Patents

Literature

1959results about How to "Guaranteed filtering effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

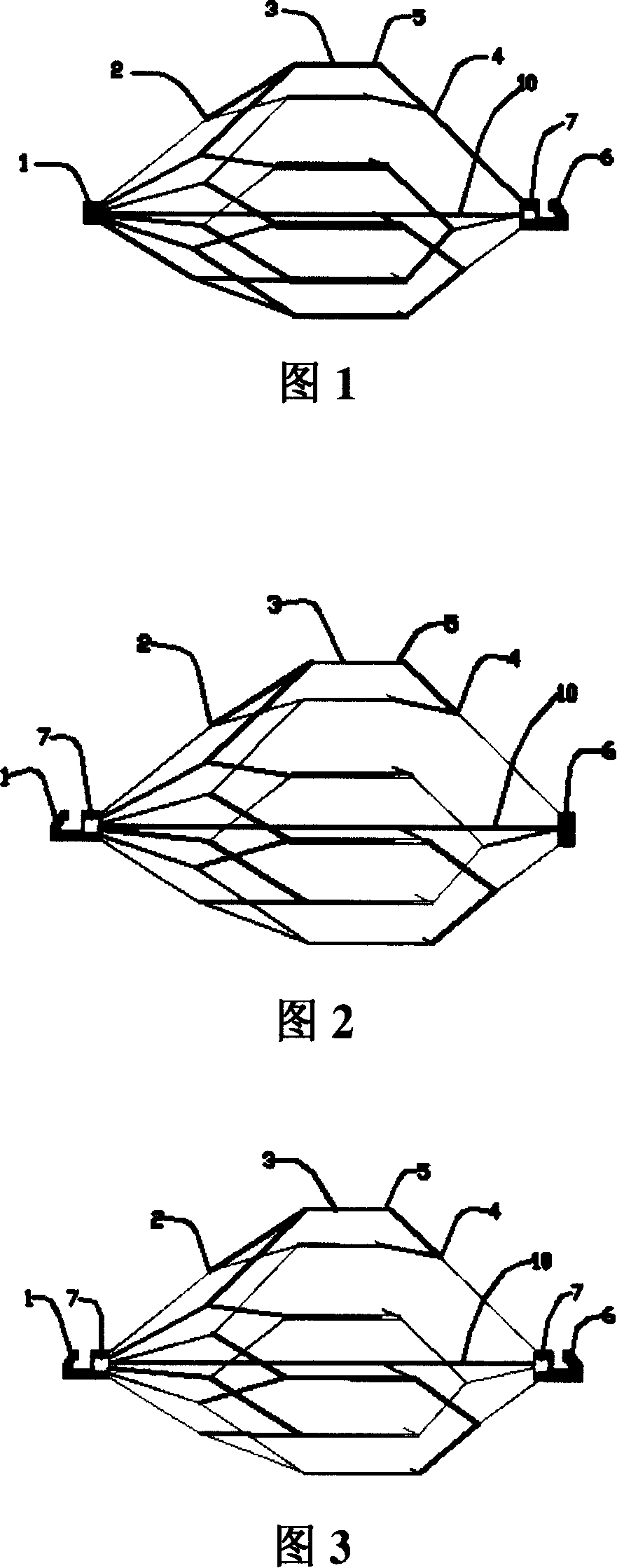

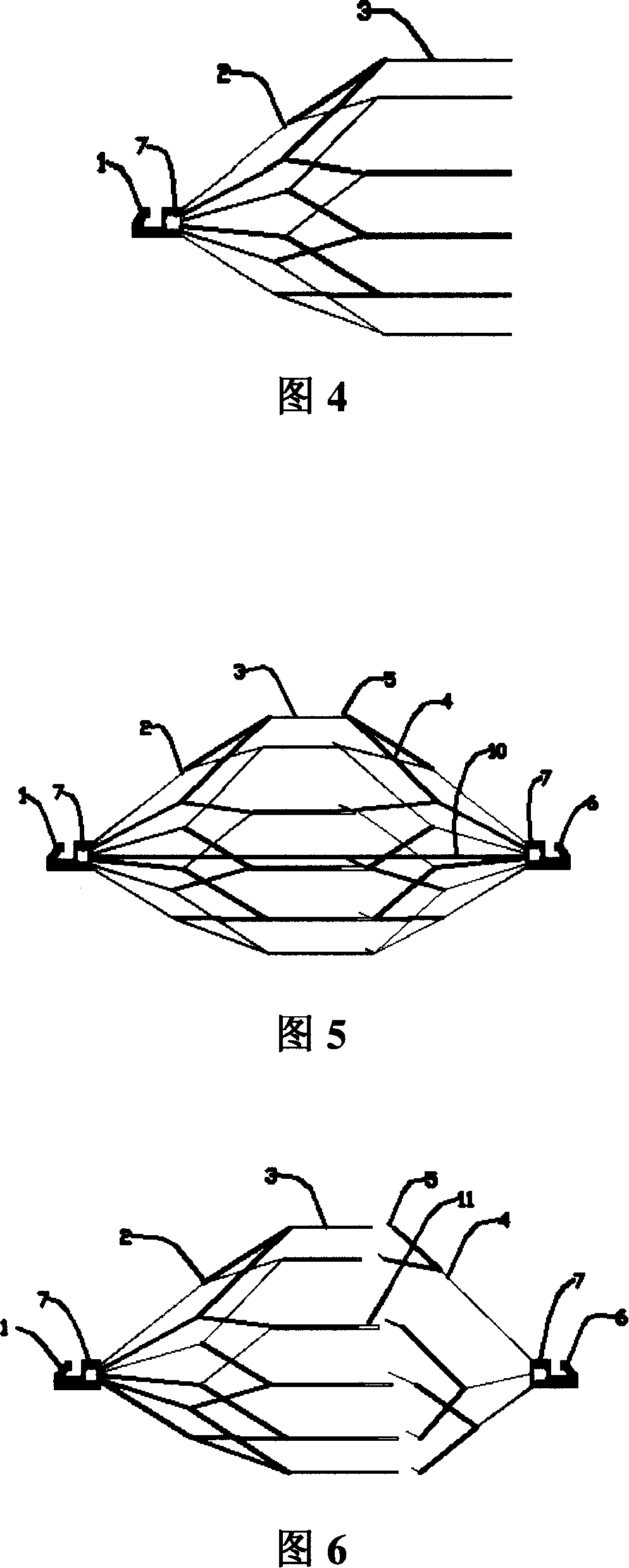

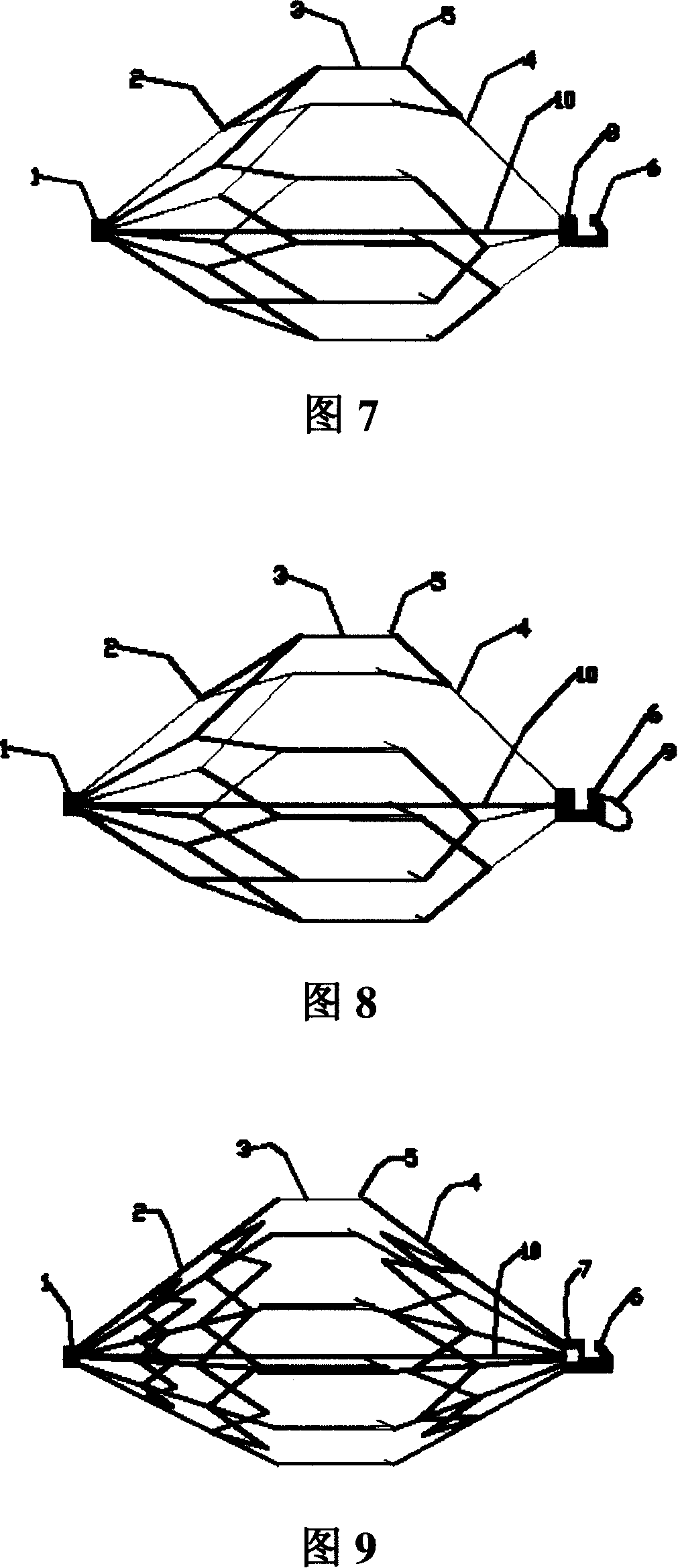

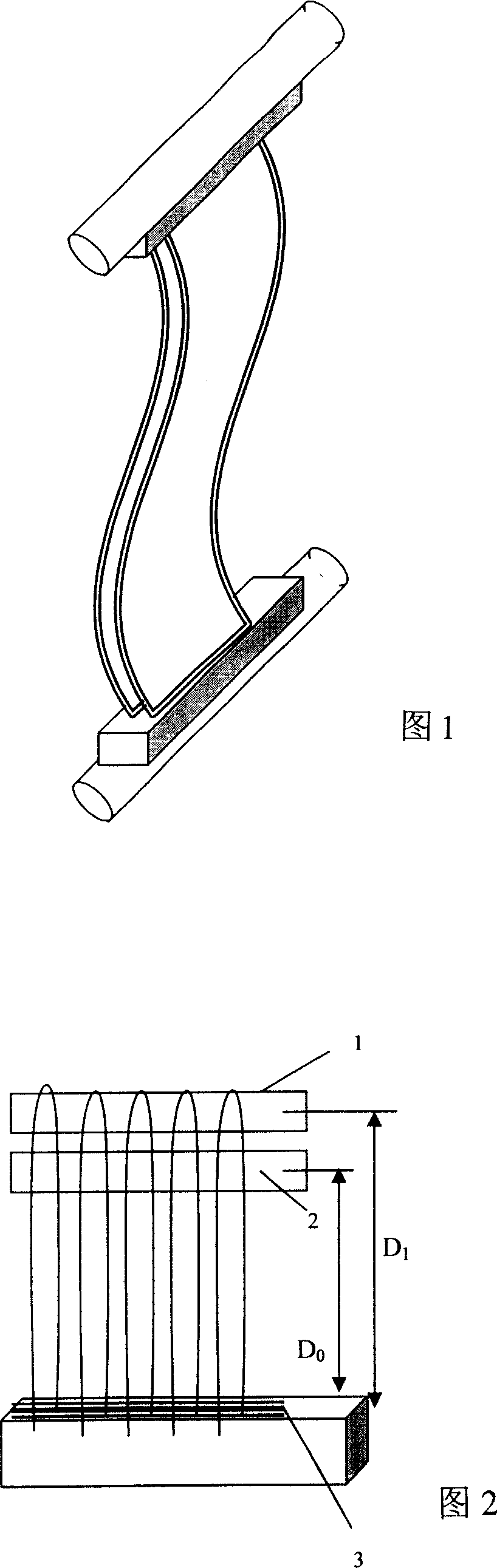

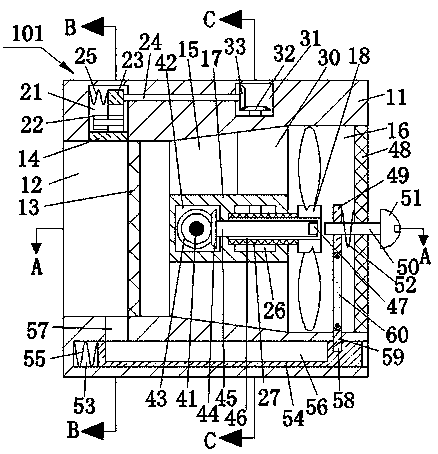

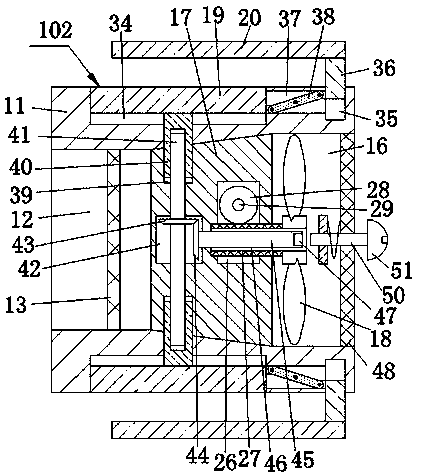

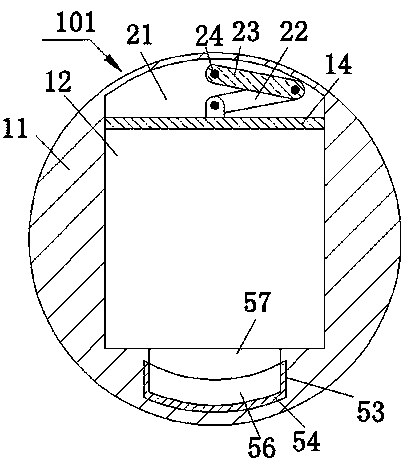

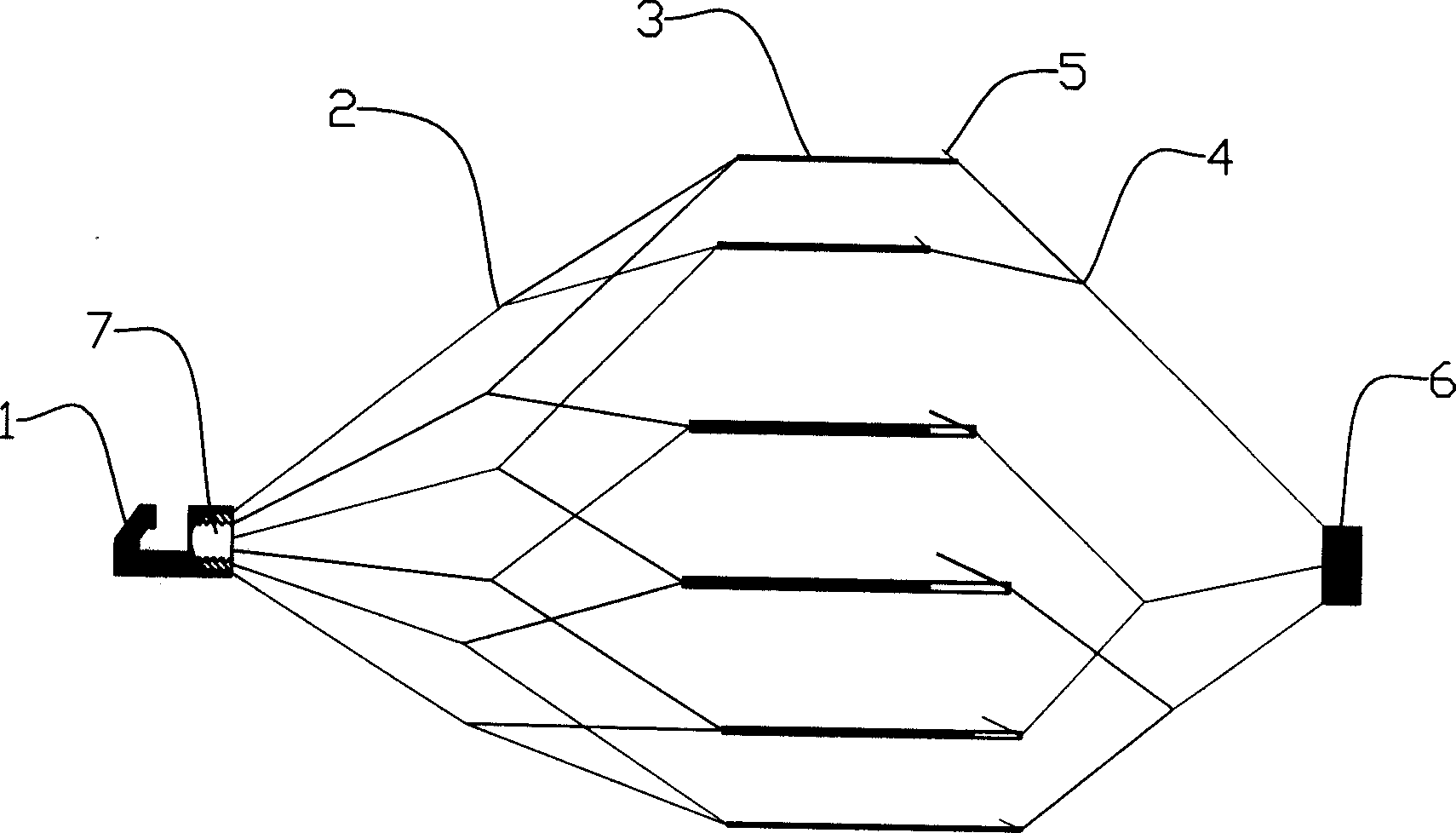

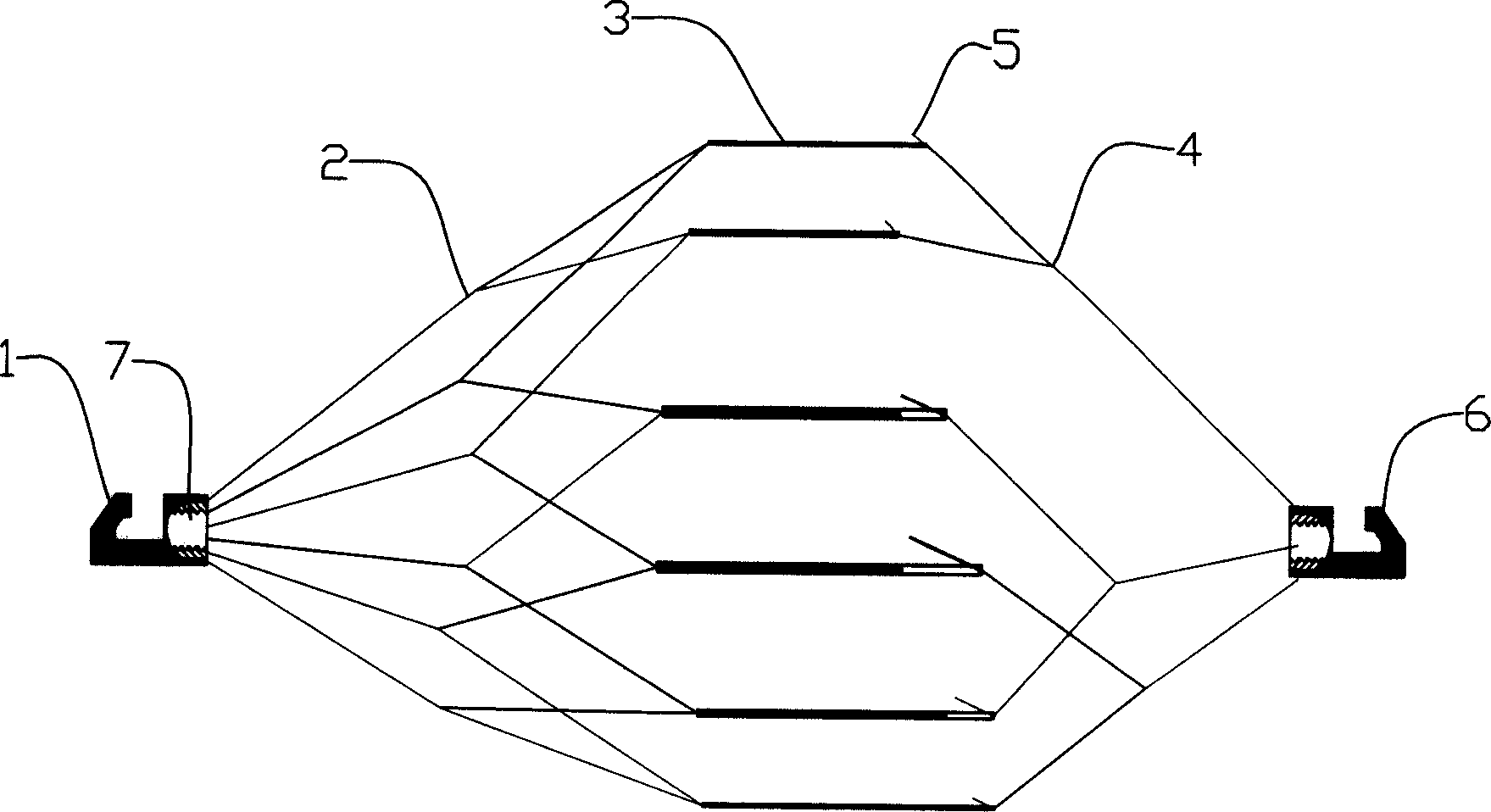

Controllable released biological ceramic thrombus filter and manufacturing method thereof

InactiveCN101147705ANo connection pointPermanent placementBlood vessel filtersThrombusLaser engraving

The present invention relates to a controllably-released bioceramic thrombus filter and its preparation method. Said thrombus filter is made up by using laser engraved metal tube, its end portion is equipped with a combination portion matched with a conveying portion, its centre is equipped with an elastic wire and its surface is convered with a layer of bioceramic membrance. It can be temporarily placed into blood vessel of human body, also can be permanently placed in the blood vessel of human body. Said invention also provides the concrete working principle of said thrombus filter.

Owner:LIFETECH SCIENTIFIC (SHENZHEN) CO LTD

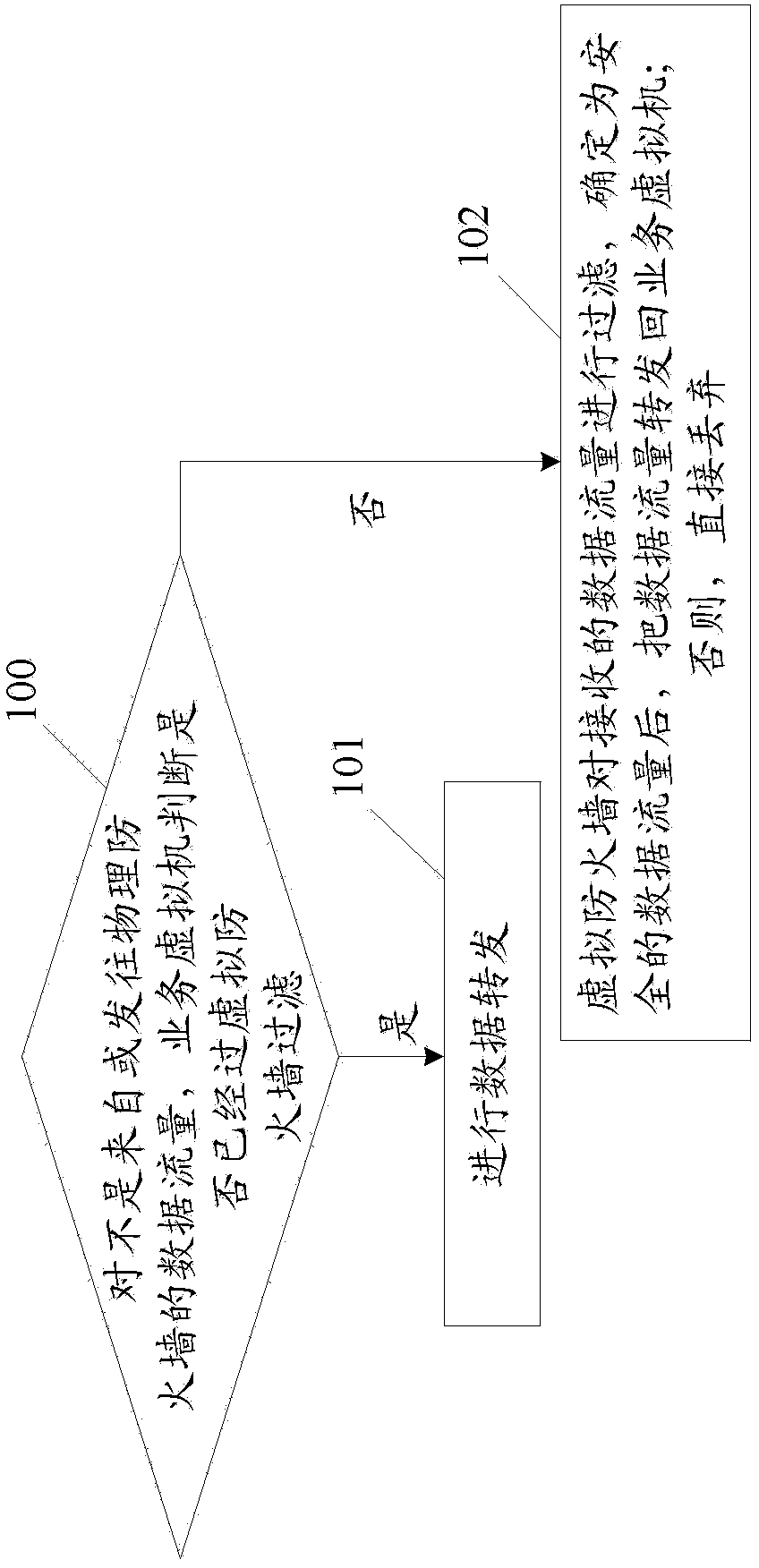

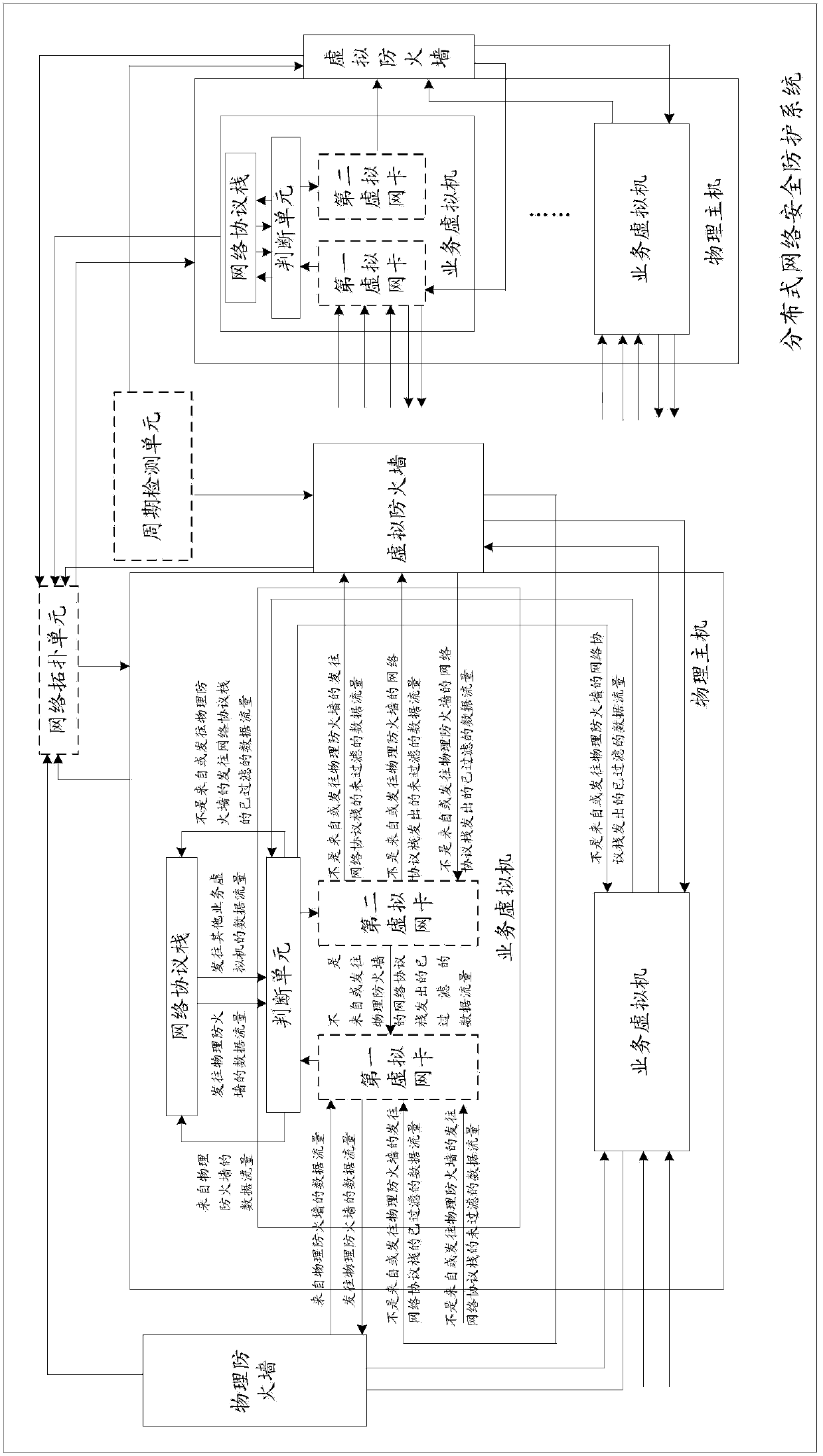

Method and system for achieving distributed network safety protection

ActiveCN104301321ATopological changes are smallLittle changeProgram controlTransmissionVirtual firewallVirtual switch

The invention discloses a method and system for achieving distributed network safety protection. The method comprises the steps that the side of a virtual firewall is hung on a virtual switch; whether data flow which is not from or sent to a physical firewall is filtered by the virtual firewall or not is judged through a service virtual machine, if yes, the data flow is forwarded, and otherwise, the data flow is sent to the virtual firewall; the received data flow is filtered through the virtual firewall, and after it is determined that the data flow is safe, the data flow is forwarded back to the service virtual switch, and otherwise the data flow is abandoned. According to the method and system, after the data flow which is not from or sent to the physical virtual wall is judged, the data flow needing to be filtered is sent to the side-hung virtual firewall to be filtered through the service virtual machine, and the data flow which does not need to be filtered is directly forwarded. Network topology is changed a little, it is guaranteed that all the data flow entering in a virtual machine system is filtered, and the resource consumed by the virtual firewall is reduced.

