Pattern forming method and gray-tone mask manufacturing method

A manufacturing method and a grayscale mask technology, which are applied in the photolithographic process of the pattern surface, semiconductor/solid-state device manufacturing, and originals for photomechanical processing, etc., can solve the problem of difficult detection of alignment marks, positional deviations, Low detection accuracy and other problems, to achieve the effect of good detection accuracy and increased contrast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

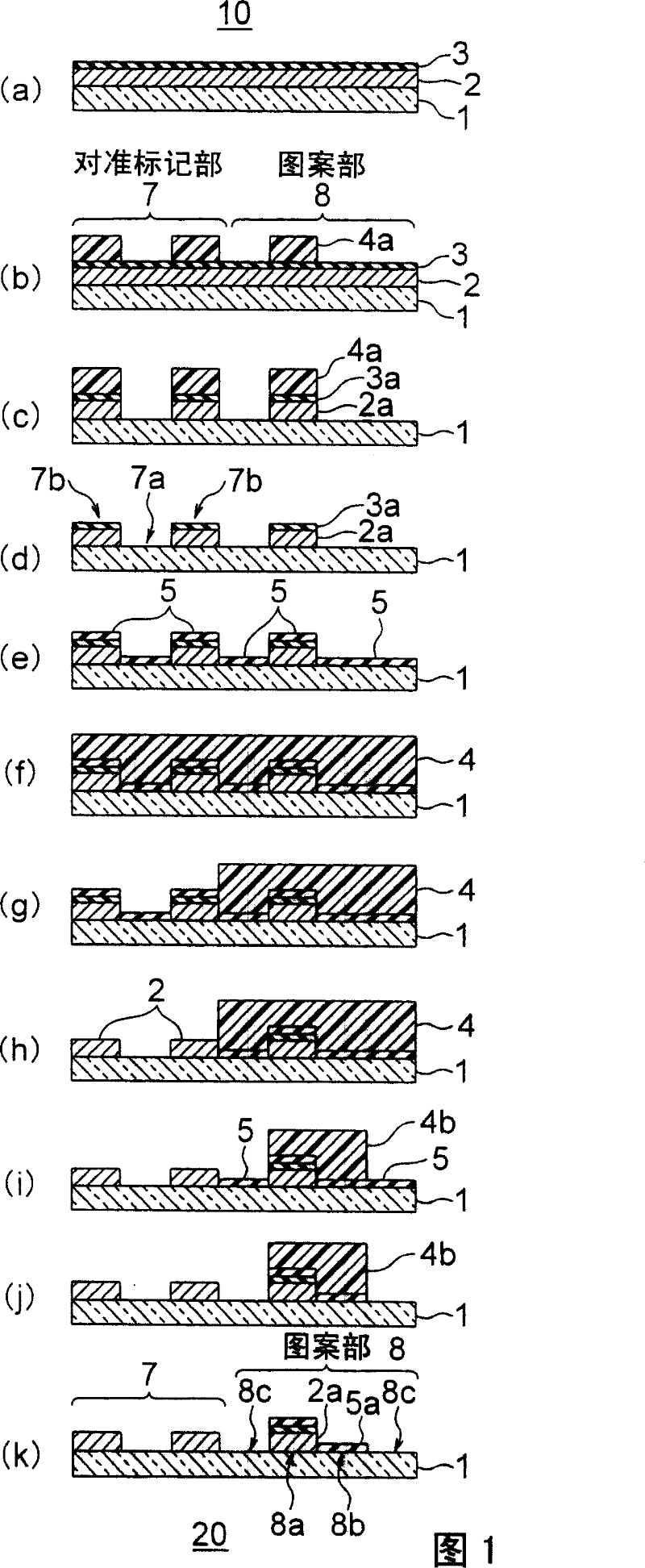

[0042] 1 shows an embodiment 1 in which the pattern forming method of the present invention is applied to the manufacturing process of a gray scale mask formed on a translucent substrate with The device pattern of the light-shielding part, the light-transmitting part and the semi-transparent part.

[0043] As shown in FIG. 1( a ), the mask blank 10 used in this example has a light-shielding film 2 and an antireflection film 3 formed on a light-transmitting substrate 1 such as synthetic quartz glass. Here, as the material of the light-shielding film 2 , a material capable of obtaining high light-shielding properties as a thin film is preferable, and examples thereof include Cr, Si, W, Al, and the like. Moreover, as a material of the antireflection film 3, oxide etc. which are mentioned above-mentioned light-shielding layer materials are mentioned, for example.

