Patents

Literature

259results about How to "Vibration relief" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

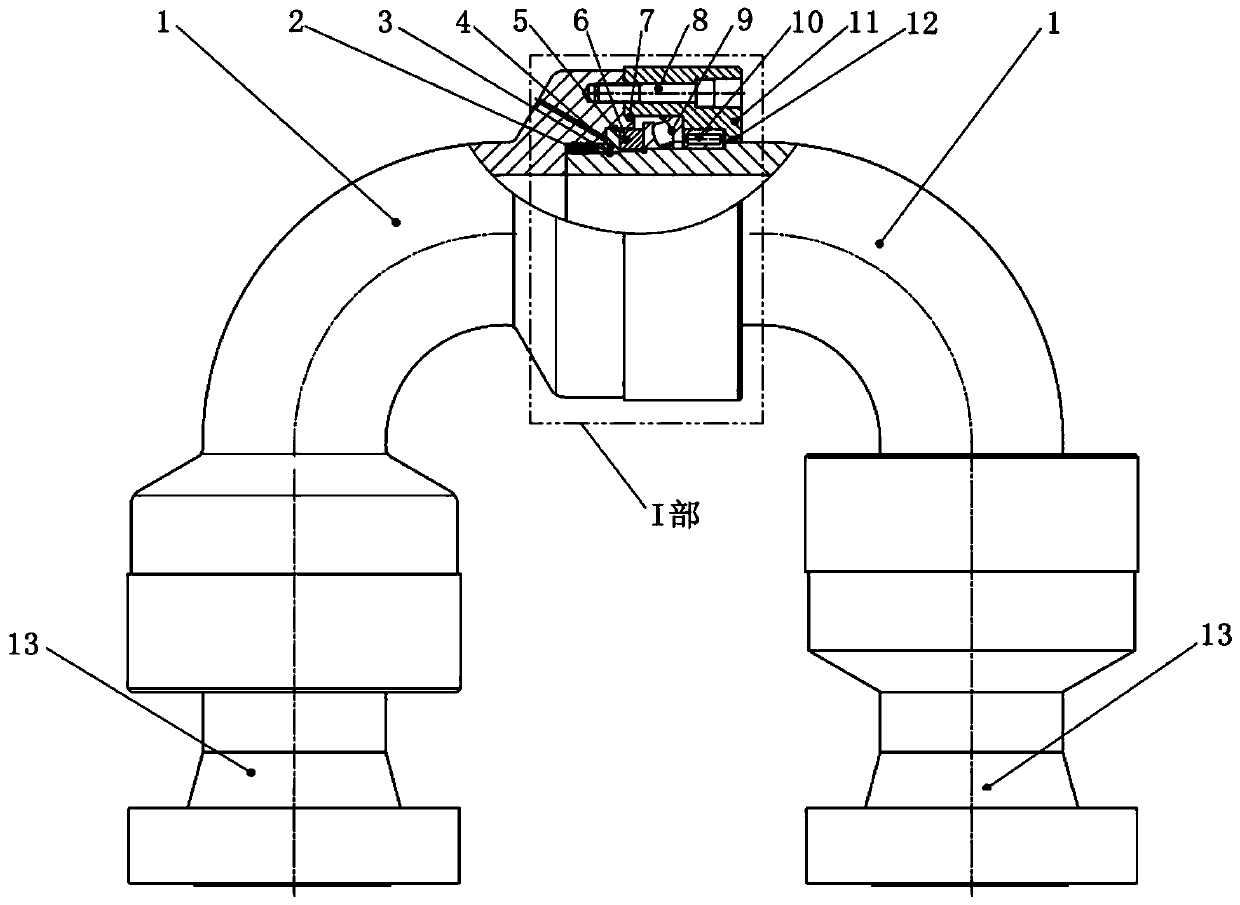

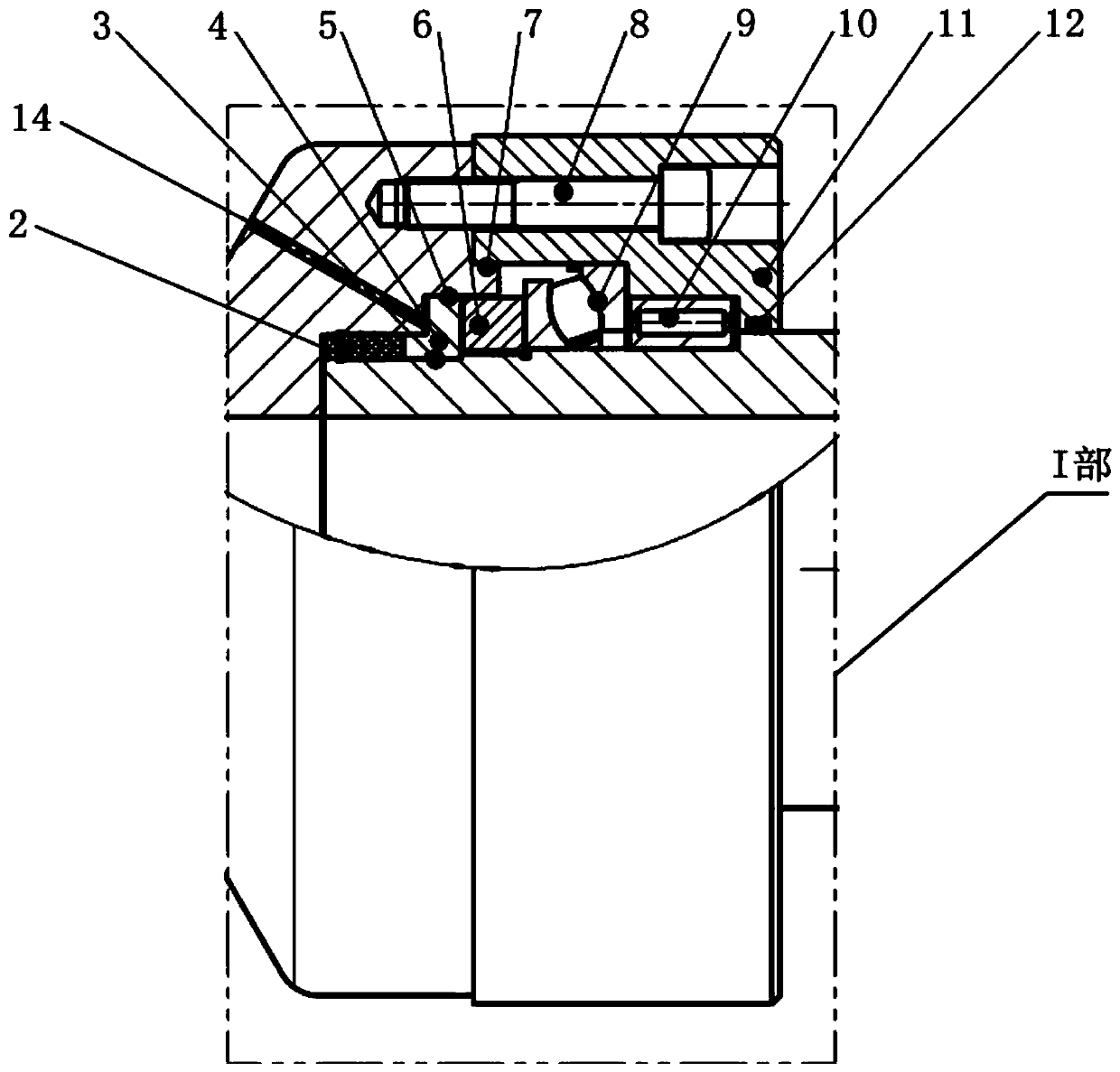

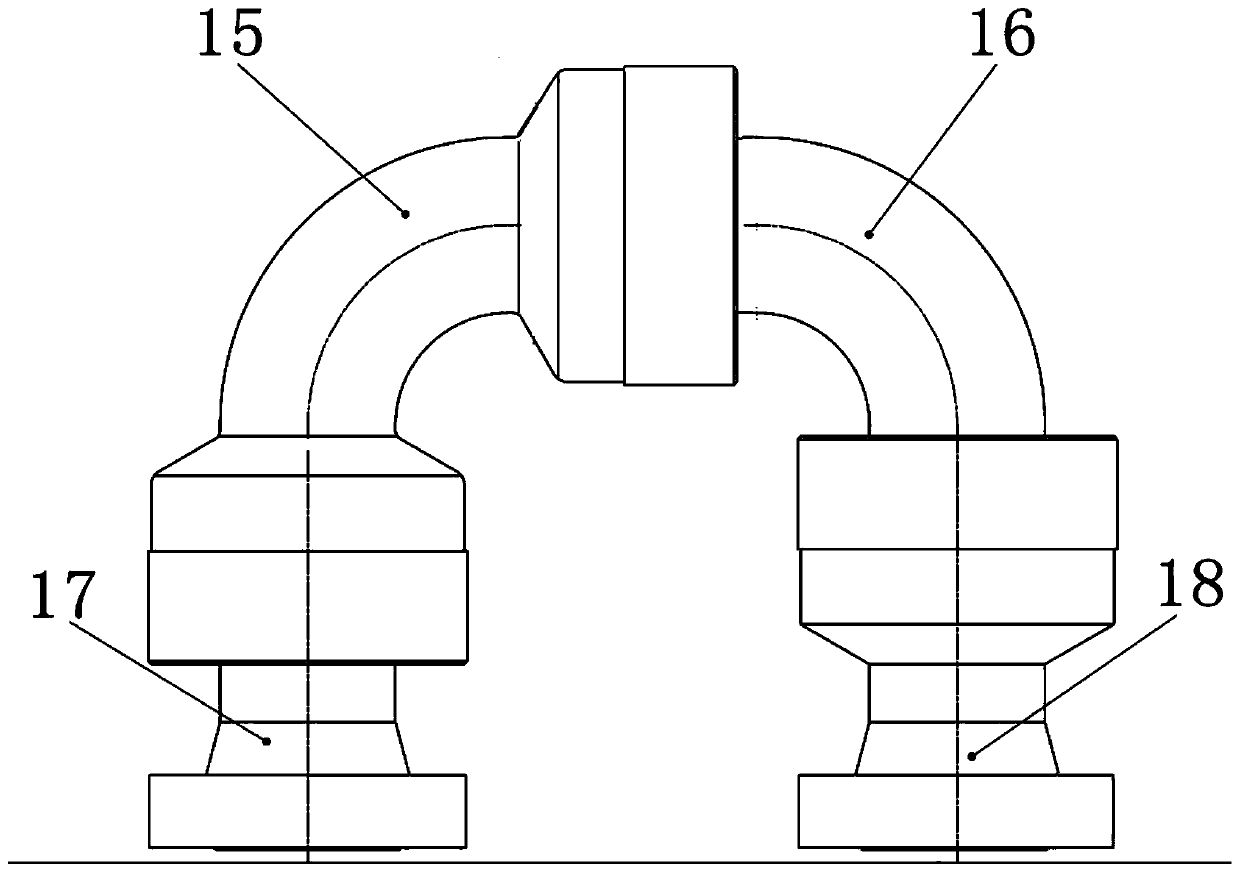

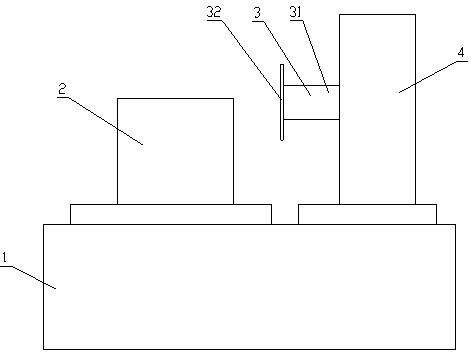

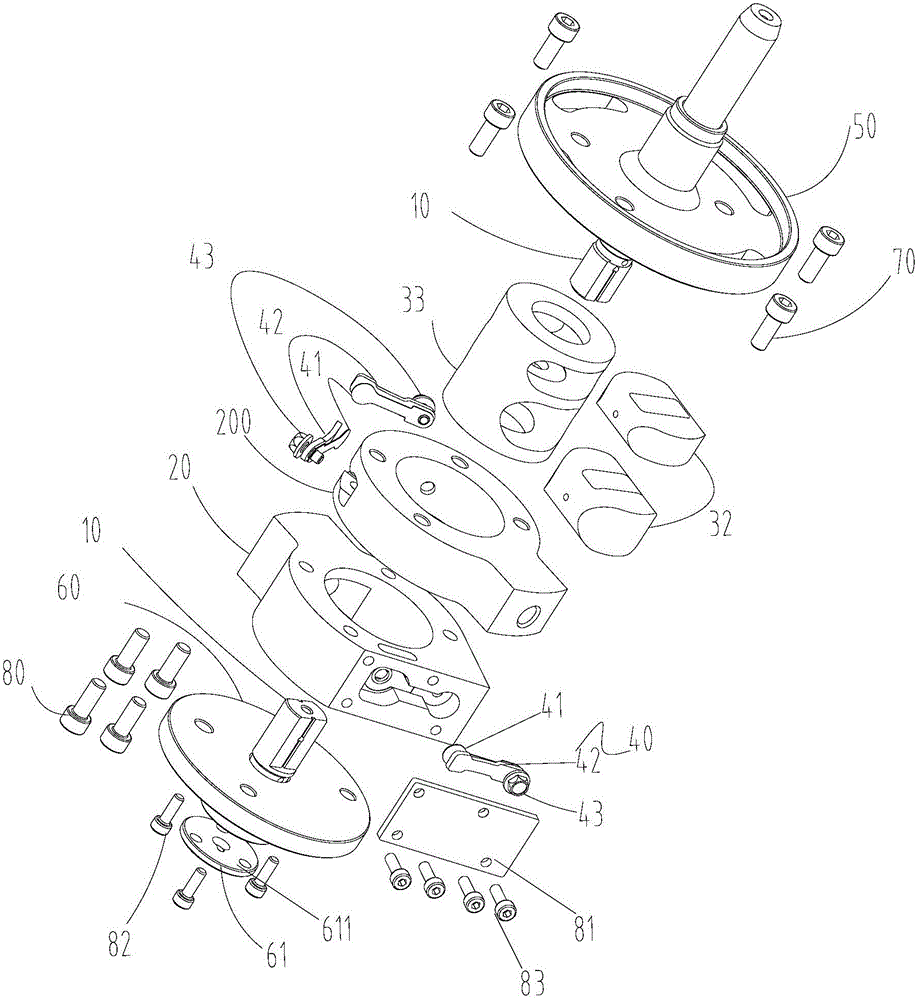

Combination bearing type large-specification movable elbow mechanism

PendingCN111594059ASimple structureReduce volumeDrilling rodsSealing/packingThrust bearingStructural engineering

The invention discloses a combination bearing type large-specification movable elbow mechanism. The combination bearing type large-specification movable elbow mechanism comprises elbows, connection heads, a pressing cover, a packing seal component and a rotating component, wherein positions between the elbows and the connection heads as wall as between the elbows are fixedly connected through thepressing cover and are sealed through the packing seal component, cavities are formed at the positions between pressing cover and the connection heads as wall as between the pressing cover and the elbows and are internally provided with the rotating component, the rotating component is used for relative rotating of the connection heads or the elbows and comprises a centripetal bearing and a thrustbearing, and the elbows and the connection heads as wall as the elbows are flexibly connected. The combination bearing type large-specification movable elbow mechanism has the beneficial effects thatthe combination bearing type large-specification movable elbow mechanism is flexible in connection, smooth in rotating, simple in structure, not limited by the pipe diameter, also not limited by theelbow structure molding method, small in volume and diversified in molding method.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

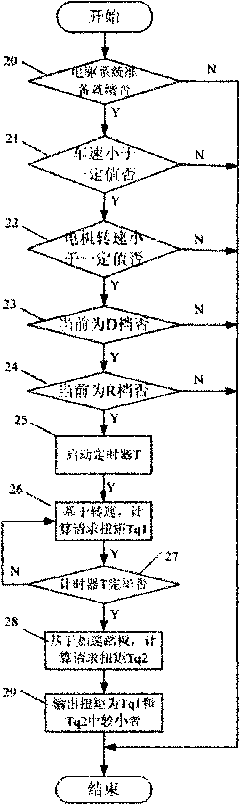

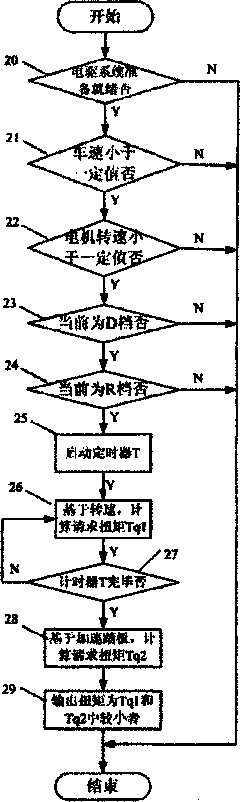

Method for controlling starting torque of electric vehicle

ActiveCN101823444AImprove NVH performanceImprove comfortSpeed controllerElectric energy managementElectricityCurrent electric

The invention relates to a method for controlling a starting torque of an electric vehicle. The method comprises the following steps of: in a step 20, detecting whether a current electric drive system is all set by using a finished vehicle controller; in a step 21, judging whether the current vehicle speed is lower than a fixed value by using the finished vehicle controller; in a step 22, judging whether a motor rotating speed is lower than a fixed value, namely judging whether the current finished vehicle is in a starting stage; in a step 23, judging whether a current gear request is a D gear or an R gear; in a step 25, starting a timer T; in a step 26, calculating a motor rotating speed-based request torque Tq1; in a step 27, judging whether the timer T is finished, if the timer is not finished, returning to the step 26 to continue timing; if the timer is finished, entering a step 28; in the step 28, calculating a driver accelerator pedal-based request torque Tq2; and in the step 29, comparing the Tq2 with the Tq2, wherein the smaller value of the Tq1 and the Tq2 is a final starting torque request value.

Owner:奇瑞新能源汽车股份有限公司

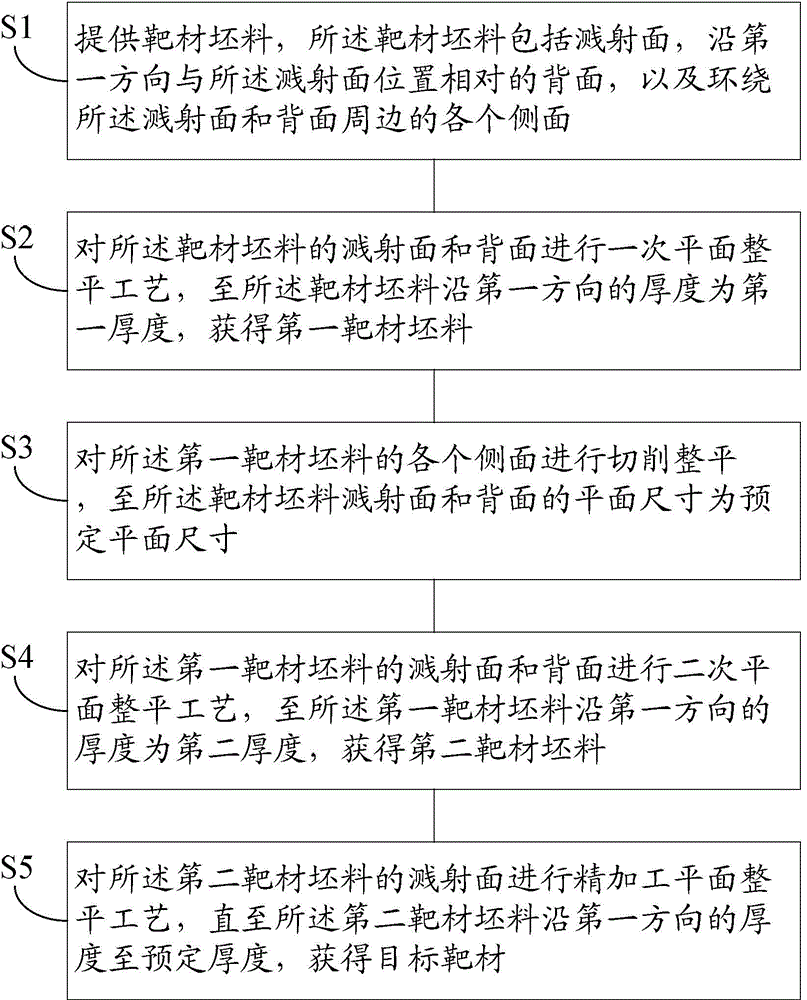

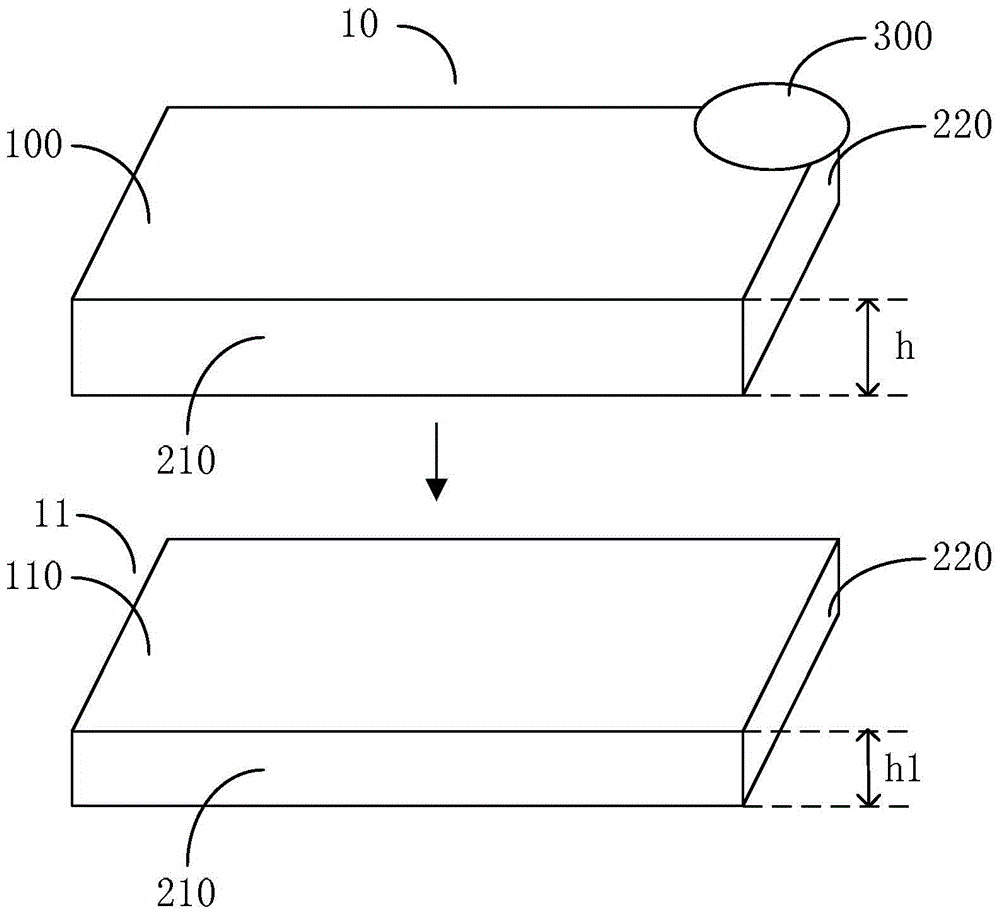

Machining method for target material

ActiveCN104561890AVibration reliefQuality improvementVacuum evaporation coatingSputtering coatingMachining processMaterials science

The invention relates to a machining method for a target material. The machining method for the target material comprises the following processing steps: levelling planes of a sputtering surface and the back face of a target material blank, and processing each side face of the target material blank so that thickness of the target material blank is the same as the predetermined thickness, and plane dimensions of the sputtering surface and back face of the target material blank are the same as the predetermined plane dimensions, wherein the levelling treatment process on the sputtering surface and back face of the target material blank comprises a primary plane levelling process and a secondary plane levelling process which are carried out on the sputtering surface and back face of the target material blank along the first direction and a finish machining plane levelling process carried out on the sputtering surface. By adopting the technical scheme, a multi-step levelling process is carried out on the sputtering surface or back face along the first direction, stress produced inside the target material and vibration produced to the target material by machining in a machining process can be effectively alleviated, so that the defects of deformation and the like can not be formed on the target material blank, quality of a machined target material is improved, and yield of the machined target materials is increased.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

