Patents

Literature

304results about How to "Achieve energy saving" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

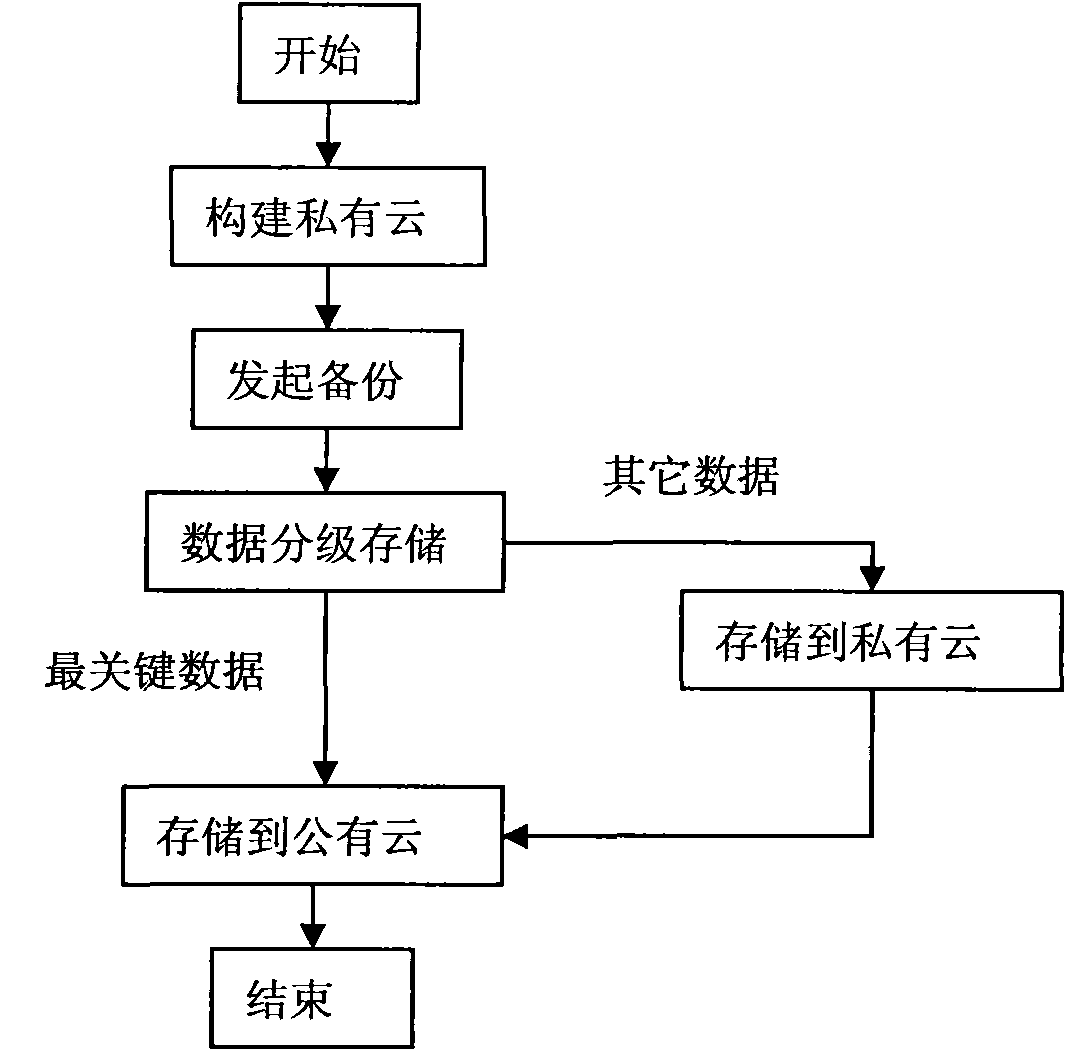

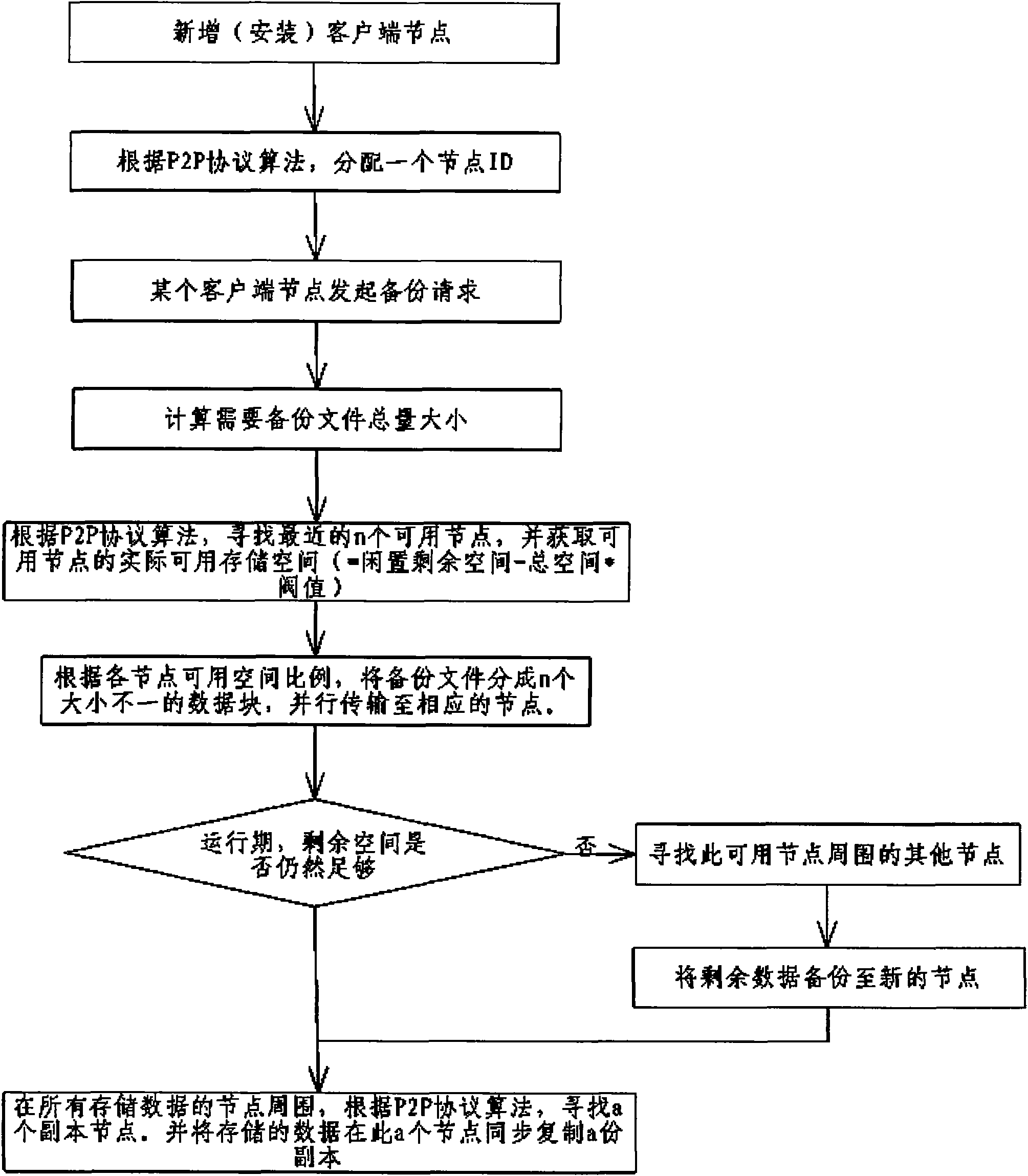

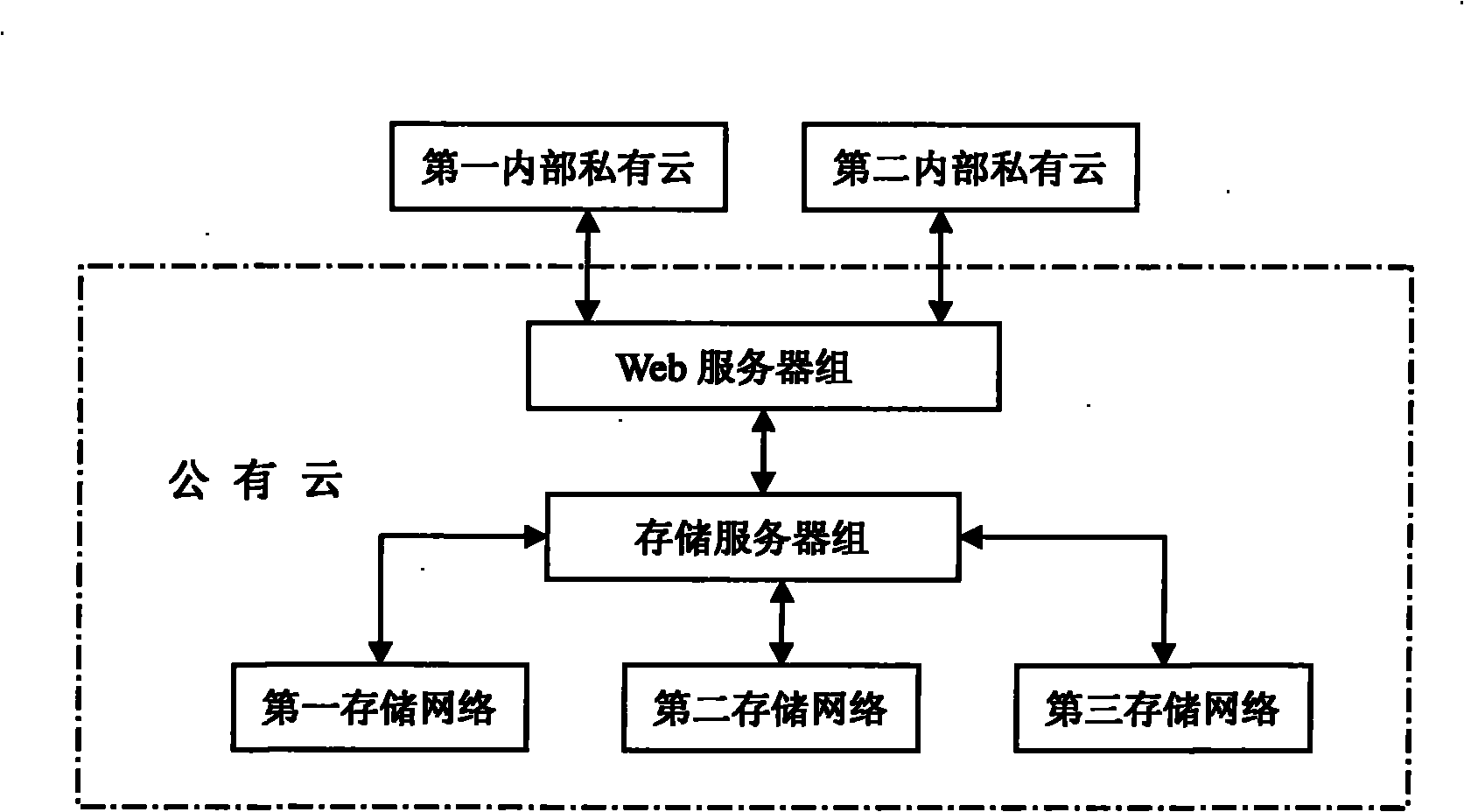

Network technology based storage cloud backup method

ActiveCN101902498AAvoid or reduce costsSolve limited storage spaceData switching networksCloud storageWeb technology

The invention discloses a network technology based storage cloud backup method. The method comprises the following steps: establishing a private cloud for idle storage space on each computer node in an internal network of an enterprise; initiating a backup request to a target node by a backup initiating node; hierarchically storing data by the backup initiating node according to data importance grade, backing up superior data in a public cloud, and other data except the superior data in the private cloud. The method solves the technical problems that data backup and recovery efficiency are affected due to the fact that storage equipment purchased by the computer has over high price, and the bandwidth of the external network of the company is not sufficient, and achieves the aims of storage backup and remote disaster recover for company data by using minimum cloud storage space under a condition that medium-small enterprises have limited network bandwidth.

Owner:广州鼎甲计算机科技有限公司

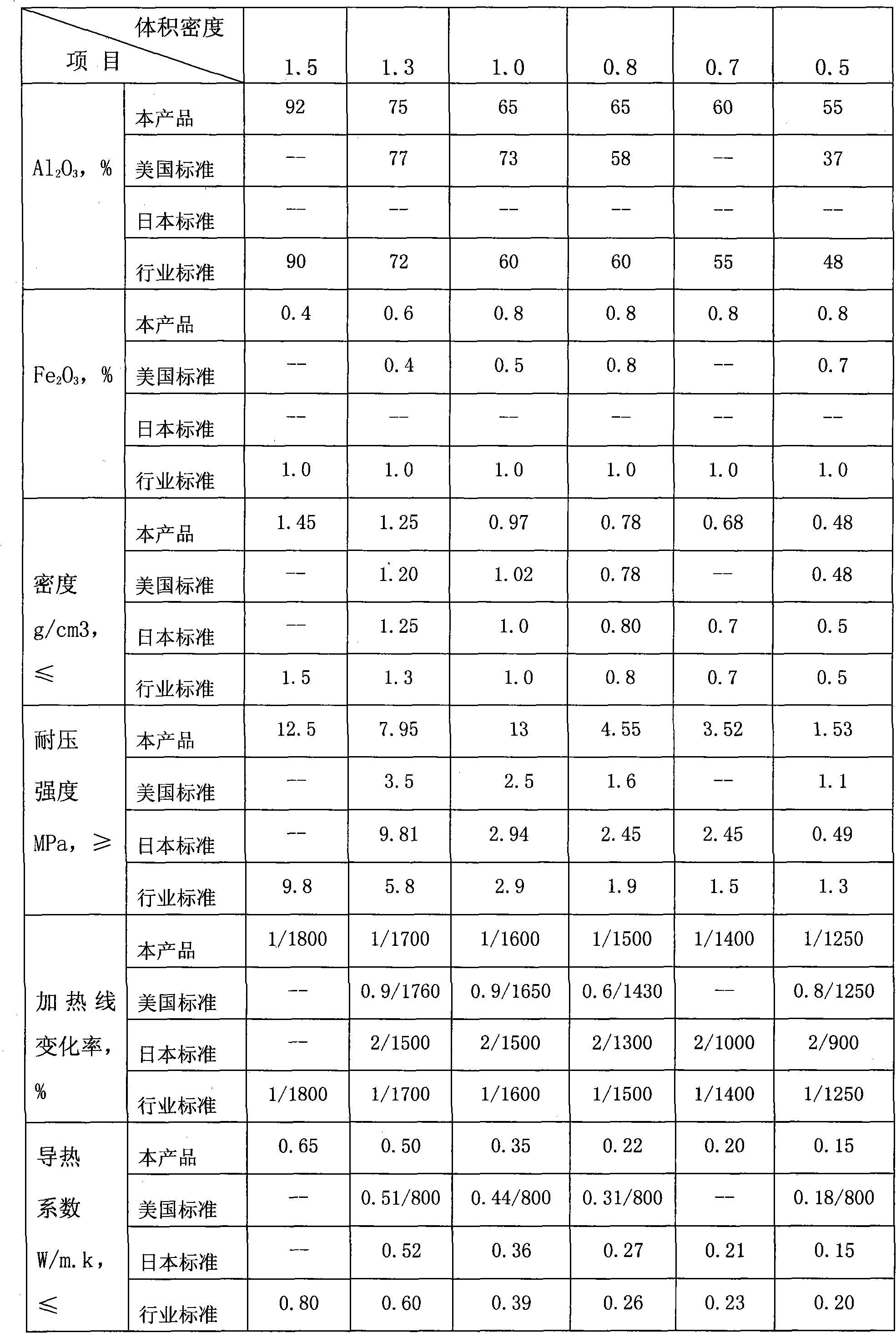

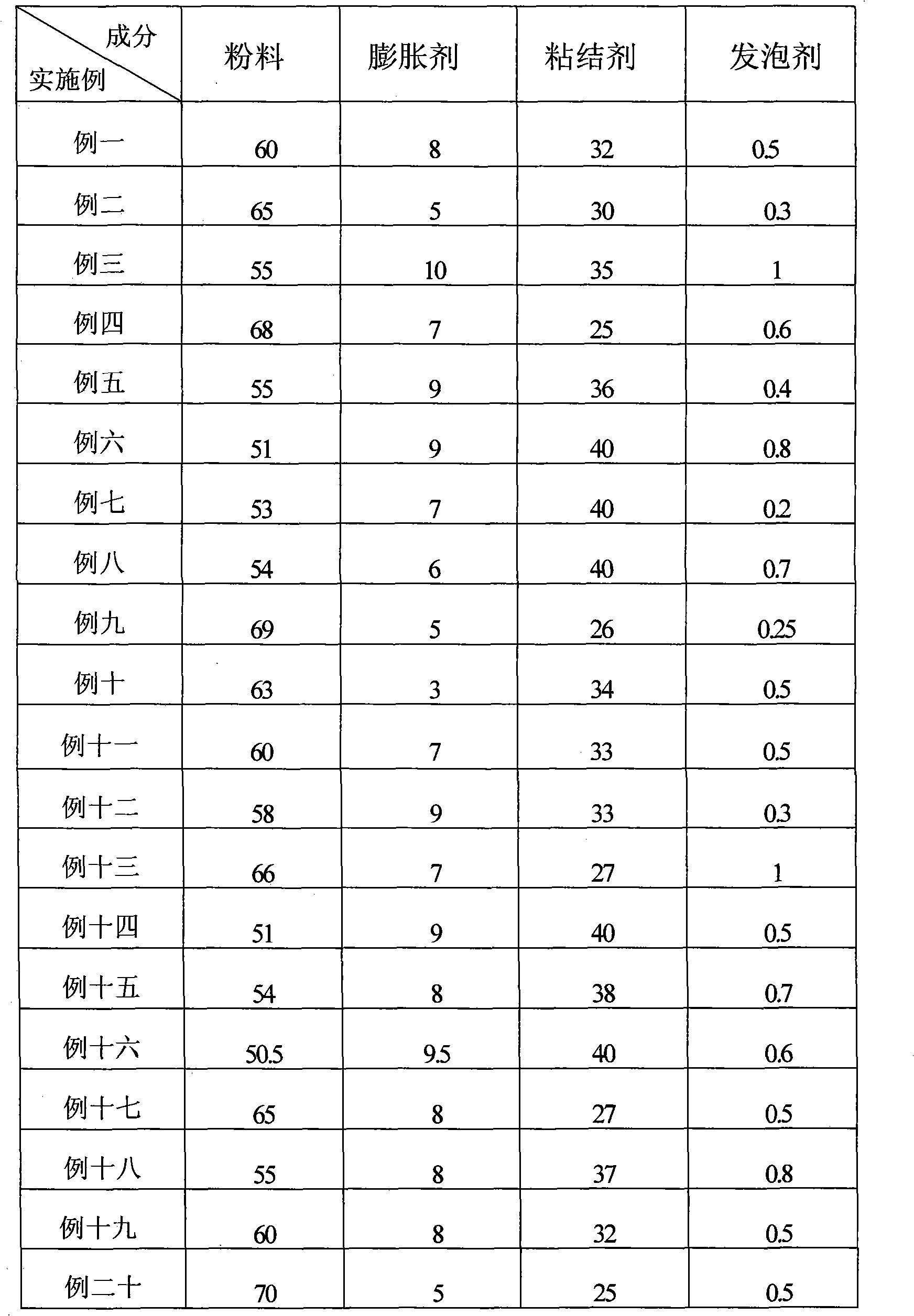

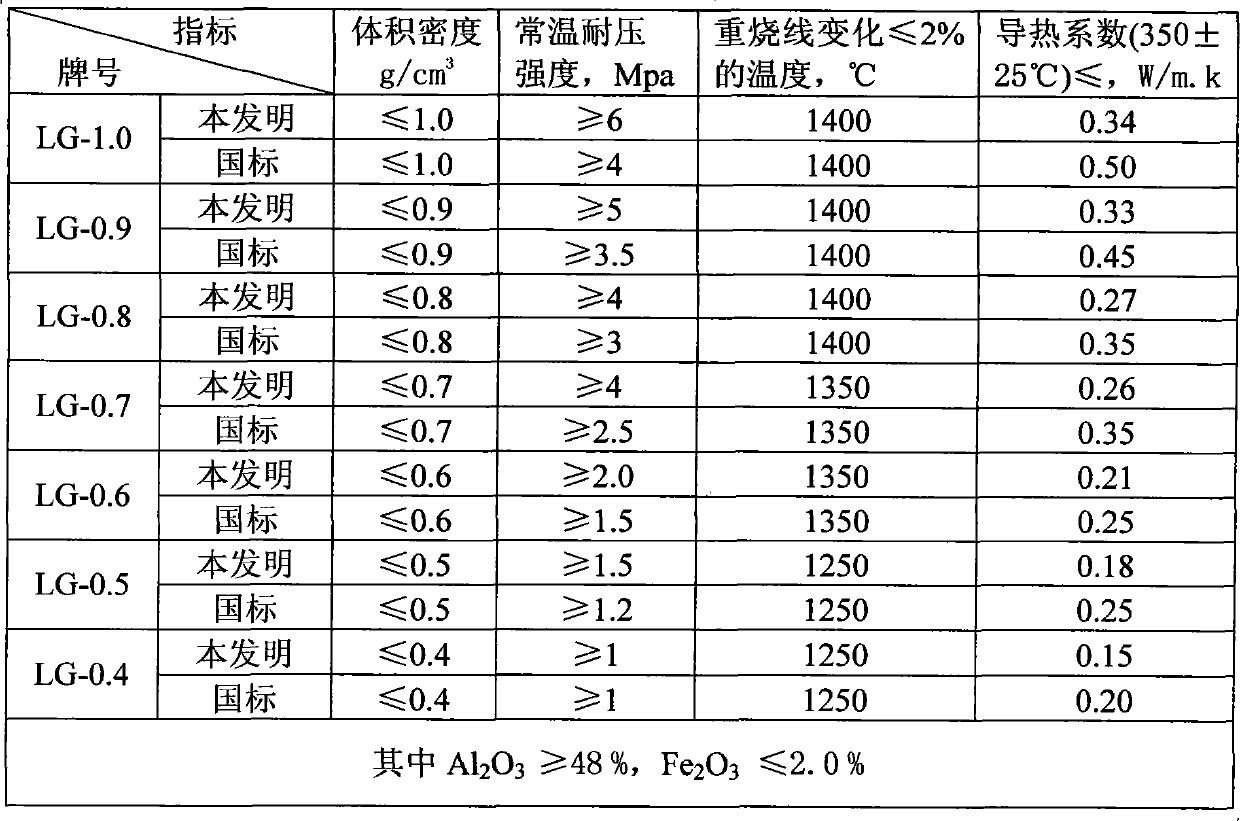

Ultra-microporous lightweight insulated firebrick and manufacture method thereof

The invention discloses an ultra-microporous lightweight insulated firebrick and a manufacture method thereof. The ultra-microporous lightweight insulated firebrick is prepared by the following raw materials in percentage by weight: powder mainly comprising 50-70 Al2O3 and SiO2, 5-10 expanding agent, 25-40 caking agent and 0.2-1.0 external foaming agent. The manufacture method comprises the following steps: uniformly mixing and stirring the raw materials into pasty material; mixing the foaming agent and water according to a ratio of 1: (15-20); adding the mixture to the pasty material to mix uniformly; then, casting into brick blanks; and drying and keeping the brick blanks at a temperature of 1200-1600 DEG C for 6-8 hours. The firebrick has the advantages of high compressive strength, low coefficient of heat conductivity and low linear change ratio and can be directly used for a fireproof coating of thermal equipment so that the product has the lightweight insulation and fireproofness functions and good insulation effect and is beneficial to energy saving and environmental protection. Compared with the prior art, the invention has obvious economic benefits.

