Patents

Literature

286results about How to "Shorten takt time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

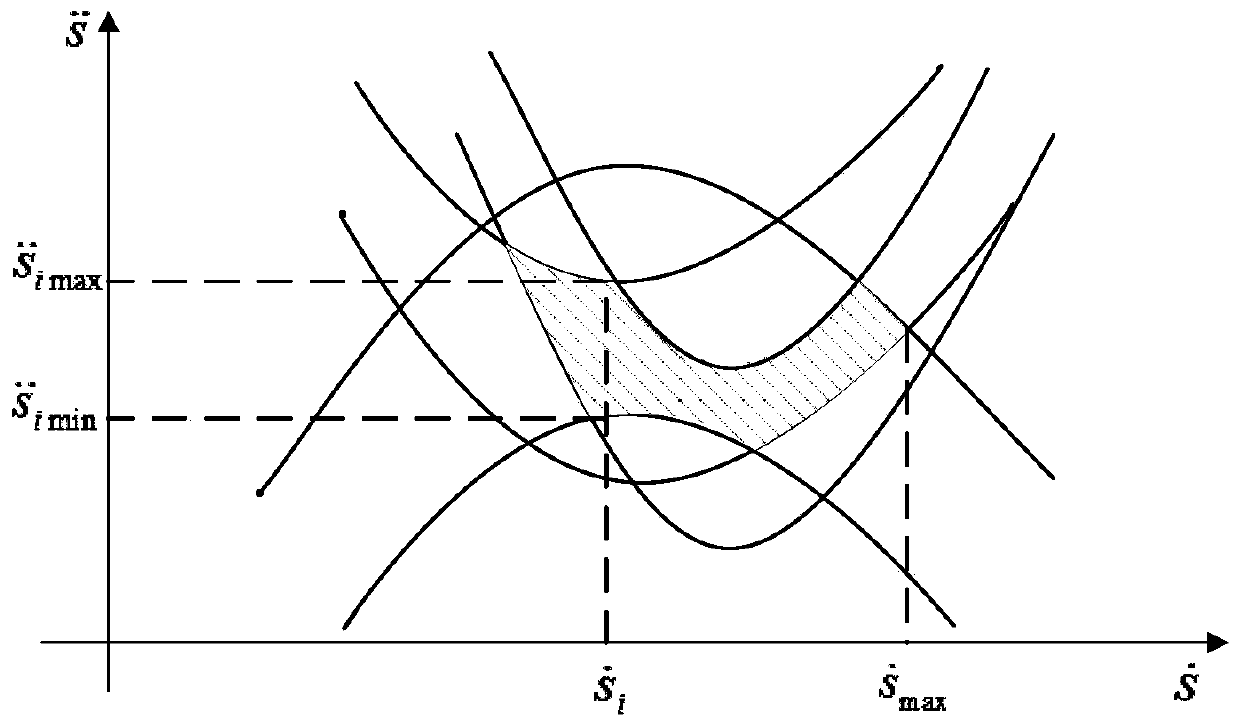

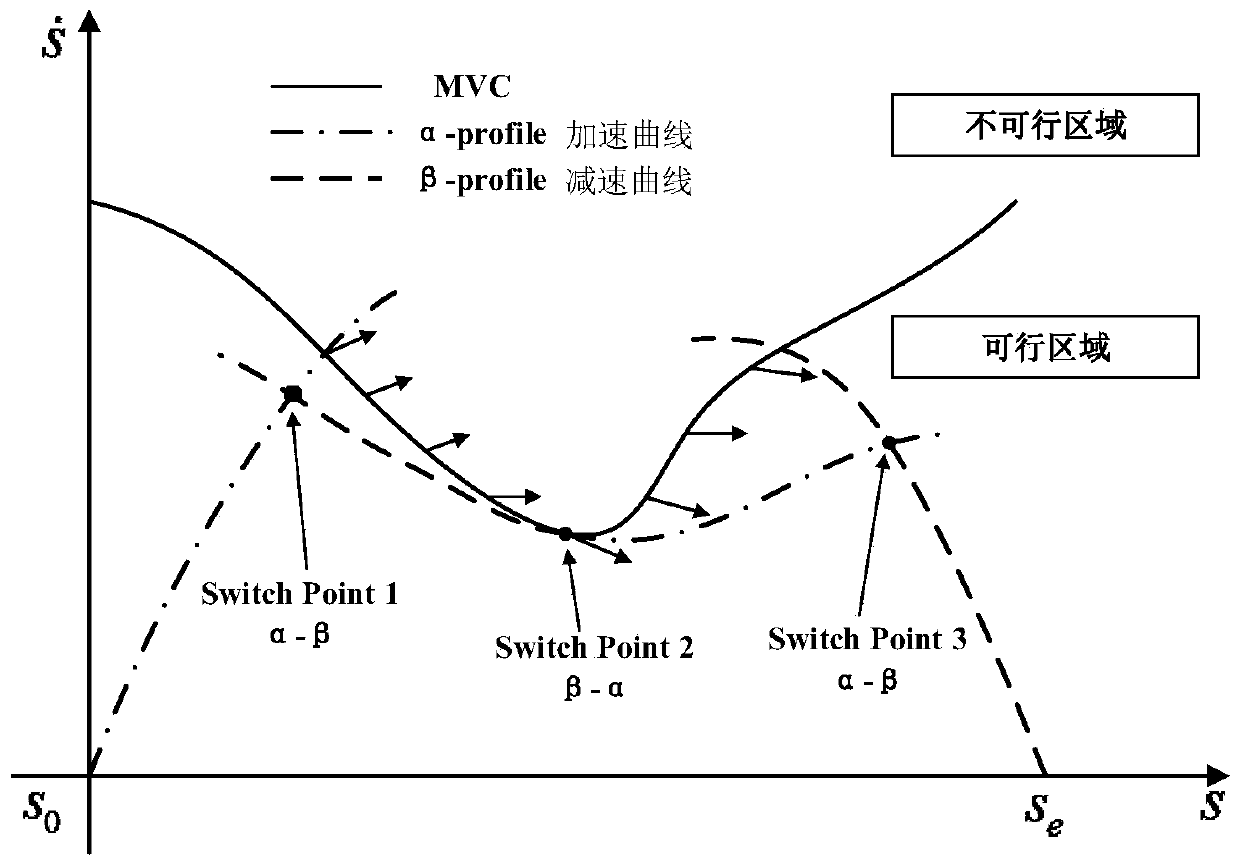

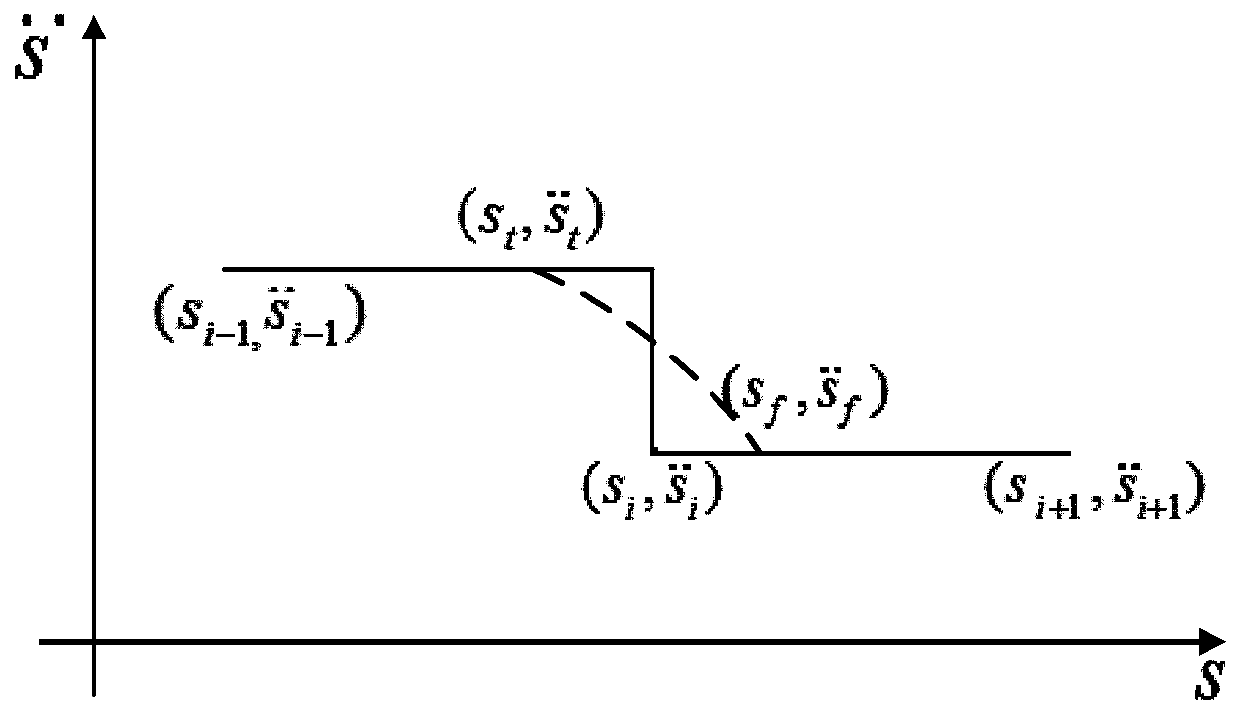

Method and device for planning robot time optimal trajectory based on dynamic model

InactiveCN110209048AOptimize motion parametersRealize high-speed movementAdaptive controlDynamic modelsMotion parameter

The invention discloses a method and a device for planning a robot time optimal trajectory based on a dynamic model. The method for planning the robot time optimal trajectory comprises the following steps: converting joint motion constraint and geometric path constraint to a parameter space through a robot motion trajectory predetermined by dynamics modeling and parameterization; taking shortest time as an objective structural optimization problem, and solving through a numerical integration method to obtain an optimal motion parameter of the robot; and carrying out spline curve smoothing on acceleration for three times on a phase plane by considering the problem of joint vibration caused by sudden change of the acceleration. Compared with the conventional trapezoid acceleration trajectoryplanning method, the motion parameter of the robot can be optimized under the joint motion constraint and the geometric path constraint; the high-speed motion of the robot can be achieved; the performance of a joint motor is fully used; the motion speed of the robot can be further improved; pitch time for executing tasks is reduced, so that the operation efficiency of the robot is improved; and the method and the device have great significance to improvement of overall performance of the robot.

Owner:SOUTH CHINA UNIV OF TECH +1

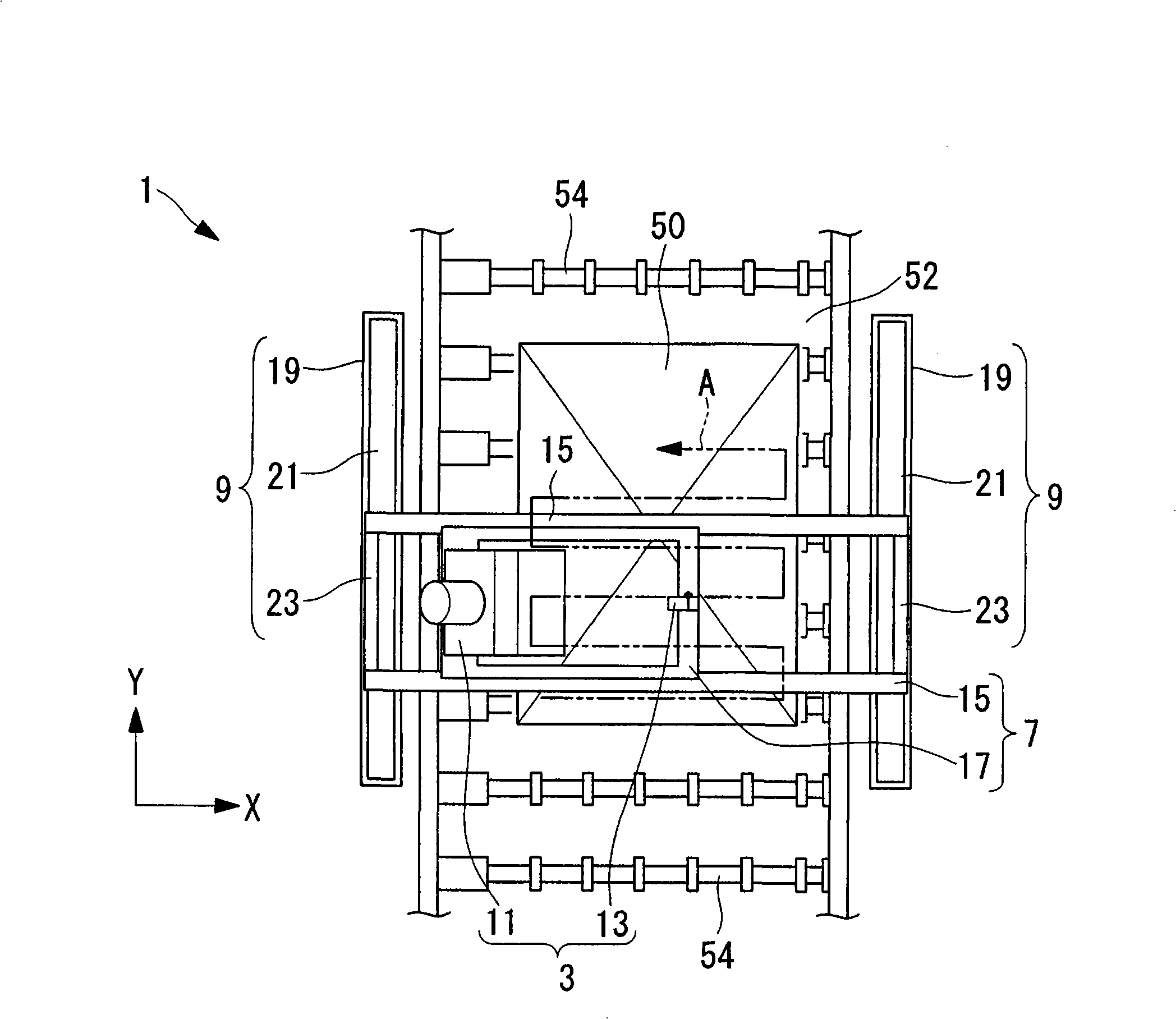

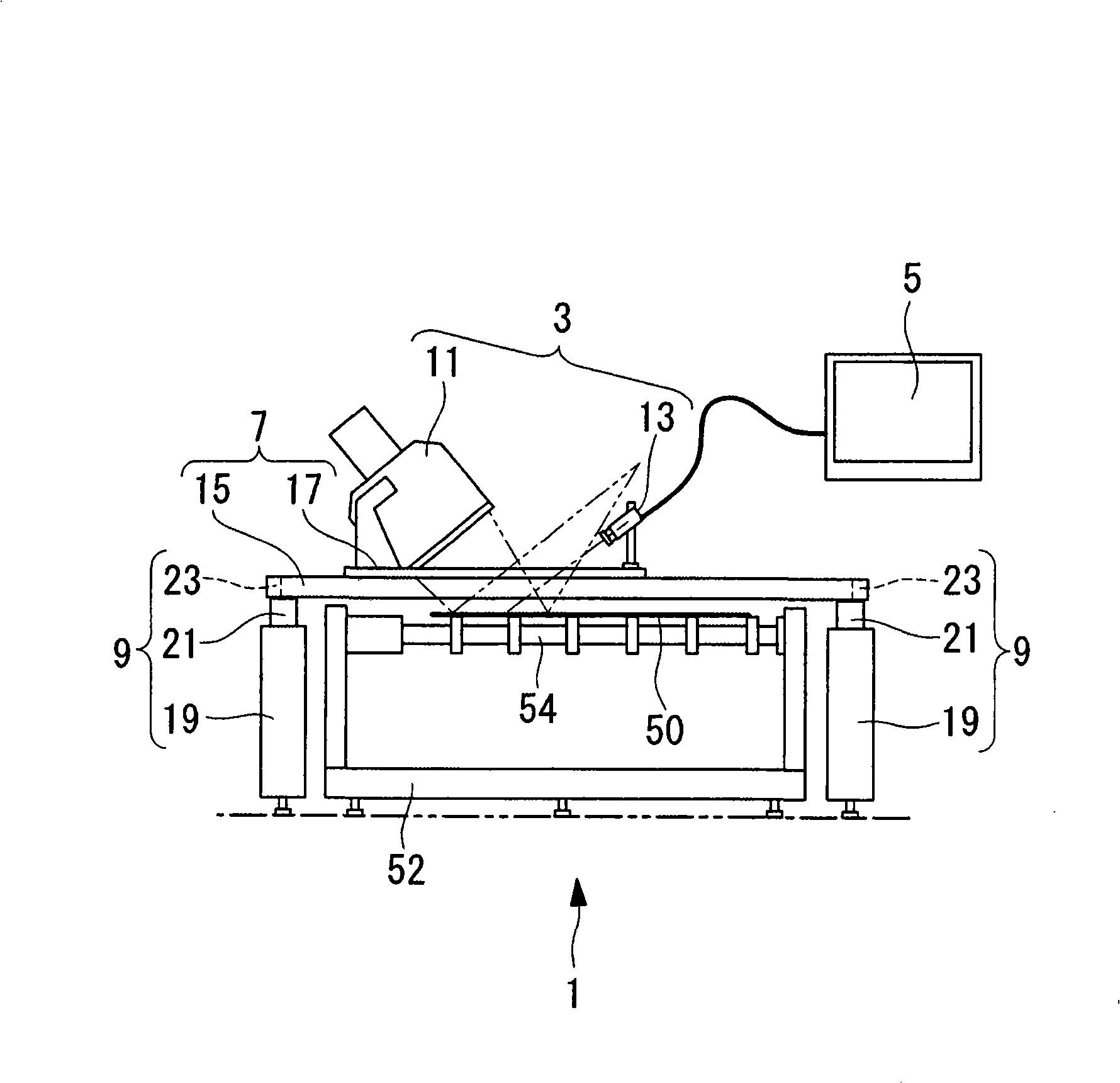

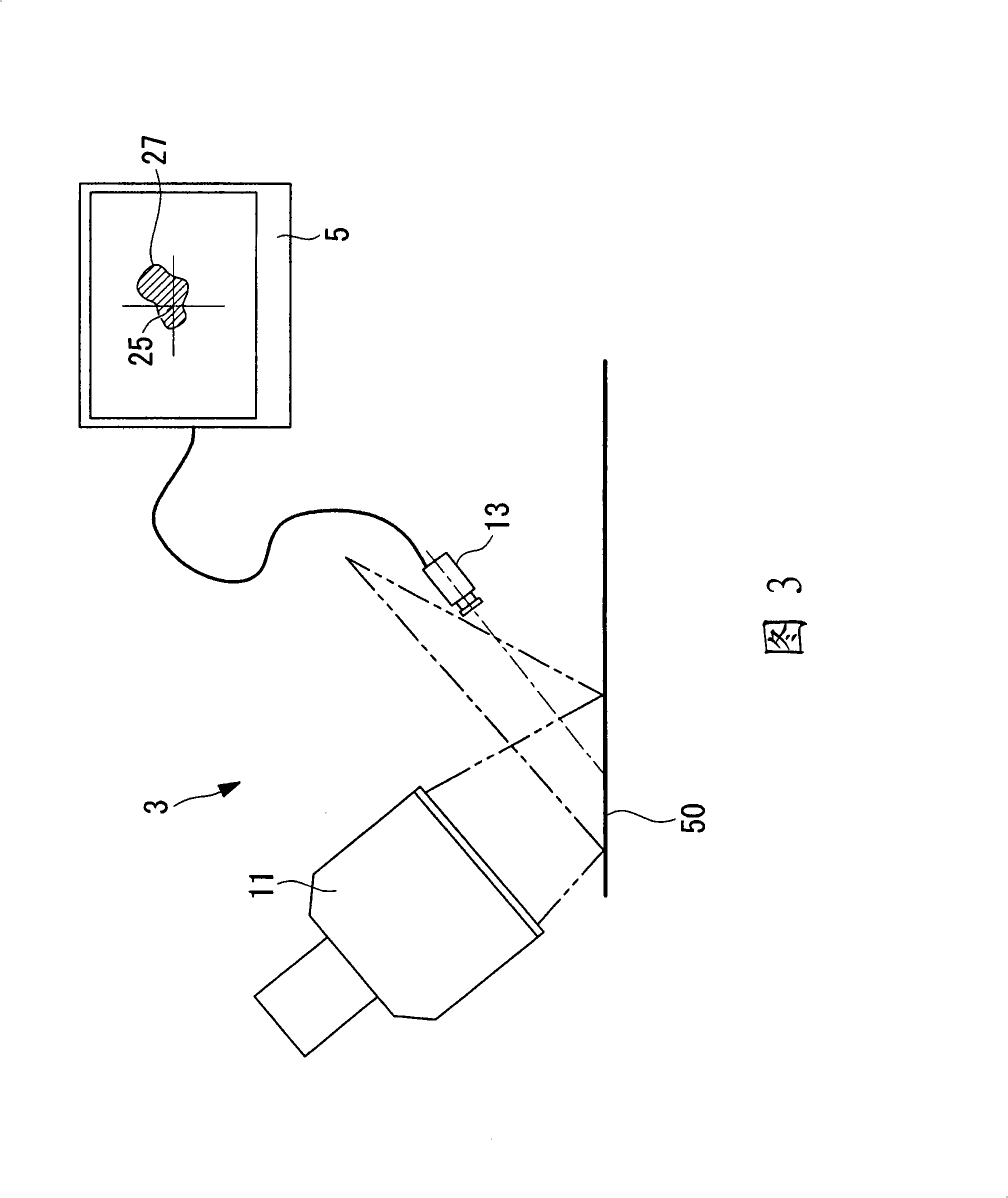

Appearance inspecting device for substrate

InactiveCN101339143ASure easyMiniaturizationMethod using image detector and image signal processingNon-linear opticsMiniaturizationLight beam

The invention provides a substrate appearance inspection device. detailed appearance inspection of whole surface can be carried out without taking out glass substrate on the product line, accordingly production period is shorten and manufacture equipment is miniaturized. The substrate appearance inspection device (1) has an illumination device (11) generating illumination light for irradiation on surface of substrate (50) on the product line (52); a camera (13) picking-up image of surface of the substrate (50) illuminated by the illumination device (11); and a moving mechanism integrally moving the illumination device (11) and camera (13) in crossed direction of transmission direction of the substrate (50) on the product line (52), the camera (13) is collocated outside of range of light beam of specular reflection light by the substrate (50) surface from the illumination light of the illumination device (11).

Owner:OLYMPUS CORP

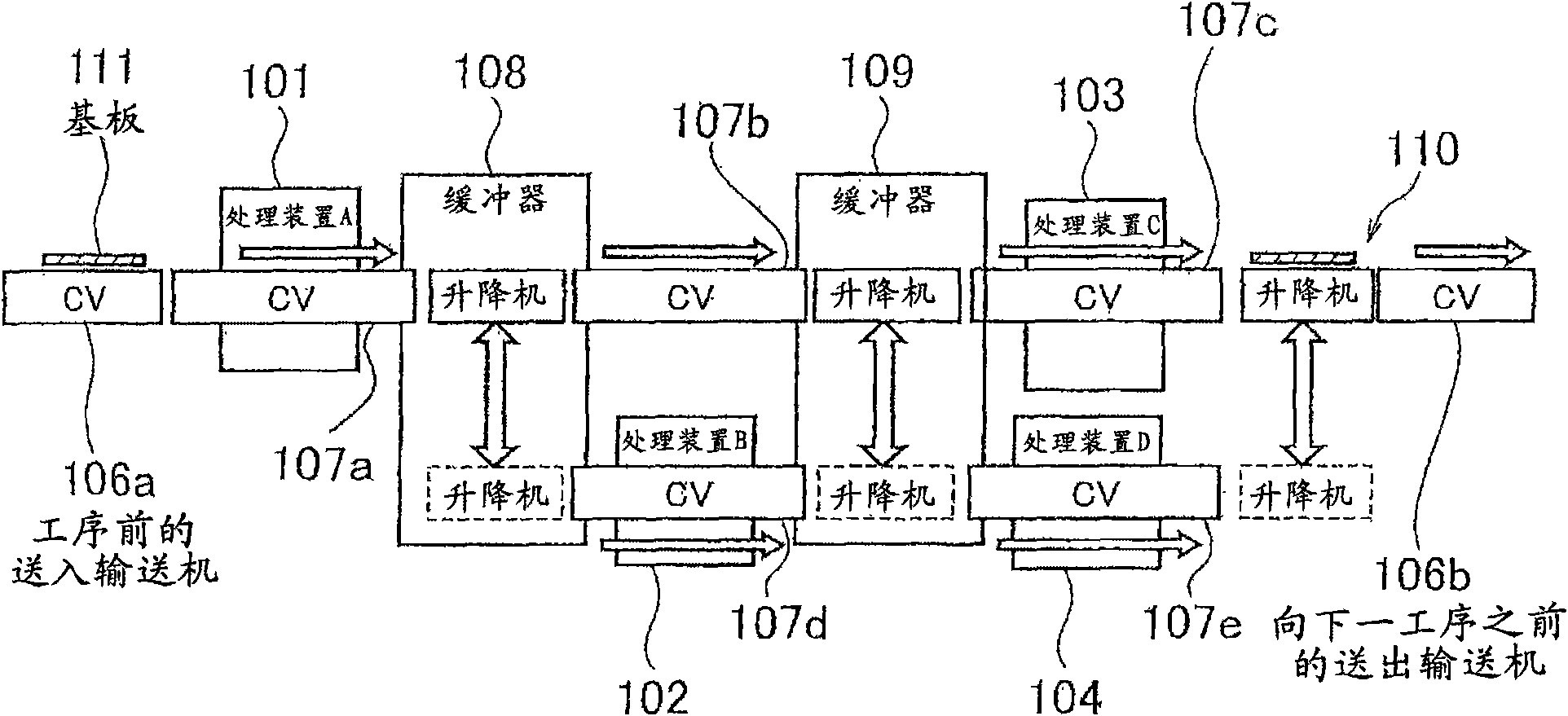

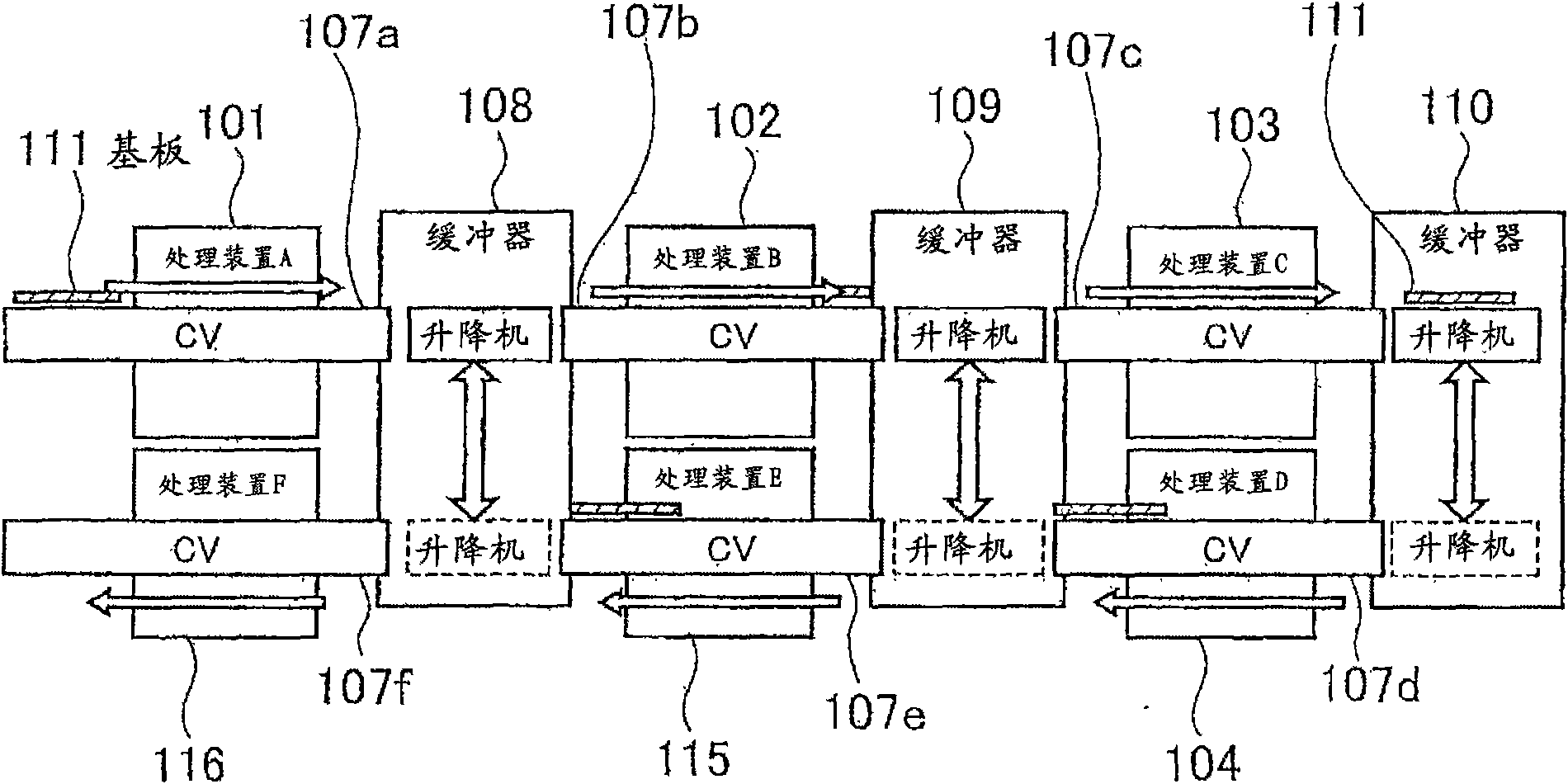

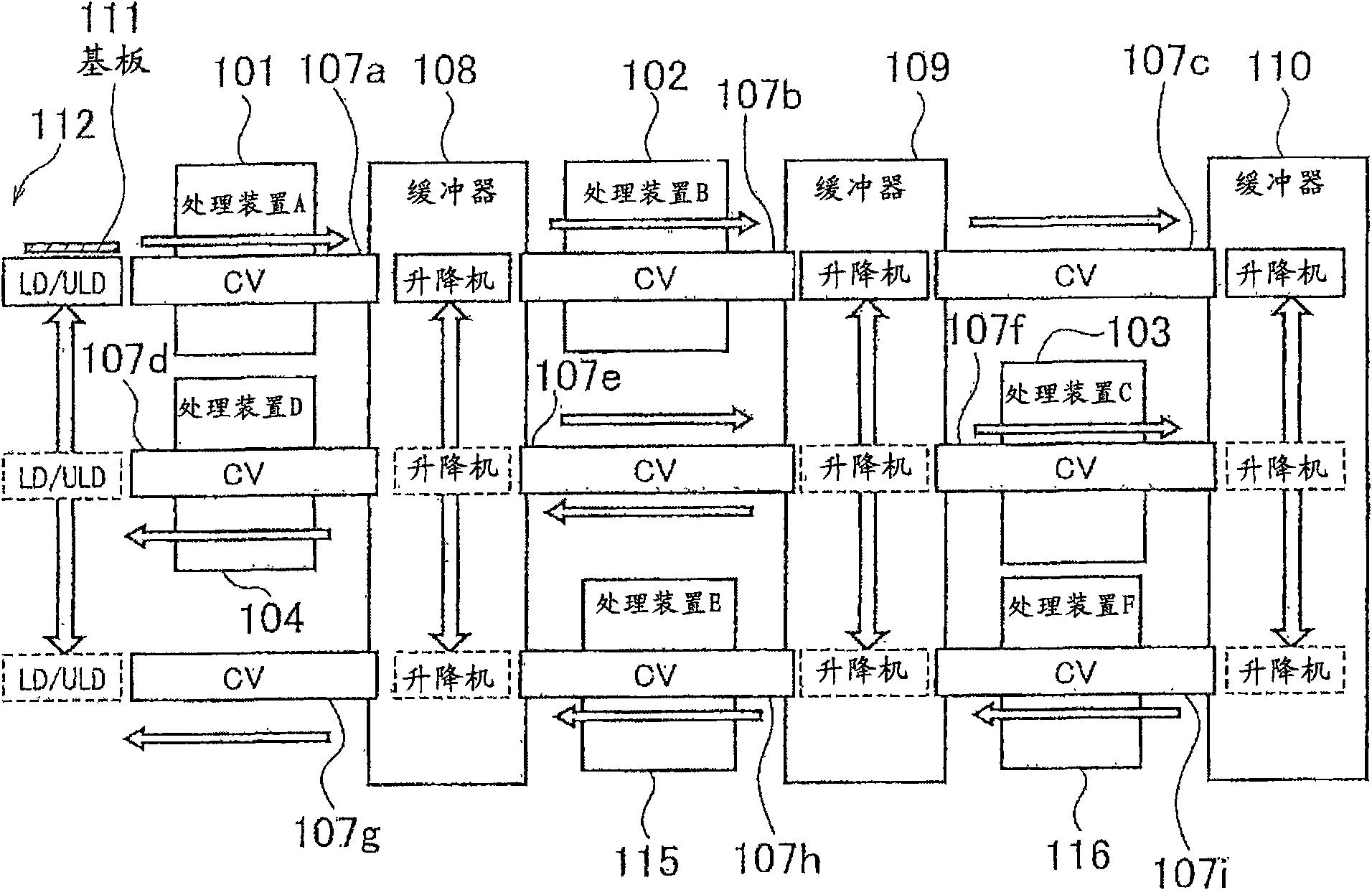

Processing equipment, conveying control device and conveying control method

InactiveCN101607634AReduce the frequency of blockingImprove efficiencyControl devices for conveyorsCharge manipulationMain processing unitEngineering

The present invention provides processing equipment, a conveying control device and a conveying control method. The processing equipment is provided with a plurality of conveying paths between each processing unit. the processing equipment weights a standby time of each object to be conveyed at each time, the load conditions of processing units of a conveying destination and a conveying source, the entire load condition of the conveying zone of each object to be conveyed, and the load condition of each conveying unit separately, the priority of each conveying treatment is calculated by the weighting alteration corresponding with the condition of the conveying zone so as to determine an object to be conveyed to the processing device to control the conveying units. The processing equipment will not be large, will not increase the period of produce and development, and has an enough conveying capacity. According to the processing equipment, when the load of the object to be conveyed to a conveying destination is high, it is capable of shortening the production pitch time of the whole processing unit.

