Fluid bed reactor used for gasoline desulfuration

A fluidized bed reactor, gasoline technology, applied in chemical instruments and methods, refined hydrocarbon oil, petroleum industry, etc., can solve the problems of increasing the labor intensity of operators, unfavorable maintenance, falling to the receiver and jamming the magnetic sphere, etc. , to reduce equipment investment and maintenance costs, improve space utilization and efficiency, and promote uniform gas distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

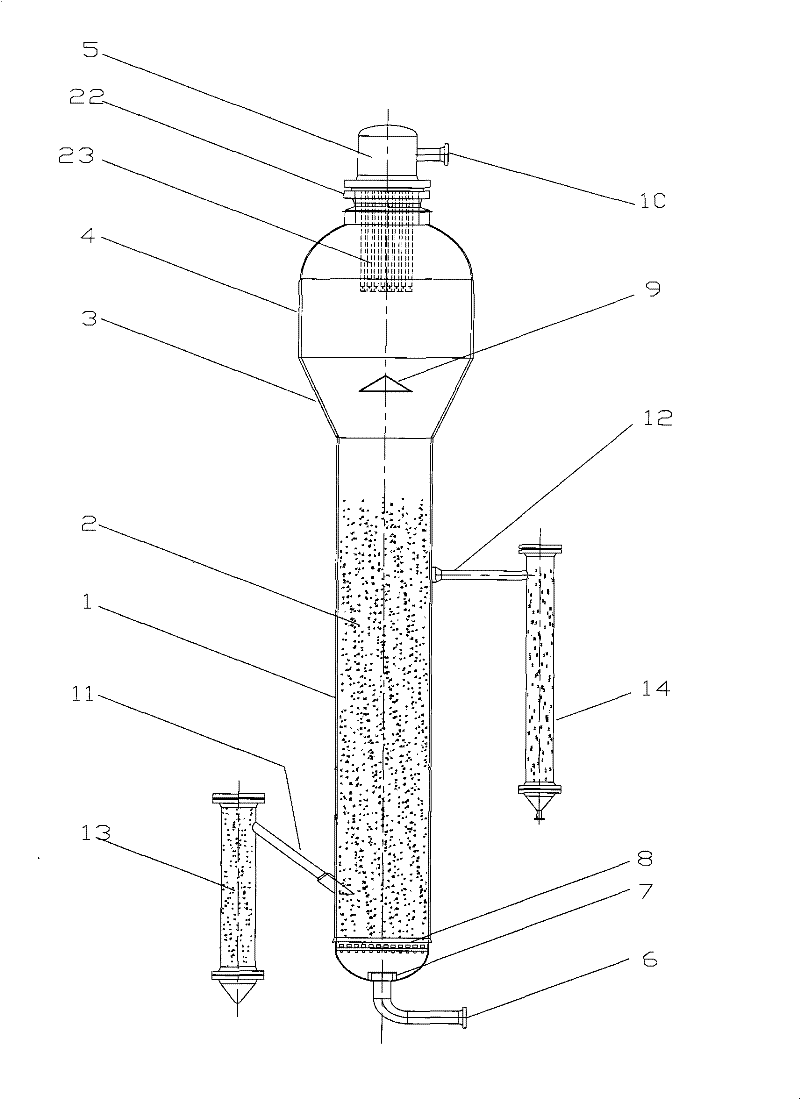

[0021] like figure 1 Shown, a kind of fluidized bed reactor that is used for gasoline desulfurization, it comprises separation section 4, expansion section 3, reaction section 1 successively from top to bottom, catalyst bed 2 is housed in described reaction section 1, in A receiver 14 is connected to the outside of the upper part of the reaction section 1 , and a reducer 13 is connected to the outside of the lower part of the reaction section 1 . Among them, the catalyst bed 2 is supported by the rising gas, and its height is jointly determined by the gas flow rate and the catalyst storage capacity of the bed. When the gas flow rate is stable, the storage volume can be increased or decreased by adding or removing catalyst, thereby adjusting the height of the catalyst bed 2 .

[0022] An automatic backwash filter 5 is arranged on the top of the separation section 4, and the automatic backwash filter 5 is paired with the reactor outlet flange 22 at the top of the separation sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com