Patents

Literature

245results about How to "Improve close contact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

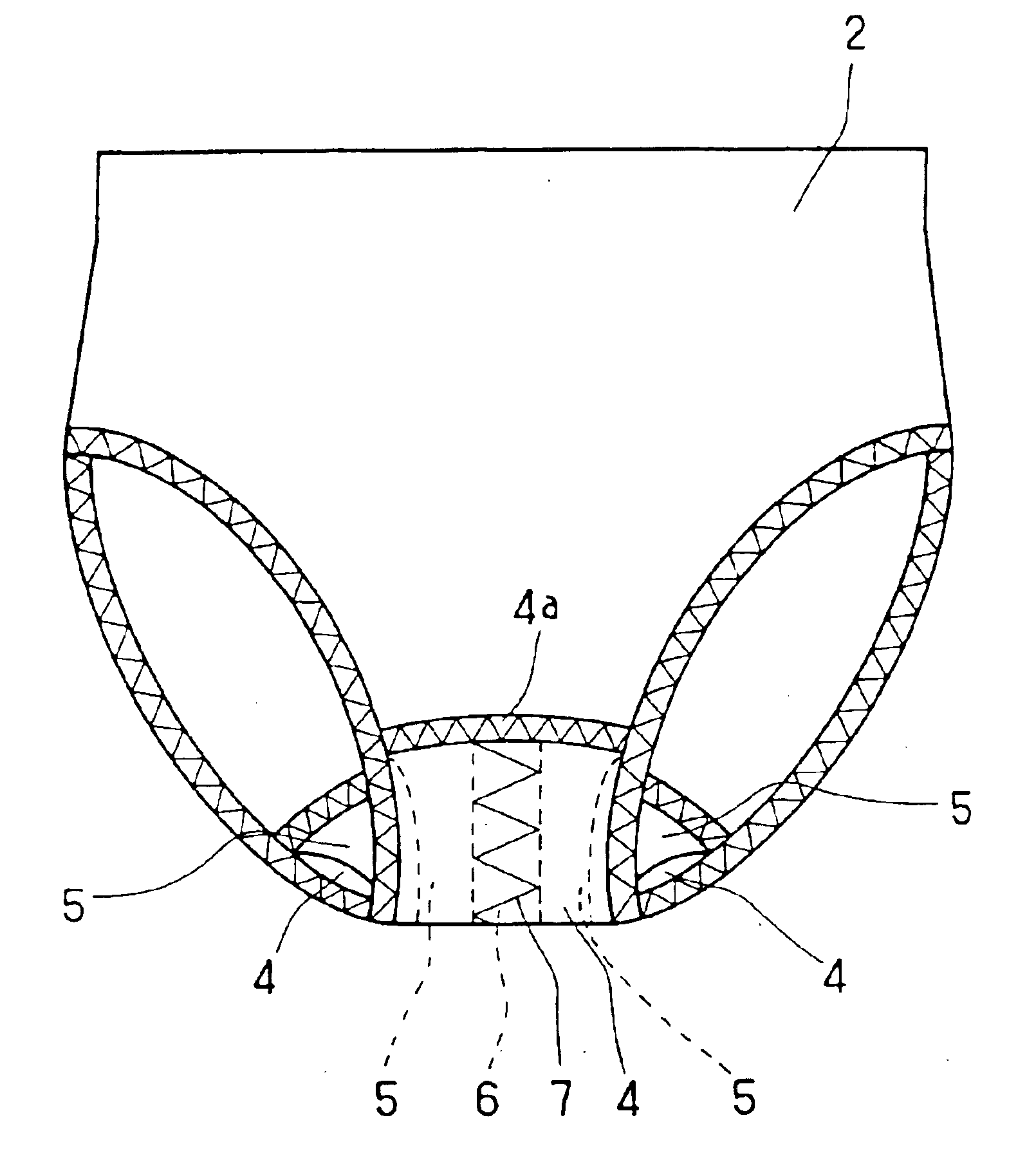

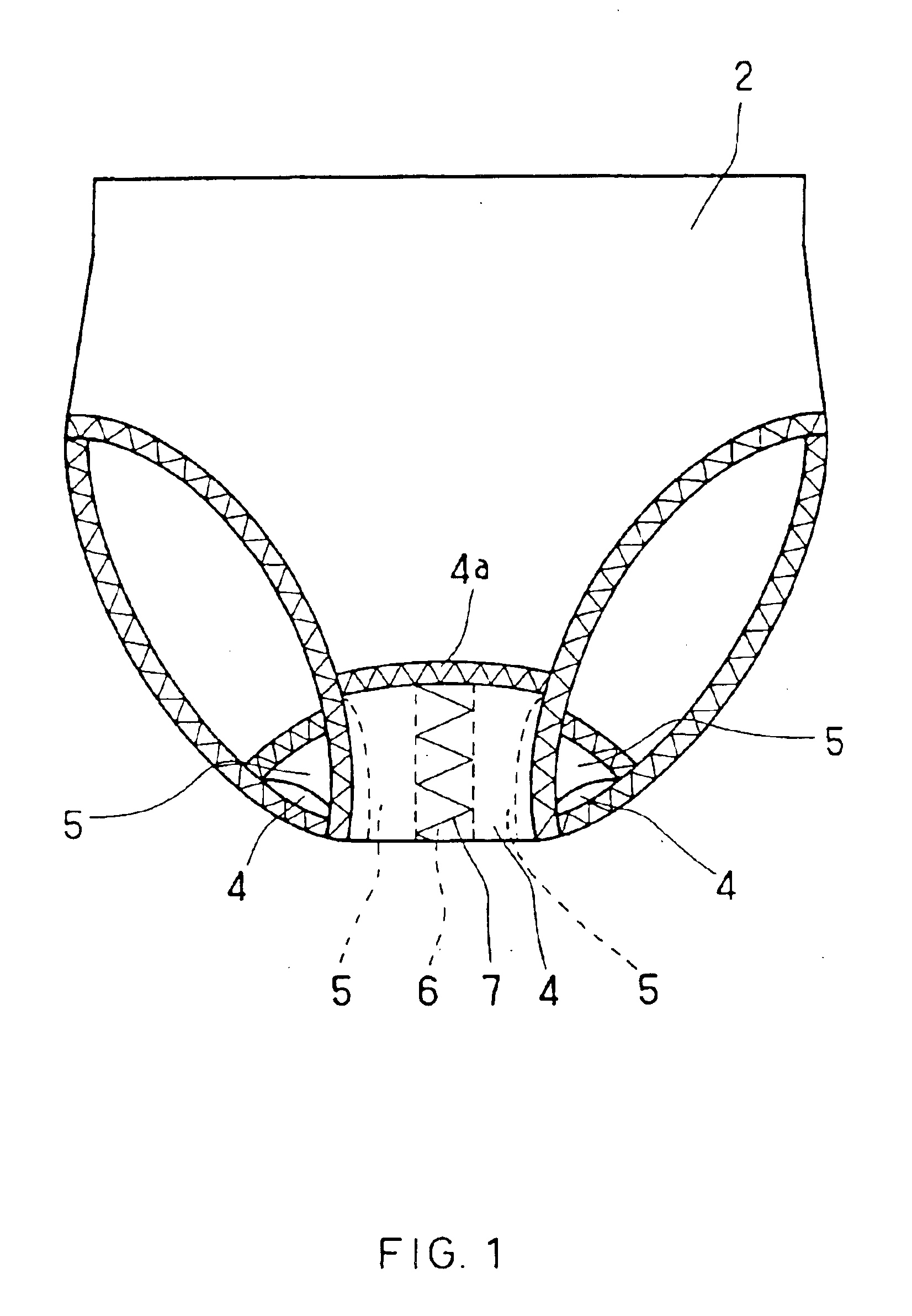

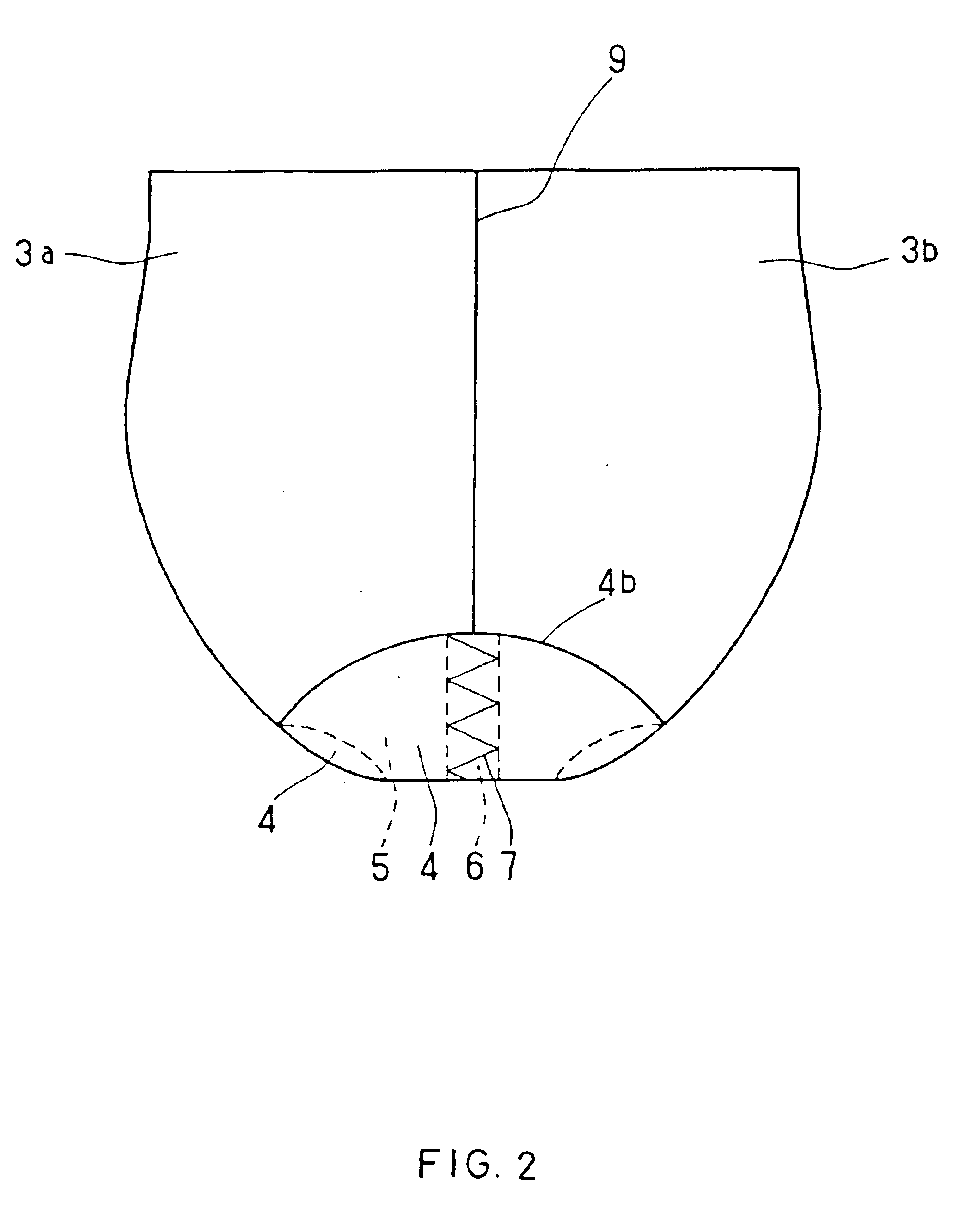

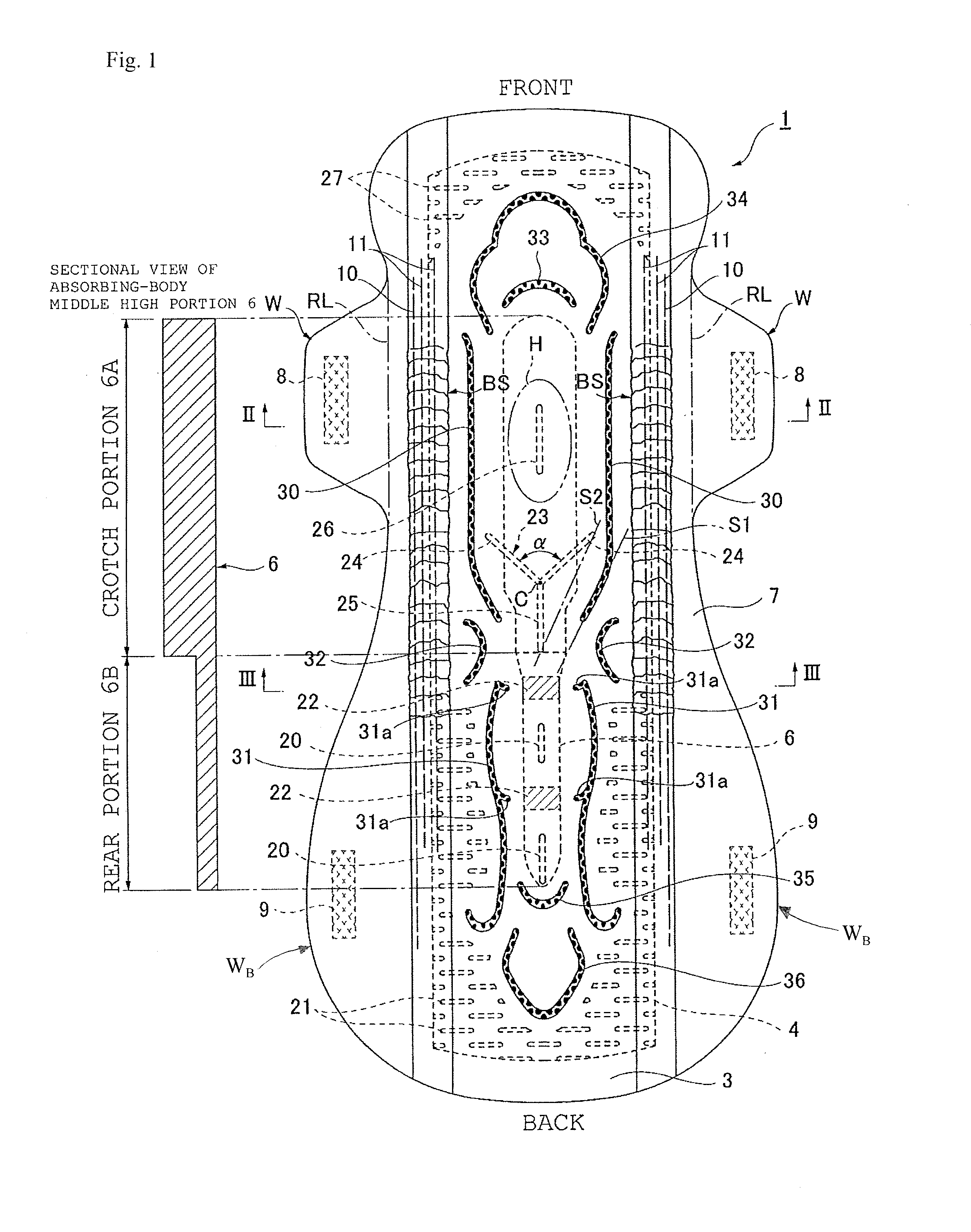

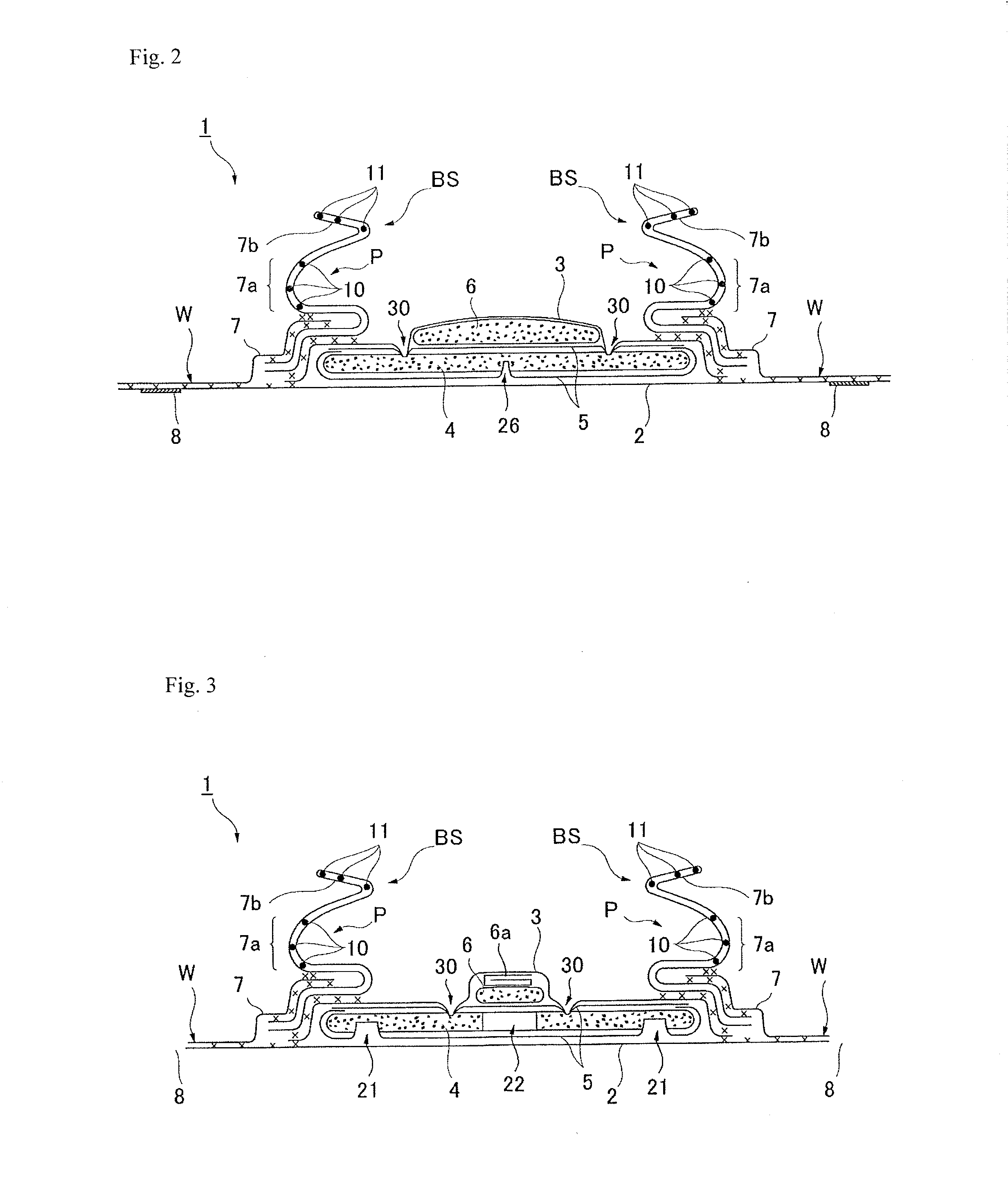

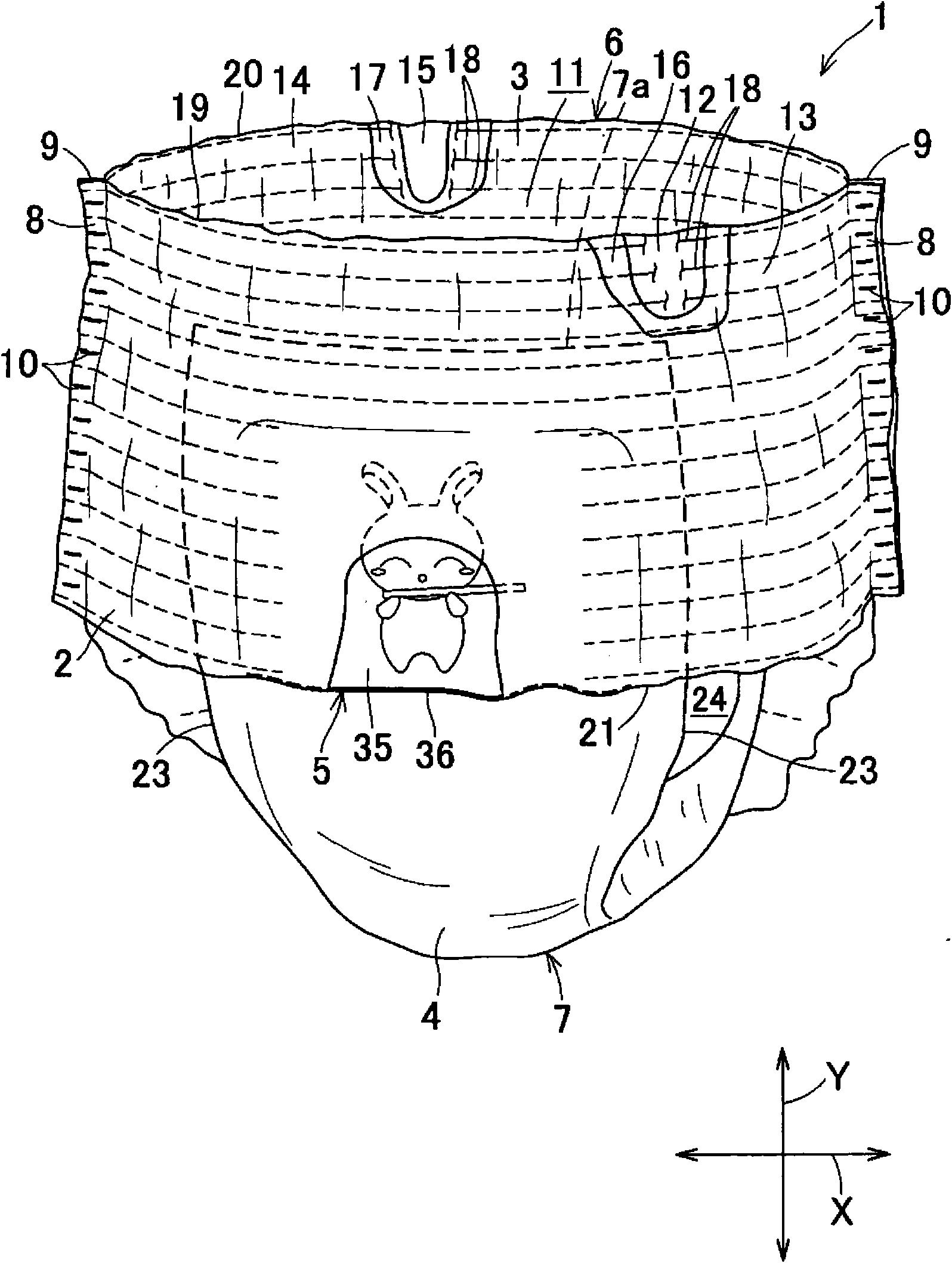

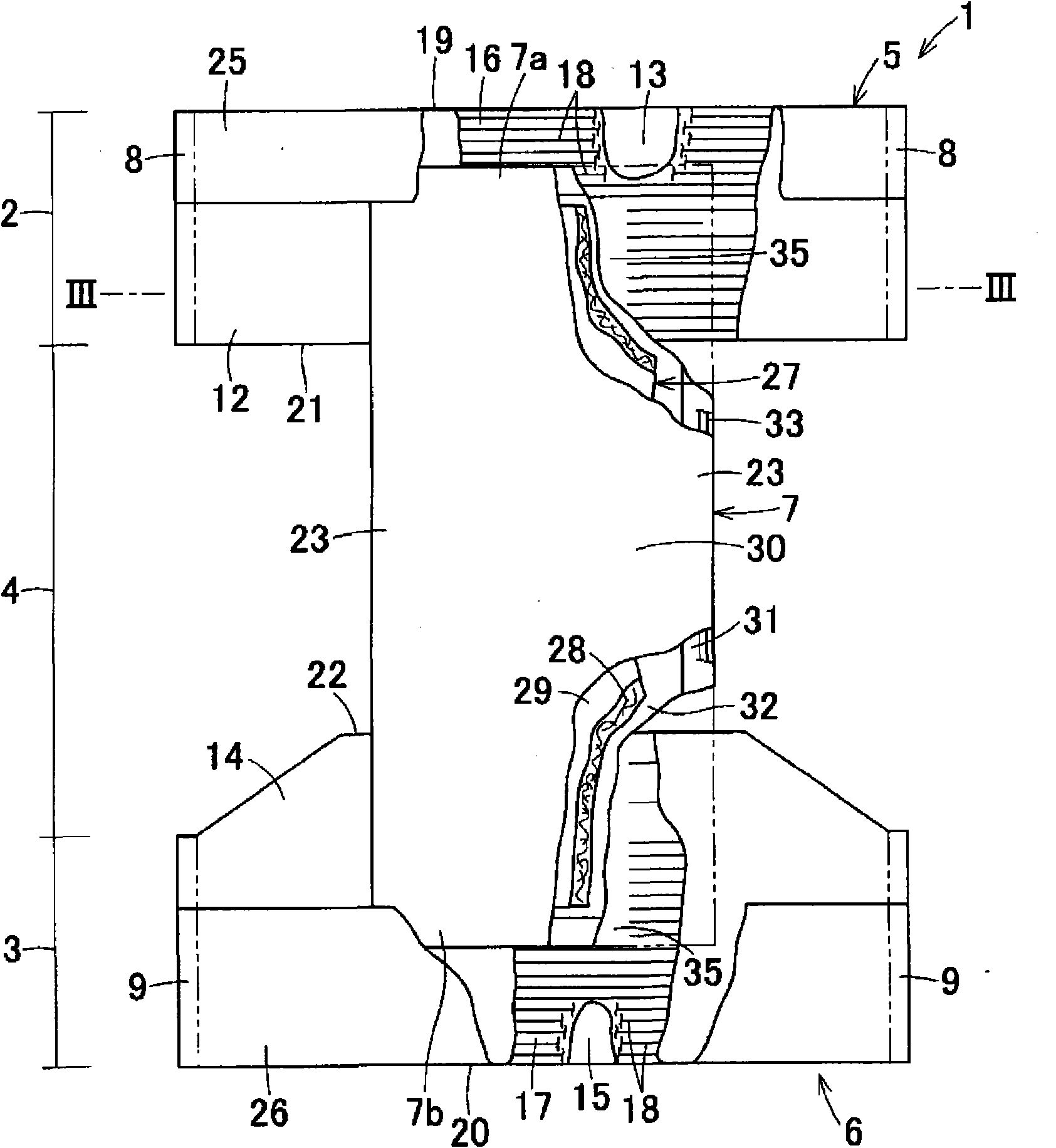

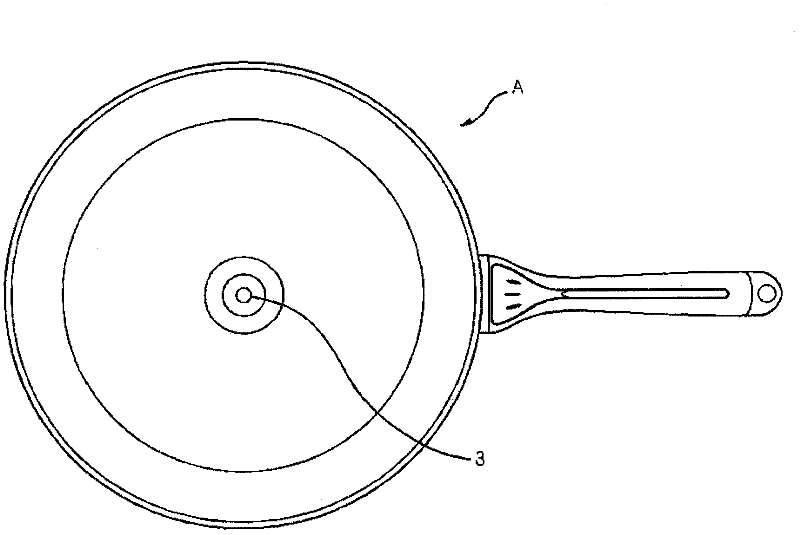

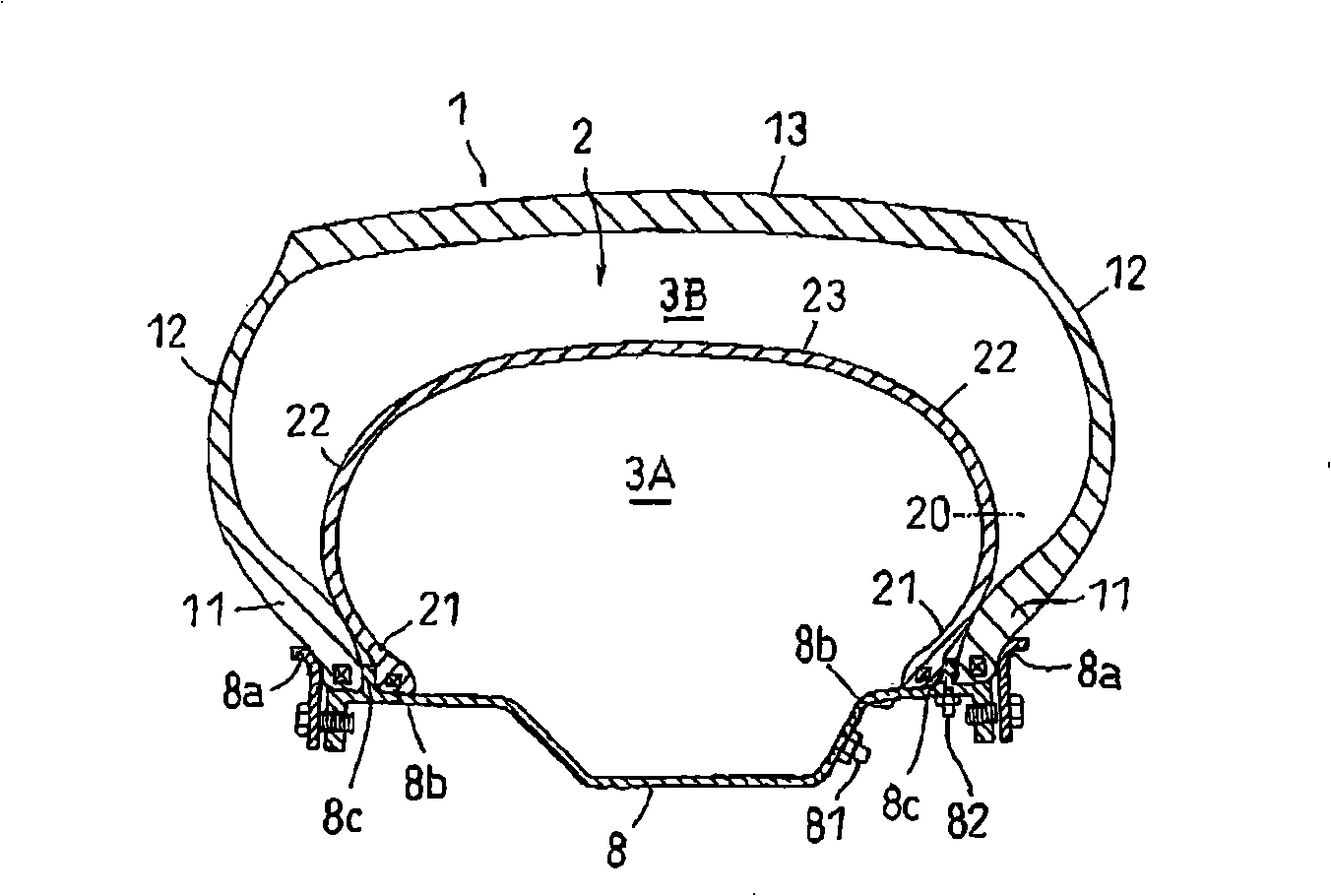

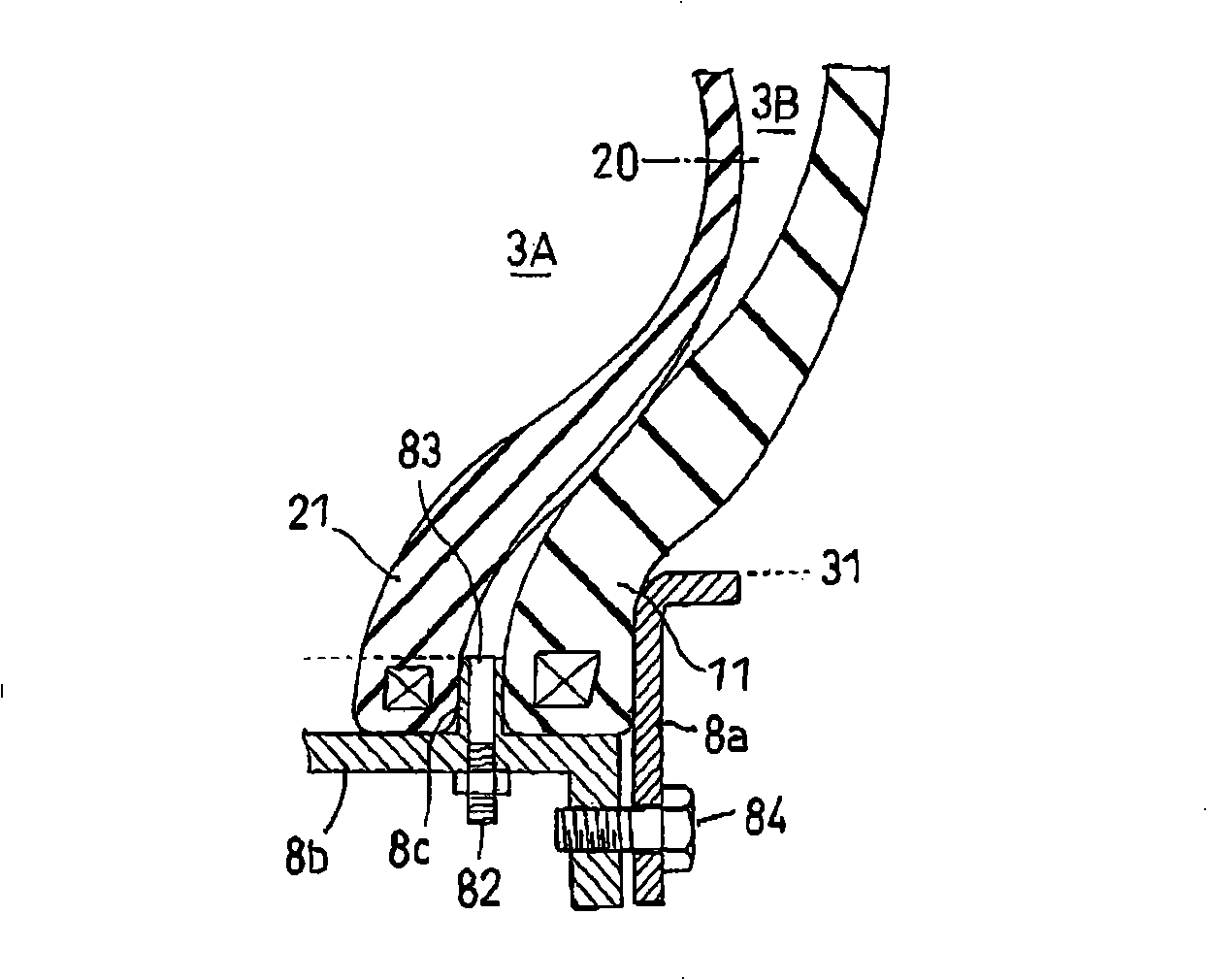

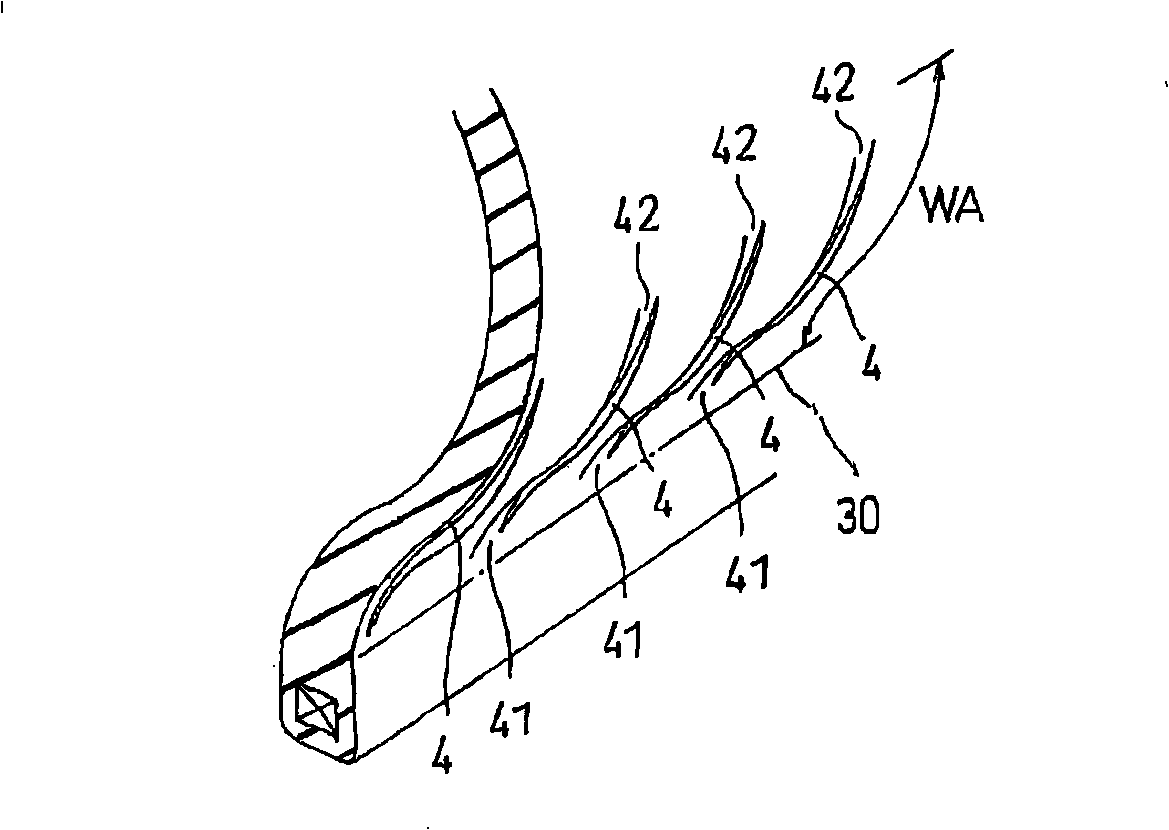

Garment with crotch part

This invention relates to a garment with a crotch part used in contact with skin, including: a garment main body including a stretchable crotch cloth piece; and a second crotch cloth piece on which an absorbent article is to be applied and held, provided on the inner side of the crotch cloth piece of the garment main body, wherein the second crotch cloth piece is mounted to the garment main body at its front and rear edges and is mounted to the crotch cloth piece of the garment main body at least in one portion of its center line, and right and left edges of the second crotch cloth piece are not bonded to the garment main body and are in free state. An absorbent article can be held at a determined position on the crotch part of the garment with stability and security. The garment also is excellent in close contact to the pudendal cleft region, is difficult to be steamed in use, and has fine appearance and good wearing comfort after mounting an absorbent article.

