Aboveground and underground combined heat injection coal bed gas extraction method

A coalbed methane and coalbed technology, applied in the field of coalbed methane extraction, can solve problems such as difficult industrial production application and difficult separation technology, and achieve the effects of increasing pressure, accelerating desorption, and increasing permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

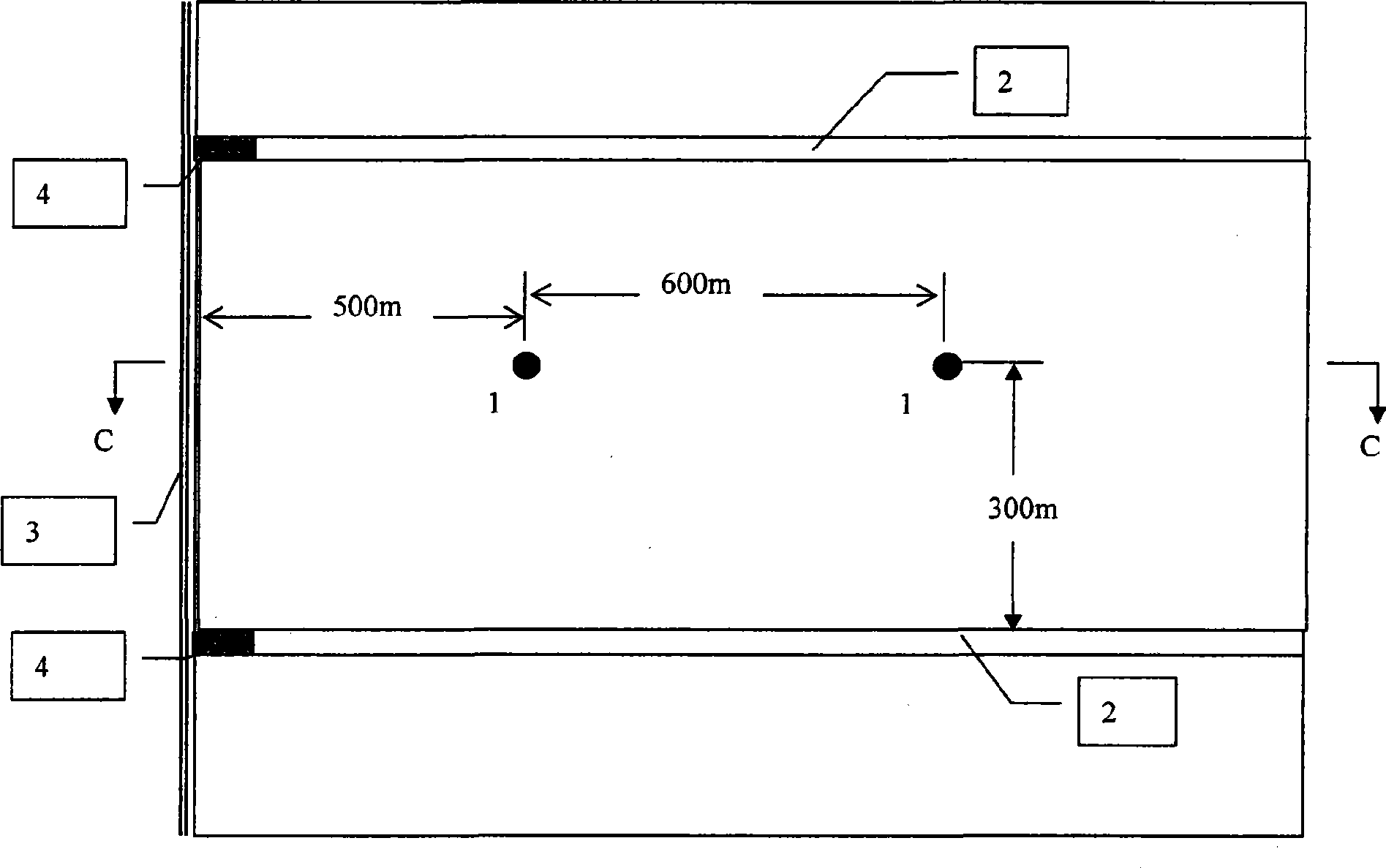

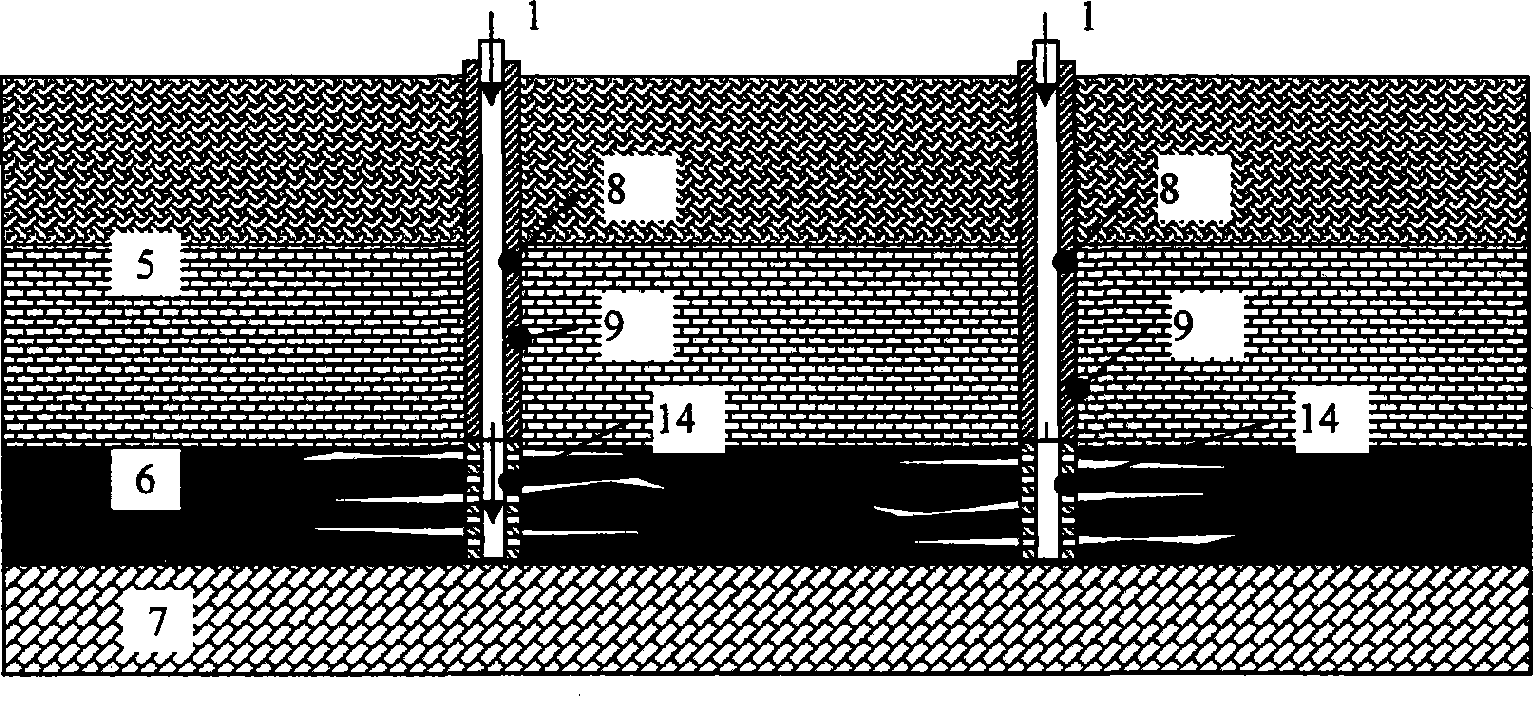

[0032] Such as figure 1 , 2 Shown, a kind of method for coalbed methane in a single coal seam combined with upper and lower heat injection and drainage, in a single coal seam with a thickness of 10m and a burial depth of 100m, two vertical heat injection wells 1 are arranged by the present invention, and the well spacing 600m, perpendicular to the underground roadway 3, each well is drilled into the coal seam 6, the double-layer annular pipe 8 is set under the roof rock section 5, and the flower pipe 14 is set under the coal seam section 6, along the outer layer of the double-layer annular pipe 8. High temperature resistant cement 9 cementing. Two extraction roadways 2 are constructed so that they are parallel to the connection line of the two heat injection wells 1 and perpendicular to the main road 3, and the drainage roadway 2 is sealed at the entrance of the main road. According to the conventional method, install the pumping station, the drainage system and the monitori...

