Patents

Literature

16645results about How to "Guaranteed tightness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

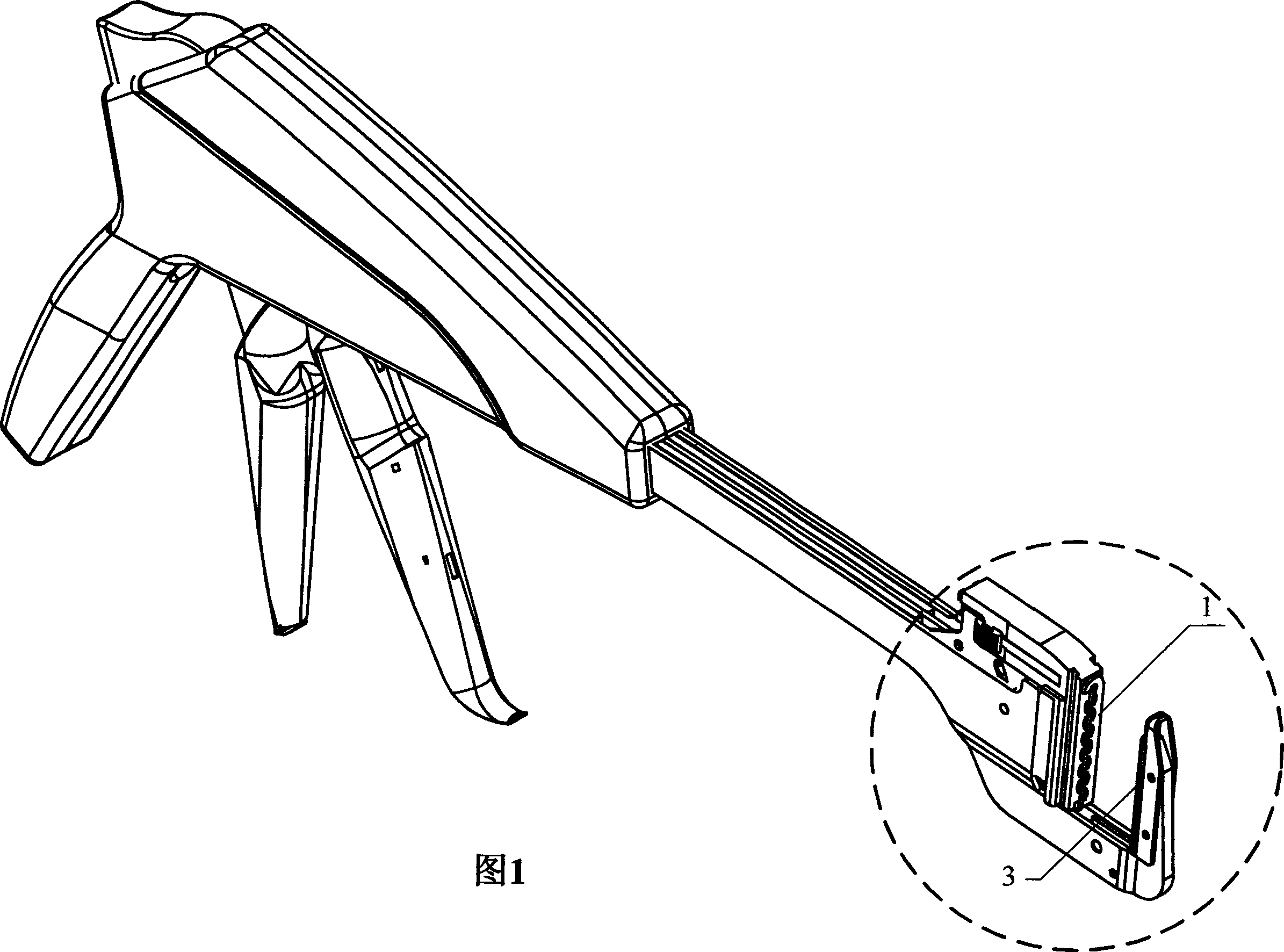

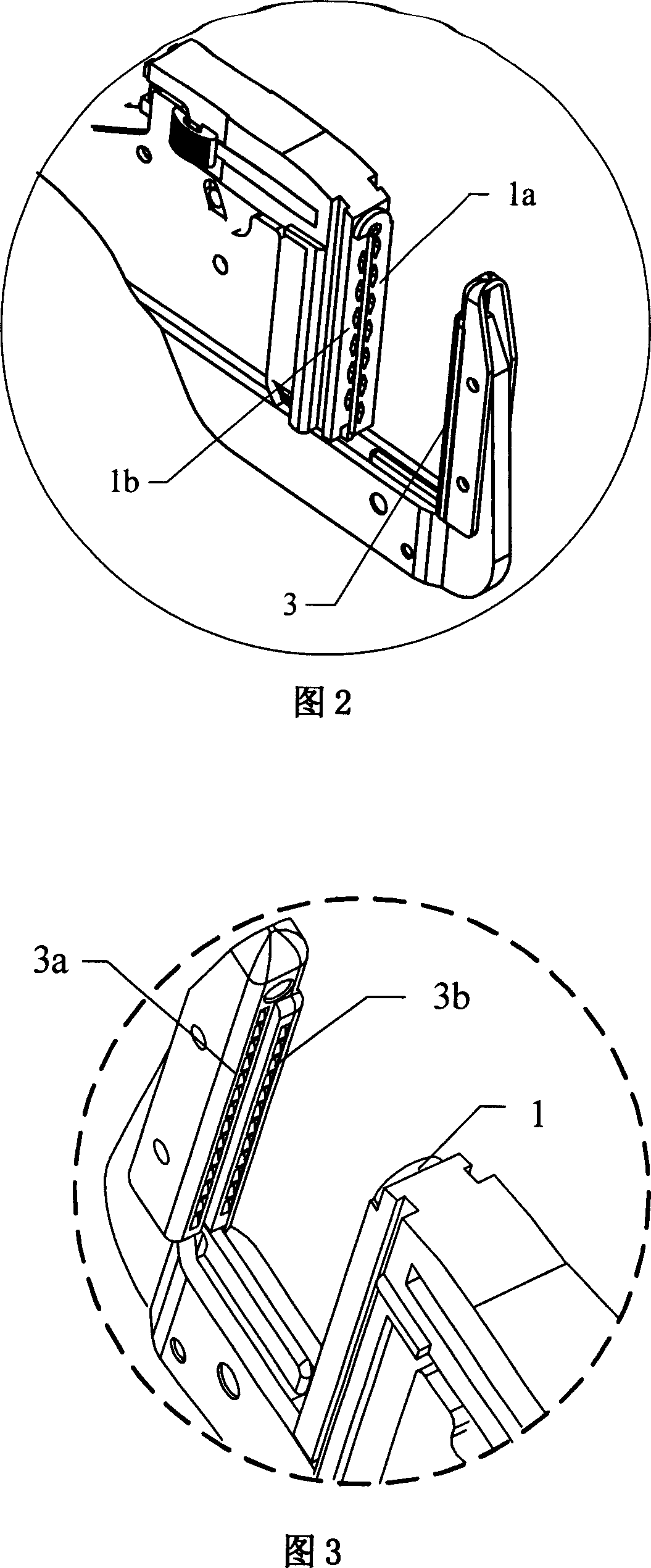

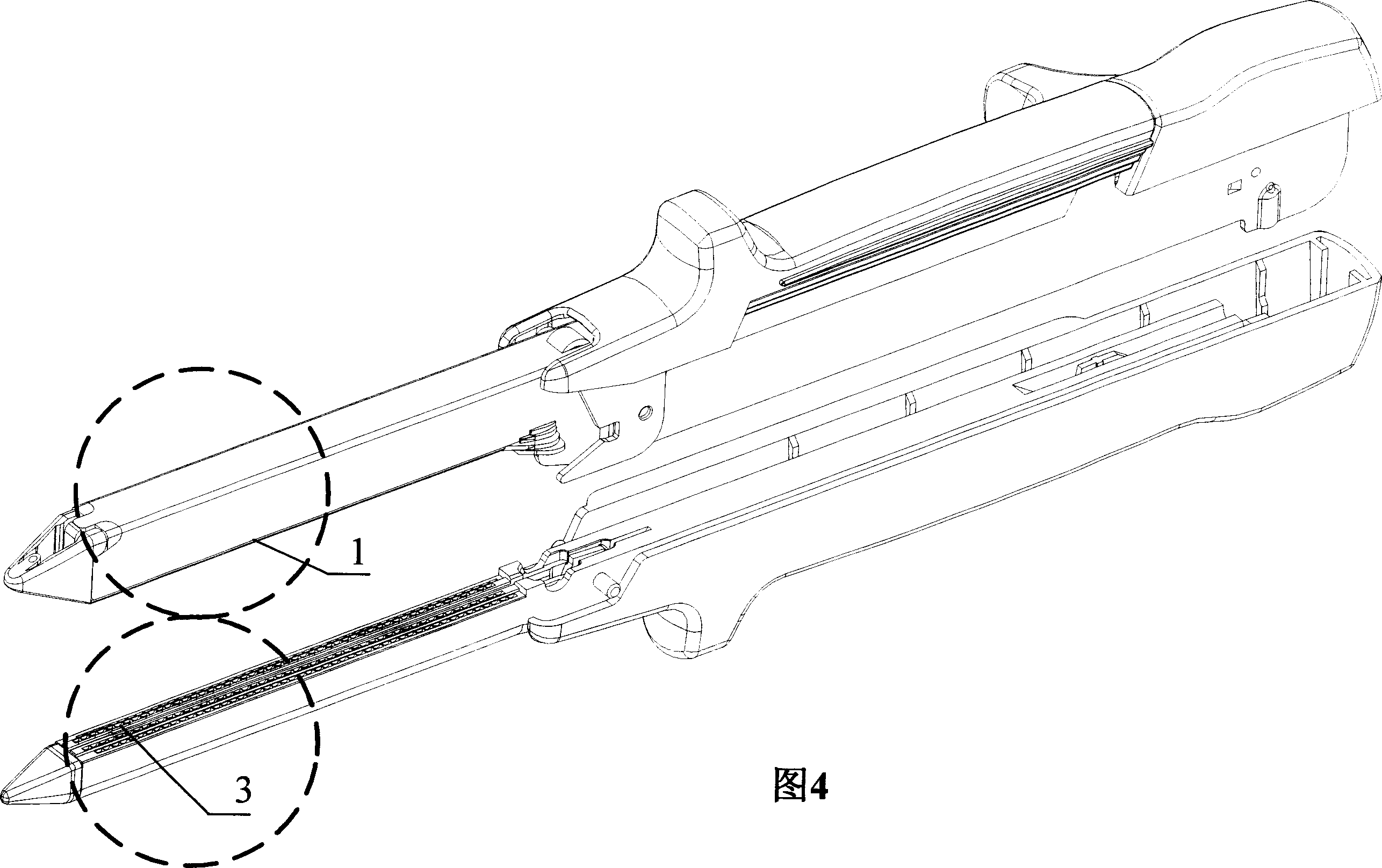

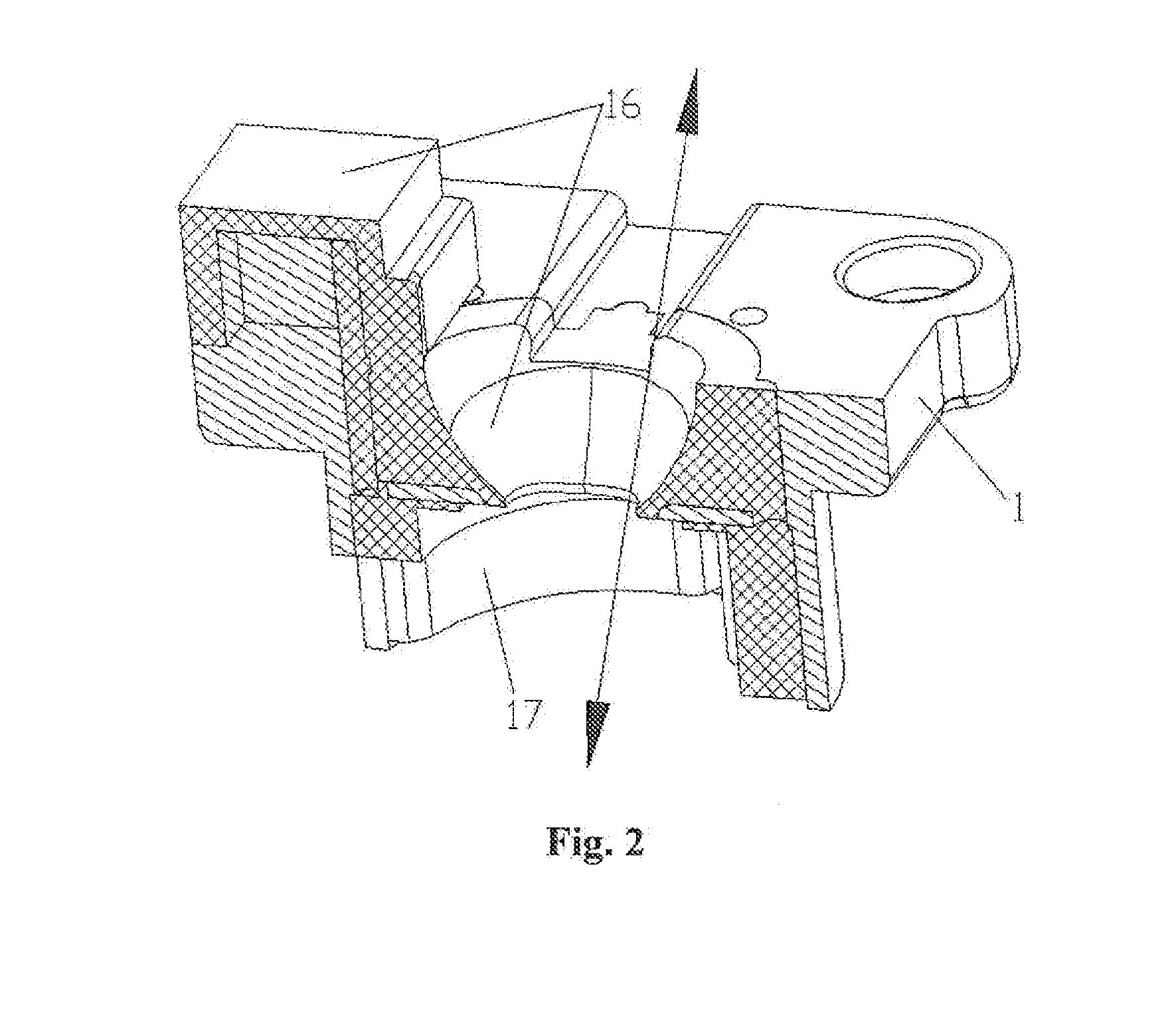

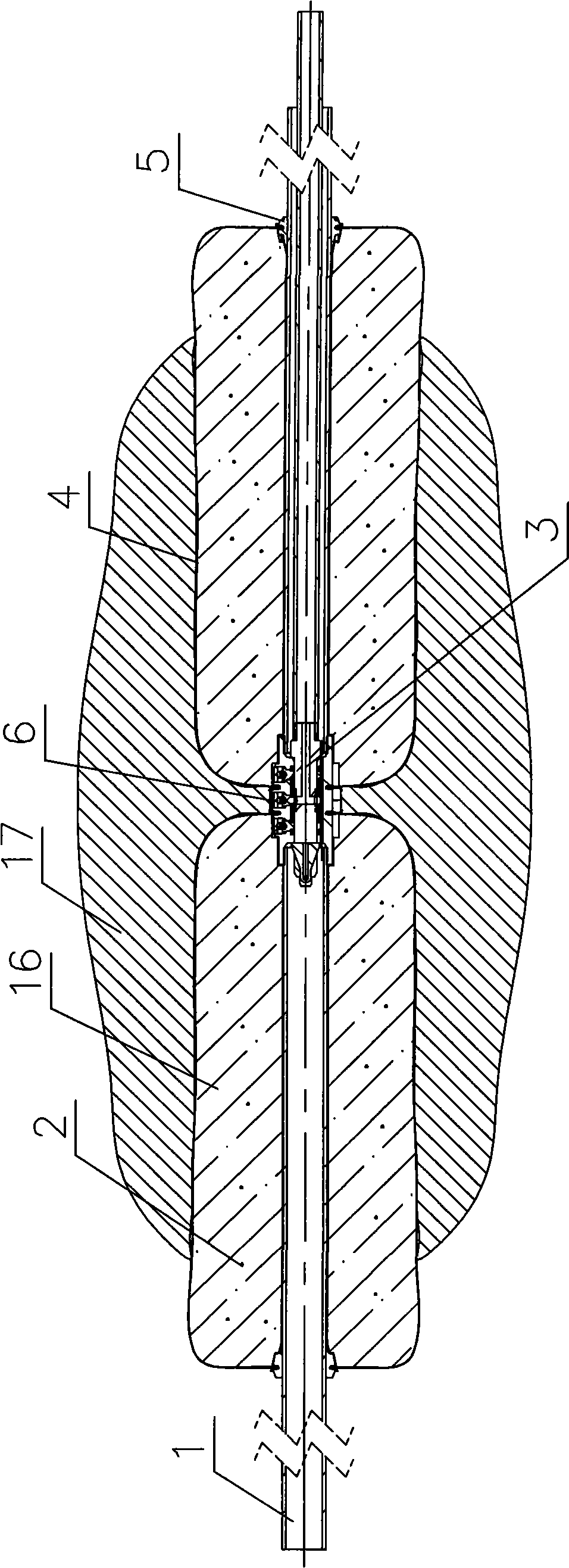

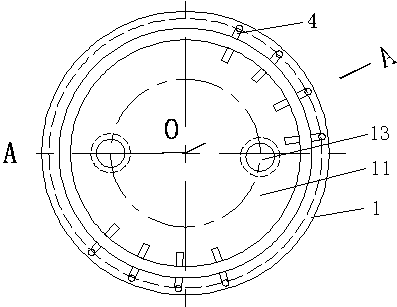

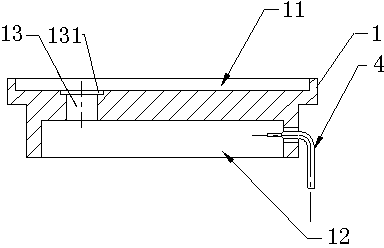

Surgical binding instrument binding mechanism

The invention relates to a binding mechanism of a surgical binding apparatus, which is placed at the head of the surgical binding apparatus and includes a nail pin, a nail pushing plate and a nail block. The nail pushing plate and the nail pin are installed inside the binding apparatus body. The positions of the nail block and the nail pushing plate are opposite. The invention is characterized in that the working faces of nail pin, the nail pushing plate and the nail block are not at the same plane and at least present a step-type fall distributed structure. When the structure is adopted to form an anastomoses opening, the distance between two lines of nails is enlarged; the elasticity of the anastomoses opening which is formed in the operation is increased and is more close to the physiological characteristic of the tissue, which is in favor of the prompt recovery of the tissue. When the nail block is set out from an anastomoses ring or a content object is put through the anastomoses ring after binding, the elasticity of the anastomoses ring becomes larger to allow the nail block or the content object pass through and reduce the probability of damaging the anastomoses ring.

Owner:TOUCHSTONE INTERNATIONAL MEDICAL SCIENCE CO LTD

Control and display device

InactiveUS6665174B1Reduce manufacturing costGuaranteed tightnessInput/output for user-computer interactionEngine sealsElectrical controlHousing design

A portable electrical control and display device is described, having an indicator panel, a keyboard with at least one key pad, and a single housing designed as a single piece and made of a temperature-resistant material, which seals the control and display device in a water-tight manner.

