Patents

Literature

96results about How to "Restore filter capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

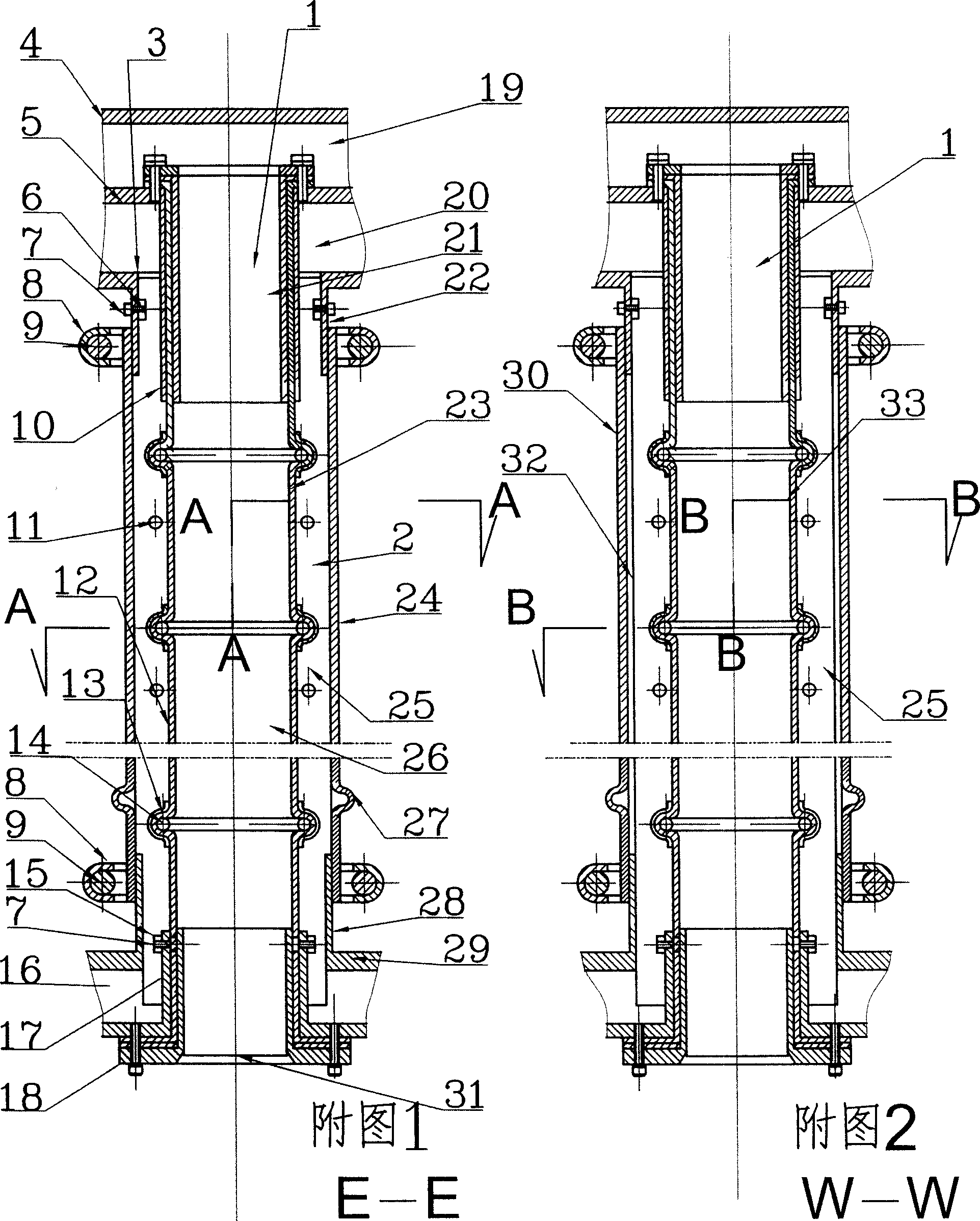

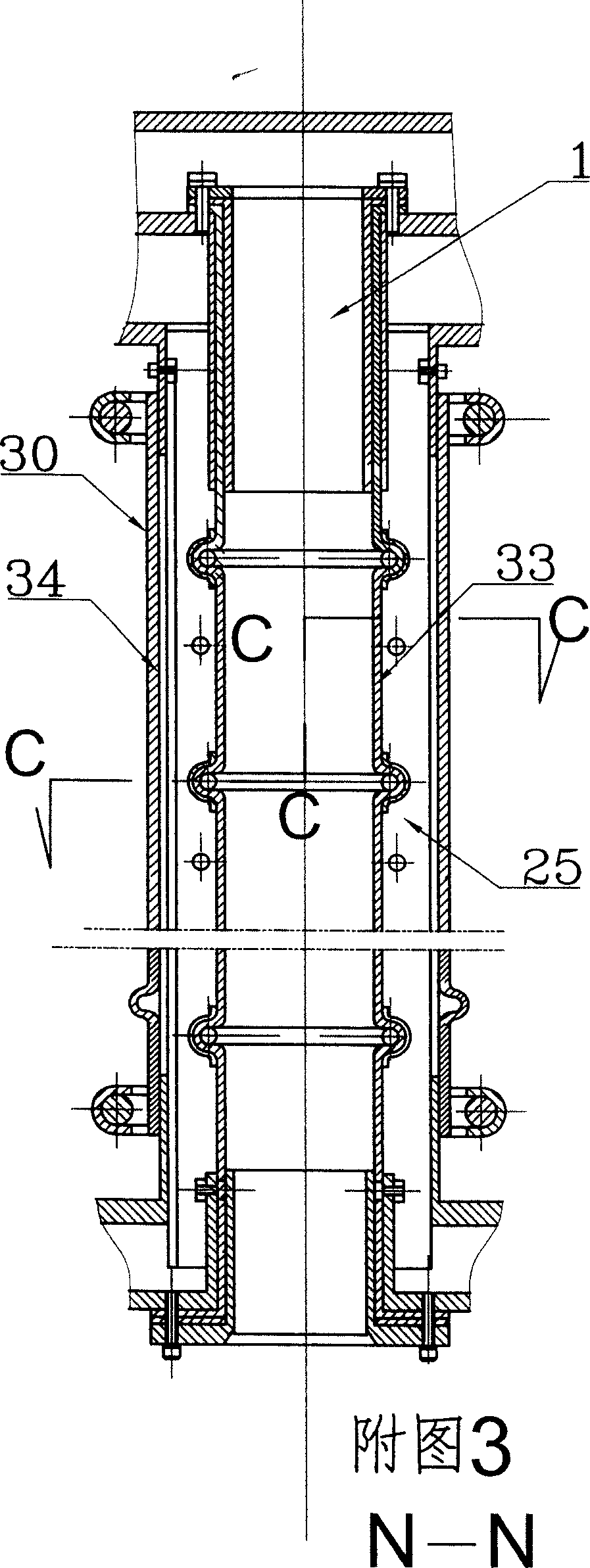

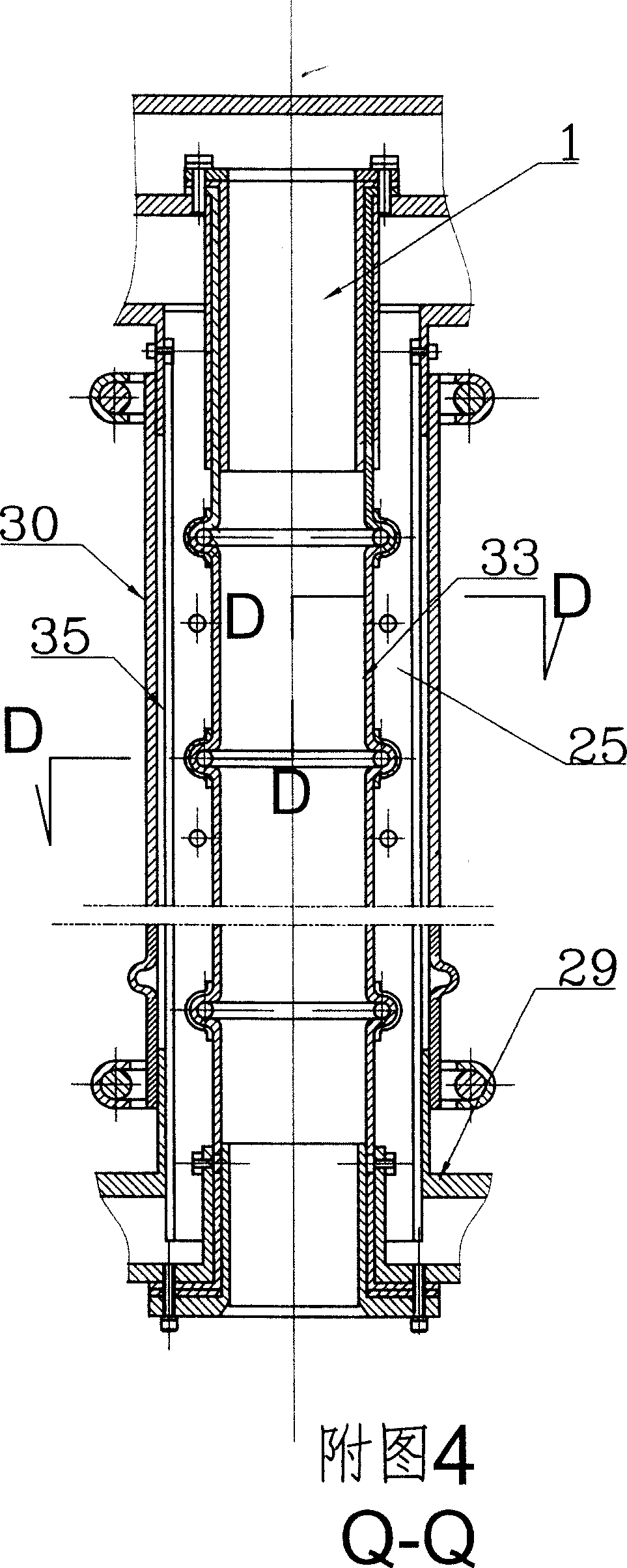

Flexible tube type solid-liquid processing machine with filtering, heat-exchange and hot compression function

InactiveCN1966129ALow costSimplify equipment componentsSemi-permeable membranesStationary filtering element filtersSlagEngineering

The invention relates to a flexible tubular solid liquid processor, with filter, heat exchange and thermal extraction functions, wherein the filter element at least comprises one flexible tubular membrane unit, upper flange room and lower flange room; the hydraulic extracting system comprises pressure container, extract pump and tubes; the material liquid of container can be filtered by the tubular filter membrane of membrane unit, and said material liquid can be used as work medium to extract the concentrated material liquid in the filter room of membrane unit and discharge filter slag; the pressure container or the filter room of membrane unit can be filled with medium to exchange heat, to realize thermal filter or extraction; the filter element is arranged on the bearing base inside the pressure container; the filter rotator can rotate the filter element to realize cross-flow filter; and the invention can be arranged with gas or water reverse tube and vacuum filter tube; the slag discharge system comprises slag discharger or tubular inner / outer membrane scraper, or vibration slag discharger, or compression slag discharger.

Owner:张民良

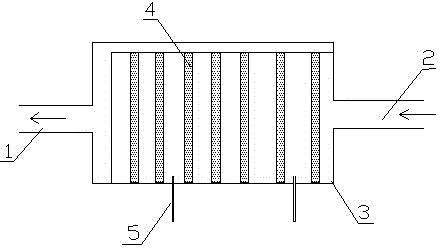

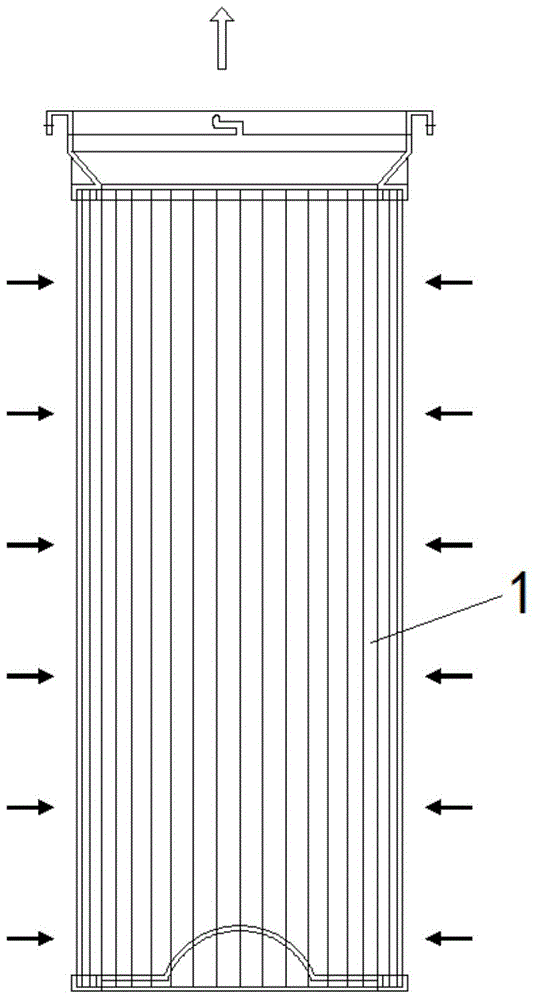

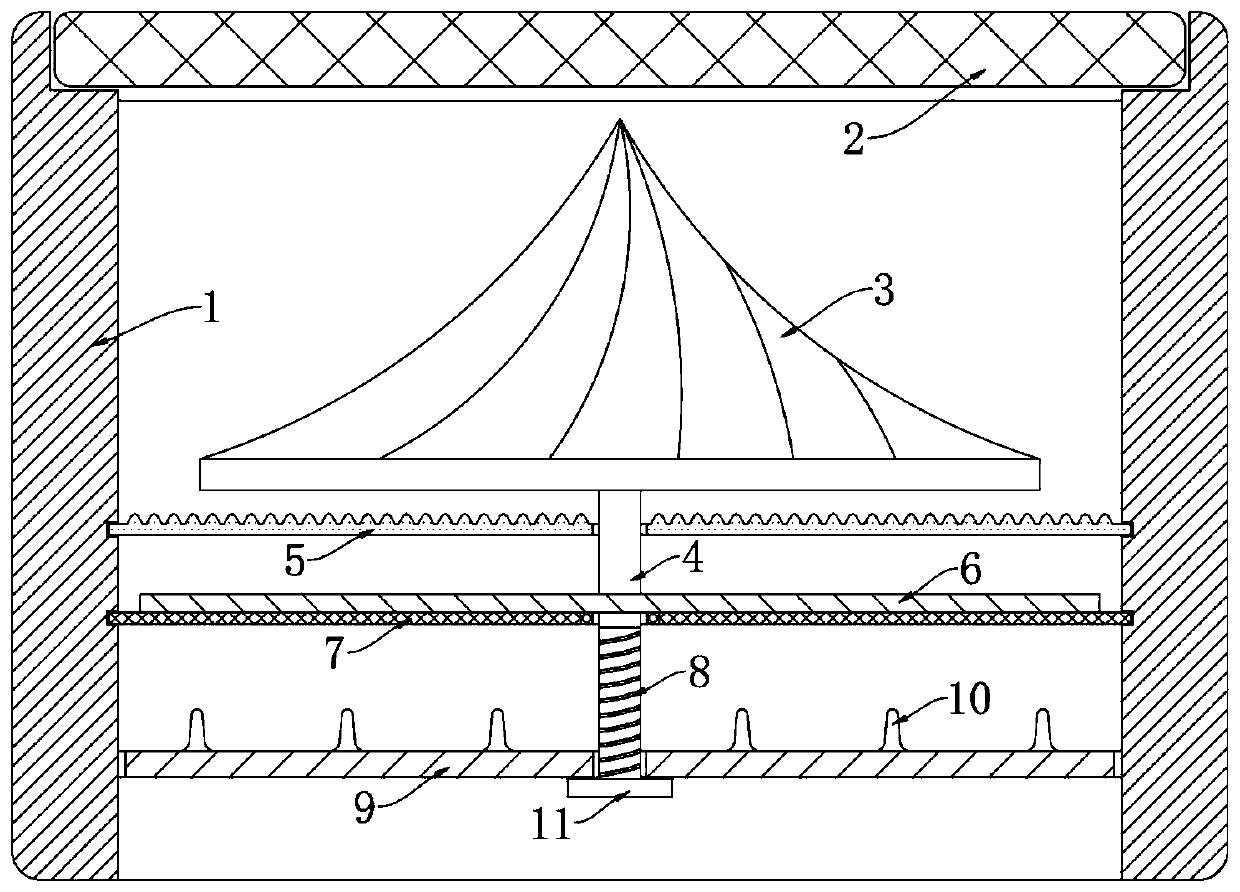

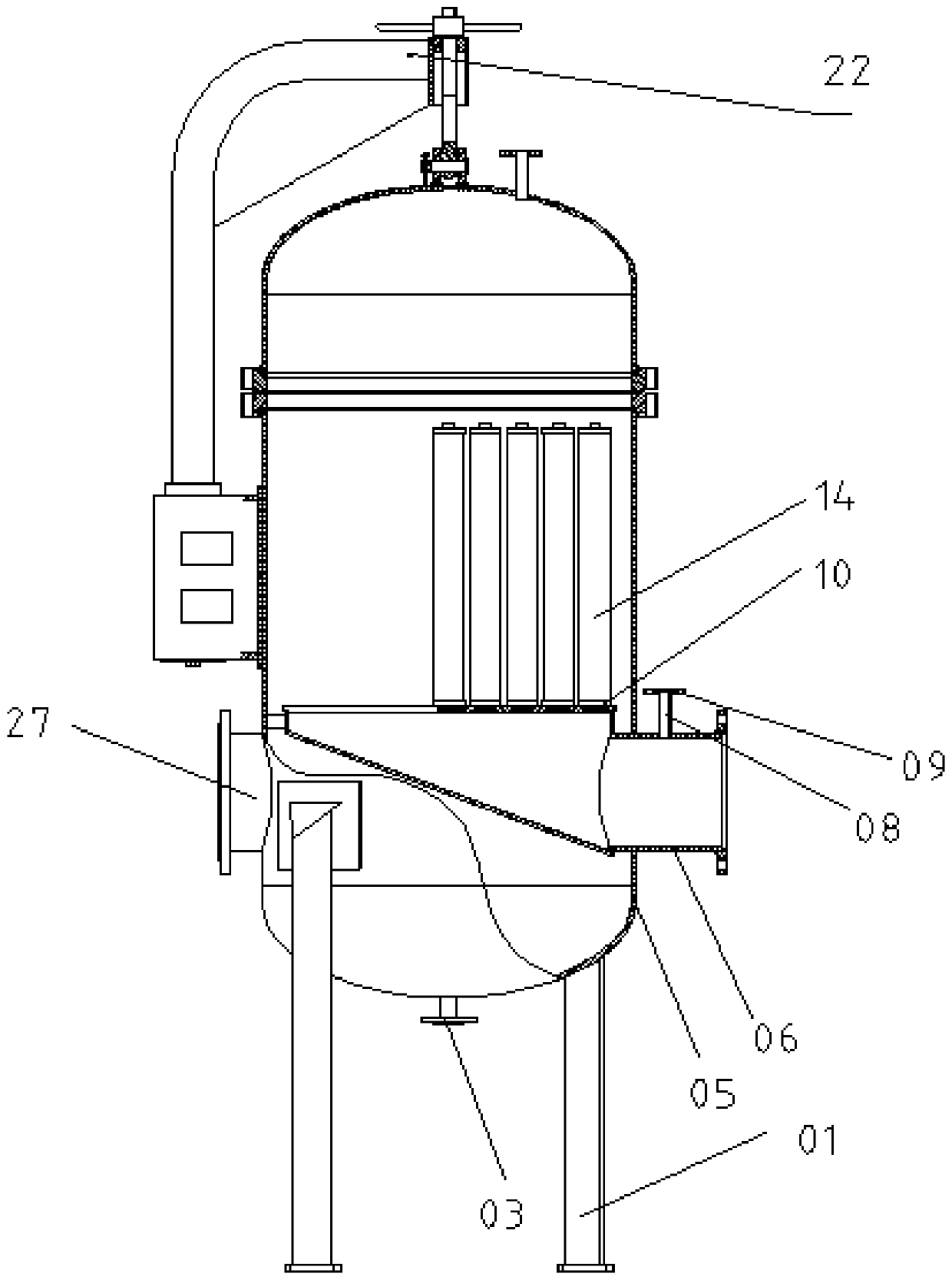

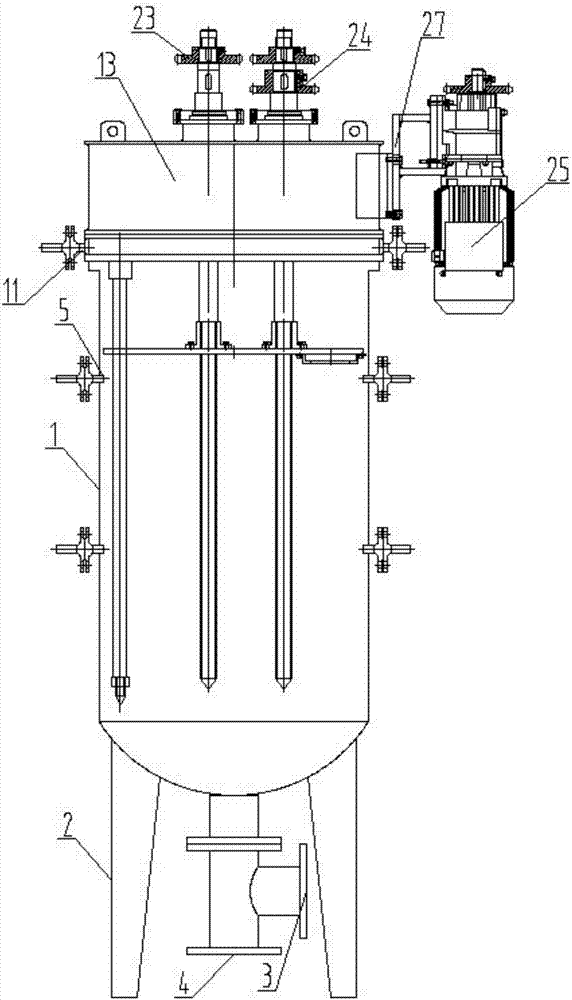

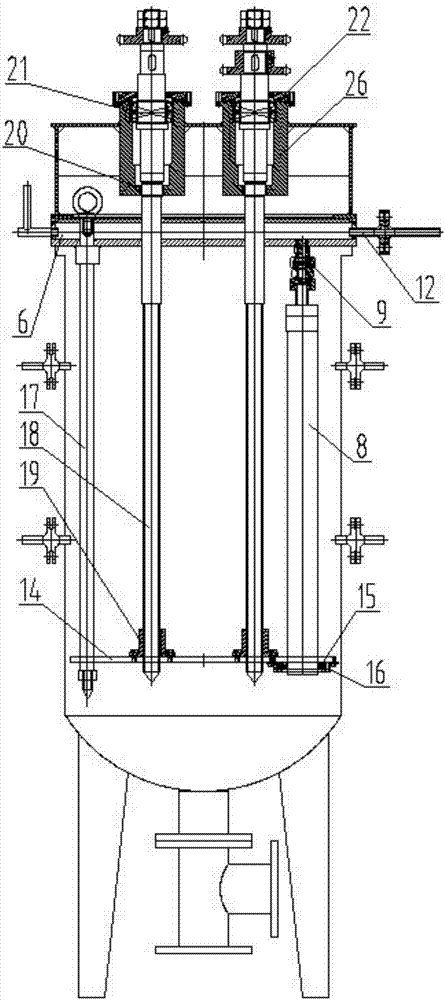

Dust filtration system of mixed gas of high-temperature oil gas, water vapour and carbonaceous easy-precipitation substances

ActiveCN104147862AReduce investmentExtended service lifeDispersed particle filtrationTransportation and packagingTarPulverized fuel ash

The invention discloses a dust filtration system of a mixed gas of high-temperature oil gas, water vapour and carbonaceous easy-precipitation substances. The system comprises a sealed separation chamber communicating a gas inlet pipe and a gas discharge pipe. A filtration mechanism is arranged in the sealed separation chamber. The outer surface of the filtration mechanism communicates with the gas inlet pipe, and the inner surface of the filtration mechanism communicates with the gas discharge pipe. A filtration body regeneration mechanism is arranged in the dust filtration system. According to the invention, the filtration body regeneration mechanism is arranged in the sealed separation chamber communicating the gas inlet pipe and the gas discharge pipe. When the filtration body works for a period of time, the filtration capacity of the filtration body cannot satisfy the requirement of normal working because the filtration capacity is greatly reduced due to tar and coal ash deposits on the surface and pores of the filtration body. The filtration body regeneration mechanism works, and the filtration body is recovered to a desired level. Regeneration is repeated, such that filtration body investment is directly reduced, and filtration body service life is greatly improved.