Owner:WACOAL

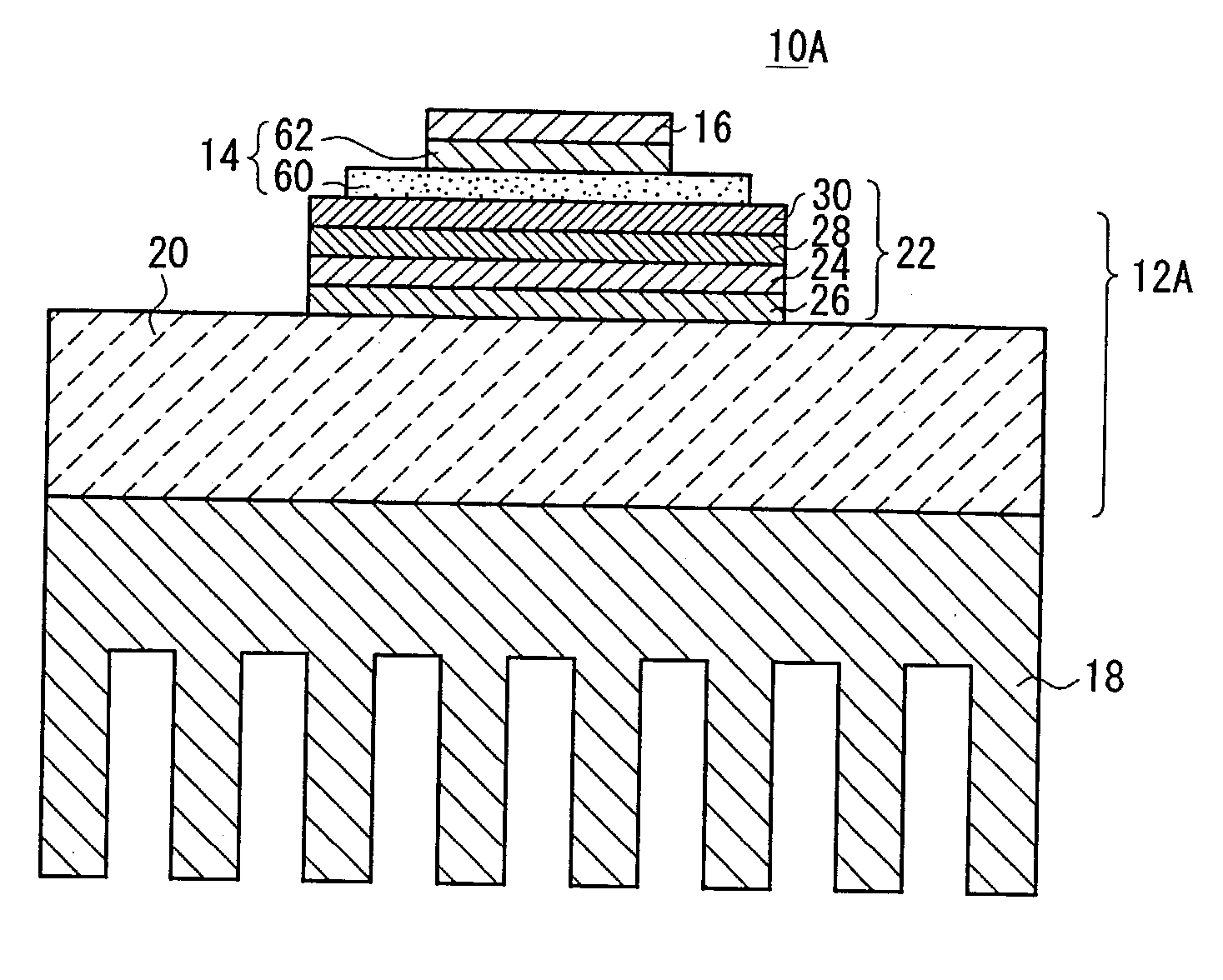

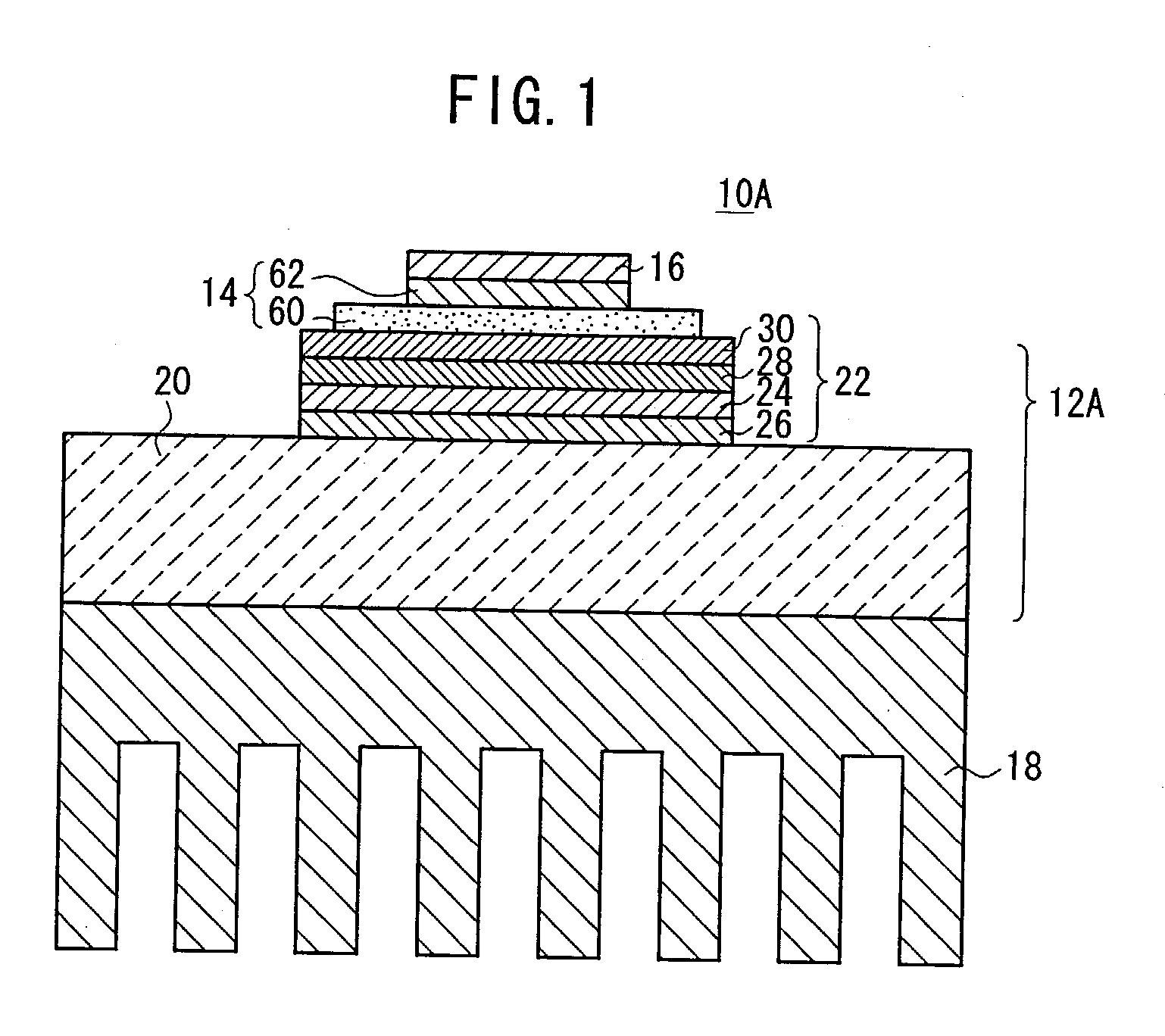

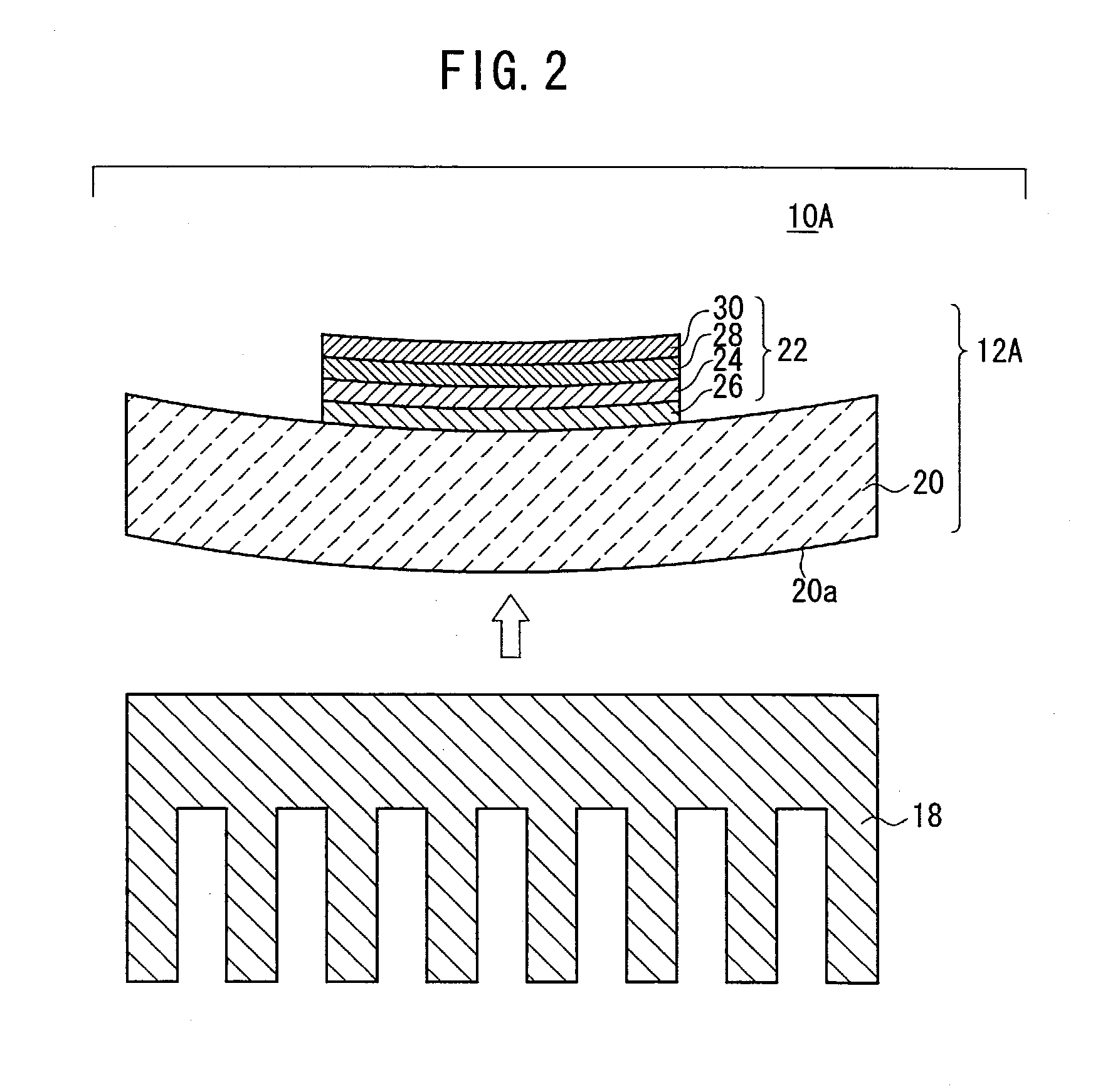

Member for electronic circuit, method for manufacturing the member, and electronic part

InactiveUS20030102553A1Reduce manufacturing stepsReduce manufacturing costInsulating substrate metal adhesion improvementSemiconductor/solid-state device detailsJoint componentEngineering

A member (12A) for use in an electronic circuit has a thermally conductive layer (22) mounted on a heat sink (20). The thermally conductive layer (22) comprises an insulating substrate (24), a first joint member (26) joining the insulating substrate (24) to the heat sink (20) and containing an active element, a second joint member (28) disposed on the insulating substrate (24), and an electrode (30) disposed on the second joint member (28). The insulating substrate (24) comprises an AlN layer or an Si3N4 layer. Each of the first and second joint members (26, 28) is made of a hard brazing material containing an active element. The heat sink (20) is made of an SiC / Cu composite material or a C / Cu composite material.

Owner:NGK INSULATORS LTD

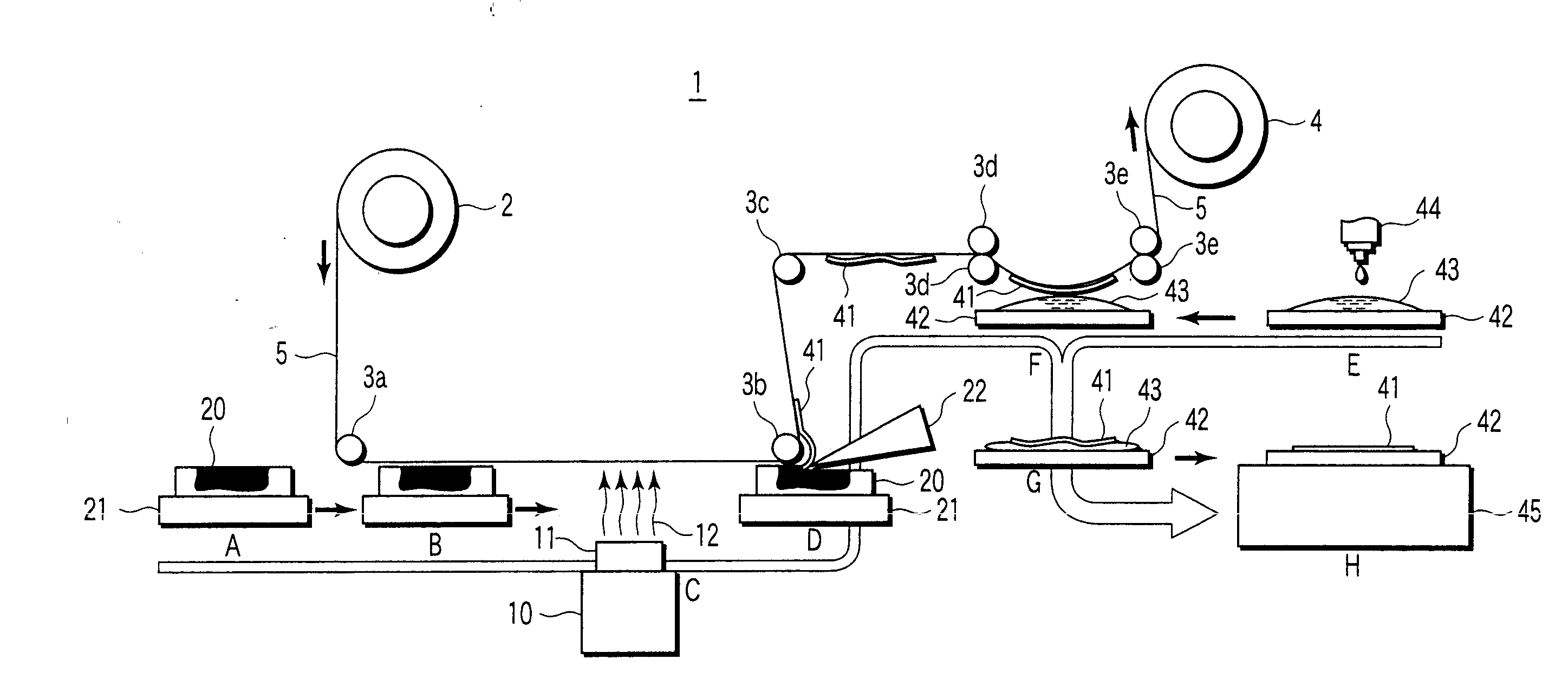

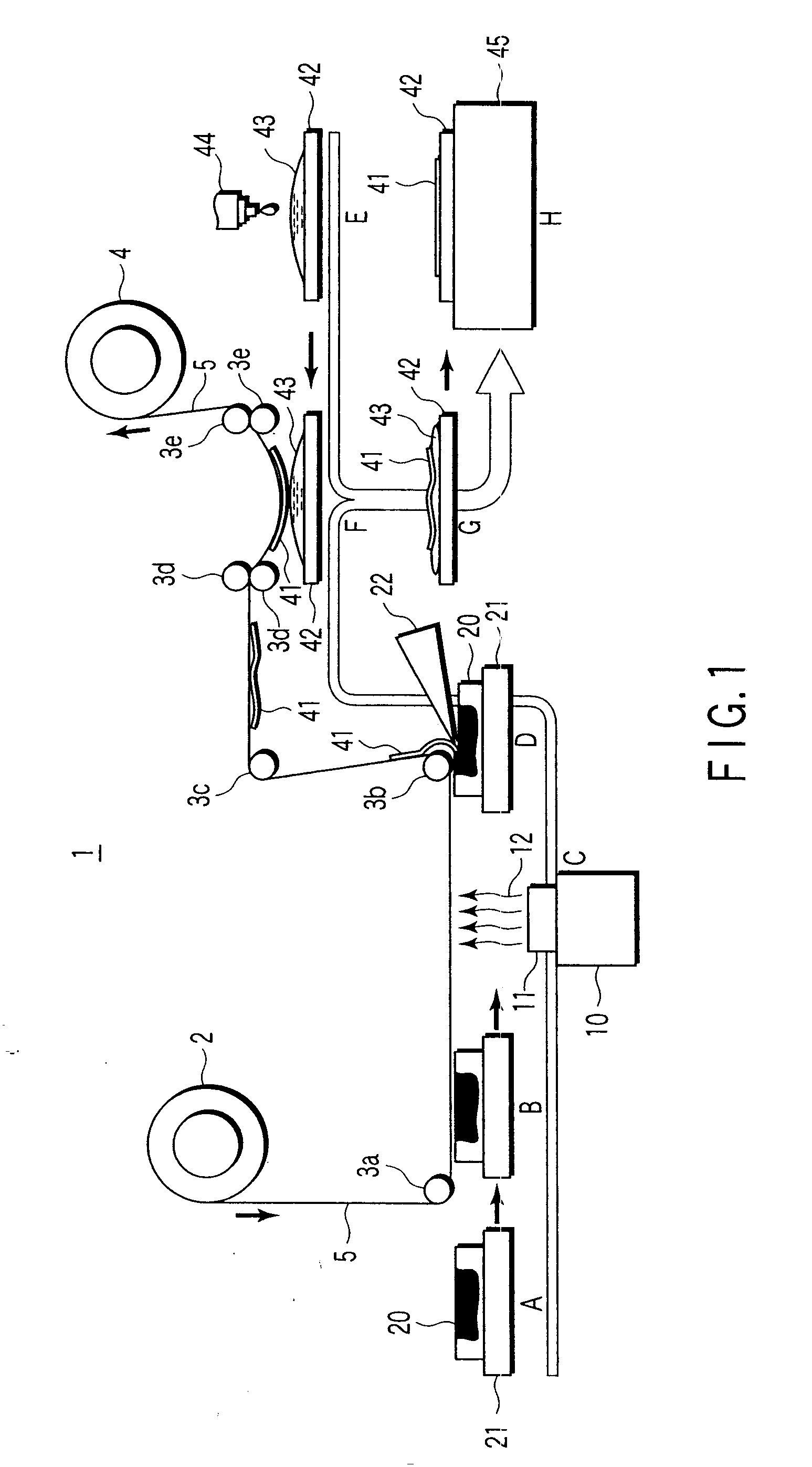

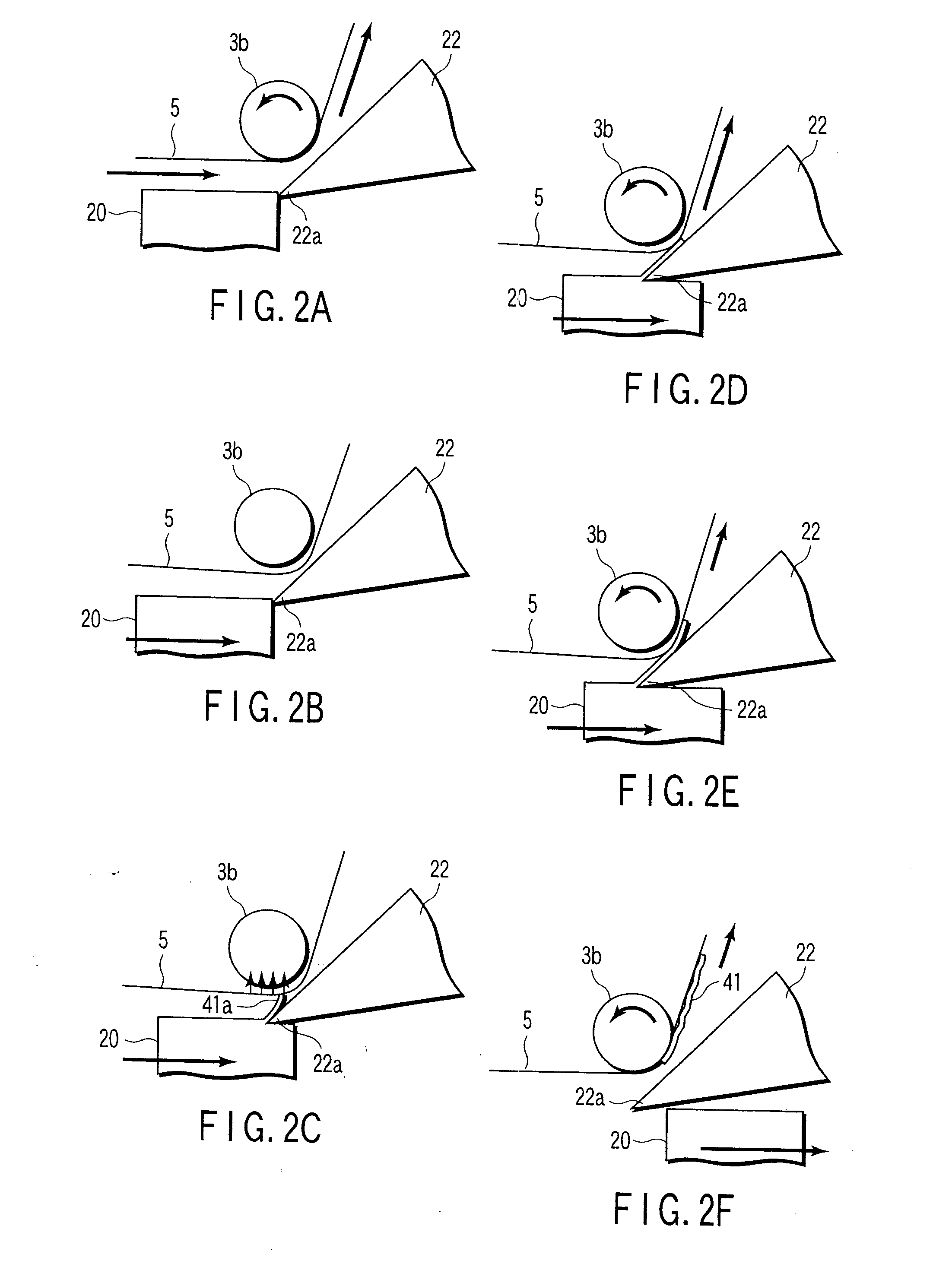

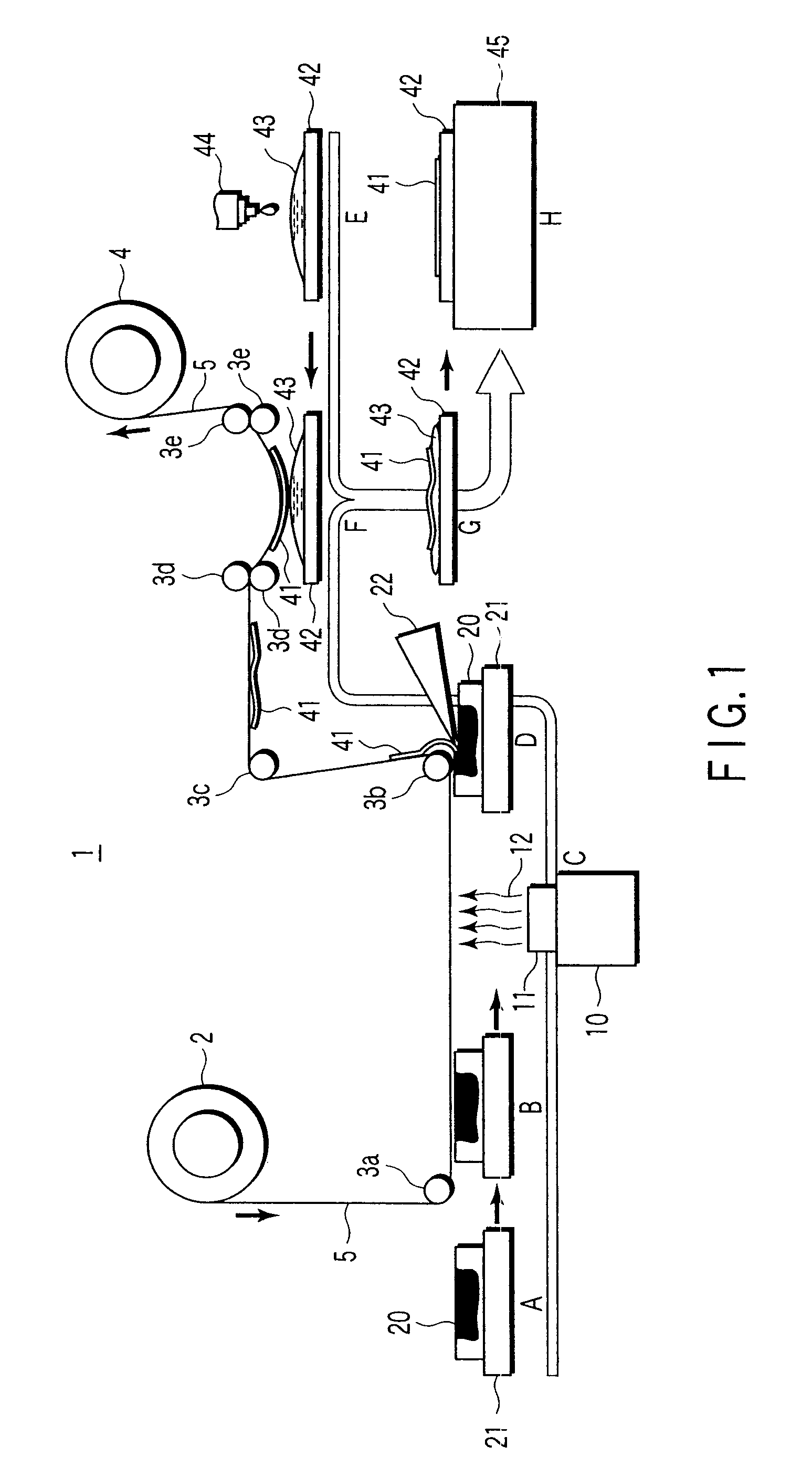

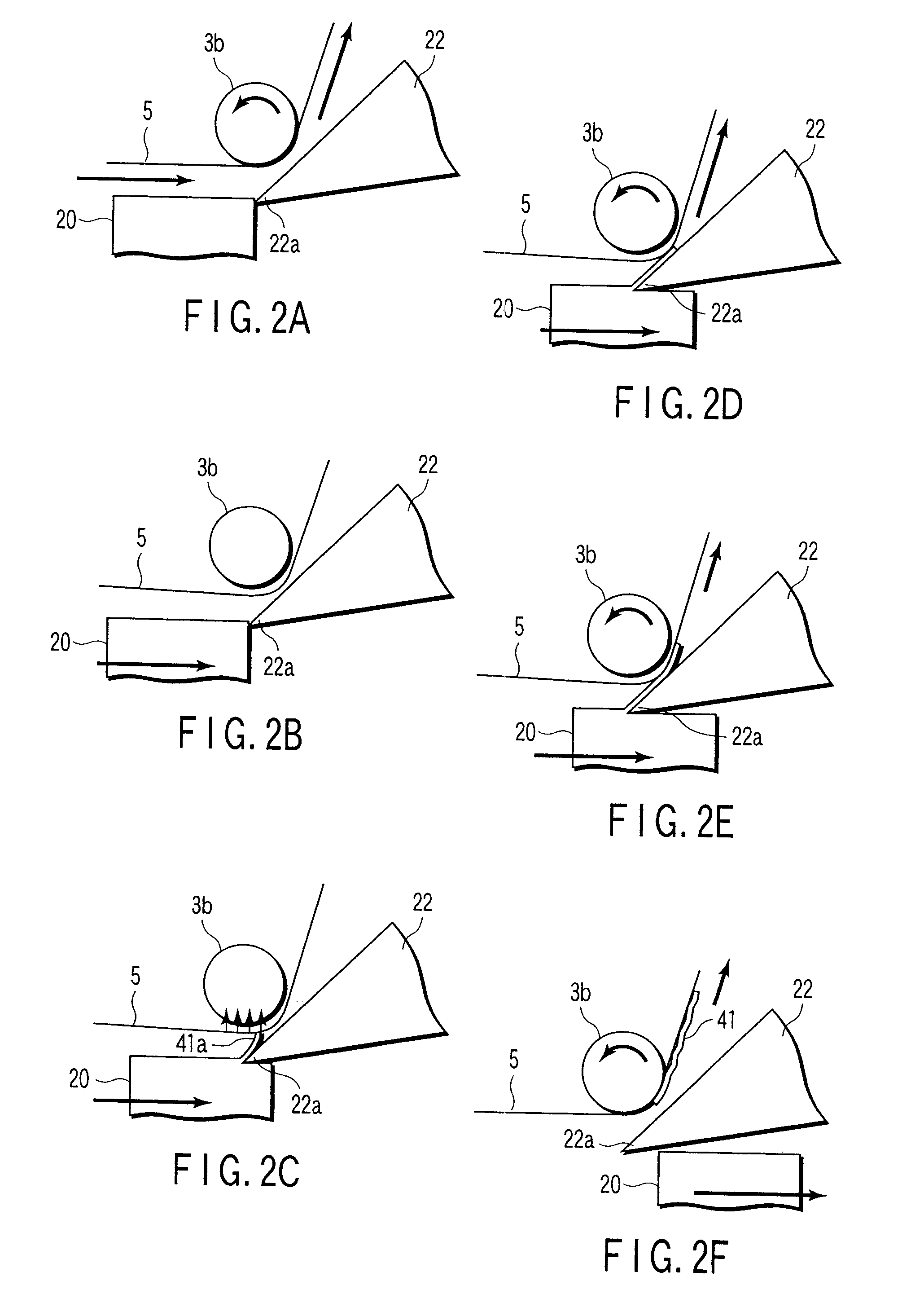

Sample slice preparation device and sample slice preparation method

ActiveUS20070039435A1Improve handlingReduce dependenceWithdrawing sample devicesSurgeryApplied waterSlice preparation

A sample slice preparation device of the present invention has a microtome which slices a solid specimen by a knife, a humidifier which imparts moisture to a carrier tape, slice conveyer means for adsorbing a slice by an adsorbing force of moisture imparted to the carrier tape to feed out the slice, transfer mechanism for applying water to the surface of a slide glass to transfer the slice from the carrier tape onto the slide glass by an adsorbing force of applied water, an extension unit which heats the slide glass having the slice adsorbed thereon to evaporate the moisture, thereby extending the slice, and slide glass conveyer means for conveying the slide glass provided with the slice.

