Patents

Literature

654 results about "Coal mine methane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coal mine methane (CMM) is a type of gas present in active, working mine sites. This gas is extracted from the air in the coal mine helping improve safety and preventing uncontrolled release of methane to atmosphere. CMM is a mixture of methane & air released during the process of coal mining and must be vented for safety reasons.

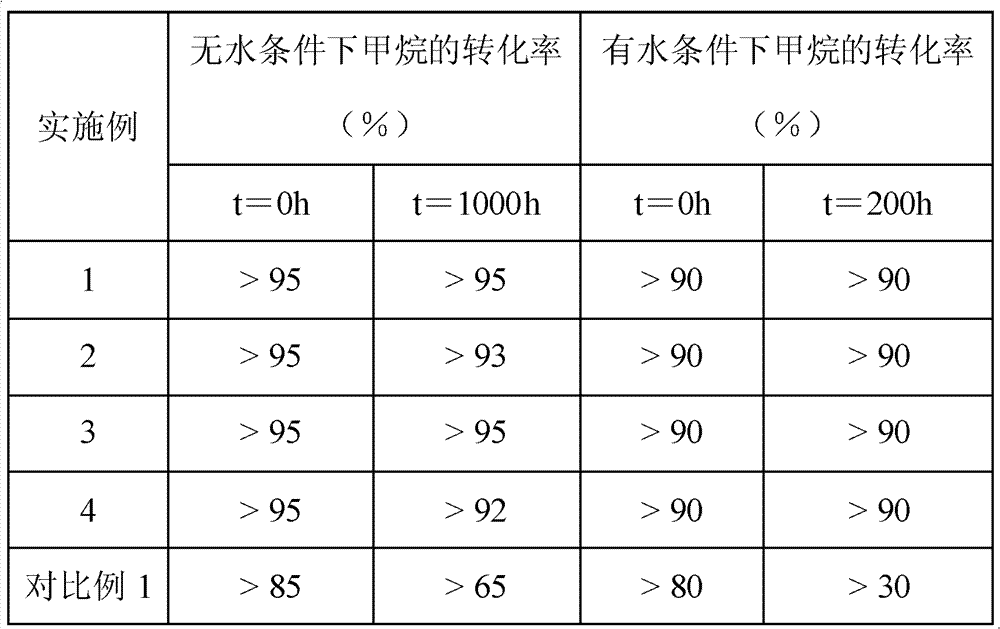

Low-concentration methane combustion catalyst and its preparation method

InactiveCN103191733APromote resultsReduced activityIncinerator apparatusMetal/metal-oxides/metal-hydroxide catalystsCoal mine methaneHigh activity

The invention provides a low-concentration methane combustion catalyst and its preparation method. The catalyst treats Al2O3 as a carrier, treats a precious metal Pd as a primary catalytic activity component, and treats one or more of precious metals comprising Pt, Rh, Ru and Ir and one or more of metal oxides comprising CeO2, ZrO2, La2O3 and TiO2 as catalytic assistants. The catalyst can be applied in particle, and Al2O3, all catalytic activity components and the assistants can be supported on honeycomb ceramic to prepare a whole catalyst. The catalyst has the advantages of high activity, high hydrothermal stability, long life and the like; and the catalyst can be used for the efficient utilization of low-concentration methane in a coal mine gas (coal mine methane), and can also be used for the efficient removal and utilization processes of other VOC gases to realize the full utilization, energy saving and environmental protection purposes of energy.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

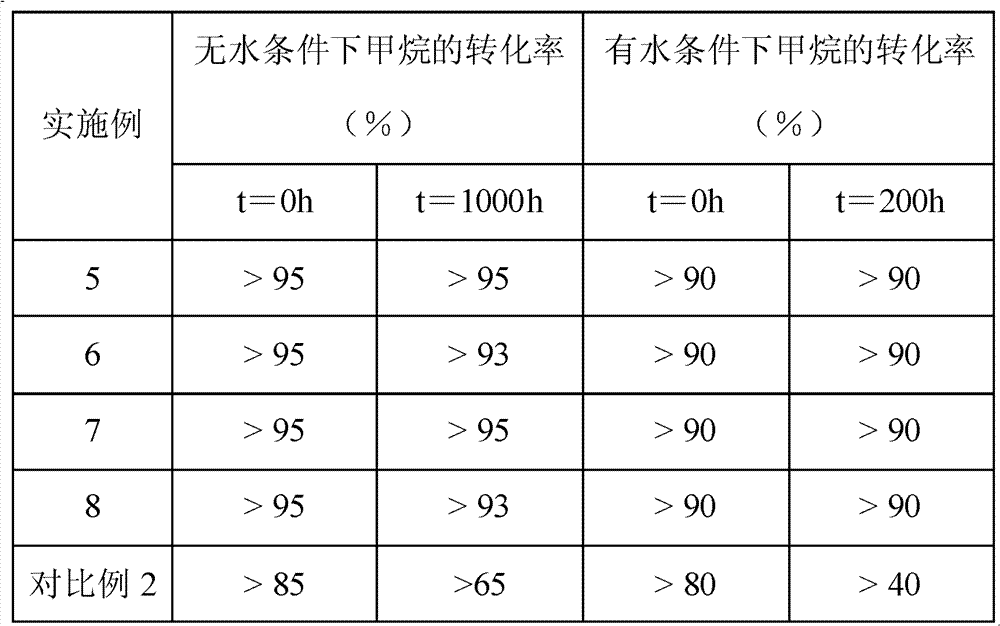

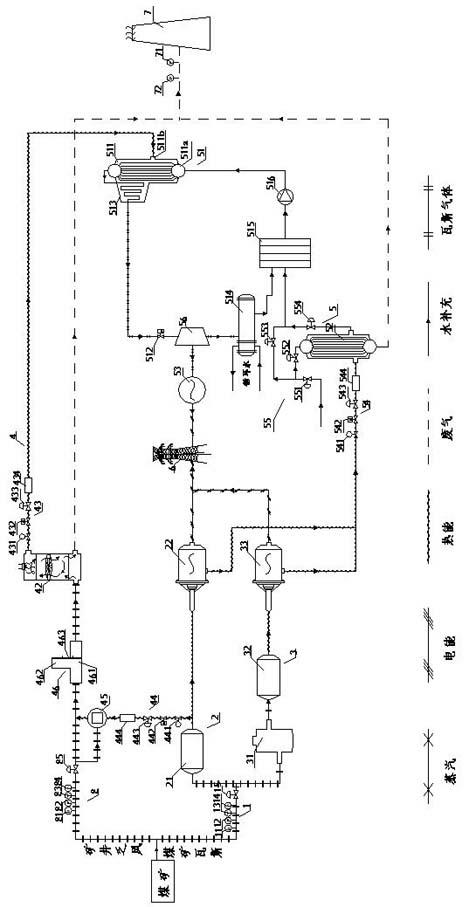

Coal mine gas comprehensive application system and application method thereof

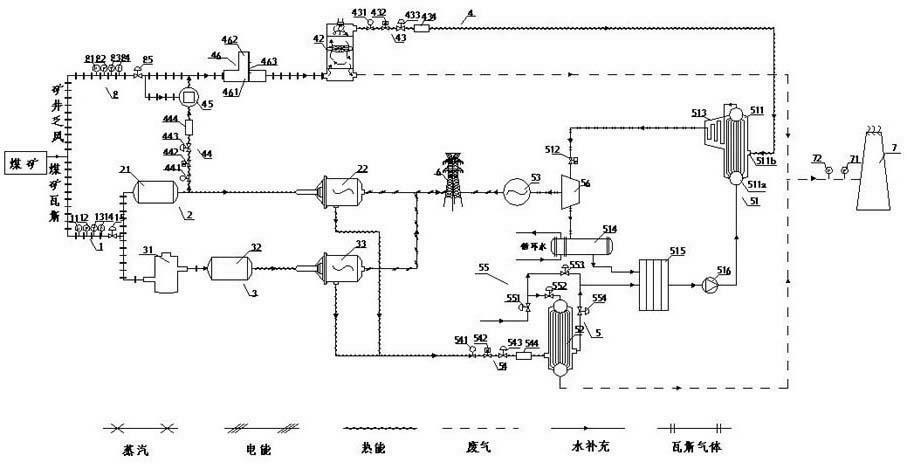

ActiveCN102562131AHigh extraction rateEnsure safe productionMining devicesInternal combustion piston enginesHigh concentrationEngineering

The invention discloses a coal mine gas comprehensive application system and an application method thereof. The system comprises a coal mine ventilation air measuring component, a coal mine gas measuring component, a high-concentration gas treatment subsystem, a low-concentration gas treatment subsystem, a coal mine ventilation air treatment subsystem and an afterheat treatment subsystem, wherein a high-concentration gas pre-treatment device and a high-concentration gas generator set are connected via a pipeline to form the high-concentration gas treatment subsystem, a safe conveying device, a low-concentration gas pre-treatment device and a low-concentration gas generator set are connected via pipelines to form the low-concentration gas treatment subsystem, the high-concentration gas generator set and the low-concentration gas generator set are respectively connected with a power grid via cables, a ventilation air delivering connecting device, a mixing device and a ventilation air oxidization device are connected via pipelines to form the coal mine ventilation air treatment subsystem, and the afterheat treatment subsystem is respectively connected with the high-concentration gas treatment subsystem, the low-concentration gas treatment subsystem and the coal mine ventilation air treatment subsystem. The coal mine gas comprehensive application system and the application method can be used for comprehensively applying gas with different concentrations, utilization rate of the gas is the highest, emission of greenhouse gas is reduced, and comprehensive recycling of energy is realized.

Owner:SHANGHAI PANGEA INVESTMENT

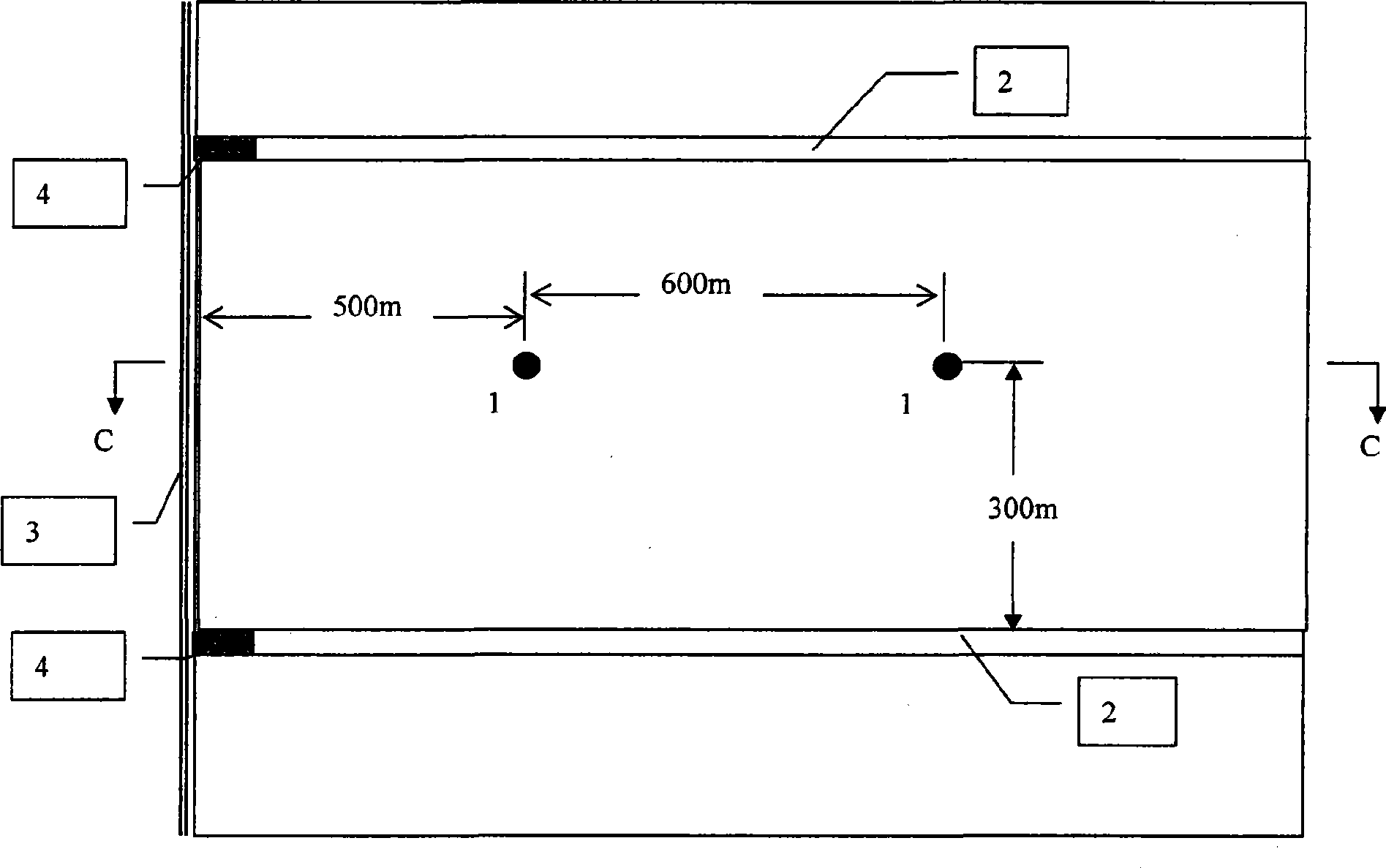

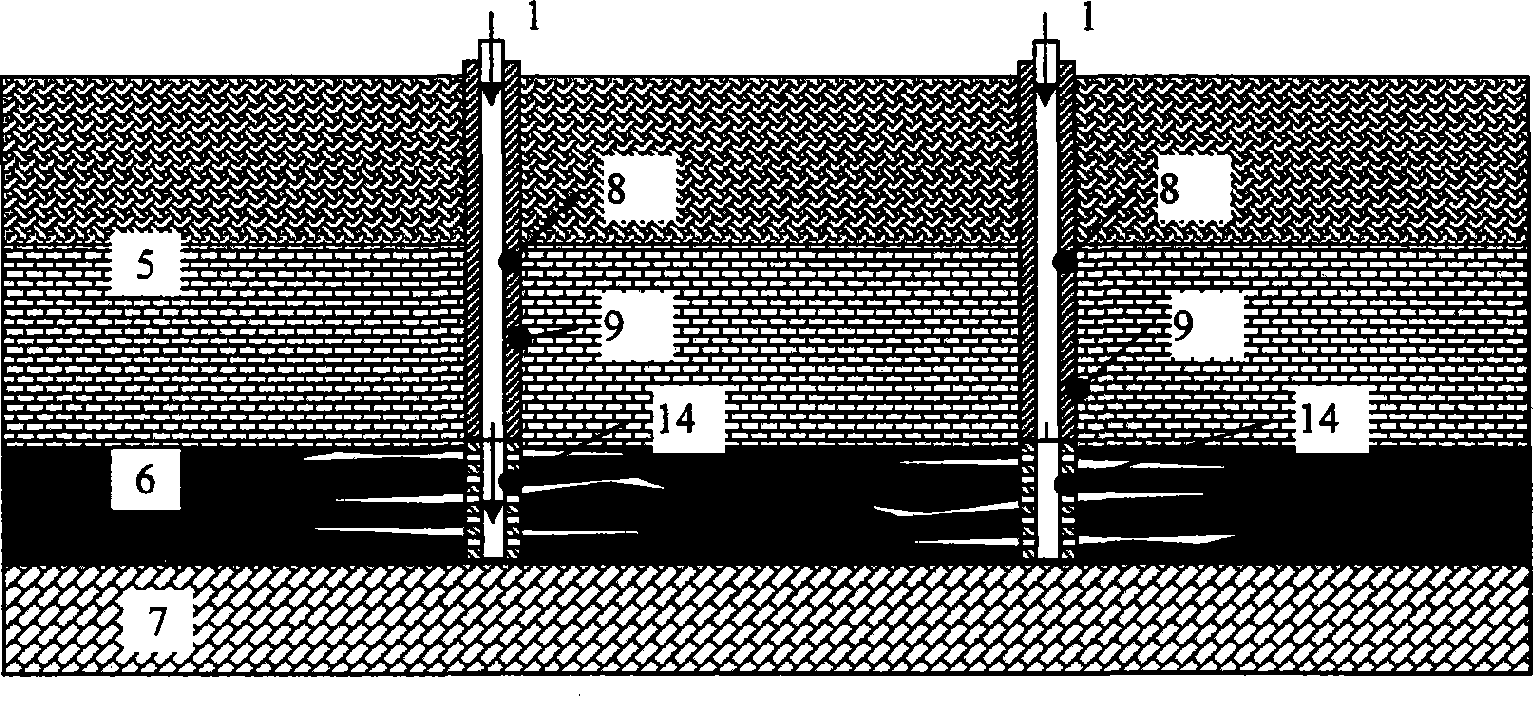

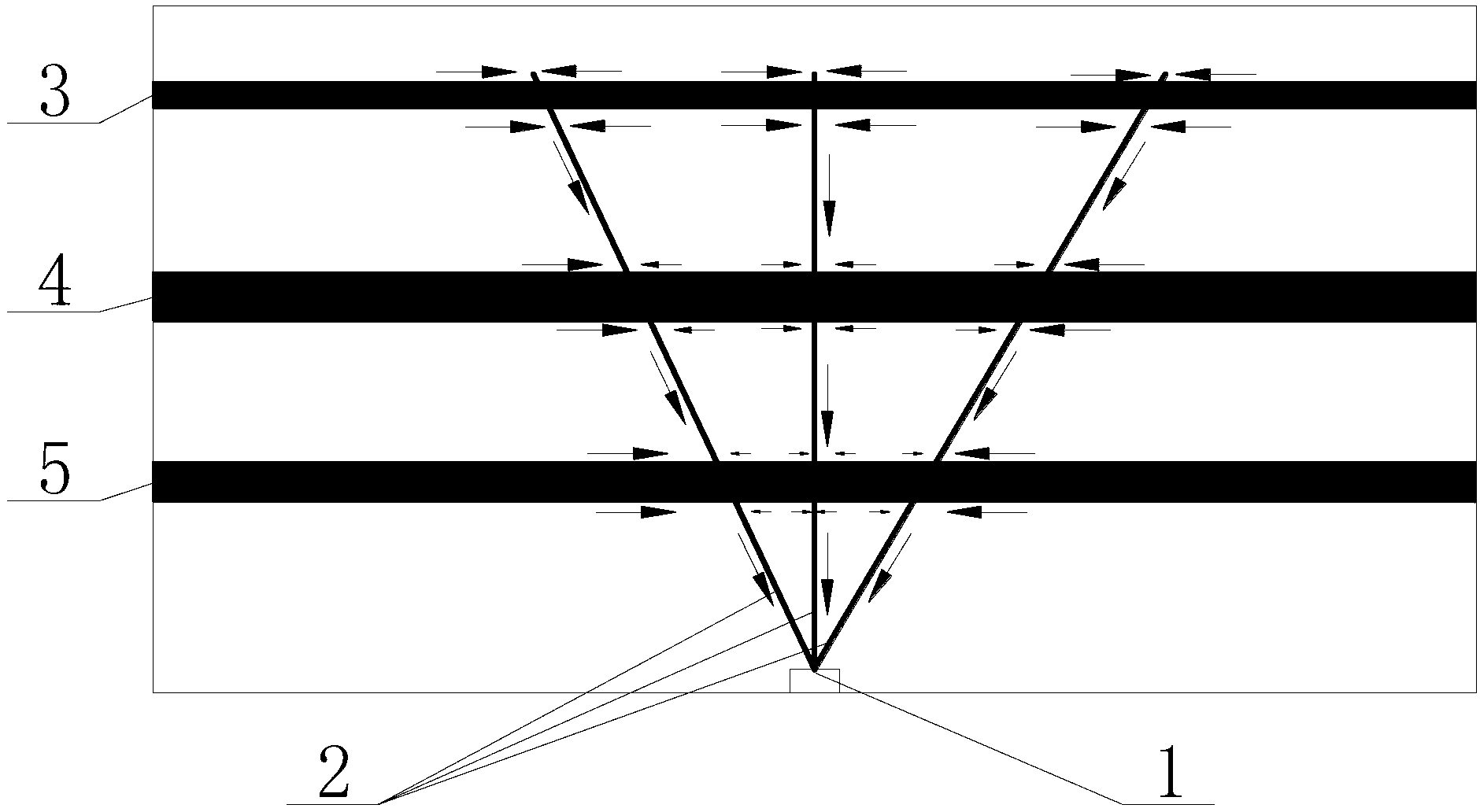

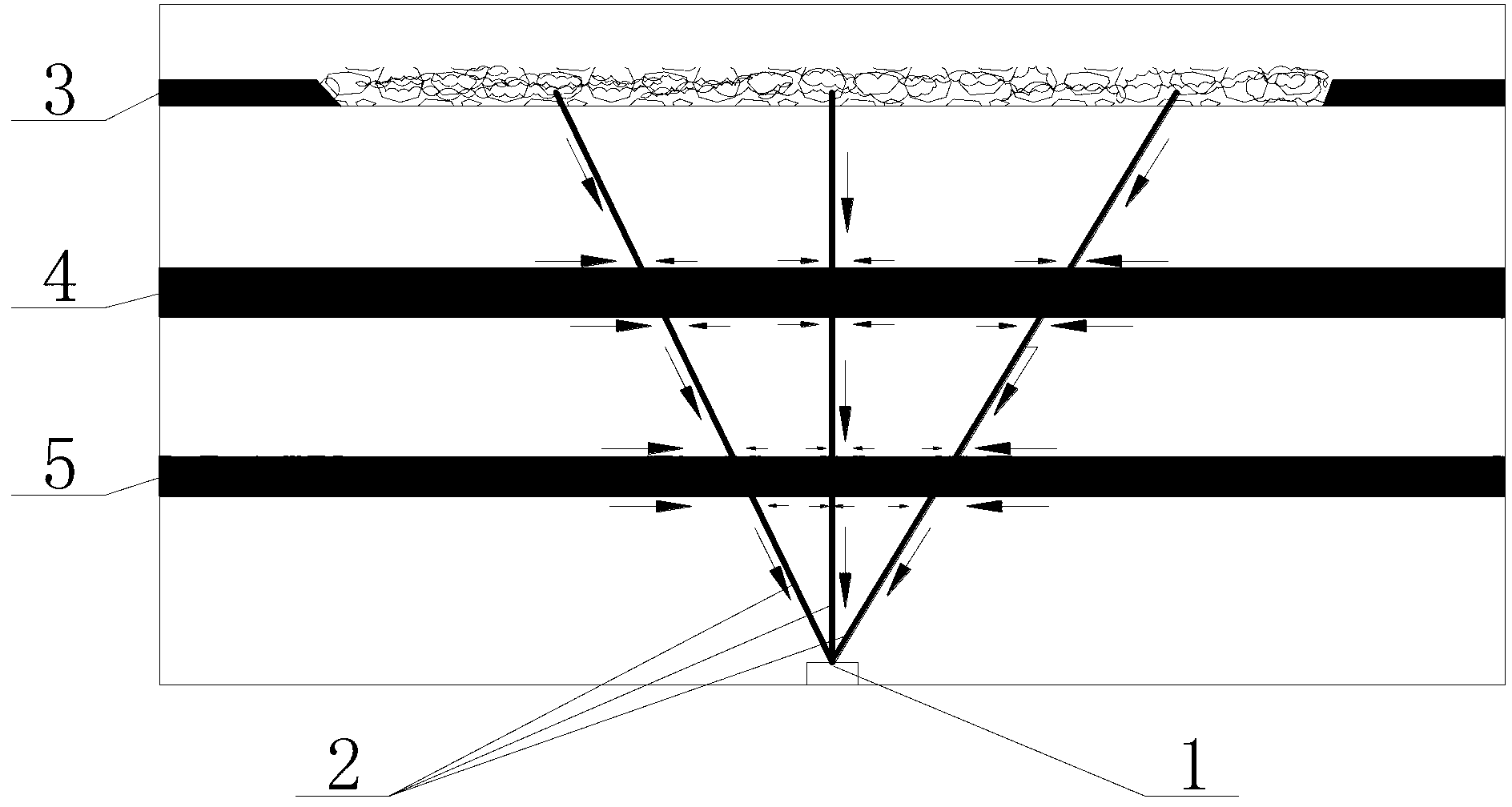

Aboveground and underground combined heat injection coal bed gas extraction method

