High precision silicon slice bench and uses thereof

A silicon wafer table, high-precision technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problem that the high-precision positioning of silicon wafers cannot be satisfied, the dynamic and static friction coefficients are difficult to keep the same, and affect the manufacturing accuracy of semiconductor equipment. and other problems, to achieve the effect of fast operation and response speed, low friction resistance, easy installation and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

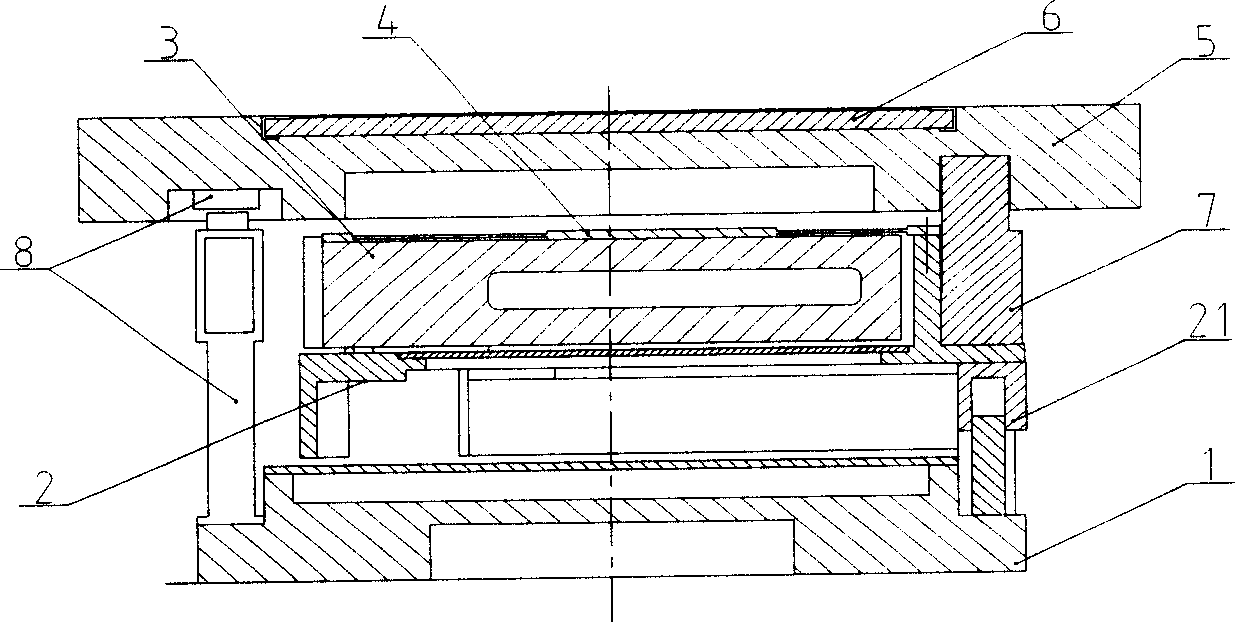

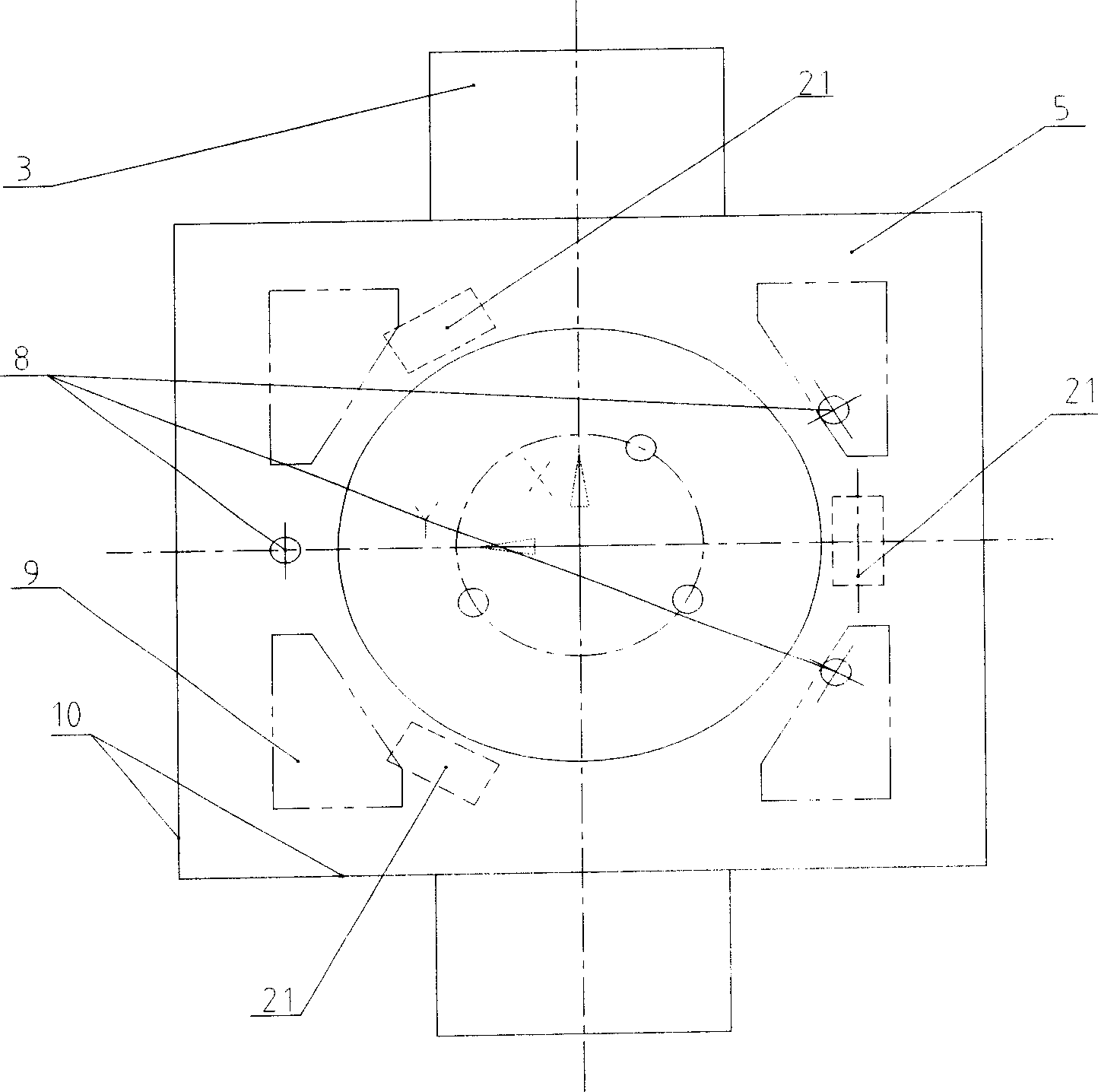

[0037] like figure 1 , 2 The shown high-precision silicon wafer stage includes an air-floating support 1, a leveling mechanism 2, a plane motor 3, and a reed 4, which are connected in sequence from bottom to top. Above the reed 4 is a square mirror 5. The upper surface is provided with a suction cup 6 for placing silicon wafers.