Embodiment 2

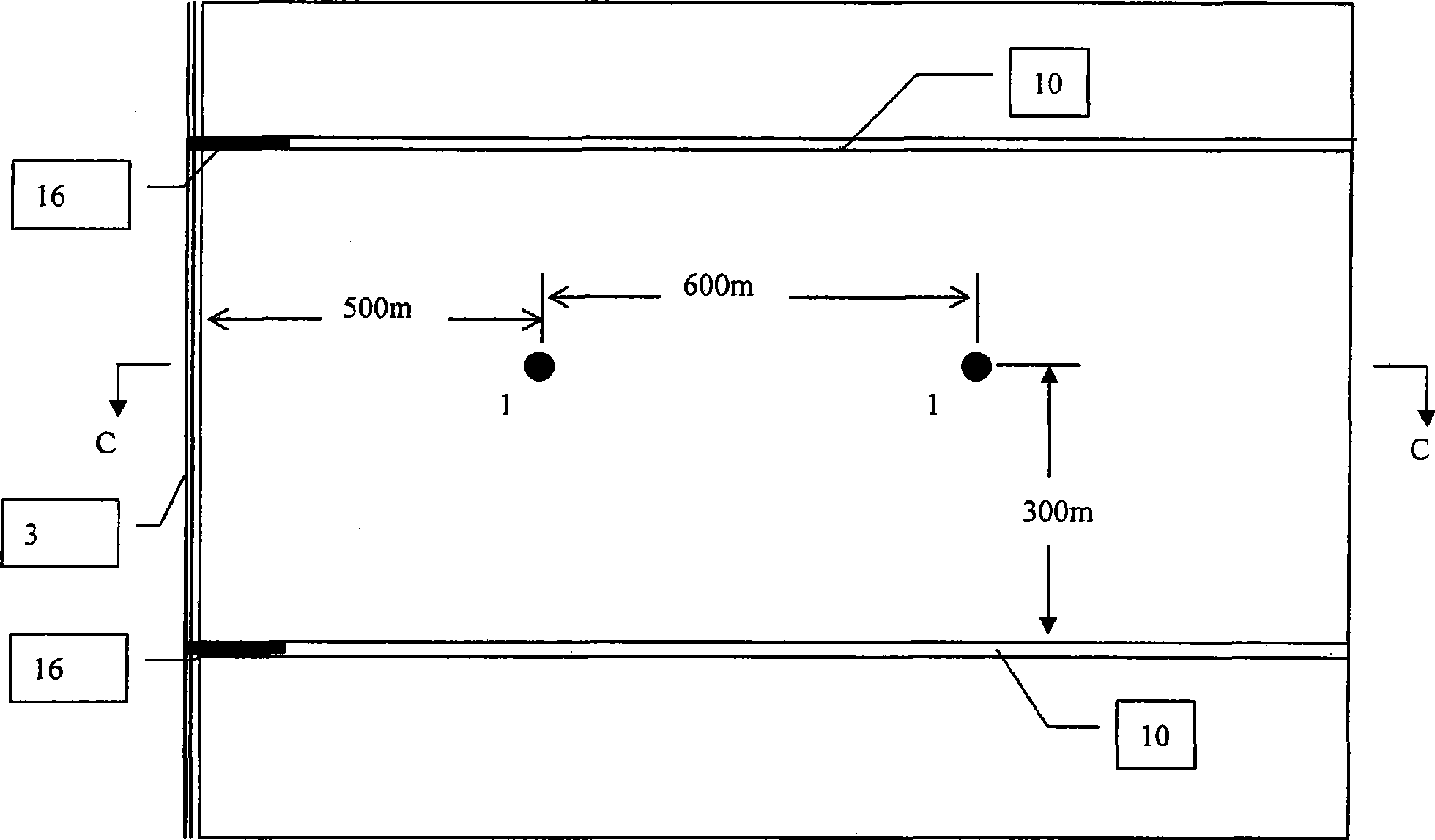

[0039] Such as image 3 , 4 Shown, a kind of method for coalbed methane in a single coal seam combined with upper and lower heat injection and drainage, in a single coal seam with a thickness of 10m and a burial depth of 100m, two vertical heat injection wells 1 are arranged by the present invention, and the well spacing 600m, the connecting line of the two wells is perpendicular to the underground roadway 3, and parallel to the two super-long drainage boreholes 10, each well is drilled into the coal seam 6, and a double-layer annular pipe 8 is set under the roof rock section 5, and the coal seam section A flower pipe 14 is arranged under the 6, and the outer layer of the double-layer annular pipe 8 is cemented with high-temperature-resistant cement 9 . Two superlong boreholes 10 for drainage are constructed so as to be parallel to the connection of two heat injection wells 1, and perpendicular to the roadway 3, and the superlong borehole 10 is airtightly drained at the entra...

Embodiment 3

[0046] Such as Figure 5 , 67 and 7, a method for extracting coalbed methane from coal seam groups by combined heat injection up and down the well. The coal seam spacing is 3m, the lower adjacent coal seam and the main mining coal seam spacing 4m, the near horizontal coal seam group of the main mining coal seam burial depth 400m, adopts the present invention to arrange two vertical heat injection wells 1, the well spacing 800m, and the underground roadway 3 vertically, each drilling well drills into the coal seams 6, 11, 12, a double-layer annular pipe 8 is set under the roof rock section 5, a single-layer casing 15 is set under the coal seam section 6, and along the double-layer annular pipe 8 and the single-layer casing The outer layer of the pipe 15 is cemented with high-temperature-resistant cement 9, and after cementing, a communication channel between the coal seam and the casing is made in each coal seam section. Construct two extraction tunnels 2 so that they are par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com