Owner:IHI CORP

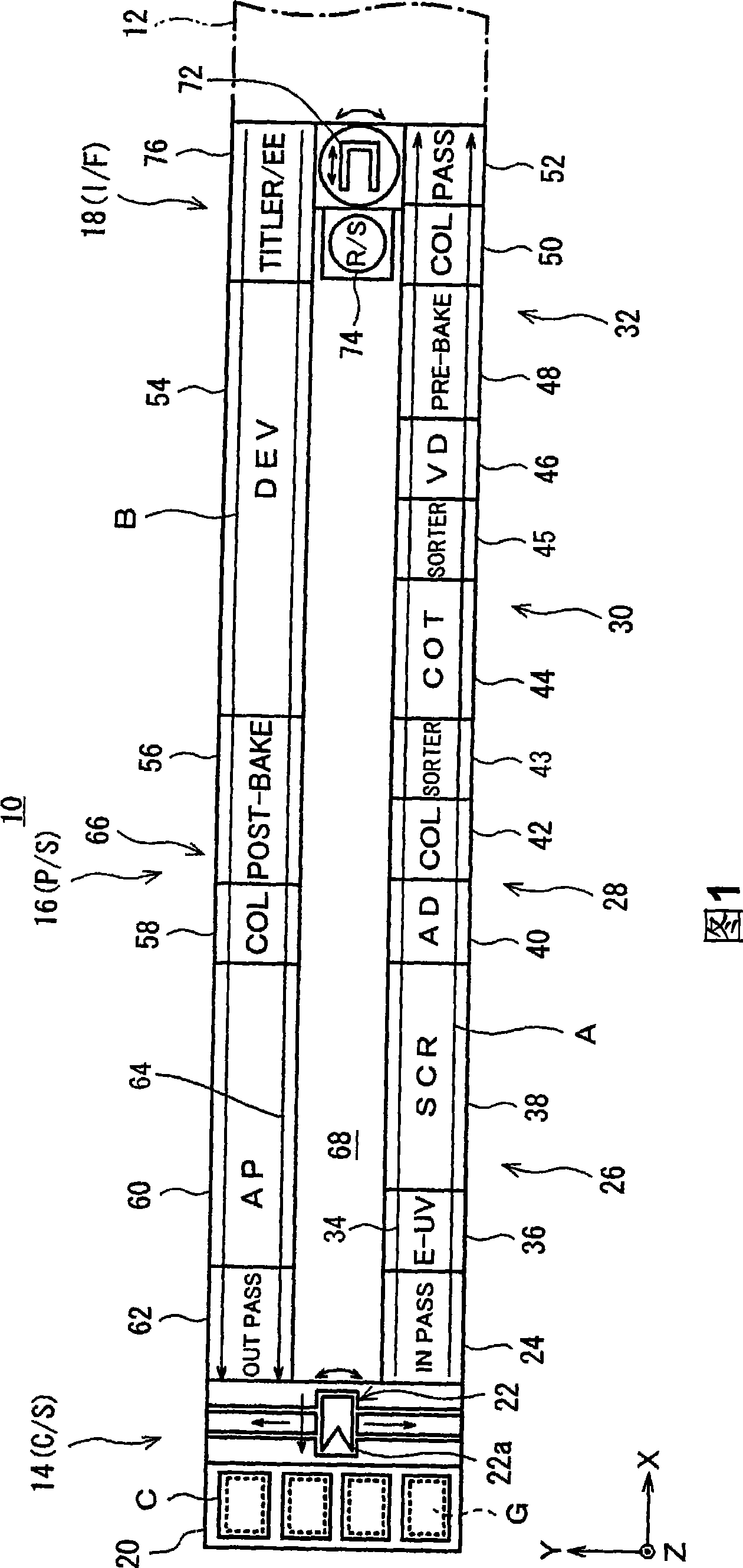

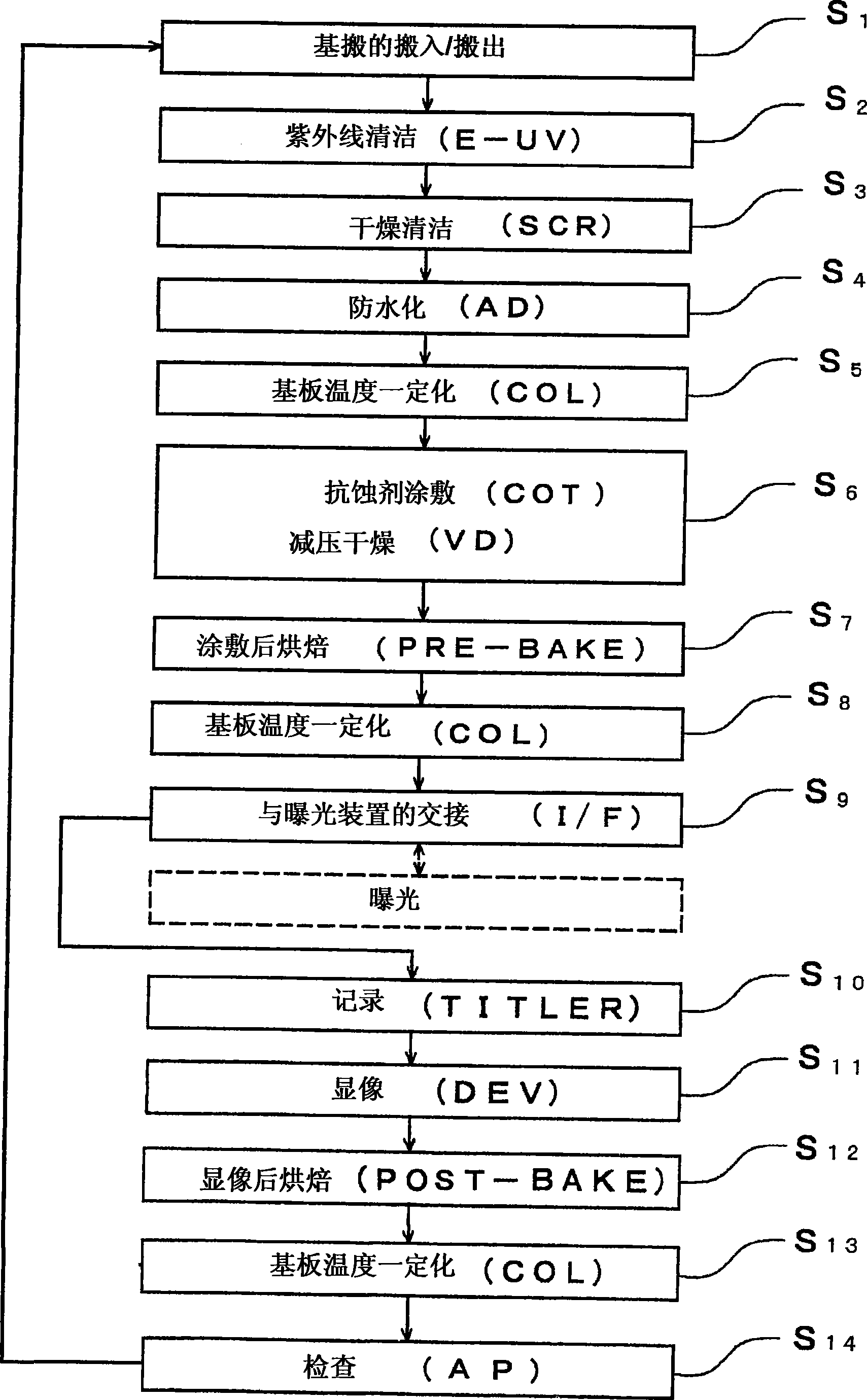

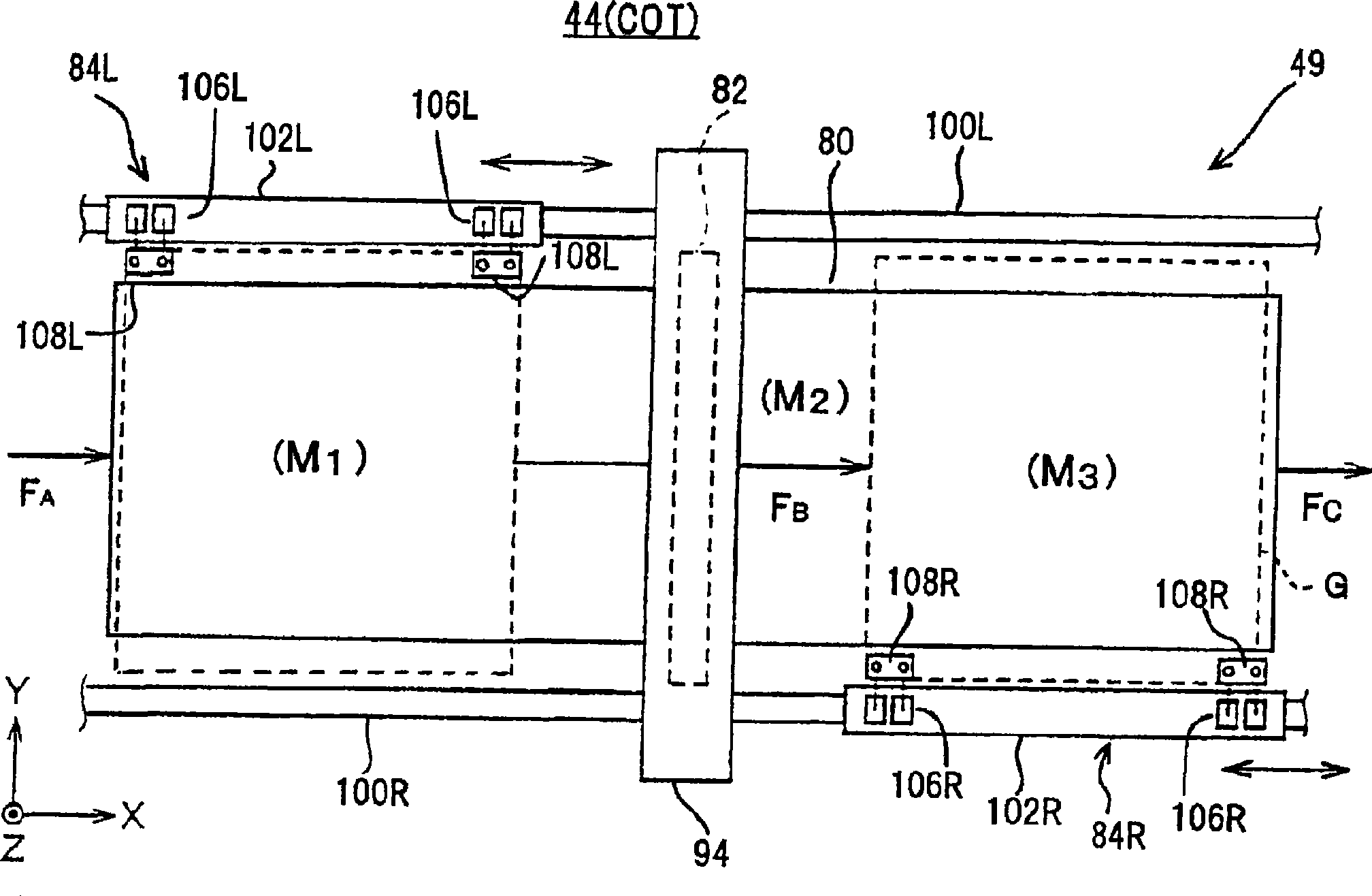

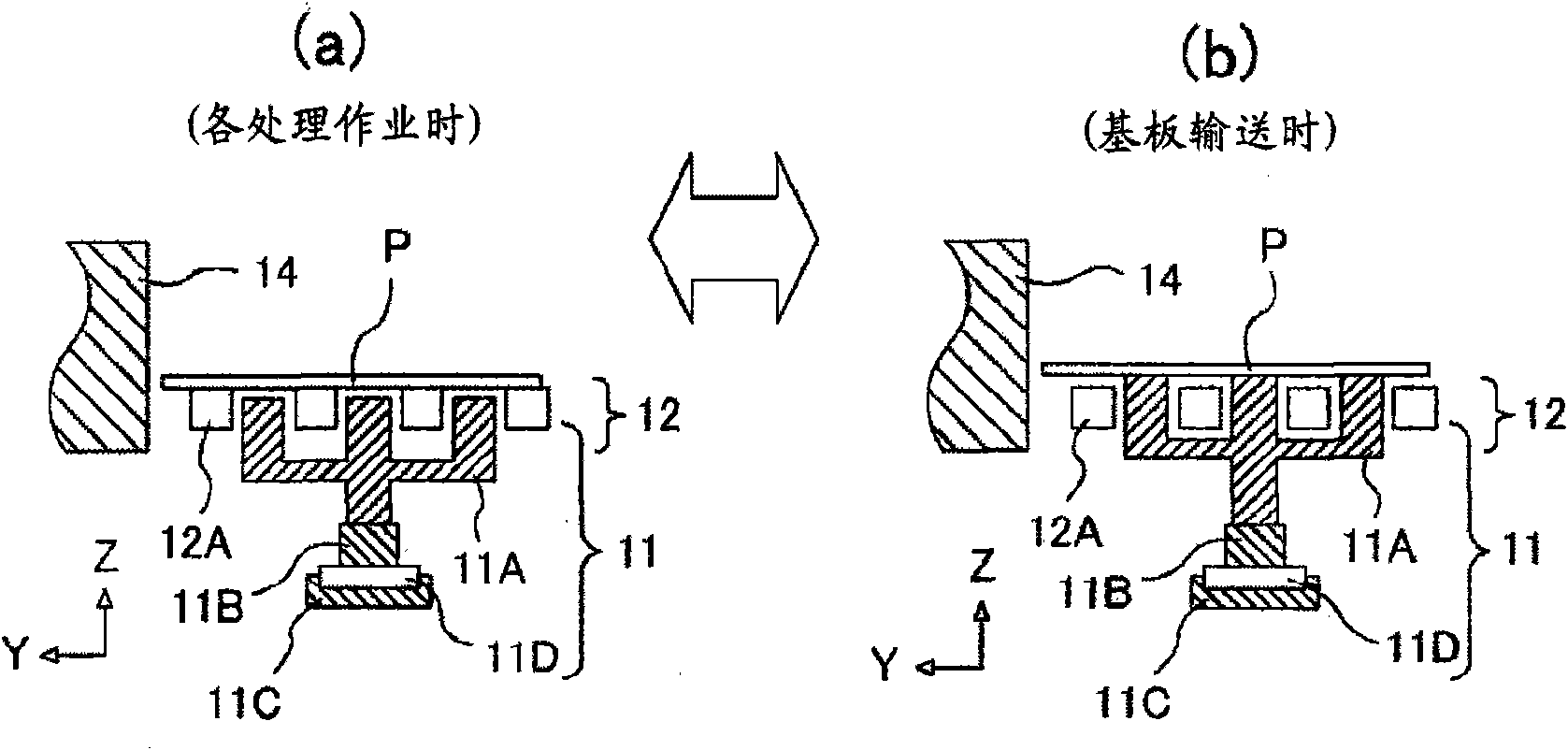

Substrate treatment device, coating device and coating method

ActiveCN101431008AStable Suspension TransportImprove coating qualityLiquid surface applicatorsSemiconductor/solid-state device manufacturingDown shiftingEngineering

The invention provides a substrate processing apparatus and a coating apparatus and a coating method characterized in that a rectangular processed substrate is kept a fitting processed posture as a simple structure for stably suspending moving on a suspension loading station. A first and a second holding parts (106L, 106R) in a first (left side) and a second (right side) moving parts (84L, 84R) comprise two adsorption pads (108L, 108R) combined at the reverse (low surface) of the two corners at left side and right side of the substrate G through a vacuum adsorption force; a pair of pad support parts (110L, 110R) for inhibiting the displacement in perpendicular direction of each adsorption pad (108L, 108R) in two positions which are separated by a prescriptive space along the moving direction (X direction); and a pair of pad actuators (112L, 112R) enabling the pad support parts (110L, 110R) to respectively independently up-down moving or up-down shifting.

Owner:TOKYO ELECTRON LTD

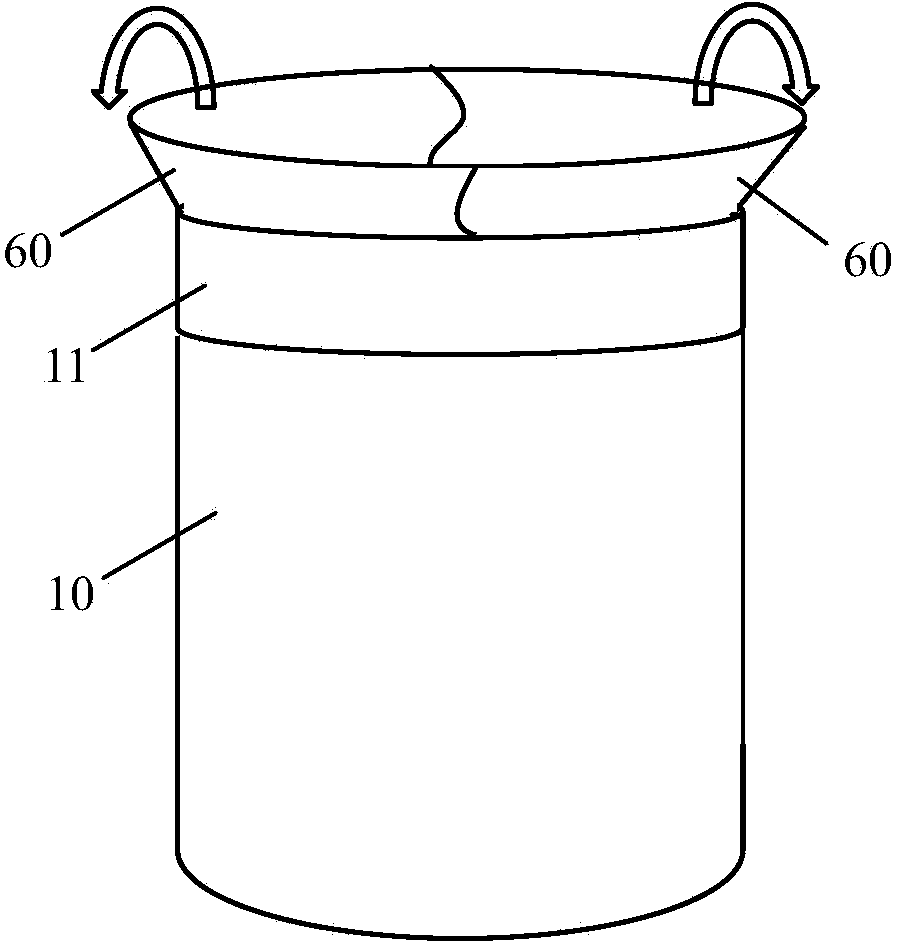

Vacuum evaporation system capable of controlling evaporating airflow distribution and components

ActiveCN102011096AImprove cleanlinessIncrease profitVacuum evaporation coatingSputtering coatingCrucibleEngineering

The invention relates to a vacuum evaporation system capable of controlling evaporating airflow distribution and components. The system comprises an evaporation gun, a high-temperature evaporation crucible and a storage tank filled with an evaporating material, wherein a nozzle with an upper conical surface and a lower conical surface is formed on the evaporation gun, and a movable airflow guidance plug is arranged inside the nozzle; a substrate to be evaporated is opposite to the front of the nozzle; the evaporation gun is connected with the high-temperature evaporation crucible which is provided with a cross baffle through a heat pipeline or a surge flask, and the other side of the crucible is connected with the storage tank through a pipeline which is provided with a feed valve; heating coils are arranged on the evaporation gun, the heat pipeline, the high-temperature evaporation crucible and the outer wall of the pipeline, and a heat coil is arranged on the outer wall of the storage tank as well; the evaporating material in the storage tank is delivered into the high-temperature evaporation crucible through the feed valve and the pipeline, so that the evaporating material to be evaporated is immediately turned to be vapor delivered to the evaporating gun; and the volume and the direction of the vapor can be controlled by changing the relative position of the airflow guidance plug and the nozzle, and the vapor is evaporated to the substrate to form an evaporating film, which is uniform and has set area and multiple components. The vacuum evaporation system has simple structure, can improve the utilization rate of the organic evaporating material, and can improve the production efficiency.

Owner:SHANGHAI UNIV

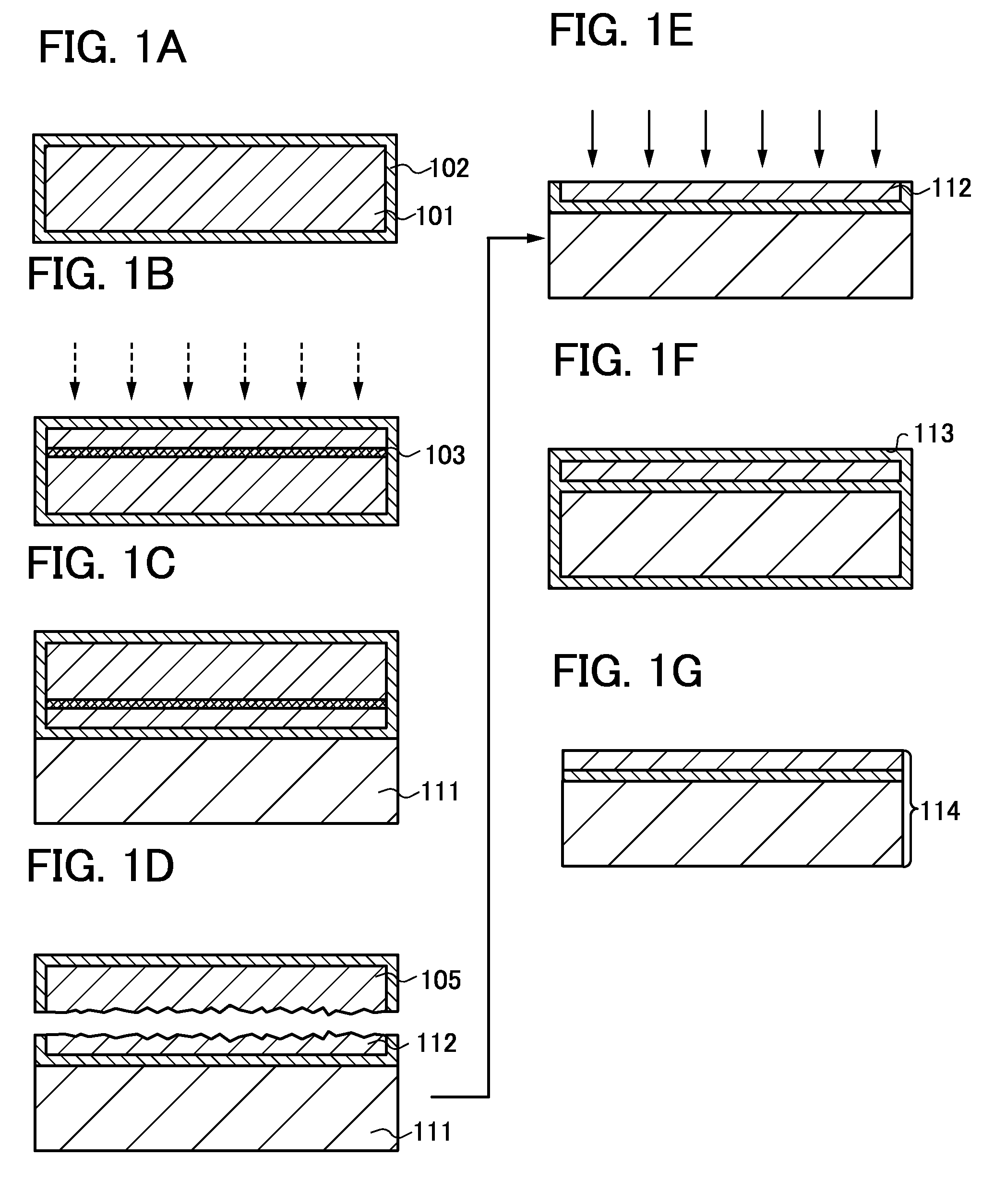

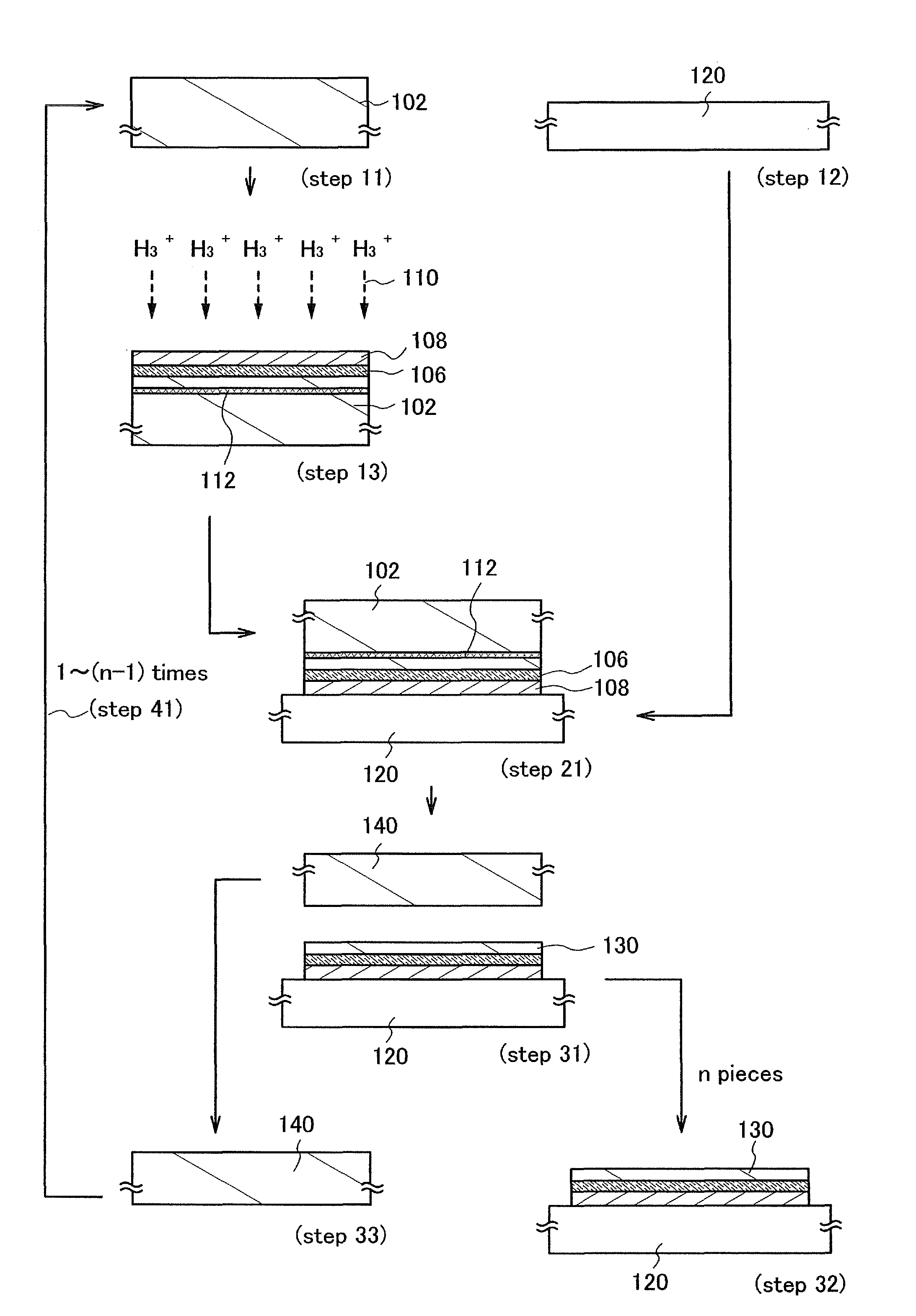

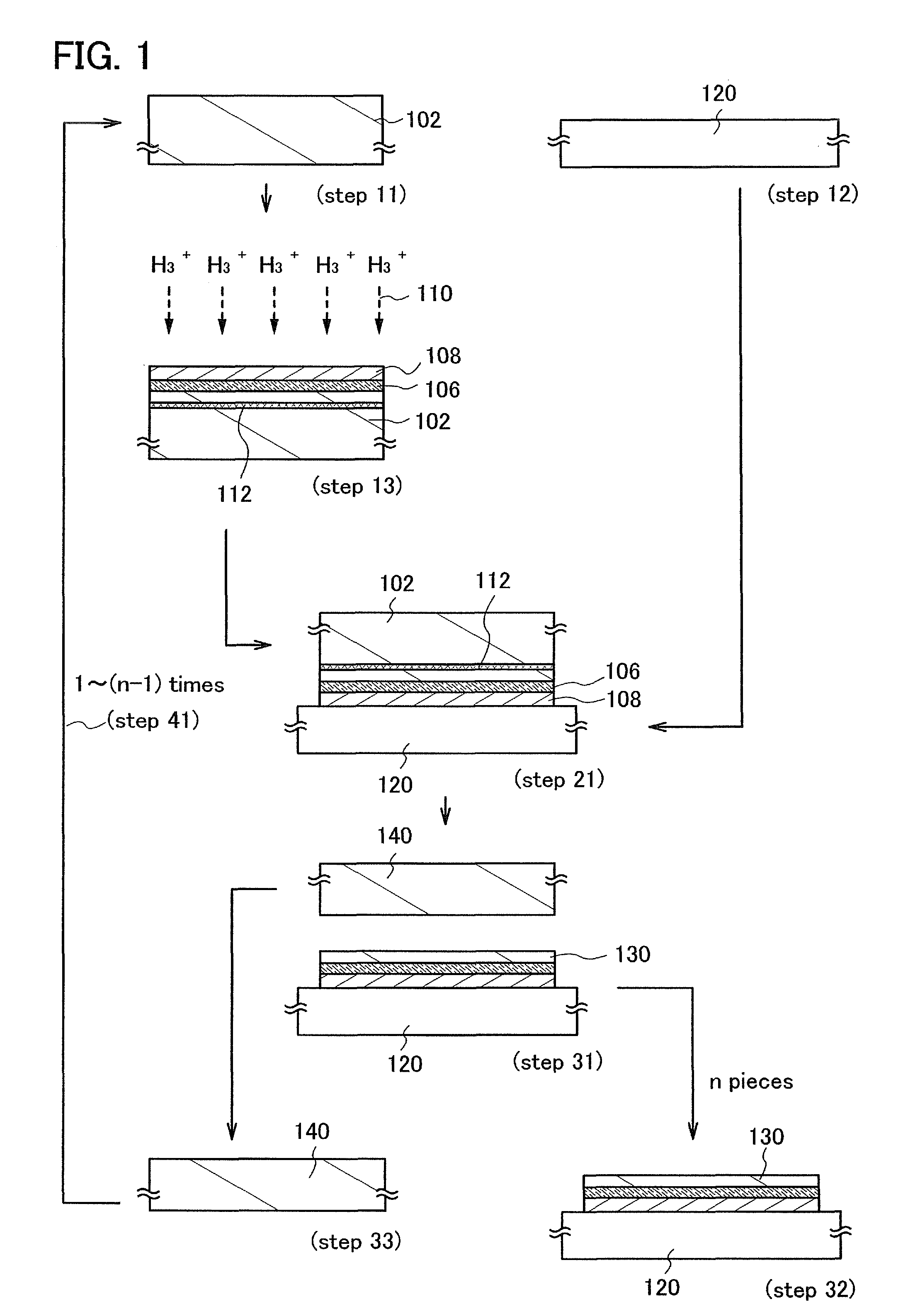

Method for manufacturing soi substrate and method for manufacturing semiconductor device

InactiveUS20090246934A1ReducedExcellent electronic characteristicSemiconductor/solid-state device manufacturingOxideCrystallographic defect

A method for manufacturing an SOI substrate in which crystal defects of a single crystal semiconductor layer are reduced is provided. An oxide film containing halogen is formed on each of surfaces of a single crystal semiconductor substrate and of a semiconductor substrate provided with a single crystal semiconductor layer separated from the single crystal semiconductor substrate, whereby impurities that exist on the surfaces of and inside the substrates are decreased. In addition, the single crystal semiconductor layer provided over the semiconductor substrate is irradiated with a laser beam, whereby crystallinity of the single crystal semiconductor layer is improved and planarity is improved.

Owner:SEMICON ENERGY LAB CO LTD

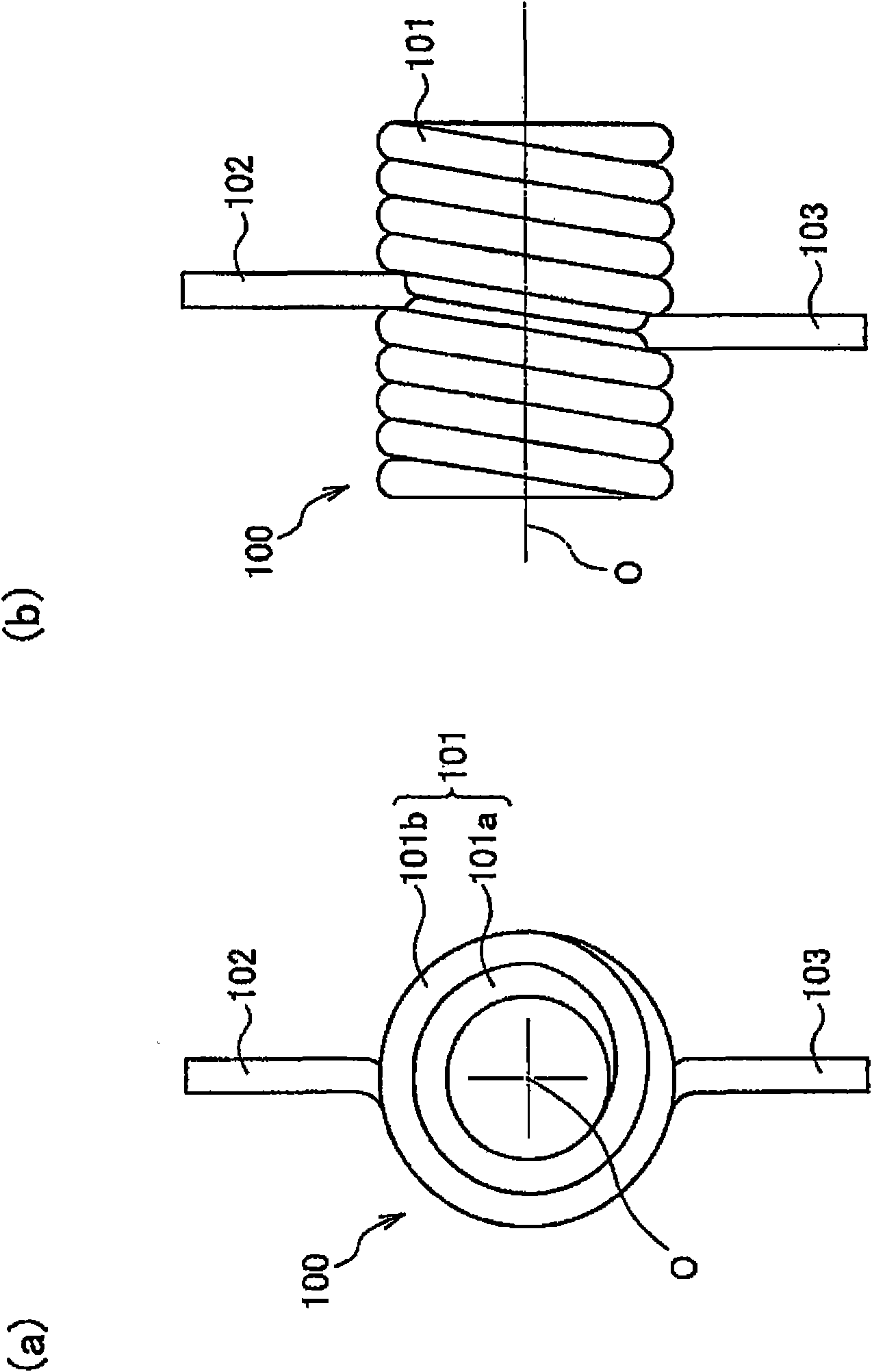

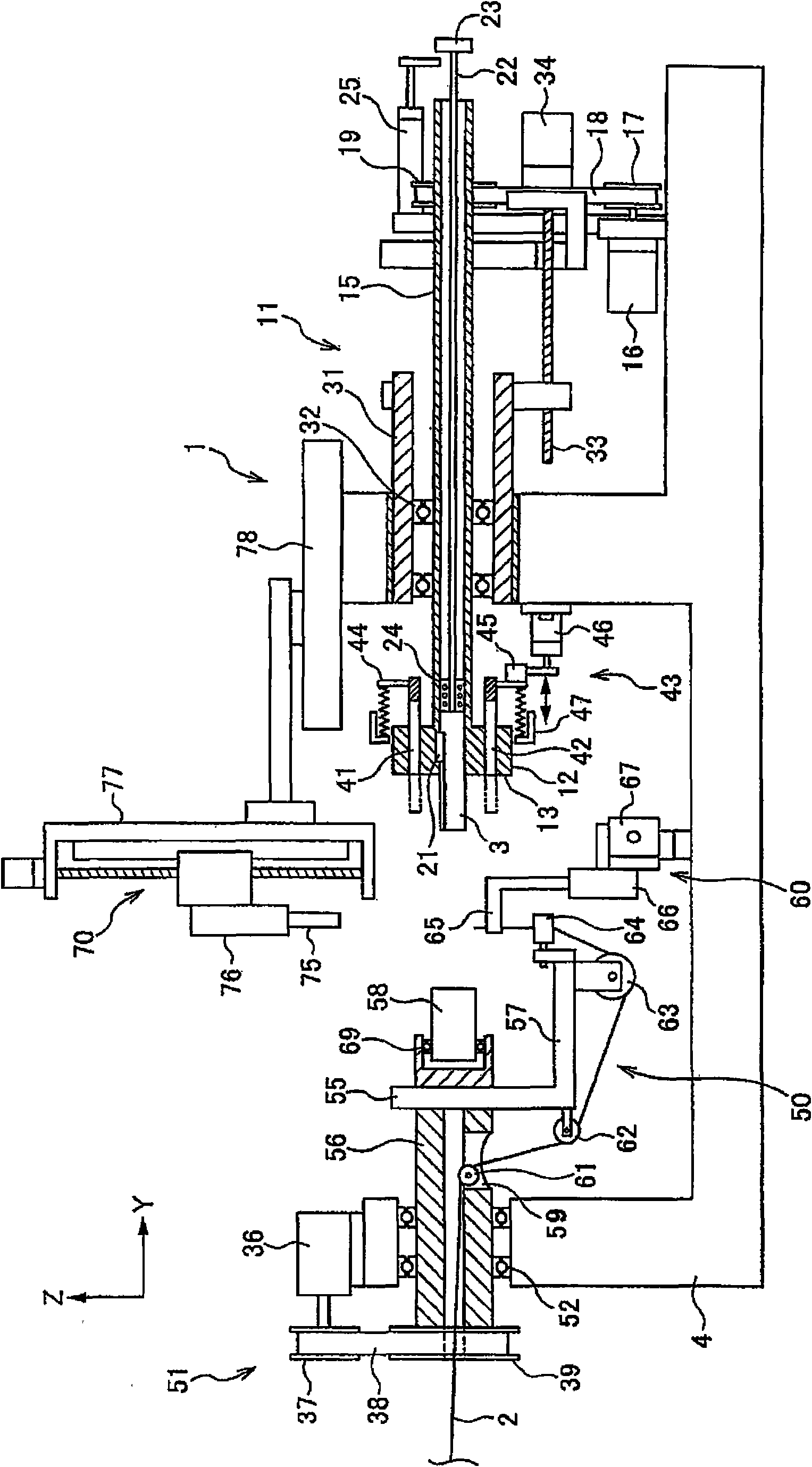

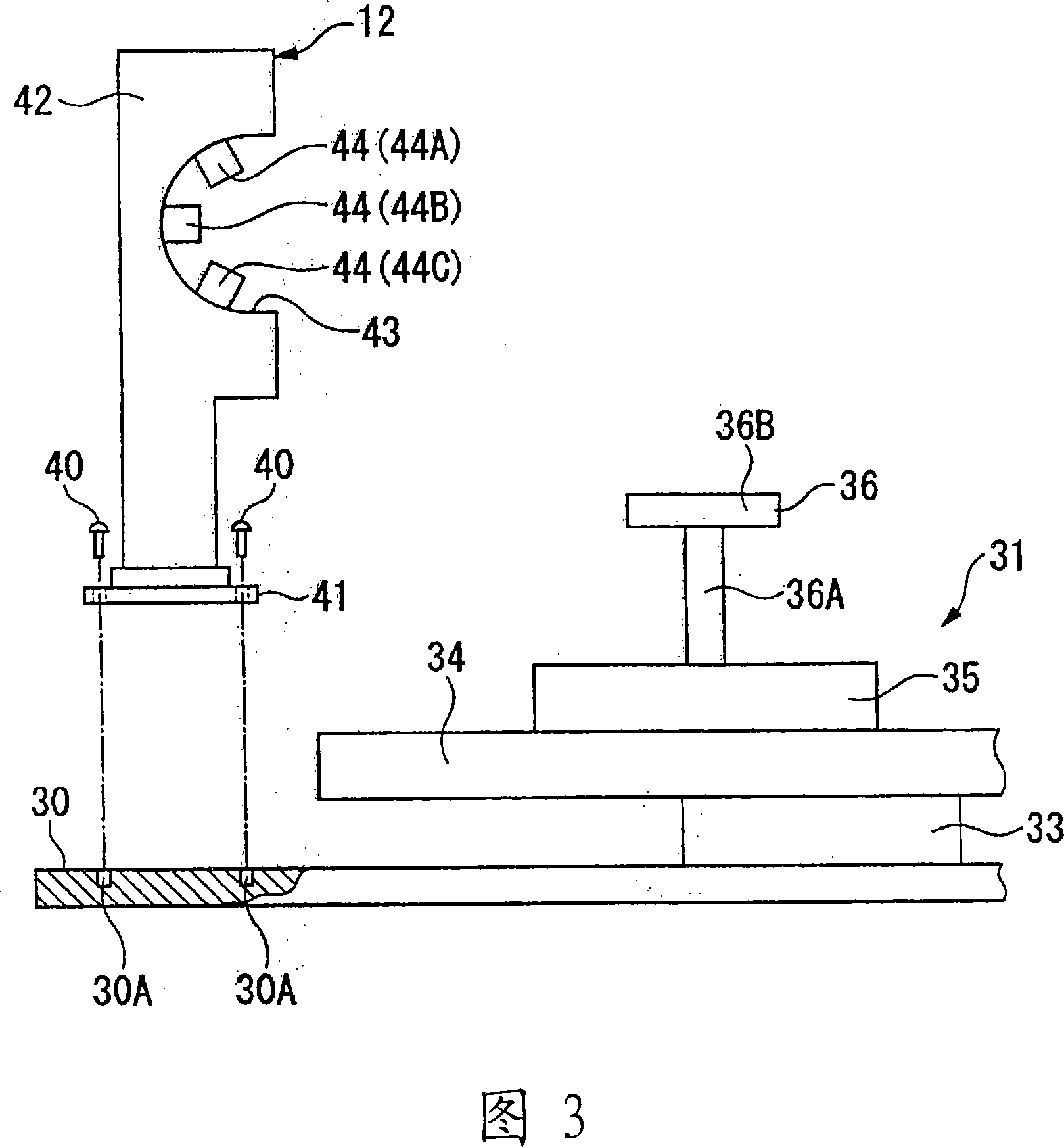

Method and device for winding coils

The present invention provides a method and device for winding coils, capable of setting arbitrarily the position and shape of a down-lead part extending from a coil part, and shaping. In the invention, the following processes are implemented by shaping pins (41, 42) projecting from a coil core flange (13) elastically, namely a winding process of winding wire (2) on a coil core (3) to form the coil part (101) under a condition that the shaping pins (41, 42) are feed into the coil core flange (13); a shaping process of shaping the down-lead parts (102, 103) by making the wire (2) extending from the coil part (101) against the shaping pins (41, 42) and bending under a condition that the shaping pins (41, 42) are projected from the coil core flange (13).

