Patents

Literature

2645 results about "Continuous feeding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Continuous Feeding. Continuous feeding is defined as the process whereby waste is fed into a combustion chamber without human assistance while the incinerator is in normal operating conditions with the combustion chamber operative temperature between 850°C and 1,200°C.

Continuous feeding and decompressing device and method

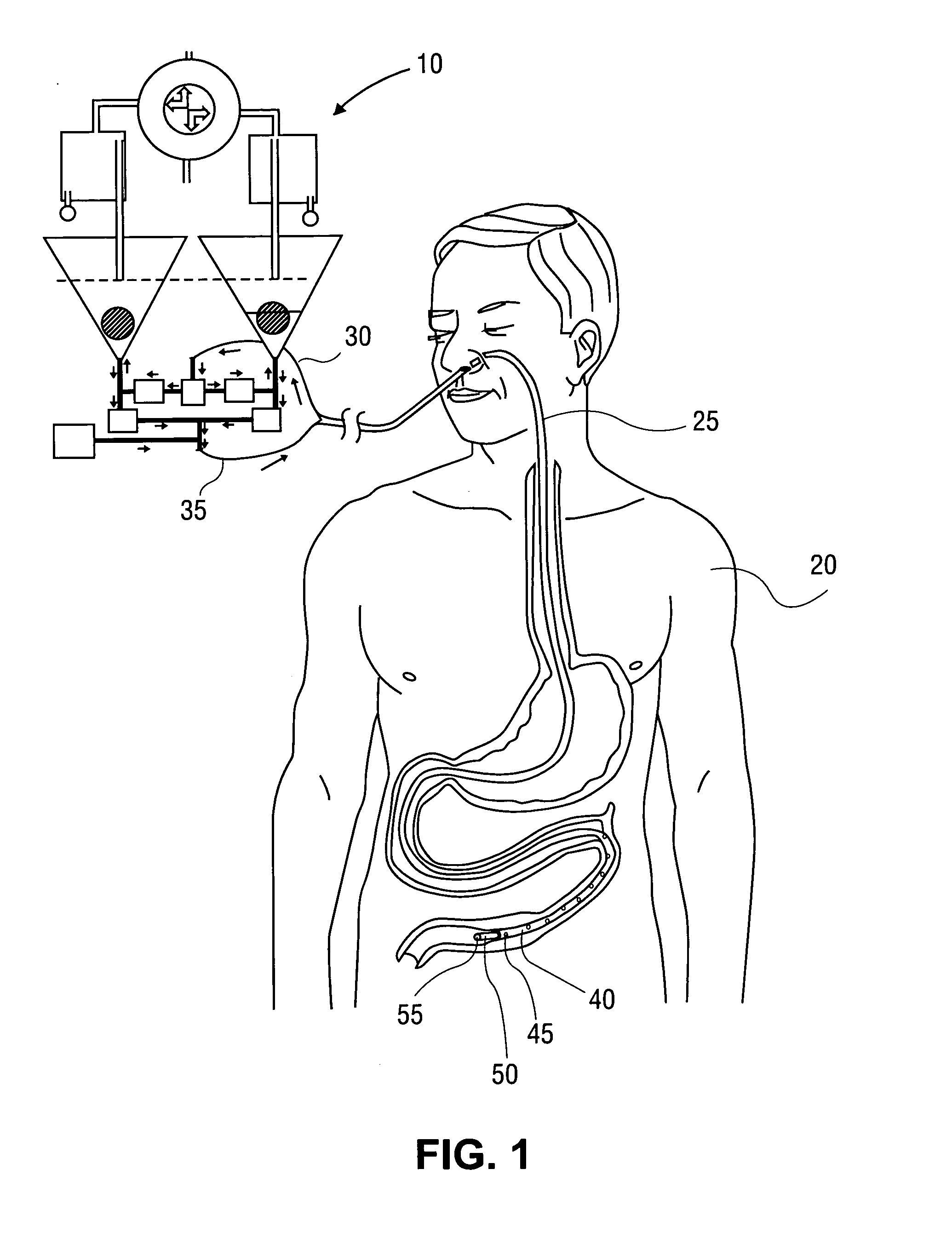

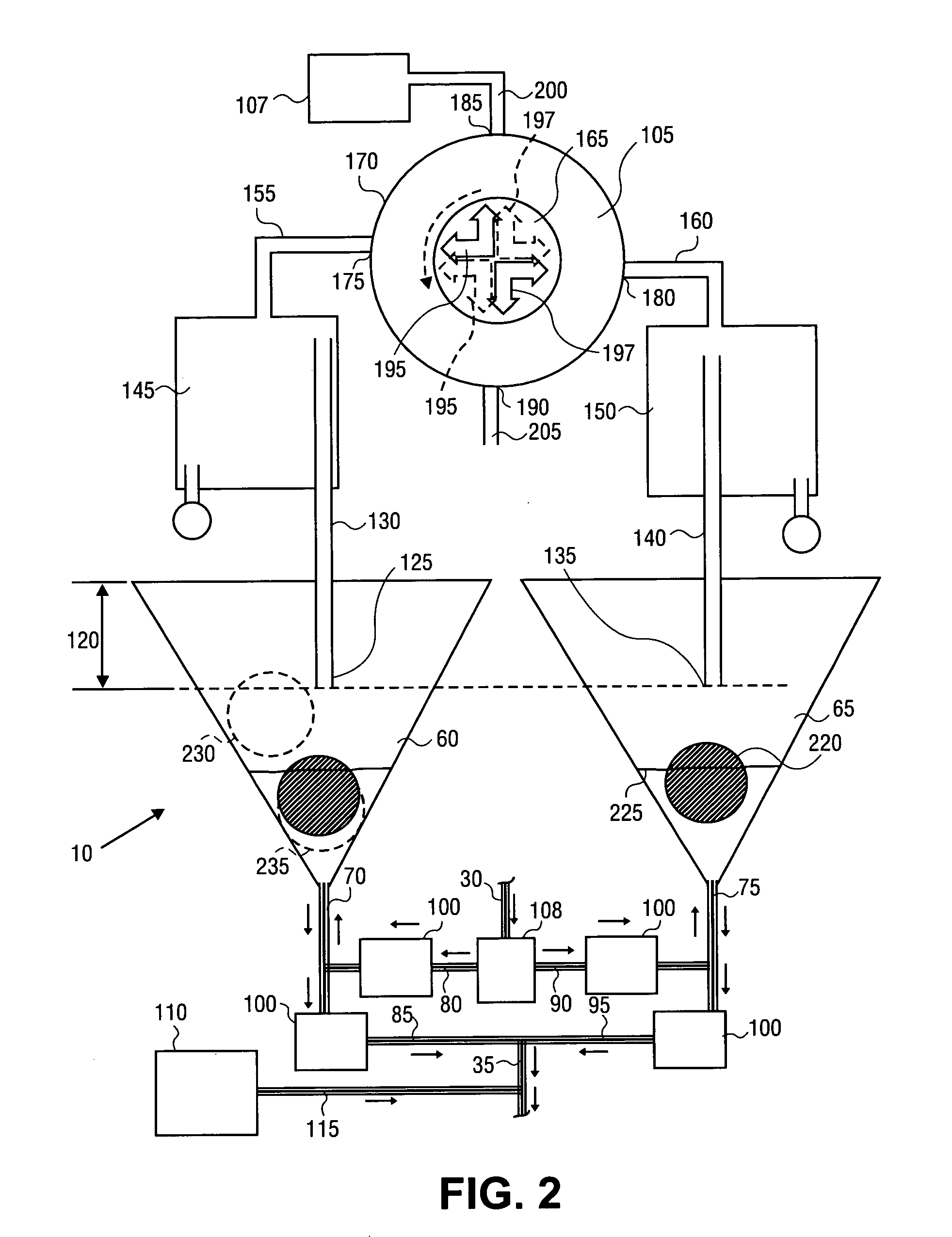

InactiveUS7048727B1Improve absorption efficiencyReduce tendency to dehydrationMedical devicesIntravenous devicesSolenoid valveBiology

A decompressing and feeding device for safely feeding in the gastrointestinal tract of a recovering patient continuously aspirates and feeds at a rate commensurate with the ability of the intestines to absorb fluids including nutrient. Air is also aspirated in the process so that neither air nor excess fluids cause distension in the gastrointestinal tract. Digestive juices and nutrients that are aspirated are continuously refed together with unused feeding material into the gastrointestinal tract at a location that more efficiently moves and digests the food. The device may include two aspirate reservoirs to which and from which aspirate is alternatingly and continuously transferred. To provide the continuous and alternating flow, a solenoid valve and timer switch device is provided. Alternatively, a device is provided with a single aspirate reservoir to which and from which aspirate is continuously transferred.

Owner:MOSS

Kitchen waste disposer

InactiveCN103100555AHigh degree of integrationEasy to centralizeSolid waste disposalEngineeringOil water

The invention discloses a kitchen waste disposer. The kitchen waste disposer comprises a rack body, a cylinder lifting and turning device, a switching door cover, a material hopper, a crushing device, a solid-liquid separating device, a squeezing and lifting device, a fermenting and drying device and an oil-water separating device, wherein the cylinder lifting and turning device, the switching door cover, the material hopper, the crushing device, the solid-liquid separating device, the squeezing and lifting device, the fermenting and drying device, and the oil-water separating device are commonly arranged on the rack body. The kitchen waste disposer provided by the invention can sequentially carry out crushing operation and solid-liquid separation operation on kitchen waste, and further carries out squeezing and dehydration operation on solid kitchen waste, fermenting and drying operation on the solid kitchen waste, and oil-water separation operation on liquid kitchen waste, so that the continuous feeding and continuous discharging production process of the kitchen waste disposer can be realized, and the production efficiency is high. The entire kitchen waste disposer is conveniently, intensively and intelligently controlled, and is particularly applicable to kitchen waste disposal in fields in a small-scale area, such as hotels and restaurants.

Owner:SHANDONG URBAN MINING REGENERATION RESOURCE

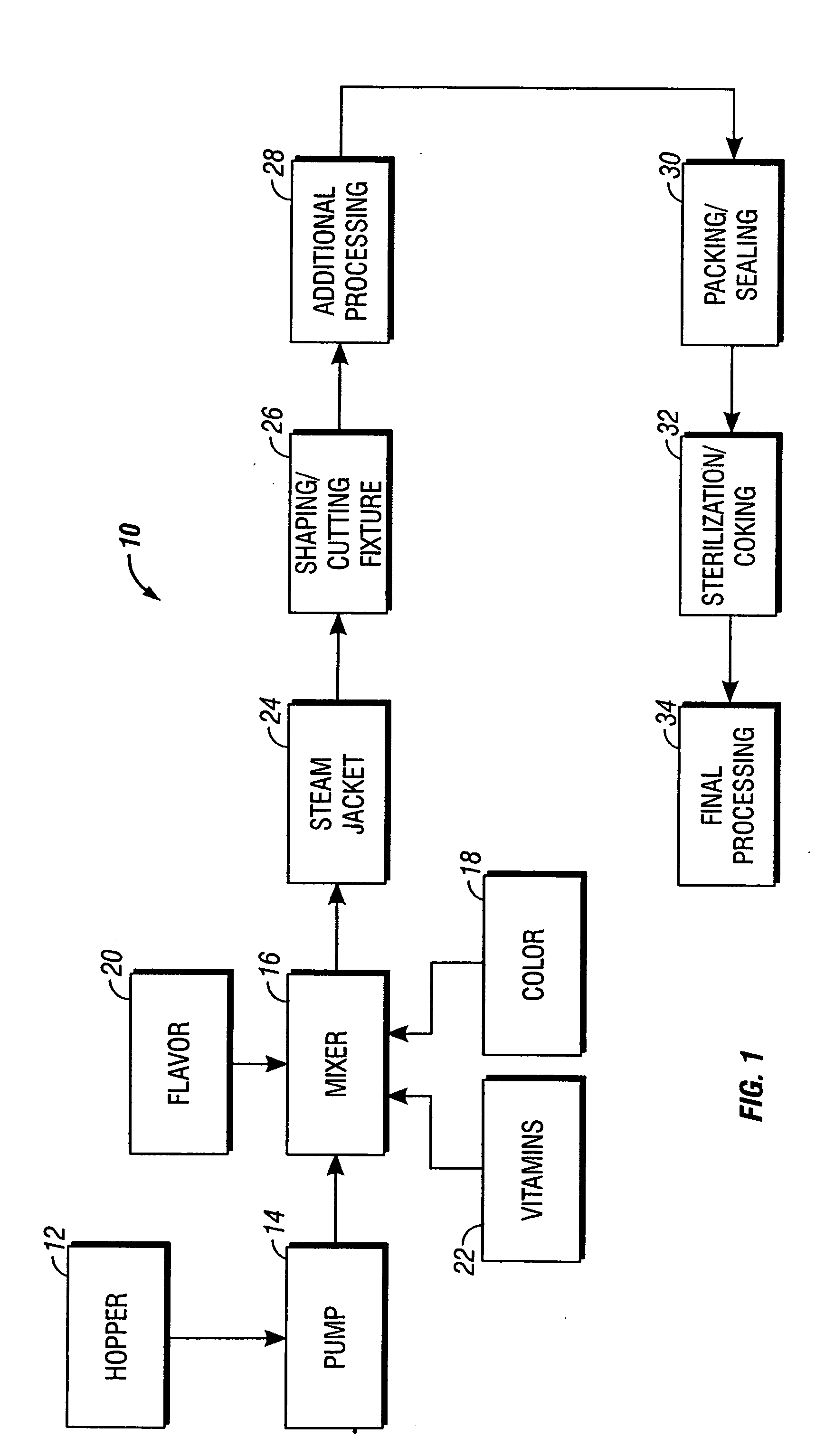

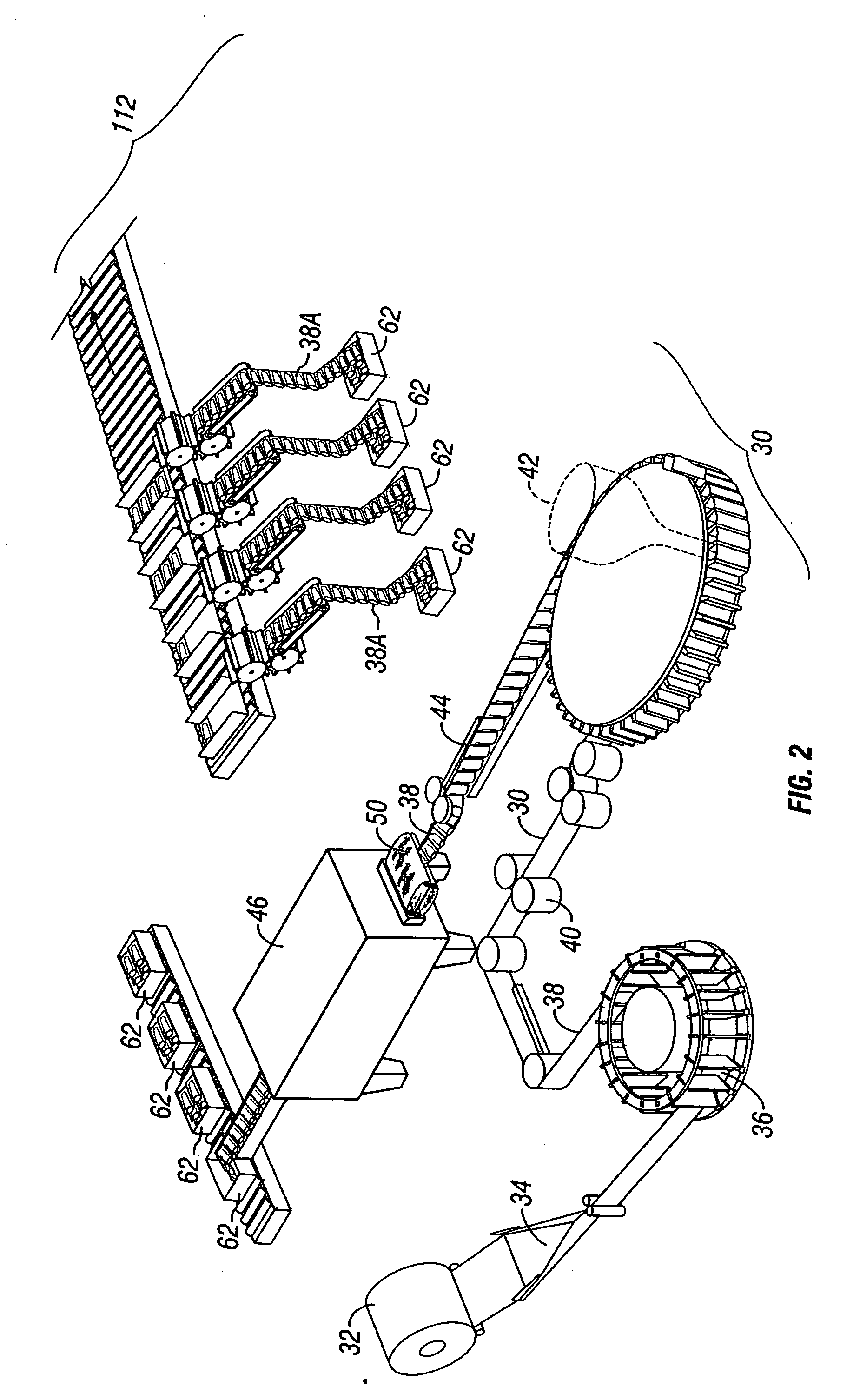

Method and apparatus for continuous processing of packaged products

InactiveUS20050123435A1Increase pressureIncrease temperatureFood preservationPackage sterilisationEngineeringPasteurization

The present invention is directed to a method for the pasteurization and / or sterilization of a continuous web of packages. The method includes the steps of providing a continuous web of individual packages; moving the continuous web through a first mechanical pressure seal into a pressure chamber; applying an increased pressure and temperature; and moving the continuous web through a second mechanical pressure seal out of the pressure chamber. The present invention is also directed to a continuous pressure seal apparatus and an apparatus for the pasteurization and / or sterilization of a continuous web of flexible packages. The apparatus includes a first mechanical continuous feeding pressure seal; a pressure chamber; and a second mechanical continuous feeding pressure seal. The first pressure seal is adjacent to an entry to the pressure chamber and the second pressure seal is adjacent to an exit of the pressure chamber.

Owner:MARS INC

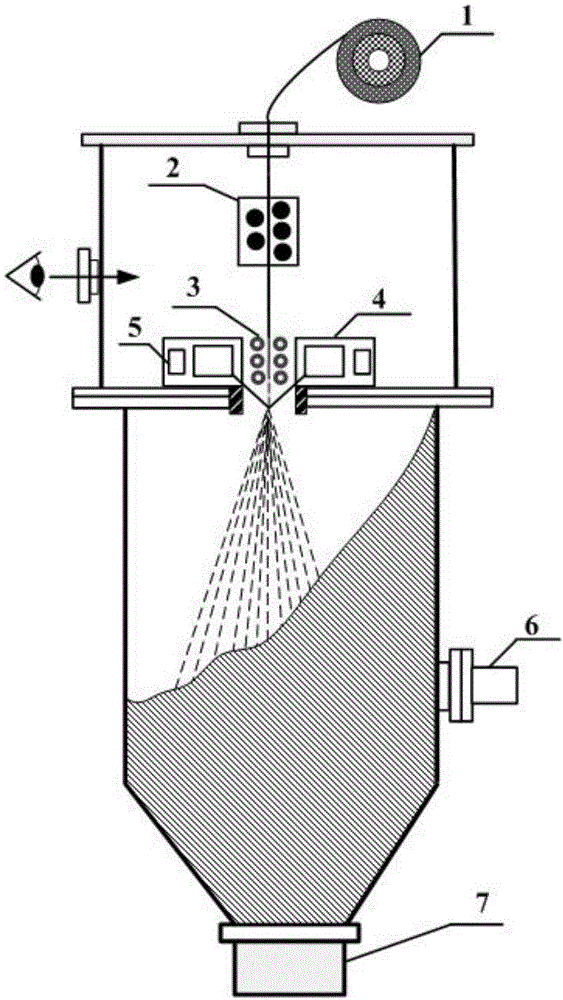

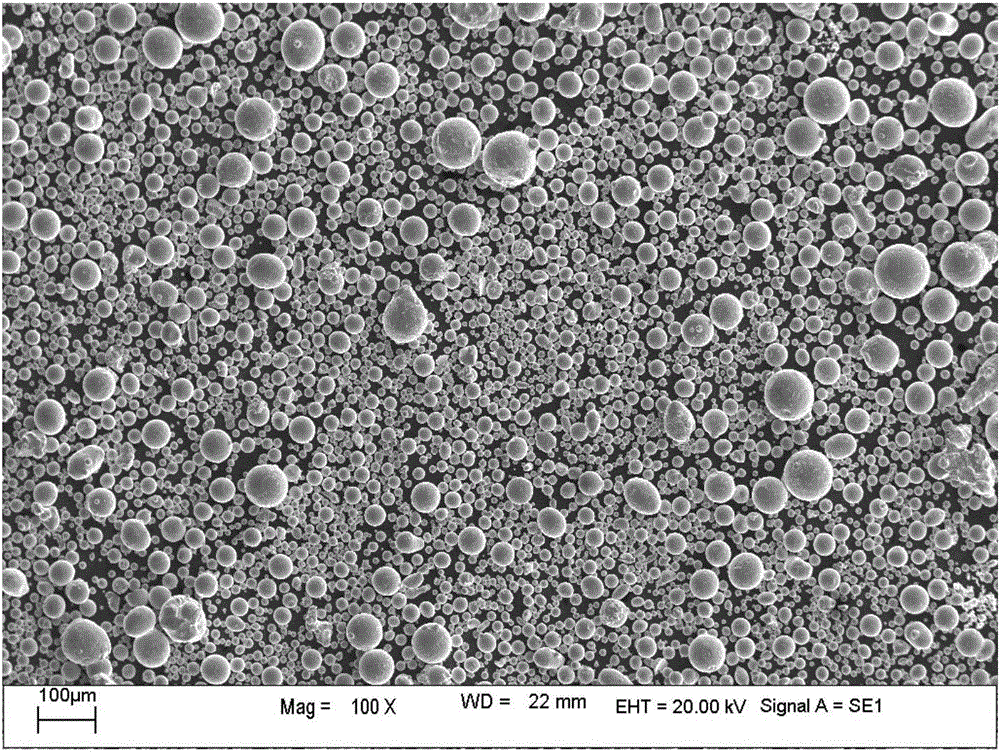

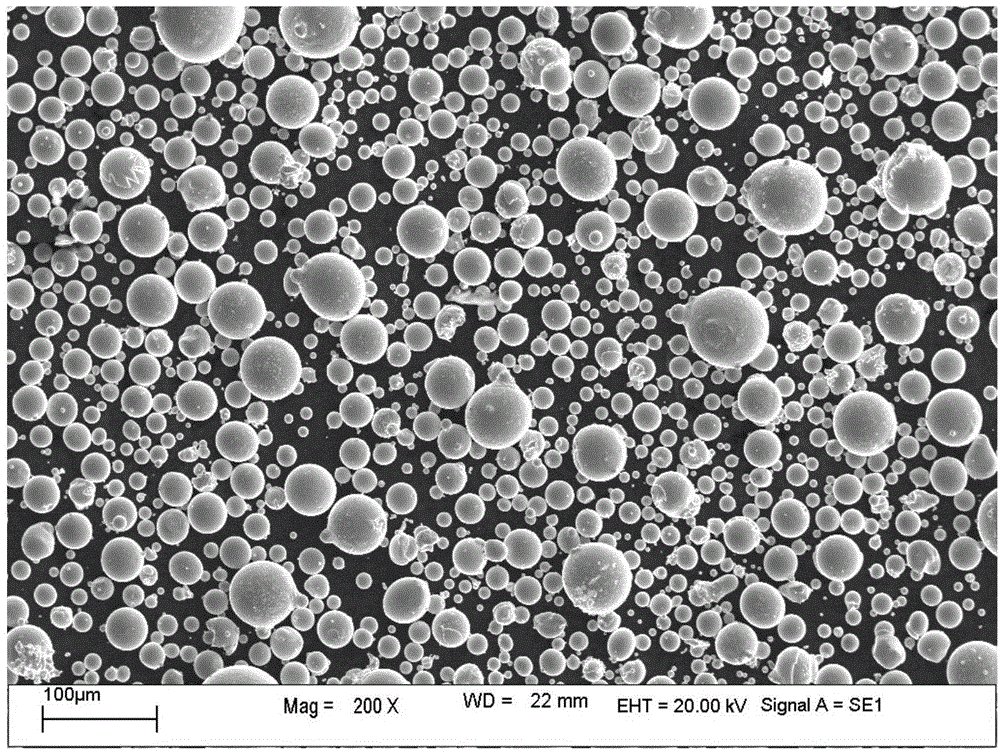

Manufacturing method of micro spherical titanium and titanium alloy powder

ActiveCN104475743AFast purification smeltingControlled purification smeltingSpherical shapedTitanium alloy

The invention relates to a manufacturing method of micro spherical titanium and titanium alloy powder, and belongs to the technical field of metal and alloy powder manufacturing. The manufacturing method comprises the steps that a titanium and titanium alloy wire or bar is manufactured by using sponge titanium in the national standard TA1 grade as a raw material; forvacuum treatment is conducted on a powder manufacturing device, and then the powder manufacturing device is filled with inert protective gas; the raw material wire or bar is fed into a smelting chamber through a continuous feeding mechanism and a straightener, the raw material is heated and smelted through a high-frequency induction coil, and the alloy raw material is molten to form stable liquid flow or drip flow; supersonic atomizing nozzles in atomizers are opened, and breakage, dispersion and forced cooling powder manufacturing are conducted on the molten liquid flow or the drip flow; powder is obtained through a powder collector, and is screened through an ultrasonic vibrating screen to obtain the micro spherical titanium and titanium alloy powder. The micro spherical titanium and titanium alloy powder manufactured through the manufacturing method is small in particle size, high in degree of sphericity, good in liquidity and low in impurity content, and has smooth surfaces.