Owner:TESTO AG

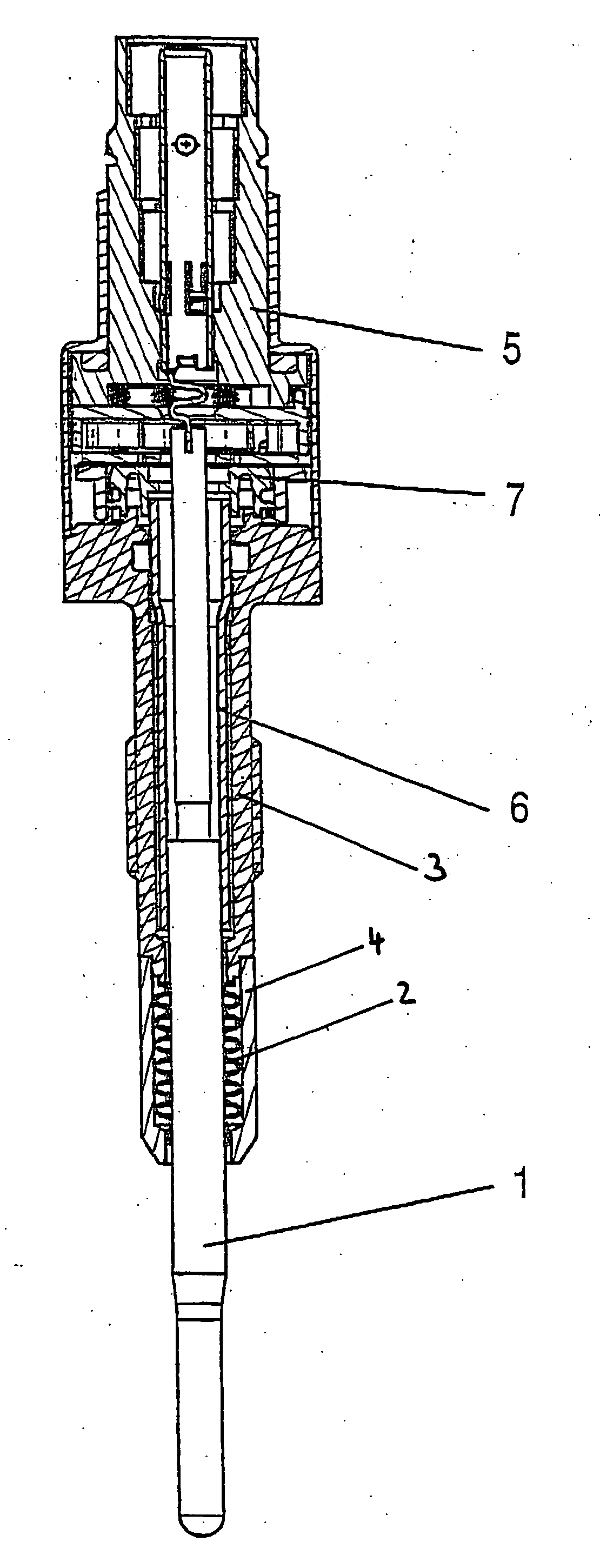

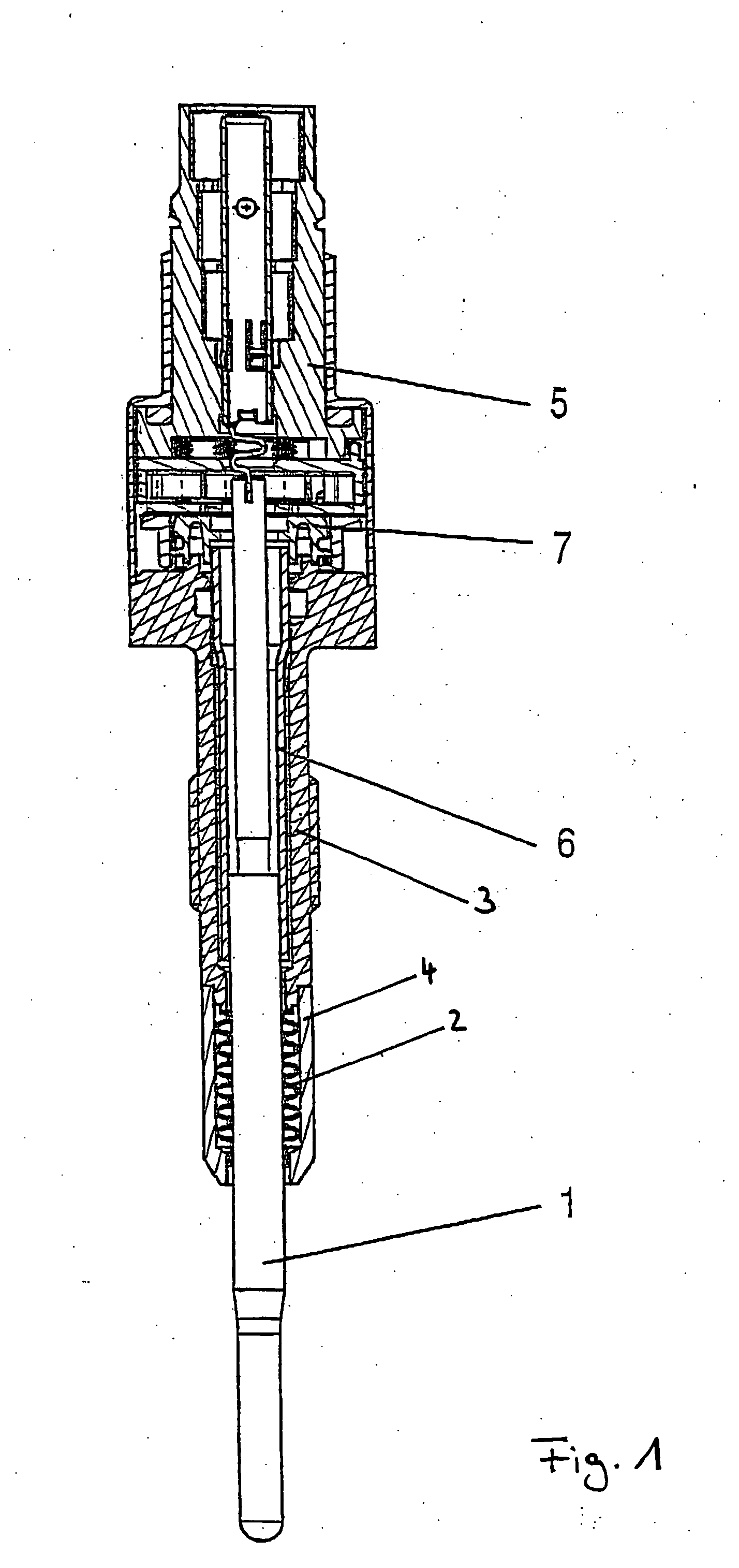

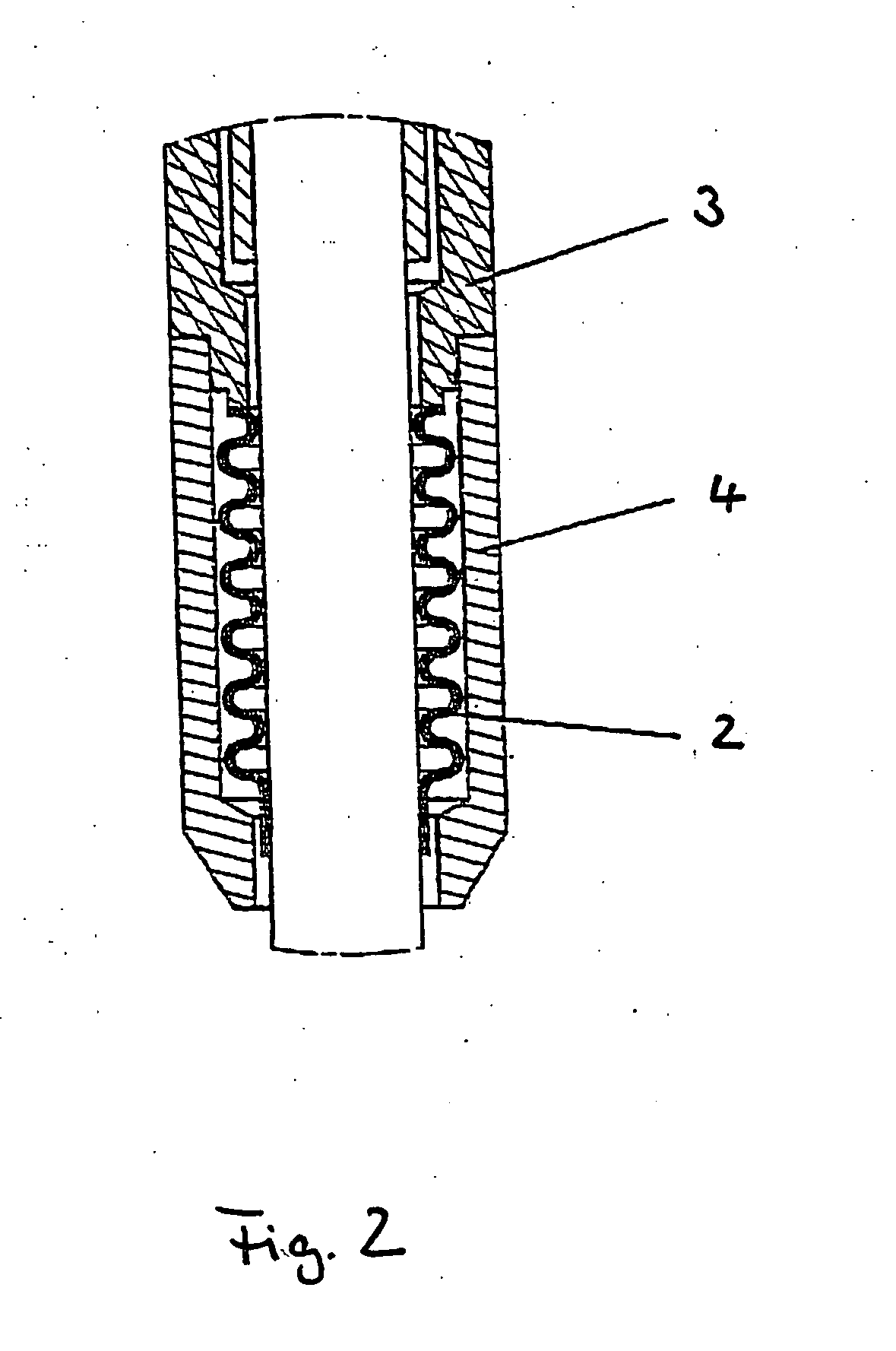

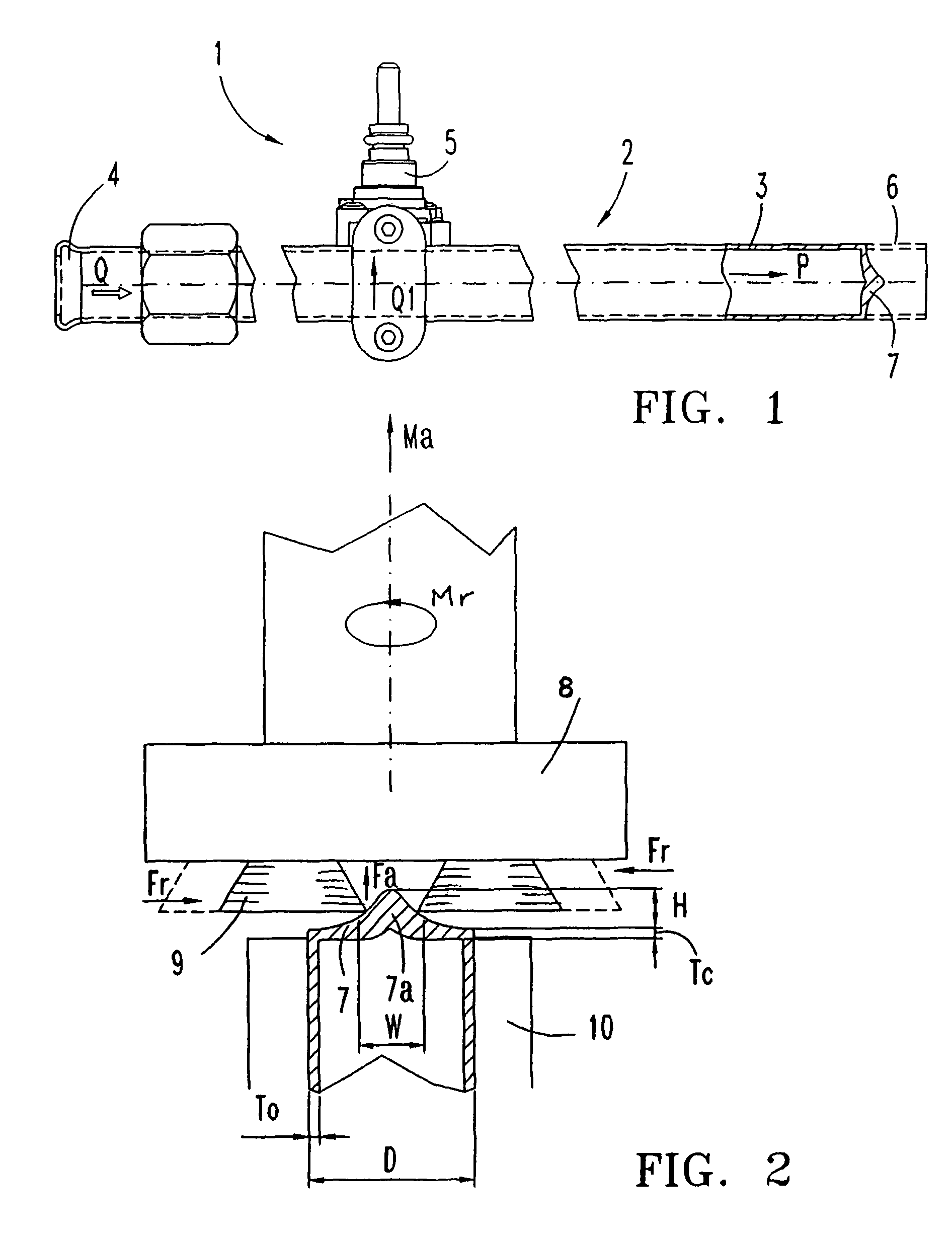

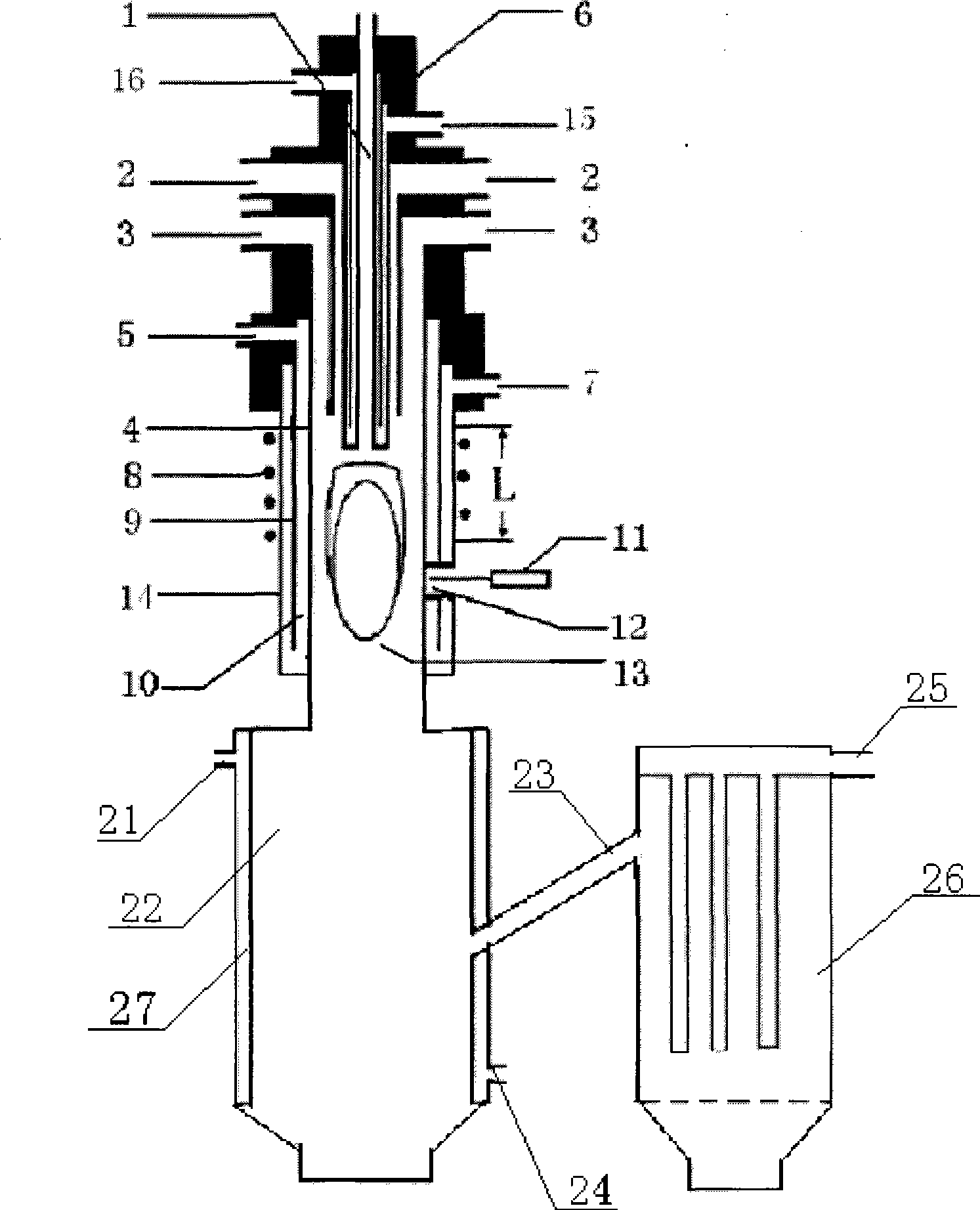

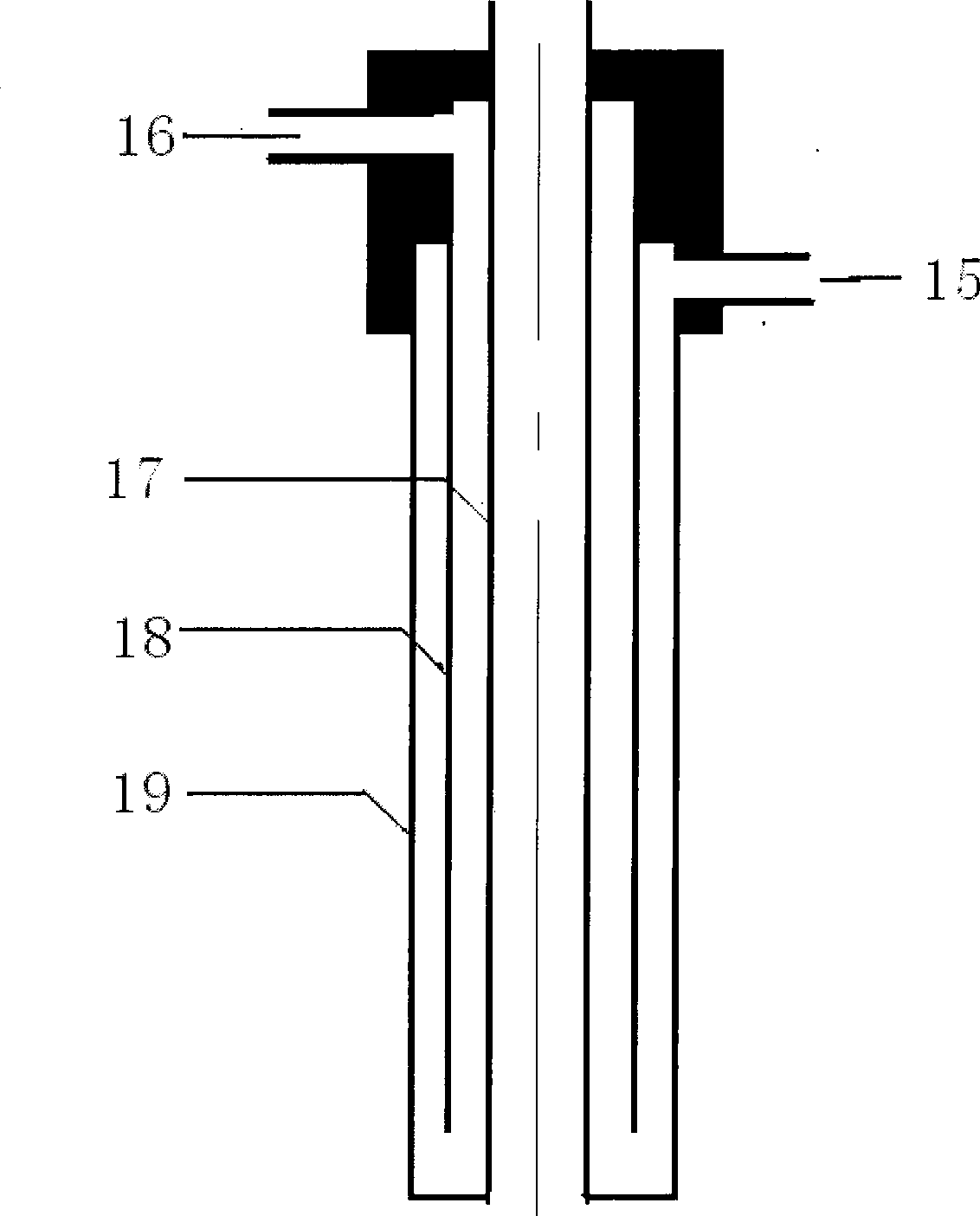

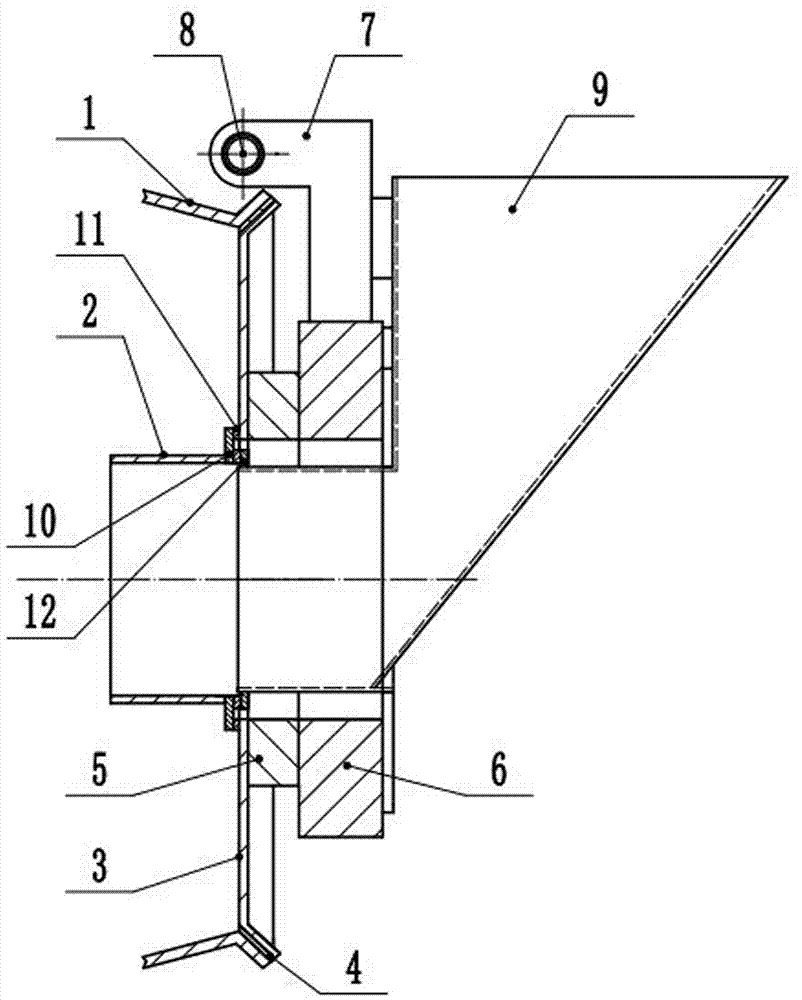

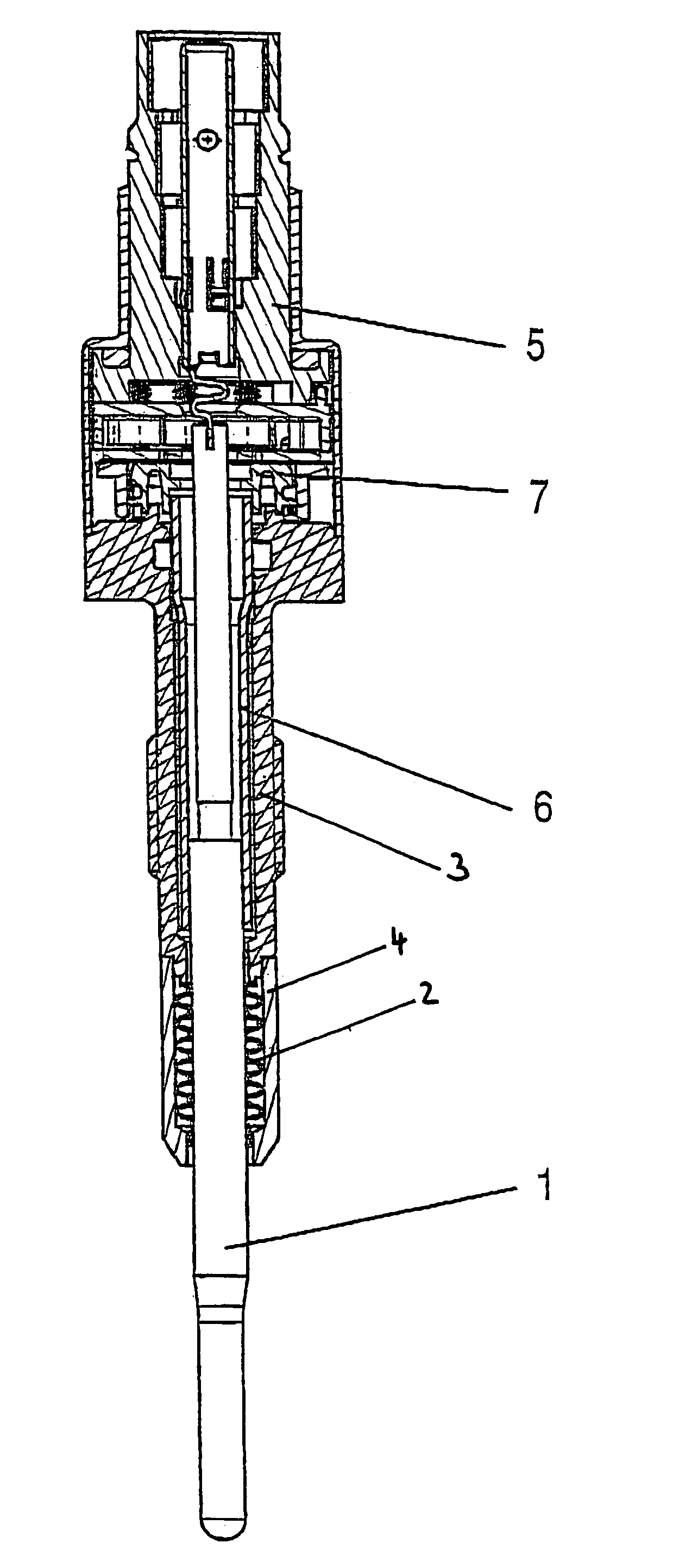

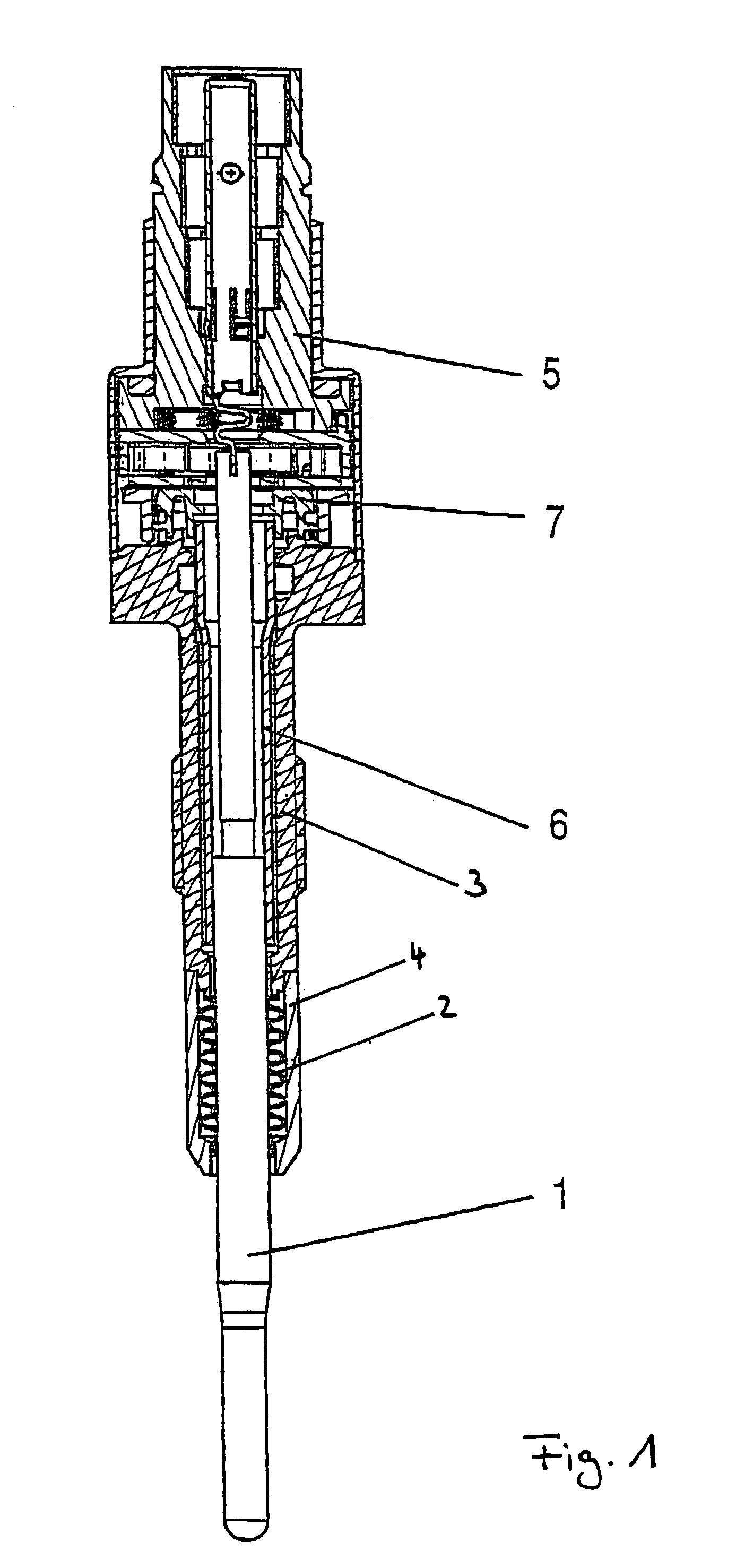

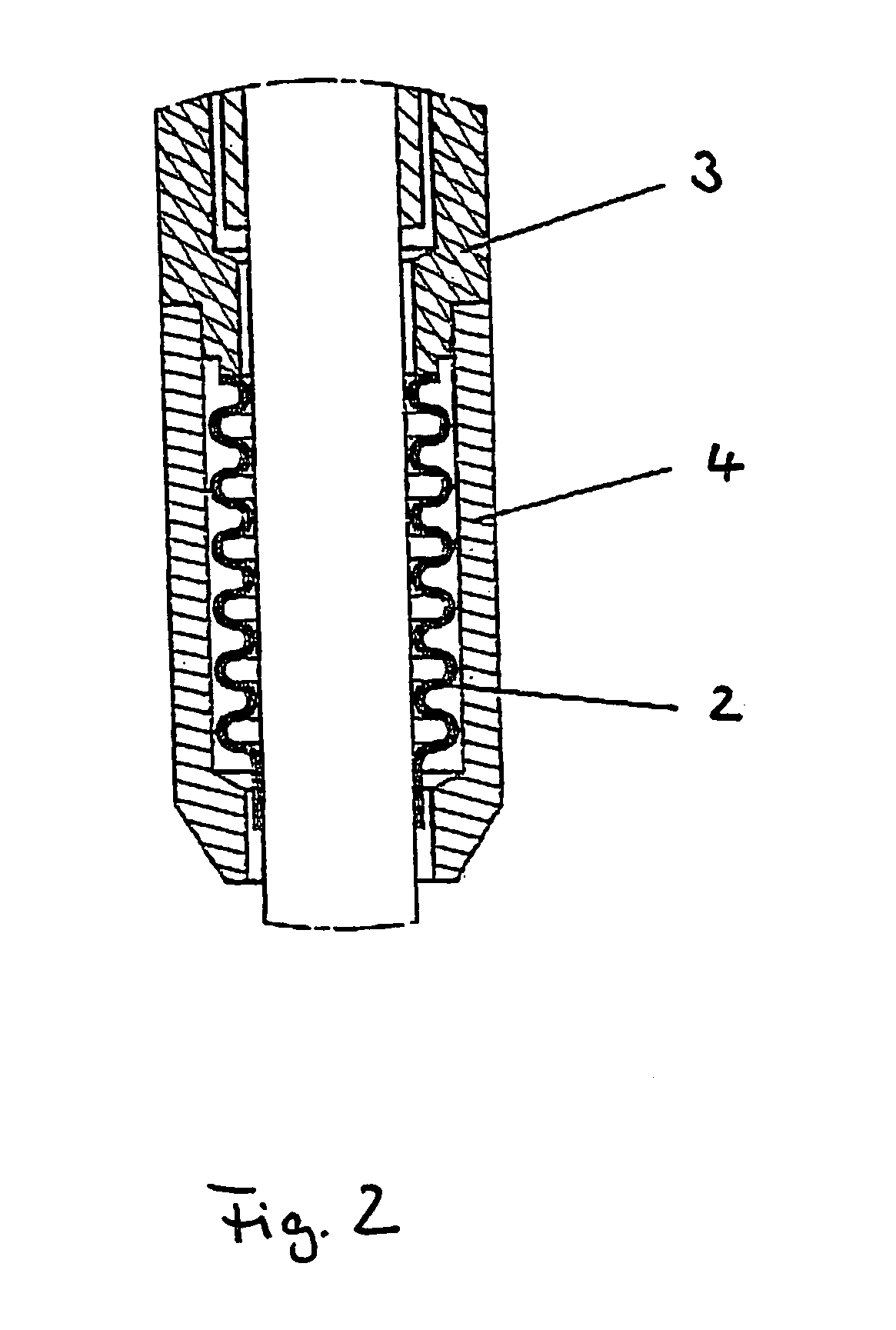

Pressure-measuring glow plug

ActiveUS20060053875A1Small spring rateRequired pressure loadingIncandescent ignitionEngine testingCombustion chamberEngineering

A pressure-measuring glow plug for a diesel engine with a plug body (3, 4) for insertion into a cylinder of the diesel engine, a heating rod (1) which is arranged in the plug body (3, 4), and a pressure sensor, which is arranged under an initial tension between the heating rod (1) and the plug body (3, 4), in such a way that the pressure sensor (7) is acted upon by the pressure prevailing in the combustion chamber of the cylinder. The heating rod (1) transmits the pressure in the combustion chamber of the cylinder to the pressure sensor (7) and is arranged so as to be displaceable in a sliding manner in the axial direction relative to the plug body (3, 4). A seal in the form of a bellows-shaped component (2) is provided between the heating rod (1) and the plug body (3, 4).

Owner:SENSATA TECH HOLLAND +1

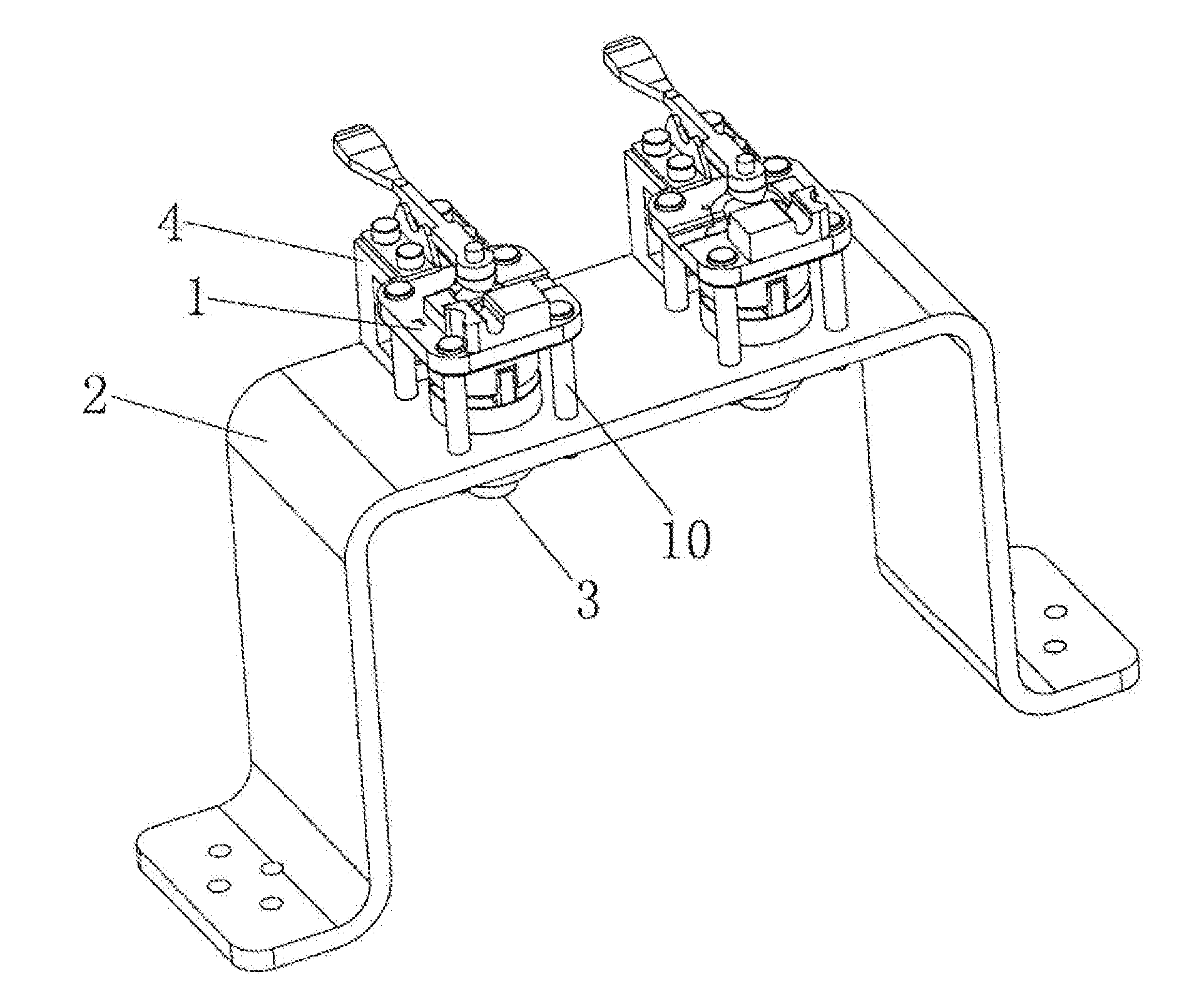

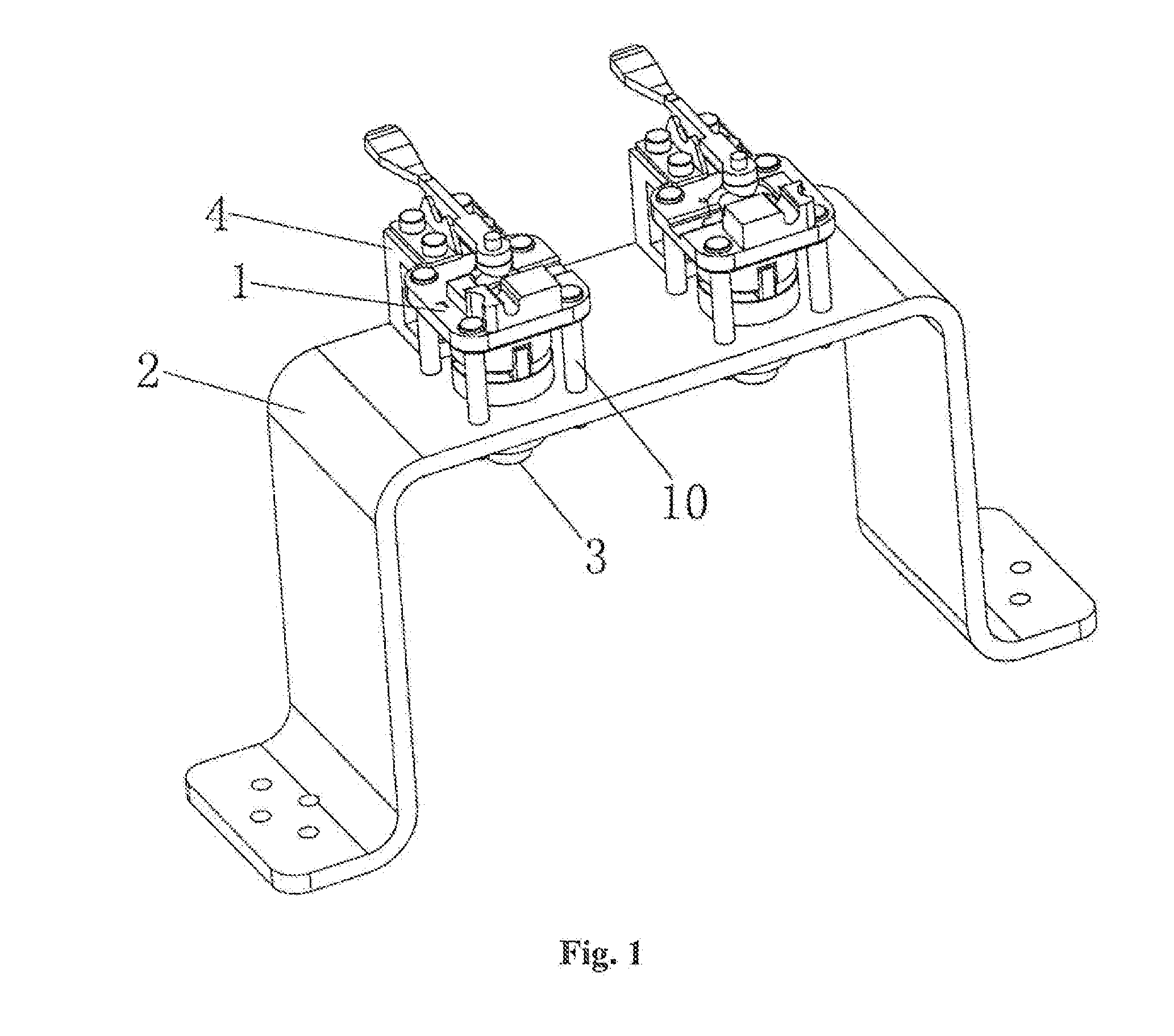

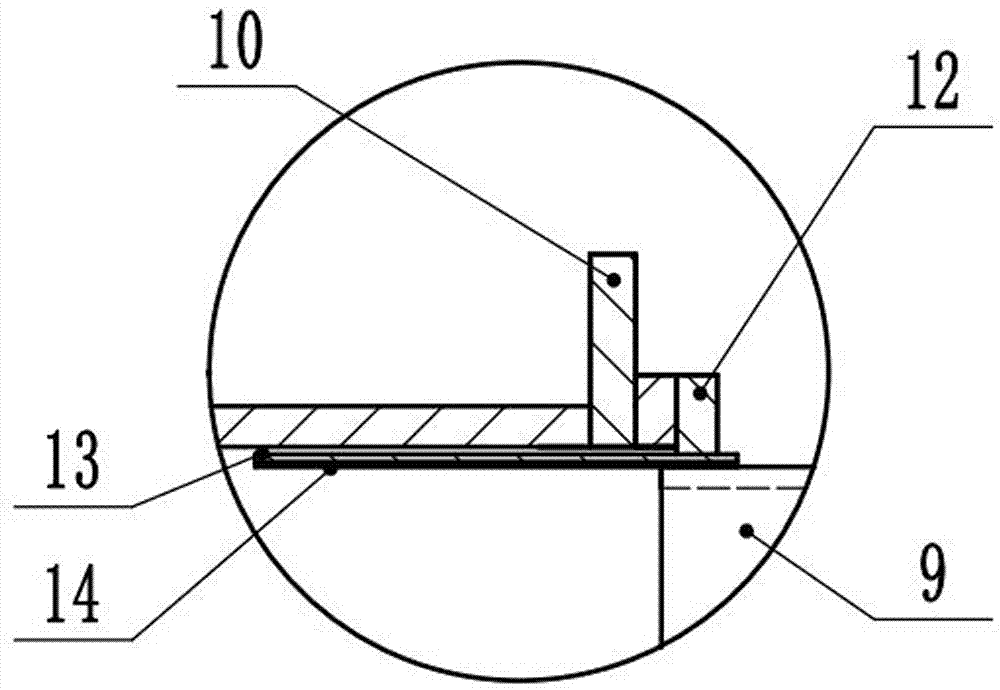

Earphone Testing Device

ActiveUS20150264501A1Guaranteed tightnessThe test result is accurateTransducer detailsHeadphonesBiomedical engineering

The present invention discloses an earphone testing device. An earphone testing device provided by the embodiments of the present invention comprises an fixation base, a standard microphone attached to the fixation base, and a fixation scaffold for attaching and fixing the fixation base and the standard microphone; the fixation base is supported and fixed on the fixation scaffold by several supporting elements; a sealer is located on the position on the fixation base in contact with the outer shell of an earphone, the sealer forms an earphone storage portion for placing the earphone; a sealer is located on the position on the fixation base in contact with the outer shell of the standard microphone, the sealer forms a microphone attachment portion for attaching to the standard microphone; the earphone placed in the earphone storage portion and the standard microphone attached onto the microphone attachment portion are communicated with each other in the fixation base. The present invention provides a stable and highly precise testing solution of earphone, which can guarantee the precision and stability of earphone testing.

