Patents

Literature

947results about How to "Reduce dust content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

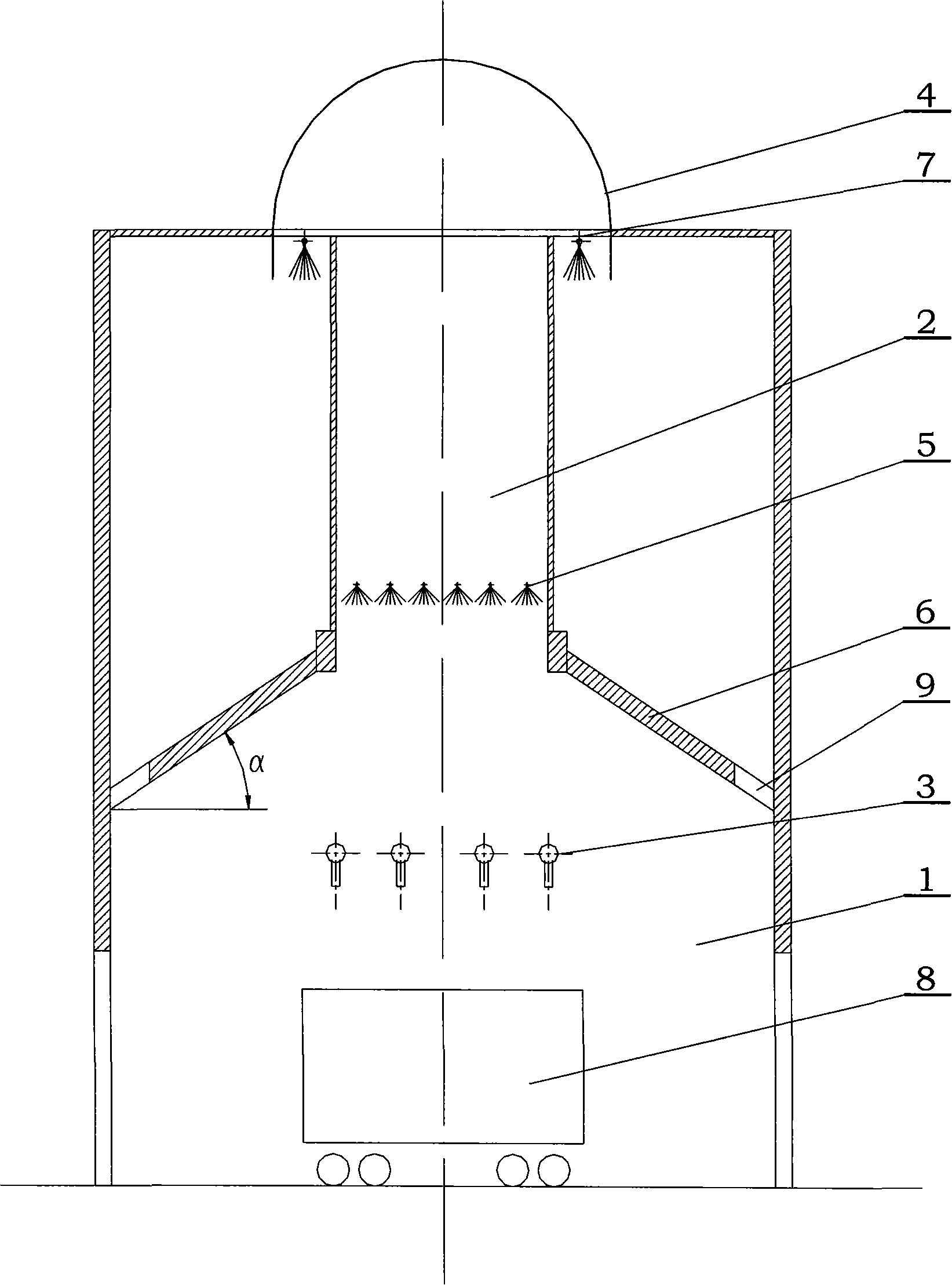

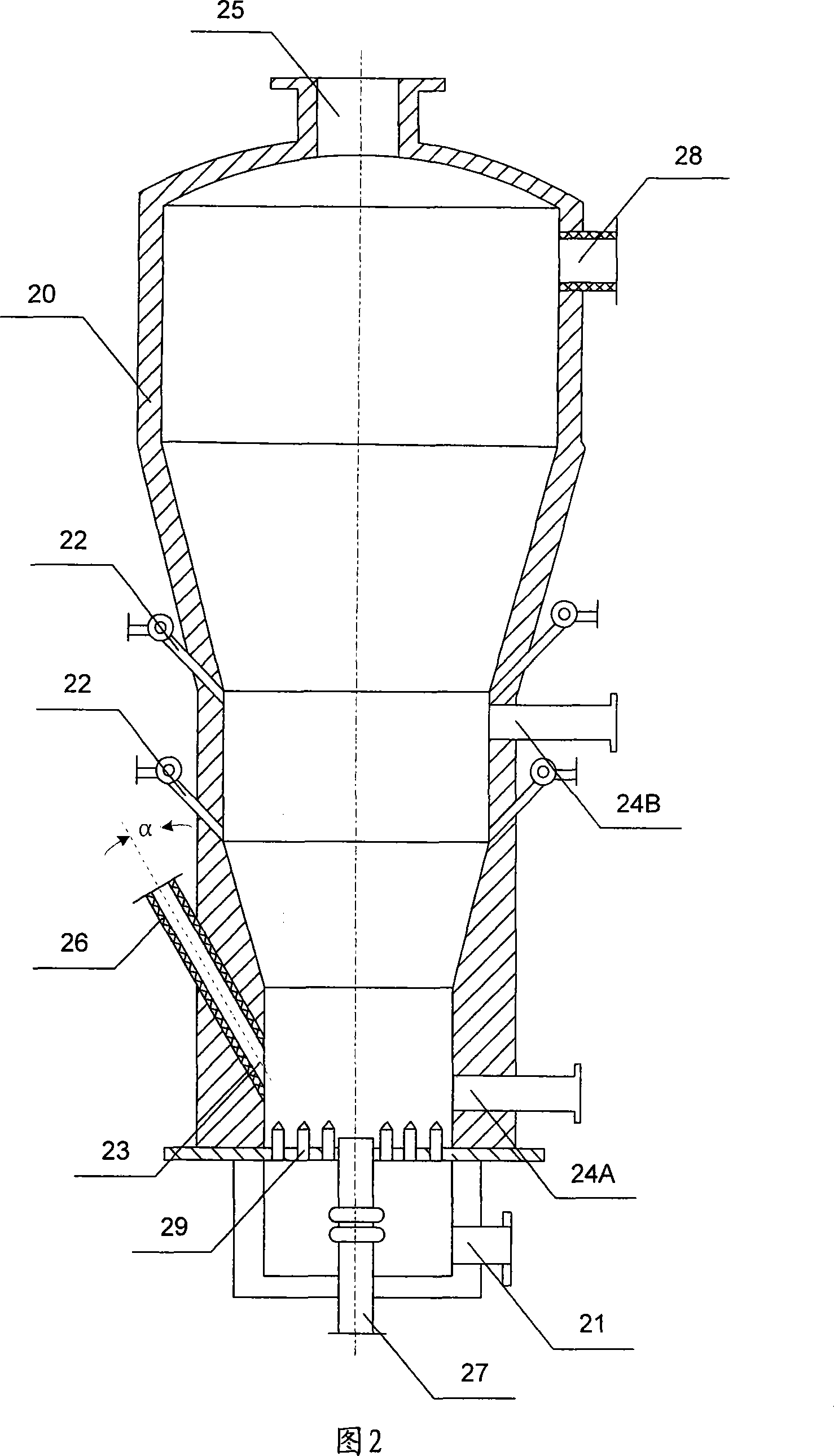

Dome type dust removing coke quenching machine

The invention relates to a dome-like dedusting coke quenching tower, which comprises the following parts: a coke quenching procedure at the bottom and a deduesting procedure at the top, wherein the coke quenching procedure is equipped with a coke quenching injecting pipe; the dedusting procedure is divided into three lattices; the bottom of two side lattices sealed by a tipping plate; the bottom of the tipping plate is equipped with blow-off hole; the included angle alpha of the tipping plate and the horizontal surface is 10-75 degree; the top of the coke quenching injecting pipe and the middle lattice entrance of the dedusting procedure are equipped with a plurality of washing and cooling devices; the top of washing and cooling devices and the top of the coke quenching tower are equipped with dome-like dedusting device which covers the middle lattice and two side lattices of the coke quenching tower dedusting procedure. The invention reduces the dust content after washing the polluting vapor with the water fog, cooling the polluting vapor, settling the polluting vapor gravitively and changing the direction of the gas flowing, which reduces the water consumption.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

Technique for producing ultra high-strength terylene industry filament yarn

InactiveCN101144195AGuaranteed purityGuaranteed viscosity uniformityArtificial filament heat treatmentMelt spinning methodsSetting timeFilament yarn

The present invention discloses a production process for an ultra high tenacity polyester industrial filament. The production process adopts a one-step method of spinning and stretching, and the method comprises the solid state tackifying, the melt spinning, the high temperature stretching, the heat setting, and the winding forming. The present invention adopts the innovative five-pair hot roll stretching heat setting process, compared with the traditional four-pair hot roll stretching heat setting, the the present invention adopts two-stage heat stretching, the processing method of the two-stage heat setting effectively reduces the stretching speed of fiber, and prolongs the heat setting time of the fiber, so that the fiber has an even stable orientation structure while the physical performance of products is ensured, the spinning condition is optimized. The ultra high tenacity polyester industrial filament prepared by utilizing the method of the present invention has the advantages that the intensity is high, the stretching and the dry heat shrinkage are reasonable, the heat resistant performance is good, and the impact resistant performance and the fatigue resistant performance are good.

Owner:JIANGSU SHENGHONG CHEM FIBRE CO LTD

Preparation technology of ultralow contraction terylene industry long filament

ActiveCN1904153AAvoid RelaysGuaranteed viscosity uniformityMelt spinning methodsMonocomponent polyesters artificial filamentTextile fiberPolyester

This invention relates to the process of a kind of ultra-low contraction polyester fiber industry filament, which introduces the spinning and stretch one-stage process, including: solid phase increases sticks, melting spinning, high temperature stretches, heat setting, coiling formation. This invention adopts the innovative 5 pairs of hot rollers stretch heat setting technique, in comparison with the tradition 4 pairs, which adopts the 2-step heat stretch and 2-step heat setting. The new level heat setting processing method can reduce the textile fiber stretch speed effectively, lengthen the textile fiber heat setting time, and enables the textile fiber possessing evenly stable orientation structure, which guarantees product physics performance, optimizes the spinning condition. This ultra-low contraction polyester fiber industry filament preparation method provided with polyester fiber industry having high density, big module, small elongate, good heat-resisting performance, resisting impingement, and bearing the fagged performance.

Owner:ZHEJIANG GUXIANDAO POLYESTER DOPE DYED YARN CO LTD

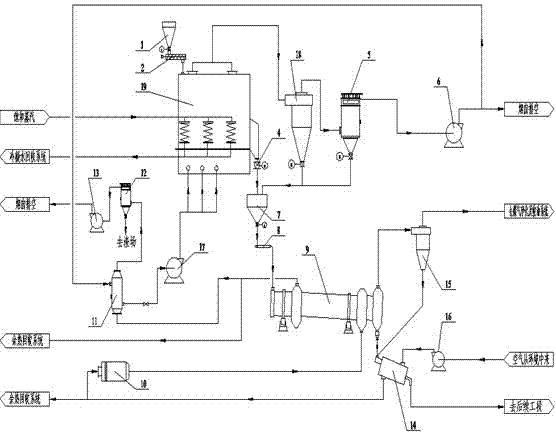

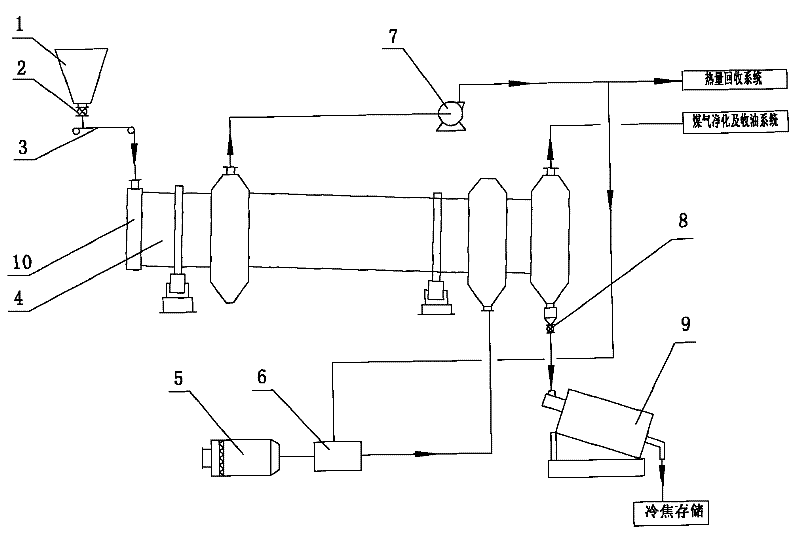

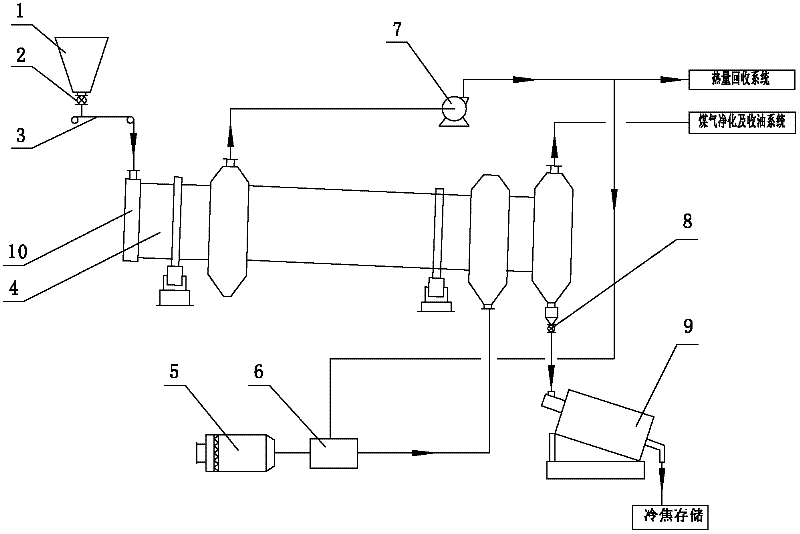

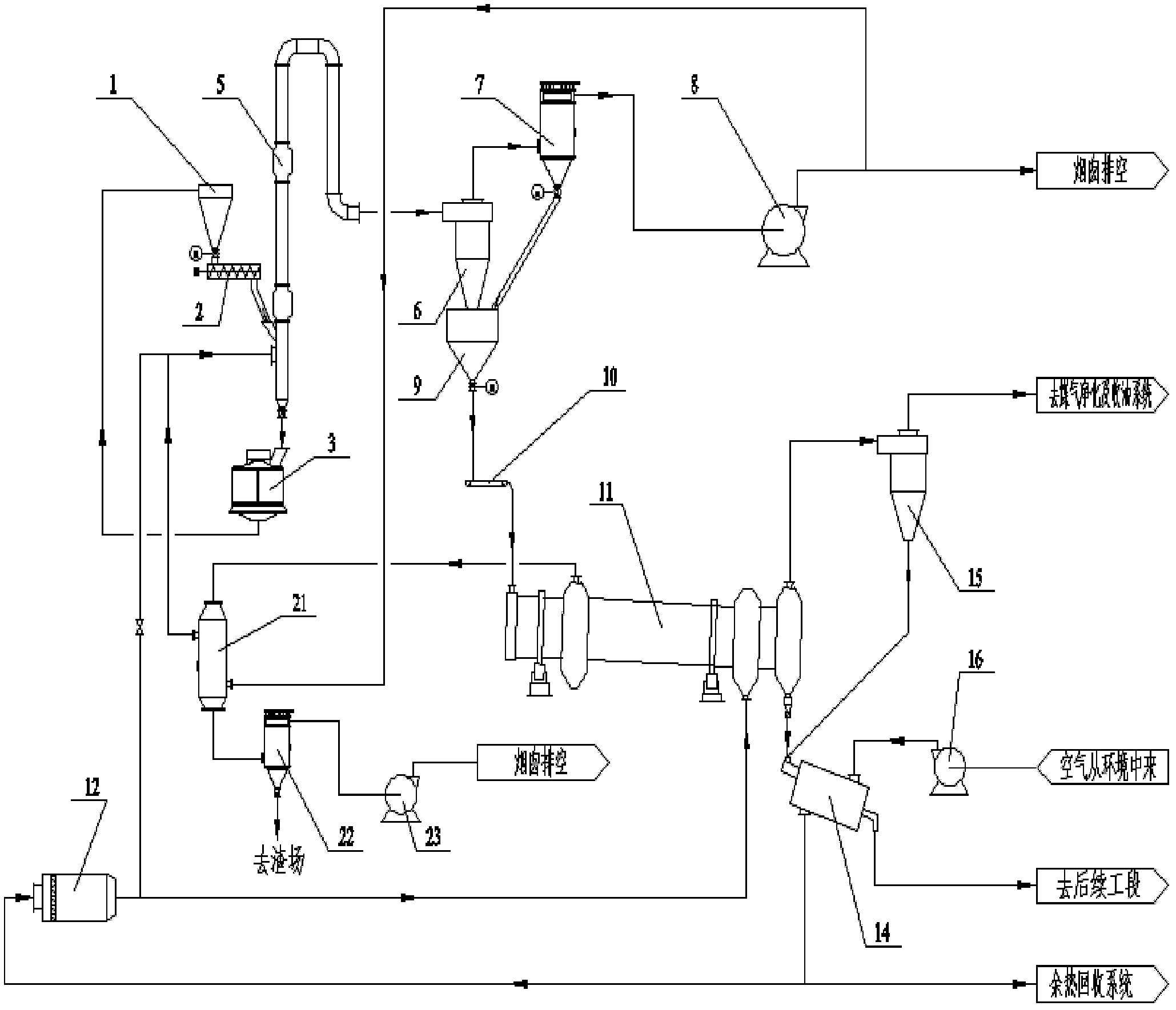

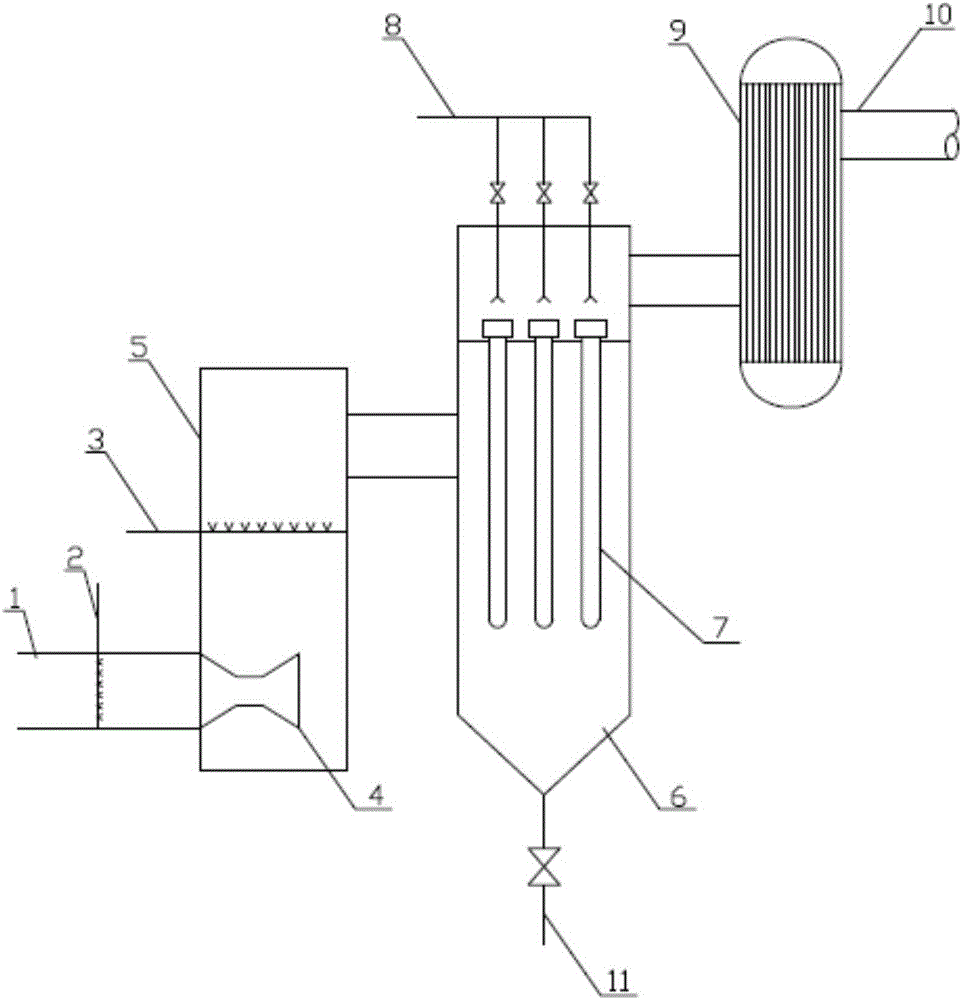

Drying and dry distillation combined quality improving process and system for low rank coal

The invention discloses a drying and dry distillation combined quality improving process and a drying and dry distillation combined quality improving system for low rank coal, which are used for overcoming the defects existing in the prior art and are particularly suitable for drying and dry distillation combined quality improvement of brown coal with high water content or other low rank coal such as long flame coal, non-caking coal or weakly caking coal, gas coal and the like. In the process, a combined quality improving method in which a steam revolving drier for drying and a multi-pipe revolving low-temperature dry distiller for dry distillation are provided is adopted, so that the problems of large coking wastewater handling capacity, large coal gas handling capacity and the like existing in a pure dry distillation process are solved. The drying and multi-pipe revolving low-temperature dry distillation combined quality improving process provided by the invention has the advantages of high energy utilization ratio, safe and stable systems, small dry distillation gas handling capacity, small coking wastewater handling capacity, high tar yield, high coal gas heat value and the like.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

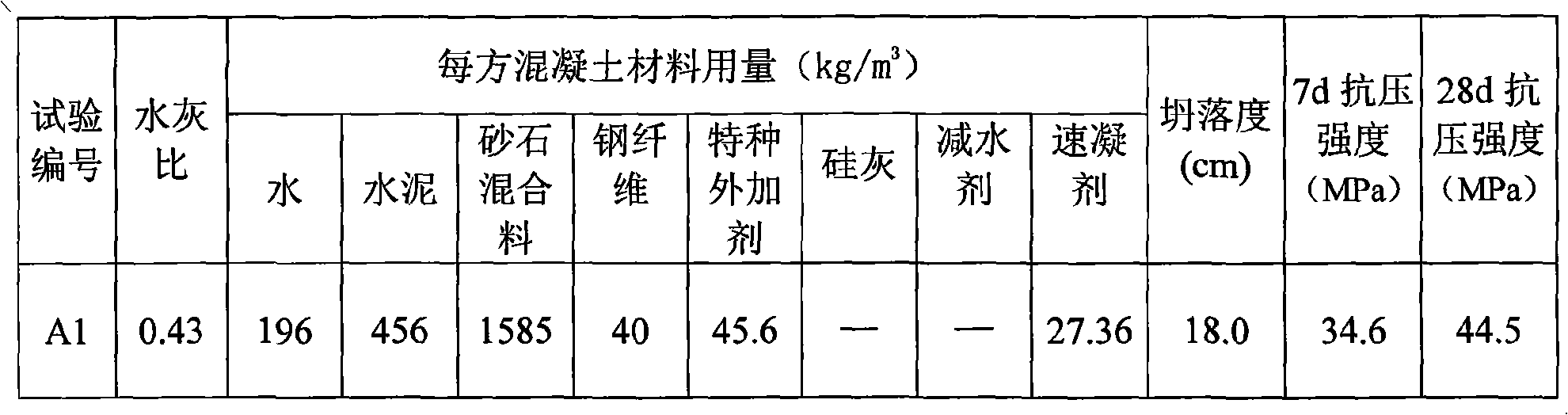

Injection concrete

The invention relates to a sprayed concrete which contains cement, sand-stone mixture, steel fiber, accelerating agent and special additive. The special additive is inorganic neutral nano-sized zeolite containing SiO2 and Al2O3 as major chemical components, wherein the weight ratio of water to cement to sand-stone mixture to steel fiber is (8.5-8.6):(16.1-20.0):(69.6-73.5):(1.7-1.8), the special additive accounts for 5-10% the weight of cement, and the accelerating agent accounts for 6-8% the weight of cement. When used in water-rich areas, the sprayed concrete can cure within 1minute and exhibits strength after 10 minutes, the rebound rate of the sprayed concrete is reduced to 7.8% from 15% in the common wet-jetting concrete, the binding strength reaches 3.5 MPa, and the spray thickness is more than 0.3 m at each time. The invention reduces the workload of lining concrete construction and avoids water leakage, and also has the advantages of rapid construction, good flexibility and improvement in working environment inside tunnel.

