Coal mine methane gas oxidation device

A technology of oxidation device and wind gas, which is used in gas emission, safety device, mining equipment and other directions, can solve the problems of large temperature drop and unstable operation of oxidation bed, achieve compact structure of the device and avoid uneven temperature field in the bed. Unstable operation and multi-stage overheating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

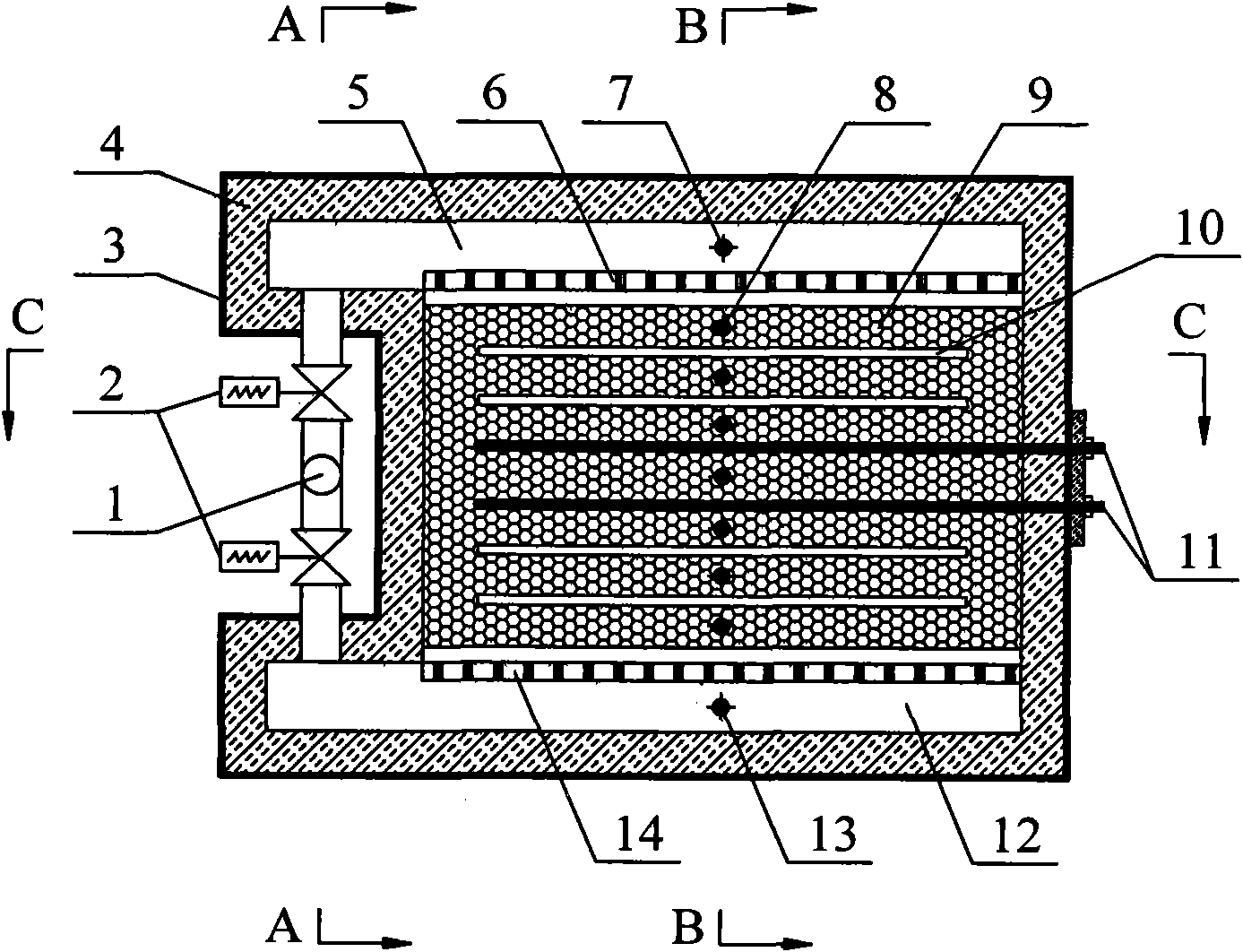

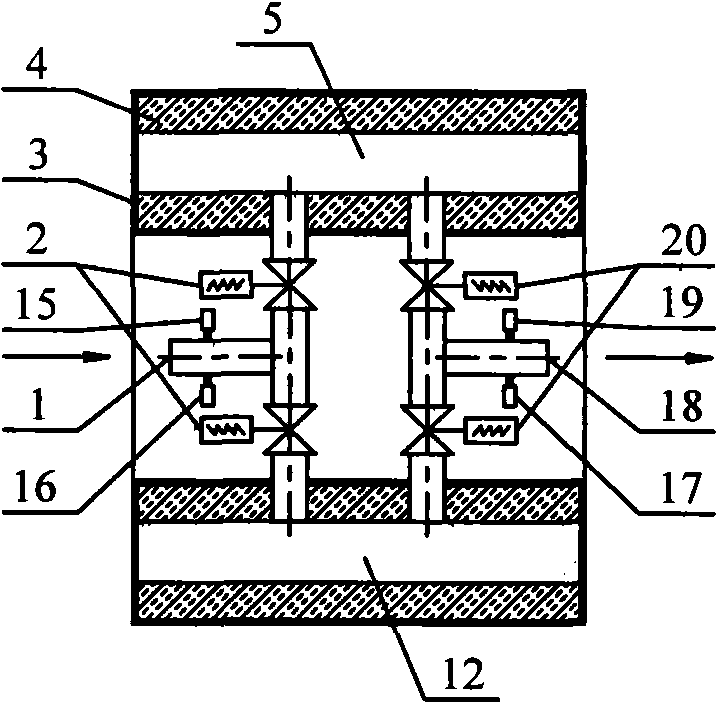

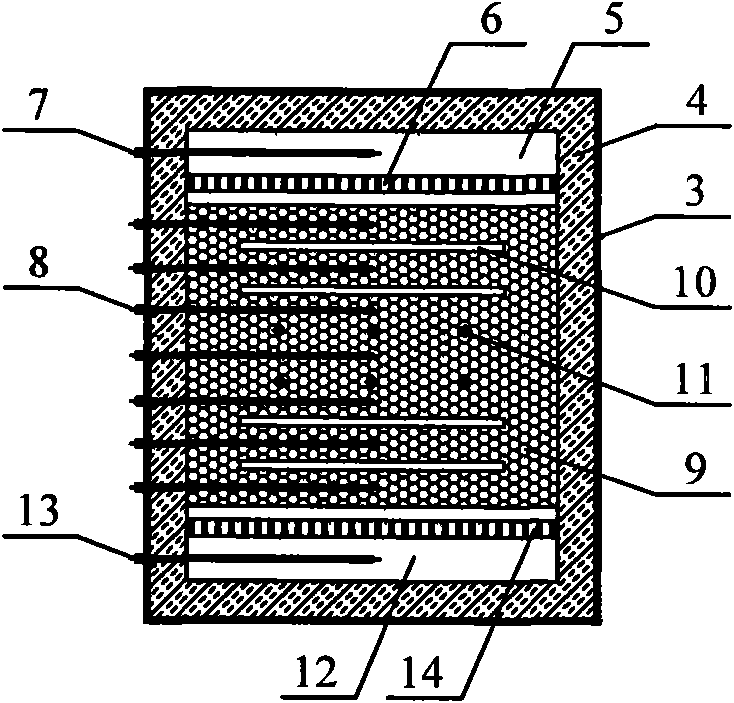

[0019] figure 1 As shown, the coal mine exhaust air gas oxidation device is arranged in a vertical structure, mainly composed of a honeycomb ceramic oxidation bed 9, upper and lower intake and exhaust rectification chambers 5 and 12, upper and lower flow equalizers 6 and 14, starting electric heater 11, built-in Type heat exchanger 10, intake and exhaust pipes 1 and 18 and various measurement and control components. The device includes a concave metal shell 3, the inner surface of the metal shell 3 is lined with a moderately thick thermal insulation layer 4, and the interior is filled with a honeycomb ceramic oxidation bed 9 composed of a regenerator; the honeycomb ceramic oxidation bed 9 is formed by a cube or The cuboid ceramic regenerator is stacked, and the ceramic regenerator is made of aluminum oxide Al 2 o 3 , silicon carbide SiC or zirconium diox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com