Owner:NITTOKU ENG CO LTD

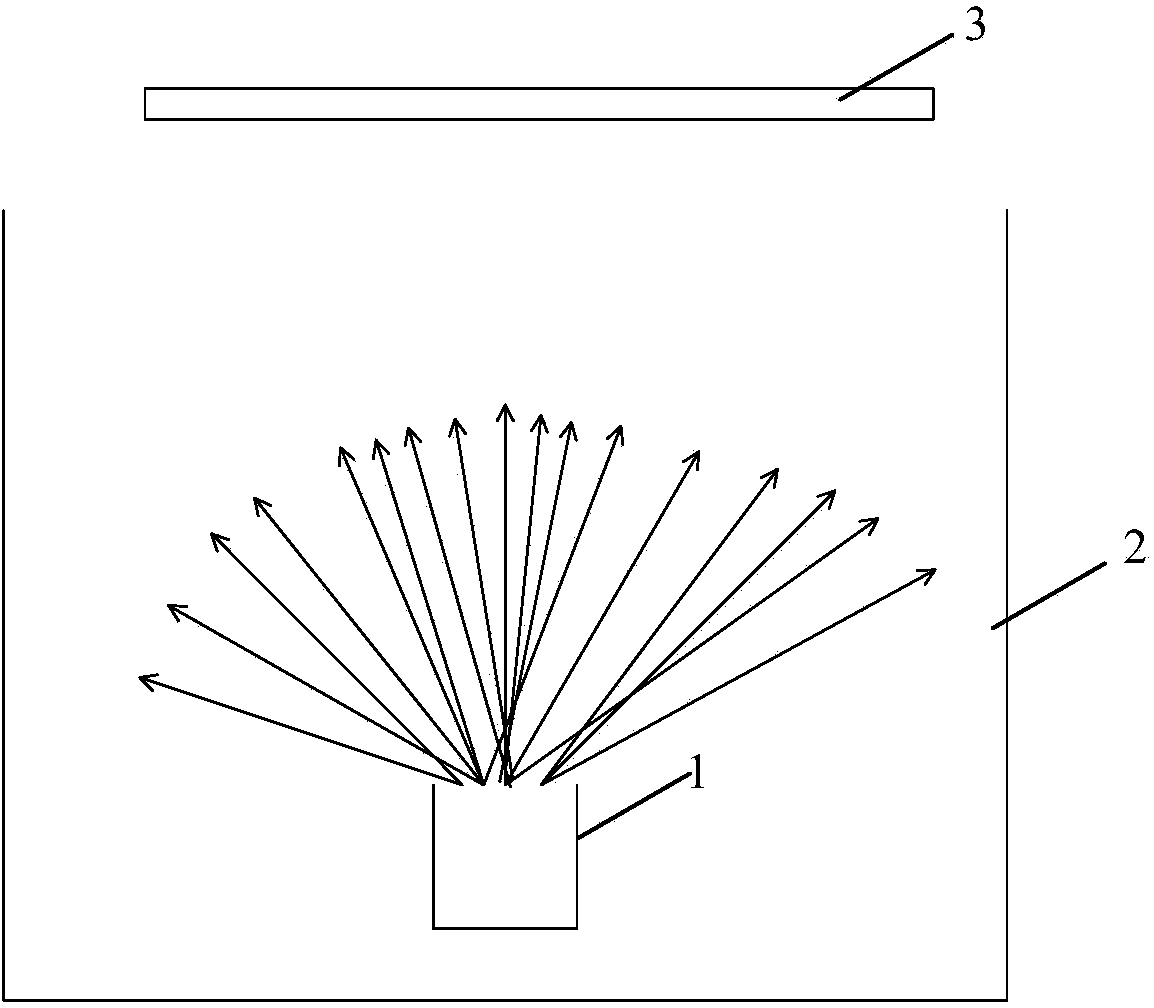

Evaporating device and evaporating method of substrate

InactiveCN103938161AIncrease profitSolve the phenomenon of uneven film thicknessVacuum evaporation coatingSputtering coatingEvaporationOptoelectronics

The invention relates to the technical field of evaporation and discloses an evaporating device and an evaporating method of a substrate. The evaporating method comprises the following steps: pre-evaporating the substrate and measuring the thickness distributing condition of an evaporated film, and dividing a thickness area according to the thickness distributing condition of the film; adjusting the distance between an evaporating source and the substrate; and selecting a mobile track of the evaporating source according to the measured thickness distributing condition of the film, and adjusting the thickness of the film of the substrate by moving the evaporating source. The device and method provided by the invention are suitable for a point evaporating source which is shifted from a stationary state to a mobile state, and the moving track of the evaporating source is set according to the thickness distributing condition of the film, so that the point evaporating source moves according to a certain track when being evaporated, so that the non-uniform point film thickness is solved. Meanwhile, the distance between the substrate and the evaporating source is adjustable, so that the pitch time can be shortened by reducing the distance and the utilization ratio of materials can be increased.

Owner:BOE TECH GRP CO LTD +1

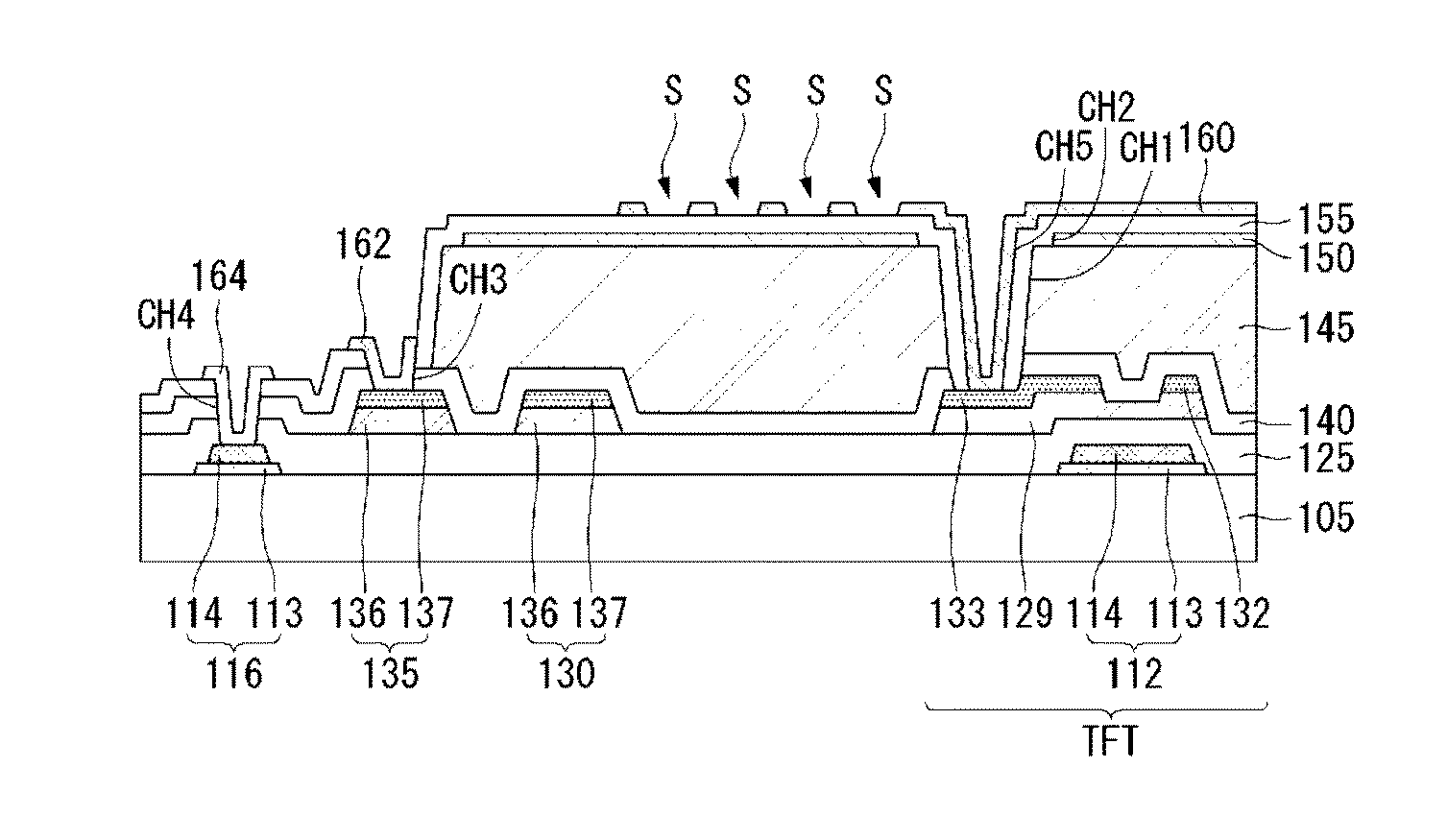

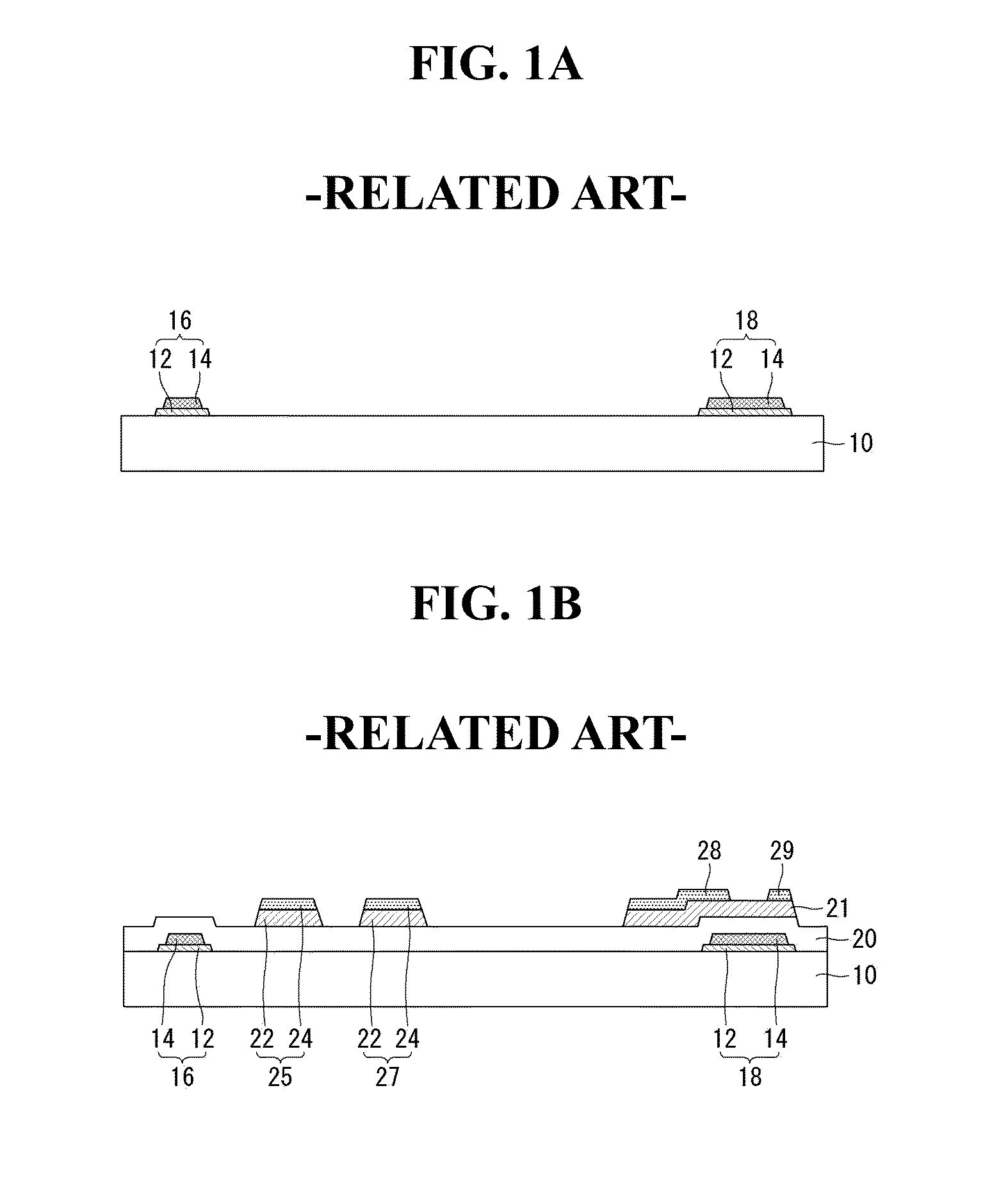

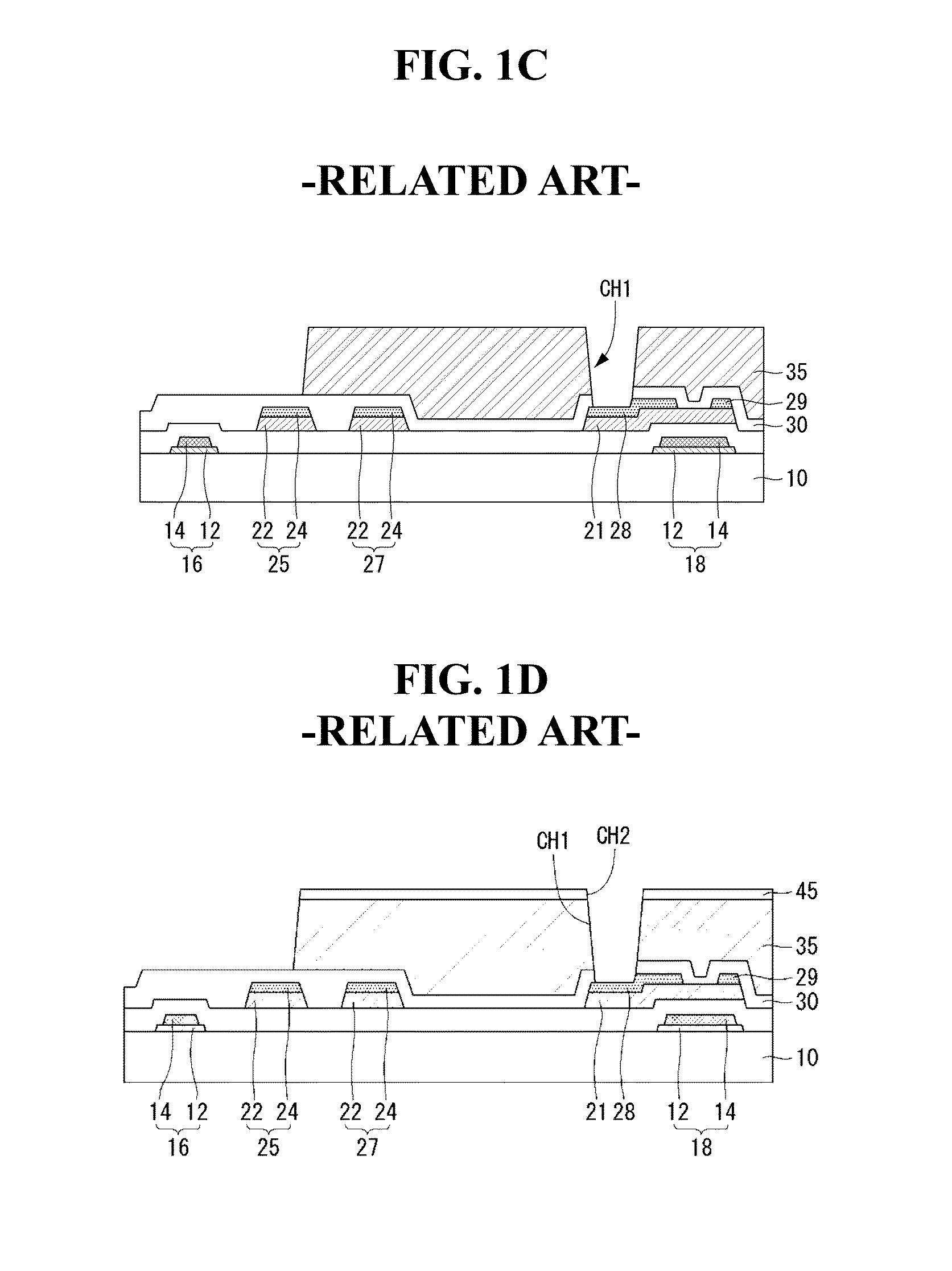

Liquid crystal display device and method for manufacturing the same

ActiveUS20150092136A1Shorten takt timeImprove productivitySolid-state devicesSemiconductor/solid-state device manufacturingLiquid-crystal displayEngineering

A disclosed liquid crystal display includes a substrate with a gate electrode, a gate insulation film, an active layer, a source electrode, a drain electrode, and a first passivation film formed on the substrate. An organic insulation film having a first contact hole and a common electrode having a second contact hole are formed on the first passivation film using a single mask. The display also includes a second passivation film on the common electrode, and a pixel electrode on the second passivation film and connected to the drain electrode via the contact hole through the second passivation film. The top surface of the organic insulation film adjacent to a side edge of the organic insulation film is uncovered by the common electrode.

Owner:LG DISPLAY CO LTD

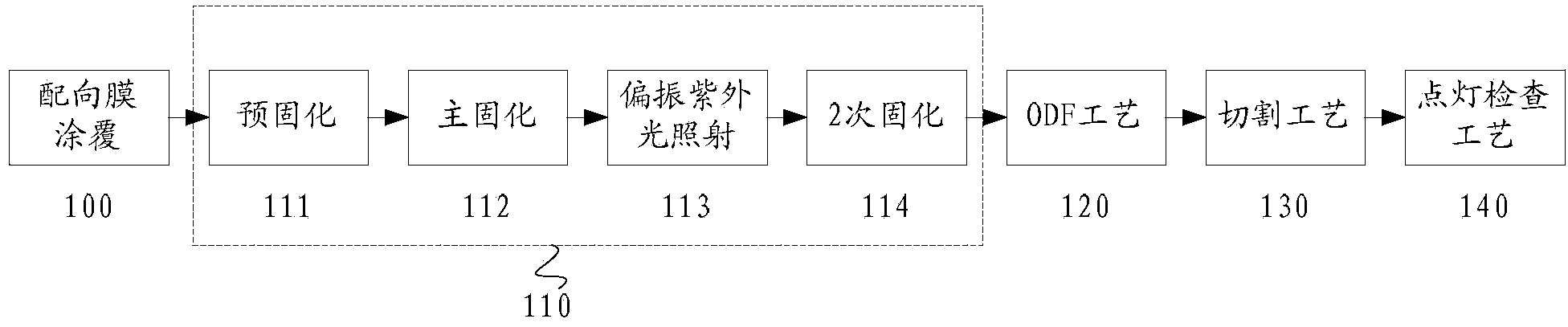

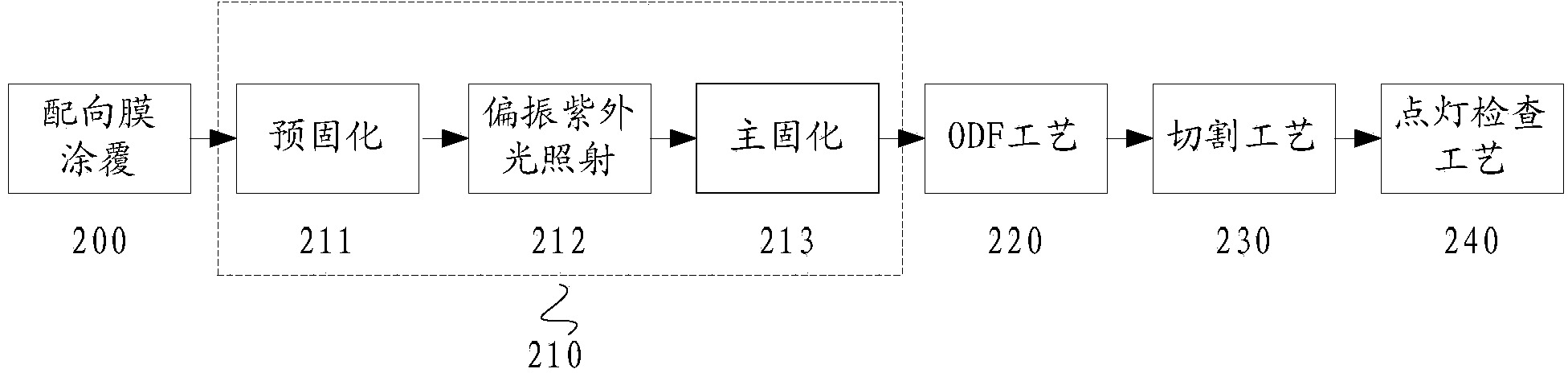

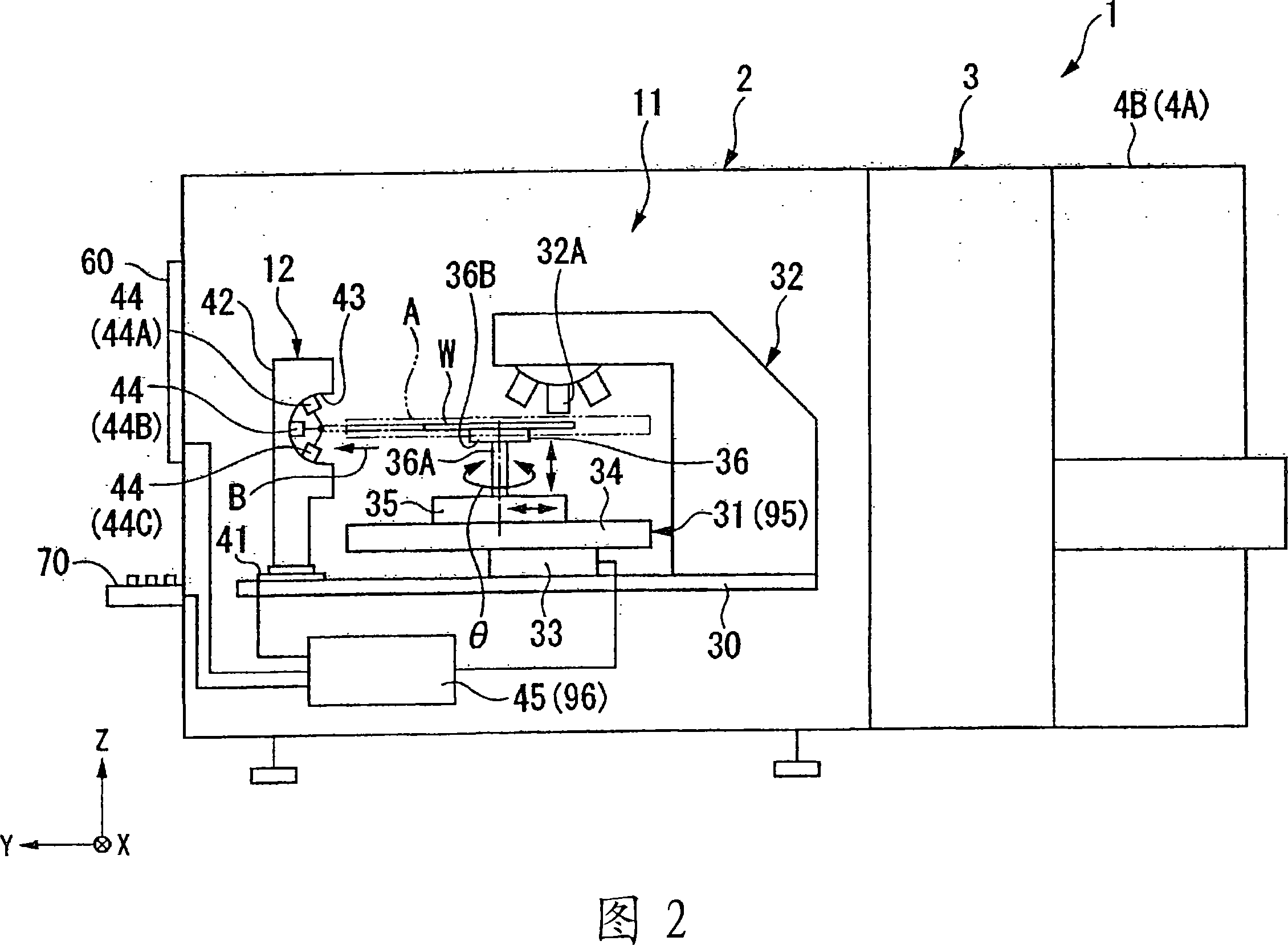

Light alignment film and preparing method thereof, liquid crystal display substrate and device

InactiveCN104166274AIncreased anisotropyEasy alignmentLiquid crystal compositionsNon-linear opticsLiquid-crystal displayDisplay device

The embodiment of the invention provides a light alignment film and a preparing method thereof, a liquid crystal display substrate and a device and belongs to the field of liquid crystal display. The light alignment film and the preparing method thereof, the liquid crystal display substrate and the device aim at improving the display effect of a display device. The preparing method of the light alignment film comprises the steps that the substrate is coated with a light alignment material film layer; the light alignment material film layer for coating is procured; the procured light alignment material film layer is irradiated with linearly polarized light, and thus the light alignment material film layer with the alignment function is formed; main curing is conducted on the light alignment material film layer with the alignment function, reaction by-products generated through the curing reaction are eliminated while the light alignment material film layer with the alignment function has the curing reaction, and the light alignment film is obtained. The light alignment film and the preparing method thereof, the liquid crystal display substrate and the device can be used in the production of the light alignment film.