Owner:CHINA RAILWAY HI TECH IND CORP LTD

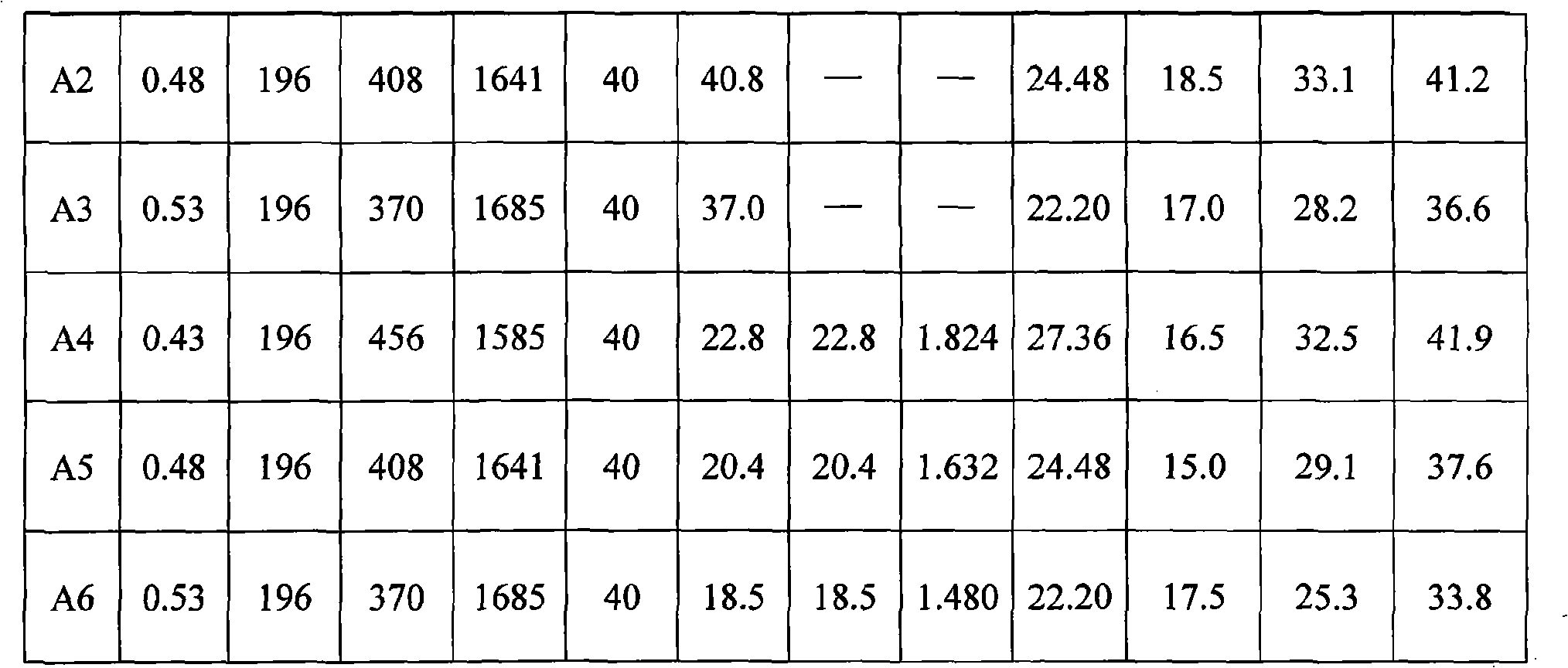

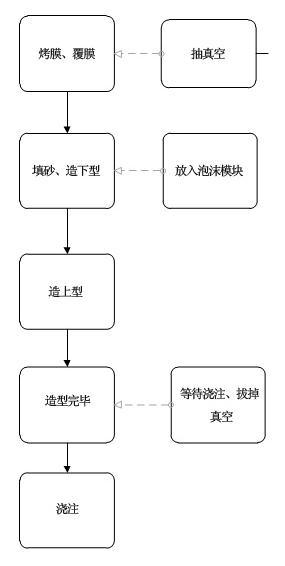

Precise casting technology for green sand vacuum sealing model

InactiveCN102218505ALow costReduce energy consumptionFoundry mouldsFoundry coresSmooth surfaceVacuum pumping

The present invention provides a precise casting technology for a green sand vacuum sealing model, which belongs the vacuum casting technical field. The invention is characterized in that the green sand is taken as a molding material, quantity of the sand core can be minimized through an effective usage of foamed materials, which is suitable for producing medium and small sized comparative precision castings. The problems of serious dust pollution, long vacuum-pumping time and production efficiency affected by using paint in a present V method can be solved. When a complex cavity is casted, the foamed material is provided at the position unsuitable for drafting to form a portion of the cavity, the foamed material is melted when casting, therefore the purposes of minimizing sand core quantity and weight can be reached, so that the production technology can be simplified as well as cost can be saved. The produced casting has the advantages of high dimensional precision, clear contour and smooth surface.