ActiveCN101503957AImprove permeabilityHigh extraction rateFluid removalWell drillingCoal mine methane

The invention provides a method for extracting coal bed gas by up-hole and down-hole combination, and relates to the technical field of extracting the coal bed gas (or named as gas). The method can solve the technical problem of pre-extracting the coal bed gas of a coal bed, in particular for a low-permeability coal bed. The method for extracting the coal bed gas by the up-hole and down-hole combination comprises the following steps: carrying out vertical drilling into the coal bed from ground to the coal bed, carrying out an extracting channel in the down hole along the coal bed, and then closing the extracting channel to form a down-hole extracting system; and injecting overheating vapor or overheating water from the ground vertical to the coal bed, displacing the coal bed to flow into the down-hole extracting channel along the coal bed, and then transporting the extracted coal bed gas into a ground coal bed gas system. The method overcomes the deficiency of the prior art, can simply, reliably and efficiently pre-extract the coal bed gas of the coal bed, and in particular for the low-permeability coal bed in large areas, and can basically solve the problems of coal mine gas disasters and the coal bed gas exploitation.

Owner:赵阳升

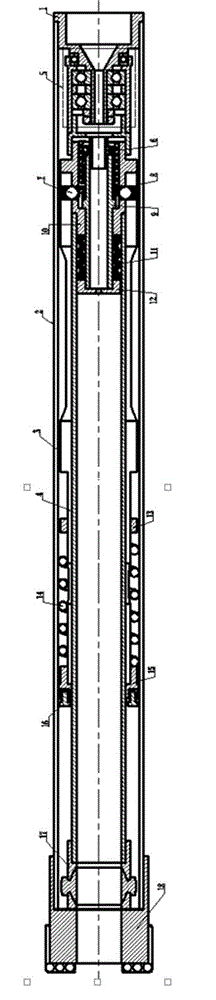

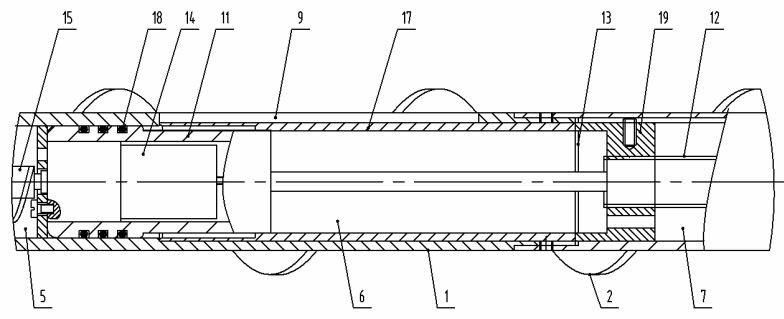

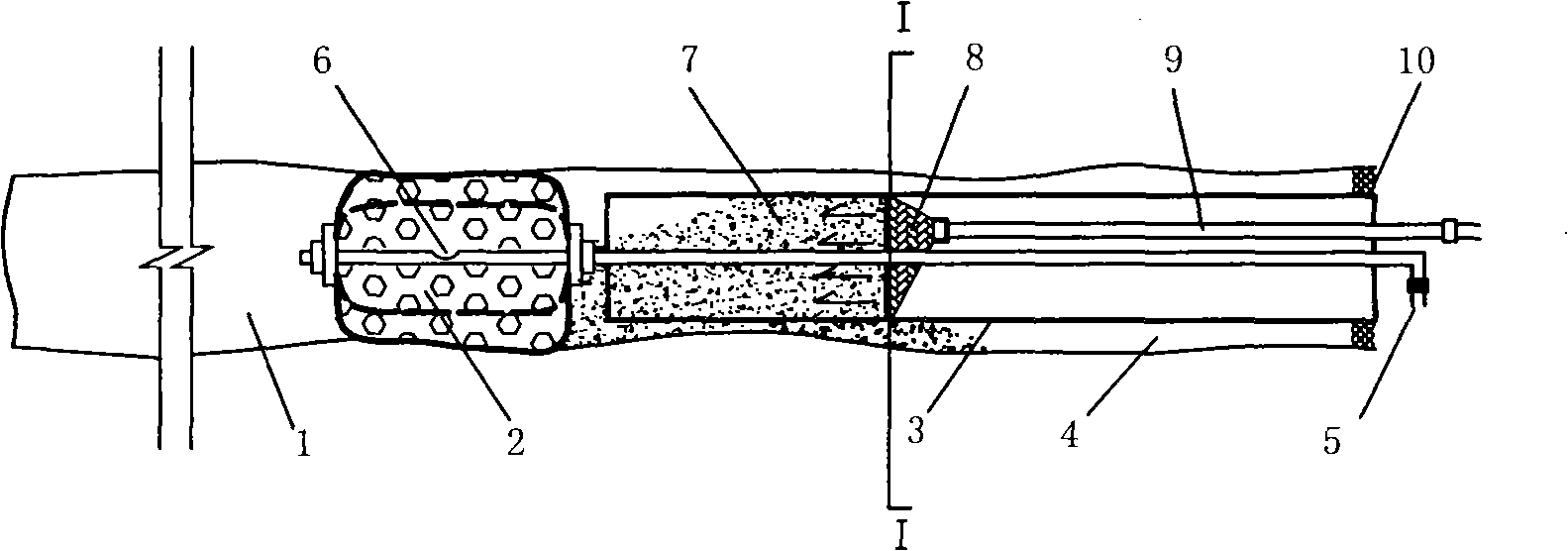

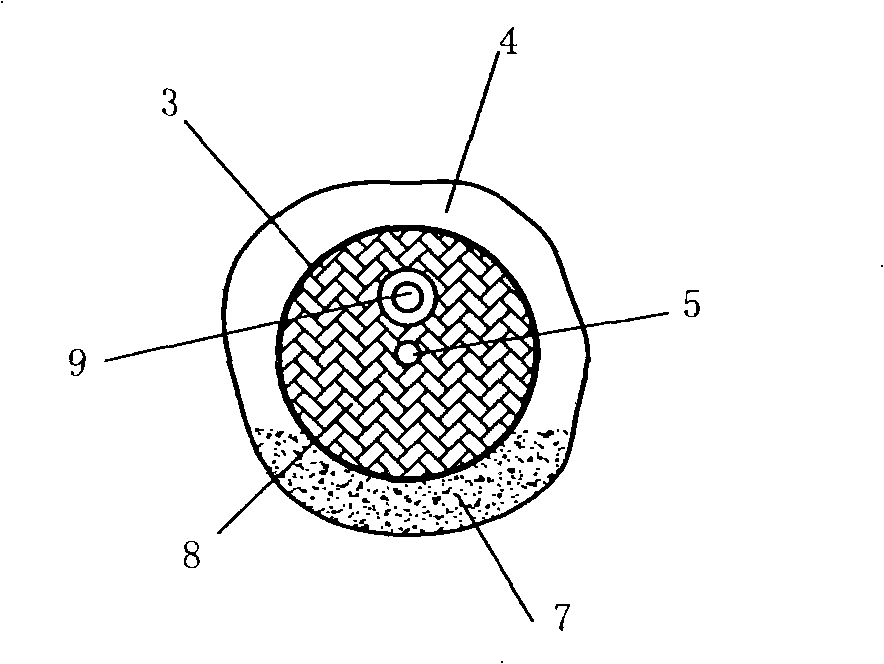

Closed coring device for testing coal bed methane and rock formation gas contents in surface well drilling

The invention discloses a closed coring device for testing coal bed methane and rock formation gas contents in surface well drilling. The closed coring device comprises a coring inner barrel, a coring drill bit, an outer barrel, a power mechanism and a startup mechanism, wherein the outer barrel sleeves the coring inner barrel; a drill rod joint is arranged at one end of the outer barrel; the coring drill bit is arranged at the other end of the outer barrel; the power mechanism and the startup mechanism are arranged inside the outer barrel. The closed coring device can take a coal (rock) core sample in a fixed-point and closed way, effectively solves the technical problems that after the existing coring equipment takes a coal core, the exposure time of the sample is long, escape of lost gas is serious, content determination on gas (coal bed methane) is not accurate and the like, and further, provides more reliable basic data for coal mine gas disaster control, exploration and exploitation of coal bed methane resources, and the like.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

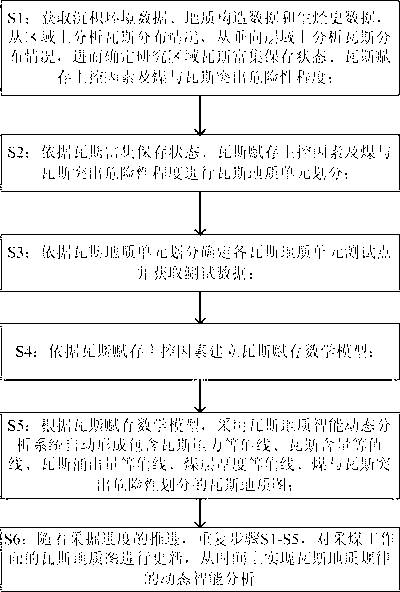

Coal-mine gas geology four-dimensional analysis method

InactiveCN102998718AReduce geological analysis workloadSolve rationalityGeological measurementsMathematical modelMining engineering

The invention discloses a coal-mine gas geology four-dimensional analysis method. The method includes acquiring depositional environment data, geologic structure data and hydrocarbon generating history data, and determining a gas enrichment save state, a gas occurrence main controlling factor and a coal and gas outburst risk degree in a study area; then performing gas geology unit division and testing point arrangement; and finally establishing a gas occurrence mathematical model and forming a gas geologic map. According to the coal-mine gas geology four-dimensional analysis method which is established from four-dimensional angles of space ( an area or a layer ) and time, original coal-mine gas geology analysis methods are broken through; the difference problems of gas occurrence or coal and gas outburst disasters on different coal layers, which can not be explained by traditional gas geological theories under same geologic structure conditions on the layer, are solved; and area and layer analysis of coal-mine gas geologies is achieved, problems that a gas geology unit is difficult to divide and different persons acquire different results according to the same data are solved, the work loads of gas geology analysis are reduced, and the guide of safety production is truly achieved.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

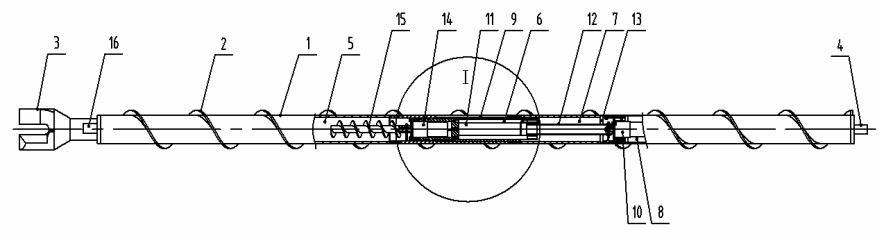

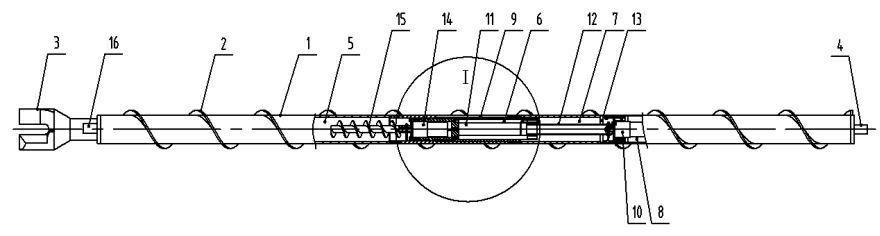

On-site sealed sampling device for coal bed gas

InactiveCN102103041ARealize in-situ seal acquisitionPrinciples of ScienceWithdrawing sample devicesPush and pullCoal mine methane

The invention discloses an on-site sealed sampling device for coal bed gas. The device comprises a hollow long rod piece, wherein the outer circumference of the long rod piece is provided with a spiral convex edge; a coal storage cabin, a closed cabin, a transmission cabin and a power and control cabin are arranged in the long rod piece from front to back respectively; the closed cabin is provided with a coal inlet; a reciprocating push and pull mechanism is arranged in the transmission cabin; a micro power speed reducing motor for providing power for the reciprocating push and pull mechanism is arranged in the power and control cabin; the front end of the reciprocating push and pull mechanism is in transmission connection with a piston sliding sleeve device for opening and closing the coal inlet; and the front end of the coal storage cabin is provided with a gas resolution hole. The device is mainly used for a sampling link before the process of measuring the content of the gas in a laboratory, has high practical value and is easy to popularize and apply, the on-site sealed acquisition of a coal sample and the gas is realized, underground resolution is not needed, loss amount is not required to be calculated in the process of measuring the content of the gas, and reliable basic parameters are provided for related fields of coal mine gas prevention and control and the like.

Owner:HENAN POLYTECHNIC UNIV

Coal mine gas explosion burst treatment method and its matched gas dissolving and elimineting agent

InactiveCN1624298AAvoid Explosion Prominent AccidentsGuarantee the safety of lifeDust removalFire preventionCoal dustCoal mine methane

This invention relates to a method and a gas dissolvant for the frequent gas explosions in coal mine. Its procedures are as following: the gas dissolvent and water are poured in turn into the coal seams containing gas. The gas dissolvent is a kind of water solution made up of acetum and yeast which selective weight ratio is 1000:5-15. The acetum is preferred to be replaced by vinegar of the same acetum. After the vinegar is added into the yeast, their dehydro-ratio is 2-8 times as heavy as the vinegar. The advantages are safety efficient, more feasible and harmless to human body.