Owner:BOE TECH GRP CO LTD +1

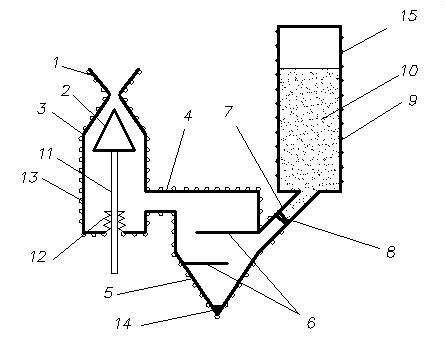

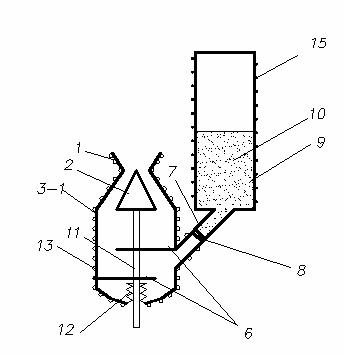

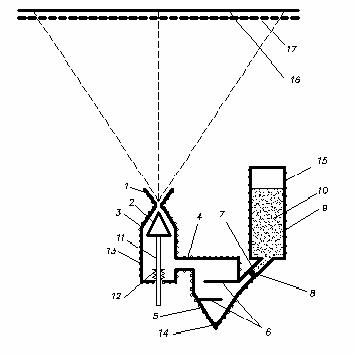

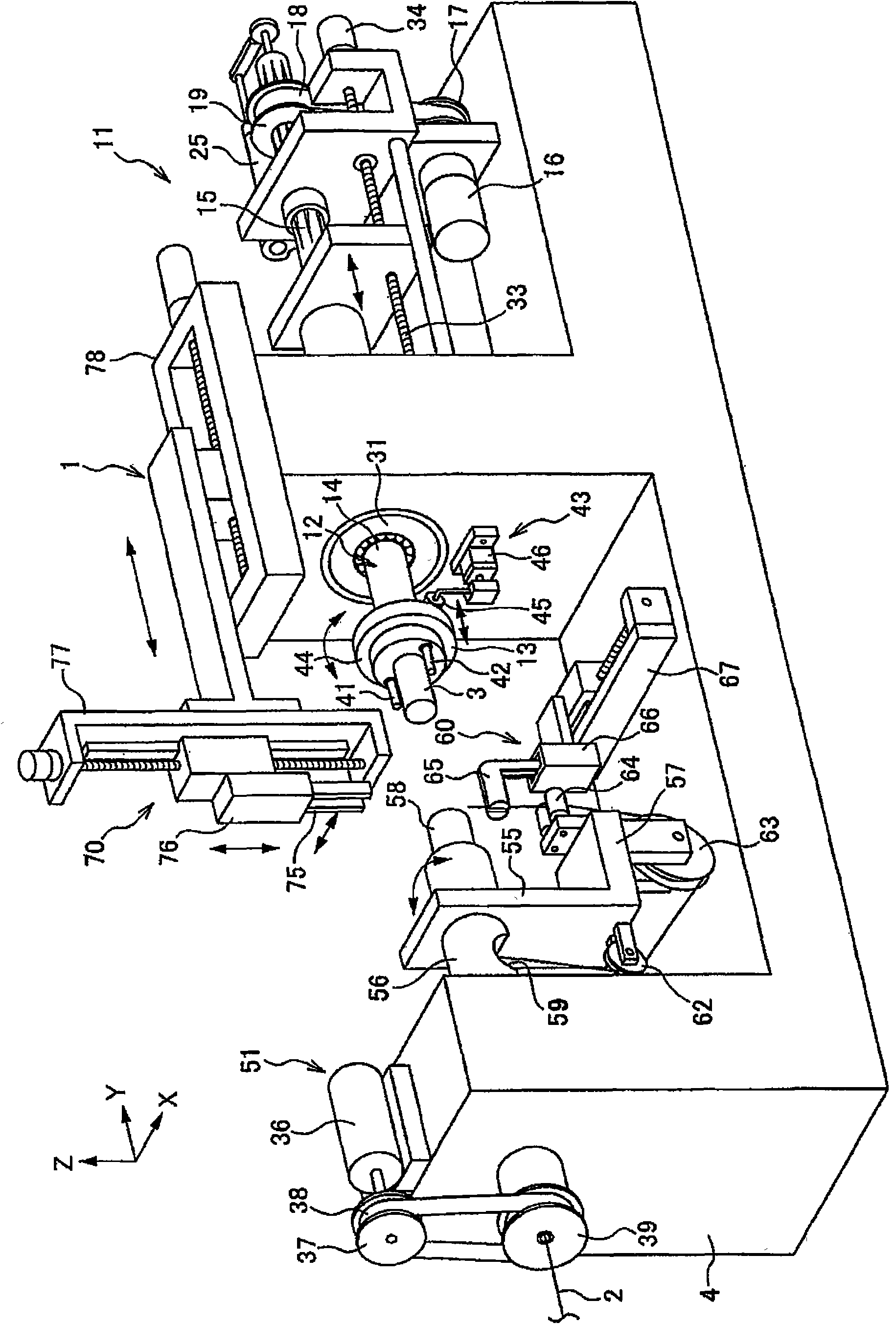

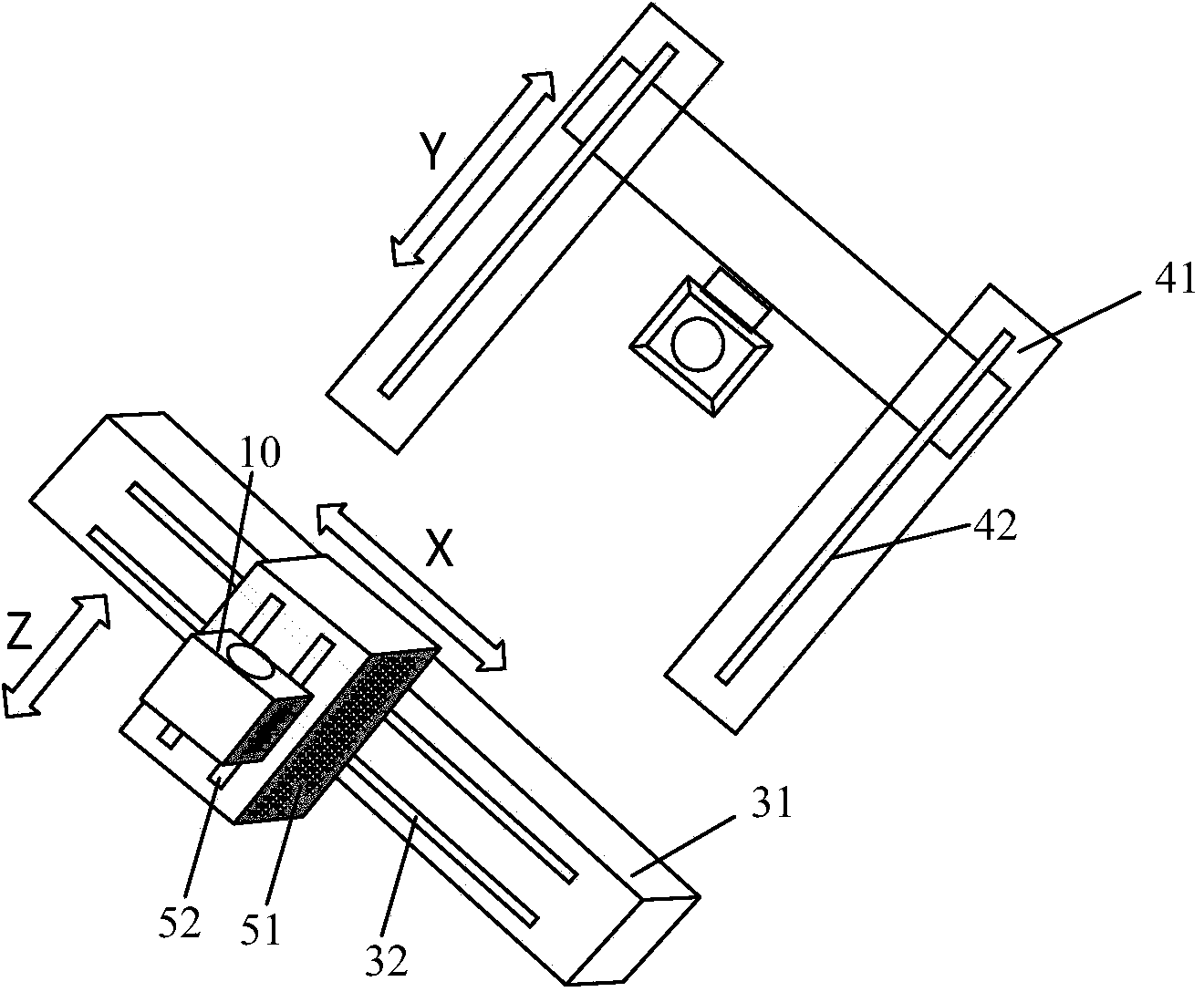

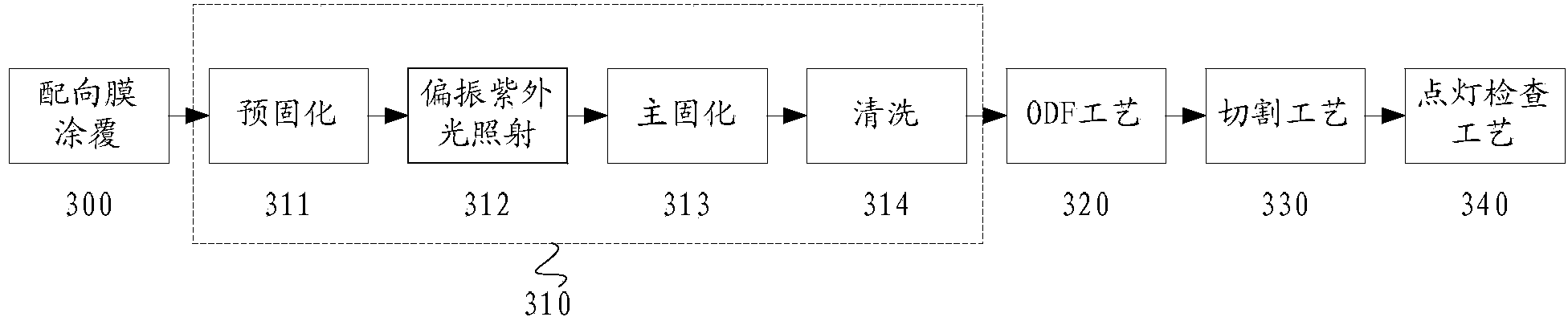

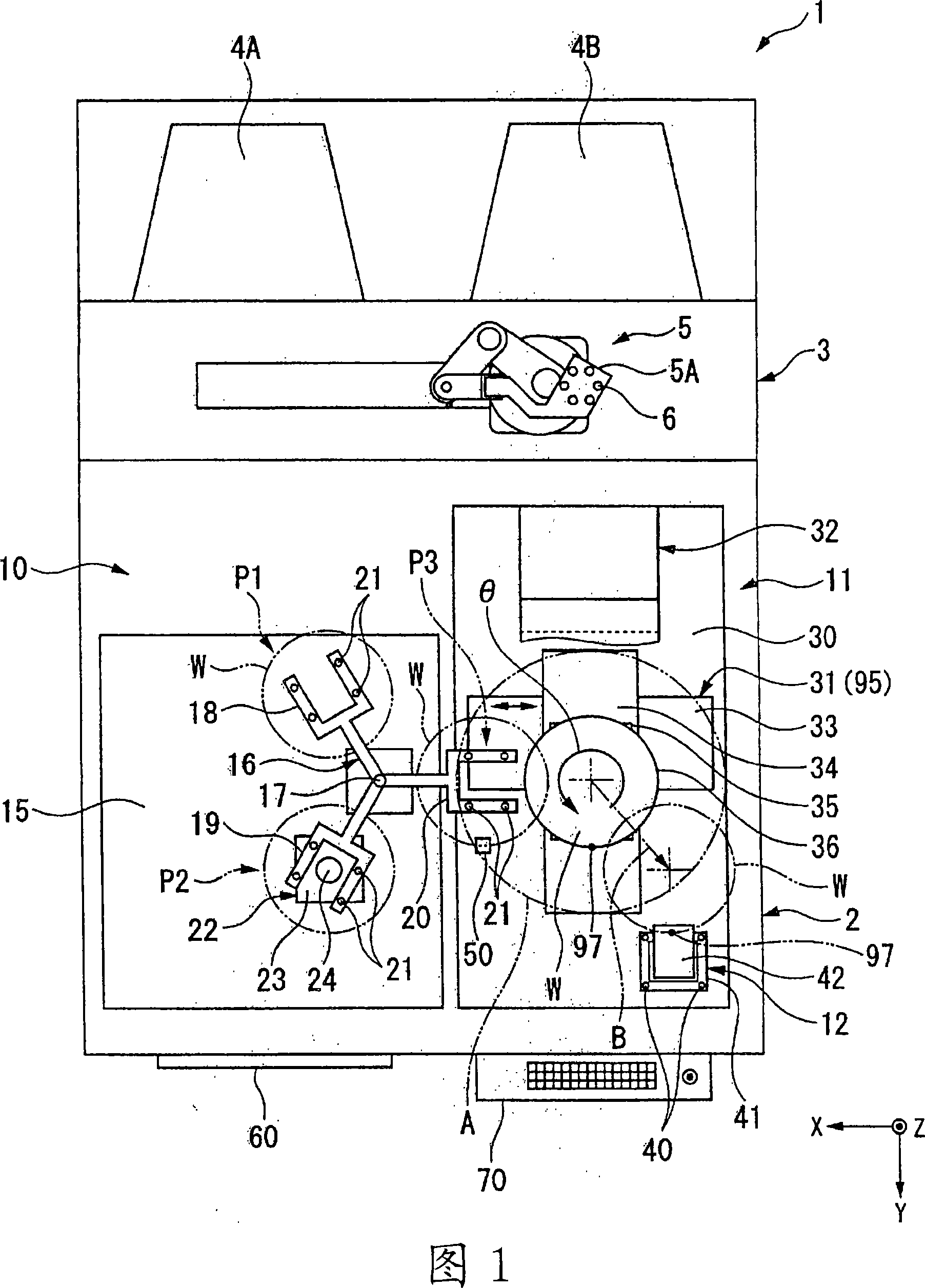

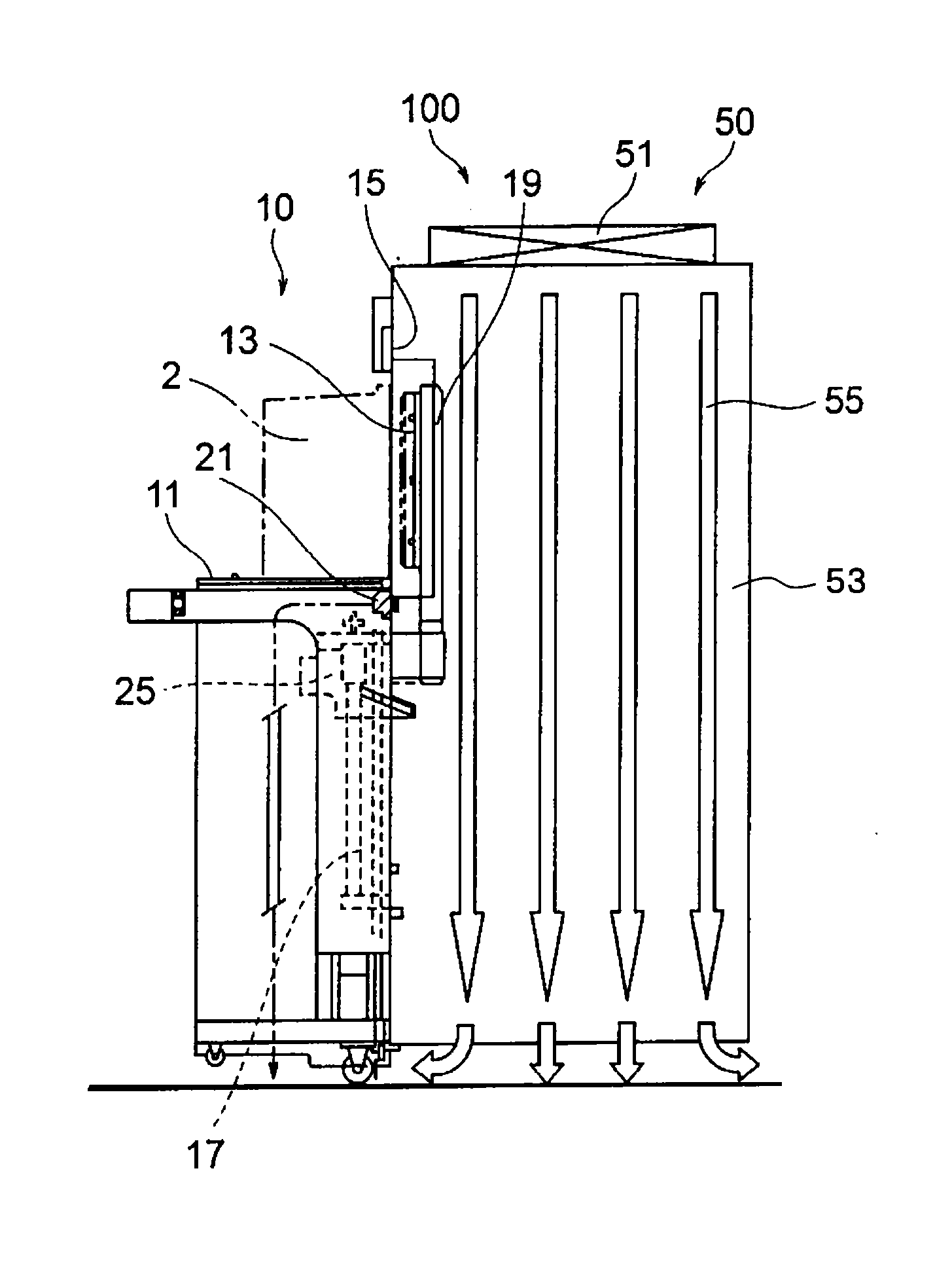

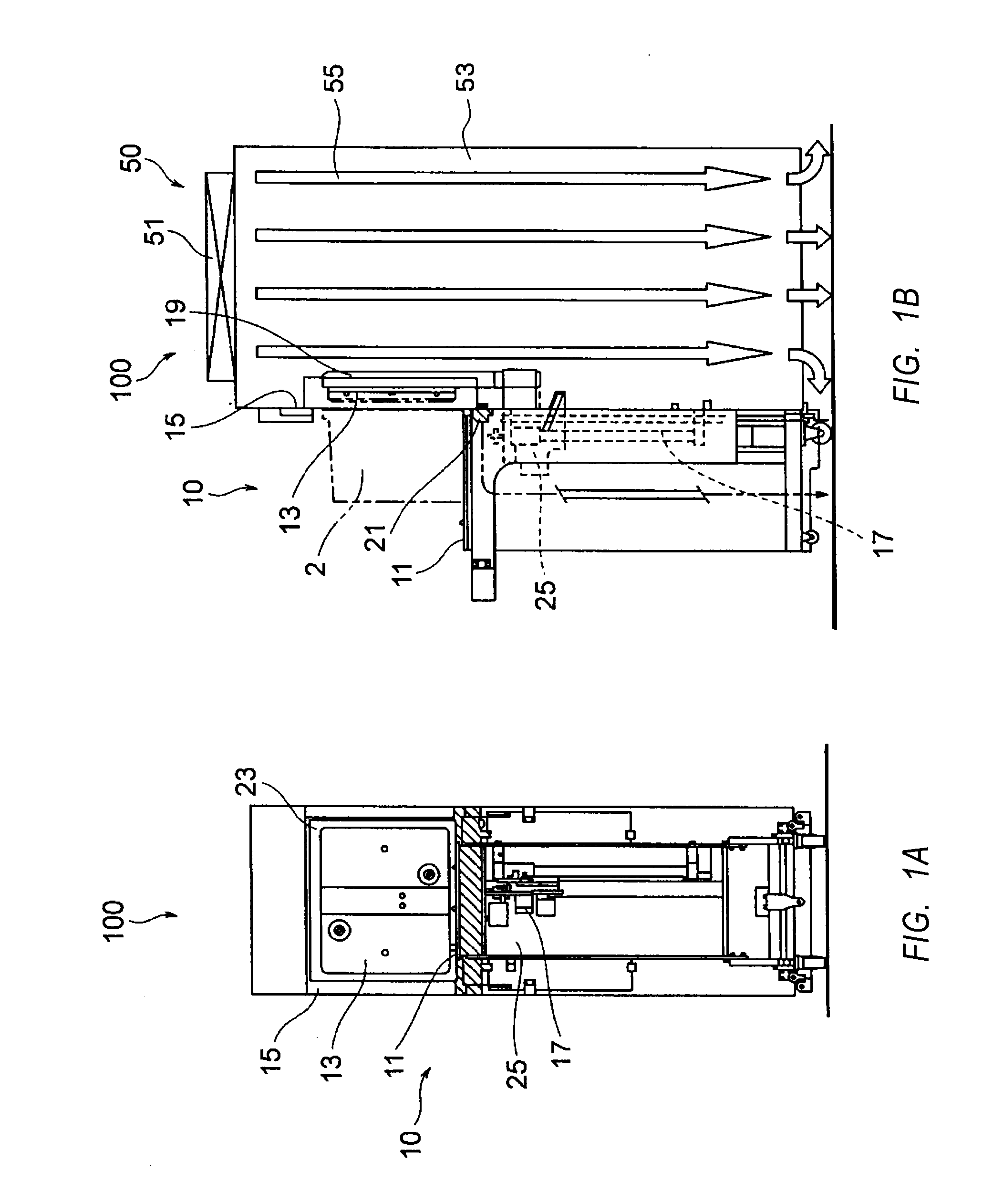

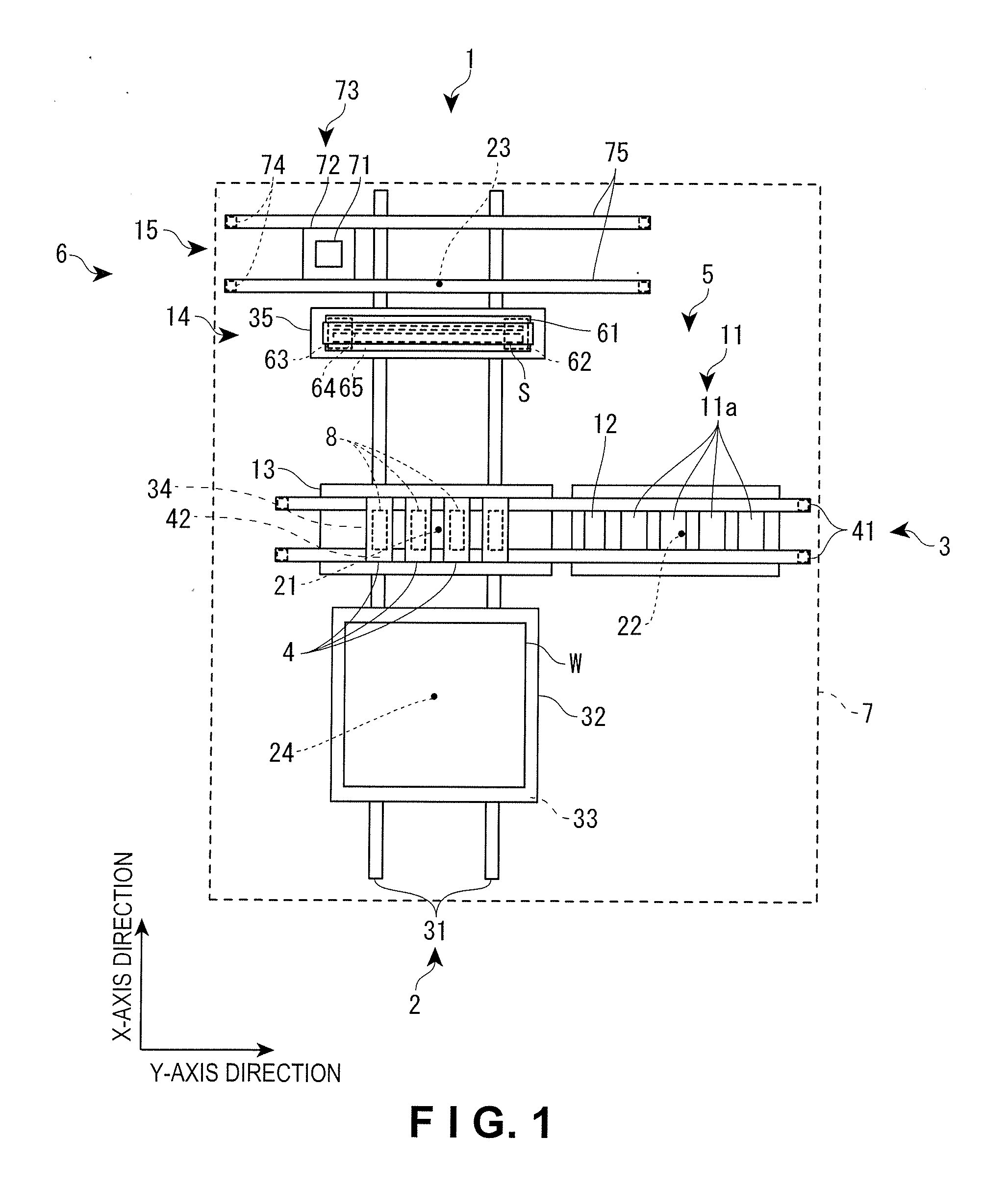

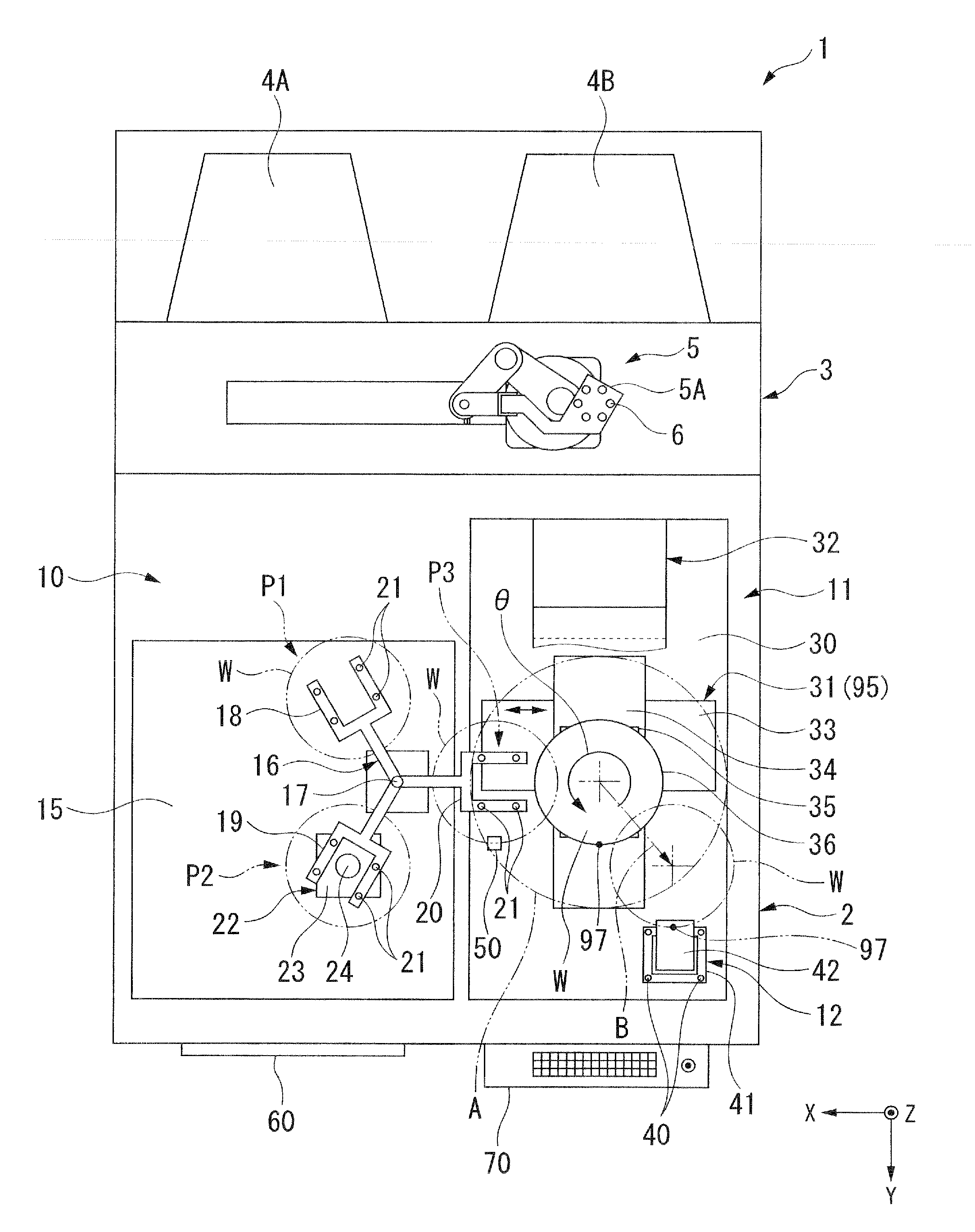

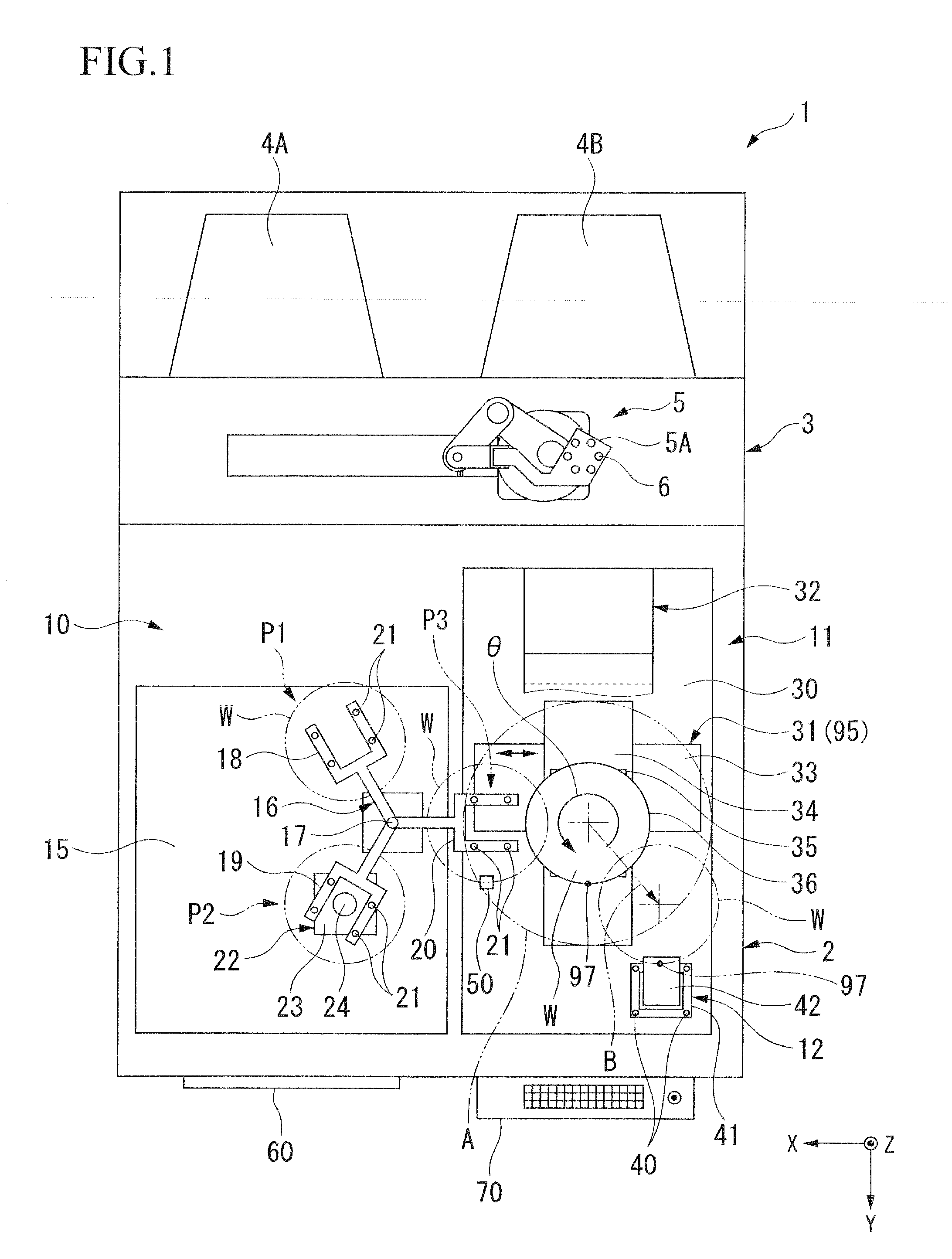

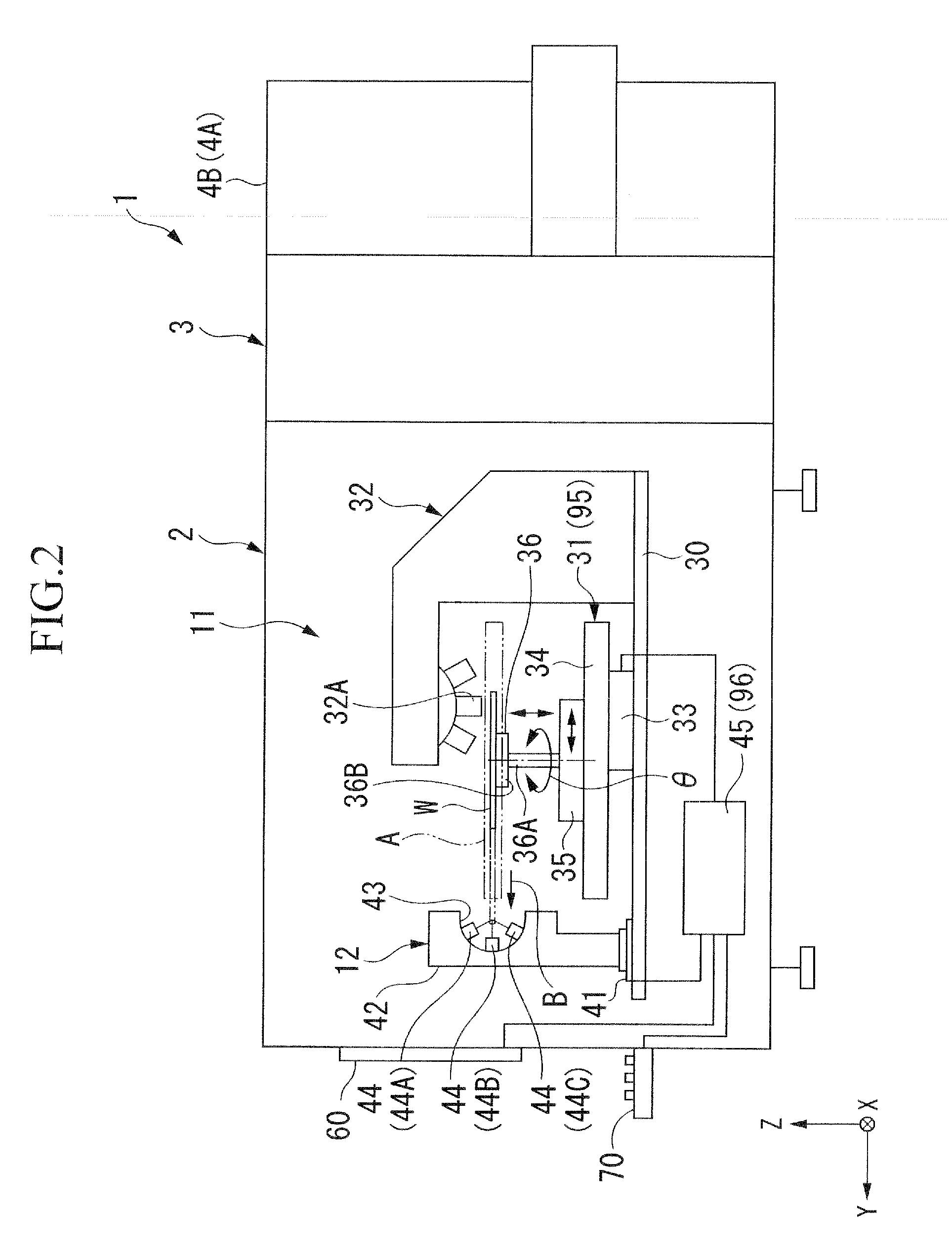

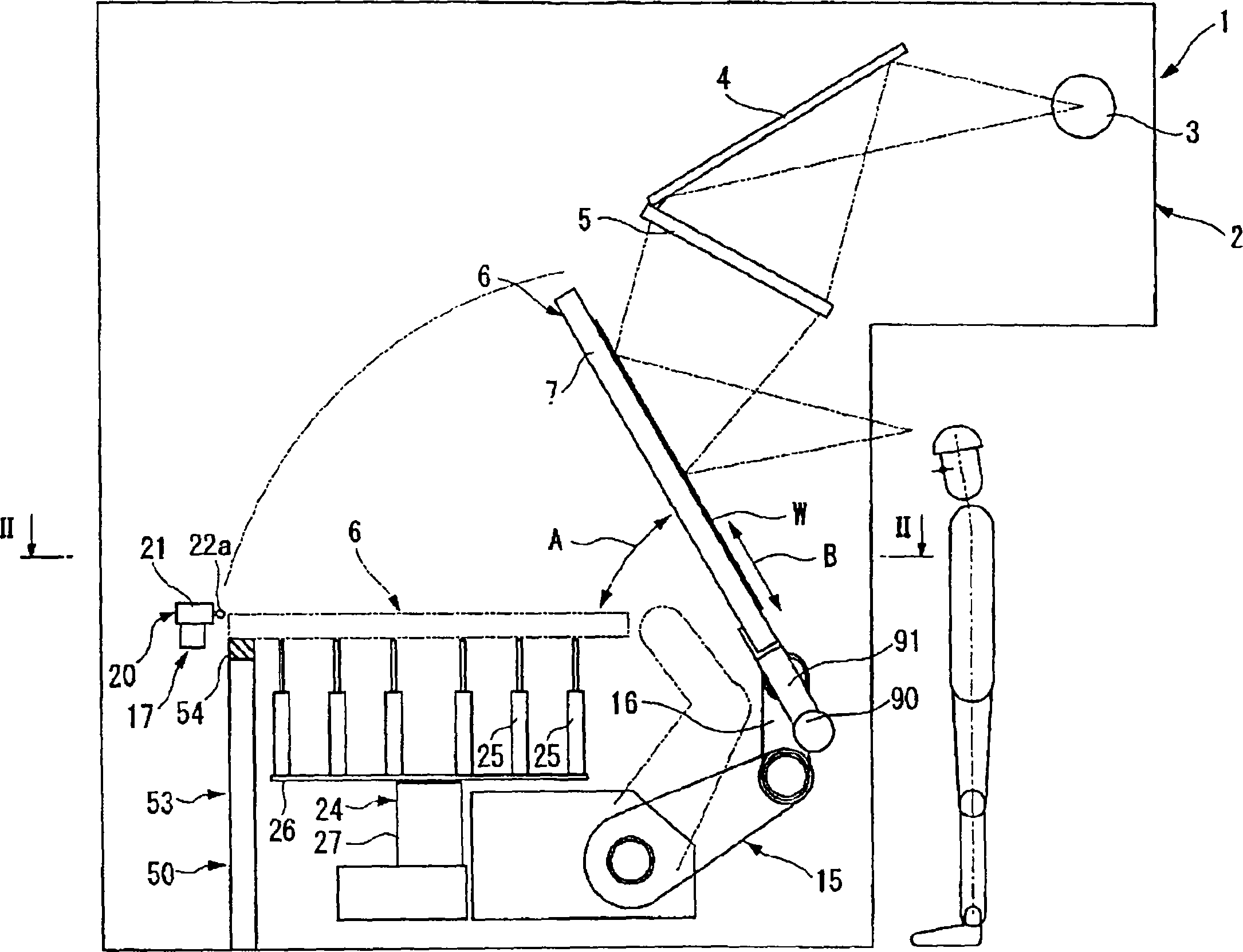

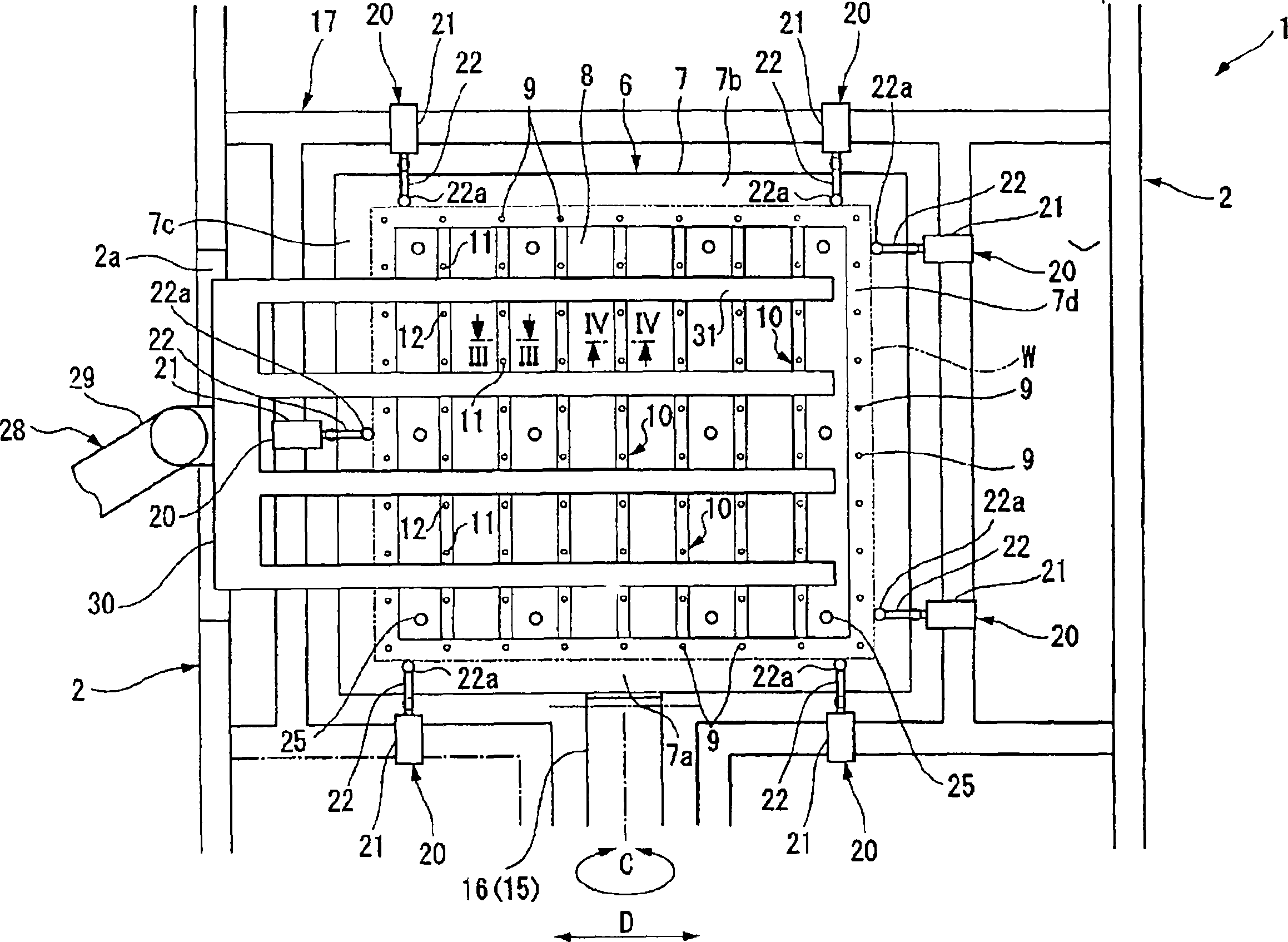

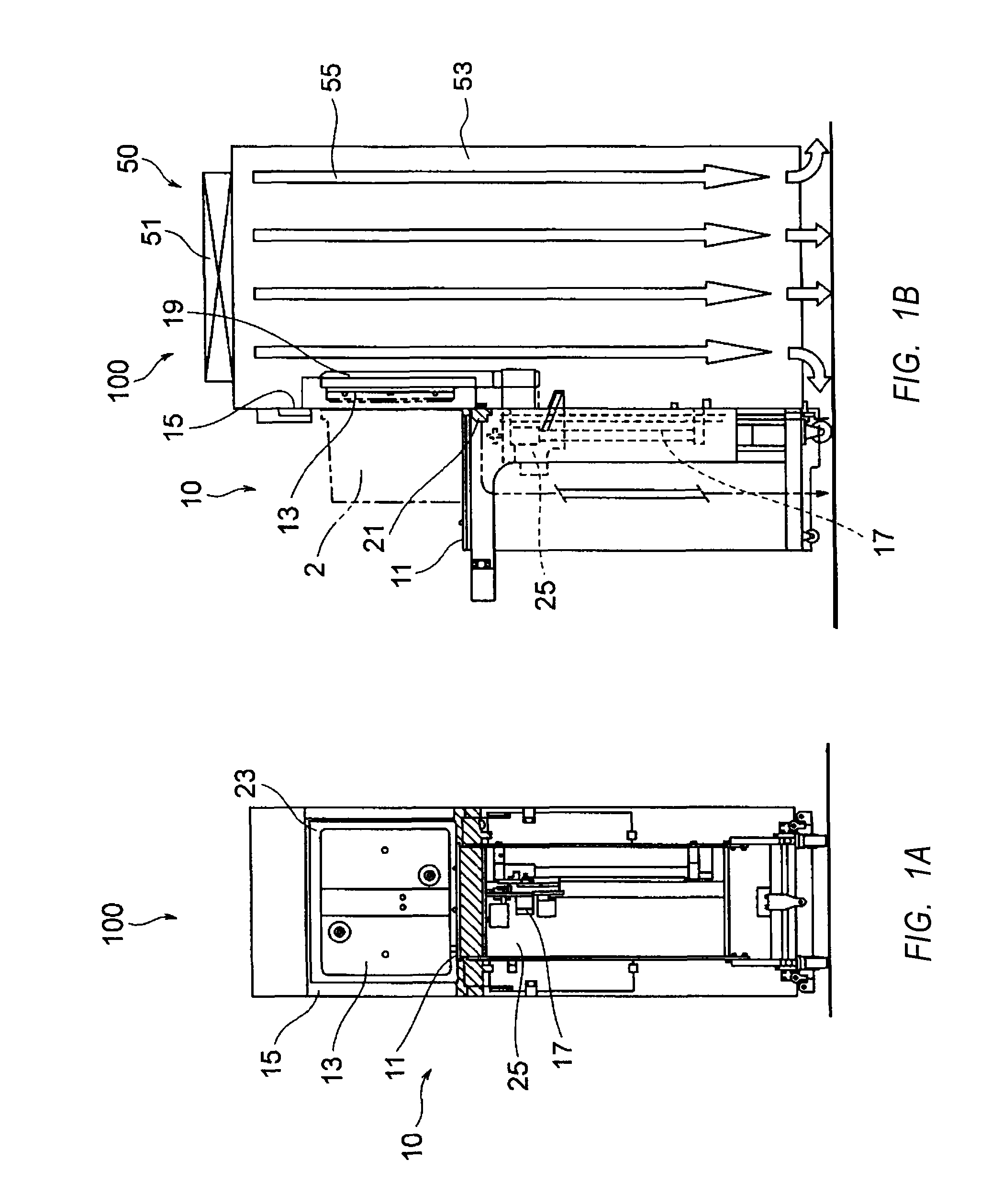

Visual inspection apparatus, visual inspection method, and peripheral edge inspection unit that can be mounted on visual inspection apparatus

InactiveCN101167171AReduced installation areaShorten takt timeSemiconductor/solid-state device testing/measurementVisual inspectionEngineering

The invention provides a visual inspection apparatus, visual inspection method, and peripheral edge inspection unit that can be mounted on visual inspection apparatus. A visual inspection apparatus is provided with a macroscopic inspecting section (10) and a microscopic inspecting section (11), and the microscopic inspecting section (11) has an inspection stage (31) and a microscope (32) on a mounting plate (30). The inspection stage (31) is movable in an X direction, a Y direction and a Z direction, and is also rotatable in a direction. Furthermore, a periphery inspecting section (12) is fixed on the mounting plate (30) for obtaining an enlarged image of a periphery of a wafer (W). The periphery inspecting section (12) is arranged to pick up an image of the periphery of the wafer (W) held by the inspection stage (31).

Owner:OLYMPUS CORP

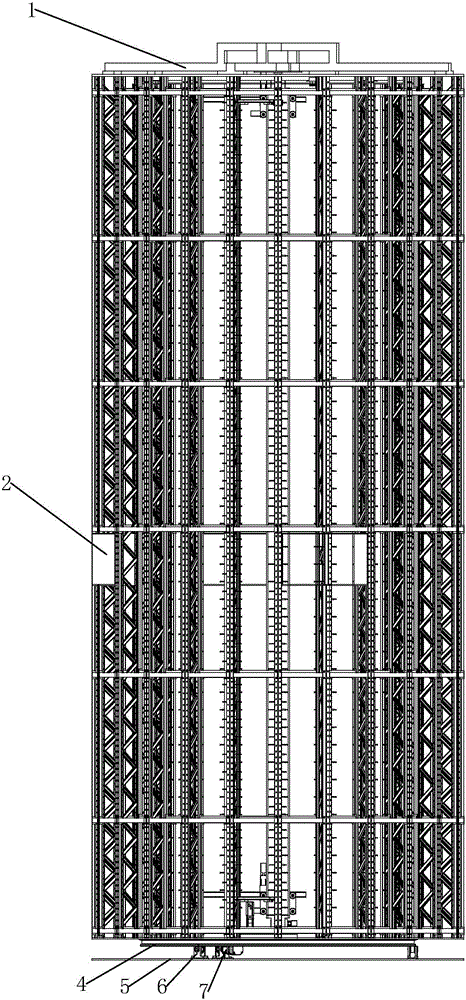

Logistics tower equipment

The invention provides logistics tower equipment and belongs to the technical field of warehouse logistics. The logistics tower equipment comprises an adjusting rack, windows, an outer layer goods shelf, an inner layer rotary goods shelf, a center rotation mechanism, a lifting mechanism, a buffer storage mechanism and a manipulator assembly. The adjusting rack is arranged at the top ends of the outer layer goods shelf and the inner layer goods shelf and connected with the outer layer goods shelf, the inner layer goods shelf, the center rotation mechanism and the lifting mechanism which are arranged in sequence. The inner layer goods shelf is connected with the adjusting rack through a top rail assembly and connected to the ground through a ground rail assembly and does circular rotational motion along top rails and ground rails. A center rotation stand column is mounted in the middle of the inner layer goods shelf. The buffer storage mechanism and the manipulator assembly are both mounted on the center rotation stand column through a vertical driving mechanism and move up and down along the center rotation stand column. A goods taking passage is formed longitudinally along the diameter, where the manipulator assembly is mounted, of the inner layer goods shelf. The outer layer goods shelf is provided with the goods taking and sending windows. According to the logistics tower equipment, the number of goods locations on the goods shelves is large, and the space utilization rate is high; and goods on the outer layer goods shelf are taken through the inner layer rotary goods shelf, and accordingly the output and input efficiency of a warehouse is improved.