Owner:JIAHE ZHONGHE CASTING +1

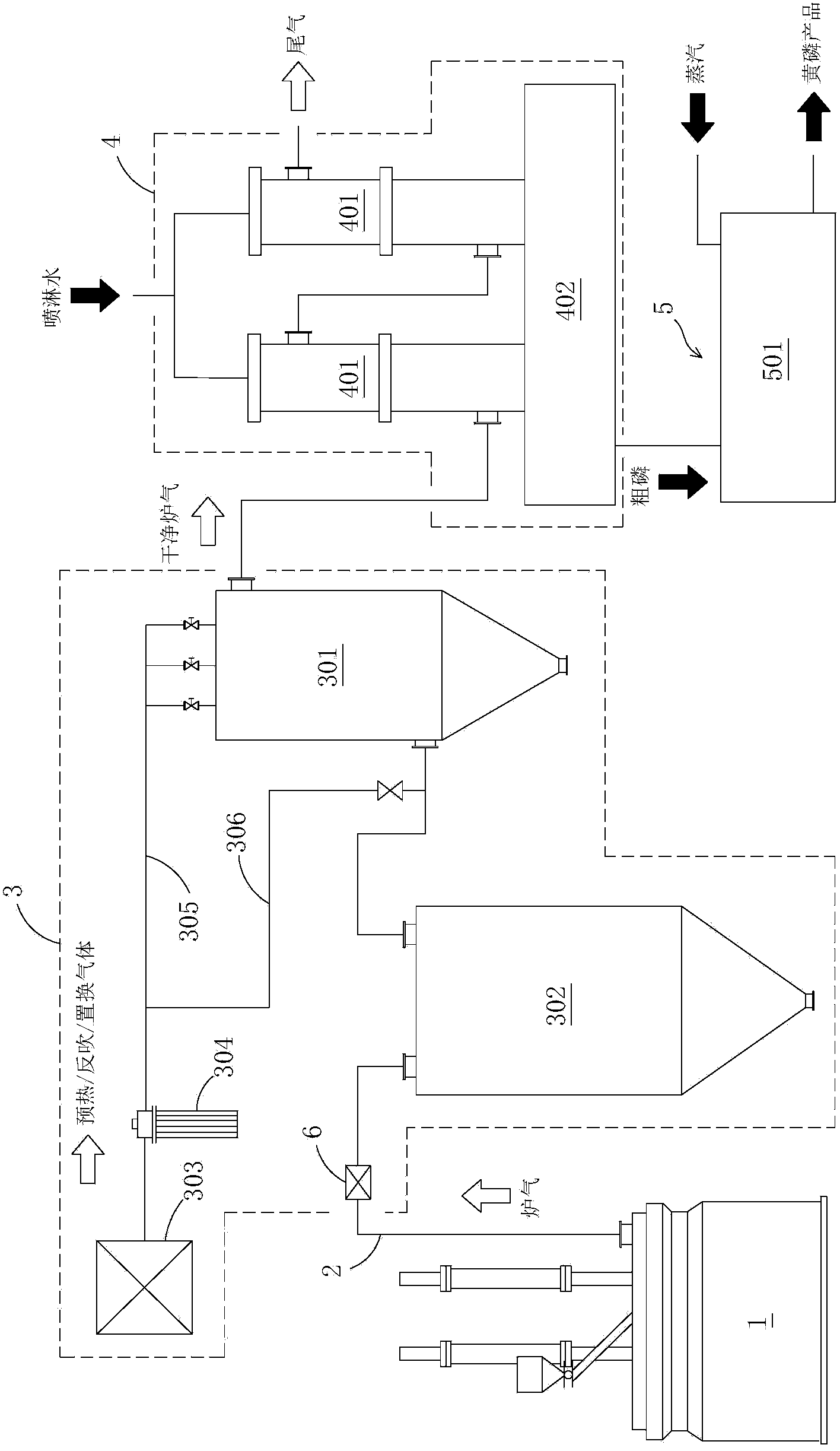

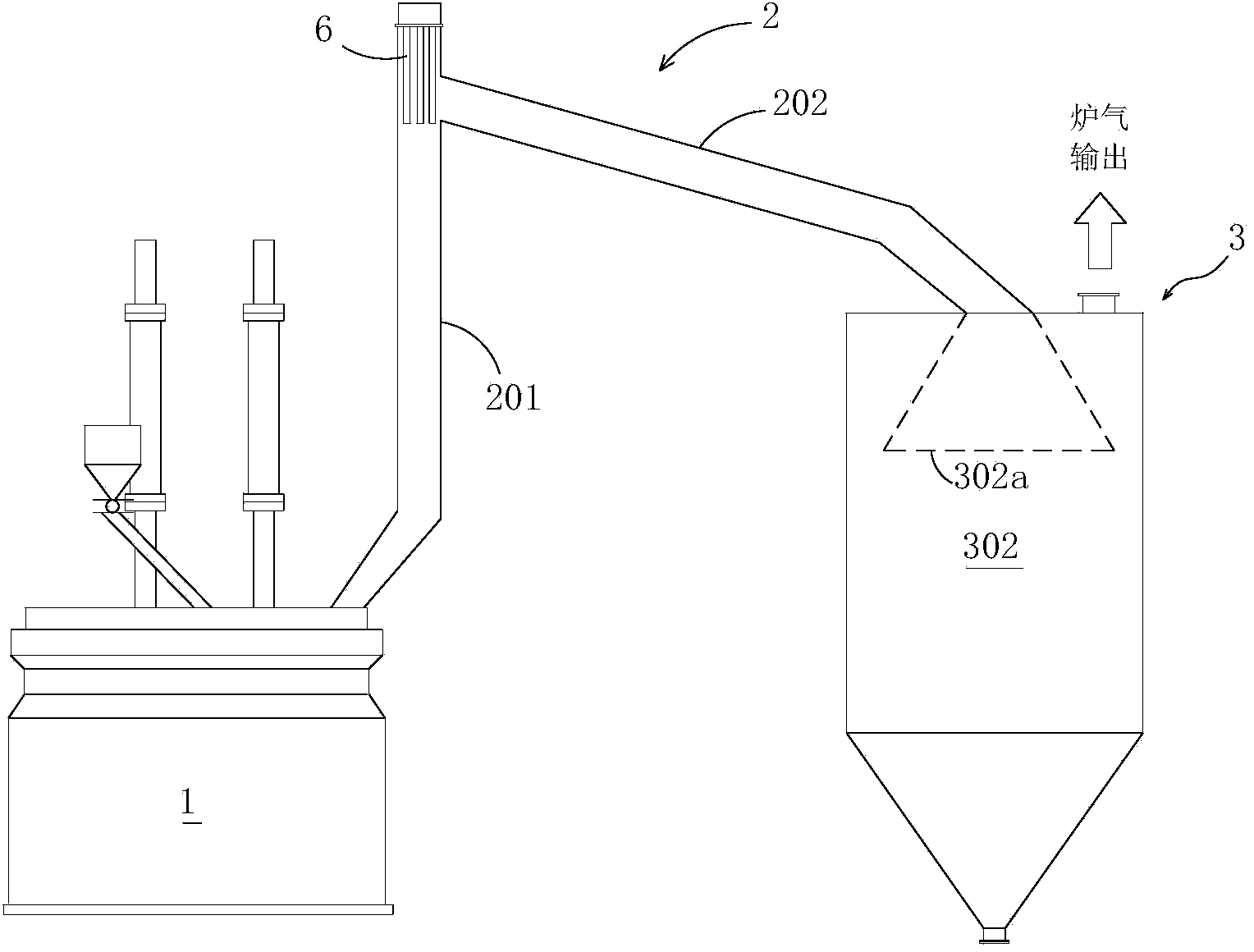

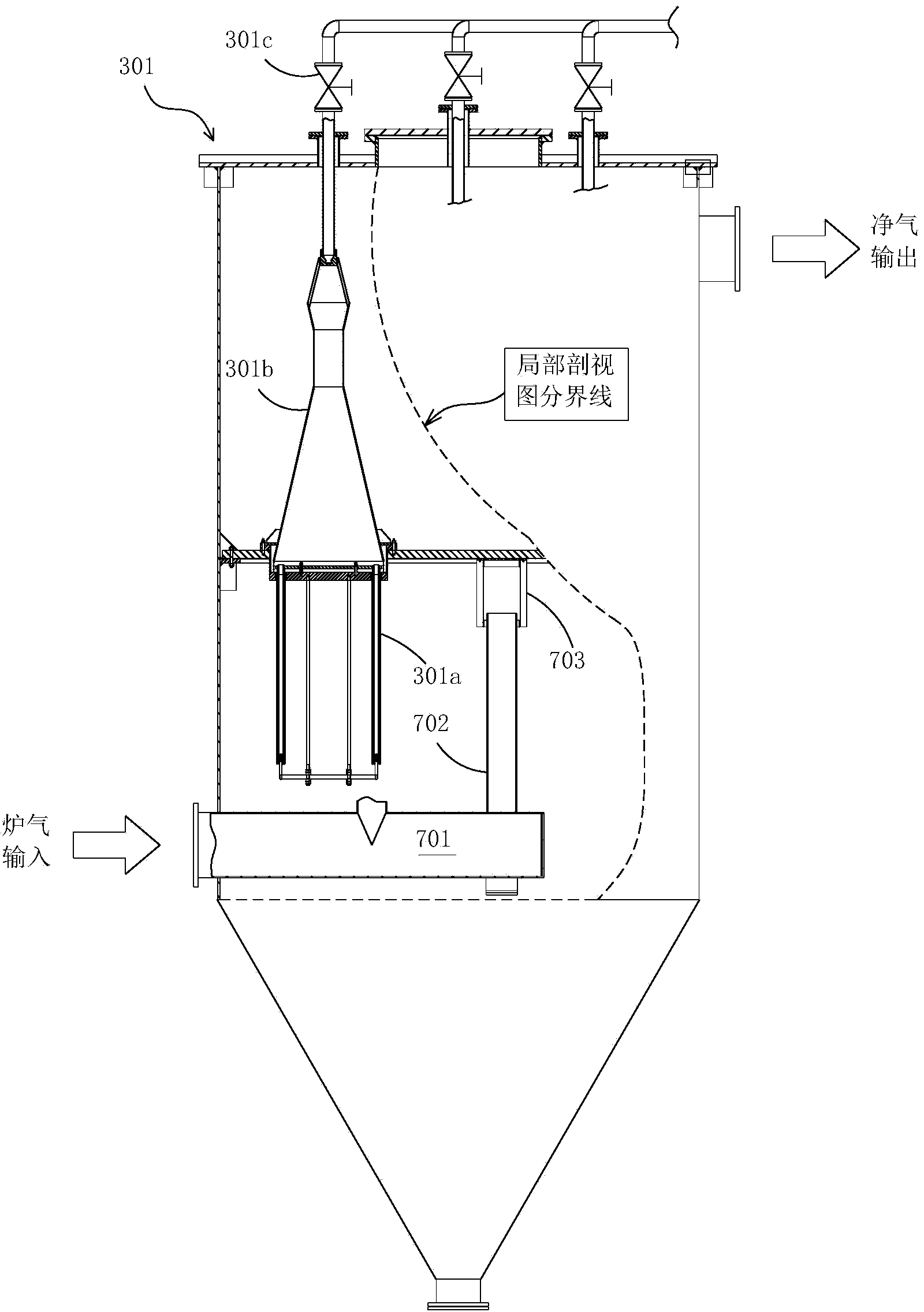

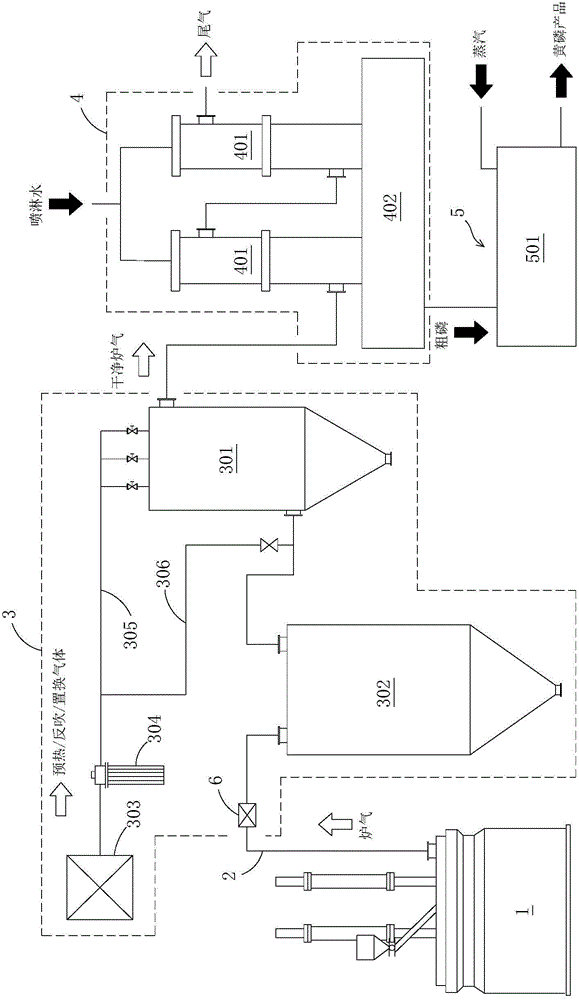

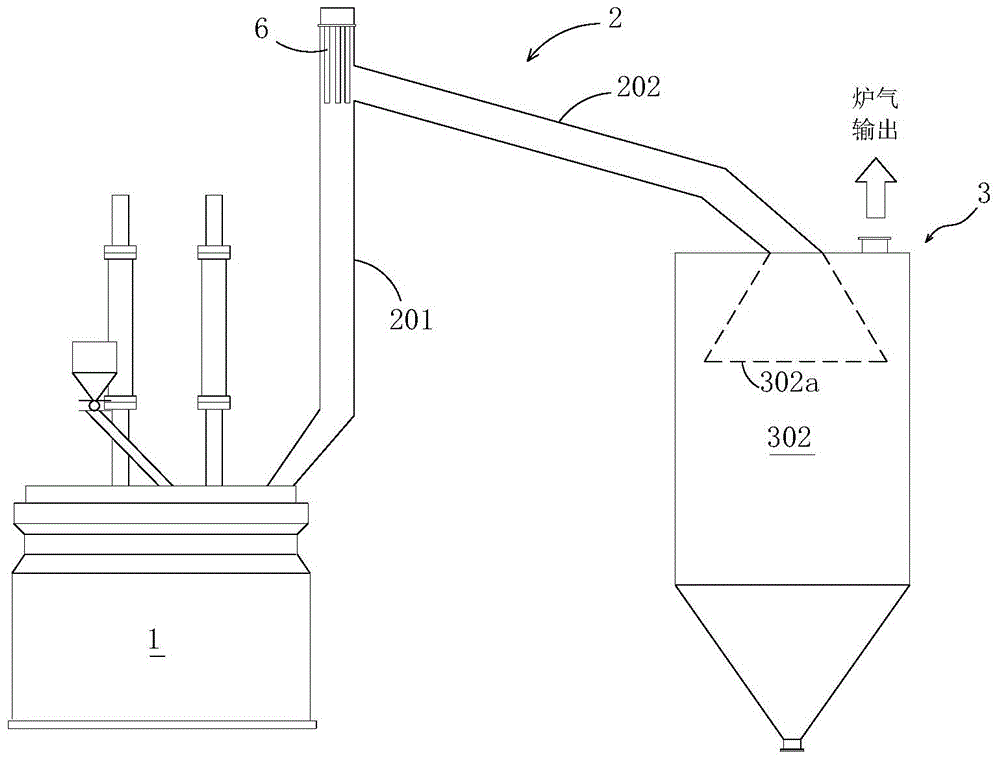

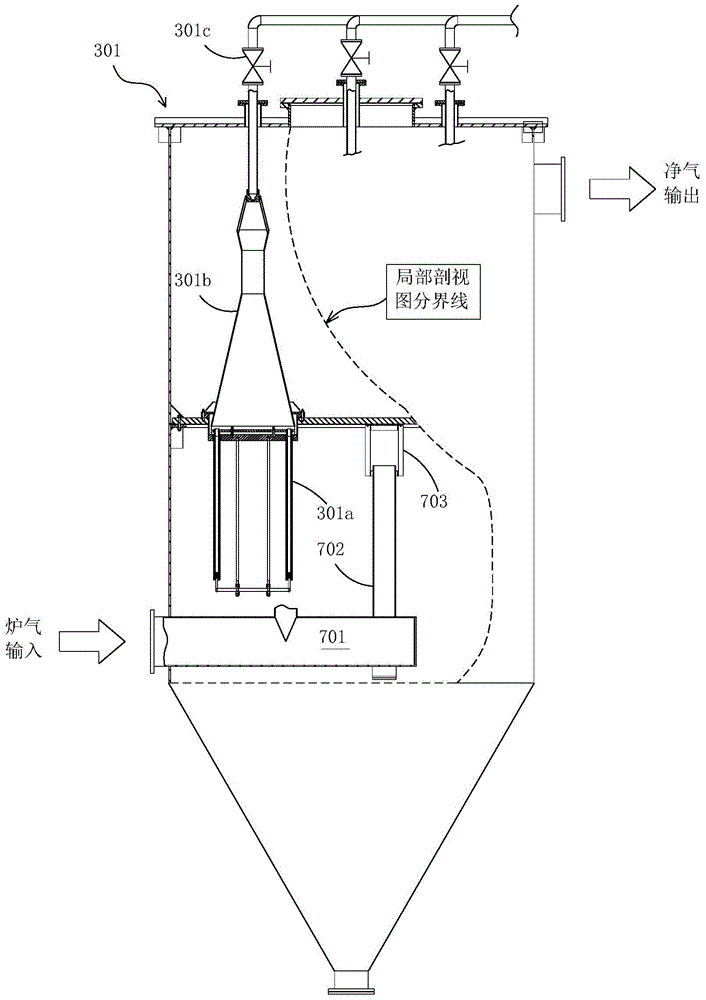

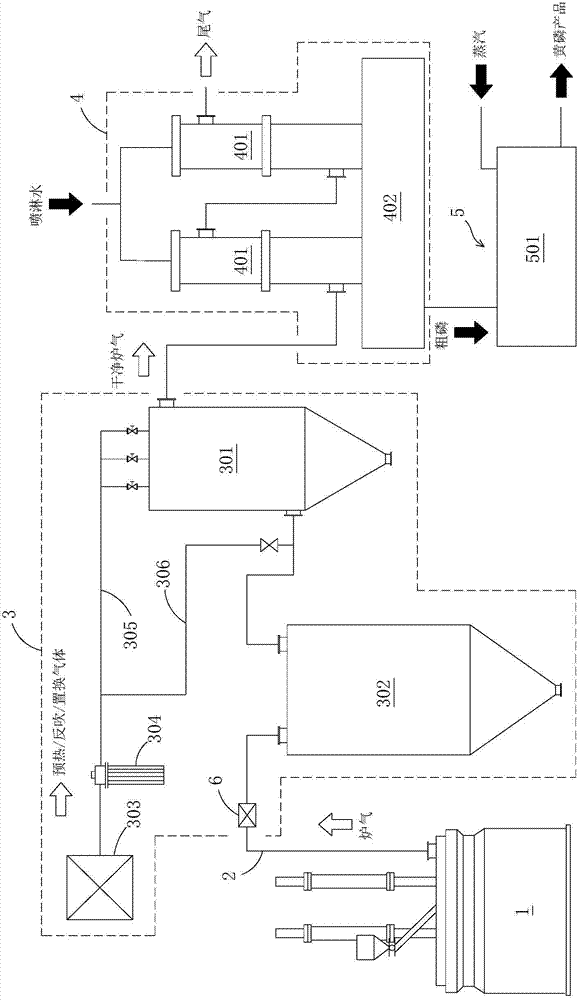

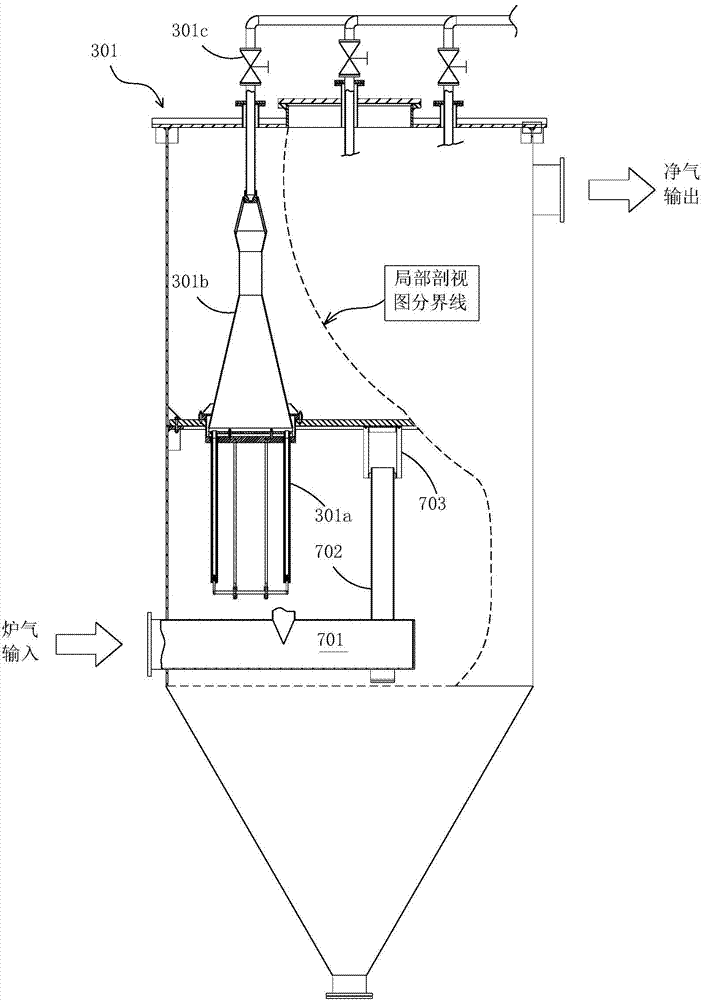

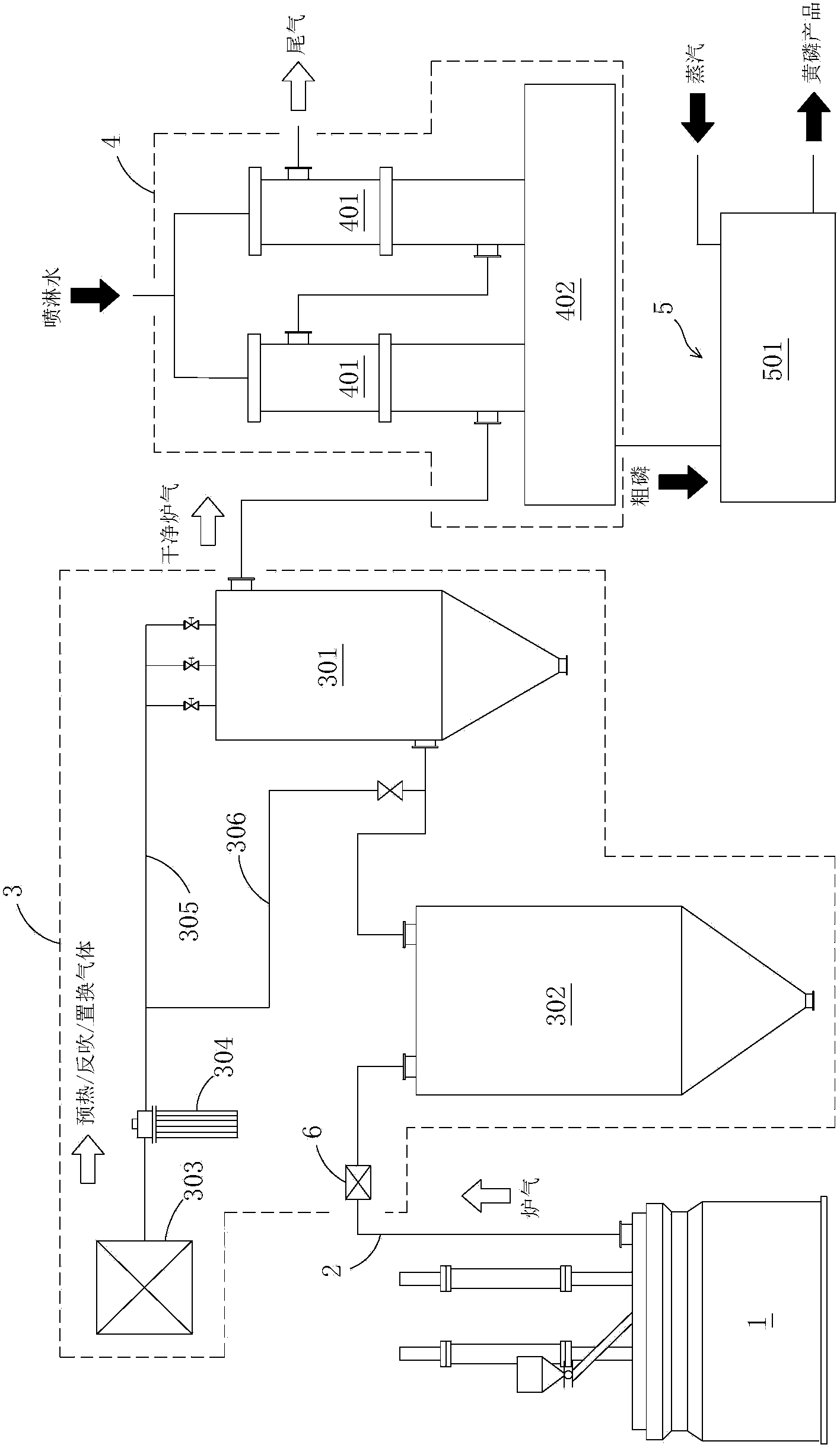

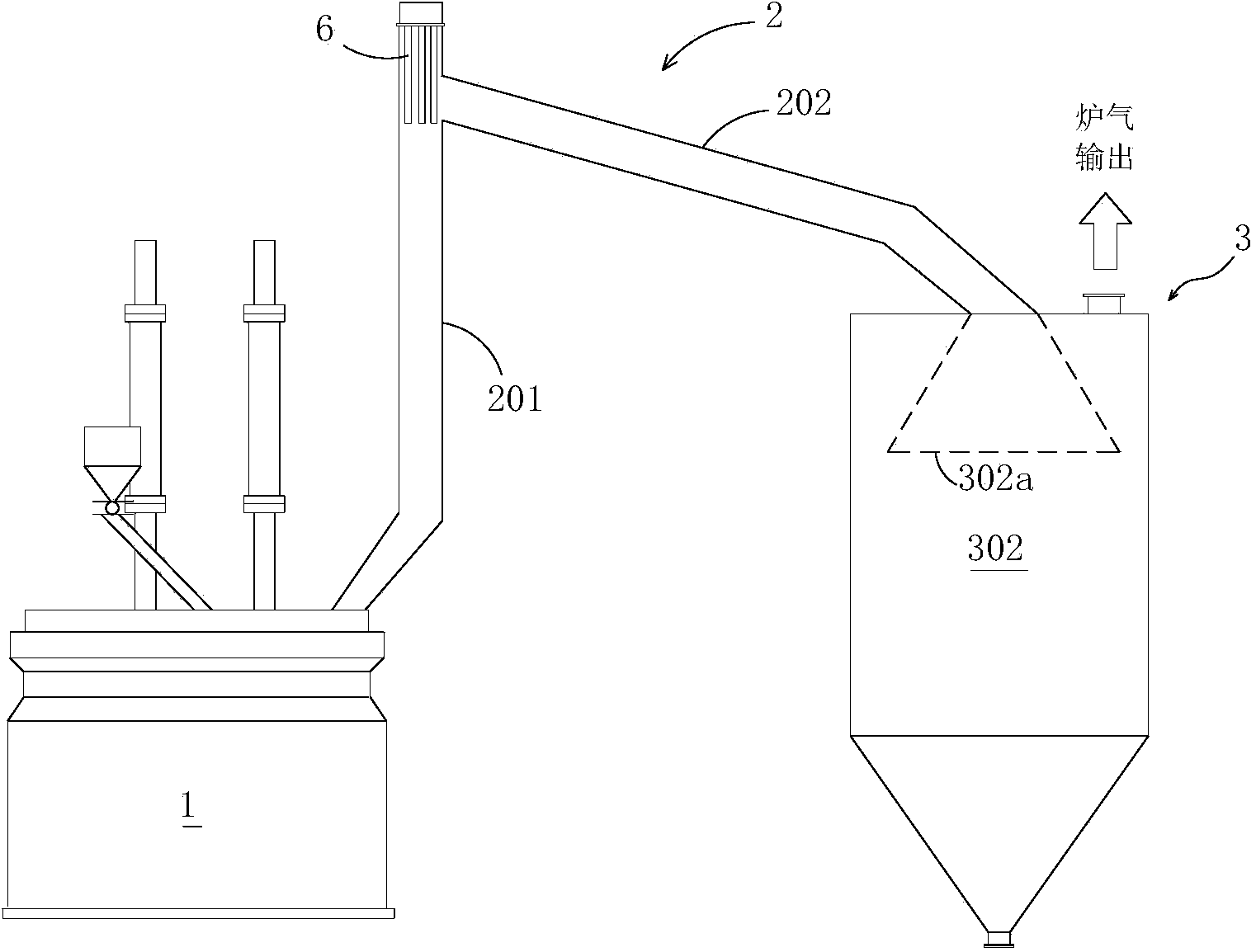

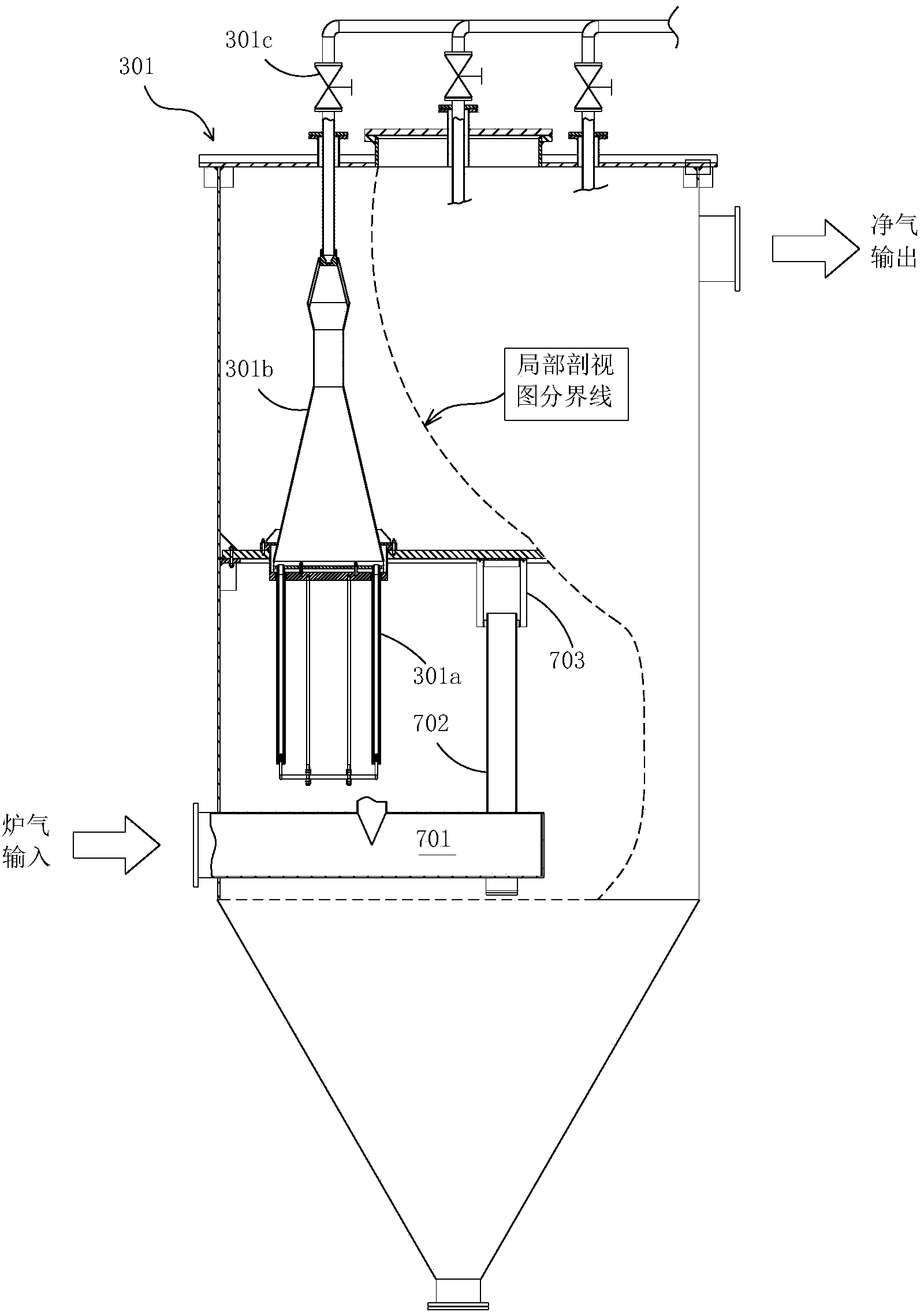

Yellow phosphorus preparation method and yellow phosphorus preparation equipment

ActiveCN103508429AHigh filtration precisionGood thermal shock resistancePhosphorus compoundsProcess engineeringSlurry

The invention discloses a yellow phosphorus preparation method and yellow phosphorus preparation equipment, which produce no phosphorous slurry and reduce the dust content of tail gas. The yellow phosphorus preparation method comprises the technological processes of electric furnace smelting, furnace gas purifying and phosphorus collecting and refining. In the process of furnace gas purifying, the furnace gas discharged out from an electric furnace is guided into a furnace gas dust-collection system through a smoke discharge pipeline, the furnace gas dust-collection system at least comprises a filter for filtering the furnace gas, the filter is provided with a sintering inorganic porous material filter element meeting the following working conditions, and the operations executed on the filter comprise the operation executed during starting a machine, the operation executed during normal operation, the operation executed during back flowing and the operation executed during stopping the machine; in the operation executed during starting the machine, pre-heated inertia gas is injected into the filter so as to preheat the sintering inorganic porous material filter element in the filter to the temperature of more than 187.5 DEG C, and in the operation executed during the normal operation, the to-be-filtered furnace gas of which the temperature is kept at 420-590 DEG C is input into the filter and the dust content of the filtered clean furnace gas is lower than 10-20 mg / m<3>.

Owner:CHENGDU INTERMENT TECH

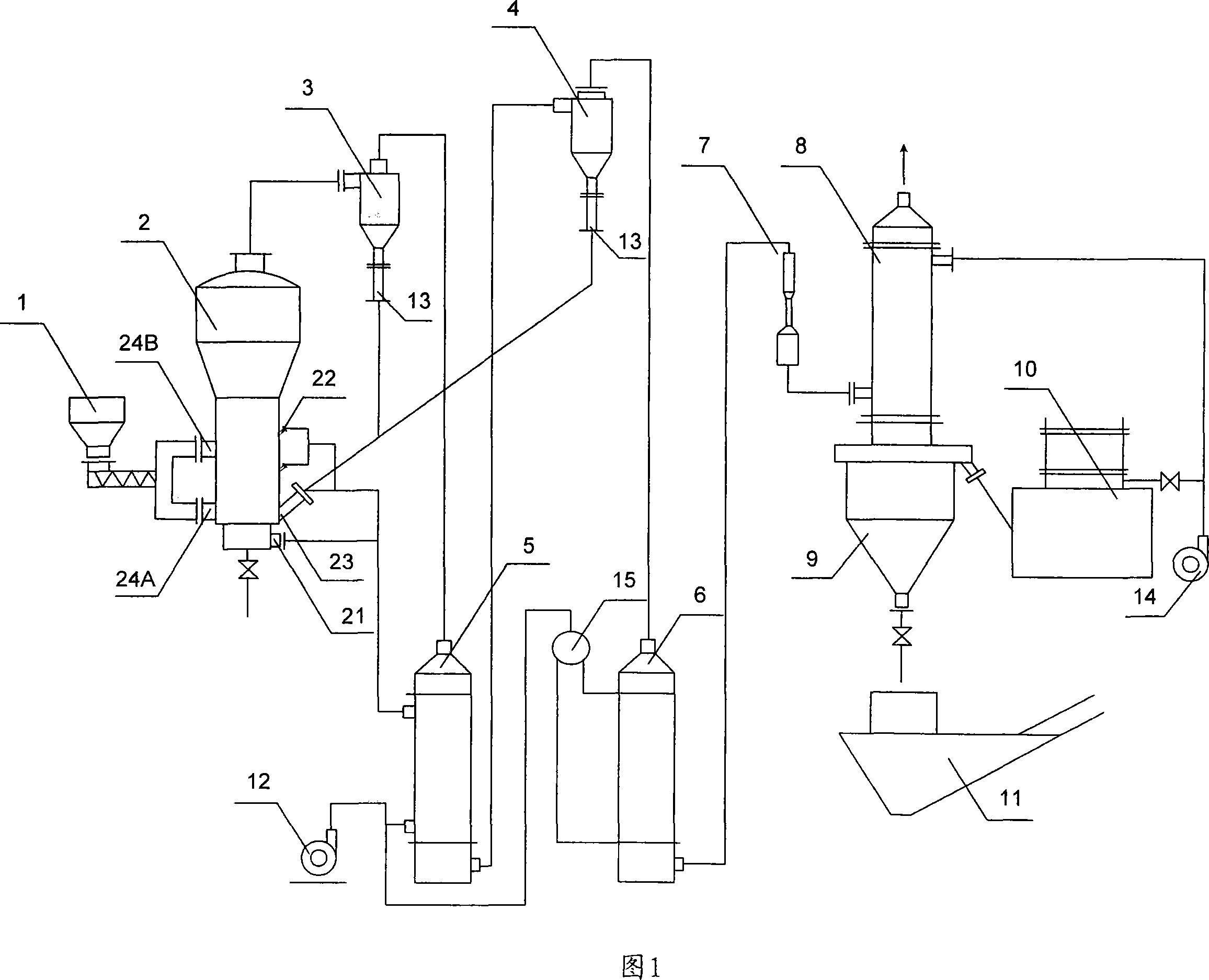

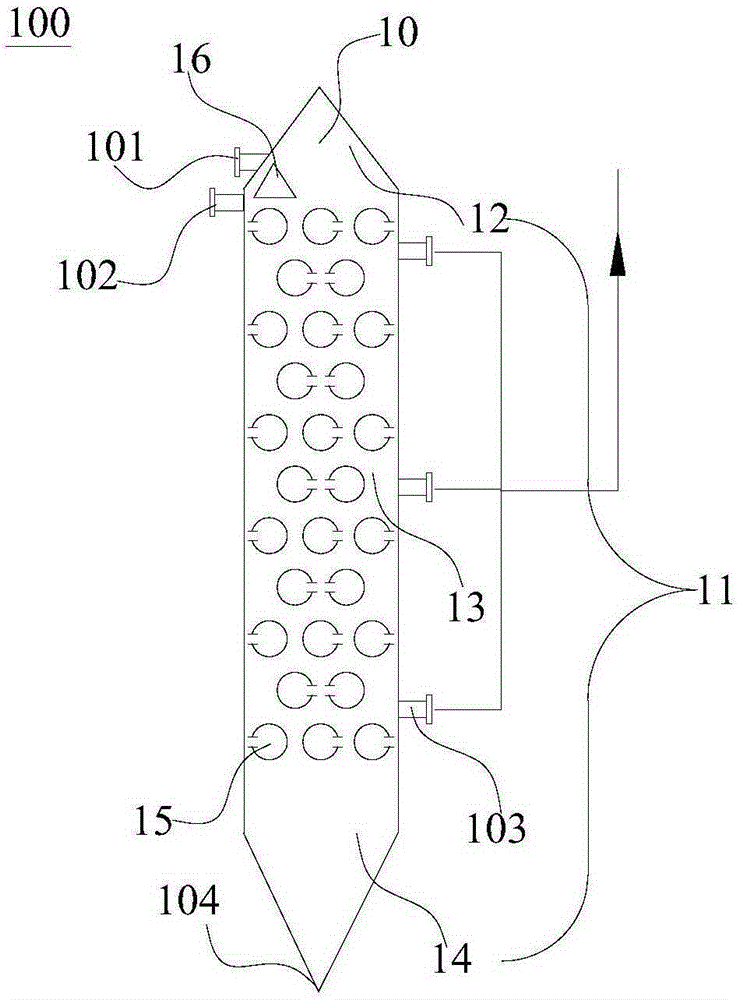

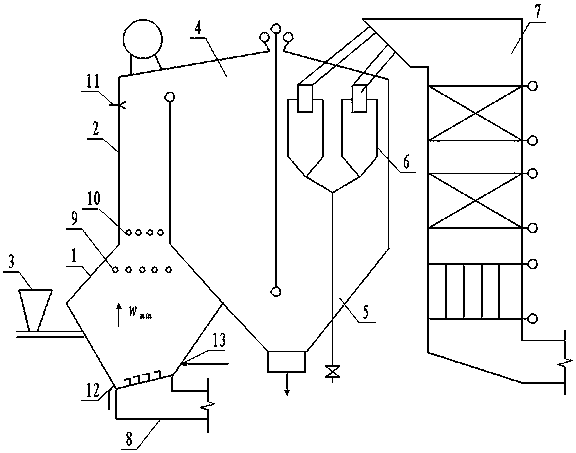

Circulating fluidized bed gas generator system

ActiveCN101063053AEfficient recyclingReduce heat of reactionEnergy inputGranular/pulverulent flues gasificationFluidized bedEngineering

The invention discloses a circulating coal fluidized bed coal gas producer system, which is characterized by the following: comprising coal-gas producer, high temperature segregator, heat exchanger, low temperature segregator and exhaust heat boiler; arranging primary air port entered high temperature gasifying agents into the burner and at least a overfire air port on coal-gas producer; equipping circling coal inlet to enter circling coal into burner; connecting the primary air port and overfire air port with heat exchanger; connecting circulating coal inlet with high temperature segregator, low temperature segregator and heat exchange; proceeding twice air intake, twice coal intake and twice separation. This invention possesses low coal consumption, high heat value, high productive efficiency and low cost, which can make the temperature of gasifying agents reach 750-850 deg. c.