Owner:TOSHIBA MASCH CO LTD

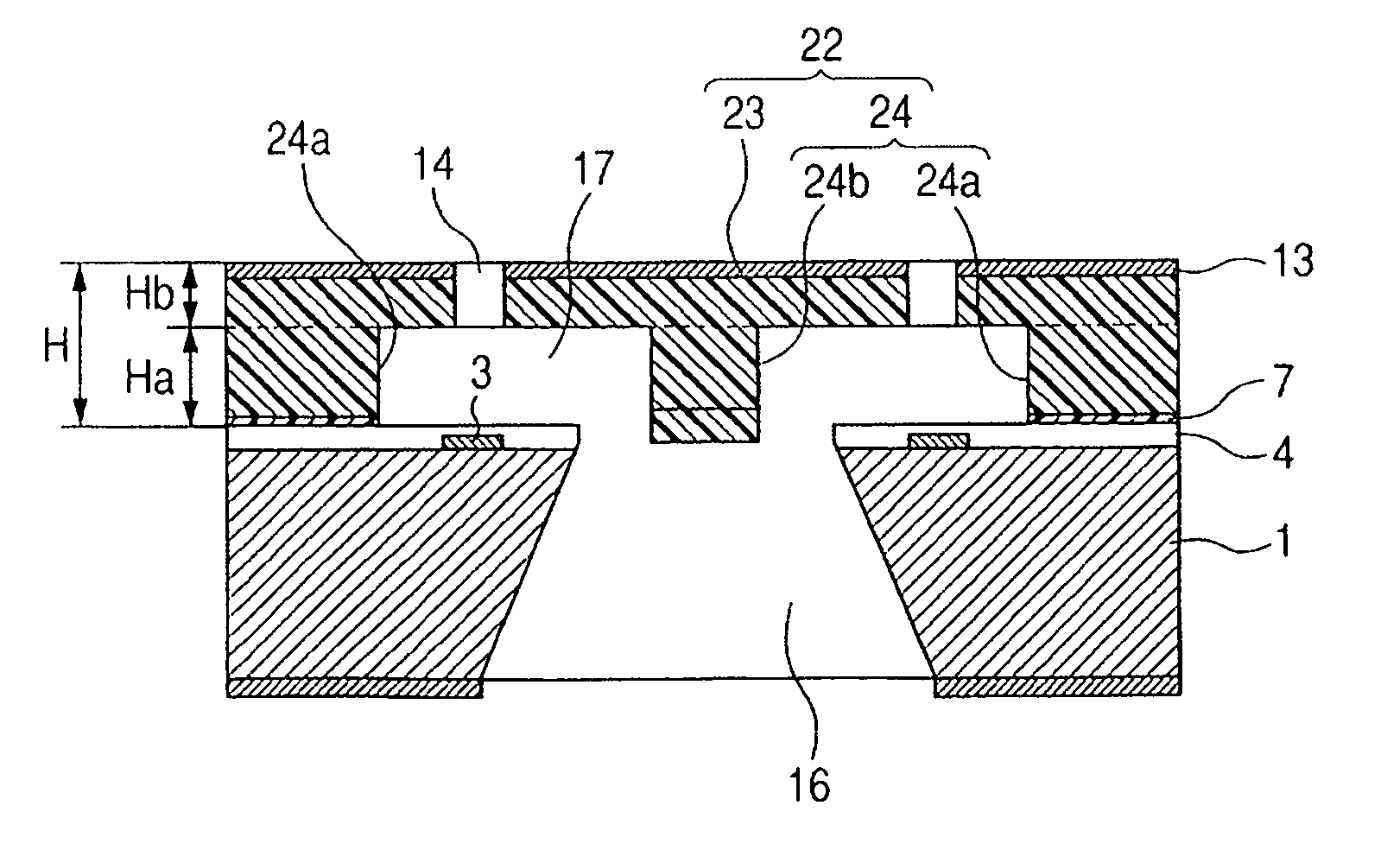

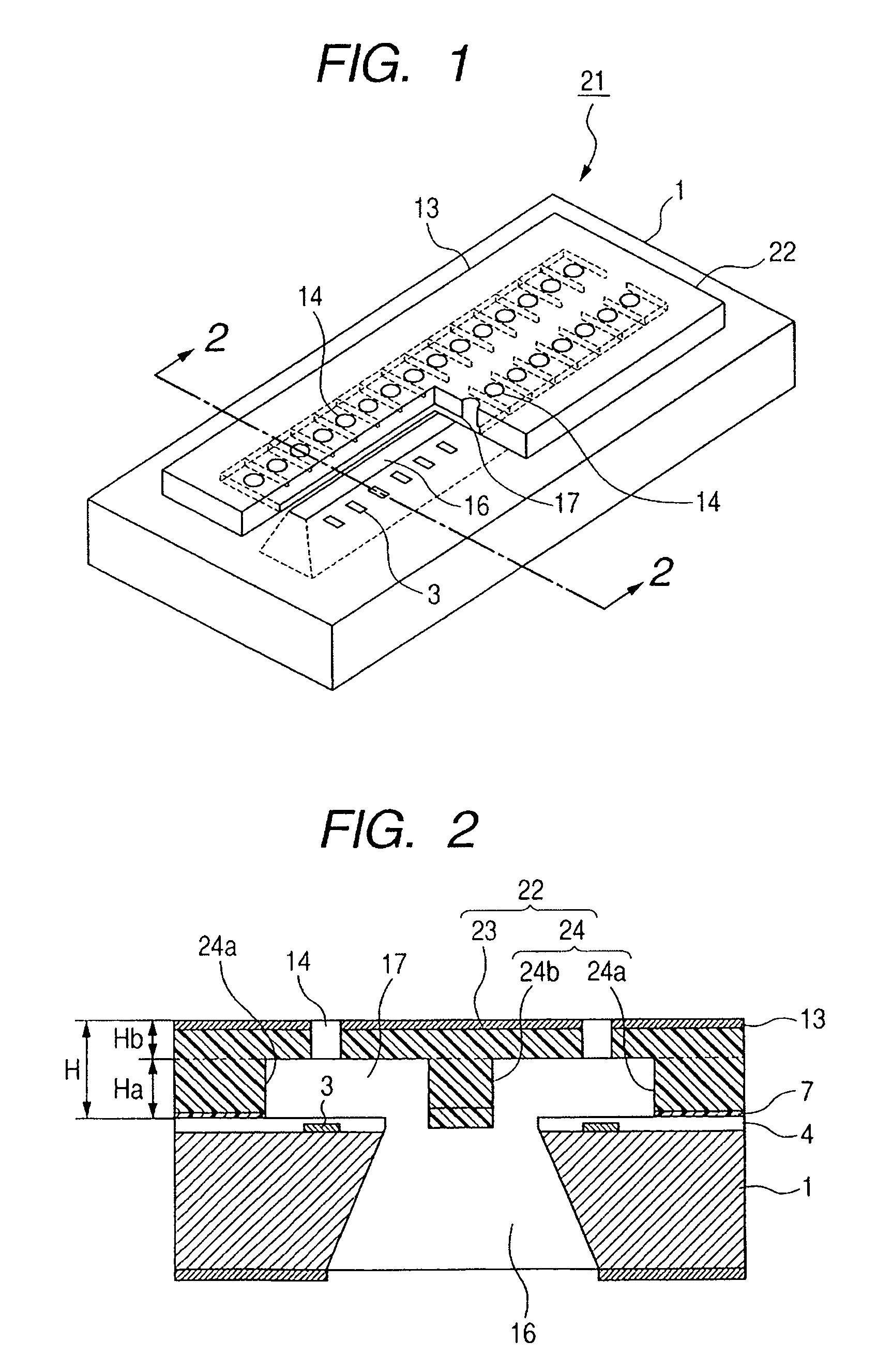

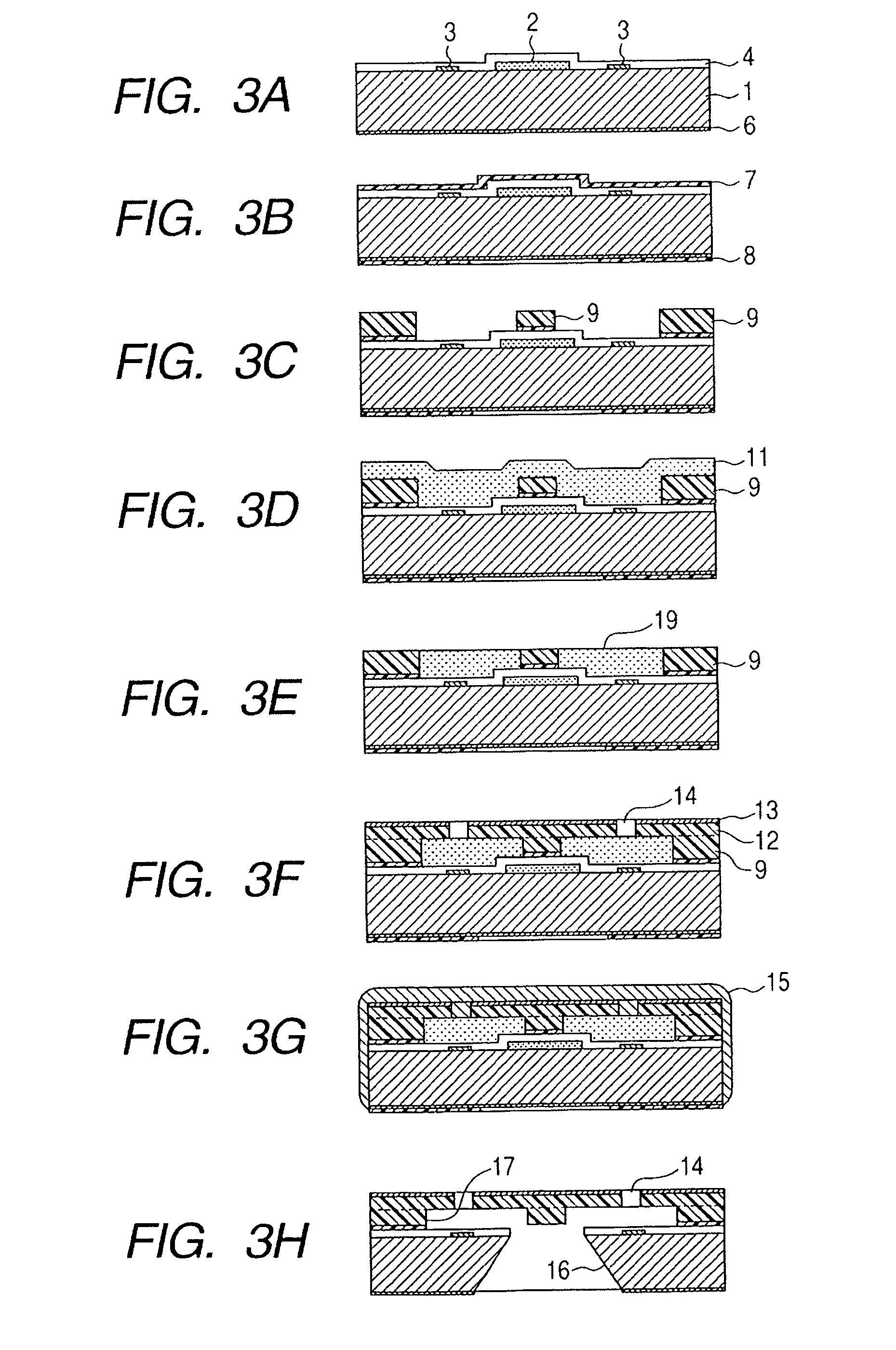

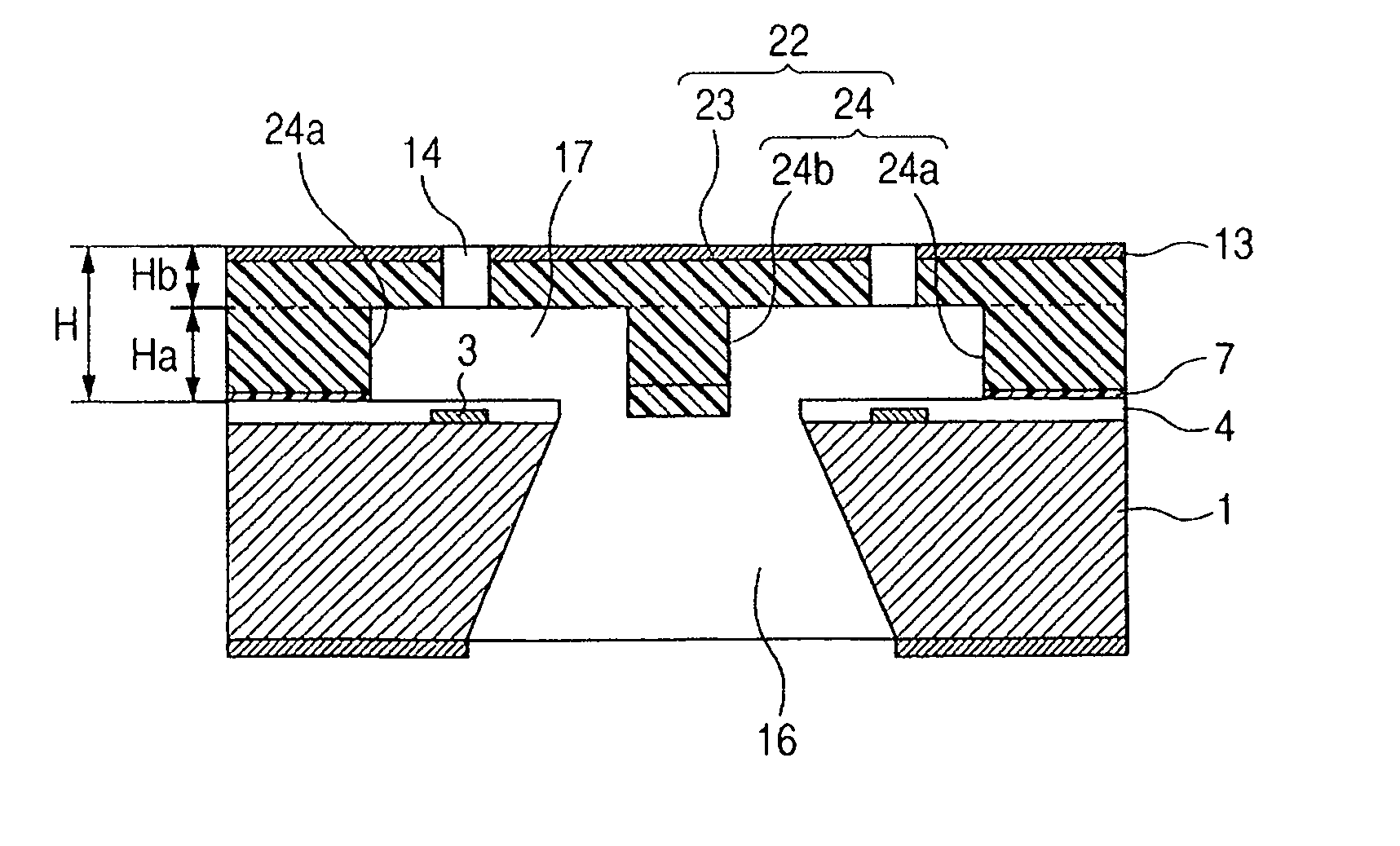

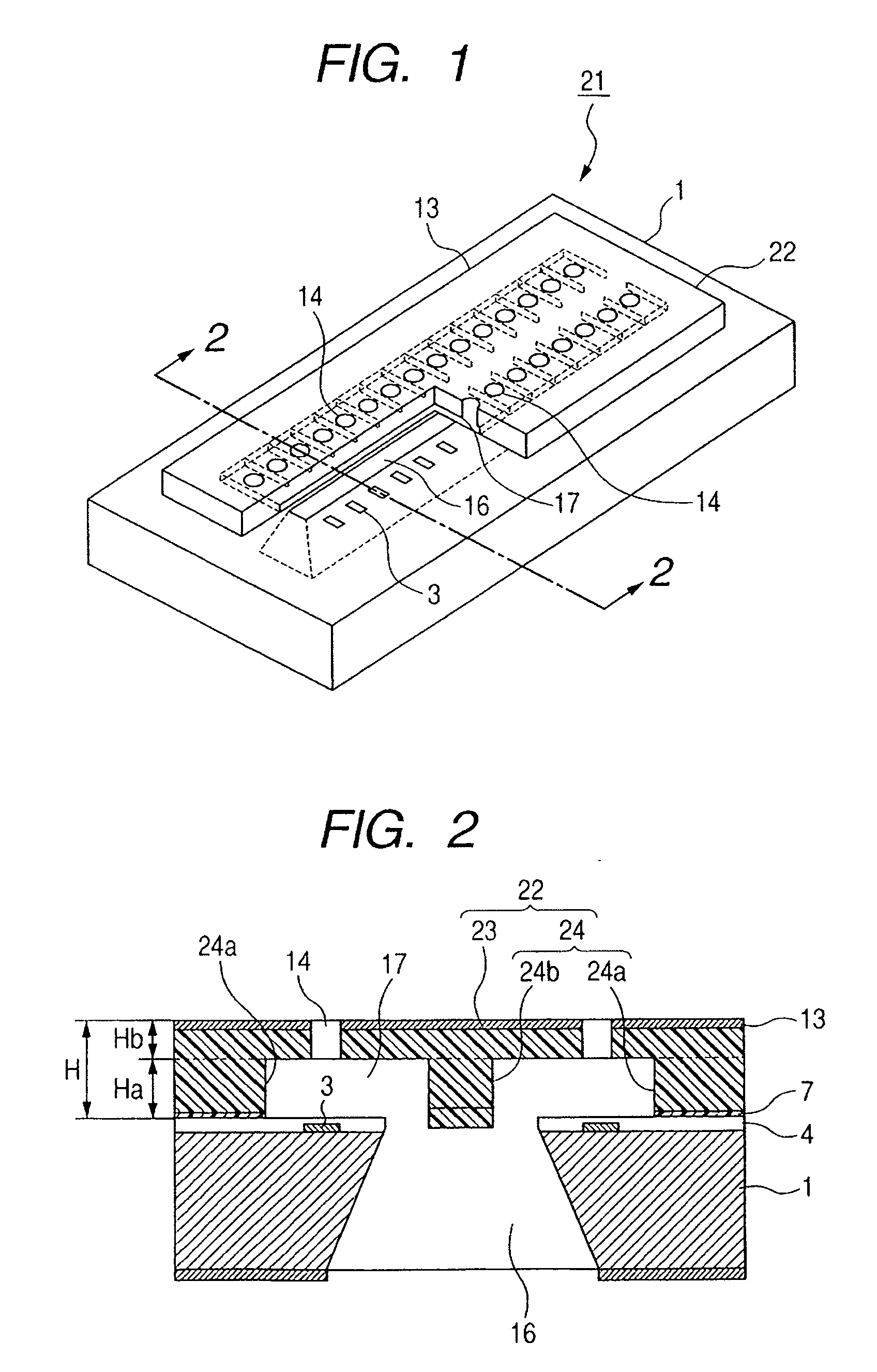

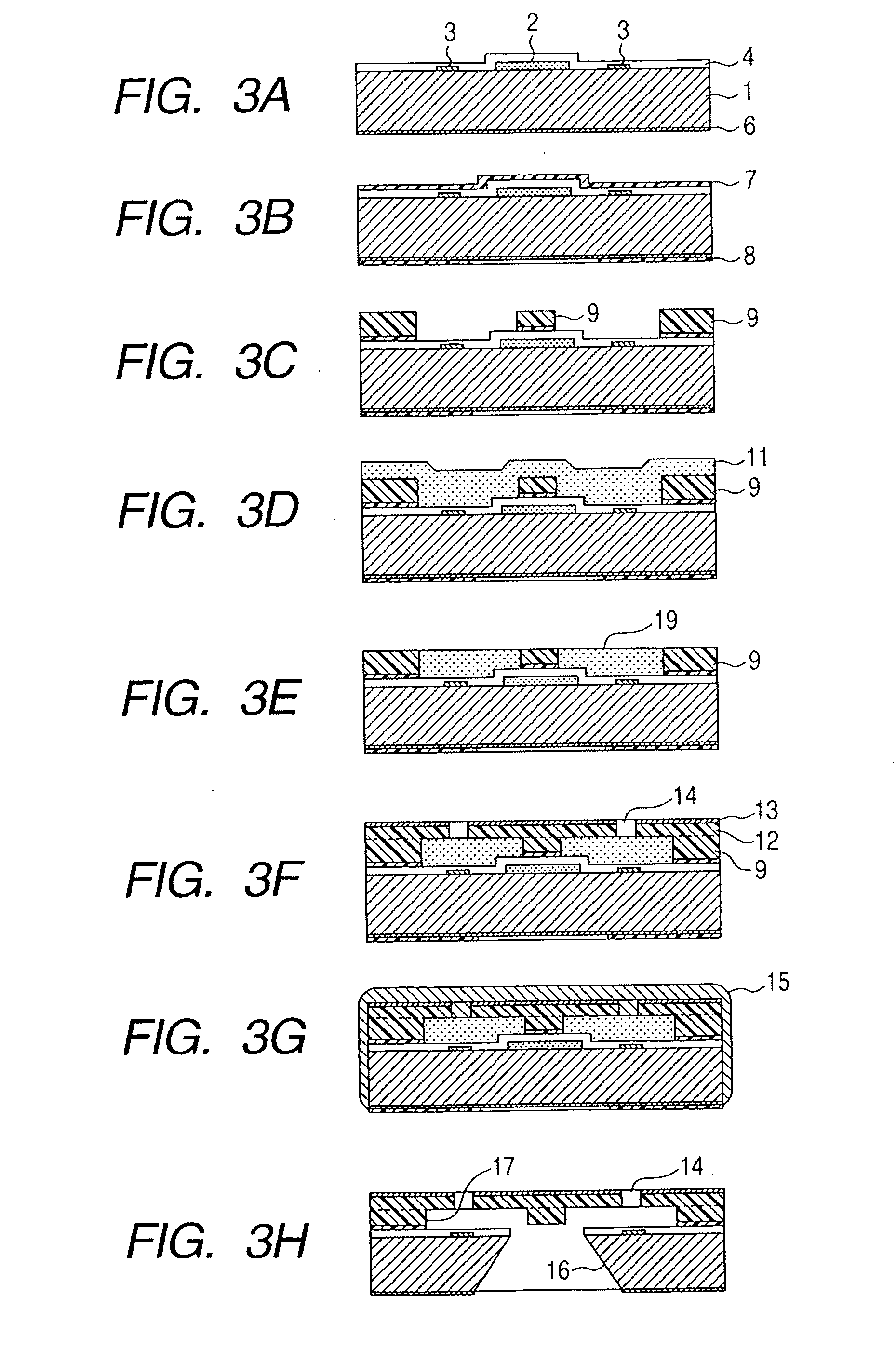

Method of manufacturing liquid discharge head

InactiveUS7300596B2Easy to manufactureImprove reliabilityRecording apparatusDecorative surface effectsVena contracta diameterEngineering

The method of manufacturing a recording head has a flow path wall forming step of forming flow path walls on a substrate having energy generating elements formed thereon, an imbedded material depositing step of depositing an imbedded material between the flow path walls and on a top of each flow path wall, a flattening step of polishing a top of the deposited imbedded material, until the top of the flow path wall is exposed, and a step of forming an orifice plate on the tops of the polished imbedded material and the exposed flow path wall. In the step of forming the flow path walls, patterning of a close contact property improvement layer is simultaneously performed to improve a close contact property between the flow path wall and the substrate.

Owner:CANON KK

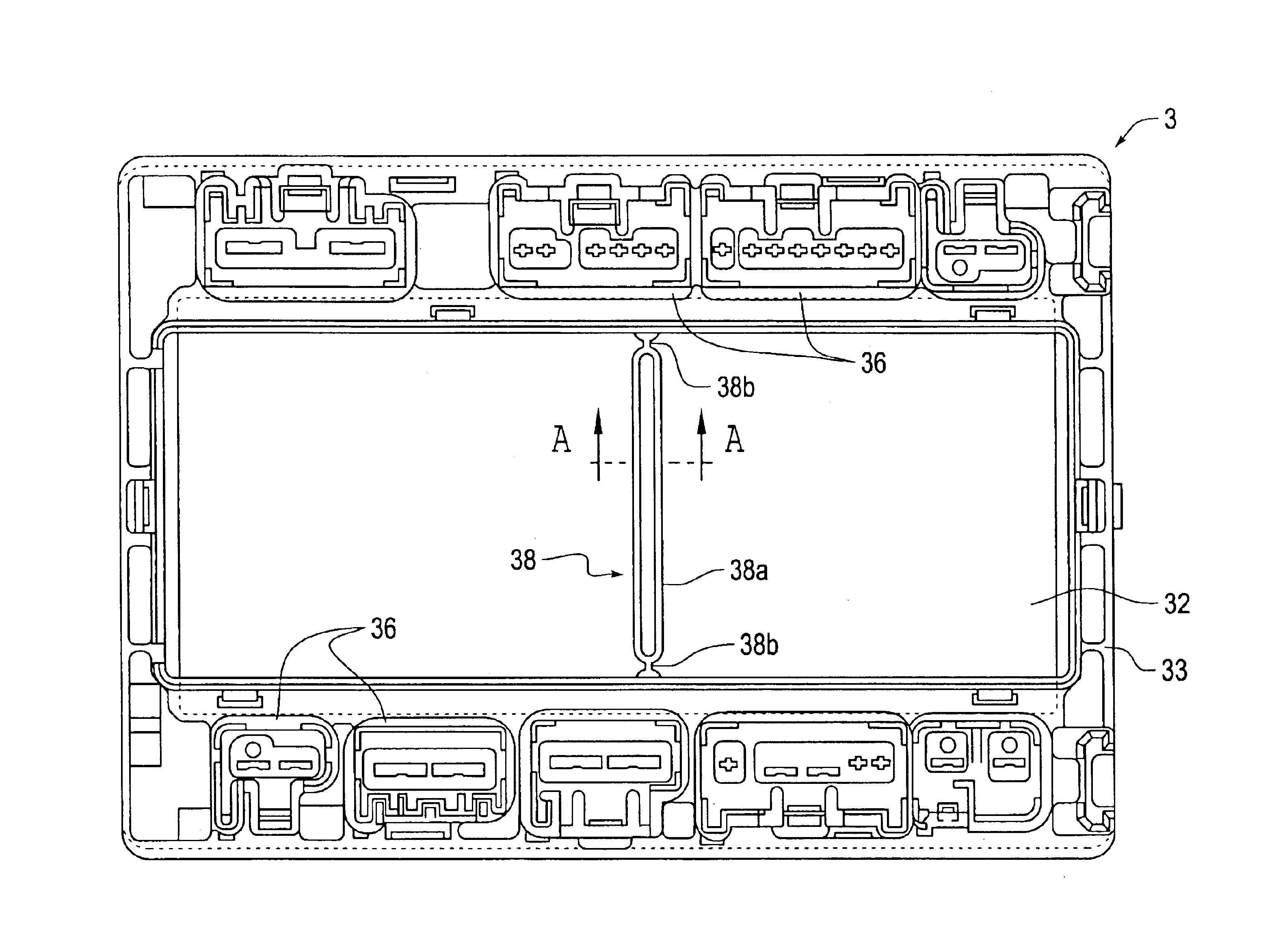

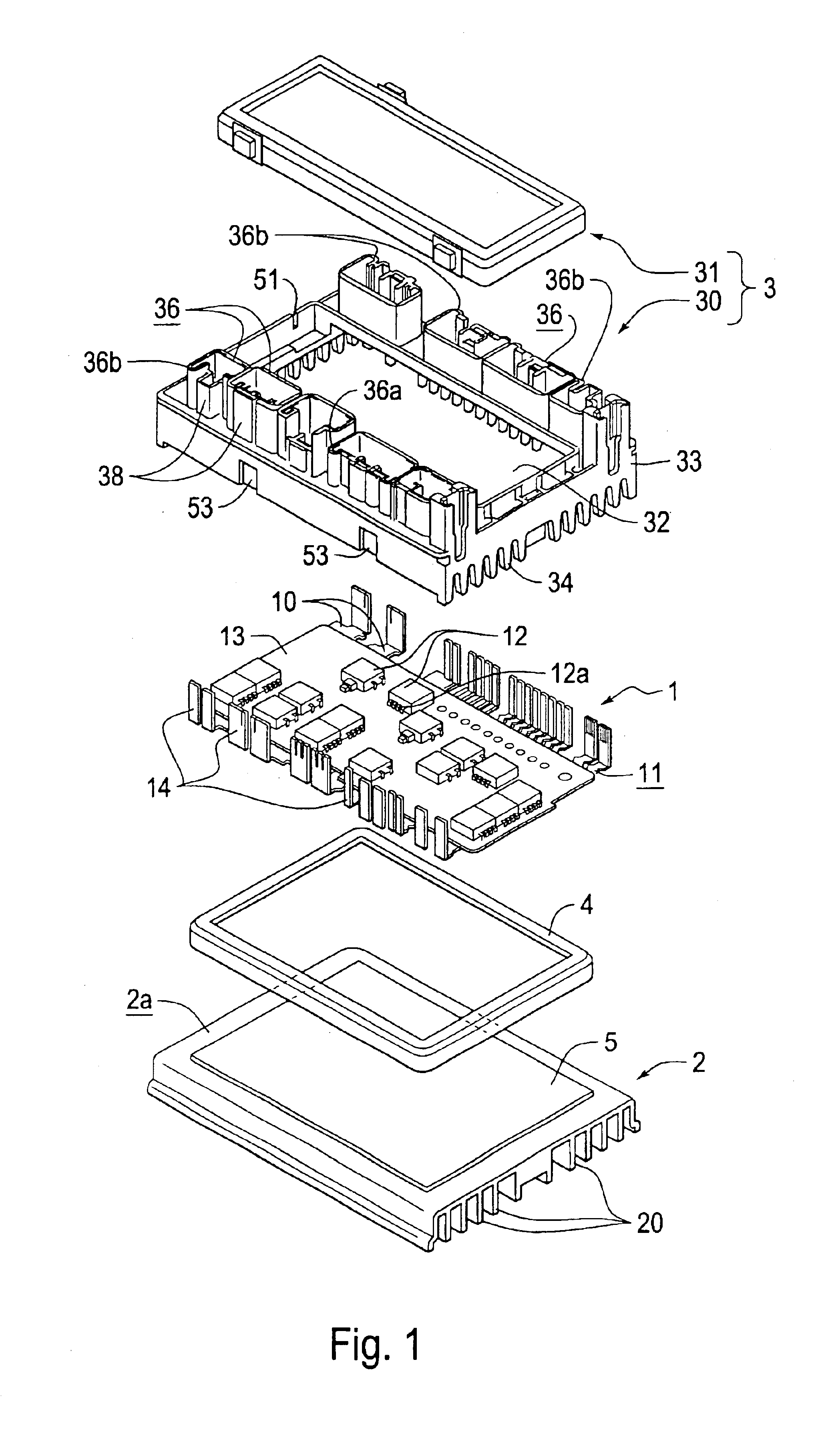

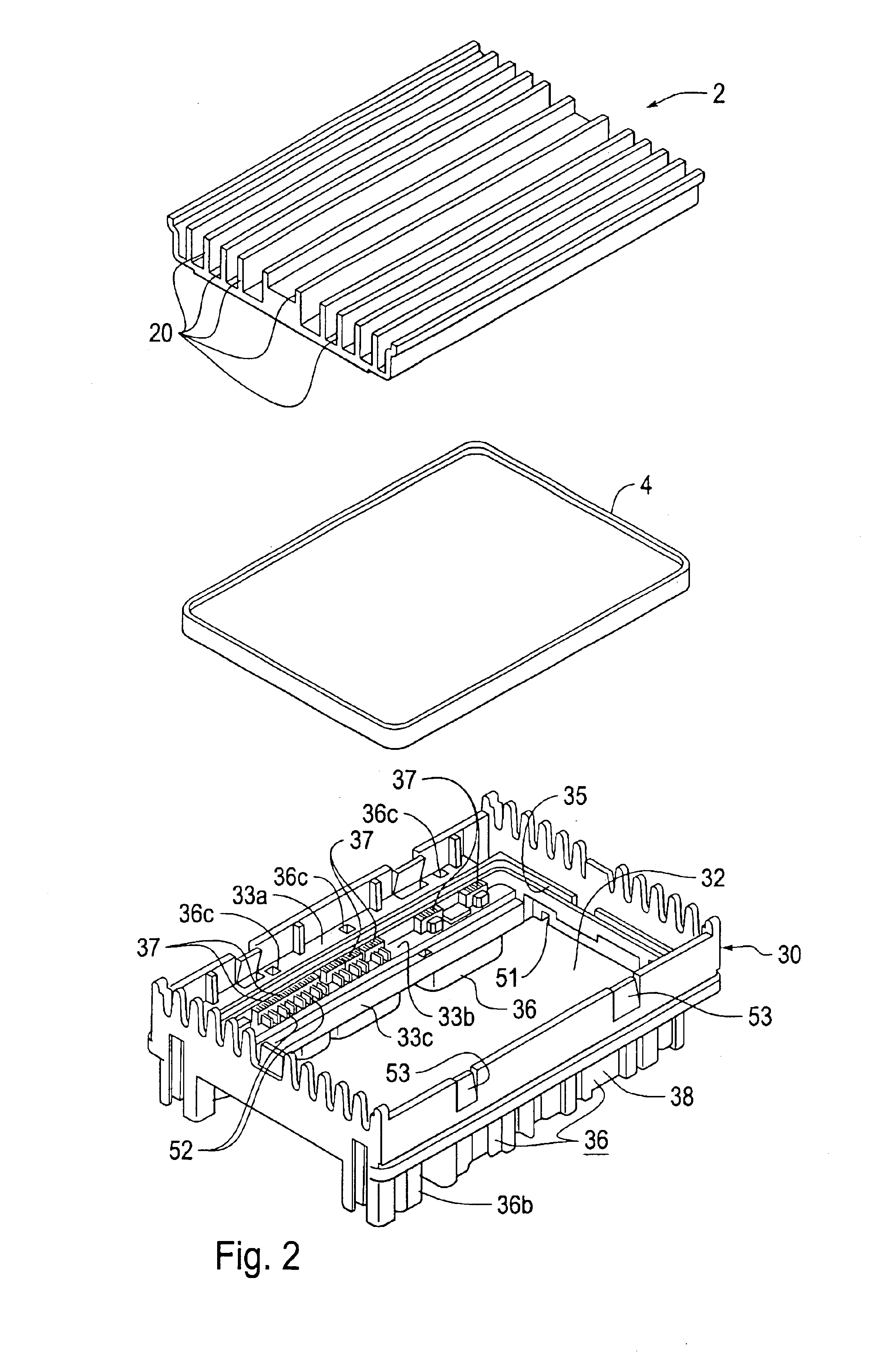

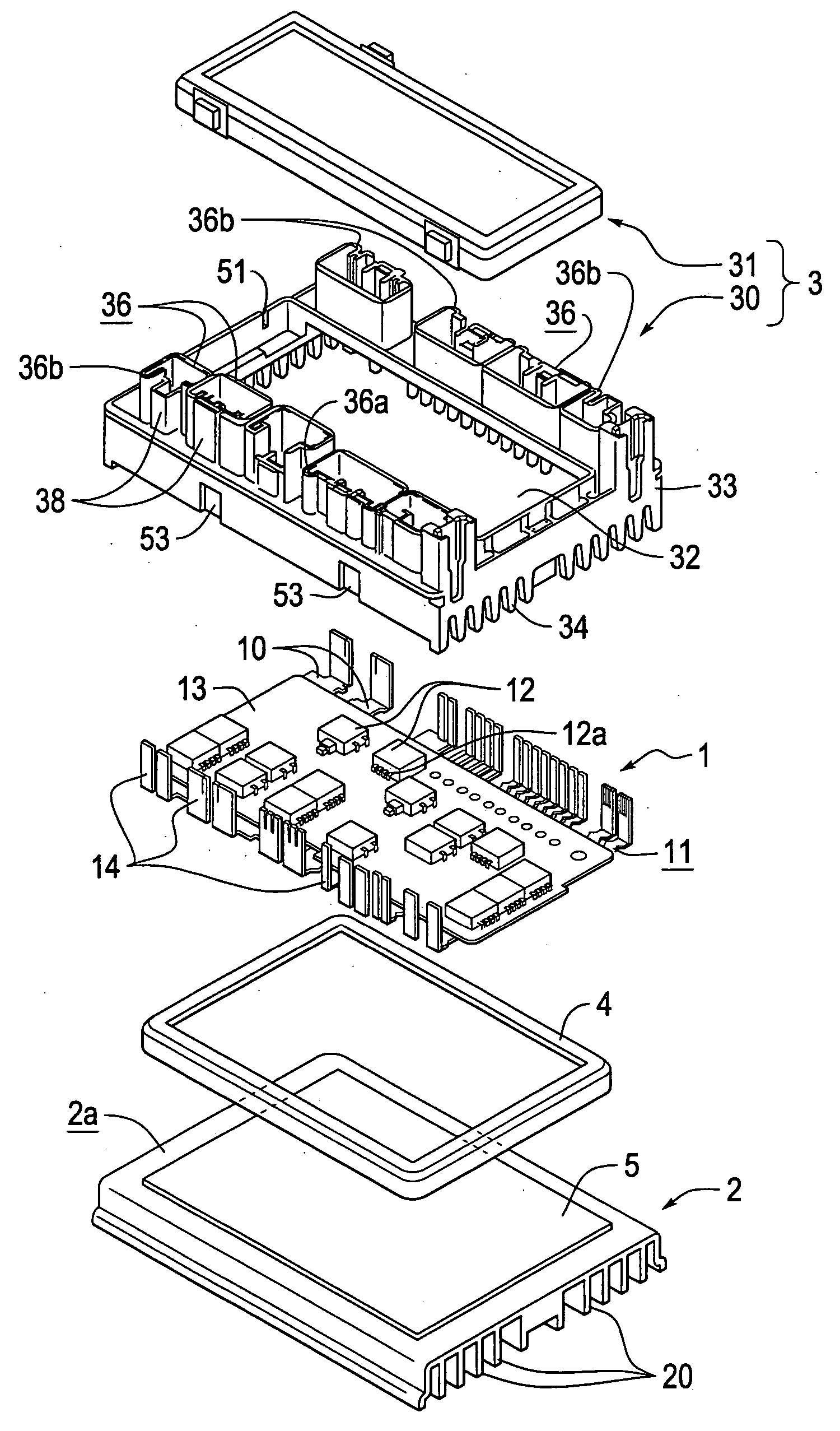

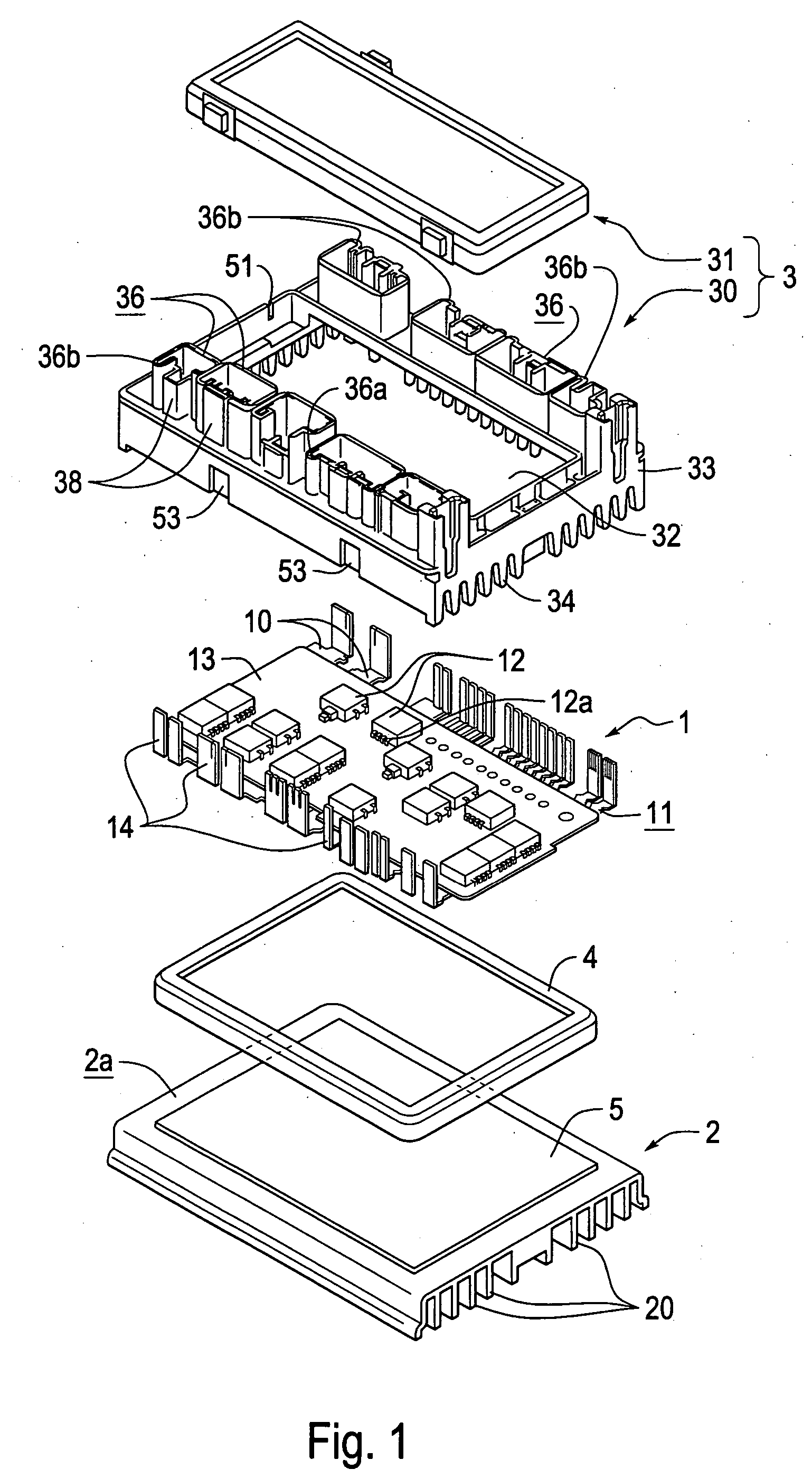

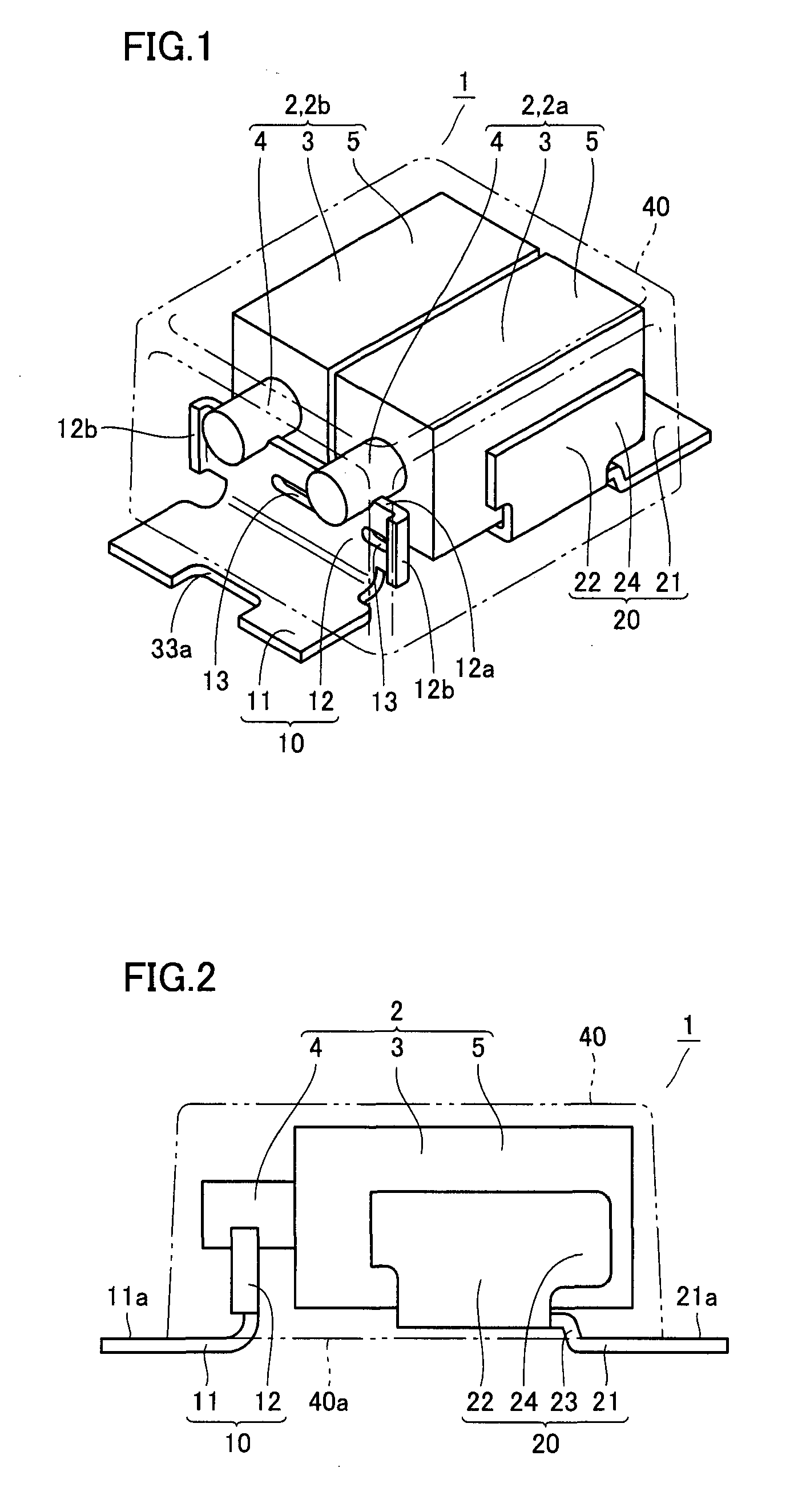

Casing unit for circuit assembly and method for producing the circuit assembly

InactiveUS6911598B2Improve adhesionEasy to checkMachine supportsCasings/cabinets/drawers detailsEngineeringThermal radiation

A power circuit section is adhered to a circuit arrangement surface on a heat radiation member to form a circuit assembly. A casing body is mounted on the heat radiation member. The casing body is provided with an opening that exposes at least the upper portion of the power circuit section. A shape retention member is disposed across the opening for interconnecting a peripheral edge of the opening to each other at a plurality of positions. A casing unit is made of a synthetic resin. The shape retention member suppresses a deformation of the casing body due to a shrinkage cavity. After cooling the casing unit, the shape retention member is removed to define a large opening, if desired.

