Patents

Literature

72results about How to "Realize high-precision adjustment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

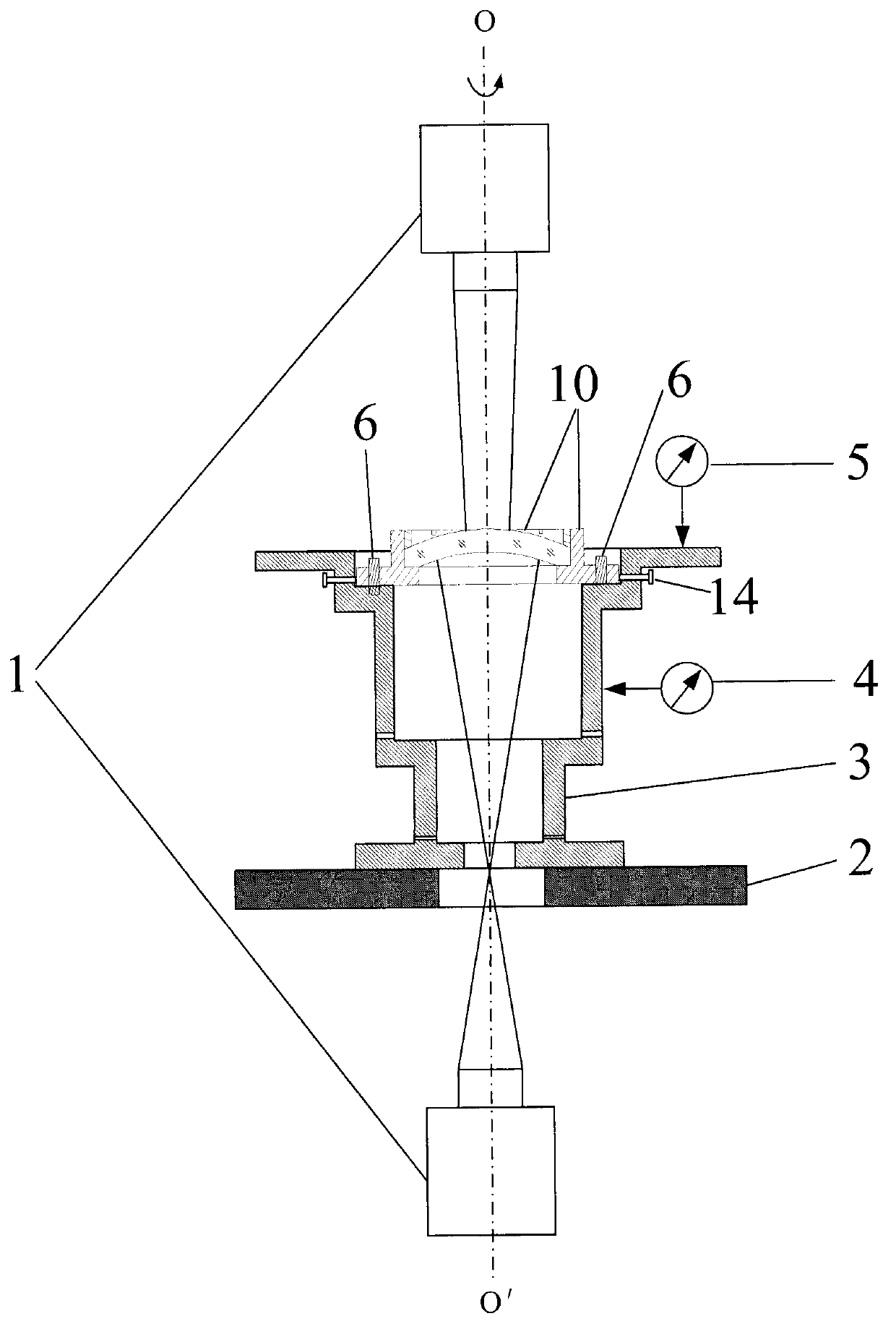

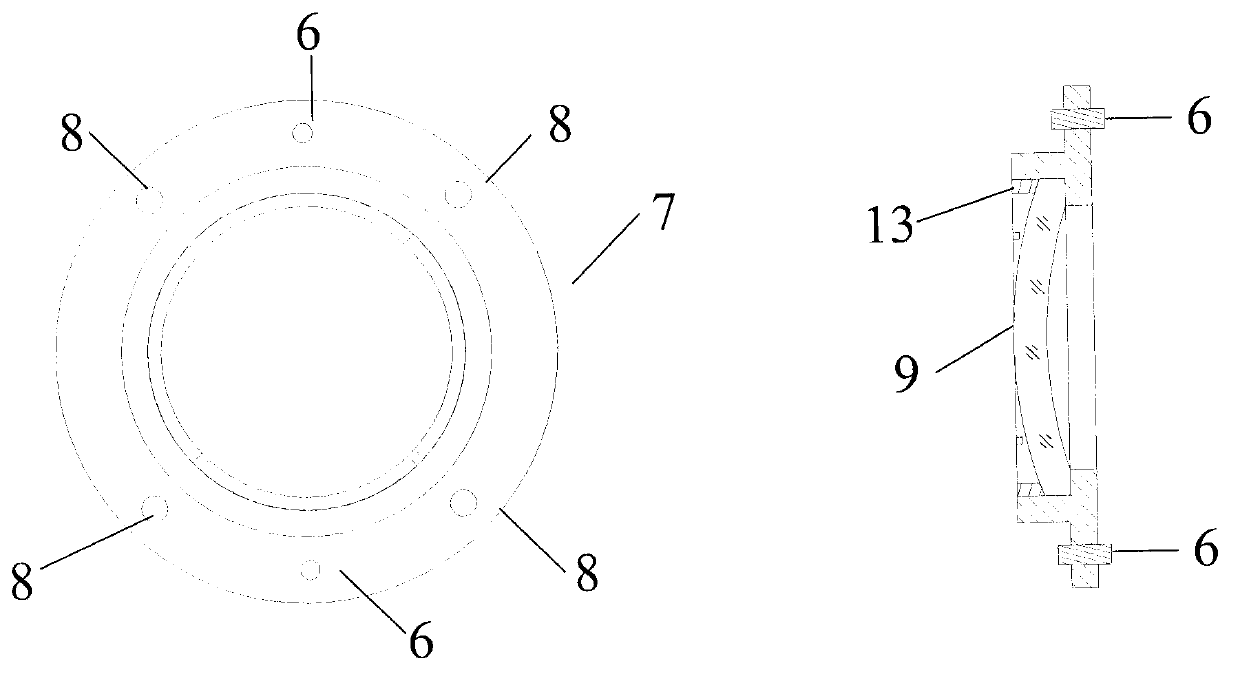

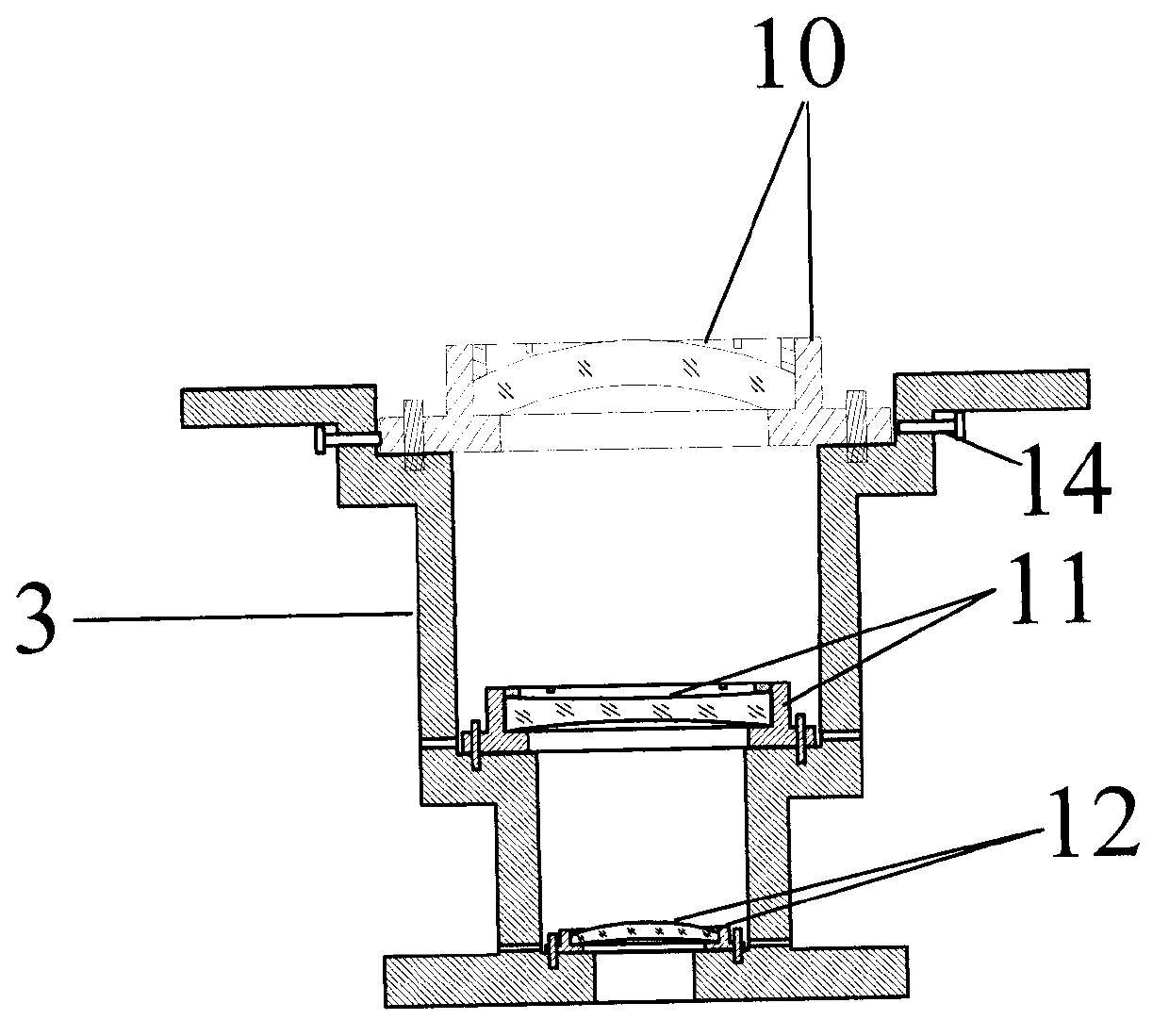

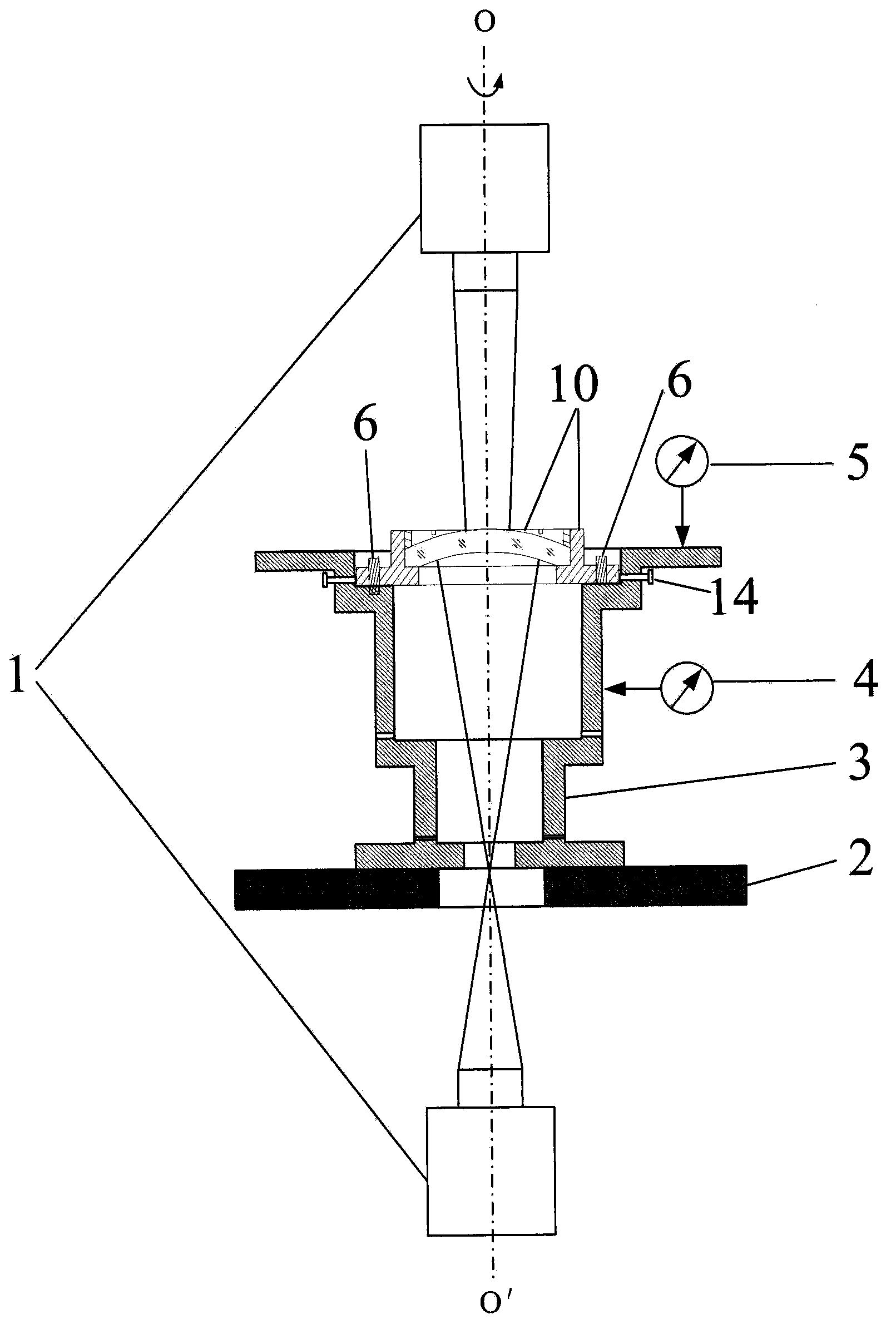

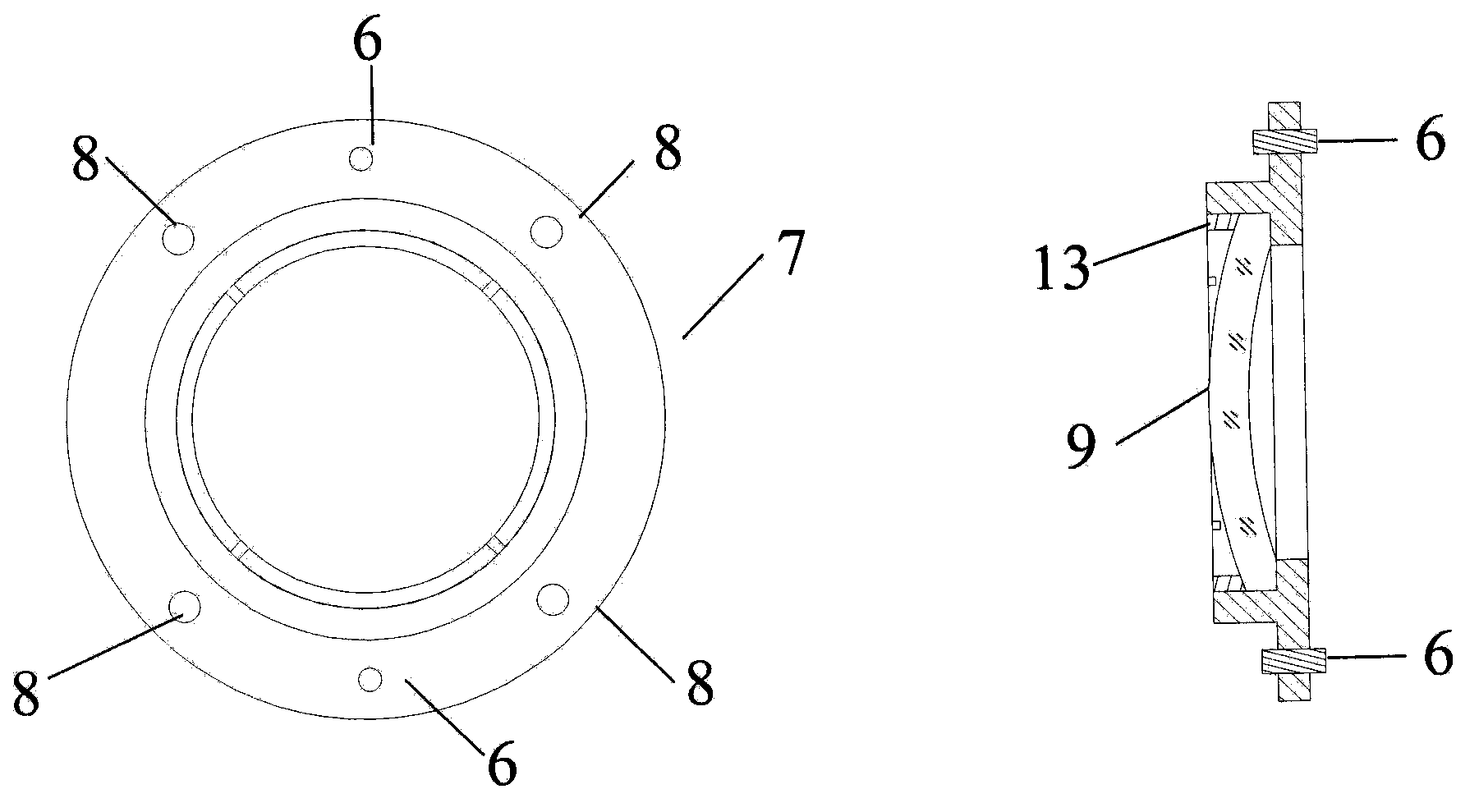

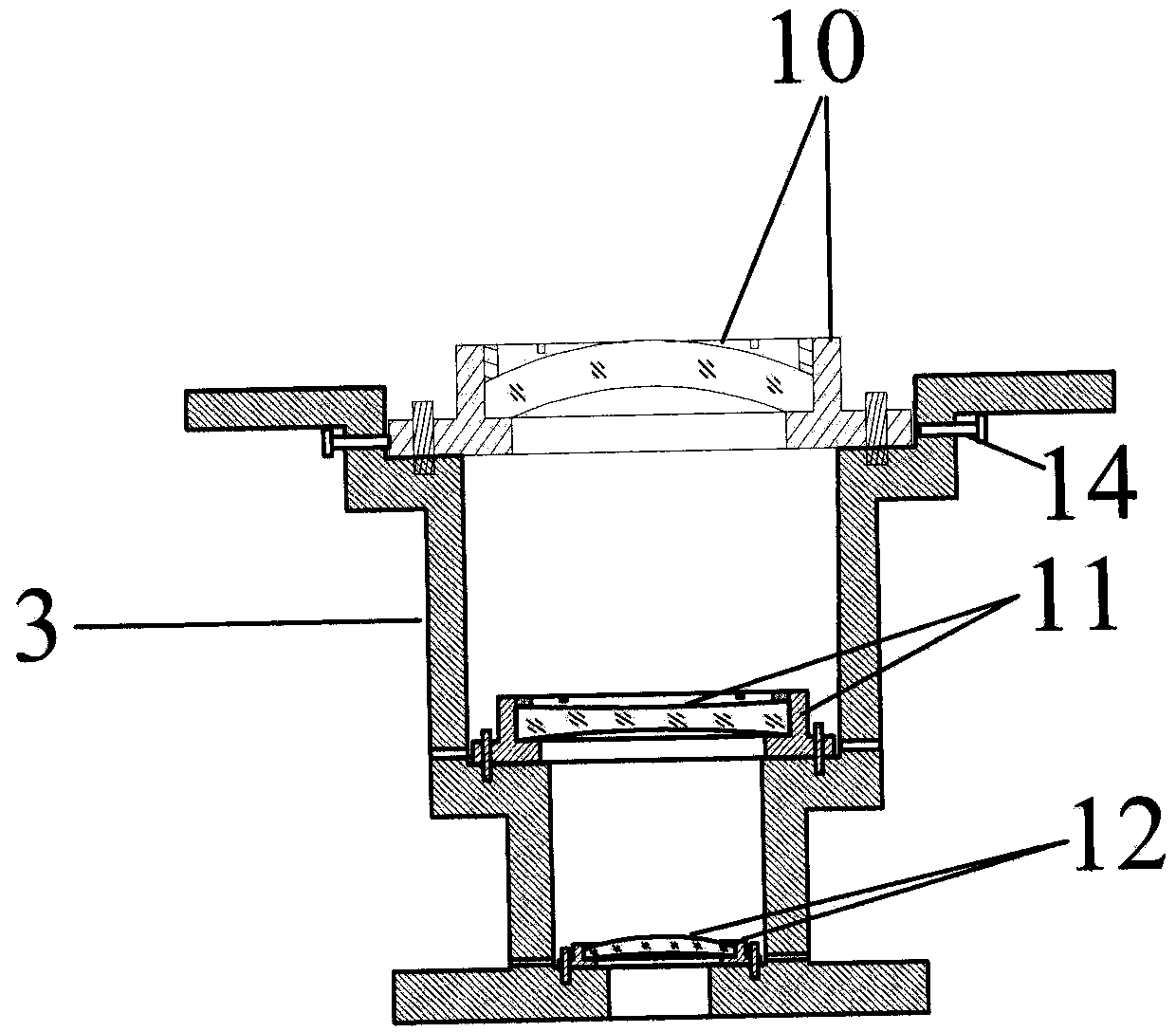

Installation and adjustment method of infrared lenses

ActiveCN102998767AHigh-precision adjustmentHigh measurement accuracyMountingsCamera lensOptical path

The invention provides an installation and adjustment method of infrared lenses. The installation and adjustment method comprises the steps of utilizing a dual-optical-path centering instrument to measure rocking amount of sphere center images of two lens surfaces of an infrared single lens assembly, adjusting translation and inclination of the infrared single lens assembly, monitoring the rocking amount of the sphere center images, striking dowels to position the infrared single lens assembly, taking off the infrared single lens assembly, positioning other infrared single lens assemblies through the same method, and installing the infrared single lens assemblies into lens cones to complete the installation and adjustment of the lenses. By means of the installation and adjustment method of the infrared lenses, high-precision installation and adjustment of the infrared lenses can be achieved, and the problem that most of visible light cannot penetrate infrared lens materials and the centering measurement of a system cannot be performed is solved.

Owner:BEIJING RES INST OF SPATIAL MECHANICAL & ELECTRICAL TECH

Precision measurement control method of metro track structure construction

ActiveCN102953304ARealize high-precision adjustmentGuaranteed smoothnessMeasuring apparatusObservational errorTotal station

The invention specifically relates to a precision measurement control method of a metro track structure construction, which solves the problems of poor safety, smoothness and comfort of a line and high equipment abrasion and noise vibration in the operation process because the existing measurement control method of the track structure construction has multiple steps and the control benchmarks for measurement can not be reused. According to the precision measurement control method, precision measurement control is performed on the track structure by utilizing a method of establishing a track basic control network in combination with a total station and a track geometrical state measurement instrument, thereby realizing high-precision adjustment on the track; and the track geometrical state measurement instrument is applied so that the precision requirements on points in the metro track measurement are improved to be requirements on the overall smoothness of the line, thereby guaranteeing that the indexes of track gauge, high-low rate of change, track orientation, high and low smoothness and the like of the track are capable of meeting higher requirements; and besides, digitization and automation are realized.