Owner:HENAN DRAGON INTO COAL TECH CO LTD

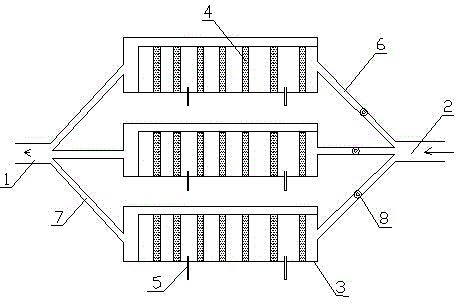

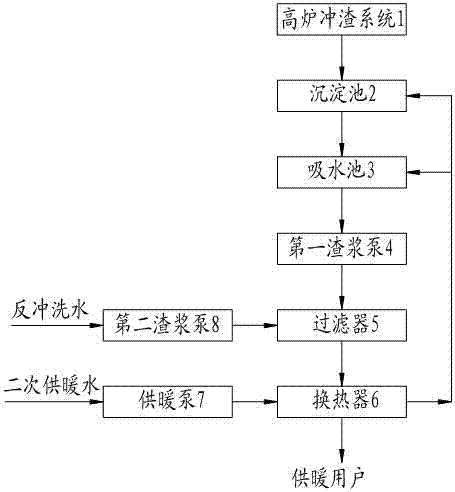

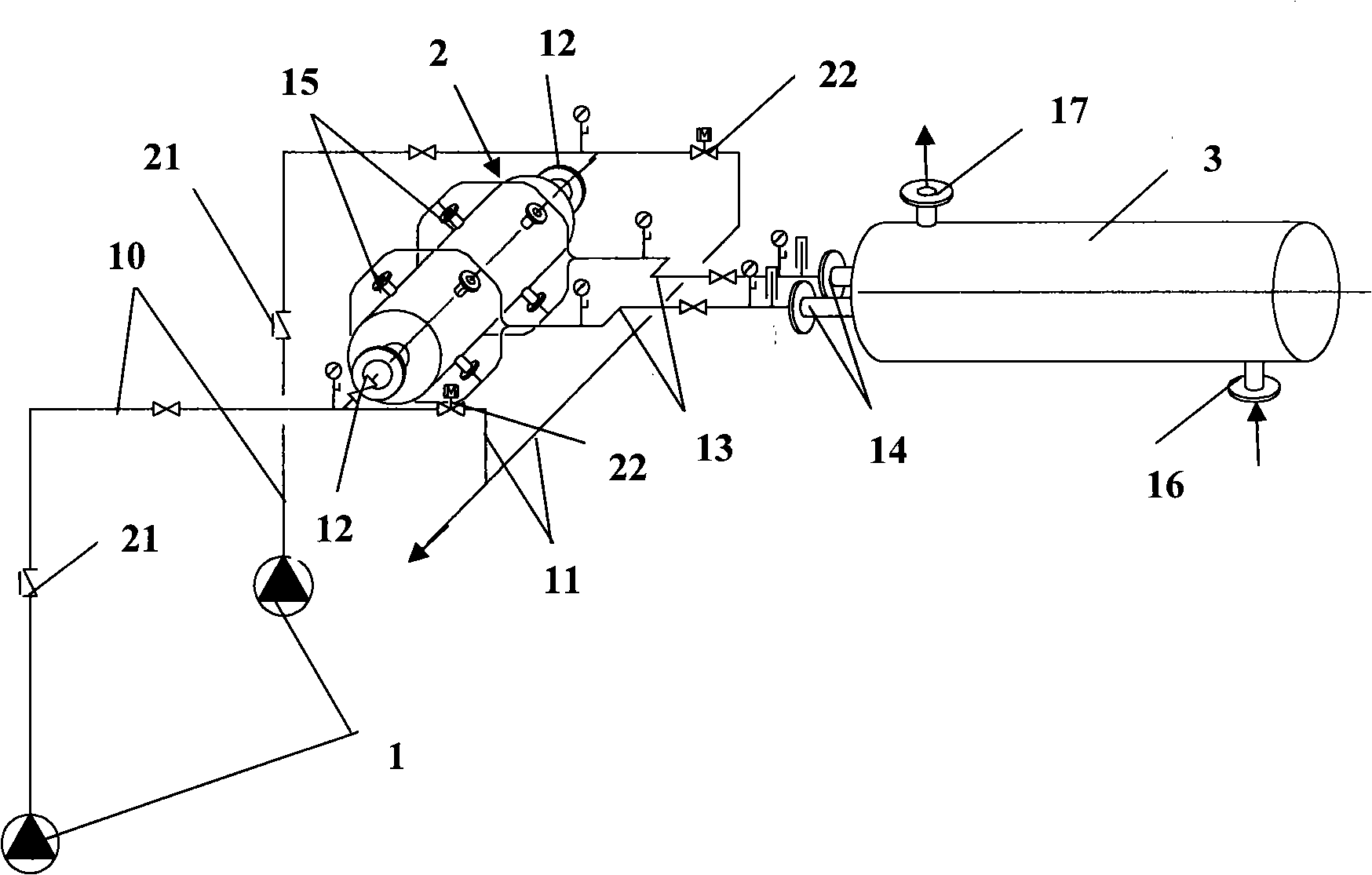

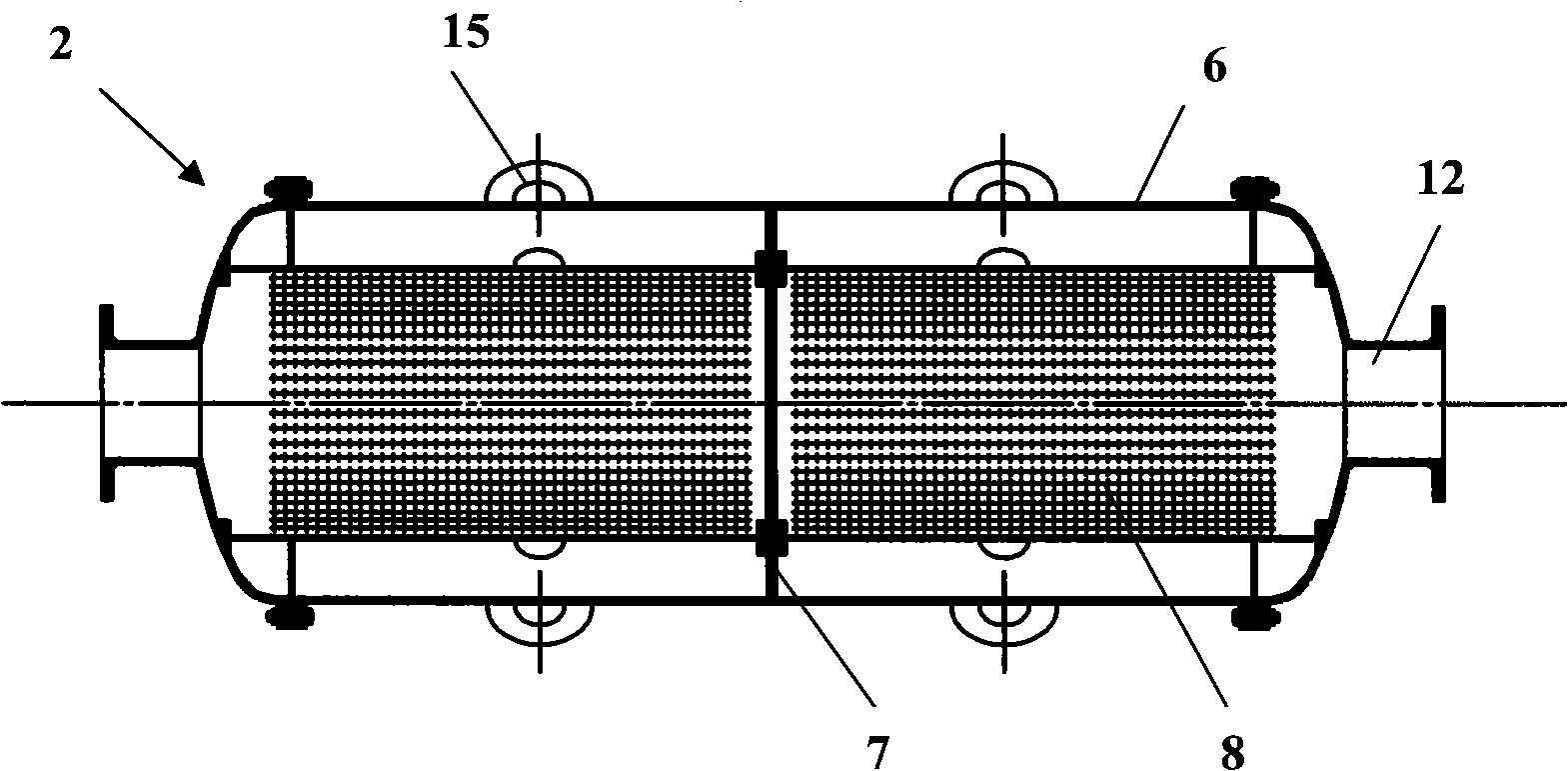

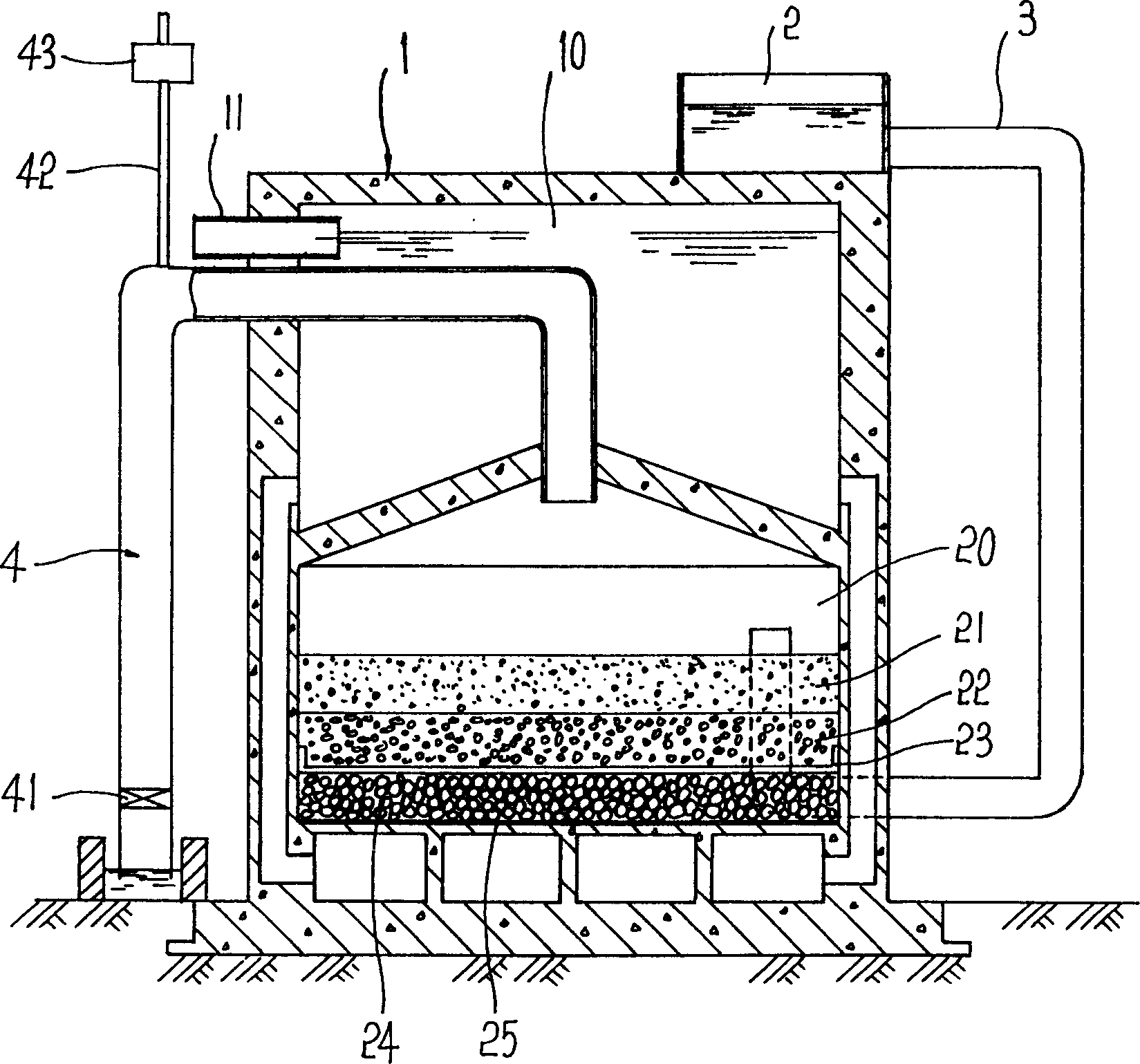

Heating system by utilization of waste heat of blast furnace slag flushing water and method thereof

InactiveCN102517411ARestore filter capacityGuaranteed filtering effectDischarge devicesProcess efficiency improvementSlagHeating system

The invention provides a heating system by the utilization of waste heat of blast furnace slag flushing water and a method thereof, so as to effectively recover waste heat of blast furnace slag flushing water, supply heating to users and achieve the purse of energy saving and emission reduction. The heating system by the utilization of waste heat of blast furnace slag flushing water contains a blast furnace slag flushing system, a sedimentation basin, a water suction pool, a first slag slurry pump, a filter, a heat exchanger and a heating pump. A slag flushing water outlet of the blast furnace slag flushing system communicates with the sedimentation basin, which communicates with the water suction pool. A water inlet of the first slag slurry pump communicates with the water suction pool. The water outlet communicates with a slag flushing water inlet of the filter. A slag flushing water outlet of the filter communicates with a first water inlet of the heat exchanger. A secondary heating water outlet of the heating pump communicates with a secondary water inlet of the heat exchanger. According to the invention, waste heat of blast furnace slag flushing water is fully utilized for heating. Therefore, investment cost is low and recovery period is short. In addition, in comparison with present bunker coal heating, the heating system provided by the invention has advantages of no discharge of gases such as SO2, NOX, CO2 and the like, energy saving and environmental protection.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

