Processing equipment, conveying control device and conveying control method

A processing device and processing equipment technology, which is applied to conveyor control devices, program control in sequence/logic controllers, conveyors, etc., can solve the problems of long development cycle and increased product volume, saving space, reducing The effect of the amount of work in process and the reduction of the lead time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

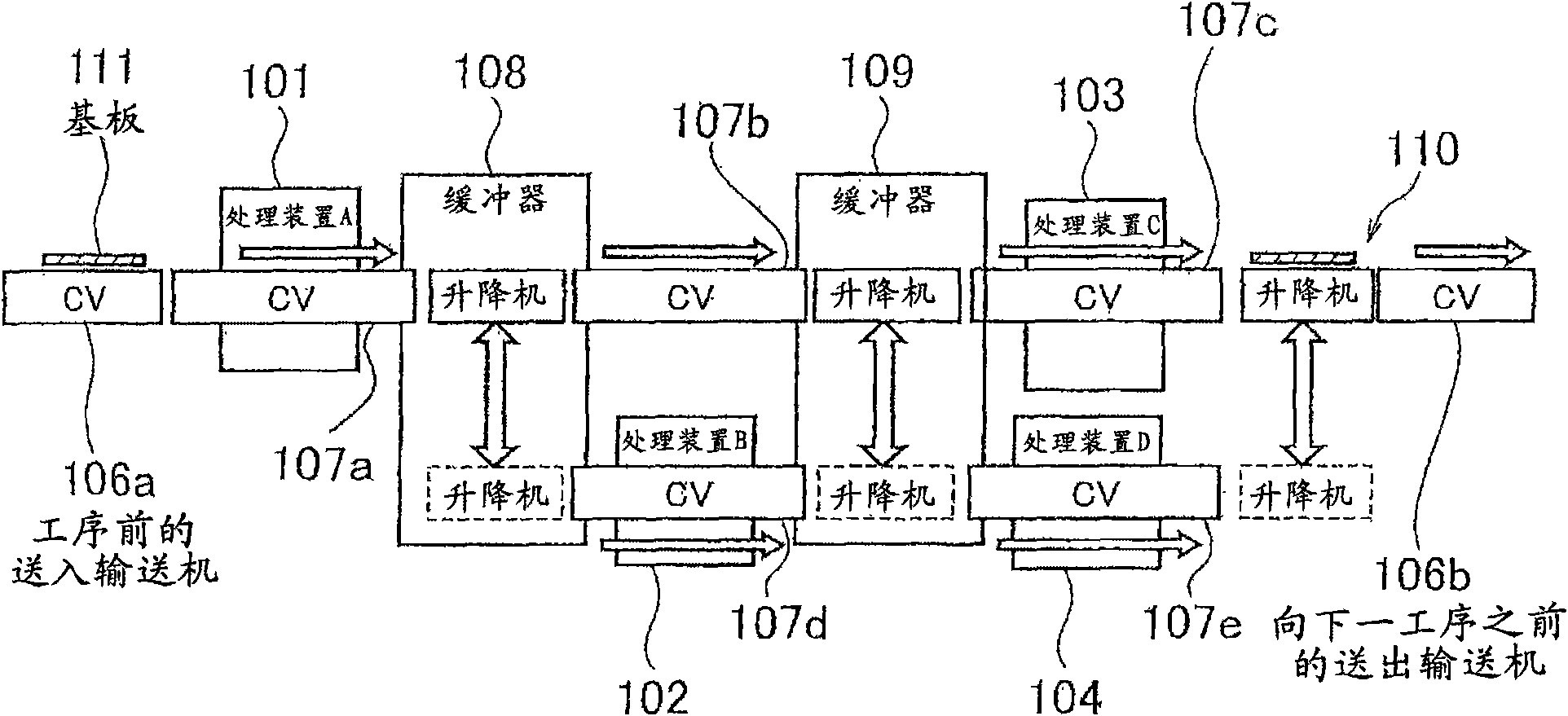

[0073] figure 1 Is a side view showing the structure of the first embodiment of the processing equipment of the present invention

[0074] In the processing equipment of this embodiment, such as figure 1 As shown, there are a plurality of conveying paths for objects to be conveyed between the plurality of processing devices 101, 102, 103, and 104. In addition, along the conveying path, a plurality of conveyors with fork functions (hereinafter referred to as fork conveyors, FCV: conveying units) 107a, 7, 107b, 107c, 107d for conveying substrates (transported objects) 111 are installed. . The plurality of substrates 111 correspond to the fork conveyors 107a, 7, 107b, 107c, and 107d.