Owner:GOERTEK INC

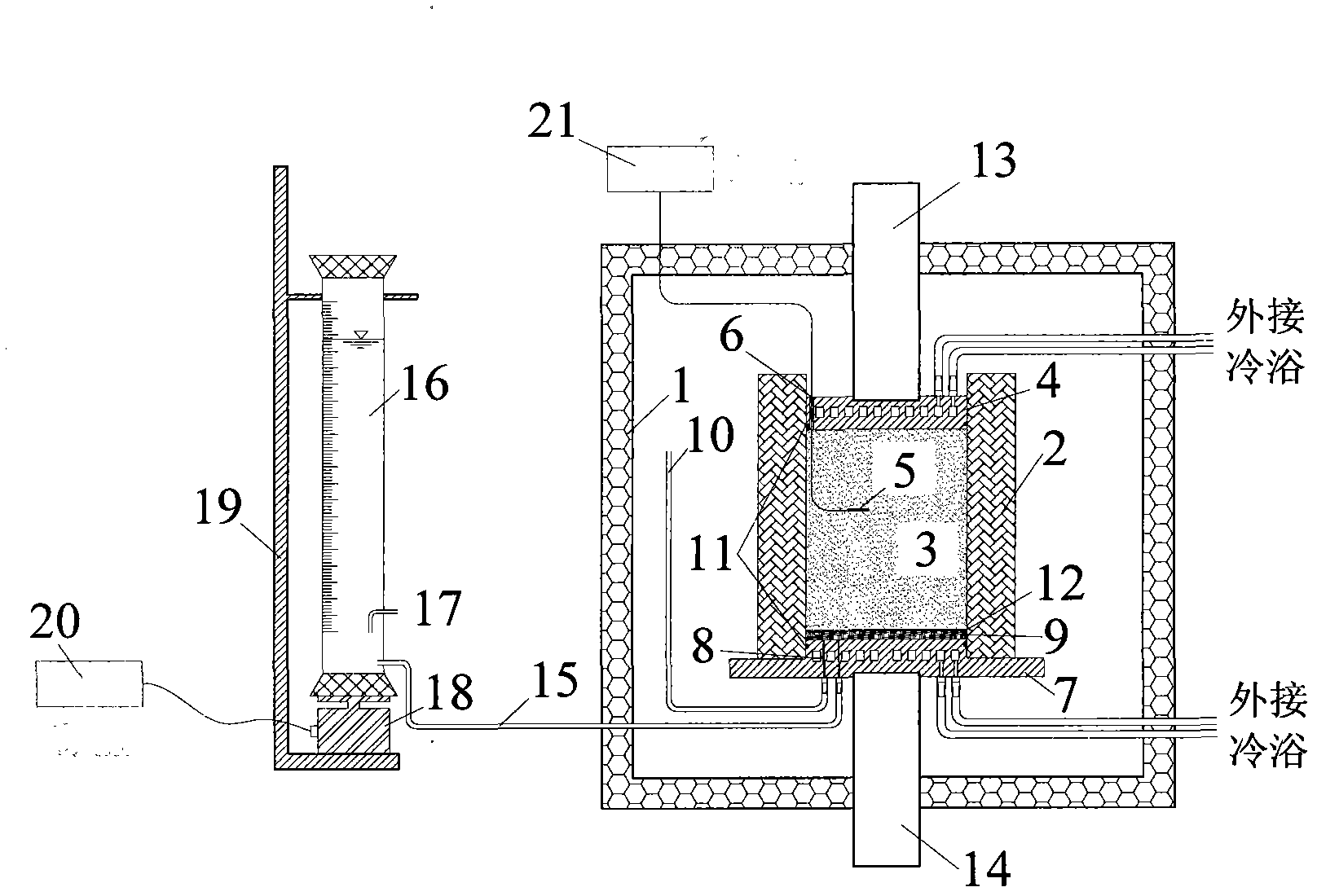

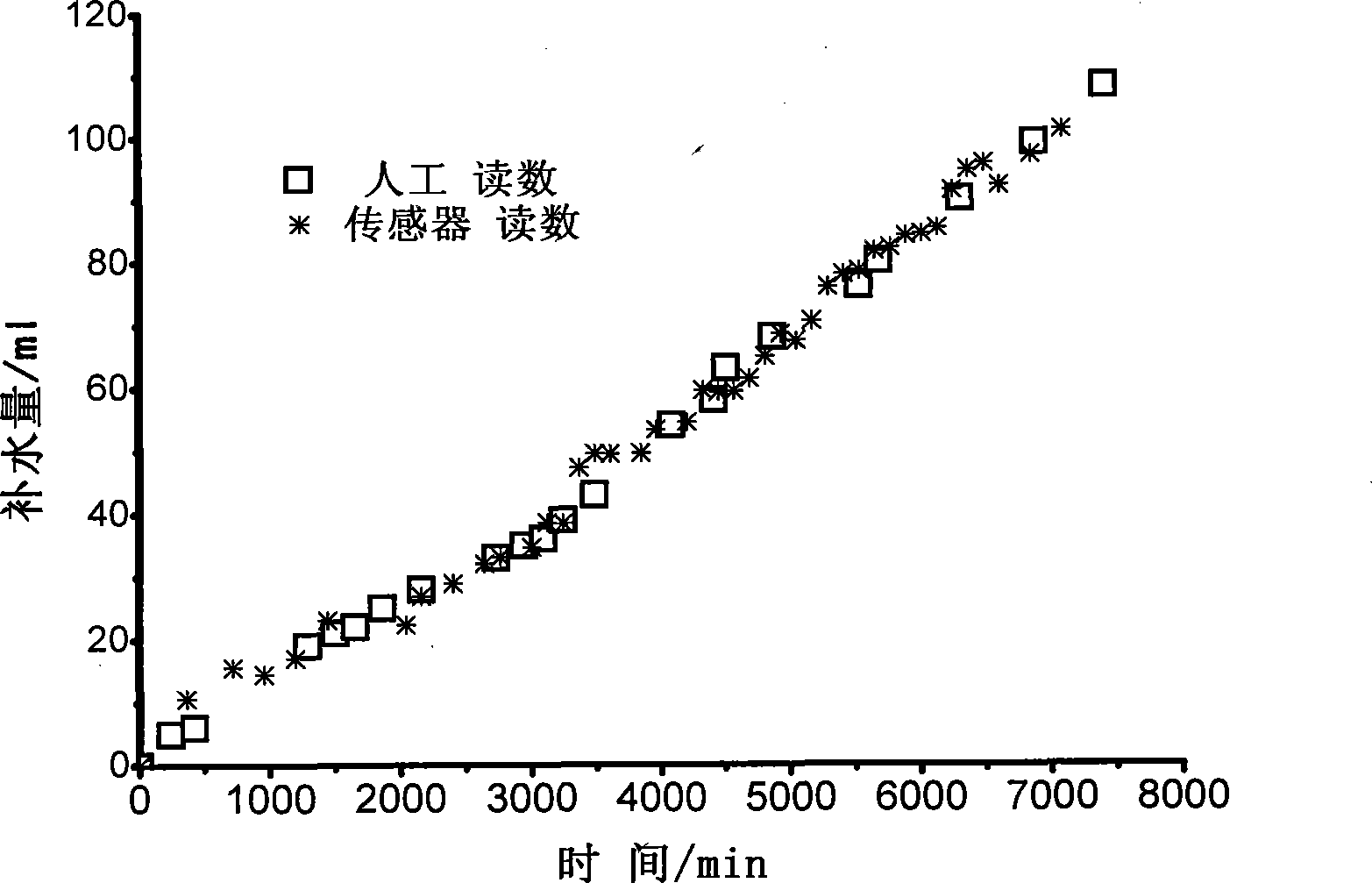

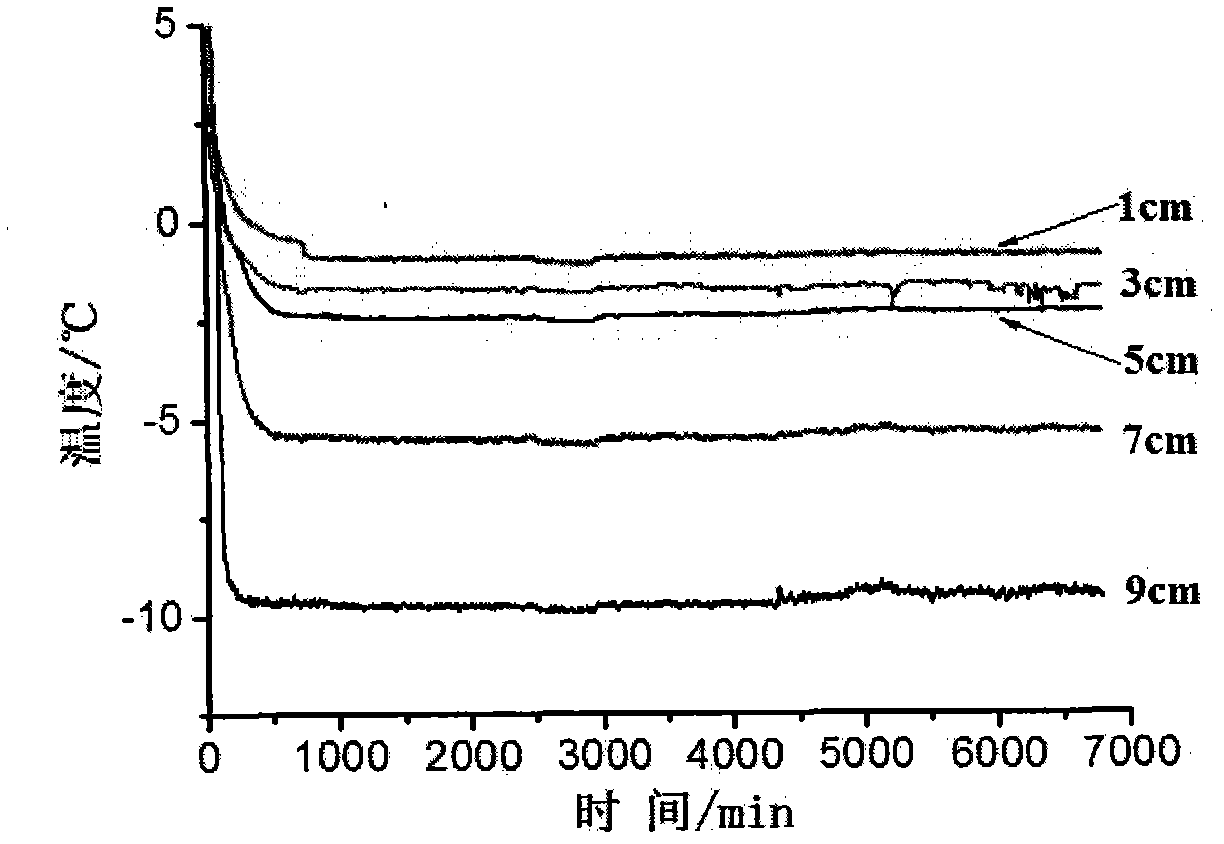

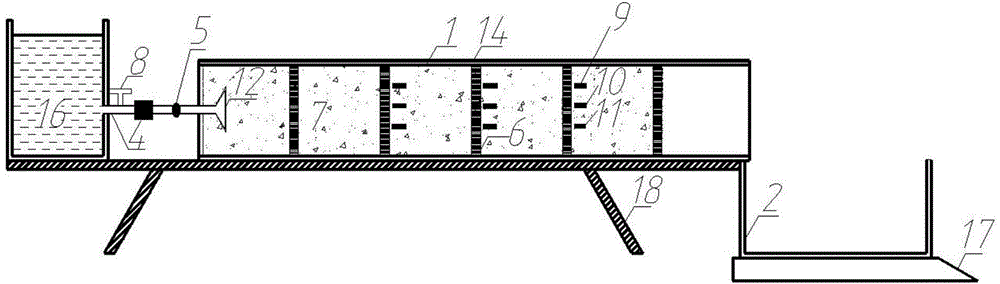

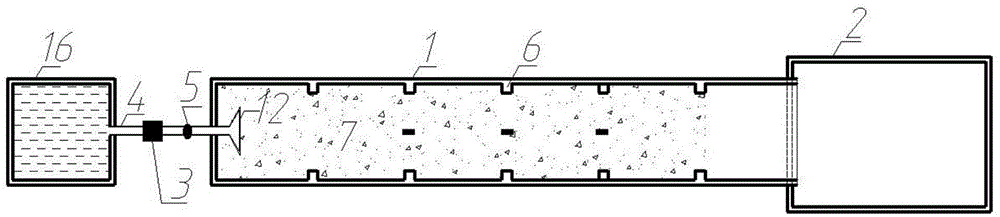

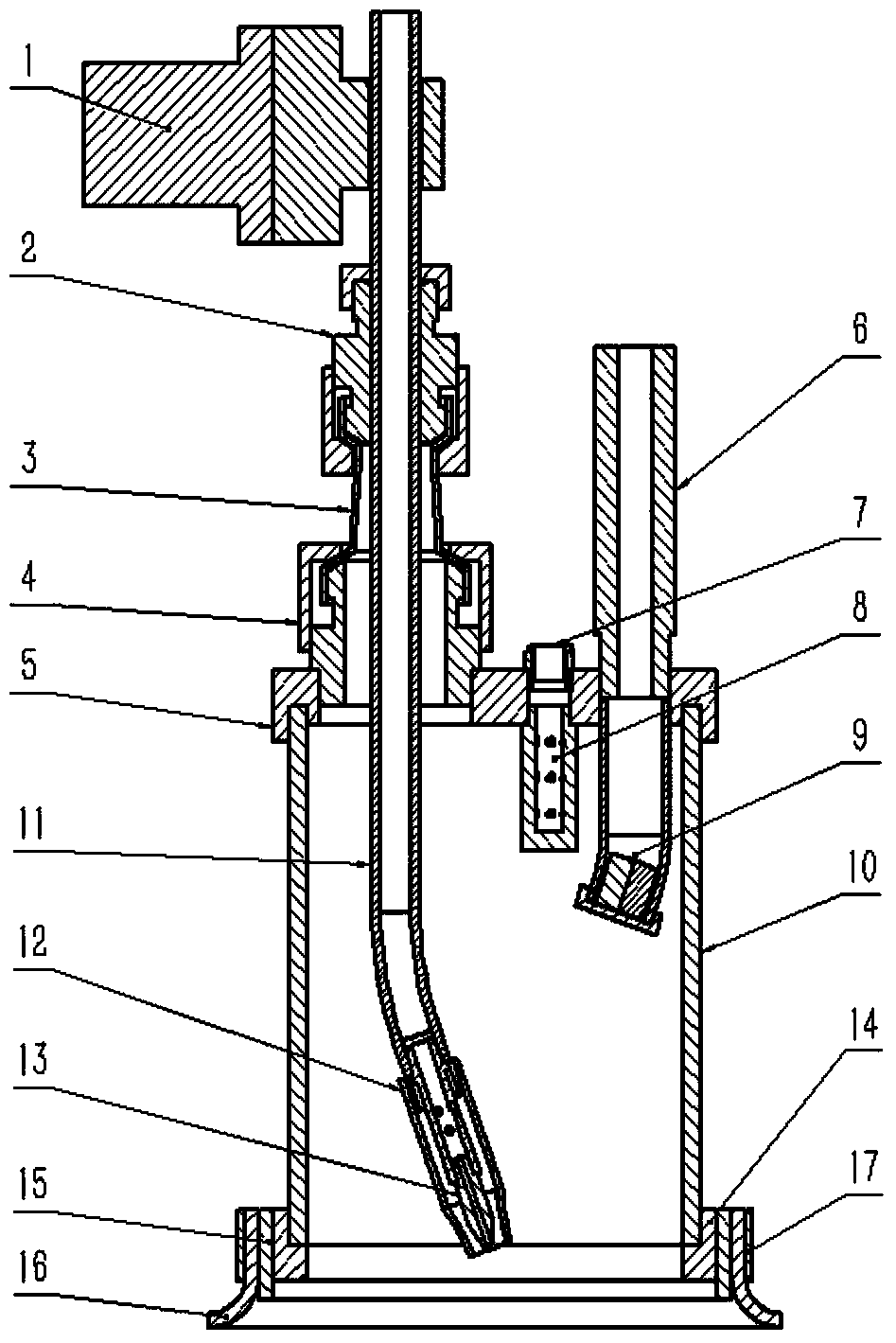

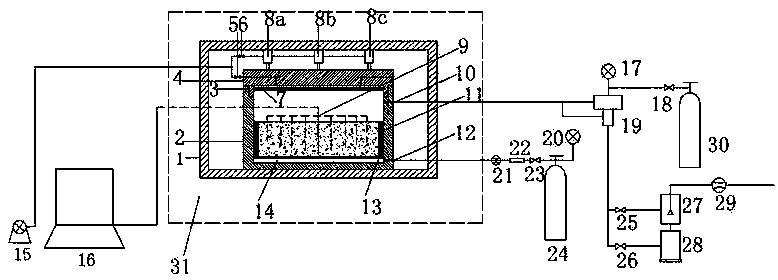

Testing system for deep soil freezing/thawing process

ActiveCN102590468AReduce distractionsMove up and down flexiblyEarth material testingGraduated cylinderCold formed

The invention relates to a testing system for deep soil freezing / thawing process, which is structurally characterized in that a temperature-controlled box is connected with an external cold bath; a high pressure-resistant organic glass cylinder is arranged on a temperature-controllable steel base; two small holes are formed in the base, one is connected with a water guide pipe, and the other is connected with a pressure adjusting pipe; a permeable stone, a piece of filter paper and a sample are sequentially arranged at the upper part of the lower base, and a temperature sensor is mounted in the sample; a temperature-controllable upper press head is arranged at the upper part of the sample; a line leading-out hole is formed in the upper press head, and is sealed through sealant after the line is lead out; the upper press head is connected with the transmission rod of a testing machine; a measuring cylinder is connected with the sample through the water guide pipe; and the measuring cylinder is arranged on a weighing sensor and fixed through a bracket. By adopting the testing system, the freezing / thawing process of the deep soil can be rather systematically researched, so as to obtain the frost heaving rate and the water absorbing / draining rate of the deep soil which is in different depths frozen under the different temperature gradients. The testing system provides the technical guarantee for the research in clarifying the action of the external load on the forming processes of the freezing soil and the frozen soil cold-formed structures, and the mutual action of the temperature, the moisture content and the pressure of the soil body in the process of freezing under the high-pressure action.

Owner:NORTHWEST INST OF ECO ENVIRONMENT & RESOURCES CAS

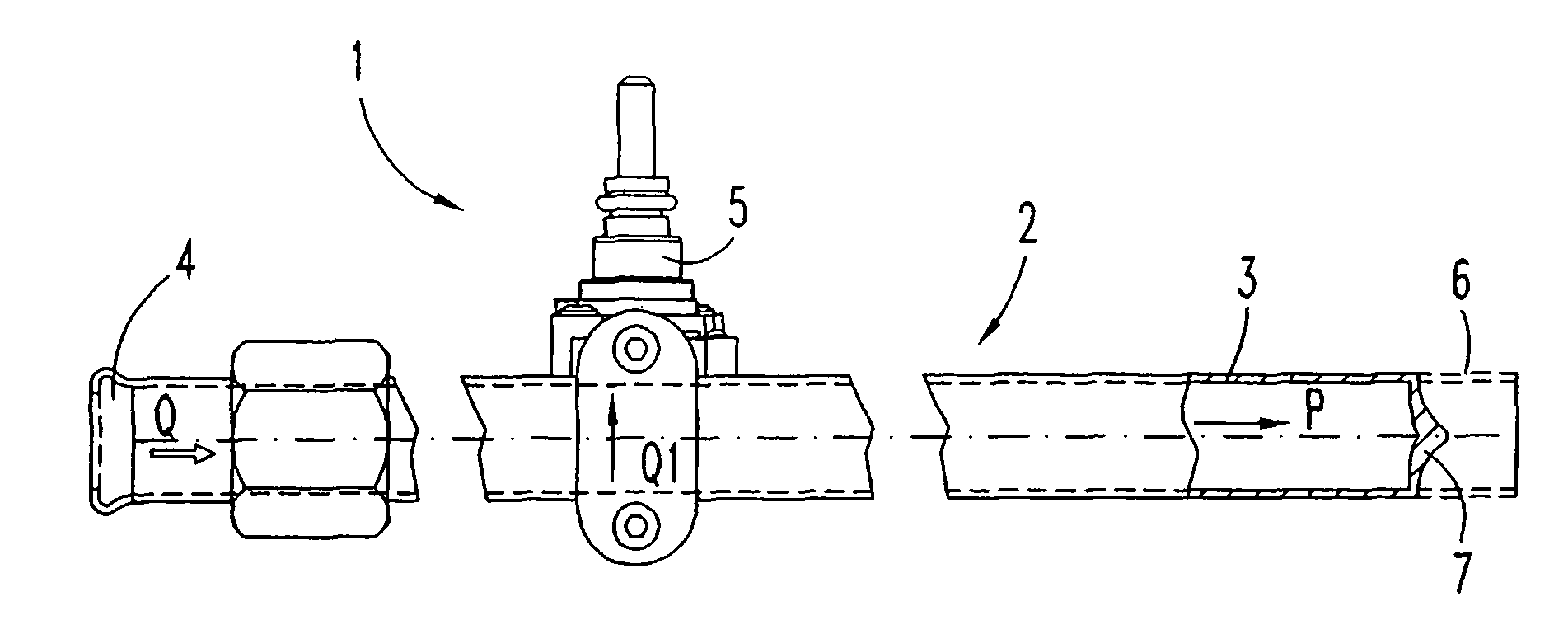

Gas manifold for a cooking range, with a pipe closure

InactiveUS7861706B2Guaranteed tightnessDomestic stoves or rangesStoves/ranges topsFriction weldingEngineering

The gas manifold (1) adapted for installation on a cooking range includes a conduit (2) for distribution of a flow (Q) at a pressure “P”, with a number of regulating taps (5) fixed to the conduit (2). The conduit is made from a metal pipe (3) with a thin cylindrical wall To and the pipe end (6) is sealed without cracks by means of friction welding with no addition of material, with a sealing wall (7) formed by means of a thickening in the form of a tip (7a) in the axial direction of an enlargement or height “H” greater than the original thickness To of the pipe. For making the gastight closure a rotary tool (8) is used that includes at least two rotary rollers (9) for the compaction of the metallic mass between two counterposed centripetal forces (Fr), in combination with an axial stretching force (Fa).

Owner:COPRECITEC

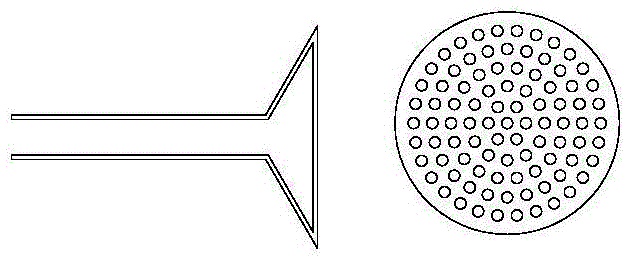

Visual model testing device and method for simulating water gushing in tunnel

ActiveCN104807960AObserving the Progressive Destruction ProcessEasy to fillMaterial analysisModel testingMonitoring system

The invention discloses a visual model testing device and method for simulating water gushing in a tunnel. The device comprises a model test box, a water tank, a high-pressure water pump, a flow meter, a runoff flow and filling collecting device, a digital photographing non-contact measuring system, an osmotic pressure monitoring system, a fiber grating displacement monitoring system and the like. The testing device is characterized in that the catastrophe evolution process of water gushing in the tunnel is simulated, and anti-gushing rock mass crack growth and water gushing channel formation during water gushing can be directly observed. The device can quantitatively research water gushing behavior of the tunnel under different water pressure, different lithological characters and different thicknesses of anti-gushing rock masses, acquire coupling information of multiple fields such as stress fields, displacement fields, seepage fields and the like during water gushing of the tunnel, determine formation processes and forms of water gushing channels under the effect of different factors, disclose mechanical characteristics and evolution laws in anti-gushing rock mass structure progressive failure processes and provide an effective basis for the tunnel water gushing disaster incoming criterion and the minimum safe thickness analysis method.

Owner:CHINA UNIV OF MINING & TECH

Globular titanium micro-powder or ultra-micro powder preparation device and method

The invention belongs to a process for preparing and processing powder material by taking plasma as a heat source, in particular to a process and an apparatus of metal titanium powder material for powder metallurgy, plasma spray, injection forming, gel injection molding and the like. The invention has the advantages that: the adoption of the high temperature spheroidization and rapid condensation special spheroidization technique can improve the sphericity and purity of titanium powder, and both a reactor and the titanium powder spheroidization process are cooled with circulating water, thereby ensuring the sealing performance of equipment, also reducing the use of inert gases, effectively reducing costs, improving the production efficiency and guaranteeing the purity of spherical titanium powder.

