Combination bearing type large-specification movable elbow mechanism

A combined bearing and movable elbow technology, applied in drilling equipment, wellbore/well components, earth-moving drilling and production, etc., can solve the problems of limited bending structure, limited volume requirements, and large structural volume, etc. Diversified molding methods, wide adaptability and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

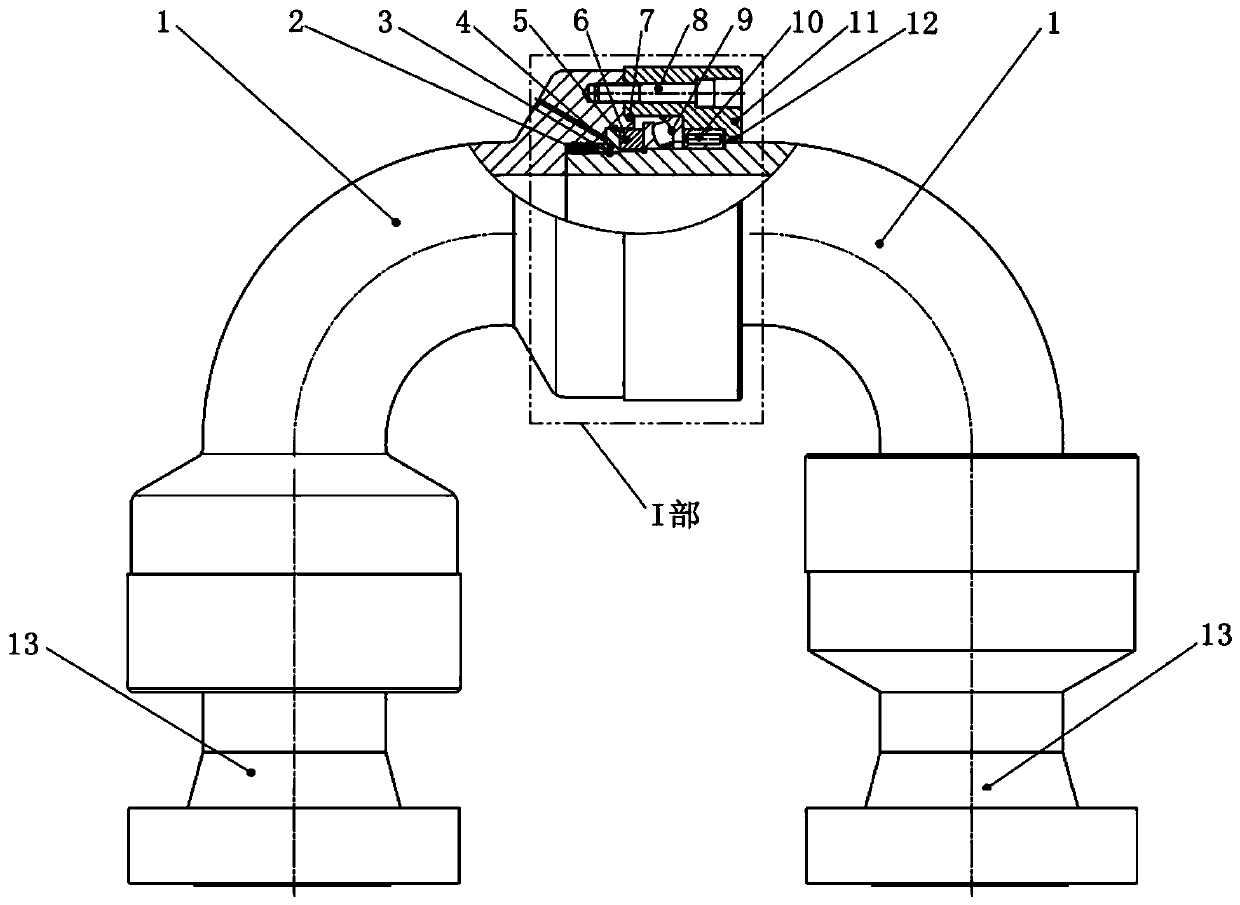

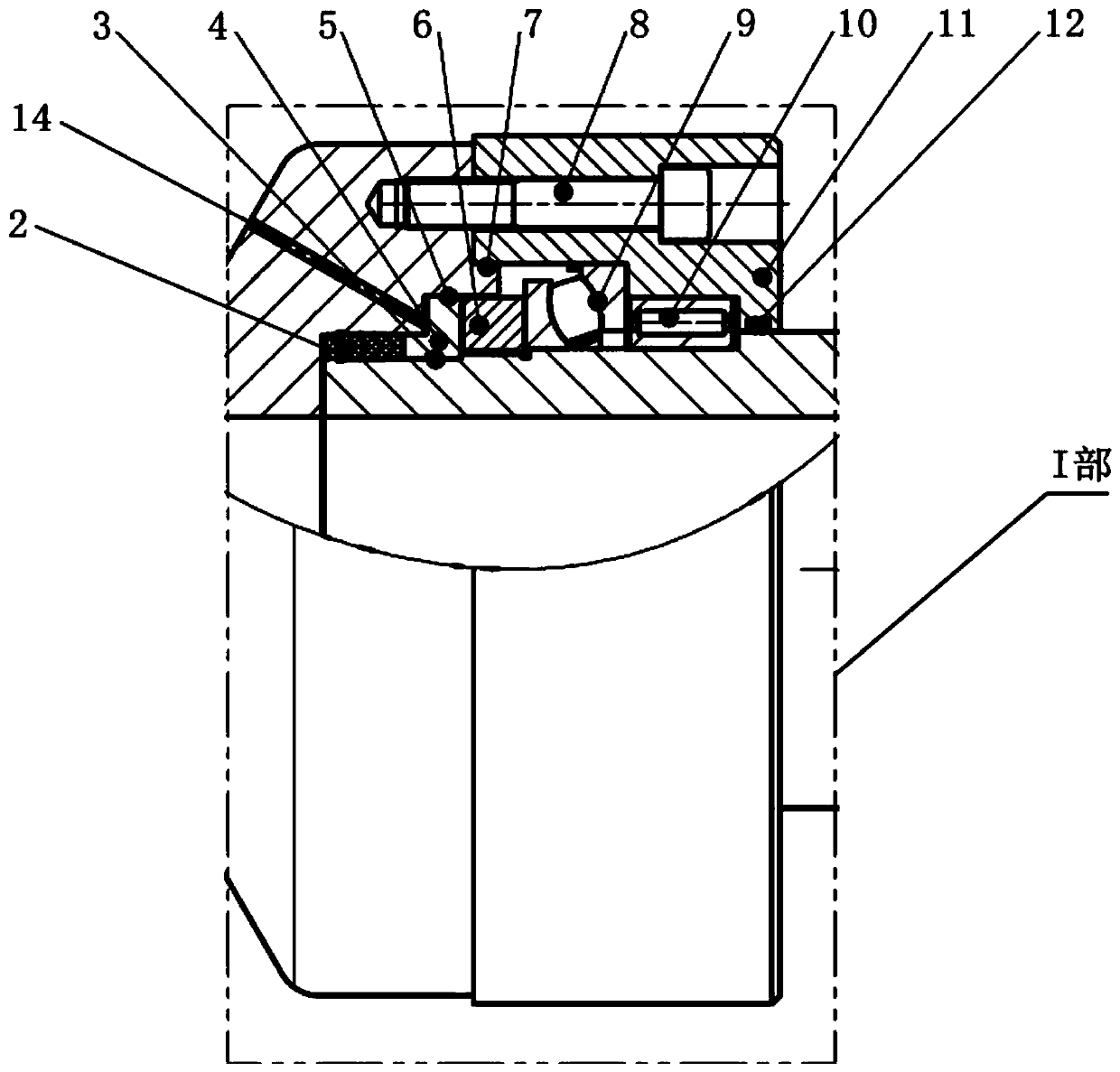