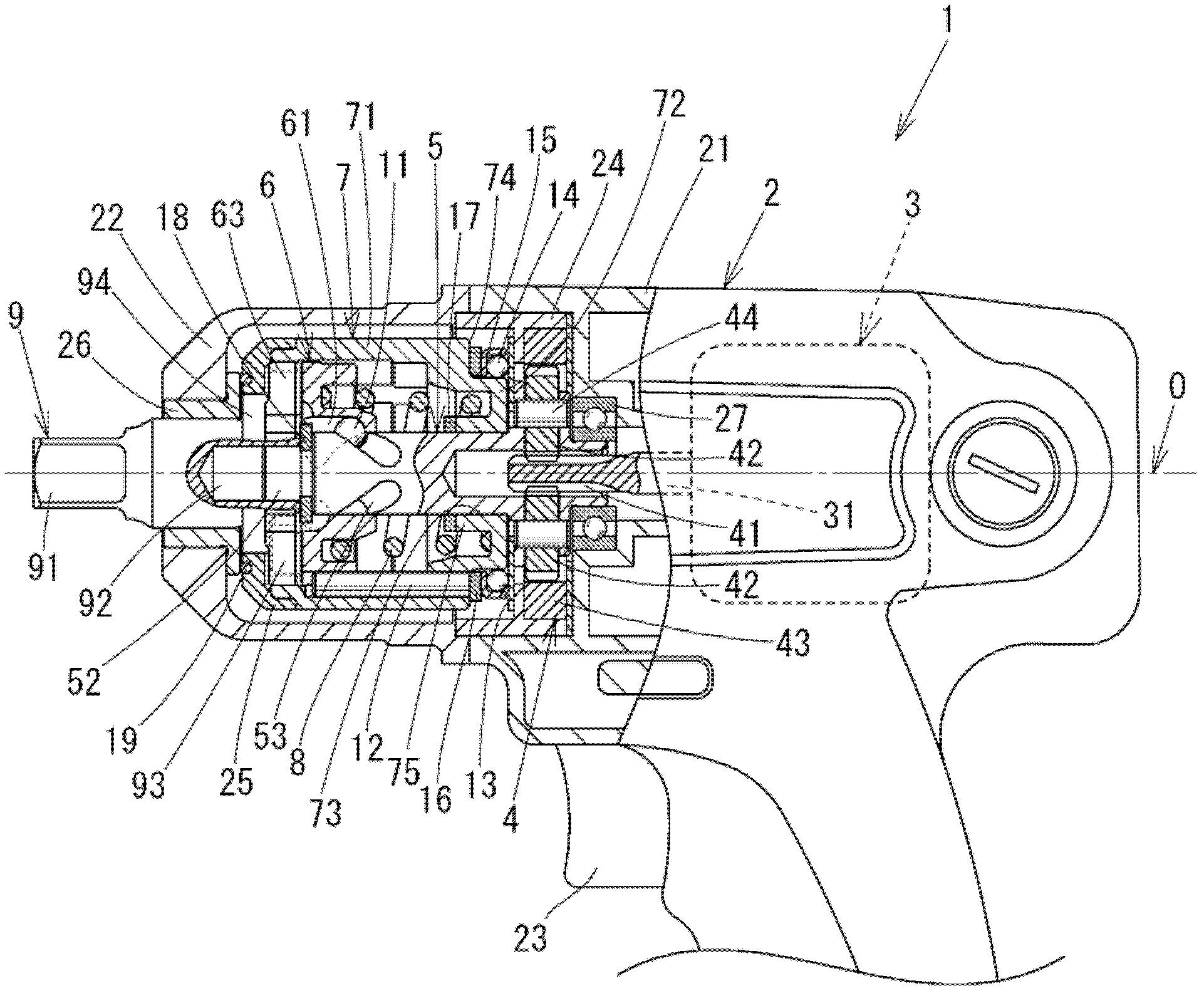

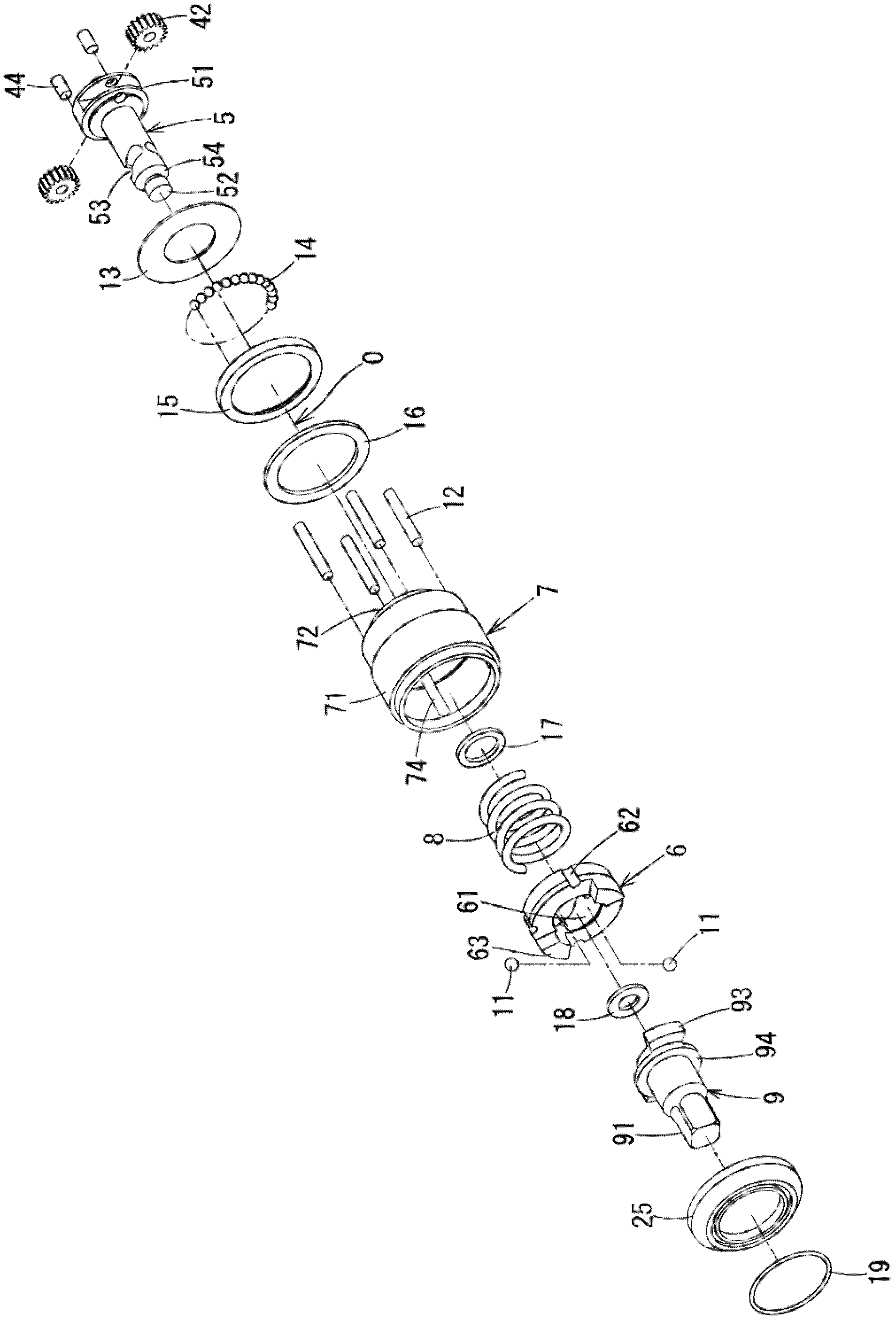

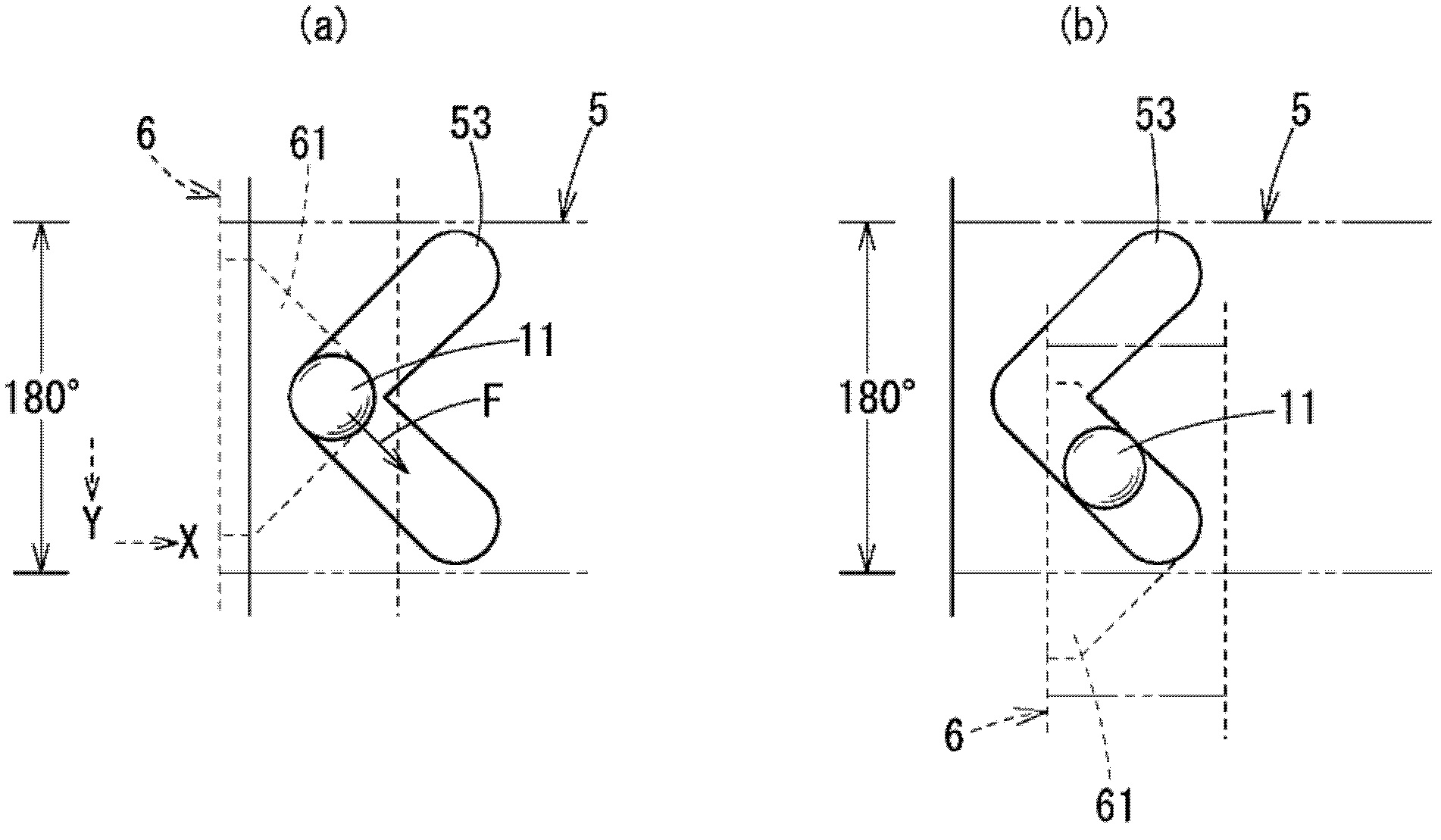

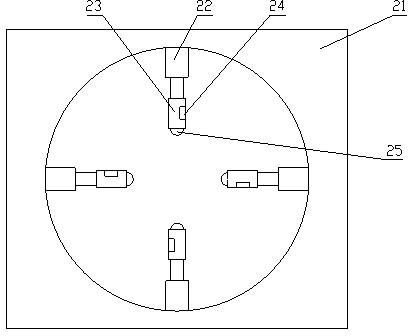

Impact wrench

An impact wrench is provided that can mitigate vibrations in the axial direction without reducing the rotary impact force of hammers. The hammers are composed of a primary hammer (6) fitted to the outer circumference of a spindle (5) and a cylindrical secondary hammer (7) that is disposed so as to cover the primary hammer (6) and that rotates together with the primary hammer (6). Furthermore, the secondary hammer (7) is held by a axis holding means in a state in which the rotational axis of the secondary hammer (7) is coincident with the axis of the spindle (5) in order to prevent precession movement. With the use of the hammer configuration of the present invention, the mass of the primary hammer (6) can be decreased compared to that of the secondary hammer (7), and therefore it is possible to mitigate vibrations in the axial direction while maintaining the rotary impact force.

Owner:KUKEN CO LTD

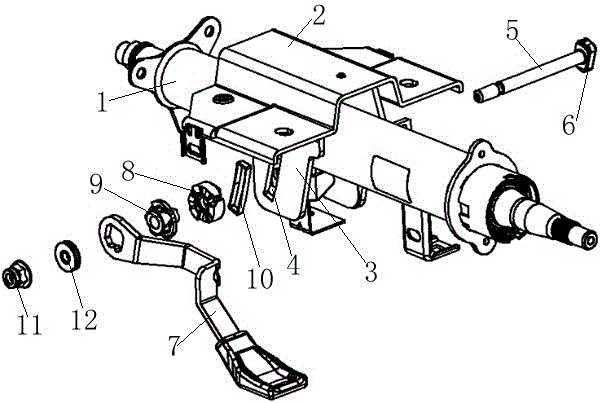

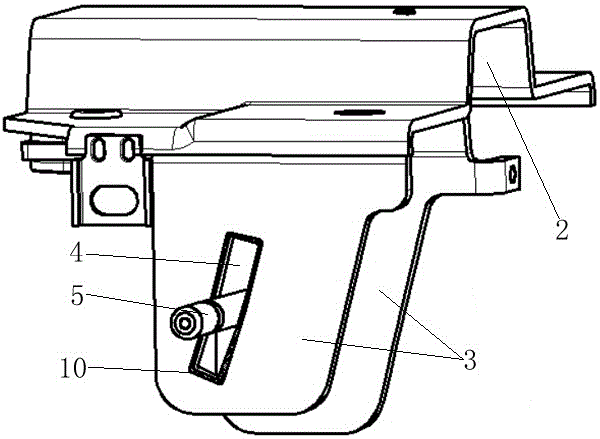

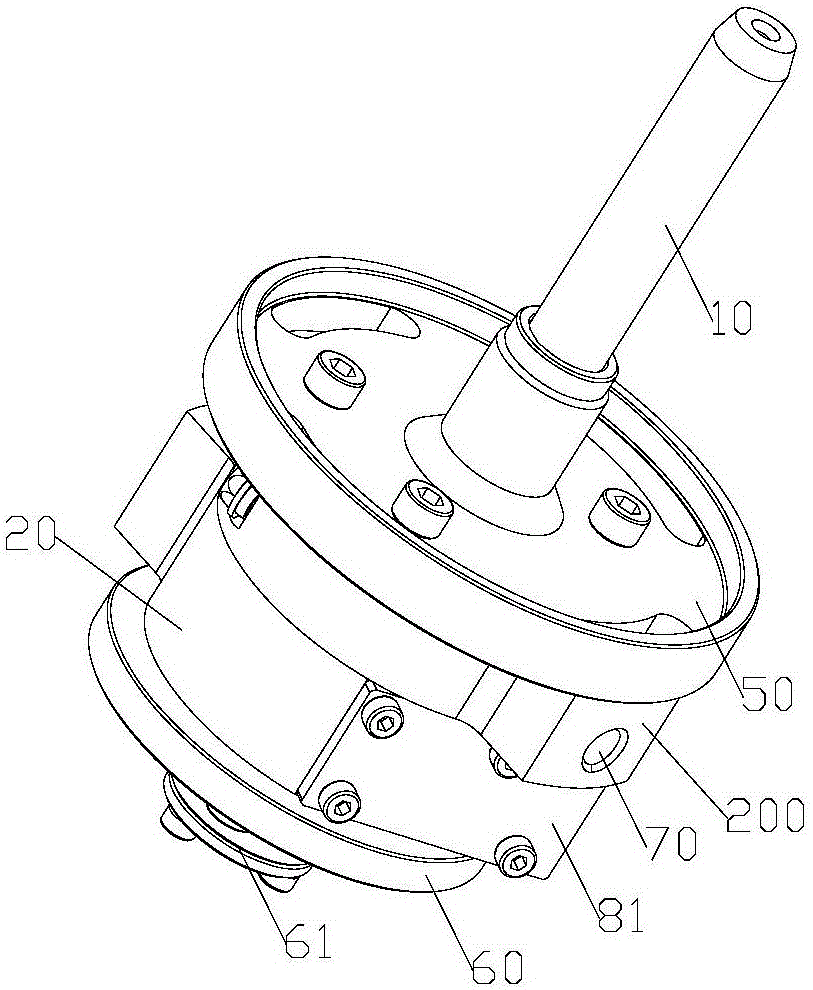

Angle adjusting mechanism of steering tubular column

The invention relates to an angle adjusting mechanism of a steering tubular column. The angle adjusting mechanism comprises the steering tubular column, an adjusting bracket and an adjusting rod, wherein a bracket is fixedly connected onto the steering tubular column; a through hole is formed in the bracket; the adjusting bracket is provided with two side plates; first strip-shaped holes are formed in the two side plates; the bracket is located between the two side plates; the adjusting rod penetrates through the through hole and the two first strip-shaped holes; a locking structure is arranged on the adjusting rod; each first strip-shaped hole is provided with an elastic lining; each elastic lining is provided with a second strip-shaped hole; one end of each second strip-shaped hole in the length direction is a large-width end, and the other end of each second strip-shaped hole is a small-width end; the width of each second strip-shaped hole is gradually reduced from the large-width end to the small-width end; the adjusting rod penetrates through the two second strip-shaped holes; and the diameter of the adjusting rod is greater than the width of the small-width end of each second strip-shaped hole. With the adoption of the angle adjusting mechanism of the steering tubular column, an abrasion problem caused by the fact that the steering tubular column is adjusted can be solved, and noises caused by the fact that the steering tubular column is adjusted can also be reduced, so that the reliability and the comfort are improved when the steering tubular column is adjusted.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

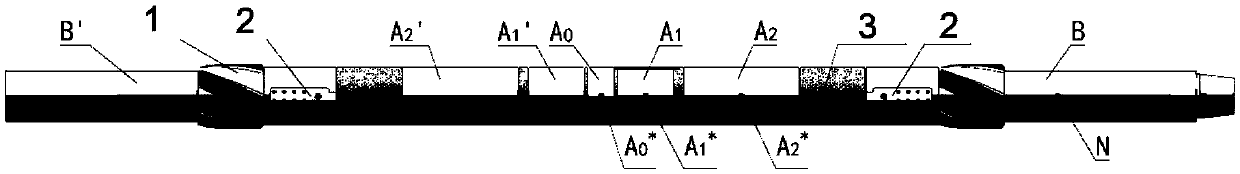

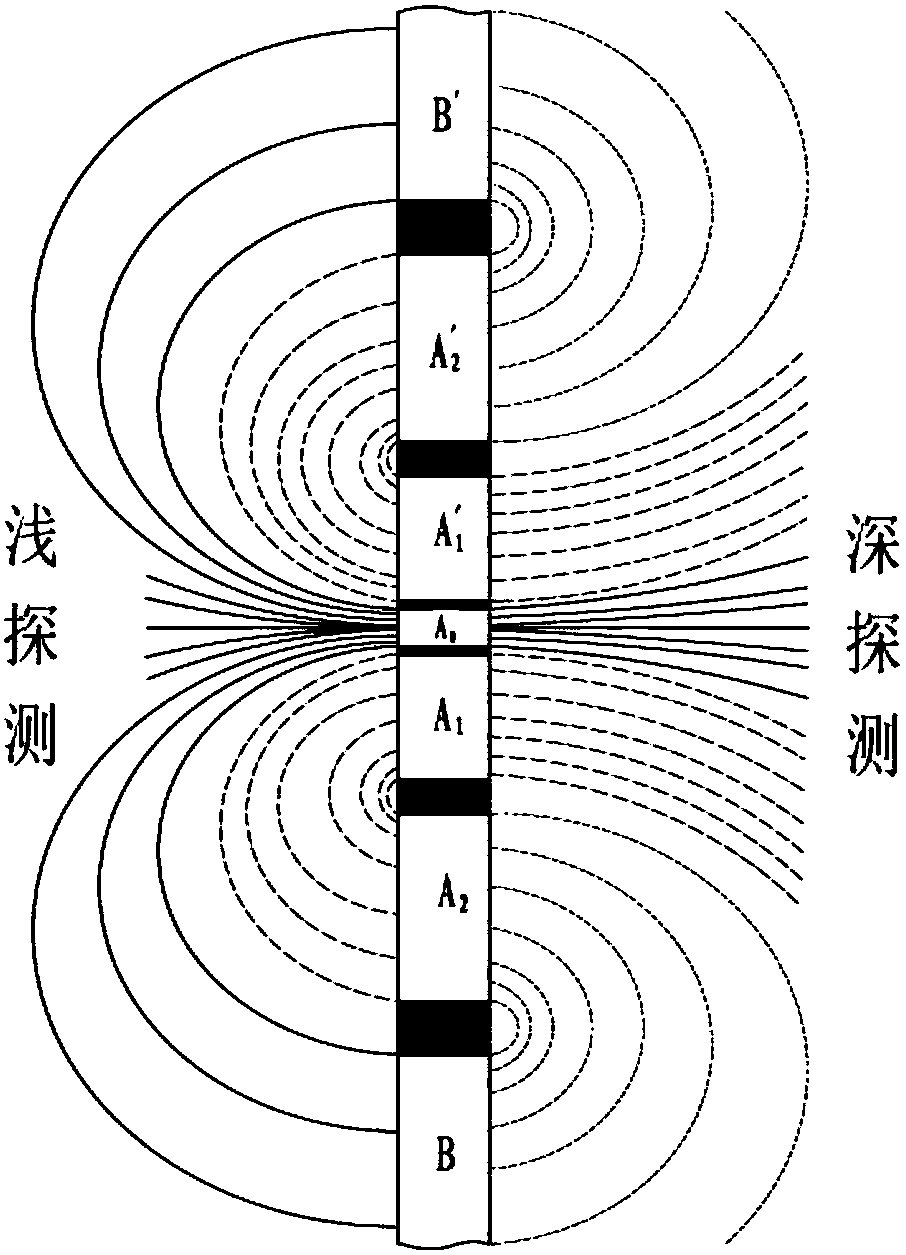

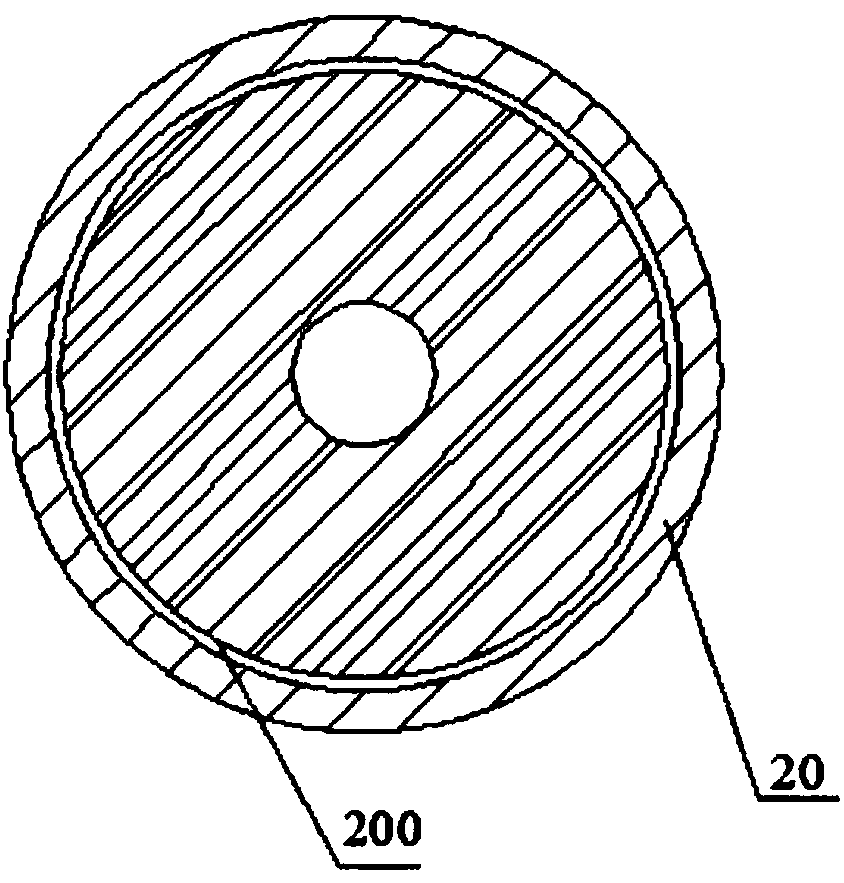

While-drilling electrode current type dual lateral specific resistance logging instrument and method

ActiveCN107762497AImprove wear resistanceImprove reliabilityBorehole/well accessoriesHigh resistanceResistivity logging

The invention discloses a while-drilling electrode current type dual lateral specific resistance logging instrument and a method. The while-drilling electrode current type dual lateral specific resistance logging instrument is mainly composed of three parts, namely a drill collar body, an electrode system and an electronic instrument body; and all electrodes of the electrode system are placed in an annular groove in the drill collar body in a 'sugarcoated haw clustering' mode, and the electronic instrument body is placed in an internal water hole of the drill collar body. According to the while-drilling electrode current type dual lateral specific resistance logging instrument and the method, stratum deep and shallow specific resistance curves are obtained in the modes of electrode currentdirect emission and electrode voltage and current measuring, and the stratum invasion characteristics are judged; and the while-drilling electrode current type dual lateral specific resistance logging instrument can measure in the well drilling process and can also measure in the drifting process after drilling, and the obvious advantage is achieved on specific resistance measuring of medium-high-resistance stratums.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

