Patents

Literature

1624results about "Vessel manufacturing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of passivating a gas vessel or component of a gas transfer system using a silicon overlay coating

A method of passivating the interior surface of a gas storage vessel to protect the surface against corrosion. The interior surface of the vessel is first dehydrated and then evacuated. A silicon hydride gas is introduced into the vessel. The vessel and silicon hydride gas contained therein are heated and pressurized to decompose the gase. A layer of silicon is deposited on the interior surface of the vessel. The duration of the silicon depositing step is controlled to prevent the formation of silicon dust in the vessel. The vessel is then purged with an inert gas to remove the silicon hydride gas. The vessel is cycled through the silicon depositing step until the entire interior surface of the vessel is covered with a layer of silicon. The vessel is then evacuated and cooled to room temperature.

Owner:SILCOTEK CORP

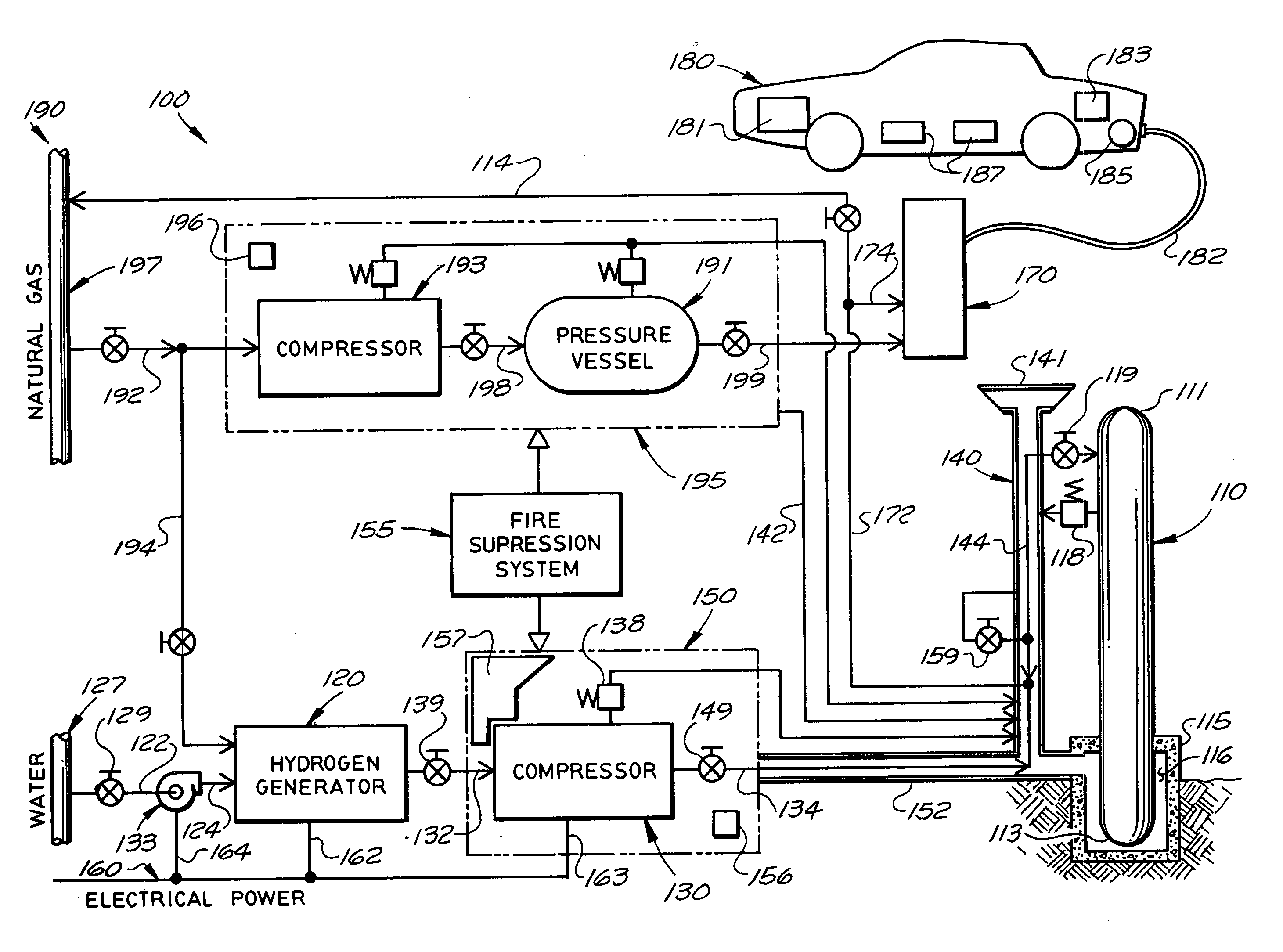

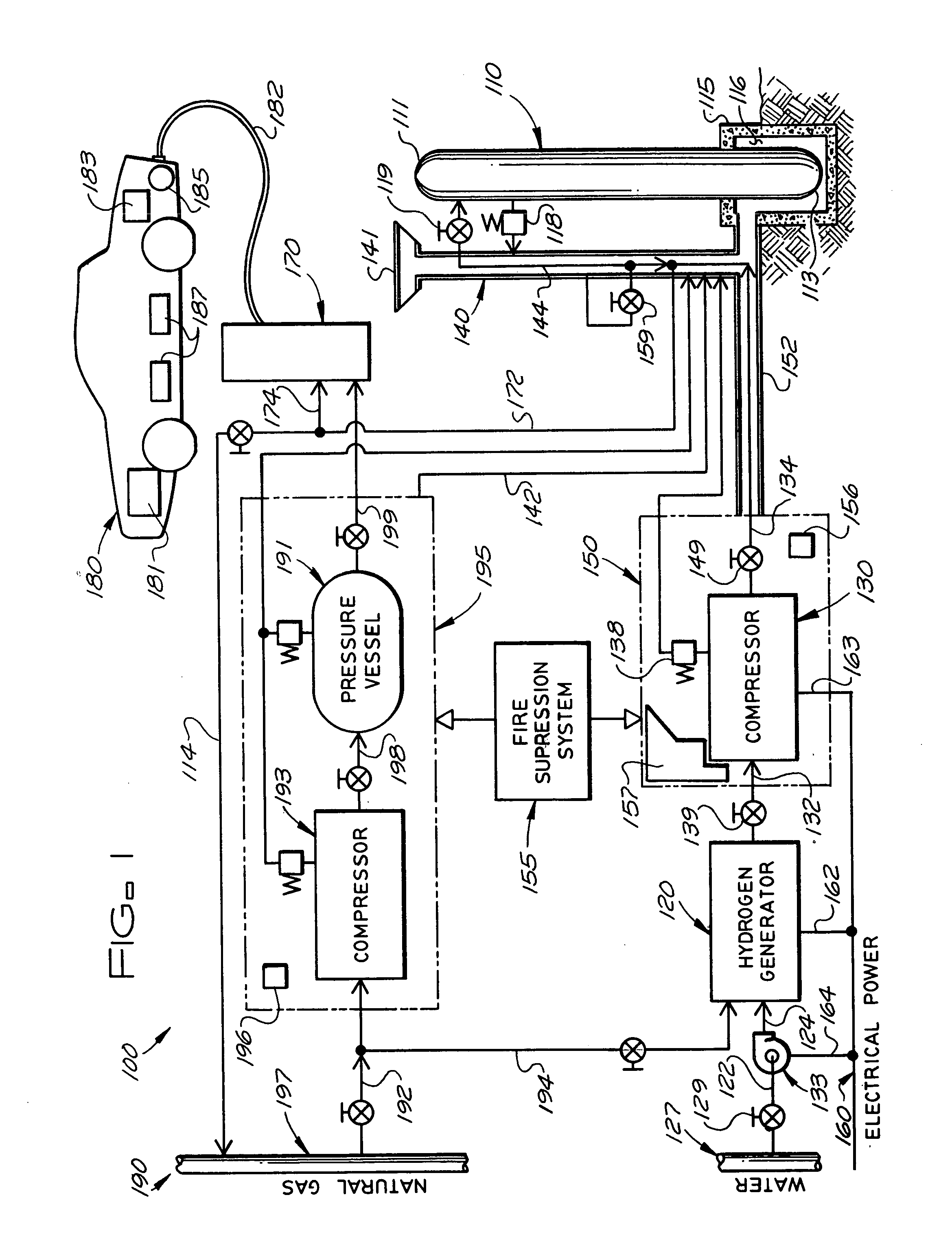

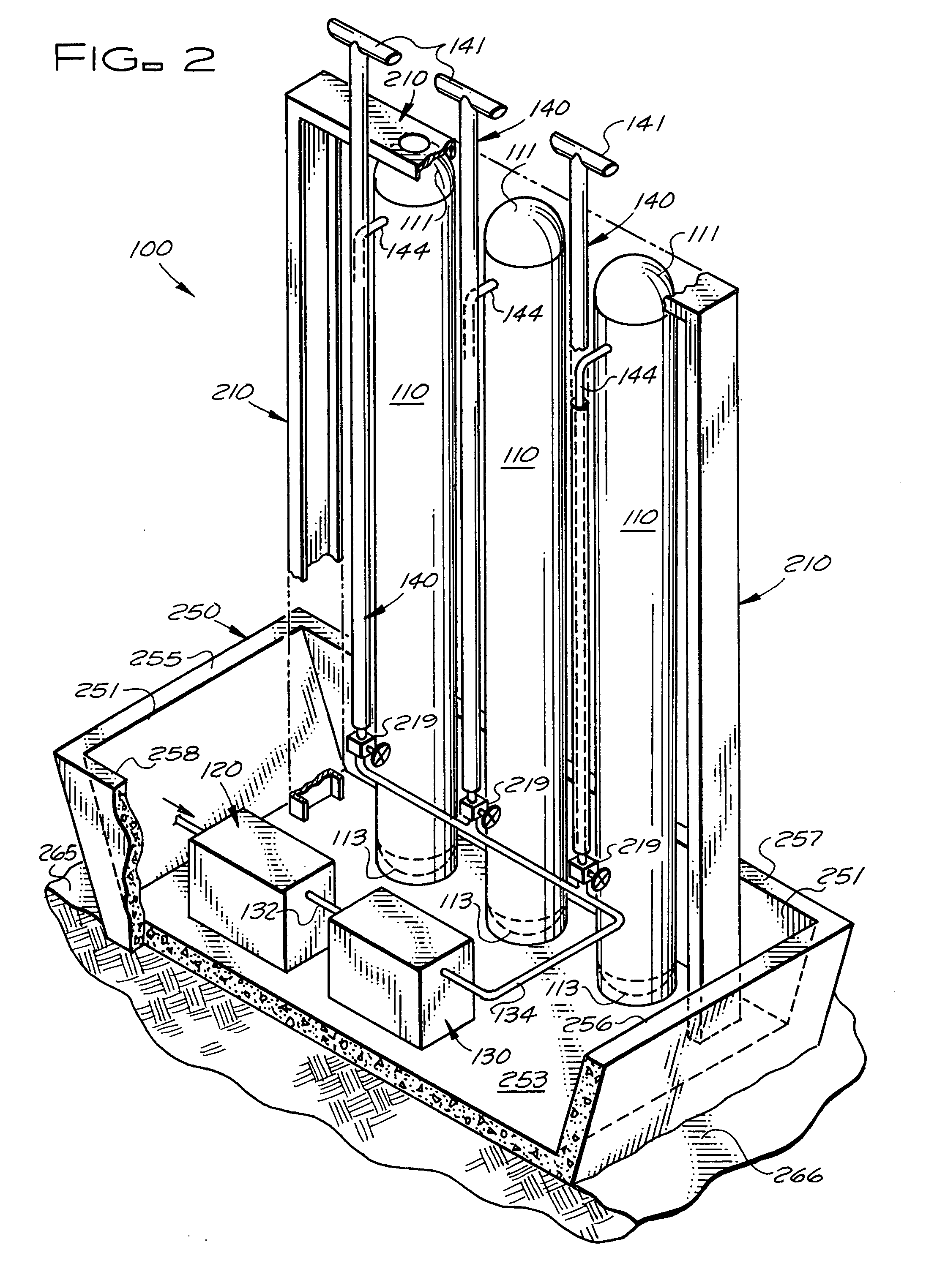

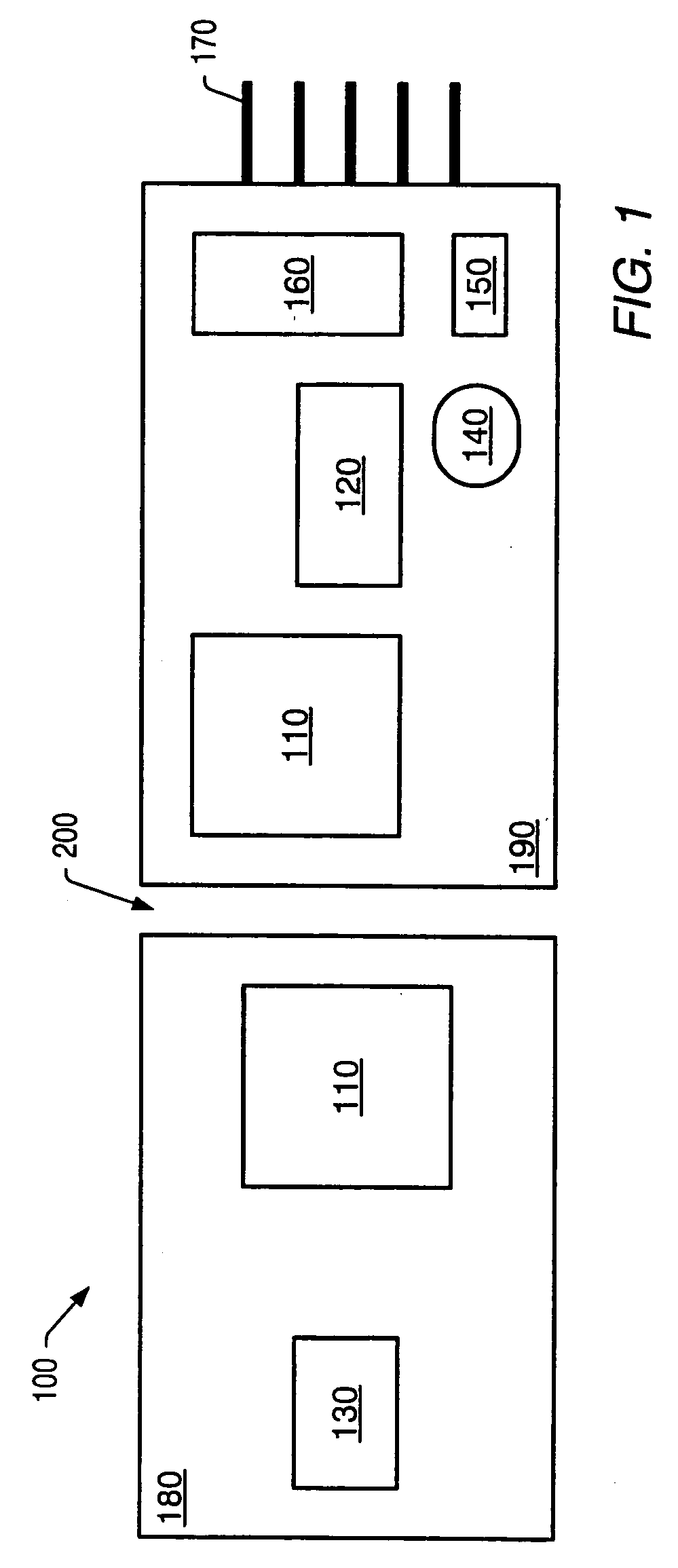

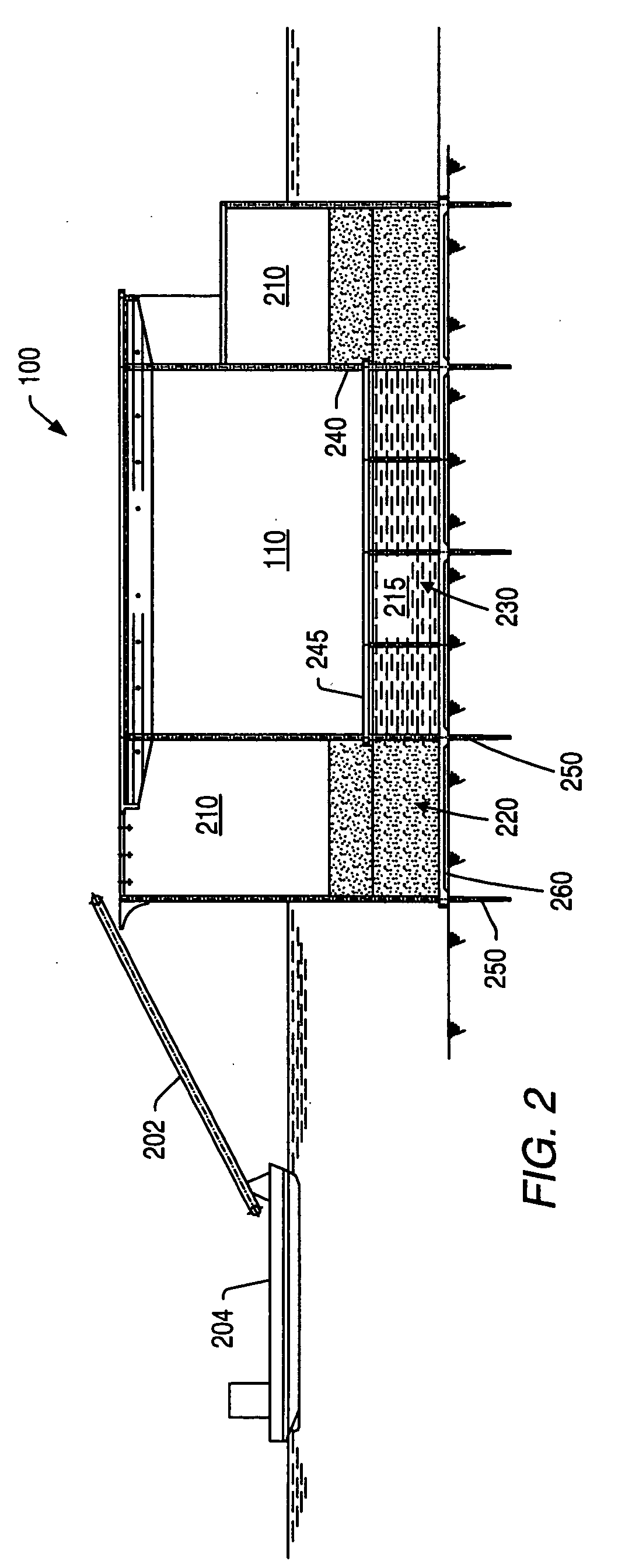

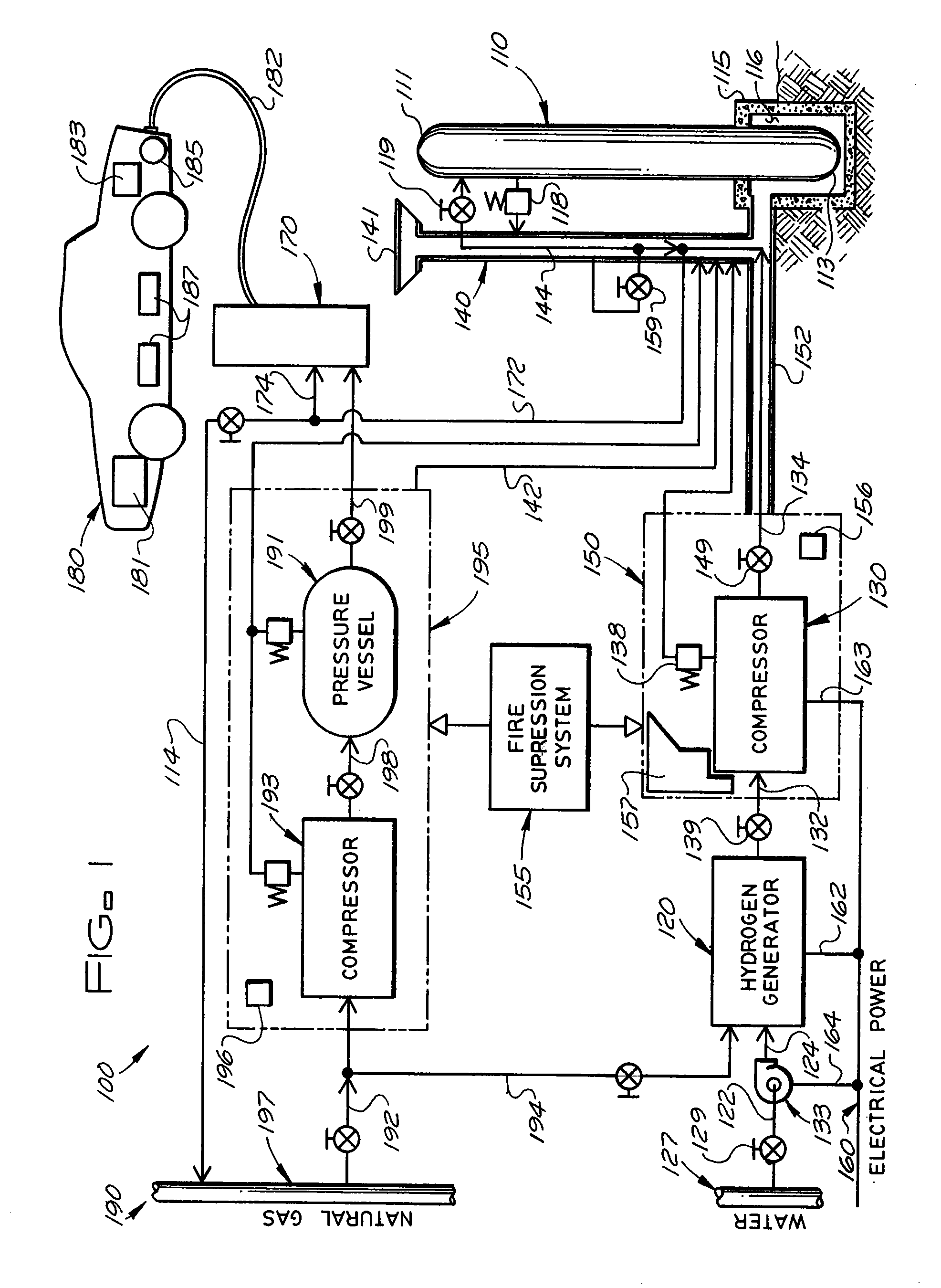

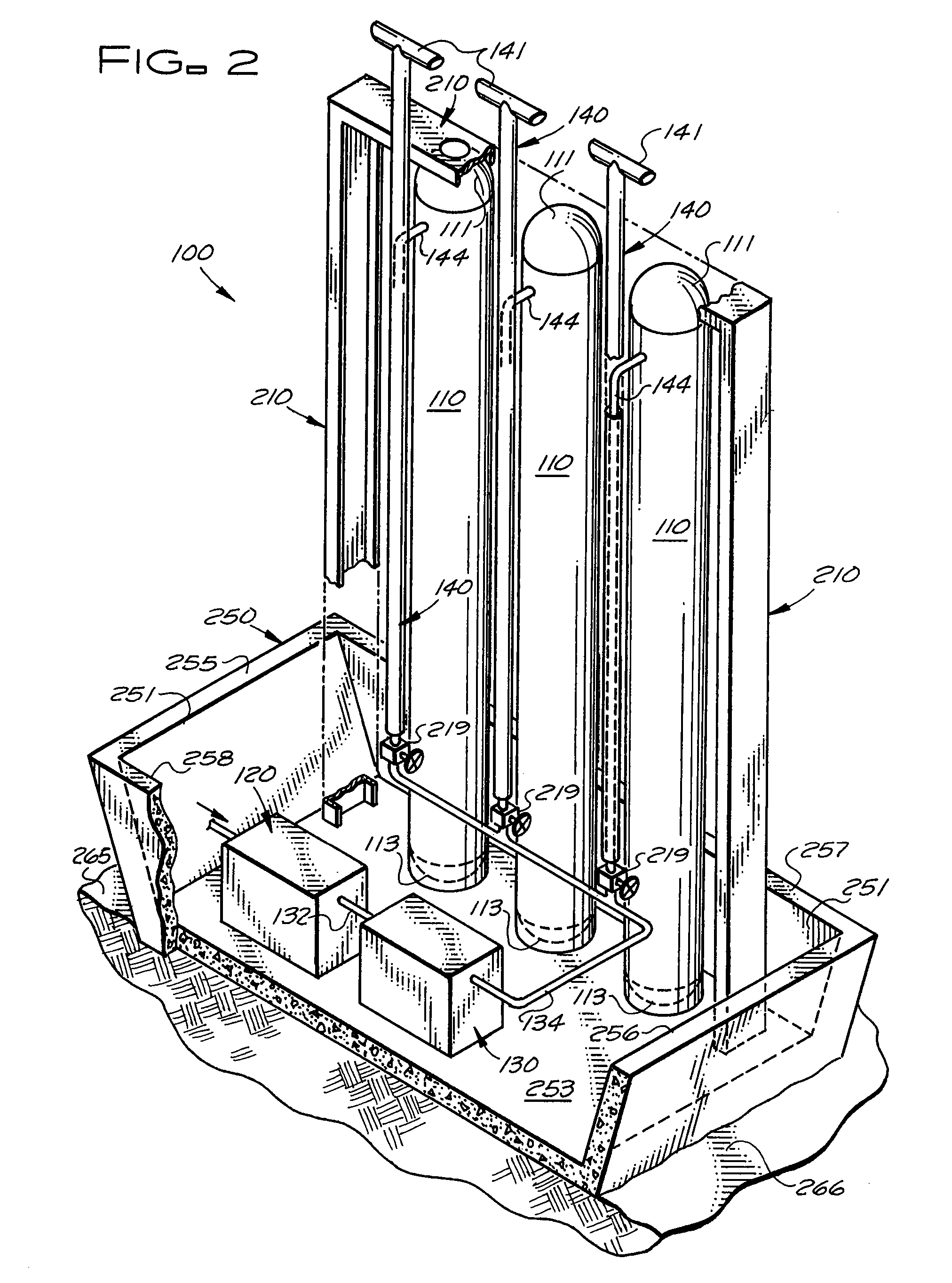

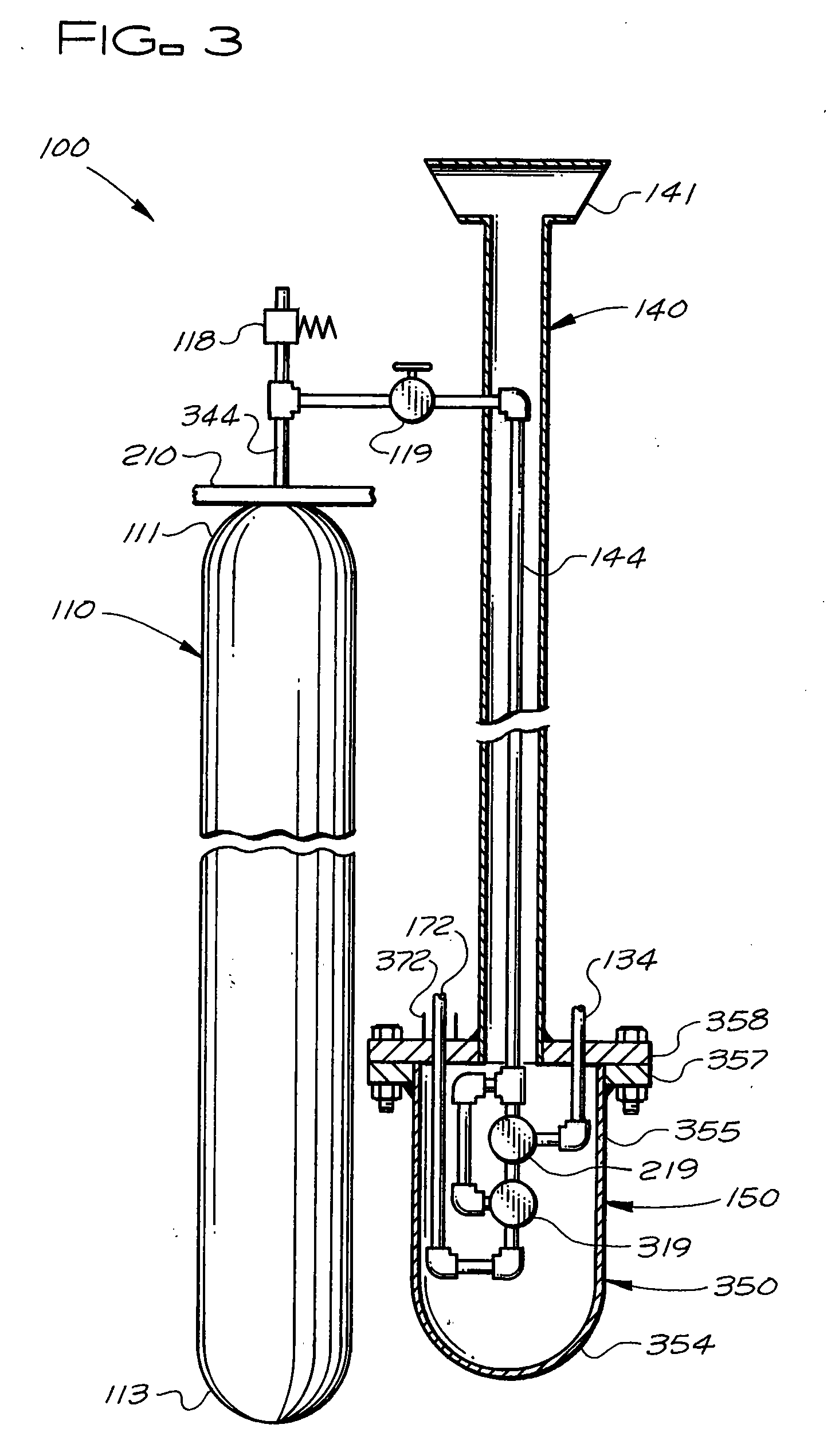

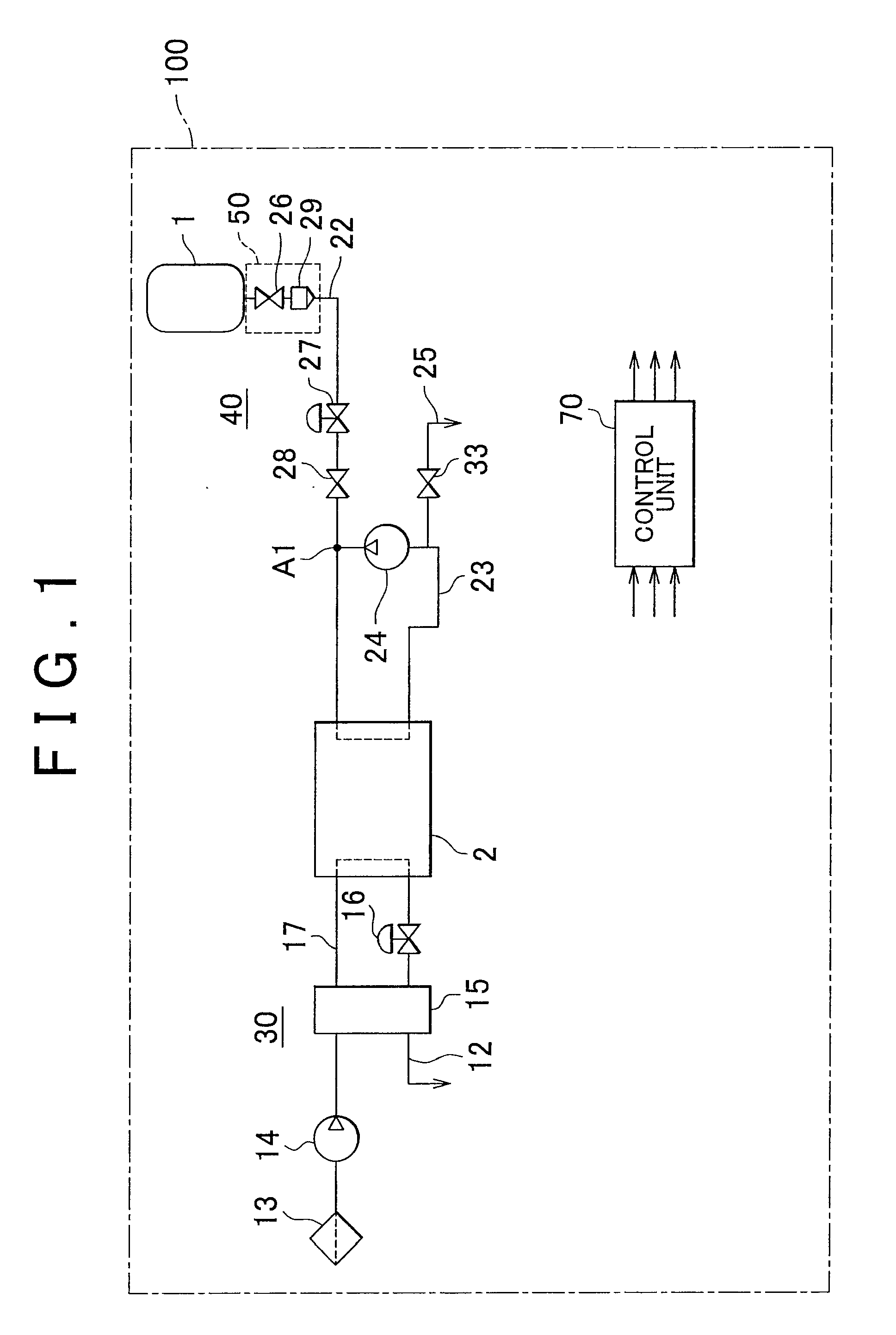

Hydrogen handling or dispensing system

InactiveUS20050000802A1Avoid burnsCheap manufacturingLiquid fillingGas handling applicationsHydrogenHuman life

Systems for handling and / or dispensing hydrogen or a mixture of fuels containing hydrogen gas including refueling stations for hydrogen-powered vehicles. Pure hydrogen or various mixtures ratios of hydrogen and CNG may be dispensed. Hydrogen handling equipment may include a hydrogen generator, a pressurizing apparatus or compressor, pressure vessels, piping, valves, vent pipes, and / or a dispenser. Substantially vertical orientation of pressure vessels may reduce the amount of land required and facilitate installation in urban environments. Pressurization may take place before hydrogen generation to reduce the power required for pressurization. Safety features include enclosures and surrounding walls that lean away from the equipment. Any leaking hydrogen, fires, or explosions may be contained and / or directed upward, protecting human life and property. Systems may be shop assembled and certified.

Owner:ARIZONA PUBLIC SERVICE

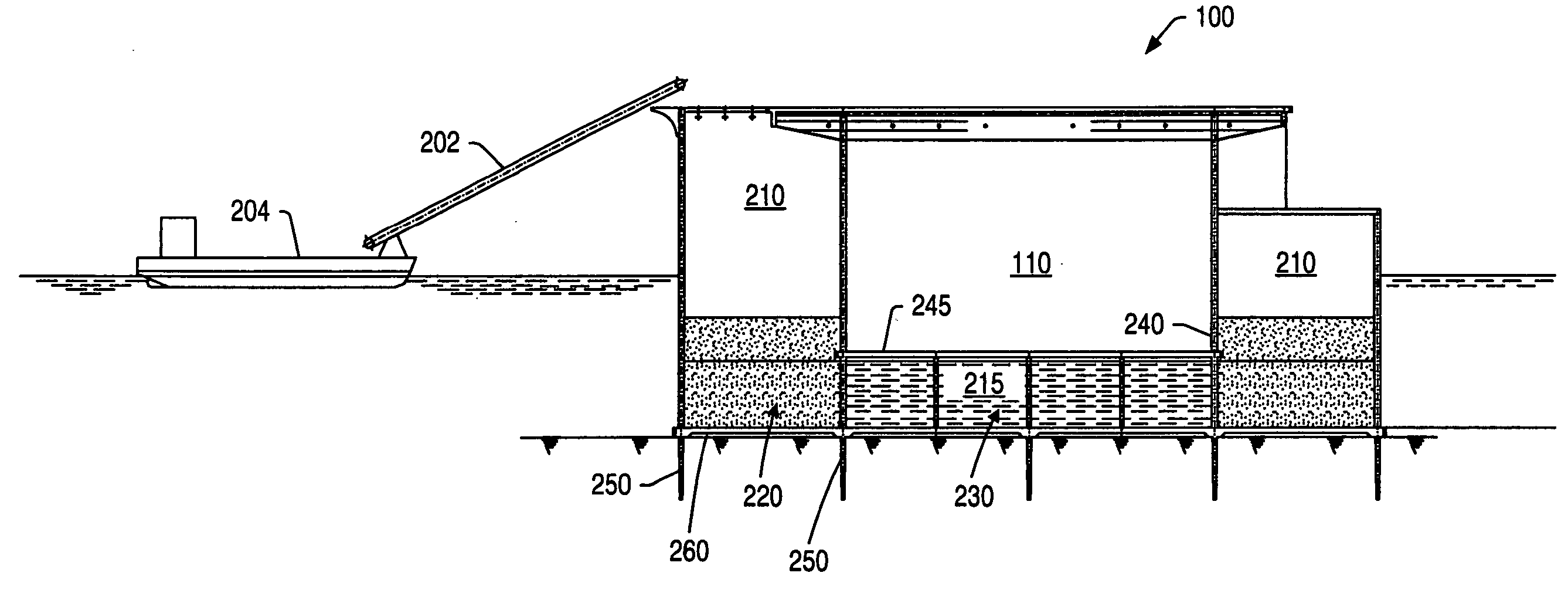

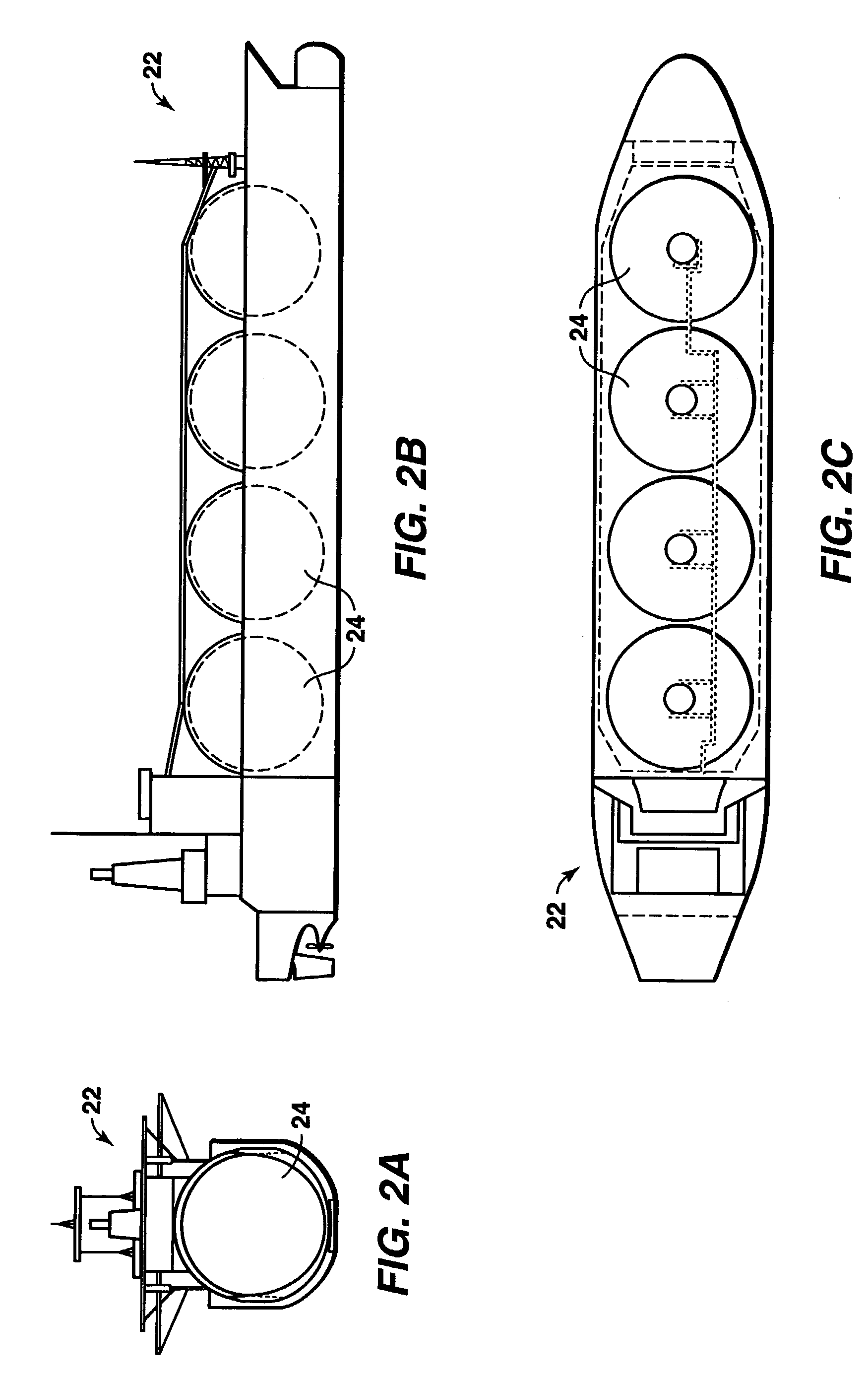

Liquefied natural gas structure

InactiveUS20050115248A1Easy transferProvide protectionGas handling/storage effectsSolid materialMarine engineeringTower

An offshore liquefied natural gas structure may receive, store, and process liquefied natural gas from carriers. A structure may be a gravity base structure. A structure may include a system of ballast storage areas, transfer equipment to offload liquefied natural gas from a carrier, docking equipment to allow direct mooring with carriers, platforms to elevate equipment, water intake systems to provide water to the structure, wave deflectors, and / or projections extending from a bottom of the structure. A portion of the structure may be composed of lightweight concrete. Pipelines may be coupled to the structure to export processed natural gas onshore. Living quarters, flare towers, and export line metering equipment may be included on the structure.

