Patents

Literature

113results about How to "Suppress position deviation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

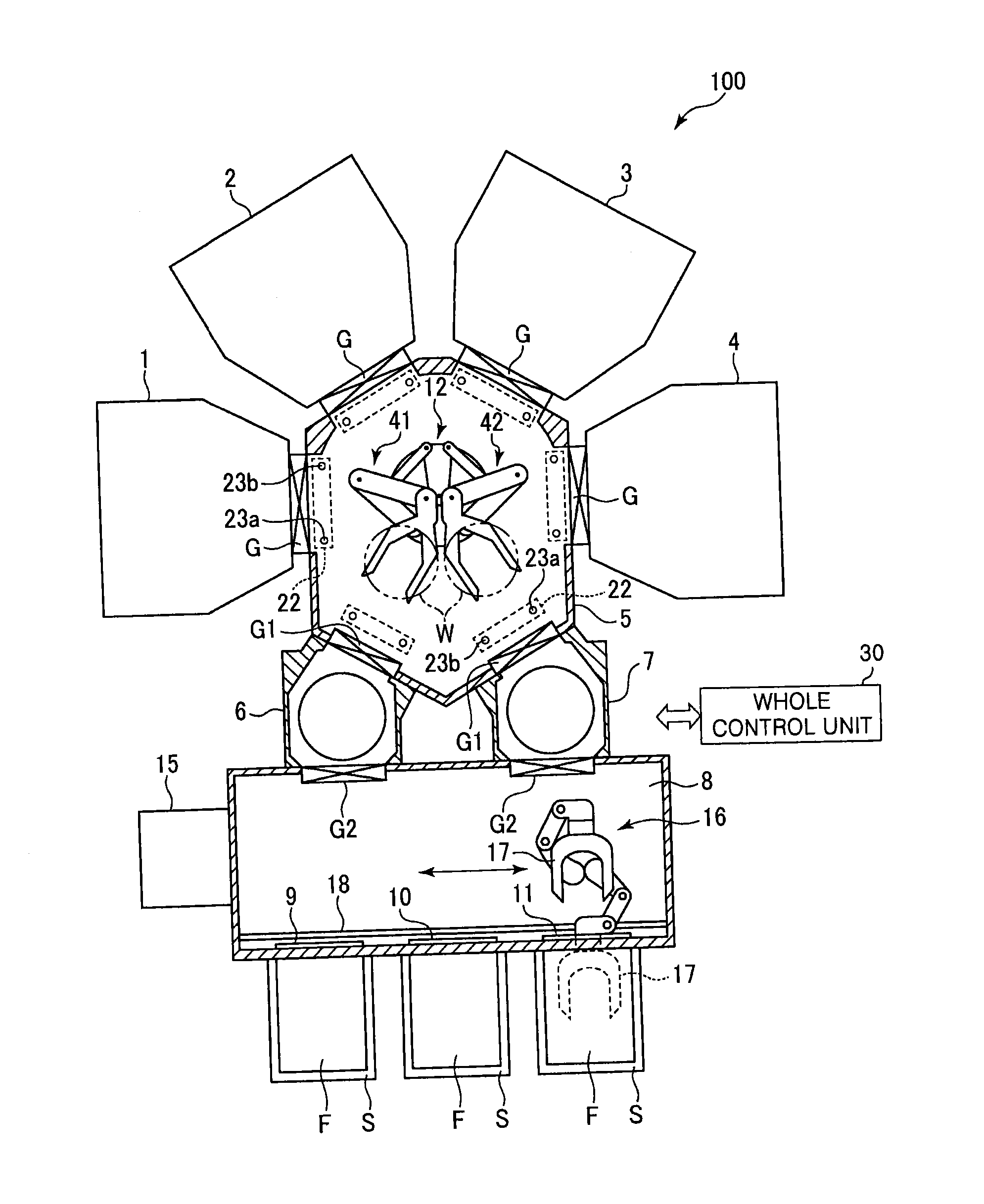

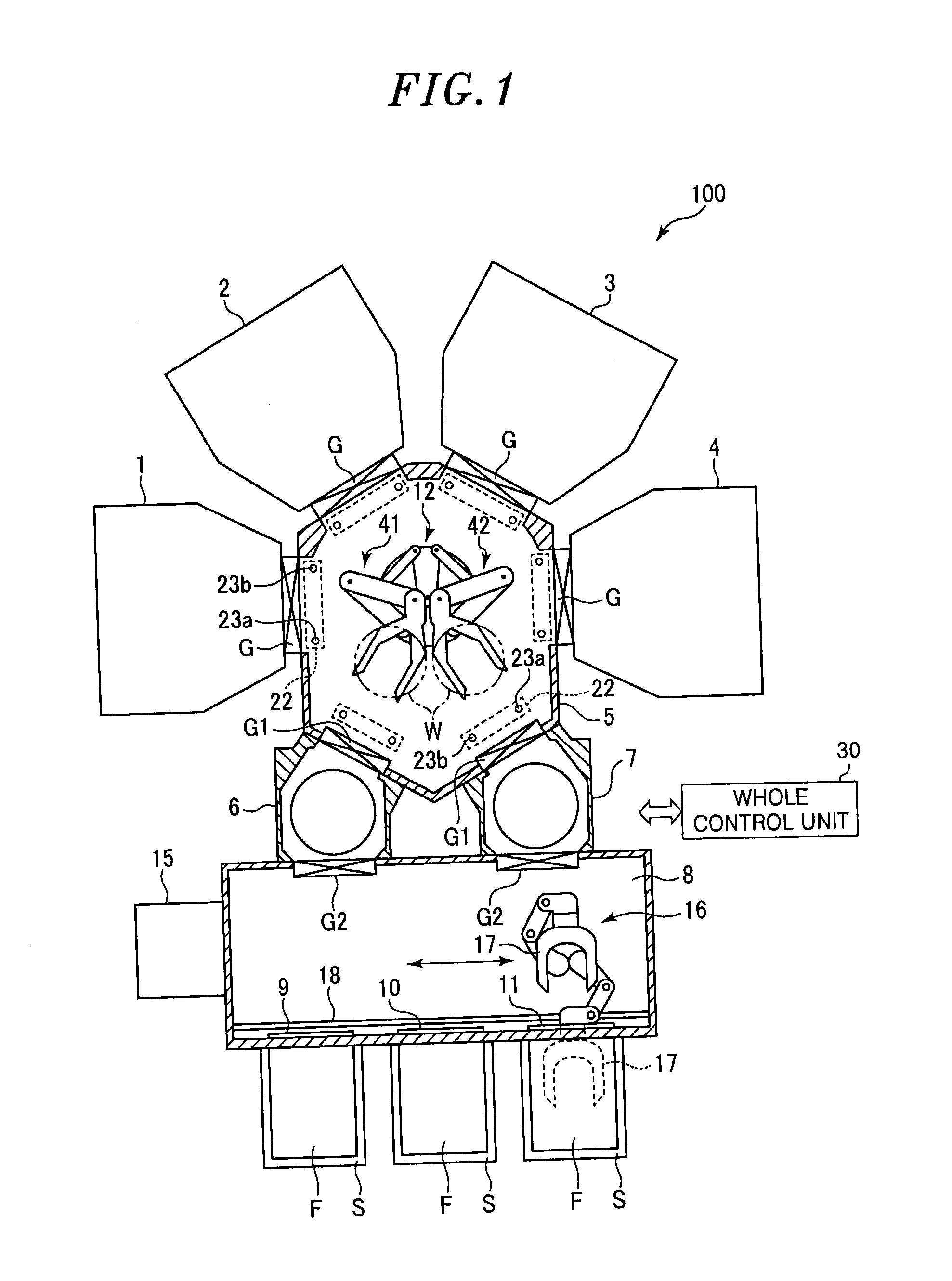

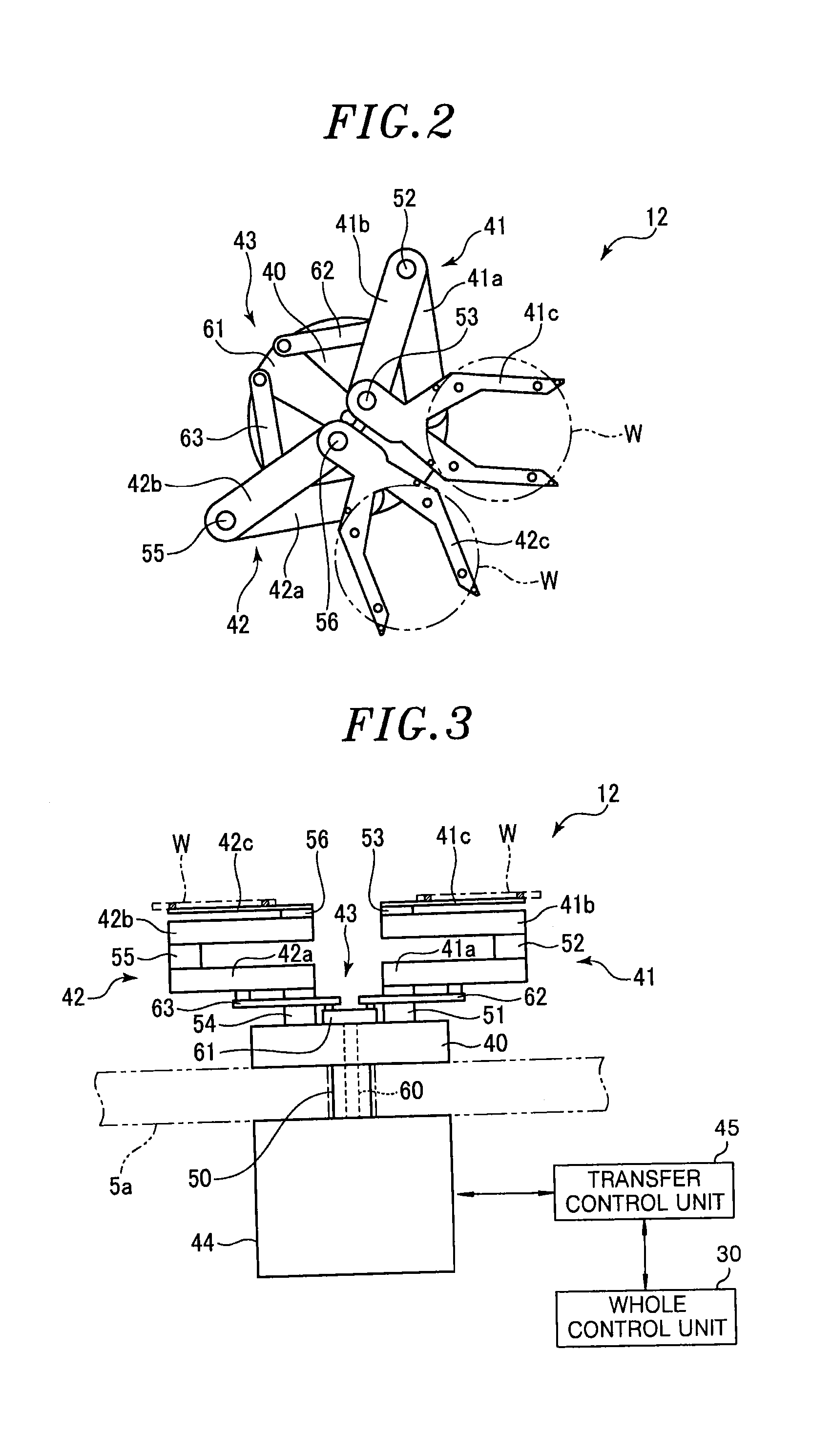

Substrate transfer device and substrate processing system

InactiveUS20130180448A1Suppress position deviationHigh positioning accuracyLiquid surface applicatorsSemiconductor/solid-state device manufacturingRoom temperatureProcessing element

A substrate transfer device includes a pick which has positioning pins to position a substrate and holds a positioned substrate; a drive unit which drives the pick such that the substrate is loaded / unloaded to / from a vacuum processing unit by using a pick; and a transfer control unit which controls a transfer operation of the substrate using the pick. The transfer control unit obtains in advance information on a reference position of the substrate at room temperature when the substrate is loaded into the vacuum processing unit, calculates a positional deviation from the reference position of the substrate when the substrate is loaded into the vacuum processing unit in actual processing, and controls a drive unit such that the substrate is loaded into the vacuum processing unit by correcting the positional deviation.

Owner:TOKYO ELECTRON LTD

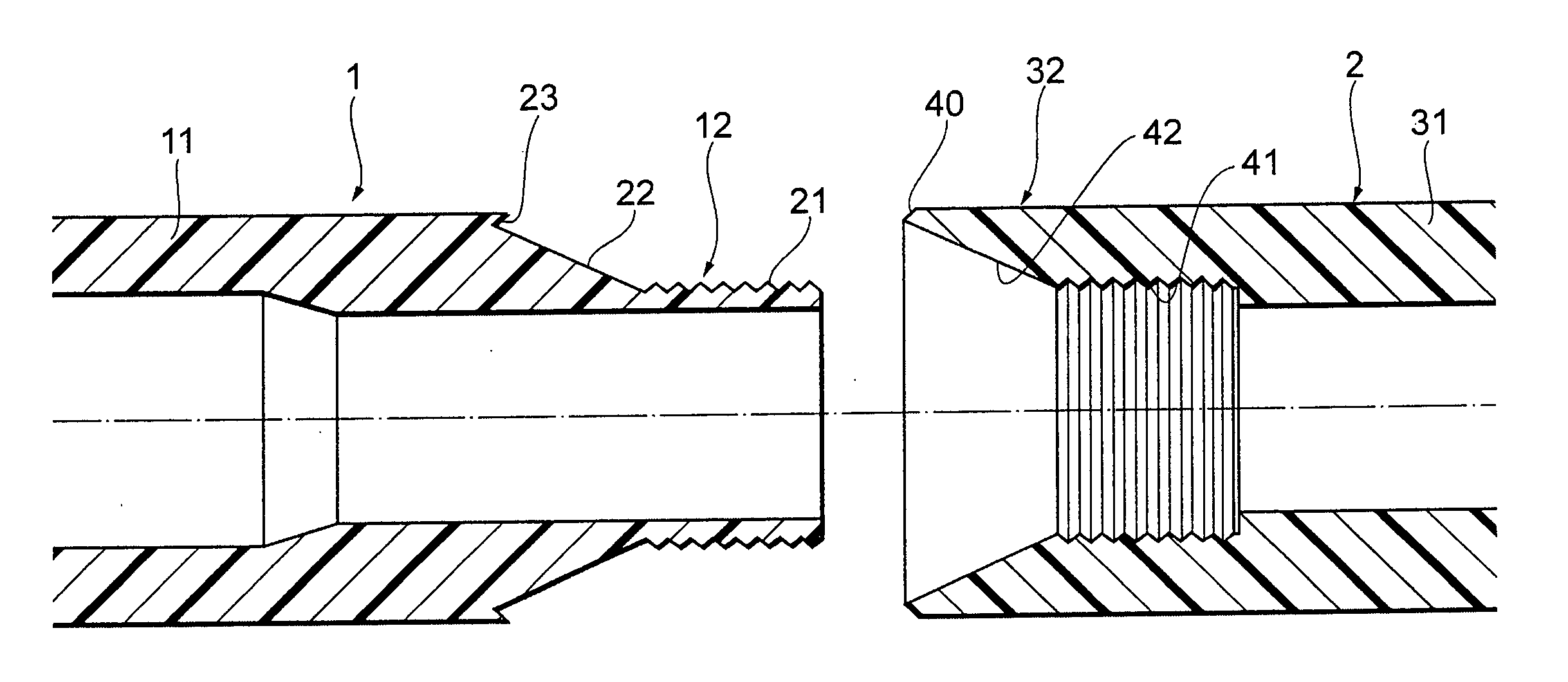

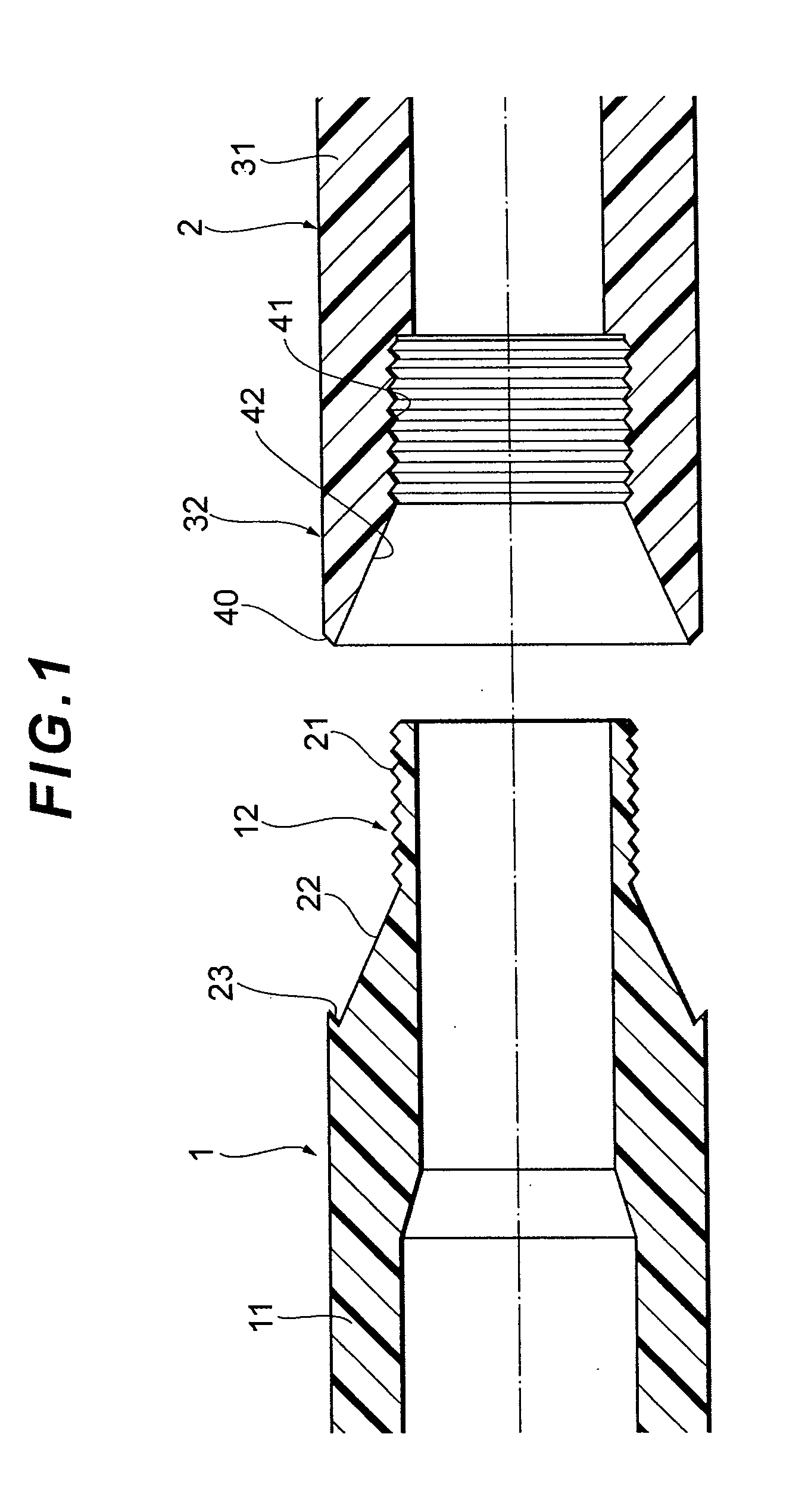

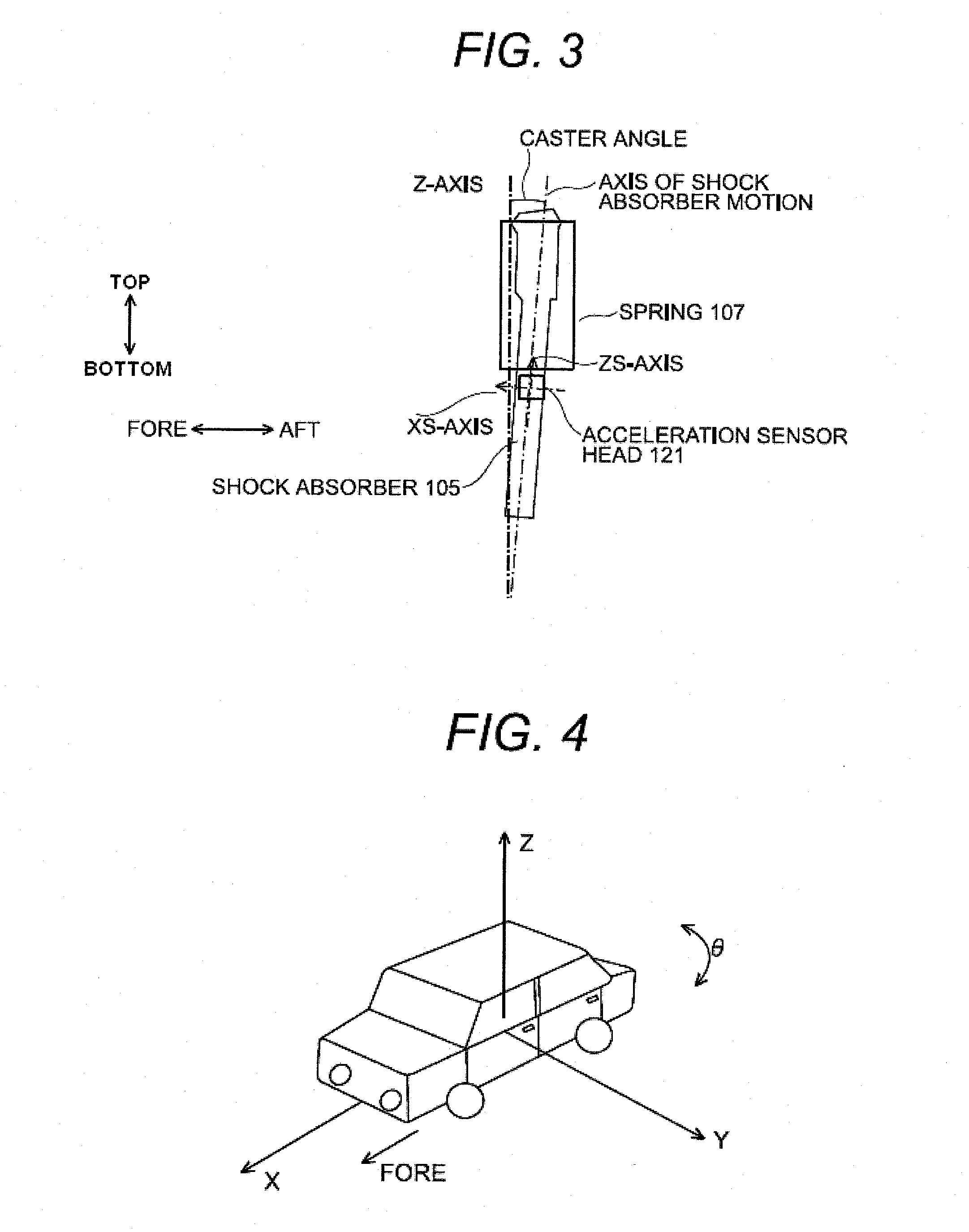

Structure and Method for Bonding Two Members, Gas Container and Method for Manufacturing Such Gas Container

InactiveUS20080187697A1Suppress position deviationPositional deviationGas handling applicationsThin material handlingEngineeringMechanical engineering

An object is to provide a bonded structure of two members, a bonding method of two members in which end portions of a pair of resin members can appropriately be bonded to each other by laser welding while easily suppressing a positional deviation between the end portions of the resin members, a gas container and a manufacturing method of the gas container. In the bonded structure of two members, an external thread provided at a substantially cylindrical end portion of a resin member is screwed into an internal thread provided at a substantially cylindrical end portion of a resin member and irradiated with laser to bond the end portions of the resin members to each other by the laser welding. In the gas container, this bonded structure is applied to a resin liner of the gas container, and liner constituting members are screwed and bonded by the laser welding.

Owner:TOYOTA JIDOSHA KK

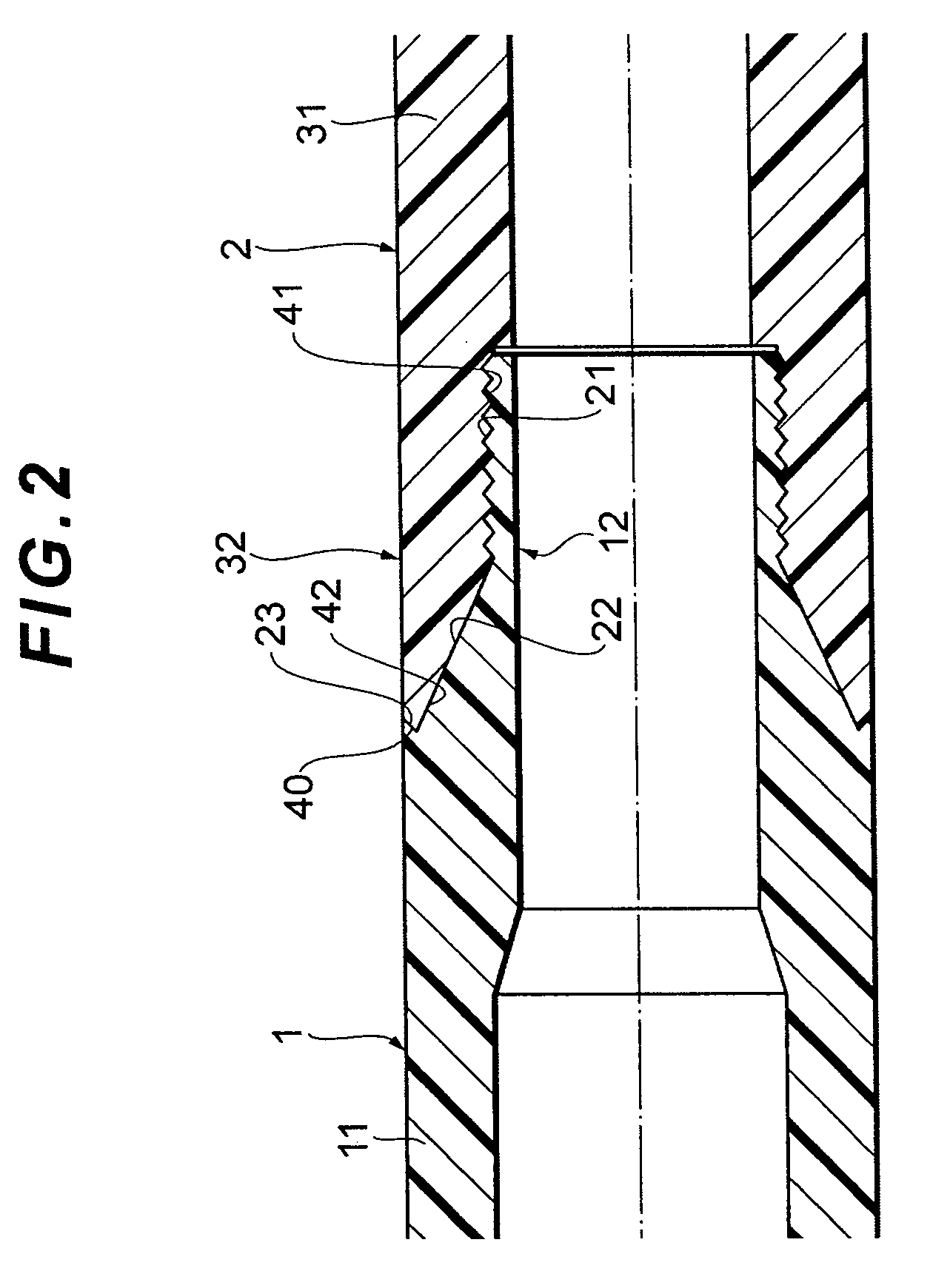

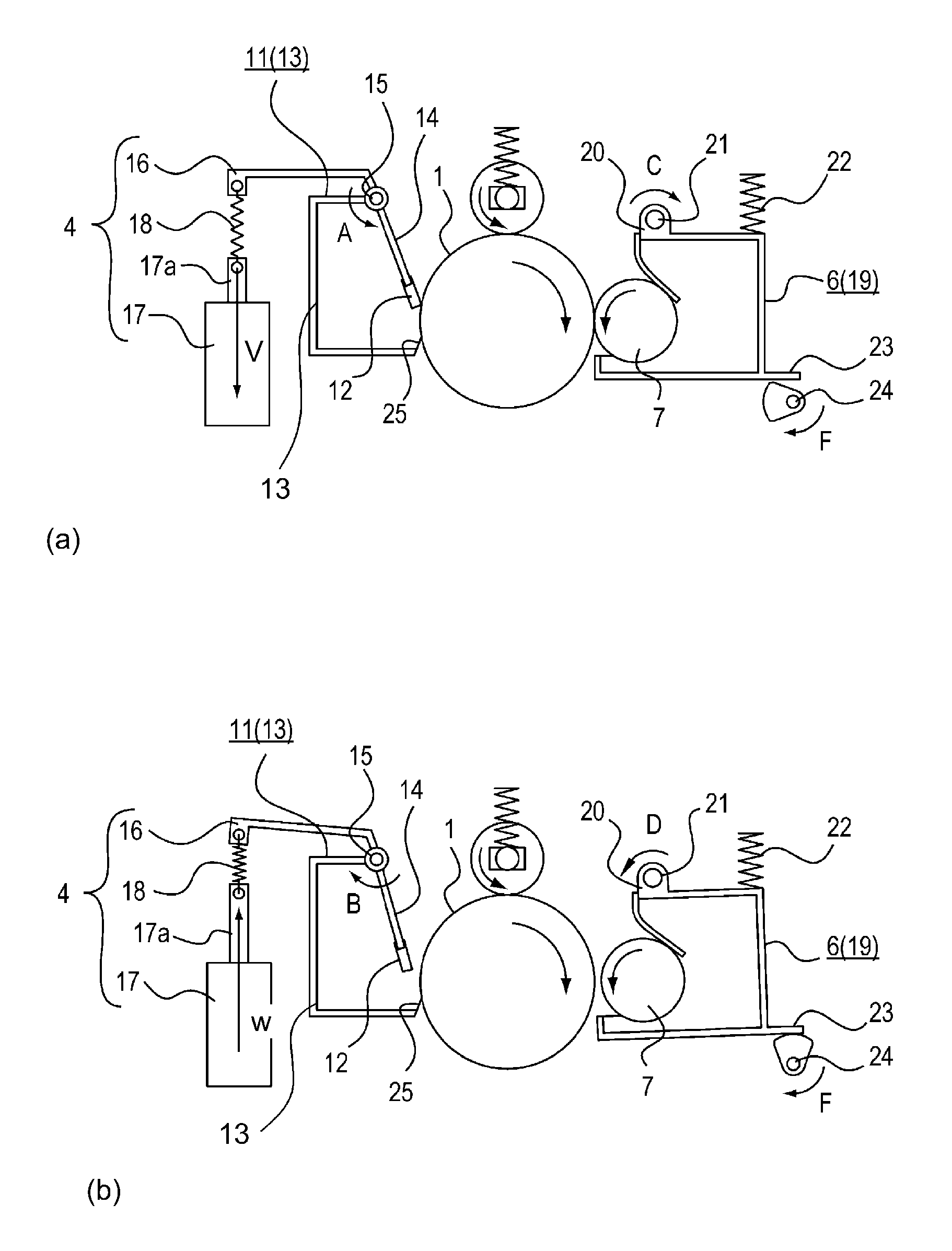

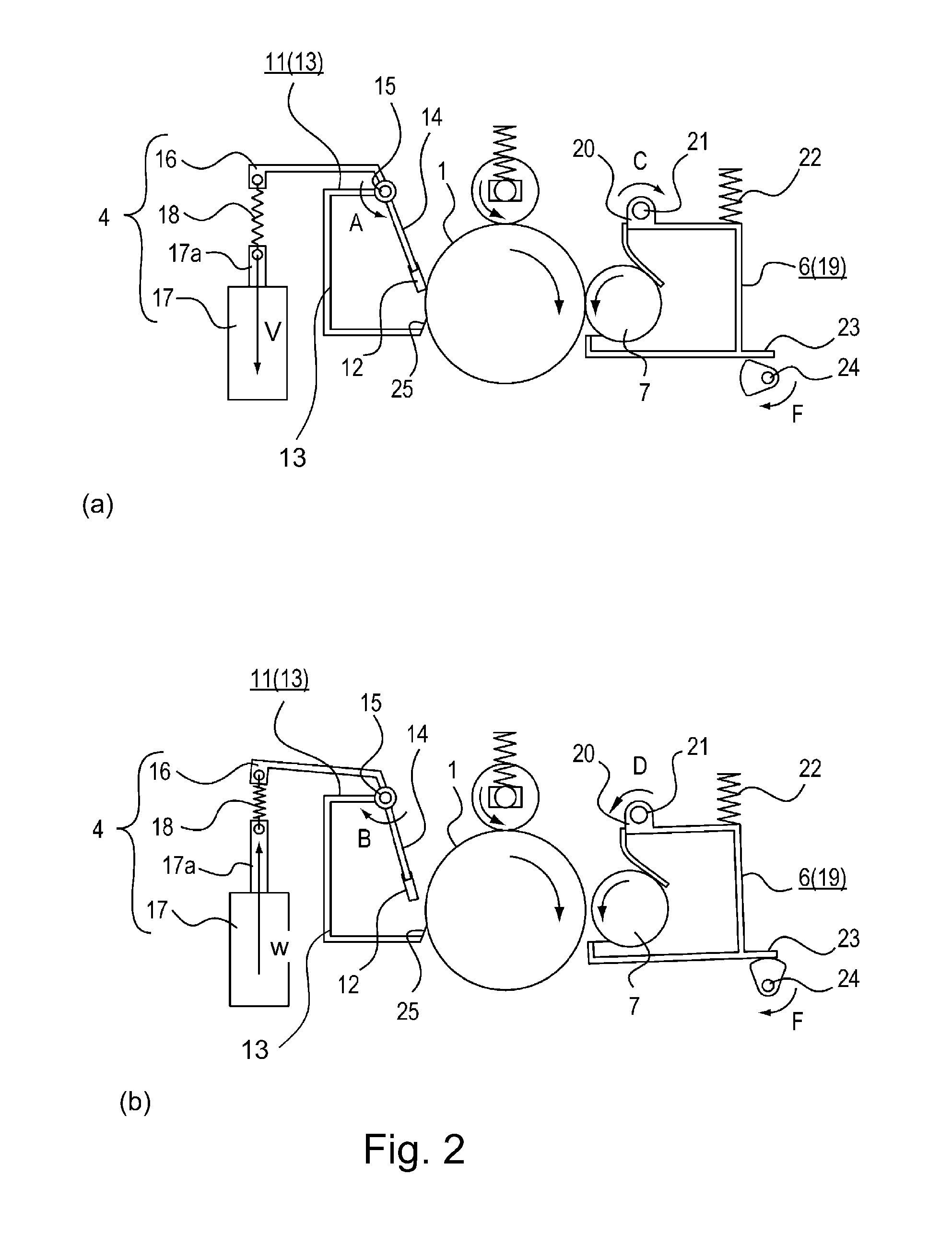

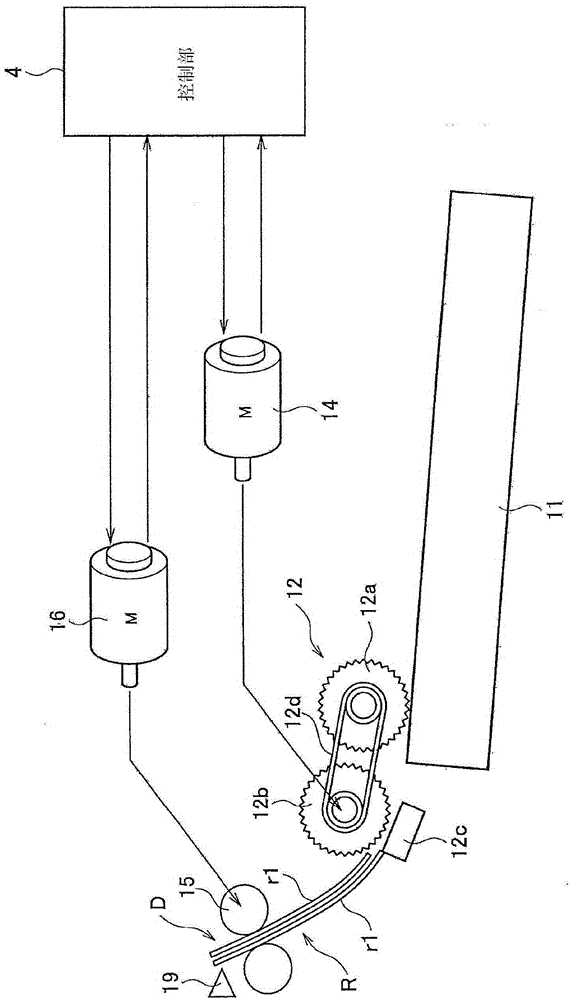

Image forming apparatus

InactiveUS20120008974A1Suppress position deviationImproper transferElectrographic process apparatusLatent imageImage formation

An image forming apparatus includes a rotatable image bearing member; a cleaning blade for removing toner in contact with the image bearing member; a load adjusting device for adjusting a contact load between the cleaning blade and the image bearing member; a developing roller for developing an electrostatic latent image on the image bearing member; a developing roller moving device for moving the developing roller between a developing position in which the electrostatic latent image is to be developed and a non-developing position retracted from the developing position; and a control device for effecting control such that the developing roller is moved from the developing position to the non-developing position by the developing roller moving device during rotation of the image bearing member and after an area on the image bearing member opposed to the developing roller at the time when the developing roller is started to be moved from the developing position to the non-developing position passes through a contact area between the cleaning blade and the image bearing member, the contact load is made smaller than that during development by the load adjusting device and then the rotation of the image bearing member is stopped.