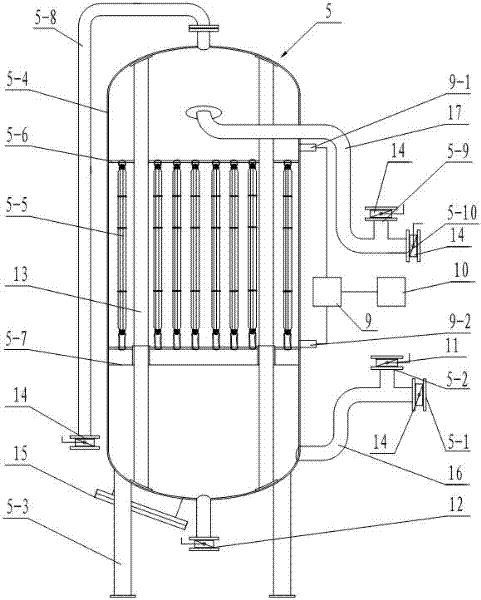

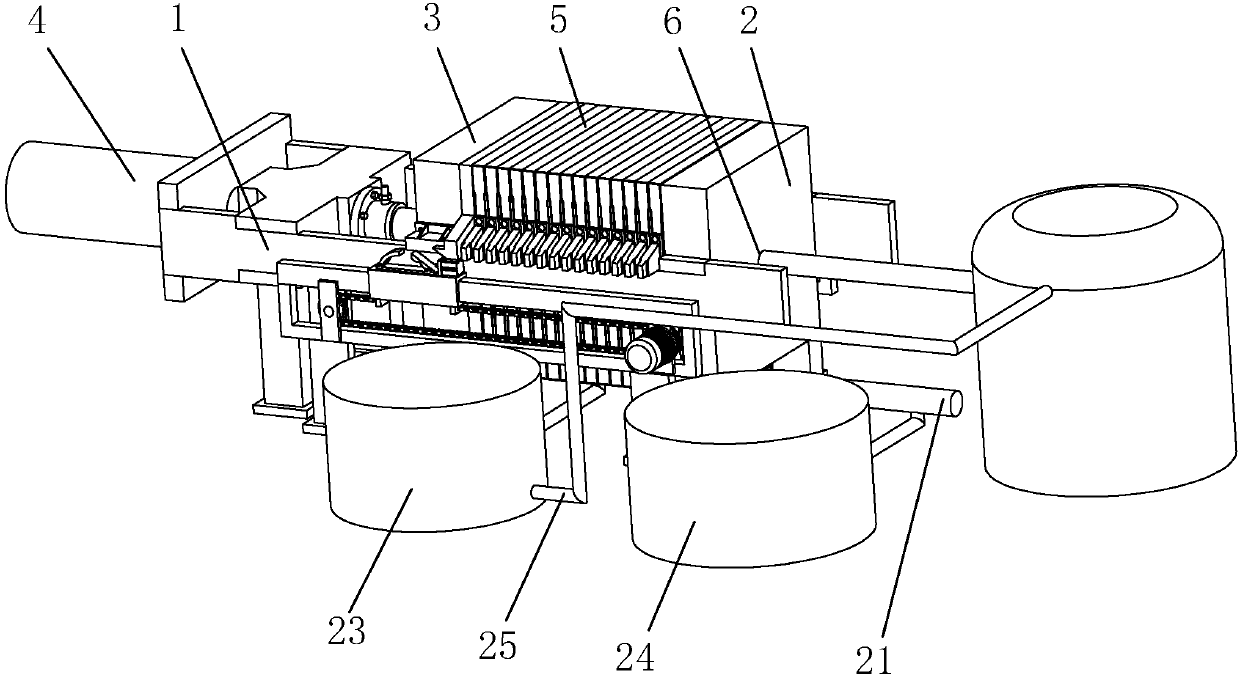

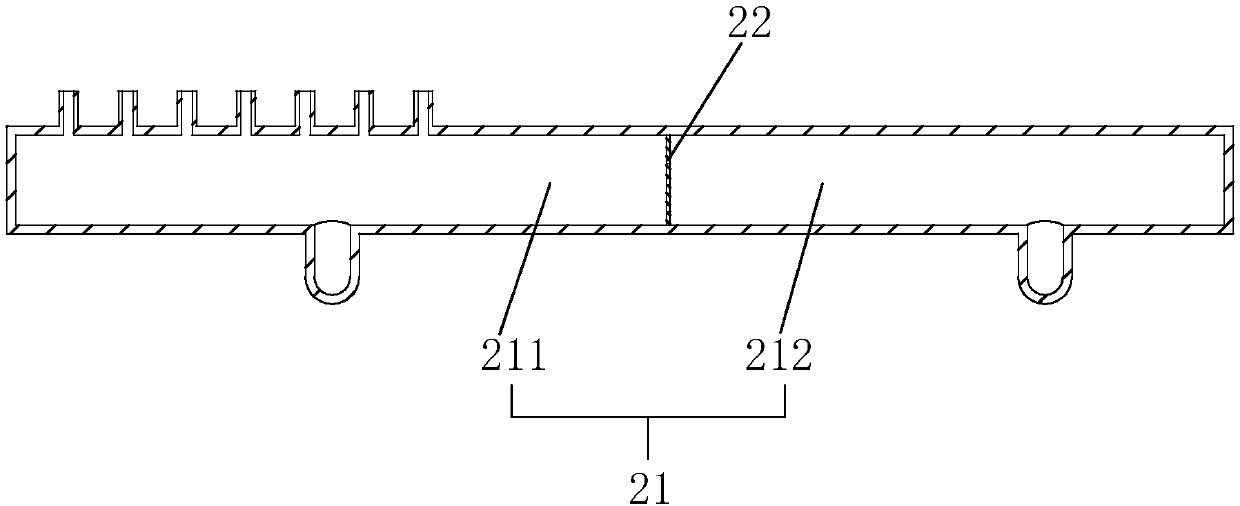

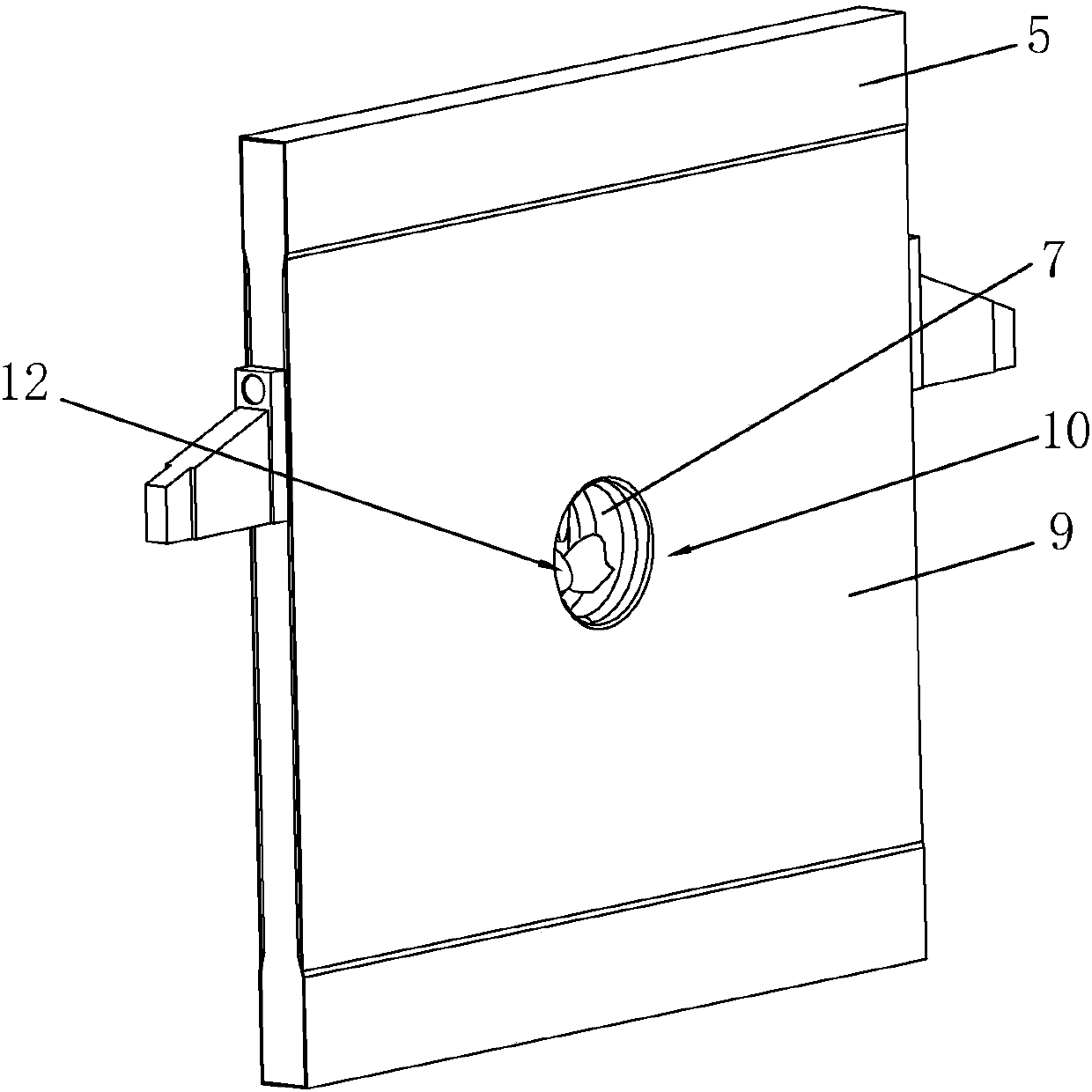

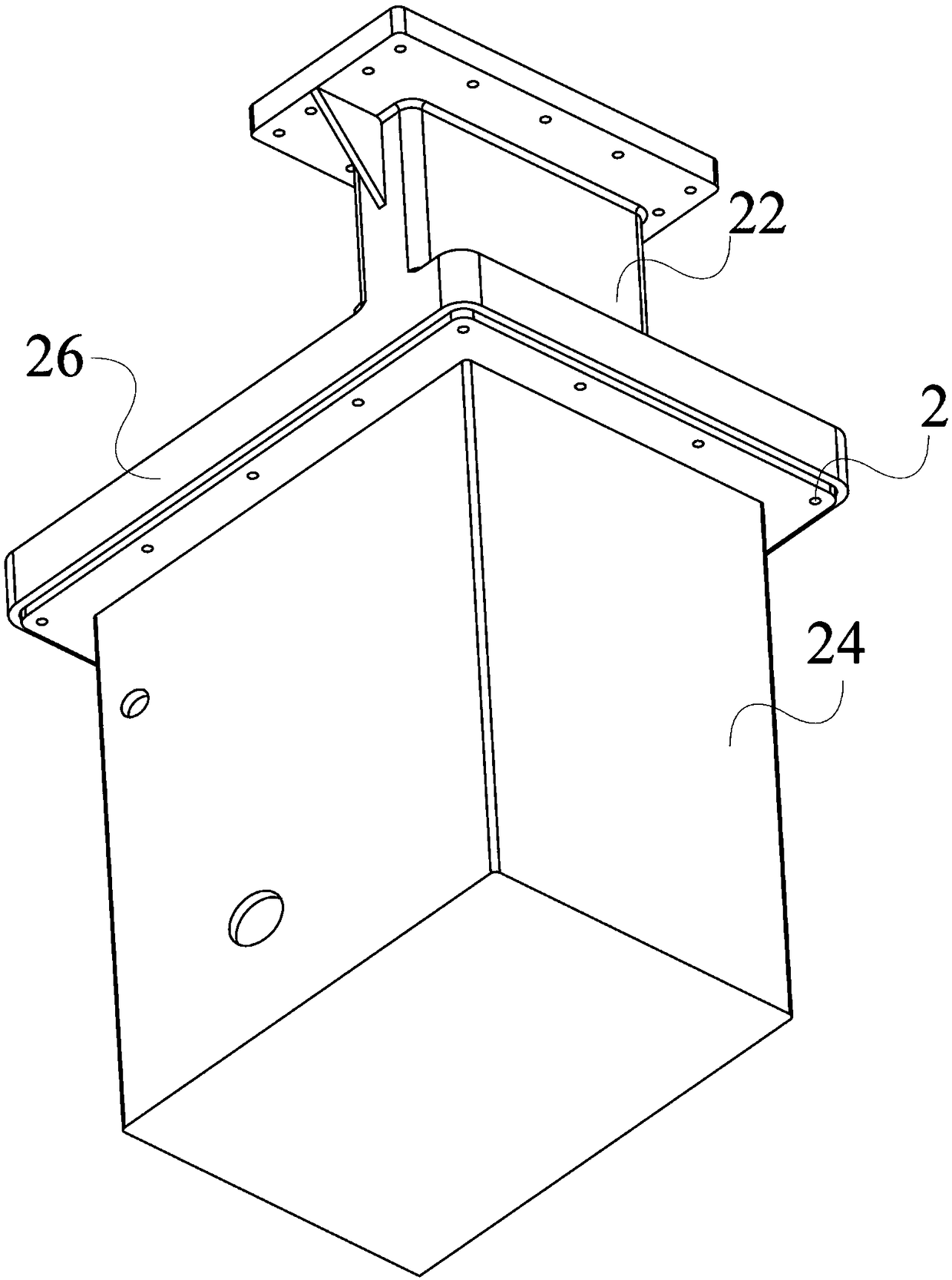

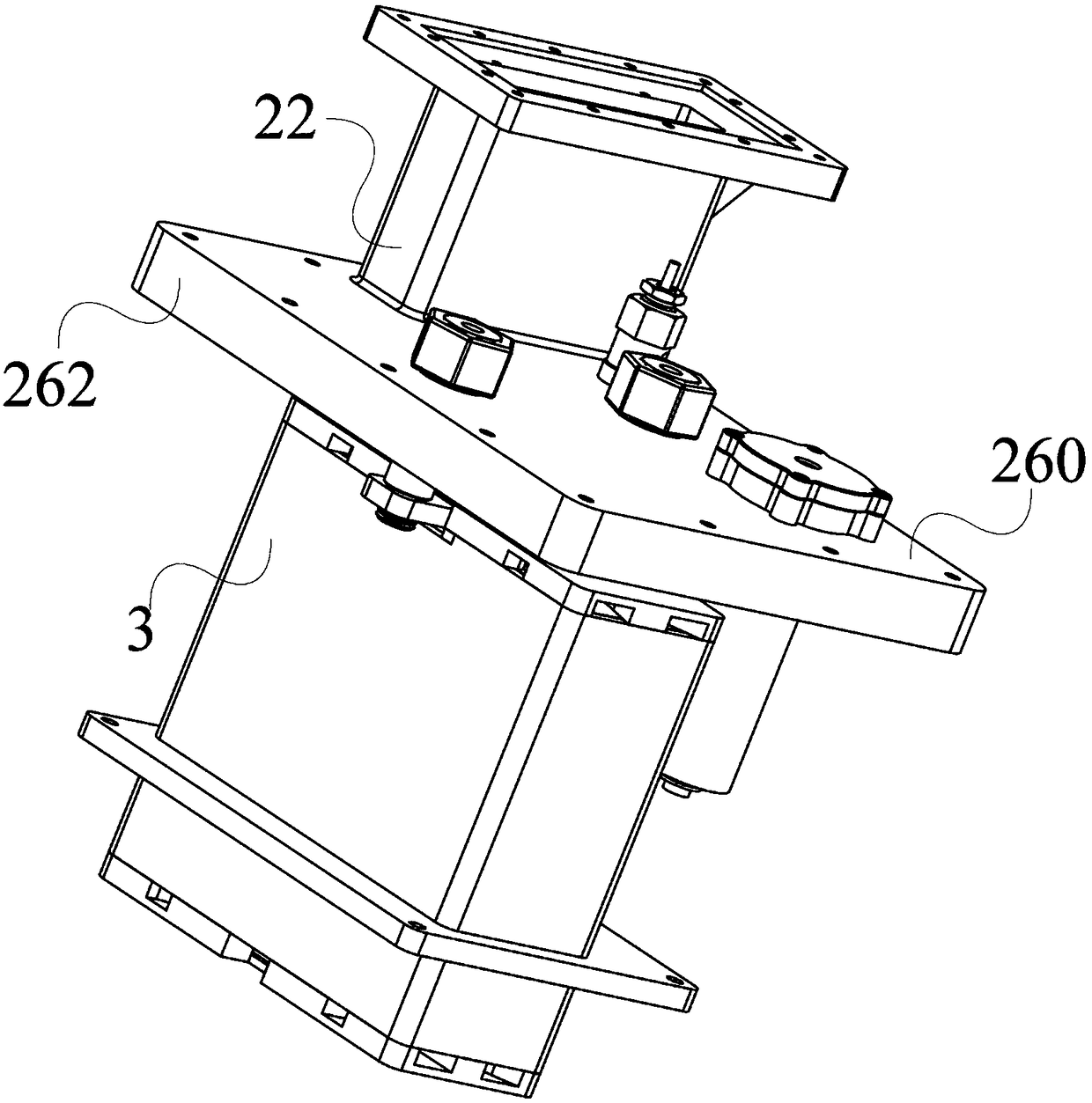

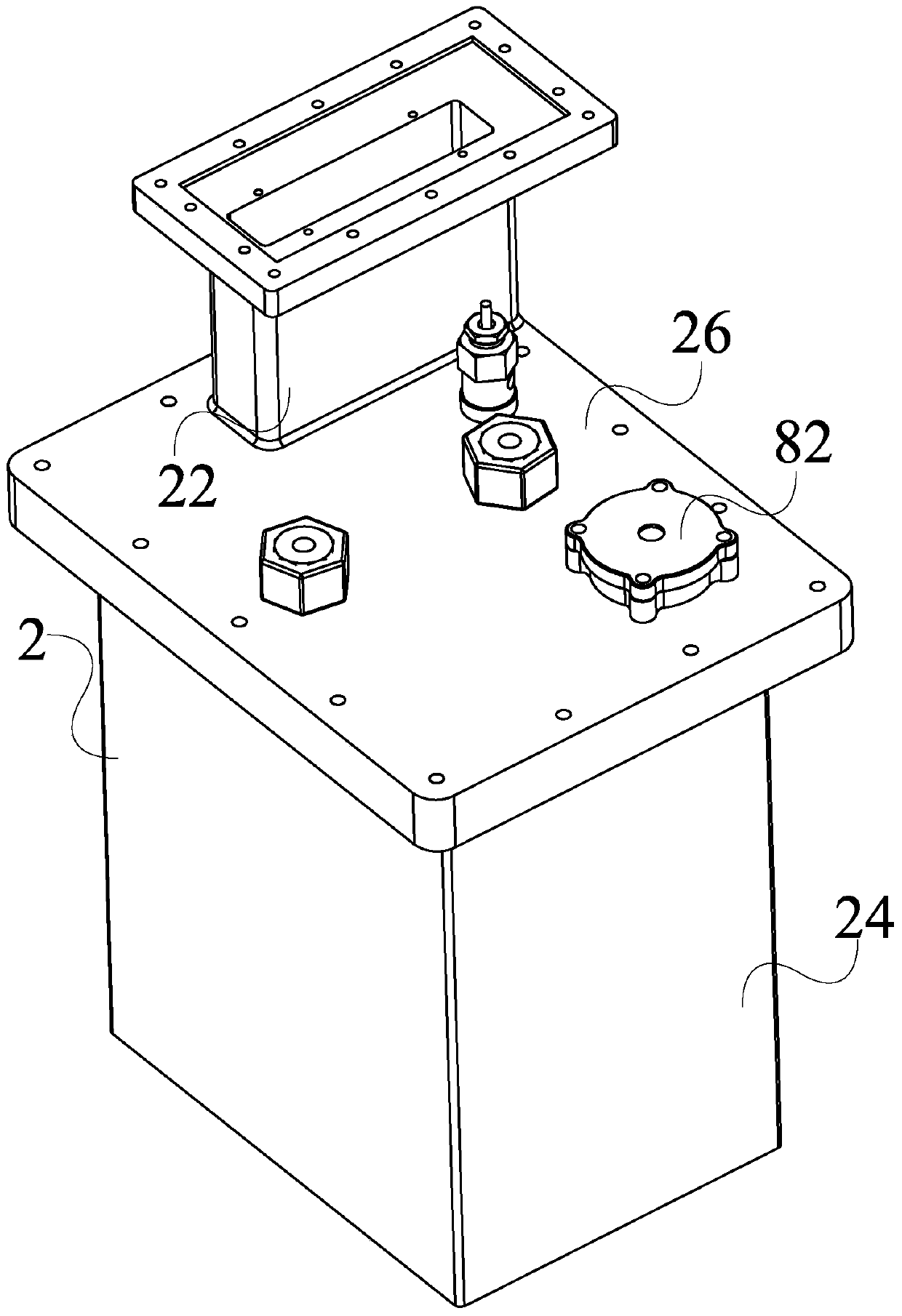

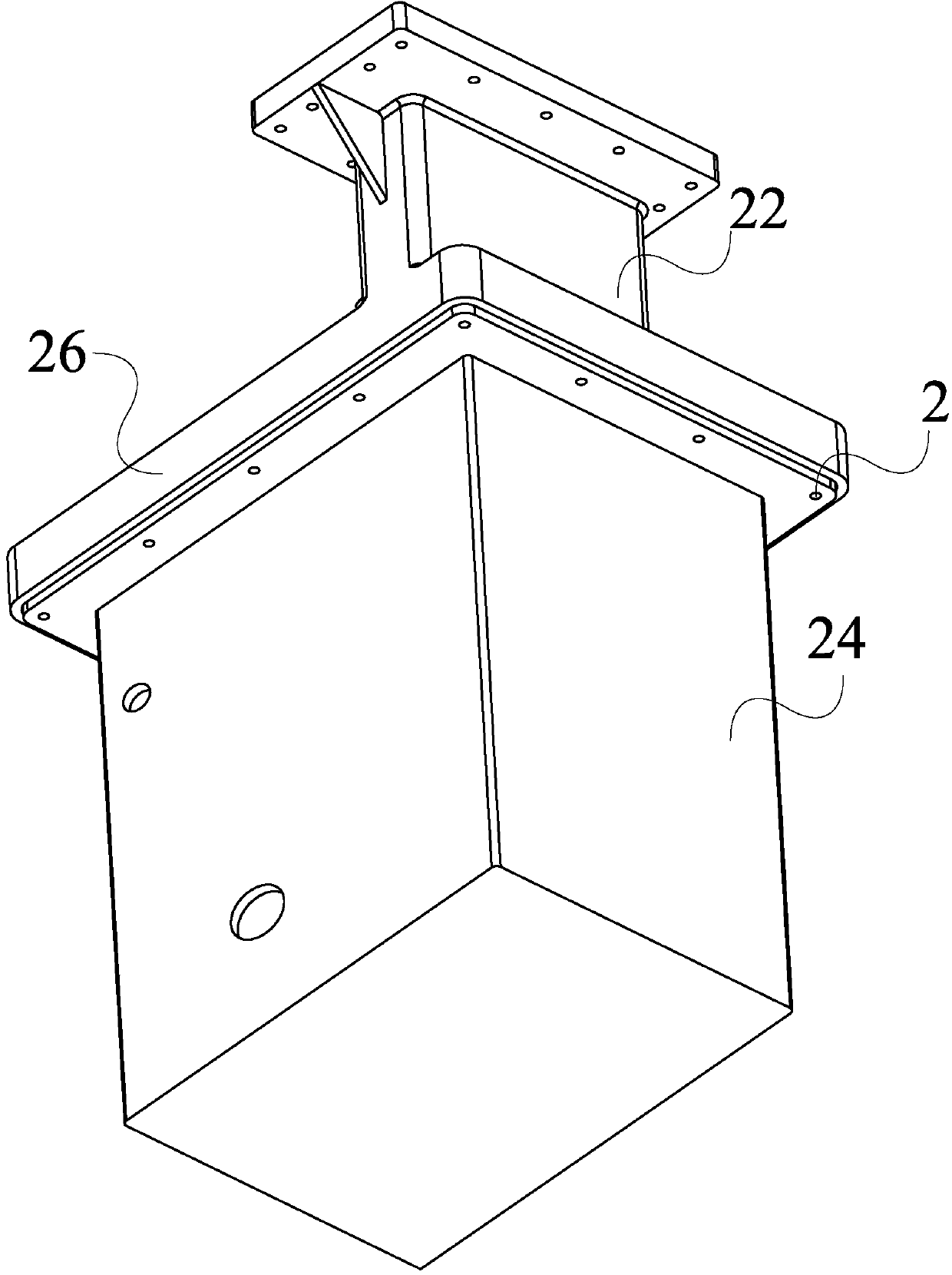

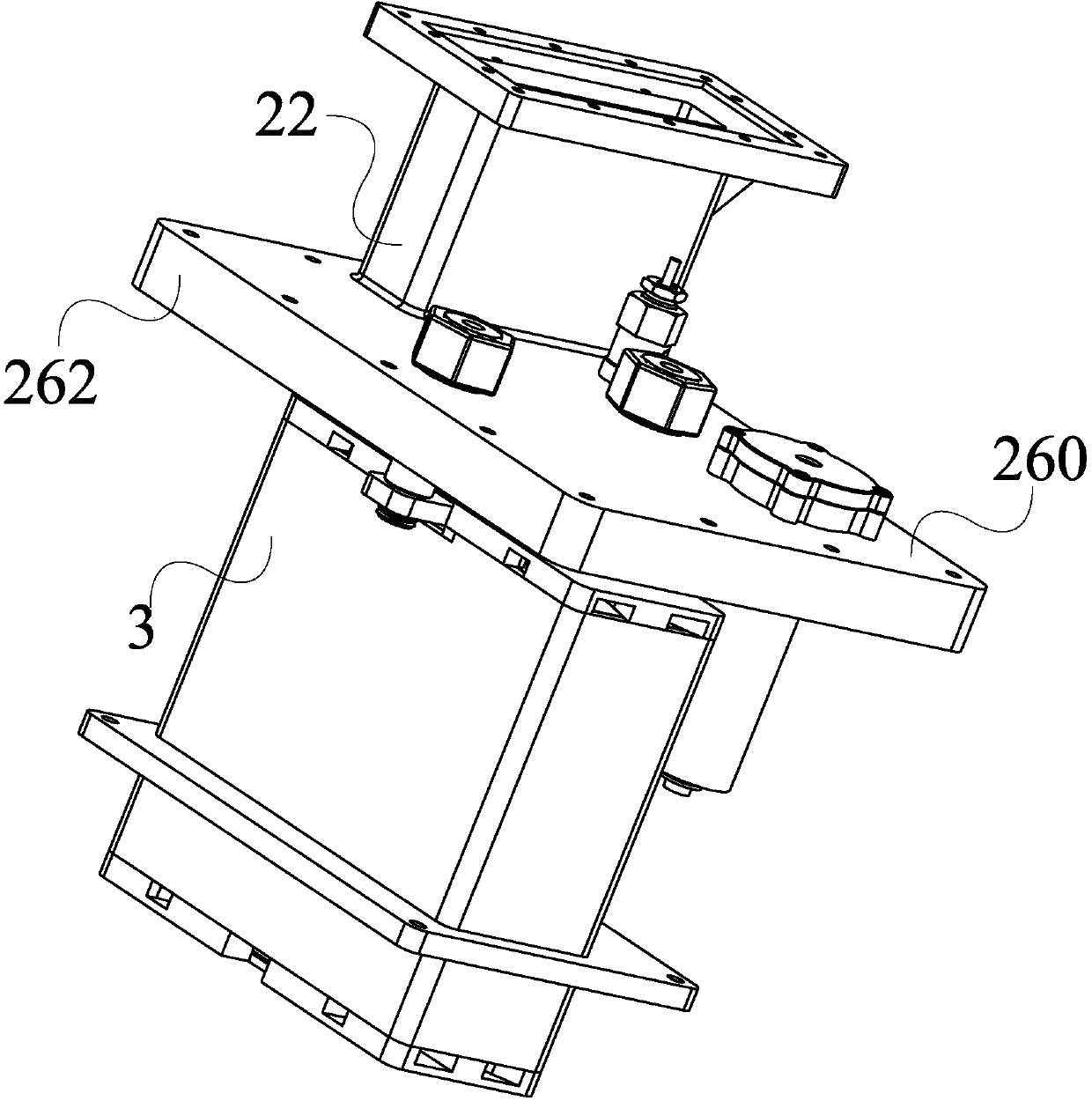

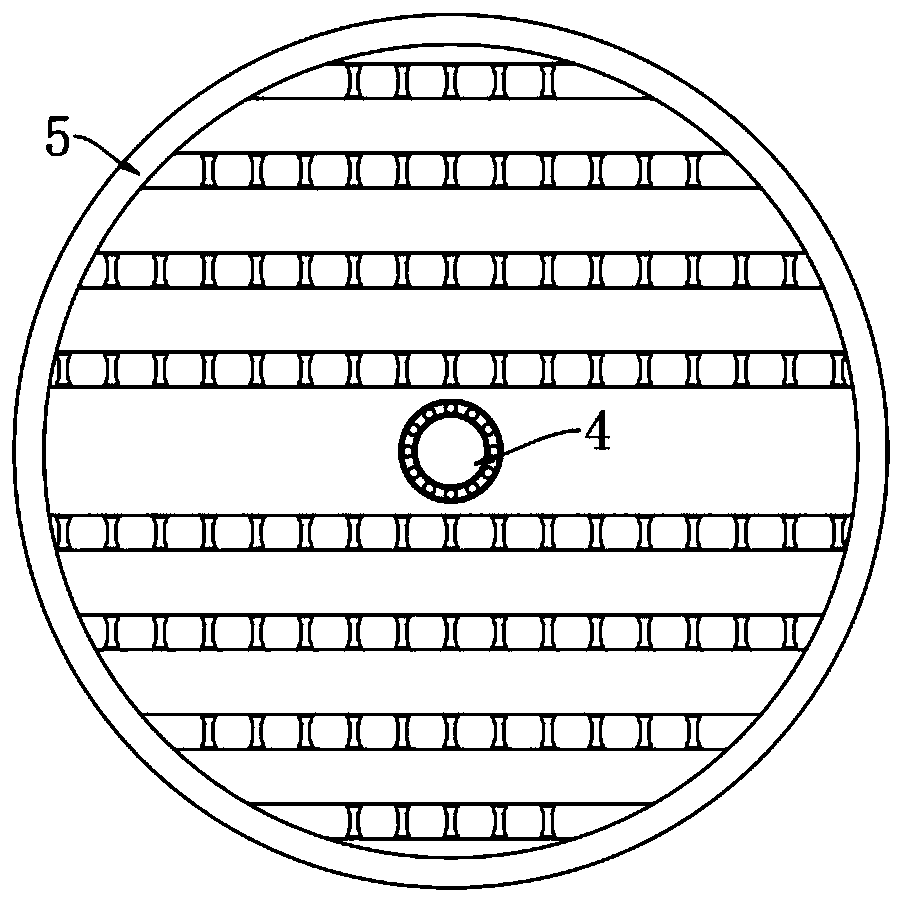

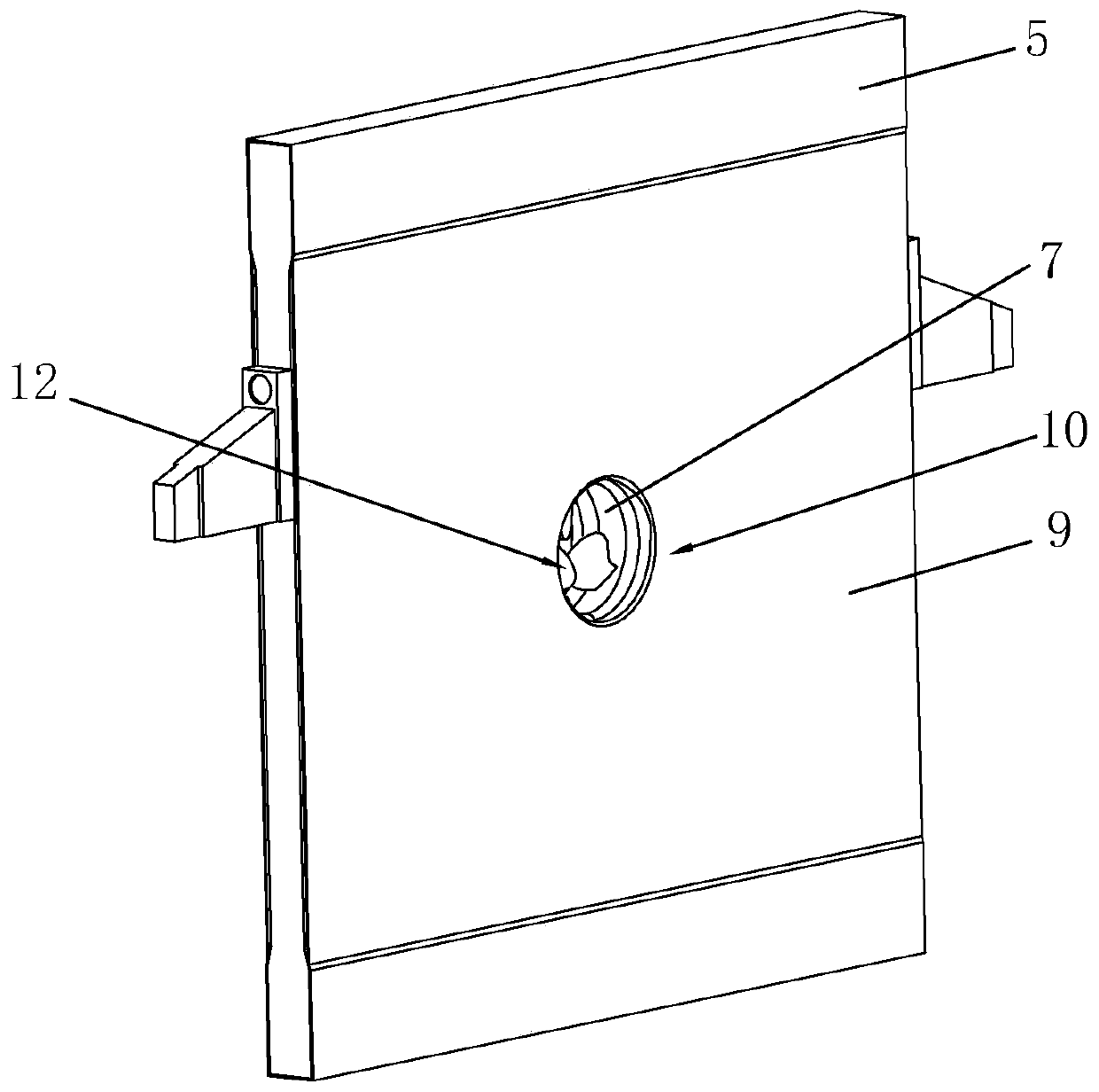

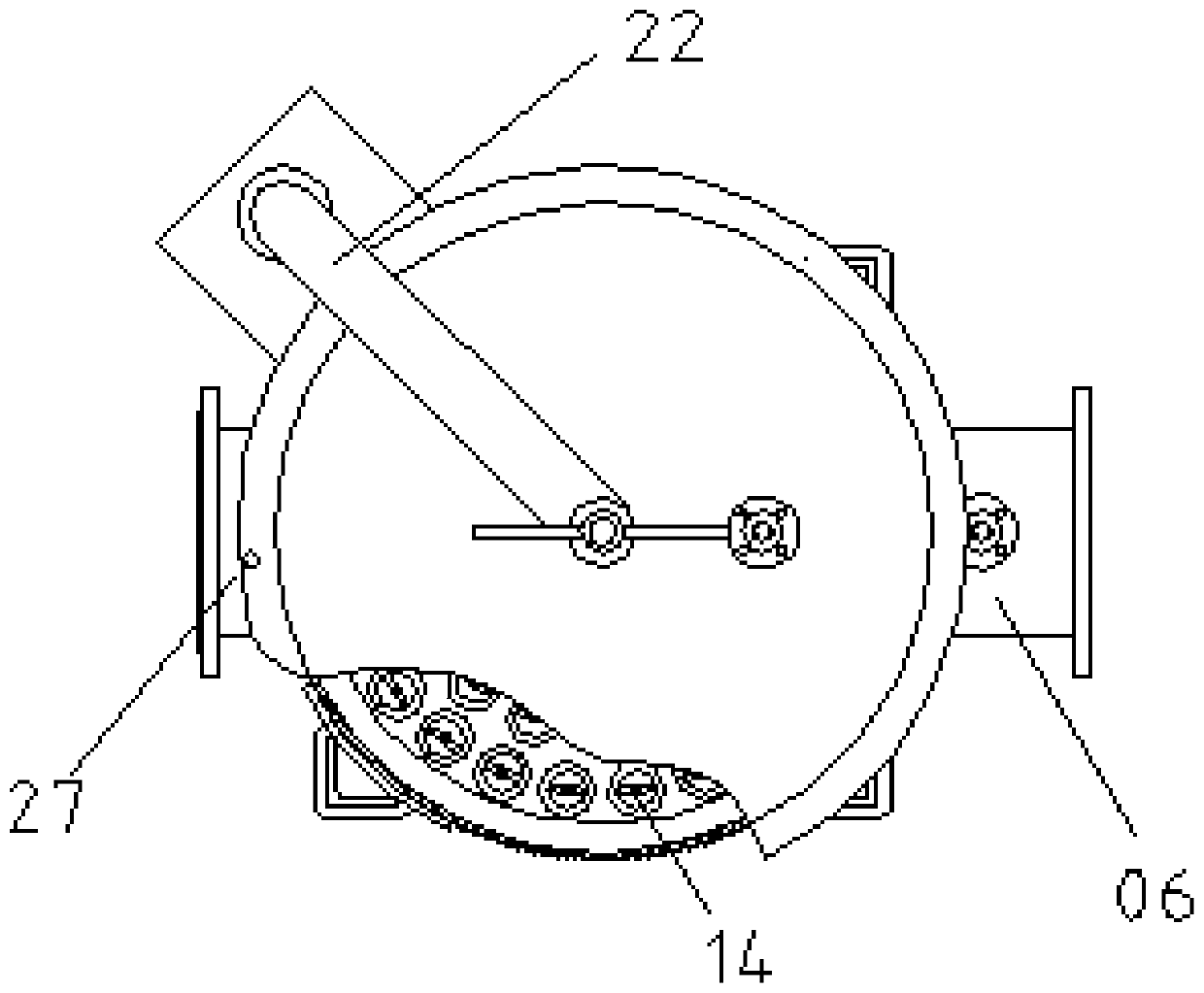

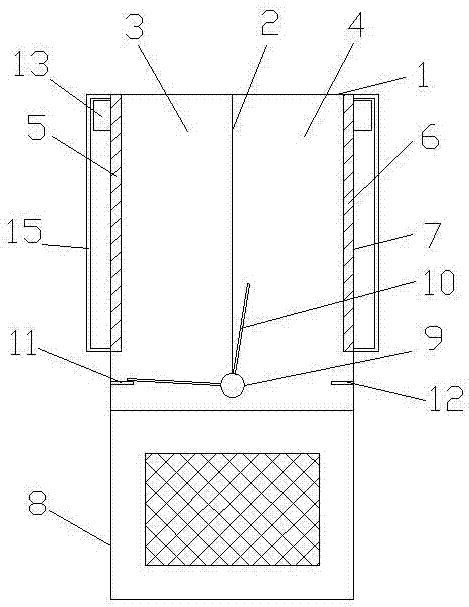

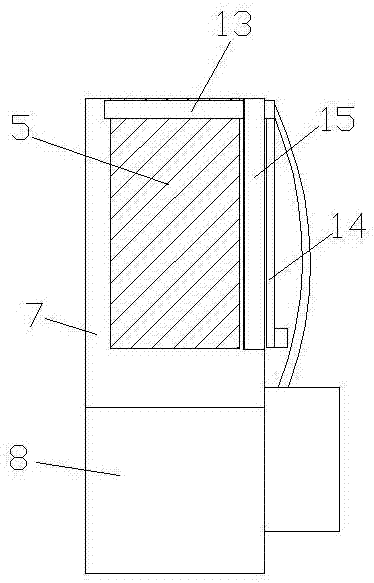

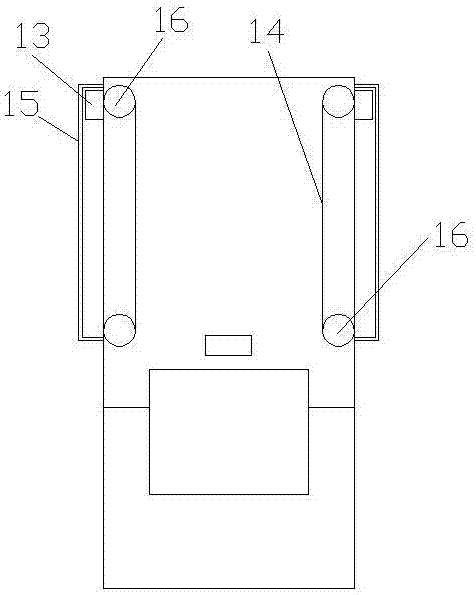

Pressure filter

ActiveCN108031154ARestore filter capacityImprove filtering effectFiltration circuitsForeign matterHydraulic cylinder

The invention discloses a pressure filter which includes: a machine frame, a thrust plate, a pressing plate, a hydraulic cylinder, and a plurality of pressure filter plates that are arranged between the pressing plate and the thrust plate. Filter clothes are arranged on the two ends of each pressure filter plate. A rotating ring is rotatably connected to each pressure filter plate. A driving member is arranged on the rotating ring. Each rotating ring is provided with two material pushing rods. An accommodating groove is arranged on the end surface of each pressure filter plate. A spring is disposed in the accommodating groove and is connected to the filter clothes. When the pressure filter is in use, the driving member drives the rotating ring to rotate the material pushing rods, and whena material pushing ring rotates to a position, the material pushing ring jacks up the filter clothes at the positions, so that the filter clothes are separated from the pressure filter plates. When the material pushing rods rotates from the positions, the spring at the position drives the filter clothes to move towards one side of the accommodating groove; at the same time, foreign matters attached to the filter clothes are removed from the filter clothes under effect of inertia, so that the filter pores in the filter clothes are not liable to be blocked by the foreign matters. The structure can ensure the pressure filter effect of the pressure filter to certain degree.