Owner:SHELL OIL CO

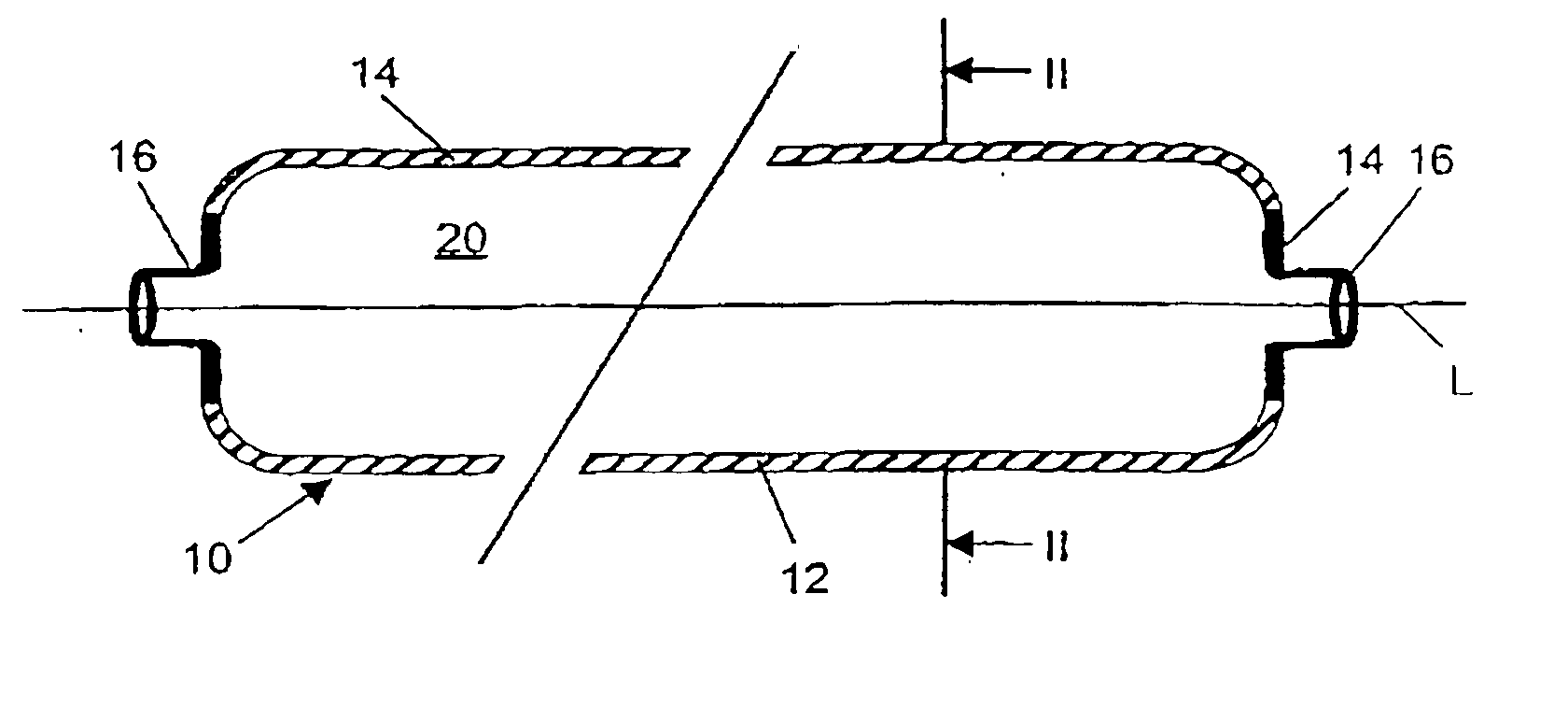

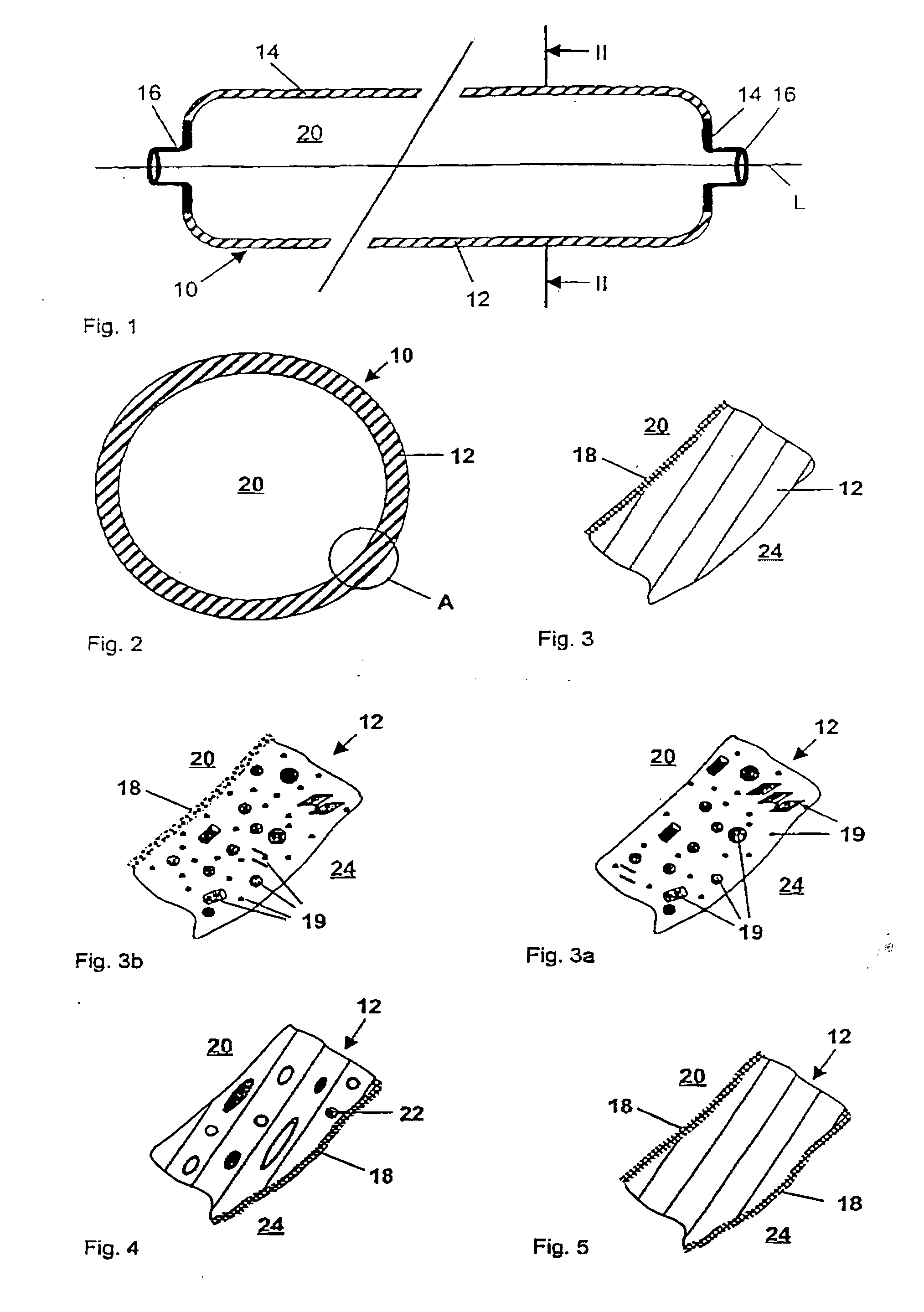

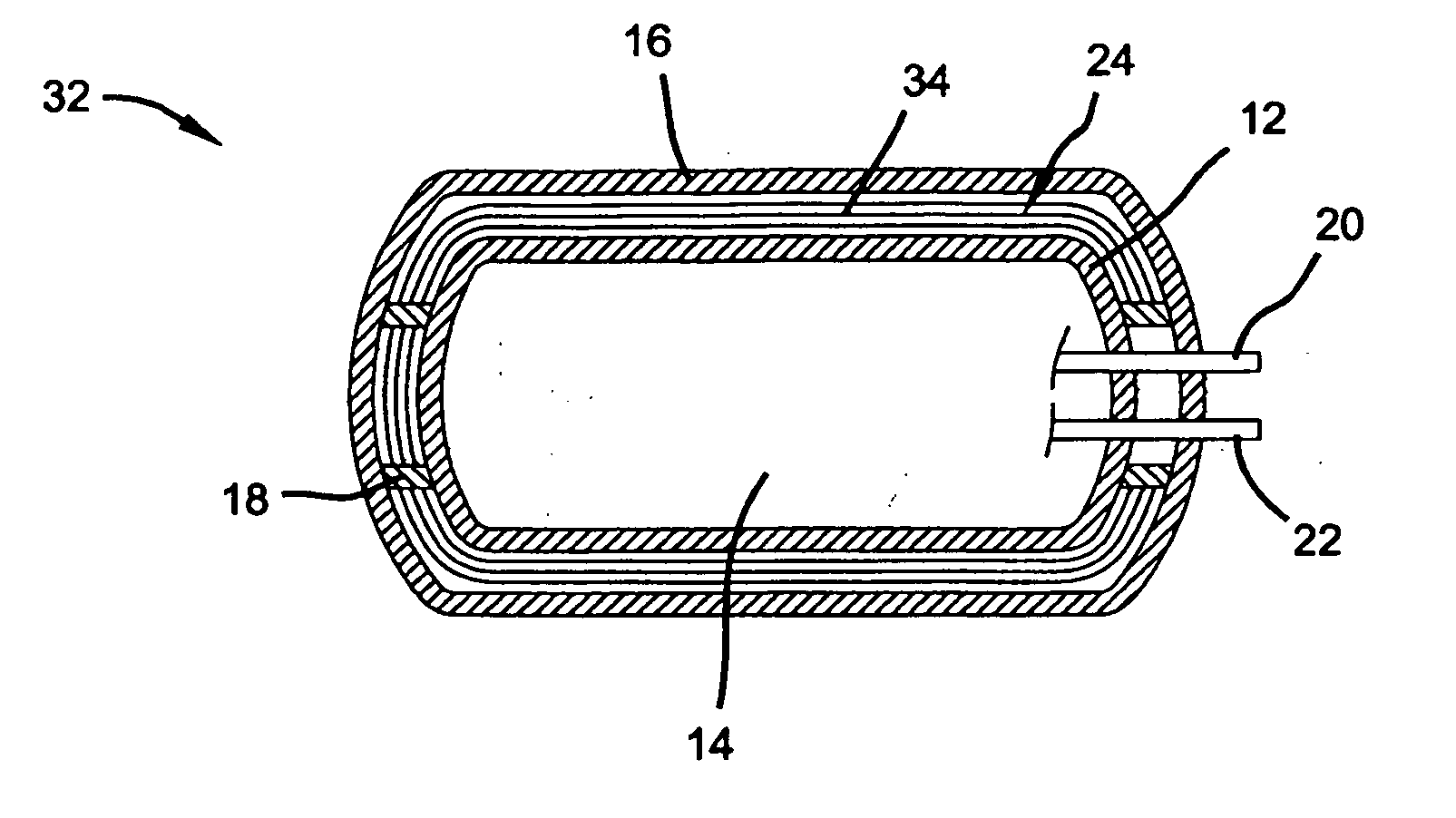

Gastight container

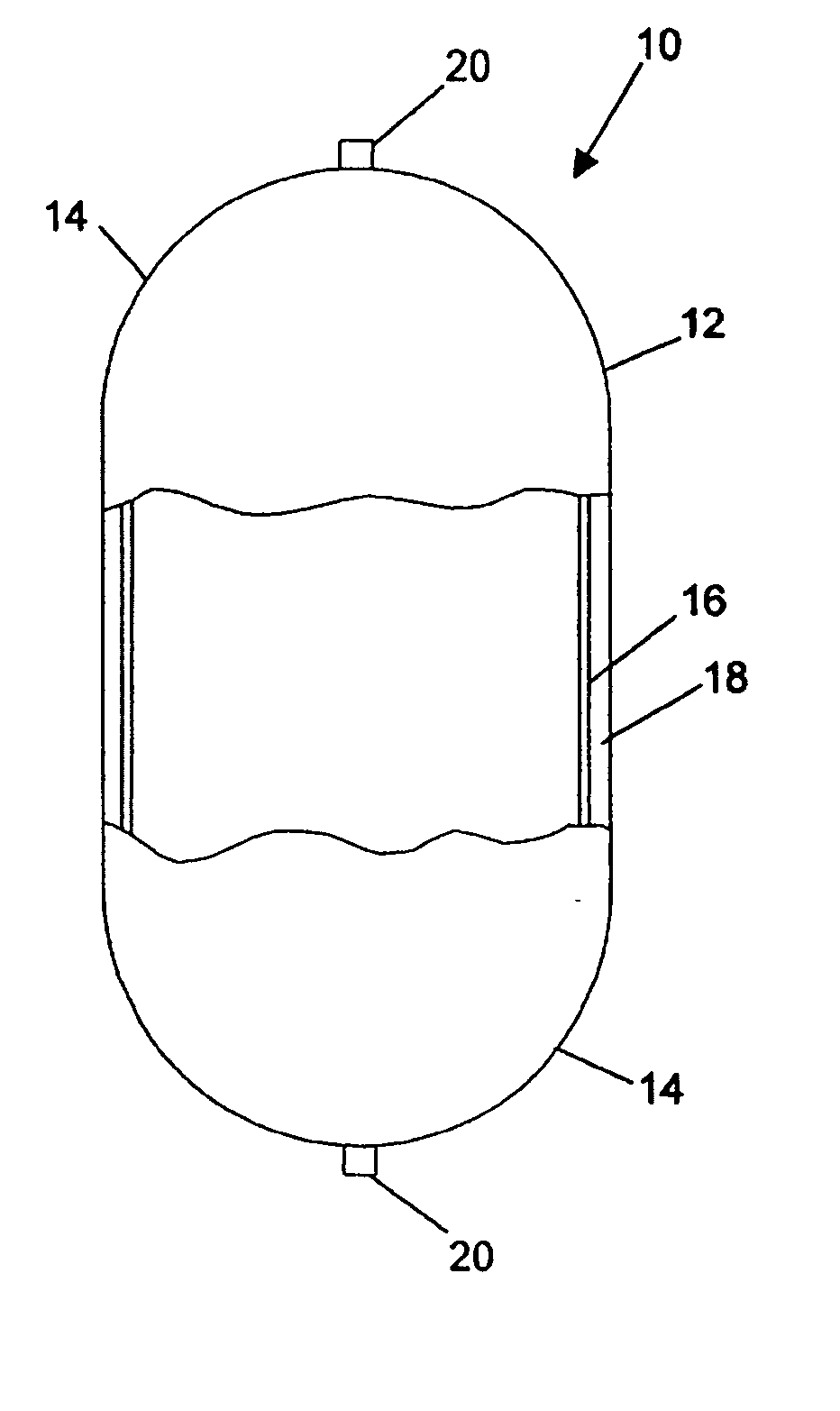

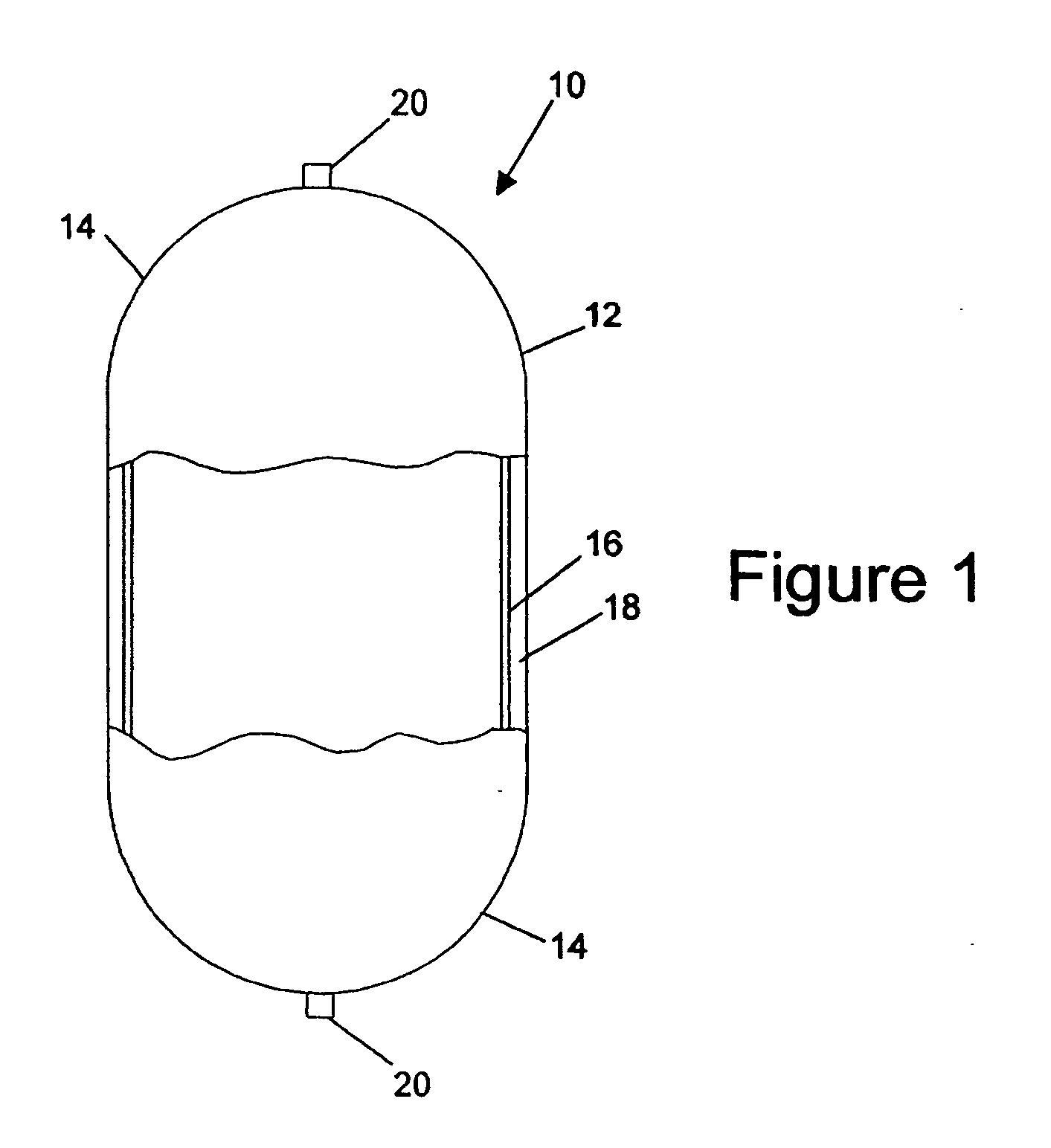

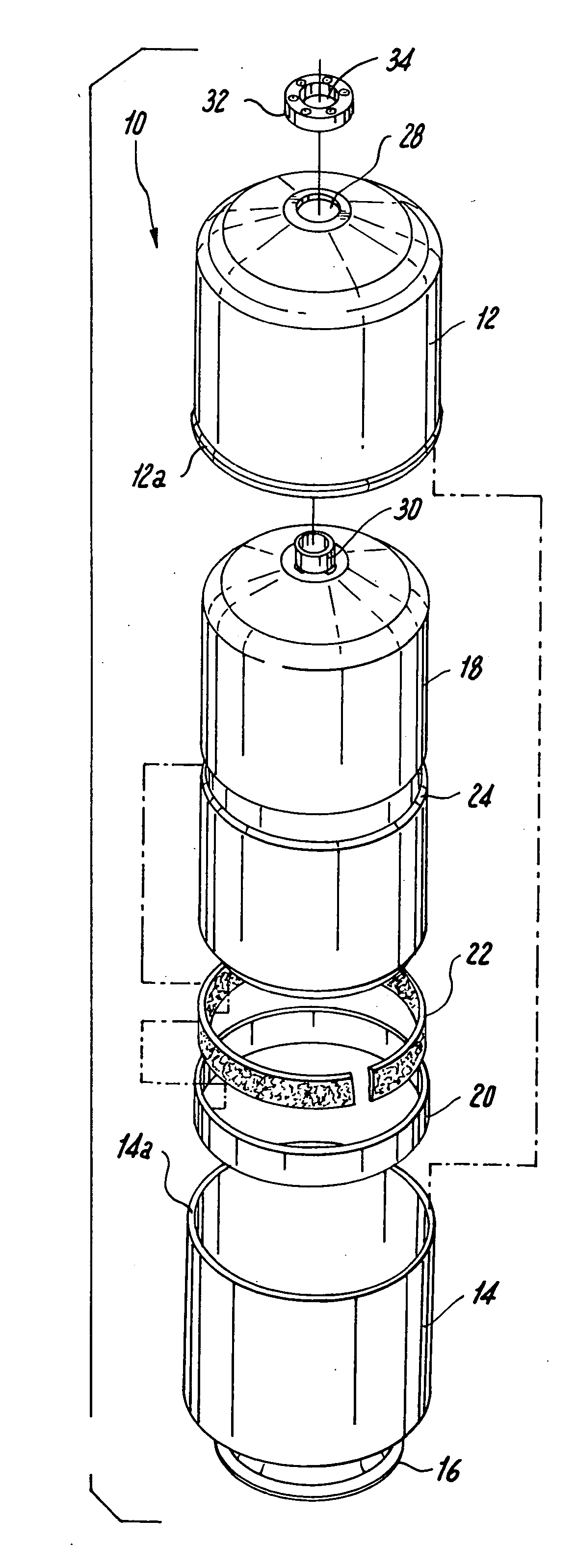

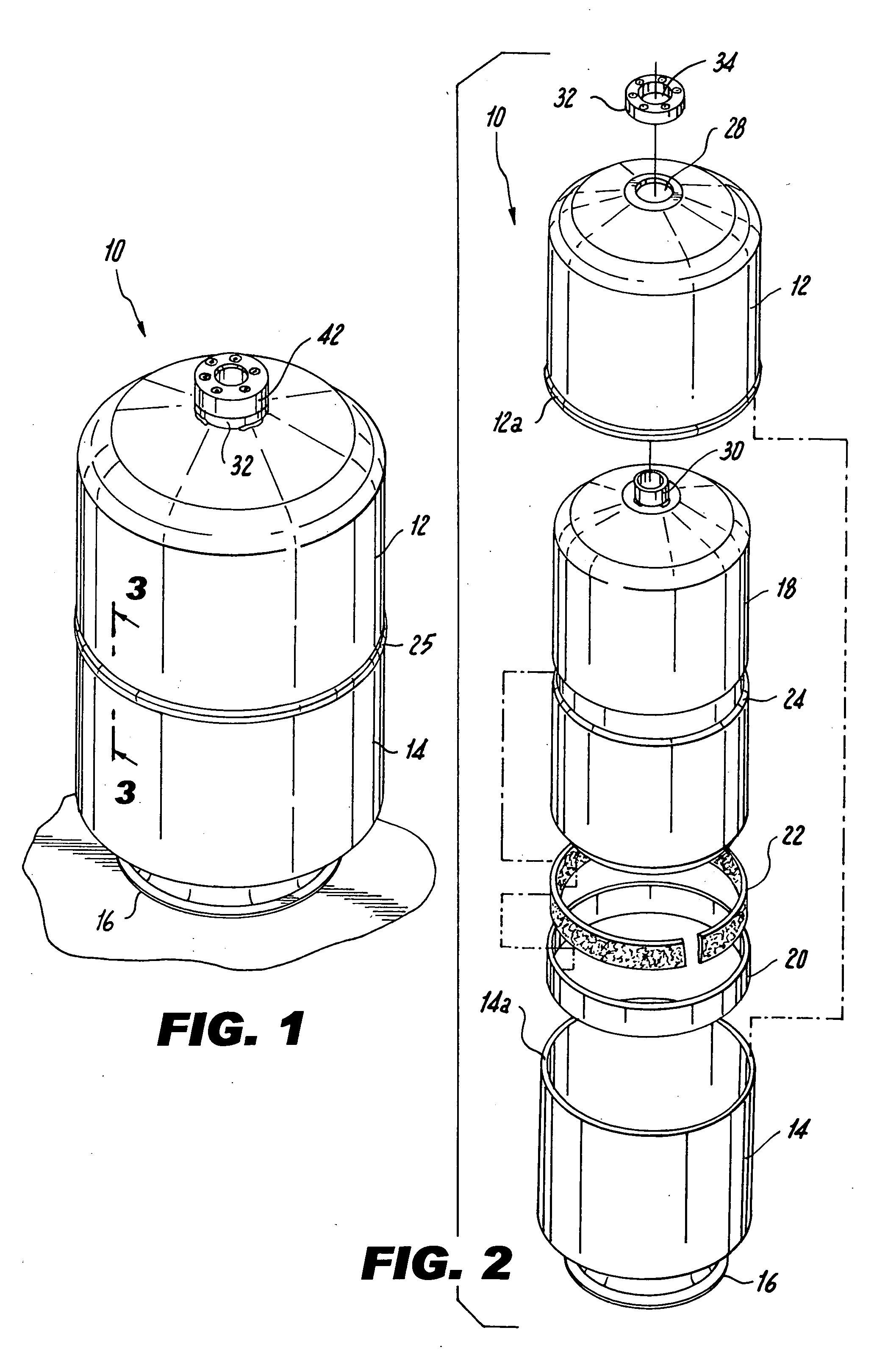

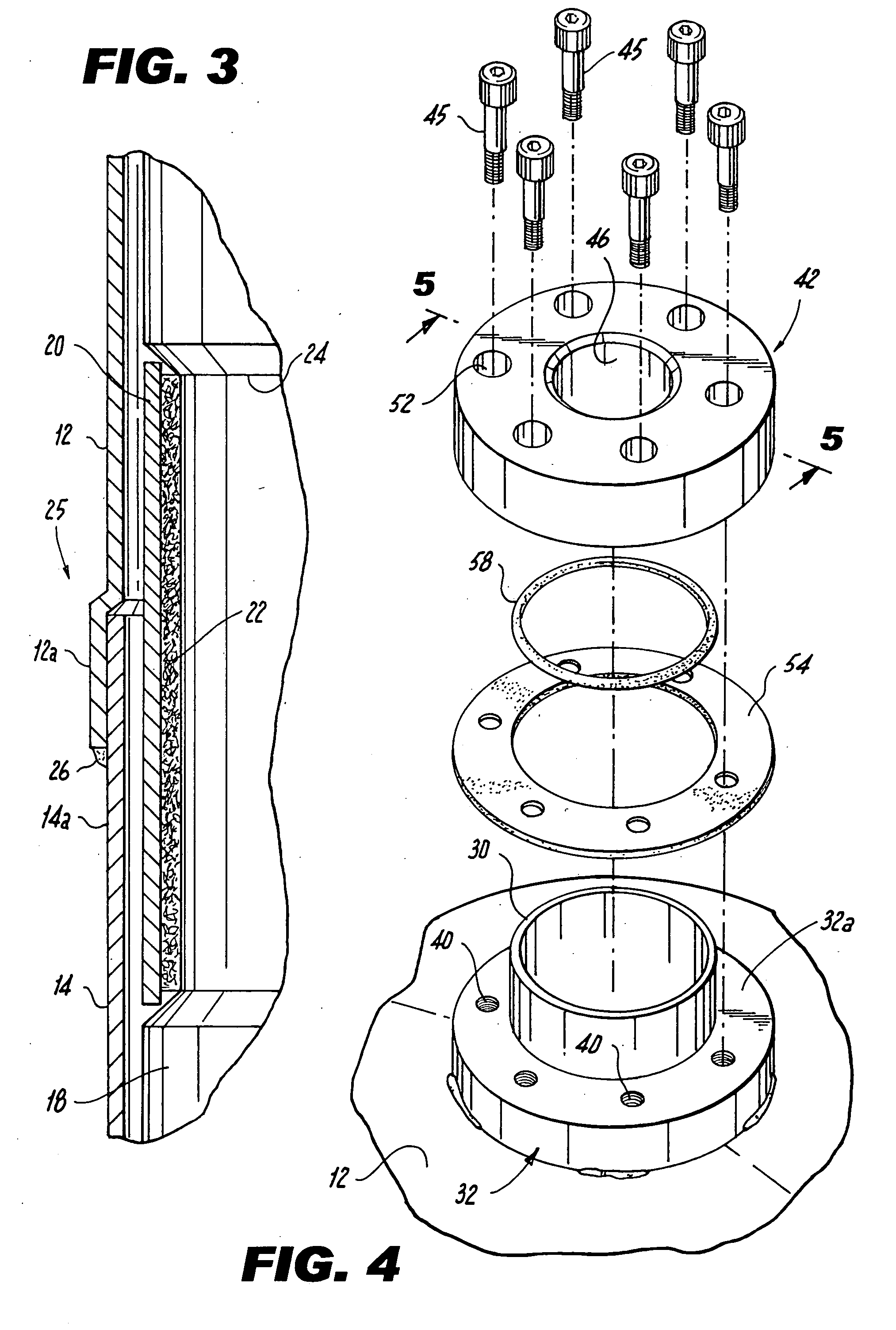

InactiveUS20040149759A1Reduce quality problemsNegligible in recyclingAircraft componentsVessel mounting detailsHydrogenComposite film

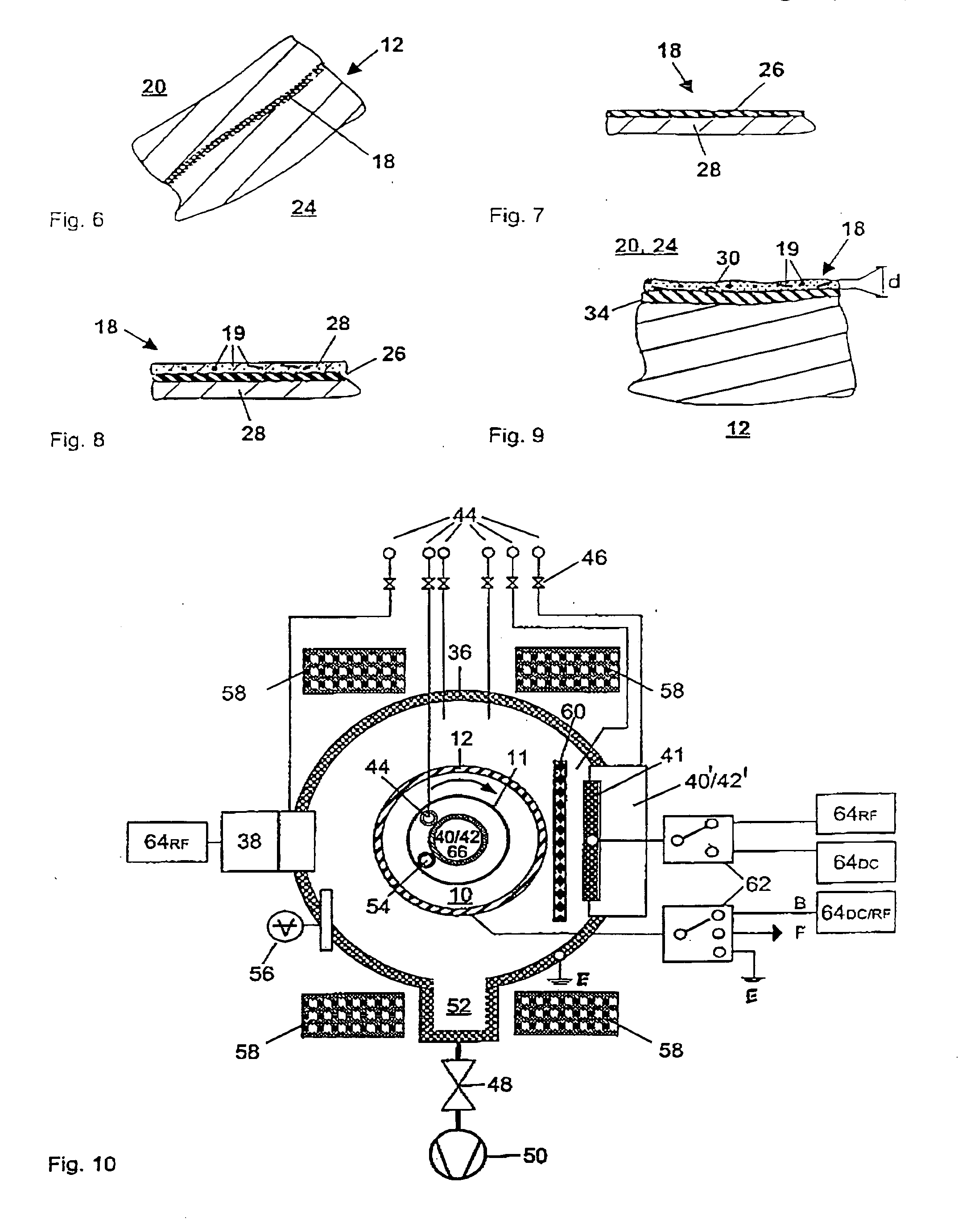

The invention relates to a gastight, pressure-resistant storage and / or transport container (10) for low-molecular, reactive filling media, especially for hydrogen, oxygen, air, methane and / or methanol. Said container has a high filling pressure and is embodied in an essentially rotationally symmetric manner, having at least one connector cap (15) with a sealing device (16). The wall (12) of the container is essentially comprised of a thermoplastic synthetic material having at least one diffusion barrier (18, 19) system and / or a diffusion barrier and anti-corrosion system (18, 19). In order to offer protection for hydrogen and oxygen containers, the diffusion barrier system can be embodied in the form of at least one compact layer and / or can contain finely dispersed, distributed reactive nanoparticles (18) in the wall (12) of the container, in at least one composite film (28) and / or in at least one diffusion barrier layer (18).

Owner:MOSER EVA MARIA +1

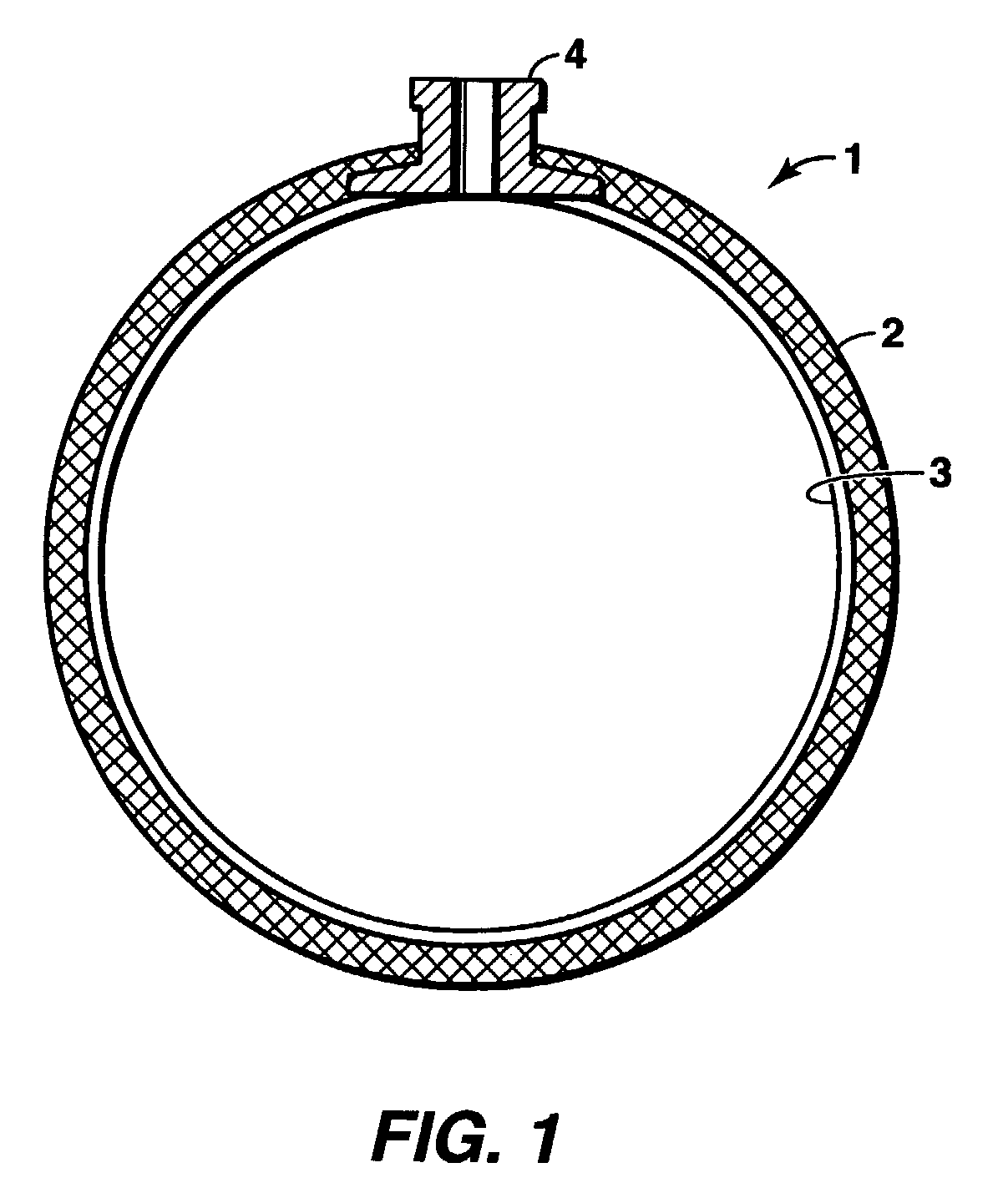

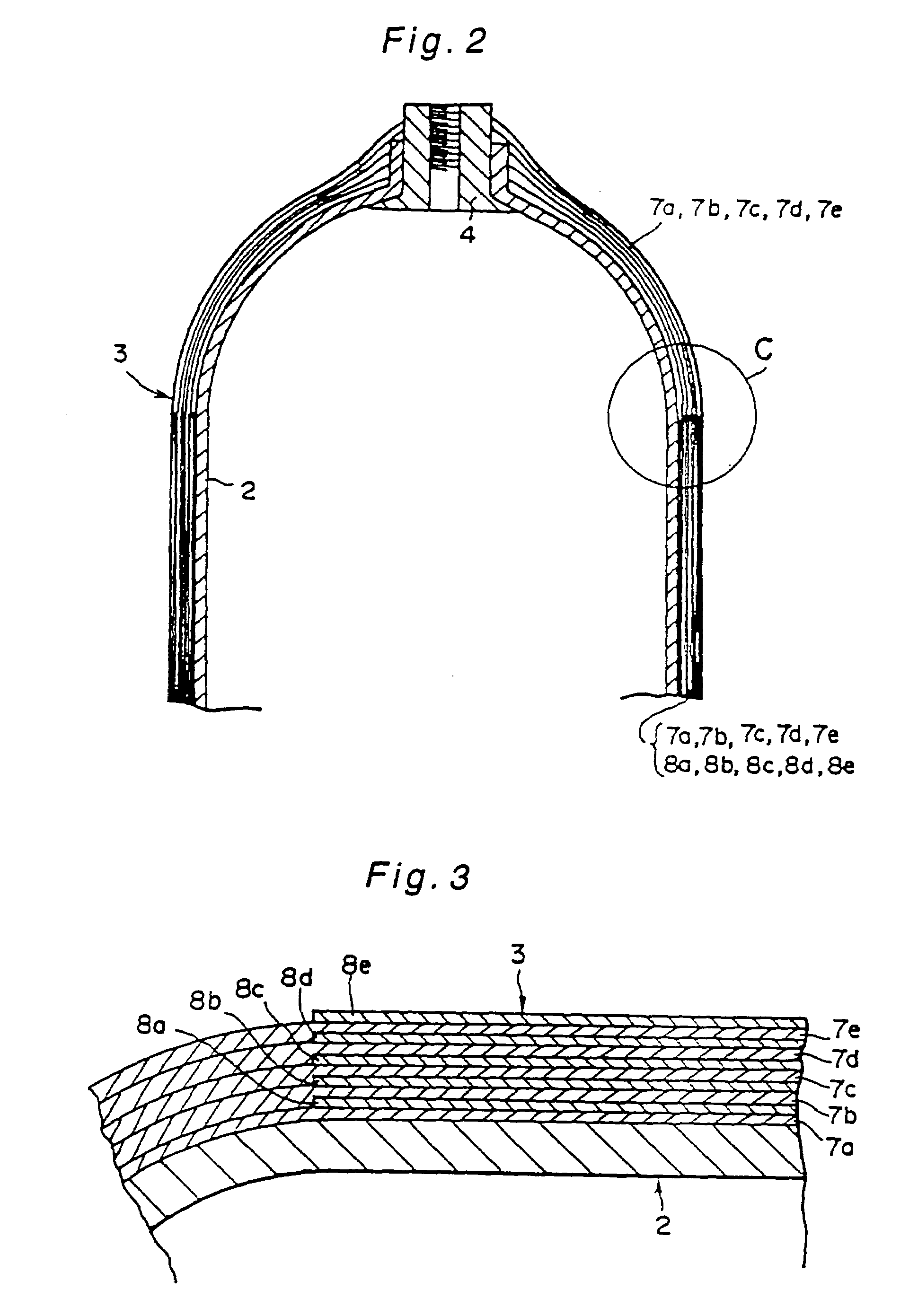

Damage and leakage barrier in all-composite pressure vessels and storage tanks

ActiveUS20090314785A1Superior barrier against leakageStrengthAdhesive processesGas handling applicationsFiberAxis of symmetry