Owner:CANON KK

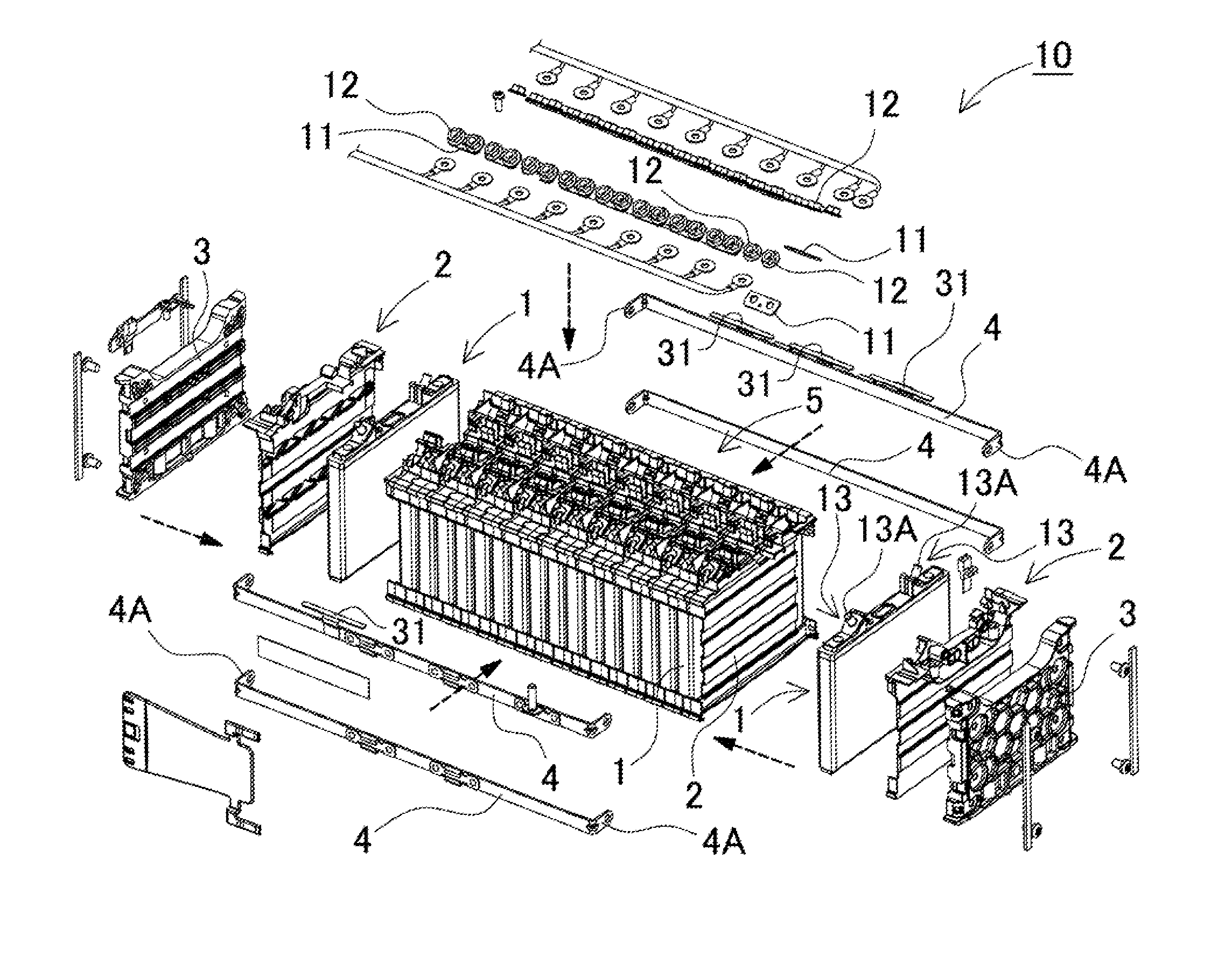

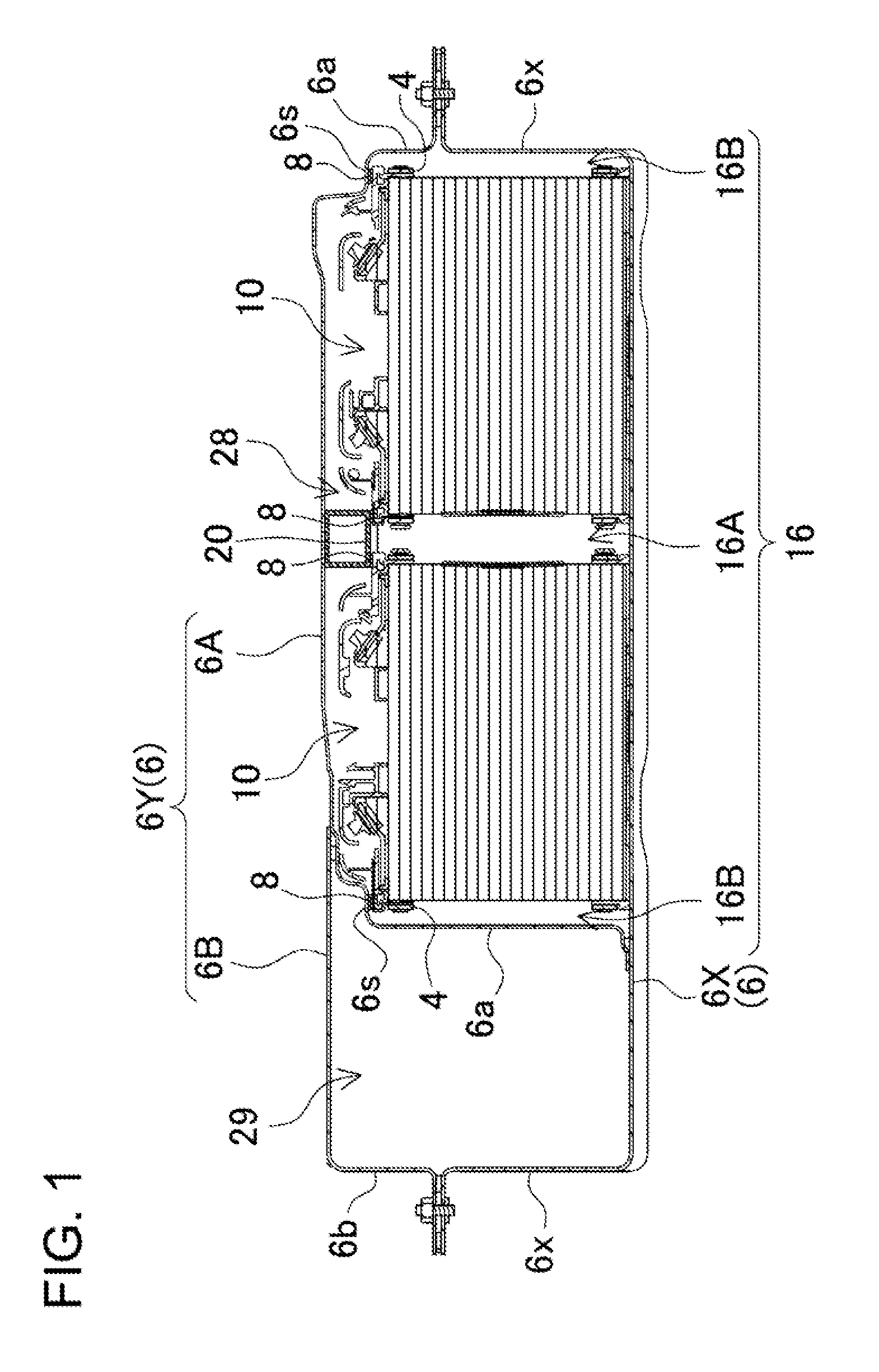

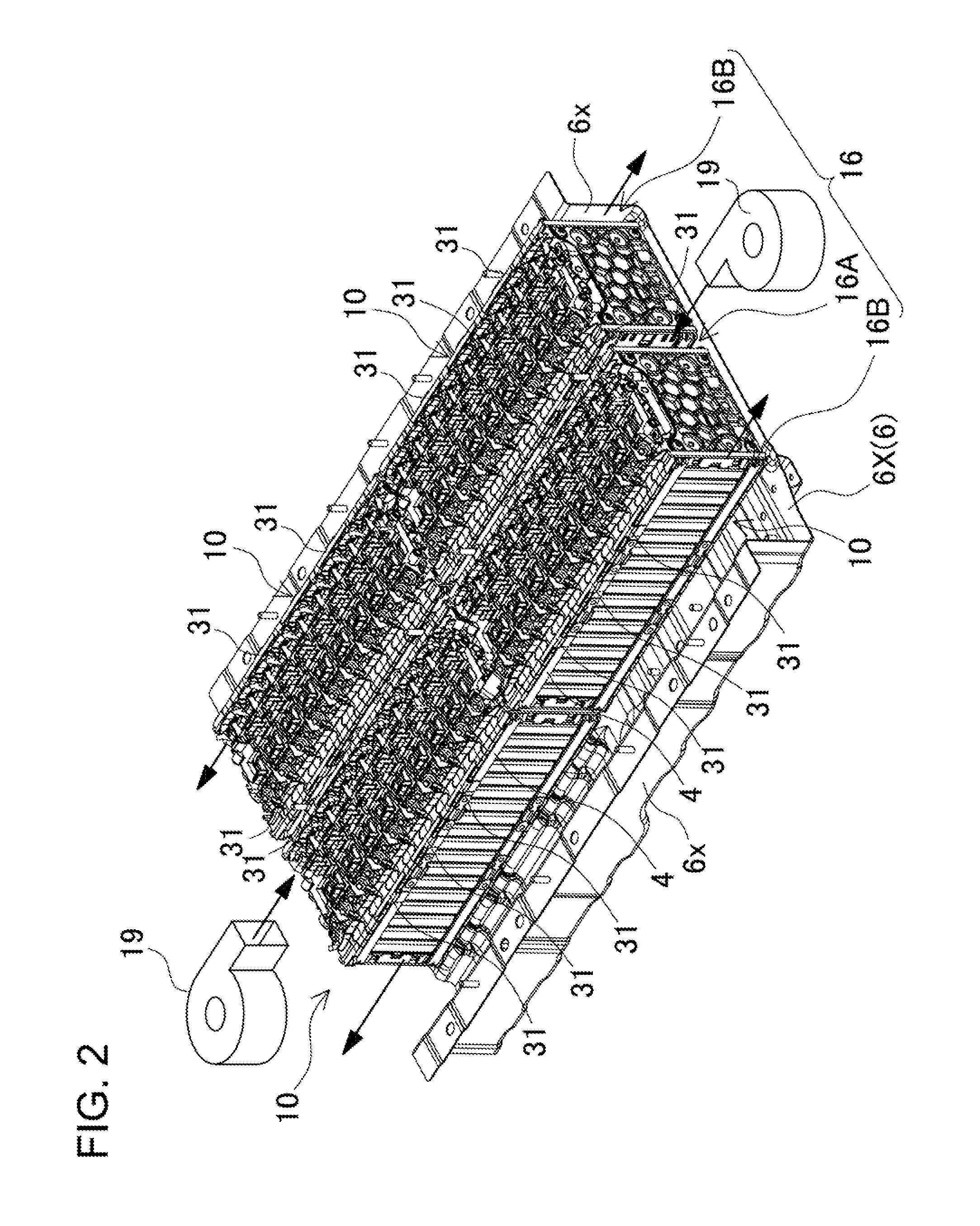

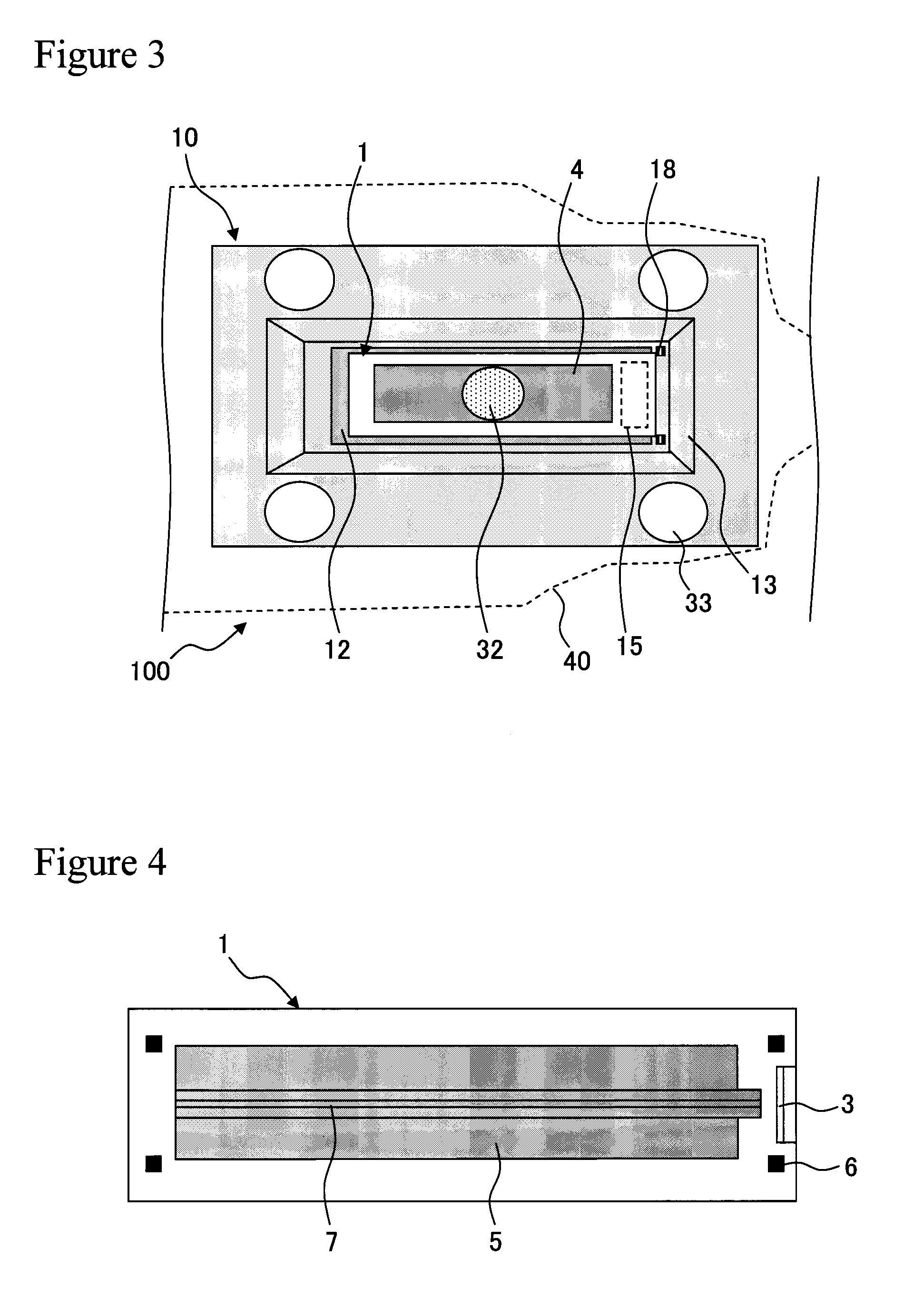

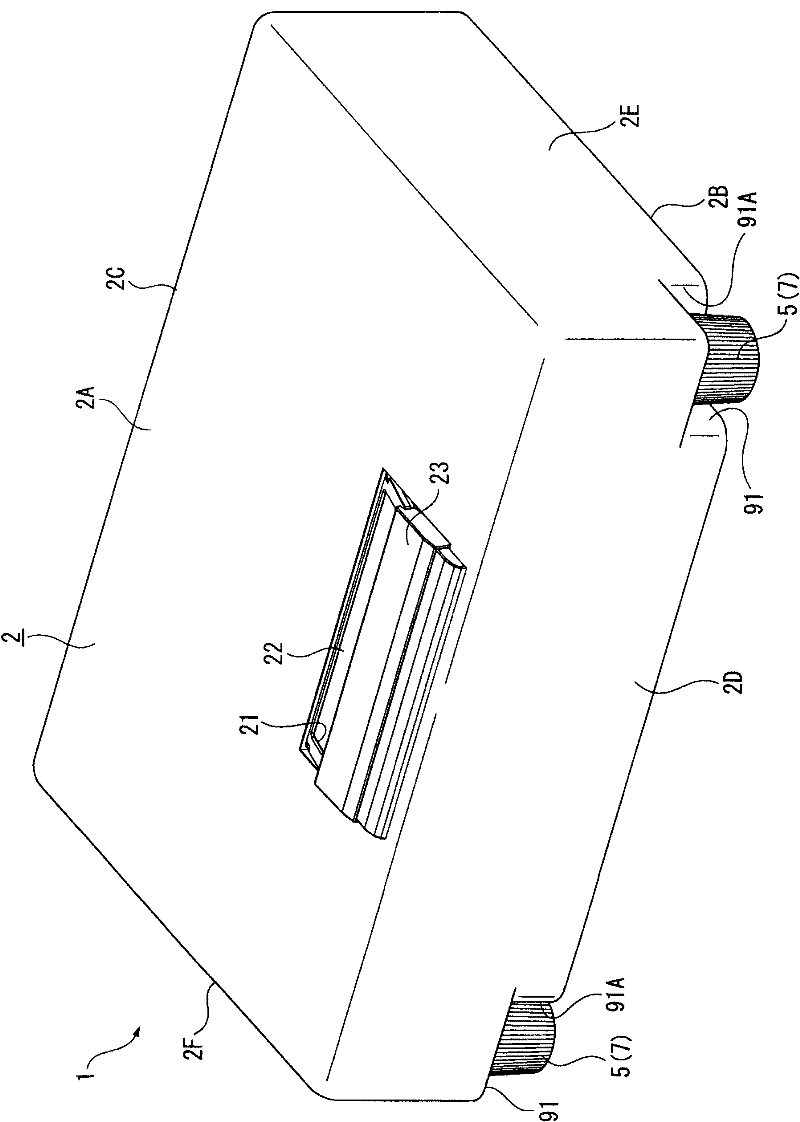

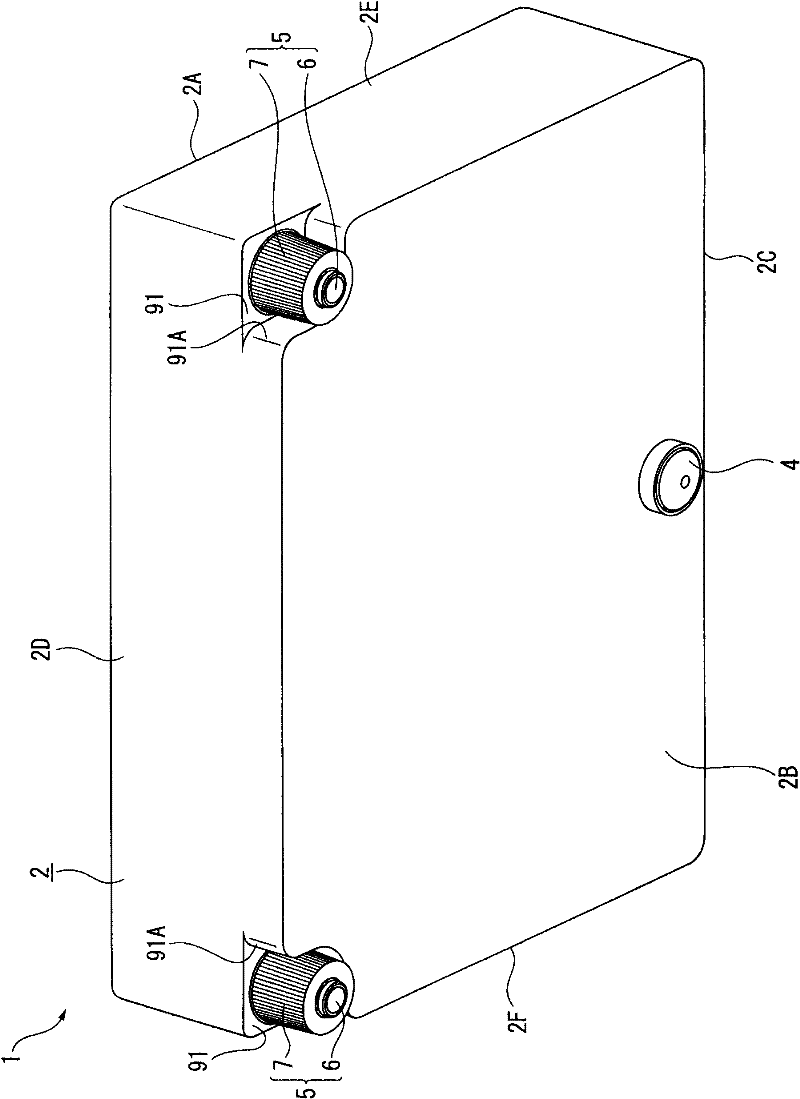

Battery pack for suppressing deviation of central battery cell and vehicle including the same

InactiveUS20120141855A1Suppress flexureStably holdCell temperature controlCell component detailsEngineeringElectrical and Electronics engineering

A battery pack device includes a plurality of battery cells 1, a bind bar 4, and a regulation member 31. The plurality of battery cells 1 has a rectangular box exterior shape. The bind bar 4 couples the plurality of battery cells 1 to each other with the battery cells 1 being arranged side by side. When the battery pack 10 is secured onto a horizontal surface, the regulation member 31 regulates upward deviation of at least one of the battery cells 1, which is located in a central part of the battery pack in the side-by-side arrangement direction of the battery cells 1.

Owner:SANYO ELECTRIC CO LTD

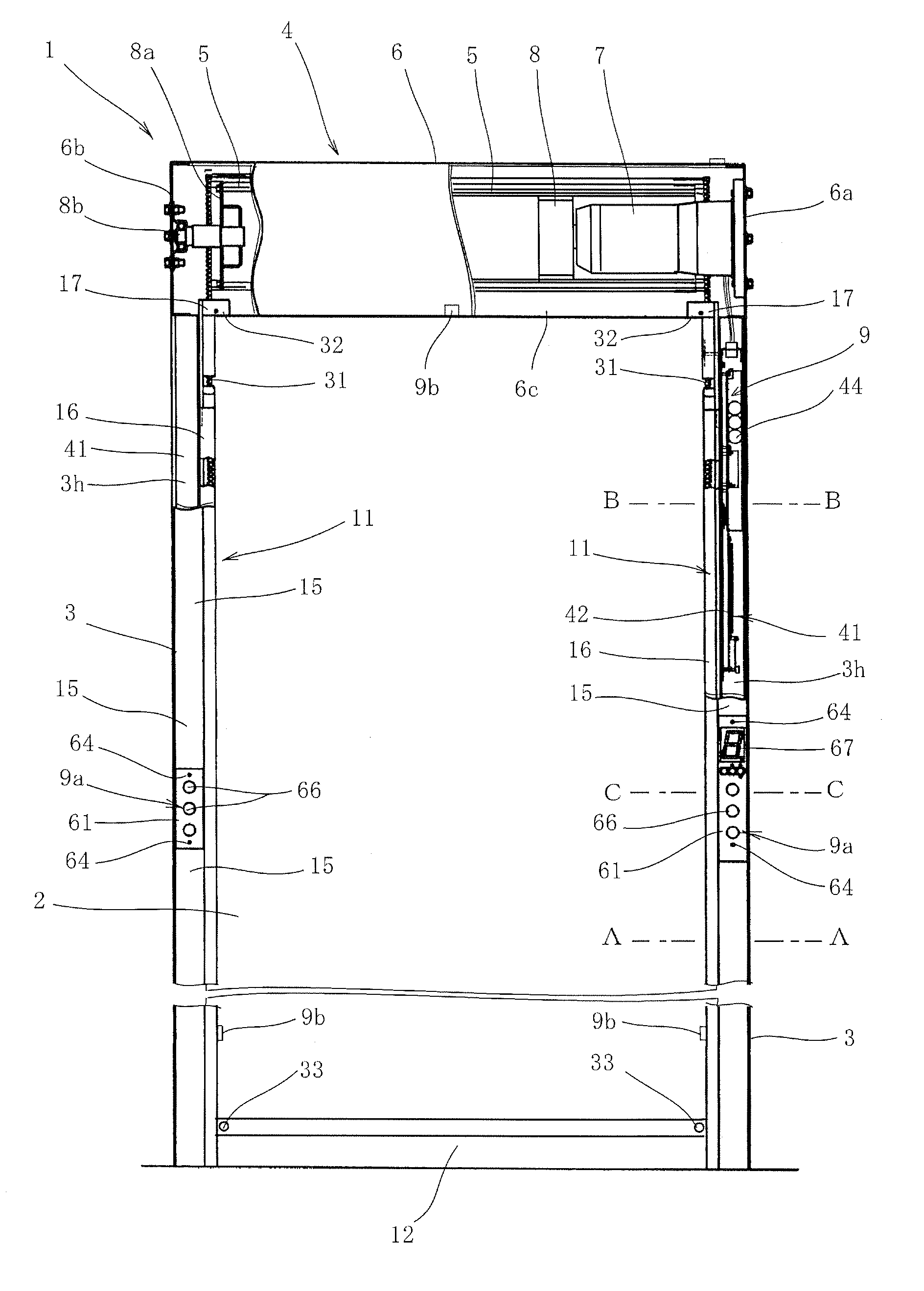

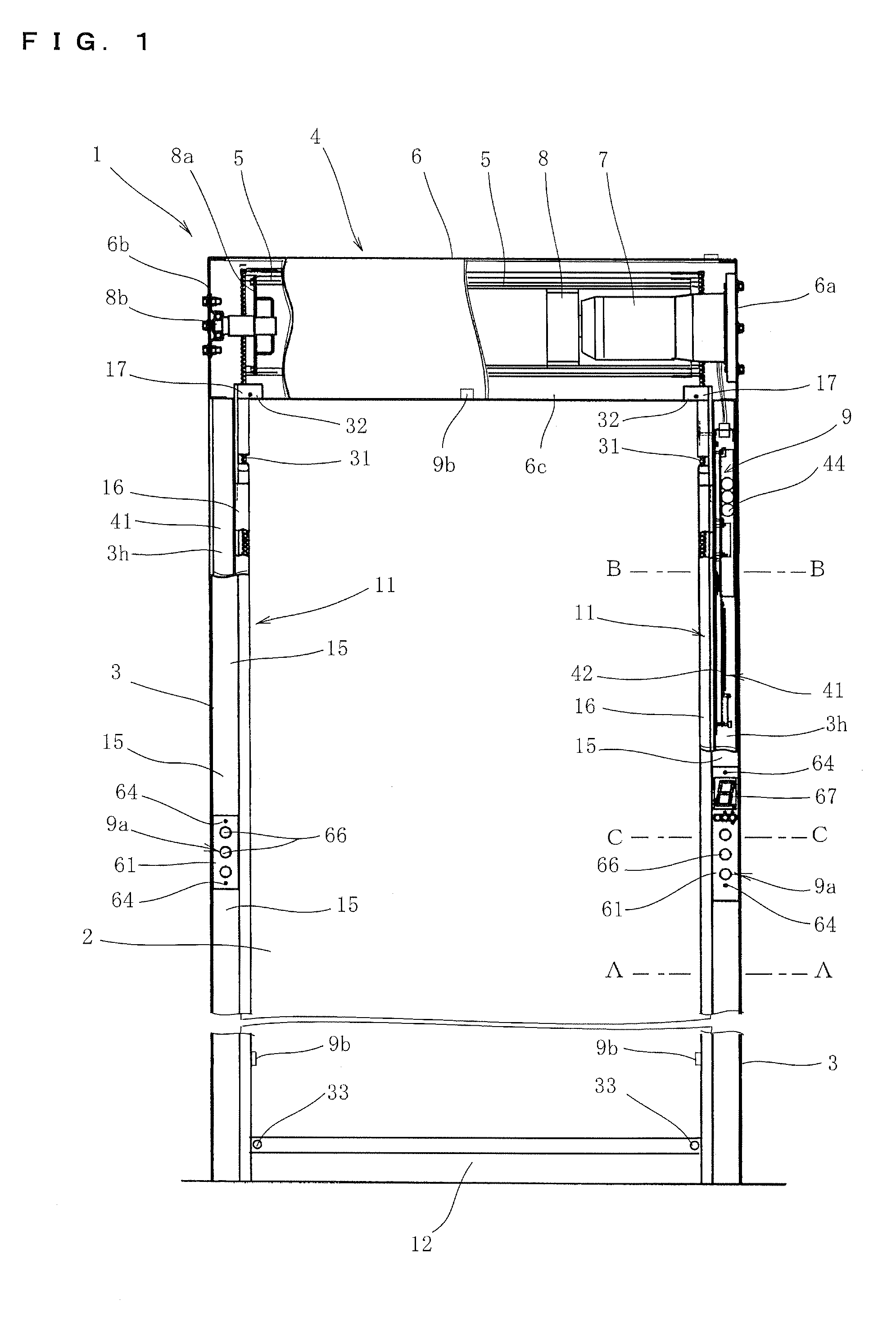

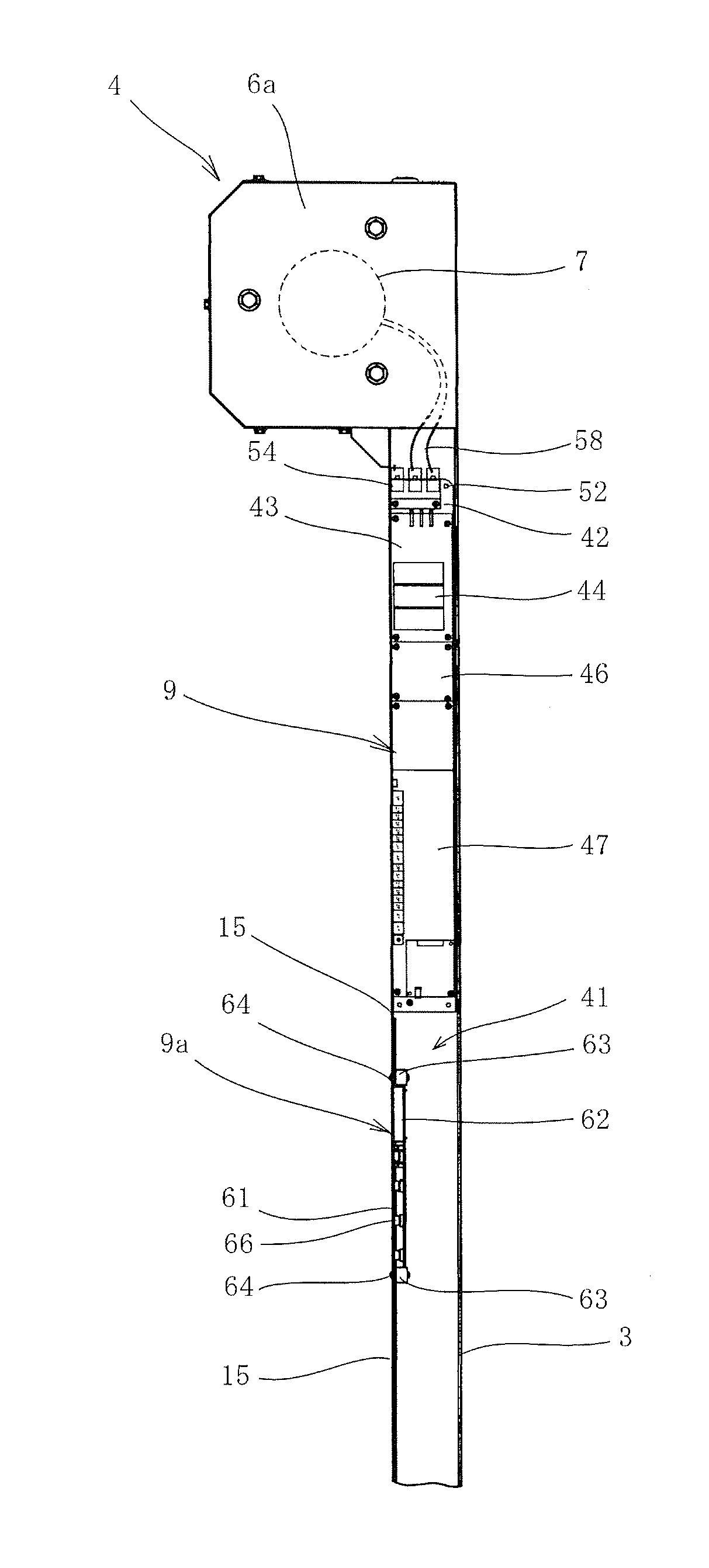

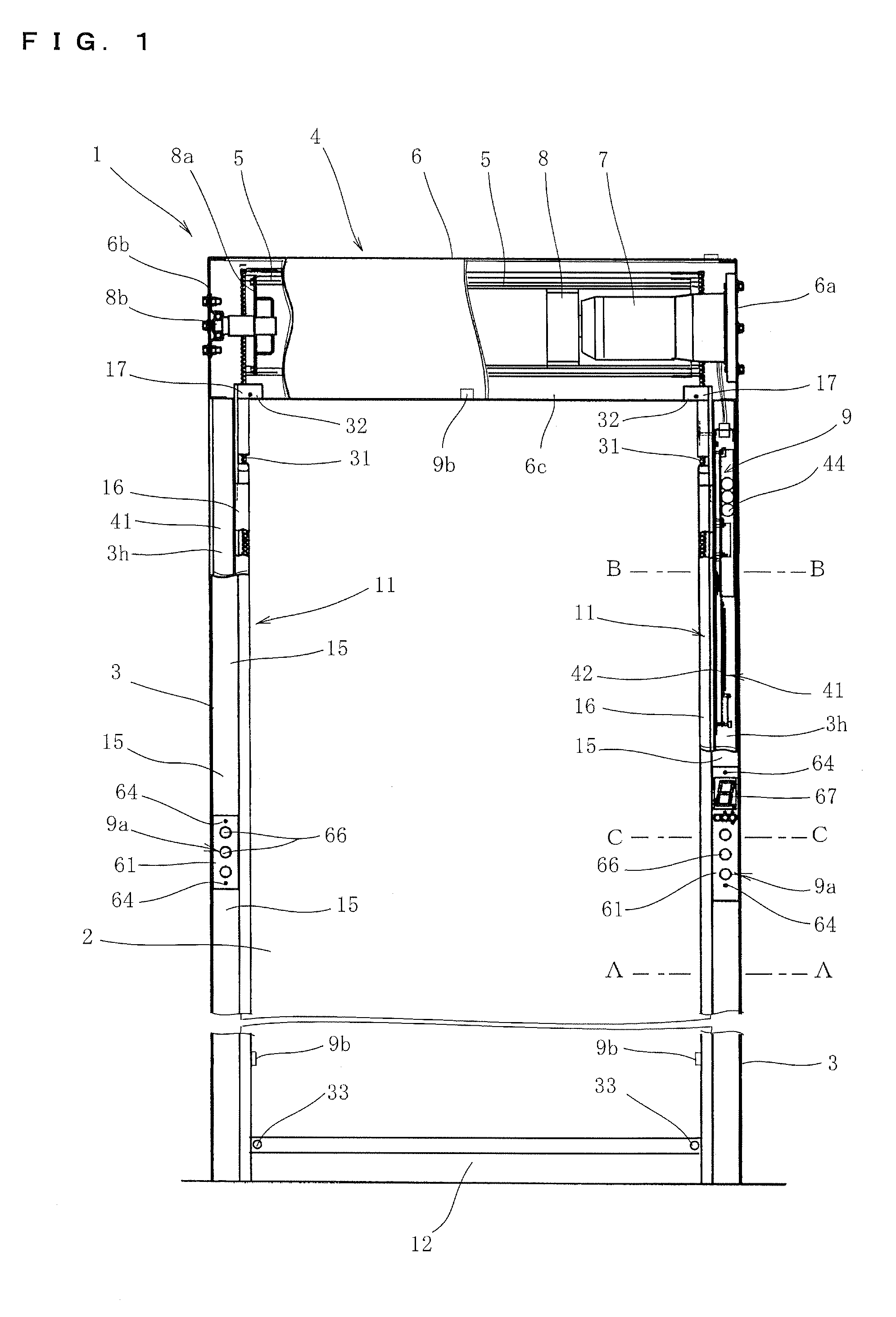

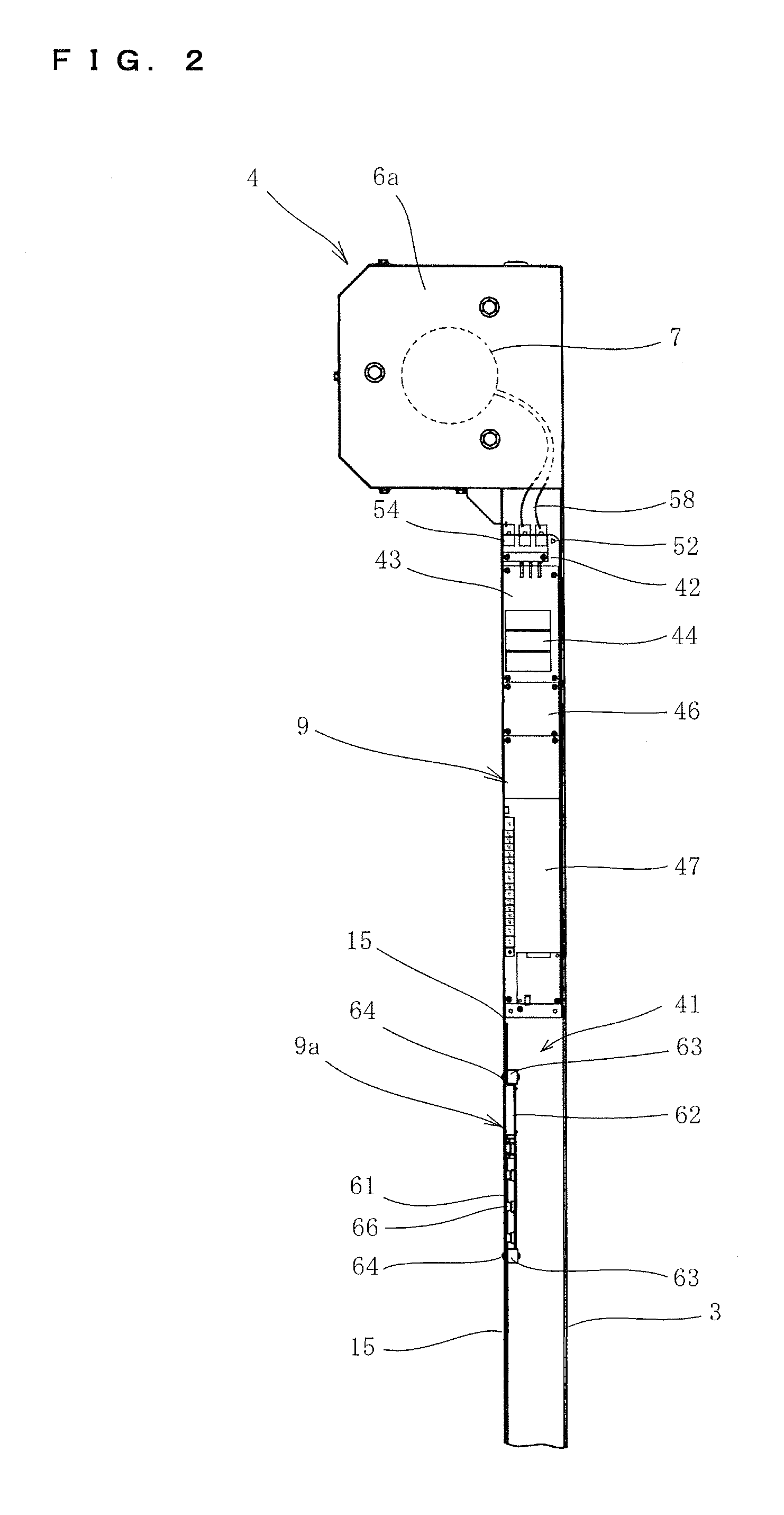

Sheet shutter

ActiveUS8602081B2Reduce impactReduce wearScreensShutters/ movable grillesEngineeringMechanical engineering

Owner:KOMATSU ELECTRIC SANGYO

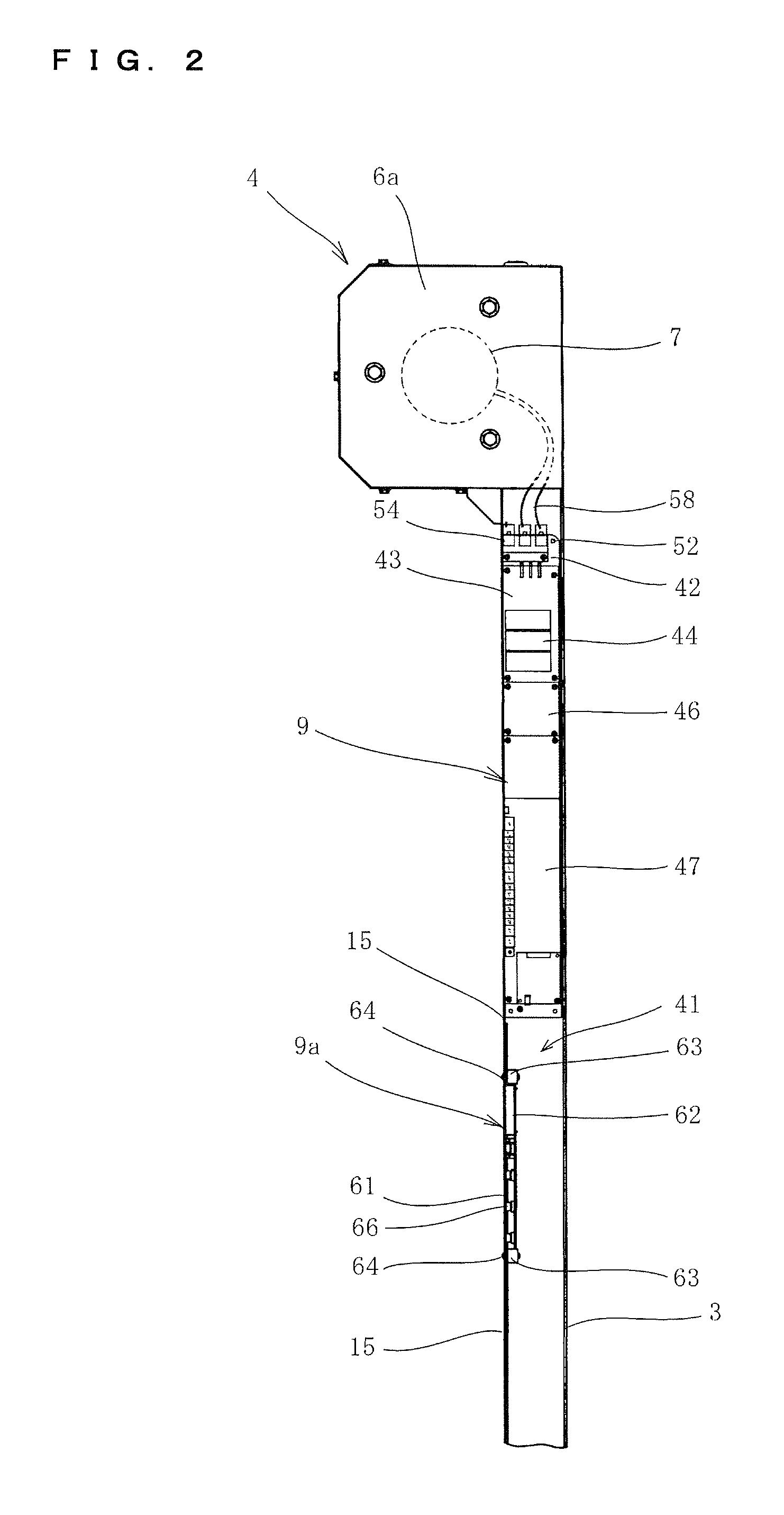

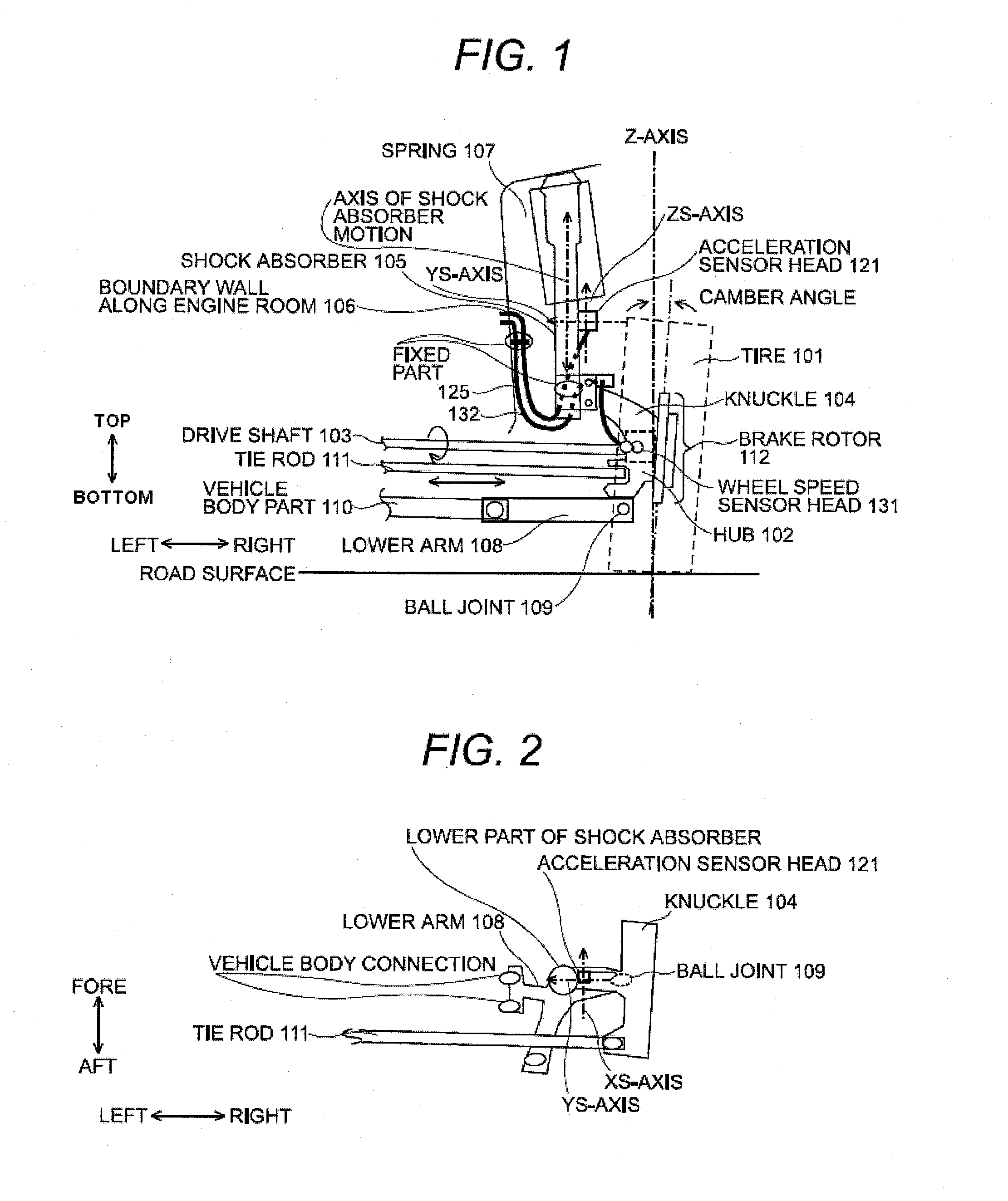

Sensor system for motion control of a moving unit and a method of installing a sensor system for motion control of a moving unit

InactiveUS20110035091A1Avoid delaySuppressing positional fluctuationSuspensionsVehicle testingEngineeringMovement control

A sensor system for motion control of a moving unit such as a vehicle, which is comprised of a uniaxial physical value sensor having a single detection axis and the uniaxial physical value sensor being installed in a unsprung mass of a suspension device provided in the moving unit, wherein the detection axis of the uniaxial physical value sensor and the working axis of a vibration-buffering member provided on the suspension device are approximately parallel.