Owner:洛阳保矿安矿山设备有限公司

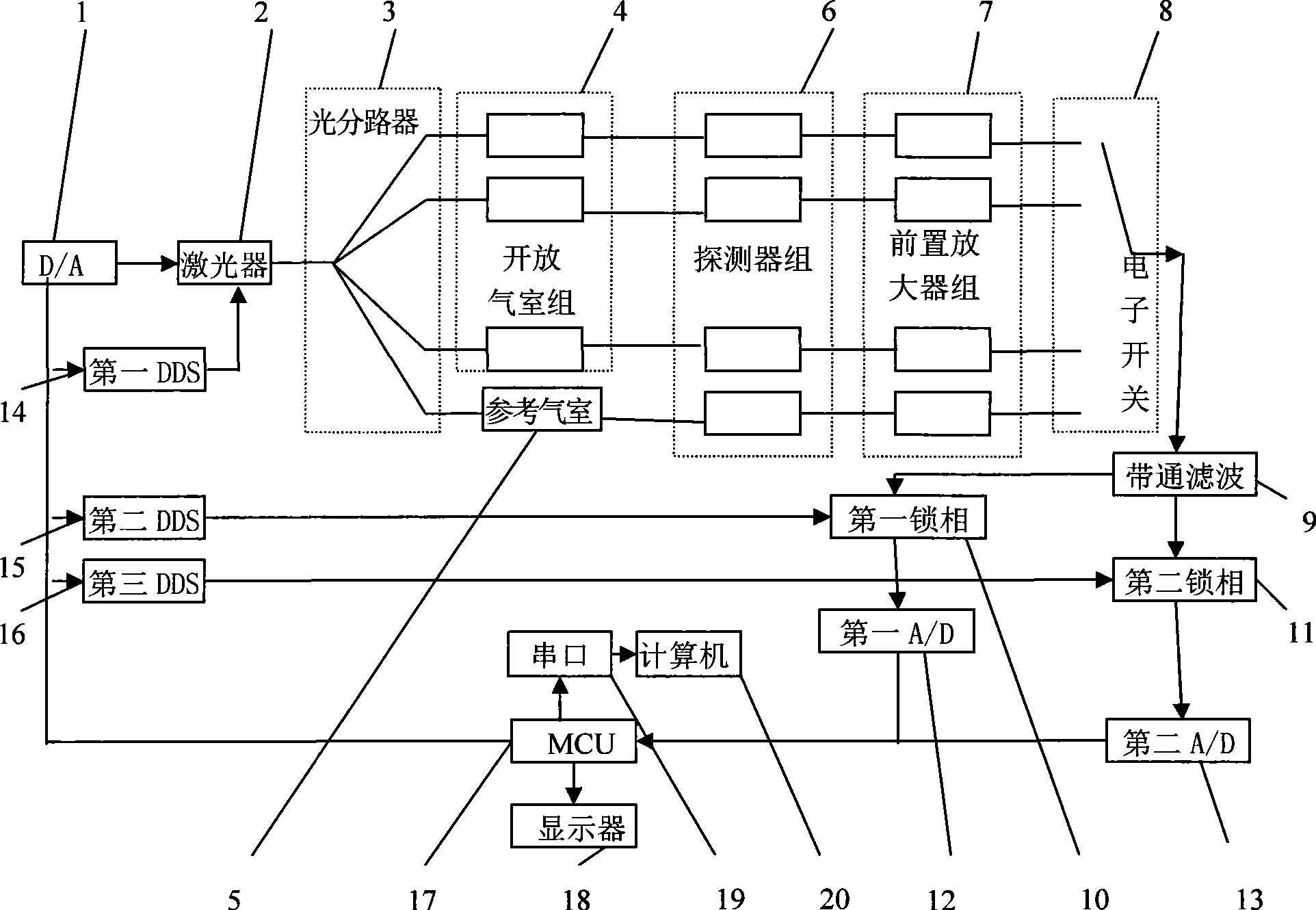

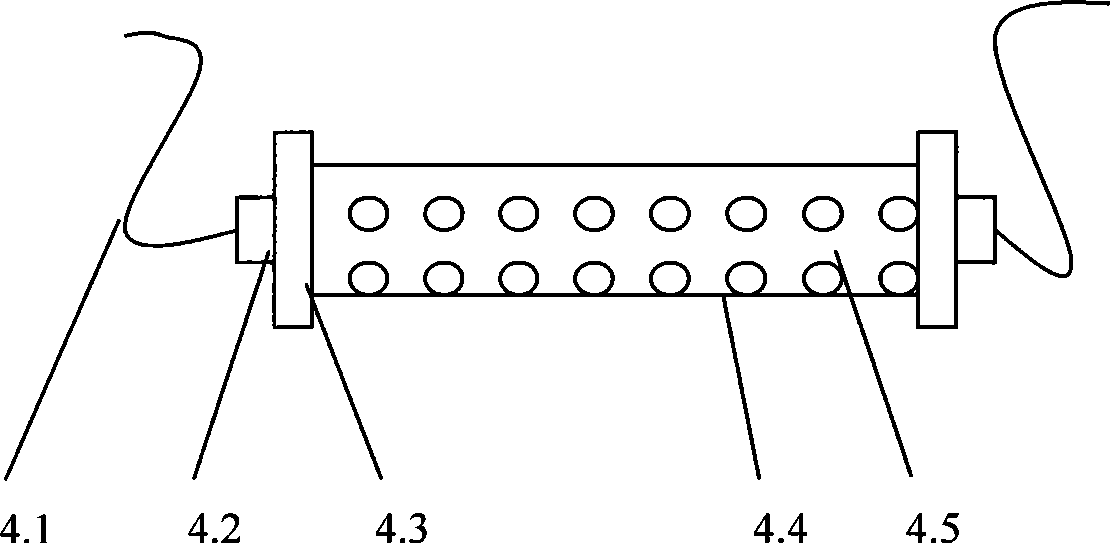

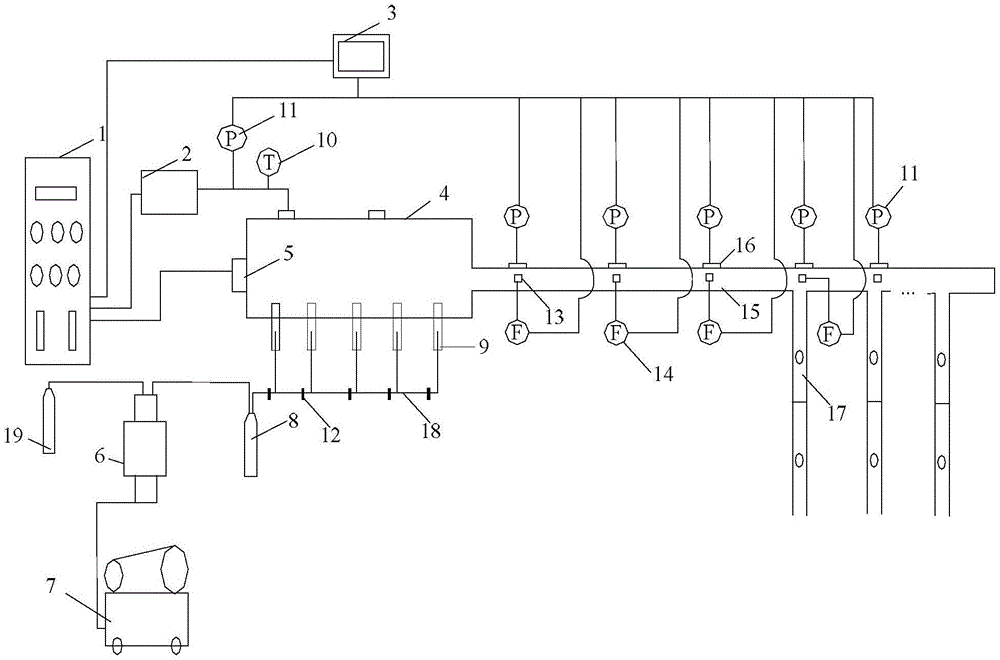

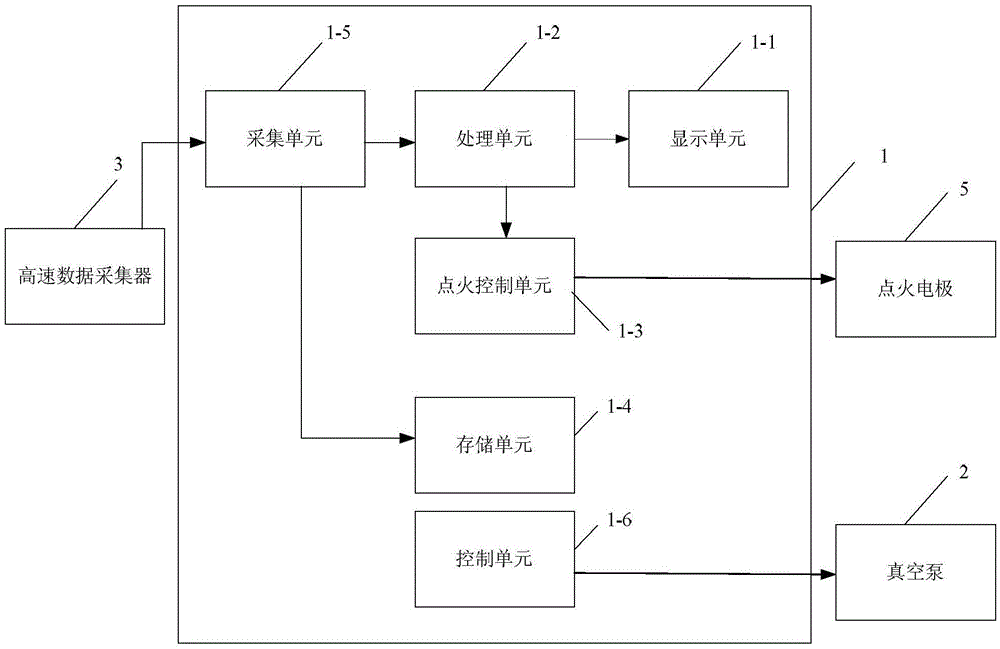

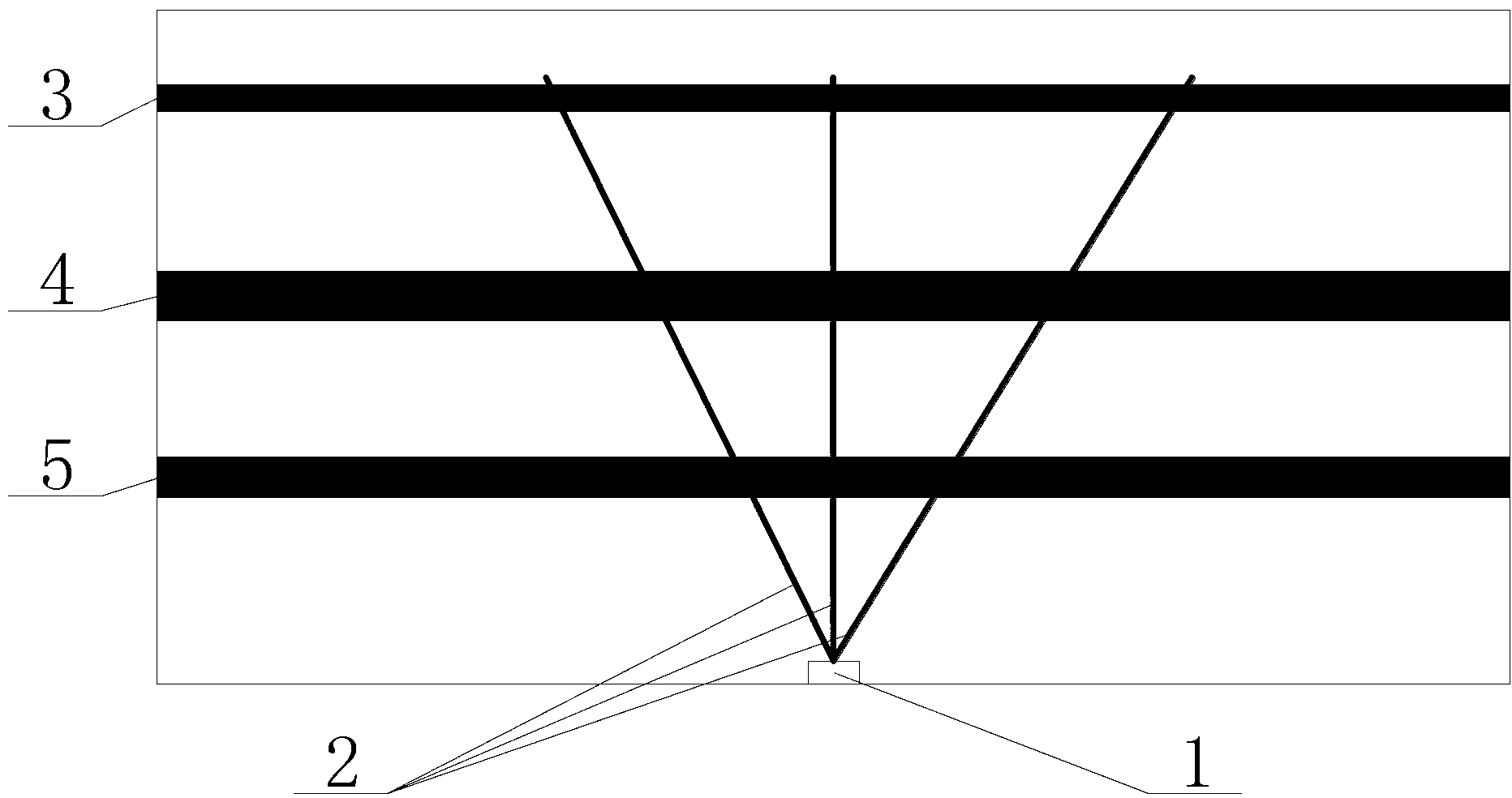

Coal mine gas multi-point on-line detection apparatus based on spectral absorption

ActiveCN101477042ANarrow spectral widthIt has the effect of dustproof and moistureproofColor/spectral properties measurementsSafety equipmentsAnti jammingPhotodetector

The invention discloses a multi-point on-line detection device for coal mine gas based on spectral absorption, and relates to a coal mine gas detection device, in particular to a multi-point on-line CH4 concentration monitoring device based on a characteristic absorption line of methane (CH4) near a near infrared band 1653nm. The device comprises a D / A conversion module, a DFB laser, a 1*N optical splitter, an open air chamber group, a reference air chamber, a photodetector group, a preamplifier group, an electronic switch, a band-pass filtering circuit, a first phase-locked amplification circuit, a second phase-locked amplification circuit, a first A / D conversion module, a second A / D conversion module, a first DDS, a second DDS, a third DDS, an MCU, a display, a serial port, and a computer. Compared with the prior methane gas monitoring device, the device has the advantages of higher sensitivity, higher gas identification ability, quick response ability, extremely strong anti-jamming ability, easy network formation, and so on, so the device is a gas monitoring device which is most suitable to be used underground at present.

Owner:WUHAN TELECOMM DEVICES

Experiment device and method for simulating gas-coal dust explosion in underworkings of coal mine

InactiveCN105548254ARich teaching effectGood demonstration simulation effectMaterial exposibilityHigh energyCoal mine methane

The invention relates to an experiment device and method for simulating gas-coal dust explosion in underworkings of a coal mine, and belongs to the technical field of safety engineering of the coal mine. Requirements on the experiment device and method for the gas-coal dust explosion in the underworkings of the coal mine are met. Gas-coal dust is poured into an explosion cavity, and when a pressure value in the explosion cavity is equal to that of outside atmospheric pressure, a high-energy ignition cabinet controls an ignition electrode on the explosion cavity to ignite, so that the explosion experiment of the gas-coal dust is realized, and exploded gas and the like are diffused through a gas explosion diffusion pipeline and gas explosion diffusion branches; pressure sensors and flame sensors are used for monitoring the pressure and the flame in the gas explosion diffusion pipeline during explosion in a real-time manner, and transmitting pressure data and flame data to a high-speed data acquisition unit, and the pressure data and the flame data are saved in an industrial computer. The experiment device and method disclosed by the invention are suitable for observing gas explosion of the coal mine.

Owner:HEILONGJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

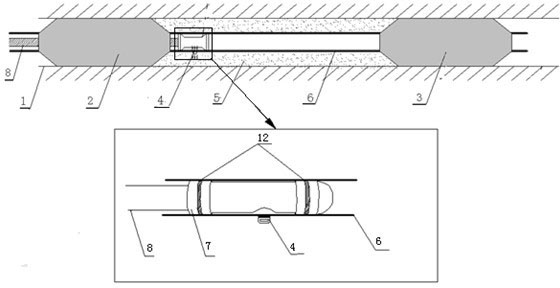

Combined hole sealing method for gas extracting and drilling delaying self-expansion capsule-paste

InactiveCN102635393AImprove air tightnessImprove the extraction effectGas removalSealing/packingThermodynamicsCoal mine methane

The invention relates to a combined hole sealing method for gas extracting and drilling delaying self-expansion capsule-paste. The technical scheme is that two delaying self-expansion capsules are adopted to plug a hole bottom and a hole opening; an annular space between the two capsules is full of paste hole sealing material with pressure so as to further seal cracks around a drilled hole; and therefore, the gas tightness of the gas extracting and drilling is guaranteed. According to the combined hole sealing method for the gas extracting and drilling delaying self-expansion capsule-paste, the gas tightness of the coal mine gas extracting and drilling is improved, the extraction effect can be enhanced, and the later-stage extraction effect is obviously improved. The combined hole sealing method for the gas extracting and drilling delaying self-expansion capsule-paste has the advantages of simple technology, is convenient to operate and the like.

Owner:CHINA UNIV OF MINING & TECH +1

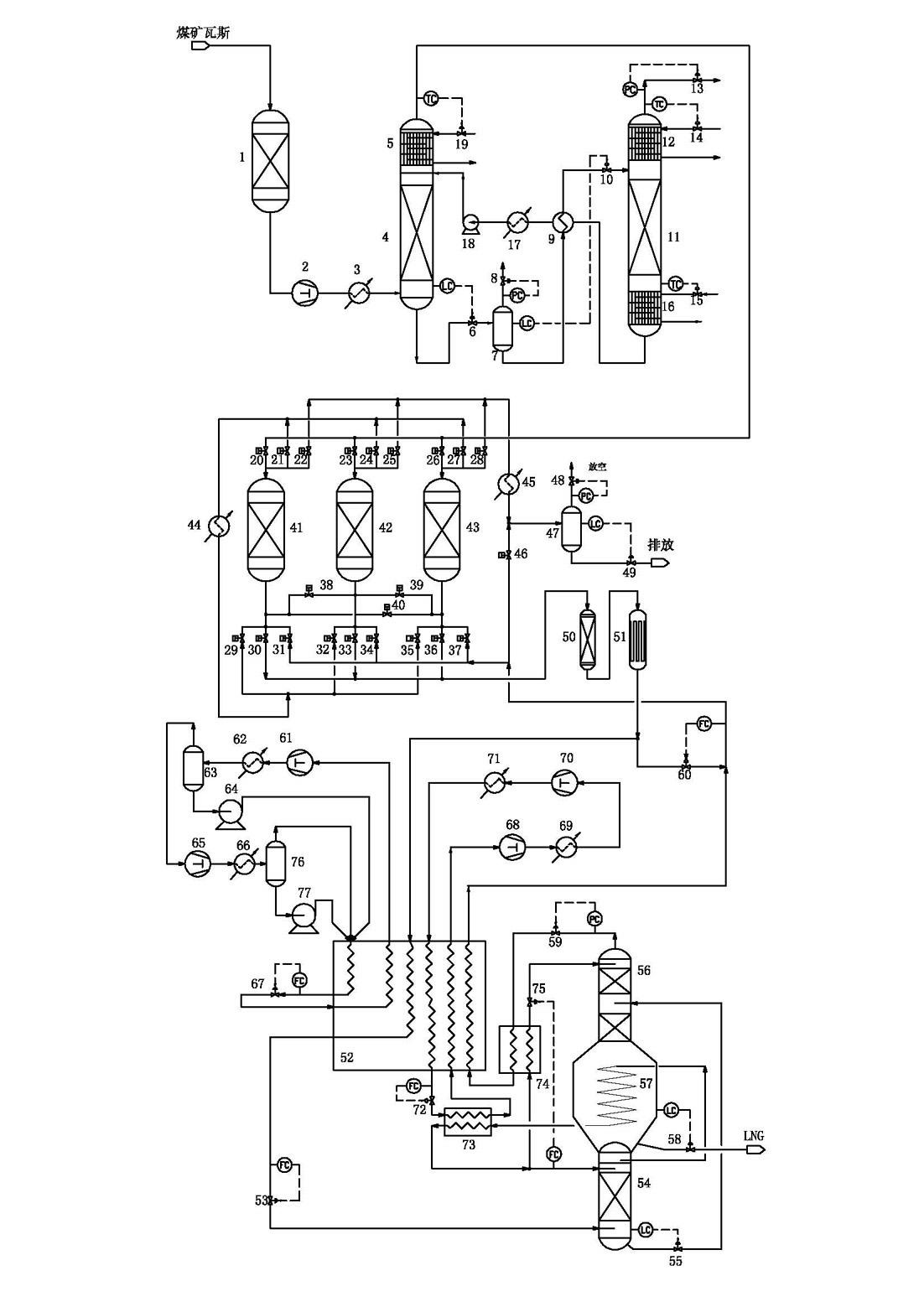

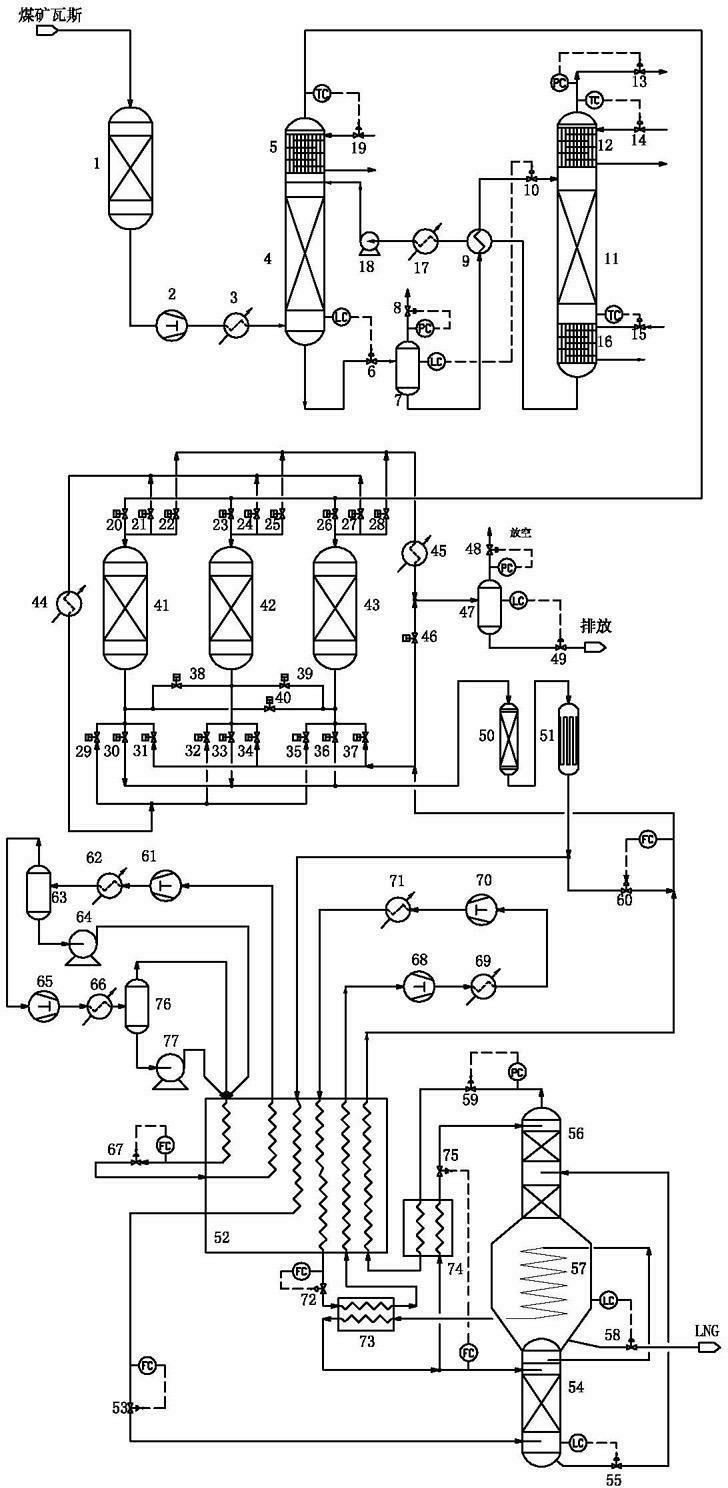

Process and system for purifying, separating and liquefying nitrogen-and-oxygen-containing coal mine methane (CMM)

ActiveCN102538398AHigh recovery rateIncrease concentrationSolidificationLiquefactionNitrogenProduct gas

The invention discloses a process and a system for purifying, separating and liquefying nitrogen-and-oxygen-containing coal mine methane (CMM). The process for purifying, separating and liquefying the nitrogen-and-oxygen-containing CMM comprises the following procedures of: pre-deoxidizing; pressurizing and cooling; deeply removing acid gas; deeply dehydrating and drying; deeply removing mercury and filtering; liquefying at low temperature; and rectifying at low temperature. The system for purifying, separating and liquefying the nitrogen-and-oxygen-containing CMM consists of a deep acid gas removing unit, a deep dehydrating and drying unit, a deep mercury removing and filtering unit, a low-temperature liquefying unit and a low-temperature rectifying unit. By the system, concentration of the produced liquefied natural gas (LNG) is as high as 99 percent, and the recovery rate of CH4 in the CMM is as high as 99 percent. The process and the system are favorable for recycling the CMM on a large scale, producing the LNG and reducing CMM accidents and environmental pollution.

Owner:HANGZHOU HANGYANG

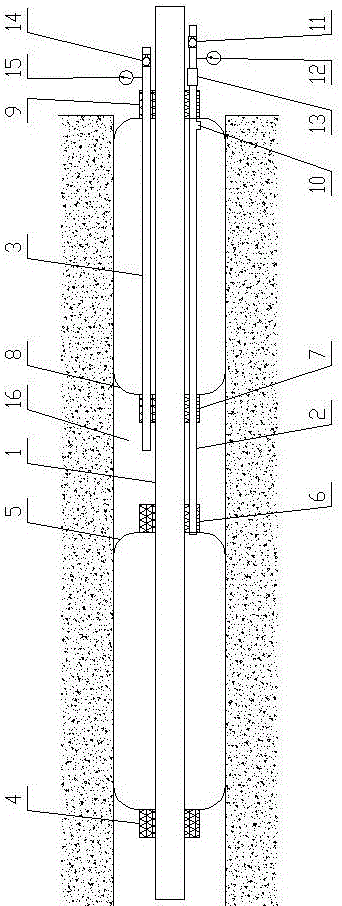

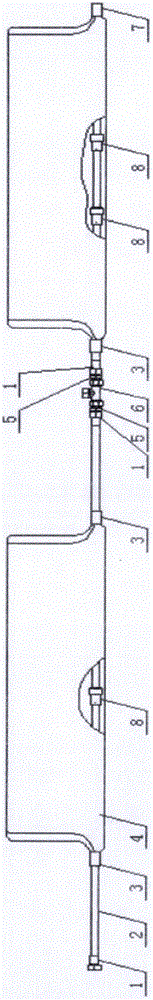

Coal mine two-end gas plug and middle water seal layer penetrating drill hole sealing device and method

InactiveCN105756599ALow costEasy to operateGas removalSealing/packingAir compressionCoal mine methane

A coal mine two-end gas plug and middle water seal layer penetrating drill hole sealing device comprises a gas extraction pipe, a gas injection pipe and a water injection pipe which are arranged in parallel.A first limiting block, a first expansion gas bag, a second limiting block, a third limiting block, a second expansion gas bag and a fourth limiting block are sequentially arranged on the gas extraction pipe from inside to outside, an inner end opening of the gas injection pipe is communicated with the interior of the first expansion gas bag, a gas injection hole communicated with the interior of the second expansion gas bag is formed in the gas injection pipe, and an inner end opening of the water injection pipe is located between the second limiting block and the third limiting block.The invention further discloses a hole sealing method.Cheap water and air are adopted as hole sealing materials in the device and the method and can be supplemented through an underground air compression system and a water supply system as needed to ensure good hole sealing quality, the whole device can be recycled and reused after the extraction work is finished, pollution to a coal body, underground water and underground air can be avoided, the safety level of a mine is improved, and popularization of the novel coal mine gas treatment technology can be easily promoted.