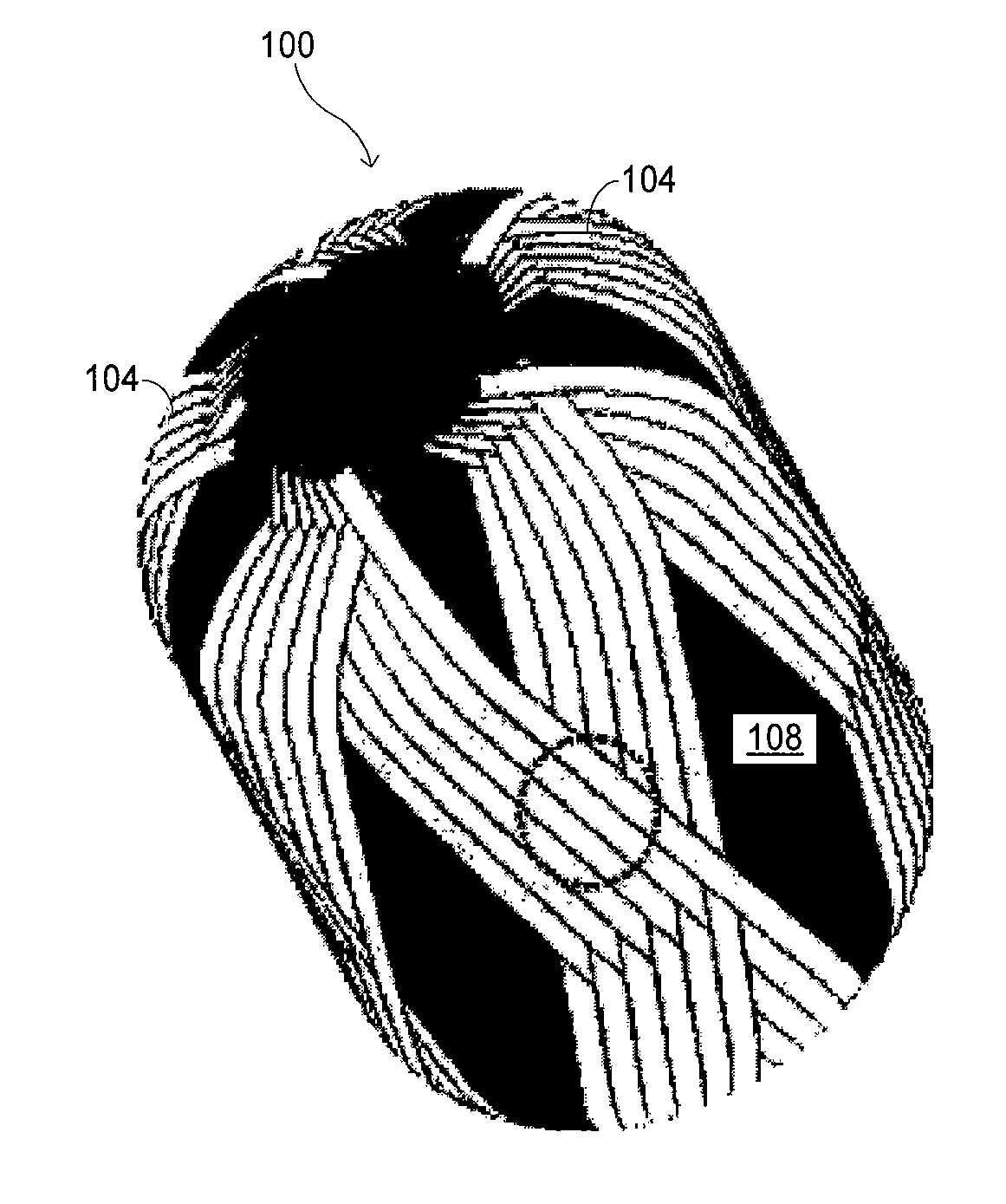

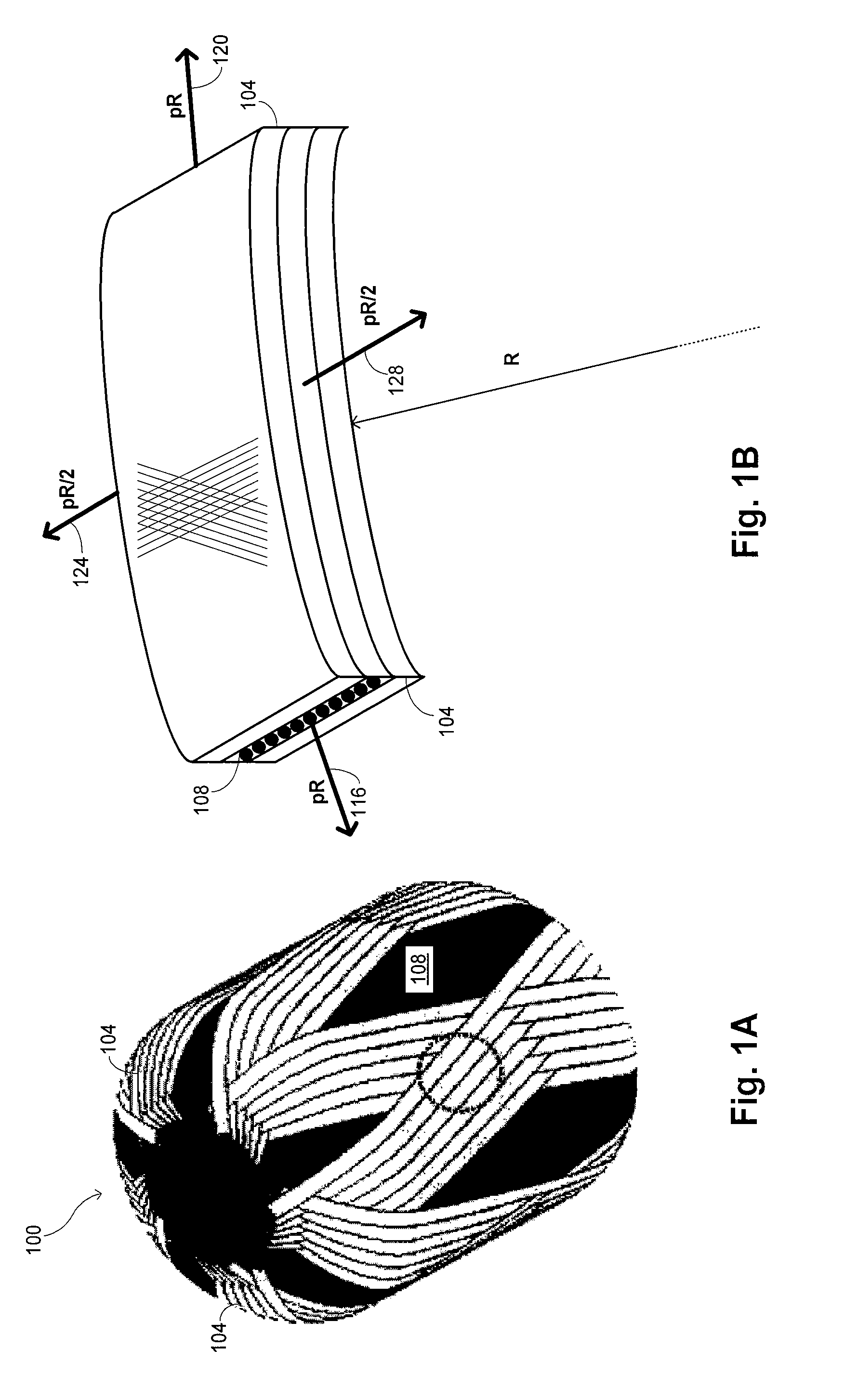

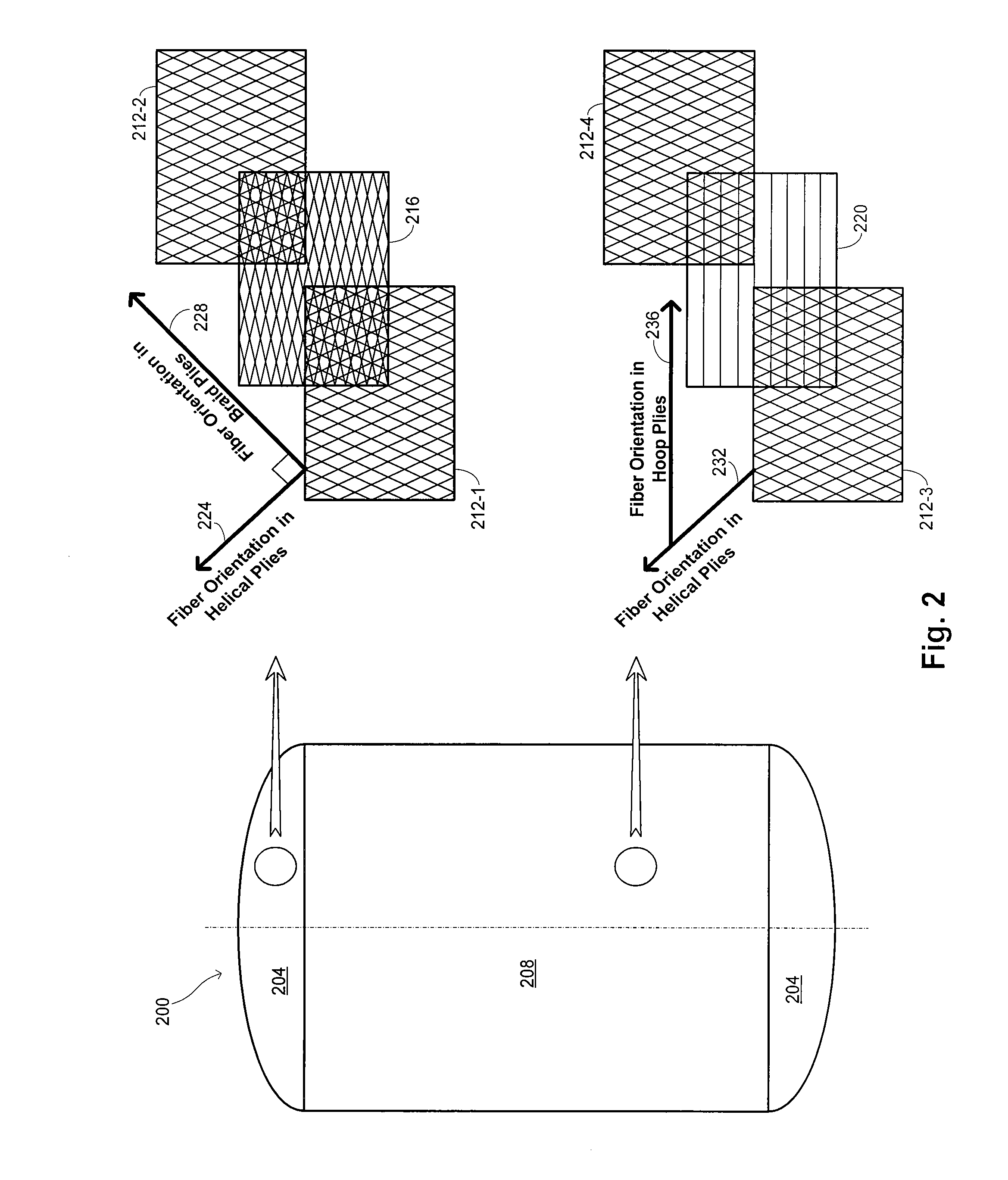

A linerless tank structure has a body that defines an enclosed interior volume. The body has a cylindrical section having an axis of symmetry and a dome section coupled with the cylindrical section. The construction of the pressure vessel includes multiple fiber plies. At least one of the fiber plies is a helical ply having fibers traversing the dome helically about the axis of symmetry. At least a second of the fiber plies is a braided or woven ply.

Owner:COMPOSITE TECH DEV

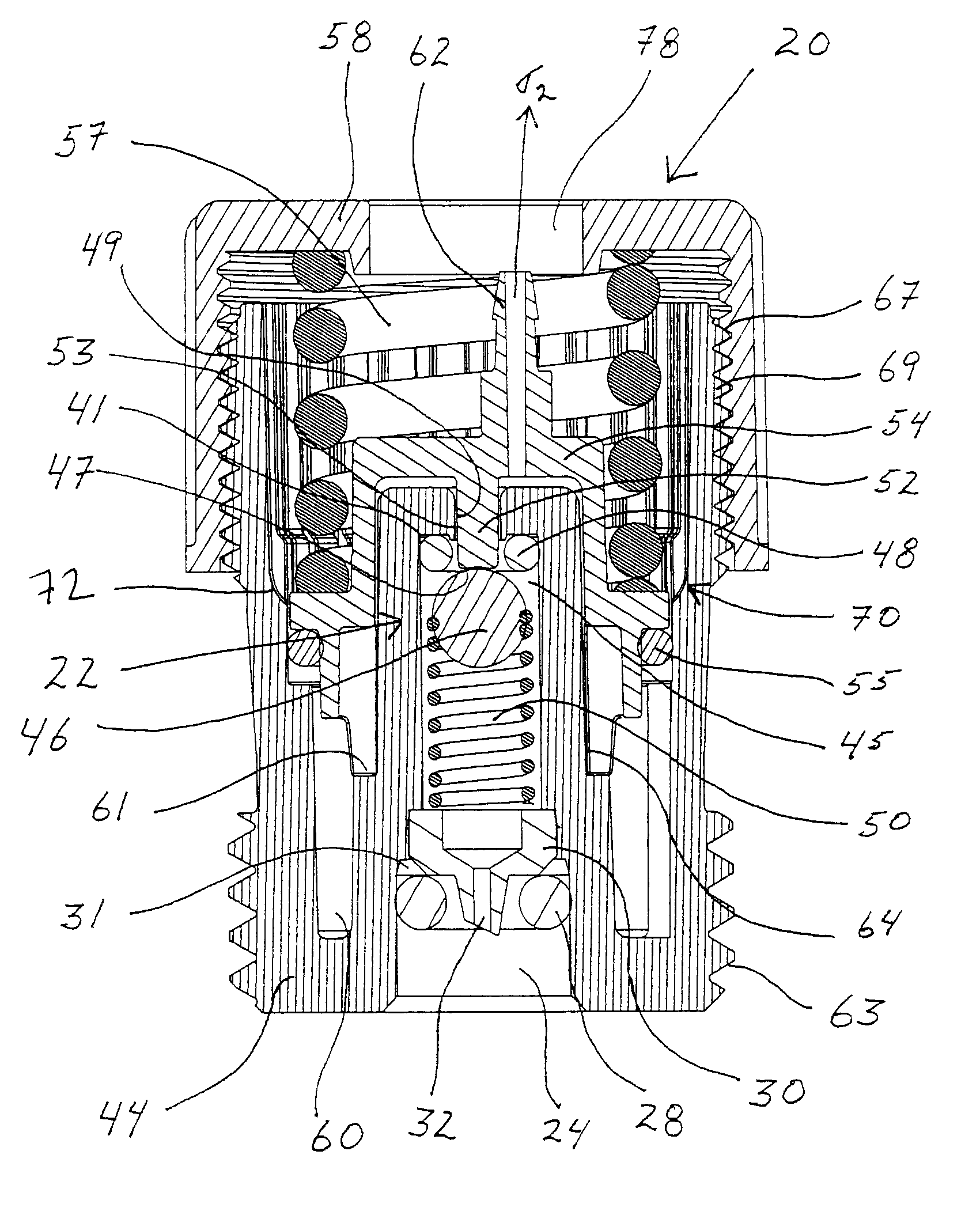

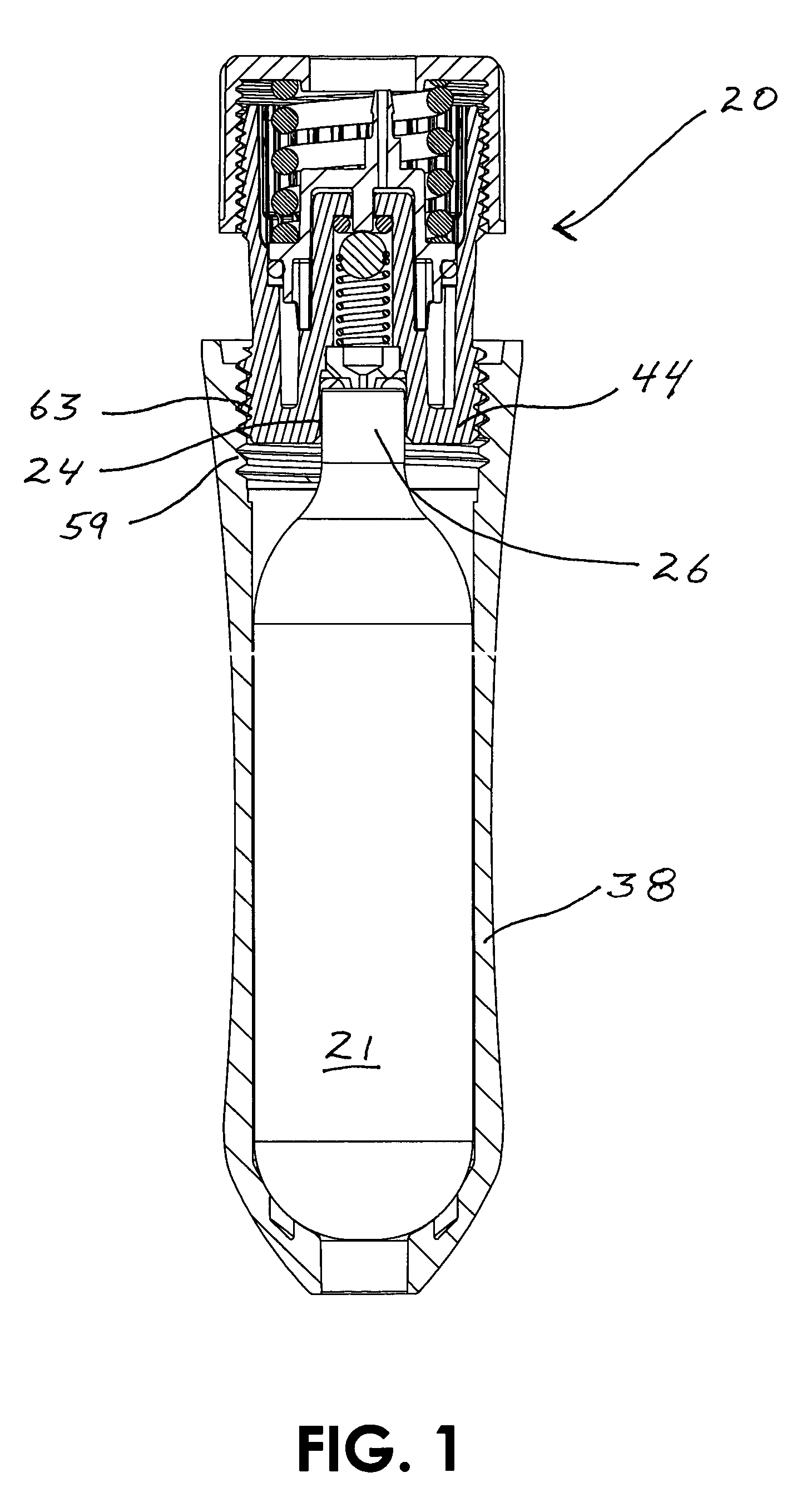

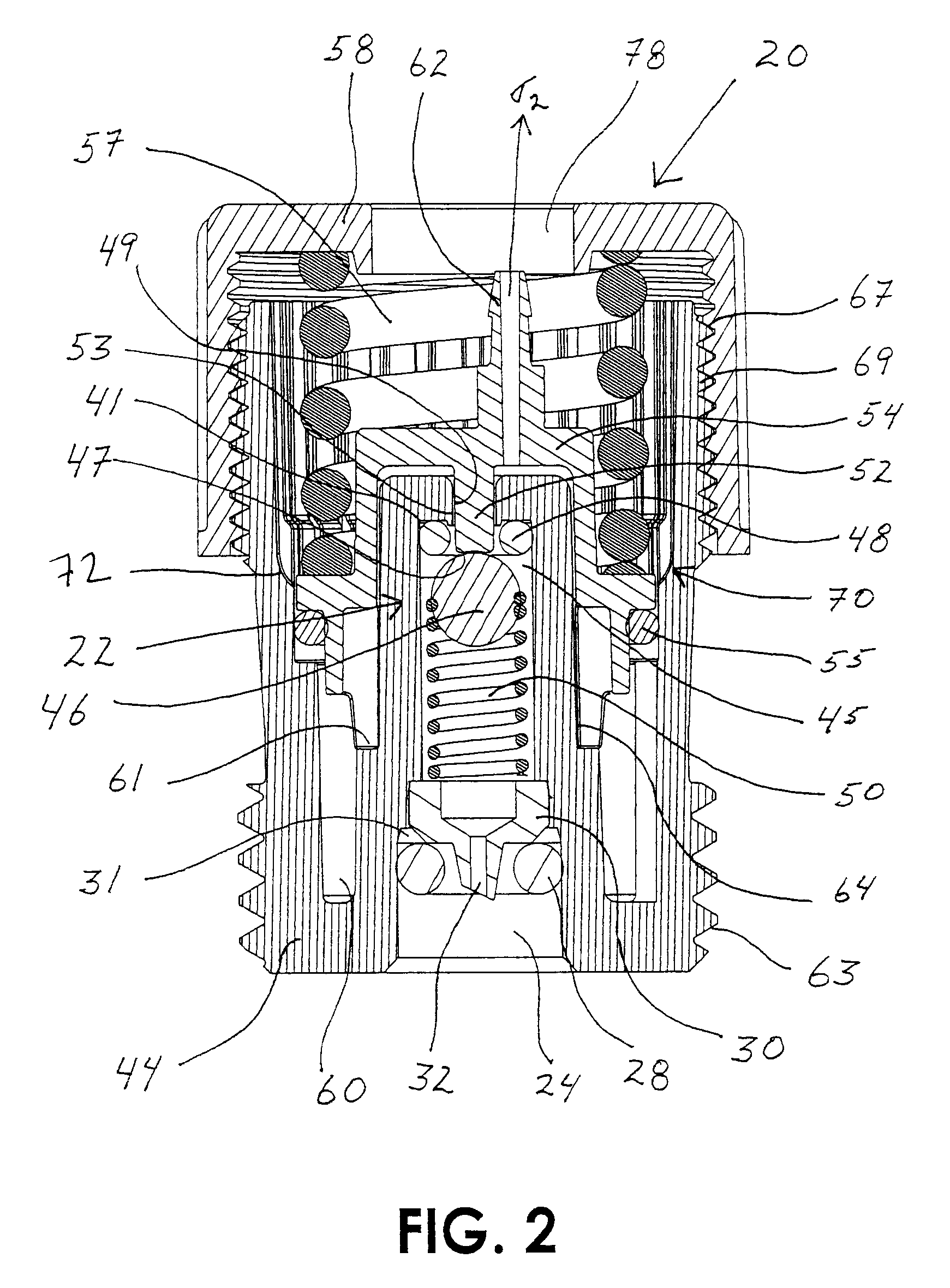

Pressure regulator adaptable to compressed gas cartridge

ActiveUS7334598B1Reduce manufacturing costImprove reliabilityContainer filling methodsGas handling applicationsEngineeringHigh pressure

This pressure regulator is specifically designed to operate with a portable compressed gas cartridge thus reducing the high vapor pressure found in compressed gas cartridges down to a substantially consistent outlet pressure. Due to the nature of the crowded regulator art, the soon to be embodied pressure regulator has been specifically embodied for use in the portable compressed gas cartridge harnessing art and this specific use is carried into the claims. Exemplified in the pressure regulator embodiments is a reduced amount of components over existing designs. Additionally, safety and reliability features have been integrated into the design and will shortly be taught in the following paragraphs. A burp-off feature in all embodiments will be exemplified that vents back-pressure spikes as well as a method of adjusting the burp-off back-pressure spikes independent of regulated pressure in some embodiments.