Owner:HITACHI CABLE

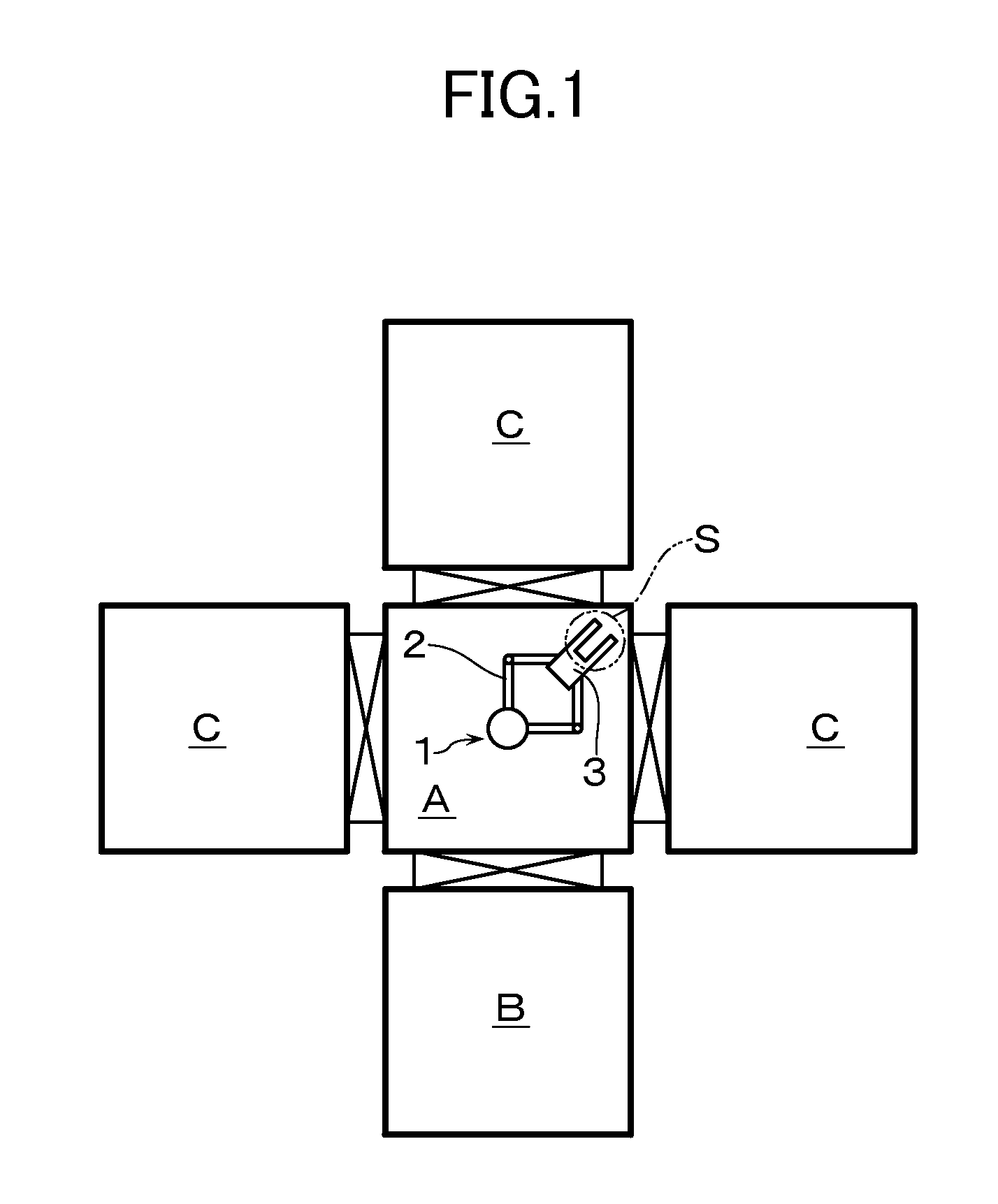

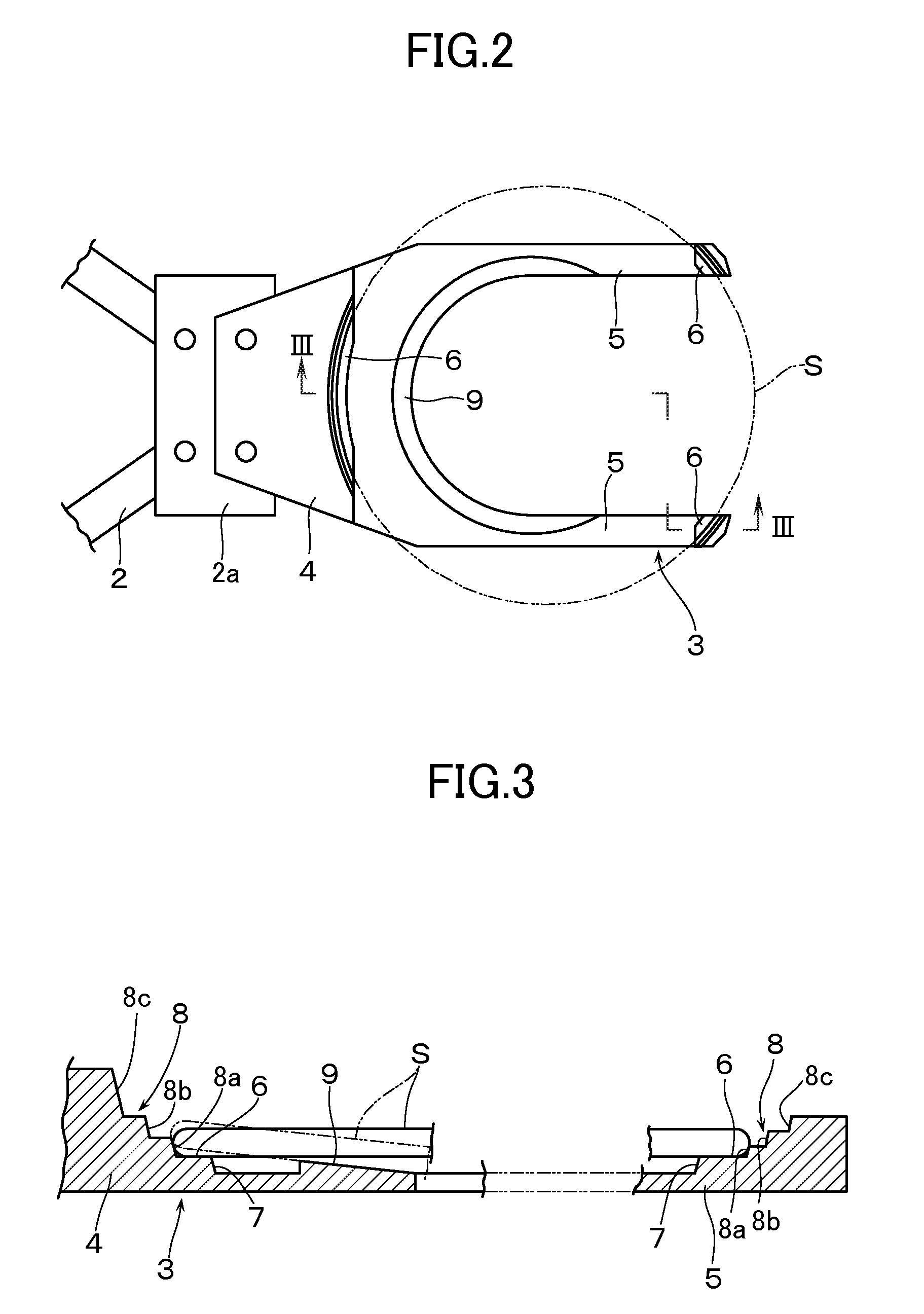

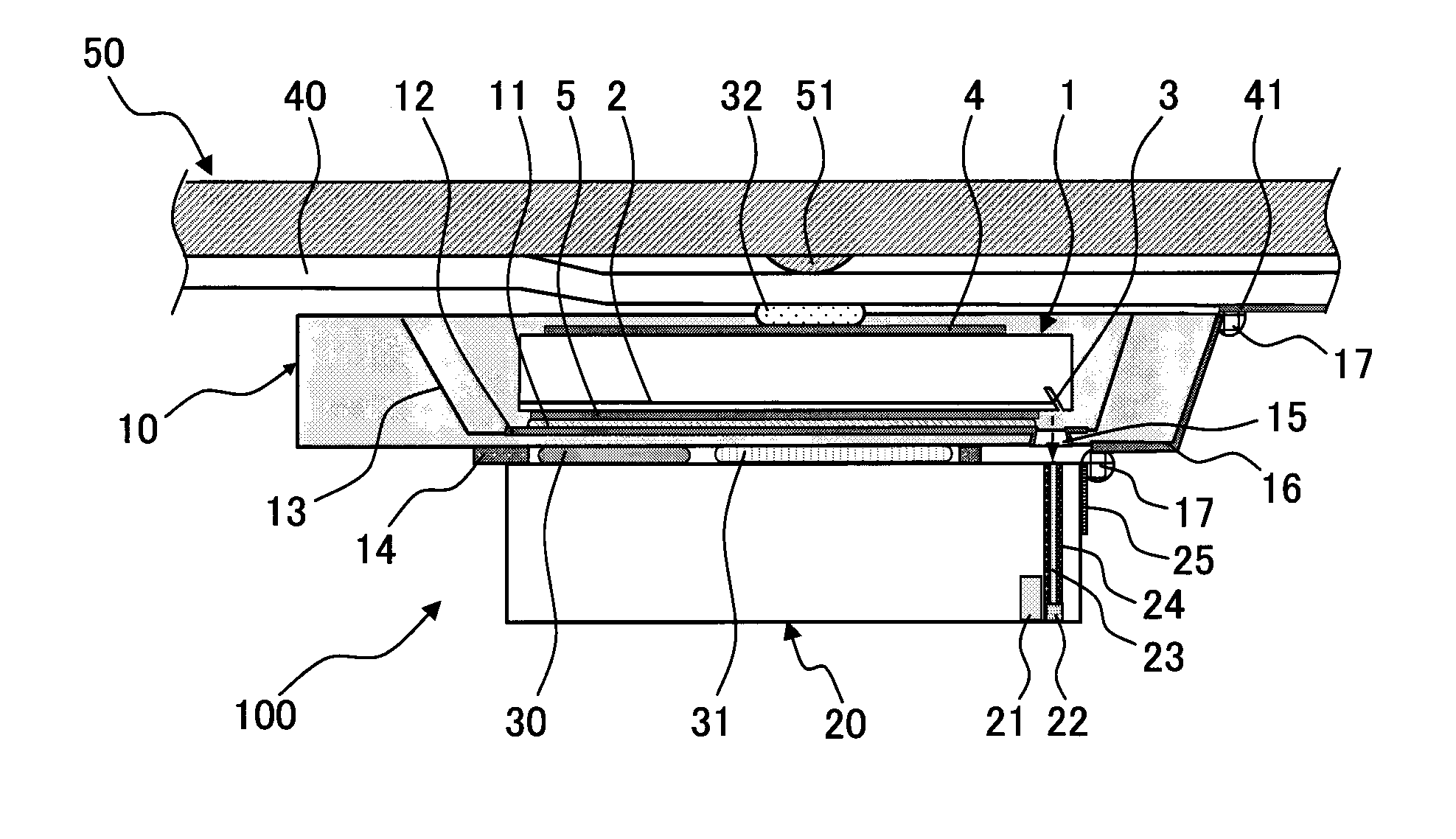

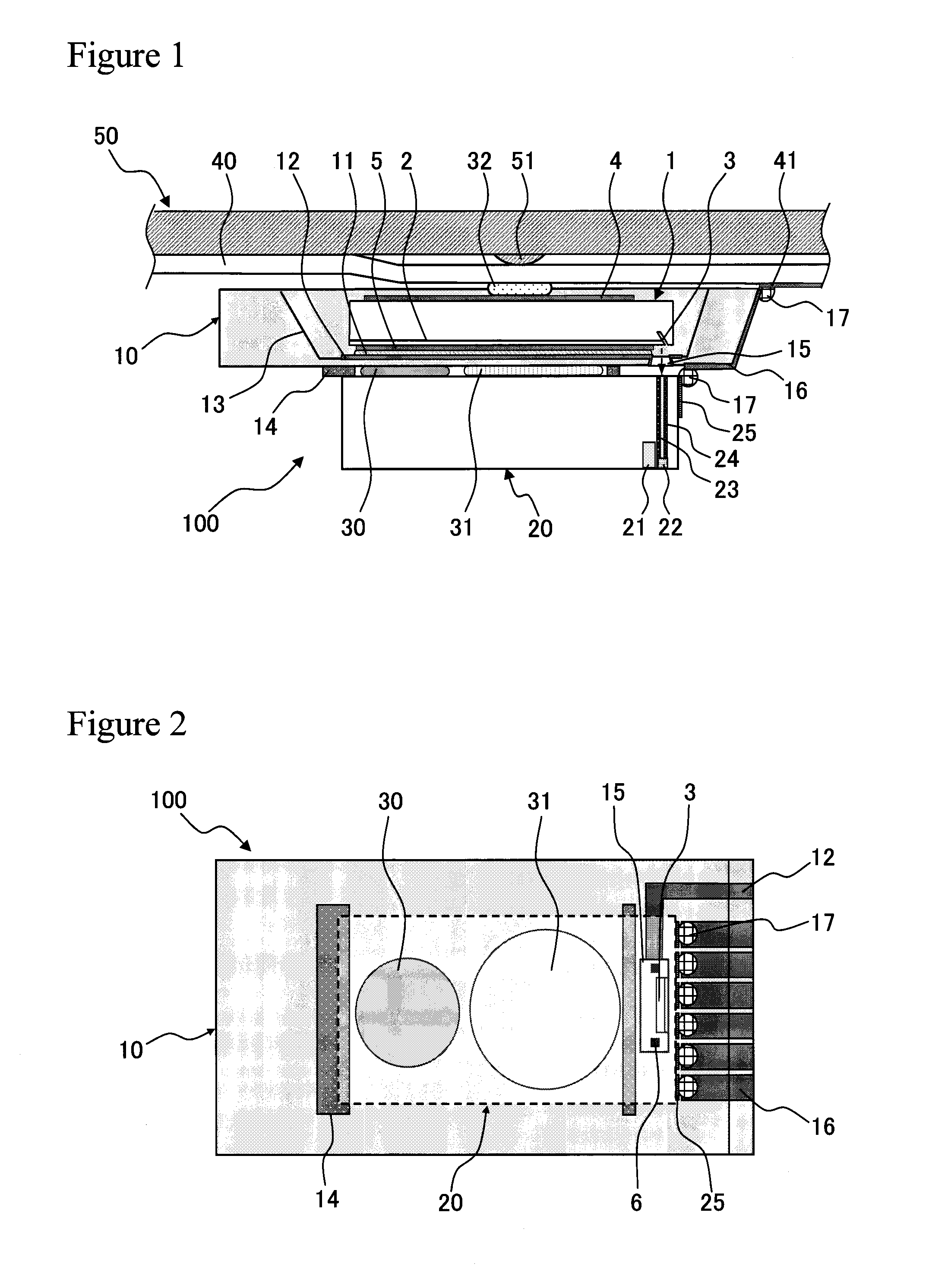

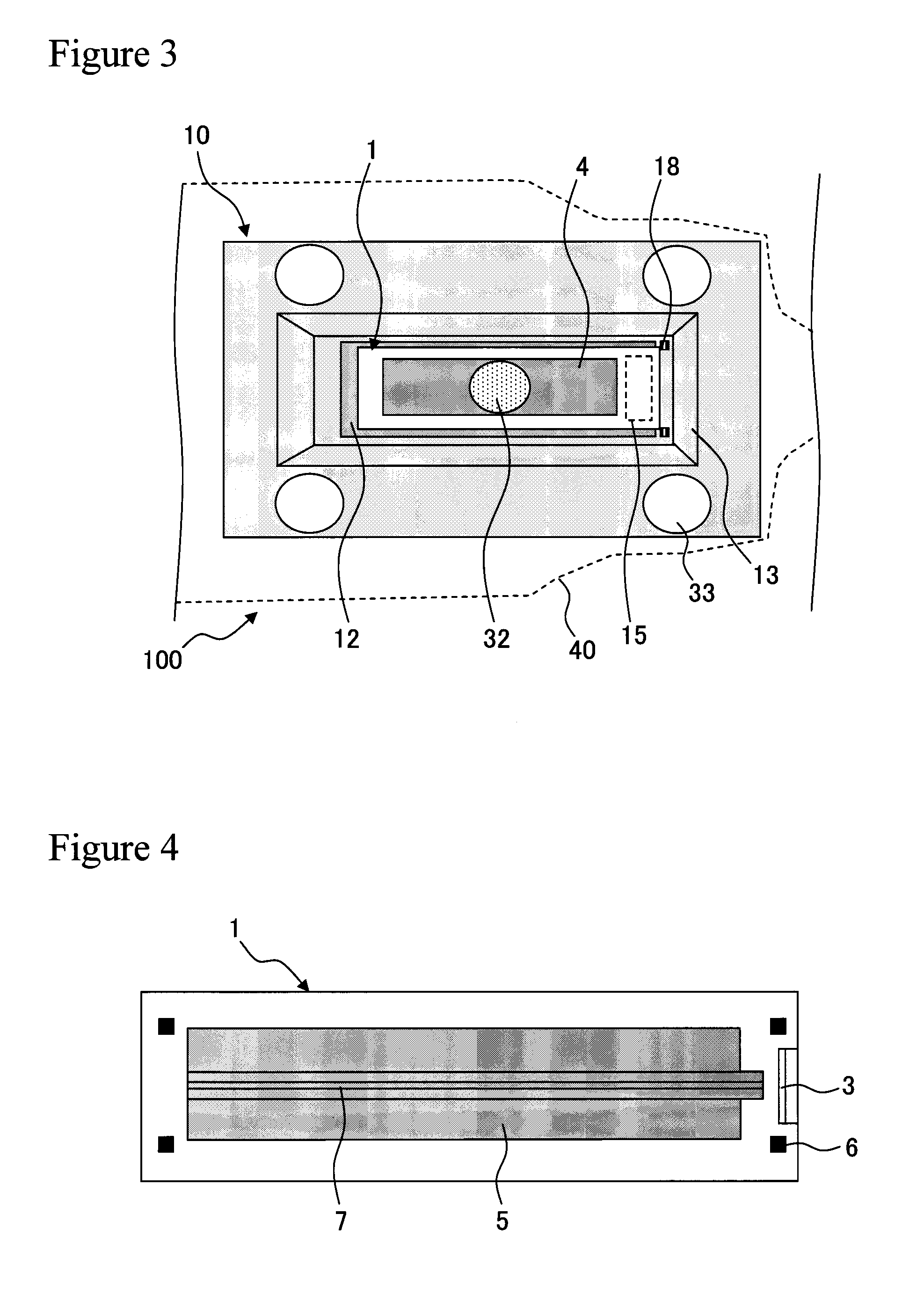

Robot hand for substrate transfer

ActiveUS20120049555A1Avoid position deviationSuppress position deviationProgramme-controlled manipulatorSemiconductor/solid-state device manufacturingRobot handEngineering

There is provided a robot hand for substrate transfer in which the robot hand is so arranged that, even in case a substrate (S) gives rise to warping, the substrate (S) can be stably supported. On an upper surface of the robot hand there is formed a first seating surface on which is seated a lower-surface peripheral portion of the substrate (S) and, on a periphery thereof, there is formed an upwardly extended step. The step is provided with a plurality of stair-shaped stages. On an upper surface of the robot hand inwardly away from the first seating surface there is provided a second seating surface which is inclined downward toward the center of the substrate (S) such that a lower surface of the substrate (S) is seated on the second seating surface when the substrate (S) is warped downward into a concave shape.