Owner:CHINA RAILWAY NO 3 GRP CO LTD +3

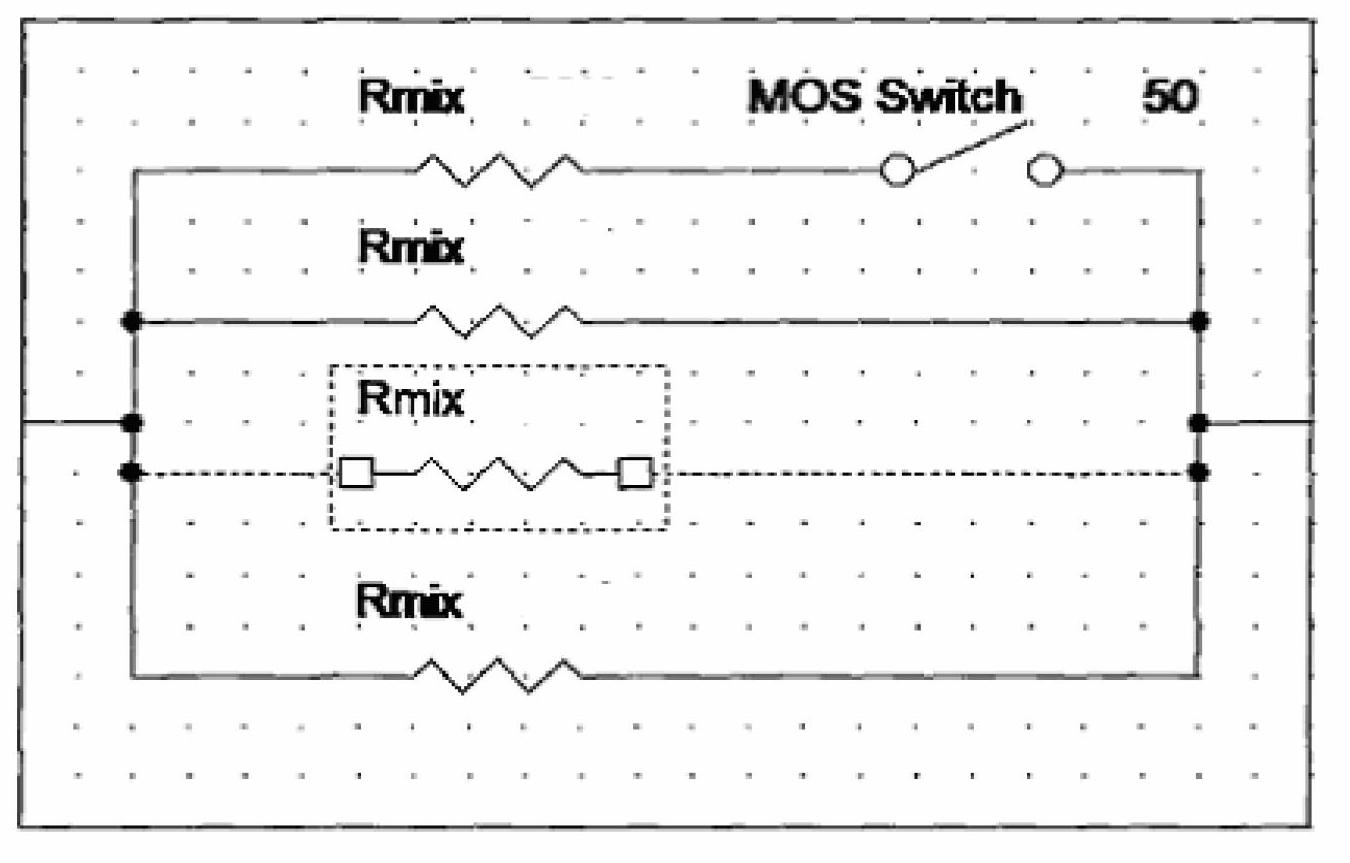

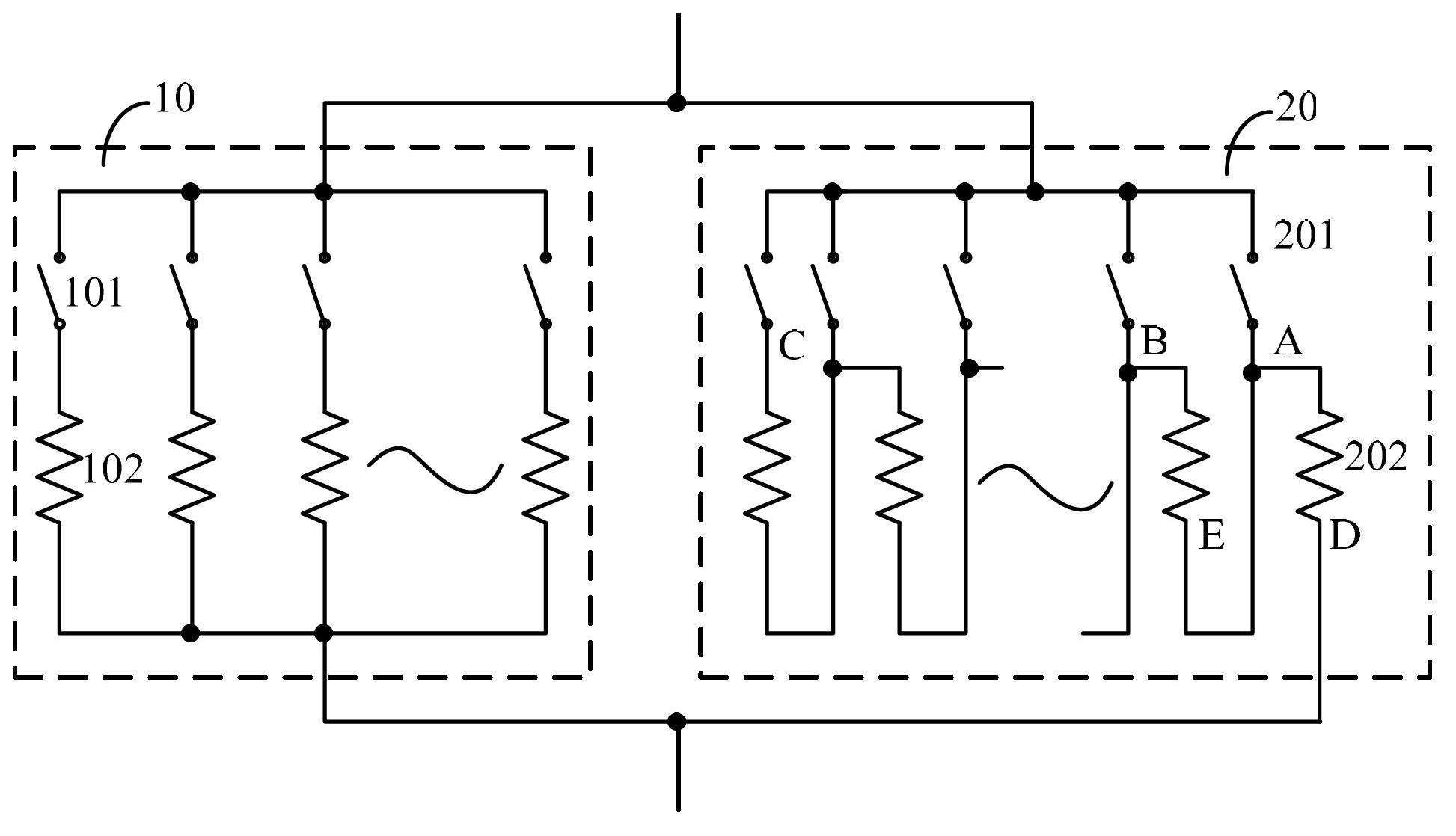

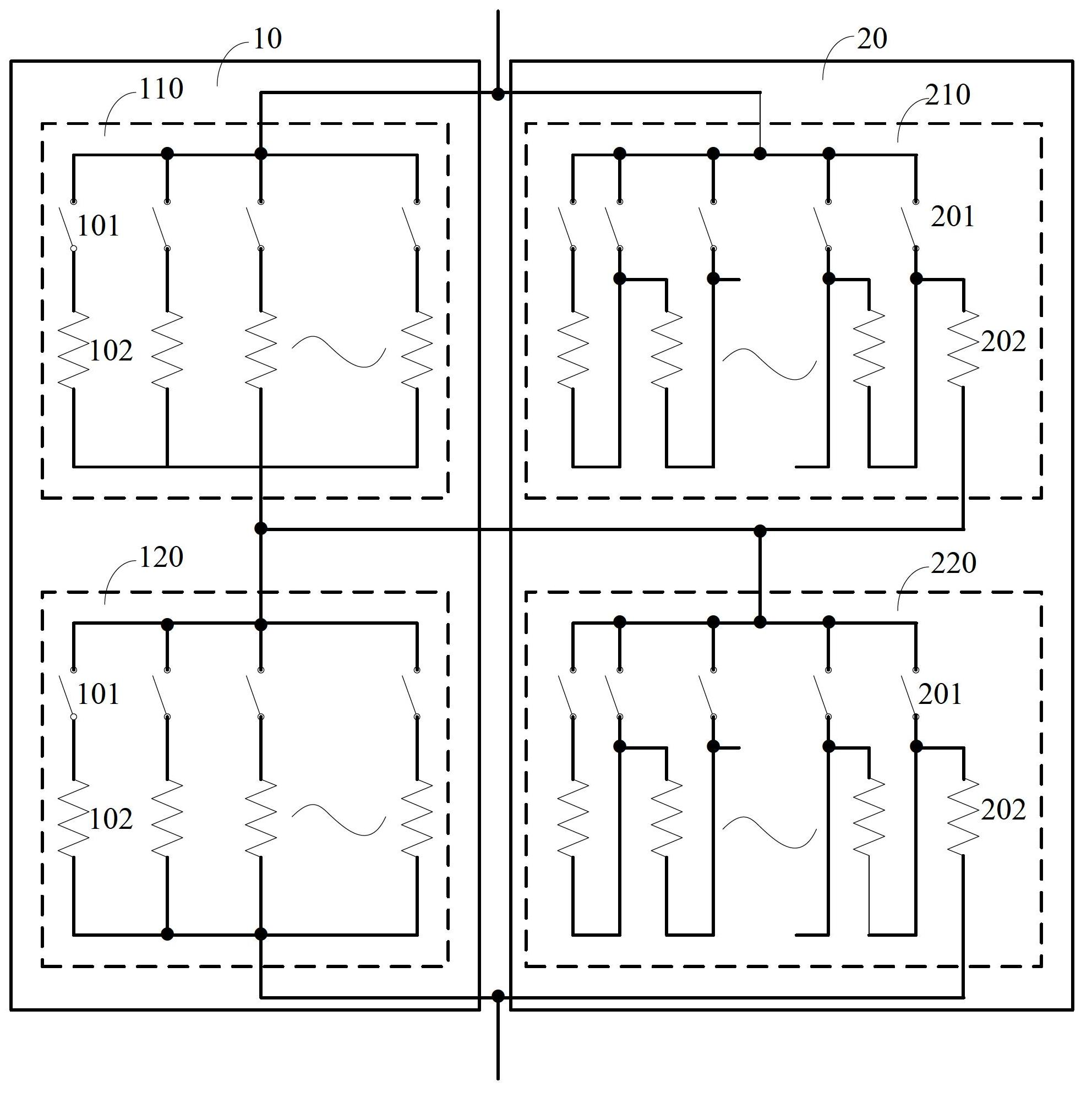

Digital adjustable resistor and adjusting method thereof

ActiveCN102693796AEasy to adjustHigh precisionResistors with plural resistive elementsElectrical resistance and conductanceResistor

Disclosed are a digital adjustable resistor and an adjusting method thereof. The digital adjustable resistor comprises a controlled resistor string and an adjustable resistor string which are connected in parallel, an approximate value of required resistance can be obtained via the controlled resistance string by means of adjusting the quantity of first resistors connected in parallel, the adjustable resistor string is connected with the controlled resistor string, the resistance of the digital adjustable resistor is adjusted by means of adjusting the quantity of second resistors connected in serial, and accordingly the required resistance is obtained. The adjusting method includes connecting a plurality of first resistors in parallel to obtain the approximate value of the required resistance; connecting a plurality of second resistors in series according to the required resistance and the approximate value of the required resistance so that the resistance of the digital adjustable resistor is adjusted; and connecting the first parallelly-connected resistors with the second serially-connected resistors in parallel to obtain the required resistance. The digital adjustable resistor and the adjusting method for the digital adjustable resistor have the advantage that small-step and high-precision adjustment of the resistor is realized.

Owner:ZHEJIANG JUEXIN MICROELECTRONICS CO LTD

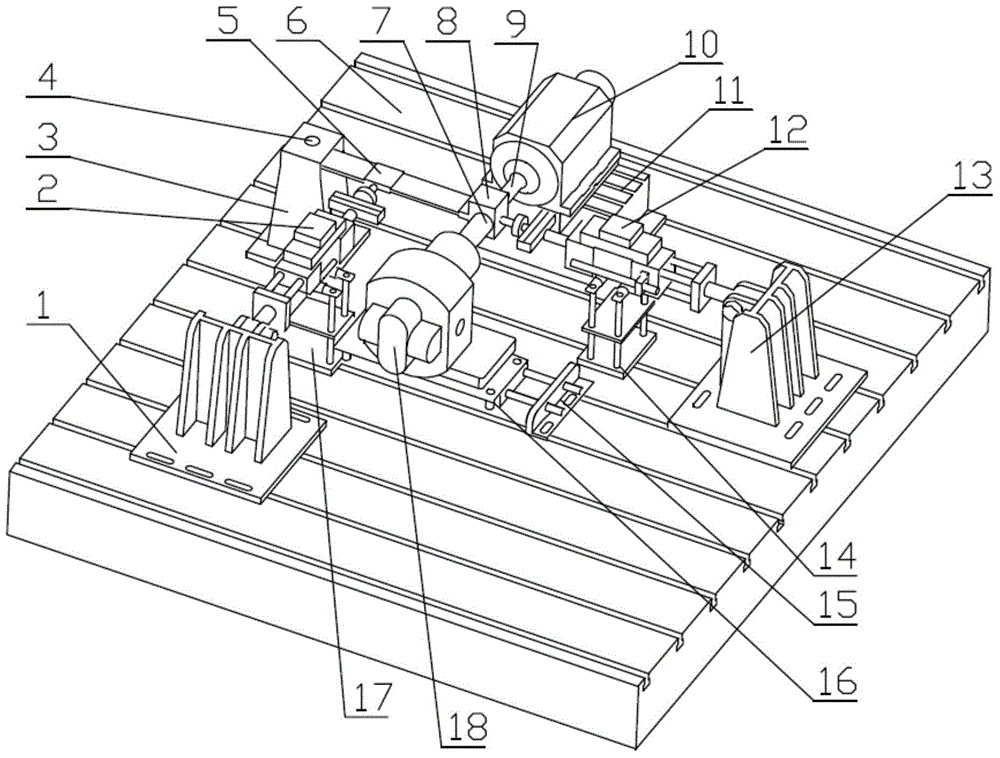

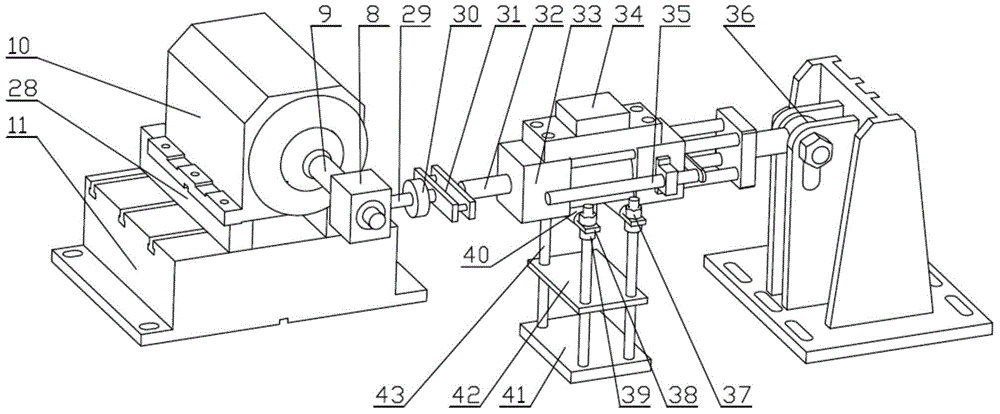

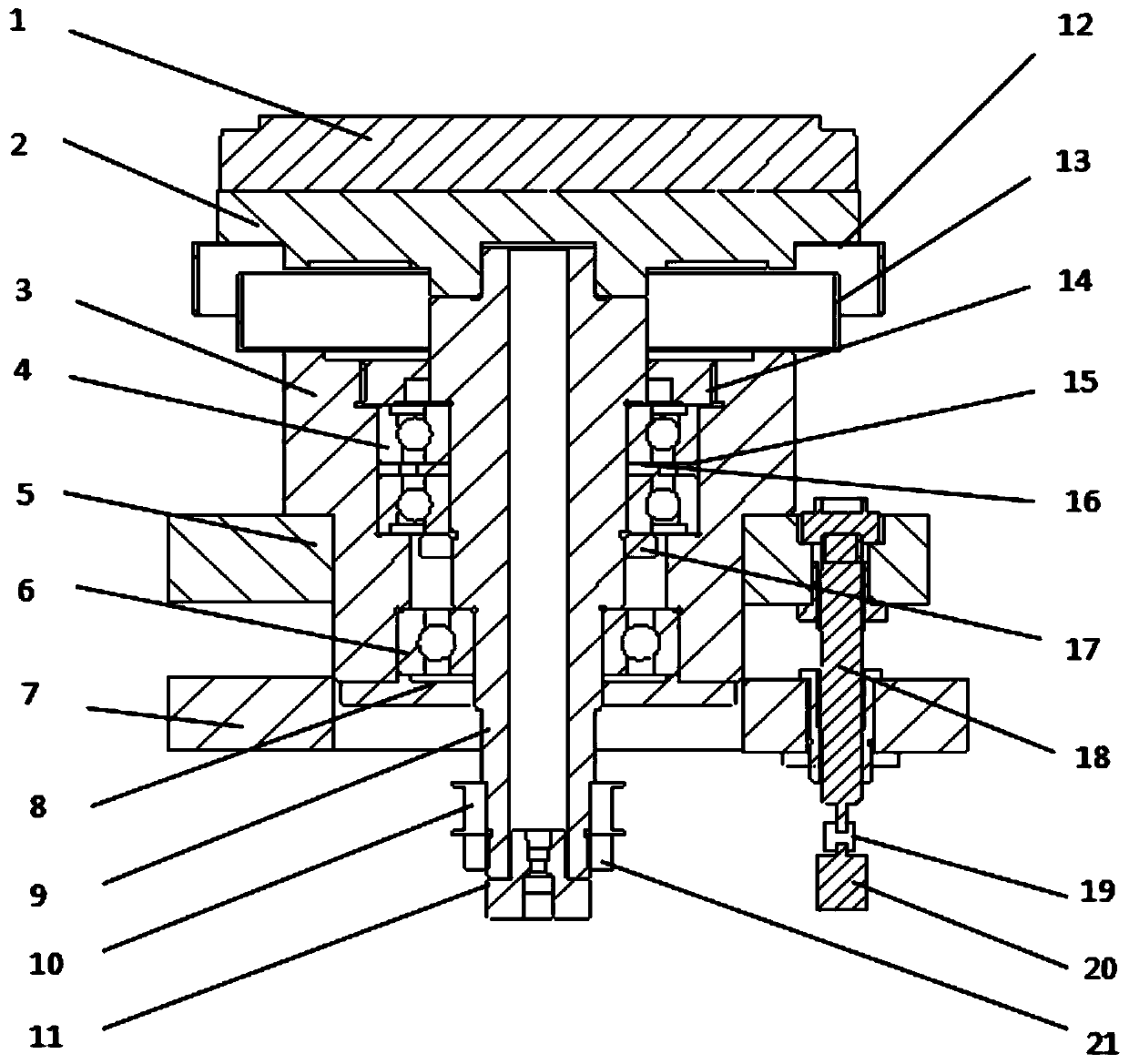

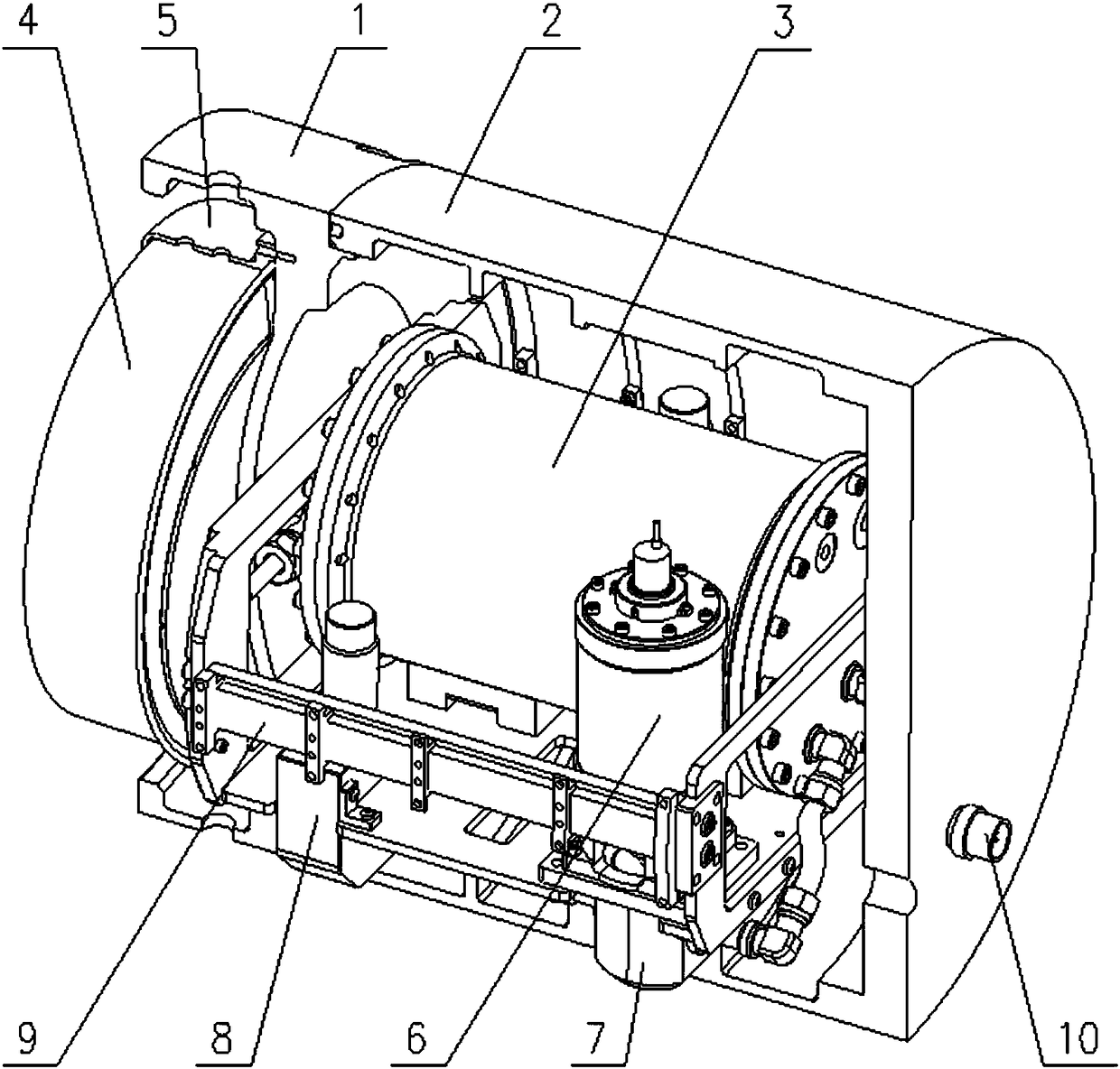

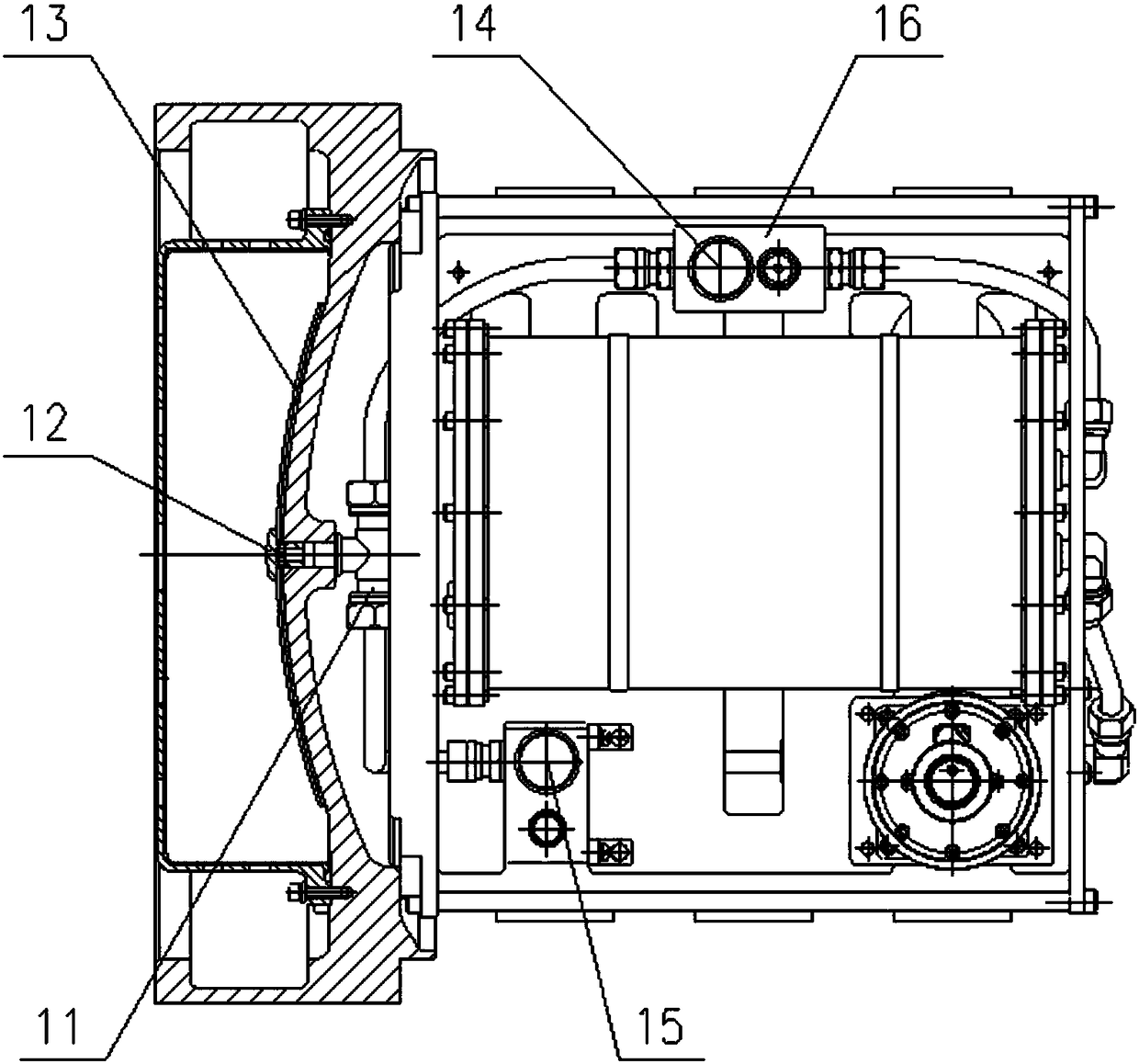

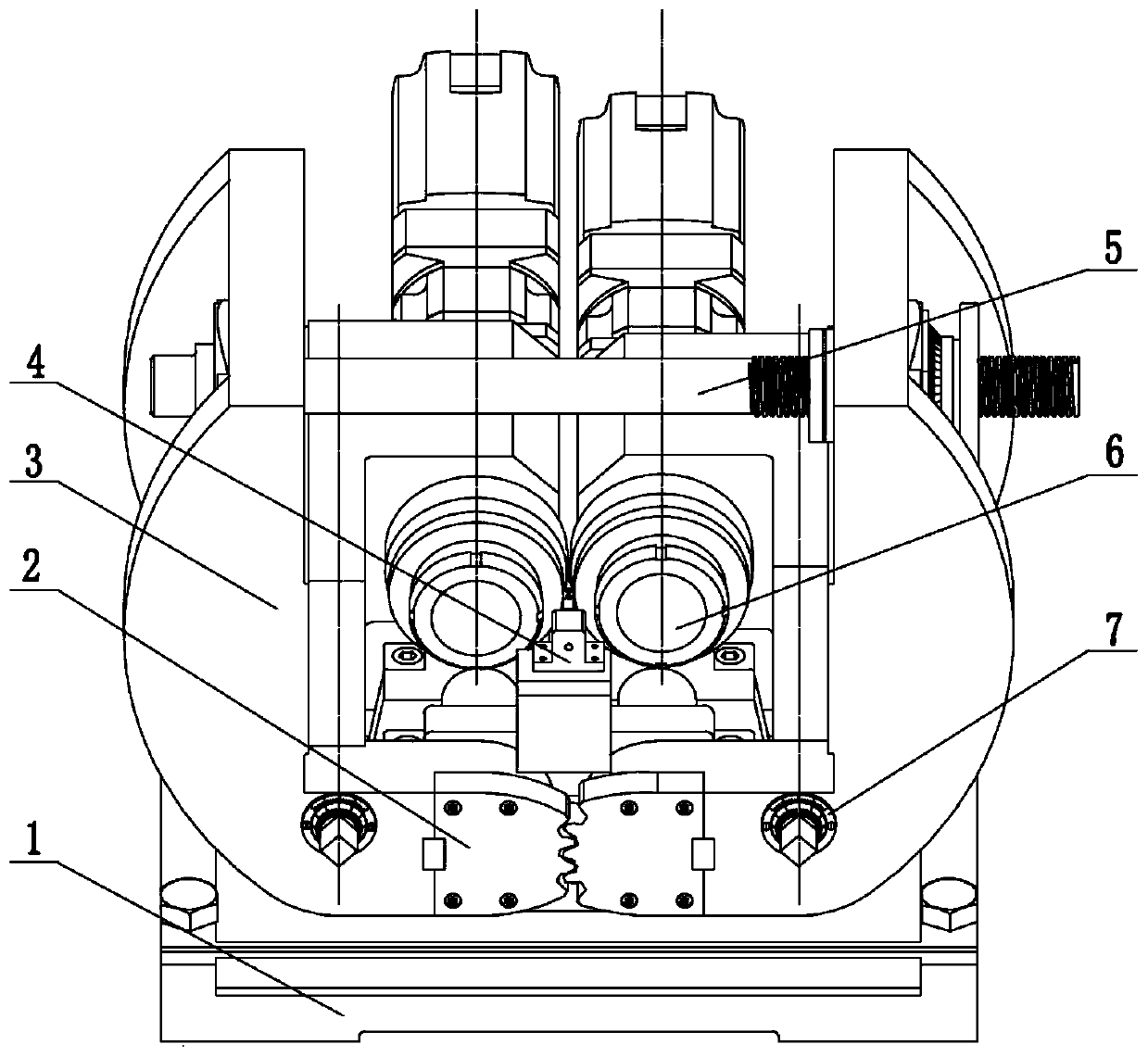

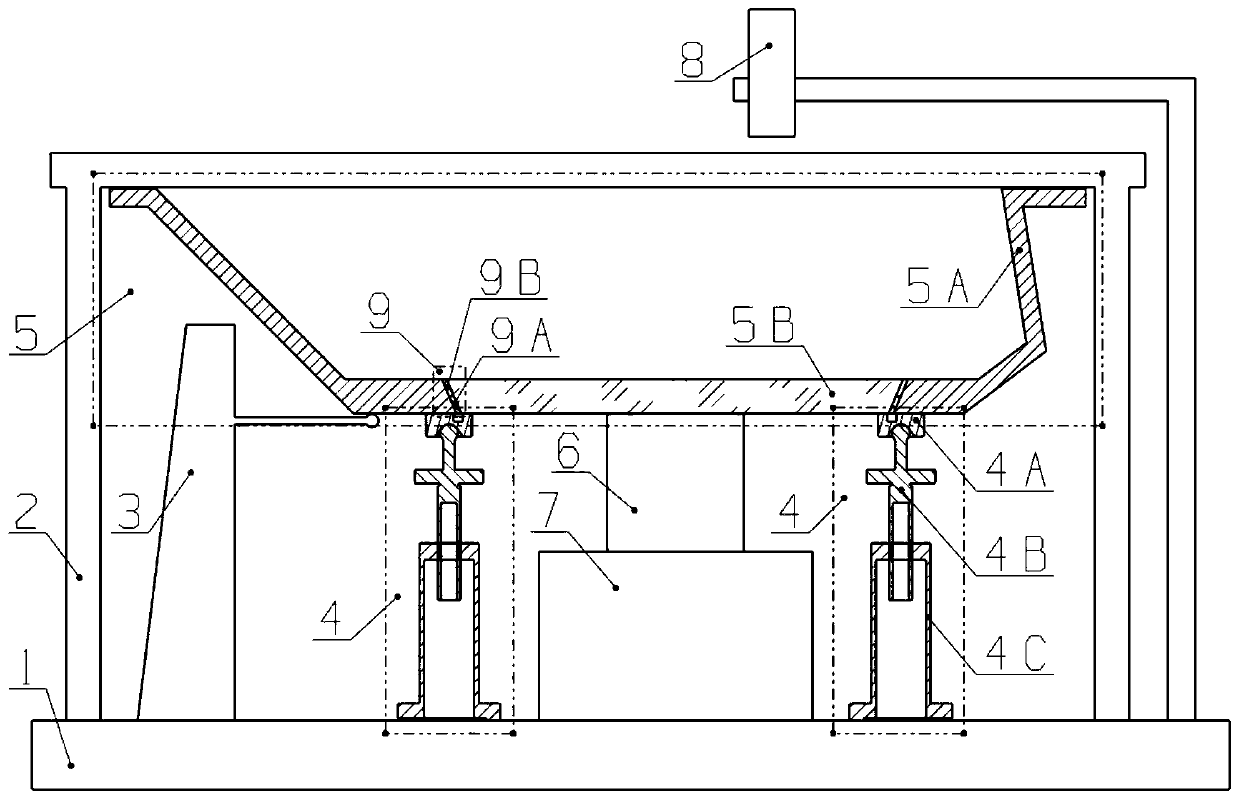

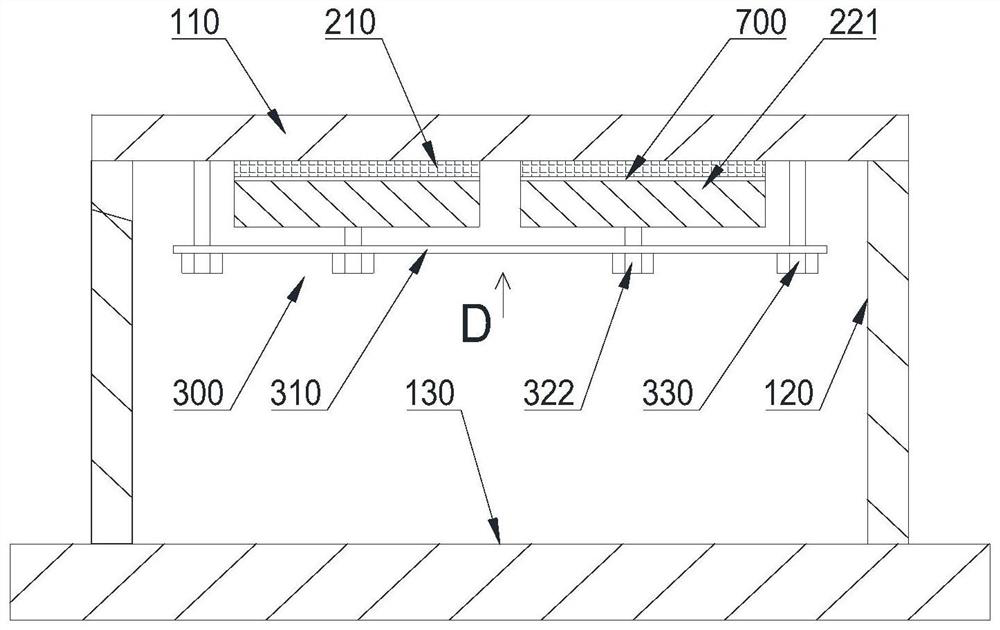

Electric spindle reliability test bed with hydraulic-type energy recovery function

ActiveCN104596759AImprove reliabilityAchieve recyclingMachine part testingNumerical controlElectricity

The invention relates to an electric spindle reliability test bed with a hydraulic-type energy recovery function. The test bed comprises an electric spindle, an electric spindle support portion, a loading bar, a bearing loading unit, a radial force loading portion, an axial force loading portion, an automatic control portion, a torque loading portion and a hydraulic oil way portion. The electric spindle, the loading bar, the bearing loading unit and a shaft axis of a hydraulic pump are coaxial. A loading rod 1 of the radial force loading portion is perpendicular to a shaft axis of the bearing loading unit. The axis of a loading rod 2 of the axial force loading portion is parallel to the shaft axis of the bearing loading unit. The electric spindle is in shaft connection with a hydraulic pump of the torque loading portion through a loading rod 3 and an elastic coupler. According to the arrangement, by subjecting the hydraulic pump and an energy storage to loading, the torque loading is performed on the electric spindle; besides, axial and radial force loading is performed to the electric spindle by the aid of hydraulic oil generated from the hydraulic pump through a hydraulic cylinder, so that the energy is recycled and saved.