Owner:郑州东方炉衬材料有限公司

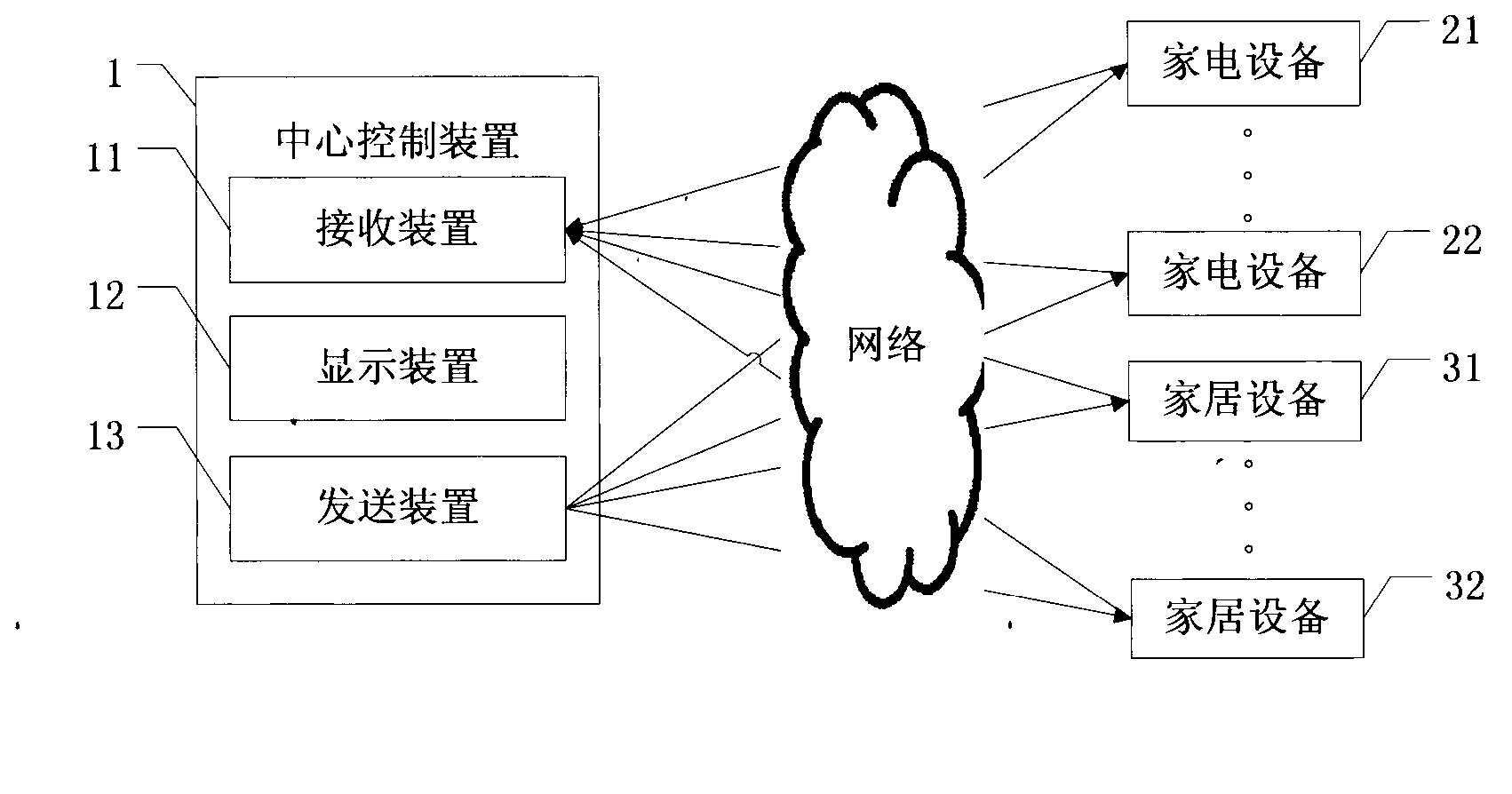

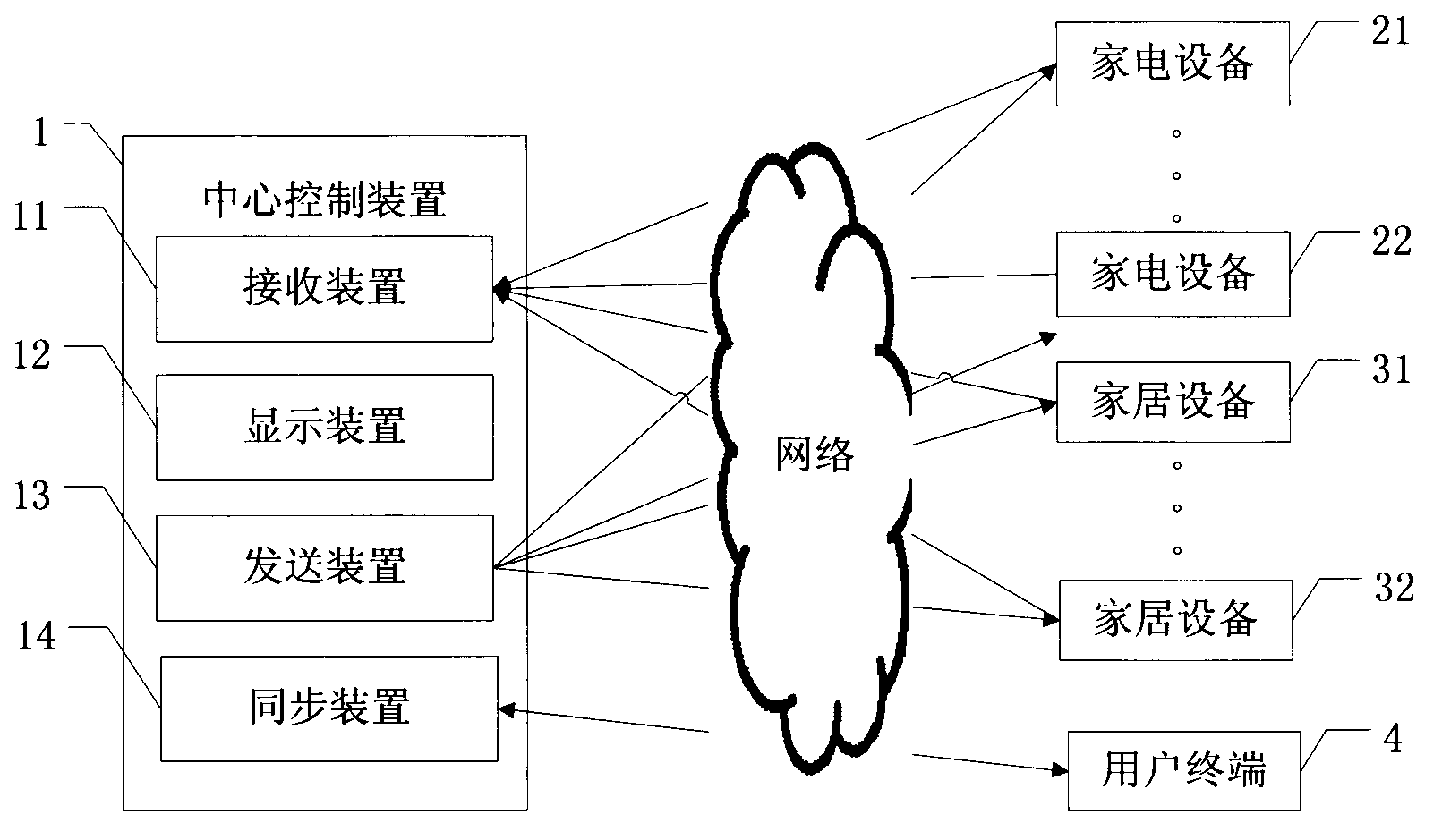

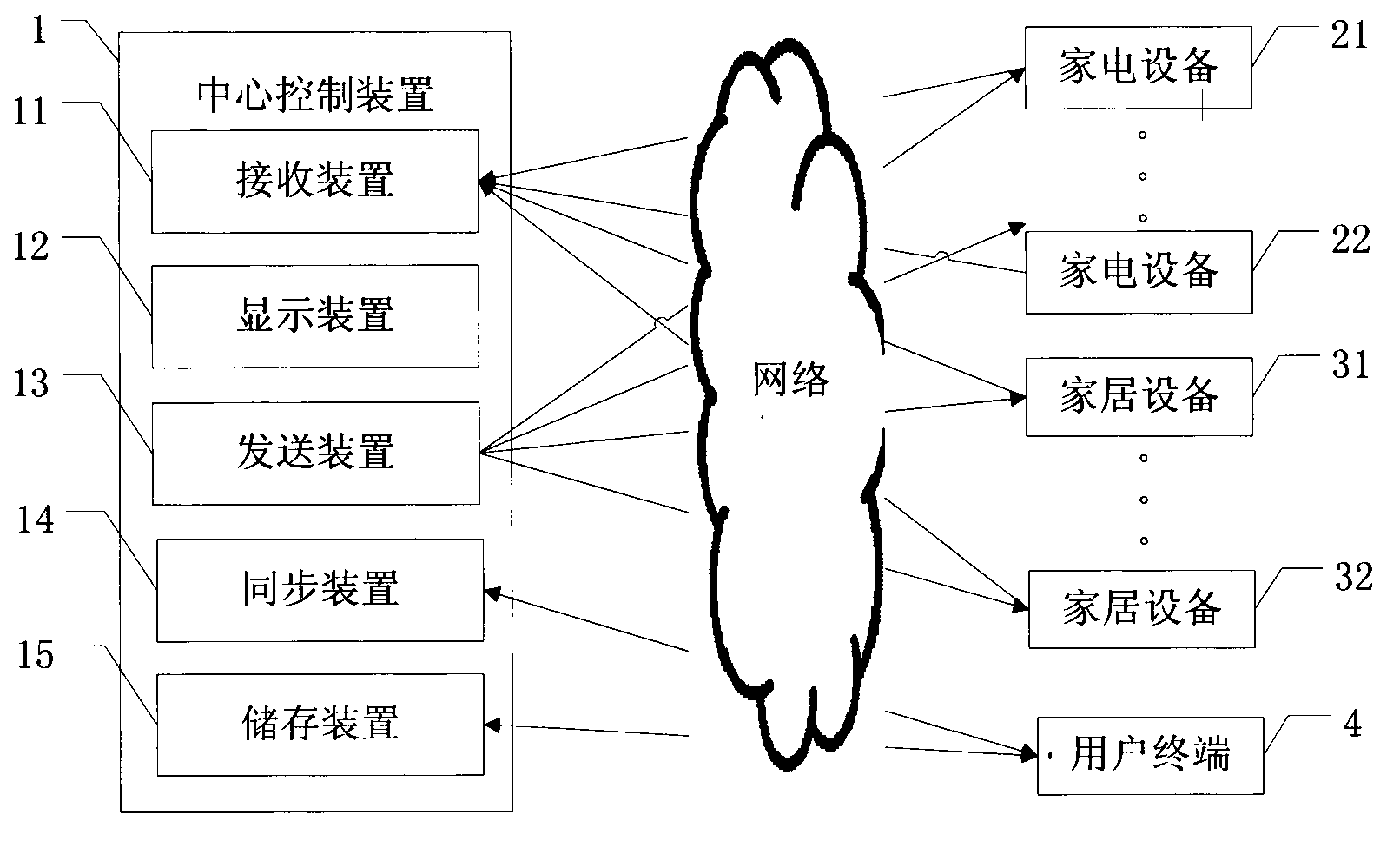

Intelligence appliance home control device and refrigerator embedded with the same

InactiveCN103019116ASuitable operating temperatureReduce the impact of noiseDomestic cooling apparatusLighting and heating apparatusDisplay deviceRefrigerated temperature

The invention relates to an intelligence appliance home centralized control device and a refrigerator embedded with the centralized control device. The centralized control device comprises a receiving device, a display device and a sending device, wherein the receiving device is used for receiving current state information of one or a plurality of household appliances or home furnishing appliances, the display device is used for displaying the current state information of the one or the plurality of household appliances or home furnishing appliances for a user to set to obtain user setting information or displaying multimedia data for the user to check, and the sending device is used for sending the user setting information to the corresponding household appliances or home furnishing appliances to update states of the corresponding household appliances or home furnishing appliances. The intelligence appliance home centralized control device uses characters of the refrigerator, provides good operating environments for the intelligence appliance home centralized control device and achieves intelligent home life.

Owner:缪军 +2

Mineral separation process of magnetic iron ore

ActiveCN101480632AReduce energy consumptionFine Concentrate SizeSievingScreeningMagnetiteMaterials science

The invention discloses a beneficiation method for a pure magnetic iron ore. A crude ore is sequentially treated according to the steps such as first crushing, first-stage dry-type magnetic dressing, medium crushing, second-stage dry-type magnetic dressing, fine crushing and third-stage dry-type magnetic dressing, fine ore is obtained after a great amount of gangues are thrown by the third-stage dry-type magnetic dressing and sent to a grinding head sieve to be griddled and separated, granules griddled by the grinding head sieve are treated in a first-section magnetic dressing process, rough ore griddled by the grinding head sieve is treated in a first-section ball grinding and then enters the first-section magnetic dressing process; ore aggregates obtained from the first-section magnetic dressing process are treated in a second-section ball grinding after discharging gangue sands till the granularity of ore powder is -200meshes being more than or equal to 60 percent, ore powder generated from the second-section ball grinder are treated in second-section magnetic dressing, ore aggregates generated from the second-section magnetic dressing are treated in a high-frequency sieve after discharging gangue sands, products positioned on the high-frequency sieve are filtered to obtain ore concentrate, and products positioned below the high-frequency sieve are treated with desliming and then treated with floatation. The invention adopts two sections of grinding ore open-way processes and distinguishes the ore aggregates during the ore dressing process, thereby greatly reducing the energy consumption of a system, lowering the production cost and enhancing the utility ratio of equipment.