Owner:SHENYANG GENERAL ROBOT TECH

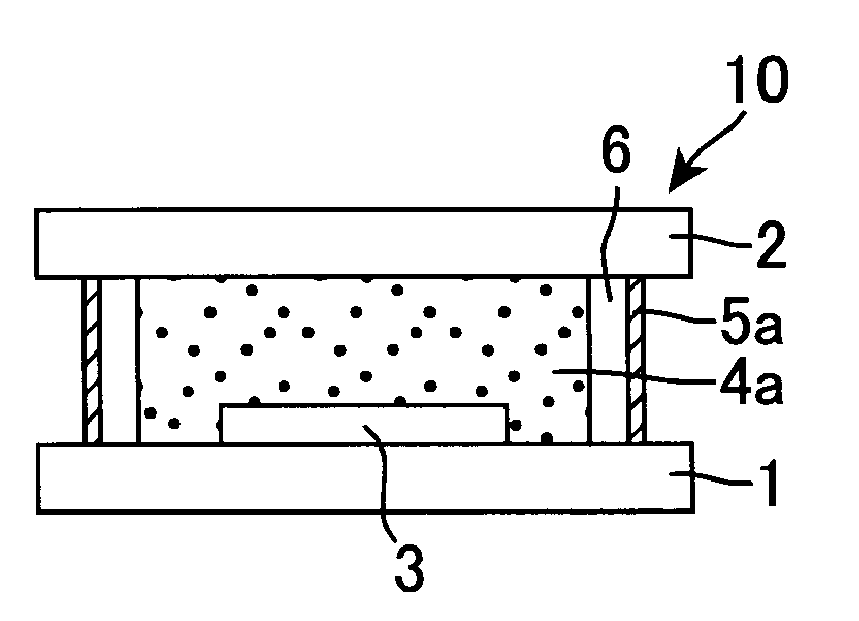

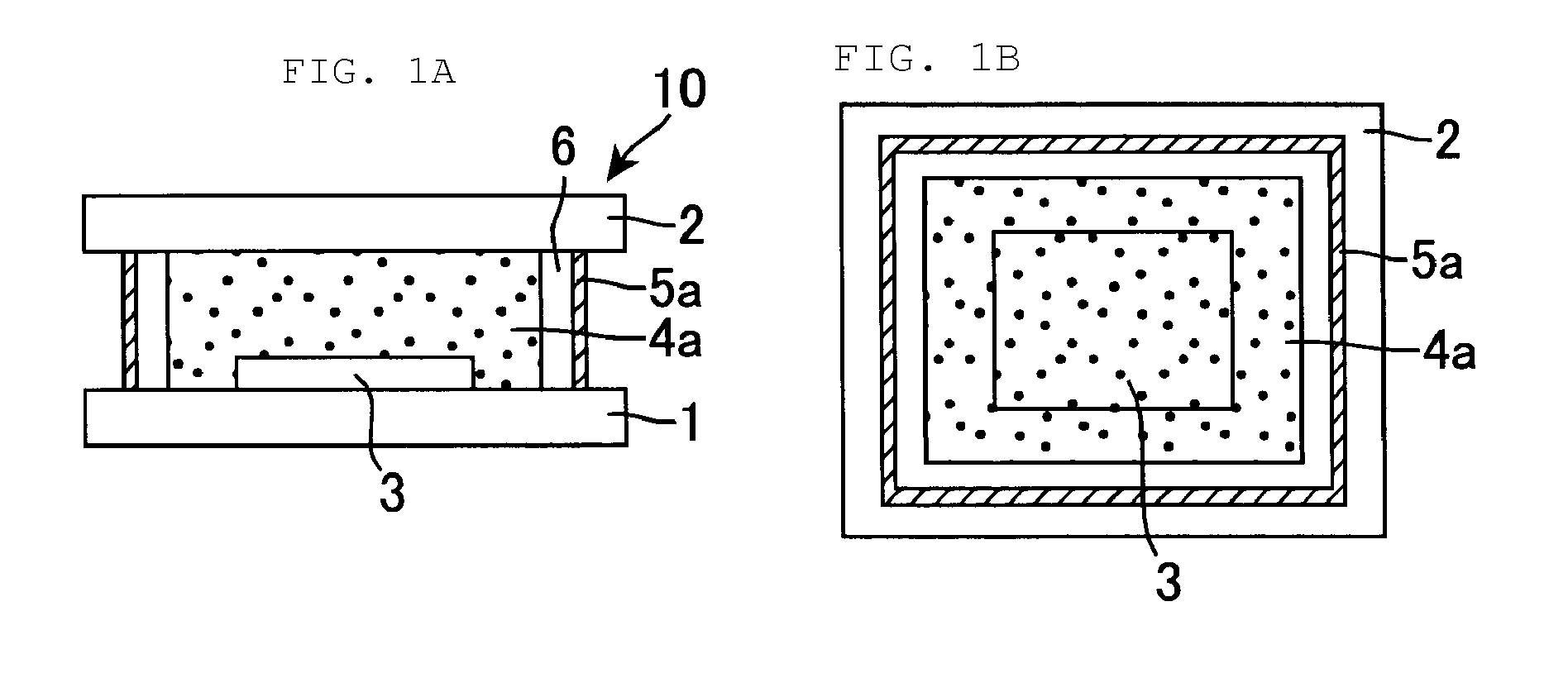

Organic electroluminescent panel, organic electroluminescent display, organic electroluminescent lighting device, and production methods thereof

ActiveUS20100090596A1Shorten heating timeShorten takt timeDischarge tube luminescnet screensLamp detailsEngineeringOrganic electroluminescence

An organic electroluminescent panel, an organic electroluminescent display, an organic electroluminescent lighting device, each include an organic electroluminescent element that maintains stable light emission characteristics for a long period of time. The organic electroluminescent panel includes an element substrate; a sealing substrate facing the element substrate; and an organic electroluminescent element disposed on a sealing substrate side of the element substrate, wherein the organic electroluminescent panel further includes a first sealing member and a second sealing member, the first sealing member sealing a gap between the element substrate and the sealing substrate, the second sealing member covering the organic electroluminescent element, the first sealing member and the second sealing member being arranged with a space therebetween, the space is in a vacuum or reduced pressure state.

Owner:SHARP KK

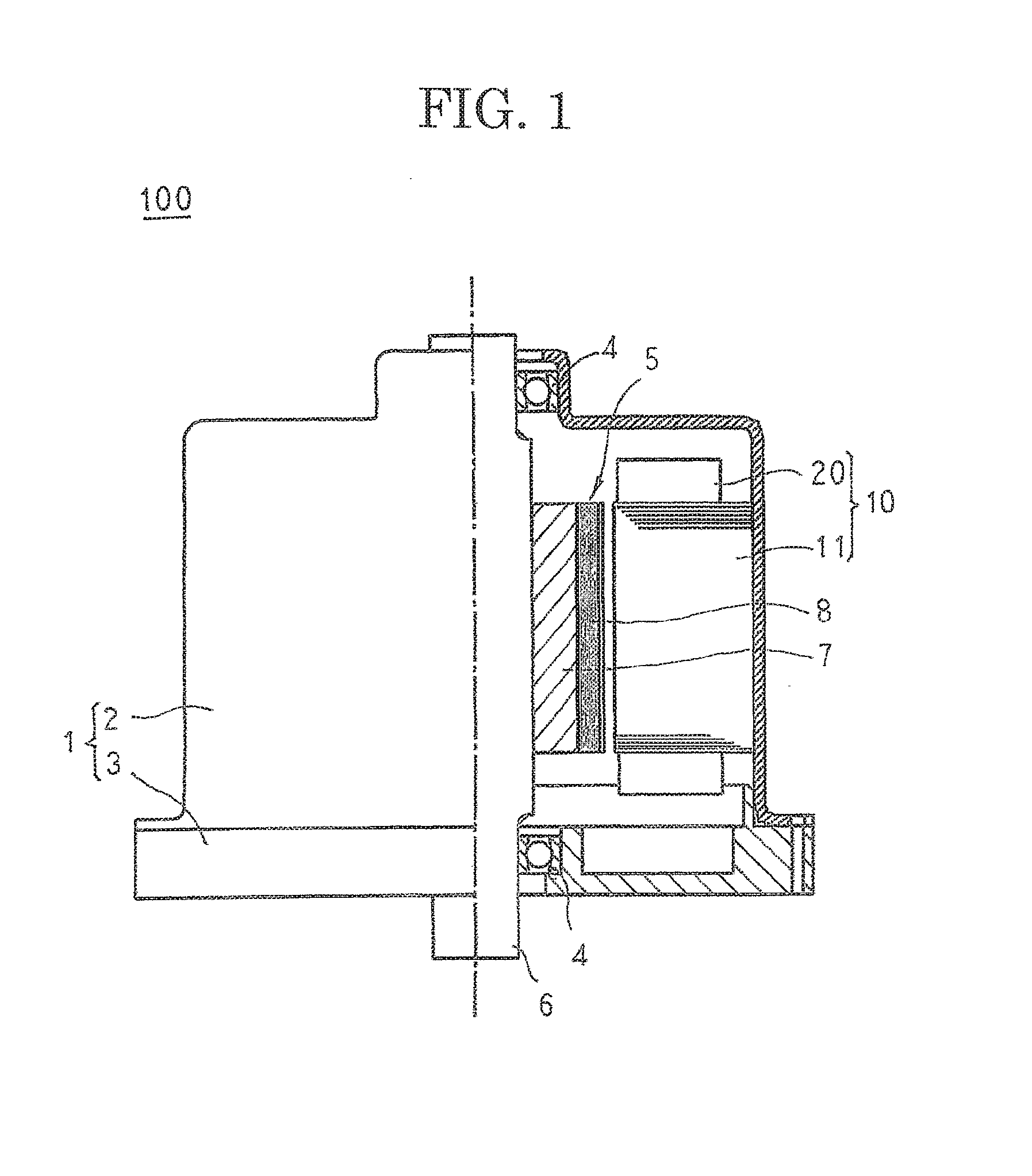

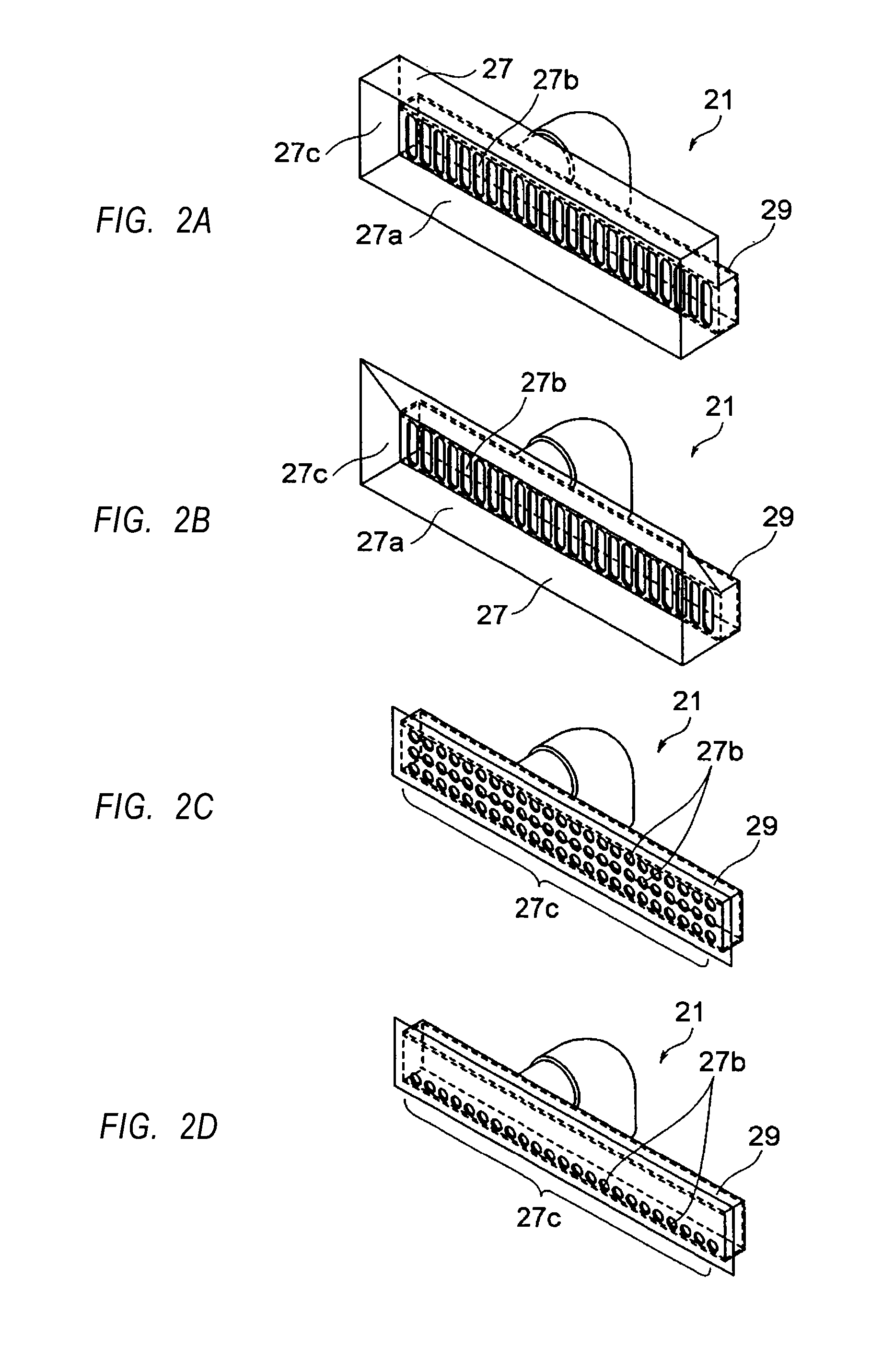

Load port unit and efem system

ActiveUS20140363258A1Increase supplyImprove working environmentSemiconductor/solid-state device manufacturingConveyor partsEngineeringElectrical and Electronics engineering

A load port unit can prevent or control leakage of inert gas from an EFEM system to the outside. The load port unit used in the EFEM system is provided with an air inlet that opens on a side facing a mini-environment between the upper end of an opener driving unit and the lower end of the pod. The width of the air inlet opening is larger than the width of the opening of the pod. With this arrangement, surplus gas is sucked from the pod when gas purging is performed on the pod.

Owner:TDK CORPARATION

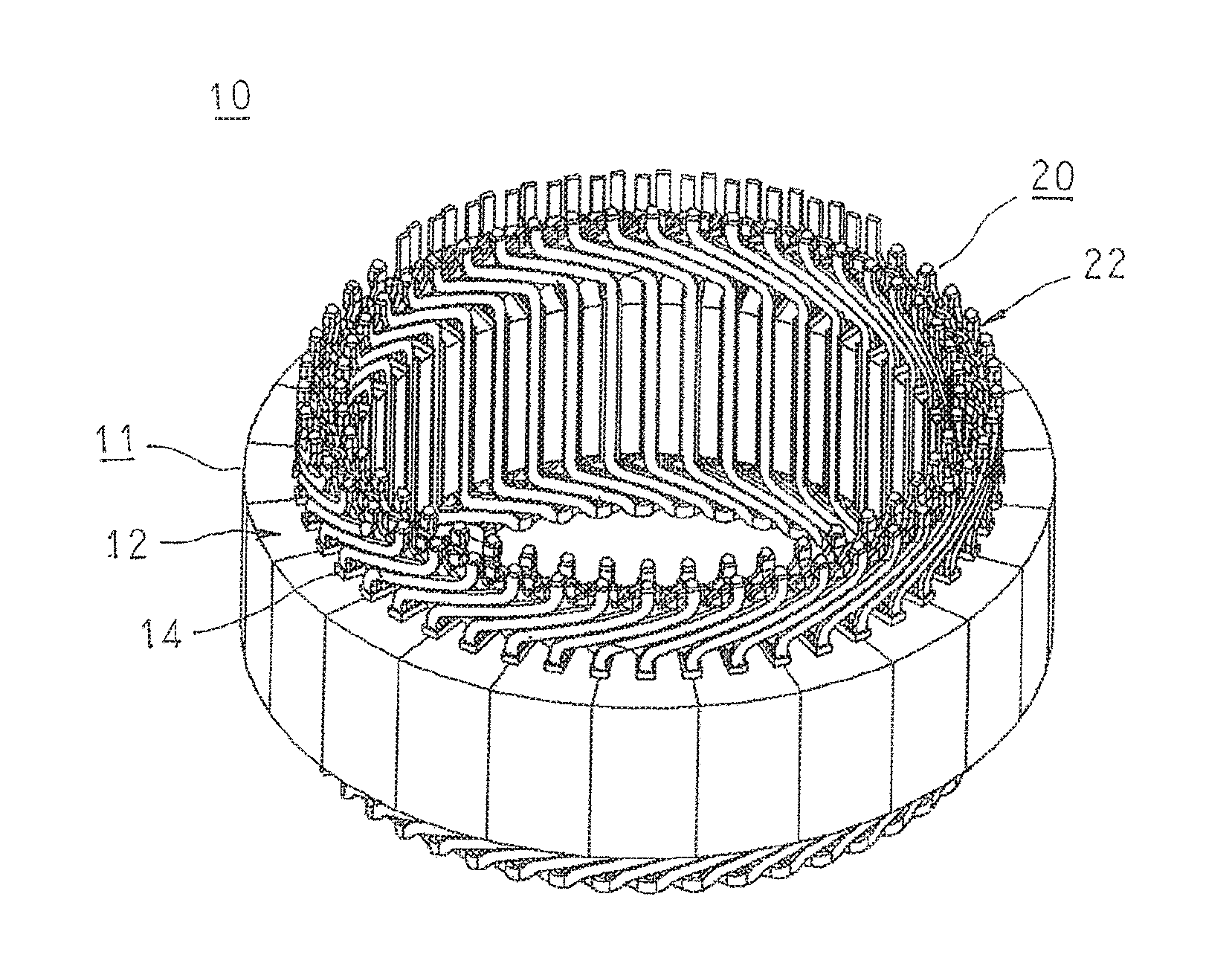

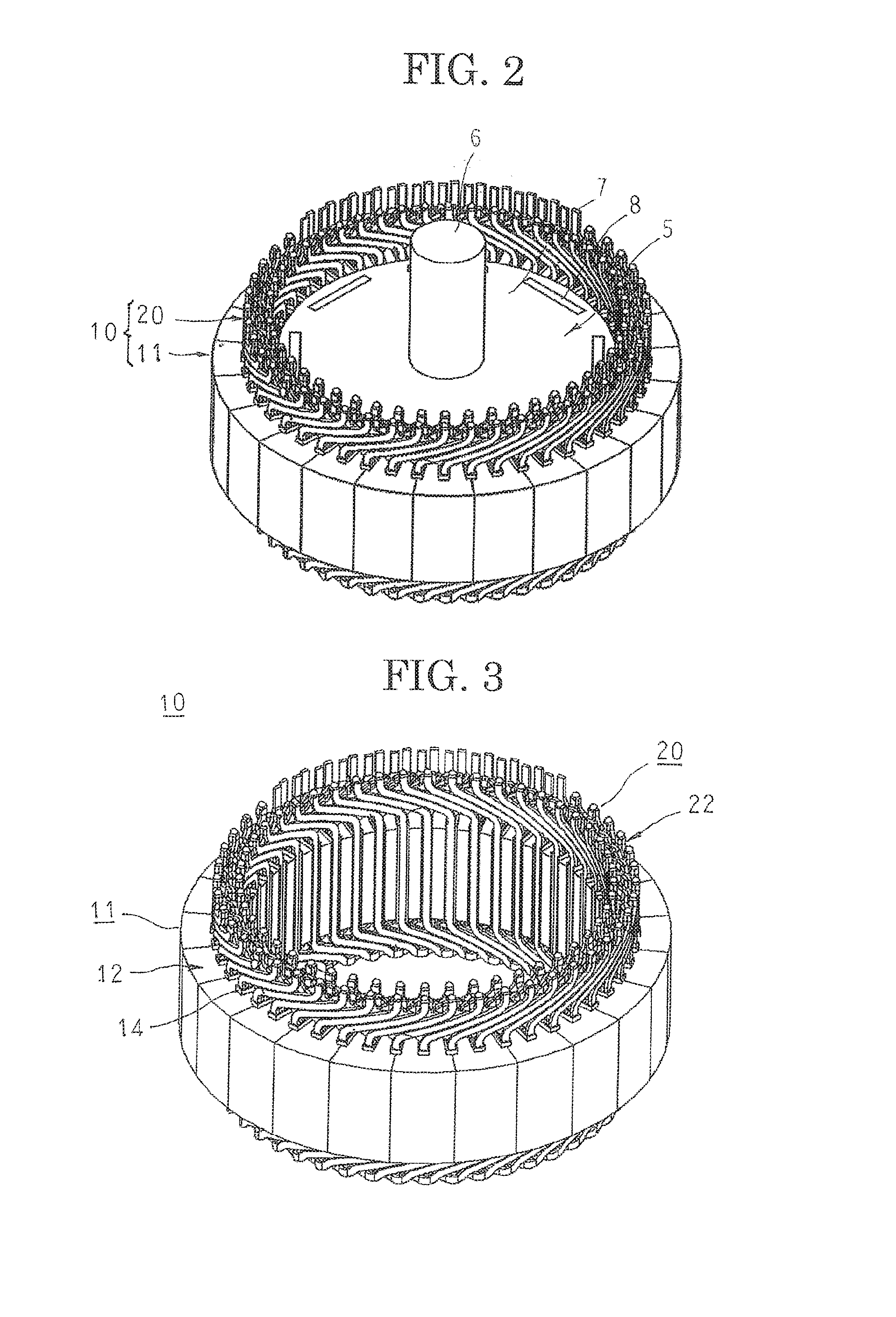

Armature for an electric machine

ActiveUS20160268860A1Bending radius is reducedReduce radial sizeWindings conductor shape/form/constructionElectric machineEngineering

An armature for an electric machine according to the present invention includes: an armature core in which a plurality of slots are arranged in a circumferential direction; and an armature winding that is mounted to the armature core, and includes a plurality of two-lane winding bodies that are each produced by stacking and winding two jointless continuous conductor wires that are coated with insulation such that the two conductor wires are stacked in a radial direction of the armature core, the two-lane winding bodies being arranged at a pitch of one slot in a circumferential direction so as to be mounted into a third slot, a first slot, and a second slot that line up consecutively in the circumferential direction at an angular spacing of six slots.

Owner:MITSUBISHI ELECTRIC CORP

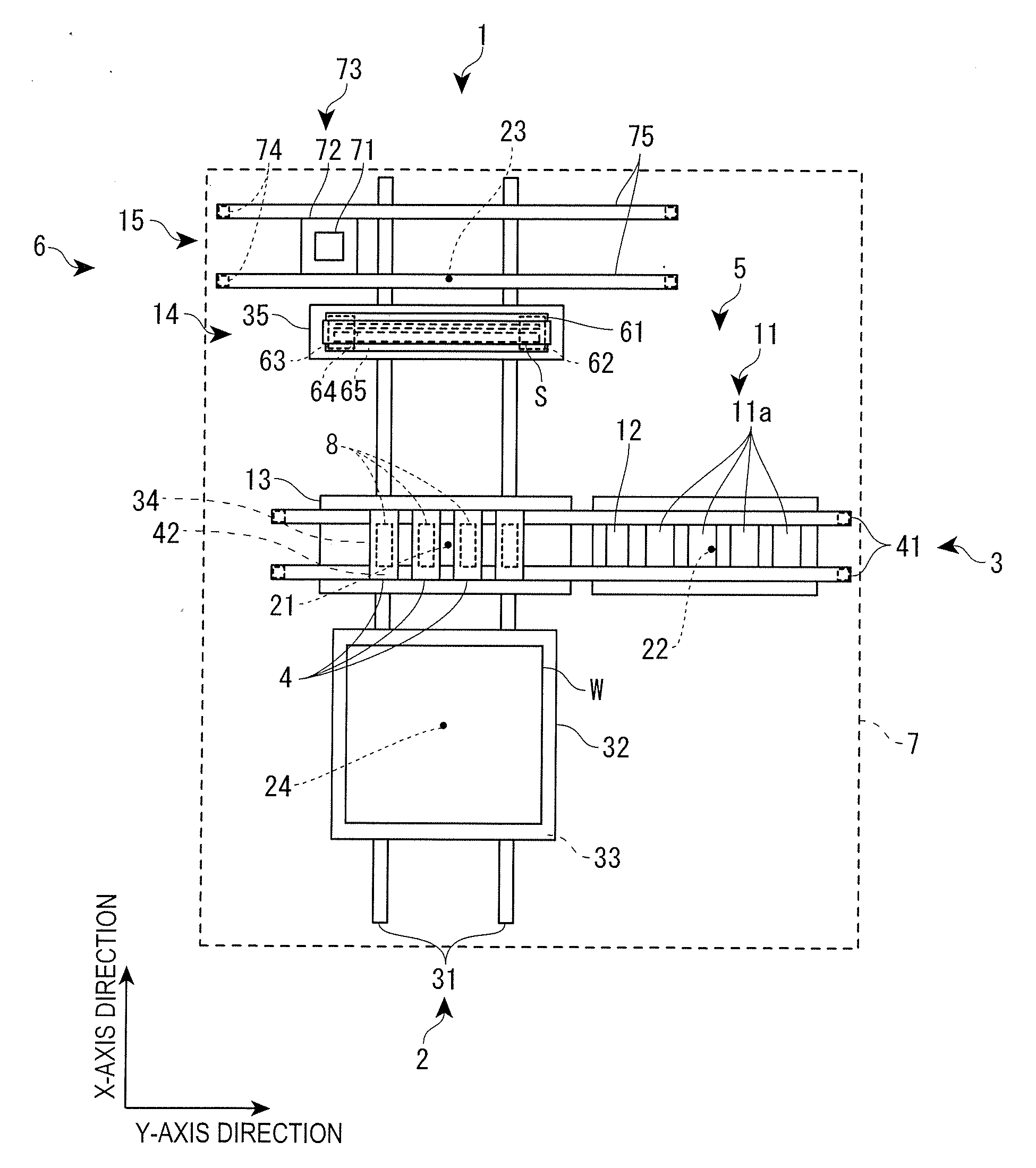

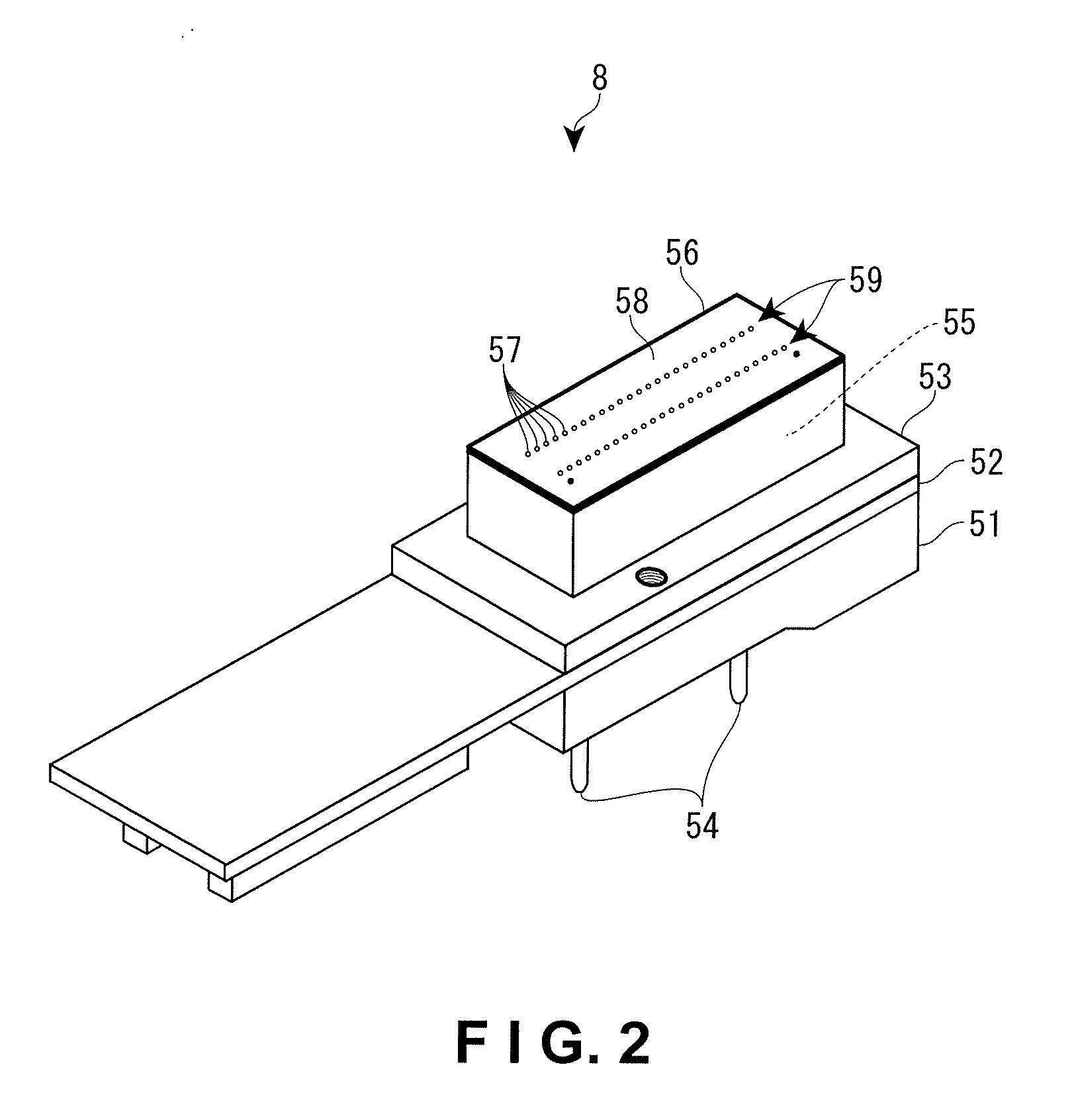

Droplet discharge device and method for controlling droplet discharge device

ActiveUS20110096119A1Enough timeReduce processing timeOther printing apparatusEngineeringEmbedded system

A droplet discharge device is adapted to perform drawing of droplets of functional liquid from a functional droplet discharge head onto a workpiece in a drawing area, and to perform discharge inspection of the functional droplet discharge head in an inspection area, which is separated from the drawing area. The droplet discharge device includes a positioning stage, a flushing unit and an inspection stage disposed in this order along a common movement axis passing through the drawing area and the inspection area so that the inspection stage is disposed at a position closer to the inspection area. An image recognition device is disposed in the inspection area. A movement mechanism is arranged to move the positioning stage, the flushing unit and the inspection stage along the common movement axis. The movement mechanism is arranged to move the inspection stage independently of the positioning stage and the flushing unit.

Owner:TOKYO ELECTRON LTD

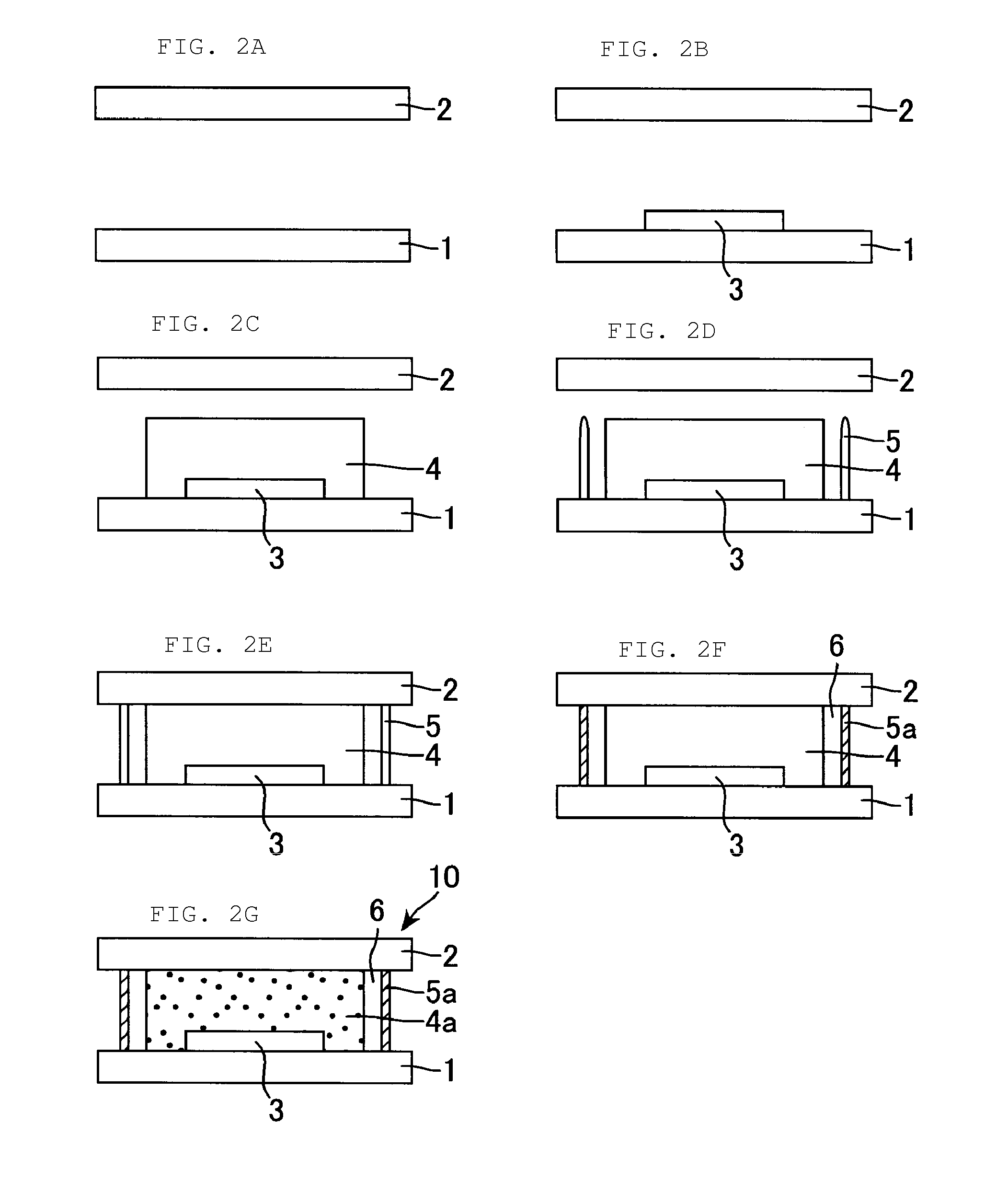

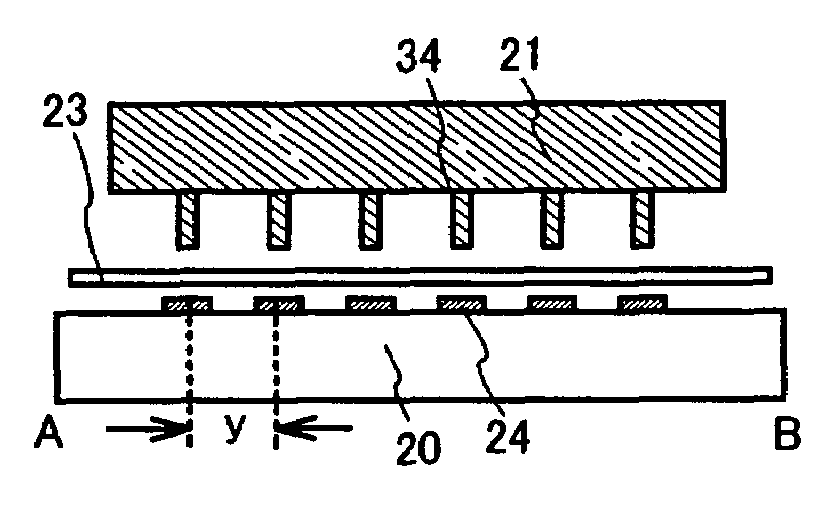

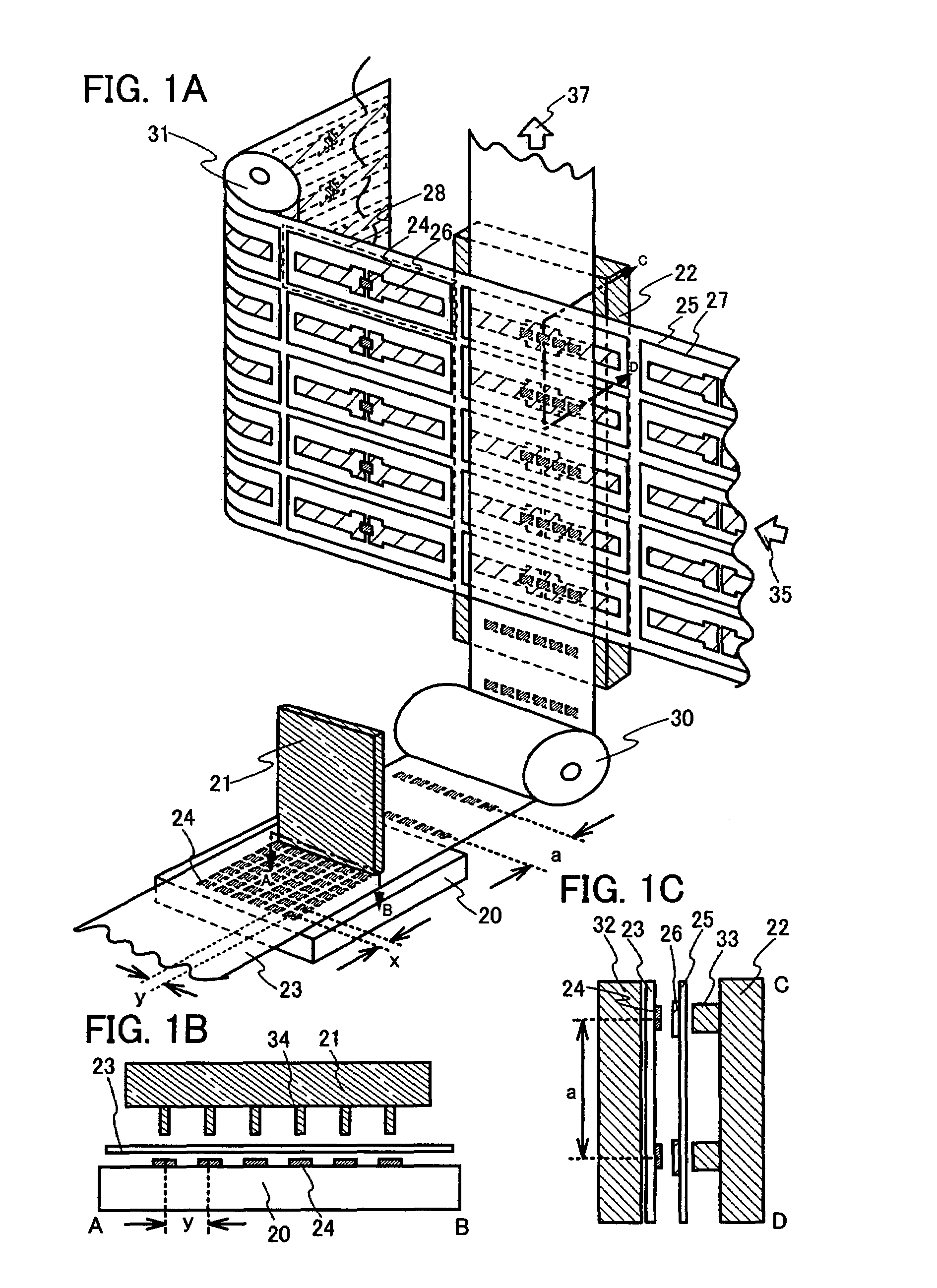

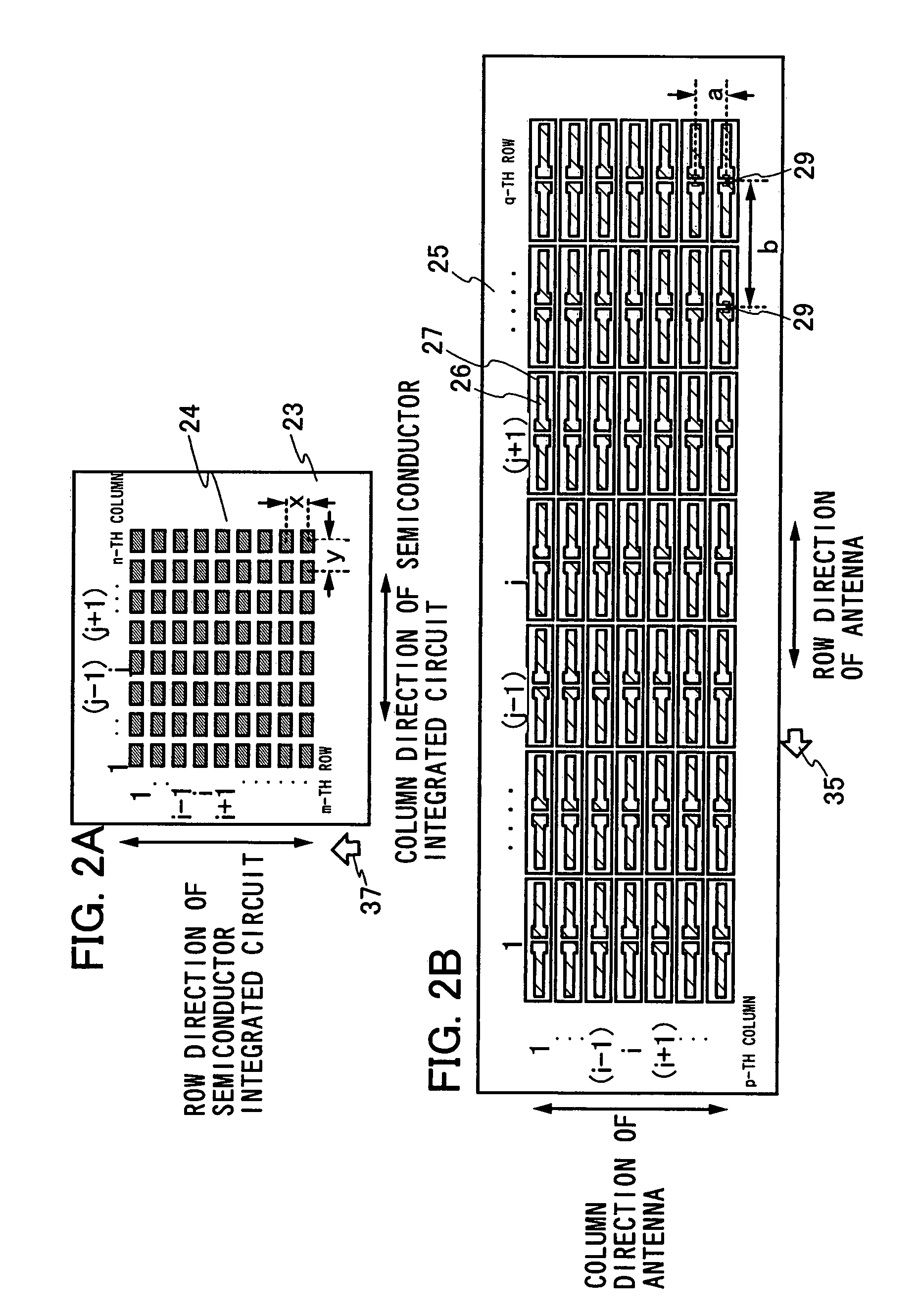

Attachment method, attachment apparatus, manufacturing method of semiconductor device, and manufacturing apparatus of semiconductor device

InactiveUS7727809B2Shorten takt timeSemiconductor/solid-state device detailsSolid-state devicesManufactured apparatusEngineering

The invention proposes a method and an apparatus for attaching a plurality of components having different arrangement densities or arrangement intervals, which can achieve shorter takt time. An object is to provide a low-cost manufacturing method of a semiconductor device and a manufacturing apparatus capable of manufacturing a semiconductor device at low cost. Plural pairs of components having different arrangement densities are simultaneously attached to each other by temporarily attaching first components to a first flexible substrate while changing an arrangement interval in an X direction, and then connecting the first components to second components over a second flexible substrate while changing an arrangement interval of the first components in a Y direction.