Owner:有研增材技术有限公司

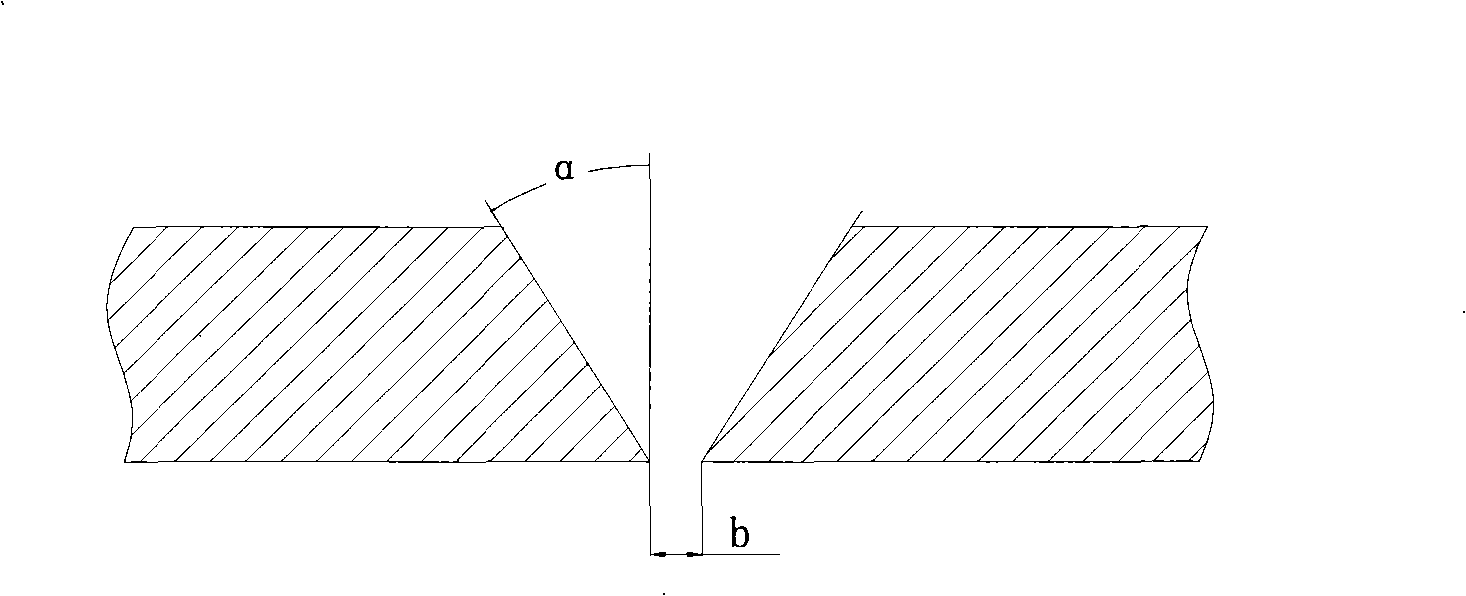

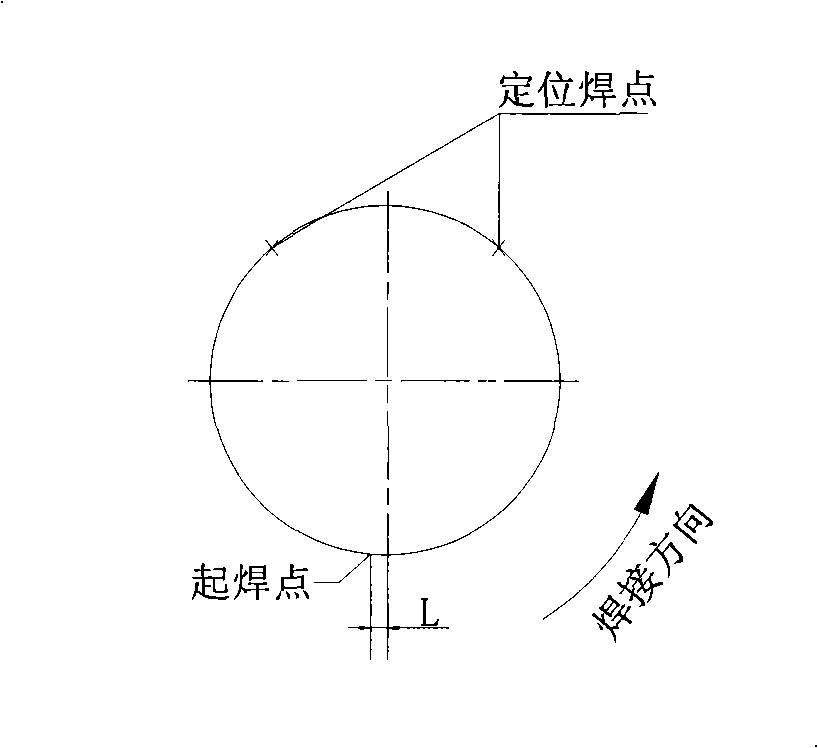

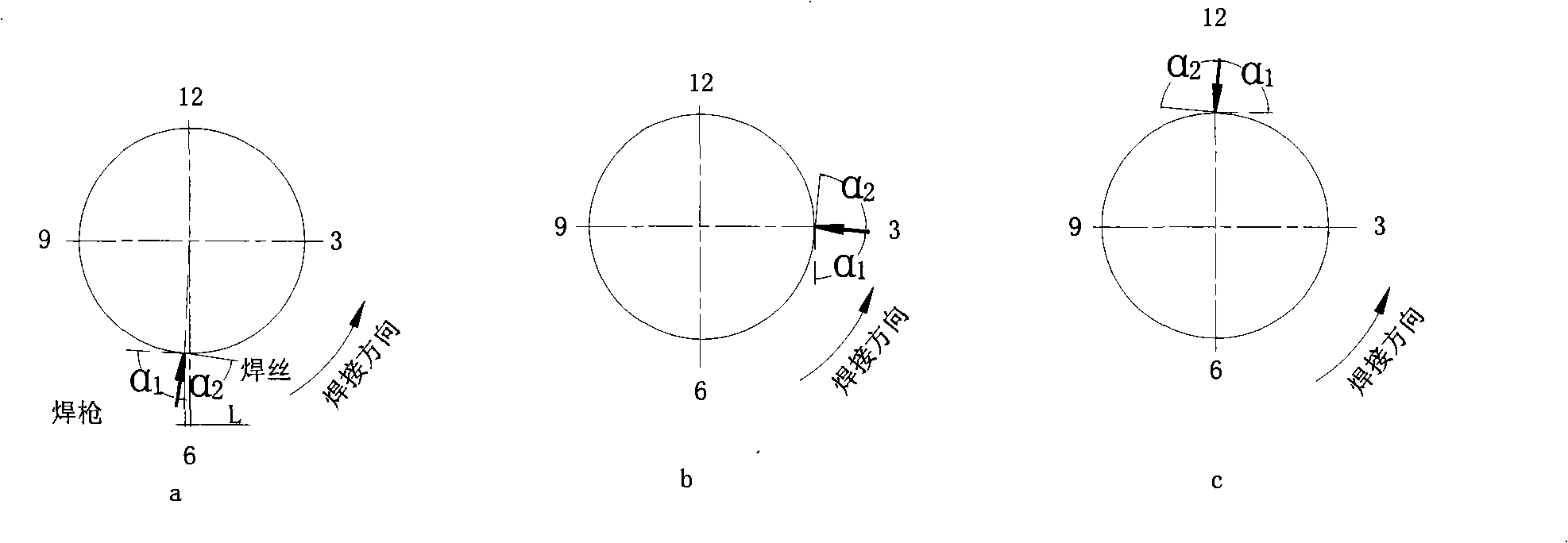

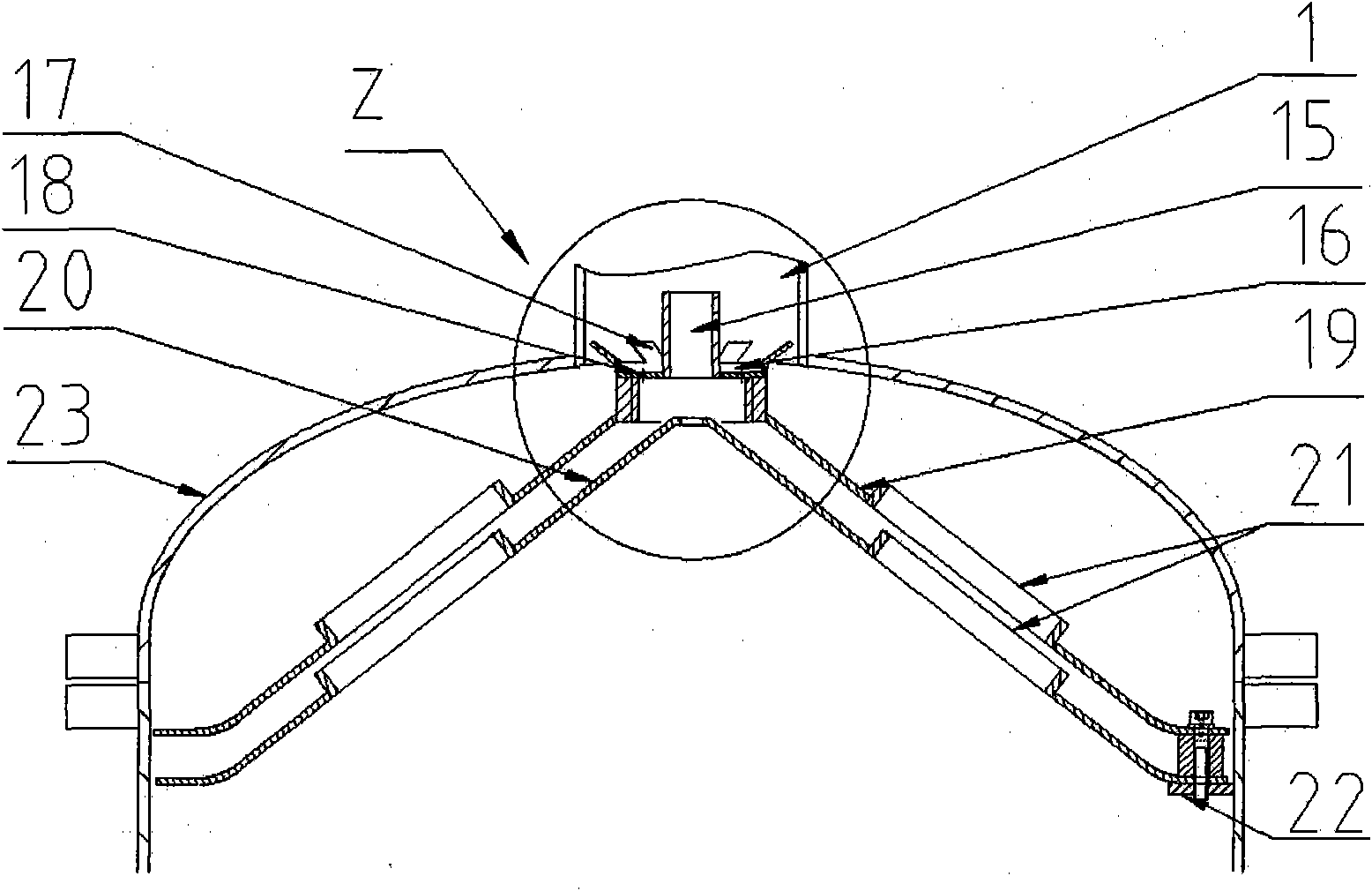

Large caliber aluminium alloy pipeline non-pad tungsten electrode argon arc single face welding and double face shaping method

InactiveCN101301699ABeautiful weldWell formed inside and outArc welding apparatusWelding/soldering/cutting articlesEngineeringWeld seam

The invention discloses a method for large-calibre aluminium-alloy pipeline no-liner tungsten electrode argon arc one-side welding both-side formation, comprising the following steps of: assembling of groove angle and clearance, grinding of tungsten electrode, cleaning before welding, adjusting welding process parameters, tack welding, and welding of a bottom coating, a filling layer and a covering layer. The pipe is horizontally fixed and the position is marked by hour; the welding sequence is left half-ring and right half-ring; each half-ring comprises overhead welding, vertical position welding and downhand welding; the welding is started at a position where L is equal to 5-10mm close to six of the overhead welding; the vertical position welding is then carried out; finally, the front half-ring is ended at 12 of the downhand welding; before the rear half-ring starts welding, the connection is grinded as a slope; the welding seam formed by the connection and the front half-ring welding position is overlapped by 3-5mm; the welding of the rear half-ring is started from 6 of the overhead welding and ended at 12 of the downhand welding through the vertical position welding; the welding is carried out by a continuous feeding method. The surface of the welding seam of the method has no pores or cracks, is completely welded and beautiful, and has good internal and external forming; by the non-destructive testing, the first-time qualification rate achieves 100%, the welding seam achieves the class-1 quality, the construction procedures are reduced, and the construction cost is reduced.

Owner:ANGANG CONSTR CONSORTIUM

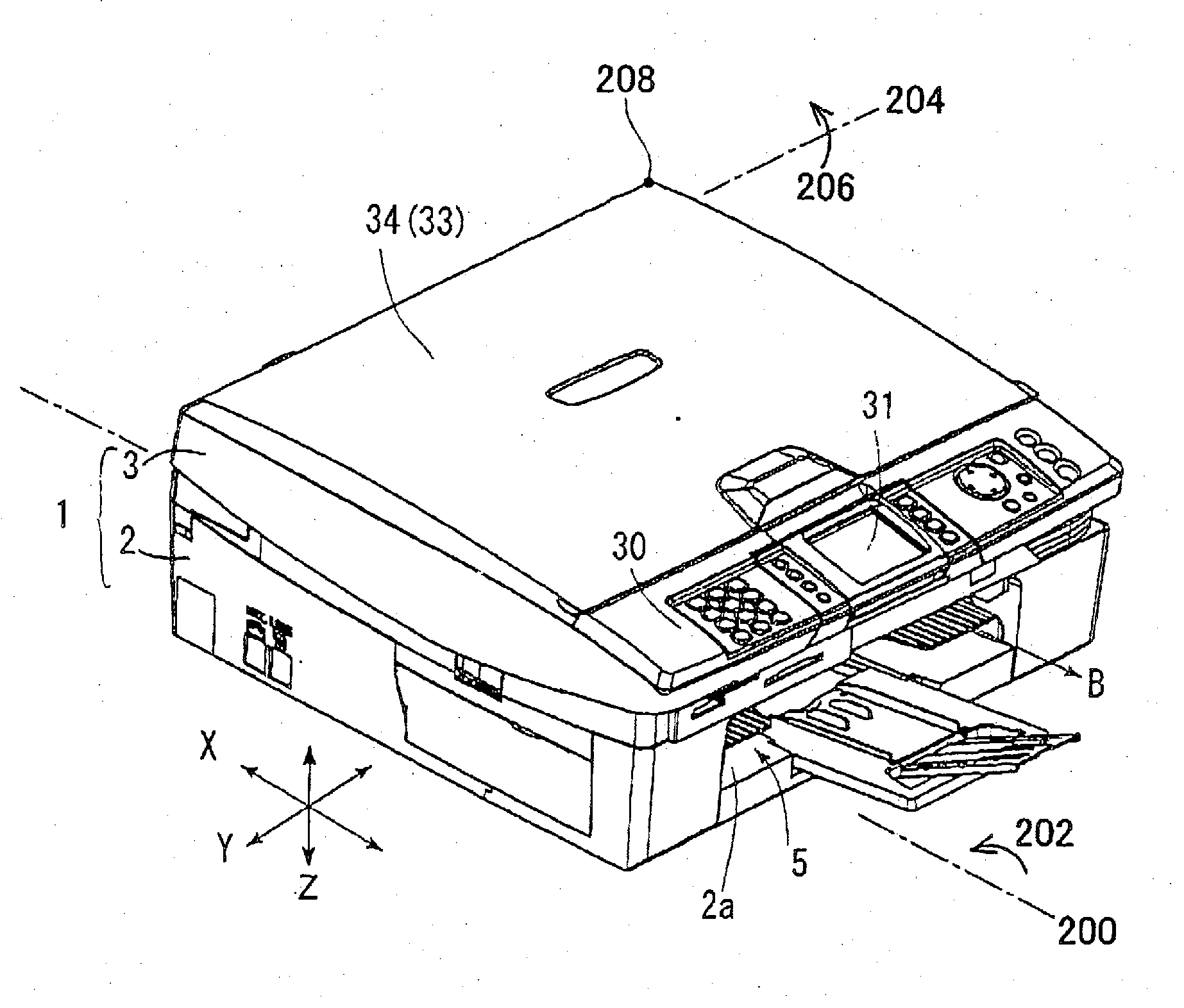

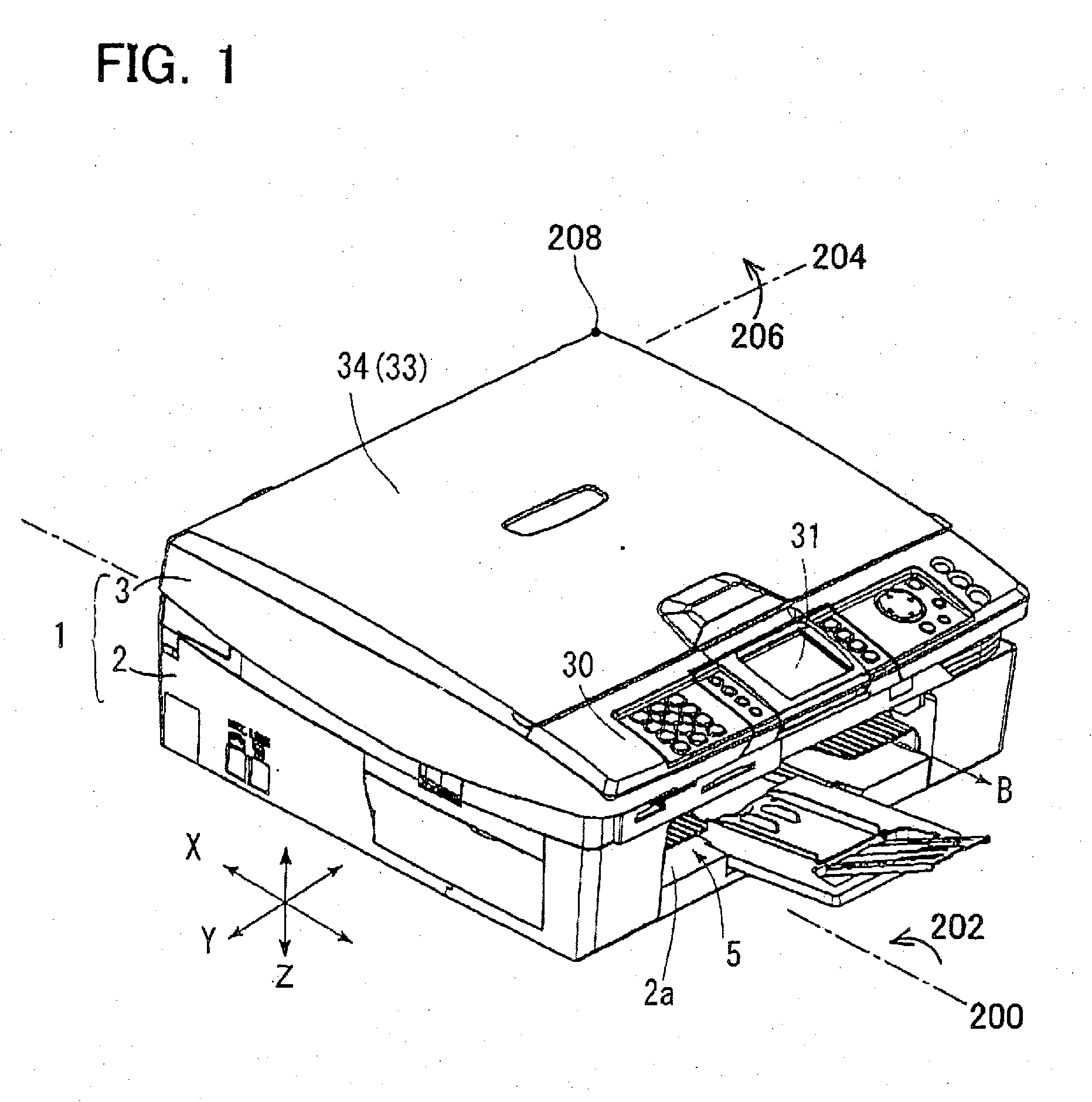

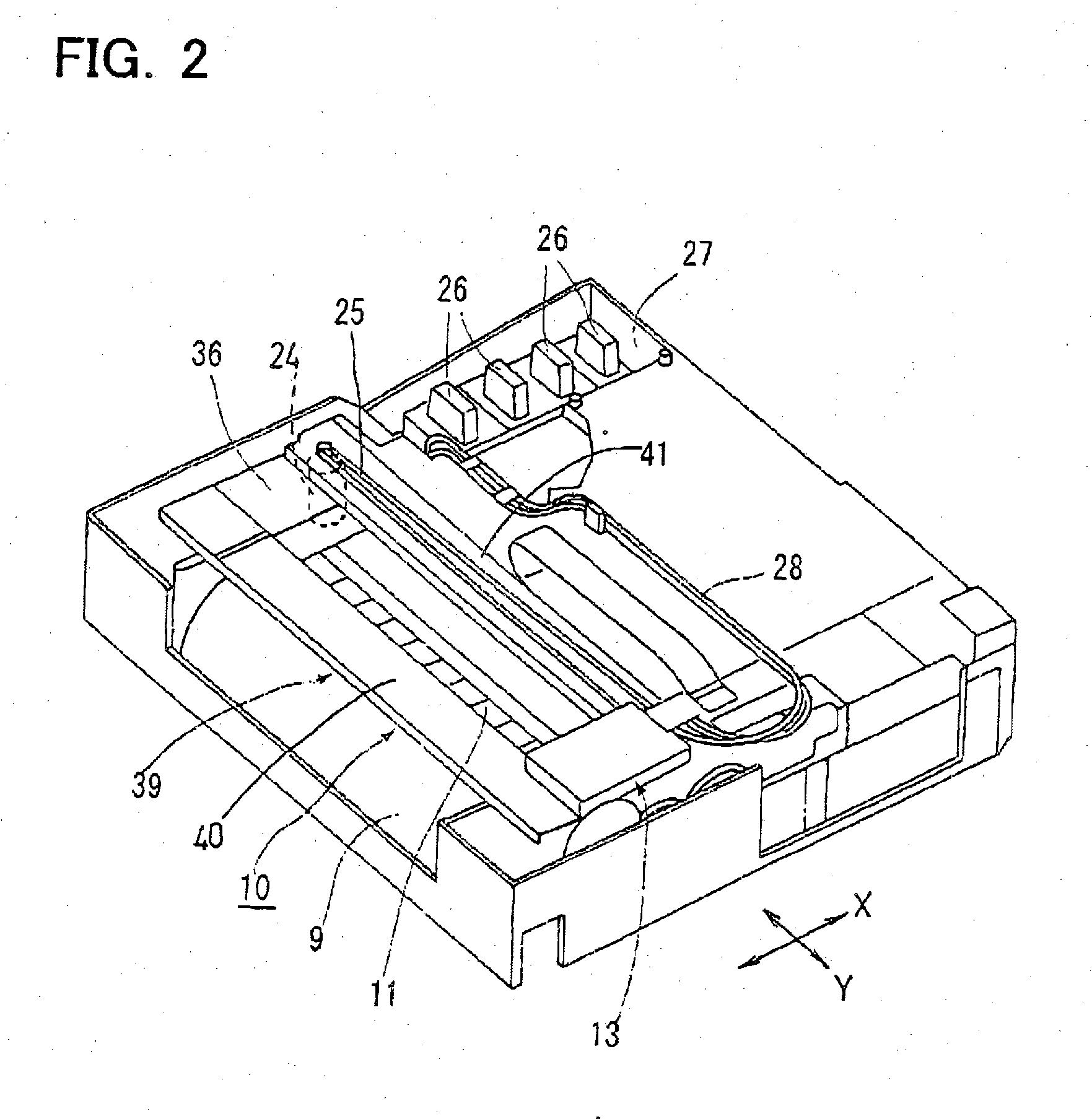

Printer with sheet sending mechanism

InactiveUS20070057447A1Increase speedSpacing mechanismsPower drive mechanismsEngineeringFeeding mode

A supply roller for sending a piece of sheet from pieces of sheets stacked within a cassette towards a sheet guide and a pair of feed-in rollers for sending the piece of sheet supplied from the sheet guide towards a printing region are provided within a printer. The pair of feed-in rollers has a feed-in drive roller driven by a motor and a feed-in driven roller driven by the feed-in drive roller. A sending speed of the pair of feed-in rollers is faster than a sending speed of the supply roller, and a sending force of the pair of feed-in rollers is stronger than a sending force of the supply roller. A controller of the printer controls the rotation of the supply roller and the pair of feed-in rollers according to a procedure that does not rely on a position of the sheet sent by the supply roller and the pair of feed-in rollers during the continuous feeding mode.