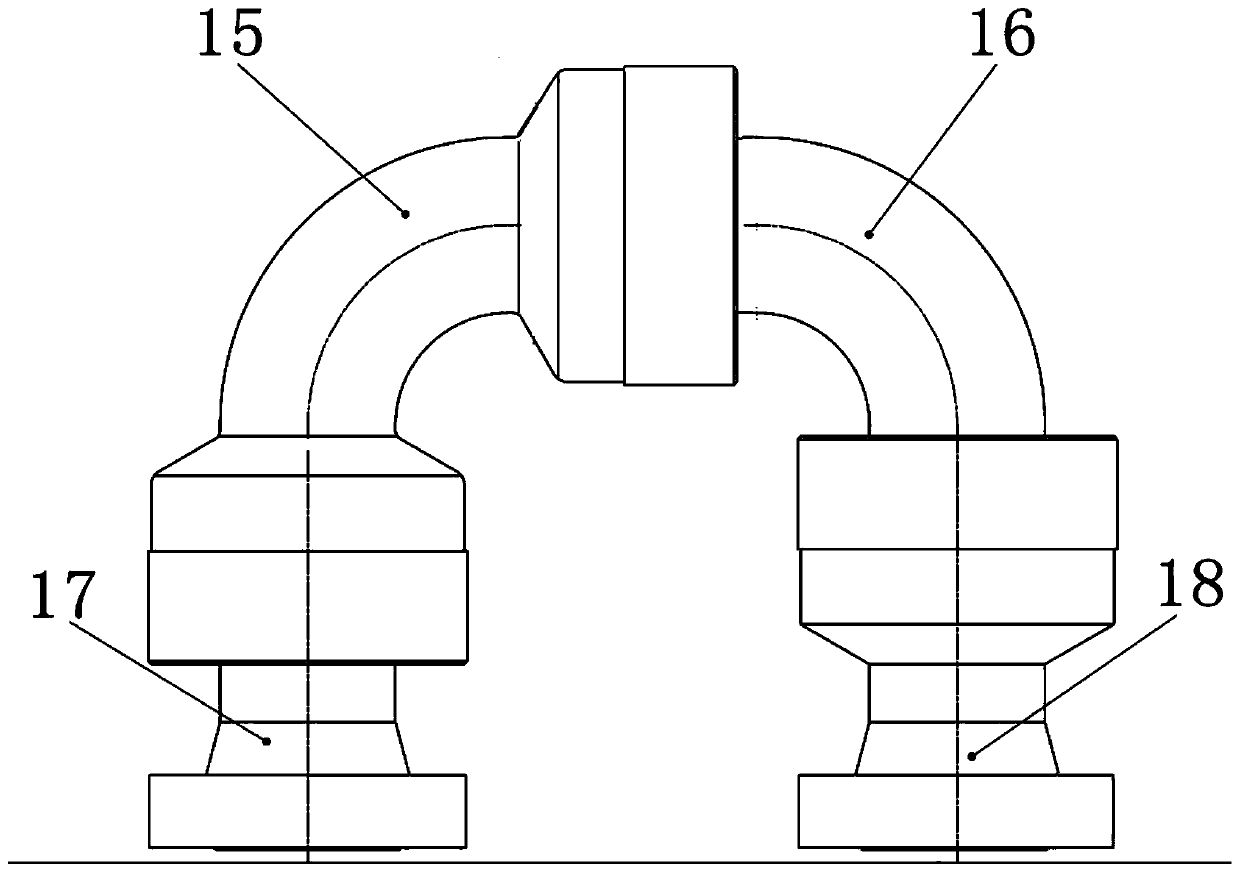

[0026] Such as Figures 1 to 4 As shown, a combined bearing type large-size swivel elbow mechanism, a combined bearing type large-size swivel elbow mechanism includes an elbow 1, a connecting head 13, a gland 11, a packing seal assembly 2 and a rotating assembly. Between the elbow 1 and the connector 13, the elbow 1 and the elbow 1 are fixedly connected by the gland 11 and sealed by the packing seal assembly 2. Between the gland 11 and the connector 13, the gland 11 A cavity is formed between the elbow and the elbow 1, and a rotating assembly is installed in the cavity. The rotating assembly is used to connect the head 13 or the relative rotation of the elbow 1. The rotating assembly includes a radial bearing 10 and a thrust bearing 9, so The flexible connection between the elbow 1 and the connecting head 13 and between the elbow 1 and the elbow 1 is described. Different numbers of elbows 1 are connected according to actual needs. According to the different distance differen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com