Owner:HOLLARS ANTHONY SCOTT

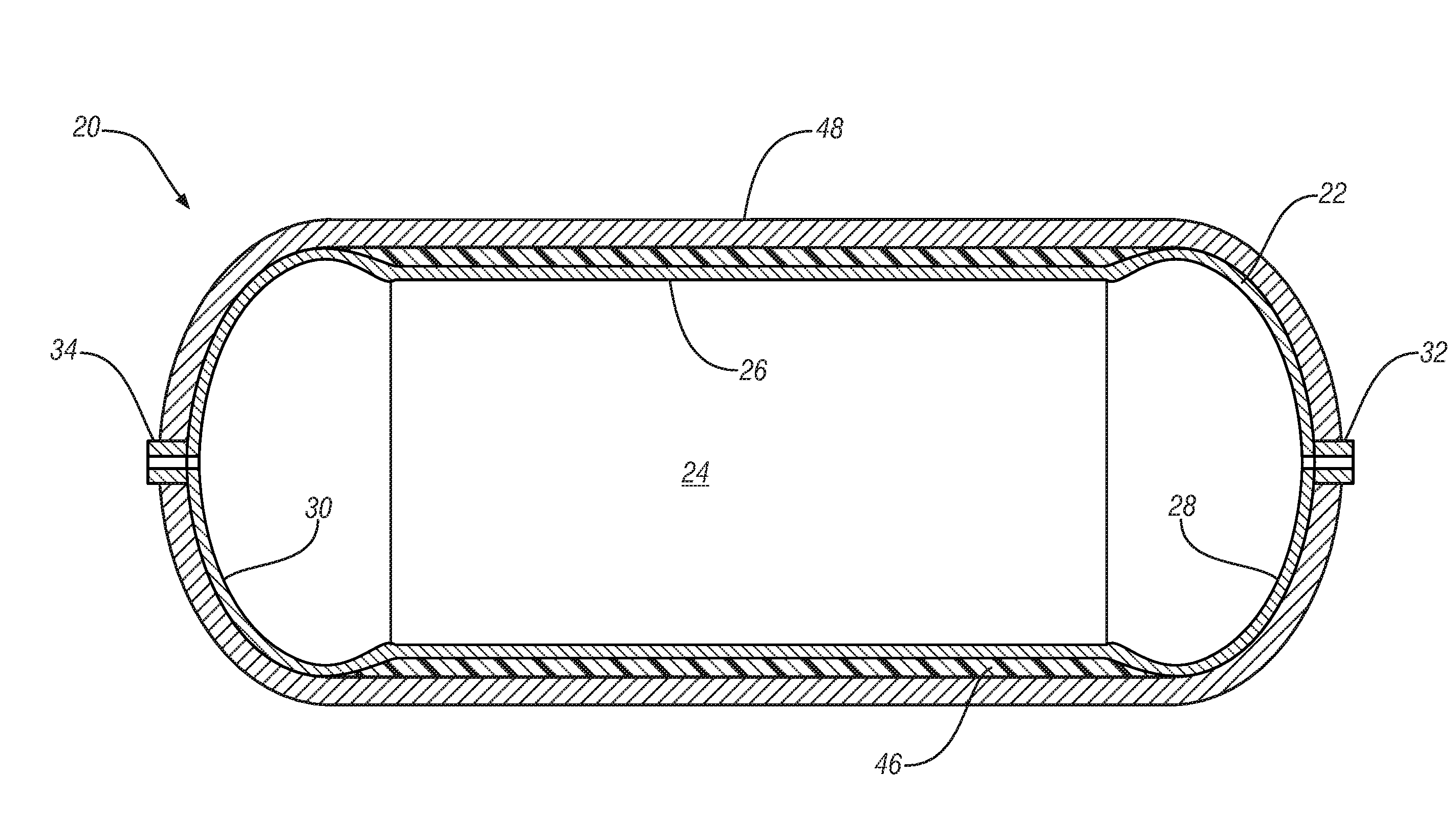

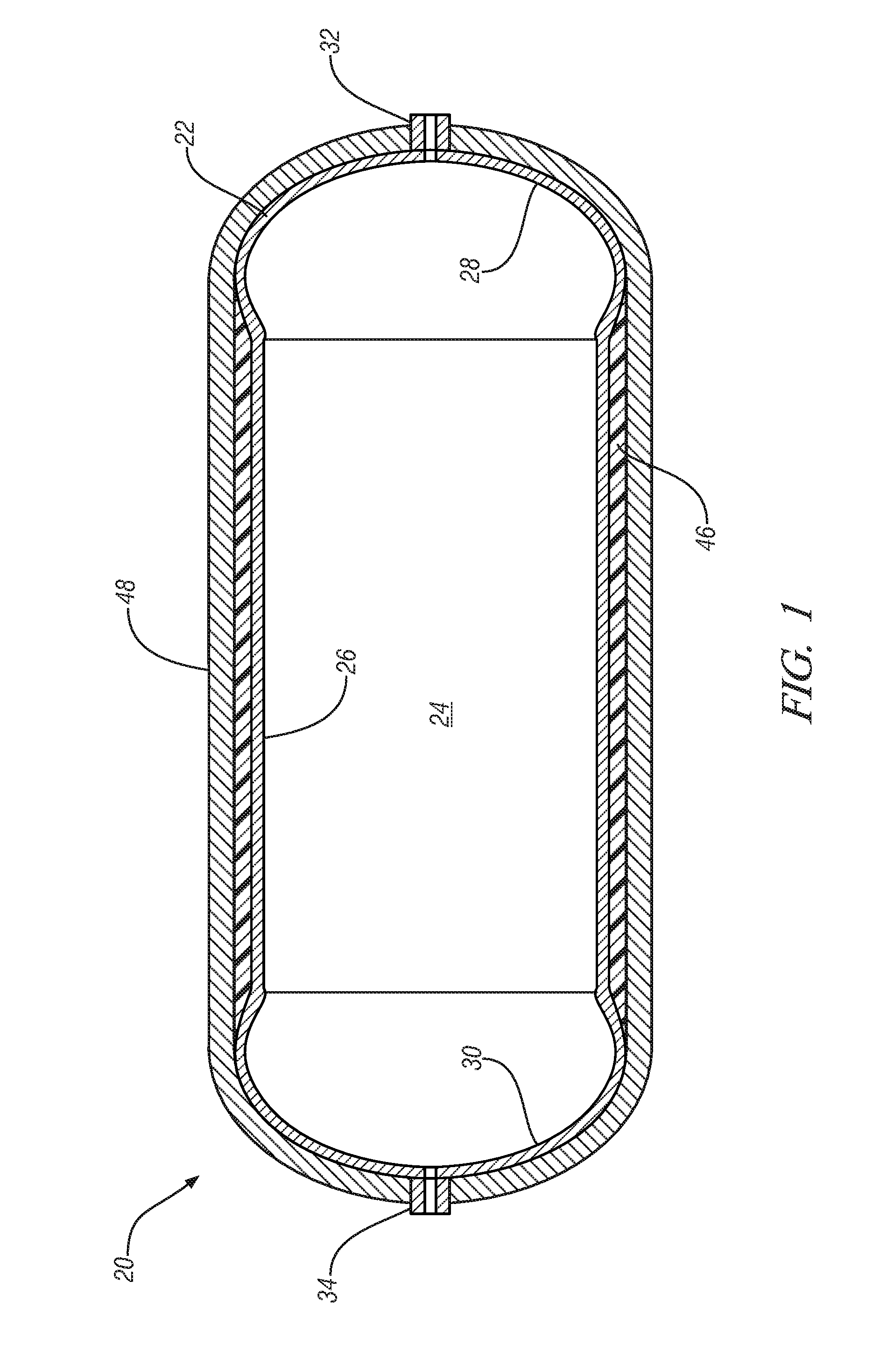

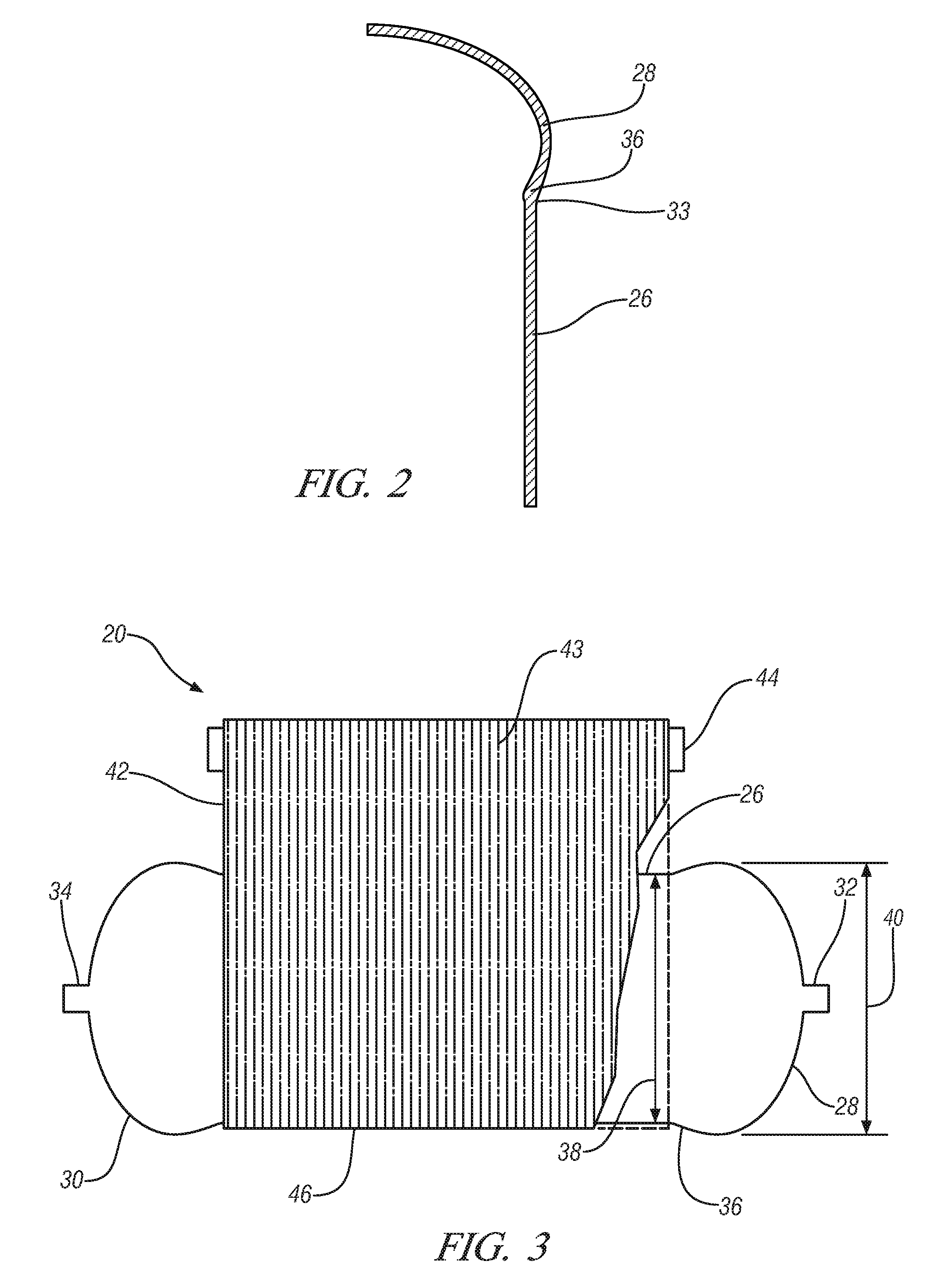

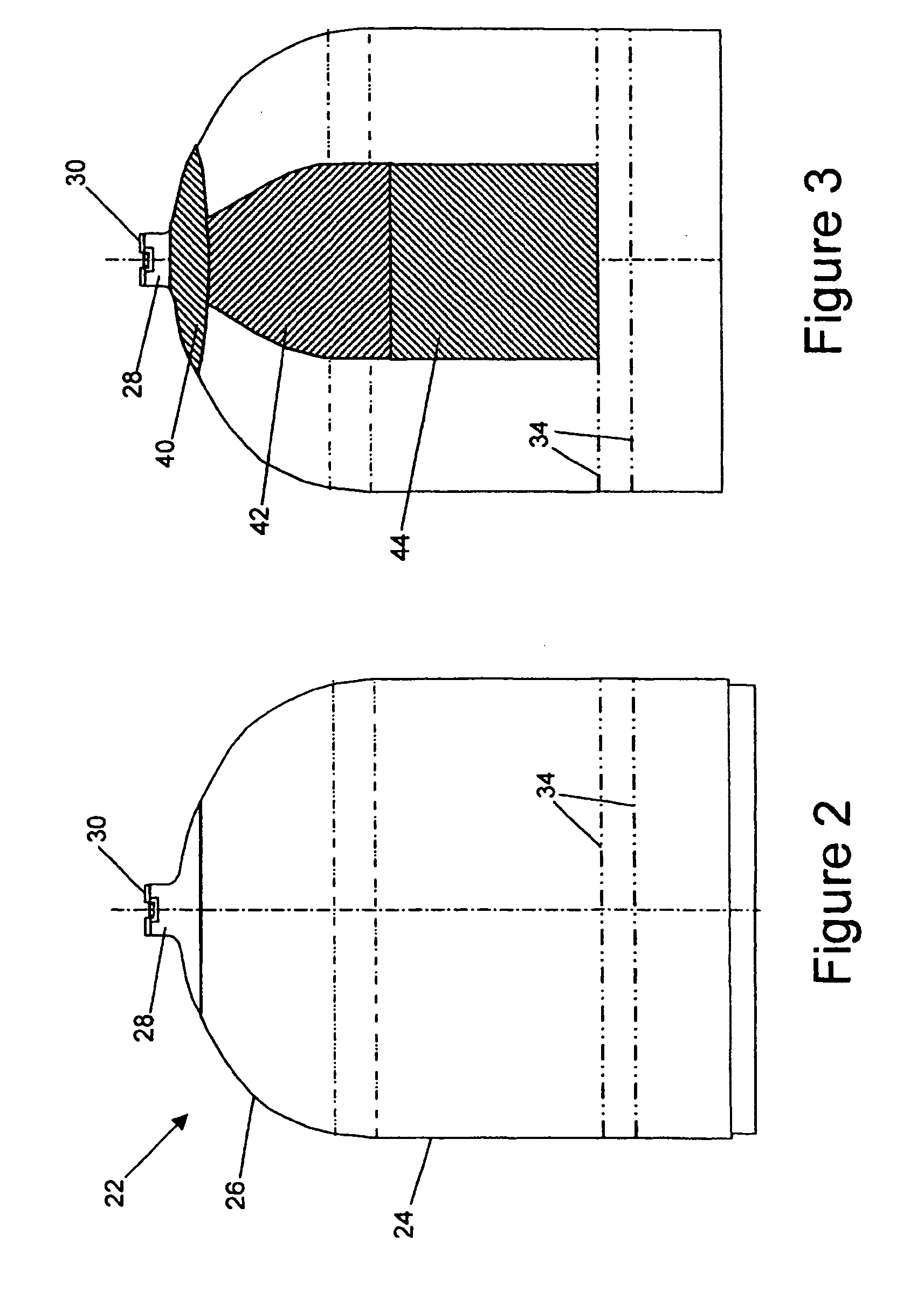

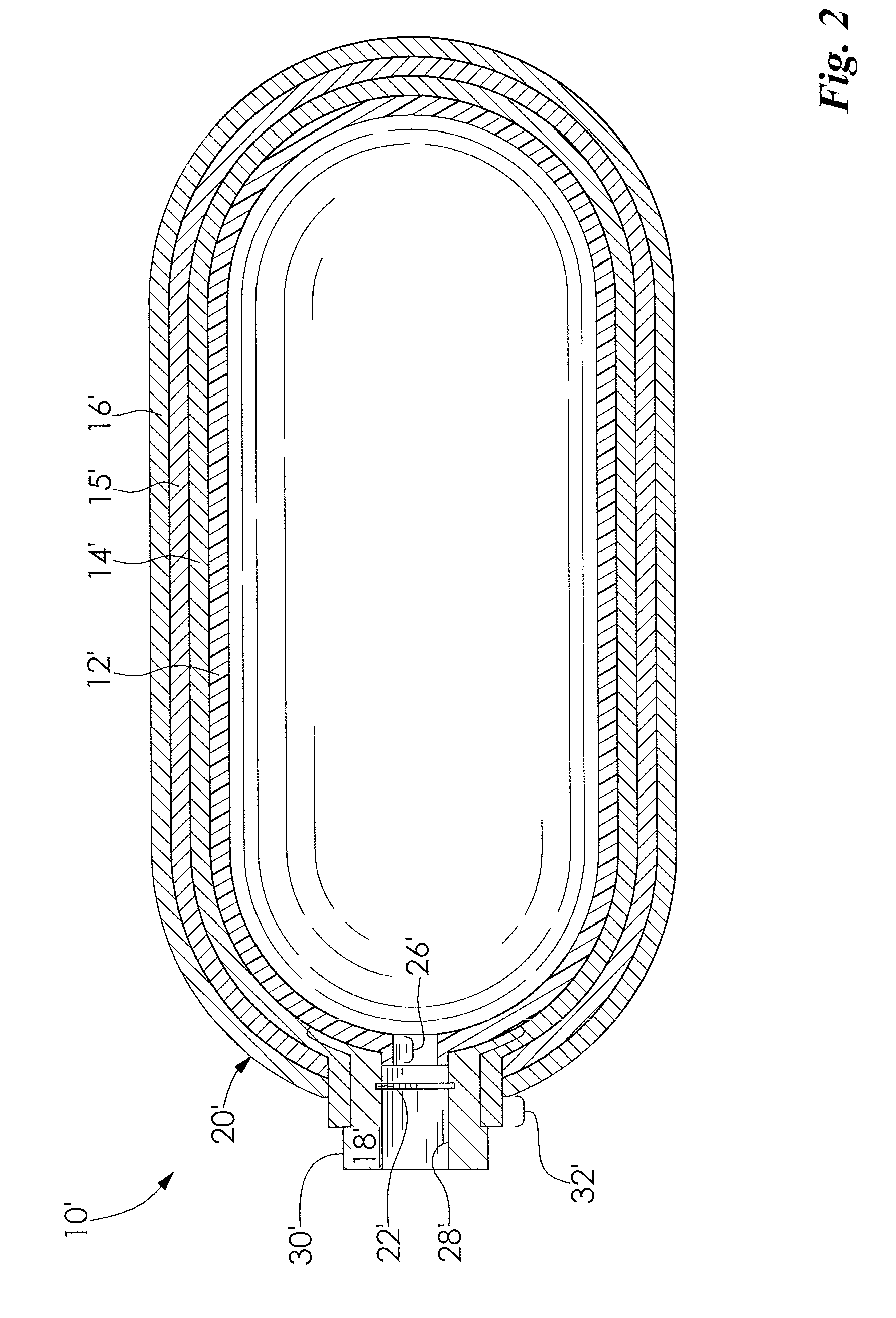

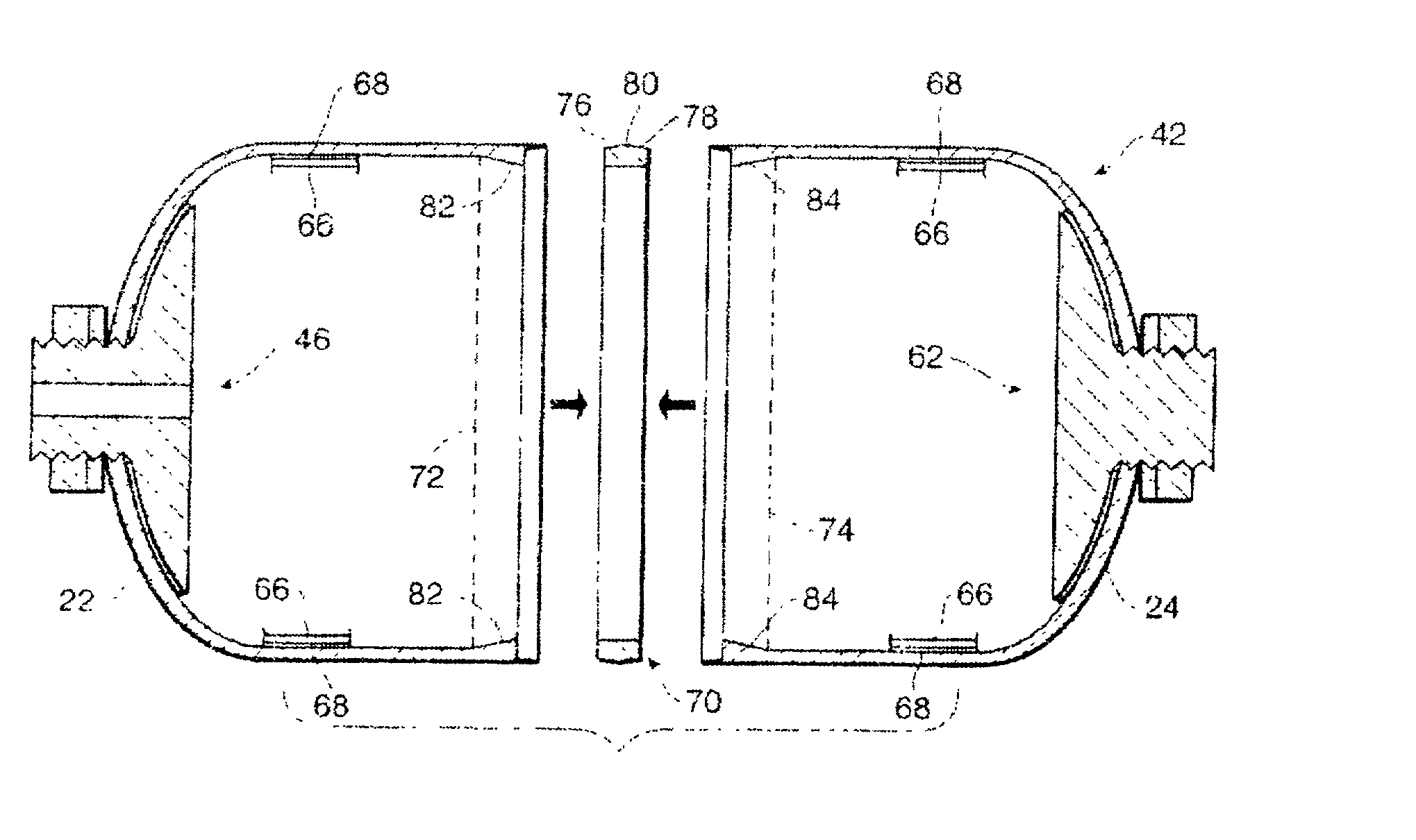

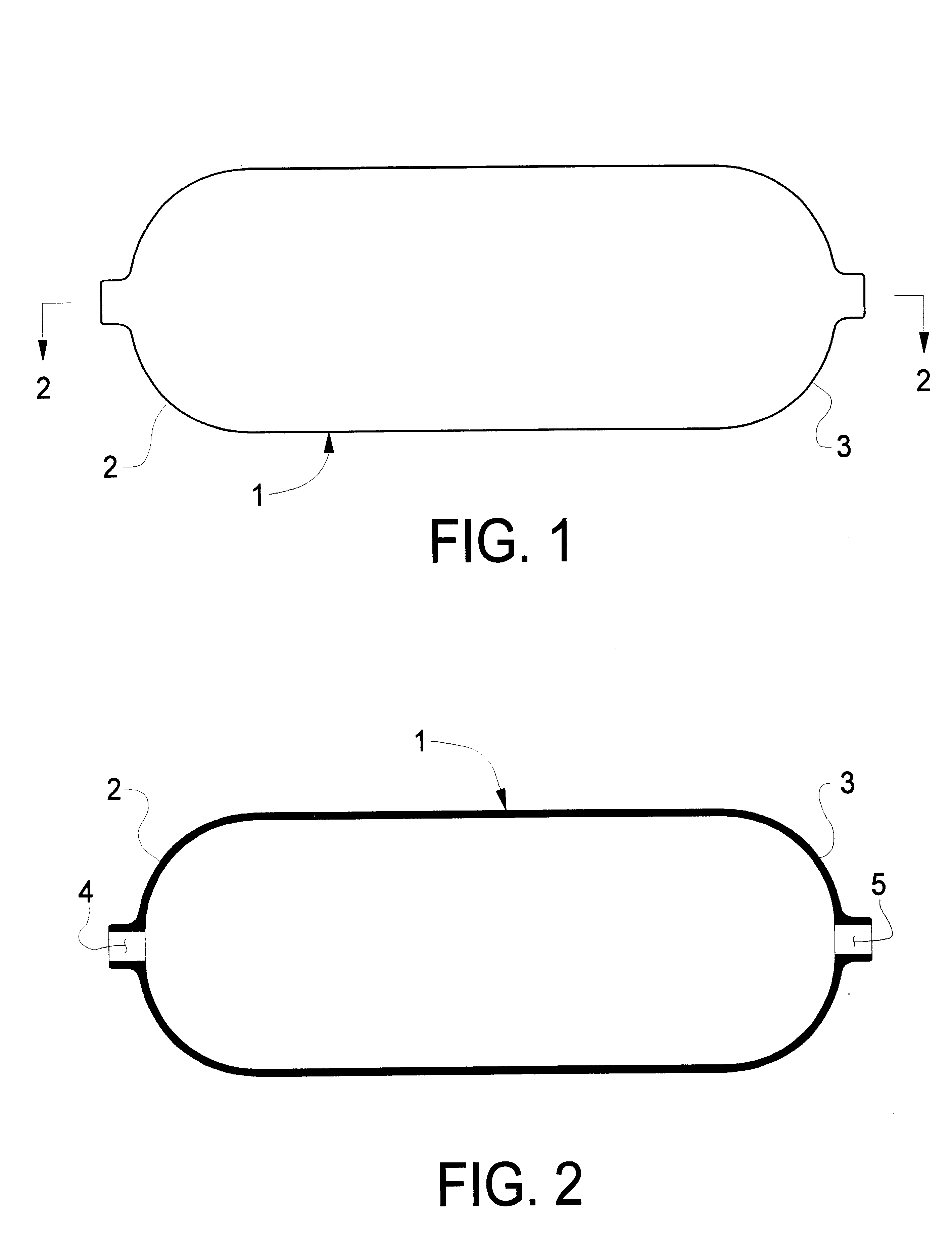

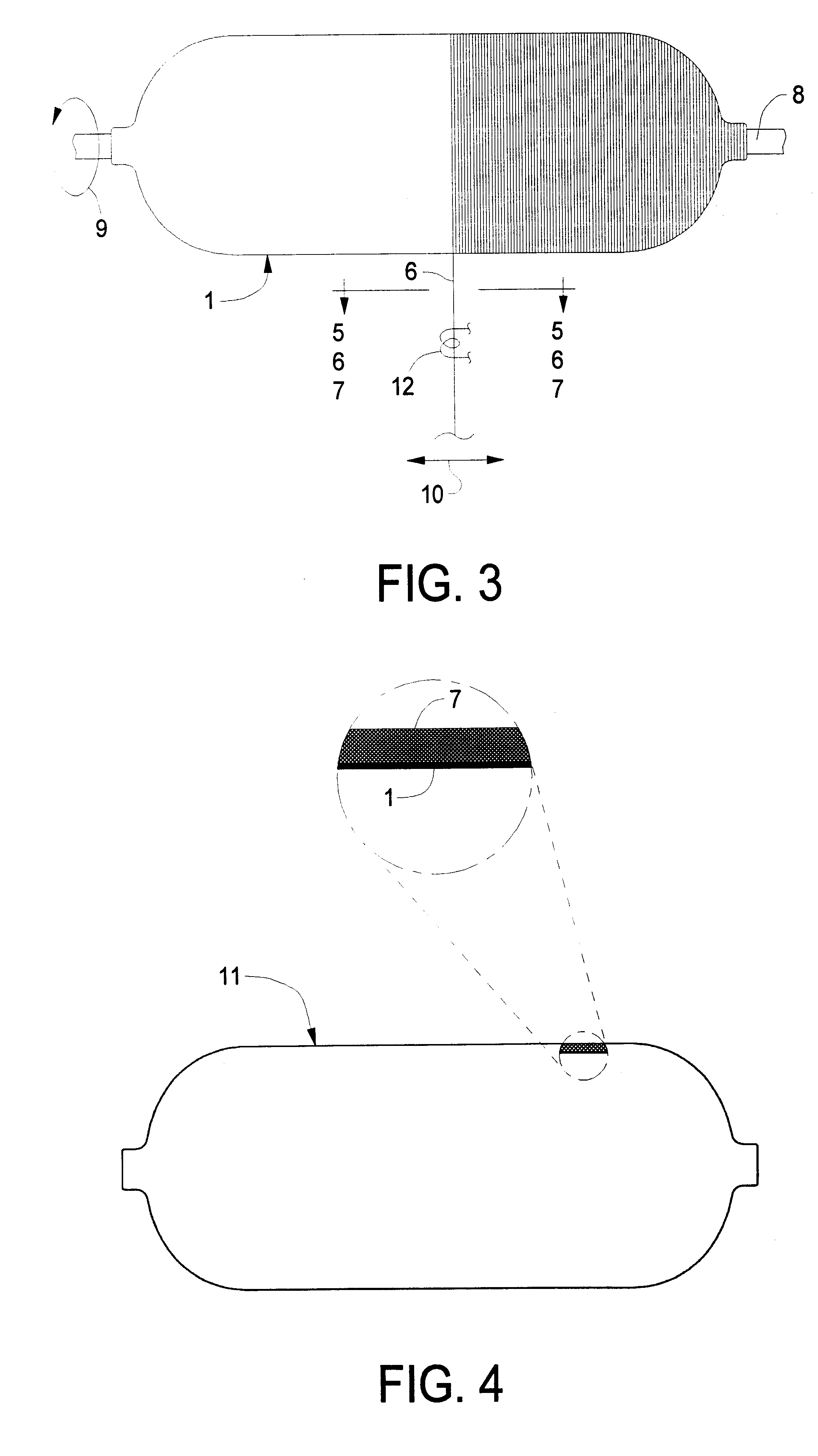

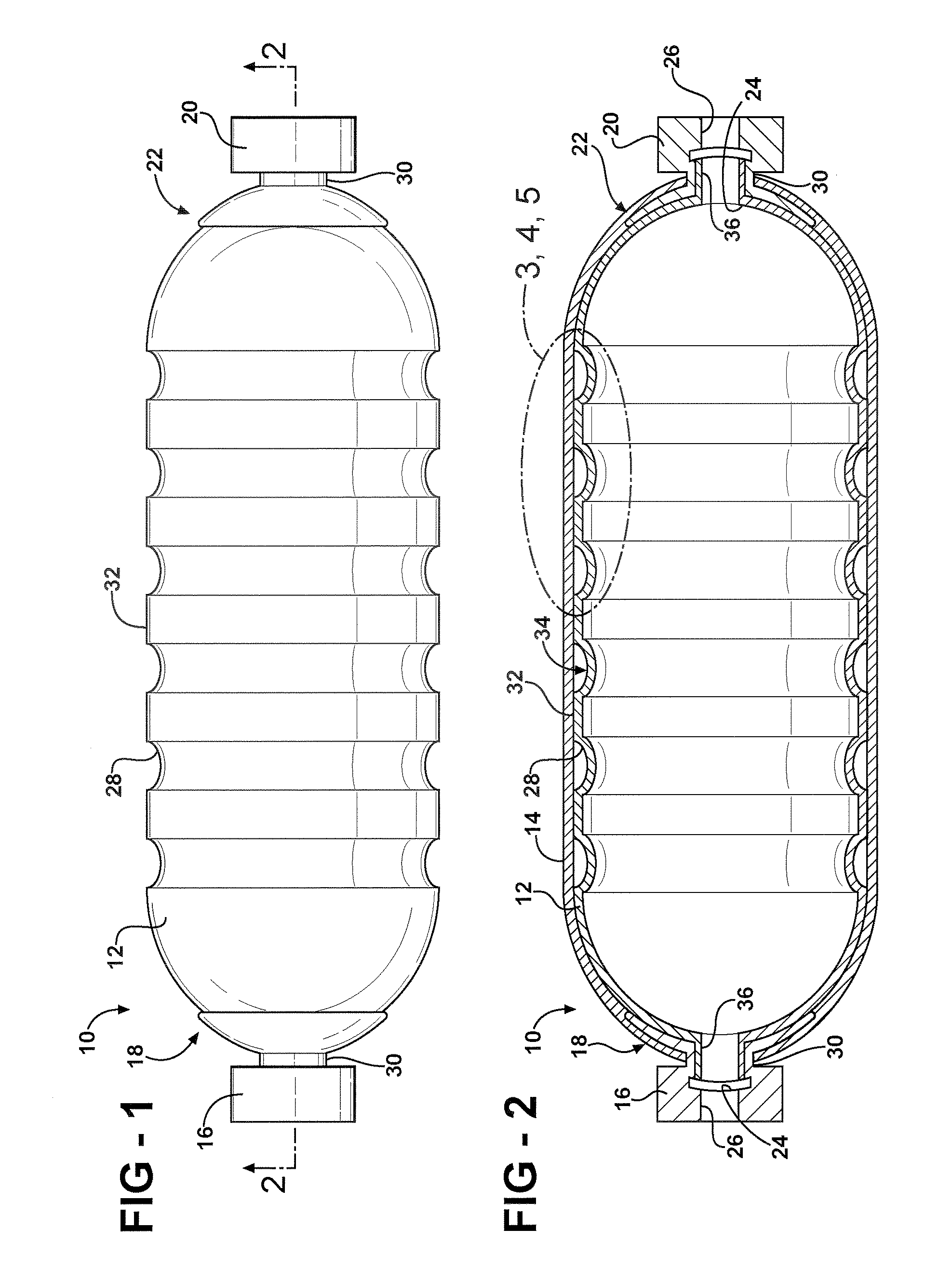

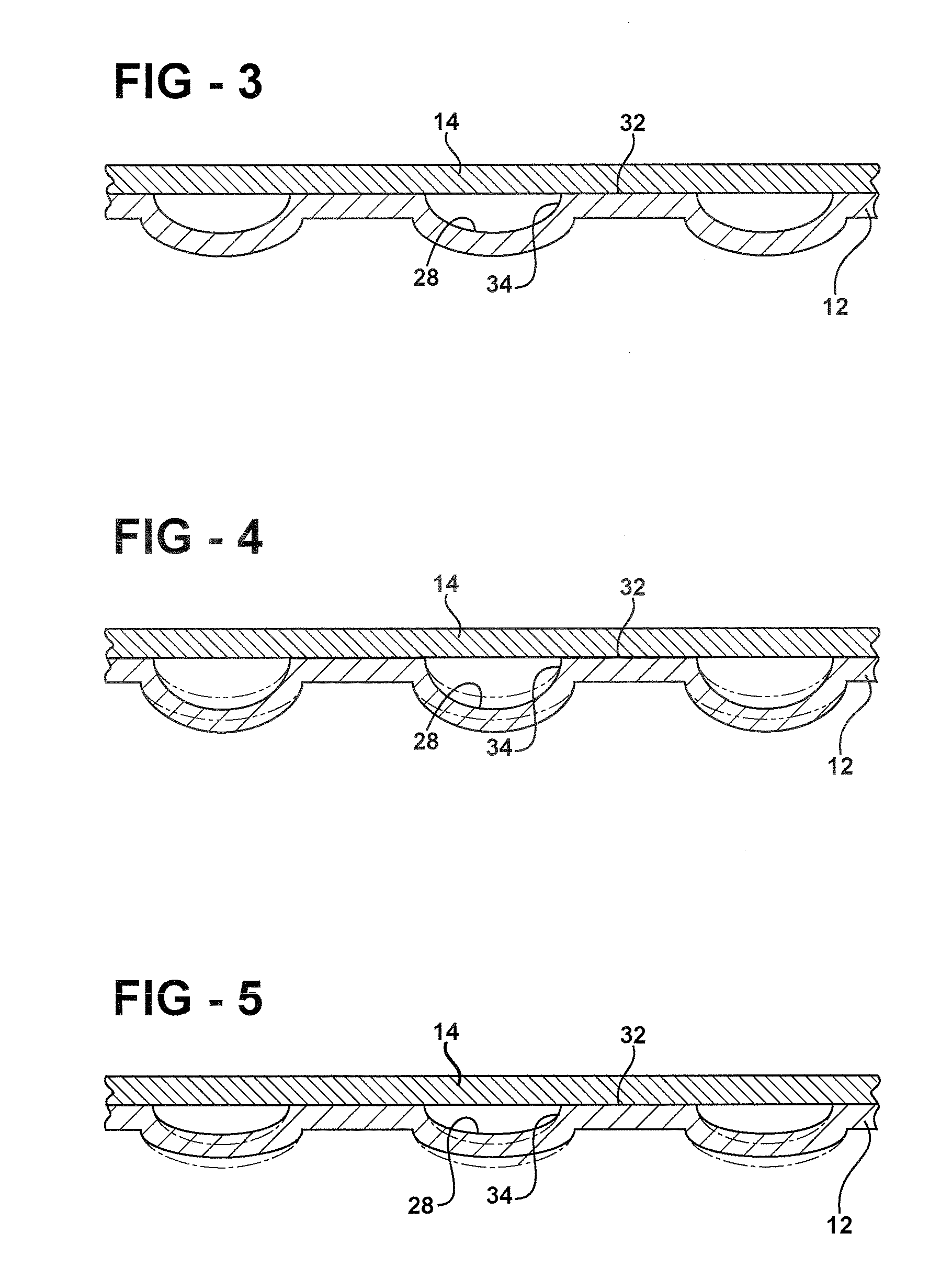

Storage vessel and method of forming

A storage vessel, such as vessels used in storing high pressure gas is provided. The storage vessel includes a liner having a center portion and a first and second end dome. A first composite layer is disposed circumferentially about the center portion. A second composite layer is disposed about said first composite layer and the first and second end dome. In some embodiments, the second composite layer is formed from a knitted or braided sleeve that is tightened over the liner and first composite layer by pulling the sleeve.

Owner:GM GLOBAL TECH OPERATIONS LLC

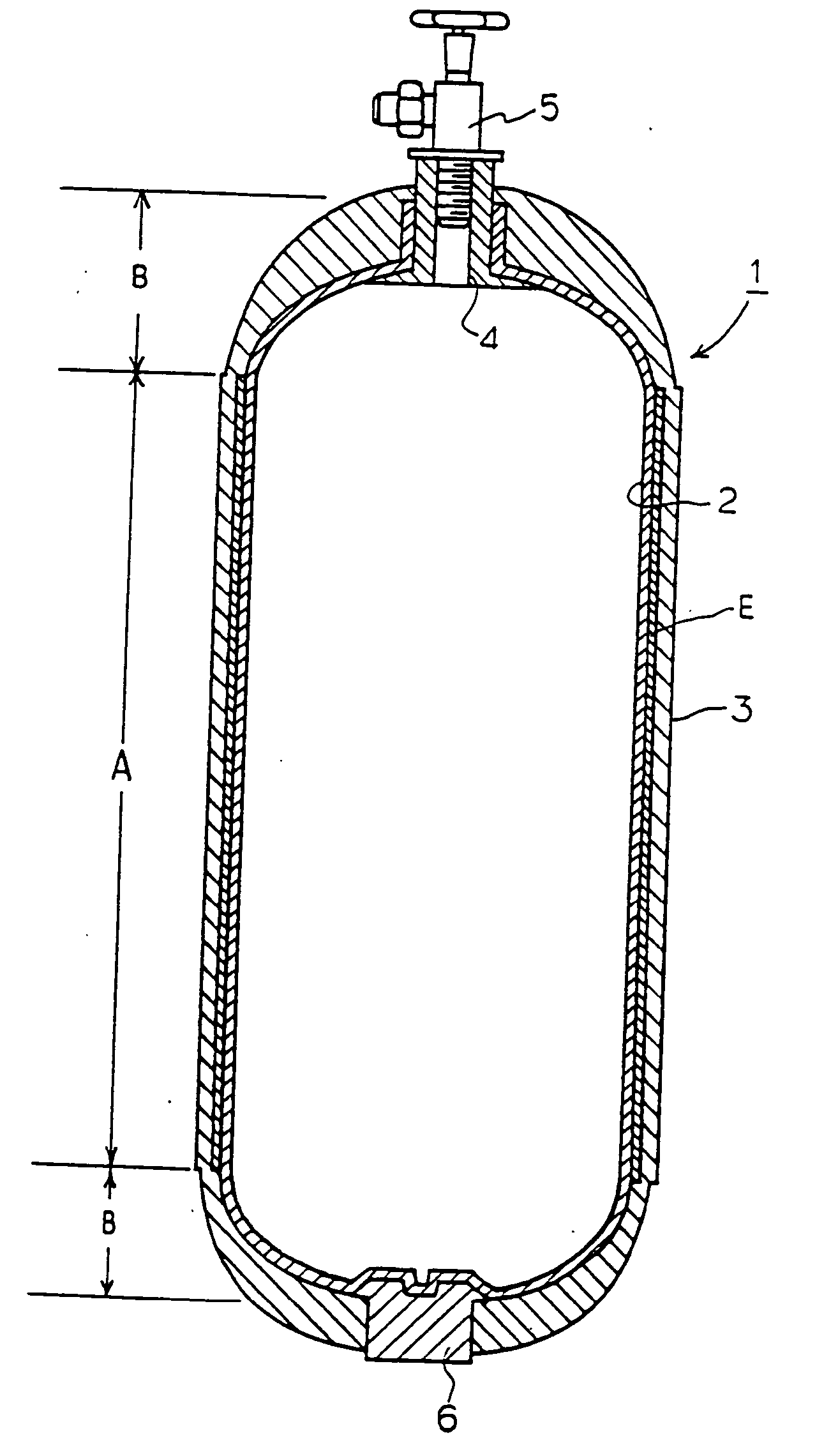

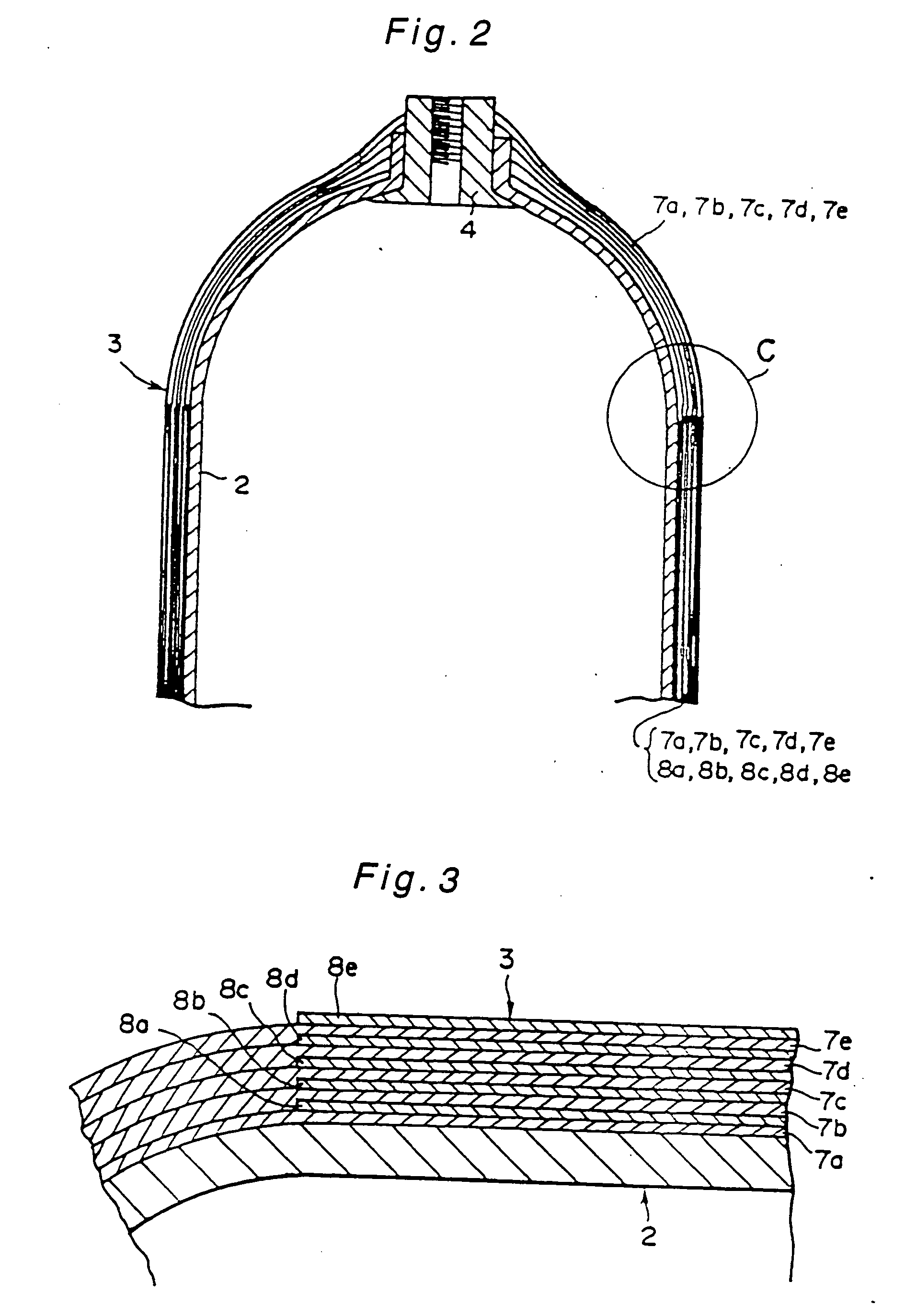

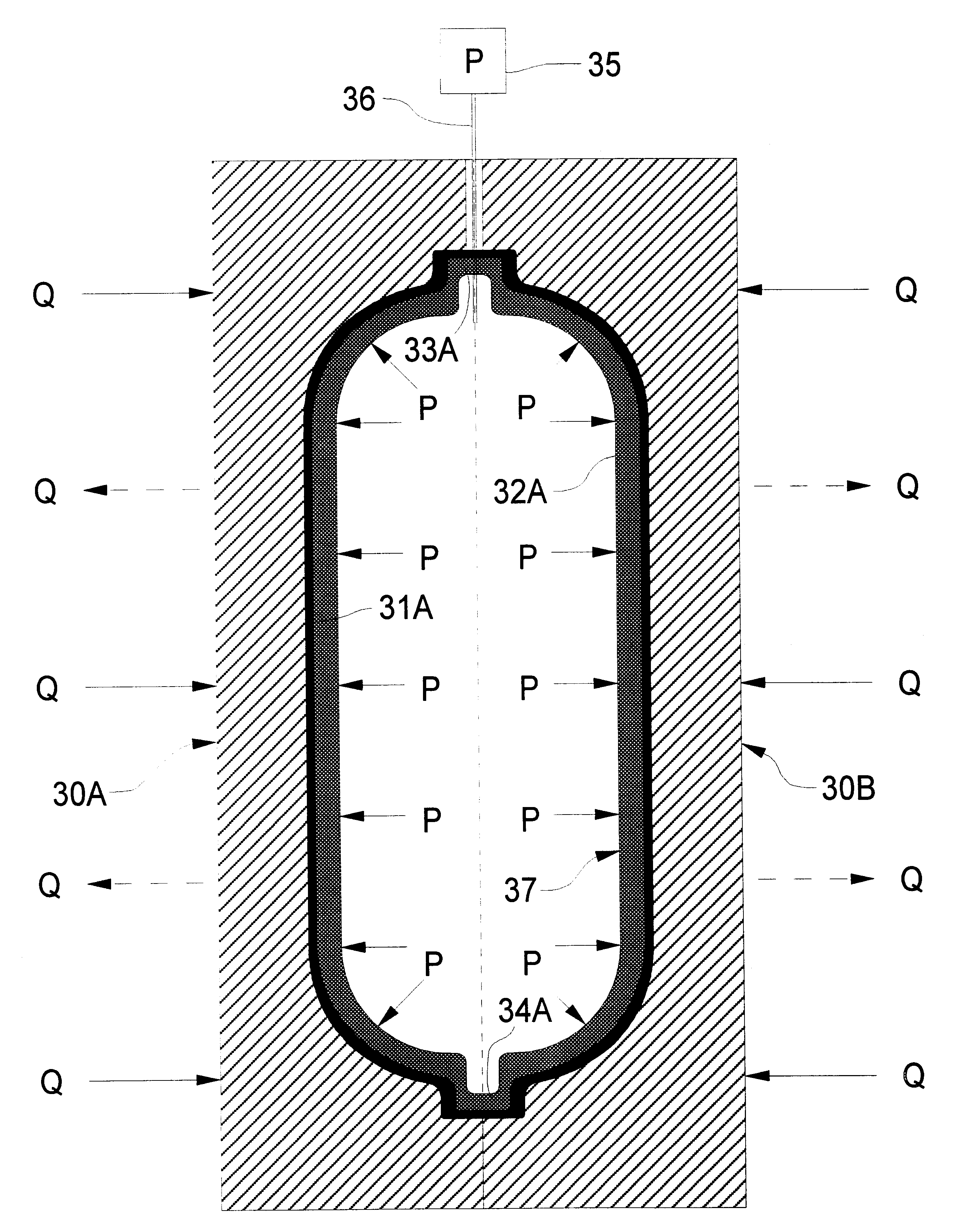

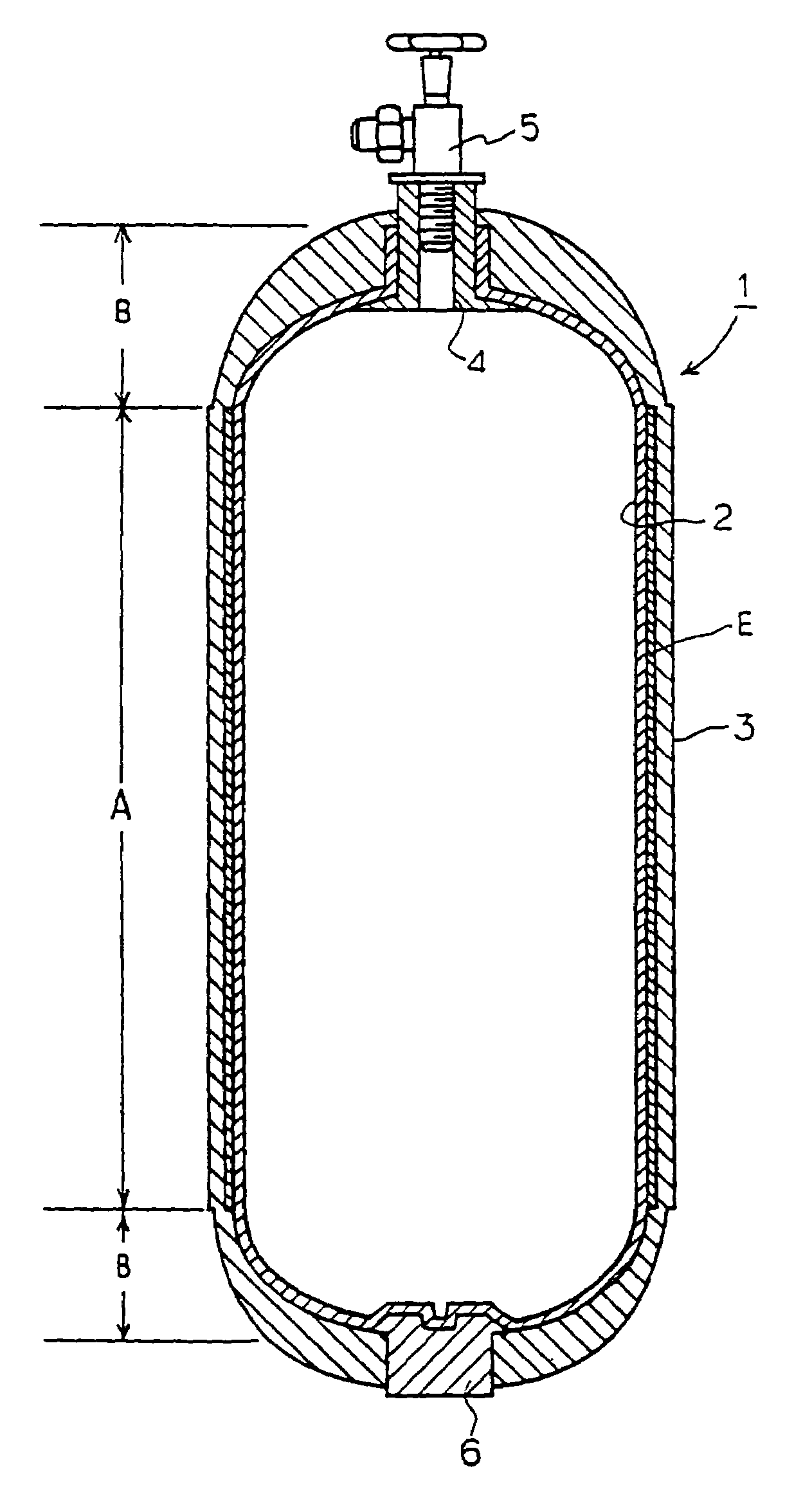

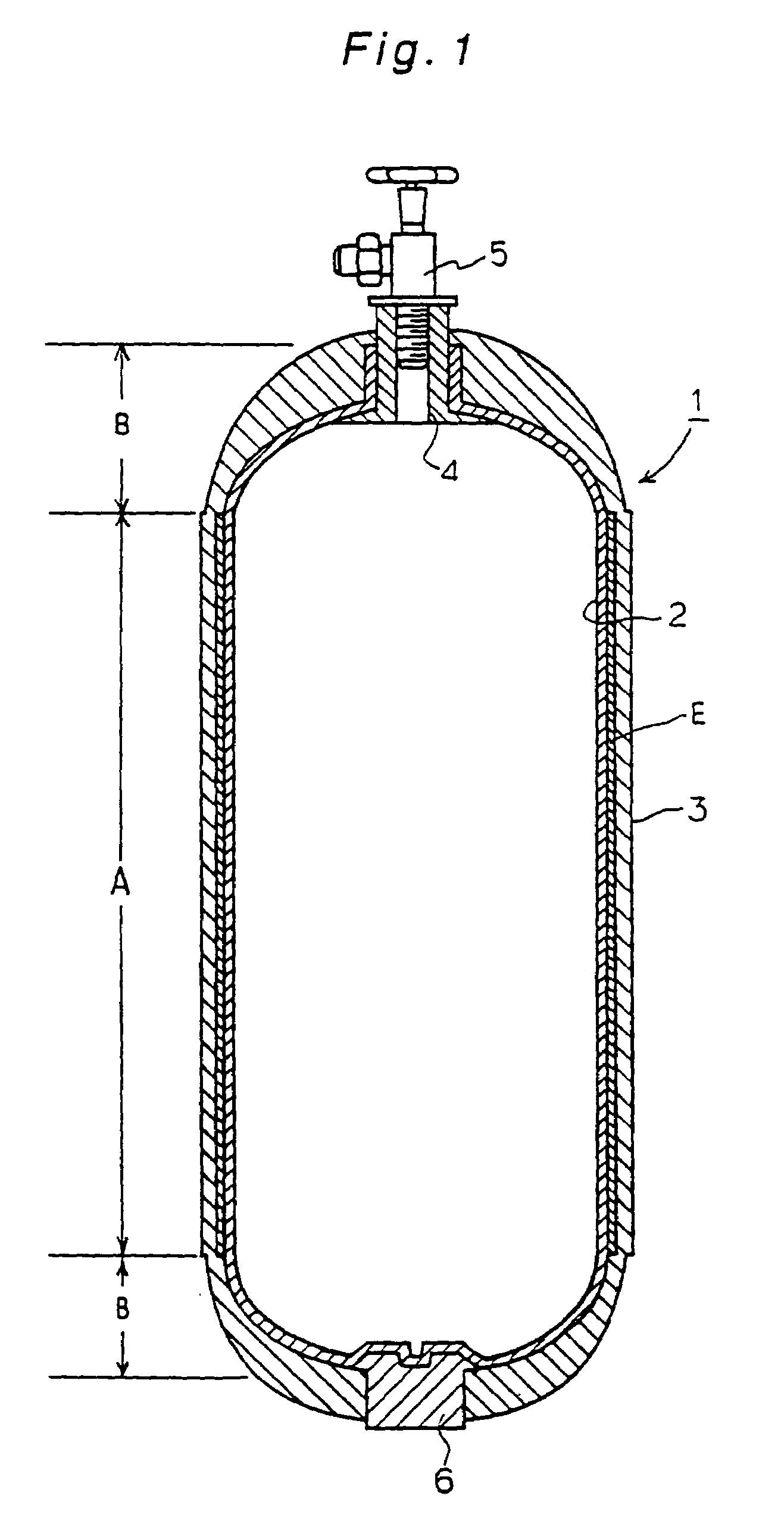

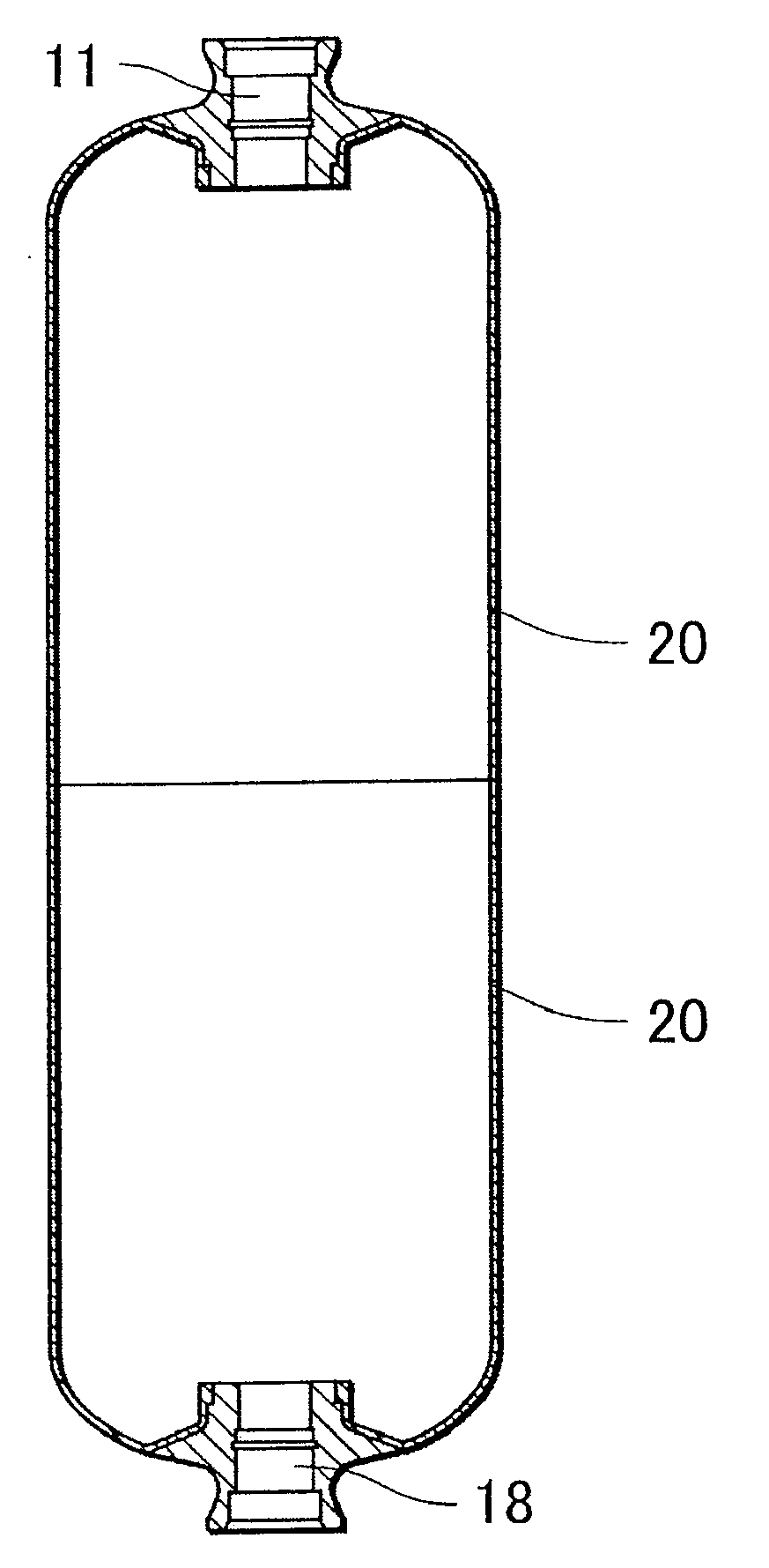

Pressure vessel and process for producing the same

InactiveUS20040206762A1Light weightIncrease pressureVessel mounting detailsVessel manufacturingInternal pressureEngineering

The pressure vessel of the present invention comprises an inner shell capable of serving as a gas barrier and a pressure resistant outer shell provided to cover the inner shell, said outer shell being made of an FRP comprising reinforcing fibers and a resin and is 35 GPa or more in tensile modulus and 1.5% or more in tensile breaking strain. The present invention can provide a pressure vessel not only light in weight,.but also excellent in retaining its internal pressure against repetitive impacts and also excellent in reliability. The process for producing a pressure vessel of the present invention comprises the step of forming a pressure resistant outer shell made of an FRP comprising reinforcing fibers and a resin and is 35 GPa or more in tensile modulus and 1.5% or more in tensile breaking strain, around an inner shell capable of serving as a gas barrier, by a filament winding method or a tape winding method. The present invention can produce a pressure vessel excellent in retaining its internal pressure, excellent in reliability, and light in weight at a low cost.