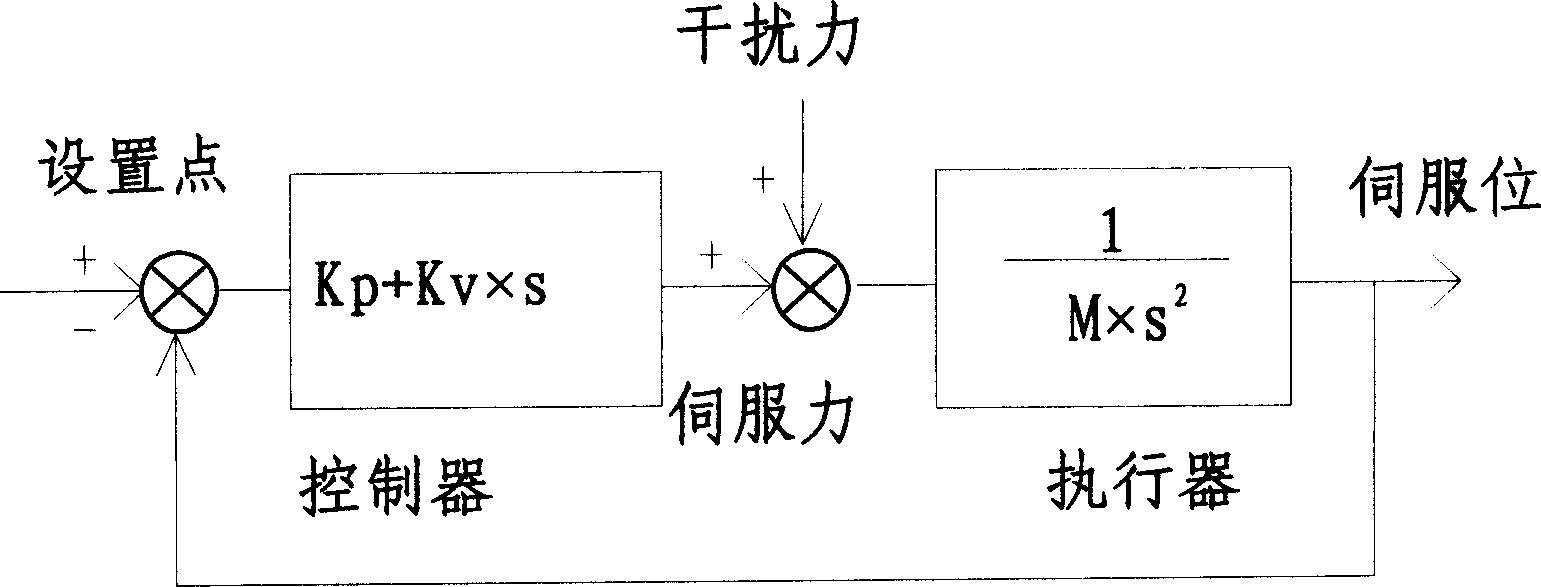

[0038] The invention uses the double-rigidity air-floating support 1 as the base to isolate the vibration of the frame, reduce the motion friction, eliminate the manufacturing error of the base platform, and ensure the speed stability of the scanning movement. In addition, it can prevent the shear pressure caused by the slight displacement caused by the overturning moment in the acceleration process to the air-bearing guide rail. In order to overcome the high-precision positioning of silicon wafers at high speed and high acceleration. The characteristics of the air flotation support 1 are: the motion friction resistance is extremely small, the cal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com