Owner:SEMICON ENERGY LAB CO LTD

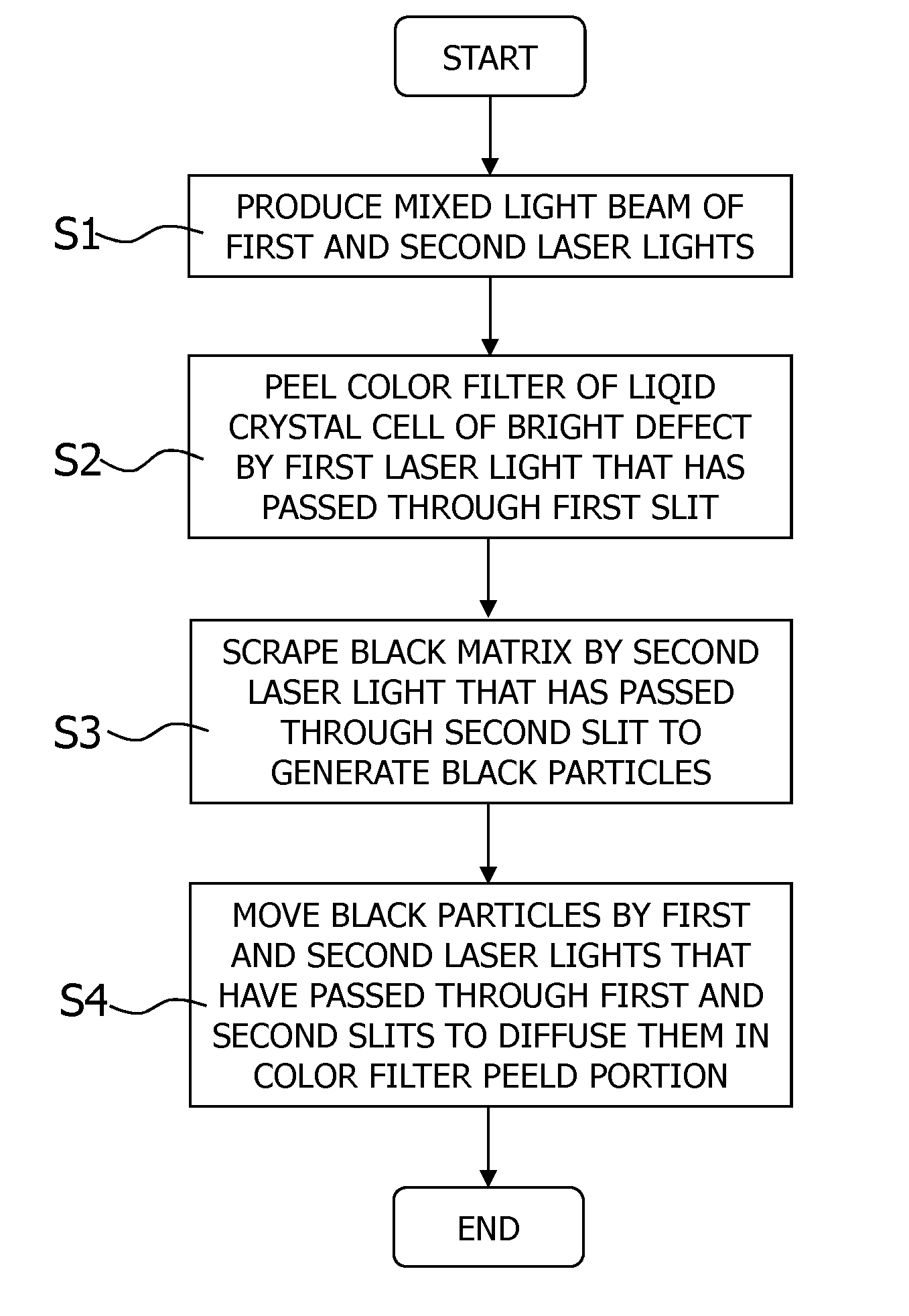

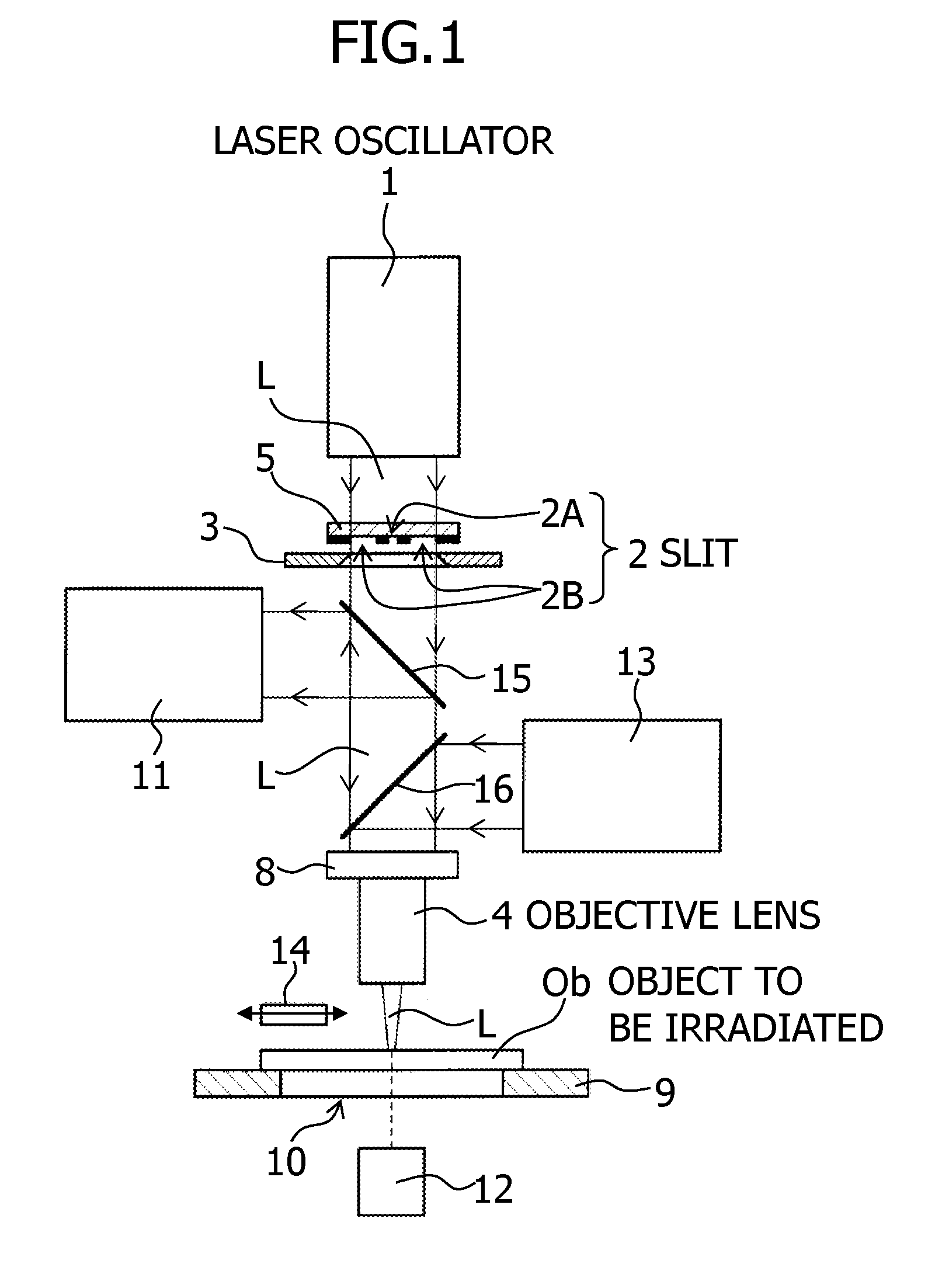

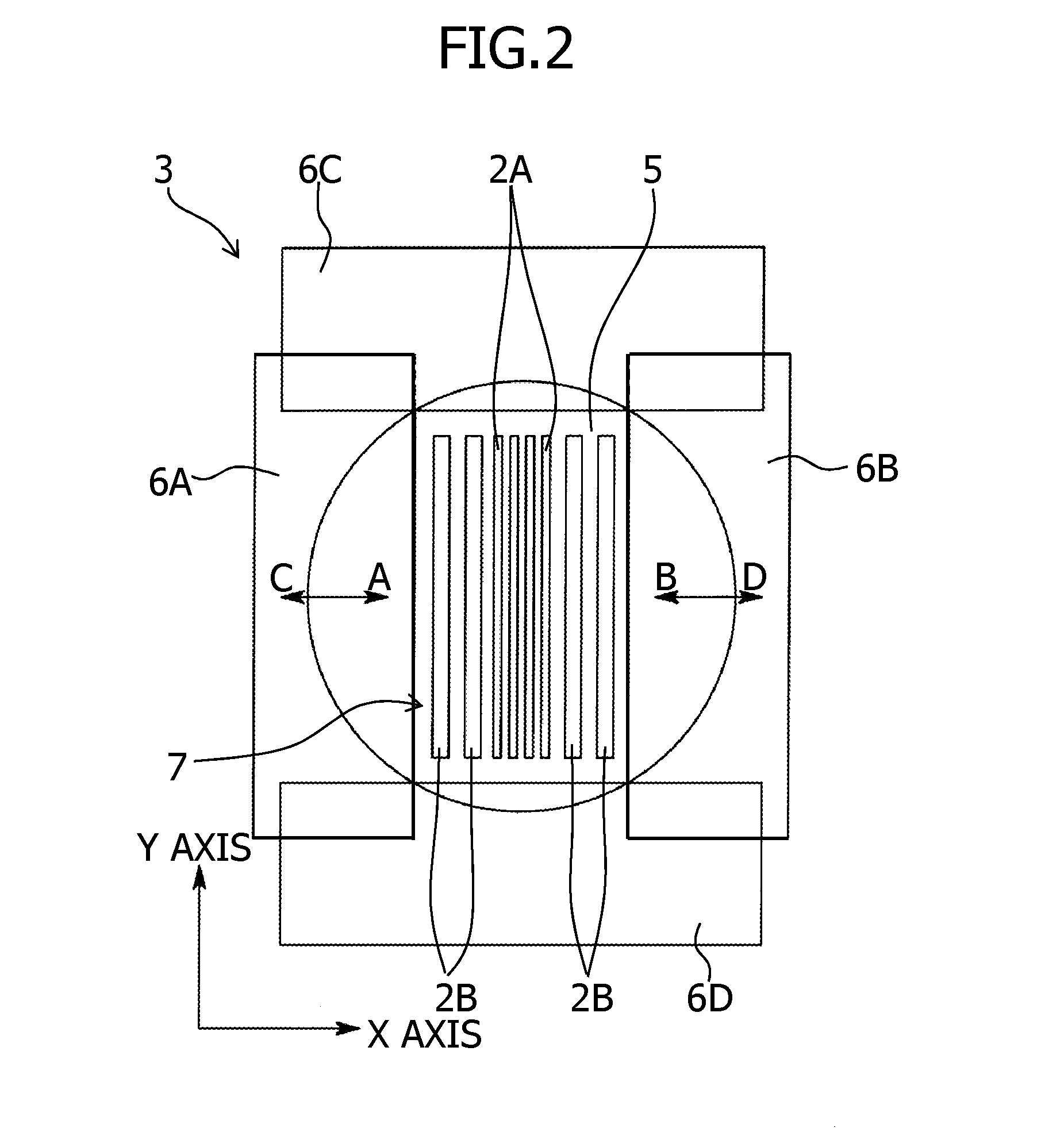

Laser irradiation apparatus and bright point correction method for liquid crystal display panel using the same

ActiveUS20140009729A1Efficiently peelReduce takt timeLaser detailsStatic indicating devicesOptical pathLaser light

The present invention is a laser irradiation apparatus which is capable of selecting among a plurality of laser lights L having different wavelengths a laser light of a wavelength according to a purpose of irradiation and irradiating an object Ob to be irradiated with the laser light having the wavelength. The laser irradiation apparatus includes: on an optical path of a mixed light beam of the plurality of laser lights L having different wavelengths, a slit having a width corresponding to a diffraction limit of the laser light having the shortest wavelength among the plurality of laser lights L having different wavelengths; and an objective lens for focusing a laser light that has passed through the slit, on the object Ob to be irradiated.

Owner:V TECH CO LTD

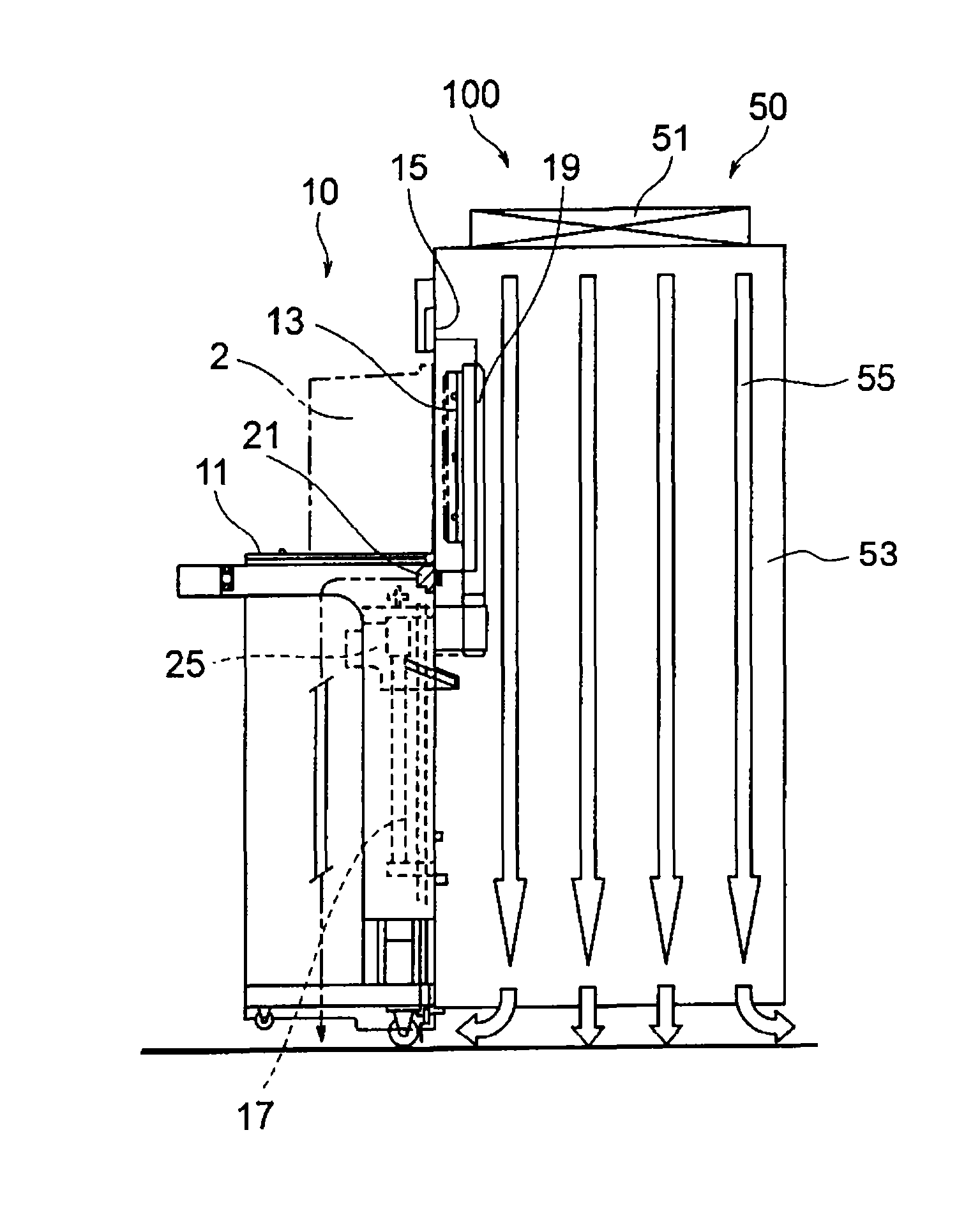

Visual inspection apparatus, visual inspection method, and peripheral edge inspection unit that can be mounted on visual inspection apparatus.

InactiveUS20090316143A1Simple configurationShorten takt timeMaterial analysis by optical meansWaferingVisual inspection

This visual inspection apparatus has a macro-inspection section and a micro-inspection section. In the micro-inspection section, a inspection stage and a microscope are loaded into a loading plate. The inspection stage can be moved in any directions of the X, Y, and Z directions, and can also be rotated in the θ direction. Moreover, a peripheral edge inspection section that acquires an enlarged image of a peripheral edge of wafer W is fixed to the loading plate. The peripheral edge inspection section is arranged so as to image the peripheral edge of wafer W held by the inspection stage.

Owner:OLYMPUS CORP

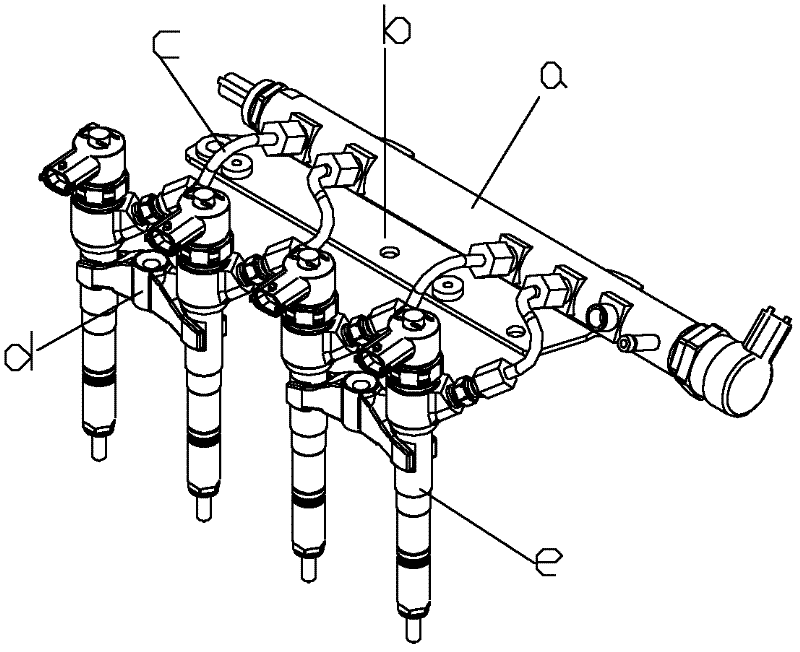

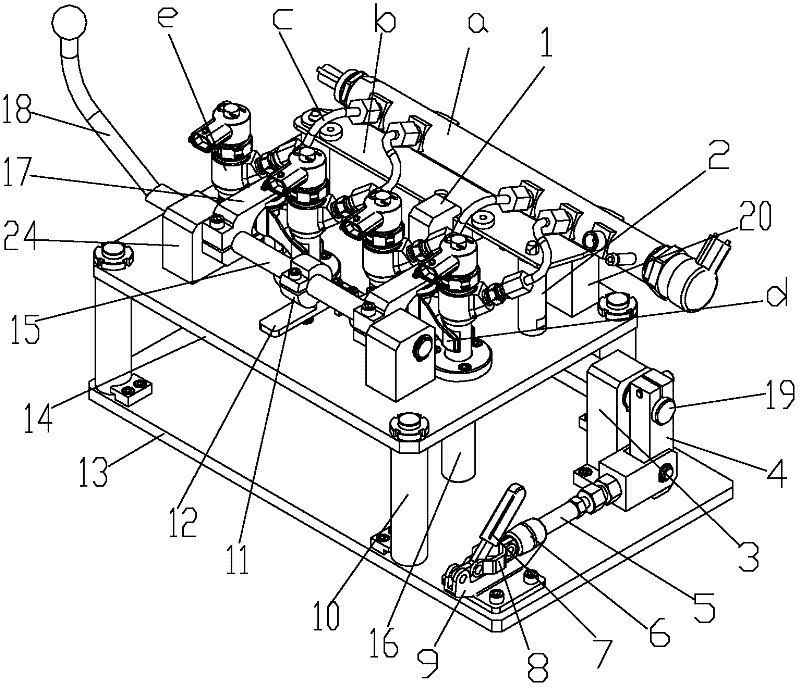

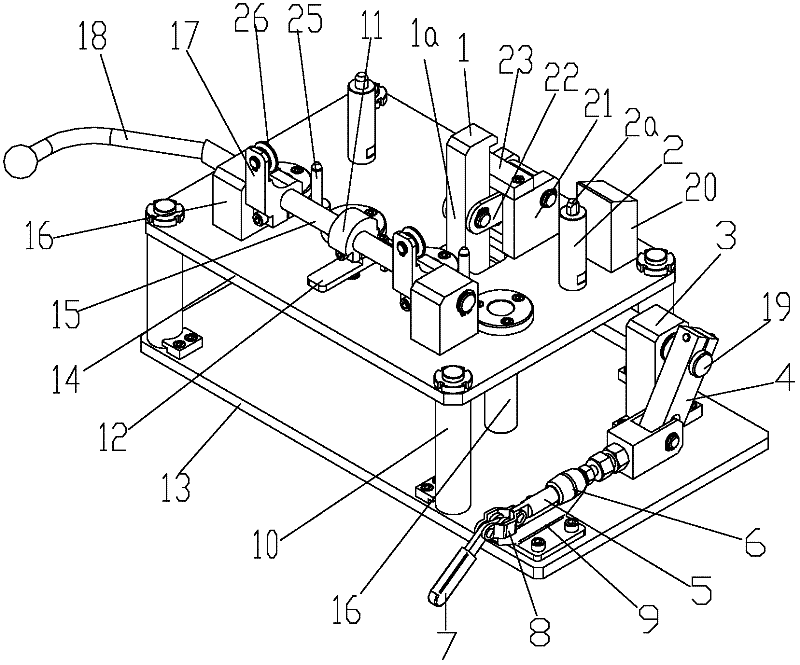

Split assembling mechanism of common rail injection system of diesel engine

ActiveCN102501193ASave assembly timeImprove assembly efficiencyWork holdersMetal-working hand toolsCommon railEngineering

The invention discloses a split assembling mechanism of a common rail injection system of a diesel engine, which comprises a base, a common rail pipe fixing component and an oil injector fixing component. In the split assembling mechanism, a common rail pipe and an oil injector are respectively fixed to mounting positions opposite to each other, and an oil pipe and relative sealing joints are mounted hermetically. After being mounted, the integral common rail injection system is subjected to hermetical detection and then mounted on an engine after being qualified in the hermetical detection. Since the assembling of the common rail injection system and the process of mounting the common rail injection system onto the engine which have the same requirements for clean environment are carried out simultaneously, assembling time is saved, assembling efficiency is higher, the single unit occupies smaller clean space but requires shorter assembling cycle, and the split assembling mechanism is applicable to assembling of diesel engines in various types. Further, to the small-size diesel engines, limitation on assembling space is removed, assembling difficulty is reduced and working efficiency is improved favorably. Meanwhile, testing of the engine body is omitted in the online leakage test for sealing joints of parts of the injection system, so that test is simplified relatively and production cost is reduced.