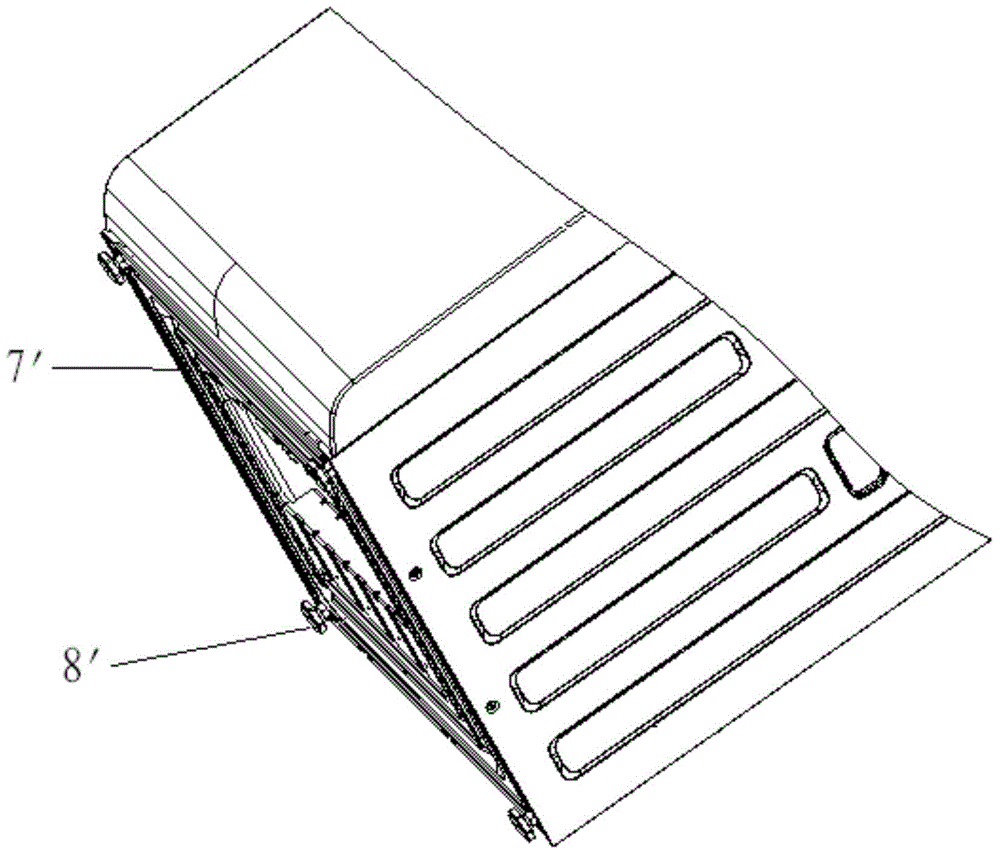

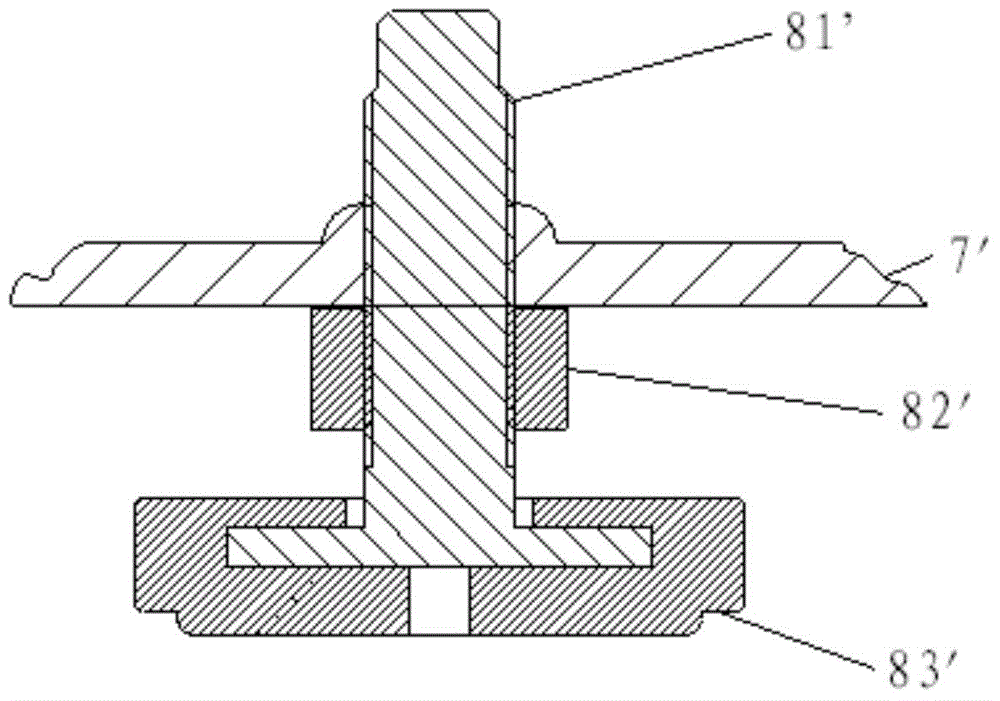

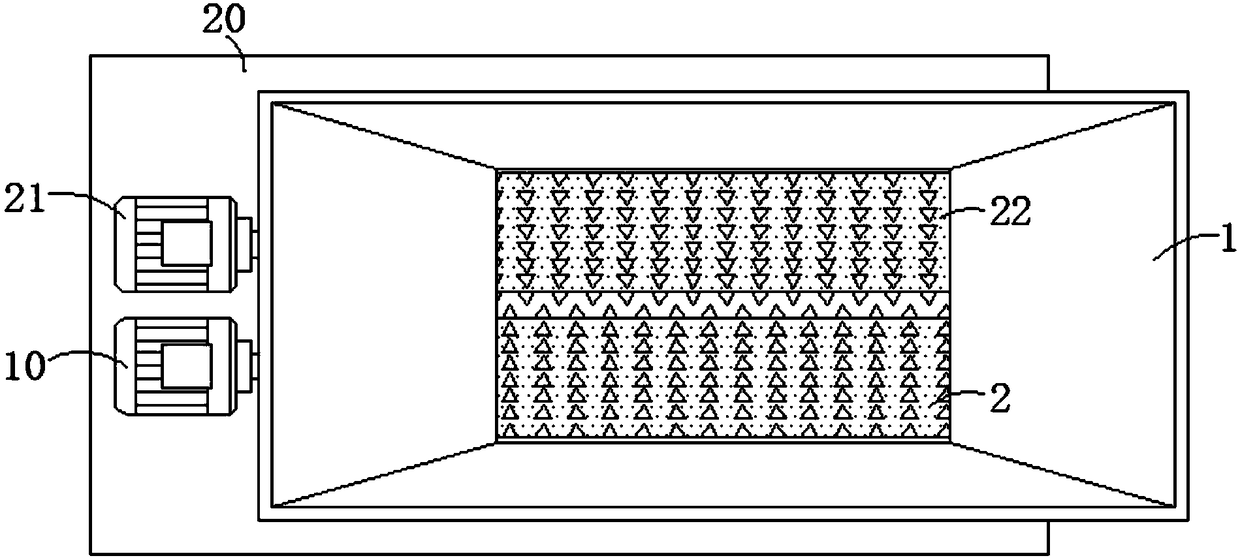

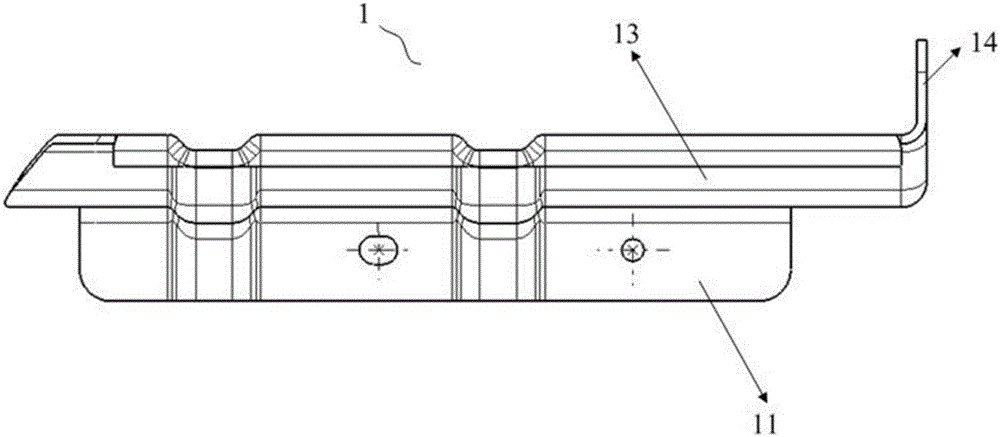

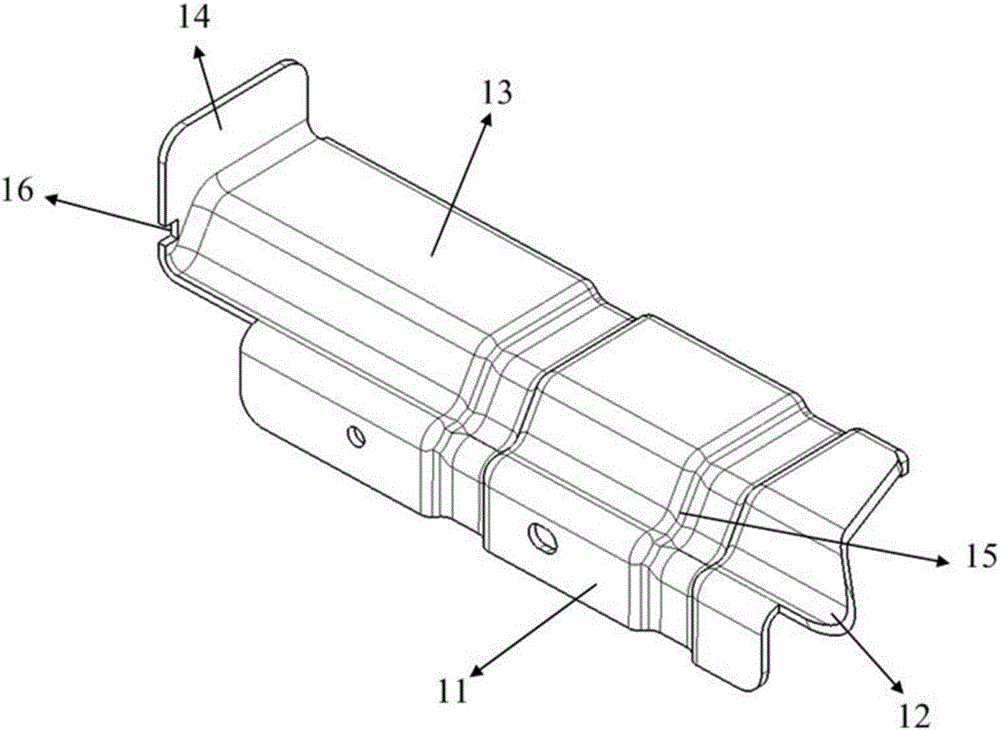

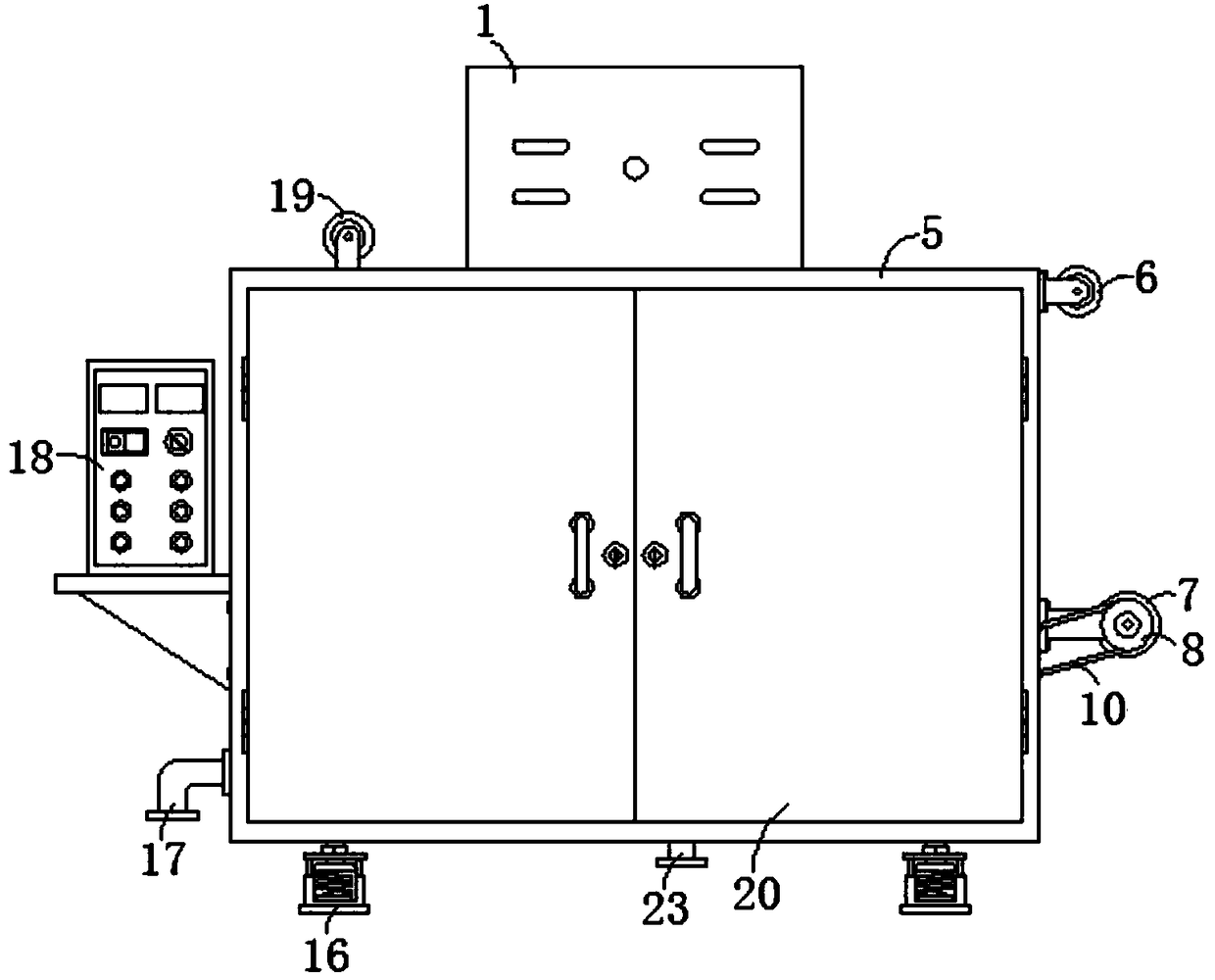

Skirting and washing machine

ActiveCN106149314AEven by forceVibration reliefOther washing machinesTextiles and paperPulp and paper industry

The invention discloses a skirting and a washing machine and relates to the technical field of washing machine fittings. The skirting comprises a first skirting unit and a second skirting unit, wherein one end of the first skirting is connected with a to-be-supported piece, the other end of the first skirting unit is matched with the second skirting unit so that the second skirting unit can support the first skirting unit, and the second skirting unit can incline within a preset angle range relative to the first skirting unit. The invention further provides the washing machine provided with the skirting. The skirting is provided with the first skirting unit and the second skirting unit, and the second skirting unit can incline within the preset angle range relative to the first skirting unit. Therefore, when the to-be-supported piece, such as the washing machine, provided with the skirting is placed on an uneven ground, the second skirting unit of the skirting can rotate around the first skirting unit, so that levelness is adjusted automatically, and the skirting is stressed more uniformly. Besides, due to the fact that the two skirting units are in flexible connection, certain vibration energy can be consumed, and accordingly the vibration relieving effect is achieved.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

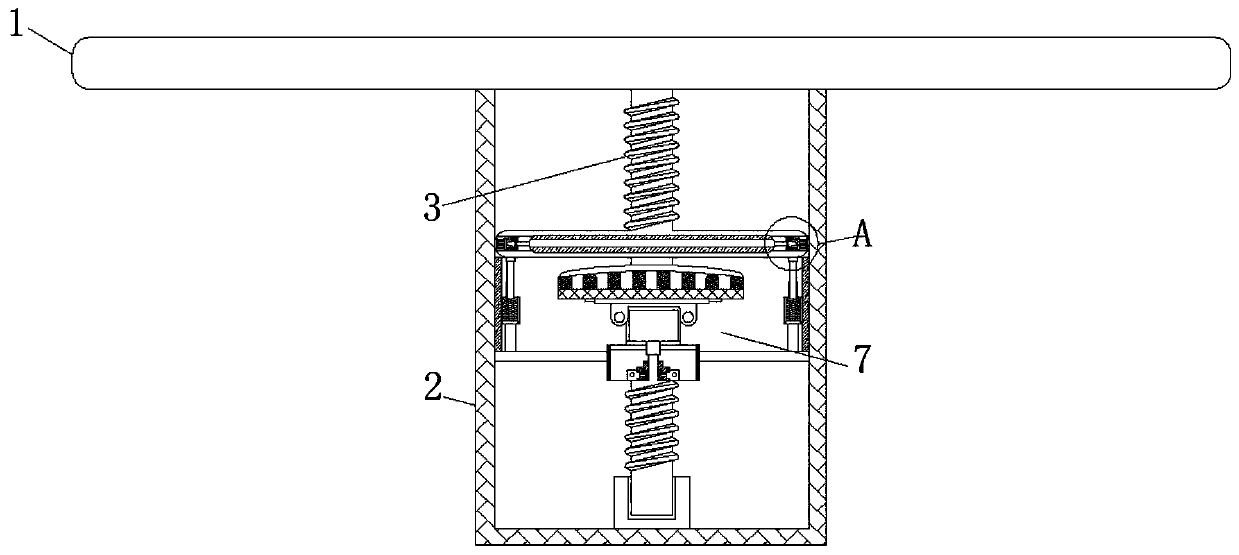

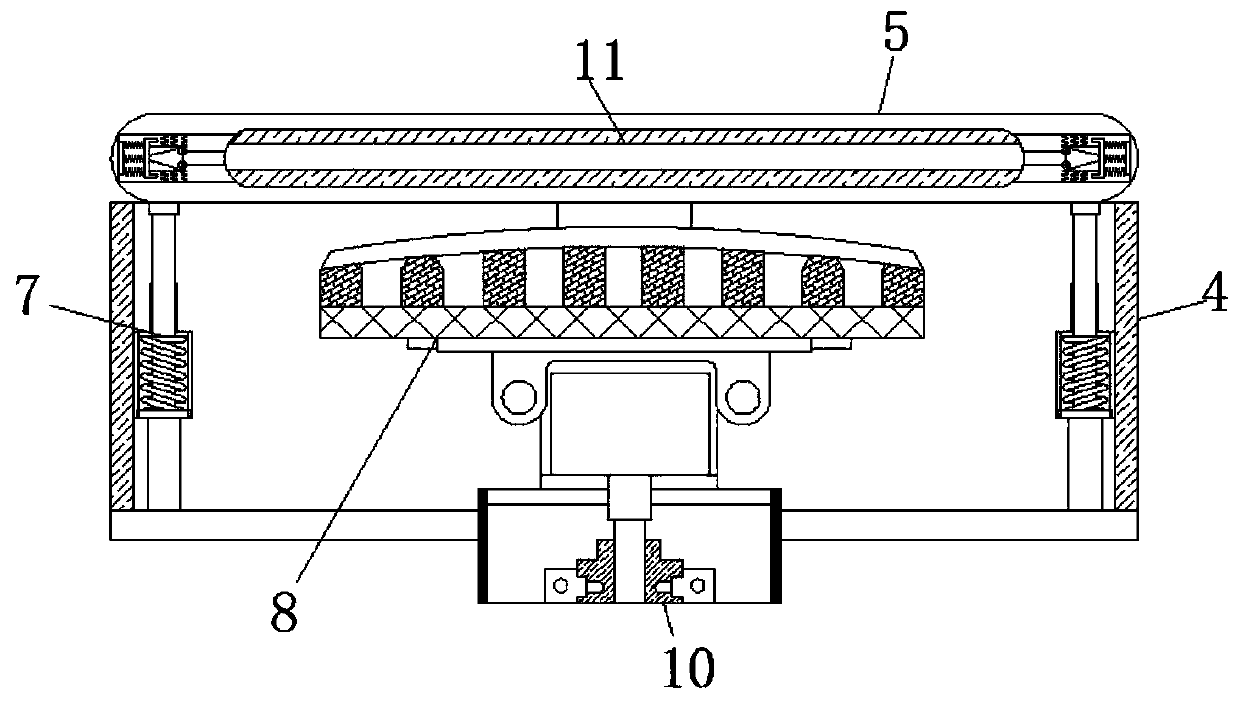

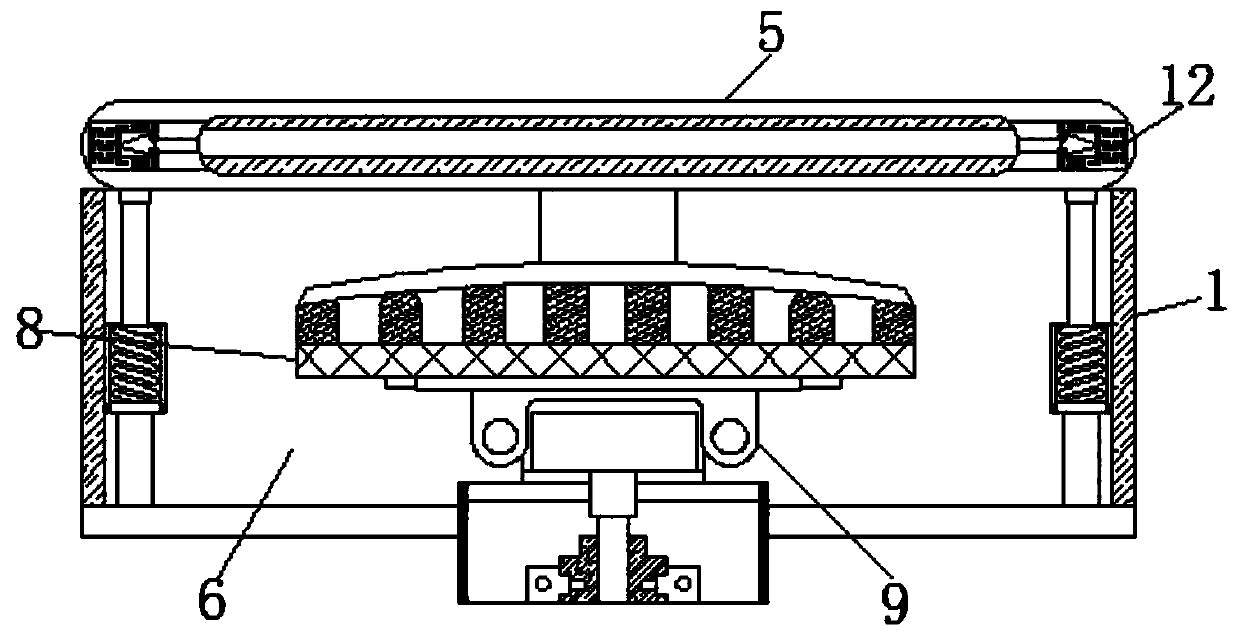

Lamp

InactiveCN103162205AVibration reliefReduce vibrationProtective devices for lightingFixed installationEngineeringMechanical engineering