Owner:BROTHER KOGYO KK

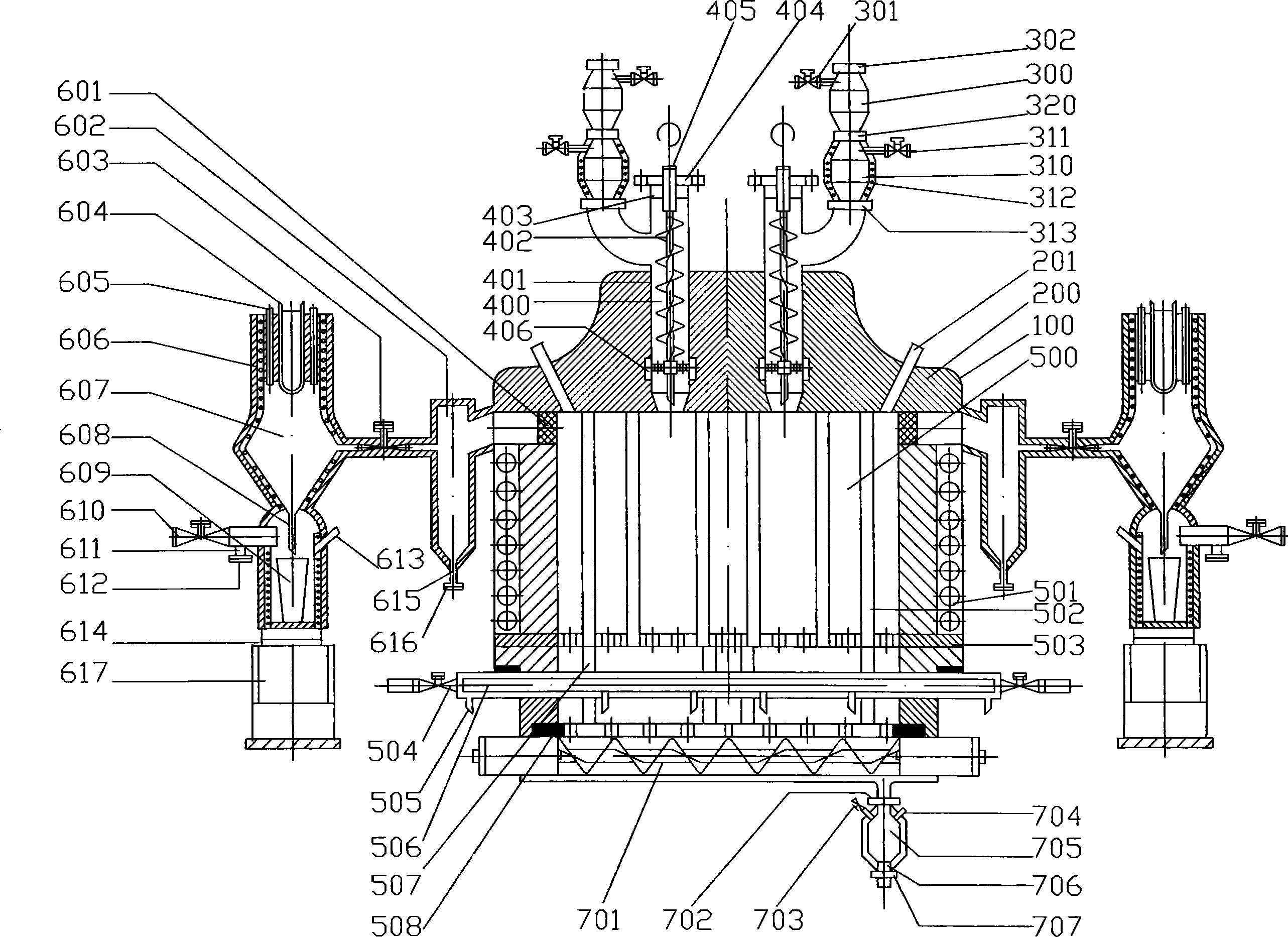

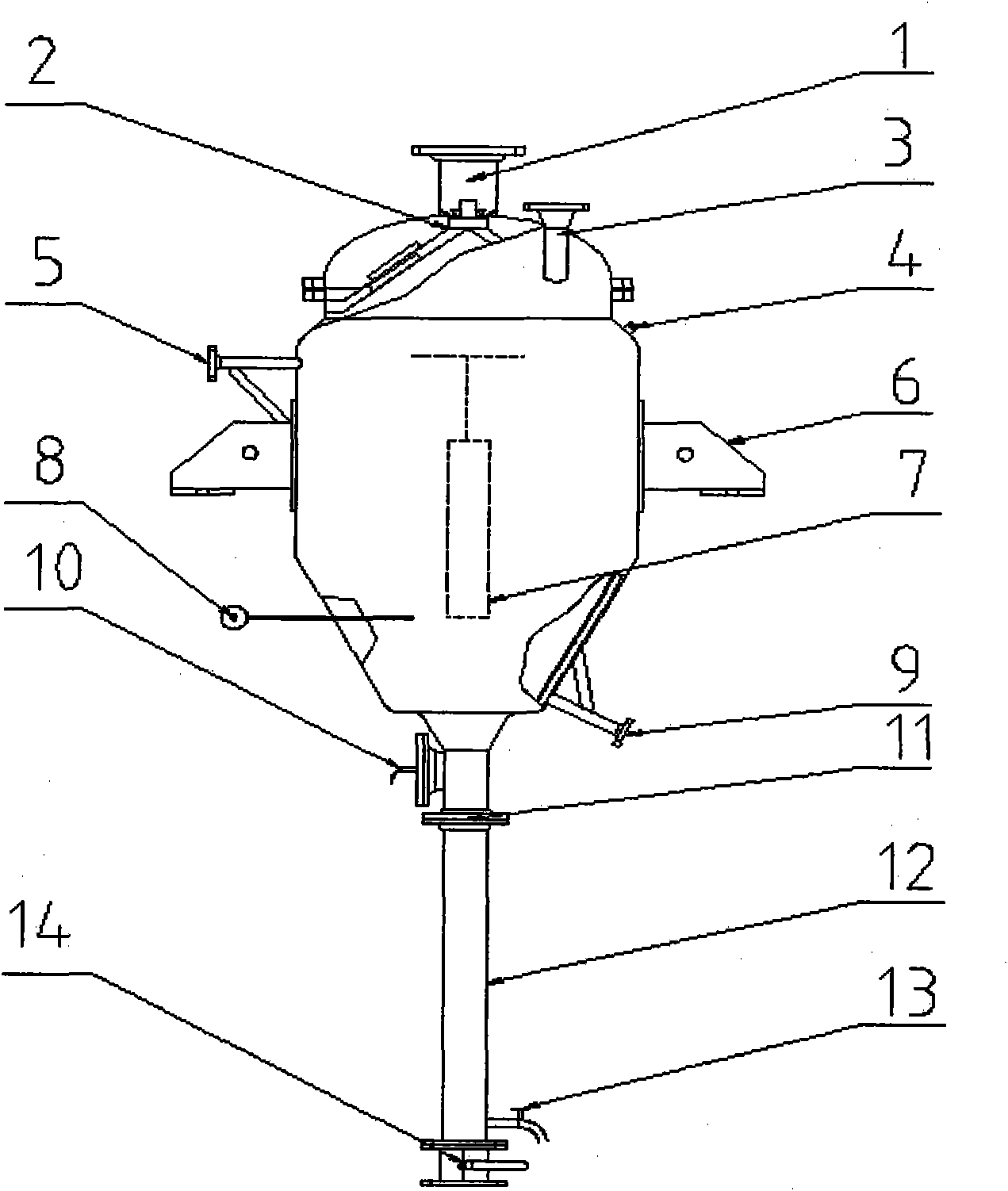

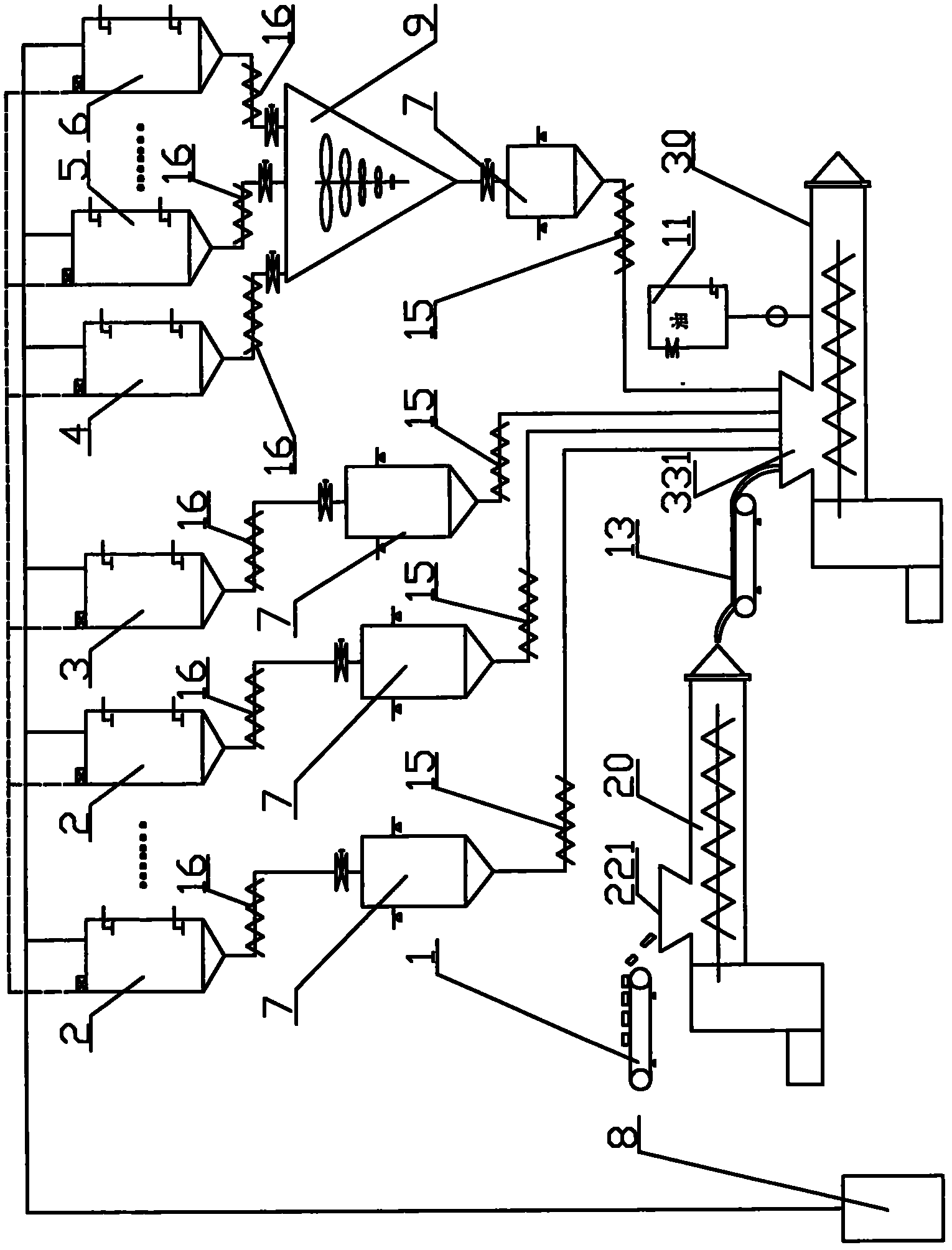

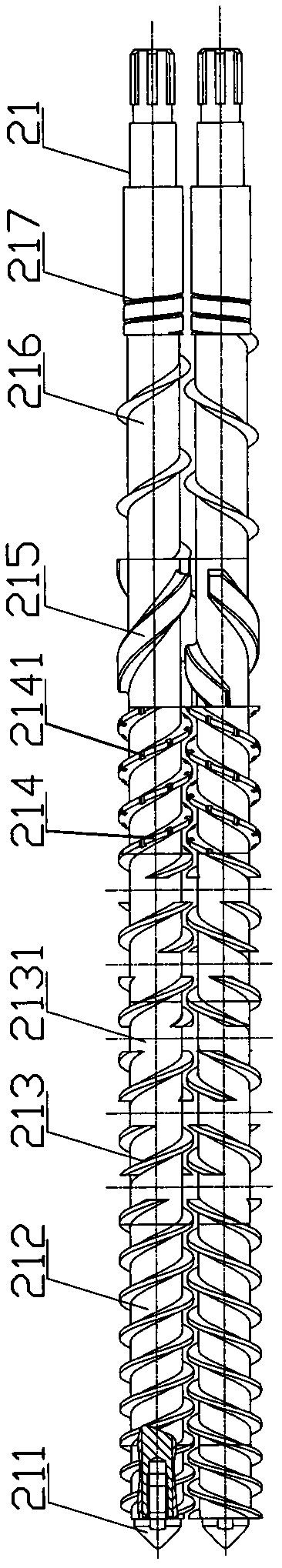

Induction heating continuous magnesium-smelting system and continuous magnesium-smelting technique

The invention discloses a system of inductive heating continuous magnesium smelting and a continuous magnesium smelting technique. The system comprises a continuous feeding device, an inductive heating reaction chamber, a magnesium steam condensing device and a continuous discharging device; wherein the feeding device consists of a feeding housing and a spiral feeding mechanism, the reaction chamber comprises an inductive heating winding, a heating element, a clapboard with holes and a slag cooling device, the condensing device consists of a mesh clapboard, a dust deposition chamber, the magnesium steam condensing chamber, the continuous discharging device comprises spiral slag discharging mechanism and slag housing. The continuous magnesium smelting technique consists of the processes of the continuous feeding of reacting burden into the reaction chamber, the continuous condensation of the magnesium steam and the discharge of liquid magnesium, and also comprises steps of the continuous feeding of reacting slag into the slag housing and slag discharging. The invention has high heat energy utilization rate, and can realize the low cost continuous production of the metal magnesium.

Owner:CENT SOUTH UNIV

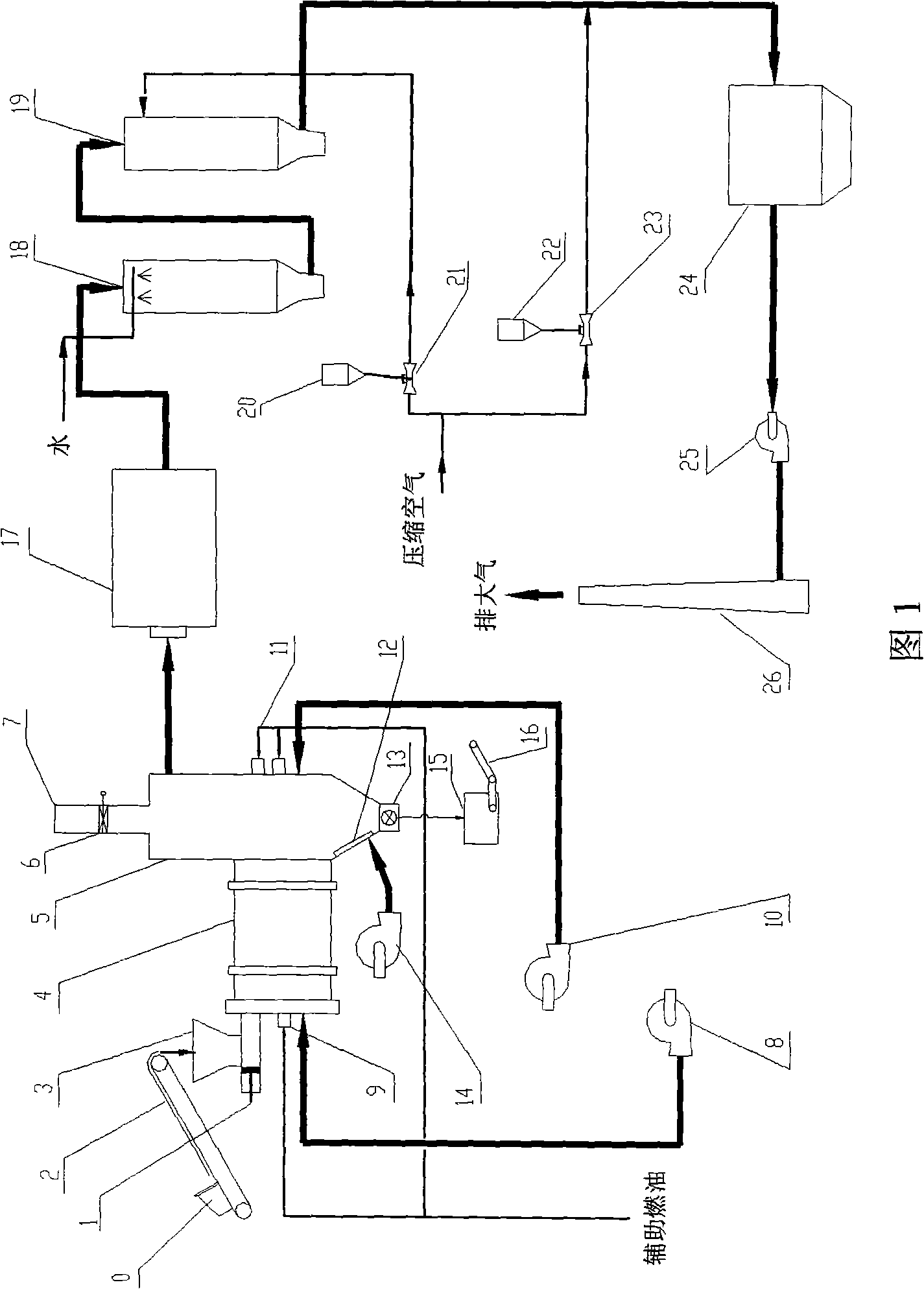

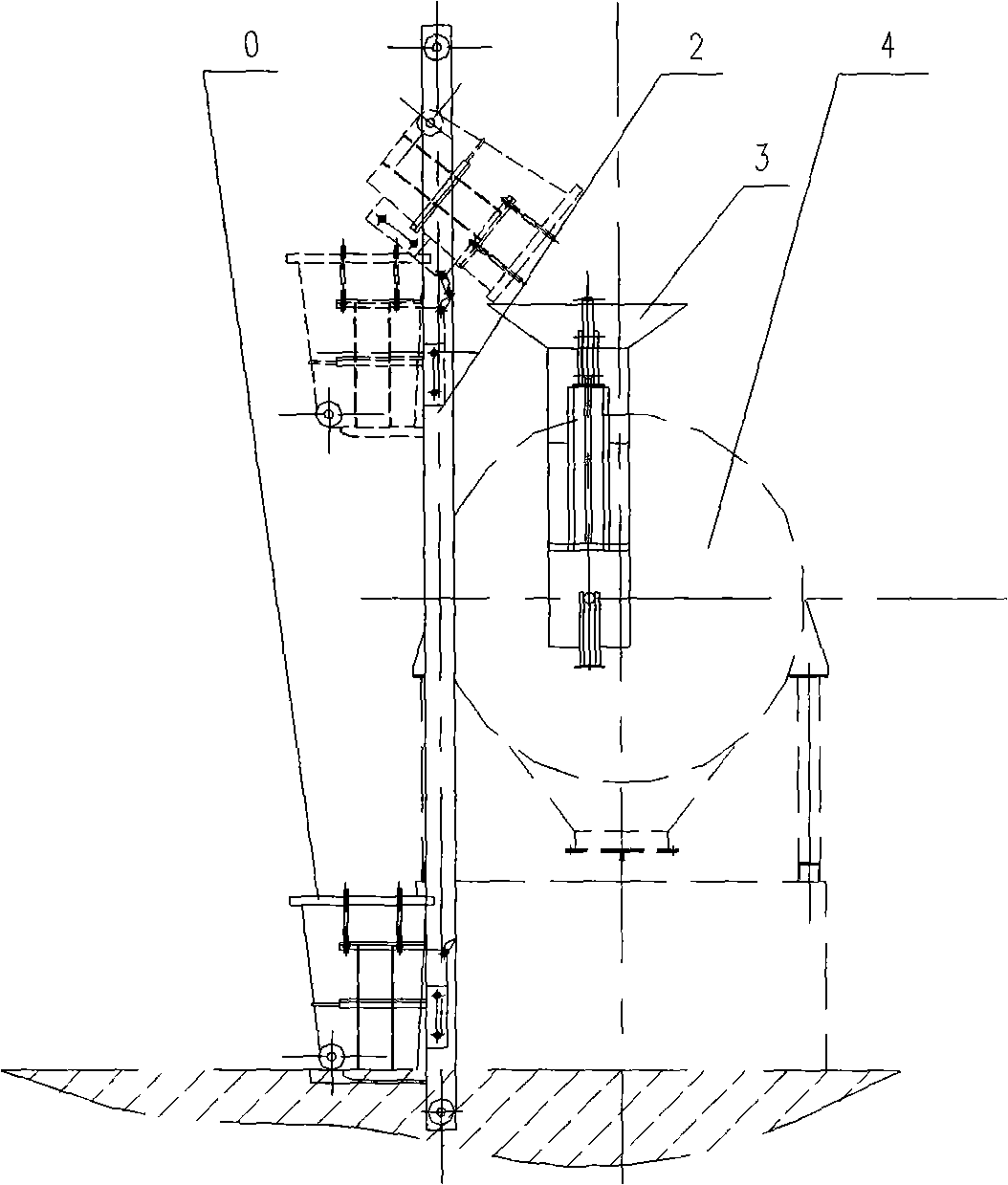

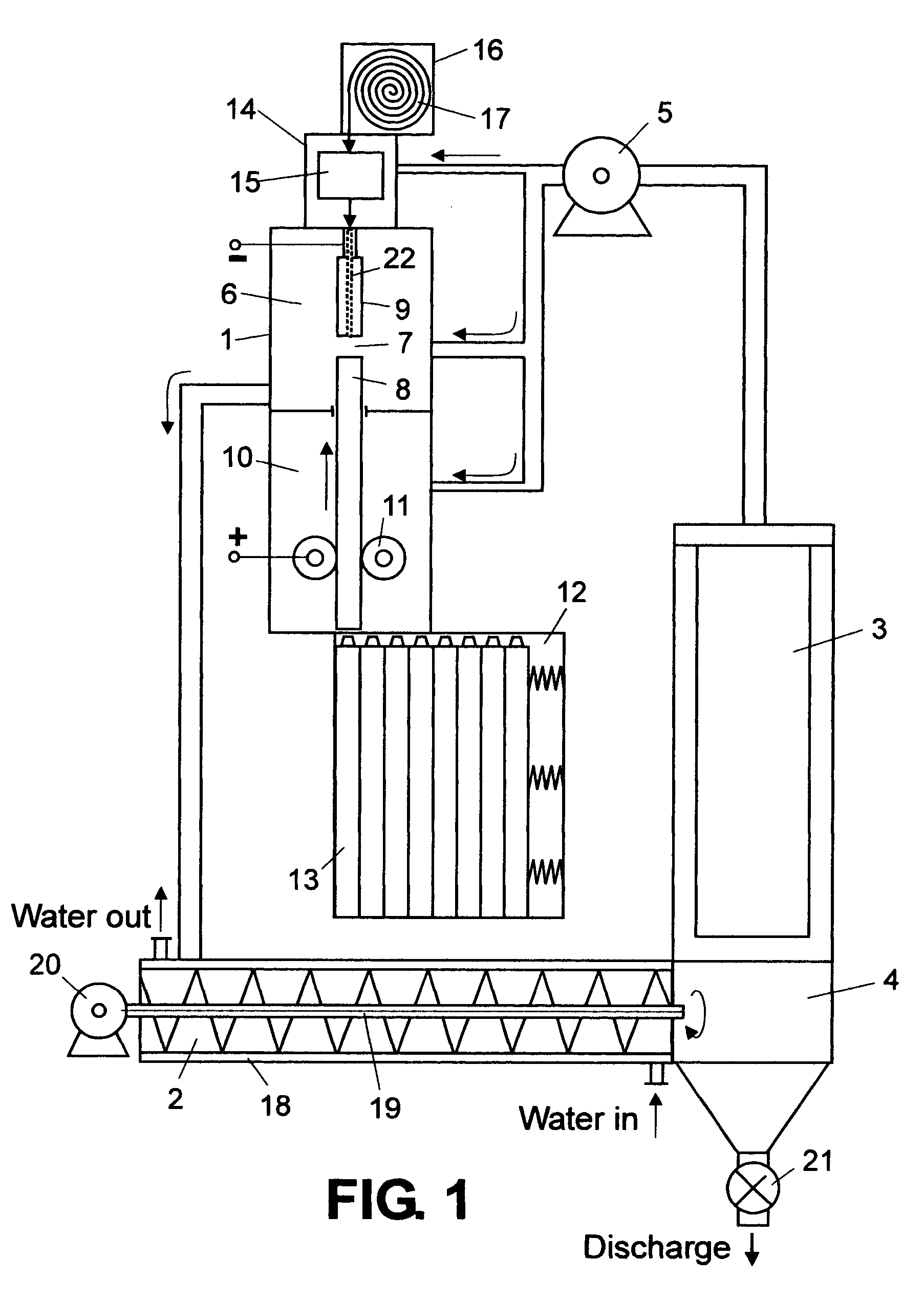

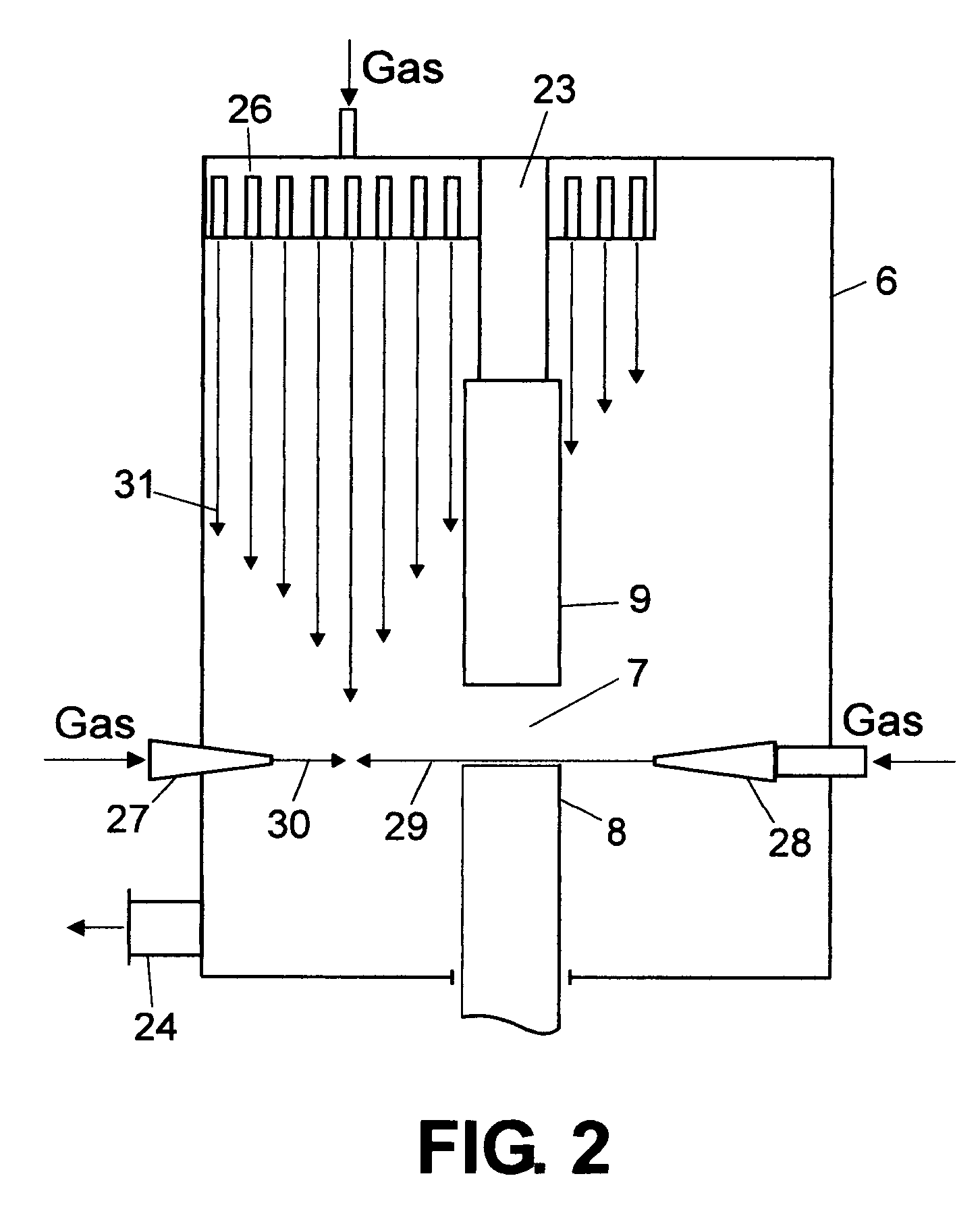

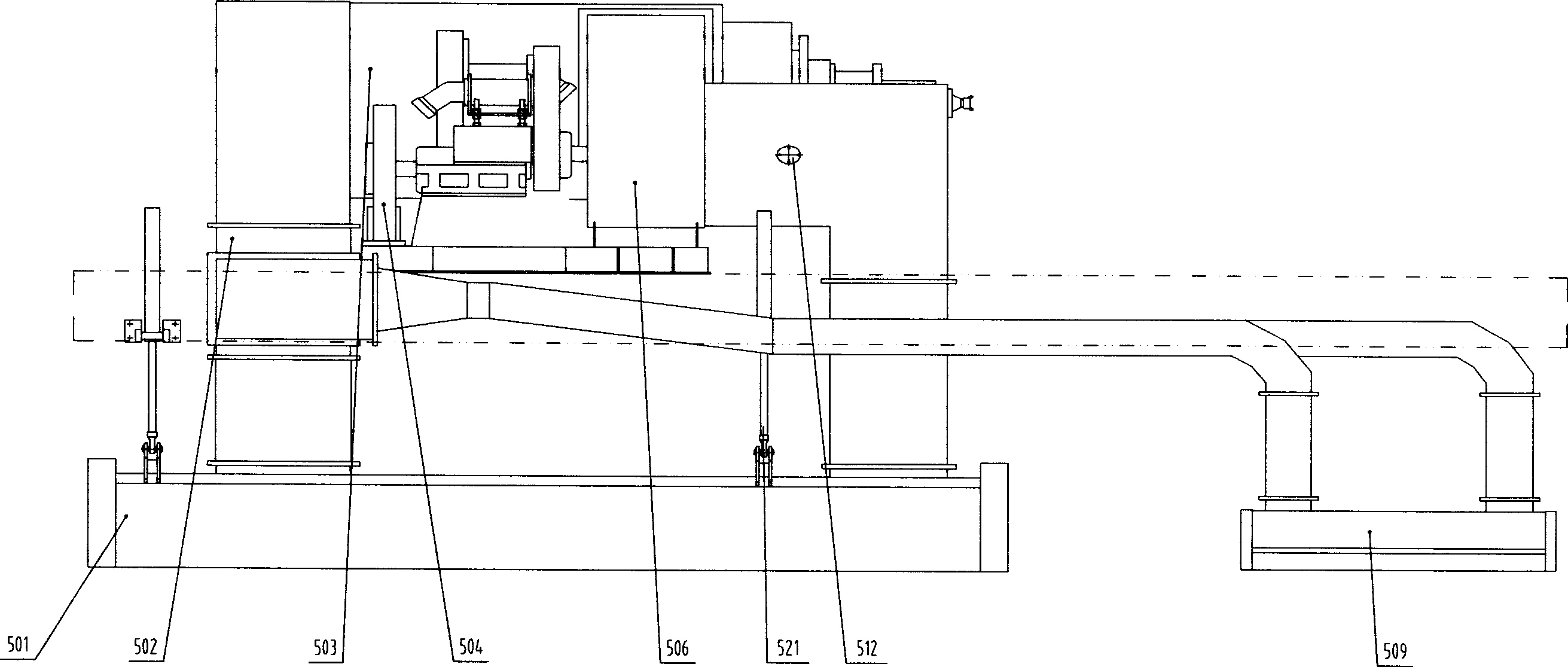

Pneumatic medical waste burning process for rotary kiln and device therefor

InactiveCN101285577AAvoid destructionAchieve turbulent combustionIndirect carbon-dioxide mitigationIncinerator apparatusCombustion chamberAtmospheric air

The invention discloses a process and a device for incinerating rotary kiln gas-controlled medical waste, relating to the environmental protection technical field. The process of the invention comprises the following steps of: collecting the whole packet of medical waste refuse bag and feeding into a feeding hopper, then feeding into a rotary kiln initial combustion chamber by a feeding mechanism which is closed by chain, and completing the processes of drying, pyrolyzing and air controlled anoxycausis of the medical waste. Waste gas generated by the rotary kiln initial combustion chamber enters to a secondary combustion chamber to undergo the process of air controlled oxygen-enriched complete combustion, wherein bottom ash with a little redial carbon is flamed at an inclined fire grate which is arranged in an ash well at the lower part of the secondary combustion chamber. The smoke gas at an outlet of the secondary combustion chamber is exhausted into the atmosphere by a draft fan through a chimney after surplus heat utilization of a surplus heat boiler, smoke gas sharp quenching of a quench tower, a dry-type deacidification and cloth-bag dust removal of a bag-type duster. Compared with the prior art, the process and the device for incinerating rotary kiln gas-controlled medical waste have the advantages of good operating economical efficiency, automatic safety continuous feeding, fluent slag tapping system and low index of pollution emission.

Owner:TSINGHUA UNIV +1

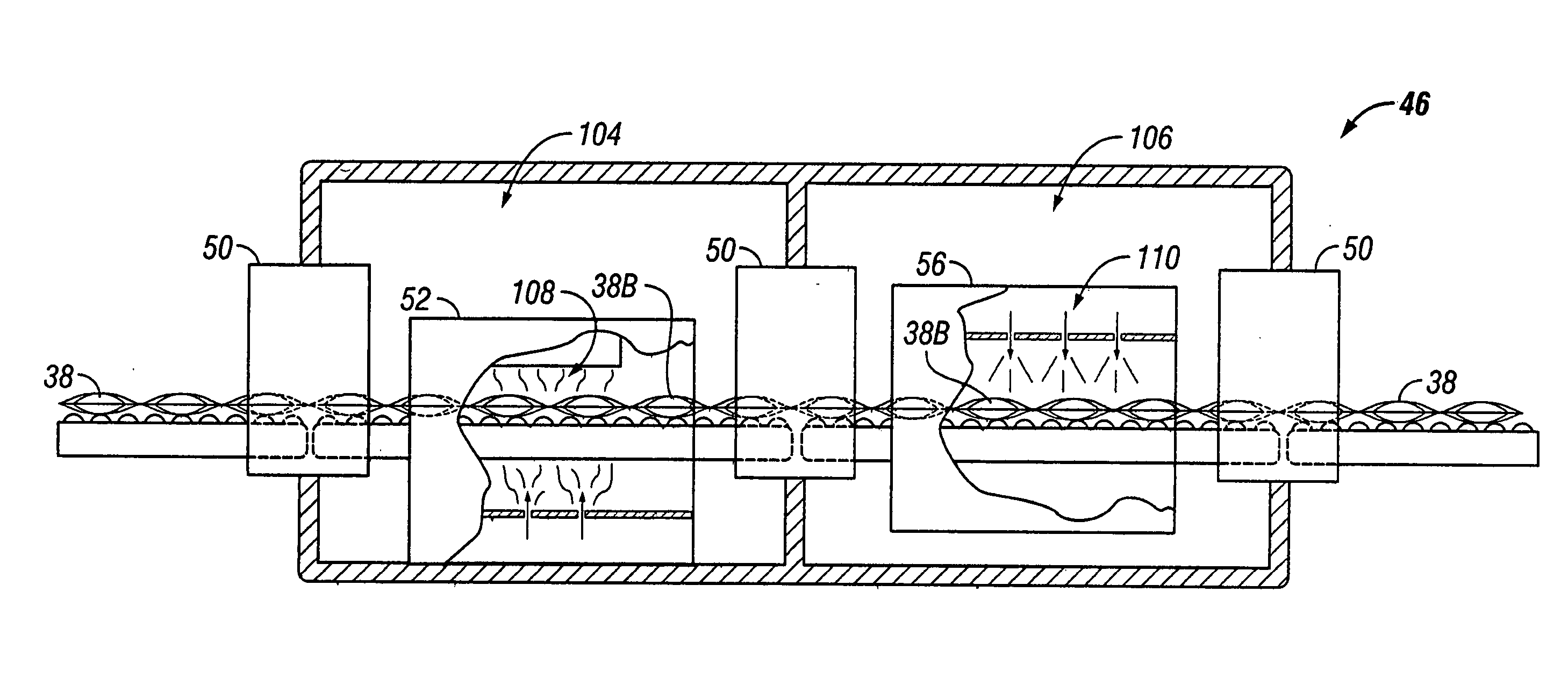

Radiation processing apparatus and method

InactiveUS6096379AFaster and uniform productionFaster air grindingLiquid surface applicatorsDough treatmentEngineeringElectron beam accelerator

A method and apparatus for the continuous feeding of polymer chips or particles to an electron beam accelerator makes use of spreading, belt conveying, irradiation and cooling. The apparatus is designed to make more efficient use of radiation through continuous feed. This method and apparatus, suitably adapted, is also used for food irradiation and decontamination, particularly for ground meats.