Owner:SOUTHWESTERN INST OF PHYSICS

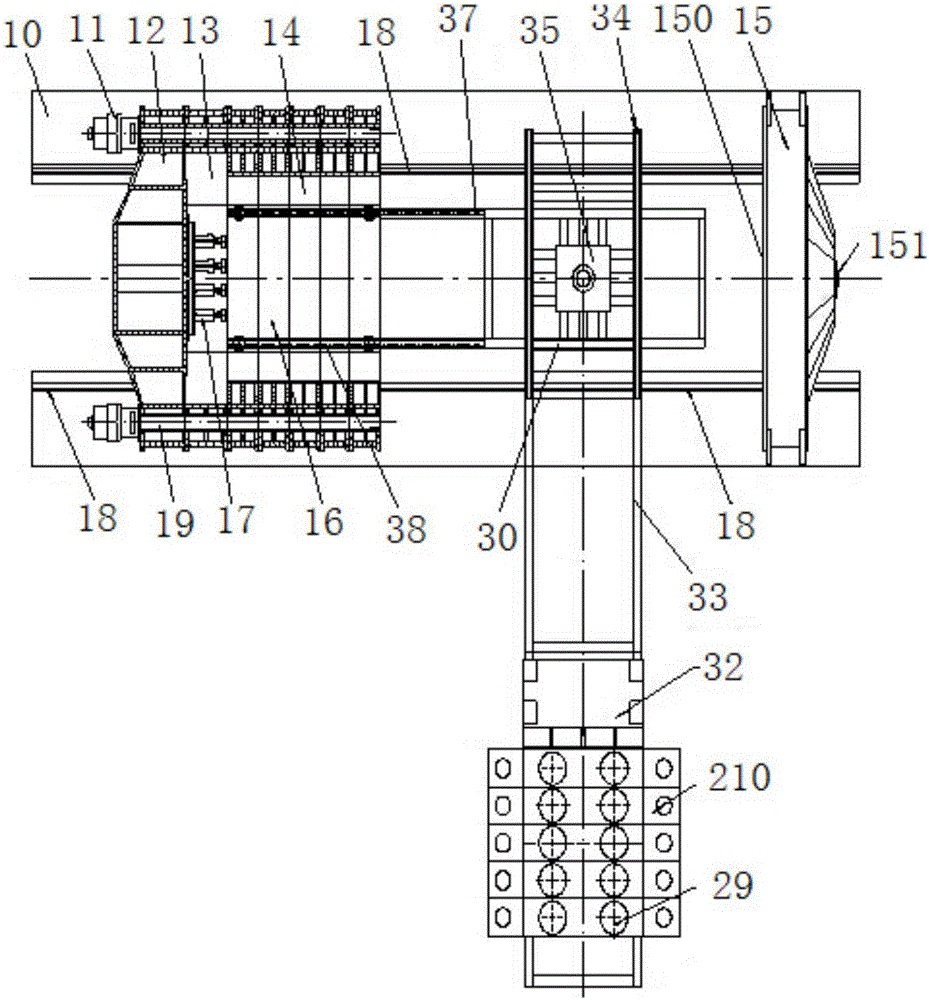

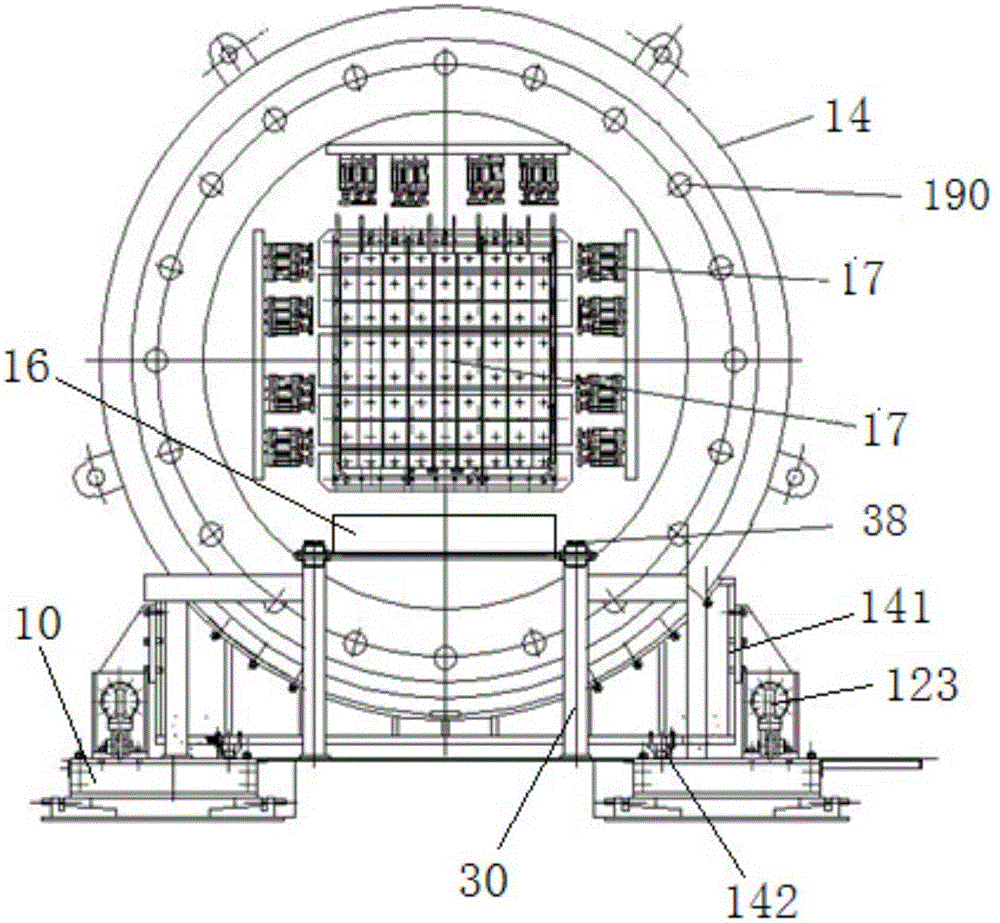

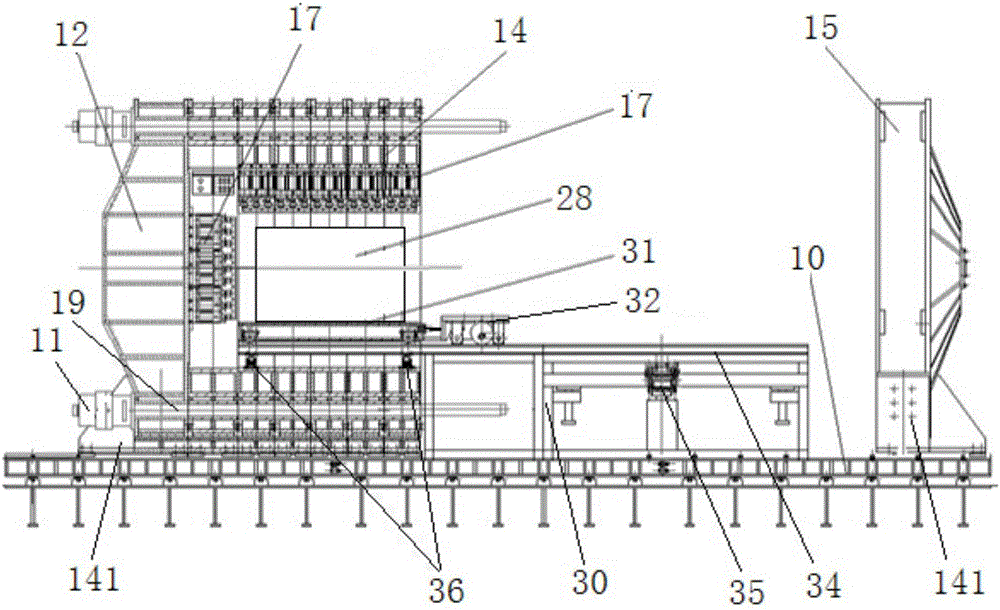

Multifunctional physical simulation test system for coal engineering and coal model test method

ActiveCN106018105AHigh loading tonnageLarge model sizeMaterial strength using tensile/compressive forcesPermeability/surface area analysisTest chamberModel test

The invention relates to a multifunctional physical simulation test system for coal engineering. The system comprises a test chamber, a model forming subsystem, a hydraulic loading control subsystem, a test subsystem and a gas pumping and injecting subsystem, wherein the test chamber comprises a loading frame and a counterforce cover detachably connected to one end of the loading frame; the loading frame and the counterforce cover are coaxially mounted on a base; a guide rail is arranged on the base in an axial direction of the loading frame; and support seats capable of sliding along the guide rail are mounted on the guide rail and are mounted at bottoms of the loading frame and the counterforce cover respectively; a track conveying subsystem for conveying models is detachably connected between the model forming subsystem and the test chamber. The invention further provides a coal model test method. According to the multifunctional physical simulation test system for coal engineering and the coal model test method, operation such as drilling, joint forming, fracturing, coal and gas outburst, excavation and support of underground construction and the like under actions of crustal stress, gas pressure and comprehensive multiple factors can be simulated, and an experimental verification means is provided for coal and gas outburst related occurrence mechanism, prediction and control.

Owner:CHONGQING UNIV

Gas extraction secondary high-pressure slip-casting hole-sealing apparatus and its hole-sealing method

InactiveCN101482026AImprove pressure bearing capacityImprove sealingGas removalSealing/packingDrill holeHigh pressure

A secondary high-press pulp injection and hole sealing device for collecting gas comprises collection pipes, bags and a secondary pulp inflow device, wherein collection pipes are connected with two sides of the secondary pulp inflow device; plugs are sleeved on the collection pipes; the bags are located between each plug and the secondary pulp inflow device; three pulp inflow holes having unidirectional valves are arranged on the secondary pulp inflow device; the pulp inflow holes on the two sides communicate with the bags on the same side; and the pulp inflow hole in the middle spatially communicates with the bags. A method of using the device for pulp injection and hole sealing comprises the following steps of: inserting a pulp injection plug in the secondary pulp injection device and performing the low-pressure pulp injection to the pulp inflow holes that communicate with the bags; and after the injected pulp is solidified, performing the high-pressure pulp injection to the pulp inflow hole in the middle of the secondary pulp inflow device by using the pulp injection plug. The invention adopts the pulp injection materials to inject the pulp to the drill hole wall so as to seal the drill hole wall and the peripheral deflated passages thereof, and basically eliminates the drill deflated cracks through the primary low-pressure pulp injection and the secondary high-pressure pulp injection close to the ground stress.

Owner:HENAN POLYTECHNIC UNIV

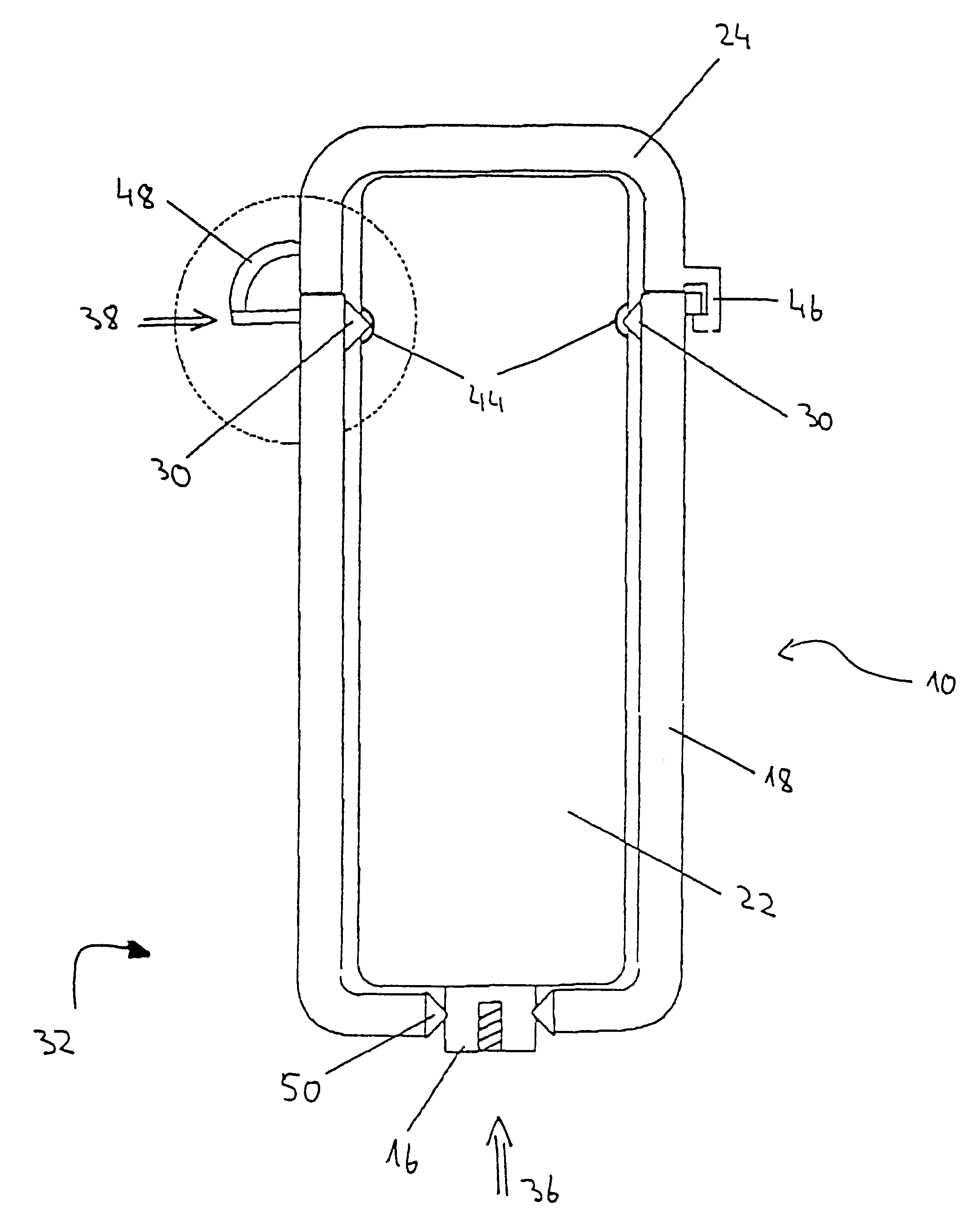

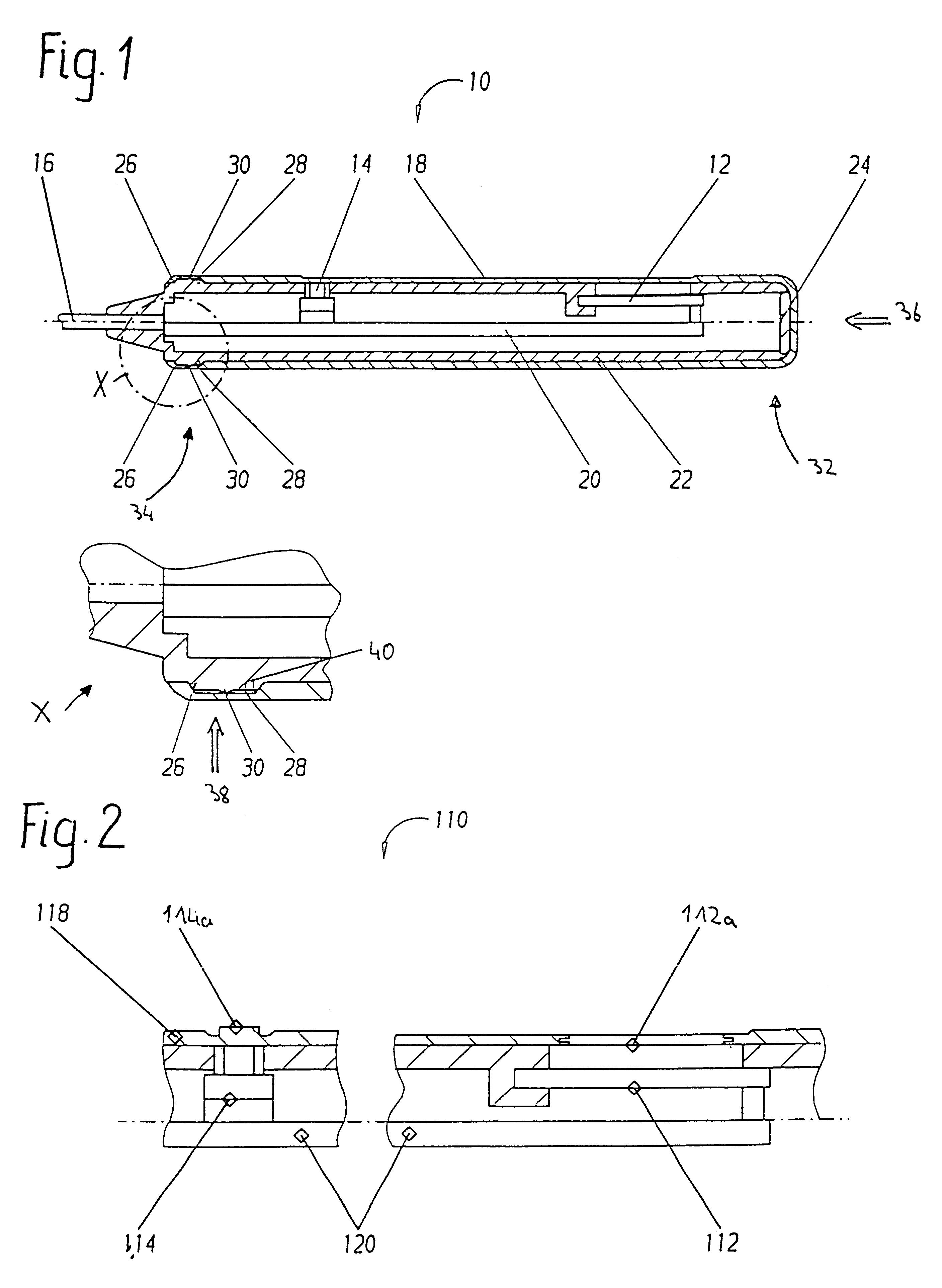

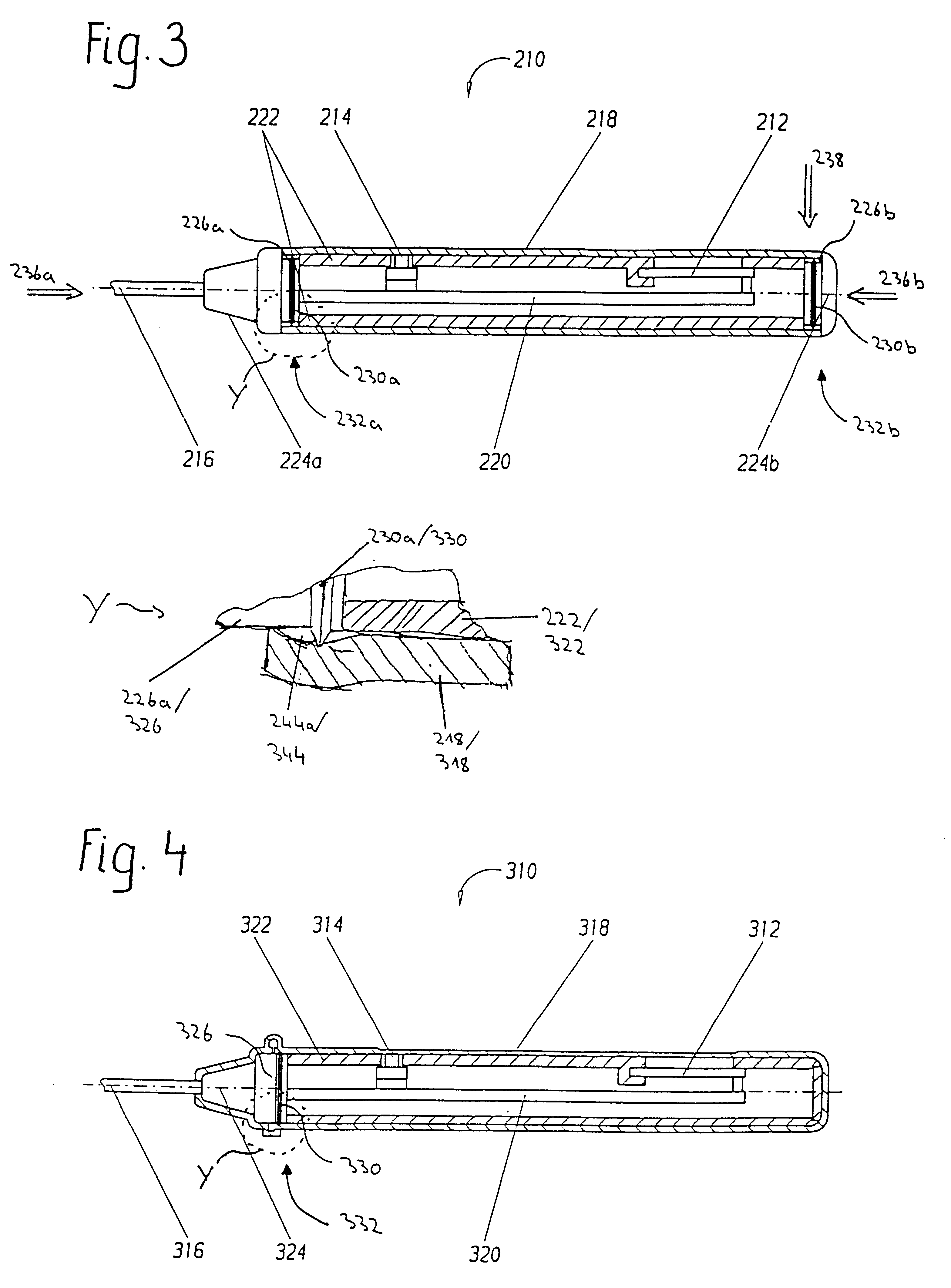

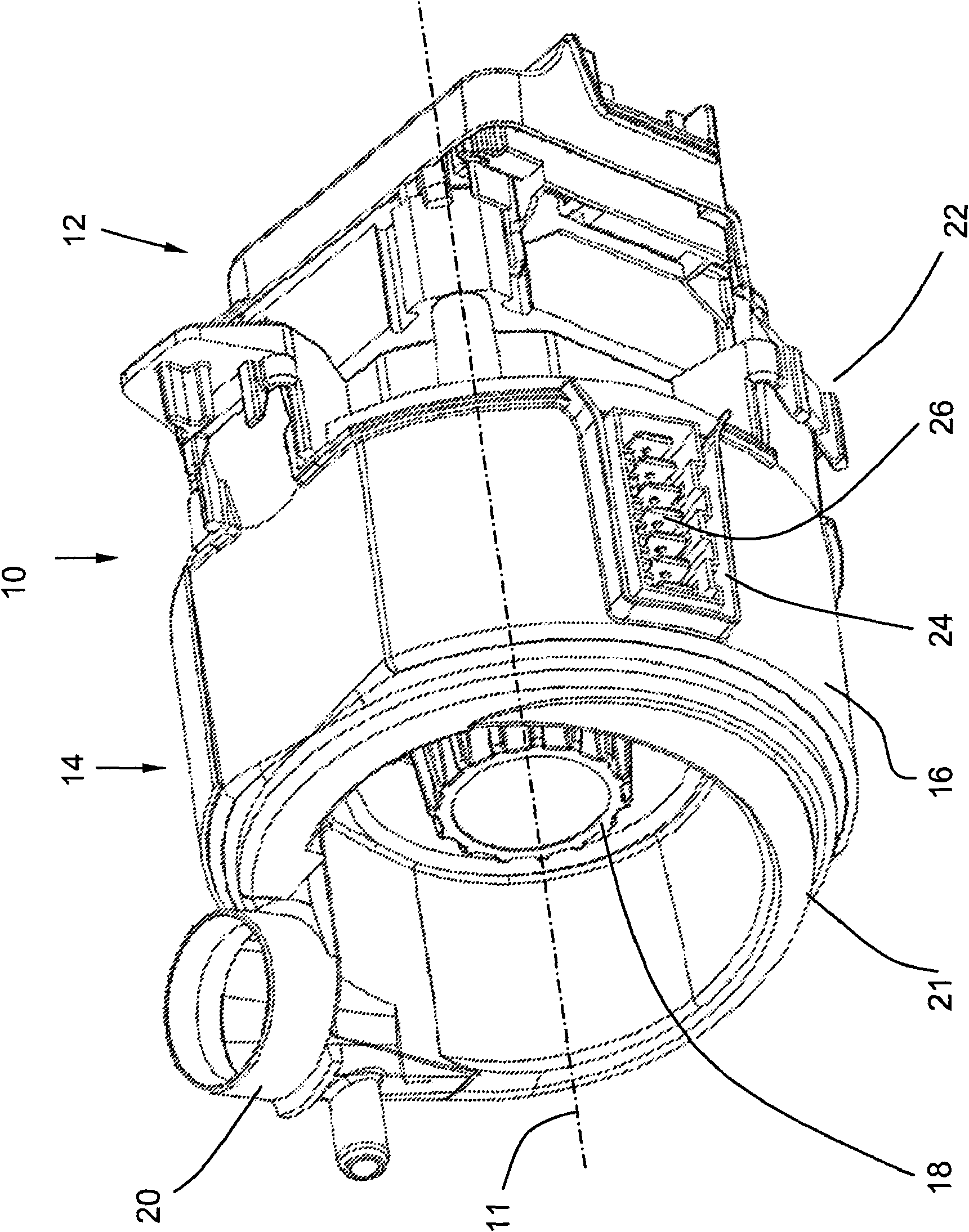

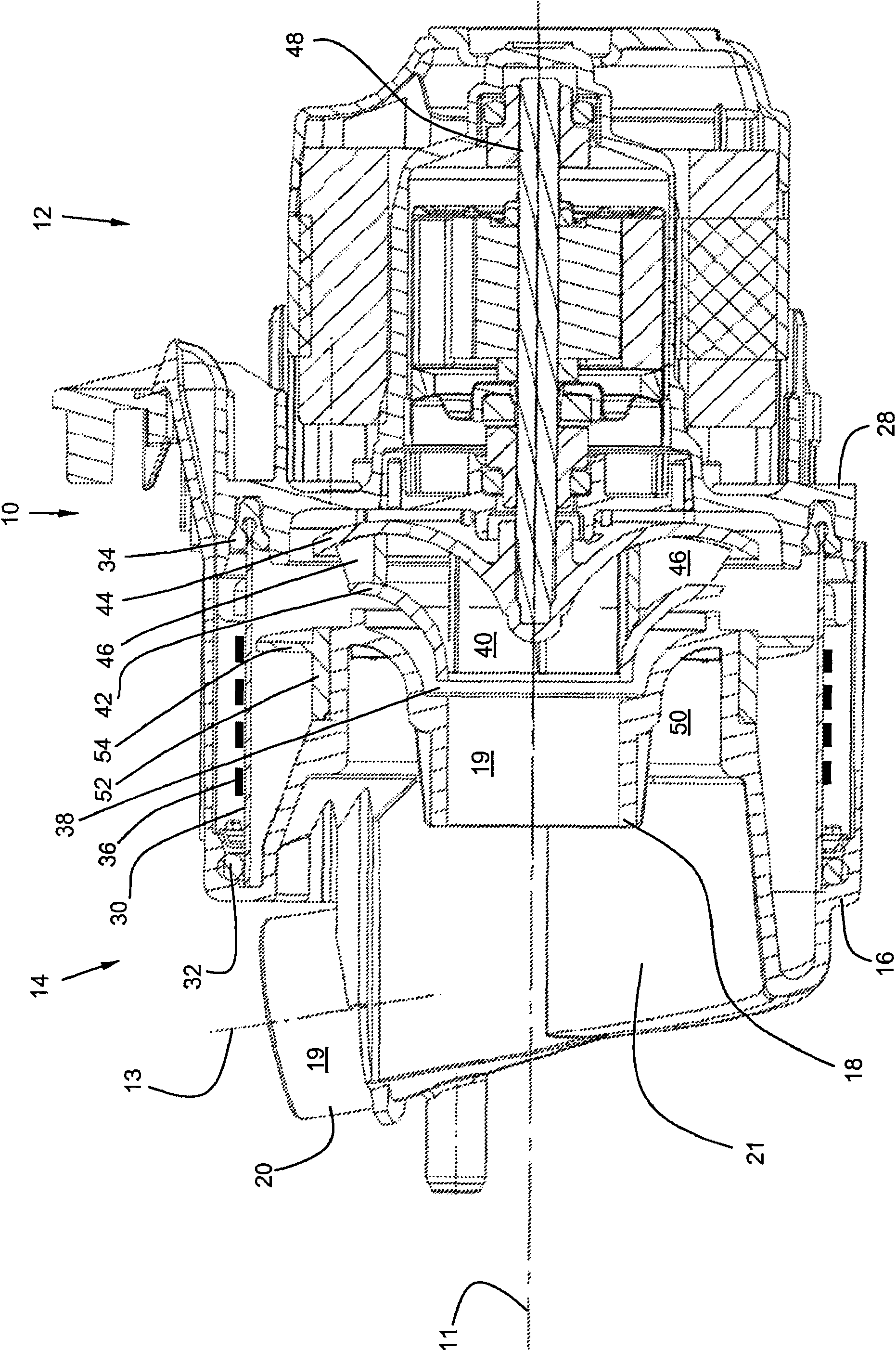

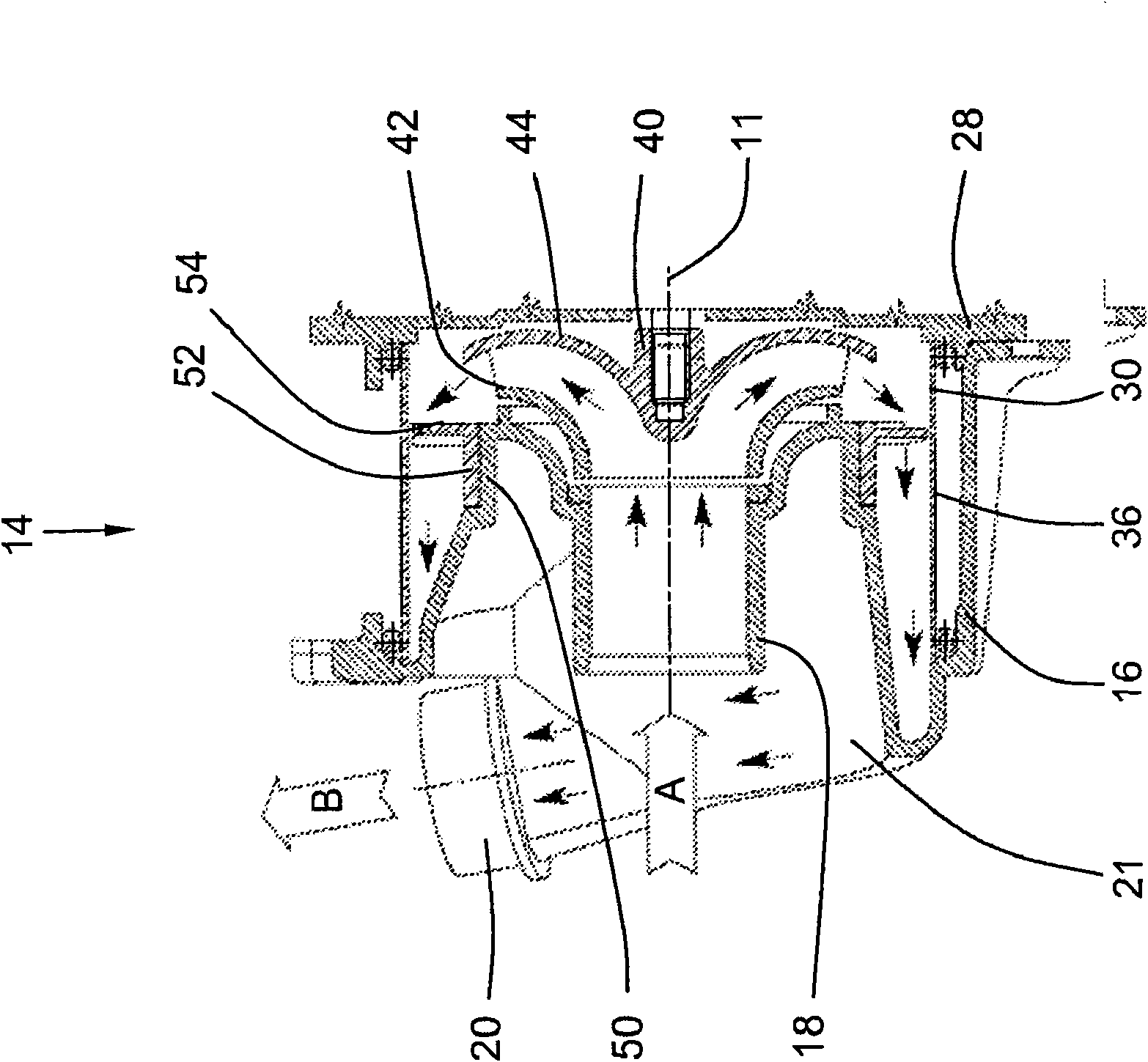

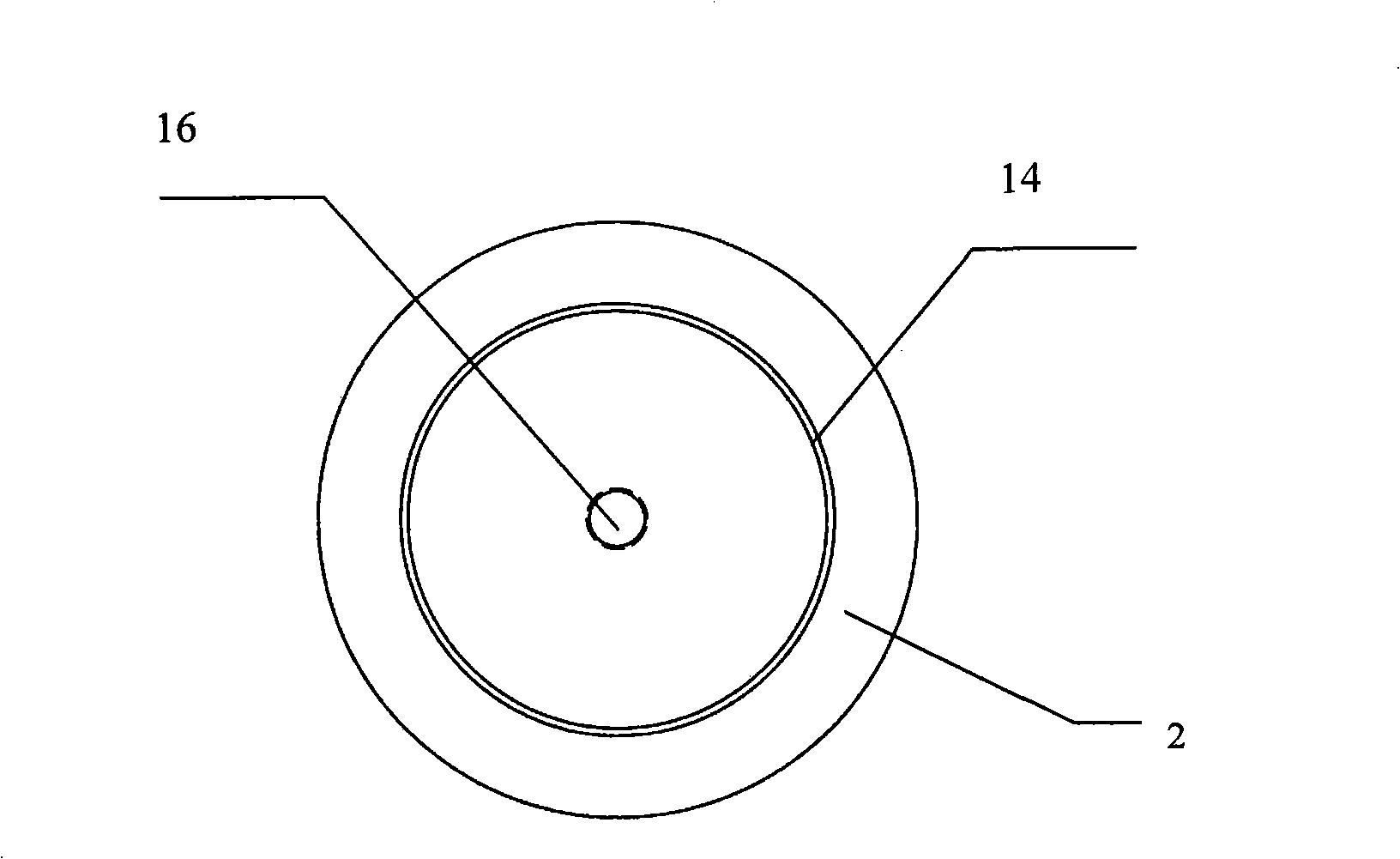

Pump having a heating device

ActiveCN101657137AHeating evenlyEasy to replaceTableware washing/rinsing machine detailsPump componentsImpellerDevice form

The present invention relates to a pump (10, 110), particularly for dishwashers, comprising a housing made of a housing bottom (28, 128), a housing cover (16, 116), and a heating device (30, 130, 36,136) disposed in between the bottom and cover for heating a washing fluid, the device forming a ring-shaped side wall of the housing, further comprising an impeller (40, 140) arranged in the housing,an intake connection (18, 118) arranged axially in the housing cover (16, 116) relative to the axis of rotation of the impeller (40, 140), and a pressure connection (20, 120), wherein the pressure connection (20, 120) is arranged in the housing cover (16, 116).