Owner:JILIN UNIV

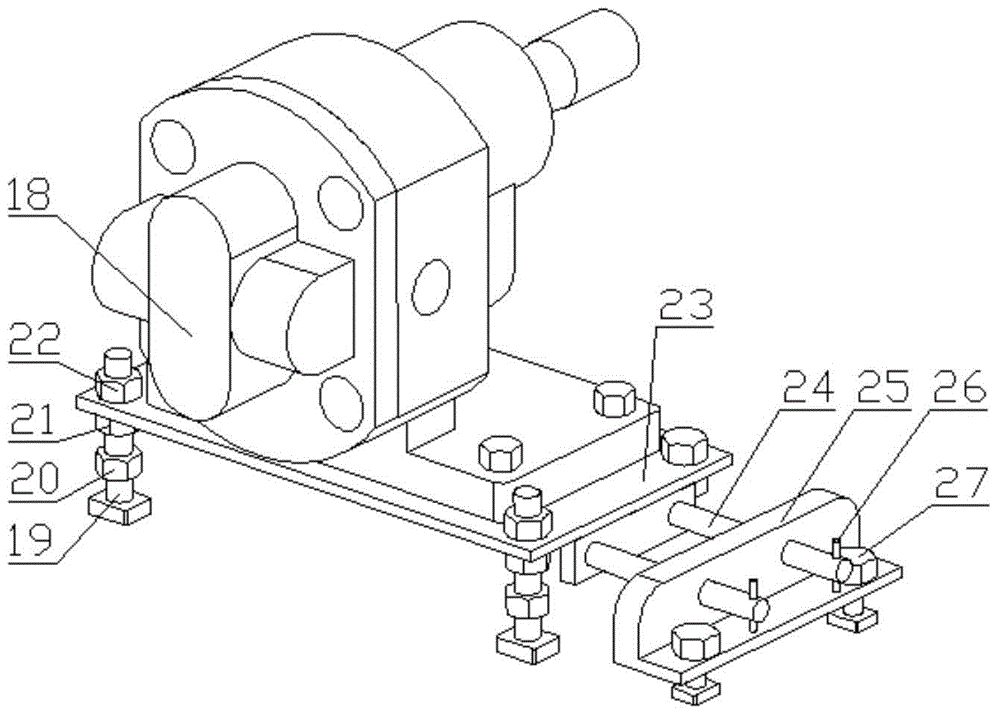

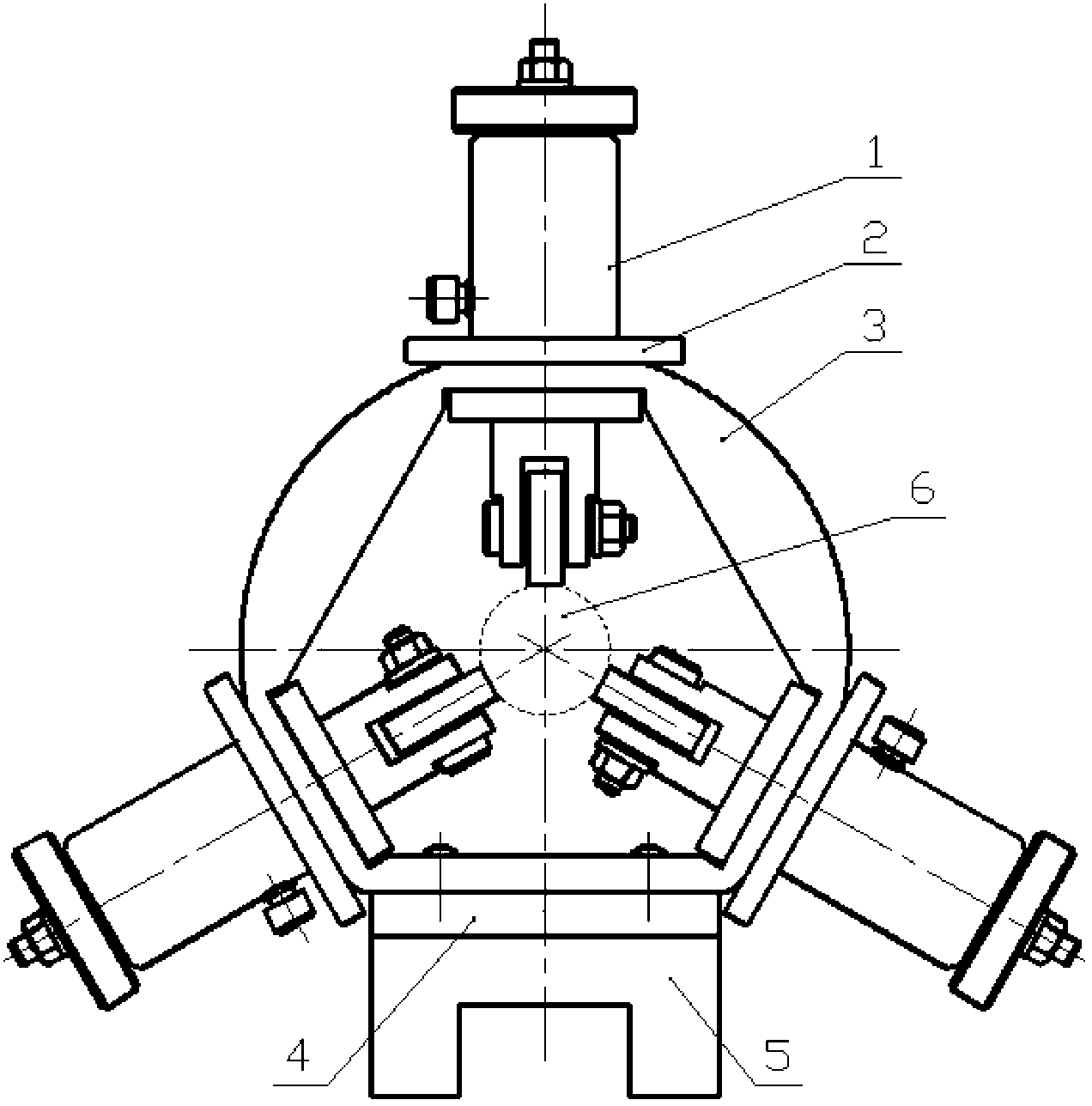

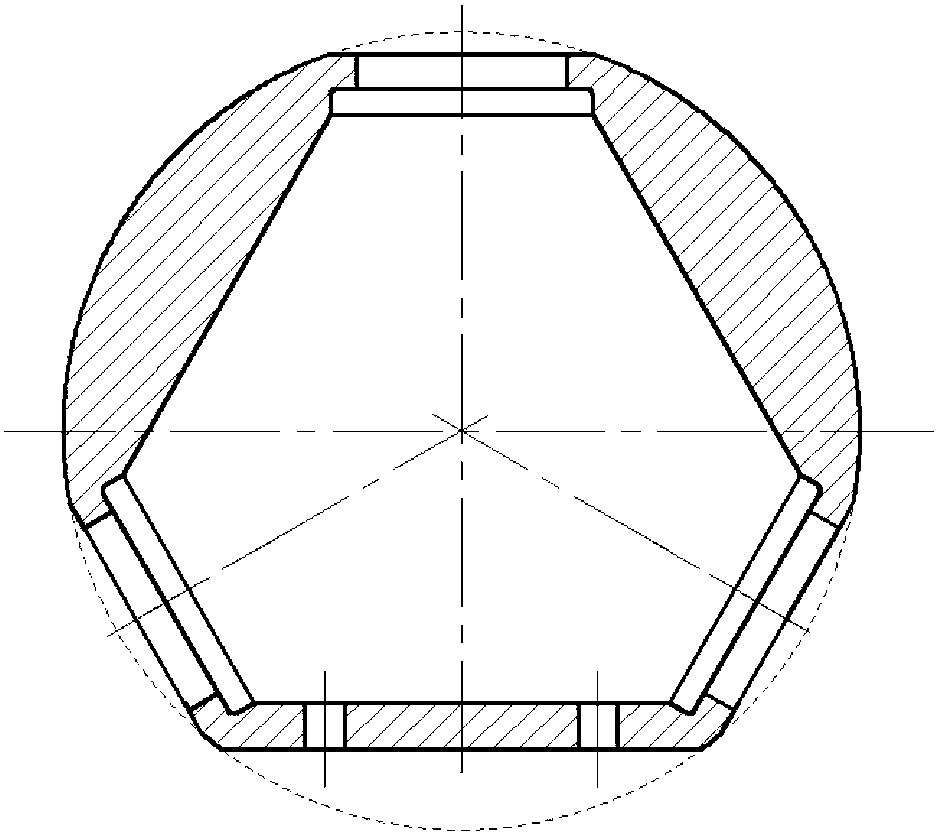

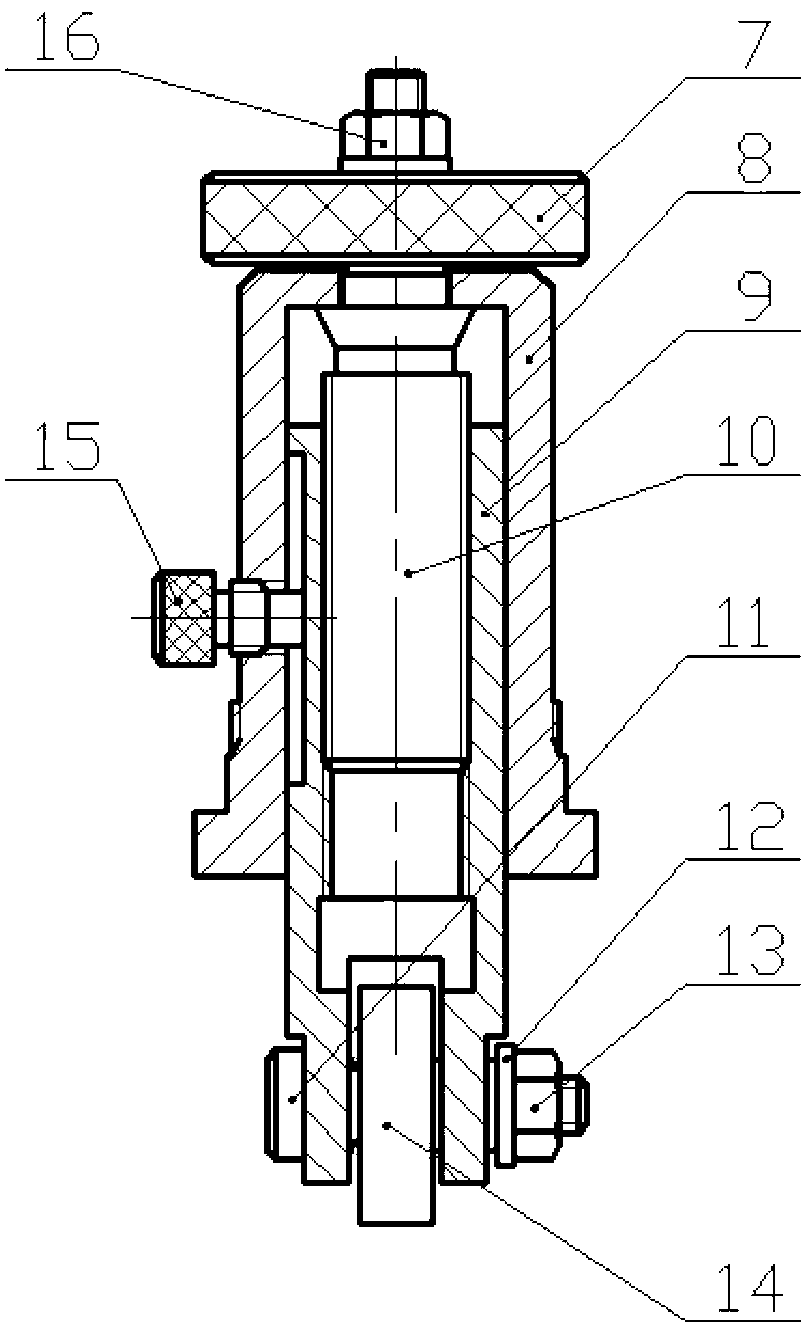

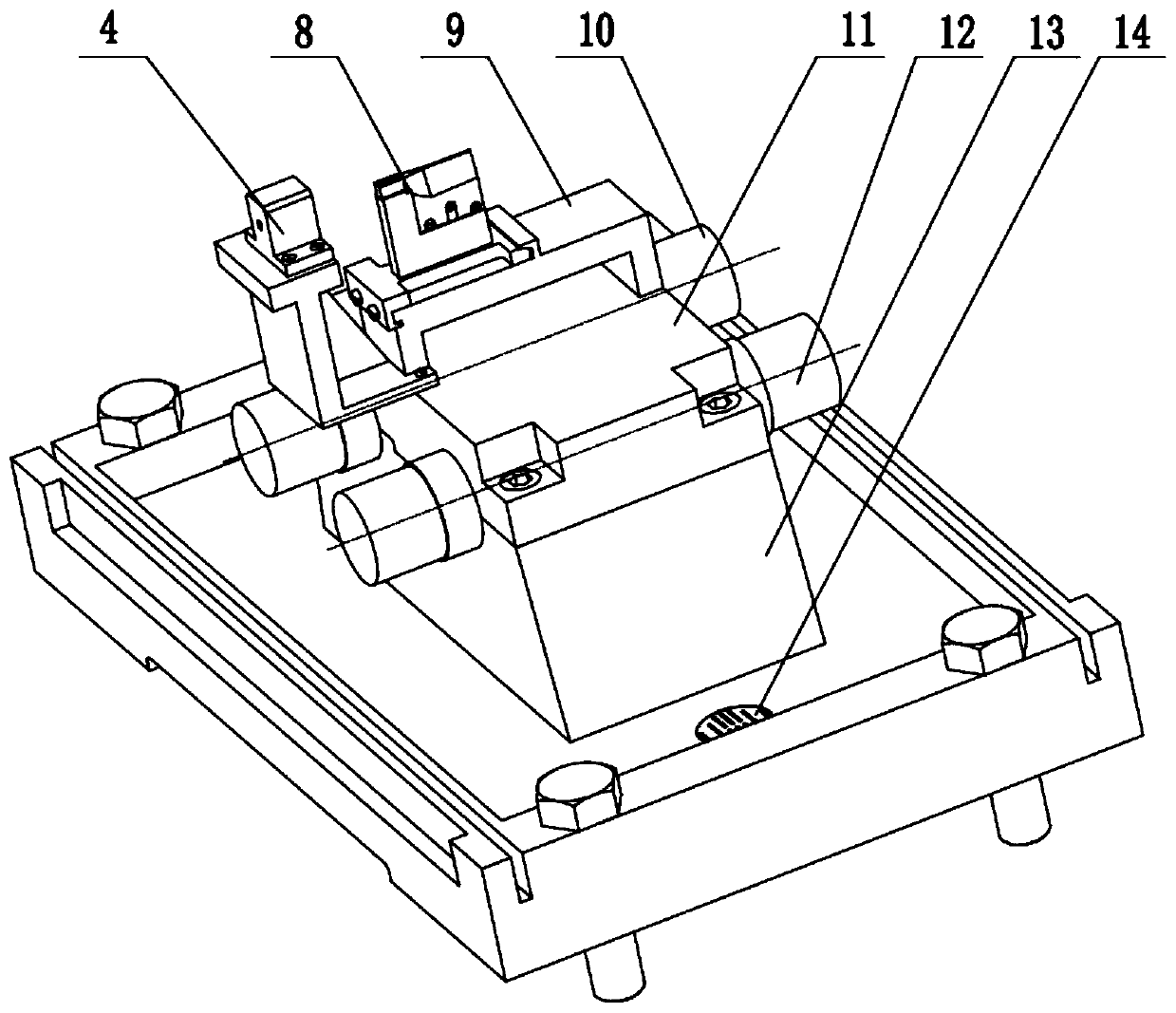

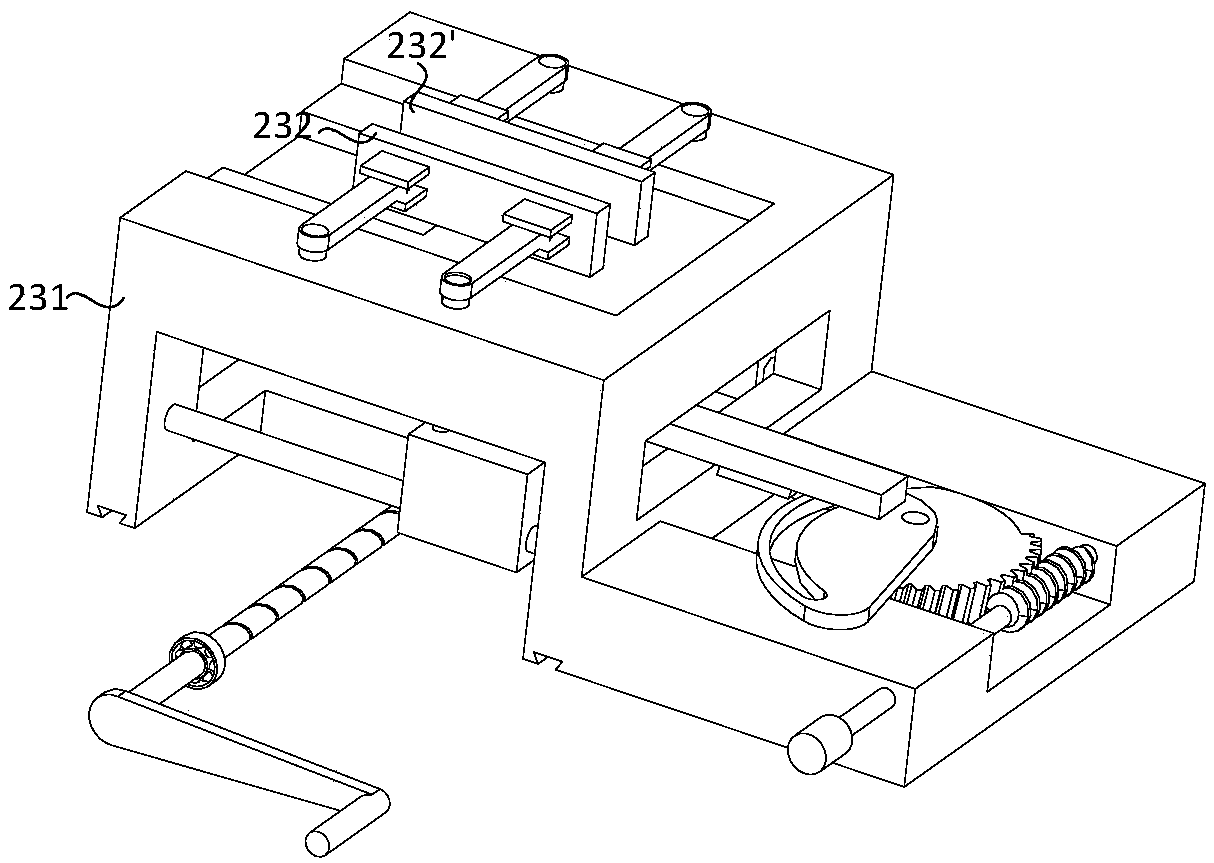

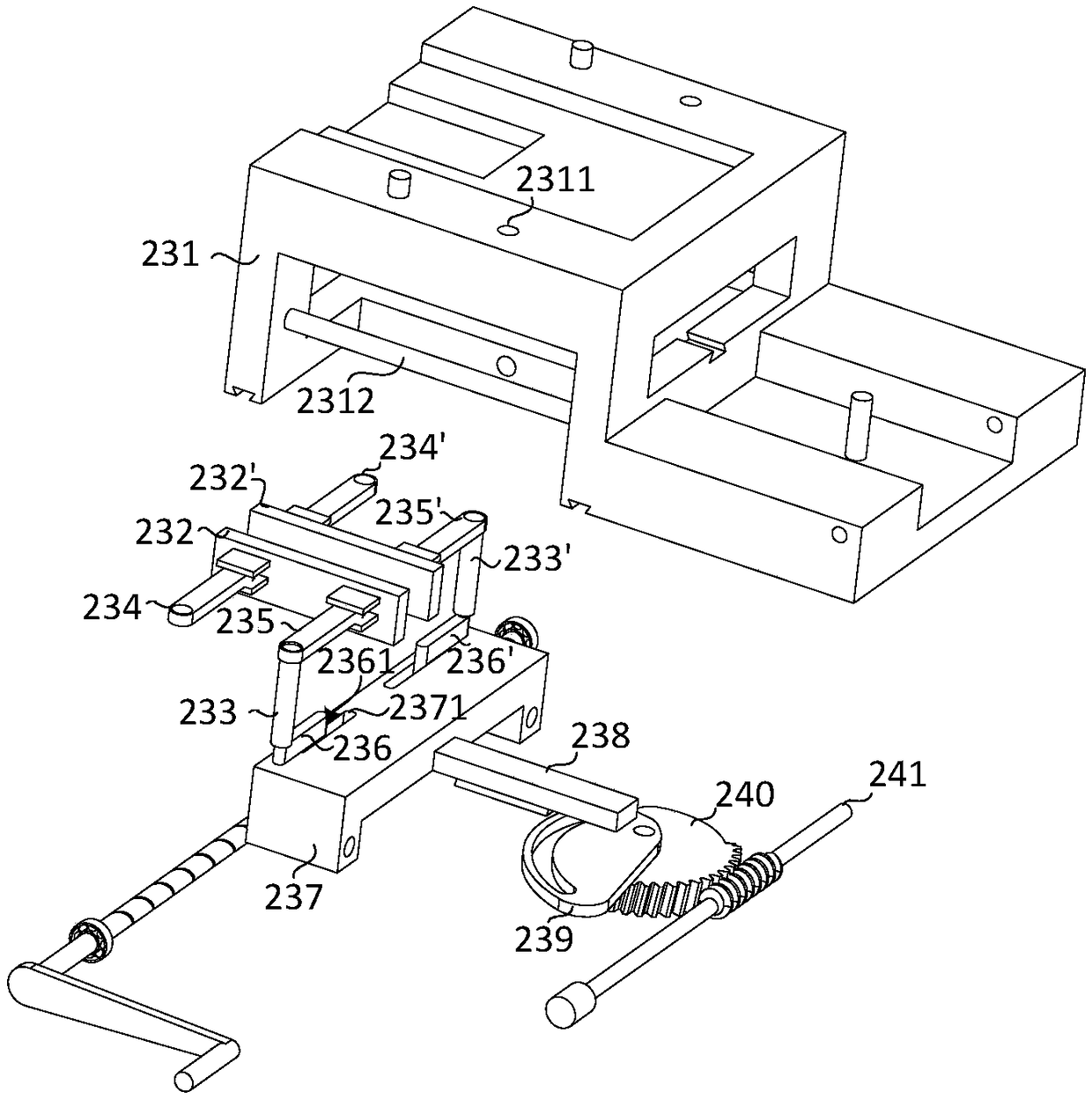

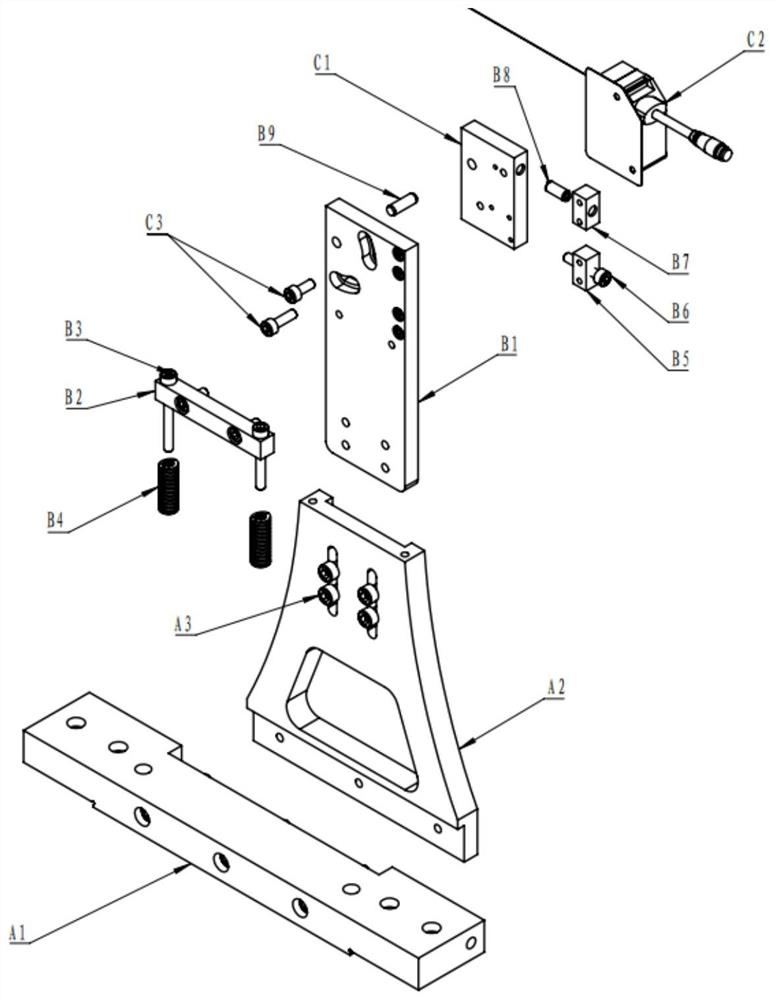

Adjustable supporting device for Hopkinson test bar piece

InactiveCN103063512AImprove machining accuracyGuaranteed coaxialityStrength propertiesDegrees of freedomMechanical engineering