Owner:安徽大昌矿业集团有限公司

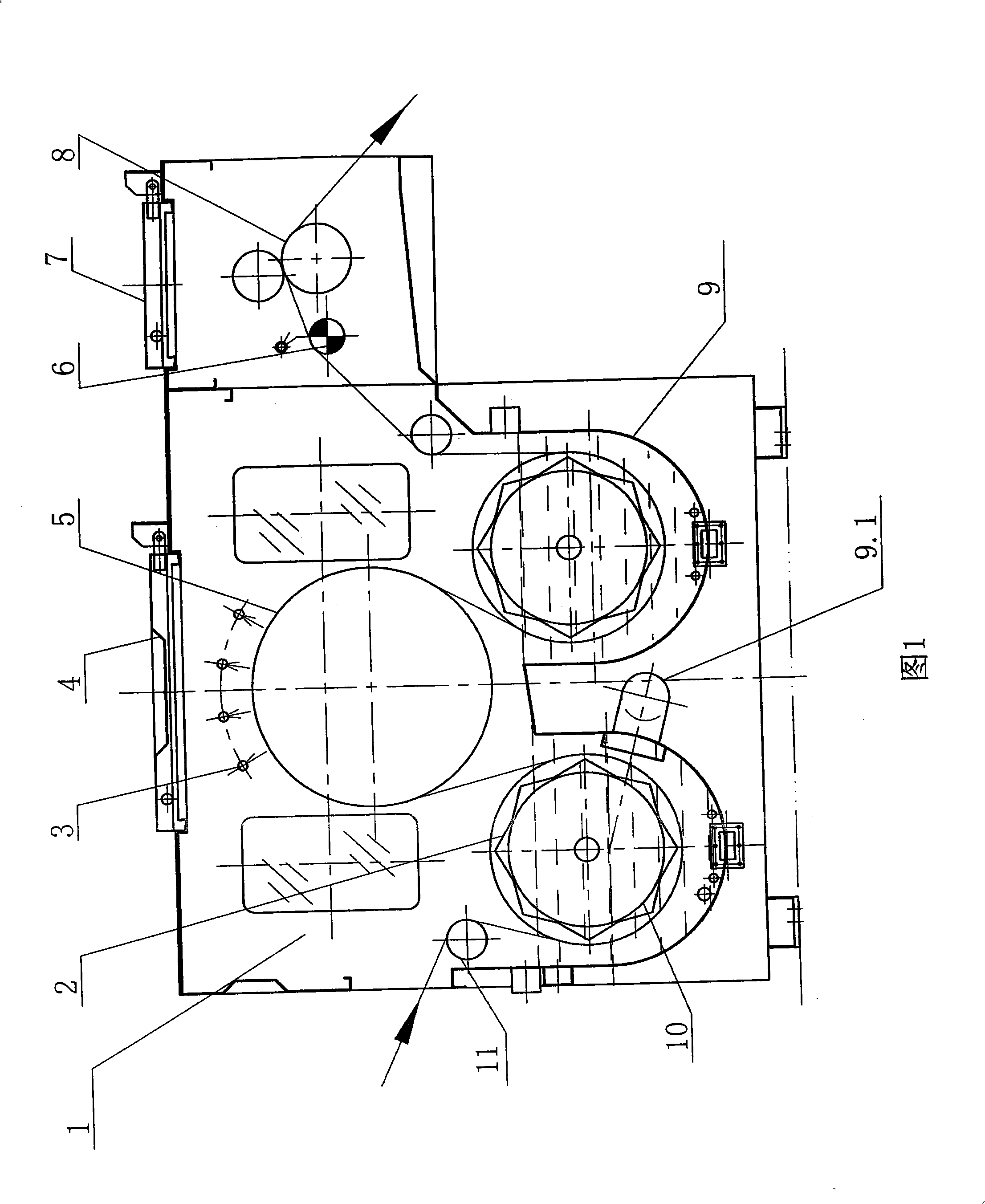

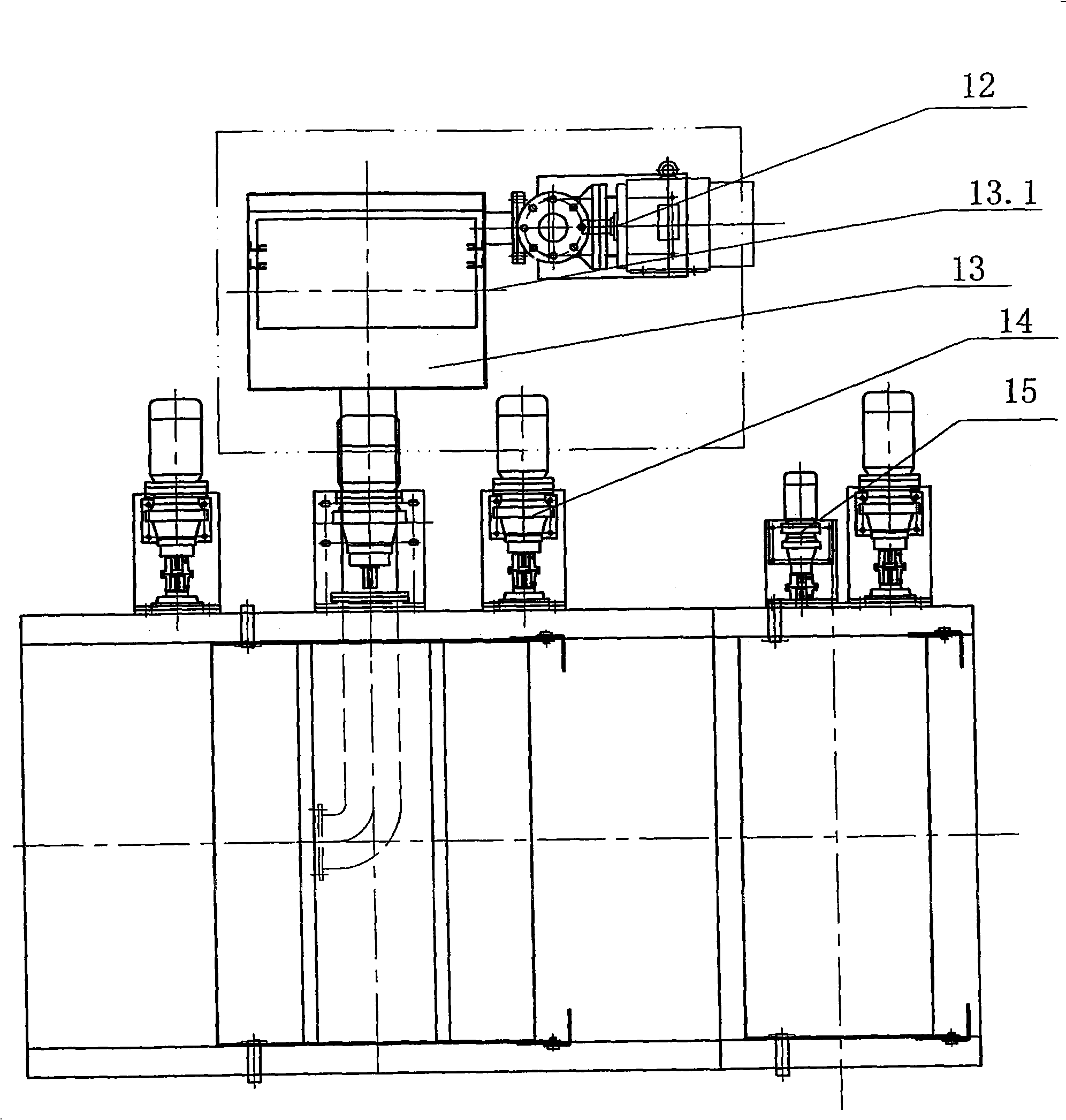

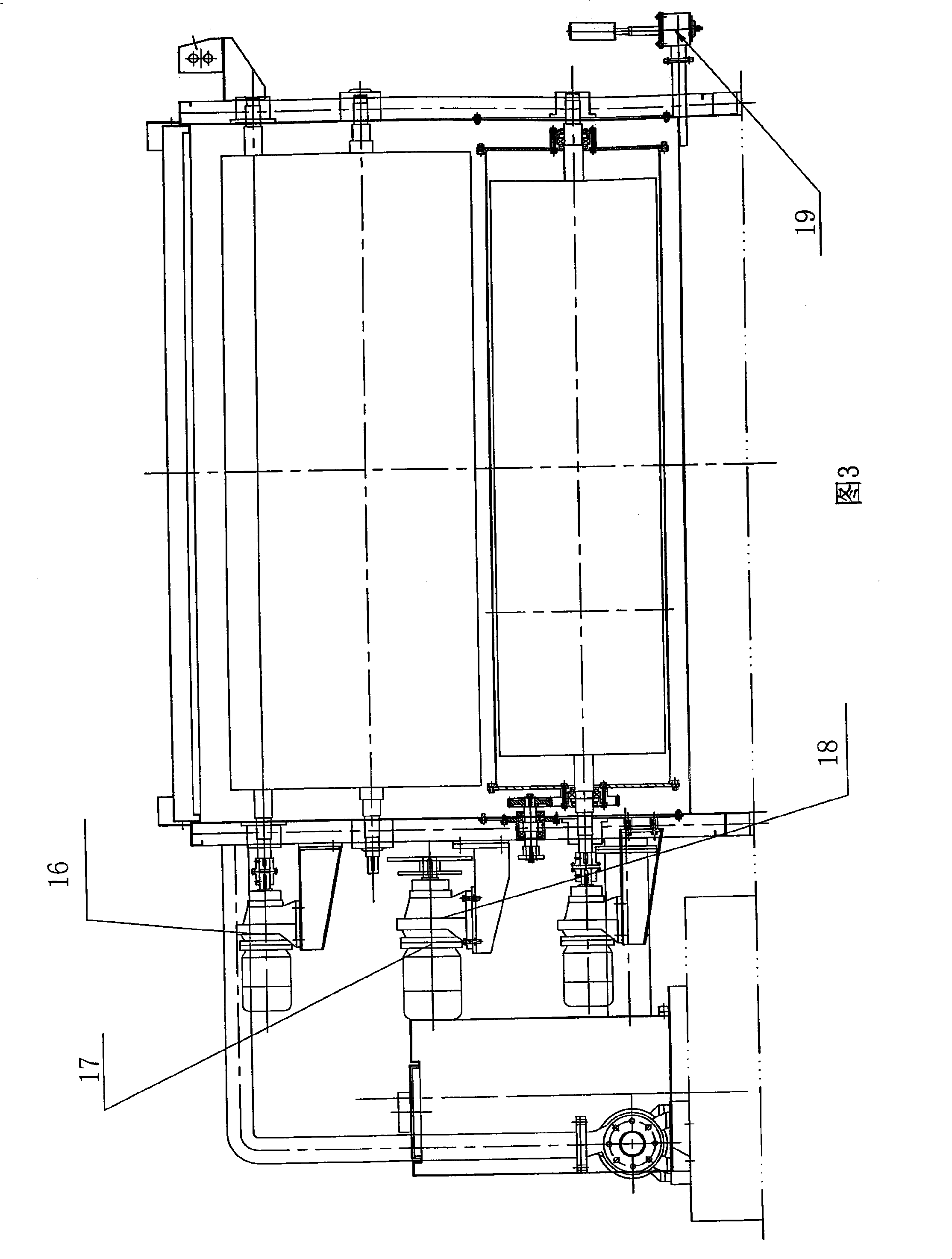

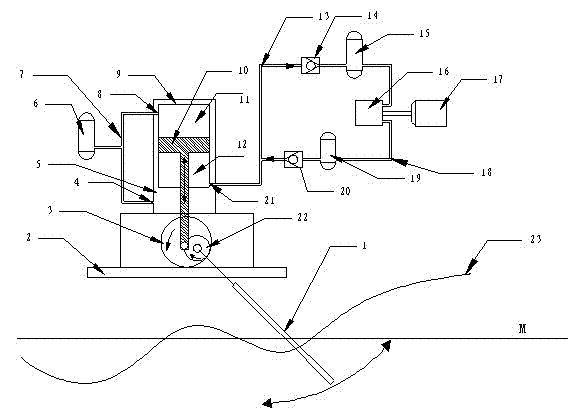

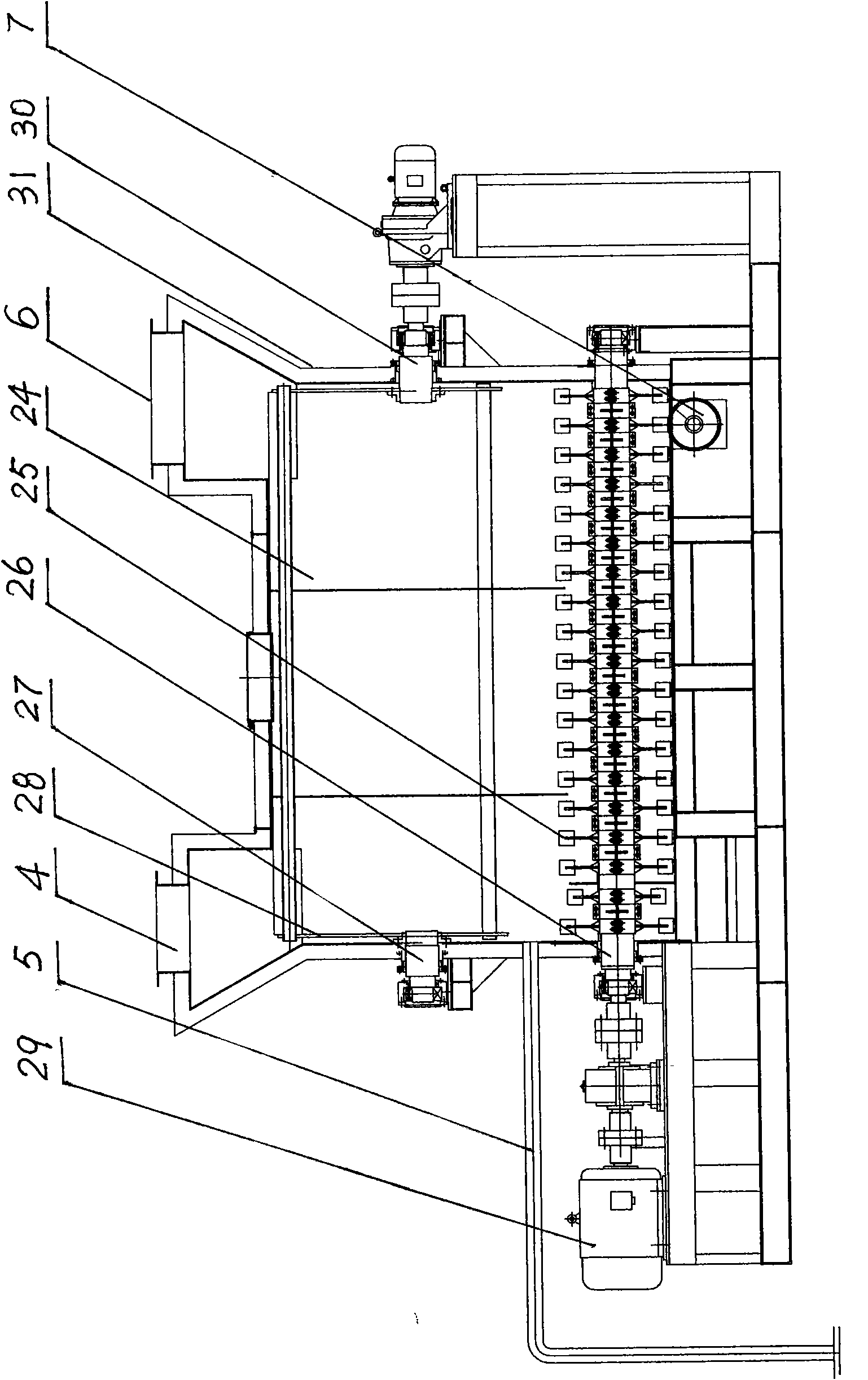

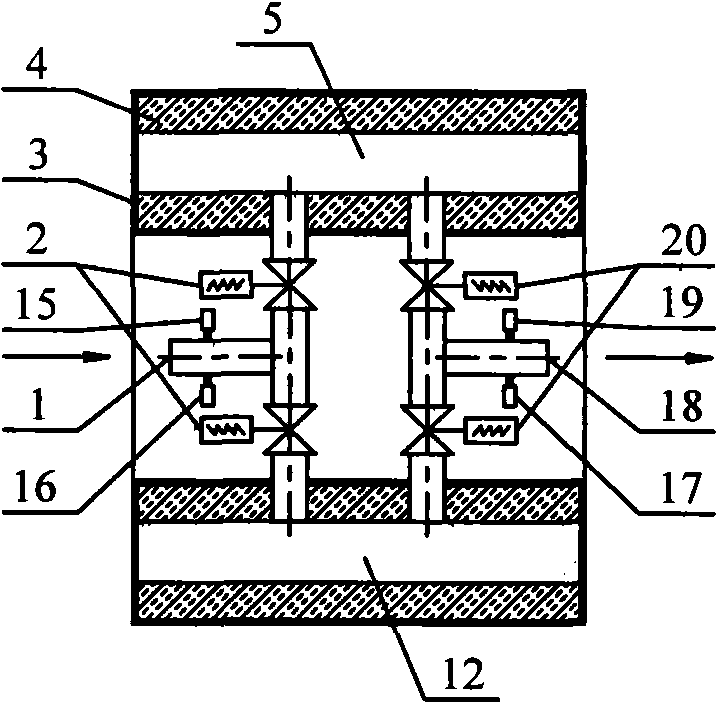

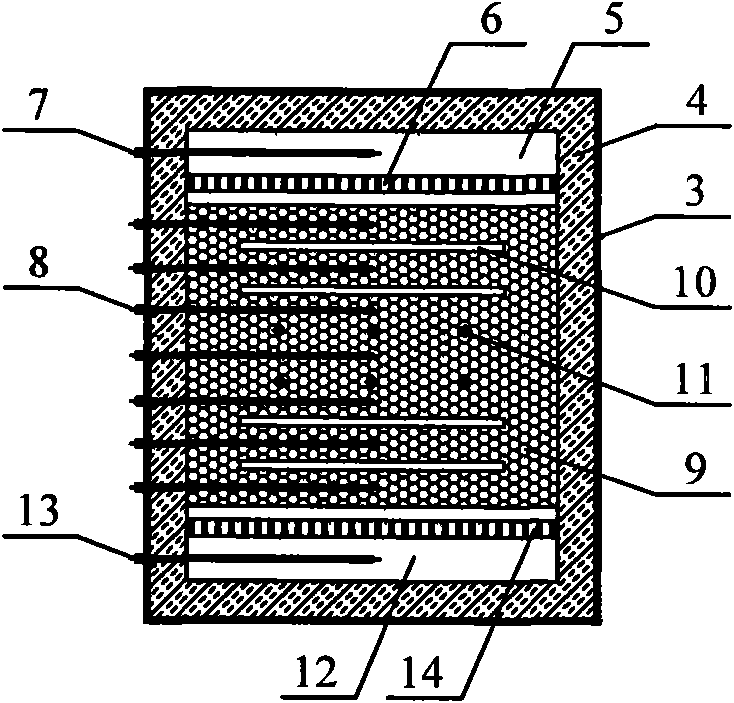

Novel double oscillation tumbling barrel scouring machine

InactiveCN101328681AFully washable exchange effectAchieve energy savingTextile treatment machine arrangementsDry-cleaning apparatus for textilesEngineeringWater washing

The invention relates to a novel dual-oscillation revolving drum washing machine, which is suitable for the water scrubbing, bleaching and open-width processing technique of knitted and woven fabrics. The novel dual-oscillation revolving drum washing machine comprises a box body (1), wherein, flumes (9) are vertically arranged on the lower part inside the box body, and the number of the flumes (9) is two, with one on the left and one on the right; an external wire roll (2) is respectively arranged inside the two flumes (9); a plum-blossom roll (10) is respectively arranged inside the two external wire rolls (2); a reticulated revolving drum (5) is vertically arranged on the middle of the upper part inside the box body (1); and the upper side of the reticulated revolving drum (5) is provided with a spray device (3). By adoption of the novel dual-oscillation revolving drum washing machine, the amount of water, steam and an auxiliary agent is small; the water scrubbing effect is good; and the quality of the textile fabrics after water scrubbing is good.

Owner:张琦

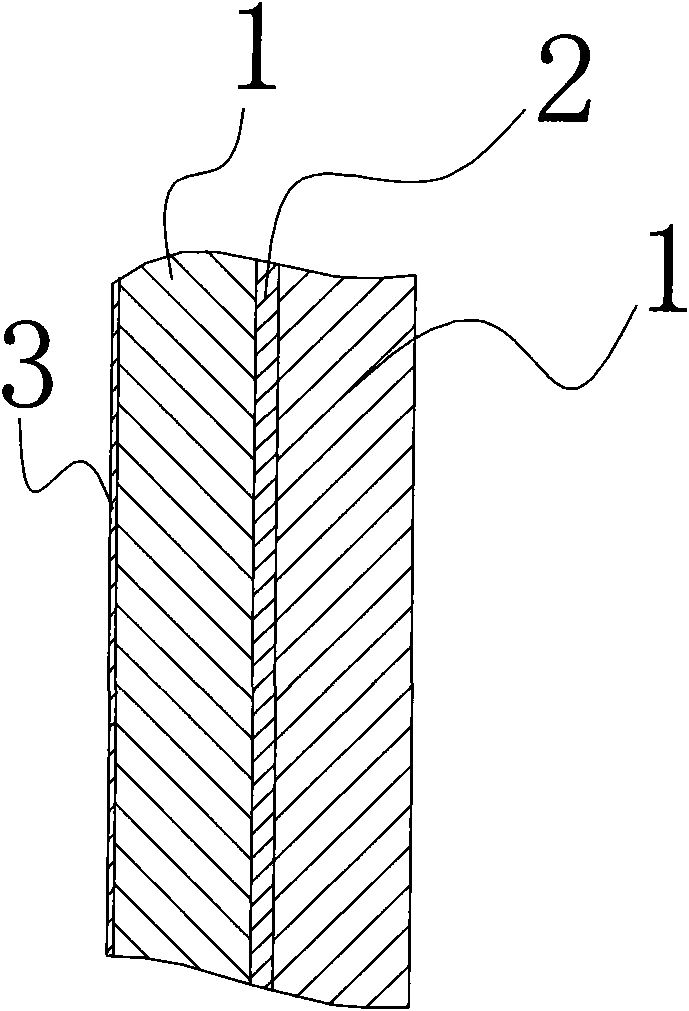

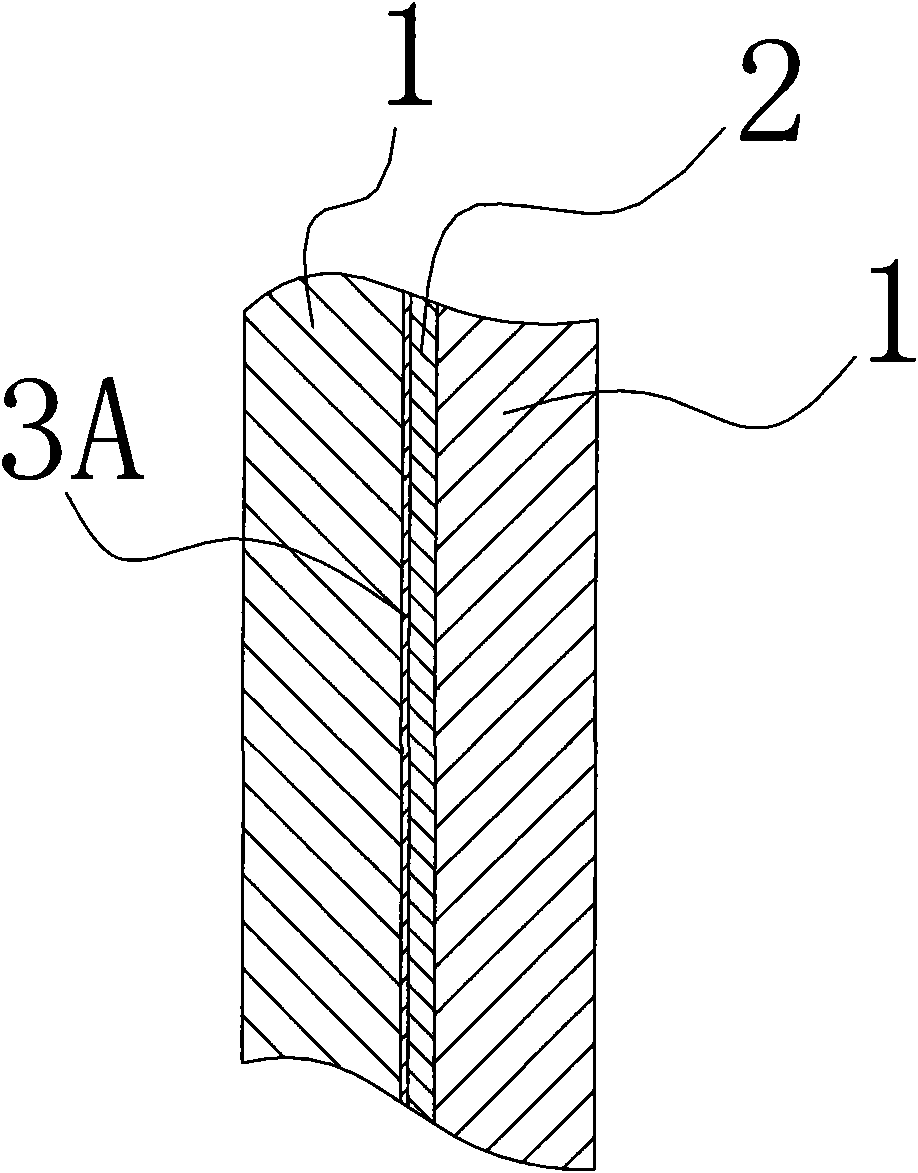

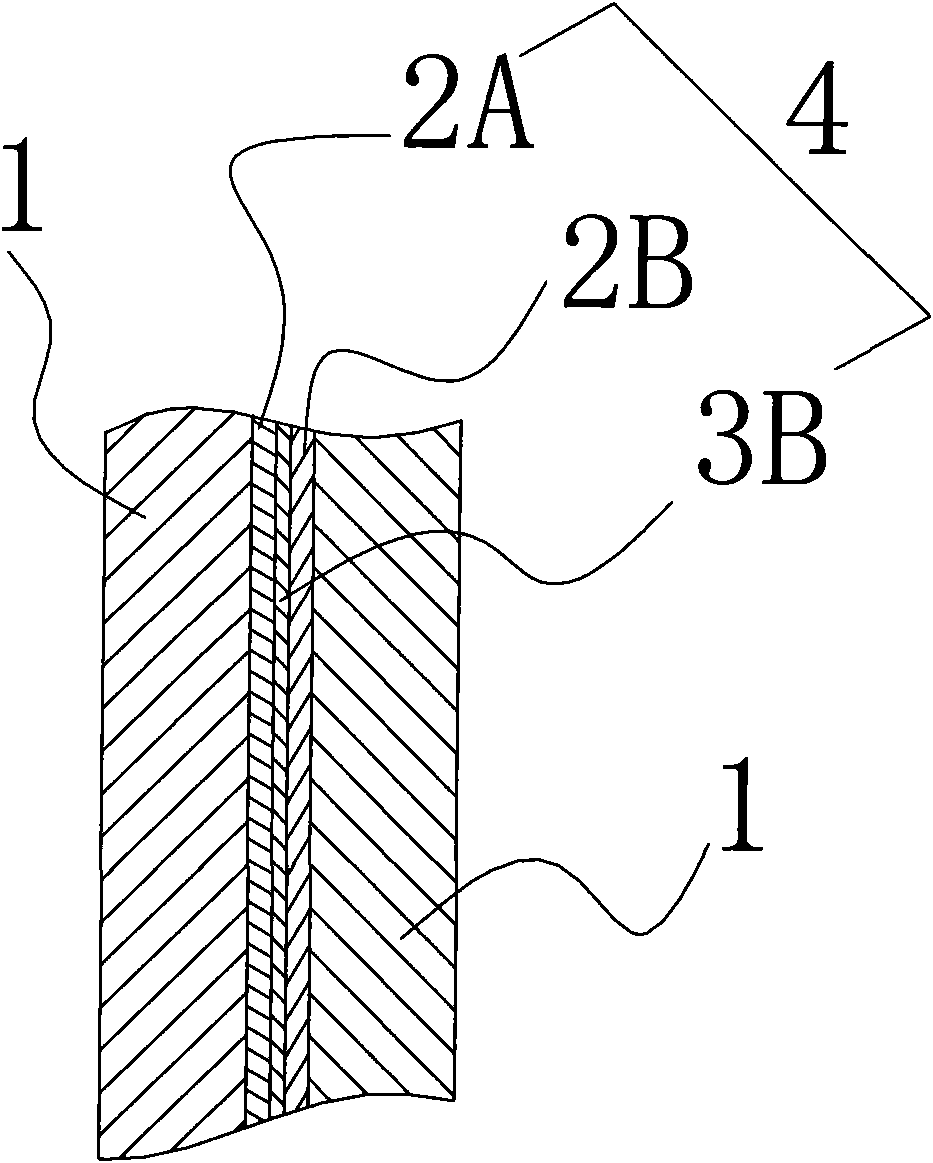

Laminated glass with nanometer thermal insulation coating and product thereof

InactiveCN101602580AEnvironmentally friendlyEnergy savingWindowsWindscreensInfraredEnvironmental resistance

