Cooking vessel processing method and cooking vessel provided thereby

A technology of cooking containers and processing methods, which is applied to the structure of cooking utensils, special materials for cooking utensils, cooking utensils, etc., which can solve problems such as unusable, limited use, and shedding of fluororesin, so as to avoid the danger of fire and prevent the waste of heat energy , good effect of close contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

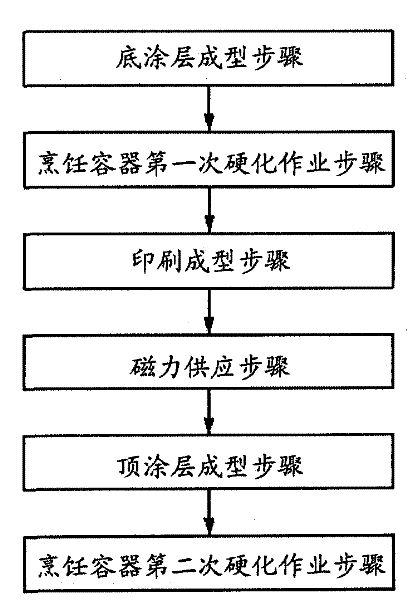

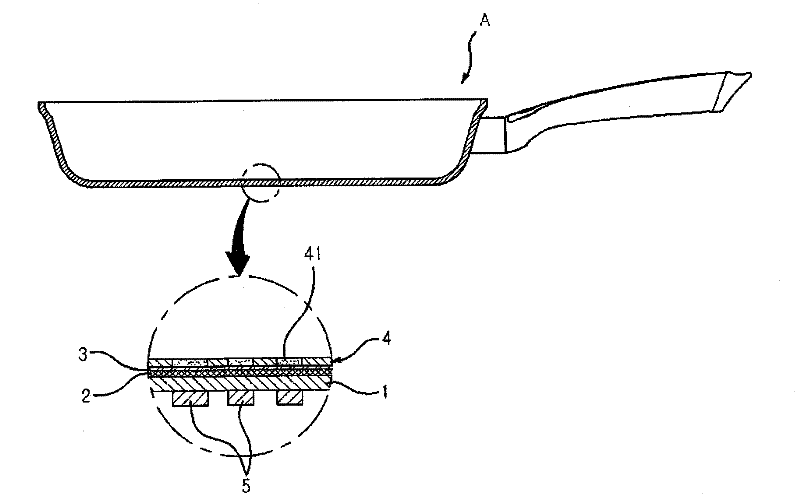

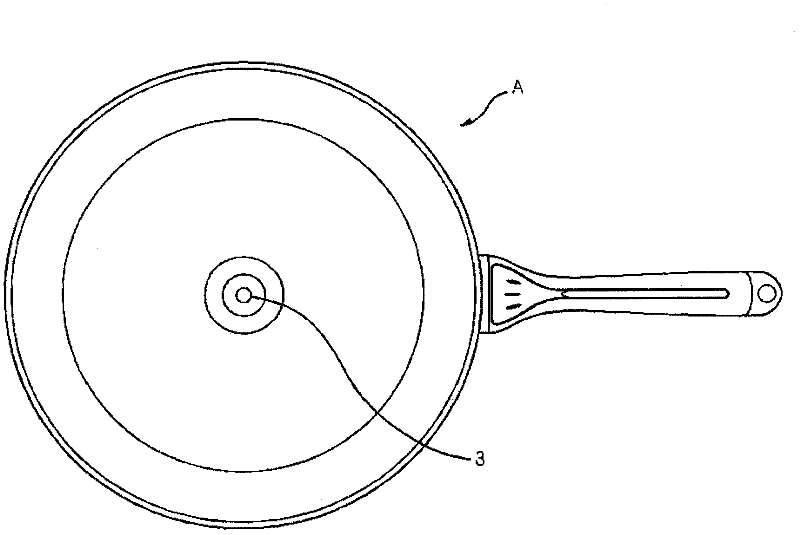

[0051] figure 1It is a block diagram of the present invention, as shown in the figure, comprising the following steps: bottom coating 2 forming step; after said bottom coating 2 forming step, the cooking container is dried at a temperature of 100-200 degrees for 30-40 minutes A first hardening operation step; after the first hardening operation step of the cooking container A, the printing forming step of forming the printing layer 3 by a printing machine; After the preheating operation, the ceramic material of transparent material is supplied to form the top coating 4 forming step of the top coating; after the top coating 4 forming step, the cooking container A is dried at a temperature of 100-200 degrees for 30- 40 minutes Ovenware A second hardening job step.

[0052] The constituent elements of the top coat 4 of the cooking container A having the above-described structure contain a magnetic substance that is sensitive to magnetic force, and the lower surface of the cooki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com