Owner:BEIJING VENUS INFORMATION TECH +1

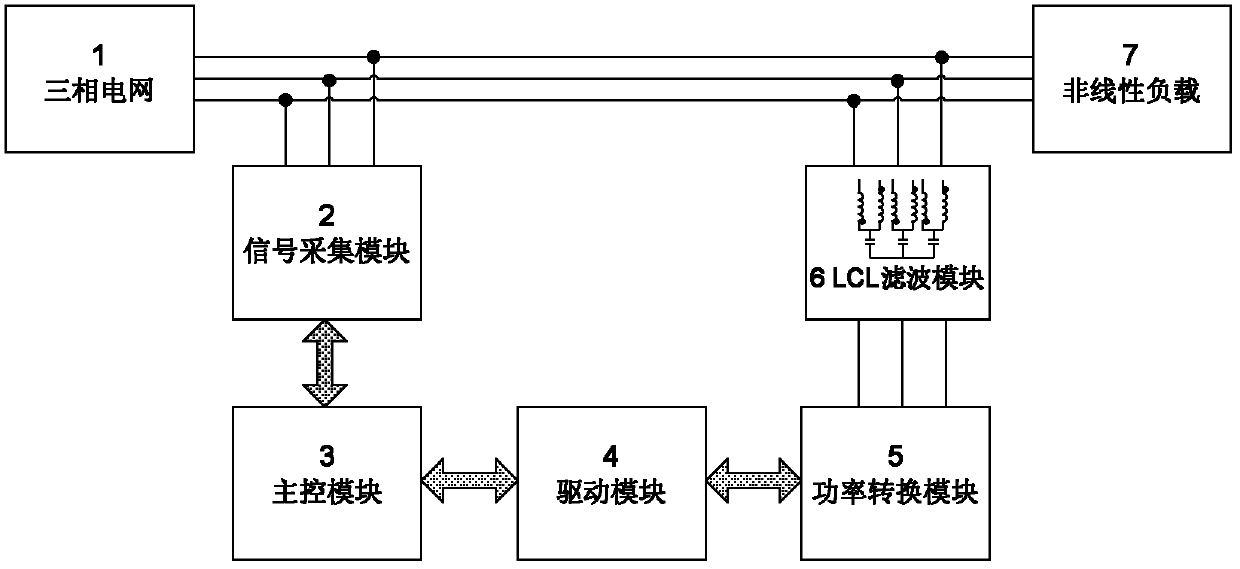

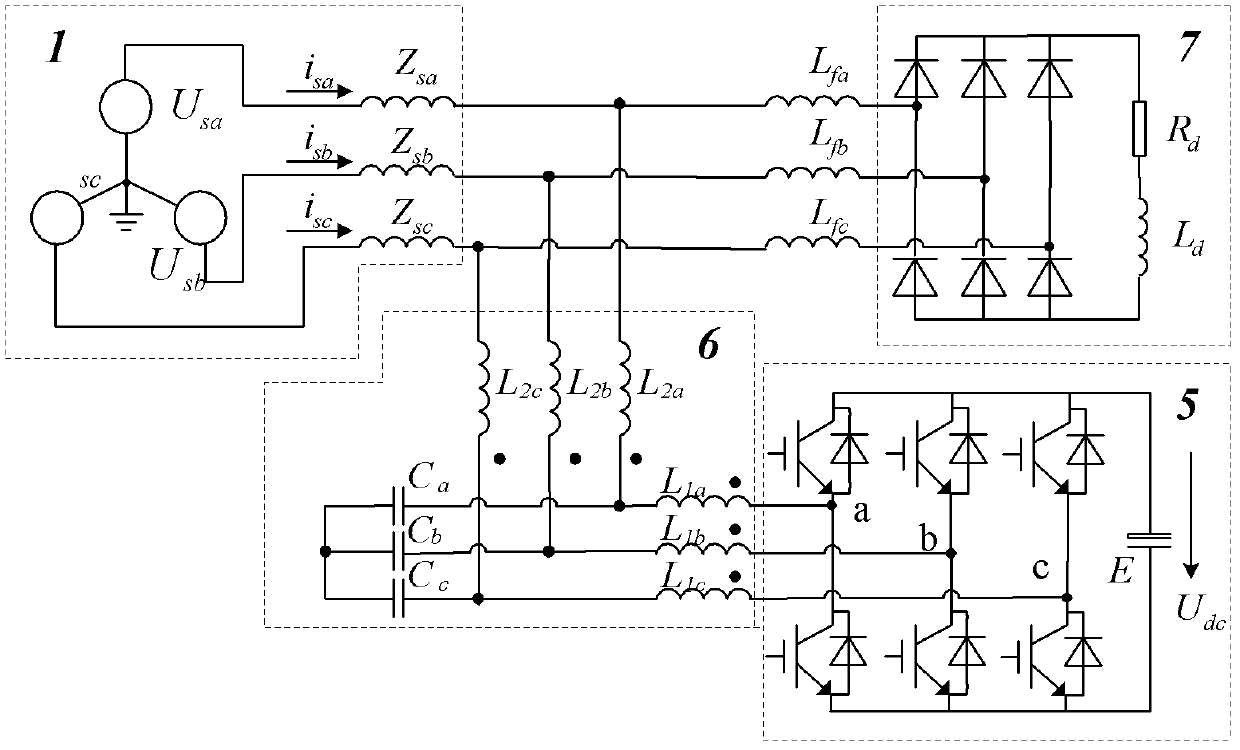

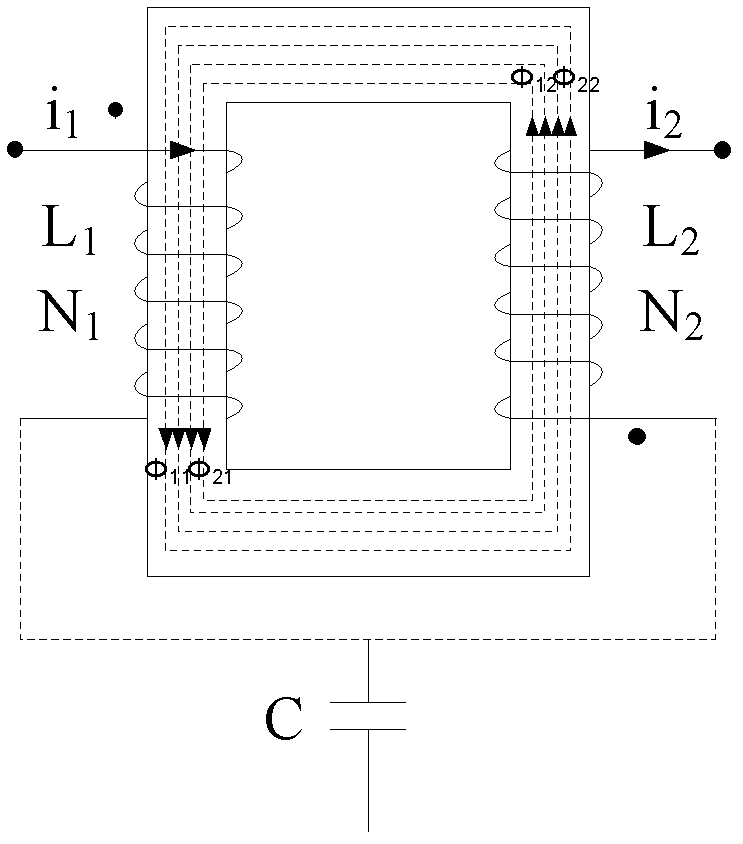

An Active Power Filter Device Based on Coupled Inductor

InactiveCN102290815AReduce volumeReduce weightActive power filteringReactive power adjustment/elimination/compensationPower gridEngineering

The invention discloses an active power filter device based on a coupled inductance, which is composed of a signal acquisition module, a main control module, a drive module, a power conversion module and an LCL filter module based on a coupled inductance. The steps of extracting command current are as follows: first, extract sinωt and cosωt which are synchronized with grid A-phase voltage ua through digital phase-locked loop; secondly, transform the three-phase grid current into dqo coordinates to obtain current id, iq in dqo coordinate system , io; the third is to perform digital low-pass filtering on id and iq to extract their DC components; the fourth is to inversely transform io, sinωt and cosωt to dqo coordinates; the fifth is to perform subtraction to obtain the three-phase grid current The fundamental reactive and harmonic currents in . After hysteresis comparison control, PWM gating signals and trigger pulses are generated to control the orderly on-off of each IGBT in the power conversion module to generate PWM voltage, which is filtered by the filter module and then injected into the grid for compensation.