Owner:ULVAC INC

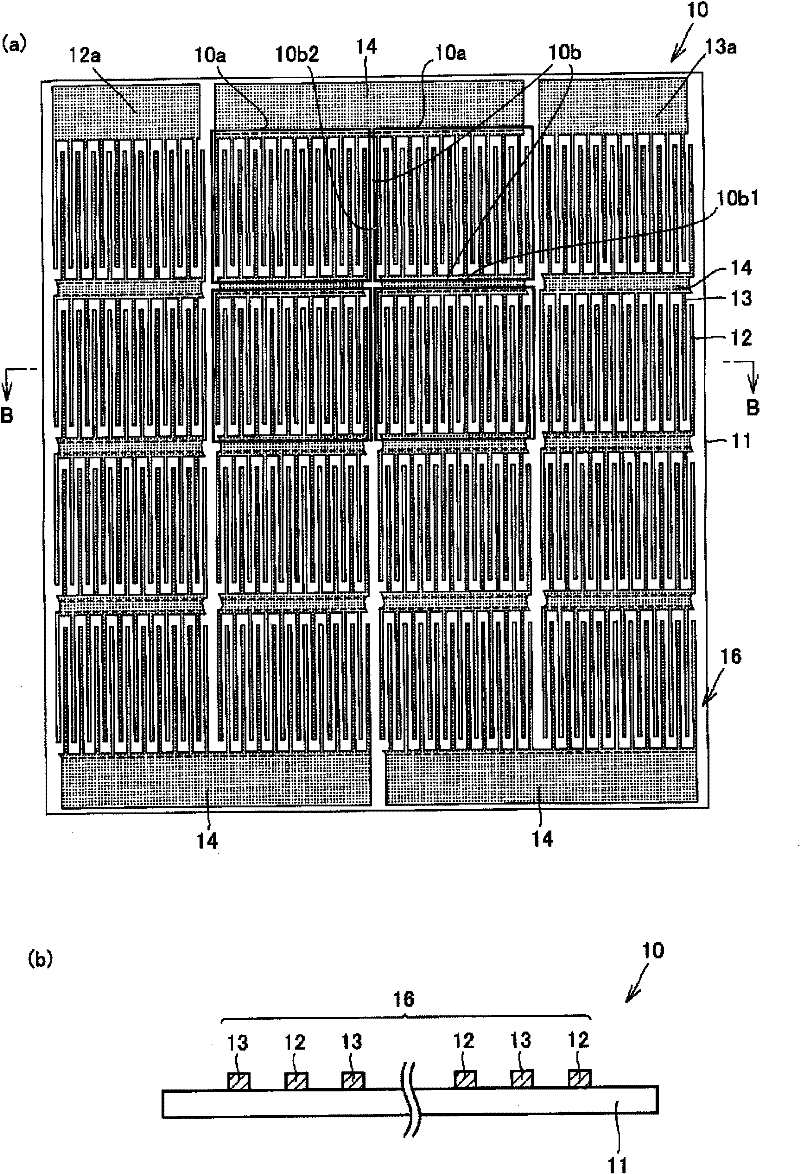

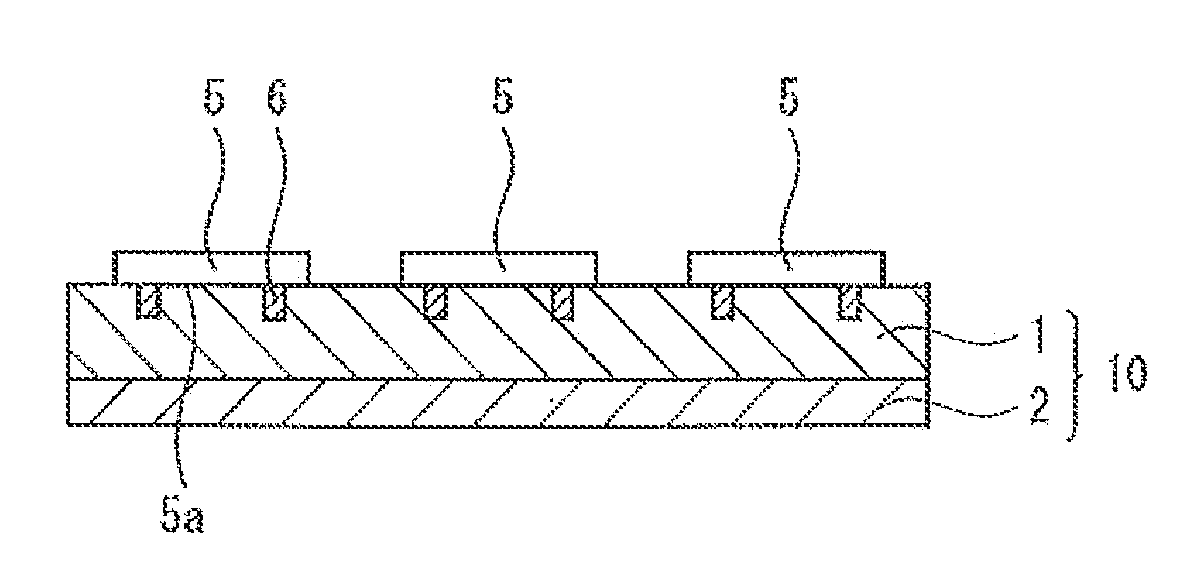

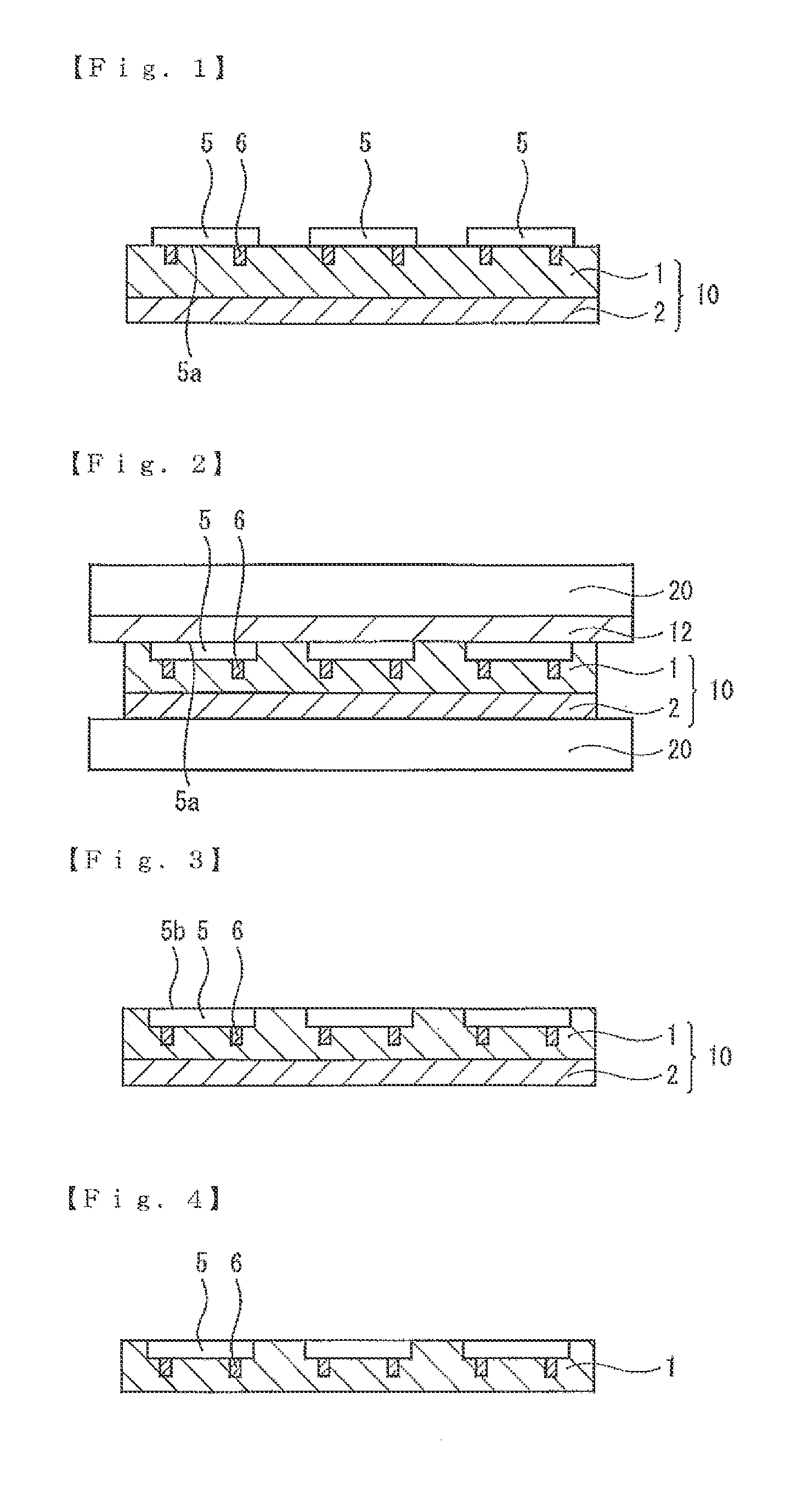

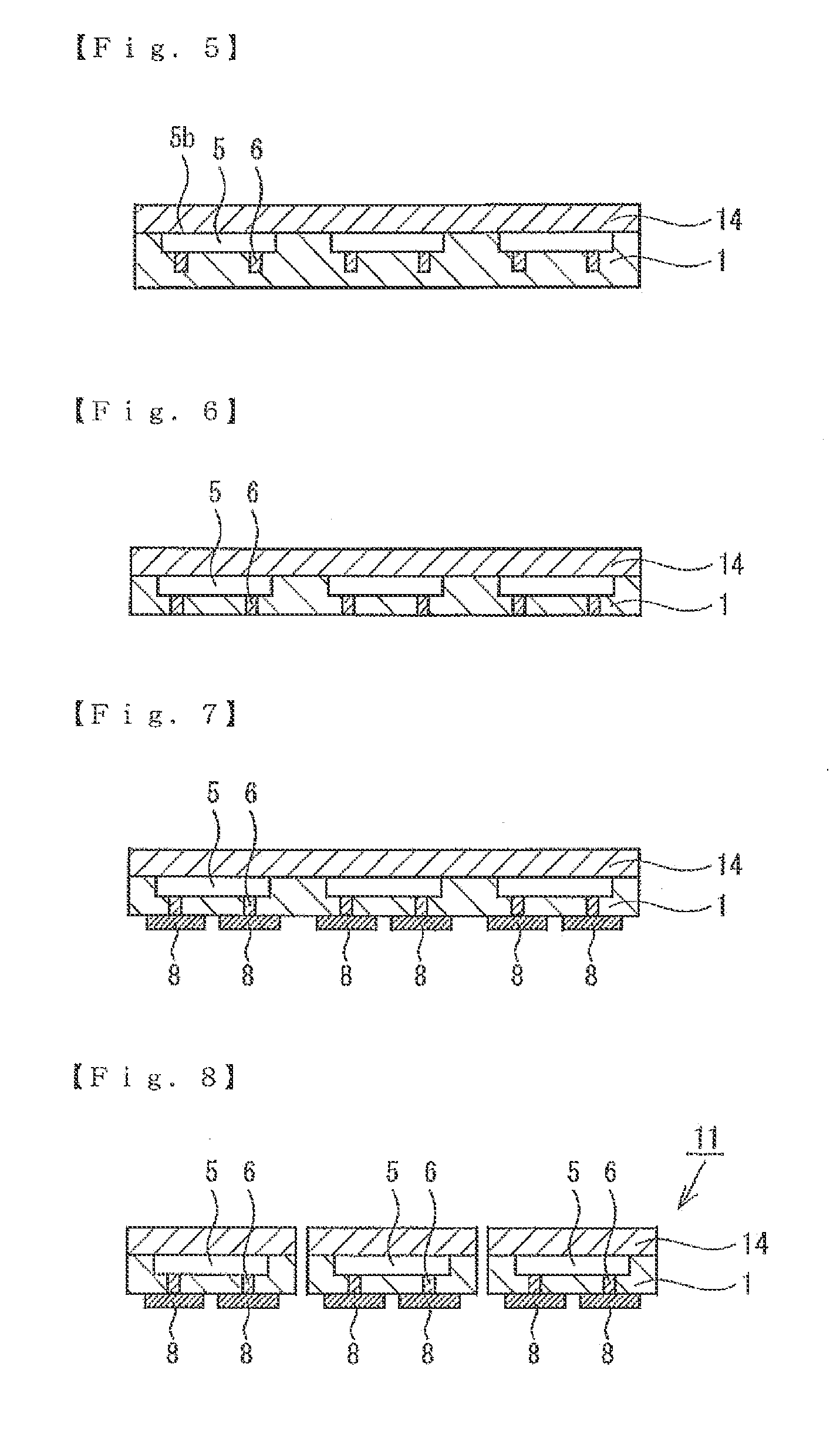

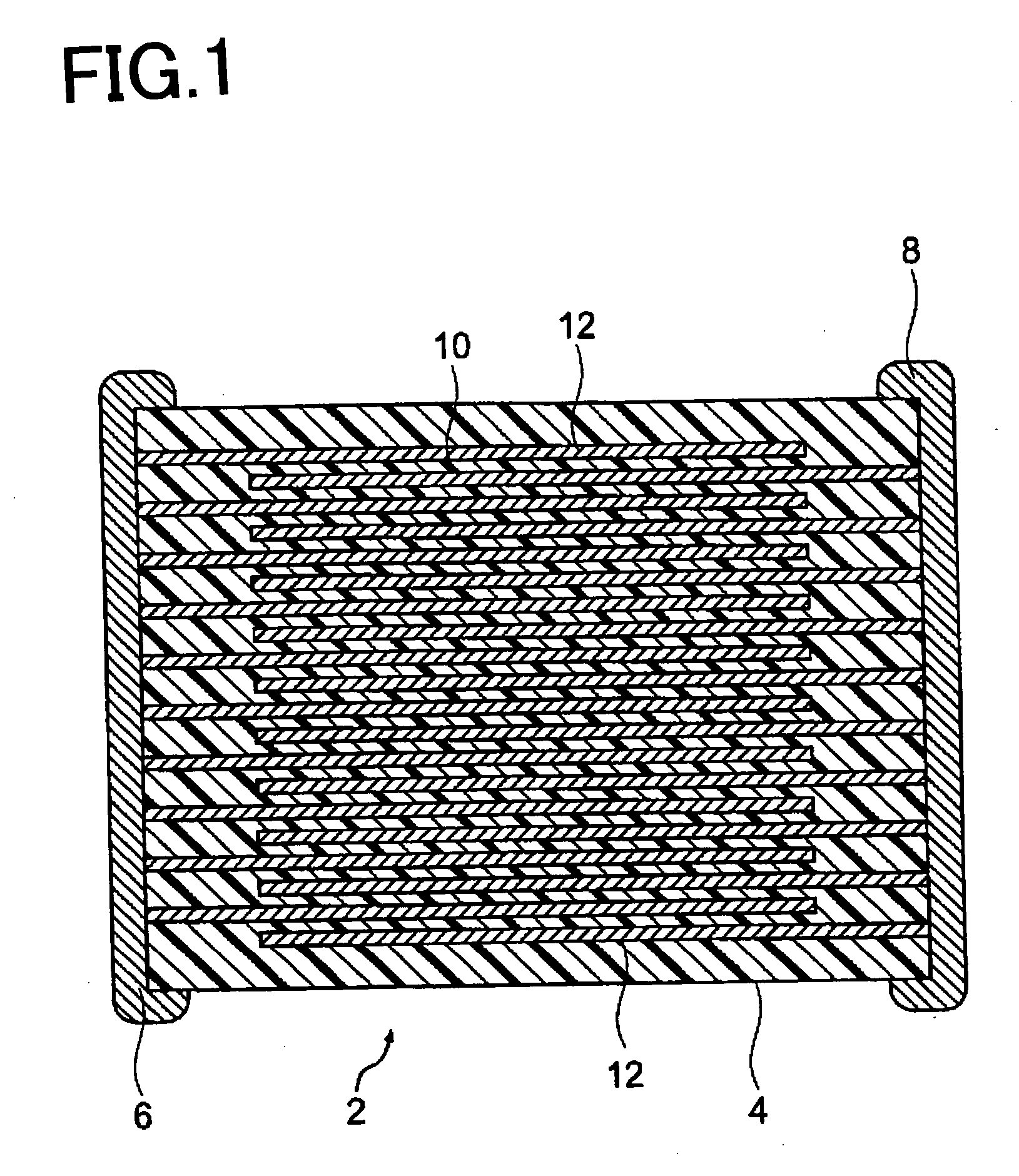

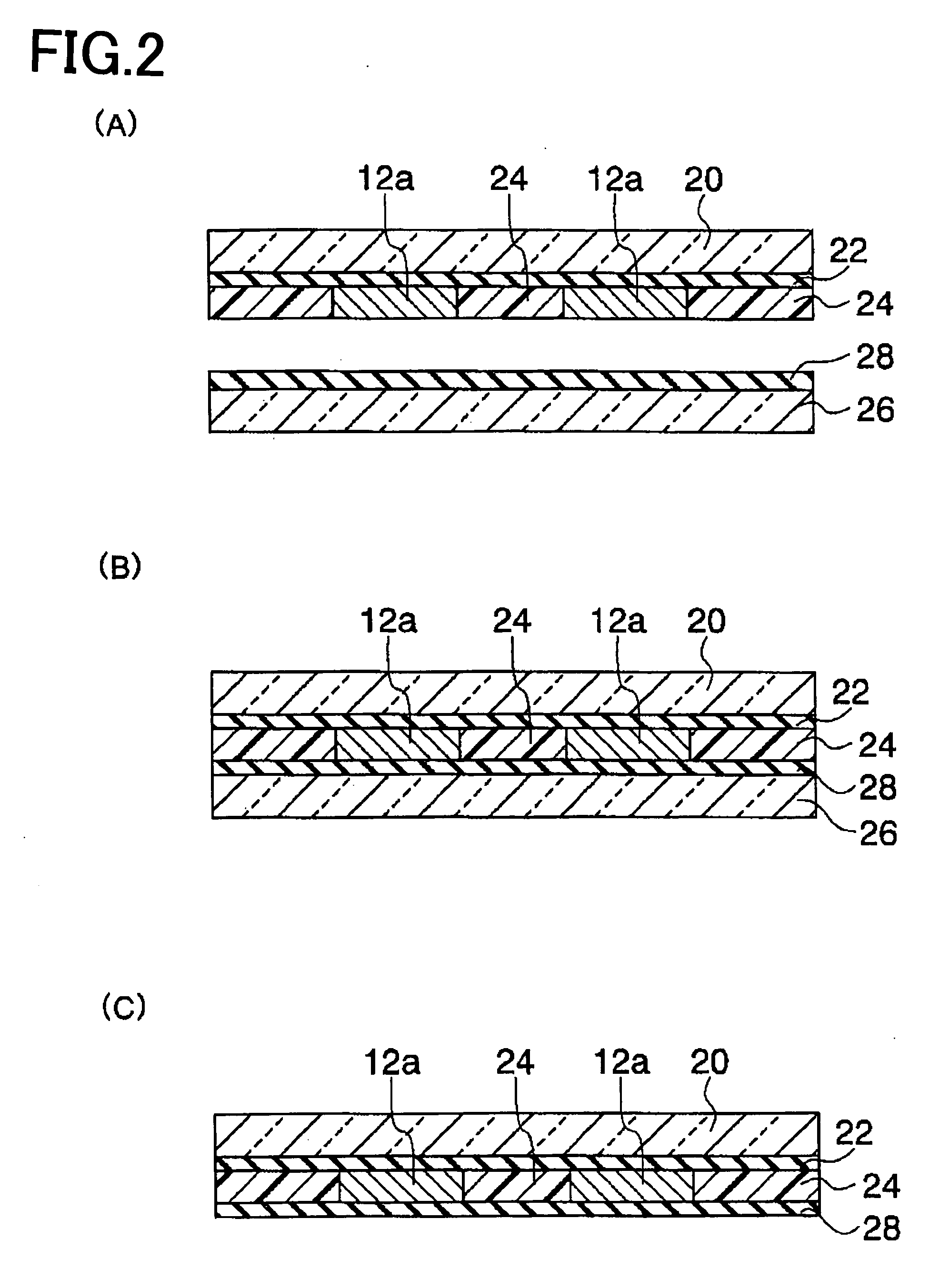

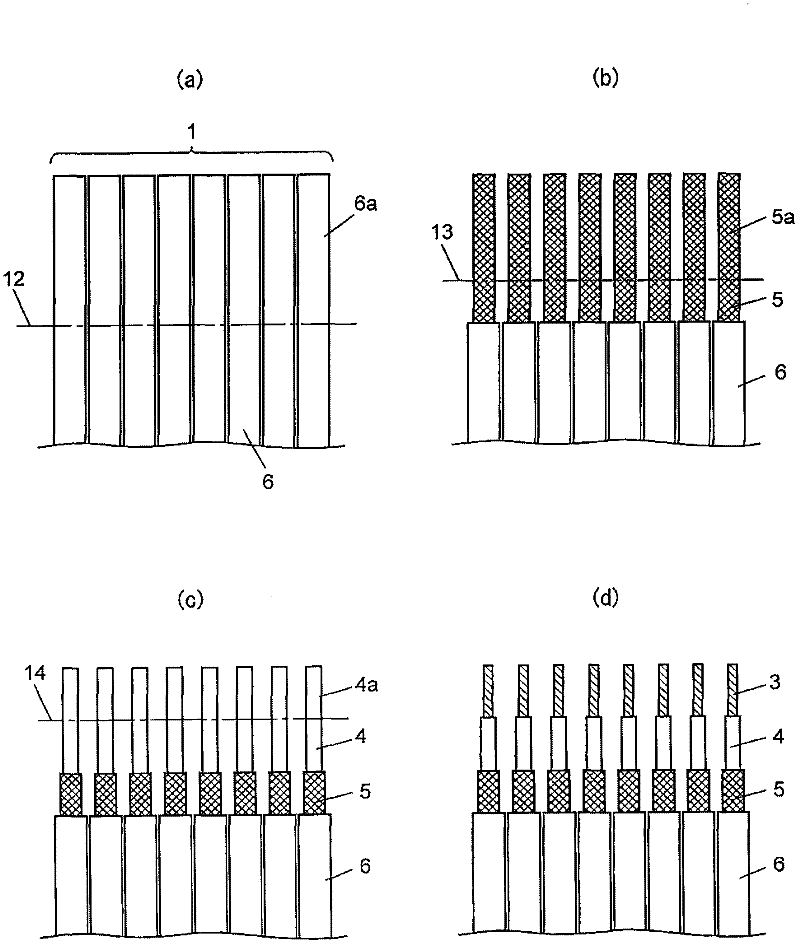

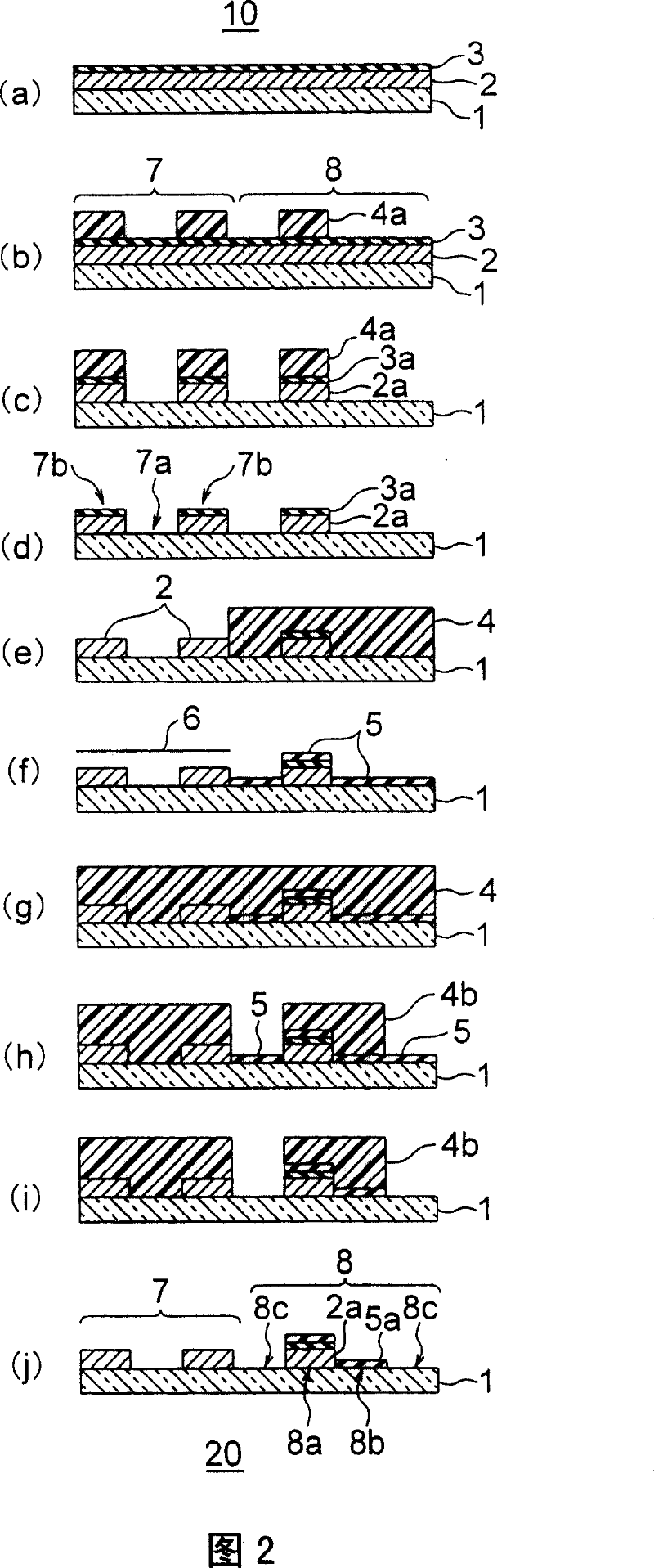

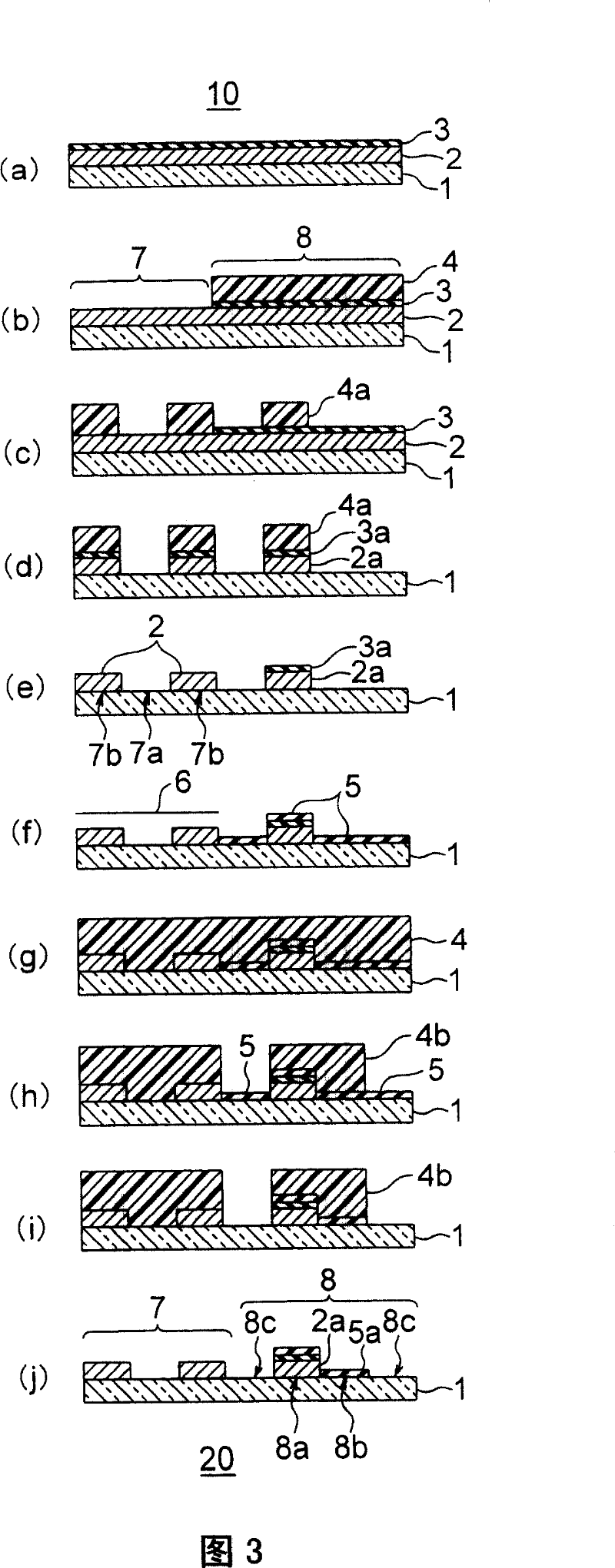

Interconnect sheet, solar cell with interconnect sheet, solar module, and method of producing solar cell with interconnect sheet

InactiveCN102365755AInhibition of poor insulationSuppress position deviationSynthetic resin layered productsElectrical equipmentSurface electrodeElectricity

An interconnect sheet (10) with insulating base material (11) on which interconnects (16) for electrically connecting a plurality of back surface electrode type solar cells (20) are placed, said interconnect sheet (10) being provided with a plurality of cell placement sections (10a) on which back surface electrode type solar cells (20) are placed, and having an insulating layer (101) provided on the cell placement side between neighboring cell placement sections (10a). Thus, disclosed is an interconnect sheet (10) used for back surface electrode type solar cells, which can limit unnecessary contact occurring between the back surface electrode type solar cells (20) placed on the interconnect sheet (10) and the interconnects (16) of the interconnect sheet (10). Further disclosed are a solar cell with the interconnect sheet, a solar module, and a method of producing the solar cell with the interconnect sheet.

Owner:SHARP KK

Sheet shutter

ActiveUS20120255683A1Reduce impactReduce wearScreensExtensible doors/windowsEngineeringSheet material

To provide a sheet shutter in which an urging member for urging an unwound, sheet toward the left and right outer side is provided so that the sheet is made to smoothly slide in the left and right direction and the wear of the urging member is suppressed. The sheet shutter according to the present invention is configured such that a rail groove is provided in each of left and right support posts, such that an inner rail is accommodated and supported in the rail grooves, such that engagement guides for guiding the lifting and lowering of the sheet formed in the inner rails, and such that, when the urging member is provided in the rail groove, an elastic sheet section for partitioning the inside of the rail groove into front and rear portions is provided at the urging member.

Owner:KOMATSU ELECTRIC SANGYO

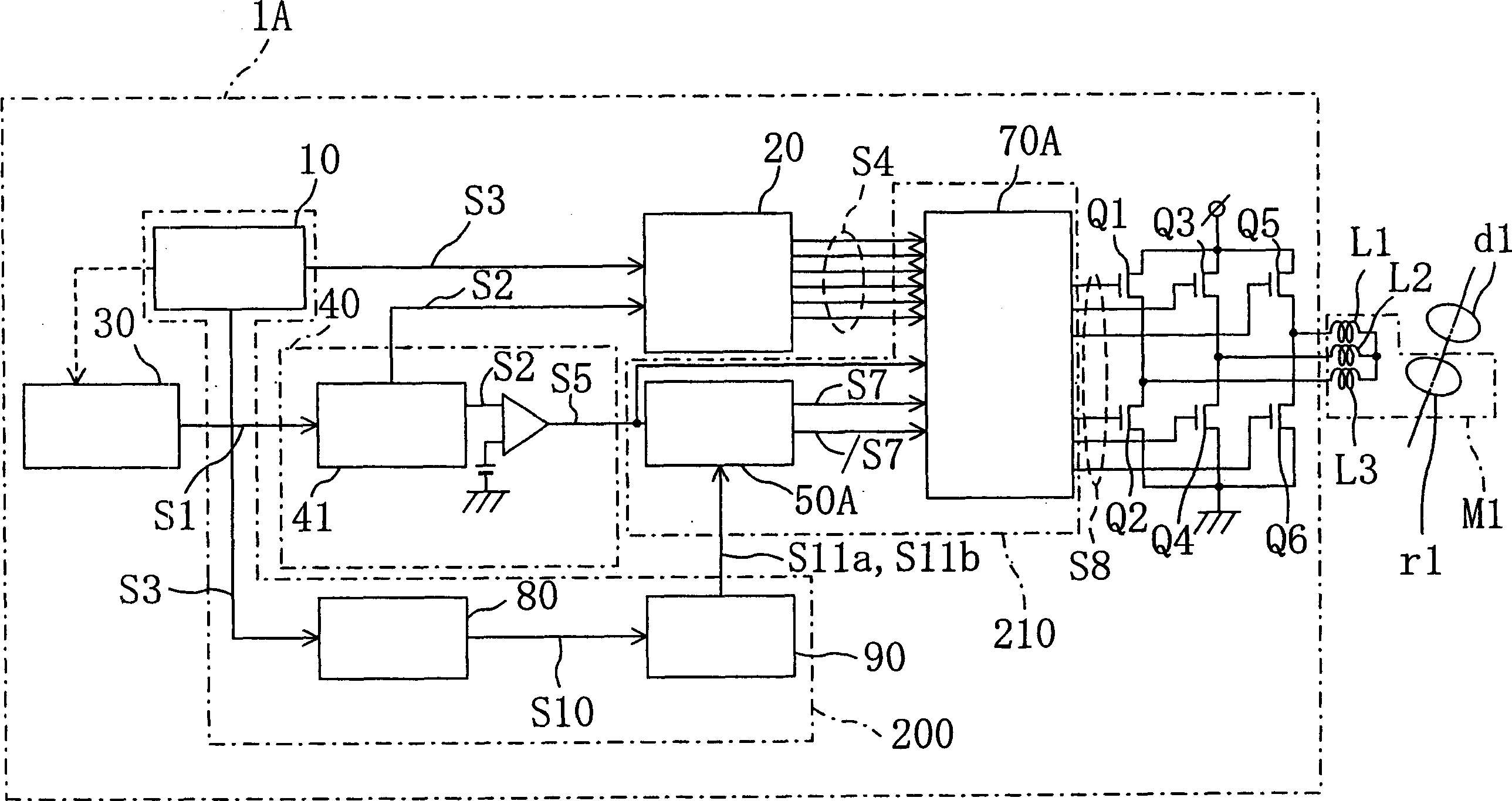

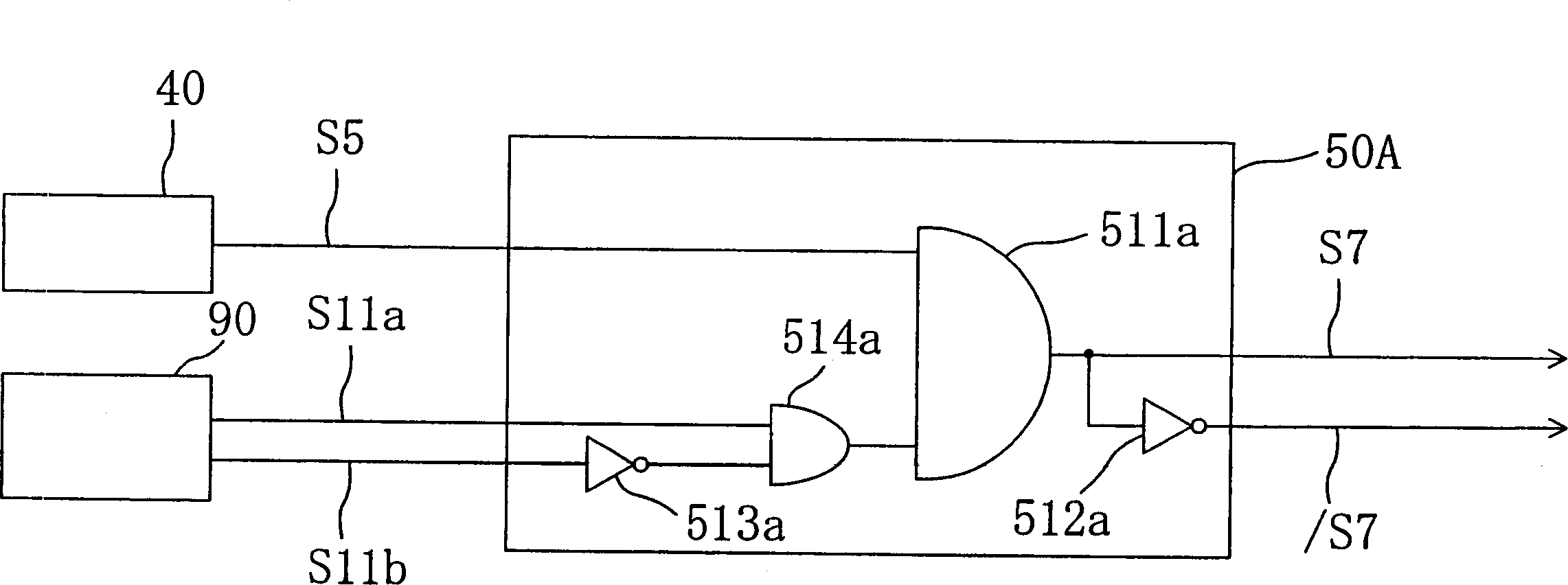

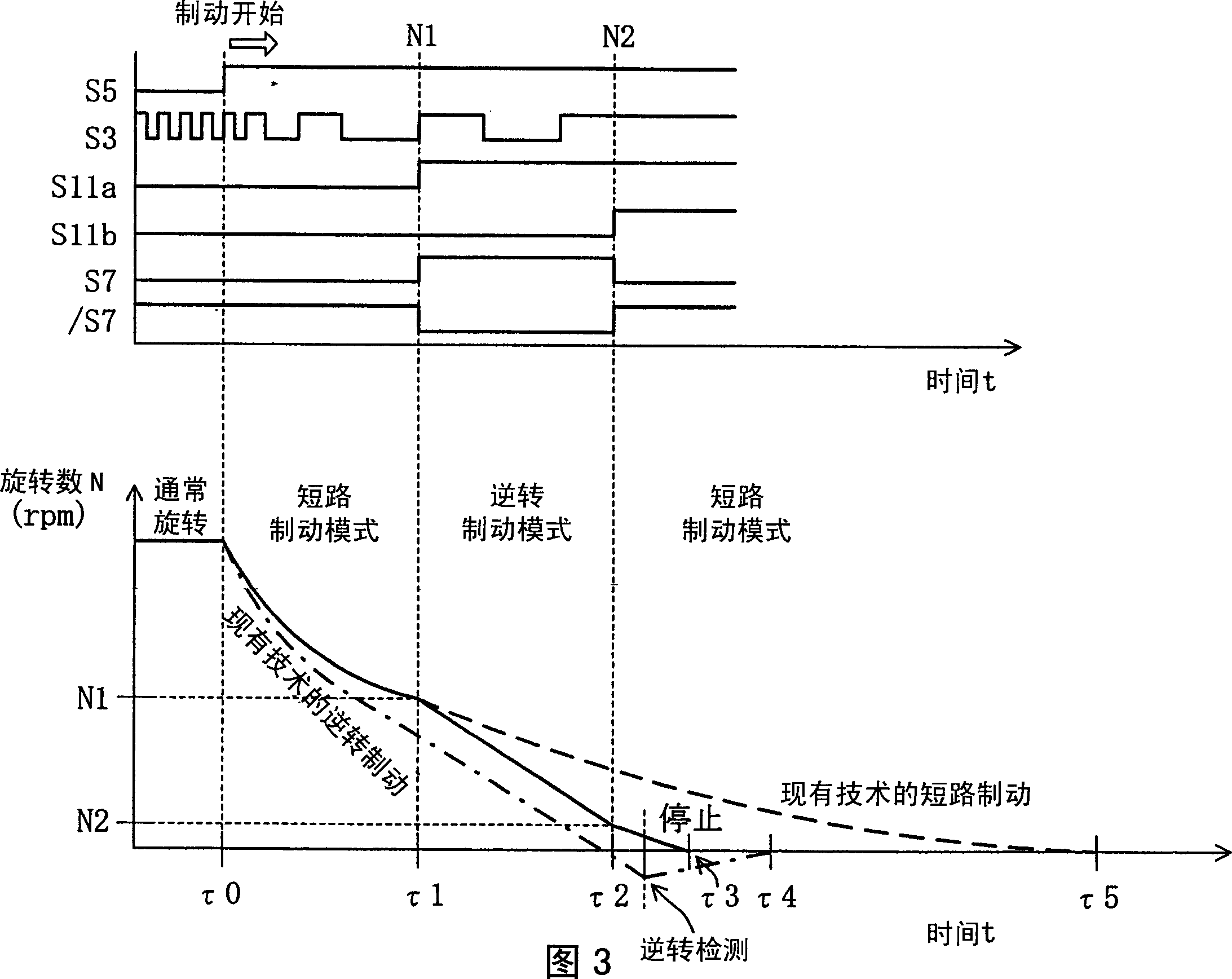

Motor driving device and method thereof

InactiveCN1423412ASuppress position deviationReduce noiseStopping arrangementsMotor driveControl signal

Brake mode switching signal production means detects the number of revolutions per unit time of a rotor according to a change in a positional relationship between motor windings of a plurality of phases and the rotor so as to output first and second brake mode switching signals for selecting either a short brake mode or a reverse brake mode for braking the rotation of the rotor based on the number of revolutions. Control means outputs an energization control signal for controlling energization of the motor windings of a plurality of phases in response to the first and second brake mode switching signals. Thus, it is possible to reduce the braking noise and the stopping time.

Owner:PANASONIC CORP

Method of manufacturing semiconductor device

InactiveUS20130157419A1Simple processLow production costSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipEngineering

The objective of the present invention is to provide a method of manufacturing a semiconductor device having less contamination of a semiconductor chip and good productivity. The present invention is a method of manufacturing a semiconductor device having a semiconductor chip, with the steps of preparing a plurality of semiconductor chips, preparing a resin sheet having a thermosetting resin layer, arranging the plurality of semiconductor chips on the thermosetting resin layer, arranging a cover film on the plurality of semiconductor chips, and embedding the plurality of semiconductor chips in the thermosetting resin layer by a pressure applied through the arranged cover film, in which the contact angle of the cover film to water is 90° or less.

Owner:NITTO DENKO CORP

Thermally Assisted Magnetic Head Assembly and Magnetic Disk Device

InactiveUS20120320719A1Suppress deviationHigh efficiencyCombination recordingArm with optical waveguideMagnetic disksAdhesive

A slider including a magnetic head part, an optical waveguide, and a near field element is fixed by first and second adhesives to a submount on which a semiconductor laser and a mirror are mounted, the mirror being placed at one end of the semiconductor laser in a resonance direction thereof and reflecting a laser in a direction intersecting with the resonance direction. At this time, at least parts of the first and second adhesives are applied to a position opposed to the semiconductor laser with an intermediation of the submount. The first adhesive having a higher Young's modulus than that of the second adhesive is applied onto an inflow end side of the slider including a solder connection portion, the second adhesive being applied onto an outflow end side of the slider.

Owner:HITACHI LTD

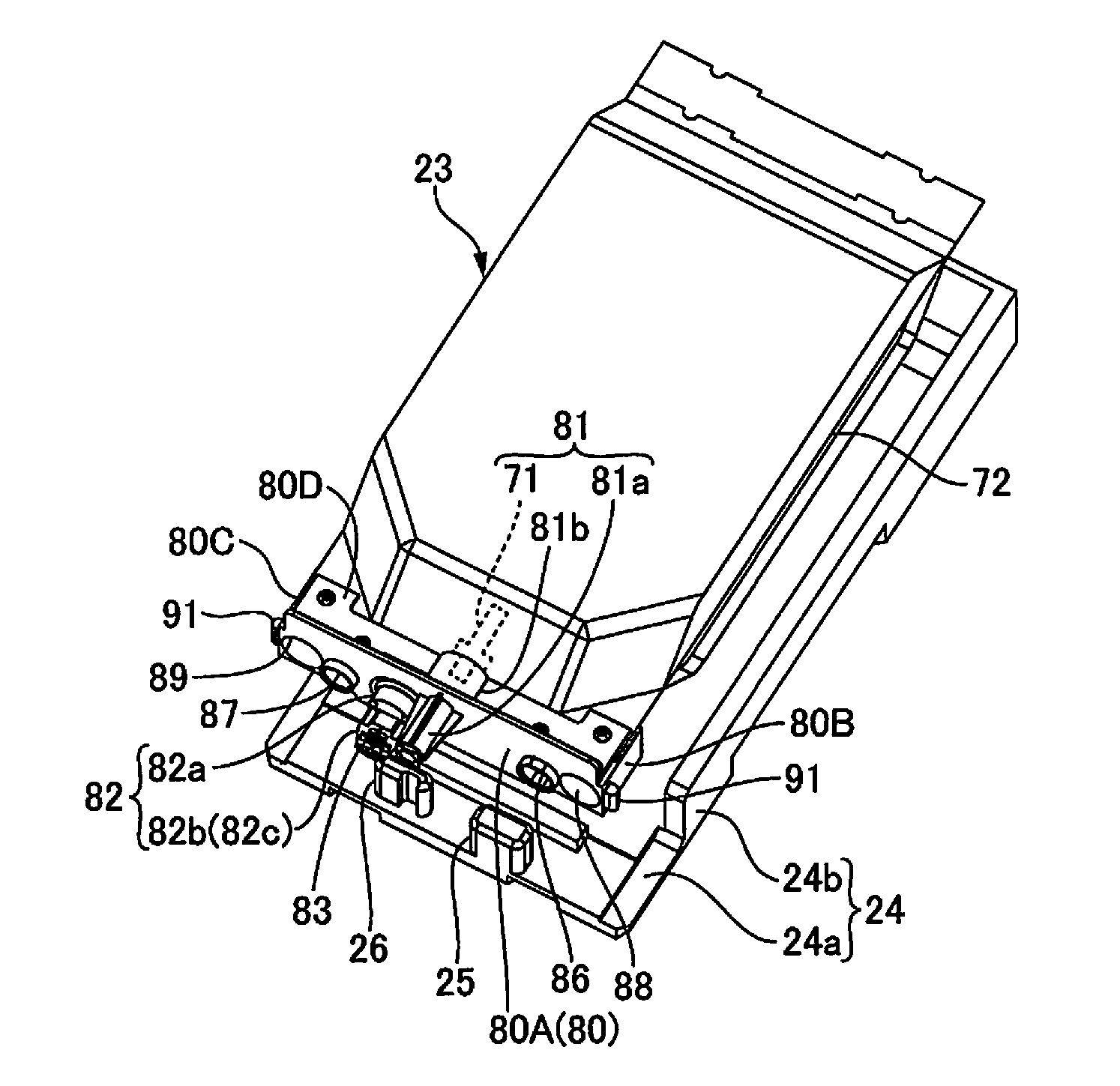

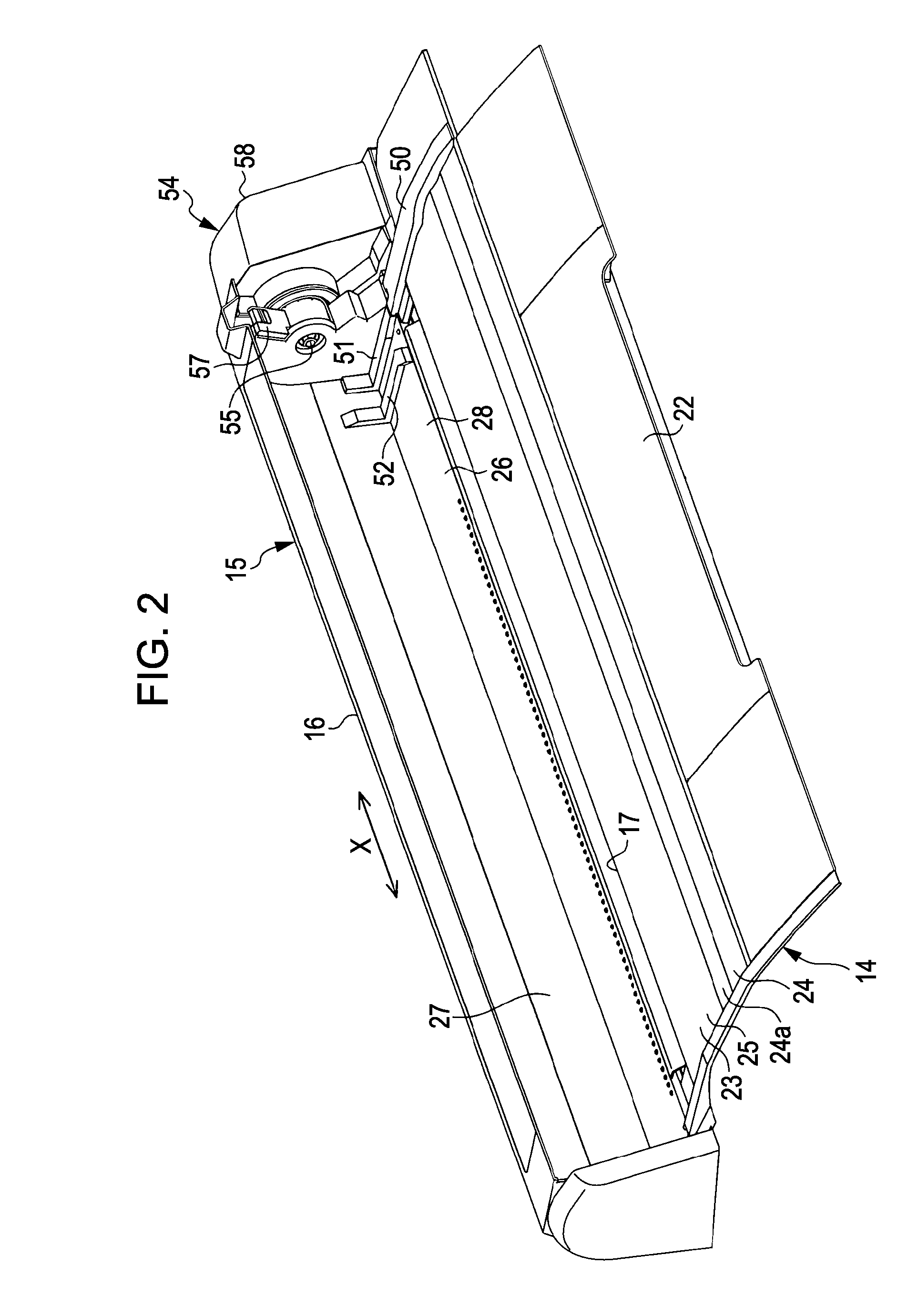

Liquid ejecting apparatus

ActiveUS20150273501A1Suppress positional deviation of coverResistance be doubleLiquid spraying apparatusMedical atomisersEngineeringMechanical engineering