Owner:KEDA INDUSTRIAL GROUP CO LTD +1

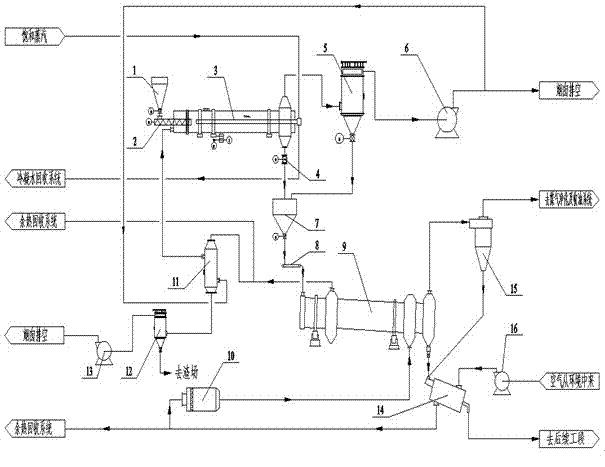

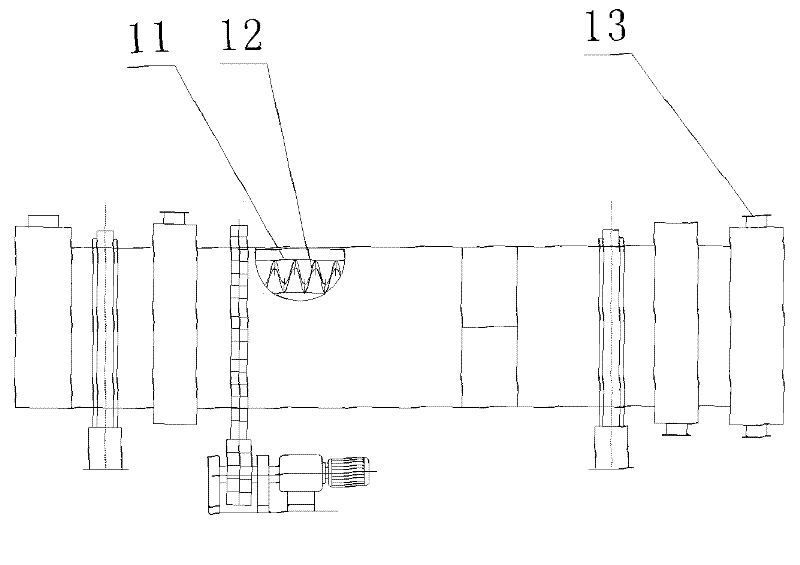

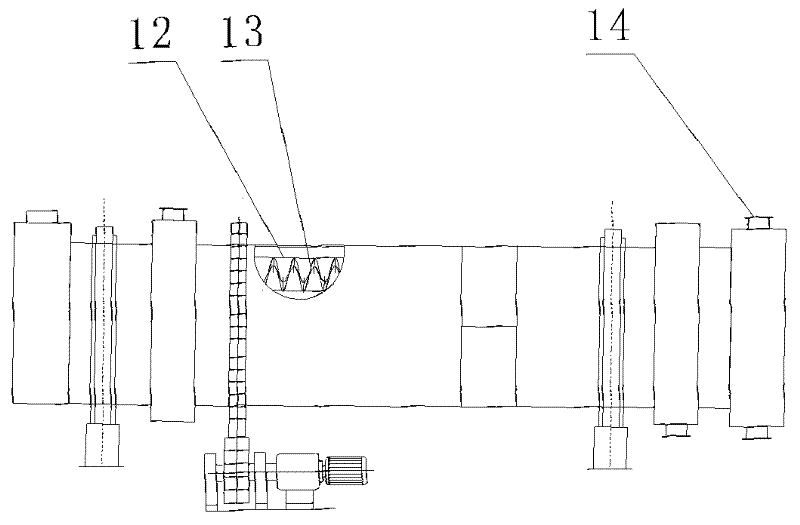

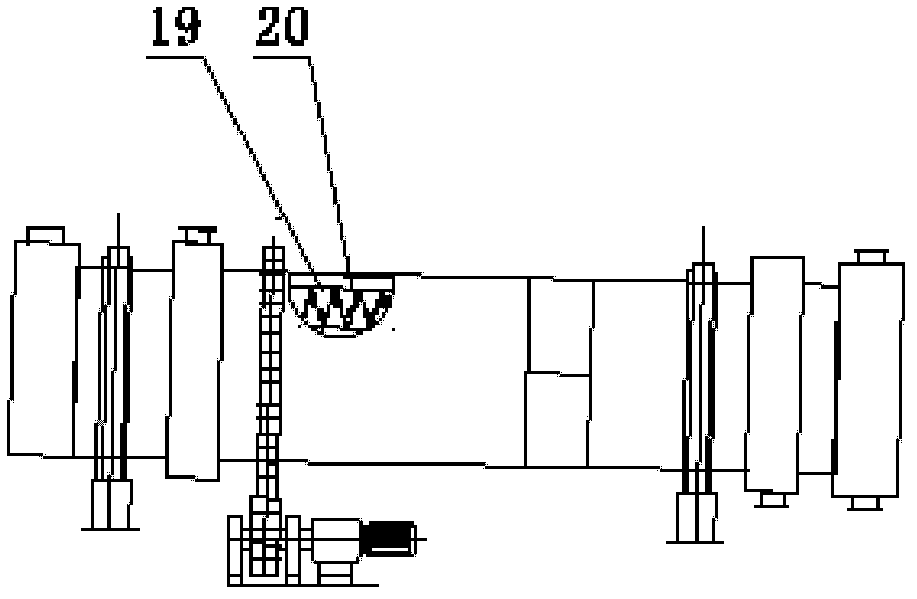

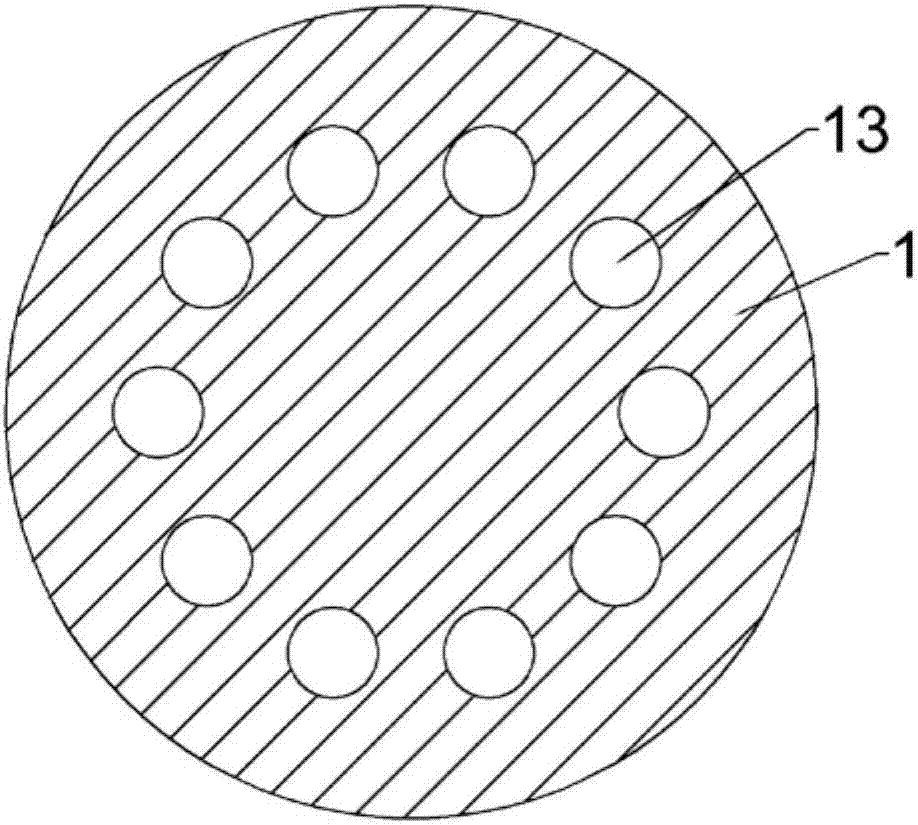

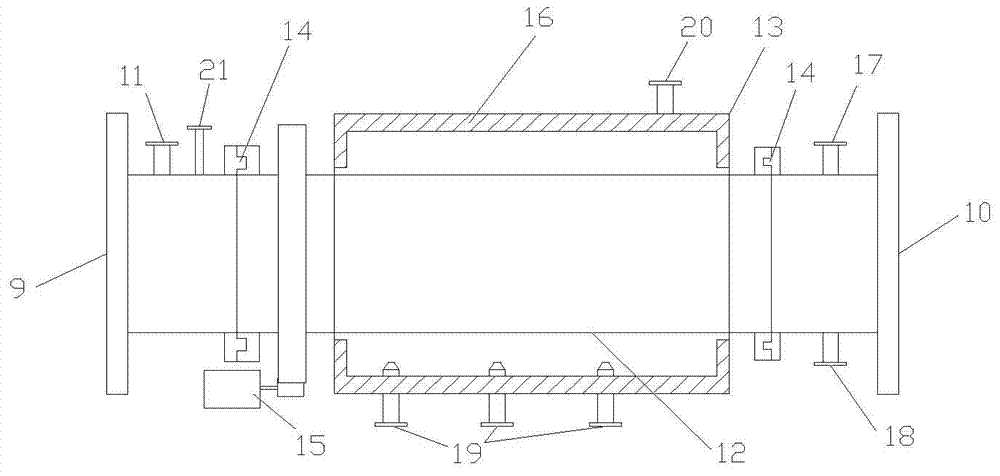

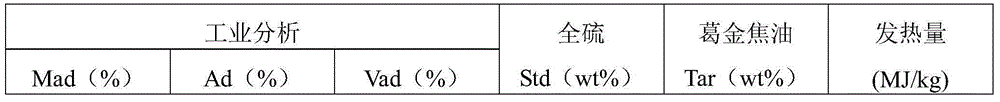

Single-stage fine coal multi-pipe rotary low-temperature destructive distillation technology and system

ActiveCN102358840AImprove thermal efficiencyEasy to handleIndirect heating destructive distillationSpecial form destructive distillationSingle stageSpiral blade

The invention discloses a single-stage fine coal multi-pipe rotary low-temperature destructive distillation technology and a system. The single-stage fine coal multi-pipe rotary low-temperature destructive distillation technology adopts a multi-pipe rotary destructive distillation machine to carry out low-temperature destructive distillation of fine coal. Multiple destructive distillation pipes for dispersing fine coal are arranged in the multi-pipe rotary destructive distillation machine. Spiral blades are arranged in the destructive distillation pipes and have the effects of diversion and disturbance on coal. The single-stage fine coal multi-pipe rotary low-temperature destructive distillation technology and the system can enhance destructive distillation effects, can increase destructive distillation effective areas, have the advantages of large fine coal treatment amount, small destructive distillation gas treatment amount, low content of tar and dust, and high calorific value of gas, can realize recovery of chemical raw materials such as coal tar and the like produced in low-temperature destructive distillation of soft coal and low-order fine coal as completely as possible, can improve a comprehensive utilization rate of coal, and can realize production of semicoke powder and high-calorific value gas from soft coal and low-order fine coal through low-temperature destructive distillation.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

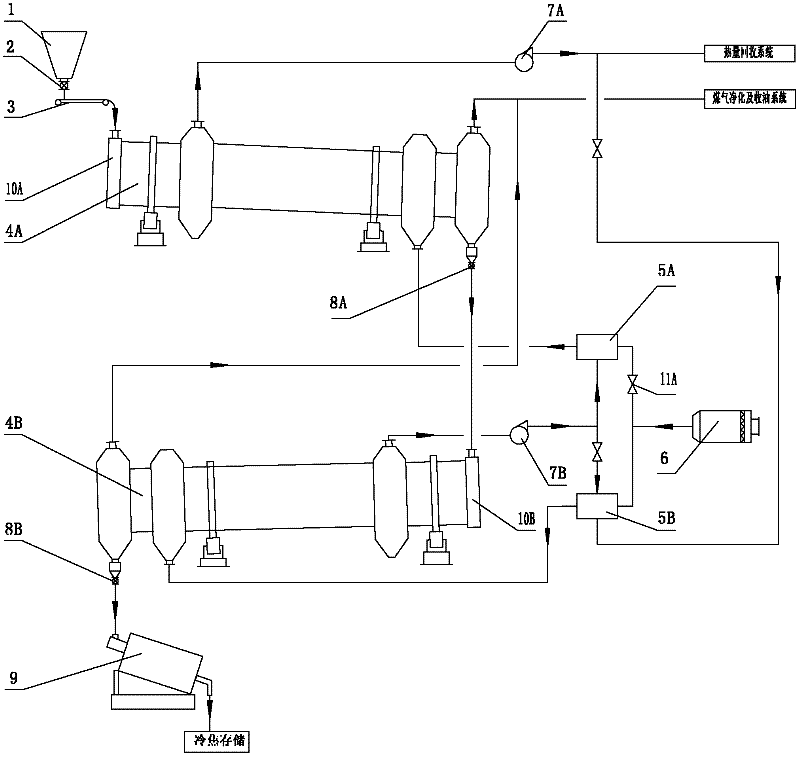

Multistage pulverized coal multiple-tube rotary low temperature dry distillation technology and system

ActiveCN102358841AEasy to handleIncrease the heat exchange areaIndirect heating destructive distillationSpecial form destructive distillationCaloric valuesHelical blade

The invention discloses a multistage pulverized coal multiple-tube rotary low temperature dry distillation technology and system. The multiple-tube rotary dry distillation machine multistage (two stages or more) series connection process is adopted to perform low temperature dry distillation on pulverized coal; a plurality of dry distillation tubes are arranged in the multiple-tube rotary dry distillation machine to disperse coal powder, a helical blade is arranged in each dry distillation tube to guide and disturb coal and reinforce the dry distillation effect and increase the dry distillation effective area, the technology has the advantages of large pulverized coal treatment capacity, large dry distillation gas treatment capacity, low tar and dust contents, high coal gas caloric value and the like; the chemical raw materials generated in the low temperature dry distillation process of bituminous coal and low-price pulverized coal can be recycled extremely, the comprehensive utilization rate of coal is increased; and semicoke powder and coal gas with high calorific value can be produced through the low temperature dry distillation of bituminous coal and low-price pulverized coal.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

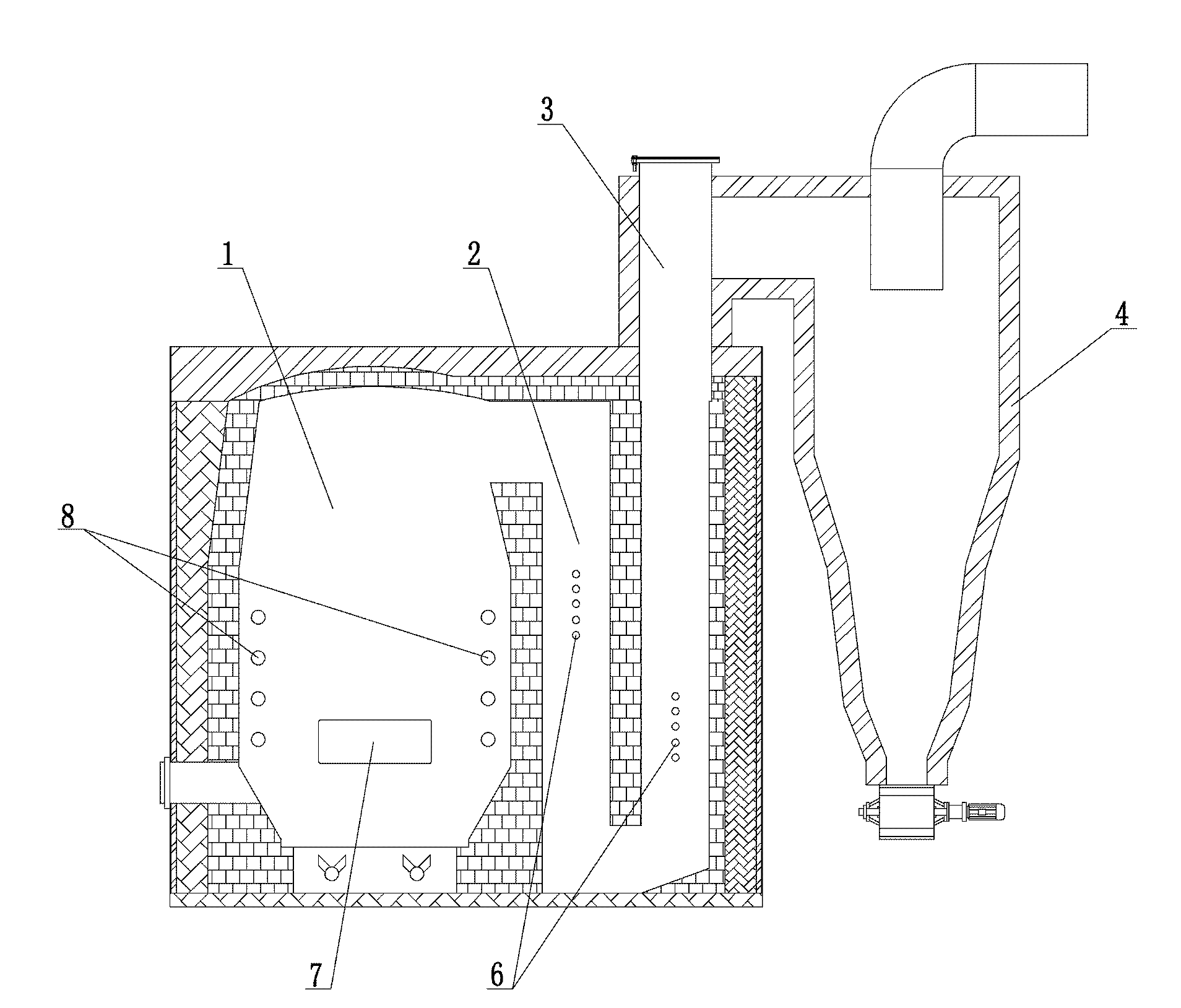

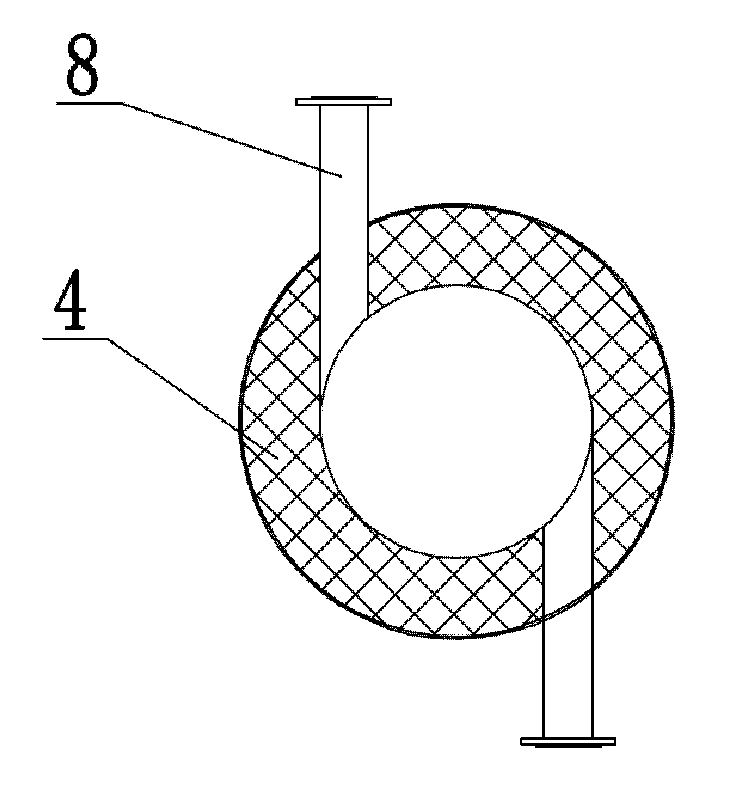

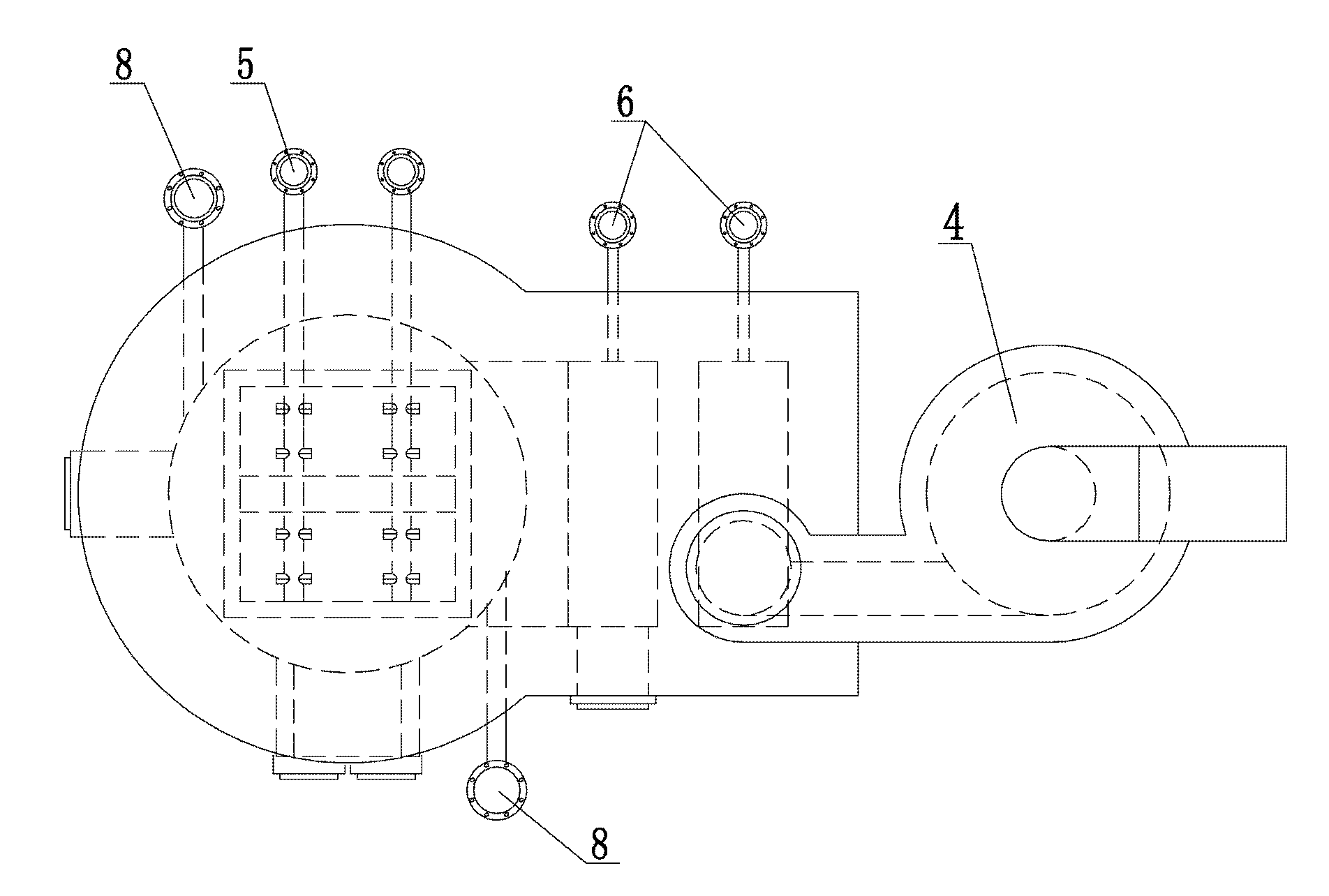

Biomass whirlwind hot blast stove

InactiveCN102192590AReduce consumptionReduce dust contentAir heatersCombustion chamberCombustible gas

The invention discloses a biomass whirlwind hot blast stove. A furnace is composed of a main combustion chamber and an auxiliary combustion chamber which are separated, wherein the main combustion chamber is used for a primary combustion and is provided with a cylinderical inner cavity; the auxiliary combustion chamber is used for a secondary combustion; the main combustion chamber and the auxiliary combustion chamber are communicated mutually at the upper part; and the side wall of the main combustion chamber is provided with a primary air hole which is communicated with an air pipe and is arranged tangentially. The primary whirlwind ensures the favorable mixing of smoke and primary air, prolongs the detention time of unburned carbon grannules in the furnace, and mainly plays a role of gasification; the auxiliary combustion chamber ensures the complete combustion of the unburned carbon granules and combustible gas in the furnace, plays a role of oxidation, and black smoke is generated by the uncomplete combustion caused by high temperature and oxygen deficit is reduced; the combustion efficiency of the hot blast stove is improved obviously, compared with the normal hot blast stove, the consumption amount of fuel is saved by about 10%, also the frequency of black smoke emission is decreased obviously, and the aim of clean combustion is achieved; and the hot blast stove can be suitable for the combustion of sawdust and meal, and is even suitable for the combustion of BMF (biomass fuel) fuel.