Owner:关红星

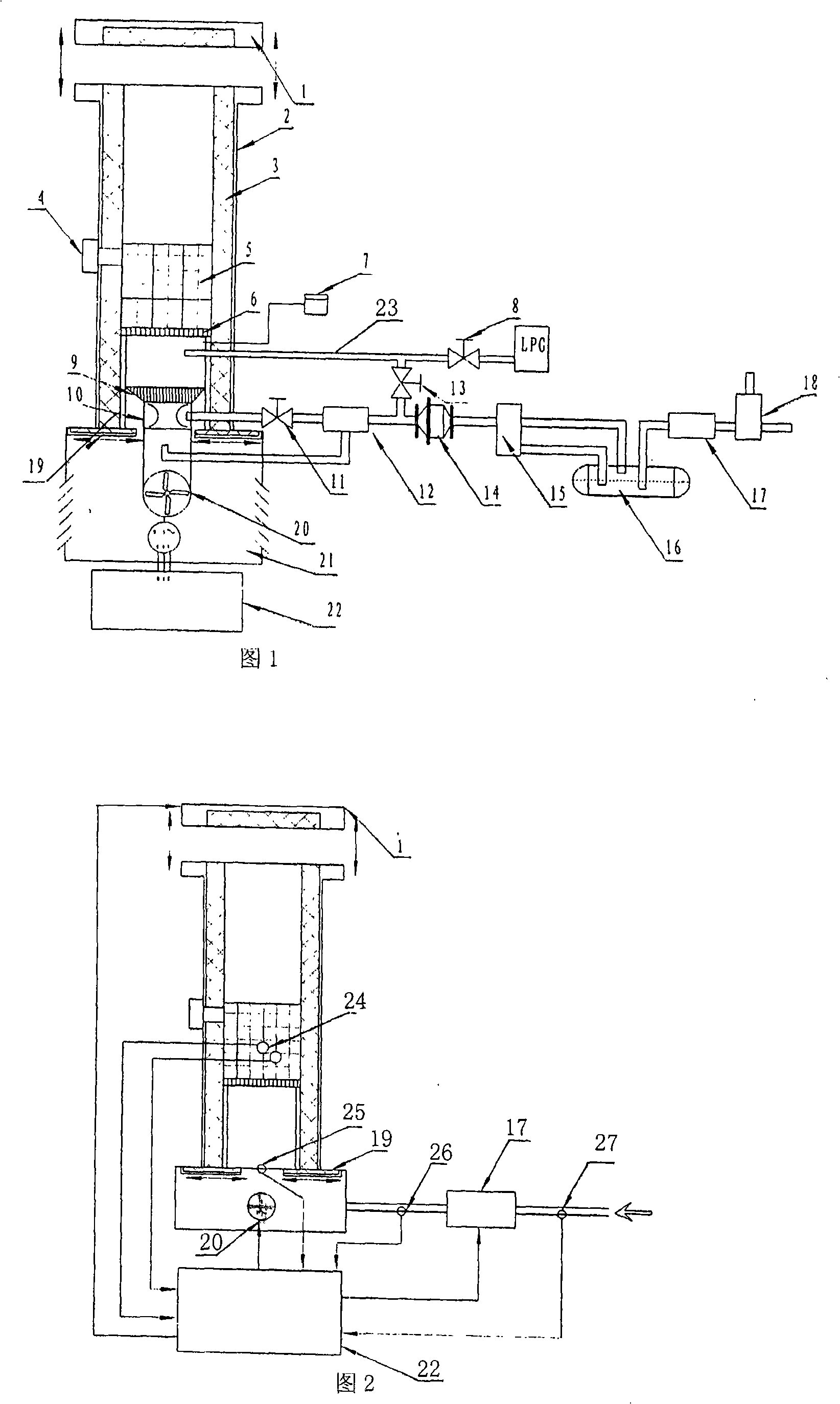

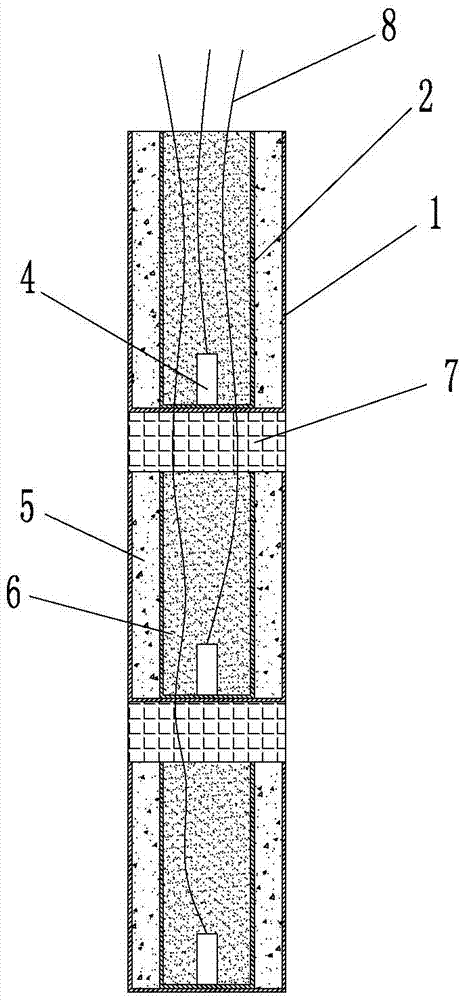

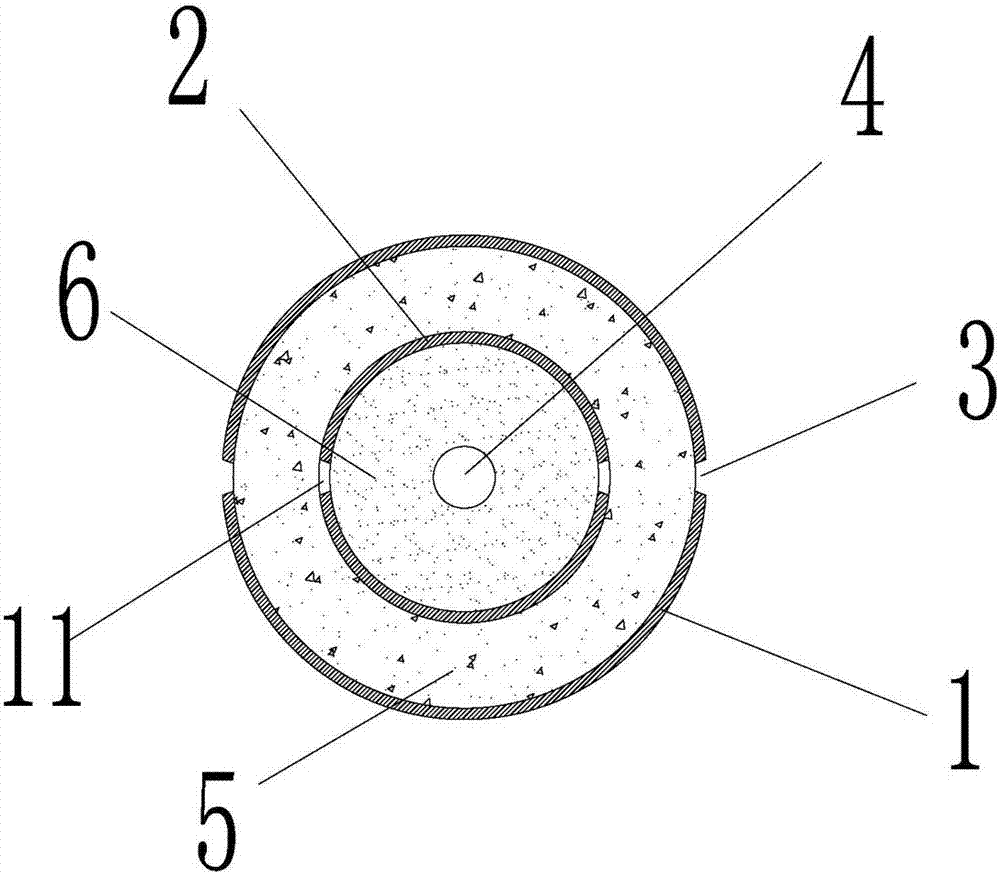

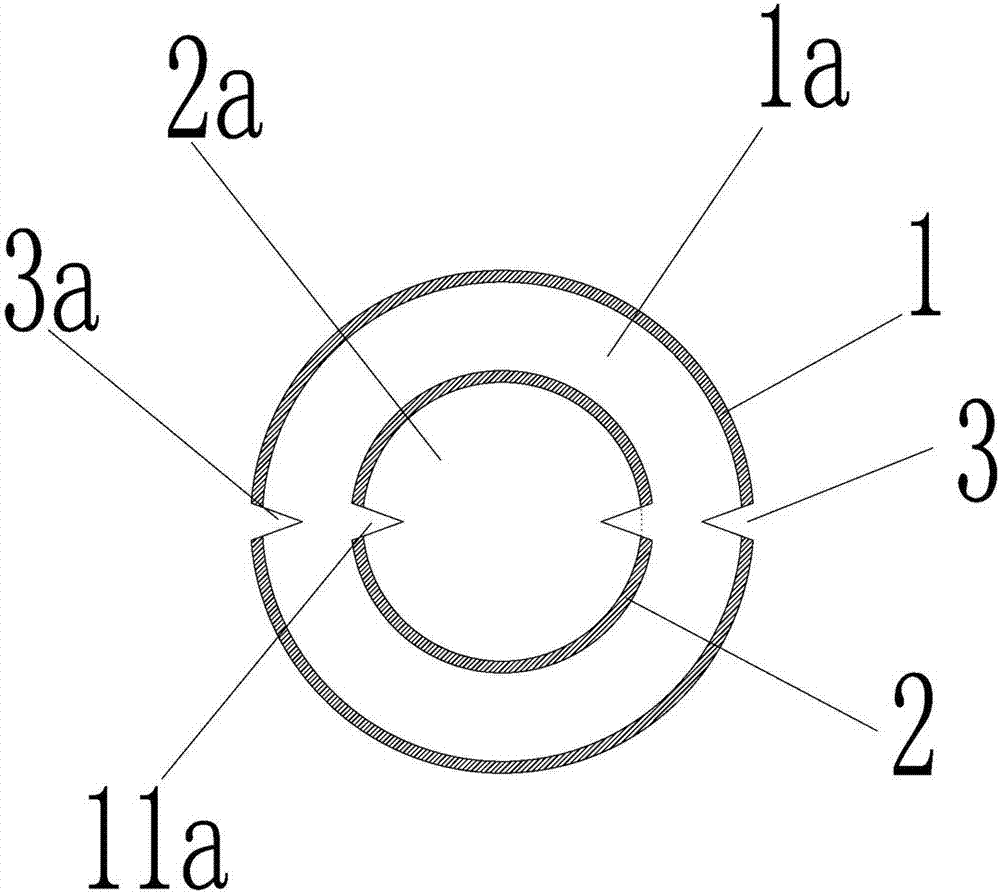

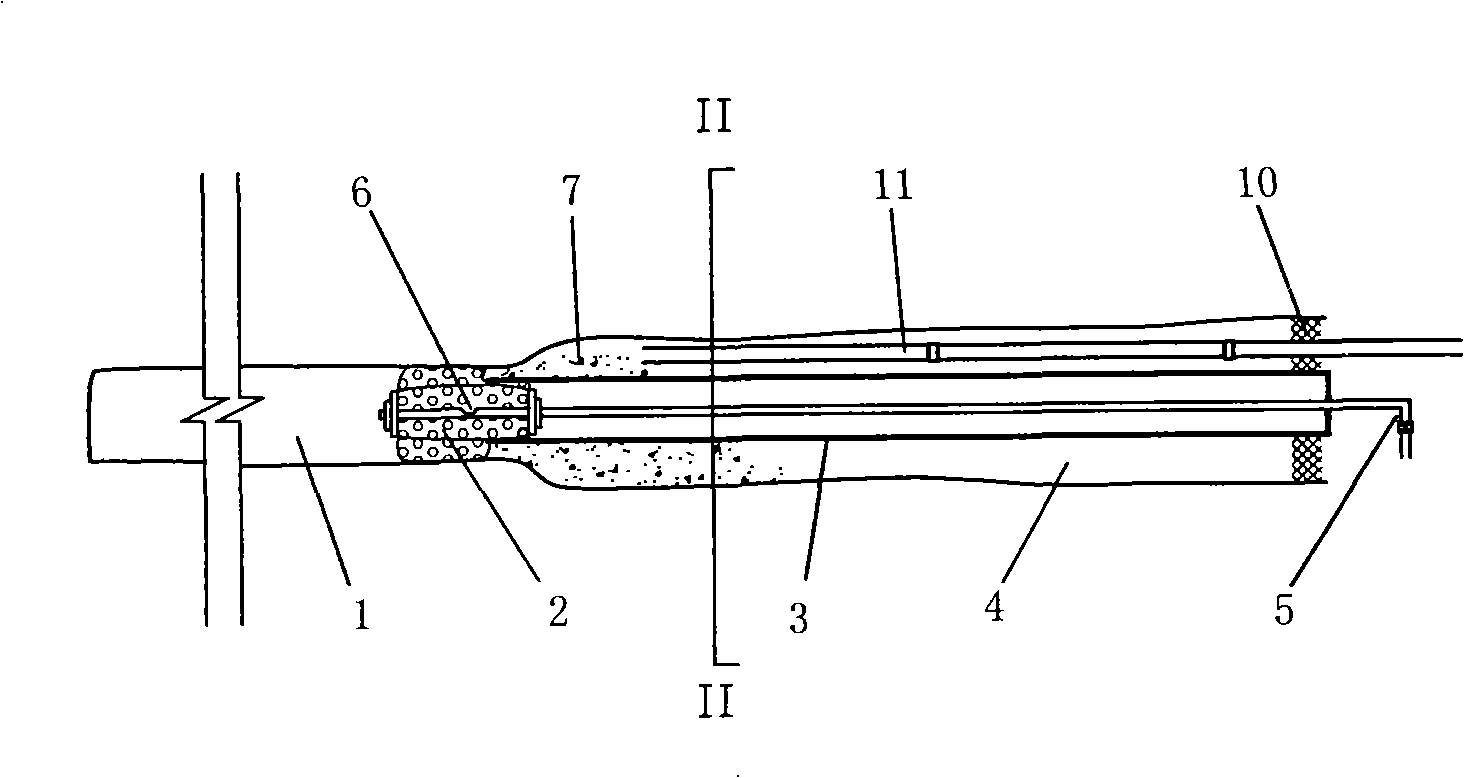

Coal mine mash gas incineration torch

InactiveCN101329067AStable lean burnBurn fullyIncinerator apparatusGaseous fuel burnerFlame arresterInsulation layer

The invention discloses a coal-mine gas-burning torch which comprises a burner and etc. systems including an insulation layer arranged inside a casing; a regenerative honeycomb ceramics and a bracket thereof which are arranged in the middle of the insulation layer, a proportioning mixer and a multi-head mixed-gas nozzle which are arranged on a lower part of the bracket; an upper sealing cover arranged at the upper end of the casing and a lower sealing cover and a base which are arranged at the lower end of the casing; a pipeline and a main gas supply valve which are connected with the proportioning mixer; a pressure-regulating valve, a flame arrester, a filtering dehydrator, a hydroseal flame arrester, an electronic-control valve and a gas diffusion valve which are sequentially connected; a fan which is arranged inside the base under the casing and connected with the lower part of the proportioning mixer; an electronic ignition system comprising an LPG fuel supply valve, a gas supply valve connected with a gas transferring pipeline and an electronic igniter communicated with the lower part of the burner; a temperature sensor arranged in the regenerative honeycomb ceramics; an air pressure sensor arranged at the back of the fan; a gas concentration sensor, a gas pressure sensor and an electronic-control valve which are arranged in the gas transferring pipeline system and a controller arranged on the lower part of the casing.

Owner:SHENGLI OIL FIELD SHENGLI POWER MACHINERY GRP

Coal mine gas extraction hole sealing material

InactiveCN104592962AHigh compressive strengthReduce fluidityDrilling compositionCeramicwareLiquid hydrogenCoal mine methane

The invention relates to a coal mine gas extraction hole sealing material. The coal mine gas extraction hole sealing material comprises, by mass, 60-80% of ordinary portland cement, 15-25% of an expanding agent (such as calcium sulphoaluminate and calcium sulphoaluminate-calcium oxide), 0-10% of gypsum, 0.1-0.3% of a foaming agent (such as solid aluminum powder or liquid hydrogen peroxide producing gas in an alkaline environment), and 0.2-0.5% of caustic soda, and the above materials and water are blended according to a mass ratio of 1: 0.6-1. The coal mine gas extraction hole sealing material has good expansibility, has an expansion coefficient greater than 10%, compressive strength greater than 10Mpa, good fluidity and short solidification time, is convenient for use and has a low cost.

Owner:HENAN SHENHUA ENERGY ENG

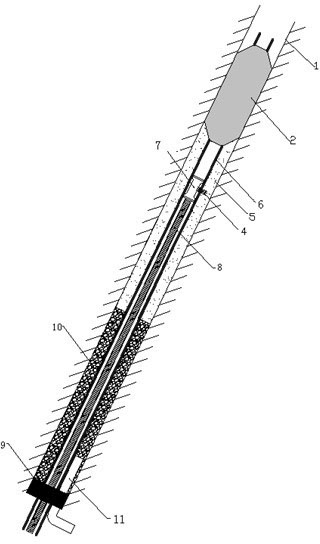

Millisecond multilevel directional blasting dry ice fracturing method and exploding pipe

ActiveCN106930744ASolve the problem of pumping efficiencyNovel structureOther gas emission reduction technologiesBlasting cartridgesDetonatorMining engineering

The invention discloses a millisecond multilevel directional blasting dry ice fracturing method and an exploding pipe. The method comprises the following steps: 1) drilling a blast hole and a pumping hole in a coal seam working surface; 2) preparing the exploding pipe; 3) filling the exploding pipe into the blast hole, connecting the end part on the inner side of the exploding pipe with the hole bottom of the blast hole, sealing an opening part at the external end of the blast hole by using the sealing tamping plug and guiding a leg wire of a millisecond delay electric detonator of each exploding unit out of the blast hole; 4) gradually exploding each exploding unit at interval of 40 milliseconds by the millisecond delay electric detonator in the sequence from interior to exterior of the blast hole. According to the invention, the generated quantity of cracks can be effectively controlled, the extending distance of the cracks can be increased without serious damage to the hole wall, CO2 generated by dry ice subliming along with the extension of the cracks can effectively displace the coal-mine gas, the gas discharging efficiency can be increased, and meanwhile, in the subliming process of the dry ice, a large quantity of exploding heat can be absorbed, the exploding temperature can be reduced and the exploding process is more safe and reliable.