Owner:ZHEJIANG FENGAN BIOPHARM

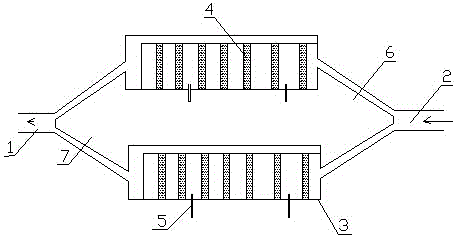

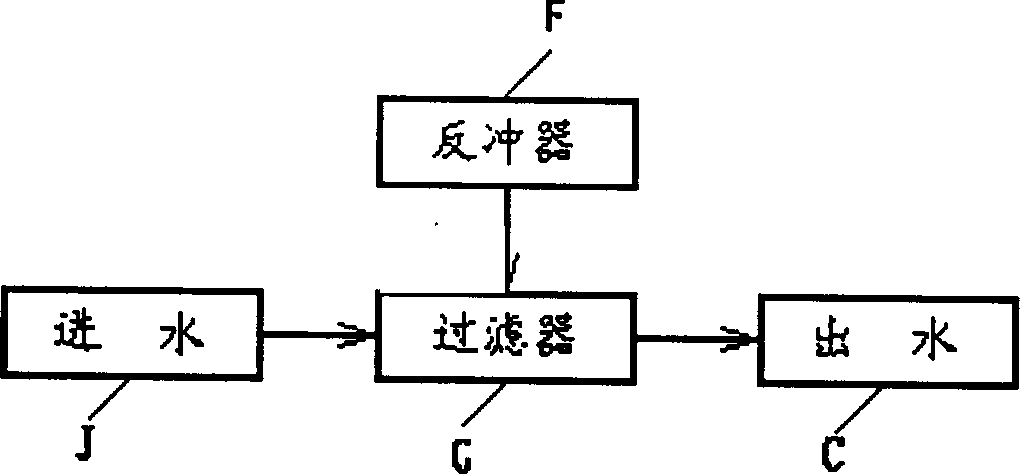

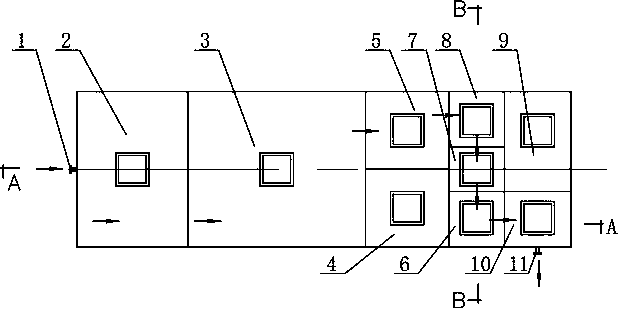

Clarification system through continuous microstraining intermdeiate water

InactiveCN1415558AHigh mechanical strengthSolution to short lifeWater/sewage treatment bu osmosis/dialysisStationary filtering element filtersCross-flow filtrationFilter system

A continuous microfilter system for cleaning reclaimed water features that the minipore filter membrane tubes are serially or parallelly combined to form membrane assembly and the staggered current filter and pulsive air-water reverse flush are used. Its advantages are high strength and high water penetrability.

Owner:金振忠

A gas generator

The invention provides a gas generator comprising an electrolysis device and a humidifying device. The electrolysis device is used for electrolyzing electrolysis water to produce a gas mixture including hydrogen and oxygen. The humidifying device comprises a hollow body for holding water; a second tube set in the hollow body and connected to the electrolysis device for receiving the gas mixture including hydrogen and oxygen; at least one outlet tube having a plurality of nano through-holes set in the hollow body and connected to the second tube. When the electrolysis device starts to electrolyze the electrolysis water to produce the gas mixture including hydrogen and oxygen, the gas mixture including hydrogen and oxygen is ejected through the plurality of nano through-holes of the at leastone outlet tube and dissolved into the water vibrated by the oscillator for human use.

Owner:林信涌

Gas generator

The invention discloses a gas generator comprising an electrolysis device and a humidification device. The electrolysis device is used to electrolyze the electrolyzed water to generate a hydrogen-oxygen mixed gas. The humidification device comprises a hollow body, a second pipe and at least one outputting pipe. The hollow body is used to contain recharged water. The second pipe is used for receiving the hydrogen-oxygen mixed gas. The at least one outputting pipe is connected to the second pipe. The surface of the at least one outputting pipe has a plurality of vias. When the electrolysis device electrolyzes the electrolyzed water to generate the hydrogen-oxygen mixed gas, the hydrogen-oxygen mixed gas is outputted through the plurality of vias of the at least one outputting pipe, and then the hydrogen-oxygen mixed gas is humidified to provide a gas suitable for being breathed in human body.

Owner:SHANGHAI ASCLEPIUS MEDITEC CO LTD

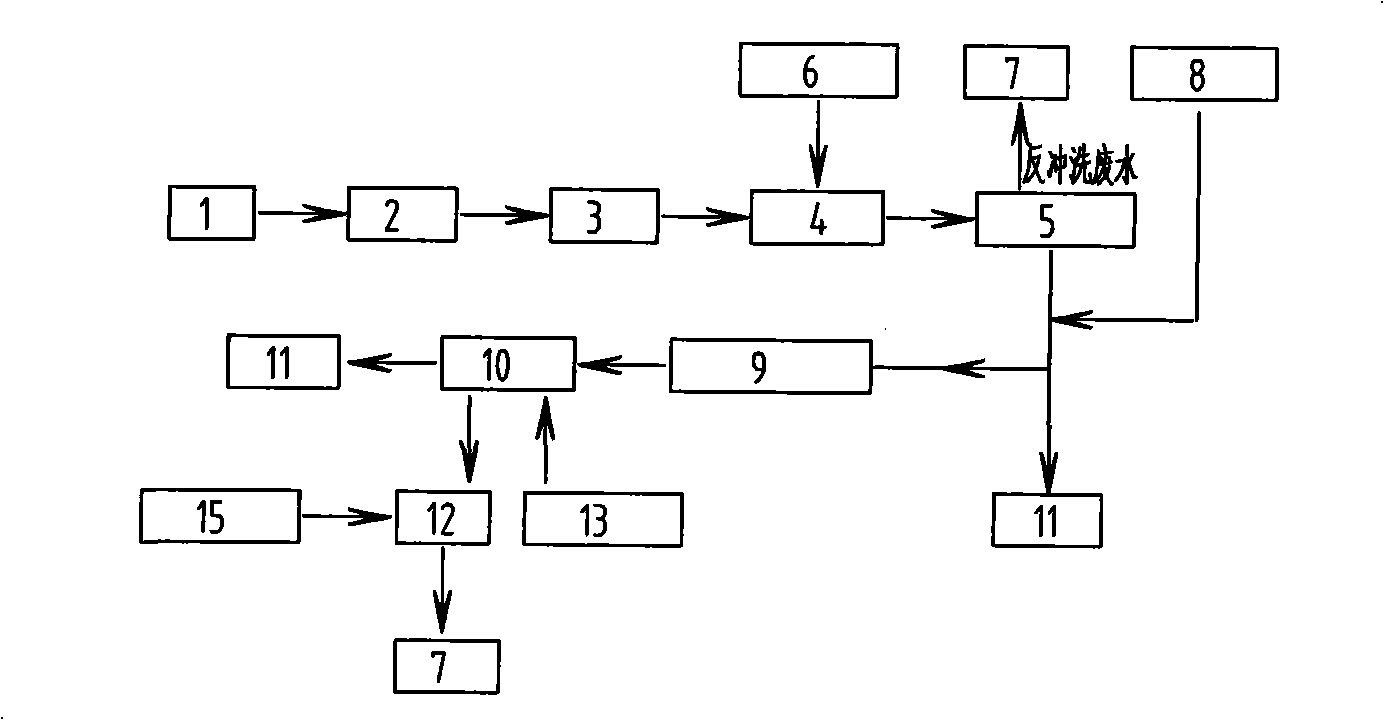

High-efficiency circulating filtration and strengthening phosphorus removal system for landscape water

InactiveCN101289258AEfficient removalImprove effluent qualityMultistage water/sewage treatmentWater/sewage treatment using germicide/oligodynamic-processWater treatment systemFiltration

The invention relates to a water treatment system for a scenic spot, which comprises an efficient circulation filtering system and a strengthening dephosphorization system, and a dosing device, a blending device, a lifter, a backwashing system, a balance pool and the alike, which are matched with the efficient circulation filtering system and the strengthening dephosphorization system. By integrating the updated filtering technique, the absorption technique for removing ammonia nitrogen, the dephosphorization technique, the algal removal technique and the medium regenerating technique, the system is an integrated water purification circulation treatment system with high efficiency.

Owner:BEIJING ORIGINWATER TECH CO LTD

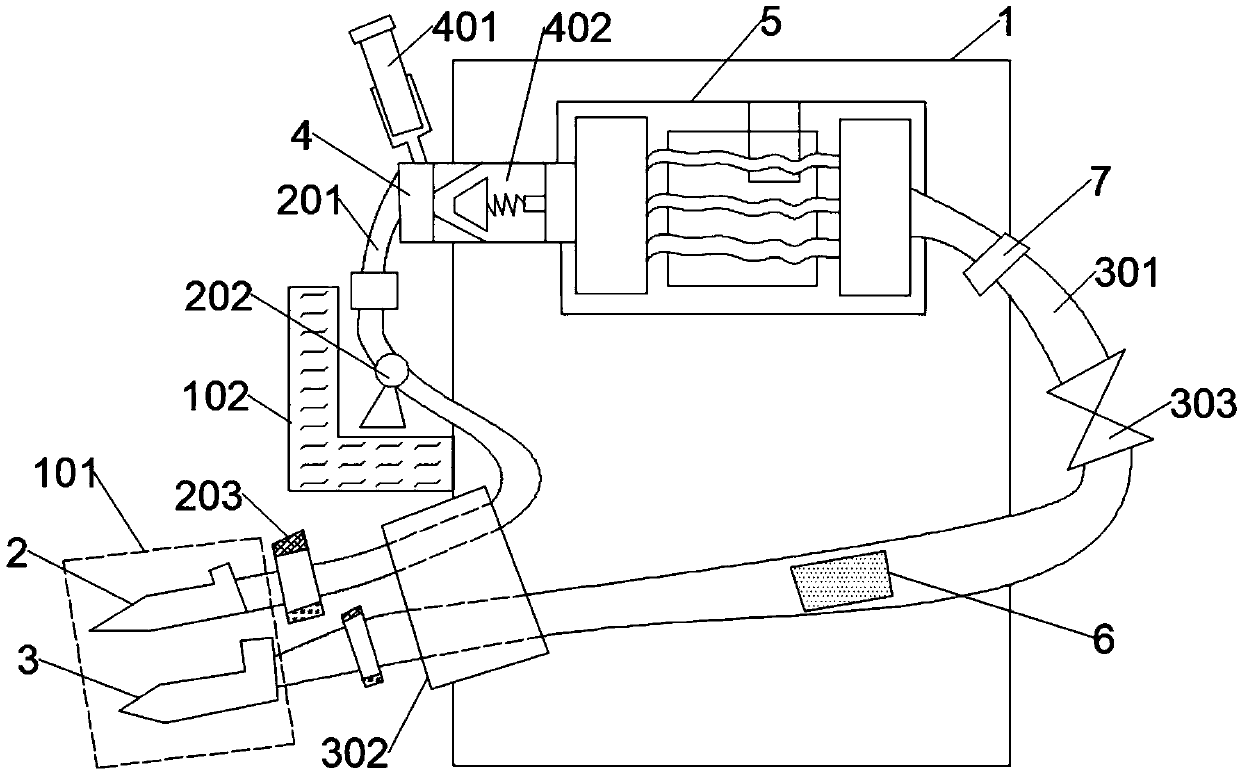

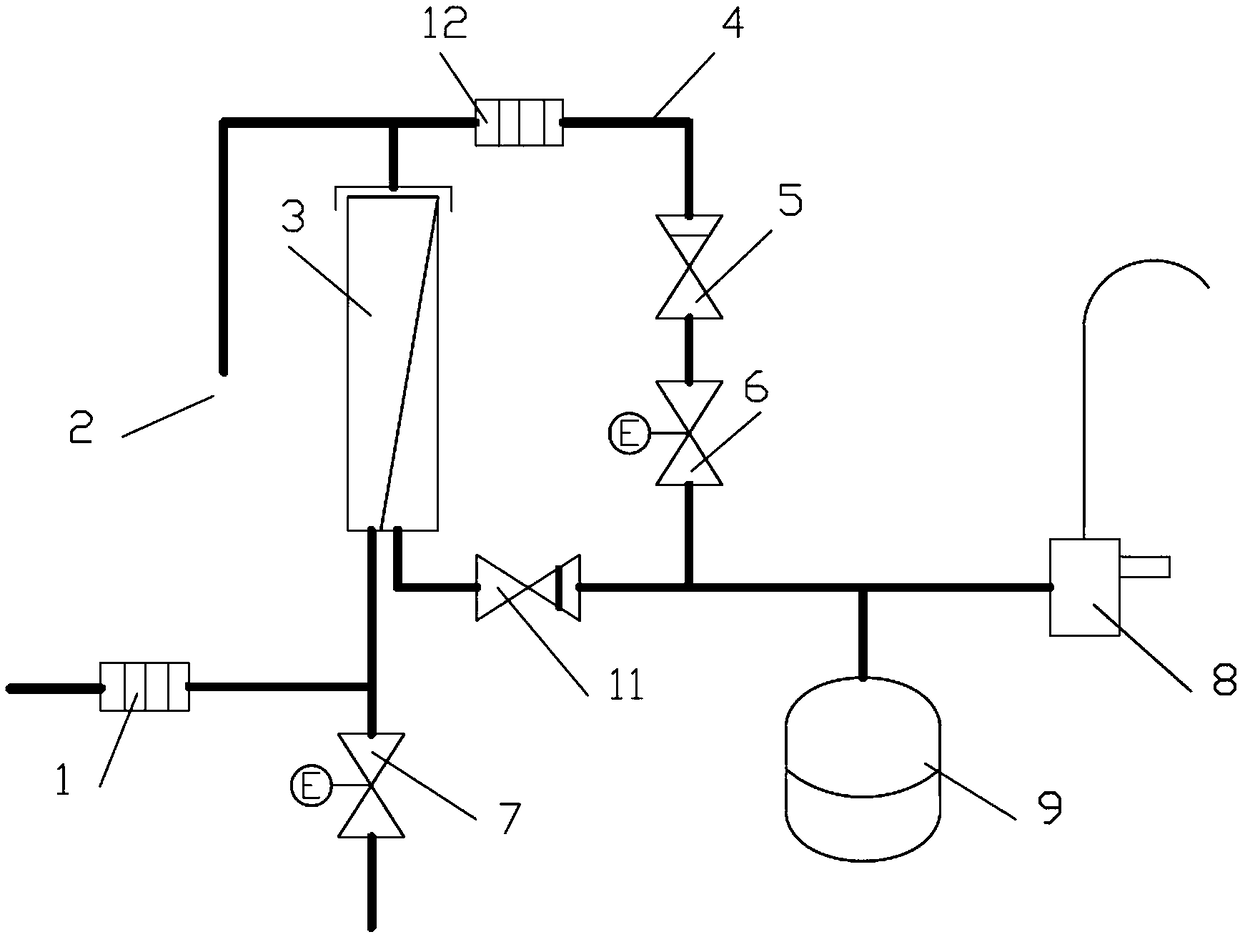

Native sewage water heat pump air conditioning system

InactiveCN101280985ARestore filter capacityReduce processing requirementsHeat pumpsWater/sewage treatmentWater cyclingSewage

An untreated sewage heat pump air adjusting system is disclosed, mainly comprising two diving sewage pumps that are interconnected though a pipeline, an untreated sewage filter, a shell pipe type heat exchanger, a plurality of medium water circulation water pump and a plurality of heat pump units. The untreated sewage heat pump air adjusting system provided by the invention utilizes two diving sewage pumps in an alternative working way to enable a steel plate filter net in the untreated sewage filter to filter the untreated sewage, meanwhile, to perform back washing to another steel plate filter net in order to recover filter ability of the filter and guarantee the filter quality, therefore the untreated sewage filter does not need power in the process of running the system and the energy consumption of the system can be reduced. In addition, as the untreated sewage filter is a fixing device, the processing requirements, cost and running expenditure are low.

Owner:天津美意机电设备工程有限公司

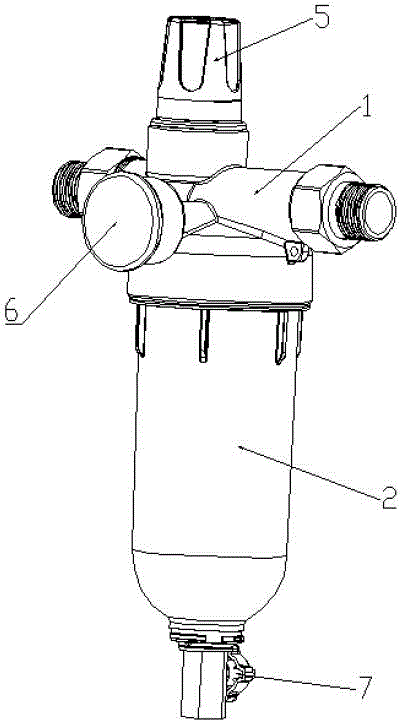

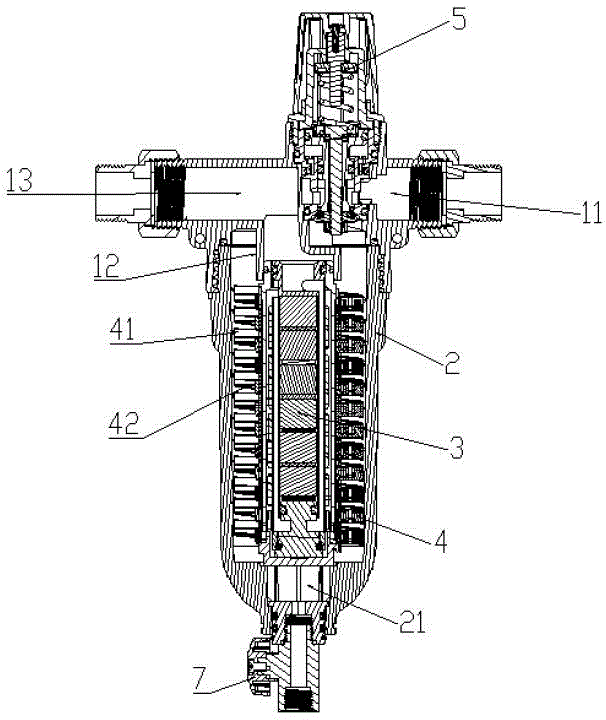

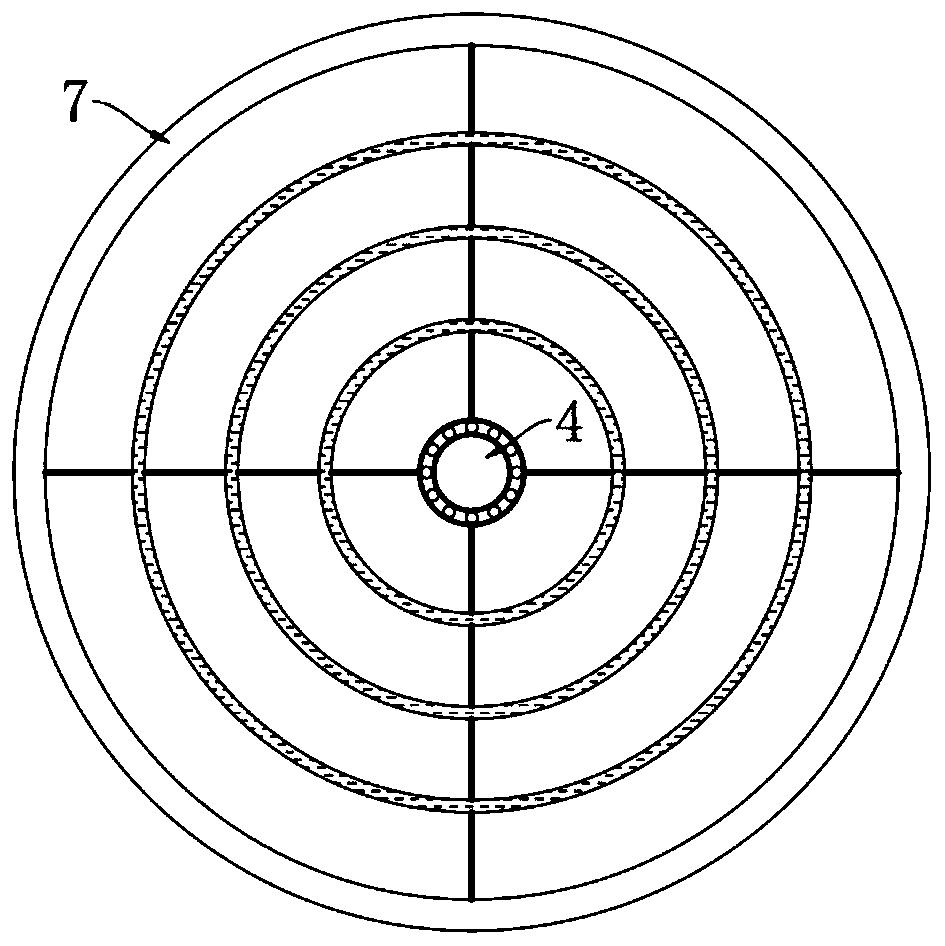

Front filter

ActiveCN104529047ASolve the technical defect of small filter areaImprove self-cleaning functionTreatment involving filtrationWater/sewage treatment by magnetic/electric fieldsFiltrationEngineering

The invention discloses a front filter which comprises an upper cover, a cylinder, a magnetization filter element and a spiral filter element, wherein the cylinder is fixed at the lower end of the upper cover; the magnetization filter element and the spiral filter element are arranged inside the cylinder; the bottom end of the upper end is opened; a water inlet and a water outlet which are isolated from each other are formed in two sides of the upper cover; the inner end of the water outlet extends downwards to form a filtration connector; the upper end of the cylinder is opened; the opening in the upper end of the cylinder is in sealed connection with the opening in the bottom end of the upper cover; the magnetization filter element is arranged in the center of the cylinder; the spiral filter element is arranged around the magnetization filter element. The magnetization filter element comprises a columnar magnetic core and outer tubes, wherein the columnar magnetic core is arranged in the center of the cylinder; the side wall of the top of the columnar magnetic core is in sealed connection with the filtration connector; the outer tubes are arranged at the periphery of the columnar magnetic core at intervals; inlets are formed in the side surfaces of the upper ends of the outer tubes; outlets which are communicated with the filtration connector are formed in the side surface of the upper end of the columnar magnetic core; the inlets and the outlets are opposite in direction. By adopting the spiral filtering net structure, not only is the filtration area increased, but also a cleaning function of a filtering net is achieved, and meanwhile due to arrangement of the magnetization filter element, filtered water can be sufficiently magnetized, so that the descaling purpose is achieved.