Owner:SUMITOMO WIRING SYST LTD

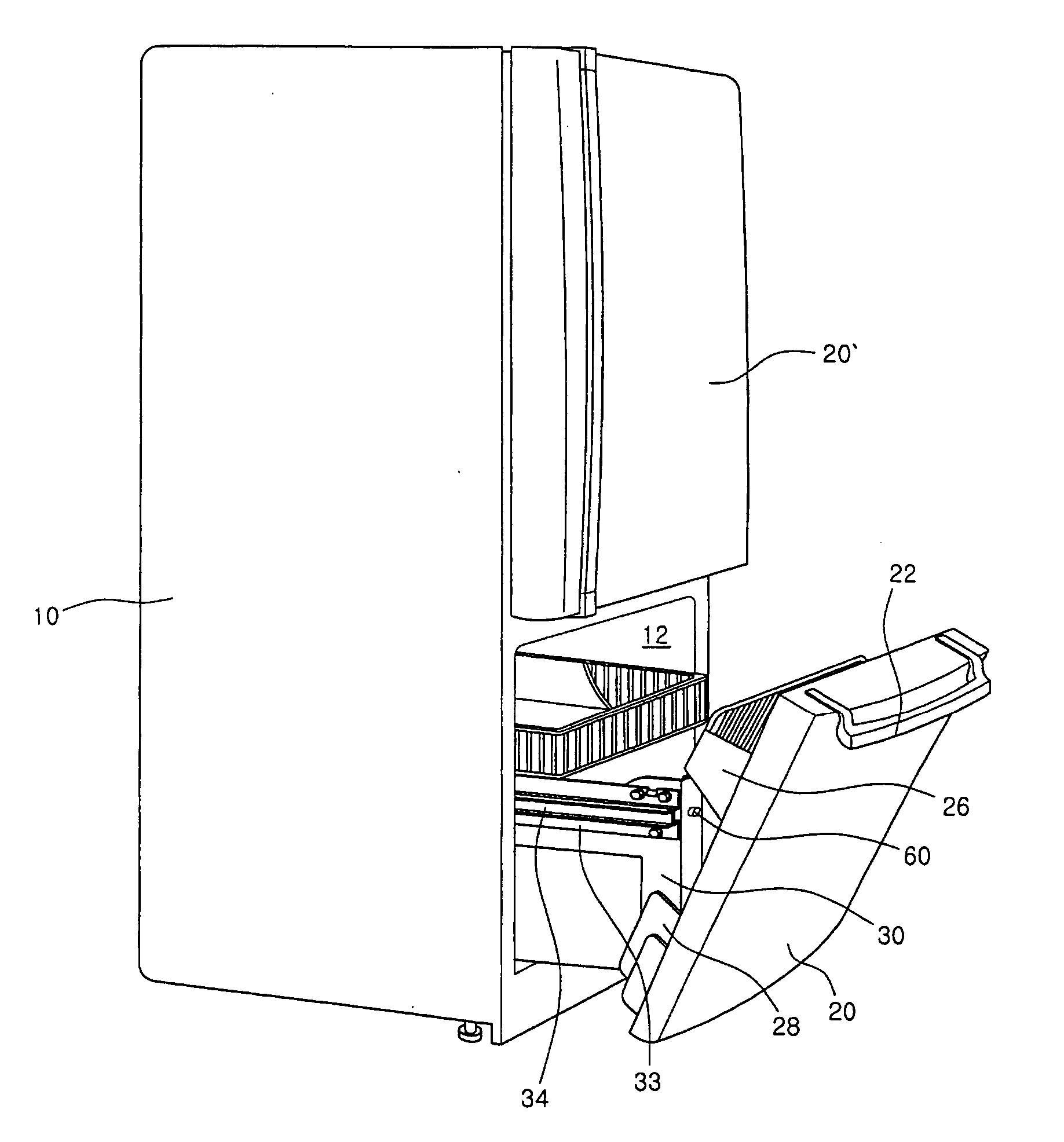

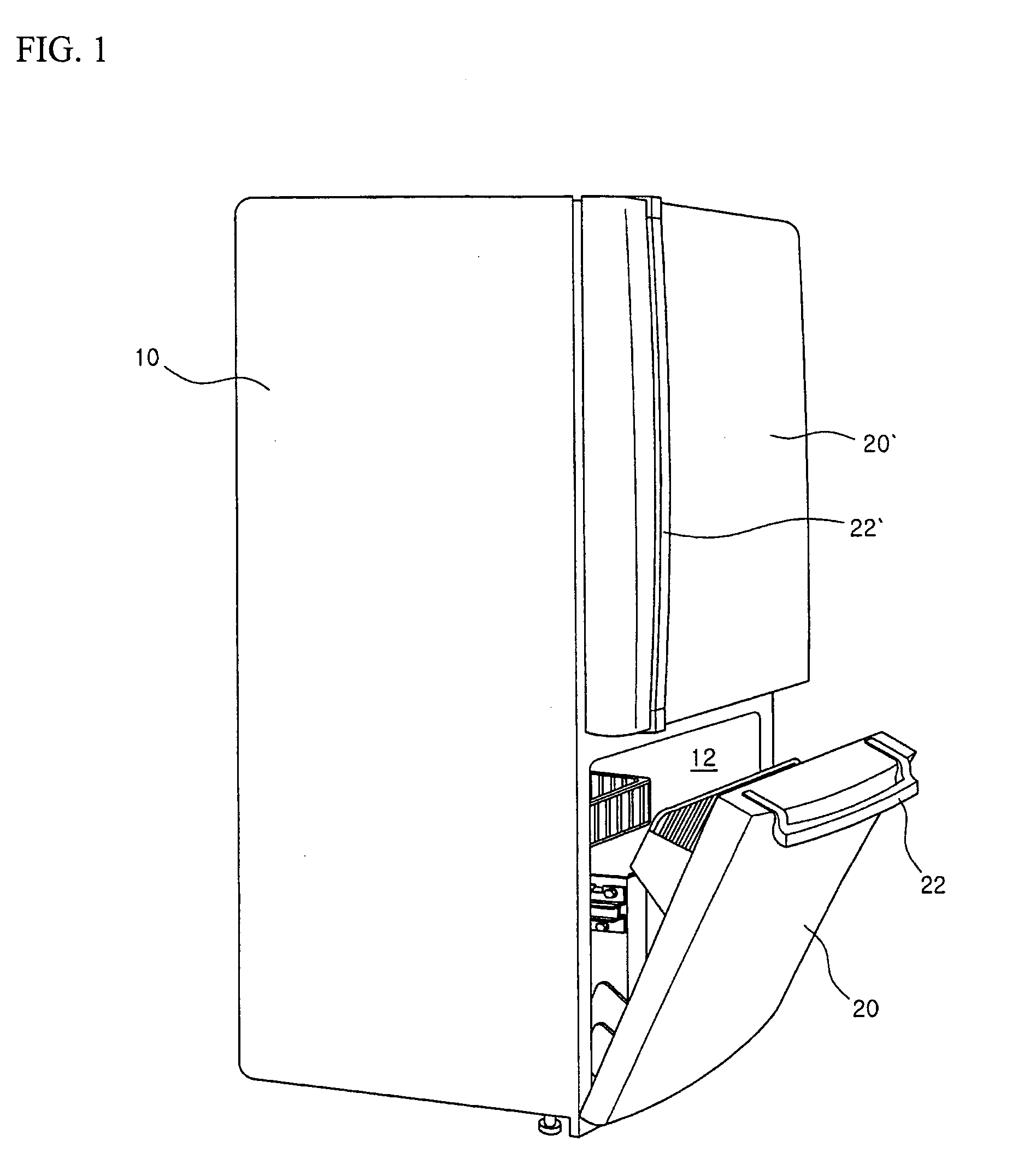

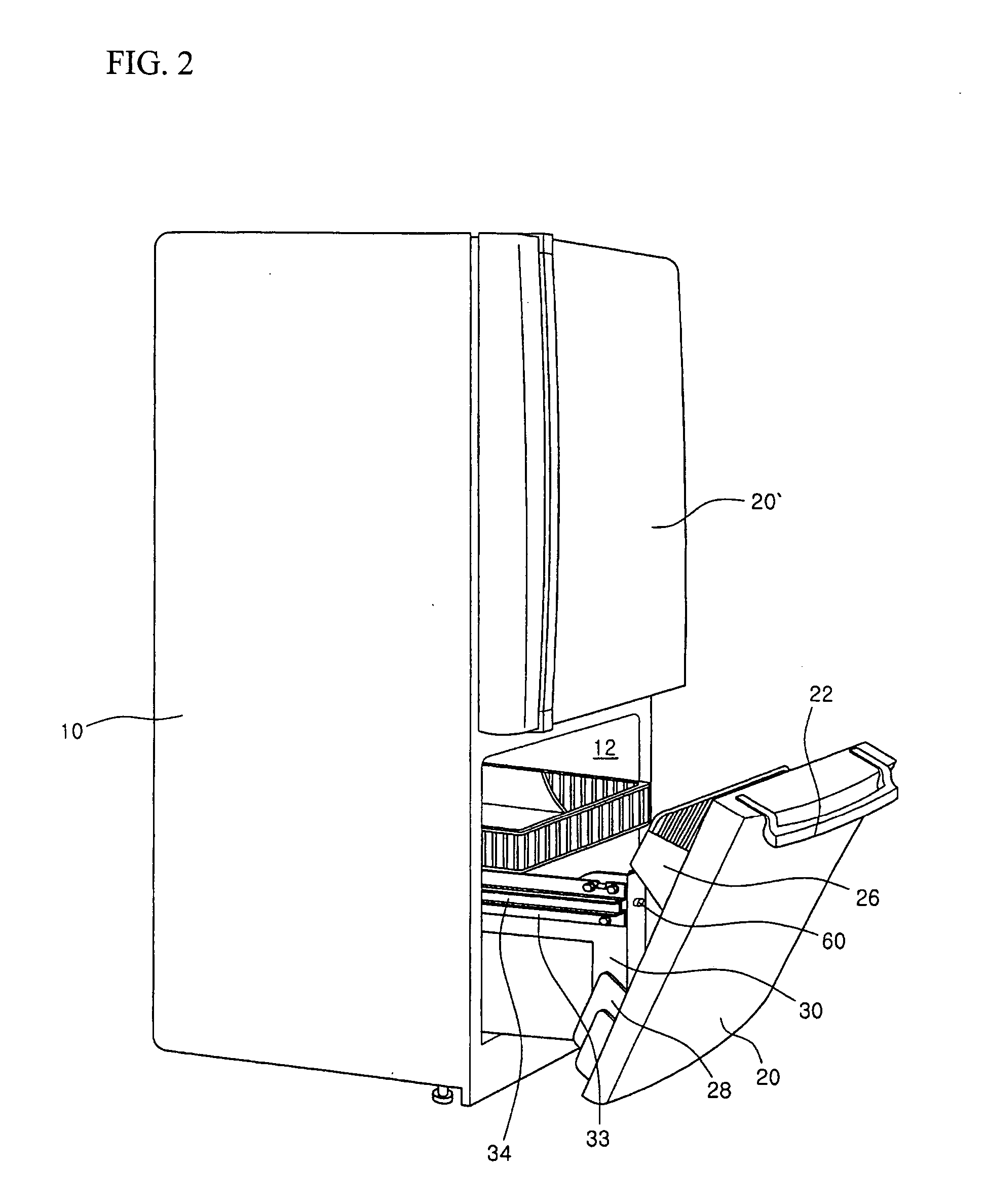

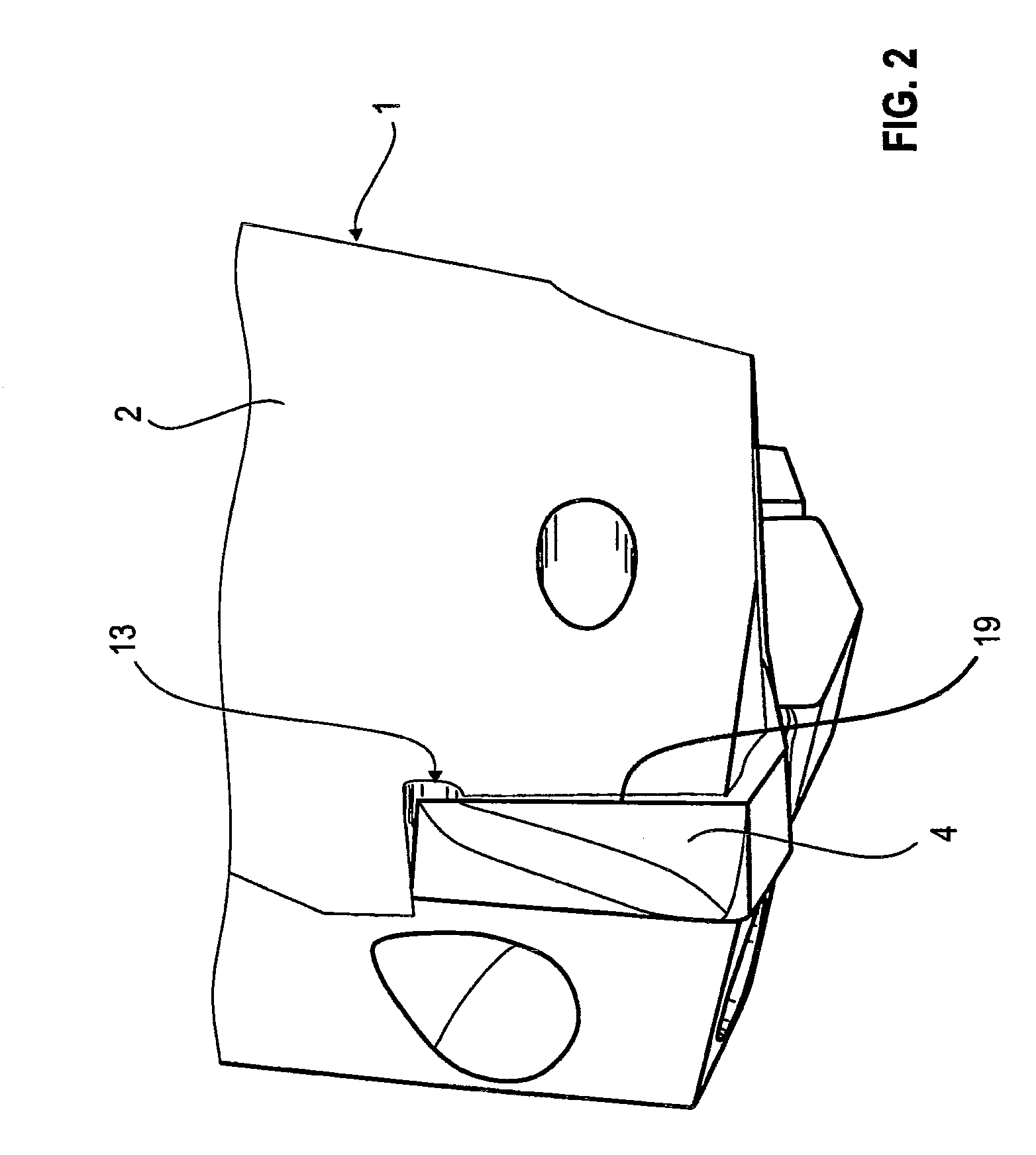

Door apparatus for drawer type refrigerator

ActiveUS20050127804A1Improve close contactTilting operationFurniture partsRefrigeration componentsEngineeringMechanical engineering

Owner:LG ELECTRONICS INC

Vacuum evaporation system capable of controlling evaporating airflow distribution and components

ActiveCN102011096AImprove cleanlinessIncrease profitVacuum evaporation coatingSputtering coatingCrucibleEngineering

The invention relates to a vacuum evaporation system capable of controlling evaporating airflow distribution and components. The system comprises an evaporation gun, a high-temperature evaporation crucible and a storage tank filled with an evaporating material, wherein a nozzle with an upper conical surface and a lower conical surface is formed on the evaporation gun, and a movable airflow guidance plug is arranged inside the nozzle; a substrate to be evaporated is opposite to the front of the nozzle; the evaporation gun is connected with the high-temperature evaporation crucible which is provided with a cross baffle through a heat pipeline or a surge flask, and the other side of the crucible is connected with the storage tank through a pipeline which is provided with a feed valve; heating coils are arranged on the evaporation gun, the heat pipeline, the high-temperature evaporation crucible and the outer wall of the pipeline, and a heat coil is arranged on the outer wall of the storage tank as well; the evaporating material in the storage tank is delivered into the high-temperature evaporation crucible through the feed valve and the pipeline, so that the evaporating material to be evaporated is immediately turned to be vapor delivered to the evaporating gun; and the volume and the direction of the vapor can be controlled by changing the relative position of the airflow guidance plug and the nozzle, and the vapor is evaporated to the substrate to form an evaporating film, which is uniform and has set area and multiple components. The vacuum evaporation system has simple structure, can improve the utilization rate of the organic evaporating material, and can improve the production efficiency.

Owner:SHANGHAI UNIV

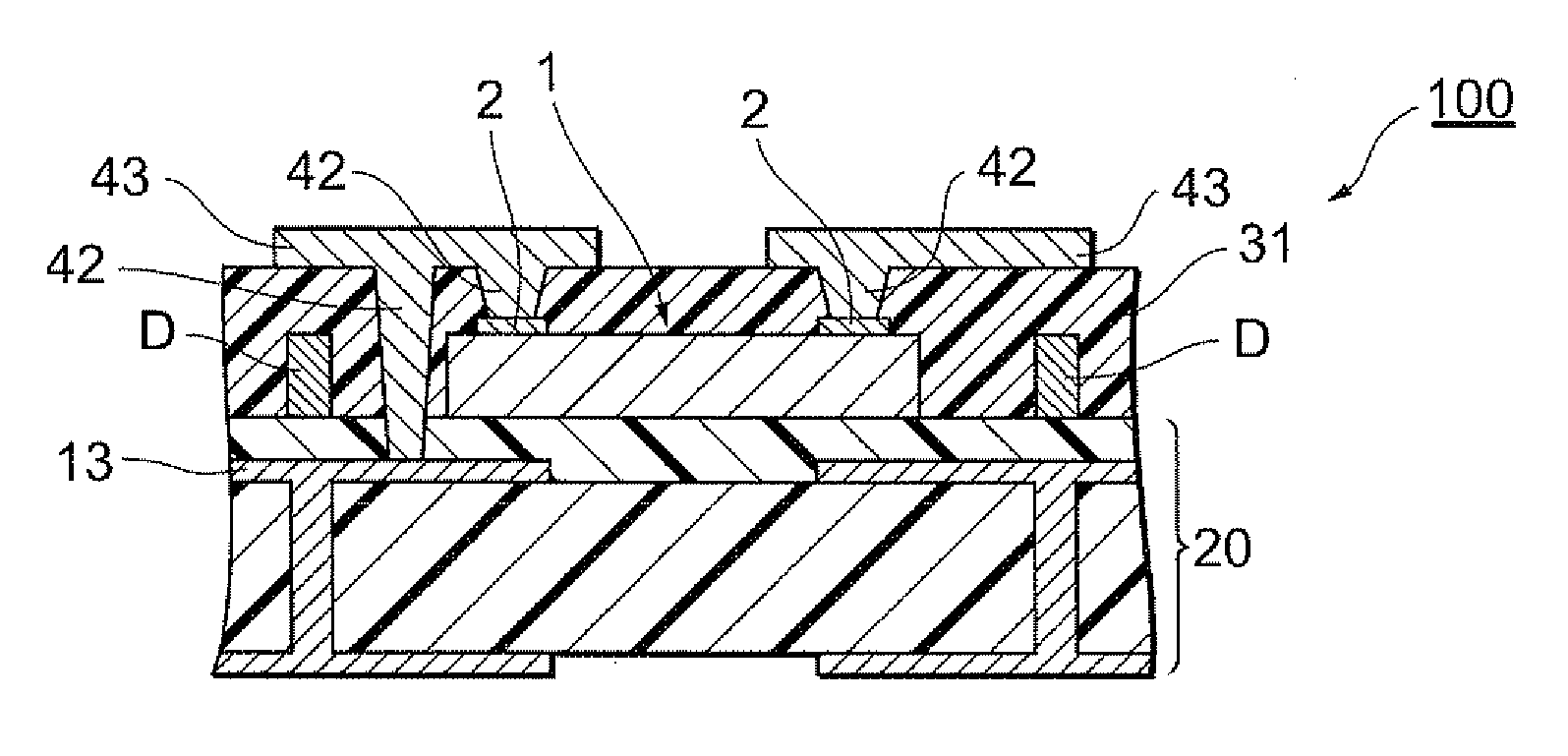

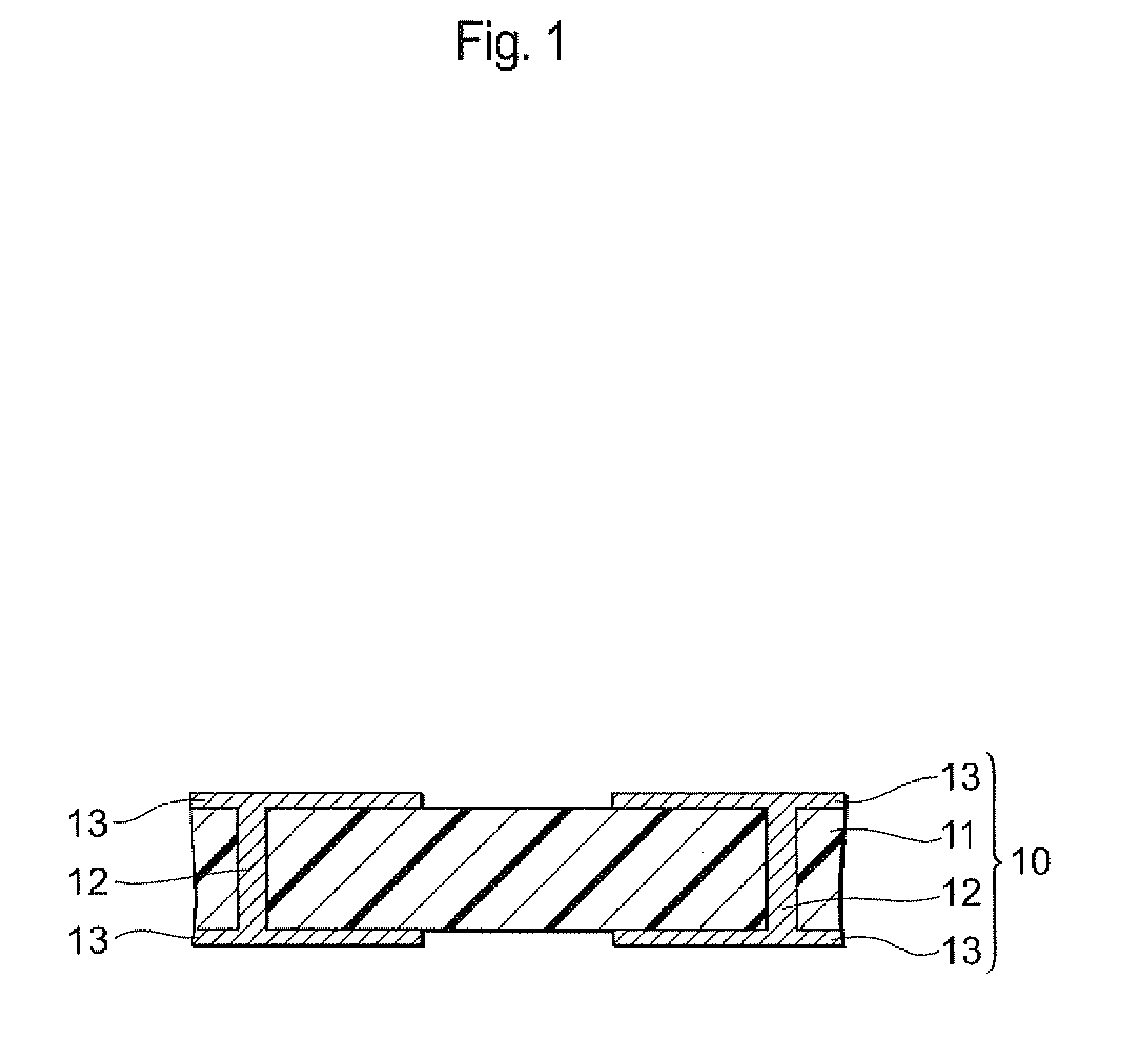

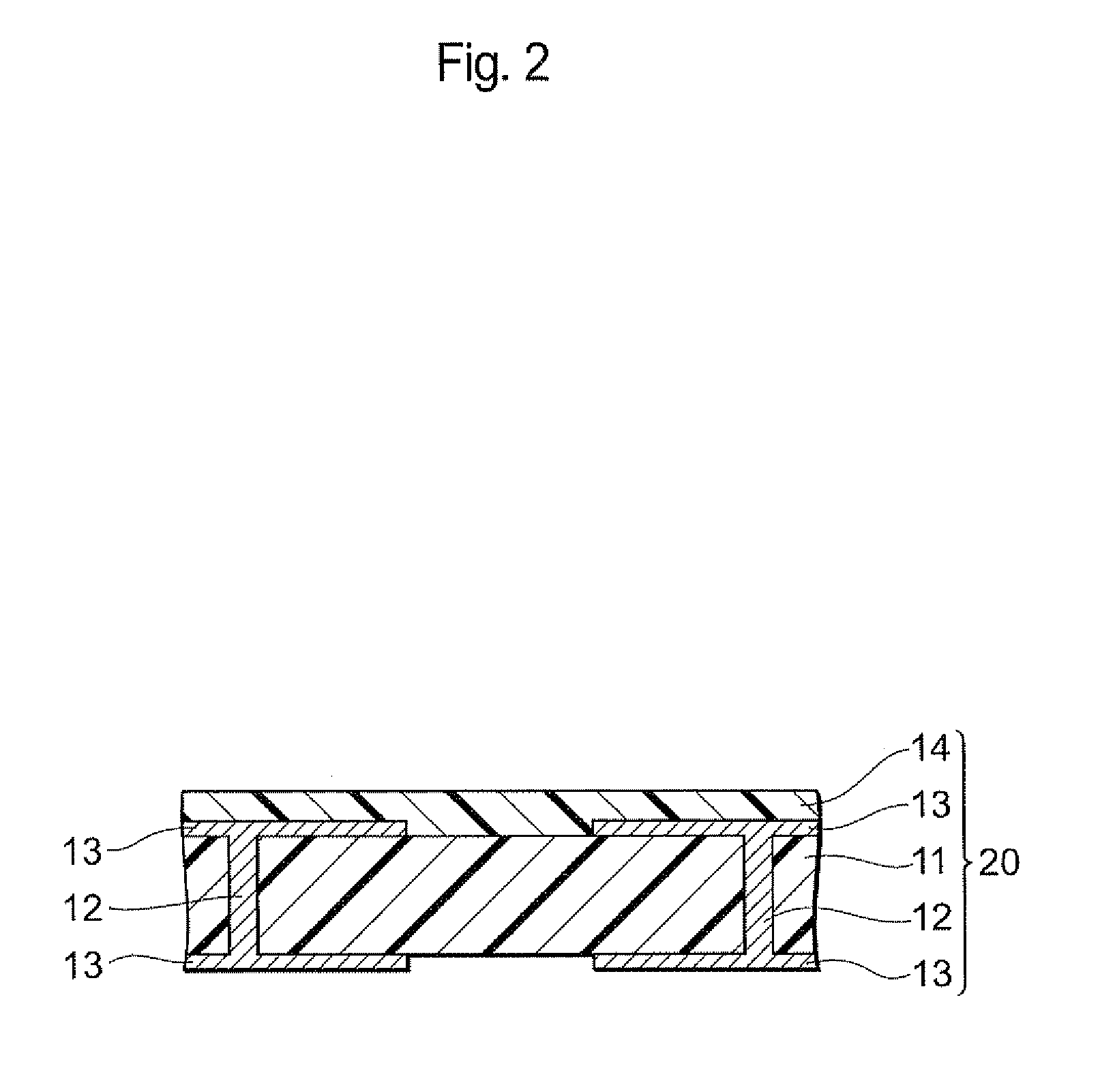

Electronic component-embeded board and method for manufacturing the same

ActiveUS20120247819A1Improve electrical resistanceIncrease resistancePrinted circuit assemblingSemiconductor/solid-state device detailsElectrical conductorElectronic component

An electronic component or the like is mounted on a substrate, and on the electronic component, an insulating layer is provided. Afterward, via-holes V are made in the insulating layer on terminals of the electronic component. Each of the terminals of the electronic component has, for example, a laminate structure of a first metal layer, a second metal layer and a third metal layer. When the via-holes V are formed, part of the third metal layer having a comparatively high electric resistance is removed, and the corresponding portion is connected to a wiring layer including via-conductors. Moreover, the third metal layer excellent in close contact properties with the insulating layer is preferably used.

Owner:TDK CORPARATION

Method of manufacturing liquid discharge head

InactiveUS20070017894A1Easy to manufactureImprove reliabilityRecording apparatusDecorative surface effectsVena contracta diameterEngineering

The method of manufacturing a recording head has a flow path wall forming step of forming flow path walls on a substrate having energy generating elements formed thereon, an imbedded material depositing step of depositing an imbedded material between the flow path walls and on a top of each flow path wall, a flattening step of polishing a top of the deposited imbedded material, until the top of the flow path wall is exposed, and a step of forming an orifice plate on the tops of the polished imbedded material and the exposed flow path wall. In the step of forming the flow path walls, patterning of a close contact property improvement layer is simultaneously performed to improve a close contact property between the flow path wall and the substrate.

Owner:CANON KK

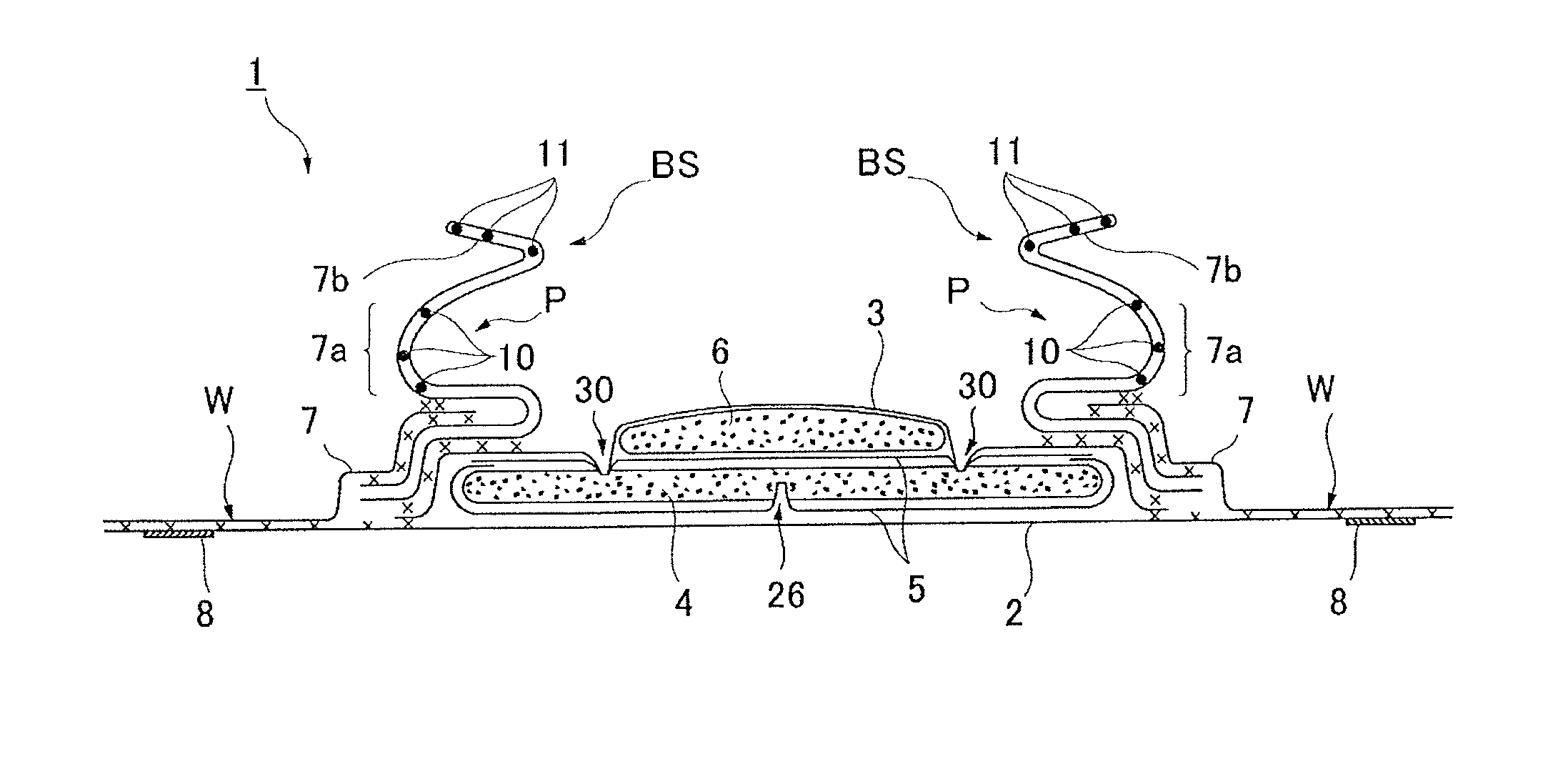

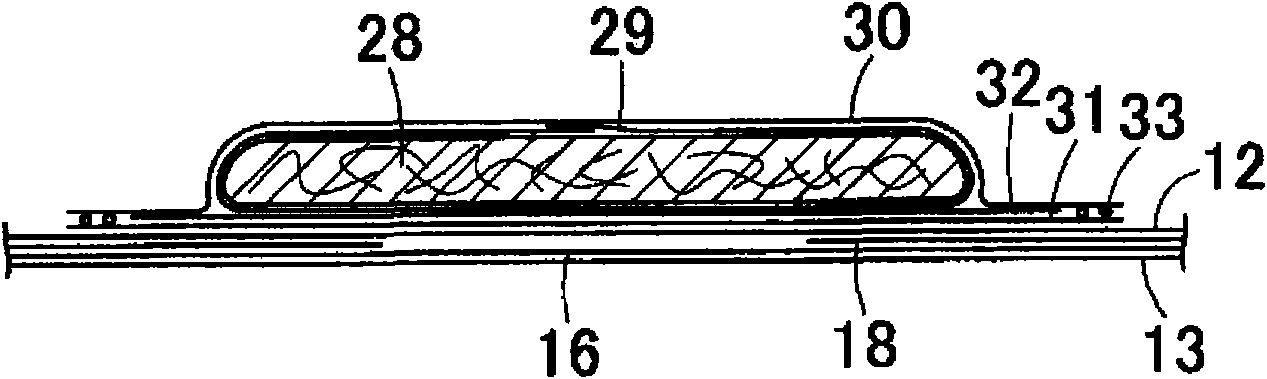

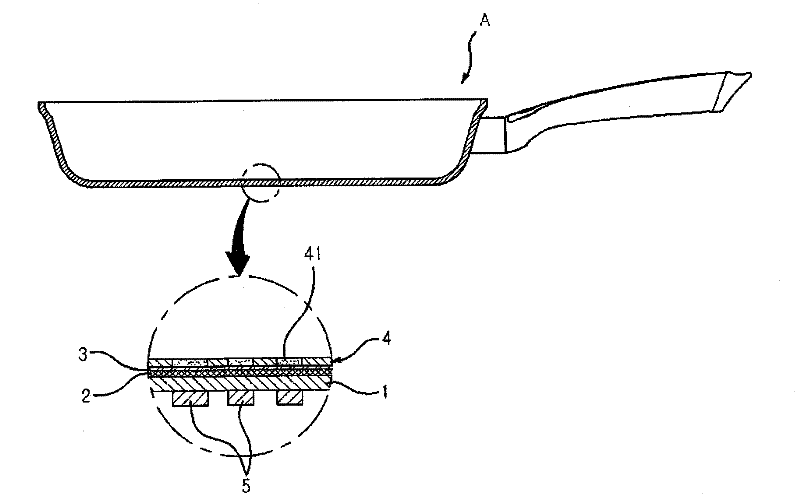

Absorbent article

ActiveUS20130165885A1Improve performanceImprove deformation abilitySanitary towelsBaby linensSkin contactBody area

An absorbent article, such as a sanitary napkin and the like, constituted of an absorbing body between permeable (skin contact surface) and impermeable (skin non-contact surface) sheets, is provided with intermittent recess grooves formed in a longitudinal direction on the absorbent article on the skin non-contact surface side of the absorbing body, a plurality of laterally elongated peripheral embosses formed at intervals in the longitudinal direction of the absorbent article on absorbent body areas located peripherally to the recess grooves, and an absorbing body deficit portion formed at least between the recess grooves. Thus achieved are close contact with buttock cleavage and prevention of leakage to the rear.