Owner:HENAN POLYTECHNIC UNIV

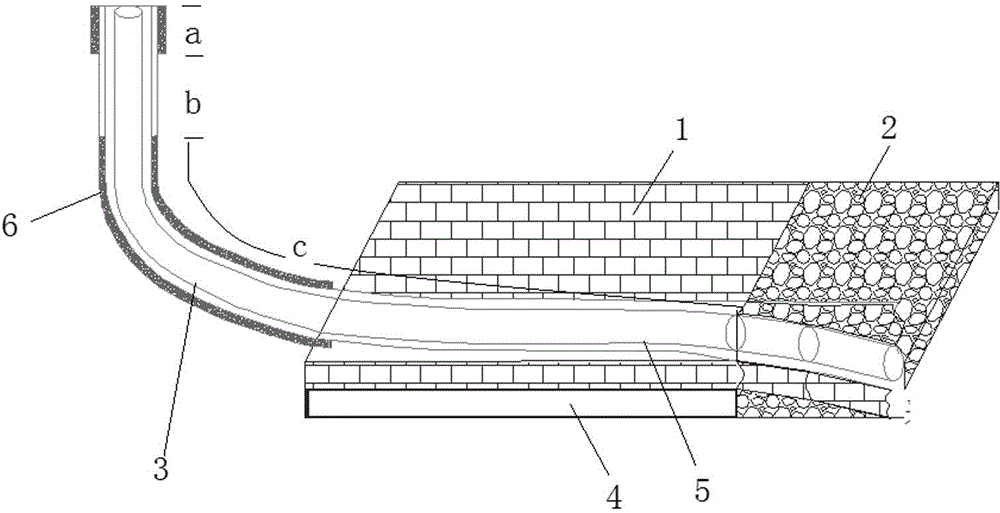

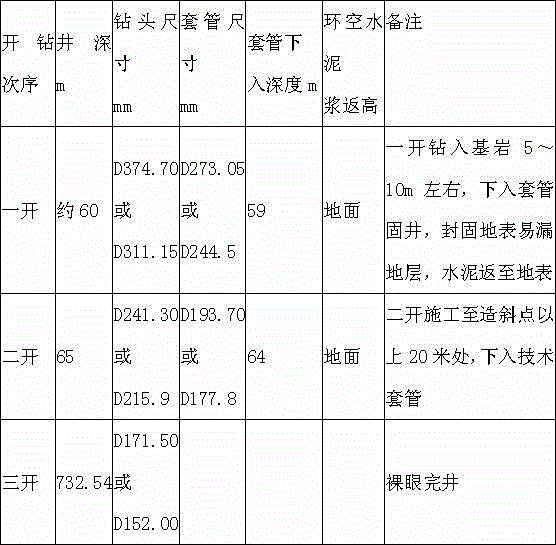

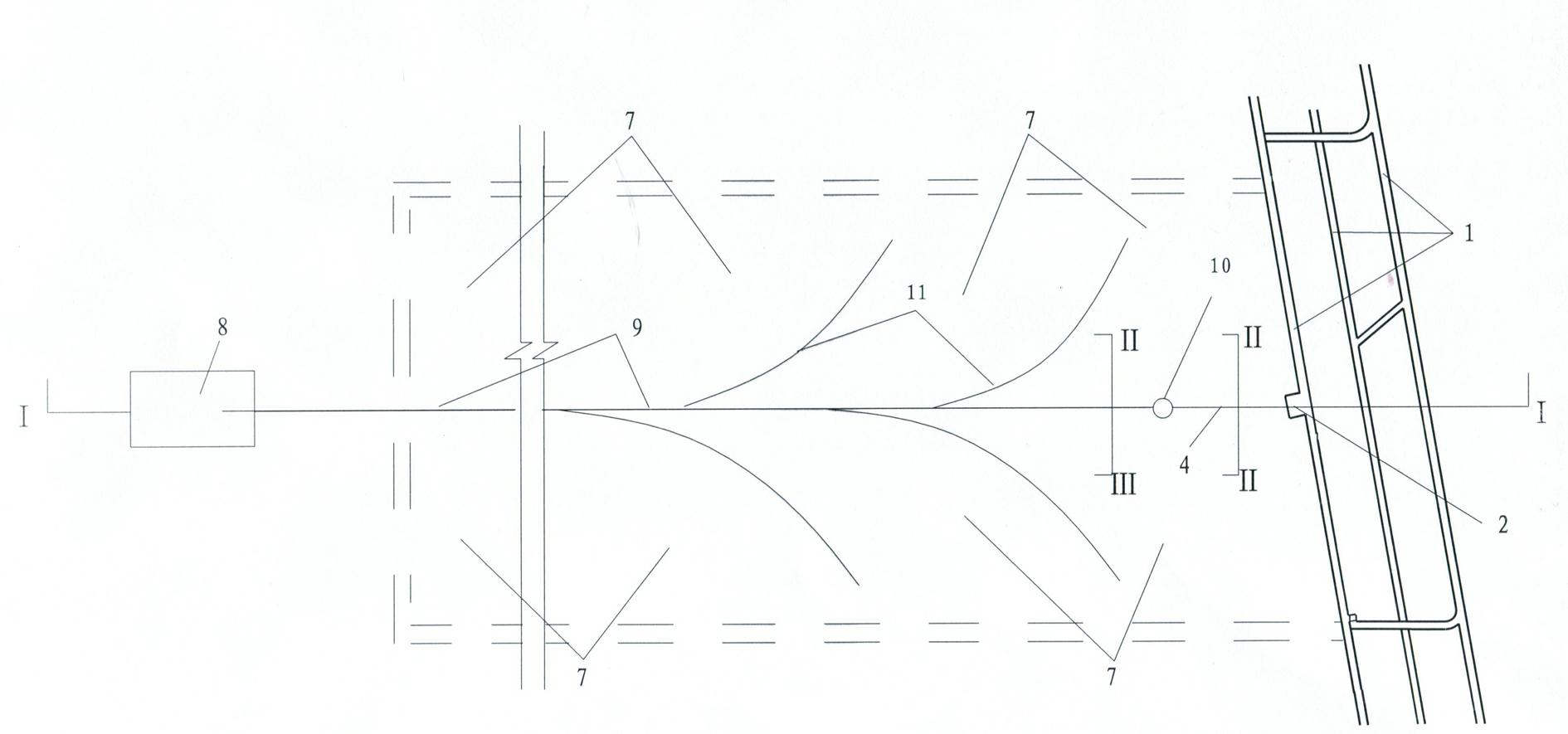

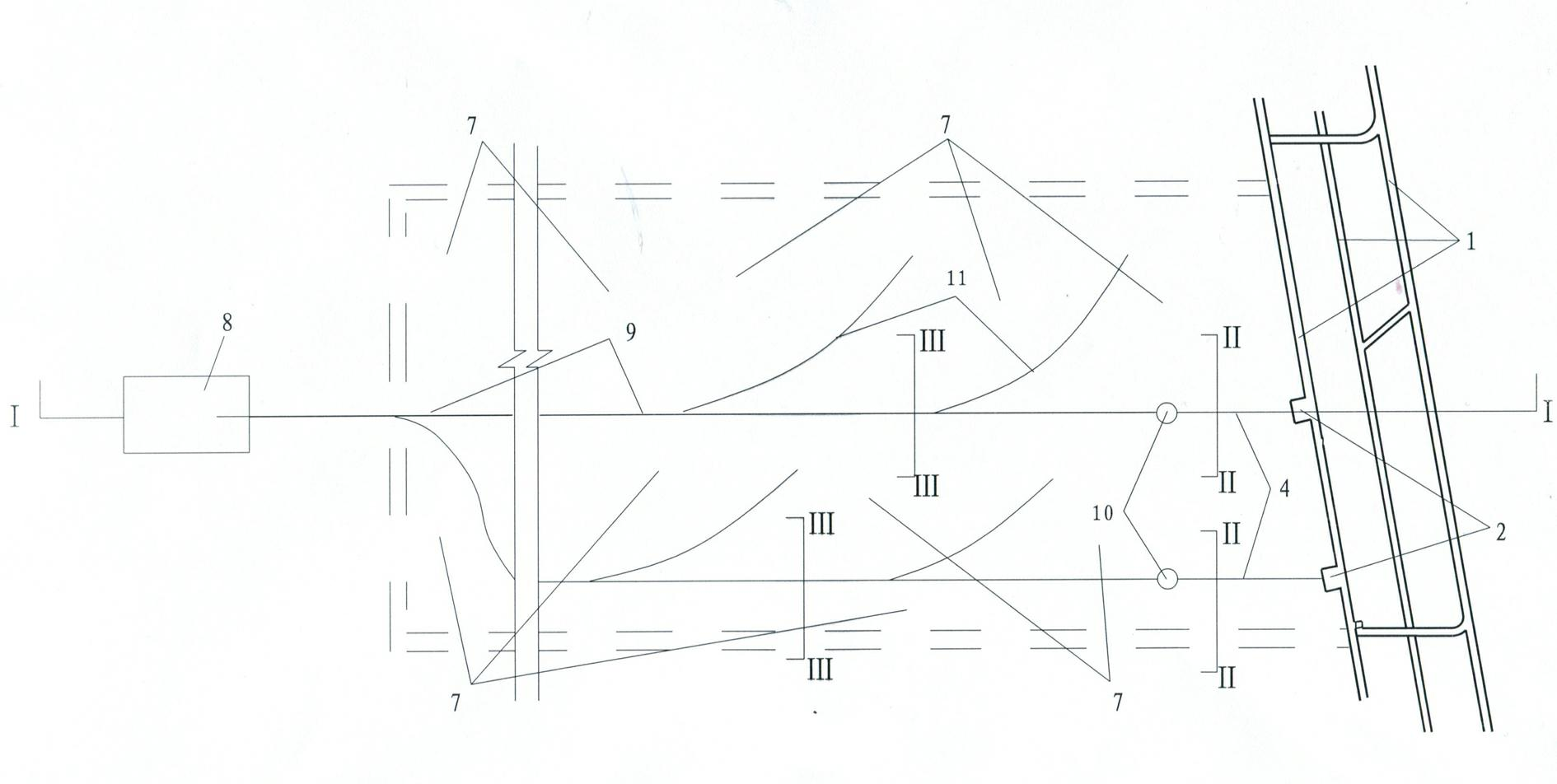

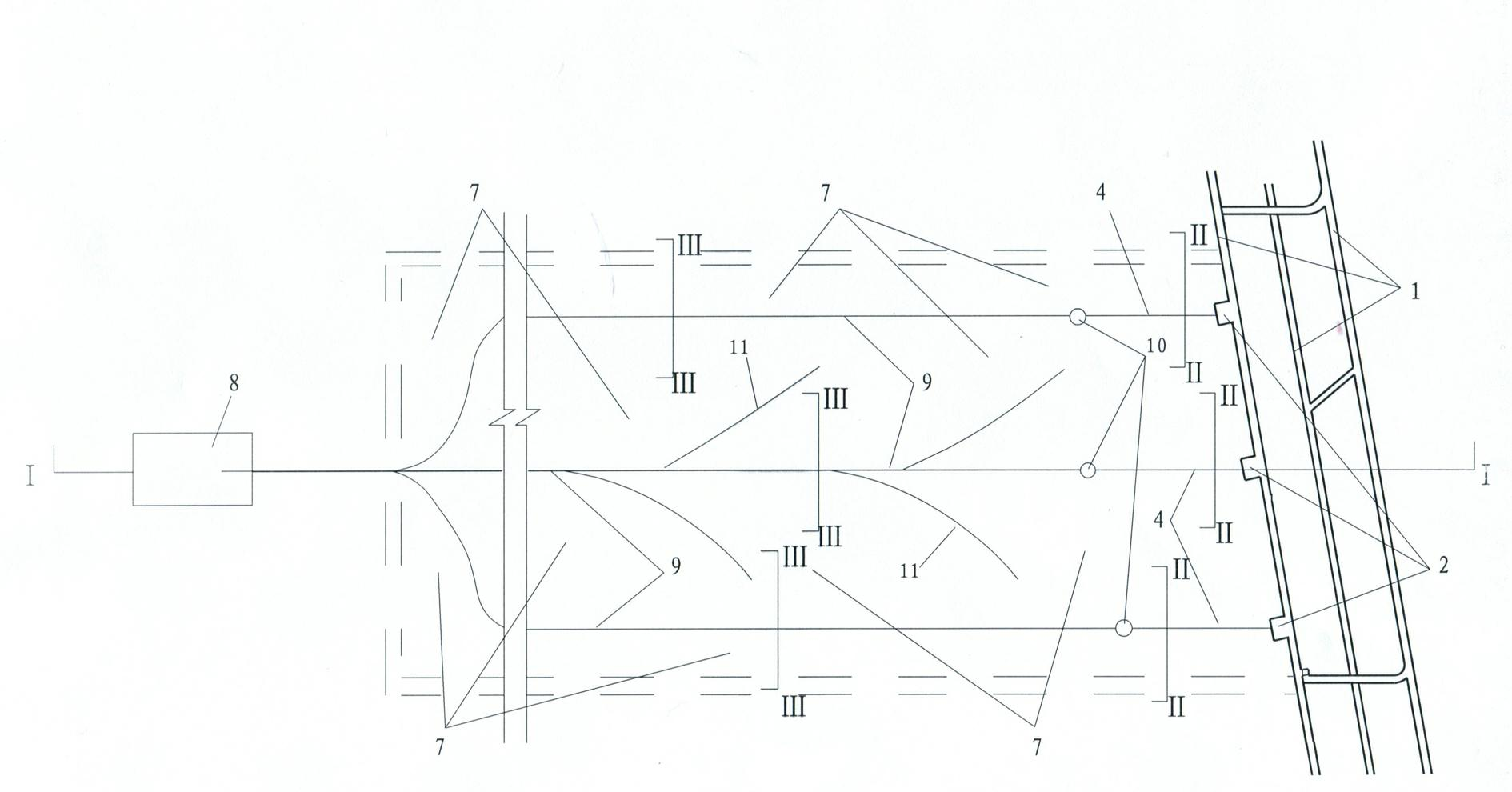

Technique for extracting gas from L-shaped ground drilling well in mining area

ActiveCN104405283AReduce construction costsShorten the construction periodDirectional drillingGas removalWell drillingCoal mine methane

The invention relates to a coal mine gas extracting technique, in particular to a technique for extracting gas from an L-shaped ground drilling well in a mining area. The technical problems of difficulty in realizing high-efficient gas extraction in the mining area are solved. The technique comprises the following steps: constructing a coal bed gas extracting well on a position away from the mining area; adopting a three-opening directional drilling technique on the ground drilling well; drilling along the direction from a main haulage roadway to an open-off position according to a three-opening hole sequence, wherein a third opening hole is horizontally formed in a rock stratum above a coal bed; connecting a ground wellhead to the inside of an independent extracting pump station. Before the underground coal back-extraction, a construction penetrating layer drilling hole is communicated with the third opening hole; during a back-extraction process, gas passes through the penetrating layer drilling hole and swarms into the three-opening hole, a ground extracting pump station is started for extracting the gas, a back-extraction surface is continuously advanced, a top layer falls, and then the three-opening hole is subjected to rock shift, so that the shearing is formed and the three-opening hole is gradually extruded and damaged; comprehensively, the ground drilling till key layer completing is adopted by the technique, a high-pumping lane is replaced for pumping and back-extracting the gas on a work surface, the construction period is short, and the desired result is quickly achieved.

Owner:SHANXI JINCHENG ANTHRACITE COAL MINING GRP CO LTD

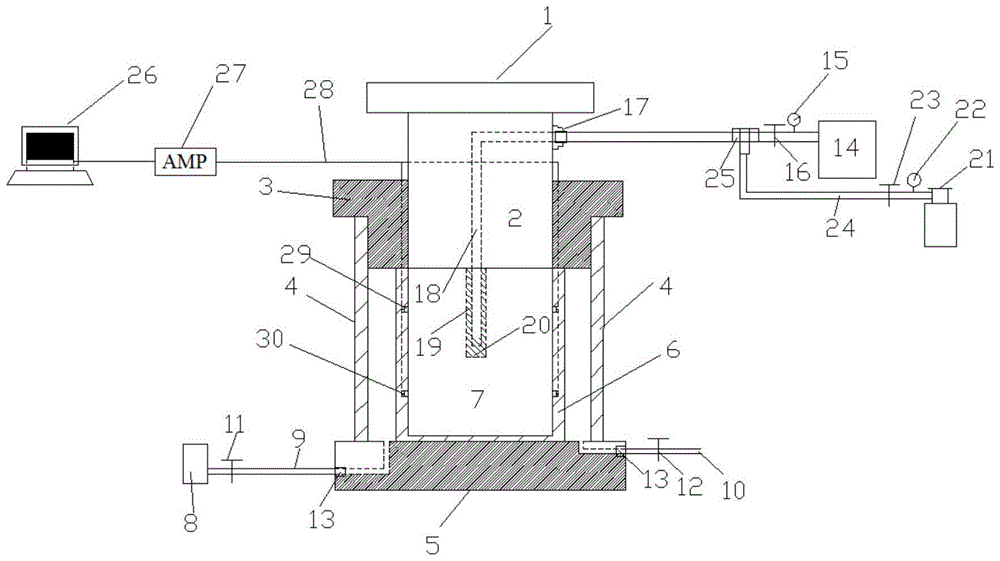

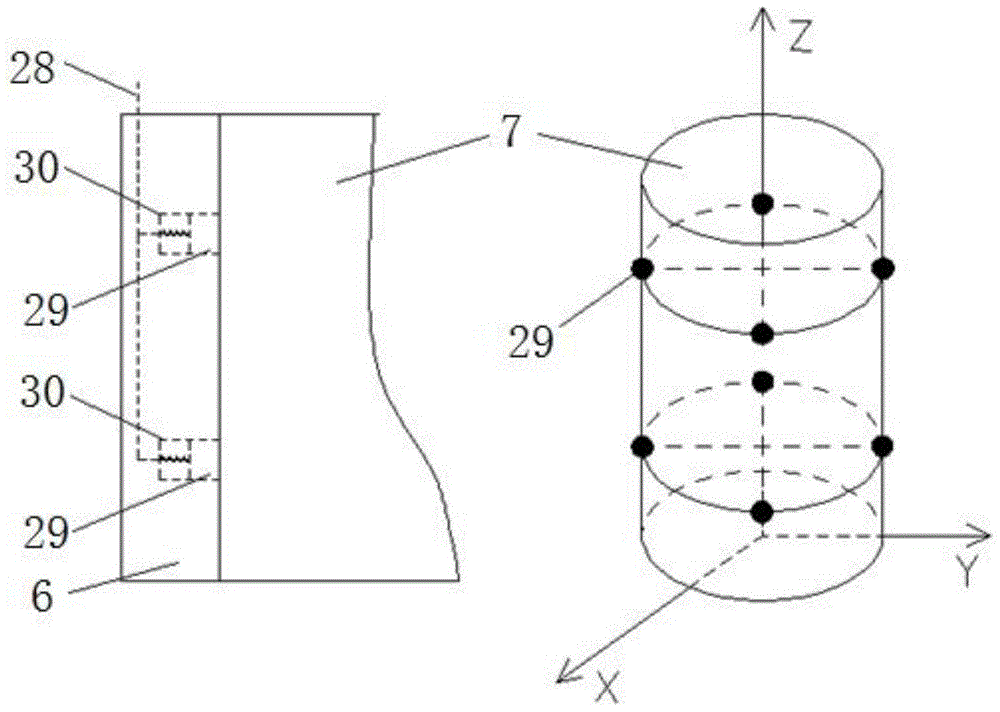

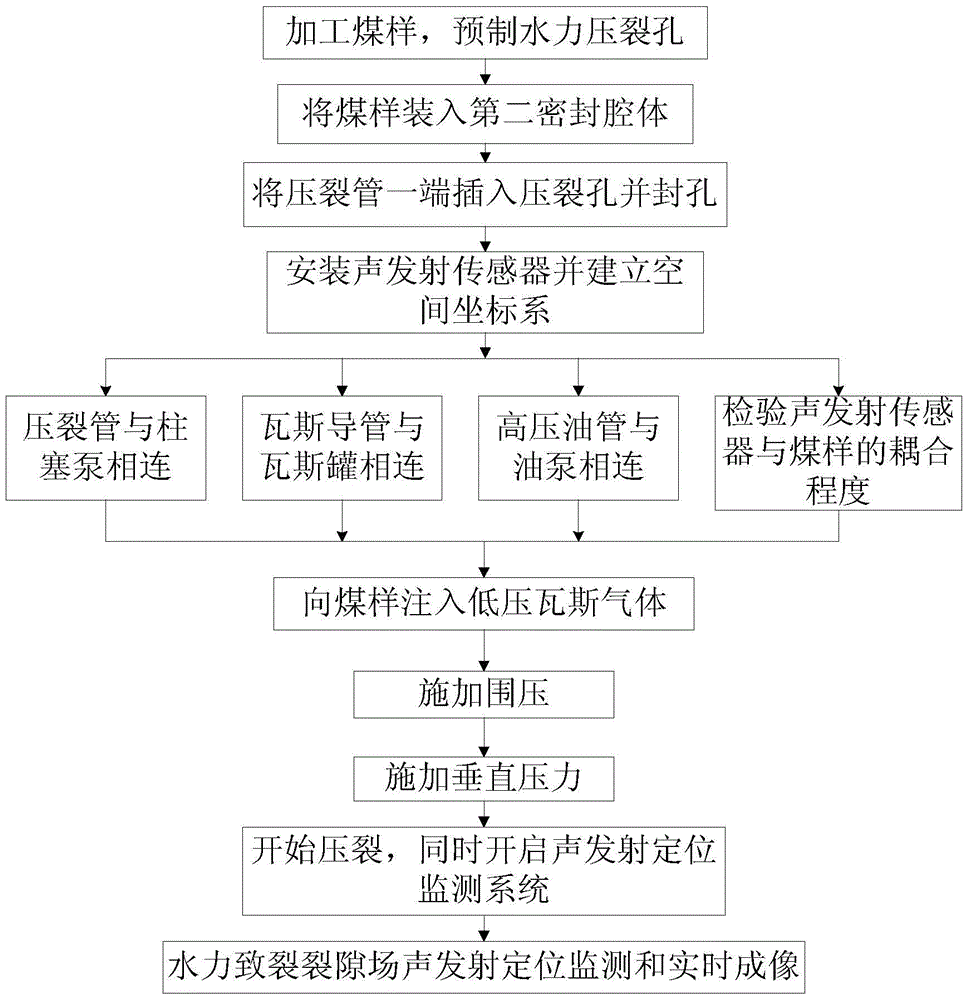

Acoustic emission positioning monitoring device and method for hydraulic fracturing fissure field of coal body containing gas

ActiveCN105675724AOptimizing hydraulic fracturing designFully adsorbedMaterial analysis using acoustic emission techniquesAcoustic emissionDesorption

The invention provides an acoustic emission positioning monitoring device and method for a hydraulic fracturing fissure field of a coal body containing gas and belongs to a coal-mine gas disaster prevention and microseism monitoring device and method. The monitoring device is characterized in that a second sealing cavity body is connected in a first sealing cavity body; the two sealing cavity bodies are connected with a ground stress simulation module; a gas adsorption and desorption module is connected with a hydraulic fracturing module and then is connected with a plunger of the second sealing cavity body; a sensor of an acoustic emission positioning monitoring module is connected onto a wall of the second sealing cavity body. The method comprises steps as follows: the acoustic emission sensor is mounted, a coal sample is placed in the second sealing cavity body, and a space coordinates system is established; gas is injected into the coal sample and is sufficiently adsorbed by the coal sample; confining pressure and vertical pressure are applied to the coal sample; high pressure water with tracing color is injected into the coal body, an acoustic emission positioning monitoring system is started and is used for analyzing monitored acoustic emission signals and performing positioning monitoring on coal body fracturing incidents caused by hydraulic fracturing, and real-time monitoring for evolution of the hydraulic fracturing fissure field is realized.