Owner:DREYER MARY E +4

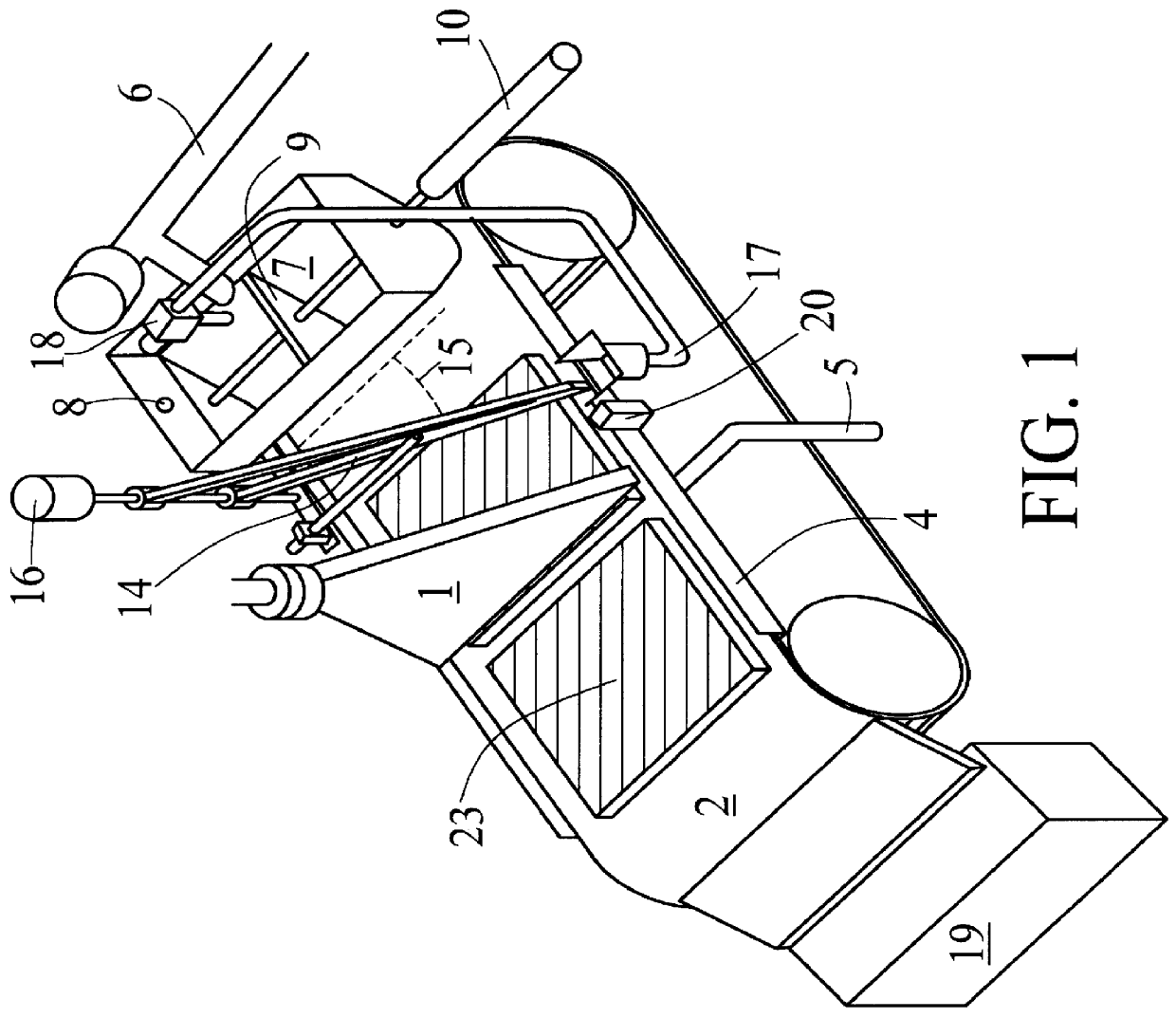

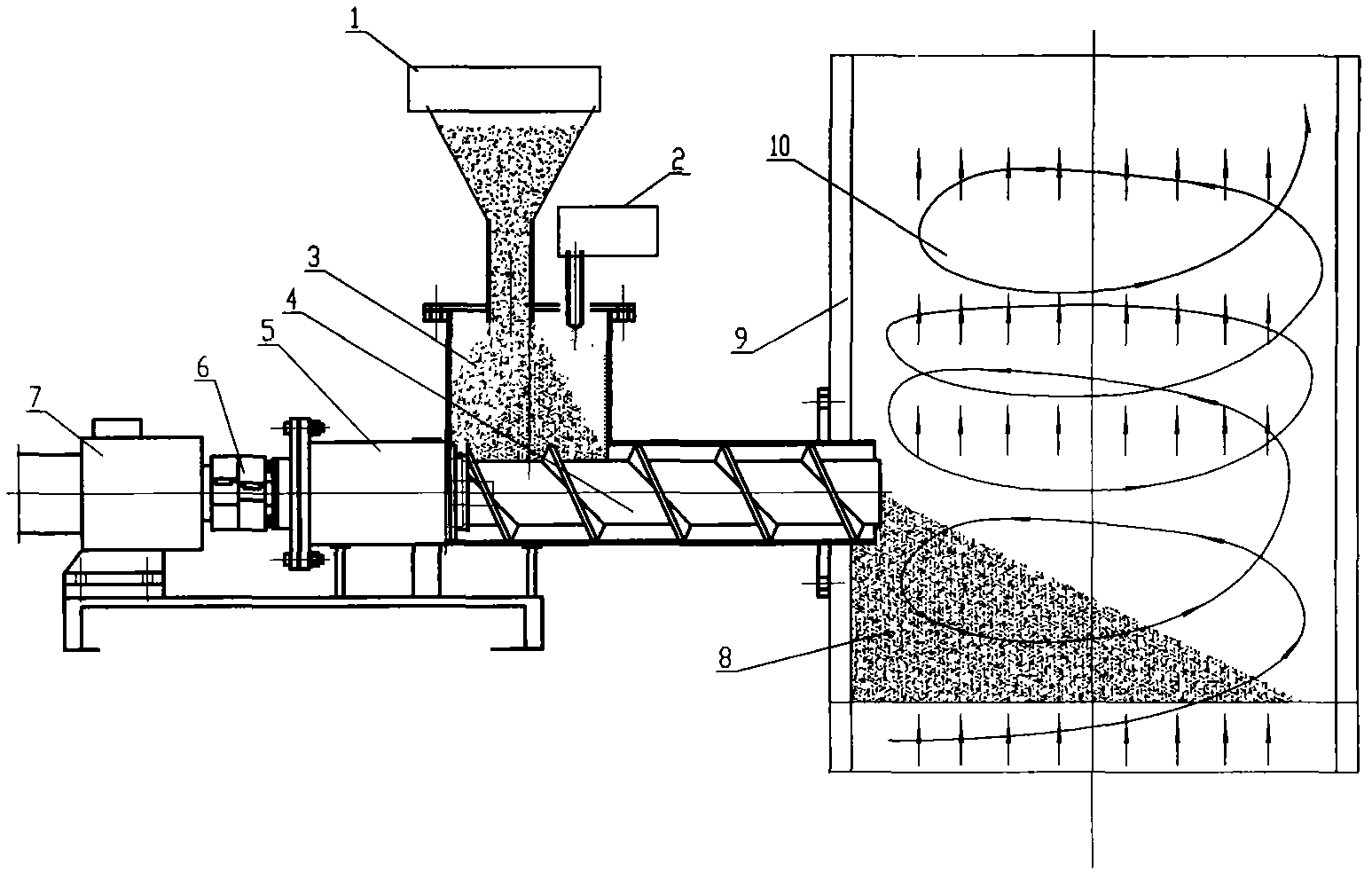

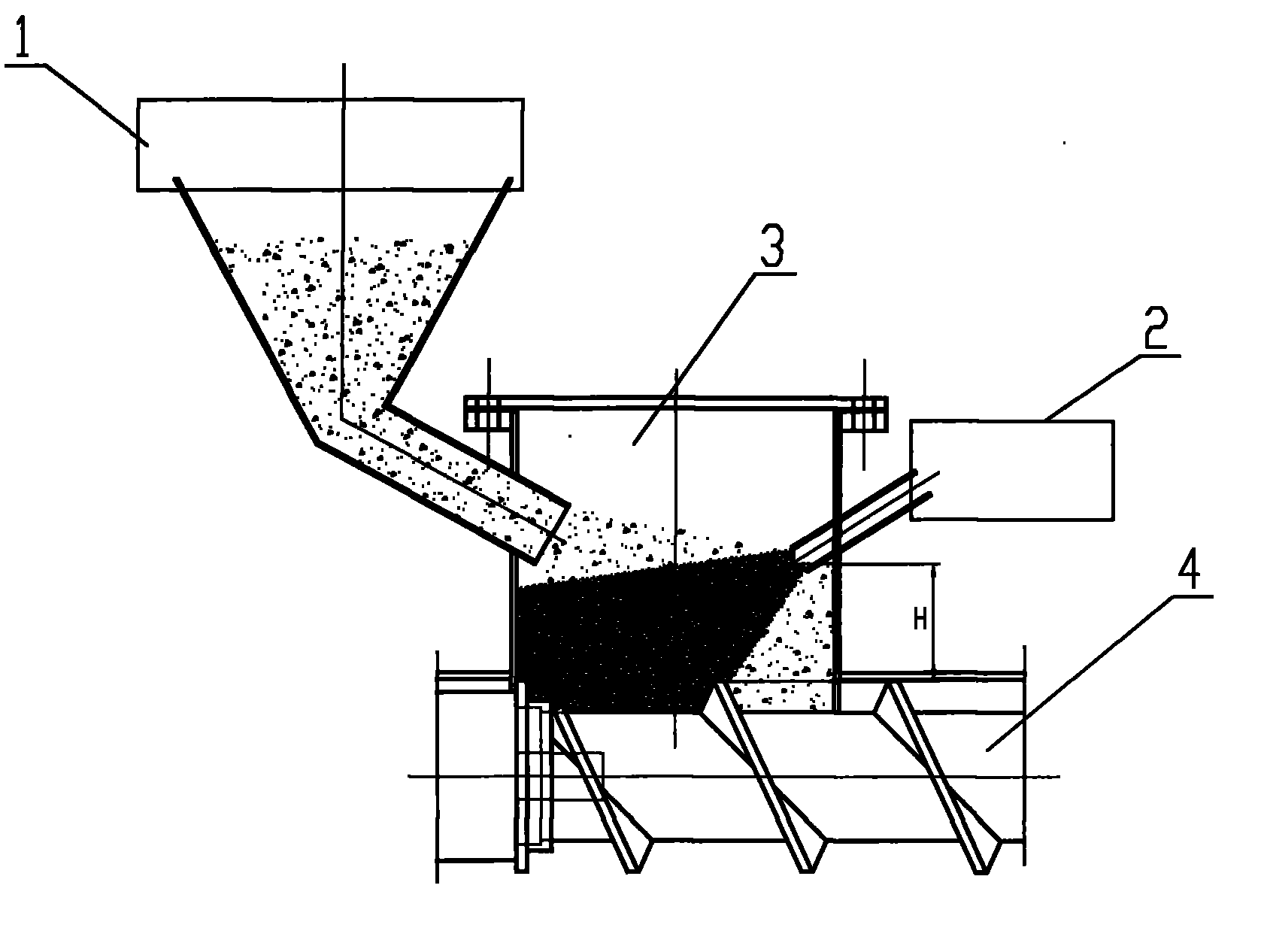

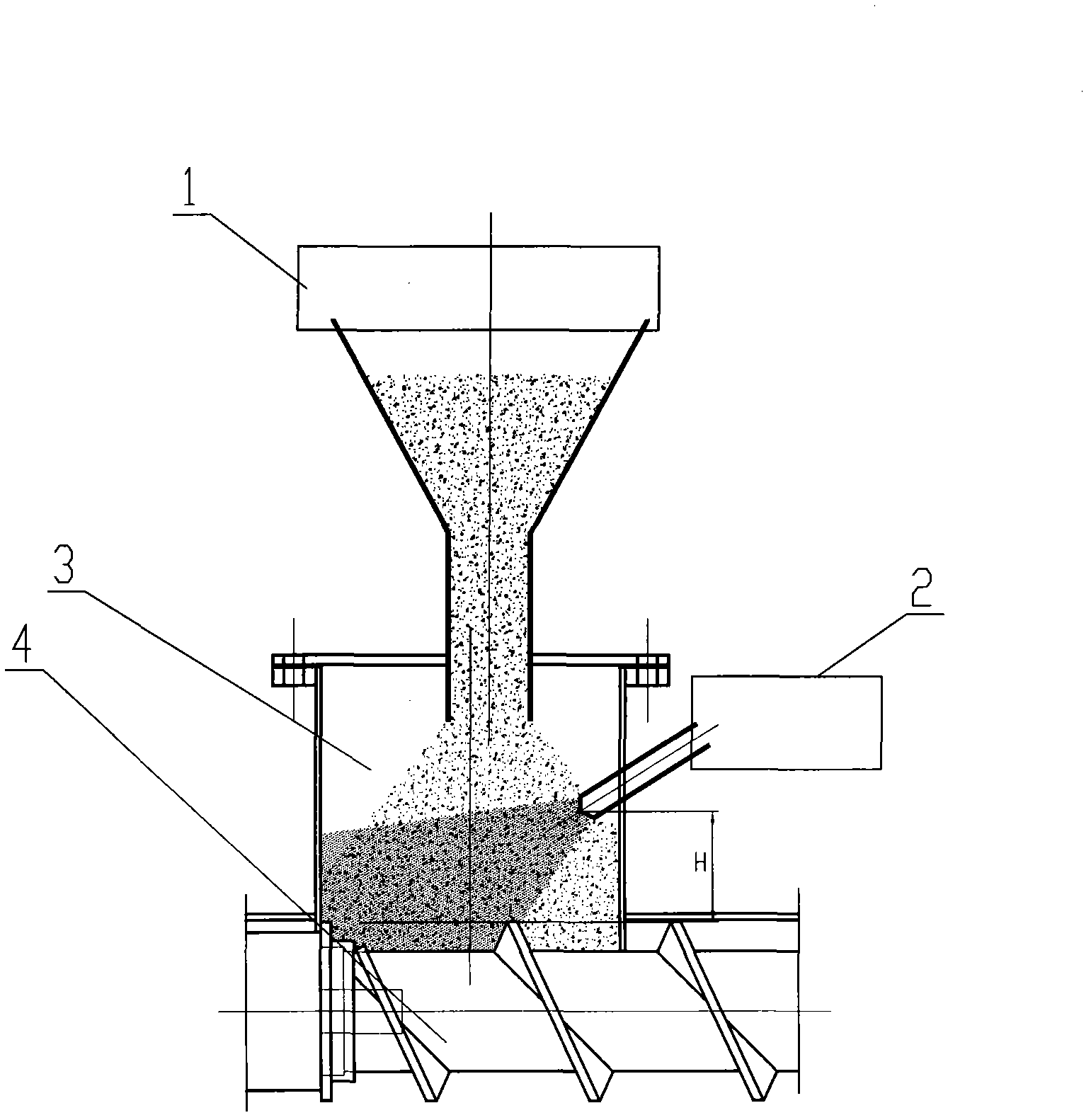

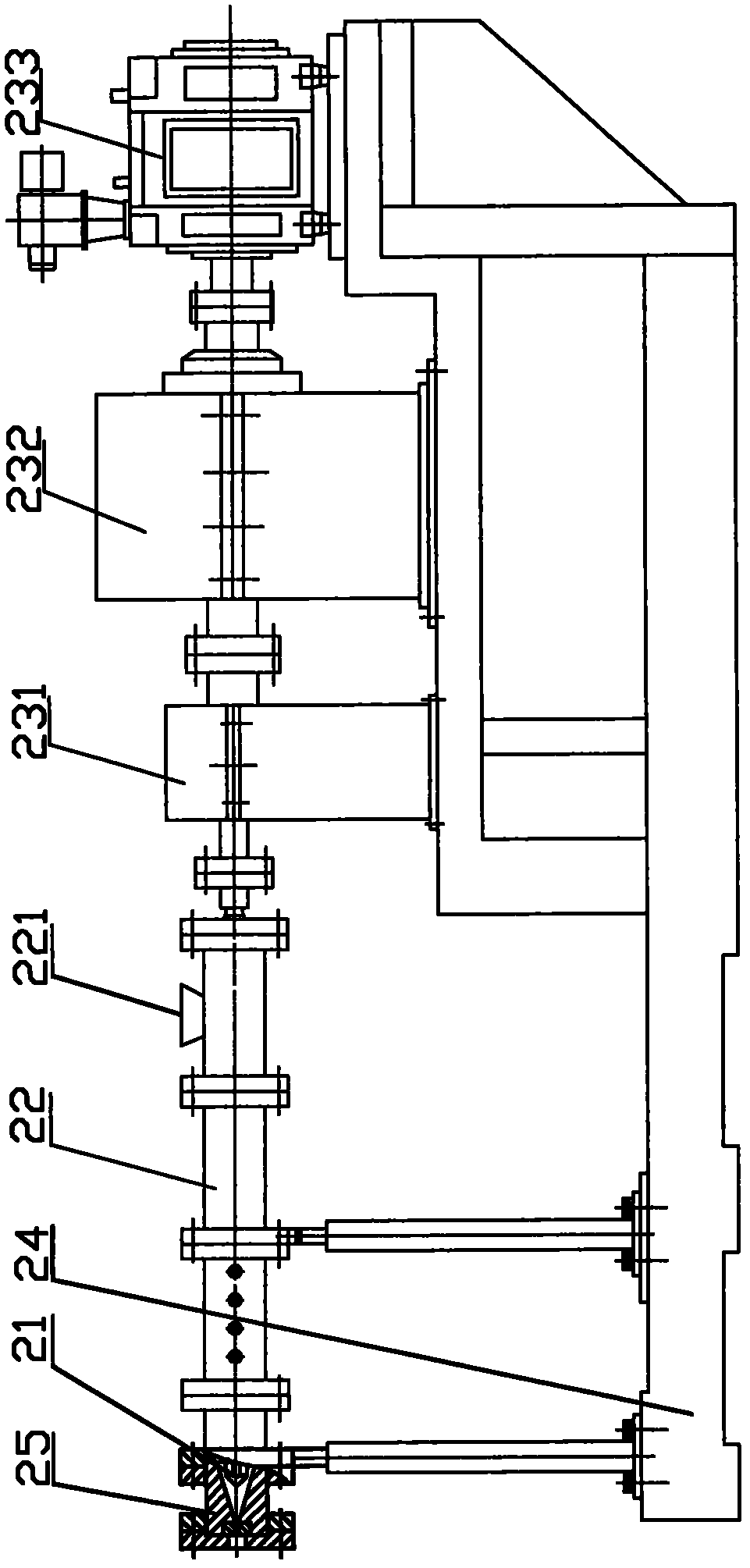

Catalyst successive impregnation equipment and method

ActiveCN102806109AImprove impregnation efficiencyImprove impregnation uniformityCatalyst activation/preparationEngineeringCatalyst support

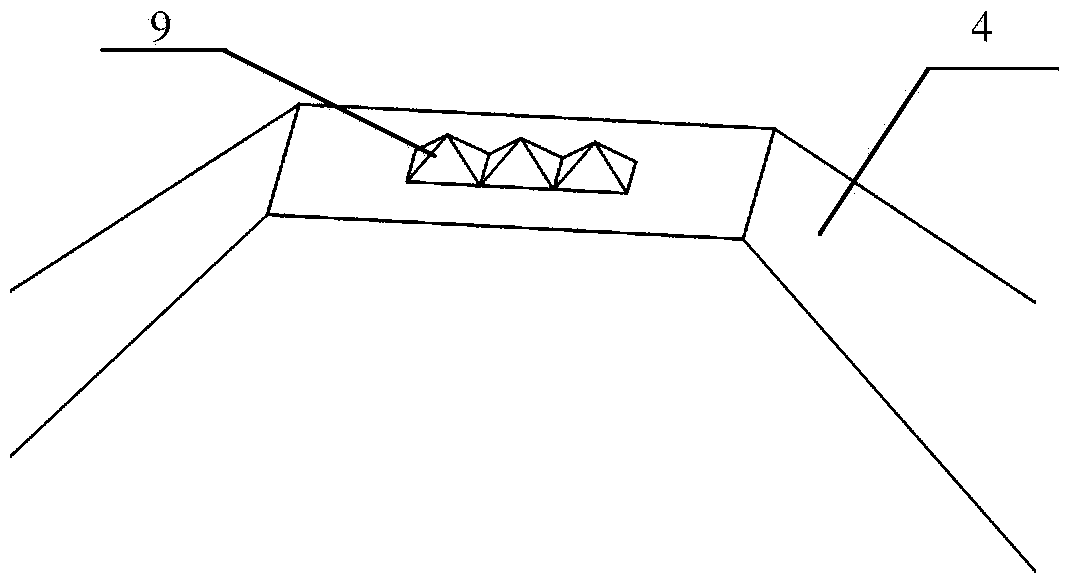

The invention relates to catalyst successive impregnation equipment and a method. The catalyst successive impregnation equipment comprises a carrier continuous feeding system (1), an impregnation liquid conveying system (2), an impregnation chamber (3), a conveying part (4), a dryer (9) and a power system; the carrier continuous feeding system (1) and the impregnation liquid conveying system (2) are open in the impregnation chamber (3); the bottom of the impregnation chamber (3) is open at the initial end of the conveying part (4); the conveying part (4) is positioned between the impregnation chamber (3) and the dryer (9); an outlet at the tail end of the conveying part (4) is communicated with the dryer (9); and power is provided for the operation of the conveying part (4) by the power system. The invention also discloses the method applying the equipment. The catalyst successive impregnation equipment and the method which are provided by the invention can be used for carrying out catalyst carrier impregnation to prepare a catalyst; a catalyst carrier is continuously impregnated; the impregnation efficiency is high; the impregnation uniformity is good; and the catalyst carrier is crushed a little.

Owner:CHINA PETROLEUM & CHEM CORP +1

Production method of eggs with high organic selenium content and low cholesterin content

InactiveCN101756072AGood for healthSufficient contentAnimal feeding stuffAnimal scienceHealth condition

The invention provides a production method of eggs with high organic selenium content and low cholesterin content, which relates to a production method of eggs. The method comprises the following steps: (1) preparing a Chinese herbal medicine mixture capable of enhancing the metabolism function of hens, selenium-enriched feedstuff A and selenium-enriched feedstuff B, feeding the selenium-enriched feedstuff A to laying hens of an age of 30 to 50 days until the age of the laying hens reaches 70 days, feeding the selenium-enriched feedstuff B to the laying hens, and stopping the feeding until the age of the laying hens is 120 days before the egg laying; and (2) preparing selenium-enriched feedstuff C, and continuously feeding selenium-enriched feedstuff C to the laying hens of the age of 120 days adaptively fed in the first step (after 15 to 20 days, the organic selenium content in the eggs is between 3.5 mg / kg and 8.36 mg / kg through detection, and the cholesterin content is between 150 mg / 100 g and 300 mg / 100 g). The invention can stably obtain the eggs with the effects that the organic selenium content in each egg is not lower than 200 mug, the egg with the cholesterin content between 150 mg / 100 g and 300 mg / 100 g, the egg contains more than 40 kinds of nutriments necessary to human bodies, the nutriments have balanced proportion and sufficient content, in addition, the health condition of the hens is good, and the yield is stable.

Owner:TIANJIN XINAIKE BIOTECH

Process for preparing Cu-Zn-Al vapor hydroformylation catalyst and products therefrom

ActiveCN1883795AImprove crystal stateHigh selectivityOrganic reductionMetal/metal-oxides/metal-hydroxide catalystsGas phaseSide reaction

The invention belongs to catalyst technique field, concretely relates to a preparation method of catalyst for copper-zinc-aluminum gas phase aldehyde hydrogenation and product thereof, which solves the problems in existing technique that the preparation process of aldehyde hydrogenation catalyst is complex, repeatability is bad, catalyst crystal-size is heterogeneous, dispersion degree of active copper is not high, mechanical strength is small, selectivity to product is bad, especially when rising reactive temperature to enhancing reactive speed and heat energy efficiency, activity, selectivity and stability are bad. The method modifies the intermittent feeding mode to continuous feeding mode by step continuous coprecipitation method, specific surface and pore volume of catalyst is large, dispersion degree of active metal is high, catalytic activity is good, selective and stability have more improvement, and side reaction of esterification and etherification is reduced.