Owner:DAIO PAPER CORP

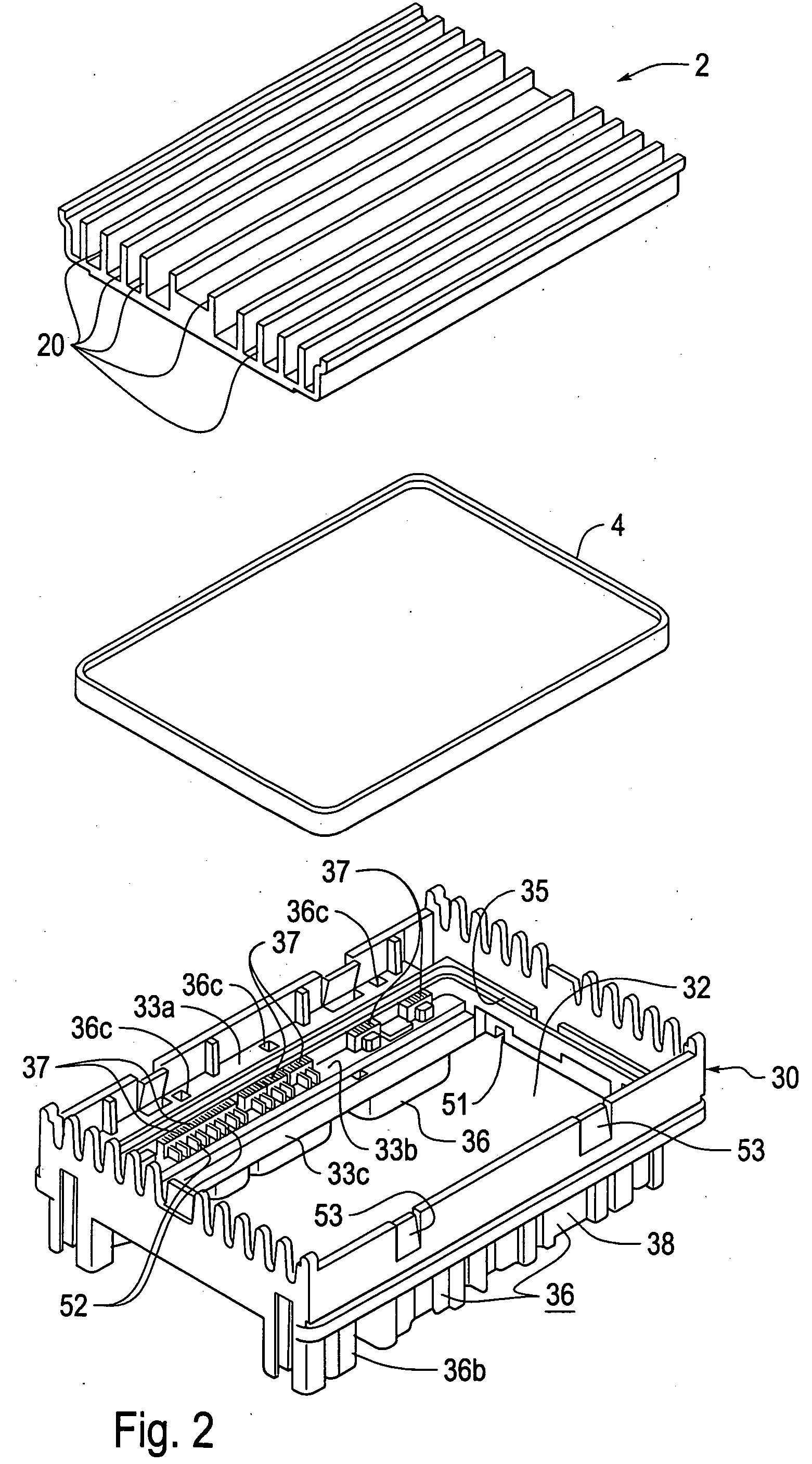

Casing unit for circuit assembly and method for producing the circuit assembly

InactiveUS20040159455A1Improve adhesionEasy to checkMachine supportsCasings/cabinets/drawers detailsEngineeringThermal radiation

A power circuit section is adhered to a circuit arrangement surface on a heat radiation member to form a circuit assembly. A casing body is mounted on the heat radiation member. The casing body is provided with an opening that exposes at least the upper portion of the power circuit section. A shape retention member is disposed across the opening for interconnecting a peripheral edge of the opening to each other at a plurality of positions. A casing unit is made of a synthetic resin. The shape retention member suppresses a deformation of the casing body due to a shrinkage cavity. After cooling the casing unit, the shape retention member is removed to define a large opening, if desired.

Owner:SUMITOMO WIRING SYST LTD

Float valve device

InactiveUS7032610B2Improve rigidityImprove close contactLarge containersVenting valvesEngineeringInjection molding machine

Owner:PIOLAX CO LTD

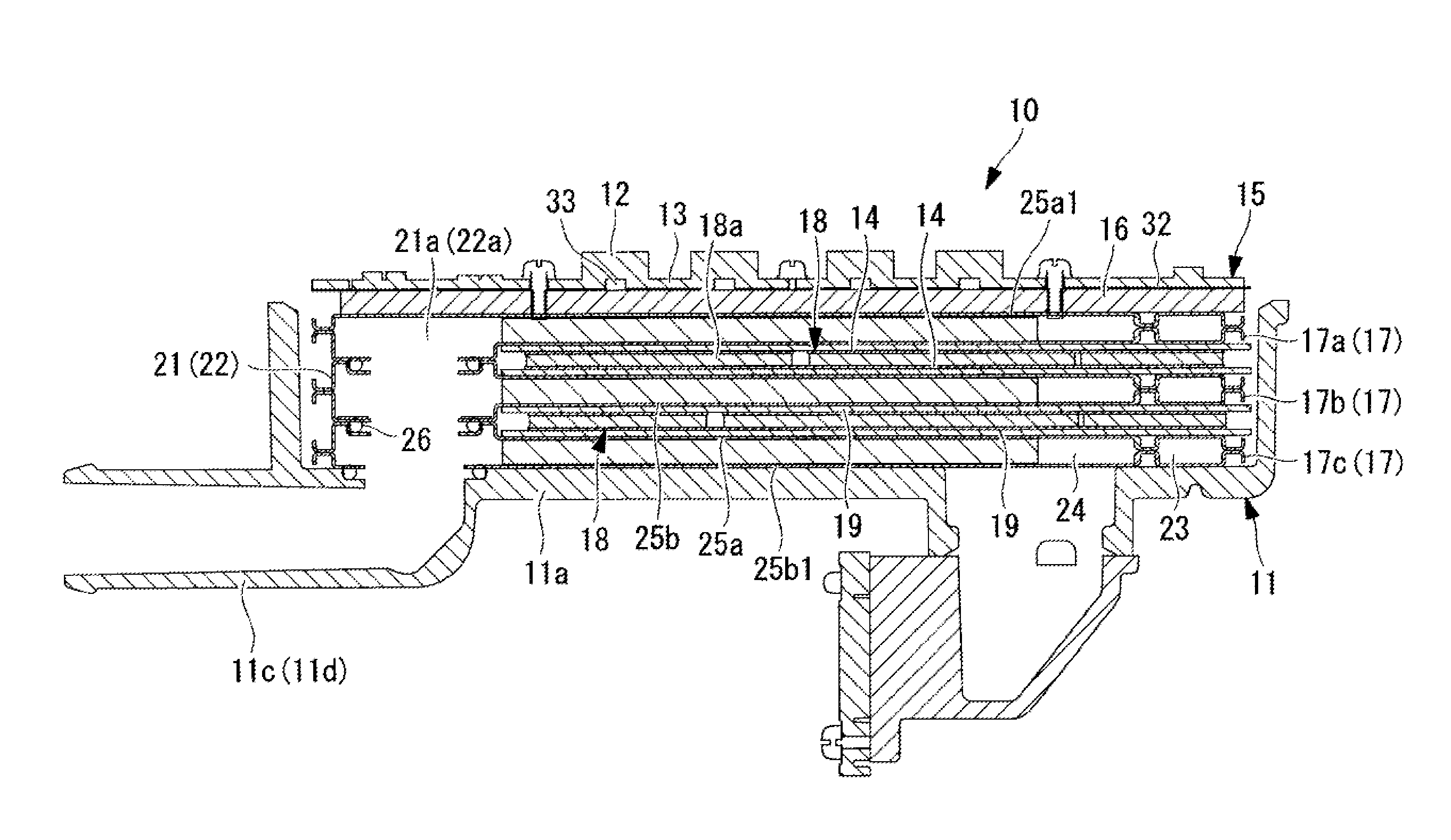

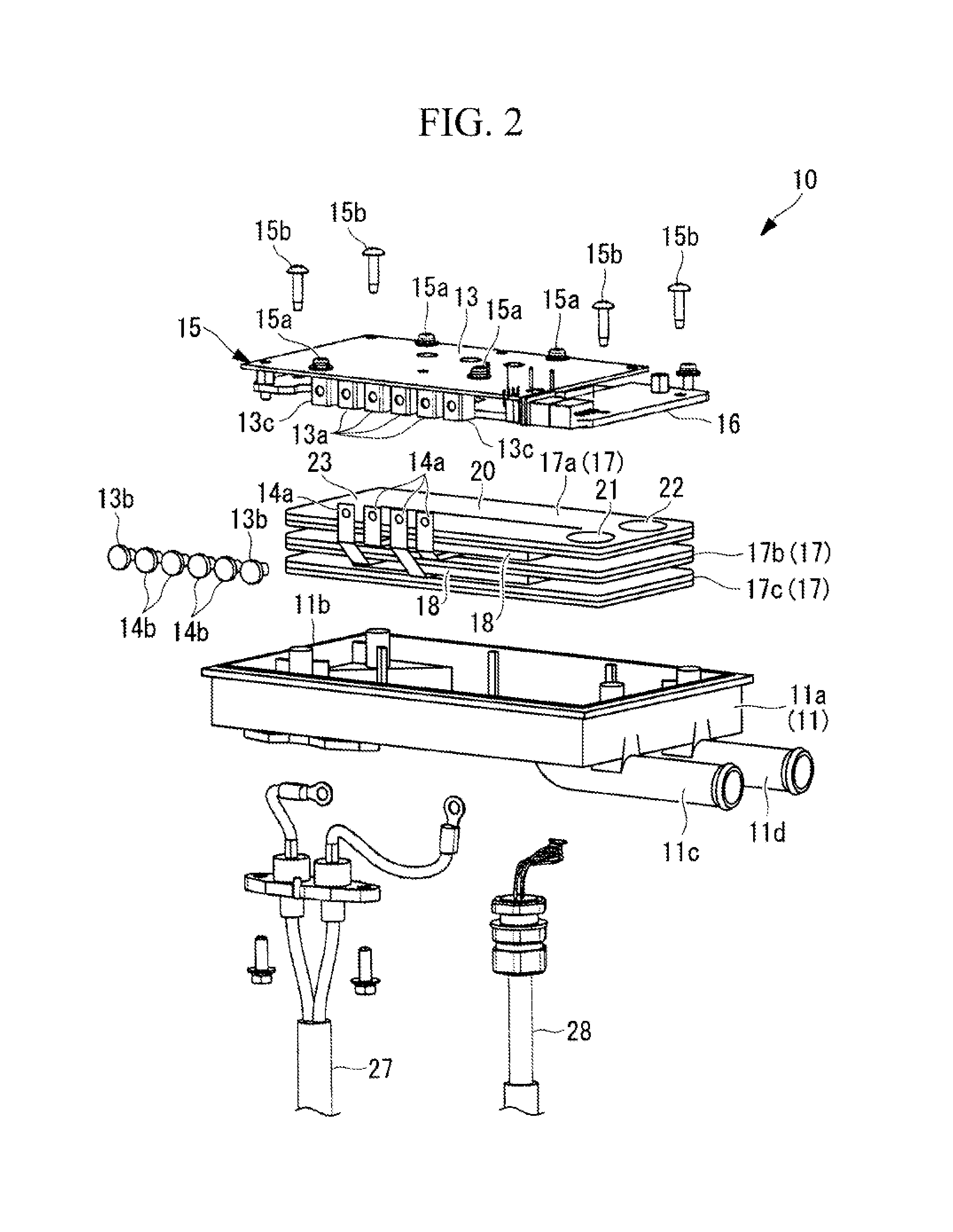

Heat medium heating device and vehicular air-conditioning device including the same

InactiveUS20140050465A1Improve close contactSealing is reliableAir-treating devicesAir heatersEngineeringAir conditioning

Provided are: a heat medium heating device capable of bringing: flat heat exchange tubes and PTC heaters; and inlet / outlet header parts of the flat heat exchange tubes, into sufficiently close contact with each other, and incorporating these components into a casing; and a vehicular air-conditioning device including the same. In a heat medium heating device, flat heat exchange tubes each including a flat tube part and inlet / outlet header parts and PTC heaters are stacked in layers, and a heat exchange holding member presses the flat heat exchange tubes from one side, whereby the stacked structure is incorporated on an inner bottom surface of a casing. In this configuration, at least uppermost one of the flat heat exchange tubes has one surface pressed by the heat exchange holding member, the one surface being formed into a planar shape in which the flat tube part and the inlet / outlet header parts are flattened.

Owner:MITSUBISHI HEAVY INDUSTIRES AUTOMOTIVE THERMAL SYST CO LTD

Solid electrolytic capacitor

ActiveUS20090147449A1Highly accurate and reliable attachmentAvoid deformationSolid electrolytic capacitorsClosuresLead frameElectrolytic capacitor

A solid electrolytic capacitor includes a capacitor element, an anode lead frame, a cathode lead frame, and a mold resin portion. The anode lead frame includes an anode terminal portion and a rising portion, and the anode terminal portion is exposed at the bottom surface of the mold resin portion. The rising portion is formed integral with the anode terminal portion, and rises to the anode portion. In the rising portion, a through hole is formed. The cathode lead frame includes a cathode terminal portion, a pair of side surface portions and a step portion. Thus, a solid electrolytic capacitor allowing highly accurate and reliable attachment of the capacitor element to the lead frame without using any additional member is provided.