Owner:CHINA UNIV OF MINING & TECH

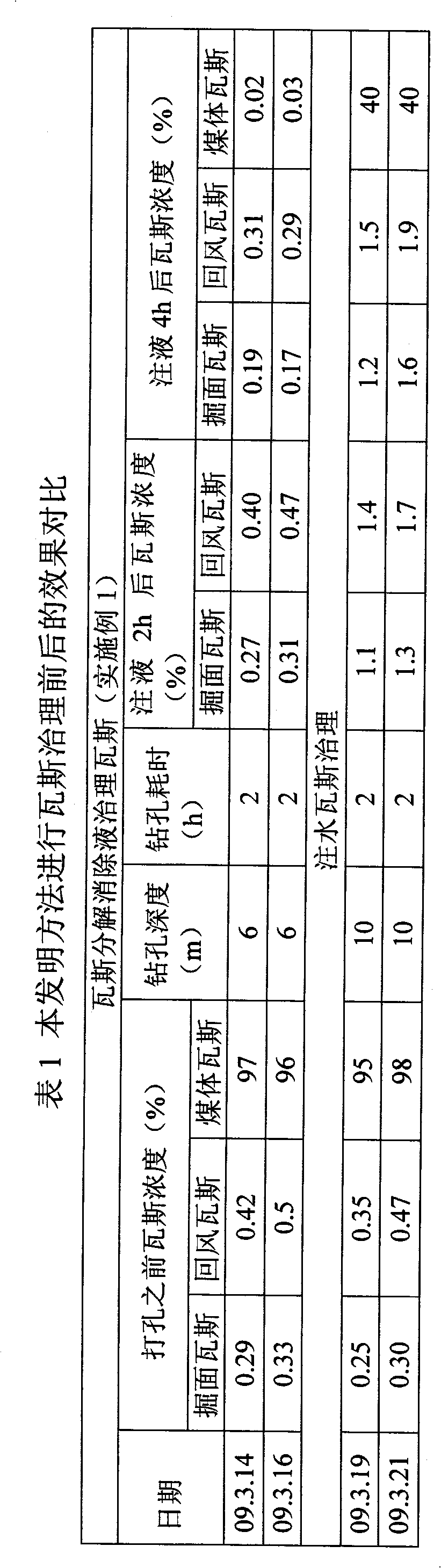

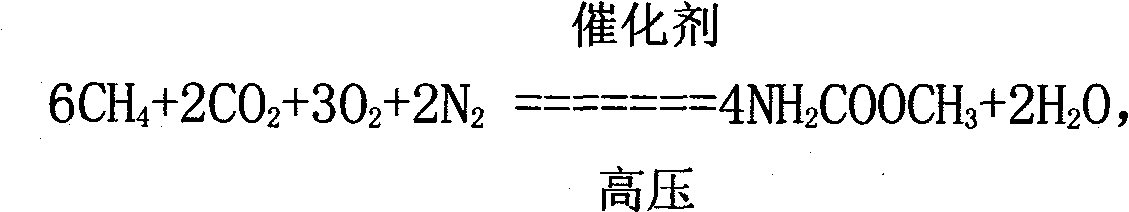

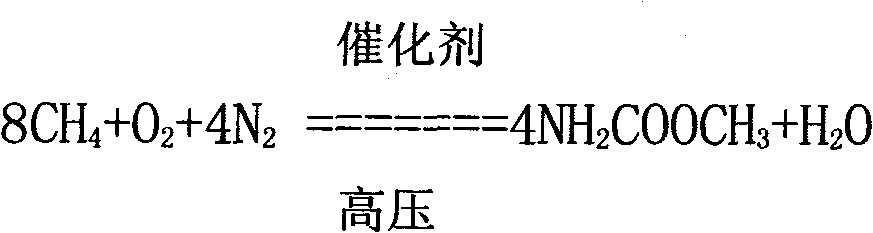

Gas decomposition eliminating liquid and coal mine gas control method

InactiveCN101906989AReduce governance costsCompliance with security governance regulationsGas removalAcetic acidCobalt acetate

The invention relates to a gas decomposition eliminating liquid and a coal mine gas control method. The gas decomposition eliminating liquid is mainly prepared by uniformly mixing beer, acetic acid, cobalt acetate and the like, the gas control method by the gas decomposition eliminating liquid comprises the steps of: drilling liquid injection drill holes on a coal mining face at an interval between 0.6m and 1.5m in the direction same as an inclined direction of a coal layer or at an inclined angle between 0 degree and 20 degrees with the inclined direction of the coal layer, and then injecting the gas decomposition eliminating liquid in the drill holes under a certain pressure to react for 3.5-5 hours. The gas decomposition eliminating liquid is green, satisfies the environmental protection requirement, and is prepared from nontoxic and harmless raw materials, and reaction products of the gas composition eliminating liquid with components of gas are also nontoxic and harmless, and have not harmful affects to the quality and use of coal. The gas control method has simple operation and low cost, and can effectively eliminate gas in coal by over 96%, and gas in coal lanes obviously reduces under a safety limit in the process of injecting the gas decomposition eliminating liquid in the coal.

Owner:吴星剑

Profile control and water plugging technology for coal bed gas

The invention relates to a coal bed air-regulating agent water shutoff technology it is based on geological features and fracturing transformation parameters of the coal bed methane, determine the water layer, constitute the overall water shutoff profile control programmes; the technology programmes of the water blocking and the amount is designed in accordance with the principle that water shutoff gel system subparagraph design , intensity gradually increased, moderate gel viscosity and various sect crosslinking time reasonable; construction in accordance with the above design programmes. The invention rational design, process is simple and easy construction, can be achieved selective water shutoff using the technology, stopping the channel between the coalbed methane wells and storage and not plug the coal reservoir cleats, fissures and cracks fracturing and thereby effectively drainage relief to ensure normal production of the coalbed methane wells.

Owner:LIAOHE GASOLINEEUM EXPLORATION BUREAU

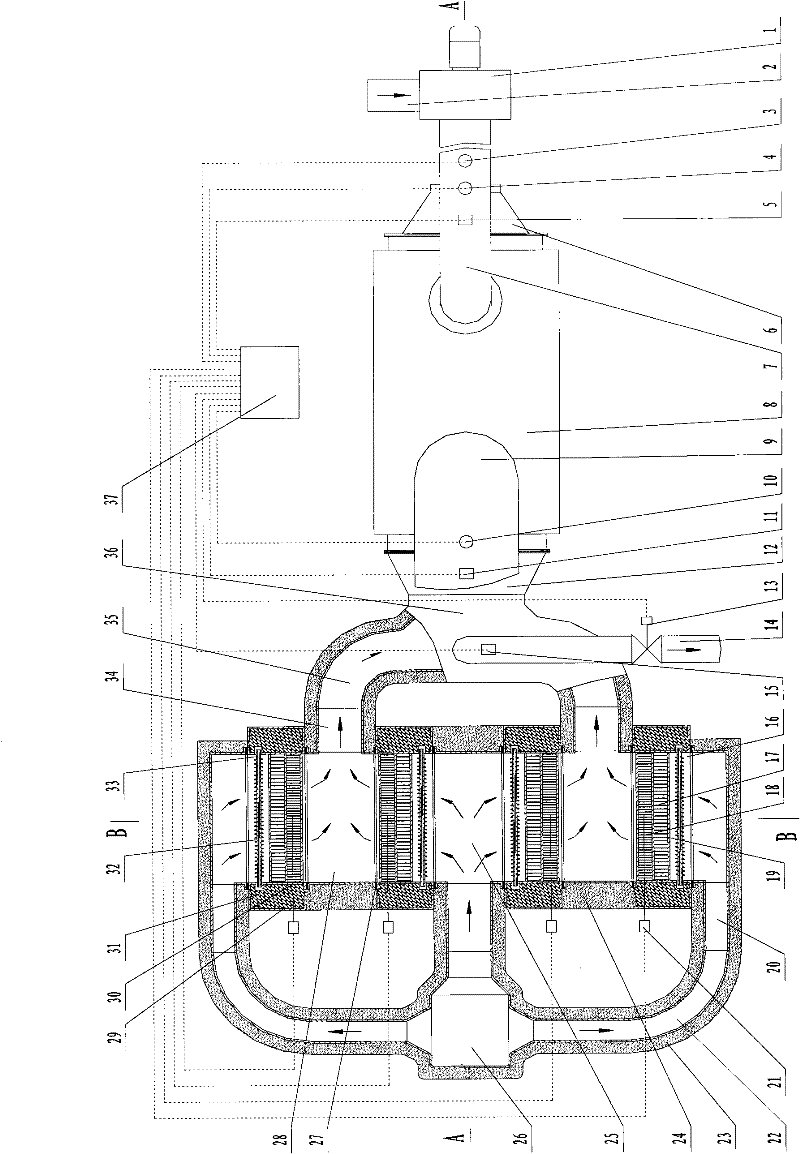

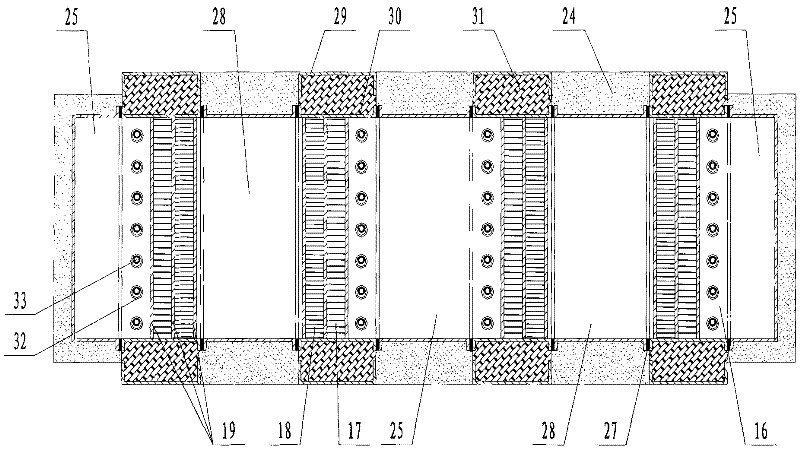

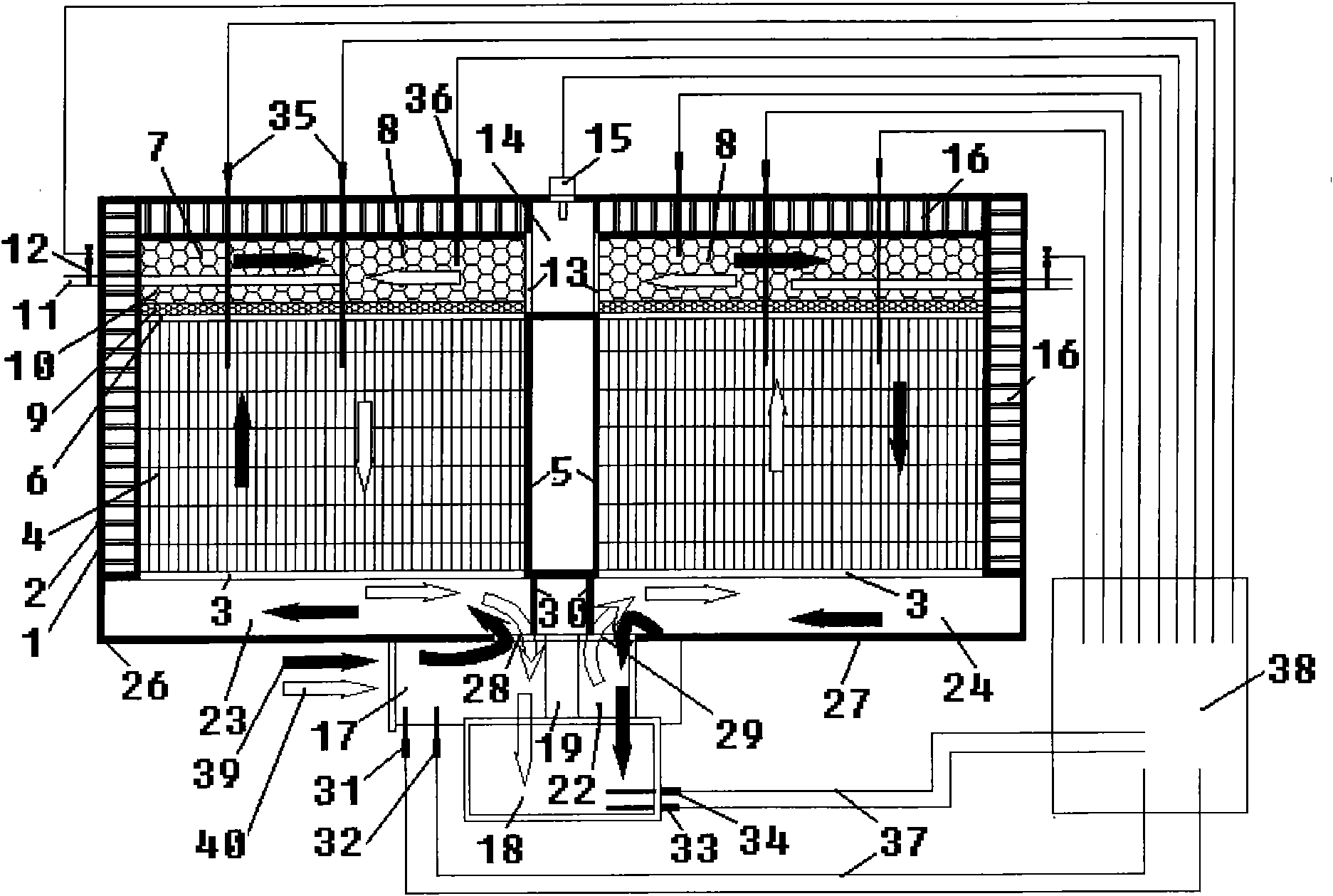

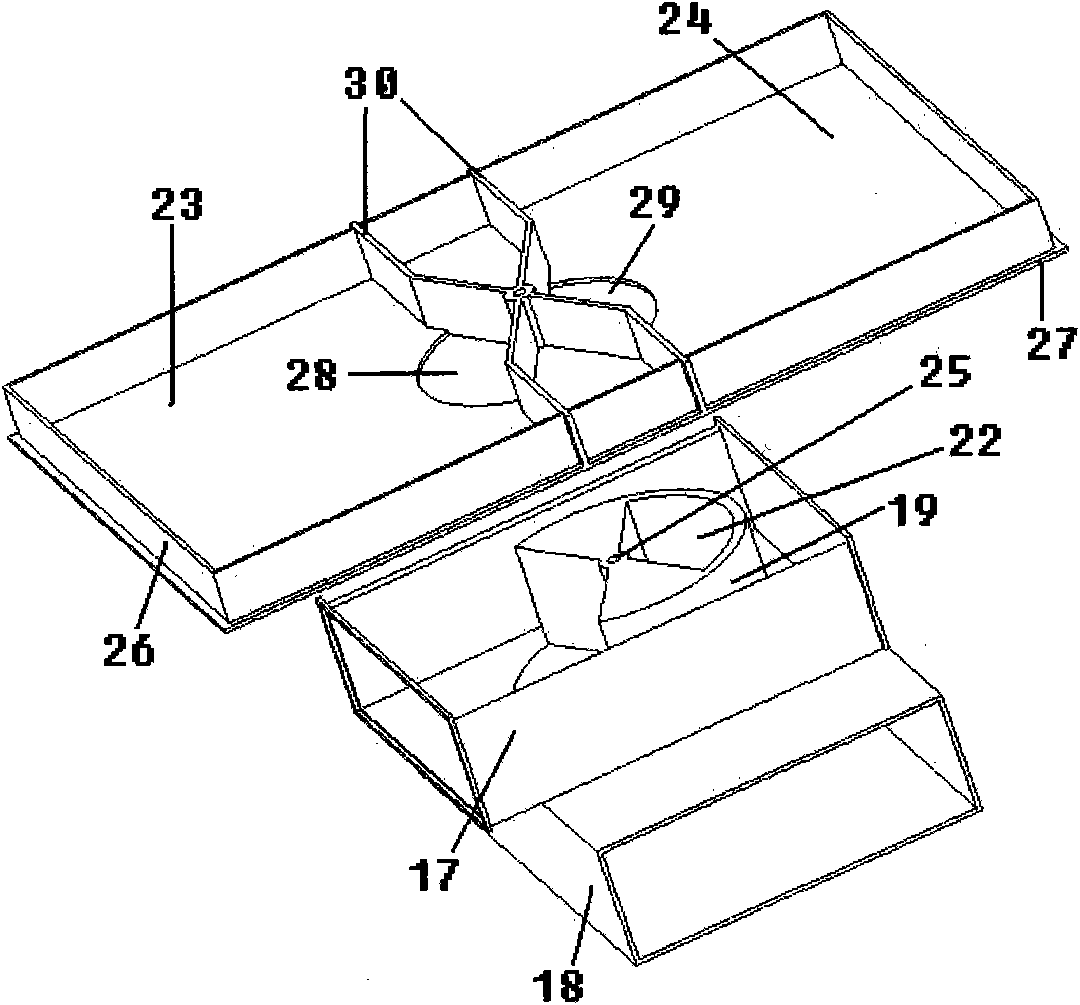

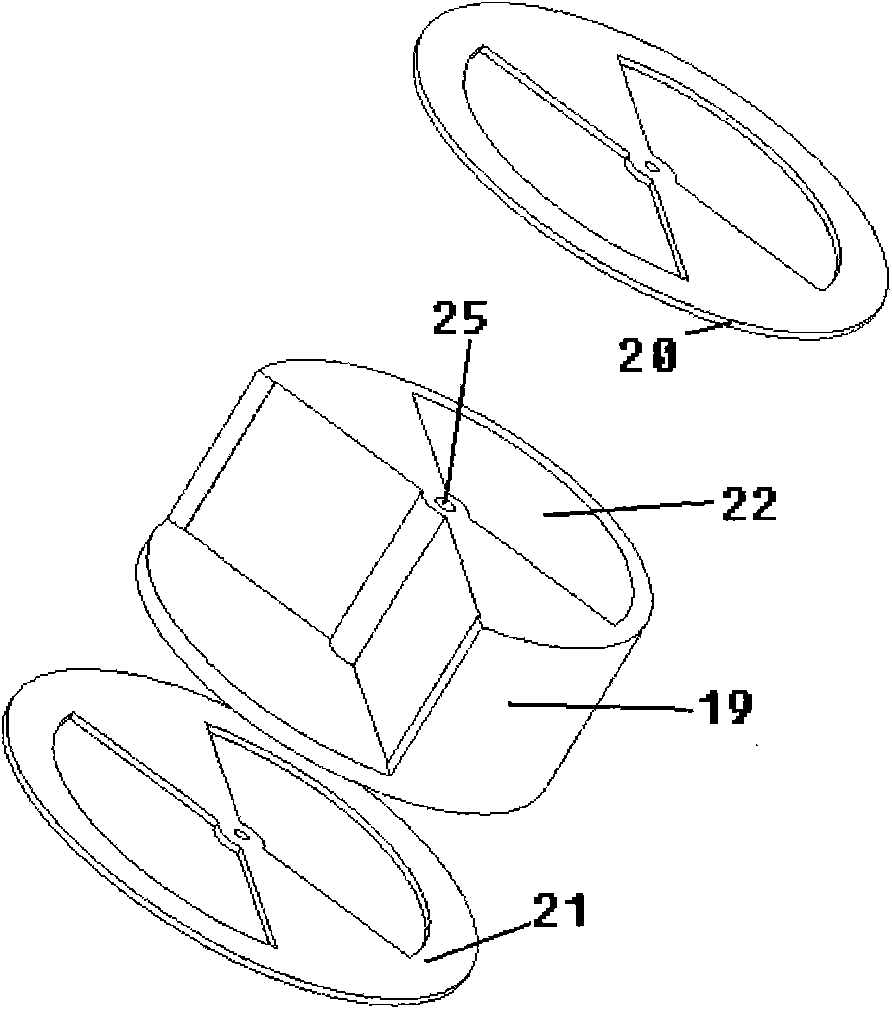

Coal mine methane preheating catalytic oxidation device with multiple reaction chambers

InactiveCN102205207AReduce volumeReduced footprintDispersed particle separationAtmospheric airControl system

The invention relates to a coal mine methane preheating catalytic oxidation device with multiple reaction chambers and belongs to technical field of ultralow-concentration methane oxidation. The device comprises a coal mine methane supply system, a pre-heater, even reaction chambers, a suction system, an exhaust system, an exhaust heating system and a measuring and controlling system, wherein an electric heater, a temperature-equalizing and flow-equalizing bed and a catalytic oxidation bed are arranged in each reaction chamber. After starting to heat, the coal mine methane is heated after entering into the pre-heater through the coal mine methane supply system; and then the coal mine methane is supplied to each reaction chamber through the suction system; carbon dioxide and water are oxidized in the catalytic oxidation bed of the reaction chamber; after the reacted heat gas is converged by the exhaust system, one part of the heat gas is used for utilizing the heat; and the residual heat gas enters into the pre-heater and transfers the heat to the fresh coal mine methane, and the residual heat gas is lastly discharged into the atmosphere after being cooled. The coal mine methane preheating catalytic oxidation device with multiple reaction chambers has the advantages of compact structure, low power consumption, simpleness in running, high reliability, and the like.