Owner:PETROCHINA CO LTD

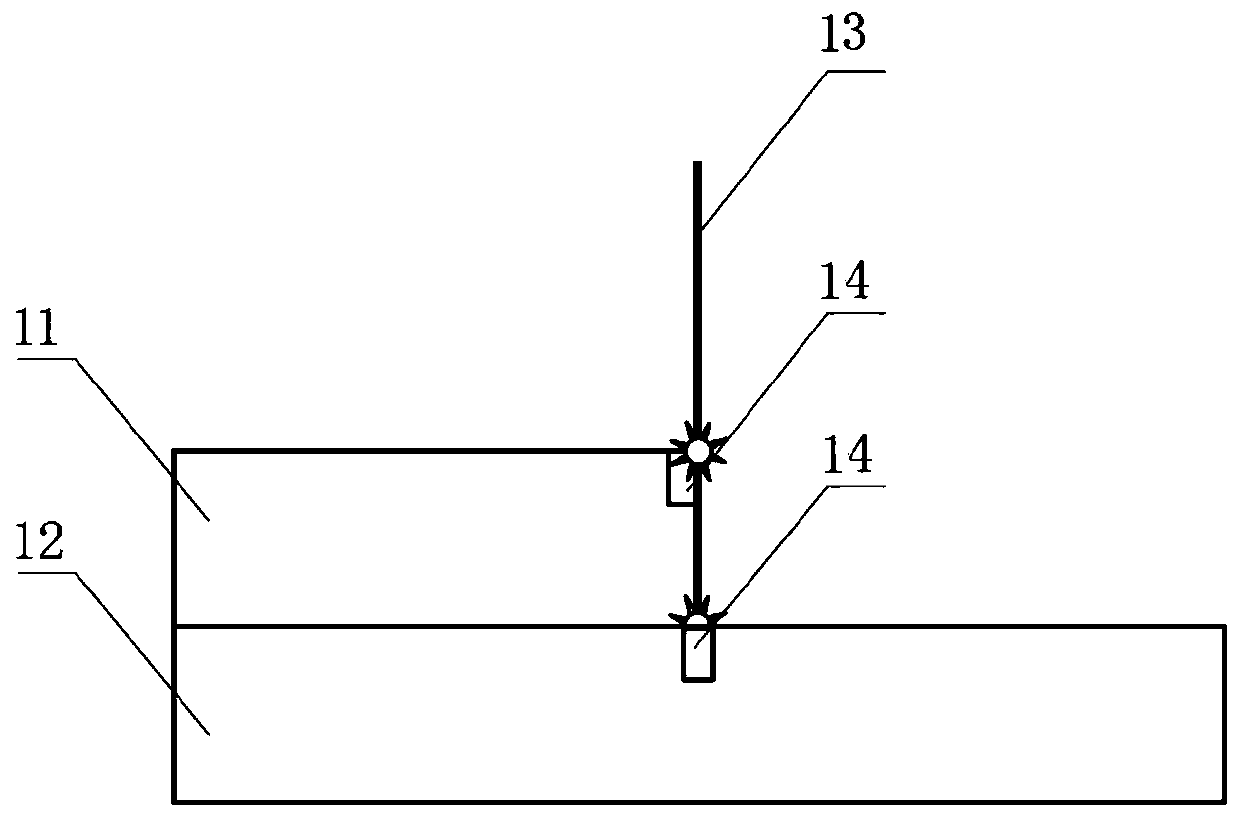

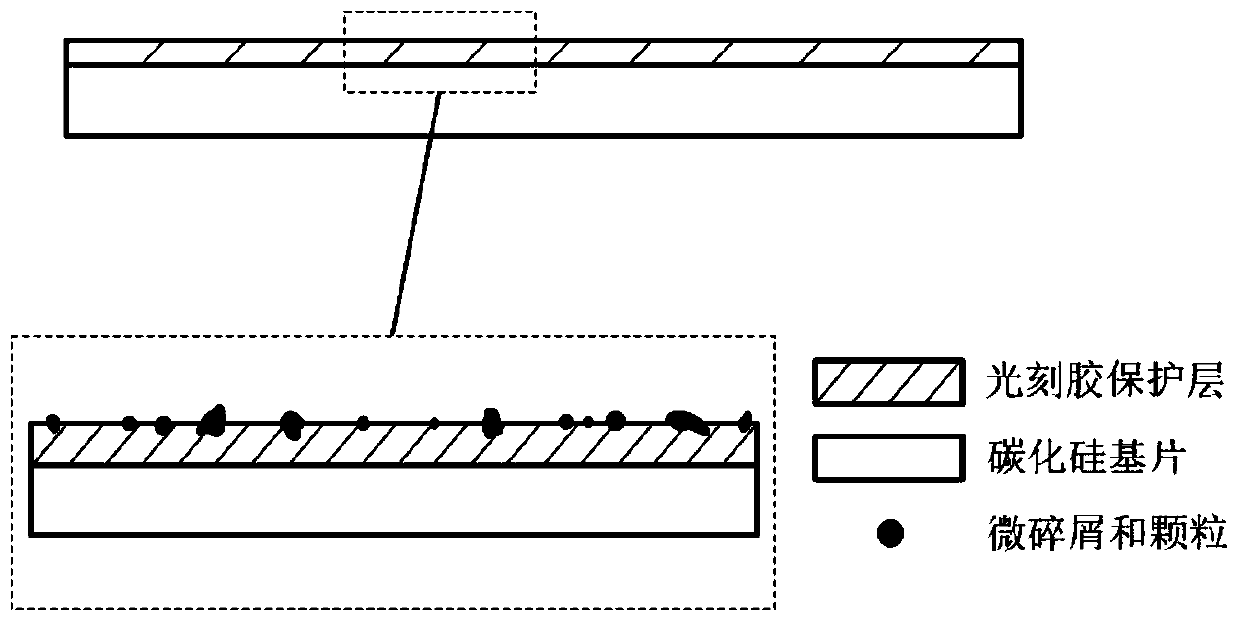

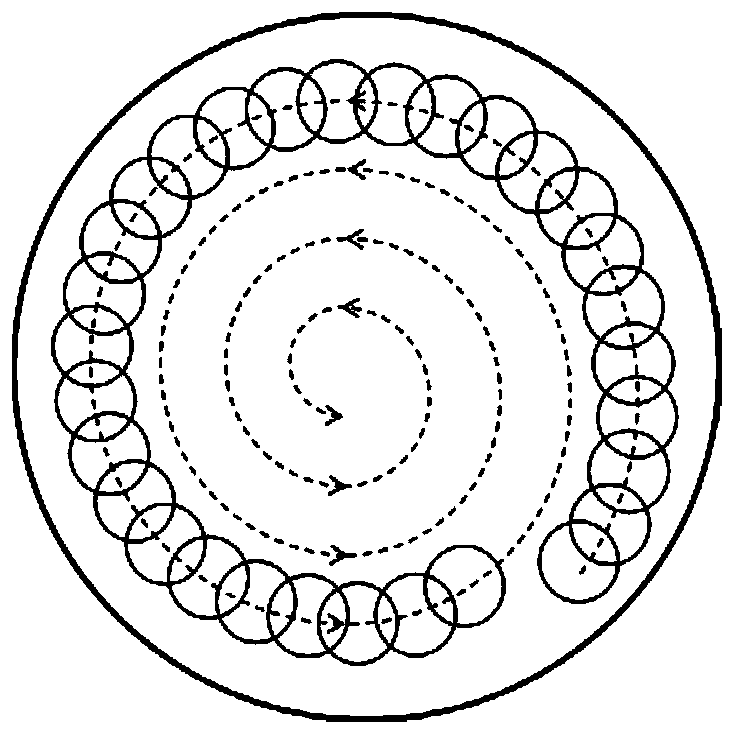

Femtosecond laser processing device and method for rapid deep etching of silicon carbide

ActiveCN110385521AFast etch qualityImprove etch qualityLaser beam welding apparatusLaser etchingLaser processing

The invention discloses a femtosecond laser processing device and method for rapid deep etching of silicon carbide. The femtosecond laser processing device mainly comprises a laser source module, a laser motion module, a shaping and focusing module, an auxiliary gas module and a laser etching module. According to the device and method, a focal plane is calibrated, a protection layer is prepared, an etching path is planned, layer-by-layer scanning etching is carried out according to parameter groups, and micro-chips are removed, so that deep etching of silicon carbide is realized. According tothe method, due to the fact that a femtosecond laser is used for processing silicon carbide, factors influencing the etching quality are controlled, namely, the laser energy density, the light spot overlapping rate and the line overlapping rate, and therefore silicon carbide is subjected to rapid and high-quality deep etching in a layer-by-layer scanning manner and a continuous feeding processingmanner according to the planned etching path.

Owner:XI AN JIAOTONG UNIV

Bacillus subtilis fermentation production technology

InactiveCN104911120AIncrease growth rateLow costBacteriaMicroorganism based processesOxygenBacillus subtilis

The invention relates to a bacillus subtilis fermentation production technology, which comprises the following steps: 1)inoculating bacillus subtilis in an aseptic culture tube, performing shaking culture and activating to obtain liquid as a first fermentation seed liquid; 2)inoculating first fermentation seed liquid in an improvement medium, continuously performing shaking culture and activating to obtain liquid as a secondary fermentation seed liquid; 3)inoculating the activated secondary seeds in a fermentation medium for fermentation culture, culturing in a fermentation cylinder; and 4)centrifuging a broth at 4000-8000rpm and collecting thalline, and drying at temperature of 30-50 DEG C. The fermentation production technology has the beneficial effect that glucose is employed as a main medium component of carbon source, and thalline growth rate can be grearly increased by continuous feeding and fermentation through dissolved oxygen linkage at anaphase. The bacillus subtilis thalline powder has the advantages of low cost, simple fermentation technology and short production period, and has wide production application prospect.

Owner:ZHEJIANG SCI-TECH UNIV

Dynamic demonomerization and defoaming method and device for carbon fiber spinning solution

ActiveCN101856570AContinuous quantitative feedingSingle and degassing continuous dynamicFoam dispersion/preventionCarbon fibersSolvent

The invention discloses a dynamic demonomerization and defoaming method and a dynamic demonomerization and defoaming device for carbon fiber spinning solution. An ultrasonic generator is arranged in the centre of a defoaming kettle; an air guide cylinder and a flow guide disk are arranged on a flow diversion and air guide cover; and the defoaming effect is improved to realize low-temperature high-vacuum demonomerization and defoaming of the spinning solution with different relative molecular masses and different charging rates by the processes of heating a demonomerization and defoaming device, continuous feeding, gravity demonomerization and defoaming, film stretch defoaming and ultrasound-assisted defoaming and controlling the defoaming temperature, the vacuum degree and the rotation speed of a demonomerization tower. The spinning solution obtained by the method has the residual monomer content of less than 0.1 percent, less than 5 small bubbles with diameter of less than 0.03mm and solvent loss of less than 5 percent during the demonomerization and defoaming. The method and the device can realize continuous dynamic demonomerization and defoaming at a low temperature under vacuum condition and has the characteristics of simple and practical process and good defoaming effect.

Owner:XIAN KANGBEN MATERIAL

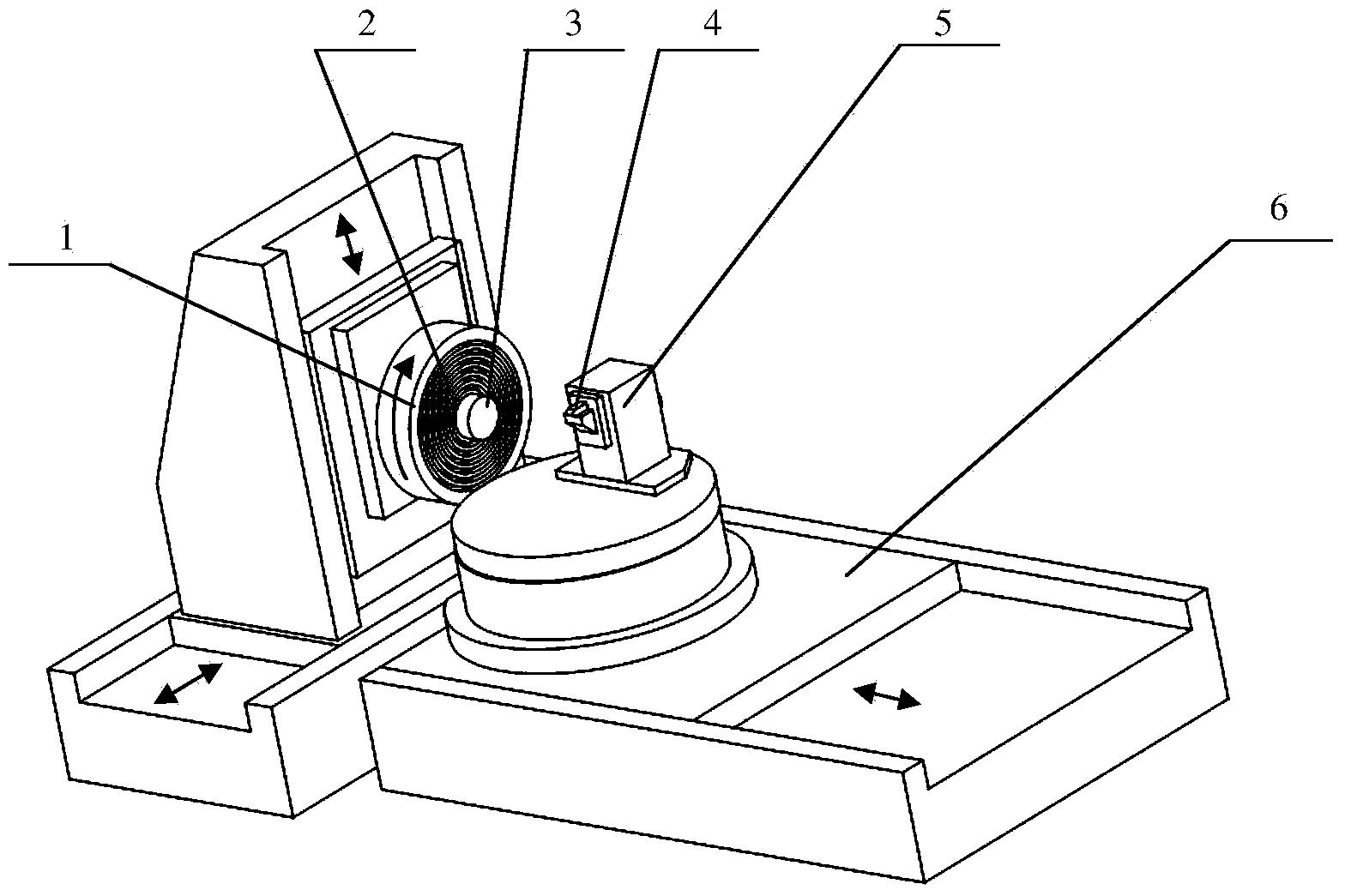

Method and device for determining grinding brittleness-ductility transformation critical cutting depth of hard and brittle material

InactiveCN103722467AImprove surface qualityHigh precisionGrinding feed controlGrinding machinesHigh surfaceRelative motion

The invention relates to the technical field of hard and brittle material ultra-precision machining. In order to achieve ductility domain grinding of the largest cutting depth, high surface quality of the hard and brittle material, and efficient and high-precision production machining, according to the technical scheme, a method and device for determining the grinding brittleness-ductility transformation critical cutting depth of the hard and brittle material comprises the following steps of (1) according to a grinding wheel used in ultra-precision grinding, determining the number, shape and distance of grains of a homemade multi-grain tool, (2) according to the grain shape, distance and front-angle parameters selected in the step (1), machining three or more grains on a grain base body, (3) controlling the multi-grain tool and a workpiece to generate relative motion, beginning to conduct scratching on the surface of the workpiece, meanwhile, controlling the multi-grain tool to conduct continuous feeding, enabling the depth of the scratch to continuously change, and observing and measuring the workpiece after scratching by utilizing a surface contourgraph and a confocal microscopy. The method is mainly applied to ultra-precision machining.

Owner:TIANJIN UNIV

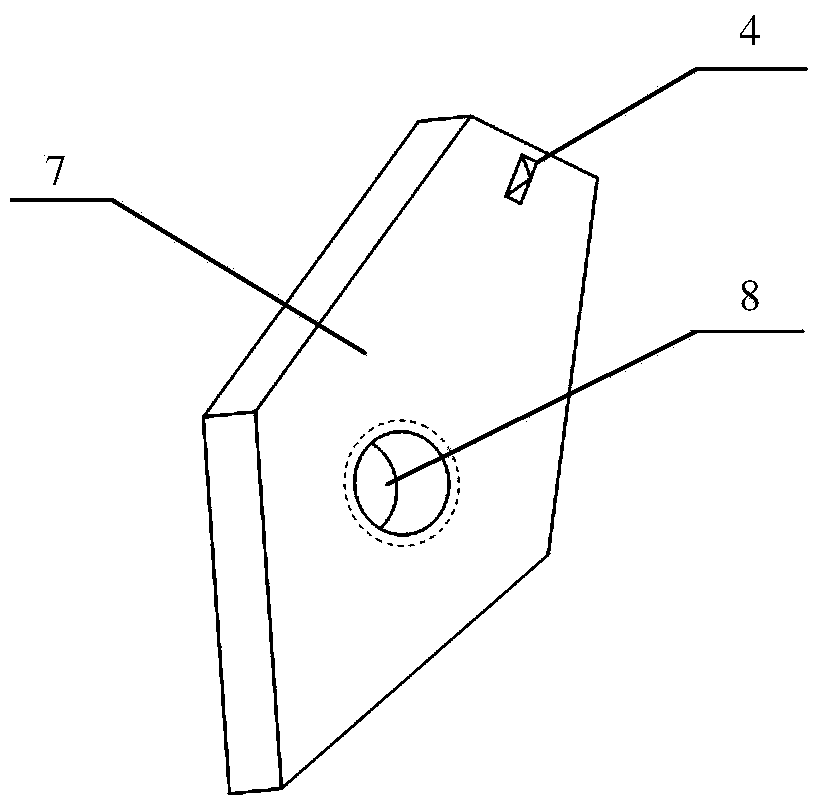

Stick-slip inertia based serial three-degree-of-freedom piezoelectric precision driving platform

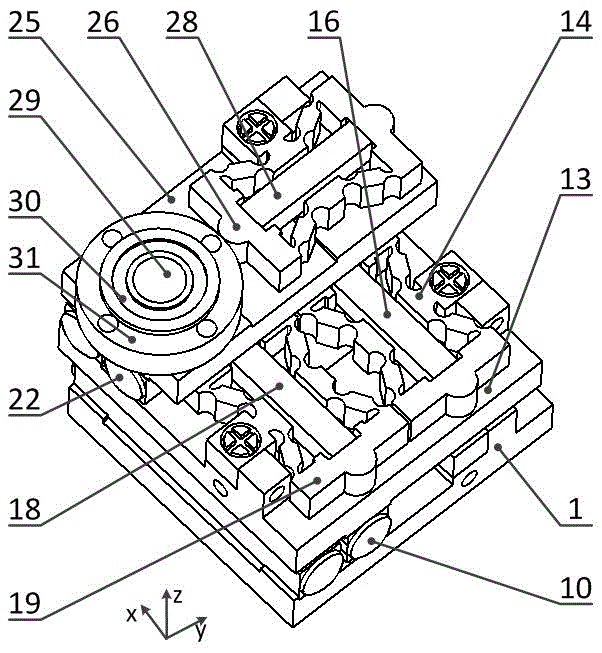

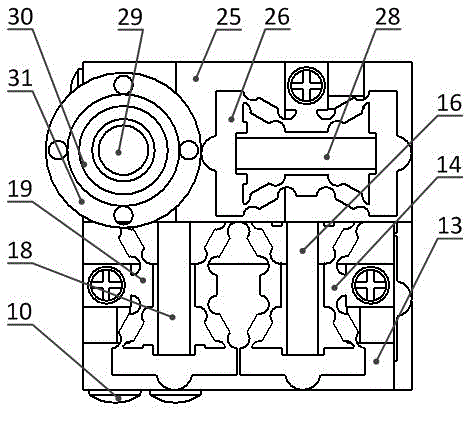

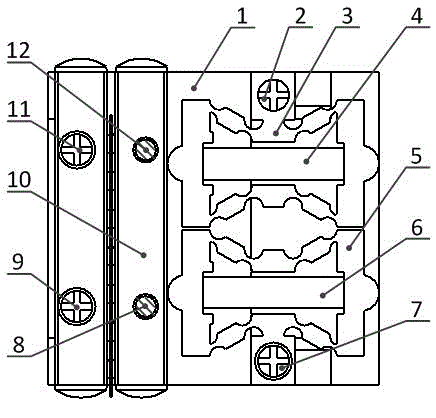

ActiveCN104320016ASports reliableReliable drivePiezoelectric/electrostriction/magnetostriction machinesLinear motionElectricity

The invention relates to a stick-slip inertia based serial three-degree-of-freedom piezoelectric precision driving platform and the linear motion along the x and y direction and the rotating motion around the z axis direction can be implemented. The stick-slip inertia based serial three-degree-of-freedom piezoelectric precision driving platform comprises a lower layer of x axis linear driver assembly, a middle layer of y axis linear driver assembly and an upper layer of z axis rotating driver assembly which are connected in turn and sawtooth waves are input towards piezoelectric stacks based on the stick-slip inertia principle to implement the stepping type continuous feeding of an output terminal. The symmetry and the frequency of the sawtooth waves are changed to change the feeding direction and speed. The positioning motion of the rapid feeding positioning and the precise feed positioning can be implemented through different modes of control on the piezoelectric stacks and accordingly the rapid and high precision positioning can be obtained simultaneously. The stick-slip inertia based serial three-degree-of-freedom piezoelectric precision driving platform has the advantages of being small and compact in structure, large in output stroke, adjustable in speed, large in bearing capacity, stable and reliable in work, good in repeatability and suitable for large stroke of precision motion control occasions with strict space size constraints.

Owner:JILIN UNIV

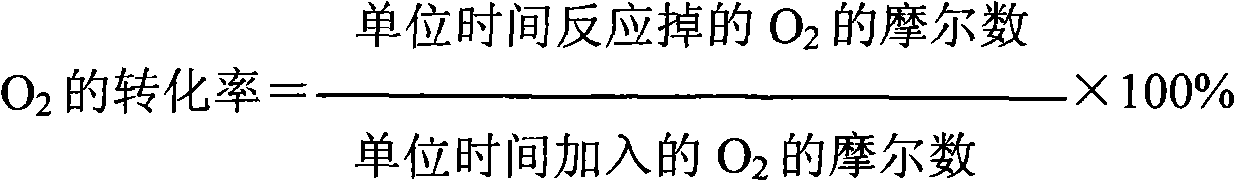

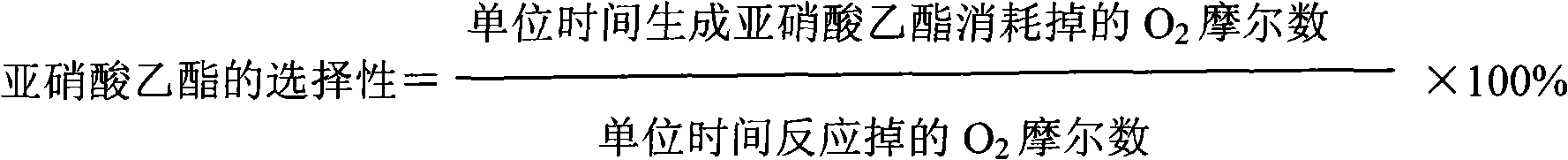

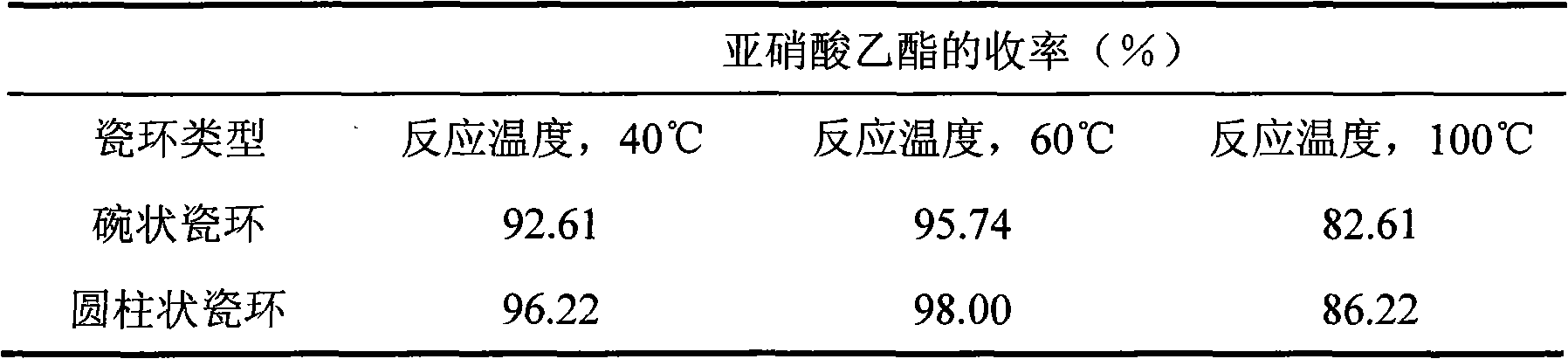

Reaction system and preparation method for nitrous alkyl ester

InactiveCN101314569AHigh yieldImprove efficiencyLiquid-gas reaction processesNitrous acid preparation ester preparationRetention timeGas phase

The invention relates to a reaction system for alkyl nitrite and a preparation method for the alkyl nitrite. The preparation method comprises the following steps that: a trickle-bed reactor is adopted and porcelain ring filler is filled into the trickle-bed reactor; liquid added into the reactor forms liquid membranes on the filler; alkyl alcohol is taken as a liquid-phase raw material and nitric monoxide, oxygen and nitrogen are taken as gas-phase raw materials; and gas and liquid phases are reacted in the trickle-bed reactor by means of co-current flow or countercurrent flow under the condition of nitrogen protection so as to generate the alkyl nitrite. The mol ratio of the alkyl alcohol to NO is between 2 to 1 and 7 to 1, and the mol ratio of the NO to O2 is between 4 to 1 and 8 to 1; the reaction temperature is between 40 and 100 DEG C, and the reaction pressure is between 0.1 and 1.0 MPa; and the retention time of continuous feeding of liquid-phase alkyl alcohol in the trickle-bed reactor is between 10 and 500 minutes, and the retention time of continuous feeding of gas phase in the trickle-bed reactor is between 0.02 and 1 minute. The reaction system and the preparation method have the advantages that: the operating condition is mild; the reaction time is short; the conversion rate of the raw materials, and the selectivity and the yield of products are high; and the whole reaction system is convenient for realizing continuous production, etc.

Owner:TIANJIN UNIV

Continuous production of carbon nanotubes and fullerenes

A method and a device for production of fullerene-related carbon nanotubes and fullerenes in direct current arc discharge between two graphite electrodes are disclosed. Two features distinctive from conventional arc discharge technique providing remarkably high productivity of the present method are introduced. The first feature comprises means for maintaining an optimal temperature of anode end surface to suppress formation of large carbon clusters and micro-crystallite carbon particles useless for synthesis of carbon nanotubes and fullerenes. The second one comprises means for maintaining an optimal concentration of carbon and catalyst vapor in vapor generation zone to ensure optimal yields of carbon nanotubes and fullerenes. Airtight plug-in cartridges are used to supply consumable electrodes and catalyst material inside closed-loop device without process being stopped. The means to perform automatic continuous feeding of consumable electrodes and catalyst, pneumatic transportation of condensables and their automatic continuous discharge are also described.