The invention discloses laminated glass with a nanometer thermal insulation coating, which comprises two or more layers of glass plates, a laminated layer arranged between the glass plates, and the nanometer thermal insulation coating consisting of nanometer painting. The laminated glass in the prior art is further innovated and designed by increasing the nanometer thermal insulation coating organically combined together with the laminated glass, so the product of the laminated glass with the nanometer thermal insulation coating has good strength, good thermal insulation effect and sound insulation effect of the laminated glass, can absorb 99 percent of ultraviolet rays, 75 percent of infrared rays and 15 to 20 percent of visible light, not only can maintain glass lighting and aesthetic needs, but also can directly block solar thermal radiation, achieves the aim of thermal insulation and energy saving, and has the characteristics of environmental protection and energy saving.

Owner:SHENZHEN DUONA TECH

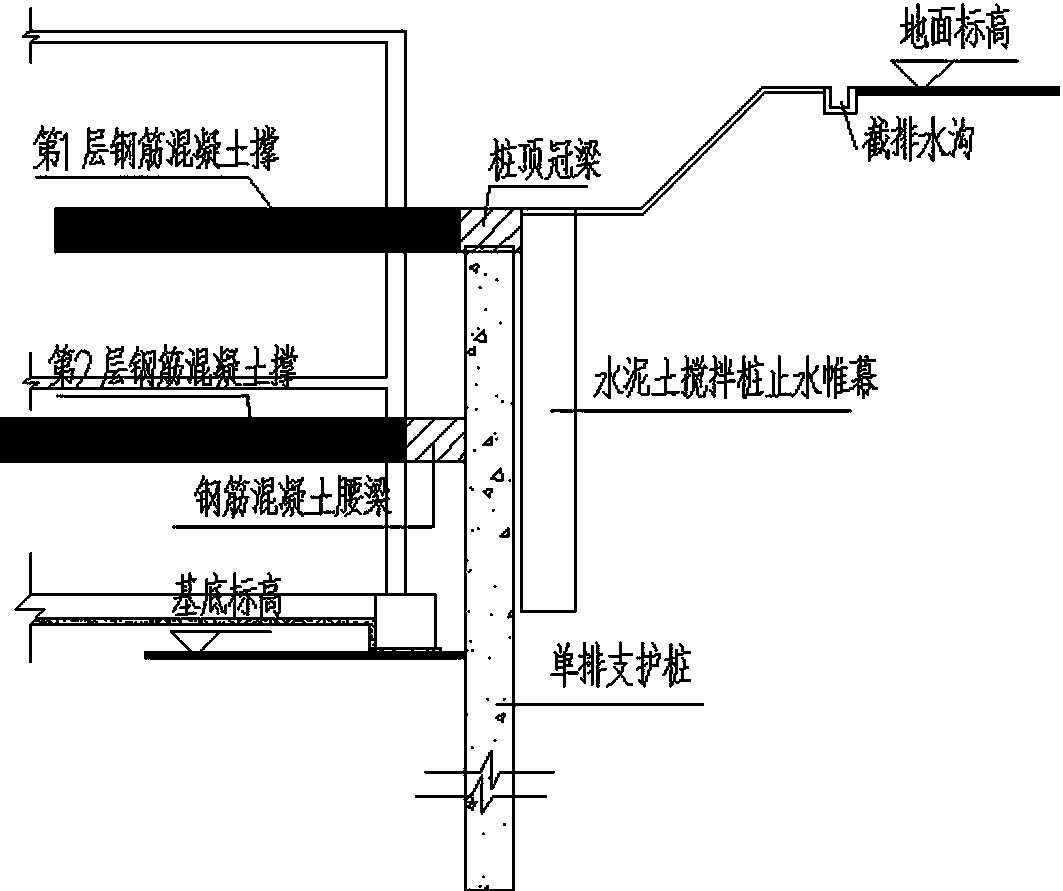

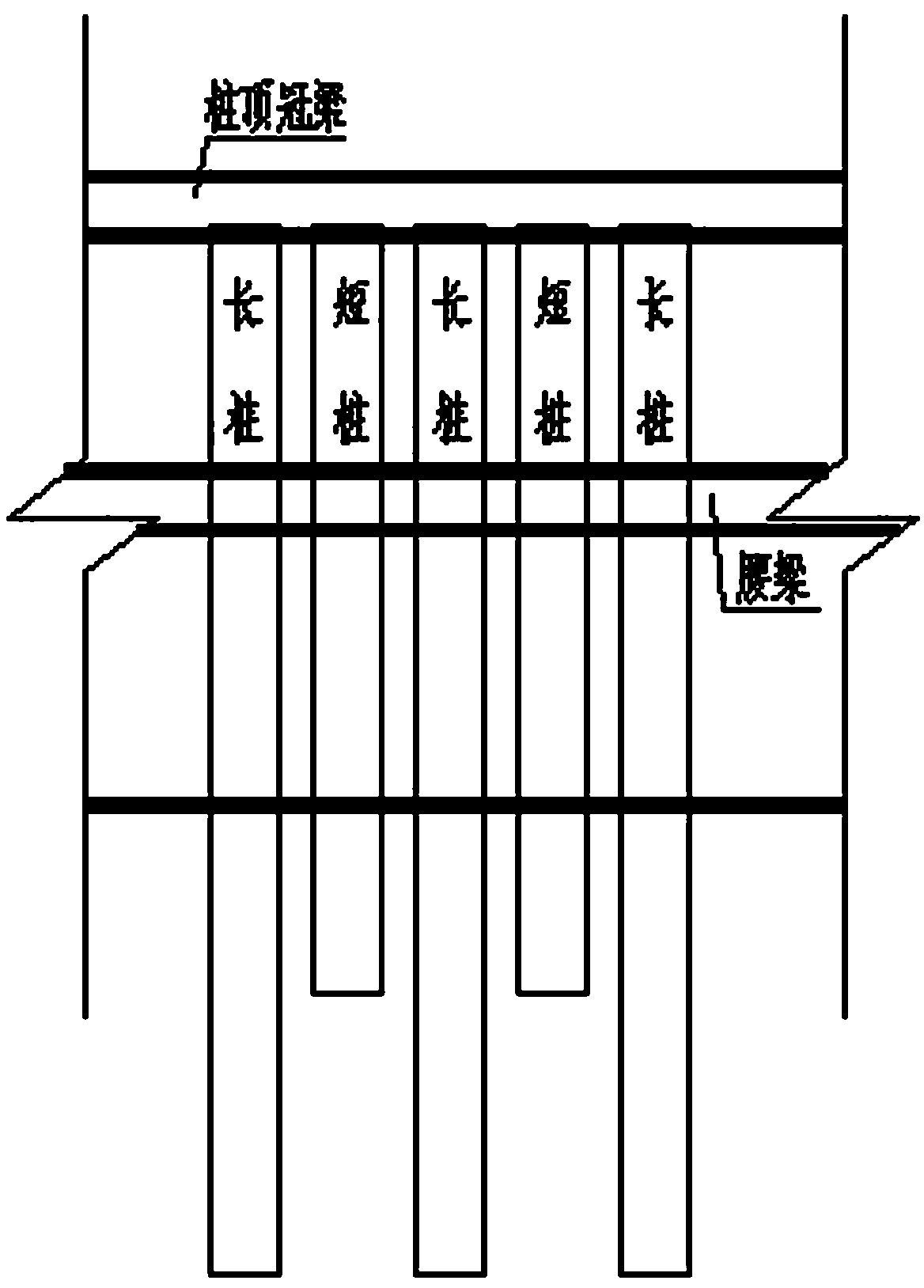

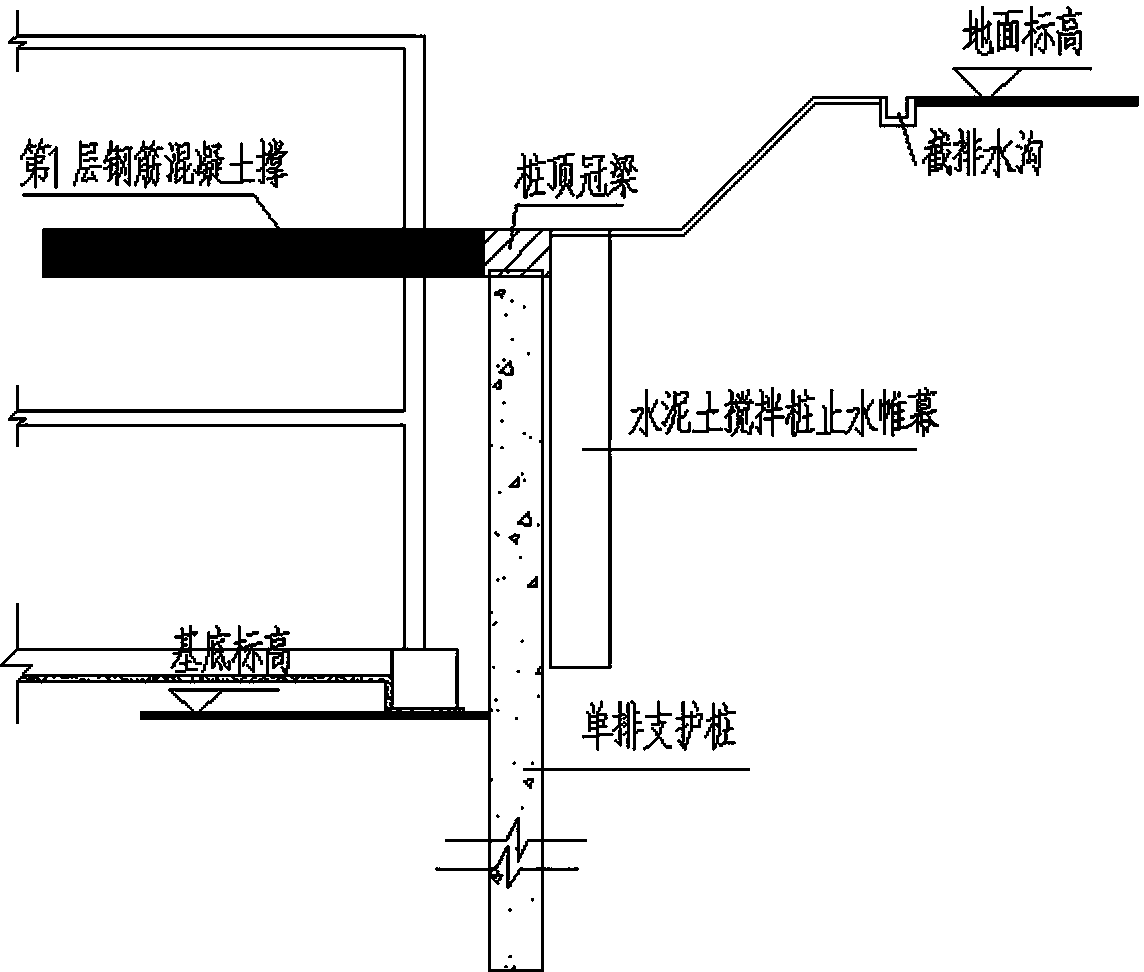

Long pile and short pile combined single-row pile and horizontal internal support pile supporting structure and construction method thereof

The invention discloses a long pile and short pile combined single-row pile and horizontal internal support pile supporting structure and a construction method thereof. The structure is characterized in that long piles and short piles are arranged in a staggering way at equal intervals in a single row of pile; the clear spacing between two adjacent piles is 200 to 400mm; two rows of concrete deep stirring piles are arranged behind a support pile to serve as a waterproof curtain; the layer number of internal supports is 1 to 3; the first layer of horizontal internal supports is generally arranged on the top of the support pile; the distance between the adjacent internal supports which are arranged up and down is 4 to 6m. When the supporting structure is designed, in all the rows of piles, parameters of the short piles are calculated to make sure that the requirements on the horizontal displacement, the bending capacity and the overturning resistance of the short piles are met and then parameters of the long piles are calculated to make sure that the requirement on the deep slide stability of the long piles is met. The construction method comprises the following main construction steps of constructing the long piles, constructing the short piles, constructing the concrete deep stirring pile curtain, hardening the ground before excavating a foundation pit, constructing a drainage facility, excavating the first layer of earth, constructing a pile top beam and the horizontal internal supports, excavating the second layer of earth, and performing the other steps until the earth is excavated to the bottom of the foundation pit.

Owner:WUHAN SURVEYING GEOTECHN RES INST OF MCC

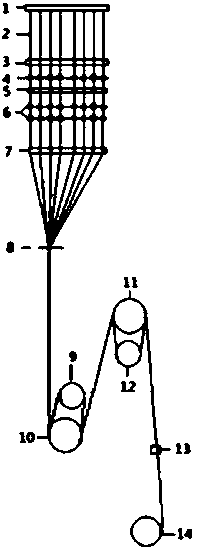

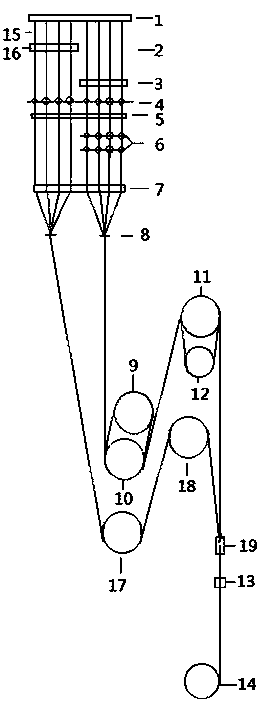

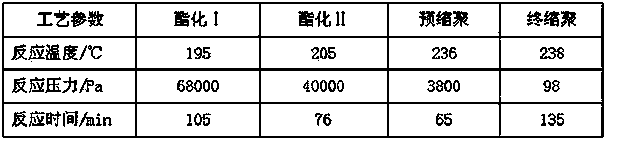

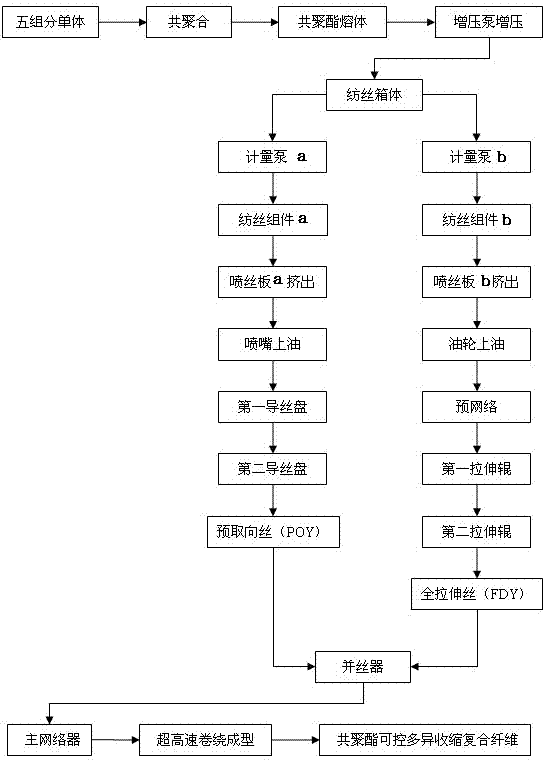

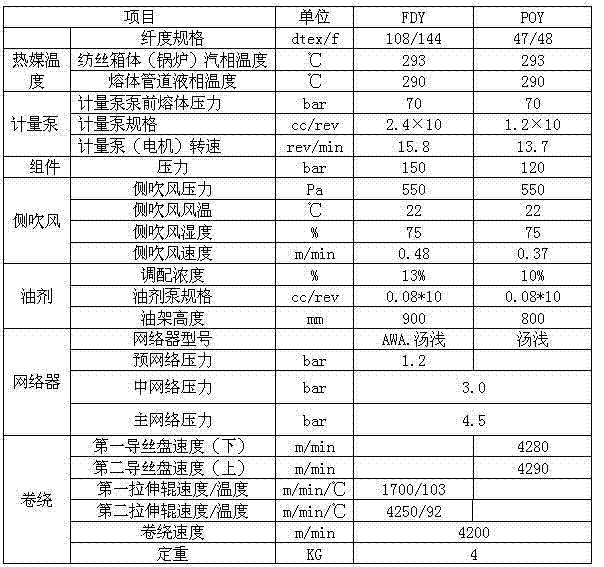

Copolyester melt direct-spinning controllable multiple differential shrinkage composite fiber and preparation method thereof

InactiveCN103526323AFull effectVersatileMonocomponent copolyesters artificial filamentMelt spinning methodsYarnPolyethylene glycol

The invention relates to a copolyester melt direct-spinning controllable multiple differential shrinkage composite fiber and a preparation method thereof. Terephthalic acid and ethylene glycol serve as raw materials, a third component of polyethylene glycol, a fourth component of diethylene glycol and a fifth component of pentaerythritol are added for copolymerization, a copolyester melt is prepared, pressurized through a melt pipeline and a pressurizing pump, conveyed to a spinning box, divided into two ways through two metering pumps, sent into a spinning assembly and a spinneret plate for extrusion and cooled and solidified to form two bundles of yarn, FDY (fully drawn yarn) is obtained after oiling wheel oiling, pre-interlacing, drawing and heat setting of one of the two bundles of yarn, the other bundle of yarn is oiled through an oil spraying nozzle and then led to two yarn guiding disks to obtain POY (polyester pre-oriented yarn), the FDY and the POY are input into a yarn doubling device and a main interlacing device simultaneously for composition, and the composite fiber is obtained after ultra-high-speed winding molding. The composite fiber adopts the better fine three-dimensional multi-layer structure and is large in potential controllable hot-shrinkage rate difference, good in fluffiness, hygroscopicity, air permeability, moisture retention, chromaticity and high color rendering uniformity, multiple in product function and high in additional value.

Owner:SUZHOU UNIV

Low-temperature dyeing process of fiber fabric

ActiveCN103966867AGuaranteed functionAvoid damageFibre treatmentDyeing processFiberProcess engineering

The invention provides a low-temperature dyeing process of a fiber fabric. The low-temperature dyeing process comprises the processes of pretreatment, pre-sizing, dyeing, reduction clearing, fixing, softening treatment, drying, sizing, calendaring and rolling. In the dyeing process, the highest temperature does not exceed 100 DEG C, mild dyeing is carried out by using a gradual warming method and pH value regulation is carried out through a buffer solution, so that a proper acid environment required during the dyeing is satisfied and the dyeing effect is excellent; during the dyeing, a leveling agent is added to ensure that the dyeing is uniform; anhydrous sodium sulphate is added to postpone the dyeing process of the pigment and the temperature rises slowly at the same time, so that the uniform dyeing is ensured; a smoothing agent is added to prevent the scratching and local fibrillation; a penetrant and a diffusant are added to ensure that the penetration and the diffusion of the dyeing are relatively good; by means of the strict control in the aspects of temperature, acid, auxiliaries, time and the like, the low-temperature dyeing process of the fiber fabric has the advantages that the dyeing firmness is high, the dyeing is uniform, the dyeing stability is good and the effect is excellent at low temperature.