Owner:HUBEI SANHUAN DEV

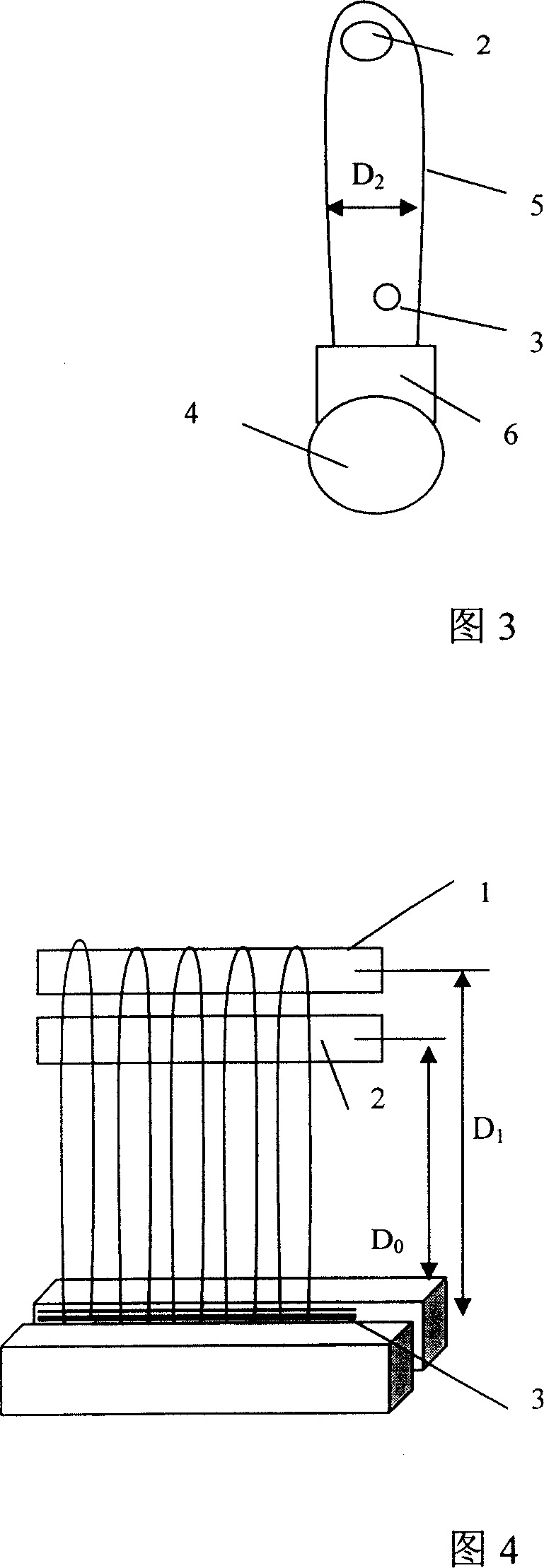

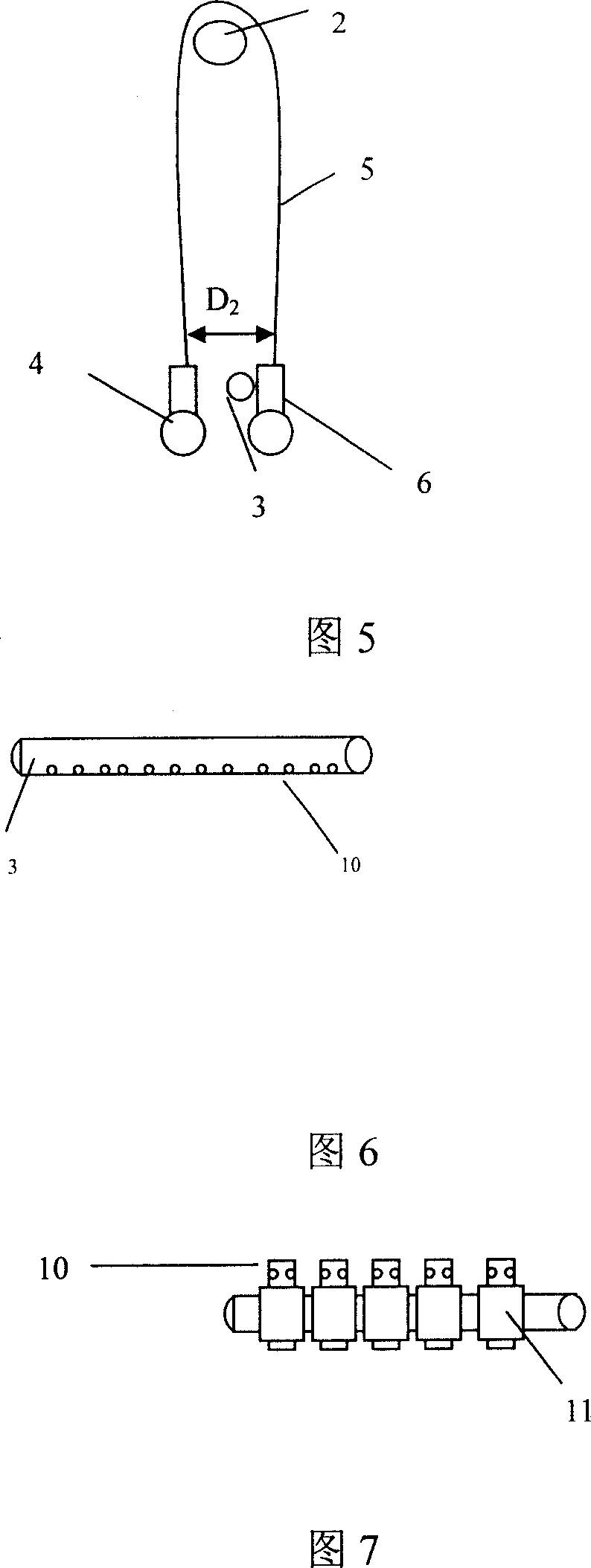

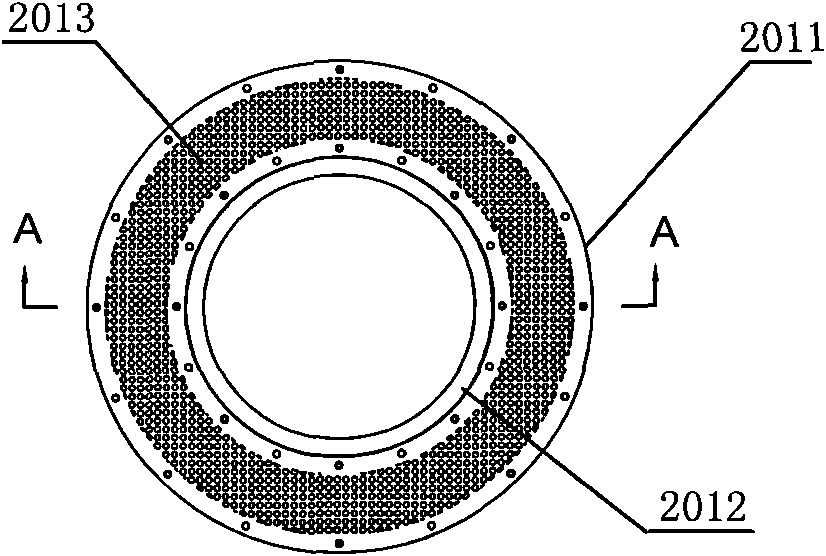

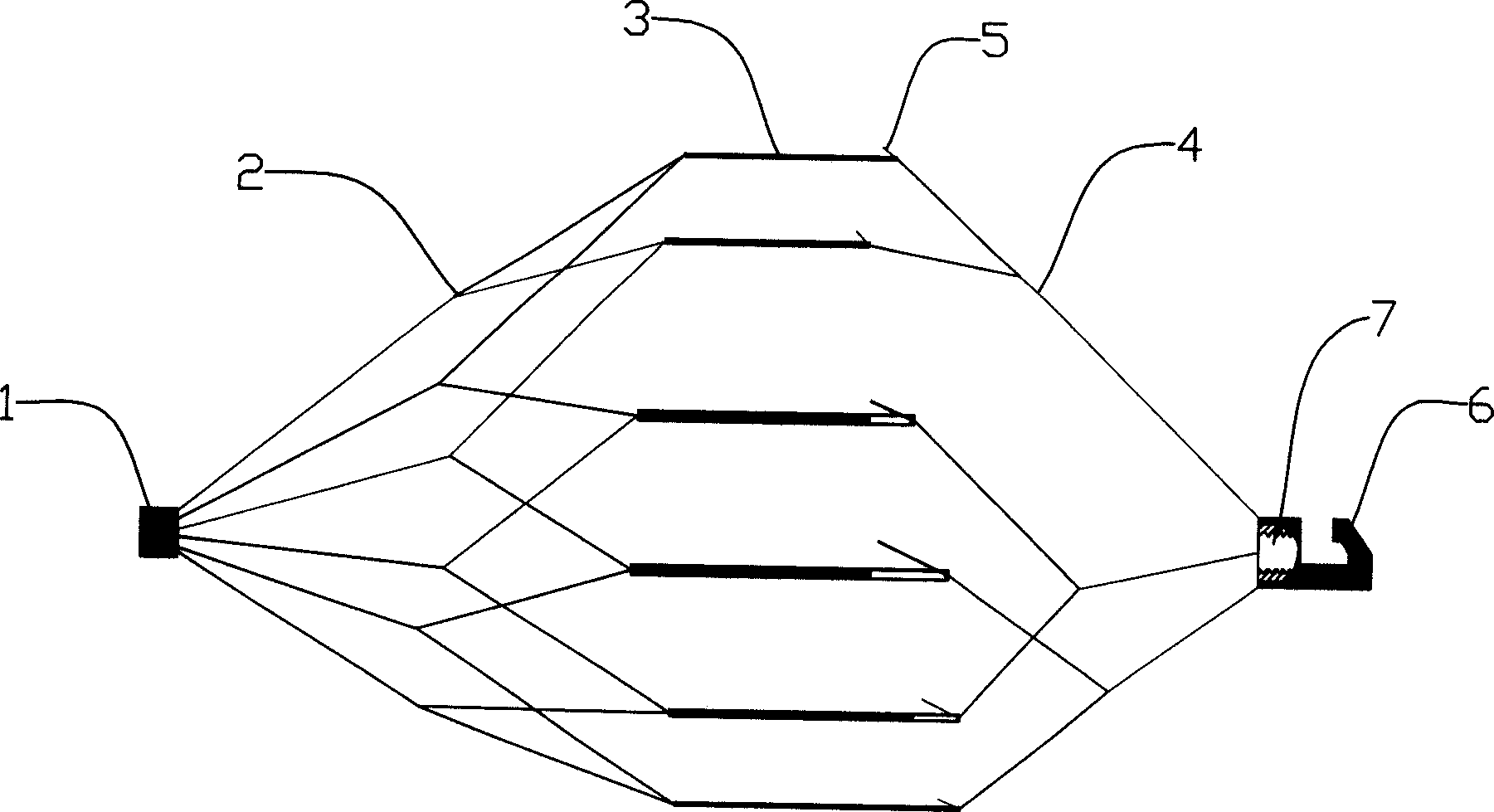

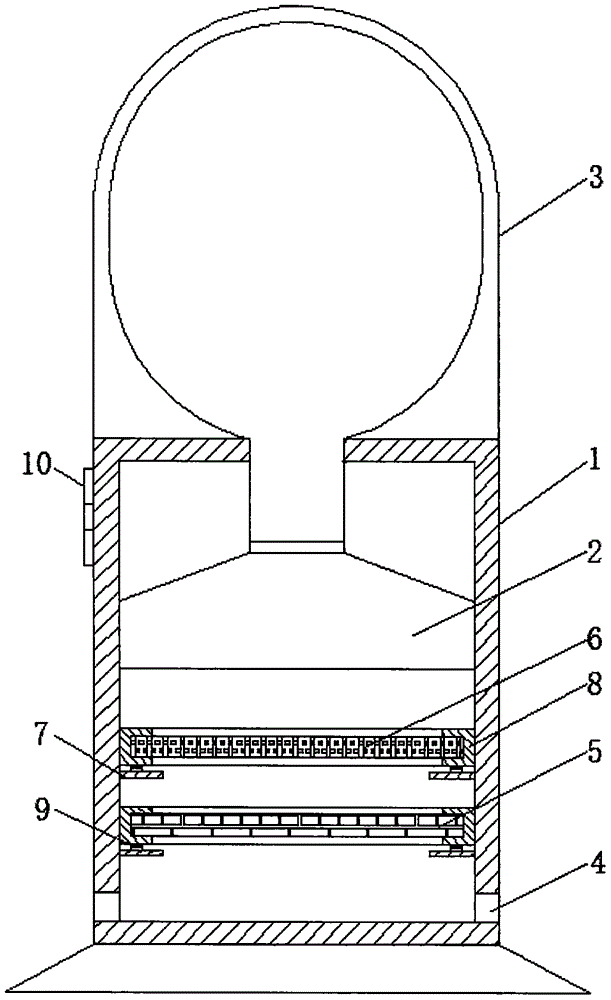

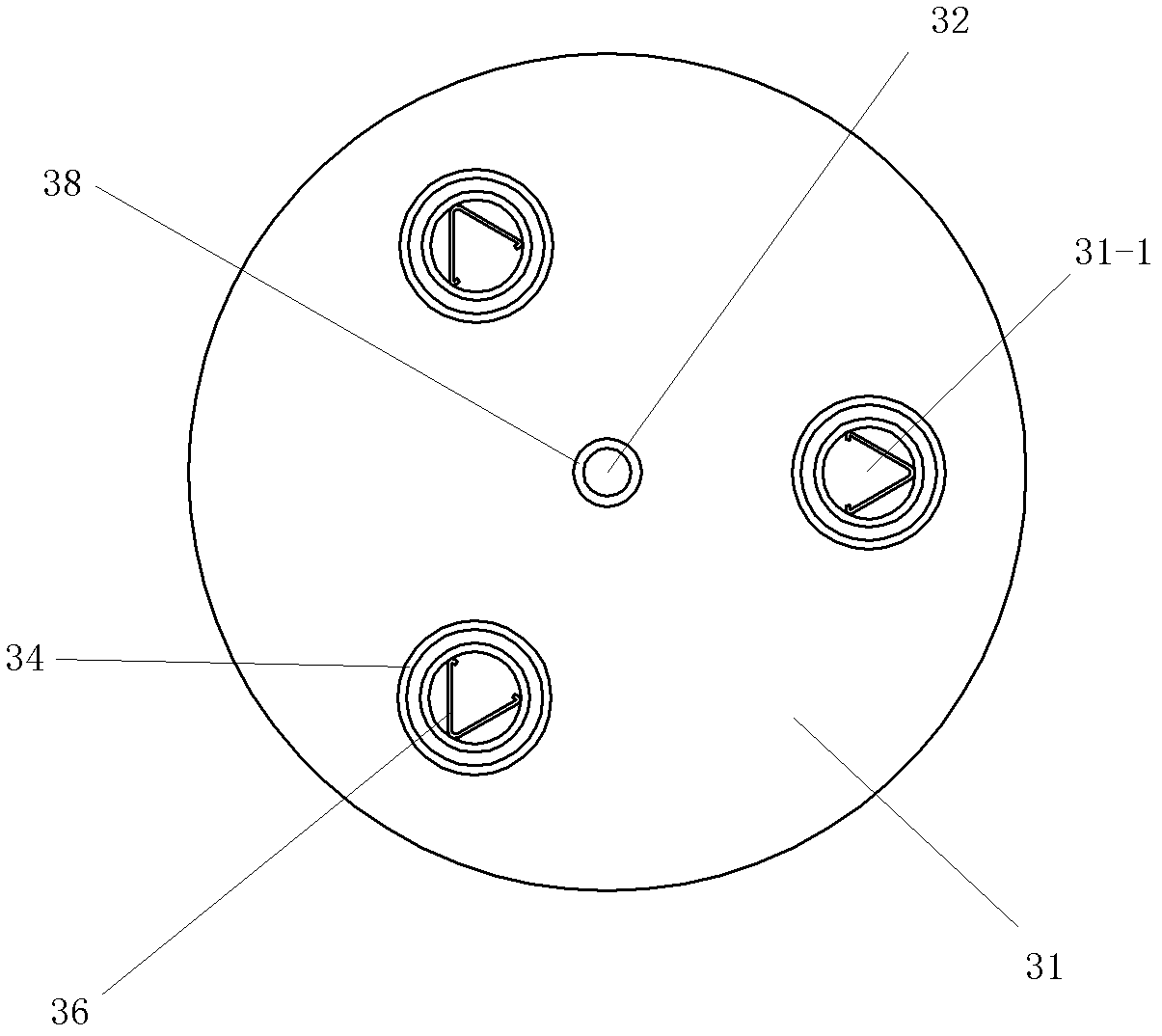

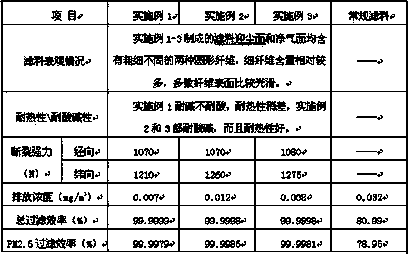

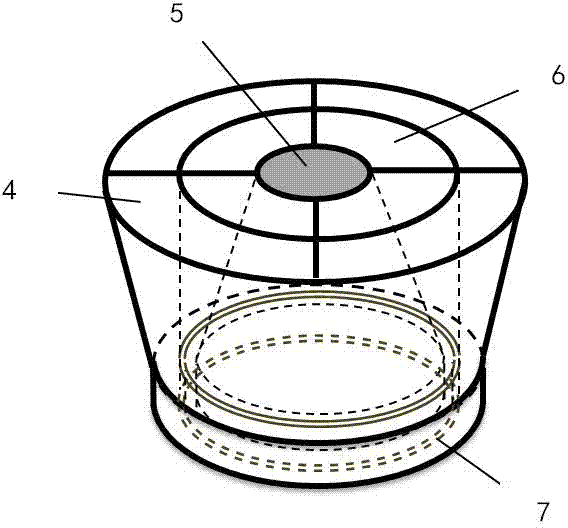

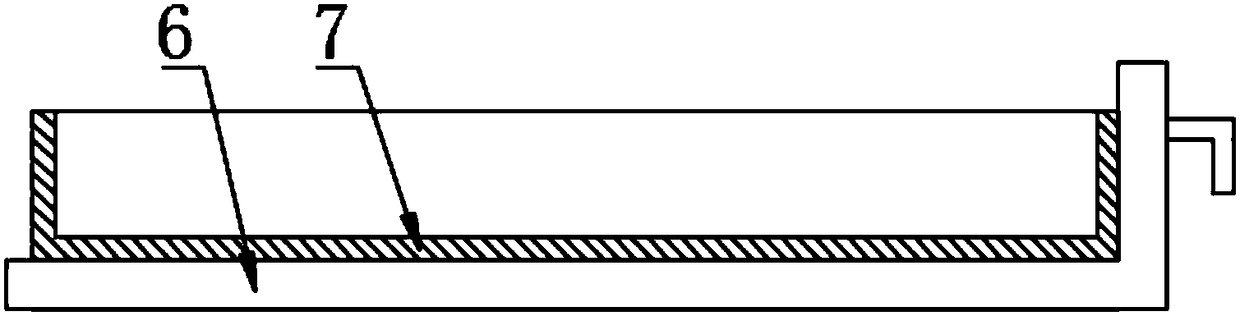

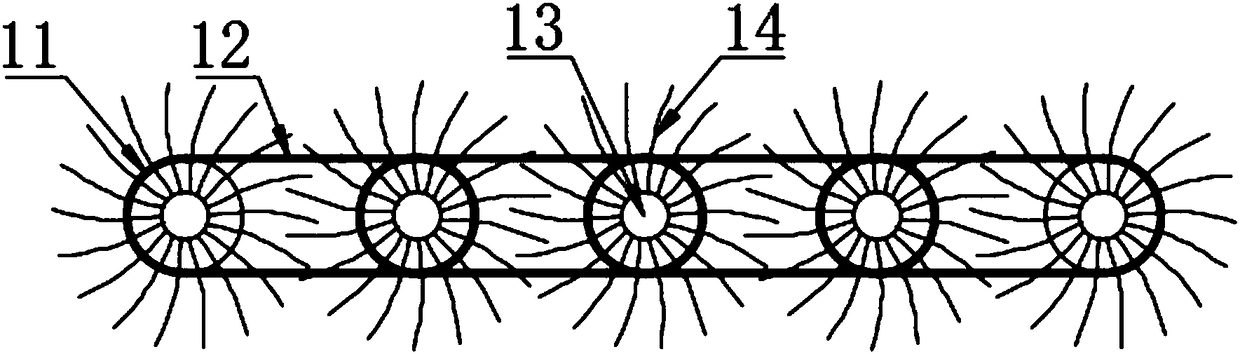

Curtain type hollow fiber membrane module

InactiveCN1951547AGuaranteed filtering effectAvoid accumulationSemi-permeable membranesHollow fibreSludge

The invention relates to a curtain hollow fiber film. Wherein, the single hollow fiber is U-reverse shaped; the upper part of bended single film is inserted with insert tube; two ends of film line are irrigated in one irrigation casting box; two rows of film lines have exposure tube between them. The invention changes the former upright irrigation casting structure into U-shape structure, while the upper end avoids irrigation fixing but the round tube fixing; therefore, the upper film line can move in some range, and the exposure gas can pass the film line, to avoid accumulating mud between lines, to improve the filter property.

Owner:TIANJIN POLYTECHNIC UNIV

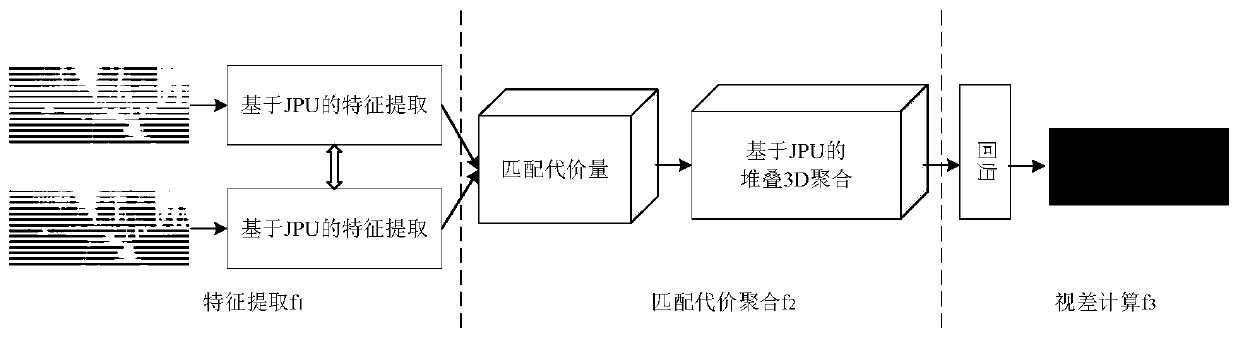

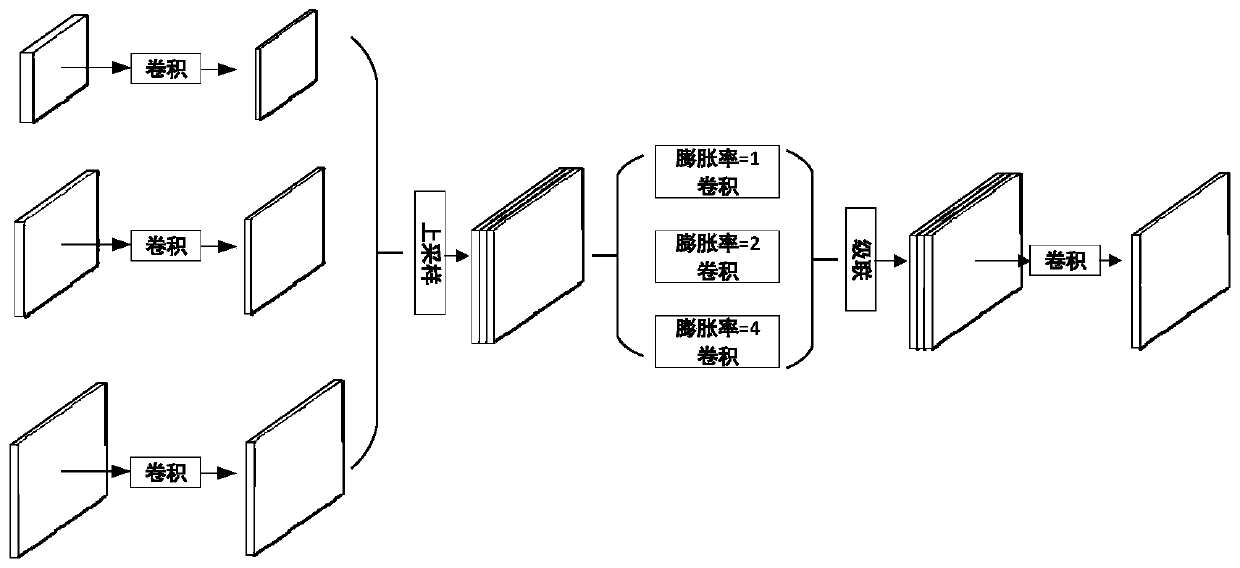

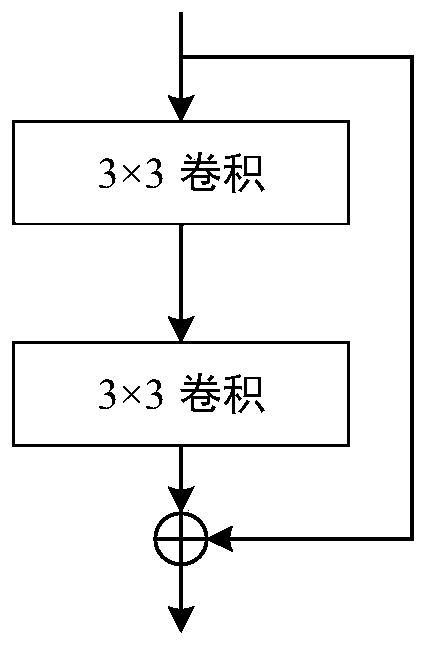

Binocular stereo matching method based on joint up-sampling convolutional neural network

ActiveCN111402129AAddress loss of detailImprove processing precisionGeometric image transformationCharacter and pattern recognitionComputation complexityFeature extraction

The invention discloses a binocular stereo matching method based on a joint up-sampling convolutional neural network. The method comprises the following steps: firstly, carrying out feature extractionon an input three-dimensional image pair by utilizing a two-dimensional convolutional neural network based on joint up-sampling; constructing an initial three-dimensional matching cost amount of thematching cost by splicing the features of the three-dimensional image pairs, further performing cost aggregation on the matching cost amount by adopting three cascaded three-dimensional convolutionalneural networks based on joint up-sampling, and finally obtaining a dense disparity map with sub-pixel precision by utilizing a regression method. Compared with an existing binocular stereo matching deep neural network, the convolutional neural network based on pyramid joint up-sampling is adopted in the decoding stage of the feature extraction and cost aggregation steps; and by fusing multi-leveland multi-scale context feature information, more detail textures can be effectively reserved in the up-sampling process, the calculation efficiency of the method is improved by adopting depth separable convolution with low calculation complexity, and the disparity map quality of binocular stereo matching is improved.

Owner:XI AN JIAOTONG UNIV

Flame-proof fusion-resistant viscose fiber and production method thereof

InactiveCN101161878AImprove strength and elongationGuaranteed filtering effectMonocomponent cellulose artificial filamentCelluloseFiltration

The present invention discloses a flame-retardant anti-melting viscose fiber. According to mass ratio, the viscose fiber mainly comprises the following components: 60-80 percent of cellulose, 15-26 percent of silicon series flame retardant (metered through silicon dioxide) and 3-20 percent of water. The present invention also discloses a production method for flame-retardant anti-melting viscose fiber, and the technical essential is that: in the adding step of flame retardant, the silicon series flame retardant is added into cellulose sulphonic acid ester in a yellowing step or viscose prepared after the yellowing step is over, and the addition amount is 20-45 percent of cellulose if metered through silicon dioxide. The flame-retardant anti-melting fiber produced by using the method is good in flame-retardant anti-melting effect and high in fiber strength, can lead viscose to keep good filtration performance in production process, reduces the production pause caused by that viscose clogs filter screens, and improves production efficiency. The viscose fiber can be widely used for the manufacturing of non-woven fabrics and so on.

Owner:CHTC HELON

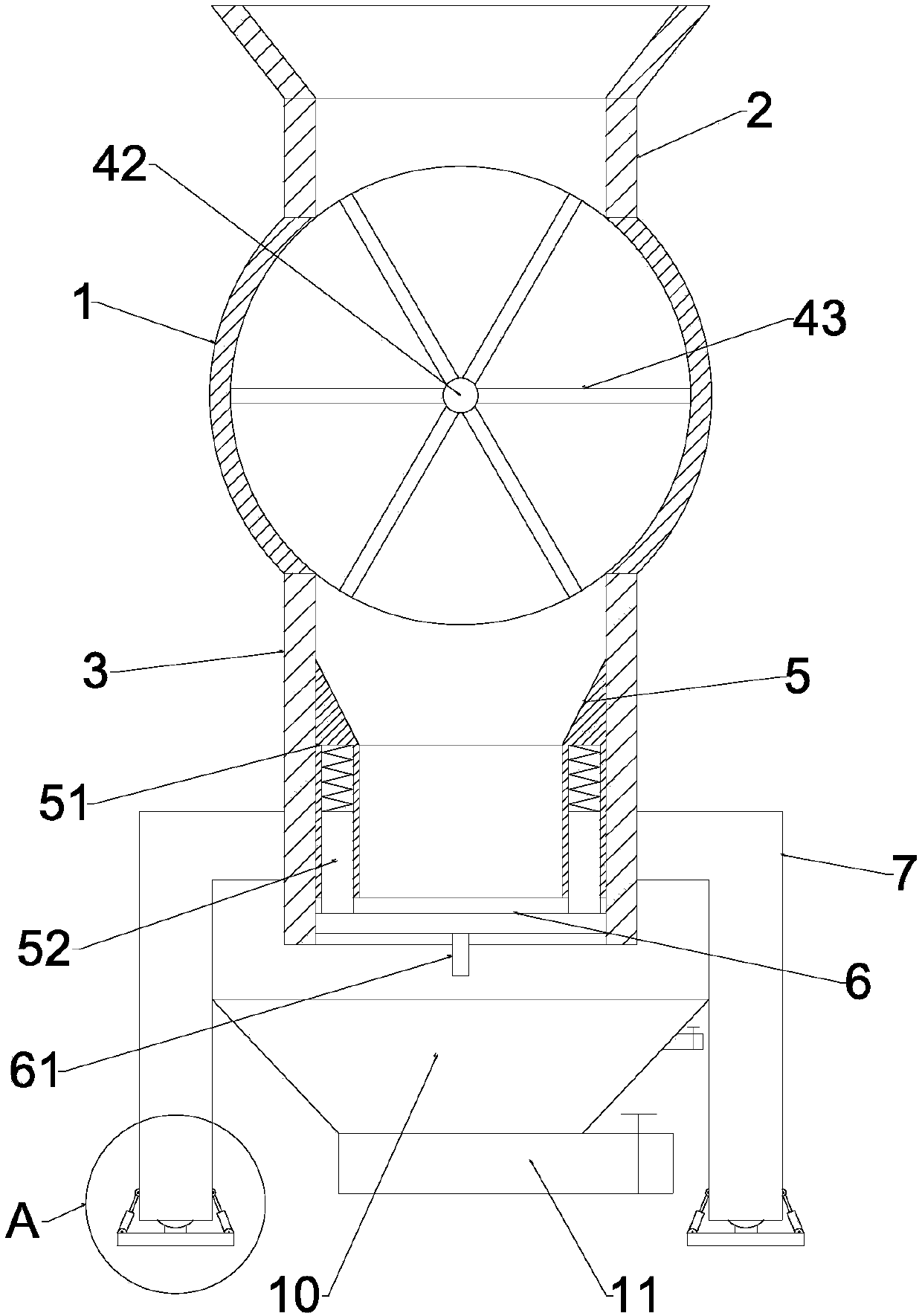

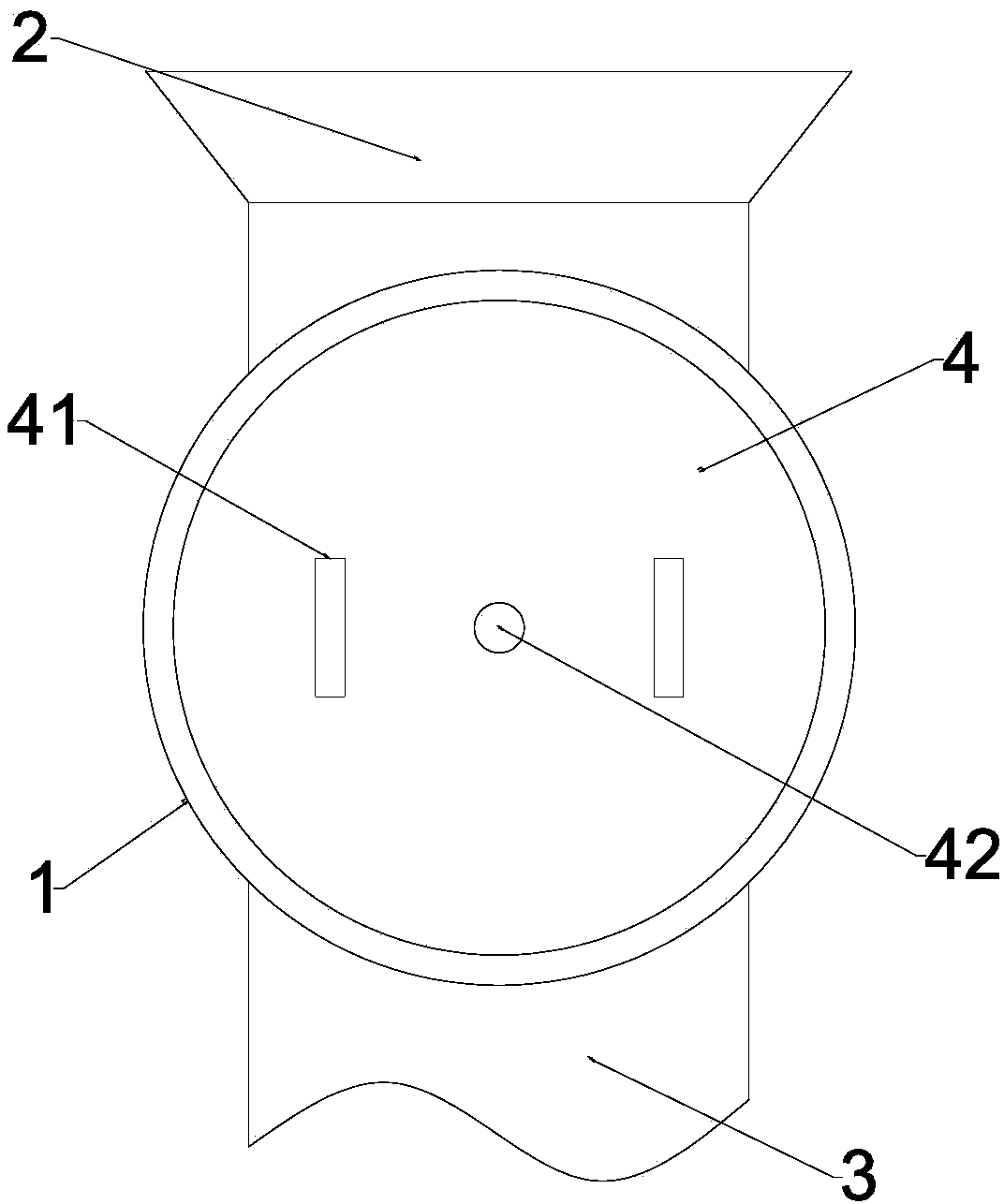

Unpowered automatic cleaning laminated filter

InactiveCN101961572AAchieve cleaningDriving realization of cleaning deviceMembrane filtersStationary filtering element filtersBallastFilter element

The invention provides an unpowered automatic cleaning laminated filter, which comprises a shell and a filter element, wherein the shell is a cylinder with end covers at two ends; a water inlet and a water outlet are arranged on the two end covers or at positions close to the end parts of the cylinder; the filter element consists of a group of hollow filter discs and a water outlet core pipe; the hollow filter discs are sleeved on the water outlet core pipe; a distance is kept between each two adjacent hollow filter discs; the effluent of the hollow filter discs flows into the water outlet core pipe; and one end of the water outlet pipe is closed, while the other end is provided with a water outlet, which is connected with the water outlet of the filter or directly serves as the water outlet of the filter. The filter also has a washing device which comprises a cleaning brush holder, a cleaning brush, a driving device and a mounting frame, wherein the mounting frame is connected with the driving device; the cleaning brush is fixed on the mounting frame; the head of the cleaning brush is positioned on the surface of the annular filter discs; and the cleaning device is driven by the driving device to rotate to realize the cleaning of the filter discs. The filter can be used for filtering ship ballast water, cooling water and the like.

Owner:FUJIAN NEWLAND ENTECH CO LTD

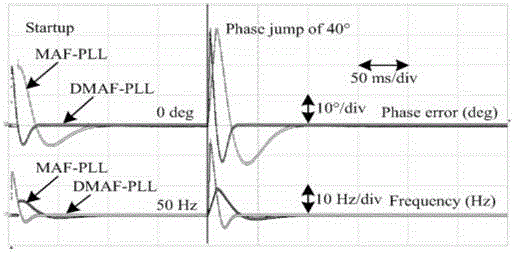

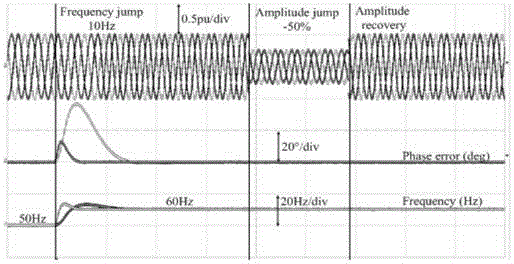

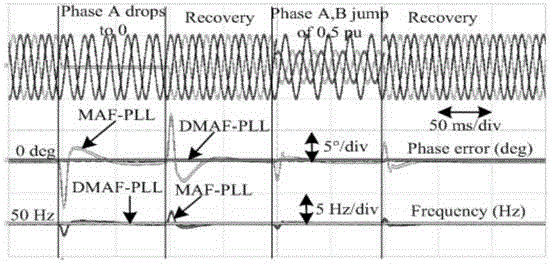

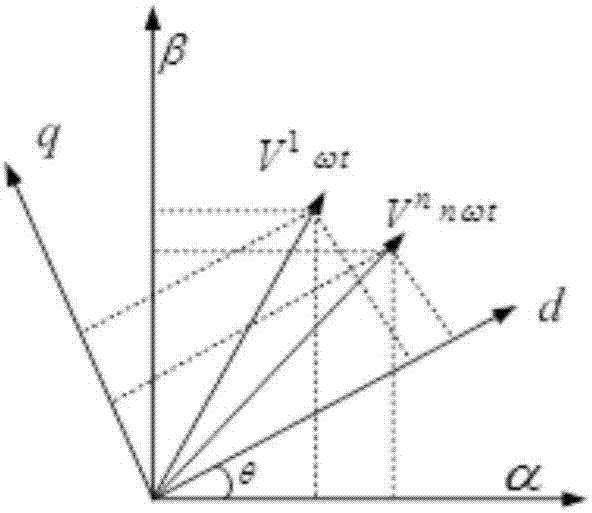

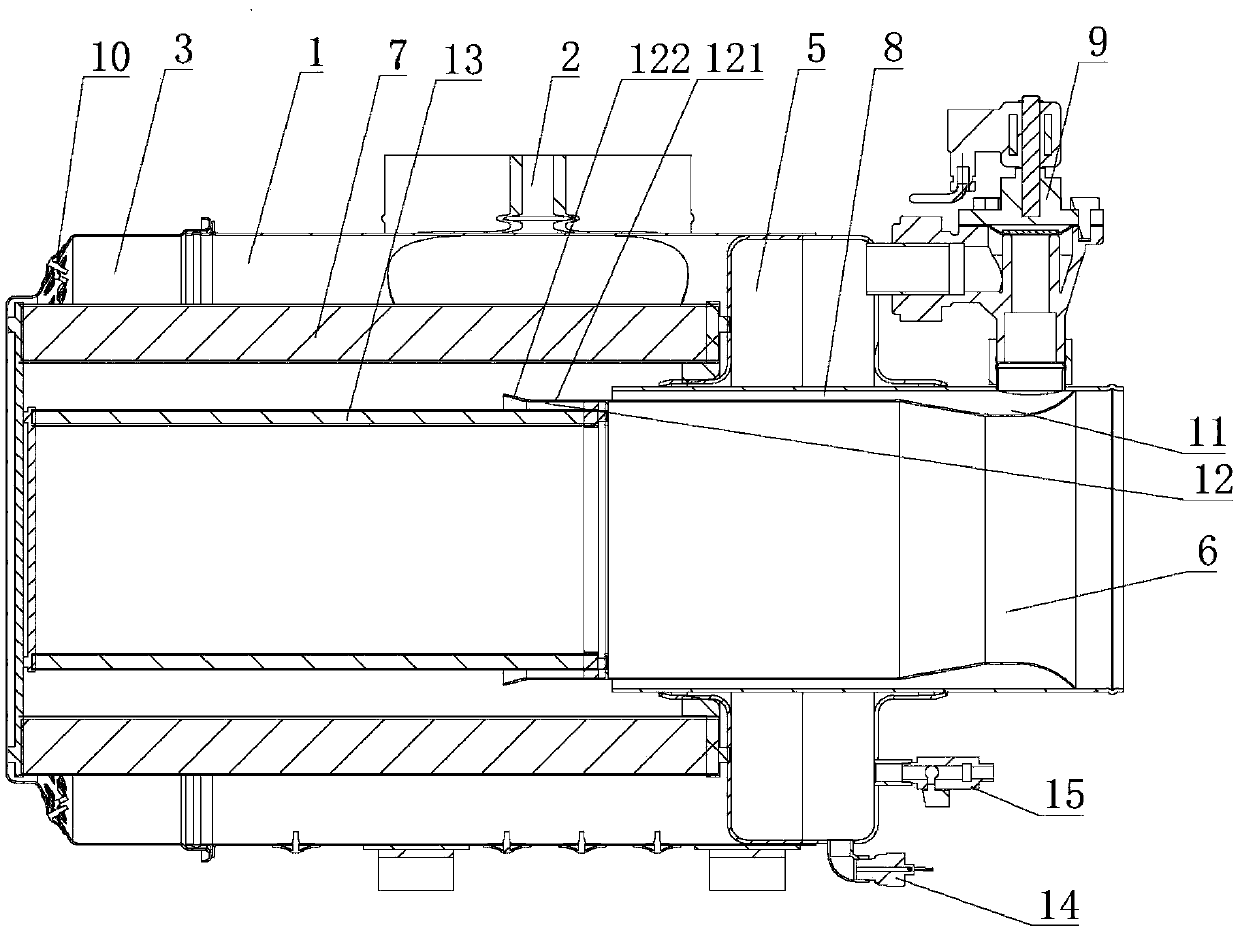

Method of modifying dynamic performance of phase-locked loop on basis of sliding filter

ActiveCN104811188AReduce window widthImprove dynamic performancePulse automatic controlMoving averageVoltage amplitude

The invention discloses a method of modifying dynamic performance of a phase-locked loop on basis of a sliding filter. The method includes: sampling three-phase grid voltage, and performing Park coordinate transform to obtain voltage components v<q> and v<d> in a two-phase dq rotating coordinate system; subjecting the voltage component v<d> to differentiation and then to dividing by an angular frequency parameter, and summing a quotient and the voltage component v<q> to obtain q ; subjecting q to differentiation and then to dividing by the angular frequency parameter, and summing a quotient and the voltage component v<d> to obtain d; subjecting d to the sliding filter to obtain a fundamental wave positive-sequence voltage amplitude V<1><+>; subjecting q to the sliding filter and a PI (proportion integration) regulator, and summing an output of the PI regulator and a preset angular frequency to obtain a grid voltage angular frequency , with the preset angular frequency being power frequency usually; subjecting to differentiation to obtain a grid voltage phase 1+; feeding back 1+ to the input end to finish closed-loop control. The method has the advantages that a proportional algorithm of input signal frequency changes is introduced to MAF-PLL (moving average filter-phase-locked loop), the lowest frequency fluctuation component in the PLL is eliminated, the window width of the MAF is decreased, and dynamic performance of the MAF-DLL is improved.