Owner:KOULIKOV DMITRI

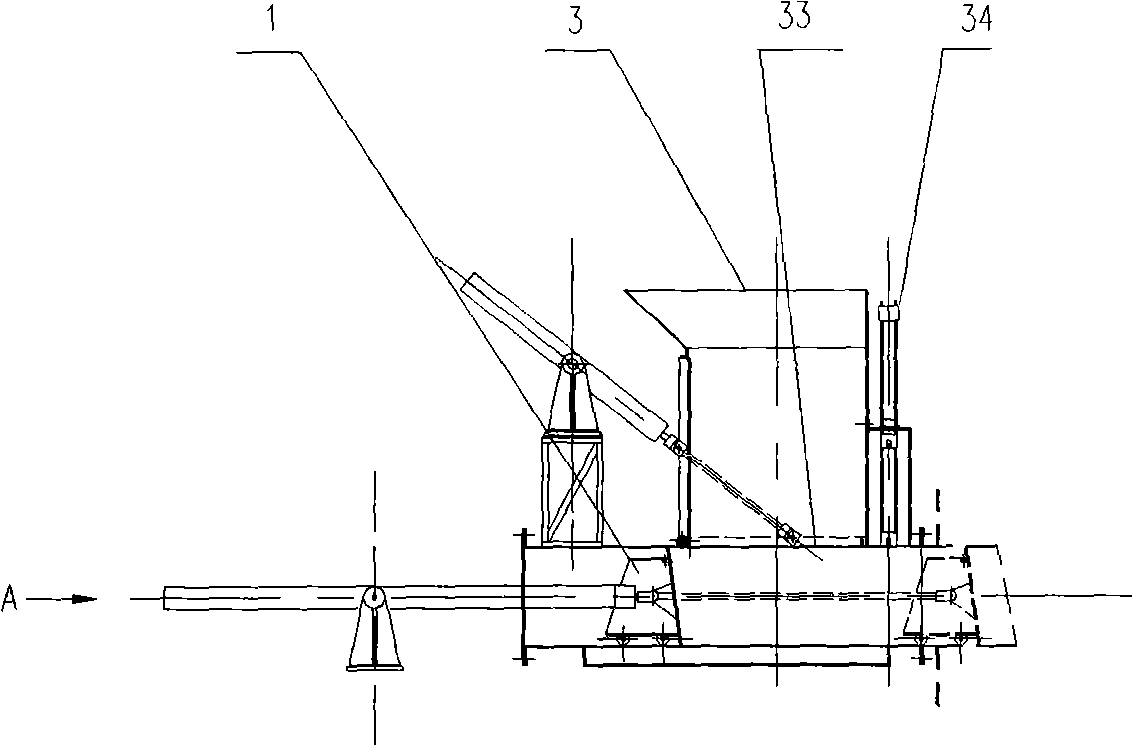

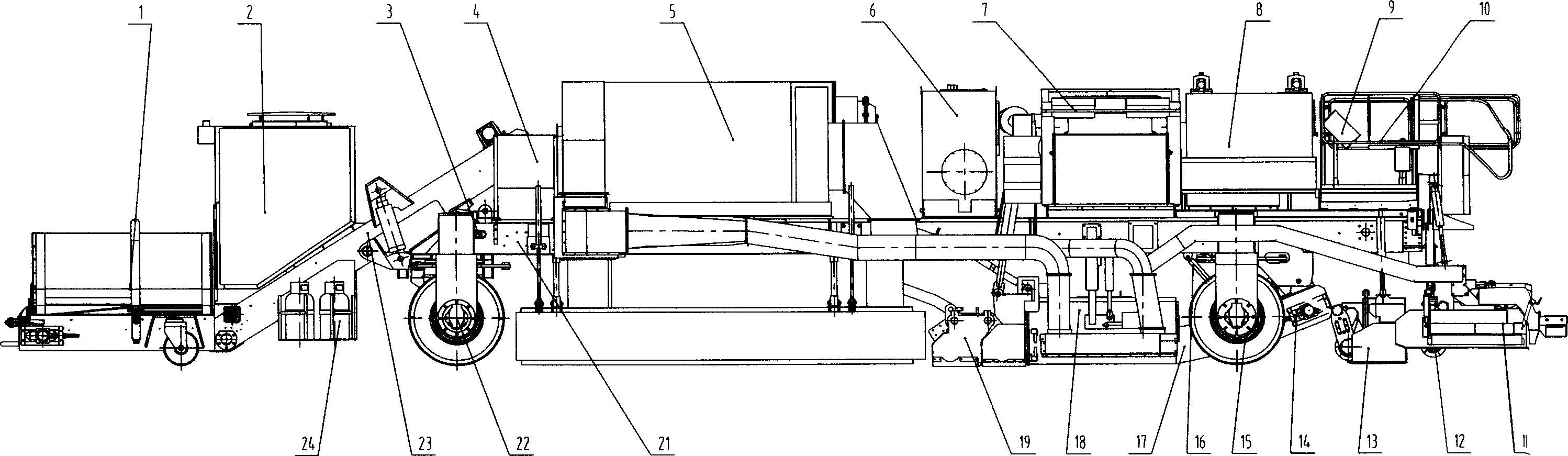

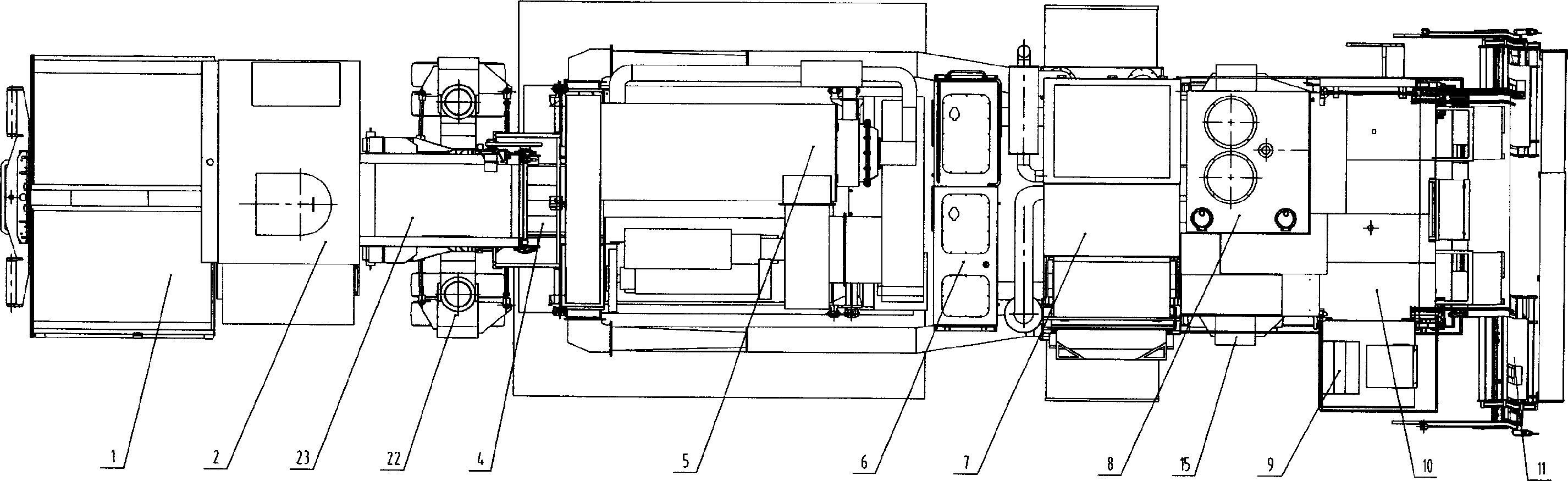

In-place heat regeneration asphalt pavement remixer

InactiveCN1908309AImprove mobilityPromote environmental protectionRoads maintainenceAir cycleSprayer

The invention relates to an earth heat regenerate pitch road mixer, which comprises: a frame, a material hopper, a sprayer, a transfer hopper, a hot air cycle heater, a regenerator, a laying device, a front bridge, a back bridge, a cabin, a control system and a power system, wherein the material hopper, sprayer, transfer hopper, hot air cycle heater and regenerator are fixed on the frame; the material hopper via the new pitch front transfer device is connected to the transfer hopper; the laying device comprises a regenerated pitch mixing laying device and new pitch mixing laying device; the outlet of continuous feeding device is connected to the inlet of regenerated pitch mixing laying device; the transfer hopper via the new pitch horizontal transfer device is connected to the inlet of new pitch mixing laying device. The invention has simple operation and high automatic degree.

Owner:ZOOMLION HEAVY IND CO LTD

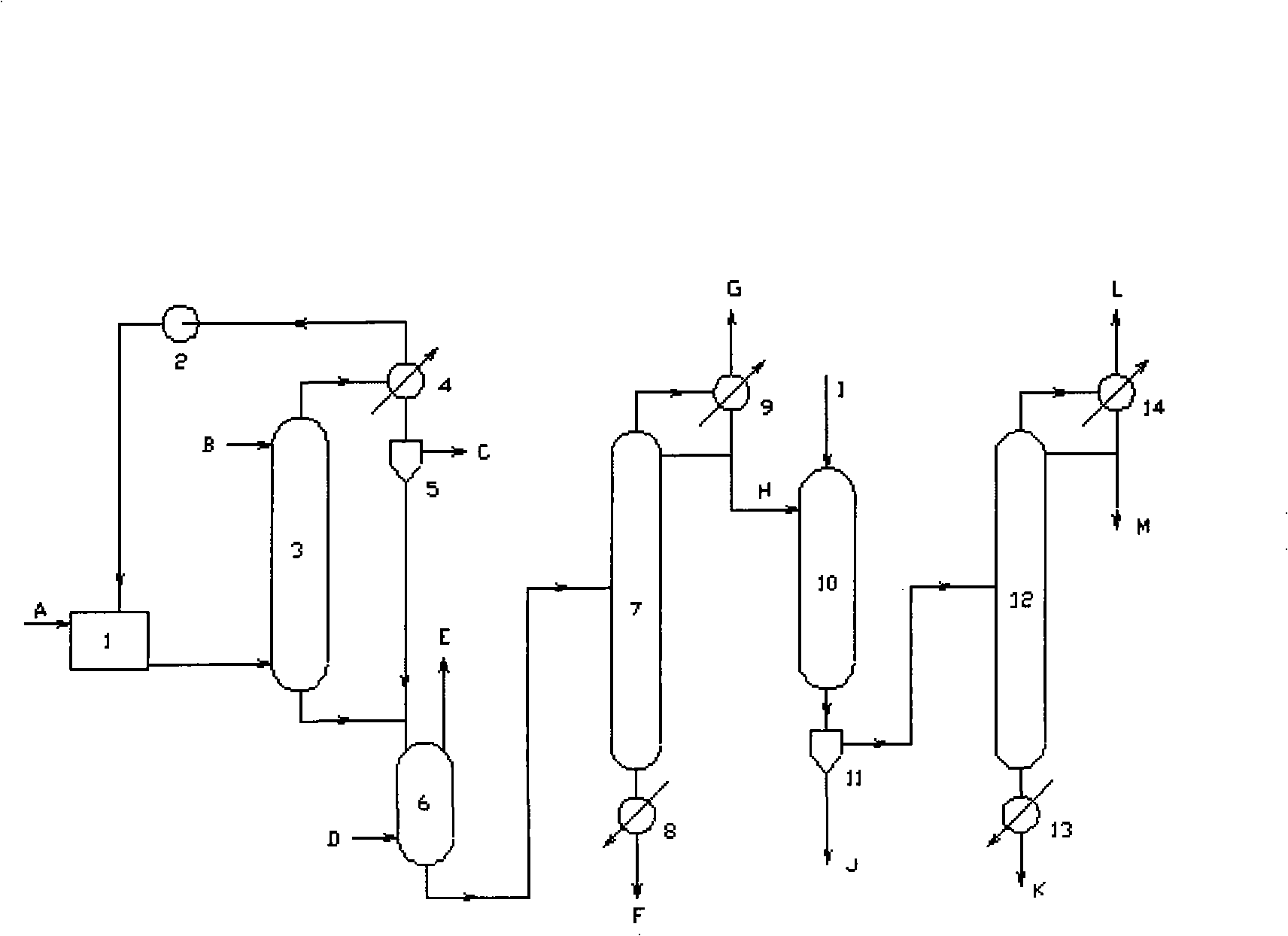

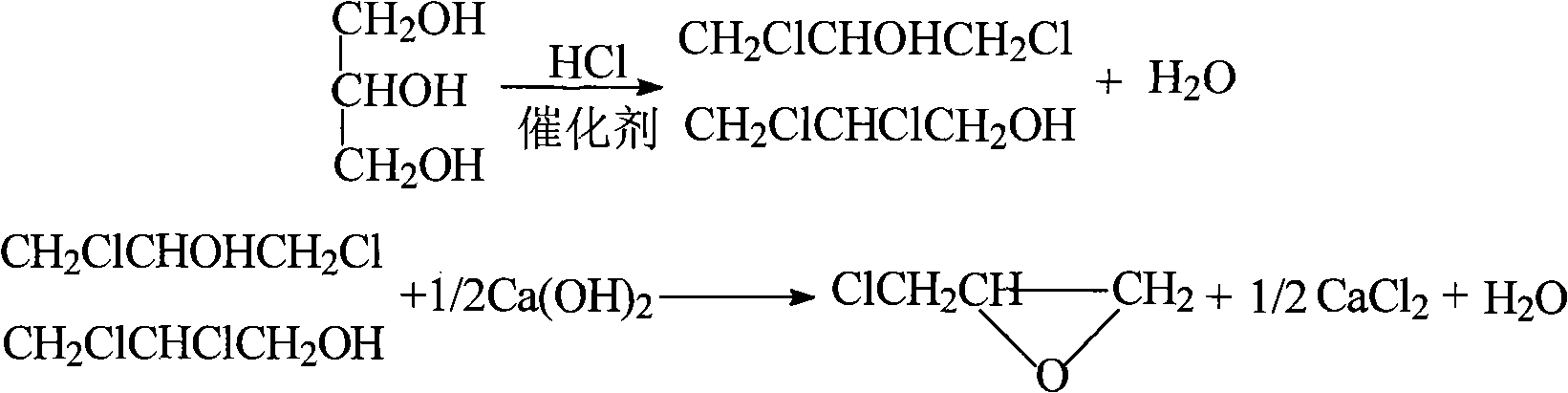

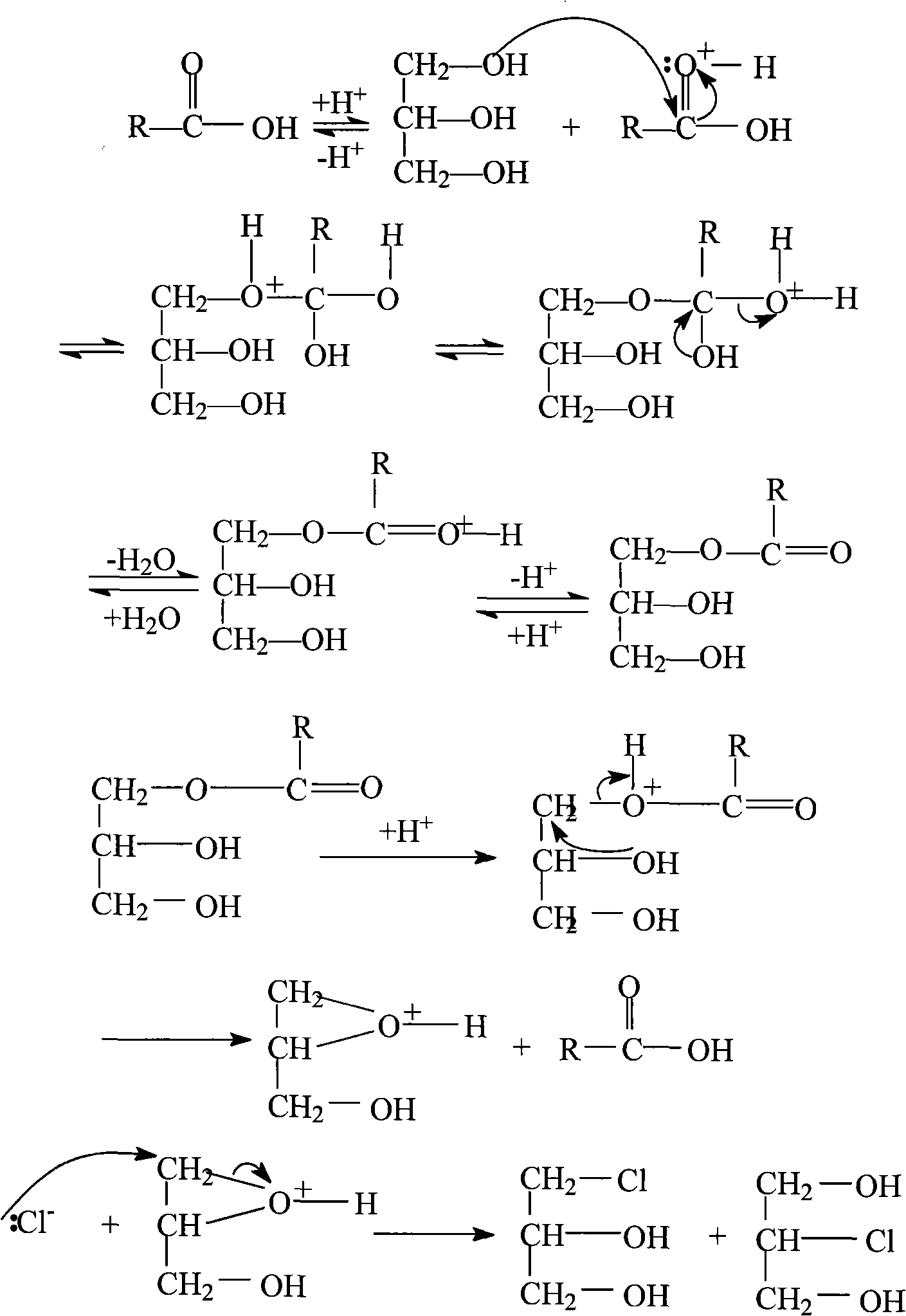

Method for continuously preparing epichlorohydrin by glycerine reaction fractional distillation

InactiveCN101337950AEfficient separationGuaranteed purityOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsBiodiesel1-Propanol

The invention relates to a method for preparing epoxy chloropropane which is obtained through successive reaction and distillation coupling technology after glycerine that is the by-product of biological diesel oil reacts with chlorine hydride through substitution reaction under homogeneous multielement catalysis and further performs saponification cyclization reaction. The method comprises the following steps: (1) chlorine hydride is pumped in glycerine that is the by-product of biological diesel oil for reaction under homogeneous multielement catalysis, and the mixture composed of 1, 3-dichloro-2-propanol and 2, 3-dichloro-1-propanol is prepared through the technologies of continuous feeding, continuous catalyzed chlorination and continuous rectification; (2) the isomeride mixture solution of 1, 3-dichloro-2-propanol and 2, 3-dichloro-1-propanol performs the saponification cyclization to generate a product of epoxy chloropropane in alkaline solution. The method has the advantages of mild reaction condition is mild, high catalyst activity, dedicated catalytic performance, high product selectivity, process 'cleaning', easy separation, continuous operation, environment-friendliness, etc.

Owner:JIANGSU POLYTECHNIC UNIVERSITY

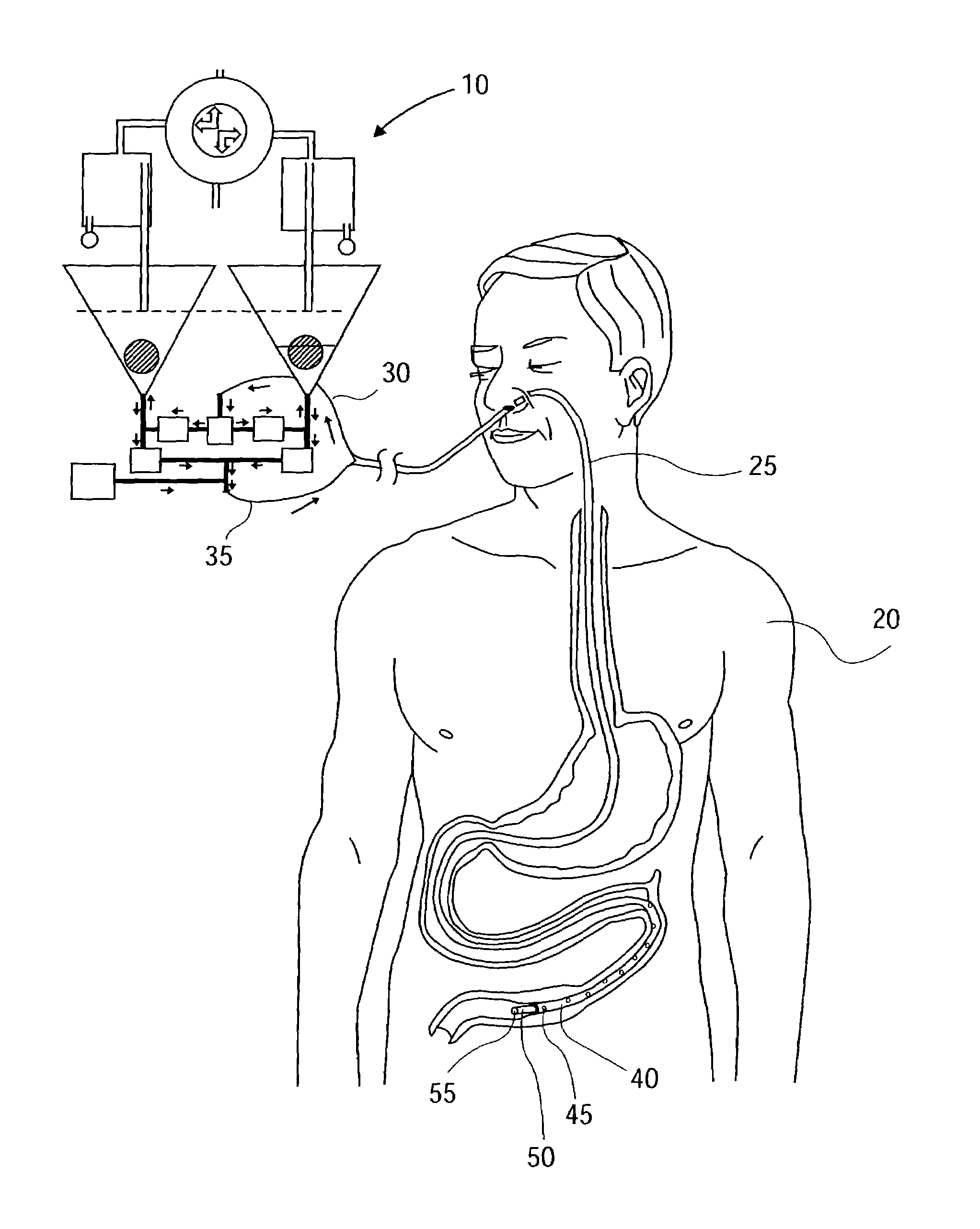

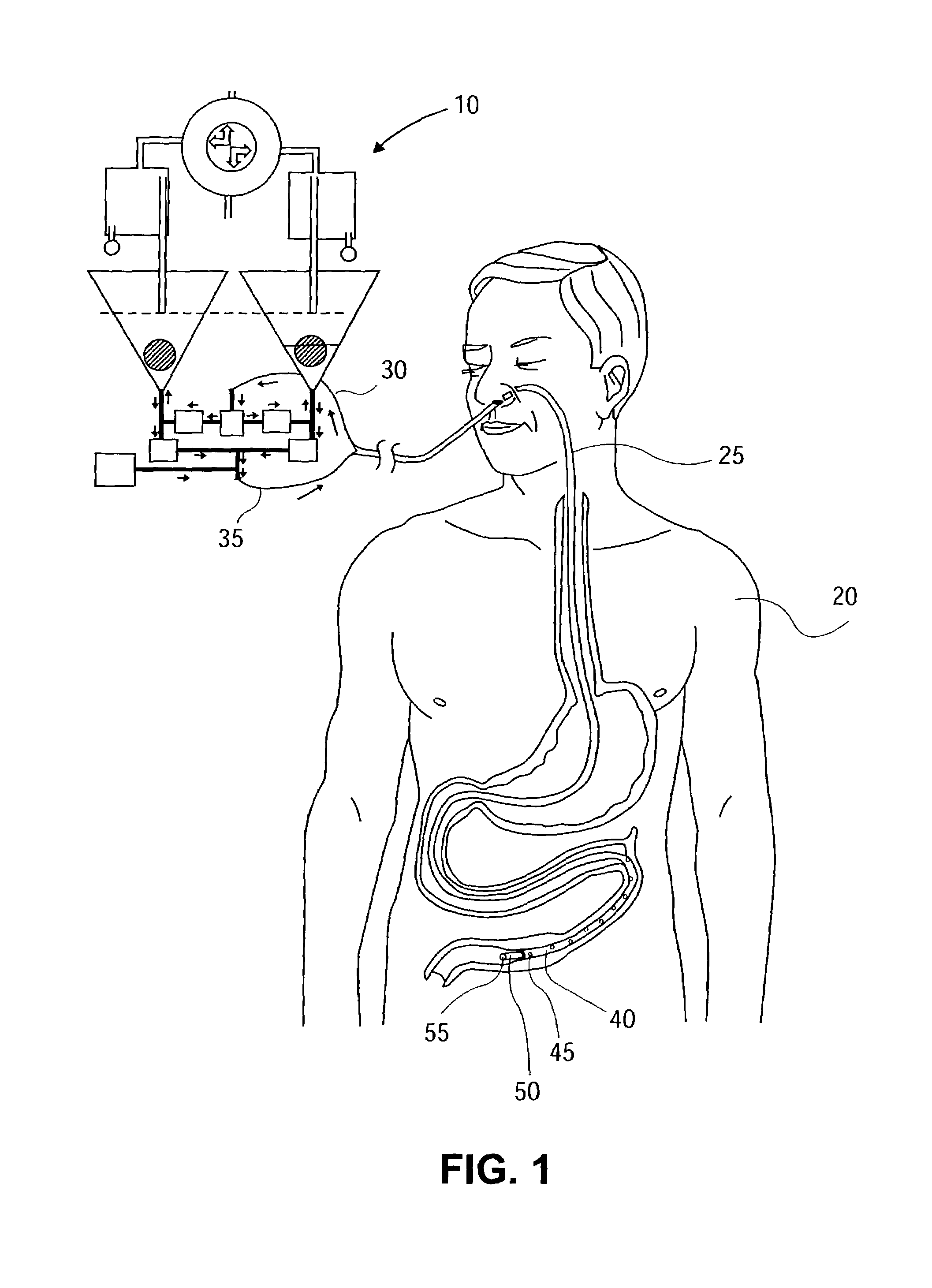

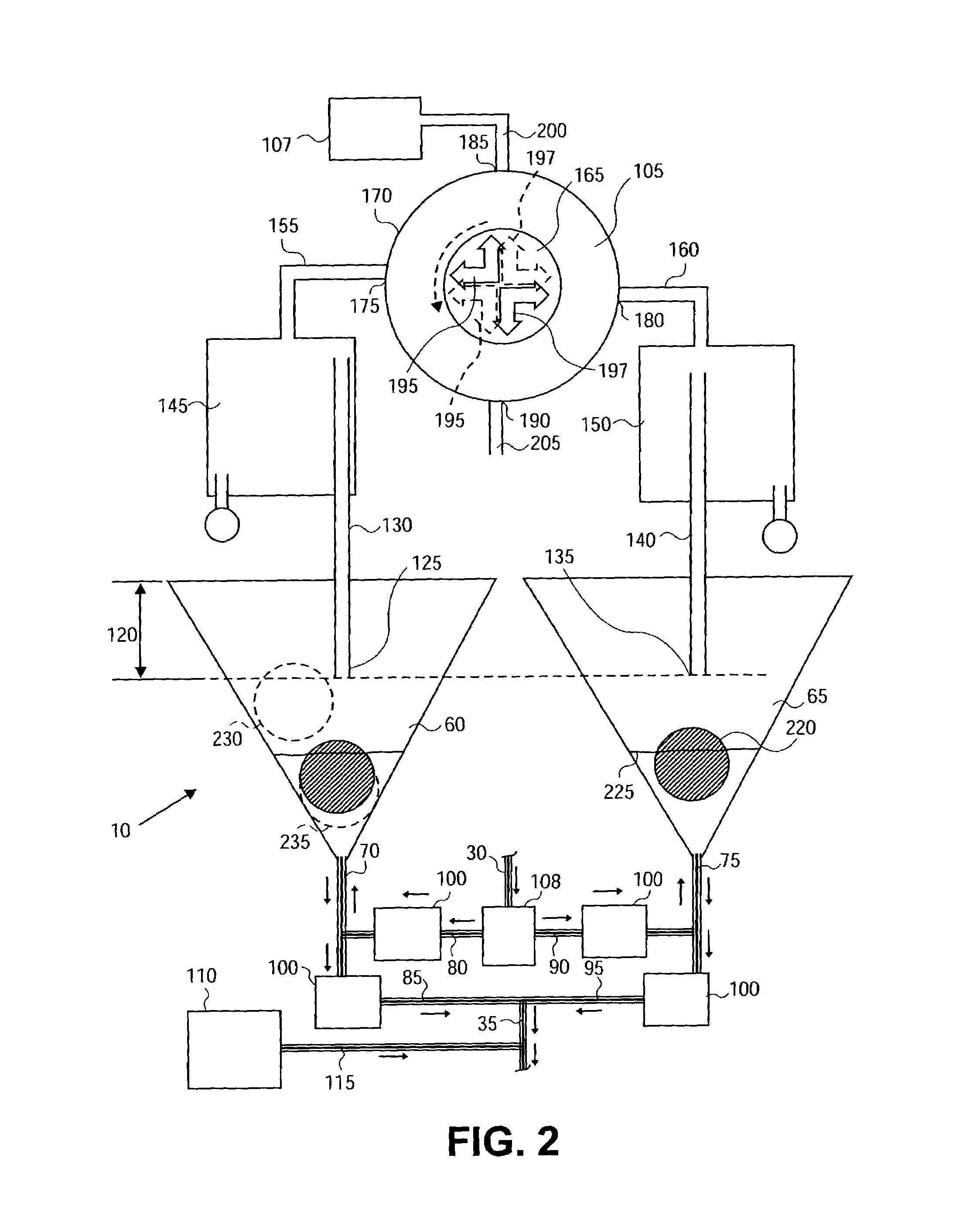

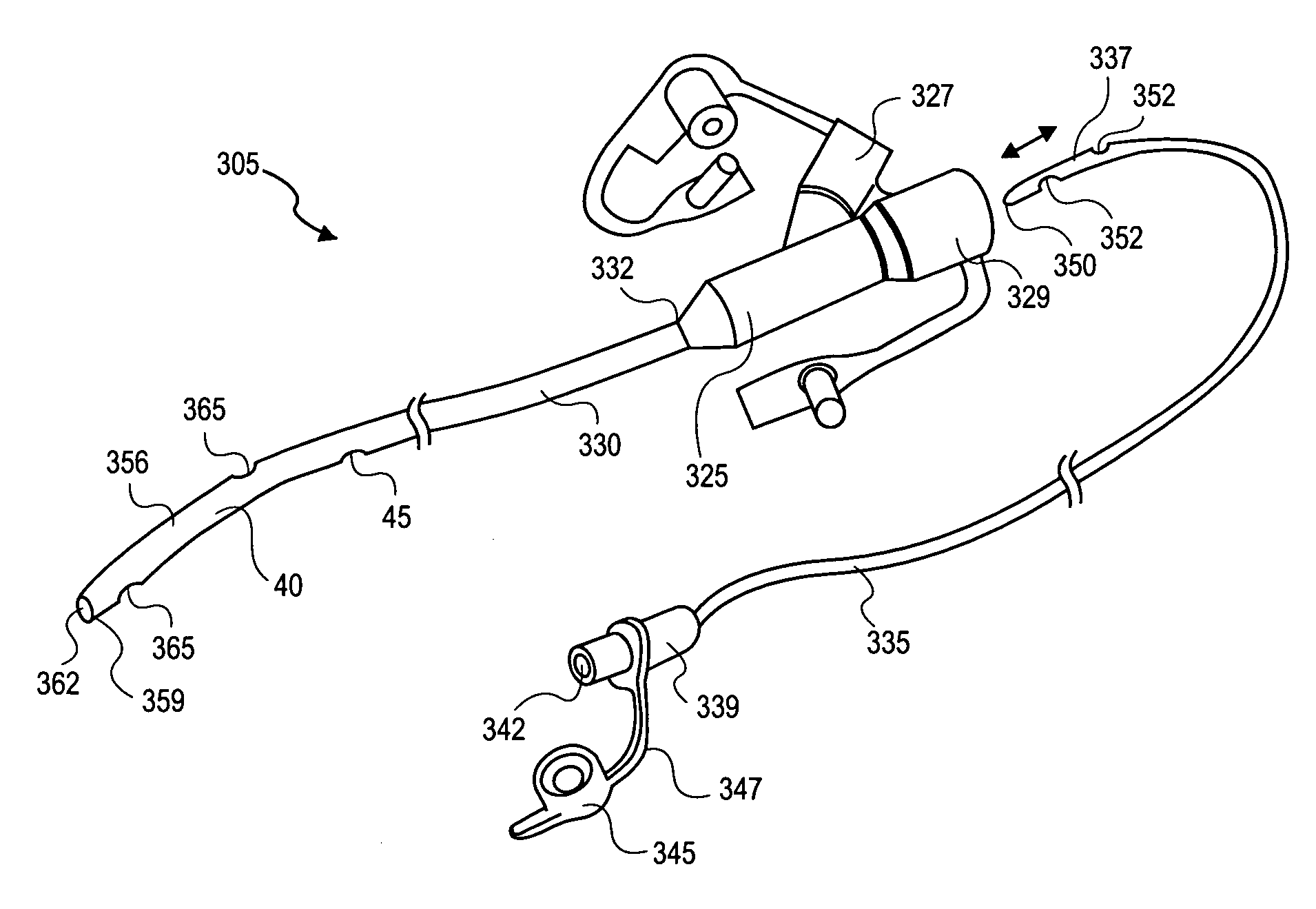

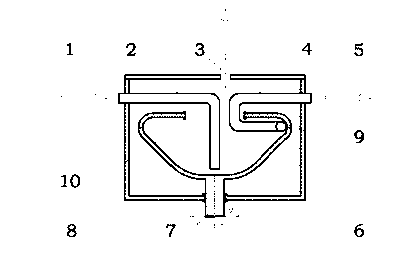

Continuous feeding and decompressing device, tube assembly, and methods

InactiveUS6949092B1Improve absorption efficiencyReduce tendency to dehydrationMedical devicesIntravenous devicesSolenoid valveBiology

A decompressing and feeding device for safely feeding in the gastrointestinal tract of a recovering patient continuously aspirates and feeds at a rate commensurate with the ability of the intestines to absorb fluids including nutrient. Air is also aspirated in the process so that neither air nor excess fluids cause distension in the gastrointestinal tract. Digestive juices and nutrients that are aspirated are continuously refed together with unused feeding material into the gastrointestinal tract at a location that more efficiently moves and digests the food. The device may include two aspirate reservoirs to and from which aspirate is alternatingly transferred. To provide the continuous and alternating flow, a solenoid valve and timer switch device is provided. Alternatively, a device with a single aspirate reservoir to which and from which aspirate is transferred can be used. A feeding and aspirating tube assembly having a plurality of separable lumens can be incorporated.