Owner:绍兴洁彩坊印染有限公司

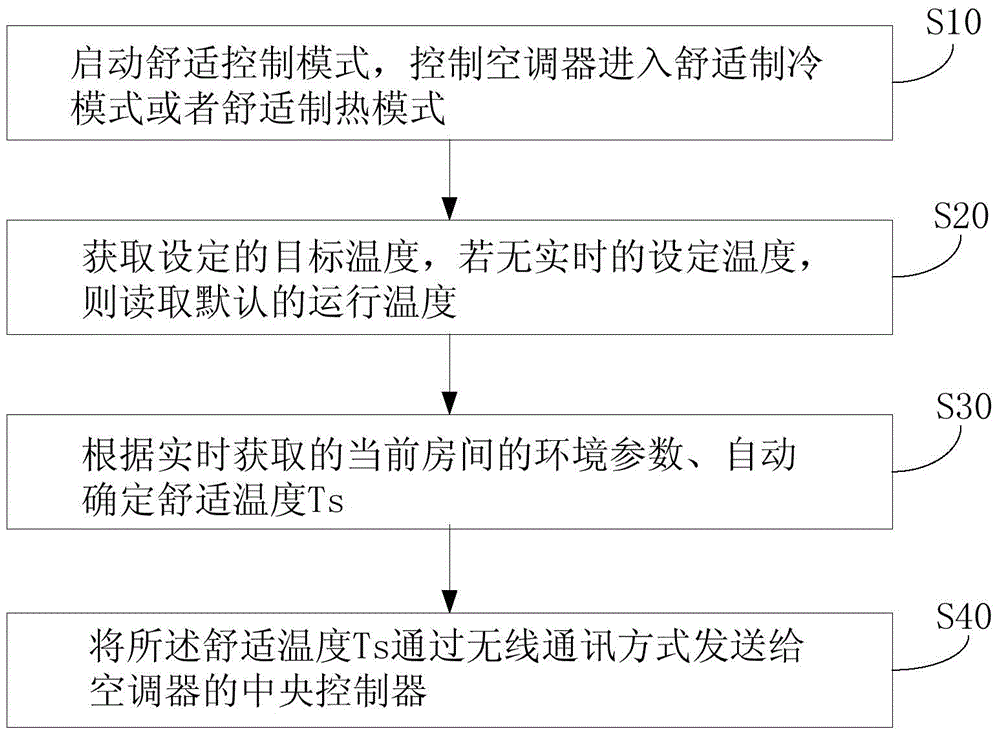

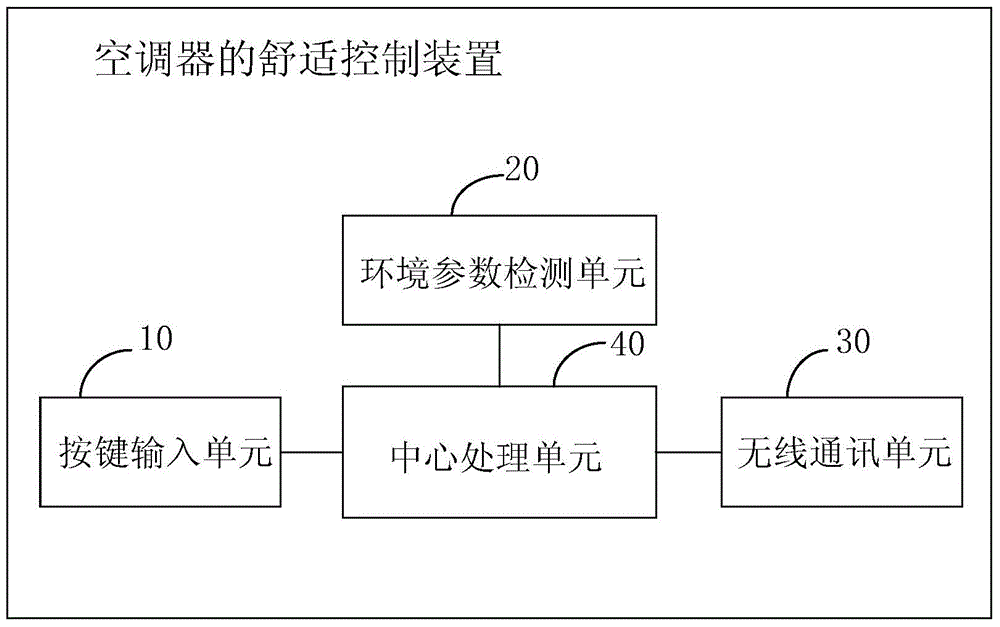

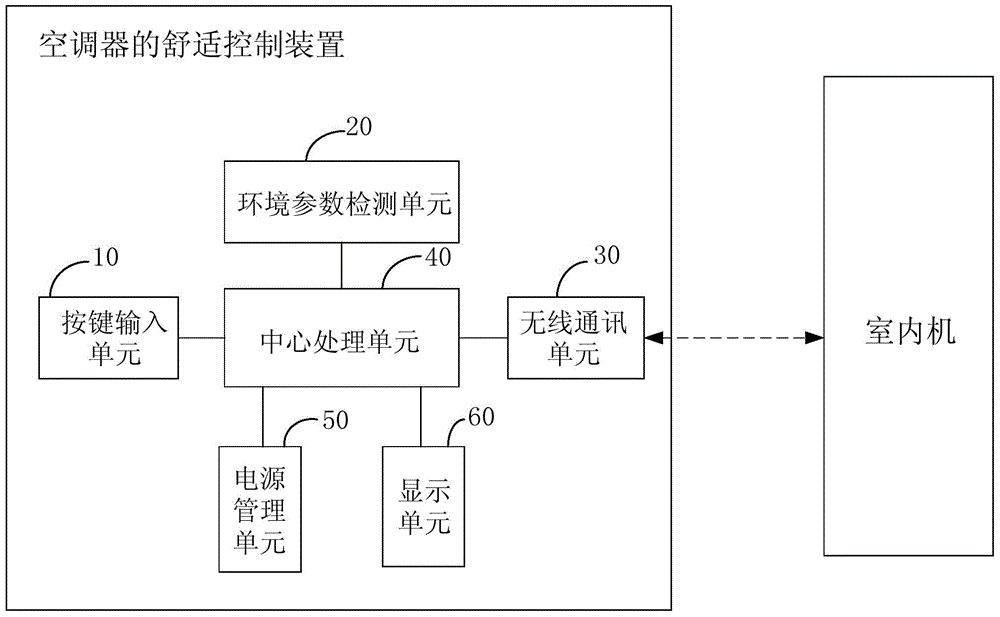

Air conditioner and comfortable control method and device thereof

ActiveCN103982986AImprove convenienceAvoid wastingSpace heating and ventilation safety systemsLighting and heating apparatusHome applianceRefrigeration

The invention belongs to the field of control on household electric appliances, and particularly relates to an air conditioner and a comfortable control method and a comfortable control device thereof. According to the air conditioner and the comfortable control method and the comfortable control device thereof, after a user starts a comfortable control mode through a key input unit, the air conditioner enters a comfort refrigeration mode or a comfortable heating mode; the air conditioner firstly runs according to a target temperature set by the user or a default temperature, then automatically determines a comfortable temperature Ts according to environment parameters, which are acquired in real time, in the current room, sends the comfortable temperature Ts to a center controller of an indoor unit of the air conditioner and finally runs according to the comfortable temperature Ts. According to the air conditioner and the comfortable control method and the comfortable control device thereof, the convenience in operation and use of the user can be improved; intelligence and comfortableness are realized through a key; furthermore, unnecessary energy waste is avoided, and dual aims of comfortableness and energy conservation are fulfilled.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

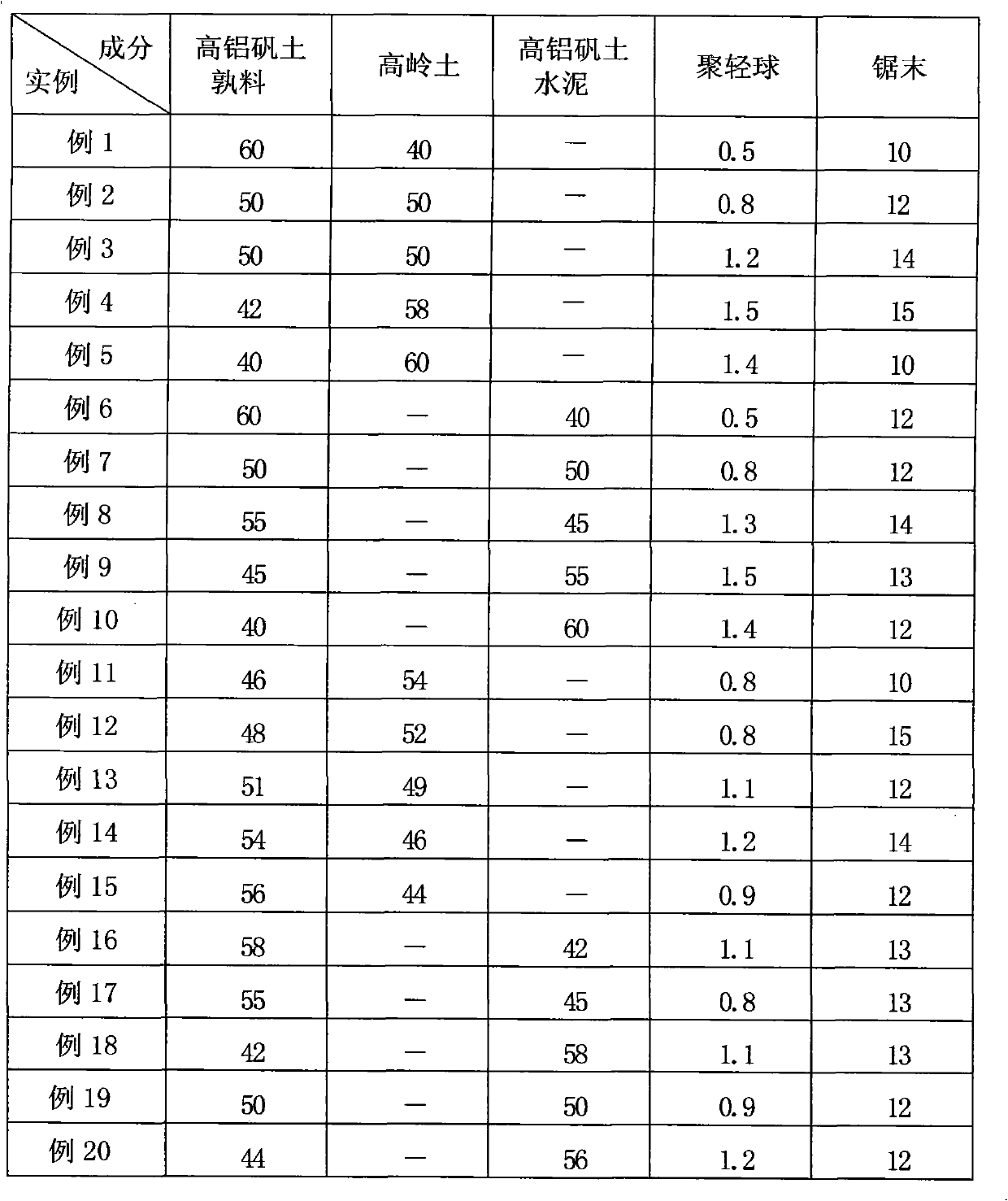

Light high-alumina insulating firebrick and preparation method thereof

The invention discloses a light high-alumina insulating firebrick and a preparation method thereof used for insulating layers of thermal equipment. The firebrick comprises the raw materials in percent by weight: 40% to 60% of high-alumina bauxite clinker and 40% to 60% of binder, polymeric light ball and sawdust respectively account 0.5% to 1.5% and10% to 15% of the total weight of the high-alumina bauxite clinker and the binder and are also added. The preparation method comprises the steps of: mixing the high-alumina bauxite clinker with the binder; then adding the polymeric light ball and the sawdust; adding water with the proportion of the dry mixed powder and the water of 1.0 to 1.75: 1; stirring into slurry-shaped materials; casting into brick blanks; drying; filling into a kiln; heating to 1270 DEG C to 1350 DEG C; and keeping the temperature for preparing the firebrick by burning. The firebrick has the advantages of simple formulation, easy acquirement of the raw materials, good compatibility, high compressive strength, low thermal conductivity, low change rate of high-temperature heavy firing line and the like, and achieves the national standards of relative products. The firebrick has simple preparation method and lower cost, can be used for the insulating layers and fireproof layers of all kinds of thermal equipment, and is beneficial to popularization and application.

Owner:郑州东方炉衬材料有限公司

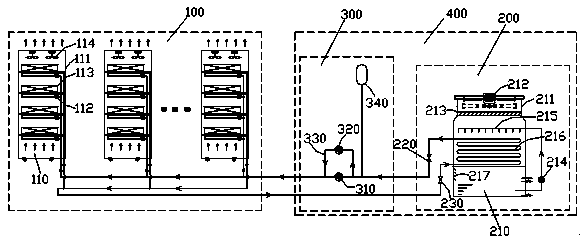

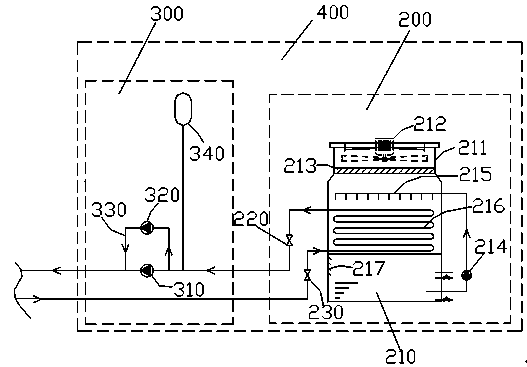

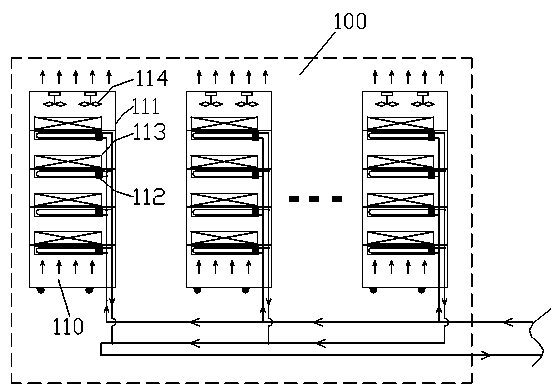

Primary water loop heat pipe radiation system for cabinet server

InactiveCN104235981AFree from pollutionImprove cleanlinessLighting and heating apparatusAir conditioning systemsCold airFree cooling

The invention discloses a primary water loop heat pipe radiation system for a cabinet server. The system comprises a machine room unit, a cooling unit and a cyclic power unit, wherein the machine room unit is connected with the cyclic power unit, and is connected with the cooling unit; the cyclic power unit is connected with the cooling unit; refrigerant water is powered by the cyclic power unit to enter the machine room unit to cool the machine room unit after being subjected to the evaporative heat absorption cooling of an outdoor air natural cooling source and spray water of the cooling unit. According to the system, a method of shortening the cold air delivery distance of a cabinet and accurately supplying air is adopted, so that the problems of local overheating and existence of hot spots of a server are solved on the basis of fully utilizing the natural cooling source and not increasing the power consumption; meanwhile, the introduction of outdoor air is avoided, so that influence on the cleanliness and the humidity of air in a machine room is eliminated; the whole system is simple in design and less in investment, the system has the characteristics of no power requirements and noise running noise in the machine room, and the aims of energy saving, synergy, safety and reliability of the data machine room are fulfilled.

Owner:CHINA MOBILE GRP GUANGDONG CO LTD

Air conditioner comfort control method

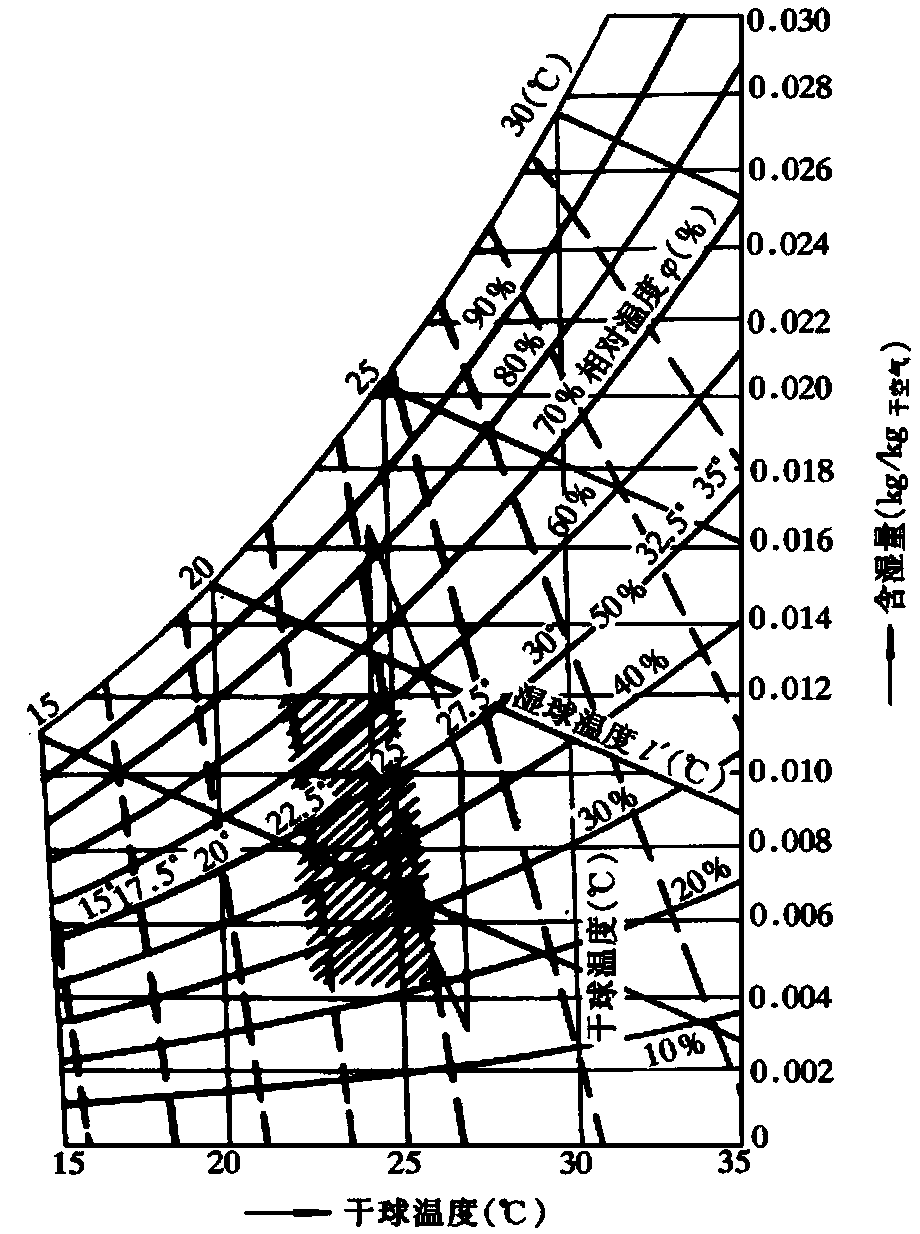

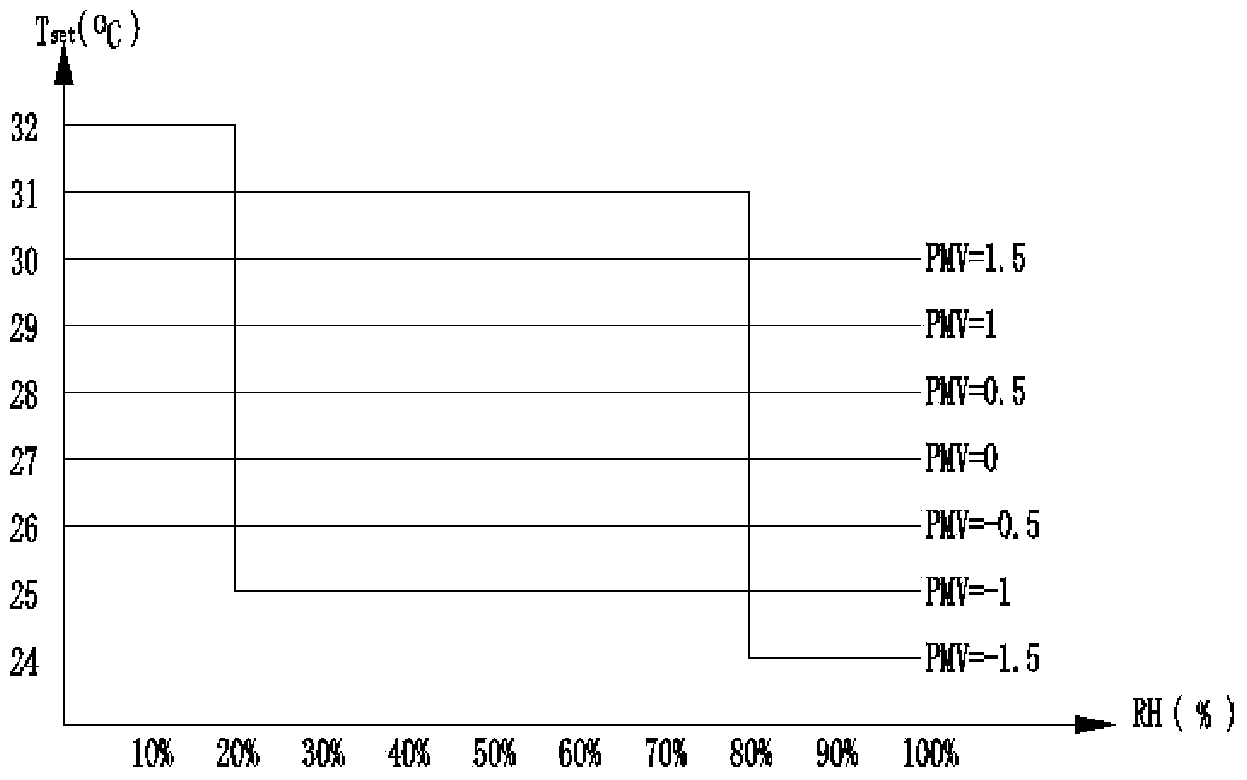

InactiveCN103471207AReduce indoor and outdoor temperature differenceAchieve energy savingSpace heating and ventilation safety systemsLighting and heating apparatusTemperature conditioningThermal comfort

The invention discloses a simple, convenient and practical air conditioner comfort control method which can control an air conditioner to work in an energy-saving and comfortable state. The method comprises the following steps that summer daily, summer sleeping, winter daily and winter sleeping air conditioner operation curves comprising different comfort levels are set through a Fanger thermal comfort equation, and a corresponding intelligent controller regulates and controls the operation temperature of the air conditioner based on the corresponding operation curves according to different indoor humidity.