Owner:BOSCH SIEMENS HAUSGERATE GMBH

Special portable miniature drainage cover for automatic underwater local dry-method welding

InactiveCN103433606ARealize free adjustmentAvoid unfusedElectrode supporting devicesWelding accessoriesEngineeringCopper

The invention provides a special portable miniature drainage cover for automatic underwater local dry-method welding. A drainage cover body of the drainage cover comprises an upper end cover, an organic glass cover and a lower end cover. A clamping rod, an air inlet quick plug connector, a lower locking sleeve, a cooling air chamber and an underwater camera component are fixed to the upper side of the upper end cover and the lower side of the upper end cover through threaded connection respectively, and the upper end cover and lower end cover are connected with the organic glass cover through threads. A welding oscillator is clamped on the upper portion of a copper welding torch of a welding gun. According to the structure of a drainage sealing device, drainage felt and a felt skirt are arranged on the periphery of the lower end cover, and the drainage felt and the felt skirt are fastened on the lower end cover through hose clamps; the copper welding torch of the welding gun is fastened through an upper locking sleeve and the lower locking sleeve, the welding gun is inserted into the organic glass cover, and an elastic rubber leather sheath is arranged between the upper locking sleeve and the lower locking sleeve. The special portable miniature drainage cover for automatic underwater local dry-method welding has the advantages of being simple in structure, exquisite, convenient and fast to use, low in cost, obvious in drainage effect, and stable and reliable in welding process. Moreover, a connector with the quality of on-land welding is formed, the welding efficiency is improved and the special portable miniature drainage cover is easy to popularize.

Owner:TIANJIN UNIV

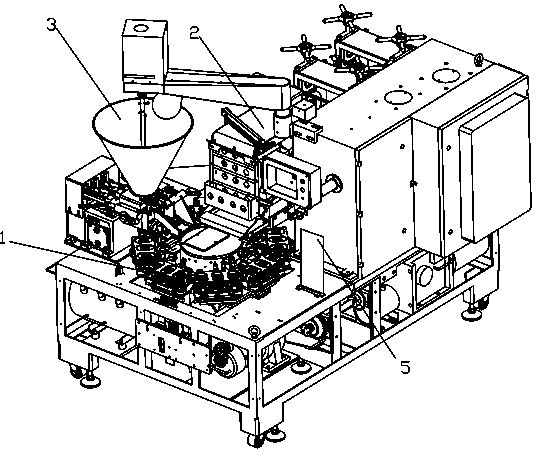

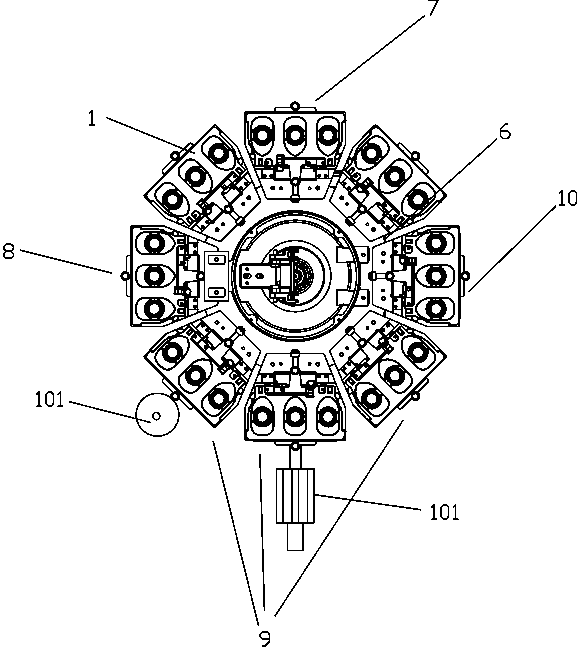

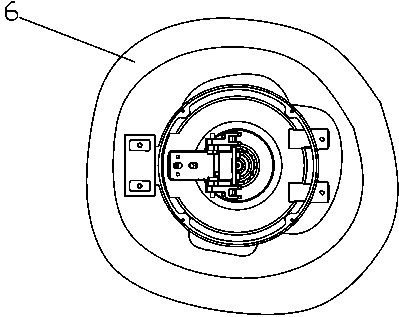

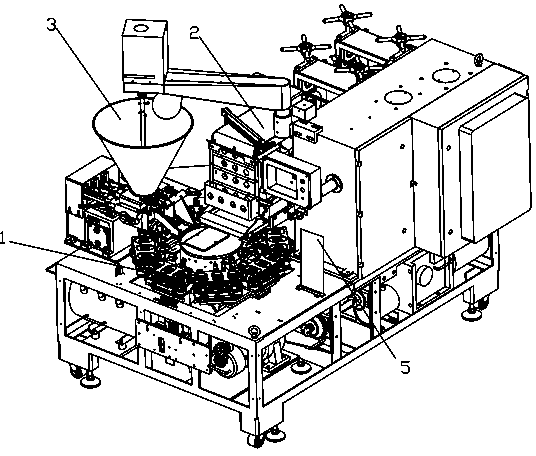

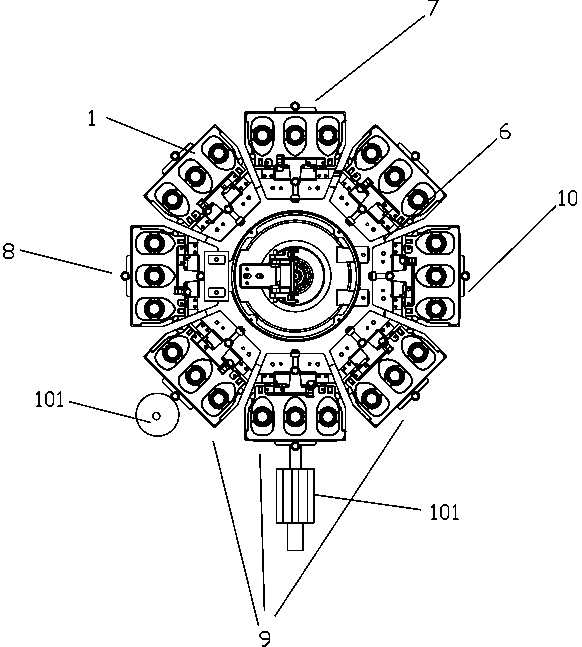

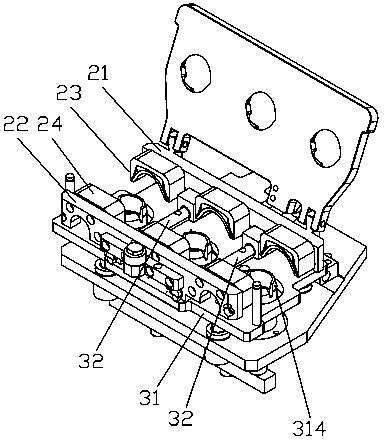

Farci food forming machine

The invention belongs to the technical field of food processing, and particularly relates to a farci food forming machine. The farci food forming machine comprises a stander and a flour wrapper transporting device, a stuffing feeding device, a flour wrapper receiving plate, a withdrawing device and an annular track arranged on the stander, wherein the flour wrapper transporting device, the stuffing feeding device and the withdrawing device are respectively and fixedly arranged on the flour receiving station, the stuffing injecting station and the withdrawing station of the annular track, the flour wrapper receiving plate capable of moving around the annular track is arranged on the annular track, a die assembly device is arranged under the flour wrapper receiving plate, the die assembly device of the farci food forming machine can provide a persistent press force when the farci food is processed, so that the compactness of the fit part of the flour wrapper of the farci food can be guaranteed, and the flour wrapper can not be opened after being pressed for a long time, so that the yield of the farci food can be guaranteed.

Owner:CHENGDU SOONTRUE MECHANICAL EQUIP CO LTD

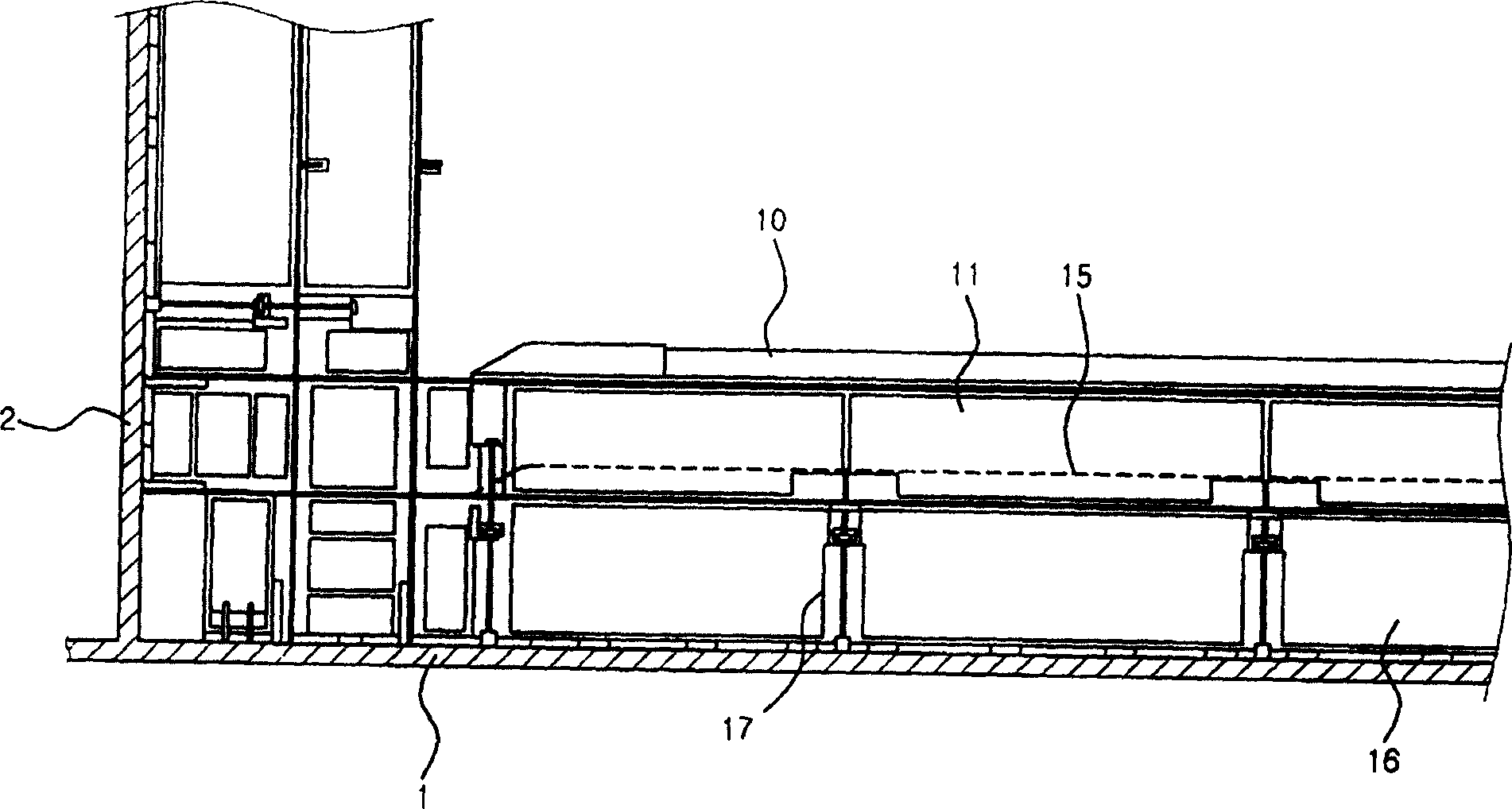

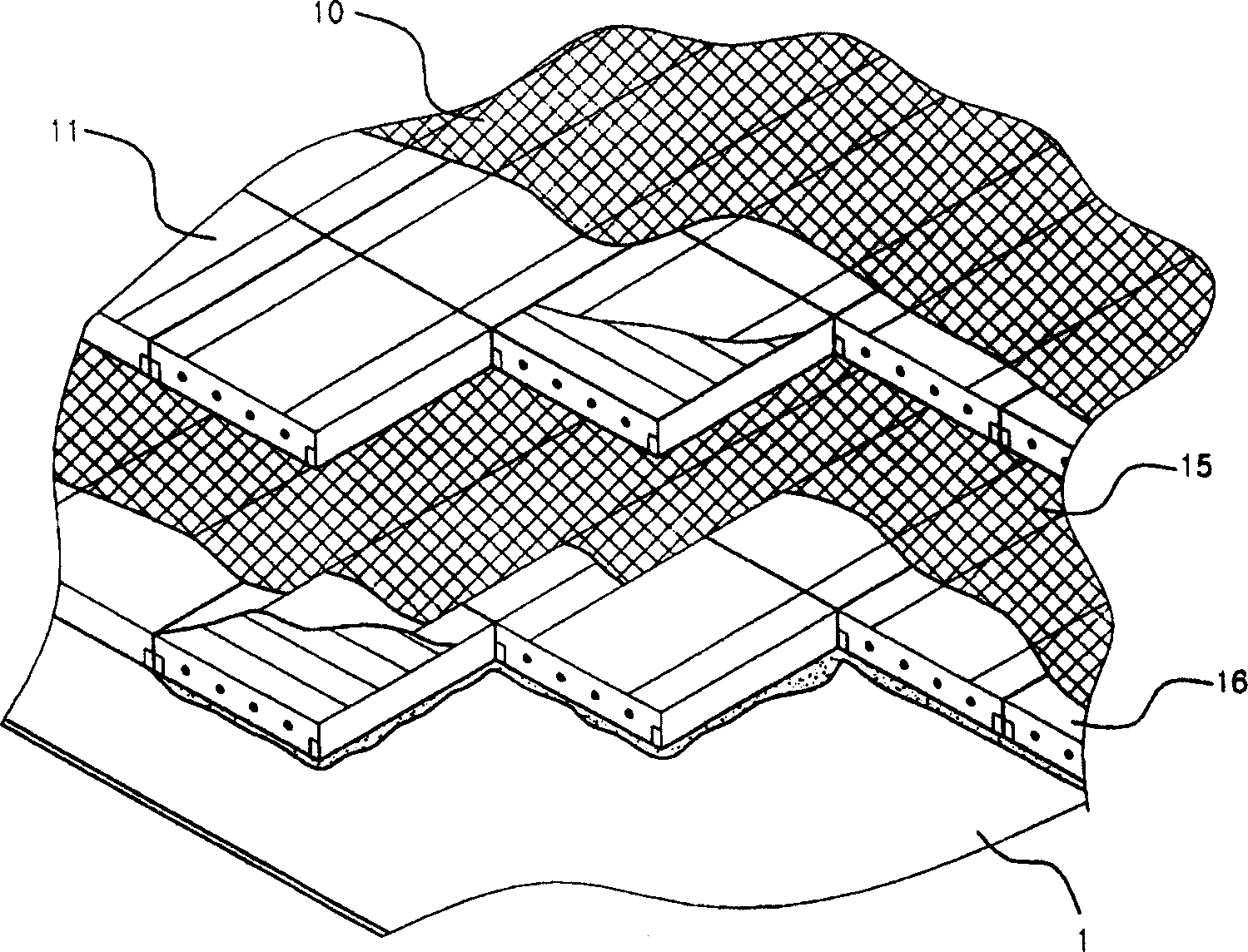

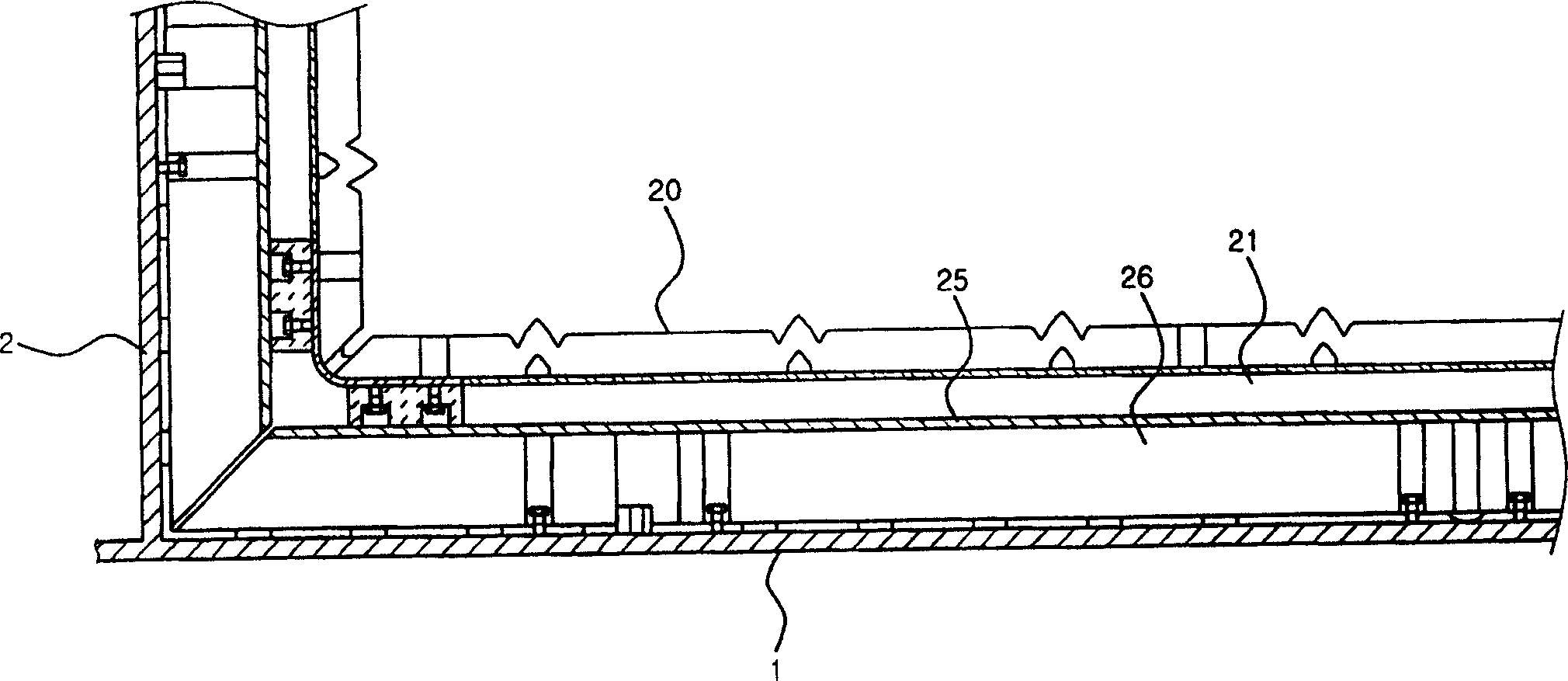

Lng storage tank and constructing method thereof

InactiveCN1898124AMaintain liquid-tight propertiesAvoid breakingContainer filling methodsRailway vehiclesEngineeringStructural engineering

Disclosed is a liquid container adapted to store liquefied natural gas (LNG). The LNG storage container include a sealing wall directly contacting liquid contained in the tank and a structural wall, which is an exterior wall or inner structure integrated with the exterior wall. The container further includes a plurality of connectors mechanically connecting the sealing wall and the structural wall and an intermediate wall structure positioned between the structural wall and the interior wall. The intermediate wall structure is configured to move relative to at least one of the interior wall and the structural wall.

Owner:KC LNG TECH CO LTD ENTIRE RIGHT

Stuffed food forming method

The invention belongs to the technical field of food processing and in particular relates to a stuffed food forming method. The stuffed food forming method comprises the following steps: 1, allowing a wrapper receiving plate to be positioned at a wrapper receiving station of an annular rail, and conveying the wrapper to the wrapper receiving plate at the wrapper receiving station through a wrapper conveying device; 2, moving the wrapper receiving plate and a die assembly device to a stuffing injection station on the annular rail, and injecting the stuffing on the surface of the wrapper through a stuffing injection device; 3, mutually closing die assembly blocks which are positioned on the die assembly device below the wrapper receiving plate and are opposite to each other, coating and forming stuffed foods, and continuously keeping the two closed die assembly blocks be in the state; and 4, simultaneously moving the wrapper receiving plate and the die assembly device to a taken-out station on the annular rail, so that the wrapper receiving plate is opened, and the die assembly blocks which are always positioned in a closed state are separated. According to the die assembly device in the method, continuous pressing force can be provided for the stuffed foods in the processing process, the tightness on the joint part of the wrapper of the stuffed foods can be guaranteed, the wrapper is not open after being pressed for a long time, and the forming rate of the stuffed foods is guaranteed.

Owner:CHENGDU SOONTRUE MECHANICAL EQUIP CO LTD

T/R assembly integrated air tightness packaging structure resistant to overload

ActiveCN103824816AAll-in-one packagingMiniaturizationAntenna supports/mountingsSemiconductor/solid-state device detailsMicrowaveMiniaturization

The invention discloses a T / R assembly integrated air tightness packaging structure resistant to overload. The T / R assembly integrated air tightness packaging structure resistant to overload comprises a cylindrical shell, a groove used for containing an antenna is formed in one end of the shell, the other end of the shell is provided with a cavity used for containing a signal processing unit, and the cavity is sealed by a cover board. An installation hole used for installing a microwave insulator is reserved in the portion, clamped between the groove and the cavity, of the shell and the microwave insulator is arranged in the installation hole through eutectic welding. Wires on the two sides of the microwave insulator are connected with the antenna and a signal processing unit substrate respectively. According to the T / R assembly integrated air tightness packaging structure resistant to overload, miniaturization and integration of a radio frequency / microwave T / R assembly are achieved. The microwave insulator is sintered on the metal shell in a gold-tin eutectic welding mode and matched with parallel seam welding (or laser welding) air tightness packaging, the sealing performance of a cavity of the signal processing unit can be guaranteed, and the reliability of the assembly can be improved. Transmission between the sending / receiving antenna and the signal processing unit is conducted through the microwave insulator, the transmission distance is shortened, and the microwave characteristic of a circuit is improved.

Owner:EAST CHINA INST OF OPTOELECTRONICS INTEGRATEDDEVICE

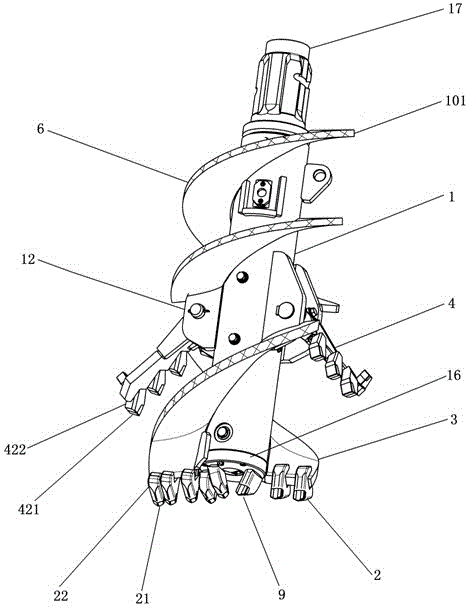

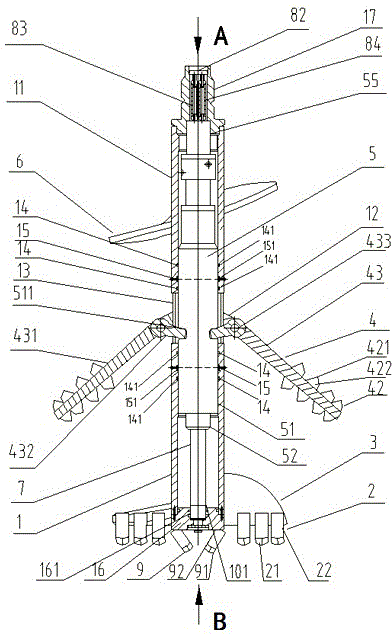

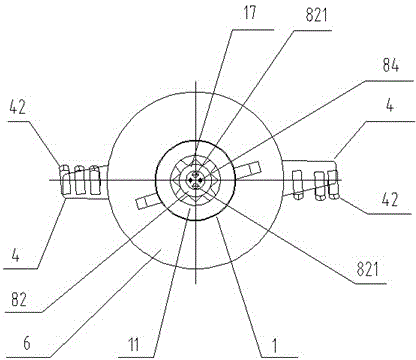

Hole expanding drill bit

The invention provides a hole expanding drill bit. The hole expanding drill bit comprises a drilling rod, a plurality of cutter bodies, hole expanding wings, lower blades, an expanding oil cylinder, an upper blade, a slurry tube and a hydraulic oil tube assembly, wherein the cutter bodies are fixed on the blades; the lower blade is horizontally uniformly distributed and fixed on the peripheral surface of the lower part of the drilling rod in a radial form; the hole expanding wings are positioned above the lower blade and symmetrically formed along the drilling rod in the radial direction; an oscillating rod is mounted on a pin seat on the peripheral surface of the drilling rod through a hinge pin pivotal shaft, and the end of the oscillating rod is positioned into a groove in a cylinder barrel; the slurry tube is positioned in holes of a piston and a piston hole of the expanding oil cylinder. According to the hole expanding drill bit, the combined drilling and excavating structure is adopted; the hole expanding wings can be opened by operating the expanding oil cylinder while expanding the bottom or hole, besides the function of drilling and excavating general piles with the same section, so that the pile end of a bearing file and the section area of a pile body can be increased; the drill bit can be used for building various bottom expanding piles and calabash piles, and has the characteristics of being high in single pile bearing capacity, ensuring the pile diameter, and being convenient to construct, stable and reliable to work, and long in service life.