Owner:TORAY IND INC

Composite pressure tank and process for its manufacture

InactiveUS20070205201A1Reduce weightLow costVessel mounting detailsVessel manufacturingBody shapeMaterials science

A pressure vessel and method for producing a pressure vessel is disclosed. The pressure vessel comprises a liner shell fabricated from composite material applied to a soluble mandrel having a body shaped to pattern an interior of the pressure vessel, the liner shell having an opening, a boss having an aperture therethrough, the boss sealingly bonded to the liner shell with the aperture adjacent the opening, and an outer shell fabricated from plies of composite material filament impregnated with matrix material wound over the liner shell and the boss, but not over the aperture.

Owner:MICROCOSM INC

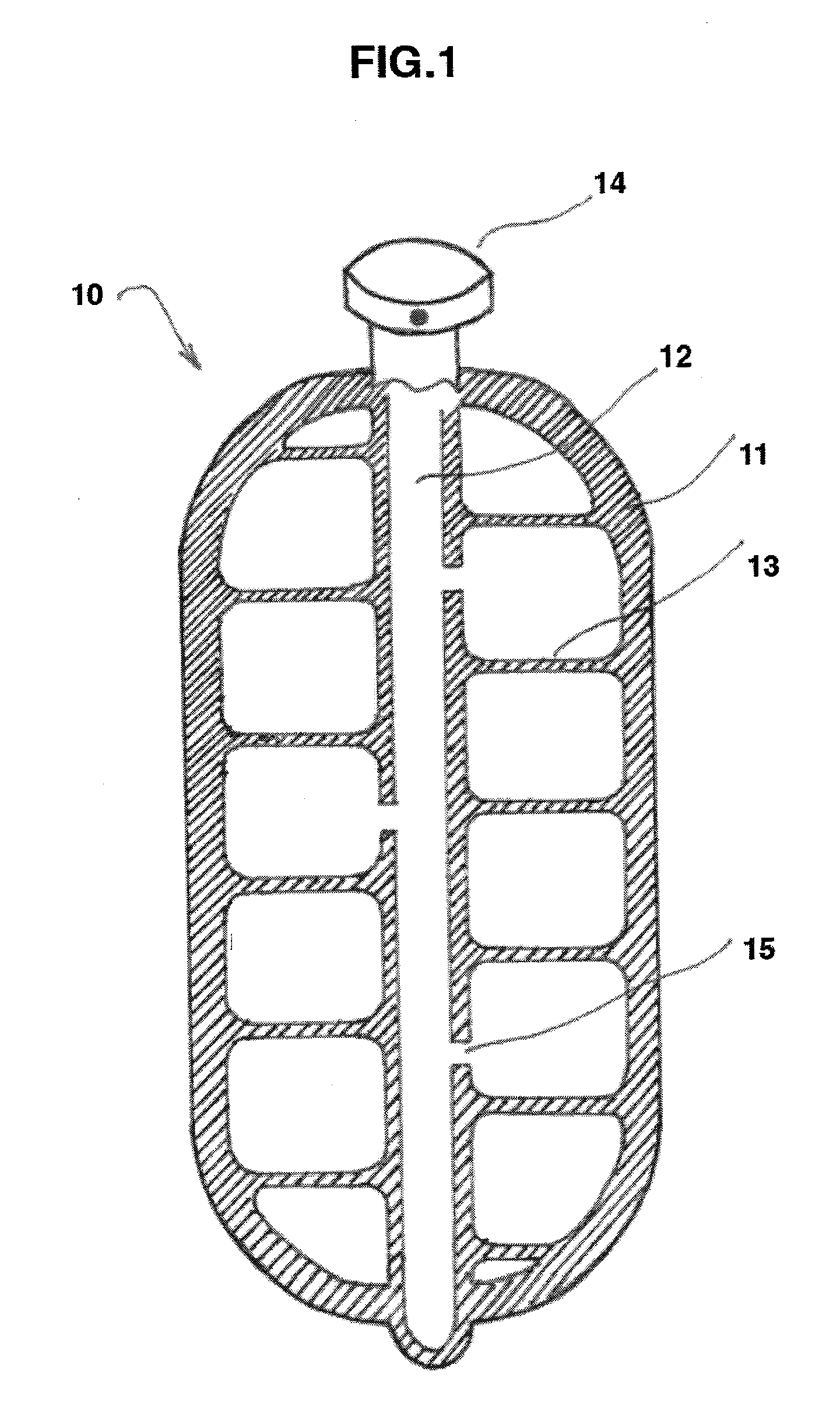

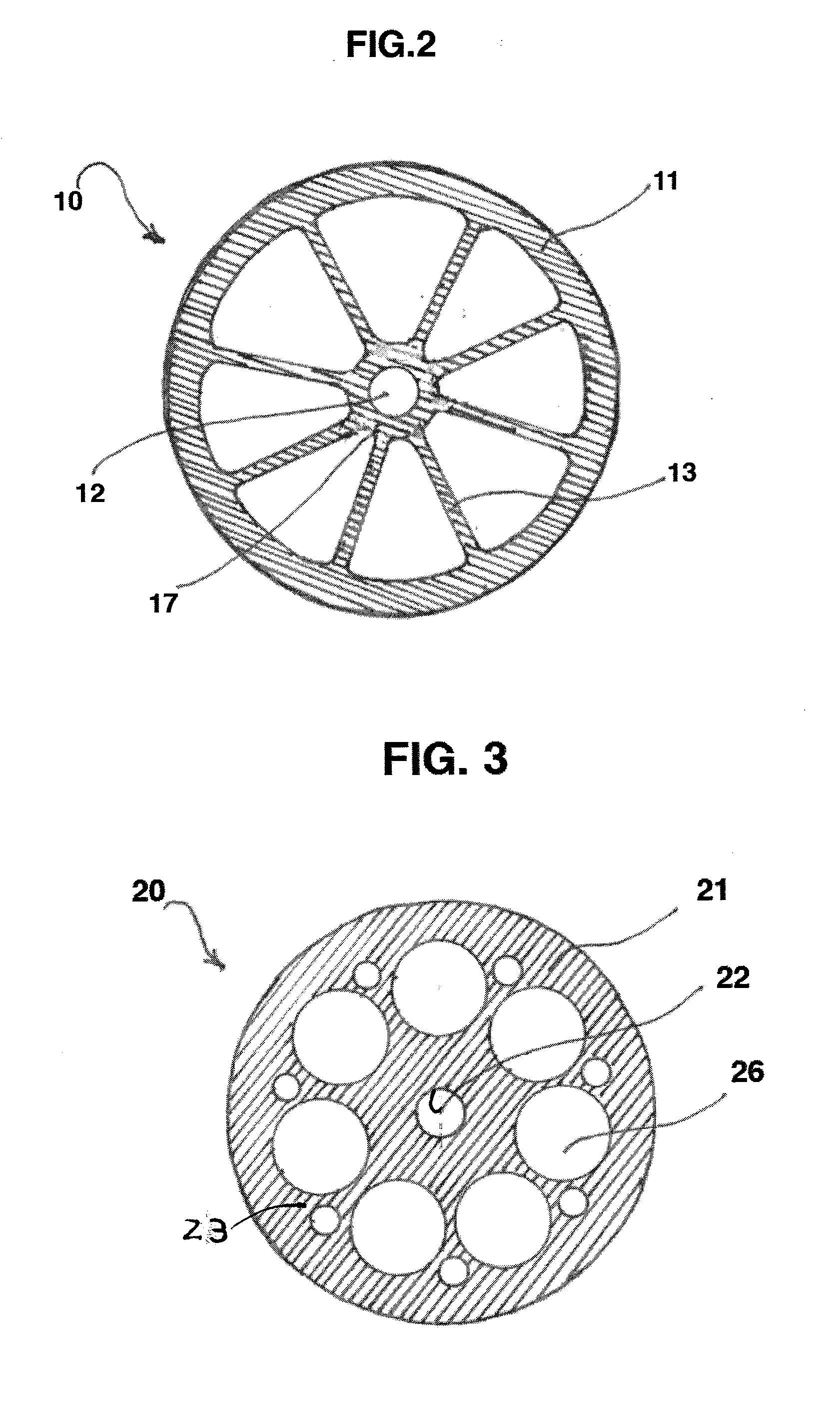

Pressure Vessels, Design and Method of Manufacturing Using Additive Printing

InactiveUS20160061381A1Less materialNo wasteLarge containersArc welding apparatusManufacturing technologyEngineering

Method and design of a pressure vessel having an internal supportive structure that reduces pressure forces applied to the external shell of the vessel by distributing such forces via internal bonds mostly connected to a central supporting element. The method and design allow making much lighter and stronger pressure vessels and containers using additive manufacturing technology, known as 3D printing.

Owner:KOTLIAR IGOR K

Diffusion layer for pressure vessels

ActiveUS20090057319A1Improve fluid flowVessel mounting detailsVessel manufacturingEngineeringDiffusion layer

Owner:GM GLOBAL TECH OPERATIONS LLC

Low weight high performance composite vessel and method of making same

InactiveUS20040026431A1Light weightSignificant portionVessel mounting detailsVessel manufacturingMechanical engineeringComposite material

Owner:KAISER COMPOSITEK

Hydrogen tank liner material and hydrogen tank liner

ActiveUS20090203845A1Improve impact resistanceSuitable for useVessel mounting detailsVessel manufacturingAlpha-olefinHydrogen tank

A hydrogen tank liner material comprises a polyamide resin composition which comprises (A) a polyamide resin at 85-40 wt %, (B) a copolyamide at 5-30 wt % and (C) an impact-resistant material at 10-30 wt % with respect to the total weight of the polyamide resin composition. Preferably, the (B) copolyamide is PA6 / 66 and the (C) impact-resistant material is an acid-modified ethylene / α-olefin-based copolymer. A hydrogen tank liner material with excellent gas barrier properties and superior impact resistance even at low temperatures is obtained.

Owner:UBE CORP +1

Method for fabricating composite pressure vessels

InactiveUS6171423B1Speed up the processRatio is limitedVessel manufacturingCylinder headsPolytetramethylene terephthalateFiber

A process for fabricating a composite vessel includes the steps of: A) preforming (e.g., by winding fiber and at least one thermoplastic substance onto a thermoplastic liner) a thermoplastic shell which has at least one opening for access to the interior; B) extruding a circular cross section of a fluid parison of thermoplastic material (which preferably is chosen to have a melting point lower than that of the thermoplastic shell) into the interior of the thermoplastic shell through the opening; C) in a mold, applying at least one force (such as gas under pressure) which tends to urge the fluid parison toward the interior walls of the thermoplastic shell (which may be preheated prior to introduction into the mold) such that the fluid parison imparts heat to the thermoplastic shell; D) continuing step C) until the thermoplastic shell and the fluid parison consolidate to form a composite vessel; E) cooling the vessel until it is solidified; and F) removing the vessel from the mold. For some composite vessels, prior to step C), an insert may be introduced into the interior of the parison and positioned in alignment with the opening in the thermoplastic shell such that the insert is rendered integral with the composite vessel during step D). Suitable thermoplastic materials include polyethylene, polypropylene, polybutylene terephthalate and polyethylene terephthalate. The resulting composite vessel exhibits superior mechanical and aesthetic properties.

Owner:FLECK CONTROLS +1

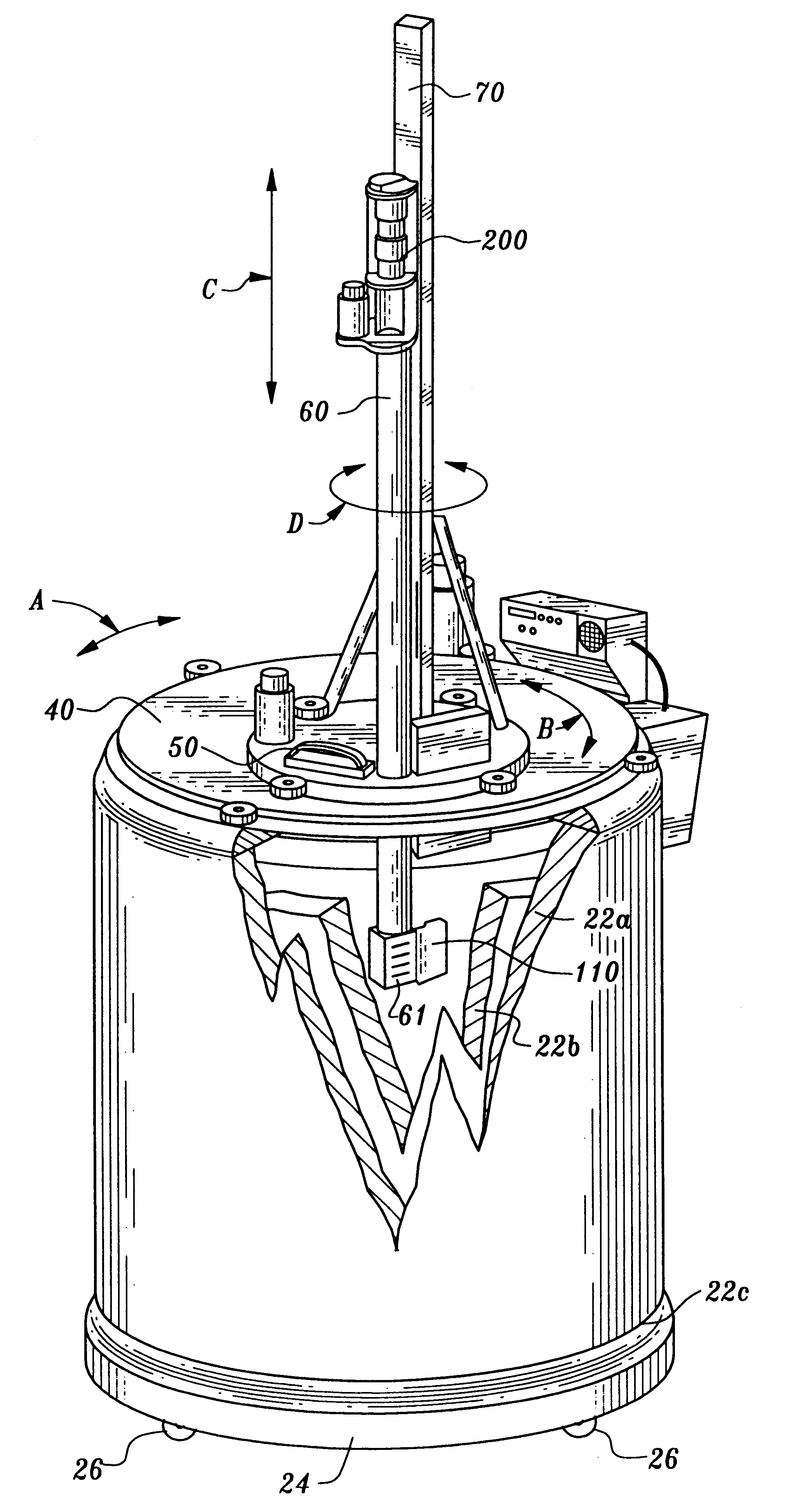

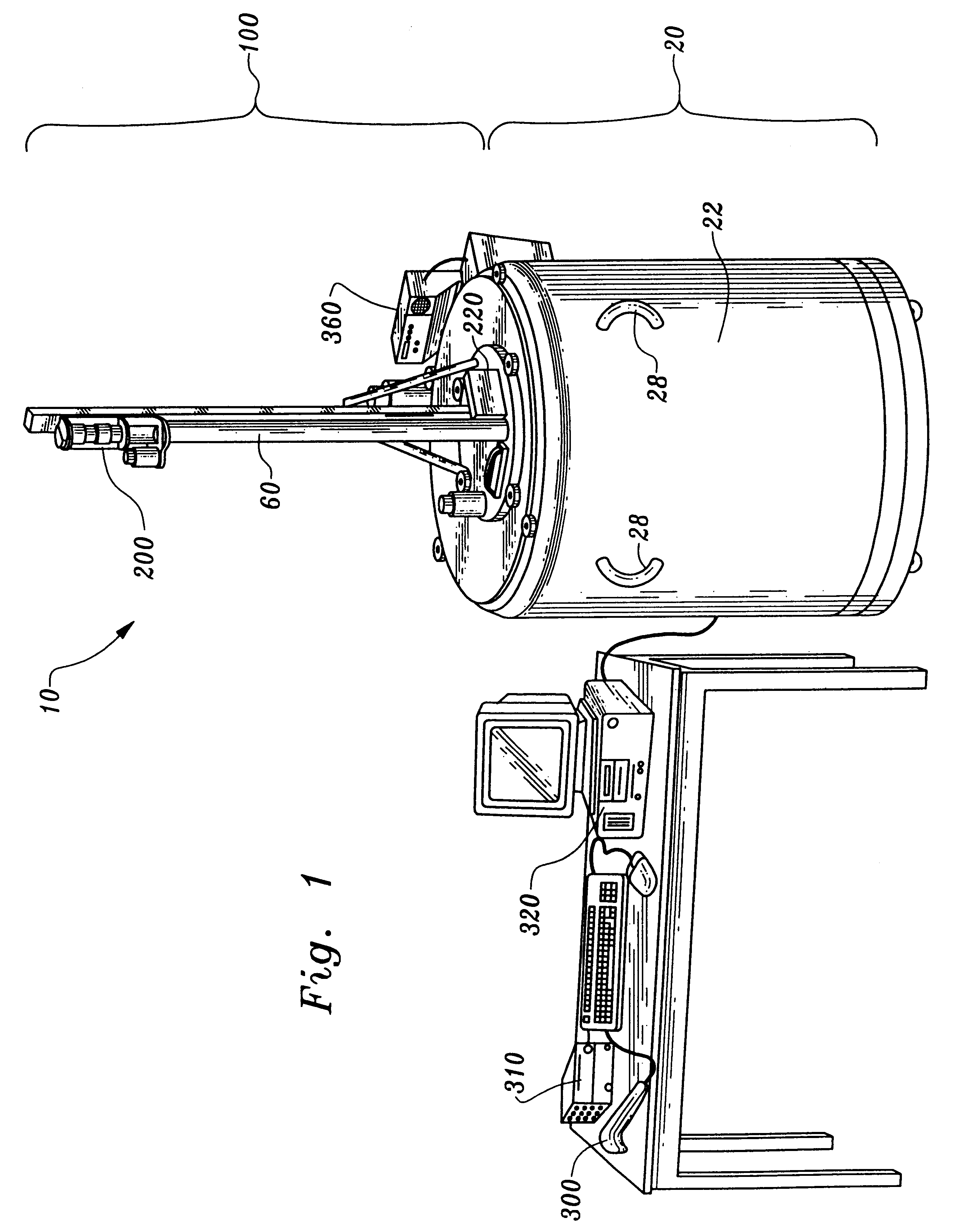

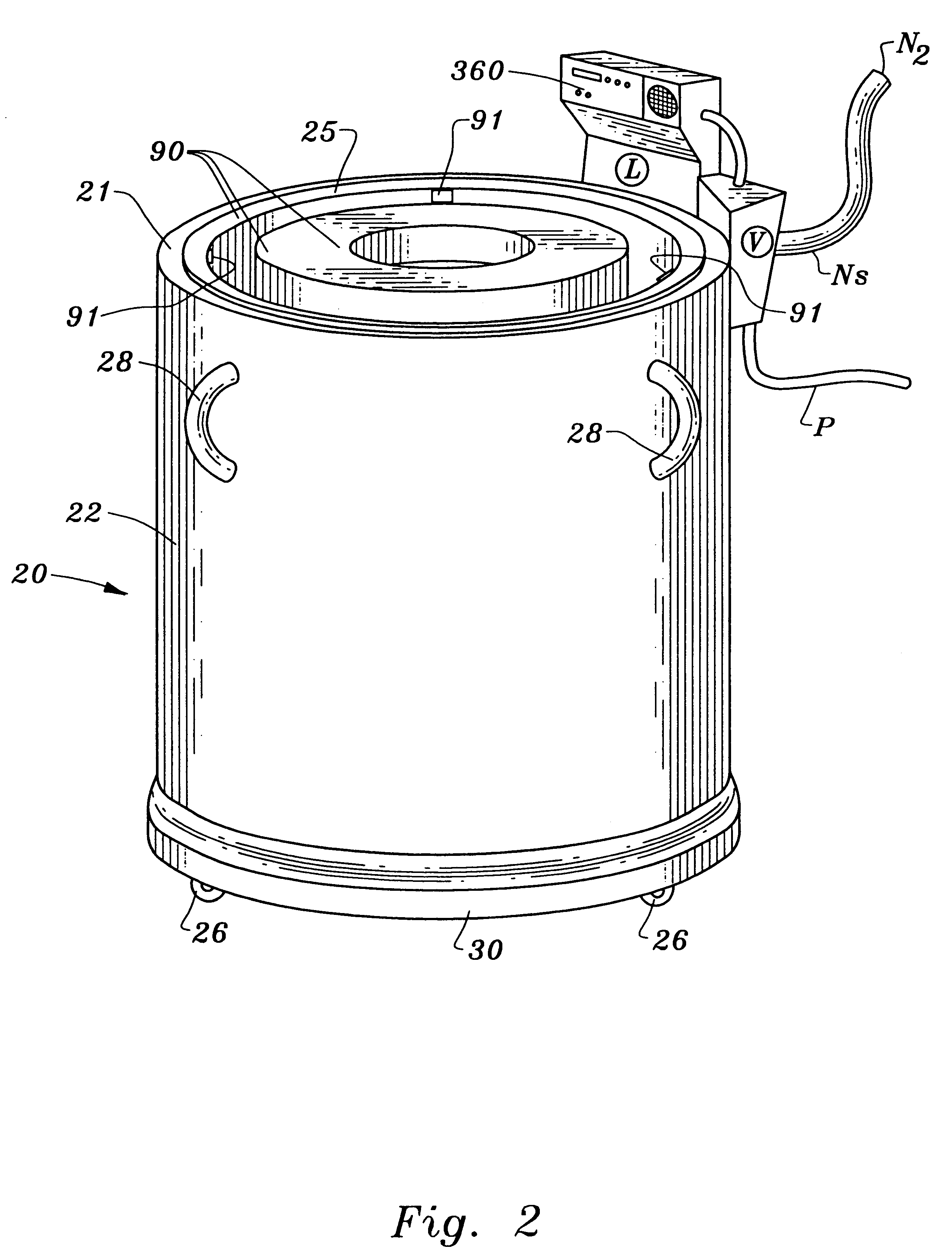

Method and apparatus for cryogenic storage of thermolabile products

InactiveUS6302327B1Raise the possibilityDurable in constructionLighting and heating apparatusGas handling applicationsComputer monitorControl system

A system and method for controlled rate freezing and storage of thermolabile substances. The system includes a storage unit for receiving product stored within a bag and an overlying protective canister associated with a robotic arm and reading device which places the canister in the preserving environment. A control system, driven by a computer monitors the ingress, egress and storage location and particularized profiles of the articles being placed in storage.

Owner:NEW YORK BLOOD CENT +1

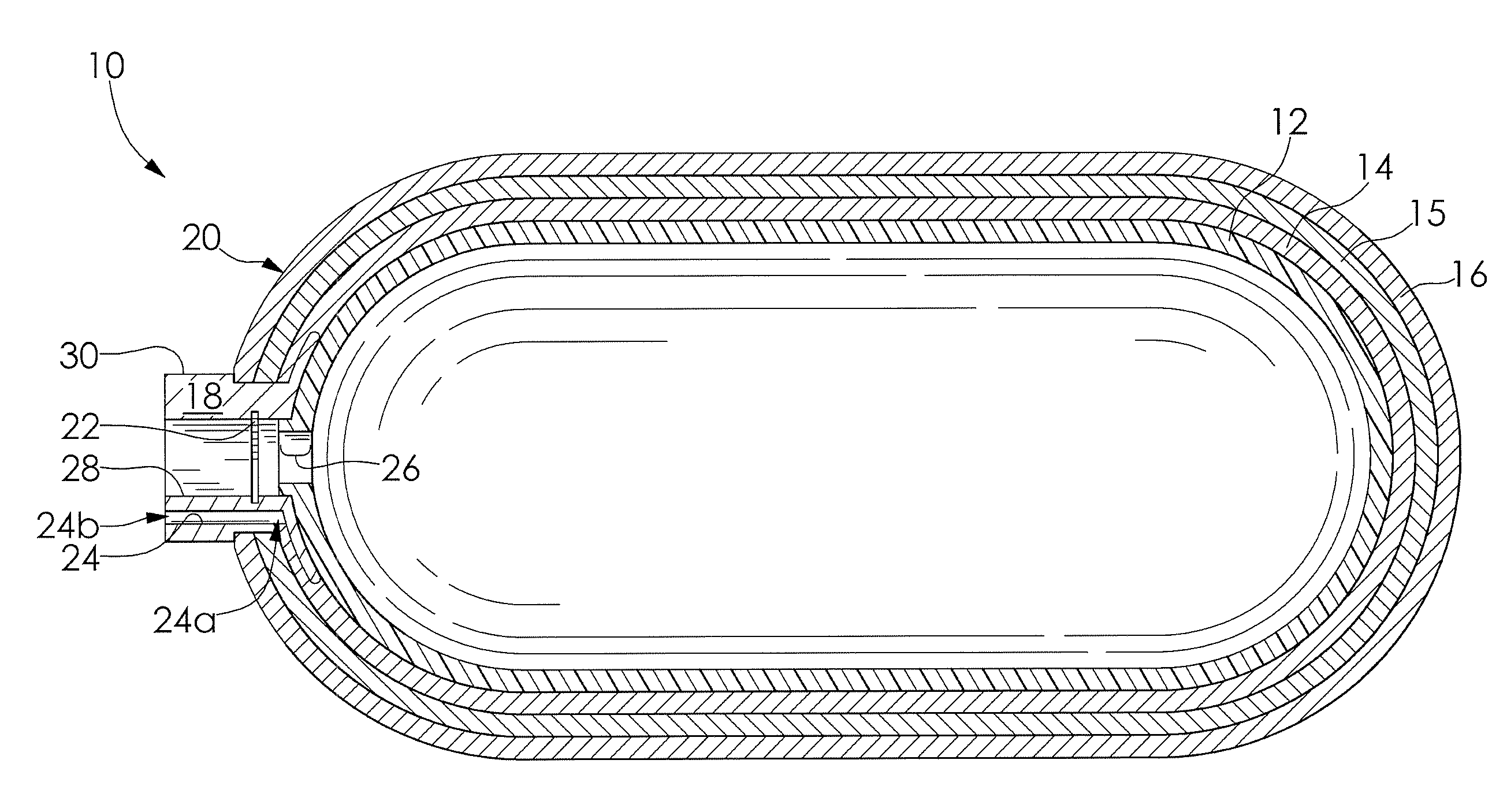

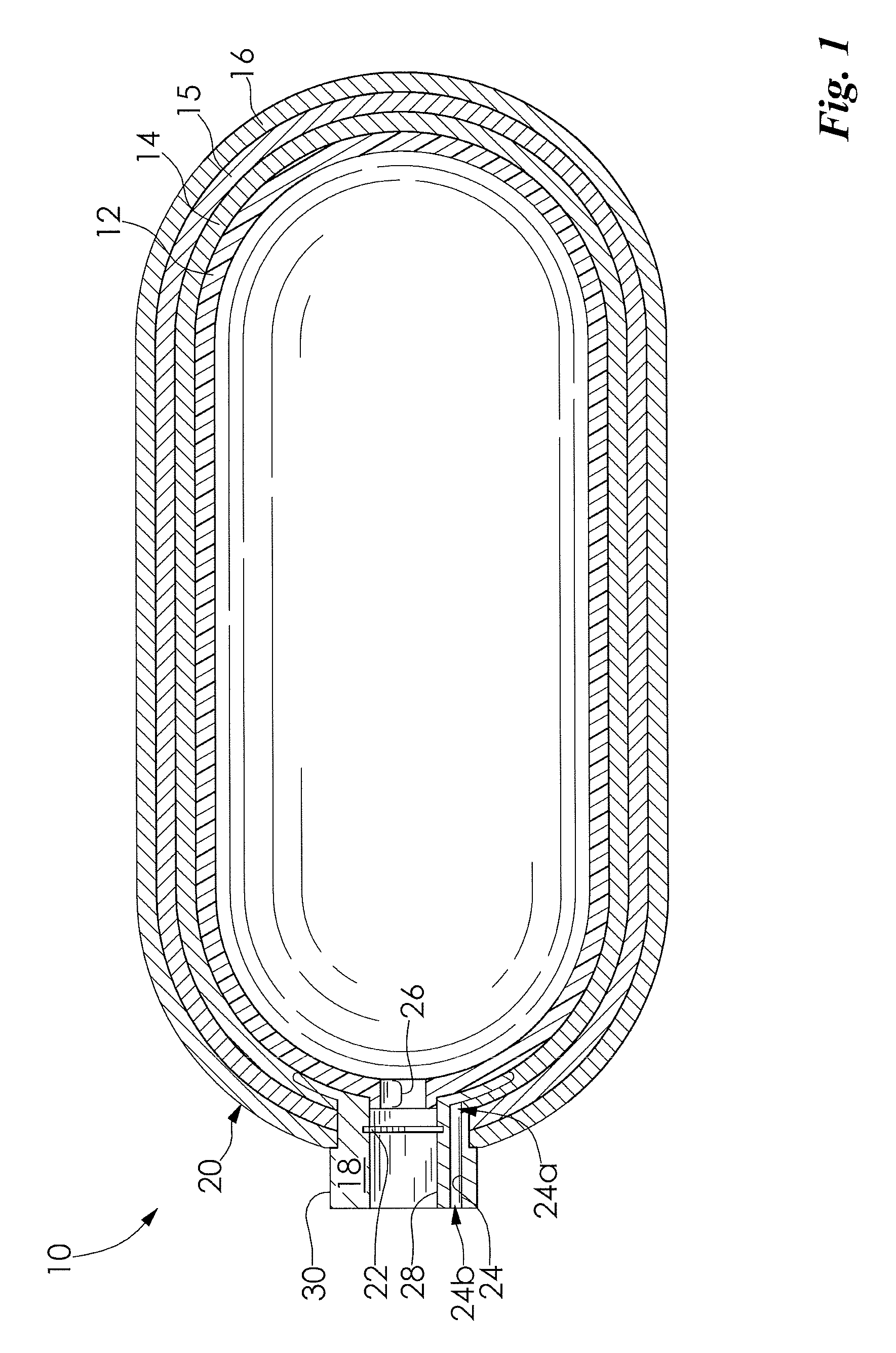

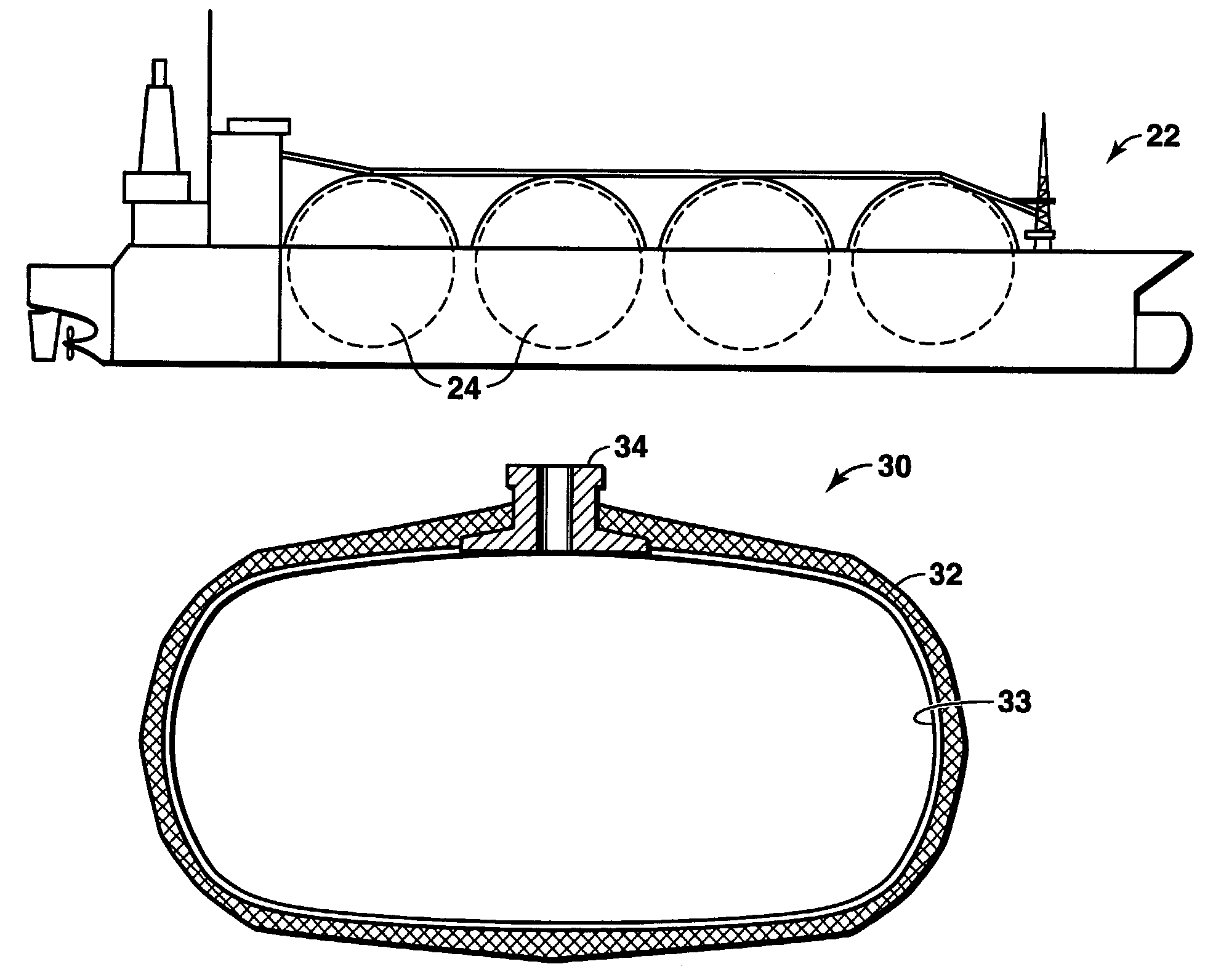

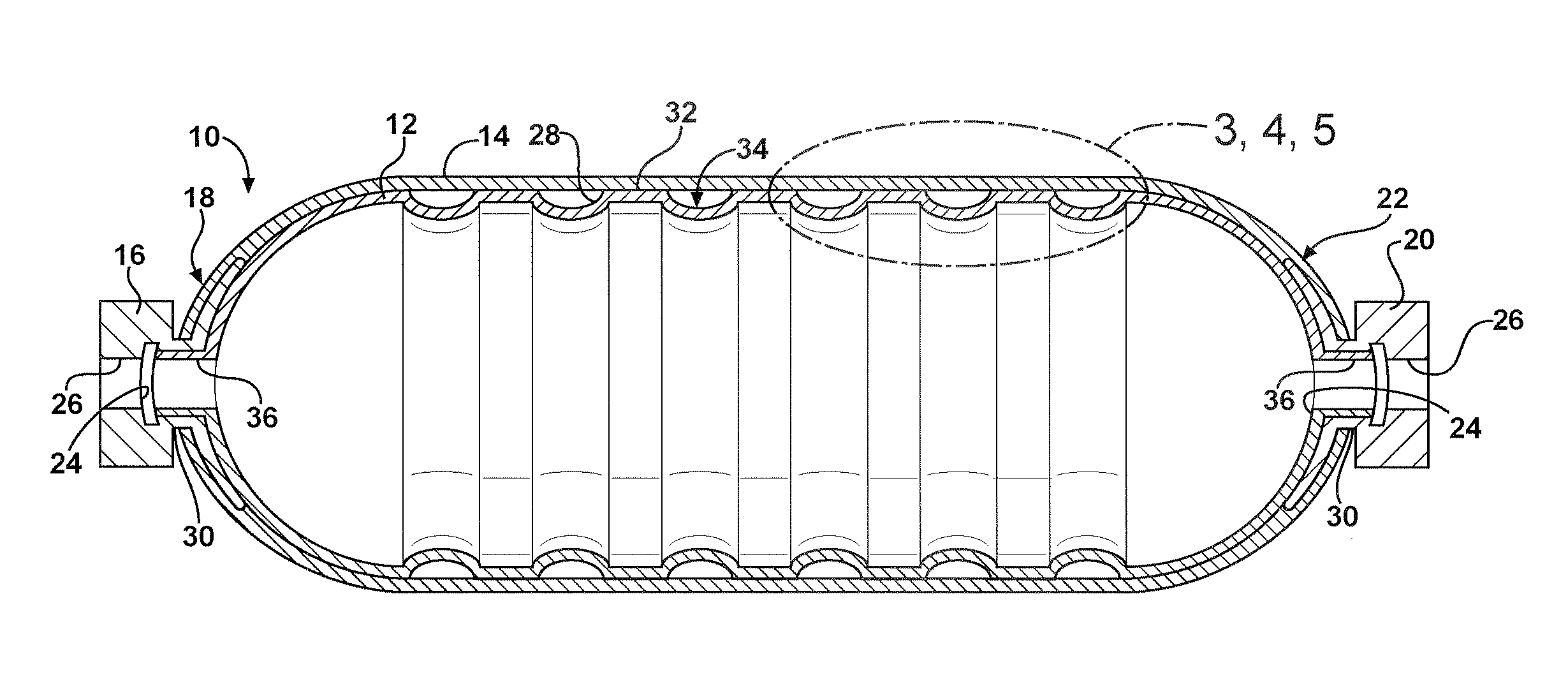

Containers and methods for containing pressurized fluids using reinforced fibers and methods for making such containers

InactiveUS7147124B2Improve creep performanceImprove compactionVessel mounting detailsVessel manufacturingFiberPolymer science

Containers suitable for storing pressurized fluids at cryogenic temperatures of −62° C. (−80° F.) and colder are provided and comprise a self-supporting liner and load-bearing composite overwrap, whereby means are provided for substantially preventing failure of the container during temperature changes.