Owner:江西麦恩科技有限公司

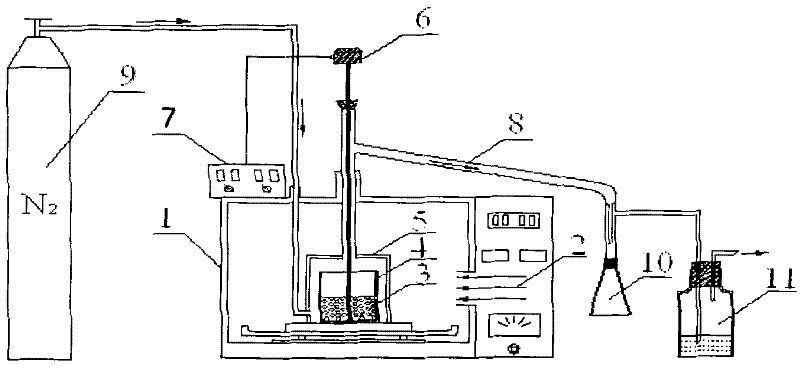

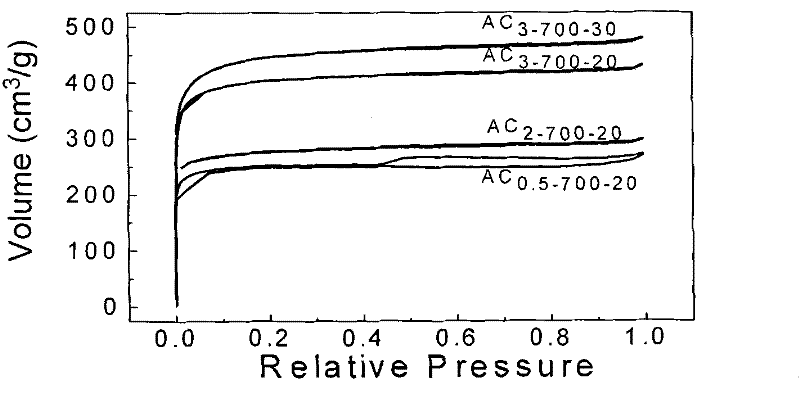

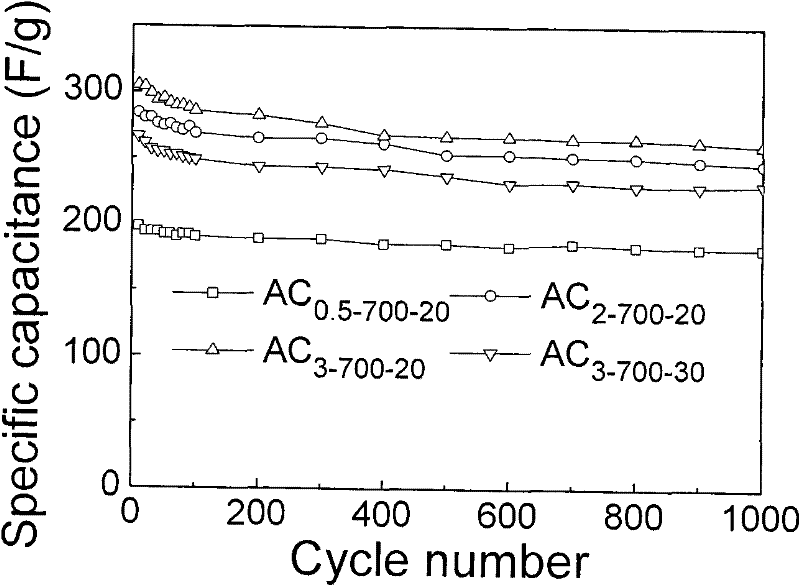

Device and method for preparing activated carbon material for electrochemical capacitor

InactiveCN102205962AFacilitate the activation of pore formationAvoid temperature gradientsElectrolytic capacitorsPotassium hydroxideBiological activation

The invention provides a device and method for preparing an activated carbon material for an electrochemical capacitor, belonging to the technical fields of coal chemical industry and microwave chemistry. The method comprises the following preparation processes of: deashing coal particles serving as raw materials by using hydrochloric acid and hydrofluoric acid, modifying the deashed coal by using nitric acid in an auxiliary way, mixing the modified coal serving as a carbon source with potassium hydroxide and deionized water, stirring to obtain a mixture, stirring and evaporating the mixture to obtain a solid mixture, and then performing microwave-assisted activating, washing, drying and grinding on the solid mixture to obtain the activated carbon. The invention has the advantages that the activation time is only 20-30 minutes, the mass ratio of potassium hydroxide to coal is (0.5-3):1, the preparation process is simple, the microwave-assisted heating is uniform, efficient and energy-saving, the consumption of the potassium hydroxide is reduced, and the activation process has the advantages of uniformity and high efficiency. The prepared activated carbon is used as an electrode material of the electrochemical capacitor and has better stability and excellent comprehensive property.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

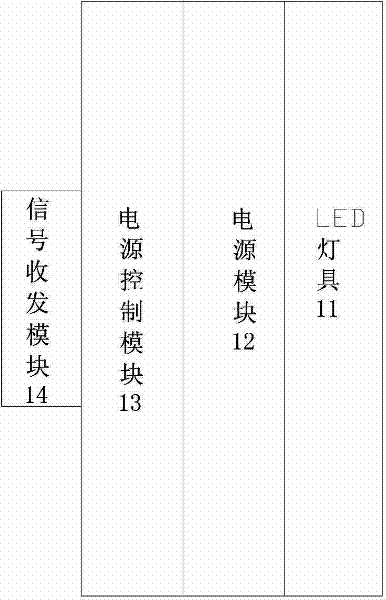

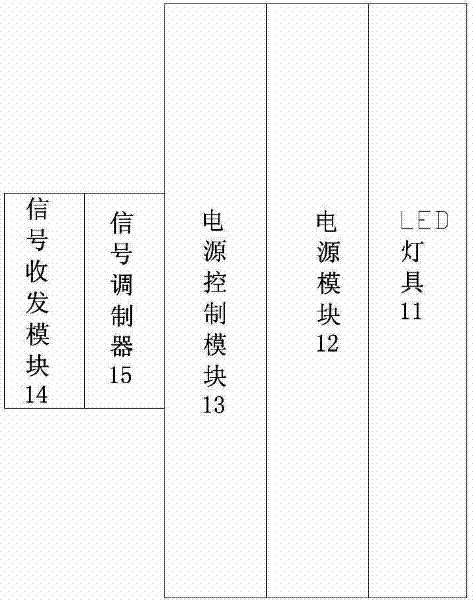

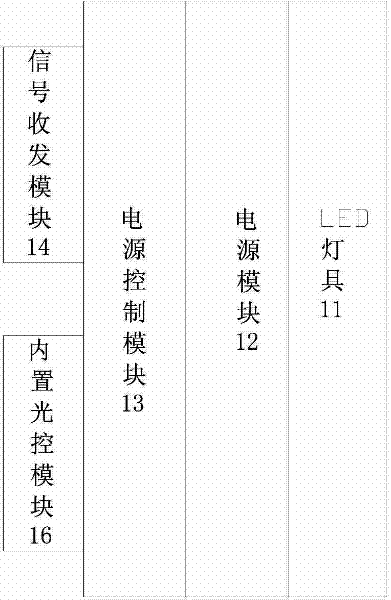

LED (Light Emitting Diode) streetlight with communication function and intelligent control system thereof

InactiveCN102523665APrecise remote managementEasy to controlElectric light circuit arrangementEnergy saving control techniquesArea networkControl signal

The invention relates to an LED (Light Emitting Diode) streetlight with a communication function and an intelligent control system thereof. The intelligent control system comprises a total network control center, an area network control center and an LED streetlight, wherein the total network control center is connected with the area network control center through a third network, receives a signal fed back by the area network control center and can transmit a control signal to the area network control center. The area network control center is in charge of collecting the state of the LED streetlight and work environment information in an area and transmitting communication or control information to the LED streetlight through a first network. The LED streetlight comprises a power supply module, an LED light, a signal transceiving module and a power supply control module. Because the intelligent control system of the LED streetlight comprises the LED streetlight with the signal transceiving module and the area network control center with the intelligent control function, the intelligent control to the LED streetlight can be realized, and the dependence degree of the entire system on people is reduced.

Owner:广东宸熙物联科技发展有限公司

Water-based polyurethane composite emulsion and preparation method thereof

ActiveCN102838713ASpeed up evaporationLower glass transition temperatureGraft polymer adhesivesWater basedPolyester

The invention discloses a water-based polyurethane composite emulsion and a preparation method thereof. The preparation method is characterized by comprising the following steps: by using acetone or butanone and acrylic monomer as solvents, polymerizing diisocyanate (HDI), isophorone diisocyanate (IPDI), mixed polyester polyalcohol, dihydroxymethylpropionic acid, 1,4-butanediol, trimethylolpropane monoene propyl ether, 2-hydroxypropyl acrylate and 2-hydroxyethyl acrylate to obtain carboxylic polyurethane; neutralizing with tertiary amine, and removing the solvents to obtain a self-emulsified double-bond-containing water-based polyurethane anionic emulsion; and by using the emulsion as a seed, adding acrylate monomer and a right amount interpenetrating-network crosslinking agent monomer to carry out pre-emulsification, and carrying out seed emulsion polymerization to obtain the composite emulsion in an interpenetrating network structure. The invention has the advantages of energy saving, environmental protection, high early bonding force, safe and reliable technique and stable product quality.

Owner:广东多正树脂科技有限公司

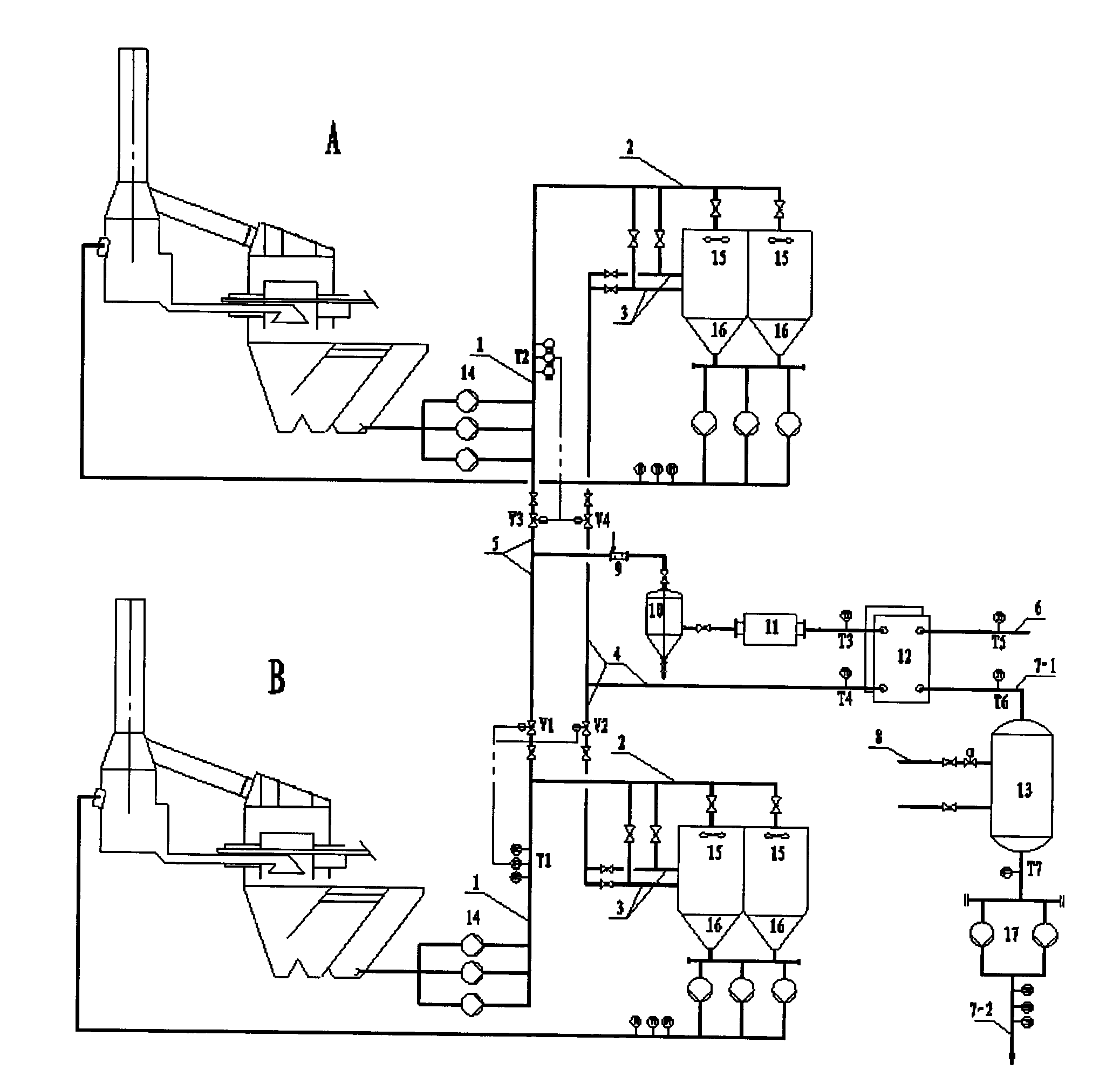

Marine wave-energy power generating device

InactiveCN102345553AAchieve energy savingAchieve environmental protectionMachines/enginesFluid gearingsSeawaterElectric generator

The invention discloses a marine wave-energy power generating device. In the invention, a hydraulic cylinder serves as an input end of a hydraulic transmission system, a piston rod of the hydraulic cylinder is linked with a pendulum-bob water baffle through a gear transmission mechanism, and the body of the hydraulic cylinder is linked with a fixed base; an oil inlet / outlet port of an oil cavity of the hydraulic cylinder is forked into two paths, one path is linked with a high-pressure energy accumulator through an oil outlet one-way valve and a high-pressure pipeline, and the other path is linked with a medium-pressure energy accumulator through an oil-return one-way valve and an oil-return pipeline; a rodless cavity of the hydraulic cylinder is linked with a low-pressure air chamber through an air outlet and an air pipe of the rodless cavity; an extending side of a piston rod of the hydraulic cylinder is consolidated and tightly fit with a hydraulic cylinder cover to form a cylinderexternal cavity which is hermetically isolated from seawater, and the cylinder external cavity is linked with the low-pressure air chamber through an air outlet and an air pipe of the cylinder external cavity so as to assist the realization of the free reciprocating motion of the piston rod; and the high-pressure energy accumulator and the medium-pressure energy accumulator are respectively connected with a hydraulic motor, and the hydraulic motor drives a generator to work. According to the marine wave-energy power generating device disclosed by the invention, the purposes of energy saving, emission reduction, low carbon and environment friendliness can be achieved.

Owner:OCEAN RES CENT OF ZHOUSHAN ZHEJIANG UNIV

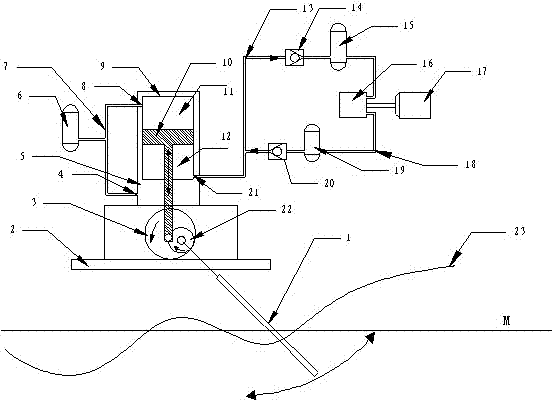

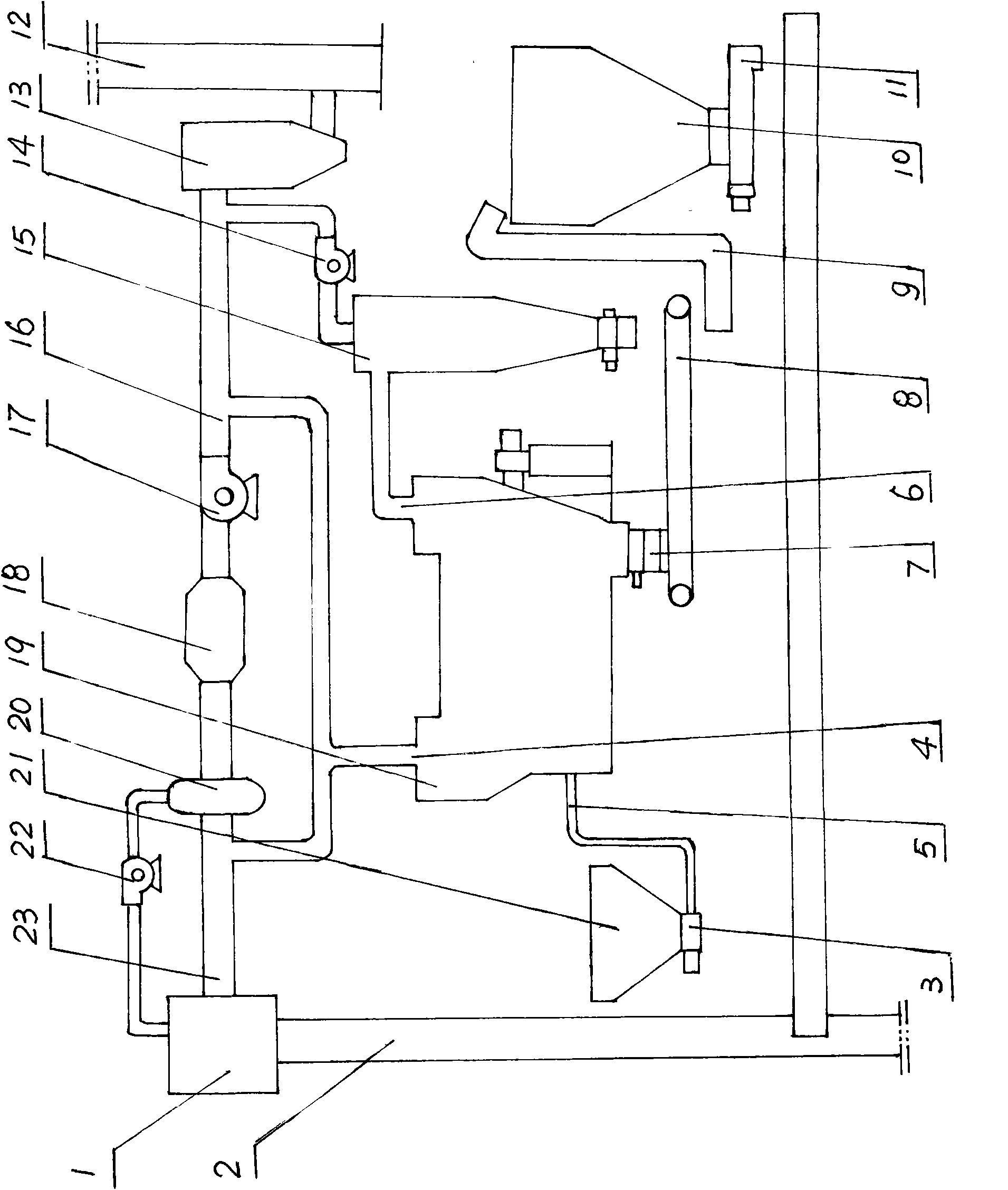

Processing system of heating by using waste heat of hot water for slag flushing in blast furnace

ActiveCN101660015AGuaranteed uptimeAchieve energy savingLighting and heating apparatusRecycling and recovery technologiesCooling towerFiltration

The invention belongs to the technical field of recovery of waste heat in a circulating water system, relating to a processing system of heating by using waste heat of hot water for slag flushing in ablast furnace. A water inlet pipe of a cooling tower and a slag-flushing water input pipeline are respectively connected to a water outlet header pipe of a slag-flushing water hot water lift pump ofthe inventive slag-flushing water circulating system, and the slag-flushing water input pipeline enters a common heating processing system, which is characterized by that the heating processing systemcomprises a pipeline mixer, a coarse filtration equipment, a fine filtration equipment and a one-stage heat exchanger; that a water return pipe of a heating system is connected to the one-stage heatexchanger and a heating water supply pipe is connected with a heating water supply pump unit via a two-stage heat exchanger; and that the heated hot water is conveyed into the heating system by the heating water supply pipe. The inventive processing system achieves the purposes of energy conservation and consumption reduction, which is applied to heating by using the waste heat of hot water for slag flushing in the blast furnace in some regions with cold winter, and which is also applicable to a circulating system for other media that are heated necessarily due to the temperature reduction after used.