[0075] In this processing facility, each processing device 101, 102, 103, 104 and each branch conveyor 107a, 7, 107b, 107c, 107d are installed in multiple stages. The first processing device 101 and the third processing device 103 are provided at the upper level, and the second processing device 102...

no. 3 approach

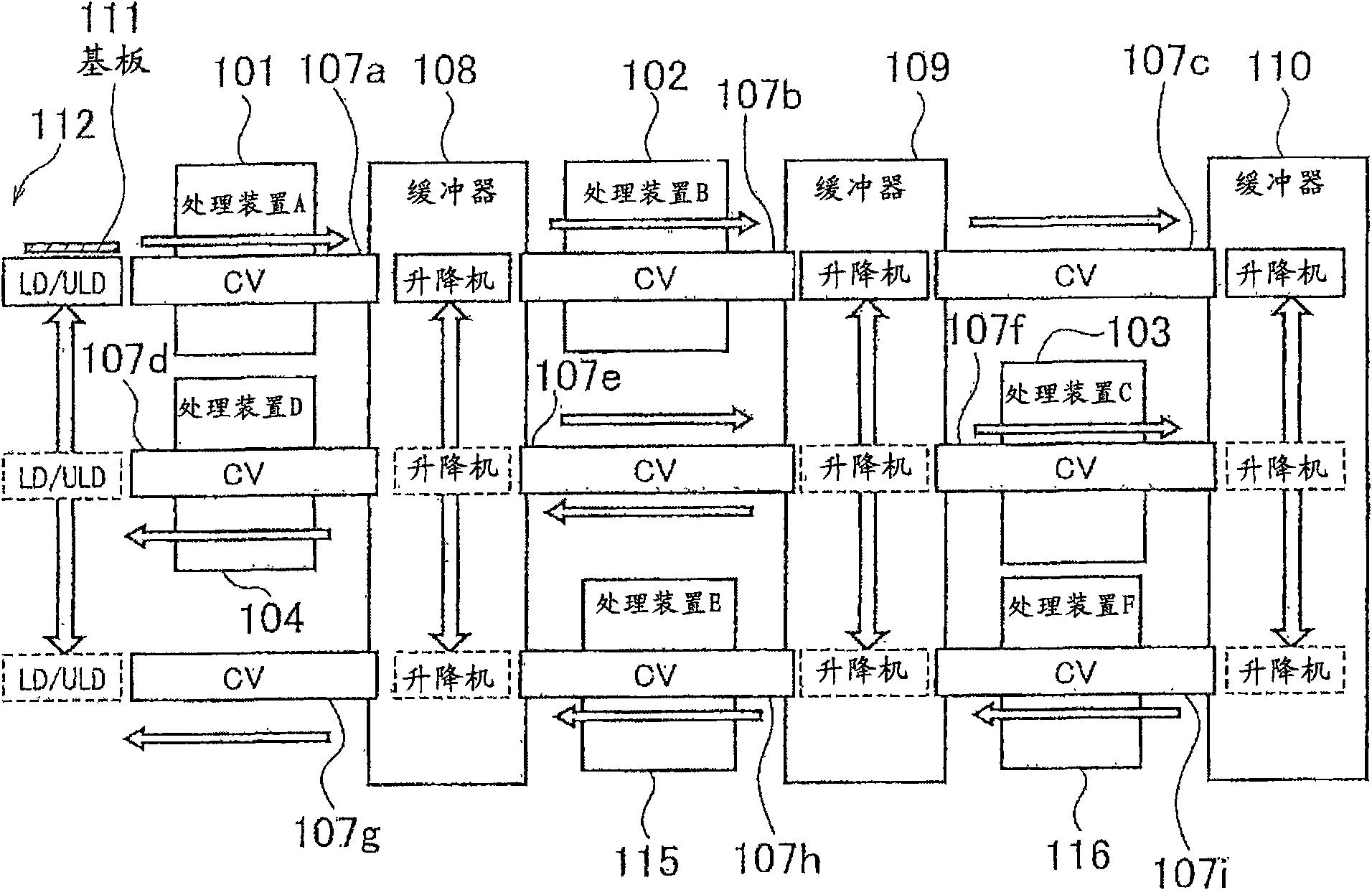

[0095] image 3 It is a side view showing the structure of the third embodiment of the processing equipment of the present invention.

[0096] In the processing equipment of this embodiment, such as image 3 As shown, the processing device and the fork conveyor are arranged in three stages. That is, in this processing facility, the first and second processing devices 101 and 102 are provided at the upper level, the third and fourth processing devices 103 and 104 are provided at the middle level, and the fifth and sixth processing devices 115 and 116 are provided at the lower level. In addition, the first to third fork conveyors 107a, 107b, 107c are installed at the upper level, the fourth to sixth fork conveyors 107d, 107e, and 107f are installed at the middle level, and the seventh to ninth fork conveyors 107g, 107h are installed at the lower level. , 107i.

[0097] In this processing facility, the substrate 111 is sent to the first fork conveyor 107a from outside the process. I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com