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

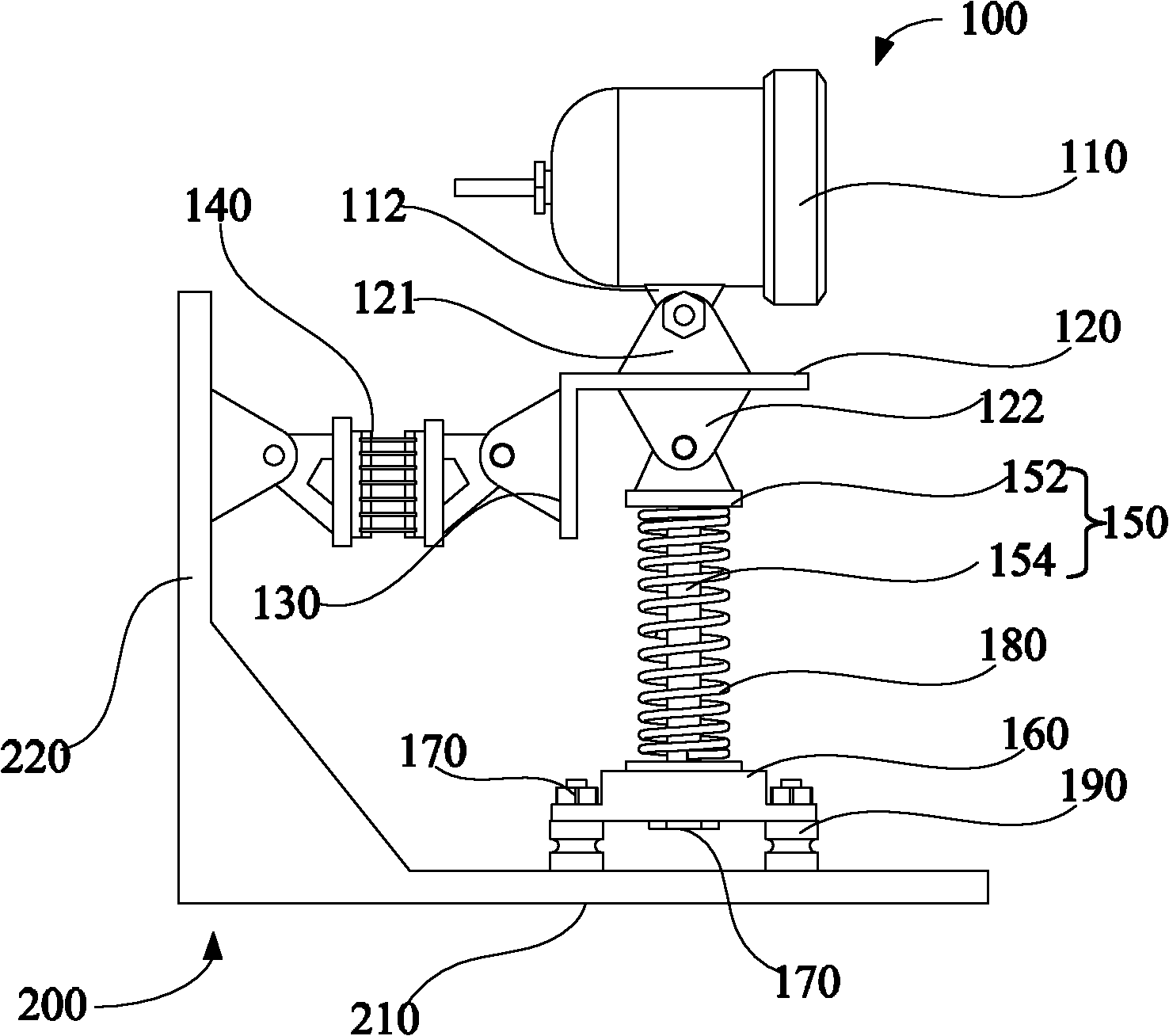

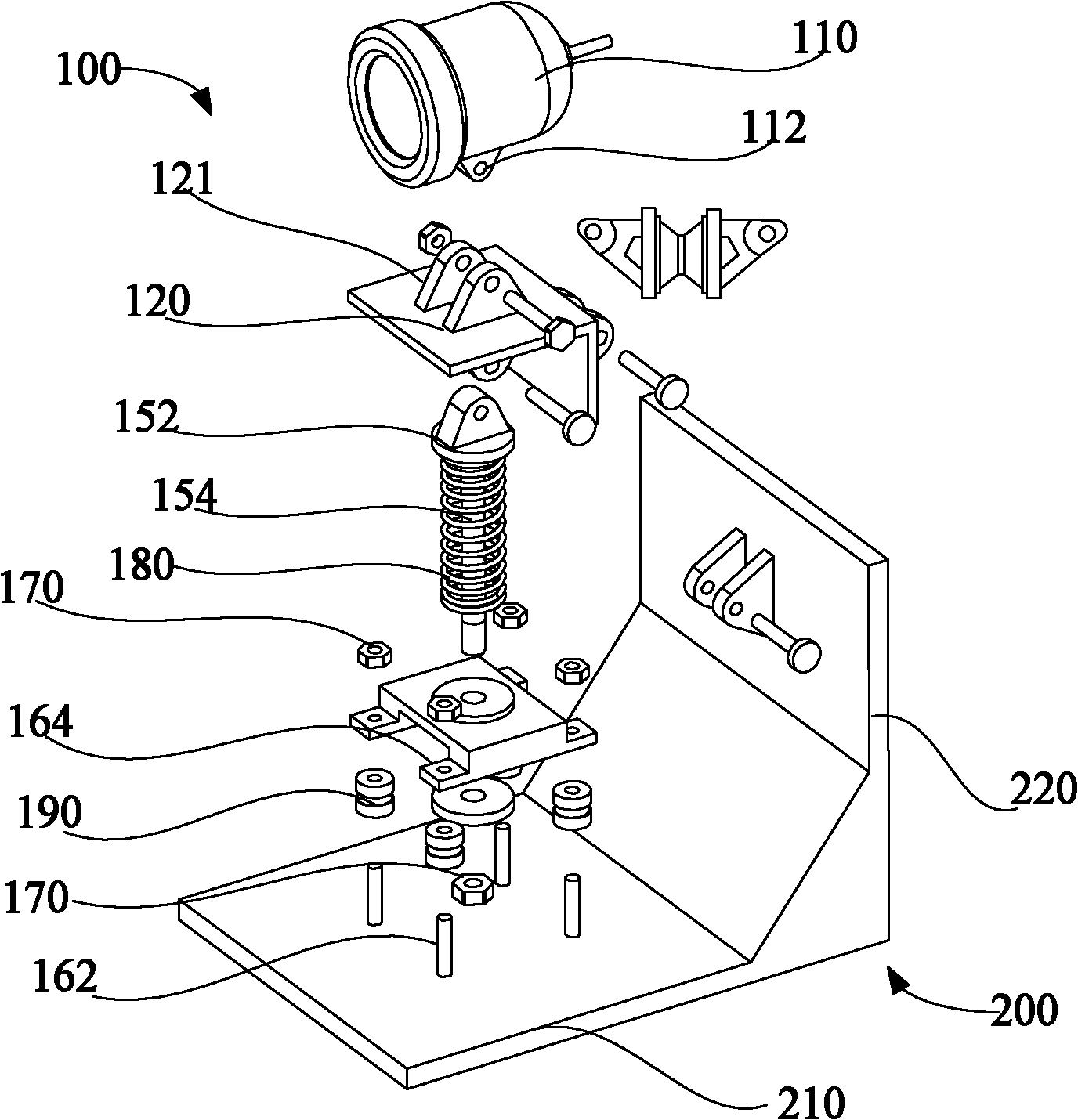

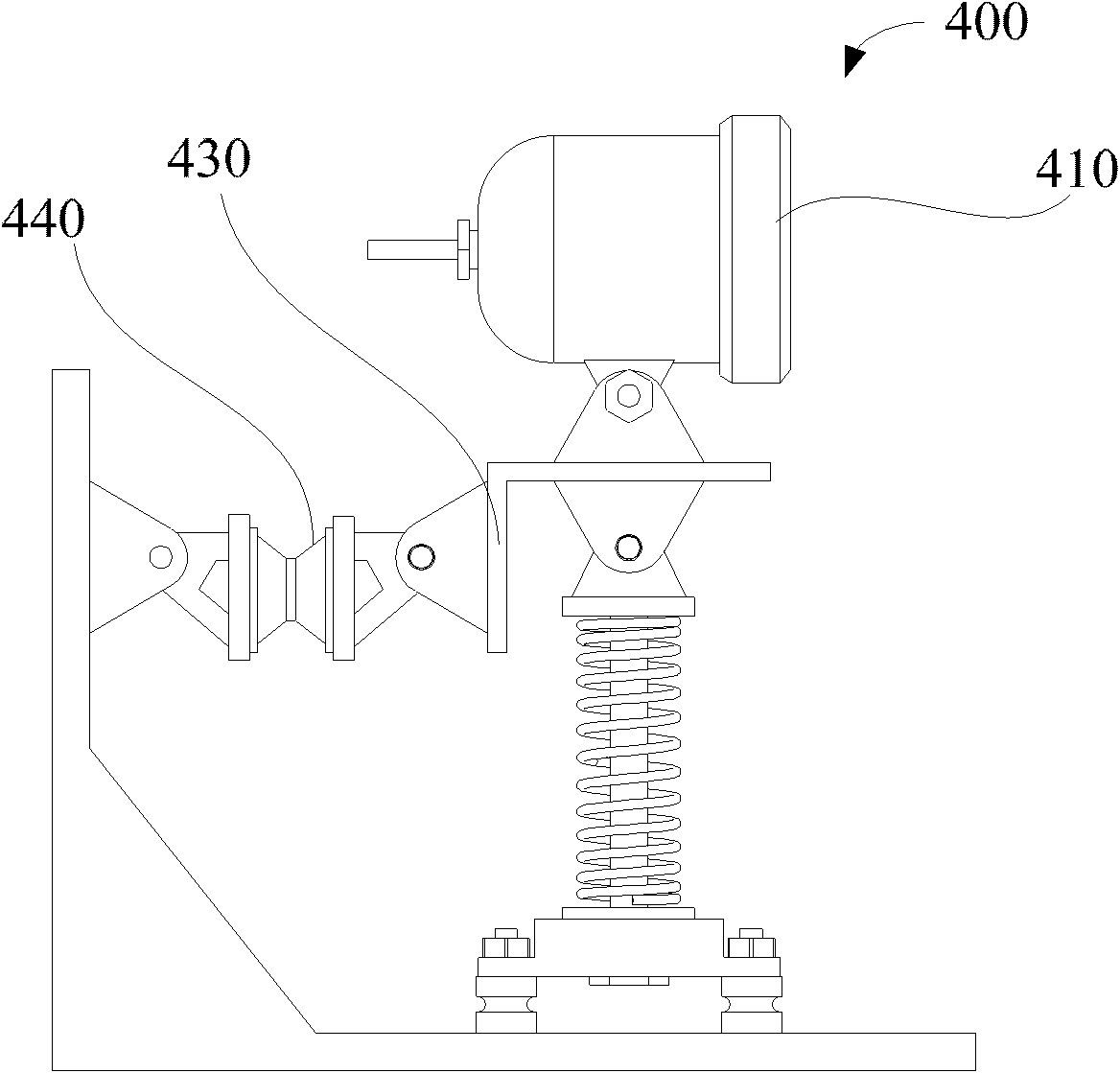

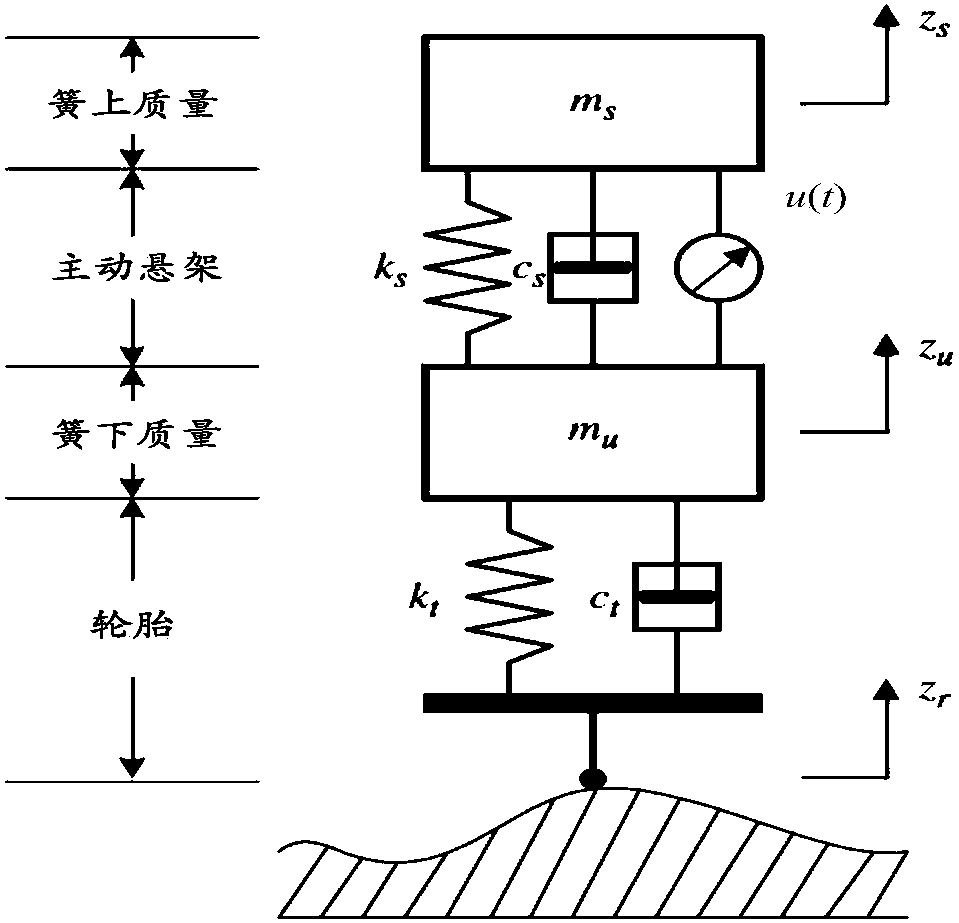

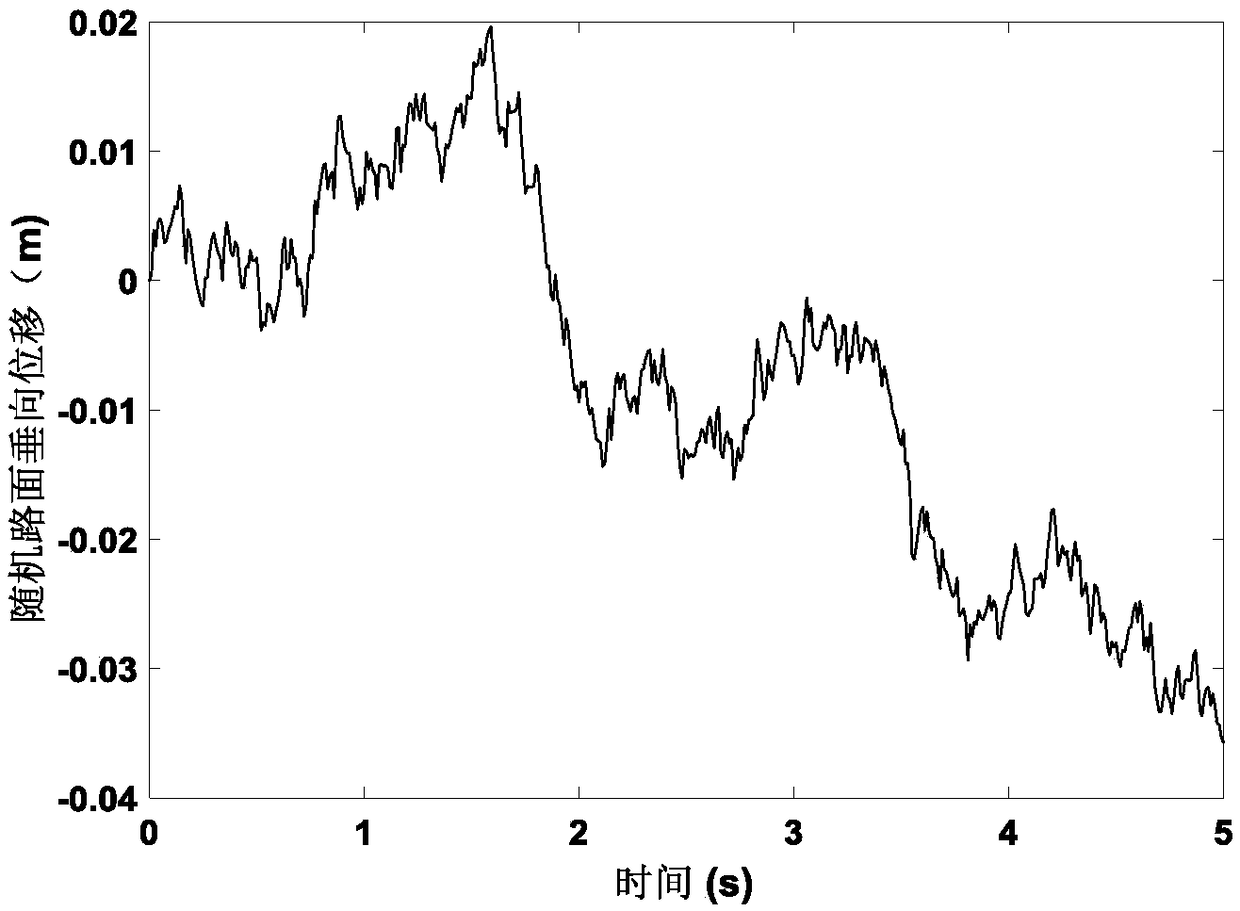

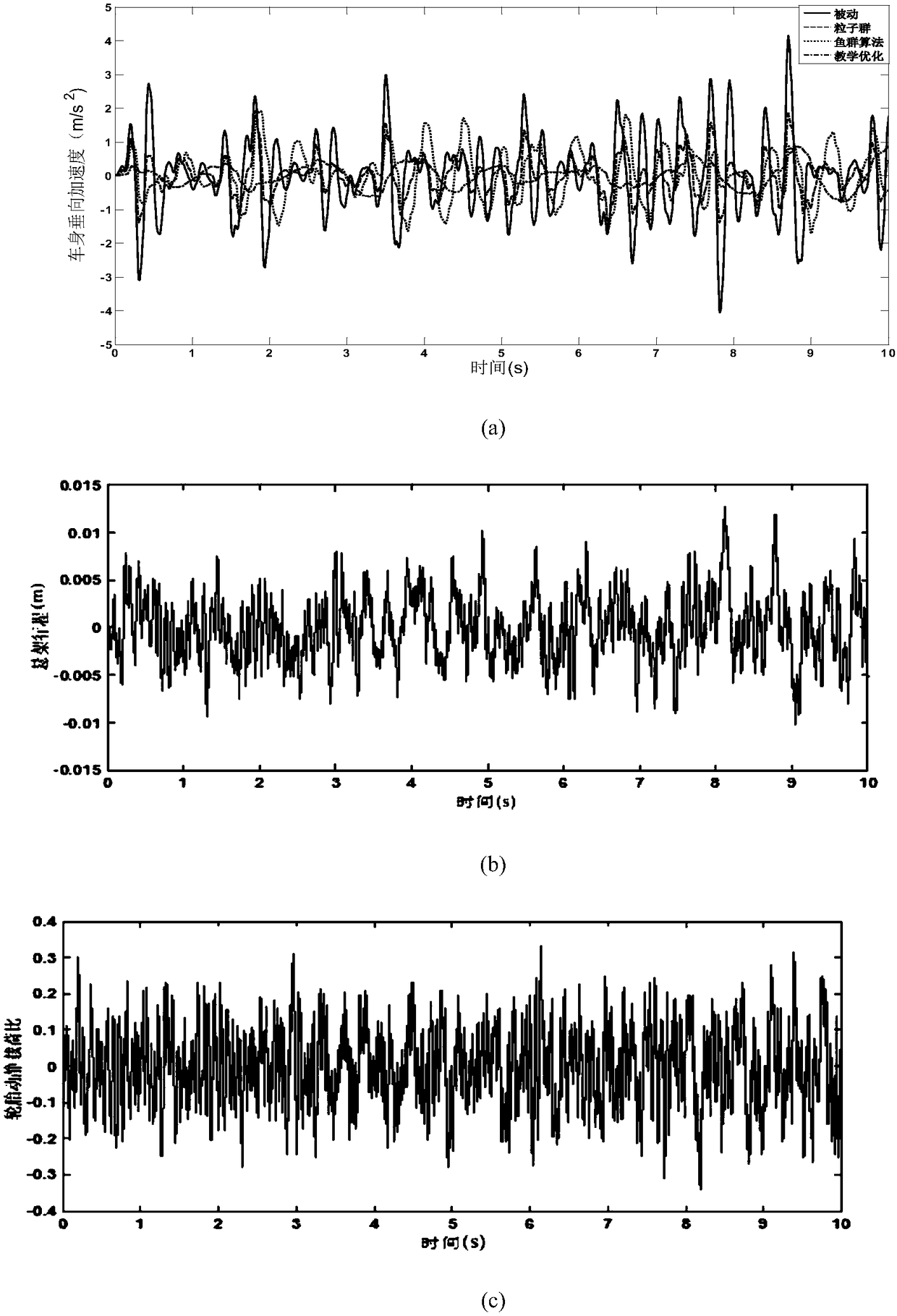

Automobile active suspension PID controller design method based on teaching optimization algorithm

InactiveCN108345218AImproved driving safety and ride comfortReduce shockAdaptive controlMathematical modelControl objective

The invention relates to an automobile active suspension PID controller design method based on a teaching optimization algorithm, and belongs to the technical field of active suspension control. An automobile active suspension system mathematical model is established according to the dynamic characteristics of the active suspension; a white noise random road surface input model is established according to the uneven road surface which can be felt at ordinary times; the design variables, the objective function and the constraint conditions of optimization design are reasonably selected according to the control objective of improving the riding comfort and guaranteeing the driving safety of the active suspension system; and the PID parameters are optimized by using the teaching optimizationalgorithm so as to obtain the optimal controller. The teaching optimization algorithm is less in independent parameter, simple in algorithm, fast in solving speed, high in accuracy and extremely highin convergence capacity. The teaching optimization algorithm is applied to the field of active suspension PID control to rapidly obtain the accurate and reliable active suspension control force so asto provide the practical basis for PID controller parameter selection. According to the method, the riding comfort and the driving safety of the vehicle can be enhanced and the product design and testcost can be reduced.

Owner:JIANGSU UNIV

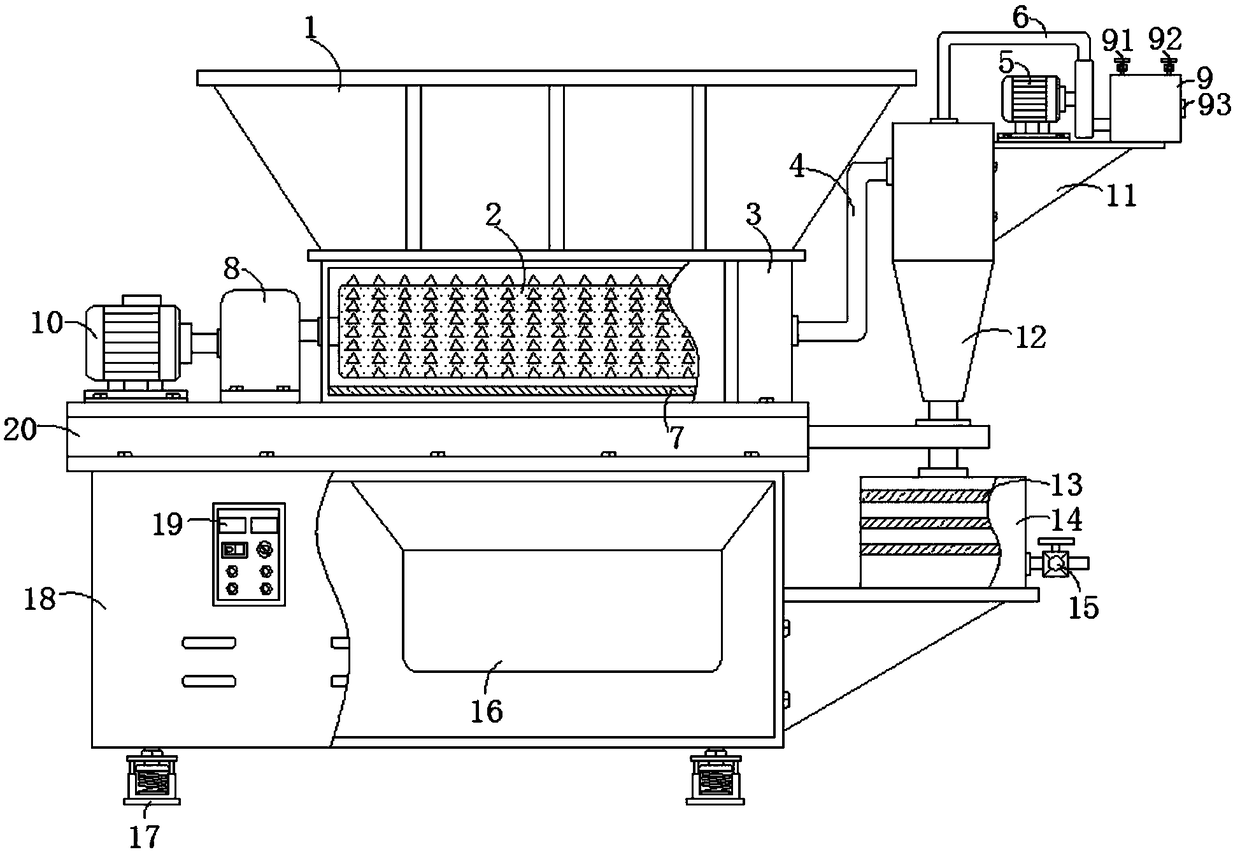

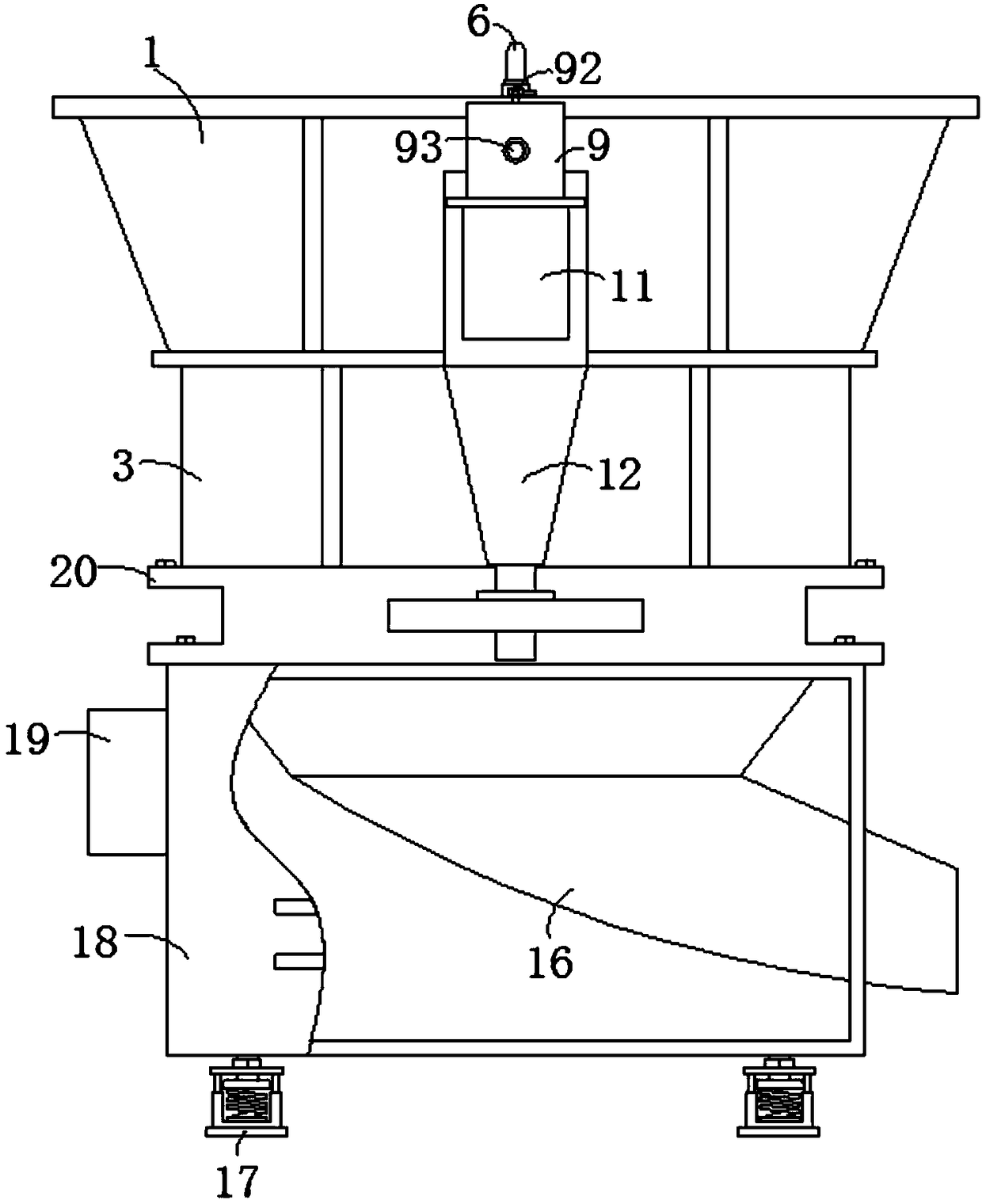

Environment-friendly tree crusher

InactiveCN108295950ATo achieve the purpose of waste heat recoveryAvoid wastingNon-rotating vibration suppressionVortex flow apparatusWater resourcesUrban water

The invention discloses an environment-friendly tree crusher. The environment-friendly tree crusher comprises a case body, wherein a fixed seat is fixed to the upper surface of the case body, and shock absorbing bases are connected to four corners at the bottom of the case body; a crushing box is fixed to one side of the upper surface of the fixed seat, and a cyclone separator is mounted on one side of the fixed seat through a fixed rack; the bottom end of the cyclone separator is connected to a filter box fixedly connected to the case body through the fixed rack through a pipeline, and a supporting rack is fixed to one side of the top of the cyclone separator; an induced draft fan is mounted on one side of the upper surface of the supporting rack, and a heat recoverer is connected to oneside of the induced draft fan through a pipeline. The environment-friendly tree crusher disclosed by the invention can recover waste heat of gas to avoid energy waste and prevent the gas from being discharged to secondarily pollute the environment, so that the crusher is more environment-friendly, and meanwhile, the water resource in the gas is recycled, so that the waste of the water resource isprevented, the pressure of urban water consumption is alleviated greatly, and the crusher is more energy-saving.

Owner:邱福祥

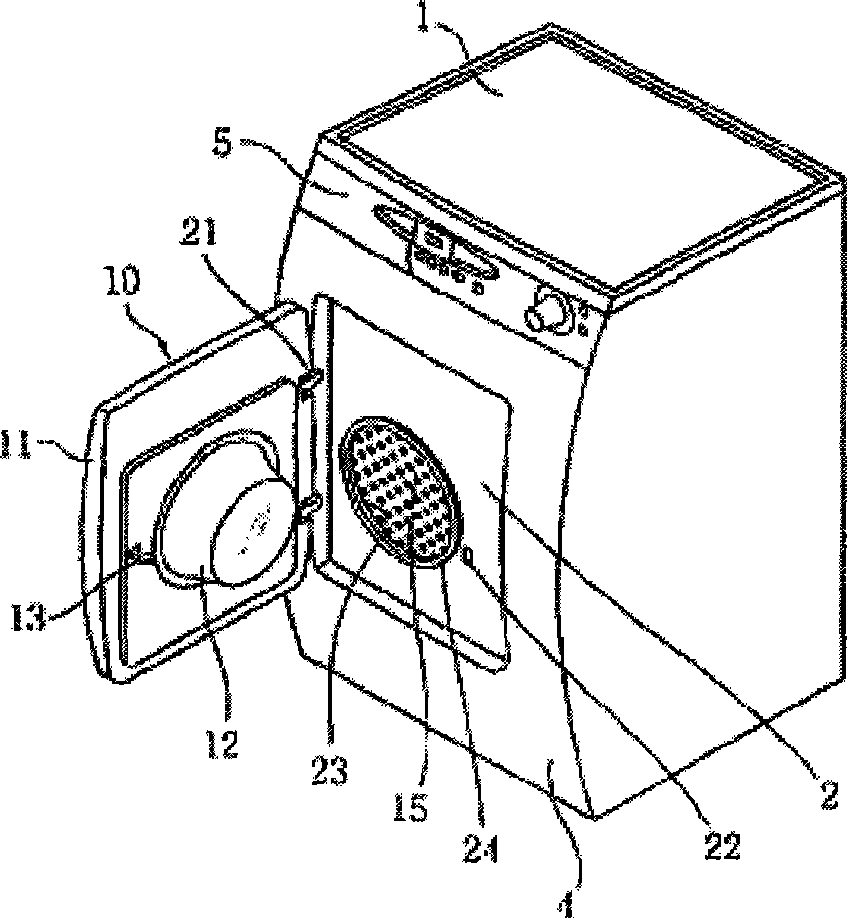

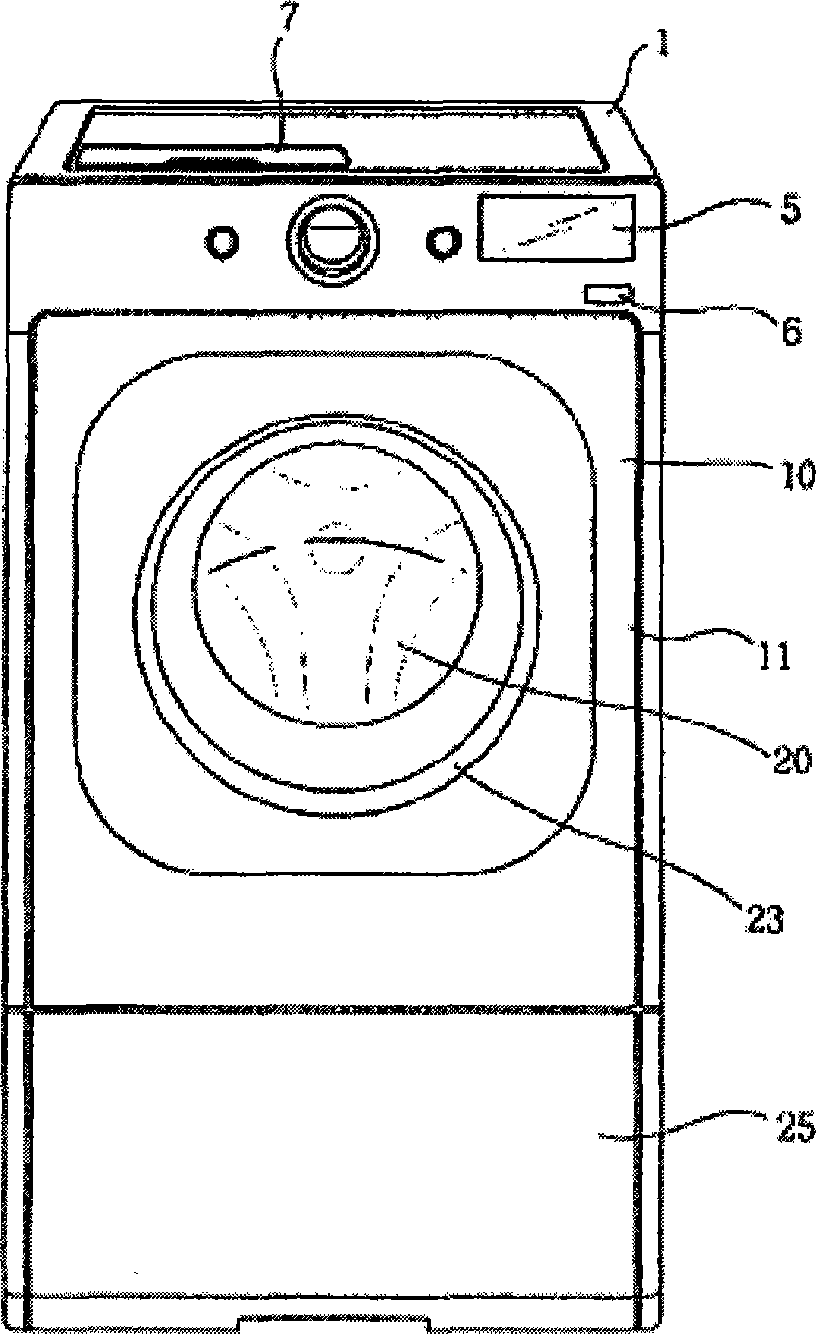

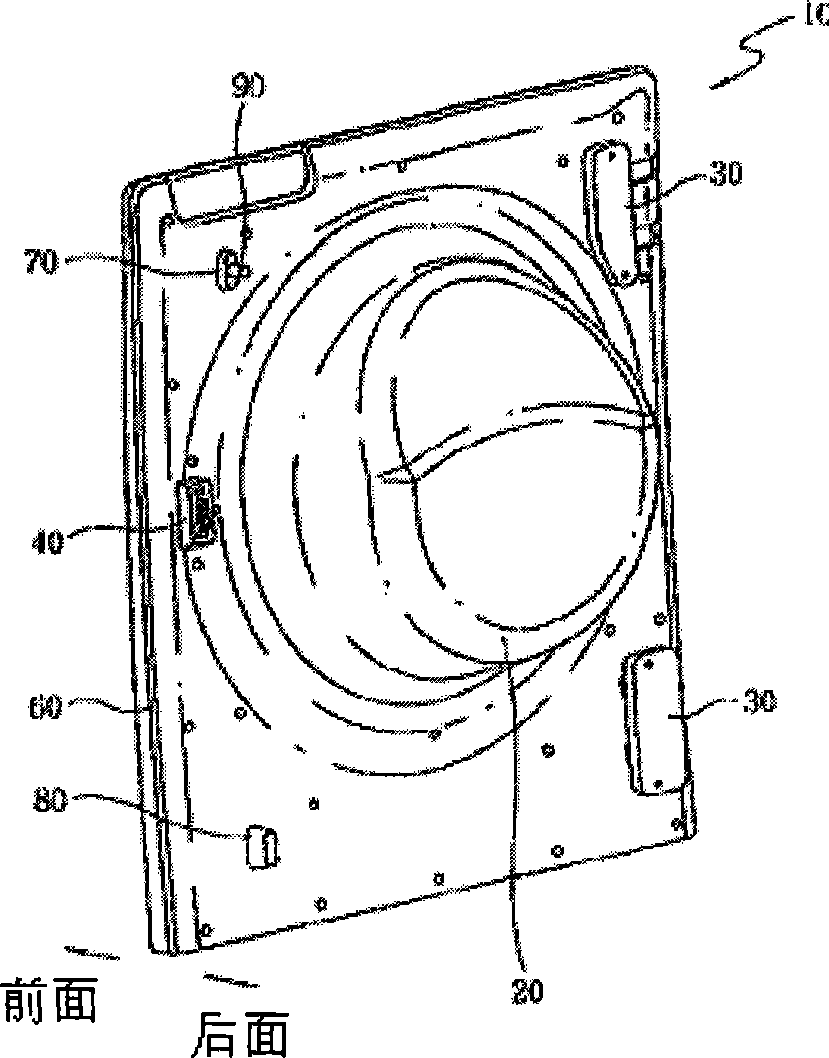

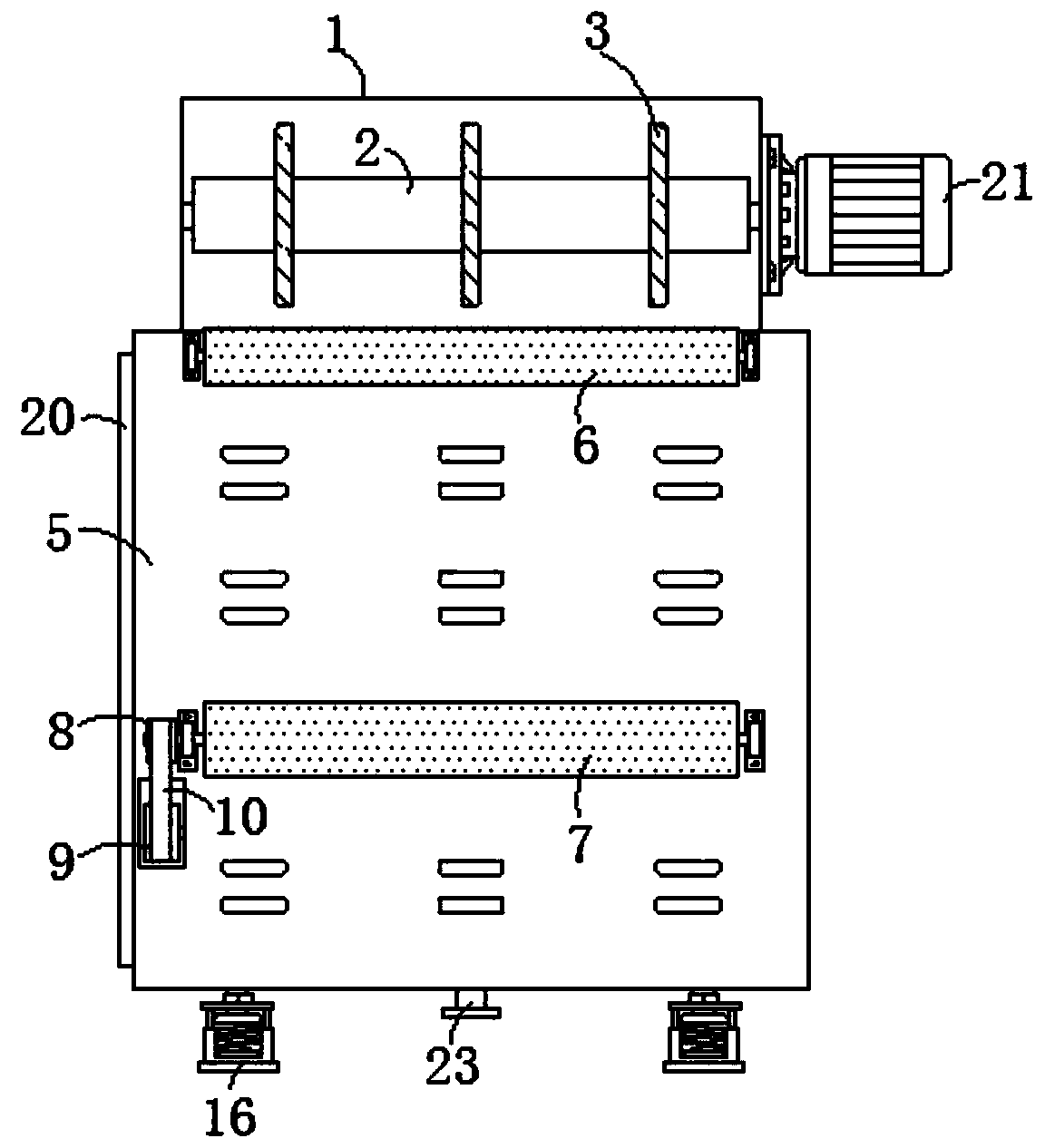

Drum washing machine

InactiveCN101476232ACushion the shockAvoid noiseOther washing machinesTextiles and paperElastic componentElastic compression

The invention relates to a door of drum-type washing machine, which is characterized in comprising the following parts: a door frame; a door glass with a protruding shape to the rear direction of the door frame; a rotatable hinged member connected with the main body of the drum-type washing machine; a locking device; an upper supporting member and a lower supporting member formed on the upper and lower part of the back of the door frame protruding to the backward of the door gate; and a elastic component formed on the upper supporting member protruding to the back of the door frame. When the door is closed, the elastic component contacts with the main body of the drum-type washing machine, and the impact is absorbed by elastic compression. The invention improves the structure of the door supporting member which contacts with the main body of the drum-type washing machine, thereby, can buffer the impact between the door and the main body while closing the door, and can make the door to open a certain angle automatically while opening the door.

Owner:NANJING LG PANDA APPLIANCES

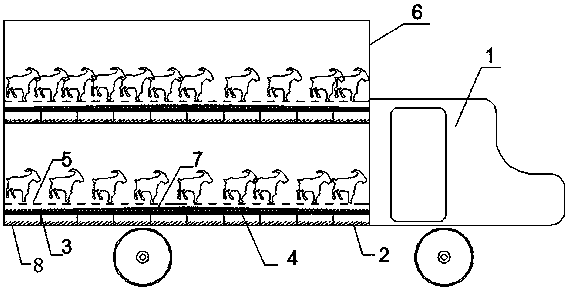

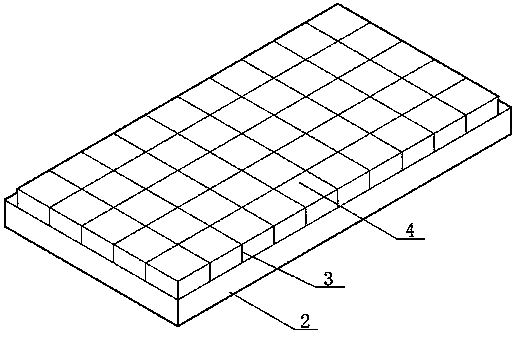

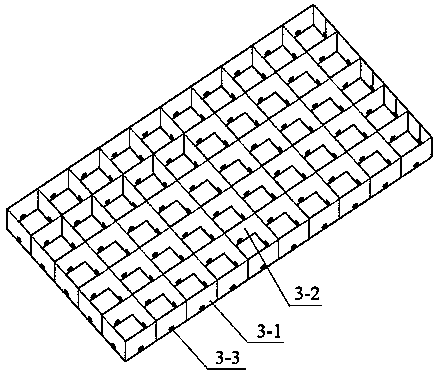

Environment-friendly livestock transport device

InactiveCN107856596AImprove hygiene and cleanlinessInhibitory activityAnimal housingAnimal transportationFecesSewage

The invention relates to an environment-friendly livestock transport device and belongs to the technical field of animal husbandry engineering equipment. A sewage tank is arranged at the bottom in a compartment of a transport wagon, a sewage damper is arranged in the sewage tank, a geotextile layer is paved on the sewage damper, and slatted floors are arranged above the geotextile layer. When livestock moves on the slatted floors, urine or sewage leaks into the sewage tank through the geotextile layer, and excrement or other solid waste is intercepted on the geotextile layer to realize timelyseparation of excrement and urine so as to effectively prevent the livestock from moving on the excrement and urine, so that the pollution is reduced, and the sanitation and cleanliness of the transport vehicle are improved; and the vibration of the sewage entering the sewage tank is relieved under the action of the sewage damper so as to avoid overflow pollution to the compartment and pavements.

