut-off fan 5 of the pulse bag filter 4 is connected to a finished screw conveyor 10, and the discharge end of the fin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com