Owner:SANYO ELECTRIC CO LTD

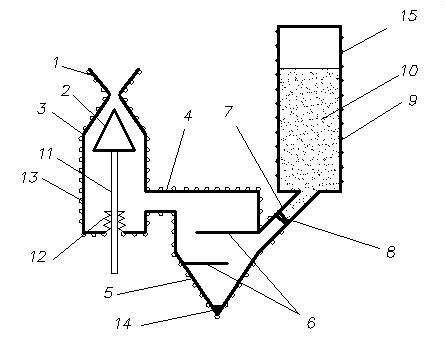

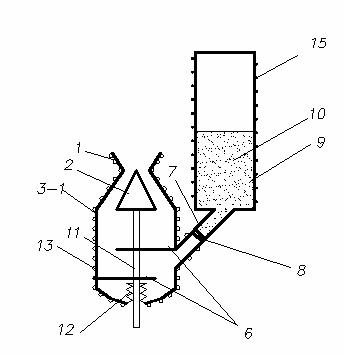

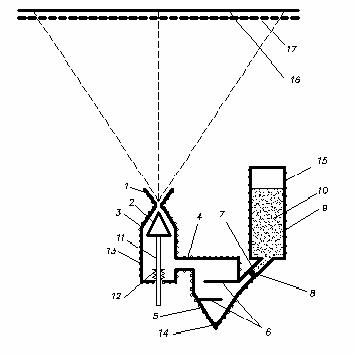

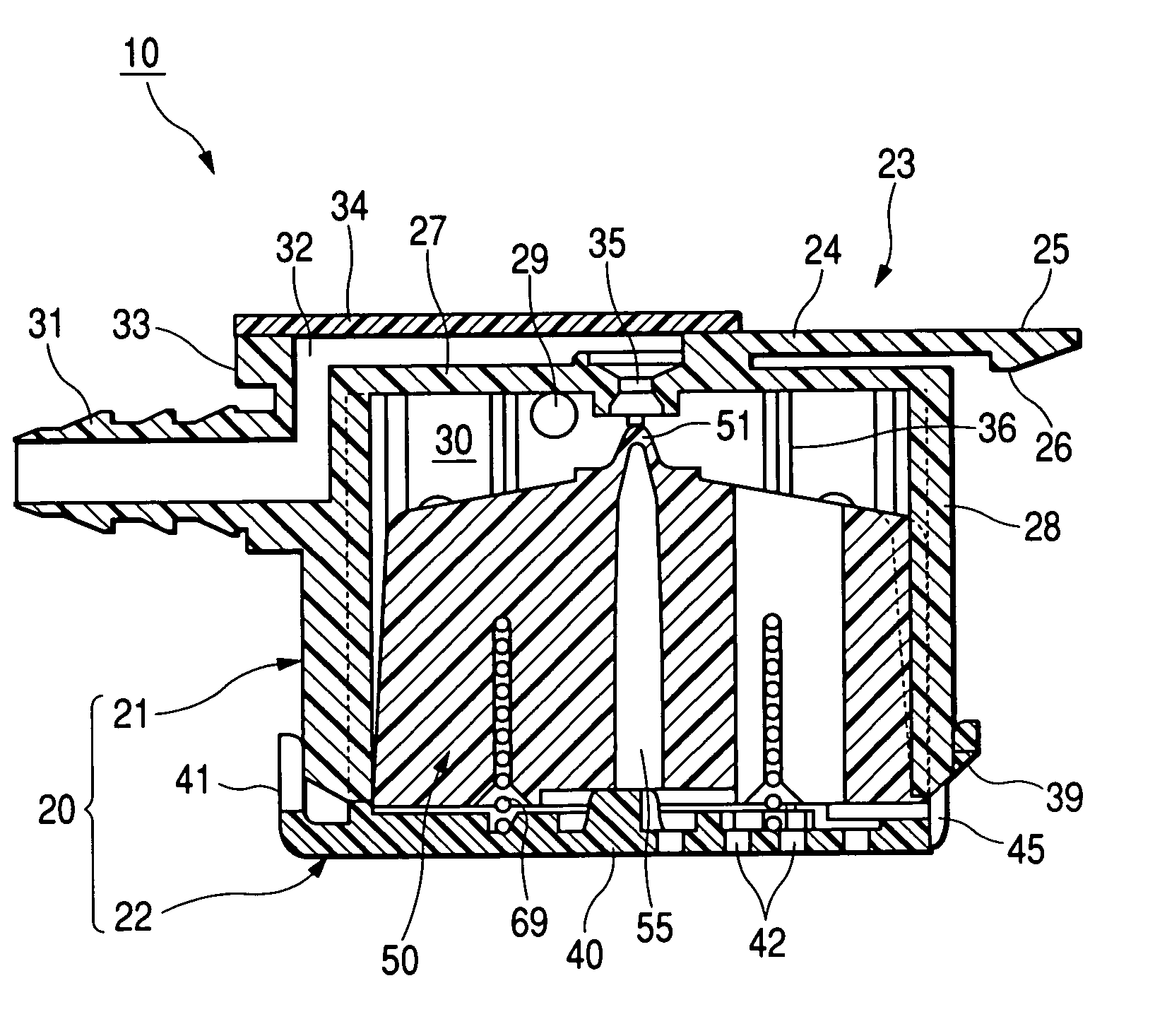

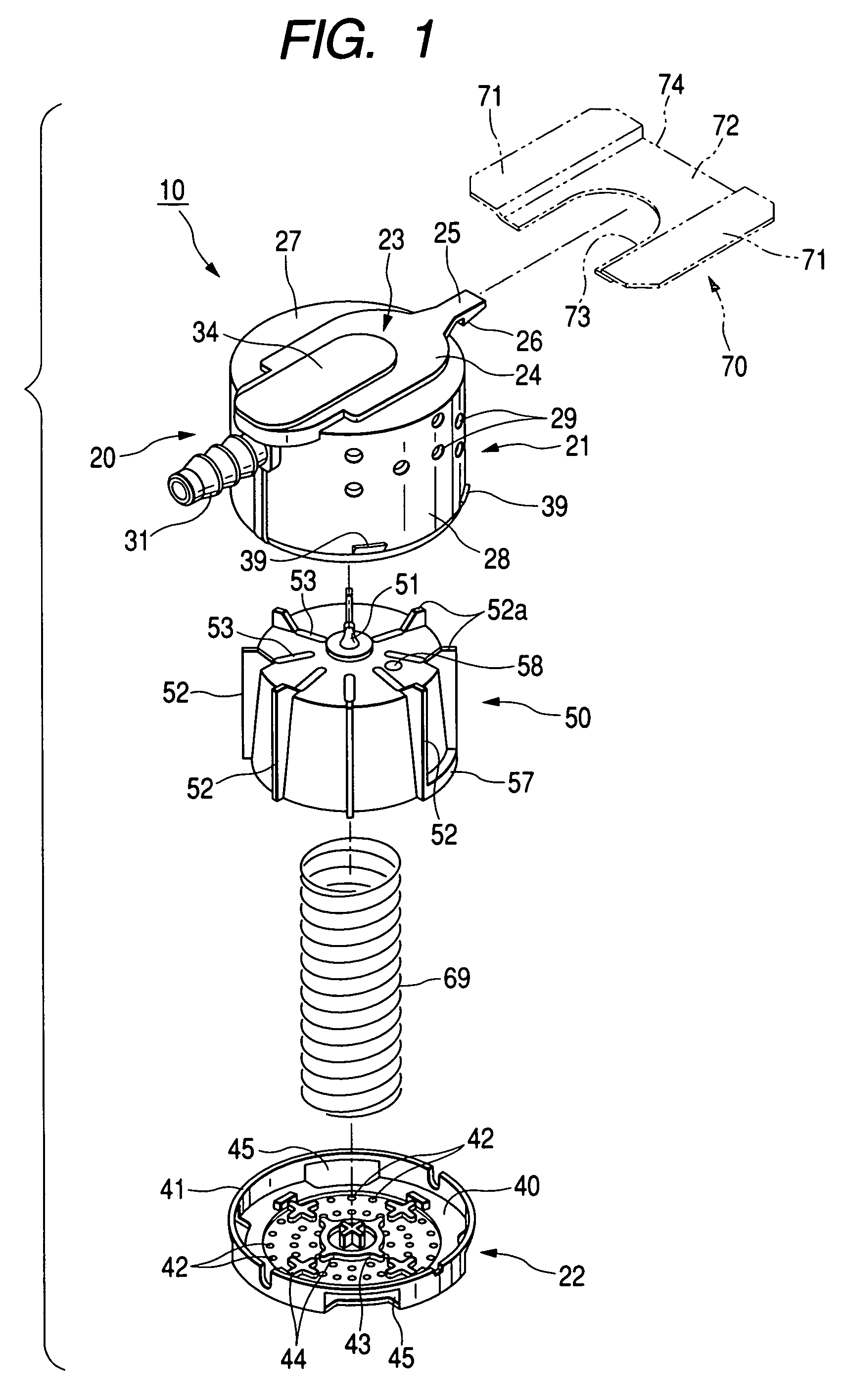

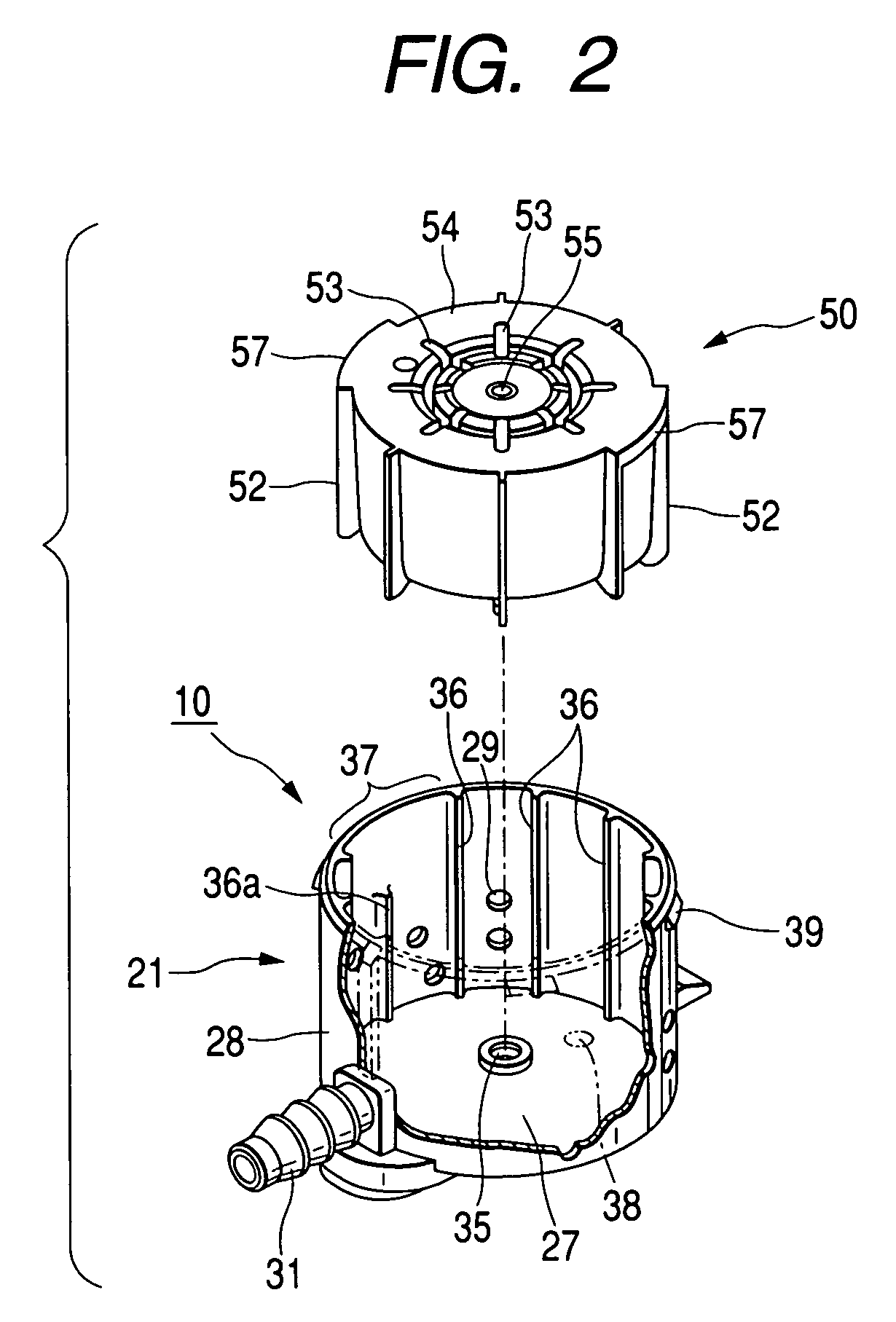

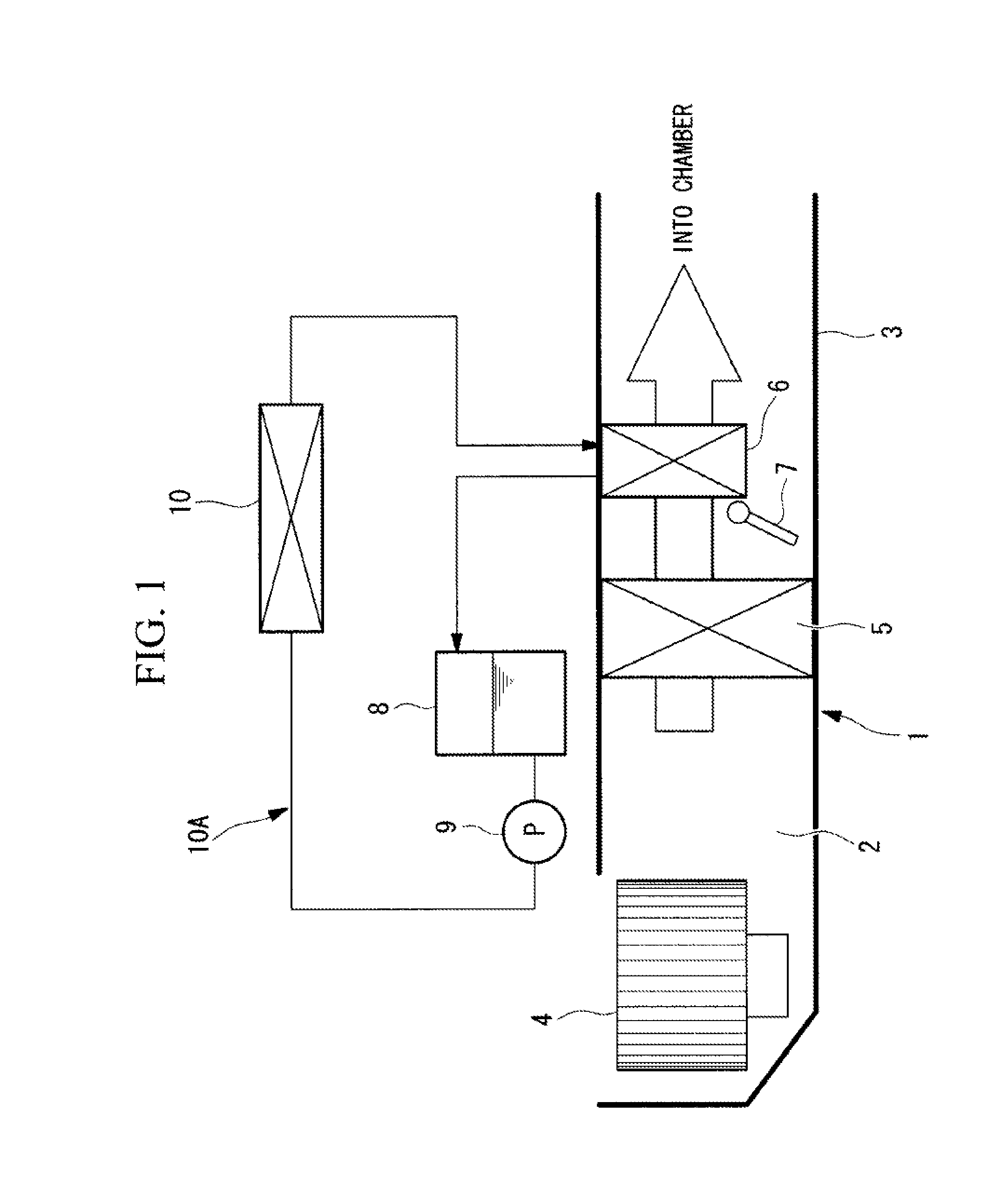

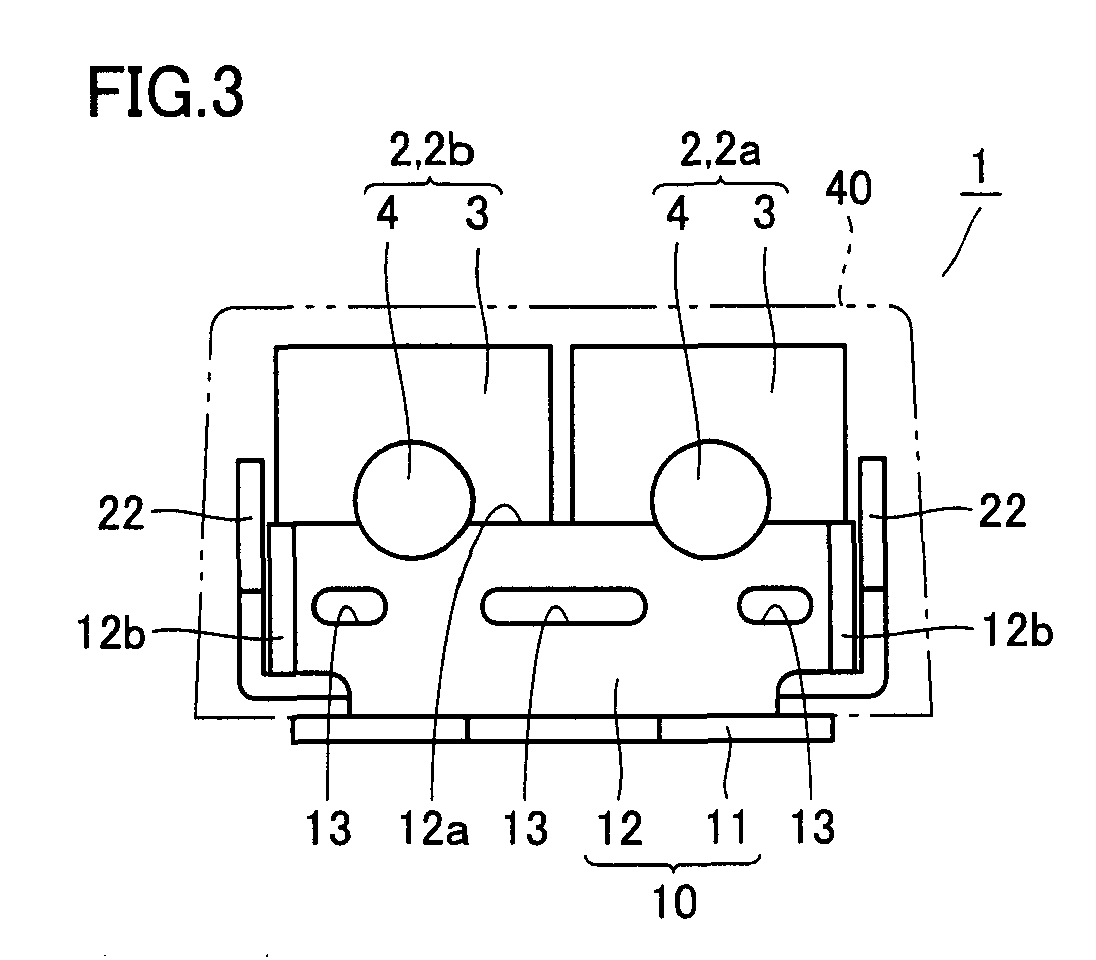

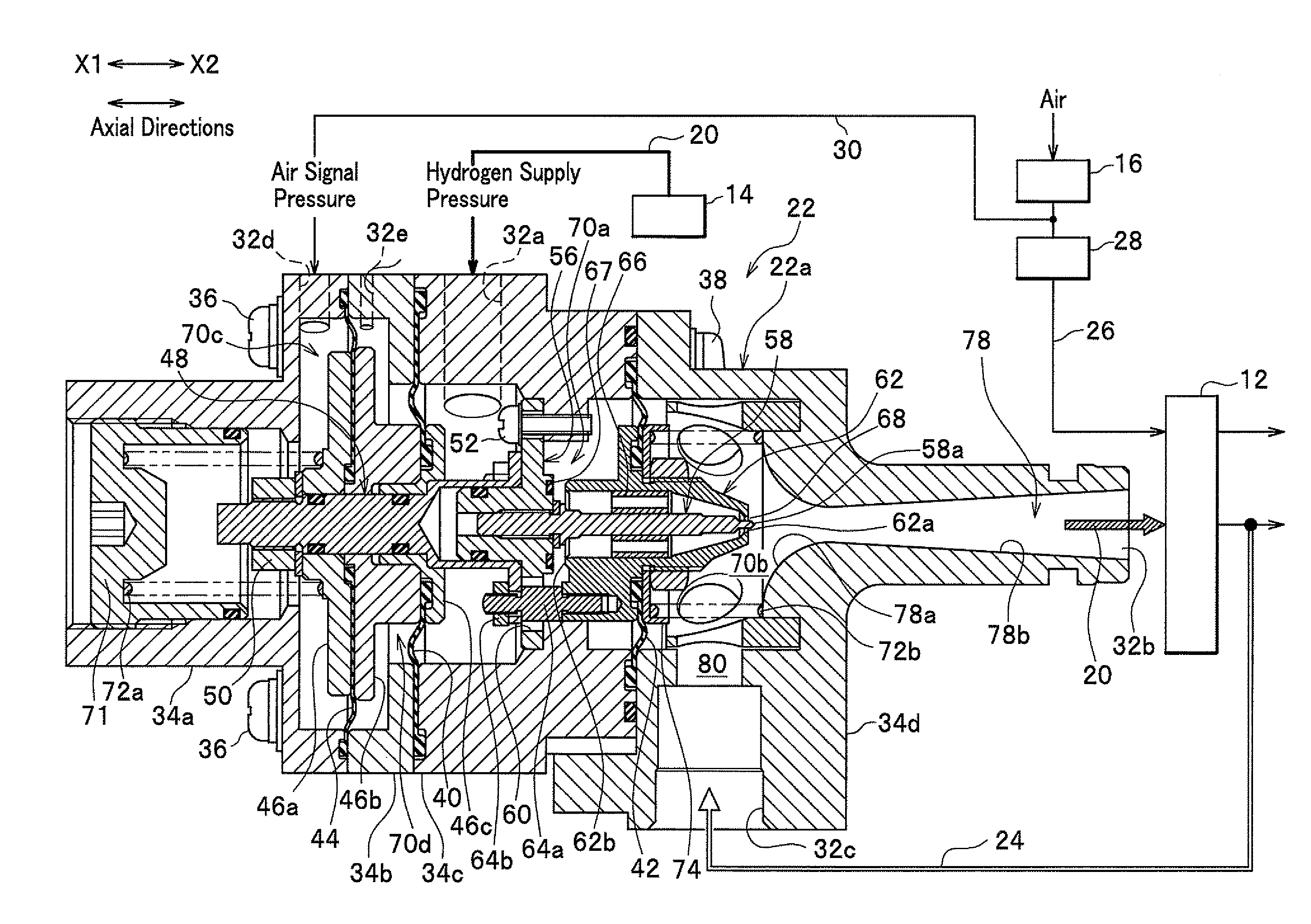

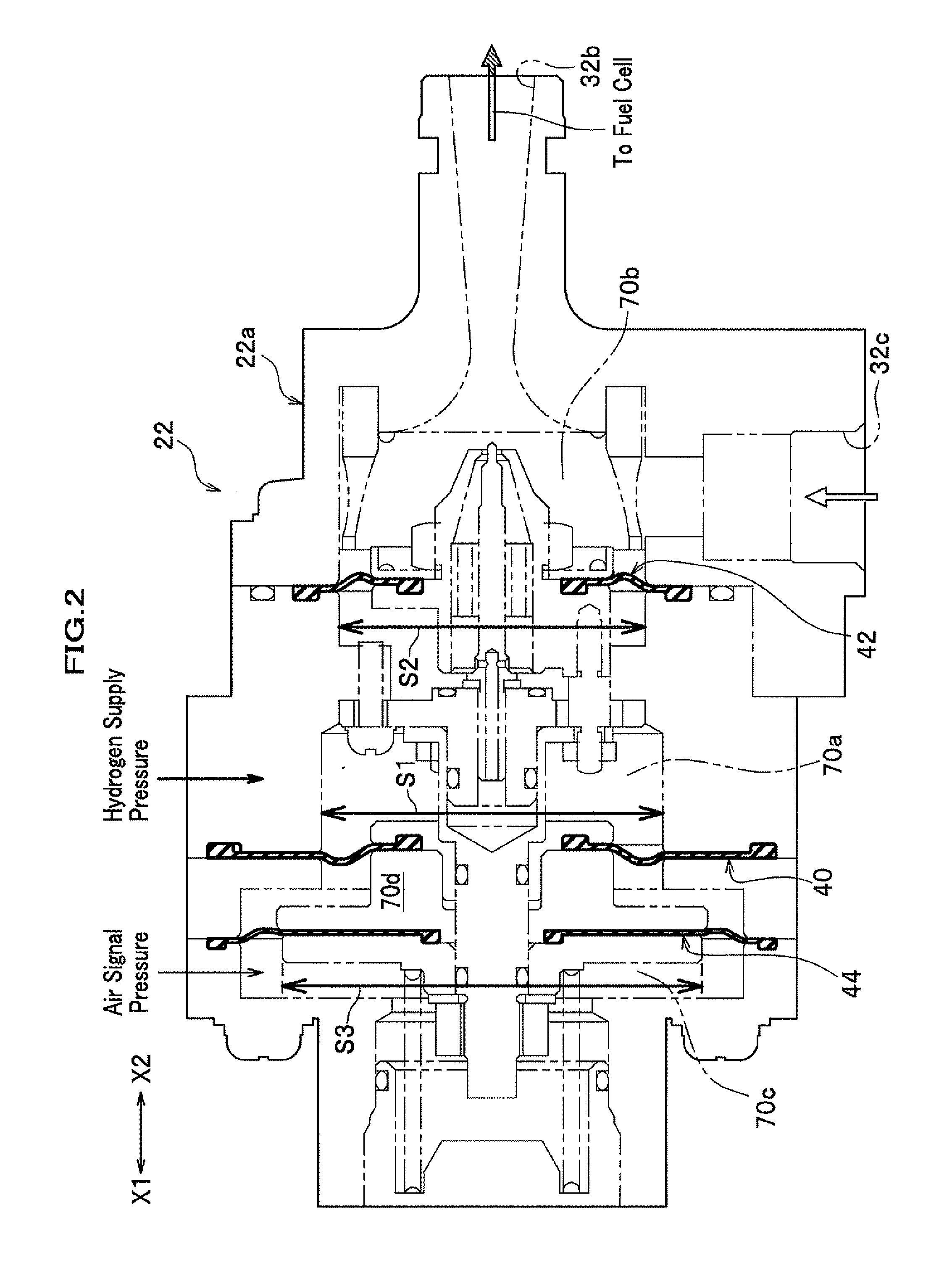

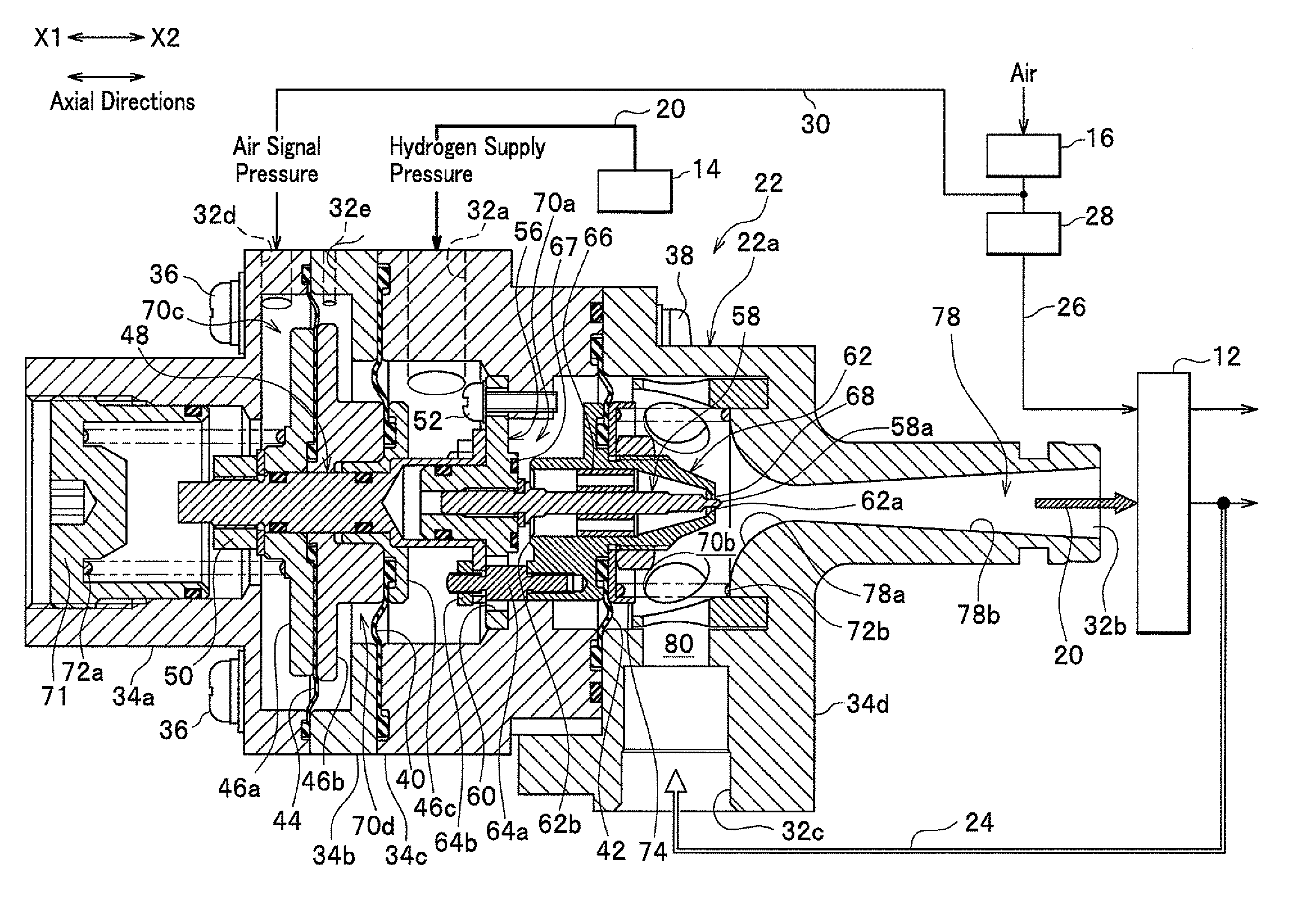

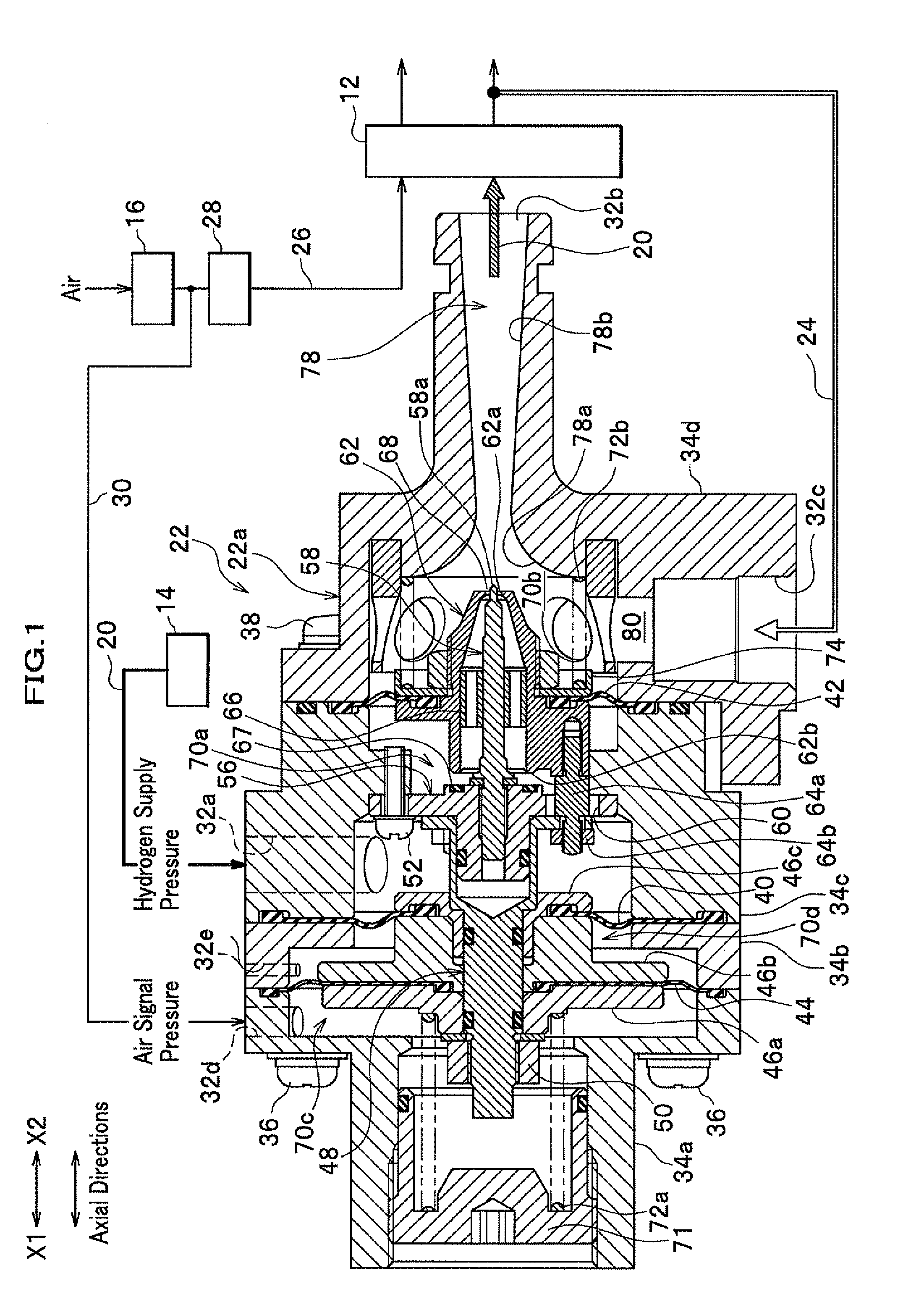

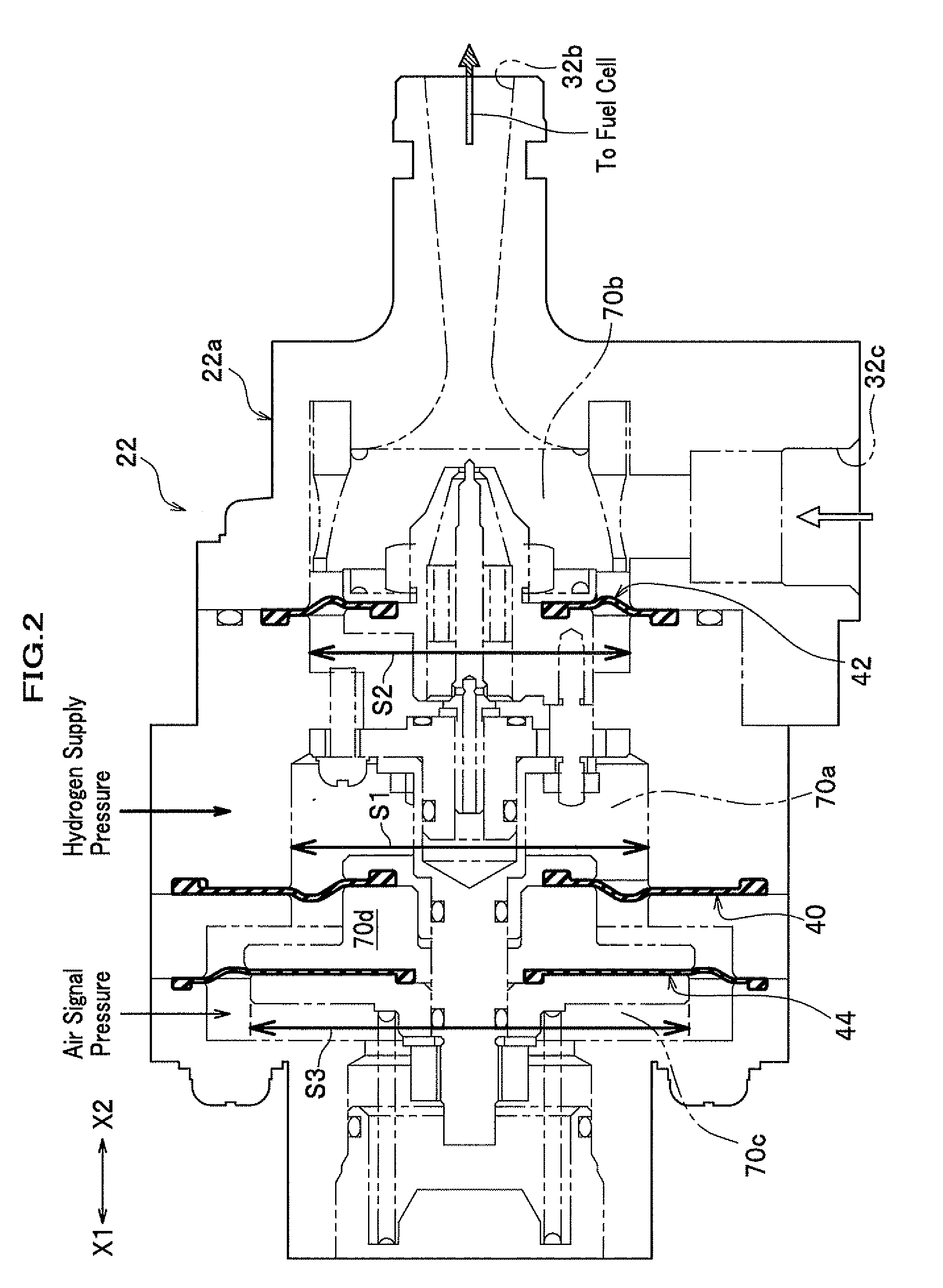

Ejector apparatus for fuel cell

InactiveUS8999593B2Avoid displacementAvoid dischargeReactant parameters controlJet pumpsFuel cellsGas supply

An ejector apparatus for a fuel cell includes an ejector main body including an inlet port, an outlet port, a suction port, and an oxidizer-gas supply port, a first to third chambers provided in the body, a nozzle having a nozzle hole discharging the fuel gas, a diffuser mixing the fuel gas discharged from the nozzle hole and the fuel offgas exhausted from the fuel cell and returned to the suction port, a needle fixed on a side of the body and extending along an axial direction of the nozzle in a hollow portion thereof, and first and second diaphragms arranged to oppose each other, and changing an opening area in a gap between the nozzle hole and an outer peripheral face of a top end of the needle, wherein a pressure receiving area of the first diaphragm is set to be larger than that of the second diaphragm.

Owner:KEIHIN CORP +1

Ejector apparatus for fuel cell

InactiveUS20120189927A1Avoid displacementAvoid dischargeReactant parameters controlJet pumpsFuel cellsGas supply

An ejector apparatus for a fuel cell includes an ejector main body including an inlet port, an outlet port, a suction port, and an oxidizer-gas supply port, a first to third chambers provided in the body, a nozzle having a nozzle hole discharging the fuel gas, a diffuser mixing the fuel gas discharged from the nozzle hole and the fuel offgas exhausted from the fuel cell and returned to the suction port, a needle fixed on a side of the body and extending along an axial direction of the nozzle in a hollow portion thereof, and first and second diaphragms arranged to oppose each other, and changing an opening area in a gap between the nozzle hole and an outer peripheral face of a top end of the needle, wherein a pressure receiving area of the first diaphragm is set to be larger than that of the second diaphragm.

Owner:KEIHIN CORP +1

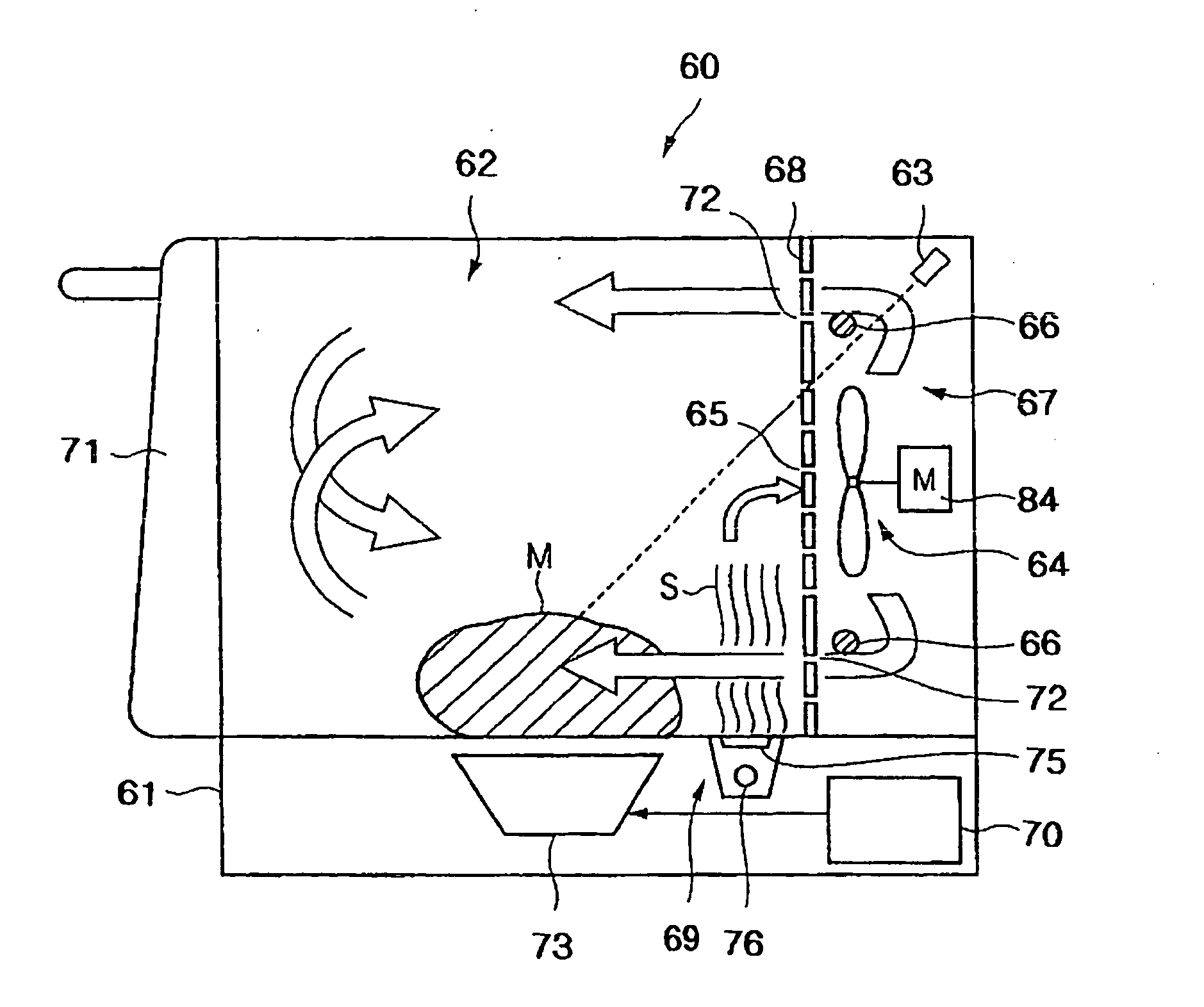

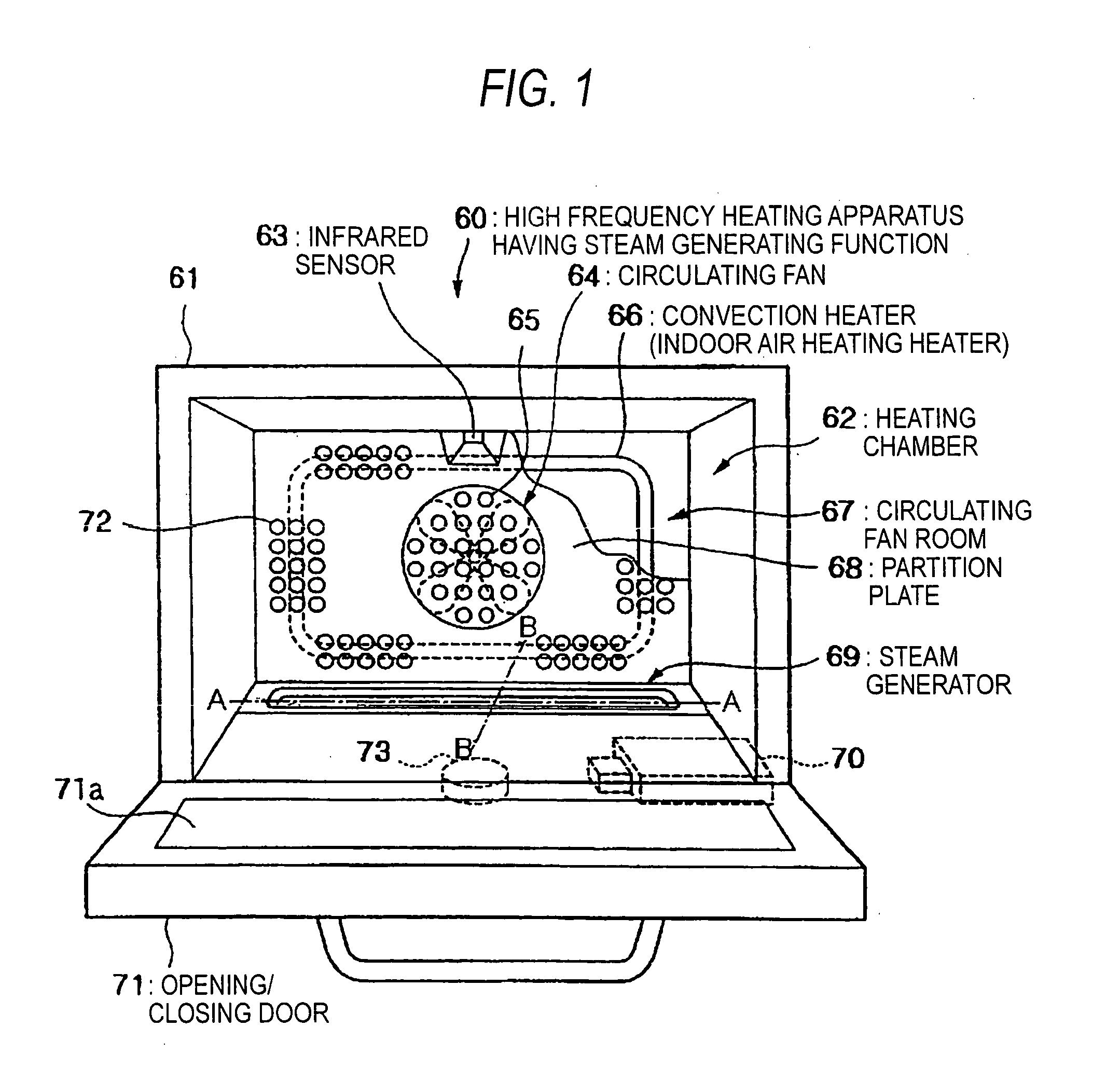

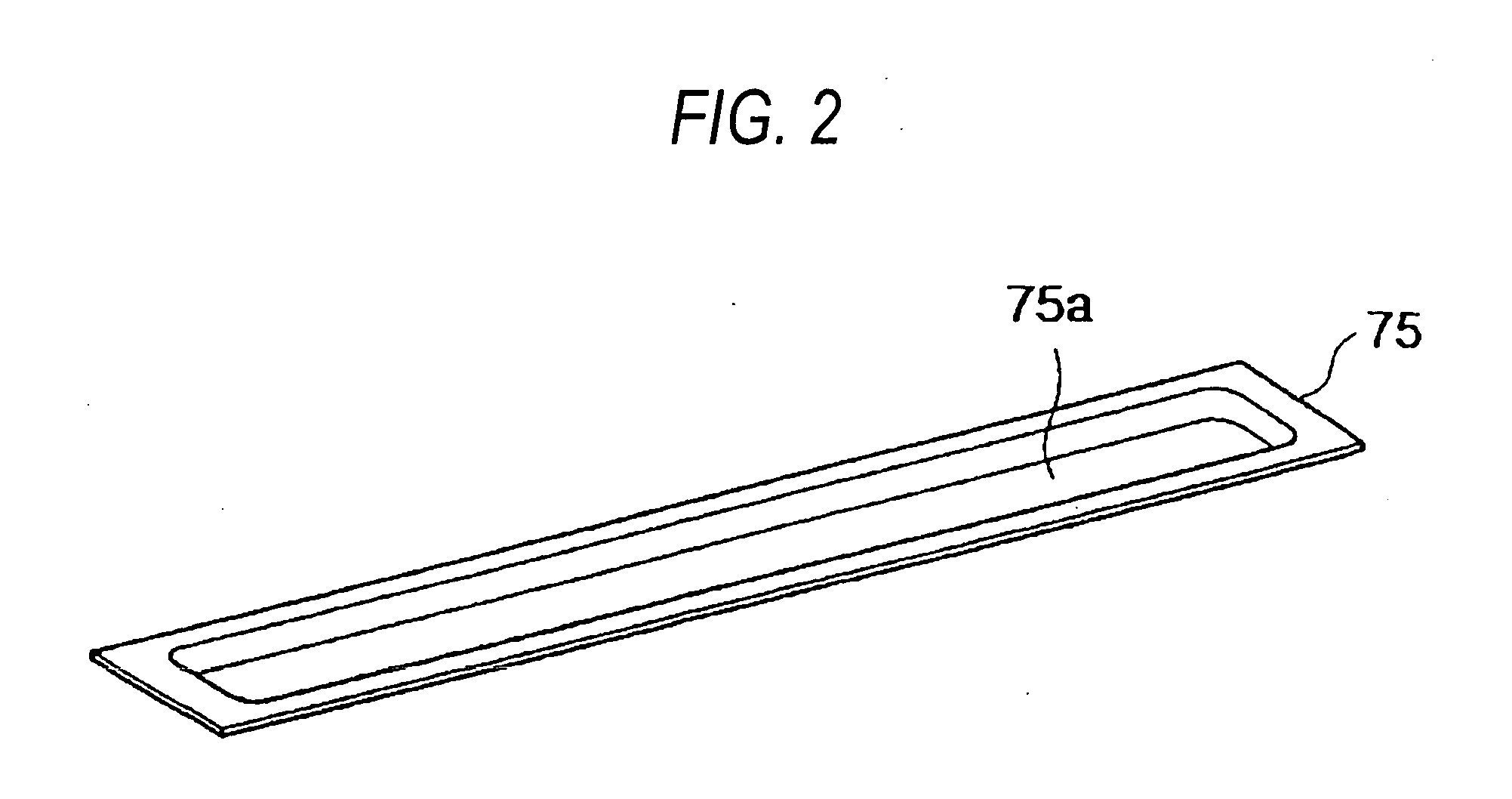

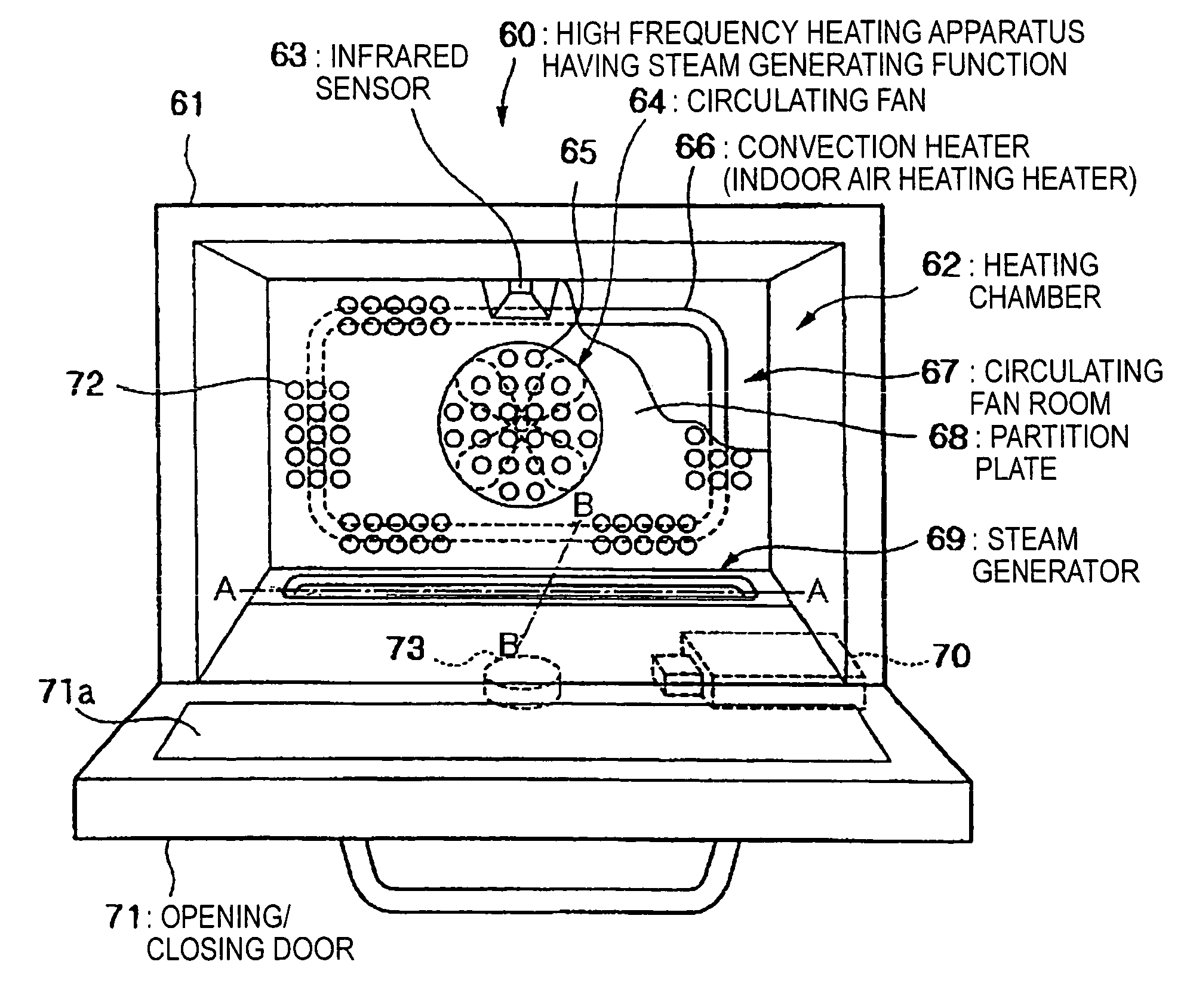

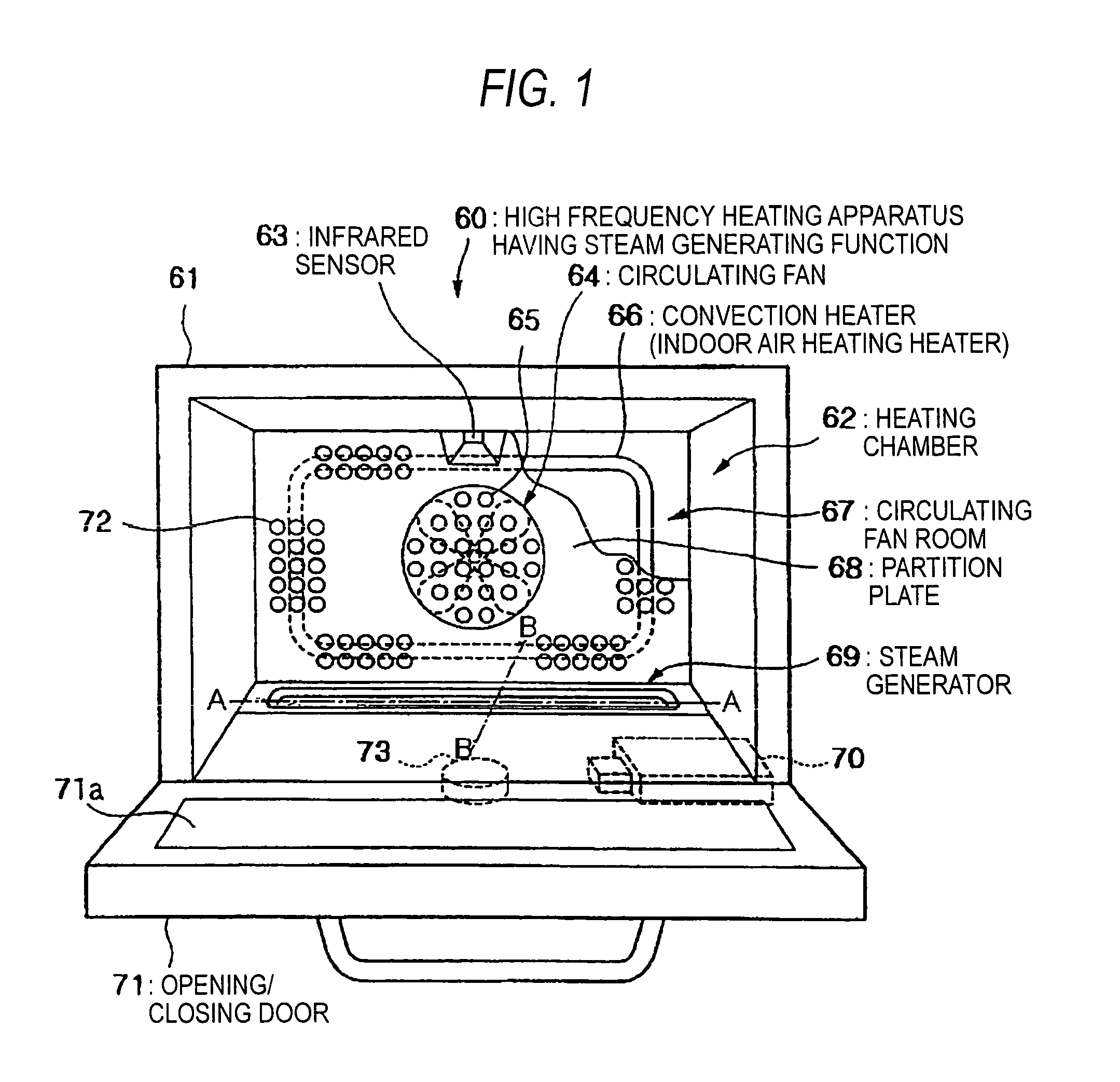

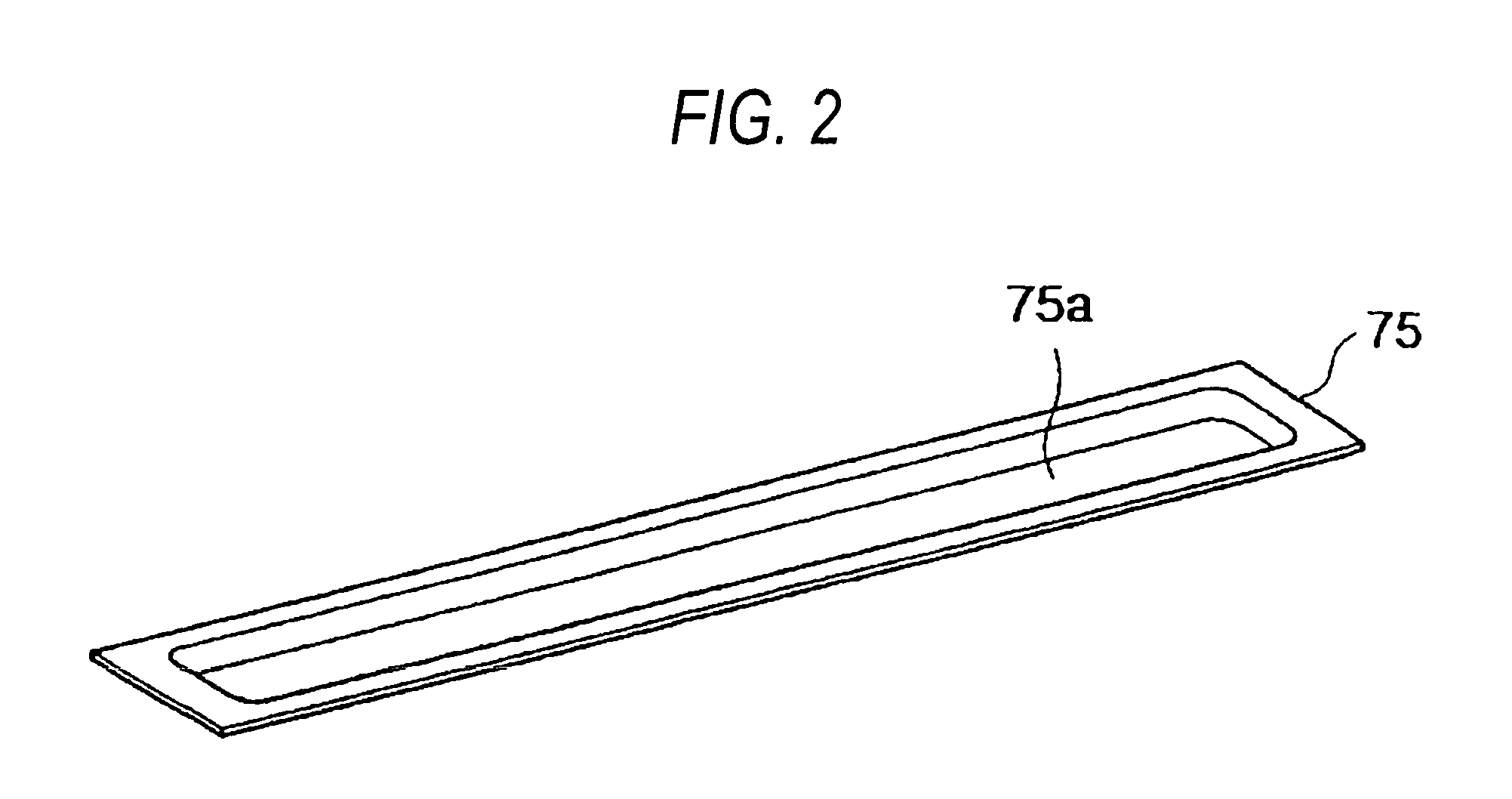

Steam generation function-equipped high-frequency heating device

InactiveUS20060088301A1Close contactImprove close contactDomestic stoves or rangesBaking ovenEngineeringHeating efficiency

An object of the present invention is to provide a high frequency heating apparatus having a steam generating function in which a time required till evaporation of dropped water can be remarkably increased when water is dropped onto an evaporation tray and the heating efficiency is high. In a high frequency heating apparatus having a steam generating function that includes a high frequency generator, and a steam generator comprising an evaporation tray provided on the bottom surface of a heating chamber in which a heating target is mounted and a heater device for heating the evaporation tray to generate steam in the heating chamber, the heater device is constructed as a heater device (11) having a sheathed heater (113) embedded in an aluminum die cast (111), and the heater device is directly attached to the back side of the evaporation tray (22).