Owner:SHANDONG UNIV

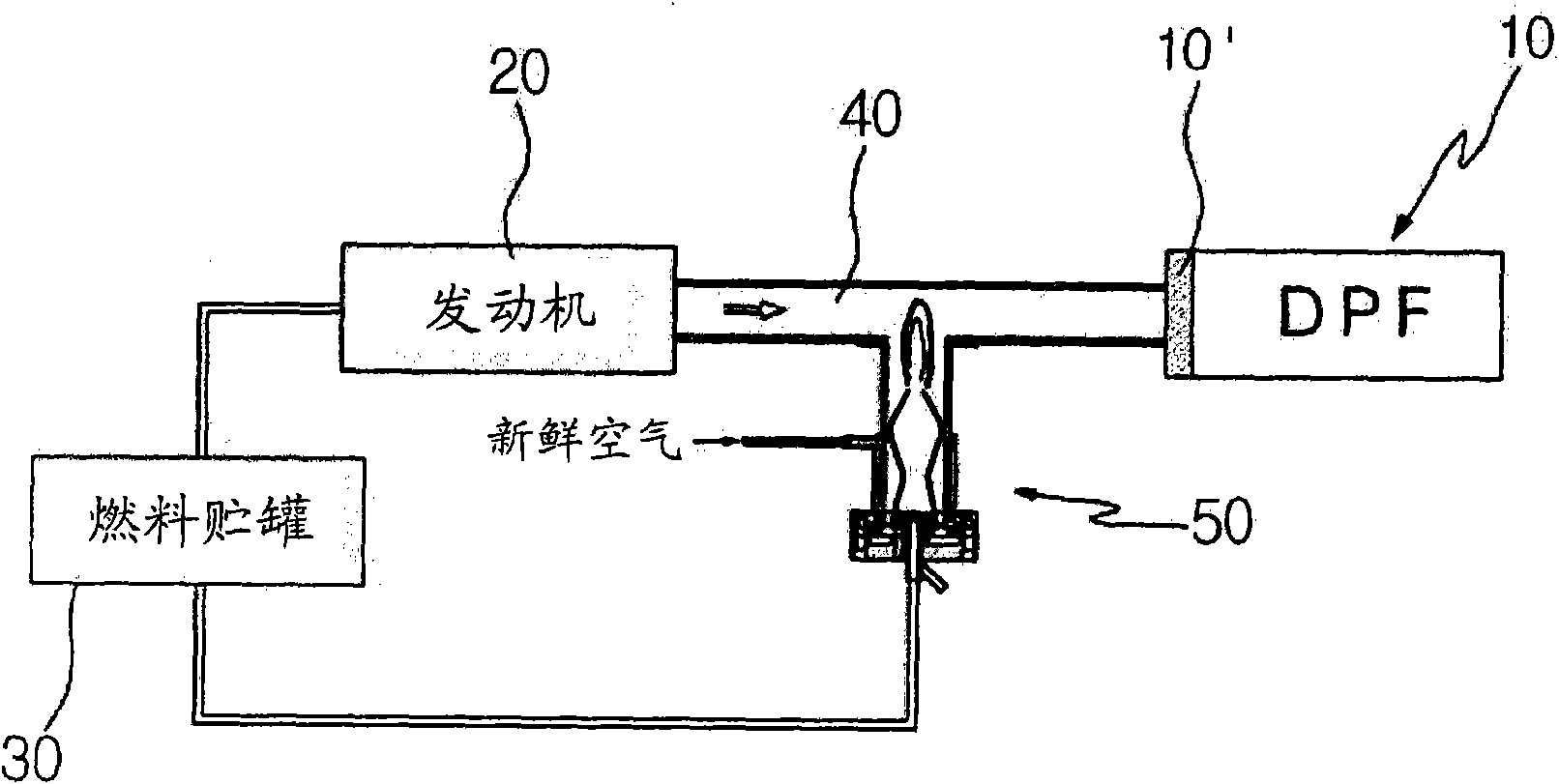

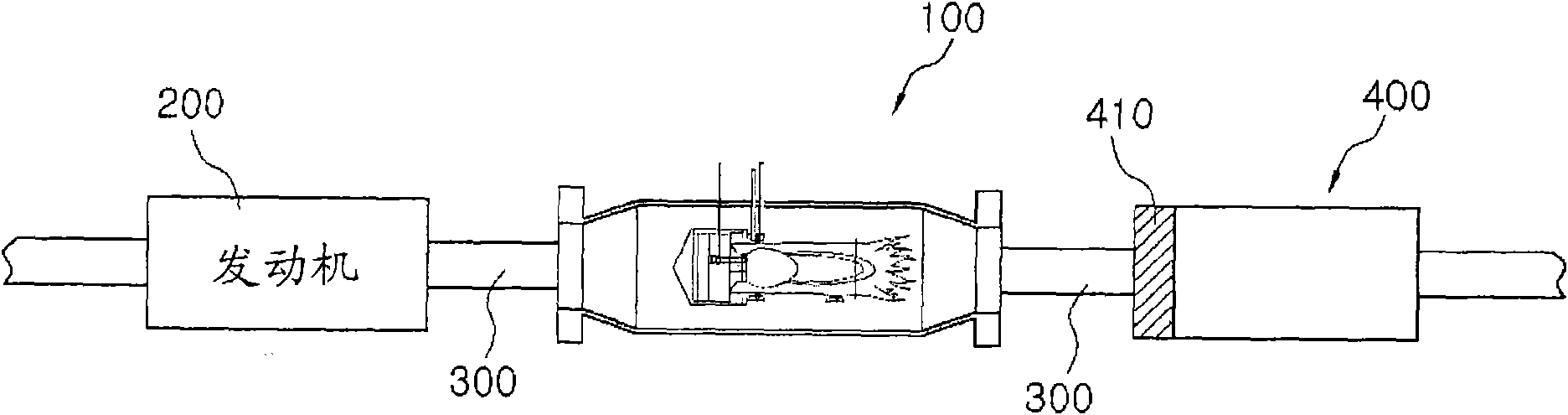

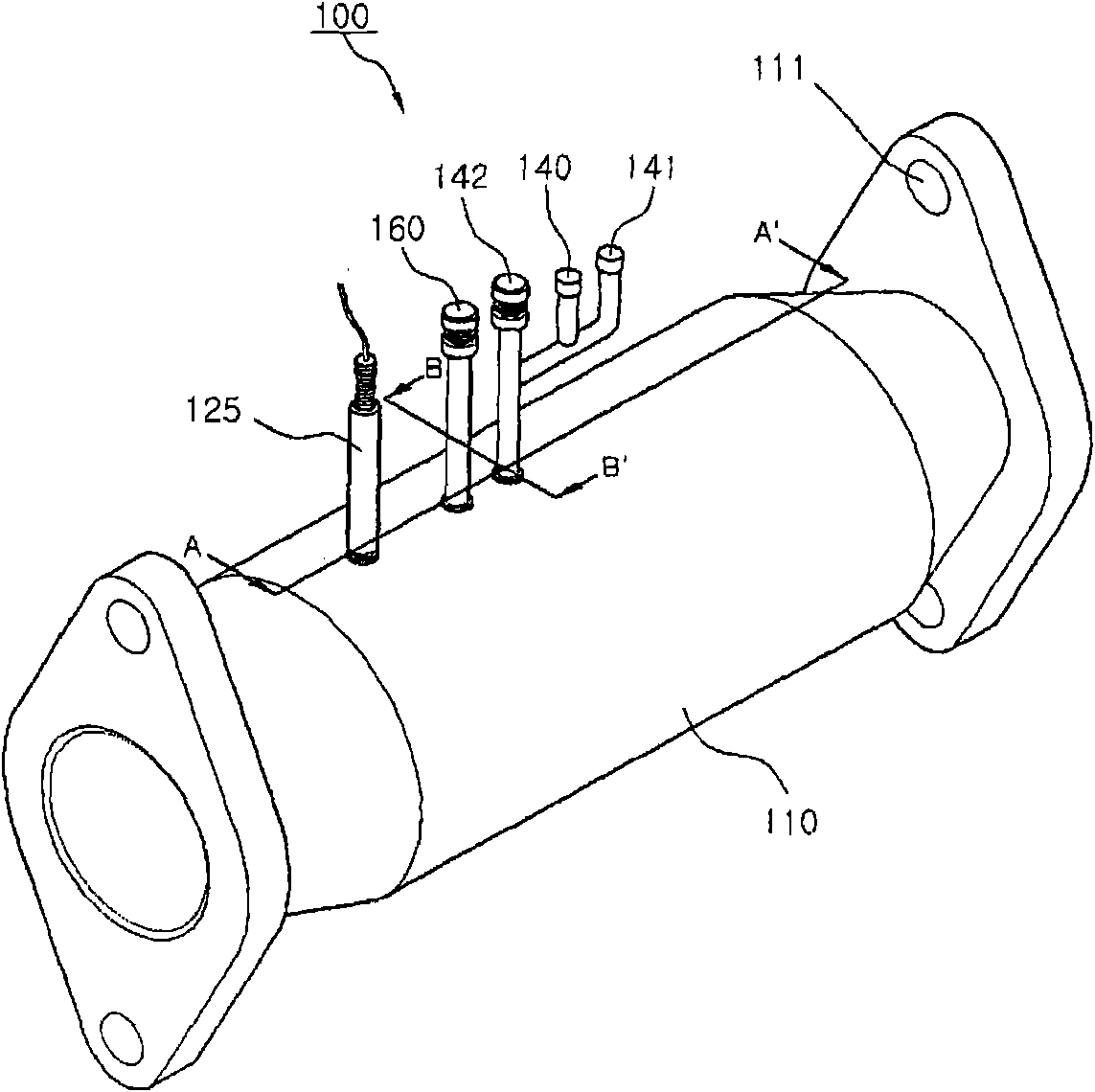

Burner for diesel particulate filter regeneration

InactiveCN101929371AGuaranteed filtering effectExtend your lifeExhaust apparatusSilencing apparatusElectricityElectric discharge

Provided is a burner using electric discharge as an ignition source such as arc or plasma rotating with flow, and more particularly, to a DPF regenerating burner that improves ignition performance of the burner by having a metal ball on a conical electrode surface where electricity is discharged, inducing accurate electric discharge through a metal ball, and supplying a fuel-air mixture toward the metal ball. The DPF regeneration burner includes a fuel-air mixture supplying unit having an injecting unit be connected to a reaction unit to supply the fuel-air mixtureto the reaction unit; and a metal ball on a circumference of the electrodeto ignite the injected fuel-air mixture. The DPF regenerating burner generates electric discharge in an electrode surface where a metal ball is located. The ignition performance is improved by accurately supplying a fuel-air mixture at a location where the electric discharge is generated.

Owner:TEMS

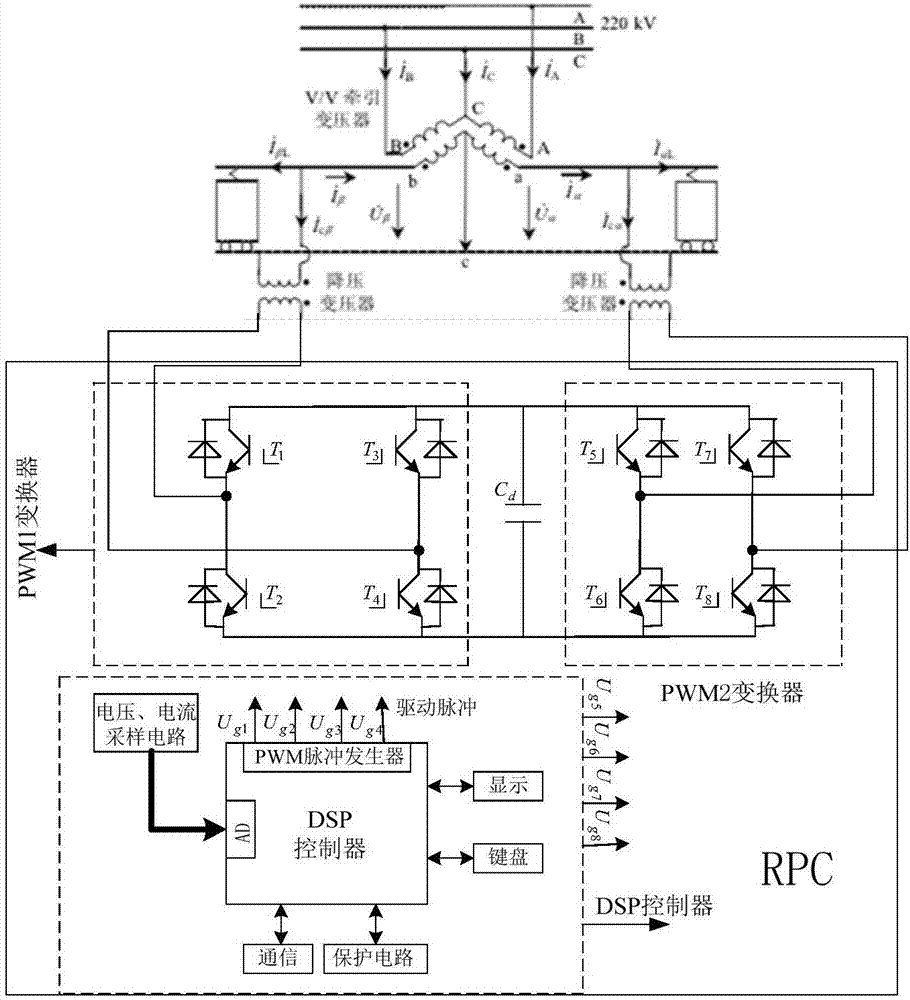

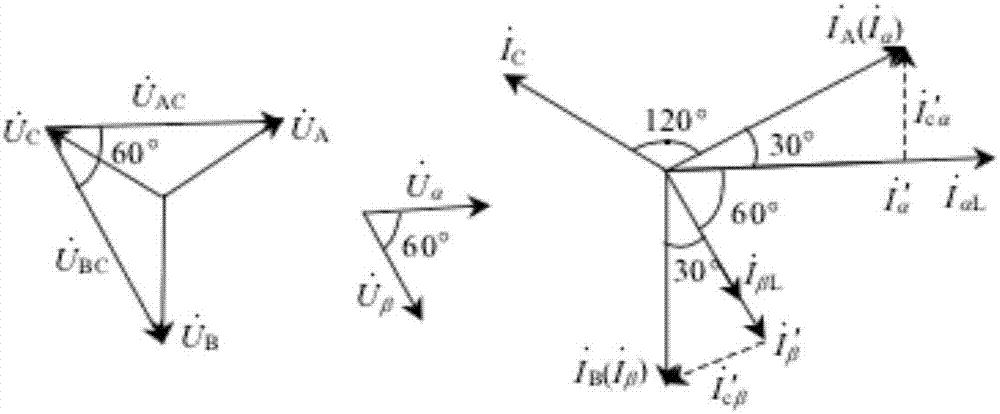

Grid-connected phase lock method for electrified railway power treatment and adjustment device

InactiveCN107196329AImprove accuracyAchieve phase lockSingle network parallel feeding arrangementsPolyphase network asymmetry elimination/reductionIntegratorEngineering

The invention relates to a grid-connected phase lock method for an electrified railway power treatment and adjustment device. The method comprises the steps that (1) power grid voltage unbalanced deformation is carried out on the three-phase alternating current component of the power grid voltage; Clark transform is carried out on the deformed power grid voltage; and the power grid voltage is mapped to an alpha beta stationary coordinate system to acquire V alpha beta; (2) the components v alpha and v beta of V alpha beta on alpha and beta axes are shifted by 90 degrees through a second order generalized integrator SOGI module respectively, and the positive-sequence component is calculated; and (3) the extracted positive-sequence component is replaced by the power grid voltage, and the phase lock loop of single synchronization coordinate system software is used to realize the phase lock function of the power grid voltage. Compared with the prior art, the method provided by the invention can effectively filter out harmonic components in the power grid voltage and extract the basic positive sequence component therein to realize successful phase lock.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Cigarette filter tip composite material and preparation method thereof

InactiveCN101816456AReduce manufacturing costRich sourcesTobacco smoke filtersCellulose acetateNetwork structure

The invention discloses a cigarette filter tip composite material, which is characterized by consisting of the following components in percentage by mass: 30 to 90 percent of polylactic acid fibers and 10 to 70 percent of cellulose acetate fibers which form a network structure through splitting and physical entanglement and the adhesion of surface points. The invention also discloses a method for preparing the cigarette filter tip composite material. The polylactic acid fibers selected by the invention have the advantages of abundant sources, low cost and good processability, and the polylactic acid fibers are used to replace part of the cellulose acetate fibers and are used as the cigarette filter tip composite material, so that the production cost of cigarette filter tips can be reduced greatly, the production efficiency is improved, and the problems of environmental contamination, resource shortage, high cost and the like which are caused by the production of the cellulose acetate fibers are reduced. The preparation method provided by the invention has the advantages of simple and mature process and easy operation.

Owner:云南西部星空卫星科技有限公司

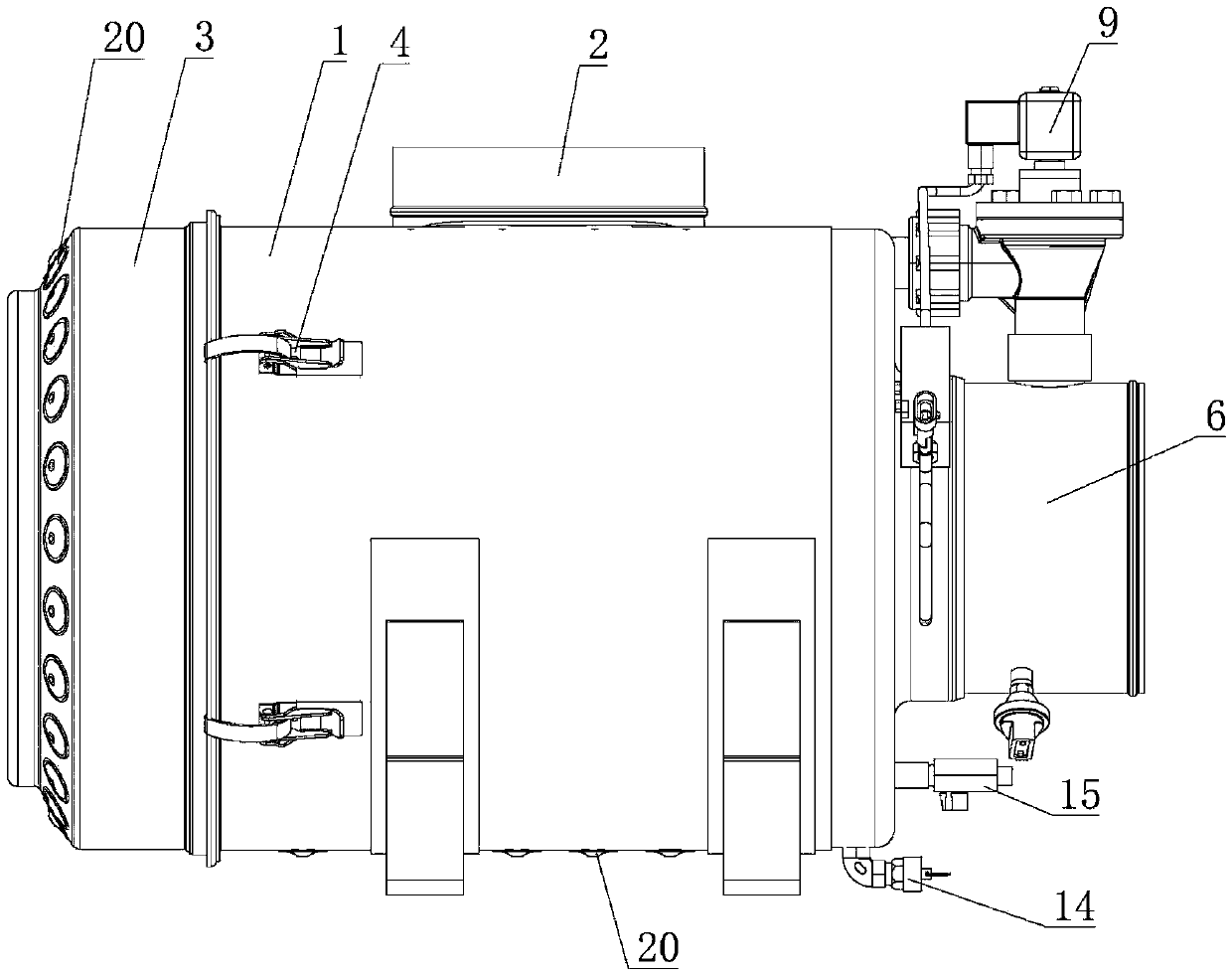

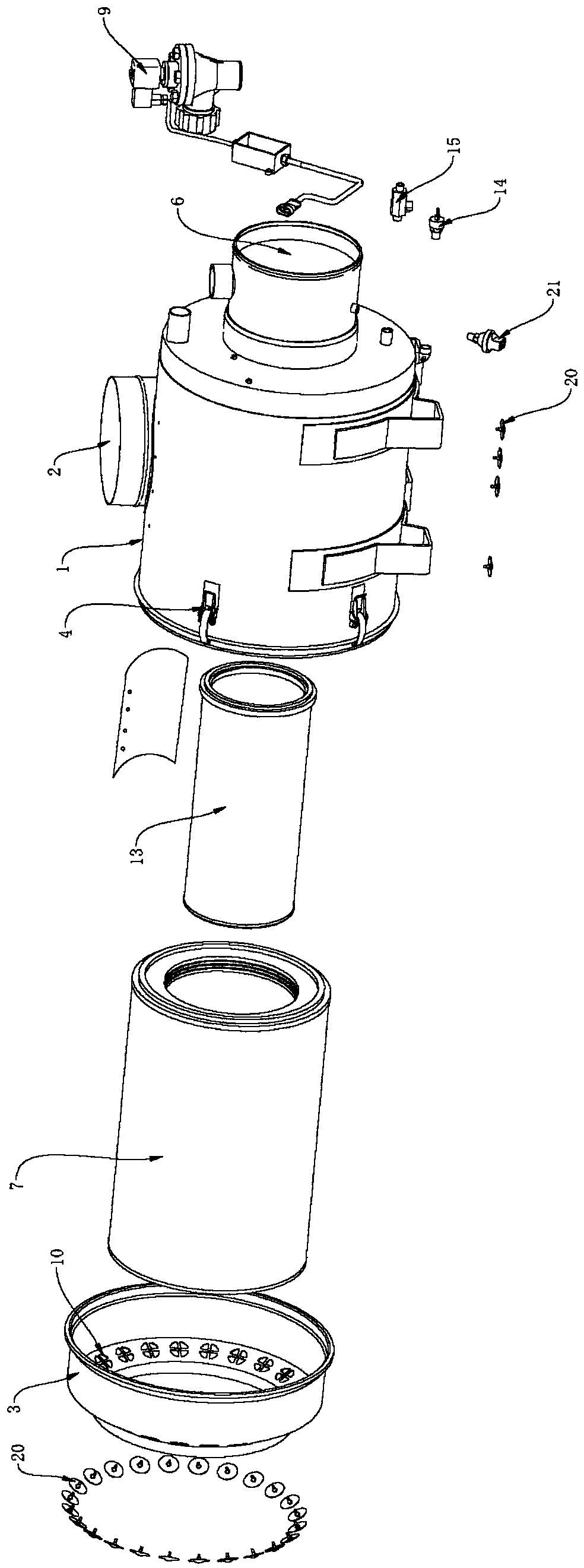

Self-cleaning air filter and control system thereof

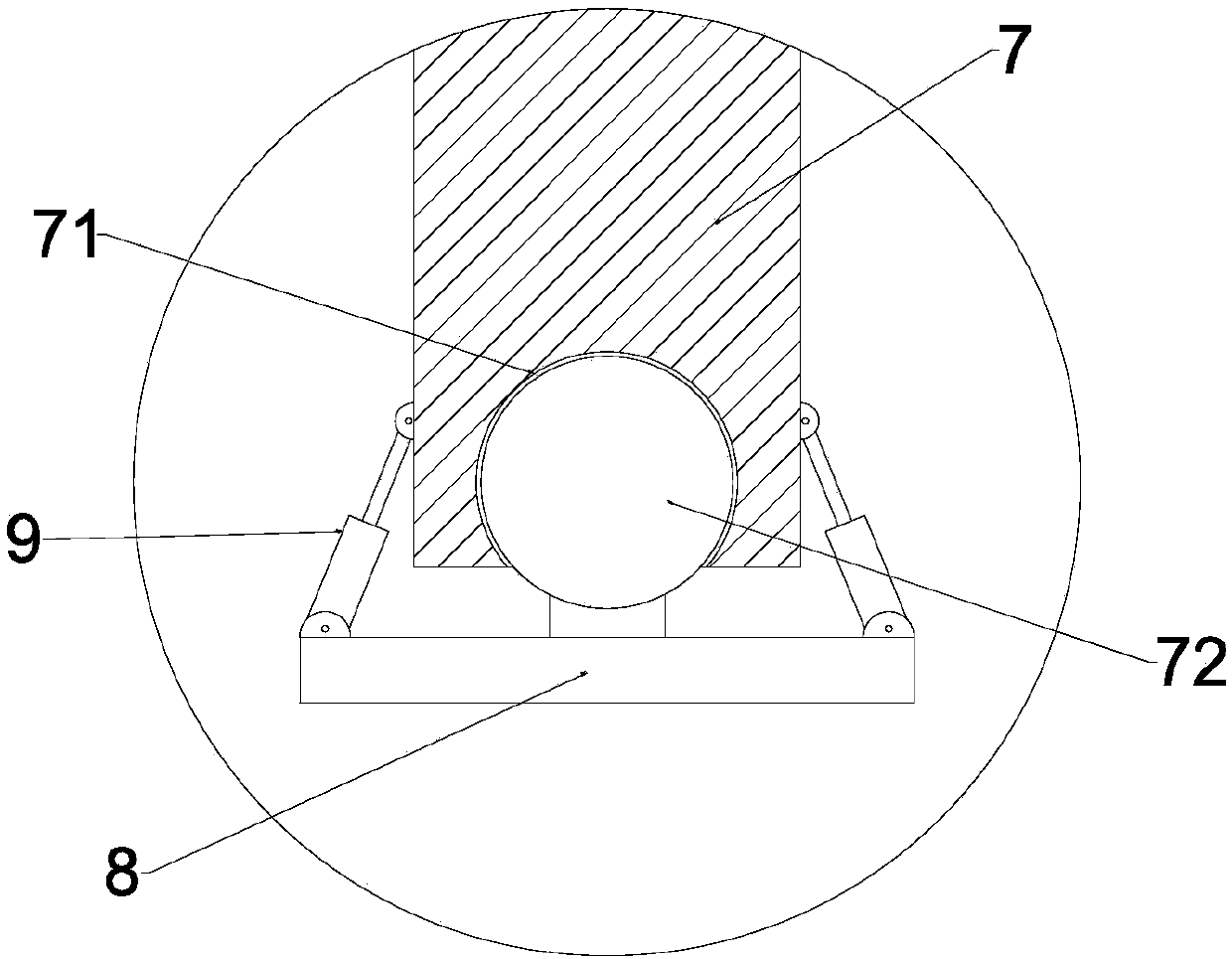

PendingCN109578181AIncrease impactGuaranteed filtering effectOperating means/releasing devices for valvesDispersed particle filtrationControl systemAir filter

The invention provides a self-cleaning air filter. The self-cleaning air filter is reasonable in structure, can remove dust accumulated on the outer surface of an air filter core quite well and is good in self-cleaning effect, and the service life of the air filter core is prolonged. The self-cleaning air filter comprises a shell; the shell is provided with an air inlet; an air filter end cover isinstalled at one end of the shell; an air bag is fixedly installed in the shell; the interior of the shell is provided with a filter air outlet; a main filter core is installed in the shell, one endof the main filter abuts against the outside of the air bag to form sealing connection; the space between the outer wall of the filter air outlet and the inner wall of the shell forms an air channel;an air storage part of the air bag is annularly arranged on the filter air outlet, an output opening of the air storage part of the air bag is externally connected with the input end of an electromagnetic pulse valve, the output end of the electromagnetic pulse valve communicates with the air feeding end of the air channel, and the air exhausting end of the air channel is located on the inner sideof the main filter core; and the outer annular surface of the air filter end cover is provided with dust discharge holes. In addition, the invention further provides a control system of the self-cleaning air filter.