Owner:NANJING UNIV OF SCI & TECH

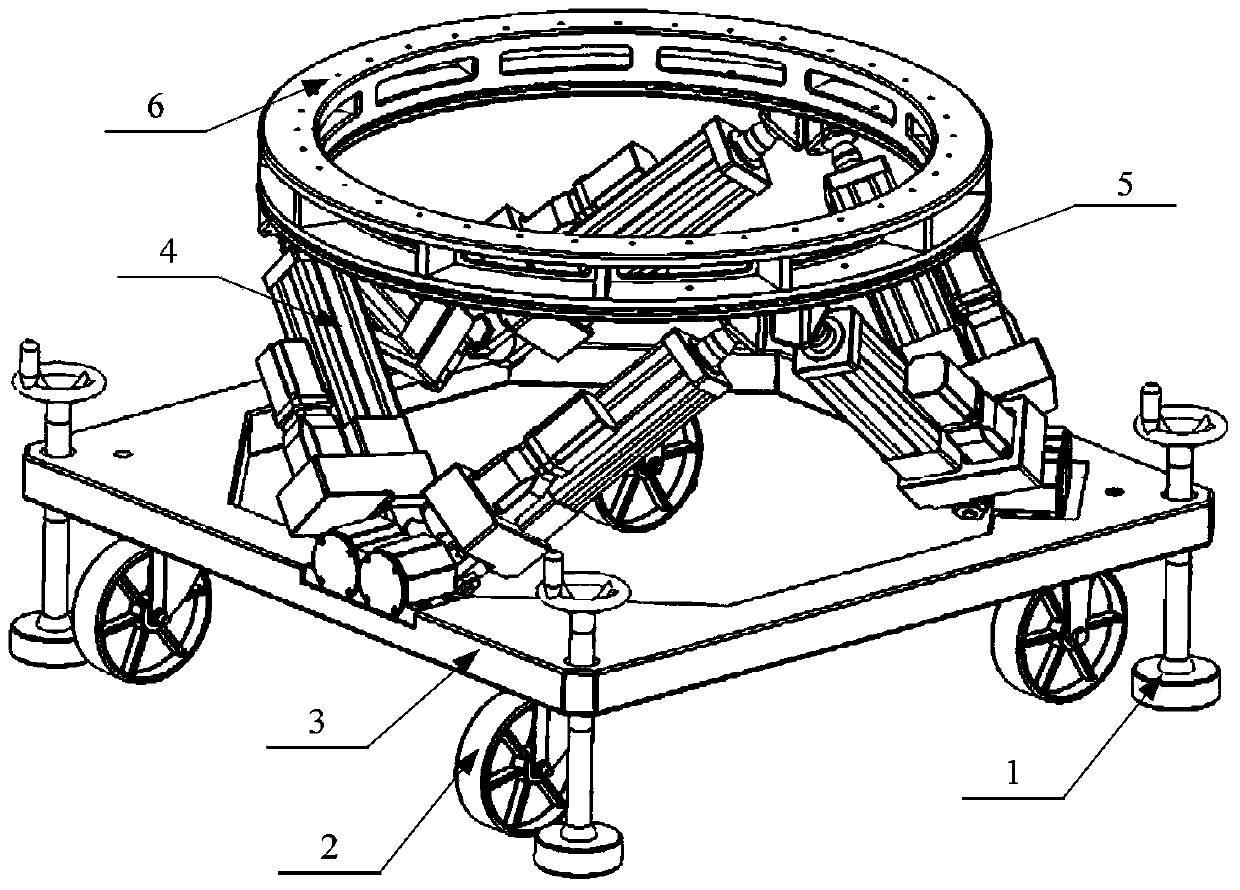

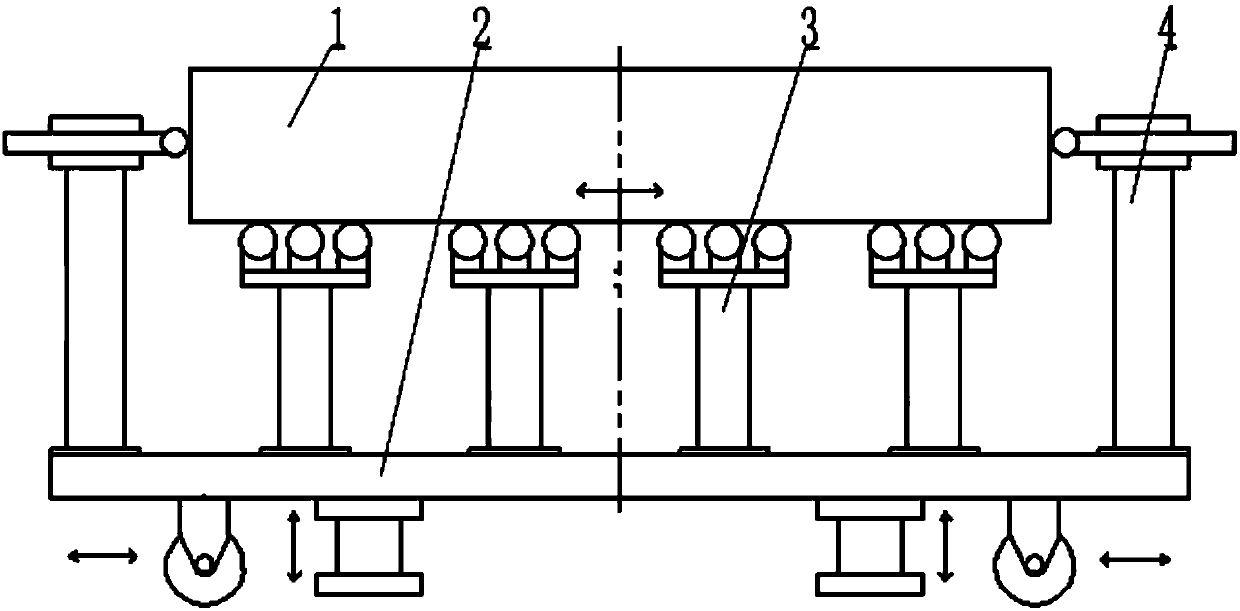

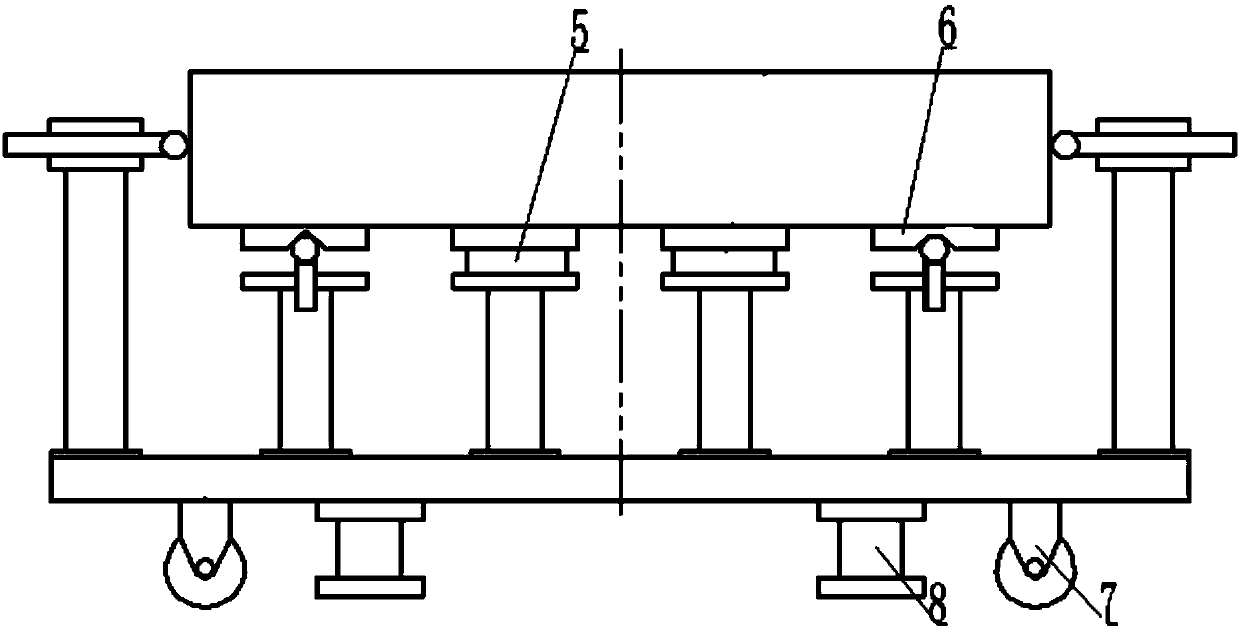

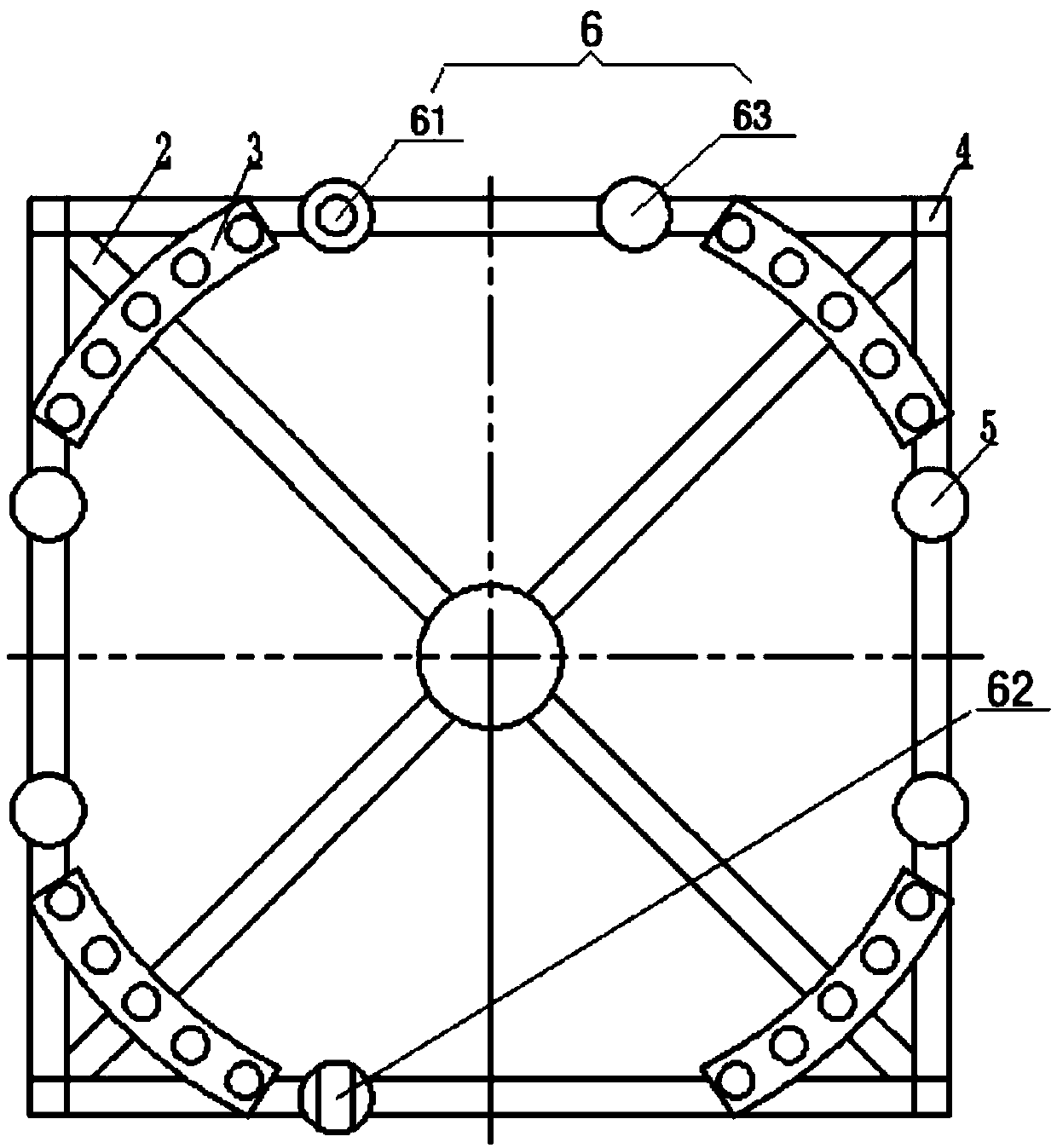

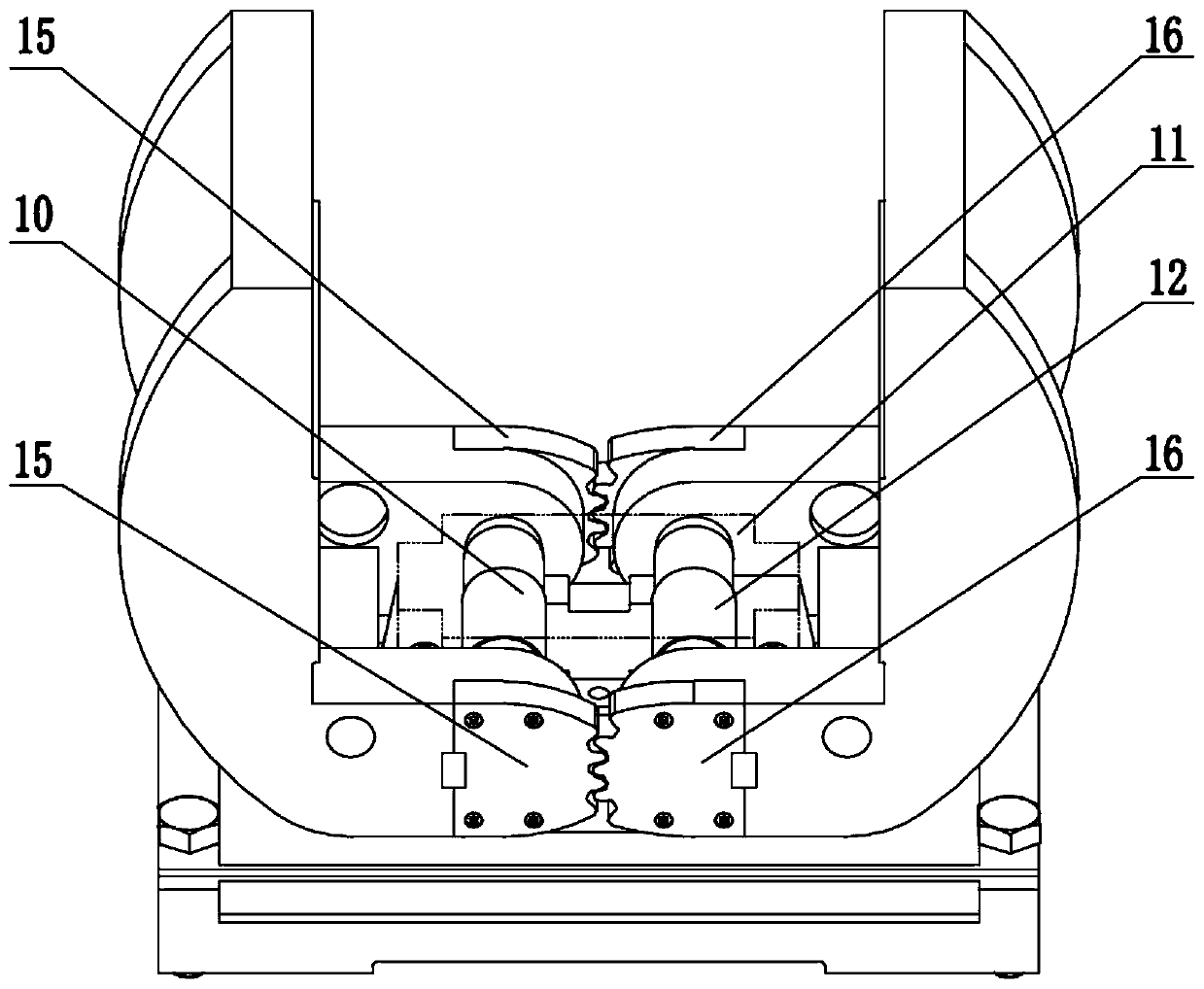

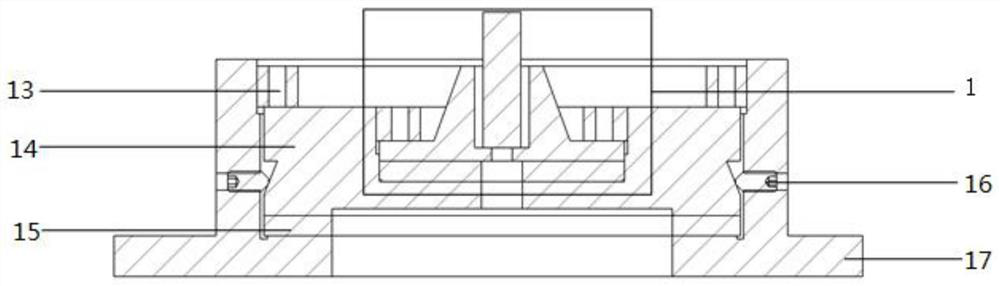

Precise adjustment device for pose of spacecraft

InactiveCN103624535ARealize high-precision adjustmentMeet high-precision docking requirementsWork benchesOther workshop equipmentSix degrees of freedomHinge angle

The invention discloses a precise adjustment device for the pose of a spacecraft. The precise adjustment device comprises adjustable supports, trundles, a fixed platform, electric cylinders, a movable platform and circular adapters. The four trundles are arranged below the fixed platform, the adjustable supports are located outside the trundles below the four corners of the fixed platform, the adapters are fixedly connected to the circular movable platform, the electric cylinders are installed between the movable platform and the fixed platform with every two electric cylinders forming one group, the tops of each group of electric cylinders are fixed to the bottom of the movable platform through two connected spherical hinges, and the bottoms of each group of electric cylinders are fixed to the top of the fixed platform through two connected Hooke joints. By means of the precise adjustment device, high-precision adjustment, in six degrees of freedom, of the spacecraft is achieved, complete decoupling in six degrees of freedom can be achieved in the adjustment process, and the requirement for high-precision butt joint, under most working conditions, of the spacecraft is met.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

High-precision adjustment device for large-aperture main mirror cell

ActiveCN109683277AAvoid destructionRelease translational degrees of freedomMountingsEngineeringOptical instrument

The invention belongs to the technical field of optical instruments, and provides a high-precision adjustment device for a large-aperture main mirror cell. The high-precision adjustment device comprises a main frame assembly, the upper portion of the main frame assembly is provided with a lifting assembly and an adjusting assembly, an advance ball is arranged on the lifting assembly, and the advance ball is connected with the main mirror cell. The lifting assembly is used for bearing the main mirror cell, the adjusting assembly is provided with an adjusting screw, one end of the adjusting screw is connected with the main mirror cell, the adjusting screw is arranged in the radial direction of the main mirror cell, and the adjusting assembly is used for translation adjustment of the main mirror cell. The high-precision adjustment device can adjust the main mirror cell at multiple degrees of freedom at a high precision.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

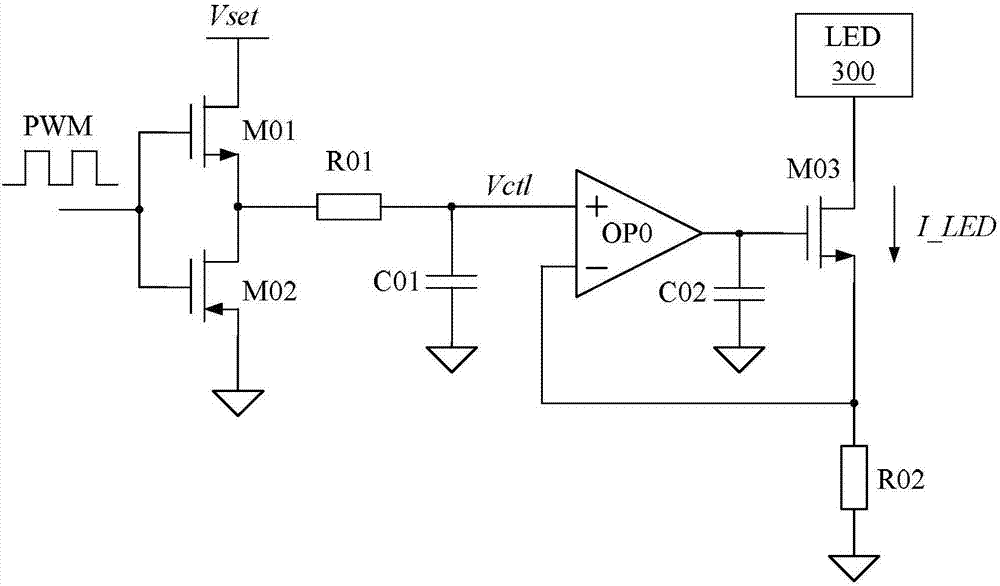

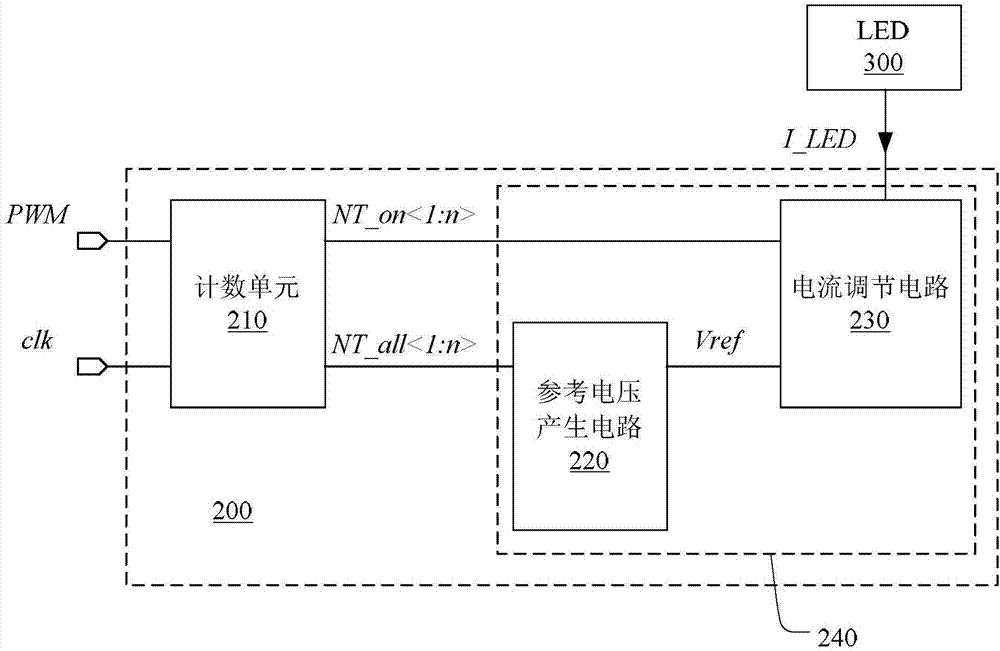

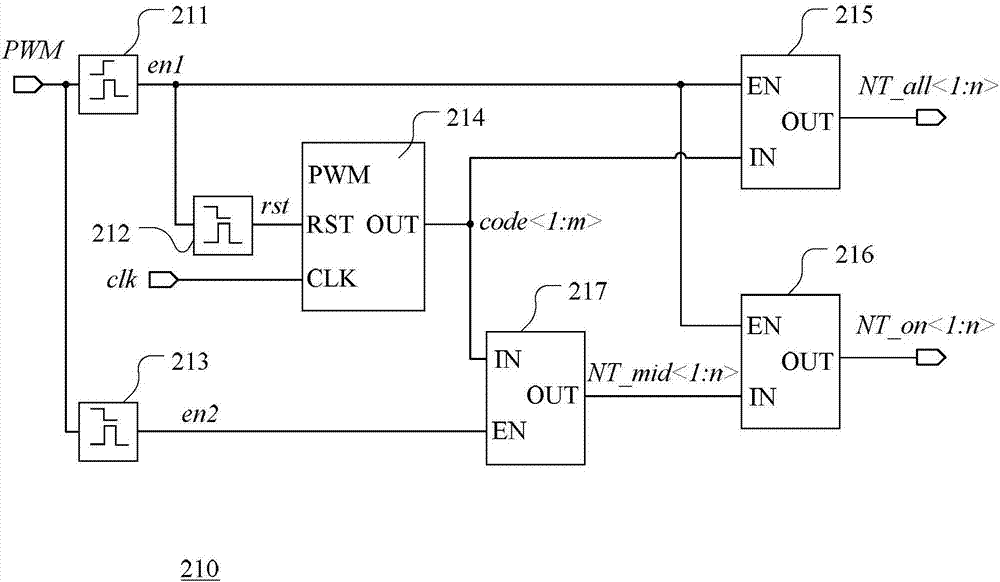

Load current regulation circuit and regulation method

ActiveCN107027222ARealize high-precision adjustmentSave extra spaceElectroluminescent light sourcesDc-dc conversionEngineeringCurrent regulation

The invention discloses a load current regulation circuit and regulation method. The load current regulation circuit comprises a counting unit and a regulation unit, wherein the counting unit is used for generating a first digital signal and a second digital signal according to a pulse signal, a relation between the first digital signal and the second digital signal is determined according to a duty ratio of the pulse signal, and the regulation unit is used for regulating a load current according to the first digital signal and the second digital signal so that the load current changes with the duty ratio of the pulse signal. With the load current regulation circuit and the regulation method, provided by the invention, the chip area can be saved, the cost is reduced, an error brought by an offset voltage is avoided, so that high-accuracy regulation of the load current within a wide frequency range of the pulse signal is achieved.

Owner:NANJING SILERGY SEMICON TECH CO LTD

Leveling mounting frame and wafer bearing device

InactiveCN111002217ARealize high-precision adjustmentReduce vibration effectsWork carriersEngineeringMachine

The invention belongs to the field of precision grinding equipment, and particularly relates to a leveling mounting frame and a wafer bearing device. The leveling mounting frame comprises a supportingframe and a machine frame which are oppositely arranged as well as at least two sets of adjusting mechanisms; a mounting position is arranged on the supporting frame; each adjusting mechanism comprises an adjusting rod, wherein a first threaded section and a second threaded section are arranged on the outer surface of each adjusting rod, and the first threaded sections and the second threaded sections are differential threads with the same spiral line direction; and adjusting holes corresponding in position are formed in the supporting frame and the machine frame correspondingly, the first threaded sections of the adjusting rods of each set of adjusting mechanisms are in threaded connection with threaded holes in the supporting frame, and the second threaded sections of the adjusting rodsof each set of adjusting mechanisms are in threaded connection with threaded holes in the machine frame. Besides the above leveling mounting frame, the wafer bearing device further comprises a waferbearing platform arranged on the mounting position of the supporting frame. According to the leveling mounting frame and the wafer bearing device, high-precision adjustment of a bearing object can beachieved, the influence of equipment vibration on the adjusted angle is small, and therefore the yield and the machining efficiency can be guaranteed.