Owner:GUANGZHOU DEVOTION THERMAL TECH

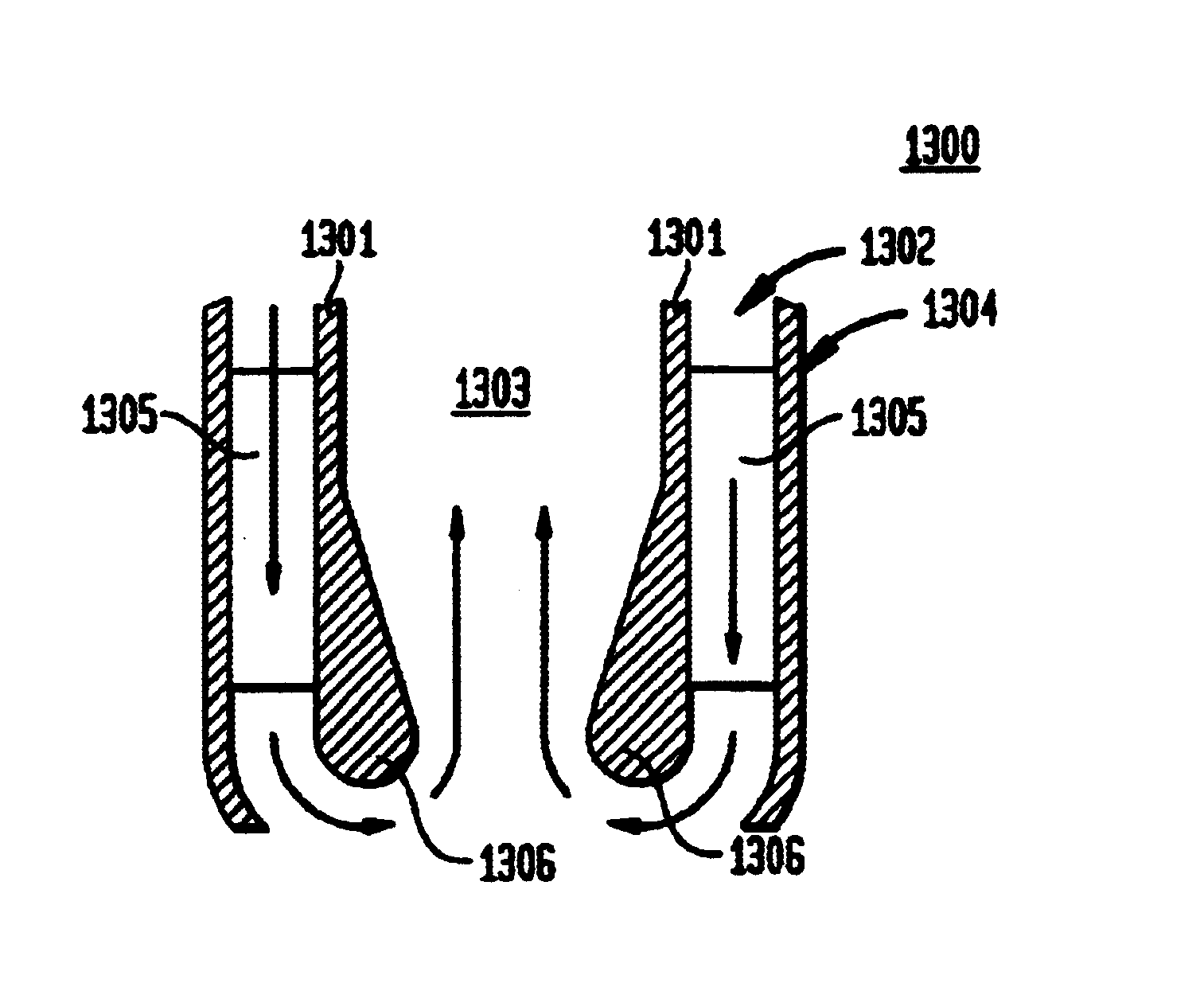

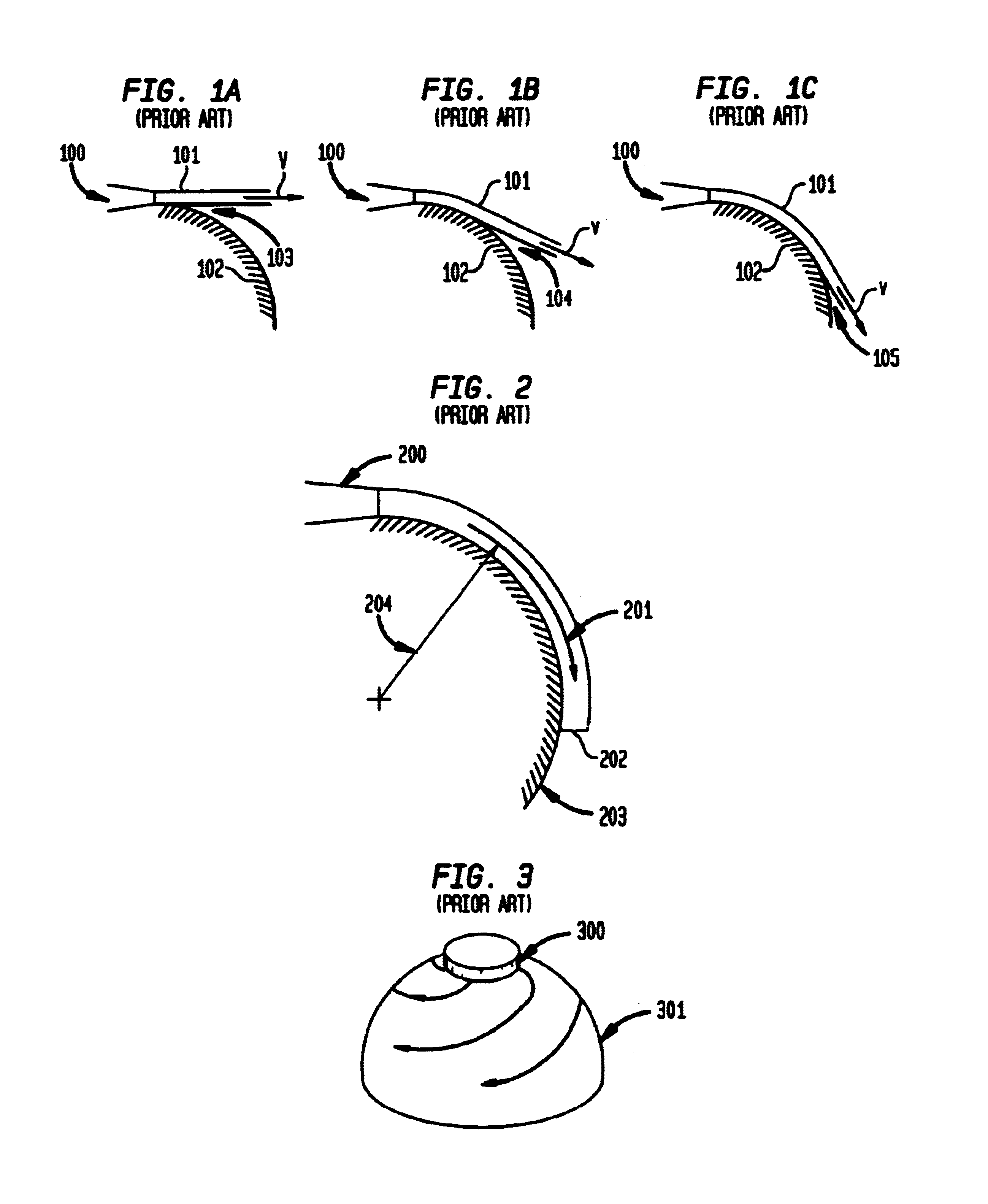

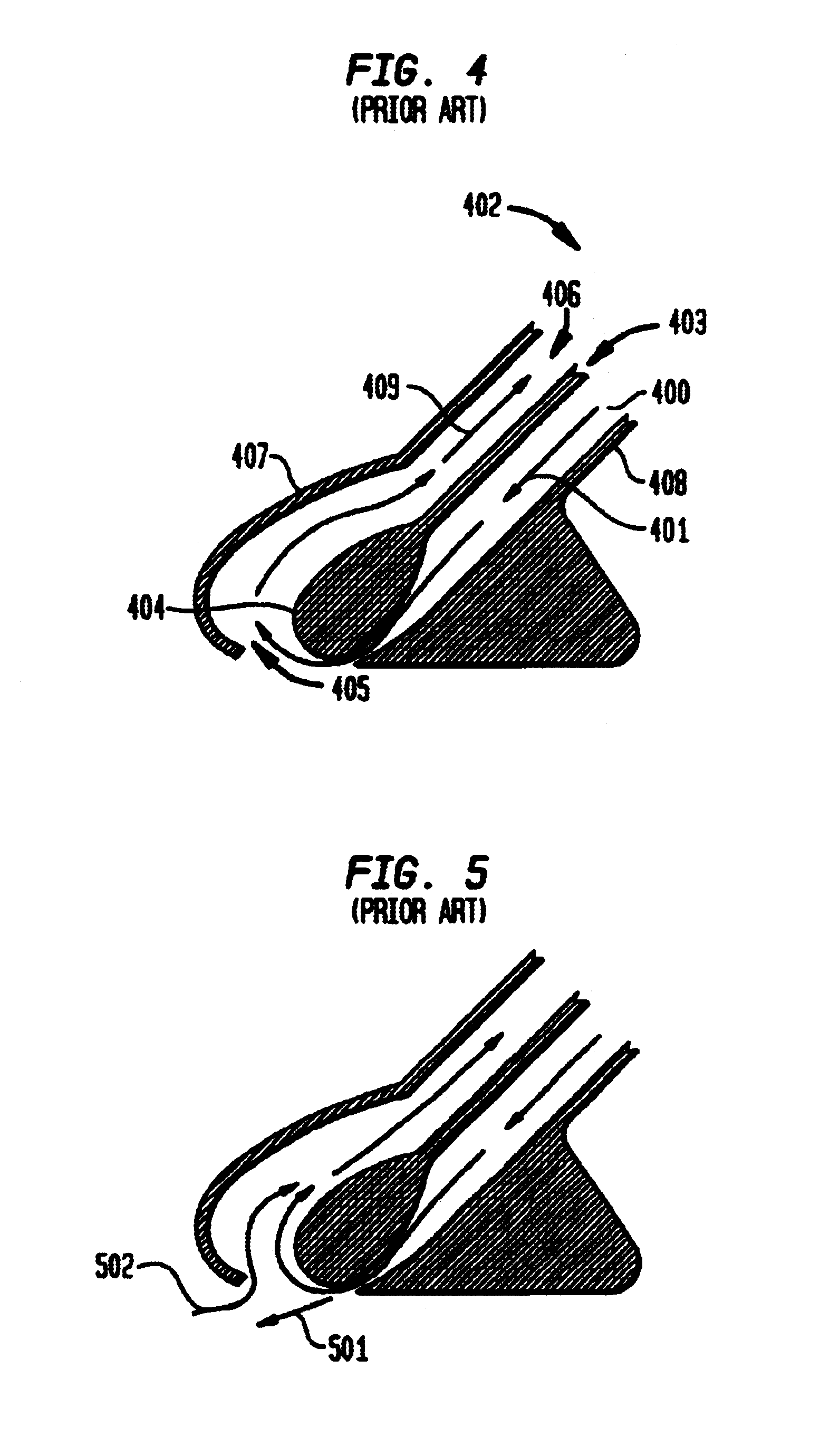

Cannister and upright vortex vacuum cleaners

InactiveUS6957472B2Simple concentric systemsEfficient damageCleaning filter meansCombination devicesEngineeringAtmosphere

The present invention relates to upright and cannister vacuum cleaners. The improved vacuum cleaners utilize toroidal vortex technology to provide efficient airflow in a sealed system. The sealed system prevents dust from escaping into the atmosphere and retains kinetic energy of flowing air. The present invention is also quieter, lighter, and simpler than conventional designs.

Owner:DMR HLDG GROUP

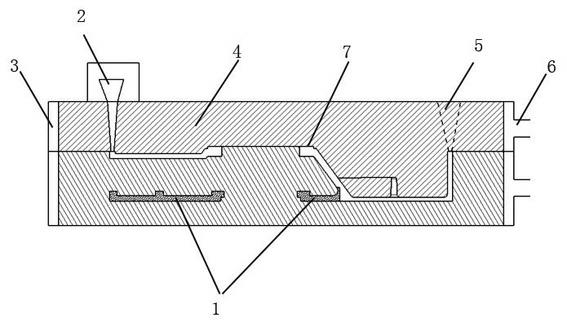

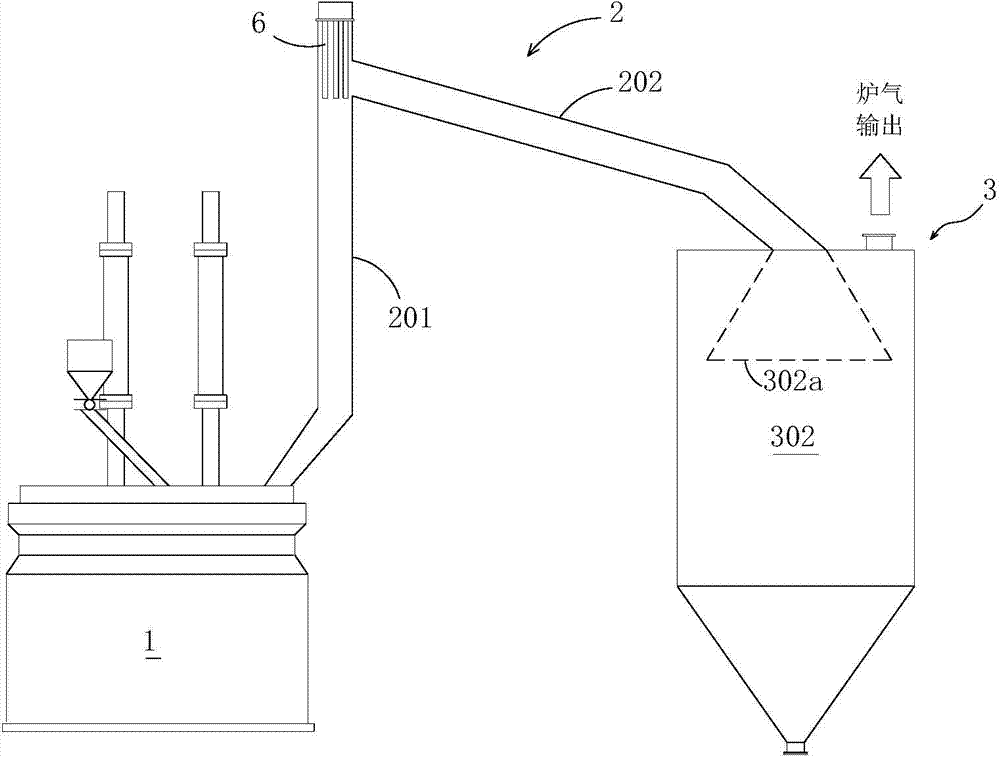

Differential motion airtight feeding electric furnace smelting device and feeding method thereof

ActiveCN102181601AShorten the lengthIncrease the feeding speedCharge manipulationElectric furnaceEngineeringHeat losses

The invention discloses a differential motion airtight feeding electric furnace smelting device and a feeding method thereof. The device comprises an electric furnace and a charging device, wherein the charging device comprises a cold receiving conveying trough and a heat conveying trough; the lower sides of the cold receiving conveying trough and the heat conveying trough are provided with an independently-controlled excitation device respectively; the outlet of the cold receiving conveying trough is provided with a conveying throat opening which is extended into the heat conveying trough; and the distance between the conveying throat opening and the bottom of the heat conveying trough is greater than or equal to the depth of the heat conveying trough. By the feeding method, shock excitation at different frequencies is applied to the two conveying troughs to realize the differential motion conveying of raw materials, so that a thicker material layer can be laid on the cold receiving conveying trough, and the material loading speed is increased; simultaneously, a shorter cold receiving conveying trough and a shorter material-conveying bottom elongated slot can be designed, so that the device and the method make project implementation convenient. In addition, due to the adoption of the throat opening and a sealed door structure, the possibility of material blocking and the air leakage rate are greatly reduced, and the device has low heat loss and a good dedusting effect, and is high-efficient, energy-saving and environment-friendly during smelting.

Owner:CISDI ENG CO LTD

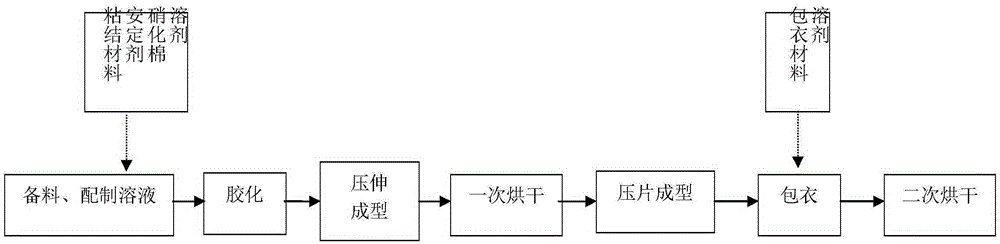

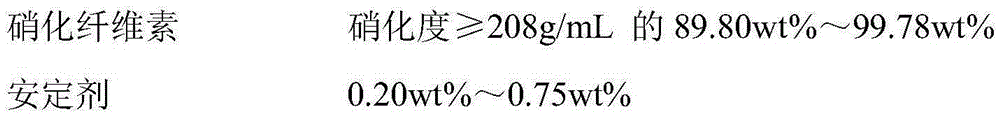

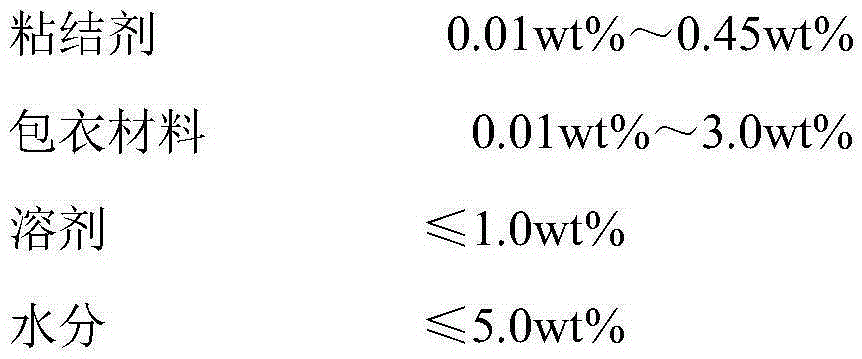

Coated priming composition-free nail-shooting ammunition pellet formula and preparation method thereof

InactiveCN105330495AImprove moisture resistanceUniform sizeNitrated explosive compositionsCombustionNitrocellulose

The invention relates to a coated priming composition-free nail-shooting ammunition pellet formula and preparation method thereof. The coated priming composition-free nail-shooting ammunition pellet formula comprises, by weight, 89.80 to 99.78% of nitrocellulose, 0.20 to 0.75% of a stabilizing agent, 0.01 to 0.45% of a binder, 0.01 to 3.0% of a coating material, a solvent with an amount<=1.0%, and water with an amount <=5.0%. According to the preparation method, nitrocellulose containing water is taken as a base material; the nitrocellulose containing water, the solvent, the stabilizing agent, and the binder are delivered into a gelling kneading machine for gelling after a certain time of mixing; an obtained mixture is pressed into particles, the particles are dried and are subjected to moulding using a tablet machine so as to obtain pellets; and the pellets are coated with the coating material in a coating kettle, and are subjected to secondary drying. The obtained coated priming composition-free nail-shooting ammunition pellets possess excellent humidity resistance, and problems of the prior art, that drying efficiency is low, energy consumption is high, a large amount of dust is generated, combustion explosion is easily caused, and technology safety is poor, are solved.