Owner:江苏函越智能科技有限公司

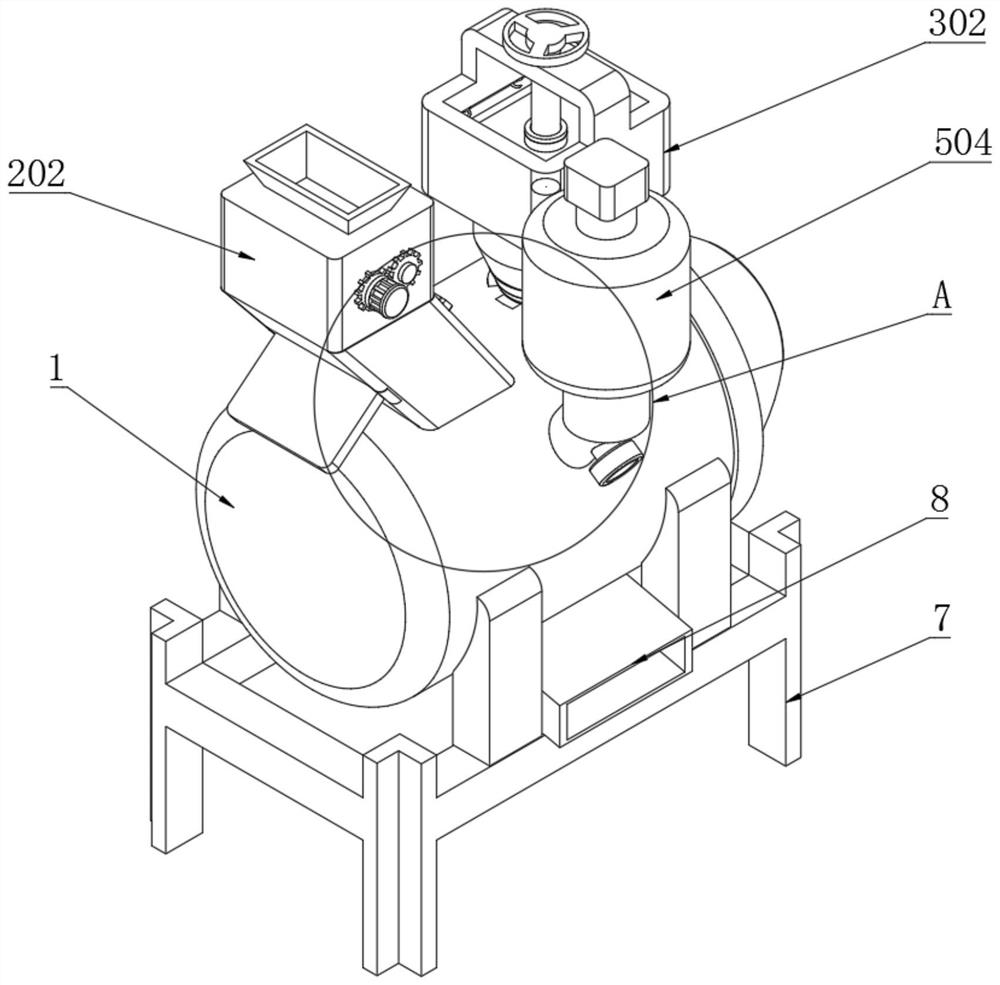

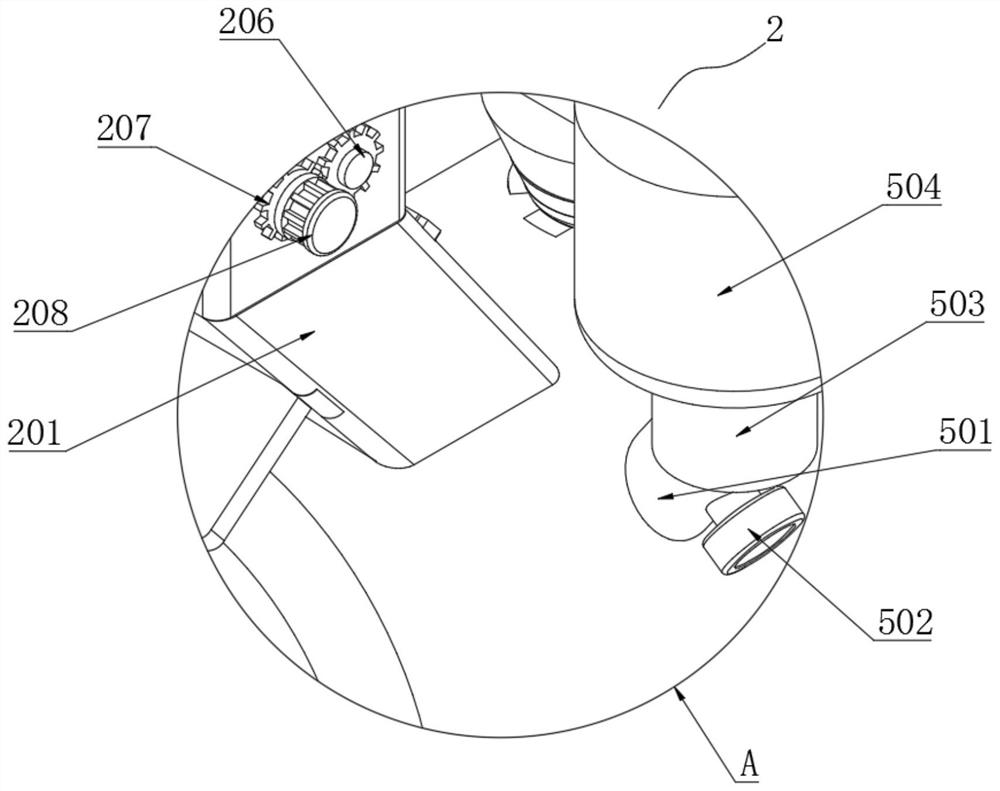

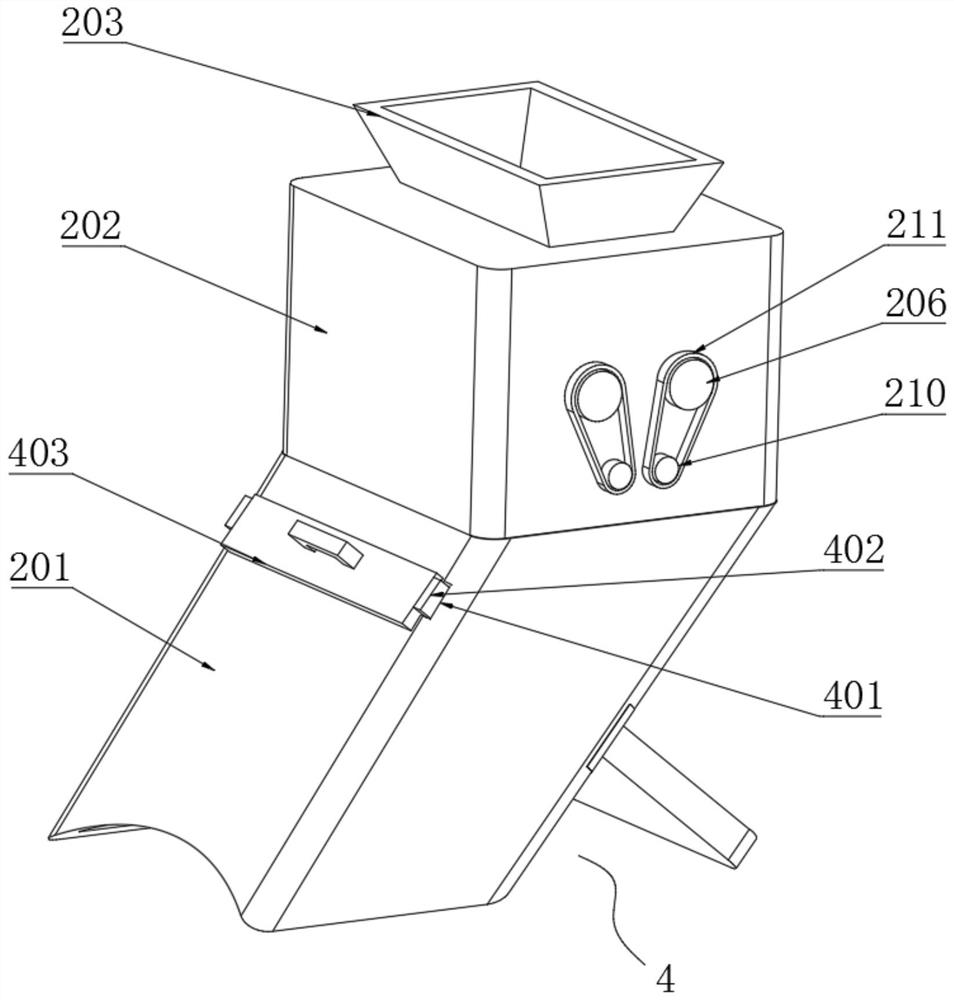

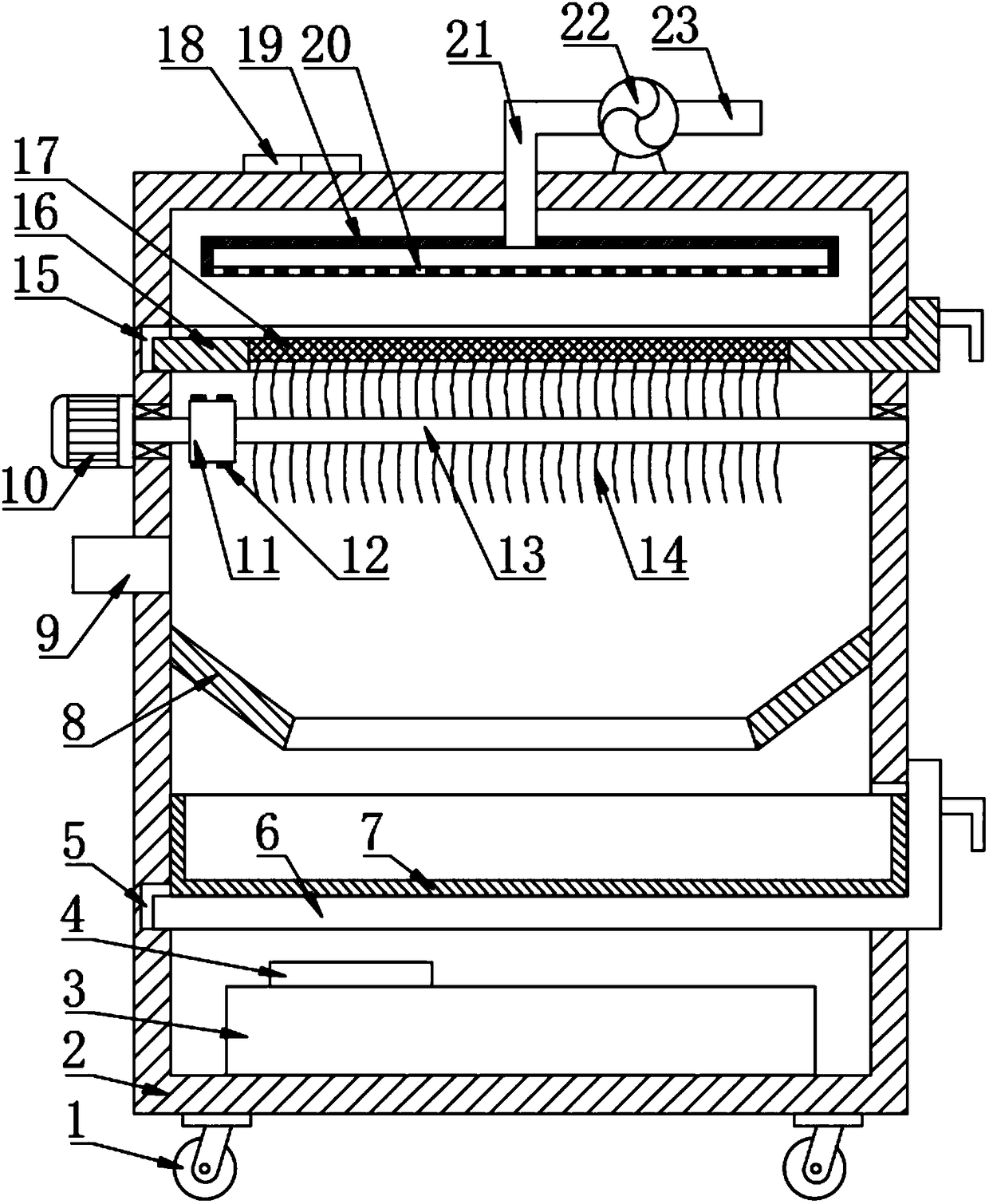

Full-automatic concrete mixing equipment capable of realizing proportioning

InactiveCN111702952AScientific and reasonable structureEasy to useMixing operation control apparatusPretreatment controlElectric machineGear wheel

The invention discloses full-automatic concrete mixing equipment capable of realizing proportioning. The full-automatic concrete mixing equipment is characterized in that a bottom frame is fixedly connected to the bottom end of a mixing drum, a discharging opening is fixedly connected to the position, corresponding to the top of the bottom frame, of the outer end of the mixing drum, a gravel feeding mechanism is fixedly connected to one side of the top end of the mixing drum, the other side of the top end of the mixing drum is fixedly connected with a cement feeding mechanism, the side edge ofthe outer end of the mixing drum is fixedly connected with a water control mechanism, and a stirring mechanism is embedded inside the mixing drum. The equipment is scientific and reasonable in structure and safe and convenient to use; the gravel feeding mechanism is arranged, a rotating motor drives first rotating rods to rotate, and through cooperation of transmission gears, two first rotating rods drive two rough grinding rollers to rotate together to crush gravel, and meanwhile, through belt transmission, the two first rotating rods drive the two second rotating rods to rotate together, sothat the two fine grinding rollers are driven to rotate, and the gravel and cement mixing effect is improved.

Owner:李彦红

Automobile exhaust treatment device capable of being installed at tail end of exhaust pipe

InactiveCN110594001AGuaranteed stabilityGuaranteed effectInternal combustion piston enginesExhaust apparatusExhaust gasEngineering

The invention discloses an automobile exhaust treatment device capable of being installed at the tail end of an exhaust pipe. The device comprises a mounting body, wherein a gas inlet with a leftwardopening is formed in the left side in the mounting body, a filter plate is fixedly arranged in the gas inlet, the filter plate can block carbon material in exhaust to the left side, a carbon scrapingdevice is arranged on the upper side of the gas inlet, a scraping plate is arranged in the carbon scraping device, the scraping plate can scrape off accumulated carbon on the left end face of the filter plate, the filtering effect of the filter plate is improved, and the right side of the gas inlet communicates with a ventilation cavity. By installing the device at the tail end of the exhaust pipe, the installation stability is ensured by internally pressing tightly the exhaust pipe and clamping the outer end surface of the exhaust pipe, the exhaust flow is utilized for continuously scraping off the accumulated carbon on the filter plate, the filtering effect is ensured, the phenomenon that blockage is caused, so that exhaust emission is influenced is avoided, and meanwhile, the installation and disassembly of the device are very convenient, so that the installation cost and maintenance cost are reduced.

Owner:嵊州塔木汽车尾气处理有限公司

Controllable releasing thrumbus filter and its making process

The present invention relates to one kind of controllable releasing thrombus filter and its making process. The thrombus filter capable of catching fallen thrombus and avoiding thrombosis is made with super elastic metal pipe with shape memory effect and through laser carving. The thrombus filter has combining part in the end for fitting the sender. Compared with available technology, the present invention has the advantages of being recoverable, capacity of being set inside blood vessel temporarily or permanently, and no position shift caused by impact during being set.

Owner:LIFETECH SCIENTIFIC (SHENZHEN) CO LTD

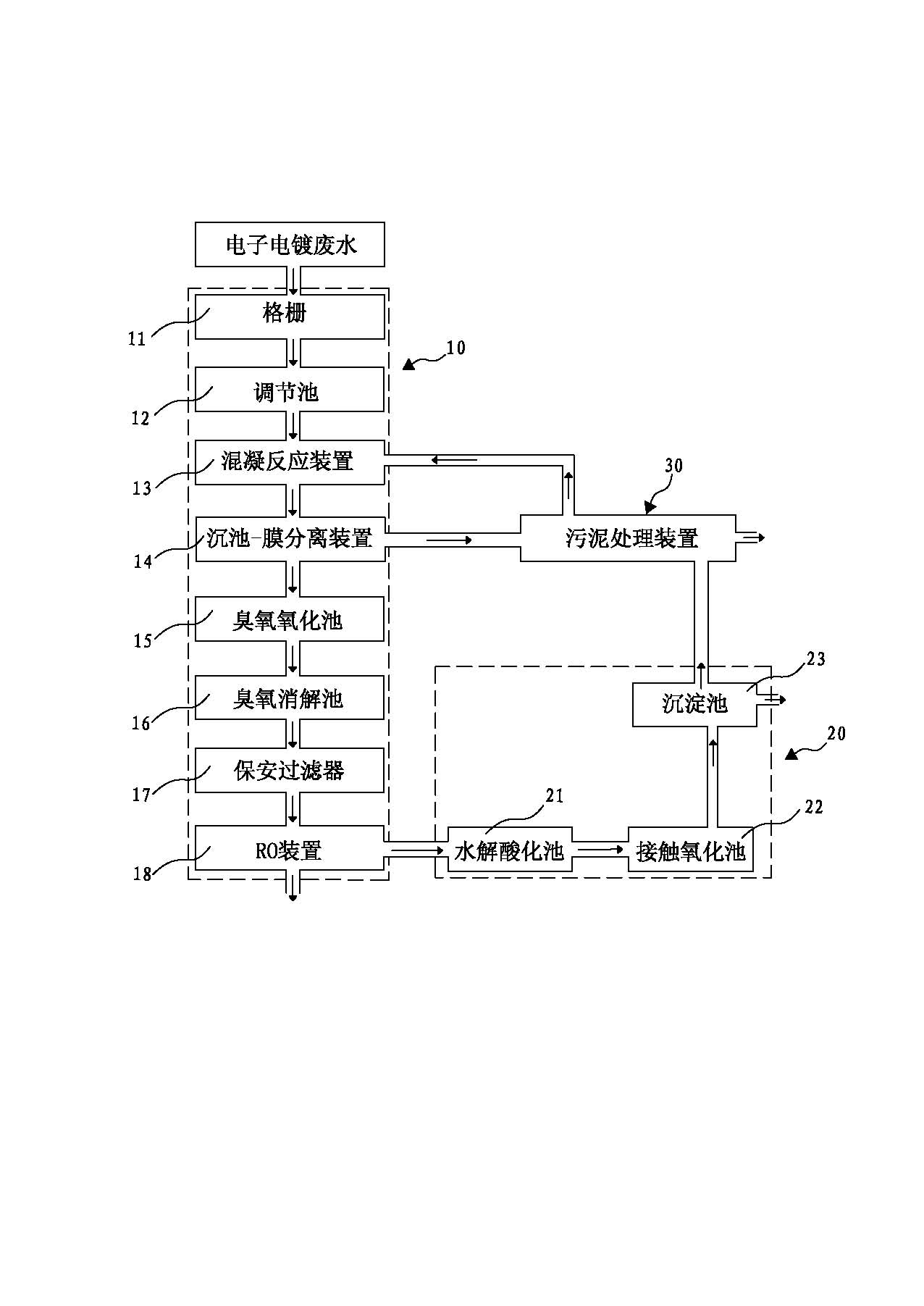

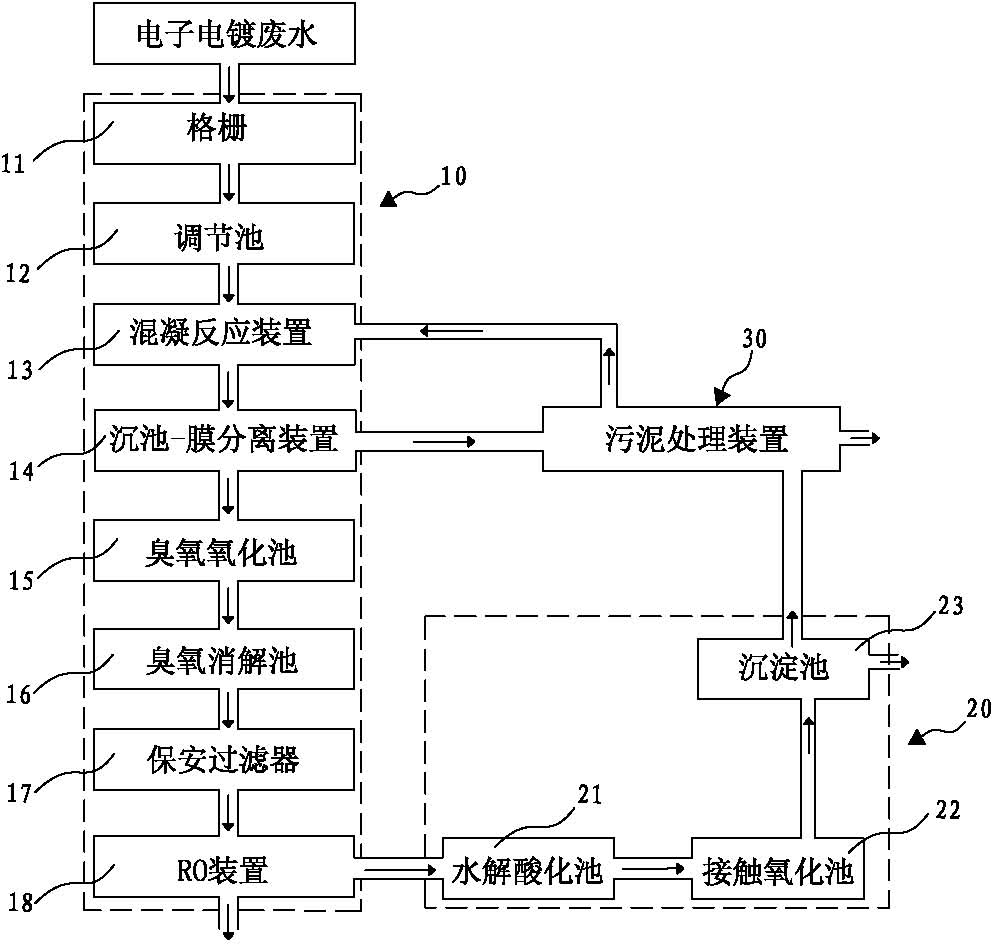

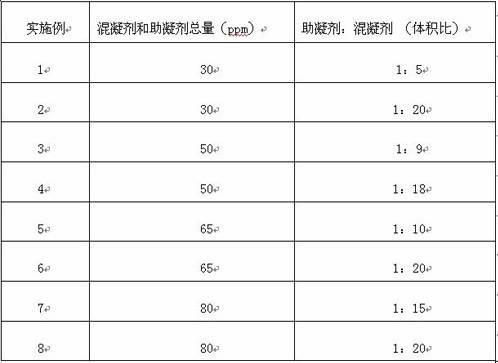

System and method for treatment and recovery of electronic electroplating wastewater

ActiveCN102674626ALong storage timeShort activation timeWaste water treatment from metallurgical processMultistage water/sewage treatmentCondensed waterEngineering

The invention discloses a system and a method for treatment and recovery of electronic electroplating wastewater. The system comprises a wastewater recovery and treatment unit and an RO (reverse osmosis) concentrate treatment unit. A grille, an adjusting tank, a coagulation reaction device, a settlement and membrane separation device, an ozone oxidation tank, an ozone digestion tank, a cartridge filter and an RO device are connected to the wastewater recovery and treatment unit sequentially. A hydrolytic acidification tank, a contact oxidation tank and a settling tank are connected to the RO concentrate treatment unit. The electronic electroplating wastewater is treated through the grille, the adjusting tank, the coagulation reaction device, the settlement and membrane separation device, the ozone oxidation tank, the ozone digestion device, the cartridge filter and the RO device. RO fresh water is then reused on an electronic electroplating line. RO condensed water is effectively treated through the hydrolytic acidification tank and the contact oxidation tank and stably meets the primary specification GB8978-1996 of integrated wastewater discharge standard, and discharge requirements DB4426-2001 of discharge limits of water pollutants of Guangdong.