Owner:BEIJING SEMICON EQUIP INST THE 45TH RES INST OF CETC

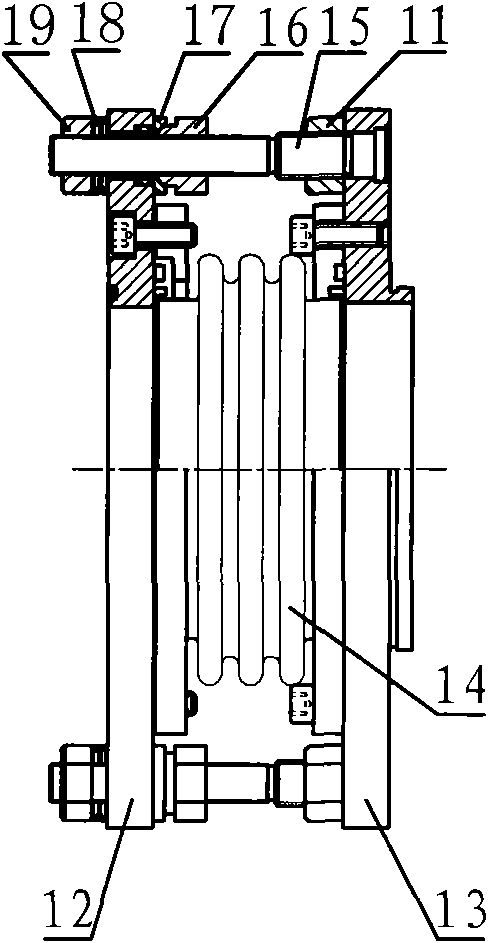

High-precision buoyancy regulating device for autonomous underwater robot

InactiveCN108116644AChange buoyancyReduce buoyancyUnderwater vesselsUnderwater equipmentLow noiseGear pump

The invention relates to the field of autonomous underwater robots, in particular to a high-precision buoyancy regulating device for an autonomous underwater robot, comprising a water permeable shelland a sealing shell, wherein an outer oil bag is arranged in the water permeable shell, and the sealing shell is provided with an inner oil cylinder, a direct-current motor, a gear pump, the valve setA and the valve set B. The gear pump is driven to rotate through the direct-current motor; the oil outlet of the inner oil cylinder is connected with the oil inlet port of the gear pump; the oil outlet port of the gear pump is connected with the first port of the valve group A; the second port of the valve group A is connected with the oil port of the outer oil bag; the oil inlet of the outer oilsac is also connected with an oil inlet port of the valve group B; and the oil outlet port of the valve group B is connected with a connection pipeline between the inner oil cylinder and the gear pump, therein, a one-way valve and a solenoid valve A are arranged in parallel in the valve group A, and an electromagnetic valve B and a throttle valve are connected in series in the valve group B. Theinvention can independently adjust the buoyancy of the underwater robot, has small volume, low energy consumption, low noise and high reliability.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

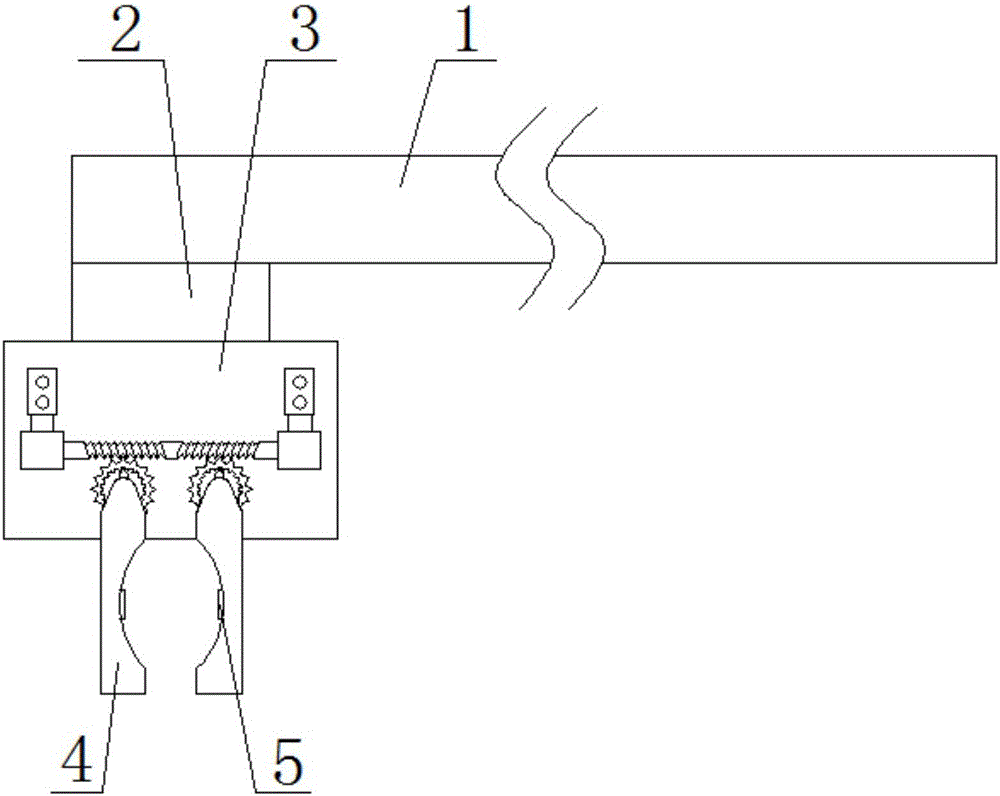

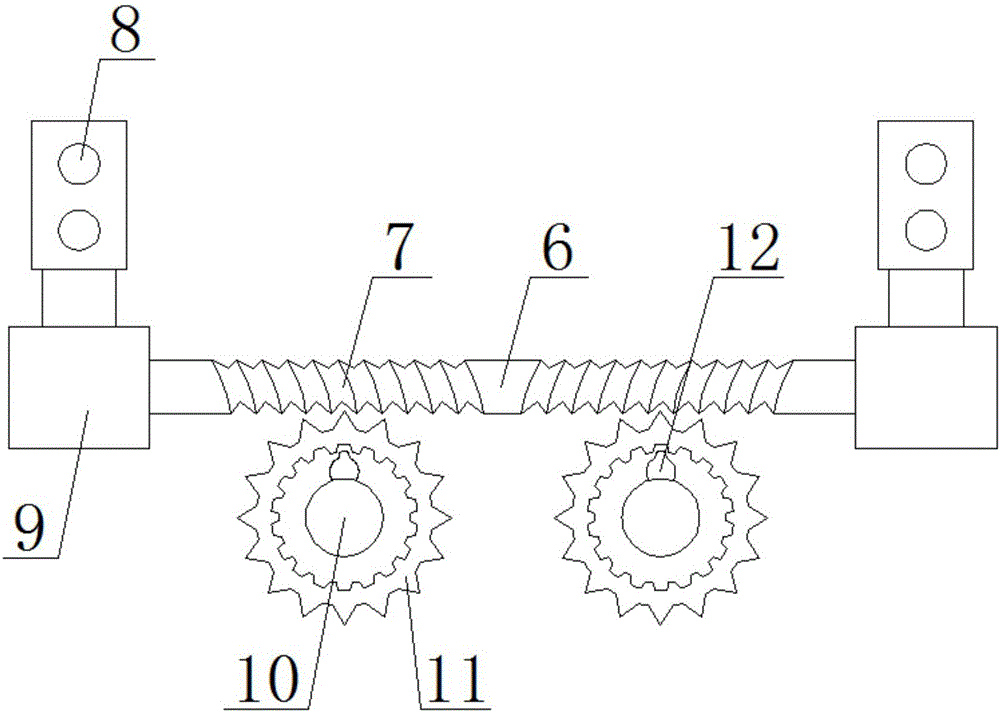

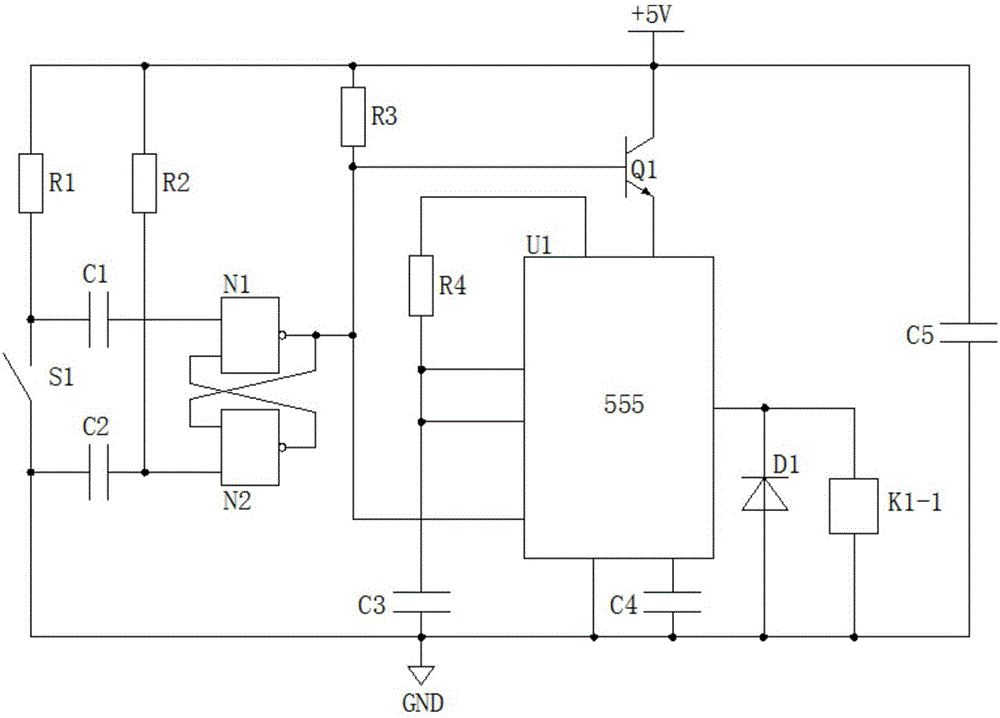

Novel carrying device for oil exploration

ActiveCN105692125ARealize remote monitoringAchieve grippingConveyorsControl devices for conveyorsNAND gateDrive motor

The invention relates to a novel carrying device for oil exploration. The novel carrying device comprises a transmission rod, a connecting rod, an angle adjusting box and two lock rings. The two lock rings are both in transmission connection with the angle adjusting box. According to the novel carrying device for oil exploration, a worker can remotely monitor the carrying device through a wireless communication module, and therefore intelligence of the device is improved. Two drive motors are used for driving a worm at the same time, two transmission worm wheels are controlled to reversely rotate, and clamping of the two lock rings is achieved. Meanwhile, by means of rotation of cams, the transmission worm wheels are driven to rotate, and high-precision adjustment of the transmission worm wheels is achieved. Meanwhile, the cams play a safety role, and therefore the clamping reliability of the two lock rings is guaranteed. Furthermore, in a timing circuit, when a monostabillity timer composed of an integrated circuit does not work, only the quiescent current 1-2uA of a first NAND gate, a second NAND gate and a triode exists, and therefore the power consumption of the circuit is greatly reduced, and the practicability of the device is improved.

Owner:JIANGSU SUYAN VALVE MASCH CO LTD

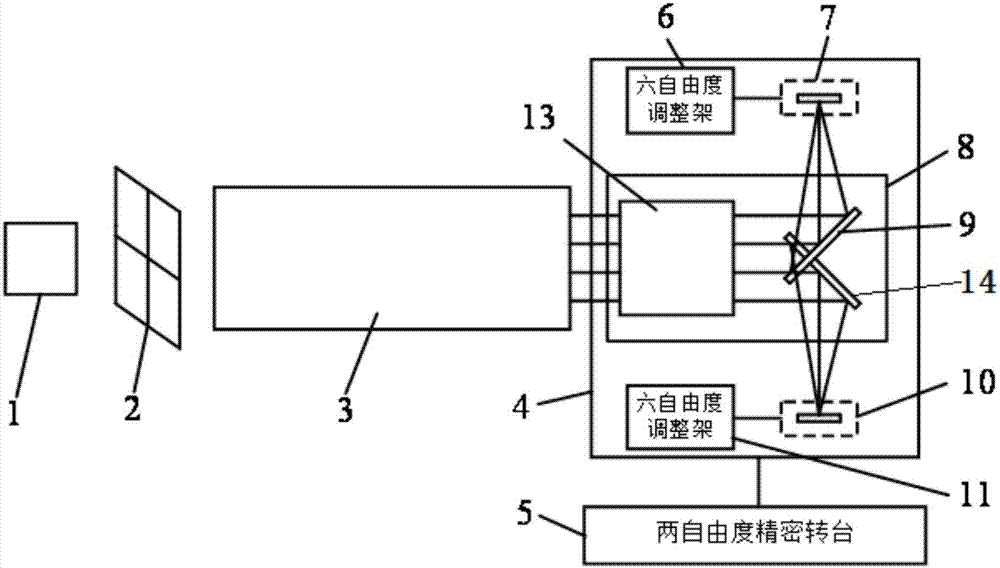

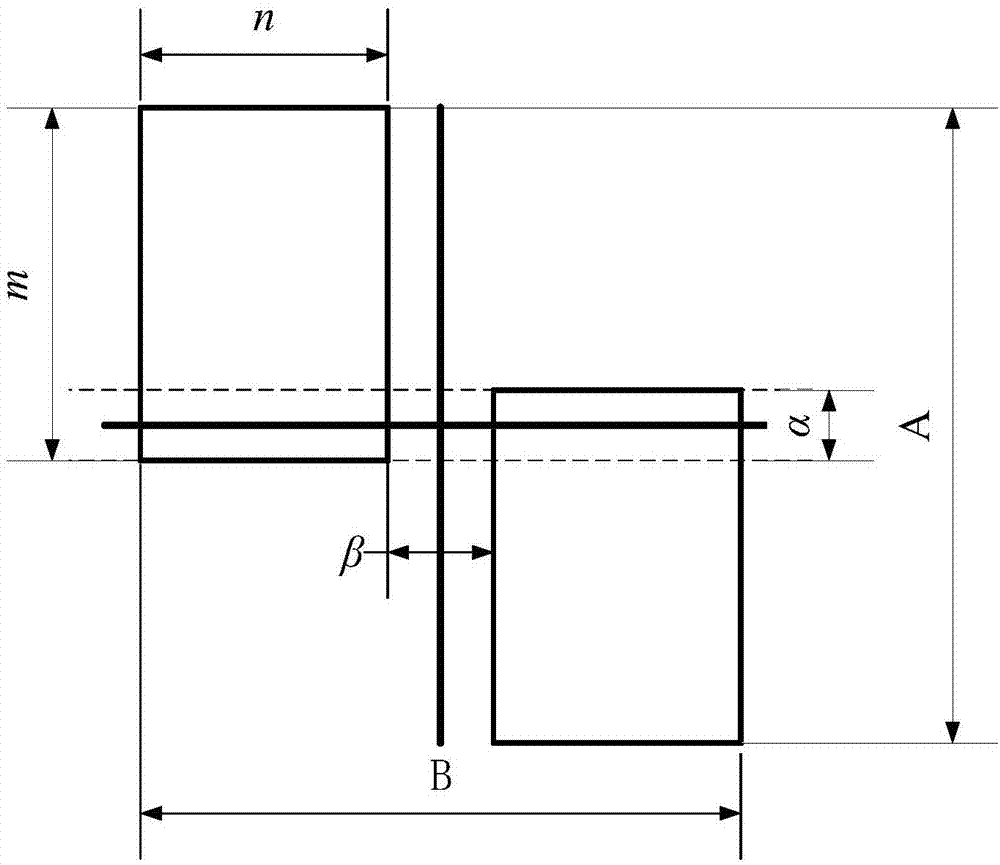

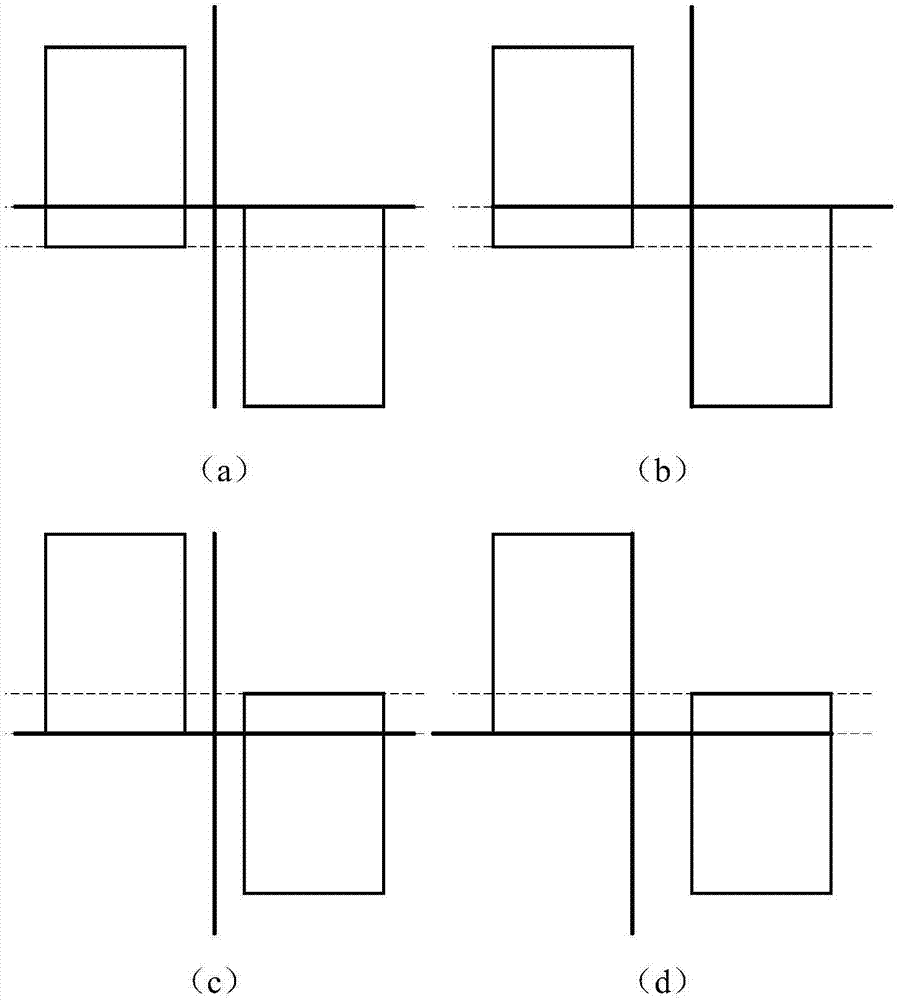

Multi-degree-of-freedom field-of-view synthesis adjustment method

ActiveCN107505722ASmall caliberRealize high-precision adjustmentOptical elementsTarget surfaceDegrees of freedom

The invention discloses a multi-degree-of-freedom field-of-view synthesis adjustment method, which is characterized by precisely controlling the field-of-view position through a two-degree-of-freedom rotary table; enabling a cross target to be imaged at a plurality of selected field-of-view positions according to a given any field-of-view segmentation mode; and with the imaged images of the cross target being as reference, carrying out precise adjustment by utilizing a six-degree-of-freedom adjusting frame to enable corresponding edge pixel elements on each detector target surface to be imaged, thereby realizing precise adjustment of detector target surface positions. The method is suitable for the cases of lapping and unparallel interval and the like between detector fields of view, can realize multi-detector high-precision adjustment under the any field-of-view segmentation mode and is wide in application range. A spliced field-of-view mirror group is small in aperture, does not need a large-scale adjusting device, is simple to operate, can realize independent imaging, and can serve as a postposition mirror group of a large-aperture infrared optical system; and through a preposition large-aperture non-focal optical system, field-of-view synthesis of detectors of the large infrared optical system is realized indirectly.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

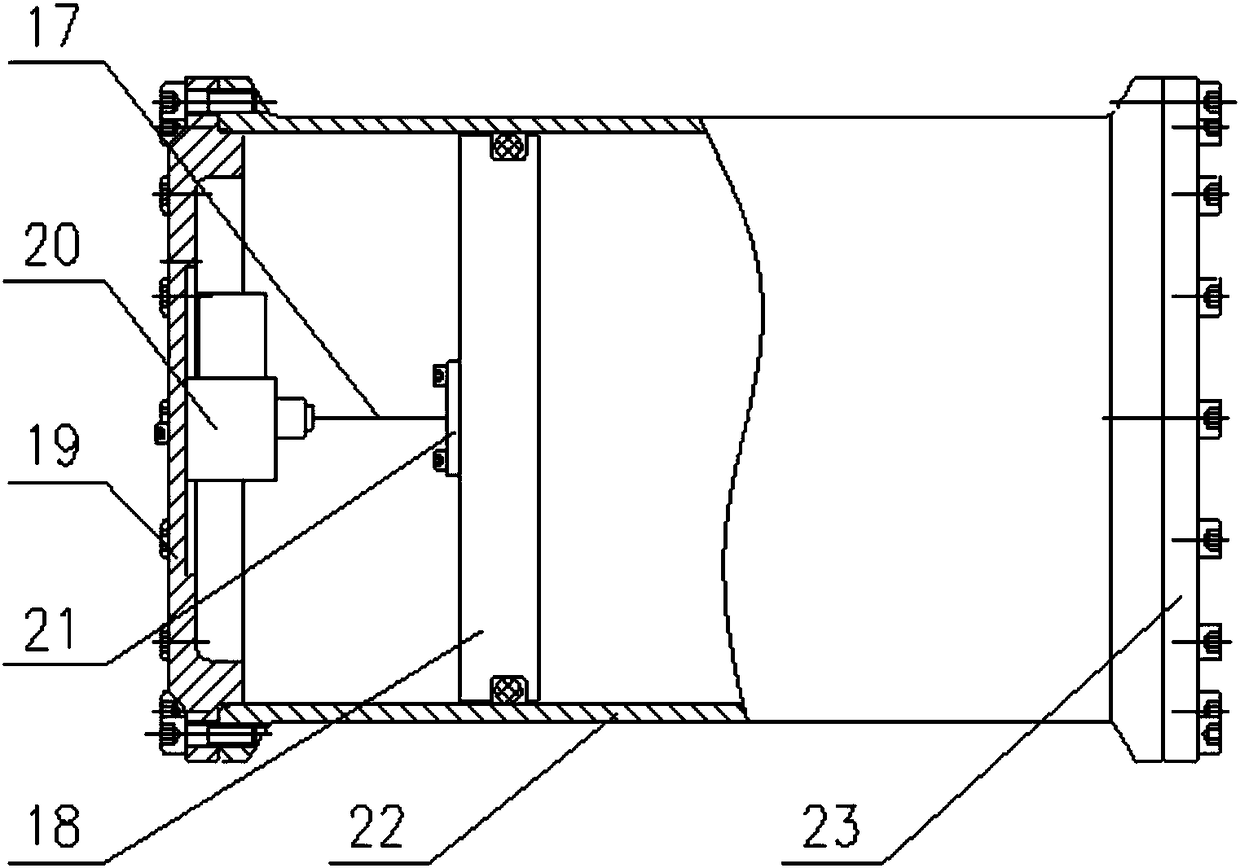

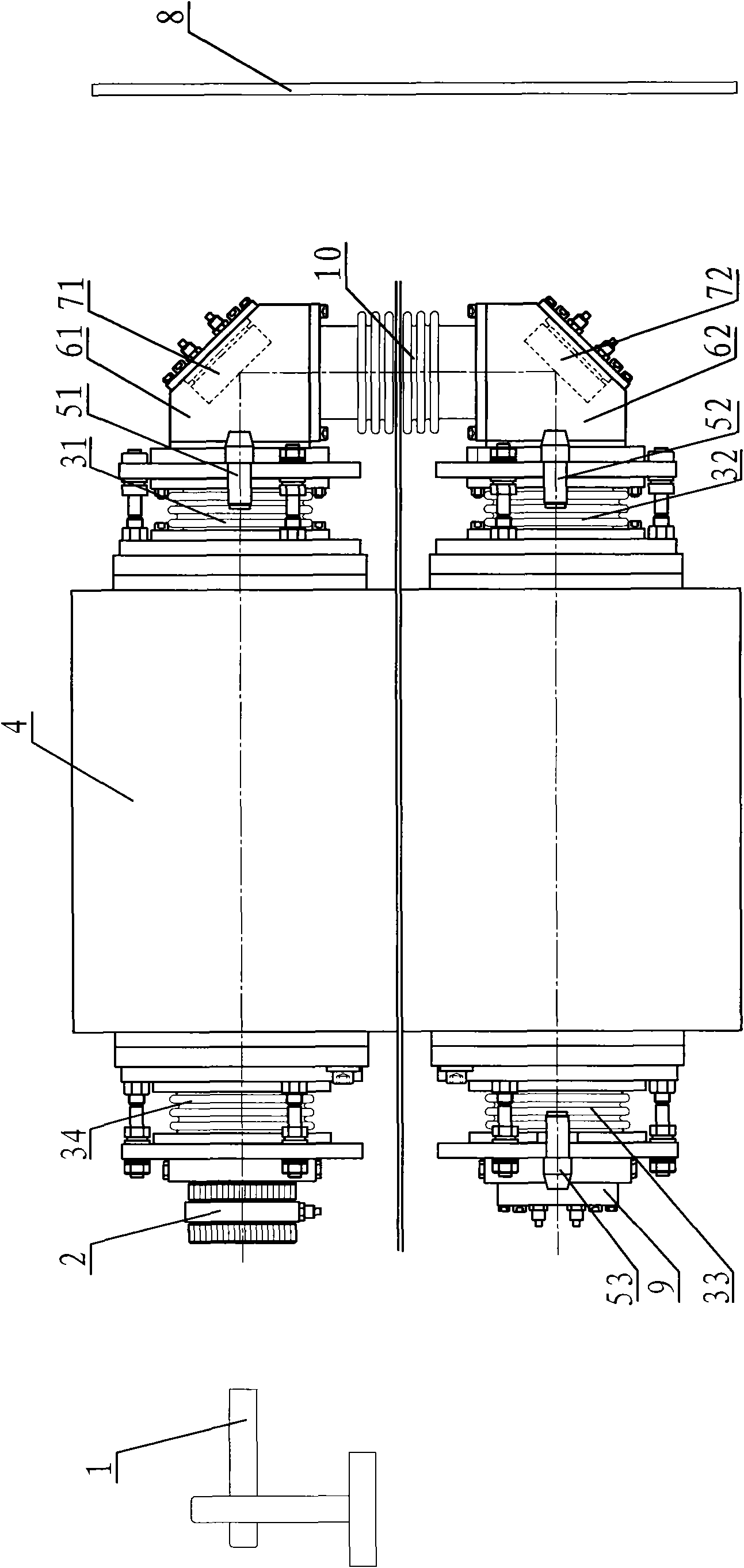

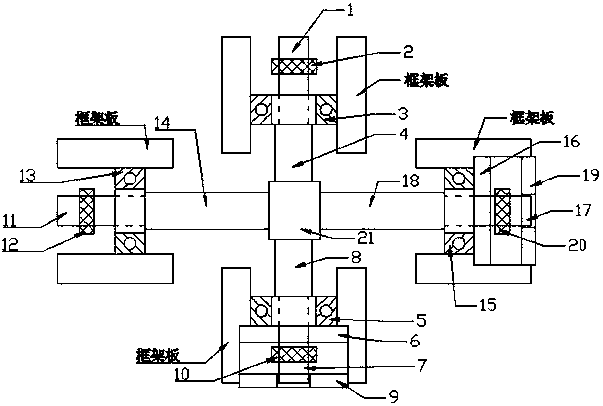

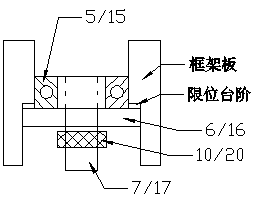

Double-rotating-shaft cantilever type skew rolling mill

ActiveCN110153339ASmall fluctuationShort to the axis of the roller systemSkewed roll standMetal rolling stand detailsGear wheelEngineering

The invention relates to the technical field of metal plastic forming processes and equipment, and provides a double-rotating-shaft cantilever type skew rolling mill. The skew rolling mill is mainly composed of a base, a cantilever type roller system, a gear synchronizing mechanism, a radial reduction mechanism, machine frames, a material guiding unit and inclination angle adjusting mechanisms, wherein the cantilever type roller system is tensioned by bolts on the backs of the machine frames of the rolling mill, and the roller system inclination angle adjustment is realized through the inclination angle adjusting mechanism below bearing seats; the two machine frames which are supported by double rotating shafts of the rolling mill base; synchronous alignment and reduction are realized on the two machine frames through the gear synchronizing mechanism, and the center line of the vertical direction of the rolling mill is ensured to be fixed; the radial reduction mechanism is arranged above the machine frames, and the roller distance adjustment of two rollers is realized by rotating reduction nuts; and the inclination angle adjusting mechanisms are arranged at the corners of the machine frames so that the space can be saved, moreover, the action line is long, and the high-precision adjustment of the inclination angle of the roller system can be realized. The double-rotating-shaftcantilever type skew rolling mill is ingenious in design, has the advantages of convenience in roller replacement, fixation of the vertical center line of the rolling mill, convenience in installationand adjustment and the like, and is suitable for the production of large-scale small-diameter steel balls.

Owner:UNIV OF SCI & TECH BEIJING

Vacuum debugging process for light cavity of high-power gas laser

ActiveCN102118006AEasy to adjustRealize real-time monitoring and correctionOptical resonator shape and constructionActive medium materialLight spotOptical axis

The invention discloses a vacuum debugging process for a light cavity of a high-power gas laser, which comprises the following steps of: fixing and adjustment of a telescope: cross scale marks in the telescope and mounting ports at two sides of a box body corresponding to the cross scale marks are arranged coaxially; preliminary adjustment of the light cavity: an angle adjusting module is adjusted to enable the cross scale marks of the telescope before and after reflection of each optical lens to be overlapped, and the angle variation of each optical lens is monitored through an optical axis monitoring system; vacuum correction of the light cavity: a laser box body adjusts the corresponding variation generated by each monitoring system in a vacuum condition and the overlap ratio according to the horizontal overlapping condition of the cross scale marks of the telescope, and the laser box body adjusts the angle adjusting modules of a front window lens module under a standard air pressure to enable the images of cross scale marks of the telescope before and after reflection to be overlapped; and online correction of the light cavity: in the light emitting process, all the angle adjusting modules are adjusted according to the angle variation of each monitoring system on a receiving screen to recover the position of a light spot of the optical axis monitoring system before light emission. The vacuum debugging process can realize real-time monitoring and correction.

Owner:NINGBO SIASUN ROBOT TECH CO LTD

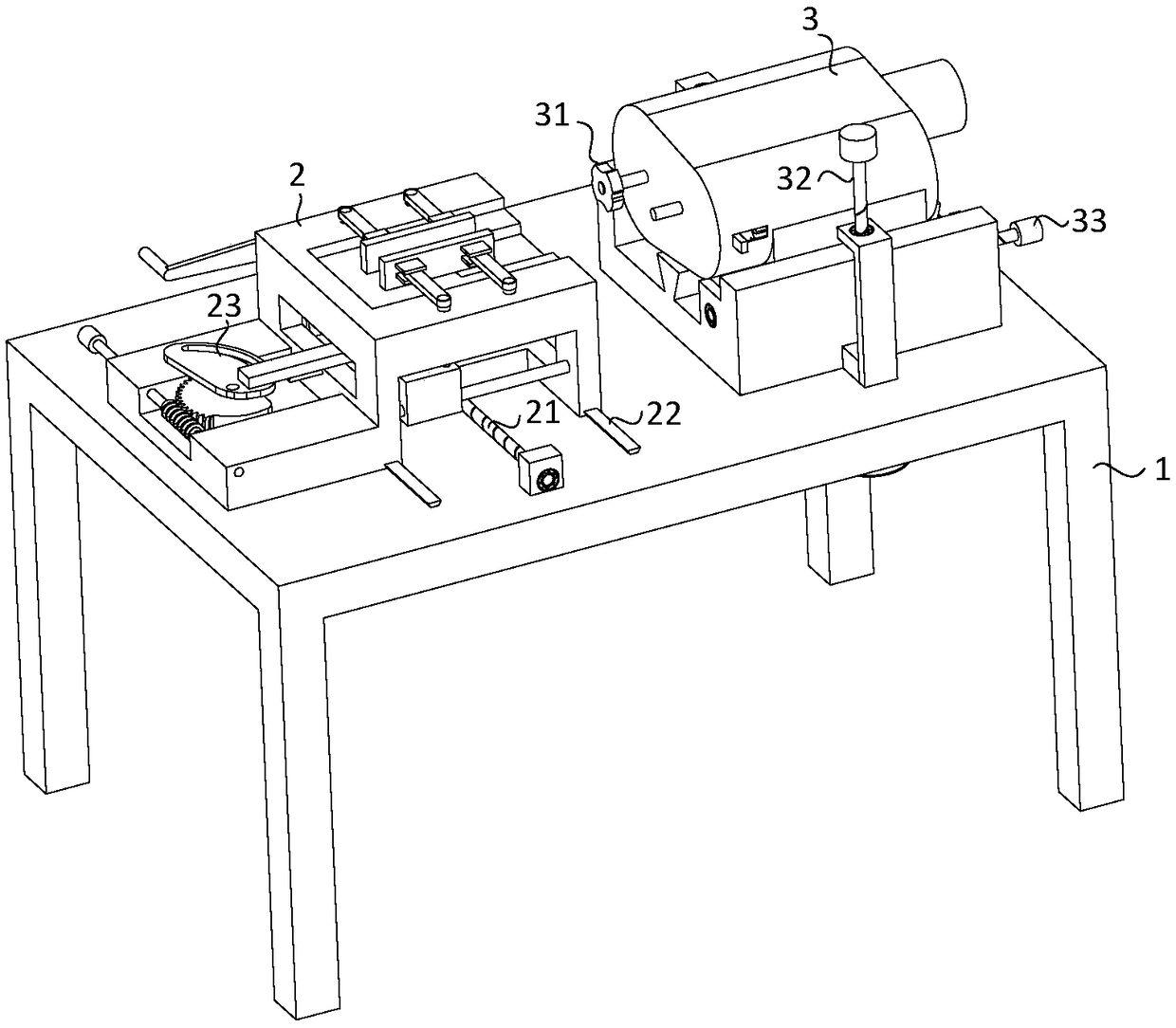

Knife grinder with ceramic tip

ActiveCN108907912ARealize high-precision adjustmentHigh melting pointOther manufacturing equipments/toolsGrinding work supportsEngineeringMechanical engineering

The invention discloses a knife grinder with a ceramic tip, and relates to the technical field of knife grinding machinery. The knife grinder with the ceramic tip comprises a frame, a clamping mechanism and a grinding mechanism; the clamping mechanism is used for clamping the knife to be ground, and the clamping mechanism can be driven by a screw rod to slide along a sliding rail; the grinding mechanism is provided with a height adjusting screw so as to adjust the height of the grinding mechanism; and a front-and-rear adjusting screw rod to adjust the front and rear positions of the grinding mechanism. By adjusting the positions of the clamping mechanism and grinding mechanism, the relative position of the tip on the grinding mechanism and the knife to be ground is conveniently adjusted.