Owner:重庆小康动力有限公司

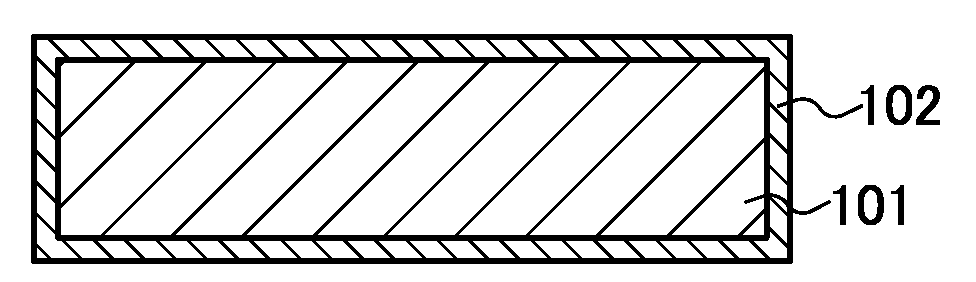

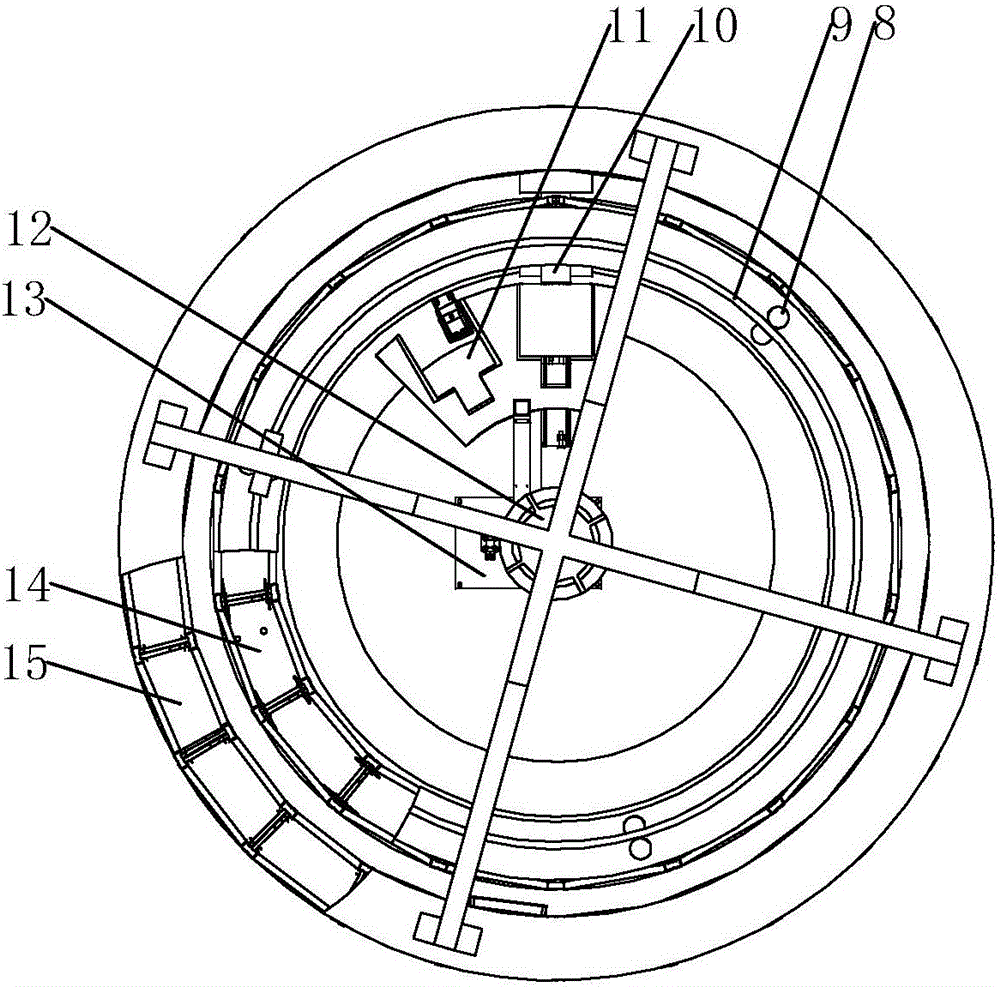

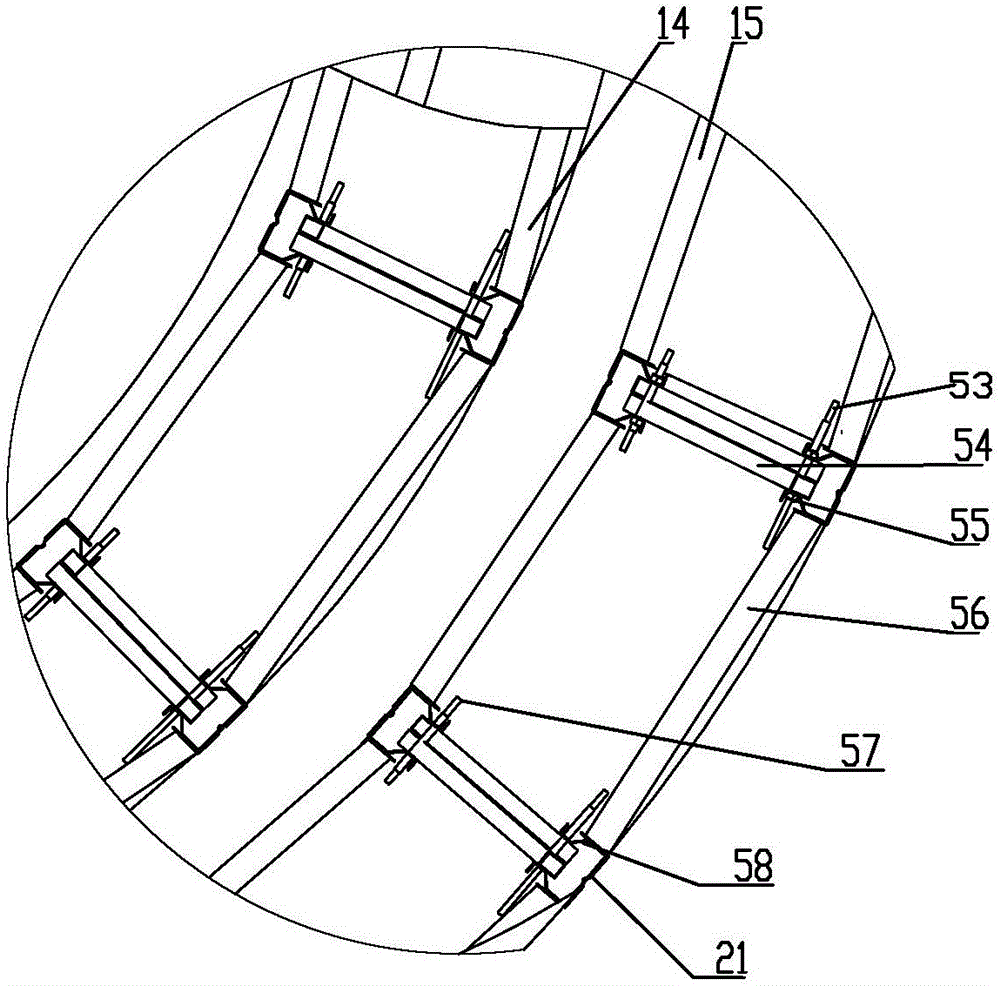

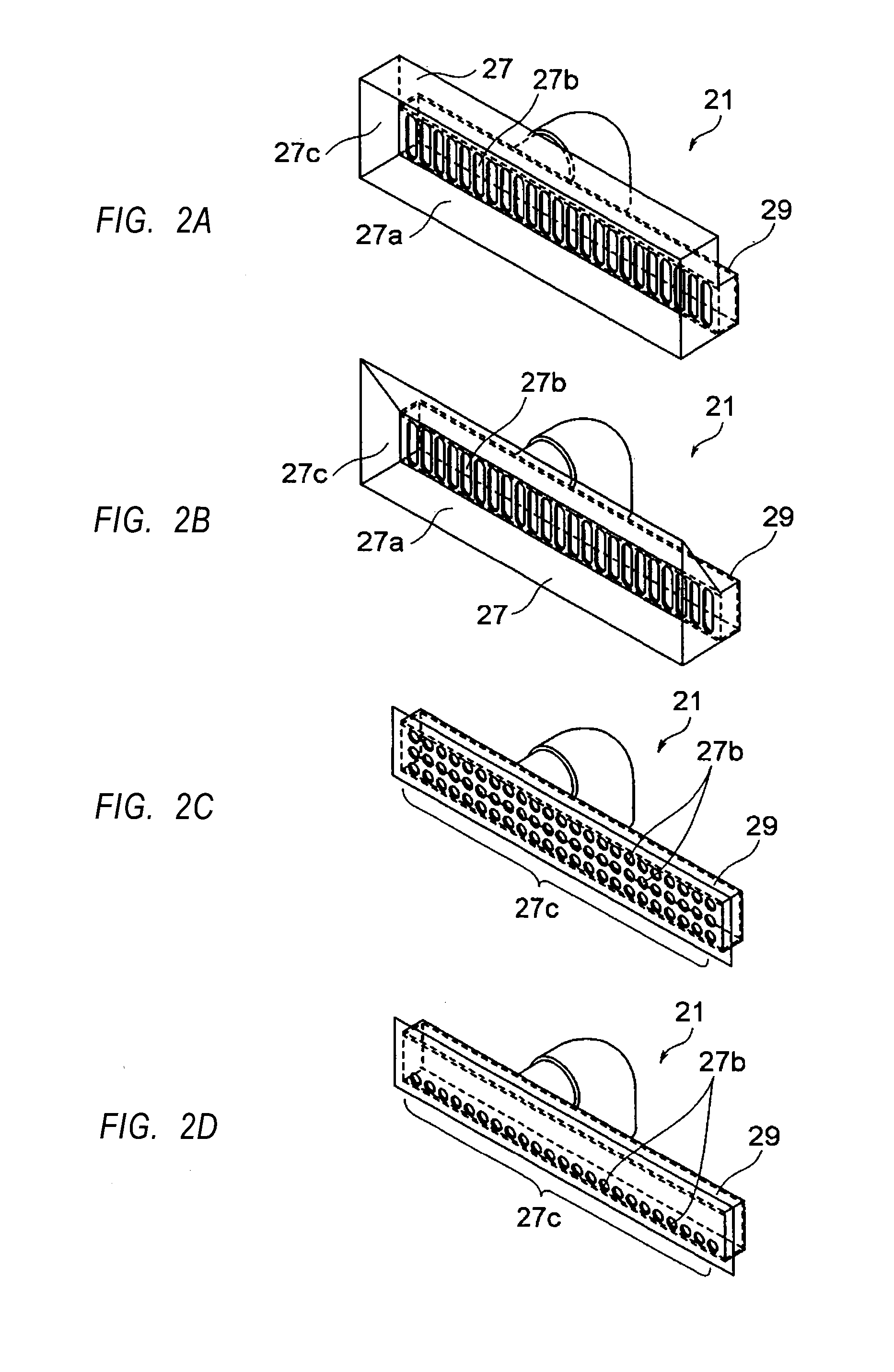

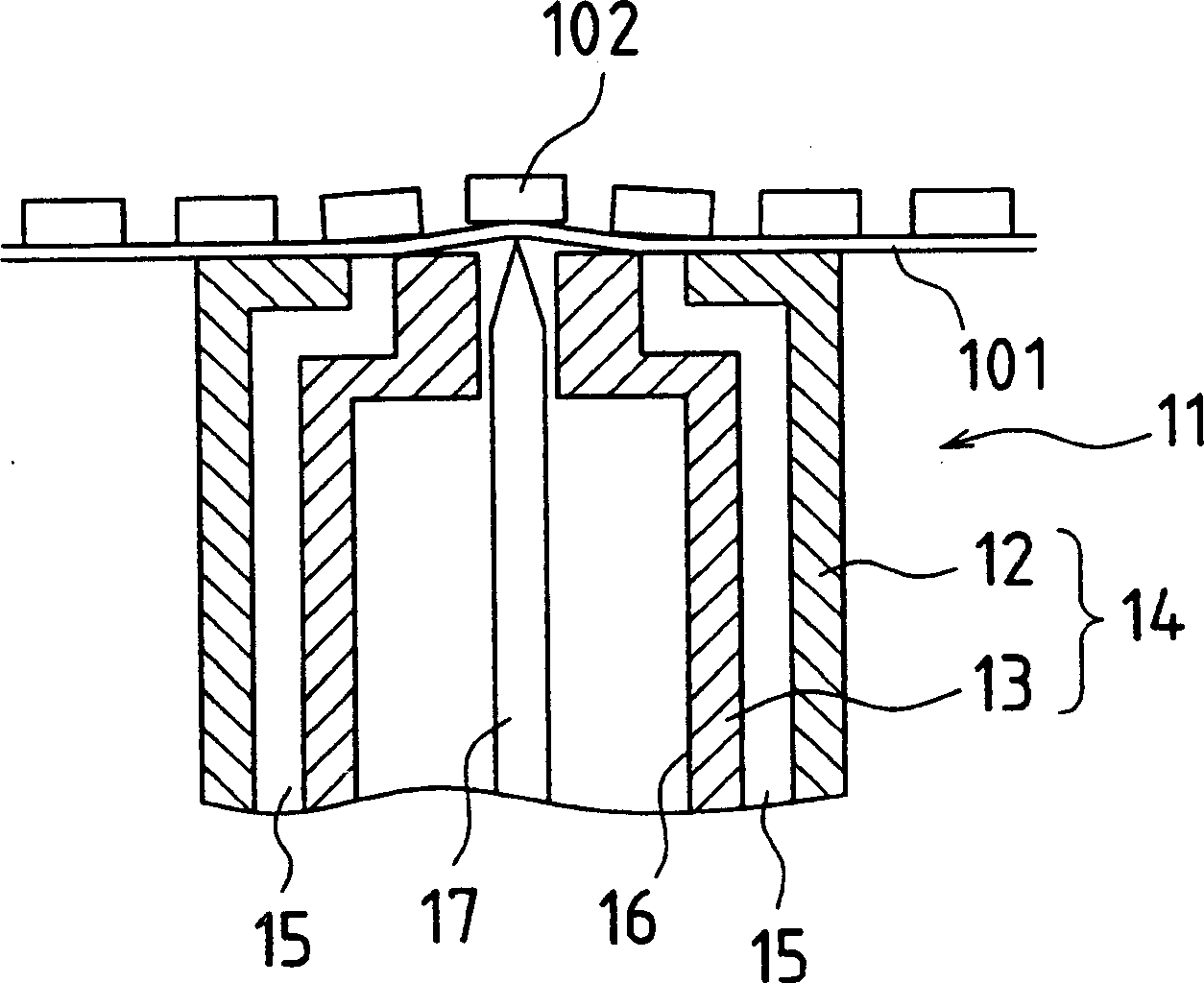

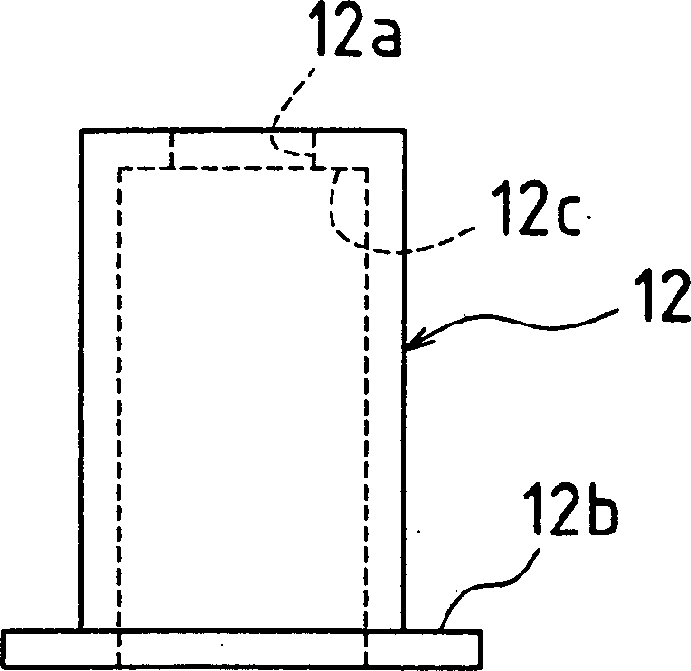

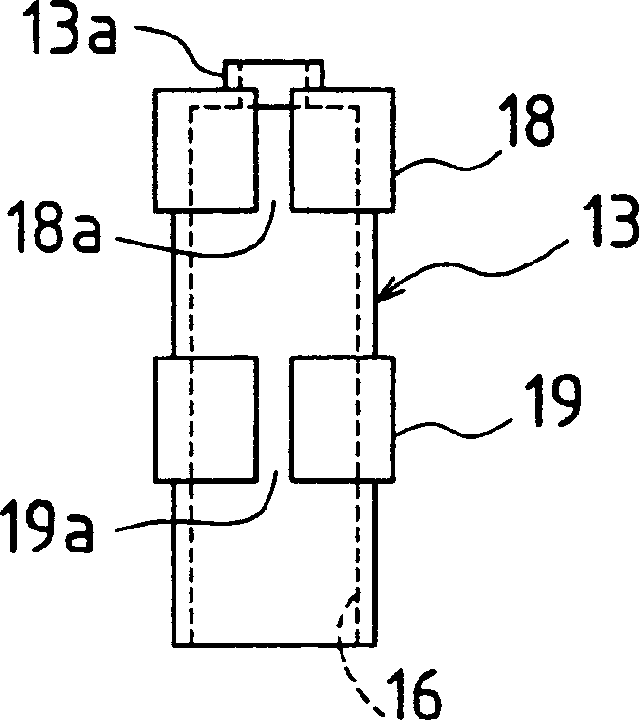

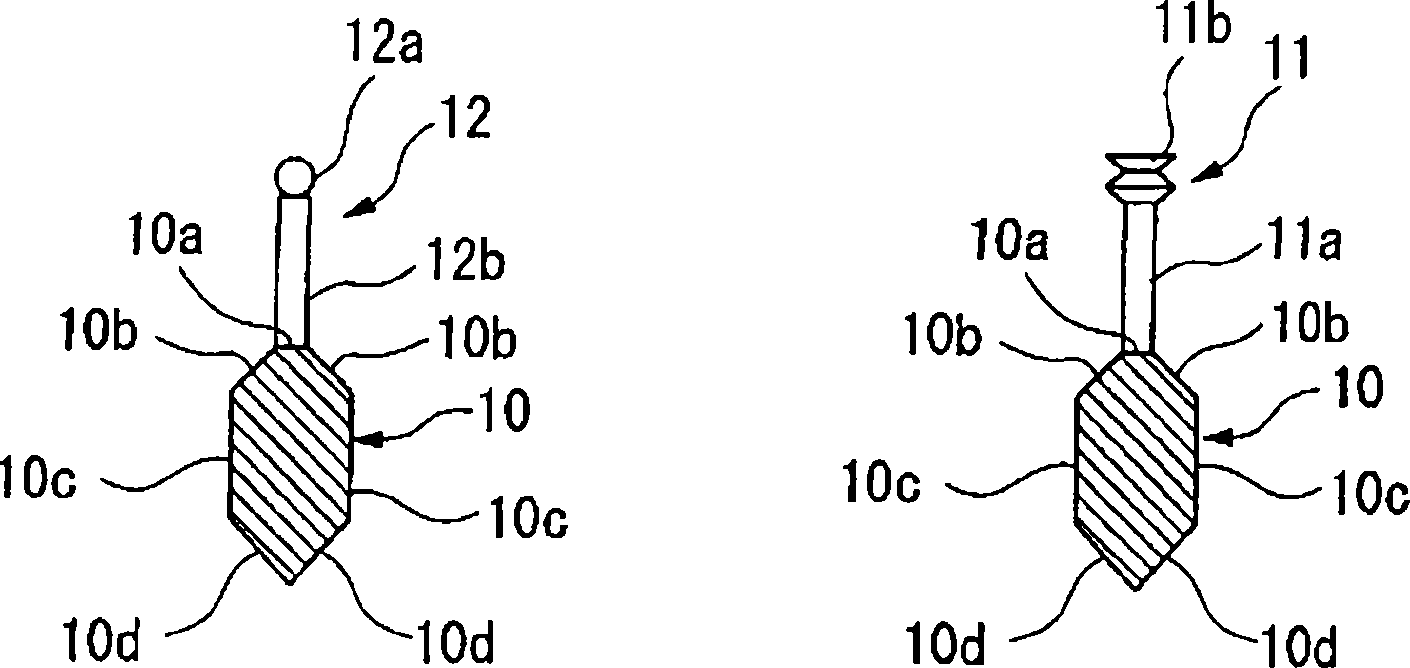

Chip pick-up device and producing method thereof and production apparatus of semiconductor

InactiveCN1437234AImprove reliabilityShorten takt timeSemiconductor/solid-state device manufacturingElectrical componentsSemiconductorEngineering

The present invention relates to a chip pickup device capable of easily peeling off chips from a passivation layer without having to particularly adjust the push-up stroke of a pushing pin and the ascending / descending position of a supporting stage. The pushing pin 17 is protruded out of a pin hole 16. The pushing pin 17 is used to push a chip 102 via a passivation layer 101. The passivation layer 101 is sucked and drawn near the venting hole 15, but is not sucked and drawn near the pin hole 16. The passivation layer 101 is propped up at the vicinity of the pin hole 16 to be separated from the supporting stage 14, thereby peeling off the chip 102 from the passivation layer 101. Therefore, it is able to keep the stroke of the pushing pin 17 constant without modifying or adjusting the position of the supporting stage 14. In addition, because there is no absorbing force of air in the pin hole 16, it is easy to peel off the chip 102 from the passivation layer 101.

Owner:SHARP KK

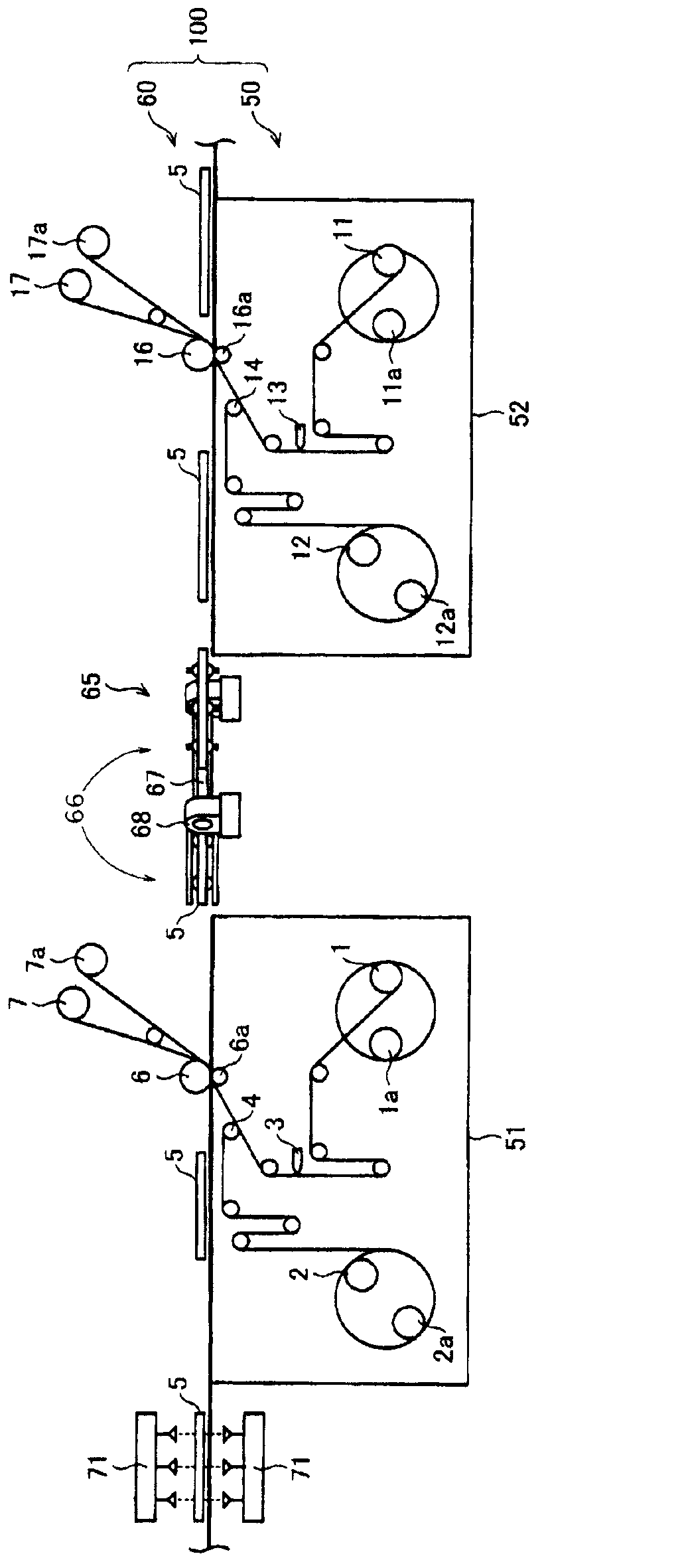

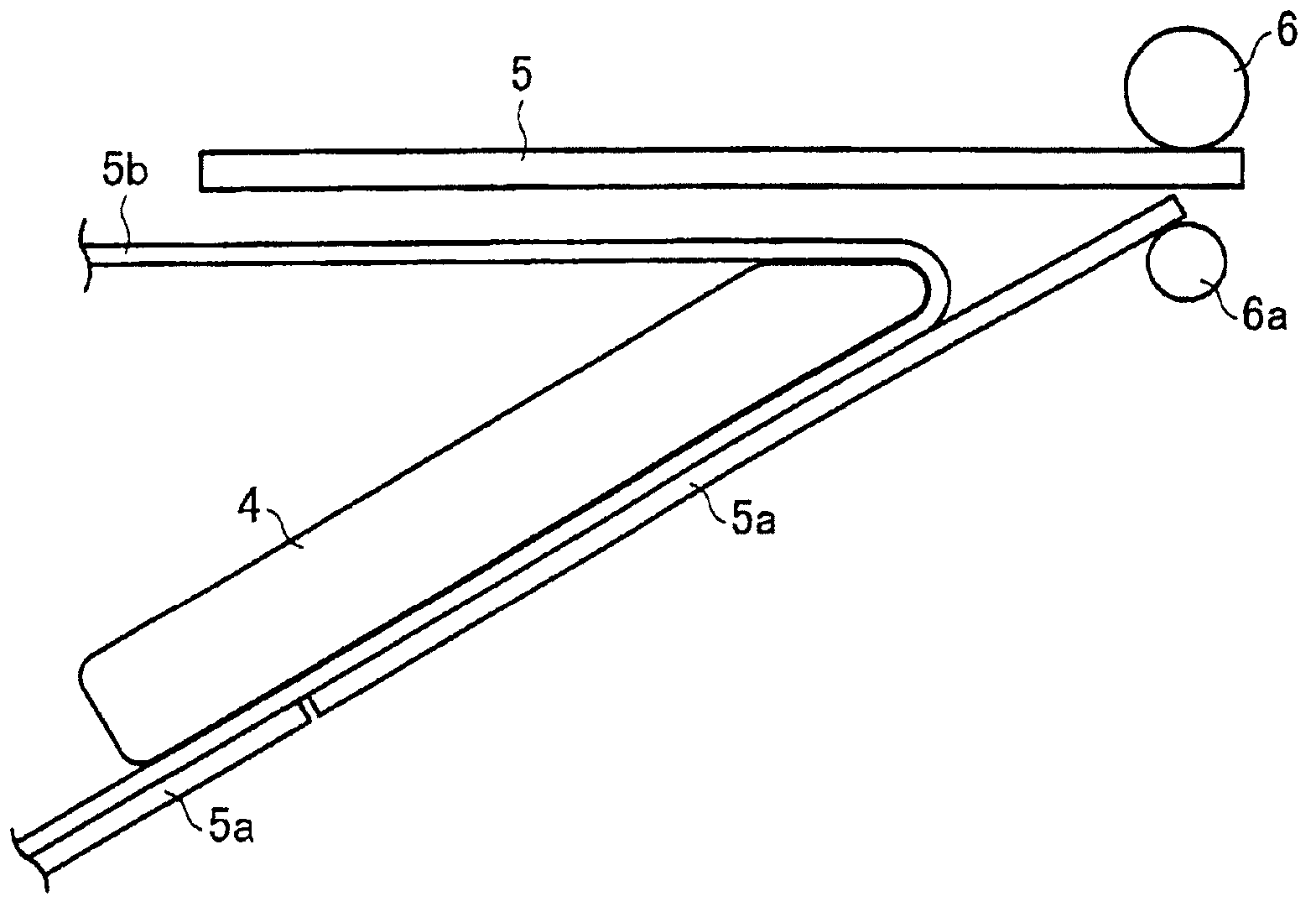

Substrate conveyance mechanism, polarizing film lamination device and LCD device manufacturing system provided therewith

ActiveCN102834771AShorten takt timeLamination ancillary operationsPolarising elementsEngineeringManufacturing systems

The disclosed substrate conveyance mechanism and polarizing film lamination device are provided with a first substrate conveyance mechanism and a second substrate conveyance mechanism. In the disclosed substrate conveyance mechanism, polarizing film lamination device and LCD device manufacturing system provided therewith, a drive control means of a substrate support device acts on a substrate support member (66), placing the aforementioned substrate support member in a state in which said member supports the substrate (5). The substrate (5), conveyed by a first substrate conveyance mechanism (61), is inverted by a substrate inversion unit (67) along an inversion axis, which is at an angle to the conveyance direction of the substrate (5), and said substrate (5) is aligned with the conveyance direction of the second substrate conveyance mechanism (62).

Owner:SUMITOMO CHEM CO LTD

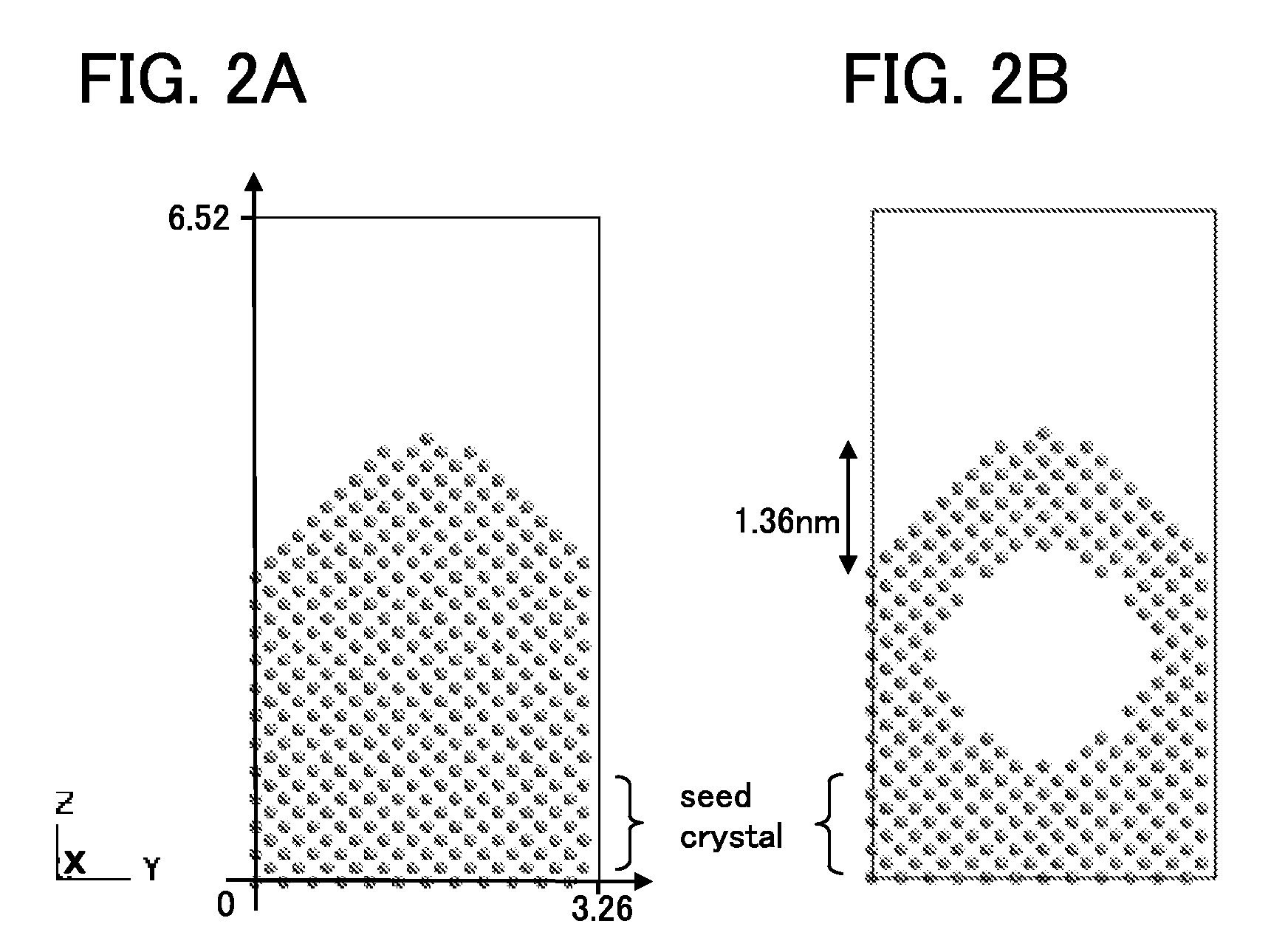

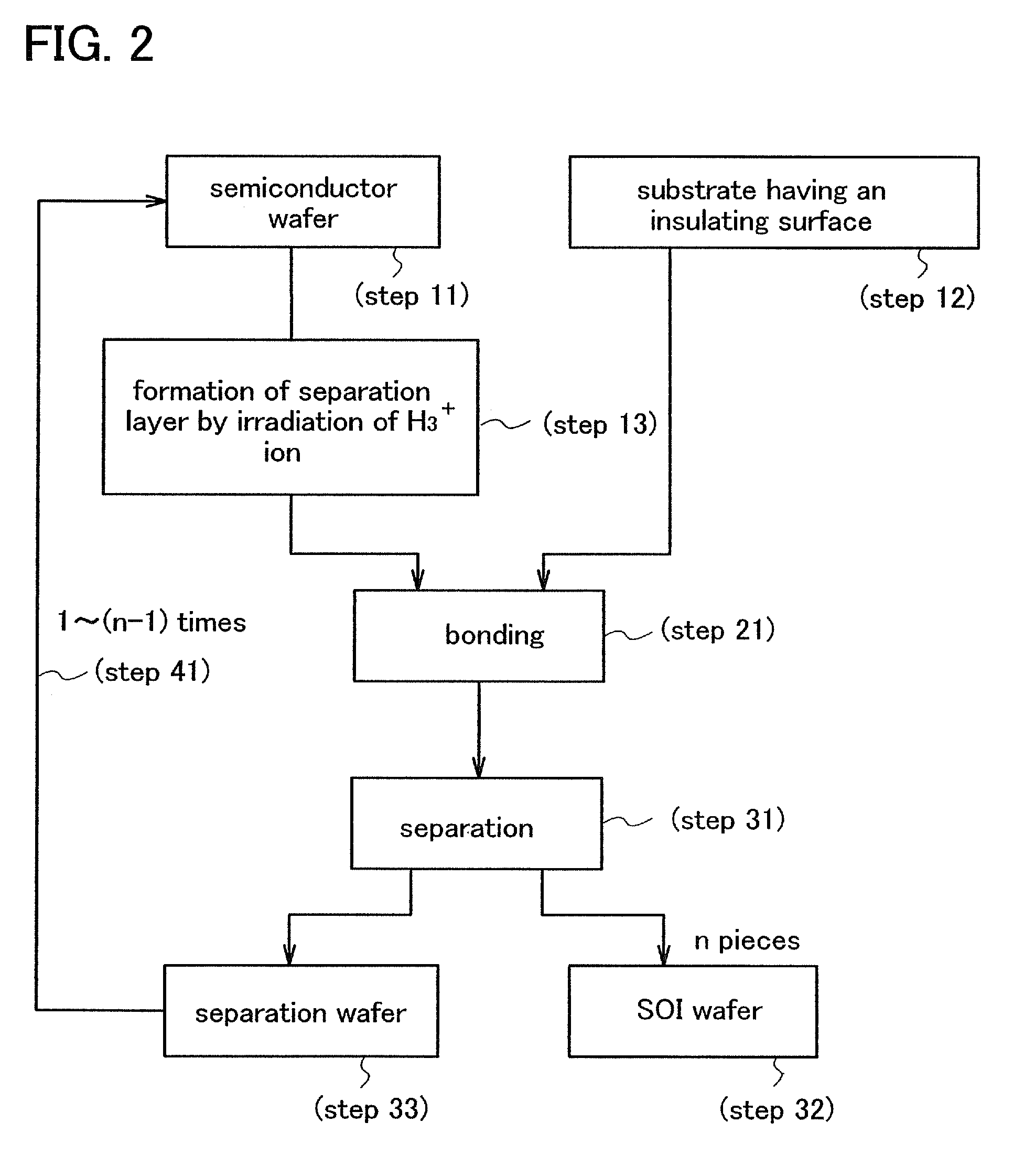

Method for manufacturing SOI substrate using cluster ion

InactiveUS7989305B2Easy to useHigh yieldSemiconductor/solid-state device manufacturingWaferingSoi substrate

Owner:SEMICON ENERGY LAB CO LTD

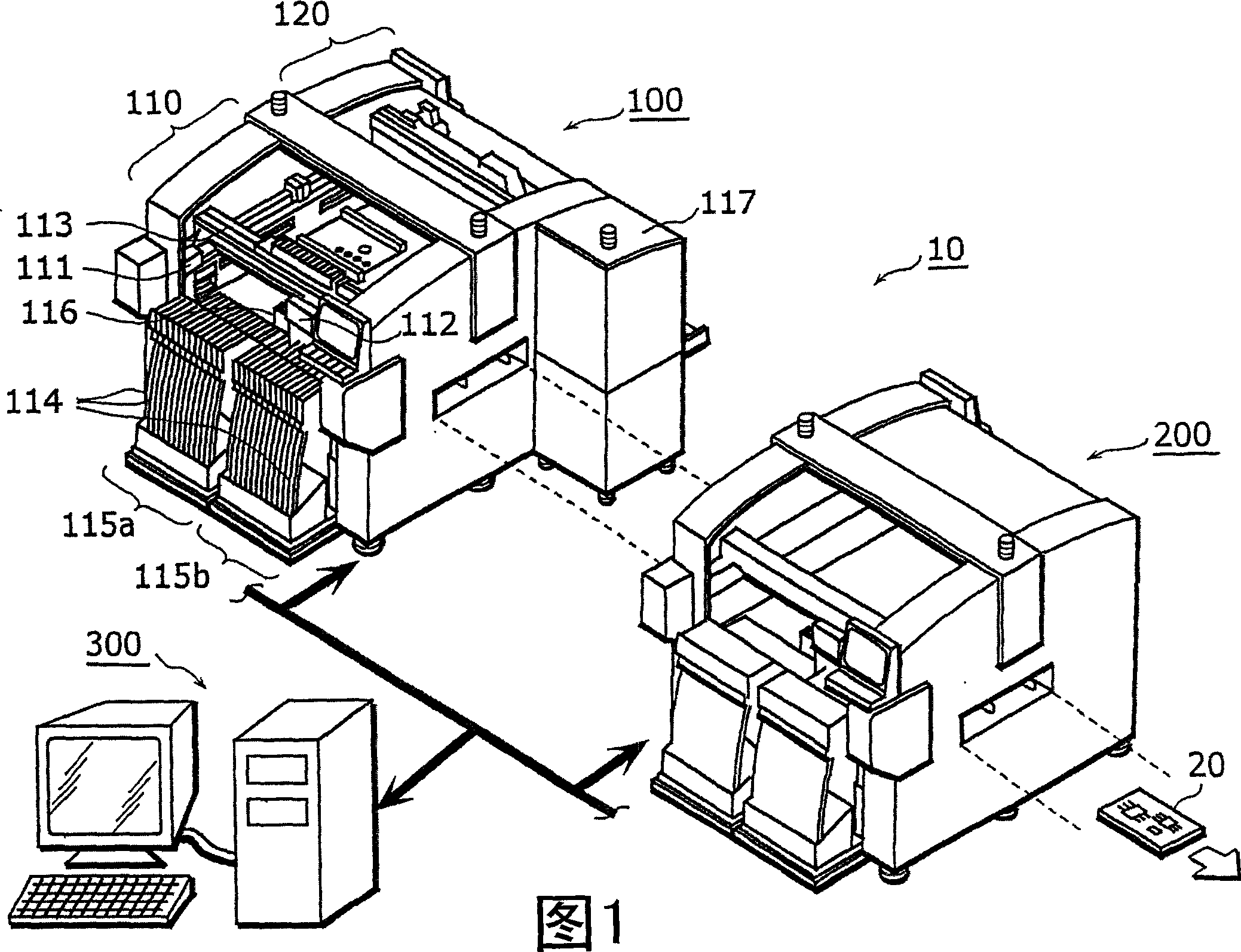

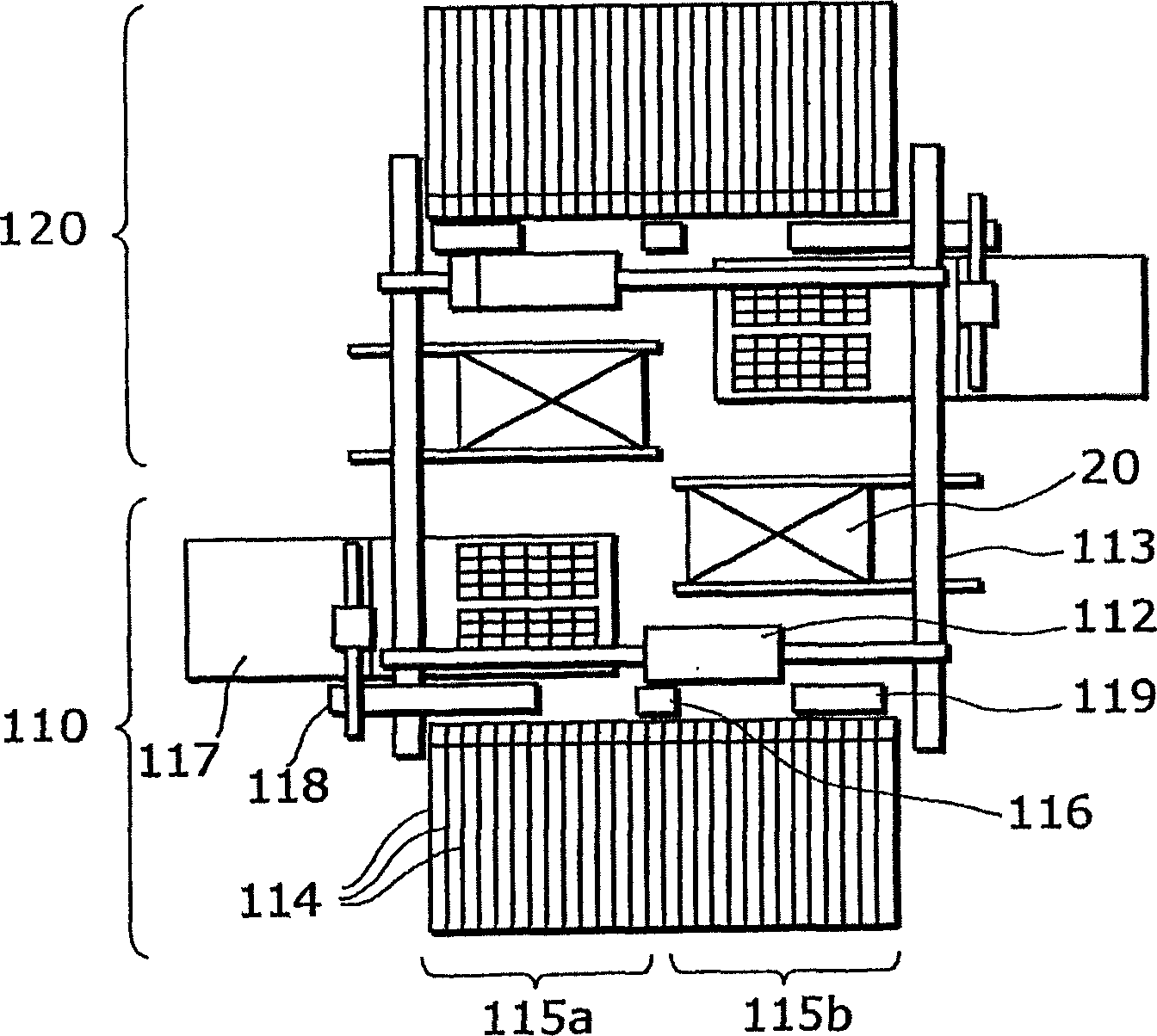

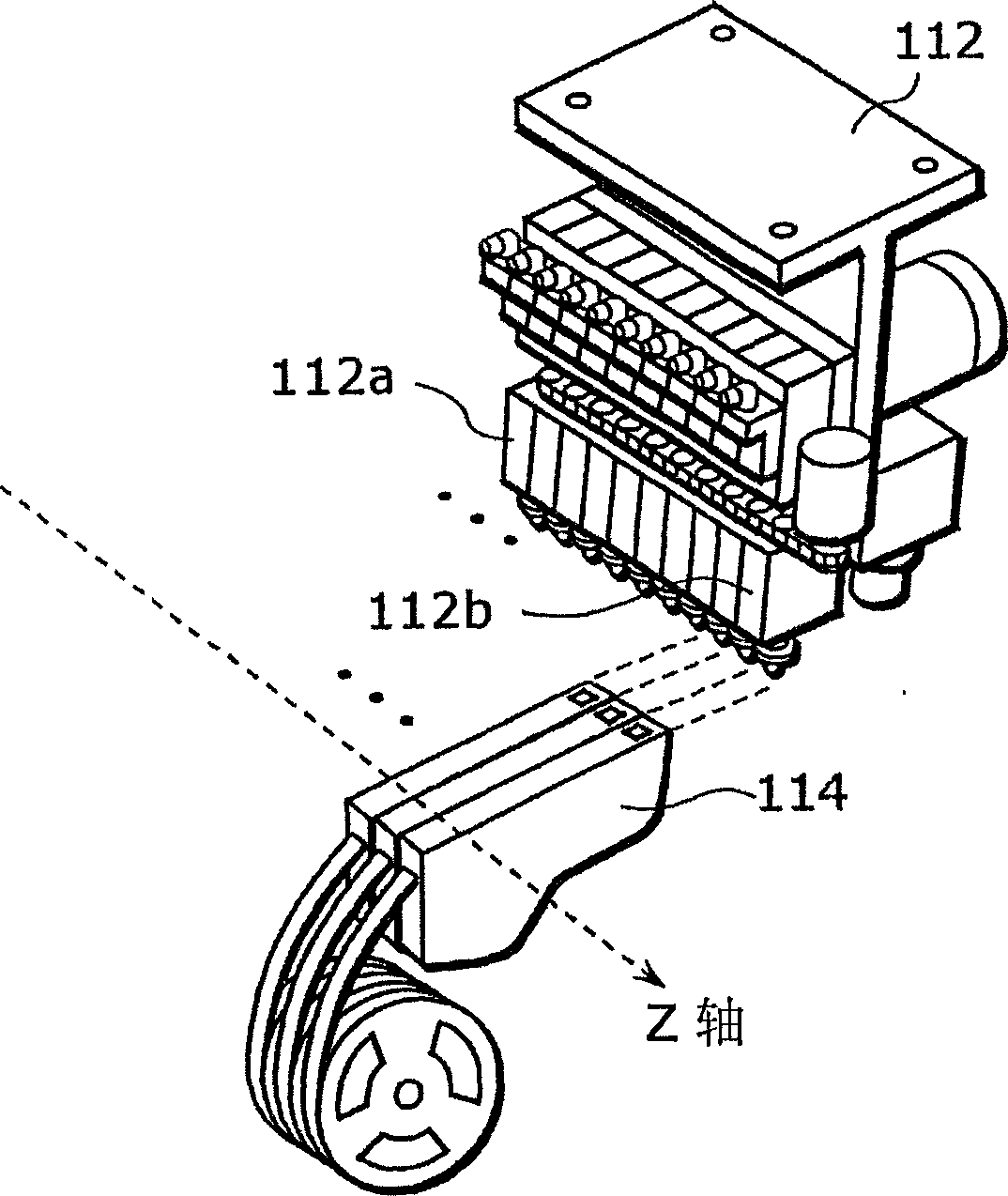

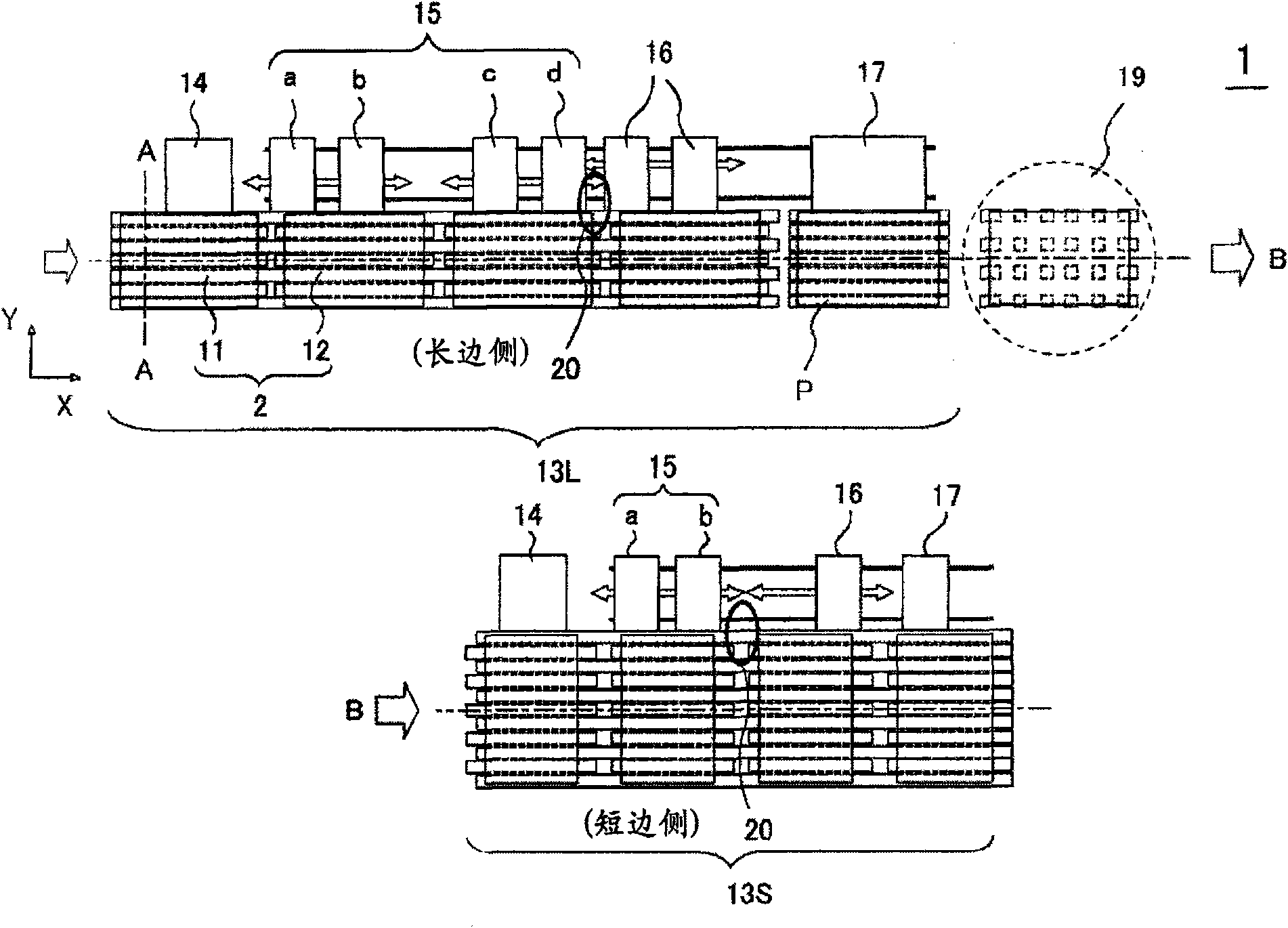

Method for optimization of an order for component mounting and apparatus for optimization of an order for component mounting

ActiveCN1846223AEasy to handleFlexible handlingMulti-objective optimisationResourcesCalculatorIndustrial engineering

The panel contains a plurality of patterns having the same component placement structure, and the plurality of patterns respectively correspond to a plurality of sub-panels obtained by dividing the above-mentioned panel. The method for optimizing the assembly order of components i) includes the step (S2) of optimizing the assembly order of components for any one of the plurality of patterns by dividing the total number of the patterns contained in the panel by the assembler to calculate the quotient and the remainder (S4), a step (S6) for determining the quotient as the number of patterns allocated when the remainder is zero, and a step (S6) for determining the quotient as the number of patterns allocated when the remainder is one or more ) determining the quotient plus 1 as the number of patterns assigned to the same number of assemblers as the remainder starting from the assembler most upstream of the processing position, and ii) determining the quotient as the number of patterns assigned to the remaining The number of patterns of the assembler (S6 to S10), and a step for assigning the assigned number of patterns to each assembler (S12).