Owner:DONGGUAN KEDA ENVIRONMENTAL PROTECTION ENG

Direct quantitative control method for indoor air purifier filter screen replacement

InactiveCN105920927AEasy to useAchieving Quantitative ControlDispersed particle filtrationRoom air cleanersParticulates

The invention relates to the field of small household appliances, in particular to a direct quantitative control method for indoor air purifier filter screen replacement. According to the direct quantitative control method for indoor air purifier filter screen replacement, a mass threshold value is set, and then controlling is conducted through the following steps that after a filtering assembly is installed, the initial weight of the filtering assembly is obtained through a weight sensor, when a filter starts working, a controller obtains the current weight of the filtering assembly by reading the weight sensor in real time, the filtrate weight is obtained by subtracting the initial weight from the current weight, and when the filtrate weight exceeds the mass threshold value, the controller controls an alarming mechanism to give an alarm. According to the method, the weight of particulate matter attached to a filter screen is obtained by monitoring the weight added value of the filtering assembly in real time, when the weight of the attached particulate matter exceeds the mass threshold value, the filter screen needs to be replaced, therefore, quantitative control over filter screen replacement is achieved, the replacement cycle of the filter screen reaches the maximum value while the filtering efficiency is guaranteed, and the method is more beneficial for being used by an ordinary family.

Owner:薛景森

Household domestic wastewater filtering and treatment device

InactiveCN107746125AEasy to cleanReduce pollutionFatty/oily/floating substances removal devicesSpecific water treatment objectivesWastewaterSewage

The invention discloses a household domestic wastewater filtering and treatment device, which comprises a filtering cavity, a sewer pipe, an interception cavity, a filtering screen plate and a separation hopper, wherein an upper water inlet pipe and the sewer pipe are vertically and symmetrically arranged on the filtering cavity; a threaded cover is arranged at the front side of the filtering cover; a rotating shaft is arranged in the middle part of the threaded cover; a filtering screen fan blade is arranged on the outer periphery of the rotating shaft; the interception cavity is formed in the inner wall of the sewer pipe; a blind hole, a sliding rod and the filtering screen plate are formed in and arranged at the lower end of the interception cavity; support rods are arranged at the twosides of the sewer pipe; a ball cavity, a metal ball, a support pad plate and a telescopic connecting rod are arranged at the lower end of each support rod; the separation hopper and a water dischargepipe are arranged between the support rods. The duplex impurity filtering can be realized; in addition, sewage can be subjected to oil water separation in the separation hopper; oil and water can berespectively collected; the filtering screen fan blade and the filtering screen plate both can be taken out to be cleaned; the support rods arranged at the two sides of the sewer pipe stably support the device through the support pad plates and the telescopic connecting rod at the tail ends.

Owner:深圳市娅安科技有限公司

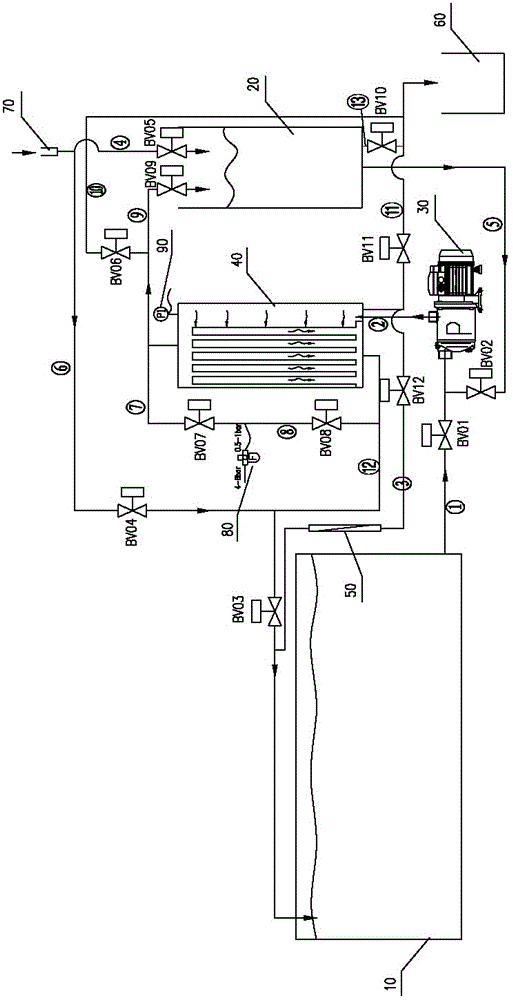

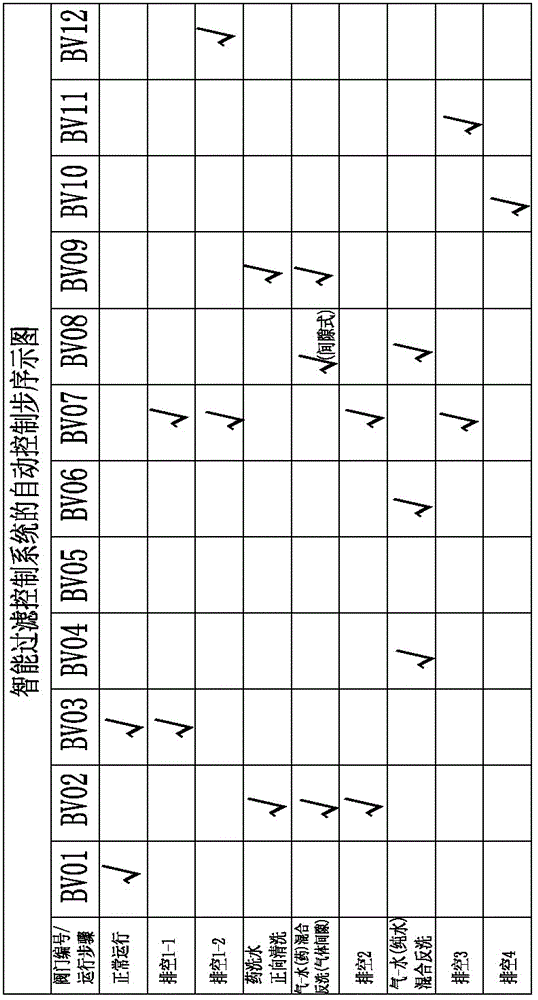

Intelligent filter control method

ActiveCN104548747AEasy to cleanReduce replacement costsCellsFiltration separationProduct gasFilter element

The invention discloses an intelligent filter control method. The method comprises the following steps: cyclically filtering electroplating liquid during normal operation, performing real-time monitoring and starting cleaning according to requirements, performing first-time emptying treatment before cleaning is needed, and returning filtrate remaining in a filter into an electroplating liquid medicine tank through a filtrate outlet of the filter; cyclically and forwardly cleaning the filter by using medicine cleaning water; performing backward gas-water mixed washing on the filter, and mixing gas and water to form cleaning foam; stopping backward gas-water mixed washing, performing second-time emptying treatment, returning the medicine cleaning water remaining in the filter into a cleaning tank from a to-be-filtered liquid inlet of the filter, and then emptying the cleaning tank to recycle the medicine cleaning water; mixing gas and clean water to backwardly washing the filter; after cleaning is completed, draining waste water in the filter from the to-be-filtered liquid inlet of the filter to a waste water drain outlet. The filter control is precise, the filter is cleaned in real time, a filter element does not need to be replaced, the cost is reduced, and the production cost of an enterprise is reduced by recycling the electroplating liquid.

Owner:GUANGDONG VICDI TECH

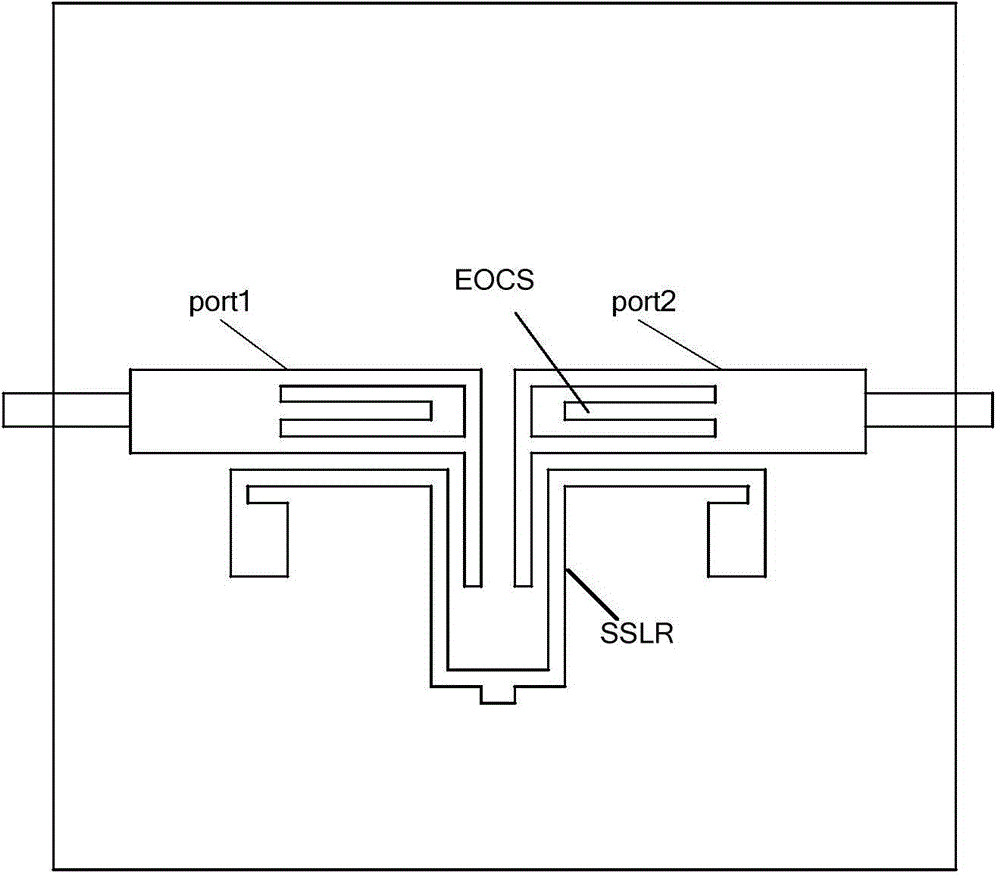

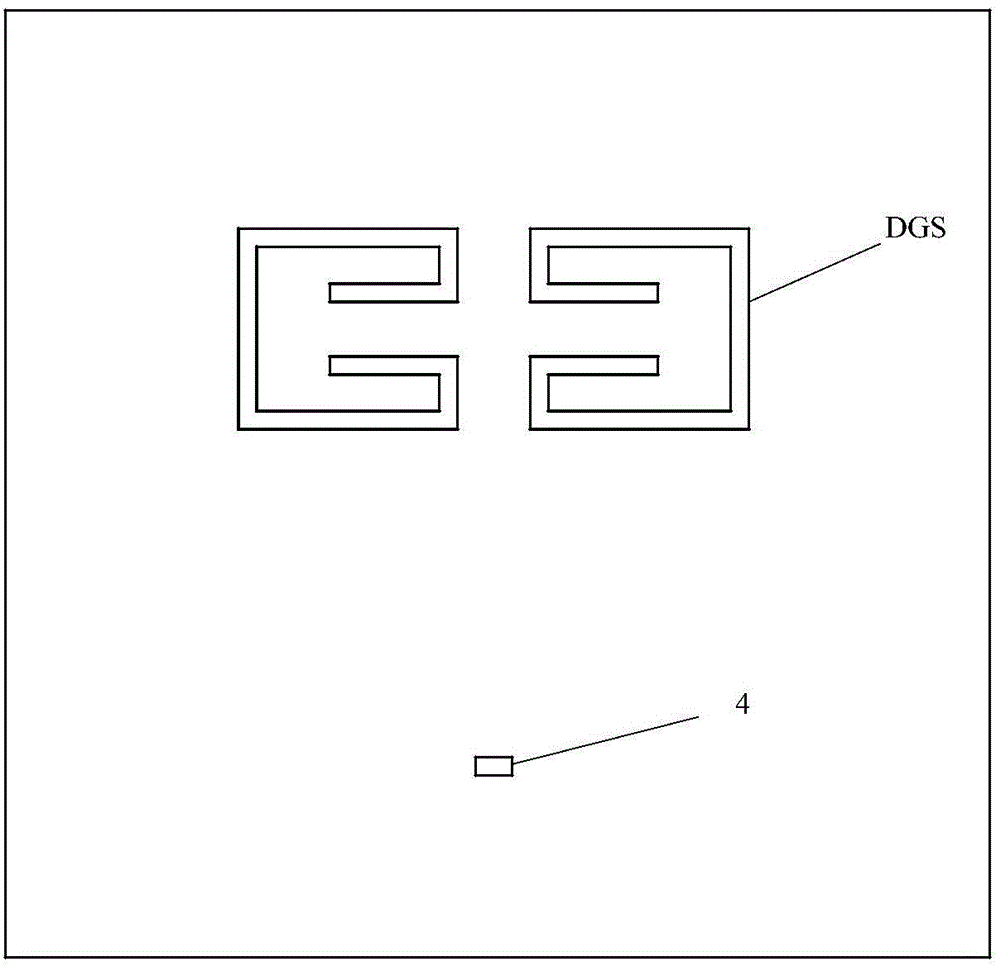

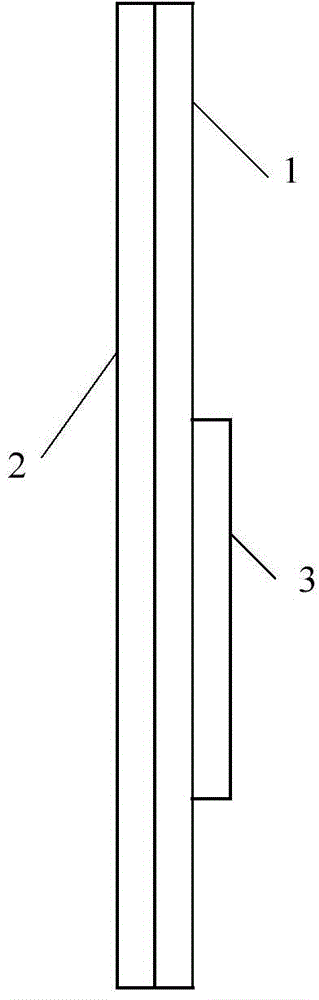

Three-pass band filter

A three-pass band filter comprises a non-conductive substrate, an input feeder line and an output feeder line, a defect ground type resonant structure and a short circuit stub type resonant structure are arranged on the two surfaces of the substrate respectively, and the input feeder line and the output feeder line are arranged on the surface of the substrate having the short circuit stub type resonant structure and are located between the defect ground type resonant structure and the short circuit stub type resonant structure, wherein the input feeder line, the short circuit stub type resonant structure and the output feeder line are coupled to form a first radio frequency access possessing a first pass band and a third pass band, and the input feeder line, the defect ground type resonant structure and the output feeder line are coupled to form a second radio frequency access possessing a second pass band. According to the present invention, the defect ground type resonant structure and the back laminated short circuit stub type resonant structure form the three pass bands of the three-pass band filter, so that the three-pass band filter is simple in structure, guarantees a filtering effect, and enables the reliability to be improved.

Owner:QINGDAO HAIER ELECTRONICS +1

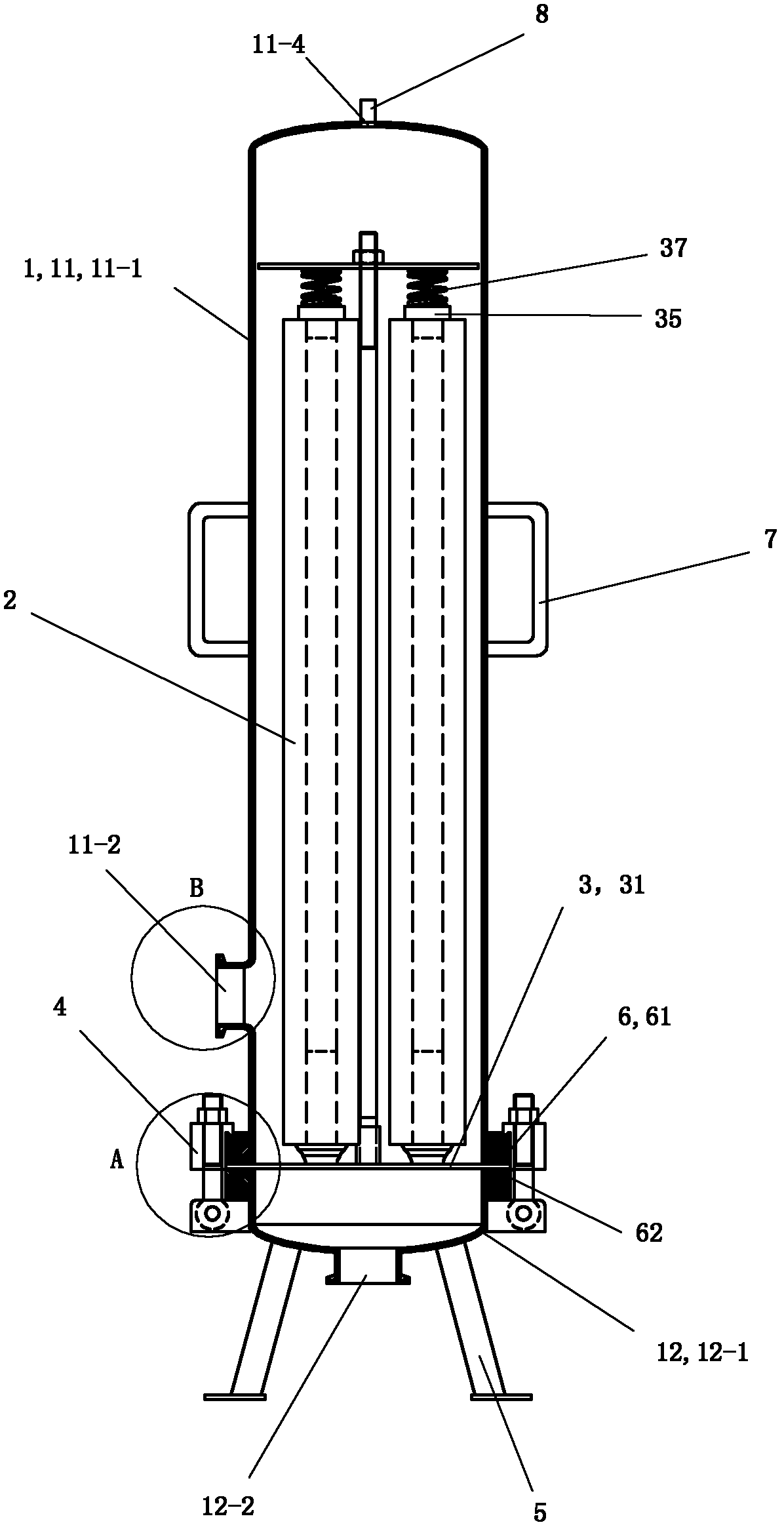

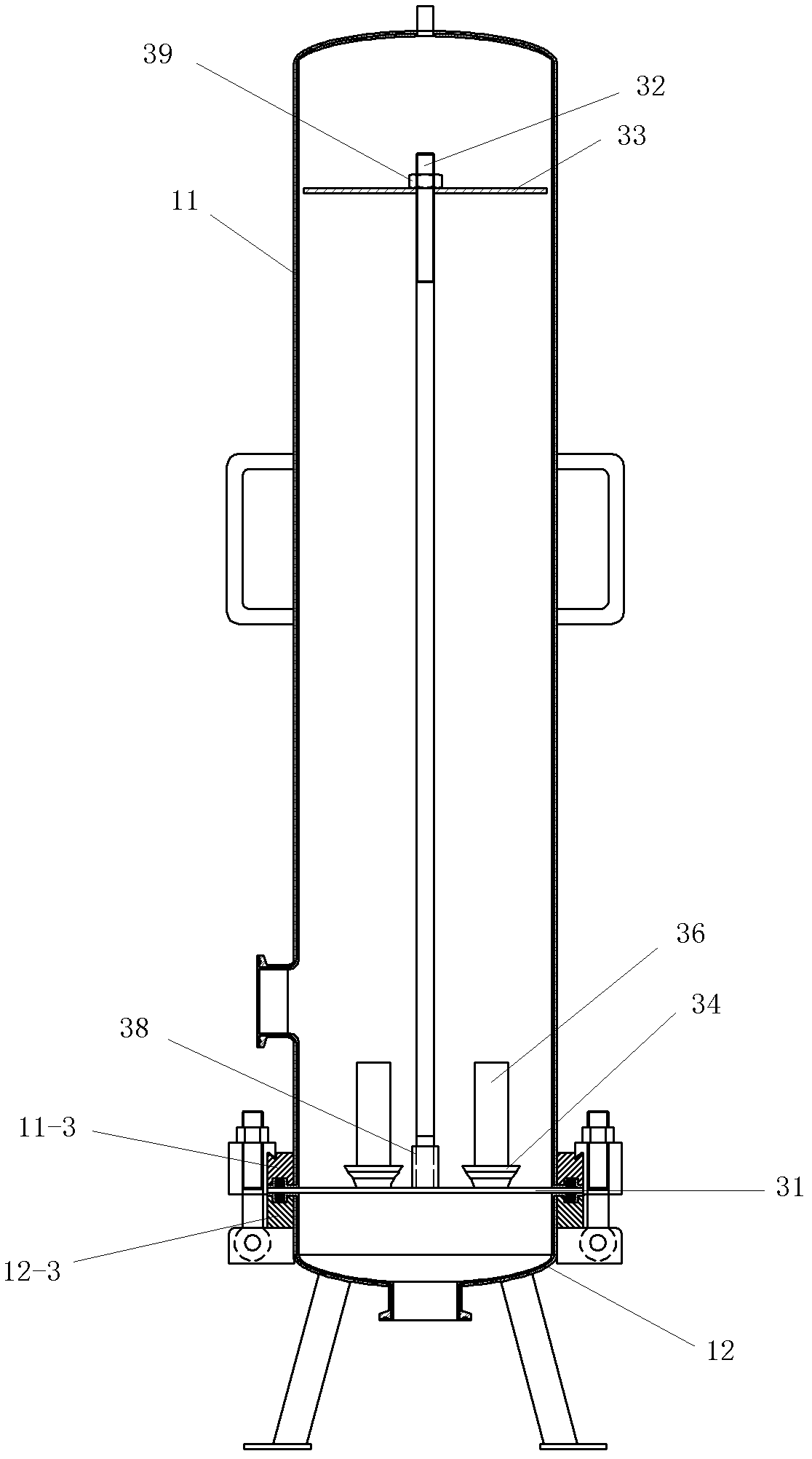

Precise filter

InactiveCN102430275ASimple structureEasy to installStationary filtering element filtersEngineeringMechanical engineering

The invention discloses a precise filter which comprises a cylinder, 2-8 filter elements, a filter element installing frame and connectors, wherein all the filter elements and the filter element installing frame are arranged in the cylinder, the filter element installing frame is fixedly connected with the cylinder, and all the filter elements are fixedly connected with the filter element installing frame. The precise filter is characterized in that the cylinder comprises a main cylinder at the upper part of the cylinder and a lower cylinder at the lower part of the cylinder, the filter element installing frame comprises a separator, a pull rod, a pressing plate, filter element lower seats, a filter element pressing seat, a compression spring and a gland nut, the end port of each filter element lower seat is respectively welded to a corresponding through hole of the separator hermetically so that the cavity of the filter element lower seat is communicated with a space at the lower side of the separator, each corresponding filter element, the filter element pressing seat and the compression spring are arranged between the filter element lower seats and the pressing plate in sequence from bottom to top, the edge part of the separator of the filter element installing frame is clamped between the lower end face of the main cylinder and the upper end face of the lower cylinder, and the separator of the filter element installing frame, the main cylinder and the lower cylinder are detachably, fixedly and hermetically connected into a whole through the connectors.

Owner:CHANGZHOU CONNECT MACHINERY EQUIP

Preparation method of polyacrylonitrile-based precursor

ActiveCN105671668AGuaranteed filtering effectNot easy to blockMonocomponent synthetic polymer artificial filamentWet spinning methodsSolventItaconic acid

The present invention relates to a preparation method of a polyacrylonitrile-based precursor, and mainly solves the problems that in the prior art bubbles in a material sprayed out by a filter cannot be completely eliminated, spinnability is poor, wire broken rate is high, and a carbon fiber precursor obtained by spinning is low in strength and unstable in performance. The preparation method well solves the problems, and the preparation method includes the following steps: 1) solvent dimethyl sulfoxide, first monomer acrylonitrile, a second monomer itaconic acid and initiator azodiisobutyronitrile are polymerized to obtain a spinning stock solution, and a high performance polyacrylonitrile copolymer spinning stock solution is obtained by filtering after demonomerisation and defoaming of the spinning stock solution; nascent fiber is obtained by jet extrusion and consolidation forming; and a high-performance polyacrylonitrile carbon fiber precursor is obtained by drawing, water washing, oiling, compacting by drying, steam stretching, heat-setting and collection of the nascent fiber; and the method can be used for the industrial production of the carbon fiber precursor.