Owner:CISDI ENG CO LTD

Porcelain granules containing carbon and preparation method thereof

InactiveCN101580349AReduce manufacturing costLight weightSolid waste disposalThermal insulationExpanded clay aggregate

The invention discloses a preparation method for porcelain granules containing carbon. According to the weight percentage, 5%-40% of carbon powder, 5%-25% of gold mine tailing powder and 35%-70% of fly ash make up main raw materials. The preparation method comprises the steps of: (1) the gold mine tailing powder is dipped in a HCl solution; (2) the carbon powder, the fly ash and the modified mine tailing powder are uniformly blended; and then water is added for wet mixing; (3) the wet material is prepared into spheric granules with the grain diameter of 5-20mm; (4) the spheric granules are dried and sintered to obtain the porcelain granules containing carbon. The porcelain granules containing carbon are multifunctional porcelain granules with the functions of adsorption, light weight, high strength, heat preservation, thermal insulation, etc.

Owner:ZHEJIANG UNIV

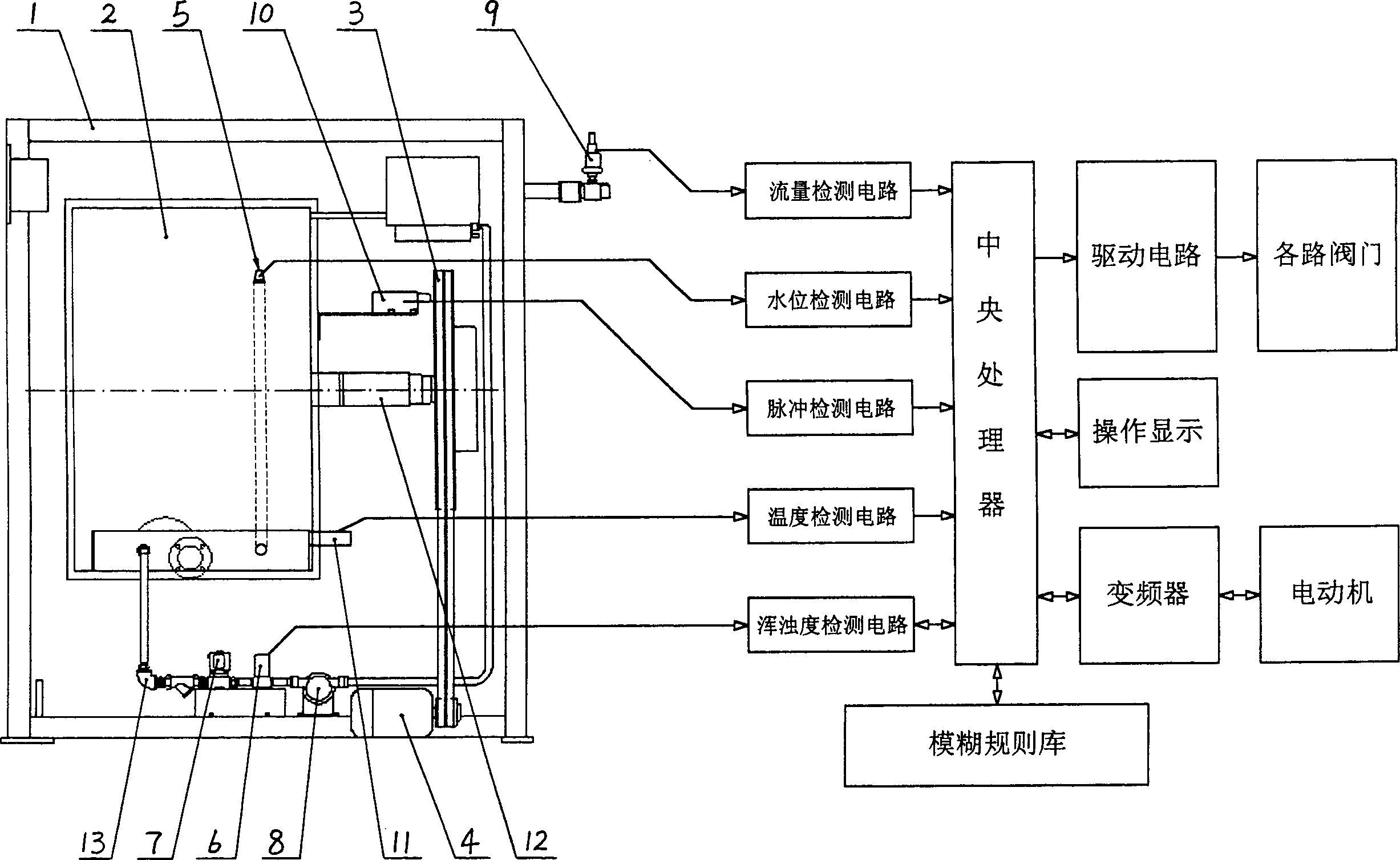

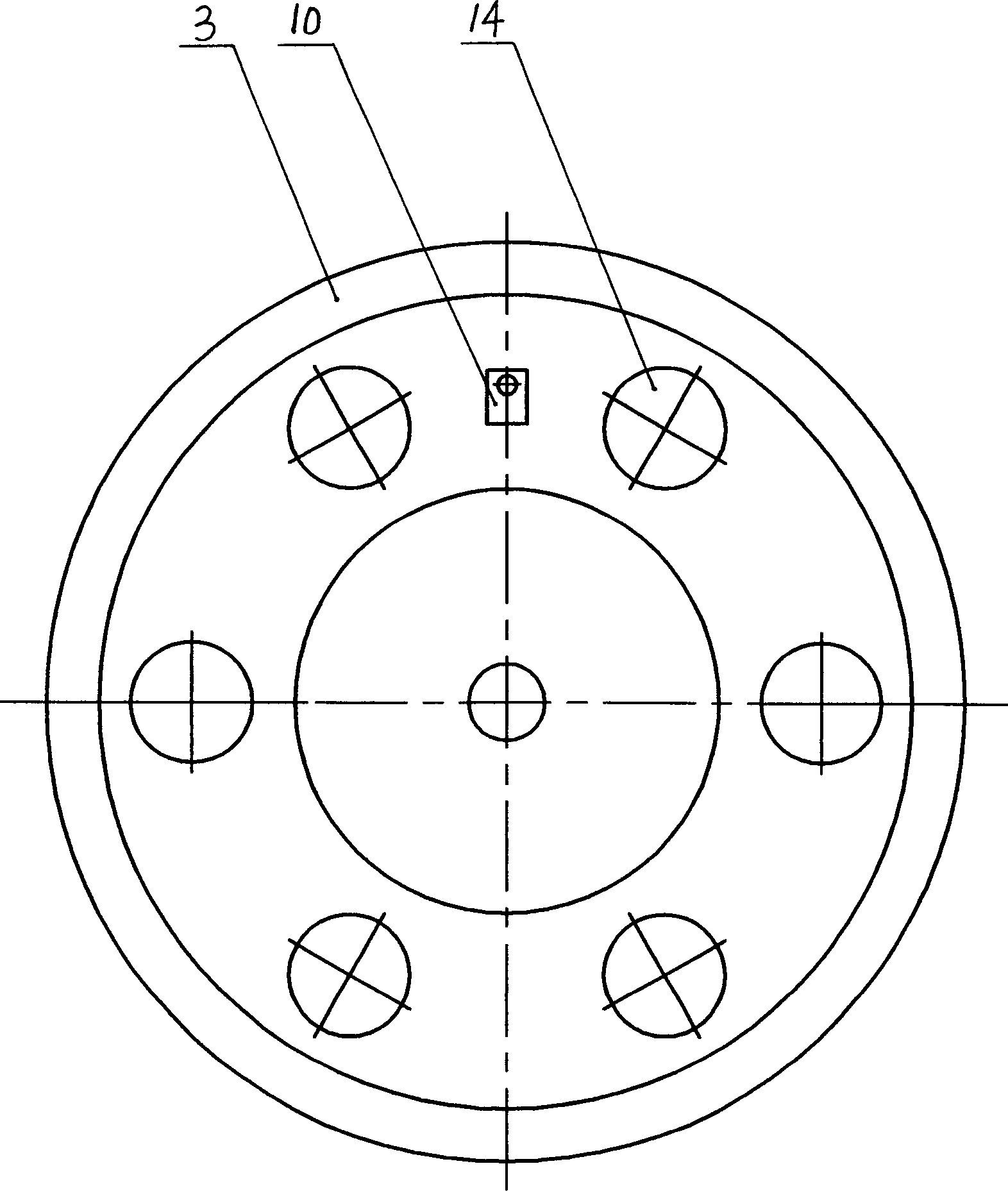

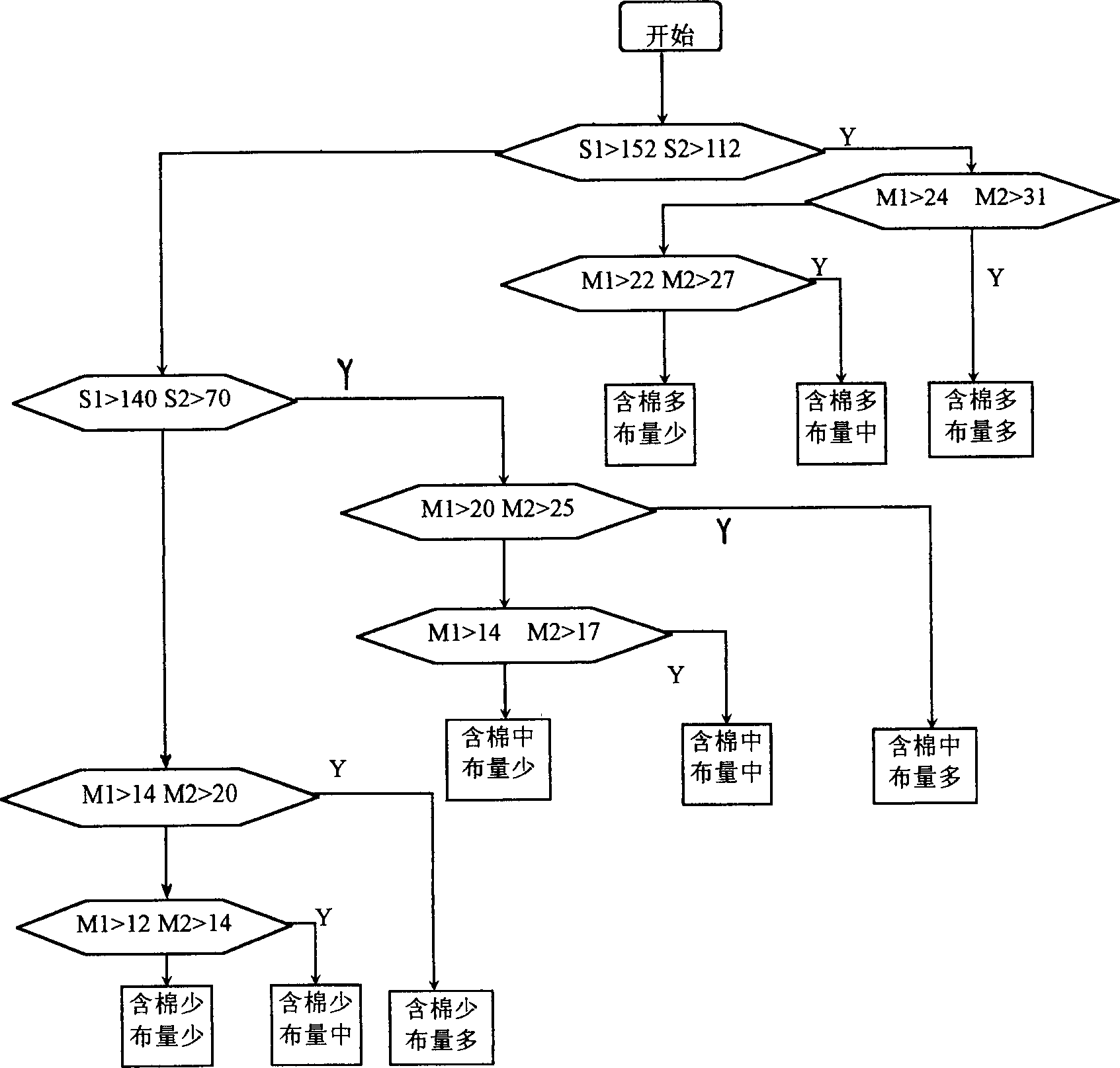

Detecting method for cloth quality and quantity of fuzzily controlled industrial washing machine

InactiveCN1378005AImprove work efficiencyHigh precisionControl devices for washing apparatusTextiles and paperWater dischargeFuzzy control system

The main principle of detecting the cloth quality and quantity is that the CPU first obtains and stored the initial water level H1, the water level H2 before the washing drum rotates and the water level H3 after the washing drum rotates, and calculates the water level differences S1=H2-H1 and S2=H3-H1; the CPU then obtains the pulse numbers M1 and M2 related to the inertial rotating numbers of the washing drum before and after water discharging; and the cloth quality and quantity is finally deduced based on the relationship between the cloth quality and quantity and the above said parameters.The said method has the advantages of accurate detection, high fuzzy control precision and high working efficiency of the washing machine.

Owner:JIANGSU SEA LION MASCH GRP CO LTD

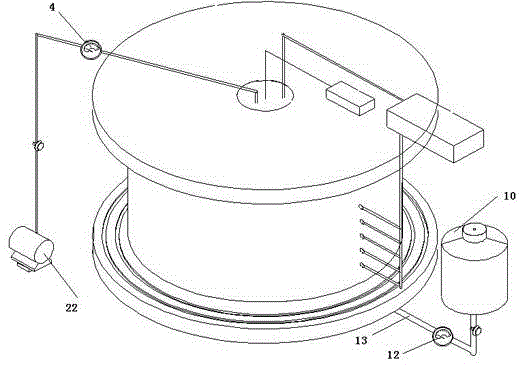

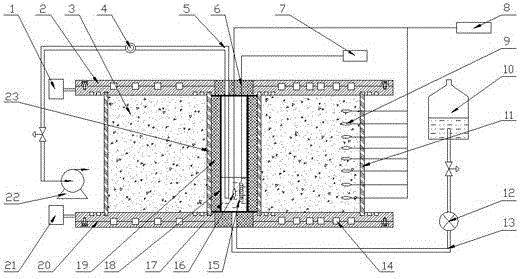

Test device for simulating permafrost region well heat insulation or heating

InactiveCN102864793AFlexible simulationReduce consumptionFoundation testingProtective foundationTemperature controlThermal insulation

The invention relates to a test device for simulating permafrost region well heat insulation or heating. The test device is characterized in that a test tank is a circular interlayer barrel body consisting of an outer ring, an inner ring, a top plate and a bottom plate, a soil body is filled in an interlayer, a refrigerating liquid circulation passage is arranged inside the top plate and the bottom plate, is connected with a refrigerating temperature control device and is in contact with the soil body, water is filled in a water tank, the water tank is arranged in the test tank, a heat insulation barrel is placed between the water tank and the test tank, heat insulation covers are placed on and under the water tank, a water replenishing device is connected with a water tank bottom plate through a water replenishing pipe, a water pressure gauge is arranged on the water replenishing pipe, a water pumping device is connected with a water tank top cover through a water pumping pipe, the water pumping pipe is inserted into water of the water tank, a flow meter is arranged on the water pumping pipe, a heating temperature control device is connected with a heating pipe through a conducing wire, the heating pipe is inserted into the water of the water tank, and temperature sensors are arranged in the solid body and the water of the water tank and are respectively connected with a digital collecting instrument. The test device has the advantages that the permafrost region well is simulated, the reasonable well diameter, the water pumping speed, the heat insulation thickness and the power of a heating device are obtained, and the goals of energy saving and environment protection are reached.

Owner:COLD & ARID REGIONS ENVIRONMENTAL & ENG RES INST CHINESE

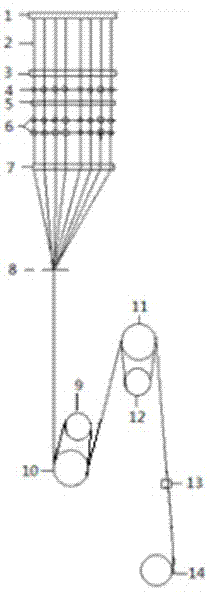

Controllable multiple-differential-shrinkage composition fiber made from copolyester melt through ultra-fast direct spinning, and preparation method of composition fiber

InactiveCN103484967AIncrease spinning speedIncrease added valueArtificial filament heat treatmentMonocomponent copolyesters artificial filamentYarnFiber

The invention relates to a controllable multiple-differential-shrinkage composition fiber made from a copolyester melt through ultra-fast direct spinning, and a preparation method of the composition fiber. The copolyester melt, which is made from five components including terephthalic acid, ethylene glycol, poly ethylene glycol, diethylene glycol and pentaerythritol, is pressurized by a booster pump and transported through a melt pipeline into a spinning box body, and is then divided by two measuring pumps into two branches, which enter a spinning component and a spinneret respectively and finally be extruded. After cooling and curing, two yarns are formed, wherein one yarn is subject to oiling by an oil wheel, pre-entwining, stretching and thermoforming to obtain an FDY yarn, and the other yarn is subject to oiling by an oil nozzle, and is guided to two spinning discs to obtain a POY yarn; the two yarns are simultaneously input into a doubling device and a main entwining device for combination, and are formed through the ultra-fast rolling, so as to obtain the composition fiber. The composition fiber has the characteristics of relatively good micro three-dimensional morphological structure, moisture absorption property, moisture preservation property, air permeability and antistatic property, easiness in dyeing, uniform dyeing, high coloration uniformity and the like; the composition fiber is high in processing speed, high in yield, low in consumption, low in manufacturing cost, high in value added, high in product functions, good in quality, and obvious in advantage of performance price ratio.

Owner:SUZHOU UNIV

High-strength and high-aluminum light heat-insulation and fire-resistant brick and production method thereof

The invention relates to a high-strength and high-aluminum light heat-insulation and fire-resistant brick, which is used in a heat-insulation layer in thermal equipment, and a production method thereof. The fire-resistant brick includes following basic raw materials: 30-35% of a high-aluminum alumina clinker, 10-20% of an expansion agent and 45-55% of a bonding agent and additionally includes 0.1-0.15% of engineering fibers and 0.15-0.2% of a water reducer on the basis of the total amount of the basic raw materials above. In addition, each ton of the basic raw materials is added with 0.7-2.0 m<3> of expandable polystyrene spheres. The bonding agent is kaolin or high-aluminum alumina cement and is 200-320 meshes in granularity. The production method includes the steps of stirring the raw materials to form a sludge material, preparing the sludge material into green bricks, drying the green bricks, and sintering the green bricks at 1350-1400 DEG C with heat insulation. The fire-resistant brick is high in pressure resistance strength, is low in heat conductivity and is low in change rate of a high temperature reburning curve. The normal-temperature pressure resistance strength of the fire-resistant brick is higher than that of a common fire-resistant brick by more than two times. The fire-resistant brick can be used in a heat insulation layer and a fireproof layer in all thermal equipment, achieves both energy-saving and fireproofing effects and is beneficial to popularization.