Owner:MOSS

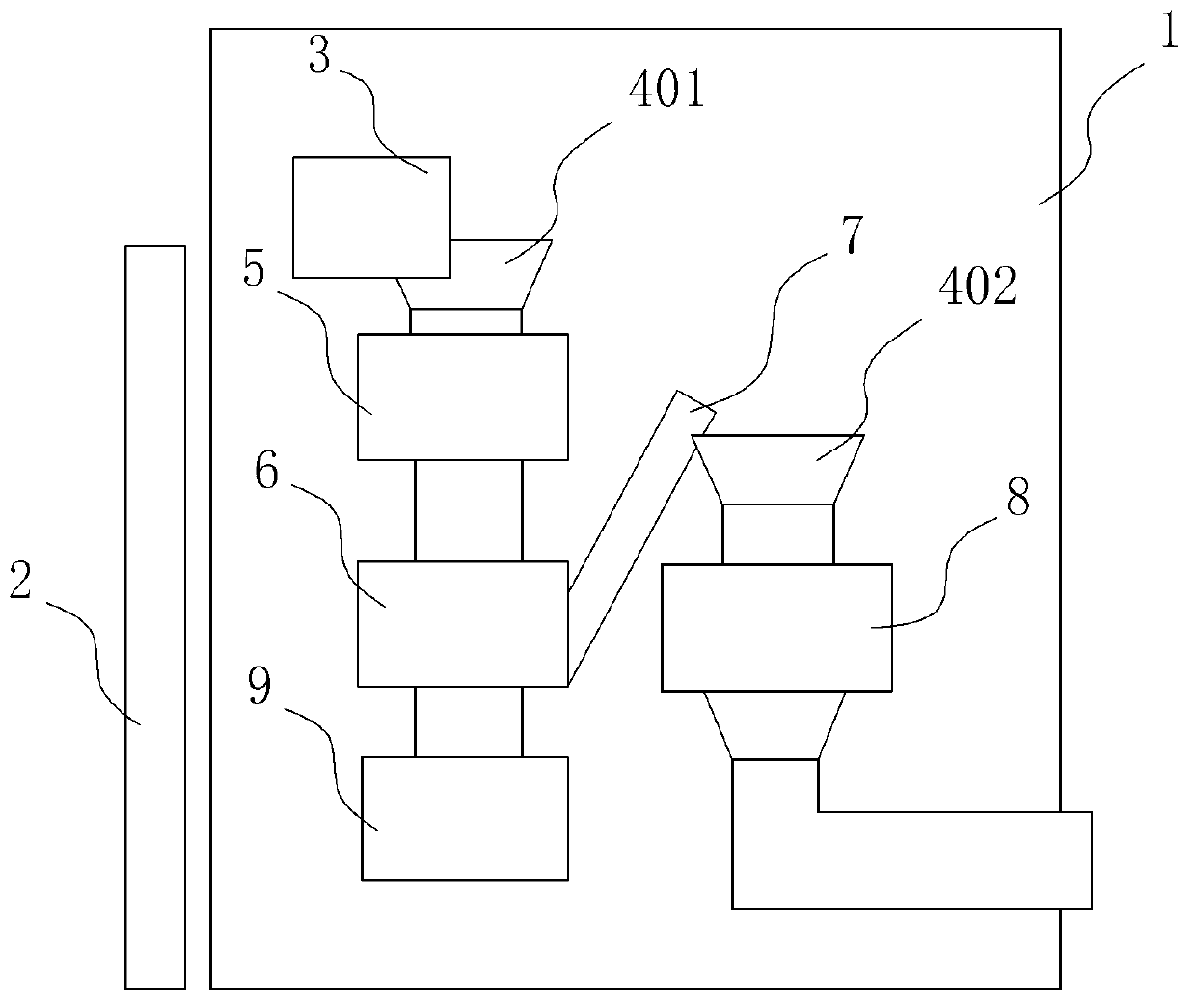

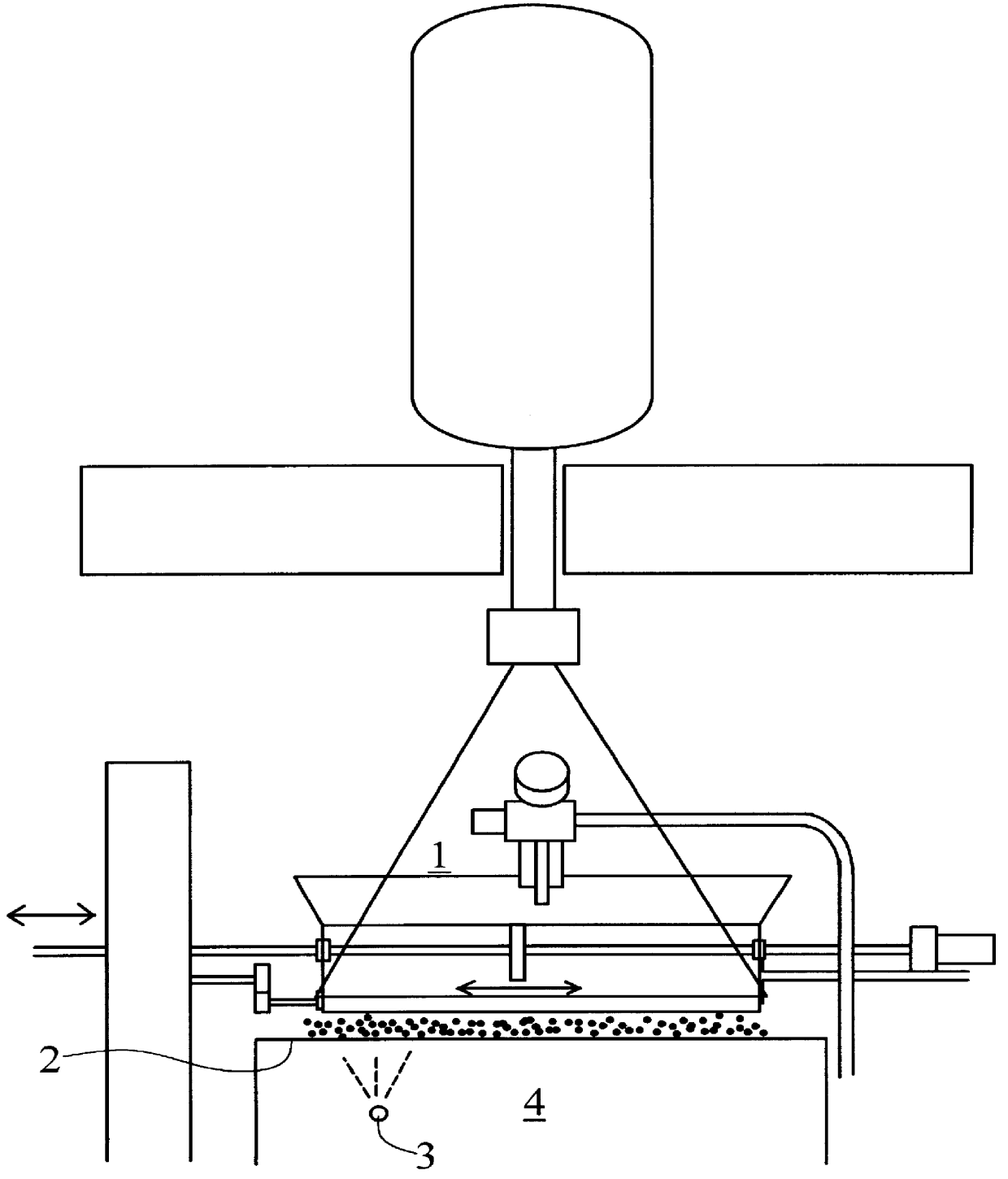

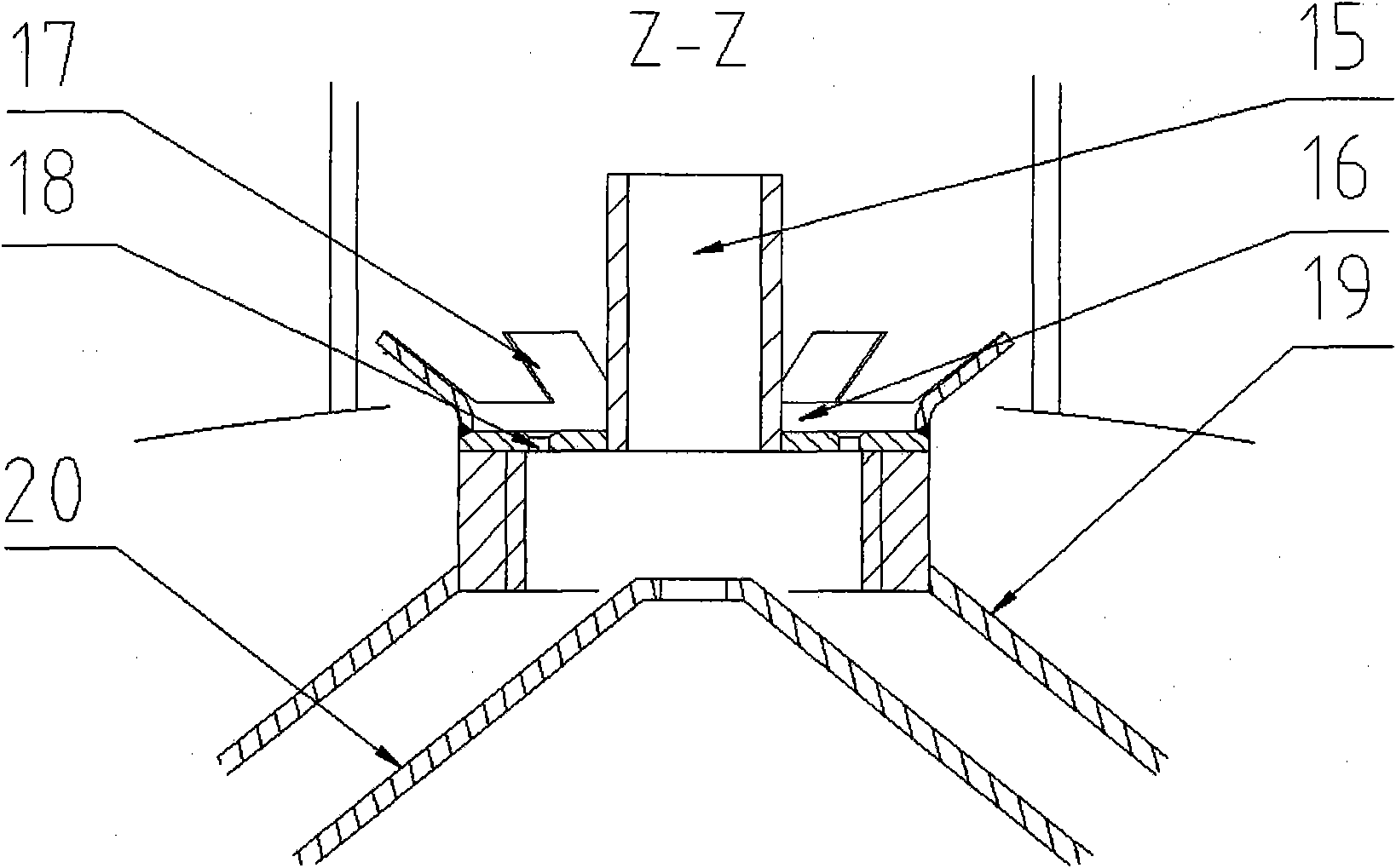

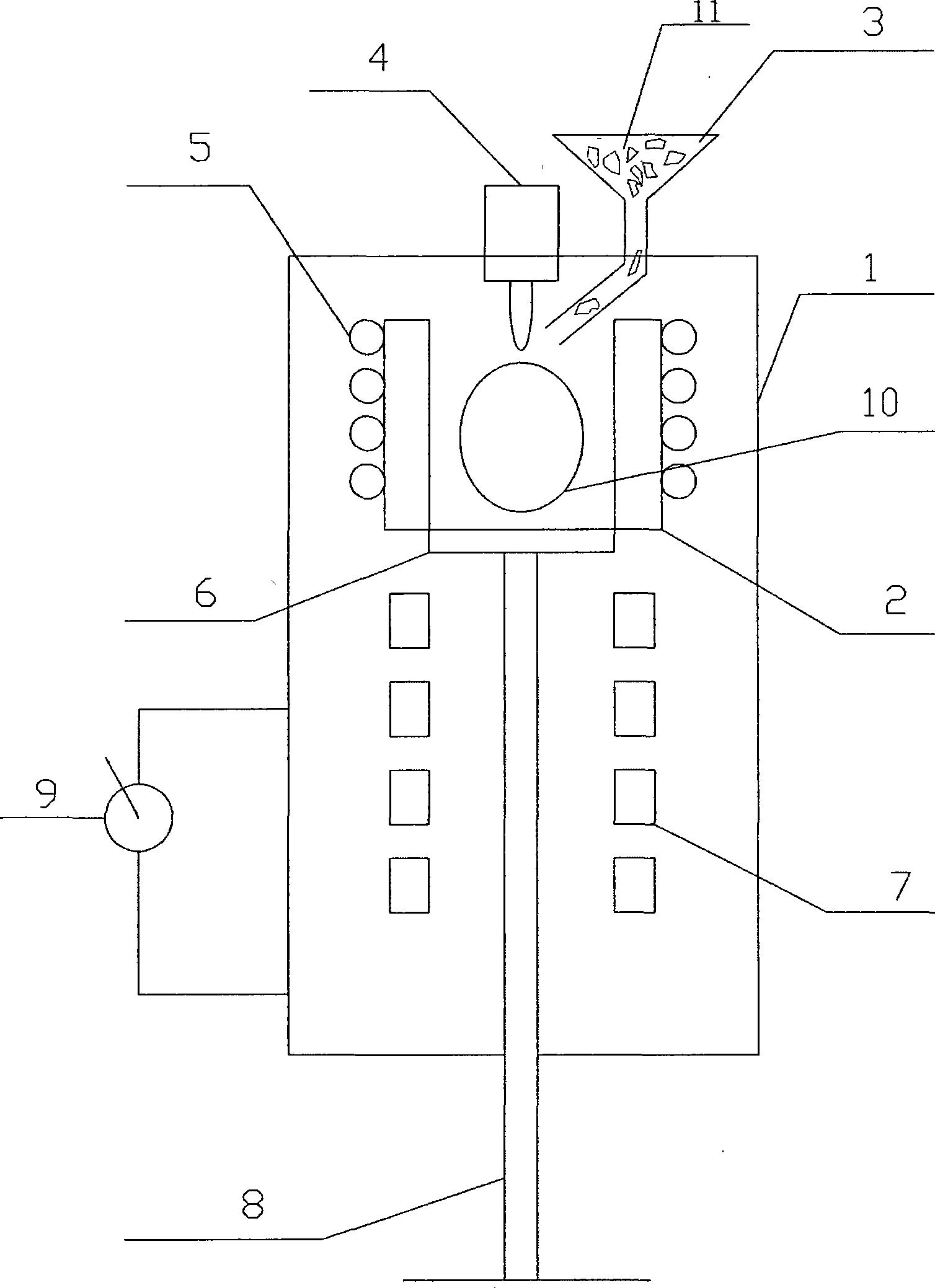

Device and method for manufacturing solar grade polysilicon

InactiveCN101377010AContinuous productionRapid productionPolycrystalline material growthBy pulling from meltPlasma generatorGraphite

The invention discloses a device used to prepare solar grade polysilicon, which comprises a vacuum chamber [1]; a feeder [3] is arranged above the vacuum chamber [1]; the vacuum chamber [1] is provided with a suspension smelting crucible [2]. A sensitive coil [5] is wound around the suspension smelting crucible [2]; a sensitive plasma generator [4] is arranged above the suspension smelting crucible [2], and a water-cooled chassis [6] and a lifting device thereof which are controlled by an oriented solidifying mechanism [8] are arranged below the suspension smelting crucible [2]. A graphite heating cover [7] is arranged around the pull-down stroke of the water-cooled chassis [6]. The invention also discloses a preparation method of the solar grade polysilicon, which comprises the following steps: 1. raw material selection; 2. melting; 3. suspension smelting; 4. plasma impurity removal; 5. oriented solidification and shaping; 6. continuous feeding. In the invention, plasma smelting, suspension smelting and oriented solidification process are realized in a device, and the beneficial effect of continuously and quickly producing low-cost solar grade polysilicon with high efficiency can be achieved.

Owner:上海太阳能工程技术研究中心有限公司 +1

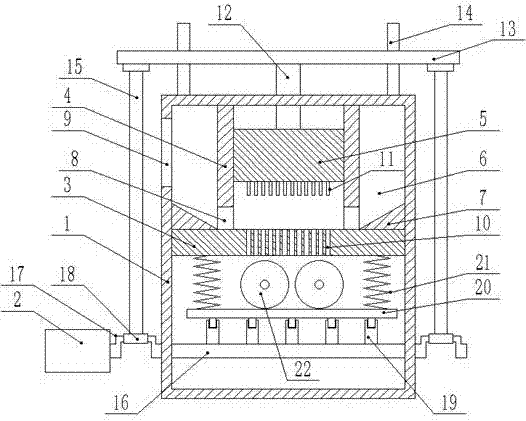

Agricultural fertilizer multi-stage crushing device

InactiveCN107413425AConvenient whereaboutsFast fallSievingScreeningAgricultural engineeringCrankshaft

The invention discloses a multistage crushing device for agricultural fertilizers, which comprises a housing, a motor, a partition and a crushing hammer; the partition is horizontally fixed in the middle of the housing, and a vertical guide is fixed on the upper surface of the partition There is a feeding trough between the guide cylinder and the housing, and a circle of inclined material guide blocks is arranged at the bottom of the feeding trough, and several crushing ribs are fixedly arranged on the lower surface of the crushing hammer, directly below the crushing ribs Corresponding extrusion holes are opened on the partition; two crushing rollers extruding each other are installed under the partition. The invention drives the lifting plate and the crushing hammer to move up and down through the set curved arm, impacts on the partition plate, squeezes and crushes the fertilizer in it, and the crushing edge can squeeze the fertilizer out of the extrusion hole to realize continuous feeding and crushing of the fertilizer. The fertilizer crushed once falls between the two crushing rollers for crushing again, and the fertilizer is crushed twice to improve the crushing efficiency and ensure the uniformity of crushing.

Owner:YANCHENG BILLION CONNAUGHT MACHINERY CO LTD

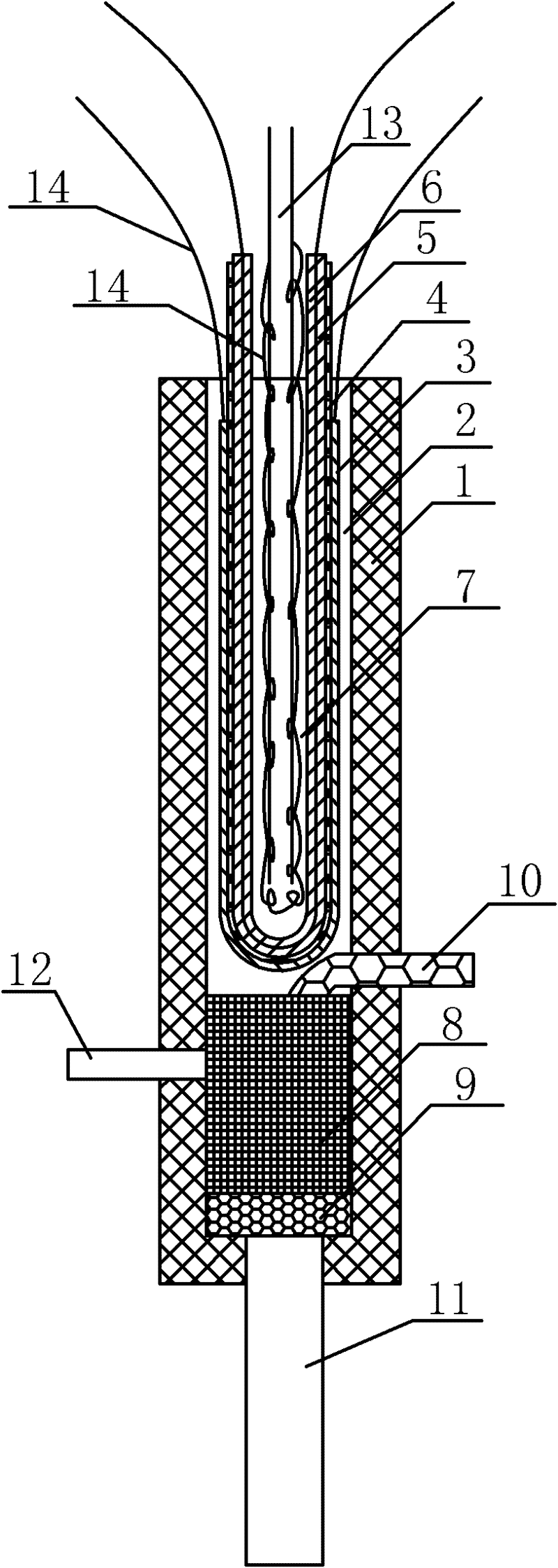

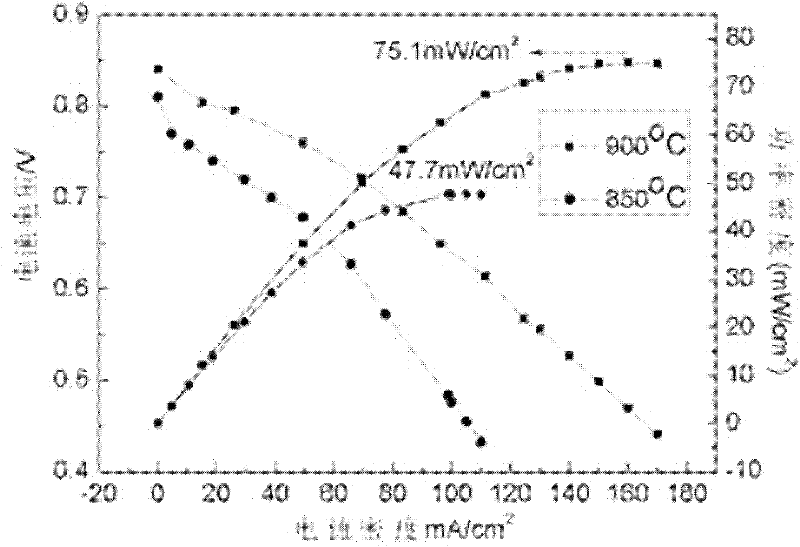

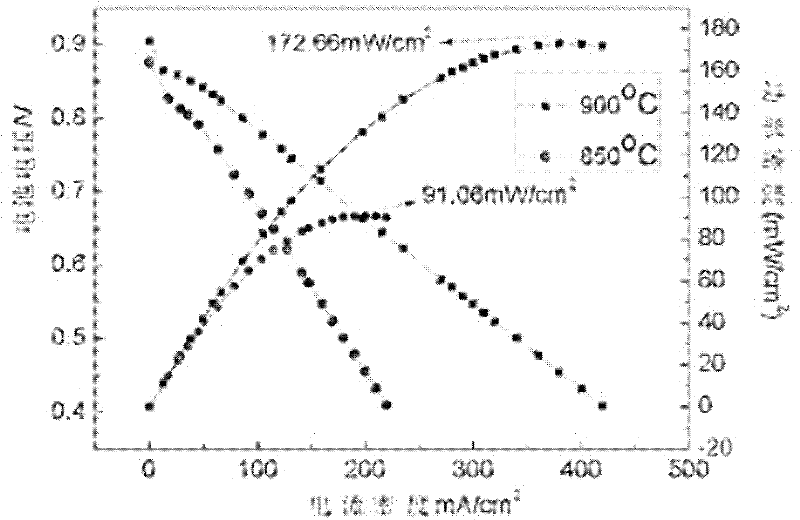

A cathode-supported direct carbon fuel cell

ActiveCN102290589ASimple structureImprove energy efficiencyElectrolyte holding meansFused electrolyte fuel cellsSolid carbonHigh energy

The invention discloses a cathode-supported direct carbon fuel cell, which comprises a fuel bin, an anode side collector layer, an anode layer, an electrolyte layer, a cathode active layer, a cathode-supporting layer, a cathode side collector layer, a carbon fuel layer, a porous ceramic layer, a carbon fuel input tube, a carrier gas intake tube, a carrier gas output tube and an oxygen or air intake tube, a cell is arranged in the fuel bin, the anode side collector layer, the anode layer, the electrolyte layer, the cathode active layer, the cathode-supporting layer and the cathode side collector layer are arranged sequentially from the outside to the inside, and moreover, the anode side collector layer, the carbon fuel layer and the porous ceramic layer are superposed in the fuel bin sequentially from the top down. Since the cell is a cathode-supported cell which directly utilizes solid carbon as fuel and the outside of the cell is provided with the fuel input tube, the cell has the advantages of simple structure, high energy efficiency, environment-friendliness, no leakage, corrosion and explosion dangers and the like, can realize the continuous feeding of fuel and the diversity of the fuel electrode, and is convenient and easy to operate.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