Owner:宁波象研科技服务发展有限公司

Vacuum nitrogen filling and humidity control device, and humidity regulating method for vacuum nitrogen filling environment

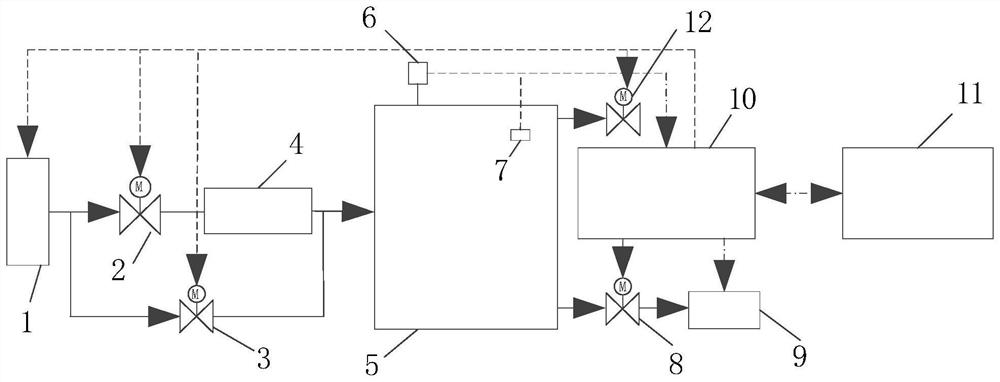

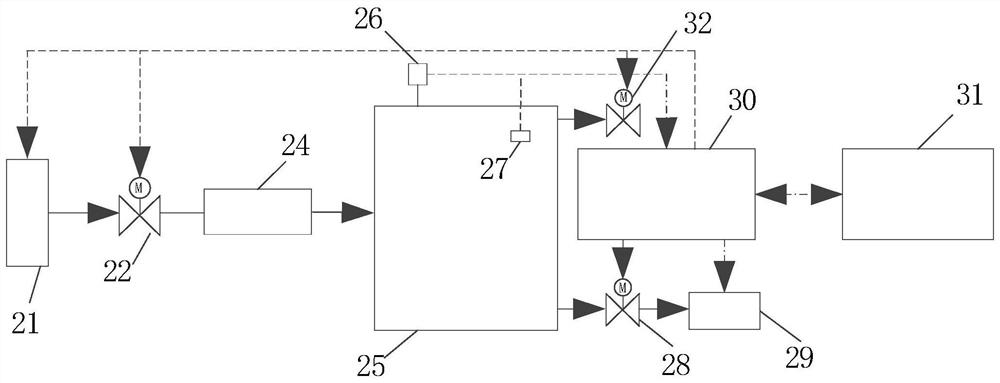

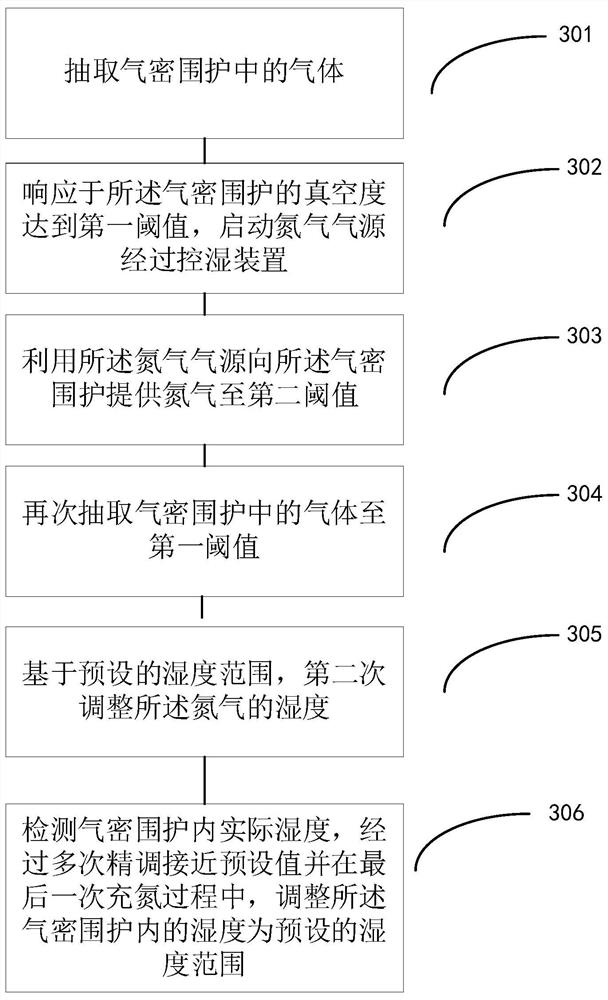

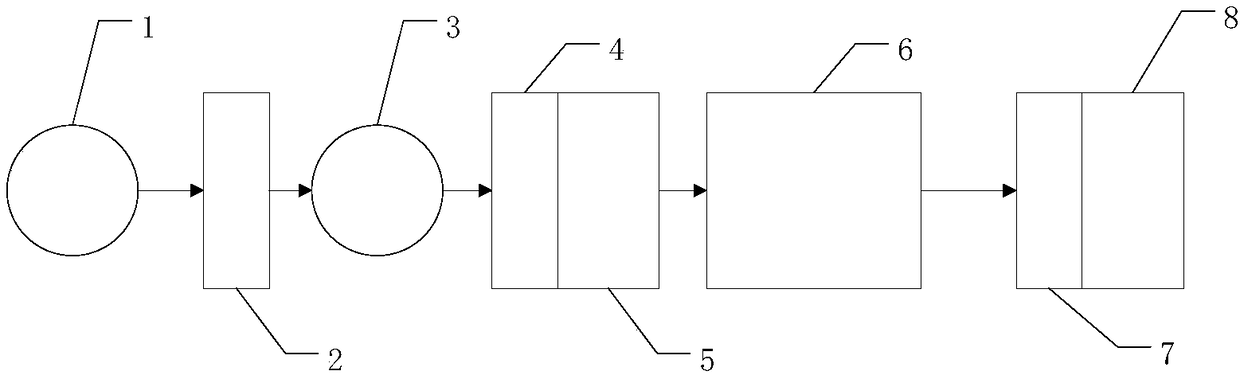

ActiveCN111891565AHumidity controlHumidity real-time monitoringLiving organism packagingPackaging under vacuum/special atmosphereNitrogen gasVacuum pump

The invention relates to a vacuum nitrogen filling and humidity control device comprising an airtight enclosure, a vacuum pump, a humidity control device body, a nitrogen gas source and a controller;the airtight enclosure is of a rigid structure, and the vacuum pump is connected with the airtight enclosure, and used for pumping gas in the airtight enclosure through configuration; the humidity control device body is connected between the nitrogen gas source and the airtight enclosure, and configured for regulating the humidity of nitrogen gas input into the airtight enclosure; the nitrogen gassource is connected with the humidity control device body, and used for providing the nitrogen gas for the airtight enclosure through configuration; and the controller is used for controlling the vacuum pump to pump the gas in the airtight enclosure through configuration, and controlling the nitrogen gas source to provide the nitrogen gas for the airtight enclosure. The invention further relatesto a humidity regulating method for a vacuum nitrogen filling environment.

Owner:TIANJIN CNRO SCI TECH

Image sensor transmission function testing device

ActiveCN108195565AHigh precisionRealize high-precision adjustmentTesting optical propertiesPhase differencePhase deviation

The invention provides an image sensor transmission function testing device which comprises an optical filter, an integrating sphere, a target, a displacement and rotation mechanism, an optical system, a to-be-tested image sensor and a displacement platform sequentially arranged along a preset optical path. The optical filter is used for filtering light output by a light source to acquire monochromatic light, the integrating sphere is used for receiving the monochromatic light to serve as a uniform face light source and projecting the light onto the target, the light is focused through the optical system to be imaged to the to-be-tested image sensor, the displacement and the rotation mechanism is used for adjusting position of the target, and the displacement platform is used for driving the to-be-tested image sensor to move. By adopting the displacement and rotation mechanism to adjust position of the target and to adjust phase difference between a target image and an image sensor image element, high-magnification imaging effect of an optical system is utilized to realize high-precision adjustment of the target image on an image sensor image plane, high-precision adjustment of phase deviation between the target image and the image sensor image pixel is realized, and testing result accuracy of the image sensor is improved.

Owner:佛山长光智能制造研究院有限公司

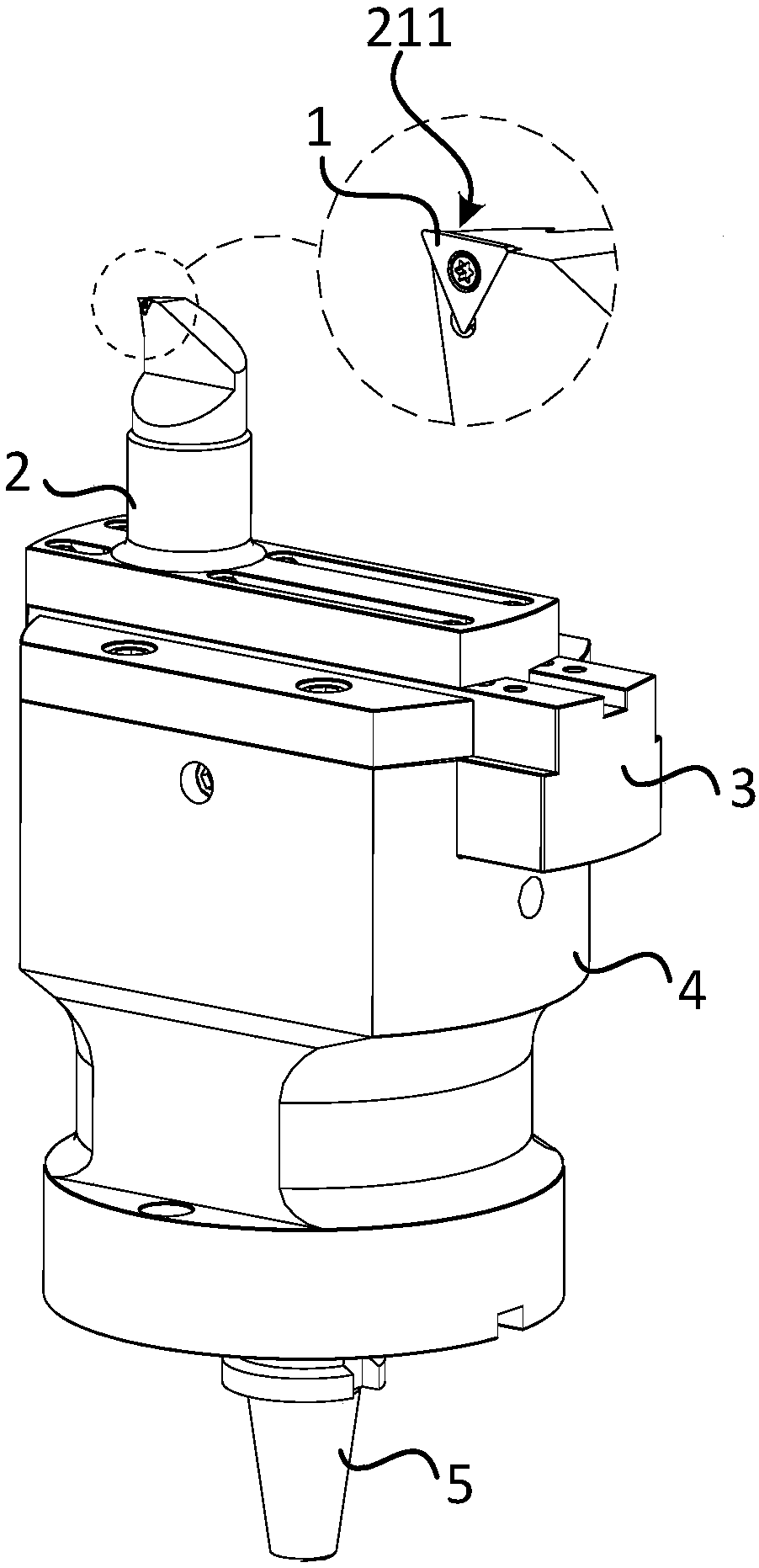

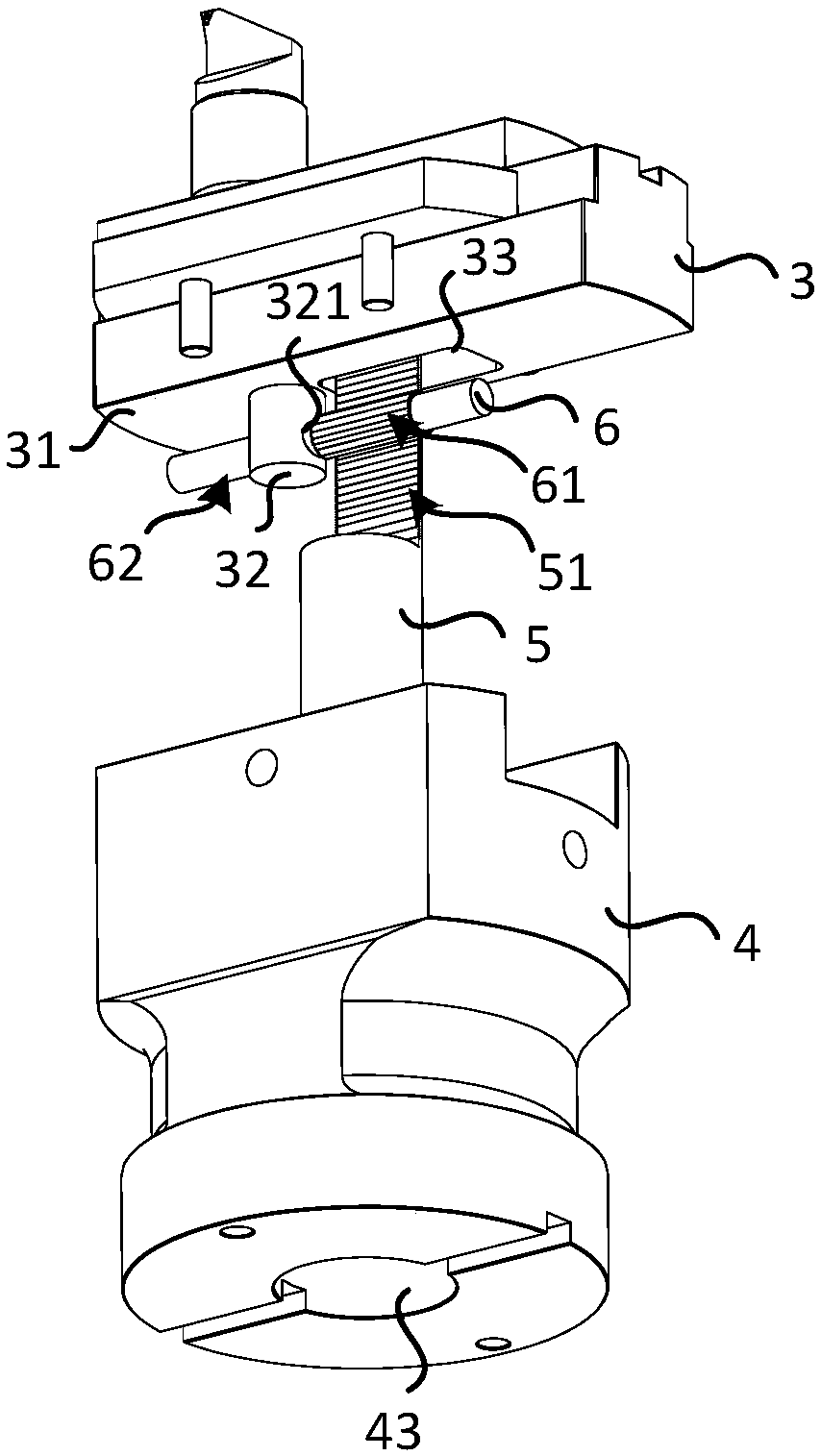

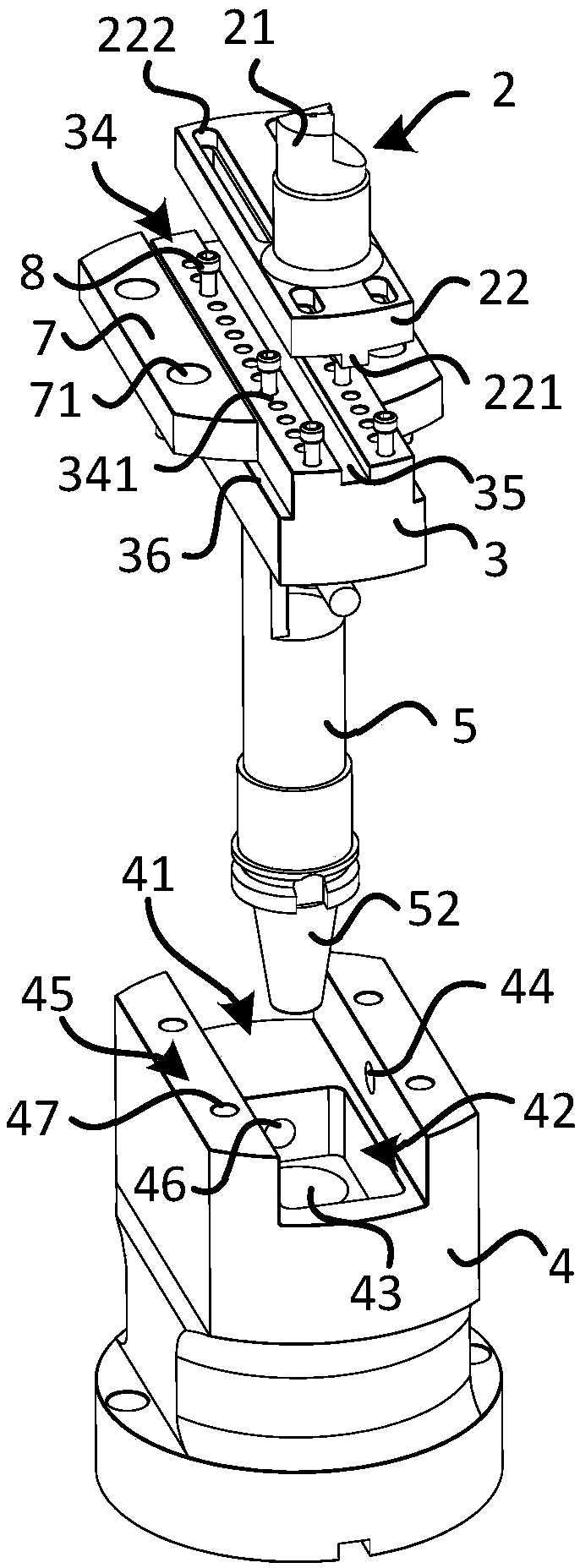

Boring tool

ActiveCN108393507ARealize high-precision adjustmentTurning toolsPositioning apparatusDrive shaftEngineering

The invention discloses a boring tool and relates to the technical field of machining tools. The boring tool comprises a tool blade, a tool blade holder, a sliding block, a boring tool body, a transmission shaft and an adjusting tool handle. The boring tool is characterized in that through gear rack transmission matching between the adjusting tool handle and the transmission shaft and thread transmission matching between the transmission shaft and the sliding block, high-precision adjusting of the boring tool machining radius is achieved, and thus high-precision machining is achieved; and theboring tool can be adjusted through internal transmission of a boring machine in the adjusting process, and convenience and easy implementation are achieved.

Owner:NINGBO DANDERUI PRECISION MACHINERY TECH CO LTD

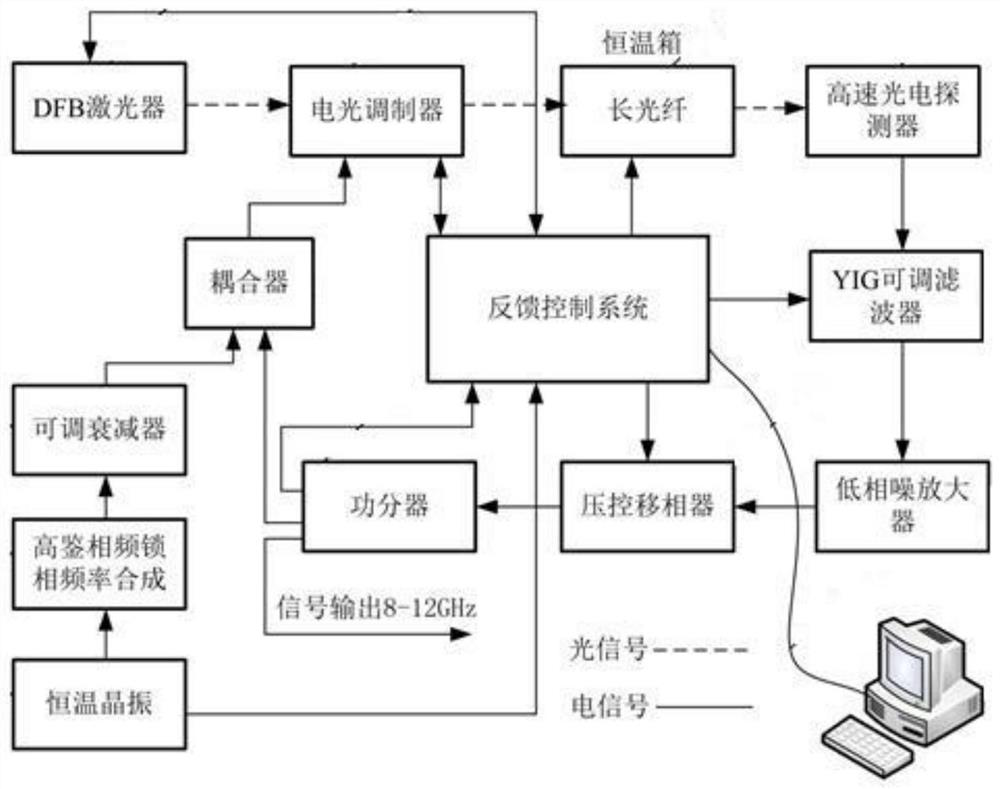

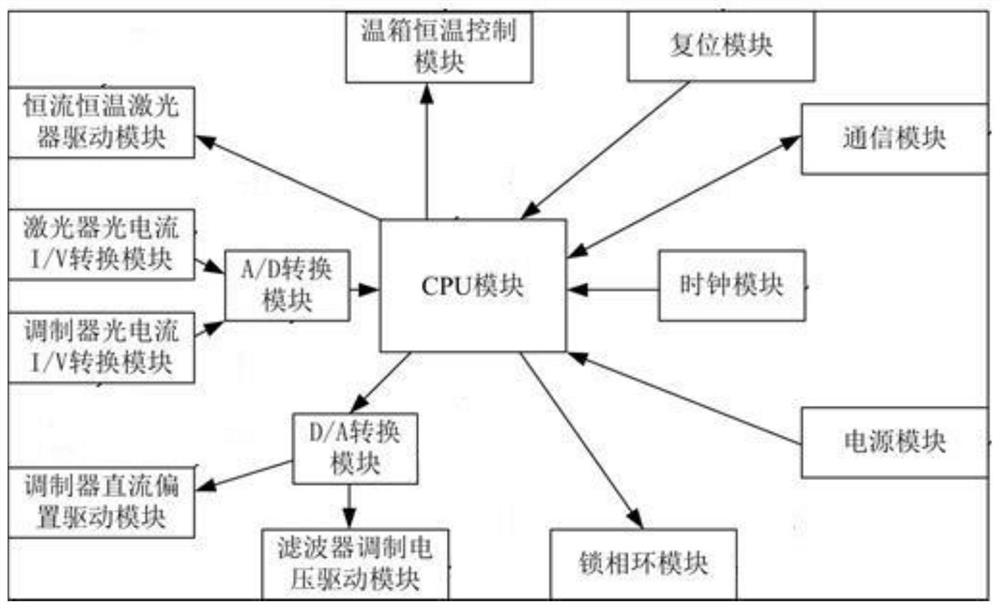

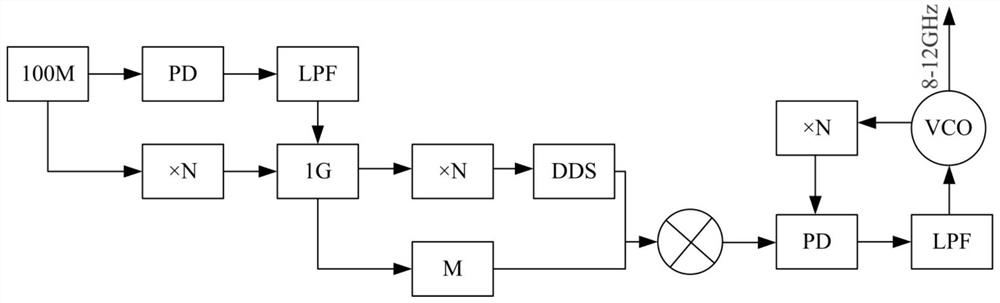

Tuning photoelectric oscillator and feedback control method thereof

ActiveCN113394646ARealize high-precision adjustmentImprove phase noise near carrier frequencySolid masersPhase noiseSoftware engineering

The invention discloses a tuning photoelectric oscillator which comprises a positive feedback oscillation system and a negative feedback oscillation system, the positive feedback oscillation system comprises a laser, an electro-optical modulator, a long optical fiber, a photoelectric detector, an adjustable filter, a low phase noise amplifier, a voltage-controlled phase shifter and a power divider which are connected in sequence, the first output end of the power divider is connected with a coupler, the coupler is connected with the radio frequency driving end of the electro-optical modulator, a second output end of the power divider is connected with the feedback control system; the feedback control system is connected with the laser and the electro-optical modulator respectively; the frequency modulation circuit comprises a coarse tuning circuit and a fine tuning circuit, the feedback control system is connected with the adjustable filter to form the coarse tuning circuit, the fine tuning circuit comprises a constant temperature crystal oscillator, a high phase discrimination frequency phase lock frequency synthesis circuit and an adjustable attenuator which are connected in sequence, and the adjustable attenuator is connected with the coupler; and the bandwidth locking circuit is formed by connecting a constant-temperature crystal oscillator with a feedback control system and connecting the feedback control system with a voltage-controlled phase shifter. According to the invention, rapid high-precision frequency modulation of the photoelectric oscillator can be realized.