Owner:PANASONIC CORP

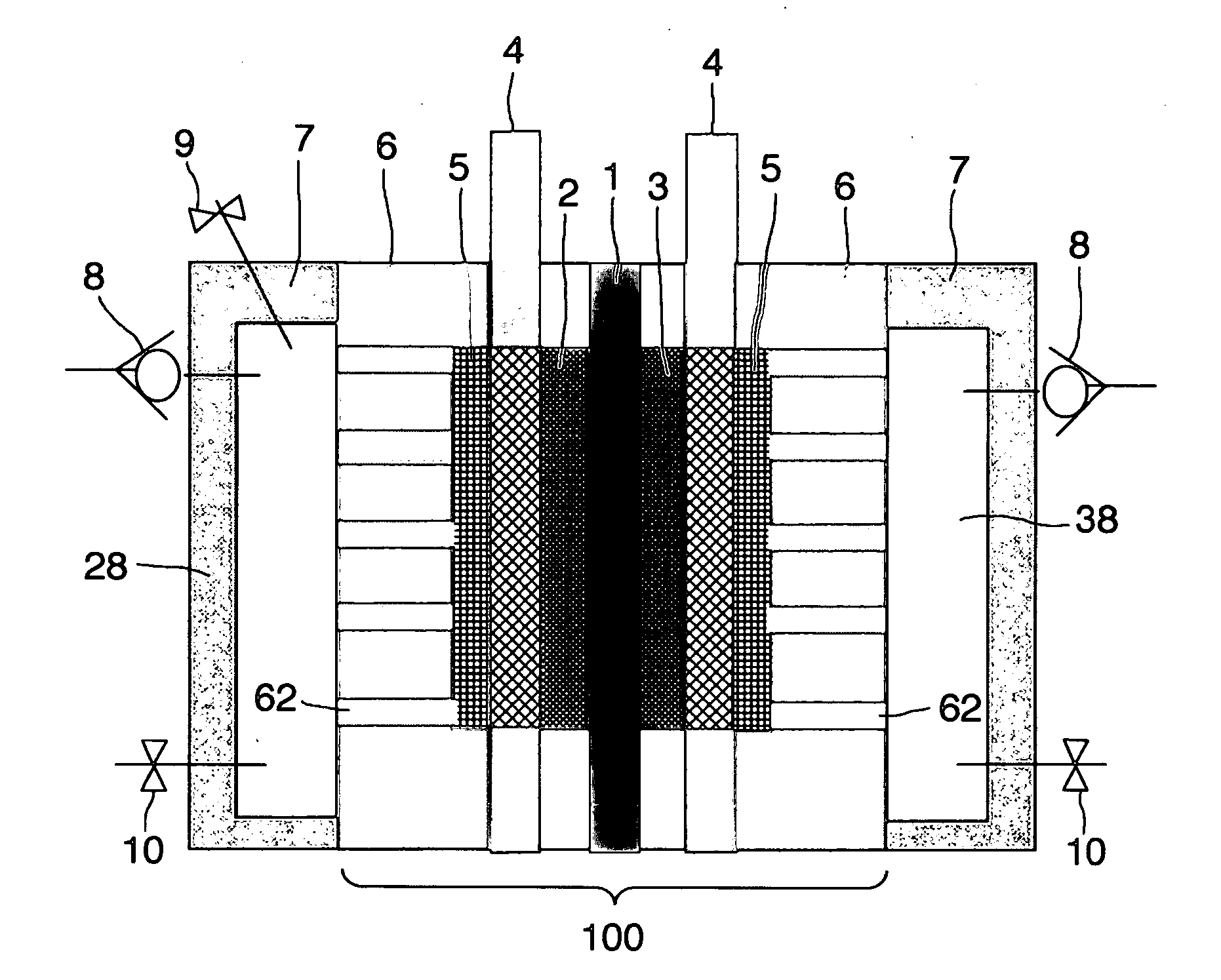

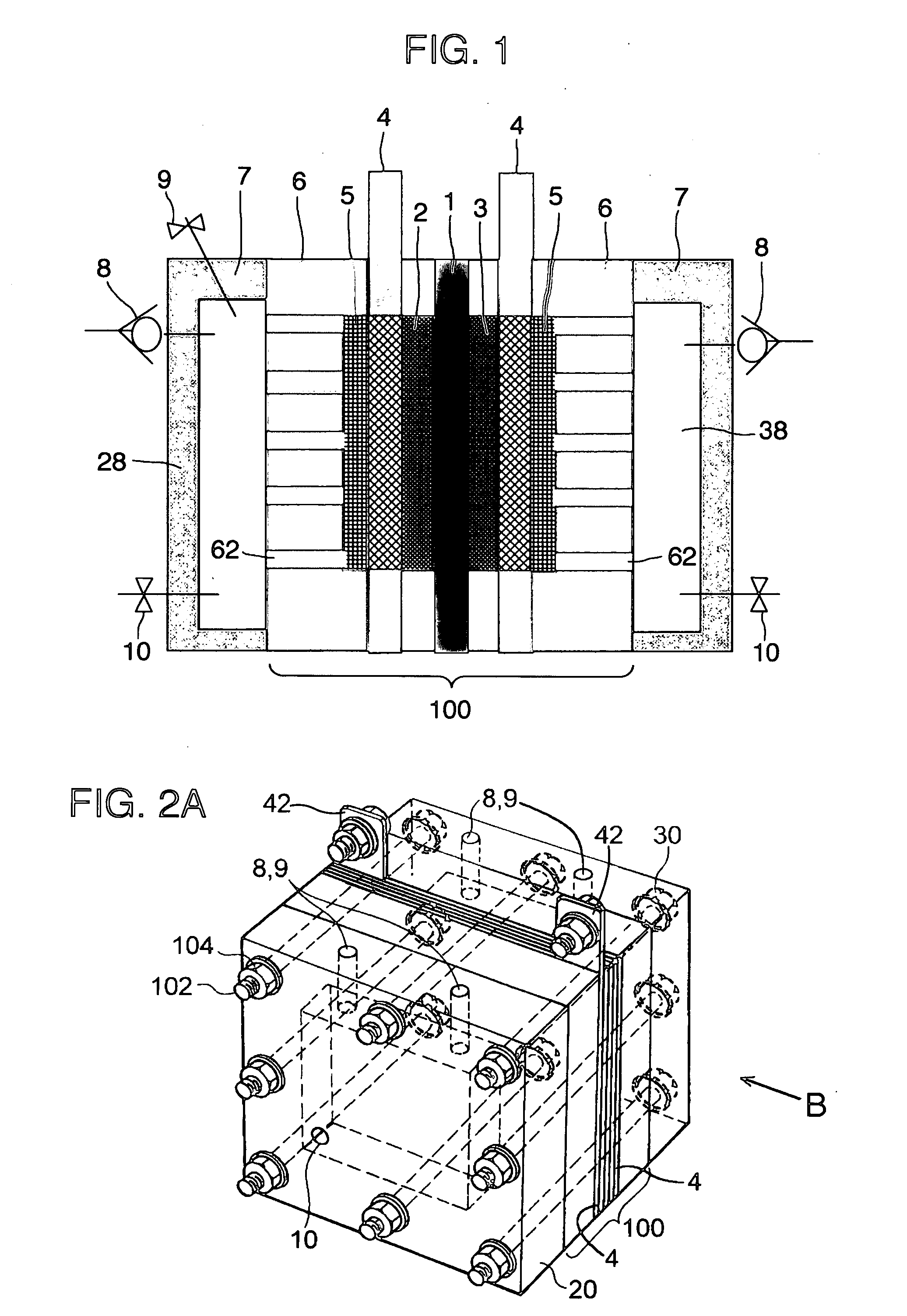

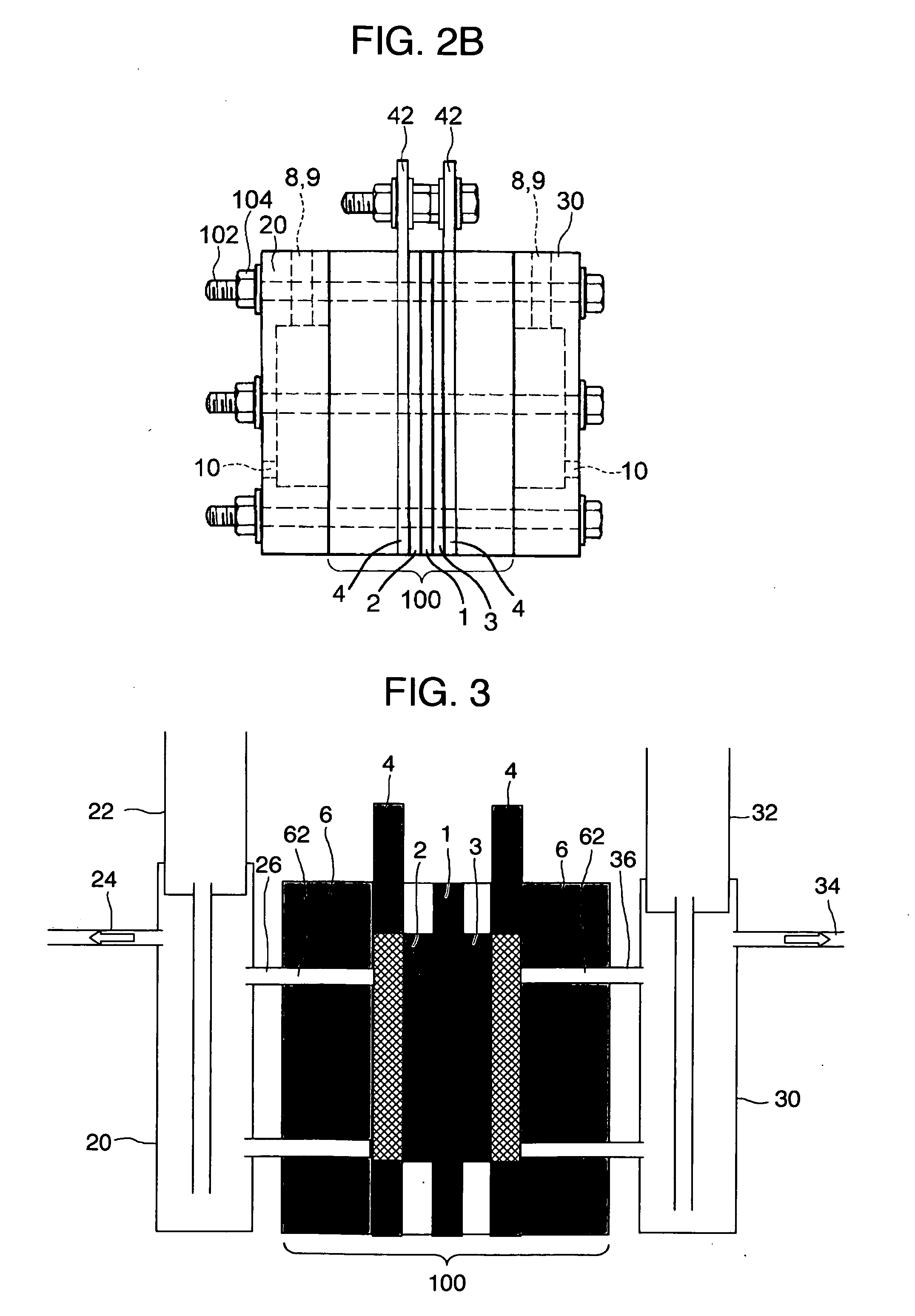

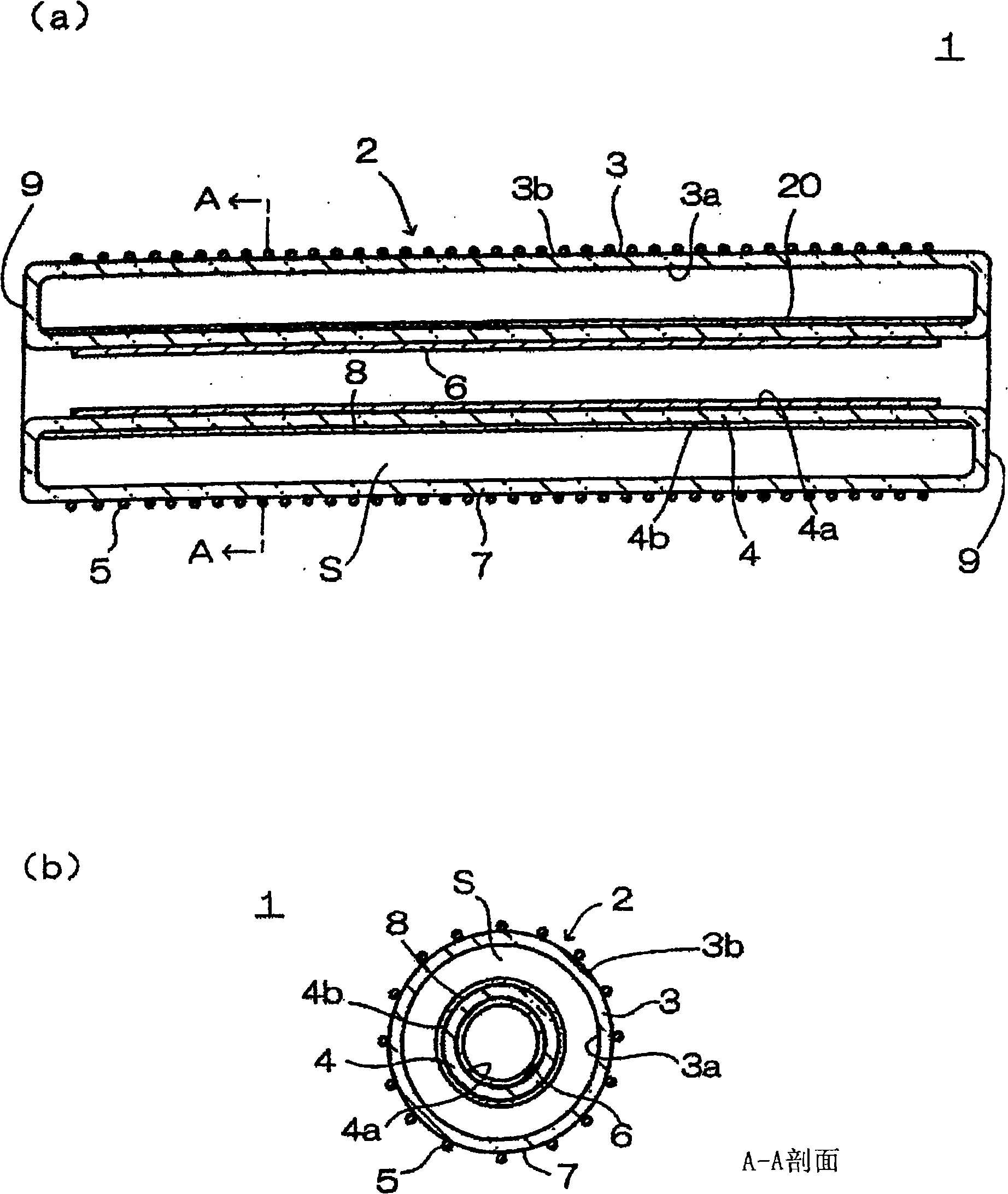

Solid polymer membrane-type water-electrolysis apparatus

A solid polymer membrane-type water-electrolysis apparatus according to the present invention includes a solid polymer electrolyte membrane, an oxygen electrode mounted in contact with one side of the solid polymer electrolyte membrane, a hydrogen electrode mounted in contact with the other side of the solid polymer electrolyte membrane, separator plates mounted adjacent the outsides of the oxygen electrode and the hydrogen electrode and serving as current collector plates having passages for water and generated gasses, fixing plates disposed outside the separator plates and made of a non-conductive material, and reservoirs disposed outside said fixing plates for storing water and the generated gasses. The fixing plates include pressing members build therein for pressing the oxygen electrode and the hydrogen electrode against the solid polymer electrolyte membrane, and flow passages are included in the pressing members. The reservoirs are fixed integrally by tie bolts by clamping the solid polymer electrolyte membrane, the oxygen electrode, the hydrogen electrode, the separator plates and the fixing plates together from outside the fixing plates. Further, the reservoirs have water supply bores provided at locations higher in level than the position of the water electrolysis level, and discharge bores for discharging the generated gasses. In this apparatus, storage tanks for the produced oxygen and hydrogen gasses are formed integrally into a compact structure. Thus, the apparatus is convenient for movement and preservation, and the oxygen and hydrogen gasses stored can be brought into a pressure equal to or higher than the atmospheric pressure and supplied to a remote place.

Owner:DAIDO METAL CO LTD

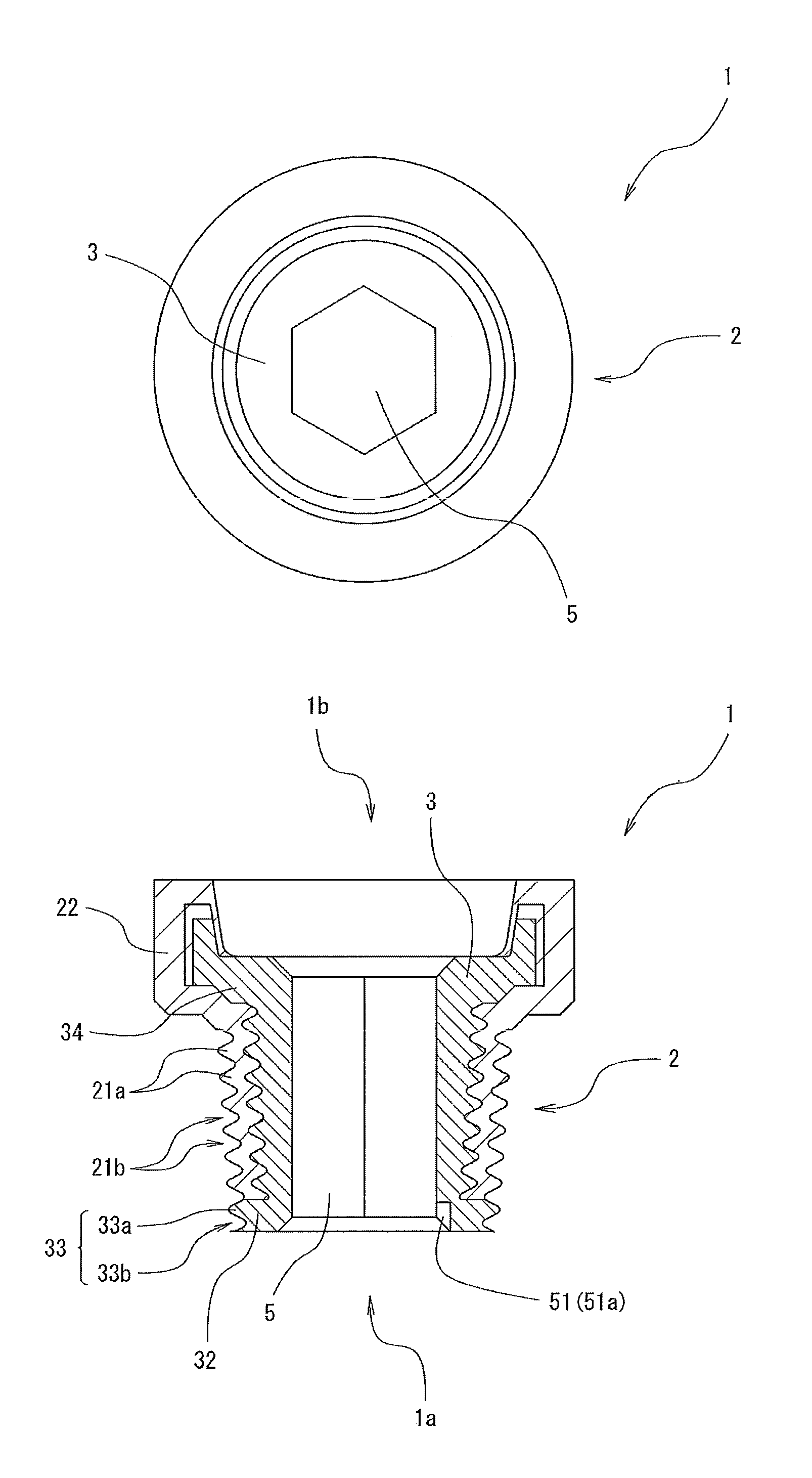

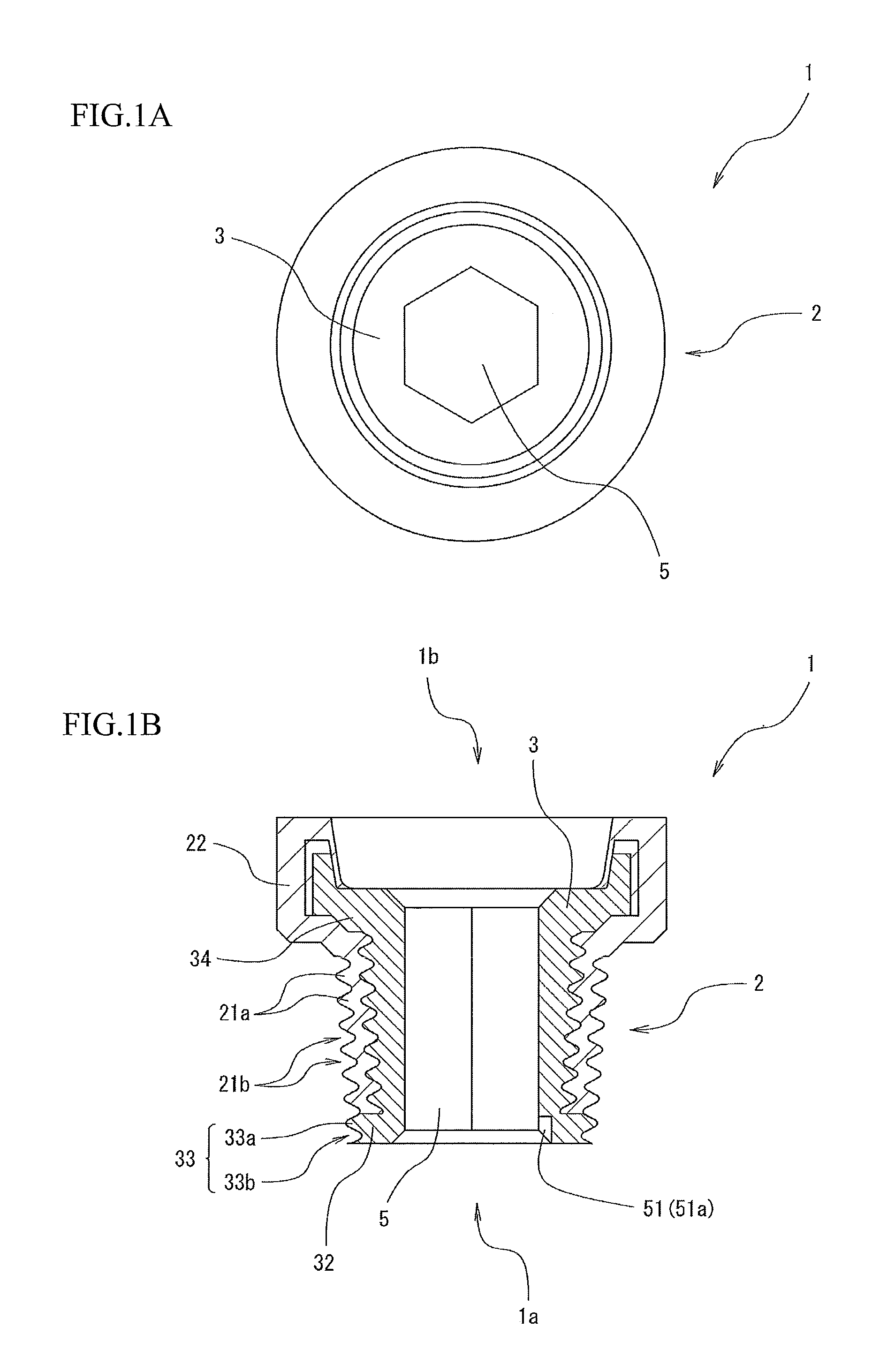

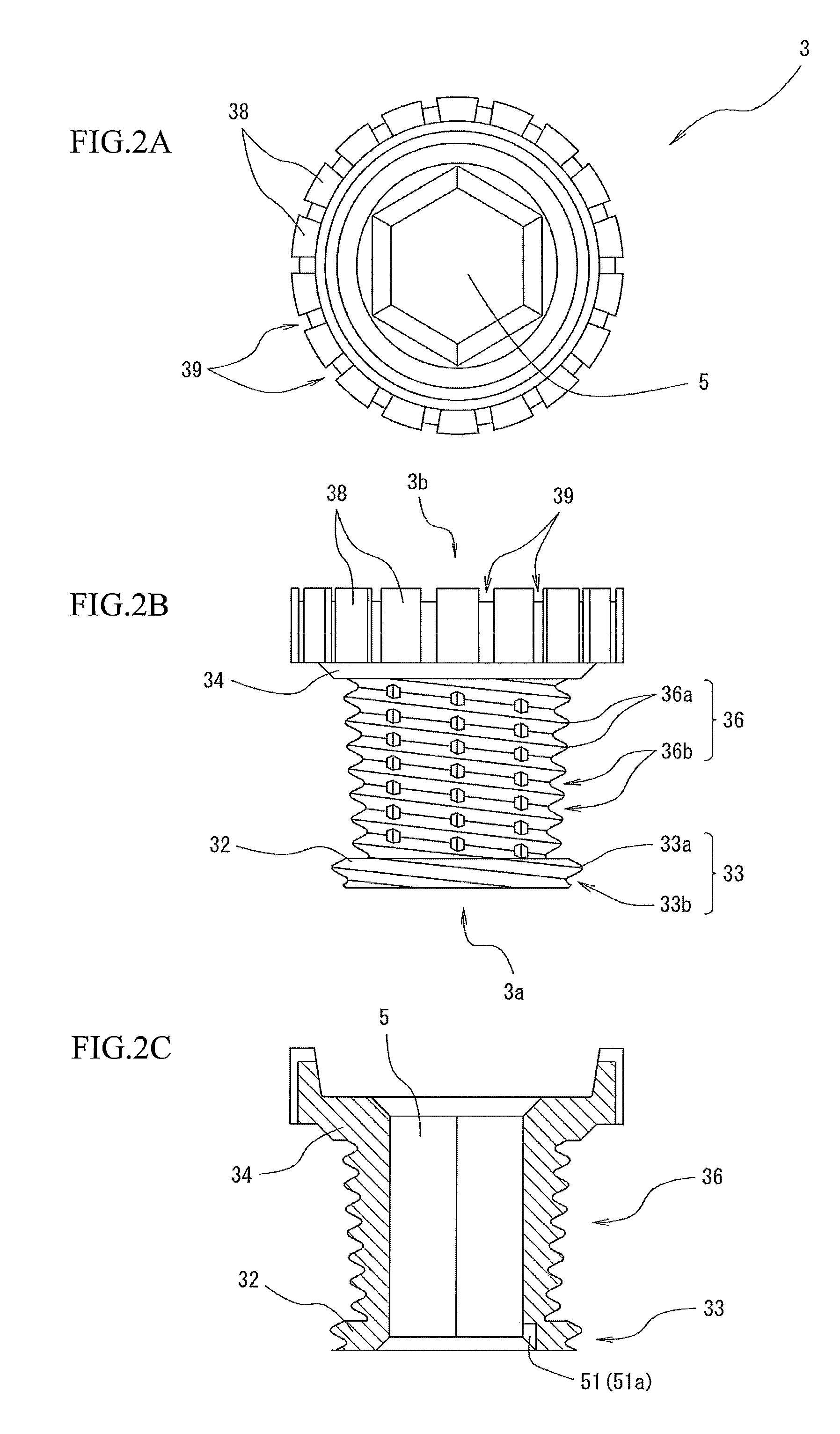

Thread, fastening system, pipe fitting and method for manufacturing thread

To provide a thread in which looseness can be prevented over a long period of time, and a high sealing properties can be maintained, a manufacturing method of the thread, a fastening system using the thread, and a pipe fitting using the thread. A thread according to the present invention is provided, wherein, a screw thread member of which screw threads are formed on an outer periphery thereof and which is made up of a softer material than that of an insert core is formed in a close contact with an outer periphery of the insert core, large-diameter parts that sandwich the screw thread member therebetween in an axis line direction are formed, in a fore end part and a rear end part of the insert core or an intermediate part nearer to the fore end part 3a from the rear end part, and screw threads that are continuous to screw threads of the screw thread member are formed on an outer periphery of a large-diameter part of the fore end part.

Owner:YUGEN KAISHA HAMA INT

Steam generation function-equipped high-frequency heating device

InactiveUS7304278B2Drop in speedClose contactDomestic stoves or rangesBaking ovenEvaporationDie casting

An object of the present invention is to provide a high frequency heating apparatus having a steam generating function in which a time required for evaporation of dropped water can be remarkably increased when water is dropped onto an evaporation tray and the heating efficiency is high.The high frequency heating apparatus has a steam generating function that includes a high frequency generator and a steam generator that includes an evaporation tray provided on the bottom surface of a heating chamber in which a heating target is mounted and a heater device for heating the evaporation tray to generate steam in the heating chamber, wherein the heater device is constructed as a heater device (11) having a sheathed heater (113) embedded in an aluminum die cast (111), and the heater device is directly attached to the back side of the evaporation tray (22).

Owner:PANASONIC CORP

Hollow structure potassium magnesium titanate whisker material and method for preparing the same

InactiveCN104947176AWide variety of sourcesReduce manufacturing costPolycrystalline material growthFrom solid stateFiltrationPhysical chemistry

The invention relates to a hollow structure potassium magnesium titanate whisker material and a method for preparing the same. The technical scheme is that the method comprises evenly mixing a titanium-containing raw material, a magnesium-containing raw material and a binding agent, performing forming, performing heat treatment and then grinding the mixture to obtain a material A with the particle size of 0.088-1 mm and a material B with the particle size smaller than 0.088 mm; evenly mixing a potassium-containing raw material, a titanium-containing raw material and a binding agent, performing forming, performing heat treatment and then grinding the mixture to obtain a material C with the particle size smaller than 0.088 mm; evenly mixing the material A, the material B, the material C and a potassium-containing raw material, performing heat treatment and then grinding the mixture to obtain a ground material; finally adding the material C, the potassium-containing raw material and water to the ground material, mixing the mixture, pressing the mixture into green bodies, drying the green bodies, performing heat treatment, and then performing washing, filtration and drying to obtain the hollow structure potassium magnesium titanate whisker material. The external diameters of whiskers of the prepared hollow structure potassium magnesium titanate whisker material are 0.1-5 microns, the internal diameters of the whiskers are 0.05-1 micron, and the lengths of the whiskers are 3-30 microns. The hollow structure potassium magnesium titanate whisker material is high in crystallinity and uniform in size.

Owner:WUHAN UNIV OF SCI & TECH

Wearing article

ActiveCN101795653AAvoid exposurePrevent hangingAbsorbent padsBaby linensEngineeringMechanical engineering

A wearing article in which non-contractible regions on which contracting force of elastic members does not act are formed in front and rear waist belts and in which the elastic members do not protrude from the non-contractible regions and are not caught by the non-contractible regions. The front and rear waist members (5, 6) have mounted thereto the waist elastic members (18) extending in the vertical direction (Y). The waist elastic members (18) form the non-contractible regions (35), on which contracting force of the waist elastic members (18) does no act, without being superposed on portions where graphics of heat-bonded sheets (16, 17) are formed. The non-contractible regions (35) are formed in center portions in the lateral direction (X) of the front and rear waist belt members (5, 6) by cutting the waist elastic members (18) mounted in a stretched state without applying an adhesive agent between inner and outer surface sheets (12, 13)(14, 15). On the crotch-side edges (21, 22) of the non-contractible regions (35) are formed joined sections (36) where the inner and outer surface sheets (12, 13)(14, 15) are joined together by heat sealing.

Owner:UNI CHARM CORP

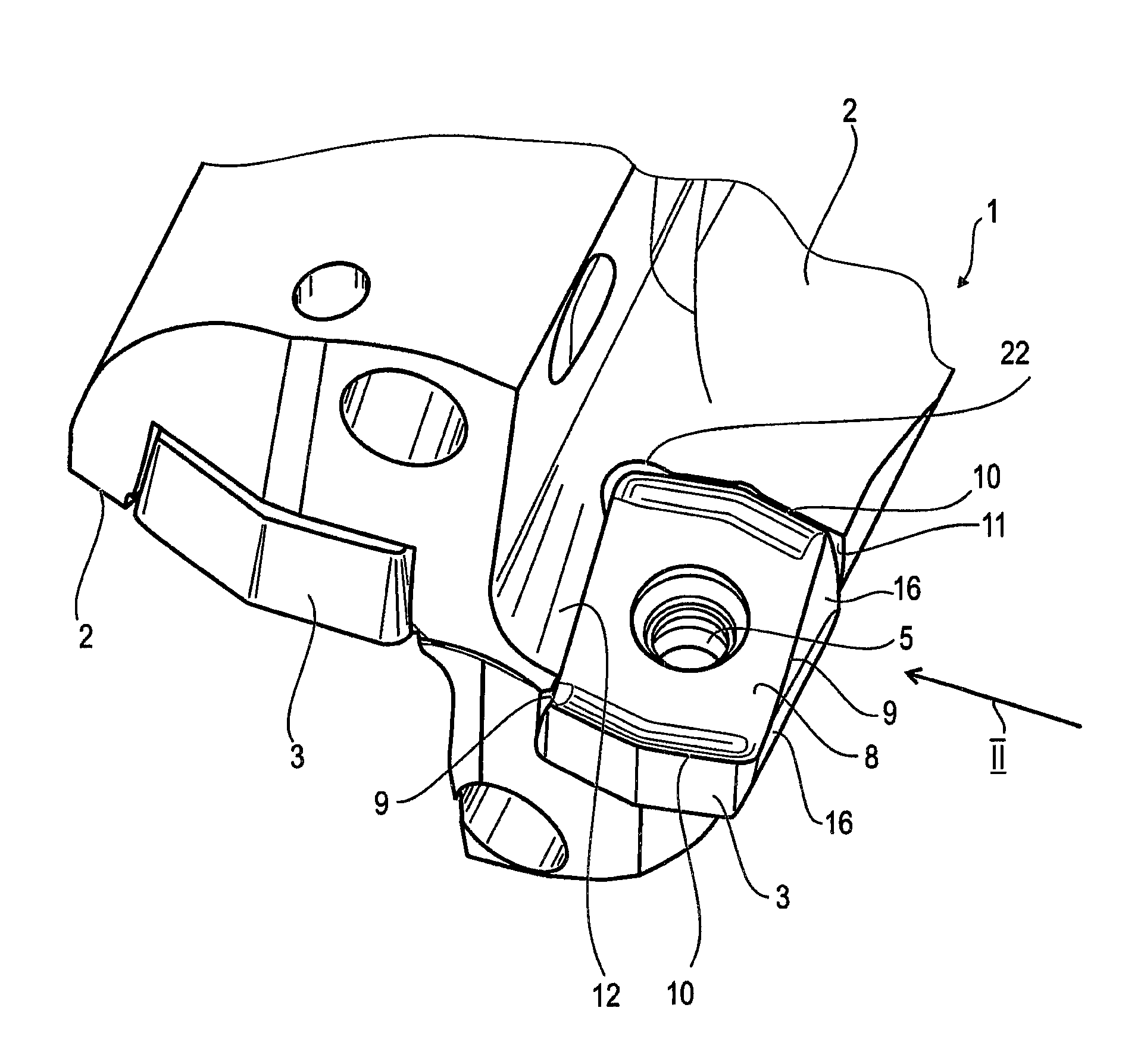

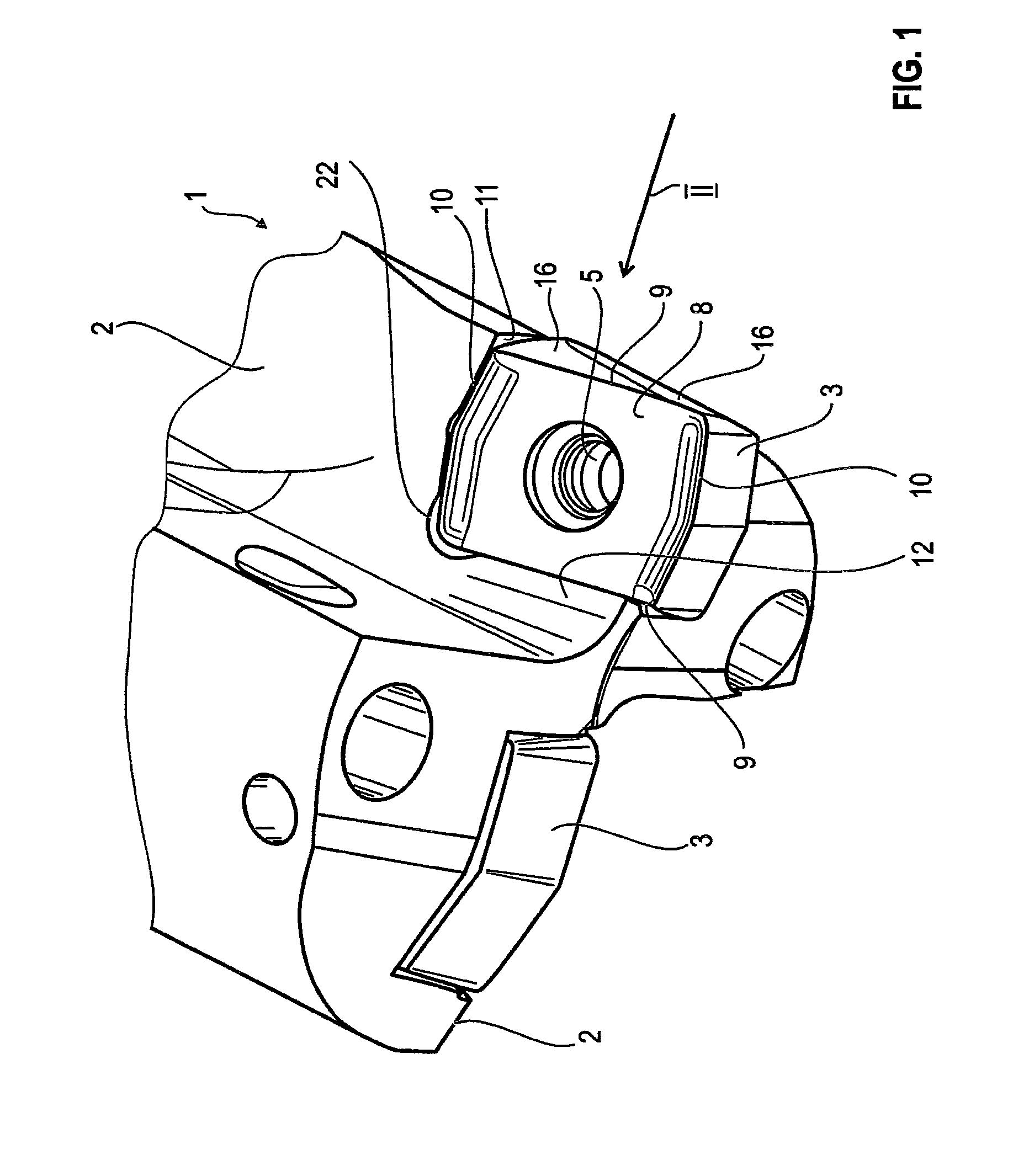

Drilling Tool

ActiveUS20100322732A1Cost advantageReduce materialWood turning toolsTransportation and packagingSwarfDrill hole

The invention discloses a drilling toll having at least one chip groove for chip removal, having an insert seat which is formed at the end of the chip groove and serves as a holder for an indexable insert with at least one main cutting edge on the two narrow sides and with at least one secondary cutting edge on the two longitudinal sides of one face side wherein the indexable insert has two face sides facing away from one another and bears with its inactive face side on a holding surface of the insert seat, and a partial region of the inactive secondary cutting edge of its active face side lies in the insert seat at a distance from the adjoining side wall of the insert seat created by a slot, and wherein a guide lip which covers the slot protrudes out of the top side of the side wall in the direction of the inactive secondary cutting edge.