Owner:CHINA PETROLEUM & CHEM CORP +1

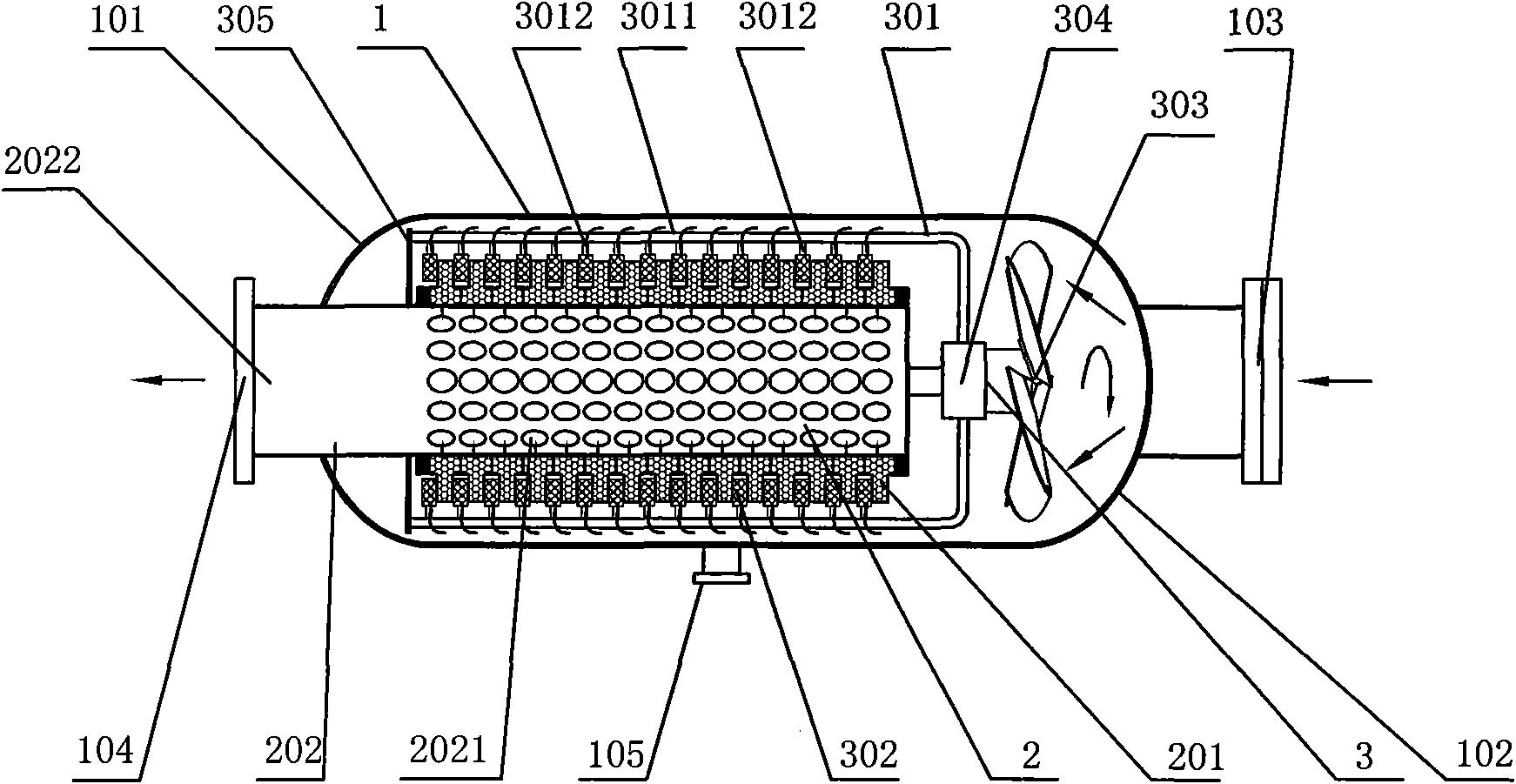

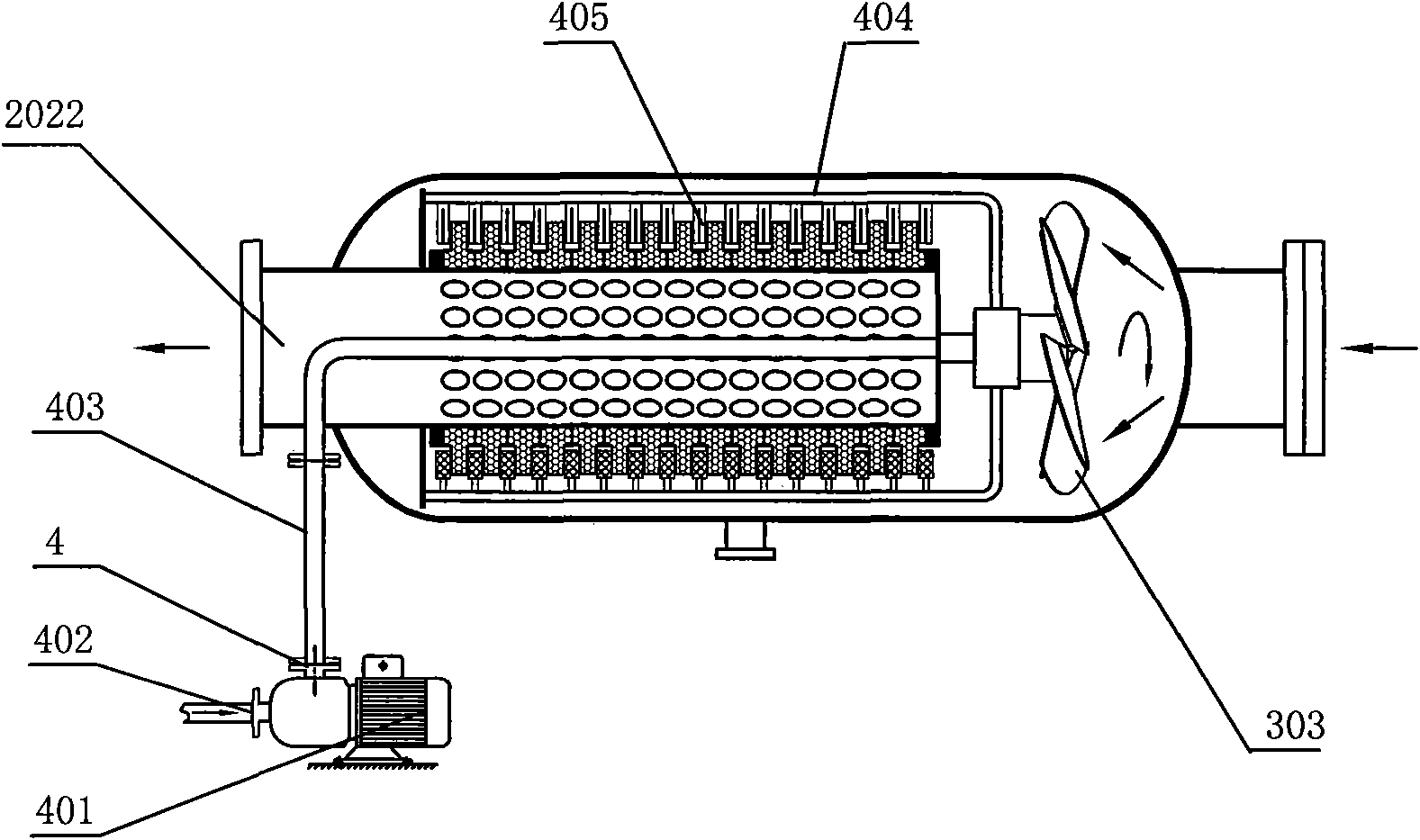

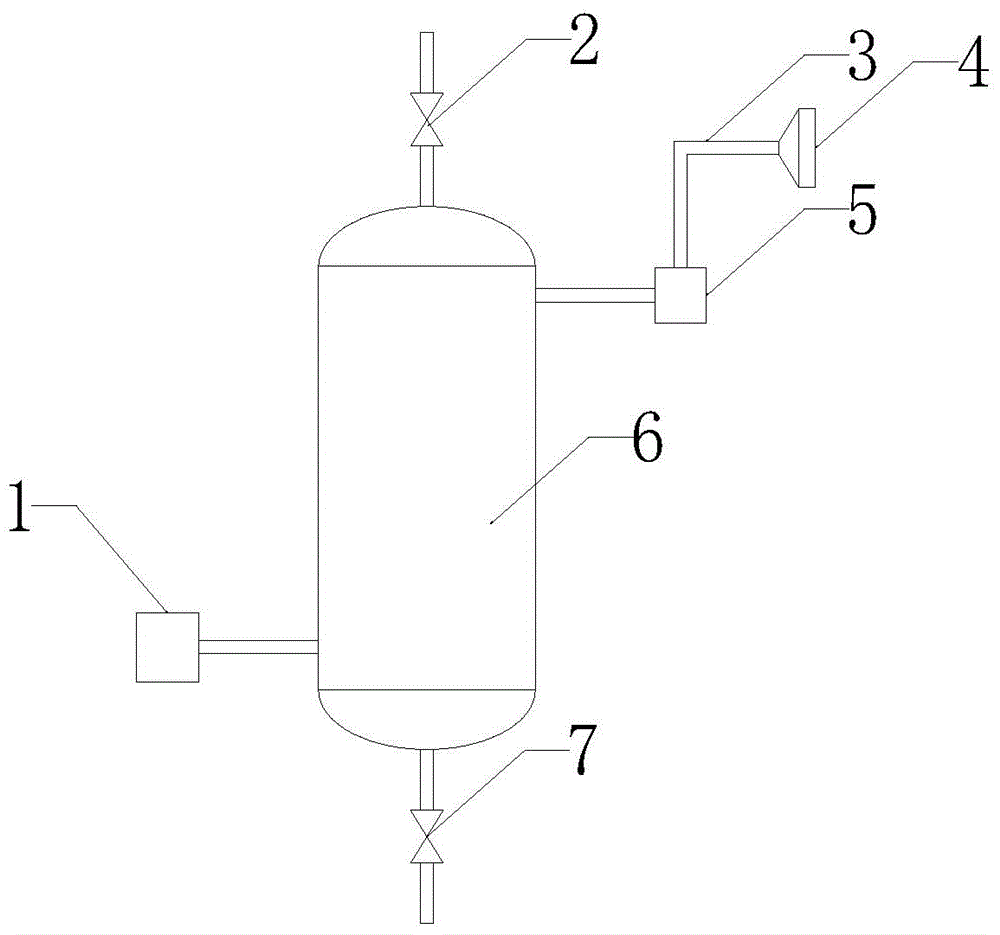

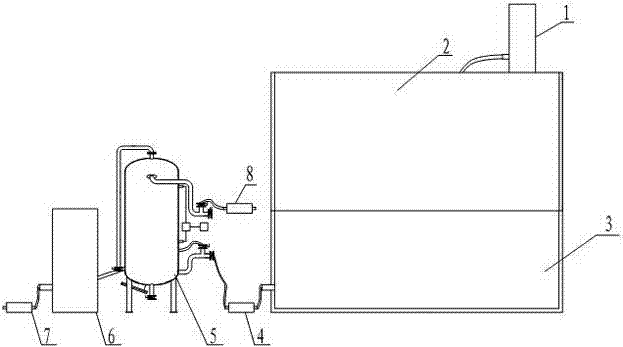

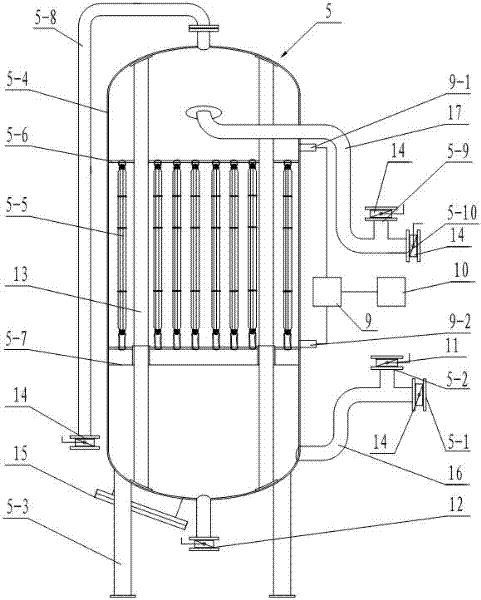

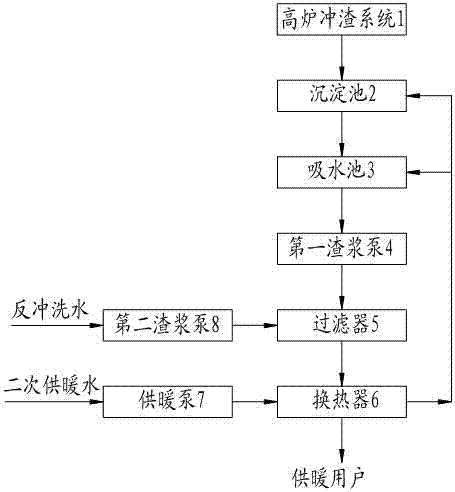

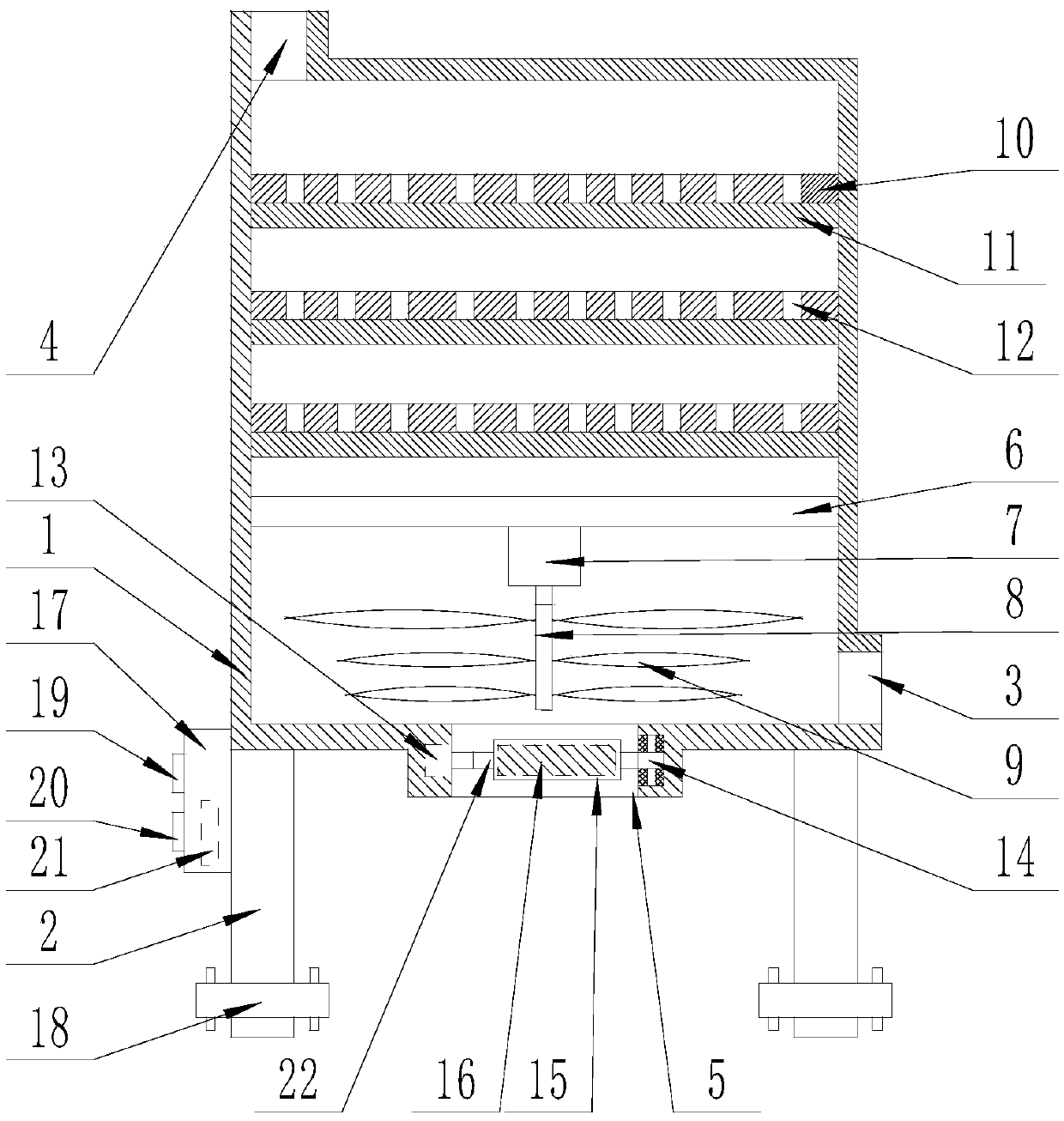

Heating system by utilization of waste heat of blast furnace slag flushing water and method thereof

InactiveCN102517411ARestore filter capacityGuaranteed filtering effectDischarge devicesProcess efficiency improvementSlagHeating system

The invention provides a heating system by the utilization of waste heat of blast furnace slag flushing water and a method thereof, so as to effectively recover waste heat of blast furnace slag flushing water, supply heating to users and achieve the purse of energy saving and emission reduction. The heating system by the utilization of waste heat of blast furnace slag flushing water contains a blast furnace slag flushing system, a sedimentation basin, a water suction pool, a first slag slurry pump, a filter, a heat exchanger and a heating pump. A slag flushing water outlet of the blast furnace slag flushing system communicates with the sedimentation basin, which communicates with the water suction pool. A water inlet of the first slag slurry pump communicates with the water suction pool. The water outlet communicates with a slag flushing water inlet of the filter. A slag flushing water outlet of the filter communicates with a first water inlet of the heat exchanger. A secondary heating water outlet of the heating pump communicates with a secondary water inlet of the heat exchanger. According to the invention, waste heat of blast furnace slag flushing water is fully utilized for heating. Therefore, investment cost is low and recovery period is short. In addition, in comparison with present bunker coal heating, the heating system provided by the invention has advantages of no discharge of gases such as SO2, NOX, CO2 and the like, energy saving and environmental protection.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Purifying separator

InactiveCN105498422AGuaranteed filtering effectReduce maintenance workloadCombination devicesGaseous fuelsEngineeringMultiple layer

The invention discloses a purifying separator. The purifying separator comprises a rectangular box, stand columns are arranged at the four corners of the bottom of the rectangular box, an air inlet is formed in the outer side surface of the lower end of the rectangular box, an air outlet is formed in the upper surface of the rectangular box, and a residue discharge port is formed in the lower surface of the rectangular box; a beam is arranged in the rectangular box, a motor is fixedly installed on the beam, a vertical rotating shaft is fixedly connected with a rotating end of the motor and fixedly sleeved with multiple layers of blades, multiple partition plates are arranged on the portion, located at the upper end of the beam, in the rectangular box, an active carbon layer is arranged on the lower surface of each partition plate, and multiple through holes are uniformly distributed in each partition plate; a tiny metal sorting and collecting mechanism is arranged in the residue discharge port, and a controller is arranged on the outer surface of the rectangular box. The purifying separator has the advantages of being simple in structure and high in practicability.

Owner:广州市白云华申空压机厂

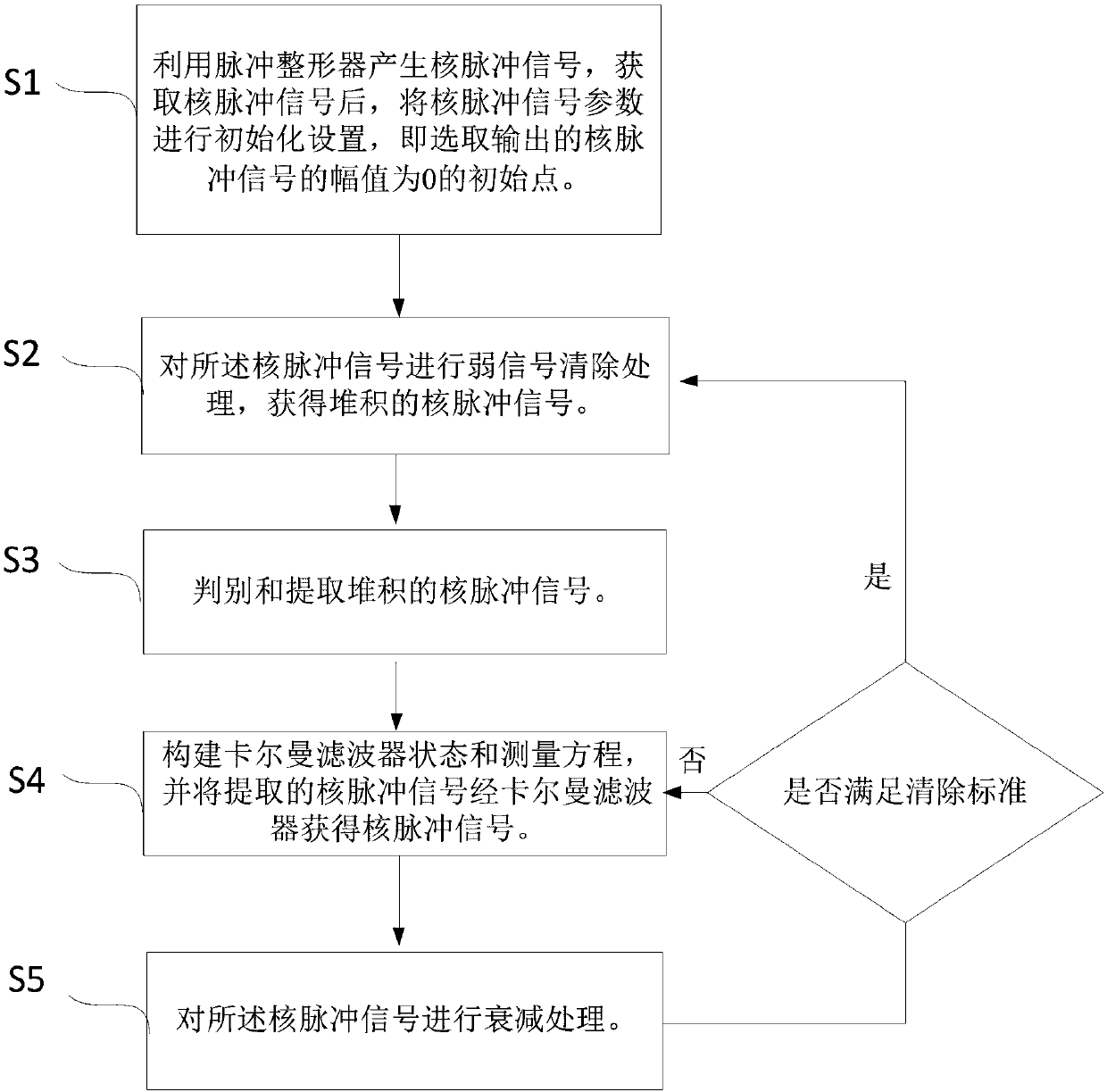

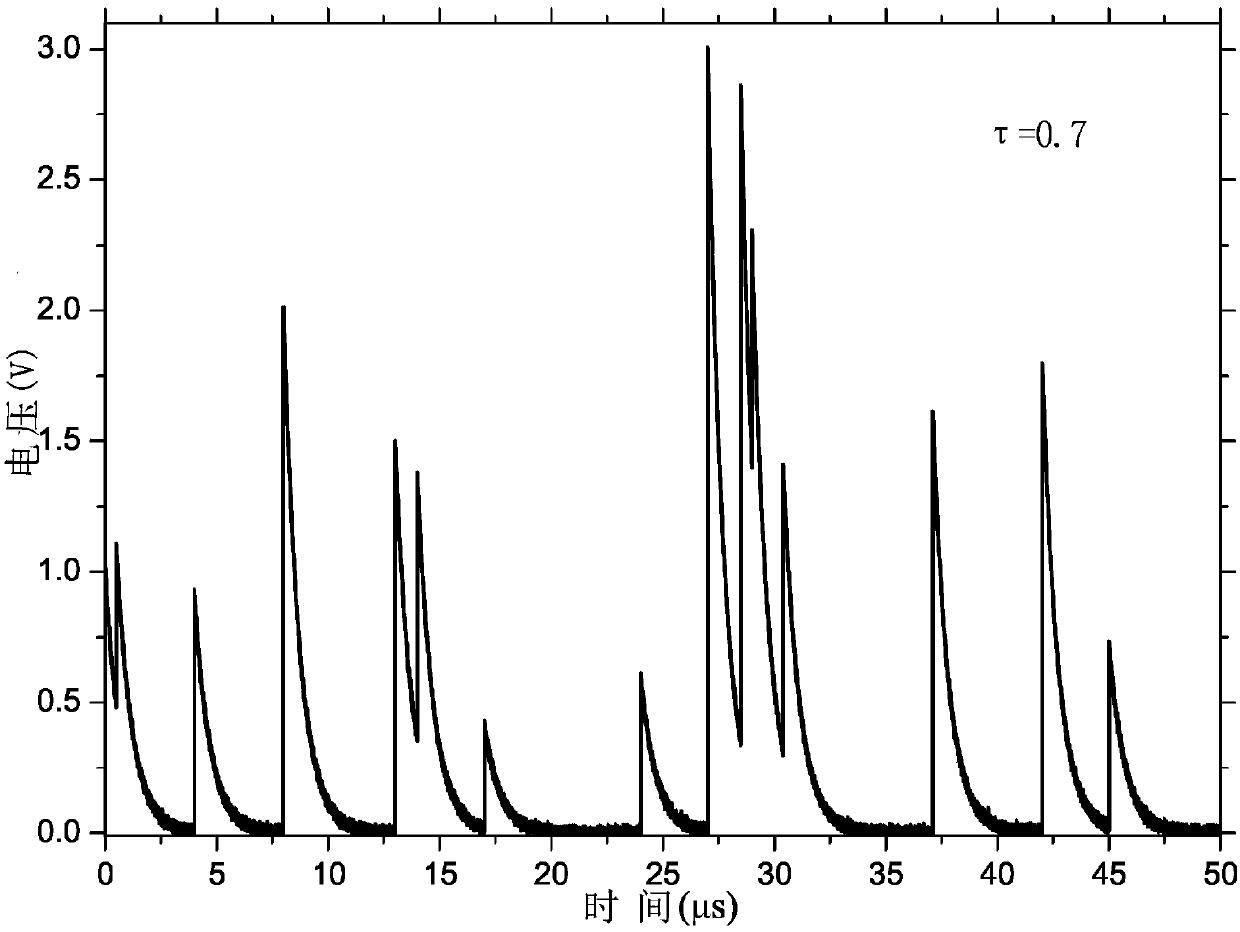

Kalman filter channel-based pulse stacking correction method

ActiveCN107589441ASave computing timeEnhanced inhibitory effectX-ray spectral distribution measurementDigital signal processingNuclear radiation

The present invention discloses a Kalman filter channel-based pulse stacking correction method which mainly solves the problems in the prior art that the calculation is complex, an energy spectrum distorts, etc. The method comprises the following steps of utilizing a pulse shaper to generate a nuclear pulse signal Sn, obtaining the nuclear pulse signal Sn and then initializing the parameters of the nuclear pulse signal Sn, namely, selecting an initial point where the amplitude X0 of the outputted nuclear pulse signal Sn is 0; carrying out the weak signal removing processing on the nuclear pulse signal Sn, and obtaining the stacked nuclear pulse signals S1n; determining and extracting the stacked nuclear pulse signals S1n; constructing a Kalman filter state and measurement equation, and using a Kalman filter to process the extracted nuclear pulse signals S1n to obtain the nuclear pulse signals S2n; attenuating the nuclear pulse signals S2n, and determining whether to satisfy a removingstandard. By the above scheme, the Kalman filter channel-based pulse stacking correction method of the present invention achieves the purpose of separating the stacked pulse events, and has the very high practical value and popularization value in the nuclear radiation detection, the nuclear electronics technology and the digital signal processing fields.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