Owner:深圳市爱瑞玛特环境科技有限公司

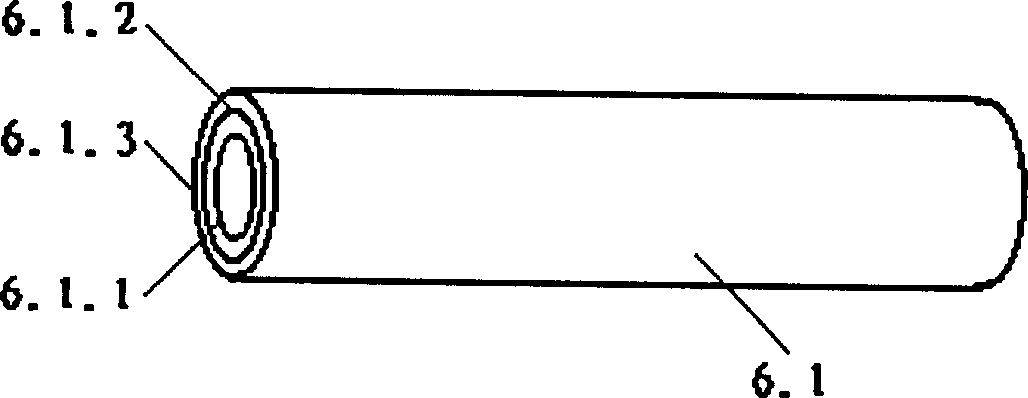

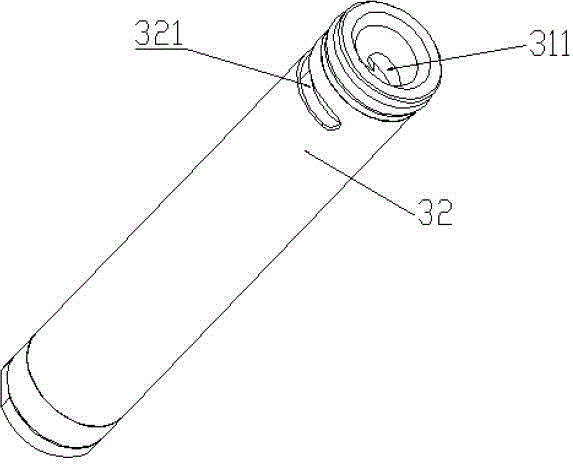

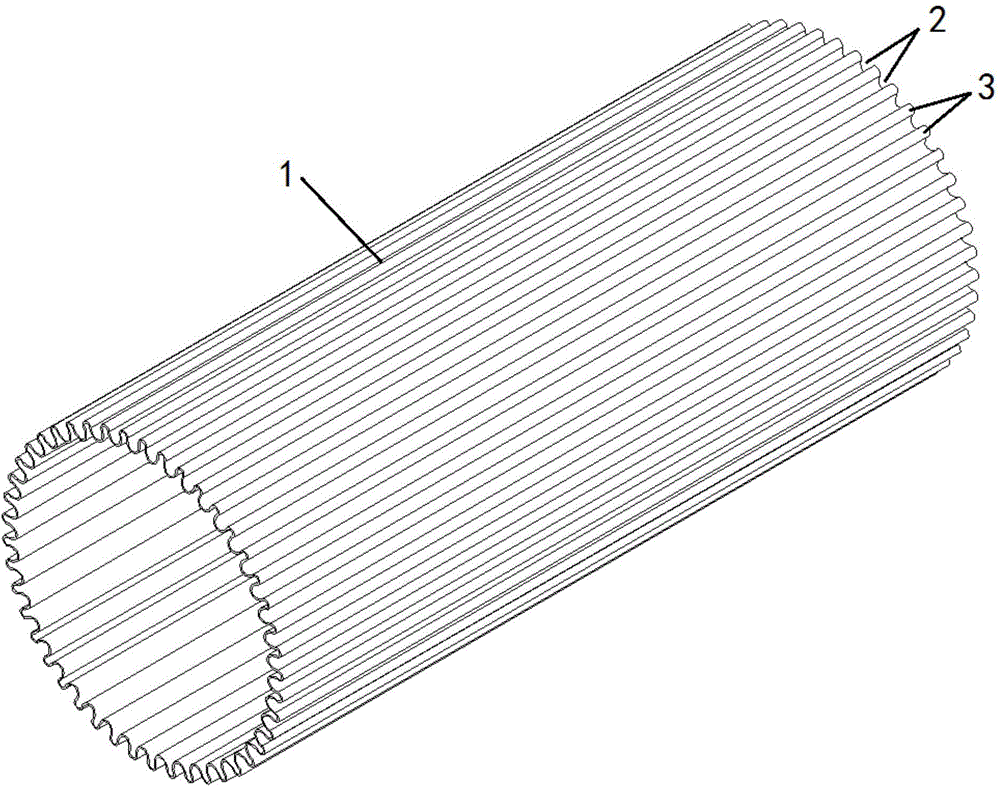

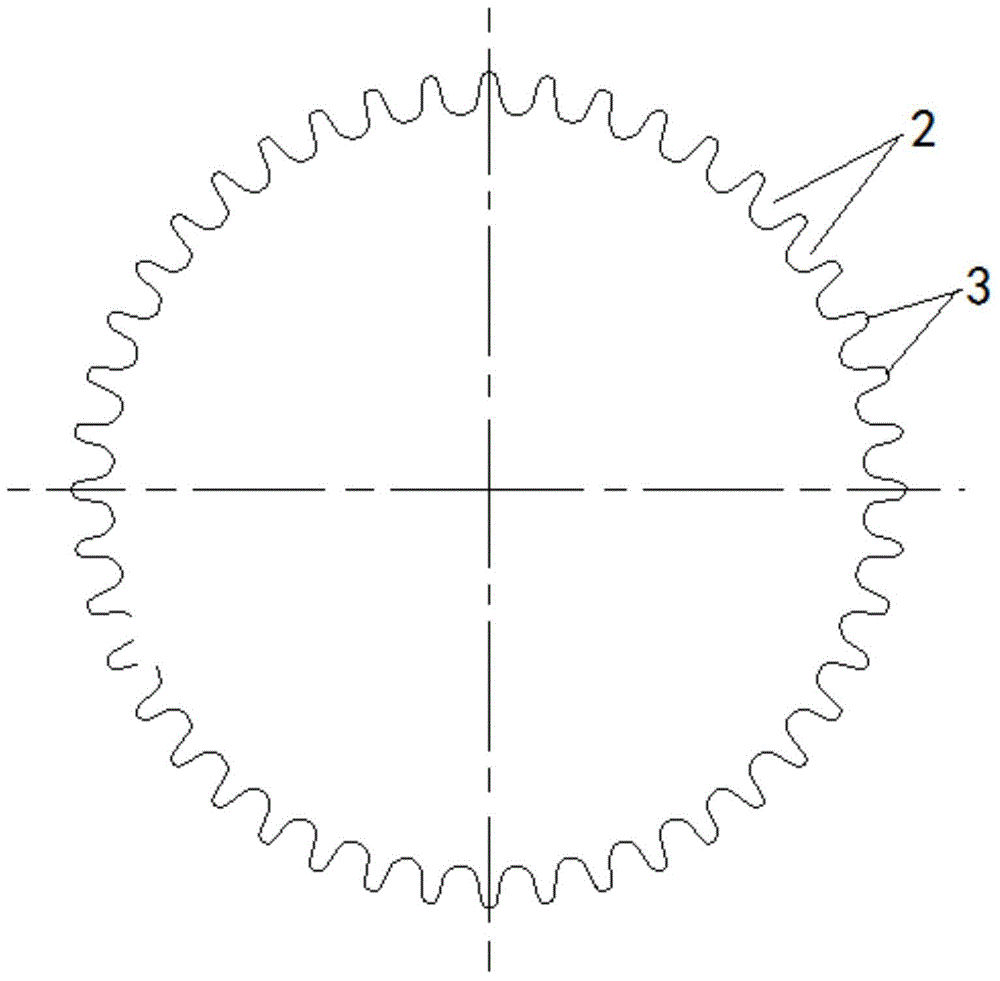

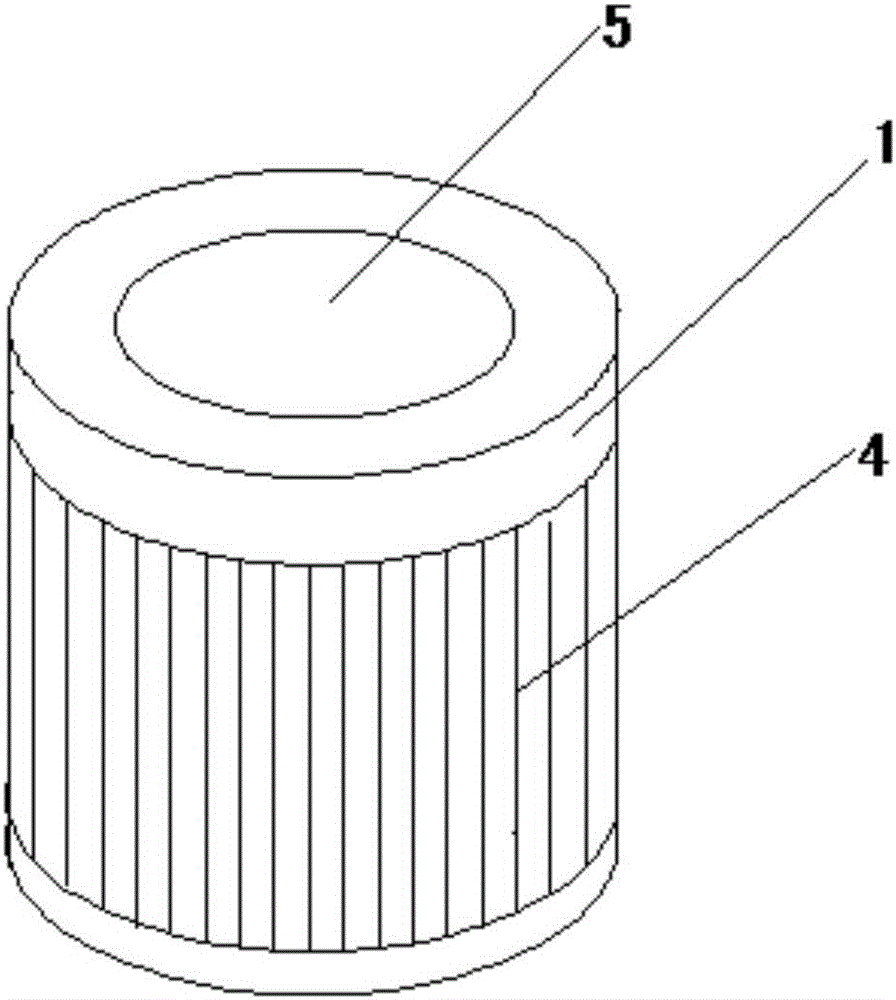

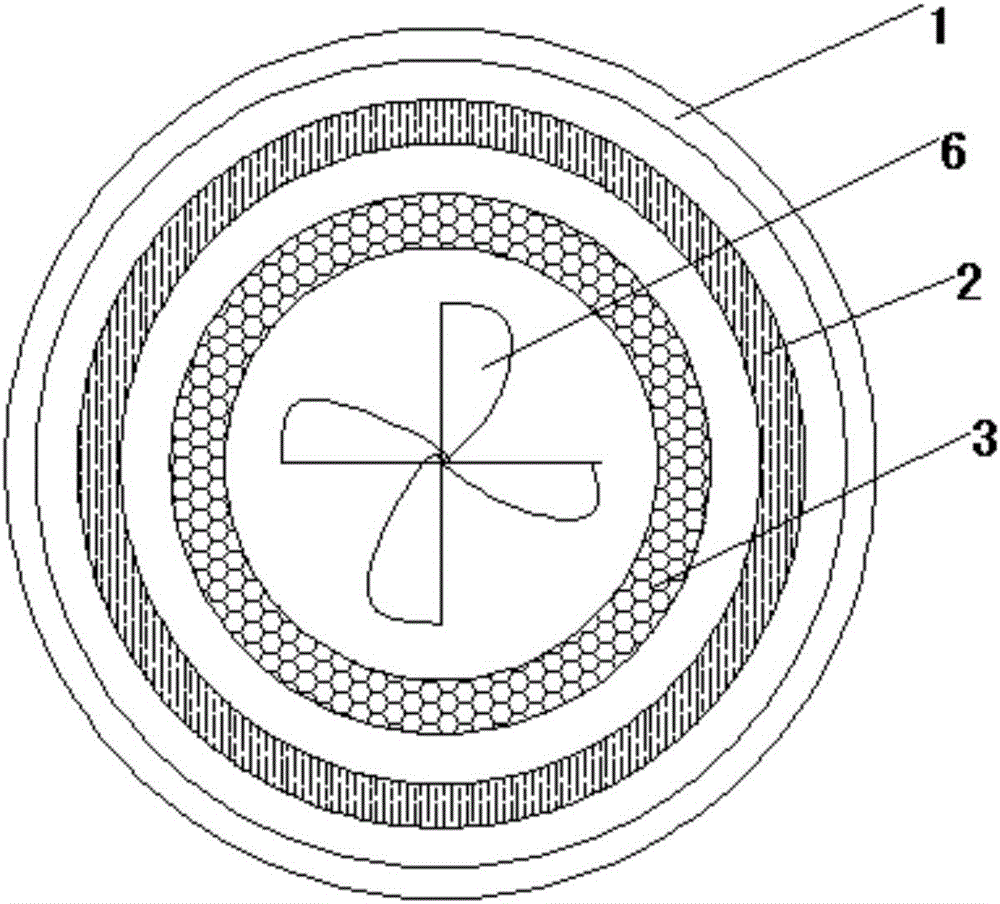

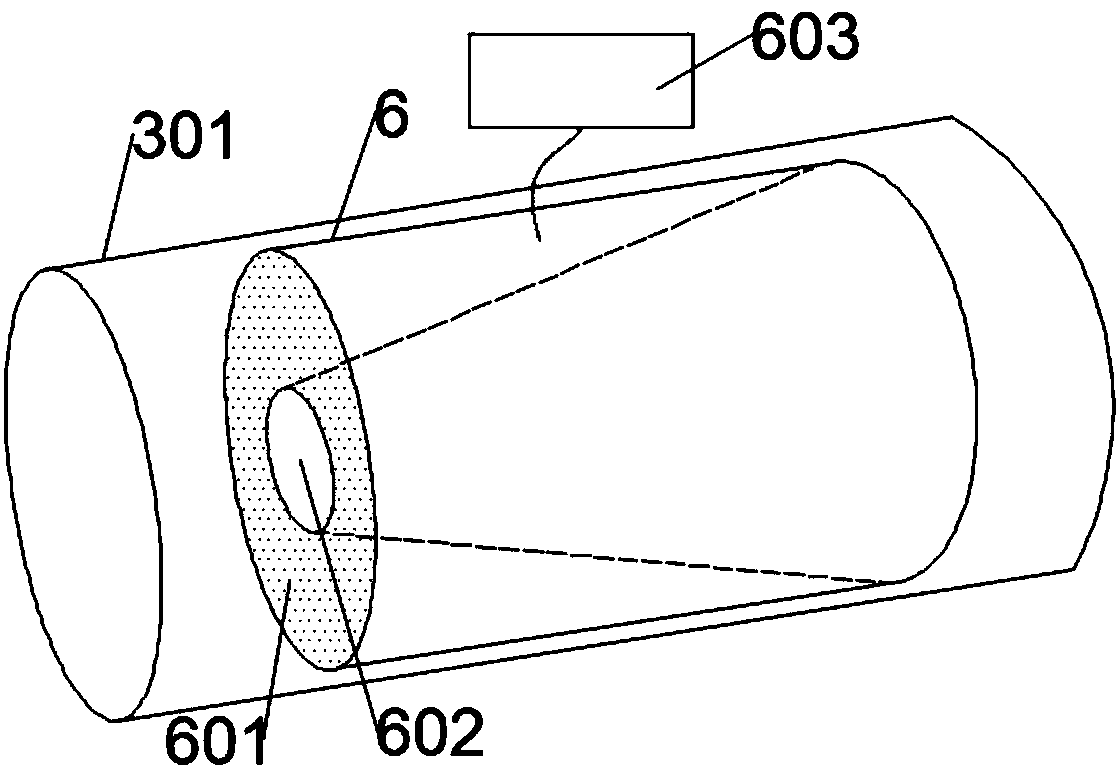

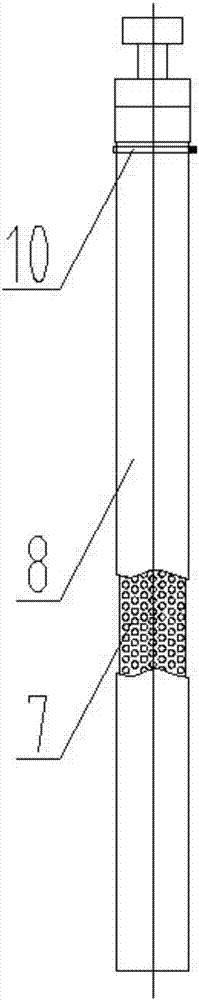

Elastomer corrugated filter tube

InactiveCN104906885AImprove filtering effectRestore filter capacityDispersed particle filtrationElastomerAcoustic wave

The invention discloses an elastomer corrugated filter tube. Metal sintered felt is coiled to form a cylindrical tubular filter element, the surface of the filter element is provided with a plurality of grooves and raised lines extending along the axial direction, the external tubular surface of the filter element is provided with the grooves and the raised lines alternately, and each raised line serves as a connection part of two adjacent grooves. The elastomer corrugated filter tube is greatly suitable for gas-solid and gas-liquid separation occasions. During the use process of the elastomer corrugated filter tube, gas with impurities impacts the grooves and the raised lines, dust in the gas with impurities falls or gathers in the grooves, the raised lines can keep good filtering performance continuously, and when the dirt holding quantity of the filter element reaches a certain limit, dirt can be cleaned in a backwashing type sound wave manner, a vibrating manner and other manners so as to recover the filter capacity. According to the invention, the metal sintered felt can be further directly prefabricated into an elastic corrugated plate sheet, the grooves and the raised lines can be in an arc transition state, and thus fatigue failure can be effectively prevented.

Owner:上海境业环保能源科技股份有限公司

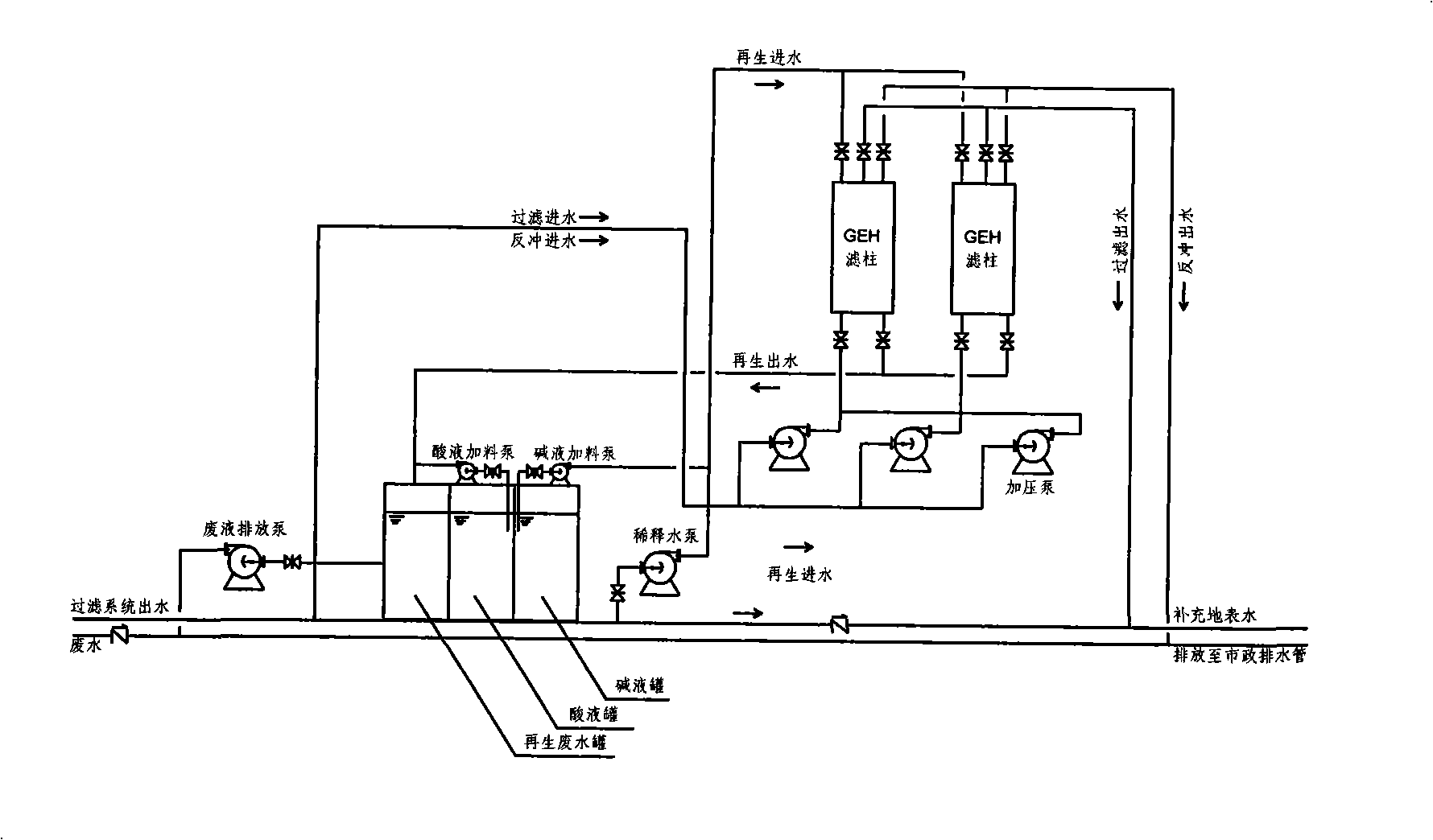

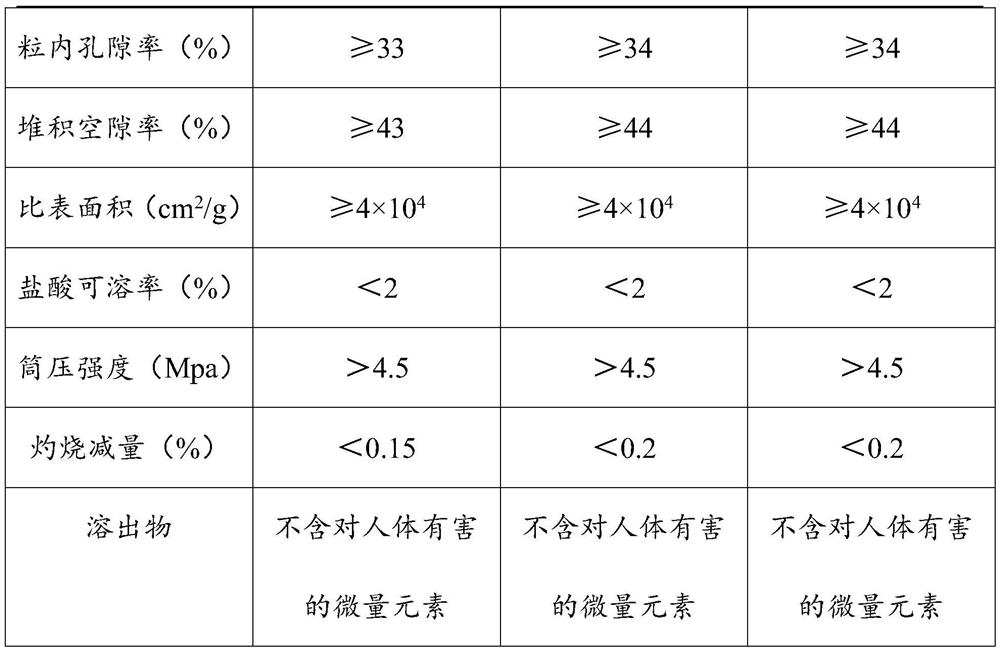

Preparation of hydroxyl oxidize iron modified filtering material and application

InactiveCN101279167ASmall particle sizeImprove adsorption removal effectFiltration separationHigh absorptionFilter media

The invention discloses a preparation method of hydroxyl oxidize iron modified filter media and application thereof, which relates to a preparation method of the modified filter media and the application thereof. The invention solves the problems that adsorption strength on a carrier is low, an absorption layer is easy to drop off and the service life of the filter media is short in the currently adopted modified filter media. The preparation method of the hydroxyl oxidize iron modified filter media comprises the steps that: first, the carrier is soaked in acid and then soaked in a ferric chloride solution; second, washing is carried out; third, drying is carried out. The hydroxyl oxidize iron modified filter media is obtained. The hydroxyl oxidize iron modified filter media of the invention is used for purifying water. The hydroxyl oxidize iron modified filter media prepared by the invention has large specific surface area and high absorption strength and does no harm to human bodies; the combination between hydroxyl oxidize iron and the carrier is relatively firm and service life is long.

Owner:HARBIN INST OF TECH

Method for repairing and modifying waste reverse osmosis membrane

PendingCN111437729ATrapped Performance RestorationPromote recyclingReverse osmosisWater/sewage treatment bu osmosis/dialysisChemistryPolyamide

The invention discloses a method for repairing and modifying a waste reverse osmosis membrane. The method comprises the following specific steps: (1) degrading a surface polyamide separation layer ofthe waste reverse osmosis membrane by adopting sodium hypochlorite; (2) physically coating the surface of the membrane with tannic acid; and (3) carrying out chemical crosslinking by using glutaraldehyde to obtain the repaired and modified reverse osmosis membrane. The method is beneficial to promotion of resource recycling.

Owner:TIANJIN POLYTECHNIC UNIV

Multi-dimensional space filter material scrubbing method

InactiveCN1640523AImprove cleanlinessRestore filter capacityLoose filtering material filtersGravity filtersWater flowAnthracite

The invented multi-dimensional space filtering material scrubbing method relates to a method for treating waste water. Said method is characterized by that in the container filled up with filtering material said invention utilizes the scrubbing air flow formed from rotary pressure air flow in the filtering material and upward pressure air flow in the lower portion of filtering material, scrubbing water flow of upward pressure water flow or / and addition of promoting agent to scrub the filtering material. Said invention is applicable to fibre ball filtering material, and also is applicable to filtering materials of quartz sand, active carbon, anthracite coal, manganese sand, magnetite granules and ceramsite, etc.

Owner:杨静

Anti-blocking floor drain

ActiveCN111501971AReduce resistanceWith drag reducing effectSewerage structuresClimate change adaptationCoil springScrew thread

The invention discloses an anti-blocking floor drain. The anti-blocking floor drain comprises a floor drain body and a fine screen net placed at the upper end of the floor drain body, a saw cutting disc and a coarse screen net are parallelly arranged in the floor drain body in a clamped mode from top to bottom, the saw cutting disc and the coarse screen net are jointly supported with a straight rod through a bearing, a conical block and a limiting plate are correspondingly and fixedly arranged at the upper end and the lower end of the straight rod, chutes are equidistantly formed in the outerside wall of the conical block in a surrounded mode, a threaded groove is formed in the side wall of the straight rod, the threaded groove is located below the coarse screen net, the straight rod is connected with a mesh grid through the threaded groove in a threaded mode, the mesh grid is slidably connected with the inner side wall of the floor drain body in a sealed mode, top columns are uniformly distributed on the upper surface of the mesh grid, the straight rod is fixedly connected with a coil spring, and the coil spring is located between the saw cutting disc and the coarse screen net. According to the anti-blocking floor drain, the drainage speed of the floor drain can be increased, the long hair can further be prevented from blocking the floor drain, and the difficulty of cleaningthe hair in the floor drain is lowered.

Owner:台州联豪自动化设备有限公司

filter press

ActiveCN108031154BRestore filter capacityImprove filtering effectFiltration circuitsForeign matterHydraulic cylinder

Owner:ZHEJIANG FENGAN BIOPHARM

Easy-to-maintain air purifier

InactiveCN106225097AReduce spawn rateExtended service lifeMechanical apparatusSpace heating and ventilation safety systemsElectrostatic adsorptionEngineering

The invention discloses an easy-to-maintain air purifier. The air purifier comprises a casing, a filter element and a fan, wherein the filter element comprises an electrostatic adsorption device and a diatomite filter element; the casing is cylindrical; the side wall of the casing is an air inlet port; the top of the casing is an air outlet; the electrostatic adsorption device is located on the inner side of the air inlet; the diatomite filter element is located on the inner side of the electrostatic adsorption device; the fan is arranged at the top of the center of the casing; the outer wall of the electrostatic adsorption device is coated with a visible-light photocatalyst coating; and an air detection device is arranged at the air outlet, comprises a particle detection module and an ozone detection module and is connected with an alarm lamp. The easy-to-maintain air purifier produces a small amount of ozone, the service life of the filter element is long, the purifying capacity can be regenerated through cleaning, automatic warning can be realized when cleaning and replacement are required, and thus later maintenance is simple, convenient and easy to operate.