Owner:GUIZHOU AEROSPACE INST OF MEASURING & TESTING TECH

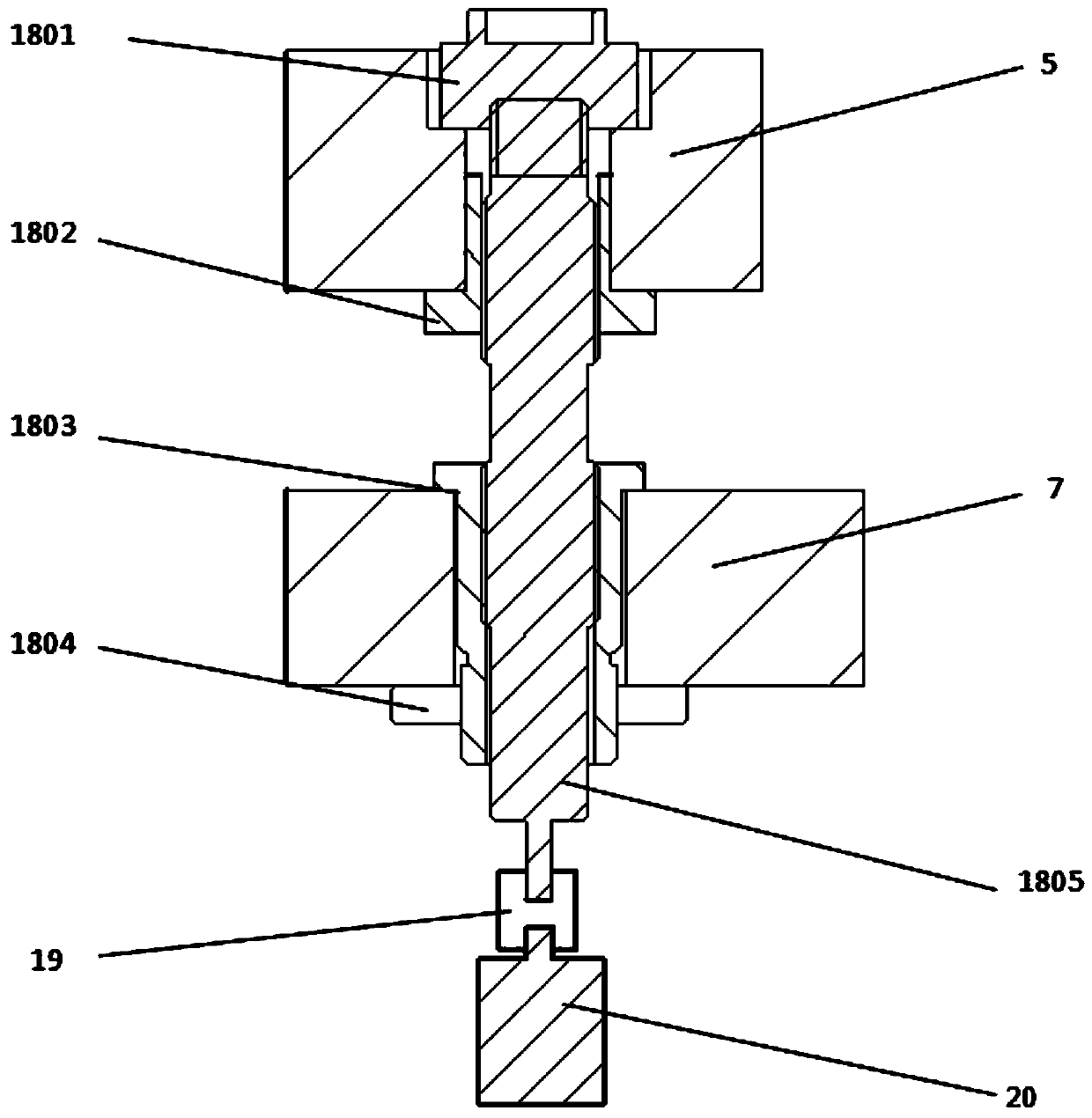

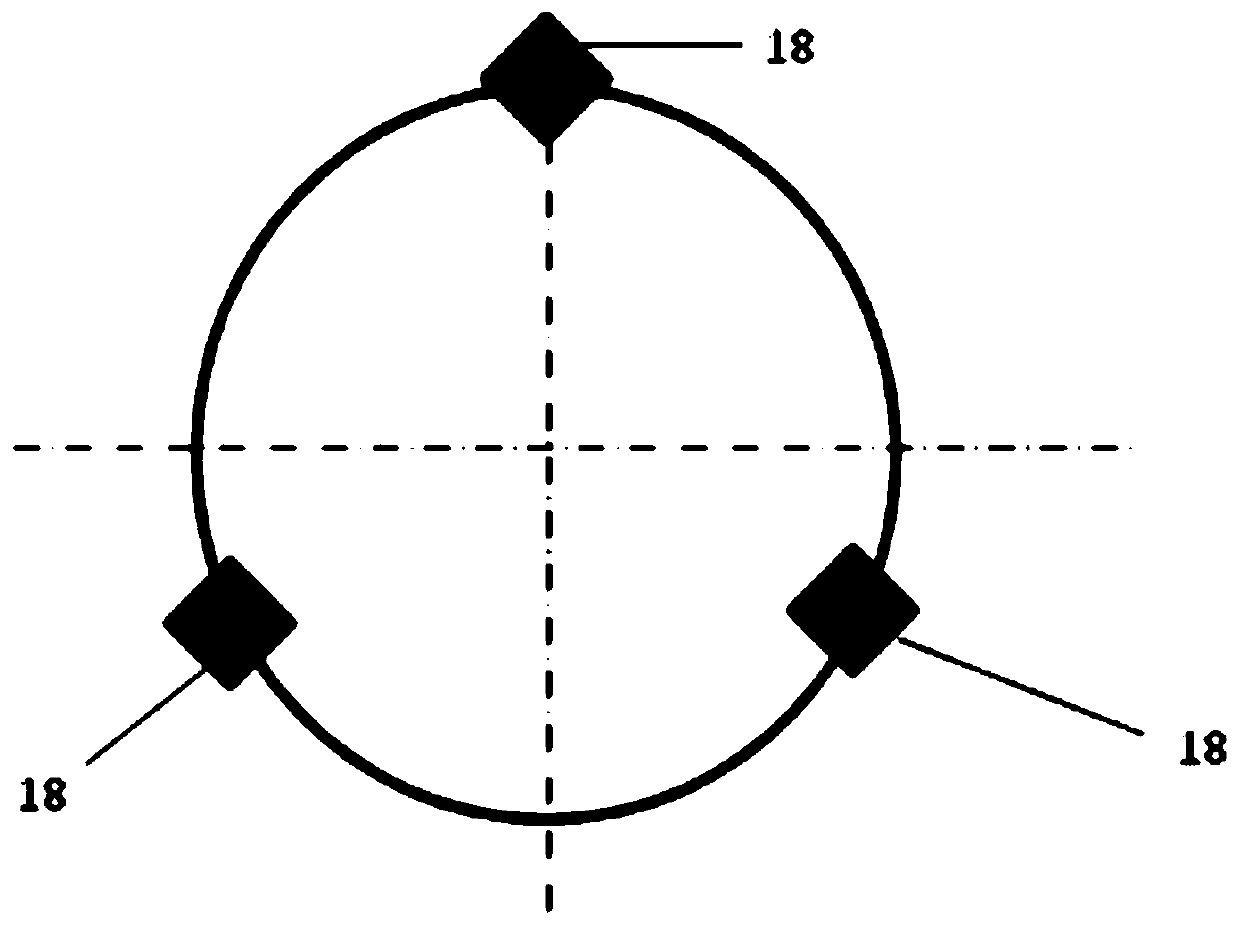

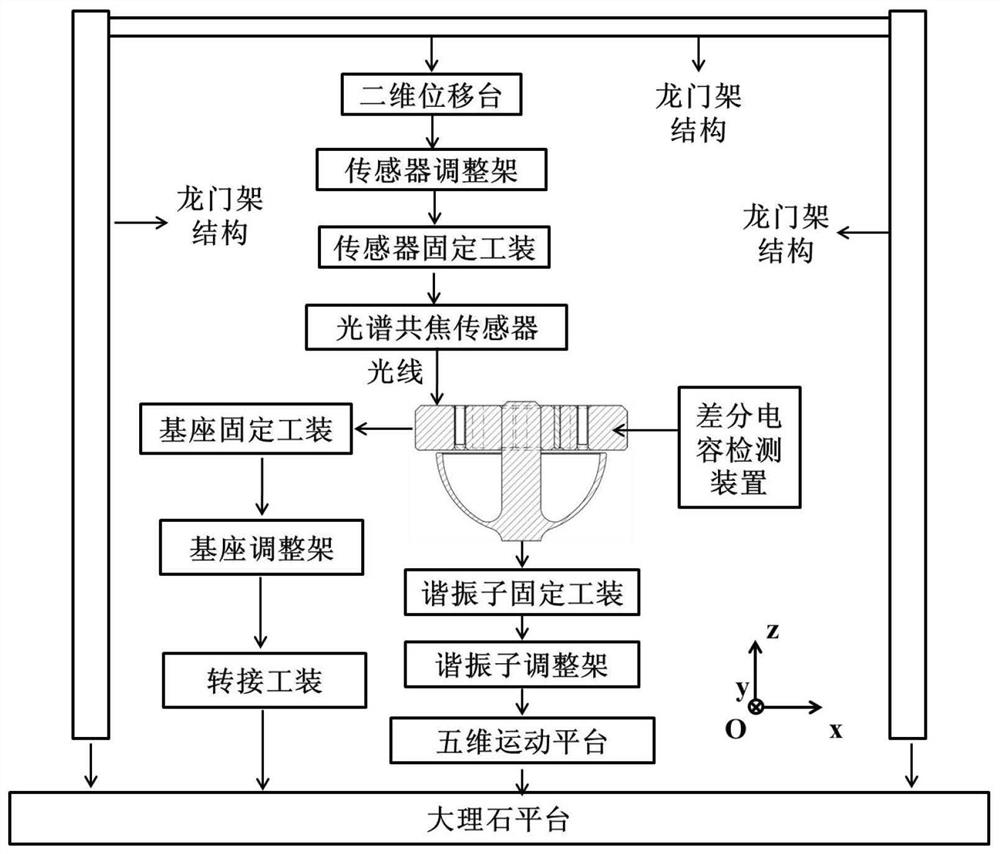

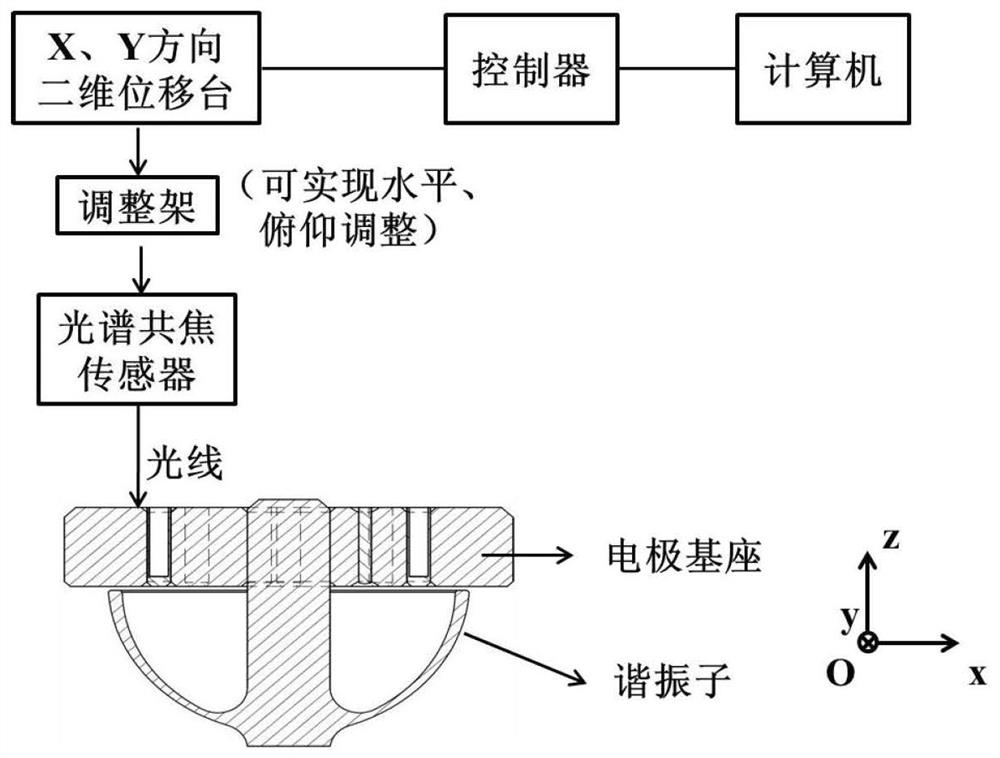

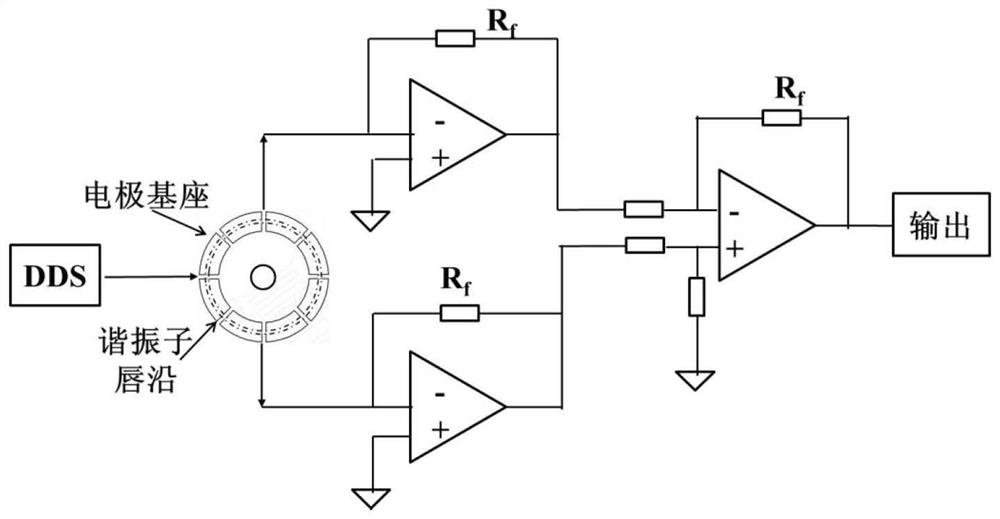

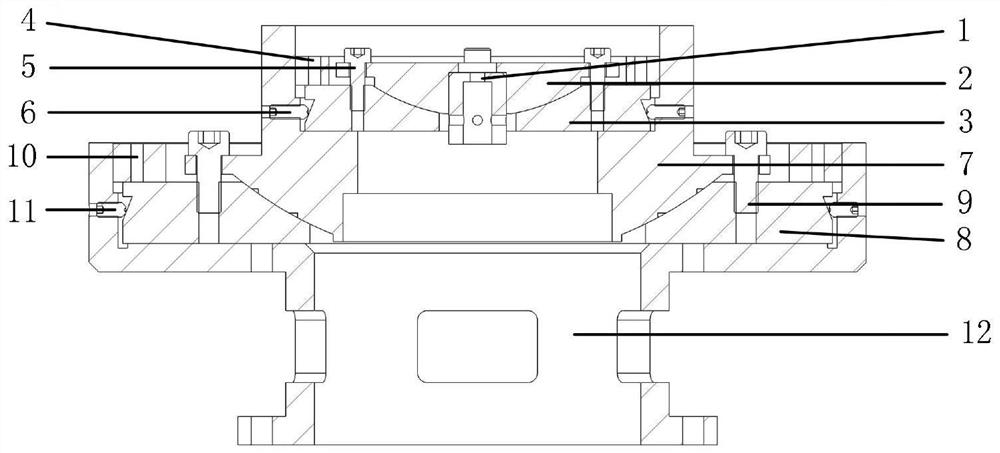

Precision assembly device and method for hemispherical resonator gyroscope with planar electrode structure

ActiveCN113804172ASolving accurate measurementsImprove performanceSpeed measurement using gyroscopic effectsGyroscopes/turn-sensitive devicesPlanar electrodeRadial position

The invention relates to a precision assembly device and method for a hemispherical resonator gyroscope with a planar electrode structure. The method comprises the steps of obtaining a gap between a harmonic oscillator and a base electrode through a spectrum confocal sensor, and achieving the adjustment of the gap through a multi-degree-of-freedom positioning platform according to the numerical values of the gap in four directions; and obtaining the radial position deviations of the oscillator and the electrode base in the X-axis direction and the Y-axis direction through a differential capacitance detection device, feeding the radial position deviations back to a multi-axis displacement platform control system, and then achieving the function of high-precision adjustment of the radial position deviation. According to the invention, the position deviation and pitching and rolling deviation between the harmonic oscillator and the electrode base in the X, Y and Z directions can be detected and adjusted in a high-precision manner, the problems of accurate measurement and adjustment of the gap and radial position deviation between the harmonic oscillator and the base electrode of the hemispherical resonator gyroscope with the planar electrode structure are solved, the consistency of a gyroscope header is improved, the gyroscope performance is further improved, and the development requirements of a high-precision hemispherical resonator gyroscope are met.

Owner:TIANJIN NAVIGATION INSTR RES INST

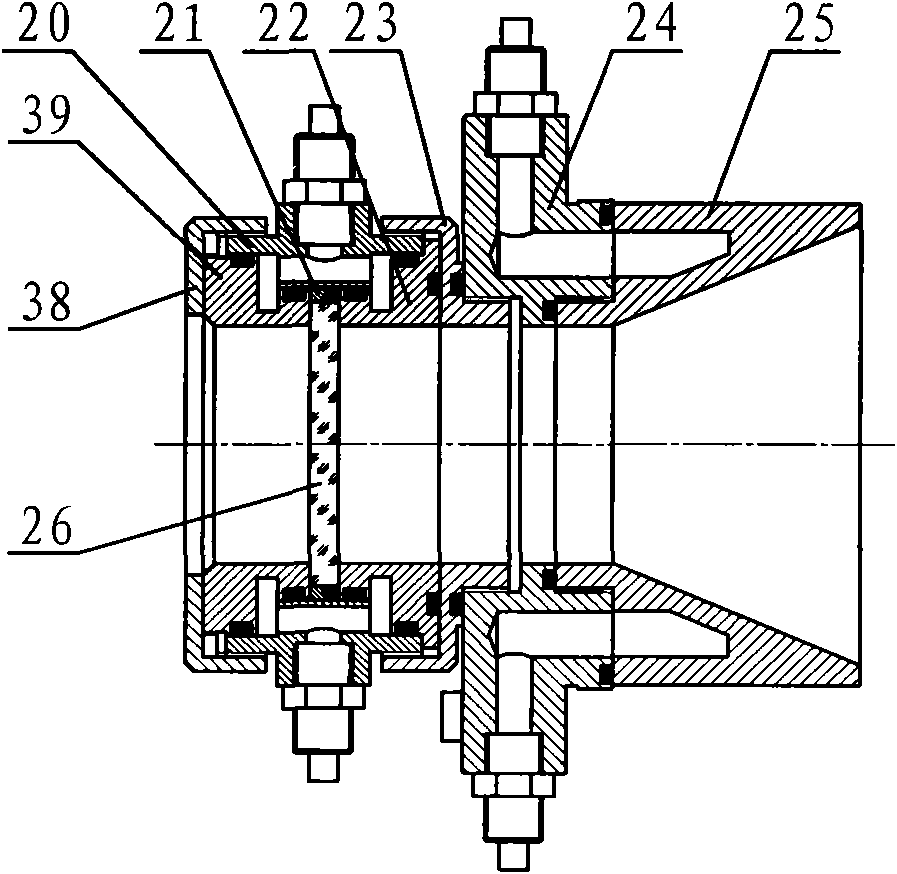

Low-stress conductive sealing adjustment device and method for aviation light window

ActiveCN110716274AImprove the accuracy of assembly and adjustmentGuaranteed tightnessScreening gaskets/sealsMountingsAviationProcess equipment

The invention relates to a low-stress conductive sealing adjustment device and method for an aviation light window. By using instruments and equipment such as a height indicator, a precise electric control adjustment table and an auto-collimation light pipe, special process equipment such as a light window adjustment reference tool and a light window supporting tool and a composite bonding layer,the adjustment reference of the aviation light window can be quickly established, the adjustment precision is improved, the clamping stress and the bonding stress are reduced, the adjustment stress isavoided, the optical performance is ensured while the sealing performance and the electromagnetic shielding performance of the aviation light window are ensured, and the adjustment efficiency and theadjustment quality of the aviation light window are greatly improved.

Owner:LUOYANG INST OF ELECTRO OPTICAL EQUIP OF AVIC

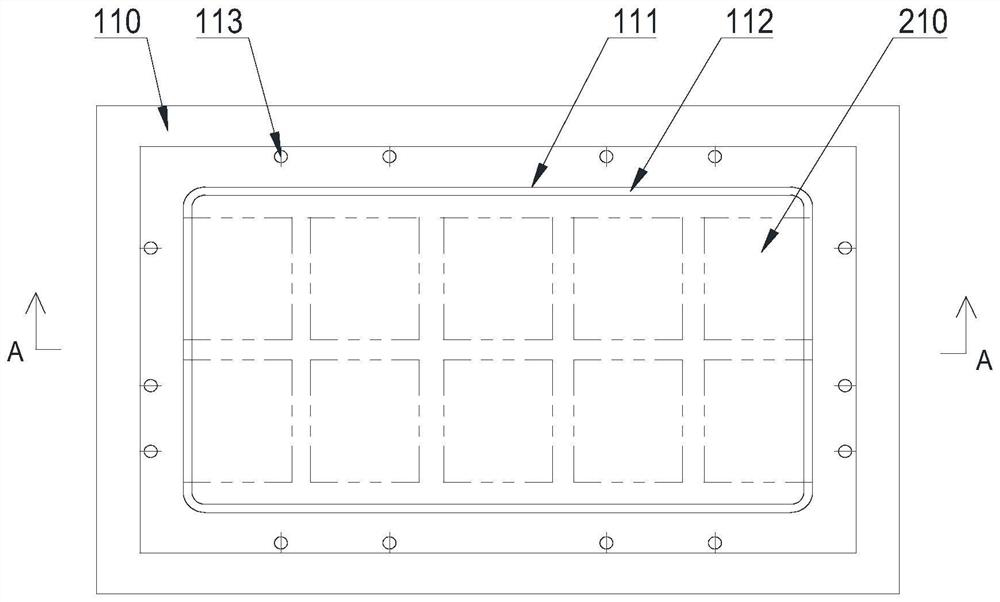

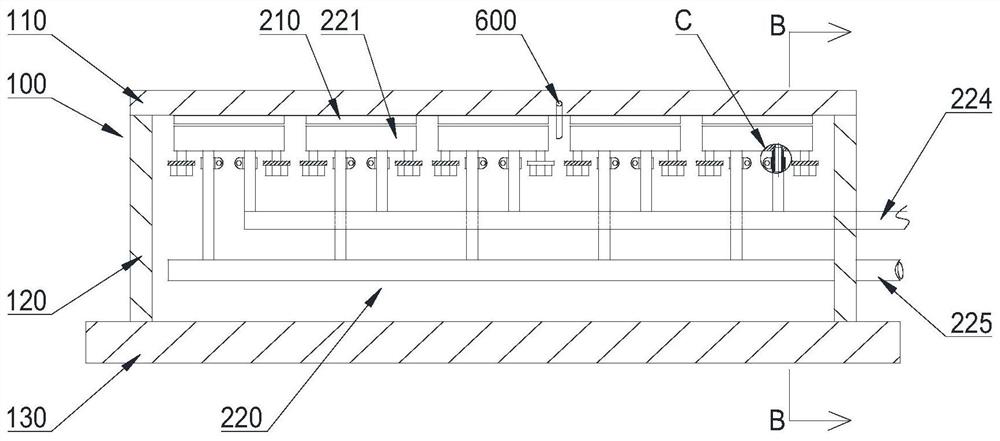

Thin-wall weak-rigidity part machining and fixing method and temperature control machining platform

PendingCN112008459ARealize high-precision adjustmentRealize cooling and heatingMachine tool componentsMachines using electric/magnetic effectsTemperature controlMachine parts

The invention discloses a thin-wall weak-rigidity part machining and fixing method and a temperature control machining platform. The temperature control machining platform comprises a platform frame body; a panel is arranged on the upper part of the platform frame body; and a refrigerating and heating assembly is fixedly installed below the panel; the refrigerating and heating assembly comprises arefrigerating sheet set and a heat dissipation device; the refrigeration sheet set comprises at least one semiconductor refrigeration sheet; the semiconductor refrigeration sheet is tightly attachedto the lower surface of the panel and can switch between a refrigeration mode and a heat dissipation mode; the heat dissipation device is tightly attached to the lower surface of the semiconductor refrigeration plate and is used for dissipating heat generated by the semiconductor refrigeration plate in the refrigeration mode. According to the method, the temperature of a bonding agent is adjustedthrough a semiconductor refrigeration plate; and when the bonding agent is solidified or softened, a machined part can be fixedly connected to the platform in a natural state, the connection speed ishigh, no extra stress is generated, stress resilience can be effectively avoided, and the machined part can be conveniently separated and taken down from the platform after the bonding agent is softened and thinned.

Owner:湖北三江航天江北机械工程有限公司

High-precision ball head optical adjustment device

ActiveCN111751949AImprove the accuracy of assembly and adjustmentSimplify the assembly processMountingsPhysicsEngineering

The invention discloses a high-precision ball head optical adjustment device, relates to the technical field of aerospace, and solves the technical problems of complex adjustment process, adjustment precision influenced by the skills of adjustment personnel and limited adjustment precision in a high-precision adjustment scheme in the prior art. The device is technically characterized by comprising: a first fixing frame; a fine adjustment mechanism mounted on the first fixing frame; a coarse adjustment mechanism arranged on the fine adjustment mechanism; and an optical device arranged on the coarse adjustment mechanism. The device has the beneficial effects that: the adjustment precision is high and is not influenced by adjustment personnel and the grinding level, the adjustment process issimple, and the structural strength and rigidity are high after adjustment.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

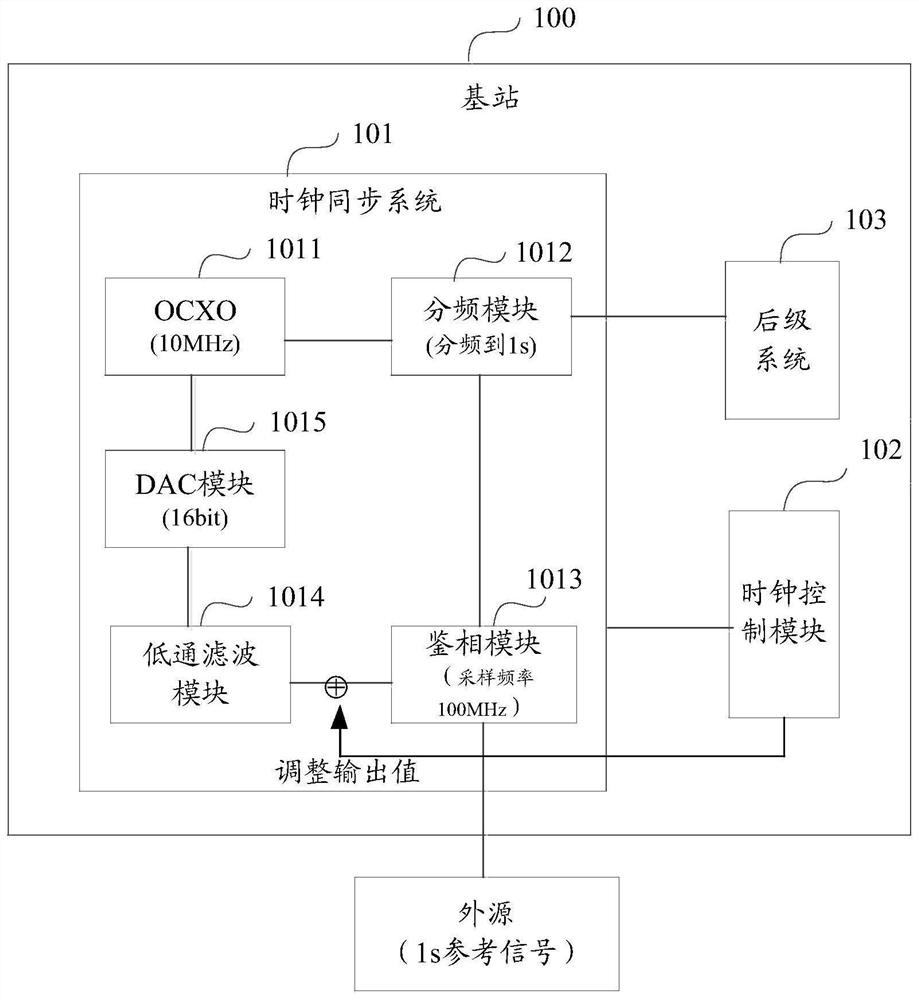

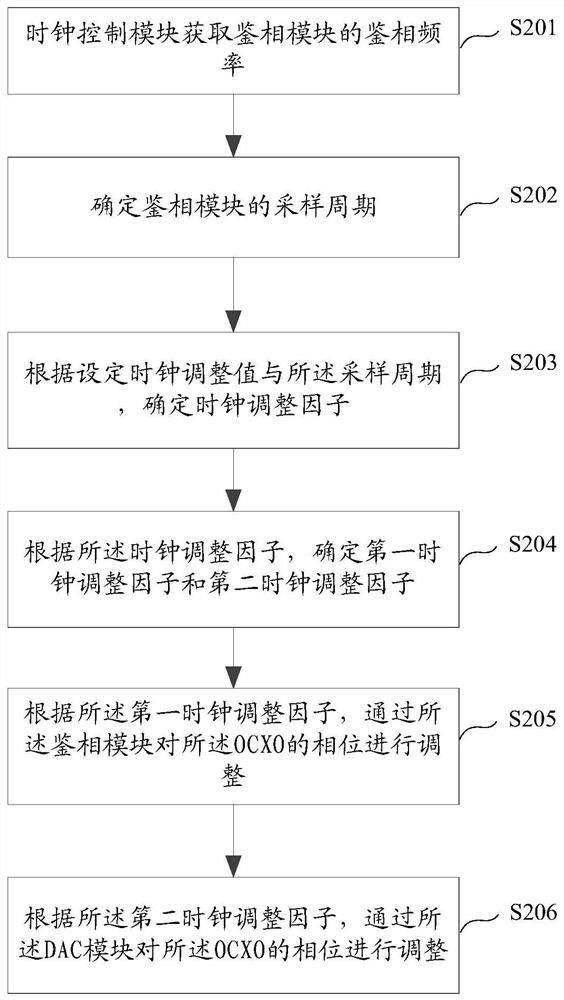

Clock adjustment method and device

ActiveCN113364550ARealize high-precision adjustmentLow costTime-division multiplexComputer hardwareTime delays

The embodiment of the invention provides a clock adjusting method and a clock adjusting device, which are used for realizing high-precision time delay adjustment on a clock. In the method, a clock control module obtains the phase discrimination frequency of a phase discrimination module, and determines the sampling period of the phase discrimination module according to the phase discrimination frequency; the clock control module determines a clock adjustment factor according to a set clock adjustment value and a sampling period; the clock control module determines a first clock adjustment factor and a second clock adjustment factor according to the clock adjustment factor; and the clock control module adjusts the phase of the OCXO through the DAC module according to the second clock adjustment factor. In the method, the clock adjustment factor is determined according to the set clock adjustment value and the sampling period, and the phase of the OCXO is adjusted through the DAC module according to the non-integer part of the clock adjustment factor, so high-precision adjustment of the clock in the clock synchronization system is realized, and the performance of the system is improved.