Owner:EXXONMOBIL UPSTREAM RES CO

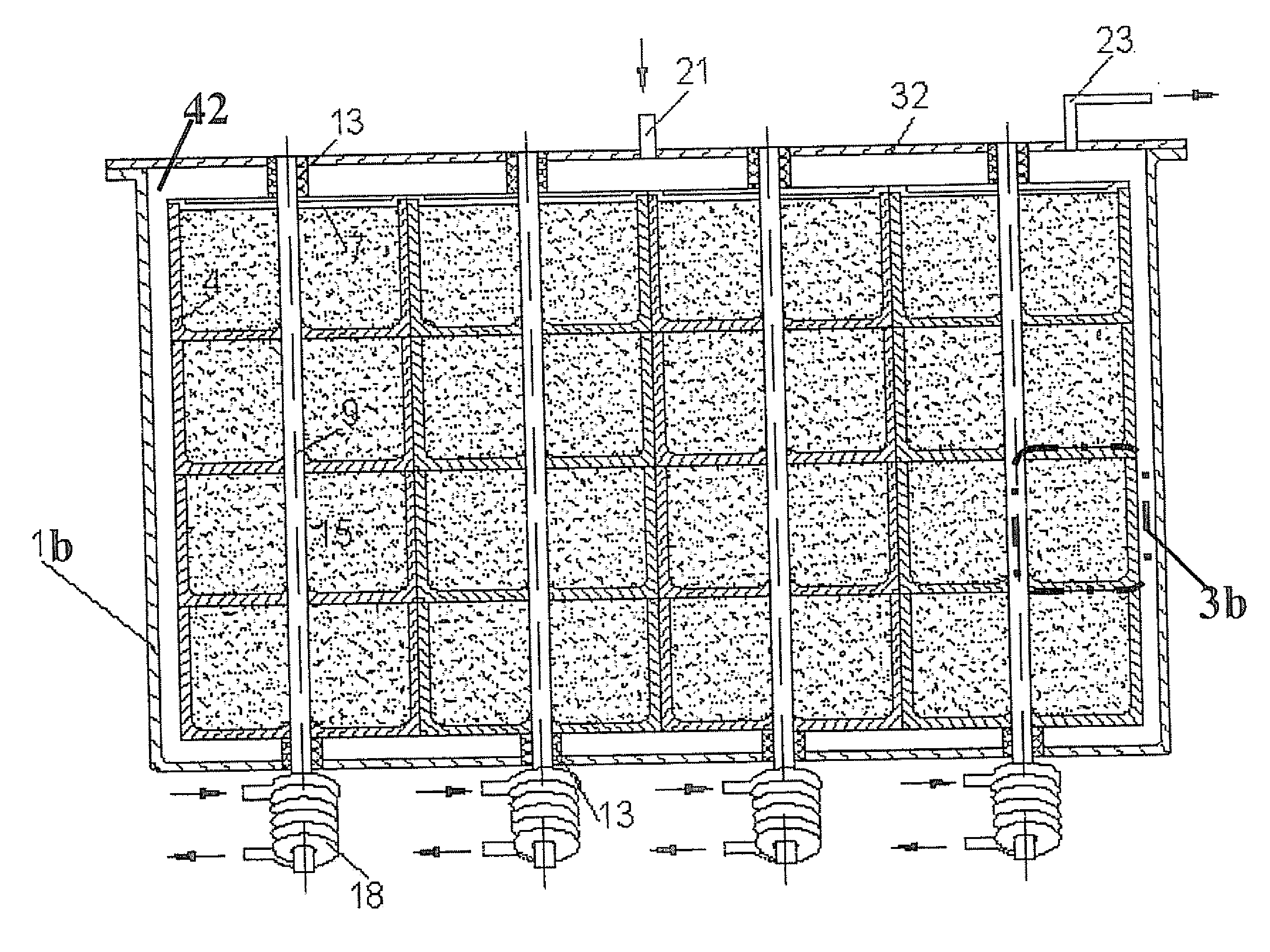

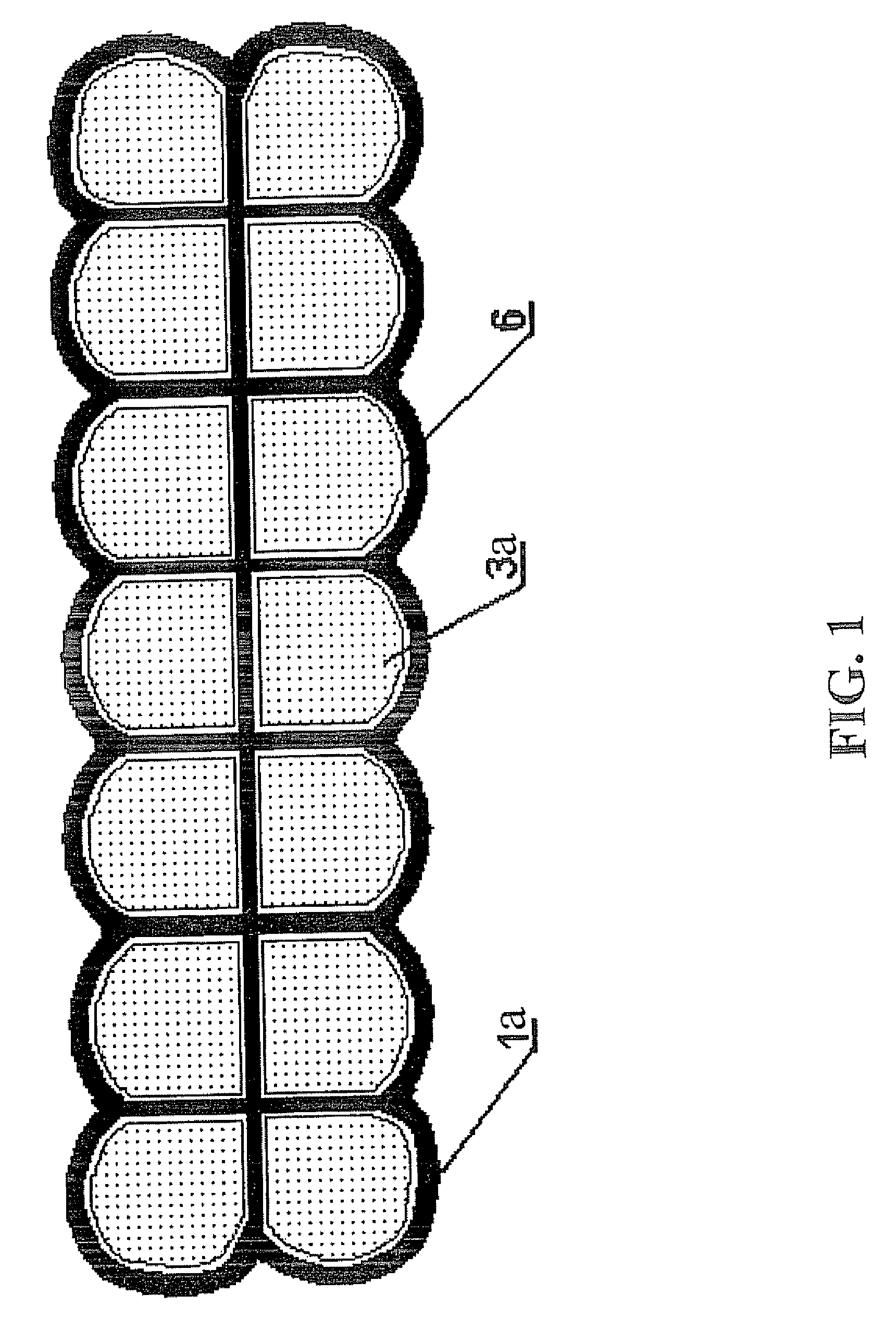

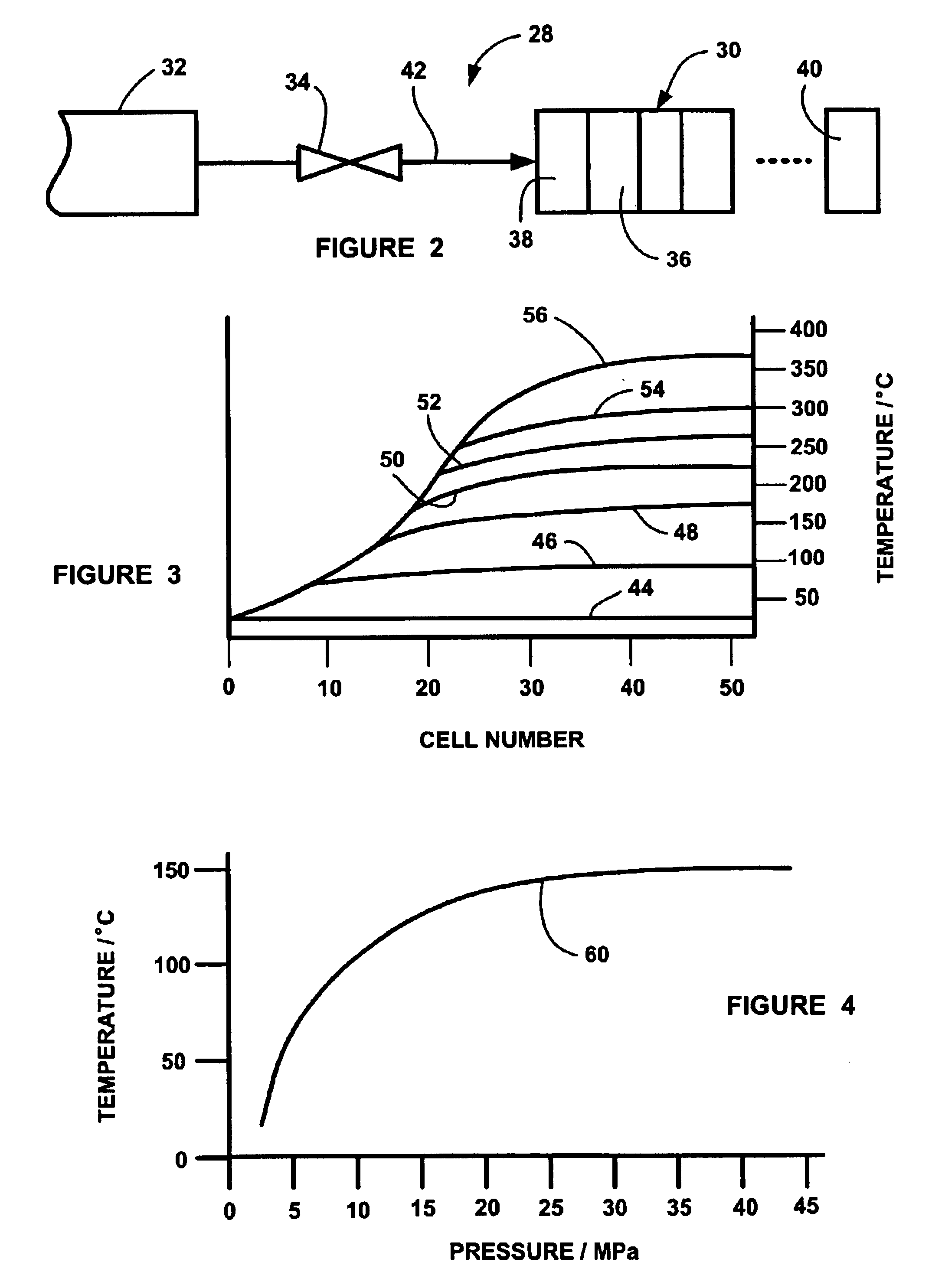

Storage Systems For Adsorbable Gaseous Fuel And Methods Of Producing The Same

InactiveUS20090229555A1Raise transfer toImprove efficiencyGas handling applicationsIsotope separationParticulatesLocal pressure

A storage system for an absorbing gas including a plurality briquette units situated within the storage tank is disclosed. In some embodiments each briquette unit includes a liner or open vessel, and compressed gas-absorbing particulate matter associated with the liner for external support In some embodiments, the liner or vessel maintains the form of the briquette unit. The liner or vessel do not form a pressure tight vessel, and in some embodiments, the local pressure rating of the liner or vessel is less than the gas pressure within the storage tank. Exemplary gas-absorbing materials include but are not limited to methane and hydrogen adsorbing materials such as activated carbon, zeolite, and other appropriate hydrocarbon gas and / or hydrogen adsorbing materials. Optionally, each briquette unit includes a wrapper for preventing circulation of said particulate matter within the storage tank. Optionally, the storage system includes a mechanism for supplying or removing heat to at least one briquette unit. Furthermore, a method for manufacturing any of the aforementioned gas storage systems is disclosed. Some embodiments of the present invention provide methane-powered motor vehicles including but not limited to automobiles, buses, trucks and ships including a storage system with compressed methane-adsorbing particulate matter

Owner:ANGSTORE TECH

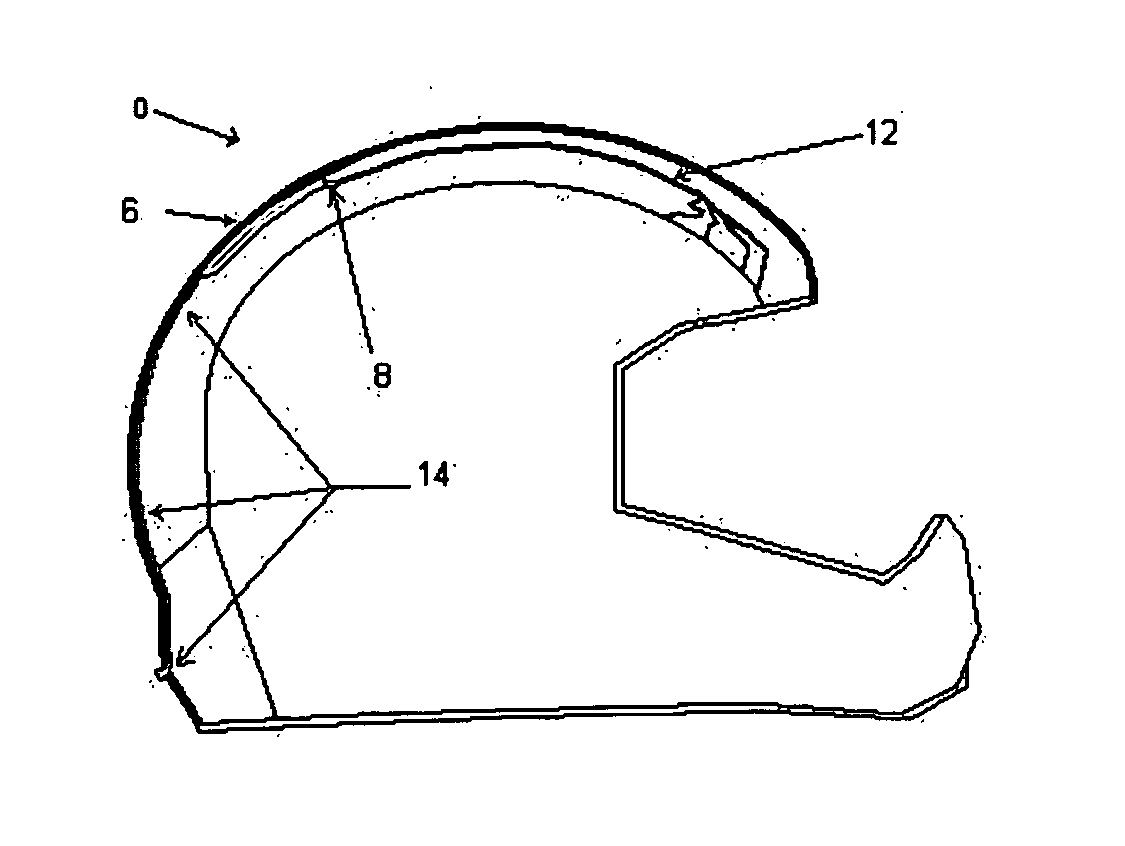

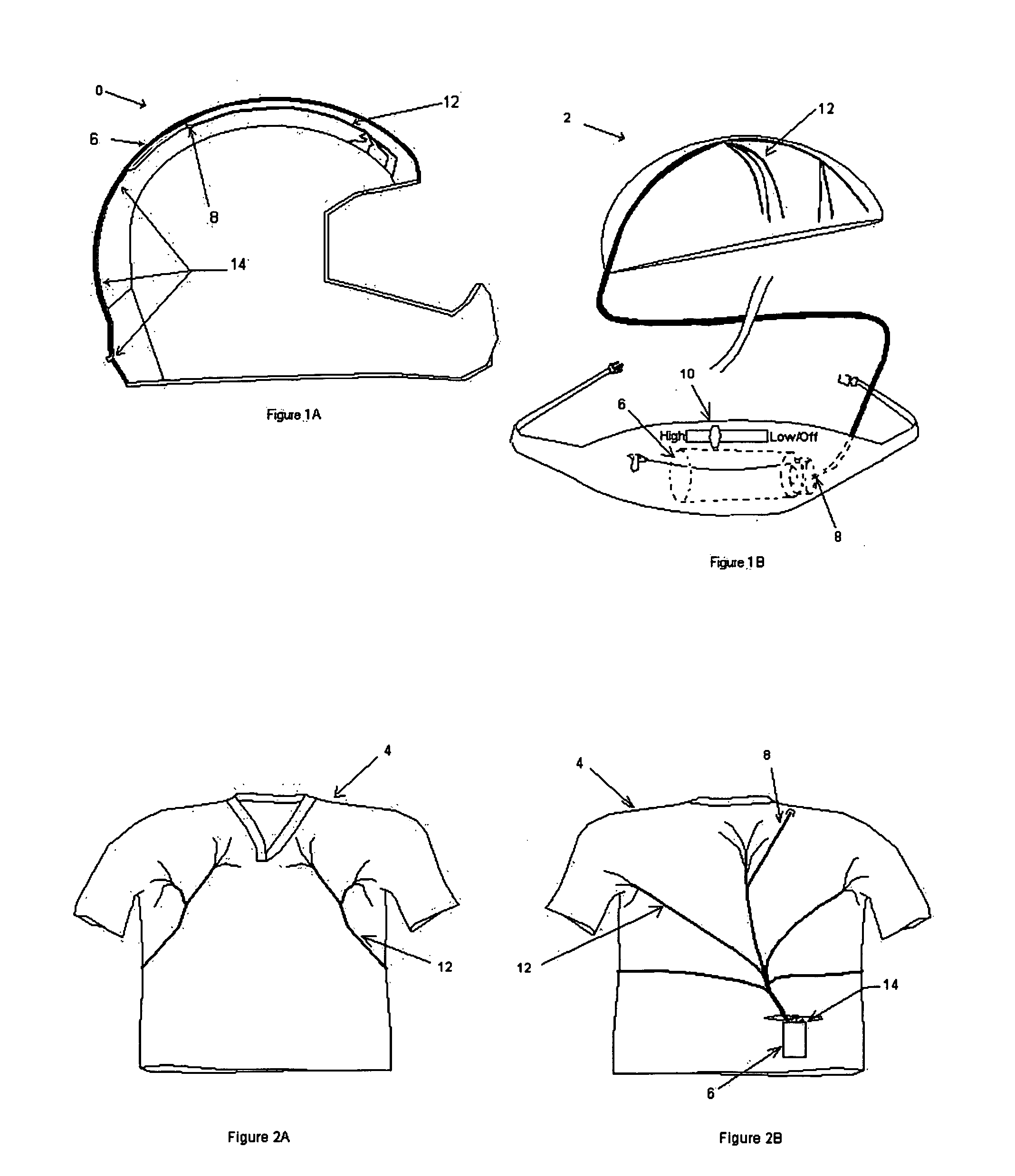

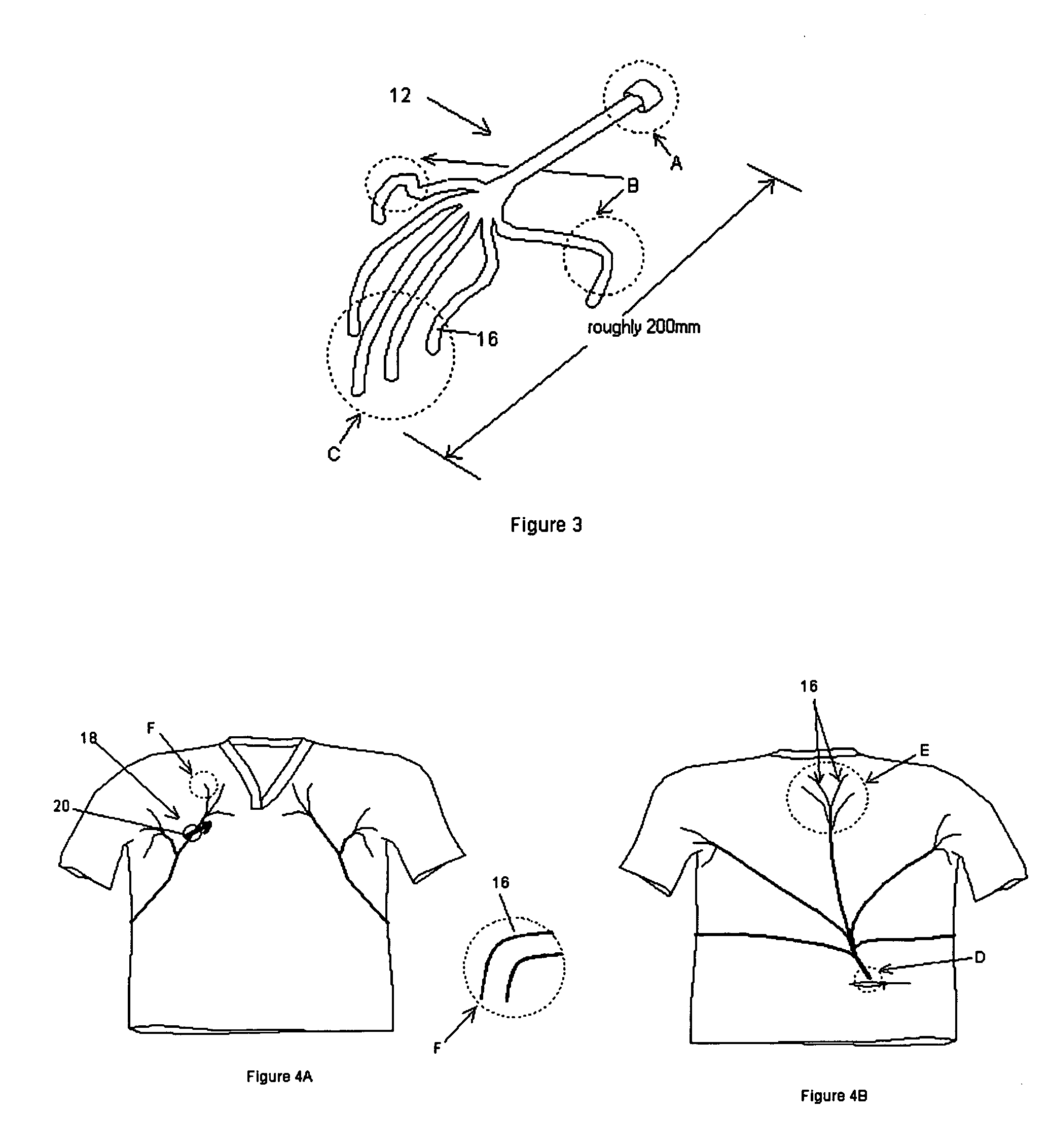

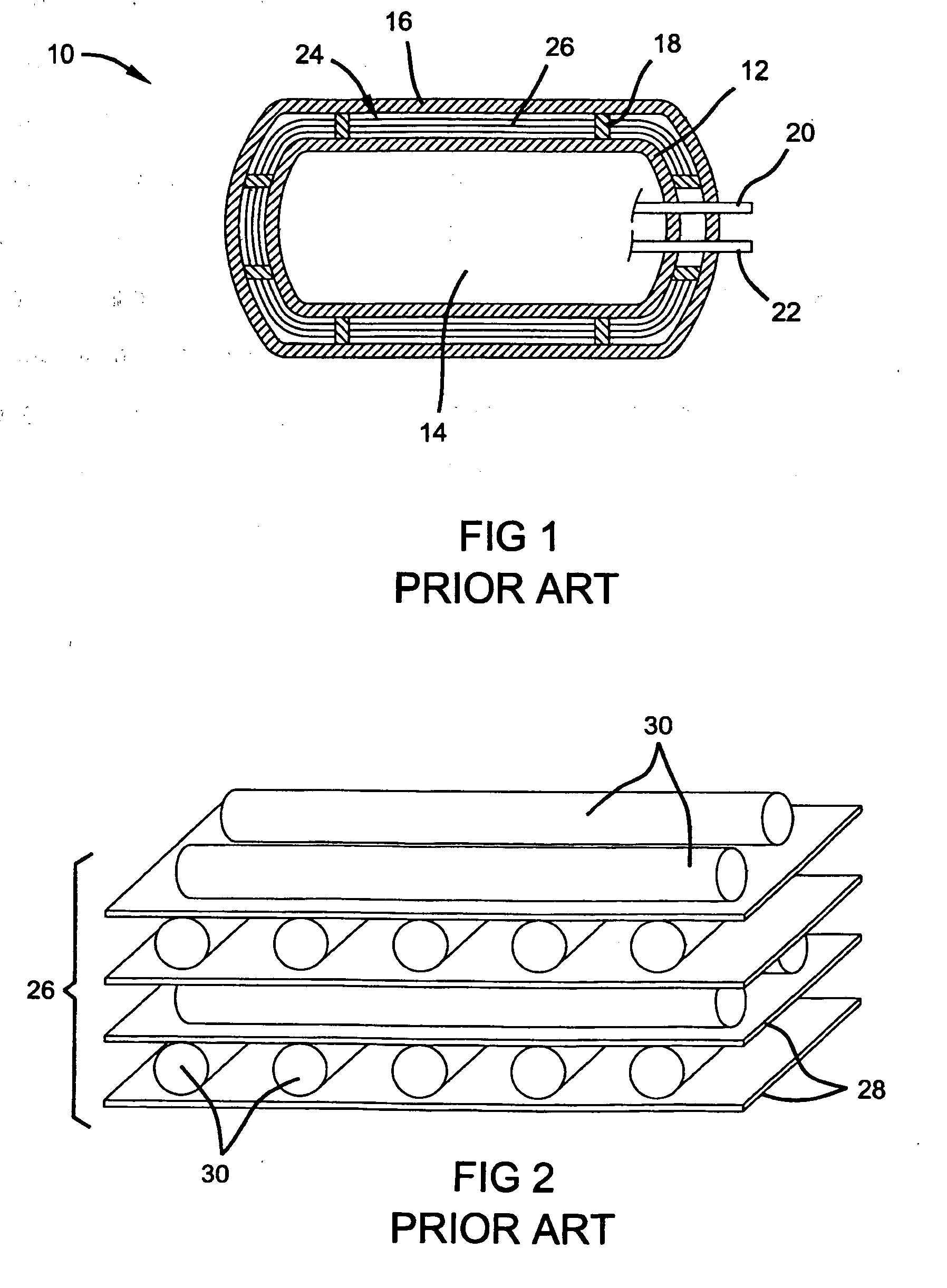

Complex-shape compressed gas reservoirs

InactiveUS20060175337A1Maximum cooling efficiencyEffectiveGas handling applicationsHatsEngineeringHigh pressure

Portable cooling systems, employing a high pressure reservoir adapted to ergonomically interface with a user and / or a wearable article to deliver a flow of cooling gas through a conduit system are provided. Such a system is adapted to provide powered cooling to locations where only very small and portable cooling systems can fit. Various user retainable appliances or articles may have cooling features incorporated therein. The molded plastic high pressure reservoir may have other uses as well.

Owner:INVENTION FACTORY

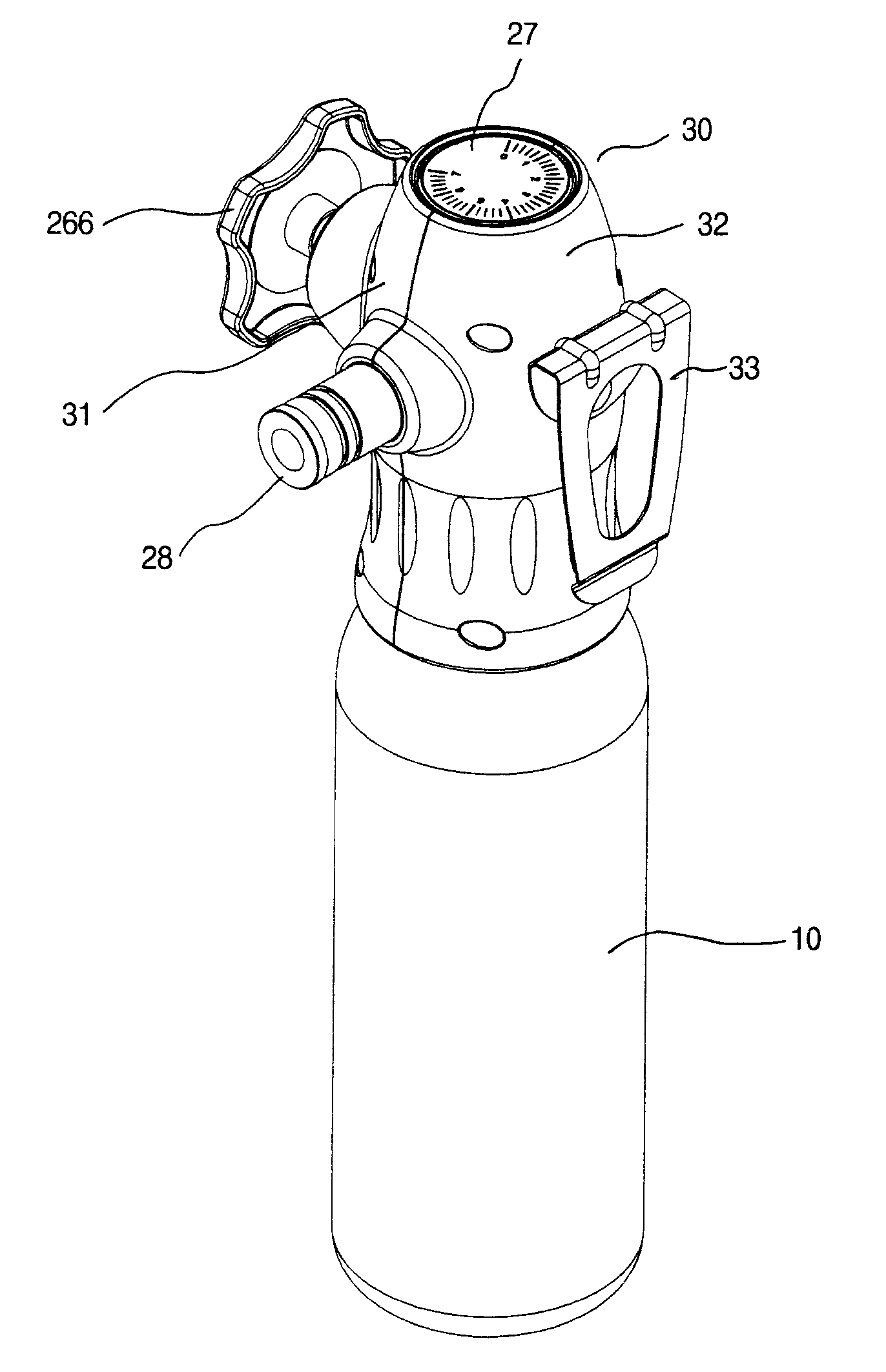

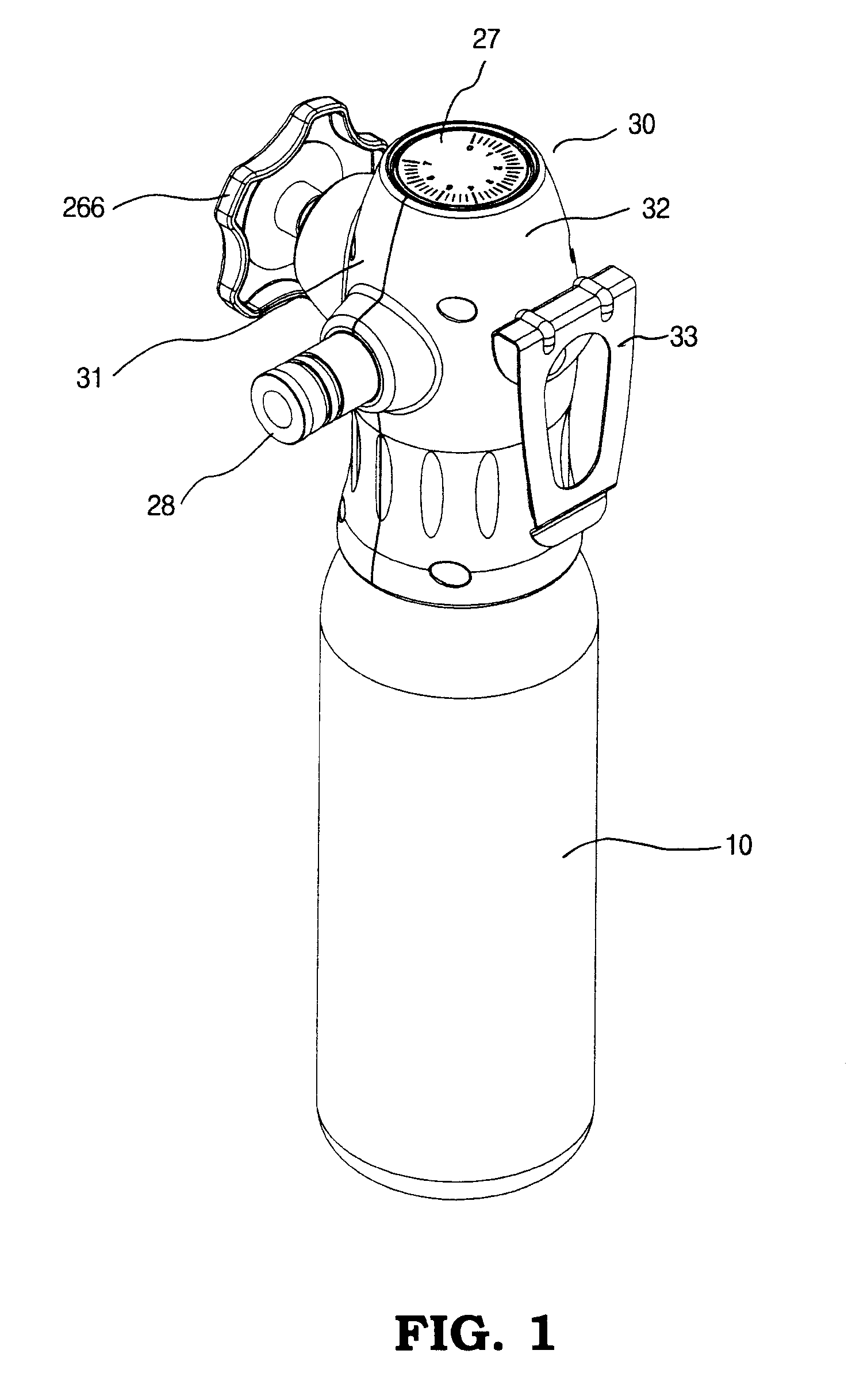

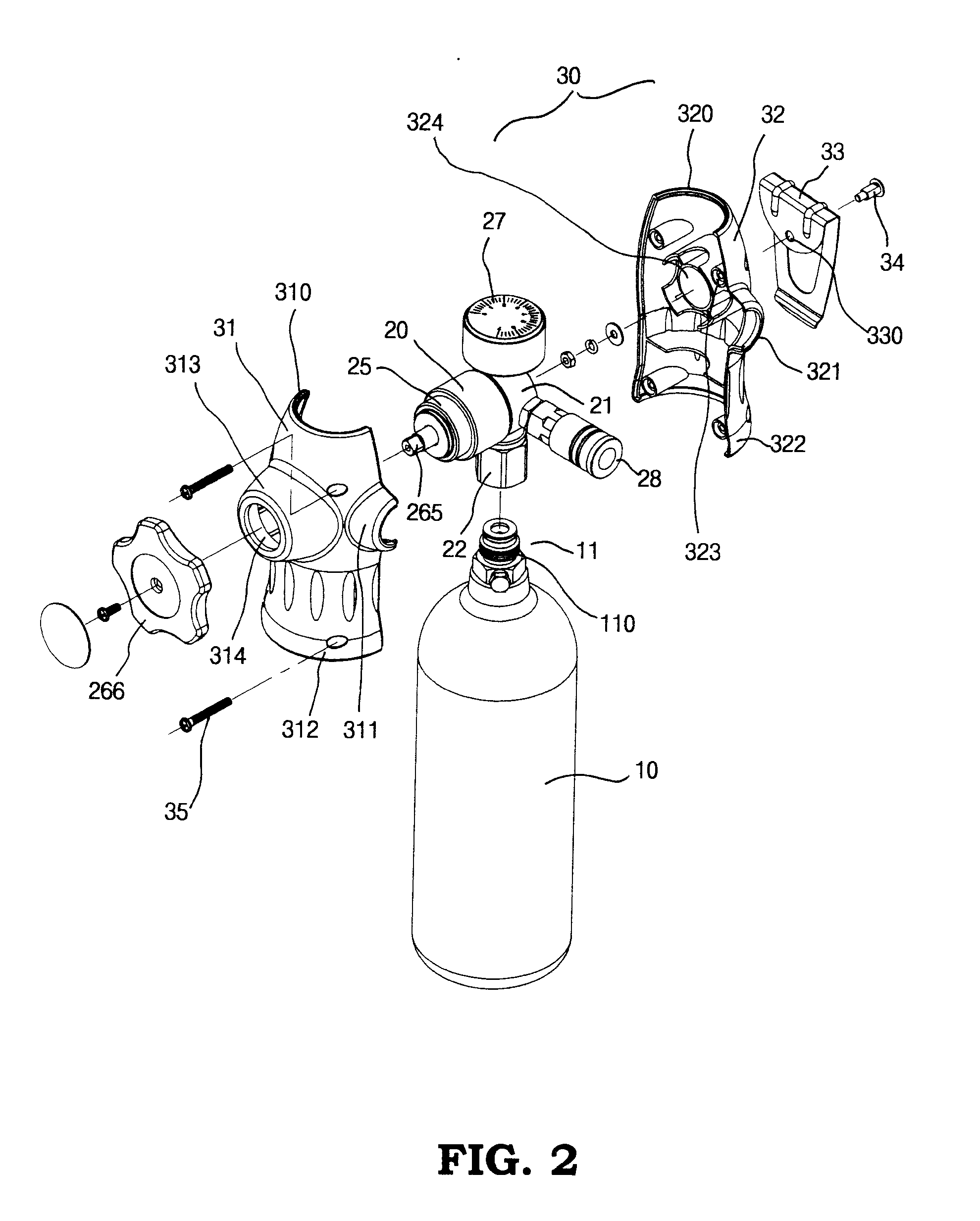

Portable device for supplying compressed CO2 from a pressure vessel to a pneumatic tool

A device includes a pressure regulator comprising a body including a control chamber adapted to connect to a portable pressure vessel filled with compressed CO2 via an inlet coupling, the control chamber having a threaded stepped diameter passageway, a relief valve, and a pressure gauge, a valve, a cap including a hand wheel, and a pressure adjustment assembly including a resilient sealing disk, a disc, a thumbtack member, a fastener for securing the thumbtack member and the sealing disk together, and a spring biased between the sealing disk and the disc; a housing for partially enclosing the pressure regulator with the hand wheel, the pressure gauge, and an outlet coupling being exposed; and a hanging member pivotably secured onto the housing.