Owner:SEIKO EPSON CORP

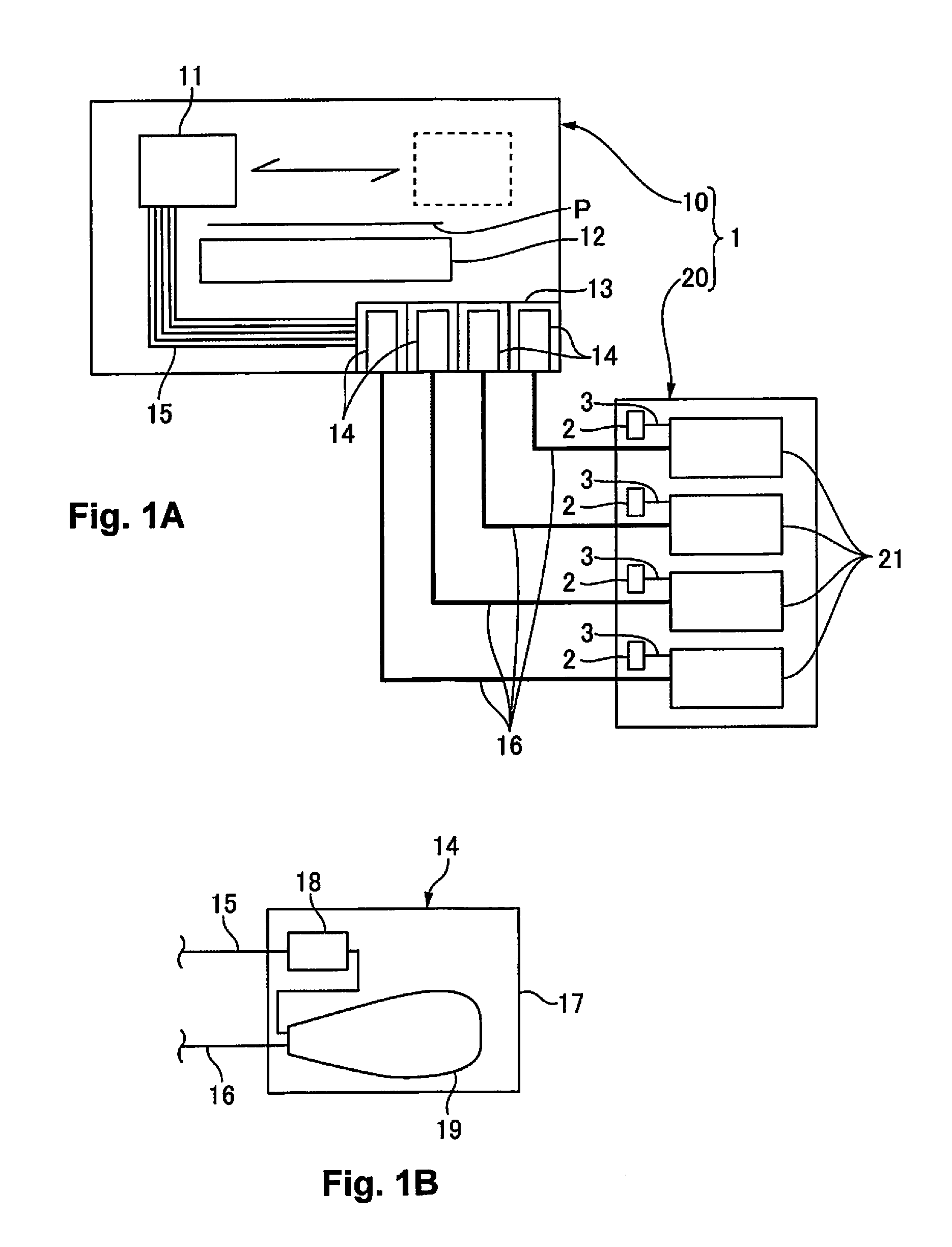

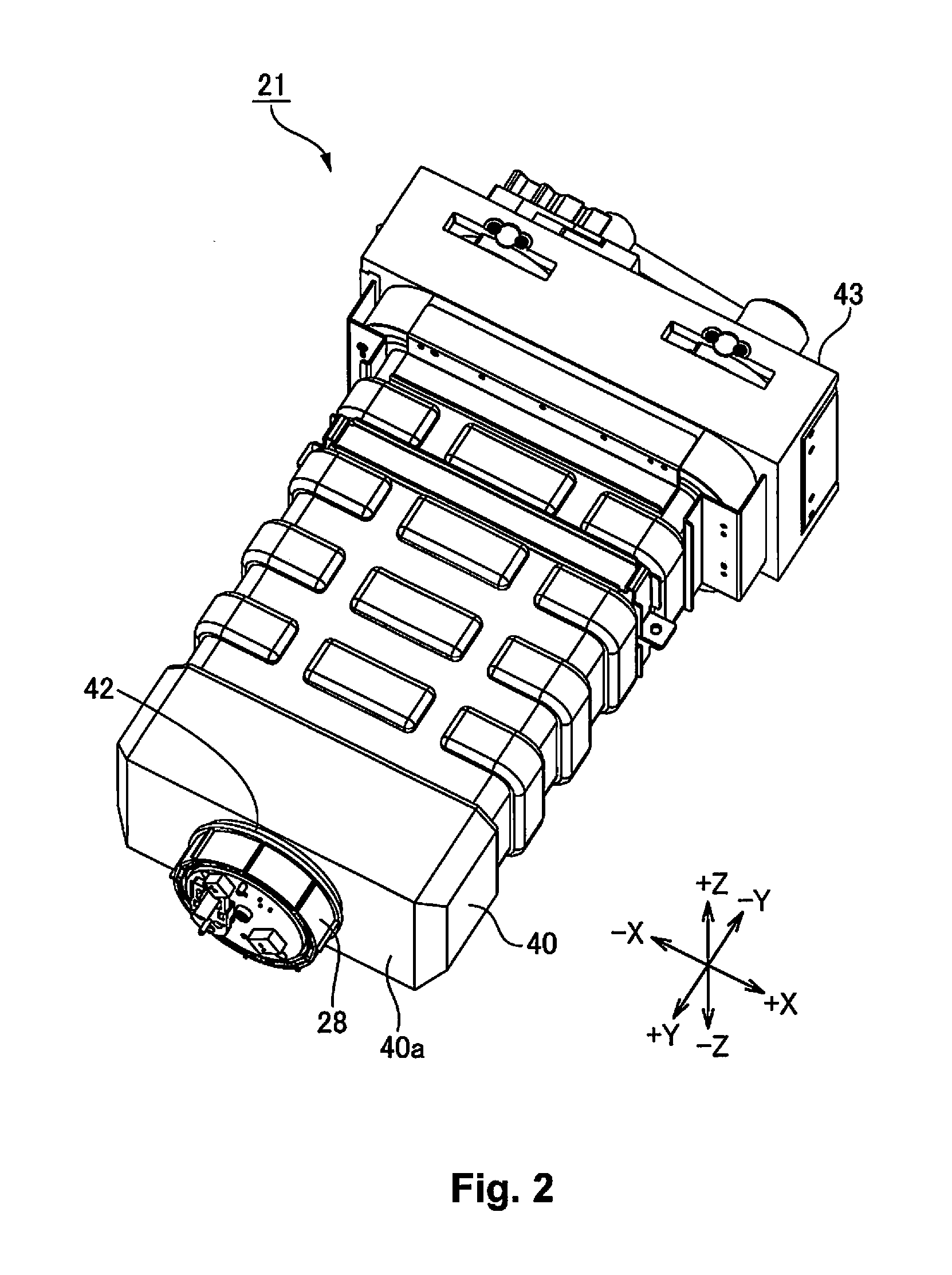

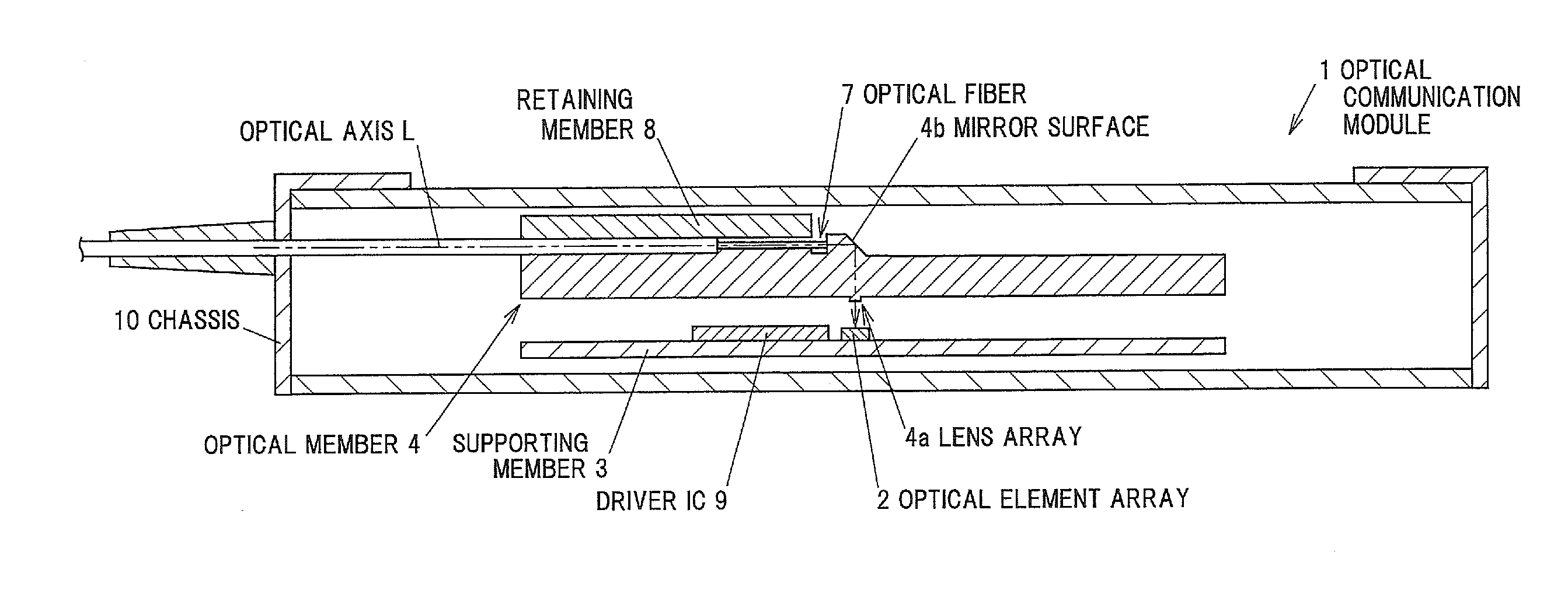

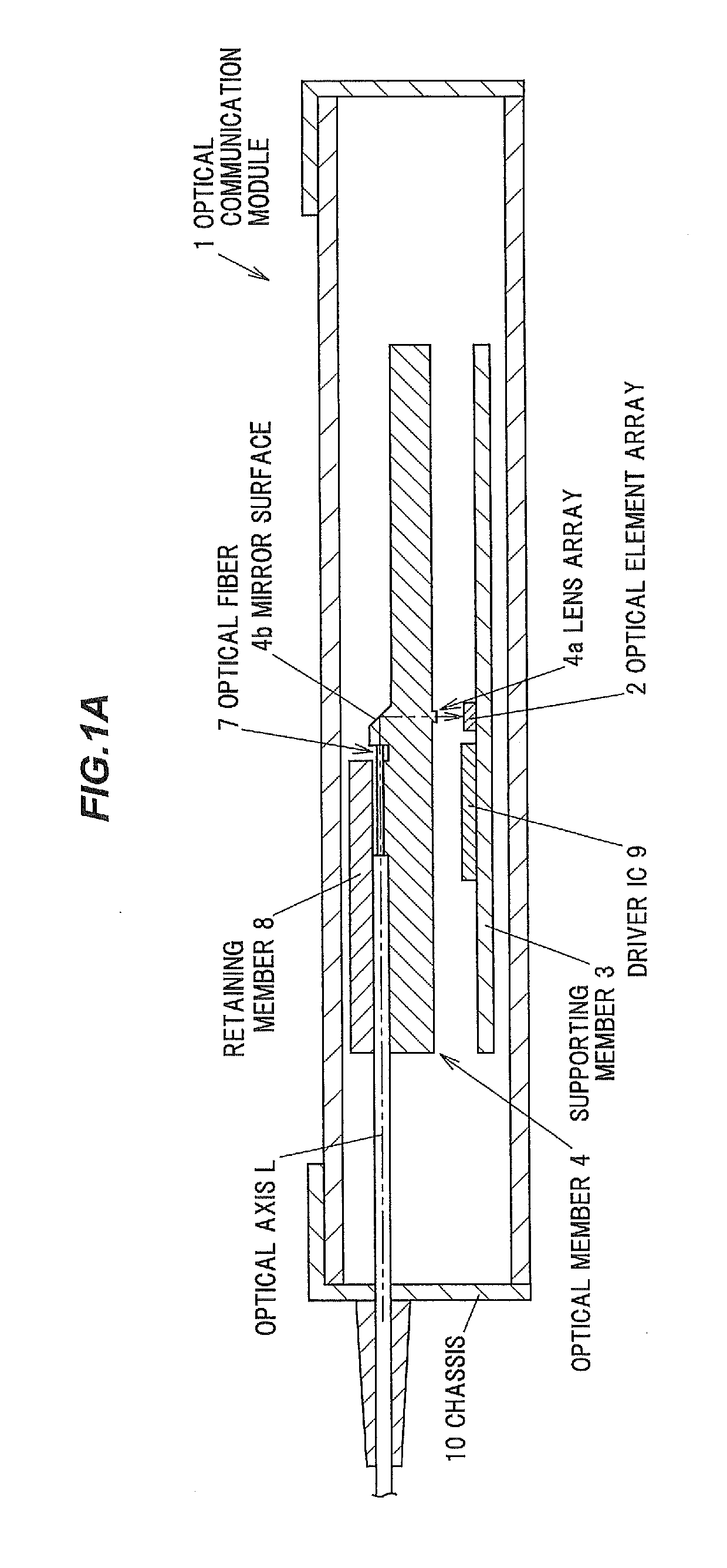

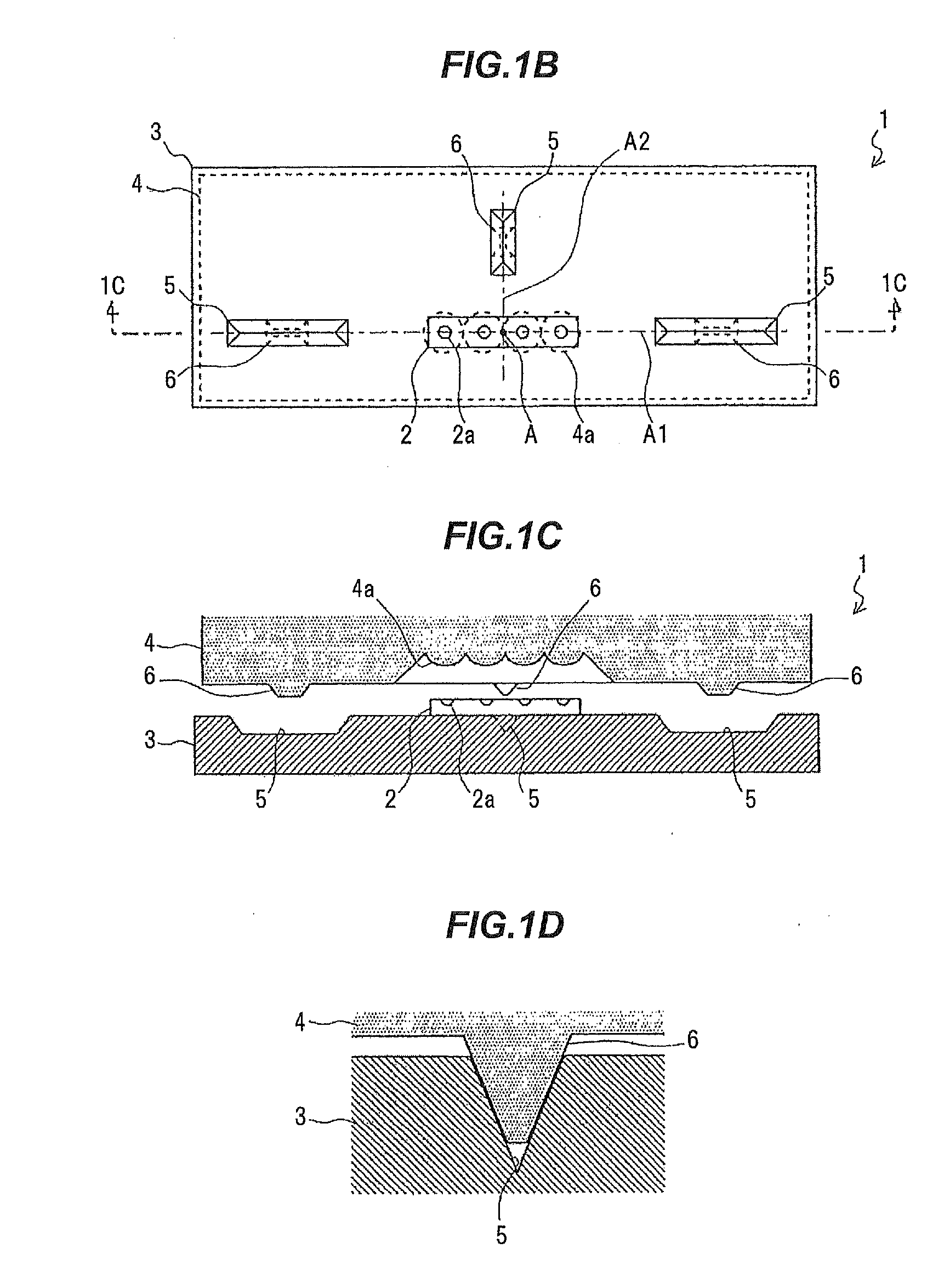

Optical communication module

InactiveUS20140086528A1Suppress position deviationEasy alignmentCoupling light guidesEngineeringOptical communication

An optical communication module includes: an optical element array; a supporting member on which the optical element array is placed; an optical member for optically coupling the optical element array and a plurality of optical fibers together; a plurality of grooves provided in the supporting member or the optical member; and a plurality of protrusions provided on the optical member or the supporting member in correspondence with the grooves respectively. The grooves and the protrusions are mated together. The grooves are provided as being widened toward their openings. The grooves and the protrusions are each provided so that a location in a width direction at which no relative locational misalignment occurs therebetween lies on a line through the center of the optical element array. The grooves and the protrusions are each provided on at least two or more different lines through the center of the optical element array.

Owner:HITACHI METALS LTD

Thermally assisted magnetic head assembly and magnetic disk device

InactiveUS8477570B2Suppress position deviationExtended service lifeCombination recordingArm with optical waveguideResonanceAdhesive

A slider including a magnetic head part, an optical waveguide, and a near field element is fixed by first and second adhesives to a submount on which a semiconductor laser and a mirror are mounted, the mirror being placed at one end of the semiconductor laser in a resonance direction thereof and reflecting a laser in a direction intersecting with the resonance direction. At this time, at least parts of the first and second adhesives are applied to a position opposed to the semiconductor laser with an intermediation of the submount. The first adhesive having a higher Young's modulus than that of the second adhesive is applied onto an inflow end side of the slider including a solder connection portion, the second adhesive being applied onto an outflow end side of the slider.

Owner:HITACHI LTD

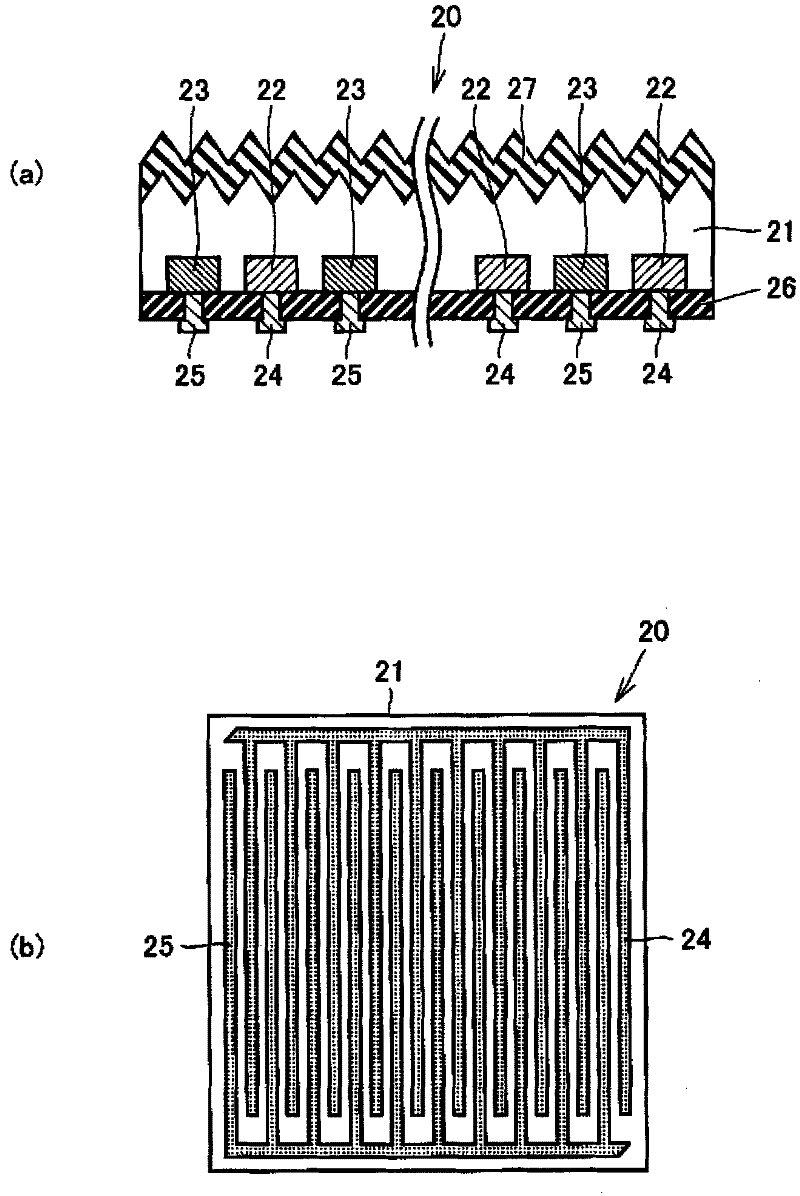

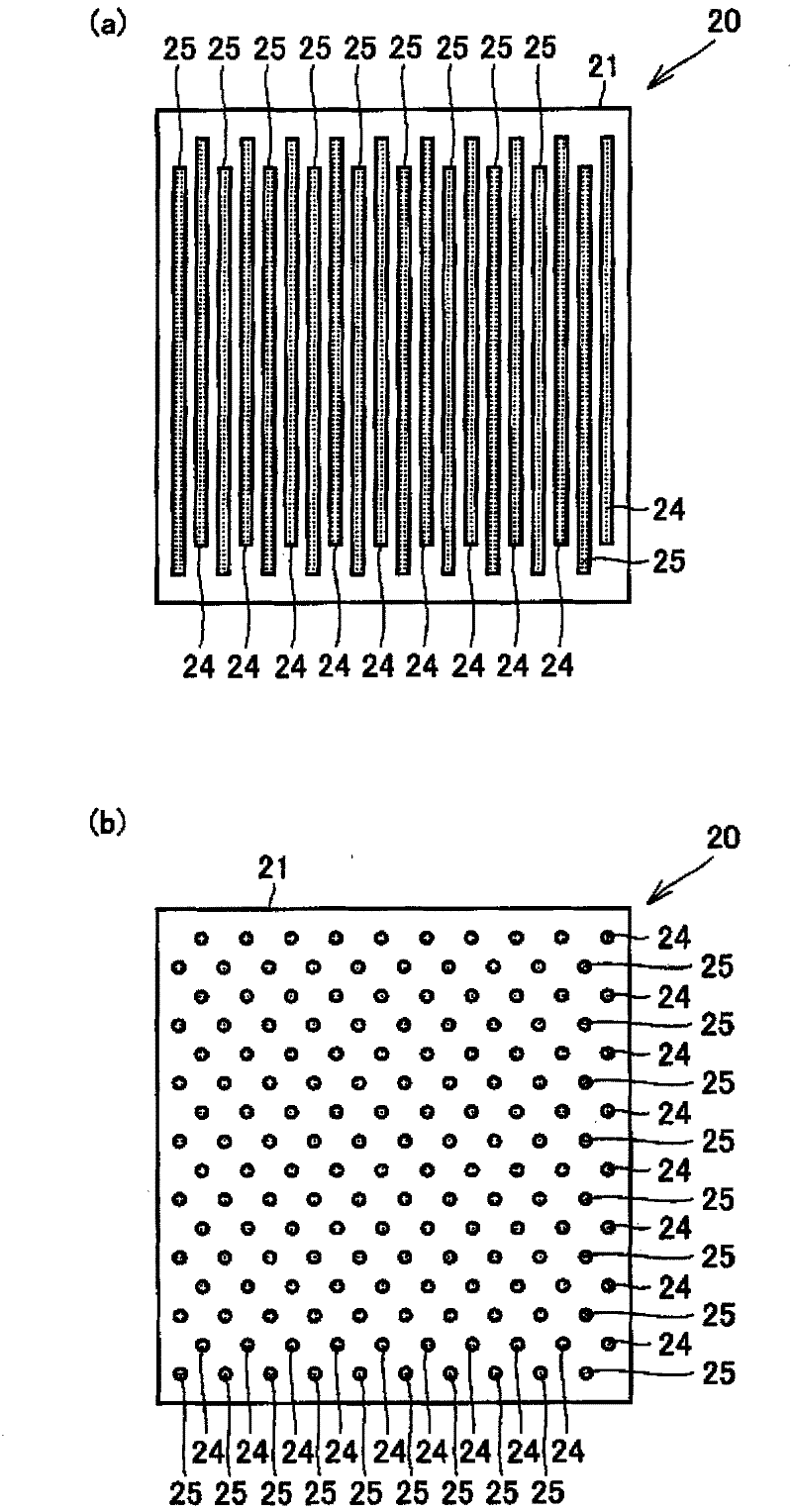

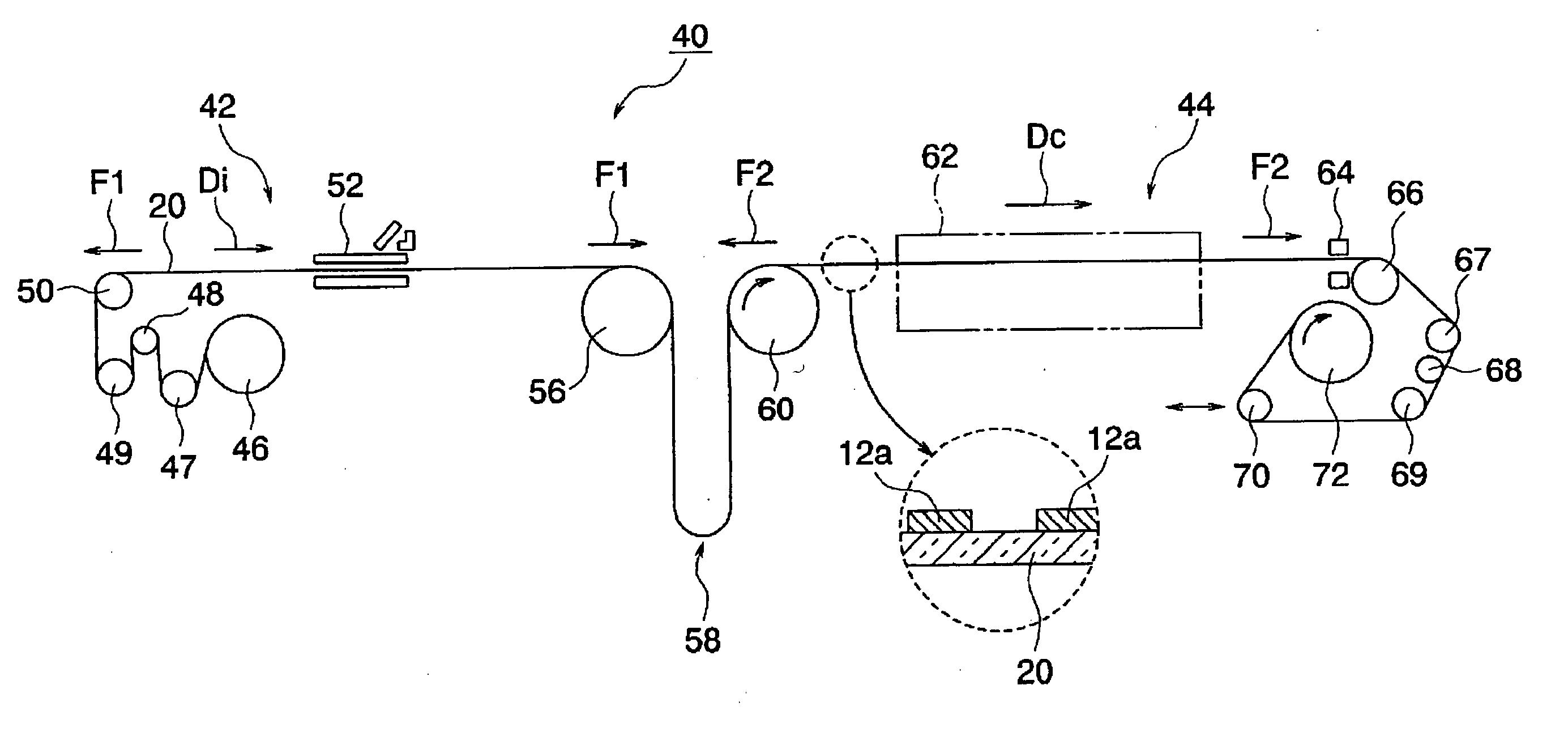

Printing and drying method, method of production of electronic device, and printing and drying system

ActiveUS20060213382A1Prevent dust depositionAvoid defectsDrying/impregnating machinesPrinted circuit dryingEngineeringMethods of production

A printing and drying method comprising laying a support sheet 20 elongated in the long direction so as to bridge both a printing zone 42 and a drying zone 44, in the printing zone 42, giving the support sheet 20 a first tension F1, in that state, printing the support sheet 20 with predetermined patterns, then feeding the support sheet 20 toward the drying zone 44, in the drying zone 44, giving the support sheet 20 on which the predetermined patterns were printed a second tension F2, and in that state, drying it in a drying chamber 62. The first tension F1 and the second tension F2 are given by separate tension giving means, and the second tension F2 is tension given along the support sheet 20 in the long direction and able to prevent shrinkage of the support sheet 20 in the long direction while passing through the drying zone 44.

Owner:TDK CORPARATION

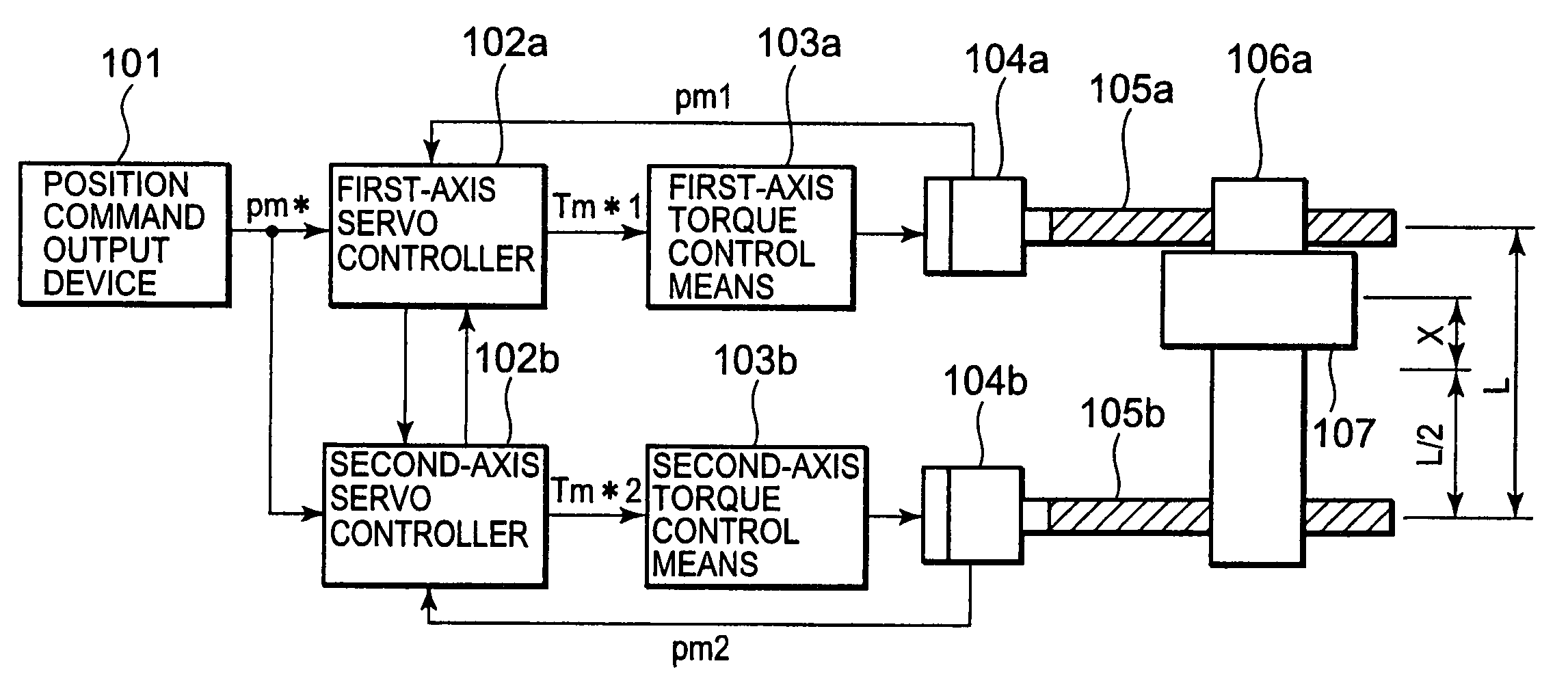

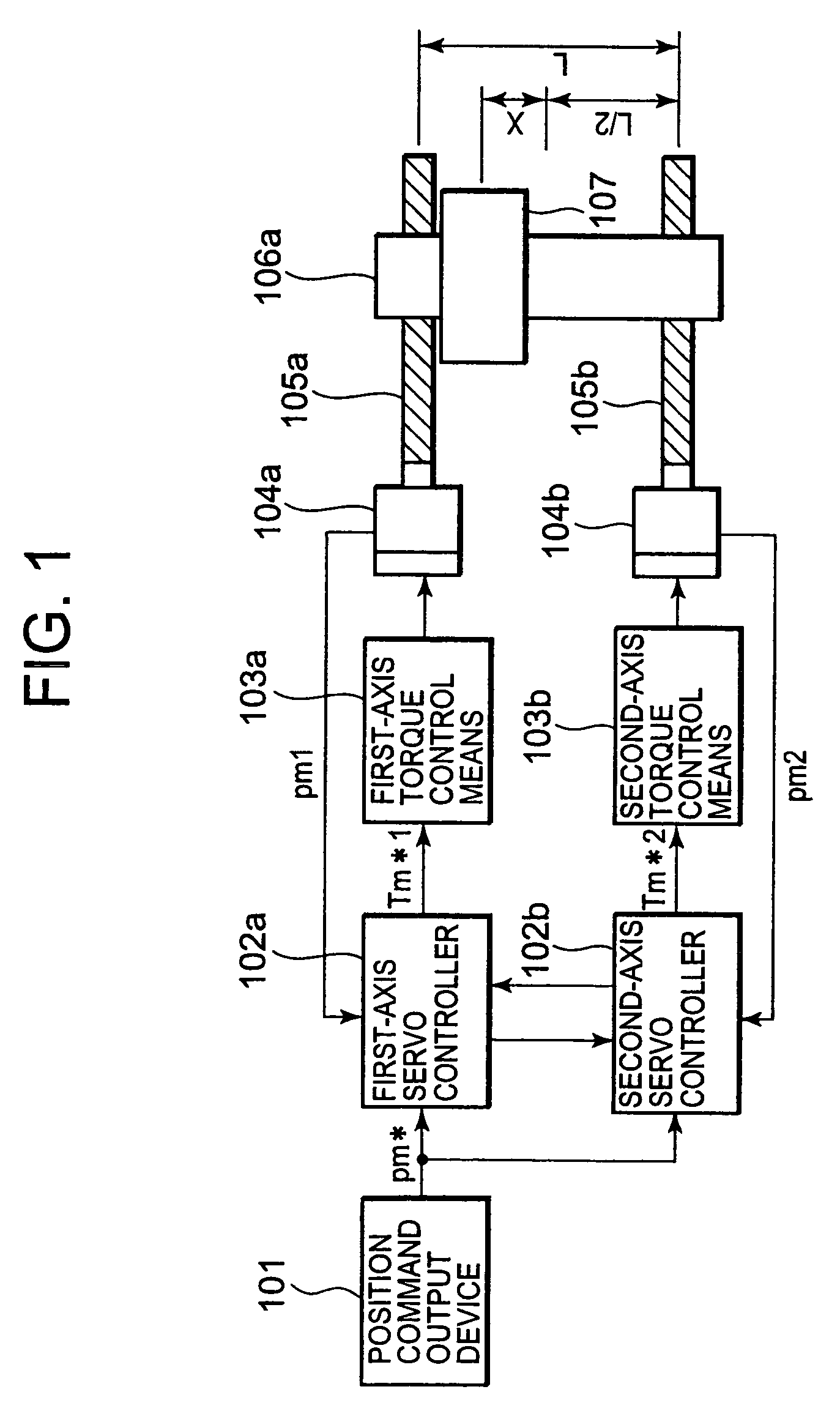

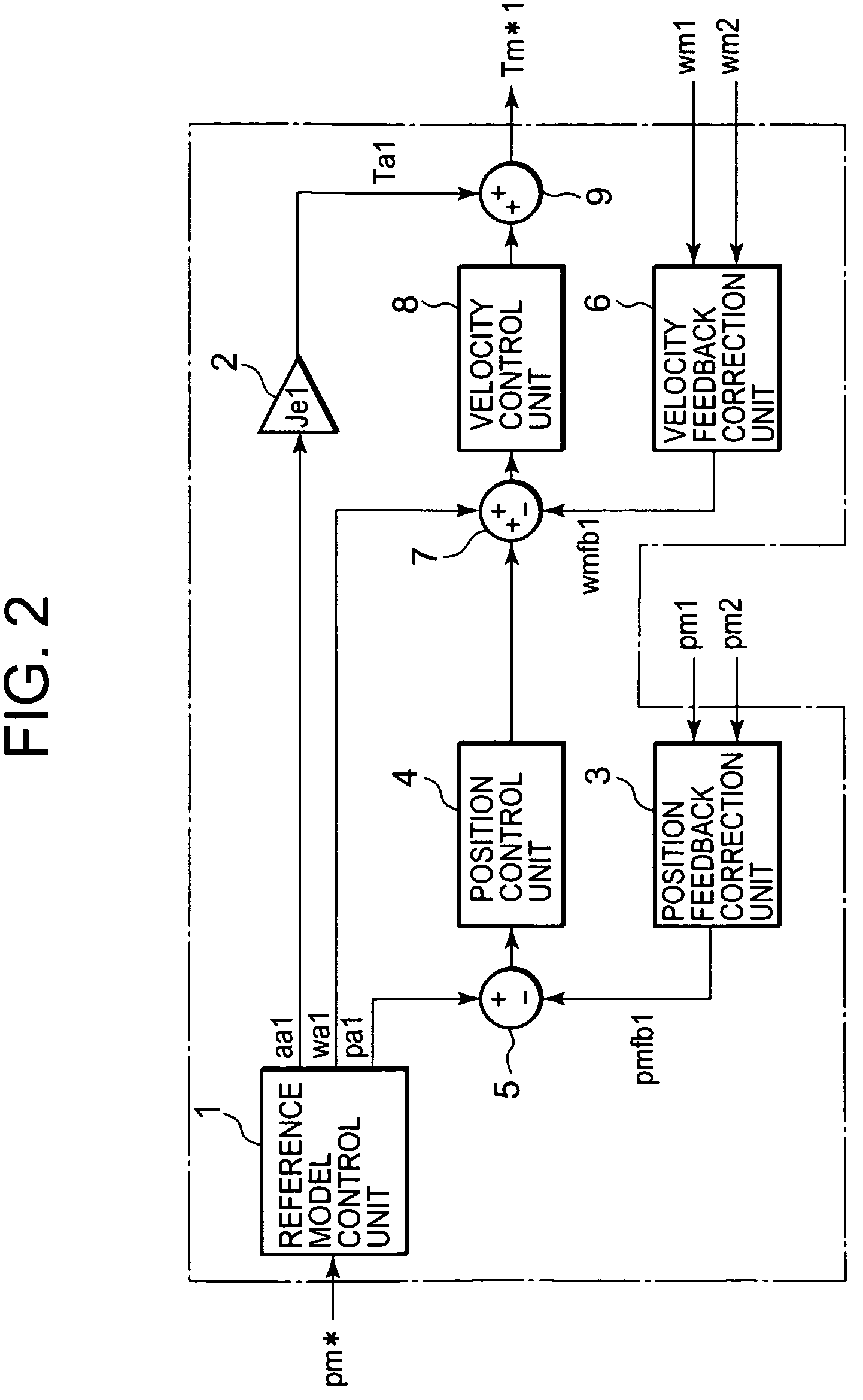

Servo controller

ActiveUS7671553B2Suppress position deviationAutomatic control devicesDC motor speed/torque controlEngineeringPosition control

In a servo controller according to the invention, a position feedback correction unit (3) calculates a first-axis position feedback signal (pmfb1) based on a first-axis position (pm1) as a self-axis position, and a second-axis position (pm2) as an other-axis position; and a deviation between a model position (pa1) and the first-axis position feedback signal (pmfb1) is inputted from a subtracter (5) to a position control unit (4), which performs positional control to output a velocity command. A velocity feedback correction unit (6) calculates a first-axis velocity feedback signal (wmfb1) from a first-axis velocity (wm1) as the self-axis velocity, and a second-axis velocity (wm2) as the other-axis velocity; and the velocity control unit (8) adds a model velocity (wa1) and the velocity command outputted from the position control unit (5), and subtracts the first-axis velocity feedback signal (wmfb1) therefrom, and outputs a feedback torque command (Tfb1) based on the corrected velocity command.

Owner:MITSUBISHI ELECTRIC CORP

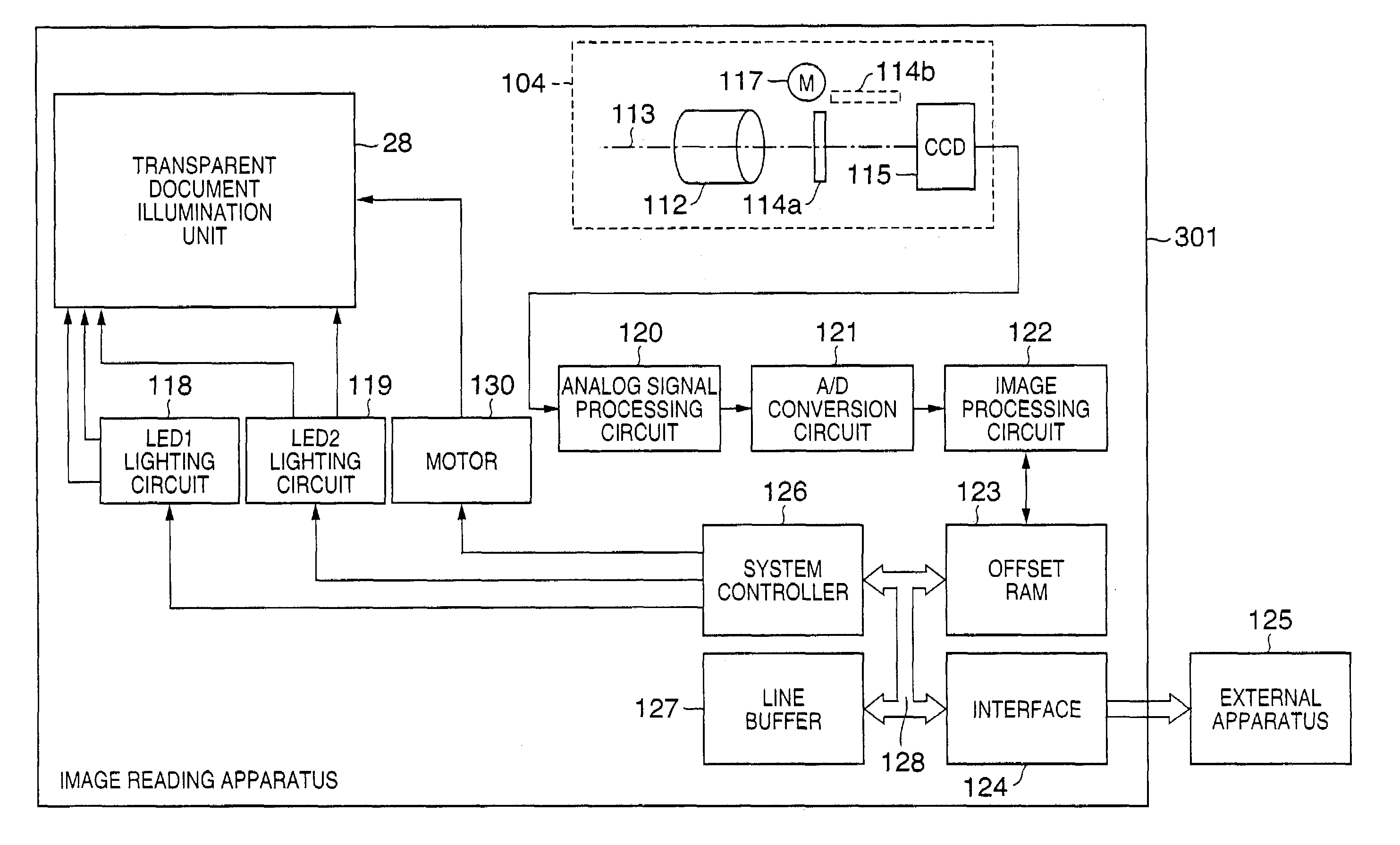

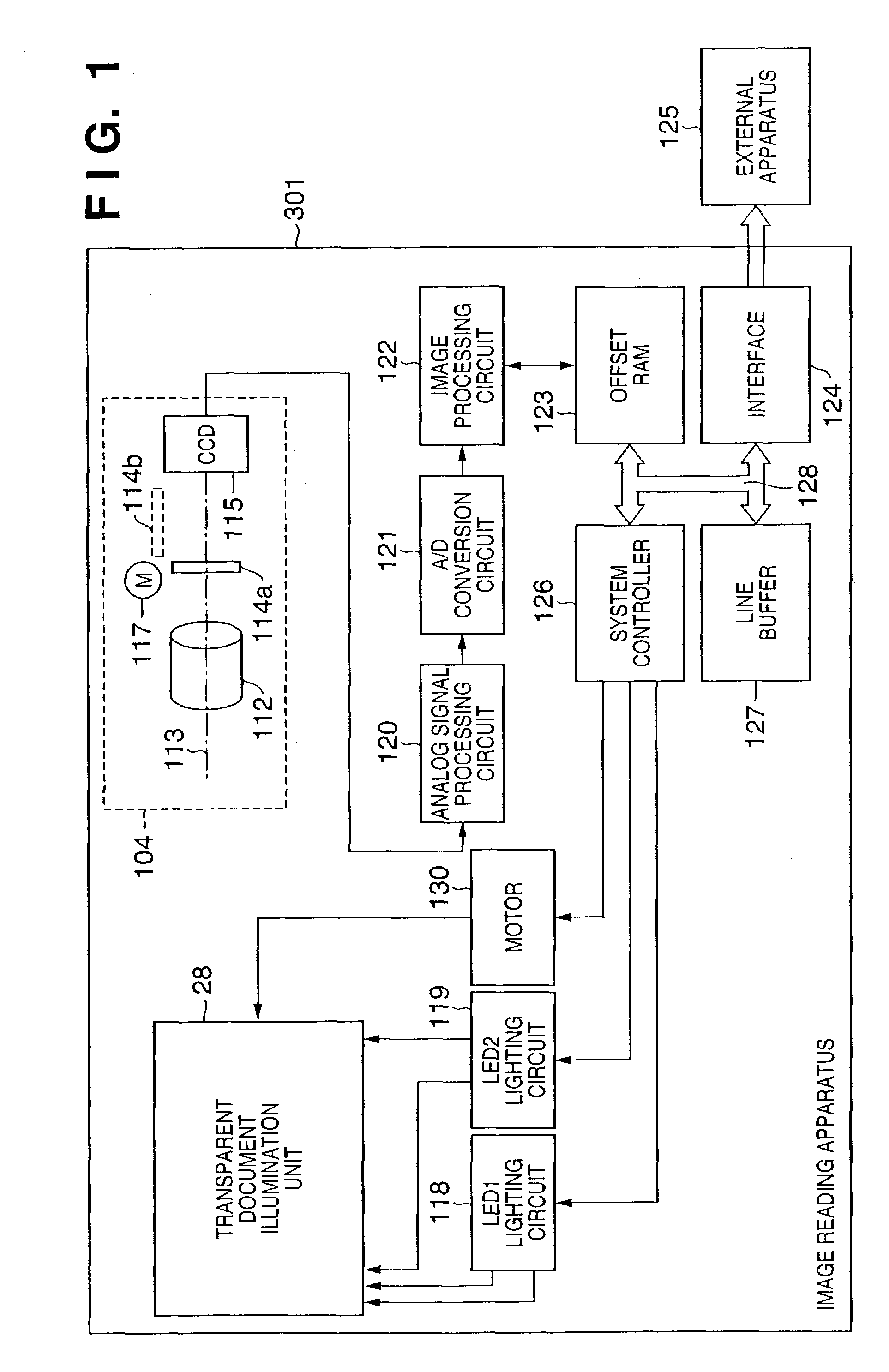

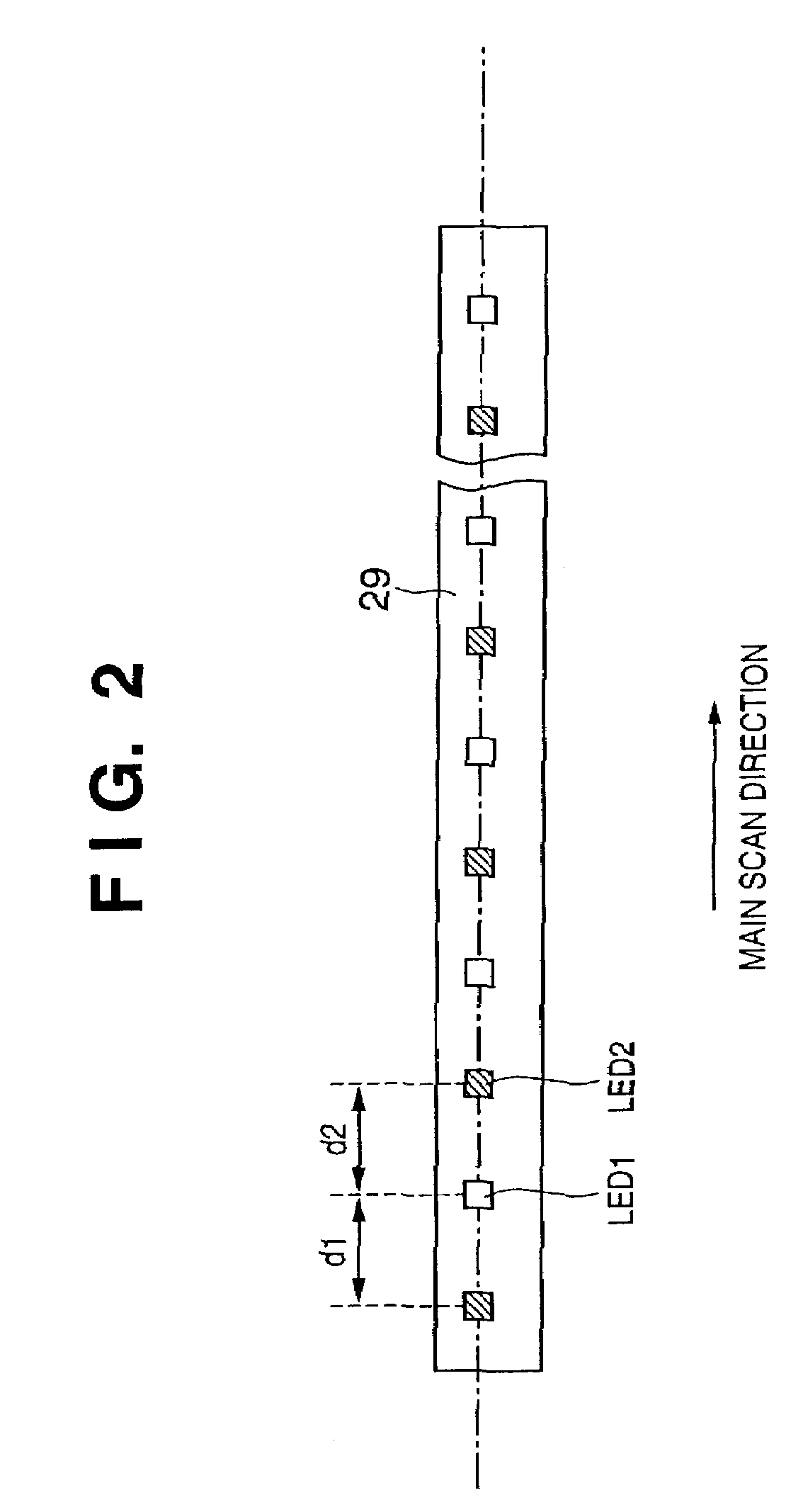

Image signal correction light source that can cope with dust and scratch on transparent document, and its control

InactiveUS7224483B2Suppress position deviationImprove S/NDigitally marking record carriersDigital computer detailsSignal correctionLight source

In a method of controlling an image reading apparatus, which has an illumination unit adapted to irradiate an object with first and second light rays in different frequency ranges, and a light-receiving unit adapted to receive light coming from the object, and to output a signal, and reads an image of the object by moving the illumination unit and light-receiving unit relative to the object, the light-receiving unit outputs a first signal in response to irradiation with the first light ray, and outputs a second signal in response to irradiation with the second light ray. Upon reading image information for one line by the image reading apparatus, the second light ray is controlled to be sequentially turned on at a plurality of timings to sandwich the ON timing of the first light ray, and image signals for one line corresponding to the first and second light rays are obtained by averaging or adding respective pieces of image information obtained at the plurality of timings for each of the first and second signals.