[0044] The mask blank 10 described above can be obtained by sequentially forming a light-shielding film 2 and an ant...

Embodiment 2

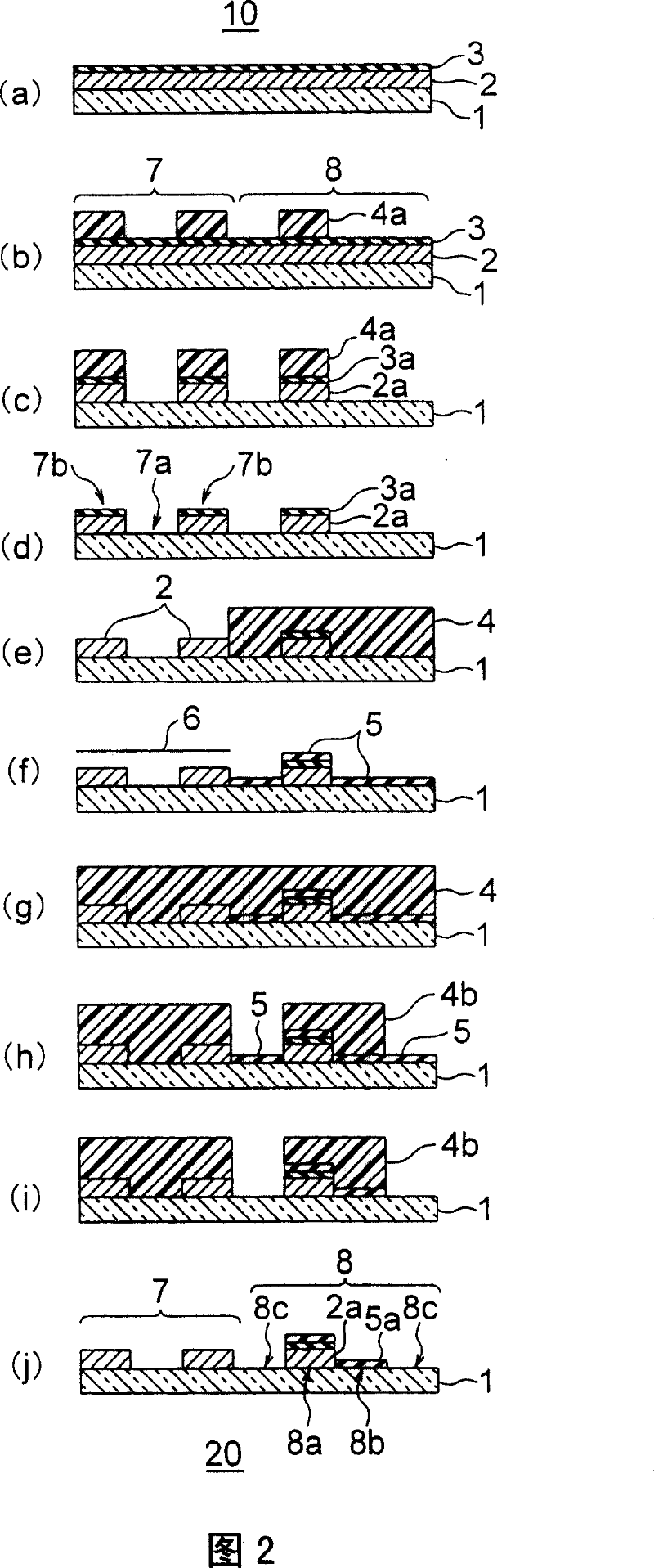

[0062] FIG. 2 is a schematic cross-sectional view showing Example 2 in which the pattern forming method of the present invention is applied to a manufacturing process of a gray scale mask.

[0063] 2( a ) to FIG. 2( d ) are completely the same as those in FIG. 1( a ) to FIG. 1( d ) in the first embodiment.

[0064] Next, as shown in FIG. 2( e ), a resist film 4 is formed on a portion other than the alignment mark 7 . As a method of forming the resist film 4 on the portion other than the alignment mark 7, after forming the resist film on the entire surface as described in Example 1, removing or removing the alignment mark 7 by spot exposure or development can be used. part, or a method of applying a resist to a part other than the alignment mark 7, etc. Then, the antireflection film 3 located on the surface of the light shielding portion 7b of the alignment mark 7 is removed by etching.