Owner:PANASONIC CORP

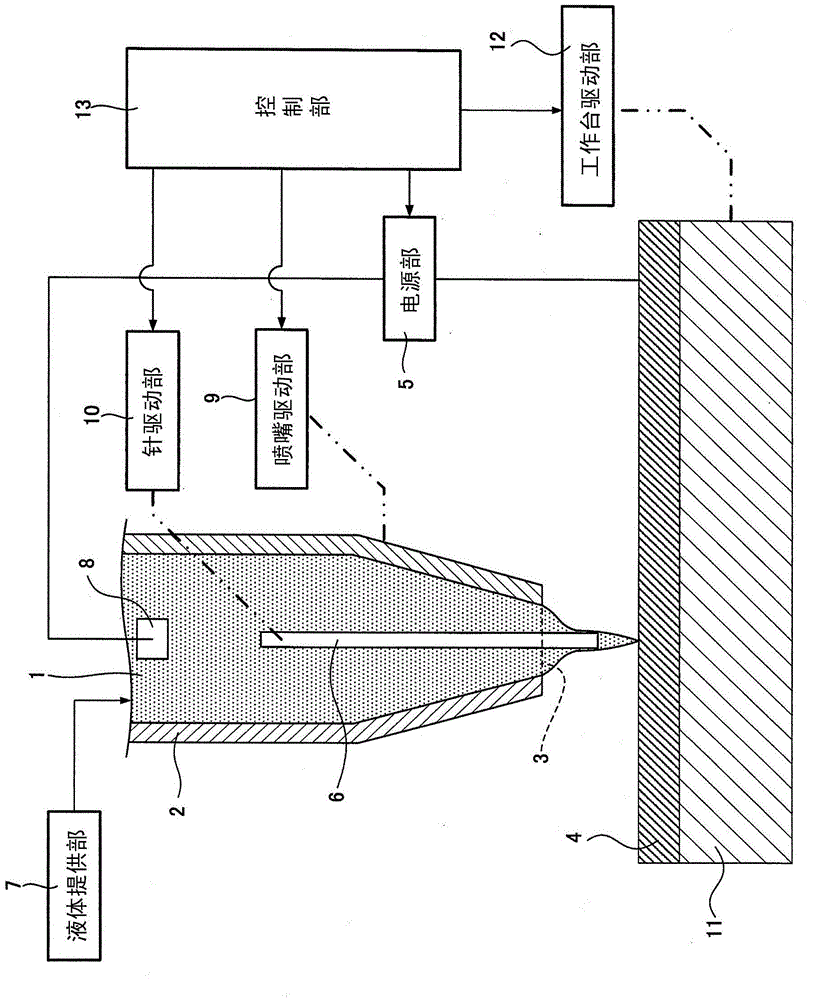

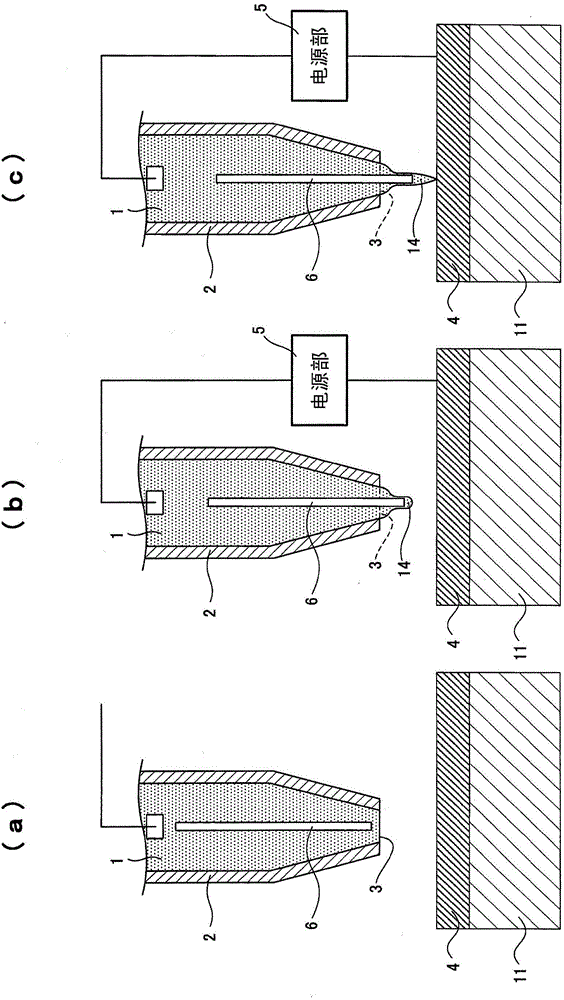

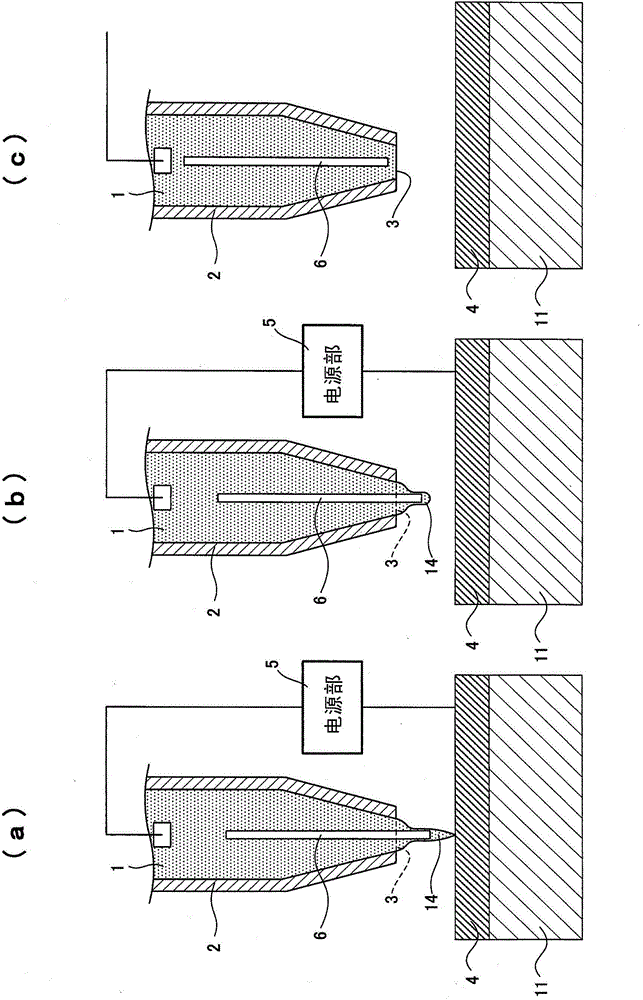

Electrostatic Application Method And Electrostatic Application Apparatus

ActiveCN104646249AImprove responsivenessAvoid confusionLiquid spraying plantsLiquid surface applicatorsApplication objectEngineering

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

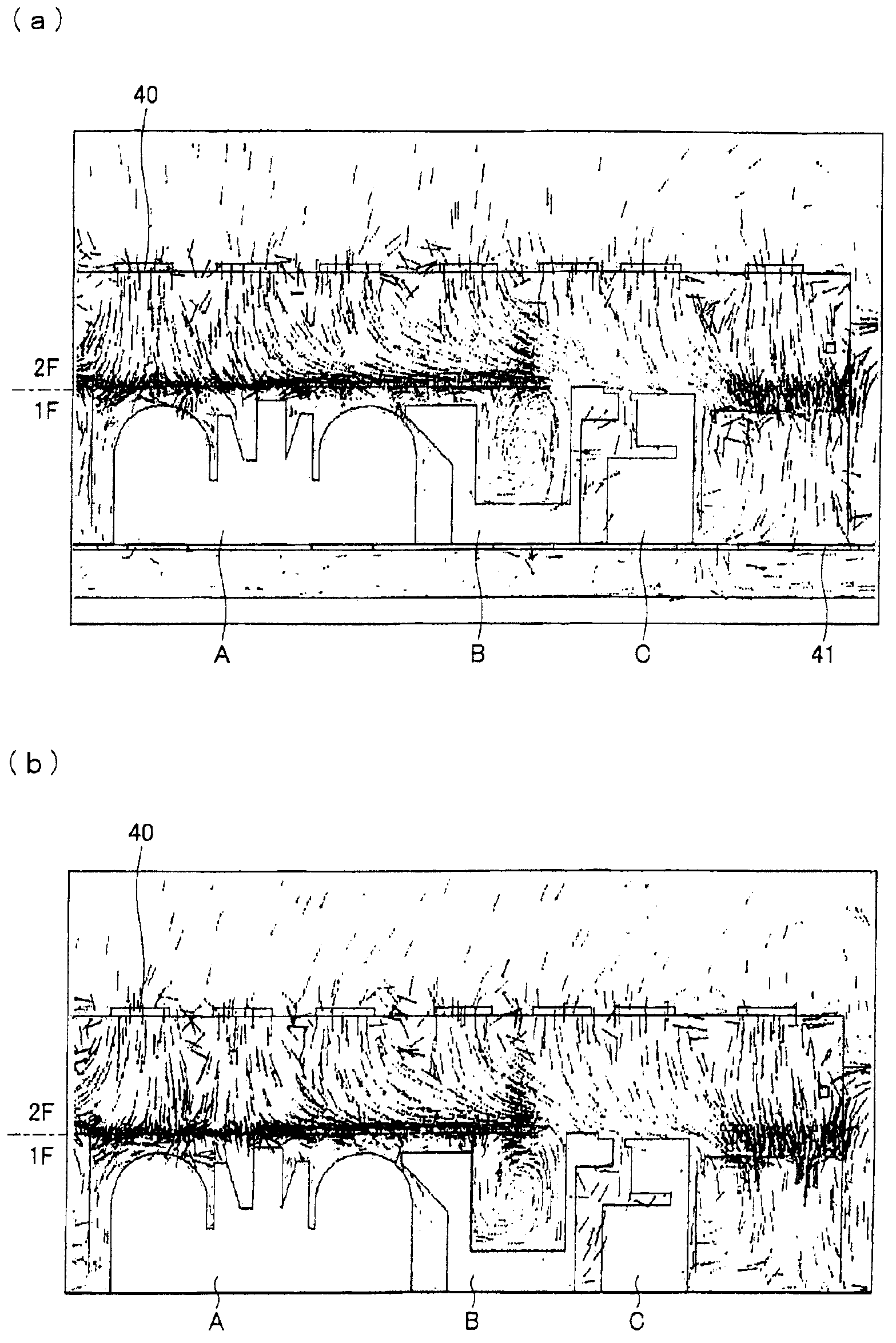

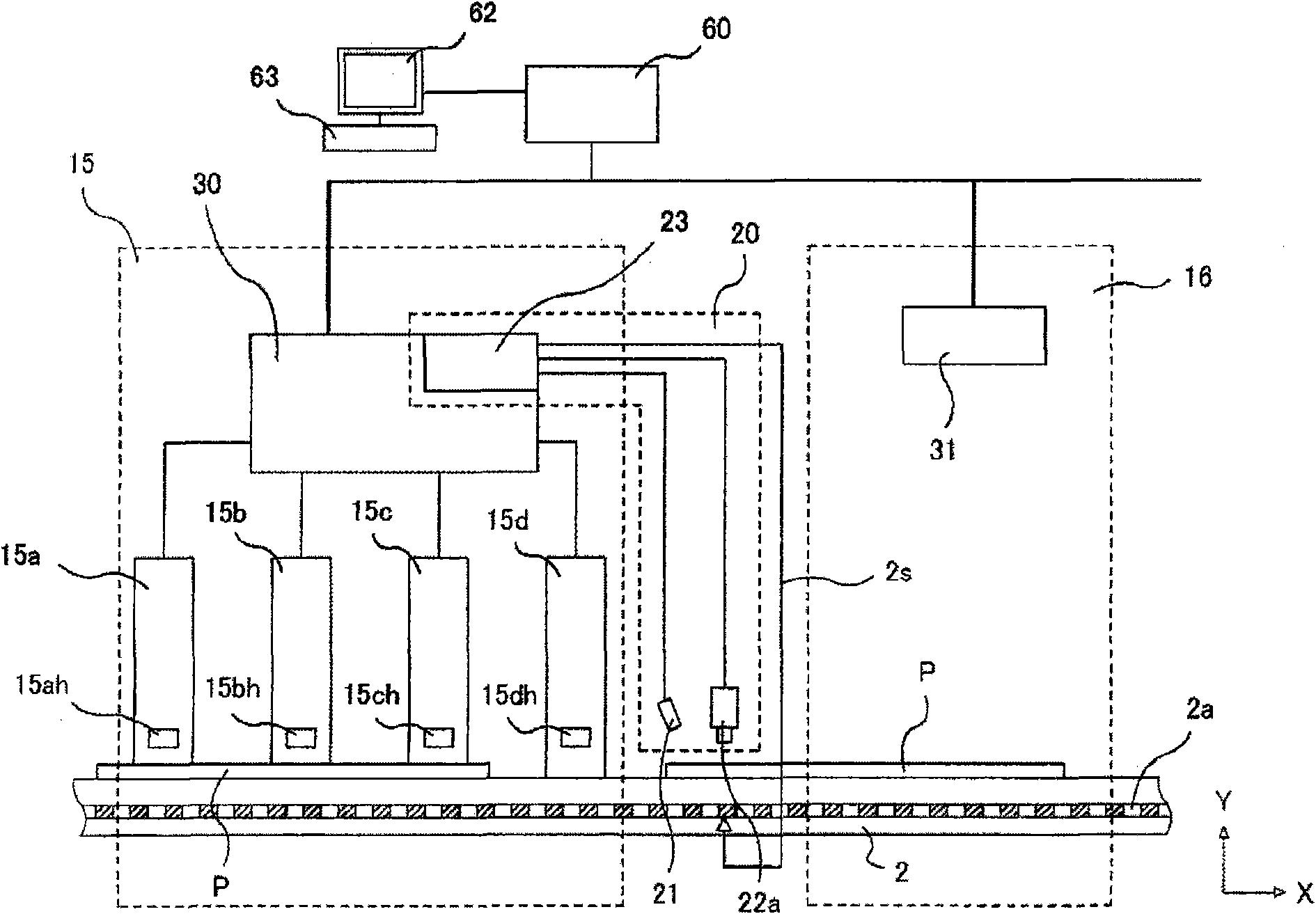

Macro inspection apparatus and macro inspection method

InactiveCN1906476ARapid positioningShorten takt timeMaterial analysis by optical meansOptical apparatus testingOptoelectronicsTransfer mechanism

A macro inspection apparatus having: a substrate holder that holds a substrate to be inspected; a macro illumination optical system that irradiates illumination light onto the substrate; a substrate holder driving mechanism that supports the substrate holder, Simultaneously, in the state where the substrate is irradiated with the illumination light, the posture of the substrate holder is controlled; a substrate conveyance mechanism that transfers the substrate to and from the substrate holder; a substrate floating mechanism , which floats the substrate from the substrate holder by spraying air on the substrate transferred to the substrate holder; a substrate positioning mechanism that makes the substrate float by the substrate floating mechanism and a substrate fixing mechanism that fixes the substrate positioned by the substrate positioning mechanism on the substrate holder.

Owner:OLYMPUS CORP

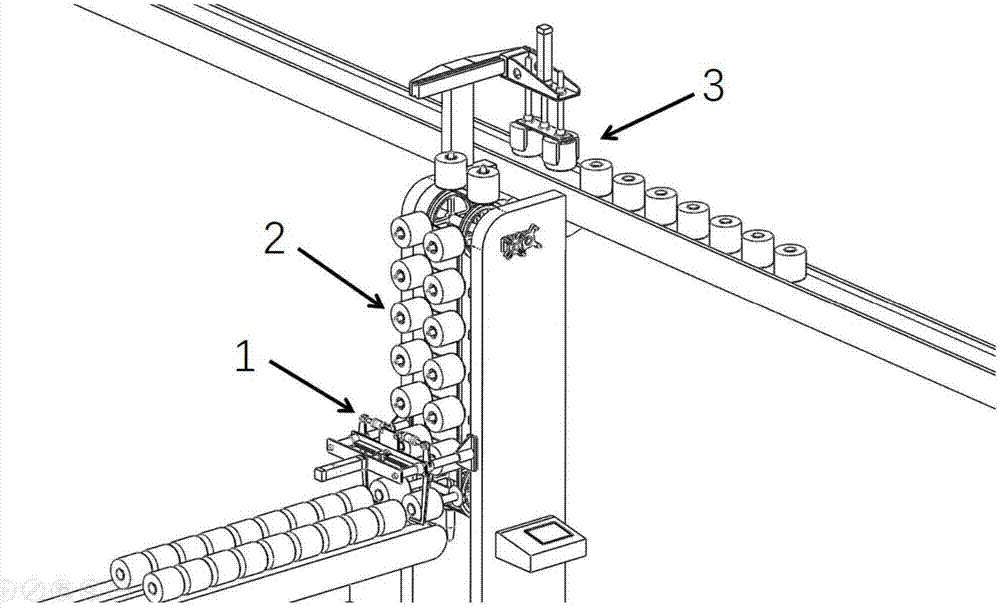

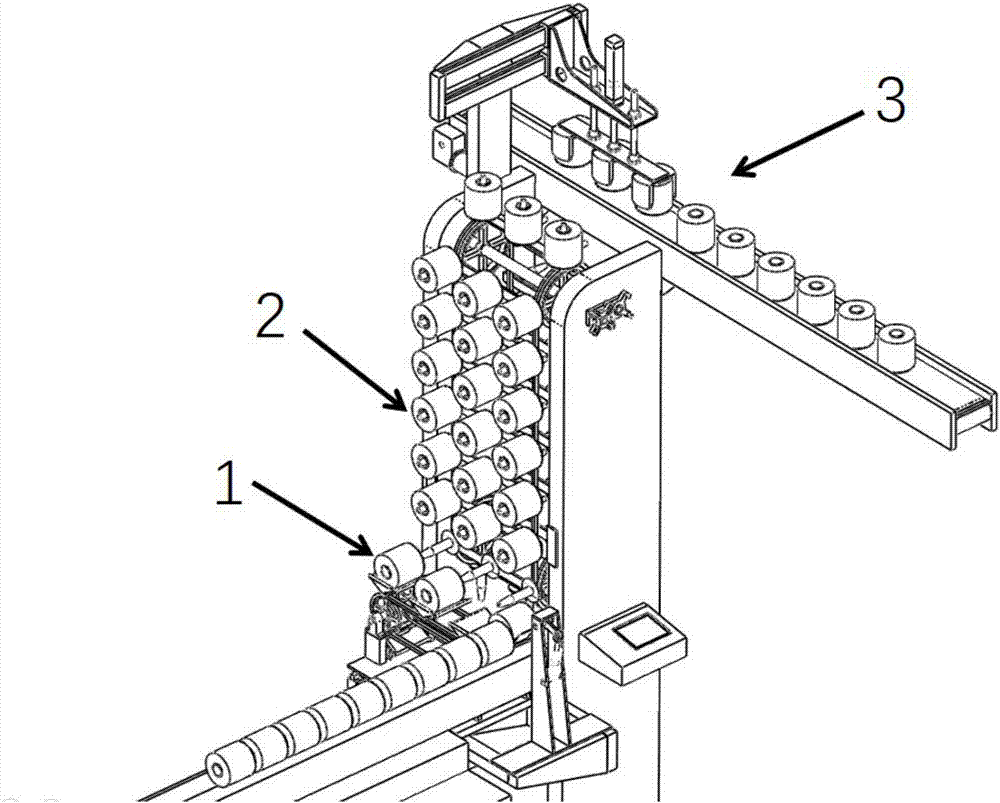

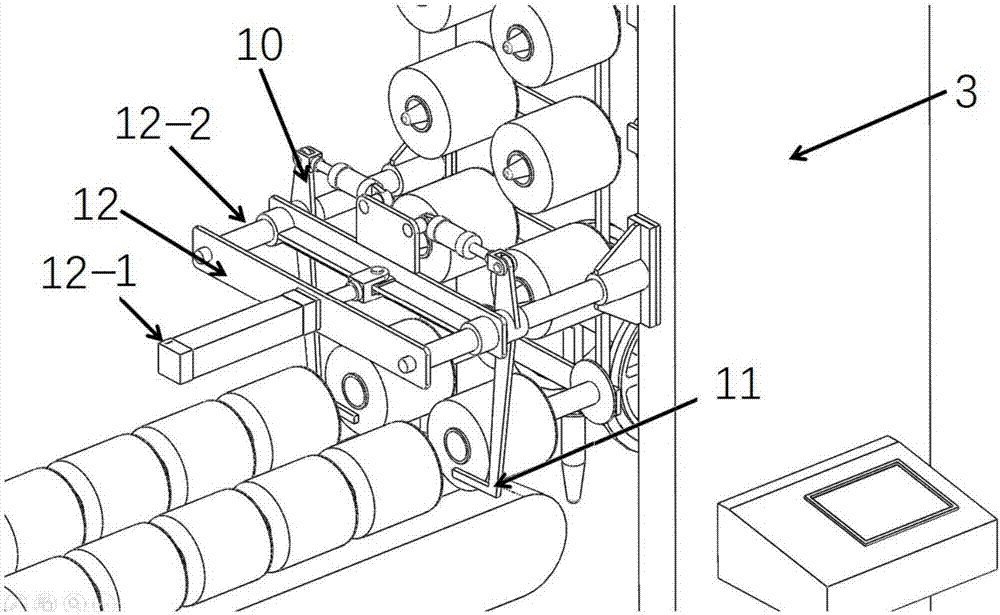

Automatic offline lifting device of cone yarns of bobbin winder

The invention relates to an automatic offline lifting device of cone yarns of a bobbin winder. The device comprises a cone yarn pushing mechanism, a chain cone yarn lifter and a cone yarn shifting manipulator; the cone yarn pushing mechanism is arranged in an outlet at the head of the bobbin winder on a double-row or single-row belt conveying line, and is connected with the chain cone yarn lifter for pushing two or single cone yarns into the chain cone yarn lifter; the cone yarns are gradually lifted to the top of the chain cone yarn lifter by the chain cone yarn lifter, and are automatically overturned by 90 degrees to change in the vertical direction perpendicular to a bobbin core; and the cone yarn shifting manipulator is mounted at the upper part of the chain cone yarn lifter for grabbing the vertical cone yarns on a cone yarn conveying line in air. The device can realize full-automatic logistics joint between the bobbin winder and subsequent production process, and reduces a lot of logistics carrying labors and carrying tools.

Owner:SHANGHAI CORAL TEXTILE MACHINERY

Load port unit and EFEM system

ActiveUS9536765B2Increase supplyImprove working environmentSemiconductor/solid-state device manufacturingConveyor partsEngineeringElectrical and Electronics engineering

A load port unit can prevent or control leakage of inert gas from an EFEM system to the outside. The load port unit used in the EFEM system is provided with an air inlet that opens on a side facing a mini-environment between the upper end of an opener driving unit and the lower end of the pod. The width of the air inlet opening is larger than the width of the opening of the pod. With this arrangement, surplus gas is sucked from the pod when gas purging is performed on the pod.

Owner:TDK CORPARATION

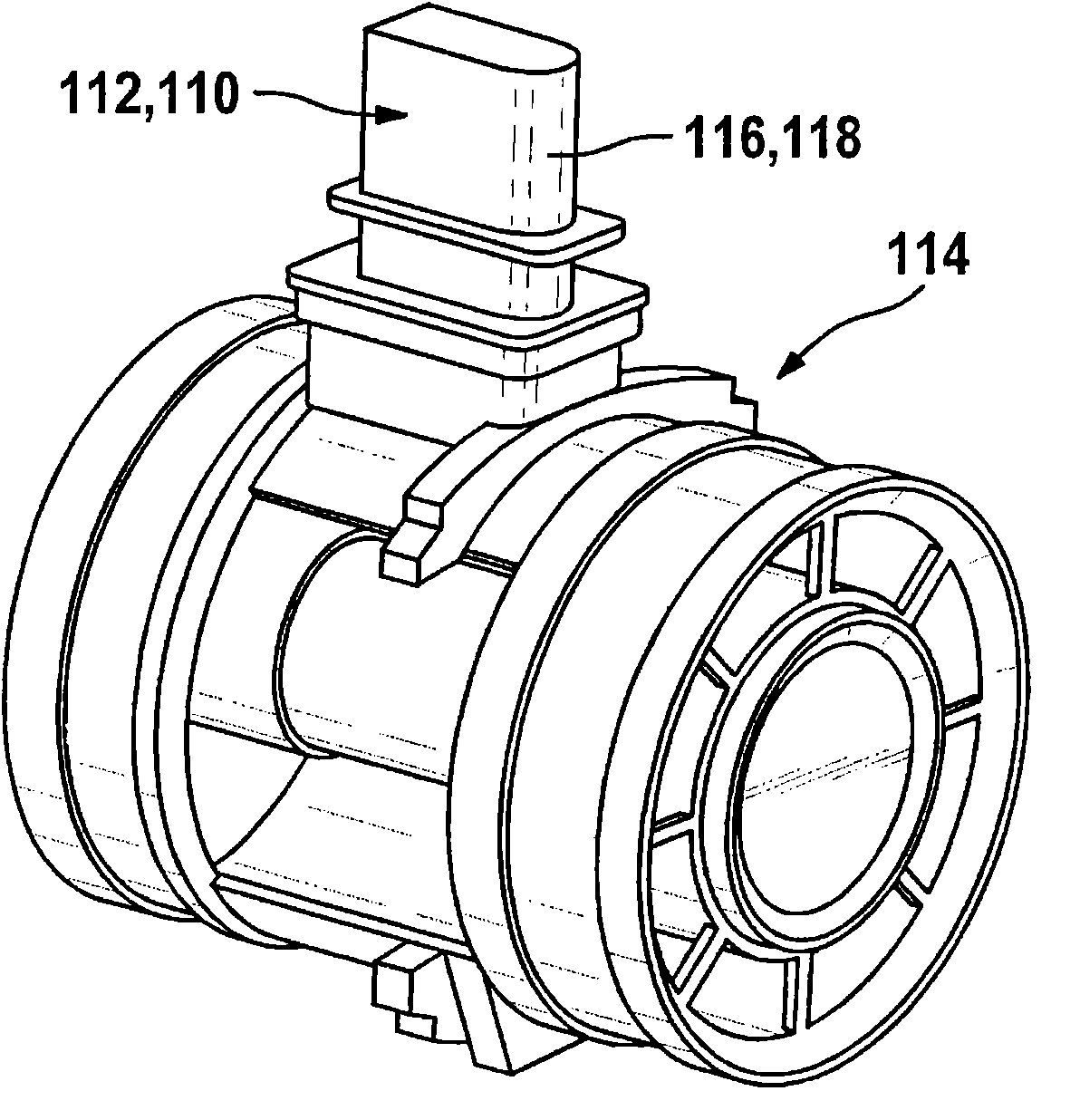

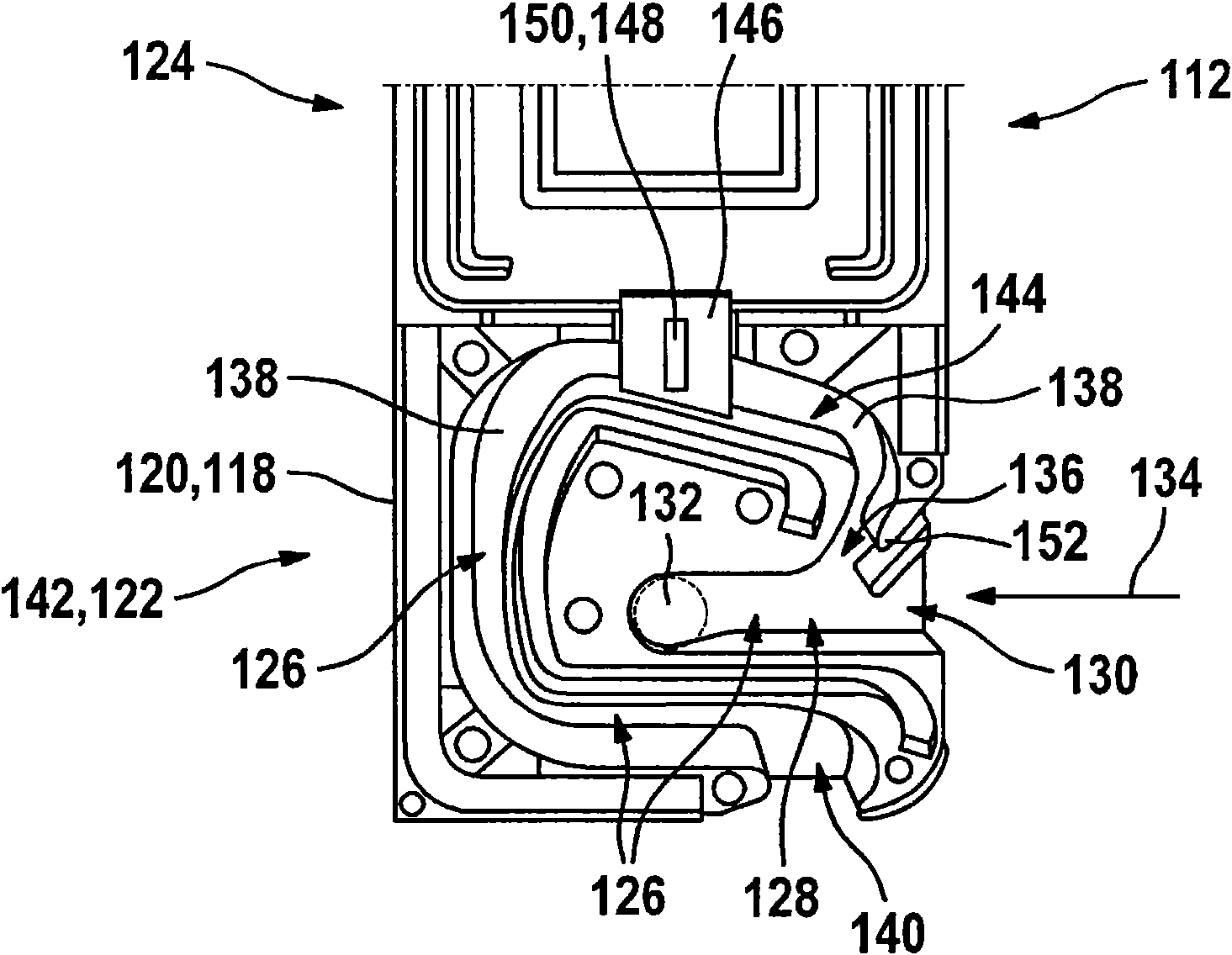

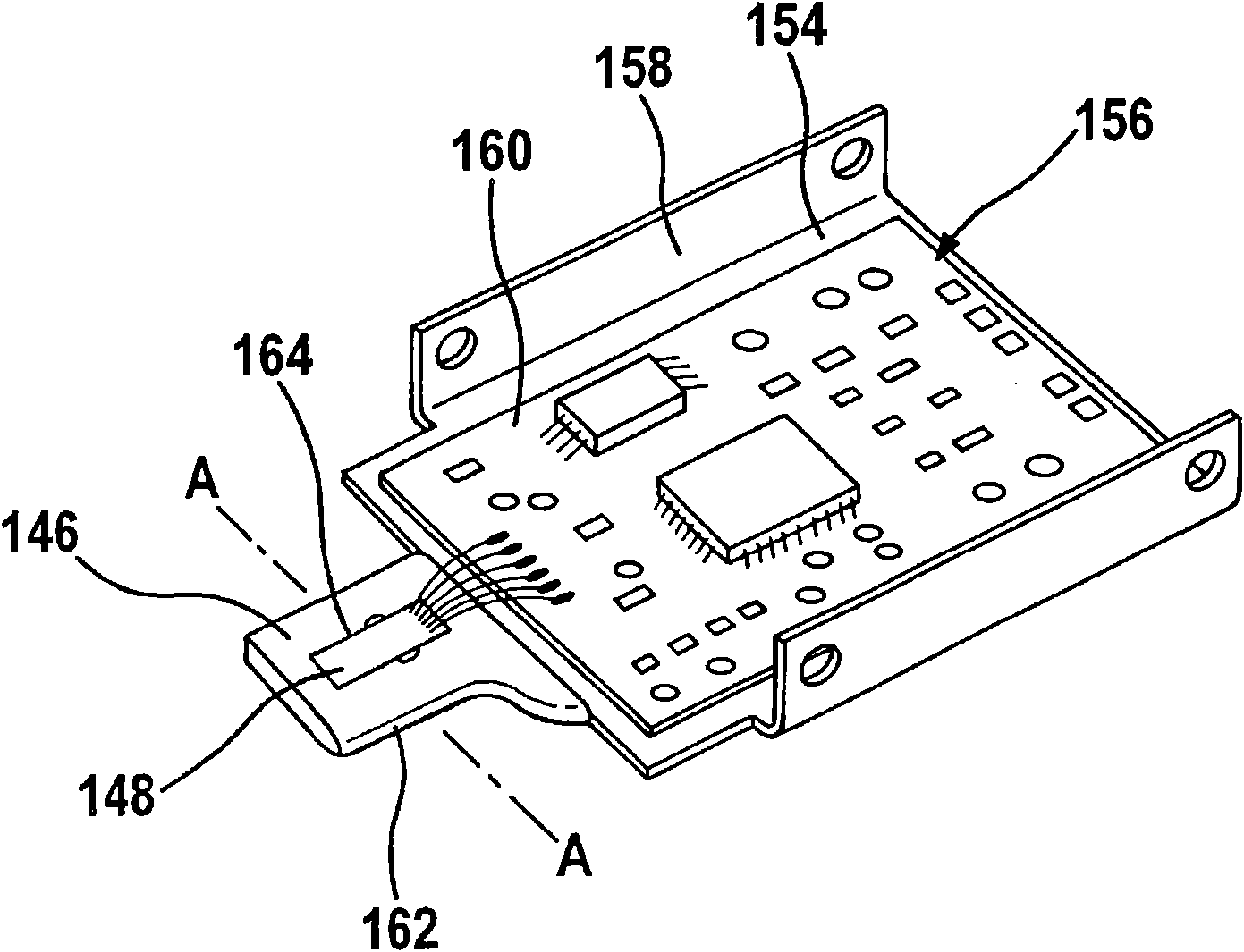

Hot film-type air flow meter and production method thereof

ActiveCN101680792AEasy to assembleManufacturing method omitsVolume/mass flow measurementSolid-state devicesHemt circuitsEngineering

The invention relates to an apparatus (110, 112) for determining at least one parameter of a fluid medium, in particular an intake-air mass of an internal combustion engine. The apparatus (110, 112) comprises a sensor chip (148) for measuring the parameter and a drive and evaluation electronic system (156) with a circuit carrier (160). The sensor chip (148) is arranged on a chip carrier (146) which can be placed into the fluid medium. The chip carrier (146) comprises a protrusion (166) of the circuit carrier (160), which protrusion is integral with the circuit carrier (160), wherein the sensorchip (148) is fixed to the protrusion (166).

Owner:ROBERT BOSCH GMBH

Processing apparatus, method for detecting ACF sticking state or display substrate assembly line

InactiveCN101846825AShorten working timeReduced processing widthMaterial analysis by optical meansNon-linear opticsAssembly lineComputer engineering

The invention provides a processing apparatus or a method for inspecting the ACF sticking state, capable of shortening the total time for the ACF sticking operation and the inspection operation of the ACF sticking state or shortening the width of the processing apparatus in the ACF sticking process, or a display substrate module assembly line, capable of shortening the beat time of the display substrate= module assemble or having short assembly line length. An ACF stuck at the predetermined positon of a display substrate is lighted and shot, when the ACF sticking state is inspected according to the shot result, the shooting and inspection are performed in the process of conveying the display substrate after the ACF is stuck.

Owner:HITACHI HIGH-TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com