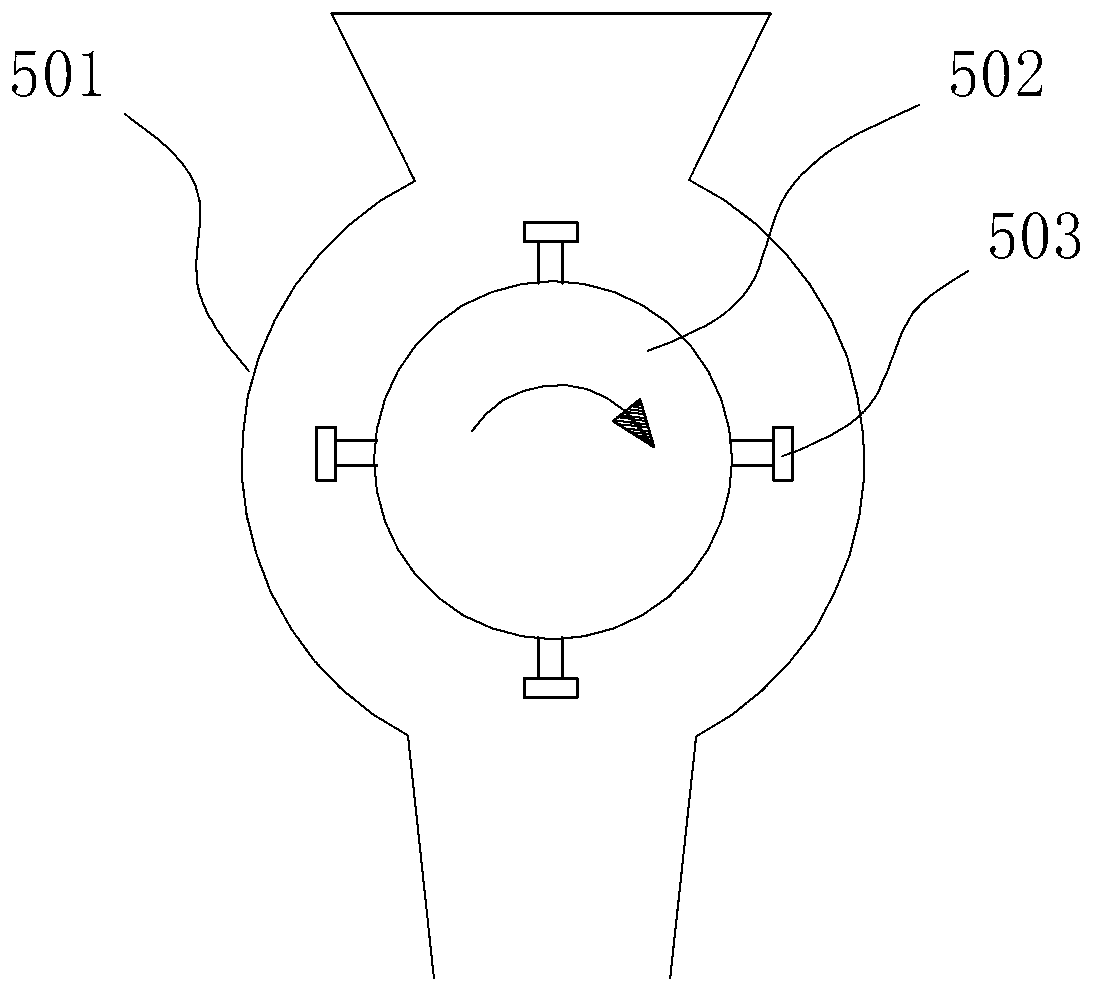

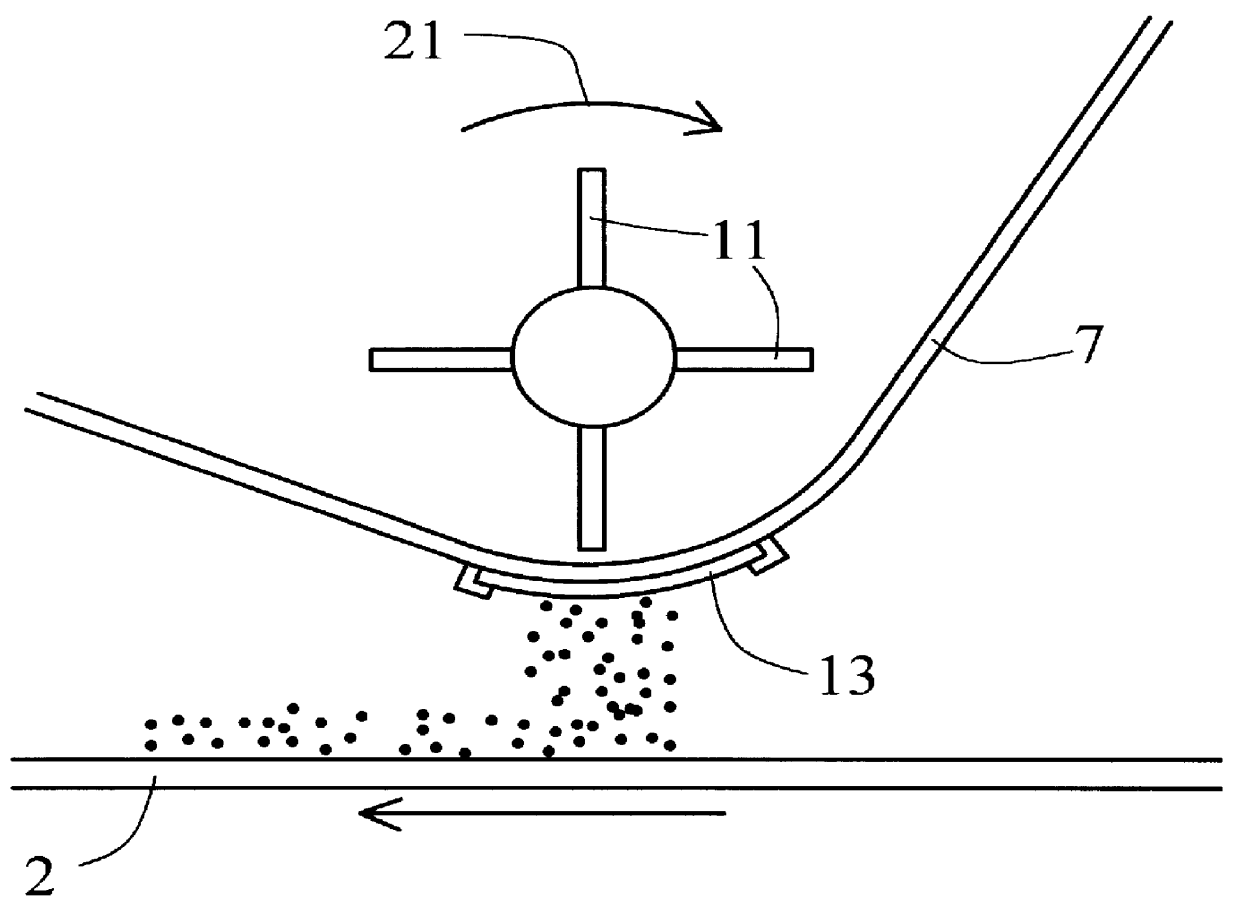

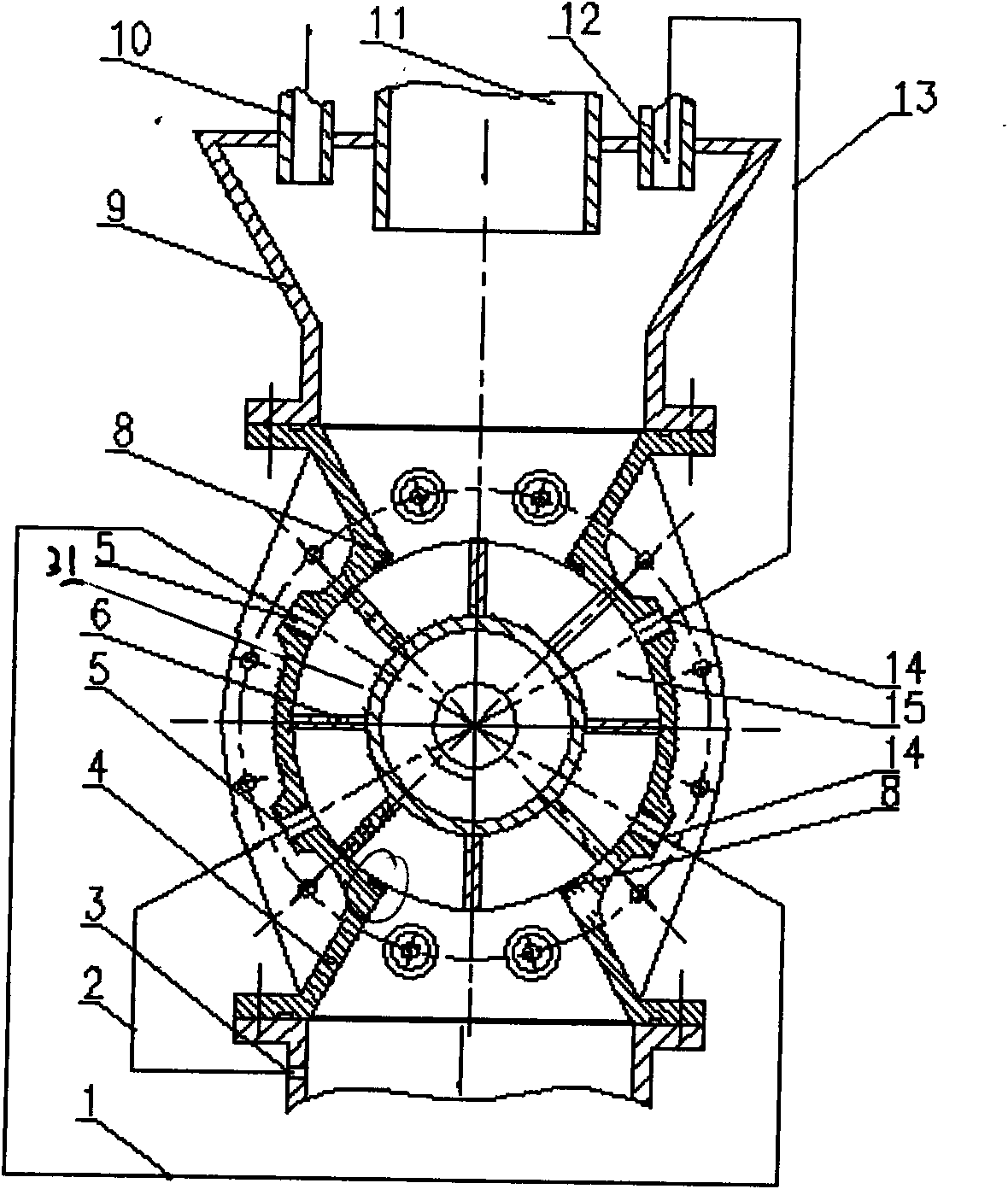

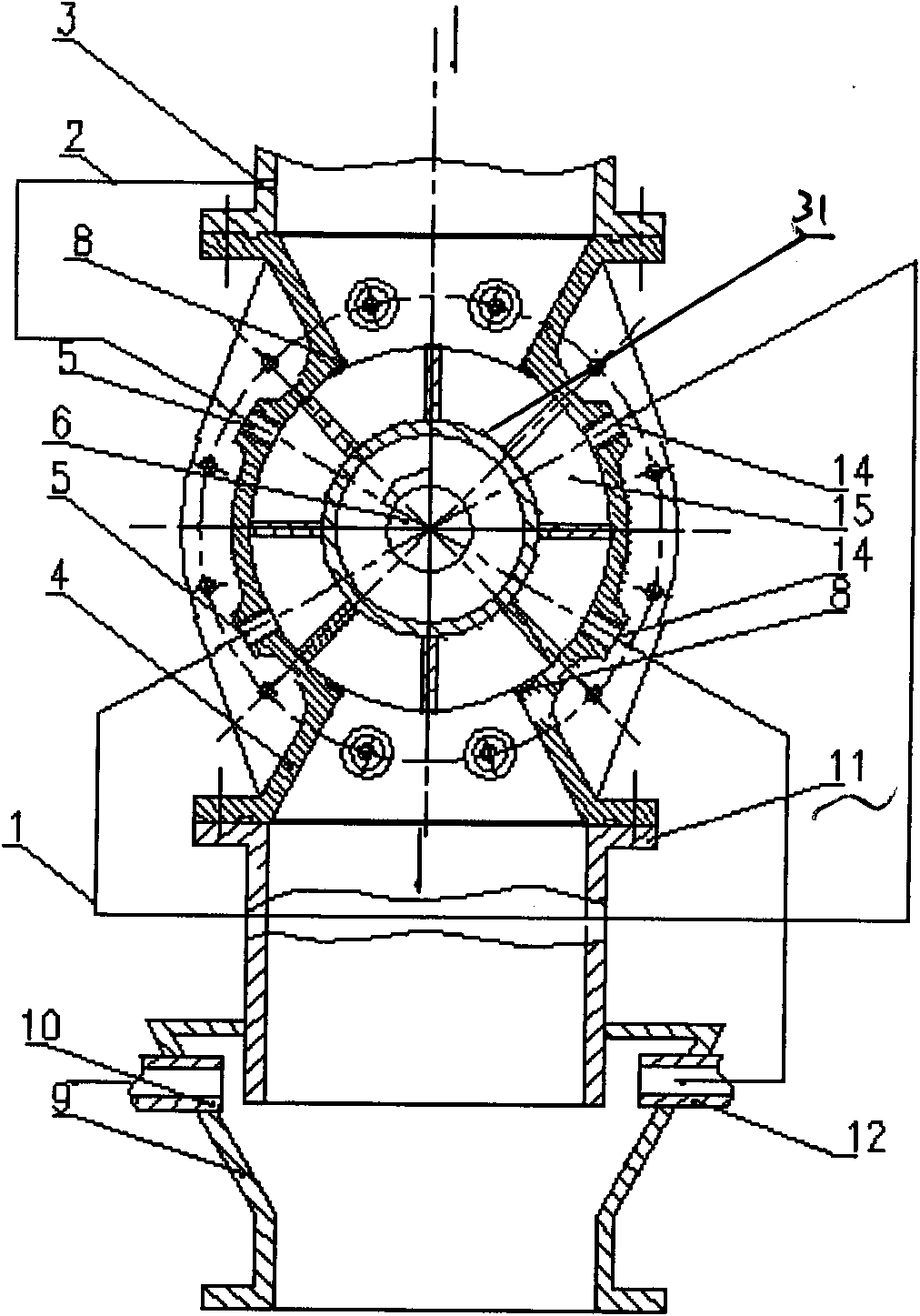

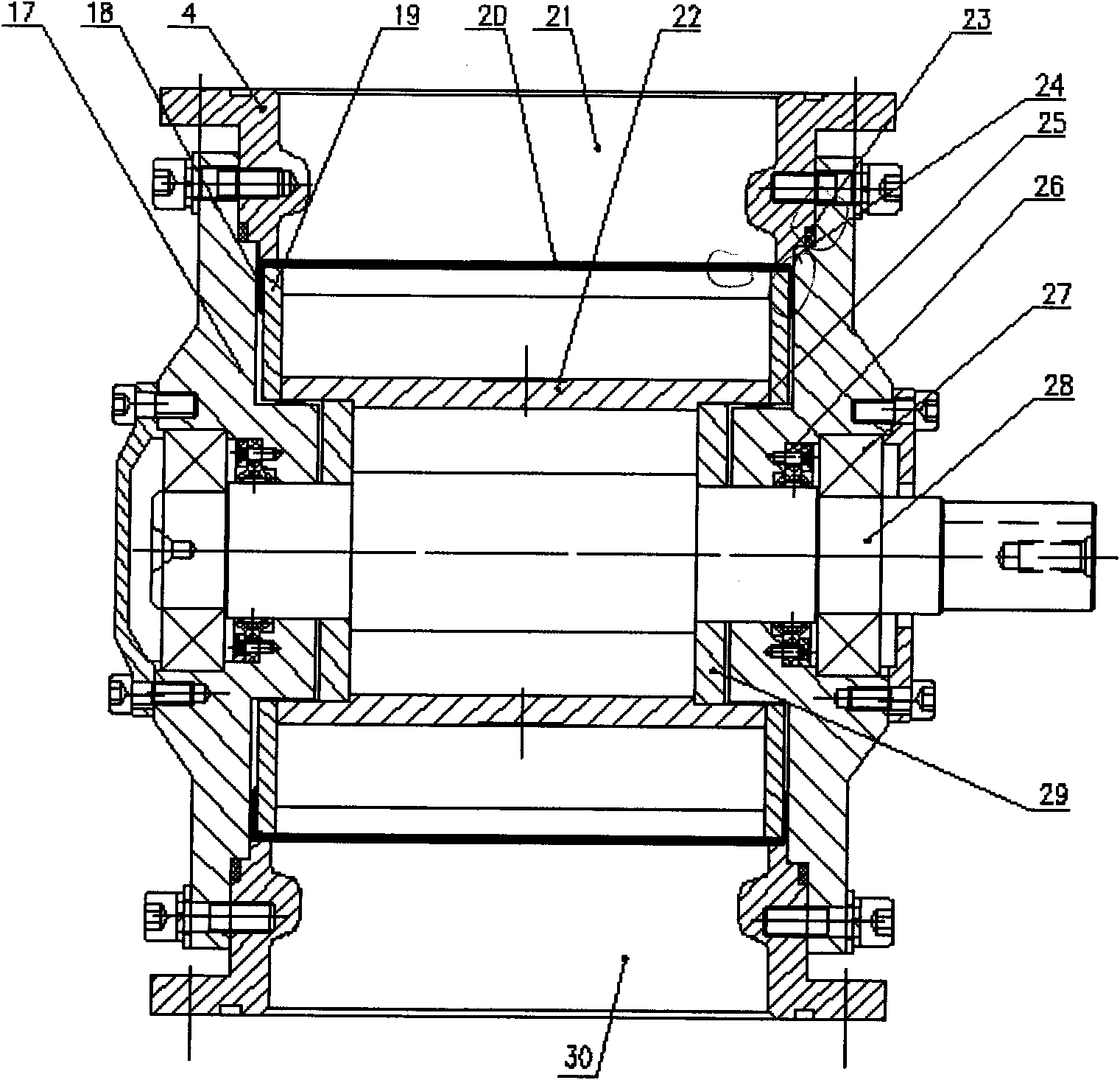

Rotary sealing feeding valve

InactiveCN101676179AImprove recycling rateSmall pressure fluctuationsBulk conveyorsRotary conveyorsRotary valveTemperature difference

The invention relates to a rotary sealing feeding valve which comprises a valve casing, side flanges which are symmetrically arranged and a star-shaped rotor, wherein the side flanges are fixedly installed at the front side and the back side of the valve casing; a main shaft is supported between the side flanges; and the star-shaped rotor is supported between two side flanges in the valve casing. The invention is characterized in that the space between each side flange and the valve casing is divided into a plurality of sealed chambers by the star-shaped rotor; a pressure-reducing balanced opening and a pressure-increasing balanced opening are arranged on the valve casing; and the valve casing also comprises a feeding opening and a discharge opening. The rotary sealing feeding valve is a rotary valve which is suitable for continuous feeding in the environment with pressure difference and temperature difference.

Owner:BEIJING INST OF AEROSPACE TESTING TECH

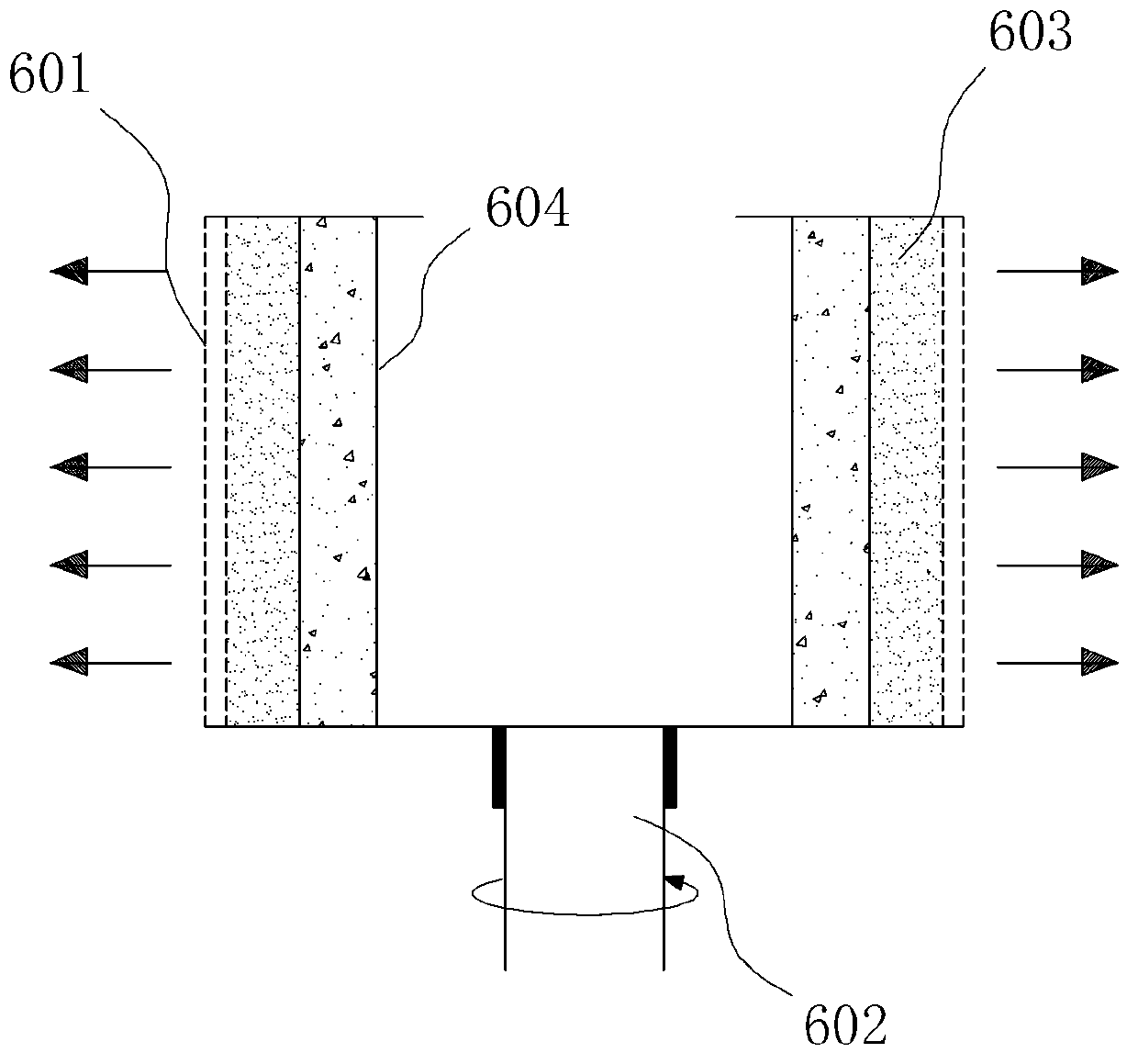

On-line continuous degassing device

ActiveCN103182200AHigh degassing treatment efficiencySave materialLiquid degasificationAir pumpElectric machinery

The invention relates to an on-line continuous degassing device for separating bubbles in defoaming, mixing and dispersing processes. The on-line continuous degassing device comprises a vacuum cavity, a transmission main shaft which is driven by a motor and extends into the vacuum cavity, and a cup stand disposed in the vacuum cavity and driven by the transmission main shaft. The on-line continuous degassing device is characterized in that a cup port of the cup stand is connected with a cup cover; the cup cover is opened with a cover hole; a material-feeding pipe passes through the vacuum cavity and the cover hole and extends into the cup stand; a material-discharging pipe passes through the vacuum cavity and the cover hole and extends into the cup stand; a gas phase-discharging pipe connected with an air pump extends into the vacuum cavity. By arranging a material feeding pipe and a material discharging pipe which extend into the cup stand and arranging a gas phase discharging pipe extending into the vacuum cavity, continuous feeding, discharging and degassing can be realized, and the on-line continuous degassing is formed. The device has high defoaming efficiency, saves materials, has a low rate of materials suffering from secondary pollutions, is simple in structure, reduces cost and has a good defoaming effect.

Owner:绵阳世诺科技有限公司

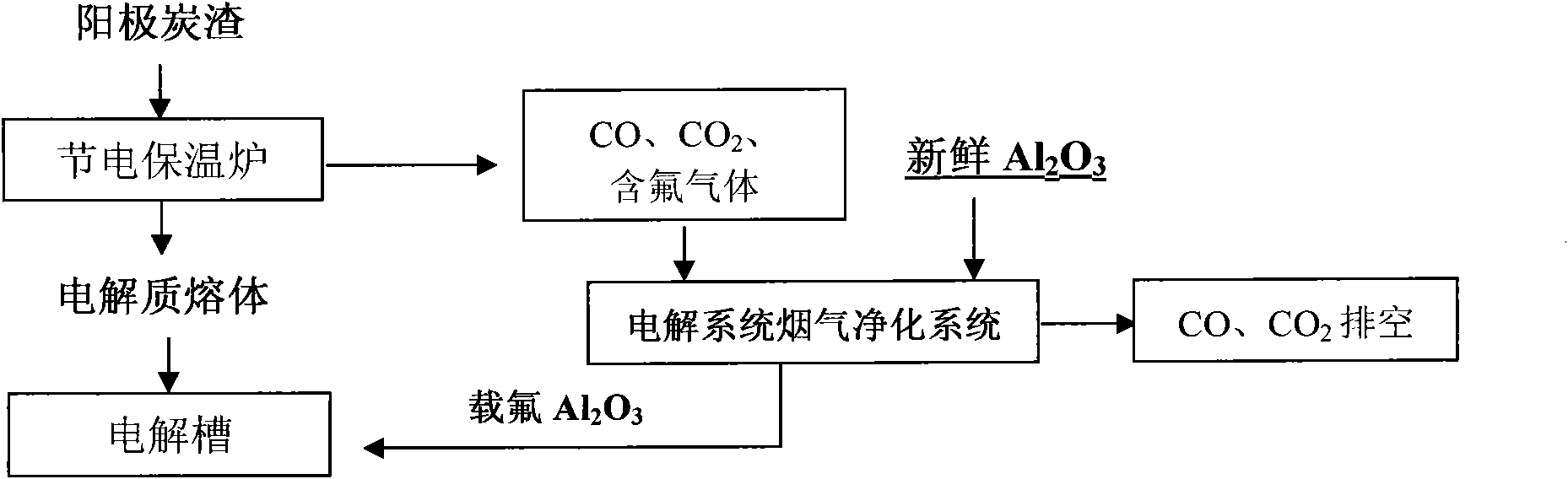

Method for innocent treatment of aluminum electrolysis anode carbon residue and recovery of electrolyte

ActiveCN102011148ARealize harmless treatmentReduce pollutionSolid waste disposalEnvironmental resistanceMaterials science

The invention discloses a method for innocent treatment of aluminum electrolysis anode carbon residue and recovery of electrolyte. The method comprises that: the anode carbon residue from an electrolytic cell is directly thrown into a power-saving holding furnace for smelting, and after a carbon material is completely combusted, the electrolyte completely forms an electrolyte melt; flue gas generated in the smelting process is introduced into an electrolysis series flue gas purification system, and fluoride gases are absorbed by alumina and returned to an electrolytic cell; the electrolyte melt directly enters the electrolytic cell for use or is cooled and ground for baking start-up of the electrolytic cell; and continuous feeding and continuous discharging are realized in the whole production process. The invention realizes innocent treatment of the anode carbon residue and comprehensive recycling of the electrolyte, and overcomes the defects that the carbon residue is needed to be crushed, ground and briquetted, various additives are needed to be added and environmentally-friendly treatment cannot be realized and the like in the prior art. The method is simple in technology, high in electrolyte recovery, low in production treatment cost and obvious in environment-friendly effects and economic benefits, and can realize harmlessness of the carbon residue after treatment.

Owner:YUNNAN YONGXIN ALUMINUM

Vanalium preparation method

The invention belongs to the field of metallurgy and particularly relates to a vanalium preparation method. The vanalium preparation method provided by the invention is low in cost and ensures high purity of obtained alloy. The technical scheme provided by the invention is as follows: in the vanalium preparation method, vanadium pentoxide and metallic aluminium are used as raw materials and are subjected to ignition reduction in a reaction device to obtain vanalium and furnace clinker; and a continuous feeding manner is adopted for the reaction device during feeding, and the feeding speed is 5-40kg / min. Compared with the prior art, the vanalium preparation method provided by the invention has the advantages that no coolant is added for controlling heat so that the cost is lower and the requirement for mass industrial production is completely met; and the produced vanalium is low in impurity content, the finished vanalium contains 65-91wt% of V, 9-35wt% of Al, not more than 0.3wt% of Fe and not more than 0.3wt% of Si, and the obtained vanalium has higher purity and meets the requirement of subsequent further processing.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

Blocky rubber continuous mixing method and device

The invention discloses a blocky rubber continuous mixing method and device. A crude rubber conveying device is used for feeding a blocky rubber raw material into a rubber continuous plastifying device and conveying a solid compounding agent and an extruded plastifying rubber sheet into the rubber continuous mixing device; a rubber feeding controlling device and a compounding agent feeding controlling device are connected with an equipment control system; and the blocky rubber raw material is directly put into the blocky rubber continuous plastifying device to be continuously plastified without prophase treatment, plastified rubber is mixed through the rubber continuous mixing device, and continuous production of continuous feeding, discharging, continuous plastifying and continuous mixing is realized. The blocky rubber continuous mixing device has the advantages of less quantity of auxiliary devices, little investment of production devices, low energy consumption, high efficiency, and high mixing quality because stable device parameters and process conditions can be realized due to strong controllability.

Owner:QINGDAO UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com