[0065] Next, as shown in FIG. 2( f ), the part of the alignment mark 7 is protected by a...

Embodiment 3

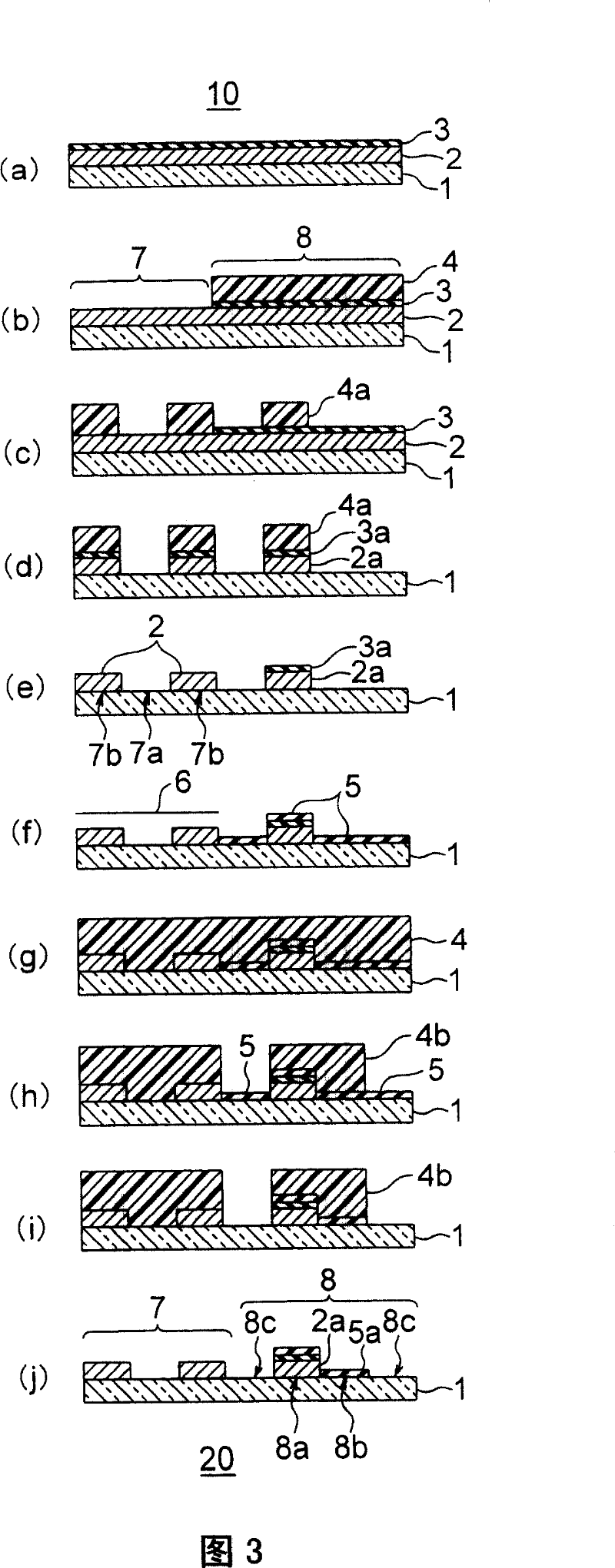

[0070] 3 is a schematic cross-sectional view showing Example 3 in which the pattern forming method of the present invention is applied to a manufacturing process of a gray scale mask.

[0071] As shown in Fig. 3(a) and Fig. 3(b), in this embodiment, a resist film 4 is formed on the region of the mask blank 10 except for the alignment mark 7, and the alignment mark 7 is removed by etching or the like. The anti-reflection film 3 of the portion marked 7 .

[0072] Next, as shown in FIG. 3( c), after peeling off the remaining resist film 4, a resist film is formed on the entire surface again, and pattern drawing including the alignment mark 7 and the first pattern is performed in the same manner as in Example 1. , and developed to form a resist pattern 4a. Next, as shown in FIG. 3( d ), by using the resist layer pattern 4 a as a mask, the exposed light-shielding film 2 is etched to remove the remaining resist layer pattern 4 a, thereby forming the resist layer pattern 4 a shown i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com