Owner:YUNNAN AGRICULTURAL UNIVERSITY

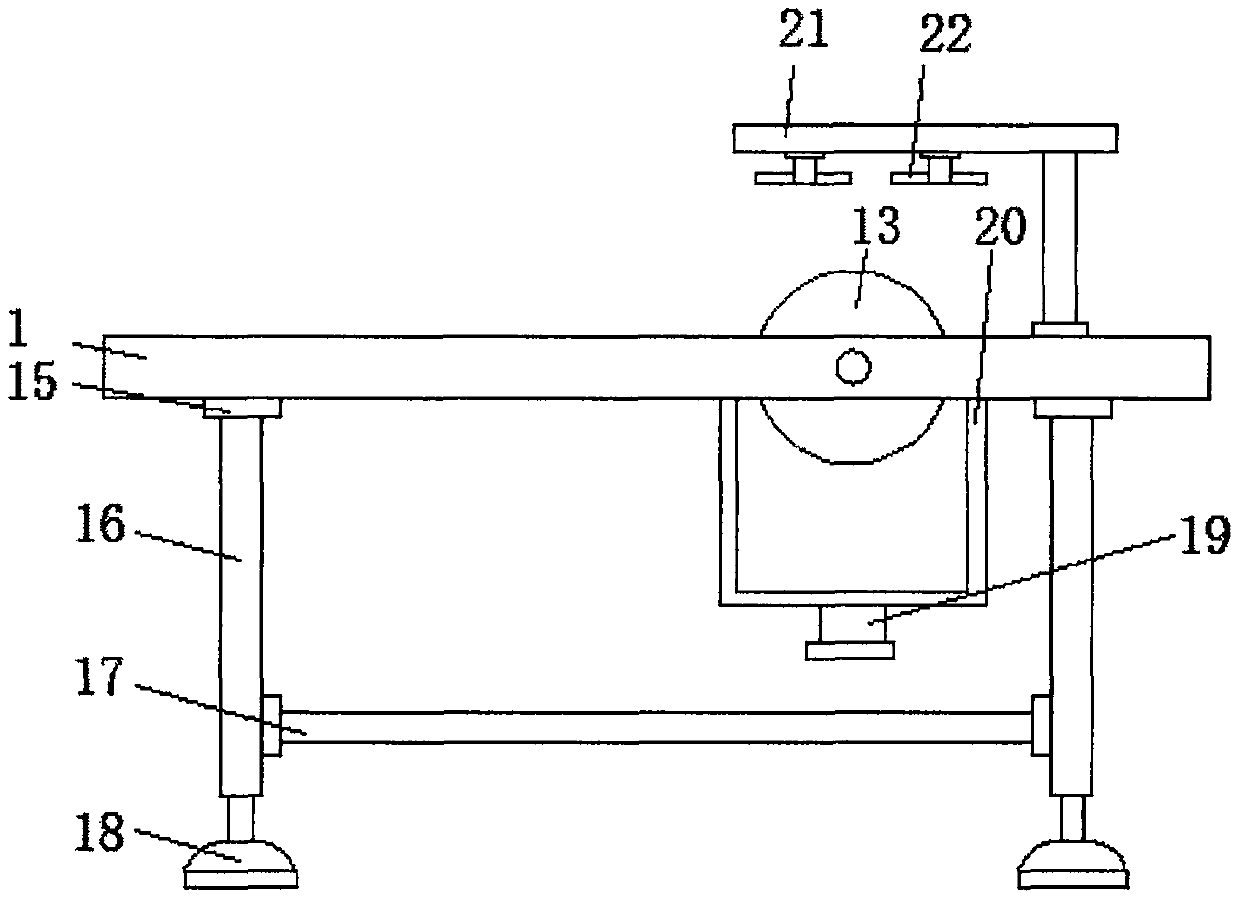

Cutting device for medium plate machining

InactiveCN107755784AAvoid driftingHigh precisionShearing machinesMaintainance and safety accessoriesHydraulic cylinderFixed frame

The invention discloses a cutting device for medium plate machining which comprises a supporting frame; a cutting desktop is fixedly arranged at the top end of the supporting frame; side plates are arranged on the two sides of the cutting desktop; compression springs are fixed to the side plates; a stainless steel pressing plate is fixedly arranged at one ends of the compression springs on each side plate; a driving motor is fixedly arranged on one side of one side plate, and is connected with a rotary main shaft; a square fixing frame is arranged on the surface of the cutting desktop; bearingpedestals are arranged on the inner walls of the square fixing frame; the bottom end of the square fixing frame is connected with a waste chipping storage box; and a hydraulic cylinder is fixedly arranged at the end, far from the square fixing frame, of the cutting desktop, and is connected with a hydraulic telescopic rod. Rollers are uniformly distributed on the surfaces of the stainless steel pressing plates, a medium plate is placed between the two stainless steel pressing plates, and the stainless steel pressing plates can clamp and fix the medium plate steadily through the compression springs, so that the medium plate is prevented from deviating in the running process.

Owner:广西容县方园工艺品有限公司

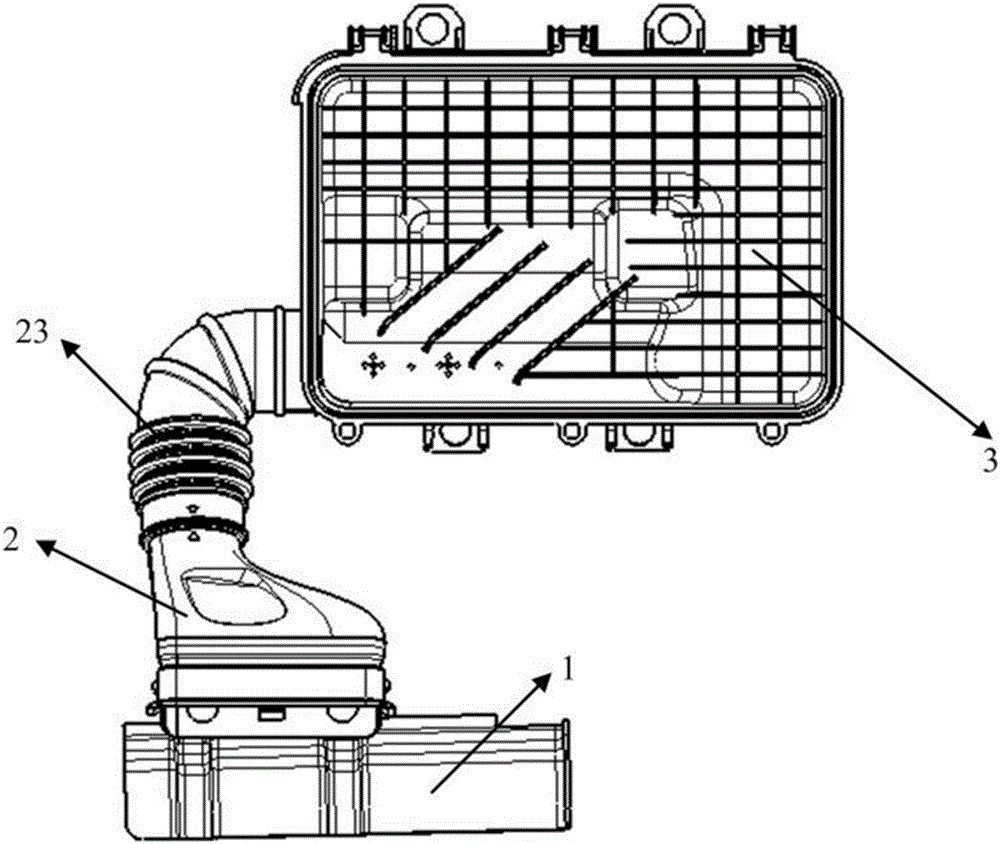

Air inflow guiding device

ActiveCN106481439AEfficient dischargeRealize the function of waterproof and snowproofInternal combustion piston enginesCombustion-air/fuel-air treatmentAir filterEngineering

The invention discloses an air inflow guiding device which comprises a snow blocking plate, an air inflow pipe, an air inlet formed in a lower end of an air filter, and a blocking piece. The snow blocking plate is located below the air inflow pipe and comprises a fixed plate, a connection plate, a snow containing plate and a side face baffle, wherein the fixed plate is fixedly connected with a radiator assembly of an automobile, the fixed plate, the connection plate and the snow containing plate jointly form a structure with the cross section in a right-angle-n shape, and the side face baffle is located at one end of the snow containing plate. The air inflow pipe is made communicated with the air inlet. The blocking piece is fixed to the inner side wall of the lower cover of the air filter. According to the air inflow guiding device, due to the arrangement of the structure of the snow blocking plate, the fixed plate, the connection plate and the snow containing plate jointly form the structure with the cross section in the right-angle-n shape, and the function of preventing water and snow is effectively achieved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

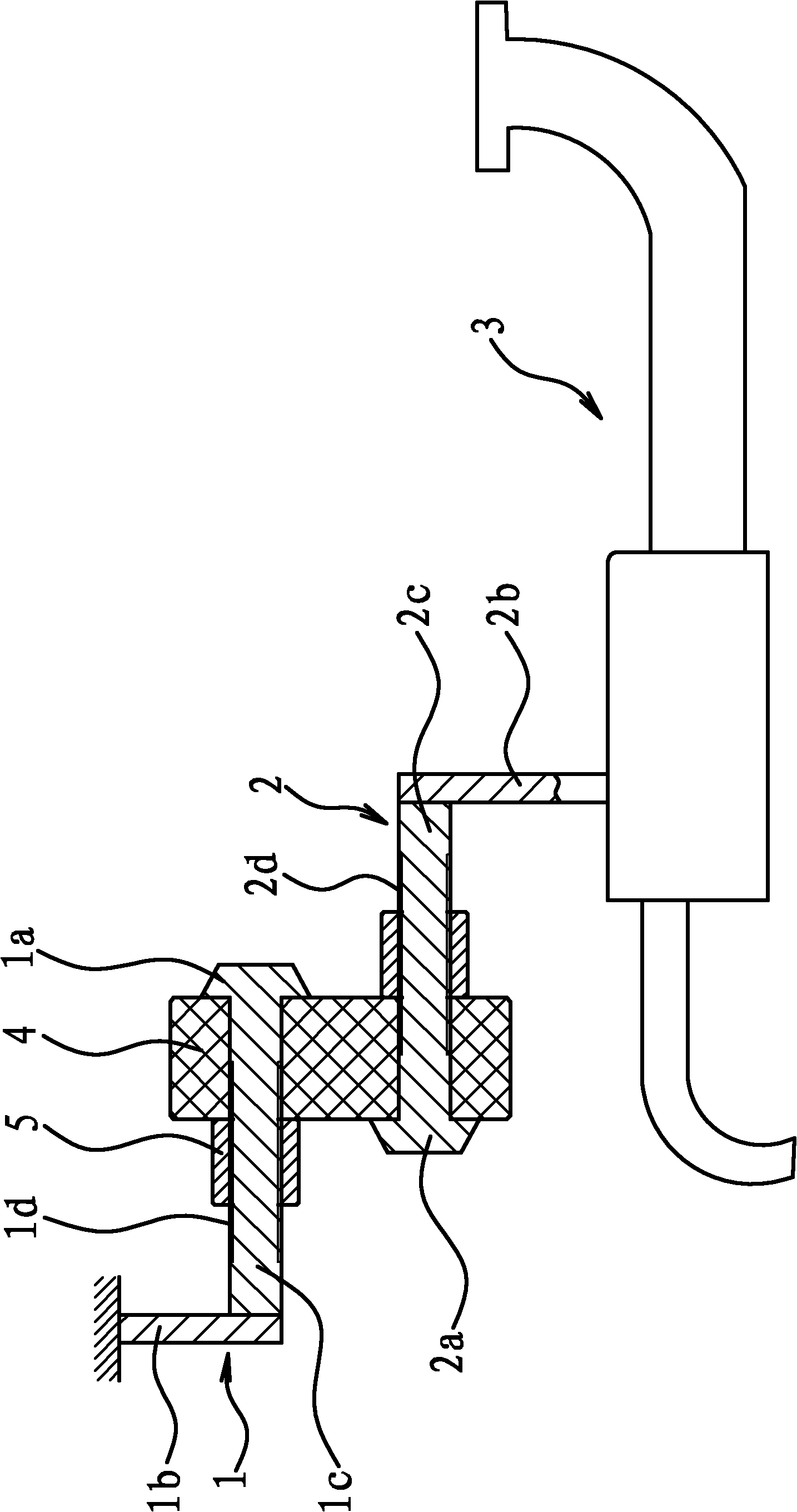

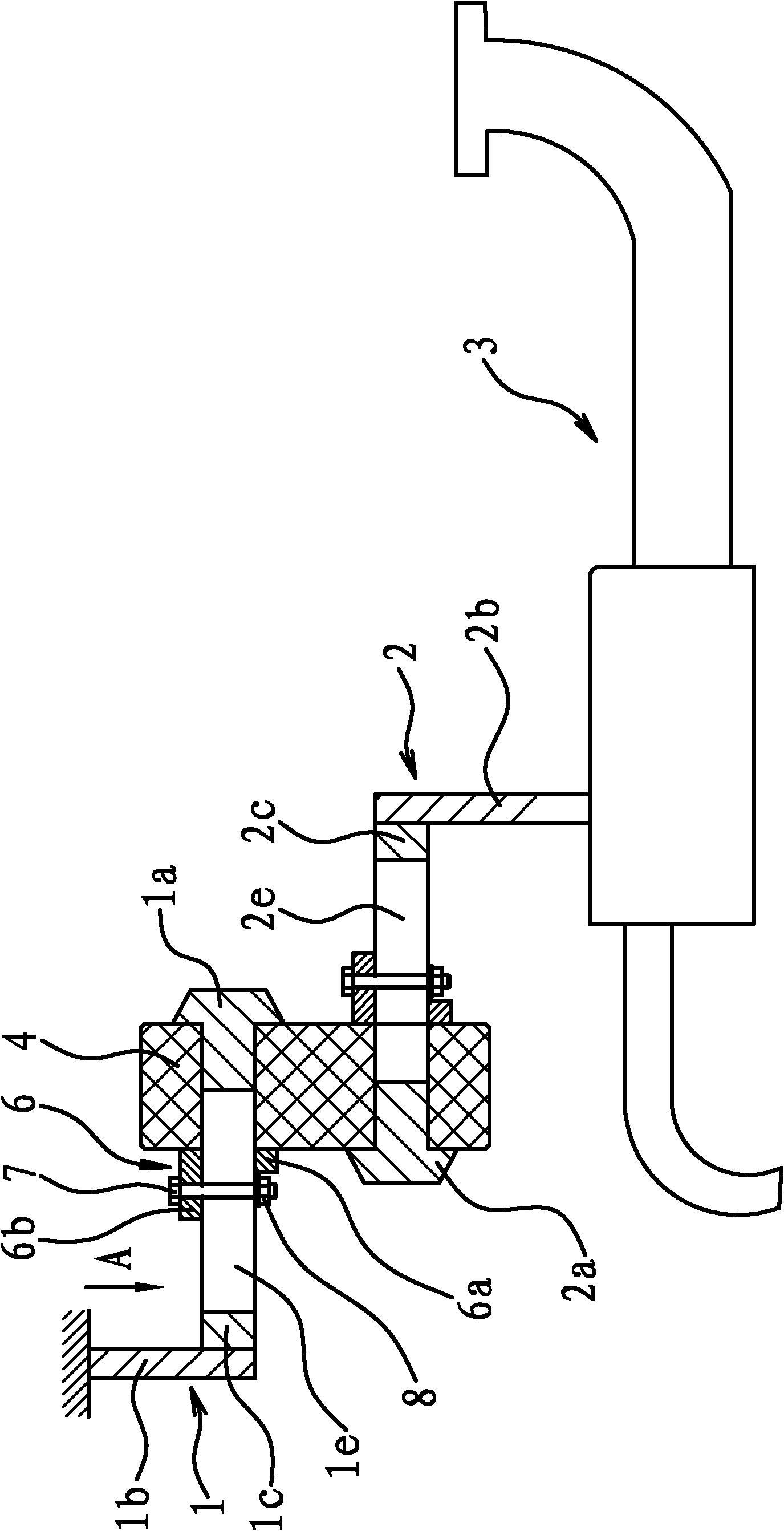

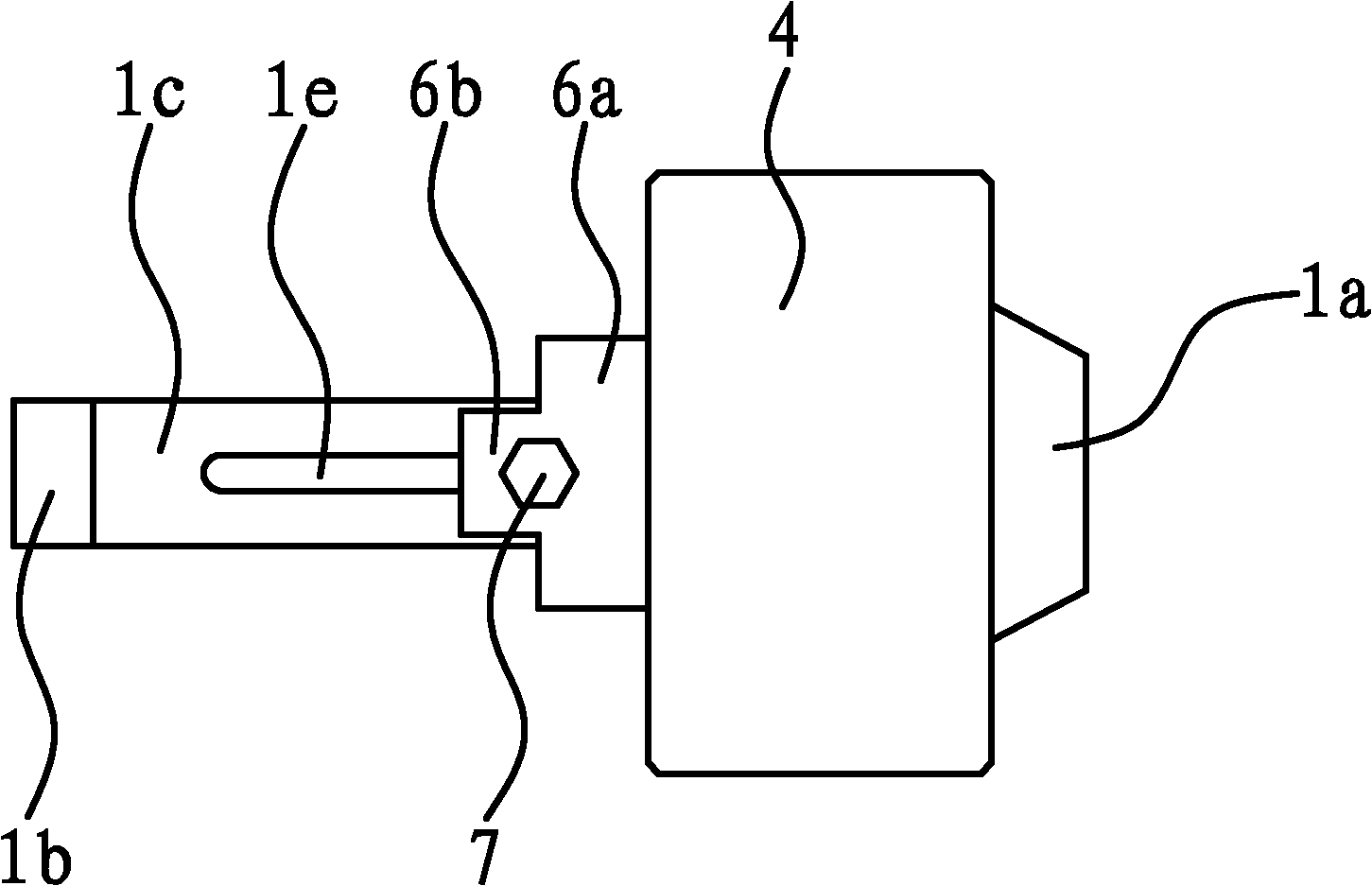

Hanging device of automobile exhaust pipe

ActiveCN101823424ASimple structureEasy to operatePropulsion unit gas exhaustRubber materialExhaust pipe

The invention provides a hanging device of an automobile exhaust pipe, belonging to the automobile field. The hanging device solves the technical problem that the existing automobile adopts a single hanger to support an exhaust pipe to cause large vibration and dropping of the exhaust pipe so as to affect exhausting performance. In the invention, the hanging device of the automobile exhaust pipe is fixedly arranged on the bottom of the automobile chassis and comprises an upper hanger and a lower hanger, wherein, the upper hanger can be fixed with the automobile chassis, and the lower hanger can be movably connected with the automobile exhaust pipe. The hanging device of the automobile exhaust pipe is characterized in that the upper hanger and the lower hanger are connected by a lifting lug made of a rubber material, the lifting lug is in a strip shape, and the upper hanger and the lower hanger respectively pass through the upper end part and the lower end part of the lifting lug. The connecting pieces (1c, 2c) of the upper hanger and the lower hanger are provided with transverse arranged spouts (1e, 2e) in order to adjust the locating part of the lifting lug. The hanging device is composed of the upper hanger, the lower hanger and the lifting lug which causes two hangers to be connected, wherein, the lifting lug made of the rubber material can greatly prevent vibration of the automobile chassis from transmitting to the exhaust pipe so as to ensure reliable operation of an exhaust system.

Owner:靖江市新航制刷厂

Thin-wall pipe cutting system

InactiveCN104057139AAchieve precise positioningNo damageTube shearing machinesShearing machine accessoriesPiston rodPressure sensor

The invention discloses a thin-wall pipe cutting system and relates to the technical field of cutting. A pipe locating device of the thin-wall pipe cutting system comprises at least three air cylinders. Locating rods are driven by piston rods of the air cylinders to move so that a pipe can be clamped. When pressure sensors on the locating rods detect that a pressure value reaches a preset valve, the piston rods of the air cylinders stop moving, and therefore the pipe is located. Due to the fact that the multiple air cylinders for localization work independently and the locating pressure is controllable, even though the shape of the outer wall of the pipe is not regular, the pipe wall can not be damaged, and the thin-wall pipe is accurately located. Multiple trapezoidal grooves and reversed trapezoidal grooves are formed in the outer circumference of an installation hole of a cutter head of a cutter and distributed alternately, by the adoption of the arrangement mode, vibration of the cutter in the cutting process can be effectively reduced, and the cutting accuracy is guaranteed. Multiple heat dissipating holes for heat dissipation are further formed in the cutter head, so that the cutter head is not prone to deformation and the service life of the cutter head is effectively prolonged.

Owner:李春霞

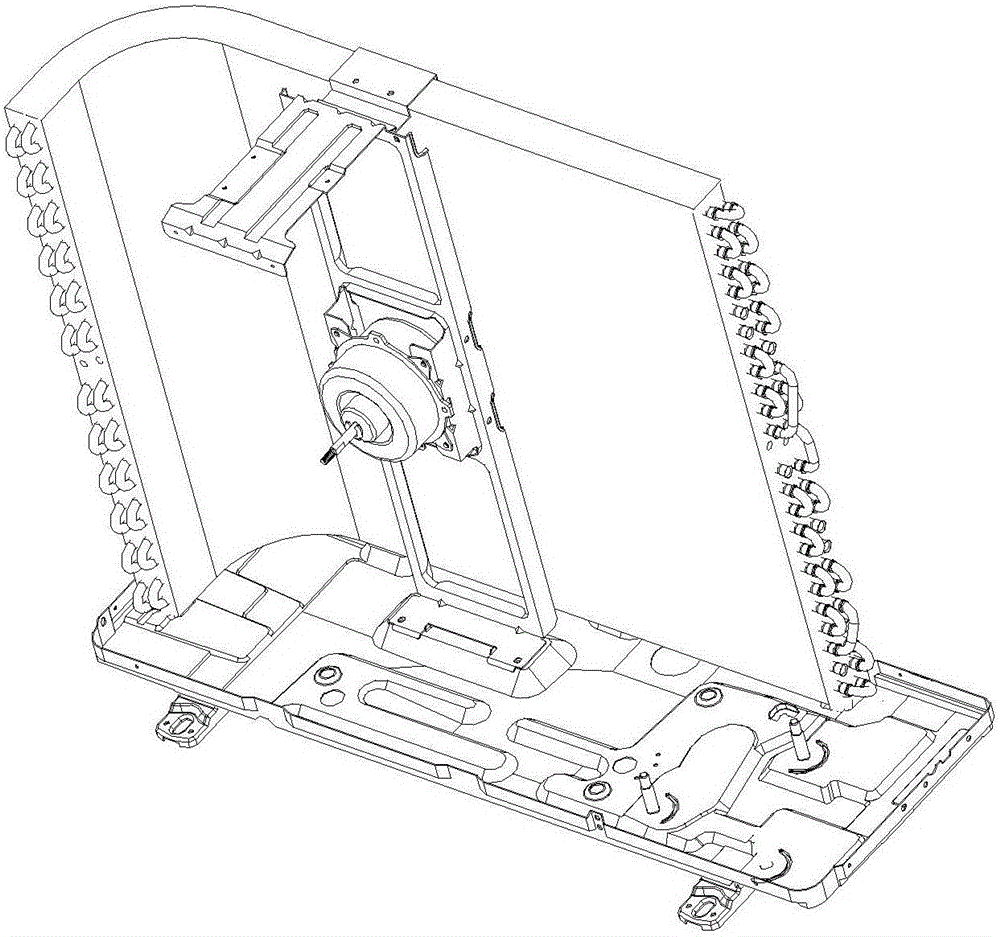

Motor support and air conditioner outdoor unit

ActiveCN105937802AImprove stabilityReduce vibrationLighting and heating apparatusNoise suppressionEngineeringRolling chassis

The invention provides a motor support. The motor support comprises a body. The body comprises two supporting structures. The tops of the two supporting structures are connected to form an inverted V-shaped structure. A motor installing part is arranged on the top of the inverted V-shaped structure and used for being fixedly connected with a motor. Foundation feet are arranged at the bottoms of the supporting structures and used for being fixedly connected to equipment. The triangular structure similar to the inverted V shape is adopted in the motor support, the principle that the triangular structure is relatively stable is adopted, the motor is arranged on the top of the inverted V shape, and the two foundation feet are connected with a bottom plate to play a supporting role. By means of the motor support, the stability of the motor support is greatly improved, vibration of the whole machine is weakened as well, noise during running of the whole machine is lowered, and the quality is improved. The invention further provides an air conditioner outdoor unit.

