Machining method for target material

A technology of mechanical processing and target material, which is applied in the direction of metal material coating process, ion implantation plating, coating, etc., can solve the problems of affecting the quality of target material, serious deformation of target material, scrapping of target material, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

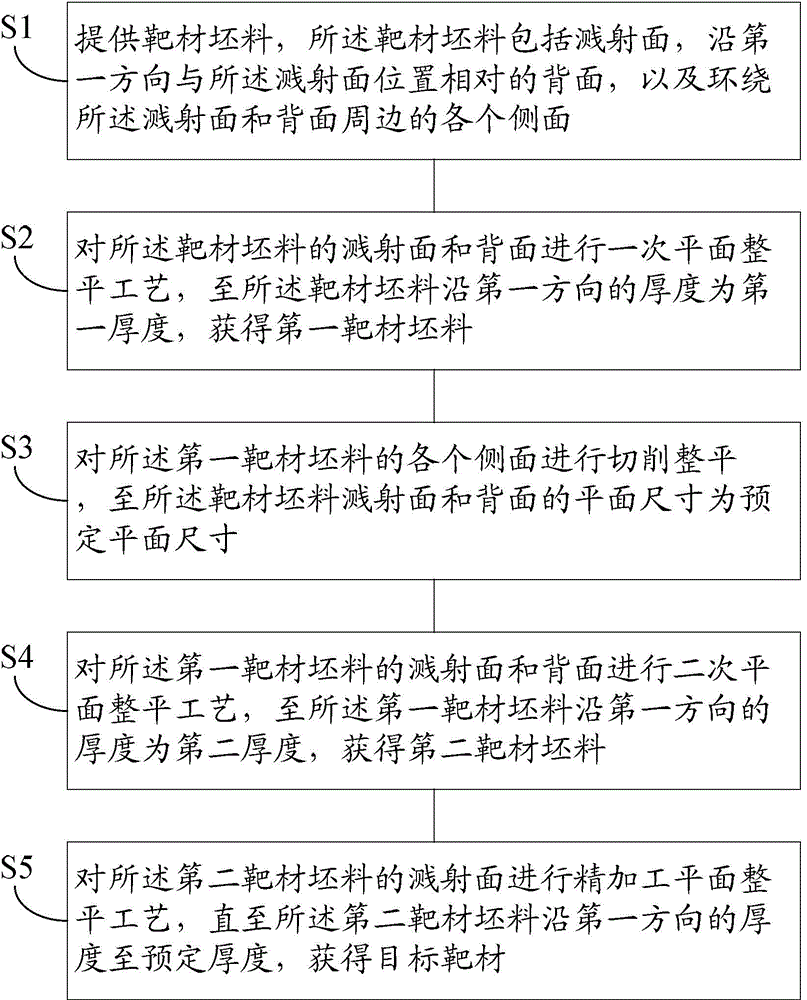

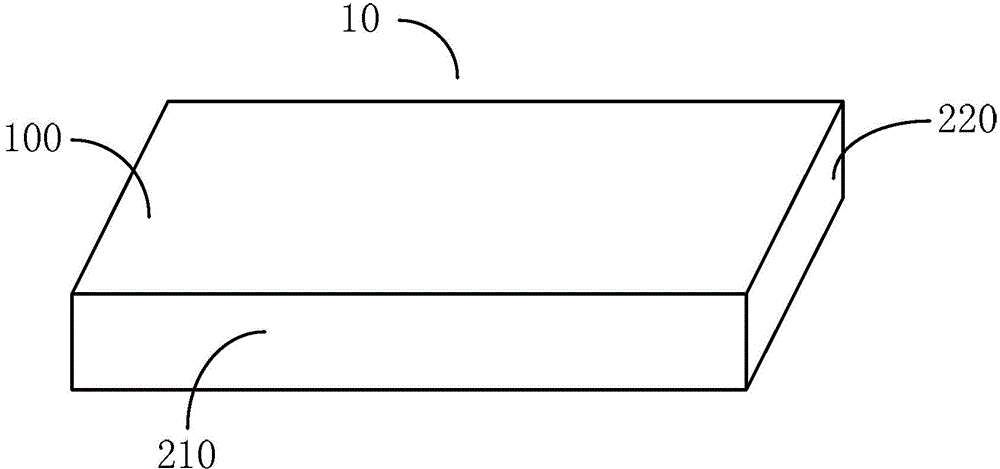

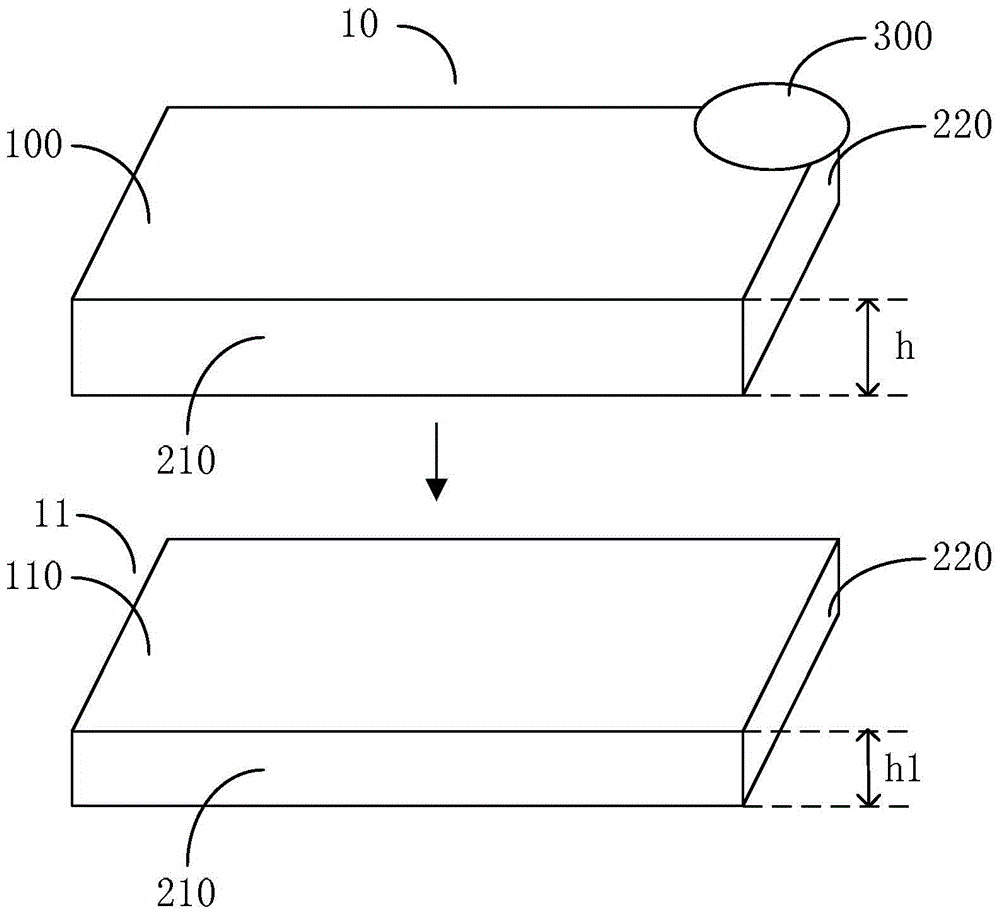

[0038] As mentioned in the background technology, in the target preparation process, it is necessary to perform a correction process of machining the sputtering surface, the back surface and the surrounding sides of the target blank, so as to improve the flatness and parallelism of the target, so that the size of the target is the same as The structure of the magnetron sputtering equipment is matched, so that the quality of the magnetron sputtering coating can be improved during the magnetron sputtering process.

[0039]However, in mechanical processing, when the target is subjected to the cutting force of the tool, in order to prevent it from deforming, an internal stress that opposes it is generated inside the material. These two forces are equal in magnitude and opposite in direction. This kind of balance, when the target is subjected to the cutting force of the tool disappears after the processing is completed, the internal balance of the target is broken, and the internal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com