Owner:上海工程机械厂有限公司

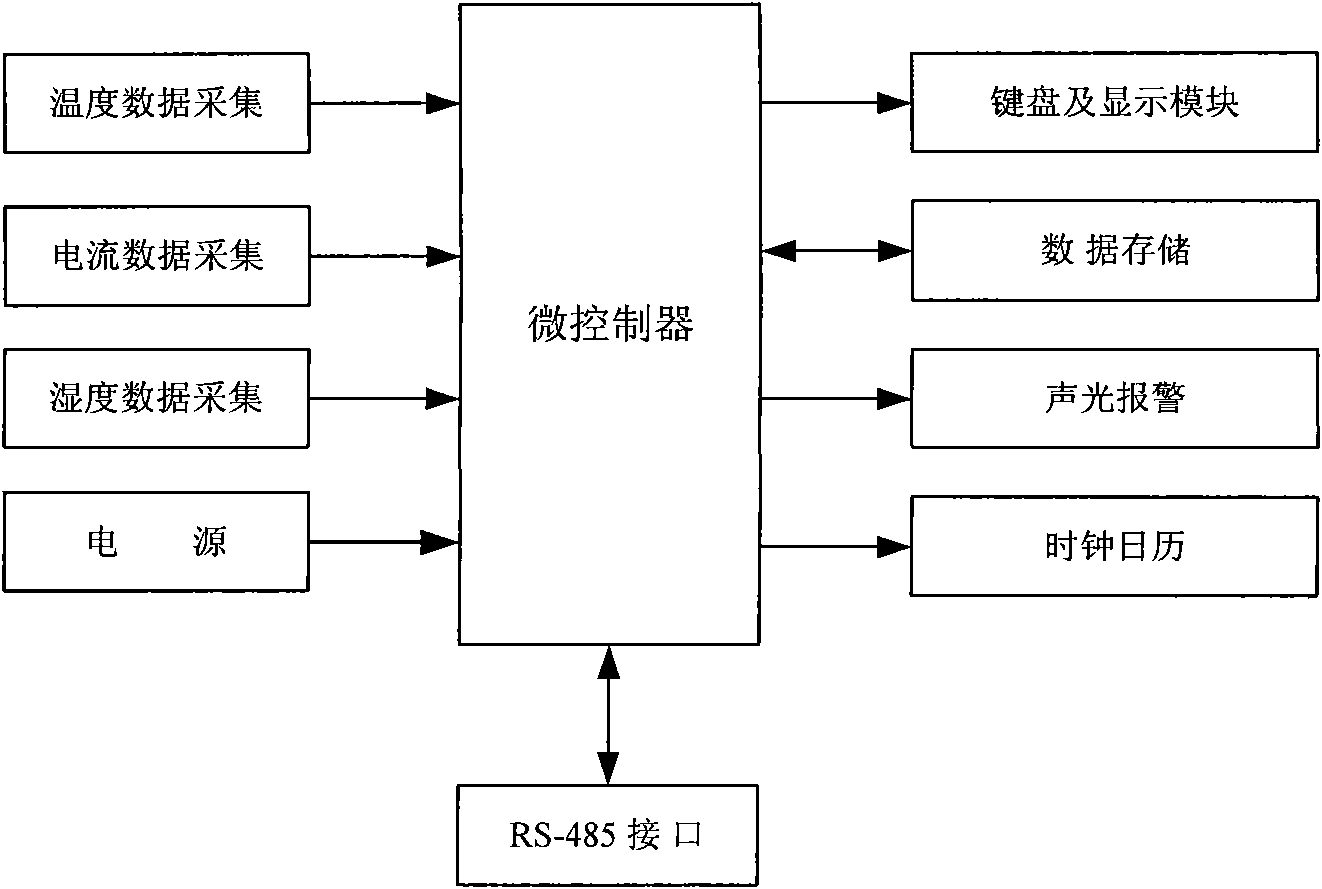

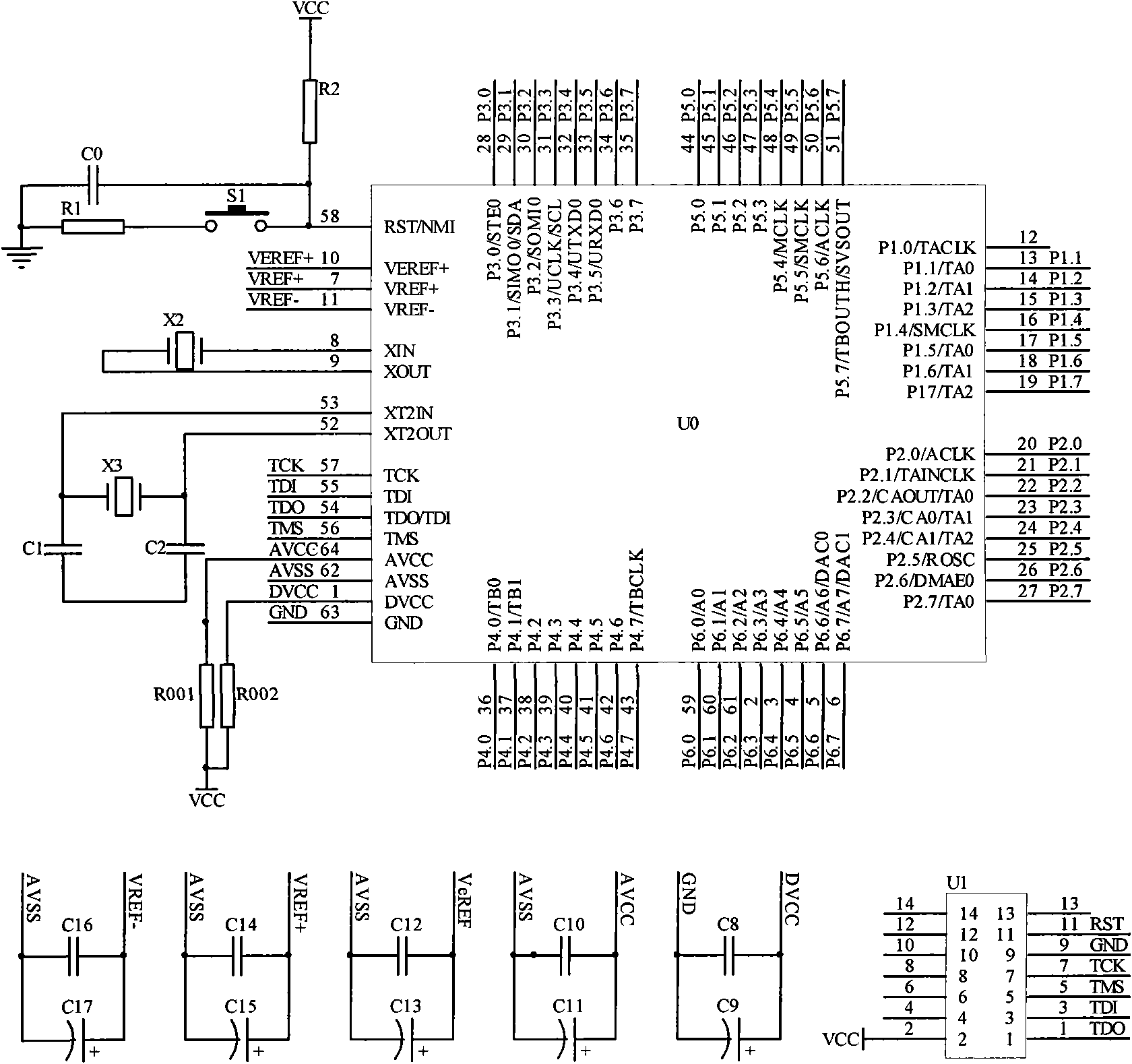

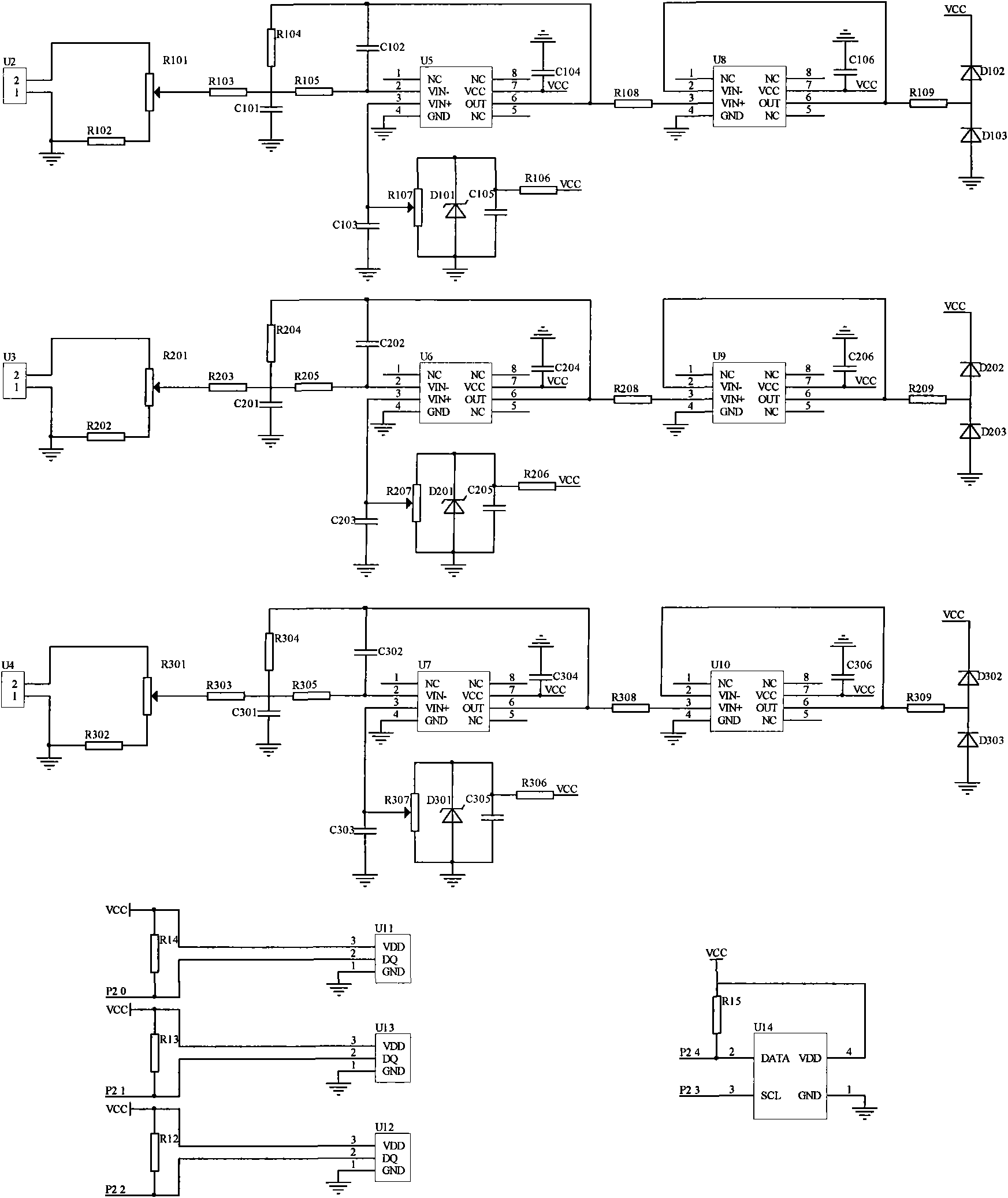

Monitoring device used for high voltage cable connector status in mine roadway

InactiveCN101614597ASolve the problem of online monitoringSimple structureCurrent/voltage measurementThermometers using electric/magnetic elementsMicrocontrollerElectric power equipment

The invention provides a monitoring device which is used for the high voltage cable connector status in a mine roadway, wherein, a temperature sensor, a humidity sensor and a current transformer are connected with a data acquisition unit through signal wires; the data acquisition unit, a data storage unit, a keyboard, a display unit, a clock unit and an acousto-optic warning unit are connected with a microcontroller unit through an I / O port; and the microcontroller unit is formed by the connection between a serial port and a communication unit. The invention is simple in structure, low in cost, safe and reliable in performance, and can monitor the temperature, current and humidity of the cable connector in real time, thus being applicable to the monitoring of high pressure cable connection device in the mine roadway and other high voltage electric power equipment.

Owner:TAIYUAN UNIV OF TECH

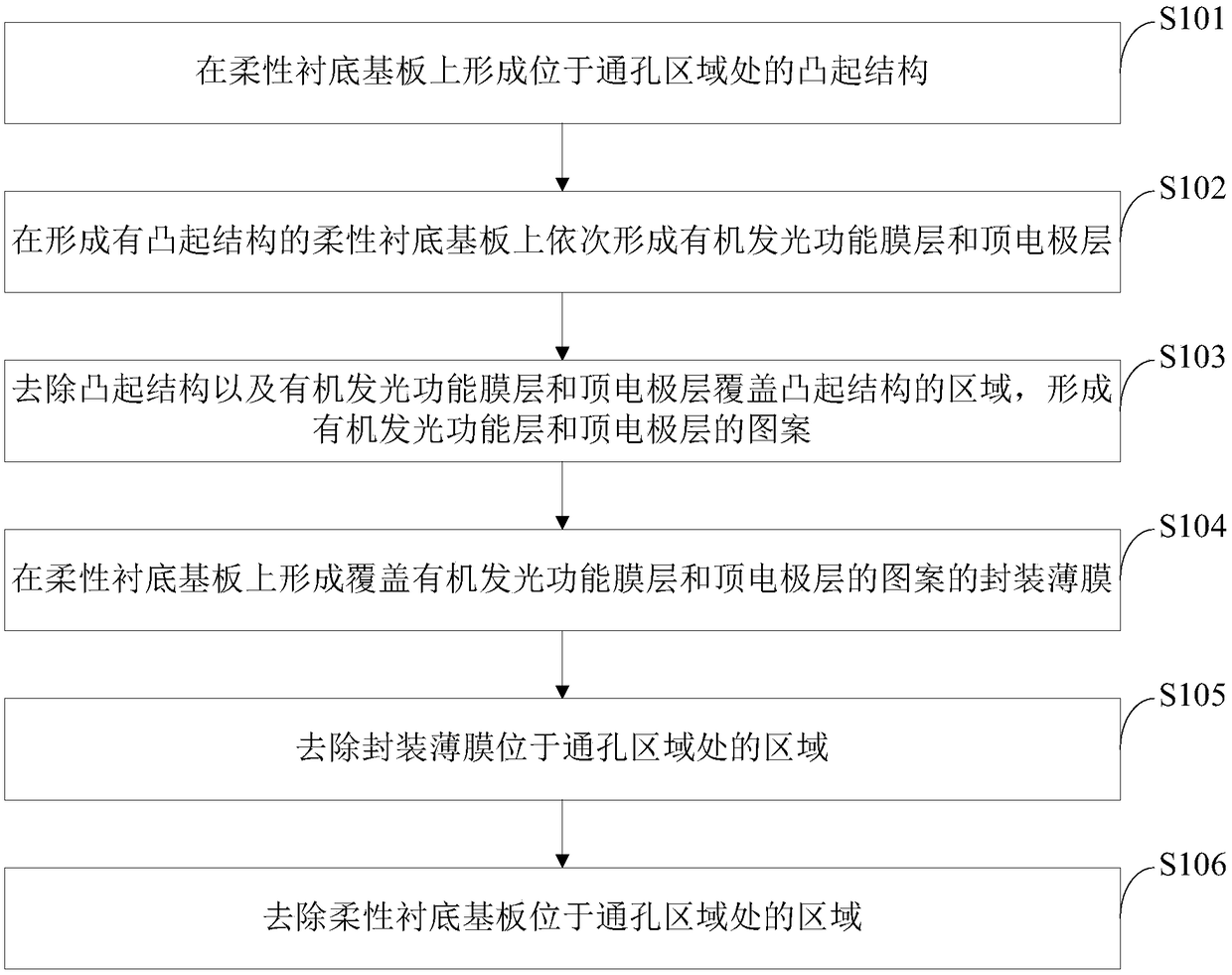

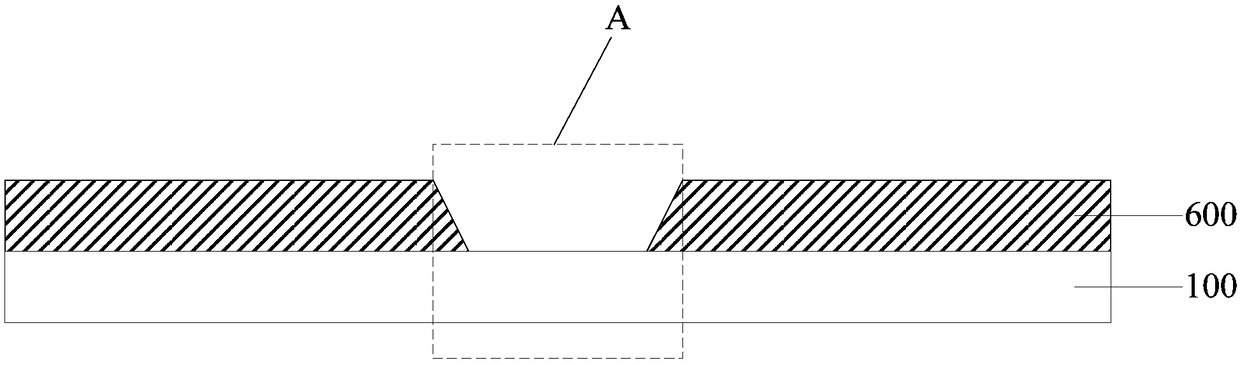

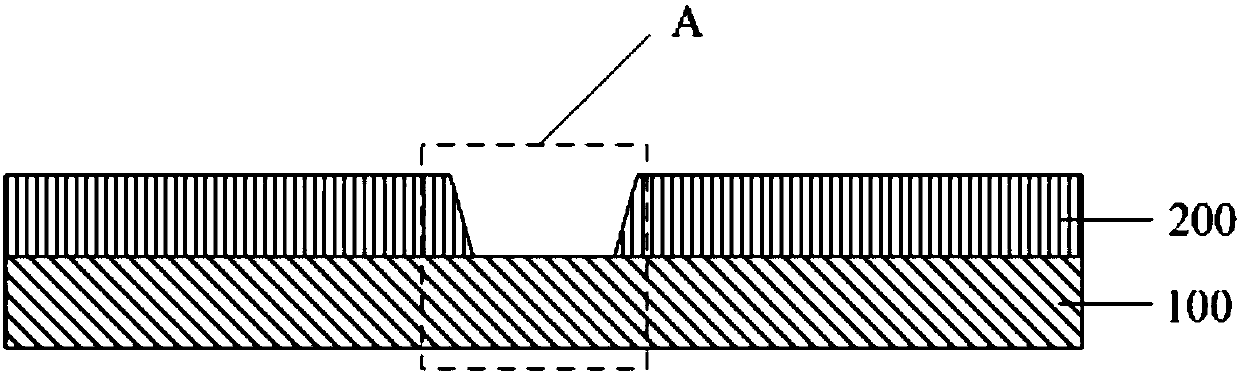

Flexible display panel, manufacturing method thereof and display device

ActiveCN108321176AGuaranteed tightnessAvoid failureSolid-state devicesSemiconductor/solid-state device manufacturingConvex structureEvaporation

The invention discloses a flexible display panel, a manufacturing method thereof and a display device. The manufacturing method of the flexible display panel comprises the steps of forming a convex structure located in a through-hole region on a flexible substrate so as to remove regions, which cover the convex structure, of an organic light-emitting functional film layer and a top electrode layerwhile removing the convex structure, thereby replacing an operation of setting a suspended through-hole region shielding component in an evaporation mask plate, and achieving a purpose that there isno pattern of the organic light-emitting functional film layer and the top electrode layer in the through-hole region; and forming a packaging film covering the pattern of the organic light-emitting functional film layer and the top electrode layer, thereby playing a role of packaging the organic light-emitting functional film layer in the through-hole region, and ensuring the sealing performanceof the flexible display panel in the through-hole region so as to prevent the failure of the display device. A step of removing a pattern of the packaging film in the through-hole region can be addedafter forming the packaging film so as to exposure the flexible substrate in the through-hole region, thereby achieving an effect of manufacturing a through hole in the flexible display panel after removing the flexible substrate in the through-hole region.

Owner:BOE TECH GRP CO LTD +1

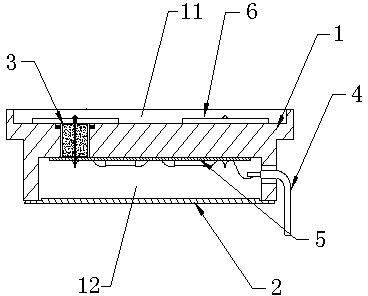

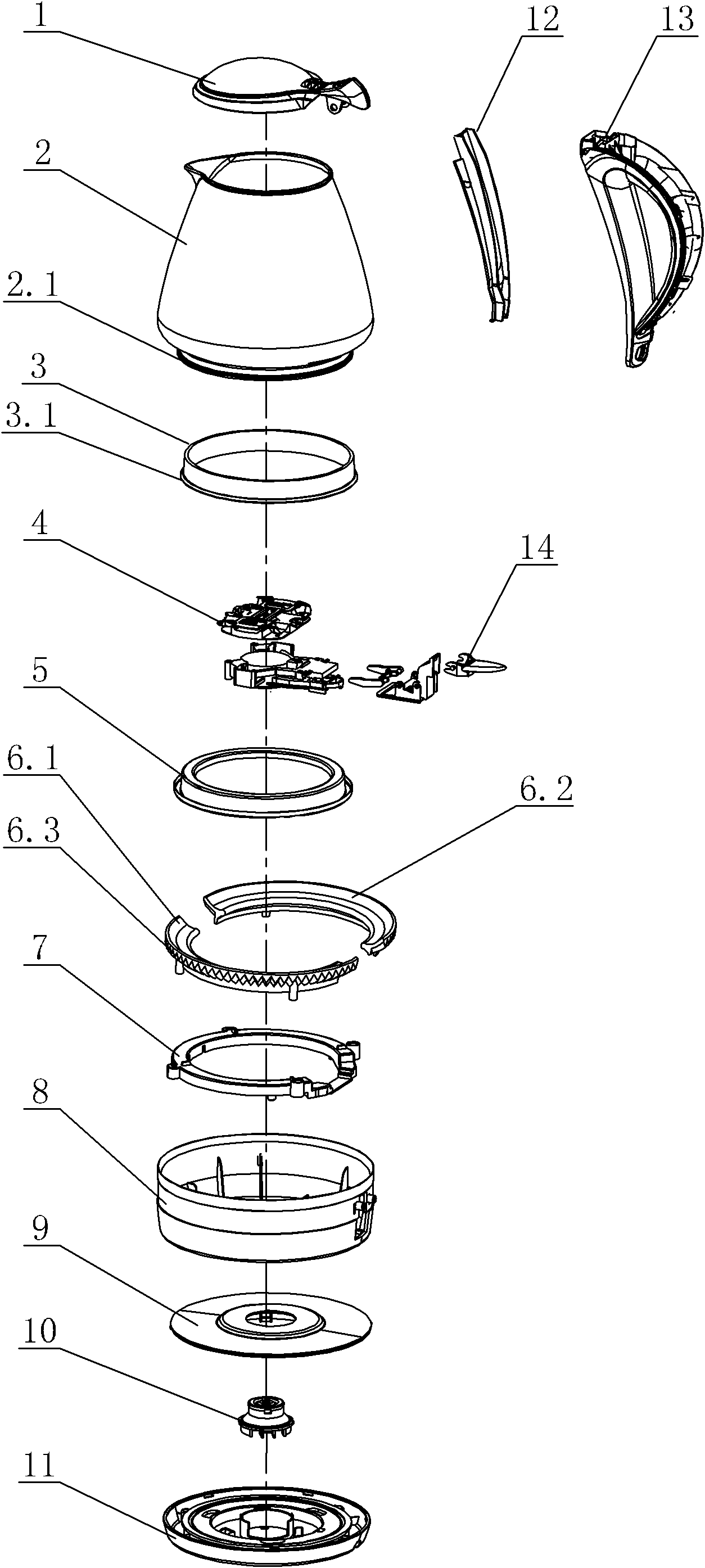

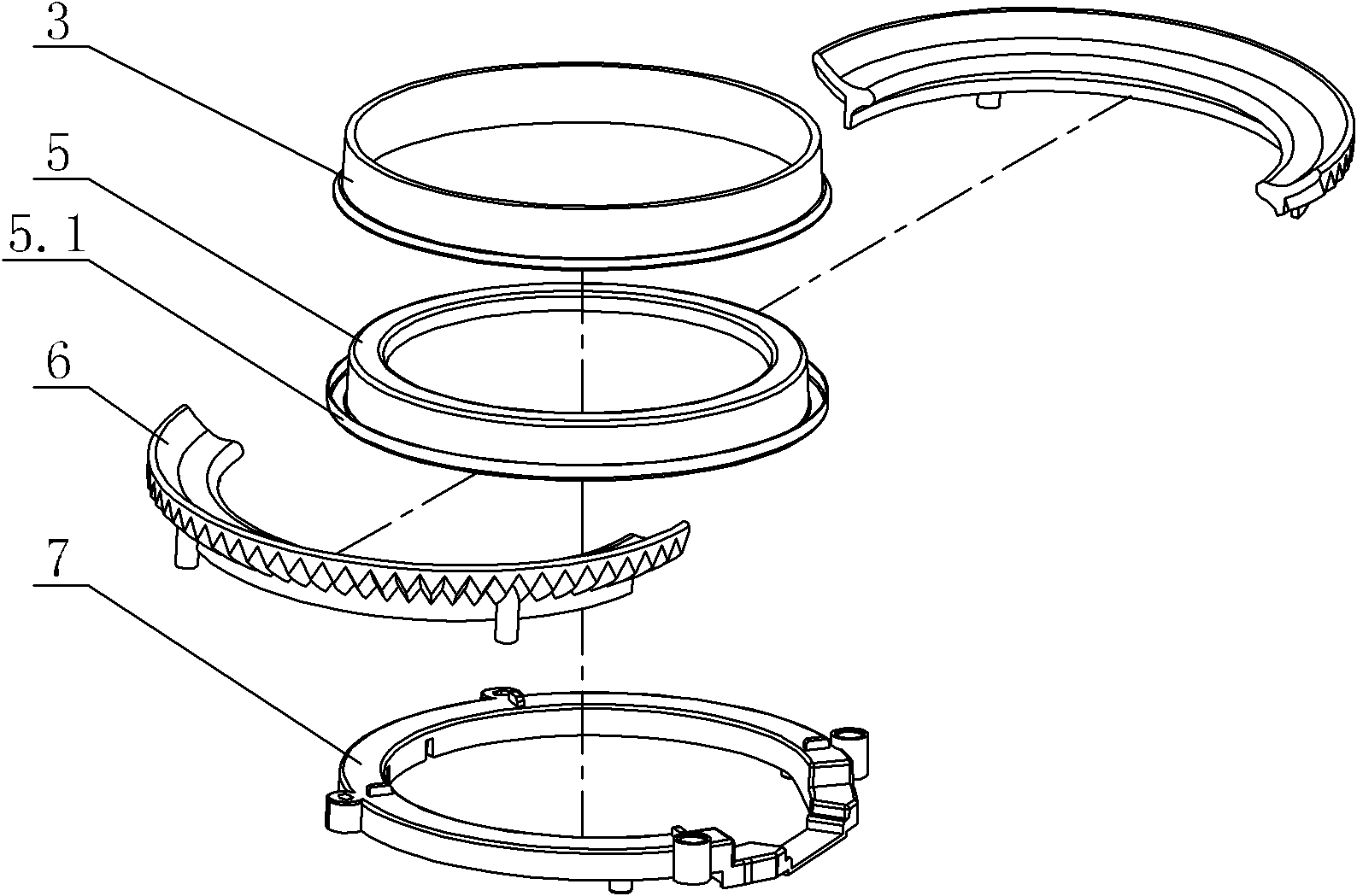

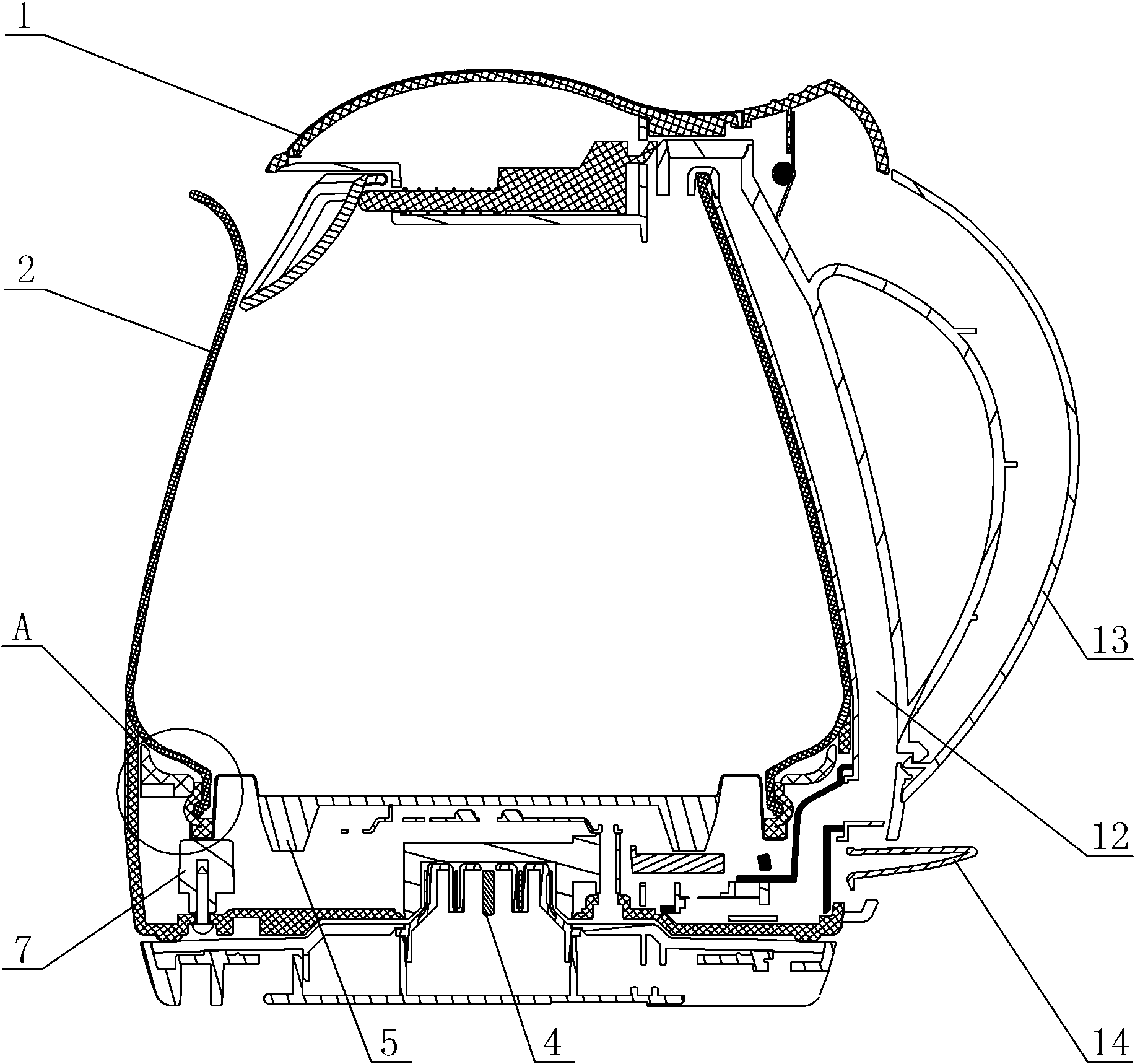

Seal structure of electric kettle

ActiveCN102631132AGuaranteed tightnessAvoid tight sealsWater-boiling vesselsElectric heatingHeating element

A seal structure of an electric kettle comprises a body with a handle and a bottom cover of the body. A heating element is disposed in the body. The body is provided with a body opening corresponding to the heating element. A seal part is disposed at the connection of the body opening with the heating element. The seal part or the body is provided with a snap ring outside. The snap ring for fixing the heating element is hermetically connected with the body, or the seal part or the body is provided with a retractable strip, or a metal tying wire for fixing the heating element is hermetically connected with the body. The seal part is provided with a groove part with an upward opening, or the inner wall of a silicone seal ring and the outer wall of the heating element form a groove part with an upward opening, or a contact face of the seal part is in extrusion-deforming fit with the cross section of the body opening. The seal part is added to the heating element and provided with the snap ring, the retractable strip or the metal tying wire outside, and accordingly the heating element is hermetically connected with the body, poor tightness, seepage and the like are effectively prevented, and product quality is improved.

