Stick-slip inertia based serial three-degree-of-freedom piezoelectric precision driving platform

A technology for driving platforms and degrees of freedom, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc. Problems such as poor carrying capacity, to achieve the effect of small and compact structure, rapid response, stable and reliable movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

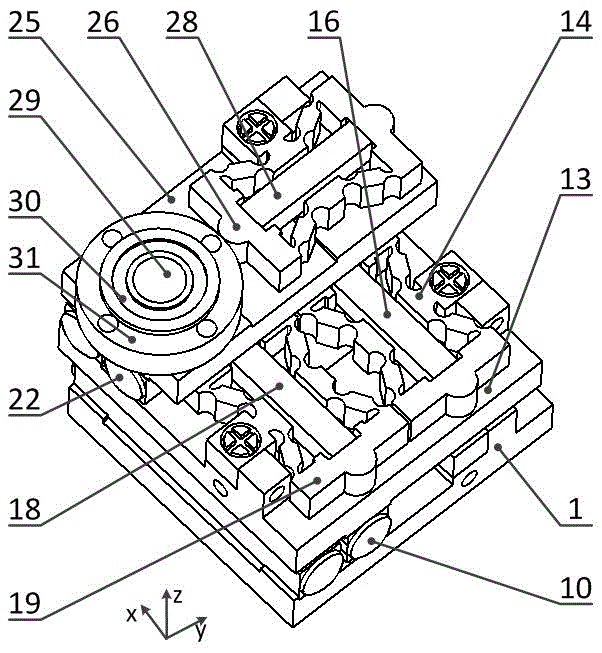

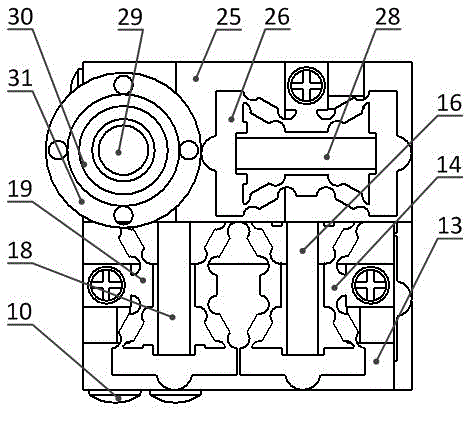

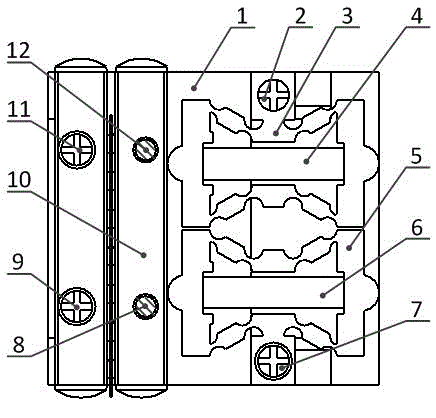

[0022] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

[0023] see Figure 1 to Figure 6 As shown, the series-type three-degree-of-freedom piezoelectric precision drive platform based on the stick-slip inertia of the present invention realizes the fast feed mode and the precision feed mode simultaneously by the bridge-type flexible hinge amplification mechanism: in the initial stage of motion, it is driven by a sawtooth wave, That is, the fast stick-slip inertial drive method is adopted to realize rapid feed of large strokes; in the later stage of motion, continuous voltage control is used to achieve high-precision precision micro-feed; specifically includes the lower x-axis linear drive assembly and the middle y-axis linear drive assembly and the upper z-axis rotary drive assembly, wherein the lower x-axis linear drive assembly has the same mechanism as the middle y-a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com