Owner:FEVER INDAL

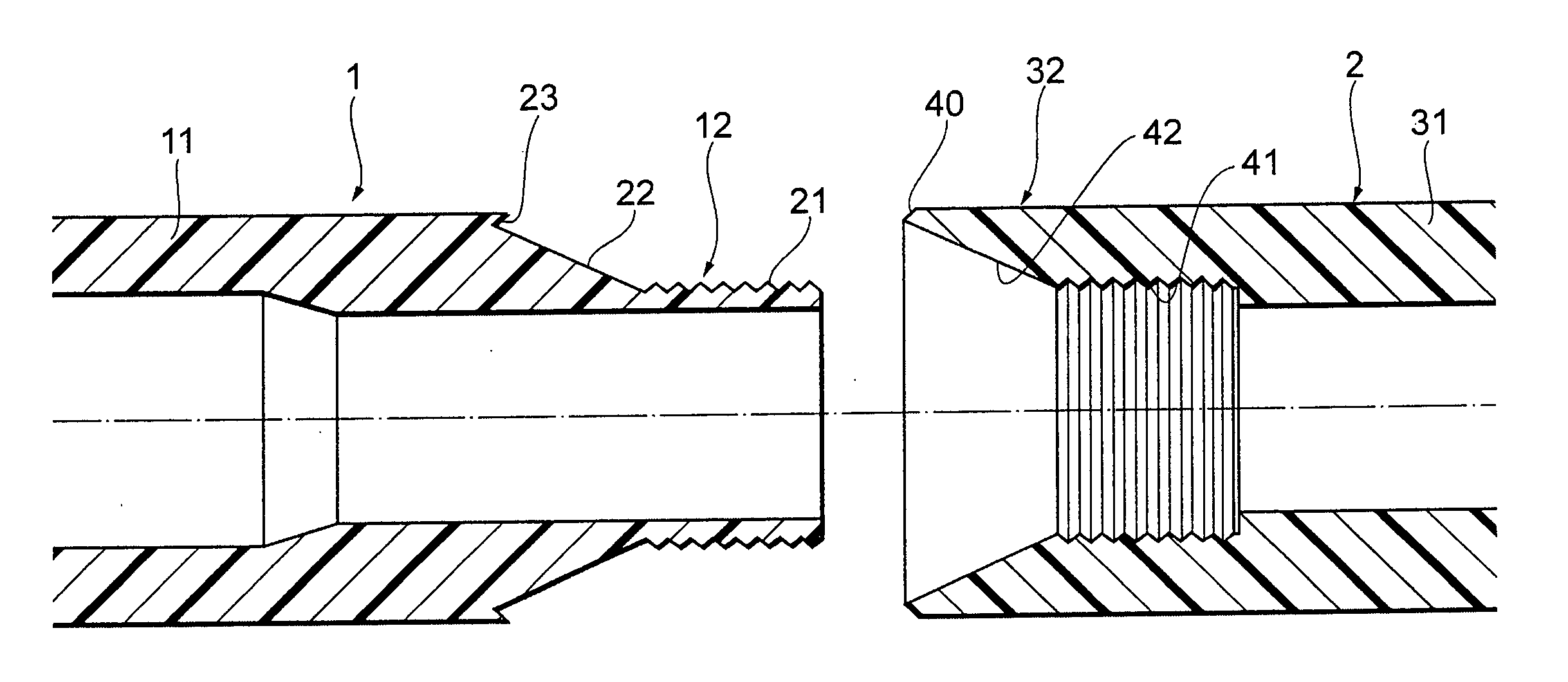

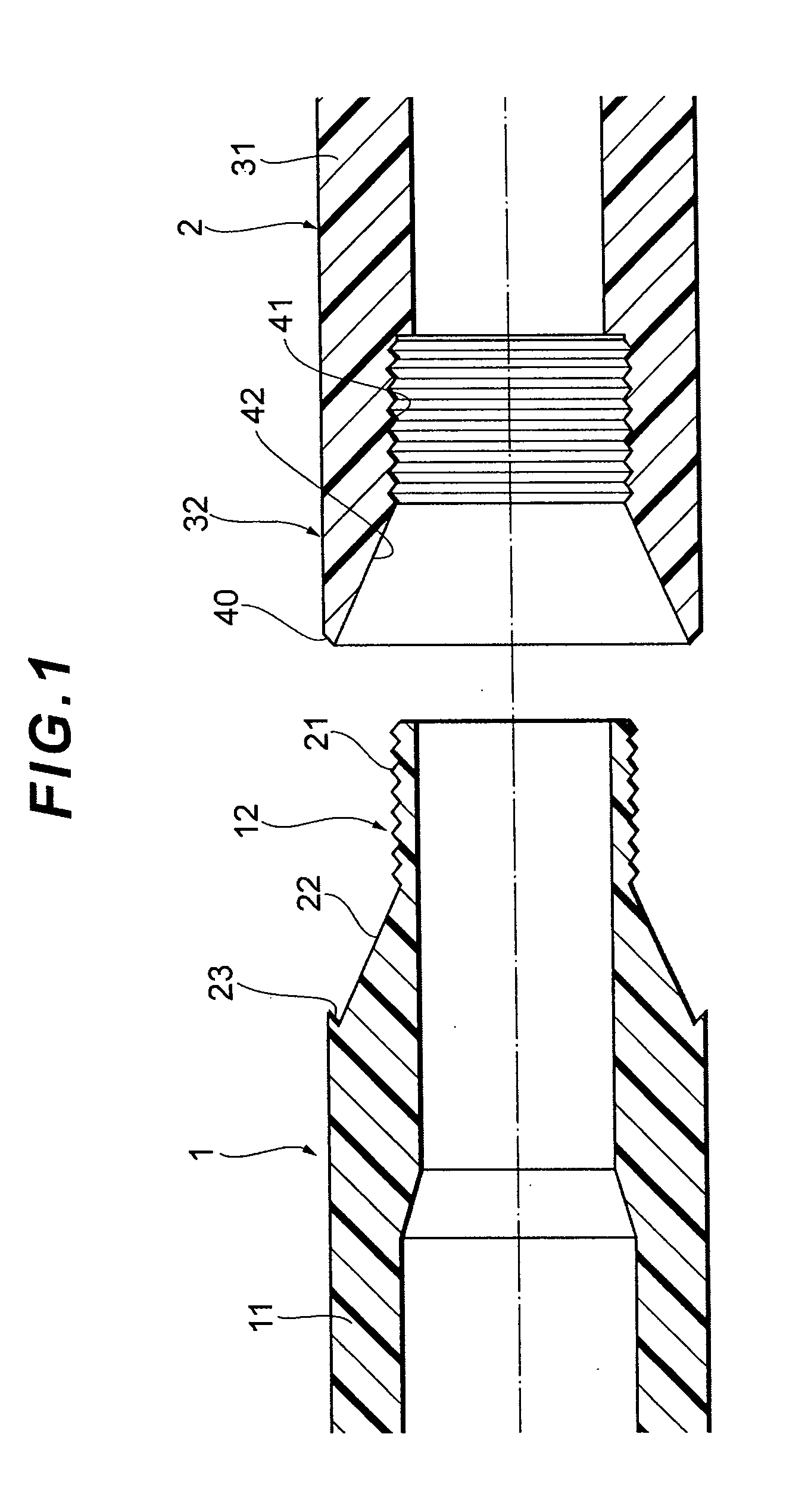

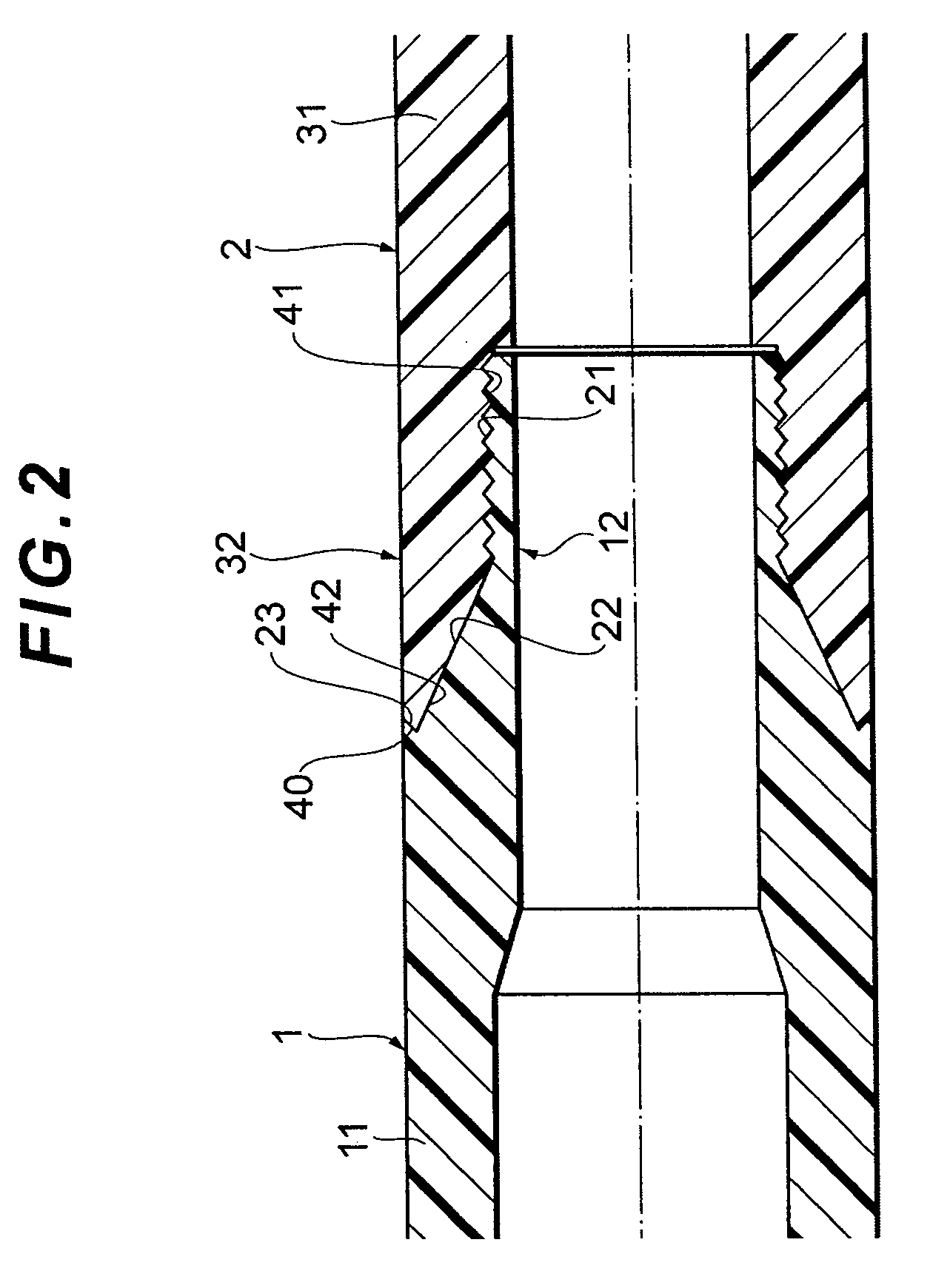

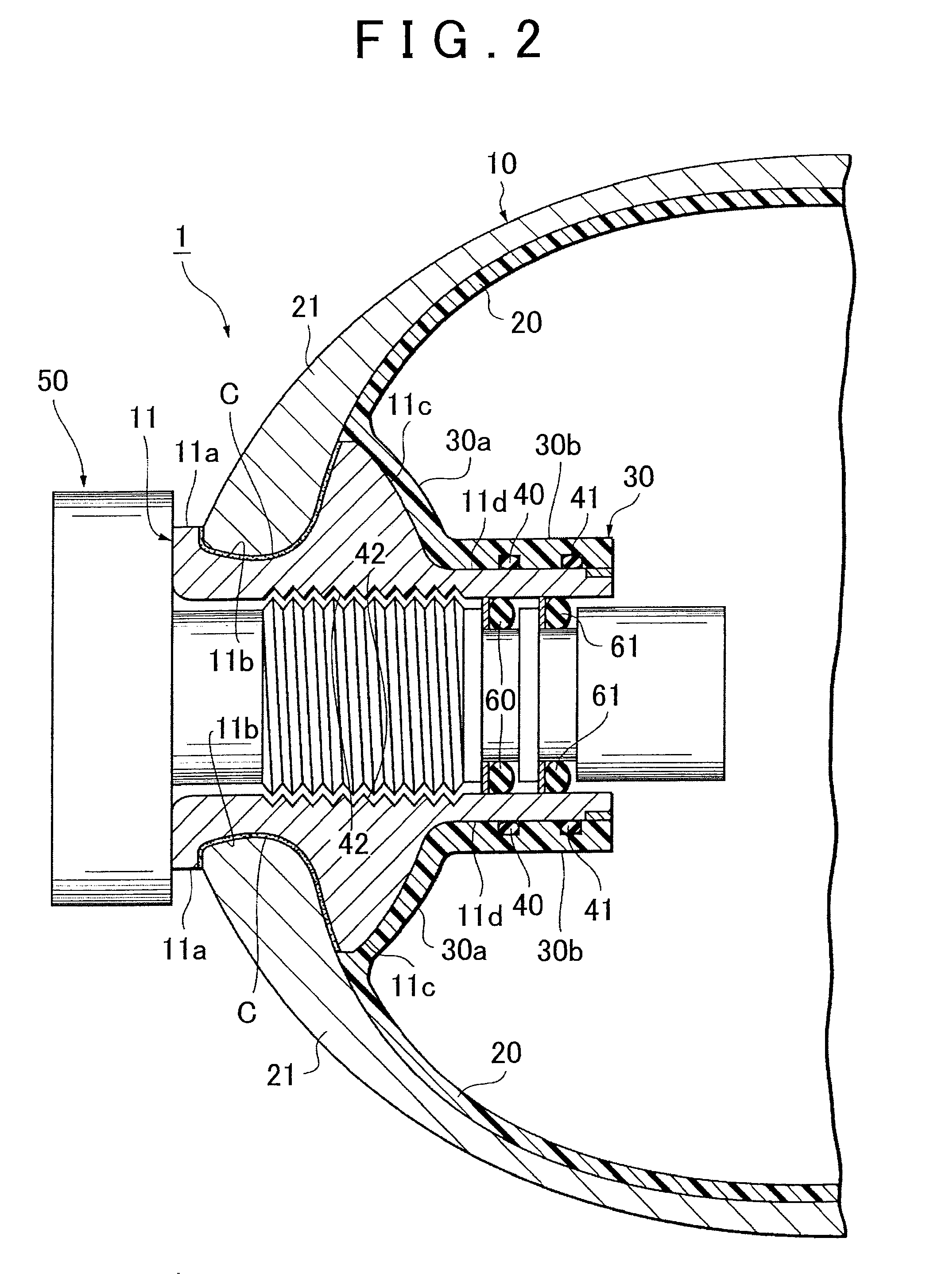

Structure and Method for Bonding Two Members, Gas Container and Method for Manufacturing Such Gas Container

InactiveUS20080187697A1Suppress position deviationPositional deviationGas handling applicationsThin material handlingEngineeringMechanical engineering

An object is to provide a bonded structure of two members, a bonding method of two members in which end portions of a pair of resin members can appropriately be bonded to each other by laser welding while easily suppressing a positional deviation between the end portions of the resin members, a gas container and a manufacturing method of the gas container. In the bonded structure of two members, an external thread provided at a substantially cylindrical end portion of a resin member is screwed into an internal thread provided at a substantially cylindrical end portion of a resin member and irradiated with laser to bond the end portions of the resin members to each other by the laser welding. In the gas container, this bonded structure is applied to a resin liner of the gas container, and liner constituting members are screwed and bonded by the laser welding.

Owner:TOYOTA JIDOSHA KK

Insulation for cryogenic tanks

InactiveUS20060196876A1Domestic cooling apparatusLighting and heating apparatusMetal foilMagnetic poles

A magnetic multi-layer insulation system for a cryogenic storage tank. The system includes multiple layers of insulation comprising a carrier support structure disposed between a first major surface of a magnetic material defining a north pole facing away from the carrier support structure, and a second and opposite major surface of a magnetic material defining a south pole facing away from the carrier support structure. A reflective surface, or metal foil, is disposed adjacent the magnetic poles to deflect radiation. The layers are repelled from one another without the use of spacers. In various embodiments, the magnetic material is a permanent magnet selected from the group consisting of Samarium-Cobalt, Alnico, Neodymium-Iron-Boron, an alloy of the Lanthanide group of elements, and mixtures and alloys thereof.

Owner:GM GLOBAL TECH OPERATIONS LLC

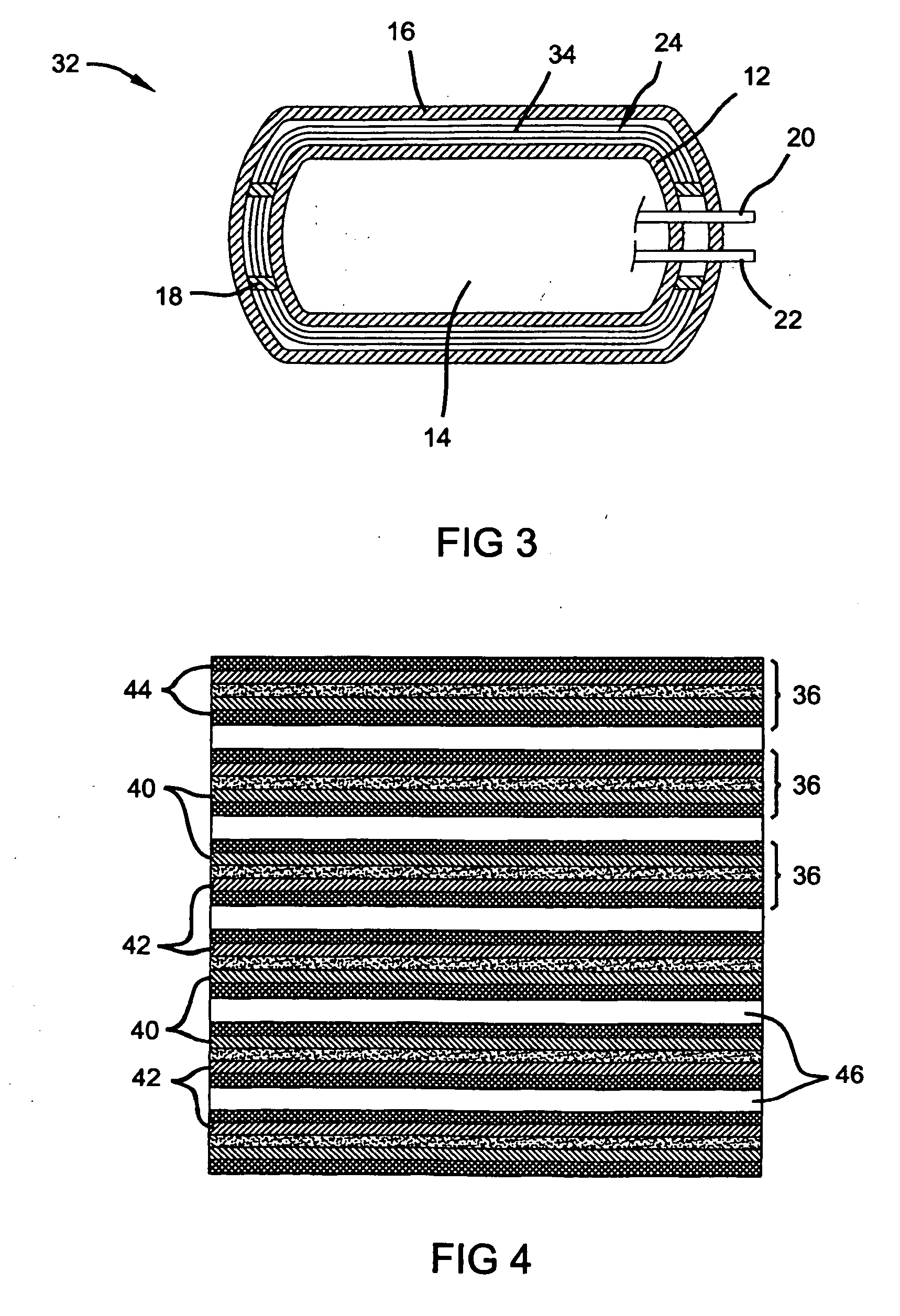

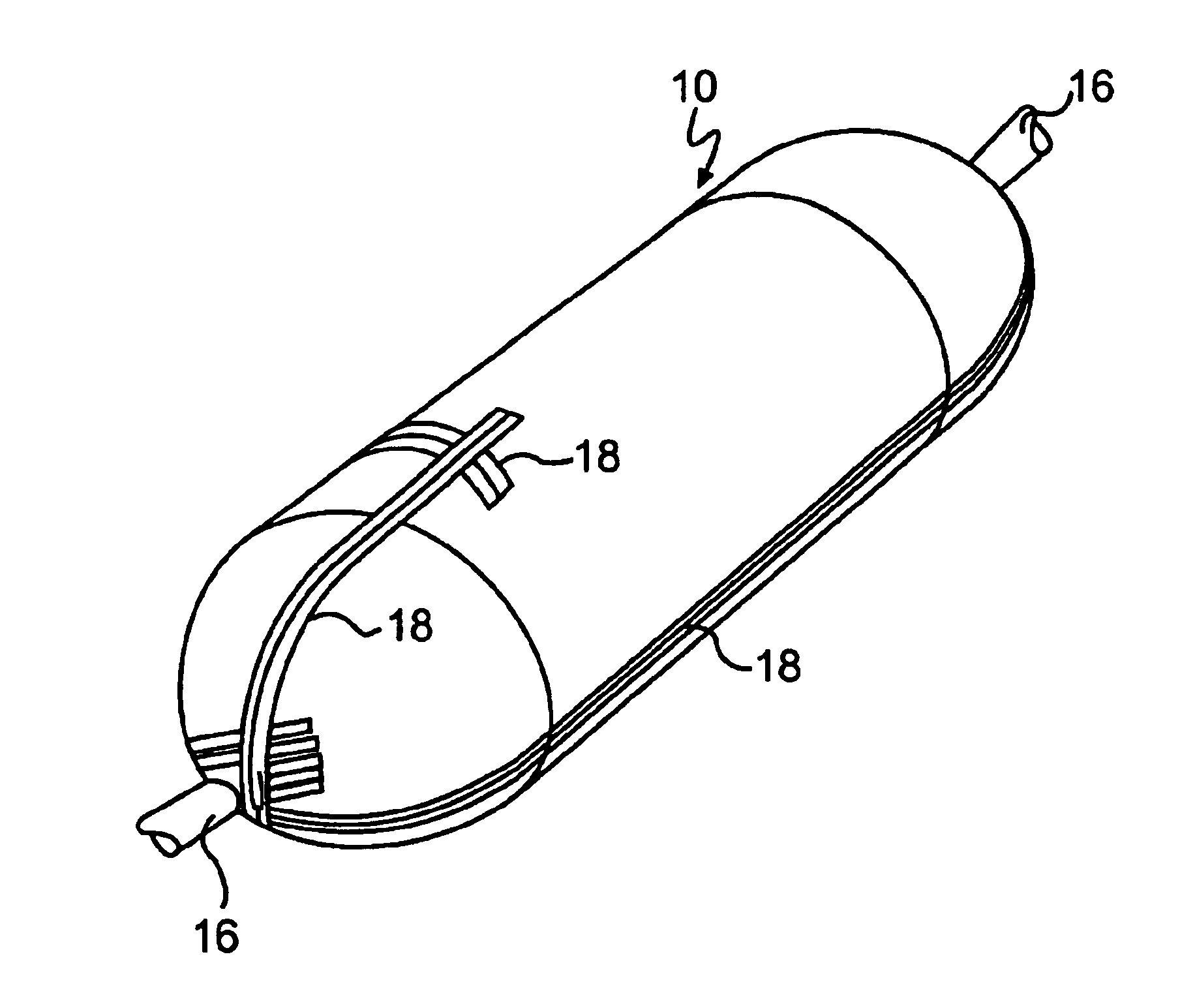

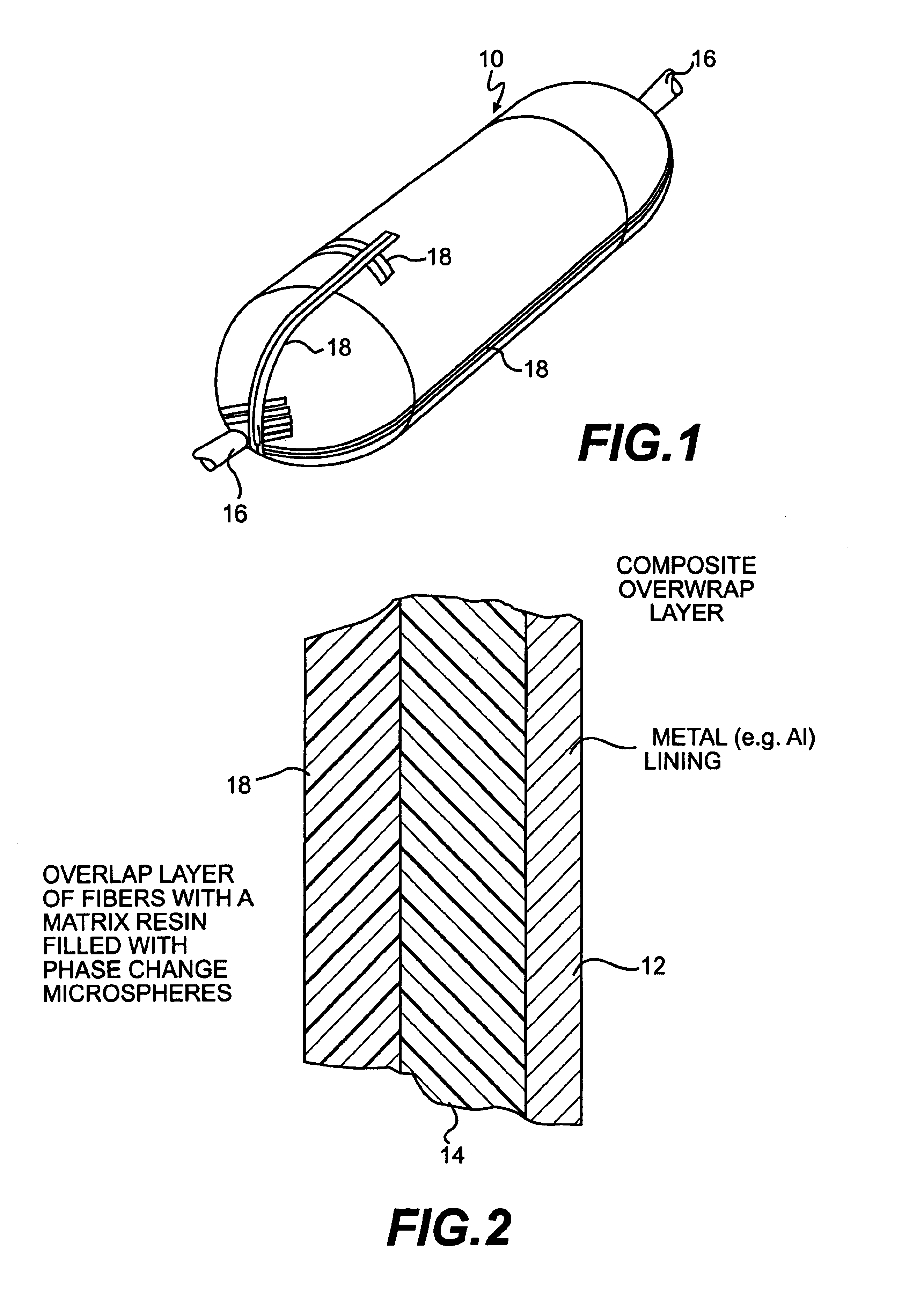

Pressure vessel with impact and fire resistant coating and method of making same

InactiveUS6953129B2Light weightIncrease heatGas handling applicationsLarge containersMicrosphereShock resistance

An impact and fire resistant coating laminate is provided which serves as an outer protective coating for a pressure vessel such as a composite overwrapped vessel with a metal lining. The laminate comprises a plurality of fibers (e.g., jute twine or other, stronger fibers) which are wound around the pressure vessel and an epoxy matrix resin for the fibers. The epoxy matrix resin including a plurality of microspheres containing a temperature responsive phase change material which changes phase in response to exposure thereof to a predetermined temperature increase so as to afford increased insulation and heat absorption.

Owner:NASA

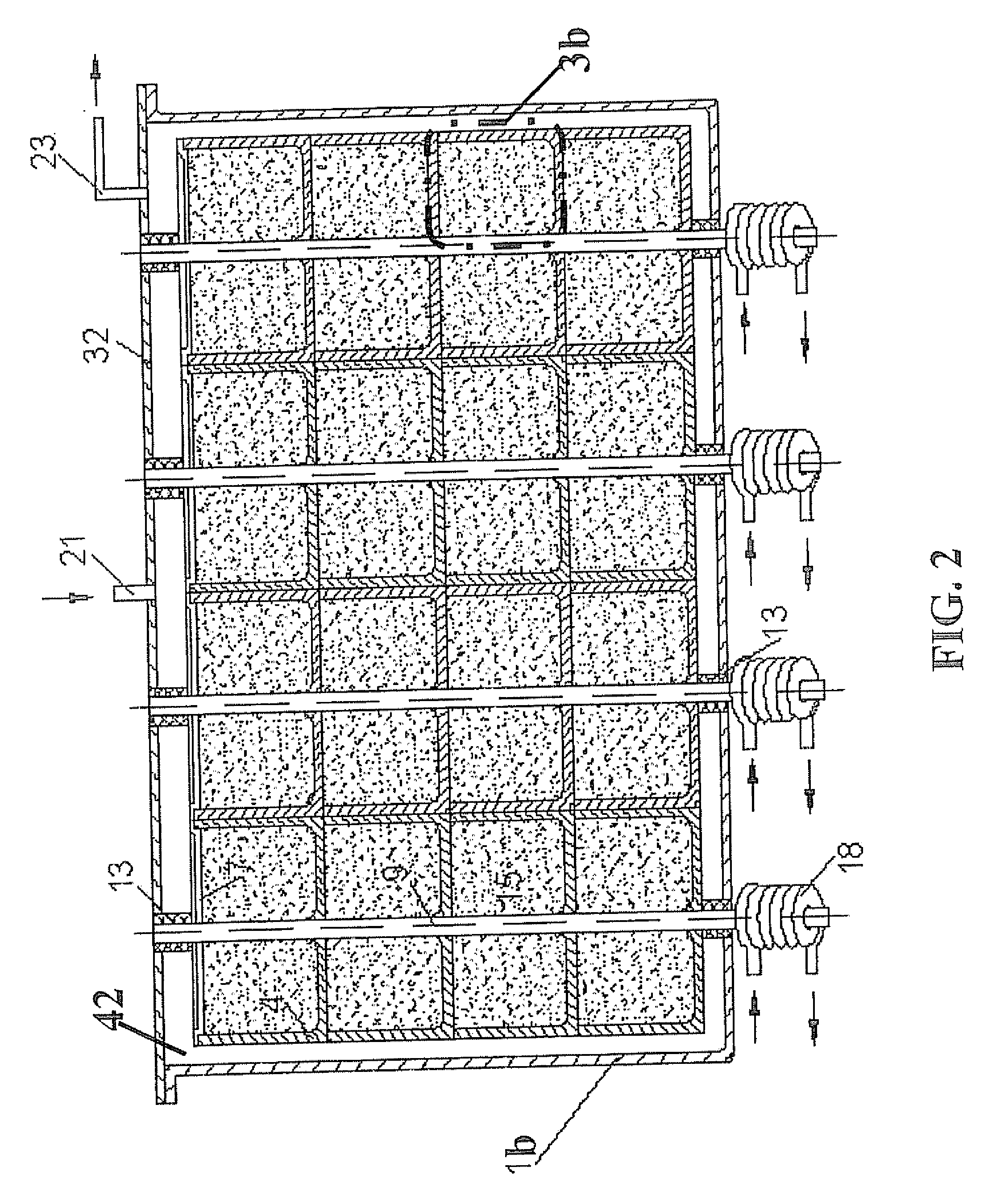

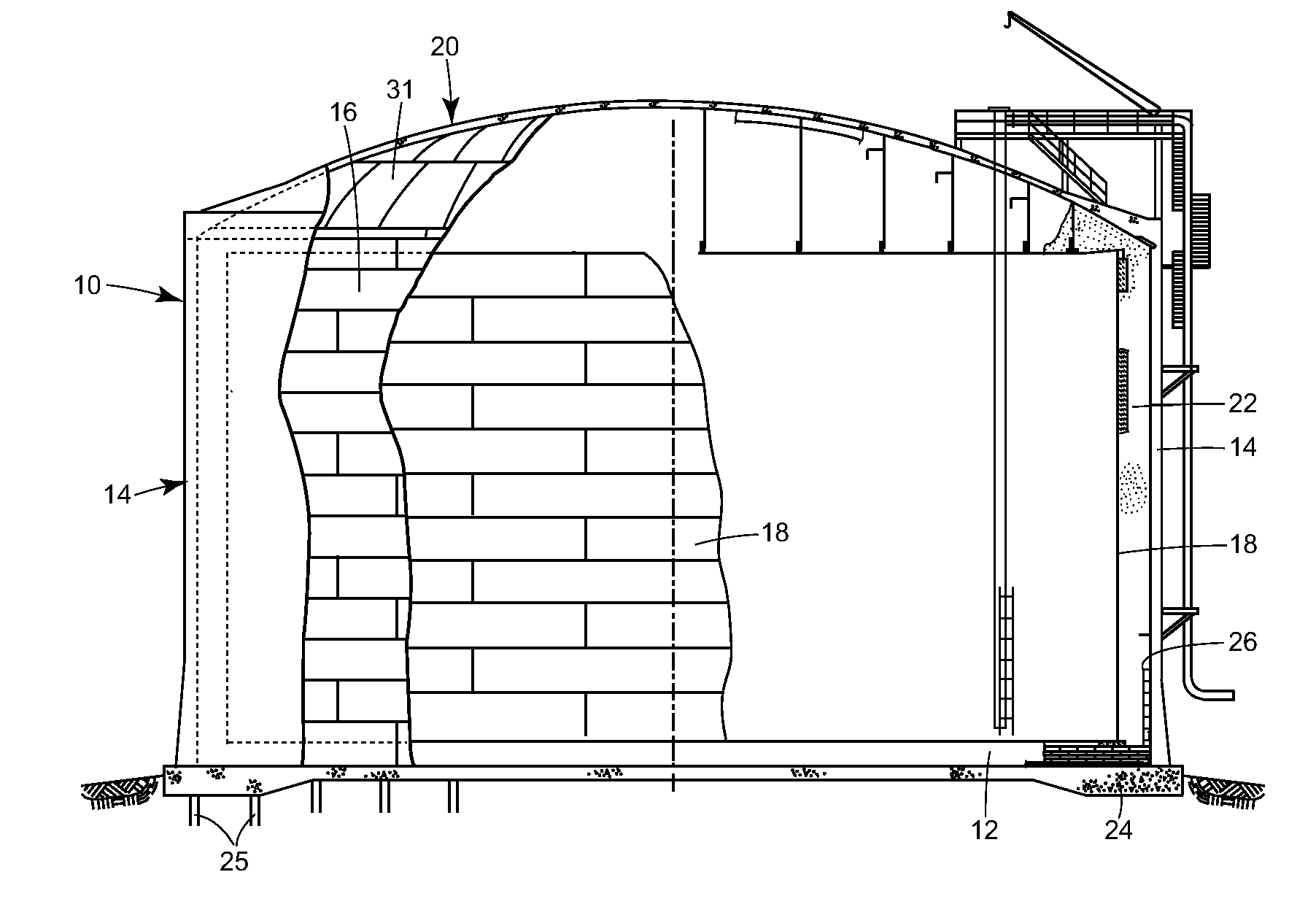

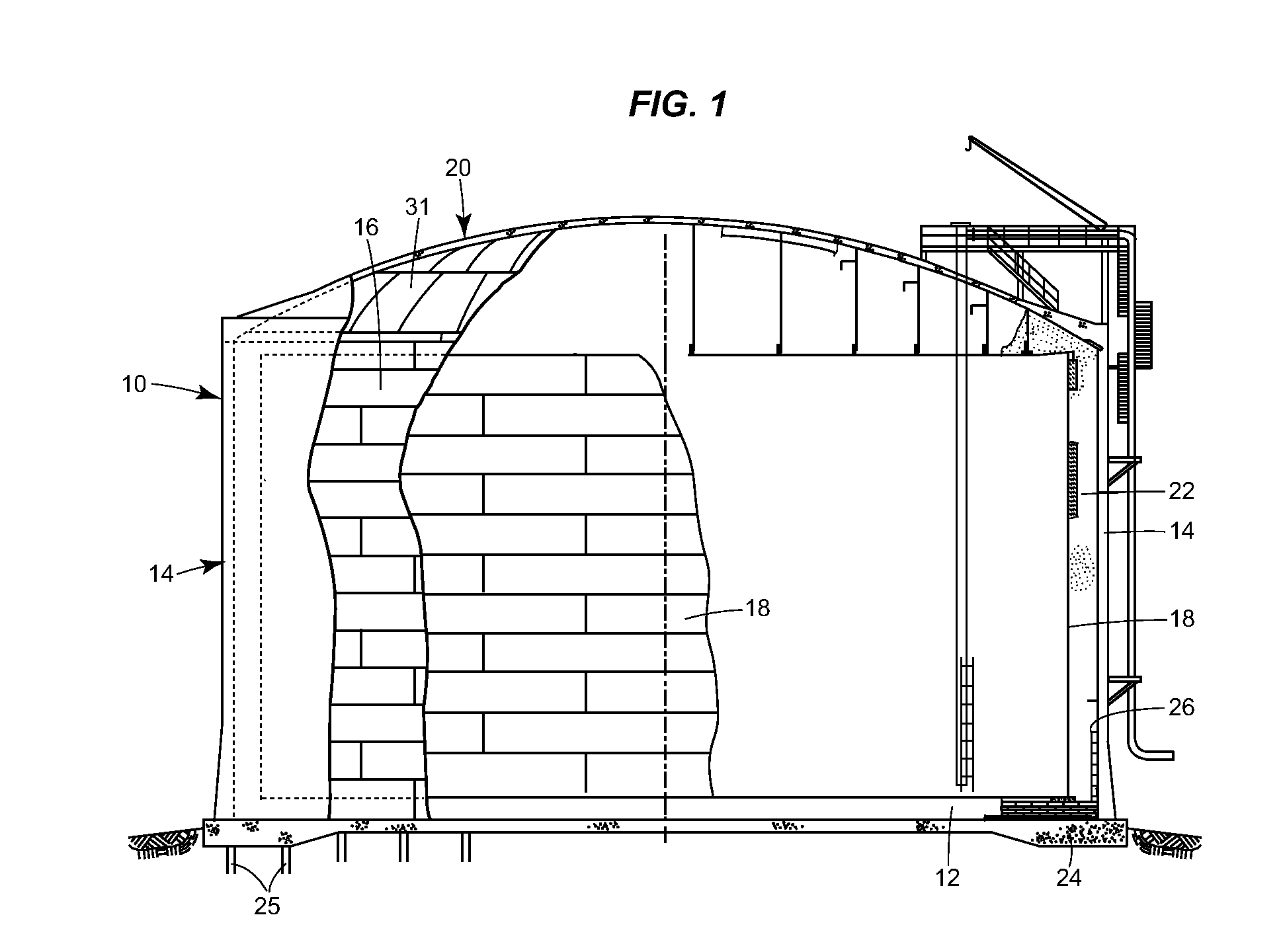

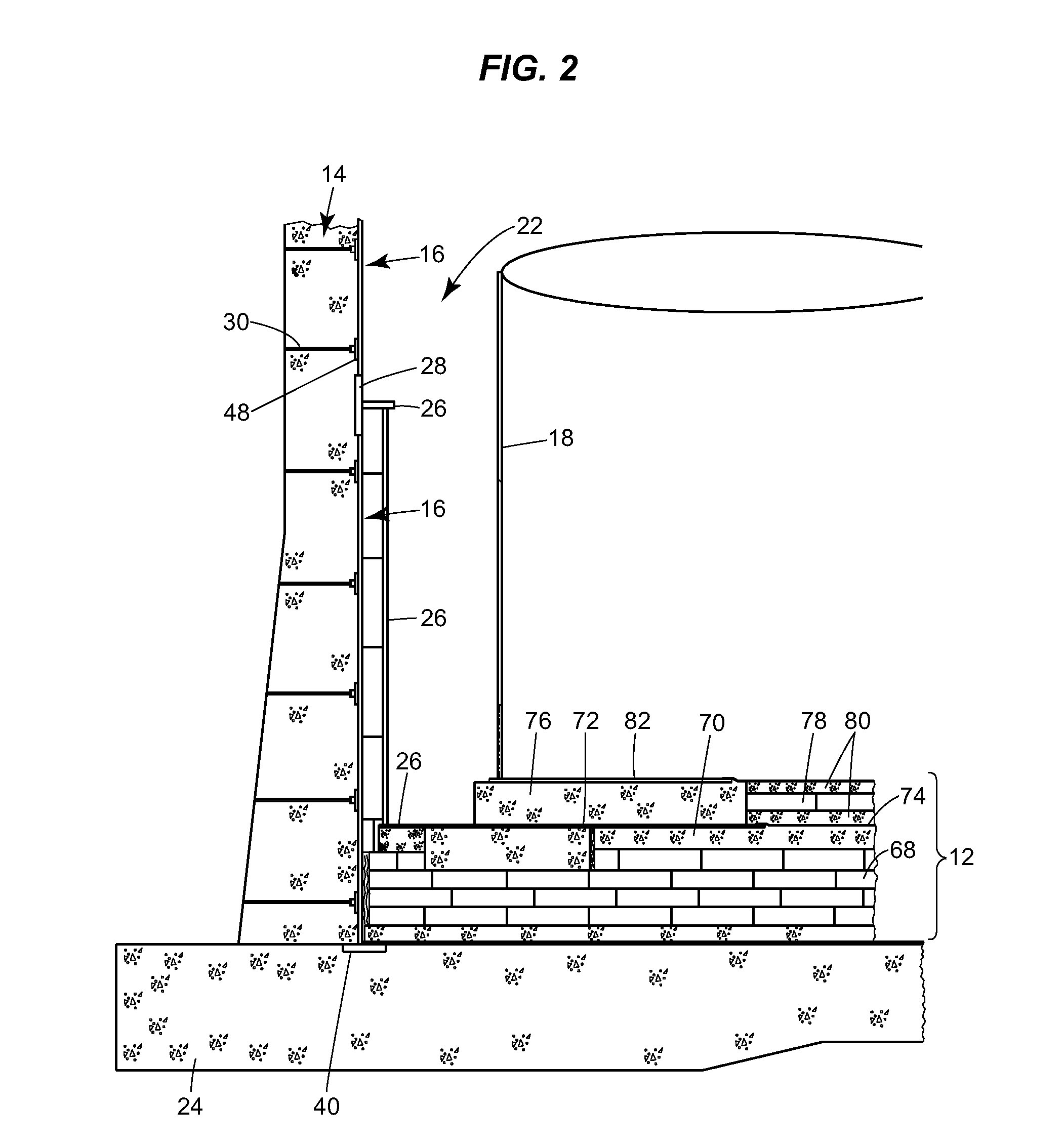

Storage tank for cryogenic liquids

ActiveUS20080302804A1Significant construction timePrecise positioningVessel manufacturingVessel geometry/arrangement/sizeEngineeringStorage tank

A new procedure for constructing cryogenic storage tanks involves erecting a freestanding metal liner. The liner is sized and configured to withstand the hydraulic forces the concrete wall of the tank being poured without the need for temporary stiffeners on the inside surface of lower portions of the liner. Lateral tension ties can be connected to anchor ties on an outward surface of the liner and used to tie the liner to outer formwork. These ties may be spaced up to about 2 m apart. Studs can also be provided on the outer surface of the liner, and a cylindrical ring of cryogenic steel can be integrated into the liner.