Owner:DATANG MOBILE COMM EQUIP CO LTD

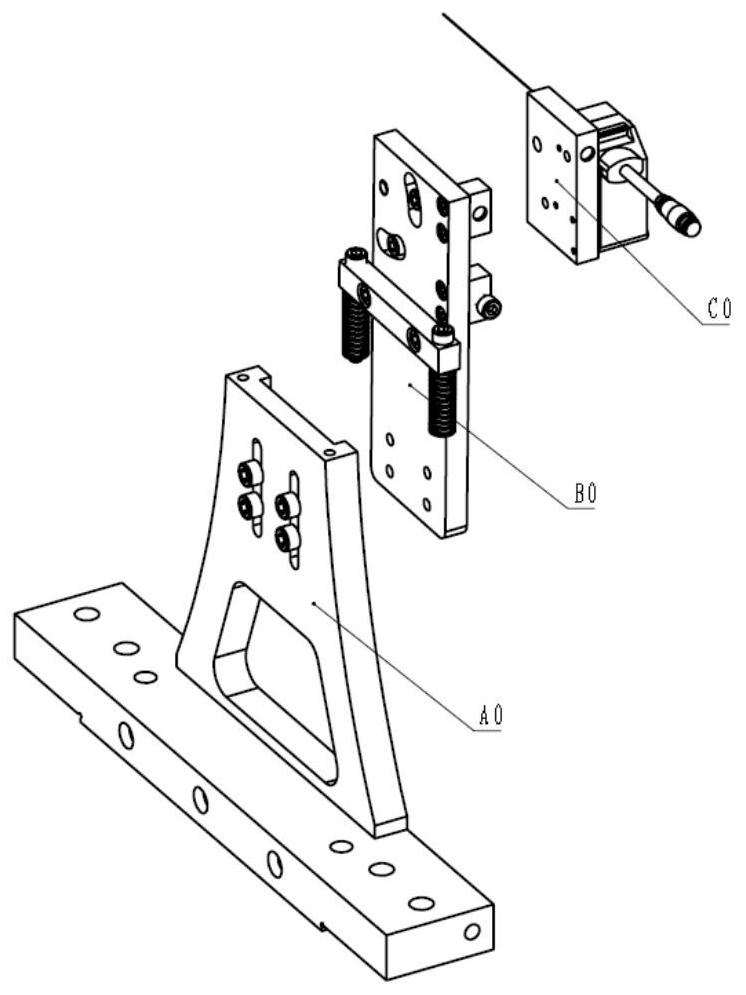

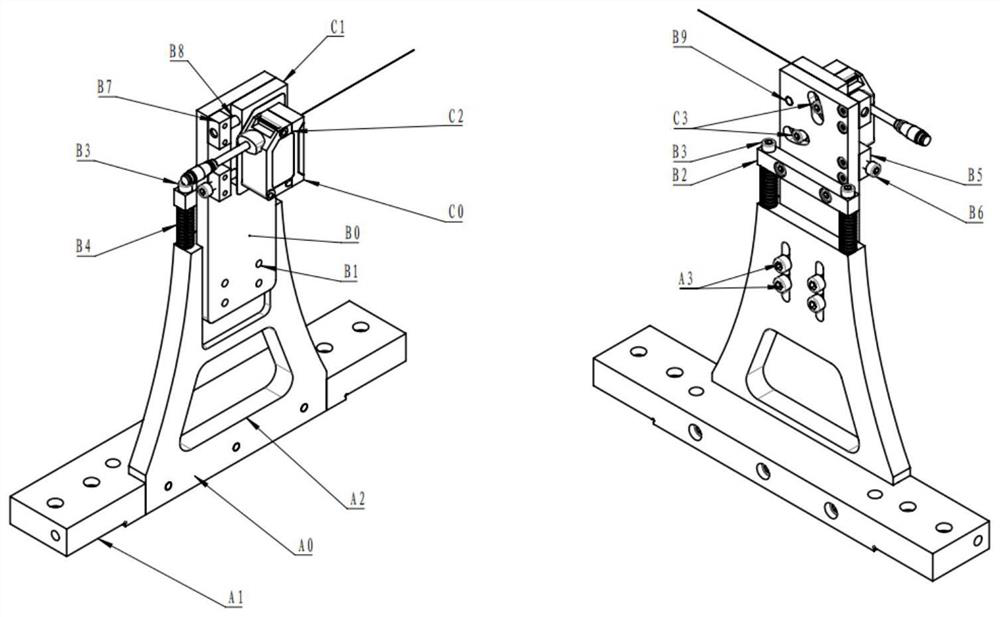

Non-contact sensor position adjusting structure for measuring shafts

ActiveCN112815189ARealize high-precision adjustmentReduce processing requirementsStands/trestlesControl engineeringProcess engineering

The invention discloses a sensor position adjusting mechanism for non-contact measurement of shaft parts. The sensor position adjusting mechanism for non-contact measurement of the shaft parts comprises an equipment measuring basis, a fixing assembly, a translation assembly and a rotating assembly, wherein the fixing assembly is fixedly installed on the equipment measuring basis; the translation assembly is installed and fixed on the fixing assembly in an up-down lifting adjustment mode; and the rotating assembly is installed on the translation assembly in a relatively rotating mode. According to the sensor position adjusting mechanism for non-contact measurement of the shaft parts provided by the invention, two adjustments of translation and rotation are alternately used, so that the final error can be converged to a relatively small value, and high-precision adjustment of a measurement point is realized; and the structure provided by the invention is beneficial to reducing the process requirements on processing and assembling, and is easy to popularize.

Owner:杭州集智机电股份有限公司 +2

Installation and adjustment method of infrared lenses

ActiveCN102998767BEnsure consistencyRealize high-precision adjustmentMountingsEngineeringLens materials

The invention provides an installation and adjustment method of infrared lenses. The installation and adjustment method comprises the steps of utilizing a dual-optical-path centering instrument to measure rocking amount of sphere center images of two lens surfaces of an infrared single lens assembly, adjusting translation and inclination of the infrared single lens assembly, monitoring the rocking amount of the sphere center images, striking dowels to position the infrared single lens assembly, taking off the infrared single lens assembly, positioning other infrared single lens assemblies through the same method, and installing the infrared single lens assemblies into lens cones to complete the installation and adjustment of the lenses. By means of the installation and adjustment method of the infrared lenses, high-precision installation and adjustment of the infrared lenses can be achieved, and the problem that most of visible light cannot penetrate infrared lens materials and the centering measurement of a system cannot be performed is solved.

Owner:BEIJING RES INST OF SPATIAL MECHANICAL & ELECTRICAL TECH

Inner and outer ring cross bearing

InactiveCN110529504ARealize high-precision adjustmentReduce cost inputBearing unit rigid supportEngineeringMachine tool

The invention belongs to the technical field of application of accessories such as a laser level meter and a laser wall adhering instrument, and particularly discloses an inner and outer ring cross bearing, which consists of a transverse positioning block, and a first support adjusting assembly and a second support adjusting assembly which are matched with the transverse positioning block for use.The inner and outer ring cross bearing has the beneficial effects that 1, the whole inner and outer ring cross bearing is of a reasonably designed combined structure, is convenient to assemble and maintain, can be used for the second time, realizes high-precision adjustment of a gap, and also reduces the cost investment of a user; and 2, the production cost is low, the inner and outer ring crossbearing can be machined on an original domestic machine, the required machining precision can be achieved without high machine tool machining, and the popularizing rate is high.

Owner:XINGHUA GUANGFU METAL PROD

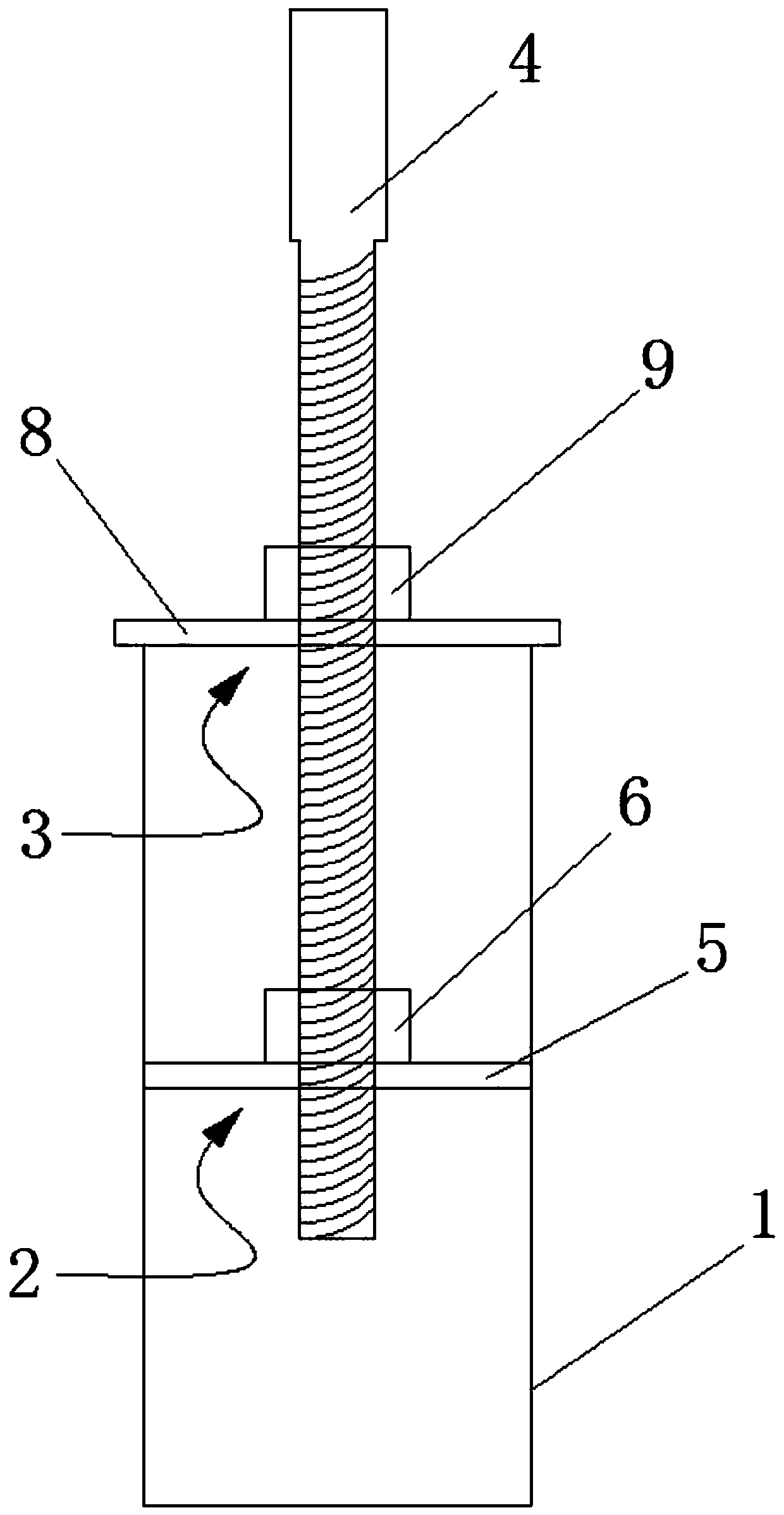

Height regulation tool and height regulation method used for sky train rail box girder elevation regulation

InactiveCN111112915ASimple structureScientific and reasonable designWelding/cutting auxillary devicesWork holdersSpot weldingBox girder

The invention discloses a height regulation tool and height regulation method used for sky train rail box girder elevation regulation. The technical problem that due to the fact that a traditional elevation regulation tool in the prior art is not ideal in regulation precision, the high-precision requirement during sky train rail box girder installation cannot be met is solved. The height regulation tool comprises a tool body, a guiding and positioning mechanism, a fixing mechanism and an elevation regulation lead screw. The elevation regulation lead screw is detachably connected with the fixing mechanism and the guiding and positioning mechanism in a screw thread manner. The height regulation method mainly includes the steps that spot welding fixation is conducted on the height regulationtool; and a fixing nut and a guiding and positioning nut are unscrewed, the elevation regulation lead screw is rotated so that the height of the elevation regulation lead screw can be precisely regulated to the required elevation position, and the guiding and positioning nut and the fixing nut are sequentially screwed so that the elevation regulation lead screw can be vertically fixed. The heightregulation tool and the height regulation method are simple in structure, scientific and reasonable in design and convenient to use, and the elevation required by the tool can be accurately obtained through regulation so that the high-precision requirement during sky train rail box girder installation can be met.

Owner:CHINA MCC5 GROUP CORP

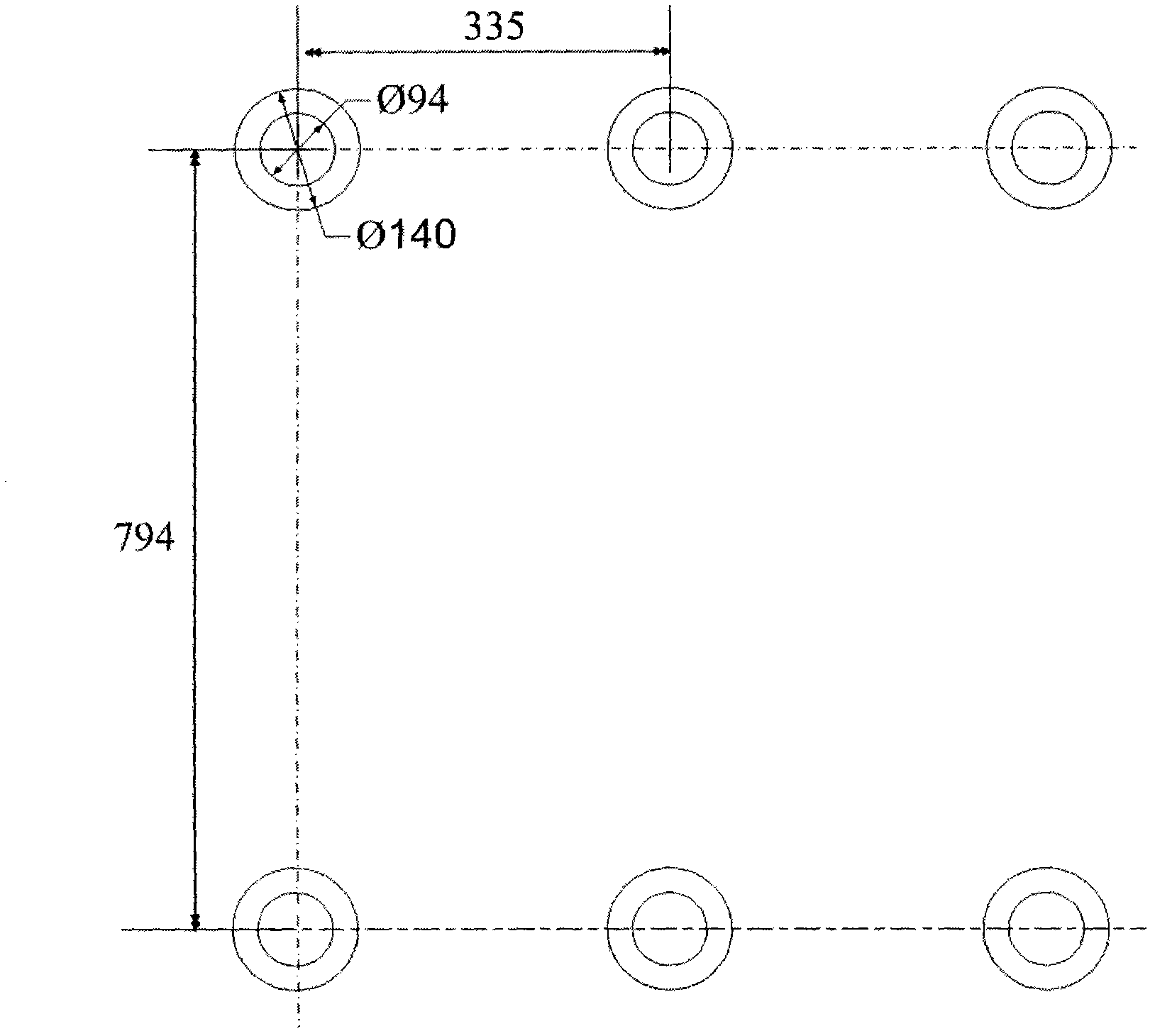

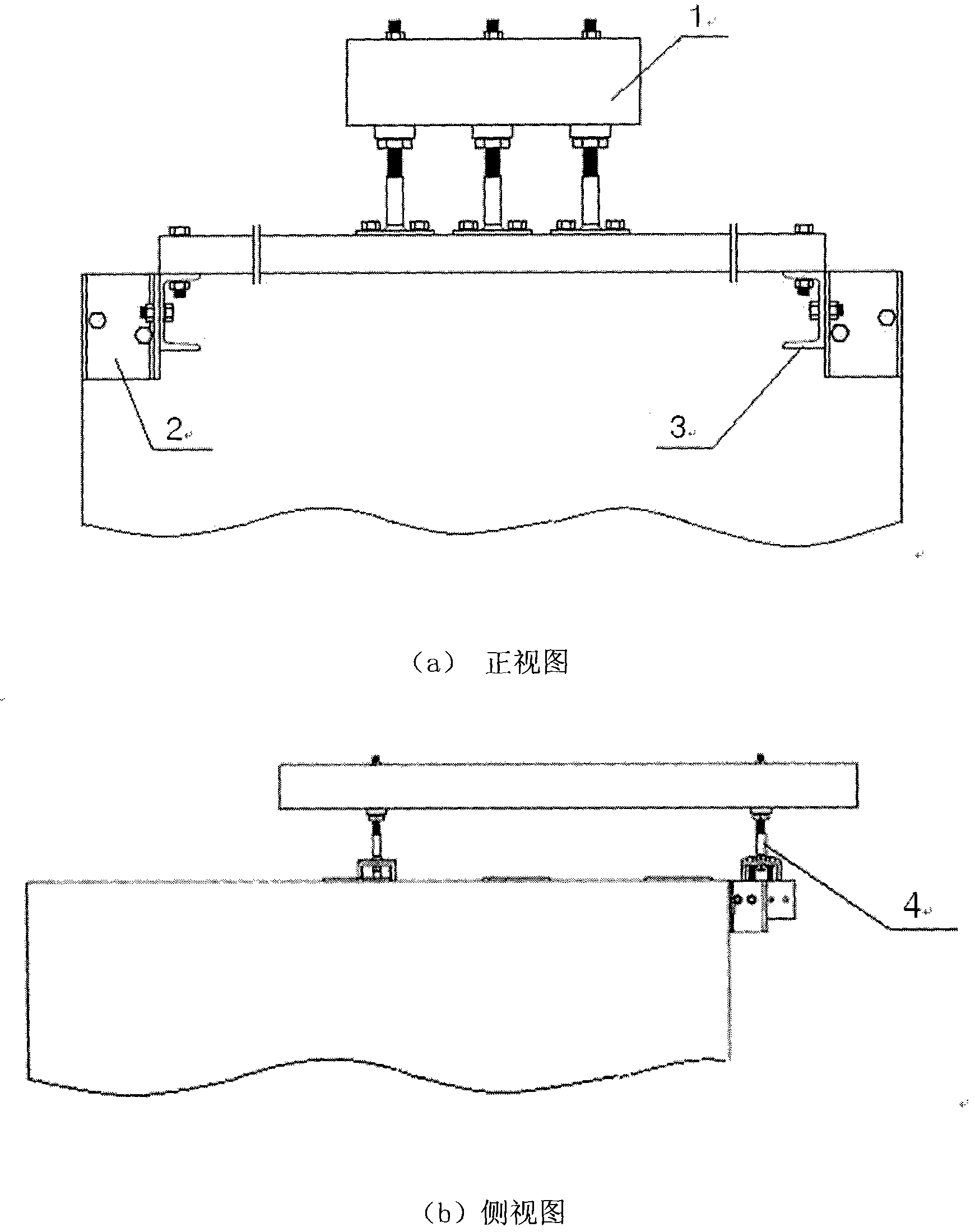

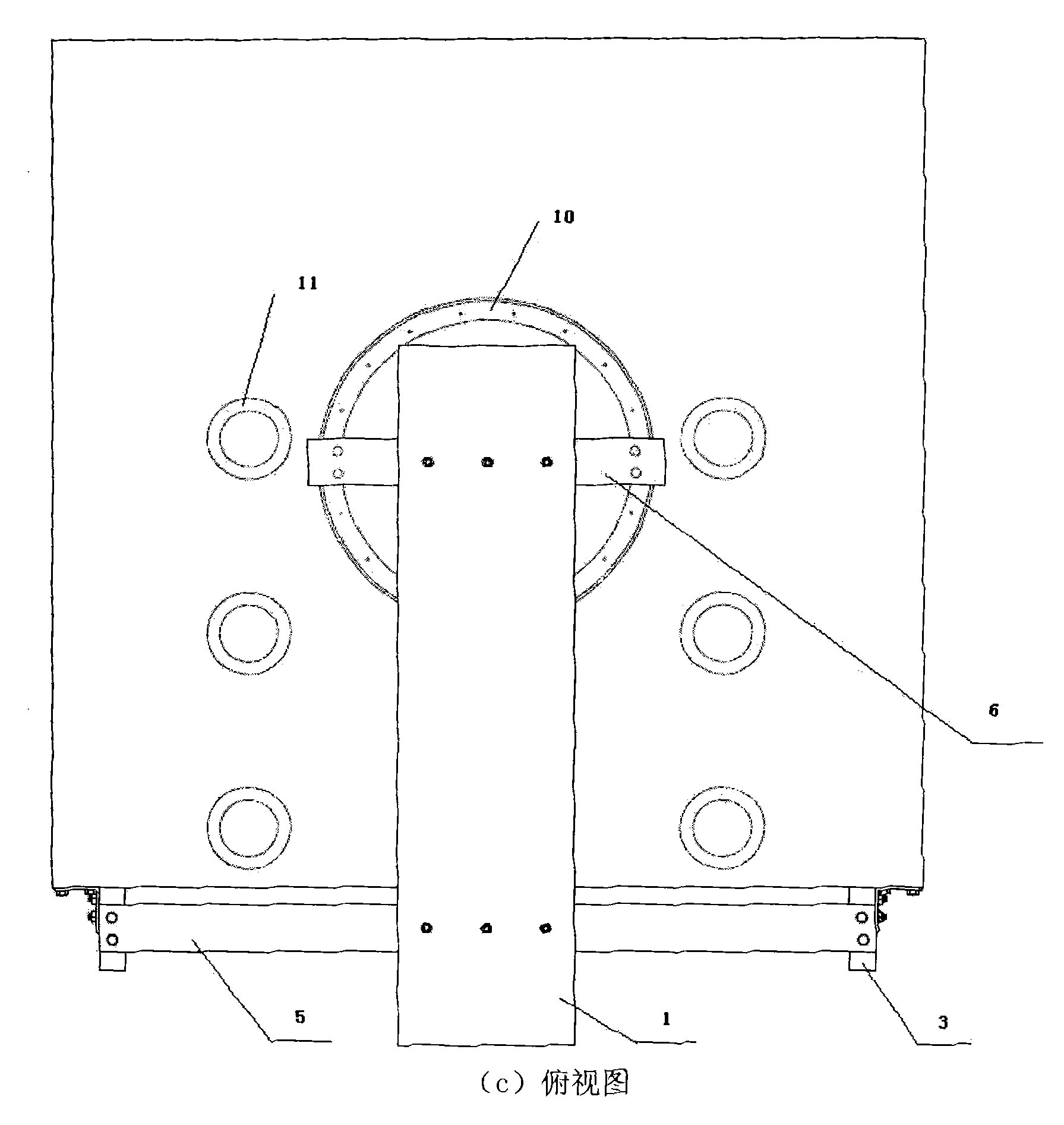

Bridge type tool for measuring high-precision camera mounting surface

The invention relates to a bridge type tool for measuring a high-precision camera mounting surface, which consists of a parallel ruler (1), an angle piece (2), a U-bar (3), a support and levelness regulating device (4), a long support beam (5), a short support beam (6), a cushion block (7), a support rod (8) and a fastening piece; and under the premise of satisfying the high precision requirement on measuring the mounting surface, a measuring datum is transferred from the ground to the parallel ruler at the upper part of a top plate, so the problem that measure within a big envelope scope cannot be realized by using the traditional method is solved.

Owner:SHANGHAI INST OF SATELLITE EQUIP

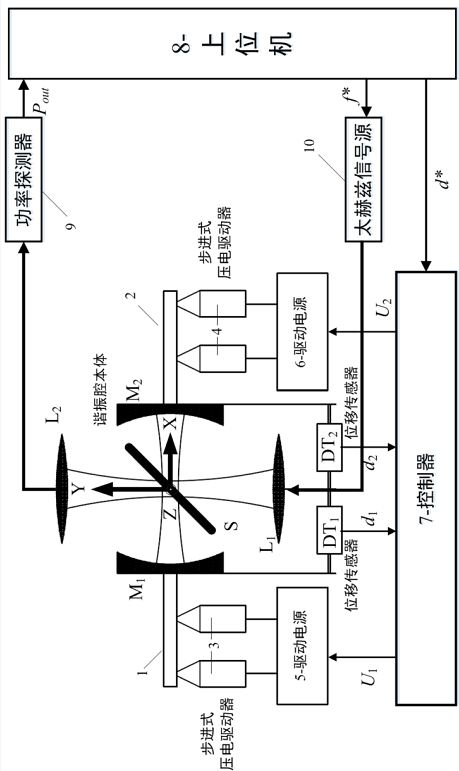

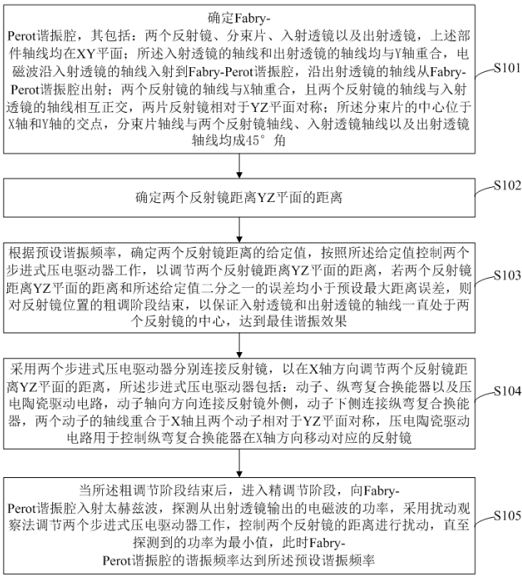

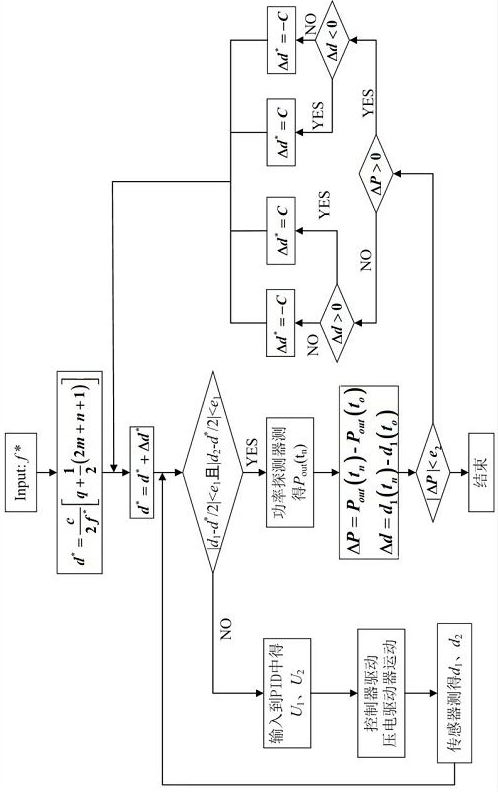

Resonant cavity system with adjustable resonant frequency and regulation and control method thereof

ActiveCN114563083AHigh precision adjustmentGuaranteed performanceRadiation pyrometryMeasurements using electron paramagnetic resonancePiezoelectric actuatorsResonant cavity

According to the resonant cavity system with the adjustable resonant frequency and the regulation and control method of the resonant cavity system, two reflectors are adopted as a resonant cavity body, a lens and a beam splitting piece are adopted for excitation coupling, the axial direction of the reflectors and the axial direction of the lens are mutually orthogonal, 45-degree angles are formed between the reflectors and the axial direction of the beam splitting piece, and the incident direction of electromagnetic waves is the axial direction of the lens. External Gaussian beams are bunched in the center of the beam splitting piece through the lens, and then the propagation direction of electromagnetic waves is deflected by 90 degrees through the beam splitting piece, so that resonance is generated. The two reflectors are installed on the stepping piezoelectric actuator, the distance between the reflectors is adjusted through the actuator, and whether the resonant cavity reaches a resonant state or not is observed through a perturbation and observation method, so that closed-loop adjustment of the resonant frequency of the resonant cavity is achieved. According to the invention, the resonant frequency of the resonant cavity is accurately regulated and controlled, so that the performance of the electron spin resonance spectrometer is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com