Elastomer corrugated filter tube

An elastomer and corrugated technology, which is applied in the field of gas-solid and gas-liquid filter structural design, can solve the problem of limited hydrolysis stability, oxidation stability, acid and alkali resistance, no obvious effect on service life, and complex overall structure and installation. problems, to achieve the effect of improving and expanding application occasions, solving strength fatigue, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

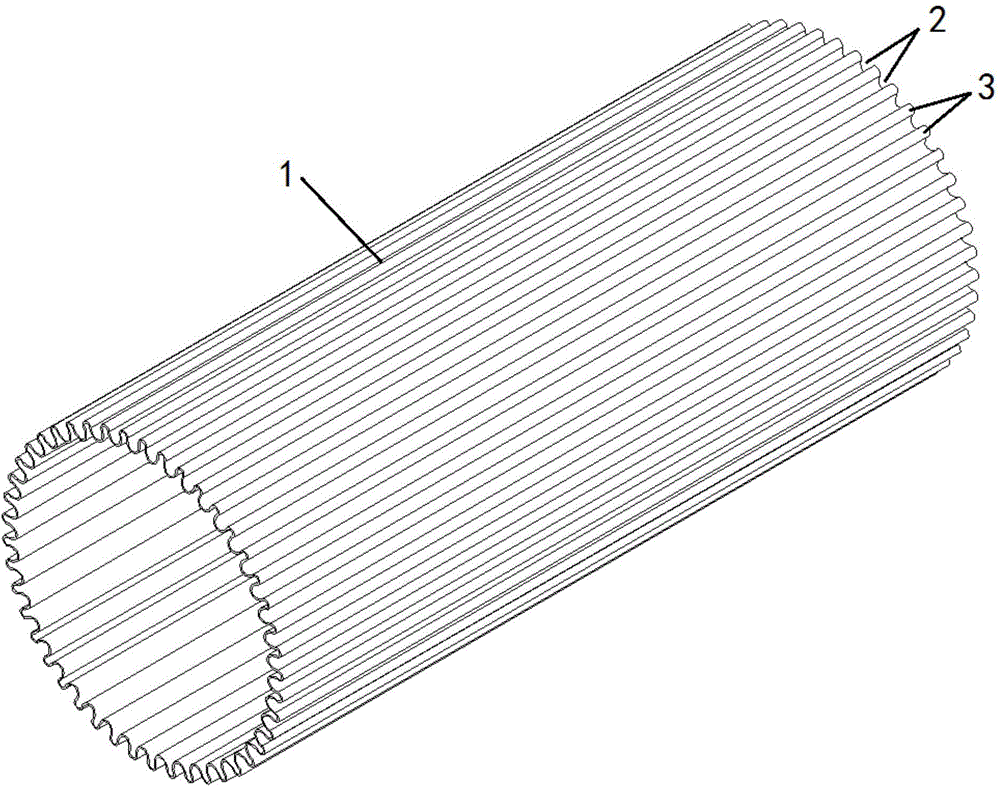

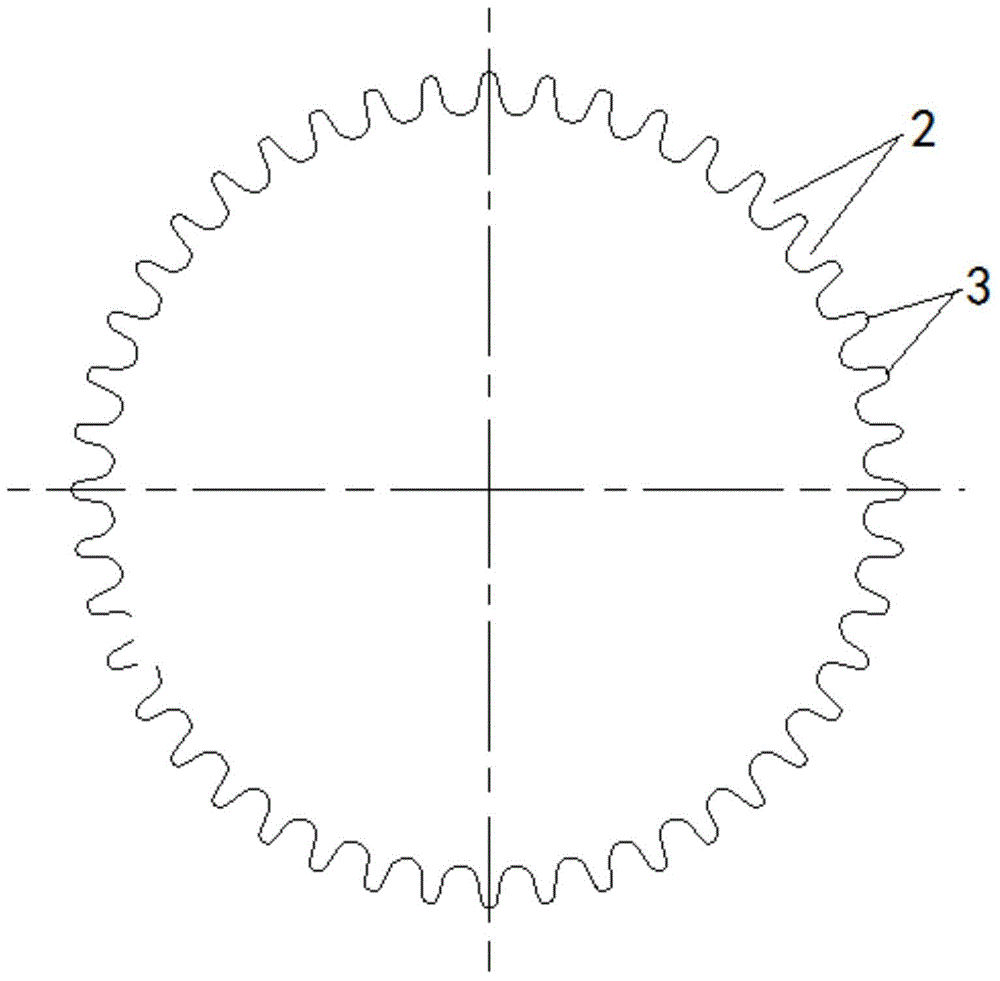

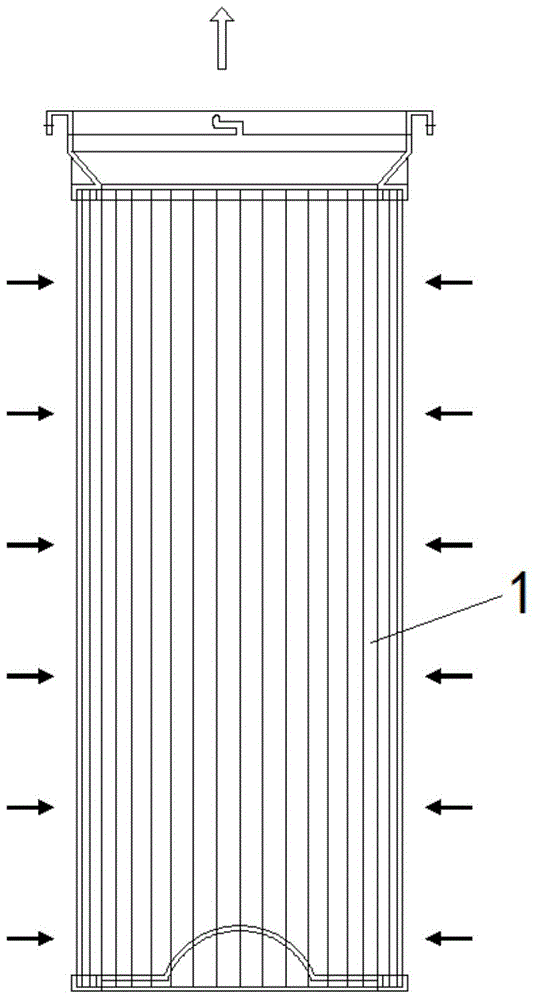

[0028] like figure 1 As shown, this embodiment discloses an elastomer corrugated filter tube, which includes a cylindrical tubular filter element made of metal sintered felt roll 1, and a plurality of grooves 2 extending in the axial direction are formed on the surface of the filter element The grooves 2 and the convex strips 3 are arranged alternately on the outer tube surface of the filter element, and the convex strips 3 are the connecting parts of two adjacent grooves 2 .

[0029] Specifically, the metal sintered felt 1 of this embodiment is made of 316L stainless steel fibers through lamination, bonding or other processes to make an elastic corrugated plate sheet, and the bottom of the groove 3 and the top of the protruding strip 3 are all set as a circle The arc shape presents a continuous circular arc transition shape, that is, the cross-sectional profile of the elastic corrugated sheet formed in this embodiment is a linear wave shape with a certain thickness and a cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com