Owner:CANON KK

Cable connection structure and cable connection method

InactiveCN102412454ASuppress position deviationLine/current collector detailsElectrically conductive connectionsCoaxial cableElectrical conductor

A cable connection structure includes a multi-core coaxial cable connected to a board. The multi-core coaxial cable (2) includes a plurality of parallel-arranged coaxial cables each including a center conductor (3) and an inner insulator (4), an outer conductor (5) and an outer insulator sequentially formed on an outer periphery of the center conductor. The board includes a signal electrode (8) connected to the center conductor (3) and a ground electrode (9) connected to the outer conductor (5). The cable connection structure further includes a positioning member (11) lying between the signal electrode (8) and the ground electrode (9) for positioning the center conductor (3) while the inner insulator is attached to the positioning member.

Owner:PROTERIAL LTD

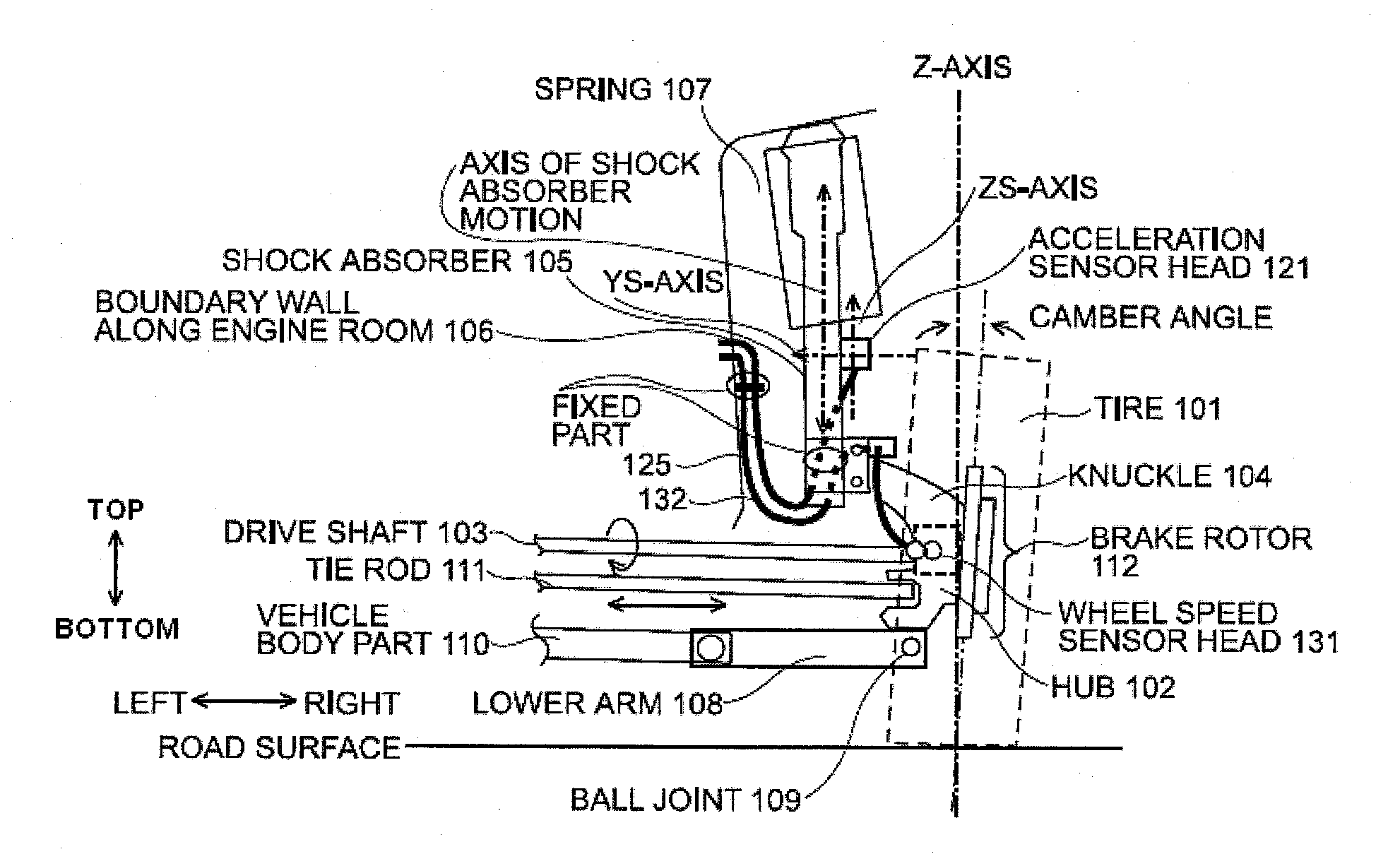

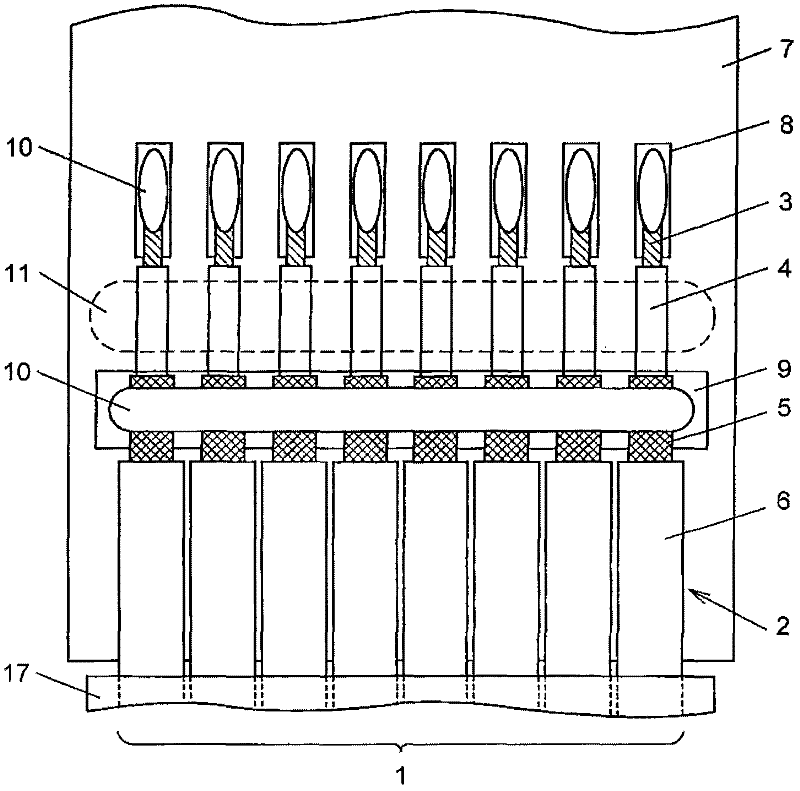

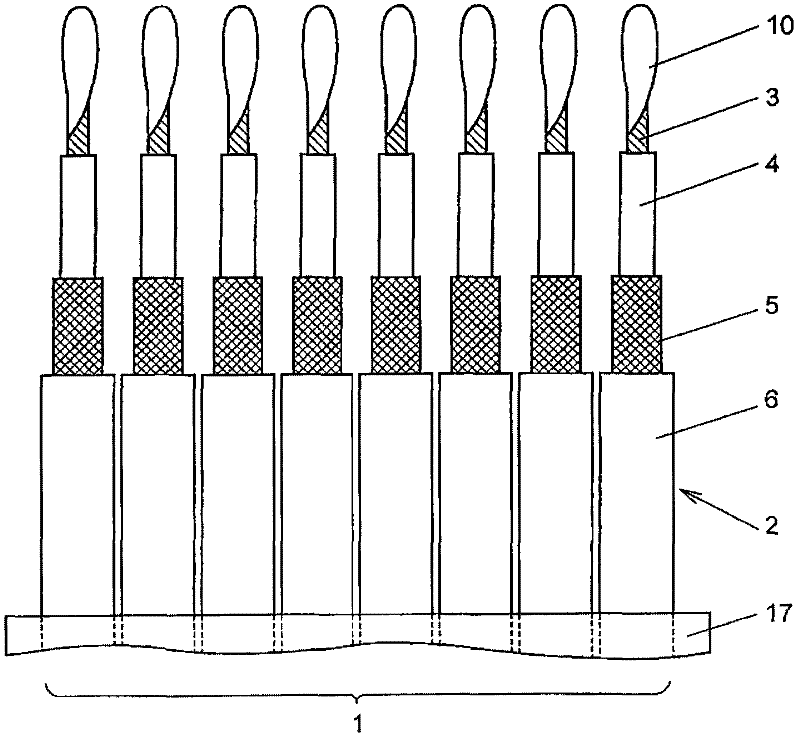

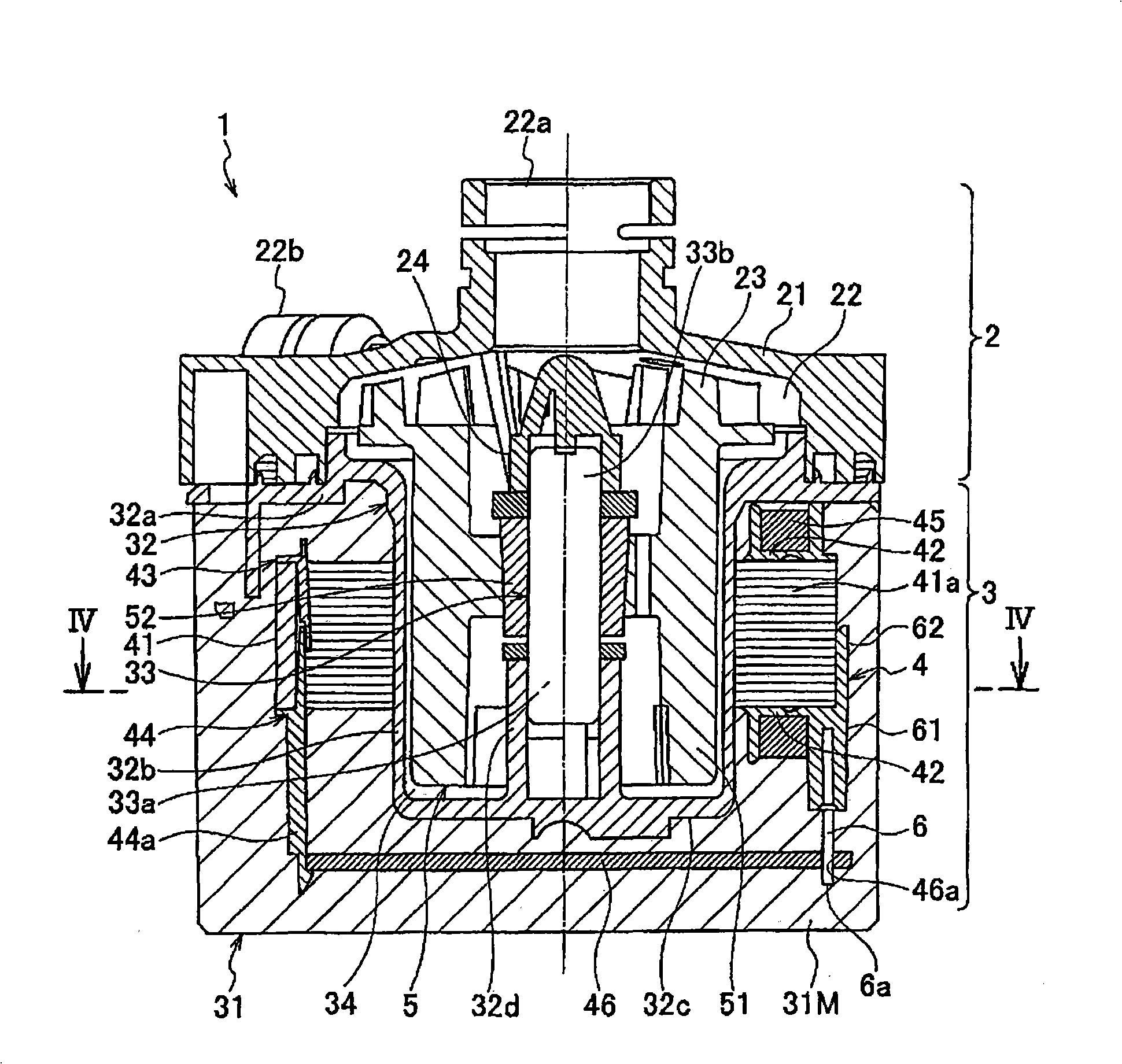

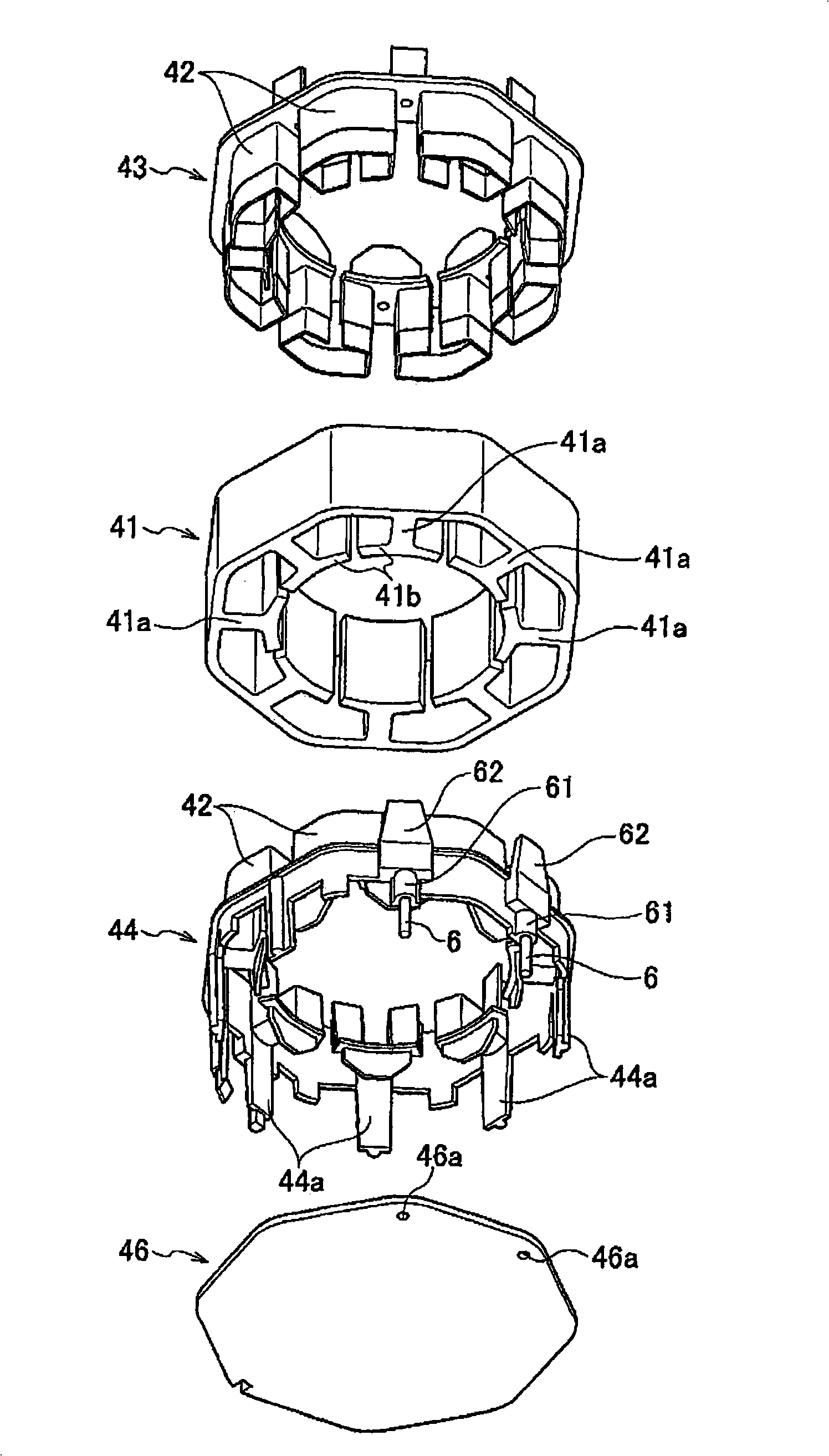

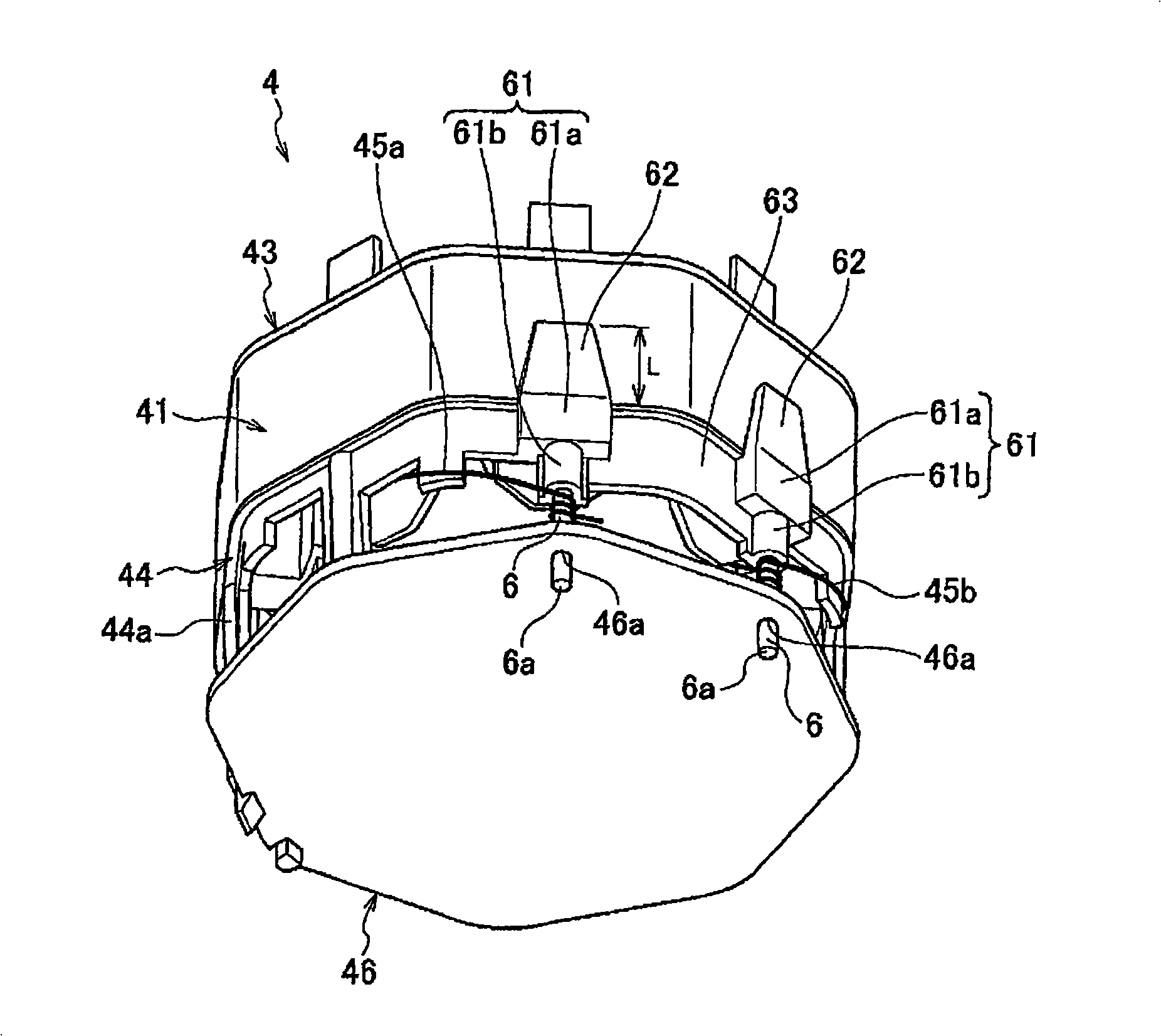

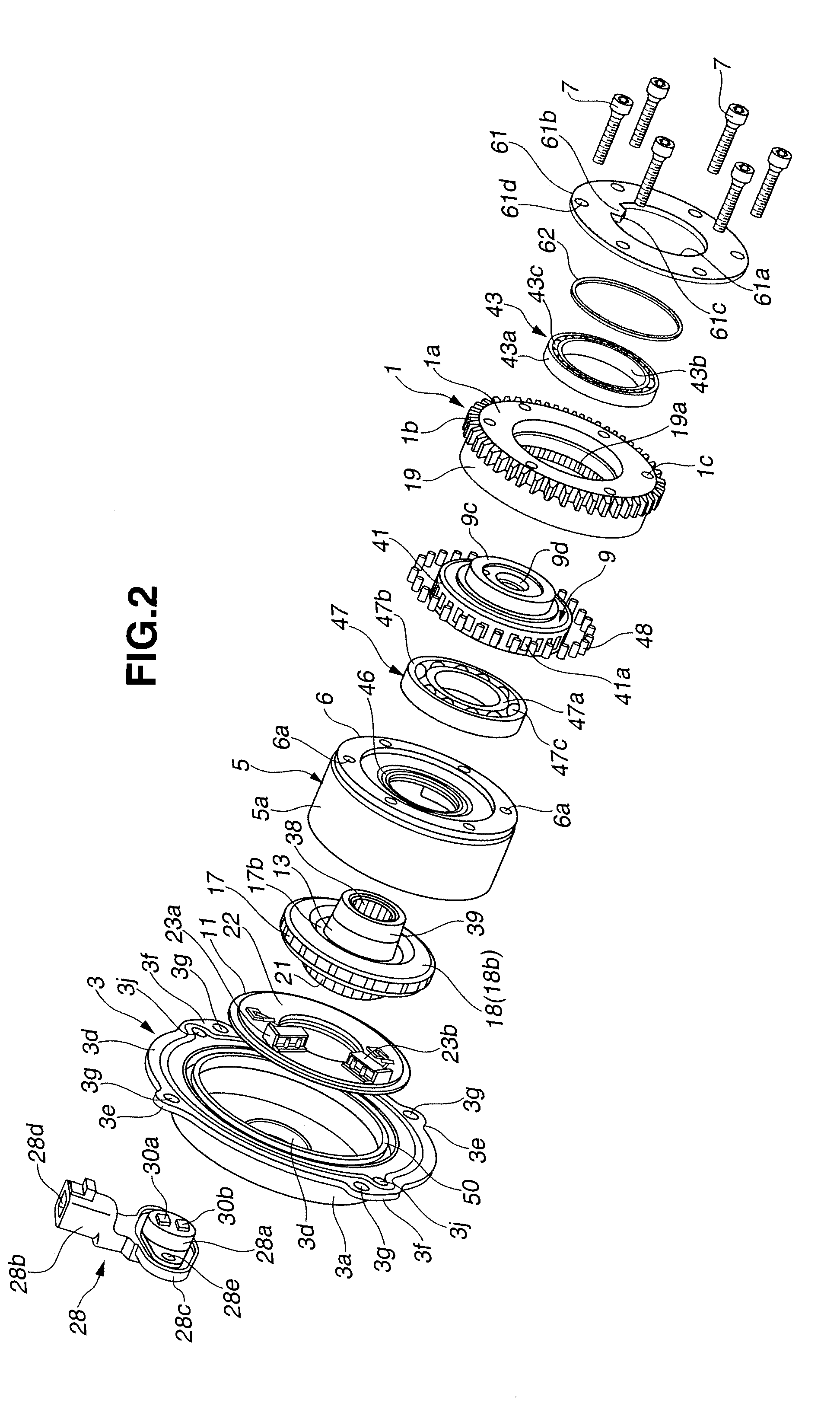

Motor and motor integrated pump with the motor

ActiveCN101494399AEasy wiringShorten takt timeWindings insulation shape/form/constructionPump installationsStatorEngineering

The invention provides a motor of wiring operation capable of winding more easily and reliably, and a motor-integrated pump equipped with the motor. At least two pins (6) are arranged for binding two end parts (45a,45b) of a winding (45) and clamping a front end part (6a) into a hole (46a) formed on a control substrate (46); a mounting part (61) is laterally protruded toward the control substrate (46) on an insulator (44), and respectively fixes the pin (6) under the condition of laterally protruding toward the control substrate (46); a strengthening wall (63) is laterally protruded toward the control substrate (46) on an insulator (44) and mutually connects between the mounting parts (61,61); further, a strengthening rib (62), which is abutted against the peripheral of a stator core (41, is arranged on the mounting part (61).

Owner:MATSUSHITA ELECTRIC WORKS LTD

Image Reading Apparatus

ActiveUS20120086988A1Good adhesionLarge biasing forcePictoral communicationEngineeringElectrical and Electronics engineering

Owner:SEIKO EPSON CORP

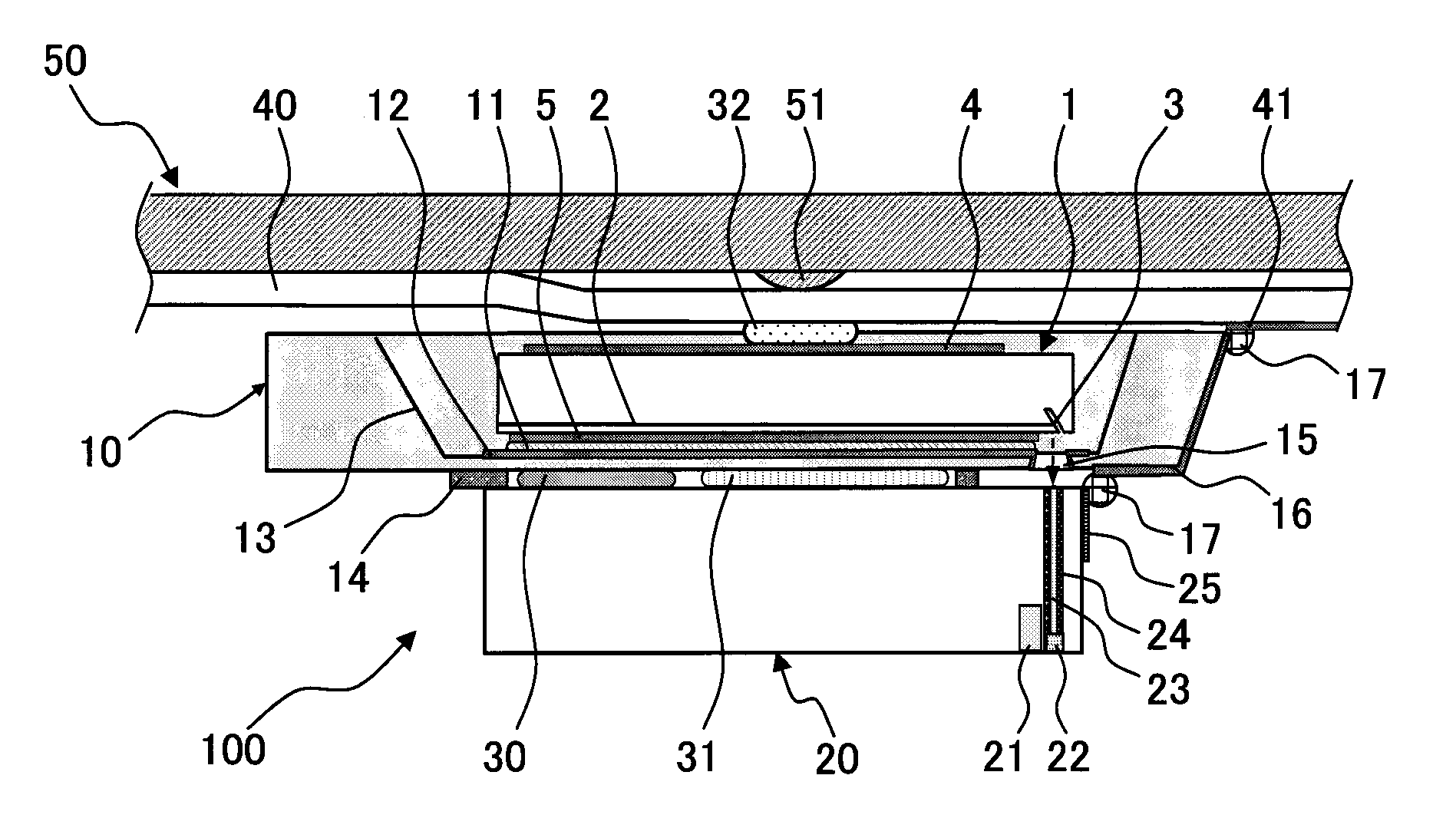

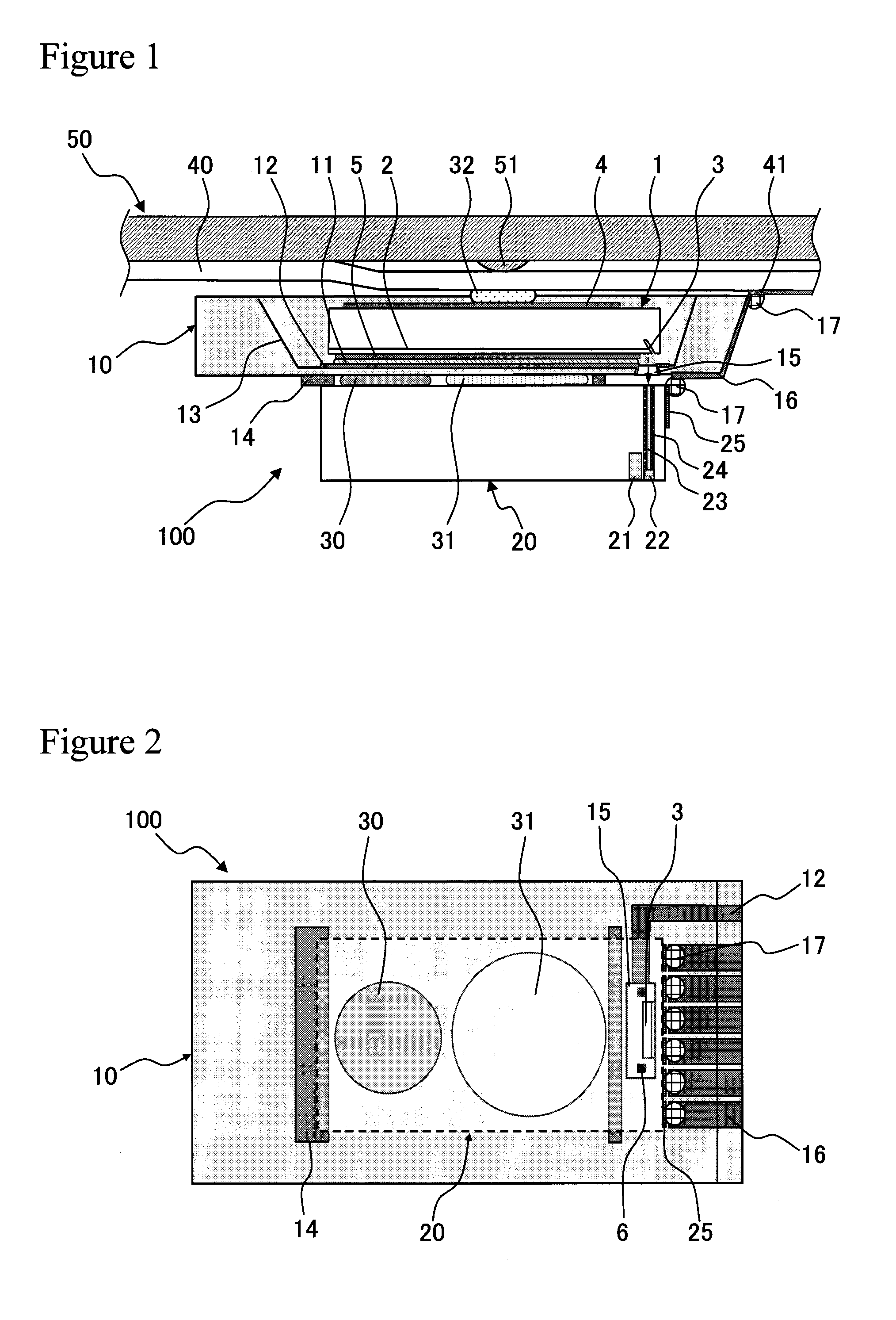

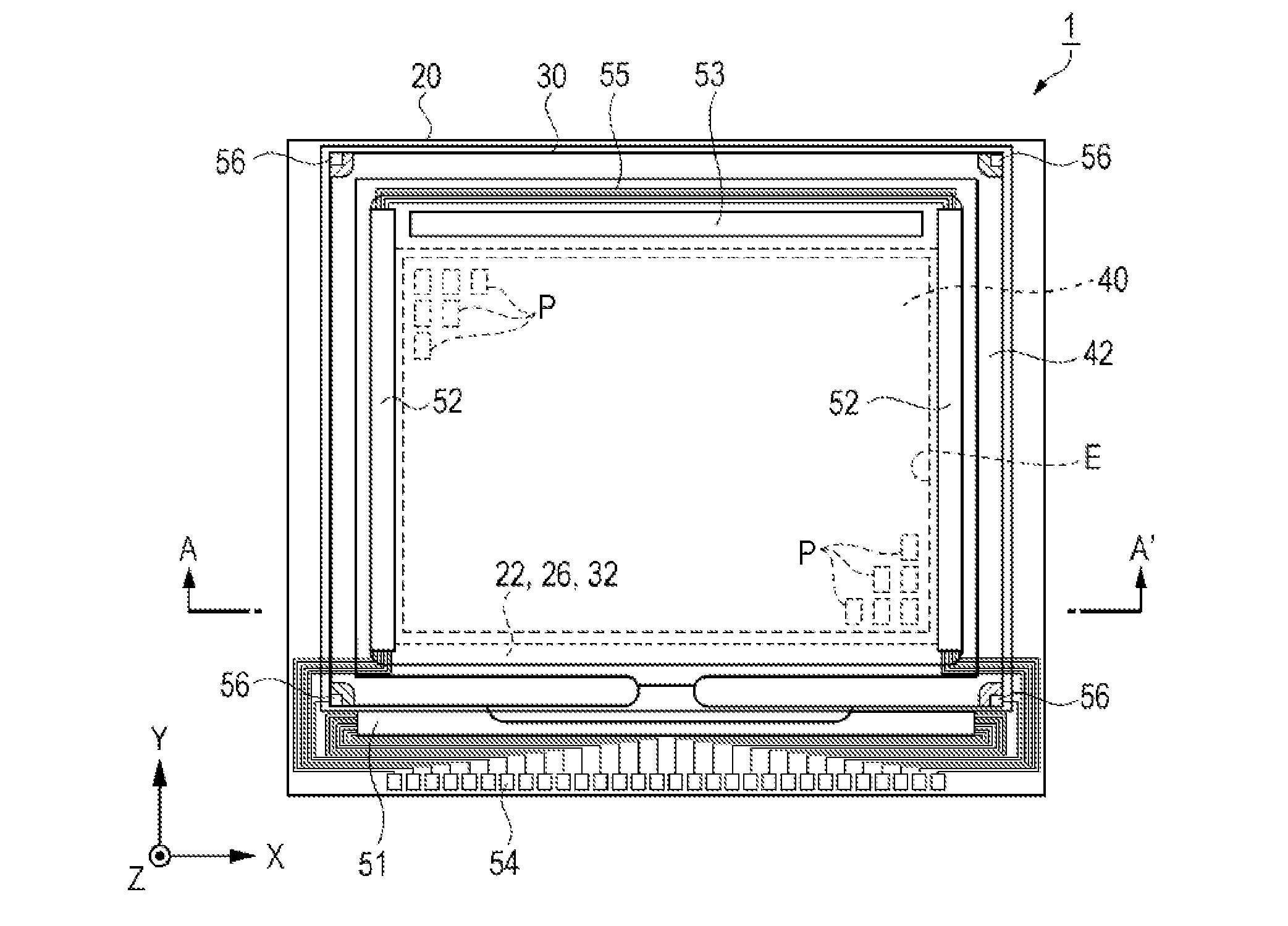

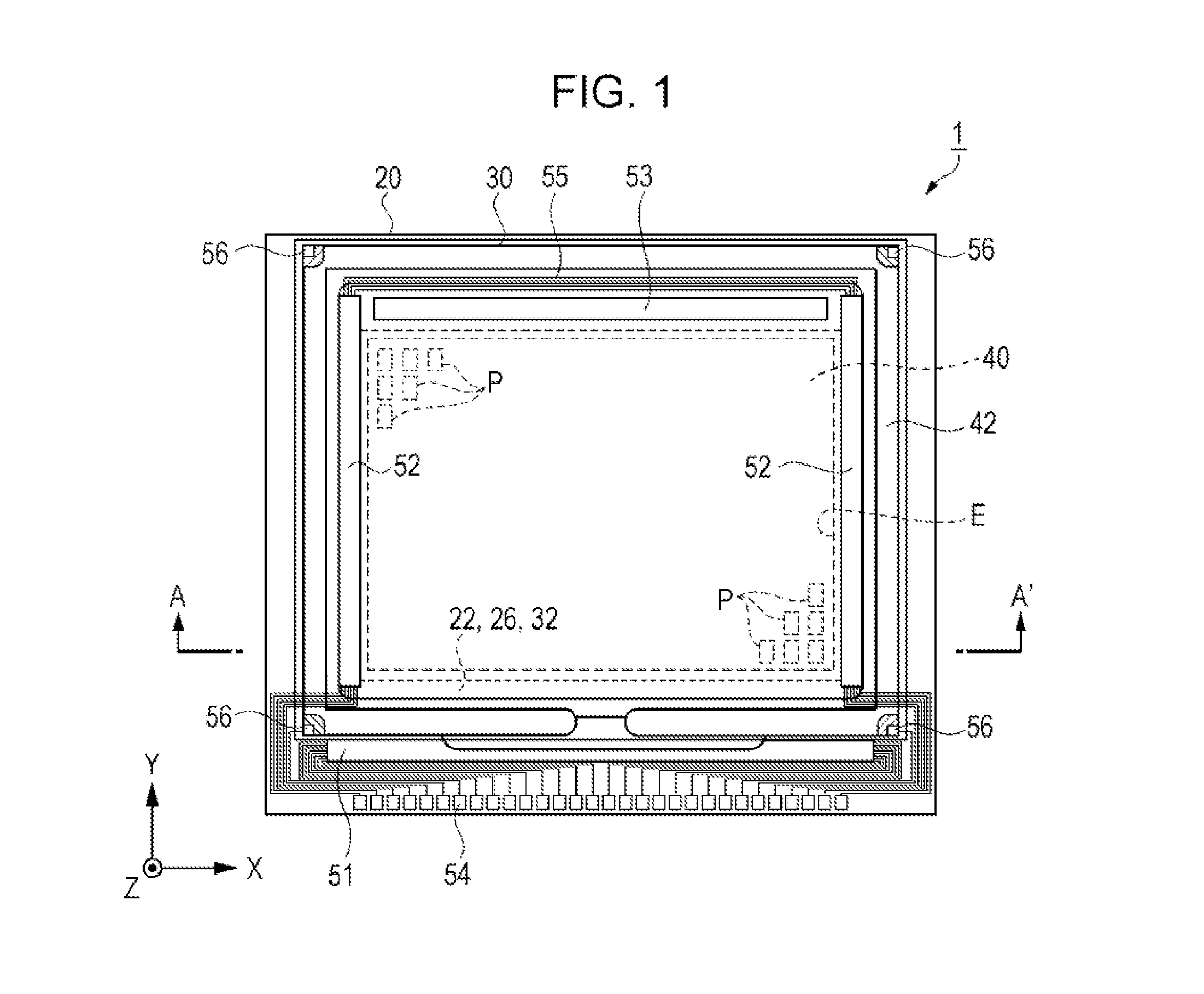

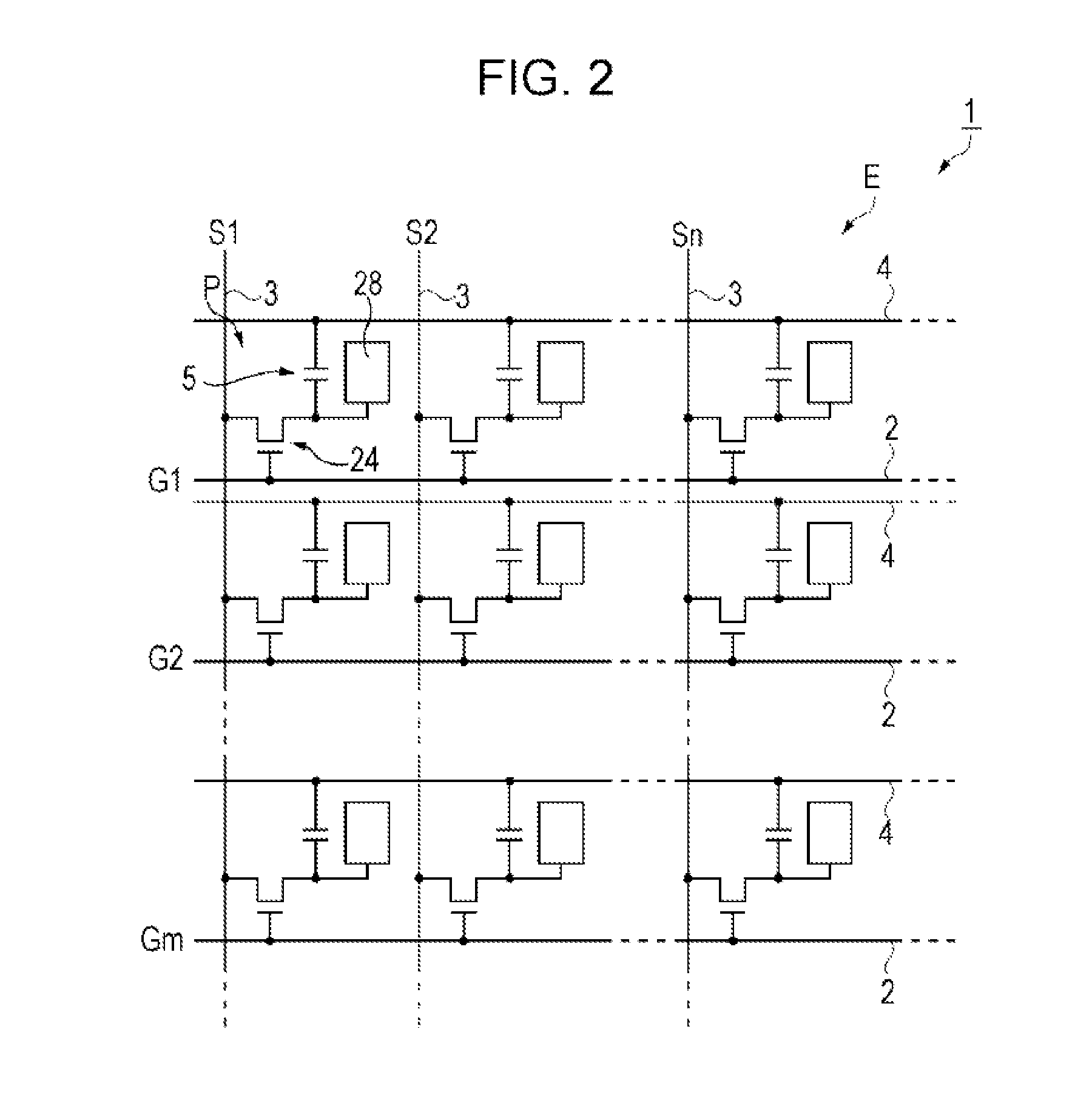

Micro lens array substrate, electro-optical device, and electronic apparatus

ActiveUS20140118664A1Improve efficiencyRelieve pressureProjectorsColor photographyOptical transparencyRefractive index

A micro lens array substrate includes a substrate having optical transparency and a lens layer having optical transparency and a different refractive index from that of the substrate, which is formed in such a manner as to fill in a concave portion arranged in one surface of the substrate in the X-direction, the Y-direction, and the W-direction. A through-hole is provided in the lens layer, between the adjacent concave portions in the W-direction in the lens layer, and the lens layer is continuous between the adjacent concave portions in the X-direction or in the Y-direction.