Owner:CHICAGO BRIDGE & IRON CO

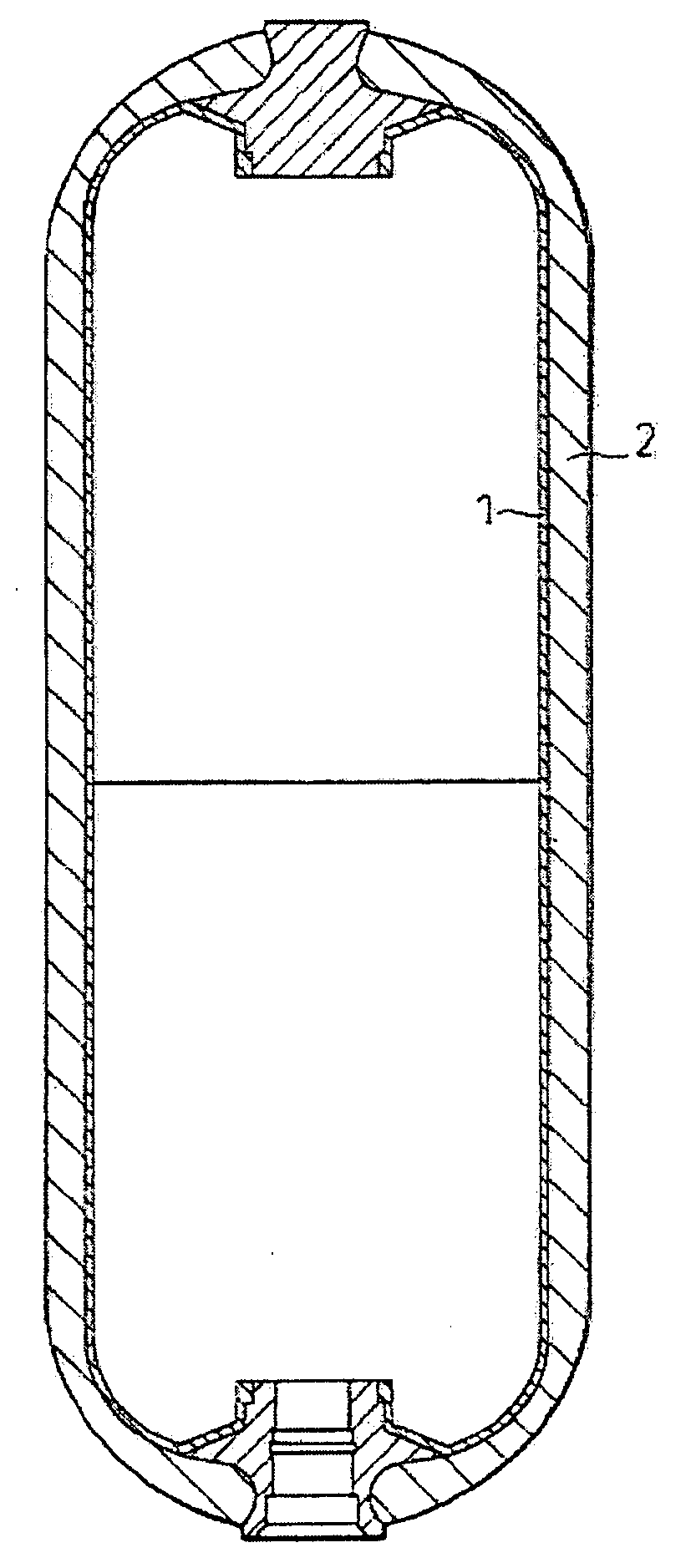

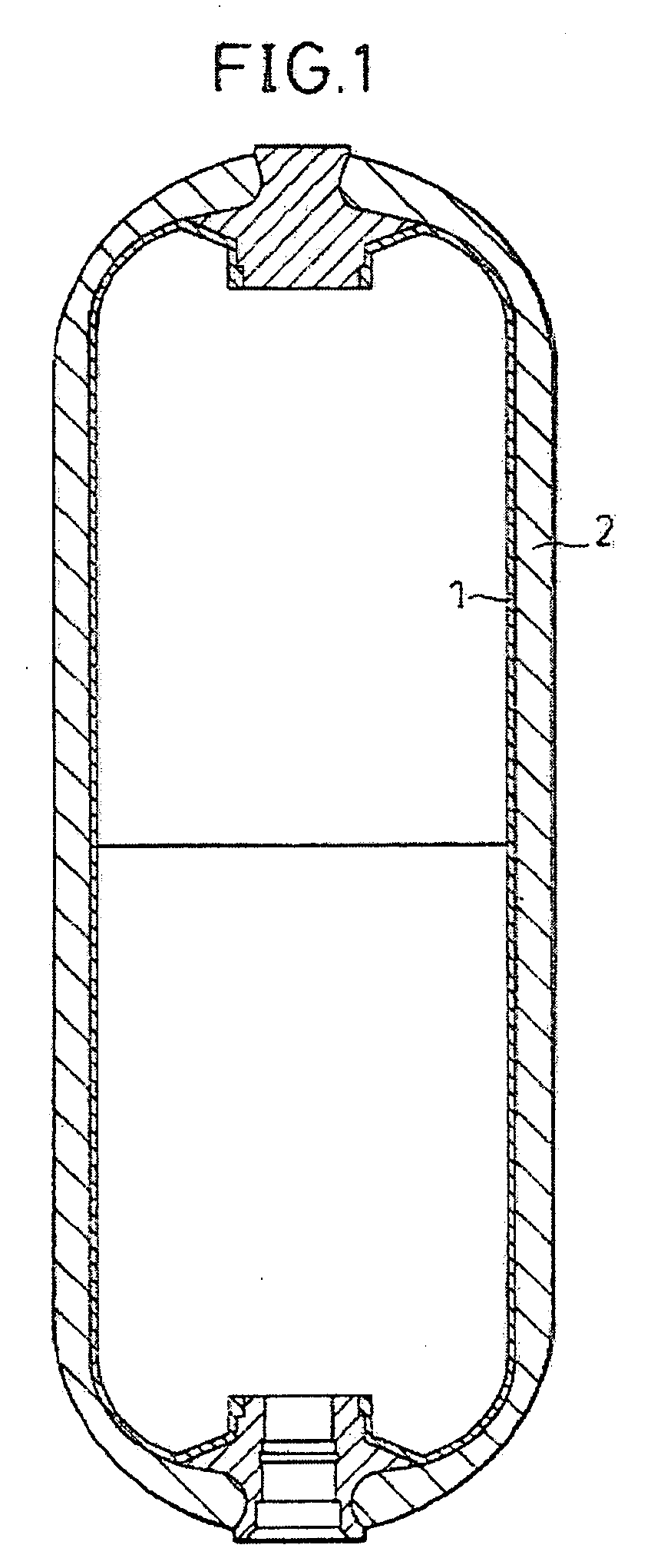

Inner shell for a pressure vessel

InactiveUS20090152278A1Minimizing affectionVessel mounting detailsVessel manufacturingEngineeringThermal expansion

Disclosed is a vessel including an outer shell and an inner shell, the inner shell having spaced apart indentations formed therein to facilitate a thermal expansion and contraction of the inner shell to militate against failure thereof.

Owner:GM GLOBAL TECH OPERATIONS LLC

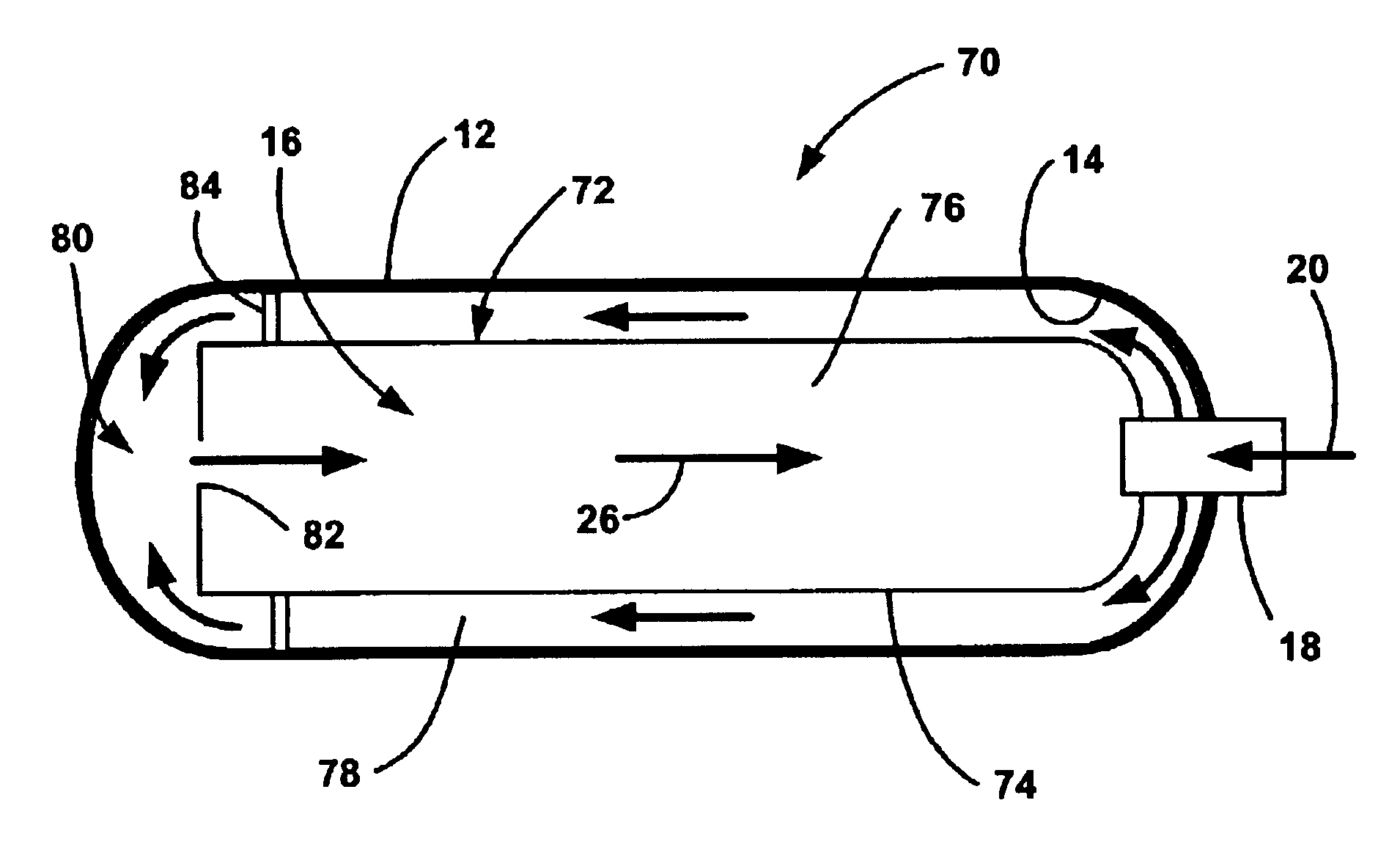

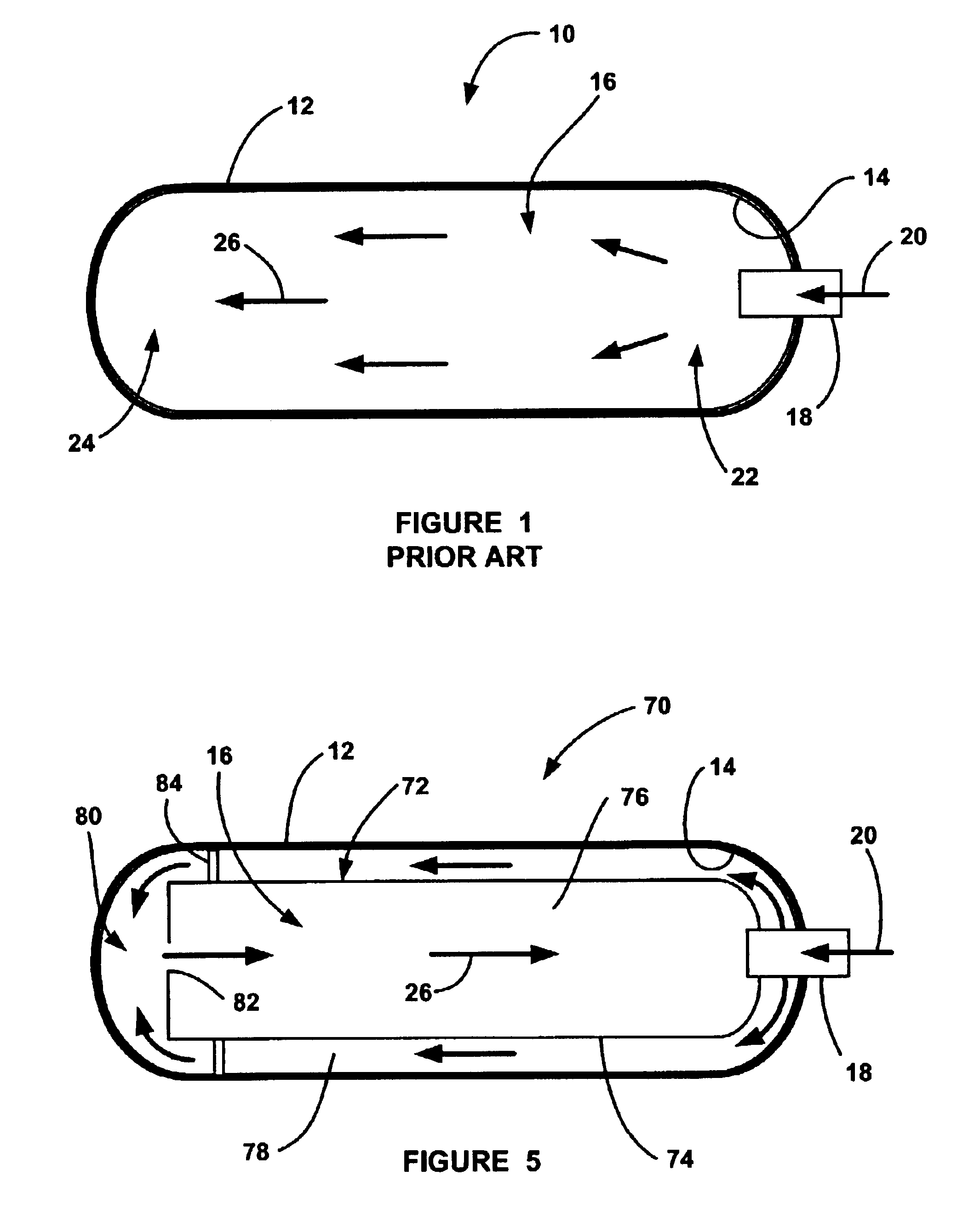

Device for overheat protection for a type 4 compressed gas container

A pressure container (70) for storing hydrogen gas (26) under pressure for a fuel cell engine. The container (70) includes an outer support layer (12) and a thermoplastic liner (14). An adapter (18) is provided in the outer layer (12) and the liner (14) to allow fill gas (20) to fill the container (70) under pressure. A fill vessel (72) is provided within the liner (14) and is sealed and thermally coupled to the adapter (18). The fill gas (20) is confined within a gap (78) between an outer surface of the fill vessel (72) and the liner (14) so that the temperature of the liner (14) is not significantly increased during the fill process. An opening (82) is provided in the fill vessel (72) so that the fill gas (20) forces the contained gas (26) within the container (70) into the fill vessel (72) through the opening (82).

Owner:GM GLOBAL TECH OPERATIONS LLC

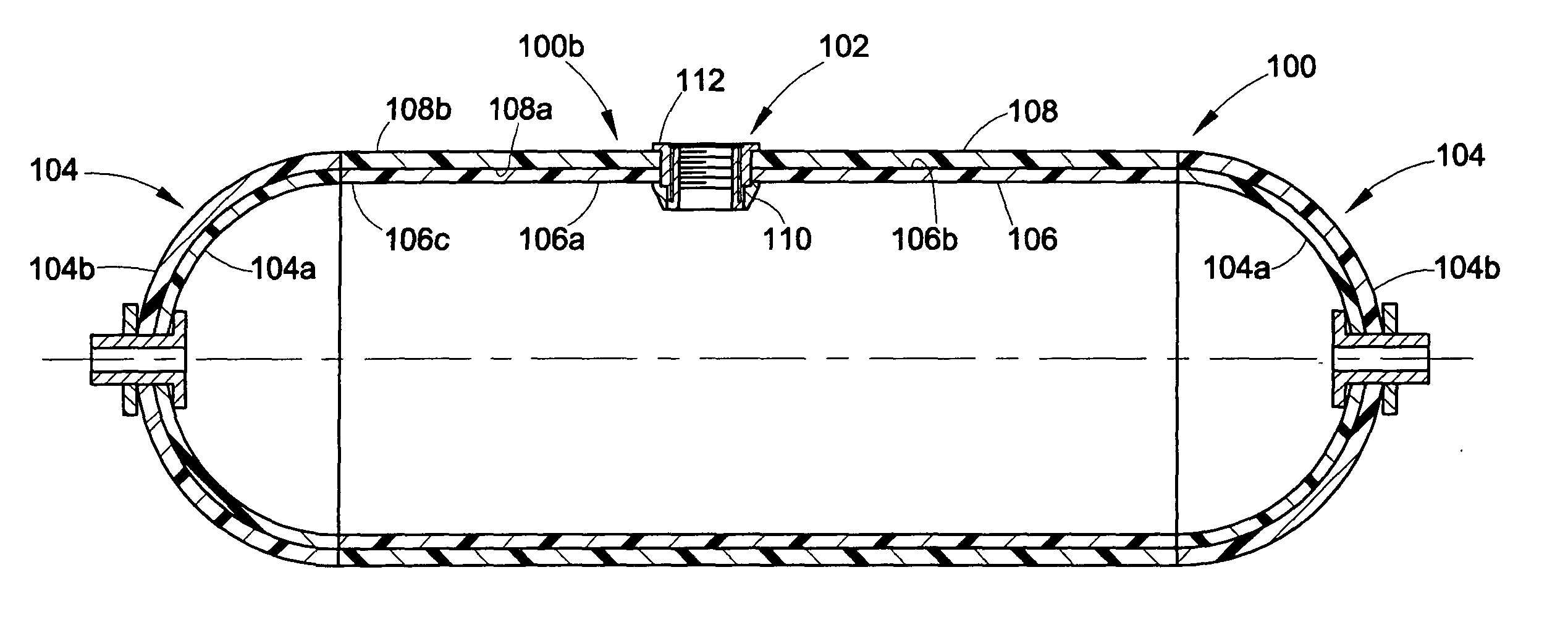

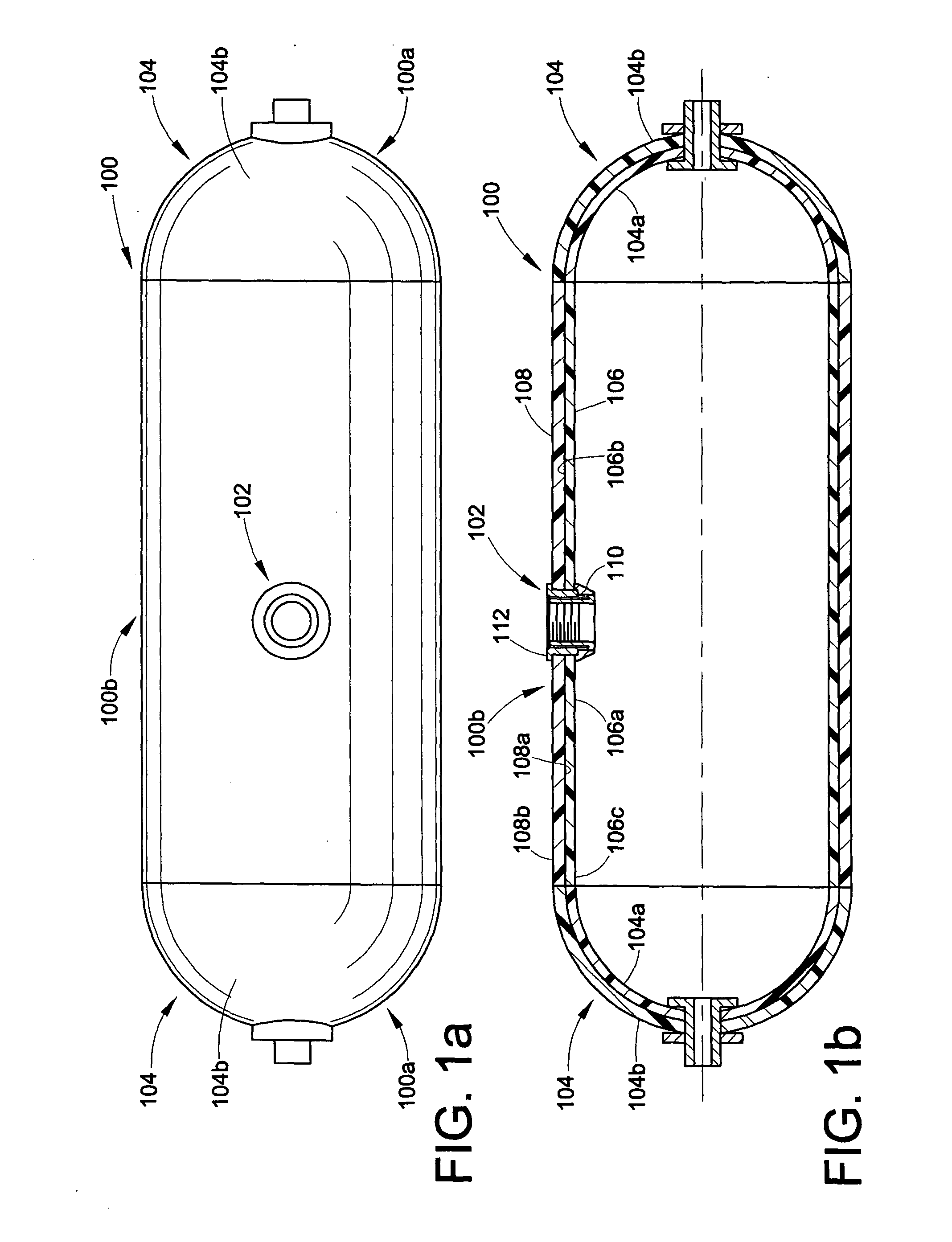

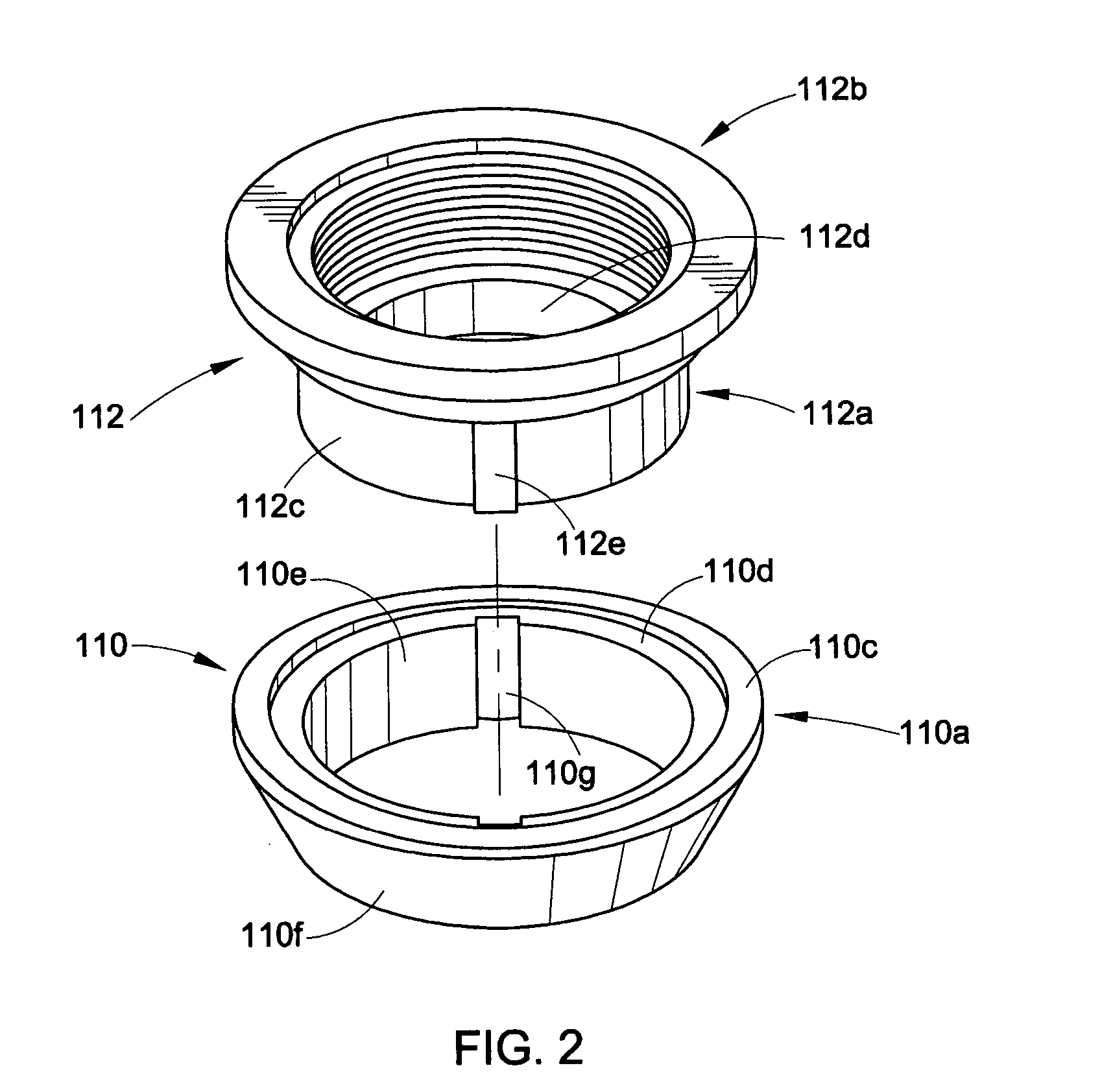

Filament-reinforced composite thermoplastic pressure vessel fitting assembly and method

ActiveUS20050006393A1Easy size adjustmentEasy to relocateCoatingsVessel mounting detailsPlastic materialsEngineering

A method of forming a fitting assembly in a filament-reinforced pressure vessel, and a pressure vessel having a fitting assembly secured therein. In the method, a first fitting portion is bonded to an inner surface of a thermoplastic liner in a fluid tight manner. A layer of commingled reinforcing filaments and plastic material is applied to an outer surface of the thermoplastic liner to form a vessel wall. A portion of the vessel wall adjacent to the opening bounded by the fluid-tight seal between the first fitting portion and the inner surface of the thermoplastic liner is removed. Then, a second fitting portion is bonded to the first fitting portion so as to define a port for access into the interior of the vessel.

Owner:ENPRESS

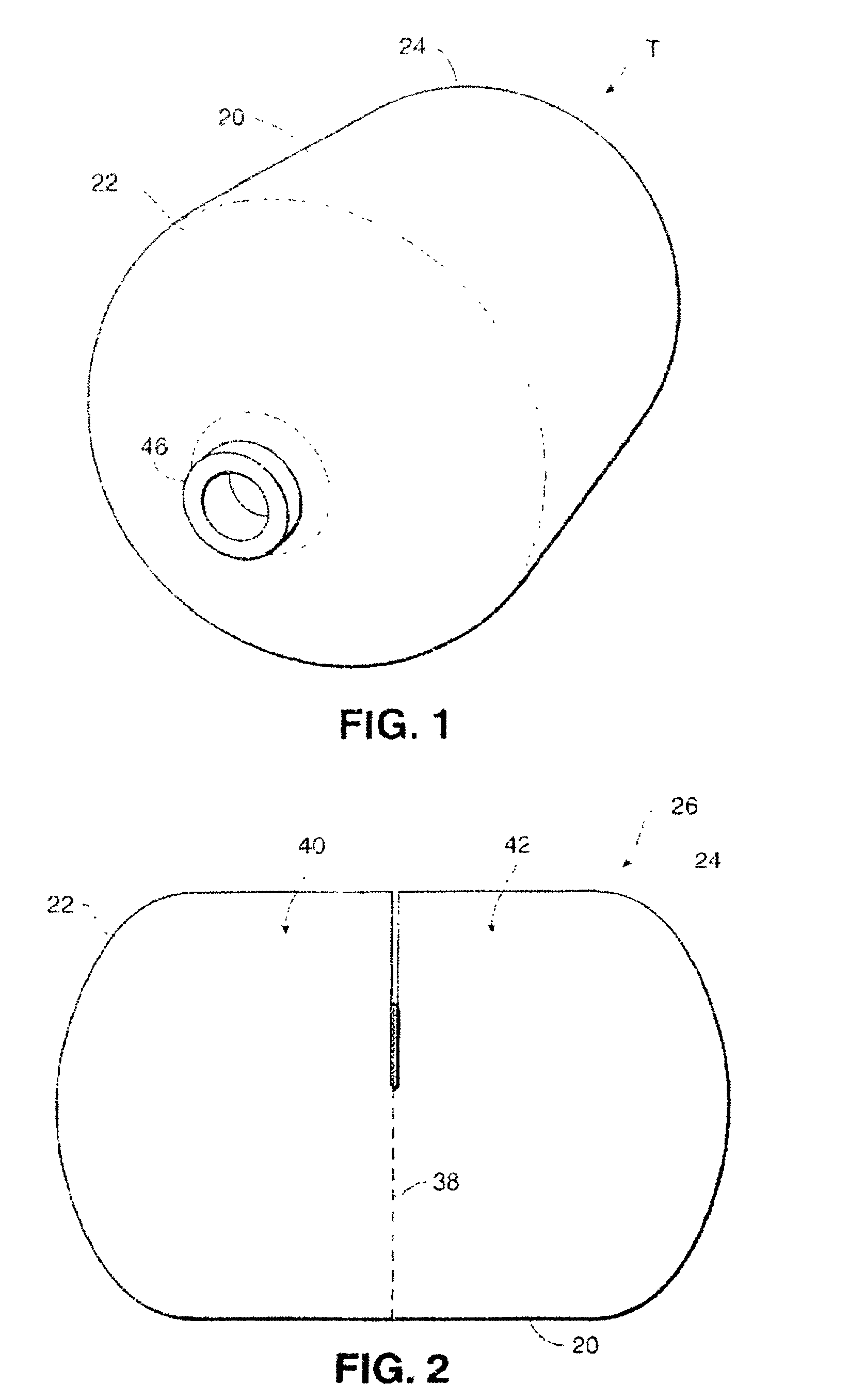

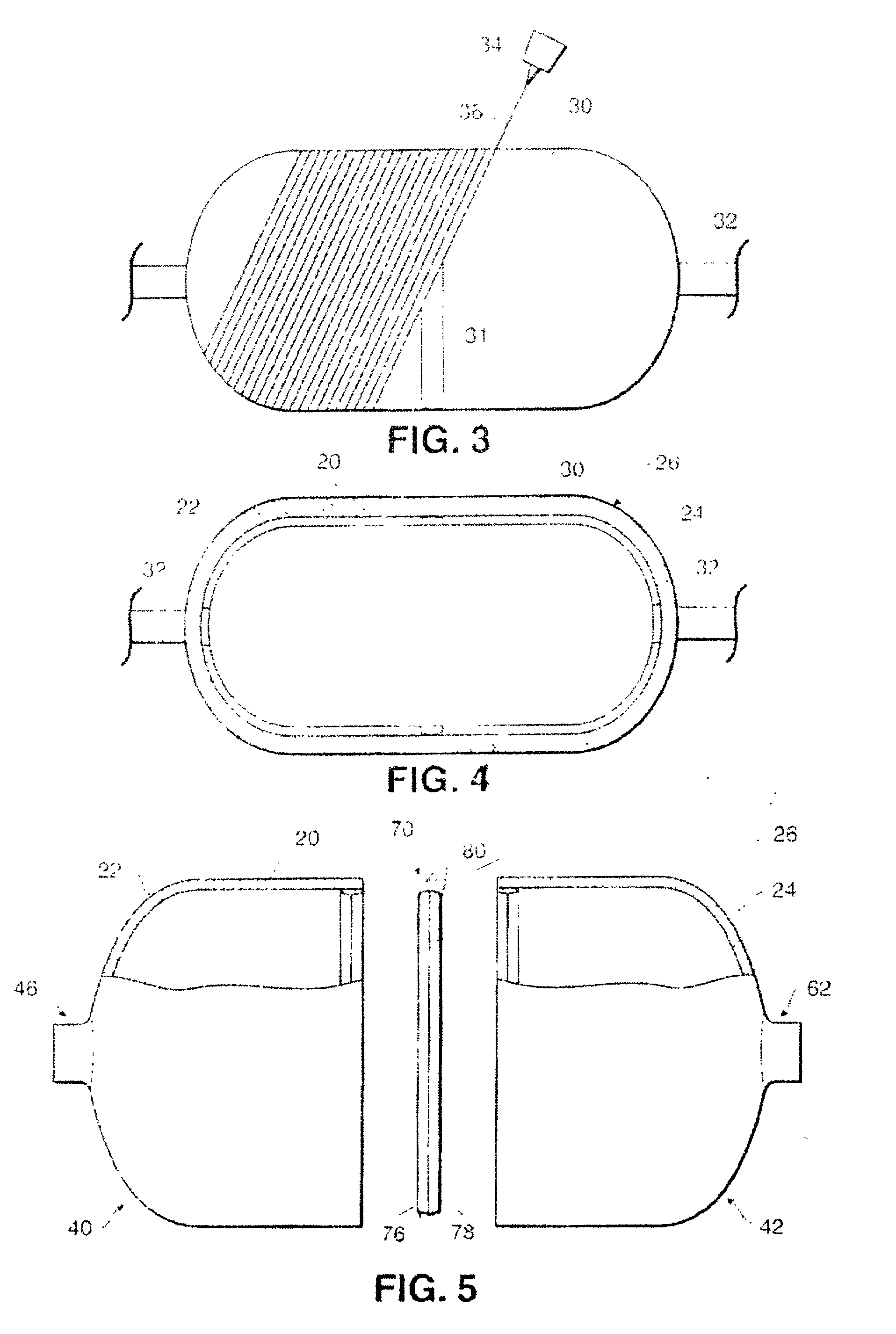

Lined pressure vessel and connector therefor

InactiveUS20060144843A1Easy to fixRelieve stressVessel mounting detailsVessel manufacturingEngineeringPressure vessel

A pressure vessel is disclosed which includes a lower metallic dome having a lower rim portion, and an upper metallic dome having an upper rim portion, a plastic liner disposed within the upper and lower metallic domes, a metallic band disposed between the plastic liner and the upper and lower metallic domes proximate the respective rim portions thereof, and an insulating material disposed between the metallic band and the plastic liner, the metallic band and insulating material protecting the plastic liner from elevated temperatures when the upper and lower rim portions of the metallic domes are welded together. A method of fabricating the pressure vessel and a connector for assembling the pressure vessel are also disclosed.

Owner:AMTROL LICENSING INC

Hydrogen handling or dispensing system

InactiveUS20060174965A1Cheap manufacturingQuantity minimizationLiquid fillingFuel cell auxillariesHydrogenPetrol station

Owner:ARIZONA PUBLIC SERVICE

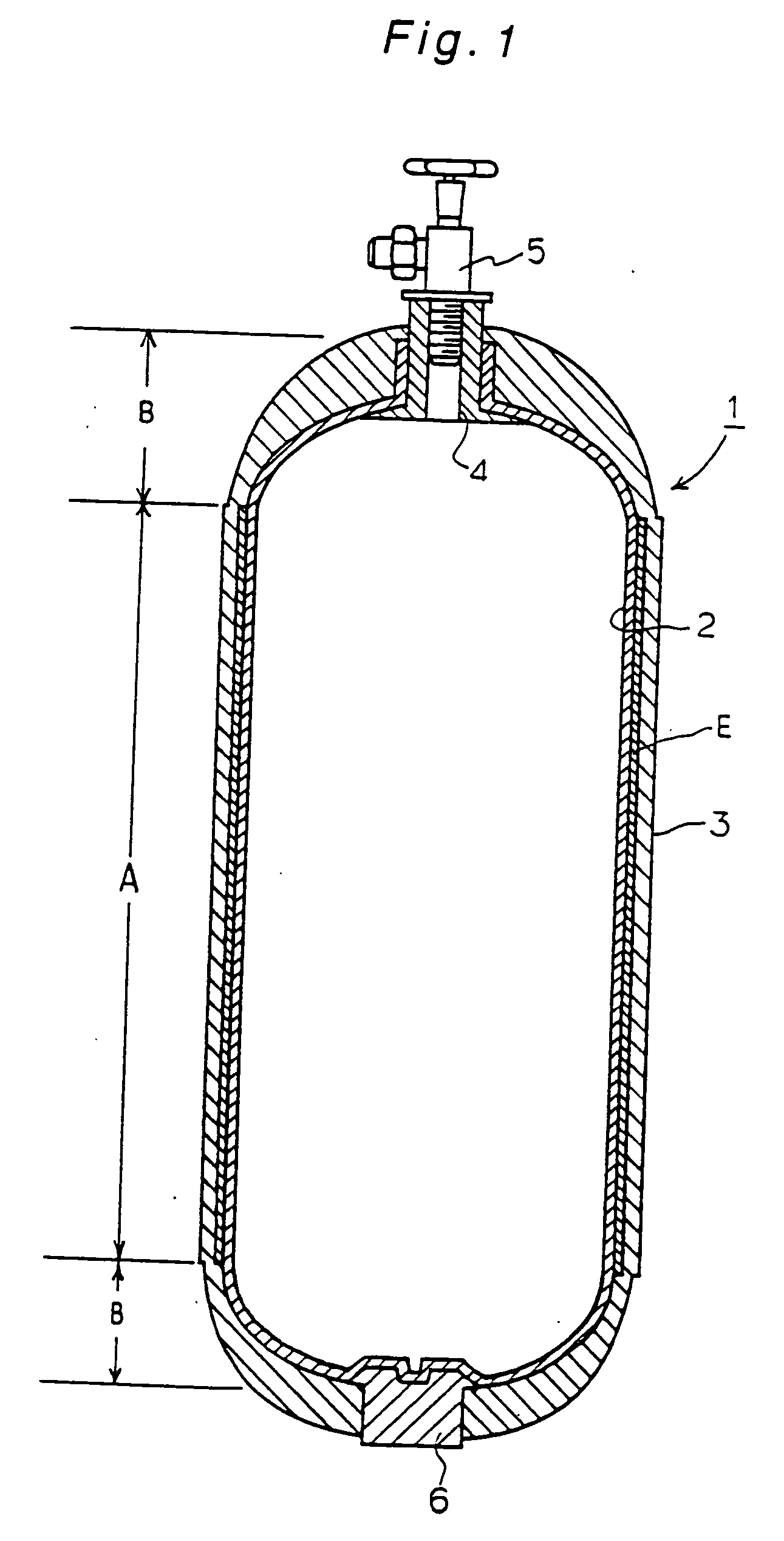

Pressure vessel and process for producing the same

InactiveUS7032769B2Light weightIncrease pressureVessel mounting detailsVessel manufacturingInternal pressureEngineering

The pressure vessel of the present invention comprises an inner shell capable of serving as a gas barrier and a pressure resistant outer shell provided to cover the inner shell, said outer shell being made of an FRP comprising reinforcing fibers and a resin and is 35 GPa or more in tensile modulus and 1.5% or more in tensile breaking strain. The present invention can provide a pressure vessel not only light in weight,.but also excellent in retaining its internal pressure against repetitive impacts and also excellent in reliability.The process for producing a pressure vessel of the present invention comprises the step of forming a pressure resistant outer shell made of an FRP comprising reinforcing fibers and a resin and is 35 GPa or more in tensile modulus and 1.5% or more in tensile breaking strain, around an inner shell capable of serving as a gas barrier, by a filament winding method or a tape winding method. The present invention can produce a pressure vessel excellent in retaining its internal pressure, excellent in reliability, and light in weight at a low cost.

Owner:TORAY IND INC

High-pressure tank, method of manufacturing high-pressure tank, and manufacturing equipment of high-pressure tank

InactiveUS20100075200A1Hindering permeation of gasSimple processConfectioneryFuel cell auxillariesHigh pressurePetroleum engineering

A high-pressure tank including: a cap; a liner; and a reinforced layer that is provided on the liner. The liner includes a gas barrier layer.

Owner:TOYOTA JIDOSHA KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com