Owner:SHANDONG UNIV OF TECH

Gas control method for triple-purpose use of drilled holes in coal floor of close distance seam group

The invention discloses a gas control method for triple-purpose use of drilled holes in a coal floor of a close distance seam group, and belongs to coal mine gas control methods. In the coal floor of a mine, drilled holes in the same drill site are used, and gas extraction is performed according to the steps as follows: firstly, before coal mining, gas in a coal seam is extracted in advance through the drilled holes in the coal floor of the mine, and danger of the outburst of coal in the coal seam at the upper part and the gas is eliminated; secondly, the coal at the upper part is mined, when the coal seam at the upper part is mined, mining pressure relief and stress relief are caused to coal seams at the upper part and in the middle, the drilled holes of the original drill site are used, and gas in the coal seams at the upper part and in the middle in a mining pressure relief zone is extracted in a negative pressure manner; and finally, the coal seam in the middle and the coal seam at the lower part are mined, and simultaneously, the original drilled hole is used again, and gas in a mining layer is extracted in the negative pressure manner. The work efficiency can be improved, the gas extraction efficiency is high, the cost is saved, the concentration of the extracted gas is high, and the utilization of the gas is facilitated. The gas control method comprises the control of gas in close distance seam groups of two or more coal seams.

Owner:CHINA UNIV OF MINING & TECH

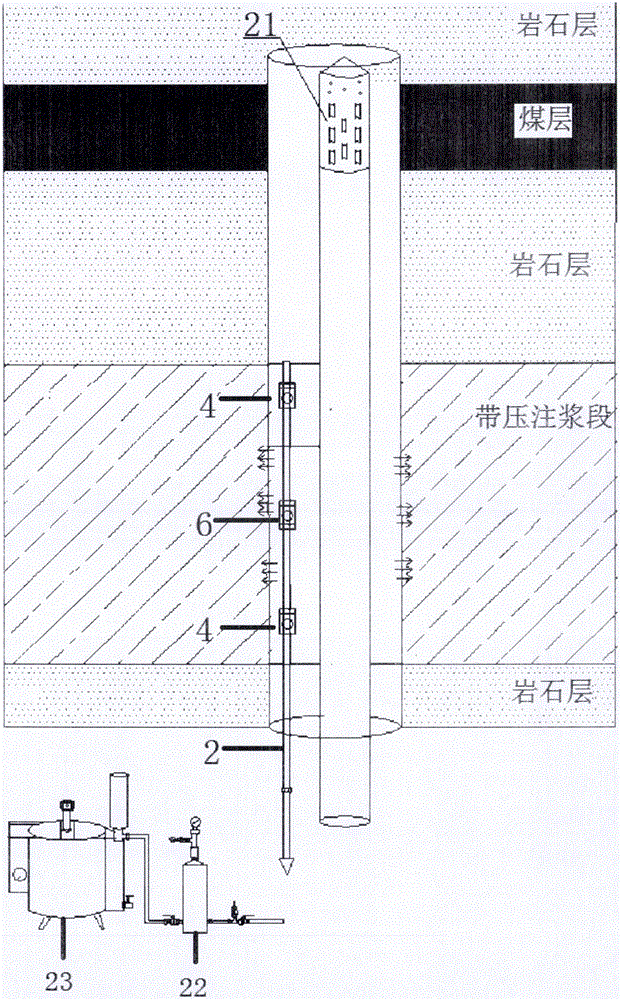

Coal-mine gas extraction drilling pressurized grouting rapid hole packer and use method thereof

InactiveCN105863556AImprove the extraction effectSolve the problem that the sealing process is cumbersome and the operation is more complicatedGas removalSealing/packingEngineeringCoal mine methane

The invention discloses a coal-mine gas extraction drilling pressurized grouting rapid hole packer and a use method thereof. A hole packer comprises a grouting pipe and capsular bags, wherein the grouting pipe is divided into a front second and a rear section; a double-circular air pressure blast valve is arranged between the front-section and rear-section grouting pipes; the double-circular air pressure blast valve is connected with the grouting pipes on the two sides through a thread head and a withholding type rubber hose connector; the front-section grouting pipe and the rear-section grouting pipe are sleeved with a capsular bag respectively; the two ends of the capsular bag on the front-section grouting pipe are withheld and fixed on the grouting pipe through a metal sleeve; the front end of the capsular bag on the rear-section grouting pipe is withheld and fixed on the grouting pipe through a metal sleeve while the rear end is fixed on the grouting pipe through a plug; and the part of the grouting pipe surrounded by the two capsular bags is provided with an annular one-way valve. In the coal-mine gas extraction drilling pressurized grouting rapid hole packer, airtight hole sealing is realized by the pressurized grouting technology; the hole packer has the advantages of multi-layer pressurized grouting and strong hole sealing airtightness; and moreover, the whole structure is simpler, the hole sealing operation is simpler and more reliable, and the airtight effect is better.

Owner:HUAINAN DATUN GROUTING ENG CO LTD

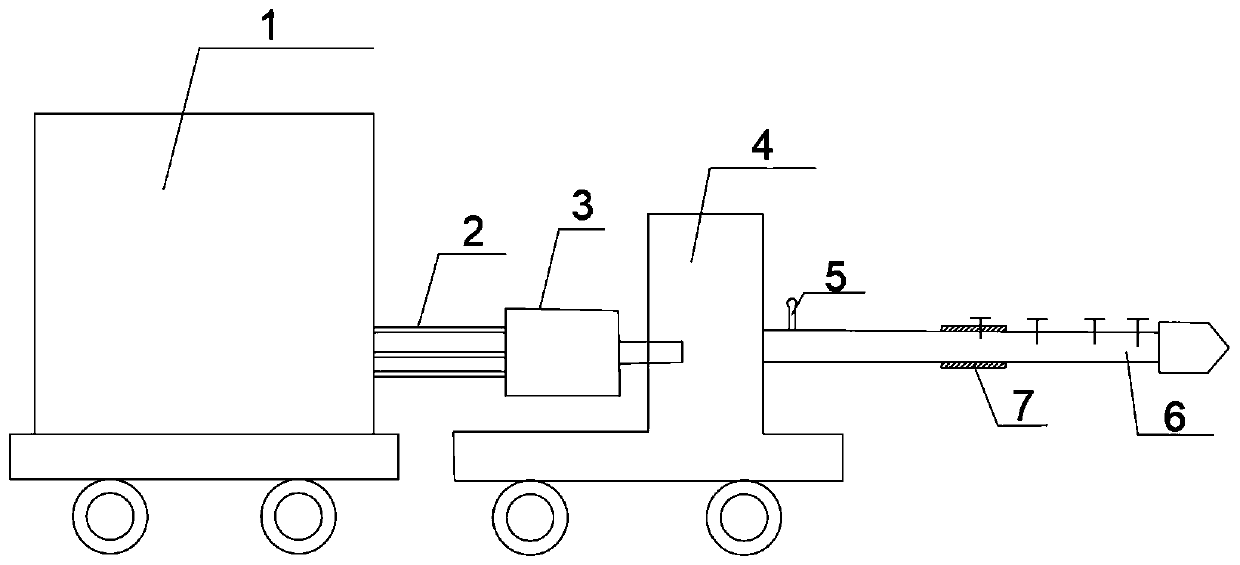

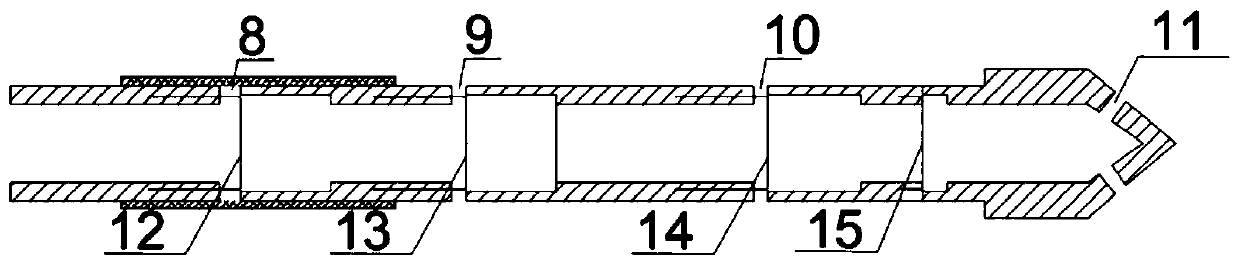

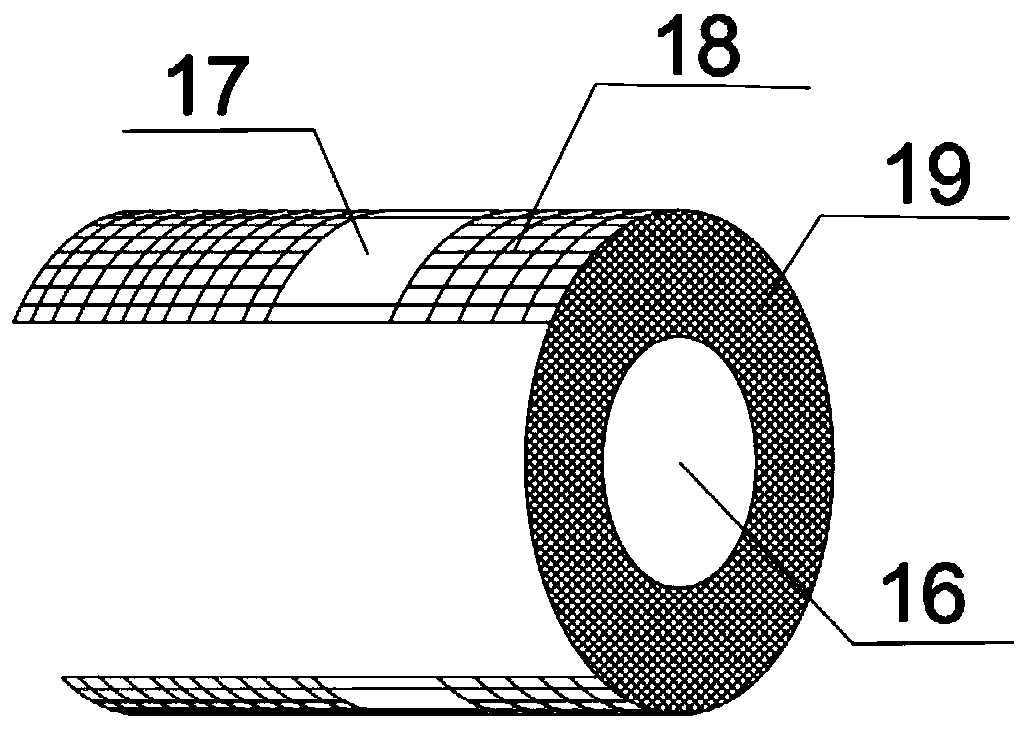

Deep low-permeability high-gas coal seam drilling-cutting-sealing-pressing drilling equipment and method

ActiveCN111088993AFacilitates efficient extractionSimple construction processDerricks/mastsLiquid/gas jet drillingMining engineeringControl system

The invention provides deep low-permeability high-gas coal seam drilling-cutting-sealing-pressing drilling equipment and method, and relates to the technical field of coal mine gas extraction and dustfall. The equipment comprises a drilling control system, a high-pressure hydrodynamic system, a water pressure grading control system and a fracturing plugging control system, wherein the drilling control system adjusts the drilling direction of a hole-drilling drilling rod and the water supply pressure of the drilling rod, high-pressure hydrodynamic system provides high-pressure water with different pressure for the equipment, and the water pressure grading control system ensures that the drilling and drilling cutting washing water pressure is smaller than 5 MPa, the water pressure for a cutting seam in the direction perpendicular to the length of the drilling rod is 25-35 MPa, the sealing water pressure of a sealing capsule is 35-40 MPa, and the water pressure of further pressure reliefand anti-reflection of a coal seam is 40-50 MPa; and the fracturing plugging control system finishes hole sealing and hydraulic fracturing construction control. According to the method for constructing drilling holes, slitting in the holes, hole sealing and the hydraulic fracturing by utilizing the equipment, the integrated construction of the single equipment is realized, and the construction efficiency of gas drainage hole drilling and coal seam dust prevention is improved.

Owner:SHANDONG UNIV OF SCI & TECH

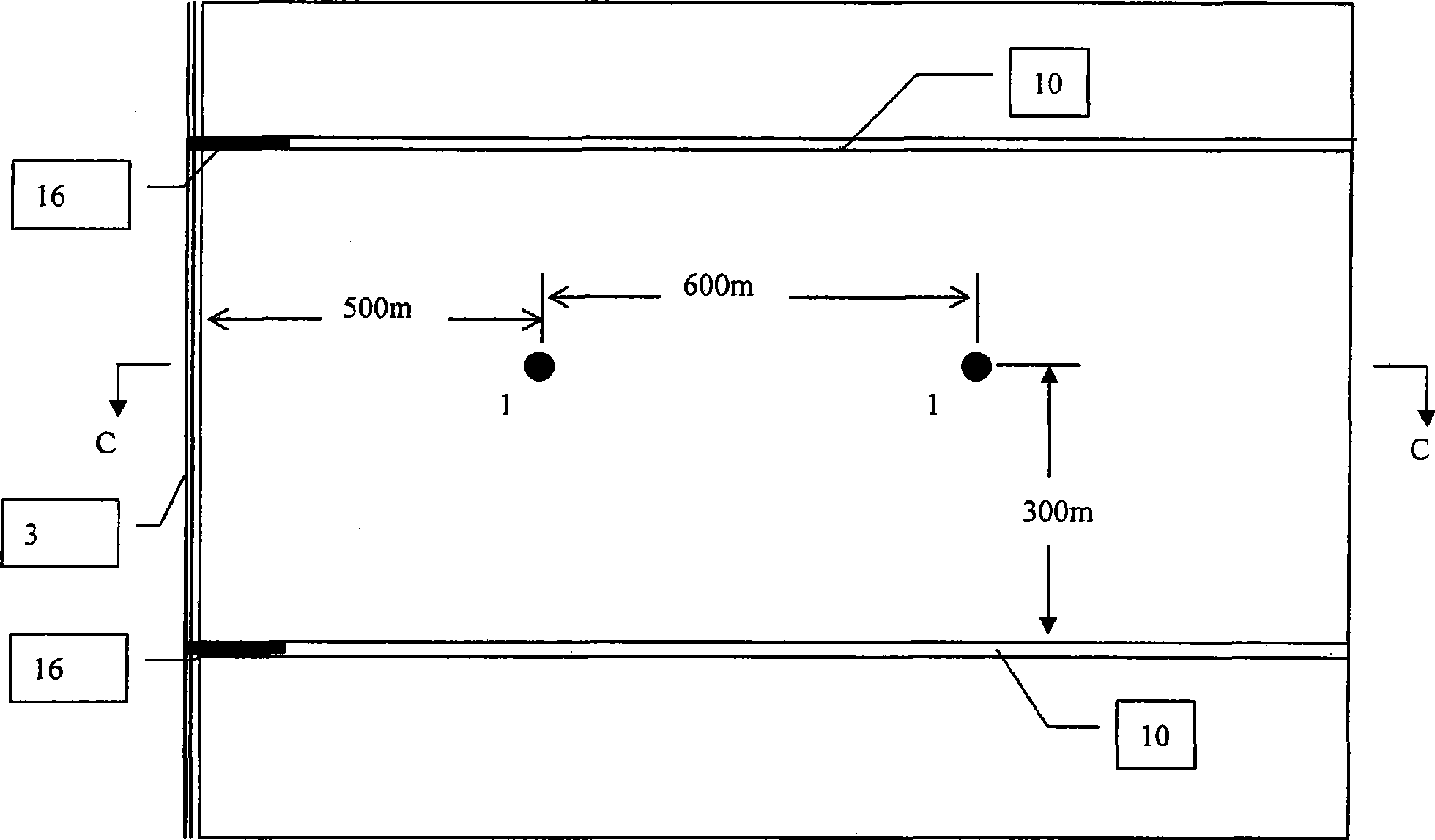

Method for draining coal seam gas

The invention relates to a method for draining coal seam gas, belonging to a method for pre-draining coal seam gas in coal mines. According to the invention, the technical problem that the existing methods for draining coal seam gas are low in drainage efficiency is solved. The technical scheme of the method for draining coal seam gas comprises the steps of: firstly opening at least one butt hole drill site in a coal mine underground preparation roadway, constructing a 30-50m long butt drill hole from the butt hole drill site to a target coal seam, lowering a seamless steel sleeve to the butt drill hole and solidifying the hole by high-quality cement, then opening a ground drill site at the far end of a designed drainage area, horizontally and directionally drilling a horizontal directional main branch hole along the target coal seam toward the underground butt drill hole, butt-jointing the horizontal directional main branch hole with the underground but drill hole, enclosing the ground orifice, arranging an orifice control valve on the head of the seamless steel sleeve, connecting the control valve with a coal mine underground gas drainage pipe network, and carrying out gas drainage by using a coal mine gas drainage pump.

Owner:华晋煤层气综合利用有限责任公司 +1

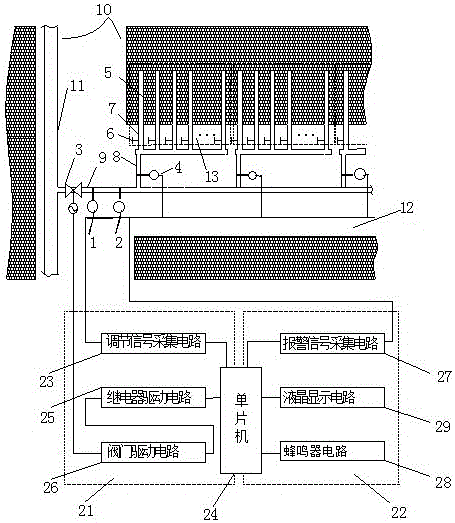

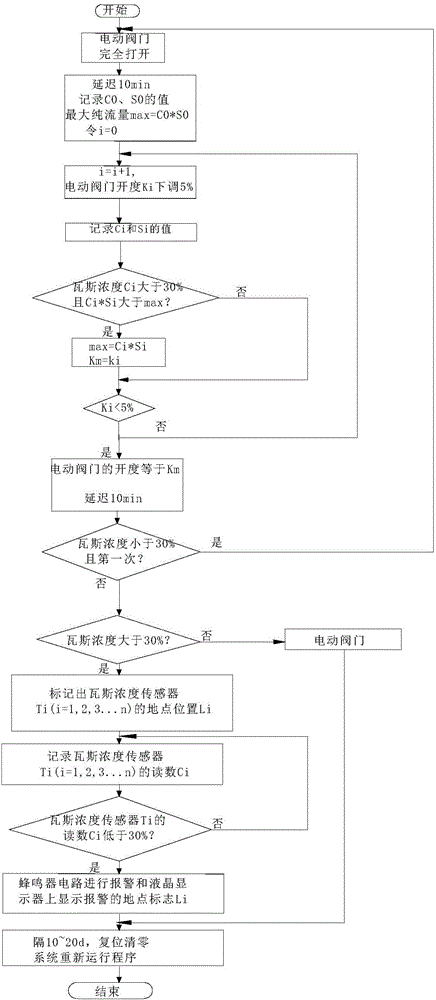

Intelligent control system for gas extraction of underground coal roadway and control method of intelligent control system

ActiveCN105003292ASolve the adjustmentSolving the problem of rule-of-thumbMining devicesGas removalCoal mine methaneGas concentration

The invention provides an intelligent control system for gas extraction of an underground coal roadway and a control method of the intelligent control system, and belongs to intelligent regulation and control of a gas extraction system of a coal mine. The intelligent control system comprises a regulation system and an alarming system; and the regulation system consists of a gas concentration sensor, a flow sensor, an electric valve, a regulation signal acquiring circuit, a single-chip microcomputer, a relay driving circuit and a valve driving circuit. According to a method of the regulation system, the opening degree of the electric valve is sequentially regulated from big to small; the maximum value of pure flow is found out under the condition that requirements on minimum concentration of gas extraction are met; the electric valve is set at the opening degree corresponding to the maximum pure flow and is automatically reset after a period of time; and the above procedures are carried out again. The alarming system consists of a gas concentration sensor, an alarming acquiring circuit, a single-chip microcomputer, a liquid crystal display circuit and a buzzer circuit. According to a method of the alarming system, alarming signals of the gas concentration sensor are processed through the single-chip microcomputer; the buzzer circuit gives an alarm; and the liquid crystal display circuit displays a gas leaking place. By the intelligent control system for gas extraction of the underground coal roadway, extraction is controlled intelligently and an optimum extraction effect is achieved.

Owner:TAIYUAN UNIV OF TECH

Coal mine gas pre-draining borehole sealing method adopting aerated capsule as temporary hole bottom

InactiveCN101307695AReduced sealing costsImprove ergonomicsGas removalSealing/packingCoal mine methaneCement mortar

The invention relates to a method for sealing a coal-mine gas pre-drainage borehole by adopting an inflatable capsule as a temporary borehole bottom. The method is mainly to solve technical problems of the prior g method for sealing the borehole, such as high sealing cost, low efficiency and inconvenient operation. The invention adopts the technical proposal that: the method for sealing the coal-mine gas pre-drainage borehole by adopting the inflatable capsule as the temporary borehole bottom comprises the following steps of: a. lifting a drilling tool and placing an borehole orifice pipe into a borehole, after a gas pre-drainage drill drills to a terminal drilling depth; b. sending the inflatable capsule into the borehole and inflating the inflatable capsule to form the temporary borehole bottom; c. filling cement mortar from the borehole orifice pipe, until the cement mortar is filled with the whole annular space; d. deflating the inflatable capsule and restoring the inflatable capsule to the original state, after the cement mortar is solidified, taking out the inflatable capsule from the borehole orifice pipe to complete sealing. The method is particularly applicable to sealing operations for the gas pre-drainage borehole which uses rigid plastic or other materials to make into the borehole orifice pipe and the gas pre-drainage borehole with poor shaping in a soft coal seam.