Owner:徐智慧 +1

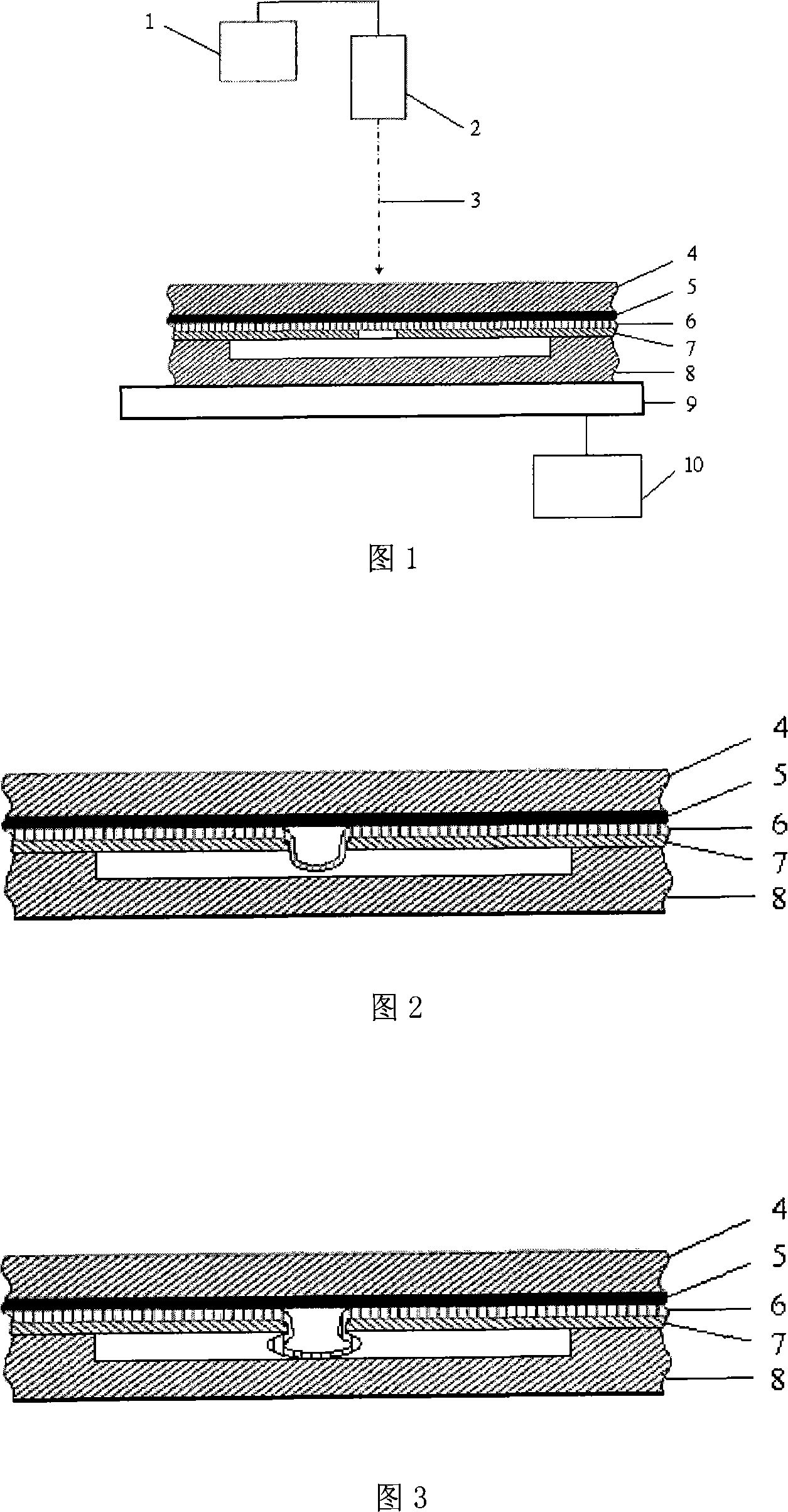

Ultra-thin sheet material pulsed laser micro rivet connection method and special-purpose device thereof

InactiveCN101214580AGuaranteed tightnessNice appearanceLaser beam welding apparatusDetonationEnergy absorption

The invention discloses an ultrathin plank stuff pulse laser micro-riveting method and a special device for realizing the method. The method relates to a method which leads laser acted on a plank stuff to form a flexible convex mold and pivots double-layer or multi-layer plank stuff together. An optimized scheme is to lead laser on an energy absorption layer covered on the surface of the plank stuff under the action of a restraint layer to generate plasma detonation waves which are used as a flexible convex mold and then act on the plank stuff to pivot double-layer or multi-layer plank stuff together. The special device realizing the ultrathin plank stuff pulse laser micro-riveting method consists of a laser generator system, a frock clamper system and a working platform system. Through the method can process the metal materials like steel, aluminum and copper, etc., and can also process the non-metal material like silicon and plastic. The invention is in particular suitable for micro-apparatus part manufacture like the fields of pivoting of a metal contact of a micro-switch and forming the micro-electric packaging for the contact area.

Owner:SHANDONG UNIV

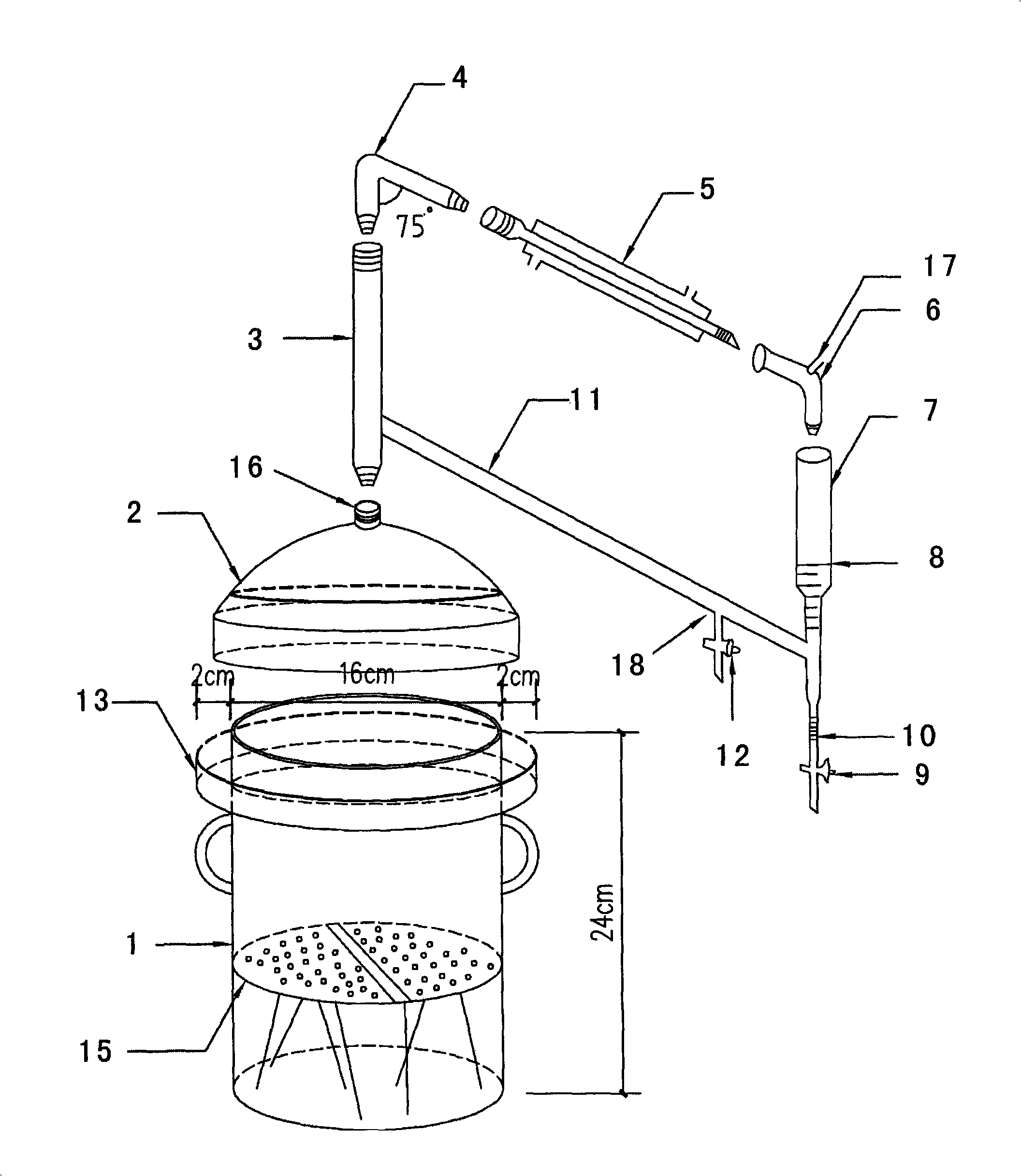

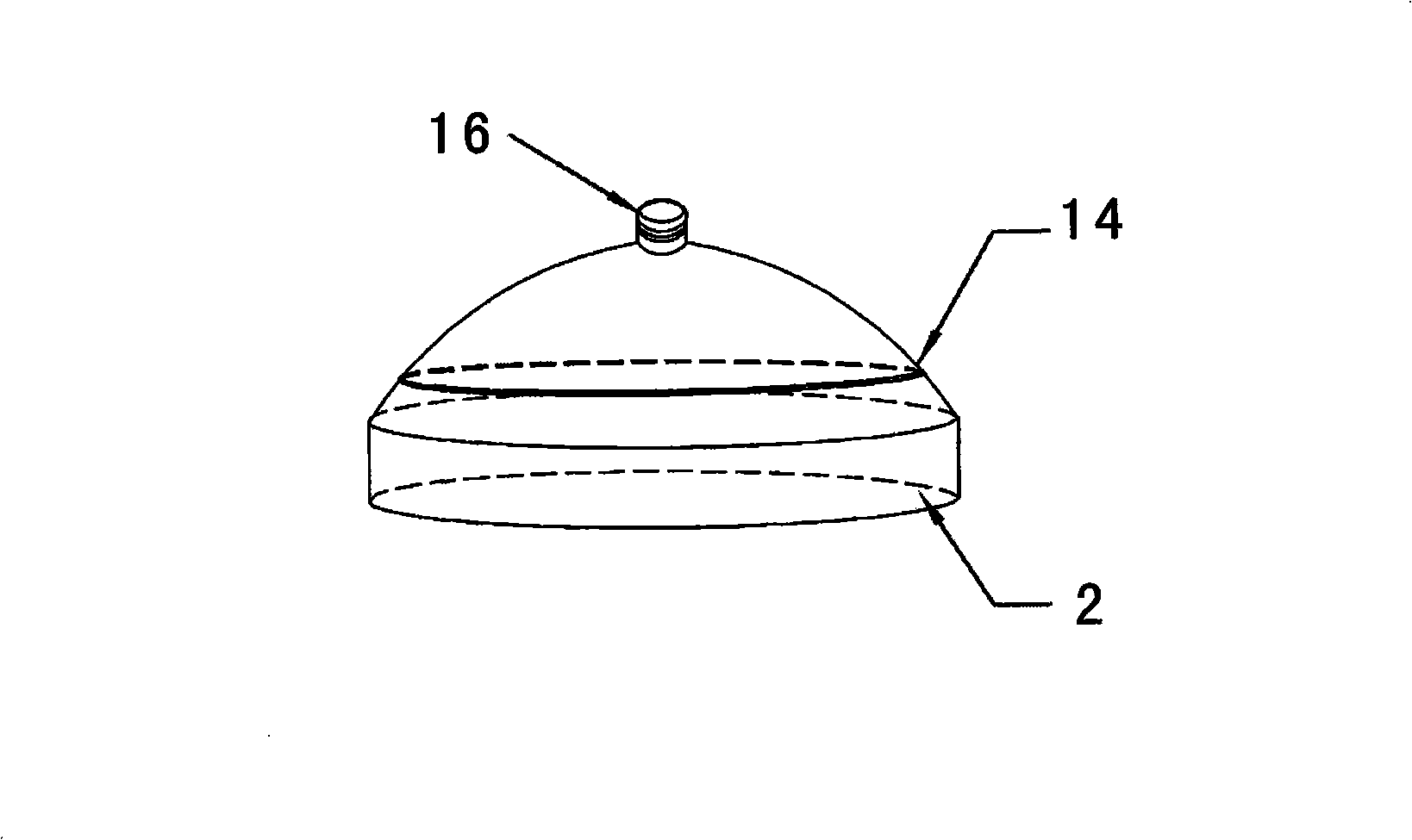

Plant volatile oil extractor and application thereof

ActiveCN101538510AQuick extractionEasy feedingEssential-oils/perfumesDistillation separationDistillationLaboratory facility

The invention discloses a plant volatile oil extractor and application thereof. The device comprises a distiller, a condenser and a collector. The distiller comprises a distilling container, a sealing cover matched with the distilling container and a water-resisting grate matched with the distilling container. The top of the sealing cover is provided with through holes. The condenser comprises a condenser pipe. The through holes at the top of the sealing cover are connected with the lower end of a vertical gas tube. The gas tube is connected with the inlet of the condenser pipe by a connecting bend. The outlet of the condenser pipe is connected with the inlet of the collector by the connecting bend. The plant volatile oil extractor in the invention can be used for fast extracting volatile oil with different specific weights in plants. The extractor has the characteristics that the extractor is convenient, easily disassembled and carried, simple to load and unload materials, and suitable for distillation requirements of water-resisting distillation, water distillation, backwater distillation and non-backwater distillation, and has high extraction rate. The extractor can be used for laboratory, in particular for field.

Owner:INST OF BOTANY CHINESE ACAD OF SCI

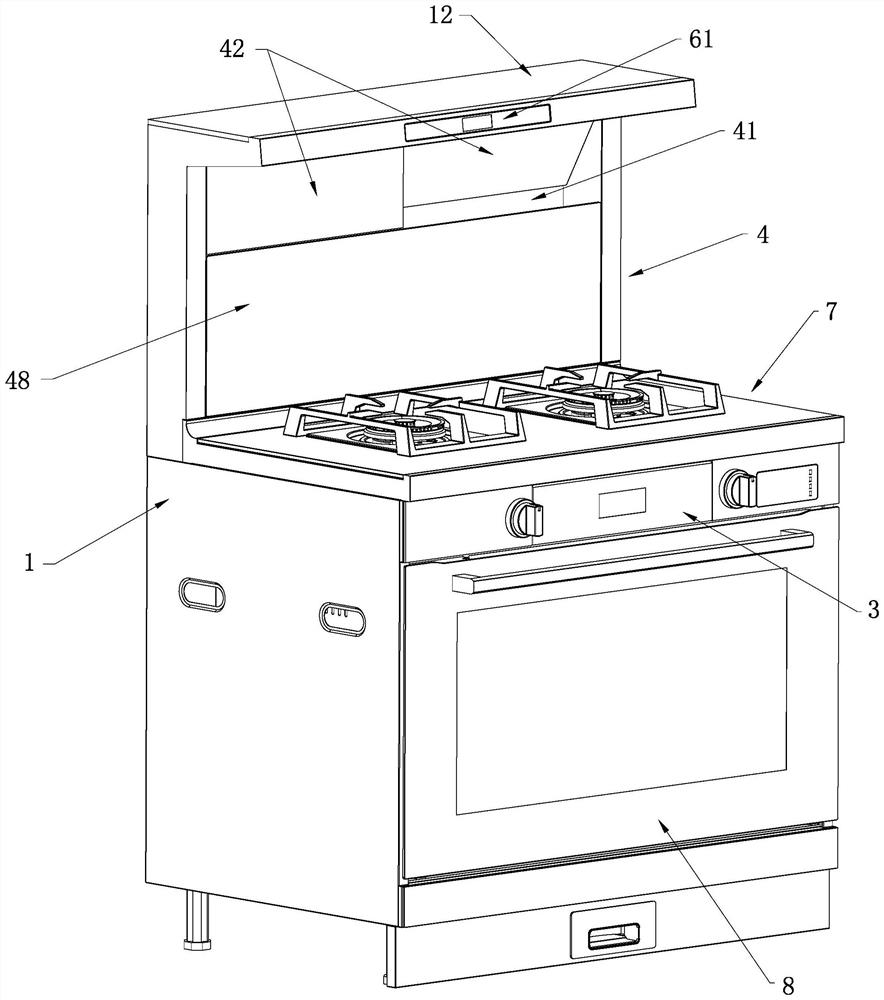

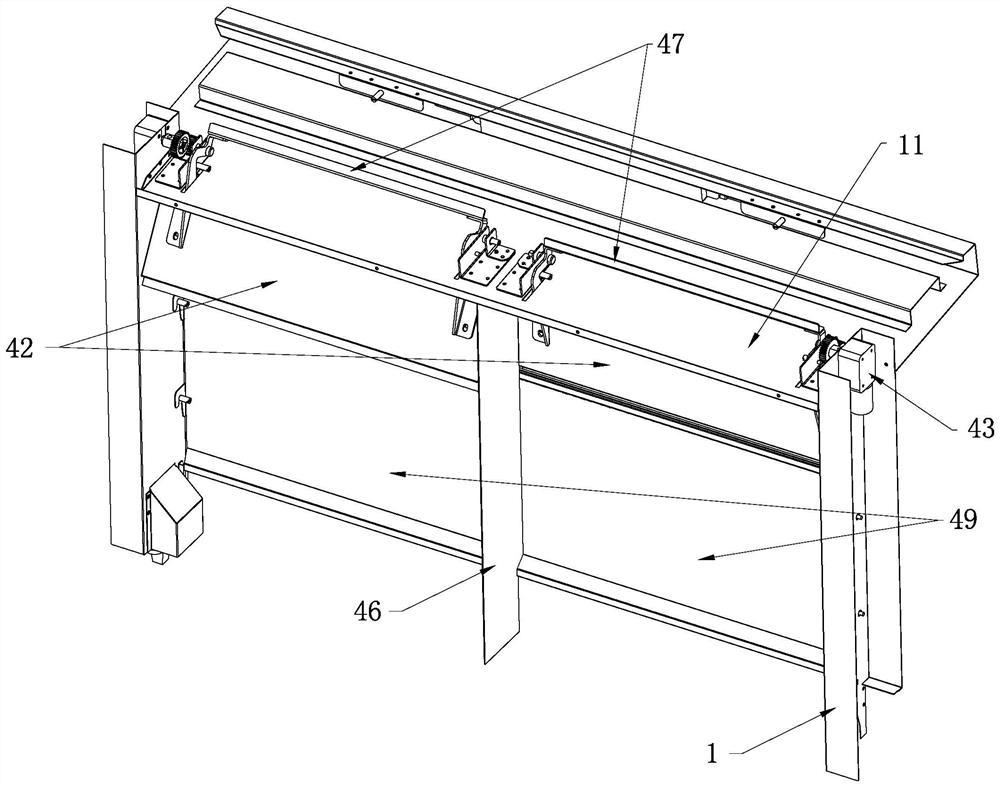

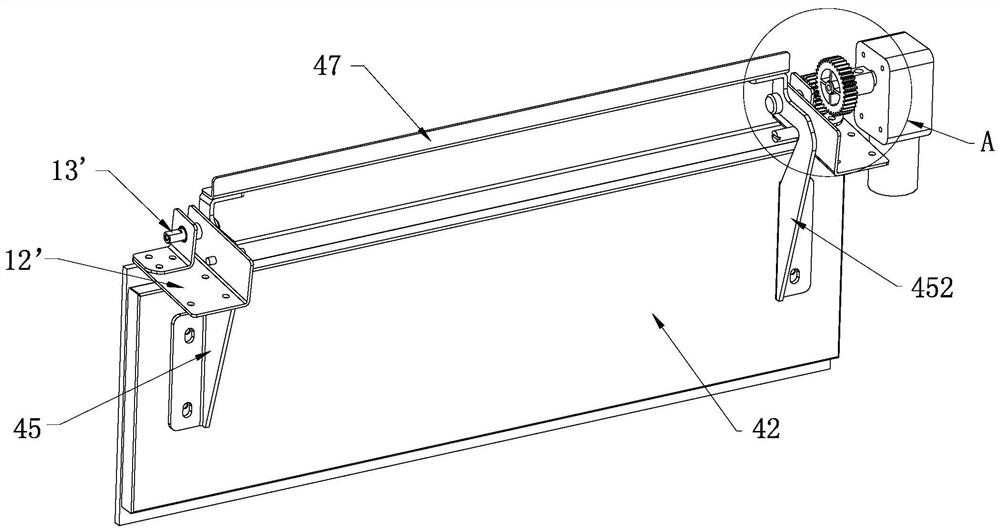

Integrated cooker

PendingCN112555906AOutstanding and Beneficial Technical EffectsGuaranteed tightnessDomestic stoves or rangesLighting and heating apparatusEngineeringCooker

The invention belongs to the technical field of kitchen appliances, and particularly relates to an integrated cooker. The integrated cooker comprises a machine body and a range hood body; the range hood body comprises an air inlet, an air collecting box and a fan assembly; the air collecting box communicates with the air inlet; the fan assembly is arranged in the air collecting box; a volute air duct of the fan assembly extends downwards to the wall face of the bottom of the air collecting box and extends out of the bottom of the air collecting box to be rotationally provided with an air outlet base; and an air outlet is formed in one side of the air outlet base. According to the integrated cooker, the volute air duct extends downwards to the wall face of the bottom of the air collecting box and extends out of the bottom of the air collecting box to be rotationally provided with the air outlet base; the air outlet base is directly located on the outer side of the air collecting box, and the situation that a channel is located inside and occupies too much space is avoided; a through hole does not need to be additionally formed in the side edge of the machine body, and leakproofnessof the side face of the machine body is guaranteed; and meanwhile, the air outlet base is rotatably arranged, so that a user can conveniently adjust the air outlet direction according to actual needs,and humanization is achieved.

Owner:浙江安德电器有限公司

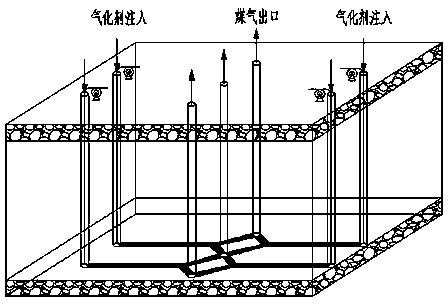

Coal underground gasification process system

InactiveCN104018820AIncrease horizontal widthIncrease widthConstructionsCoal gasificationThermodynamicsWater vapor

The invention relates to a coal underground gasification process system. The coal underground gasification process system comprises a gasification agent injection drill hole, coal gas outlet drill holes, a main gasification channel, branch gasification channels, a drill hole supporting tube, a gasification agent injection tube, a combustion agent injection tube, a sealing device and an ignition point shifter. The gasification agent injection drill hole is connected with the coal gas outlet drill holes through the main gasification channel and the branch gasification channels, and the combustion agent injection tube is sleeved with the gasification agent injection tube and is connected through the sealing device. A gasification process includes the steps of carrying out ignition, judging whether water vapor is fed into, feeding into water vapor, judging whether an ignition point is moved forward, starting the ignition point shifter and continuing to conduct combustion. The coal underground gasification process system has the advantages that the transverse gasification area and longitudinal gasification area can be enlarged, coal reserves for gasification are increased, autoignition and controllable back gas injection are achieved in a well-free coal underground gasification process, meanwhile the problem of short circuit of gasification agents in the gasification channels is solved, the probability of back mixing of product gas and the gasification agents is lowered, and safety operation of the gasification process is guaranteed.

Owner:北京中矿科能煤炭地下气化技术研究中心

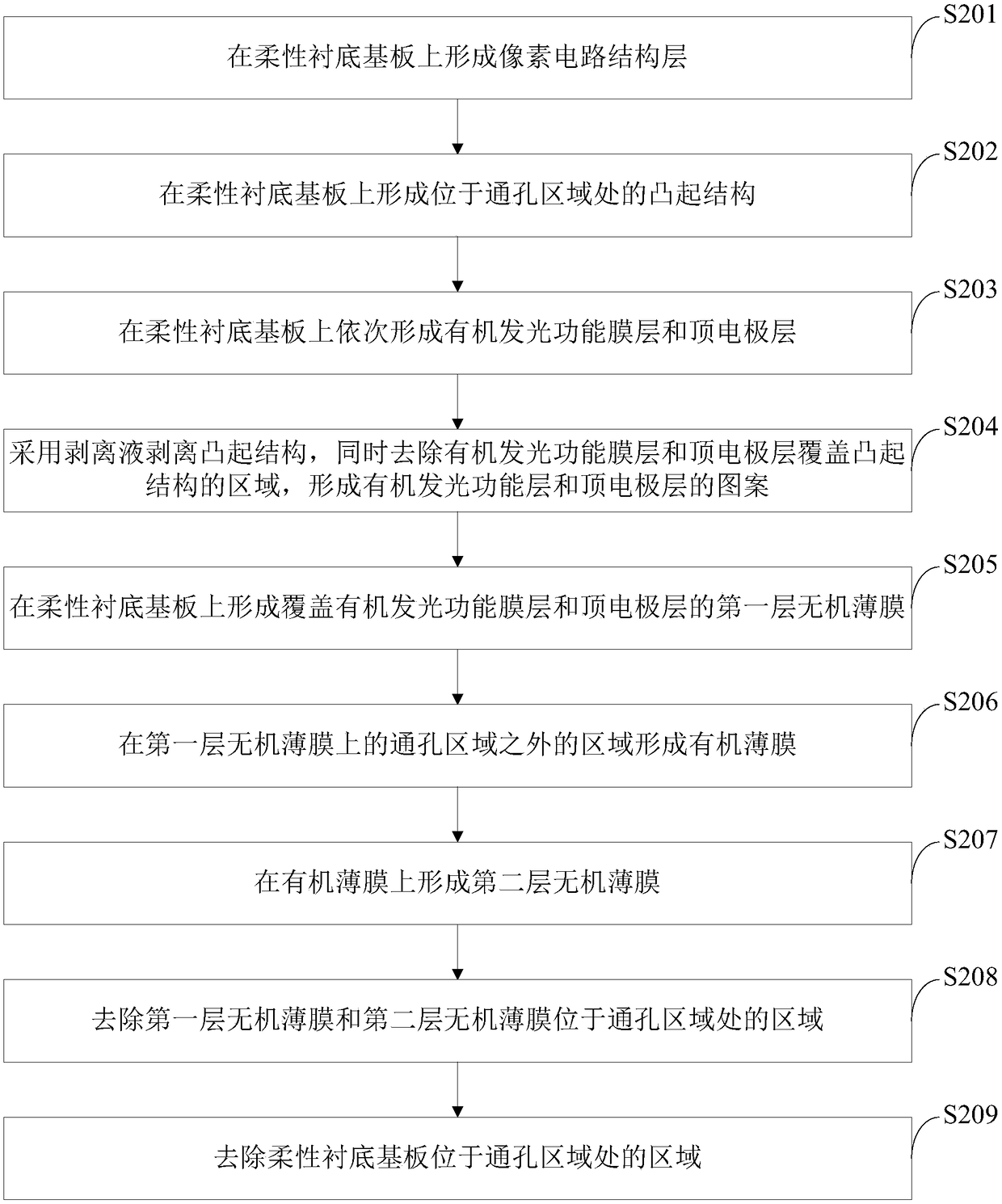

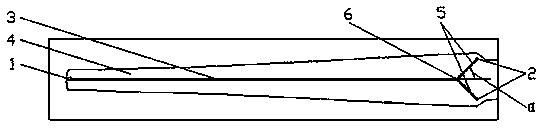

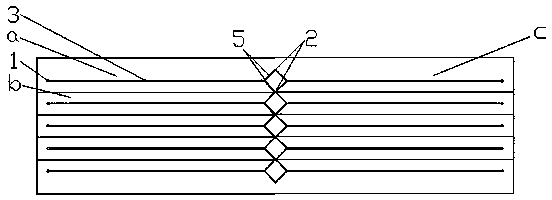

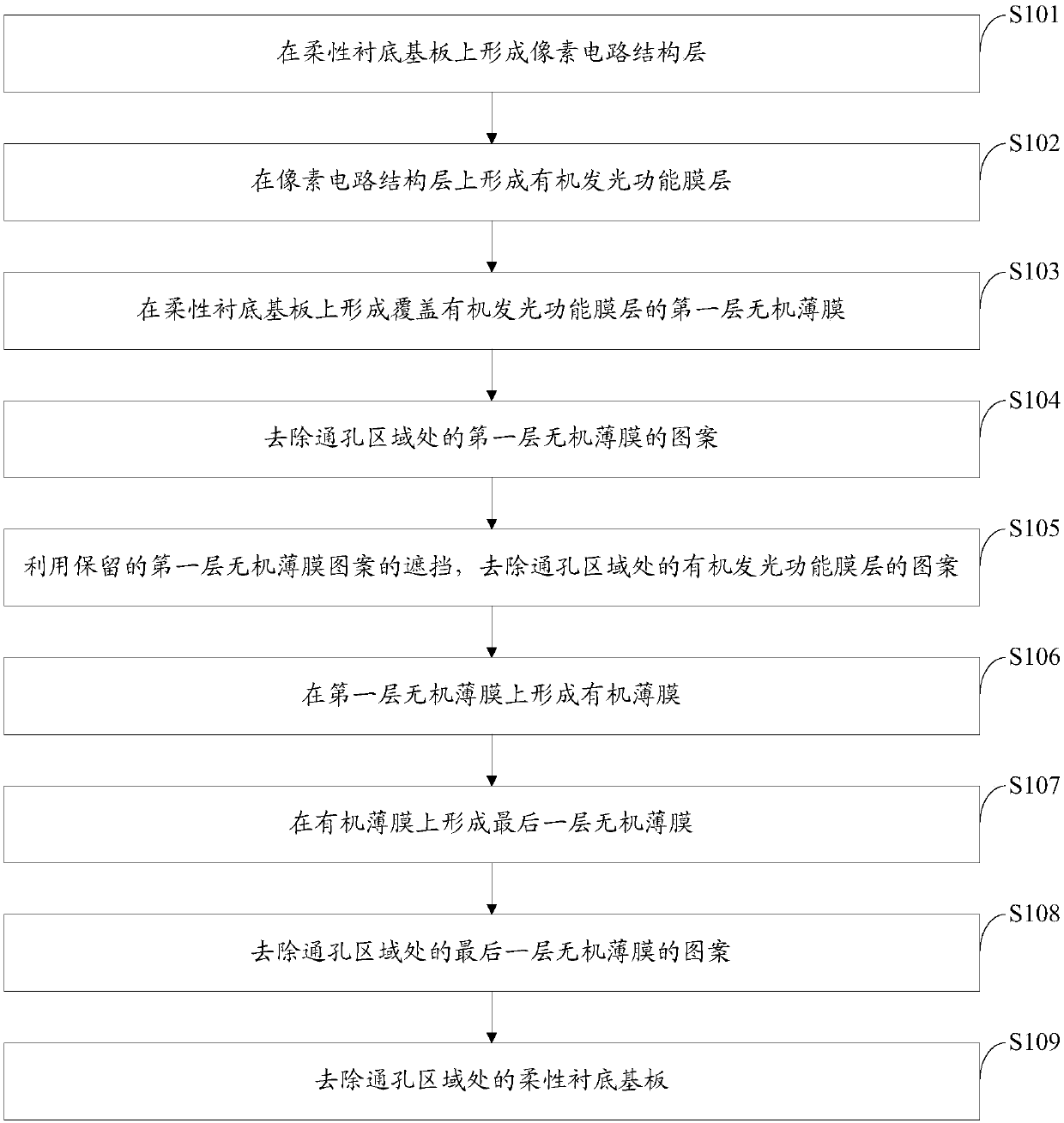

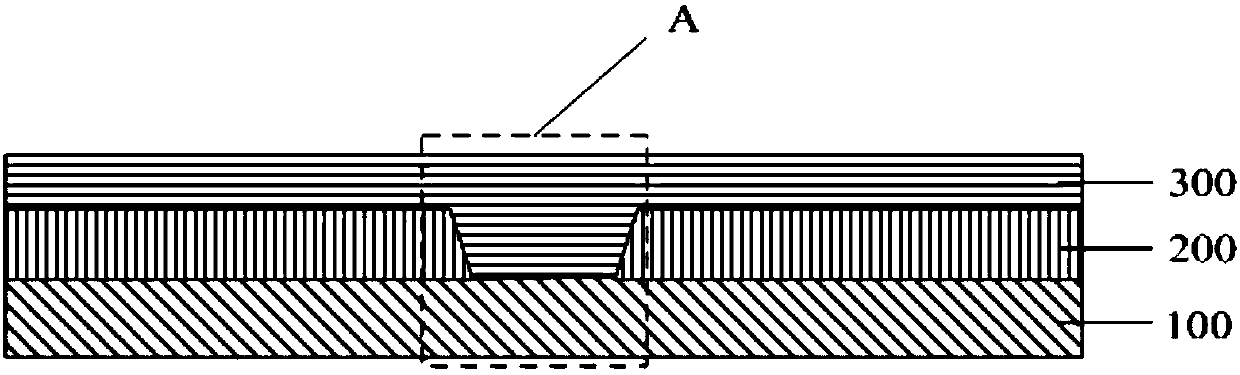

Flexible display panel and making method thereof and display device

ActiveCN107731888AGuaranteed tightnessPlay a role in encapsulationSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEvaporation

The invention discloses a flexible display panel and a making method thereof and a display device. The making method comprises the steps that after a first layer of inorganic thin film in an encapsulated thin film is formed, the pattern of the portion, in a through hole area, of the first layer of inorganic thin film is removed, and the patterns of the other portions of the first layer of inorganic thin film are used for masking so as to remove the pattern of the portion, in the through hole area, of an organic luminous functional film layer, so that an overhead through hole area masking partin an evaporation mask is replaced, and the aim that there are no patterns of the organic functional film layer in the through hole area is achieved. The inorganic thin film which is subsequently formed in the encapsulated thin film can achieve an encapsulation effect on the organic luminous functional film layer in the through hole area, and the airtightness of the flexible display panel in the through hole area is ensured so as to prevent the failure of a displayer. After the last layer of inorganic thin film is formed in the encapsulated thin film, the step that the pattern of the portion,in the through hole area, of the last layer of inorganic thin film is removed is added, and the effect that a through hole is formed in the flexible display panel is achieved after a flexible substrate in the through hole area is removed.