Owner:昆山初本电子科技有限公司

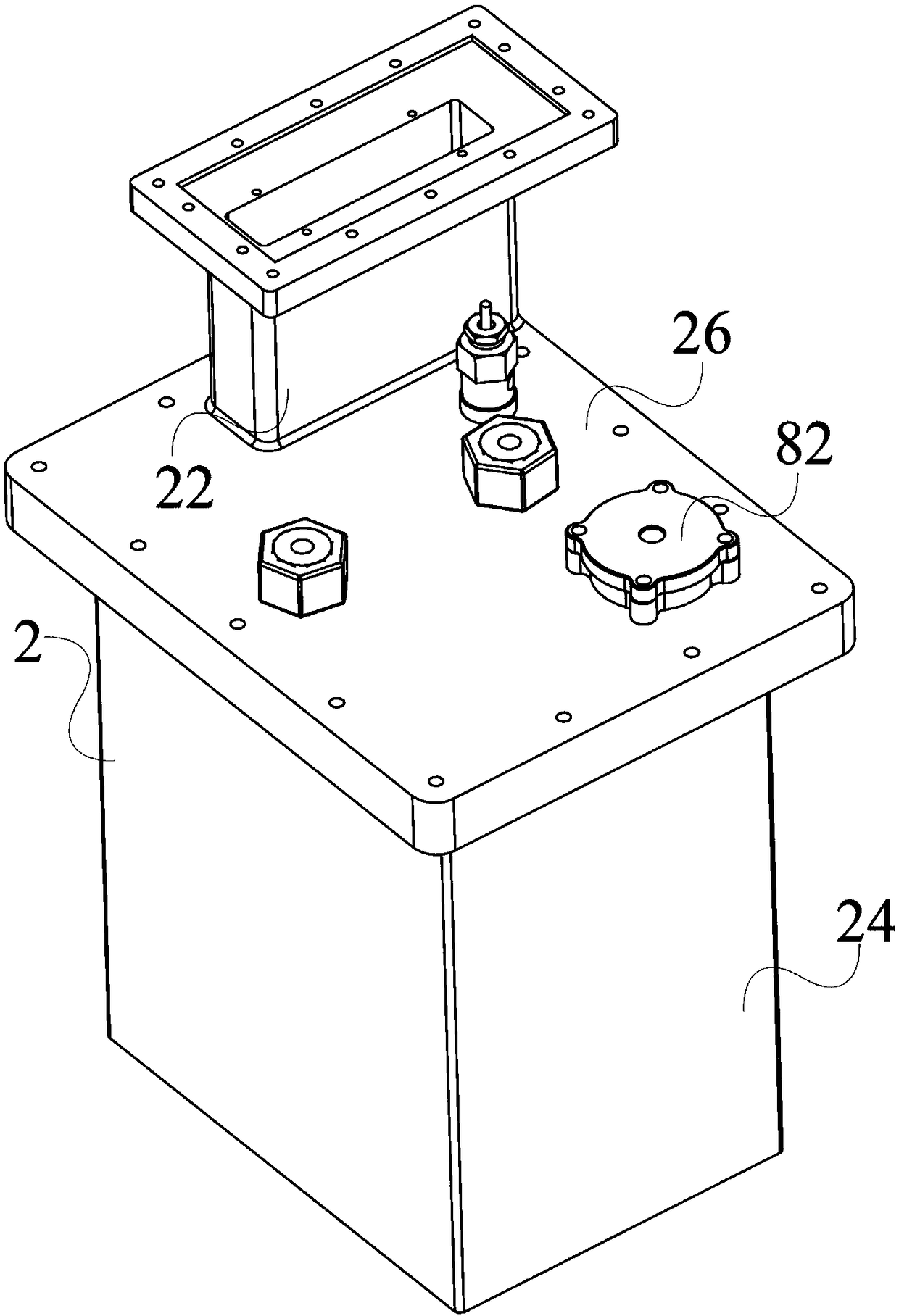

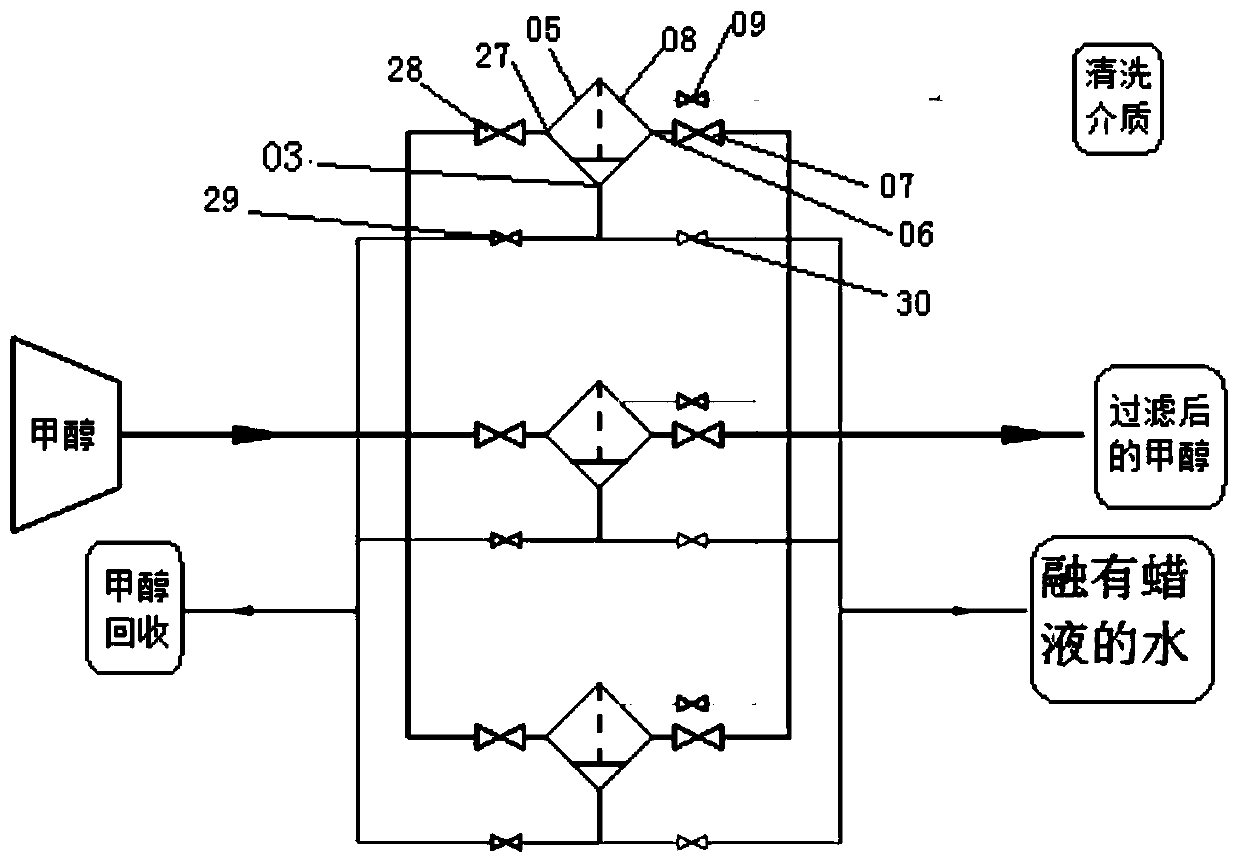

Methanol filtering device, system and method for wax removal of methanol system

PendingCN109758821AReduce lossesReduce pollutionFiltration separationHydroxy compound separation/purificationWax removalChemistry

The invention belongs to the technical field of methanol filtrating equipment, and provides a methanol filtering device, system and method for wax removal of a methanol system. The technical problem that wax is formed in a water system of an existing device for preparing olefin from methanol and is prone to blocking pipelines and equipment is solved. The methanol filtering device comprises a tankbody, an inner tank and a filtering unit, wherein the inner tank is arranged in the tank body, and a liquid storage cavity is formed by the outer wall of the inner tank and the inner wall of the tankbody. The tank body is provided with a methanol inlet and a methanol outlet. The methanol inlet is in communication with the liquid storage cavity, and the methanol outlet is in communication with theinner tank. The filtering unit is disposed on the inner tank to form a flow passage. The methanol outlet is provided with a cleaning medium inlet. A discharge outlet is formed in the lower part of the tank body. The methanol filtering system includes at least two methanol filtrating devices. A methanol inlet valve is arranged on the methanol inlet of each methanol filtrating device, and a methanol outlet valve is arranged on the methanol outlet of each methanol filtrating device. Cleaning medium valves are arranged on the cleaning medium inlets. A tee is arranged at each discharge outlet, anda methanol recovery valve and a wax liquid discharge valve are correspondingly disposed on each tee.

Owner:无锡联合超滤净化设备科技有限公司

Cleaning method of filter press

ActiveCN103933763ASave labor and timeReduce labor intensityFiltration separationHigh pressureExhaust valve

The invention discloses a cleaning method of a filter press. The method comprises the steps of arranging a drug inlet pipeline valve on a mud inlet pipeline of the filter press, arranging a flange blind plate at an outlet of a filtrate pipeline, and arranging an exhaust valve and a reflux pipeline valve on the filtrate pipeline above the filter press; in a state that the filter press is pressed, opening the drug inlet pipeline valve, the exhaust valve and the reflux pipeline valve, and sending a cleaning reagent pump into the filter press until drug liquid flows outside from a reflux pipeline; then, closing the drug inlet pipeline valve and the reflux pipeline valve, and soaking for 8-24h; loosening a filter plate, emptying the cleaning reagent, and cleaning the residue attached on the filter plate, a filtrate hole and a piece of filter cloth by a high-pressure water gun. After the cleaning method is adopted, the matter which is attached on the filter plate and the filter cloth of the filter press and is difficult to dissolve and clean can be cleaned once, so that a great deal of labor force and time can be saved, the labor intensity of operators can be lightened, and the process is simplified; the cleaning method is capable of prolonging the service lives of the filter plate and the filter cloth of the filter press as well as other accessory equipment.

Owner:GUANGDONG ESQUEL TEXTILES

Hemodialysis device for kidney internal medicine

ActiveCN107929838AEasy to fixReduce preparation timeOther blood circulation devicesMedical devicesHemodialysisVein

The invention discloses a hemodialysis device for kidney internal medicine. The hemodialysis device comprises a shell, a blood inlet and outlet device is connected to the shell, a wire rack is installed outside the shell, the blood inlet and outlet device includes an arterial needle and a venous needle, the arterial needle and the venous needle are connected with a blood outlet vessel and a bloodreturn vessel respectively, the blood outlet vessel is connected with a blood pump, the blood pump is connected with a dialysis device through an intermediate tube, the dialysis device is installed inthe shell, an anticoagulant injector and a one-way valve are respectively installed at the top side and right end of the intermediate tube, and a blood insulation device is installed in the blood return vessel. According to the hemodialysis device, the hemodialysis preparation time is short, medical hollow fibers have good quality and high filtration efficiency for blood of a patient and can be washed through a cleaning tube, long-term high-efficiency hemodialysis can be effectively performed, the blood in the blood return vessel is similar to the blood temperature in the body of the patientafter insulation, the blood flow is smooth, and the patient is more comfortable.

Owner:QINGDAO MUNICIPAL HOSPITAL

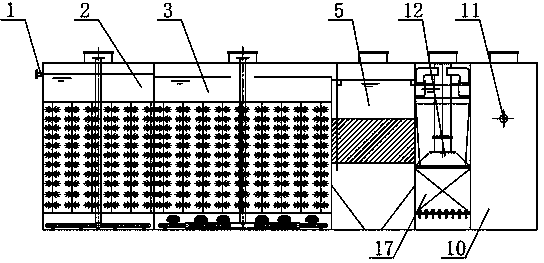

Integrated domestic wastewater treatment device

ActiveCN103819059AEnsure consistencyGuaranteed integrityMultistage water/sewage treatmentControl mannerFiltration

The invention discloses an integrated domestic wastewater treatment device. The integrated domestic wastewater treatment device comprises a hydrolysis acidification tank, a contact oxidation tank, a secondary sedimentation tank, a biological filtration tank and a quartz sand filtration tank which are connected in sequence, wherein an intermediate water tank is arranged between the biological filtration tank and the quartz sand filtration tank, and the three tanks are closely adjacent to each other in sequence; the filtering materials in the filtration areas of both the biological filtration tank and the quartz sand filtration tank are located below the filtration tanks, and a reversely cleaning device is arranged above the filtration areas. According to the invention, the tank-type biological filtration tank and the tank-type filter are integrated in previous treatment equipment so as to form integrated treatment equipment, as a result, a water flow naturally flows through each functional area from top to bottom, extra lifting pump is needless, valves and connecting pipelines are not required to be arranged in the biologic filtration tank and the filtration area, the consistency and integrity of the equipment are fully ensured, the filed mounting can be quickly performed, besides, embedding is convenient to perform, the occupied area is decreased, the control manner is simplified, the working energy consumption and noise pollution are lowered, and the formation of modularized and mass standard product is facilitated.

Owner:JIANGSU XINYU TIANCHENG ENVIRONMENTAL PROTECTION ENG

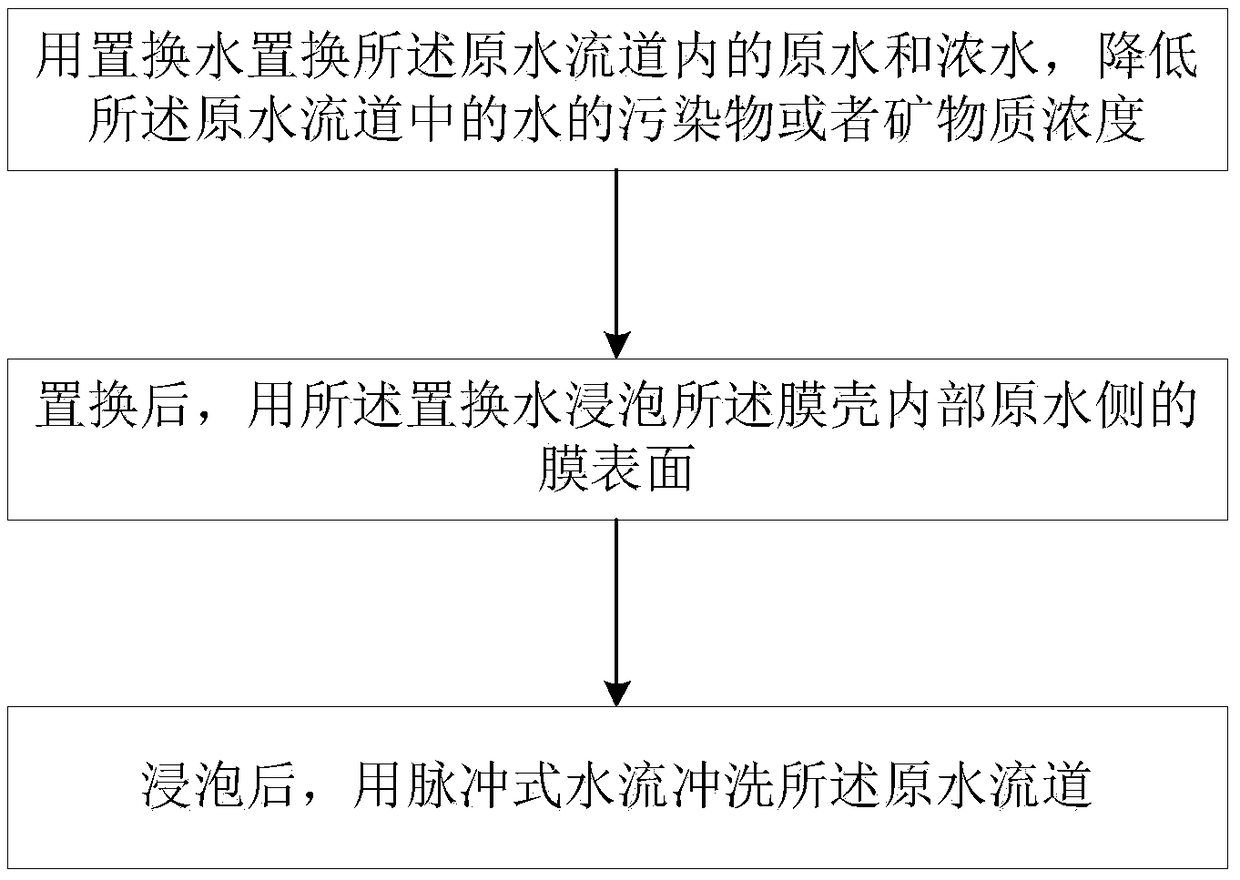

Method capable of recovering filter performance of roll type membrane assemblies for household water purifiers

PendingCN109078499ARestore filter capacitySemi-permeable membranesSpecific water treatment objectivesHigh concentrationSilt Density Index

The invention discloses a method capable of recovering the filter performance of roll type membrane assemblies for household water purifiers. The method includes a displacement step: displacing raw water and concentrated water in raw water flow channels by displacement water and reducing the concentration of pollutants or minerals in water in the raw water flow channels; a soaking step: soaking the surfaces of membranes on raw water sides inside membrane shells in the displacement water after the raw water and the concentrated water are displaced; a pulse rinsing step: rinsing the raw water flow channels by pulse type water flow after the surfaces of the membranes are soaked in the displacement water. The displacement water for displacing the raw water and the concentrated water at the displacement step is purified water or pure water. Compared with the prior art, the method capable of recovering the filter performance of the roll type membrane assemblies for the household water purifiers has the advantages of applicability to recovering the filter performance of the membranes blocked by SDI (silt density index) pollutants due to a large quantity of colloid in the water and applicability to recovering the filter performance of the membranes blocked by calcium carbonate and magnesium carbonate which are deposited on the surfaces of the membranes due to high concentration of calcium and magnesium ions in the water.

