Lng storage tank and constructing method thereof

A technology for liquefied natural gas and storage tanks, which can be used in container filling methods, container structure manufacturing, container discharge methods, etc., and can solve problems such as stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

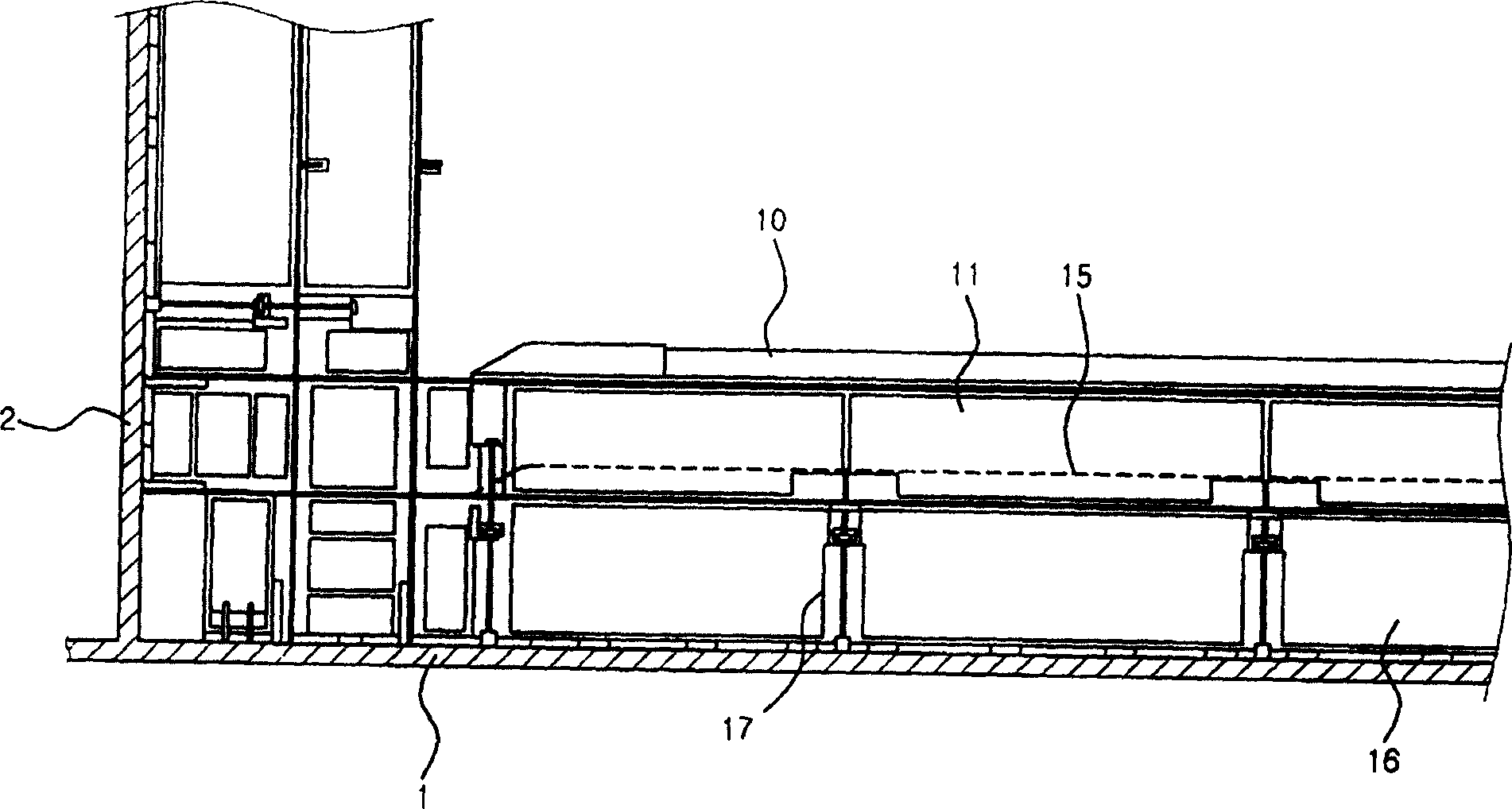

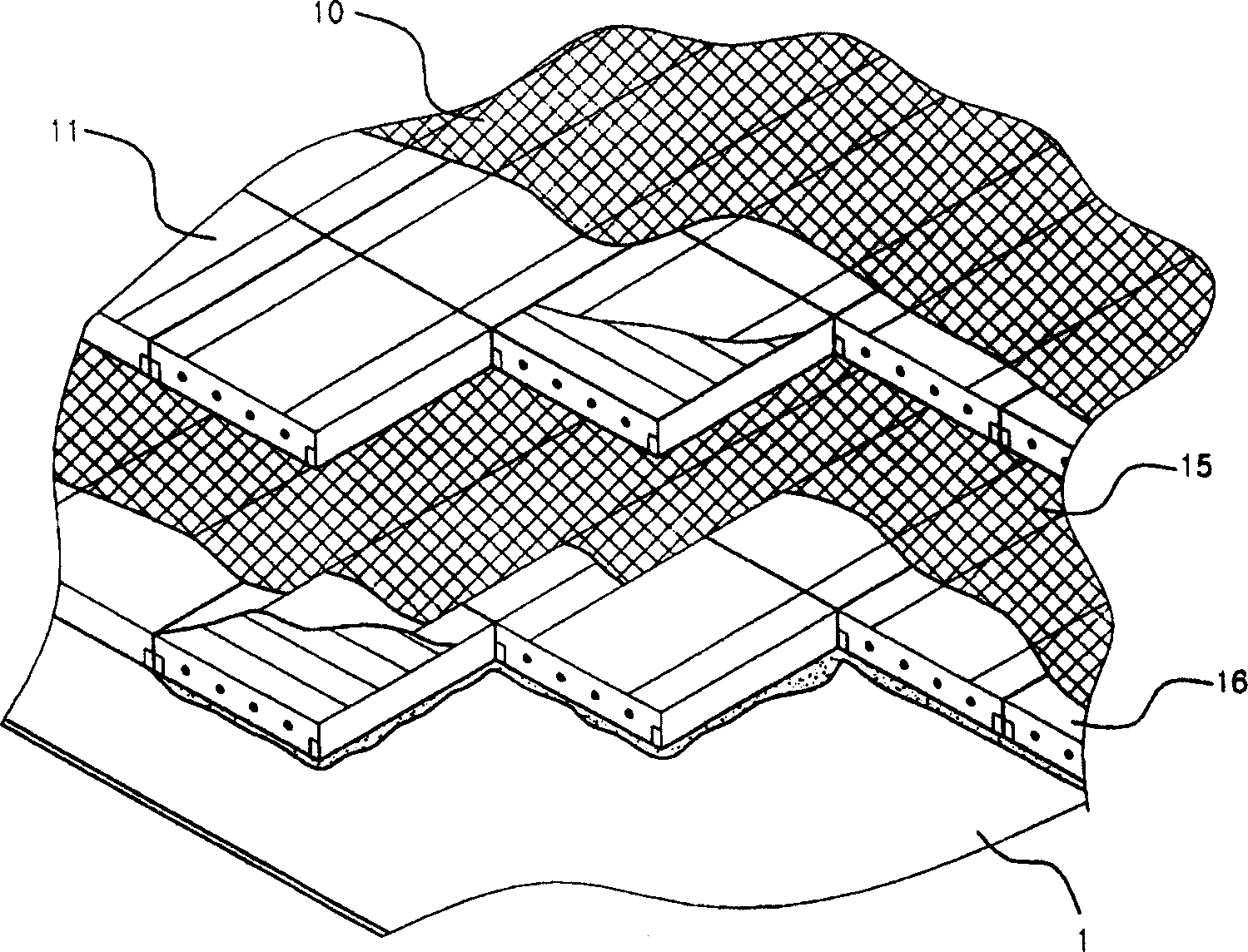

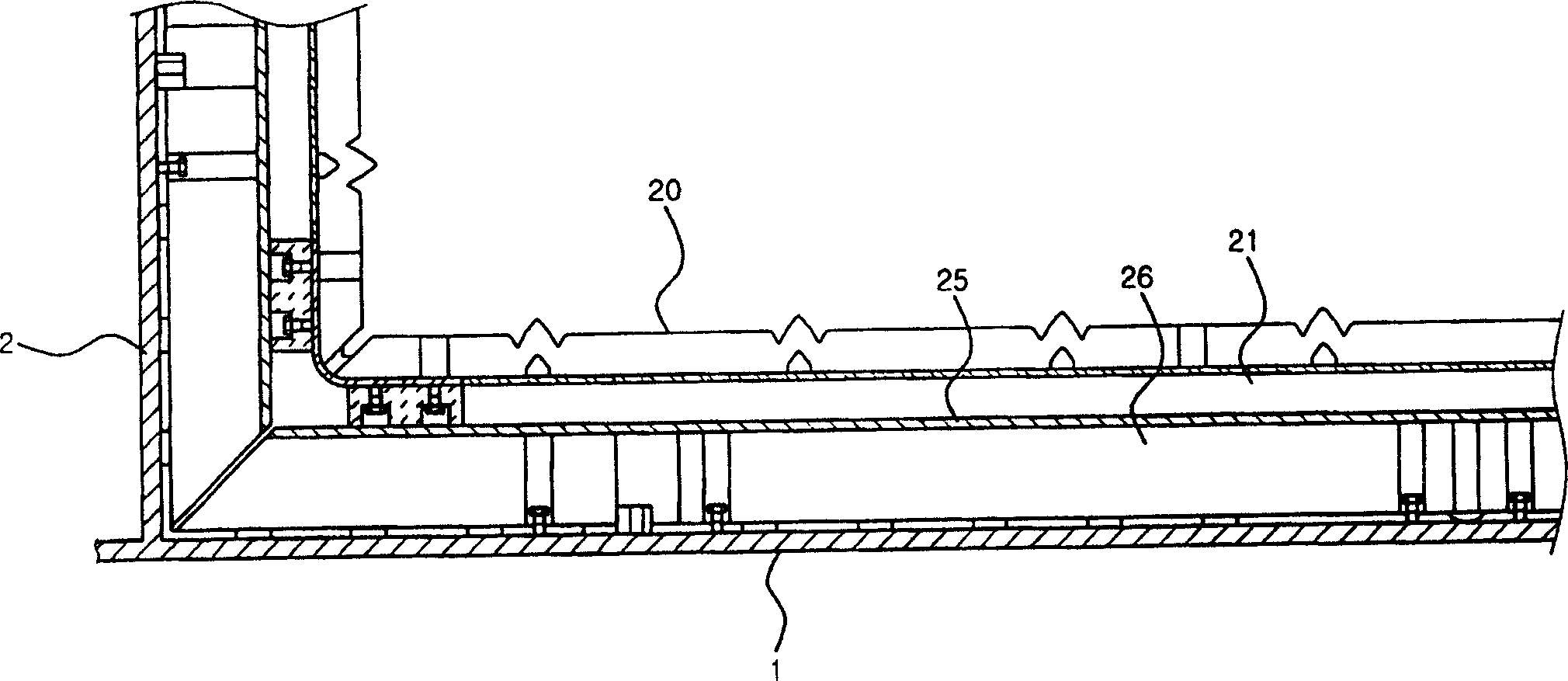

[0071] The structure of the present invention will be described in detail below with the accompanying drawings.

[0072] The invention relates to a liquefied natural gas storage tank for storing high-pressure and low-temperature liquefied natural gas. All the while, this LNG storage tank is constructed to be impact resistant and liquid tight at all times.

[0073] The LNG storage tank installed on a car or ship in which cargo moves is different from an underground storage tank that hardly moves because suitable countermeasures should be prepared to eliminate mechanical stress due to cargo moving inside the tank. However, the same mechanical stress relief measures used for LNG storage tanks installed on ships can also be used for underground storage tanks. Therefore, here, a liquefied natural gas storage tank installed on a ship is taken as an example to introduce its structure in detail.

[0074] The liquefied natural gas storage tank of the present invention includes a seco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com