Owner:BOE TECH GRP CO LTD +1

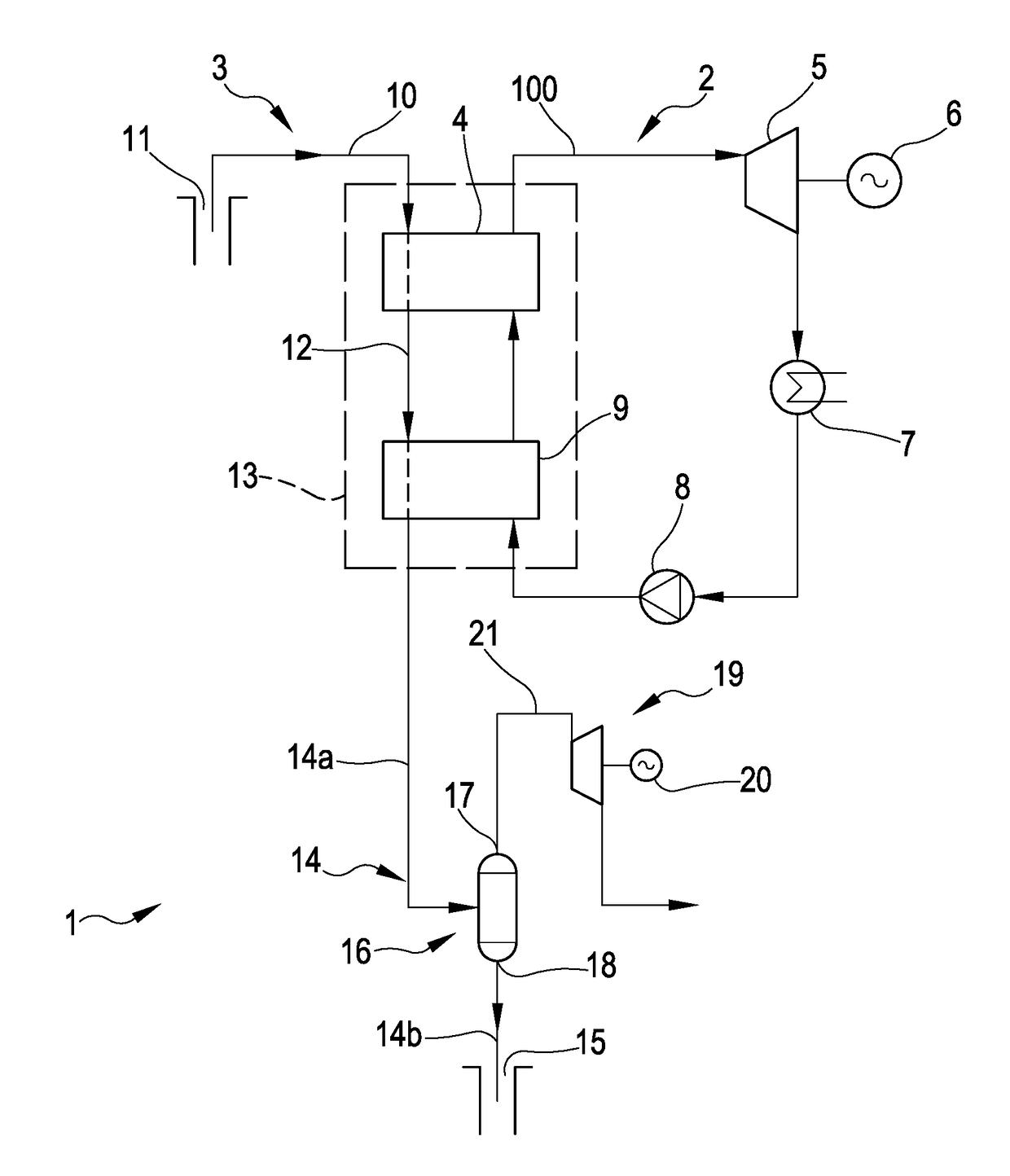

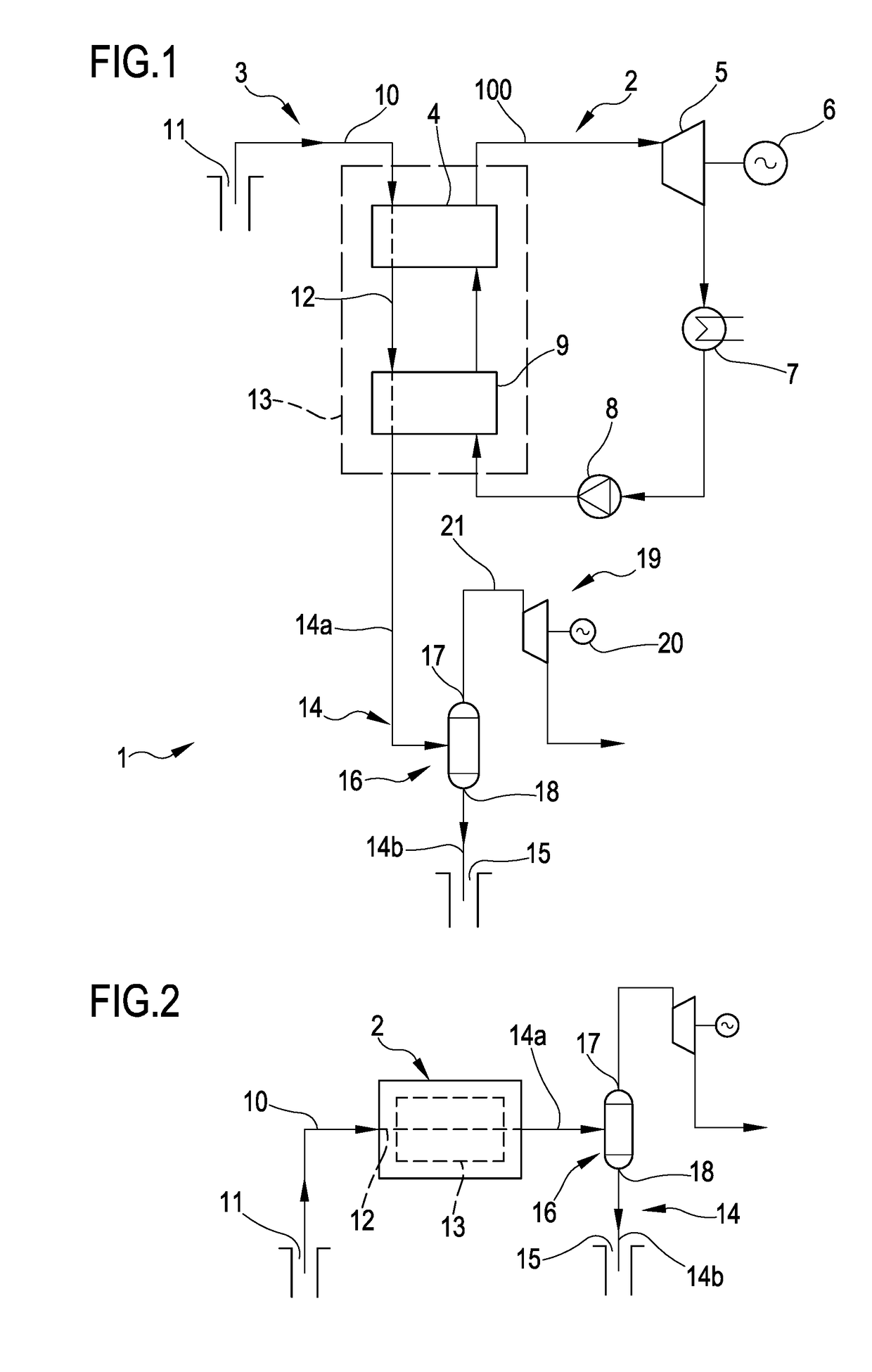

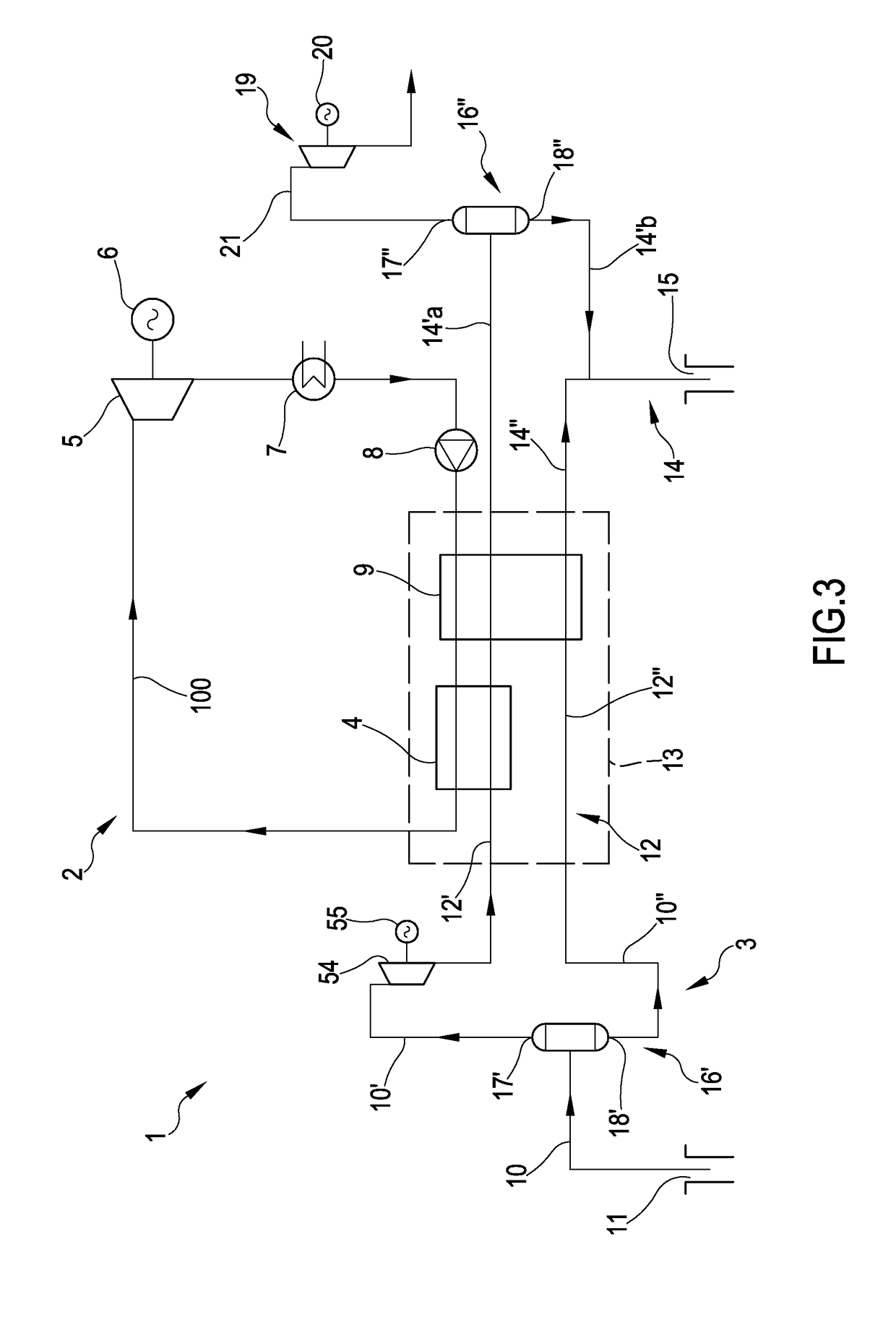

Orc binary cycle geothermal plant and process

InactiveUS20180313340A1Prevent leakageReduce maintenanceGeothermal energy generationMachines/enginesLine tubingWorking fluid

An ORC binary cycle geothermal plant, including at least one ORC closed-cycle system and a geothermal system. The geothermal system includes at least one intake line of a geothermal fluid connected to at least one geothermal production well, wherein the fluid includes non-condensable gases; one interface line connected to the intake line, coupled to the ORC system in an interface zone, wherein the fluid exchanges heat with the organic working fluid; one reinjection line connected to the interface line and to at least one geothermal reinjection well. Further at least one separator device configured to separate at least the gases from the fluid; one expander connected to an outlet of the gases by the separator device; and one auxiliary generator connected to the expander. The expander is for interfacing with the system to receive and expand at least the gases after they have exchanged heat with the organic working fluid.

Owner:EXERGY

Hollow shaft rotary sealing concrete mixing truck

ActiveCN107344401ASmall turning radiusRelatively low linear speedCement mixing apparatusEngineeringTruck

The invention discloses a hollow shaft rotary sealing concrete mixing truck which comprises a mixing drum that is arranged on a truck body and can rotate relative to the truck body. A feeding cylinder is arranged in the middle of an outlet of the mixing drum. The hollow shaft rotary sealing concrete mixing truck further comprises a moving component which is arranged on the truck body and can move relative to the truck body; a sealing cover is arranged on the moving component through a rotary support; the external edge of the sealing cover is in contact with the external edge of the outlet of the mixing drum, and a first sealing device is arranged at the contact part; and the sealing cover, under the driving of the mixing drum, rotates relative to the moving component along with the mixing drum. The sealing cover for plugging the mixing drum is in a rotary structure and synchronously rotates along with the mixing drum, and a dynamic sealing part is changed to be positioned between the feeding cylinder and a feeding hopper accordingly, thus the rotating radius of the dynamic sealing part is reduced substantially, the relative linear velocity of the dynamic sealing part is reduced, the abrasion to a sealing component is reduced when the sealing effect is ensured, the reliability of the hollow shaft rotary sealing concrete mixing truck is improved, and the maintenance difficulty is lowered.

Owner:YANTAI SHENGLIDA ENG TECH

Experimental device for simulating generation and exploition of benthonic combustible ice and application method thereof

ActiveCN103980970AAchieve synthesisGuaranteed tightnessGaseous fuelsFluid removalDecompositionEngineering

The invention discloses an experimental device for simulating the generation and the exploition of benthonic combustible ice and an application method thereof. The experimental device comprises a stainless steel cylinder body, a middle penetration plate, a bottom rubber airbag, a top sealing device and an external frame, wherein the cylinder body is divided into three parts by the middle penetration plate of the whole device, i.e., a simulated seawater layer, a sedimentation layer (hydrate layer) and a free air layer from top to bottom; three windows are respectively designed in the front surface and the rear surface of the cylinder body, thereby being convenient for observation of phenomena during the generation and the decomposition of hydrates; the top sealing device works in a combined mechanical sealing mode, so that the sealing effect of the device can be guaranteed; the pore ratio of a combustible ice storage layer can be controlled according to experimental designs; and a magnetizer-induced heating temperature controller is wrapped around the combustible ice storage layer, so that the temperature can be accurately controlled so as to realize the heating of the storage layer. According to the experimental device, the conventional hydrate synthesis and decomposition experiment can be carried out; meanwhile, the large-scale simulation of the benthonic hydrates can be realized; and particularly, the phenomena in synthesis and exploition processes can be recorded by a high-speed CCD (Charge Coupled Device) camera during the generation and the exploition of seepage-type hydrates, so that the simulation visualization is realized.

Owner:SHANDONG UNIV OF SCI & TECH

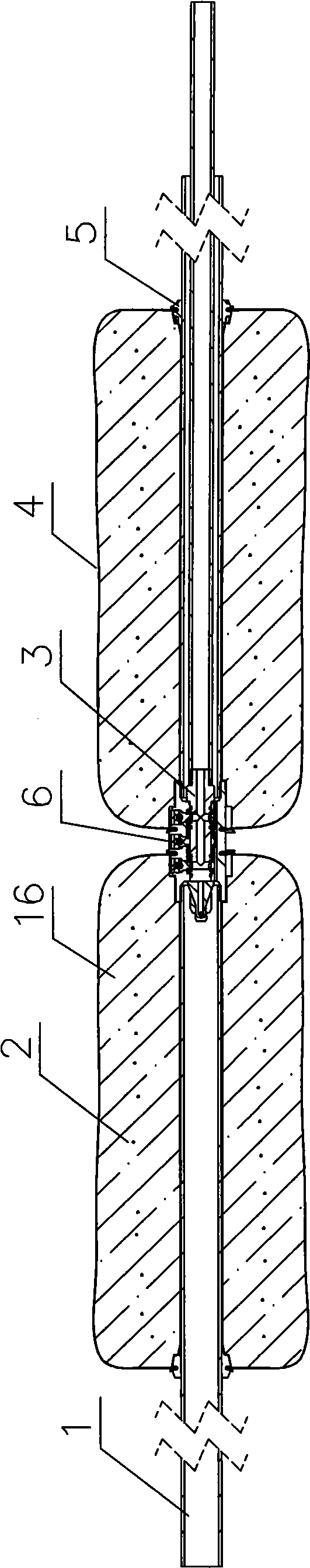

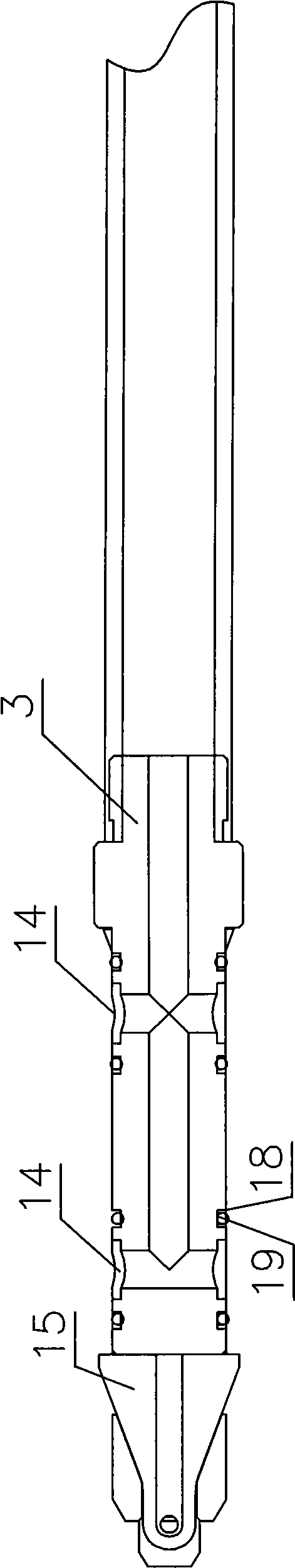

Pressure-measuring glow plug

ActiveUS7228730B2Absolute tightness of the pressure-measuring glow plugGuaranteed tightnessIncandescent ignitionEngine testingCombustion chamberEngineering

A pressure-measuring glow plug for a diesel engine with a plug body (3, 4) for insertion into a cylinder of the diesel engine, a heating rod (1) which is arranged in the plug body (3, 4), and a pressure sensor, which is arranged under an initial tension between the heating rod (1) and the plug body (3, 4), in such a way that the pressure sensor (7) is acted upon by the pressure prevailing in the combustion chamber of the cylinder. The heating rod (1) transmits the pressure in the combustion chamber of the cylinder to the pressure sensor (7) and is arranged so as to be displaceable in a sliding manner in the axial direction relative to the plug body (3, 4). A seal in the form of a bellows-shaped component (2) is provided between the heating rod (1) and the plug body (3, 4).

Owner:SENSATA TECH HOLLAND +1

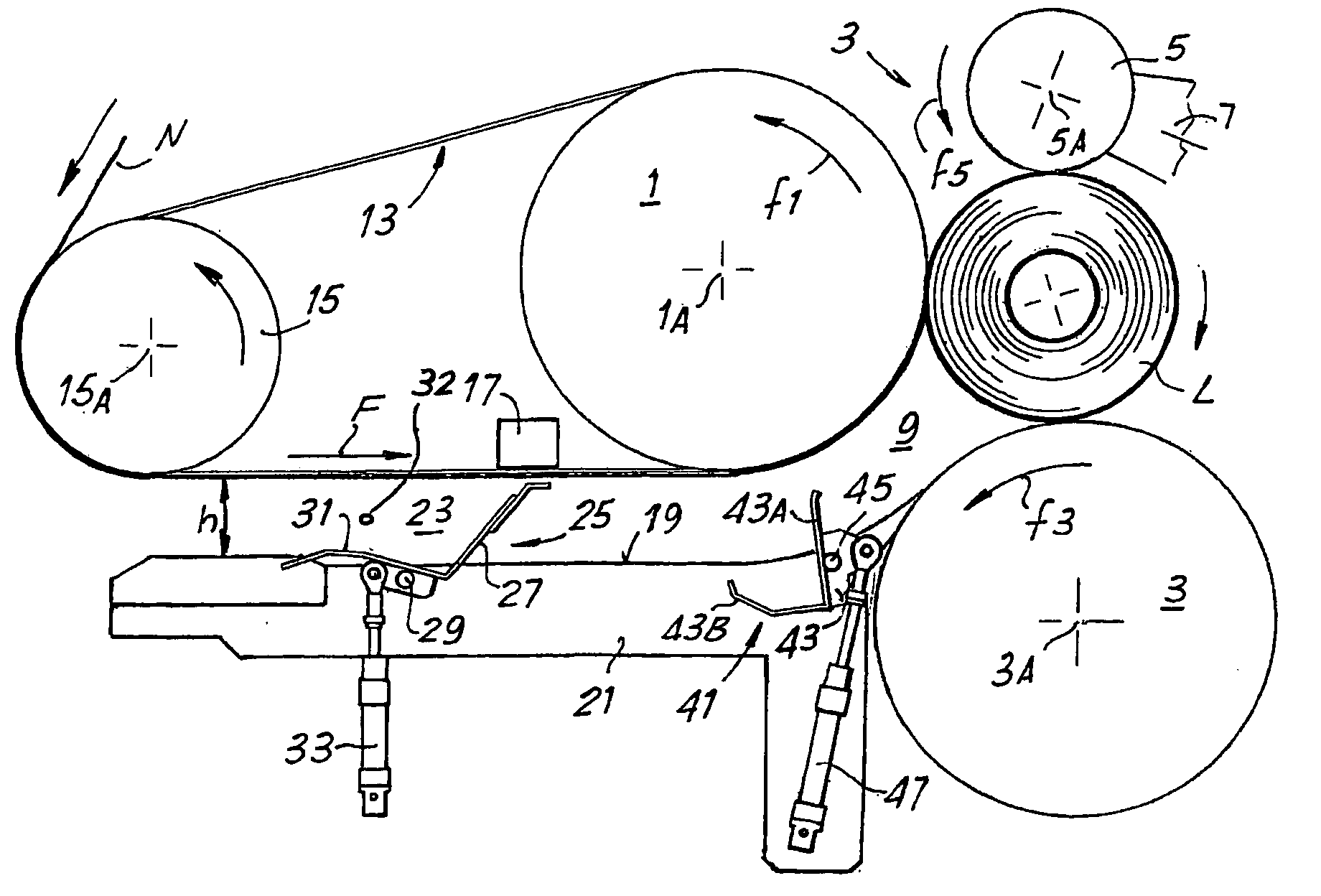

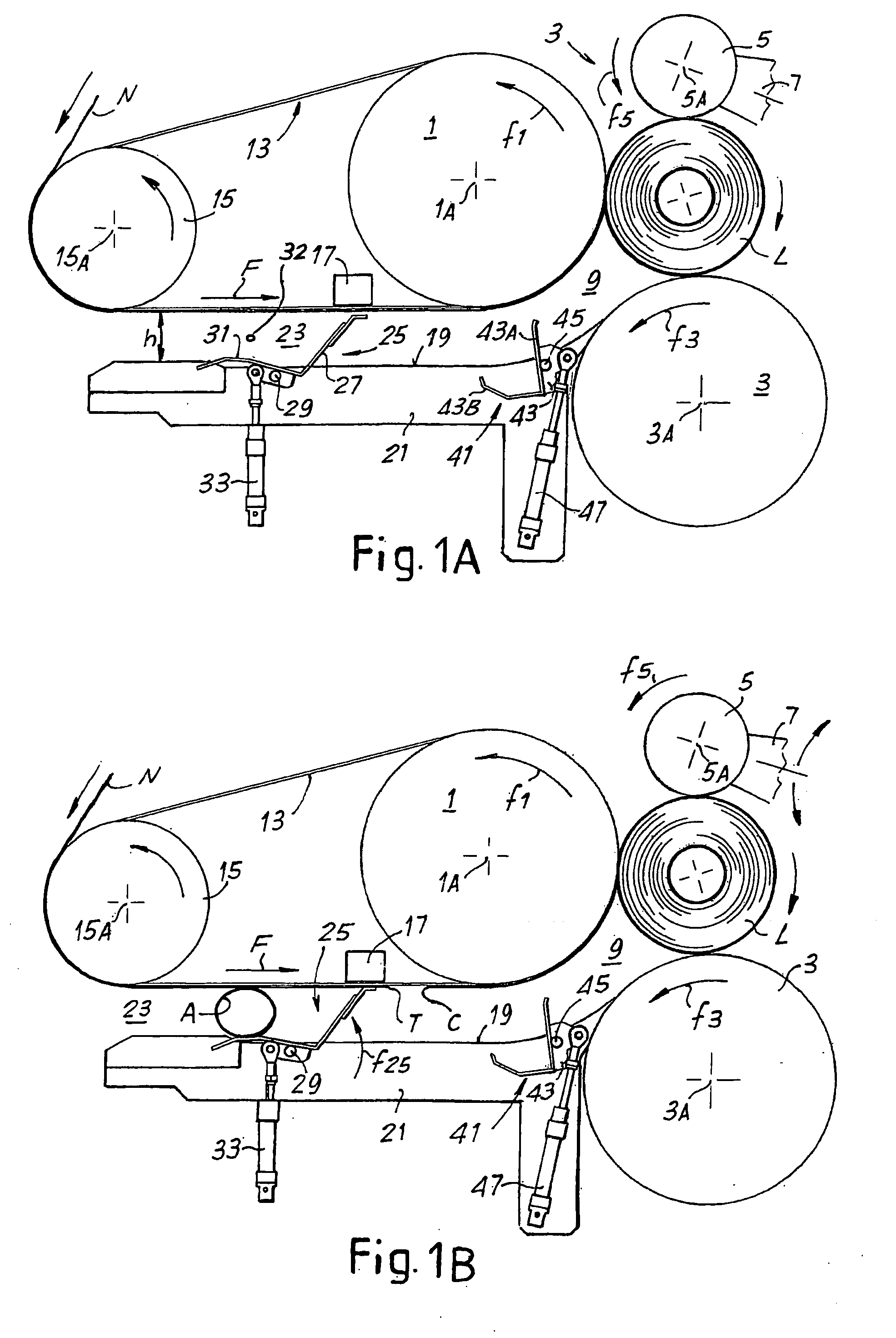

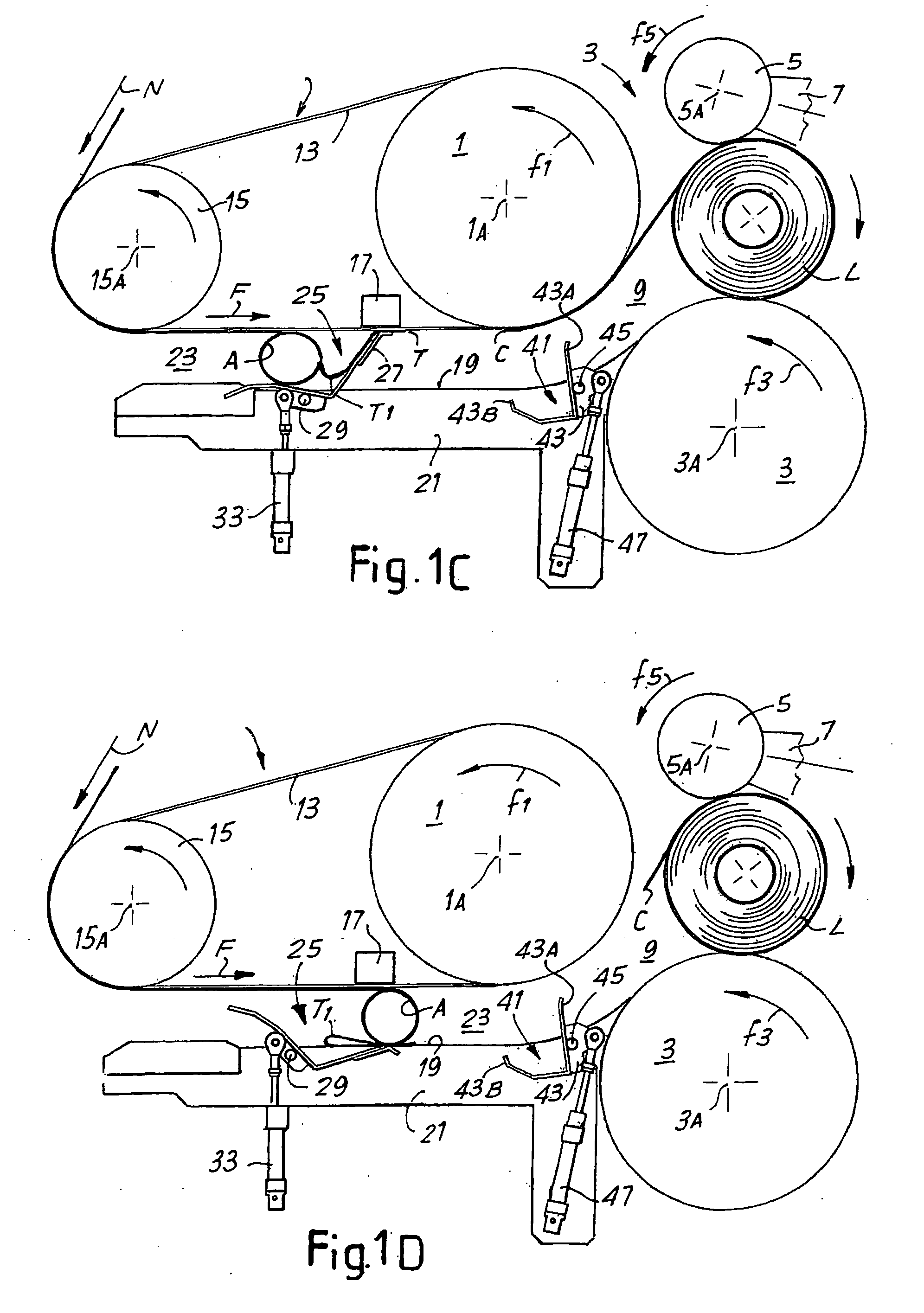

Method and Machine for Forming Logs of Web Material, with a Mechanical Device for Forming the Initial Turn of the Logs

ActiveUS20090272835A1Overcomes drawbackReliable windingFilament handlingArticle deliveryEngineeringMechanical engineering

The rewinding machine includes a winding unit; a feed path of a web material; a separator device to sever the web material upon completion of winding each log; an insertion path of the winding cores towards the winding unit; a movable mechanical member to facilitate forming a first turn of web material around each winding core inserted in the insertion path.

Owner:FABIO PERINI SPA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com