Owner:SEIKO EPSON CORP

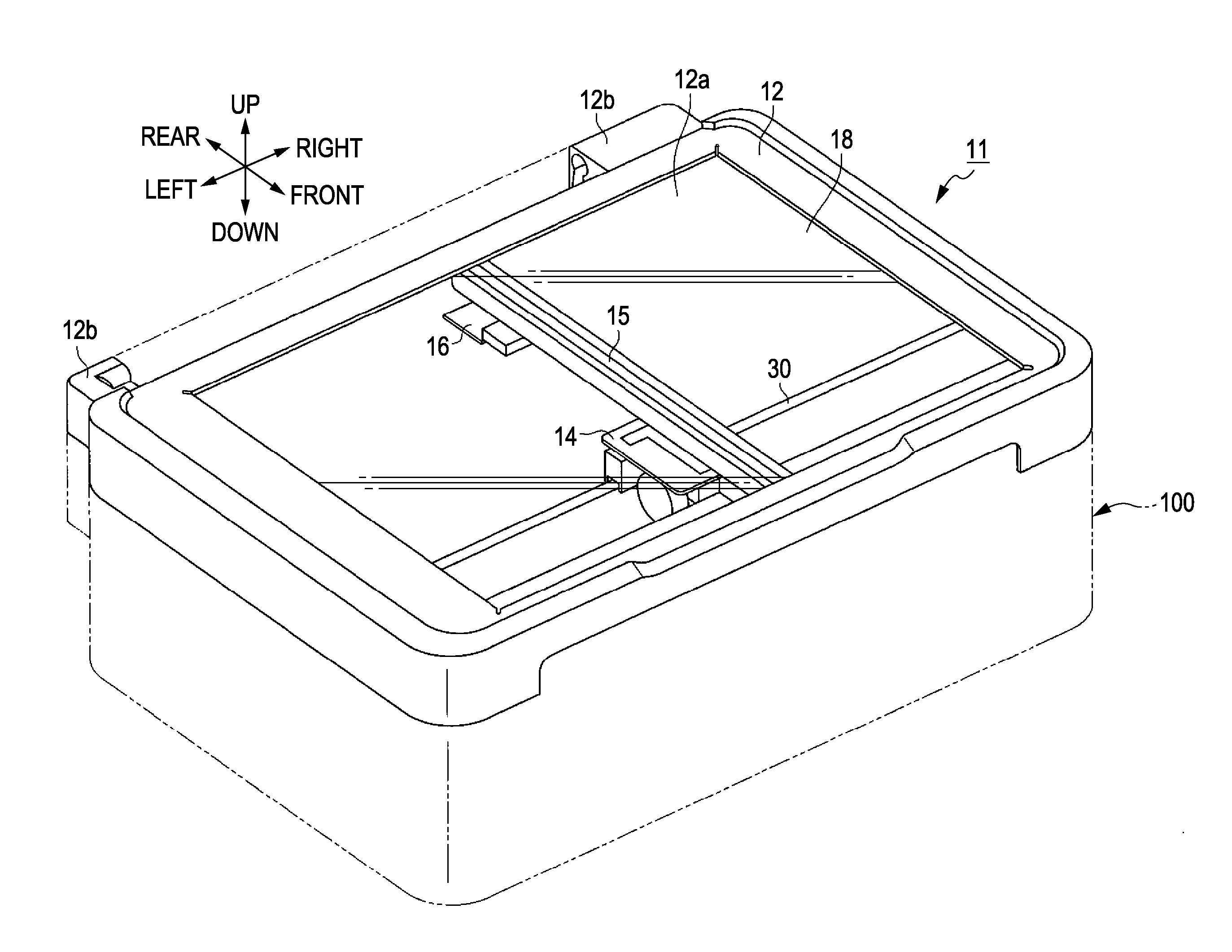

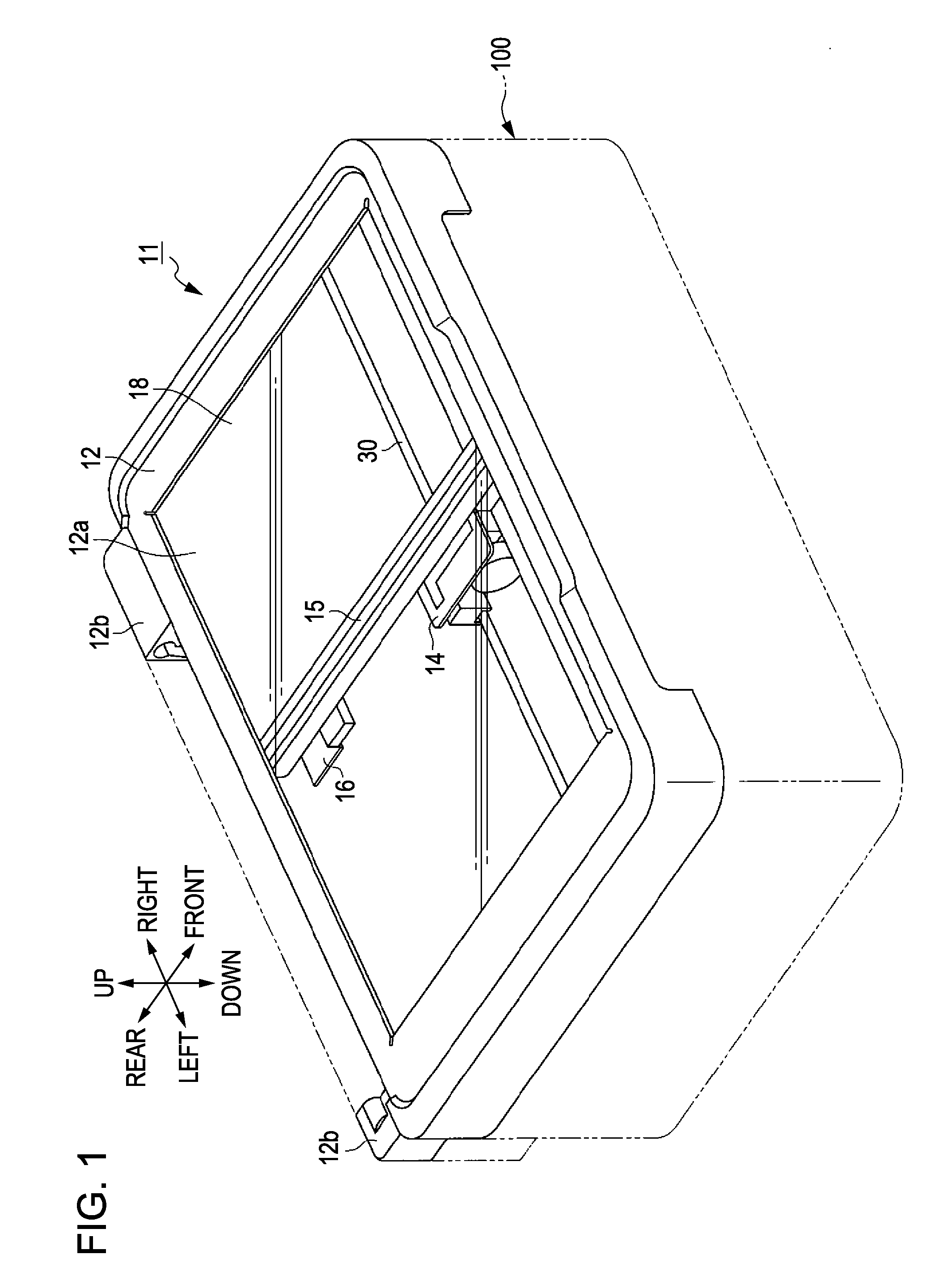

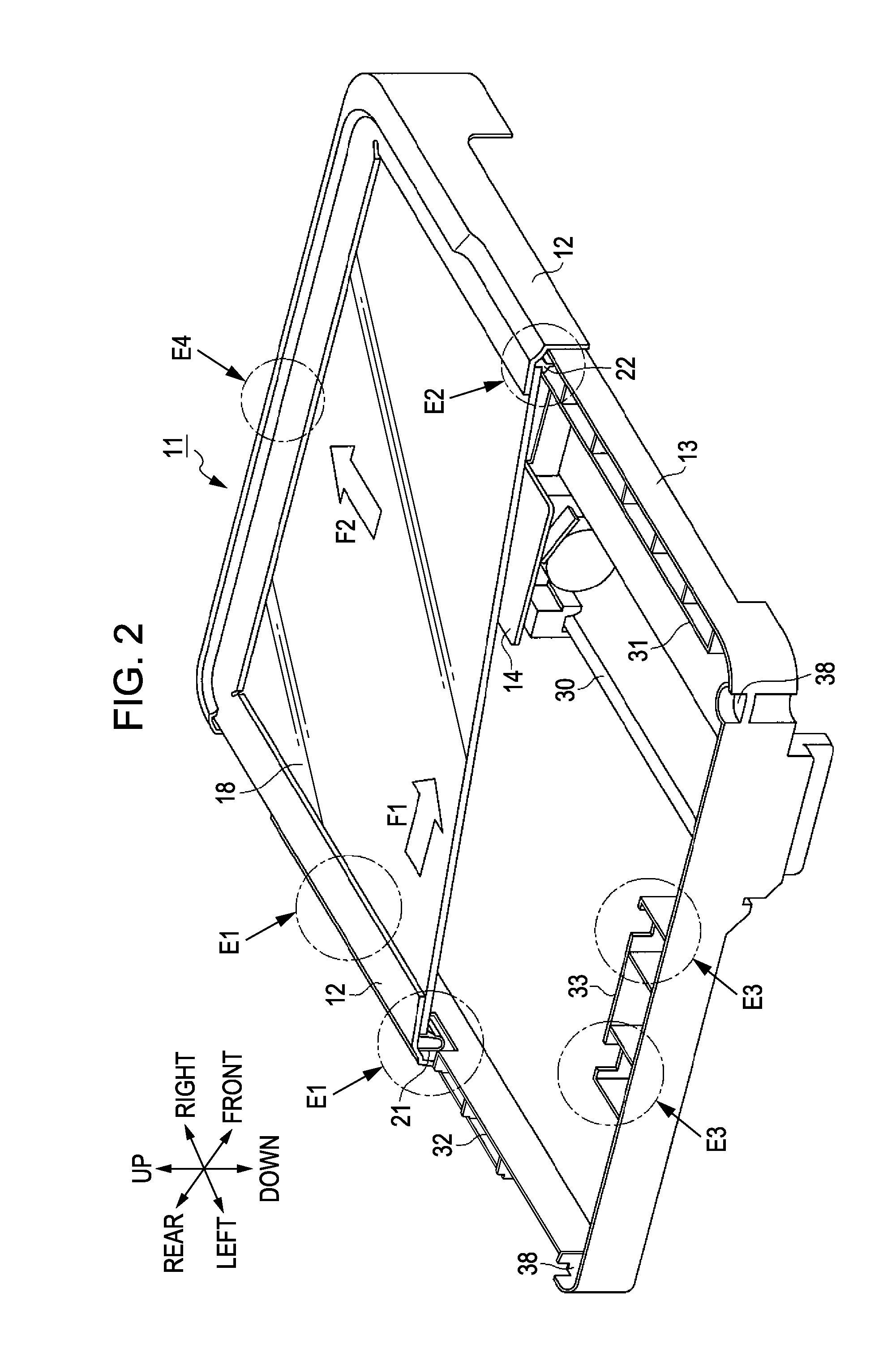

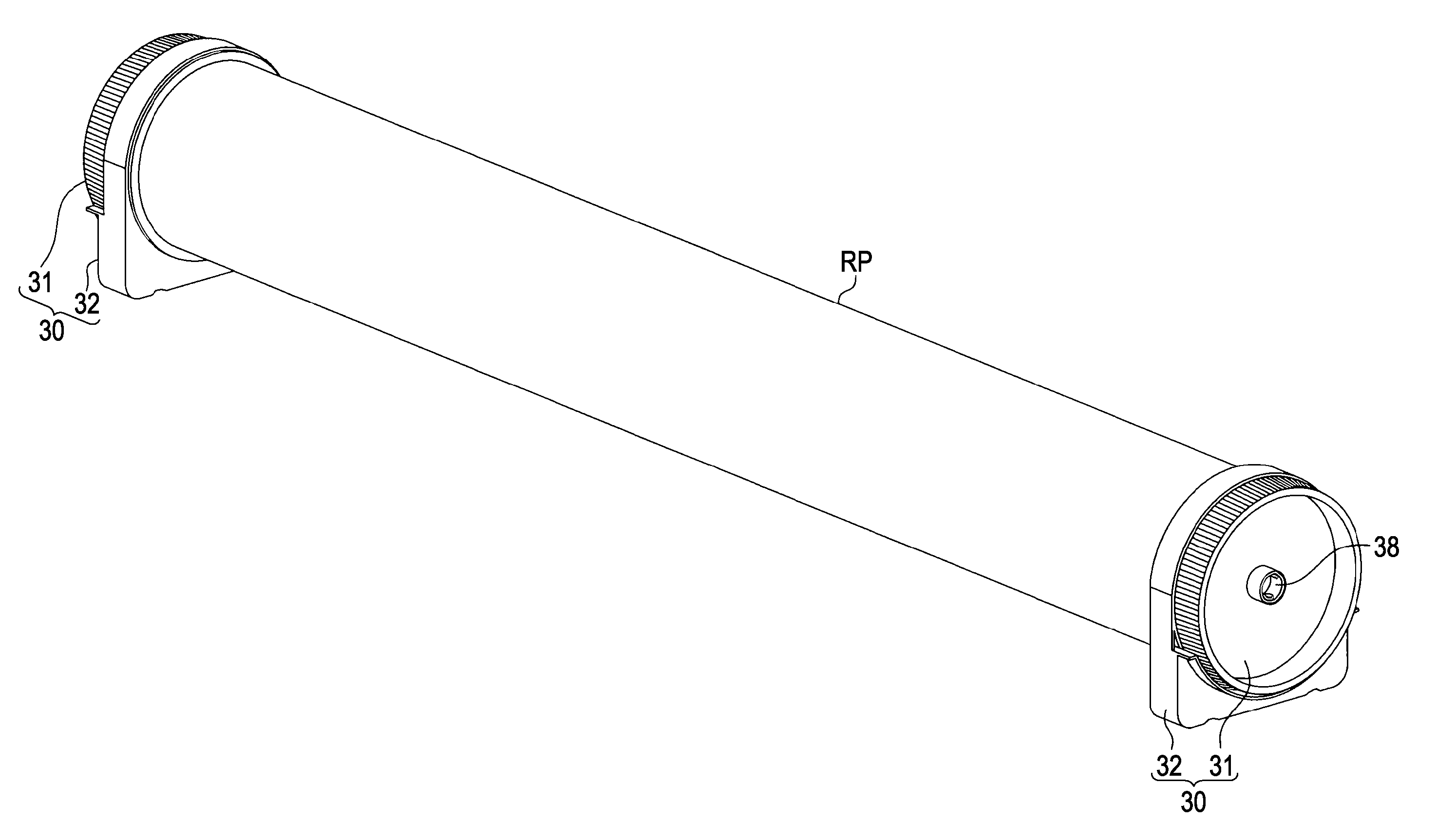

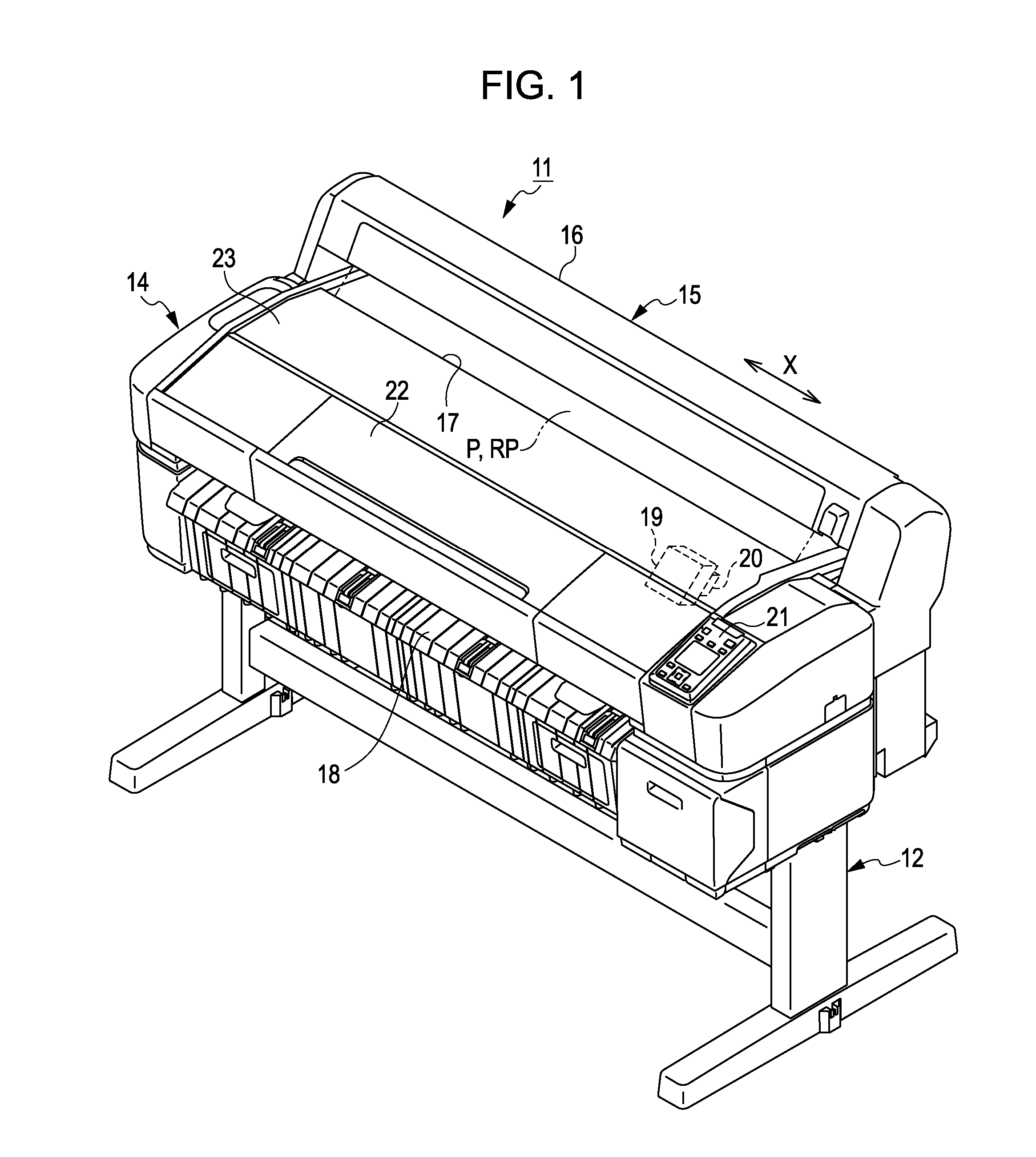

Medium loading apparatus and recording apparatus

ActiveUS20130278696A1Small sizeSmall overall lengthFilament handlingOther printing apparatusRolling paperEngineering

Owner:SEIKO EPSON CORP

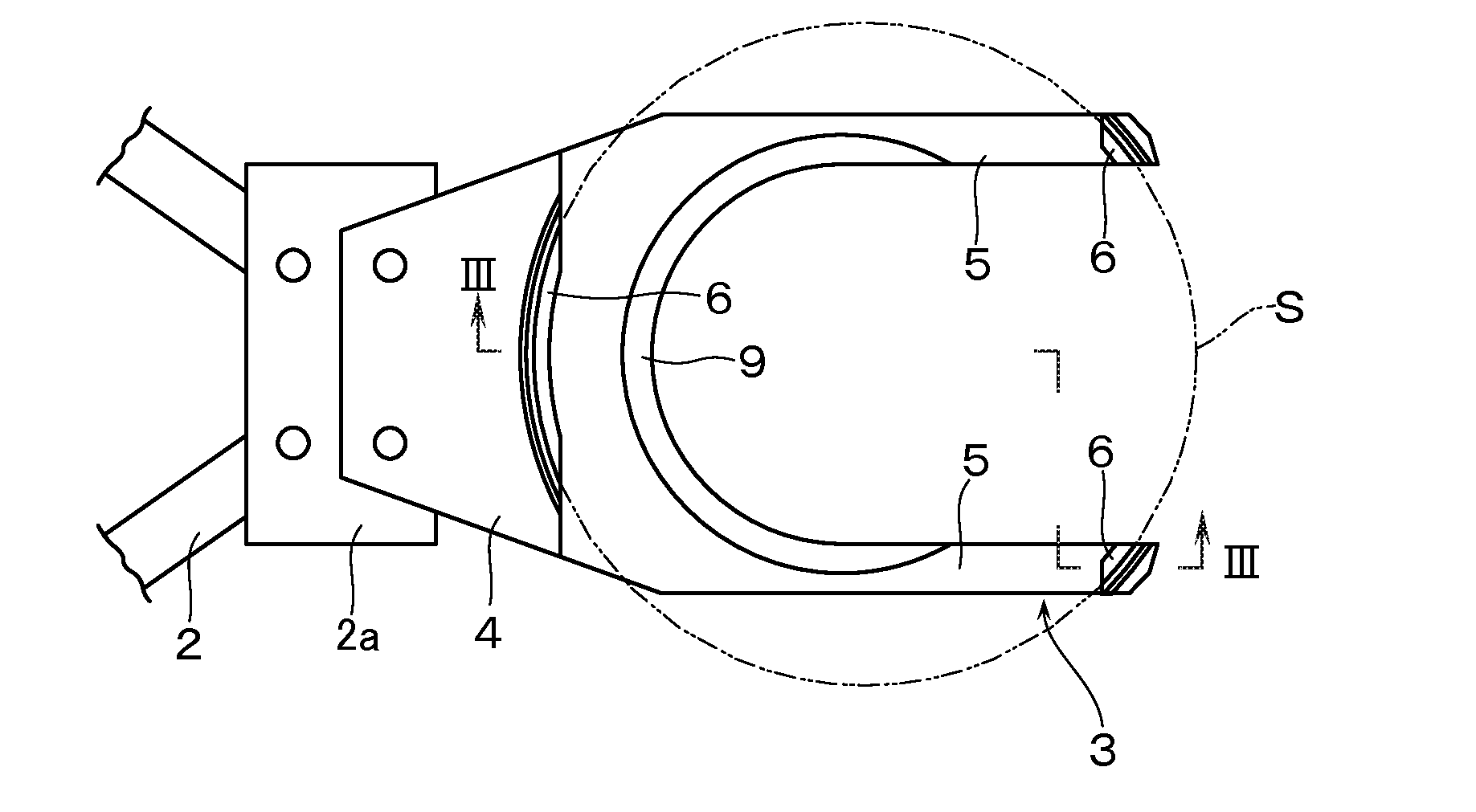

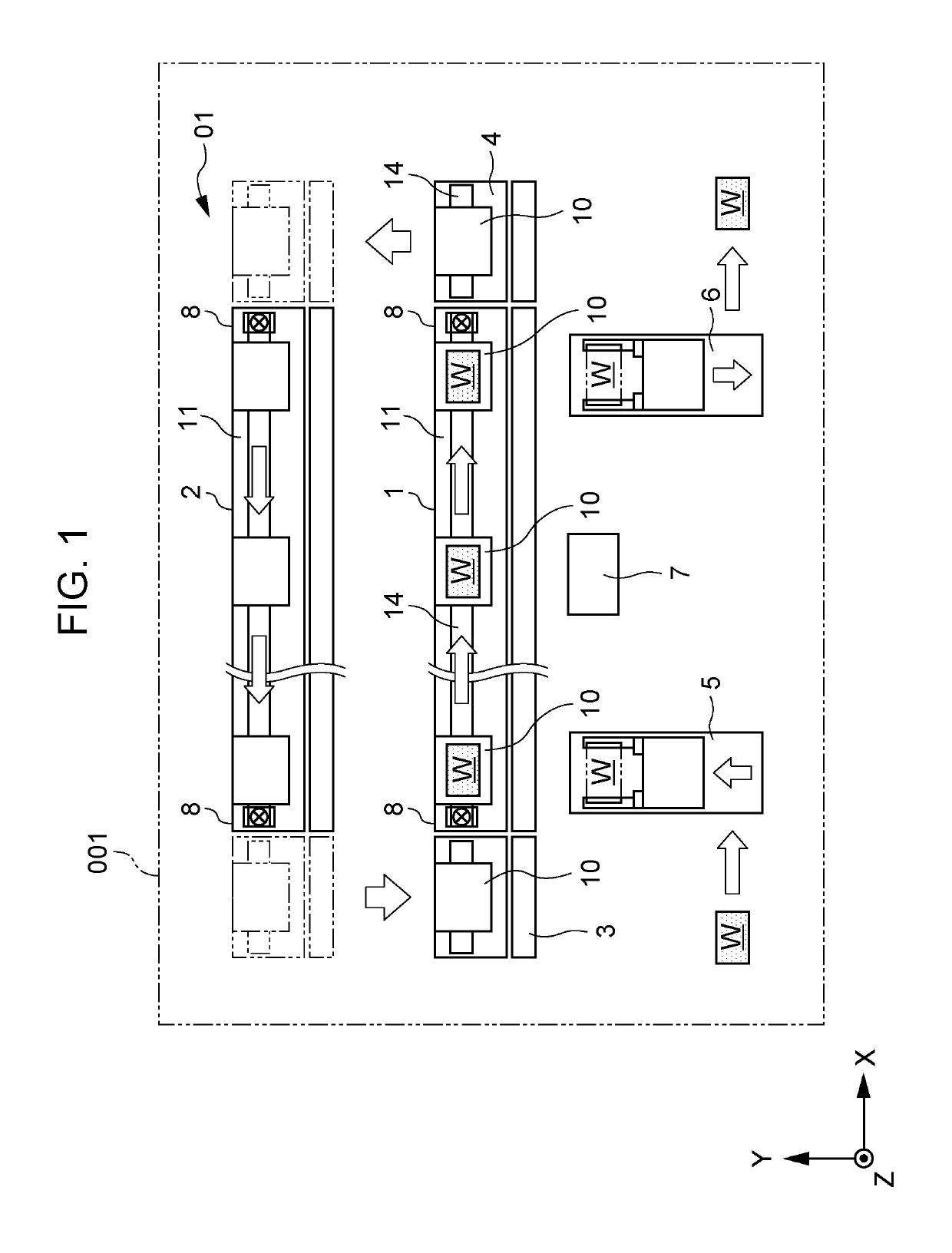

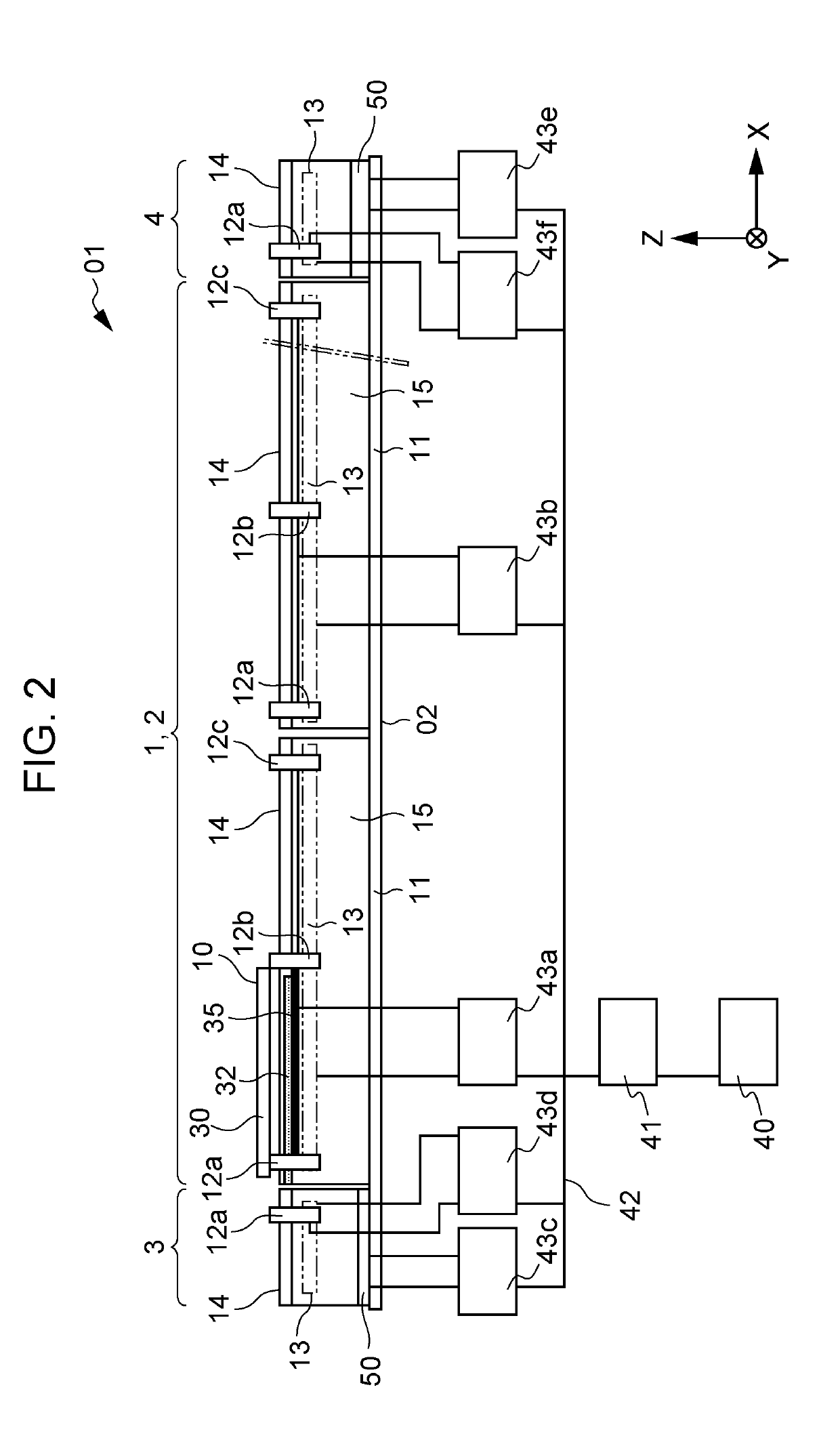

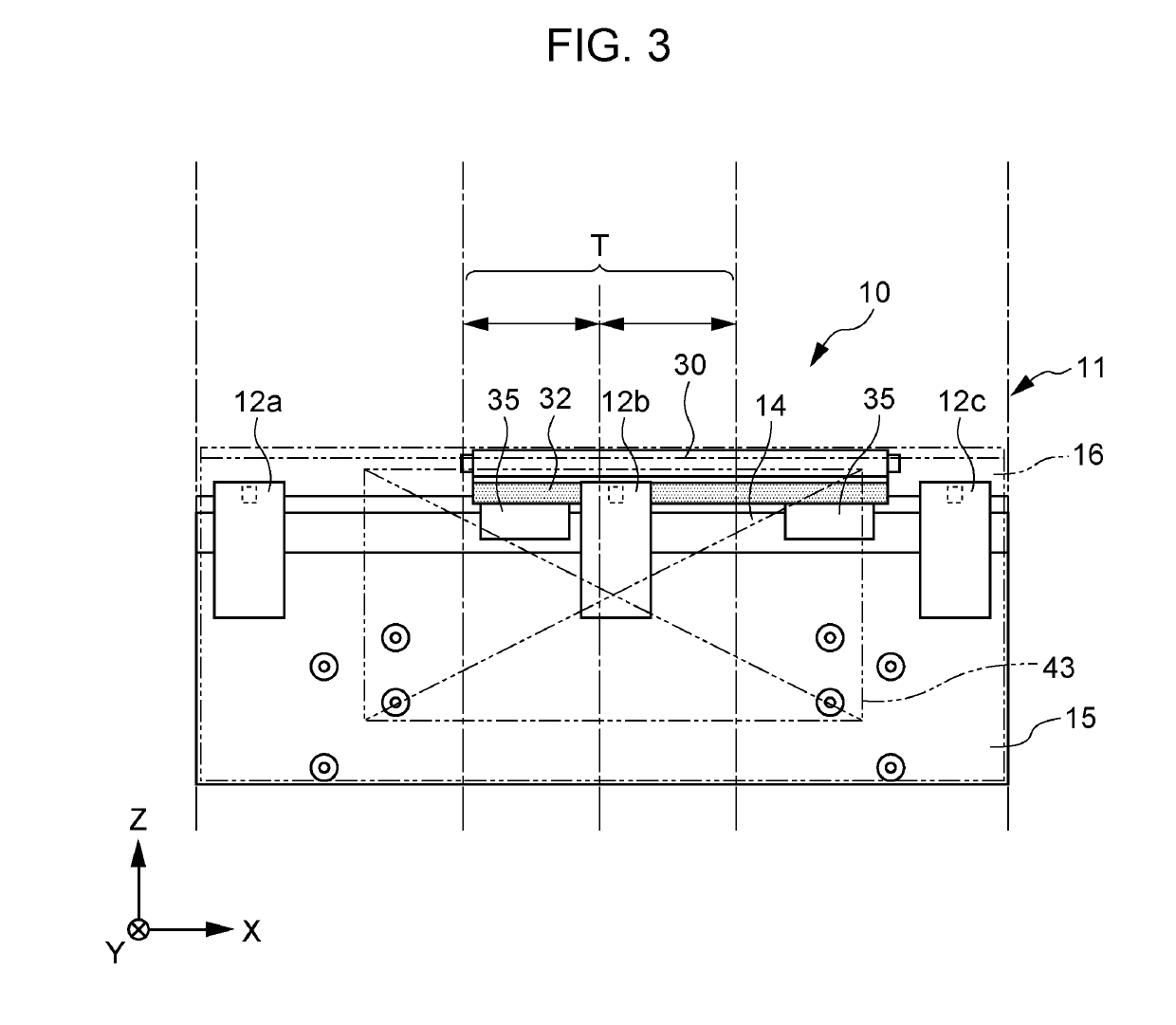

Transport system, processing system, and article manufacturing method

ActiveUS20190131860A1Precise positioningSuppress position deviationNon-mechanical conveyorsMetal working apparatusTransfer systemEngineering

In a transport system that moves a moving portion, which moves in a transport direction along a fixed portion, while detecting a position of the moving portion by a scale and a sensor, a guide block is installed on a second surface of a first part of the moving portion, a guide rail is installed on a first surface of the fixed portion, the scale is installed at an end of the first part of the moving portion on an opposite side across the guide block, and a sensor that has a detecting unit at a position facing the scale is installed in the fixed portion.