Owner:KENNAMETAL INC

High-infrared reflectivity high-aluminum light fire-resistant thermal insulating material and preparation method thereof

InactiveCN104944987AWide variety of sourcesReduce manufacturing costPhysical chemistryThermal treatment

The invention relates to a high-infrared reflectivity high-aluminum light fire-resistant thermal insulating material and a preparation method thereof. According to the technical scheme of the High-infrared reflectivity high-aluminum light fire-resistant thermal insulating material and the preparation method thereof, 20-40 wt% of potassic raw material, 50-70wt% of titaniferous raw material and 5-10 wt% of binding agents are uniformly mixed, grinding is conducted after molding and thermal treatment are conducted, and A material with particle size ranging from 0.088-1 mm and B material with particle size smaller than 0.088 mm are obtained. 20-40 wt% of alumina particles, 10-25 wt% of alumina fine powders, 5-15 wt% of A material, 5-15 wt% of B material, 5-15 wt% of aluminiferous raw material and 2-10 wt% of potassic raw material are used as mixture, water containing 2-8 wt% of the micture are added, a green body is made by stirring, drying is conducted, cooling is conducted after the thermal treatment is conducted, the green body is soaked with water, then drying is conducted, and the high-infrared reflectivity high-aluminum light fire-resistant thermal insulating material is obtained. The high-infrared reflectivity high-aluminum light fire-resistant thermal insulating material has the advantages that the volume density is low, the compression strength is high, and the high-temperature heat conductivity coefficient is low. The high-infrared reflectivity high-aluminum light fire-resistant thermal insulating material can also be applied to the heat insulation field within 1300 DEG C for a long time.

Owner:苏安能建筑新材料(苏州)有限公司

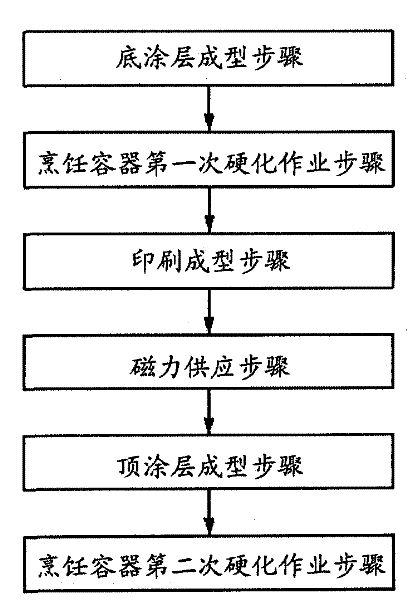

Cooking vessel processing method and cooking vessel provided thereby

InactiveCN102186388AMeet needsWon't fall offCooking-vessel materialsPretreated surfacesCeramic coatingHigh surface

The present invention relates to a cooking vessel processing method and a cooking vessel provided thereby, and more specifically, to a cooking vessel processing method, which involves forming a base-coating layer over a base that is formed at the bottom of the cooking vessel; forming a printing layer over the base-coating layer by pad printing or screen printing; and forming a top-coating layer over the printing layer, and to a cooking vessel provided by the processing method. Conventional cooking vessels commonly use fluorine resin based materials as a non-stick coating material, but they have a weak surface strength (H 2~3) and the coating comes off during use or can be plasticized at high temperature (400? or above), thereby deforming the base materials.; However, a ceramic coating method using a sol-gel technique provides a high surface strength (H 8~9) and a coating provided thereby does not come off even when cleaned with a scrubbing sponge or pad or scraped down by a metal spatula such that a cooking vessel having such a coating can be washed with water and used continuously in a hygienic manner. Further, the coating provided by the sol-gel technique gets plasticized at a low temperature (200? or below), thereby preventing the base materials from being deformed, and the coating is possible over a variety of materials.; In the cooking vessel thus configured according to the present invention, the printing layer formed over the base-coating layer has various patterns, and the color of the printing layer changes depending on a heating temperature being transferred to the cooking vessel, which in turn helps a user determine the temperature being transferred to the cooking vessel with the naked eye. In addition, the top-coating layer formed over the base-coating layer contains a blend of magnetic elements such as iron, magnesium, cobalt and the like, and displays various patterns on the top of the cooking vessel depending on the angle of view and attracts the interest of users.

Owner:河相薰

Pneumatic tire assembly

InactiveCN101348056AEasy to installGuaranteed uniformityRimsWith separate inflatable insertsEngineeringFlange

A pneumatic tire assembly comprising a rim, a pneumatic tire that has a double structure including an outer tire and an inner tire inserted thereinto, and is assembled with the rim, and air chambers formed inside and outside the inner tire, wherein the rim includes a pair of bead seats on which bead portions of the outer tire and the inner tire are placed, a first rim flange protruding outward in a diameter direction of the tire from a side end of the bead seat, a second rim flange disposed inside the first rim flange in a rim width direction and formed on at least one of the bead seats while protruding therefrom, and an air valve provided to the second rim flange, the outer tire is held by the first rim flange and the second rim flange with the bead portion thereof being nipped therebetween, the inner tire is mounted with the bead portion thereof being in internal contact with the second rim flange, and in an outer wall surface area of the inner tire extending outward from a position of a maximum height of the second rim flange in a diameter direction of the tire, a groove portion for feeding air supplied via the air valve into the air chamber formed outside the inner tire is formed into a concave shape.

Owner:TOYO TIRE & RUBBER CO LTD

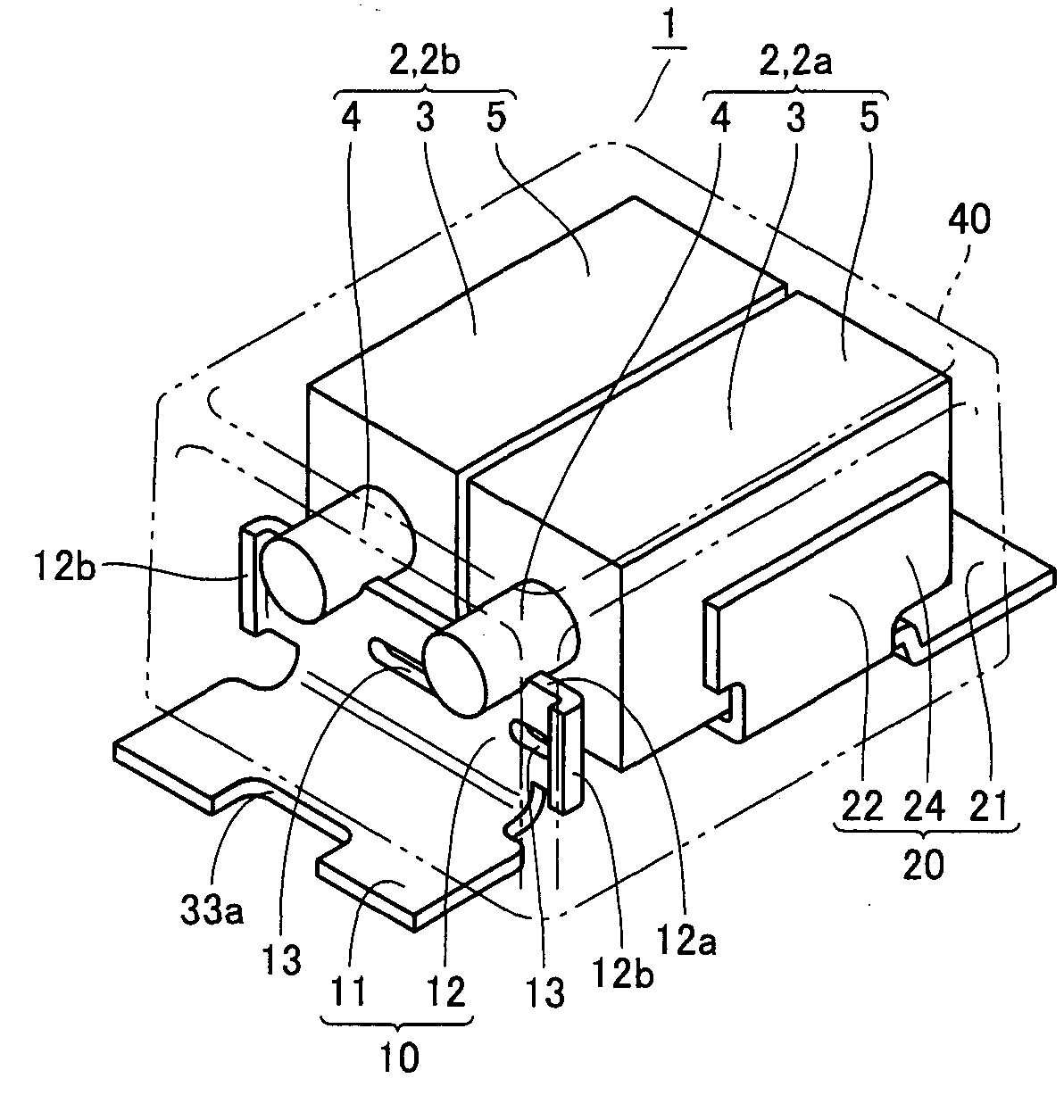

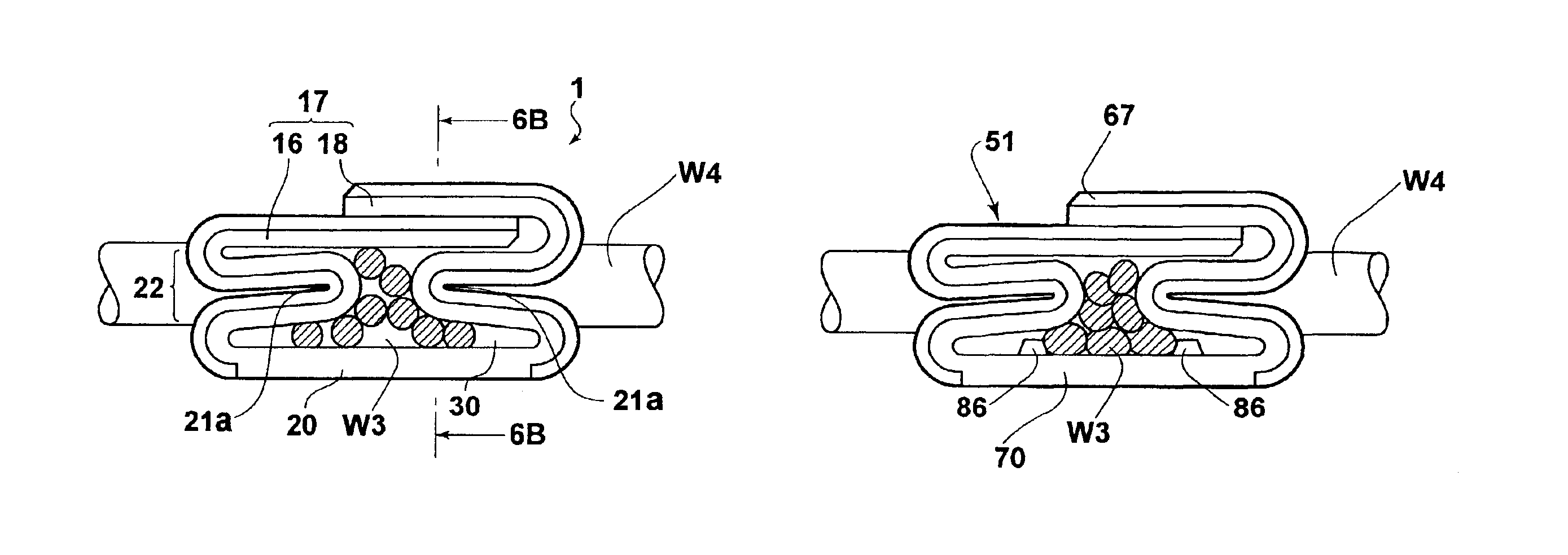

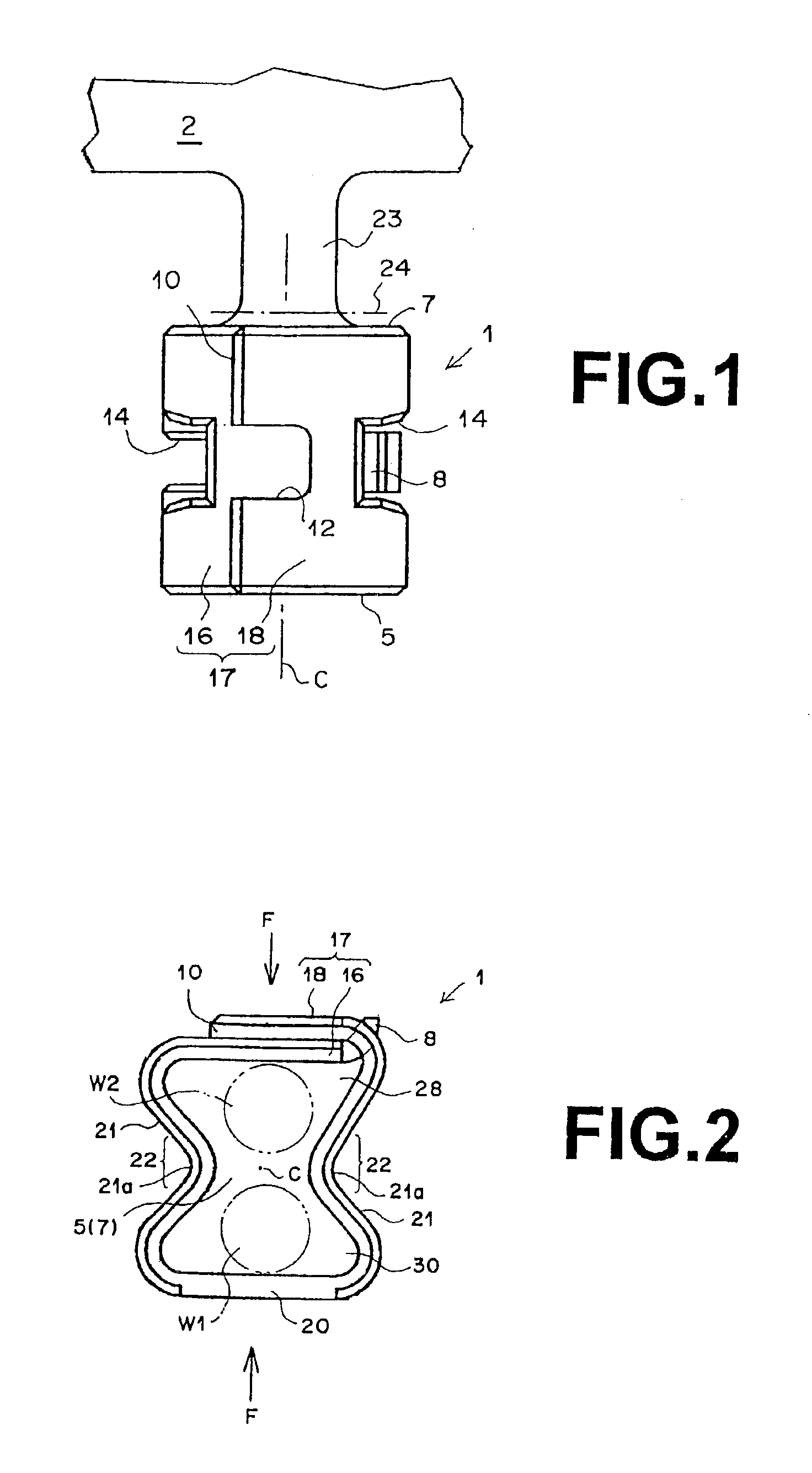

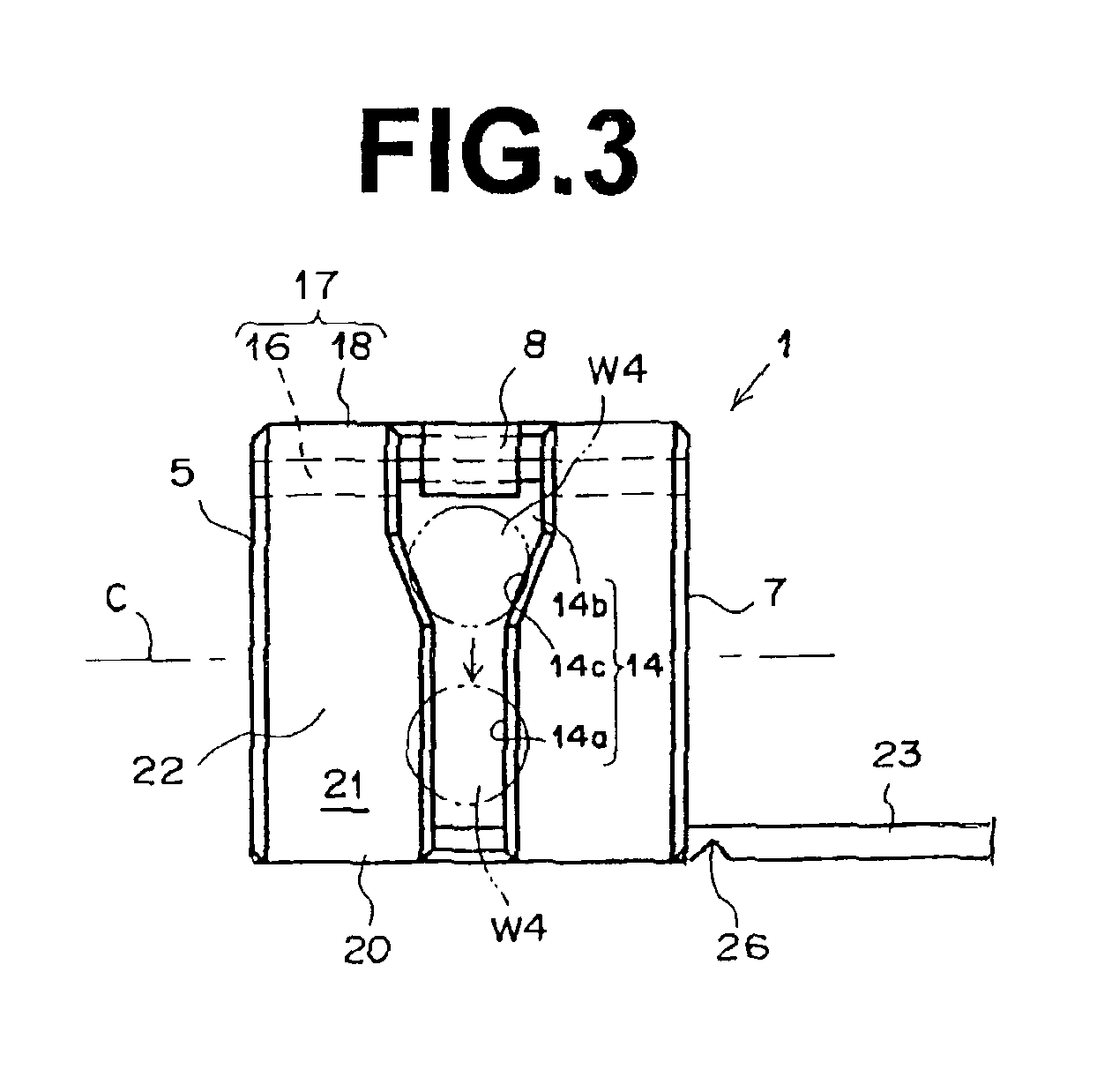

Wire connector suitable for miniaturization

InactiveUS6881104B2High mechanical strengthNot likely to deformConnections effected by permanent deformationContact members penetrating/cutting insulation/cable strandsEngineeringElectric wire

A wire connector for connecting wires to each other having a small wire collection space and which transmits a small shock load to the wires connected therein is formed by bending a metal plate at both sides of a central portion to form a closed ring having open ends at both ends thereof. Depressions that protrude toward the interior of the closed ring so that they approach each other are formed at the central portions of both side walls of the closed ring. A vertically extending slot is formed in each of the side walls. Wires are inserted through each of the open ends and the slots, then pressure is applied so that the portion where the ends of the bent metal plate are coupled and the central portion approach each other. The pressure compressively deforms the connector, and the wires are electrical connected to each other.

Owner:THE WHITAKER CORP

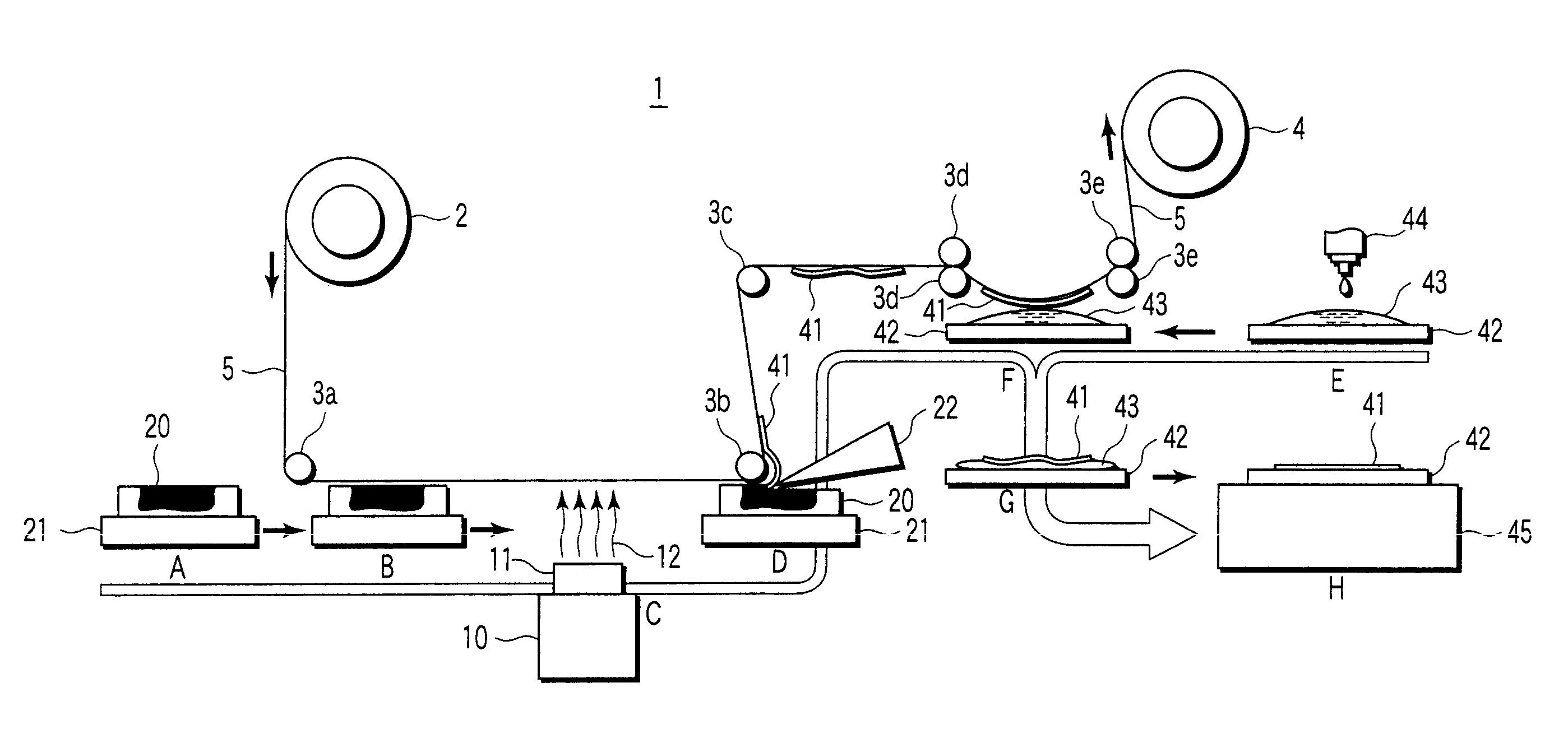

Sample slice preparation device and sample slice preparation method

ActiveUS7811518B2Improve handlingReduce dependenceWithdrawing sample devicesSurgeryApplied waterSlice preparation

A sample slice preparation device of the present invention has a microtome which slices a solid specimen by a knife, a humidifier which imparts moisture to a carrier tape, slice conveyer means for adsorbing a slice by an adsorbing force of moisture imparted to the carrier tape to feed out the slice, transfer mechanism for applying water to the surface of a slide glass to transfer the slice from the carrier tape onto the slide glass by an adsorbing force of applied water, an extension unit which heats the slide glass having the slice adsorbed thereon to evaporate the moisture, thereby extending the slice, and slide glass conveyer means for conveying the slide glass provided with the slice.

Owner:TOSHIBA MASCH CO LTD

Rolling connection method for dissimilar refractory metal molybdenum and stainless steel composite board

InactiveCN101362148AUniform tissueUniform performanceTemperature control deviceMetal rolling arrangementsCopper foilVacuum chamber

A rolling and connecting method of heterogeneous refractory metal molybdenum and stainless steel clad plates relates to a composition method of a heterogeneous refractory metal molybdenum and the stainless steel clad plate, aiming at the problems that owing to the great difference between the physical properties of molybdenum and stainless steel, the welding stress is high, great amount of intermetallic compounds with high hardness and great brittleness can be easily produced due to direct connection, and the impact ductility of molybdenum is low in the condition of low temperature, etc. The method comprises the steps that: the connecting surface of a stainless steel plate and a molybdenum plate is milled to be flat; after the acid cleaning of the stainless steel plate, the molybdenum plate and purple copper foil, the purple copper foil is placed and fixed between the stainless steel plate and the molybdenum plate to form the clad plate which is then placed into a vacuum chamber; the vacuity is (1 to 3) multiplied by 10<-3>Pa, the heating temperature is 850 to 1050 DEG C, and the heating speed is 300 to 600 DEG C / h; after the insulation for 10 to 45 minutes, the clad plate is rolled and connected; the rolling temperature is 850 to 1050 DEG C, the compression rate is 15 to 35 percent and the rolling speed is 0.038 to 0.2m / s; the clad plate after being rolled is cooled to be below 200 DEG C in vacuum and then the clad plate is taken out. The method can realize the purpose of the high strength connection between the molybdenum, the ductility of which is low in the condition of low temperature, and the stainless steel.

Owner:HARBIN INST OF TECH

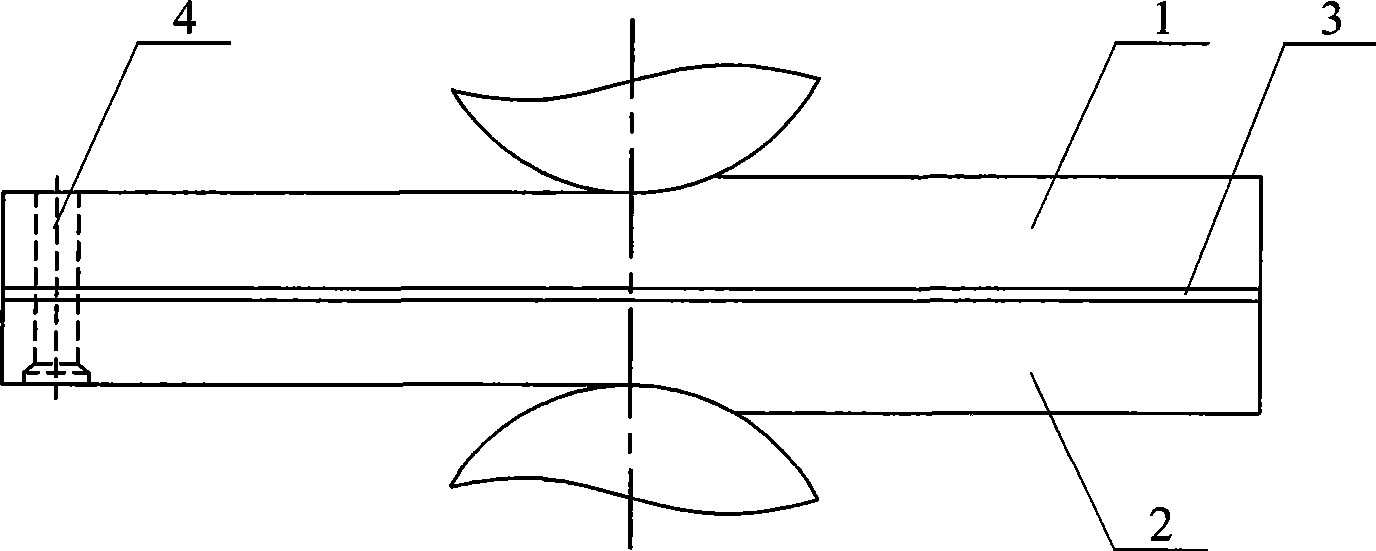

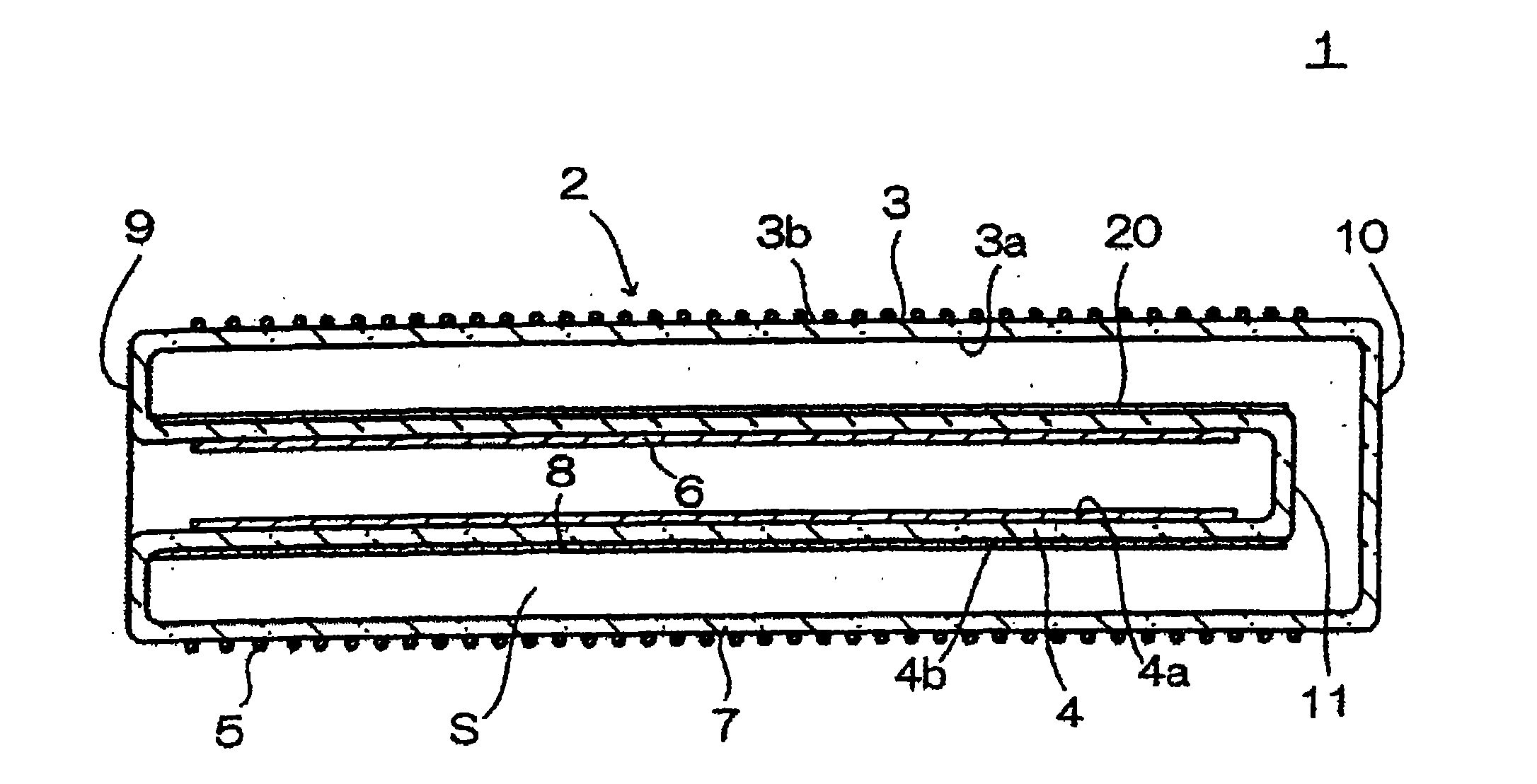

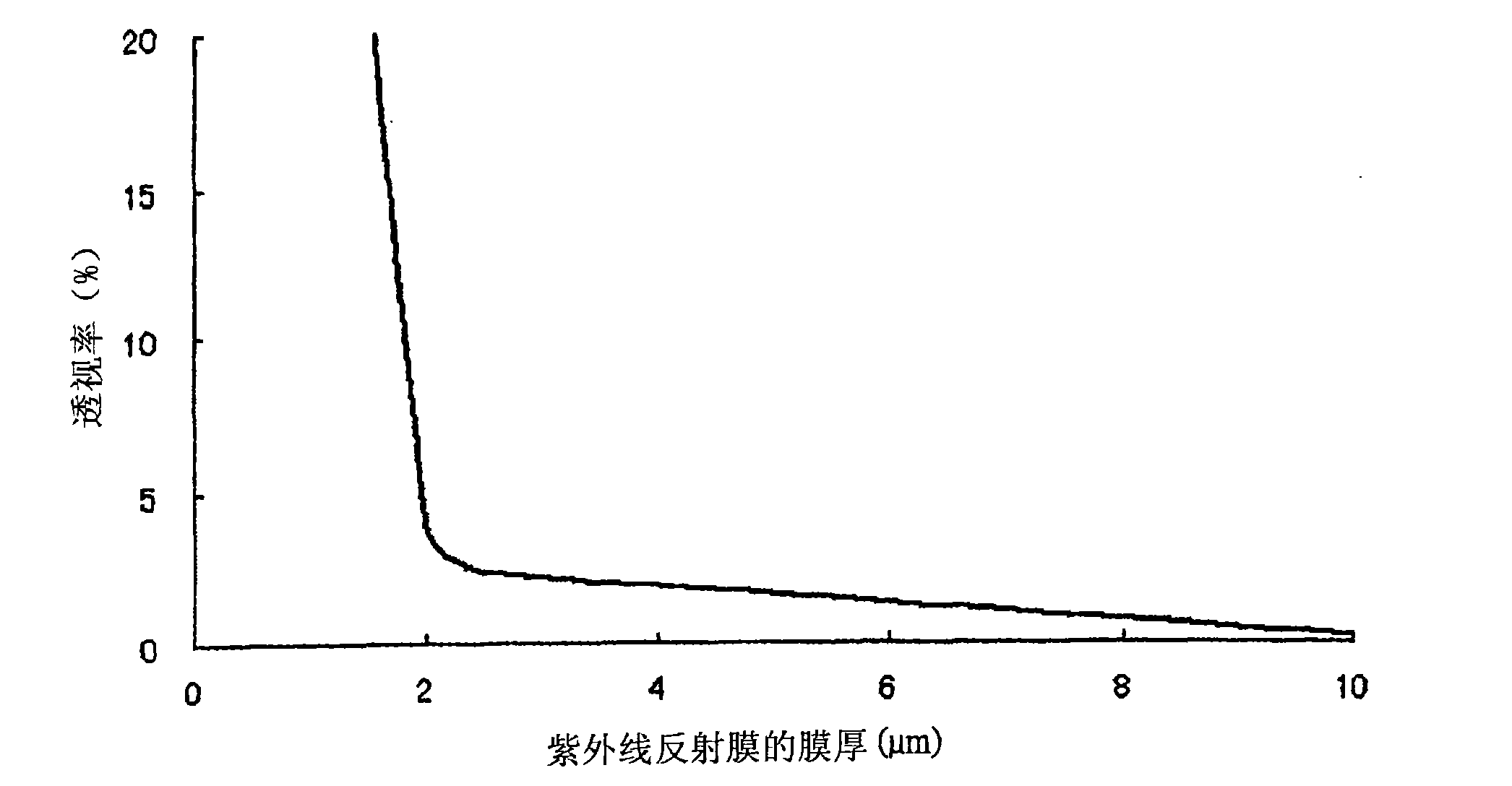

Excimer lamp

ActiveCN101540264AResolve the breakAvoid exposureElectric discharge tubesGas discharge lamp detailsEngineeringXenon

The invention provides an excimer lamp which generates excimer discharge in discharge space to radiate vacuum ultraviolet light. Melted quartz glass forms a part of a discharge container. The excimer lamp (1) has a discharge container (2) made of quartz glass and composed of a dual pipe of which the inside pipe (4) and the outside pipe (3) are disposed in the coaxial direction; a pair of electrodes (5), (6) is disposed in a state of the quartz glass forming the discharge container (2); xenon gas is sealed in the discharge space (S); excimer discharge happens in the discharge space (S) of the discharge container (2). The invention is characterized in that the inside pipe (4) is made from melted quartz glass and the outside pipe (3) is made from synthesized quartz glass.

Owner:USHIO DENKI KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com