Owner:GREE ELECTRIC APPLIANCES INC

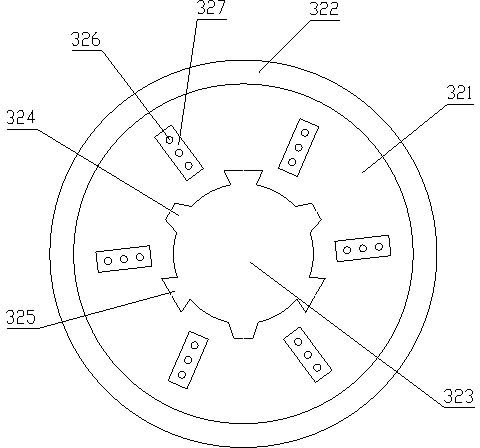

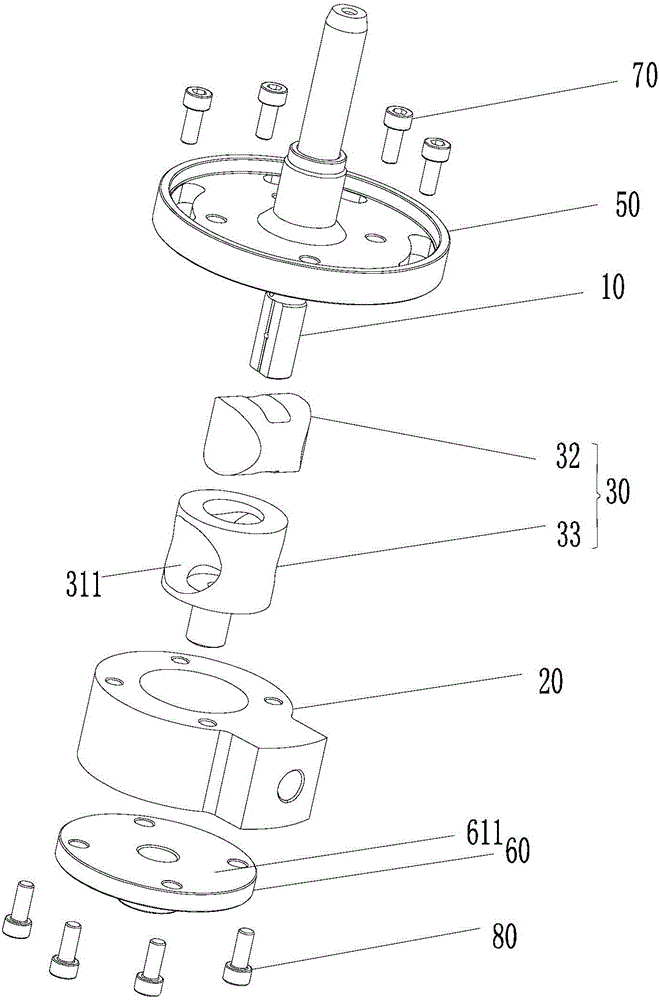

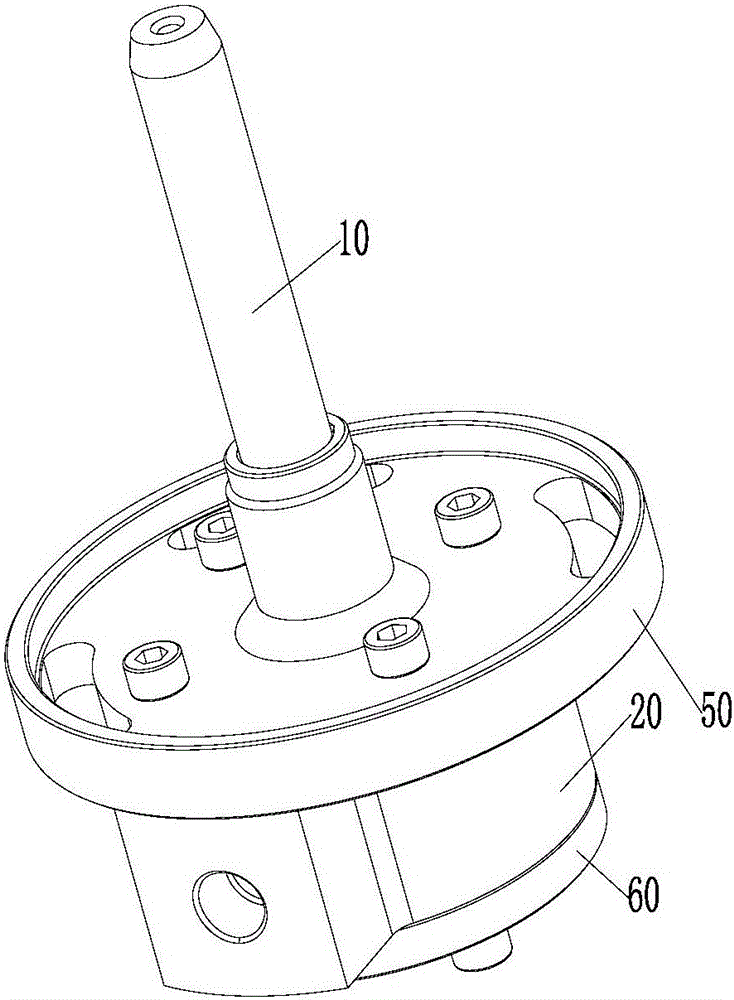

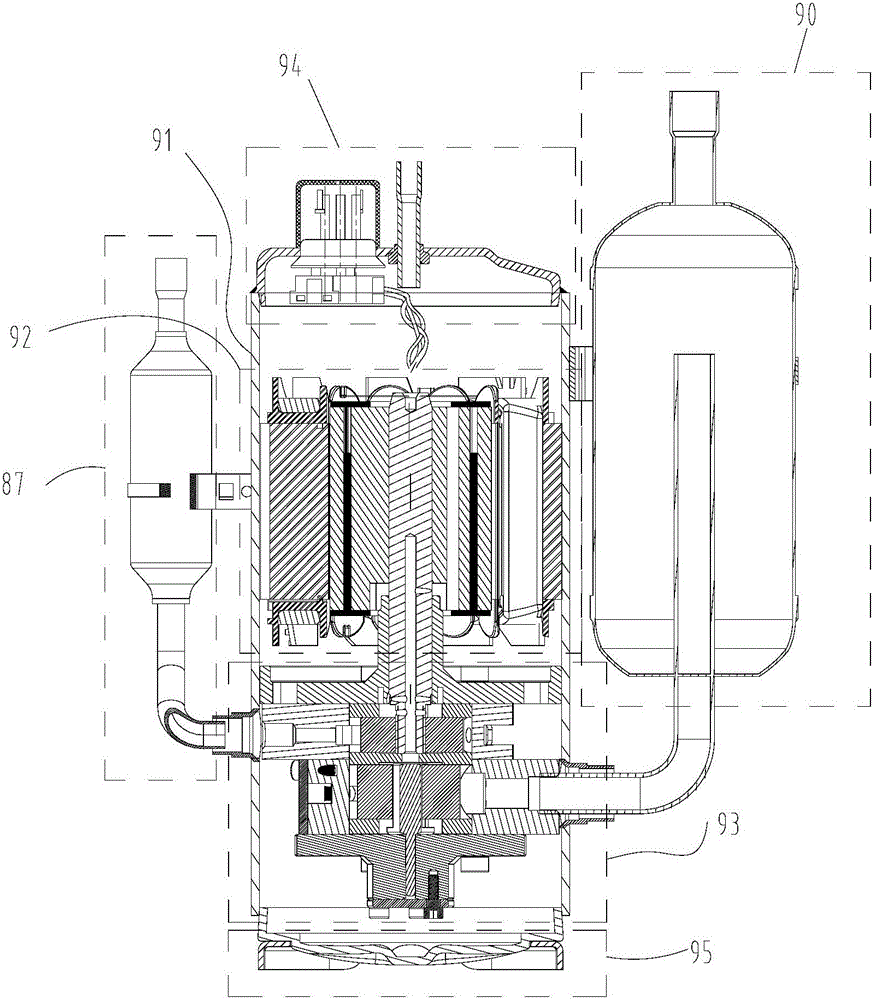

Fluid machine, heat exchange apparatus and running method of fluid machine

ActiveCN106704183AVibration reliefReduced clearance volumeRotary piston pumpsRotary piston liquid enginesPistonEngineering

The invention provides a fluid machine, a heat exchange apparatus and a running method of the fluid machine. The fluid machine comprises: an upper flange; a lower flange; a cylinder clamped between the upper flange and the lower flange; a rotating shaft, wherein the axle center of the rotating center and the axle center of the cylinder are eccentrically arranged, the eccentric distance is constant, and the rotating shaft sequentially traverses through the upper flange and the cylinder; and a piston assembly, wherein the piston assembly has a variable volume chamber, the piston assembly is pivotally arranged in the cylinder, and the rotating shaft is in driving connection with the piston assembly to change the volume of the variable volume chamber. The eccentric distance between the rotating shaft and the cylinder is constant, the rotating shaft and the cylinder rotate around respective axle centers in the movement process, and the positions of mass centers do not change, so the piston assembly stably and continuously rotates when moving in the cylinder, vibration of the fluid machine is effectively alleviated, regular volume change of the variable volume chamber is guaranteed, and the clearance volume is reduced, thereby the running stability of the fluid machine is improved, and the working reliability of the heat exchange device is improved.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

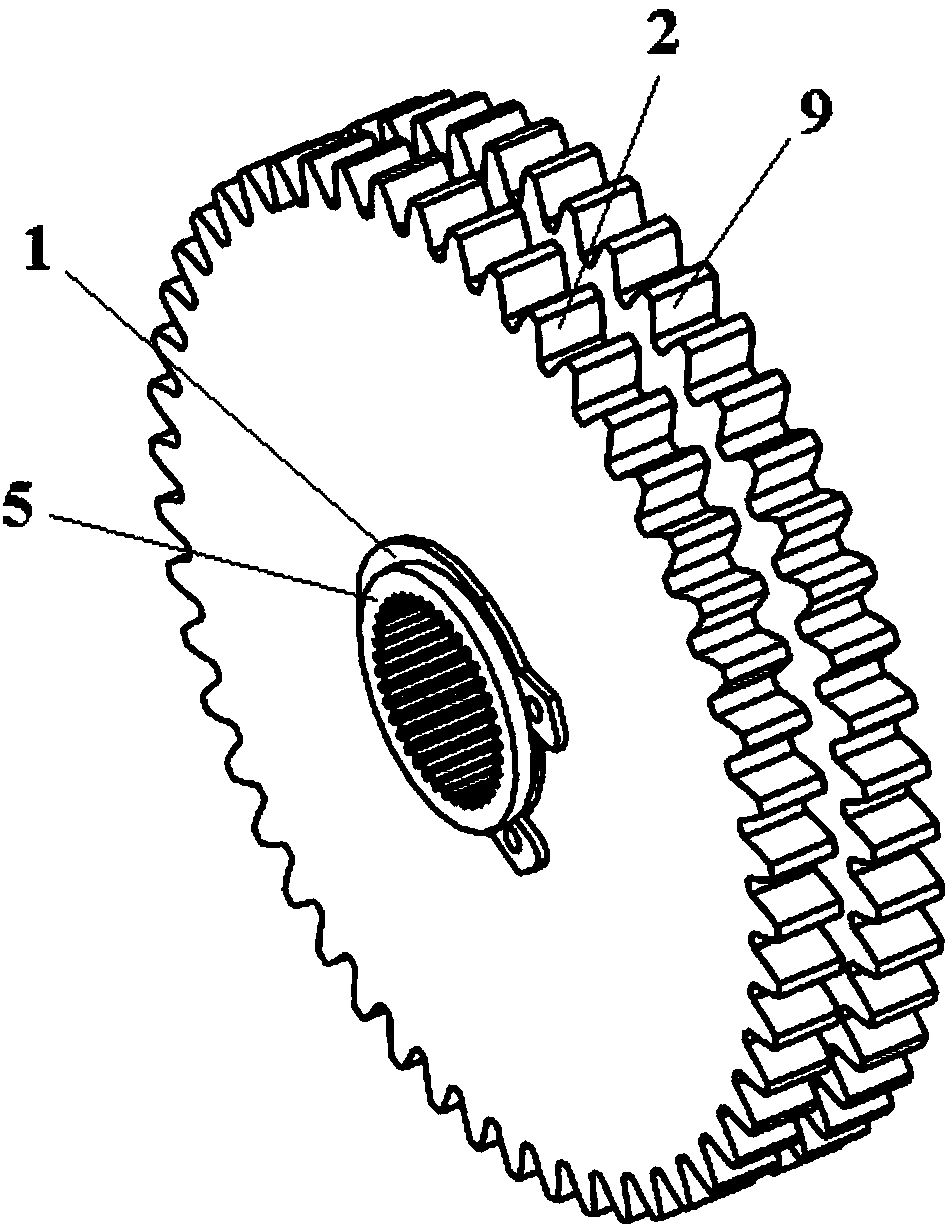

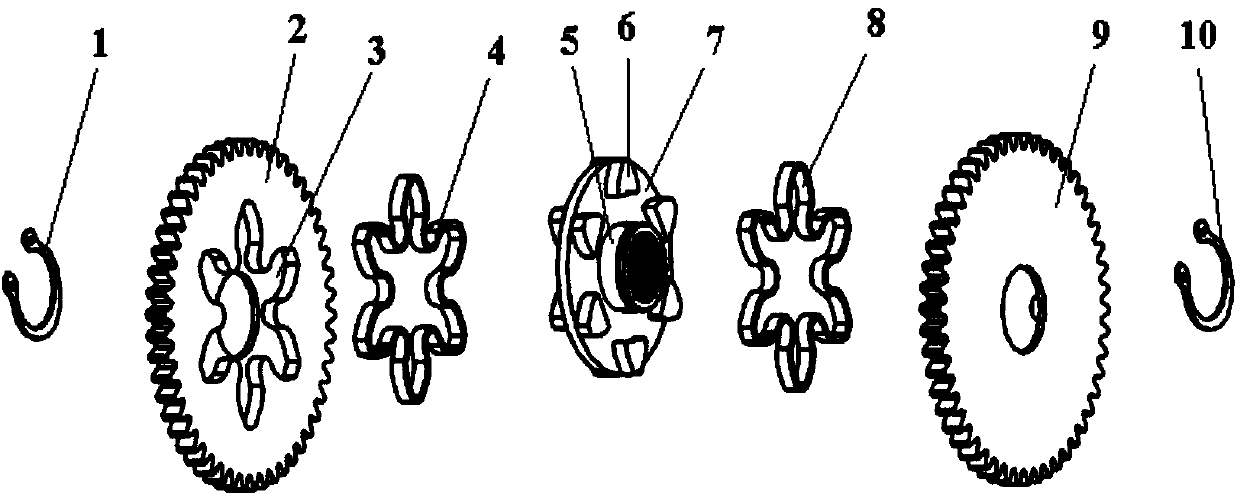

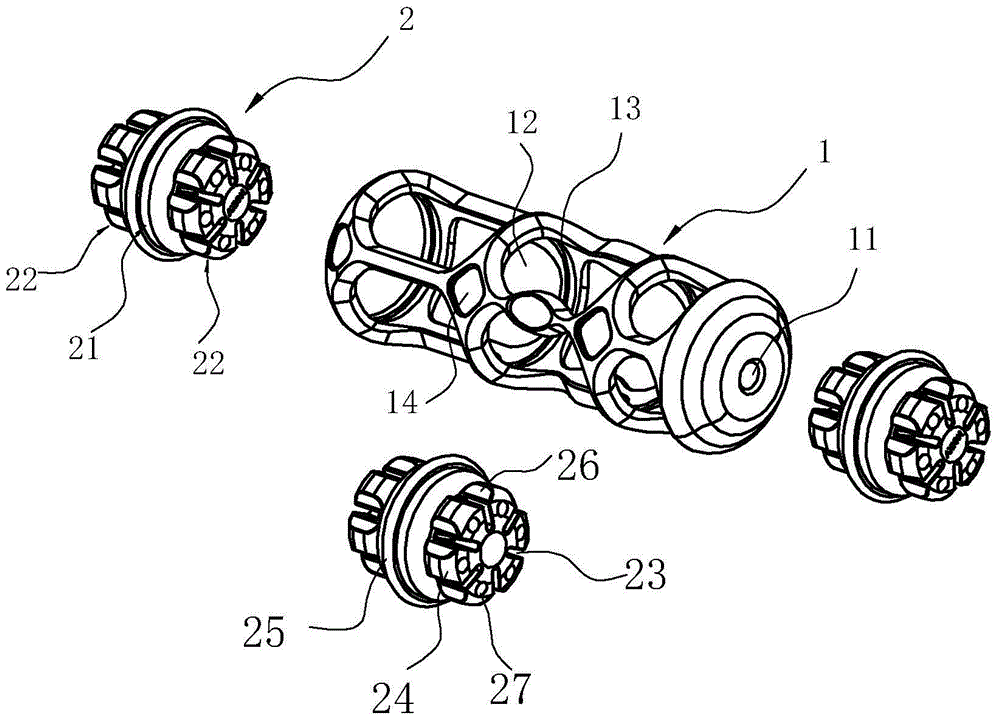

Anti-backlash gear

The invention relates to the technical field of power transmission and particularly discloses an anti-backlash gear. The anti-backlash gear comprises a first side gear, a second side gear and a middle hub, wherein two sides of the middle hub are provided with a first clamping convex block and a second clamping convex block, the first side gear is provided with a first clamping concave opening corresponding to the first clamping convex block, the second side gear is provided with a second clamping concave opening corresponding to the second clamping convex block, the first side gear is connected on one side of the middle hub through matching of the first clamping concave opening and the first clamping convex block, the second side gear is connected on the other side of the middle hub through matching of the second clamping concave opening and the second clamping convex block, and the first side gear and the second side gear are relatively staggered in the peripheral direction. Two side gears of the anti-backlash gear can be directly assembled through the middle hub in a staggered mode, the time and labor are saved, and the anti-backlash gear is simple and compact in structure and small in occupied space while the purpose of eliminating gear backlashes is achieved.

Owner:GREAT WALL MOTOR CO LTD

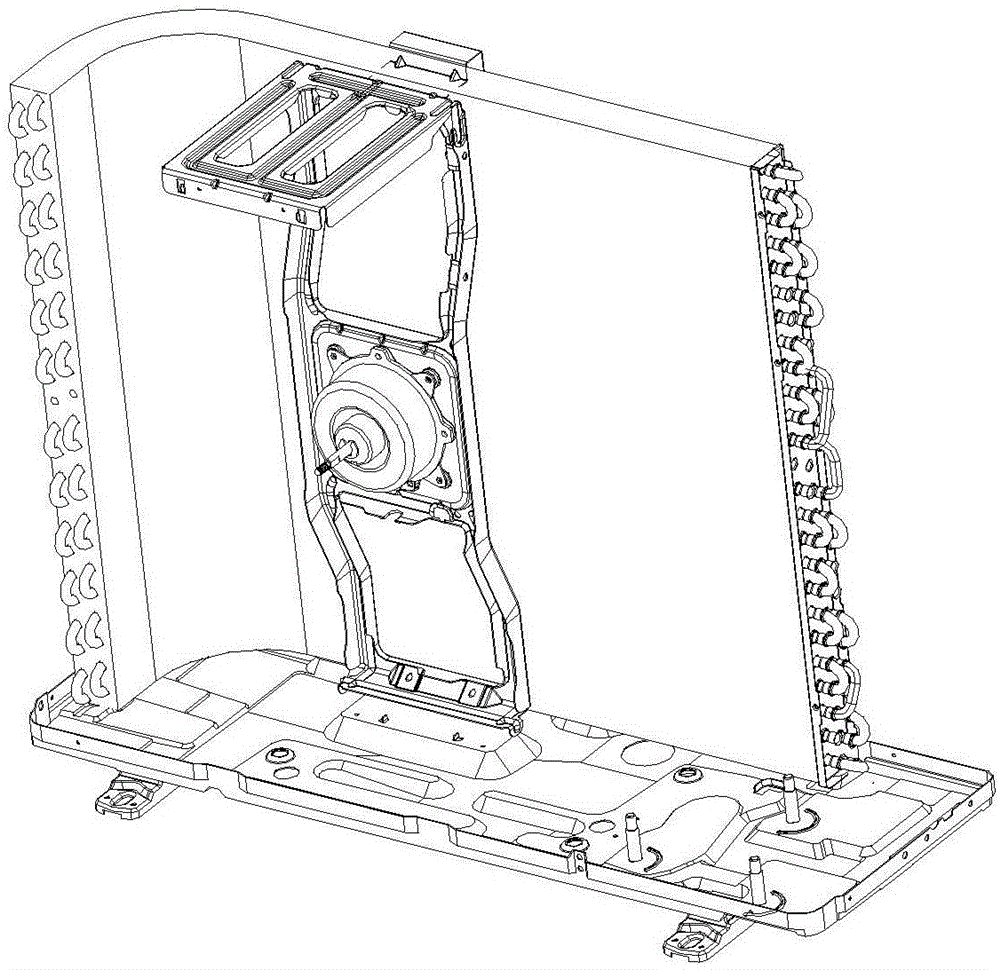

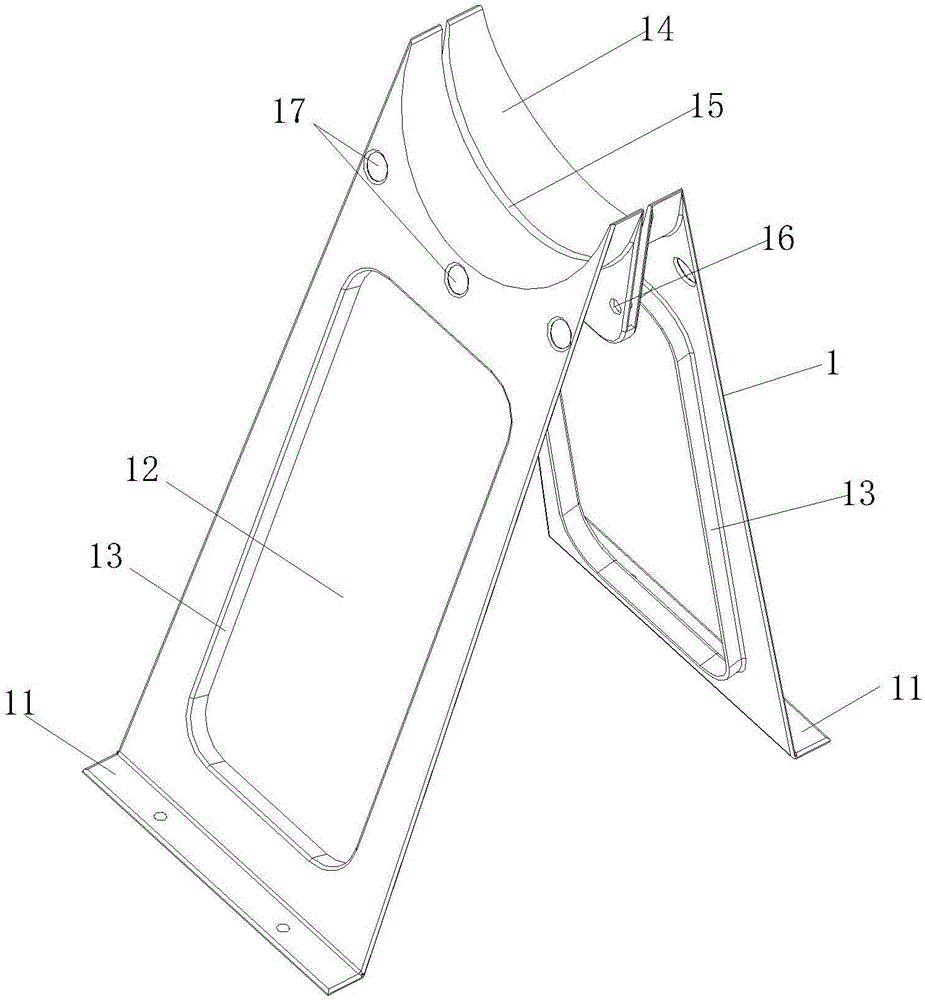

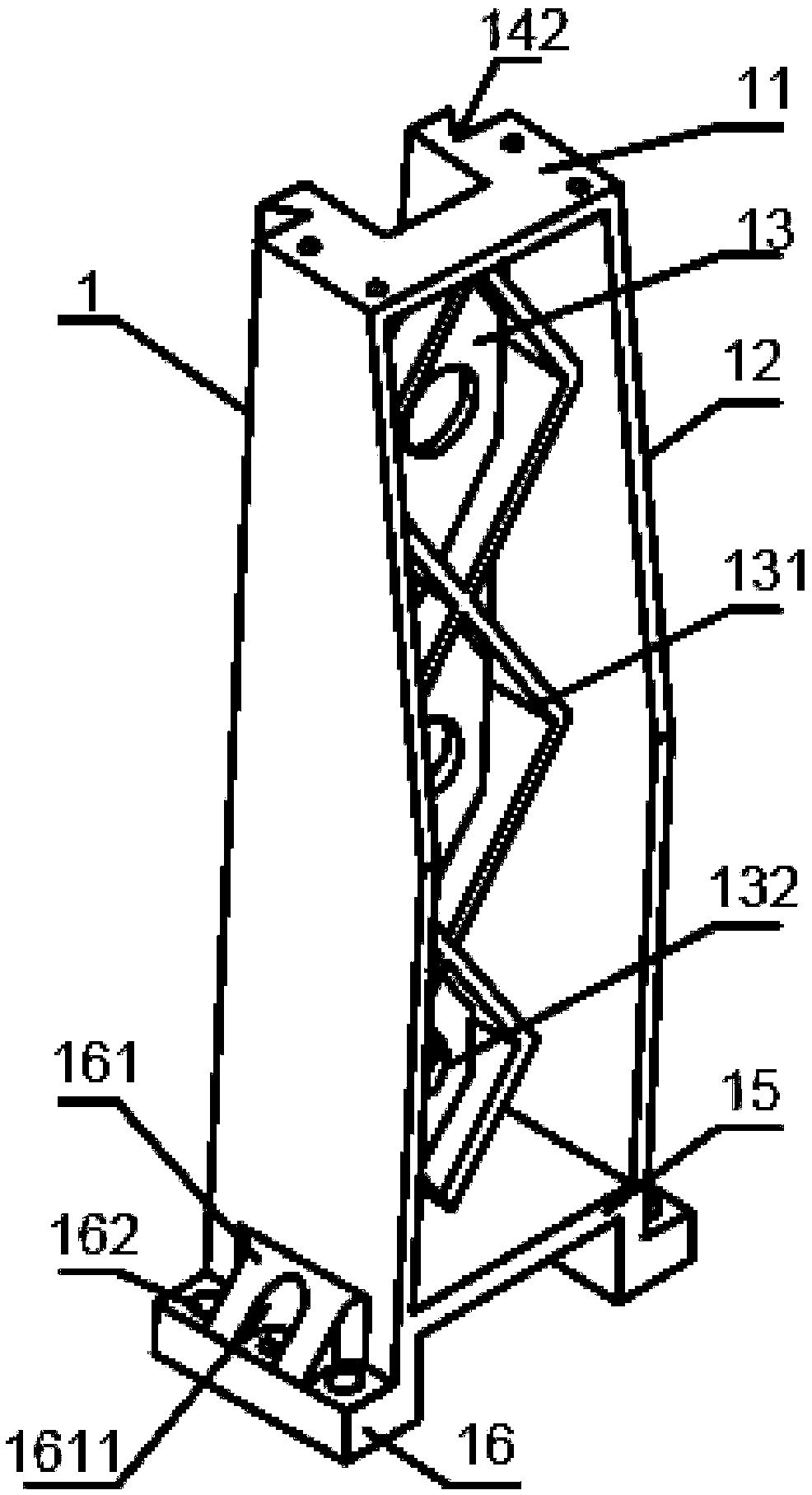

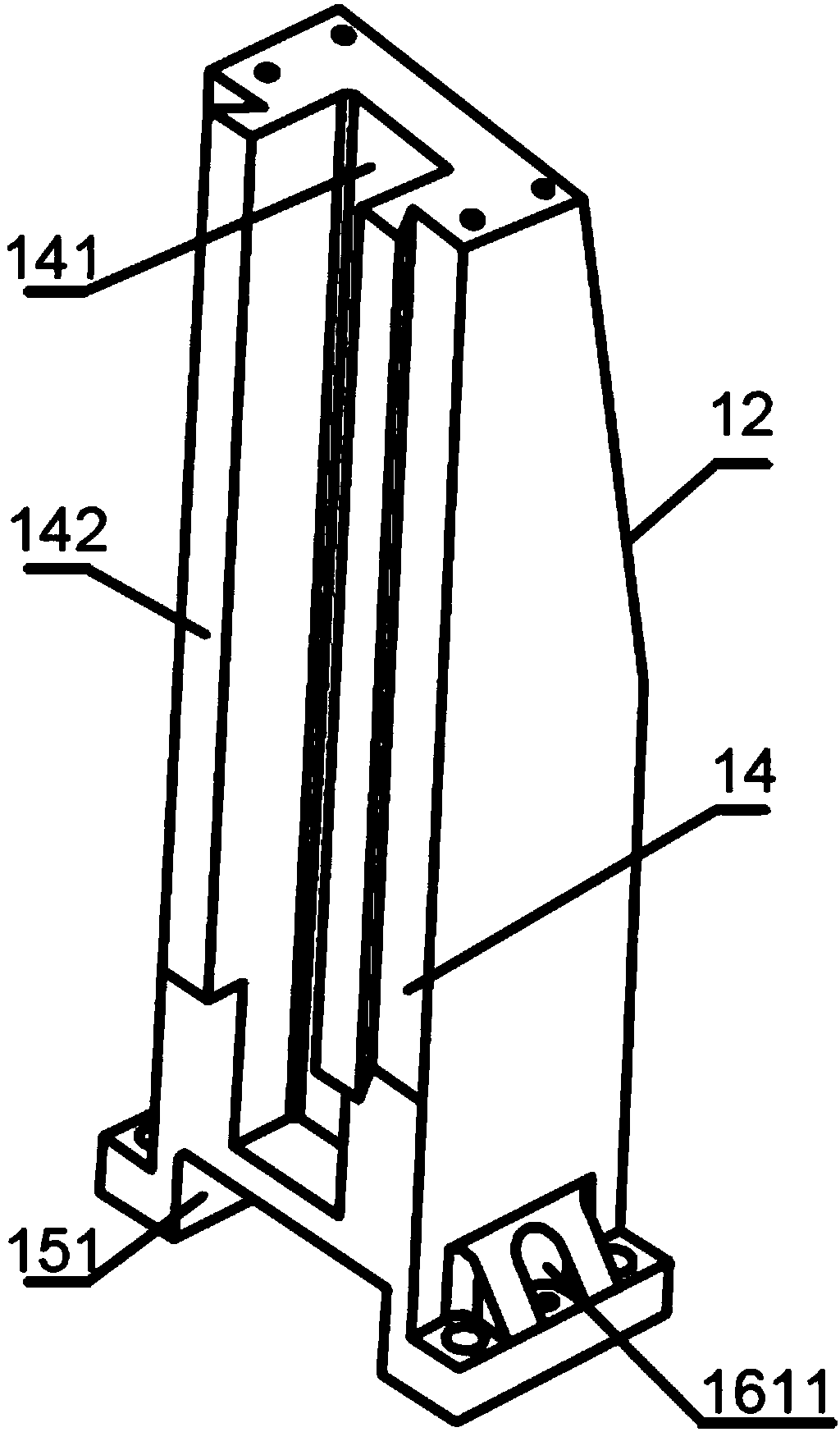

Stand column

InactiveCN108188760AReduce weightGuaranteed working strengthLarge fixed membersStructural engineeringEngineering

The invention provides a stand column. The stand column comprises a stand column body, wherein the stand column body comprises a connecting surface; the connecting surface perpendicularly extends to the bottom surface from the top surface of the stand column body, and divides the stand column body into a front cavity and a back cavity; hoisting holes are formed in the connecting surface; a plurality of connecting surface reinforcing ribs which are arranged on the connecting surface are arranged in the front cavity, are connected with the left side wall and the right side wall of the stand column body, and are connected to the top surface and the bottom surface of the stand column body; the connecting surface reinforcing ribs and the hoisting holes are staggered; the back cavity does not have a top surface; mounting slide tracks are integrally formed on the back of the back cavity, are symmetrically arranged on two sides of the outside of the back cavity, and downwards extend to the position above the bottom surface from the top surface of the stand column; supports are arranged on the lower portion of the stand column body, extend to two sides from the position below the bottom surface and are symmetrically distributed, so that a bottom groove is formed below the bottom surface; and mounting holes are formed in each support. The stand column is low in cost and high in strength,and is firmly and stably combined to a base of a machine tool.

