Hot film-type air flow meter and production method thereof

一种质量、吸入空气的技术,应用在已知装置领域,能够解决利润率减少、电子装置损害、构件公差等问题,达到减少制造步骤的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

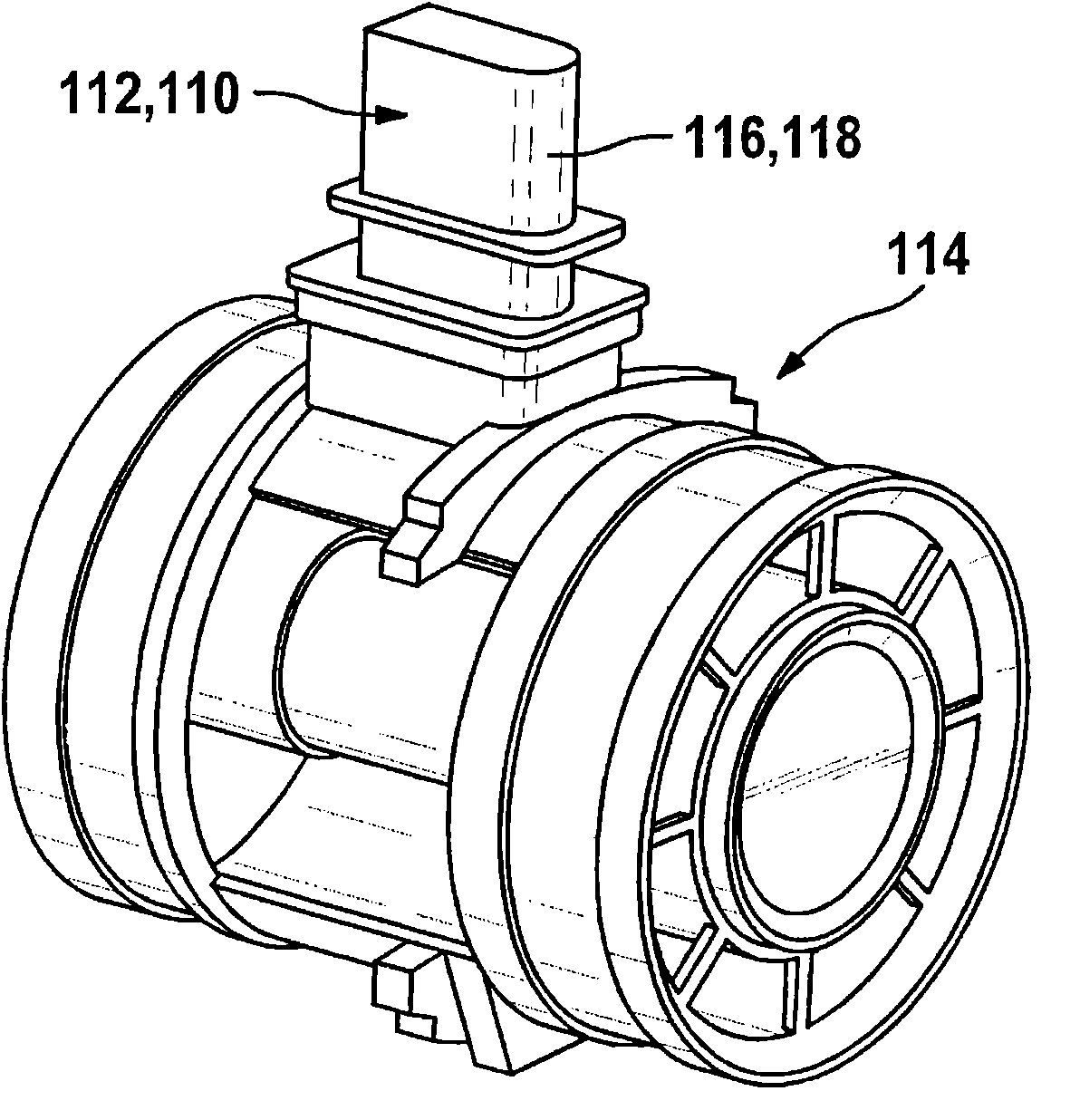

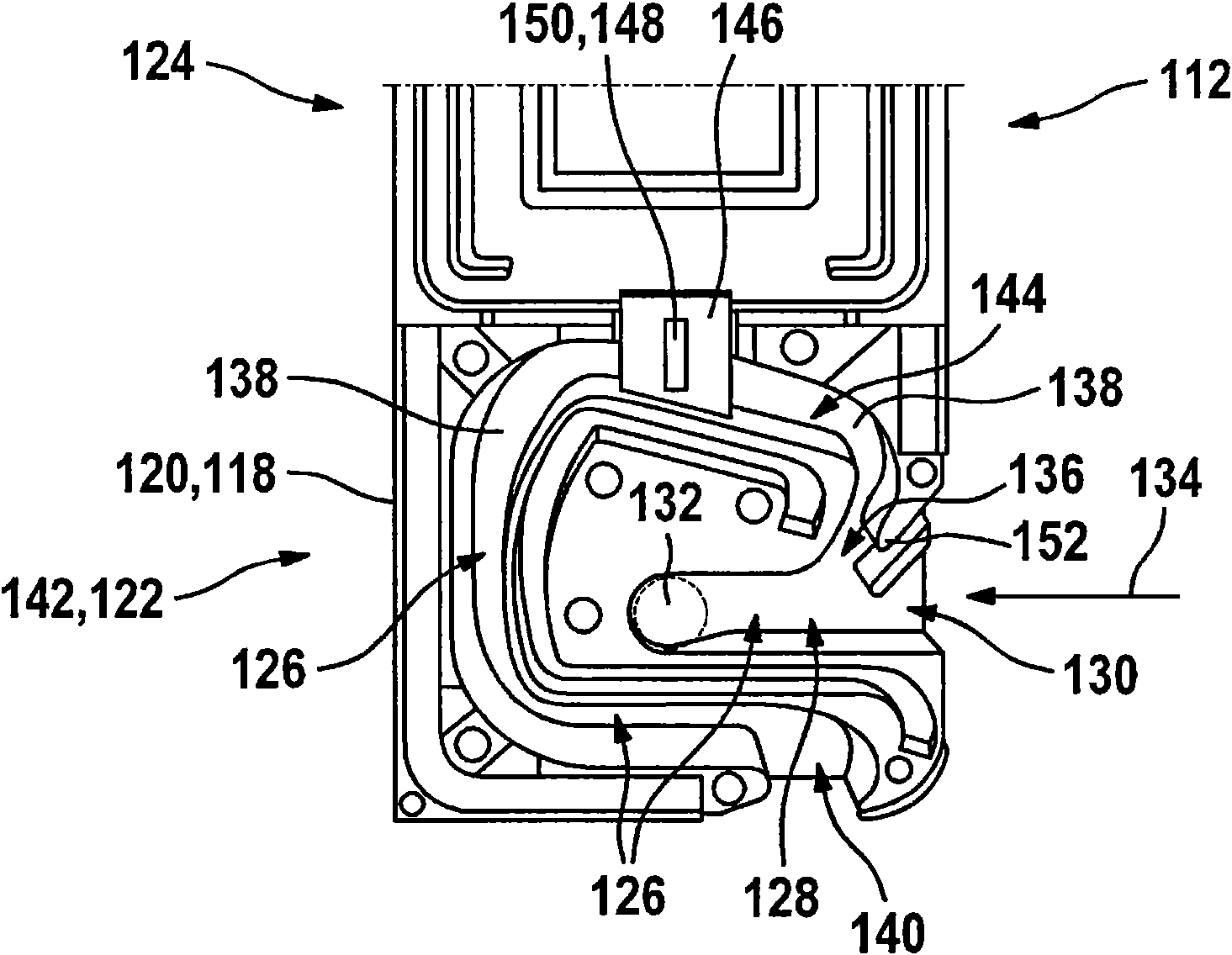

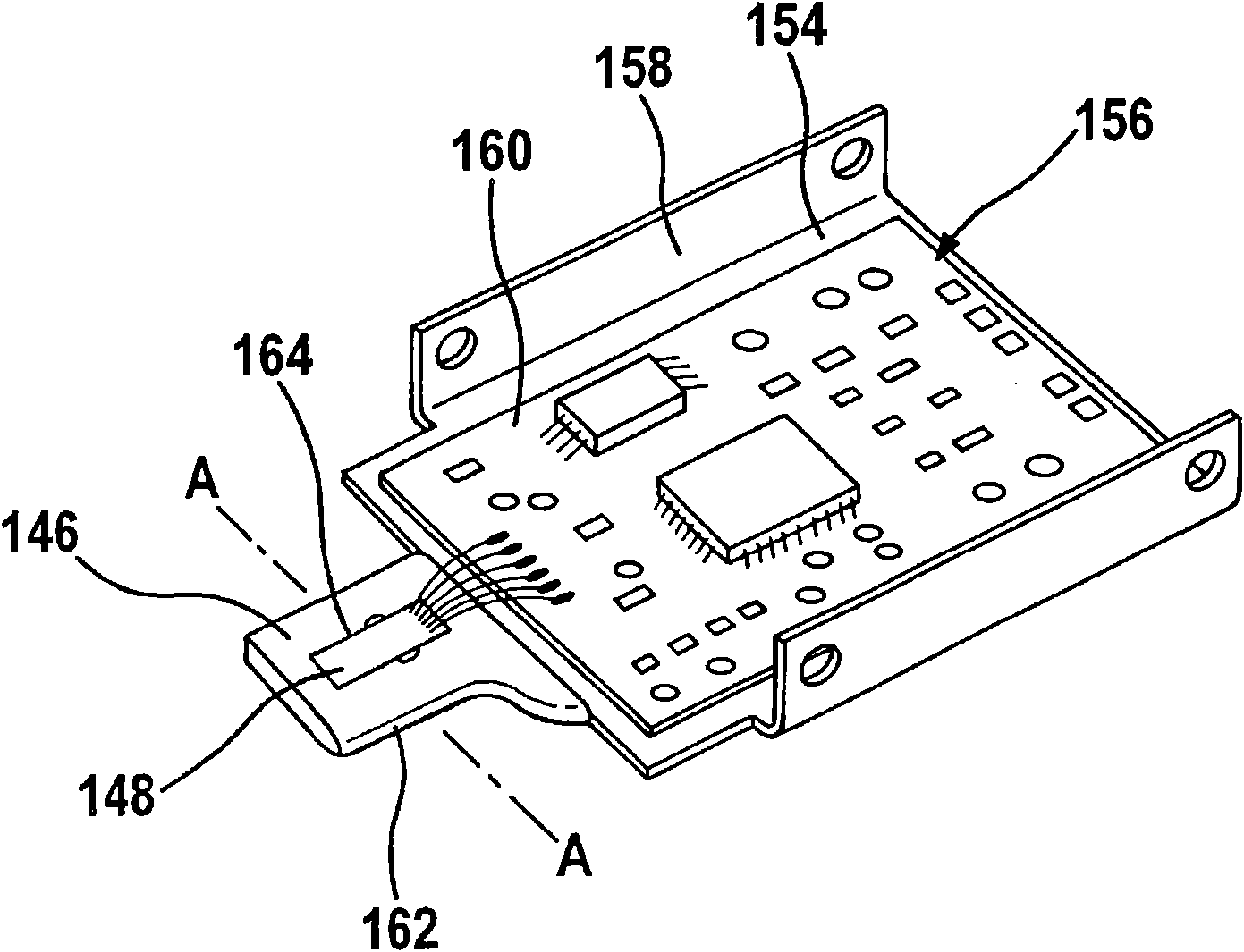

[0025] exist figure 1 An example of a device 110 for determining a parameter of a fluid medium flowing in a main flow direction is shown in . In this embodiment, the device 110 is, as also in the following embodiments (without limiting the scope of the invention) a hot-film air mass flow meter 112 inserted into (in figure 1 not shown in the air intake part 114 of the internal combustion engine. Such hot-film air mass flow meters 112 are commercially available and are described, for example, in DE 102 46 069 A1 or DE 103 48 400 A1.

[0026] The hot-film air mass flow meter 112 is designed to detect the flow direction of the exhaust gas flow in a pulsed flow and is designed for load detection when the internal combustion engine has gasoline or diesel fuel injection. The hot-film air mass flowmeter 112 is usually installed between the air filter and the throttle device and is usually installed as a pre-assembled component in the form of a plug-in probe 116 with a measuring hous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com