Owner:CANON KK

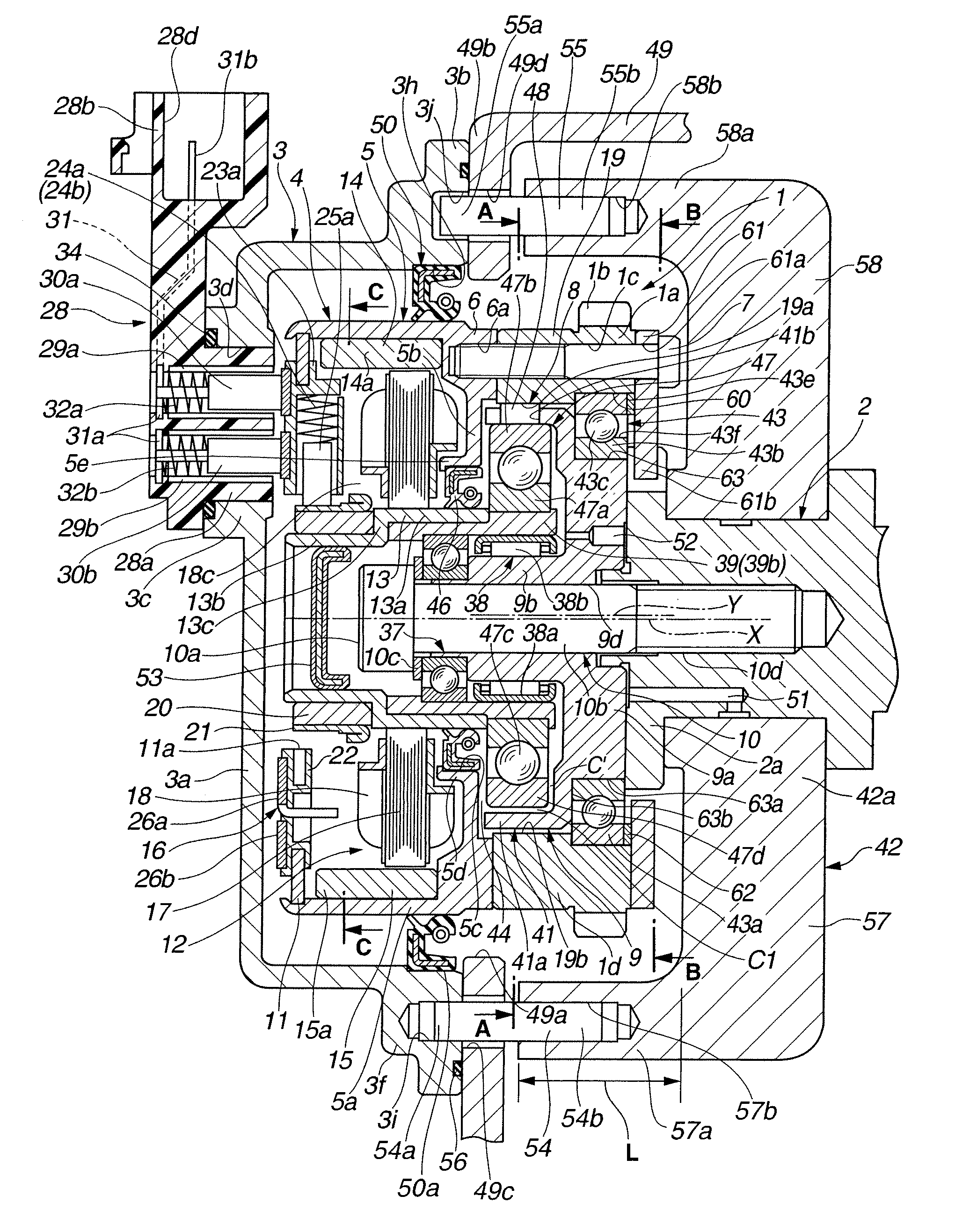

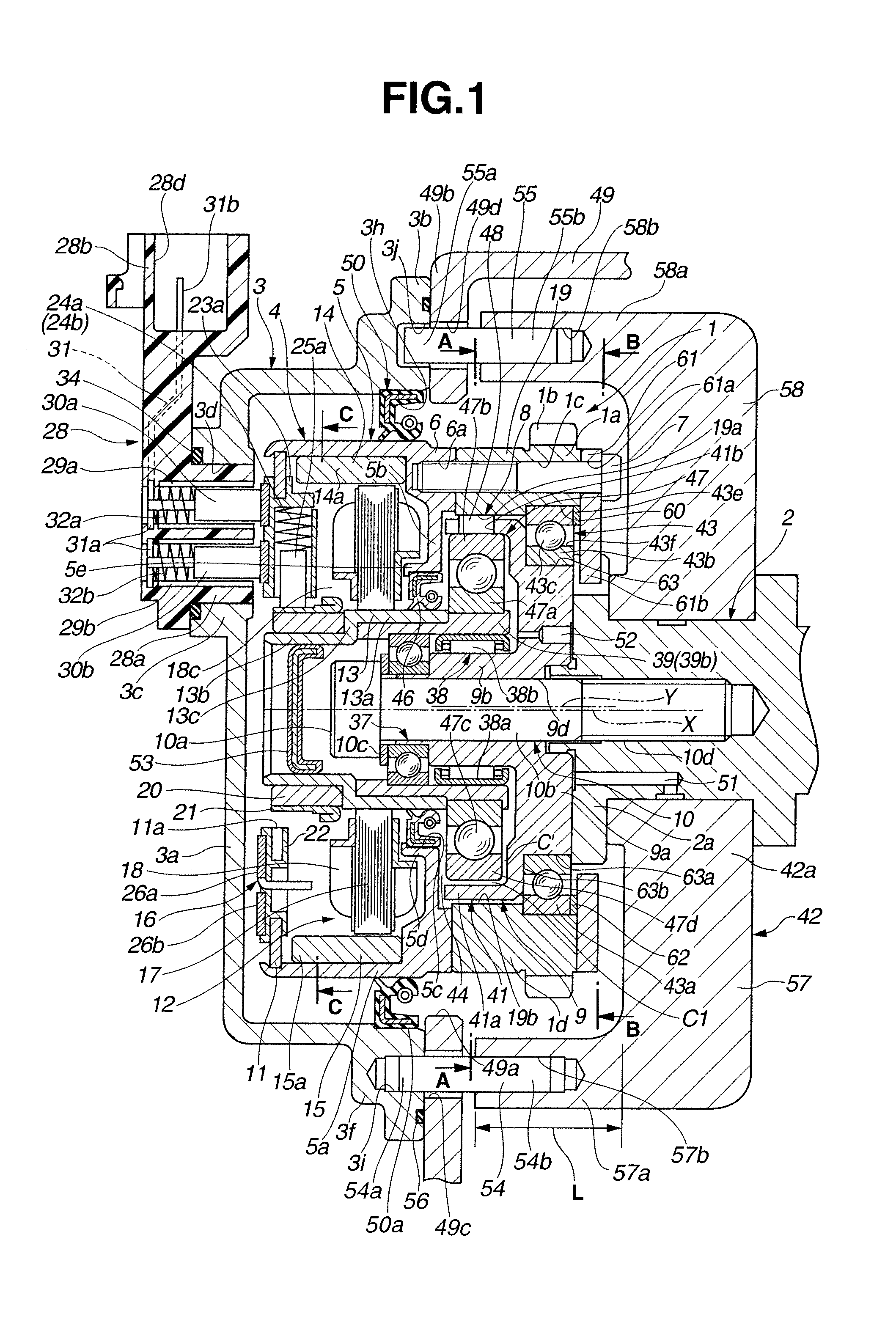

Valve timing control apparatus for internal combustion engine

InactiveUS20140123922A1Easy to assembleSuppress position deviationValve arrangementsMachines/enginesExternal combustion engineEngineering

In a valve timing control apparatus for an internal combustion engine, a plurality of projection sections projected toward a cover member are integrally mounted on a bearing member configured to rotatably journalize a camshaft and a plurality of positioning pins are mounted across (or extended over) the cover member and the respective projection sections.

Owner:HITACHI AUTOMOTIVE SYST LTD

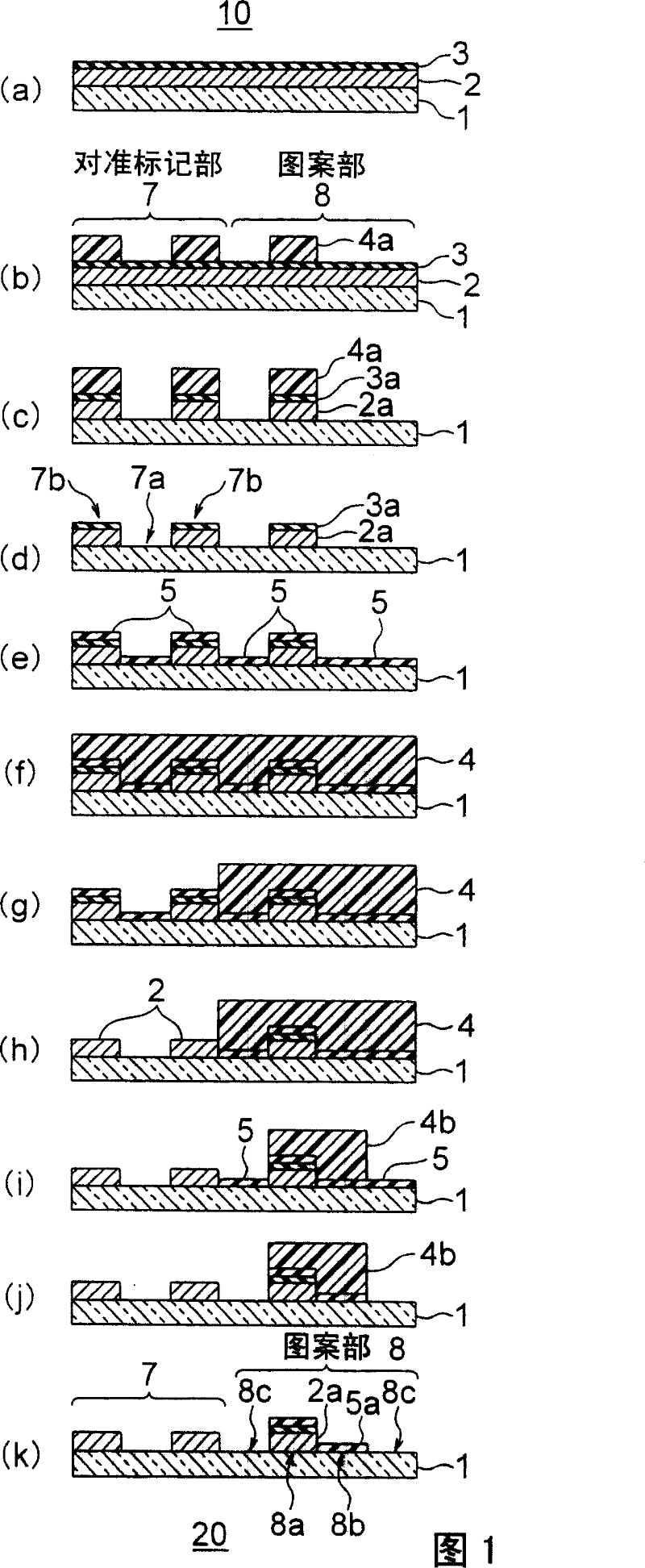

Pattern forming method and gray-tone mask manufacturing method

InactiveCN101038445AIncrease contrastImprove detection accuracySemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusForming processesMaterials science

The invention provides a method for forming pattern, has plural pattern forming processes using photoetching process. The processes for forming same substrate at least has: A process for forming alignment mark used for depicting alignment; and a process for depicting pattern by using the alignment mark for alignment, wherein the alignment mark is comprised by lightproof portion and translucent portion, and before depicting the pattern, the reflection proof membrane of the lightproof portion of the alignment mark which has the reflection proof membrane on top layer is eliminated.

Owner:HOYA CORP

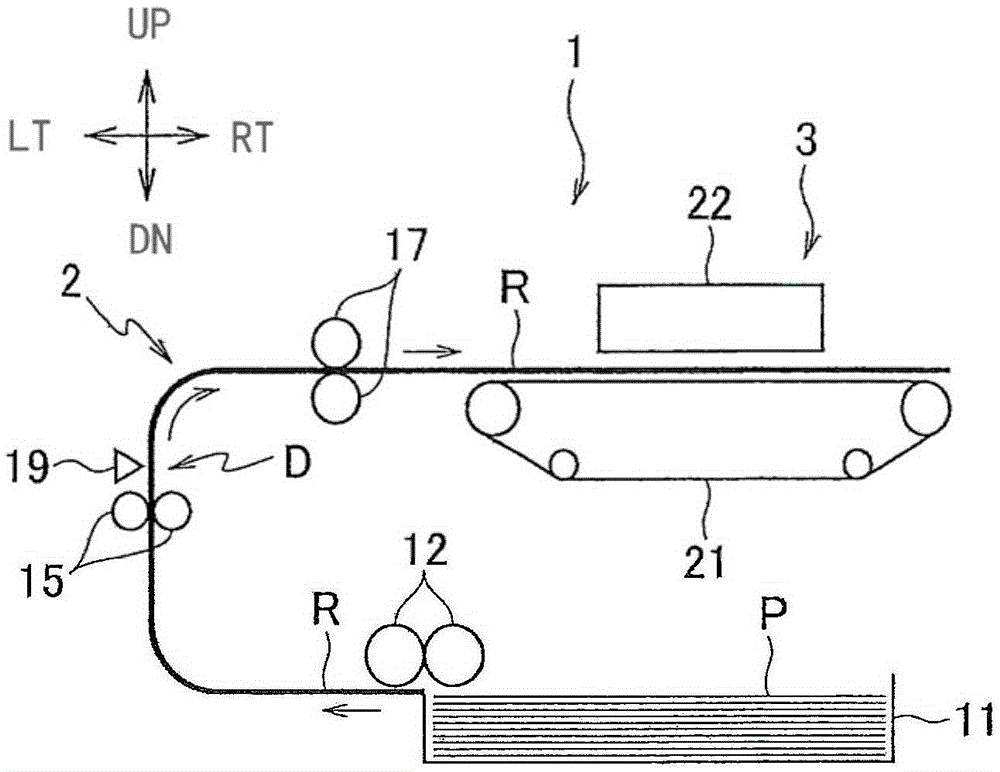

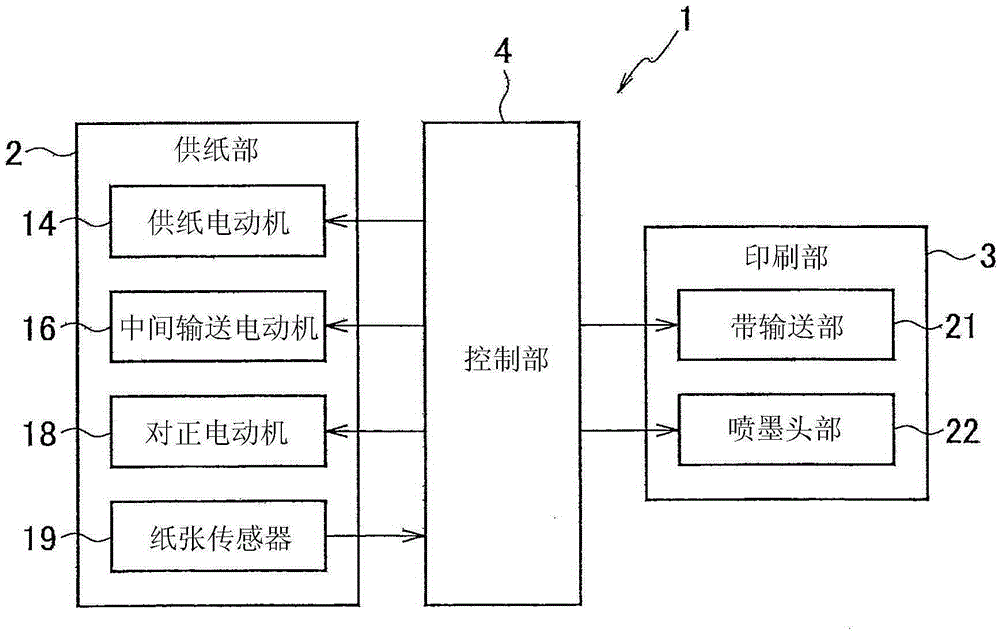

Paper feeding device

ActiveCN105645146ASuppress position deviationFunction indicatorsOther printing apparatusTrailing edgePaper sheet

A paper feeding device. A braking content determiner determines a content of braking control on a rotating operation such that rotation of a paper feeding motor stops within a time required for stopping from a time point of detection of a sheet by a sheet sensor to a time point of passing of a trailing edge of the sheet through a paper feeding roller, the time required for stopping being determined based on a length of the sheet in a sheet conveying direction, a predetermined speed of the paper feeding roller, and a distance between the paper feeding roller and the sheet sensor in a sheet conveying route. A controller performs the braking control on the rotating operation of the paper feeding motor, according to the content determined by the braking content determiner, upon or prior to the detection by the sheet sensor of the sheet sent out by the paper feeding roller.

Owner:RISO KAGAKU CORP

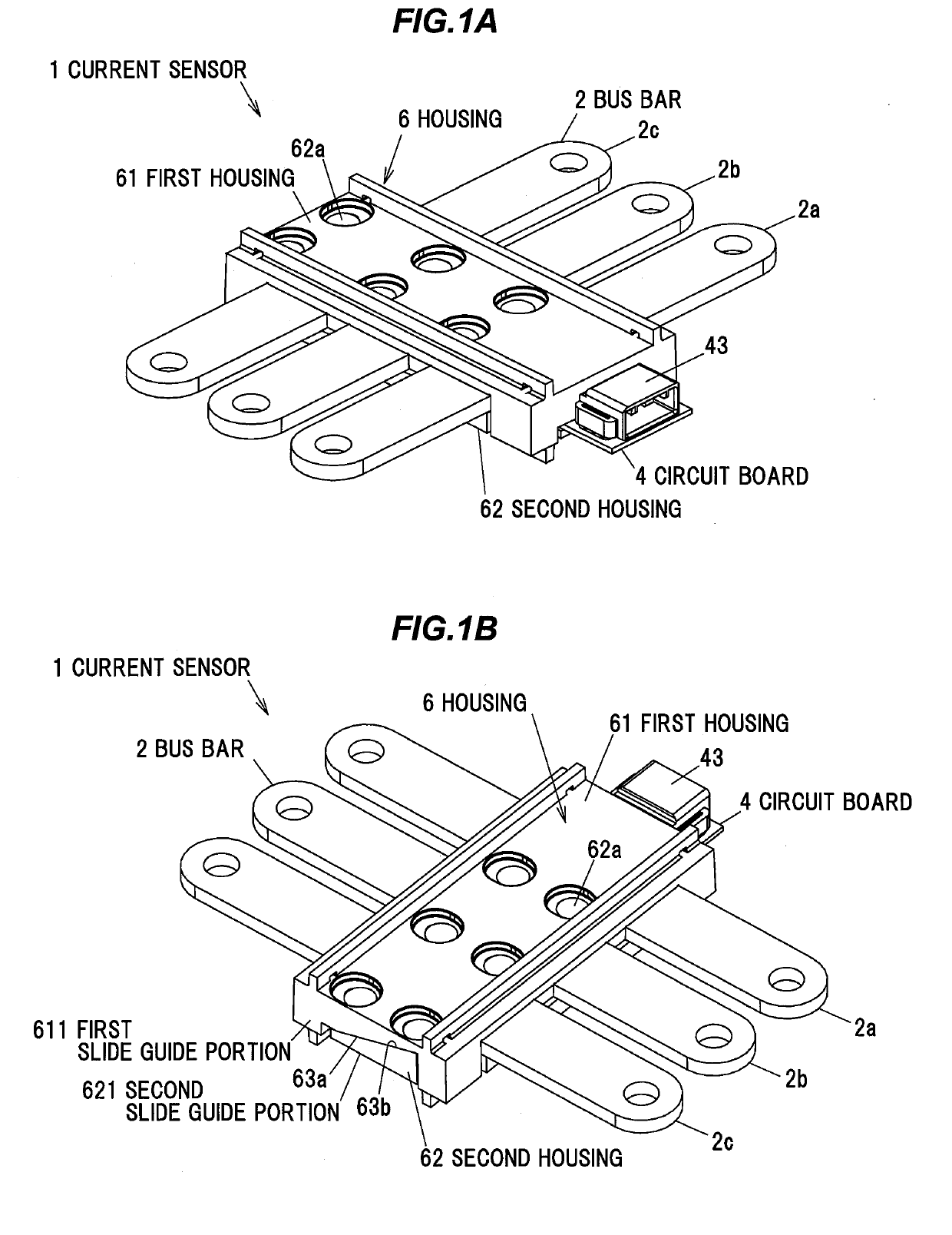

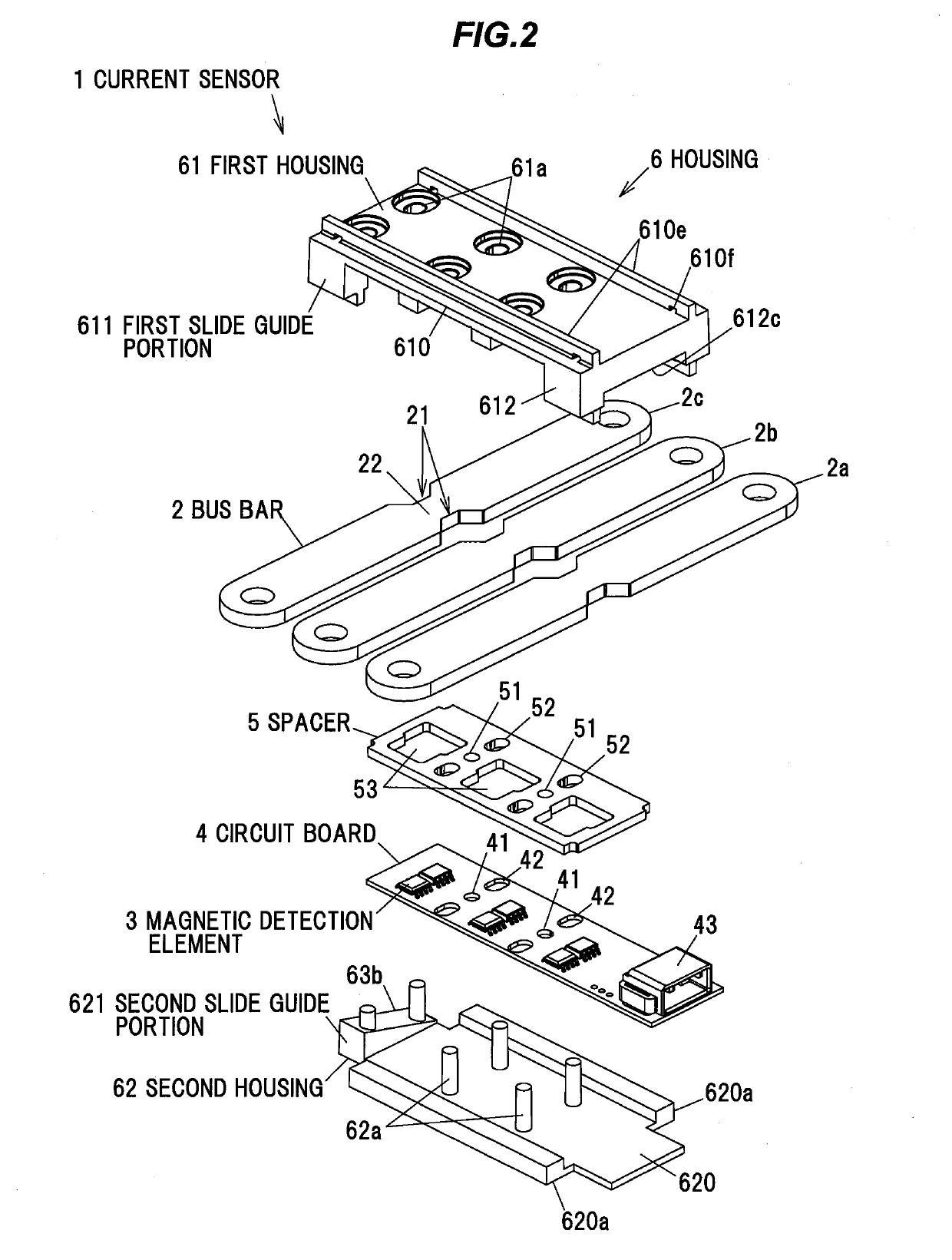

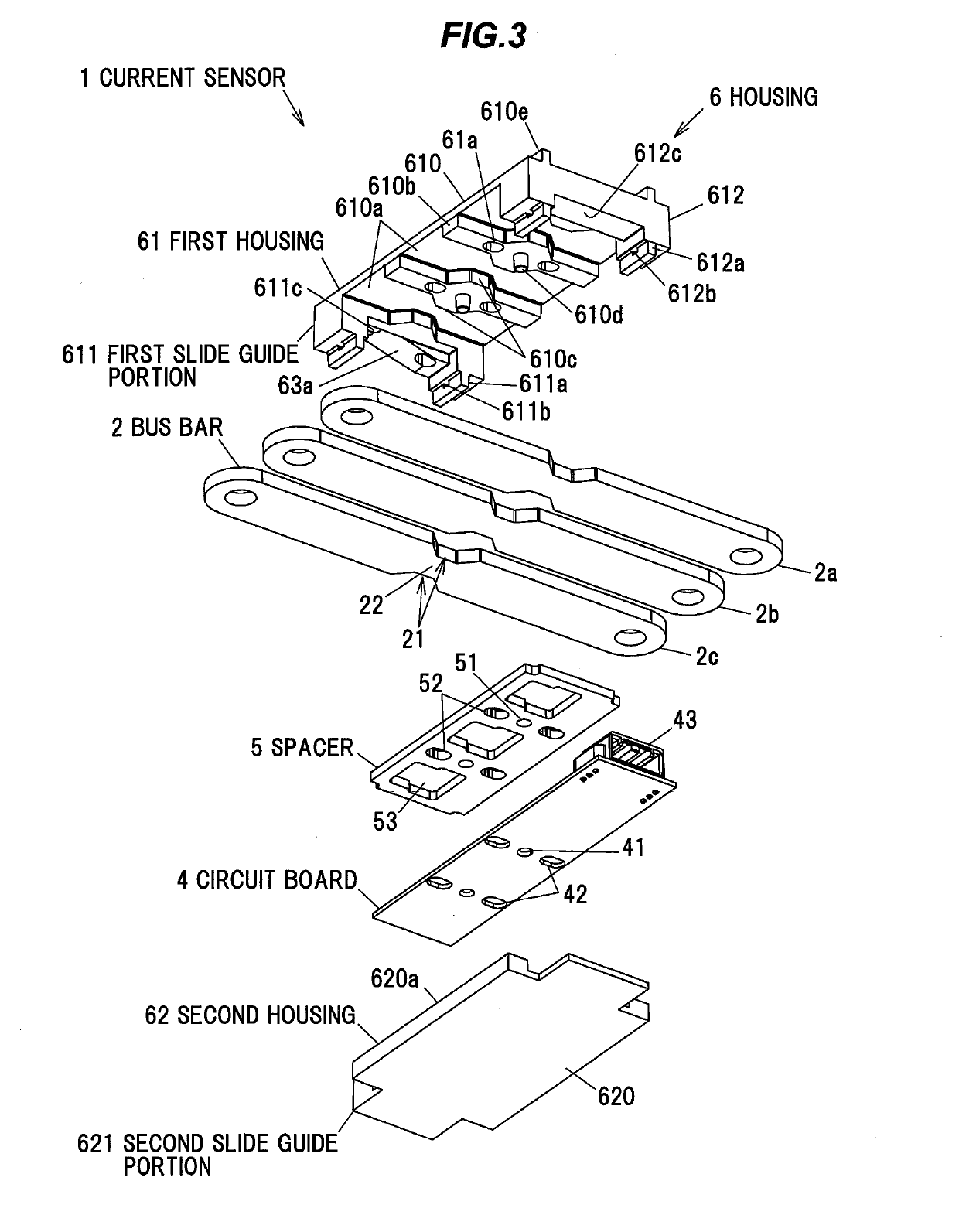

Current sensor

ActiveUS20190187187A1Suppress position deviationCoupling device connectionsWeather/light/corrosion resistancePower flowCurrent sensor

A current sensor includes a bus bar in which a current to be detected flows, a circuit board mounted with a magnetic detection element thereon to detect a strength of a magnetic field generated by a current flowing in the bus bar, and a housing including first and second housings provided in such a manner as to sandwich the bus bar and the circuit board therebetween in a plate thickness direction of the bus bar. The first and second housings include slide guide portions respectively which are relatively slidable in a sloping direction with respect to the plate thickness direction of the bus bar while abutting each other in the plate thickness direction of the bus bar.

Owner:HITACHI METALS LTD

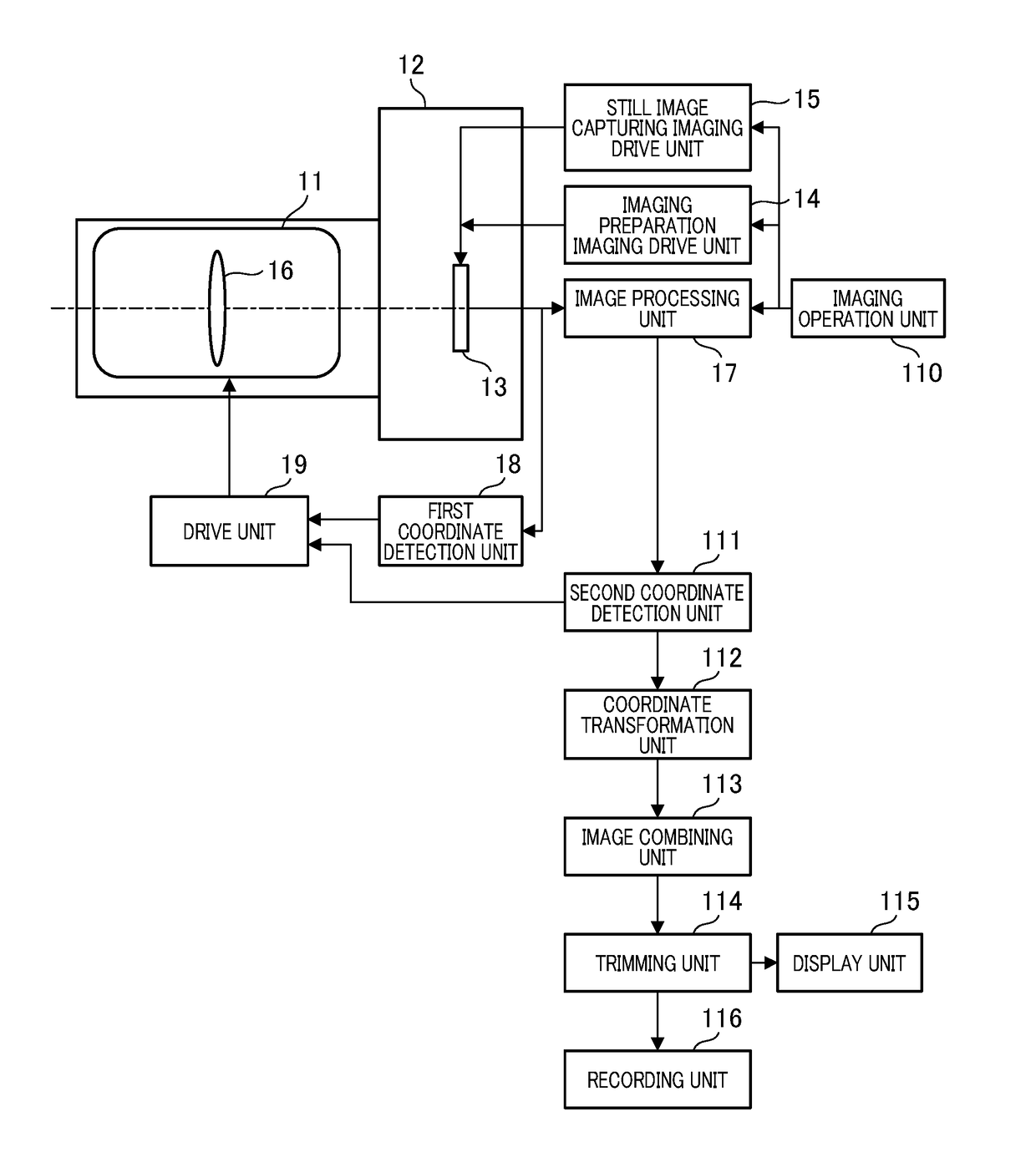

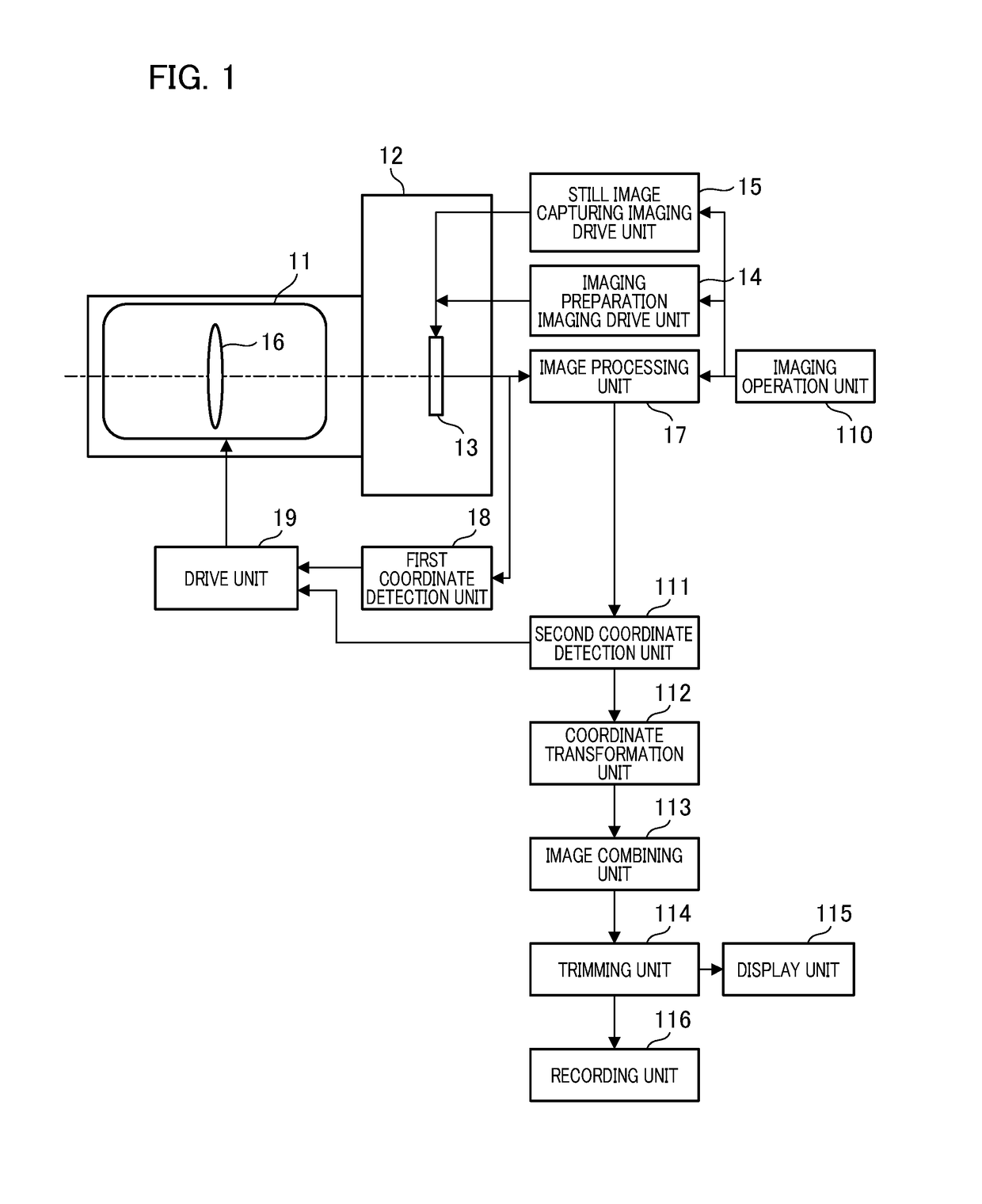

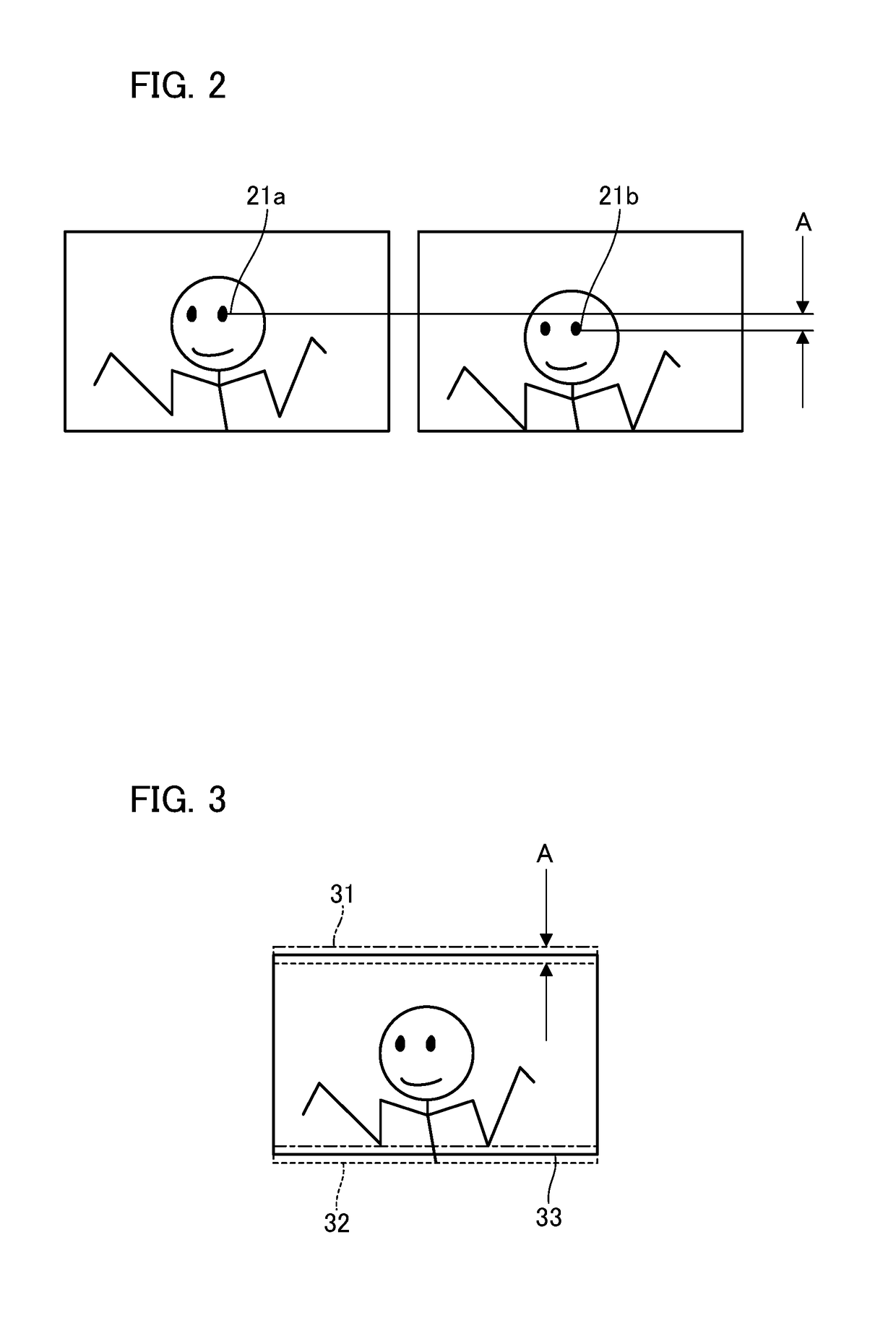

Imaging apparatus and control method therefor

ActiveUS20180041716A1Suppress position deviationImage enhancementTelevision system detailsImage basedImage capture

An imaging apparatus that performs positioning of a plurality of images that has been continuously captured and combines the images comprises an imaging unit; a detection unit configured to detect a difference in position between the images captured by the imaging unit; a drive unit configured to drive a shake correction unit that optically corrects image blur of the image based on the difference in position detected by the detection unit; a coordinate transformation unit configured to perform positioning of the images in which the image blur has been corrected based on the difference in position detected by the detection unit; and an image combining unit configured to combine the images to which the positioning has been performed by the coordinate transformation unit and generate a combined image.

Owner:CANON KK

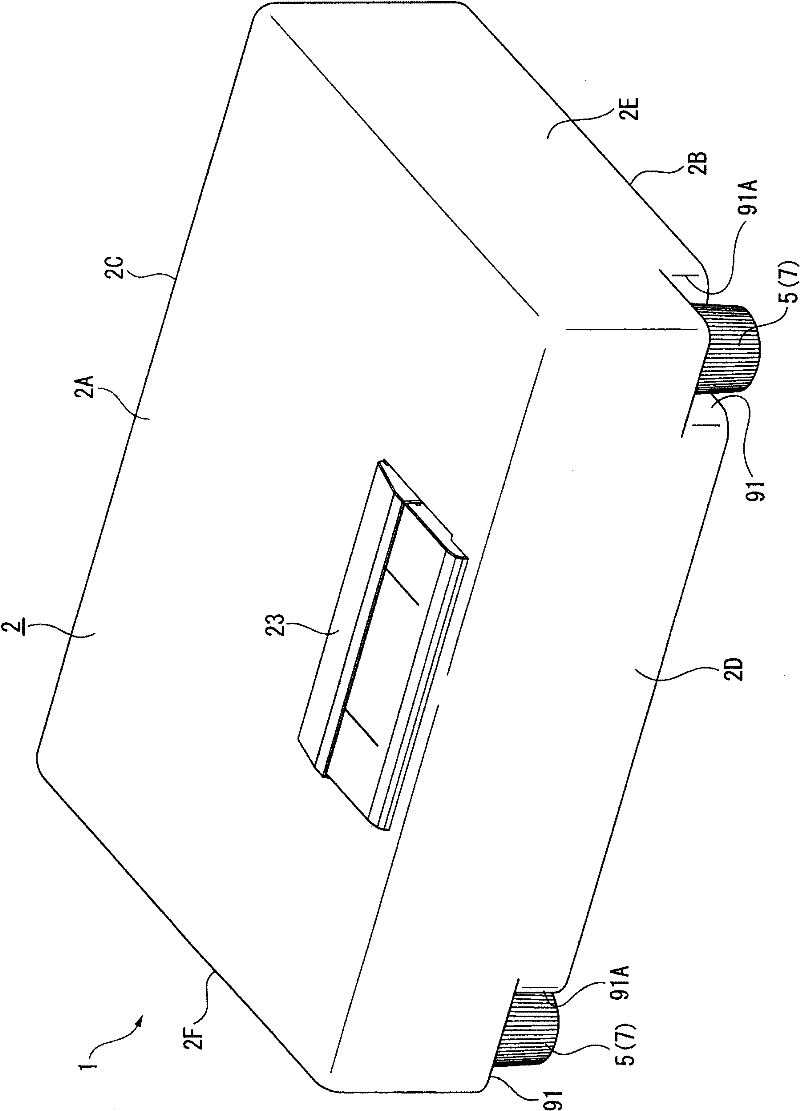

Projector

The invention provides a projector with easily operated foot and improved convenience. A projector includes: an outer housing which forms an external case; and a foot attached to the outer housing and brought into contact with an installation surface when the projector is placed on the installation surface, wherein the foot includes a foot main body which contacts the installation surface, and a rotational member supported rotatably with respect to the outer housing in such a condition that at least a part of the rotational member is exposed to the outside of the outer housing, and the foot main body engages with the rotational member and shifts in the direction along a rotation axis of the rotational member in accordance with rotation of the rotational member.

Owner:SEIKO EPSON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com