Owner:安徽金义得机械有限公司

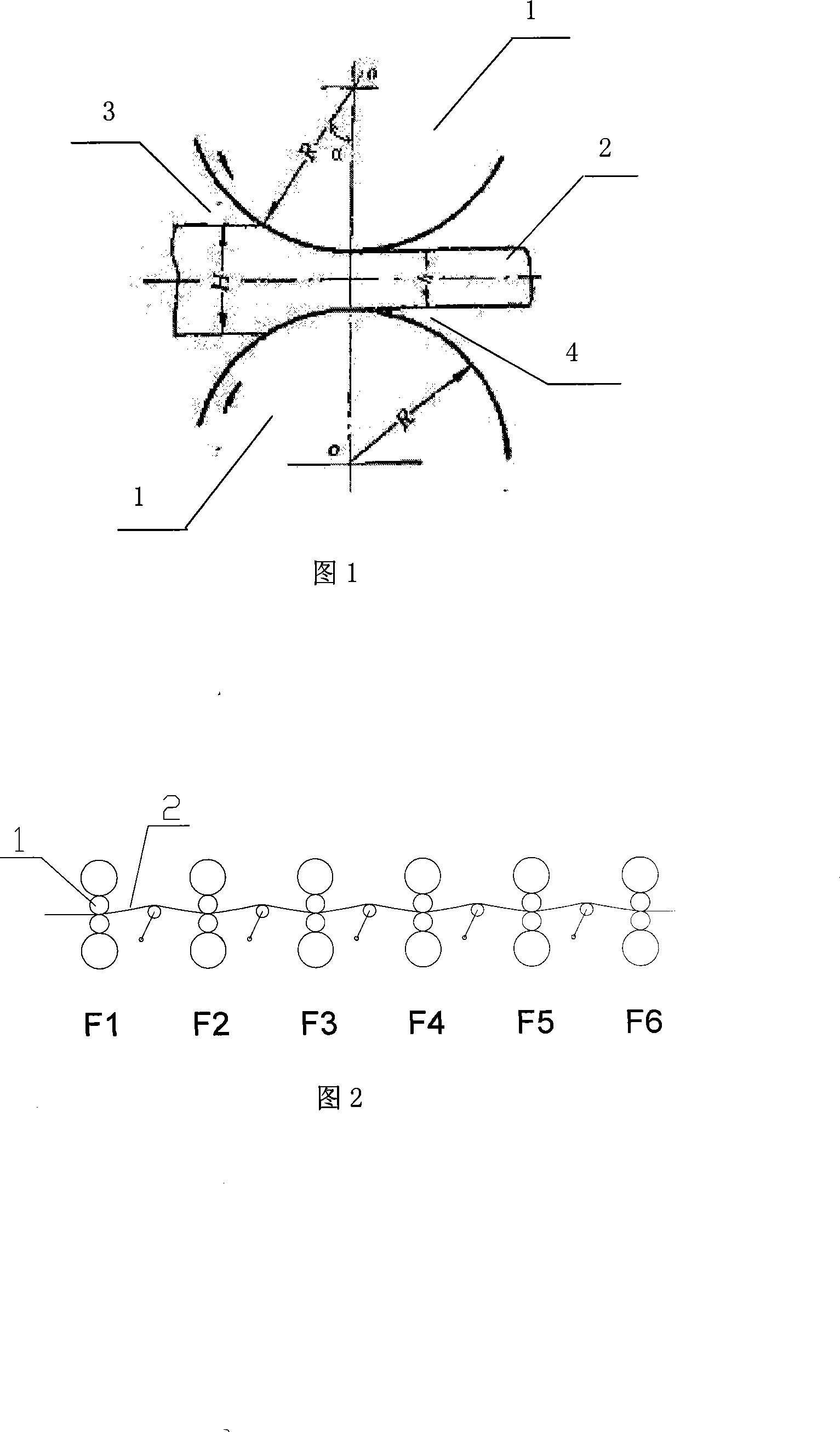

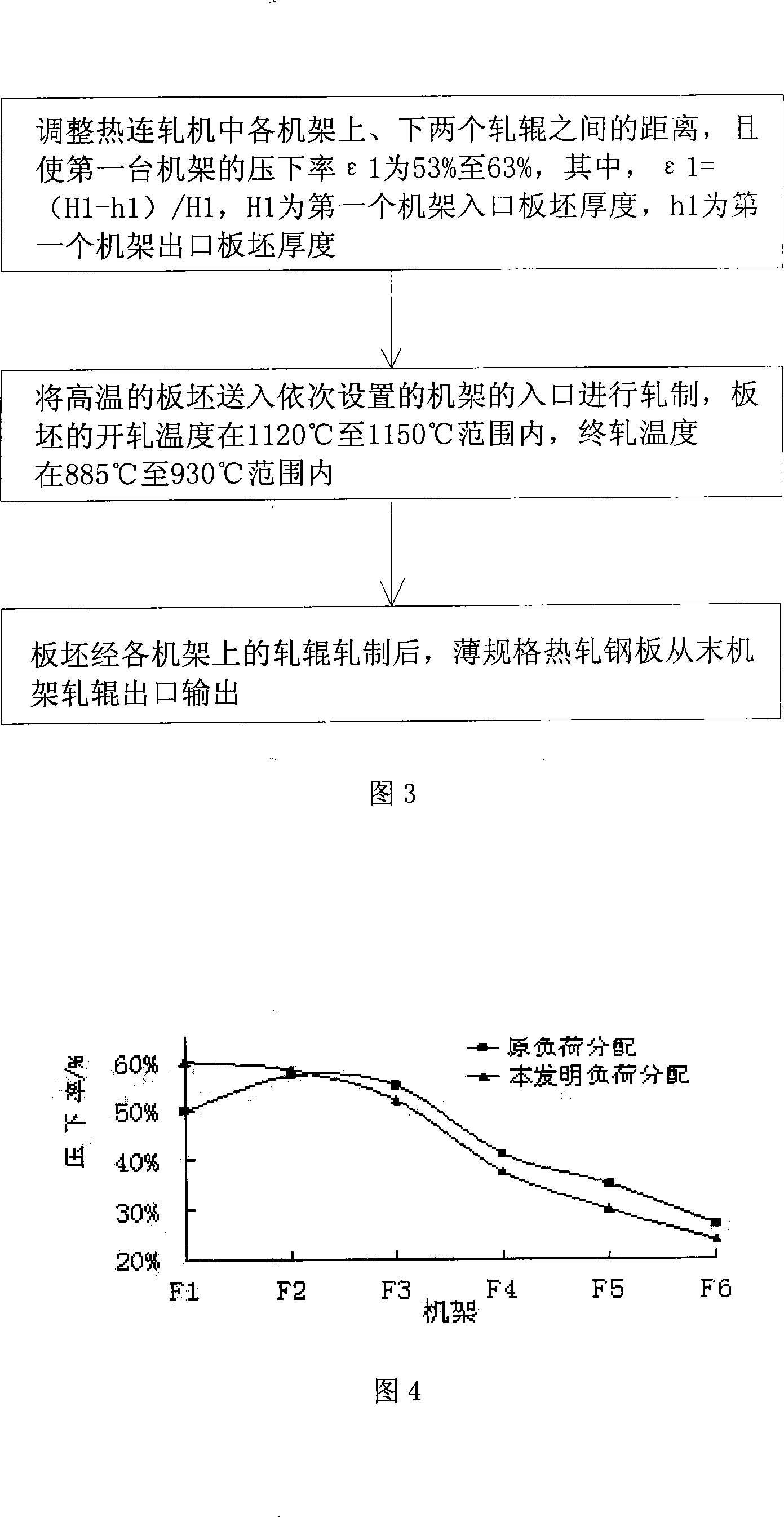

Method for producing thin format hot rolled steel plate

InactiveCN101219439ALarge amount of deformationReduce rolling loadRoll force/gap control deviceTemperature control deviceSheet steelHot rolled

The invention discloses a production method for a light-gauge hot rolled steel plate, which comprises the steps that: a. the distance between an upper roller and a lower roller of each frame of a hot strip mill is adjusted and the percent of reduction epsilon 1 of a first frame is adjusted to be 53 percent to 63 percent, wherein, the epsilon 1 is equal to (H1-h1) / H1, therein, H1 is the thickness of a slab at an inlet of the frame, h1 is the thickness of a slab at an outlet of the fame; b. high temperature slabs are sent to a rolling inlet of the frames that are arranged in sequence for rolling; c. the light-gauge hot rolled steel plate is output from a rolling outlet of a last frame after the slabs are rolled by the varied frames. The invention promotes the percent of reduction of the first frame as high as possible when ensuring security to reduce the load of rollers of rear frames, thereby improving rolling efficiency and product quality.

Owner:GUANGZHOU PEARL RIVER STEEL & IRON

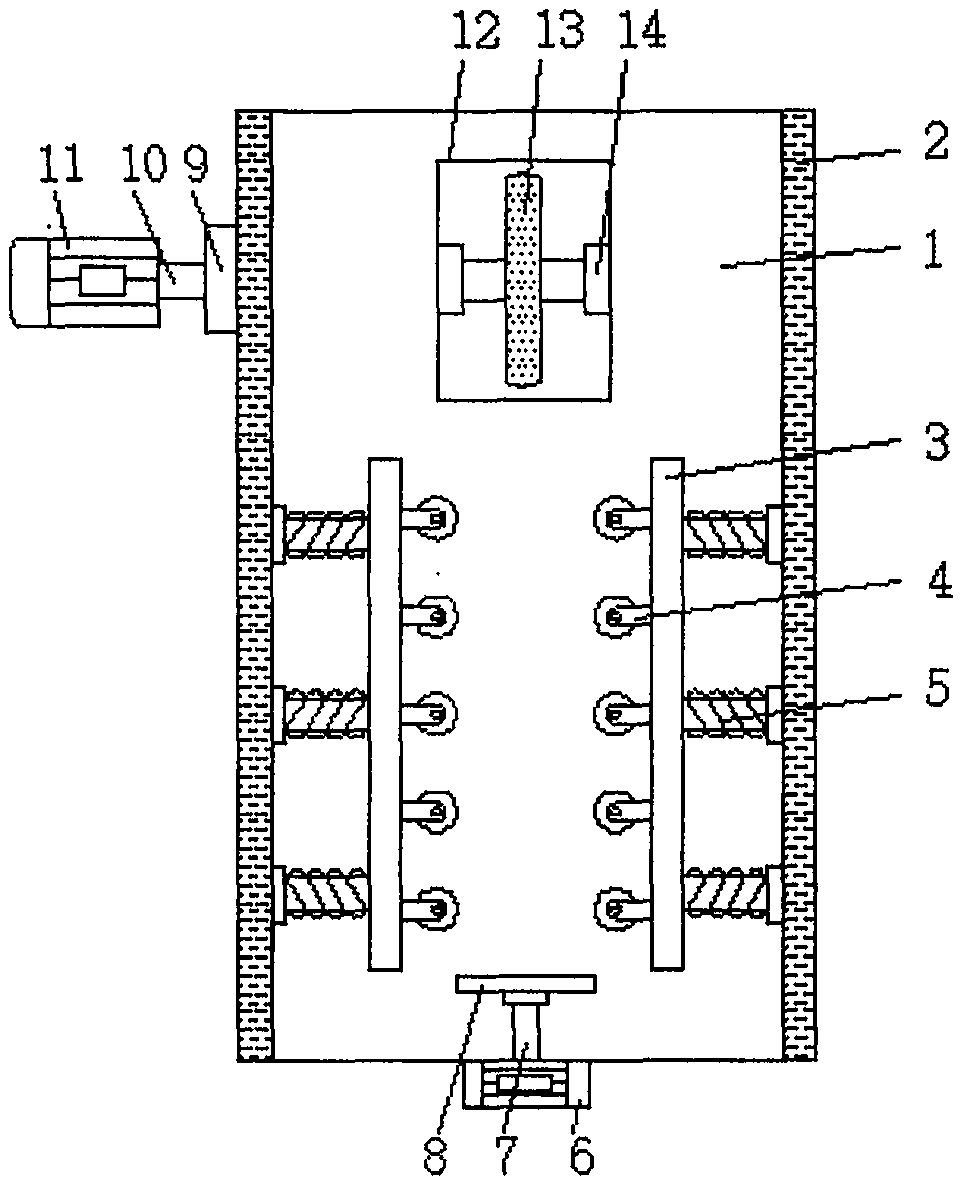

Synthesis kettle with sufficient stirring function

ActiveCN108295796AStir fully and stablySame rotation rateChemical/physical/physico-chemical stationary reactorsReaction rateMechanical energy

The invention discloses a synthesis kettle with a sufficient stirring function. The synthesis kettle comprises a buffer outer tank, a heating interlayer, a synthesis inner kettle, a first motor, a first rotating shaft and a base. An electric control telescopic cylinder is arranged between the outer wall of the bottom of the heating interlayer and the inner wall of the bottom of the buffer outer tank; a fastening hoop surrounds the side wall of the heating interlayer, and a V-shaped plate is arranged on the side wall of the buffer outer tank; a mounting hole is formed in the V-shaped plate, andthe fastening hoop is fixedly connected with the V-shaped plate through a bolt penetrating through the mounting hole; the lower end of the first rotating shaft is connected with a first coupler, anda first stirring assembly is arranged at the lower end of the first coupler; the first stirring assembly comprises a main stirring rod, a first stirring blade set and a second stirring blade set. Thesynthesis kettle promotes sufficient and stable stirring of reaction materials in the synthesis kettle, electric energy and mechanical energy are saved, it is guaranteed that large turbulence is not generated in the kettle, and the reaction rate is increased.

Owner:NANJING FORESTRY UNIV

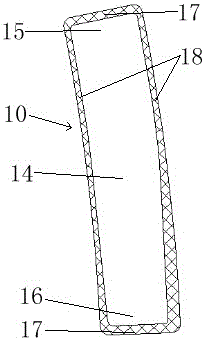

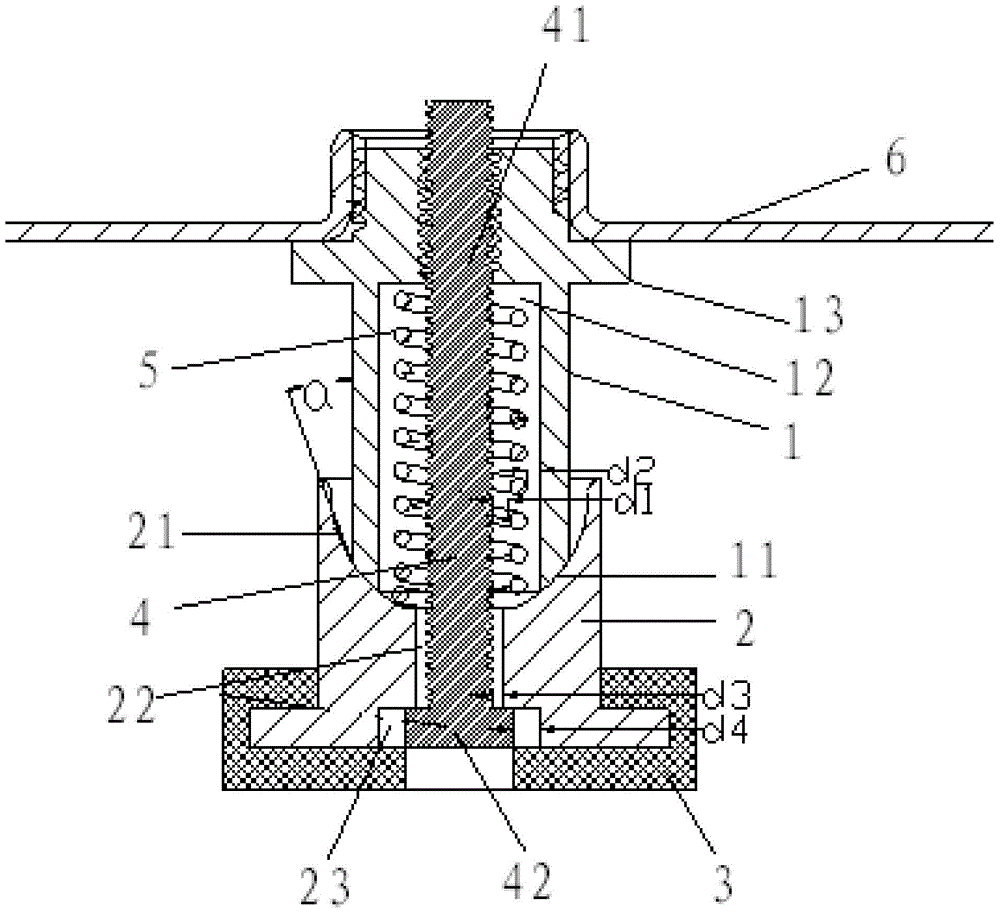

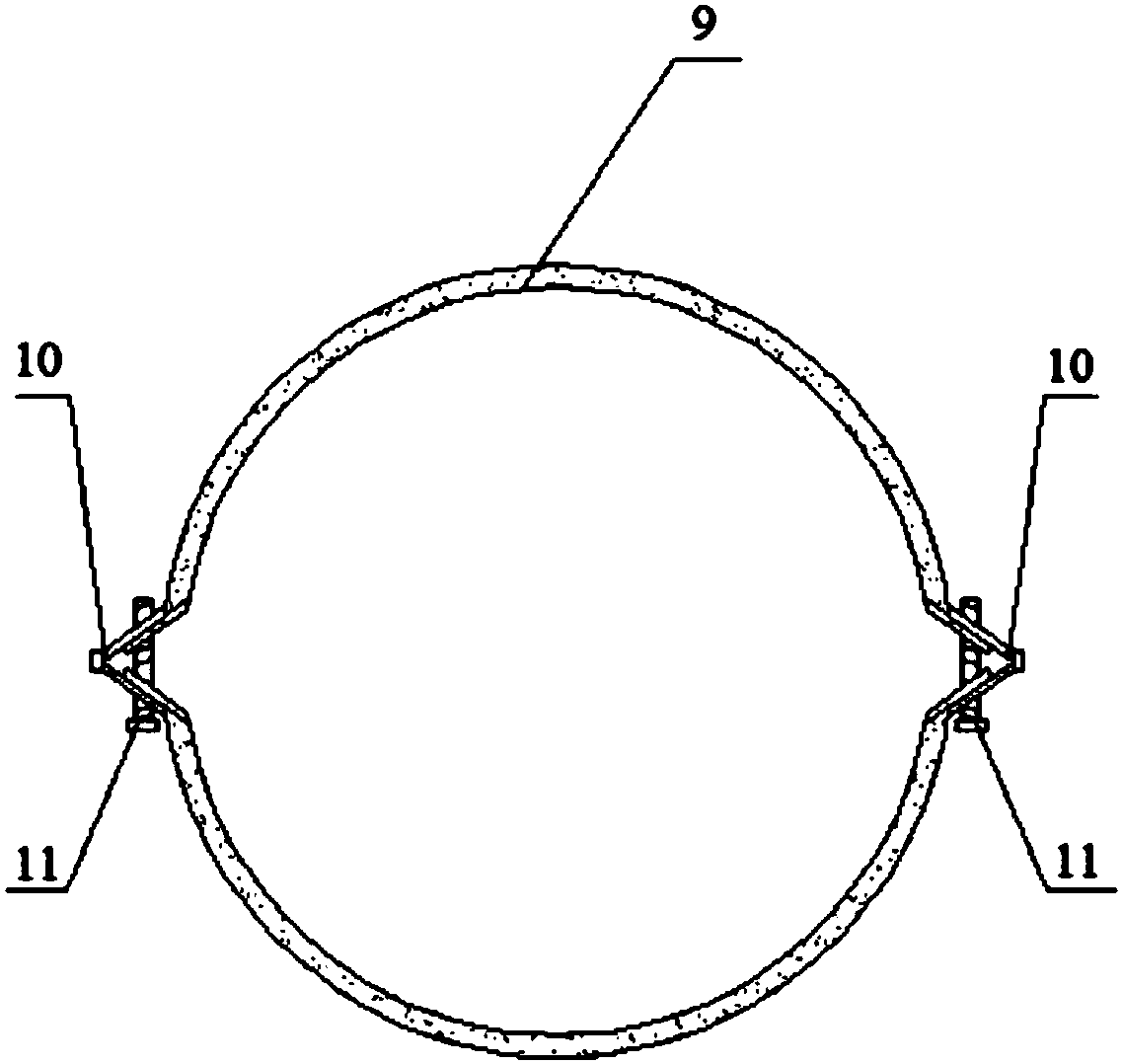

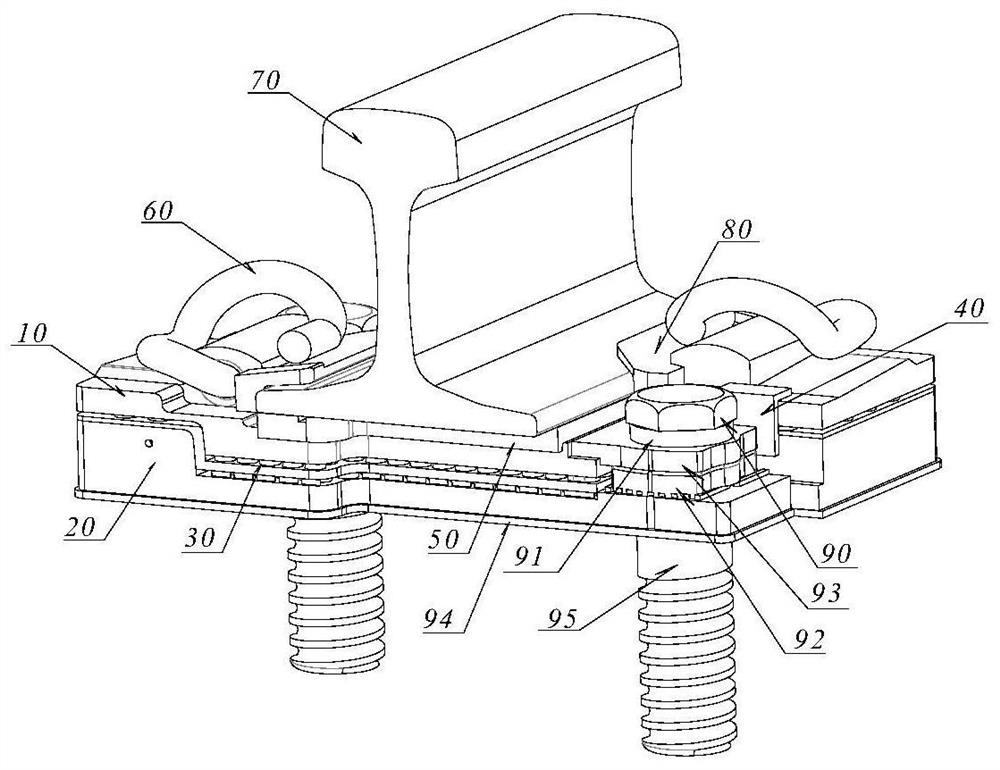

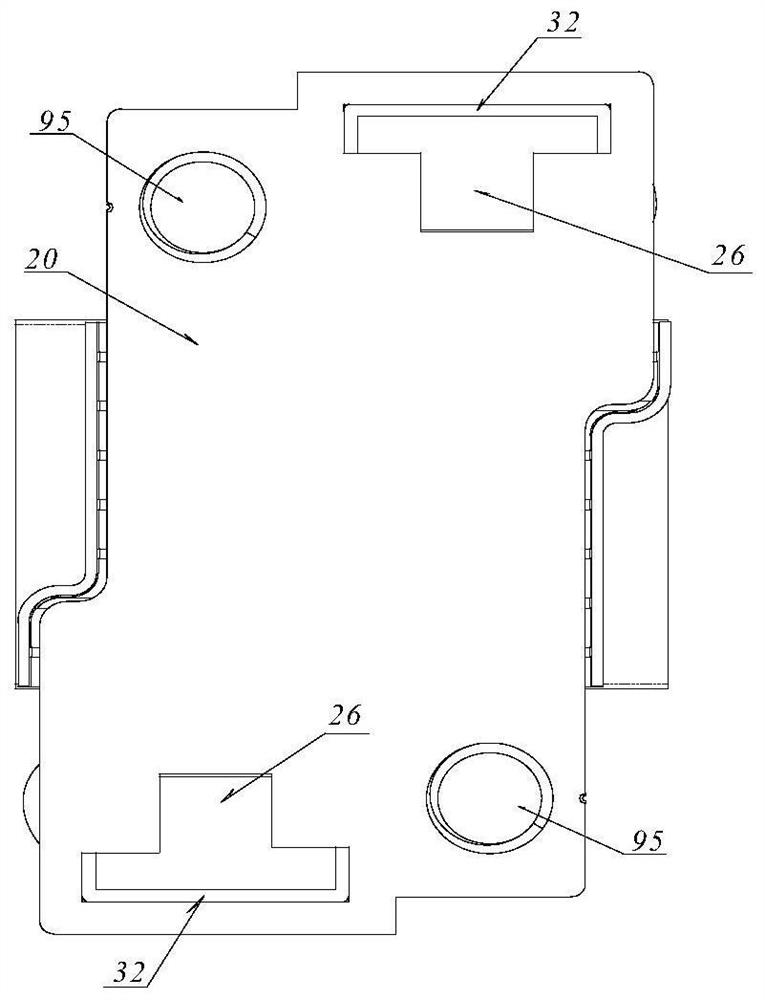

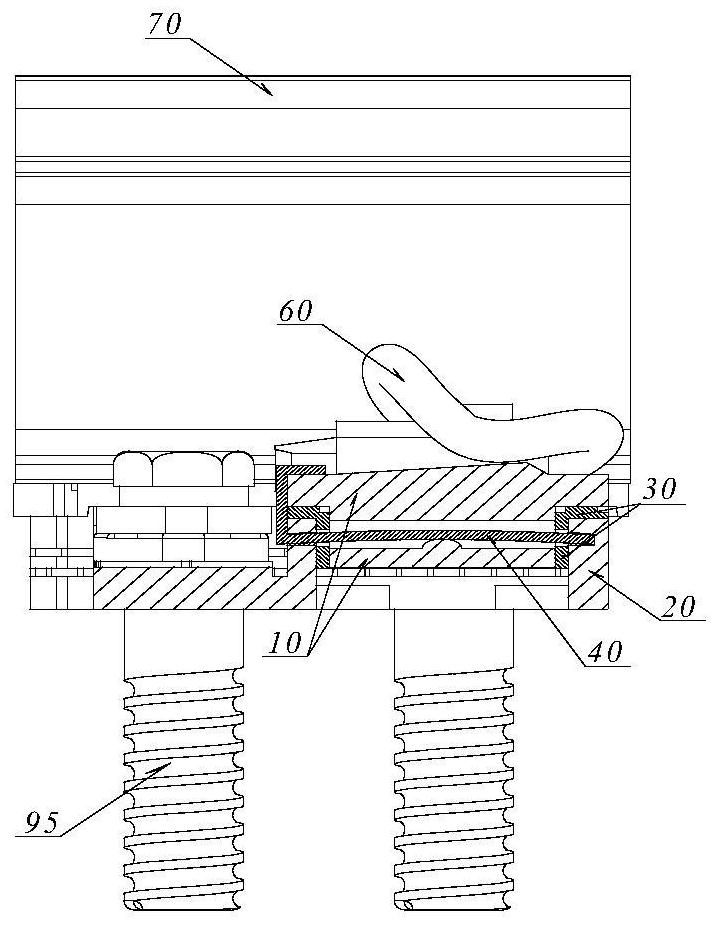

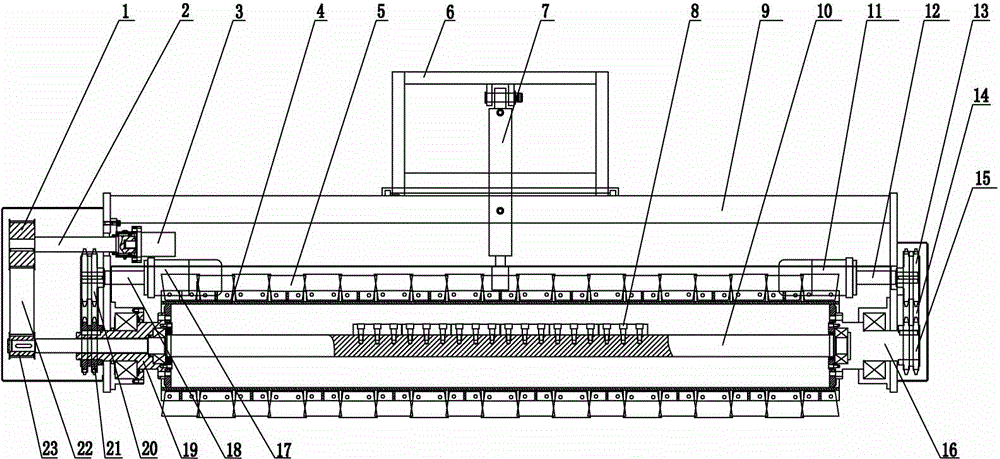

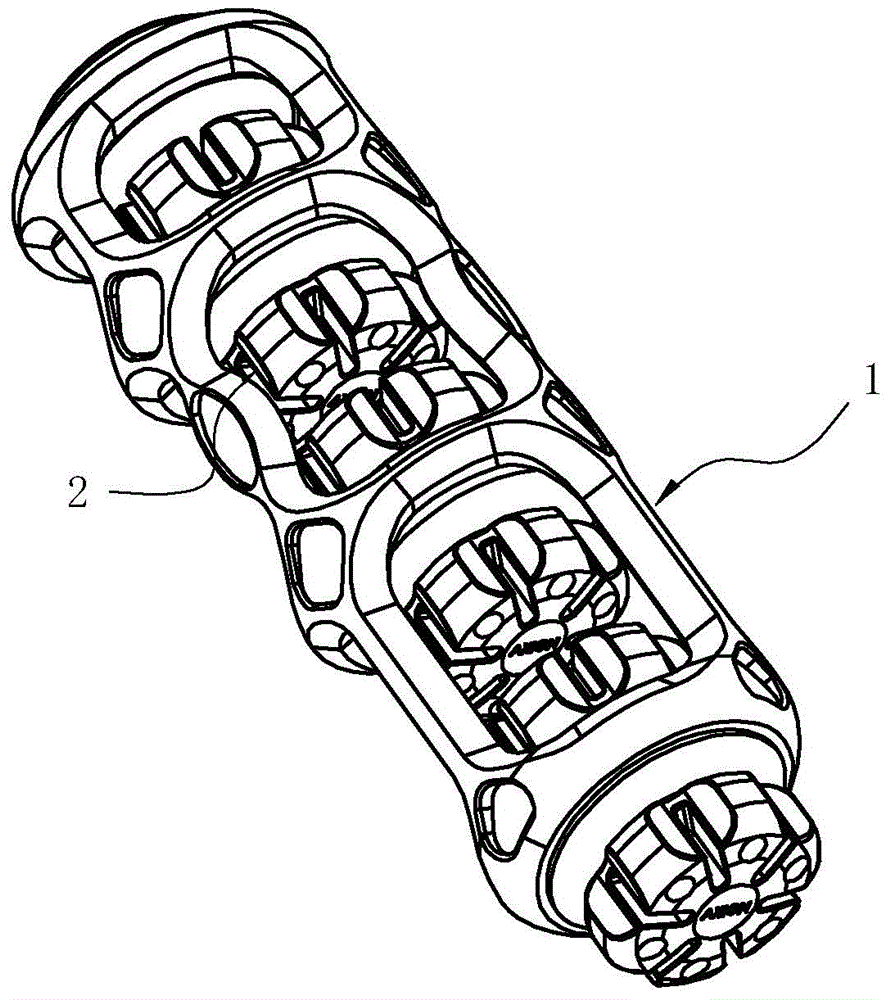

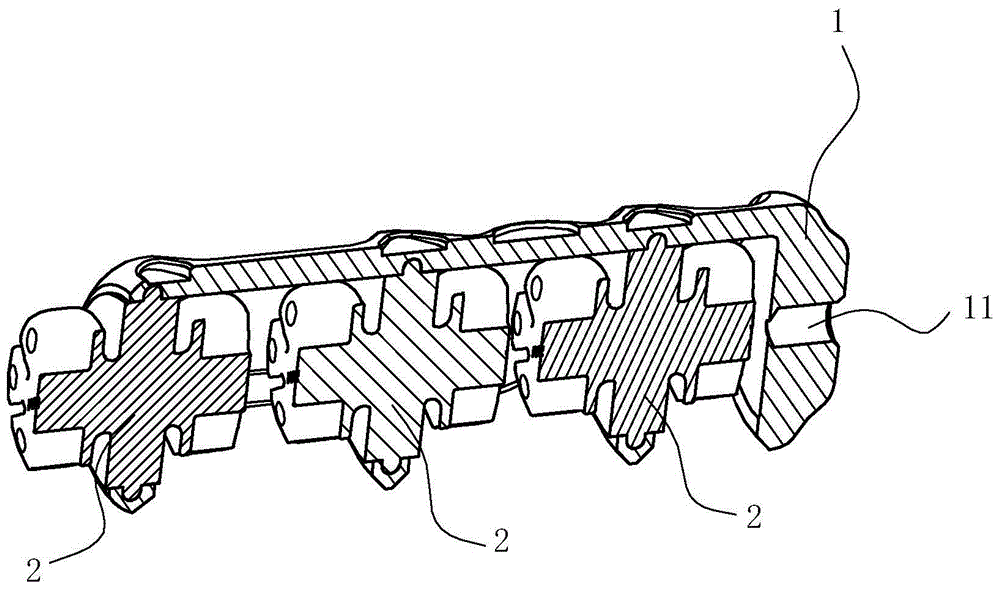

Double-layer rail vibration reduction fastener with blocking shoulder

The invention relates to a double-layer rail vibration reduction fastener with a blocking shoulder, which aims to simplify the locking mode of the double-layer vibration reduction fastener, relieve the vibration of an elastic strip, overcome the problem that a connecting part is easy to wear, improve the transverse and longitudinal rigidity and deflection rigidity of the fastener and effectively reduce the noise and the wear of a steel rail in the operation process. The vibration isolation sleeper comprises an under-plate insulating substrate, a lower iron substrate, a vibration isolation substrate and an upper iron substrate which are sequentially stacked from bottom to top from the surface of the sleeper, and is characterized in that corresponding square limiting blocking shoulders are arranged on the two sides of the vibration isolation substrate and the two sides of the lower iron substrate; locking pins which longitudinally penetrate through the lower iron substrate, the vibrationisolation substrate limiting blocking shoulder and the lower protruding portion of the upper iron substrate and vertically lock the lower iron substrate, the vibration isolation substrate limiting blocking shoulder and the lower protruding portion are arranged on the two sides of the steel rail. The lower iron substrate and the vibration isolation substrate are anchored on the sleeper through anchor bolts; an under-rail substrate is laid on the plate face of the middle of the upper iron substrate, a steel rail is located on the under-rail substrate, and an elastic strip installed and locked on the upper iron substrate acts on the steel rail through an insulation gauge cushion block and tightly presses the steel rail.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD +1