Owner:JIANGSU CIKON ENVIRONMENTAL APPLIANCE CO LTD

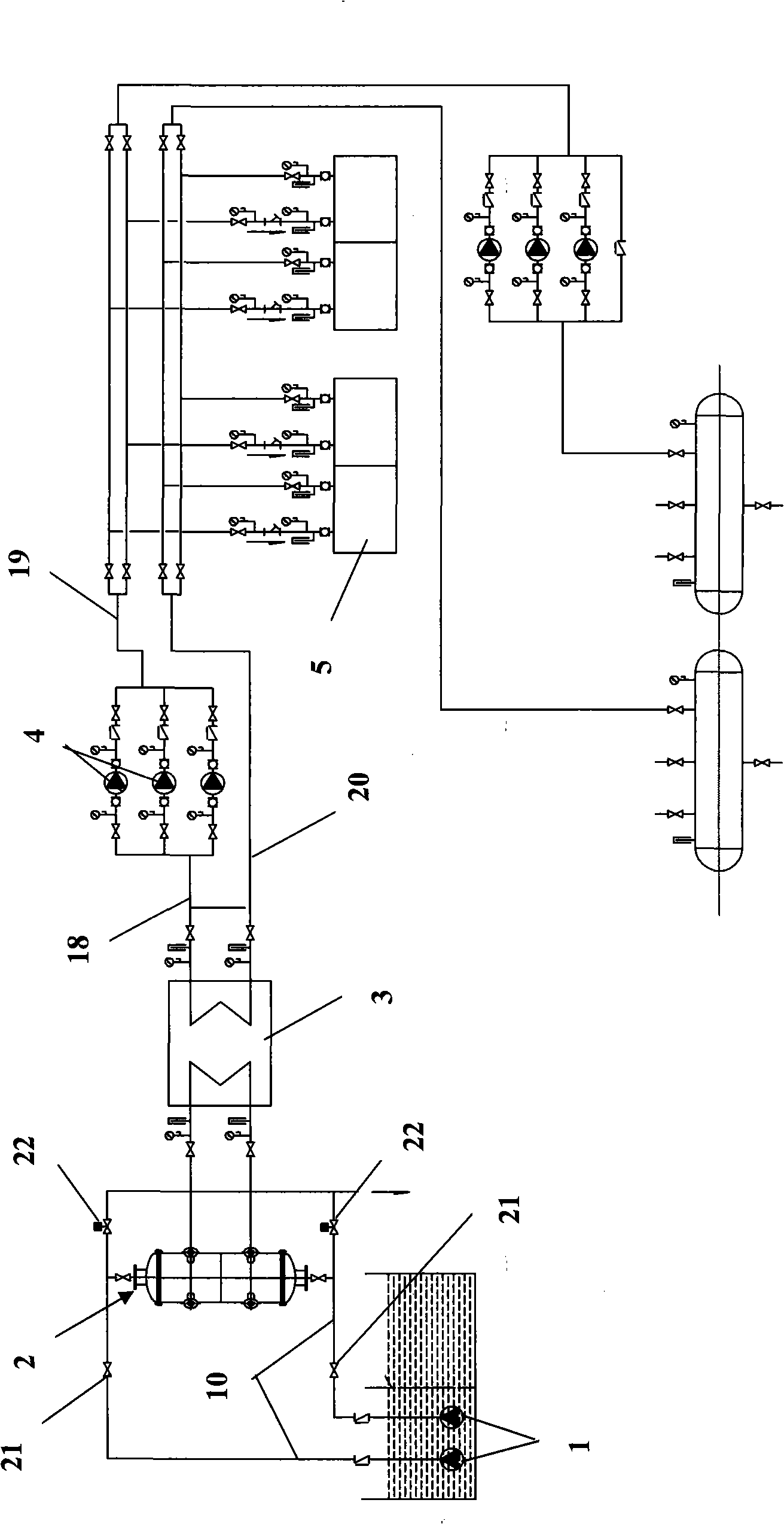

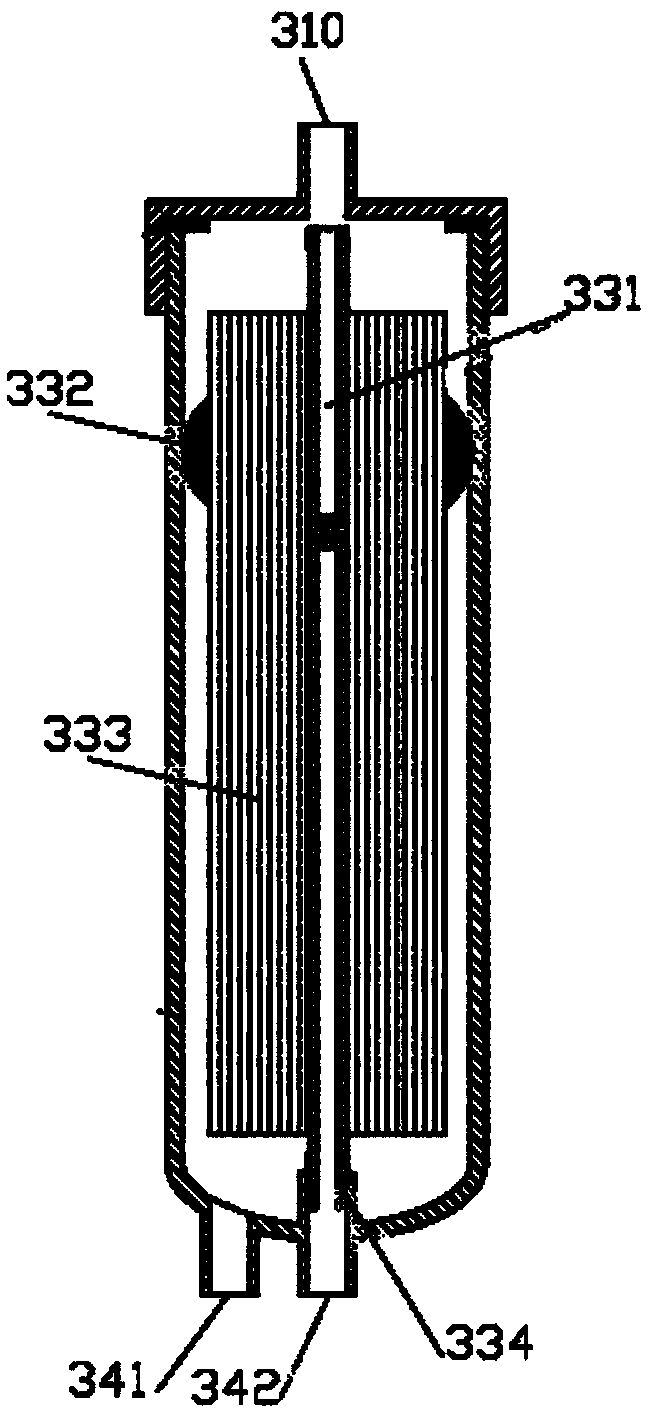

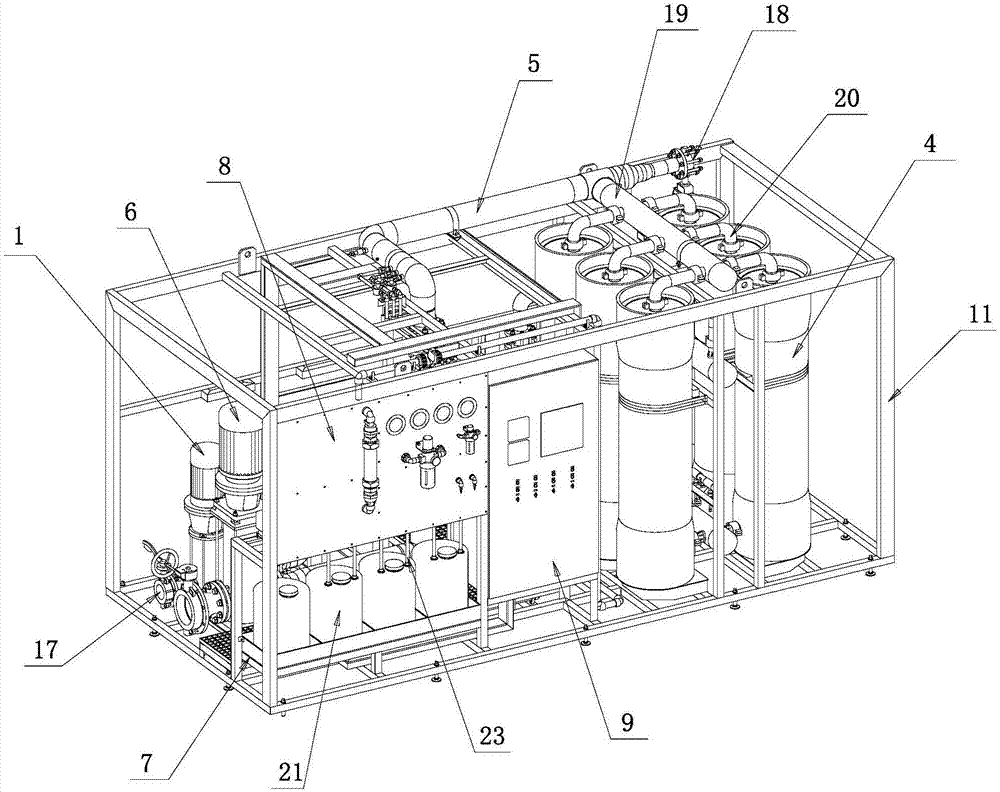

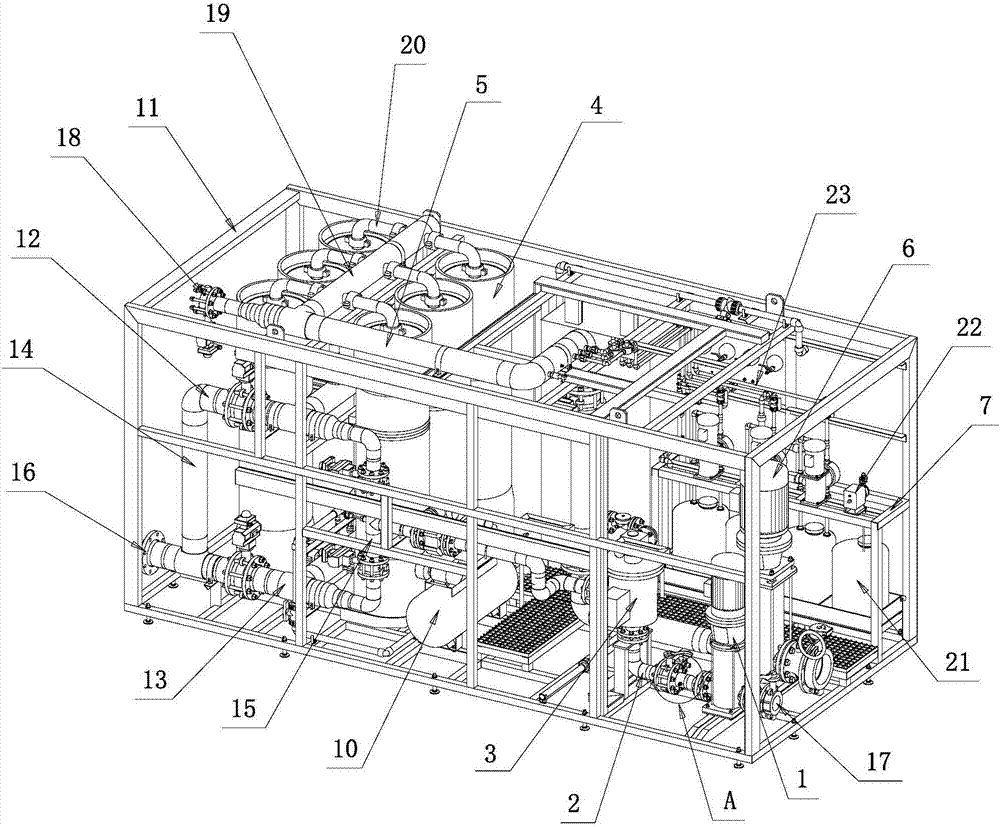

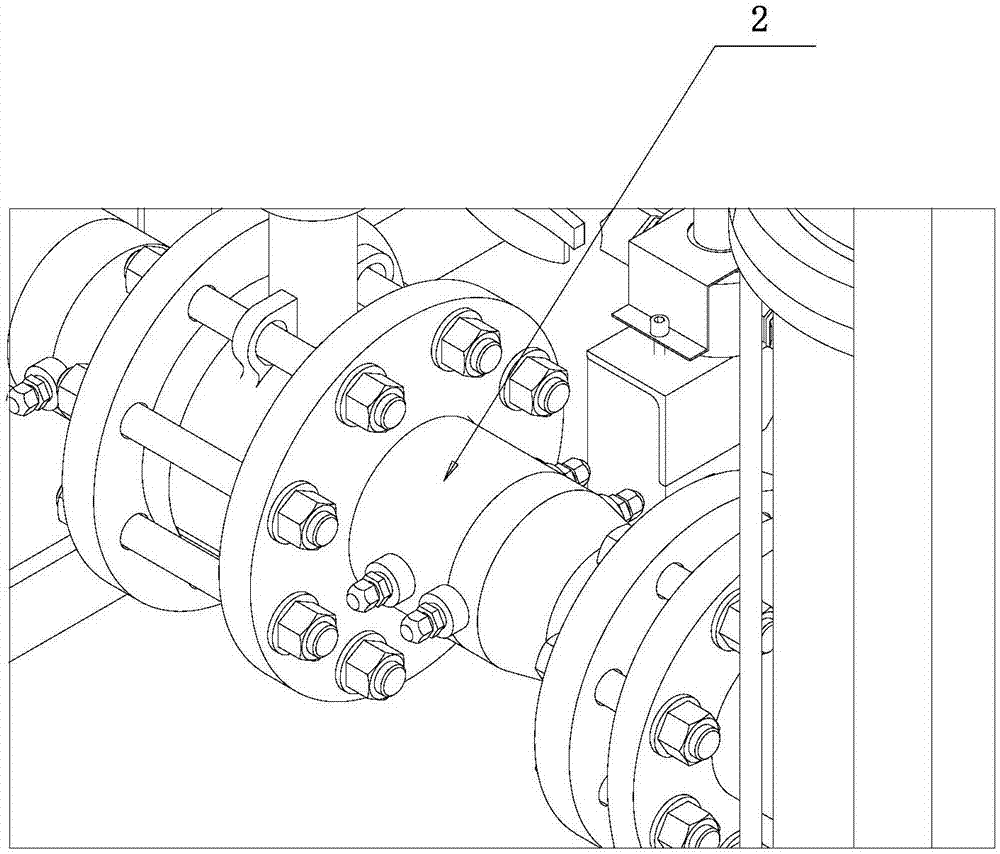

Integrated ultrafiltration water purification device

PendingCN107224877AReduced membrane fluxRestore filter capacityWater contaminantsUltrafiltrationUltrafiltrationRaw water

The invention discloses an integrated ultrafiltration water purification device, comprising an integrated rack, an ultrafiltration membrane group, a water feed system, a water production system, a backwash system, an online cleaning and filtering device, a selective agent adding device and a control system, wherein the ultrafiltration membrane group comprises at least one ultrafiltration membrane pressure container with at least ten membrane filaments arranged on an inner plumb bob; the water feed system is communicated with raw water, is communicated with each ultrafiltration membrane pressure container, and is also communicated with the selective agent adding device and the online cleaning and filtering device in succession; the front and back ends of the water production system are communicated with each vertical ultrafiltration membrane pressure container and a water production tank respectively; the backwash system is communicated with backwash water and each vertical ultrafiltration membrane pressure container respectively; the control system is connected with other parts respectively. The integrated ultrafiltration water purification device disclosed by the invention is simple in structure, achieves general use and interchange of various membrane elements or pressure containers, is suitable for purification of various water qualities, is high in purification efficiency, and can effectively reduce the cost.

Owner:GREENTECH ENVIRONMENTAL CO LTD

Air filter device of industrial machine

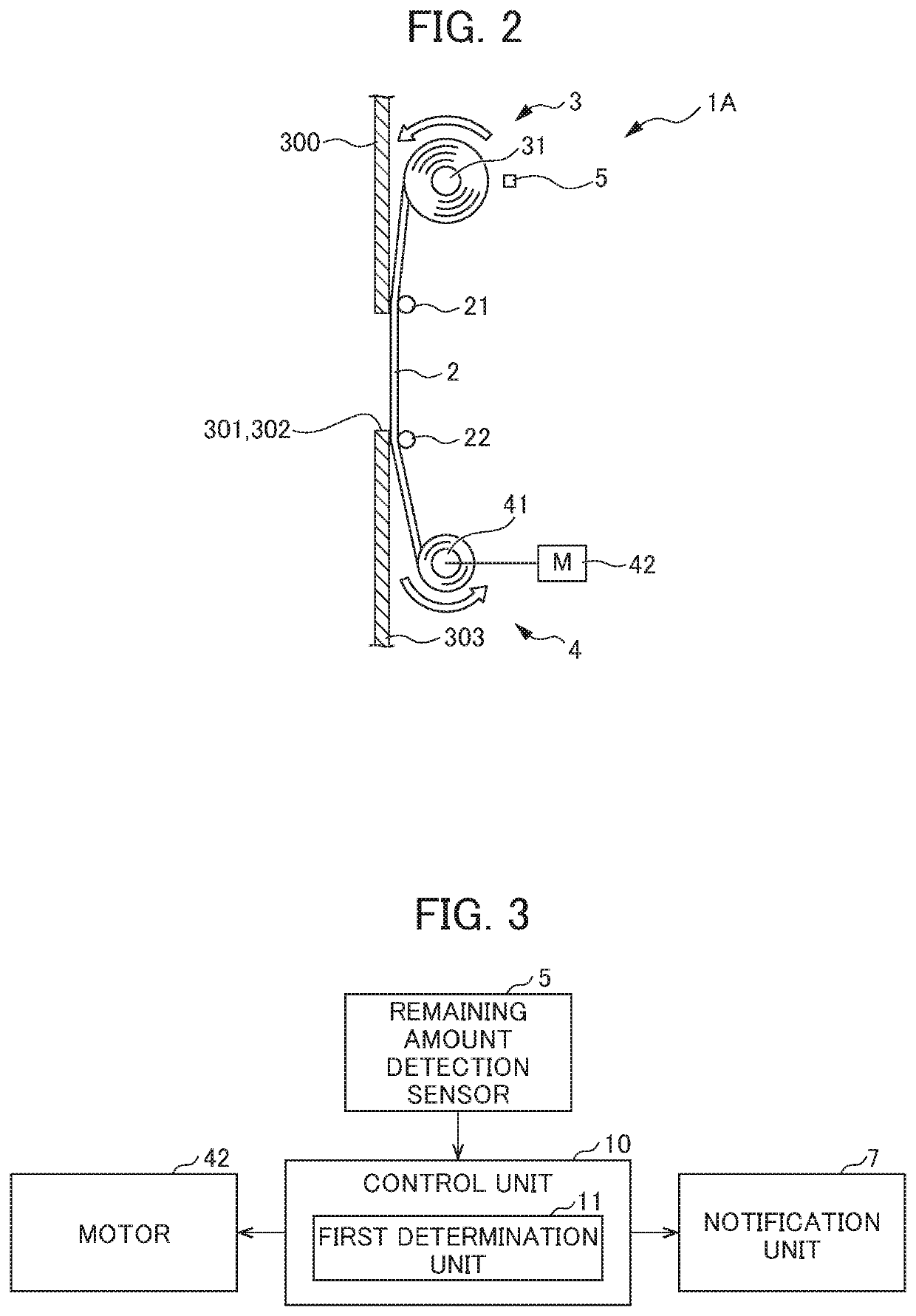

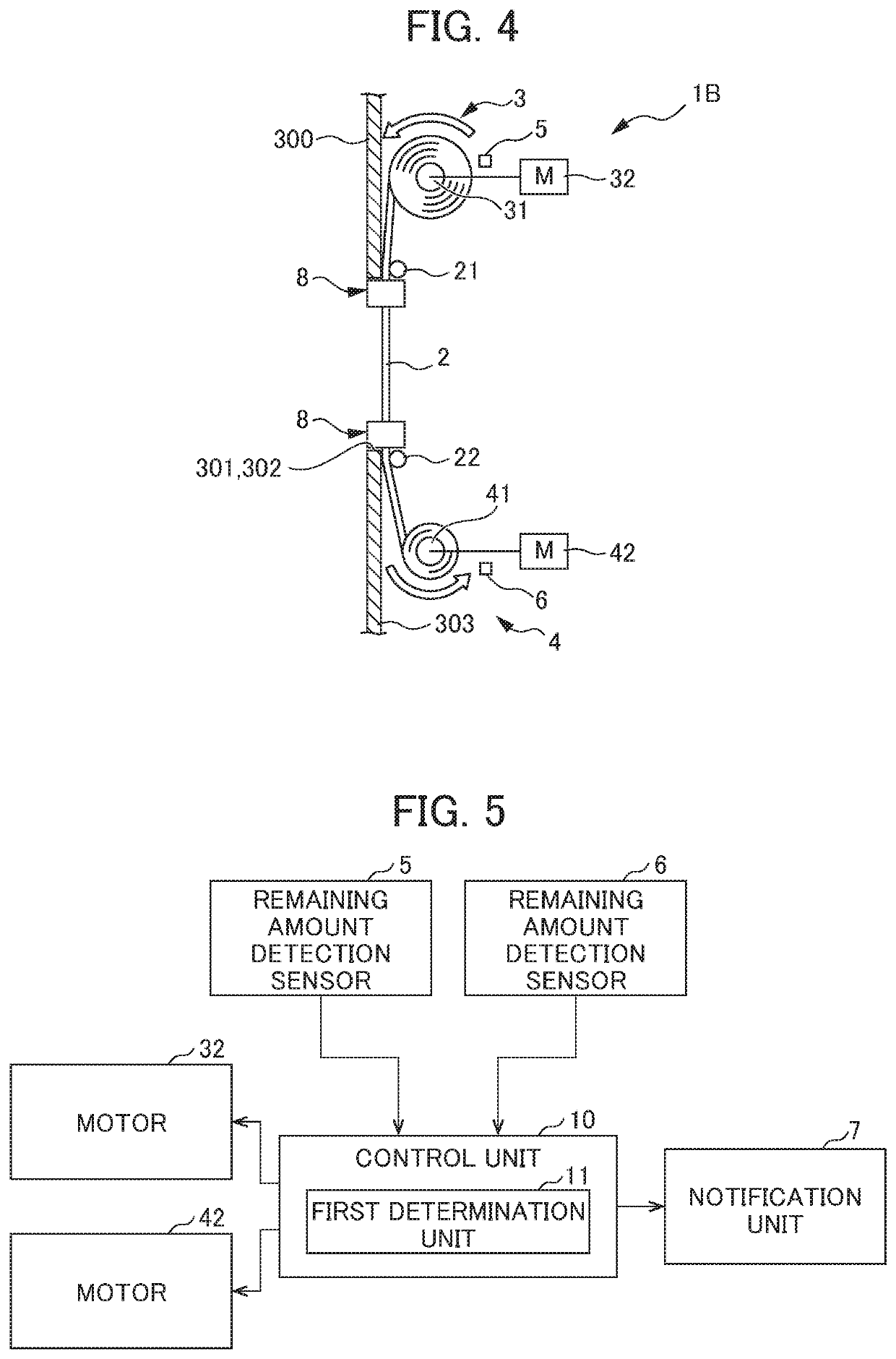

PendingUS20200338491A1Maintain performanceRestore filter capacityDispersed particle filtrationTransportation and packagingAir filtrationAir filter

An air filter device of an industrial machine in which an air filter is arranged in a filtered portion of the industrial machine is provided, the air filter device includes: a first operation unit which transports the long air filter toward the filtered portion; a second operation unit which collects the air filter transported from the first operation unit and used in the filtered portion; and a control unit which controls the drive of the first operation unit and the second operation unit and the control unit includes a first determination unit which determines whether or not the air filter in the first operation unit is about to run out or runs out, and outputs, when the first determination unit determines that the air filter is about to run out or runs out, a signal indicating that the air filter needs to be replaced.

Owner:FANUC LTD

Self-cleaning tank type filtering separator

ActiveCN107080994ACompact structureSpeed up filteringStationary filtering element filtersWaste managementSelf adaptation

The invention discloses a self-cleaning tank type filtering separator which comprises a tank, a filtering assembly and a self-cleaning assembly. The filtering assembly comprises a filter pipe, a filter bag and the like. A filter hole is formed in the filter pipe, the upper end of the filter pipe is communicated with the interior of a water tank through a spherical pipe joint, and the filter pipe is sleeved with the filter bag which is fixed in a clamped mode. A water box and the tank are fixed. The self-cleaning assembly comprises a tank cover, a scraper blade, a scraping ring, a lead screw and the like; the tank cover is provided with a bearing pedestal and fixedly connected with the water box; the scraping ring is clamped into the scraper blade and provided with a movable clearance; the scraping ring penetrates through the filter bag and the filter pipe; a lead screw nut and the scraper blade are fixed; one end of the lead screw and the lead screw nut form a screw pair, and the other end of the lead screw is provided with a movable sealing ring, a bearing and a chain wheel and the like and assembled with the tank cover; under the drive the forward and backward rotation of the motor, the chain wheel and the chain, the lead screw automatically rotates synchronously, the scraper blade is driven by the lead screw nut to horizontally move up and down, self-adaptation adjustment of the scraping ring on the scraper blade is achieved, and the filter bag is scraped and cleaned. The self-cleaning tank type filtering separator has the advantages that the structure is novel and reasonable, the sealing performance is good, the filtering capability is high, various self-cleaning modes are adopted, and long-term automatic operation can be achieved easily.

Owner:HUBEI JUNJI WATER TREATMENT

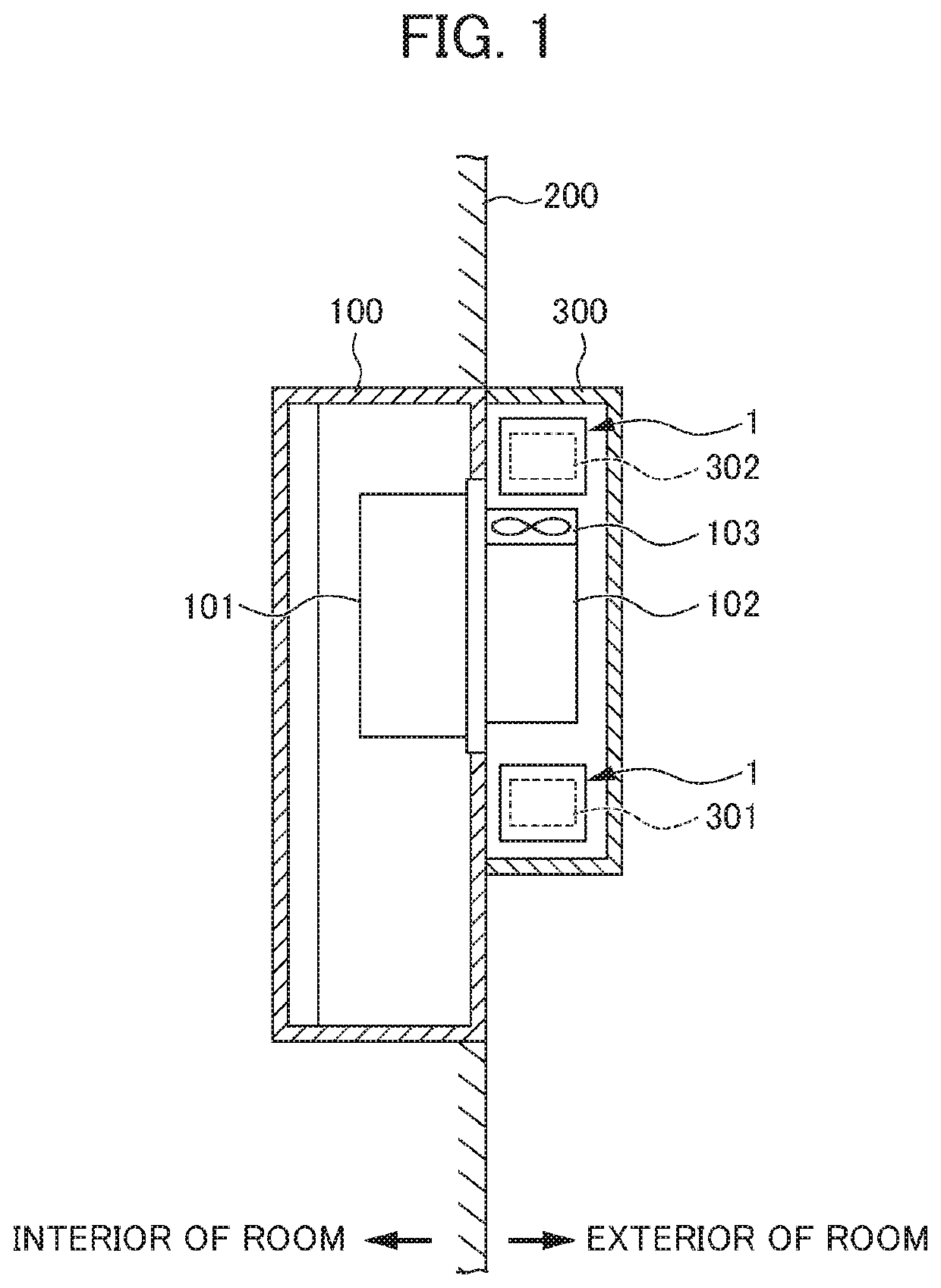

Indoor air purification device

PendingCN107036202ARestore filter capacityGuaranteed filtering effectMechanical apparatusSpace heating and ventilation safety systemsEngineeringIndoor air

An indoor air purification device comprises a housing and a controller, the housing comprises an air inflow part and an air changing part, a partition plate is disposed in the center of the air inflow part and divides the air inflow part into a left passage and a right passage, a left end of the air inflow part is provided with a left filter screen while a right end of the air inflow part is provided with a right filter screen, a direction-changing wind shield device is connected in a mobile manner at an inner end of the partition plate, both the left filter screen and the right filter screen are provided with circulating cleaning devices, an air extracting device is disposed inside the air inflow part, and a controller is connected with the direction-changing wind shield device, the circulating cleaning devices and the air extracting device. When the indoor air purification device is used for purifying indoor air, the cleaning efficiency of the device can be maintained, and troubles of cleaning the filter screens are avoided.