Owner:LUZHOU NORTH CHEM IND

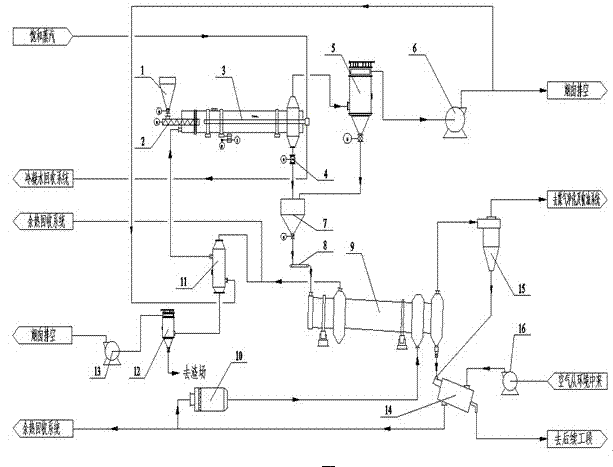

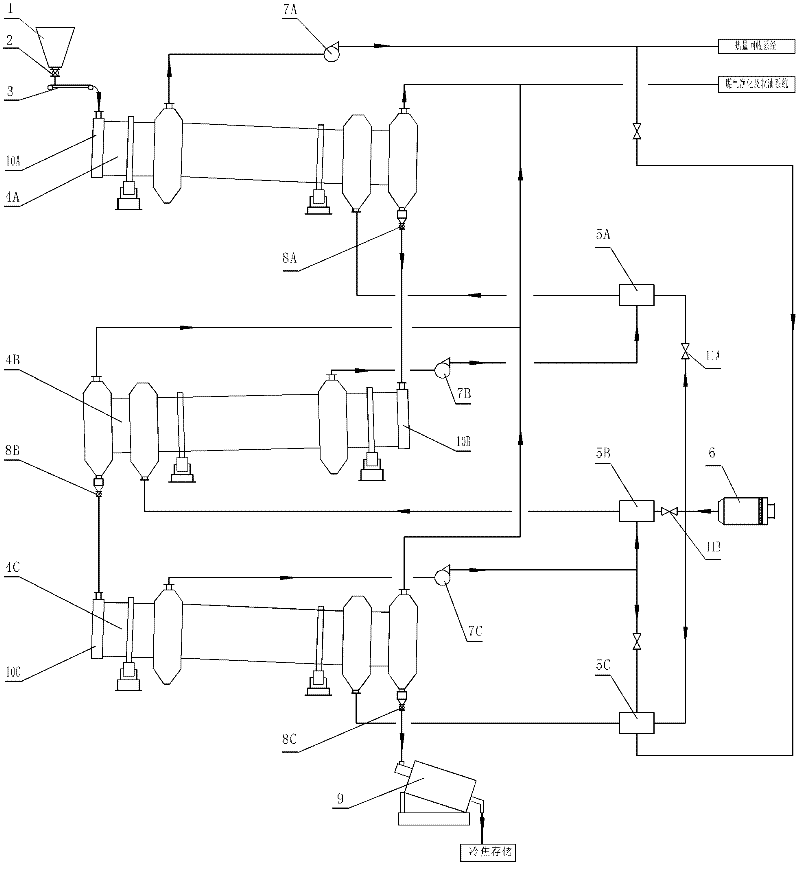

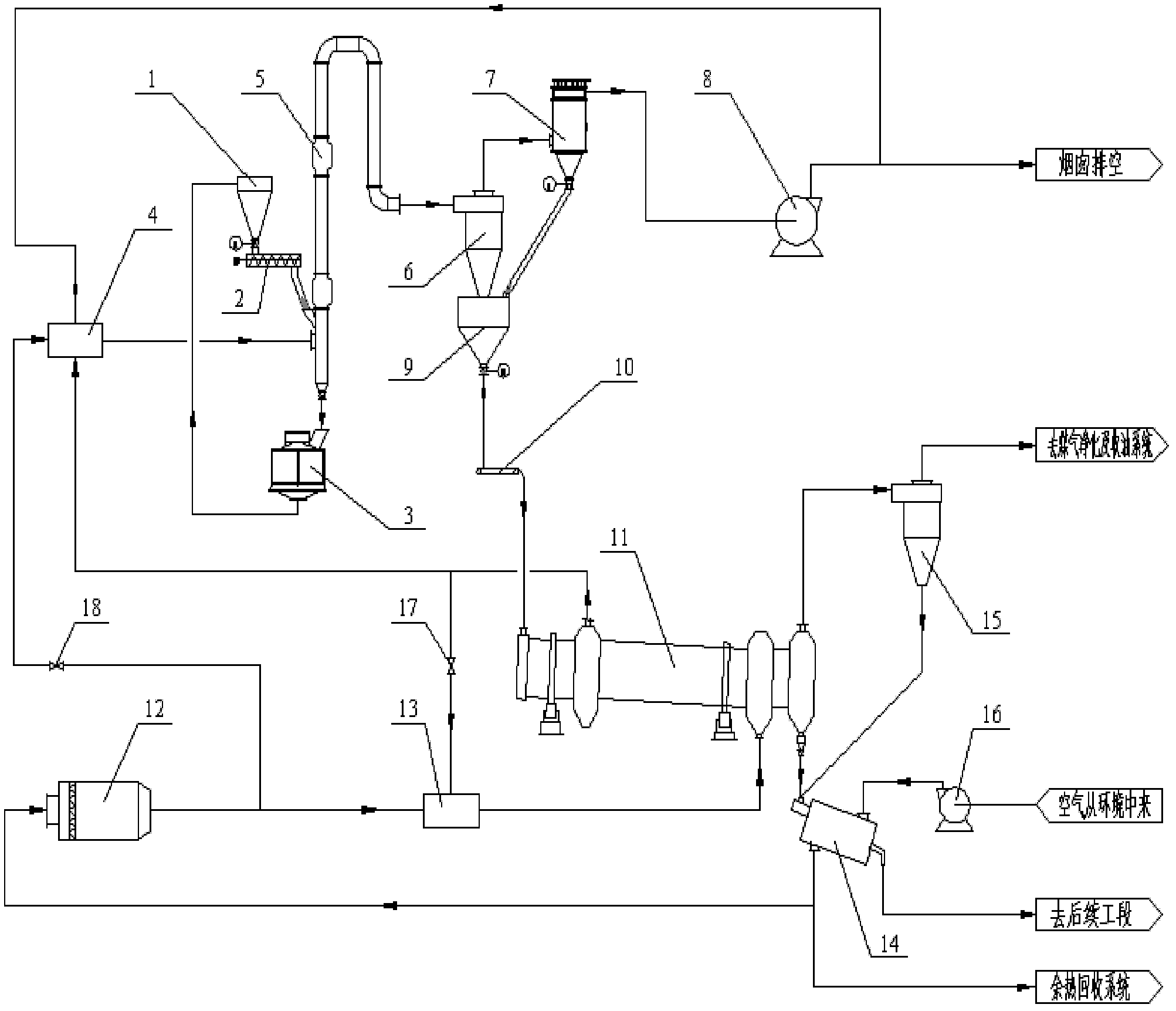

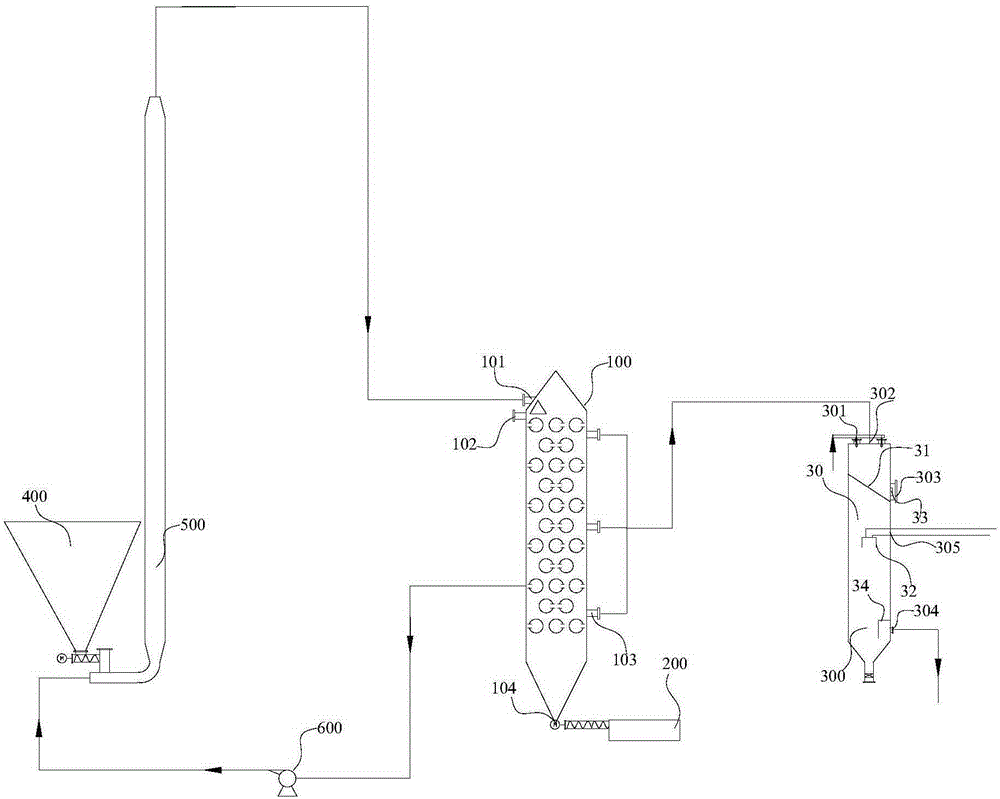

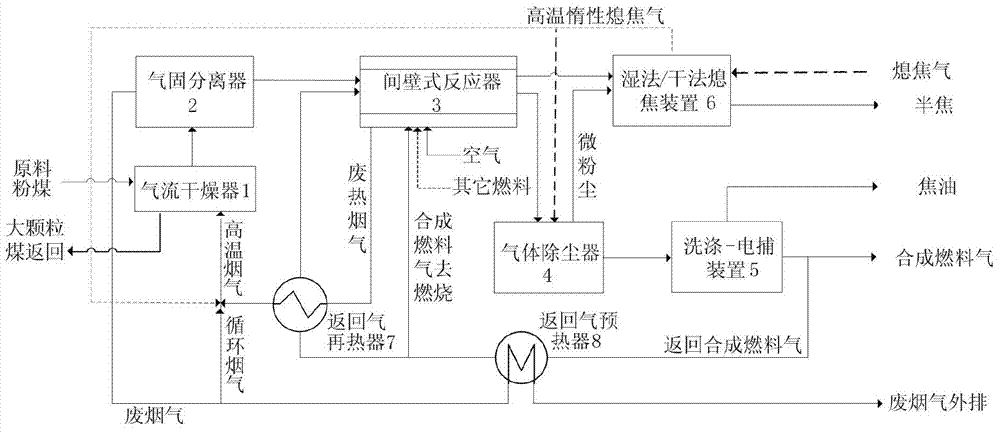

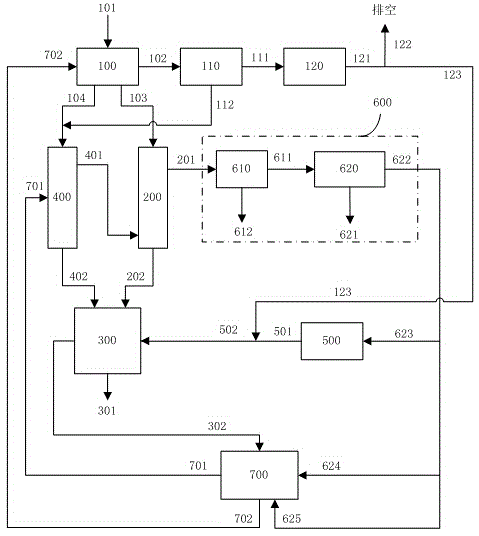

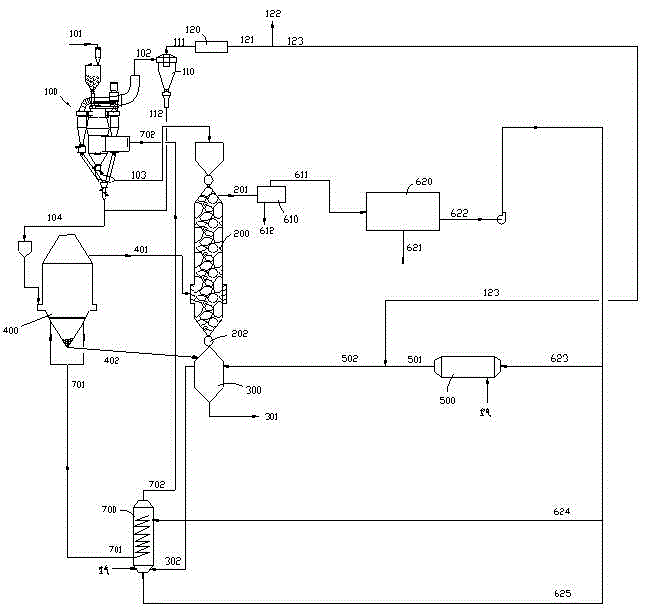

Quality-improving technique combining low-rank coal pneumatic drying with multi-tube revolving destructive distillation and system for same

ActiveCN102433142AEasy dischargeLow investment costCoke quenchingEnergy inputHigh energyCoking wastewater

The invention discloses a quality-improving technique combining a low-rank coal pneumatic drying with a multi-tube revolving destructive distillation and a system for the same, wherein the technique comprises a coal flow and a hot smoke flow, and both of the coal flow and the hot smoke flow comprise a drying process and a destructive distillation process which are connected with each other; the system comprises a gas flow drying system and a multi-tube revolving destructive distillation system which are connected with each other. The quality-improving technique combining a low-rank coal pneumatic drying with a multi-tube revolving destructive distillation and the system for the same disclosed by the invention realize a cascade efficient utilization for a high-temperature smoke, and increase the energy utilization rate of the whole system. The quality-improving technique combining a low-rank coal pneumatic drying with a multi-tube revolving destructive distillation and the system for the same disclosed by the invention have the advantages of high energy utilization rate, safe and stable system, small treatment capacity for destructive distillation gas, small treatment capacity for coking wastewater, high yield of tar, high calorific value of coal gas etc. The quality-improving technique combining a low-rank coal pneumatic drying with a multi-tube revolving destructive distillation and the system for the same disclosed by the invention also can recover chemical raw materials such as coal tar generated during a low-rank coal low-temperature destructive distillation process, and increase the comprehensive utilization rate of coal. Via the technique, a powdery or granular semicoke which is low in volatile matter, high in low caloric value and good in stability is produced by a quality-improving technique using a low-rank coal low-temperature destructive distillation. The technique is suitable for producing a civil or industrial coal gas with a medium caloric value by a quality-improving technique using a low-rank coal low-temperature destructive distillation.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

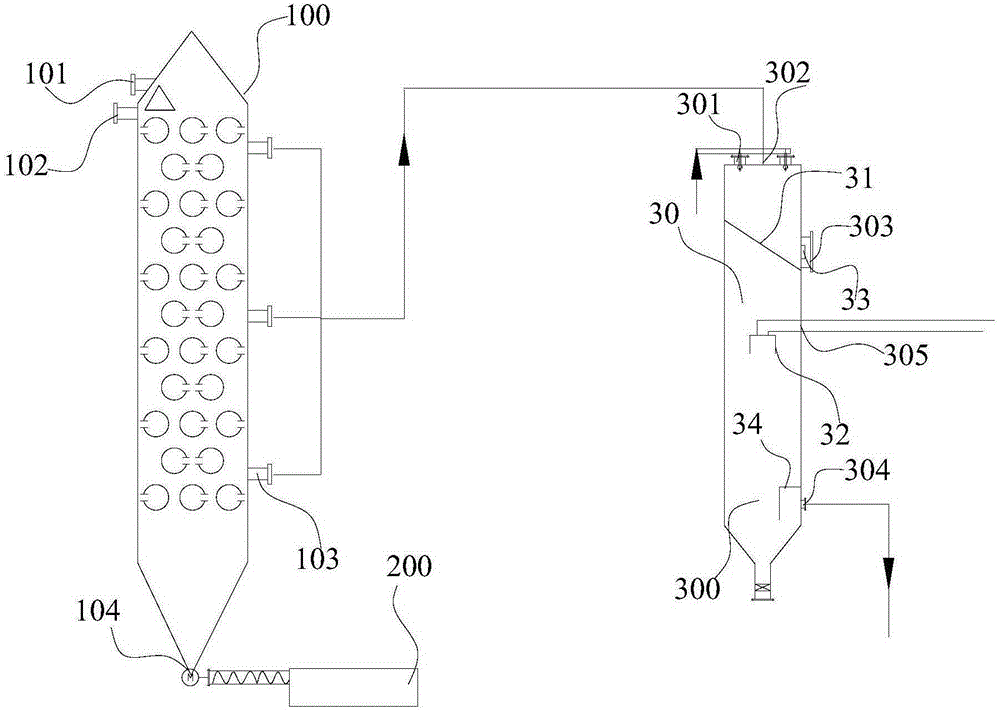

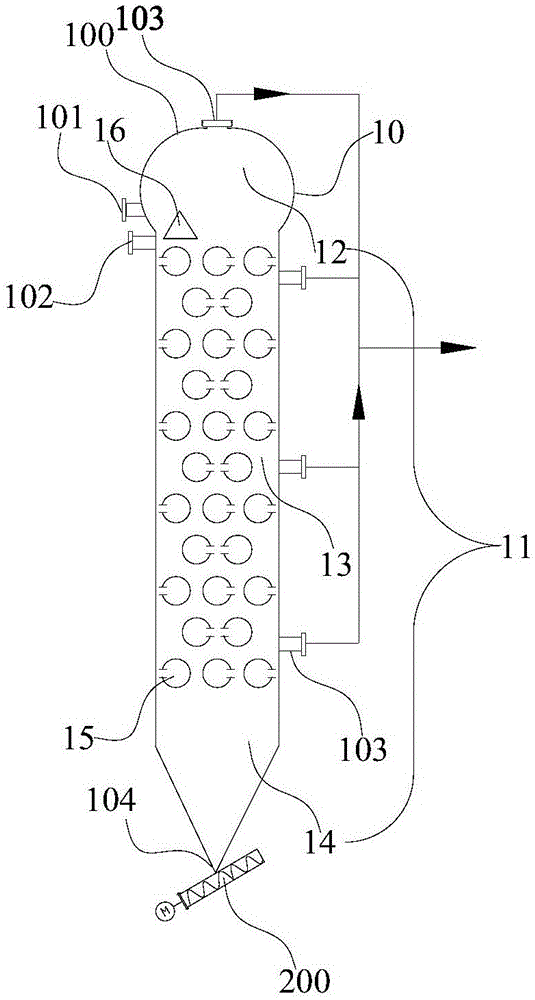

Rapid biomass pyrogenation system and method

ActiveCN105176563AEvenly dispersedImprove running stabilityBiofuelsLiquid hydrocarbon mixture productionSpray towerProcess engineering

The invention discloses a rapid biomass pyrogenation system and method. The system comprises a rapid pyrogenation reactor, a residue cooling machine and a spraying tower. The rapid pyrogenation reactor comprises a reactor body, a multi-layer heat storage type radiation pipe, a biomass inlet, a material distributor, a distribution gas inlet, a plurality of pyrogenation gas outlets and a semicoke outlet. The residue cooling machine is connected with the semicoke outlet and suitable for cooling semicoke. The spraying tower is connected with the pyrogenation gas outlet and suitable for spraying pyrogenation gas through cooling liquid so that bio-oil and fuel gas can be obtained. The system can convert biomass into bio-oil with high value-added, and therefore efficient and clean utilization of biomass is achieved, and the rapid pyrogenation reaction technological process is greatly simplified.

Owner:SHENWU TECH GRP CO LTD

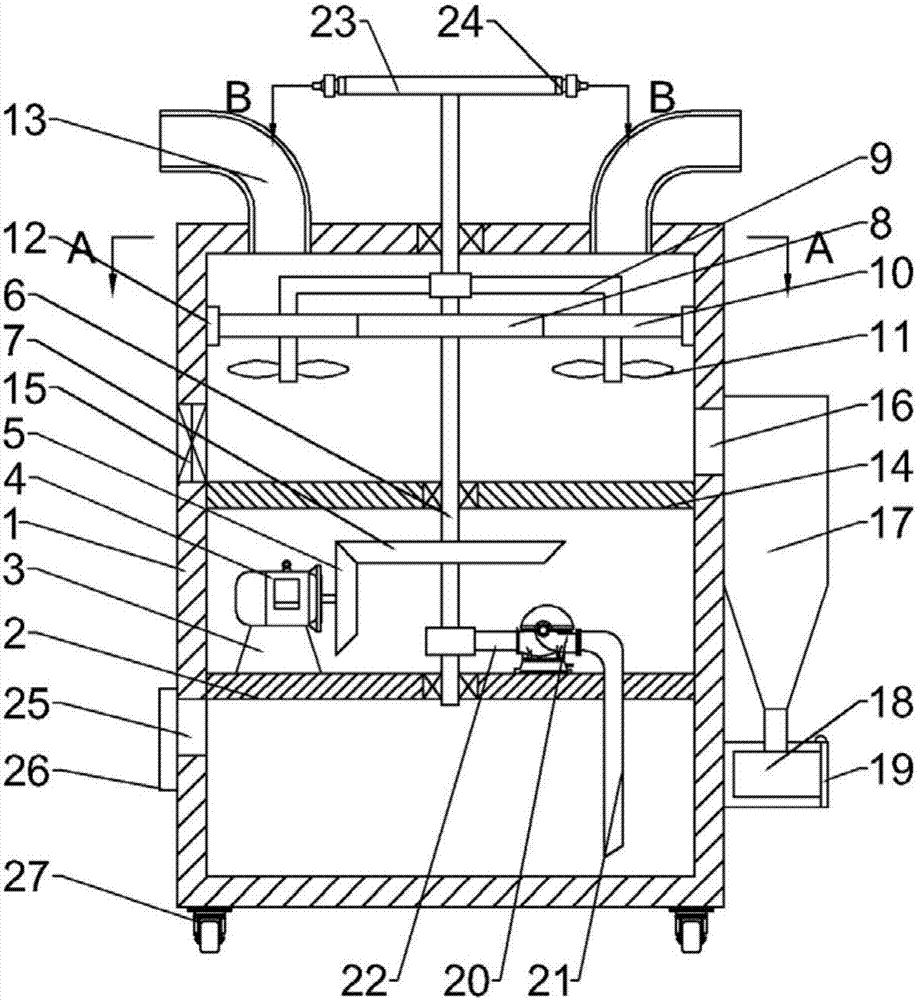

Dust absorbing and treating device for building site

InactiveCN107497233AAbsorb cleanReduce dust contentCombination devicesDirt cleaningEngineeringMechanical engineering

The invention discloses a dust absorbing and treating device for a building site. The dust absorbing and treating device comprises a shell, a lower partition is fixedly connected below the inside of the shell, a motor seat is fixedly connected on the left side above the lower partition, a motor is fixedly connected above the motor seat, an output end of the motor is fixedly connected with a driving bevel gear, a longitudinal rotating shaft is rotatably connected in the middle above the lower partition through bearing and is of a tubular structure, a driven bevel gear is fixedly connected below the longitudinal rotating shaft, and the driven bevel gear and the driving bevel gear are meshed. Compared with the prior art, the dust absorbing and treating device has the advantages that the device is simple in structure and convenient to use; through omnibearing dust absorbing, dust in each direction of the device can be absorbed more cleanly; the device combines two modes of dust collection for convenience of treatment with water spraying to lower dust content in air, so that environment of the building site is better, and the device is worthy of popularization.

Owner:陆春土

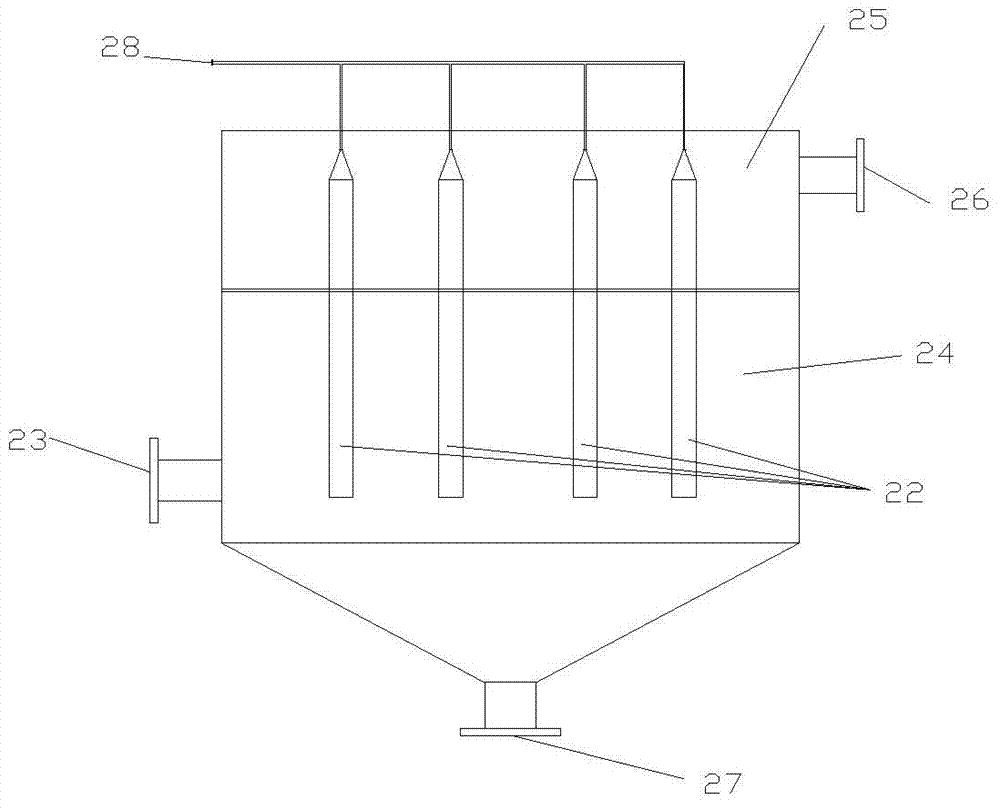

Method for producing tar, semi-coke and synthetic fuel gas by low-degree of coalification powdered coal

ActiveCN103497784AReliable waySafe wayLiquid hydrocarbon mixture productionSpecial form destructive distillationCoal conversionPollution

The invention relates to a method for producing tar, semi-coke and synthetic fuel gas by low-degree of coalification powdered coal. The method comprises the steps of low-degree of coalification powdered coal pre-drying, dry powdered coal separation, low-degree of coalification powdered coal conversion, light gaseous product dedusting, light gaseous product separation and collection, pyrolysis product semi-coke recovery and the like. The method provided by the invention provides a safe and reliable way for realizing efficient utilization of the powdered coal. The method provided by the invention is high in throughput and high in heat exchange efficiency, and can automatically sieve raw material grains, so that load on a coal preparation system is reduced, and yield of a light product is increased. Compared with the prior art, the method provided by the invention has the advantages that inert component content and tar dustiness in the synthetic fuel gas are effectively reduced, heat transfer efficiency and conversion reaction speed are effectively improved, and yield of tar and synthetic fuel gas products is increased, wherein the tar dustiness is less than 0.1mg / kg. The method has the characteristics of low energy consumption and low environment pollution, thereby having very important economic significance and social significance and having a great application prospect.

Owner:THE NORTHWEST RES INST OF CHEM IND

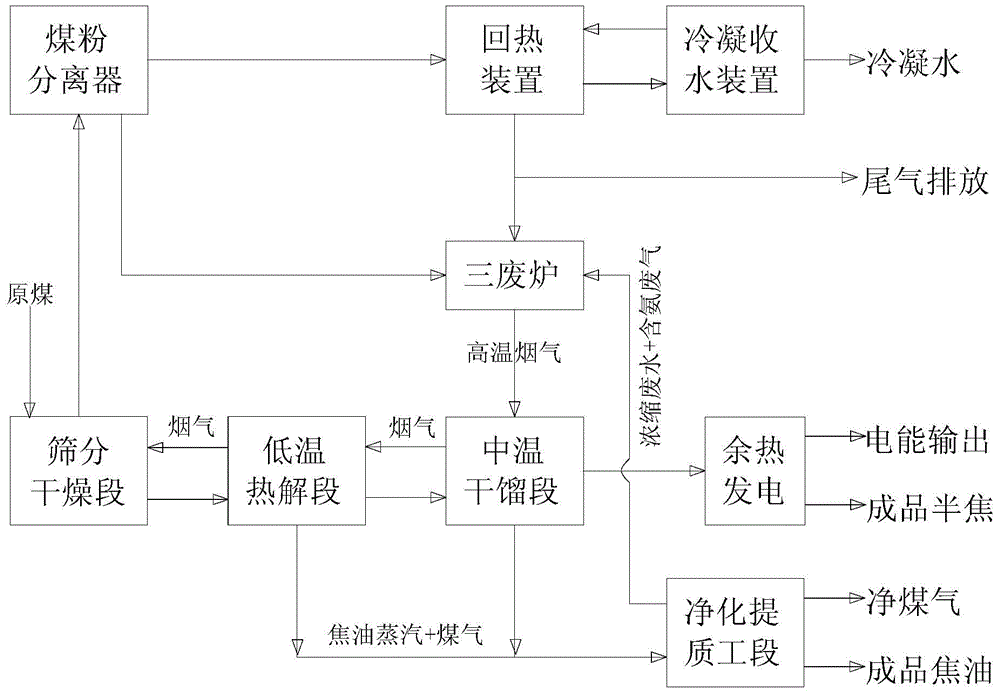

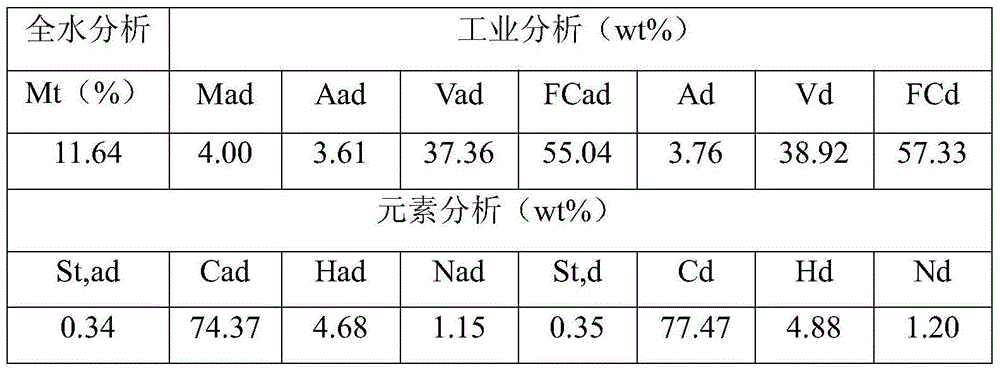

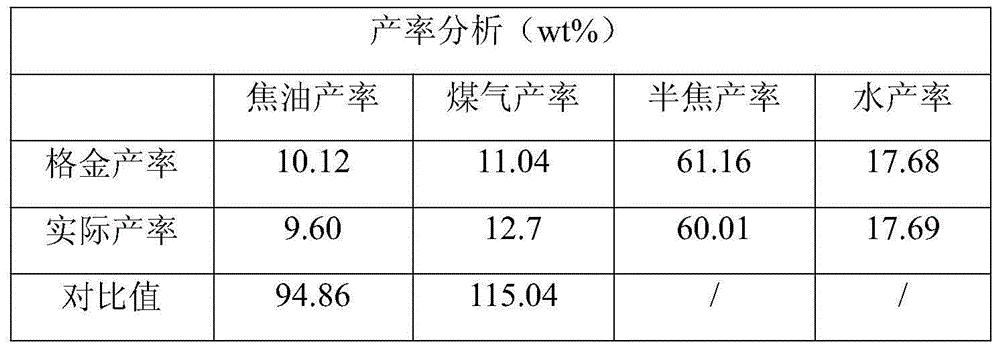

Method for preparing tar, coal gas and semi-coke by virtue of pyrolysis of bituminous coal

InactiveCN104531187AMaximize oil productionIncrease productionEnergy inputSpecial form destructive distillationSocial benefitsThree stage

The invention discloses a method for preparing tar, coal gas and semi-coke by virtue of pyrolysis of low-rank coal. The method comprises the following steps of processing pulverized raw material coal as in a three-stage manner, namely, a screening drying stage as the first stage, a low-temperature pyrolysis stage as the second stage and a medium-temperature pyrolysis stage as the third stage, wherein in the first stage, most moisture in the raw material coal is removed, the pulverized coal having the size of below 1mm is screened by wind power and used as a combustion raw material of a three-waste furnace for providing a heat source for a system, dust having the size of below 50 microns in the system is almost removed so that the pre-dust removal effect is achieved and the content of the dust in the end product coal tar is greatly reduced; during the second stage, the reaction temperature is controlled to be about 550-570 DEG C, and thus the highest tar yield is ensured; during the third stage, the reaction temperature is controlled to be about 690-710 DEG C the yield of the coal gas is increased. The products have the advantages of good quality, high yield, energy conservation and environment friendliness and the method has good economic and social benefits and is worthy in popularization and application.

