Paper feeding device

A paper feeding device and paper feeding technology, which are applied in the directions of printing device, object supply, transportation and packaging, etc., can solve the problem of not being able to send out the paper regularly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Hereinafter, embodiments of the present invention are described with reference to the drawings. In addition, the same or similar reference numerals are assigned to the same or similar parts and components in the drawings, and descriptions of these parts or components are omitted or simplified. In addition, the drawings are schematic and therefore differ from actual ones.

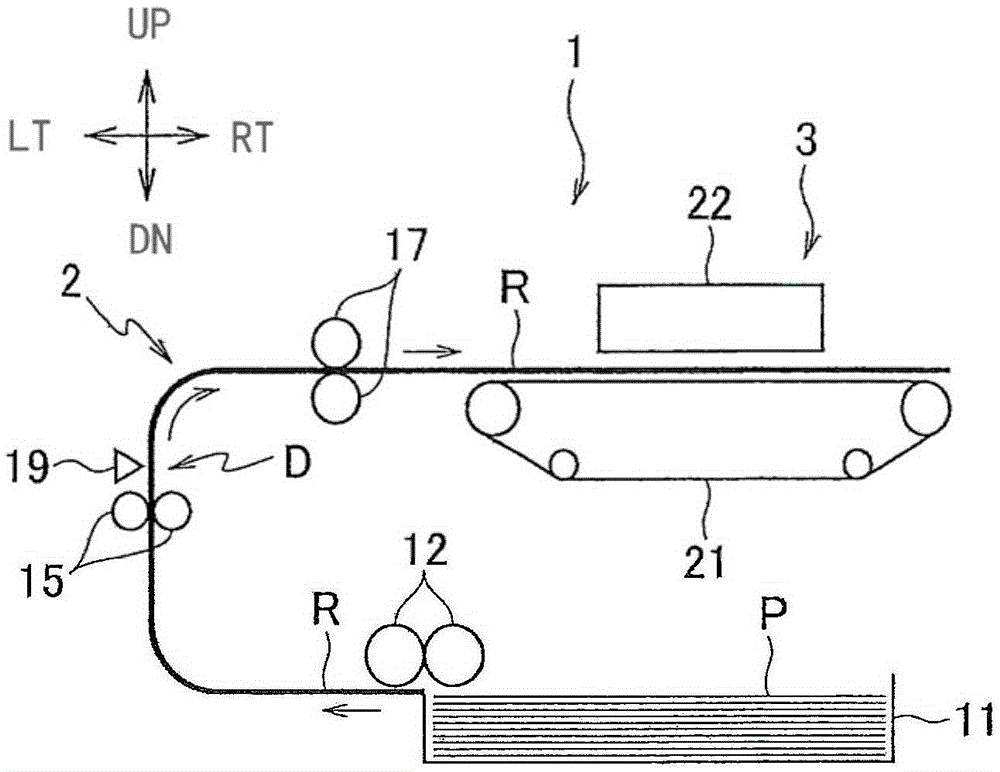

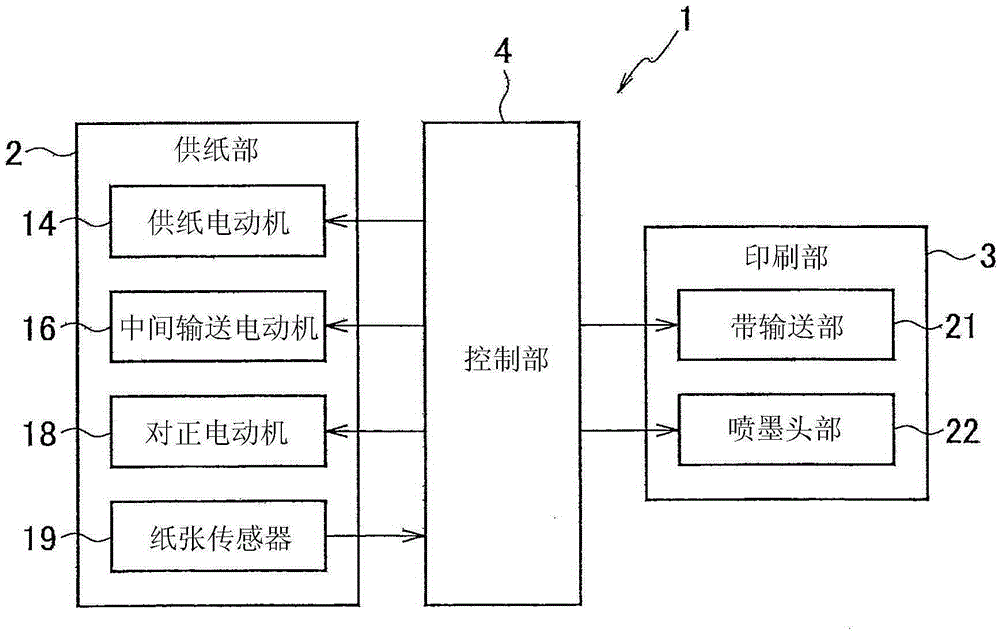

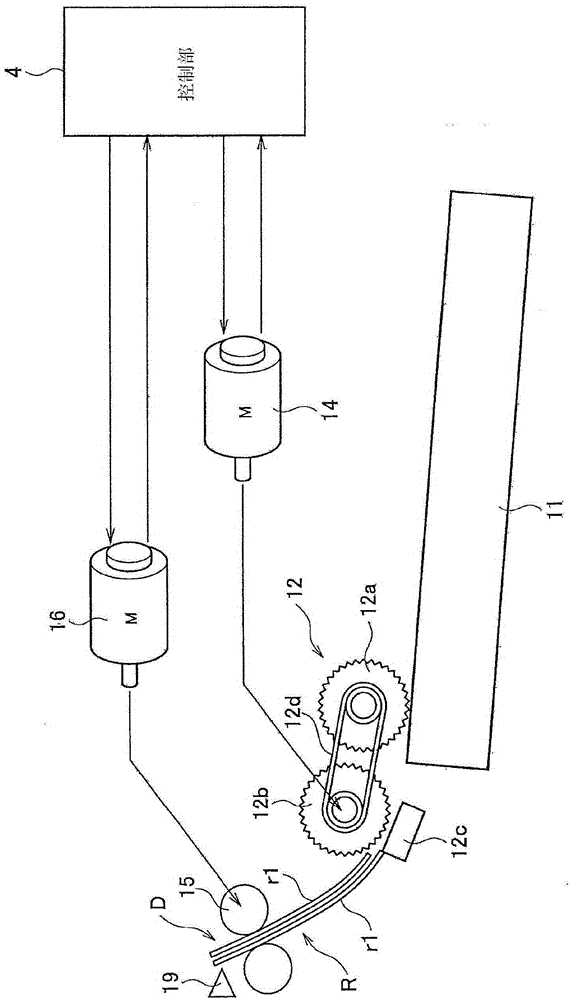

[0036] figure 1 is an explanatory diagram showing a schematic configuration of a printer including a paper feeding device according to an embodiment of the present invention, figure 2 yes means figure 1 A block diagram showing the structure of the printer's control system. In the instructions below, the figure 1 The direction perpendicular to the surface of the paper is defined as the front-rear direction, and the surface direction of the paper is defined as the front. exist figure 1 In , RT, LT, UP, and DN are used to represent right, left, up, and down, respectively. In addition, in figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com