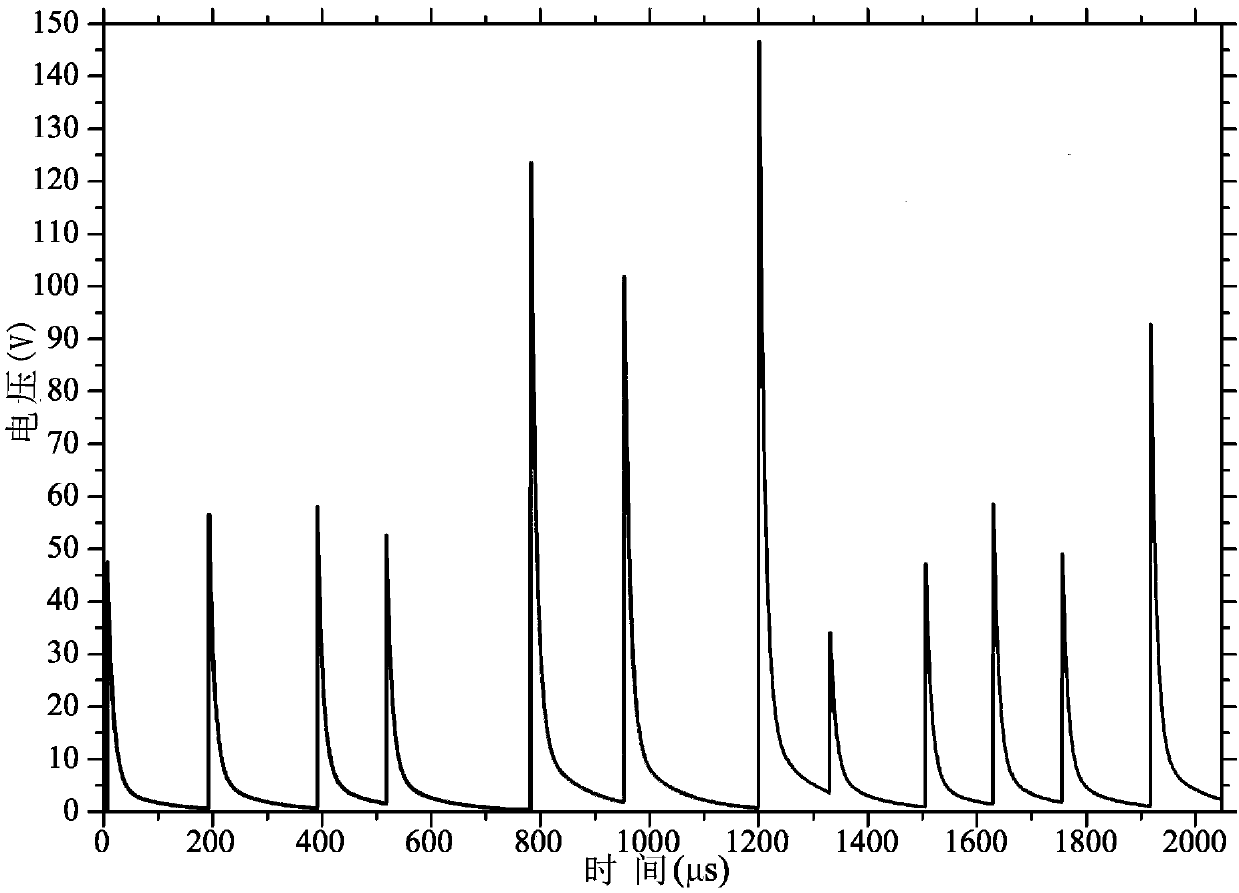

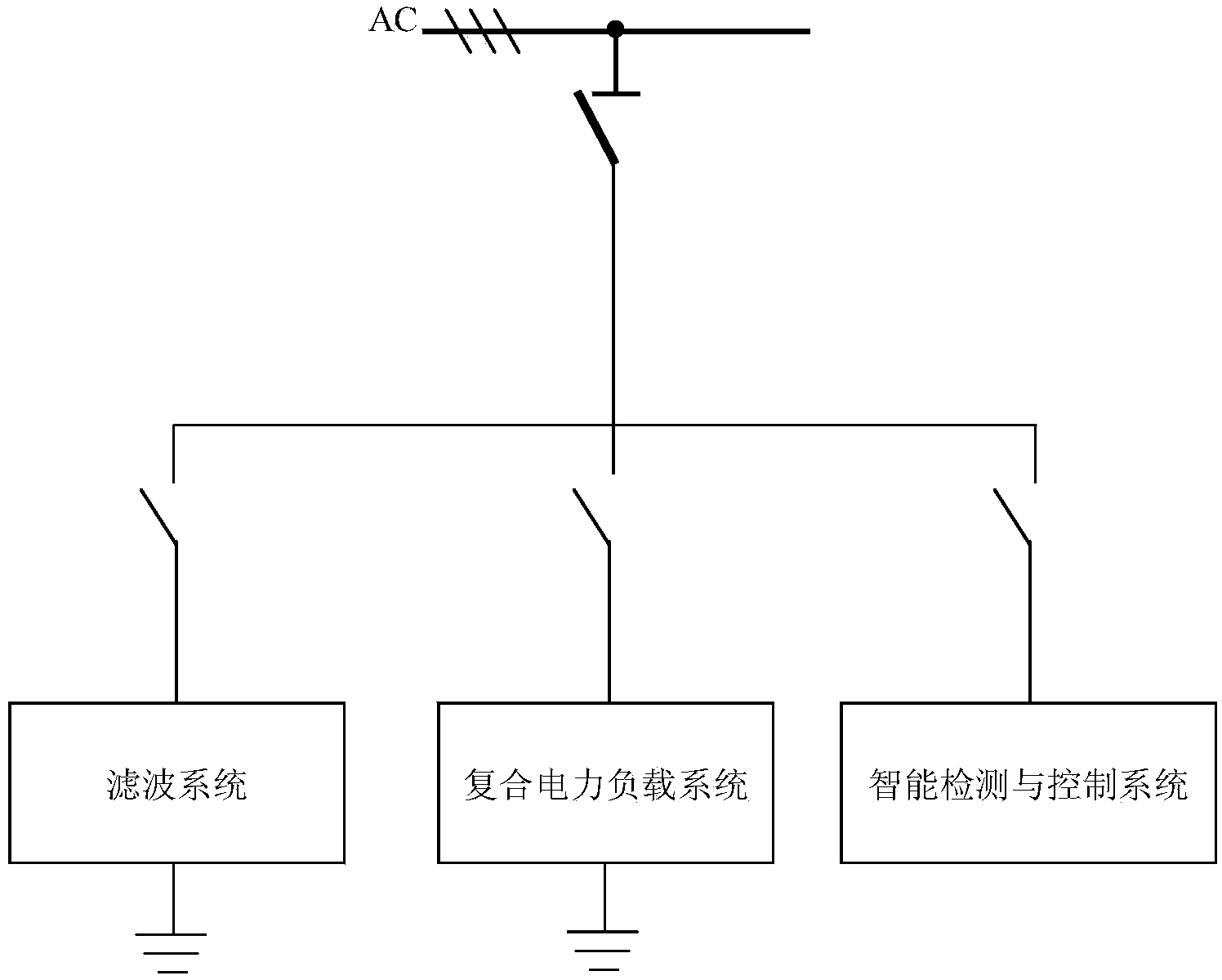

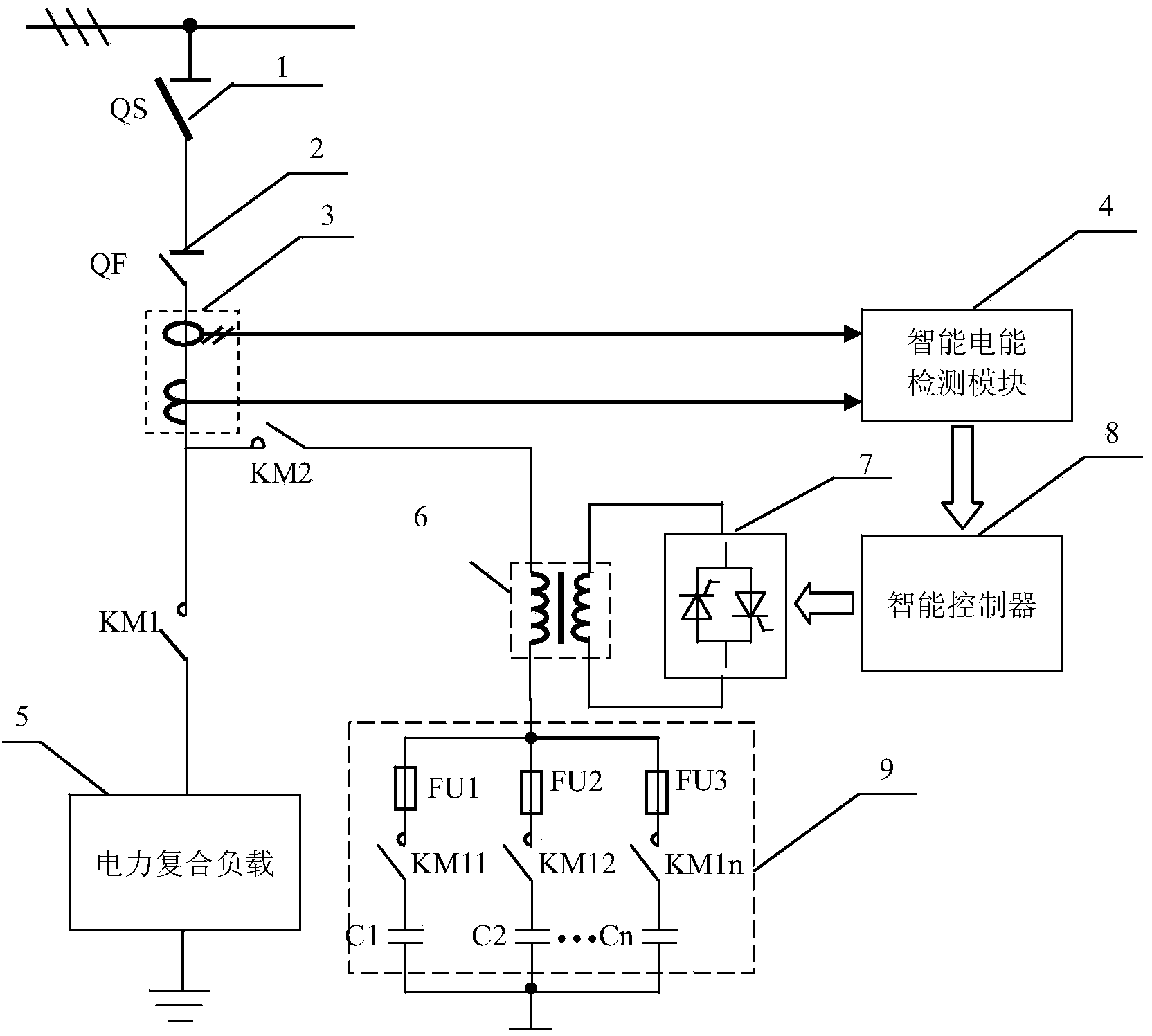

Coordination control method of composite electrical load dynamic harmonic filter

InactiveCN103825276AStay in resonanceThe resonant frequency point does not changeHarmonic reduction arrangementAc network to reduce harmonics/ripplesElectric power systemControl system

The invention provides a coordination control method of a composite electrical load dynamic harmonic filter. The composite electrical load dynamic harmonic filter is composed of a composite electrical load system, a filtering system and an intelligent detection and control system, and can realize a dynamic harmonic filtering function. The coordination control method is applied to carrying out harmonic filtering on electrical load; along with the operation of an electrical power system, when the harmonic quantity generated by composite electrical loading changes or the capacitor bank capacitive reactance in the harmonic filter changes, the condenser capacity in the filtering system and the inductance value of a variable electric reactor are controlled by an intelligent controller, and a capacitor bank is firstly switches to absorb the harmonic waves of a power grid and then tuned.

Owner:WUHAN UNIV OF TECH

Sea-island composite fiber filtering material and preparation method thereof

ActiveCN104208950AImprove performanceAvoid reductionLayered productsFiltration separationPolyesterMaterials science

The invention discloses a sea-island composite fiber filtering material and a preparation method thereof, relating to the technical field of non-woven filtering materials. The sea-island composite fiber filtering material is characterized in that sea-island composite fiber meshes are arranged on an upper layer and a lower layer of the sea-island composite fiber filtering material respectively; a common polyester fiber mesh and three layers of polyester basic cloth are arranged between the upper-layer sea-island composite fiber mesh and the lower-layer sea-island composite fiber mesh. By virtue of improvement on the structure of the sea-island composite fiber filtering material, due to optimization of sea-island components of ultrafine composite fibers, a mixed mesh laying ratio of common fibers and pre-puncturing, splitting and spunlace reinforcing technologies, the prepared filtering material is smooth in surface, and the filtering and interception efficiency is high.

Owner:CHINA TEXTILE ACAD JIANGNAN BRANCH

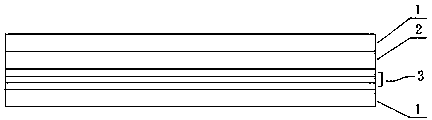

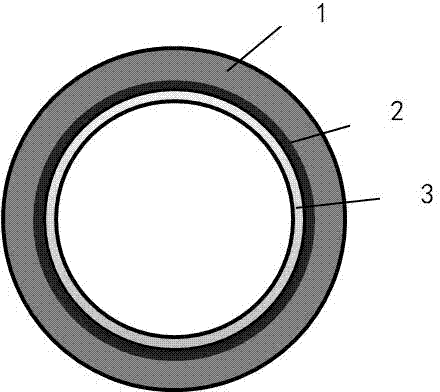

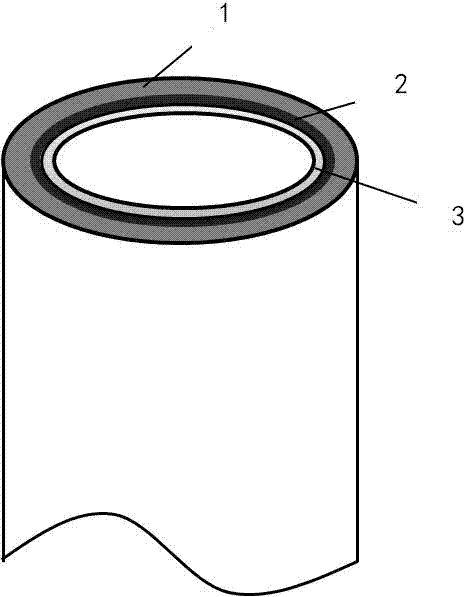

Asymmetrical stainless steel filter membrane tube and production method thereof

ActiveCN102962464AGuaranteed filtration accuracyImprove air permeabilityMetal layered productsComposite materialStainless steel fiber

The invention provides an asymmetrical stainless steel filter membrane tube and a production method thereof. The asymmetrical stainless steel filter membrane tube produced by the production method for the asymmetrical stainless steel filter membrane tube comprises a support layer and a control layer and is characterized by further comprising stainless steel fiber felts between the support layer and the control layer. According to the asymmetrical stainless steel filter membrane tube disclosed by the invention, the stainless steel fiber felts are additionally arranged among different powder layers, so that the filtering precision and the filtering performance of the filtering tube in performance are ensured; and meanwhile, the problems of cracking, peeling and the like of the stainless steel filter membrane with mutant fluctuant gradient in the sintering process are solved to the great degree.

Owner:江苏云才材料有限公司

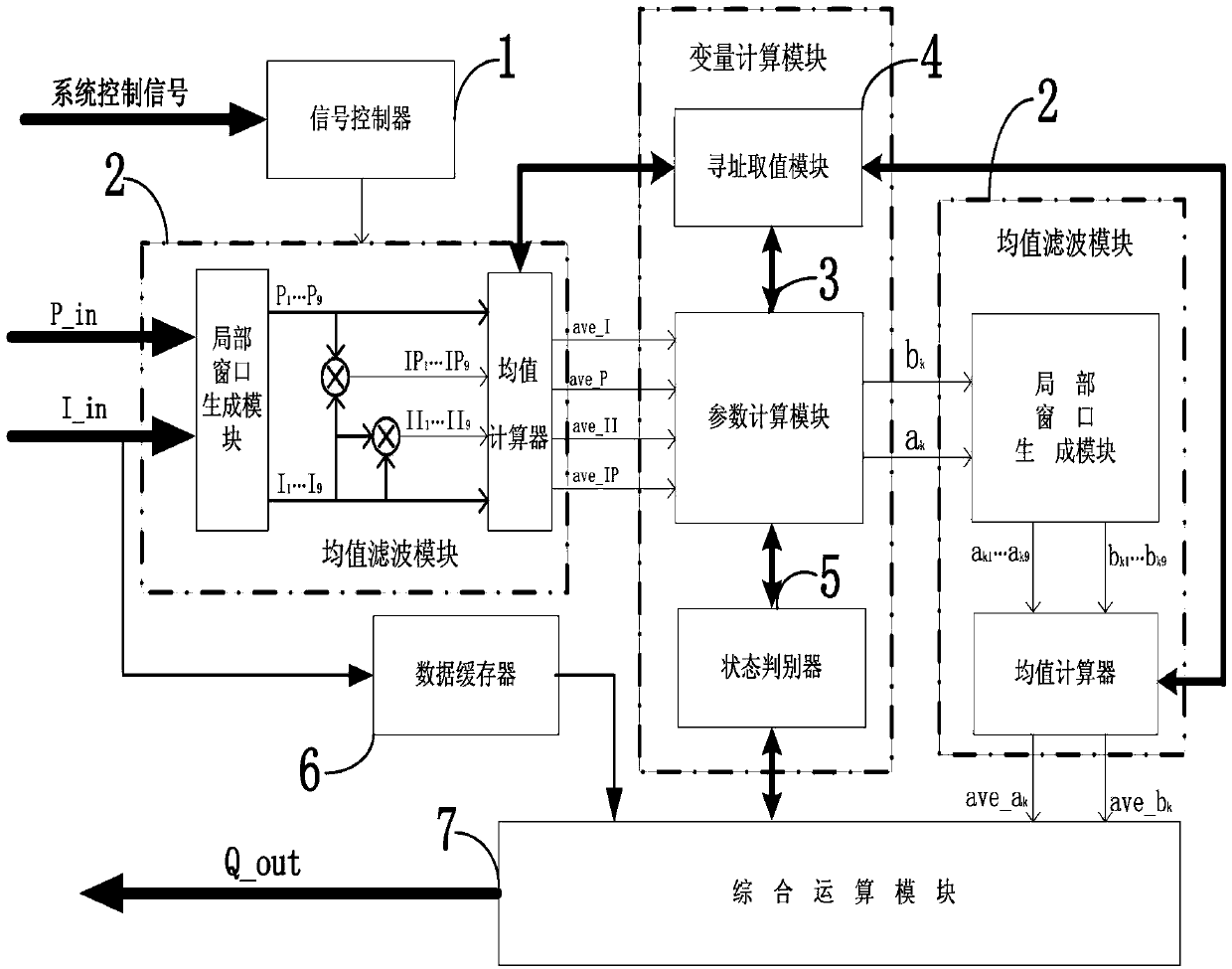

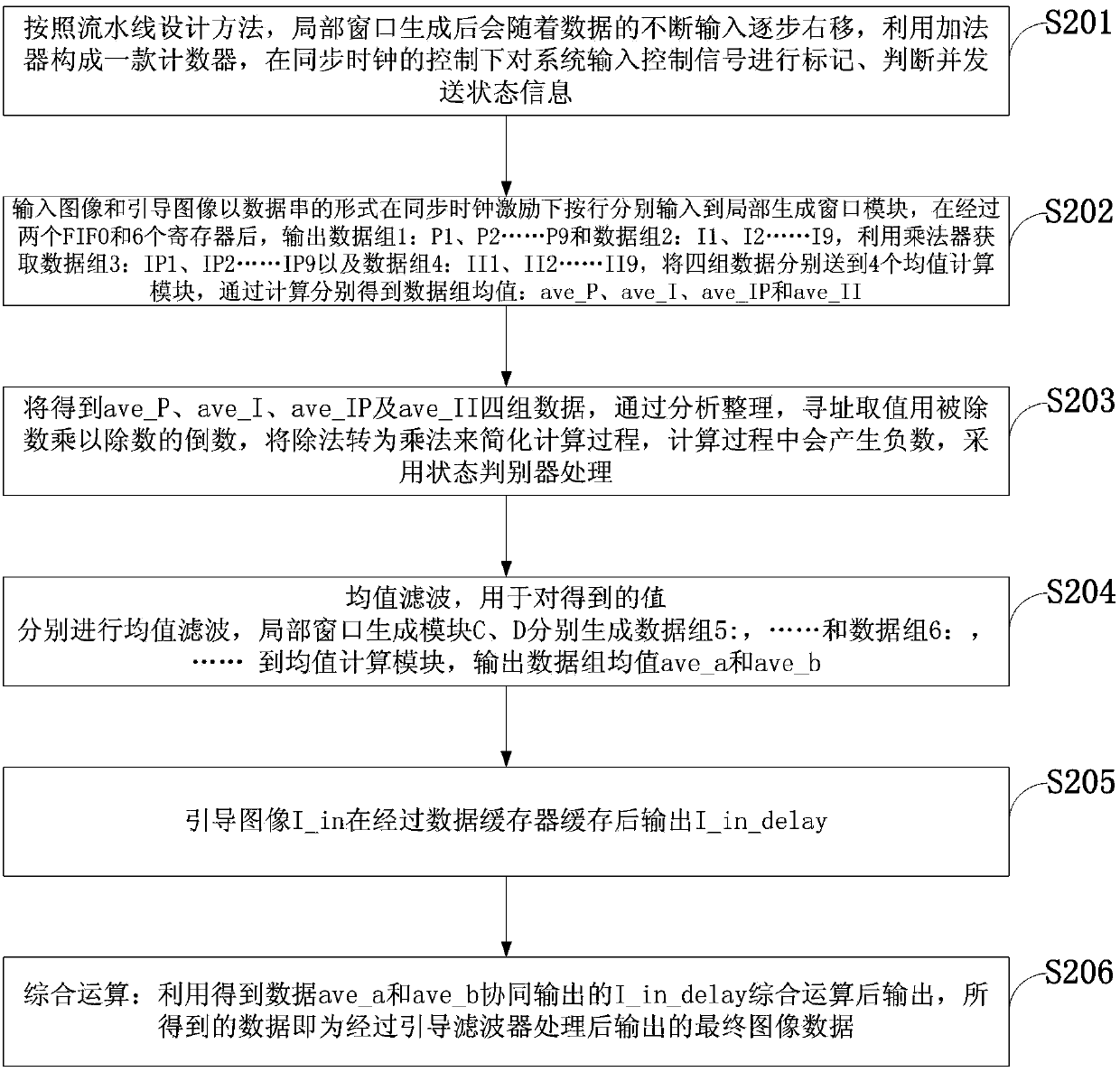

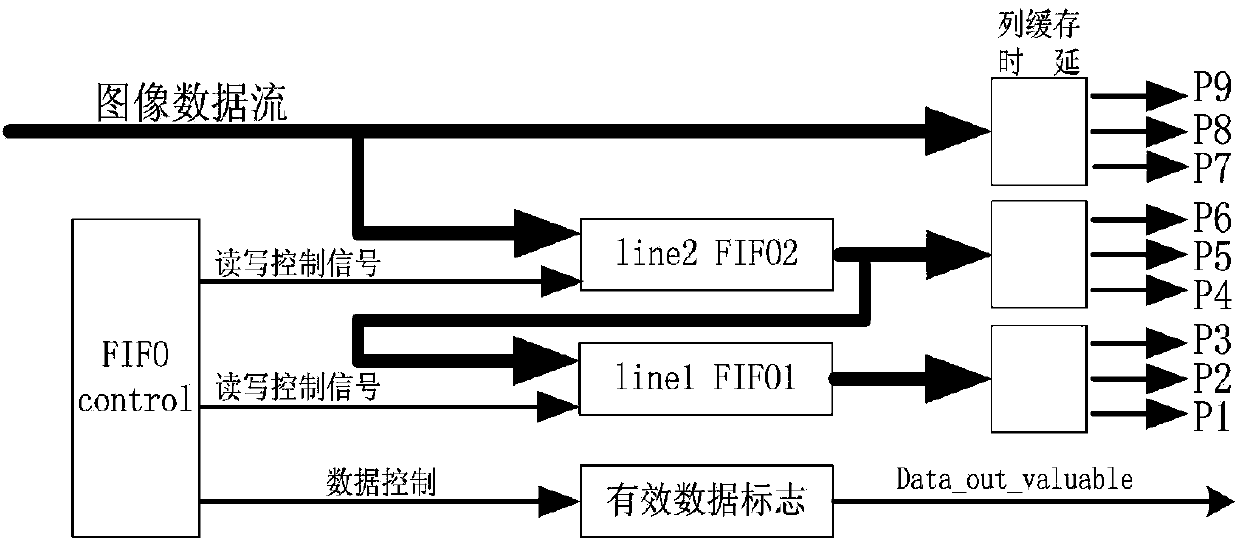

FPGA based guide filter and achieving method thereof

InactiveCN104063847AEasy to implementGuaranteed filtering effectImage enhancementAverage filterComputer module

The invention discloses an FPGA based guide filter and an achieving method thereof. The FPGA based guide filter comprises a signal controller, an average filtering module, a parameter calculating module, an addressing dereferencing module, a state judging device, a data cache and a comprehensive operation module. The achieving method of the FPGA based guide filter is combined with an FPGA chip, fully utilizes a characteristic that large-scale parallel operation of the FPGA is easy to achieve and improves the operation speed and reduces the complexity level of the guide filter hardware design while ensuring the filter effect. A filtering treatment parallel structure is given wholly, and the filtering speed is improved. The binary division operation is improved in an addressing dereferencing mode, hardware achievement is facilitated, and the system running time is shortened. A binary division algorithm is improved through the judging device, and the system reliability is improved.

Owner:CHANGCHUN UNIV OF SCI & TECH

Dust collection device with filtering net cleaning function

InactiveCN108126434AEvenly dispersedImprove filtering effectDispersed particle filtrationTransportation and packagingLeft directionEngineering

The invention discloses a dust collection device with a filtering net cleaning function. The dust collection device comprises a dust collection tank, wherein a first chute and a second chute are respectively formed in the inner side wall of the dust collection tank; the second chute and the first chute are respectively formed in the upper side and the lower side of an air inlet tube; the first chute and the second chute are respectively connected with a first drawer and a second drawer in match in a sliding manner; an opening is formed in the second drawer; a filtering net is fixedly connectedwith the opening; a fan is fixedly arranged at the top of the dust collection tank; an exhaust tube is connected with the air inlet end of the fan; the exhaust tube penetrates through the top wall ofthe dust collection tank; a plurality of rotating shafts are arranged at equal heights in the left direction and the right direction inside the dust collection tank; a plurality pieces of brush hairare fixedly connected with the rotating shafts; and the brush hair is propped against the bottom of the filtering net. The filtering net is convenient to replace or clean and is low in maintenance cost, and the filtering net can be cleaned through rotation of the brushes, so that impurities such as dust adhered to the filtering net can be swept off, the filtering net then can be recycled and reuse, and the cost can be reduced.

Owner:郭庆平

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com