Owner:CHENGDU HOT NEW ENERGY TECH

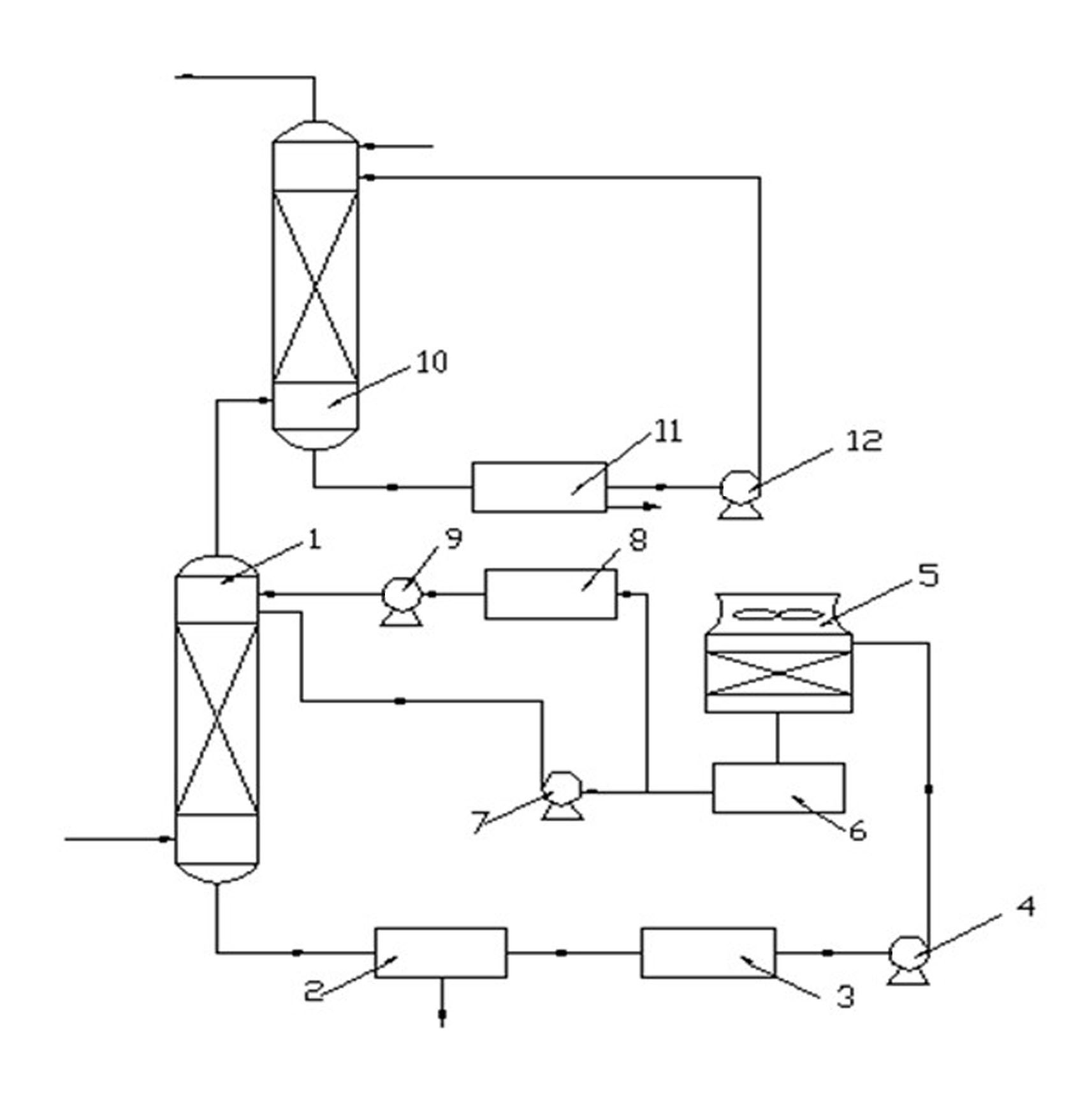

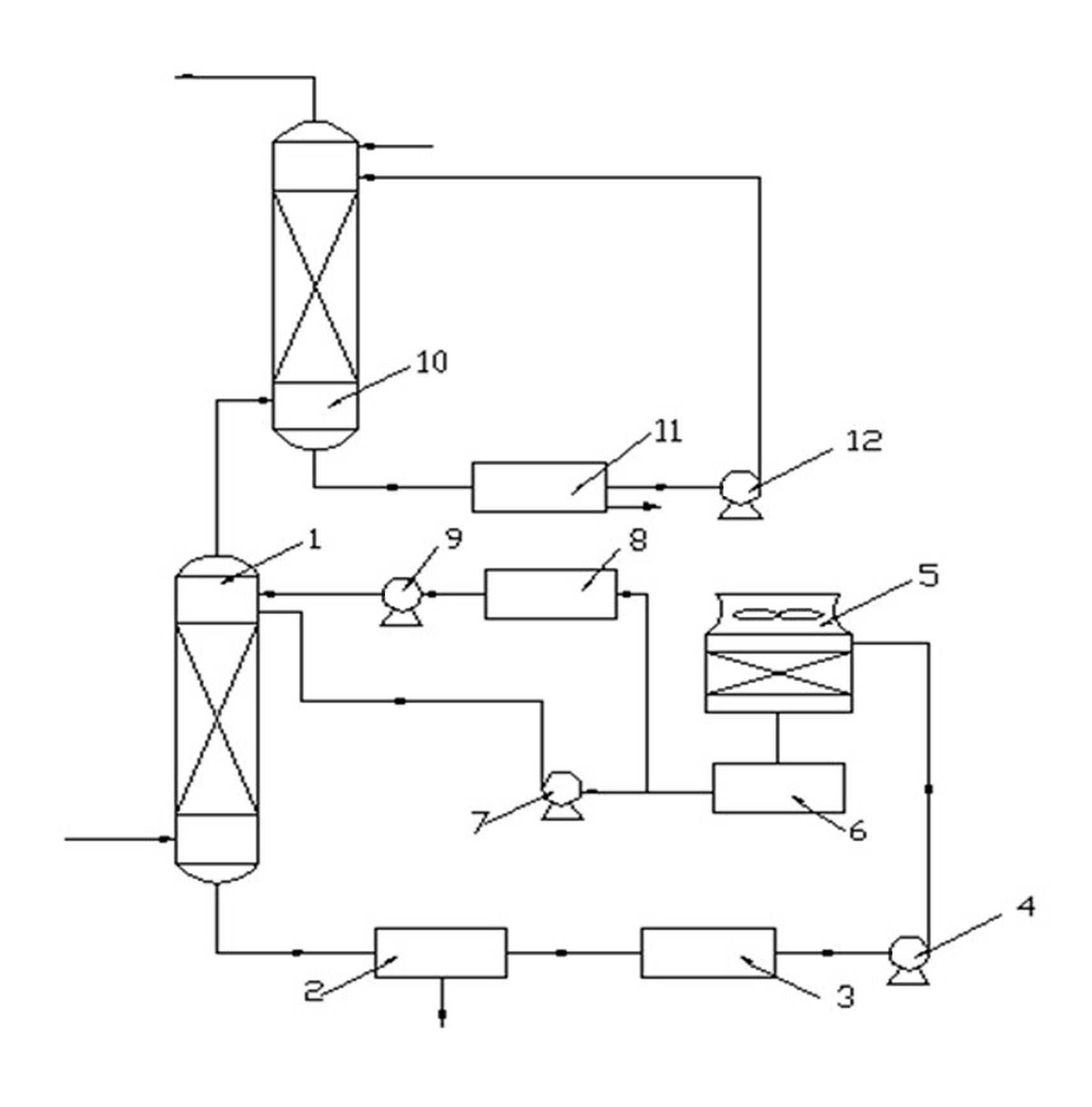

Coal gas washing, dedusting and purifying process

ActiveCN102010760ANo purification effectTo achieve the purification effectGas dust removalSaline waterWastewater

The invention relates to a coal gas washing process, in particular to a coal gas washing, dedusting and purifying process. The process can solve the problems of non-complete dedusting and non-complete purification of the traditional coal gas washing process. The coal gas washing, dedusting and purifying process is realized by adopting the following steps: a) introducing coal gas containing dust into a dedusting and washing tower; b) leading waste water after dedusting and washing to flow into a sedimentation tank for sedimentation via the tower bottom of the dedusting and washing tower; c) leading the coal gas after washing to enter into a purifying and washing tower, thereby being in countercurrent contact with circulating water at the upper part of the purifying and washing tower for washing and then further being in countercurrent contact with desalted water at the tower top of the purifying and washing tower for further washing and purifying; and d) leading the water after purifying and washing to flow into a circulating tank via the tower bottom of the purifying and washing tower and then leading the water to be divided into two lines. The coal gas washing, dedusting and purifying process can effectively solve the problems of non-complete dedusting and non-complete purification of the traditional coal gas washing process and is suitable for coal gas washing during the coal gas making process.

Owner:SHANXI JINCHENG ANTHRACITE COAL MINING GRP CO LTD

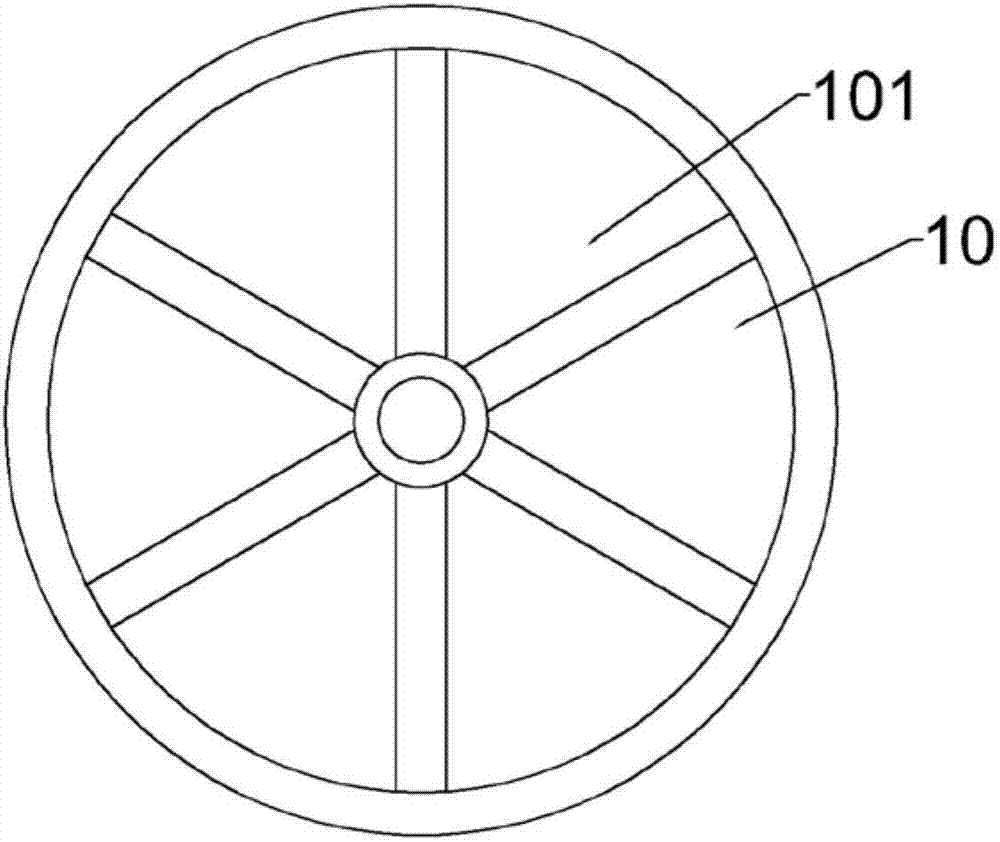

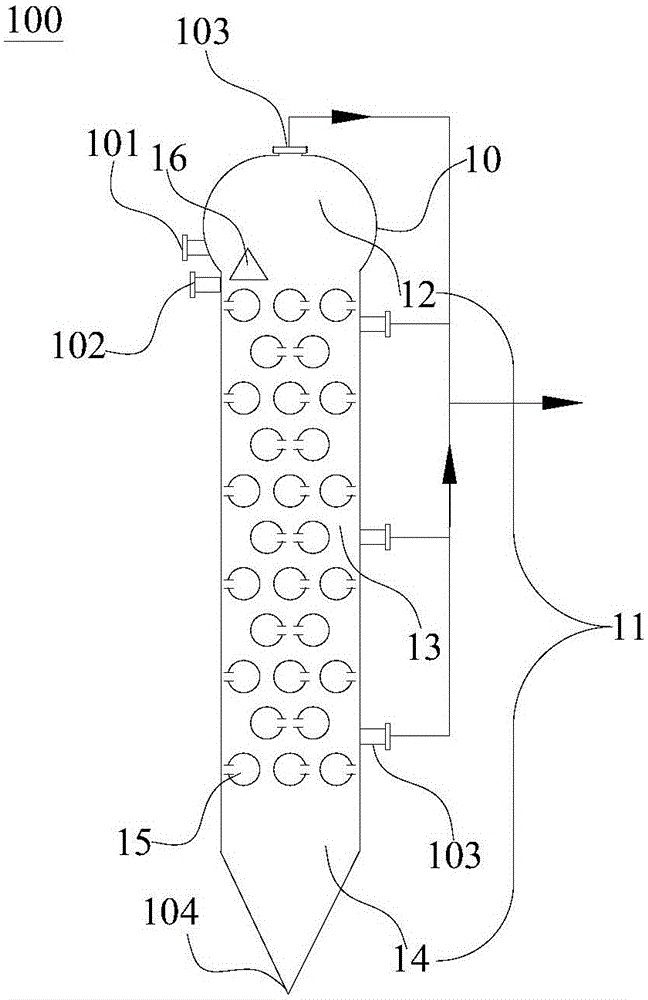

Flash pyrolysis reaction device

ActiveCN105154119AEvenly dispersedImprove running stabilityIndirect heating destructive distillationSpecial form destructive distillationDistributorStorage type

The invention discloses a flash pyrolysis reaction device. The flash pyrolysis reaction device comprises a reactor, multiple layers of heat storage type radiant tubes, a distributor, a material inlet, a distribution gas inlet, multiple pyrolysis gas outlets and a semicoke outlet. The reactor comprises a reactor body, and a reaction space is defined in the reactor body and forms a dispersion zone, a pyrolysis zone and a discharge zone from top to bottom. The multiple layers of heat storage type radiant tubes are distributed at intervals in the pyrolysis zone in the height direction of the reactor body, and each layer of heat storage type radiant tubes comprises multiple heat storage type radiant tubes distributed at intervals in the horizontal direction. The material inlet is located in the position, above the distributor, in the dispersion area. The distribution gas inlet is located in the dispersion zone and communicated with the distributor so that materials in the distributor can be conveniently blown out through distribution gas to enter the dispersion zone and then evenly fall into the pyrolysis zone. The multiple pyrolysis gas outlets are formed in the dispersion zone and / or the pyrolysis zone. The semicoke outlet is formed in the discharge zone. The device can significantly increase the tar yield and greatly simplify the flash pyrolysis reaction technological process.

Owner:SHENWU TECH GRP CO LTD

Yellow phosphorus preparation method and yellow phosphorus preparation equipment

ActiveCN103508429BHigh filtration precisionGood thermal shock resistancePhosphorus compoundsElectric arc furnaceSlurry

The invention discloses a yellow phosphorus preparation method and yellow phosphorus preparation equipment, which produce no phosphorous slurry and reduce the dust content of tail gas. The yellow phosphorus preparation method comprises the technological processes of electric furnace smelting, furnace gas purifying and phosphorus collecting and refining. In the process of furnace gas purifying, the furnace gas discharged out from an electric furnace is guided into a furnace gas dust-collection system through a smoke discharge pipeline, the furnace gas dust-collection system at least comprises a filter for filtering the furnace gas, the filter is provided with a sintering inorganic porous material filter element meeting the following working conditions, and the operations executed on the filter comprise the operation executed during starting a machine, the operation executed during normal operation, the operation executed during back flowing and the operation executed during stopping the machine; in the operation executed during starting the machine, pre-heated inertia gas is injected into the filter so as to preheat the sintering inorganic porous material filter element in the filter to the temperature of more than 187.5 DEG C, and in the operation executed during the normal operation, the to-be-filtered furnace gas of which the temperature is kept at 420-590 DEG C is input into the filter and the dust content of the filtered clean furnace gas is lower than 10-20 mg / m<3>.

Owner:CHENGDU INTERMENT TECH

Yellow phosphorus production method and equipment

ActiveCN103523762BHigh filtration precisionGood thermal shock resistancePhosphorus compoundsEngineeringYellow phosphorus

The invention discloses a yellow phosphorus production method and equipment which do not produce mud phosphorus and can reduce the dust content in tail gas. The method comprises the technology links as follows: 1, electric furnace smelting; 2, furnace gas purification, furnace gas discharged from an electric furnace is guided into a furnace gas dust collecting system through an exhaust pipeline, the furnace gas dust collecting system comprises at least a filter used for filtering the furnace gas, the filter is provided with a sintering inorganic porous material filter element capable of meeting following work conditions, and the operation performed according to the filter comprises the steps as follows: 1), the operation executed during driving: inert preheating gas is injected into the filter, and the sintering inorganic porous material filter element in the filter is heated to 187.5 DEG C or above; 2), the operation executed during normal operation: to-be-filtered furnace gas with the temperature maintained to be 187.5-280 DEG C is input into the filter, and the dust content in the filtered clean furnace gas is below 10-20 mg / m <3>; and 3), the operation executed during reverse blowing and 4) the operation executed during parking; and 3, phosphorus collecting and refining.

Owner:CHENGDU INTERMENT TECH

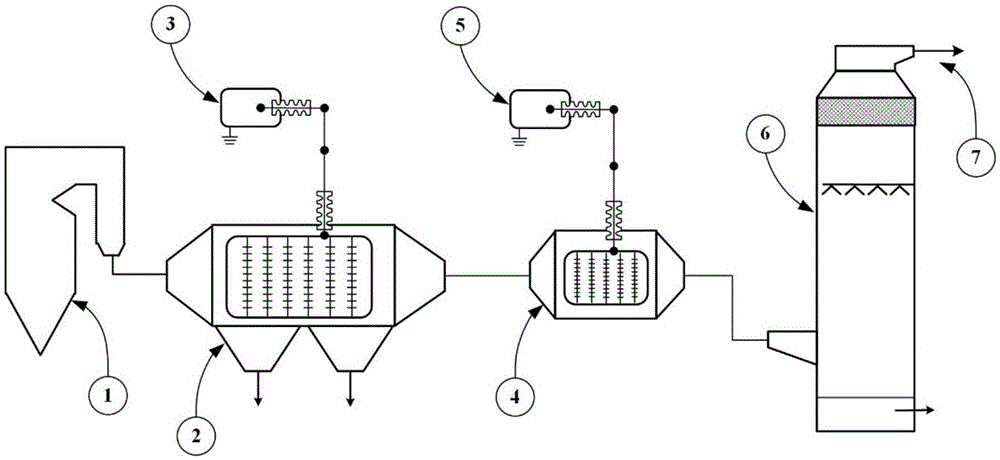

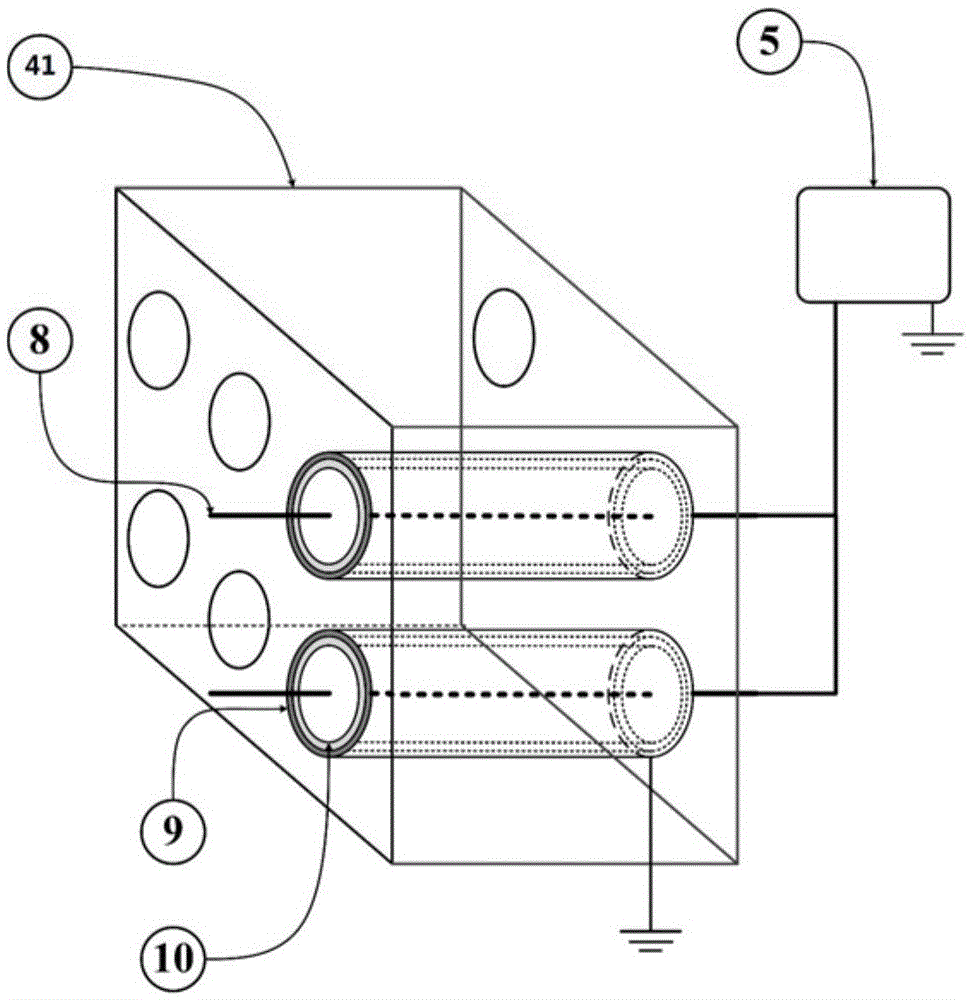

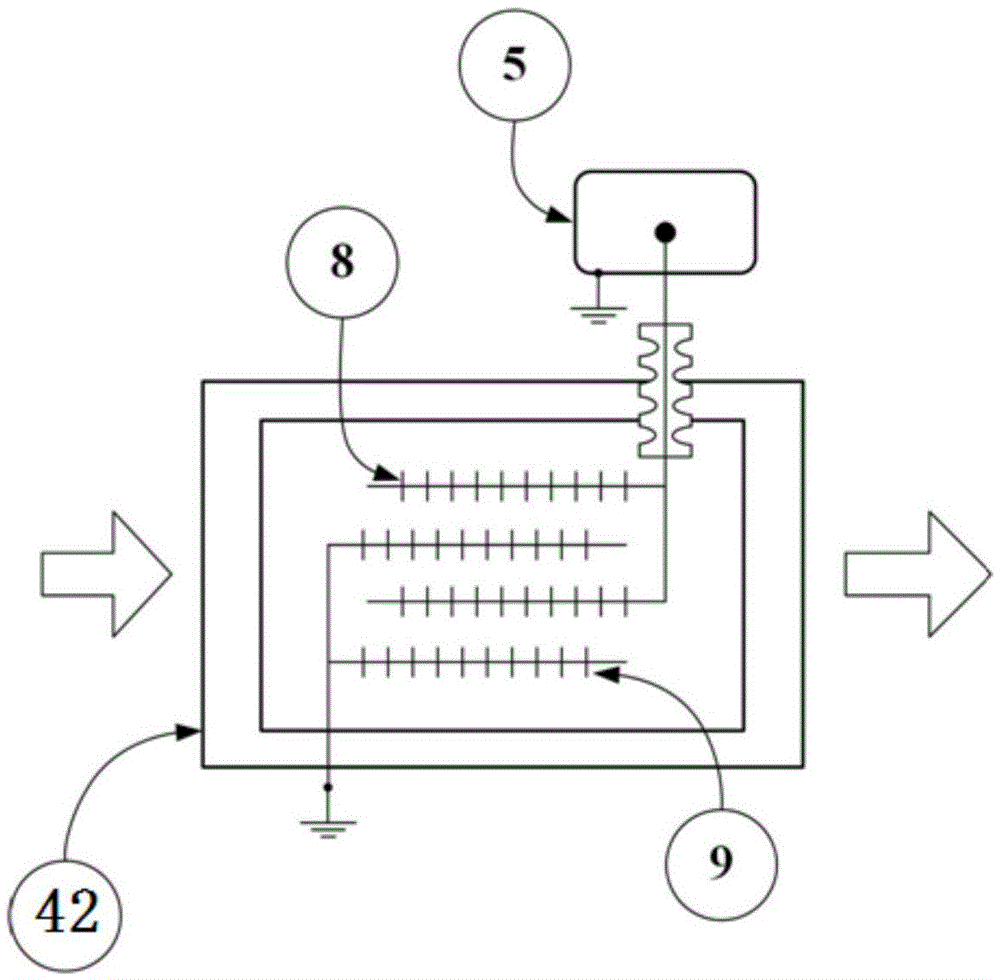

Desulphurization, denitration and dust removal integrated treatment process of exhaust gas

InactiveCN105664717AAchieve desulfurizationAchieve dust removalGas treatmentDispersed particle filtrationOperational costsFlue gas

The invention relates to a desulphurization, denitration and dust removal integrated treatment process of exhaust gas. The treatment process comprises the following steps: introducing the flue gas into an integrated catalytic agent ceramic filter drum device at an appropriate temperature section, wherein the integrated catalytic agent ceramic filter drum device is provided with a back flushing ash removal device; injecting a desulphurization agent and a denitration agent before the exhaust gas enters the integrated catalytic agent ceramic filter drum device; arranging a flue gas mixing device in front of the integrated catalytic agent ceramic filter drum device; and introducing the treated flue gas reaching the standard into an energy recycling system to recycle the heat by virtue of a pressurizing fan, and finally discharging the flue gas into a chimney, wherein the appropriate temperature section is 280 to 420 DEG C. The process has the advantages of stable and reliable system, small maintenance workload, long product service life, low device operation cost and small device occupation area; and the flue gas flowing into a waste heat boiler is clean gas, so that the heat exchanging efficiency of the energy recycling device is greatly improved, the service life of the energy recycling device is greatly prolonged, and the economic benefit is vast.

