Heating system by utilization of waste heat of blast furnace slag flushing water and method thereof

A blast furnace slag flushing and slag flushing water technology is applied in hot water central heating systems, heating systems, heating methods, etc., and can solve the problems of large investment in urban heating network construction, difficult adjustment of heating load, and large station area. , to achieve the effect of small footprint, fast filtration speed and low investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

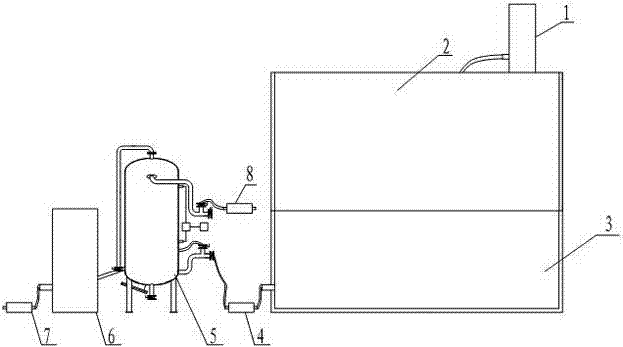

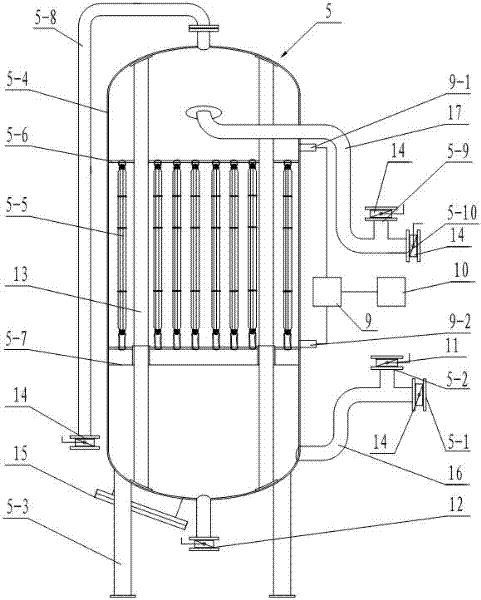

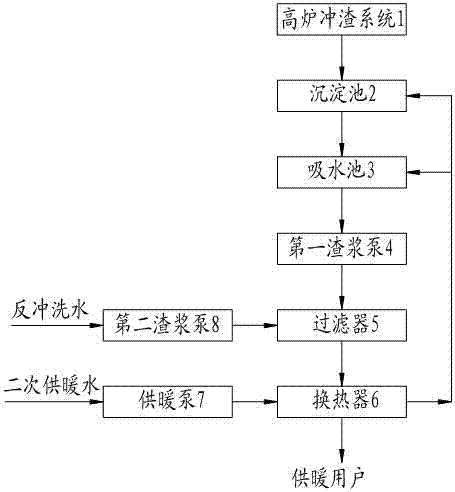

[0029] refer to figure 1 with figure 2As shown, the present embodiment is a heating system utilizing waste heat of blast furnace slag flushing water, including a blast furnace slag flushing system 1, a sedimentation tank 2, a water absorption pool 3, a first slurry pump 4, a filter 5, a heat exchanger 6 and The heating pump 7 and the slag flushing system of the blast furnace adopt the slag flushing system used in the existing INBA water slag flushing process. The water inlet of the filter 5 is connected with the water absorption pool 3, and its water outlet is connected with the slag flushing water inlet 5-1 of the filter 5, and the slag flushing water outlet 5-2 of the filter 5 is connected with the first water inlet of the heat exchanger 6 for heating. The secondary heating water outlet of the pump 7 communicates with the second water inlet of the heat exchanger 6 . Among them, the water absorption tank 3 is used for storage and secondary precipitation of the slag washing...

Embodiment 2

[0042] Different from the above-mentioned embodiment, in this embodiment, the set value of the pressure difference between the upper and lower parts of the fiber bundle filter layer 5-5 is 0.05MPa, the backwash water pressure is 0.4MPa, the backwash time is 20min, and the single fiber bundle The diameter is 20μm, the length is 2m, the porosity is 98%, and the distance between adjacent fibers in the fiber bundle is 15mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com