Owner:黎凤岐

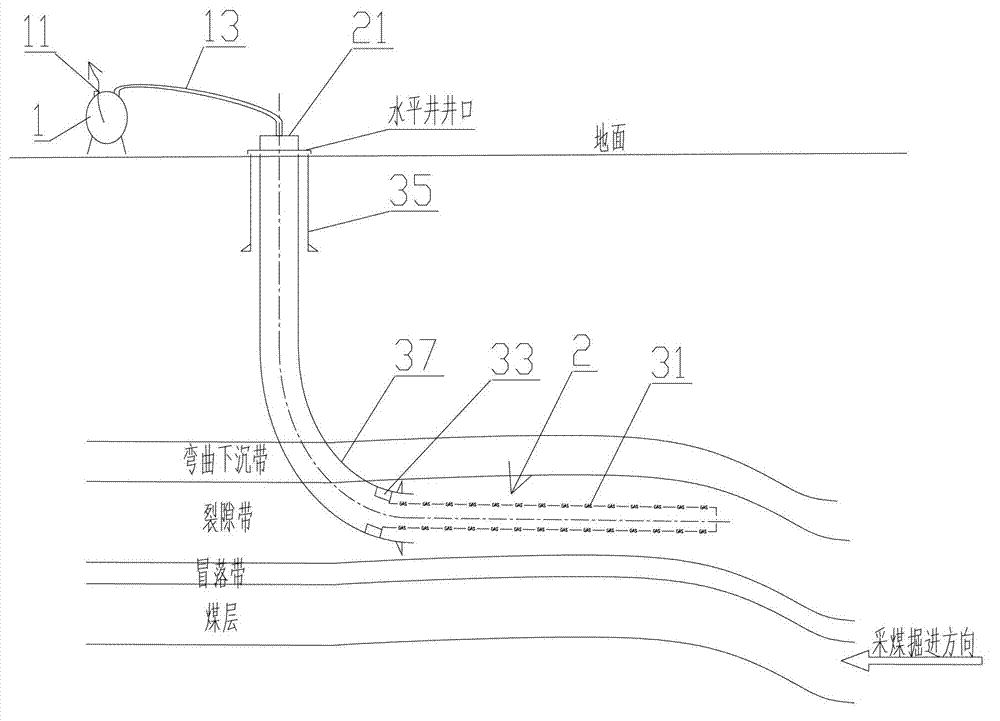

Method and system for gas pumping of high-gas coal mines

InactiveCN102828768AAvoid the dangers of underground constructionImprove securityGas removalWell drillingCoal mine methane

The invention provides a method and a system for gas pumping of high-gas coal mines. The method for gas pumping of high-gas coal mines includes: setting a wellhead of a horizontal well on the ground; setting the horizontal well communicated with the wellhead of the horizontal well in a fissure zone; and setting a vacuum pump on the ground and enabling the vacuum pump to extend into the wellhead of the horizontal well to pump the horizontal well. The system for gas pumping of high-gas coal mines comprises the horizontal well and the pump, wherein the horizontal well is arranged in the fissure zone and communicated with the ground, and the pump is positioned on the ground and communicated with the horizontal pump. Horizontal well drilling and coal mining theories are organically combined to transplant underground works to the ground for implementation, so that risks of coal mine underground construction are reduced.

Owner:YUWU COAL CO LTD OF SHANXI LUAN GRP +1

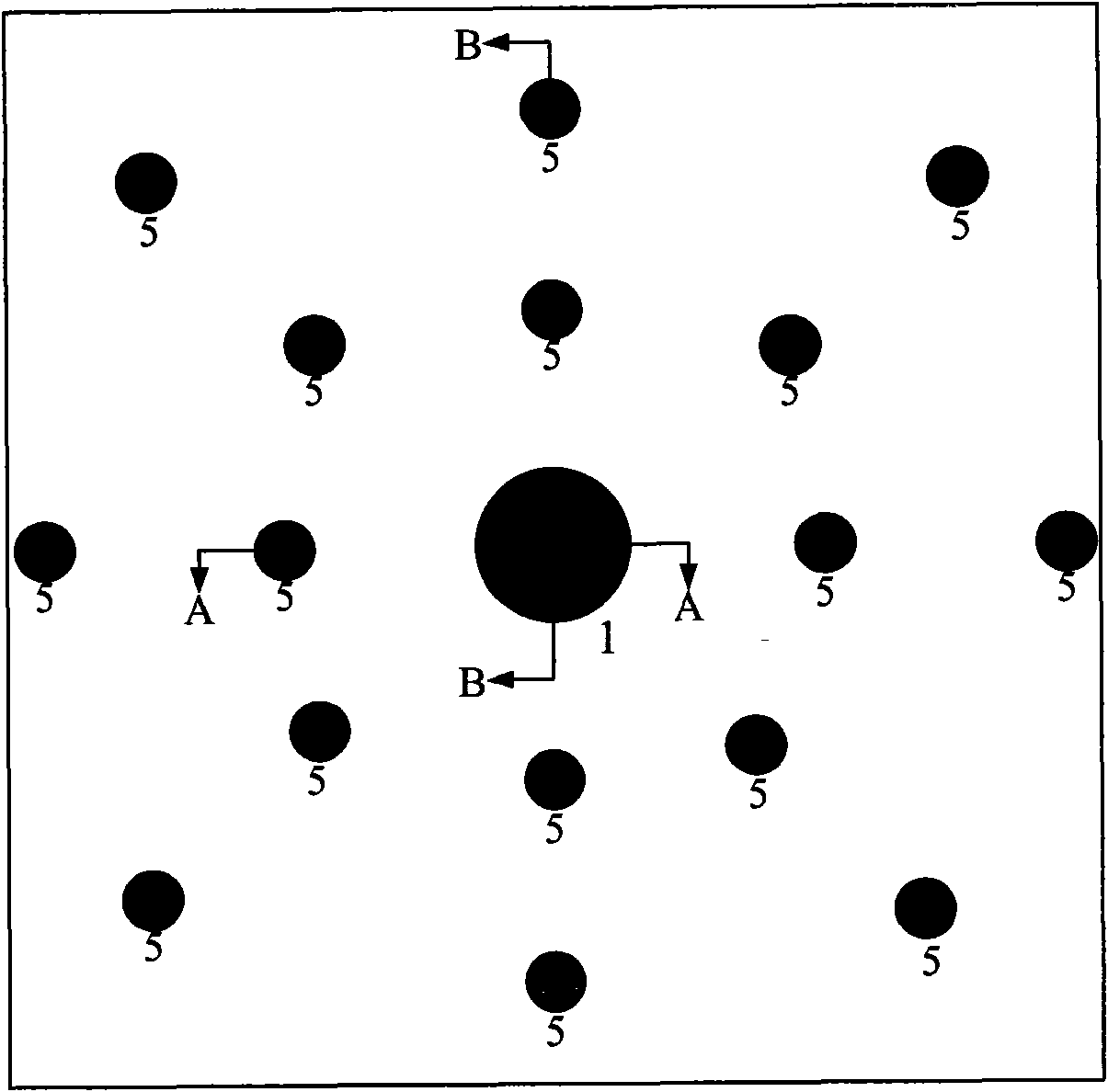

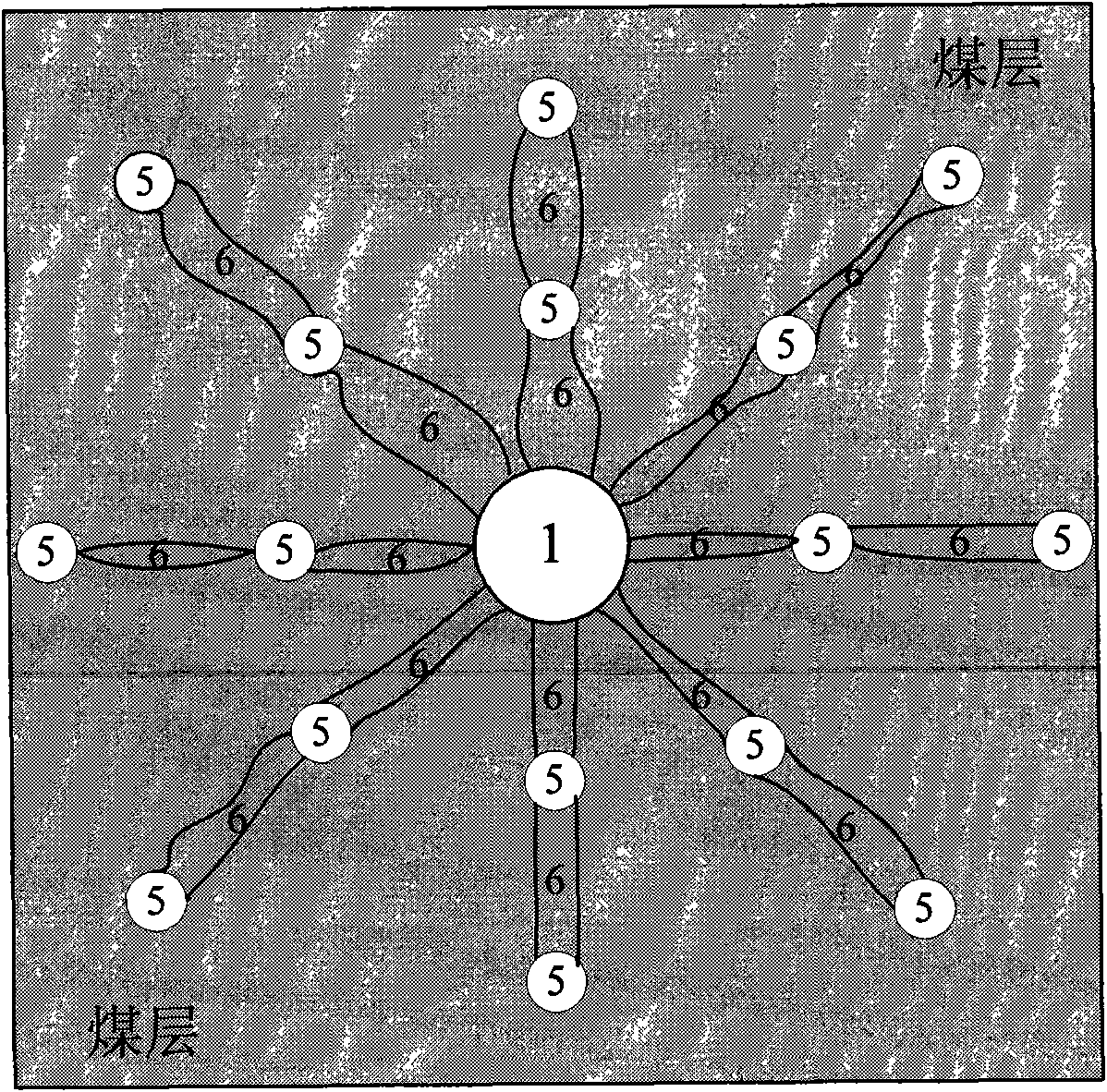

Method for exploiting coal bed methane (CBM) by water transportation and pressure relief in butted well

InactiveCN101775974AAchieving extraction complianceRealize regional conflict eliminationFluid removalSealing/packingCoal waterWater flow

The invention discloses a method for exploiting coal bed methane (CBM) by water transportation and pressure relief in a butted well, relieving pressure. A coal water and gas discharging well (1) and a plurality of injection gas discharging wells (5) are arranged, wherein the coal water and gas discharging well (1) collects a discharged coal-water mixture and CBM, the injection gas discharging wells (5) are used for injecting water and collecting the CBM, a gas-coal-water separating device is arranged at the well mouth of the coal water and gas discharging well (1), the separated water is recycled, the injection gas discharging wells (5) are arranged a well-closing position for feeding water and discharging gas, the bottom of the coal water and gas discharging well (1) is caved, and the injection gas discharging wells (5) and the coal water and gas discharging well (1) are butted by a fluid pressure difference or mechanical drilling and other methods. Then, water is injected in the injection gas discharging wells (5), a stream flushes a coal body, moves to the coal water and gas discharging well (1), is discharged and forms a pressure-discharging space (6), and the rest coal layers yield the CBM. The technology can solve the problem of preliminarily pumping CBM from a floppy and low-permeability coal reservoir, eliminate the outburst risks and decrease the gas content of the coal body.

Owner:ZHENGZHOU UNIV +2

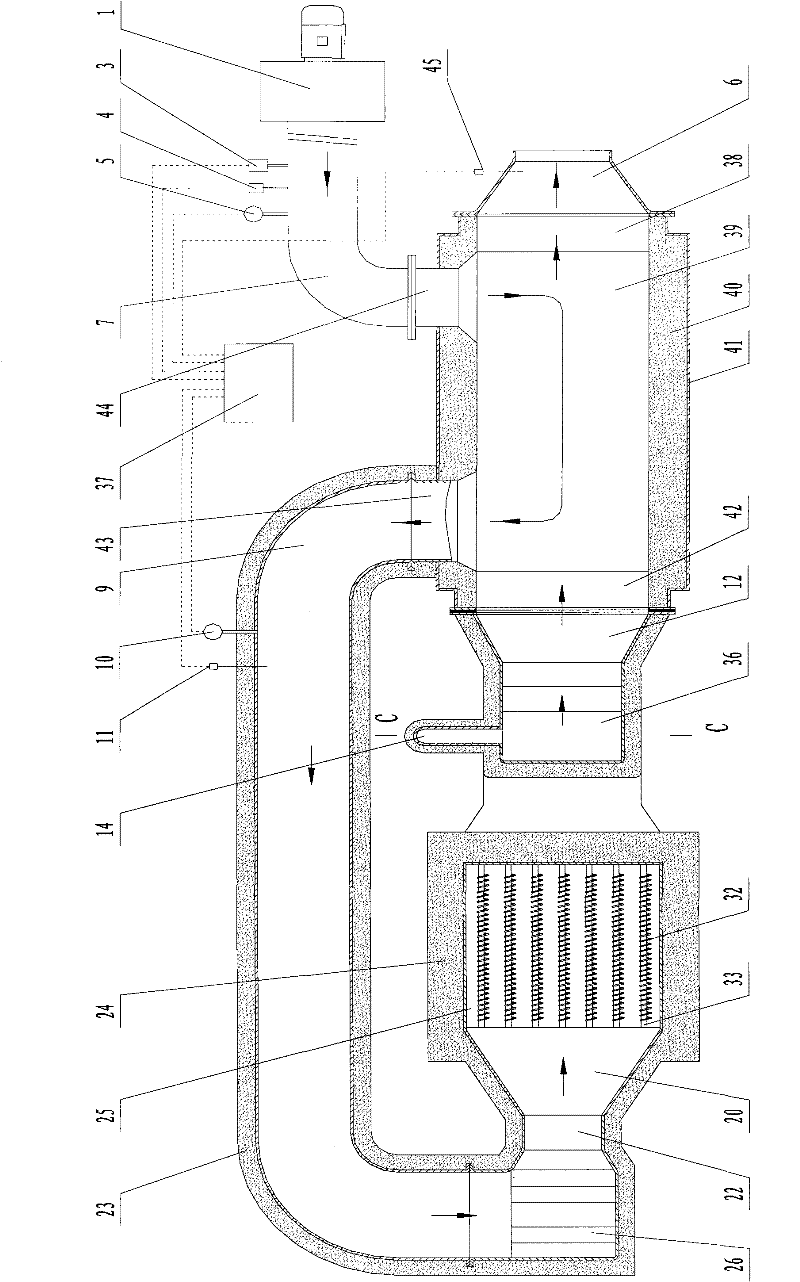

Heat accumulation type super-low calorific value fuel gas treatment and energy utilization device

InactiveCN101900332AAvoid pollutionAchieve self-sustaining combustionIndirect carbon-dioxide mitigationWater heatersSelf maintenanceCombustion chamber

The invention discloses a heat accumulation type super-low calorific value fuel gas treatment and energy utilization device, which is applied to reciprocal flow heat accumulation type combustion technology of the super-low calorific value fuel gas in industrial production. The device consists of a device body, a periodic reverse gas flow circulating pipeline and a measurement and control system. The self-maintenance combustion of super-low calorific value fuel gases with extremely low methane concentration, such as coal mine methane, gases produced in municipal solid waste landfill, combustible gases produced during pyrolysis and smolder (such as battery heating) of biomass in nature and in the lives of human society and the like, can be realized in the device; and because the aperture of low-porosity porous medium filled in a porous medium packed bed of a combustion chamber is less than the quenching diameter, the combustion can be controlled within the combustion chamber. In addition, a part of heat produced by the combustion of the super-low calorific value fuel gas is pumped out by a smoke suction device and conveyed to the conventional exhaust heat boilers for heating water for heating or producing super-heated steam for power generation; and thus the device has the advantages of energy conservation and environmental friendliness.

Owner:DALIAN MARITIME UNIVERSITY

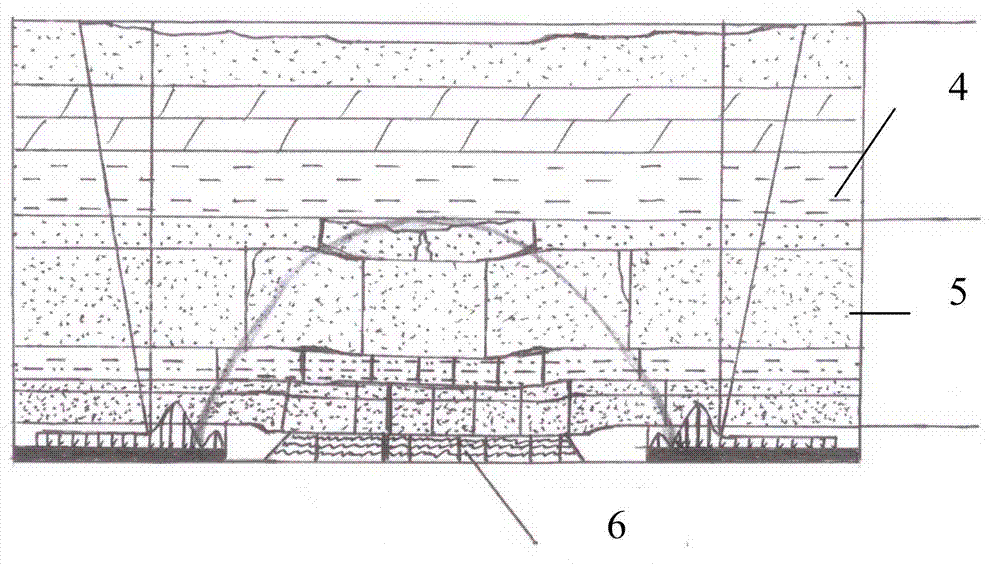

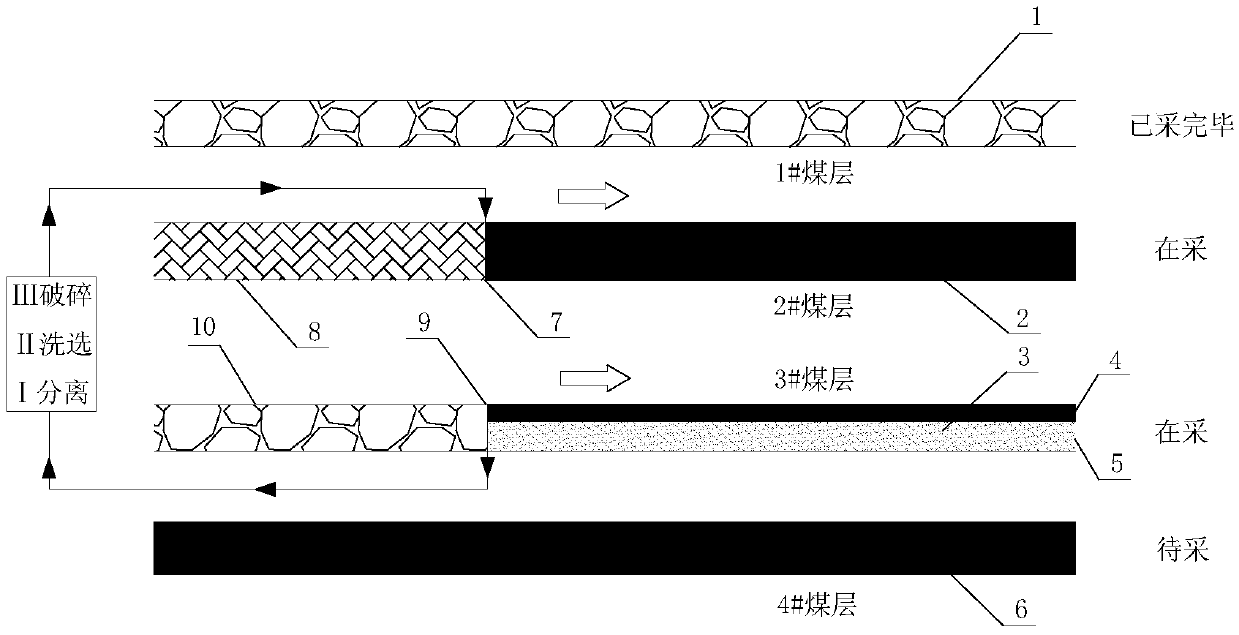

Coal-rock simultaneous production protecting seam and protected seam collaborative mining method

ActiveCN105507903AExpand the scope of miningEfficient governanceUnderground miningFluid removalSocial benefitsCoal mine methane

The invention relates to a coal-rock simultaneous production protecting seam and protected seam collaborative mining method applicable to multi-seam combined mining under poor mining conditions of protecting seams. According to the time-space relationship characteristics that one coal-rock protecting seam and one previous protected seam are mined simultaneously during multi-seam combined mining, when the coal-rock protecting seam is mined, the mined coal and rock are separated, washed and crushed according to size and conveyed to a mined out area of the previous protected seam for filling the mined-out area, gangue mined out excessively is prevented from being discharged out of a mine, the gangue does not need to be lifted from the mine, and the lift cost is reduced; the mined rock can be used as underground mine-fill after being treated, the problem about sources of the mine fill is solved, and ground surface settlement is prevented effectively. By the method, pressure-relief mining of the coal-rock protecting seams is realized, meanwhile, green fill mining of the previous protected seams is realized, high-efficient treatment of coal-mine gas is ensured, the coal-rock protecting seam mining is safer, more efficient and greener, and significant economic and social benefits are obtained.

Owner:CHINA UNIV OF MINING & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com