Owner:陈永胜

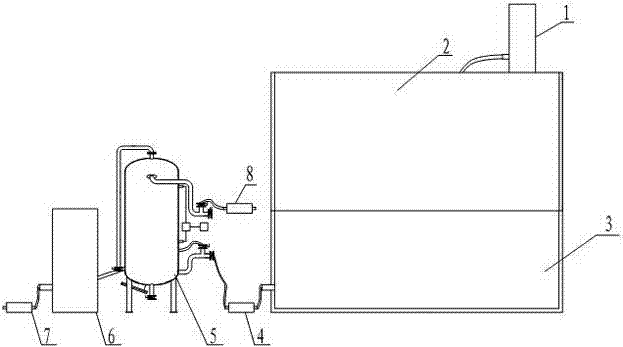

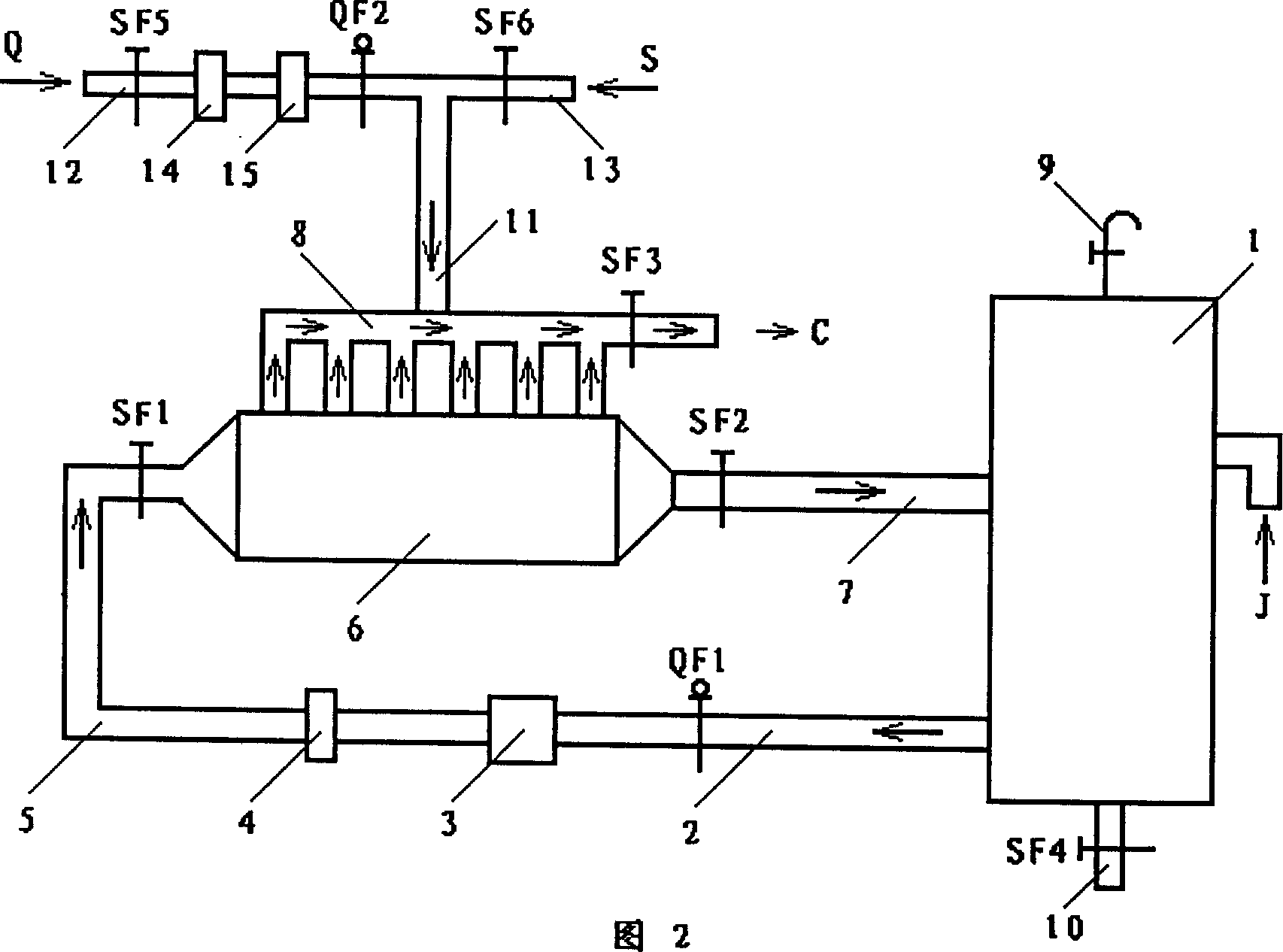

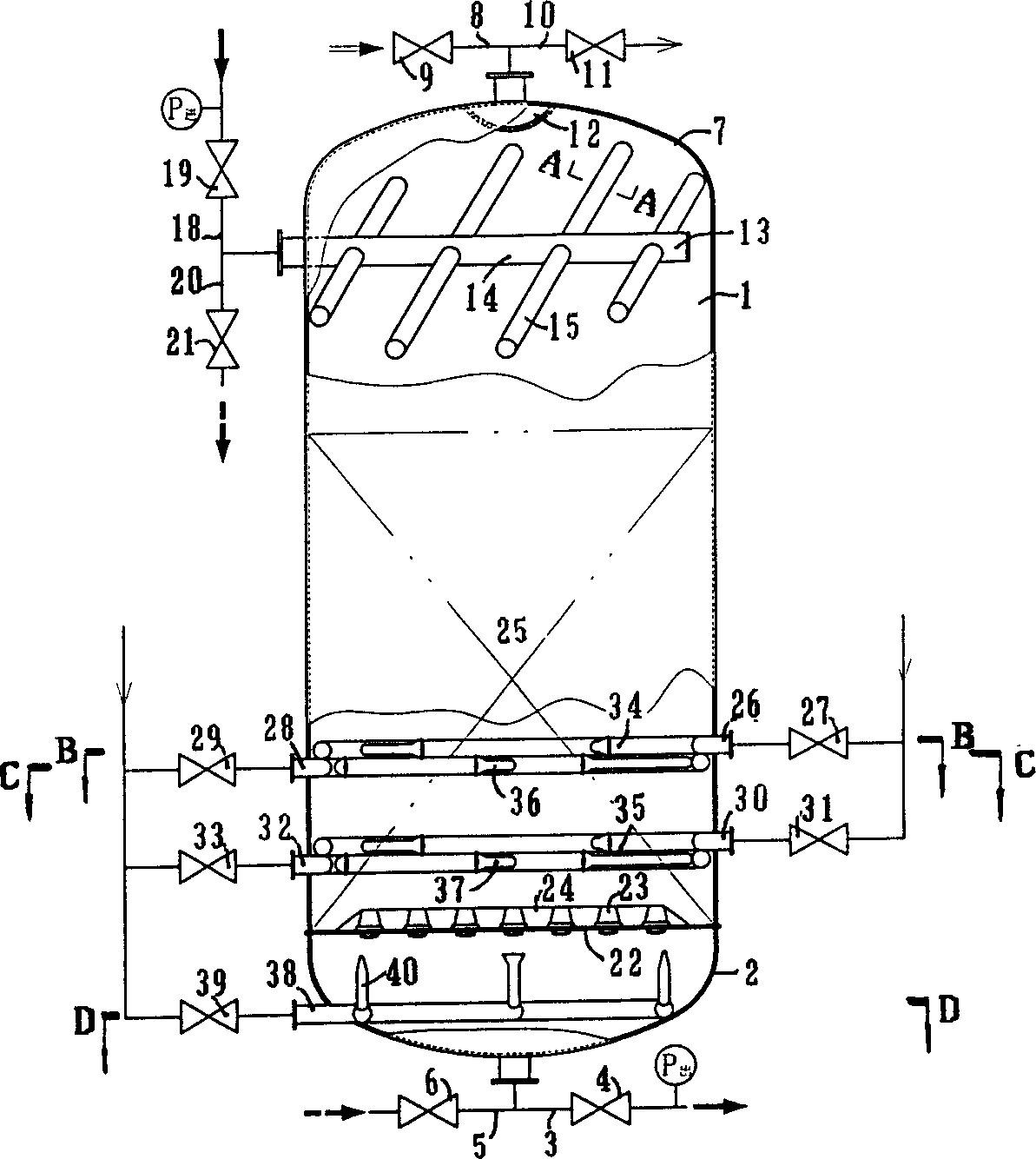

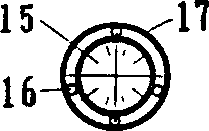

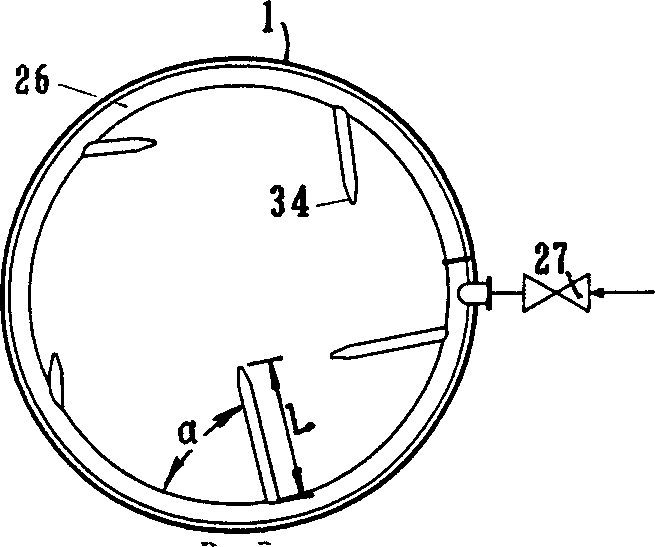

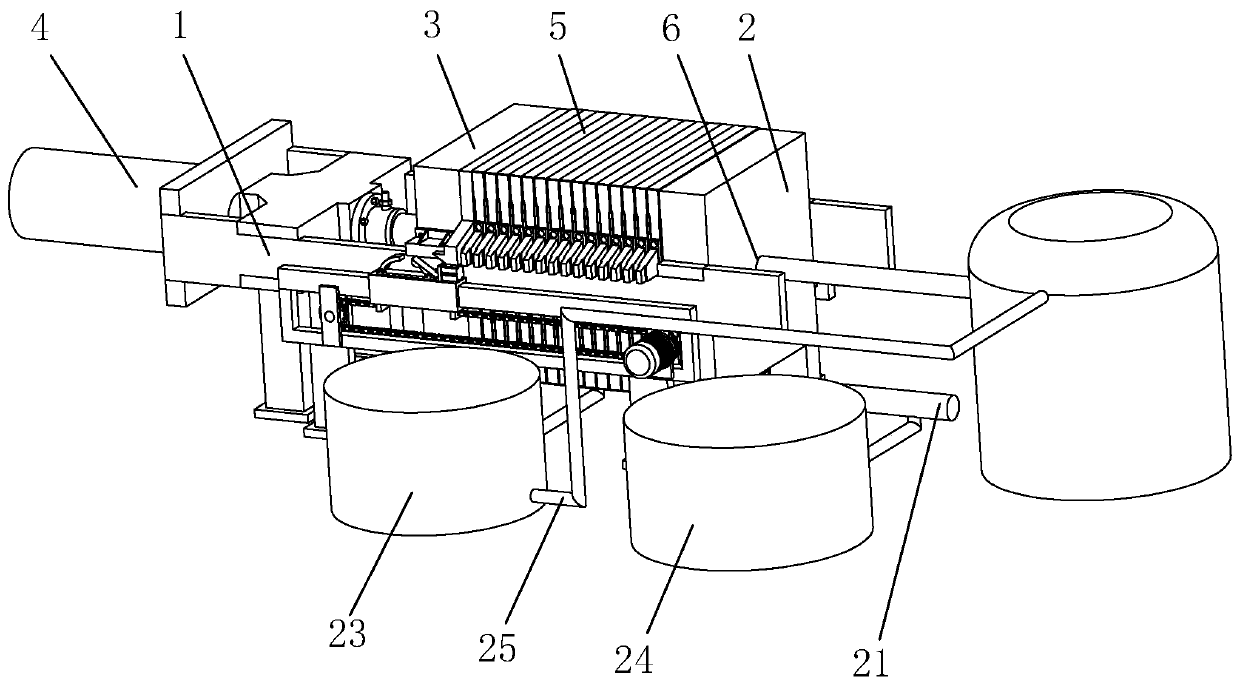

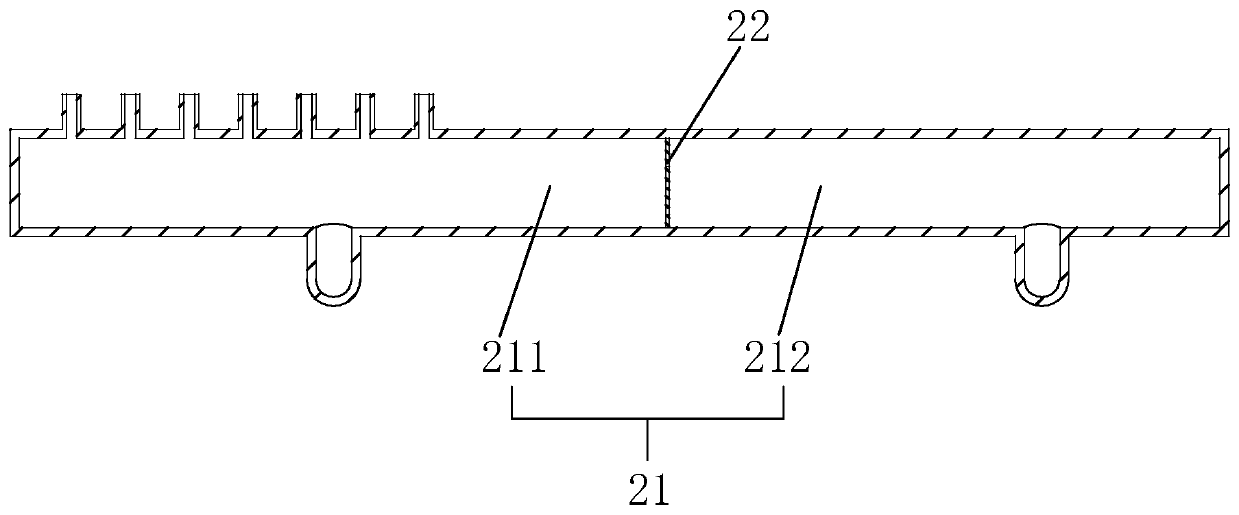

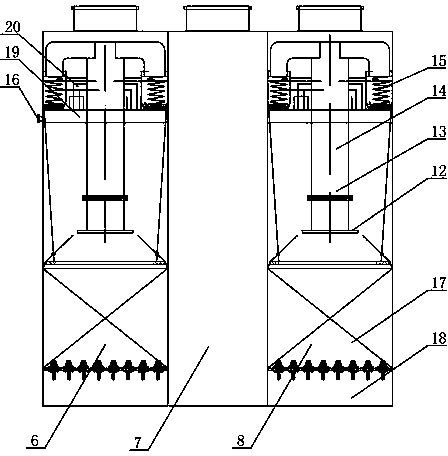

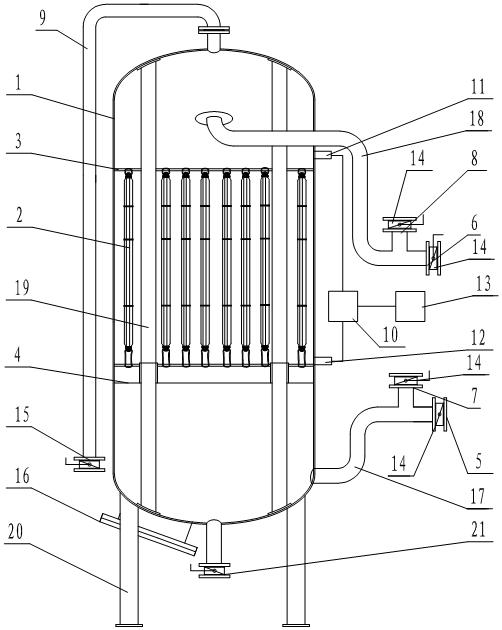

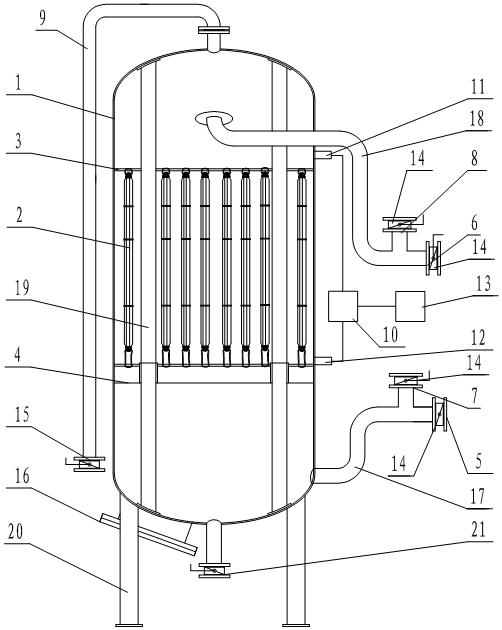

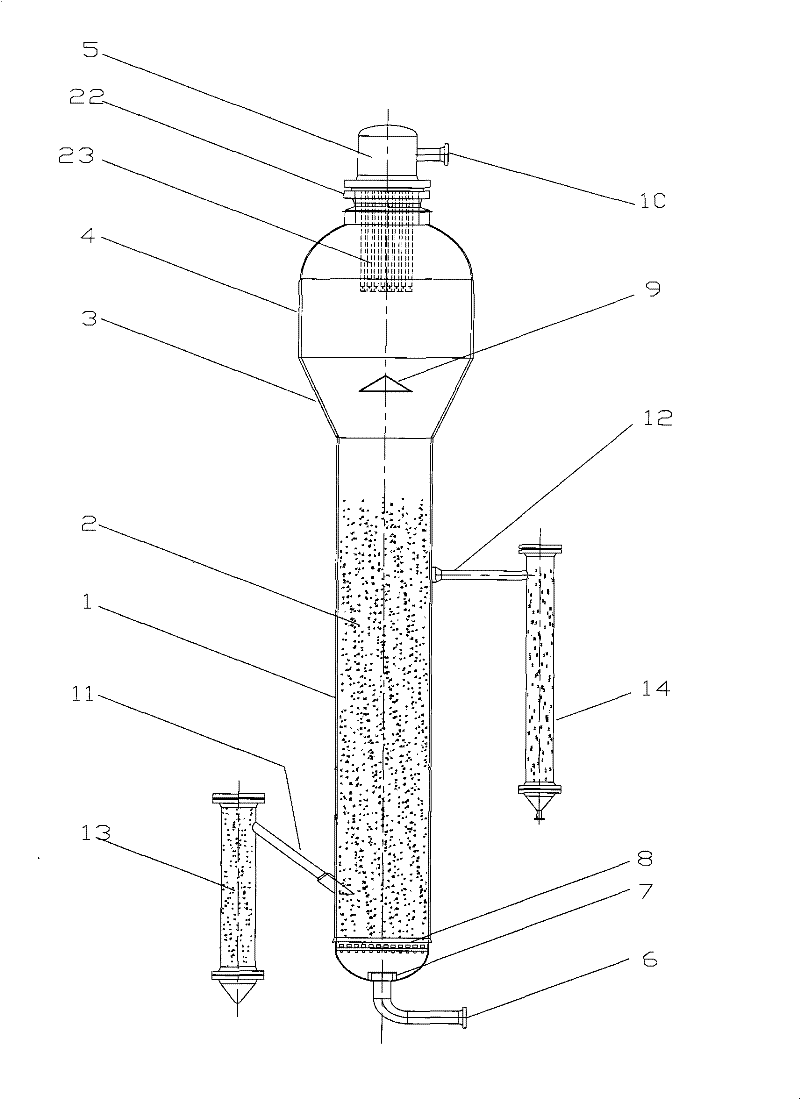

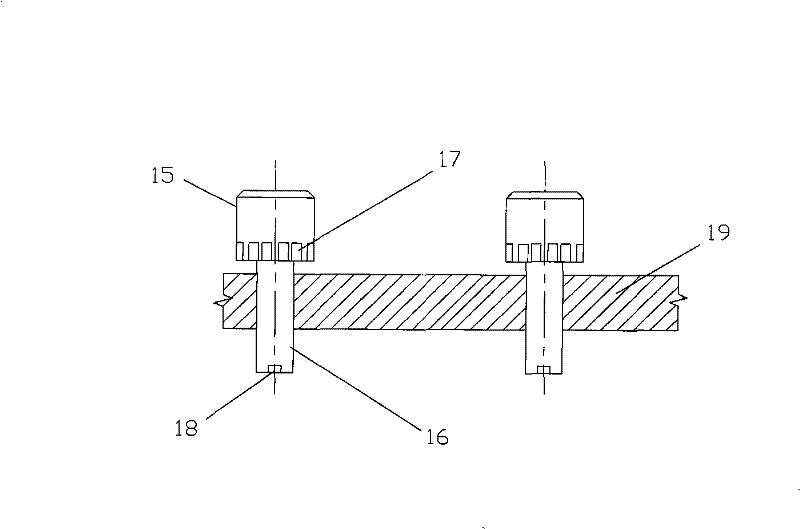

Full-automatic back flushing fiber bundle filter of slag flushing water of blast furnace and back flushing control method

InactiveCN102489055ARestore filter capacityAvoid cloggingLoose filtering material filtersGravity filtersAutomatic controlFiber bundle

The invention provides a full-automatic back flushing fiber bundle filter of slag flushing water of a blast furnace and a back flushing control method, solving the problems that the conventional fiber bundle filter can not effectively remove slag wool suspended substances, back flushing can not be controlled automatically, and the effect is poor. The full-automatic back flushing fiber bundle filter comprises a tank body, a slag flushing water inlet, a slag flushing water outlet, a back flushing water inlet, a back flushing water outlet, a fiber bundle filtering layer, an upper fixed filter plate and a lower movable filter plate, wherein the top end at the upper part of the tank body is communicated with a floating slag discharge pipeline and connected with a differential pressure transmission, the differential pressure transmission is connected with a control system, and an electric regulating valve is arranged on each of all the water inlets and the water outlets. A control program and a set value of differential pressure between the upper part and the lower part of the fiber bundle filtering layer are inputted in the control system, the differential pressure transmitter is used for detecting the differential pressure between the upper part and the lower part of the fiber bundle filtering layer, transmitting a detected differential pressure signal to the control system for real-time treatment and comparing with the set value, and the control system is used for controlling the water inlets and the water outlets to interchange to realize back flushing when the set value is reached. Through adoption of the full-automatic back flushing fiber bundle filter and the back flushing control method, disclosed by the invention, self-discharge of floating slag and constant pressure full-automatic back flushing can be realized.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

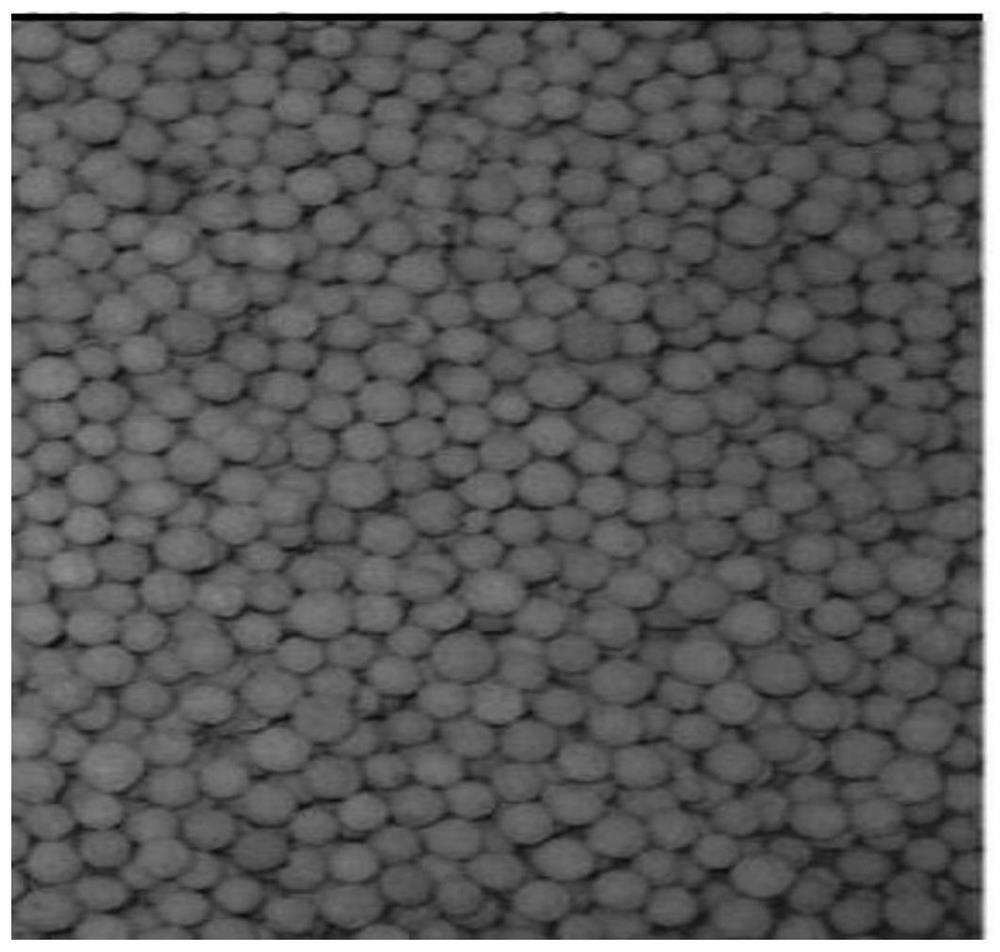

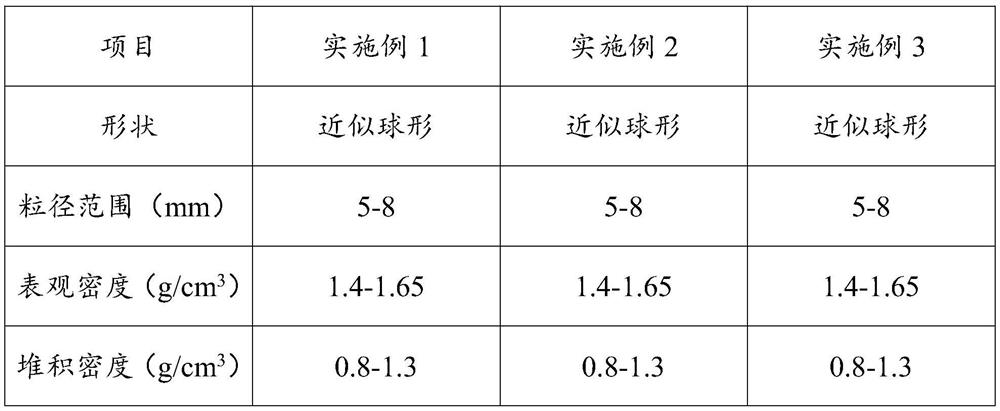

Novel lightweight high-porosity ceramic filter material and preparation method thereof

ActiveCN112608130AAlleviates acidic deficienciesReduce miningTreatment using aerobic processesWater contaminantsCellulosePorosity

The invention relates to the technical field of sewage treatment, and discloses a novel lightweight high-porosity ceramic filter material and a preparation method thereof. Fly ash floating beads, coal gangue and diatomite are used as aggregates, hydroxymethyl cellulose is used as a binder, dolomite powder, a pore-forming agent and limestone are used as auxiliary materials to prepare the ceramic filter material, and carbon nanofibers are attached to the surface of the ceramic filter material. The filter material is strong in pollutant holding capacity, high in filter material utilization rate and slow in water head loss increase, the filter speed can reach 16m / h, the working period is more than 24h, and the periodic water yield reaches 800-1000m < 3 > / m3 and is 1.5-2 times of that of a quartz sand filter material under the same condition.

Owner:TIANJIN UNIV +1

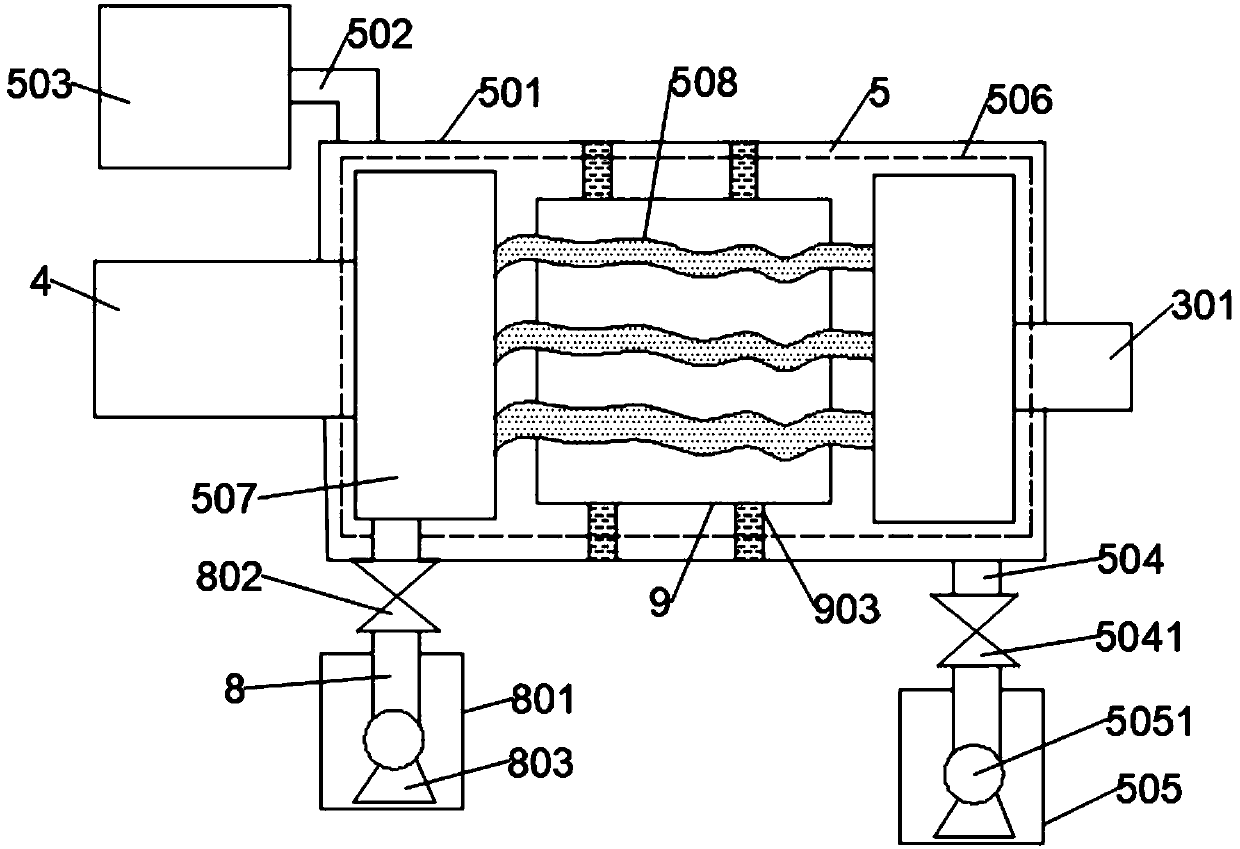

Fluid bed reactor used for gasoline desulfuration

ActiveCN101780389BRestore filter capacityEasy to hang outCombination devicesHydrocarbon oils refiningGasolineProduct gas

The invention provides a fluid bed reactor used for gasoline desulfuration, which belongs to the field of petrochemical industry and is characterized in that an automatic back wash filter, a dust reduction machine, a catalyst bed, a backflow prevention distributor and an impact prevention distributor are arranged in a reactor, and the reactor is externally connected with a reductor and an acceptor. By utilizing the reactor, the filtering performance of the filter can be automatically and efficiently restored in time, thereby reducing the labor strength; catalyst particles are prevented from flowing back below the reactor, thereby enabling gas to be evenly distributed on the section of the whole reactor; the dust content of the gas is effectively reduced, thereby greatly reducing the load of the automatic back wash filter, effectively prolonging the operating period of the automatic back wash filter and reducing equipment investments and maintenance charges; the influent gas is prevented from impacting the backflow prevention distributor, thereby promoting the even distribution of the gas and improving the benefit of the reactor; and moreover, reaction gas and a catalyst flow out of different paths after entering the reactor through different paths, thereby realizing high-treatment capacity continuous operation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Water purification and filtration processing tank

InactiveCN1654339ARestore filter capacityEasy maintenanceWater/sewage treatmentWater filterFiltration

The water purifying filter basin has water tank, water inlet tank on the water tank, clear water chamber in the upper part inside the water tank and filtering chamber in the lower part inside the water tank. The filtering chamber is provided with fine, middle and course filtering layers, and has lower part communicated with the clear water chamber, water inlet pipe communicated with the water inlet tank and backwash pipe. The backwash pipe has one end connected to the top of the filtering chamber and the other end set outside the water tank, has top lower than the water inlet tank and outlet lower than the clear water chamber, and is provided with valve and back permeating pipe. The present invention has convenient maintenance, low use cost, high efficiency and other advantages, and may be used widely in water filtering treatment.

Owner:沈展荣 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com