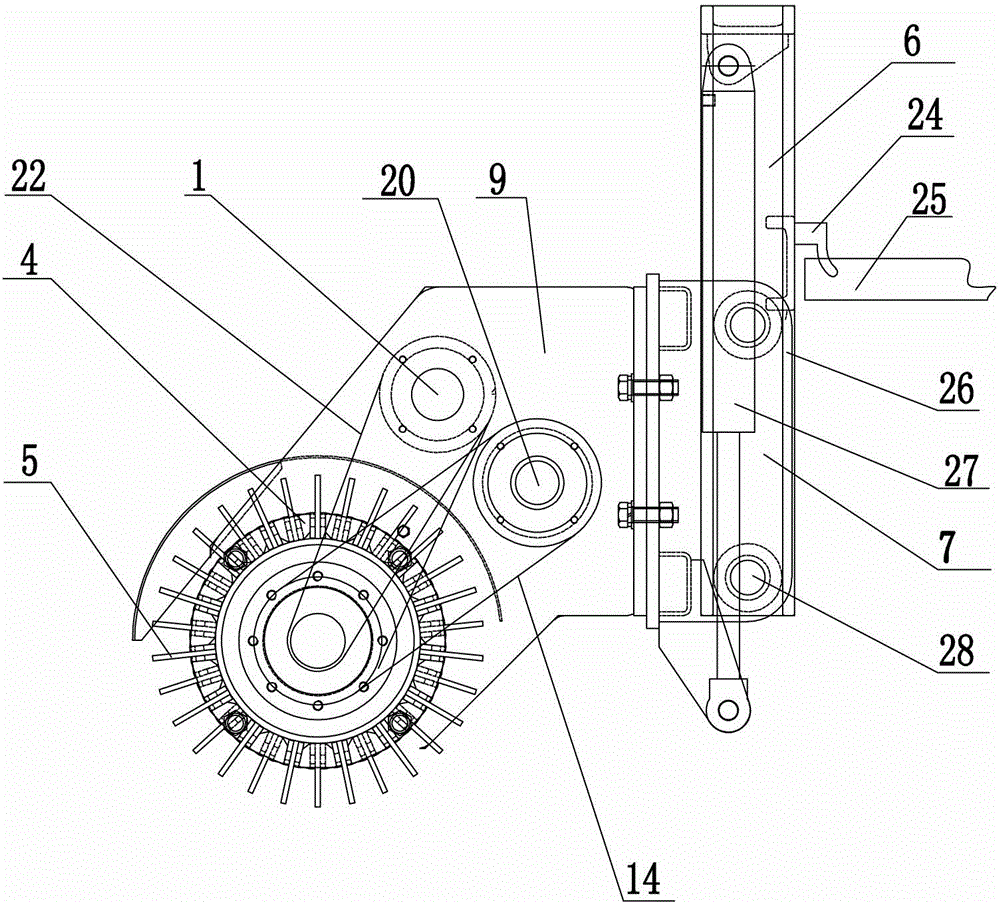

Icebreaking roller

The invention belongs to the technical field of deicing equipment, and in particular relates to an icebreaking roller which comprises a connecting rack, a roller rack, a rolling device and a vibrating device which are arranged on an icebreaking automobile, wherein the rolling device comprises an icebreaking roller body, a rotating sleeve and a connecting short shaft; and the vibrating device comprises a main vibrating shaft. The icebreaking roller is characterized in that the main vibrating shaft is rotationally connected with the icebreaking roller body; the main vibrating shaft is connected with the vibrating motor through a small synchronous pulley and a large synchronous pulley; the icebreaking roller body is connected with a driving motor through chain transmission; and the roller rack is connected with the connecting rack on the icebreaking automobile through a lifting device. The icebreaking roller provided by the invention has a floating vibration function, the icebreaking roller lightly touches the ground all the time, the ice on the road is transversely scraped and grinded by an impacting force generated by the main vibrating shaft, and power sources of vibration and rolling are separated, so that the icebreaking roller is high in overload bearing capability, good in icebreaking effect and high in breaking efficiency.

Owner:ANSHAN SENYUAN ROAD & BRIDGE

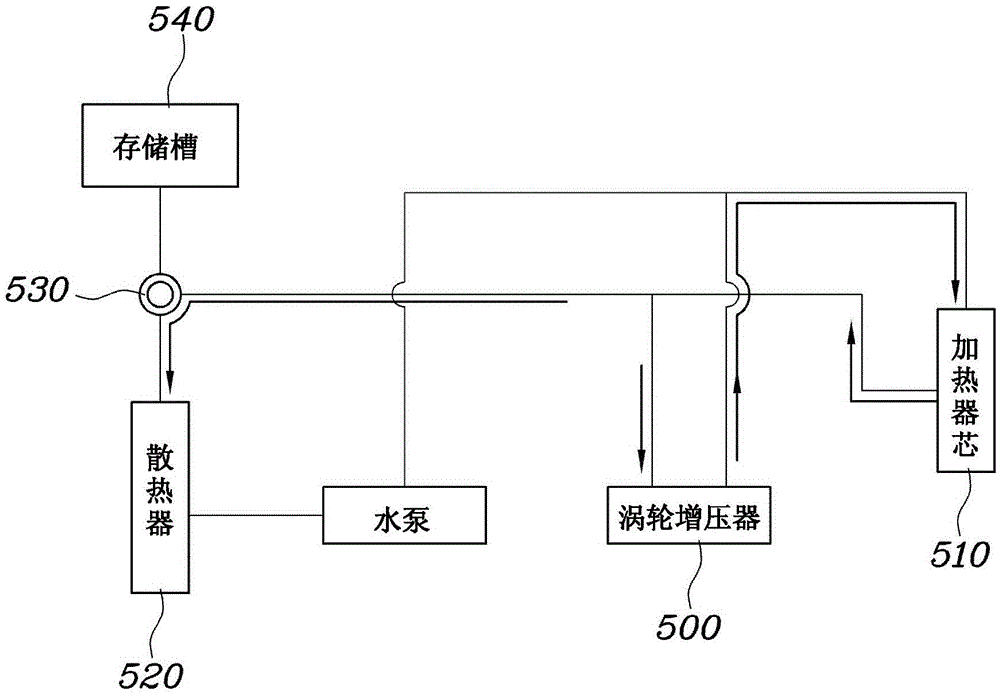

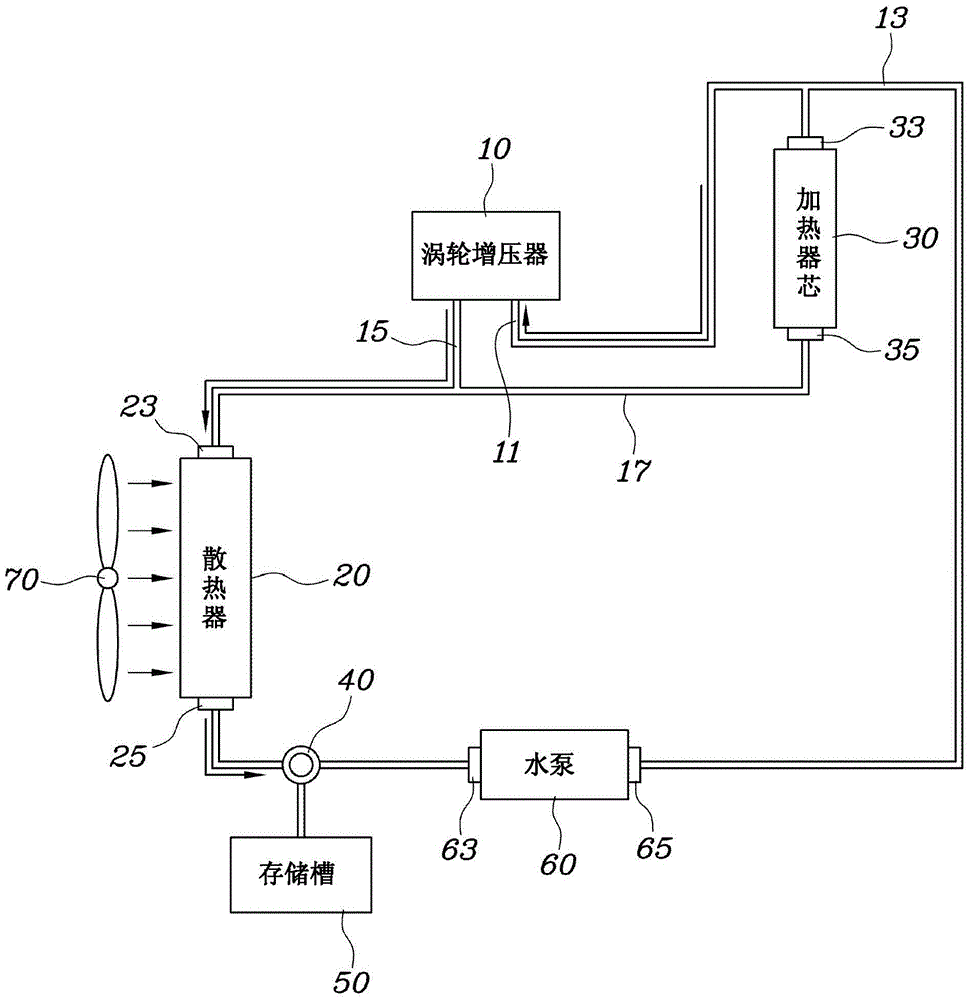

Coolant circulation system for turbocharger

ActiveCN106351733AReduce noiseVibration reliefLiquid coolingCoolant flow controlTurbochargerEngineering

A coolant circulation system for turbochargers is provided. The coolant circulation system includes a turbocharger provided with a coolant outlet line and a coolant inlet line. The coolant is discharged from the turbocharger through the coolant outlet line. The coolant outlet line is connected to a first flow path connecting an inlet port of a radiator to an outlet port of a heater core. The coolant is supplied into the turbocharger through the coolant inlet line. The coolant inlet line is connected to a second flow path connecting a first end of a water pump to an inlet port of the heater core.

Owner:HYUNDAI MOTOR CO LTD +1

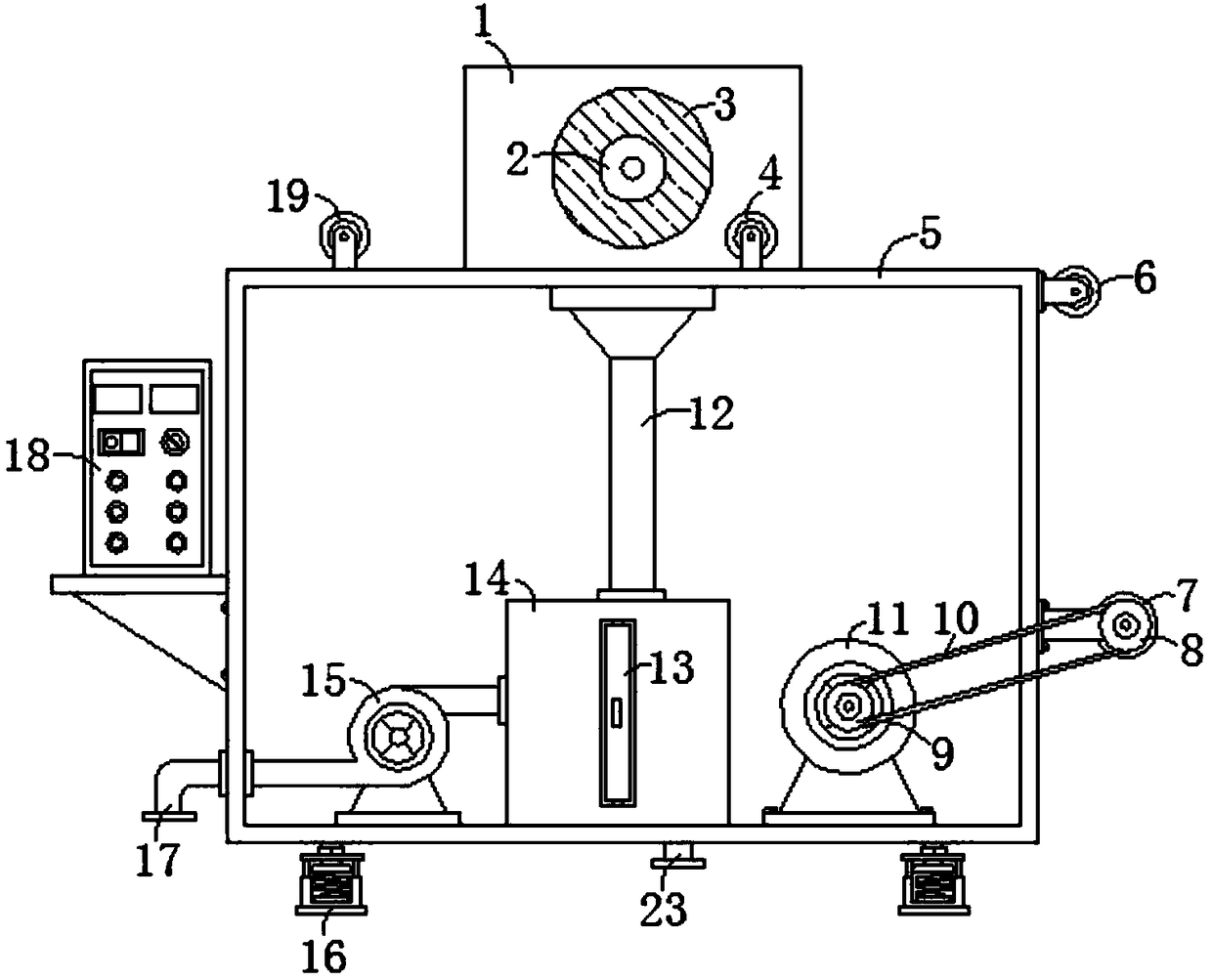

Common cropping equipment for ultralow-temperature environment-friendly leather lining cloth machining

InactiveCN108556034AImprove the quality of the working environmentGuaranteed filtering effectDispersed particle filtrationNon-rotating vibration suppressionEngineeringFiber

The invention discloses common cropping equipment for ultralow-temperature environment-friendly leather lining cloth machining. The common cropping equipment comprises a machine case body, a croppingbin is installed at the middle portion of the upper surface of the machine case body, damping bases are fixed to the four corners of the bottom of the machine case body, a filtering box is installed at the middle portion of the bottom of the interior of the machine case body, an isolating plate of a hollow structure is arranged at the connecting position of the machine case body and the cropping bin, an air conveying pipe is connected to the middle position of the top end of the interior of the machine case body, and the isolating plate communities with the filtering box through the air conveying pipe. The common cropping equipment is provided with the filtering box, a drawer type filtering net and an induced draft fan, crushed filters easily generated in the cloth cropping process are collected, worker working environment pollution caused by discharge of air inside the cropping bin is prevented, the worker working environment quality is improved, and the equipment environment-friendlyperformance is improved; and the damping bases are arranged, vibration generated during equipment cropping is buffered, equipment stable cropping is achieved, and the lining cloth cropping quality isimproved.

Owner:长兴瑞韬纺织科技有限公司

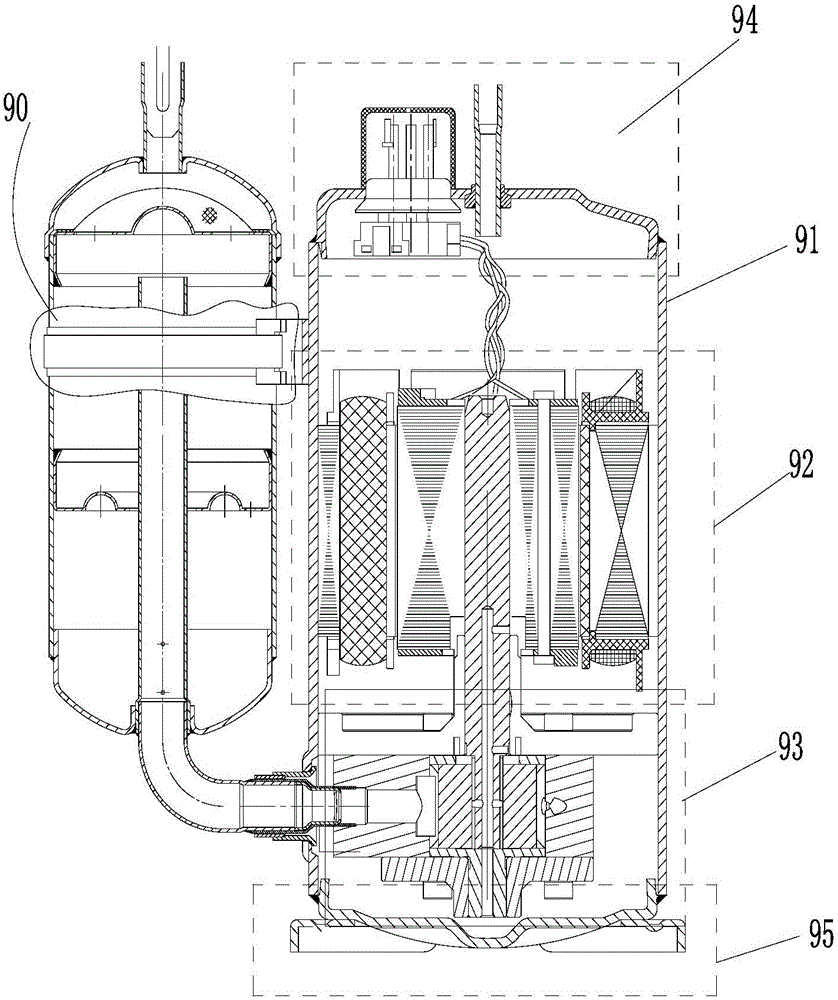

Compressor, heat exchange equipment and running method of compressor

ActiveCN106438359AVibration reliefImprove running stabilityRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsGas cylinderEngineering

The invention provides a compressor, heat exchange equipment and a running method of the compressor. The compressor comprises an upper flange, a lower flange, at least two gas cylinders, a rotating shaft assembly and a piston assembly; the at least two gas cylinders are sandwiched between the upper flange and the lower flange, and any two adjacent gas cylinders communicate with each other, so that the compressor is a multi-stage compressor; the rotating shaft assembly sequentially penetrates through the upper flange, the gas cylinders and the lower flange and comprises subsidiary rotating shafts in one-to-one correspondence with the at least two gas cylinders, axes of the subsidiary rotating shafts and axes of the gas cylinders corresponding to the subsidiary rotating shafts are arranged eccentrically, and the eccentric distance is fixed; the piston assembly comprises variable-volume cavities in one-to-one correspondence with the gas cylinders and can be arranged in the gas cylinders in a pivoted manner, and at least one subsidiary rotating shaft is in driving connection with the piston assembly to change the volume of the variable-volume cavities. With the compressor, vibration can be effectively alleviated, the volume change of the variable-volume cavities has a rule, and the clearance volume is reduced, so that the running stability of the compressor is improved.

Owner:GREE ELECTRIC APPLIANCES INC

Damper suite for composite bow

The invention relates to a damper suite for a composite bow. The damper suite is characterized by comprising a damping seat and a plurality of cushioning parts. A plurality of mounting holes identical in number to the cushioning parts are formed in the damping seat. Each cushioning part comprises a body detachably embedded in the mounting hole and a damping column extending from the two ends of the body to the outside. Radial grooves extending to the circumferences of the damping columns are formed at intervals circumferentially at the ends of the damping columns to divide the damping columns into a plurality of elastic portions connected in roots, and the elastic parts are exposed from the corresponding mounting holes. During use, the cushioning parts can be increased or decreased conveniently at any time as required, and after shooting, after part of vibration energy is absorbed by the damping seat, remaining vibration energy is attenuated by the cushioning parts. Particularly, flares and axial blind holes are formed in the elastic portions of the cushioning parts, and accordingly, the damping effect can be further improved. Moreover, when the damping seat is designed into a circular handle, the damping seat can be used as a handle for holding the bow, so that the damper suite is multifunctional.

Owner:NINGBO HAIBO PRECISION MACHINERY MFG

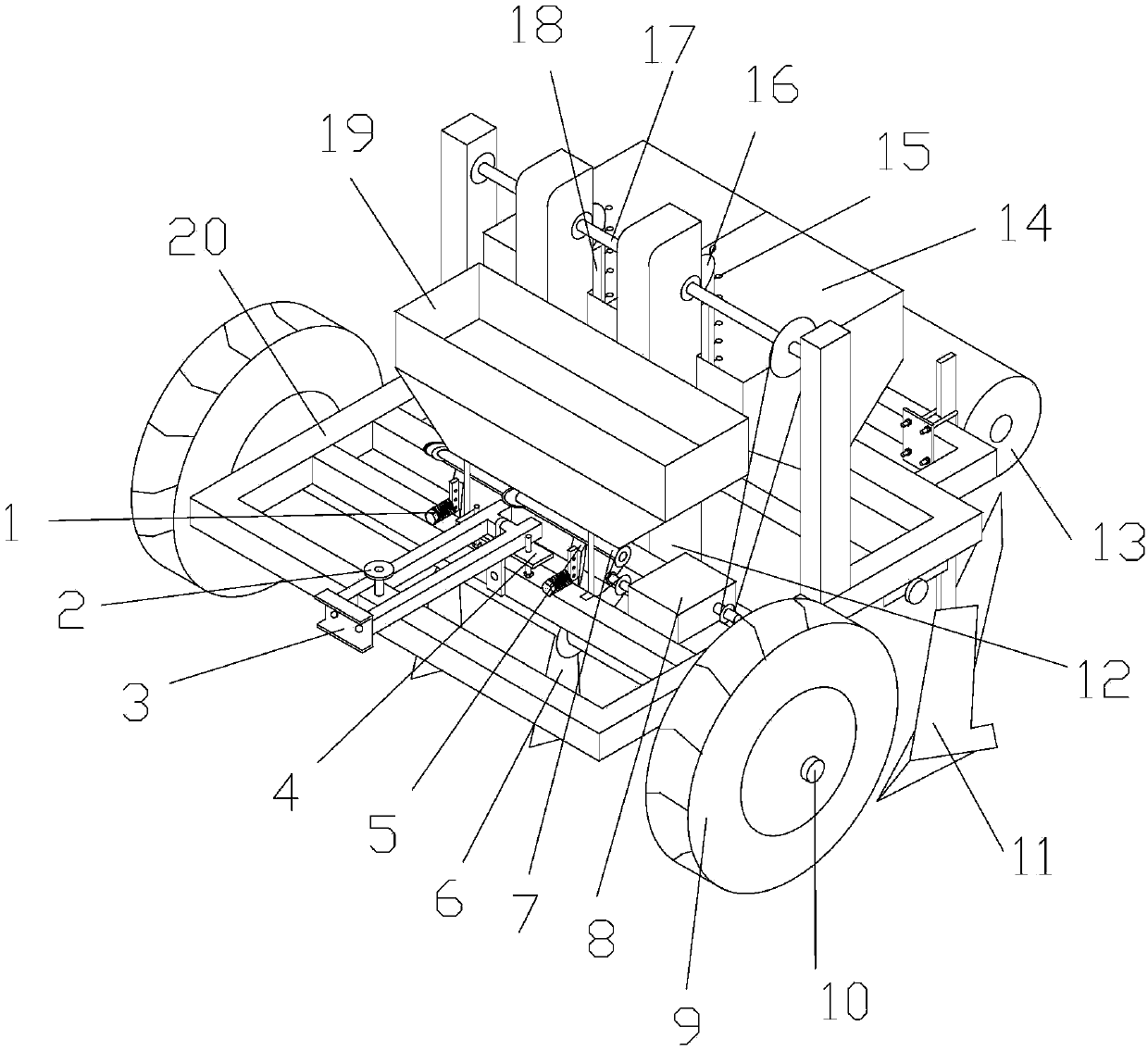

Potato planting machine matching with hand tractor for use

InactiveCN103385055AFreely adjustable sowing distancePrevent falling backFertiliser distributersPotato plantersAgricultural engineeringTractor

A potato planting machine matching with a hand tractor for use is disclosed. The machine comprises a big rack; a driving rack, which is used for connecting a hand tractor, is arranged on the front end of the big rack; ground wheels, which are used for moving, are arranged on the bottom of the big rack; a seed box is arranged on the big rack; a vertical seed transporting pipe is arranged in front of the seed box; a seed lifting shaft is arranged above the seed box, a seed lifting chain with a seed lifting spoon is arranged between the seed lifting shaft and one output shaft of a four-speed speed controller; a wood vibration preventing board is arranged on the side wall of the seed box behind the seed lifting chain; and the input shaft of the four-speed speed controller is connected to a ground wheel shaft through a chain. The potato planting machine integrates the functions of ditching, fertilizing, sowing, ridging and pressing together, and is capable of precisely lifting the potatoes to the seeding transporting pipe and sowing the potatoes evenly. The wood vibration preventing board can prevent the potato seeds from falling back to the seed box because of vibration, and thus the seed lifting rate is improved. The free adjustment of the row spacing of the potatoes in a certain range is achieved through the design of the four-speed speed controller, and the requirement of farmers is satisfied. The vibration and resistance during the work process can be relieved by the damping spring.

Owner:青海林丰农牧机械制造有限公司

Chip integrated manufacturing auxiliary equipment based on light pressure principle

InactiveCN110854015AAchieve non-splatter effectReduce the exposure areaSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

The invention relates to the technical field of chip manufacturing and discloses chip integrated manufacturing auxiliary equipment based on a light pressure principle. The equipment comprises a rotarydisc, wherein a closed box is fixedly and movably connected with the bottom of the rotary disc, a rotary shaft is movably connected into the closed box, a surface of the rotary shaft is sleeved witha shell, a shading disc is movably connected with a top wall of the interior of the shell, a light pressure mechanism is movably connected with the bottom of the shading disc, adjusting springs are movably connected with two sides of the light pressure mechanism, and the light pressure mechanism comprises a light emitting plate. The limiting spring is pulled to move, a carving plate is in contactwith the shading disc, specific images are formed, after glue uniformizing is completed, the wavelength generated by a light wave box is adjusted, the light emitting plate generates a light source, anadjusting plate and the adjusting springs are moved according to an imaging distance between the carving plate and the rotary disc, an irradiation range of the light emitting plate can be enlarged and shrunk, developing photoetching is conducted on the light emitting plate, and thereby the effect that the photoetching process can be completed through one-time positioning without transferring is achieved.

Owner:冯聪

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com