Owner:NANJING CEEP TECH

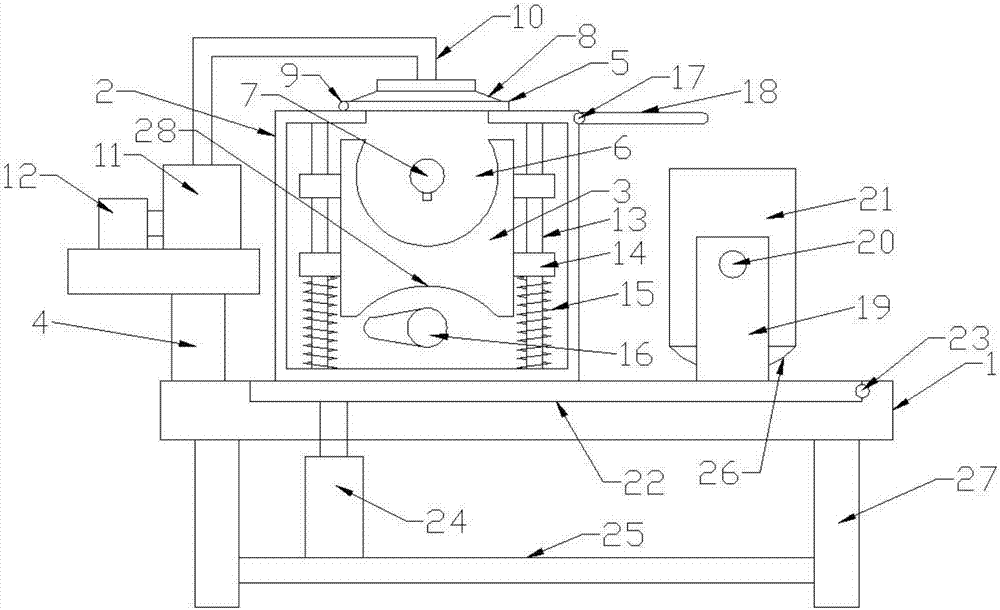

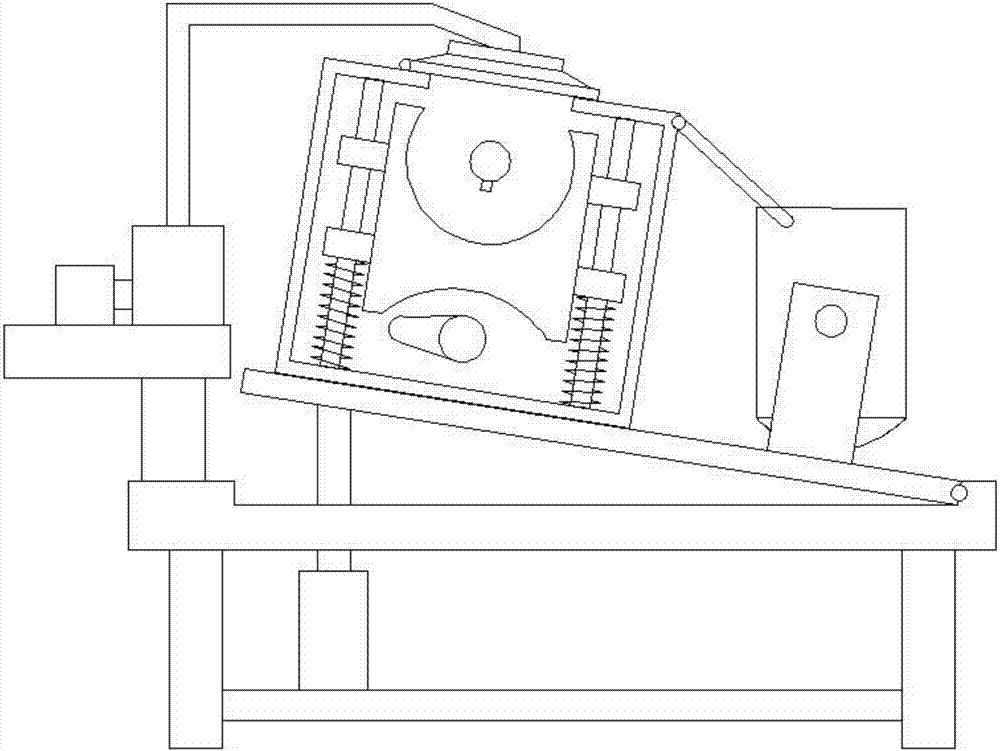

Vibration dust removing machine of traditional Chinese medicines

InactiveCN107138477AImprove cleanlinessQuality improvementCleaning using gasesEngineeringChinese herbology

The invention discloses a vibrating dust remover for traditional Chinese medicinal materials, which comprises a frame, a shell, a bracket, an upper cover and legs; Mechanism; the housing is fixed on the movable plate, and a vibrating seat is arranged in the housing, and a downwardly recessed trough is provided at the upper end of the vibrating seat, and an upwardly recessed arc surface is provided at the lower end of the vibrating seat. A cam is provided below the upper cover, and a wind collecting hood is communicated on the upper cover; a collection device is also provided on the movable plate, and the collection device includes a support plate, a second rotating shaft, a collection bucket and a counterweight; The top of the top is rotatably connected with a material guide plate through the first rotating shaft. The present invention drives the vibrating base to move up and down through the set cam, shakes off the soil on the surface of the medicinal material, makes the soil finer, facilitates dust raising, has good dust removal effect, greatly reduces the carrying amount of soil in the medicinal material, and ensures that the medicinal material is clean.

Owner:HANGZHOU XIAOCHENG IND DESIGN CO LTD

Vaporizing combustion turbulence incinerator

PendingCN108758643AReduce dust contentImprove qualityIncinerator apparatusNon-combustible gases/liquids supplyCombustion chamberCombustor

A vaporizing combustion turbulence incinerator comprises a vaporizing combustor, a burning-out section, a cooling section, a separator, a tail smoke flue and a feeding device, wherein the vaporizing combustor communicates with the upper portion of the burning-out section, the burning-out section communicates with the bottom of the cooling section to form a steering separation chamber, the upper portion of the cooling section is connected with an inlet of the separator, and a smoke outlet of the separator communicates with the tail smoke flue. The vaporizing combustor comprises a variable-section vaporizing section and a constant-section combustion section which are integrally arranged. The vaporizing section is provided with a gradually-expanding area and a gradually-contracting area in sequence from bottom to top, and the top of the gradually-contracting area is connected with the combustion section. A slag discharge channel is arranged on one side of the bottom of the vaporizing section. A plurality of secondary air ports and / or a plurality of tertiary air ports are arranged in the middle of the vaporizing combustor, the multiple secondary air ports are evenly arranged in the topof the vaporizing section in a surrounding mode, and the multiple tertiary air ports are evenly arranged in the bottom of the combustion section in a surrounding mode. The vaporizing combustion turbulence incinerator has the advantages of good fuel adaptability, good initial discharging property and high burning-out rate.

Owner:BEIJING ONE A HI TECH ENERGY TECH CO LTD

Device and method for purifying flue gases

InactiveCN105642080ANot easy to wearExtended maintenance cycleElectrostatic separationDispersed particle separationElectricityFlue gas

low-temperaturetes to the field of flue gas treatment and discloses a device and a method for purifying flue gases. The device for purifying the flue gases comprises an electrical precipitator (2), a low-temperature plasma reactor (4) and wet desulphurization equipment (6) which are connected in sequence, wherein an outlet of the electrical precipitator (2) is connected with an inlet of the low-temperature plasma reactor (4); an outlet of the low-temperature plasma reactor (4) is connected with an inlet of the wet desulphurization equipment (6). The method for purifying the flue gases comprises the following steps of introducing the flue gases containing dust and nitrogen oxide into the electrical precipitator (2) for performing dust removing treatment; enabling the flue gases subjected to the dust removing treatment to enter into the low-temperature plasma reactor for oxidation treatment; then introducing the flue gases formed by the oxidation treatment into the wet desulphurization equipment for absorption treatment. By adopting the device and the method disclosed by the invention, the oxidation and dust charging efficiency of nitric oxide is high; the device is not easy to wear and is good in purifying effect of the flue gases.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

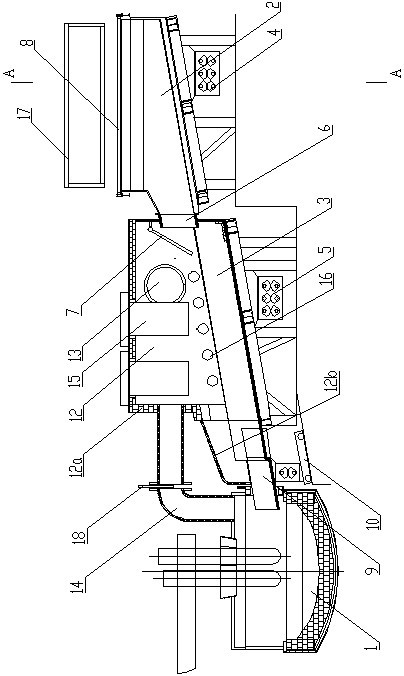

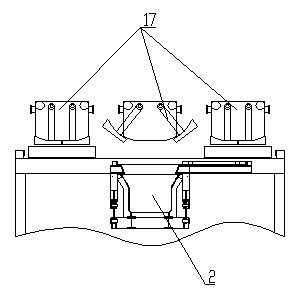

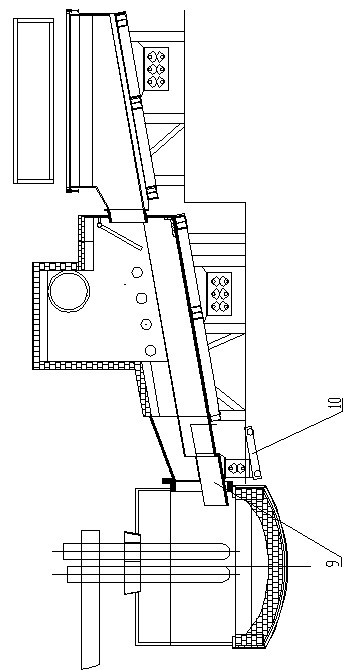

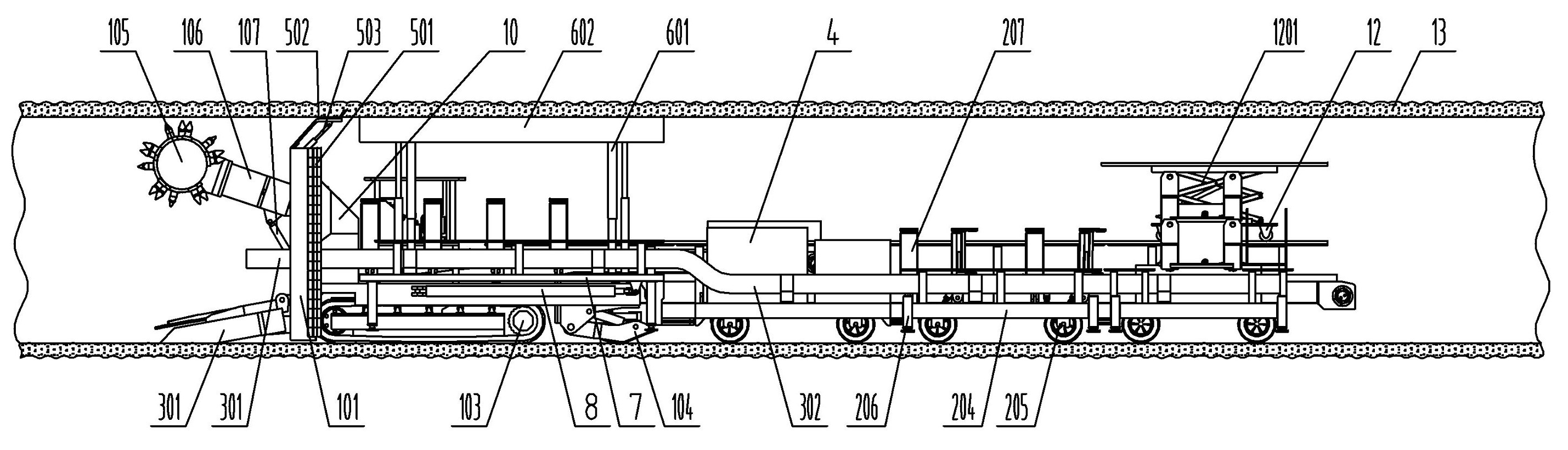

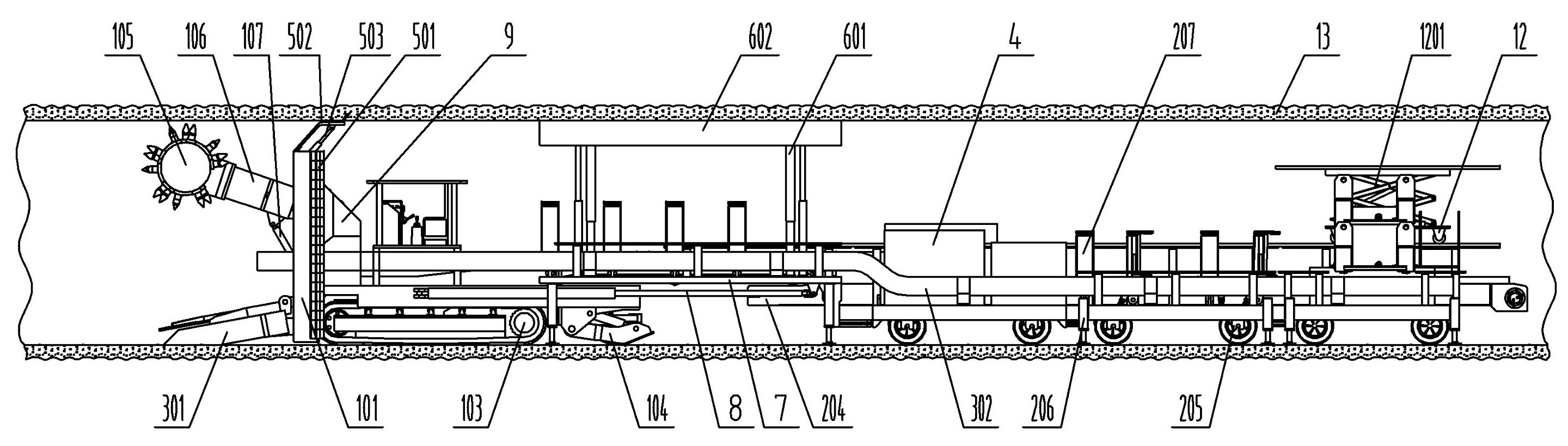

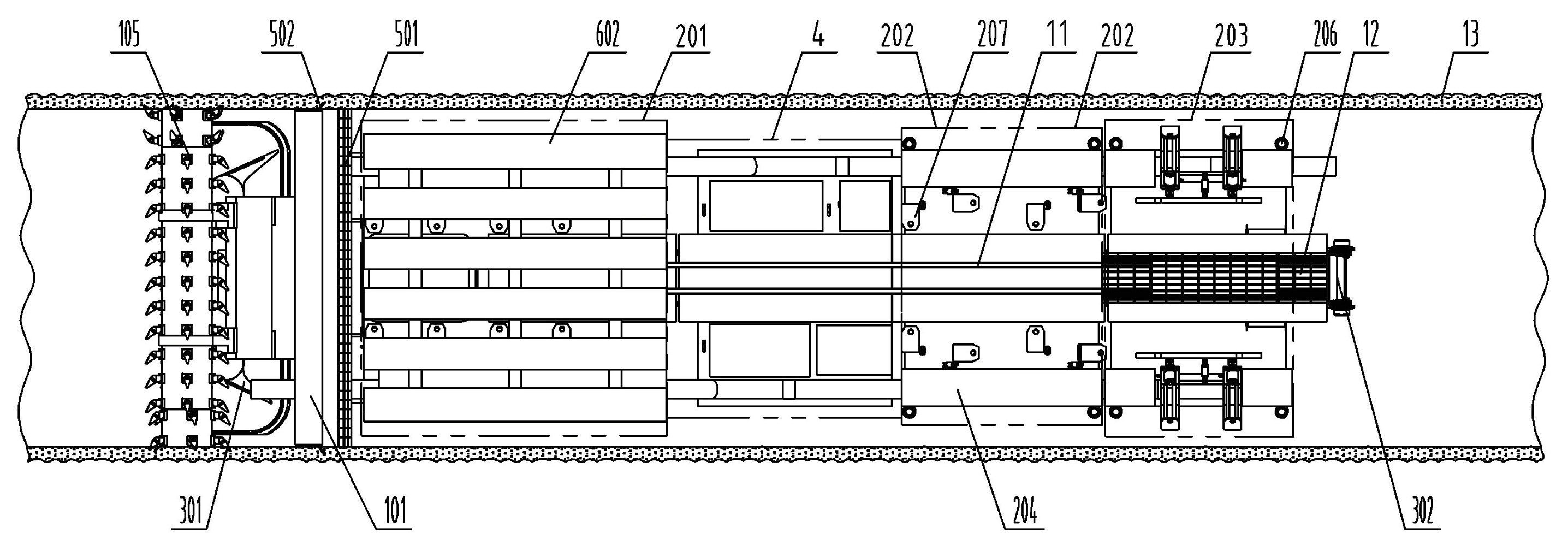

Fully sealed coal roadway tunneling and anchoring synchronous machine

ActiveCN102606153AImprove tunneling efficiencyImprove safety factorSlitting machinesAnchoring boltsVehicle frameMining engineering

The invention relates to coal mine roadway tunneling machinery, in particular to a fully sealed coal roadway tunneling and anchoring synchronous machine, comprising a tunneling device, a sealing and dust removing device, an anchoring device, a coal loading and conveying device, a power system and a hydraulic system, wherein the tunneling device comprises a body part, a telescopic cutting part arranged at the front end of the body part, a walking part arranged at the lower part of the body part and a rear support part arranged at the rear end of the body part; the anchoring device comprises at least one first anchor rod drill carriage; the first anchor rod drill carriage is arranged between the cutting part of the tunneling device and the power system; other anchor rod drill carriages are arranged behind the power system sequentially; each anchor rod drill carriage comprises a frame, an anchor rod drilling machine group fixedly arranged on the frame, wheels arranged at the four corners of the lower part of the frame and a hydraulic oil cylinder; the body part of the tunneling device is in overlap joint with the two sides of the frame of the first anchor rod drill carriage through a sliding rail and is fixedly connected with a dragging oil cylinder; and the anchor rod drill carriages are hinged with one another. The fully sealed coal roadway tunneling and anchoring synchronous machine is unique in design, reasonable in structure, high in the degree of automation, efficient and safe and is very suitable for extended application.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

Coal full-grain size grading pyrolysis and active coke preparation coupling process and system in coal gas circulating

InactiveCN104164244AAchieve water savingAchieve energy savingCarbon compoundsChemical industryWater savingFlue gas

The invention provides a coal full-grain size grading pyrolysis and active coke preparation coupling process and system in coal gas circulating. The process comprises the following steps: dividing raw coal into slack coal and pea coal through a raw coal preheating and grading system and drying the raw coal by utilizing high temperature flue gas discharged by a coal gas heating furnace; with the obtained steam-containing tail gas as an activating agent and pyrolysis coal gas generated by the coal gas heating furnace per se as an activating agent heating flue, enabling the obtained high temperature activating agent to be in direct contact with high temperature semicoke from a slack coal pyrolyzing furnace and a pea coal pyrolyzing furnace to activate the semicoke. The process provided by the invention has the advantages that raw coal pyrolysis is coupled with active coke preparation and the coal gas generated by the pyrolysis is utilized to serve as the energy of active coke activation, so that the production cost is low; water carried by the raw coal per se serves as the source of a steam activating agent, so that water is saved in the production process; the high temperature semicoke from the pyrolyzing furnaces is in direct contact with the high temperature activating agent to be activated and the sensible heat of the high temperature semicoke is utilized, so that the production energy consumption is low; gas containing combustible components generated by activation serves as the compensatory fuel of the pyrolysis, so that the energy recycling efficiency is high.

Owner:BEIJING QIANHAI ENVIRONMENTAL PROTECTION TECH

Yellow phosphorus production method and equipment

ActiveCN103523762AHigh filtration precisionGood thermal shock resistancePhosphorus compoundsEngineeringYellow phosphorus

The invention discloses a yellow phosphorus production method and equipment which do not produce mud phosphorus and can reduce the dust content in tail gas. The method comprises the technology links as follows: 1, electric furnace smelting; 2, furnace gas purification, furnace gas discharged from an electric furnace is guided into a furnace gas dust collecting system through an exhaust pipeline, the furnace gas dust collecting system comprises at least a filter used for filtering the furnace gas, the filter is provided with a sintering inorganic porous material filter element capable of meeting following work conditions, and the operation performed according to the filter comprises the steps as follows: 1), the operation executed during driving: inert preheating gas is injected into the filter, and the sintering inorganic porous material filter element in the filter is heated to 187.5 DEG C or above; 2), the operation executed during normal operation: to-be-filtered furnace gas with the temperature maintained to be 187.5-280 DEG C is input into the filter, and the dust content in the filtered clean furnace gas is below 10-20 mg / m <3>; and 3), the operation executed during reverse blowing and 4) the operation executed during parking; and 3, phosphorus collecting and refining.

Owner:CHENGDU INTERMENT TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com