Owner:郑州东方炉衬材料有限公司

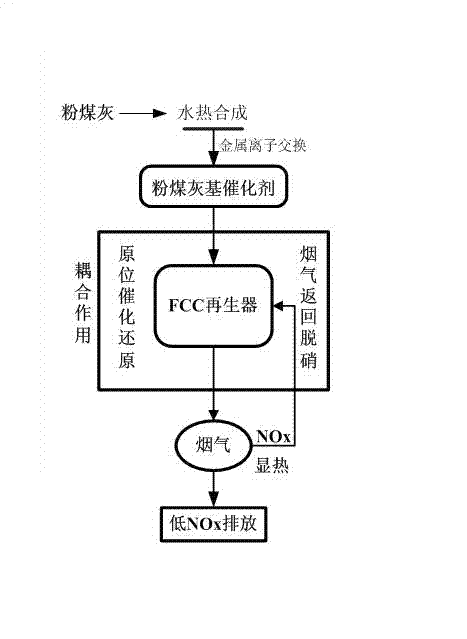

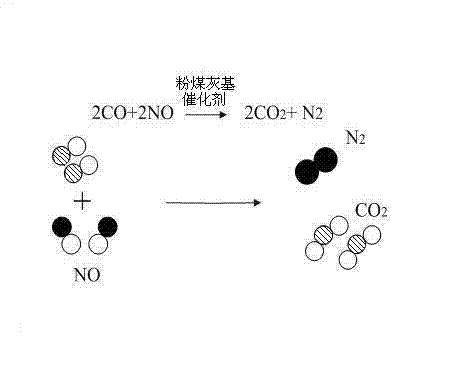

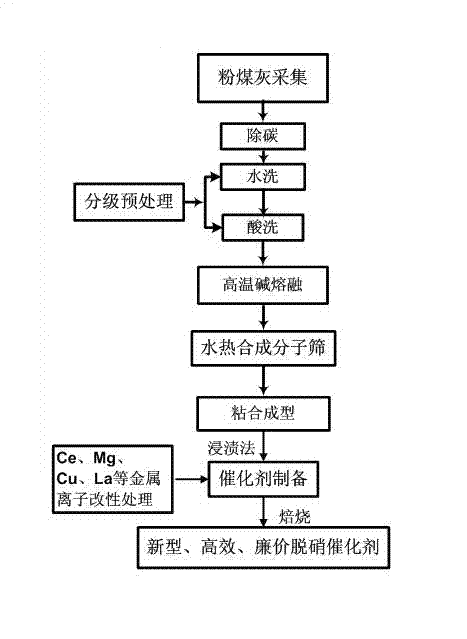

Method for reducing NOx emission in FCC (Fluid Catalytic Cracking) regeneration process

InactiveCN102824849AReduce concentrationReduce energy consumptionMolecular sieve catalystsDispersed particle separationChemical reactionFlue gas

The invention relates to a method for reducing NOx emission in an FCC (Fluid Catalytic Cracking) regeneration process. The method for reducing NOx emission in an FCC regeneration process comprises the following steps of: adding a fly ash based denitration catalyst manufactured by using fly ash as a raw material into an FCC regenerator, wherein the adding quantity of the catalyst is 5% of the mass of a reactant in the FCC regenerator, petroleum coke attached to the surface or duct of the catalyst generates the gases of NOx, CO2, H2O, CO and SO2 in the combustion process, NOx and reducing gas CO directly carry out a chemical in-situ reaction of the fly ash based denitration catalyst, and the NOx is reduced into N2; while the in-situ catalytic reduction effect on the fly ash based denitration catalyst is carried out, returning regeneration flue gas in 20%-40% volume of the flue gas discharge capacity into the FCC regenerator by using an air blower, the flue gas returned into the FCC regenerator carries out a chemical in-situ reaction again of the fly ash based denitration catalyst, the NOx returned into the flue gas is reduced into N2, so that low NOx emission is realized. The reducing gas is completely provided by petroleum coke at the in-situ combination of the catalyst so that the concentration of the regeneration flue gas NOx is decreased by 50%-80%, and simultaneously the energy consumption can be decreased by 10%-30%.

Owner:NORTHEAST GASOLINEEUM UNIV

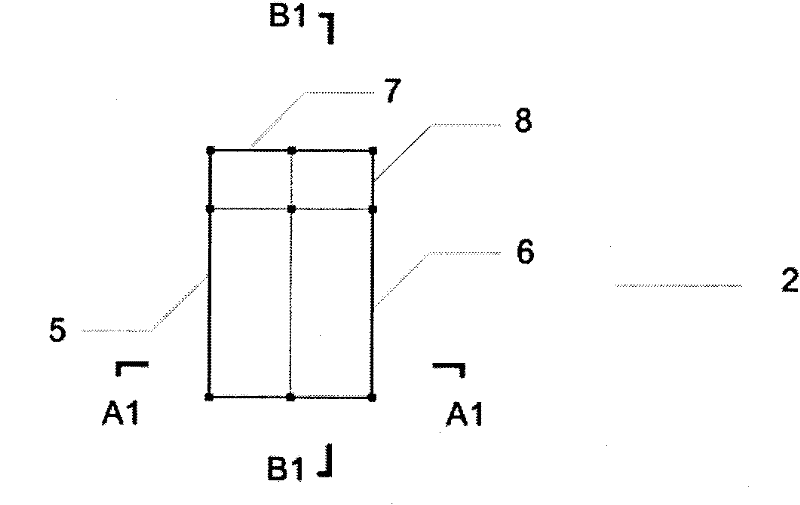

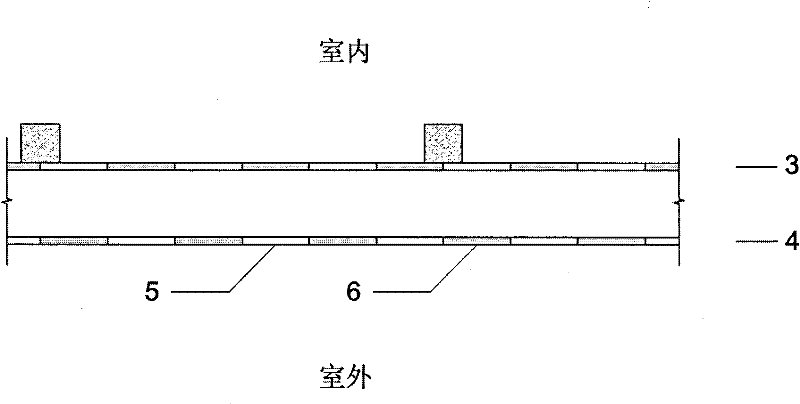

Novel adjustable double-layer glass curtain wall

The invention relates to an adjustable double-layer glass curtain wall. Through movable adjustability of the glass curtain wall, radiation quantity of sunlight can be artificially controlled, and soft natural light can be continuously introduced into a building; response is made to change of external light by superposition of transparent and translucent glass and relative movement of an inner curtain wall and an outer curtain wall, thereby flexibly meeting various different daylighting requirements; a cavity is formed by the double-layer glass curtain wall, thereby achieving the technical requirements of heat insulation, heat isolation, ventilation, energy conservation, sound insulation and the like, and contributing to energy conservation and environmental protection of buildings; furthermore, during the movement adjustment process, the effect that the building elevation changes continuously can be created through the relative movement relationship between the transparent and the translucent glass of the double-layer curtain wall, thereby achieving a concise and uniform overall appearance with multi-level changes.

Owner:叶芸

Method for preparing reinforced tungsten carbide abrasion-resistant composite plate

InactiveCN102212821AIncrease productivityReduce manufacturing costMetallic material coating processesMetal layered productsSlagComposite plate

The invention discloses a method for preparing a reinforced tungsten carbide abrasion-resistant composite plate. The method comprises the following steps of: selecting a low-carbon steel plate or a low-alloy steel plate adapted with the size of a hearth of a heating furnace as a substrate, uniformly spreading film removing agent, alloy powder, tungsten carbide powder and slag forming agent powder on a cleared surface, horizontally putting the substrate into the heating furnace, and heating the substrate to obtain the reinforced tungsten carbide abrasion-resistant composite plate. The abrasion-resistant alloy surface of the working layer of the reinforced tungsten carbide abrasion-resistant composite plate produced by using the method is flat and attractive; the composite plate can be directly used for the working conditions (such as a baffle plate and the like) requiring flat surfaces, so a machining process and corresponding production cost are saved; and the composite plate can be widely applied to the working condition of high abrasive abrasion, and has longer service life.

Owner:SHANDONG UNIV

Anti-aging UV curing coating

InactiveCN104927628AGuaranteed aging resistanceMoisture-absorbing and breathablePolyurea/polyurethane coatingsEpoxy resin coatingsFiberCrack resistance

The invention relates to the field of coatings, in particular to an anti-aging UV curing coating. The anti-aging UV curing coating comprises the following raw materials in parts by weight: 35-45 parts of polyurethane acrylate, 10-15 parts of grapheme, 3-6 parts of bamboo carbon fiber, 25-30 parts of hydrobisphenol-A epoxy resin, 3-5 parts of a photoinitiator, 3-8 parts of an anti-aging agent, 7-12 parts of a reactive diluent, 0.3-0.6 part of a leveling agent, 0.2-0.5 part of an anti-settling agent and 1-1.5 parts of a foam breaking agent. The anti-aging UV curing coating is excellent in aging resistance, can ensure long-term effectiveness after being used, and has the characteristics of good corrosion resistance, excellent crack resistance and the like.

Owner:CHENGDU NASHUO TECH

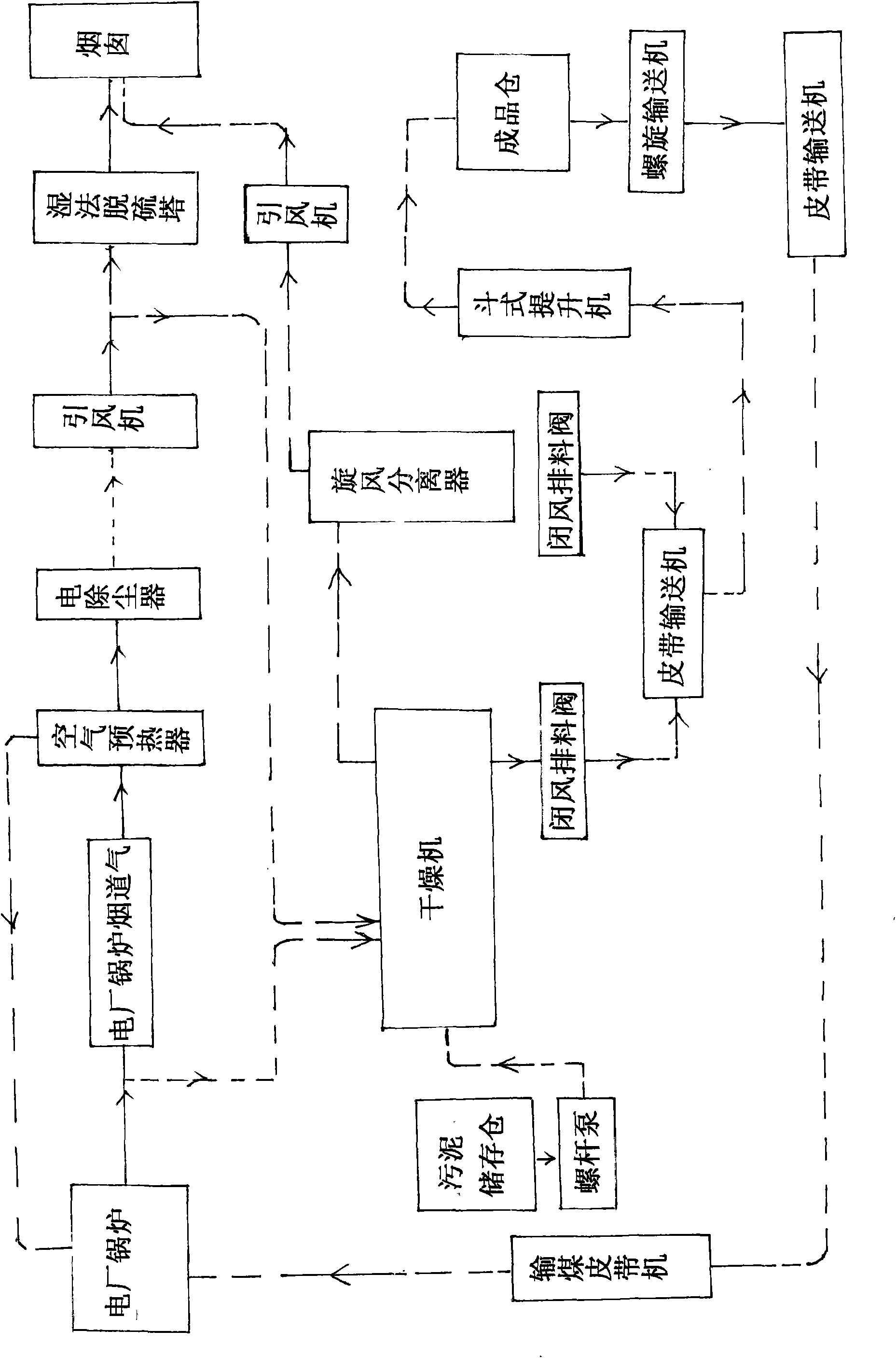

Sludge treatment device using waste heat of boiler and treatment process thereof

ActiveCN101885573AReduce the temperatureTake advantage ofSludge treatment by de-watering/drying/thickeningDispersed particle separationCombustionSludge

The invention provides a sludge treatment device using waste heat of a boiler and a treatment process thereof, relates to a sludge treatment device using waste heat of a boiler and improvement of a treatment process thereof, in particular to a sludge treatment device using waste heat discharged by fume of a boiler and a treatment process thereof. The sludge treatment device comprises the boiler, wherein the boiler is respectively connected with a coal conveying belt device and a fume discharge treatment device. The sludge treatment device is characterized in that the fume channel of a fume discharge device is connected with a drier through an induced draft fan and a cyclone separator; the side of the drier is connected with a sludge storage warehouse; the drier and the bottom of the cyclone separator are connected with a finished product warehouse through a belt conveyer; and the finished product warehouse is connected with the coal conveying belt device through a spiral conveyer. The treatment process comprises the following steps: firstly, introducing fume in the fume discharge channel of the boiler into the drier to dry sludge; and sending tail gas in the dried sludge into the fume discharge channel of the boiler, and then returning the residual sludge to the boiler to participate in combustion.

Owner:沈阳禹华环保有限公司

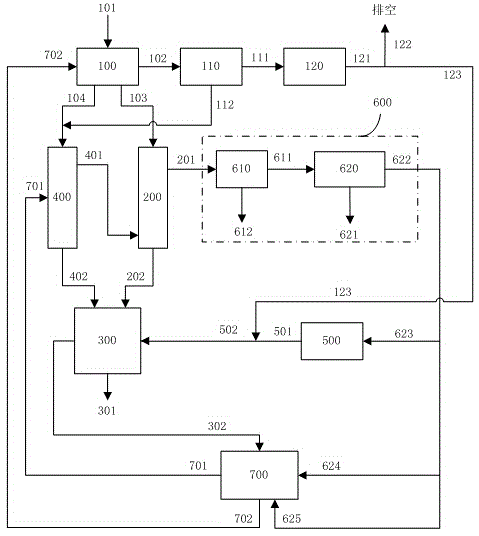

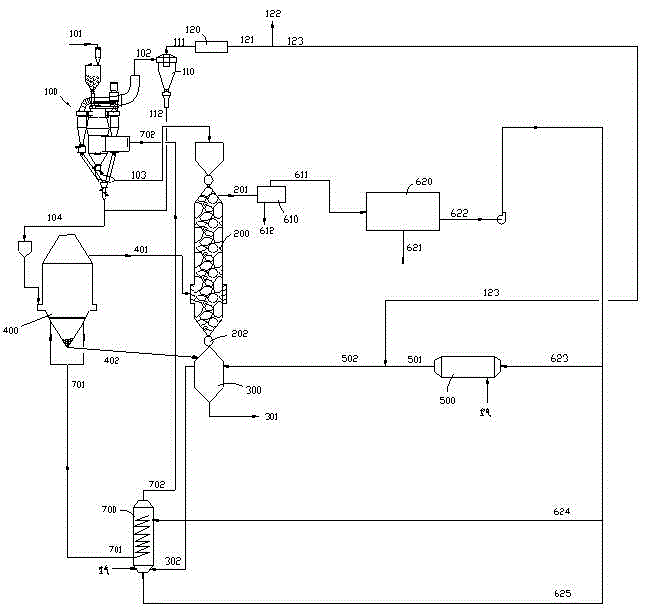

Coal full-grain size grading pyrolysis and active coke preparation coupling process and system in coal gas circulating

InactiveCN104164244AAchieve water savingAchieve energy savingCarbon compoundsChemical industryWater savingFlue gas

The invention provides a coal full-grain size grading pyrolysis and active coke preparation coupling process and system in coal gas circulating. The process comprises the following steps: dividing raw coal into slack coal and pea coal through a raw coal preheating and grading system and drying the raw coal by utilizing high temperature flue gas discharged by a coal gas heating furnace; with the obtained steam-containing tail gas as an activating agent and pyrolysis coal gas generated by the coal gas heating furnace per se as an activating agent heating flue, enabling the obtained high temperature activating agent to be in direct contact with high temperature semicoke from a slack coal pyrolyzing furnace and a pea coal pyrolyzing furnace to activate the semicoke. The process provided by the invention has the advantages that raw coal pyrolysis is coupled with active coke preparation and the coal gas generated by the pyrolysis is utilized to serve as the energy of active coke activation, so that the production cost is low; water carried by the raw coal per se serves as the source of a steam activating agent, so that water is saved in the production process; the high temperature semicoke from the pyrolyzing furnaces is in direct contact with the high temperature activating agent to be activated and the sensible heat of the high temperature semicoke is utilized, so that the production energy consumption is low; gas containing combustible components generated by activation serves as the compensatory fuel of the pyrolysis, so that the energy recycling efficiency is high.

Owner:BEIJING QIANHAI ENVIRONMENTAL PROTECTION TECH

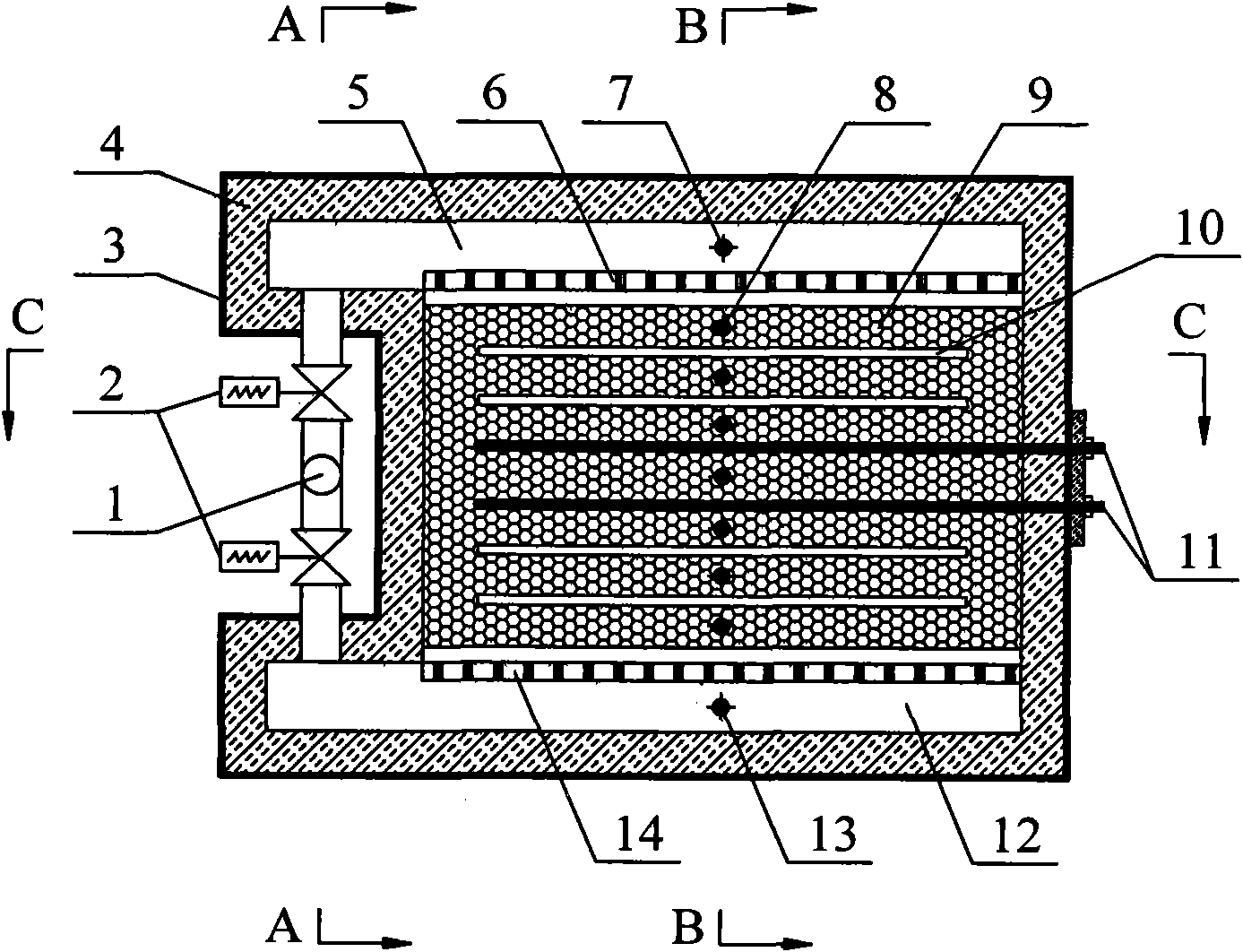

Coal mine methane gas oxidation device

InactiveCN101915117AAchieve multi-stage superheatingAvoid temperatureGas removalInsulation layerCoal mine methane

The invention relates to a coal mine methane gas oxidation device, comprising an outer shell and a honeycomb ceramic oxidation bed, wherein a heat insulation layer is distributed on the inner wall of the outer shell; the upper and lower ends of the honeycomb ceramic oxidation bed are respectively provided with upper and lower rectifying chambers; the side parts of the upper and lower rectifying chambers are provided with ports which are respectively communicated with an intake pipe and an exhaust pipe; the intake pipe and the exhaust pipe are respectively provided with an intake reversing valve, an exhaust reversing valve, an intake pipe temperature sensor, an exhaust pipe temperature sensor, an intake pipe gas concentration sensor and an exhaust pipe gas concentration sensor; the upper and lower parts of the honeycomb ceramic oxidation bed are respectively provided with upper and lower flow homogenizers; the middle part of the honeycomb ceramic oxidation bed is provided with a starting electric heater; the upper and lower parts of the starting electric heater are provided with built-in heat exchangers at intervals; and the back of the shell is provided with an upper rectifying chamber temperature sensor in the middle of the upper rectifying chamber, a temperature sensor at the middle of the honeycomb ceramic oxidation bed and a lower rectifying chamber temperature sensor at the middle of the lower rectifying chamber which are inserted at intervals. The invention has the advantages of compact structure, convenient operation, small occupied area and low investment and operation cost.

Owner:CHINA UNIV OF MINING & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com